Chemical foamed concrete and preparation method thereof

A foaming concrete and chemical foaming technology, applied in the field of building materials, can solve the problems of long molding speed, uneven foam diameter, poor heat preservation effect, etc., and achieve stable foaming speed, uniform foam diameter, sound insulation and heat insulation Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Embodiment 1 (the amount of cement and tailings powder in the two embodiments is not within the scope of the claims and needs to be modified)

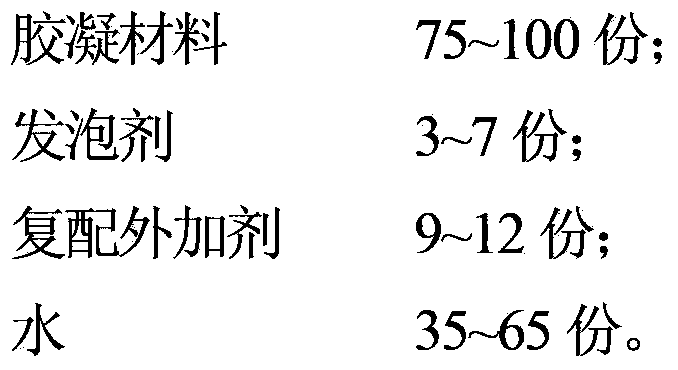

[0029] Provide a kind of foam concrete material, comprise cementitious material, blowing agent, compound admixture and water, the mass fraction of described component is:

[0030]

[0031] Its process steps are as follows:

[0032] Mix the cementitious material and compound admixture evenly to form a mixed dry material;

[0033] Stir the mixed dry material and water evenly at 40°C to form cement slurry;

[0034] Add hydrogen peroxide solution (30wt%) to the cement slurry, stir rapidly for 60s, place it in the mold, foam at room temperature, and demould after hardening and molding, and the foamed concrete product is obtained.

[0035] The test data is as follows:

[0036] 28d compressive strength 3.61MPa, bulk density 387kg / m 3 , thermal conductivity 0.06W / (m·k).

Embodiment 2

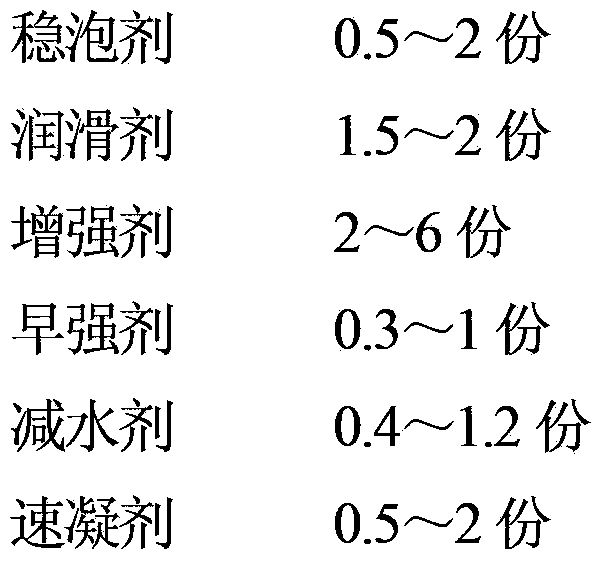

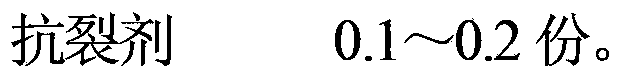

[0038] Provide a kind of foam concrete material, comprise cementitious material, blowing agent, compound admixture and water, the mass fraction of described component is:

[0039]

[0040]

[0041] Its process steps are as follows:

[0042] Mix the cementitious material and compound admixture evenly to form a mixed dry material;

[0043] Stir the mixed dry material and water evenly at 35°C to form cement slurry;

[0044] Add hydrogen peroxide solution (30wt%) to the cement slurry, stir rapidly for 60s, place it in the mold, foam at room temperature, and demould after hardening and molding, and the foamed concrete product is obtained.

[0045] The test data is as follows:

[0046] 28d compressive strength 3.59MPa, bulk density 390kg / m 3 , thermal conductivity 0.069W / (m·k).

PUM

| Property | Measurement | Unit |

|---|---|---|

| compressive strength | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com