Patents

Literature

1240 results about "Gallium" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Gallium is a chemical element with the symbol Ga and atomic number 31. Elemental gallium is a soft, silvery blue metal at standard temperature and pressure; however in its liquid state it becomes silvery white. If too much force is applied, the gallium may fracture conchoidally. It is in group 13 of the periodic table, and thus has similarities to the other metals of the group, aluminium, indium, and thallium. Gallium does not occur as a free element in nature, but as gallium(III) compounds in trace amounts in zinc ores and in bauxite. Elemental gallium is a liquid at temperatures greater than 29.76 °C (85.57 °F), above room temperature, but below the normal human body temperature of 37 °C (99 °F). Hence, the metal will melt in a person's hands.

Phosphors containing boron and metals of Group IIIA and IIIB

A phosphor comprises: (a) at least a first metal selected from the group consisting of yttrium and elements of lanthanide series other than europium; (b) at least a second metal selected from the group consisting of aluminum, gallium, indium, and scandium; (c) boron; and (d) europium. The phosphor is used in light source that comprises a UV radiation source to convert UV radiation to visible light.

Owner:GENERAL ELECTRIC CO

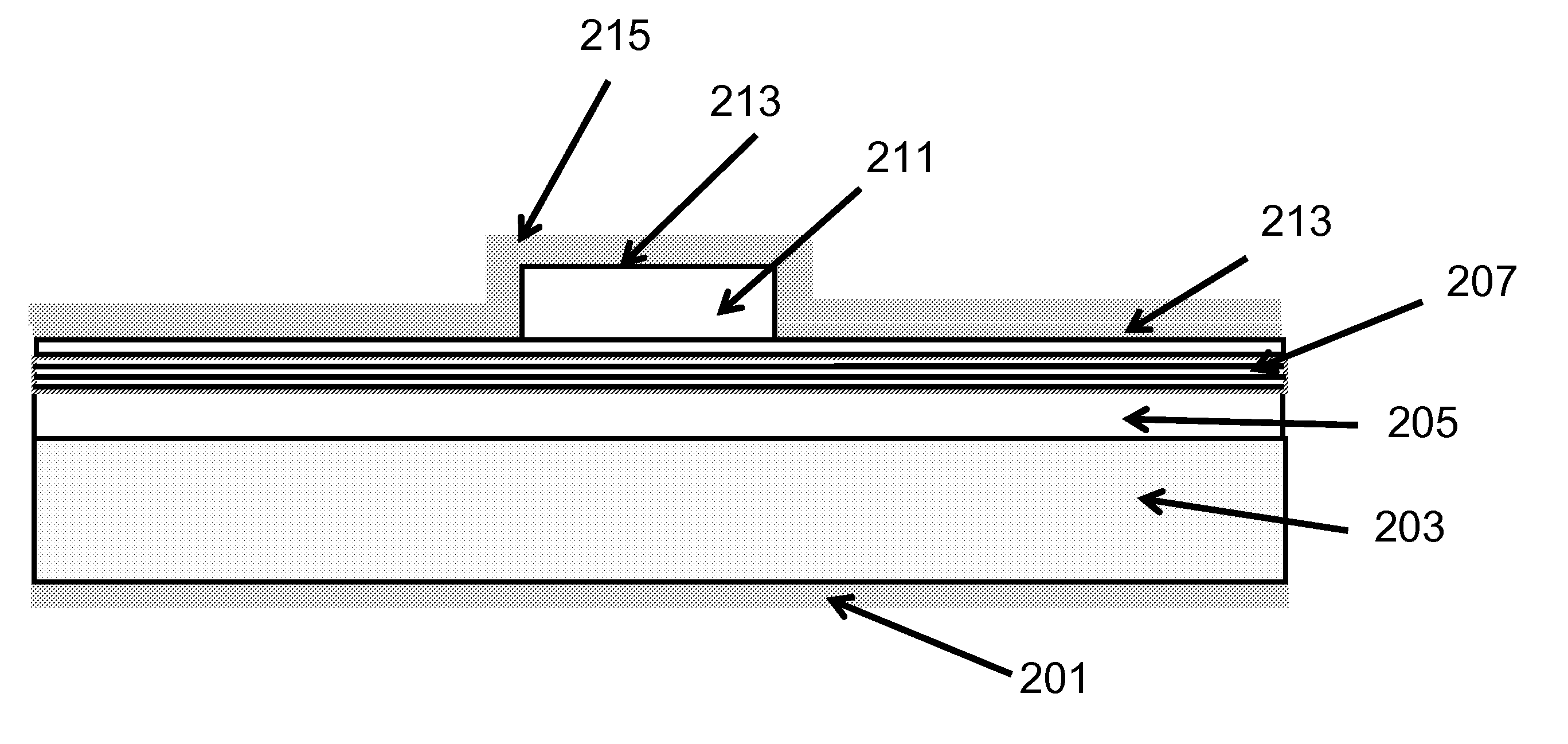

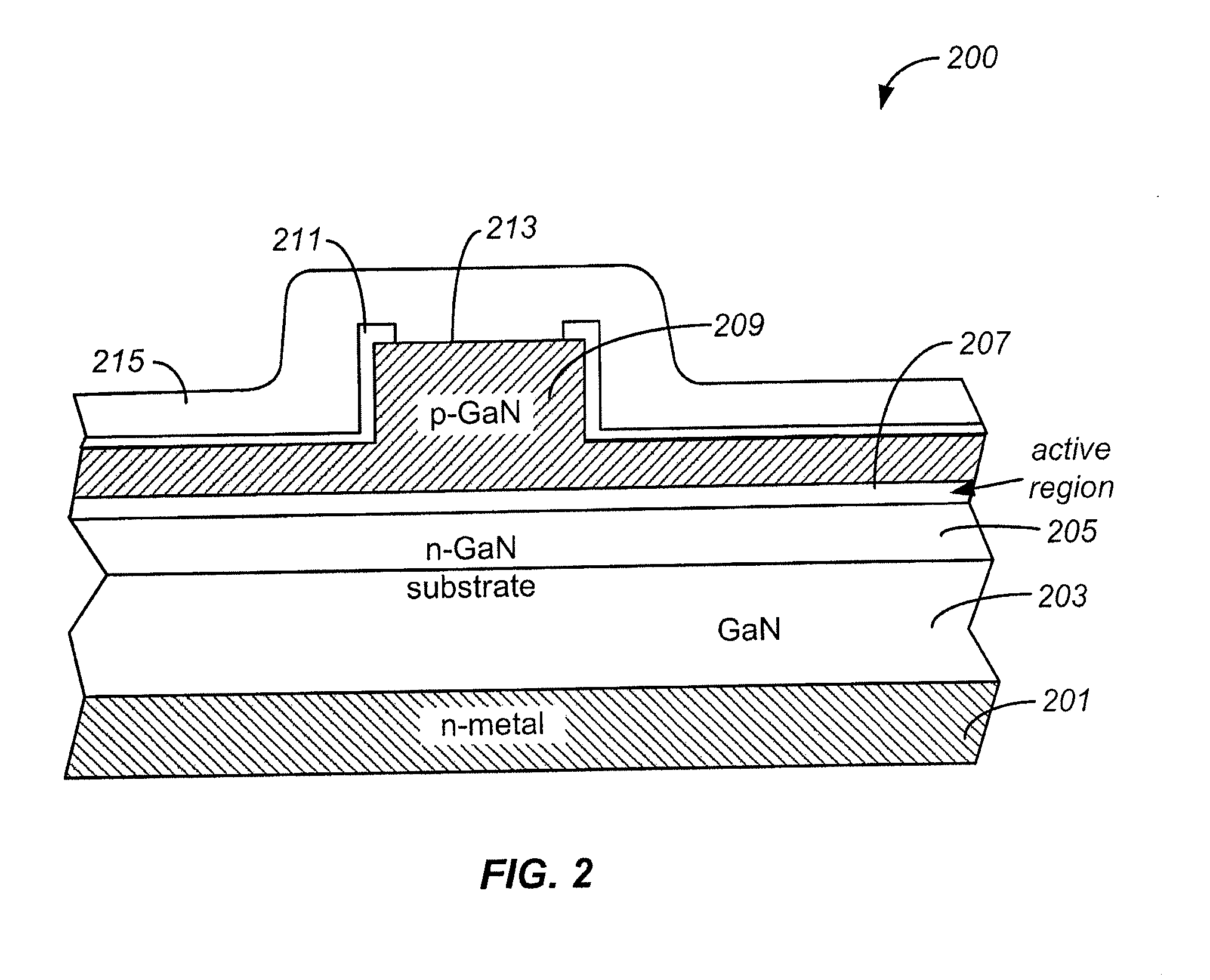

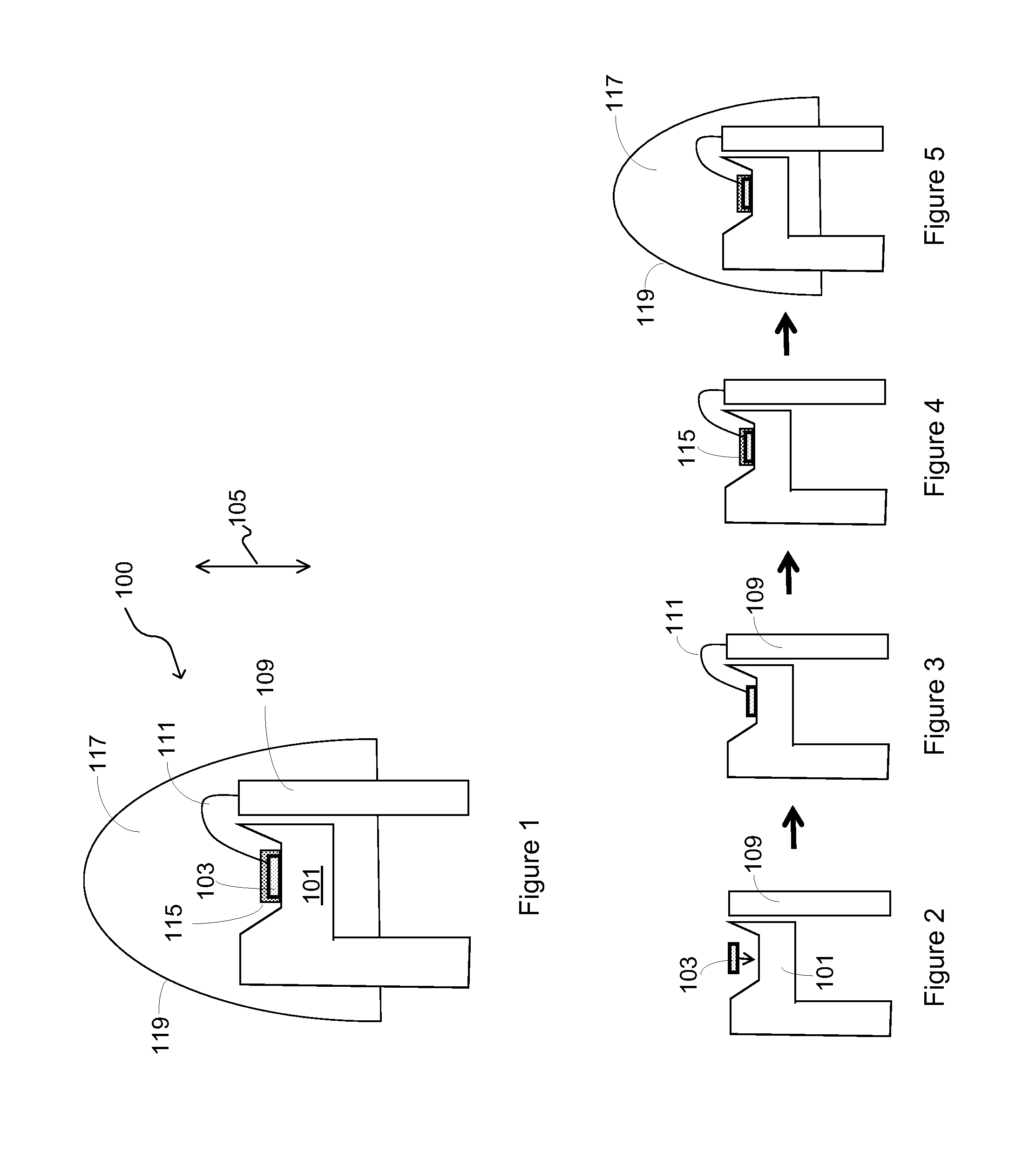

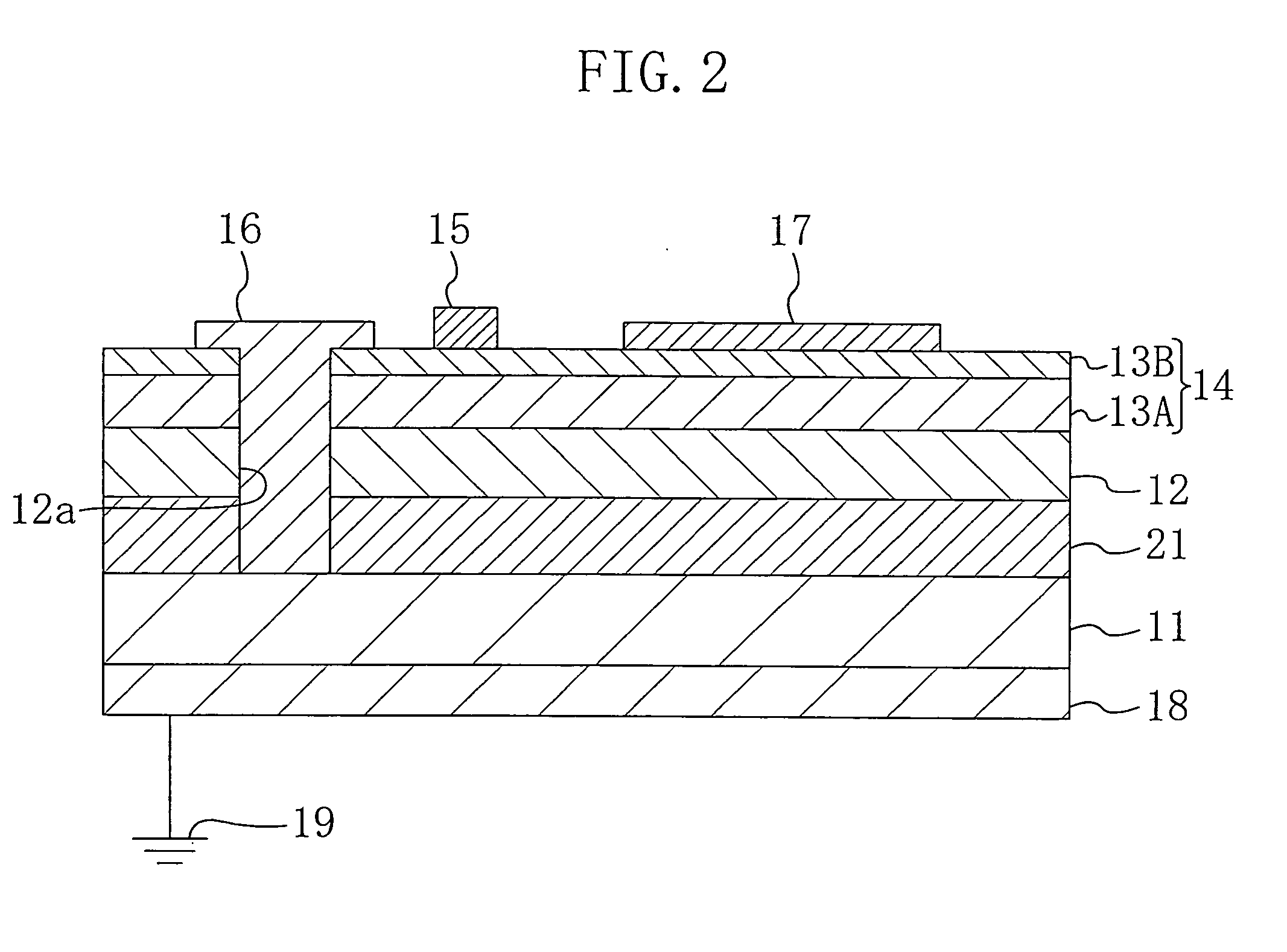

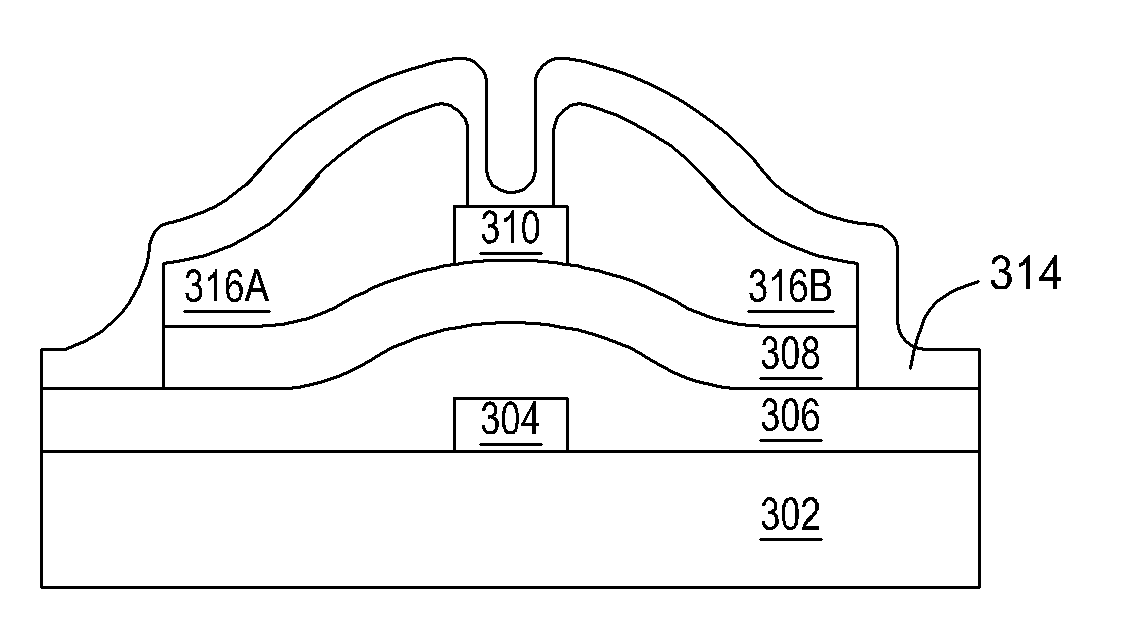

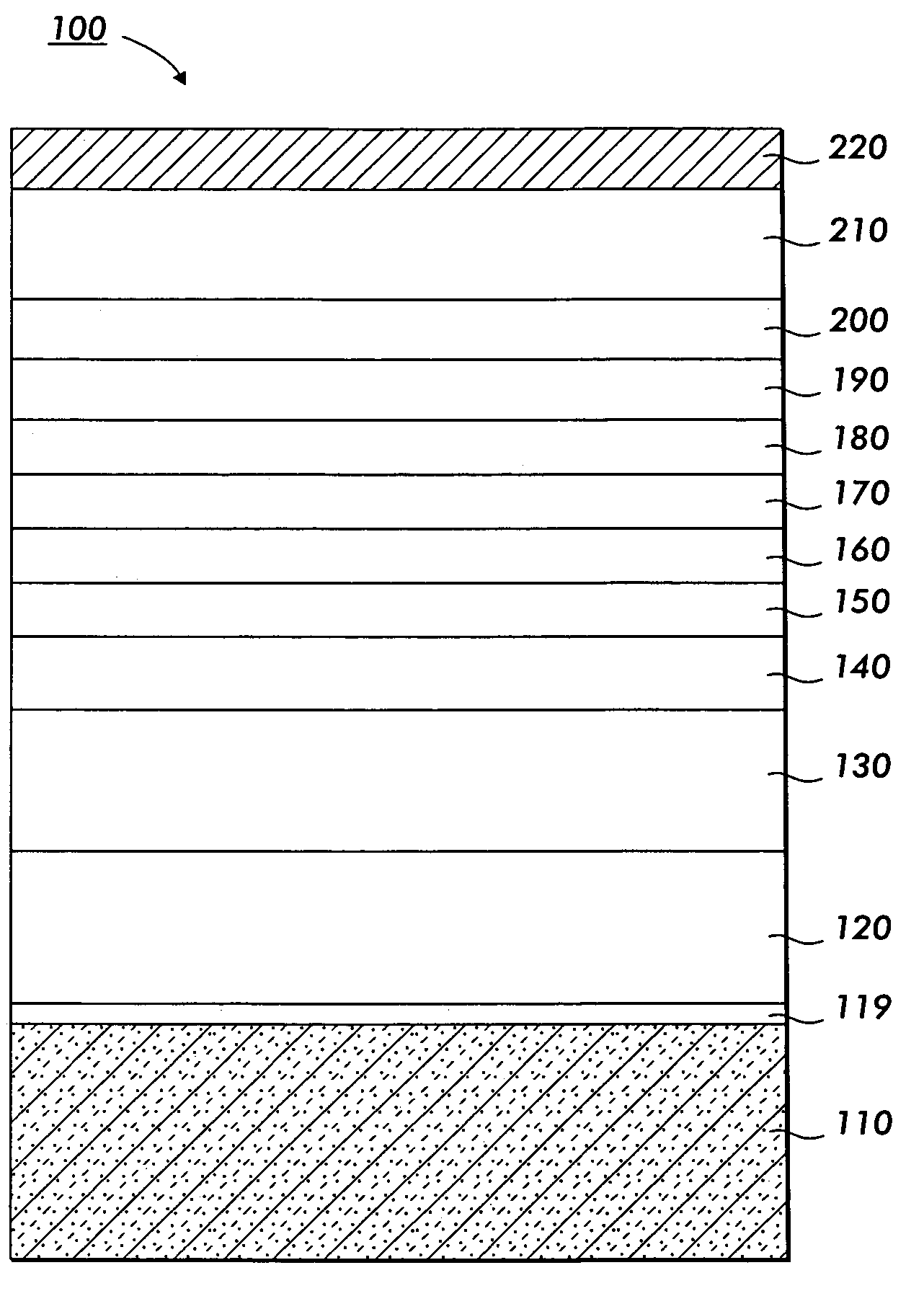

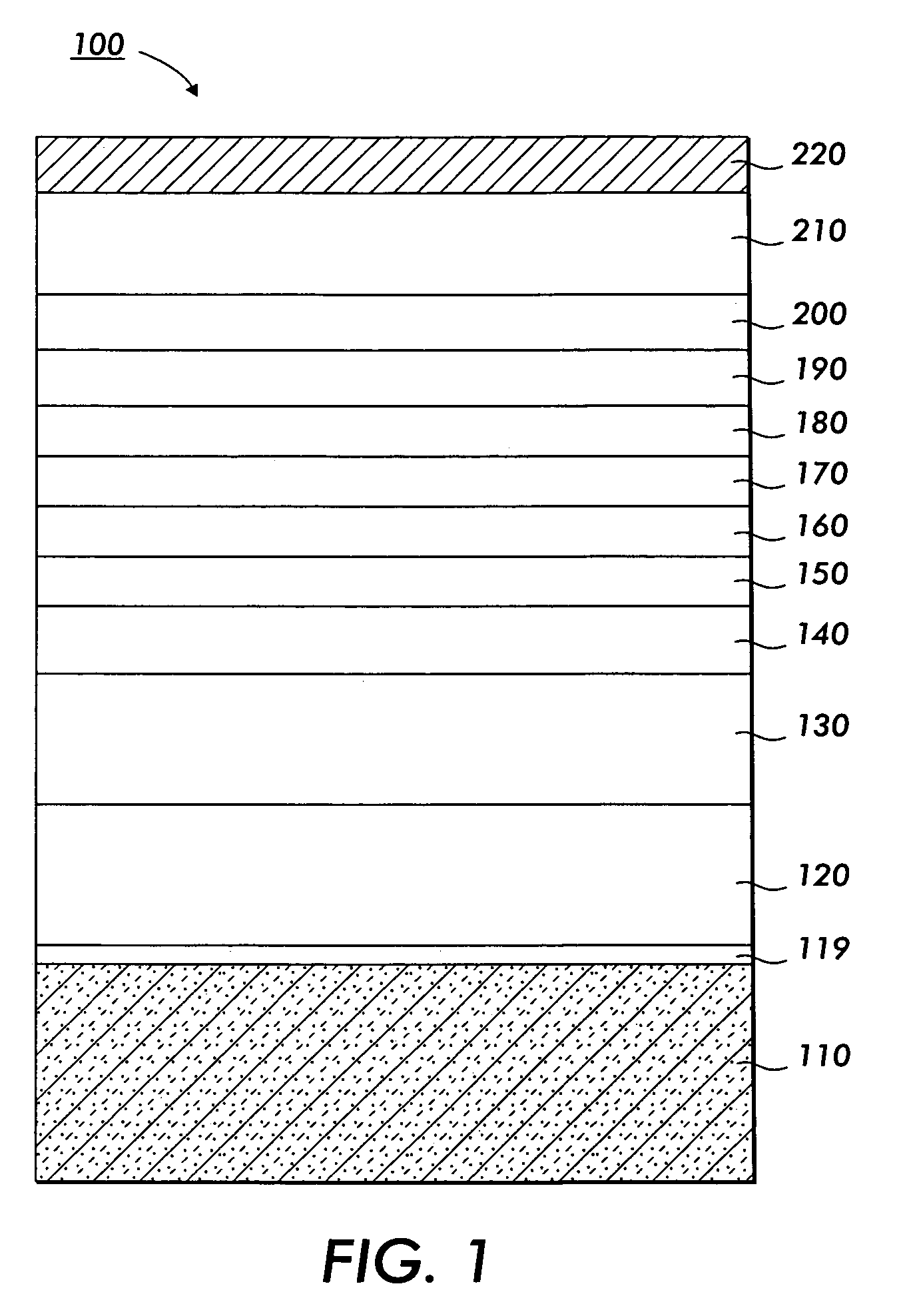

Rapid Growth Method and Structures for Gallium and Nitrogen Containing Ultra-Thin Epitaxial Structures for Devices

InactiveUS20110056429A1Quick upgradeReduce processing timePolycrystalline material growthSemiconductor/solid-state device manufacturingEpitaxial materialNitrogen

A method for rapid growth of gallium and nitrogen containing material is described. The method includes providing a bulk gallium and nitrogen containing substrate. A first epitaxial material of first thickness is formed over the substrate, preferably with a pseudomorphical process. The method also forms a second epitaxial layer over the first to create a stacked structure. The stacked structure consists of a total thickness of less than about 2 microns.

Owner:SORAA

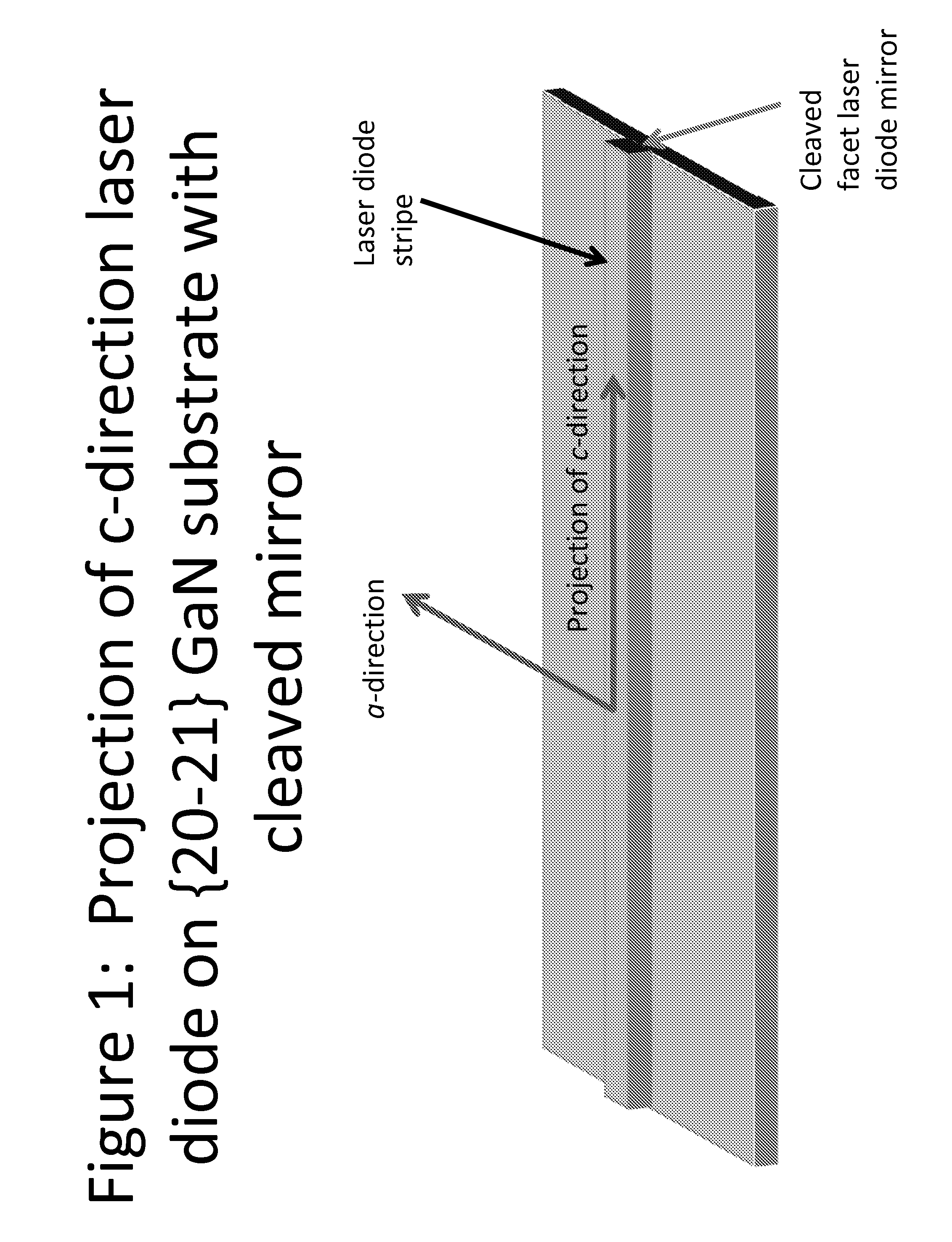

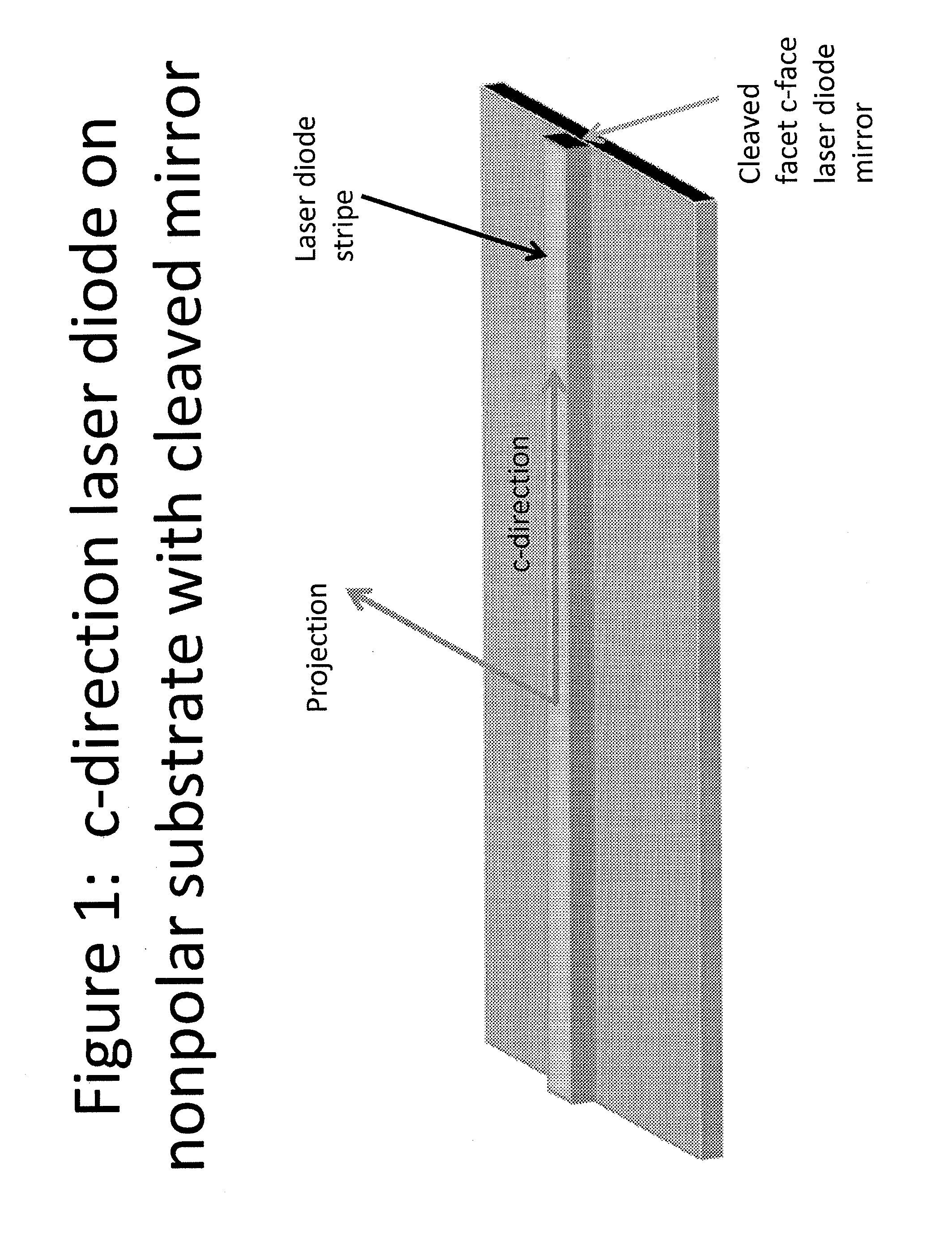

Growth structures and method for forming laser diodes on {30-31} or off cut gallium and nitrogen containing substrates

ActiveUS8351478B2Improved cleavesCost-effectiveLaser detailsSemiconductor/solid-state device manufacturingNitrogenGallium

Owner:KYOCERA SLD LASER INC

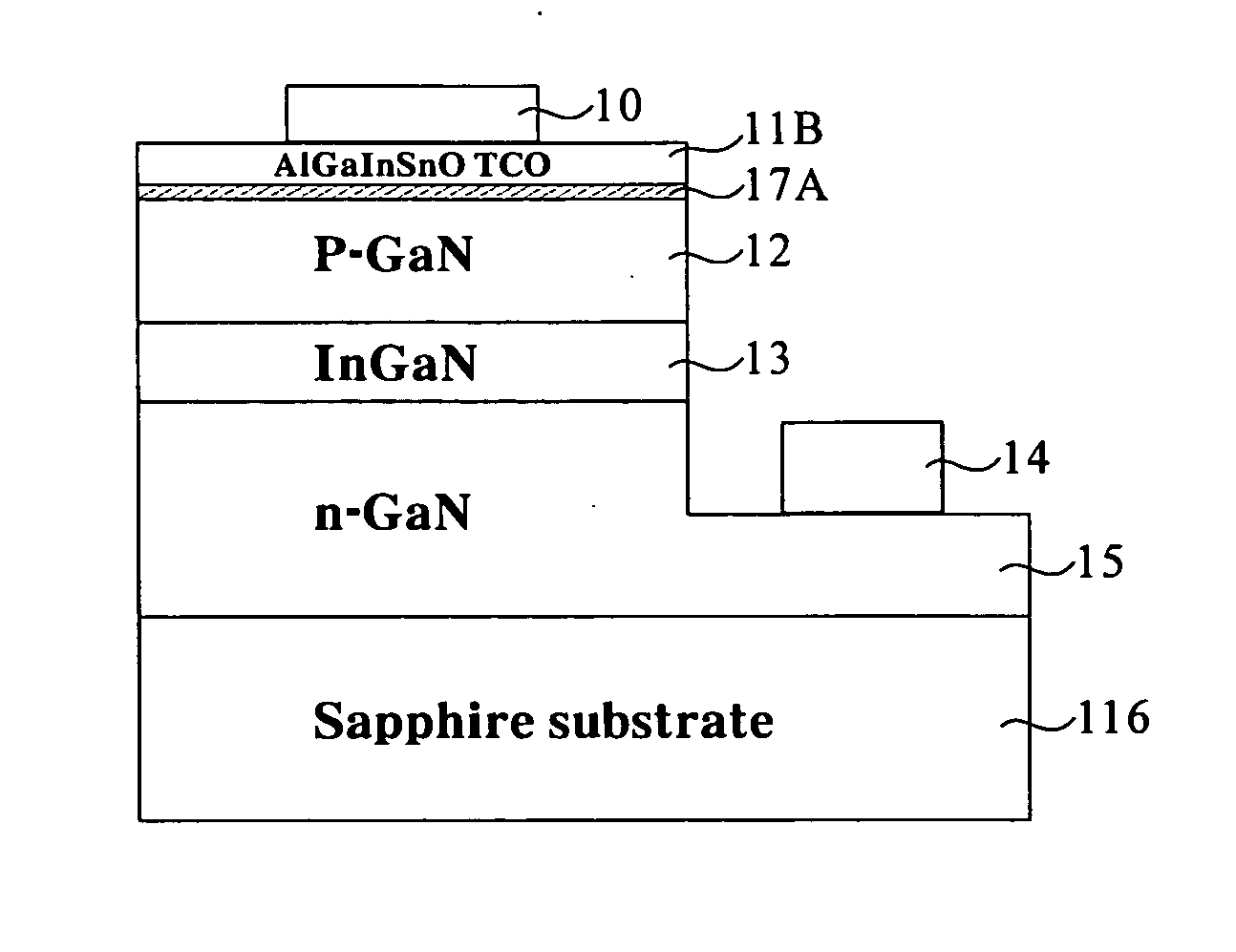

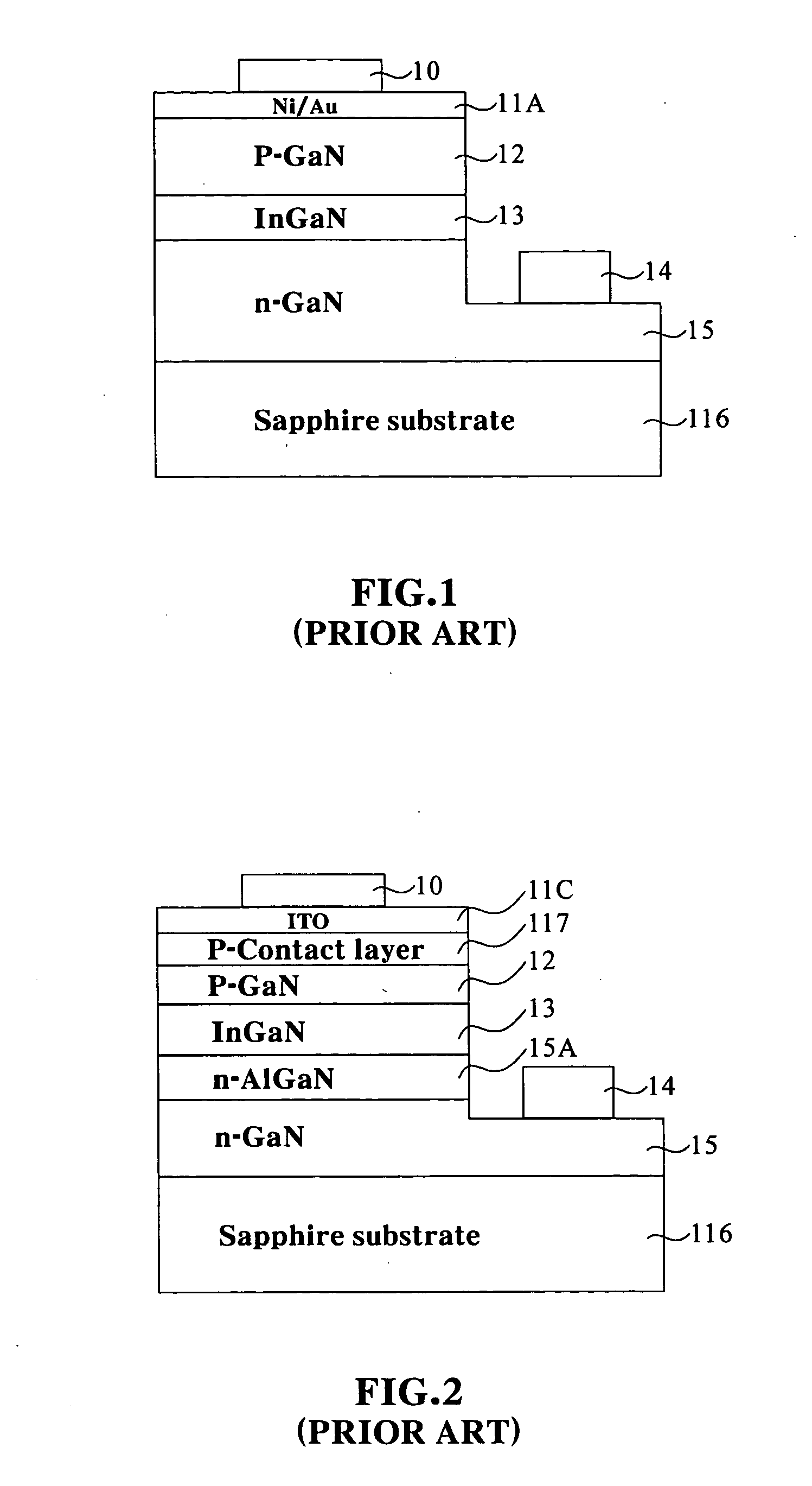

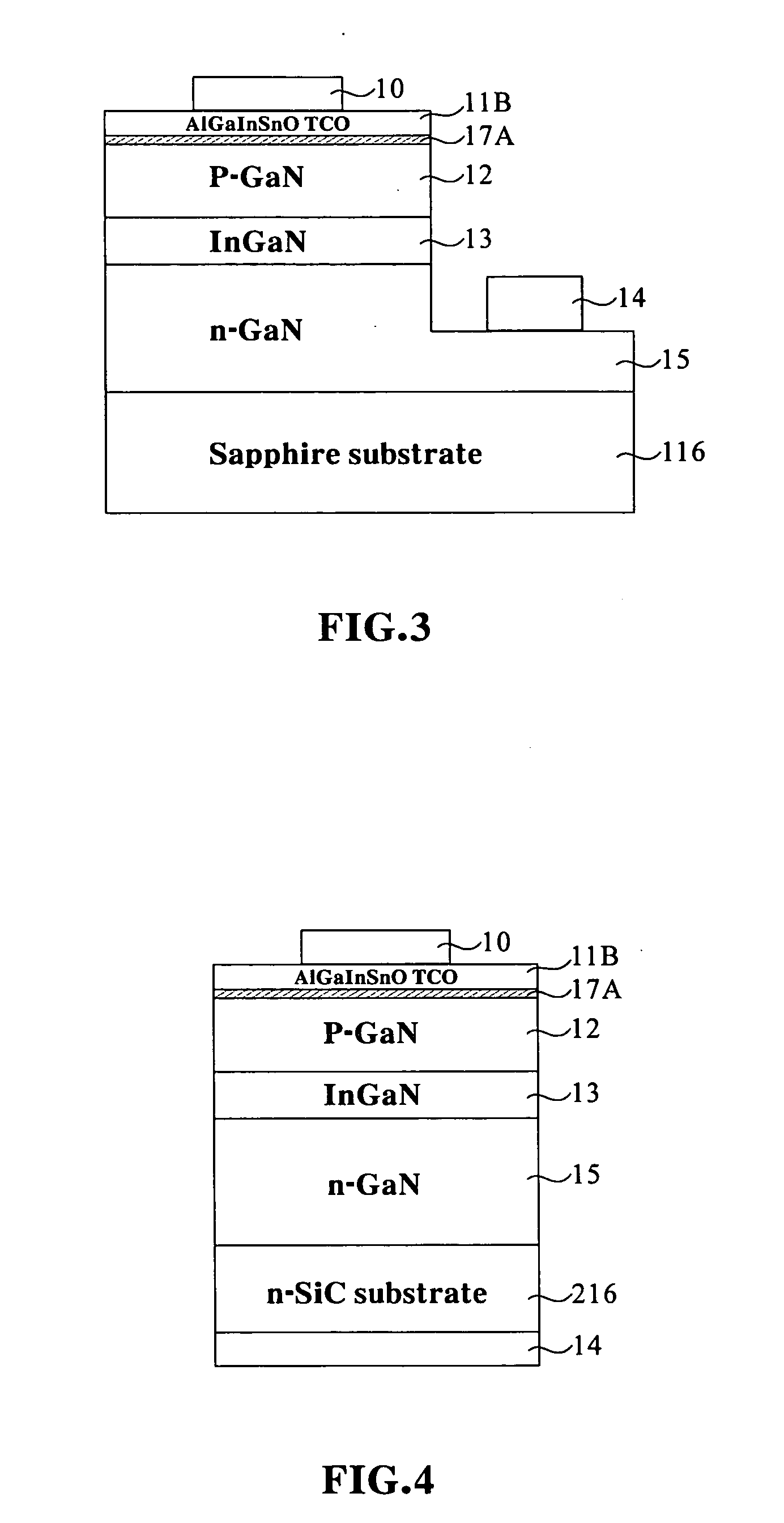

High brightness gallium nitride-based light emitting diode with transparent conducting oxide spreading layer

InactiveUS20050230701A1Reduce contact resistanceReduce the impactFibre treatmentSolid-state devicesOptical propertyGallium

A new transparent conducting oxide (TCO), which can be expressed as AlxGa3−x−yIn5+ySn2−zO16−2z; 0≦x<1, 0<y<3, 0≦z<2, has been used to improve the brightness and current spreading in GaN base LED process. The optical properties of this system are superior to regular Ni / Au transparent conducting layer in blue-green region, and the new Al2O3—Ga2O3—In2O3—SnO2 system is able to increase the brightness at 1.5˜2.5 time to compare to regular process. Furthermore, the new transparent conducting oxide thin film has the highest conductivity, which is better than the Ni / Au transparent conducting thin film.

Owner:ARIMA OPTOELECTRONICS

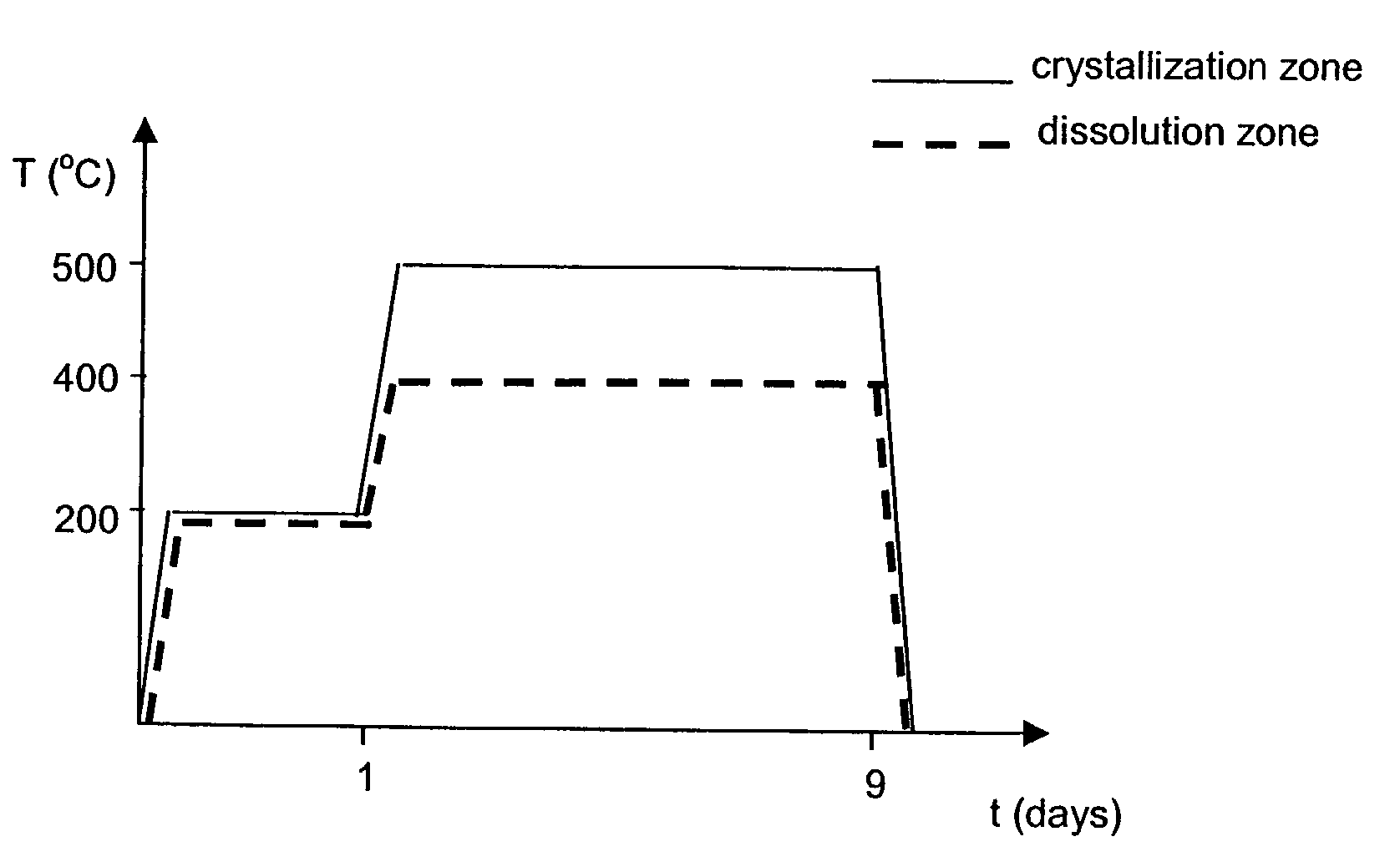

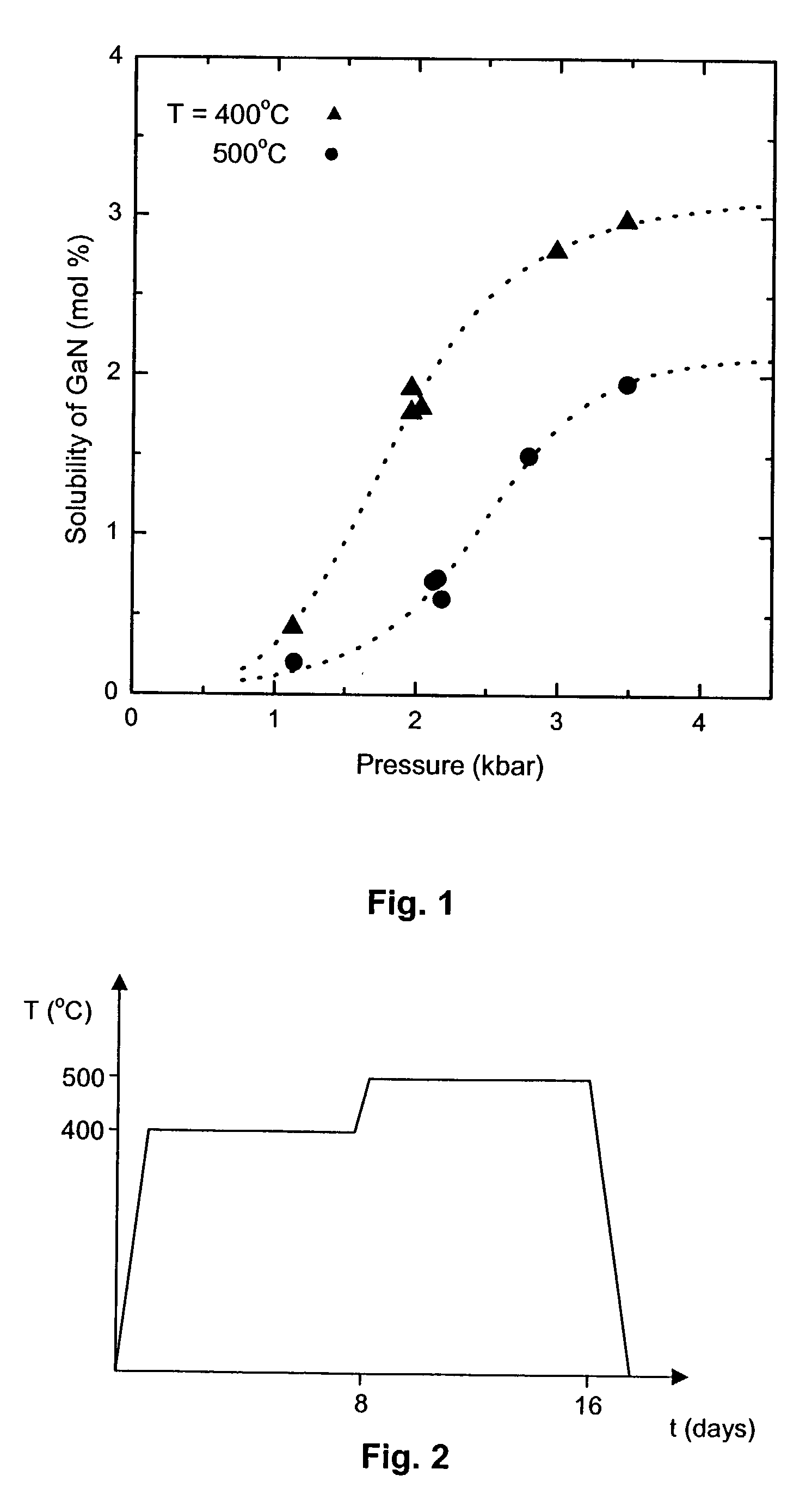

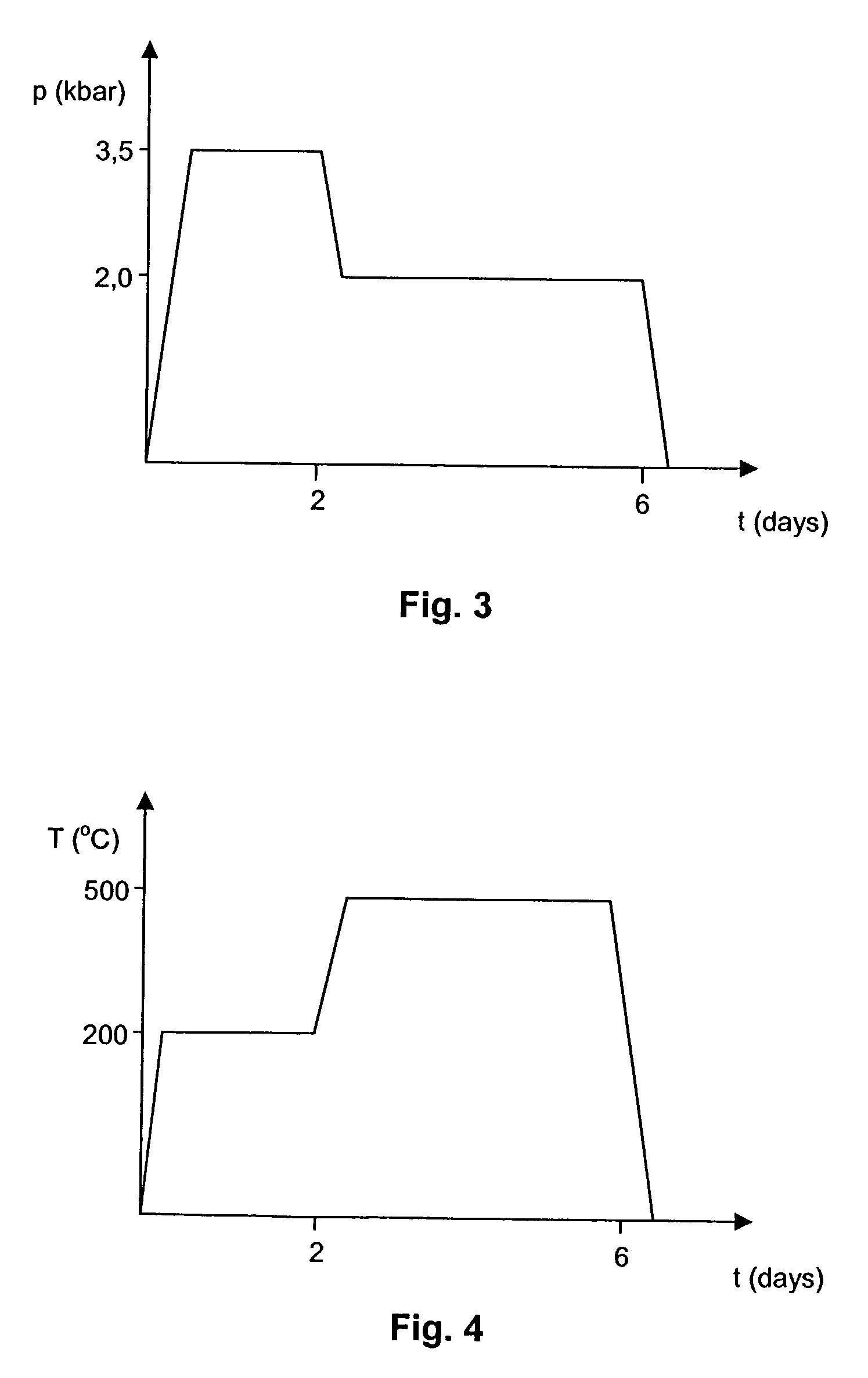

Process and apparatus for obtaining bulk monocrystalline gallium-containing nitride

Owner:AMMONO SP Z O O (PL) +1

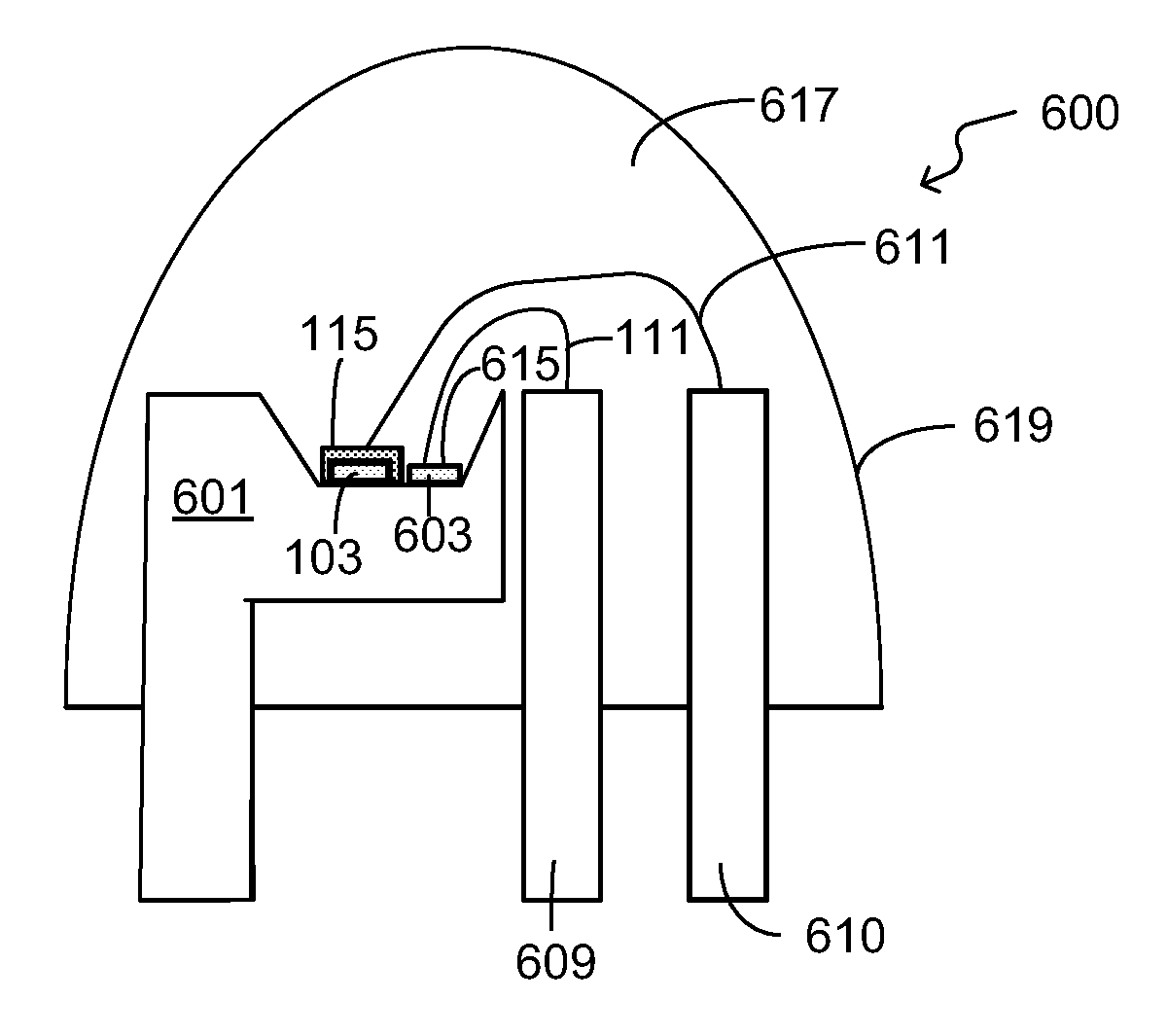

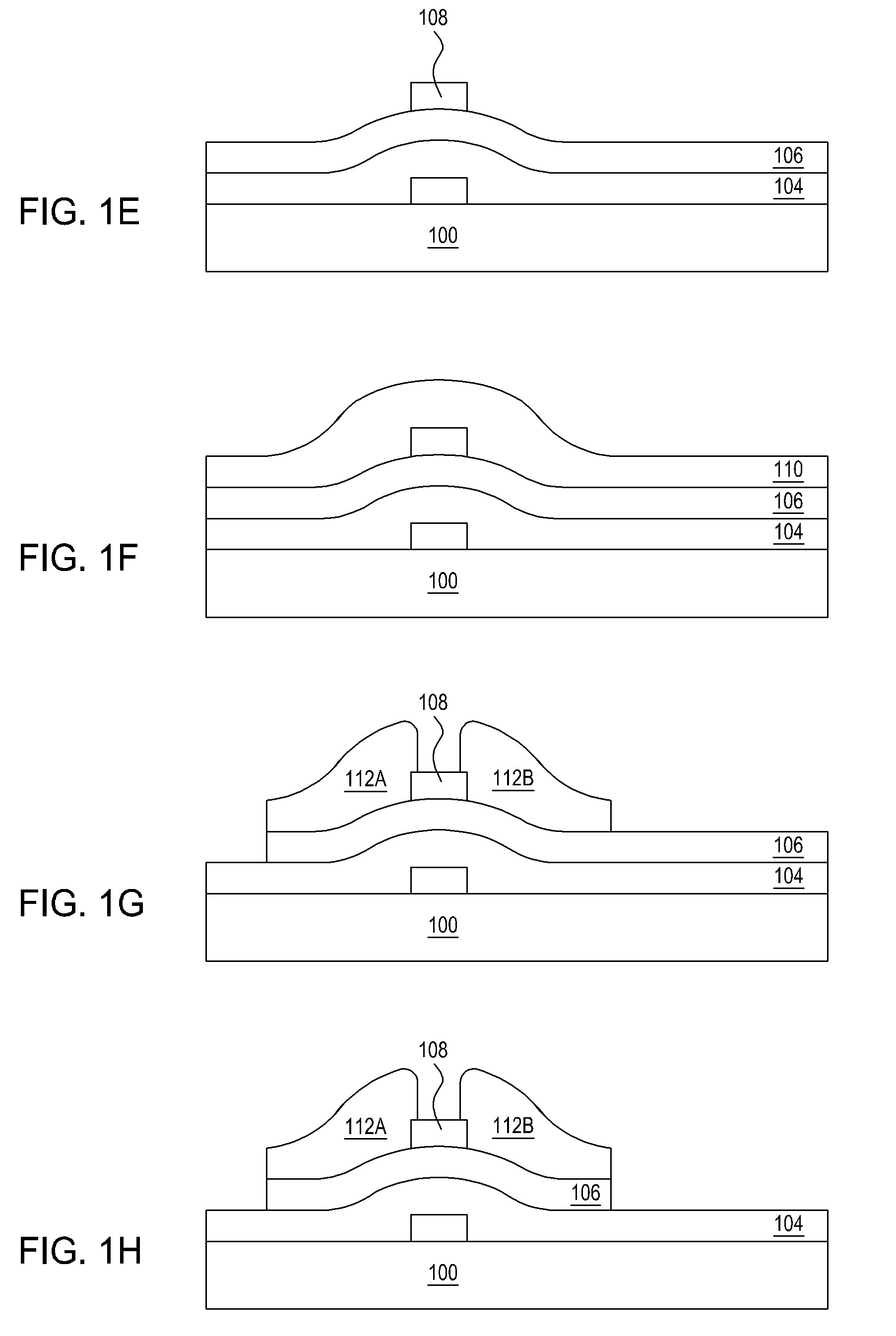

Method of Fabricating Optical Devices Using Laser Treatment of Contact Regions of Gallium and Nitrogen Containing Material

ActiveUS20120104359A1Improve device performanceSmooth connectionSolid-state devicesSemiconductor/solid-state device manufacturingNitrogenGallium

Owner:KYOCERA SLD LASER INC

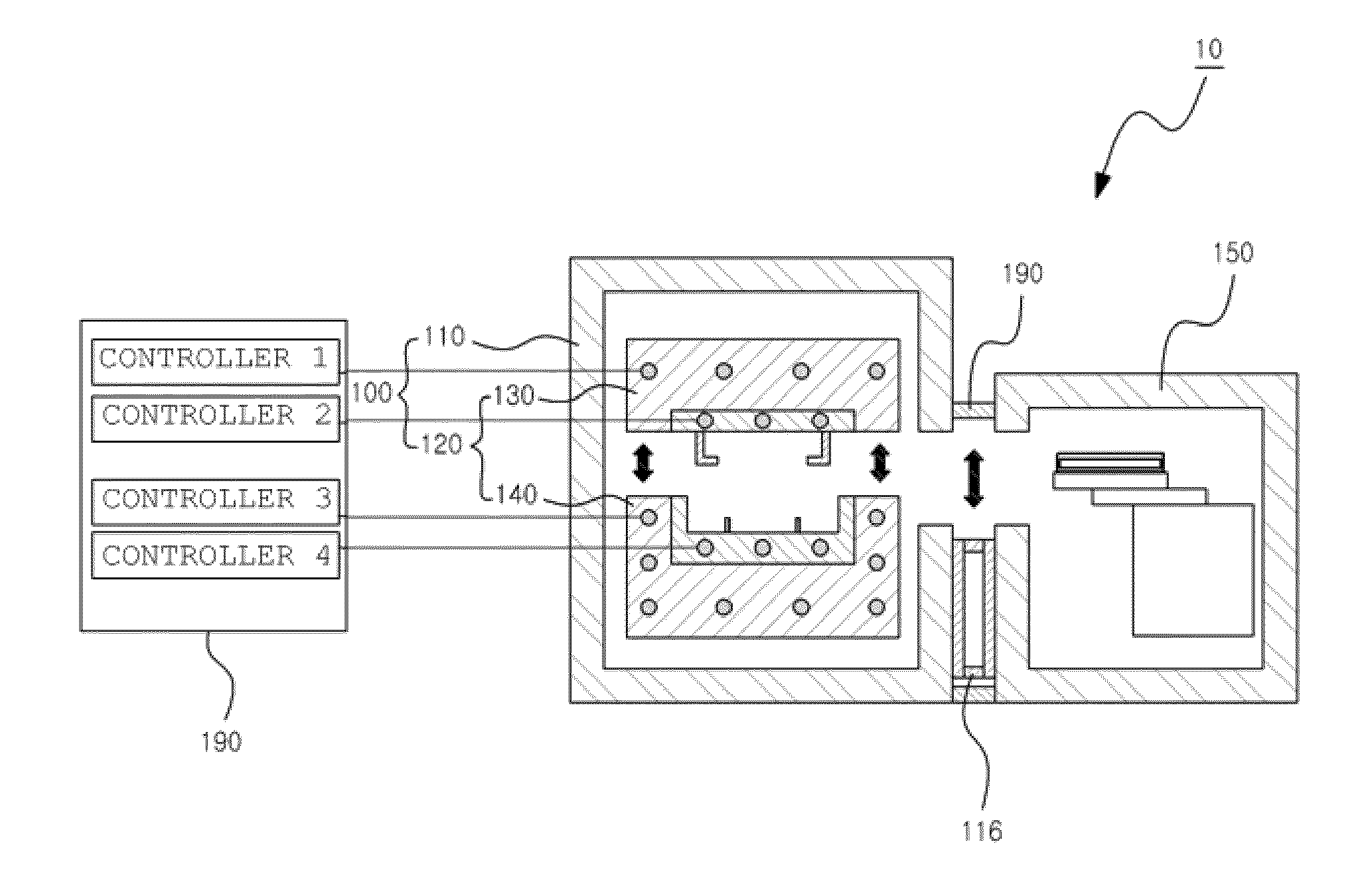

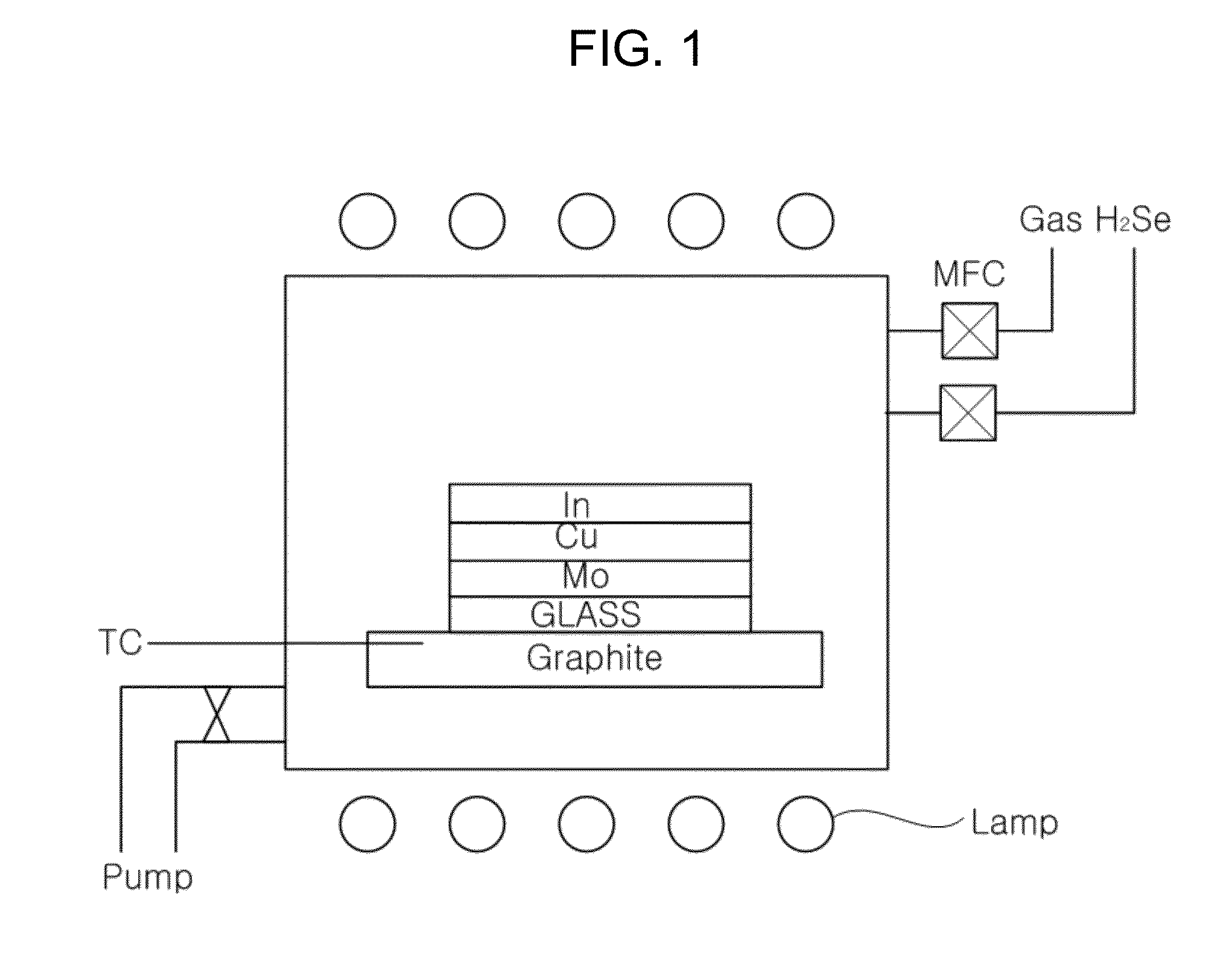

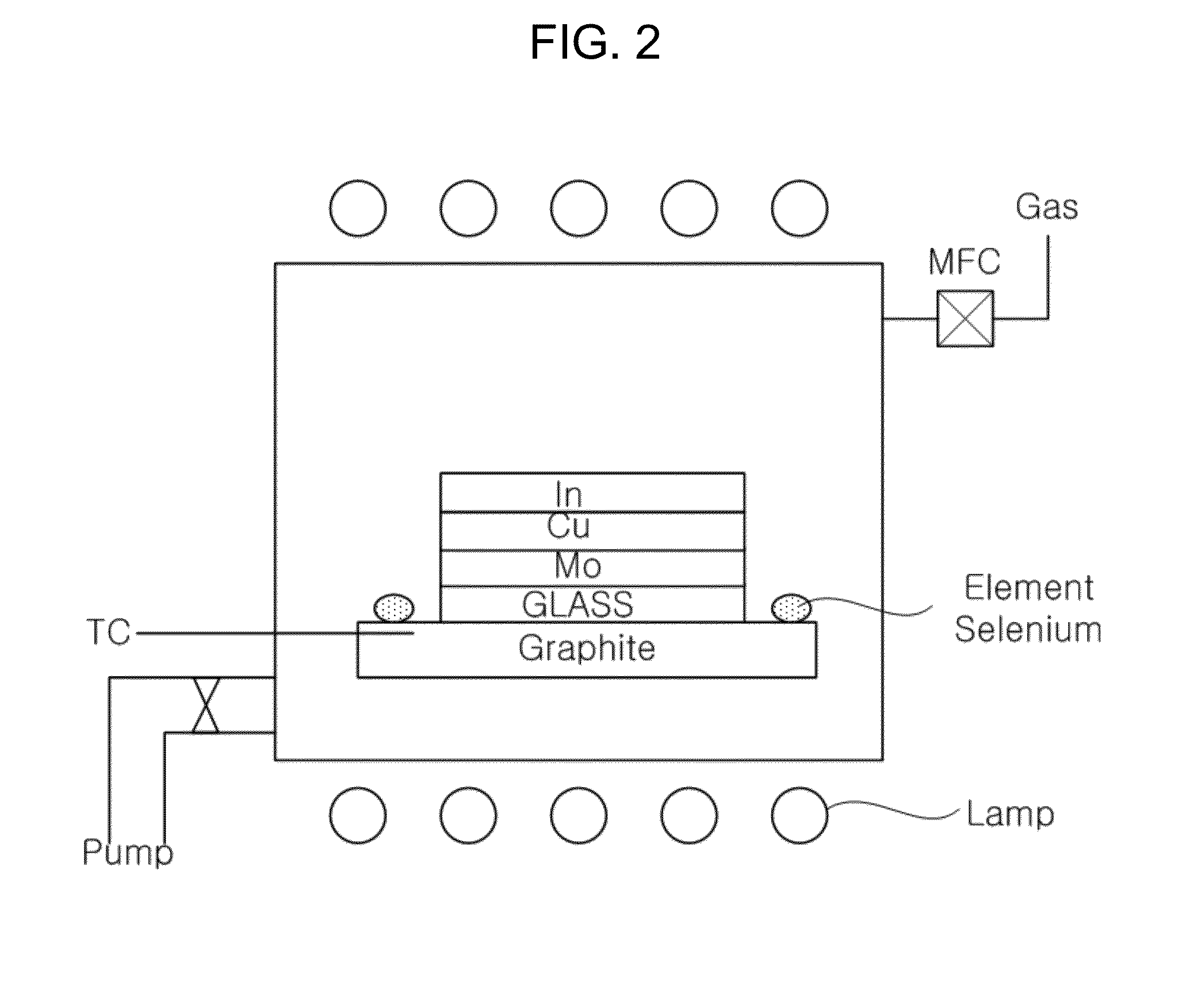

Method of manufacturing light - absorbtion layer of solar cell through selenization process under elemental selenium vapor atmosphere and thermal processing apparatus for manufacturing light - absorbing layer

InactiveUS20140073082A1Low production costImprove efficiencyFinal product manufactureSemiconductor/solid-state device manufacturingSusceptorIndium

The method of manufacturing a light absorbing layer for a solar cell by performing thermal treatment on a specimen configured to include thin films of one or more of copper, indium, and gallium on a substrate and element selenium, includes steps of: (a) heating a wall of a chamber up to a predefined thin film formation temperature in order to maintain a selenium vapor pressure; (b) mounting the specimen and the element selenium on the susceptor at the room temperature and loading the susceptor in the chamber; and (c) heating the specimen in the lower portion of the susceptor and, at the same time, heating the element selenium in the upper portion of the susceptor, wherein, in the step (c), in order for liquefied selenium not to be condensed on the specimen which is loaded at the room temperature and is not yet heated, the temperature of the element selenium and the specimen loaded in the chamber are individually controlled, so that the selenium vapor pressure of an inner space of the chamber does not exceed a saturation vapor pressure corresponding to the temperature of the specimen.

Owner:SOLARDIN INC

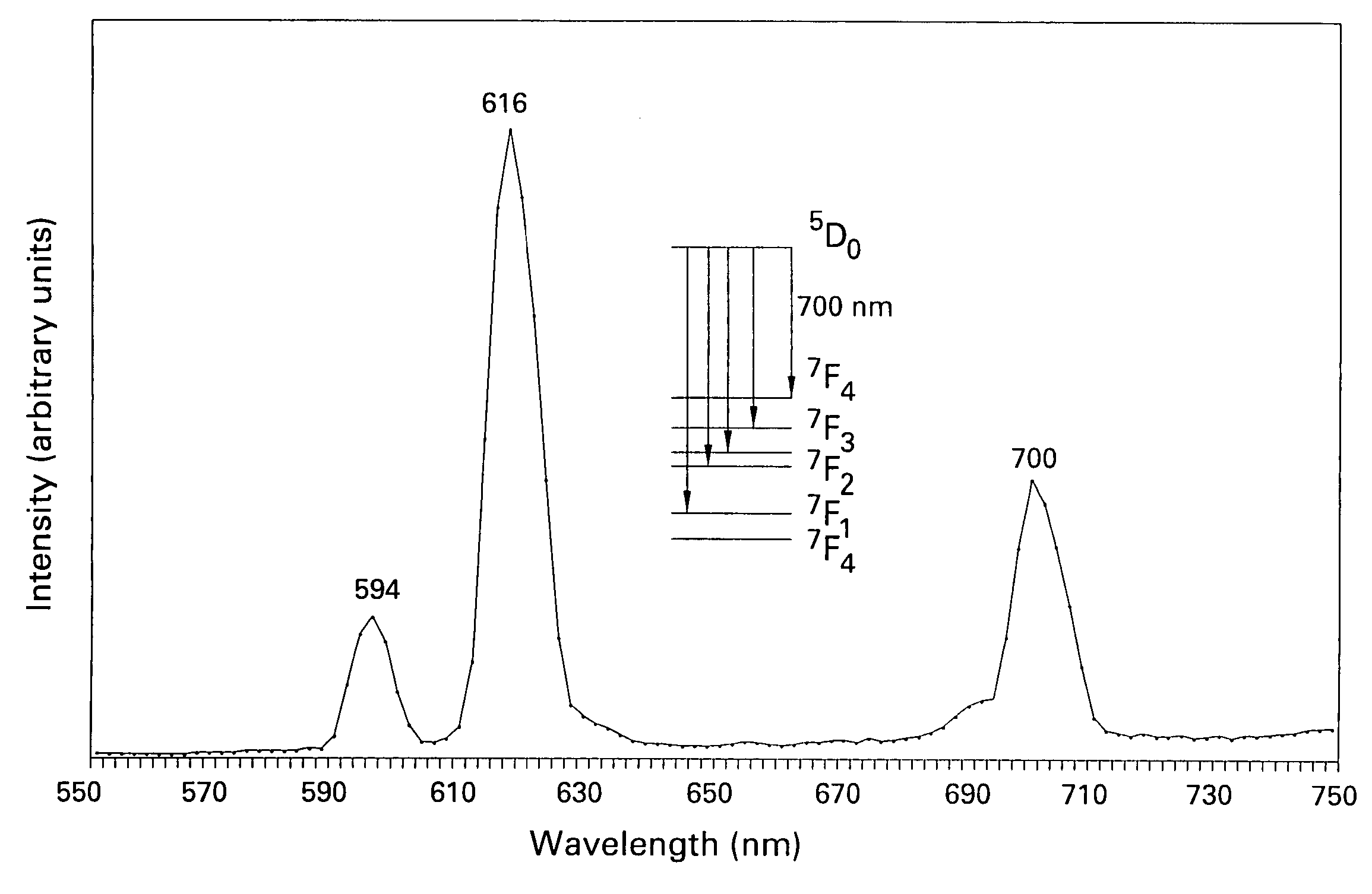

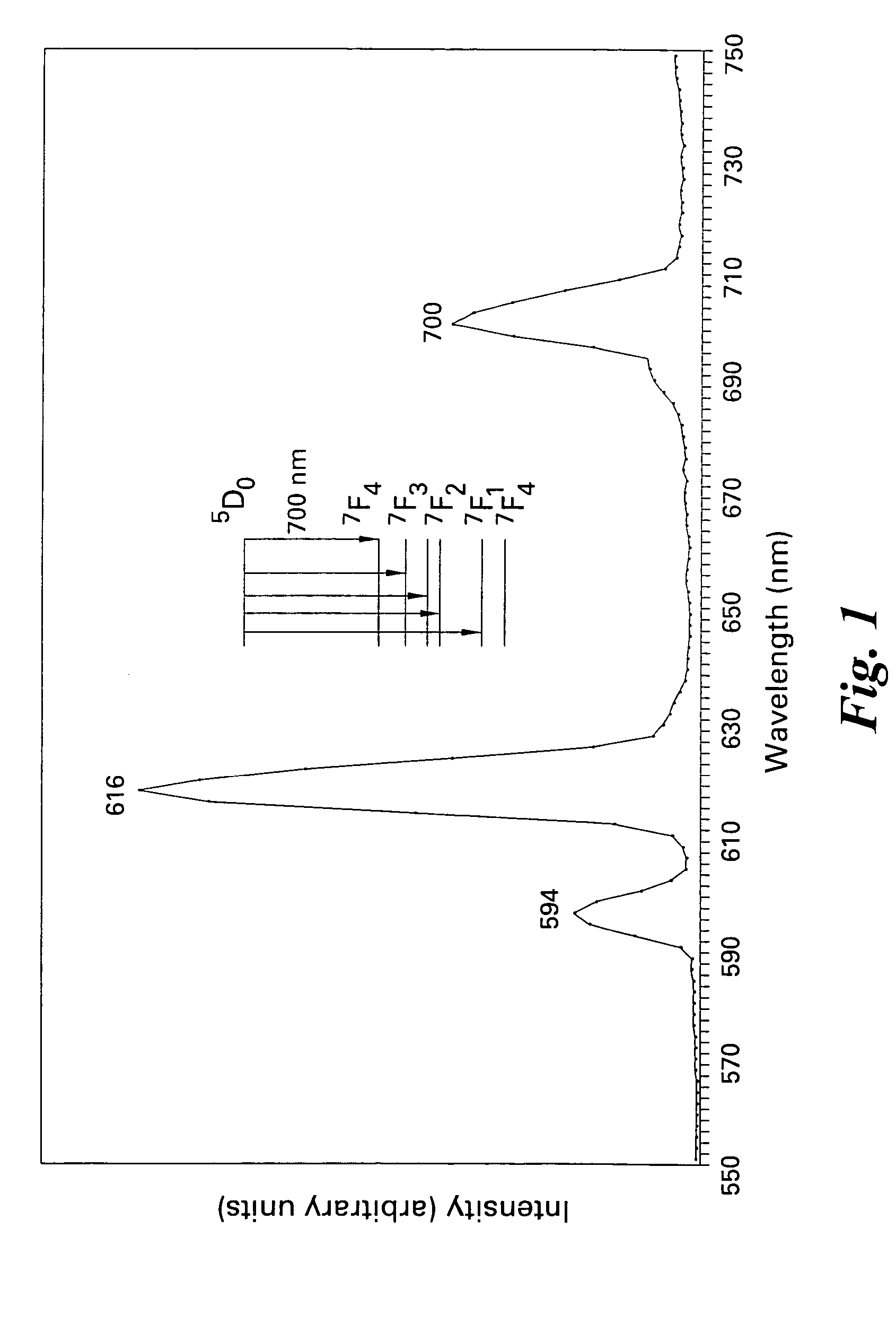

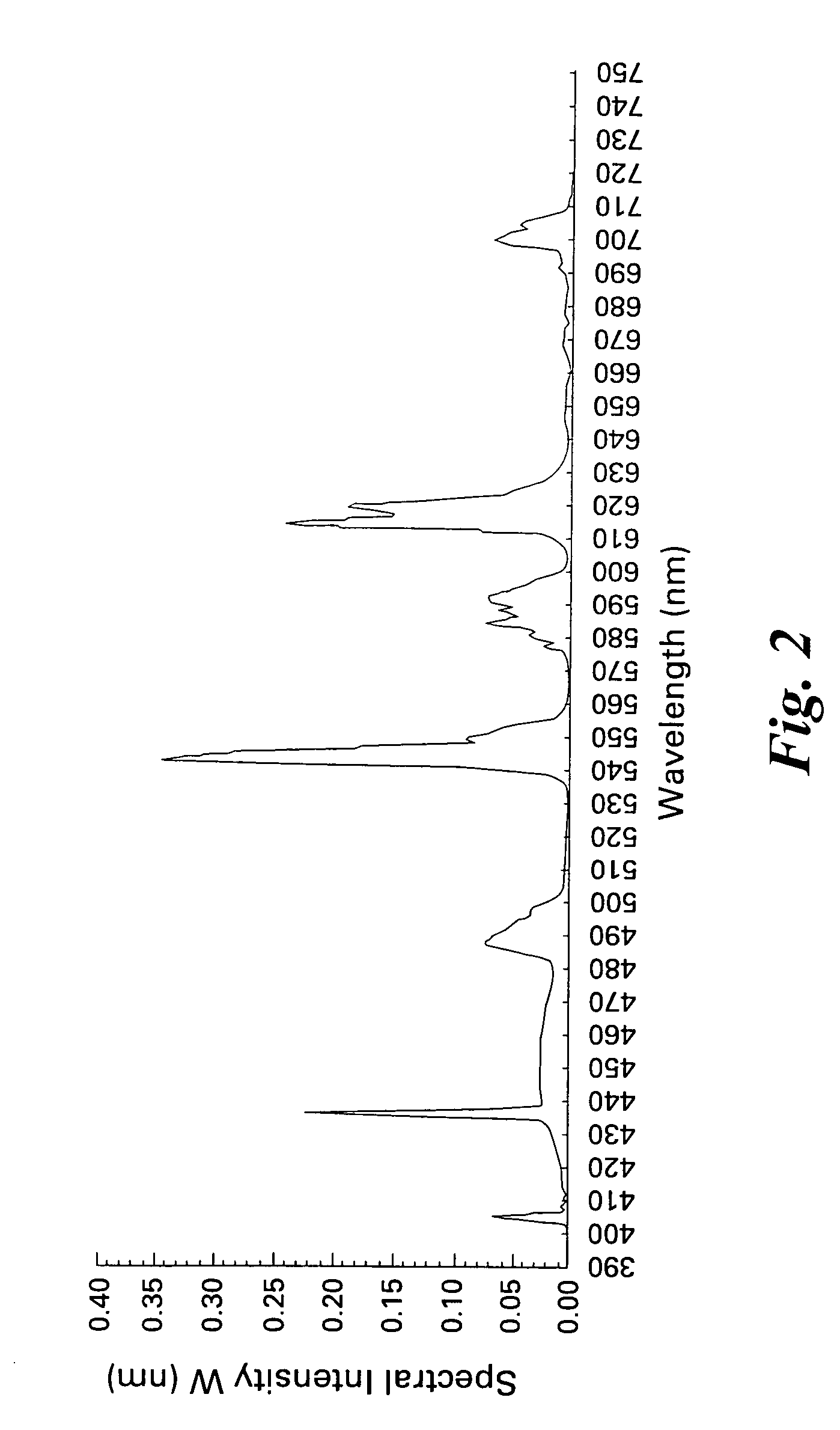

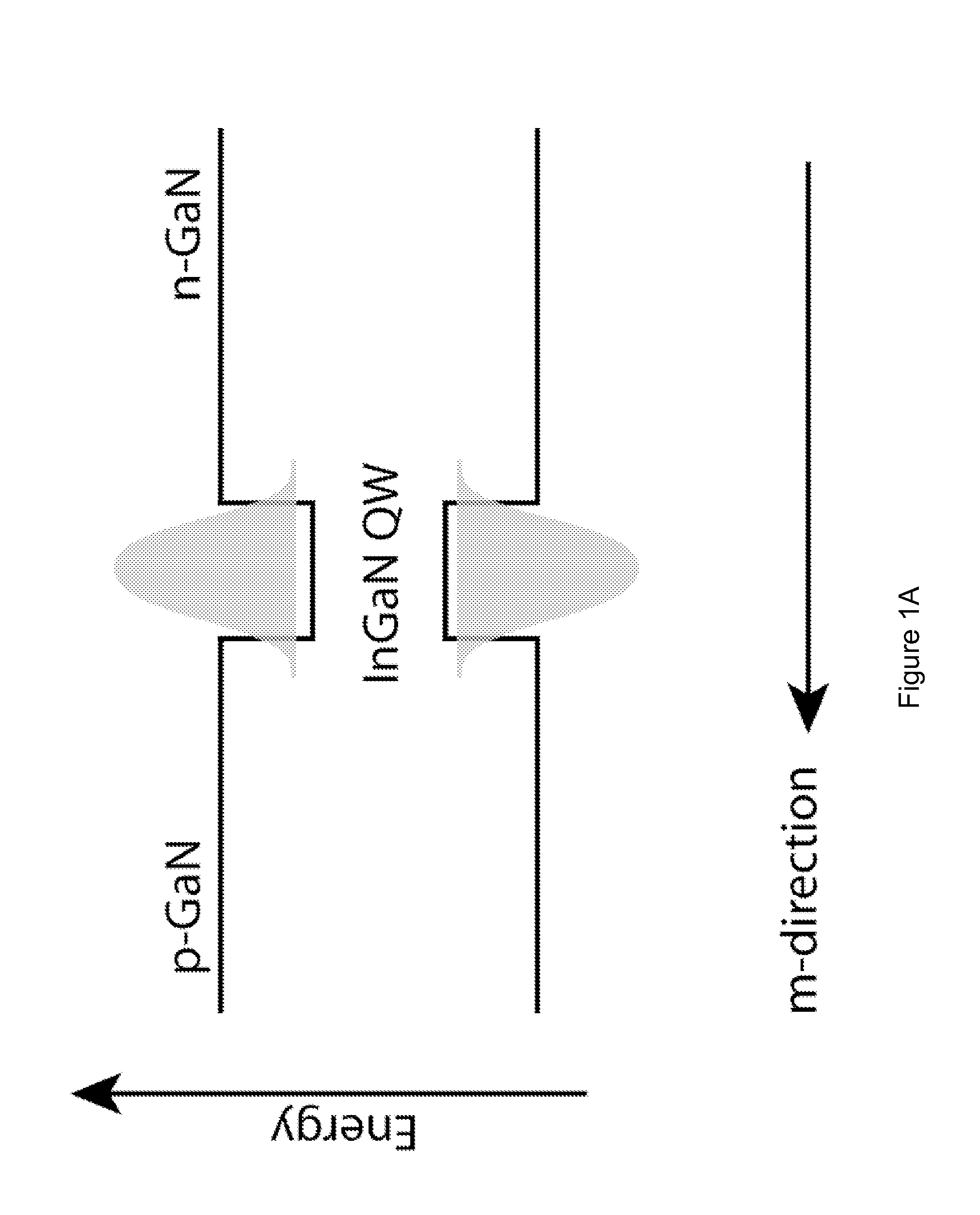

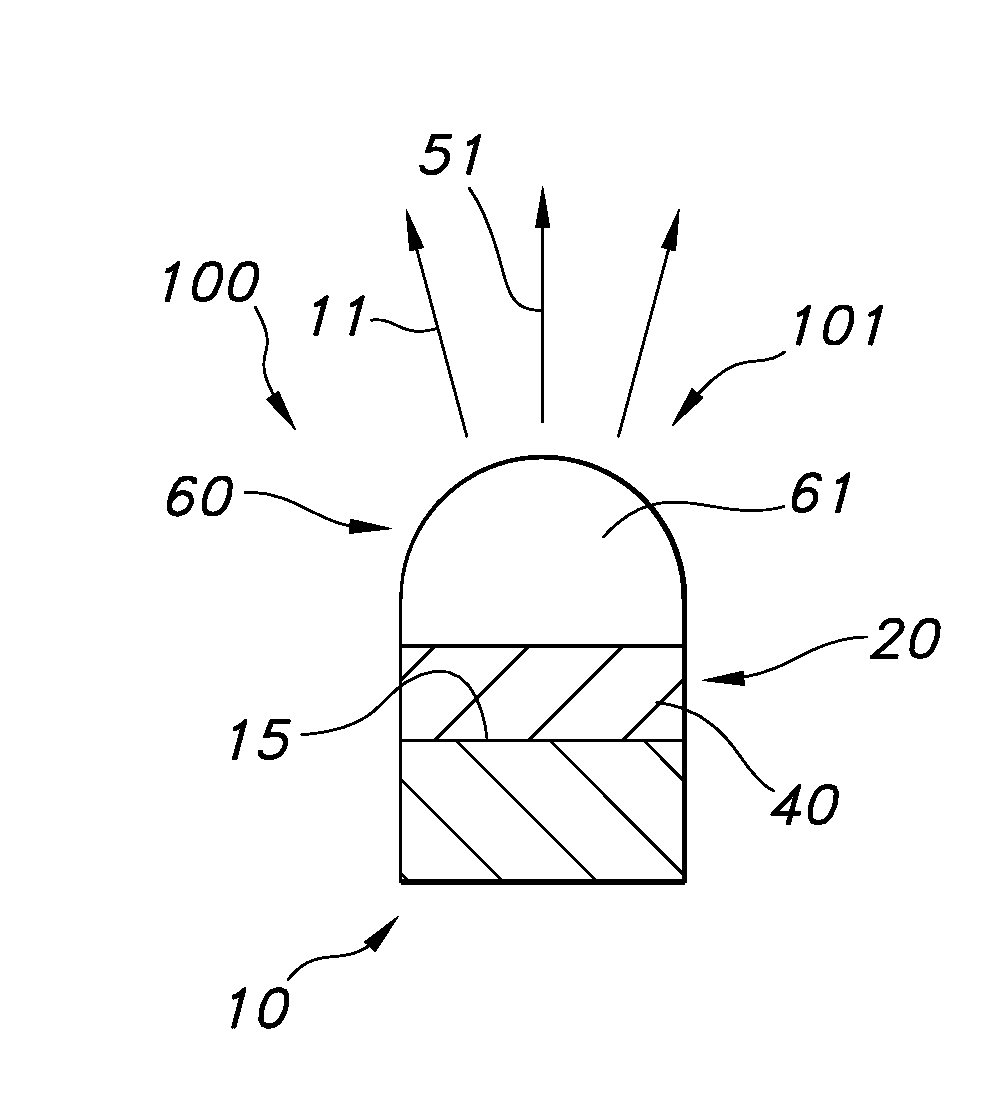

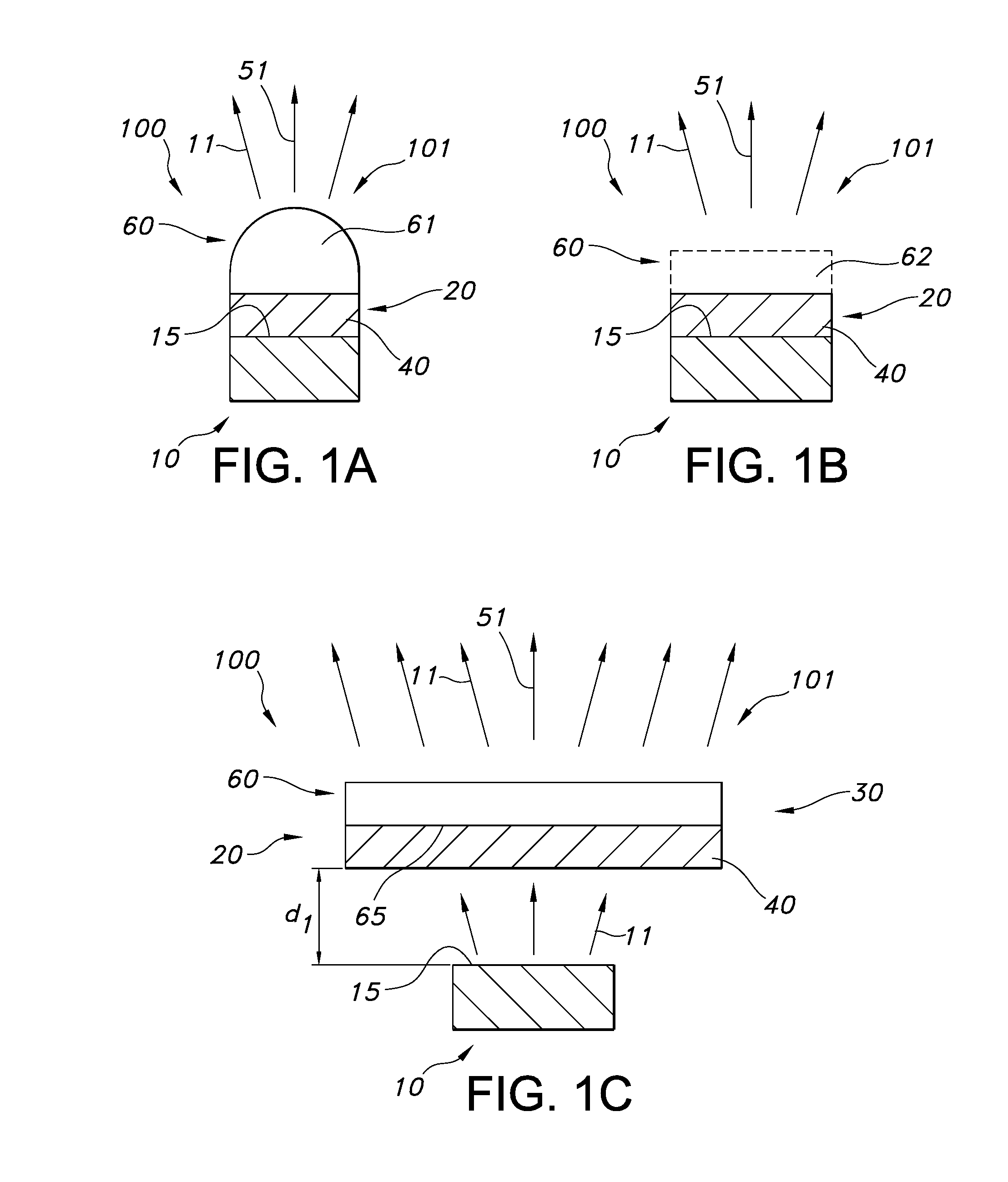

White Light Devices Using Non-polar or Semipolar Gallium Containing Materials and Phosphors

ActiveUS20120187371A1Easy to implementLighting techniqueSolid-state devicesNanotechnologyPhosphorGallium

A packaged optical device includes a substrate having a surface region with light emitting diode devices fabricated on a semipolar or nonpolar GaN substrate. The LEDs emit polarized light and are characterized by an overlapped electron wave function and a hole wave function. Phosphors within the package are excited by the polarized light and, in response, emit electromagnetic radiation of a second wavelength.

Owner:SLT TECH

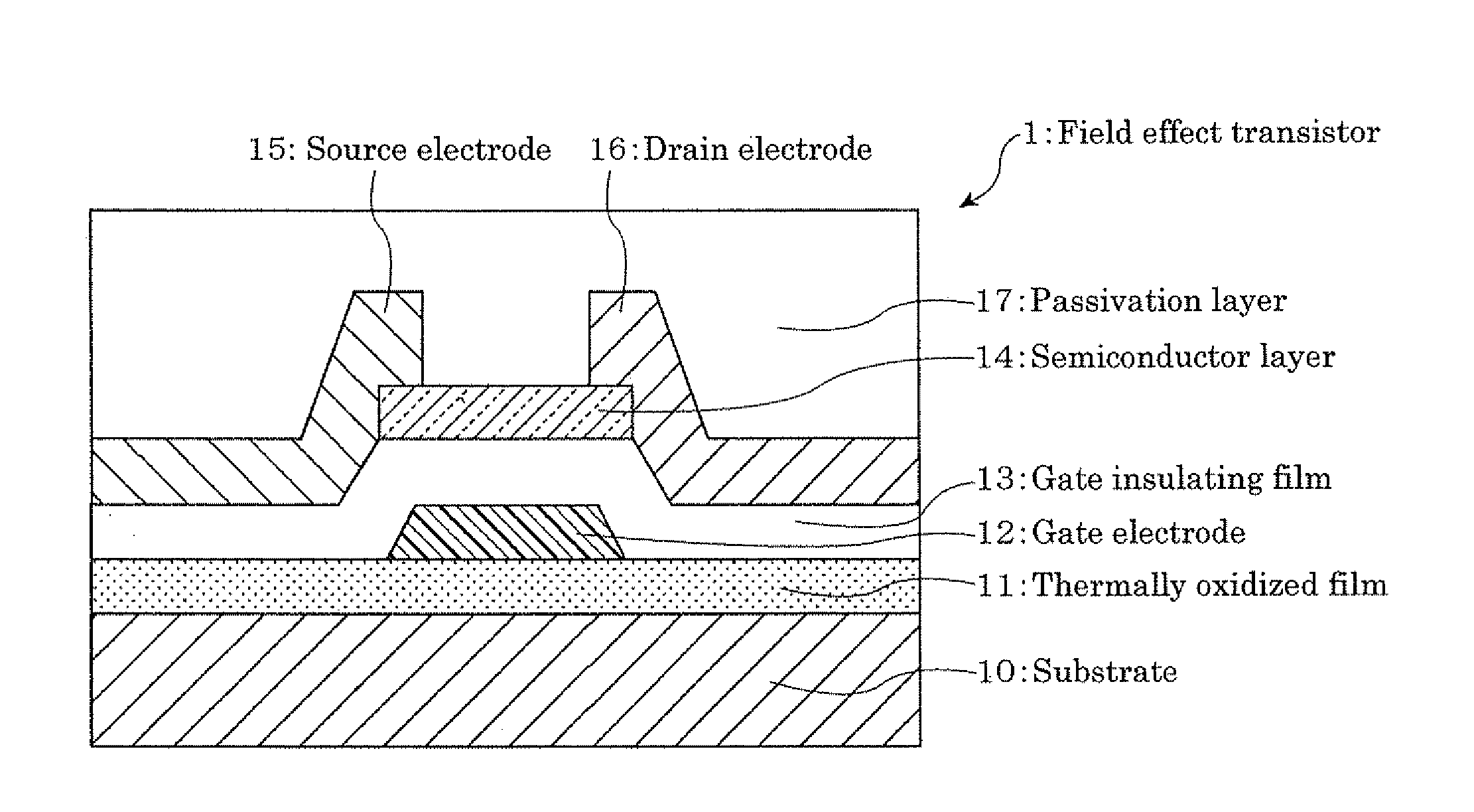

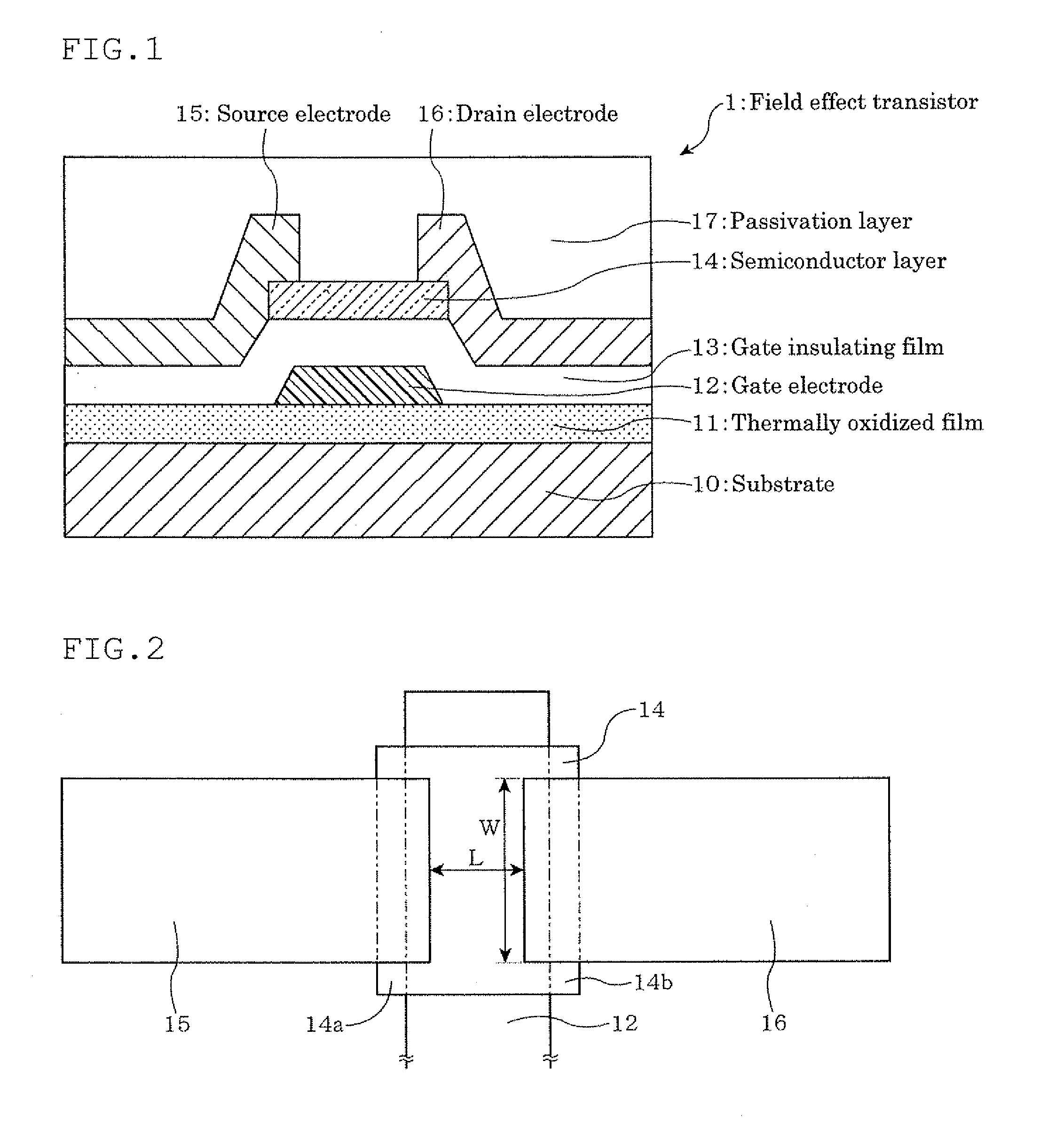

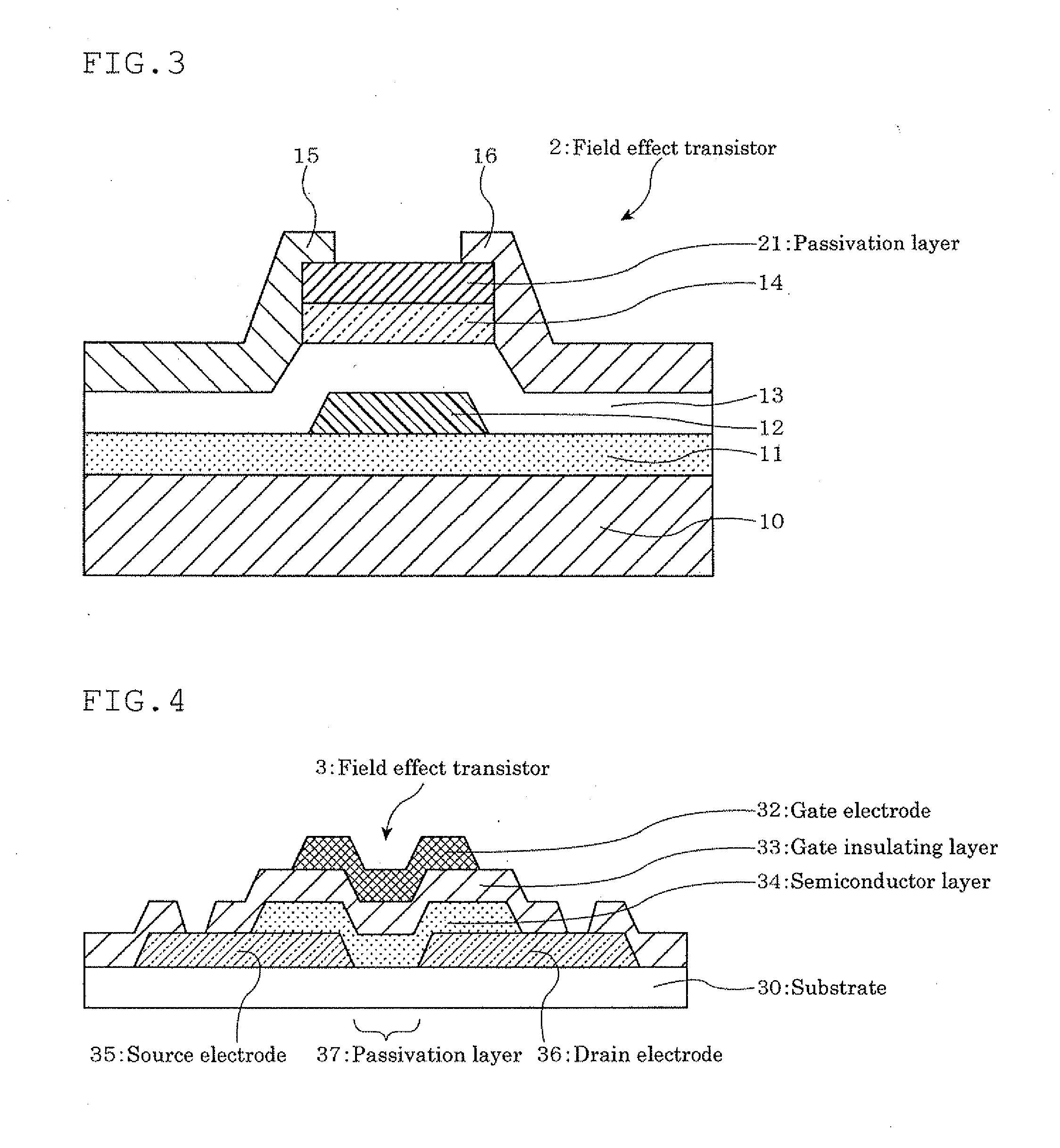

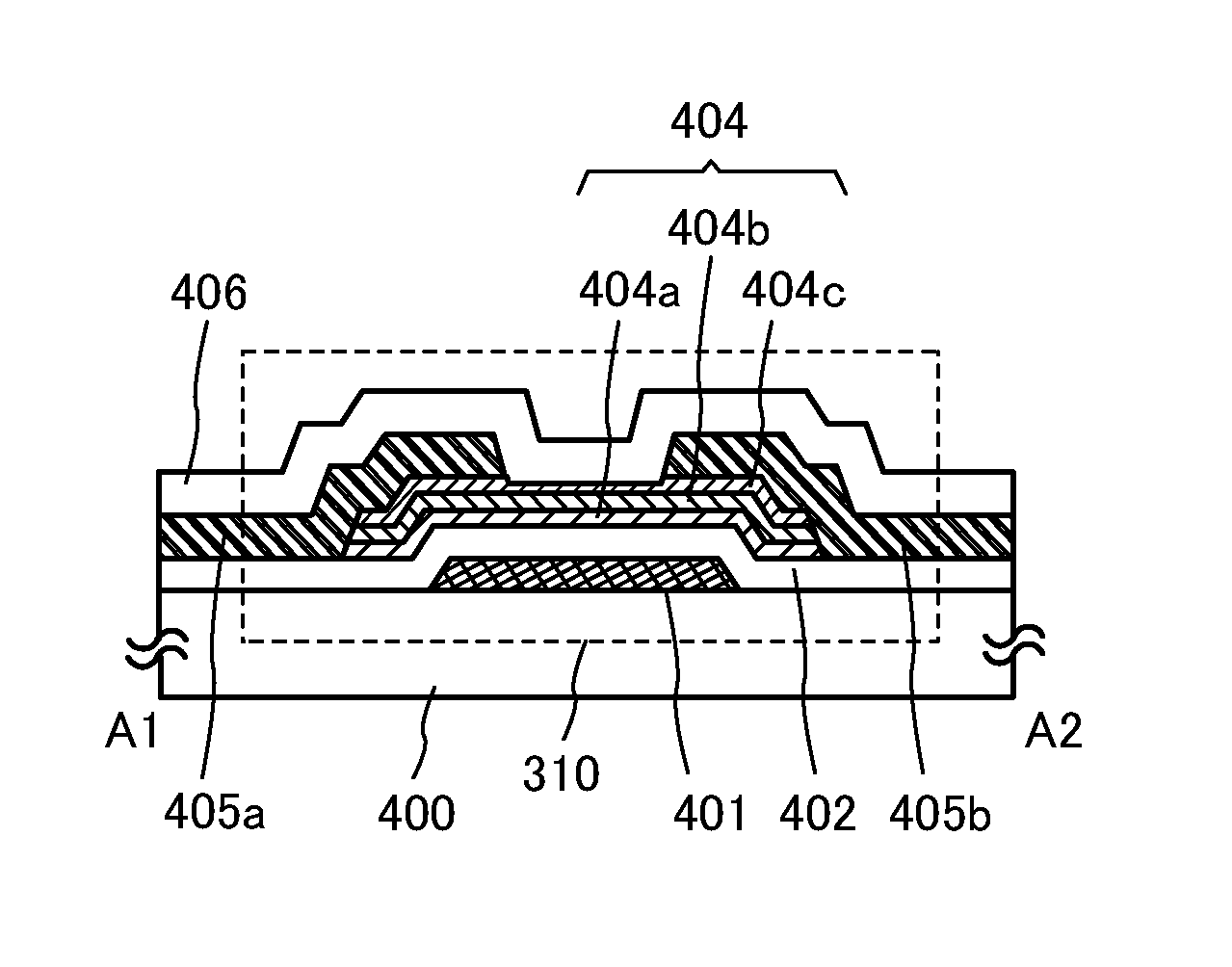

Field effect transistor using oxide semicondutor and method for manufacturing the same

ActiveUS20100289020A1Easy to produceReduce contact resistanceTransistorSemiconductor/solid-state device manufacturingIndiumField-effect transistor

A field effect transistor which includes, on a substrate, at least a semiconductor layer, a passivation layer for the semiconductor layer, a source electrode, a drain electrode, a gate insulating film and a gate electrode, the source electrode and the drain electrode being connected through the semiconductor layer, the gate insulating film being present between the gate electrode and the semiconductor layer, the passivation layer being at least on one surface side of the semiconductor layer, and the semiconductor layer including a composite oxide which comprises In (indium), Zn (zinc) and Ga (gallium) in the following atomic ratios (1) to (3):In / (In+Zn)=0.2 to 0.8 (1)In / (In+Ga)=0.59 to 0.99 (2)Zn / (Ga+Zn)=0.29 to 0.99 (3).

Owner:IDEMITSU KOSAN CO LTD

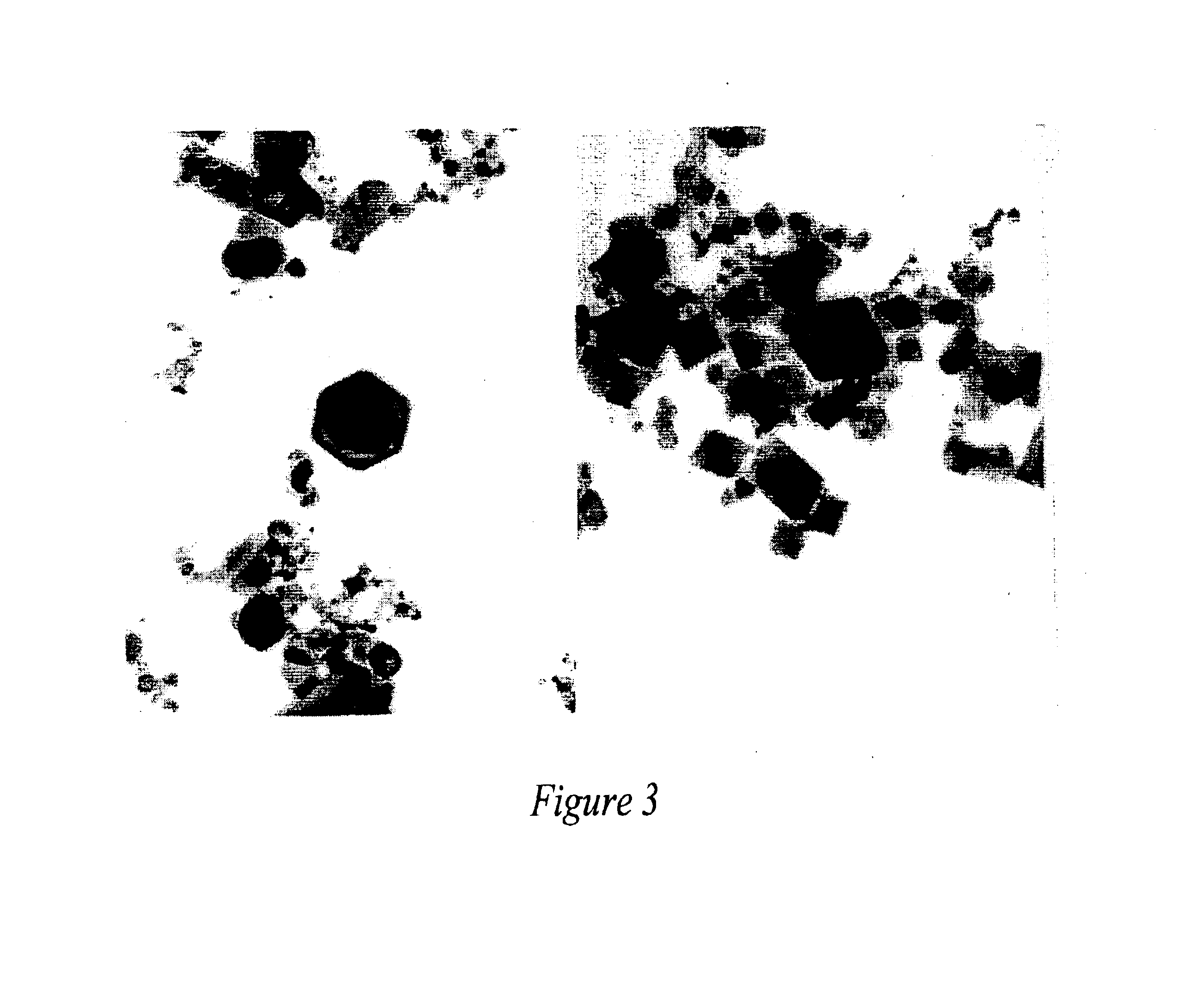

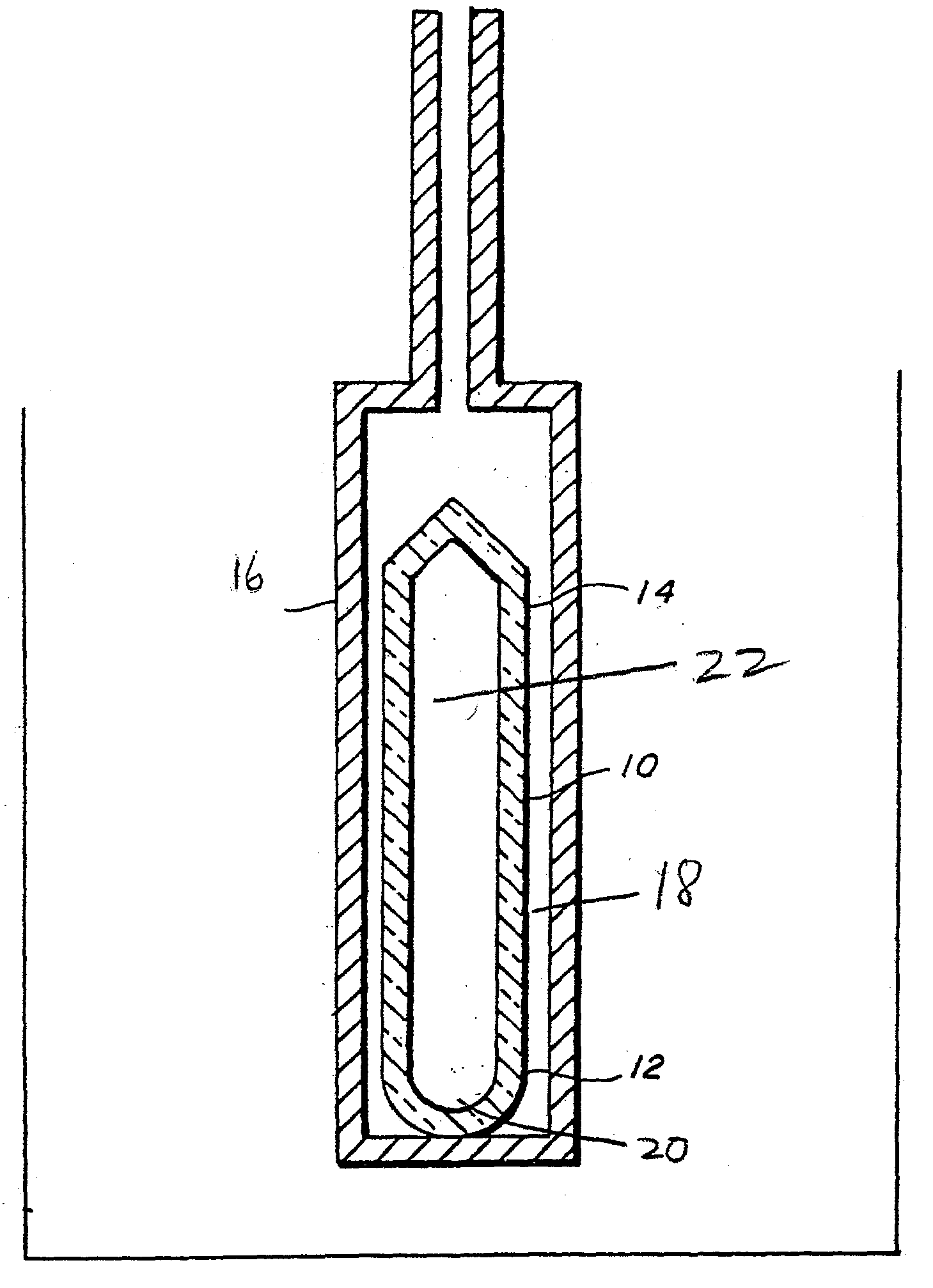

Inorganic dopants, inks and related nanotechnology

InactiveUS6849109B2Facilitated DiffusionLower transition temperatureSelenium/tellurium compundsCell electrodesIndiumCerium

Ink compositions with modified properties result from using a powder size below 100 nanometers. Colored inks are illustrated. Nanoscale coated, uncoated, whisker inorganic fillers are included. The pigment nanopowders taught comprise one or more elements from the group actinium, aluminum, antimony, arsenic, barium, beryllium, bismuth, cadmuim, calcium, cerium, cesium, chalcogenide, cobalt, copper, dysprosium, erbium, europium, gadolinium, gallium, gold, hafnium, hydrogen, indium, iridium, iron, lanthanum, lithium, magnesium, manganese, mendelevium, mercury, molybdenum, neodymium, neptunium, nickel, niobium, nitrogen, oxygen, osmium, palladium, platinum, potassium, praseodymium, promethium, protactinium, rhenium, rubidium, scandium, silver, sodium, strontium, tantalum, terbium, thallium, thorium, tin, titanium, tungsten, vanadium, ytterbium, yttrium, zinc, and zirconium.

Owner:PPG IND OHIO INC

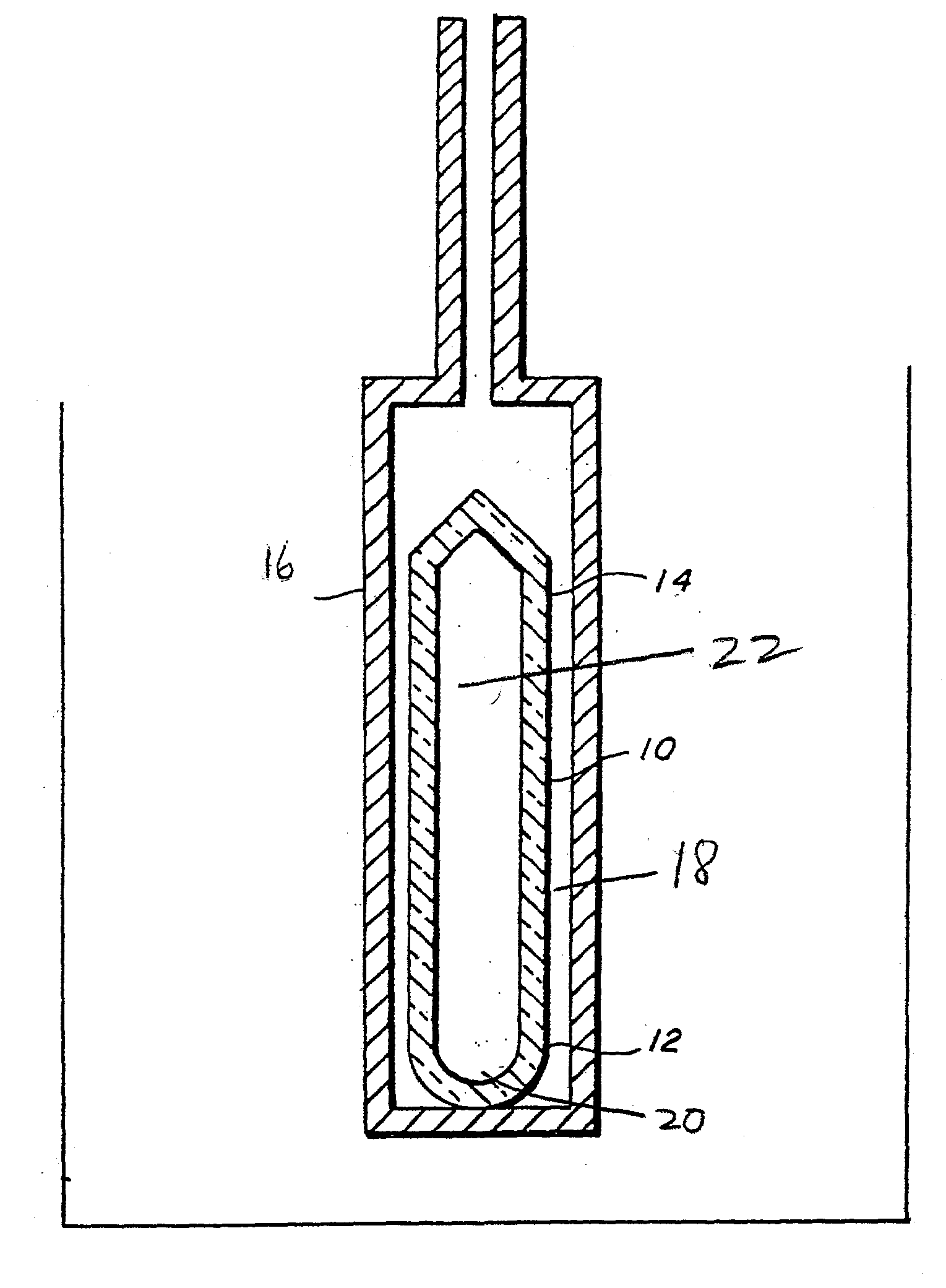

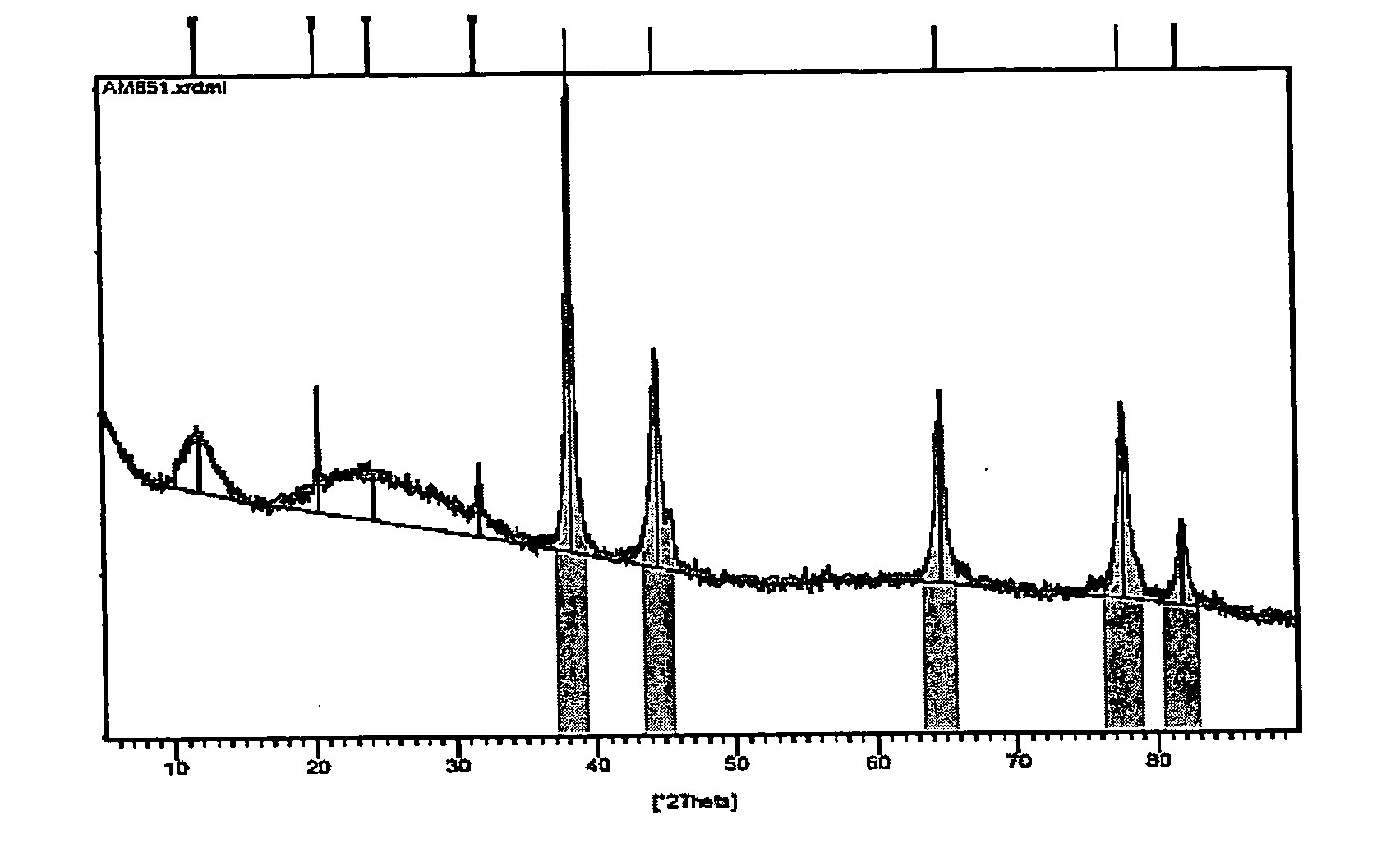

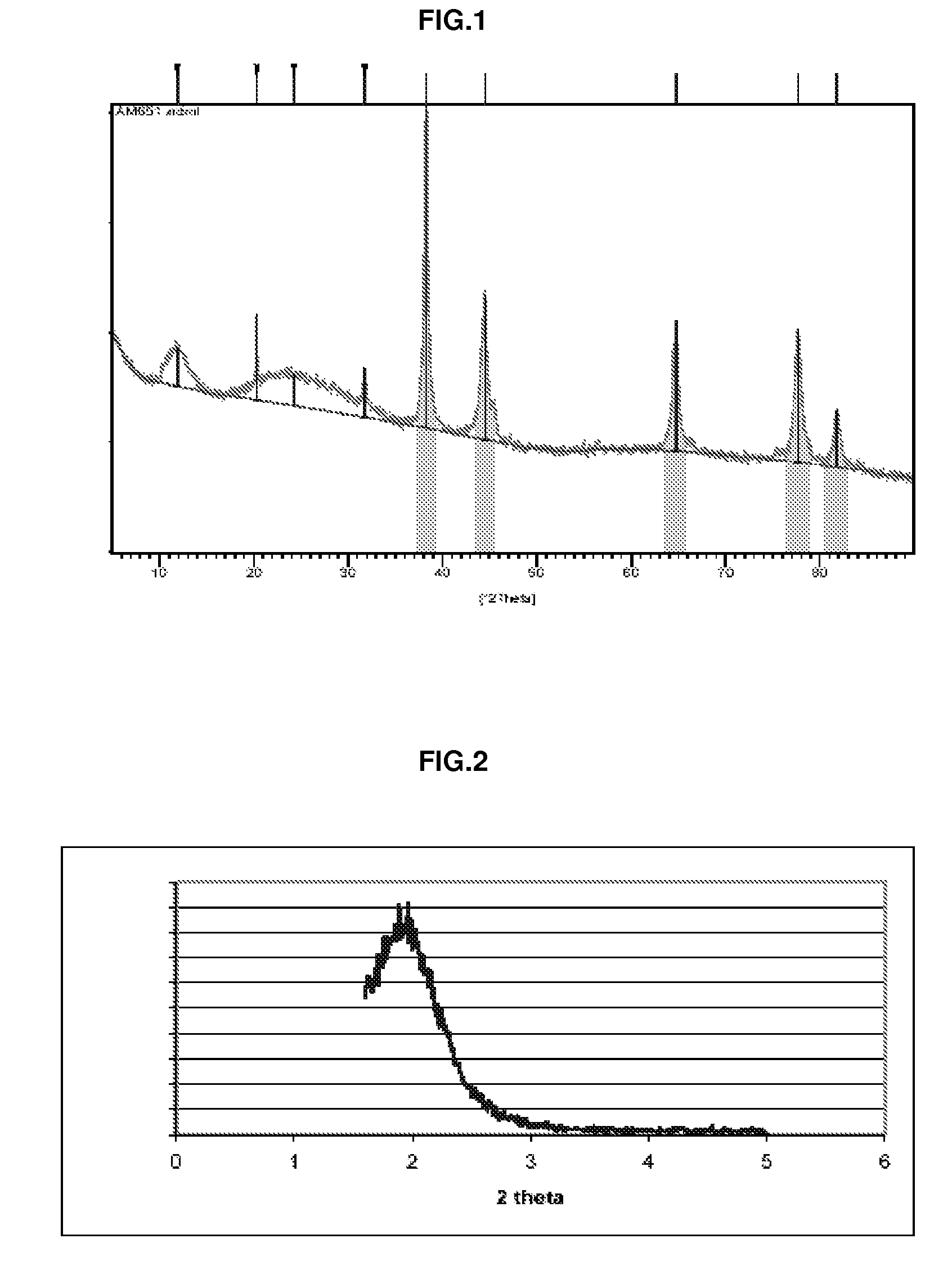

Ammonothermal process for bulk synthesis and growth of cubic GaN

InactiveUS20030209191A1Easy to transportQuality improvementPolycrystalline material growthFrom chemically reactive gasesLanthanideSingle crystal

A method of growing single-crystals of a cubic (zinc blende) form of gallium nitride, the method comprising the steps of: placing into a reaction tube or acid resistant vessel a gallium source, anhydrous ammonia, an acid mineralizer and a metal halide salt selected from the group consisting of alkali metal halides, copper halides, tin halides, lanthanide halides and combinations thereof; closing said reaction tube or vessel; heating said reaction tube; cooling said reaction tube or vessel; and collecting single-crystals of cubic (zinc blende) form of GaN; wherein said reaction tube or vessel has a temperature gradient with a hot zone of at least 250° C., wherein said reaction tube or vessel has a temperature gradient with a cool zone of at least 150° C., and wherein said acid mineralizer has a sufficient concentration to permit chemical transport of GaN in said reaction tube or vessel from said hot zone to said cool zone due to said temperature gradient within said reaction tube or vessel.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

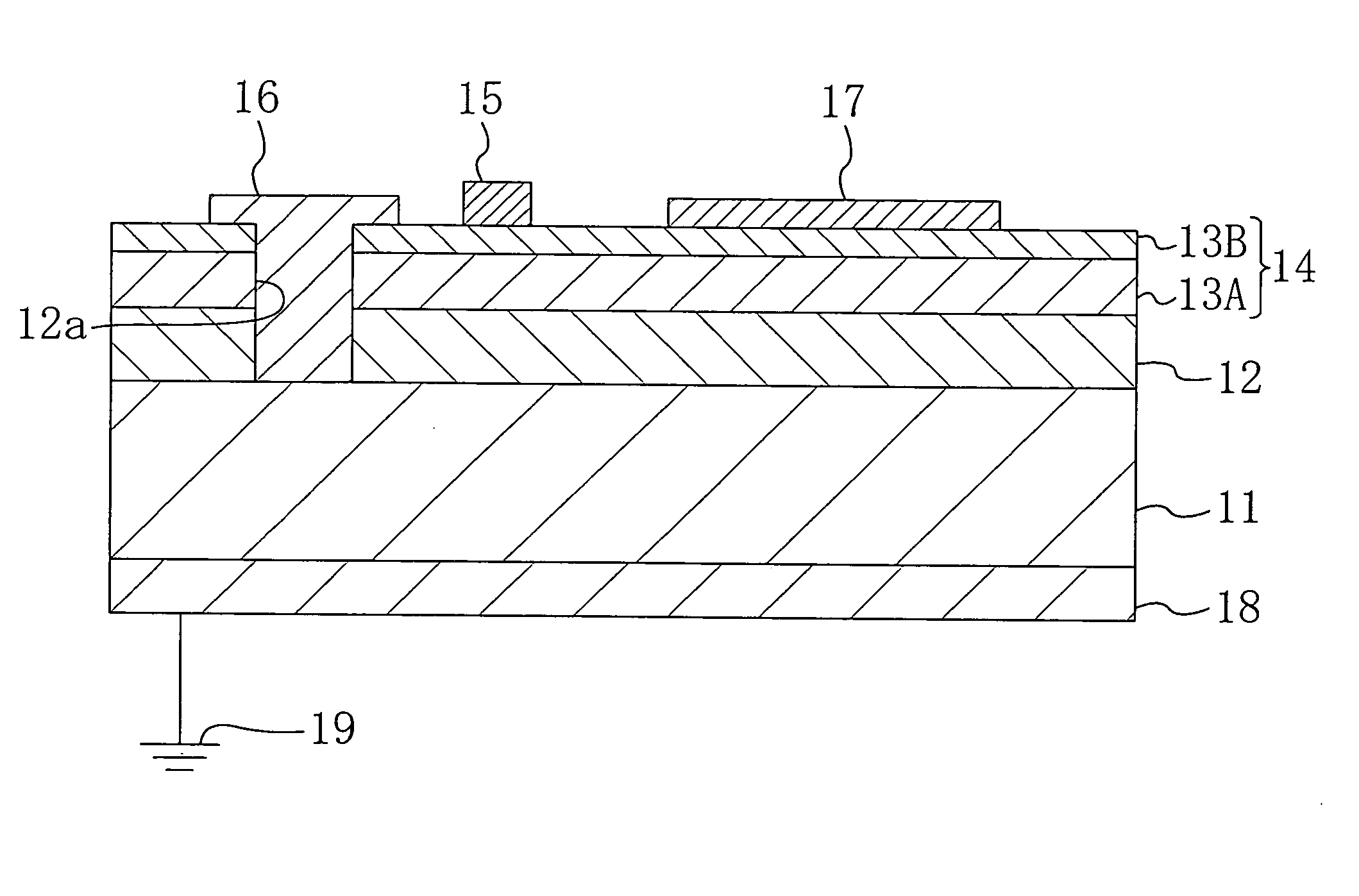

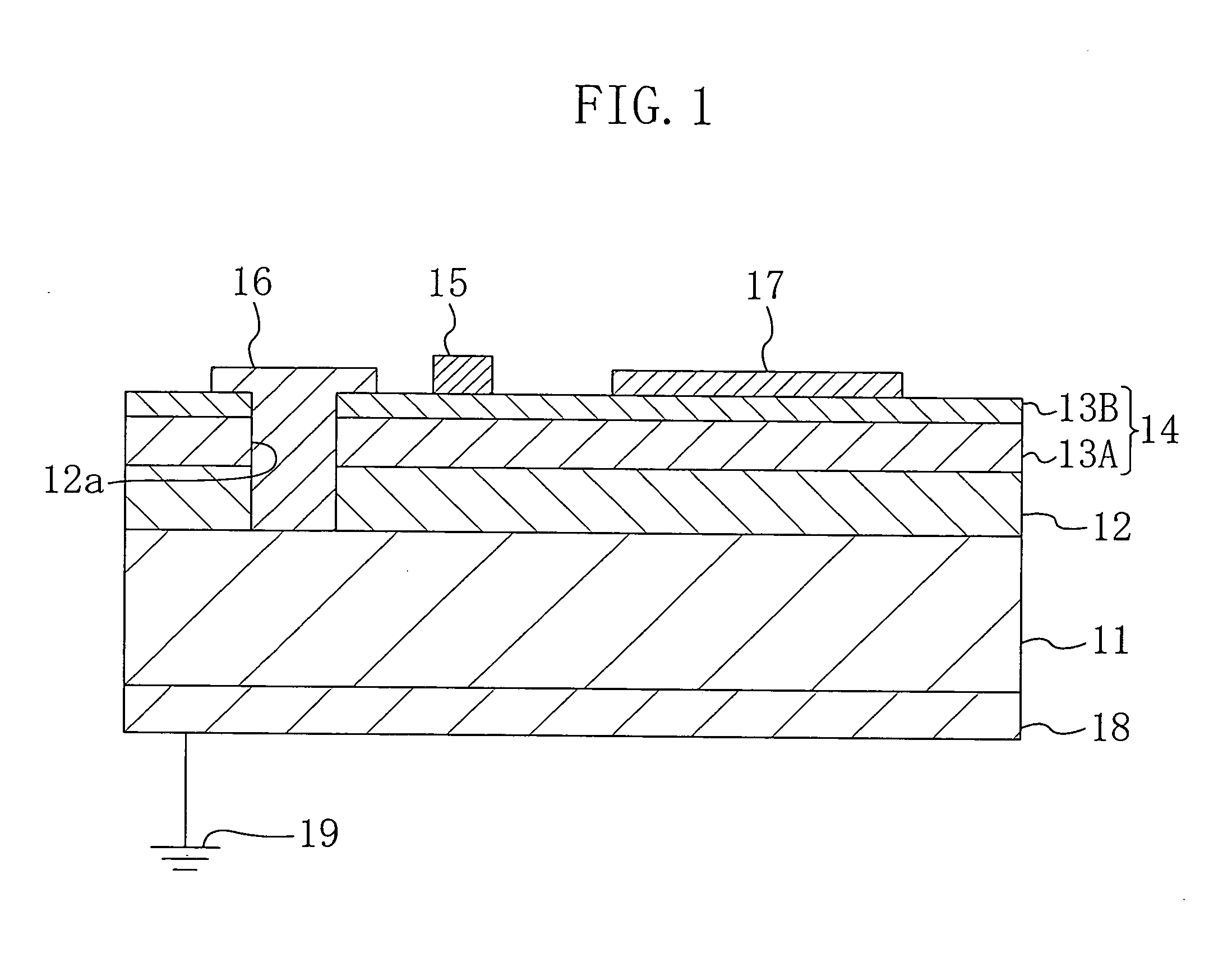

Semiconductor device

ActiveUS20050001235A1Promote formationObstruction is producedLaser active region structureSemiconductor/solid-state device manufacturingHigh resistanceDevice material

A semiconductor device has: a buffer layer formed on a conductive substrate and made of AlxGa1-xN with a high resistance; an element-forming layer formed on the buffer layer, having a channel layer, and made of undoped GaN and N-type AlyGa1-yN; and a source electrode, a drain electrode and a gate electrode which are selectively formed on the element-forming layer. The source electrode is filled in a through hole provided in the buffer layer and the element-forming layer, and is thus electrically connected to the conductive substrate.

Owner:PANASONIC CORP

High performance lithium ion battery anode material lithium manganate and preparation method thereof

The invention provides a high performance lithium ion battery anode material lithium manganate and a preparation method of the material. The lithium manganate is a doped lithium manganate LiMn2-yXy04 which is doped with one kind or a plurality of other metal elements X, wherein X element is at least one kind selected form the group of aluminium, lithium, fluorine, silver, copper, chromium, zinc, titanium, bismuth, germanium, gallium, zirconium, stannum, silicon, cobalt, nickel, vanadium, magnesium, calcium, strontium, barium and rare earth elements lanthanum, cerium, praseodymium, neodymium, promethium, samarium, europium, gadolinium, terbium, dysprosium, holmium, erbium, thulium, ytterbium and lutetium, and y is larger than 0 but less than or equal to 0.11. The lithium ion battery anode material lithium manganate provided in the invention has extraordinary charge and discharge cycle performance both in the environments of normal temperature and high temperature. According to the invention, the preparation method of the material is a solid phase method, the operation is simple and controllable and the cost is low so that it is easy to realize large-scale productions.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

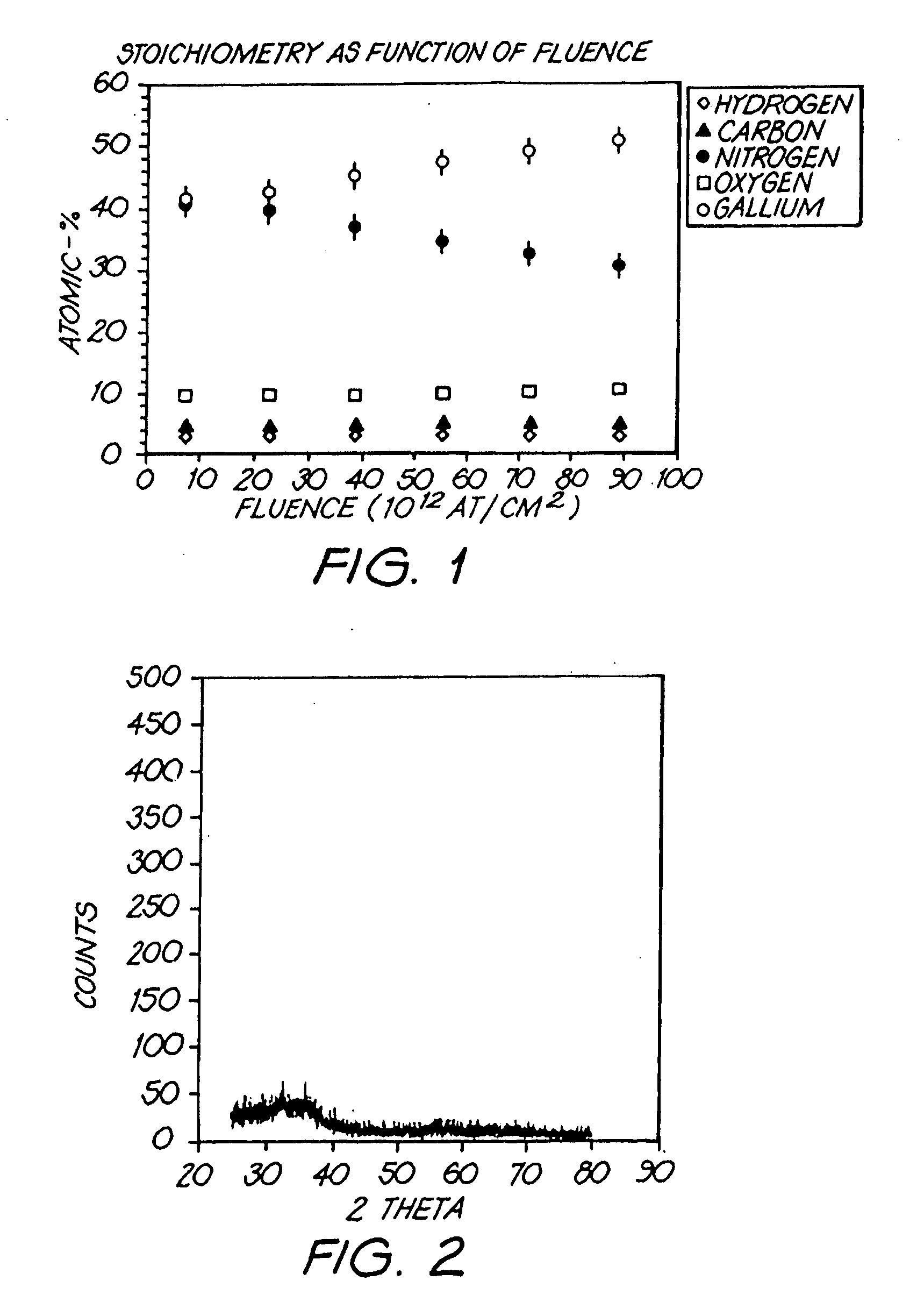

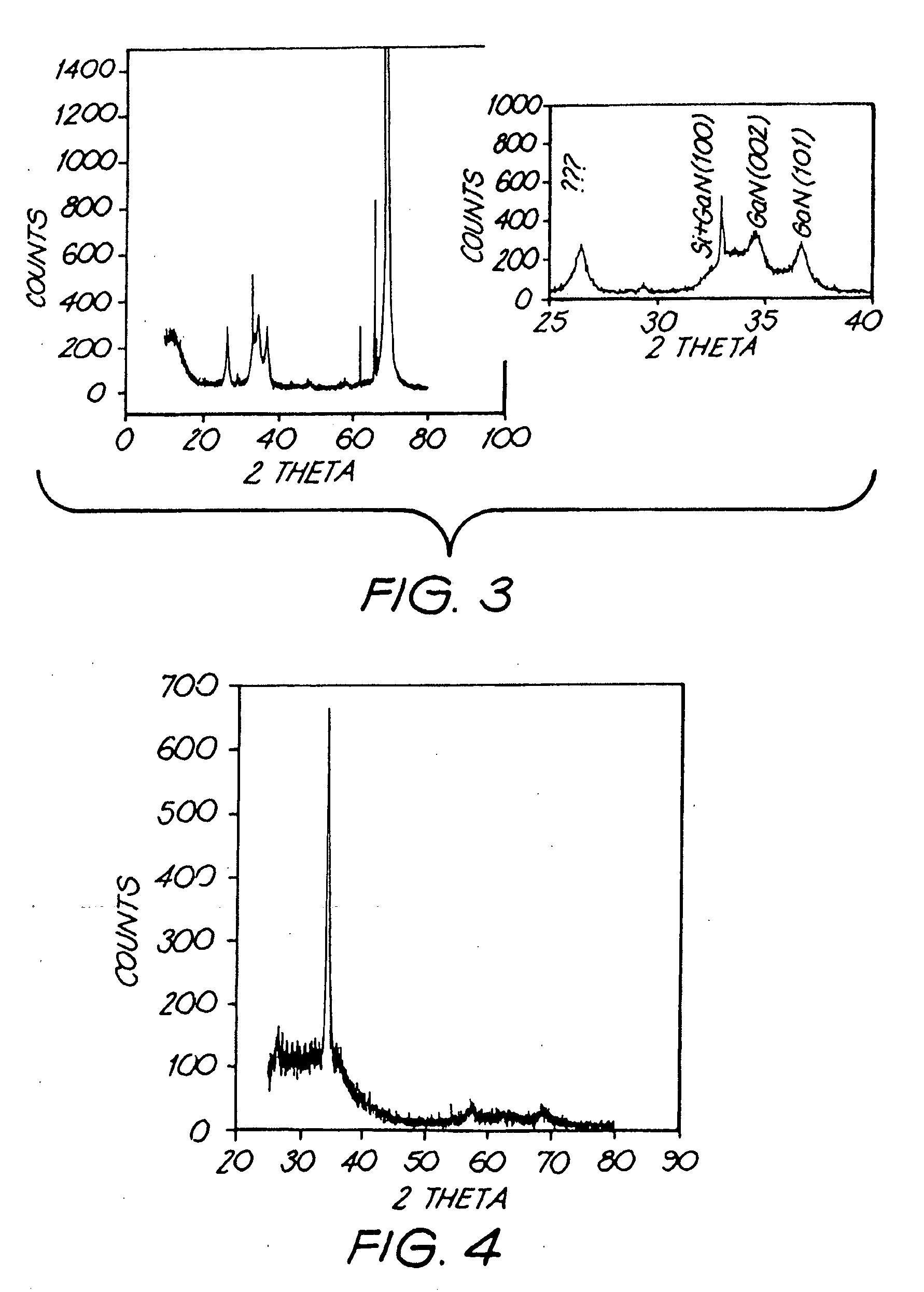

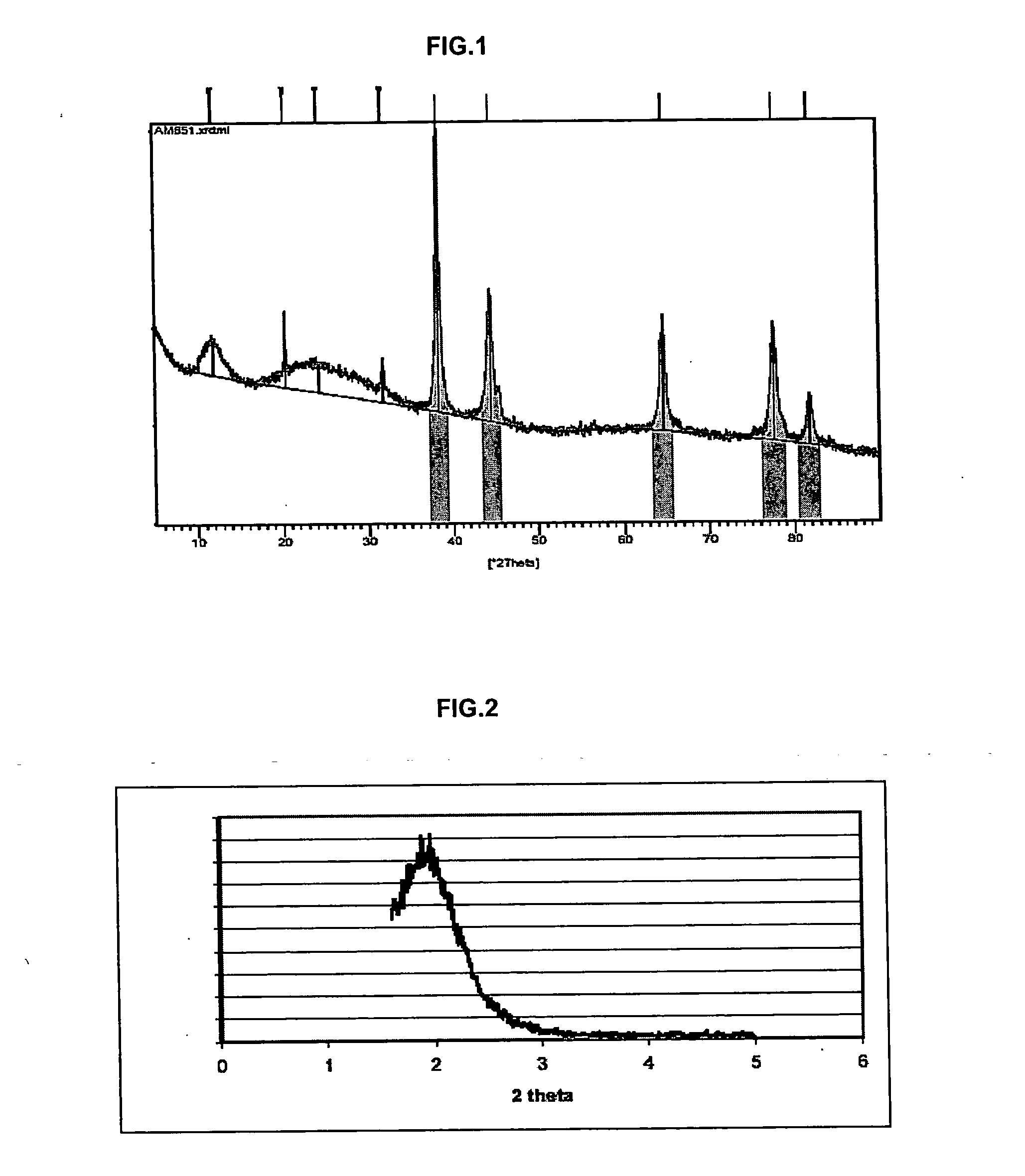

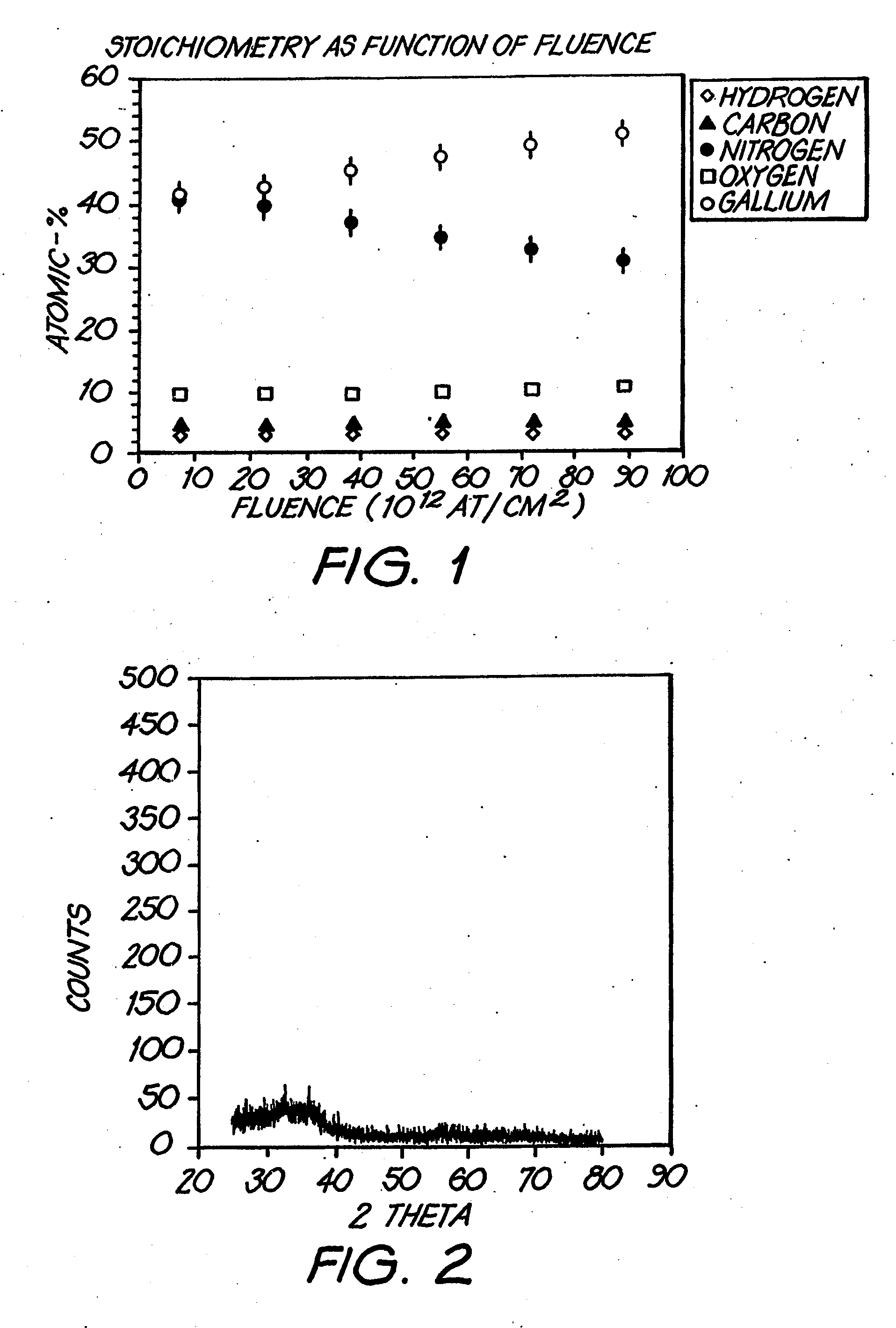

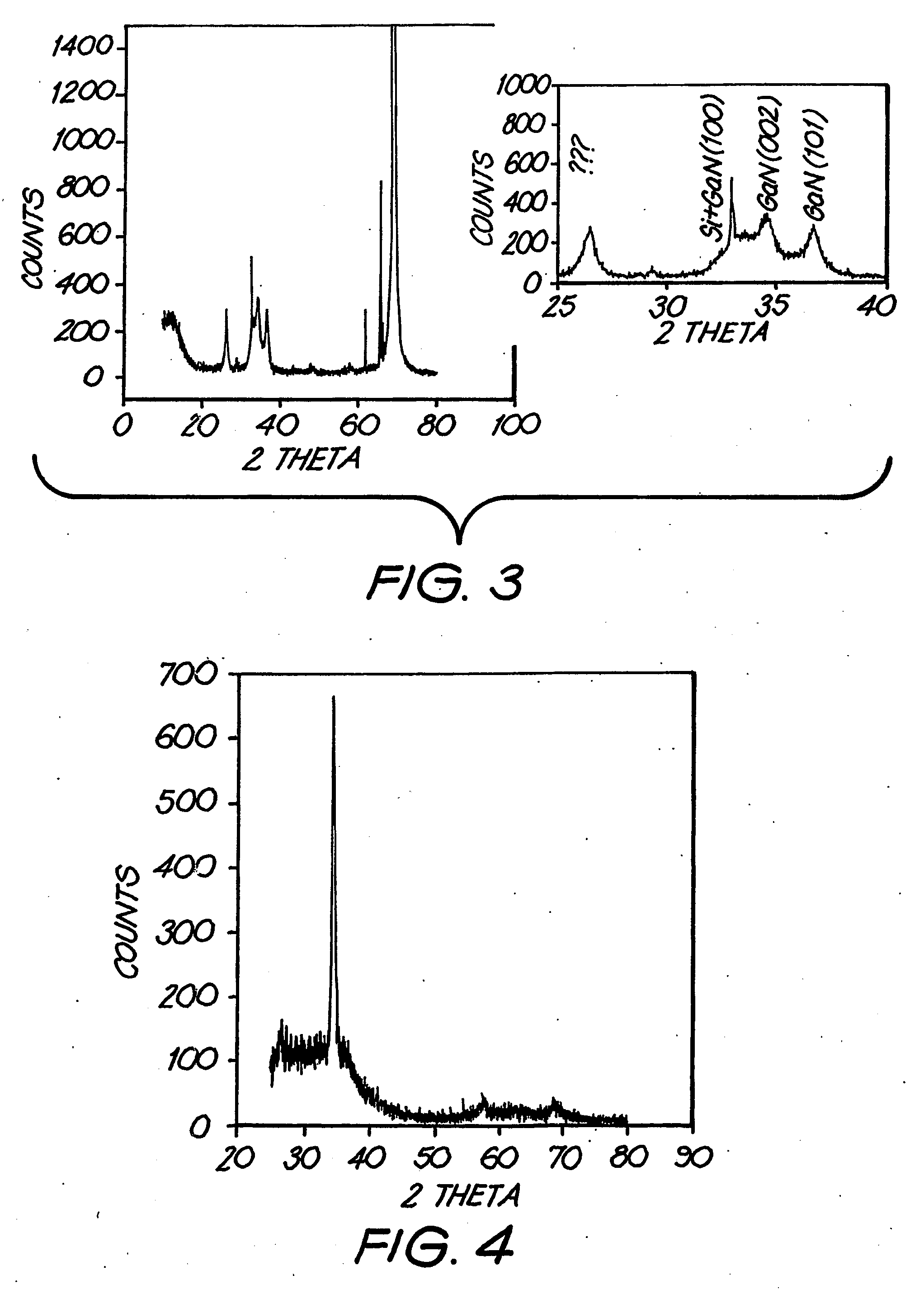

Process For Manufacturing A Gallium Rich Gallium Nitride Film

InactiveUS20080282978A1Improve conductivityLow resistivityPolycrystalline material growthAfter-treatment detailsGalliumGallium nitride

A process for the manufacture of a gallium rich gallium nitride film is described. The process comprises (a) preparing a reaction mixture containing a gallium species and a nitrogen species, the gallium species and the nitrogen species being selected such that, when they react with each other, gallium nitride is formed; and (b) growing the gallium rich gallium nitride film from the reaction mixture, by allowing the gallium species to react with the nitrogen species and to deposit gallium nitride on a substrate selected from the group consisting of silicon, glass, sapphire, quartz and crystalline materials having a lattice constant closely matched to gallium nitride, including zinc oxide, optionally with a zinc oxide buffer layer, at a temperature of from about 480° C. to about 900° C. and in the presence of a gaseous environment in which the partial pressure of oxygen is less than 10−4 Torr, wherein the ratio of gallium atoms to nitrogen atoms in the gallium rich gallium nitride film is from 1.01 to 1.20. The invention also provides the option of annealing the gallium rich gallium nitride film at a temperature of from about 20° C. to about 650° C. and for a time sufficient to decrease the resistivity of the film so that it becomes electrically conductive, for instance to a resistivity below 100 ohm.cm.

Owner:BUTCHER KENNETH SCOTT ALEXANDER +2

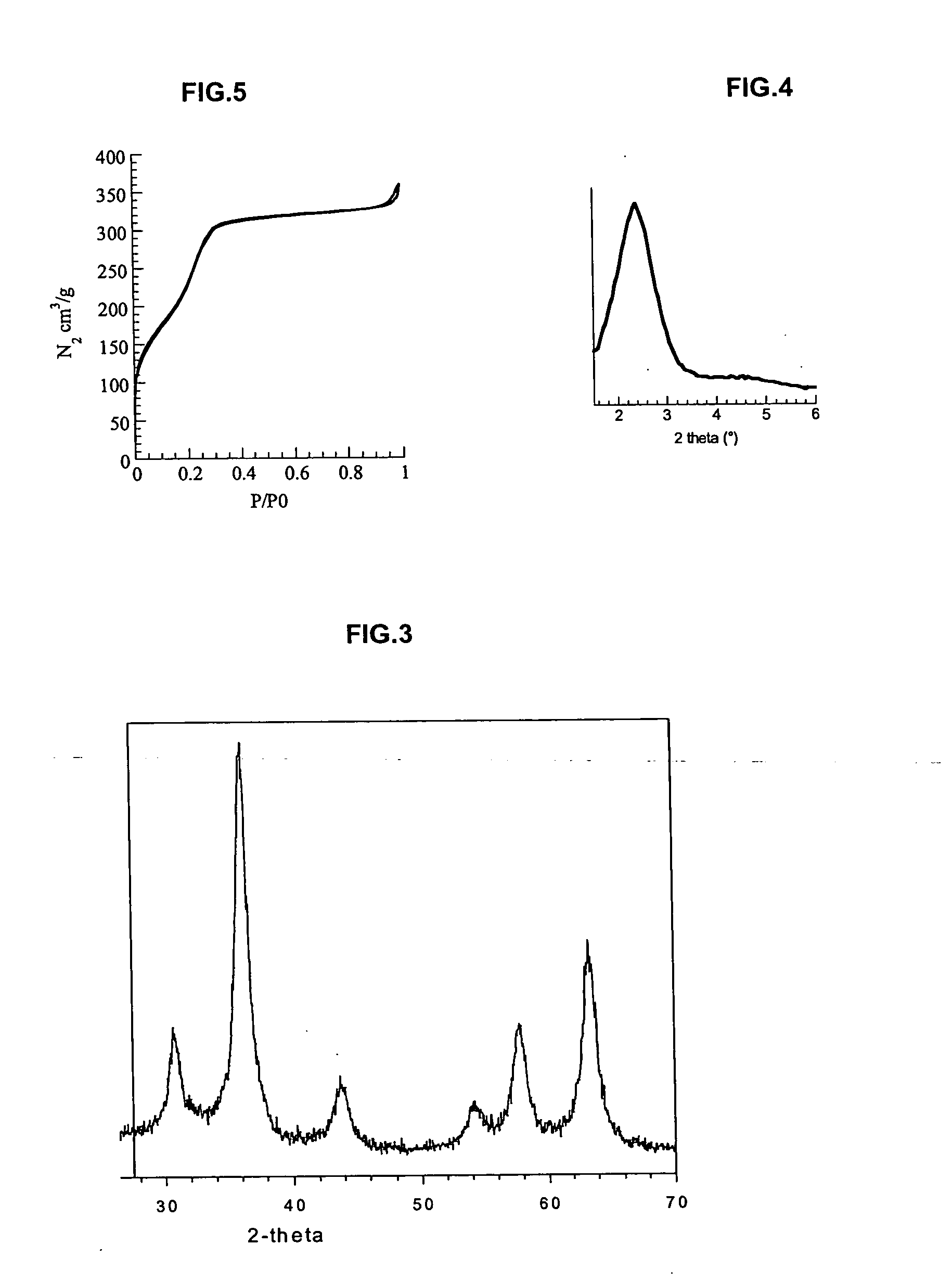

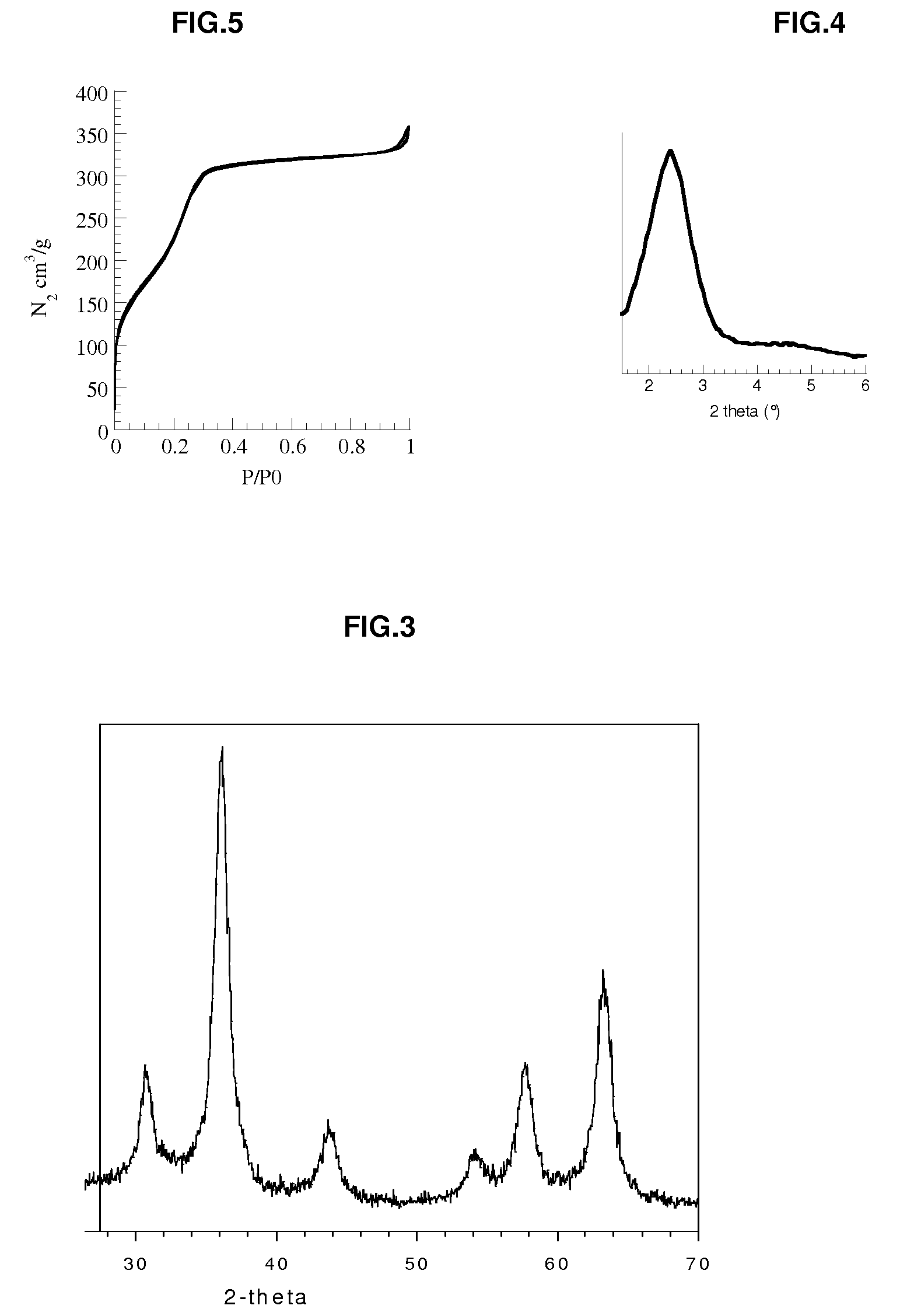

Inorganic material that has metal nanoparticles that are trapped in a mesostructured matrix

An inorganic material that consists of at least two elementary spherical particles, each of said spherical particles comprising metal nanoparticles that are between 1 and 300 nm in size and a mesostructured matrix with an oxide base of at least one element X that is selected from the group that consists of aluminum, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium is described, whereby said matrix has a pore size of between 1.5 and 30 nm and has amorphous walls with a thickness of between 1 and 30 nm, said elementary spherical particles having a maximum diameter of 10 μm. Said material can also contain zeolitic nanocrystals that are trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

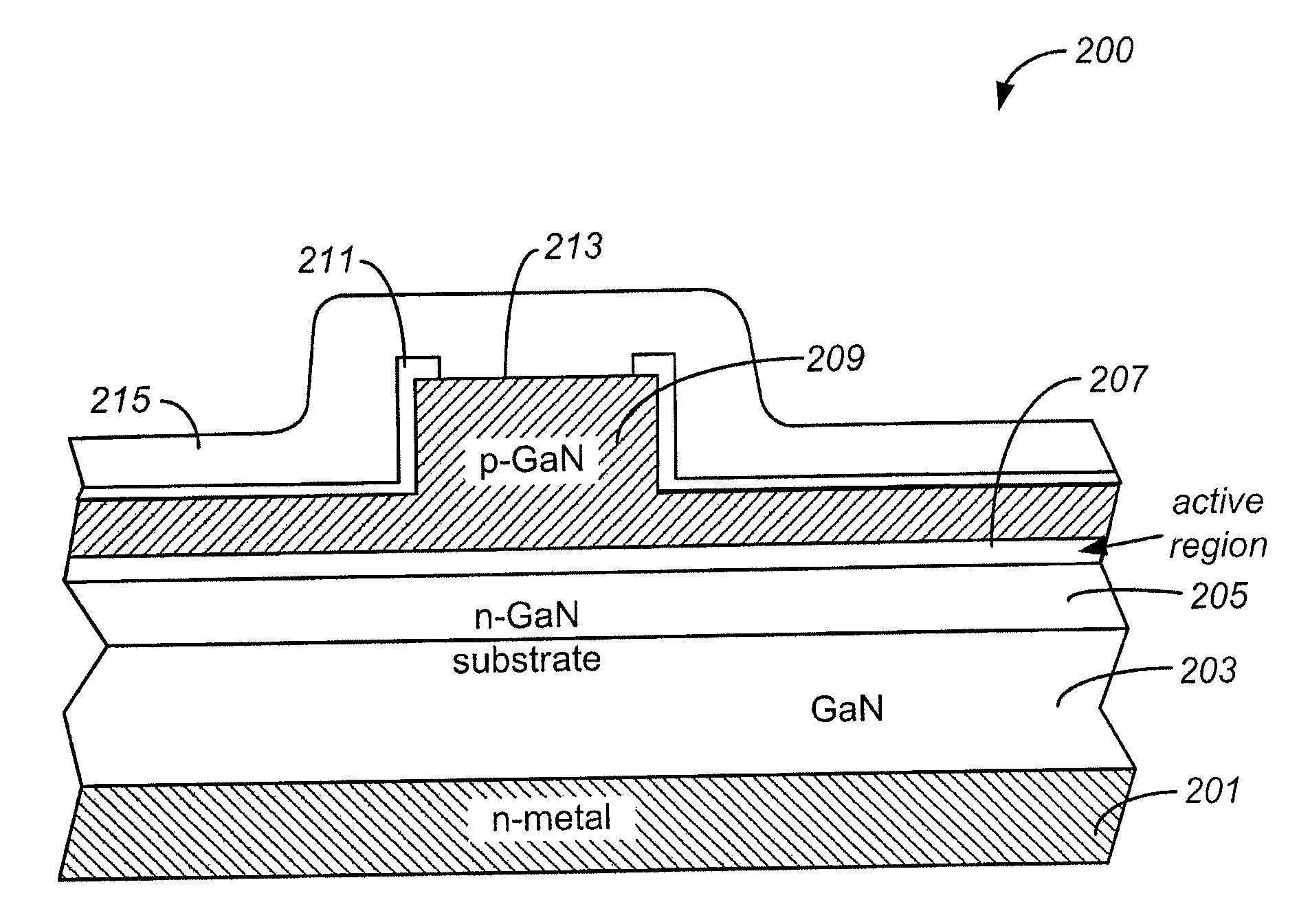

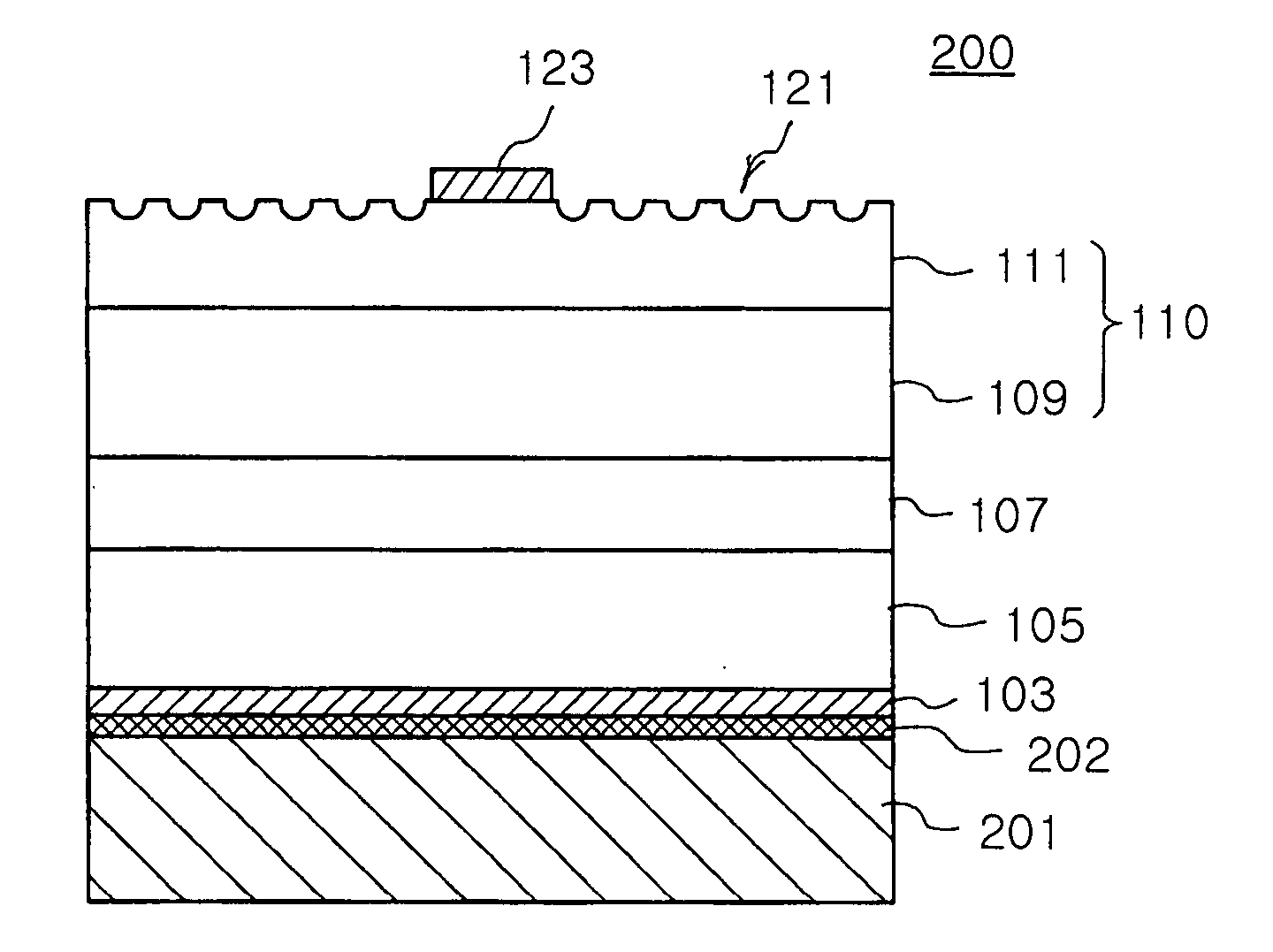

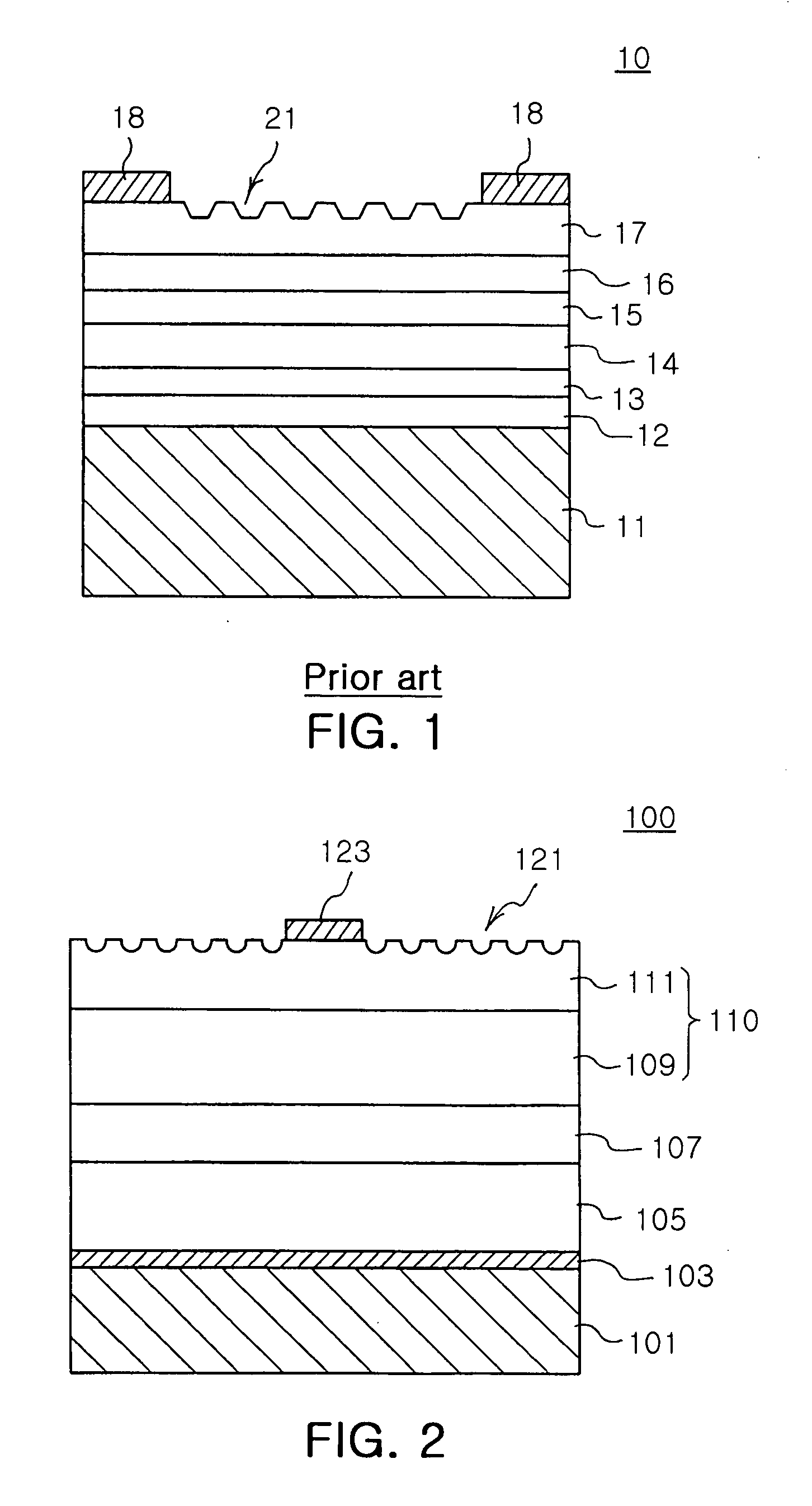

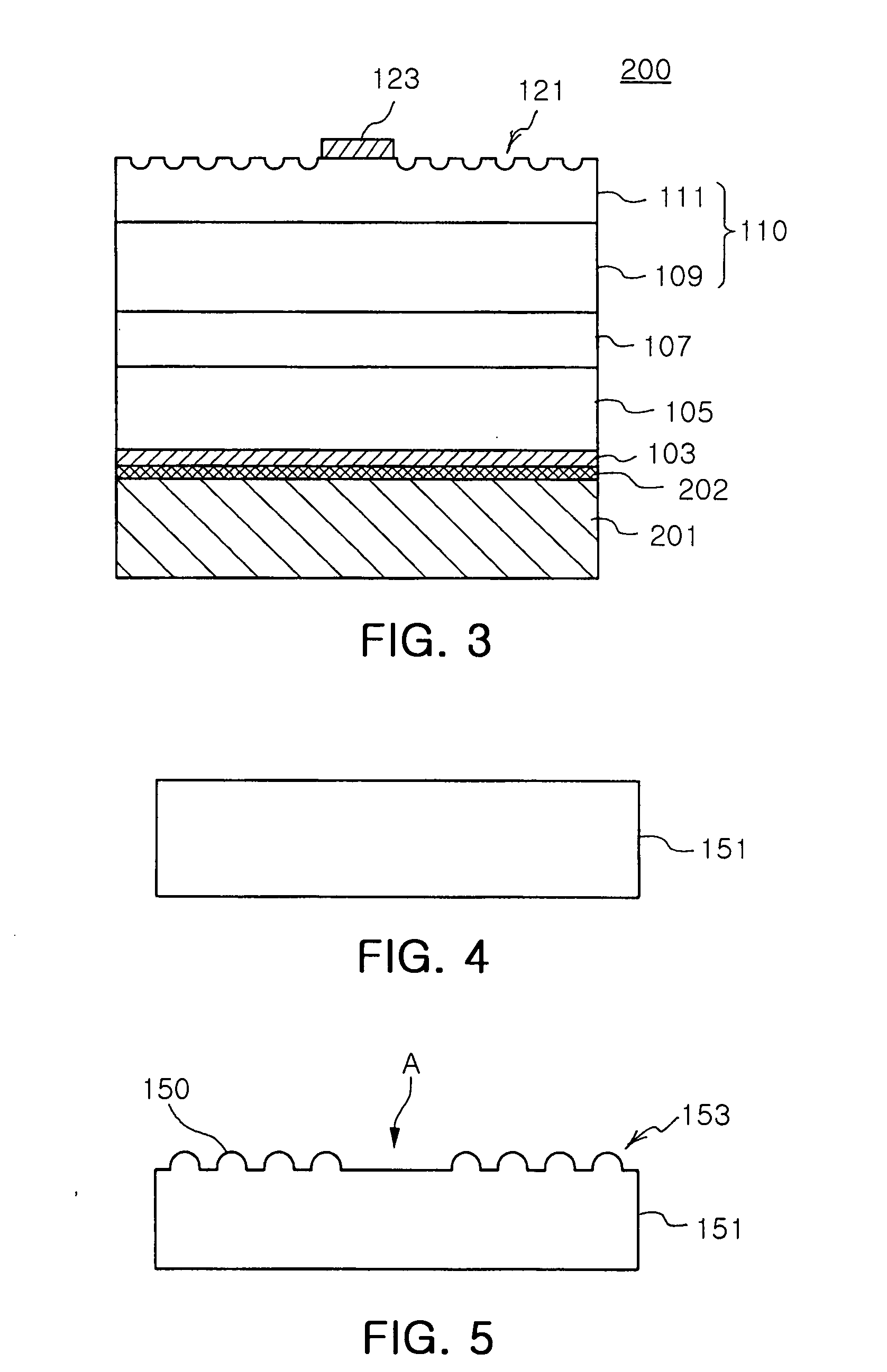

Vertical group III-nitride light emitting device and method for manufacturing the same

InactiveUS20060225644A1Light efficiencyLight propertiesPolycrystalline material growthIn situ pavingsGalliumActive layer

A vertical group III-nitride light emitting device and a manufacturing method thereof are provided. The light emitting device comprises: a conductive substrate; a p-type clad layer stacked on the conductive substrate; an active layer stacked on the p-type clad layer; an n-doped AlxGayIn1-x-yN layer stacked on the active layer; an undoped GaN layer stacked on the n-doped layer; and an n-electrode formed on the undoped GaN layer. The undoped GaN layer has a rough pattern formed on a top surface thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

Inorganic material that has metal nanoparticles that are trapped in a mesostructured matrix

An inorganic material that consists of at least two elementary spherical particles, each of said spherical particles comprising metal nanoparticles that are between 1 and 300 nm in size and a mesostructured matrix with an oxide base of at least one element X that is selected from the group that consists of aluminum, titanium, tungsten, zirconium, gallium, germanium, tin, antimony, lead, vanadium, iron, manganese, hafnium, niobium, tantalum, yttrium, cerium, gadolinium, europium and neodymium is described, whereby said matrix has a pore size of between 1.5 and 30 nm and has amorphous walls with a thickness of between 1 and 30 nm, said elementary spherical particles having a maximum diameter of 10 μm. Said material can also contain zeolitic nanocrystals that are trapped within said mesostructured matrix.

Owner:INST FR DU PETROLE

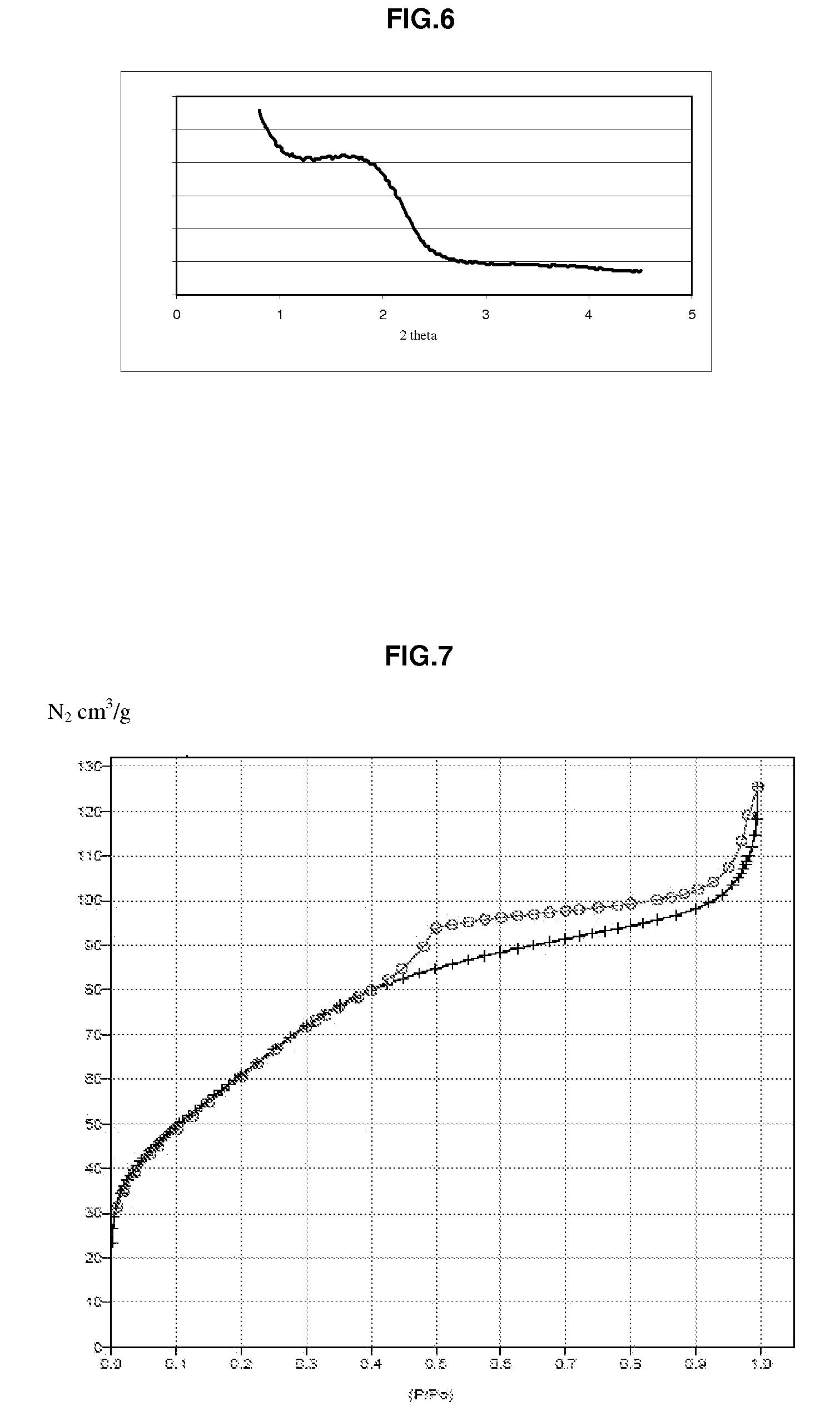

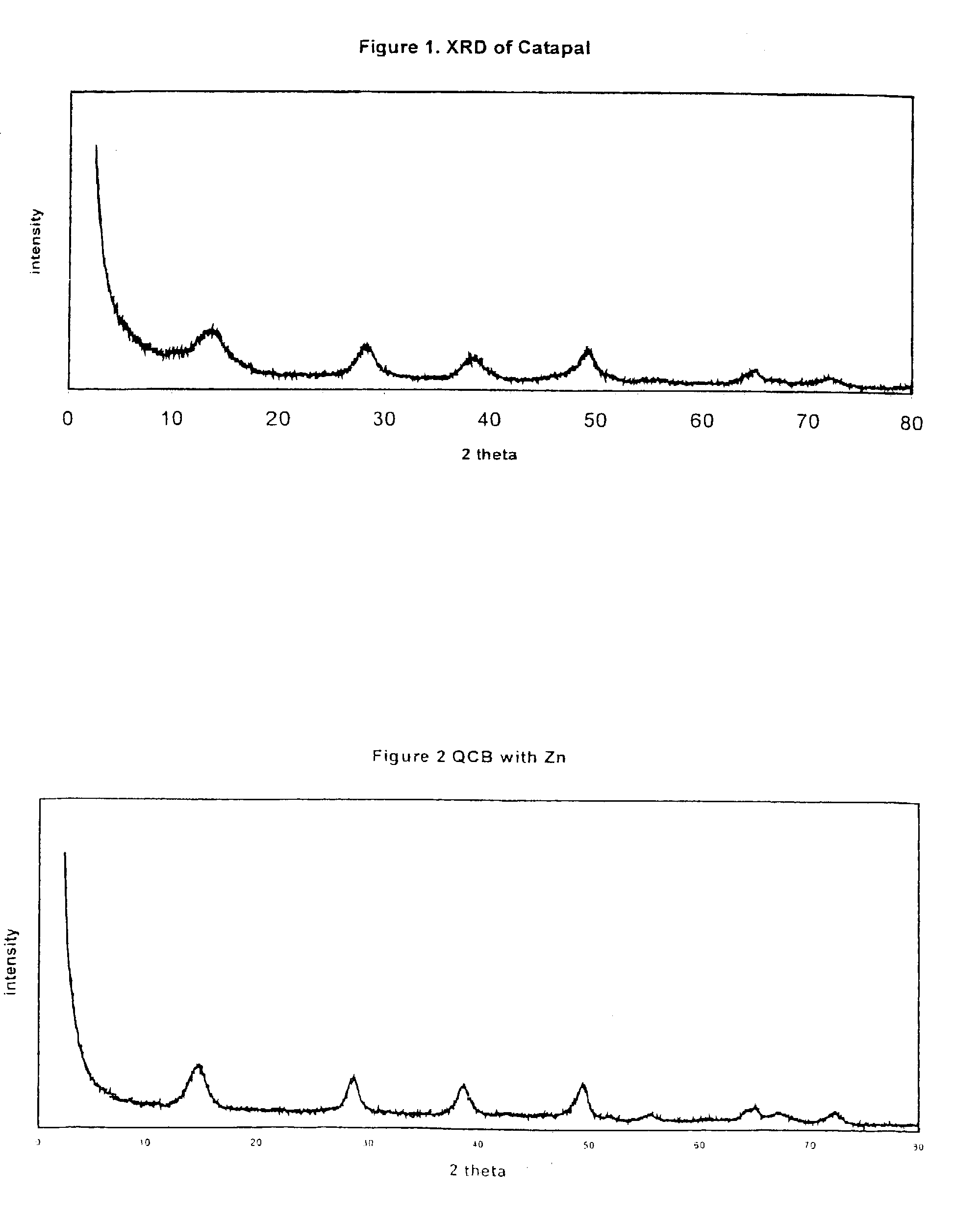

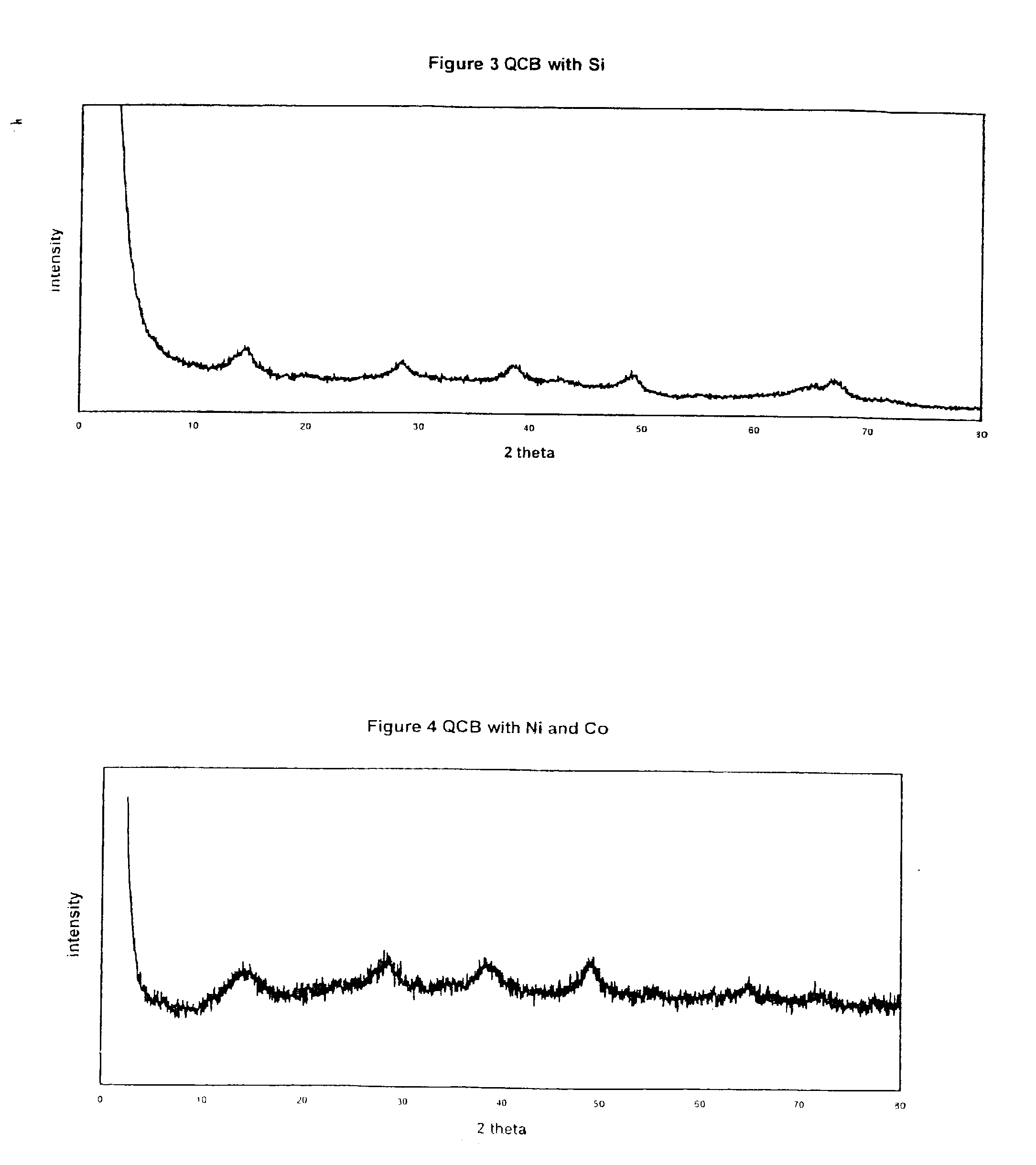

Quasi-crystalline boehmites containing additives

The present invention pertains to a quasi-crystalline boehmite containing additive in a homogeneously dispersed state. Suitable additives are compounds containing elements selected from the group of alkaline earth metals, alkaline metals, rare earth metals, transition metals, actinides, silicon, gallium, boron, titanium, and phosphorus. Said QCBs according to the invention may be prepared in several ways. In general, a quasi-crystalline boehmite precursor and an additive are converted to a quasi-crystalline boehmite containing the additive in a homogeneously dispersed state.

Owner:ALBEMARLE NETHERLANDS BV

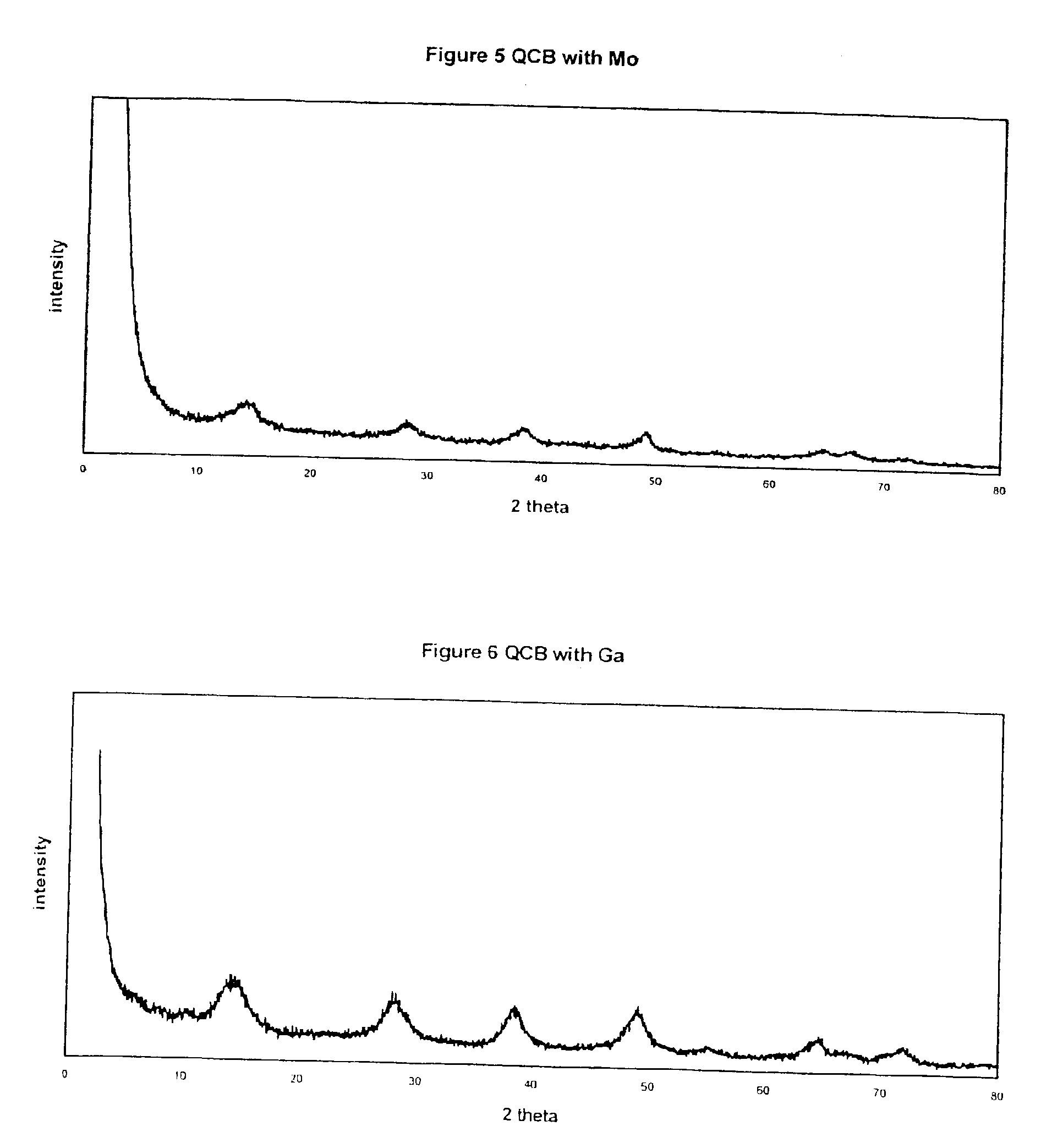

Process to make metal oxide thin film transistor array with etch stopping layer

The present invention generally relates to thin film transistors (TFTs) and methods of making TFTs. The active channel of the TFT may comprise one or more metals selected from the group consisting of zinc, gallium, tin, indium, and cadmium. The active channel may also comprise nitrogen and oxygen. To protect the active channel during source-drain electrode patterning, an etch stop layer may be deposited over the active layer. The etch stop layer prevents the active channel from being exposed to the plasma used to define the source and drain electrodes. The etch stop layer and the source and drain electrodes may be used as a mask when wet etching the active material layer that is used for the active channel.

Owner:APPLIED MATERIALS INC

Method for making MTT zeolites without an organic template

InactiveUS6099820ALow raw material costMinimize wasteAluminium compoundsMolecular-sieve and base-exchange compoundsSufficient timeX-ray

The invention includes a method for preparing a crystalline zeolite having the X-ray diffraction lines of Table 1. The method includes preparing a template-free reaction mixture including at least one active source of a first oxide selected from the group consisting of an oxide of silicon, germanium or both, optionally at least one active source of a second oxide selected from the group consisting of an oxide of aluminum, boron, gallium, iron or a mixture thereof; and heating the reaction mixture at crystallization conditions for sufficient time to form a crystallized material containing zeolite crystals having the X-ray diffraction lines of Table 1, where said zeolite crystals have a first oxide / second oxide molar ratio greater than 12.

Owner:CHEVROU USA INC

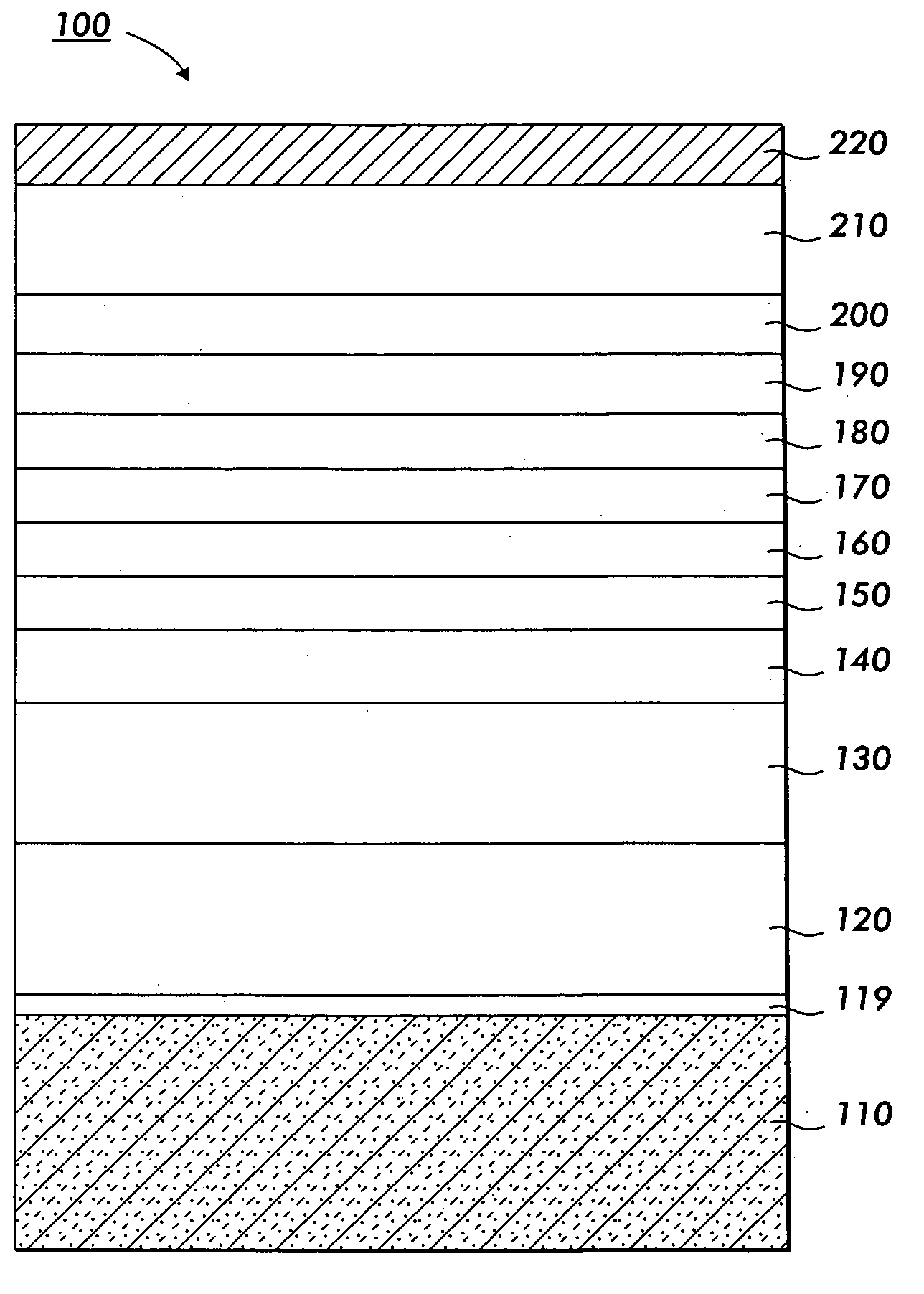

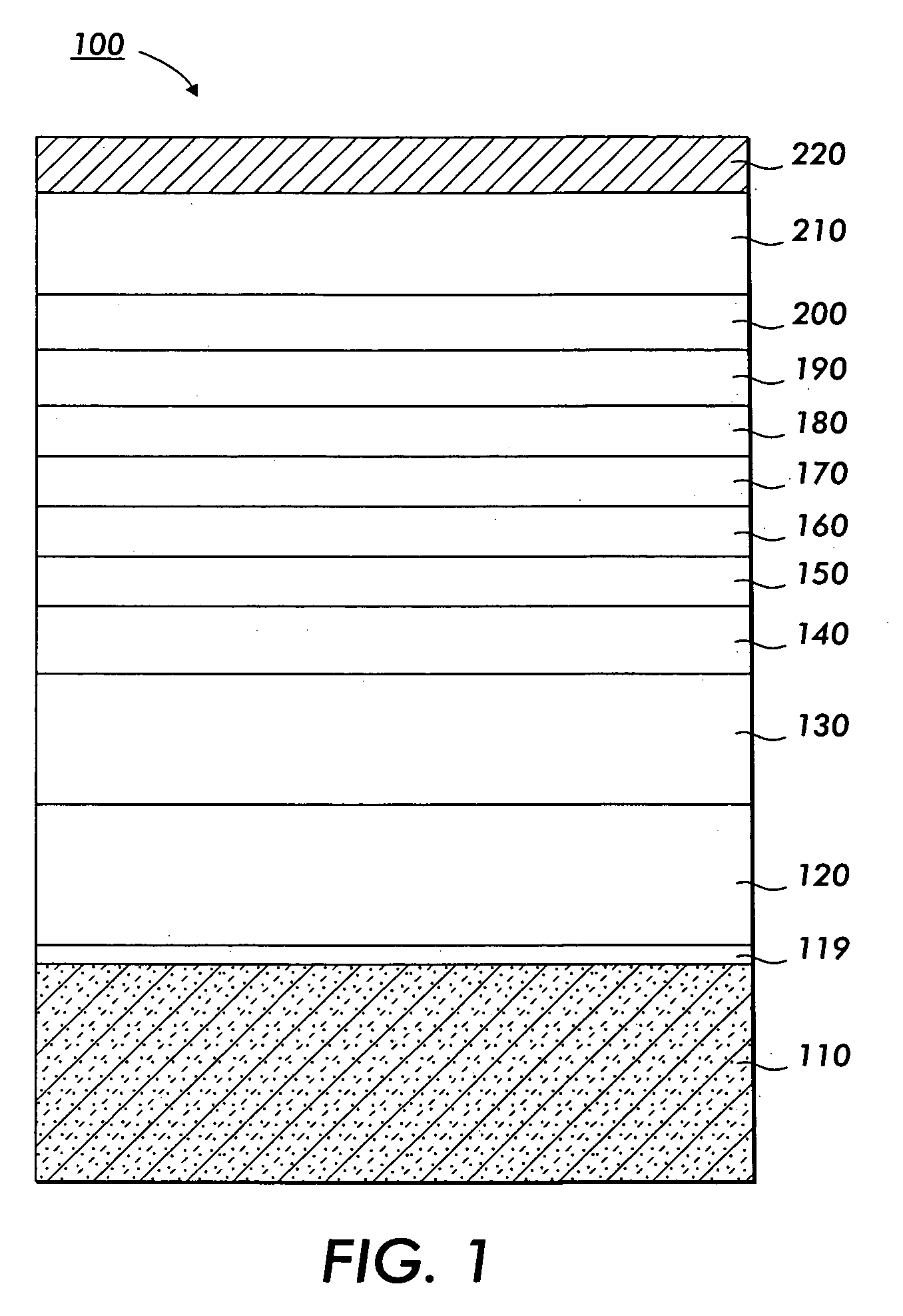

Ultraviolet group III-nitride-based quantum well laser diodes

InactiveUS20050224781A1Sufficient carrier confinementAvoid structural degradationOptical wave guidanceLaser detailsUltravioletGallium

A pair of undoped spacer layers are provided adjacent to, or near to, a single quantum well aluminum gallium nitride active region. In various exemplary embodiments, the undoped spacer layers are provided between the single quantum well aluminum gallium nitride active region and carrier confinement layers. The undoped spacer layers reduce the threshold current for the laser device and improve the output characteristics.

Owner:PALO ALTO RES CENT INC

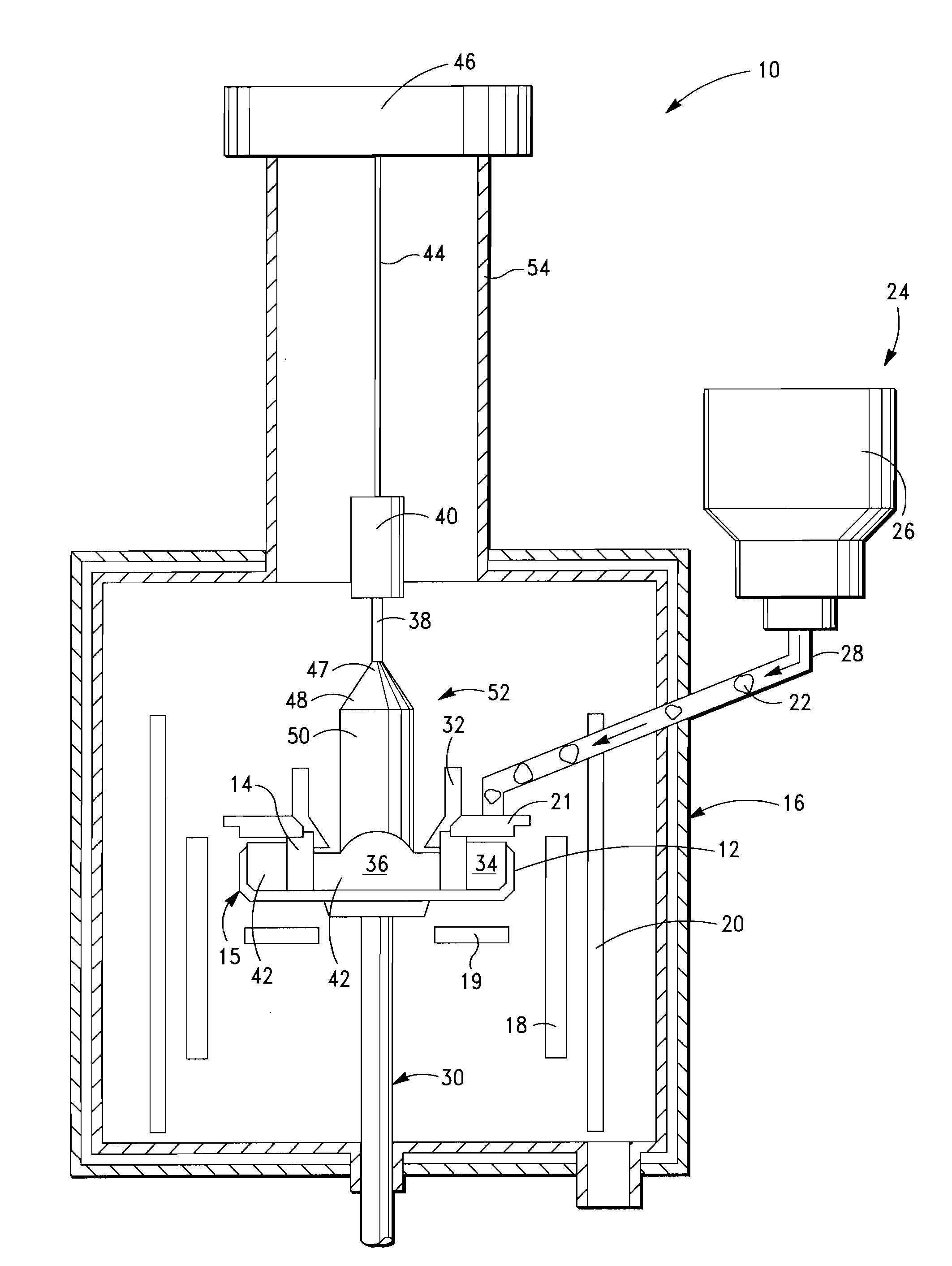

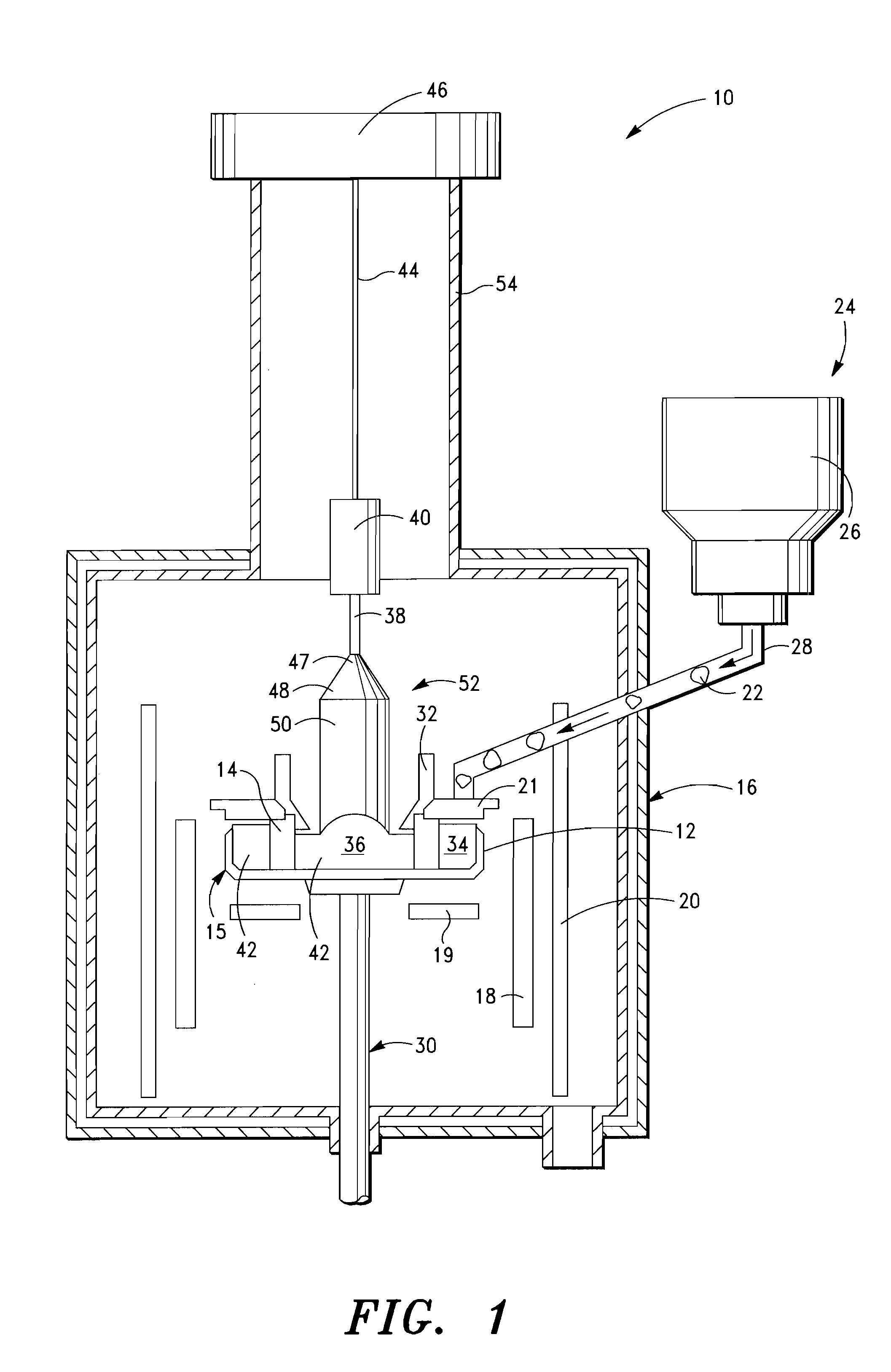

Silicon Single Crystal Doped with Gallium, Indium, or Aluminum

ActiveUS20120056135A1Reduces downtimeUniform resistivityPolycrystalline material growthConductive materialSeed crystalIndium

A doped silicon single crystal having a resistivity variation along a longitudinal and / or radial axis of less than 10% and a method of preparing one or a sequential series of doped silicon crystals is disclosed. The method includes providing a melt material comprising silicon into a continuous Czochralski crystal growth apparatus, delivering a dopant, such as gallium, indium, or aluminum, to the melt material, providing a seed crystal into the melt material when the melt material is in molten form, and growing a doped silicon single crystal by withdrawing the seed crystal from the melt material. Additional melt material is provided to the apparatus during the growing step. A doping model for calculating the amount of dopant to be delivered into the melt material during one or more doping events, methods for delivering the dopant, and vessels and containers used to deliver the dopant are also disclosed.

Owner:GTAT IP HLDG

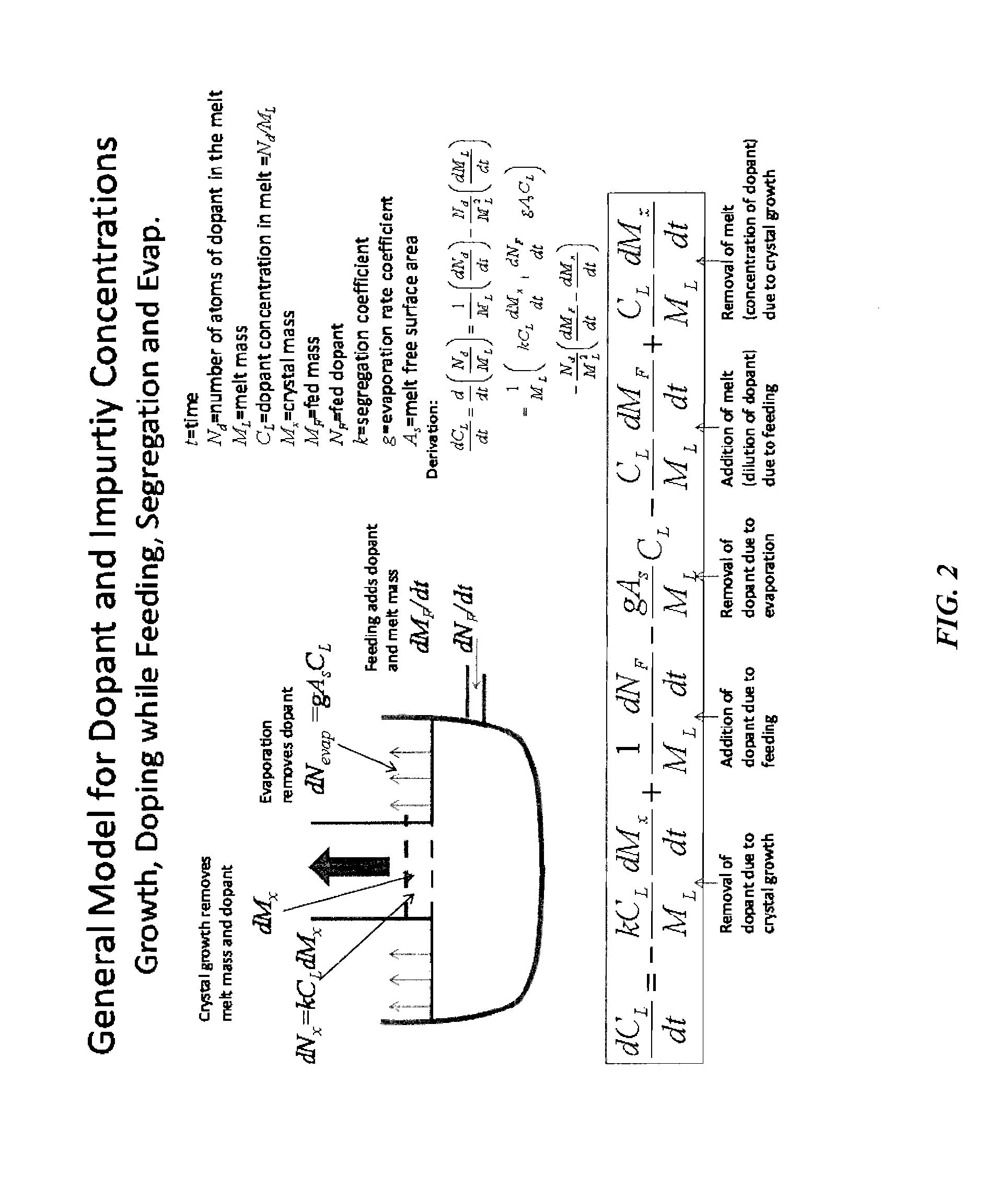

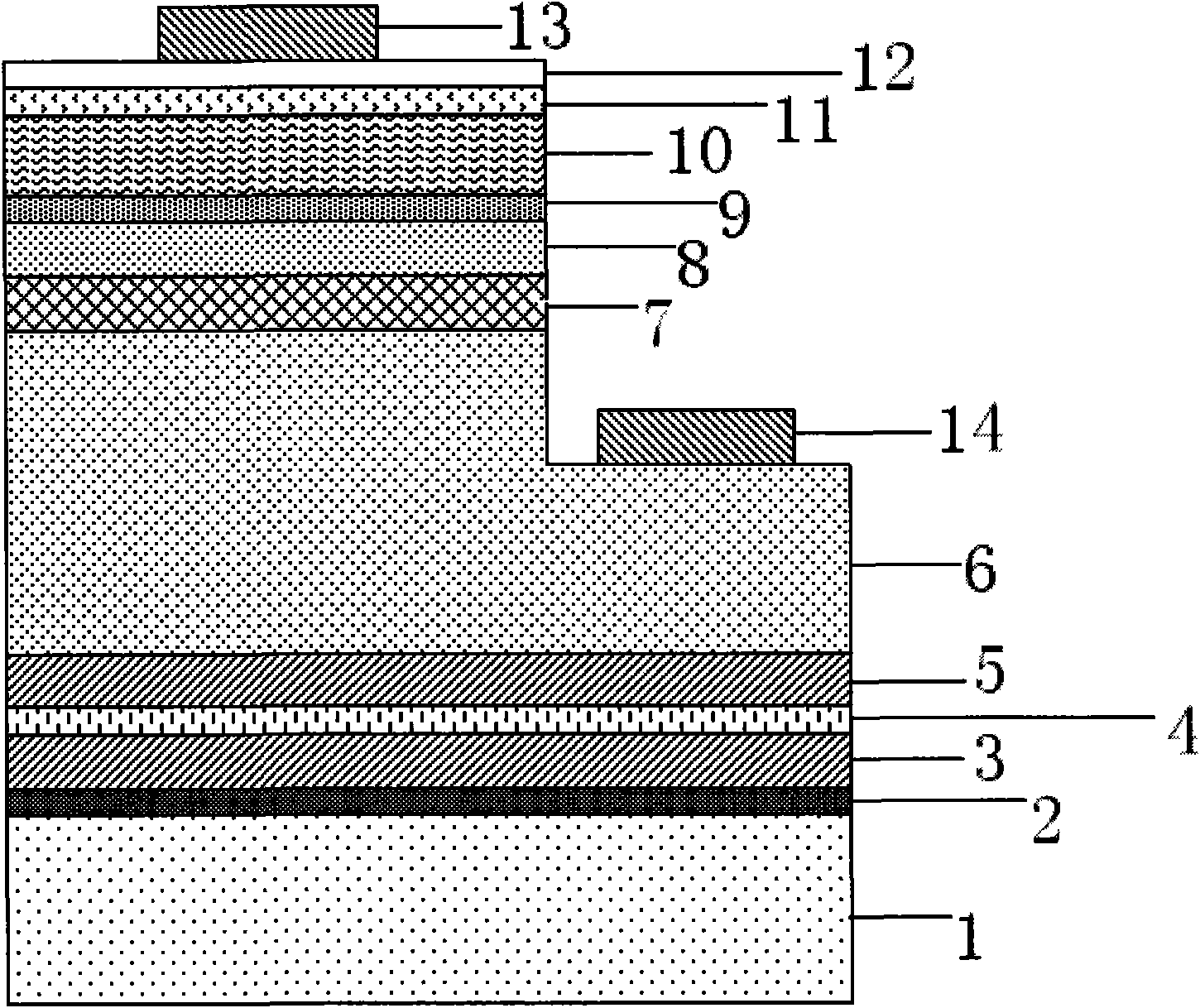

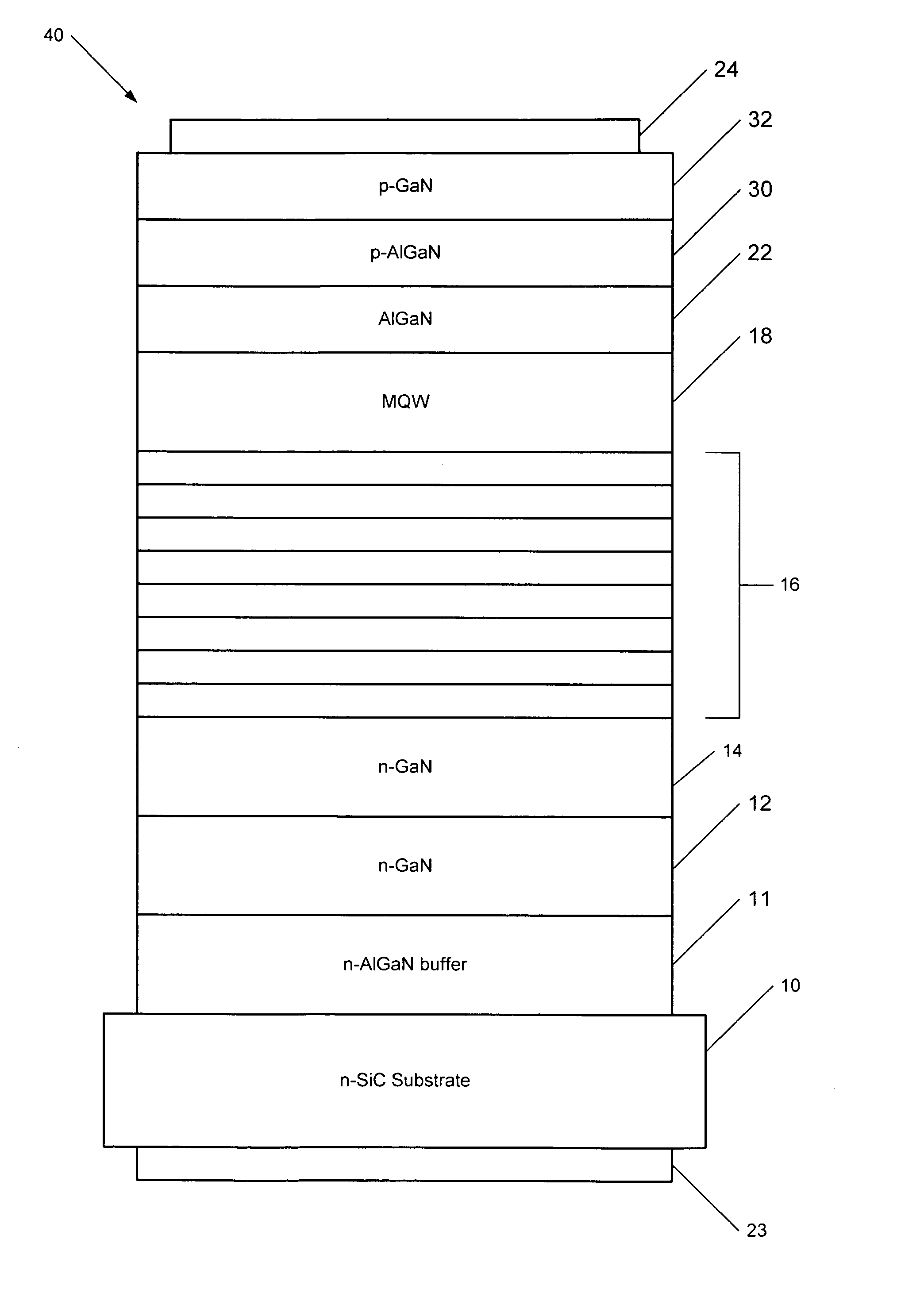

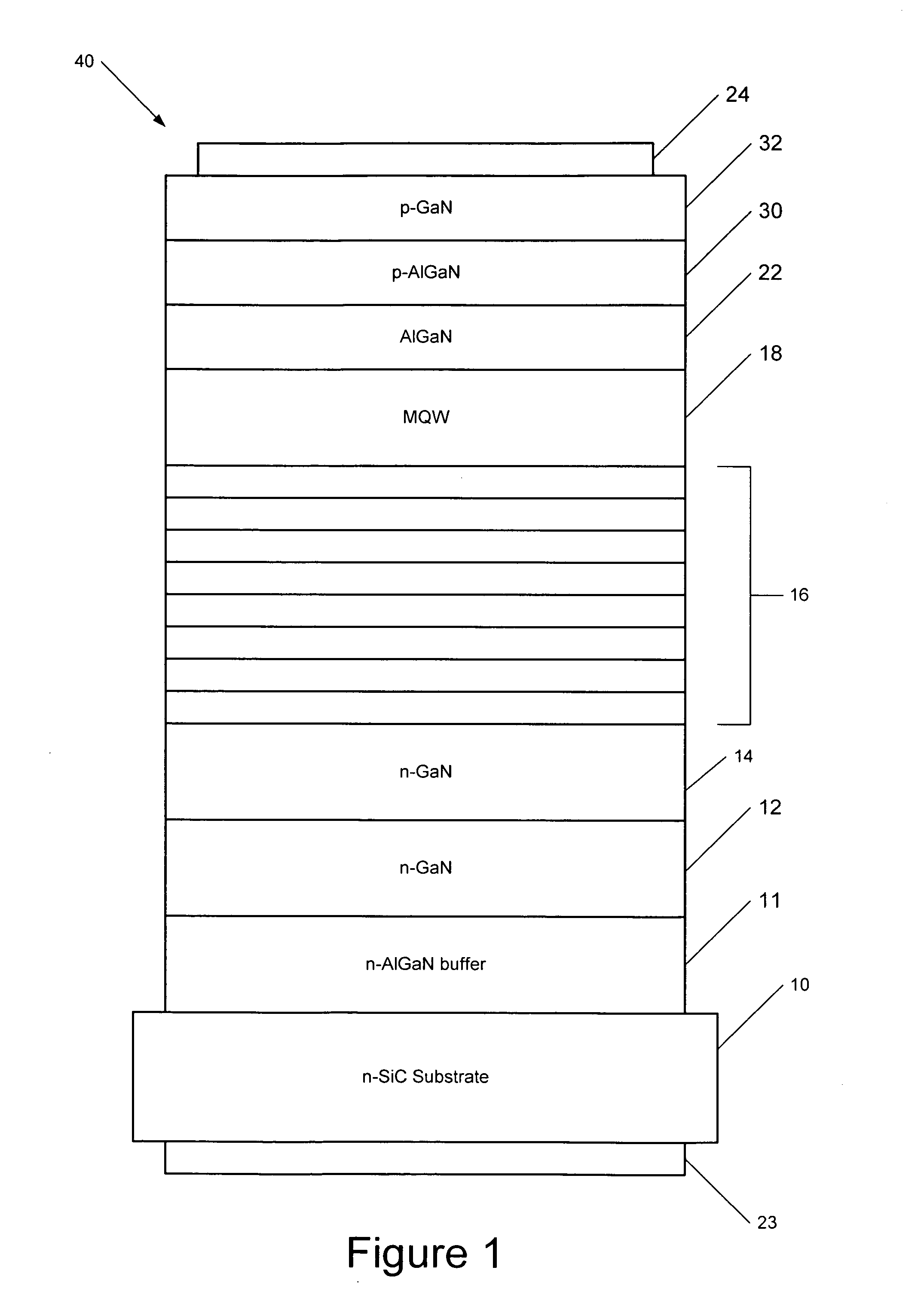

Method for enhancing antistatic ability of GaN-based light-emitting diode

ActiveCN101645480AImprove crystal qualityImprove antistatic performanceSemiconductor devicesGalliumContact layer

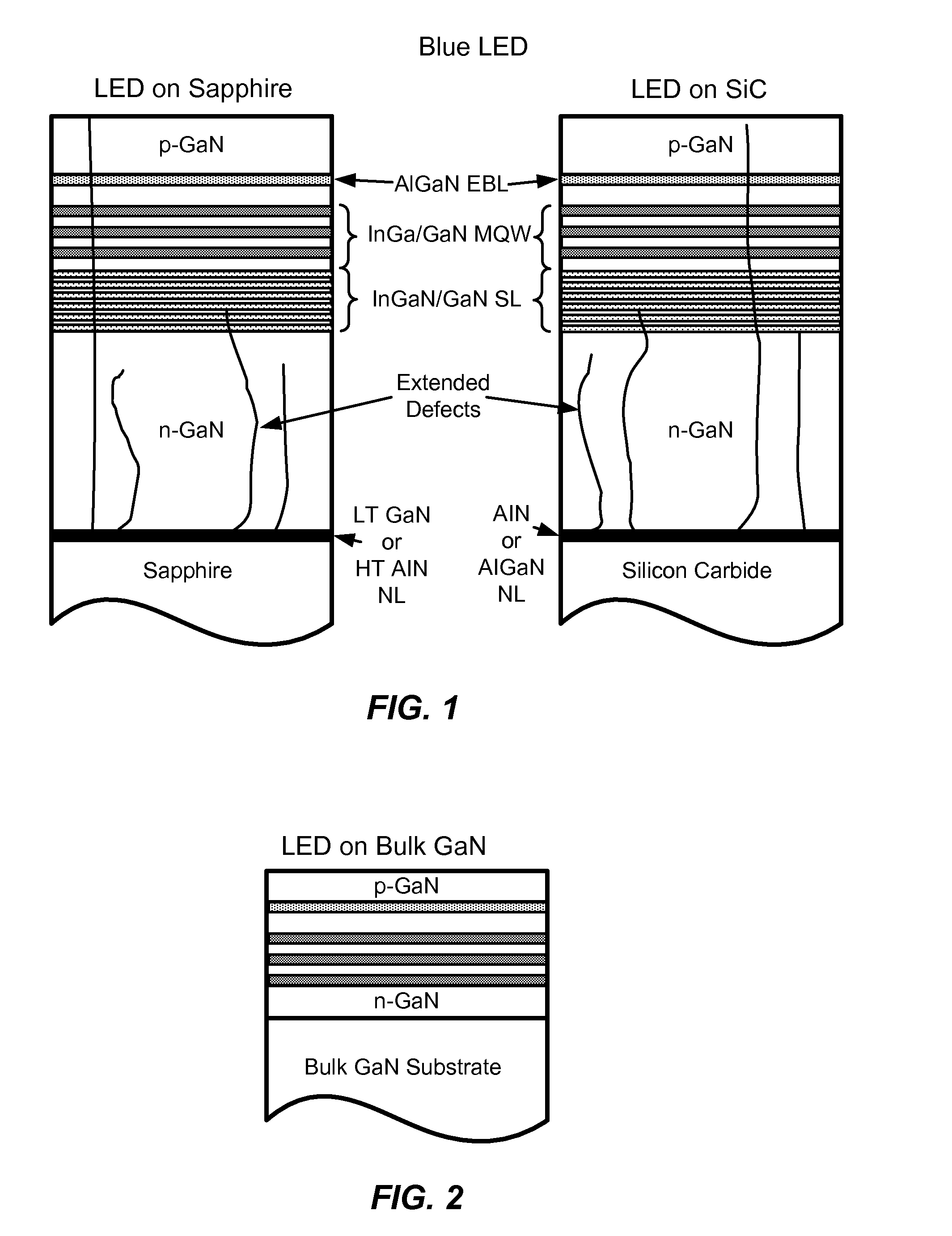

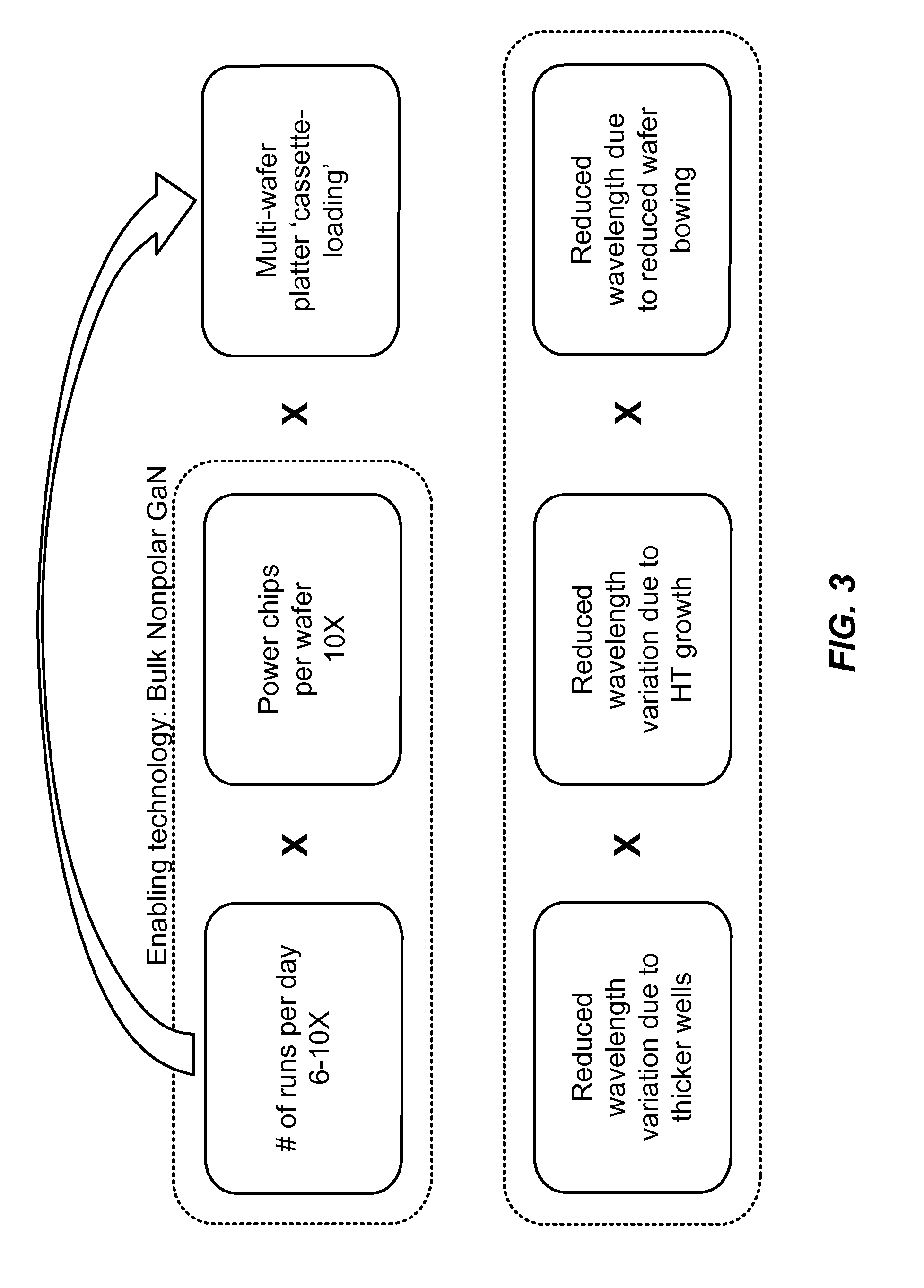

The invention discloses a method for enhancing the antistatic ability of GaN-based light-emitting diode. The epitaxial wafer structure of the light-emitting diode sequentially comprises an underlay, alow-temperature buffer layer, an unadulterated GaN high-temperature buffer layer, an aluminum gallium nitride / GaN superlattice structure, the unadulterated GaN high-temperature buffer layer, an N type contact layer, an N type GaN conductive layer, a light-emitting layer multiple quantum well structure MQW, a P type aluminum gallium nitride electric barrier layer, a P type GaN conductive layer and a P type contact layer in a sequence from down to up. In the invention, the aluminum gallium nitride / GaN superlattice periodic structure is inserted in the unalloyed GaN high temperature buffer layer. The insertion of the aluminum gallium nitride / GaN superlattice periodic structure can effectively improve crystal quality of materials, thereby enhancing the antistatic ability of the GaN-based light-emitting diode and improving the reliability and the stability of devices.

Owner:HC SEMITEK CORP

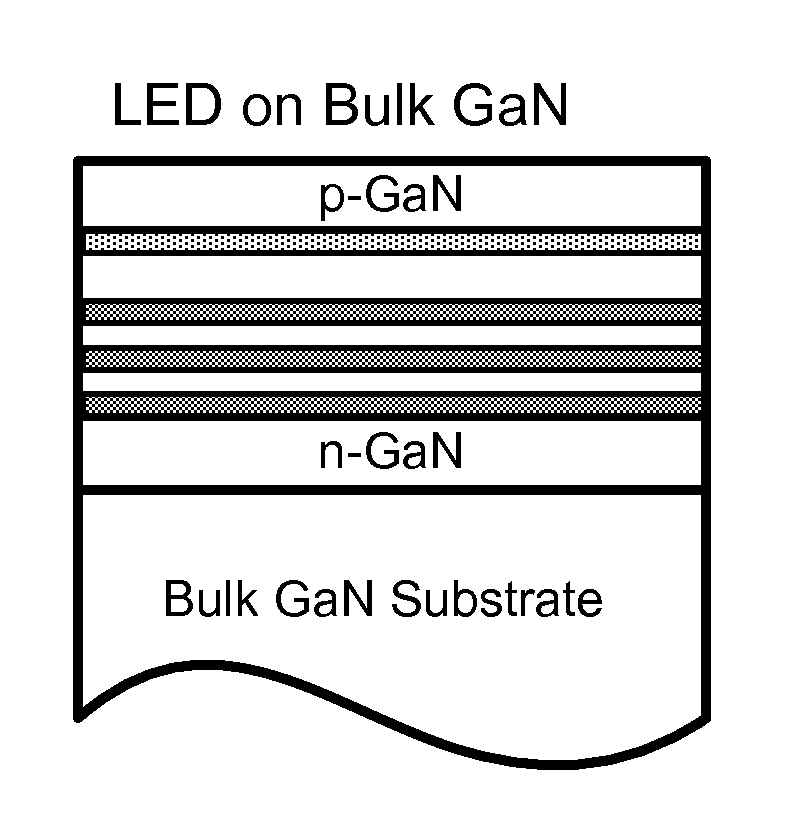

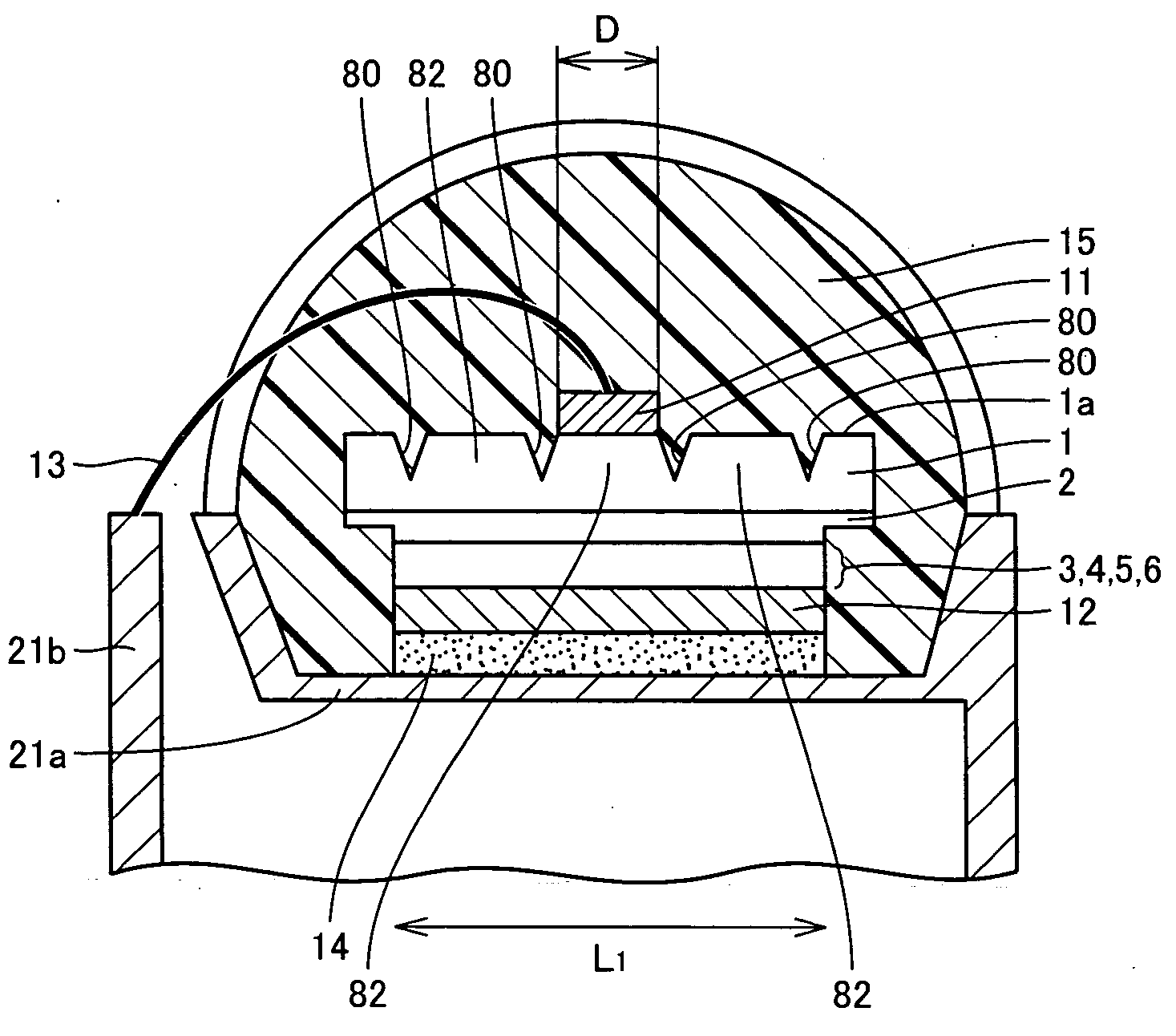

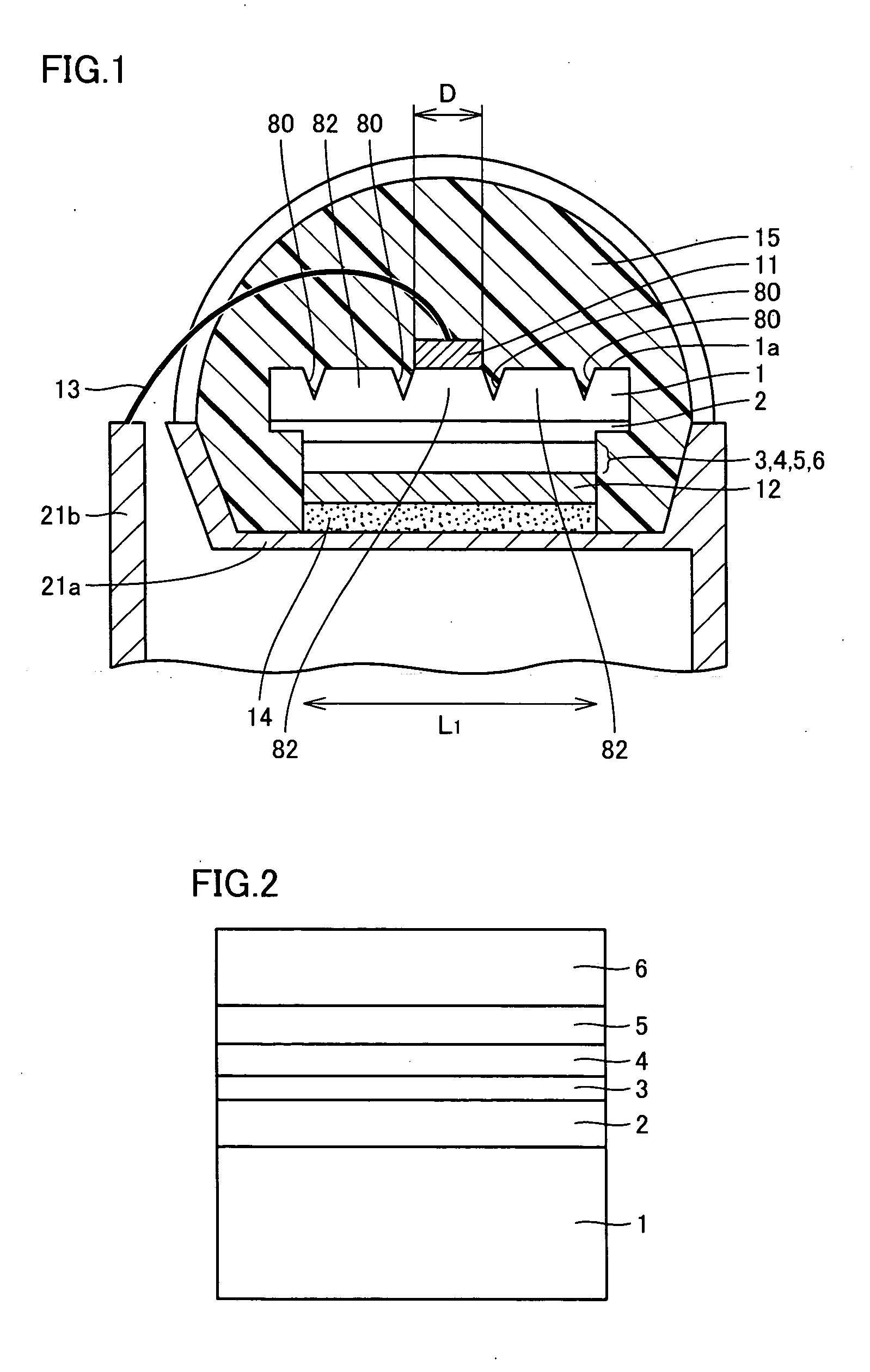

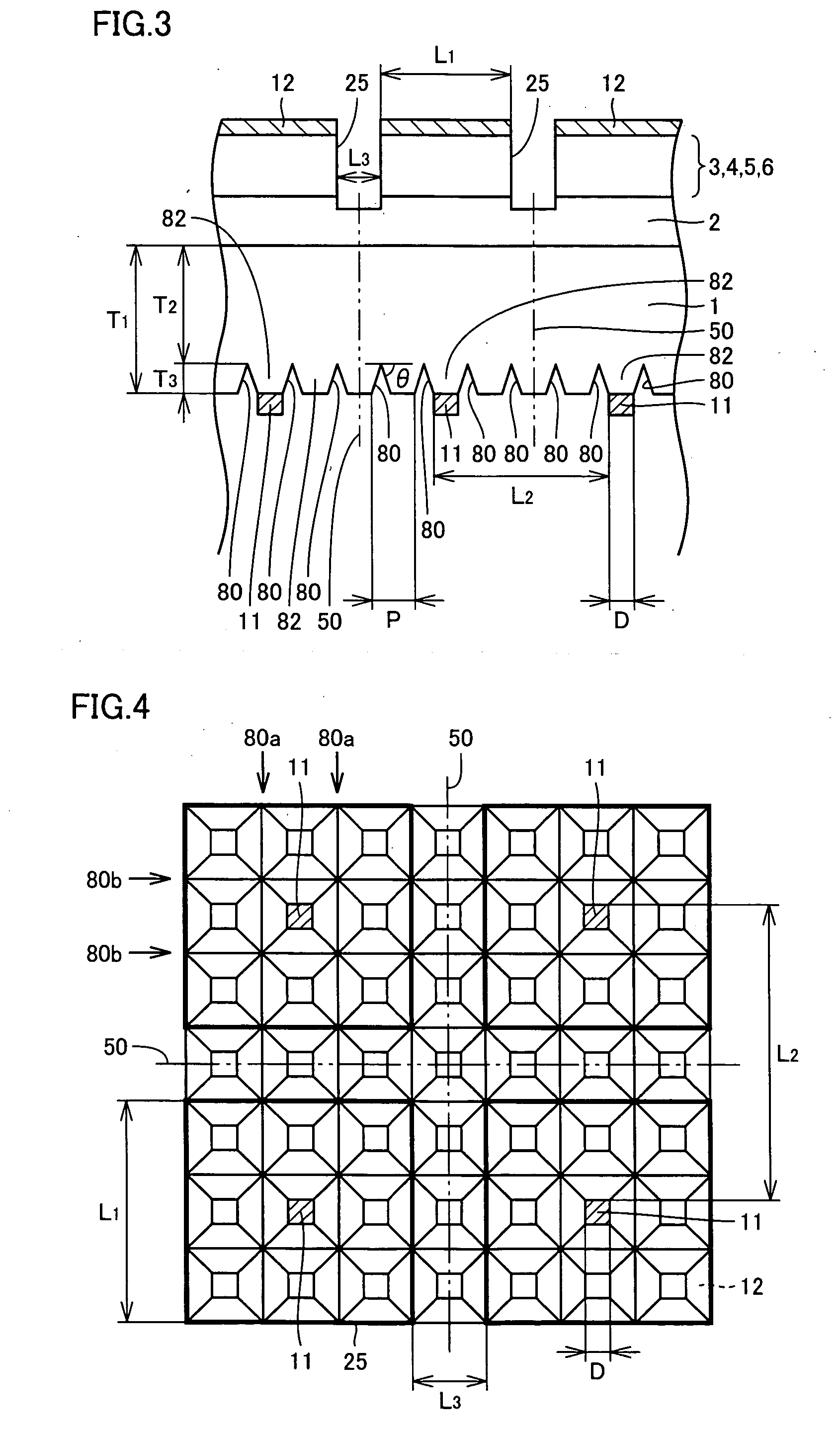

Light emitting device

InactiveUS20060157717A1Simple structureEasy to manufactureSolid-state devicesSemiconductor devicesQuantum wellGallium

A light emitting device having a simple structure that can be easily manufactured, attaining high light emitting efficiency stably for a long time is obtained, which light emitting device includes: a GaN substrate as a nitride semiconductor substrate and, on a first main surface of the nitride semiconductor substrate, an n-type AlxGa1-xN layer, a p-type AlxGa1-xN layer positioned further than the n-type AlxGa1-xN layer viewed from the nitride semiconductor substrate, and a quantum well positioned between the n-type AlxGa1-xN layer and the p-type AlxGa1-xN layer. In the light emitting device, specific resistance of the nitride semiconductor substrate is at most 0.5 Ω·cm, the side of p-type AlxGa1-xN layer is mounted face-down, and the light is emitted from the second main surface 1a that is opposite to the first main surface of the nitride semiconductor substrate. The second main surface 1a of nitride semiconductor substrate has trenches formed therein.

Owner:SUMITOMO ELECTRIC IND LTD

Ultraviolet group III-nitride-based quantum well laser diodes

InactiveUS7138648B2Sufficient carrier confinementAvoid structural degradationOptical wave guidanceLaser detailsUltravioletGallium

A pair of undoped spacer layers are provided adjacent to, or near to, a single quantum well aluminum gallium nitride active region. In various exemplary embodiments, the undoped spacer layers are provided between the single quantum well aluminum gallium nitride active region and carrier confinement layers. The undoped spacer layers reduce the threshold current for the laser device and improve the output characteristics.

Owner:PALO ALTO RES CENT INC

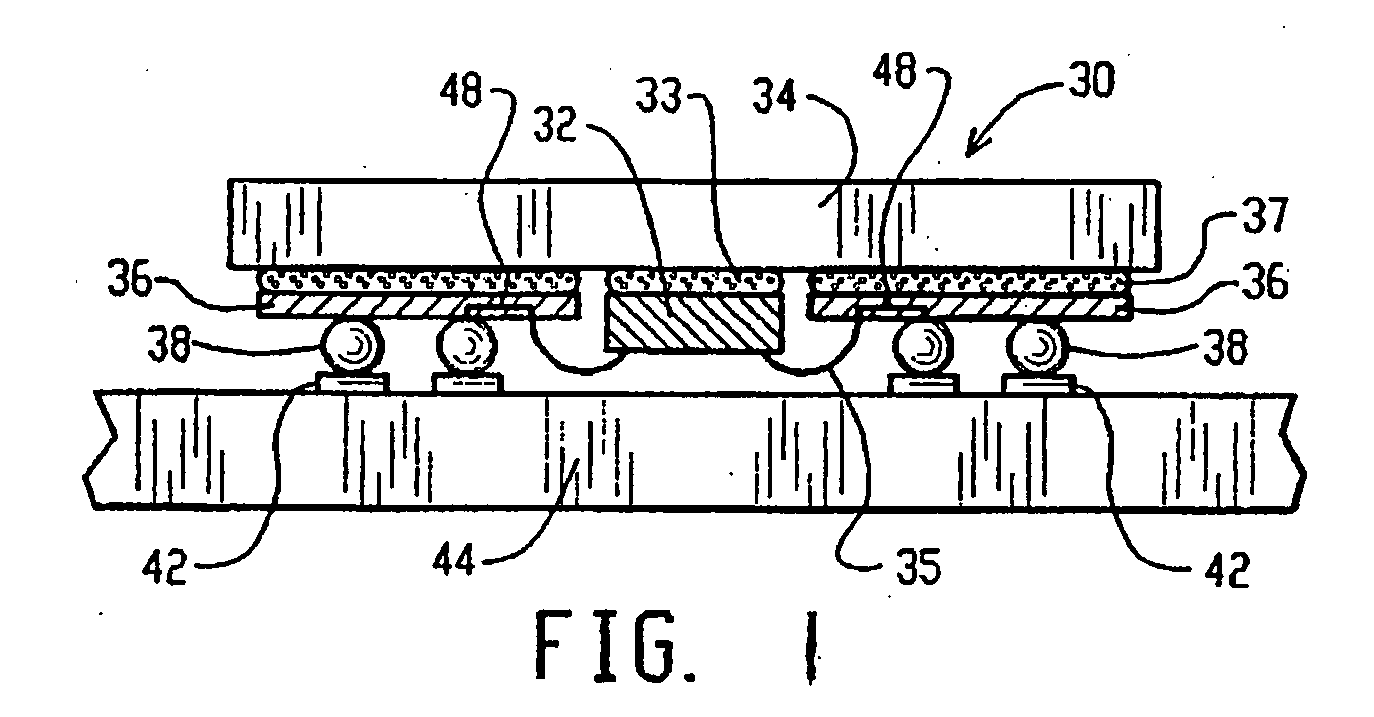

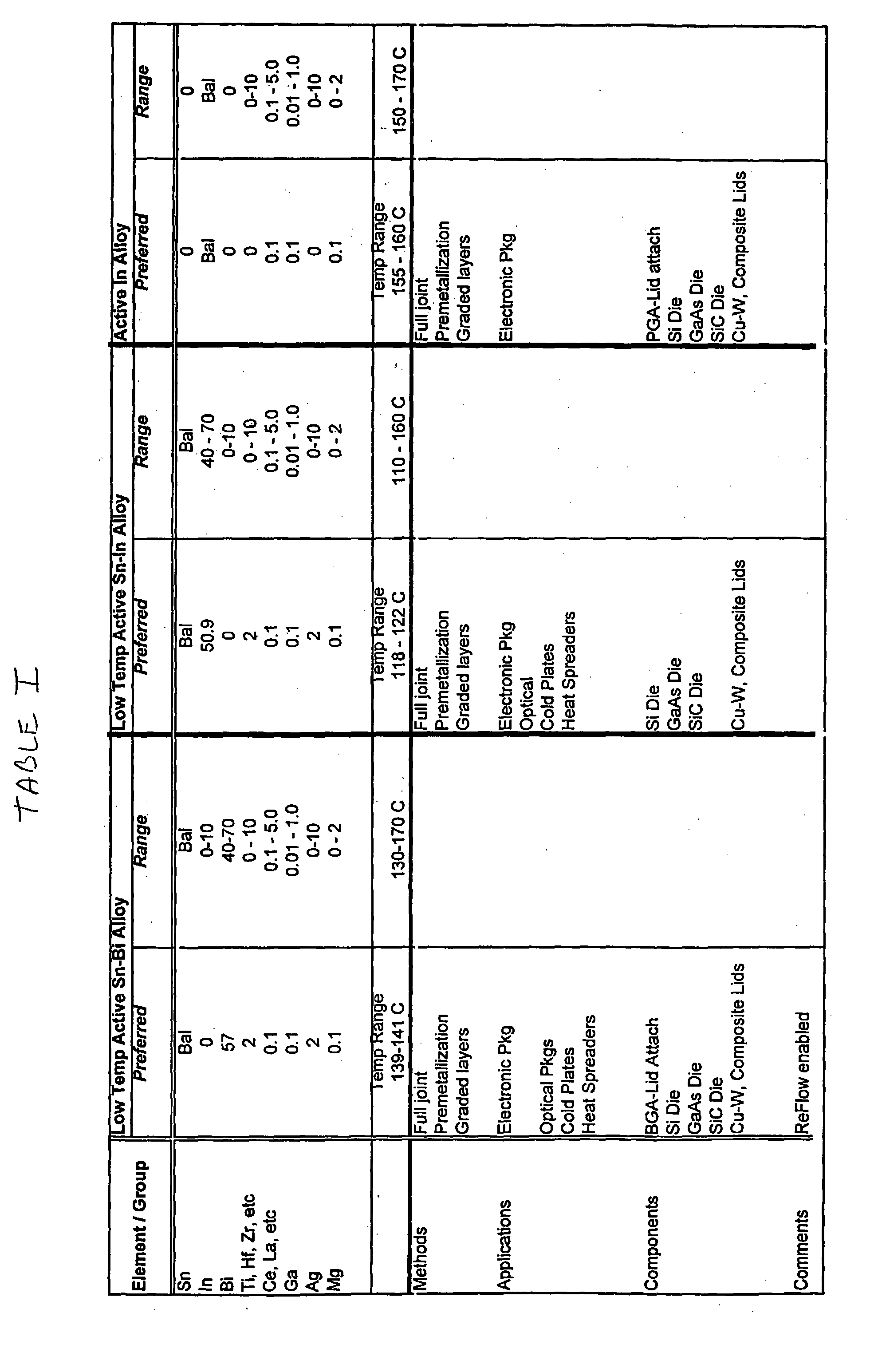

Electronic Package Formed Using Low-Temperature Active Solder Including Indium, Bismuth, and/or Cadmium

InactiveUS20070228109A1Increase concentrationHigh-strength, high-thermal conductivity jointsCooking-vessel materialsExhaust apparatusIndiumNiobium

An active solder alloy, an electronic device package including the active solder alloy bonding an electronic device to a substrate, and a method of forming high-strength joints by soldering using the solder alloy. The alloy contains up to about 10% by weight of an element or a mixture of elements selected from the group consisting of titanium, zirconium, hafnium, vanadium, niobium, or tantalum; between about 0.1 and 5% by weight of an element or a mixture of elements selected from the group of the lanthanides (rare earths); between about 0.01 and 1% by weight of gallium up to about 10% by weight of silver; up to about 2% by weight of magnesium; and a remainder consisting of tin, bismuth, indium, cadmium, or a mixture of two or more of these elements. The alloy enables low-temperature (less than about 180° C.) soldering within relatively narrow melting ranges (less than about 10° C.).

Owner:S BOND TECH

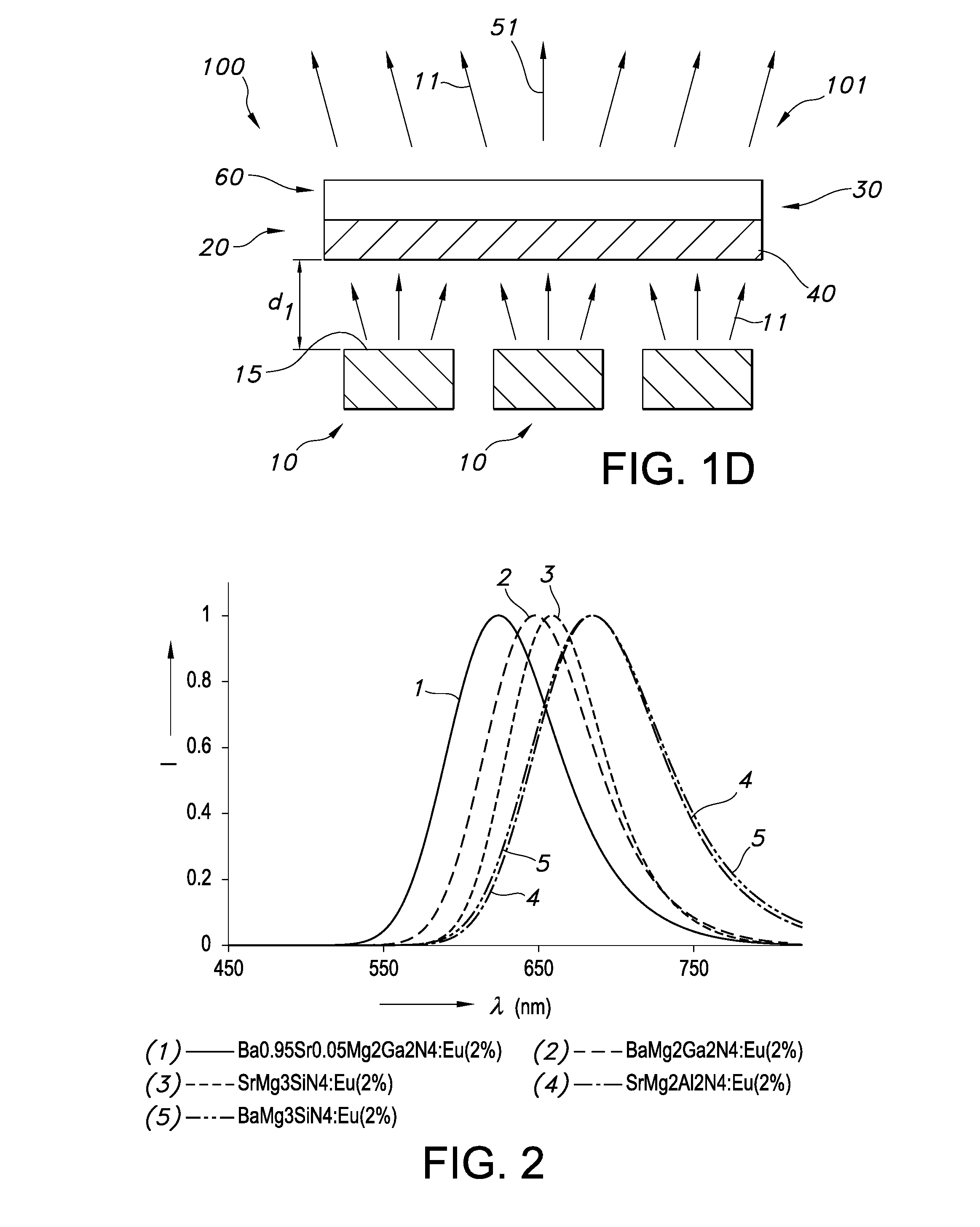

Phosphors, such as new narrow-band red emitting phosphors for solid state lighting

ActiveUS20150123155A1Improve stabilityExtended Spectral RangeElectroluminescent light sourcesLuminescent compositionsPhosphorEffect light

The invention provides, amongst others for application in a lighting unit, a phosphor having the formula M1−x−y−zZzAaBbCcDdEeN4−nOn:ESxREy (I), with M=selected from the group consisting of Ca, Sr, and Ba; Z=selected from the group consisting of monovalent Na, K, and Rb; A=selected from the group consisting of divalent Mg, Mn, Zn, and Cd; B=selected from the group consisting of trivalent B, Al and Ga; C=selected from the group consisting of tetravalent Si, Ge, Ti, and Hf; D=selected from the group consisting of monovalent Li, and Cu; E=selected for the group consisting of P, V, Nb, and Ta; ES=selected from the group consisting of divalent Eu, Sm and Yb; RE=selected from the group consisting of trivalent Ce, Pr, Nd, Sm, Eu, Gd, Tb, Dy, Ho, Er, and Tm; 0≦x≦0.2; 0≦y≦0.2; 0<x+y≦0.4; 0≦z<1; 0≦n≦0.5; 0≦a≦4 (such as 2≦a≦3); 0≦b≦4; 0≦c≦4; 0≦d≦4; 0≦e≦4; a+b+c+d+e=4; and 2a+3b+4c+d+5e=10−y−n+z.

Owner:LUMILEDS

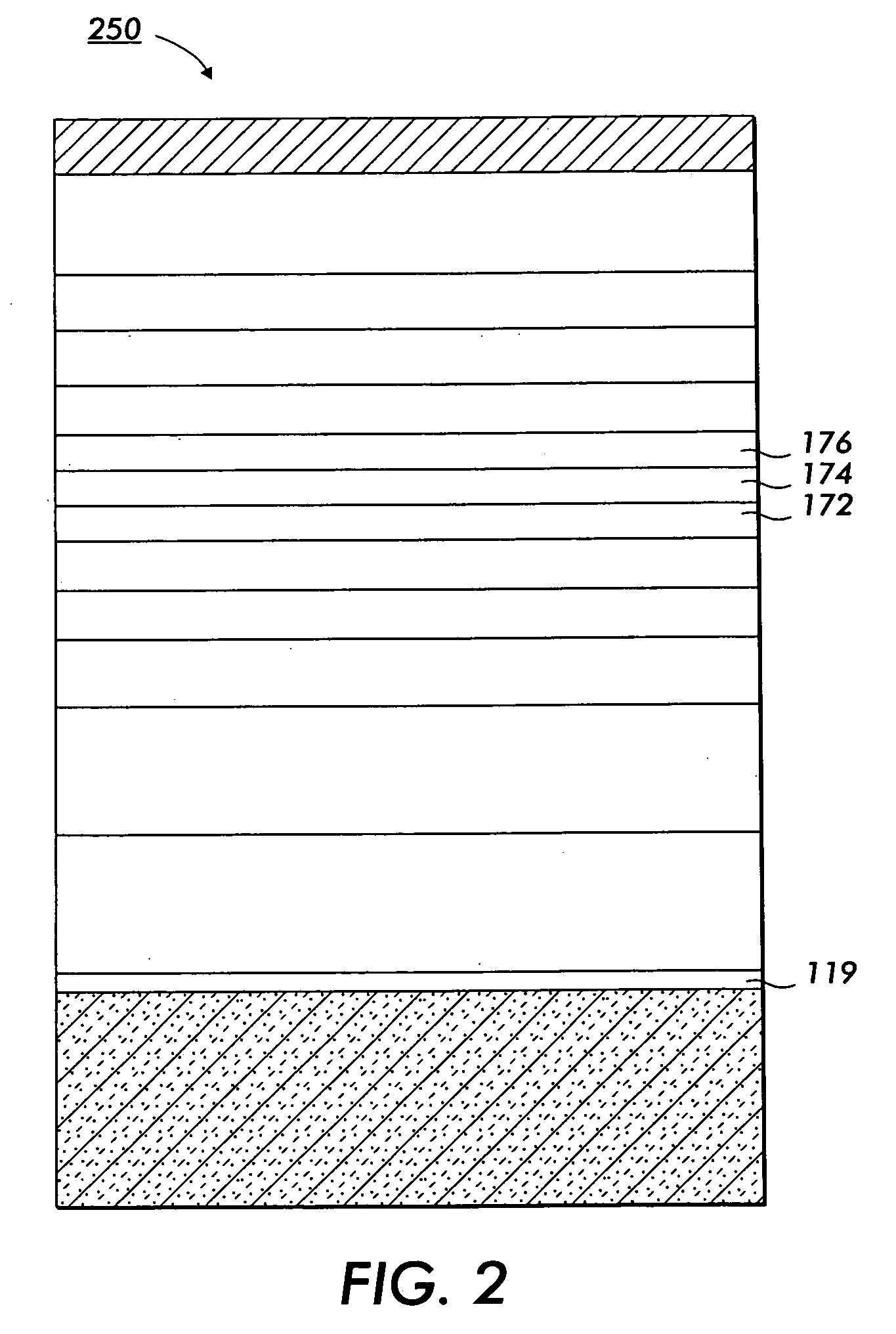

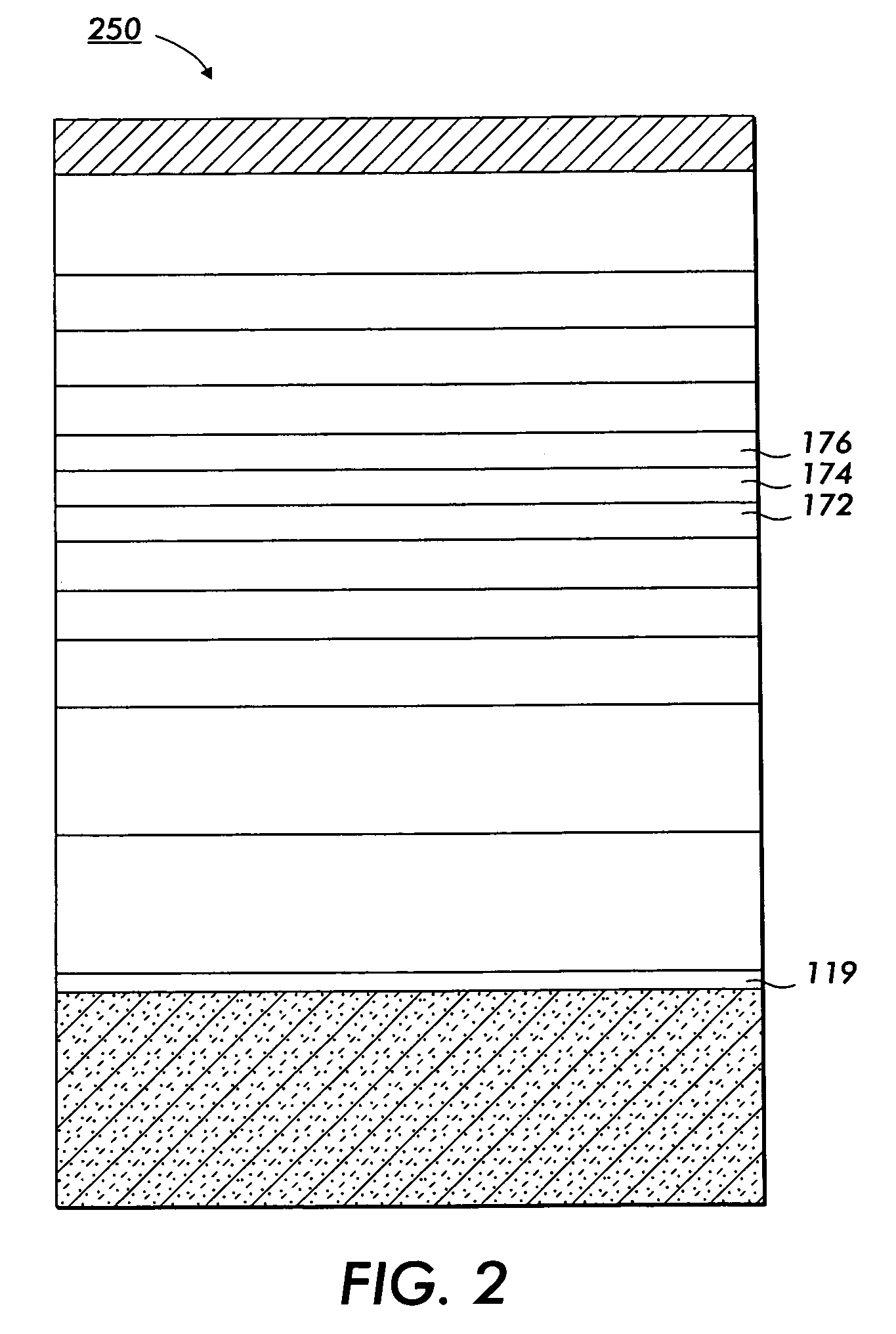

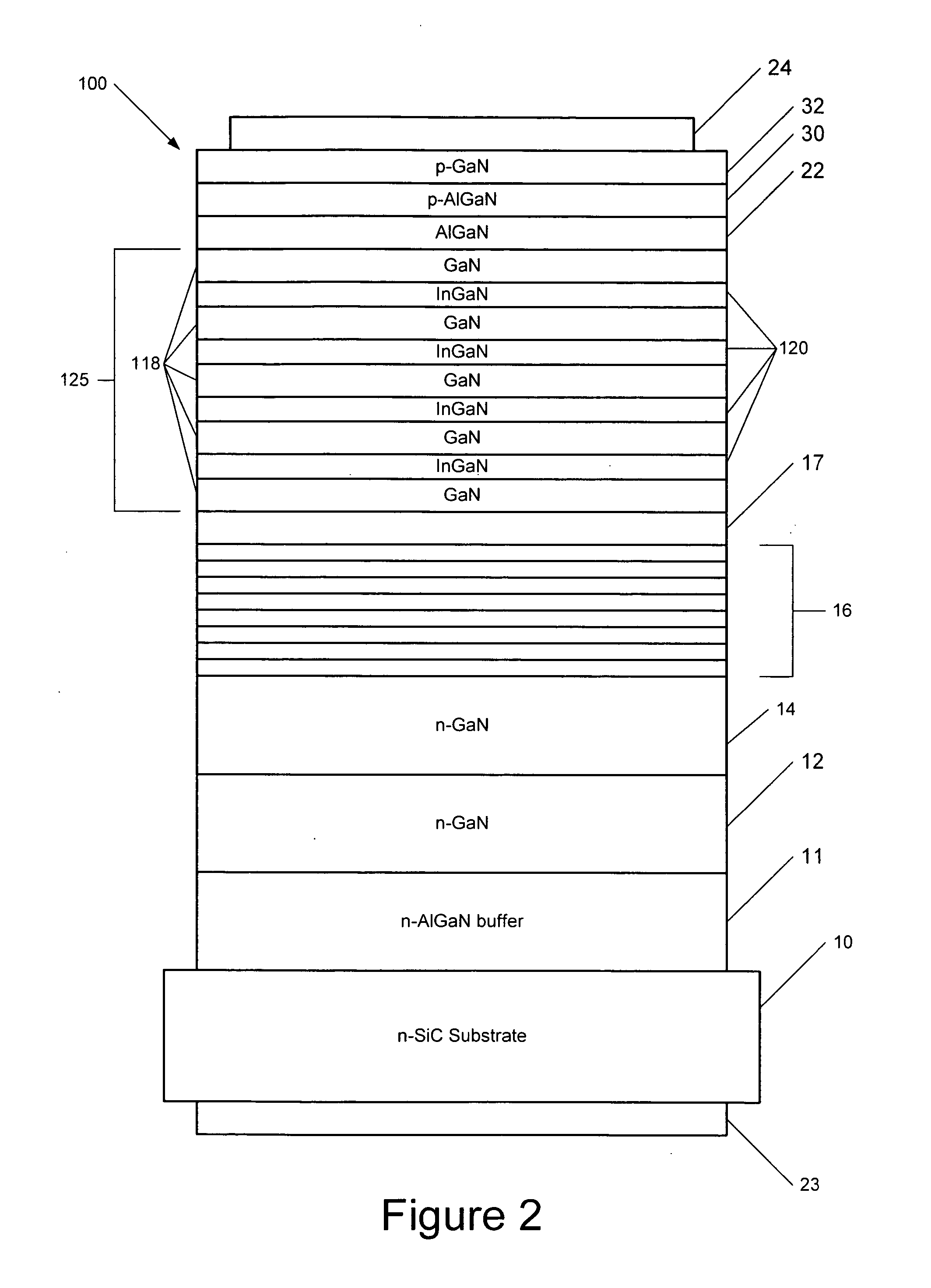

Group III nitride based light emitting diode structures with a quantum well and superlattice, group III nitride based quantum well structures and group III nitride based superlattice structures

InactiveUS20050045895A1Semiconductor/solid-state device manufacturingNanoopticsDevice materialGallium

A light emitting diode is provided having a Group III nitride based superlattice and a Group III nitride based active region on the superlattice. The active region has at least one quantum well structure. The quantum well structure includes a first Group III nitride based barrier layer, a Group III nitride based quantum well layer on the first barrier layer and a second Group III nitride based barrier layer. A Group III nitride based semiconductor device and methods of fabricating a Group III nitride based semiconductor device having an active region comprising at least one quantum well structure are provided. The quantum well structure includes a well support layer comprising a Group III nitride, a quantum well layer comprising a Group III nitride on the well support layer and a cap layer comprising a Group III nitride on the quantum well layer. A Group III nitride based semiconductor device is also provided that includes a gallium nitride based superlattice having at least two periods of alternating layers of InXGa1-XN and InYGa1-YN, where 0≦X<1 and 0≦Y<1 and X is not equal to Y. The semiconductor device may be a light emitting diode with a Group III nitride based active region. The active region may be a multiple quantum well active region.

Owner:CREELED INC

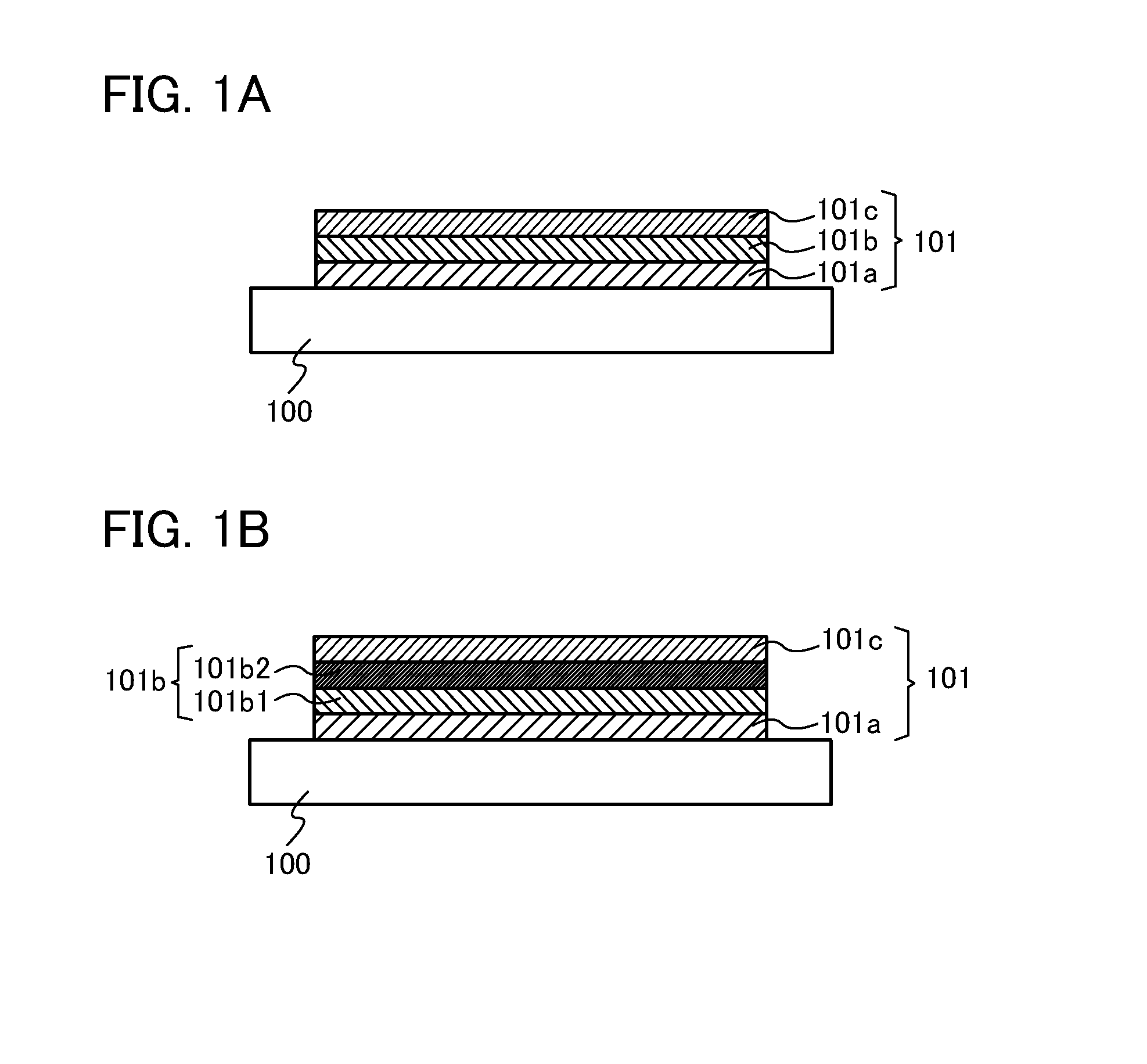

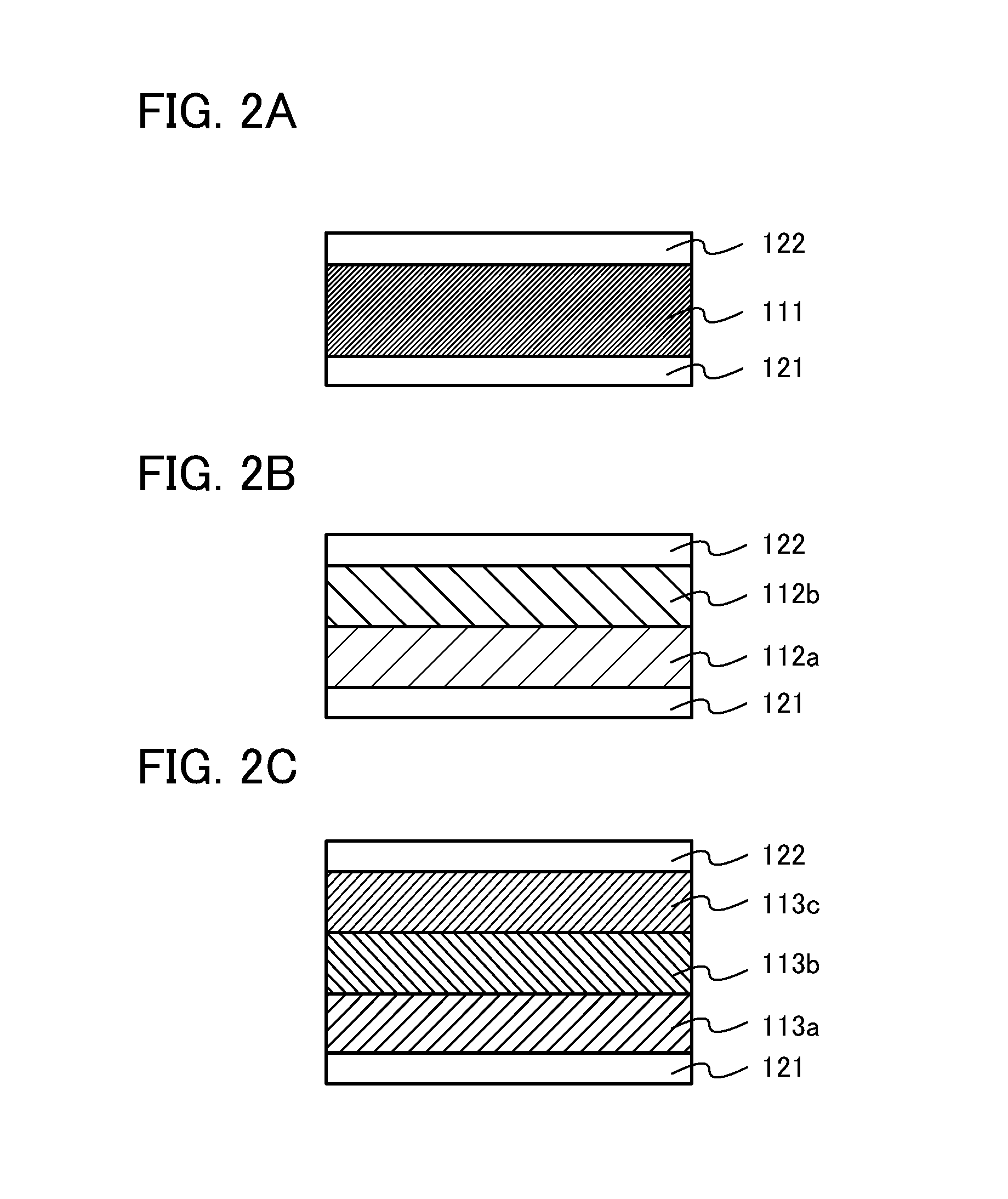

Oxide semiconductor stacked film and semiconductor device

ActiveUS20140034946A1Improve stabilityStable electrical characteristicsTransistorSemiconductor/solid-state device testing/measurementPower semiconductor deviceIndium

An oxide semiconductor stacked film which does not easily cause a variation in electrical characteristics of a transistor and has high stability is provided. Further, a transistor which includes the oxide semiconductor stacked film in its channel formation region and has stable electrical characteristics is provided. An oxide semiconductor stacked film includes a first oxide semiconductor layer, a second oxide semiconductor layer, and a third oxide semiconductor layer which are sequentially stacked and each of which contains indium, gallium, and zinc. The content percentage of indium in the second oxide semiconductor layer is higher than that in the first oxide semiconductor layer and the third oxide semiconductor layer, and the absorption coefficient of the oxide semiconductor stacked film, which is measured by the CPM, is lower than or equal to 3×10−3 / cm in an energy range of 1.5 eV to 2.3 eV.

Owner:SEMICON ENERGY LAB CO LTD

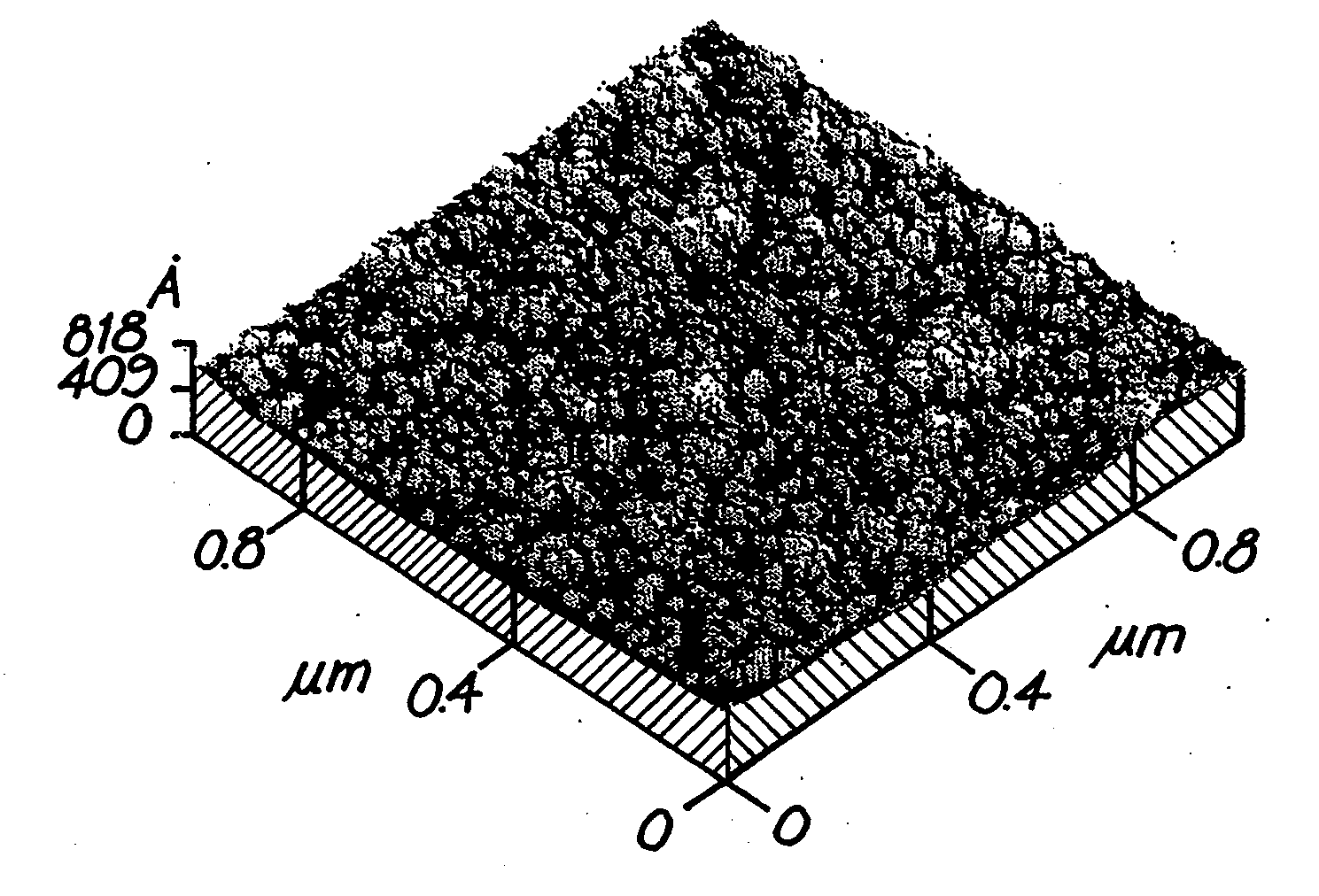

Process for manufacturing a gallium rich gallium nitride film

ActiveUS20060174815A1Increase conductivity and crystallinityImprove conductivityPolycrystalline material growthAfter-treatment detailsOhmOxide

A process for the manufacture of a gallium rich gallium nitride film is described. The process comprises (a) preparing a reaction mixture containing a gallium species and a nitrogen species, the gallium species and the nitrogen species being selected such that, when they react with each other, gallium nitride is formed; and (b) growing the gallium rich gallium nitride film from the reaction mixture, by allowing the gallium species to react with the nitrogen species and to deposit gallium nitride on a substrate selected from the group consisting of silicon, glass, sapphire, quartz and crystalline materials having a lattice constant closely matched to gallium nitride, including zinc oxide, optionally with a zinc oxide buffer layer, at a temperature of from about 480° C. to about 900° and in the presence of a gaseous environment in which the partial pressure of oxygen is less than 10−4 Torr, wherein gallium atoms to nitrogen atoms in the gallium rich gallium nitride film is from 1.01 to 1.20. The invention also provides the option of annealing the gallium rich gallium nitride film at a temperature of from about 20° C. to about 650° C. and for a time sufficient to decrease the resistivity of the film so that it becomes electrically conductive, for instance to a resistivity below 100 ohm·cm.

Owner:GALLIUM ENTERPRISES

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com