Patents

Literature

286results about How to "Light efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

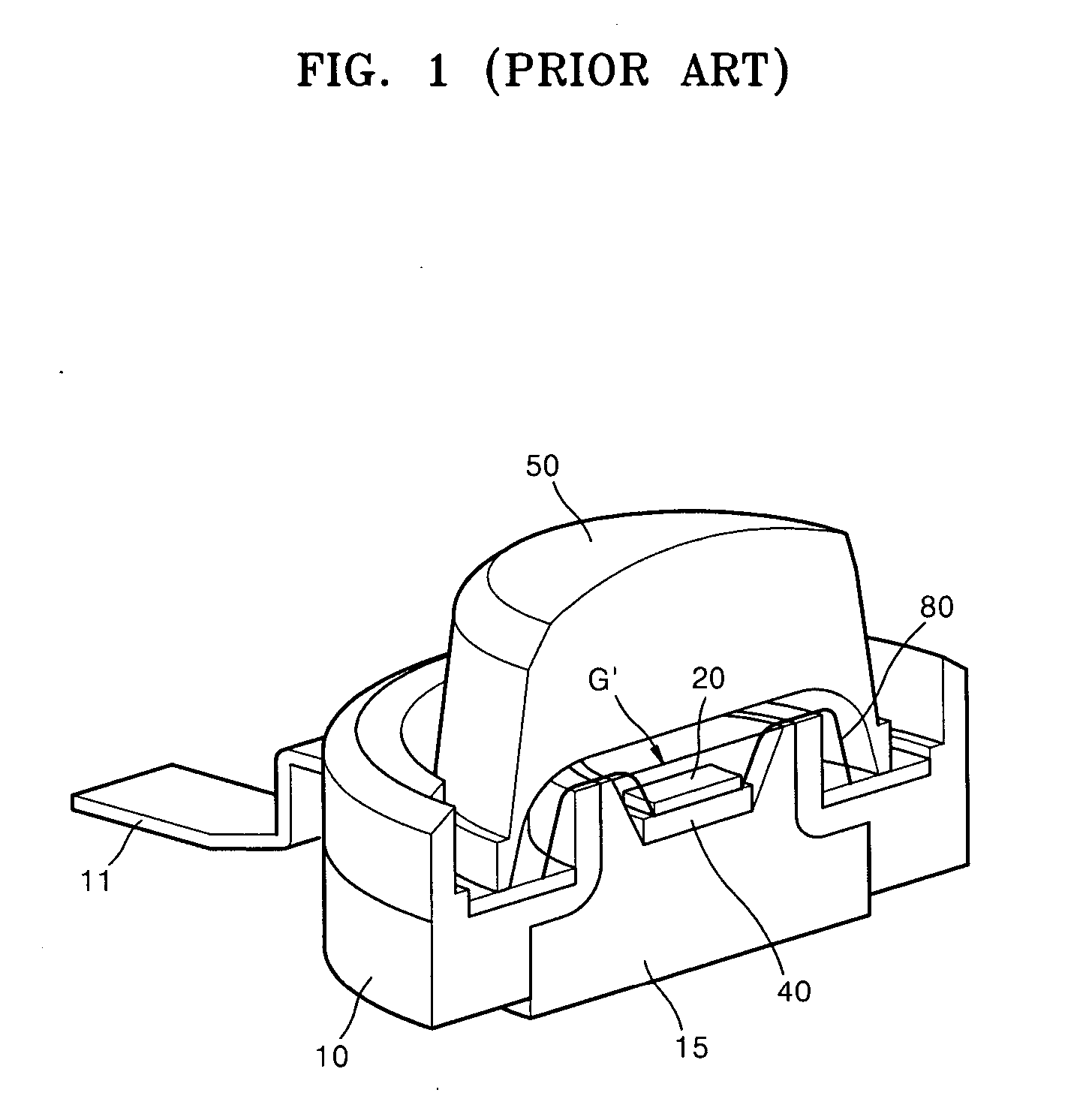

Light mixer and backlight module having the same

ActiveUS7654687B2Easy to makeSimplify the manufacturing processNon-electric lightingPoint-like light sourceOptoelectronicsReflective layer

Owner:HKC CORP LTD

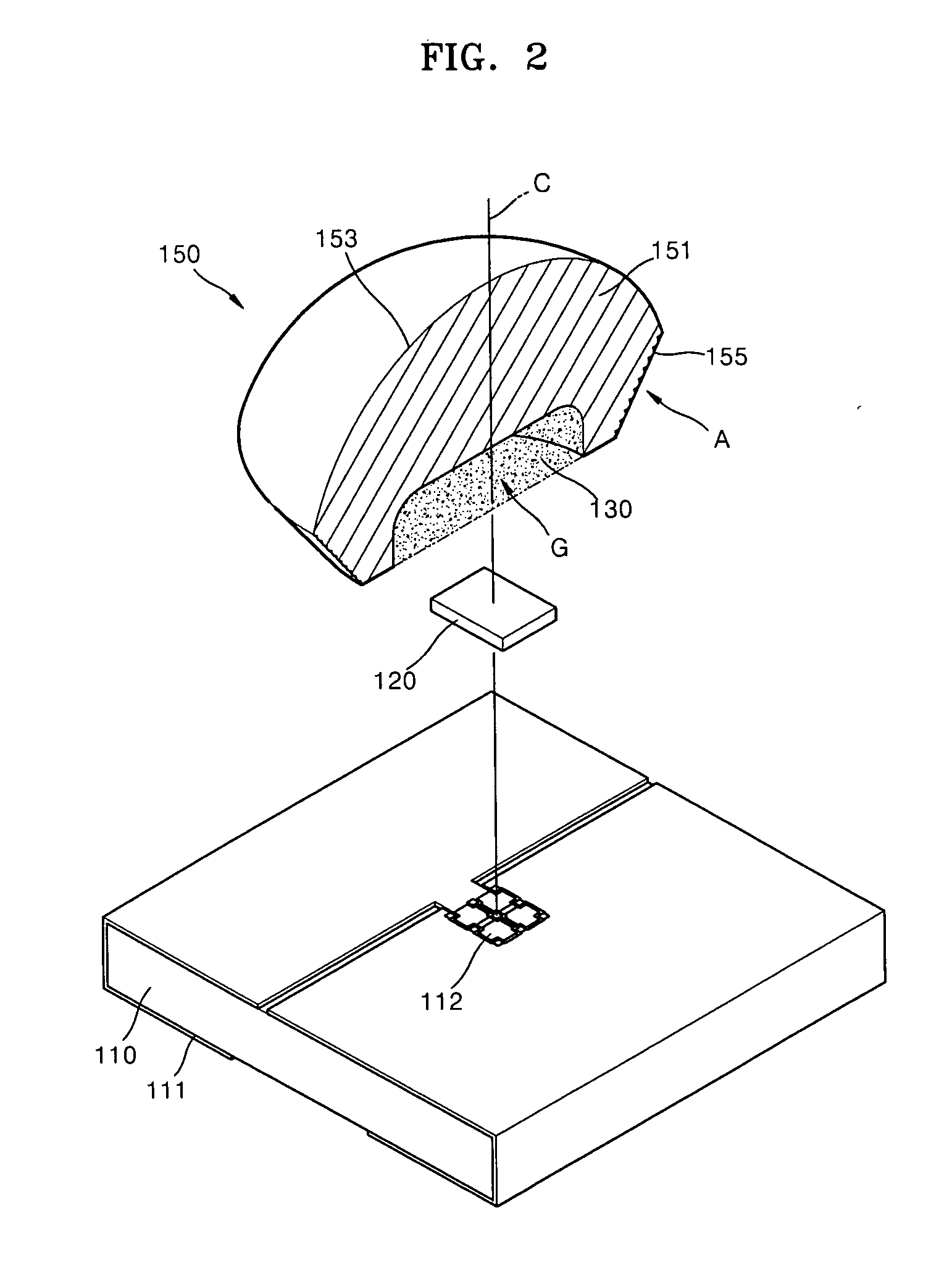

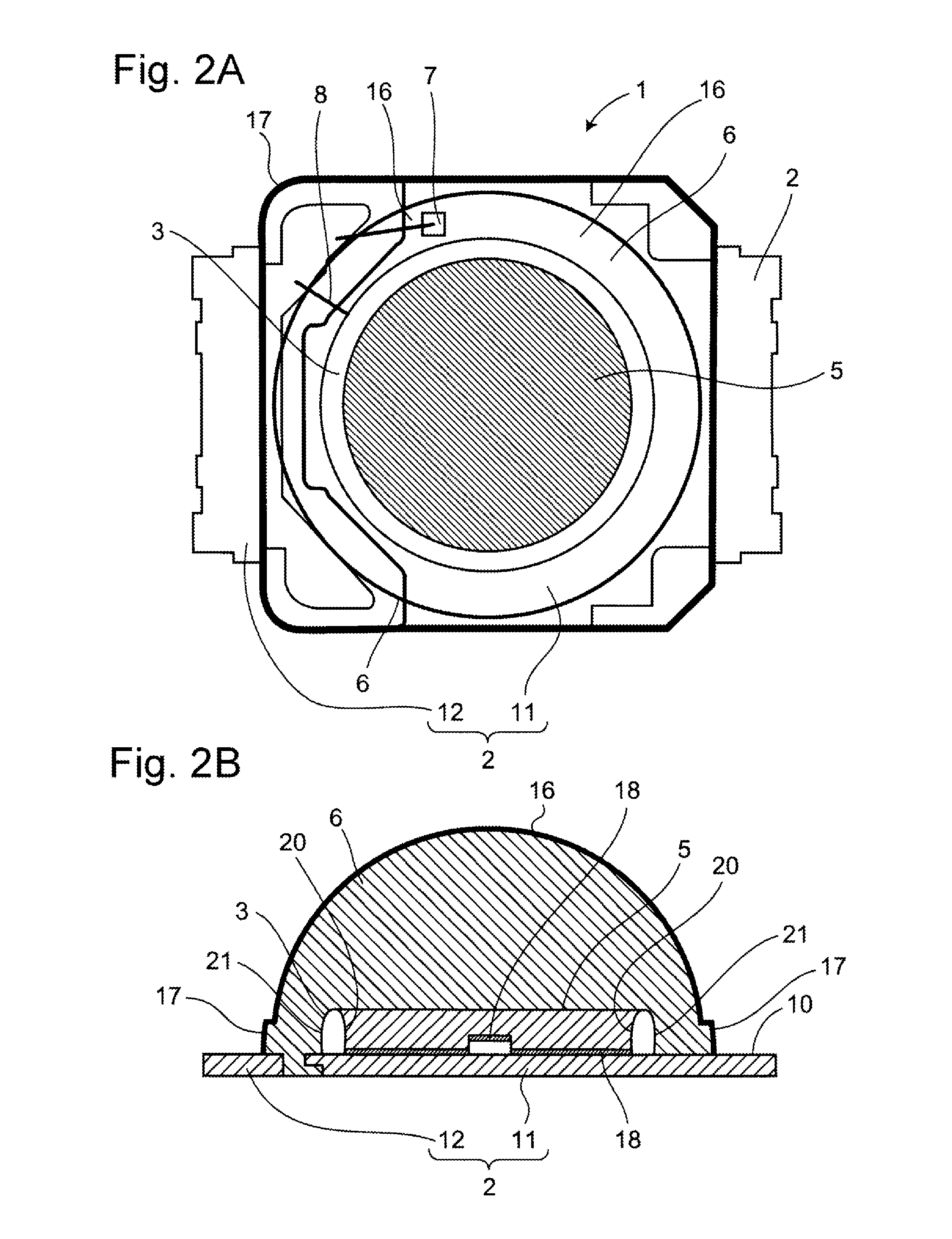

Light emitting device package

ActiveUS20060284209A1Simple structureImprove light extraction efficiencySolid-state devicesSemiconductor/solid-state device manufacturingInterior spaceProcess loss

A light emitting device package is provided. The light emitting device package comprises a base substrate on which a wiring pattern is formed; a light emitting device mounted on the base substrate to emit light when supplied with driving power through the wiring pattern; a molded lens stably seated on the base substrate and having an inner space for sealing the light emitting device and reflective surfaces formed along outer sides facing the inner space to guide light from the light emitting device in an effective display direction; and a sealing resin between the inner space to bond the base substrate to the molded lens, whereby the packaging structure is simplified so that an assembly process and reliability testing are simplified, process losses due to defects are minimized, and the light extraction efficiency from the light emitting device and heat-dissipation performance are improved.

Owner:SAMSUNG ELECTRONICS CO LTD

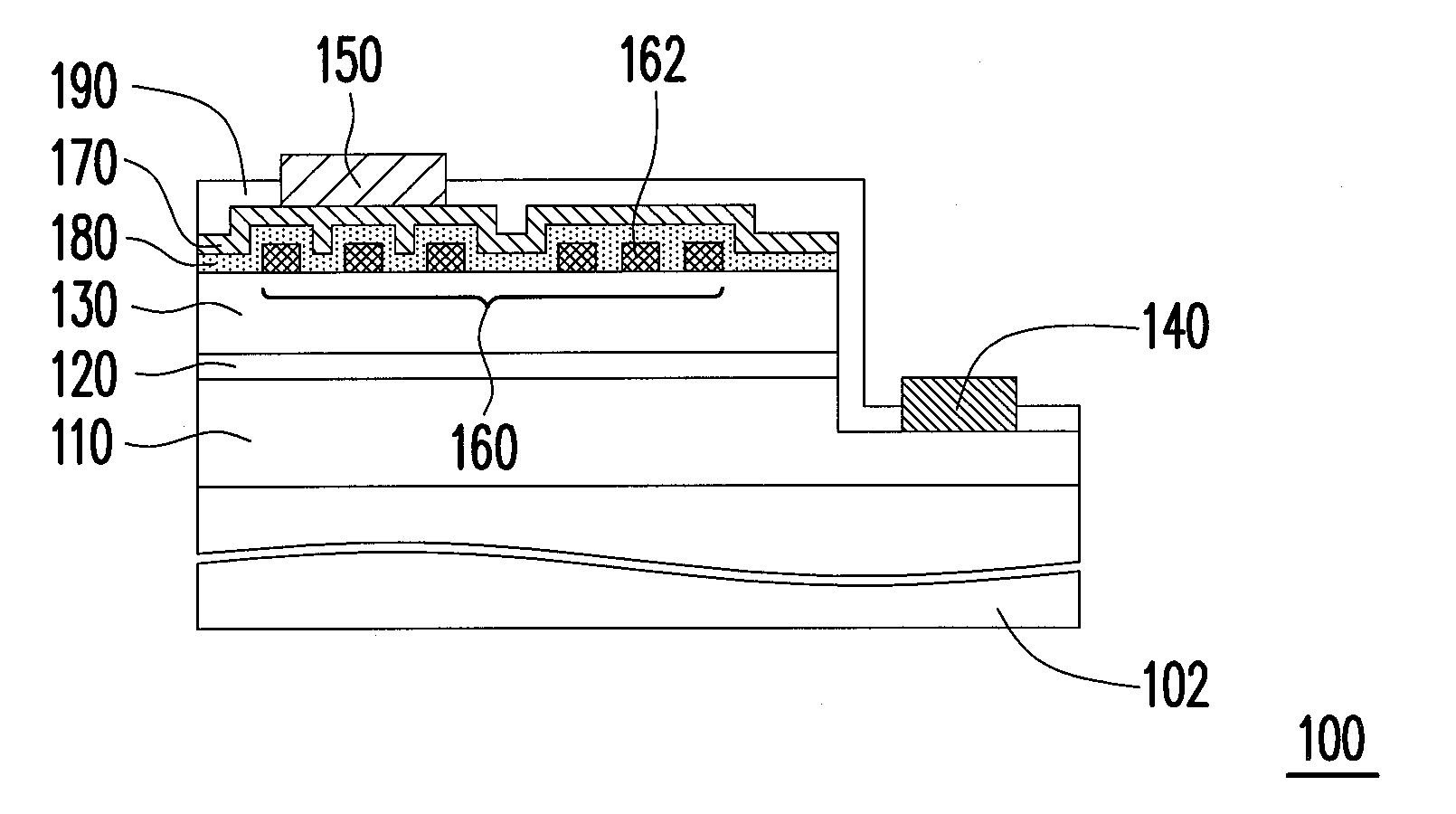

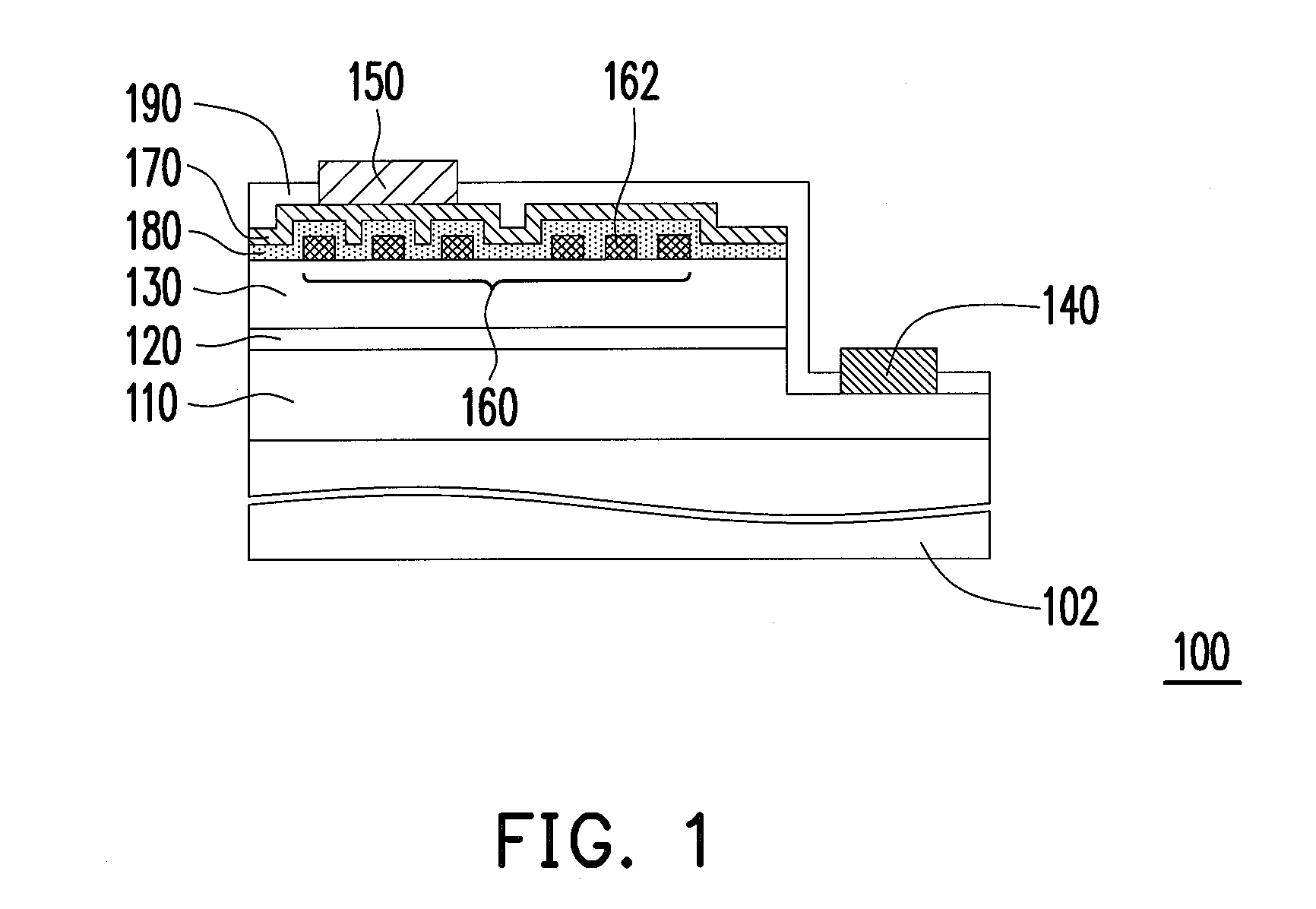

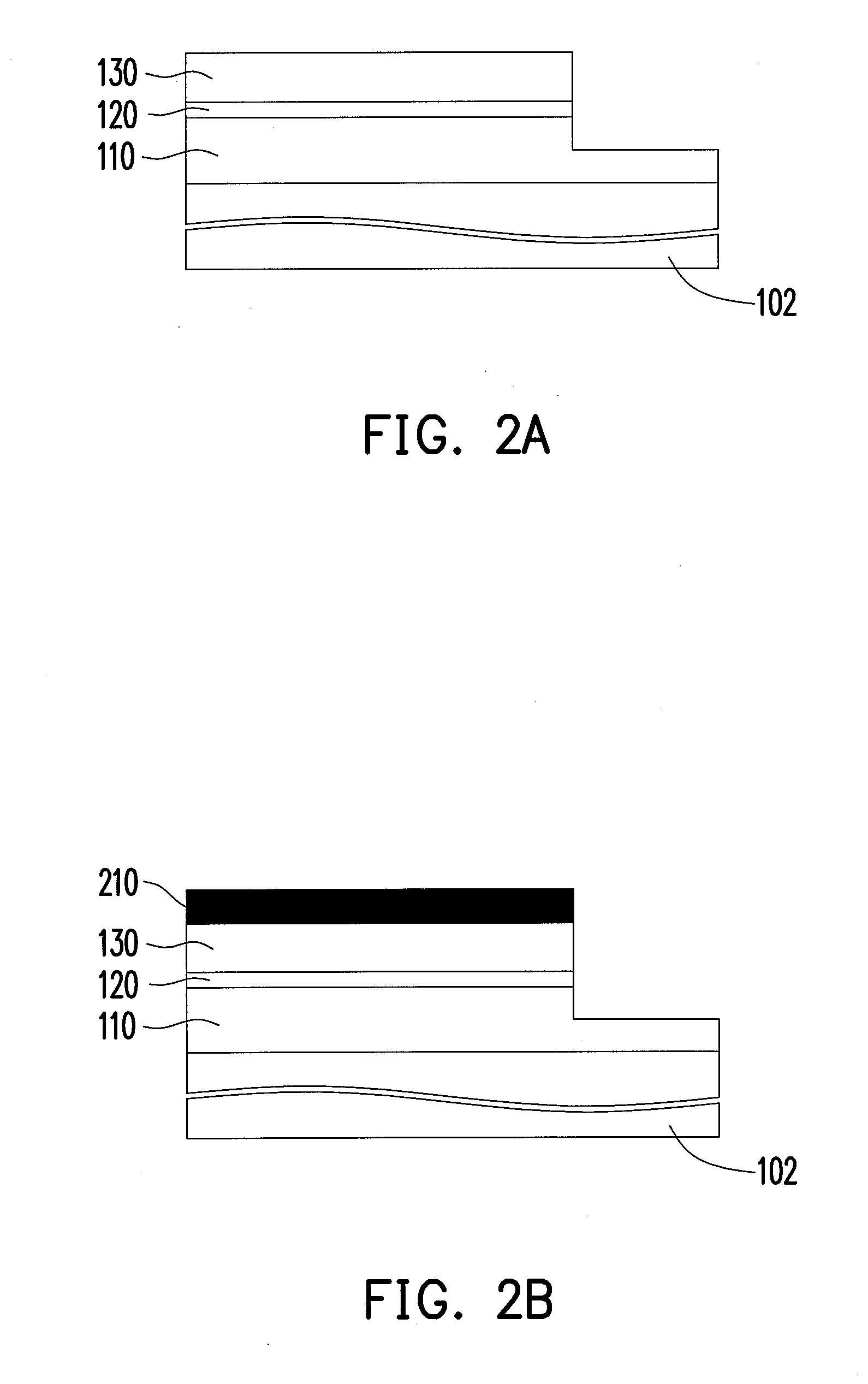

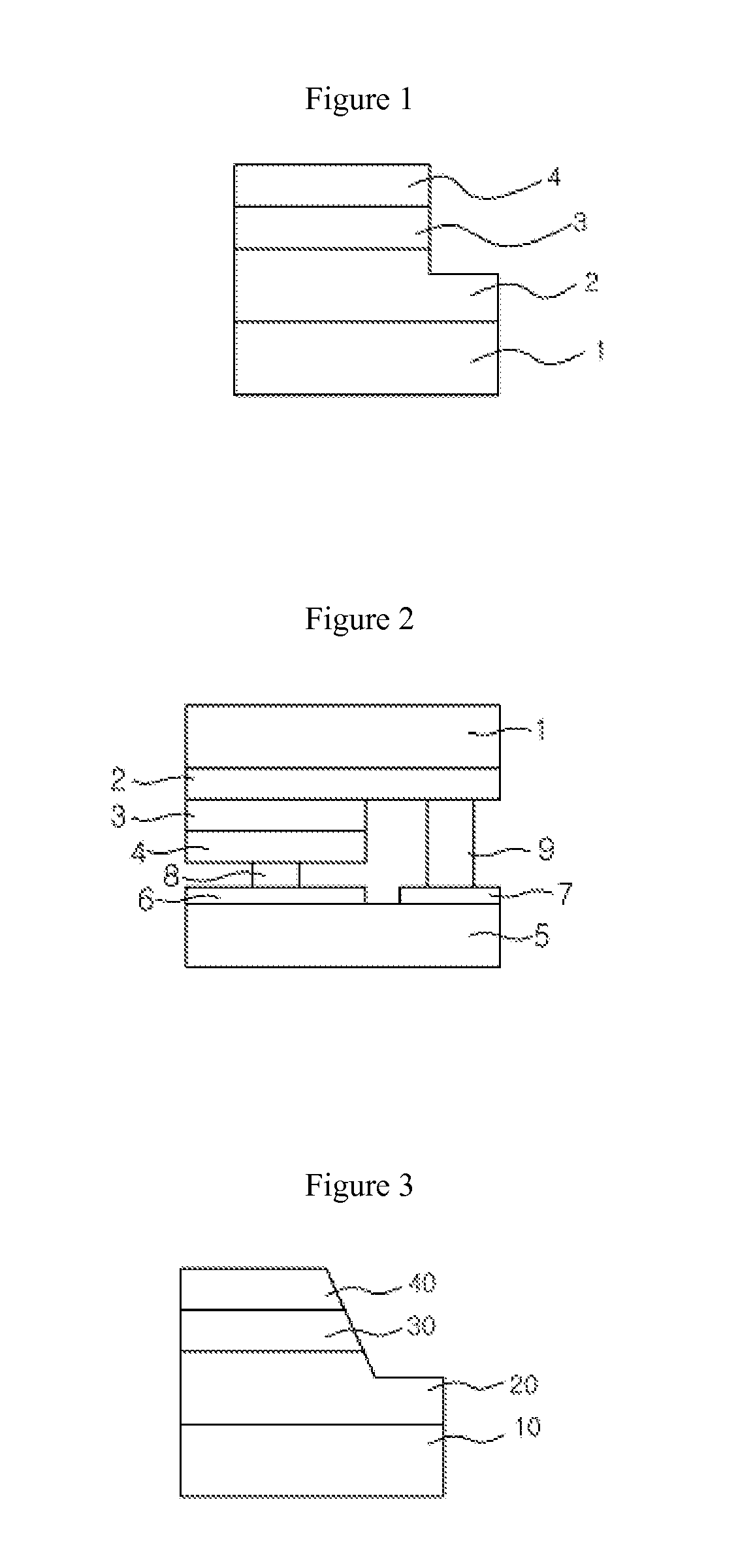

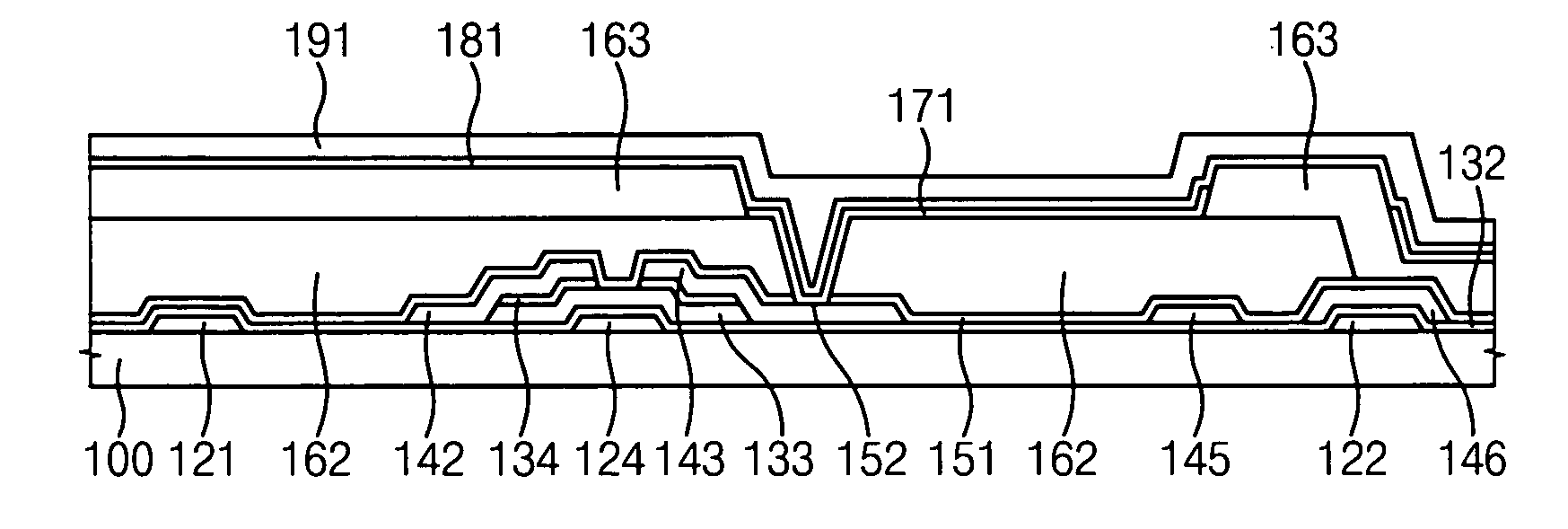

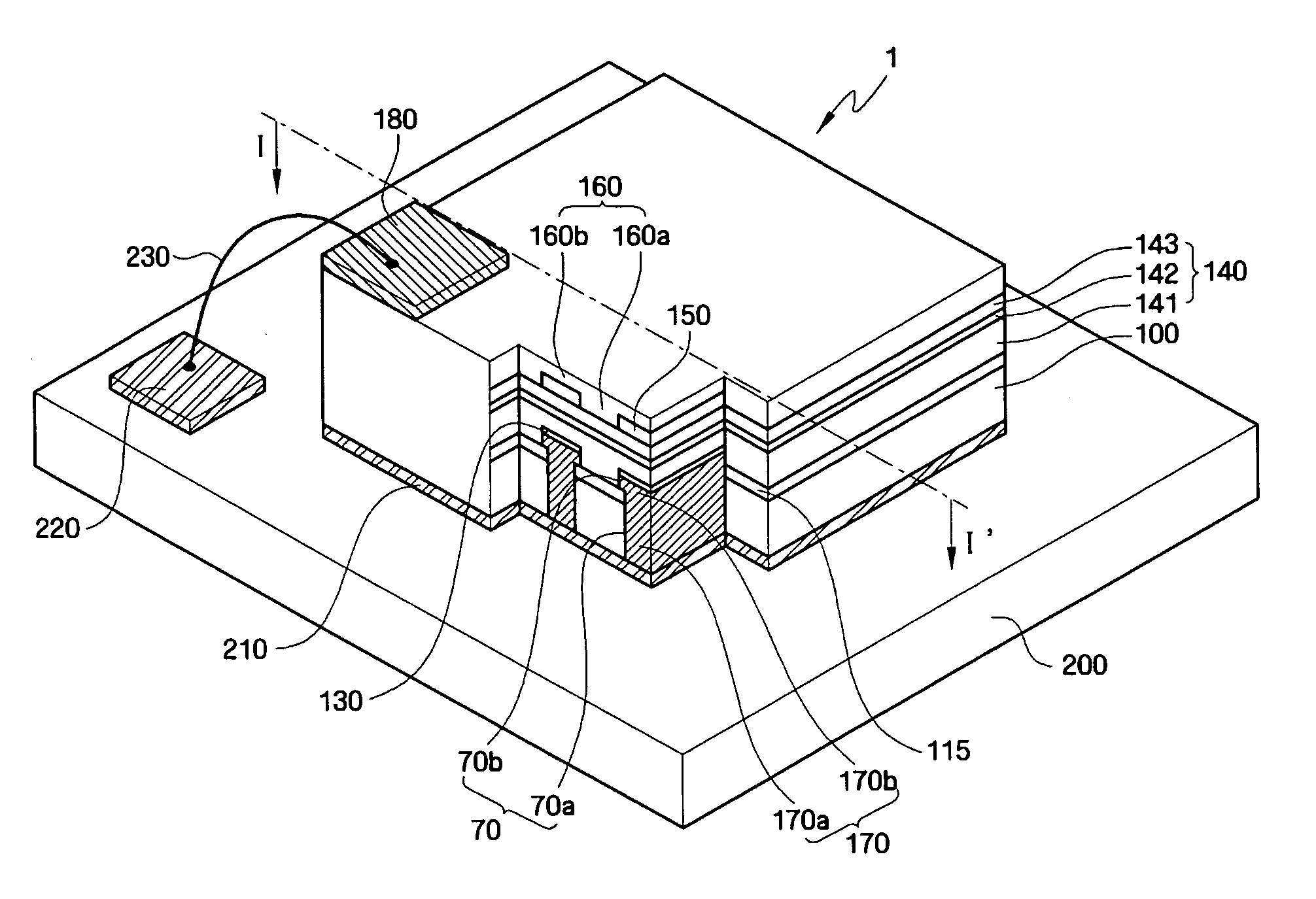

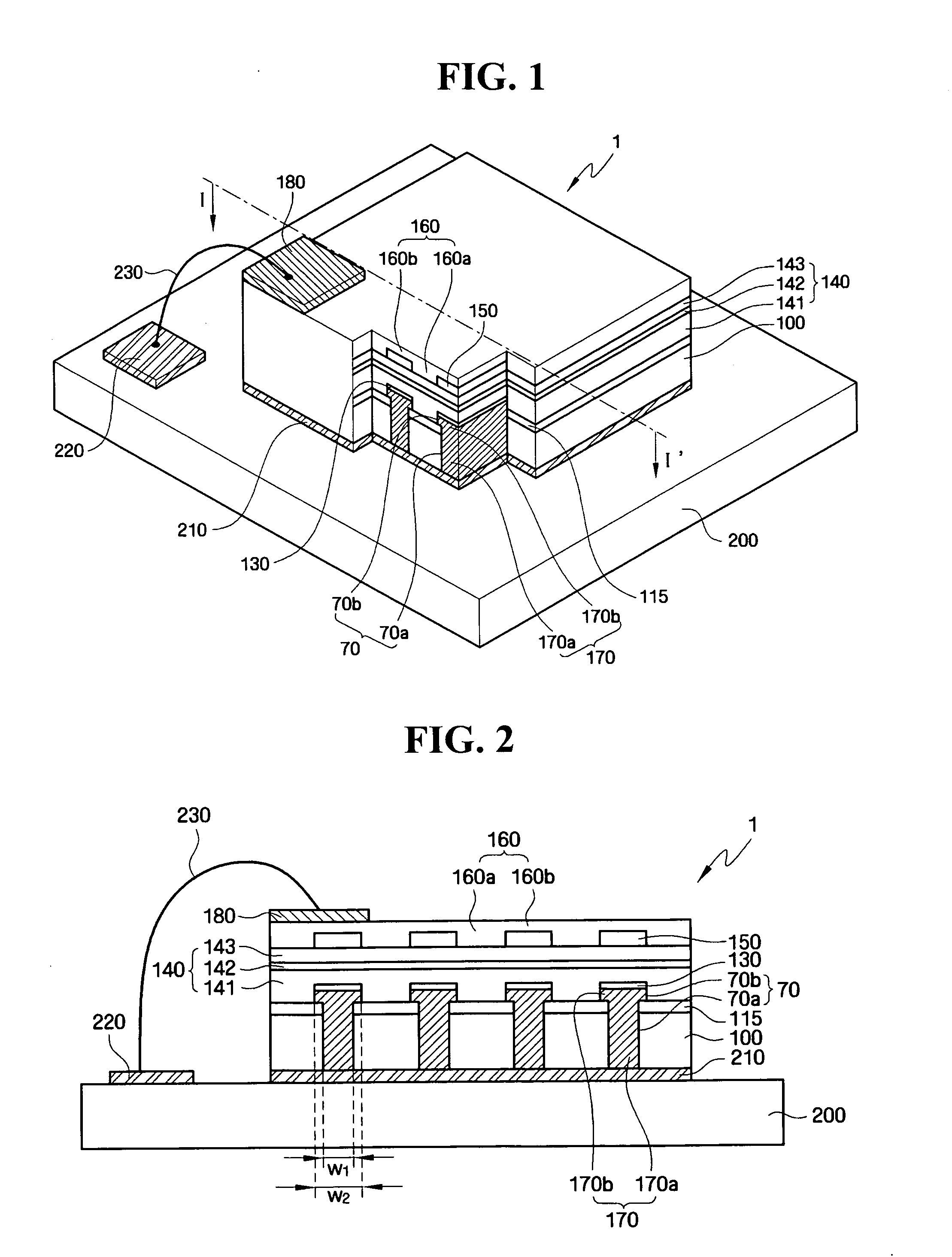

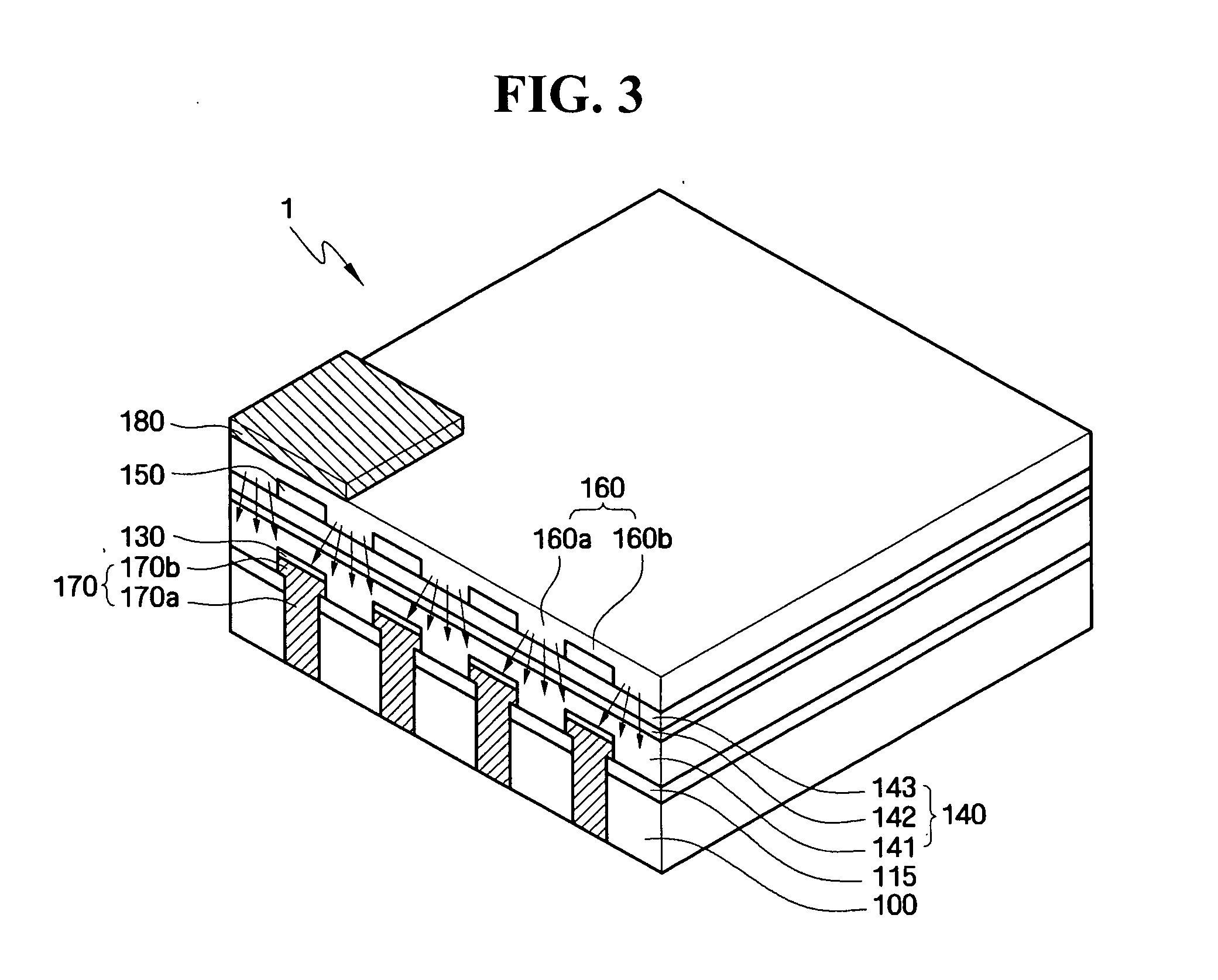

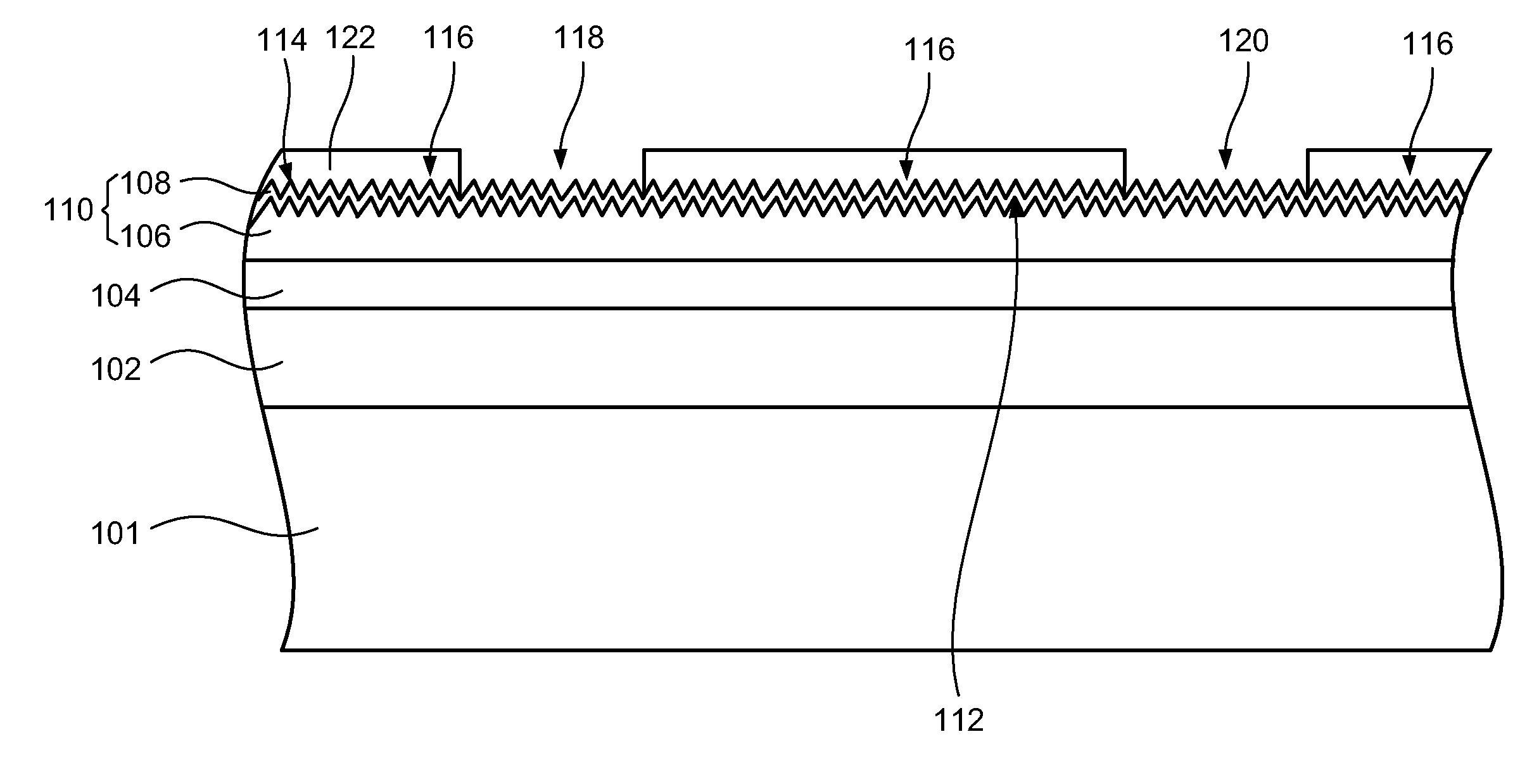

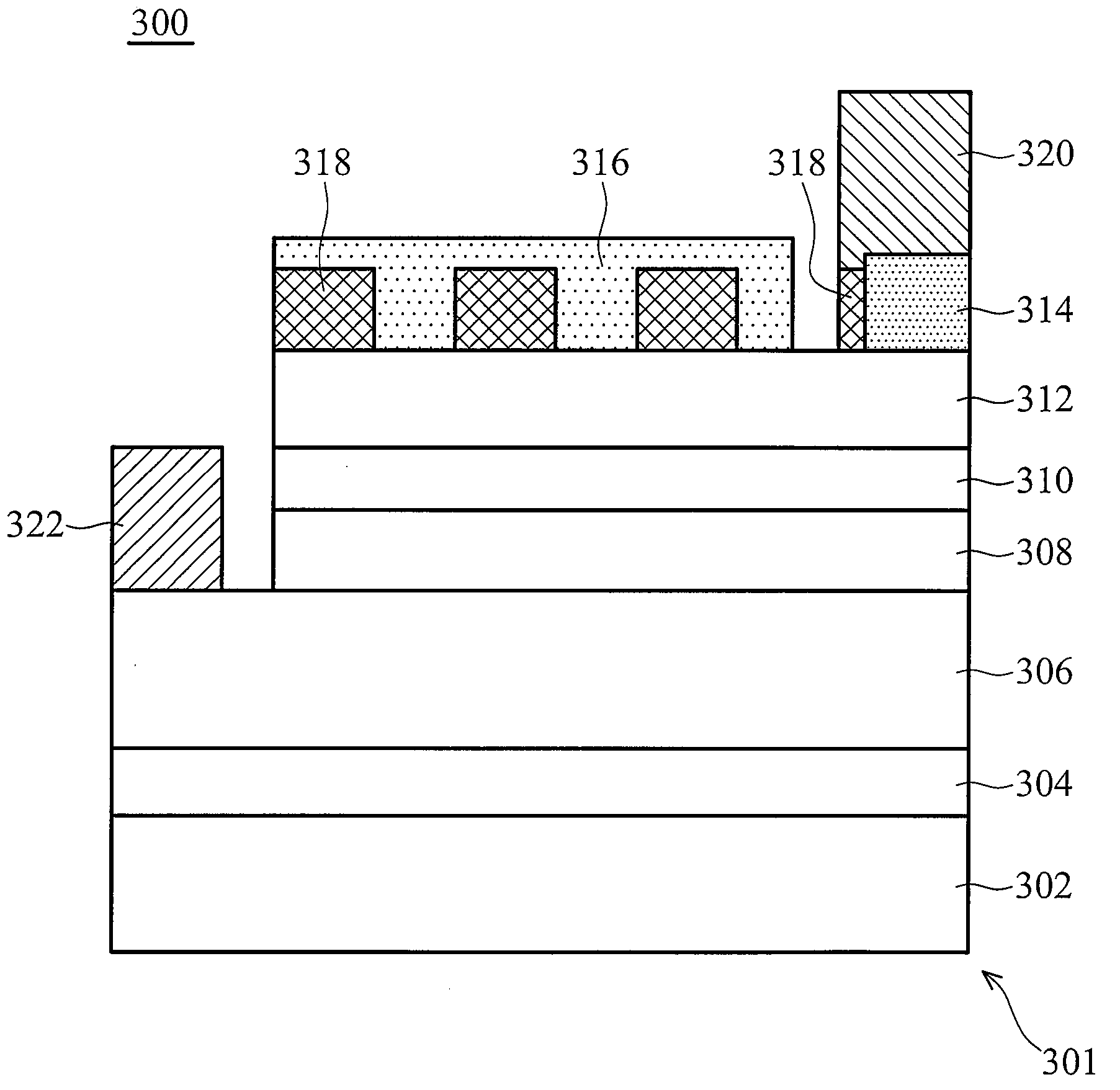

Light emitting diode, package structure and manufacturing method thereof

ActiveUS20100072487A1Efficient light emissionImproved light emissionSolid-state devicesSemiconductor/solid-state device manufacturingElectrical conductorCurrent distribution

A light emitting diode (LED), a fabricating method thereof, and a package structure thereof are provided. The LED includes a substrate, a first semiconductor layer disposed on the substrate, an active layer disposed on the first semiconductor layer, a second semiconductor layer disposed on the active layer, a current distribution modifying pattern, a first electrode and a second electrode. The active layer and the second semiconductor layer form a mesa structure and expose a part of the first semiconductor layer. The current distribution modifying pattern is disposed on the second semiconductor layer. The first electrode is disposed on and electrically connected to the first semiconductor layer exposed by the mesa structure. The second electrode is disposed on the current distribution modifying pattern and is electrically connected to the second semiconductor layer. The LED has superior light emitting efficiency.

Owner:IND TECH RES INST

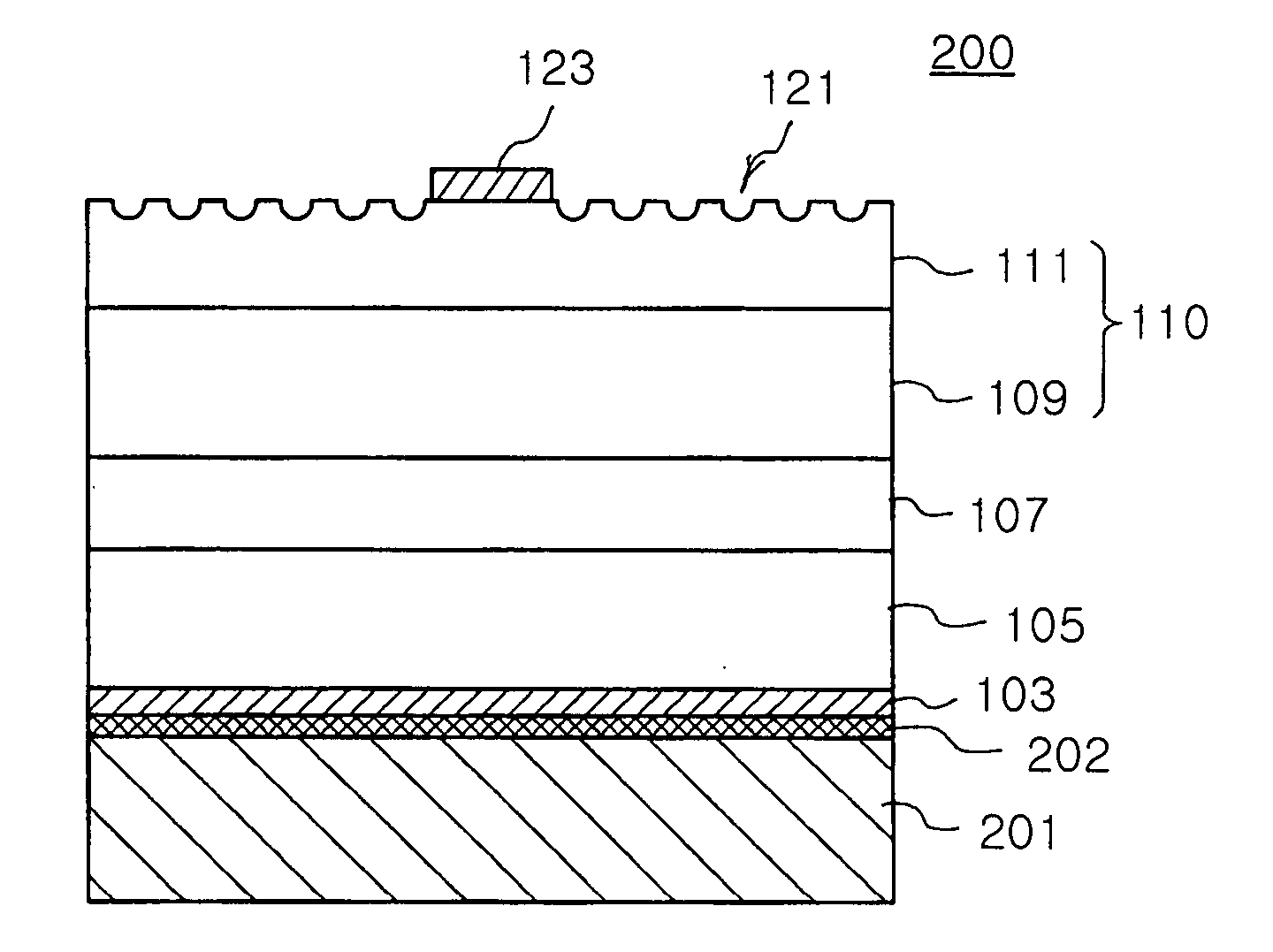

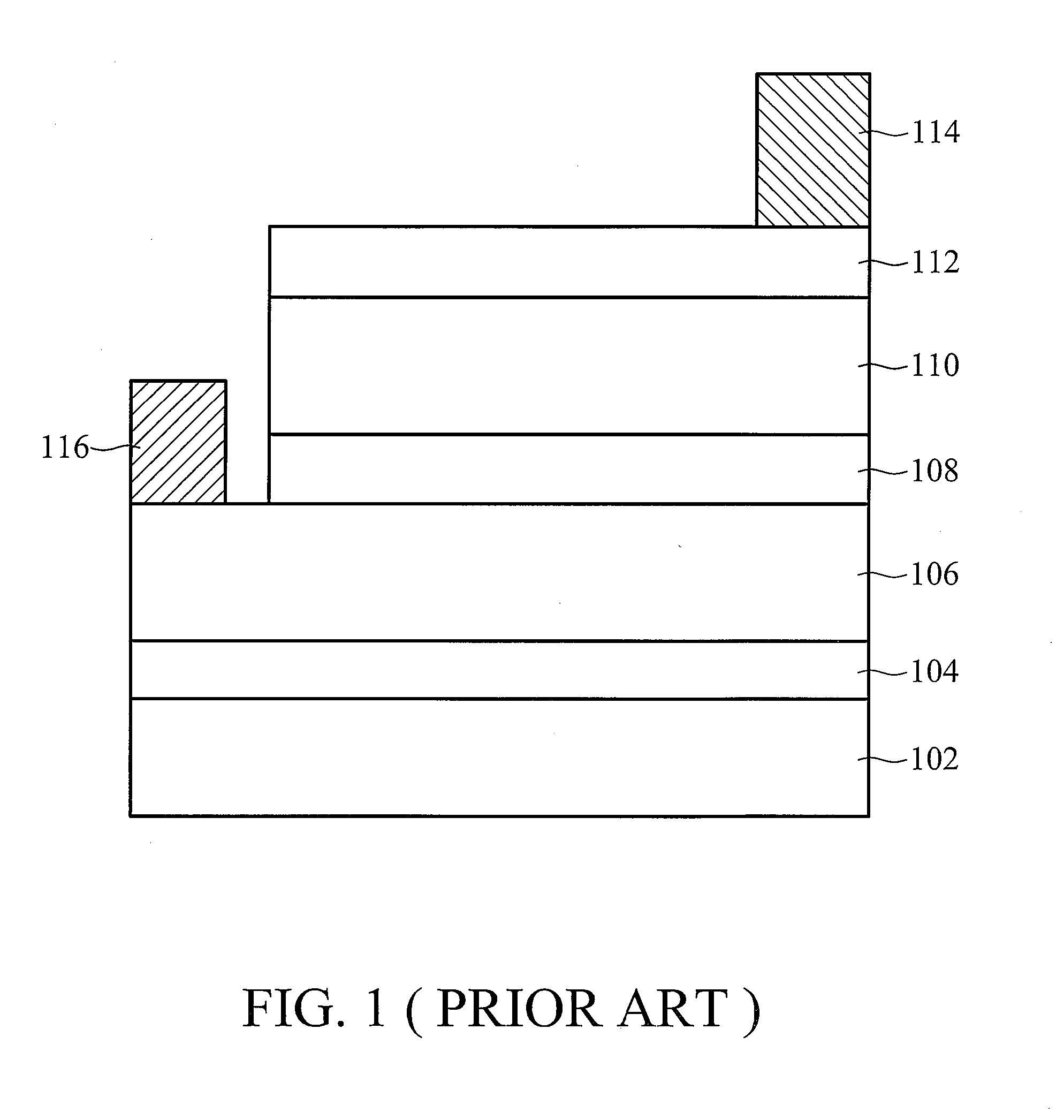

Vertical group III-nitride light emitting device and method for manufacturing the same

InactiveUS20060225644A1Light efficiencyLight propertiesPolycrystalline material growthIn situ pavingsGalliumActive layer

A vertical group III-nitride light emitting device and a manufacturing method thereof are provided. The light emitting device comprises: a conductive substrate; a p-type clad layer stacked on the conductive substrate; an active layer stacked on the p-type clad layer; an n-doped AlxGayIn1-x-yN layer stacked on the active layer; an undoped GaN layer stacked on the n-doped layer; and an n-electrode formed on the undoped GaN layer. The undoped GaN layer has a rough pattern formed on a top surface thereof.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

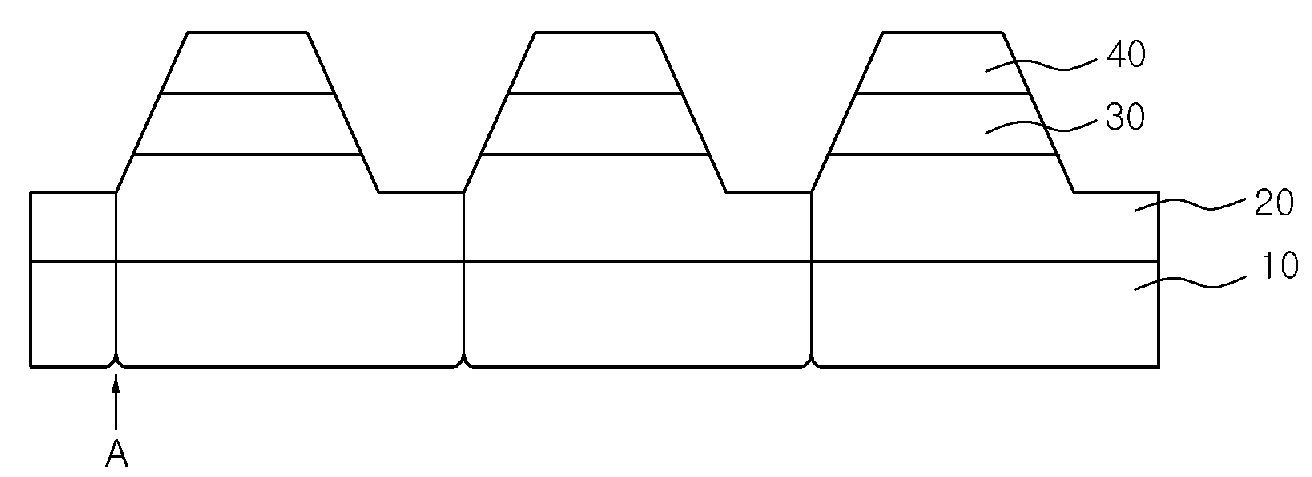

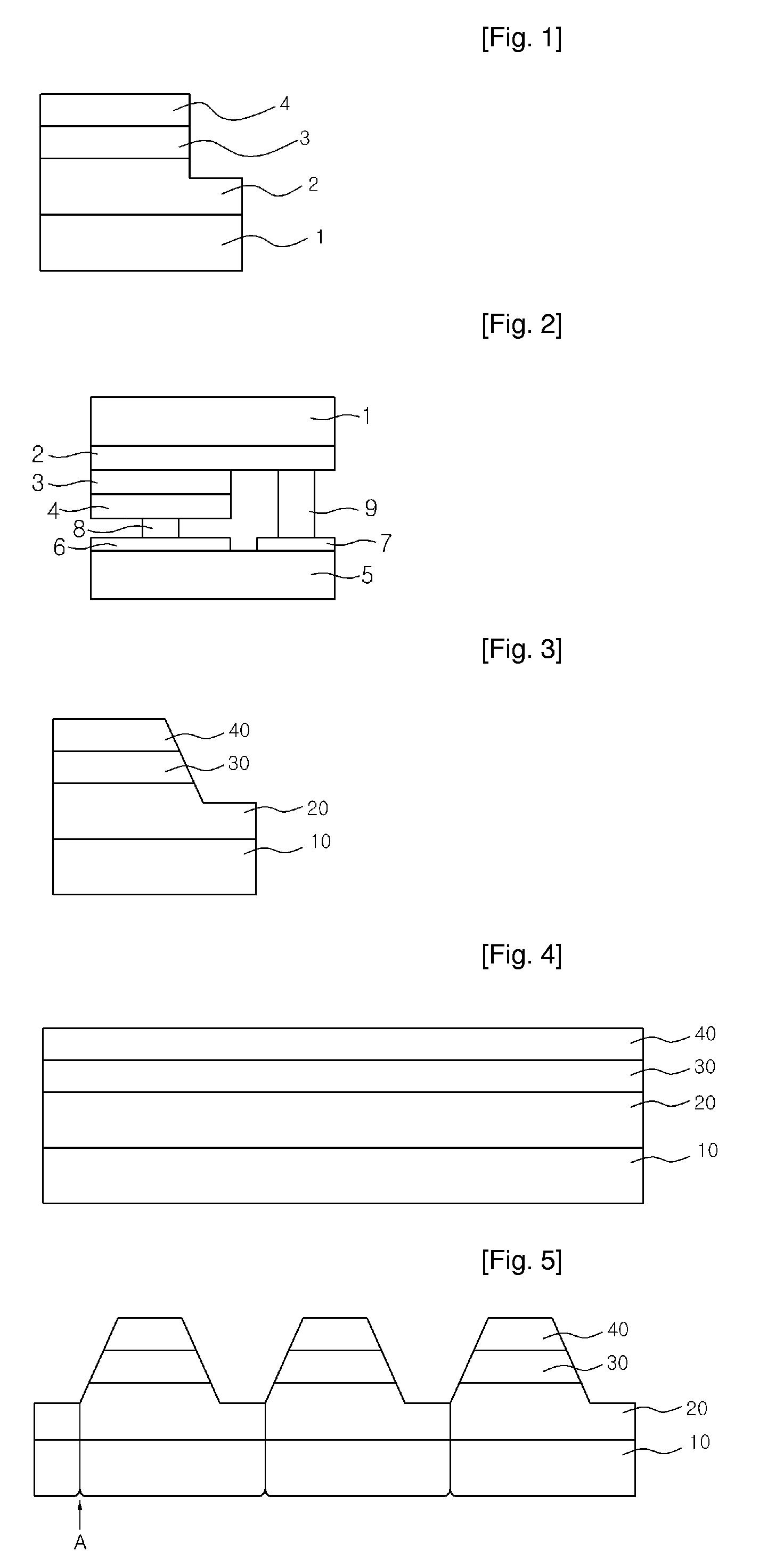

Light Emitting Device and Method of Manufacturing the Same

ActiveUS20080251796A1High luminous intensityIncrease brightnessSolid-state devicesSemiconductor/solid-state device manufacturingQuantum efficiencyLuminous intensity

The present invention relates to a light emitting device and a method of manufacturing the light emitting device. According to the present invention, the light emitting device comprises a substrate, an N-type semiconductor layer formed on the substrate, and a P-type semiconductor layer formed on the N-type semiconductor layer, wherein a side surface including the N-type or P-type semiconductor layer has a slope of 20 to 80° from a horizontal plane. Further, the present invention provides a light emitting device comprising a substrate formed with a plurality of light emitting cells each including an N-type semiconductor layer and a P-type semiconductor layer formed on the N-type semiconductor layer, and a submount substrate flip-chip bonded onto the substrate, wherein the N-type semiconductor layer of one light emitting cell and the P-type semi-conductor layer of another adjacent light emitting cell are connected to each other, and a side surface including at least the P-type semiconductor layer of the light emitting cell has a slope of 20 to 80° from a horizontal plane. Further, the present invention provides a method of manufacturing the light emitting device. Accordingly, there is an advantage in that the characteristics of a light emitting device such as luminous efficiency, external quantum efficiency and extraction efficiency are enhanced and the reliability is secured such that light with high luminous intensity and brightness can be emitted.

Owner:SEOUL VIOSYS CO LTD

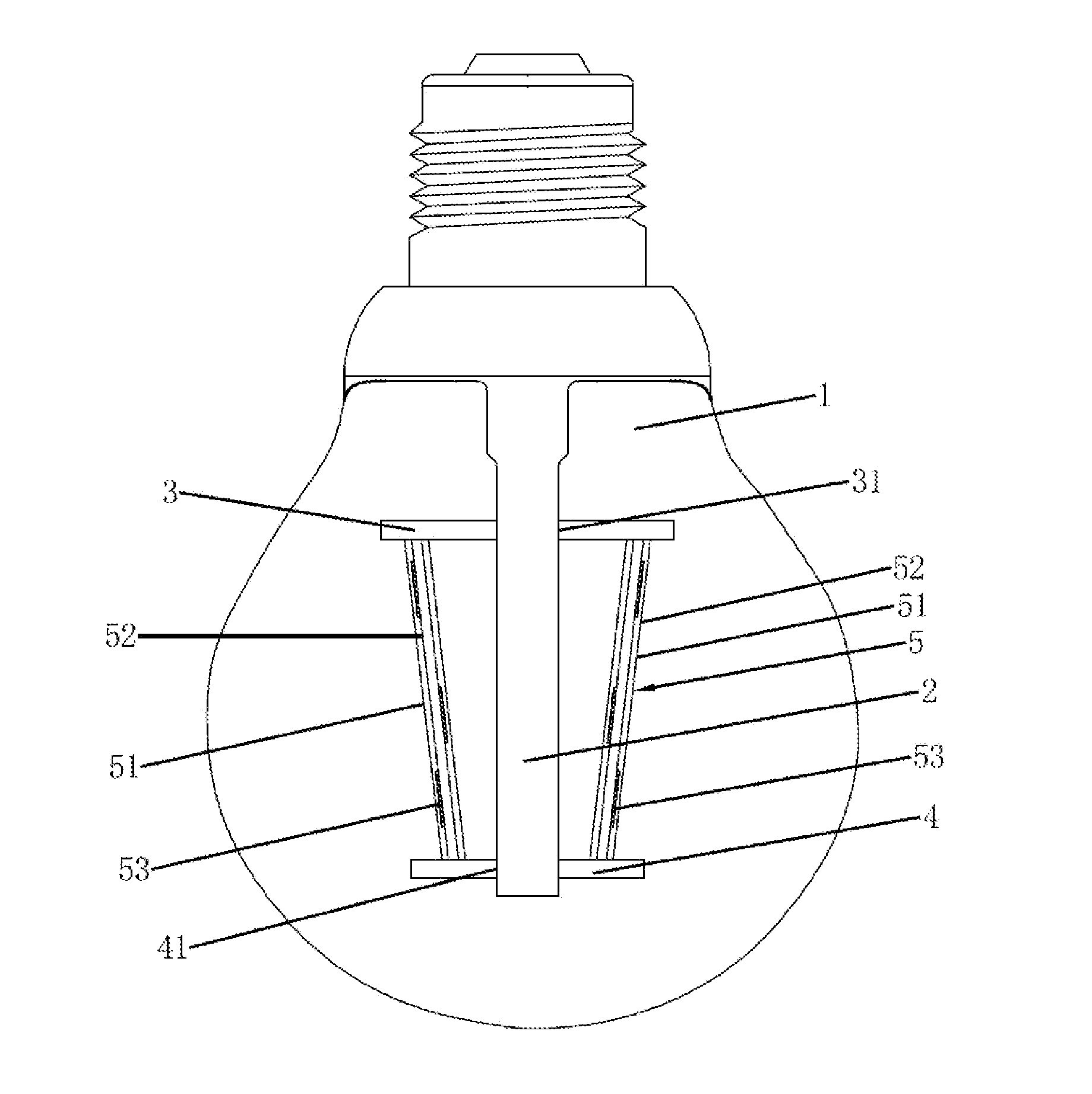

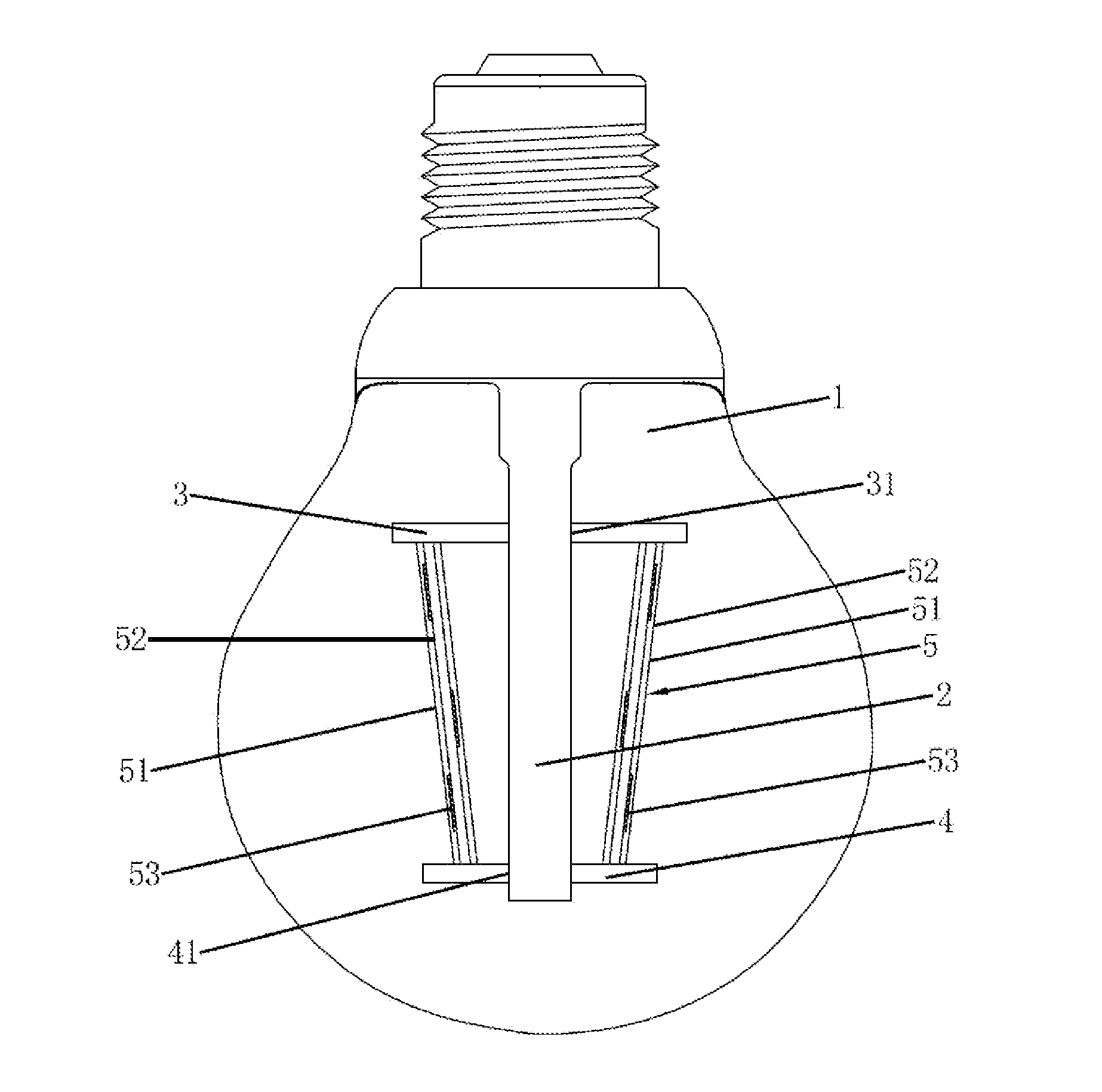

Kind of lamp holder structure of LED bulb

InactiveUS8933619B1Higher luminous fluxImprove efficiencyLighting support devicesPoint-like light sourceElectricityEngineering

The utility model discloses a kind of lamp holder structure of LED bulb comprising a transparent stem, an upper PCB board with upper mounting hole and a lower PCB board with lower mounting hole while the transparent stem is nested to the upper mounting hole and the lower mounting hole in sequence, a LED tube installed between the upper PCB board and the lower PCB board as well as separately electrically-connected to them. The LED tube can be secured by soldering to the appropriate welding position on the upper and lower PCB board. The transparent stem is equivalent to a fixed support for the upper and lower PCB board. When illuminated, the LED tube lights up and all give out light at 360 degree. The structure design makes the higher luminous flux and efficiency for the utility model. Thereby, the utility model is advanced in higher luminous flux, high efficiency and novel structure design.

Owner:DONGGUAN QIJIA ELECTRONICS CO LTD

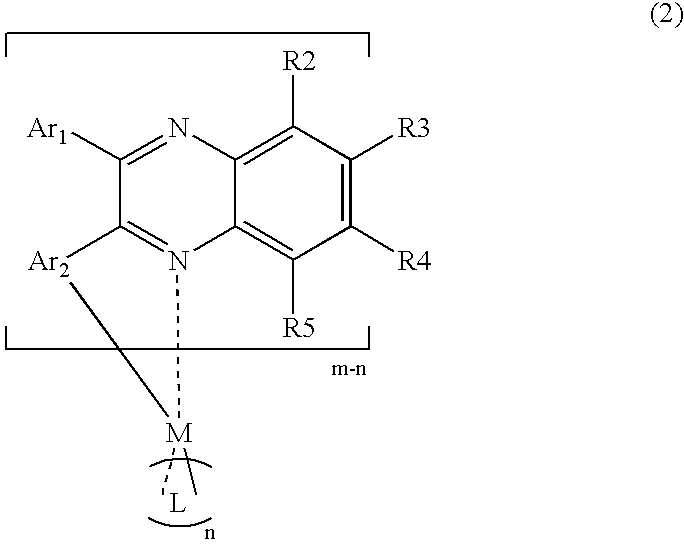

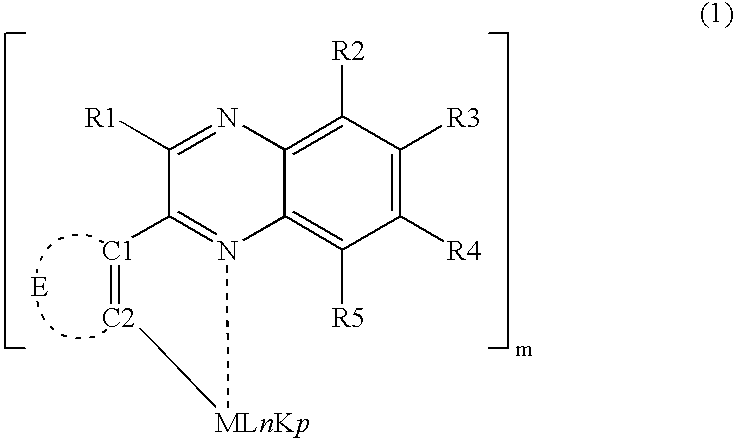

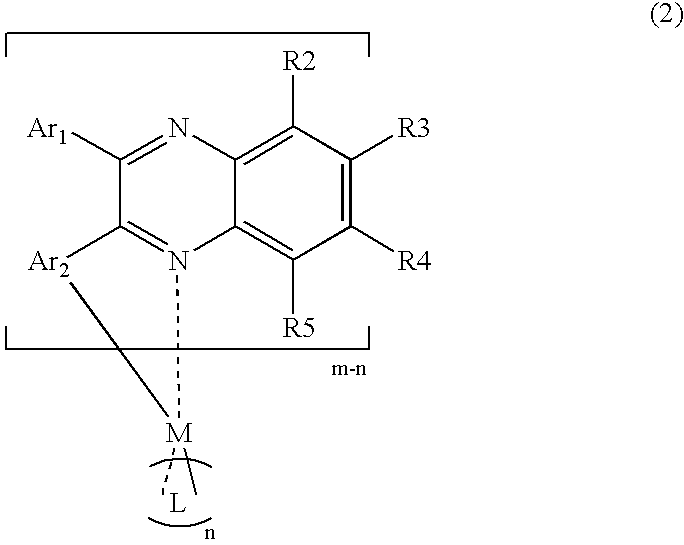

Organometallic compound containing quinoxaline structure and light emitting element

InactiveUS20050191527A1Excellent in emitting color property and light emitting efficiencyLight efficiencyIndium organic compoundsElectroluminescent light sourcesQuinoxalineAryl

An organometallic compound comprising a quinoxaline structure, and having a structure represented by the following general formula (2), wherein M represents a monovalent to trivalent metal, L represents a ligand, Ar1 and Ar2 represent an aryl group in which a part of hydrogens may be substituted, and the same or different, m represents an integer of 1 to 3, n represents an integer of 0 to 2, and m-n is an integer of 1 to 3.

Owner:SANYO ELECTRIC CO LTD

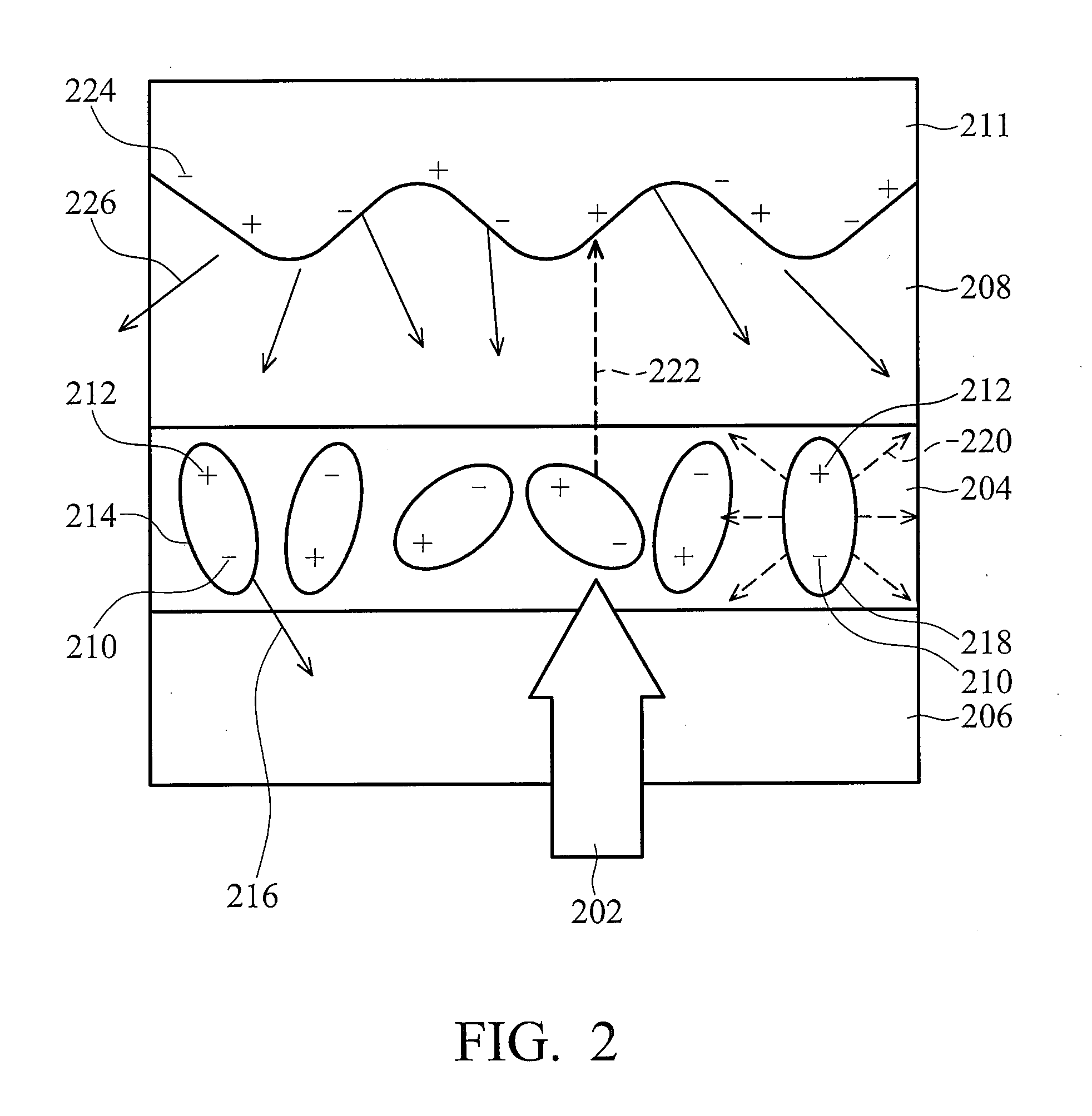

Light-emitting device having optical resonance layer

ActiveUS20060097264A1Simple structureIncreased light coupling efficiencyElectroluminescent light sourcesSolid-state devicesLight emitting deviceLight-emitting diode

Provided is a light-emitting device which has a simple structure and can be manufactured in a simple process, has increased light coupling efficiency and brightness, and can reduce adverse effects of optical resonance on a view angle and emission spectrum. The light-emitting device includes a substrate; a light-emitting diode formed on the substrate; and an optical resonance layer formed outside the light-emitting diode that induces resonance of light emitted from the light-emitting diode.

Owner:SAMSUNG DISPLAY CO LTD

Light emitting device

ActiveUS20100006870A1High luminous intensity and brightnessExcellent characteristicsSolid-state devicesSemiconductor devicesInsulation layerConductive materials

Owner:SINOTECHNIX LLC

Optical fiber and the manufacturing method thereof

InactiveUS20080158905A1Reduce riskLight efficiencyGlass making apparatusMechanical apparatusAdhesiveVolumetric Mass Density

An optical fiber is disclosed, which is comprised of: a core, having a plurality of microstructures formed thereon; and a cladding layer, surrounding the core. In a preferred embodiment, as light is transmitting along the axis of the aforesaid optical fiber and strikes on the plural microstructures, it is scattered and reflected out of the optical fiber through a side wall thereof so as to achieve a side-emitting effect. As the microstructures are formed inside the core of the aforesaid optical fiber, not only they are prevented from being damaged by normal usage, contacting to adhesive directly, but also they can lower the risk of the optical fiber being snapped / deformed while the optical fiber is subjecting to an external force and bended. In addition, by controlling the shape, quantity, size, distribution density and location of the microstructure, the brightness of the side-emitting optical fiber can be adjusted correspondingly.

Owner:IND TECH RES INST

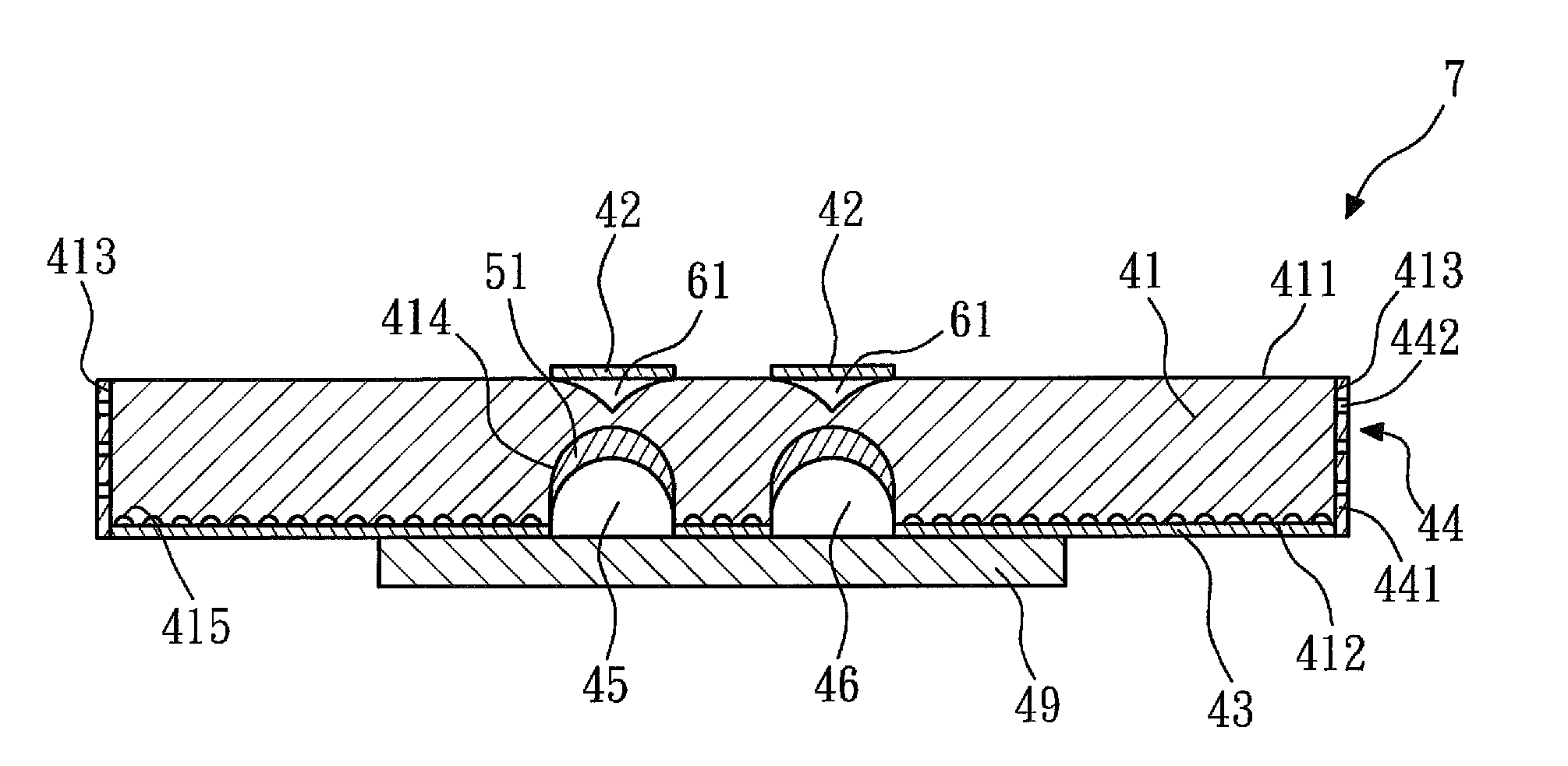

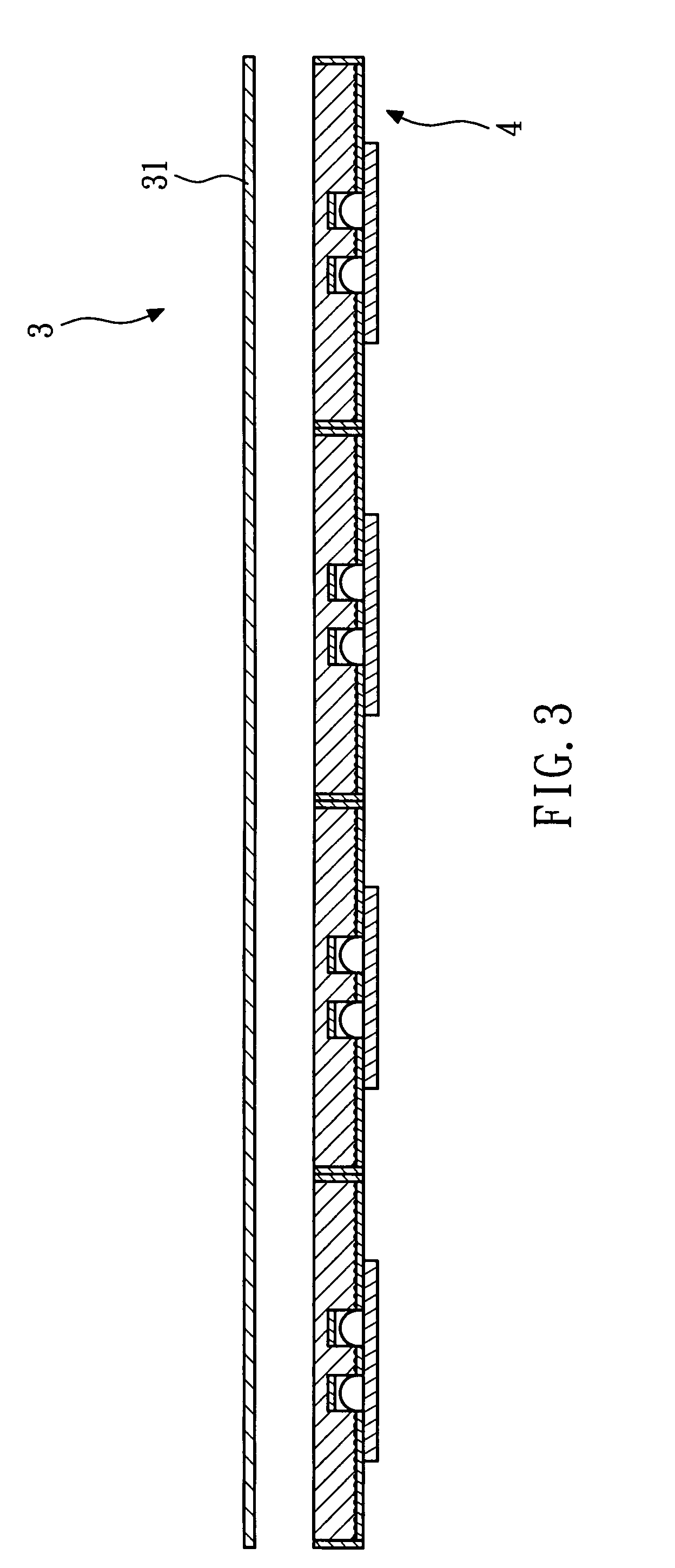

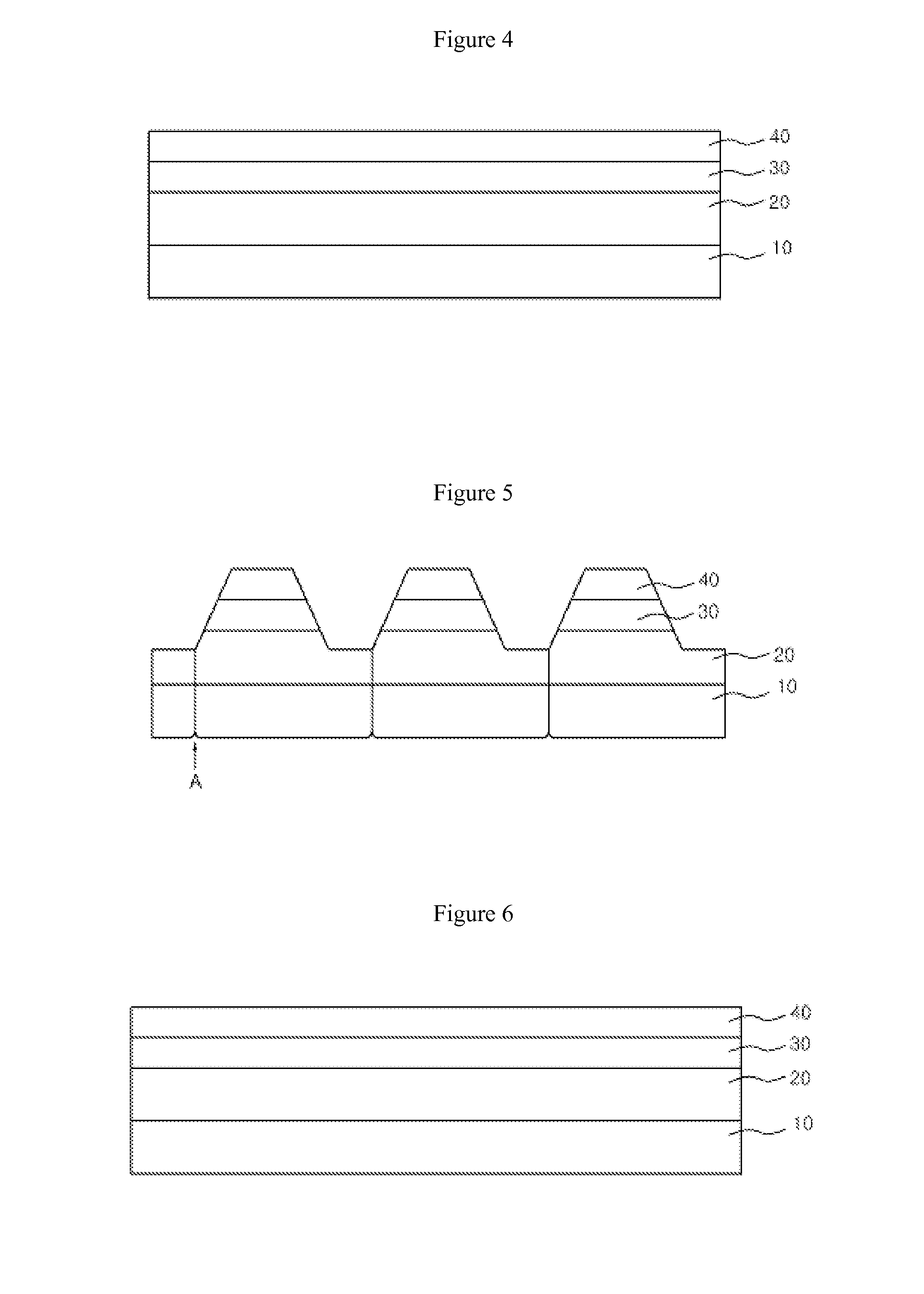

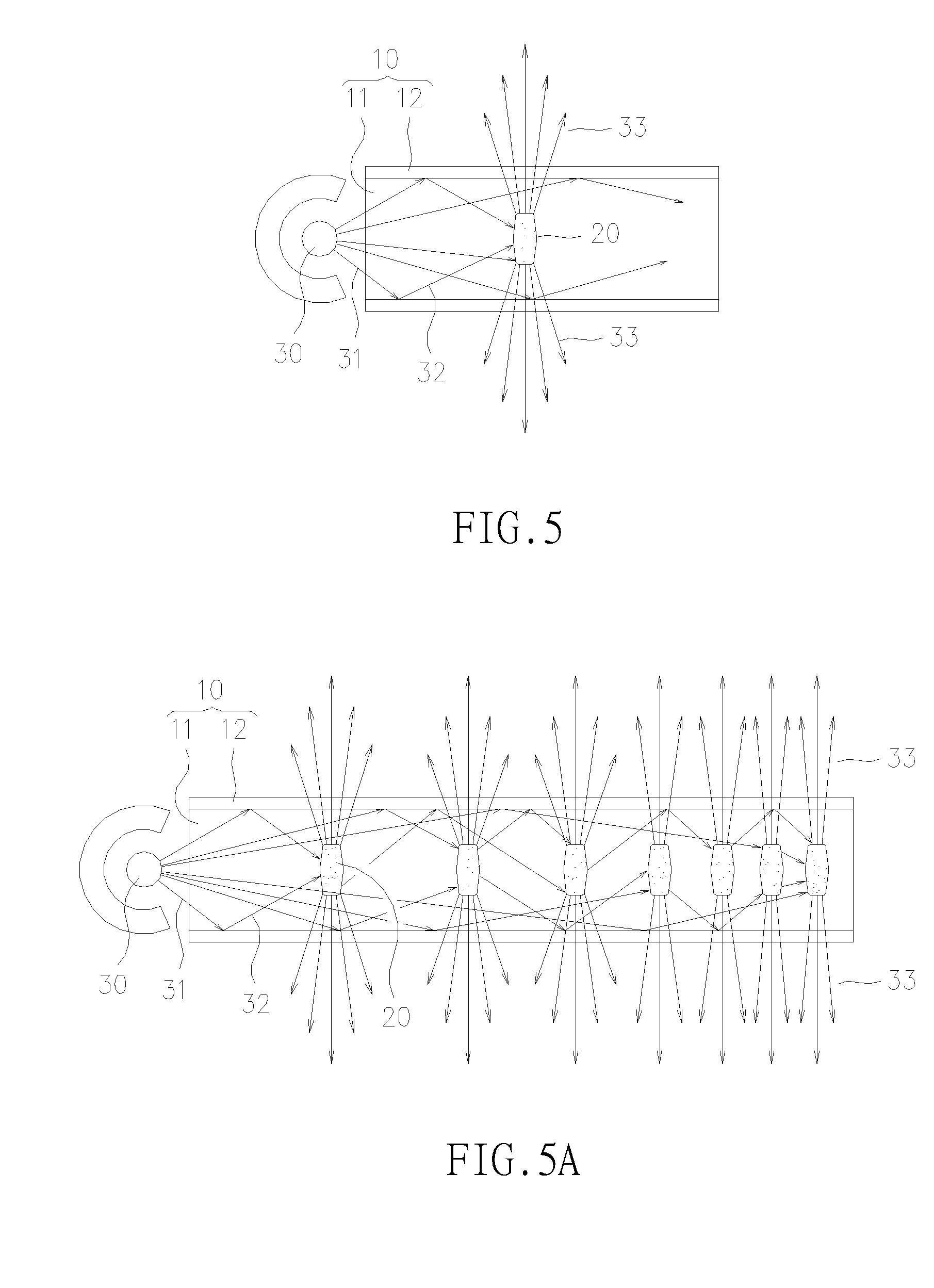

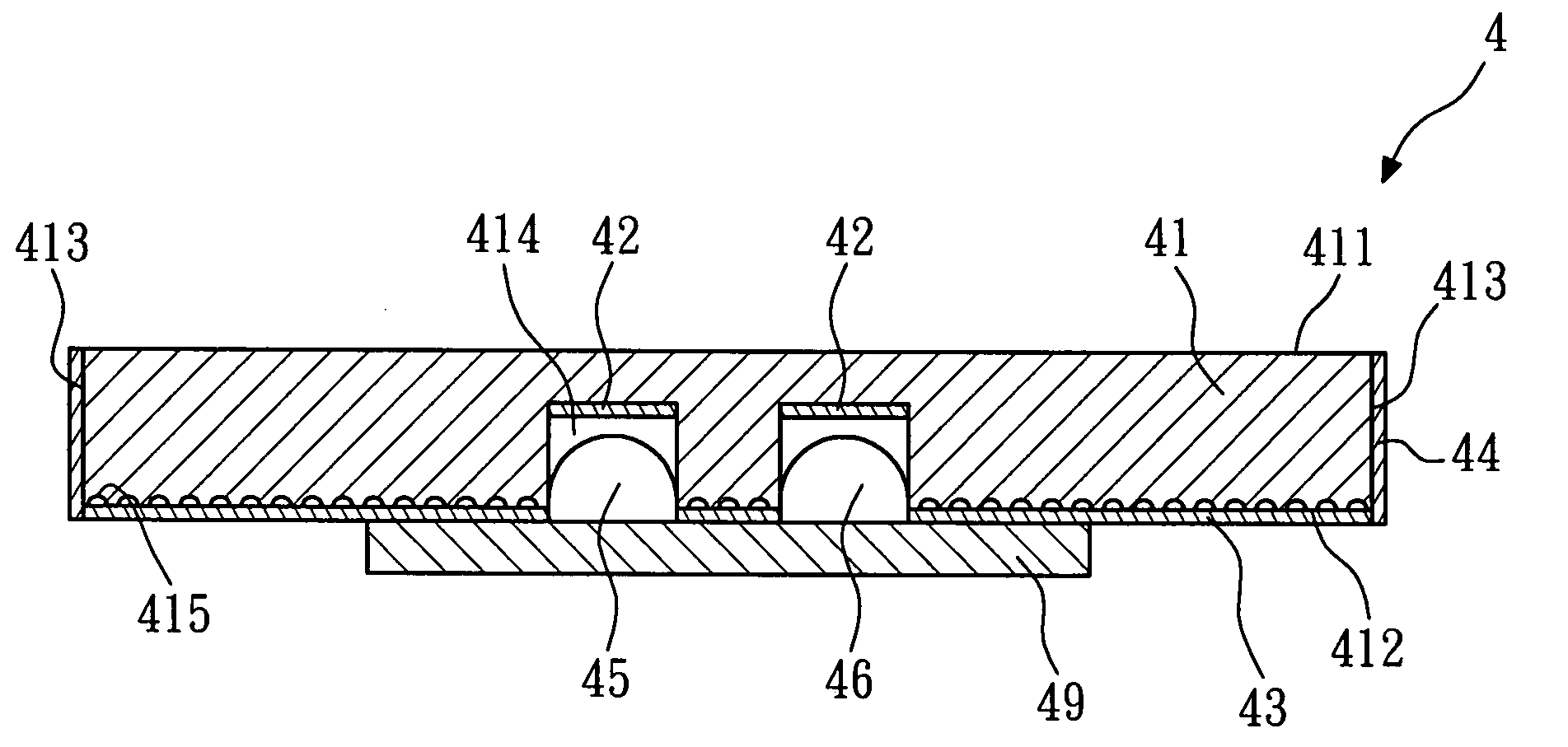

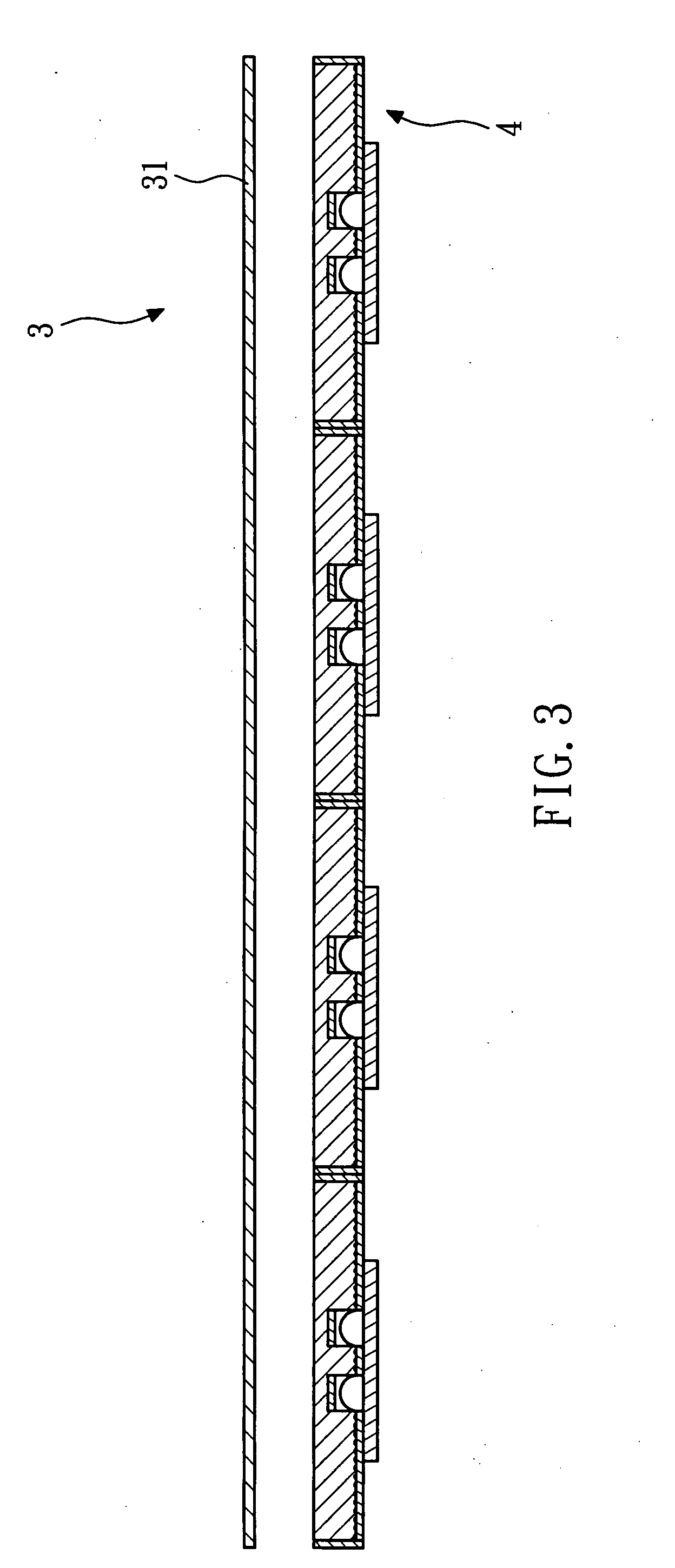

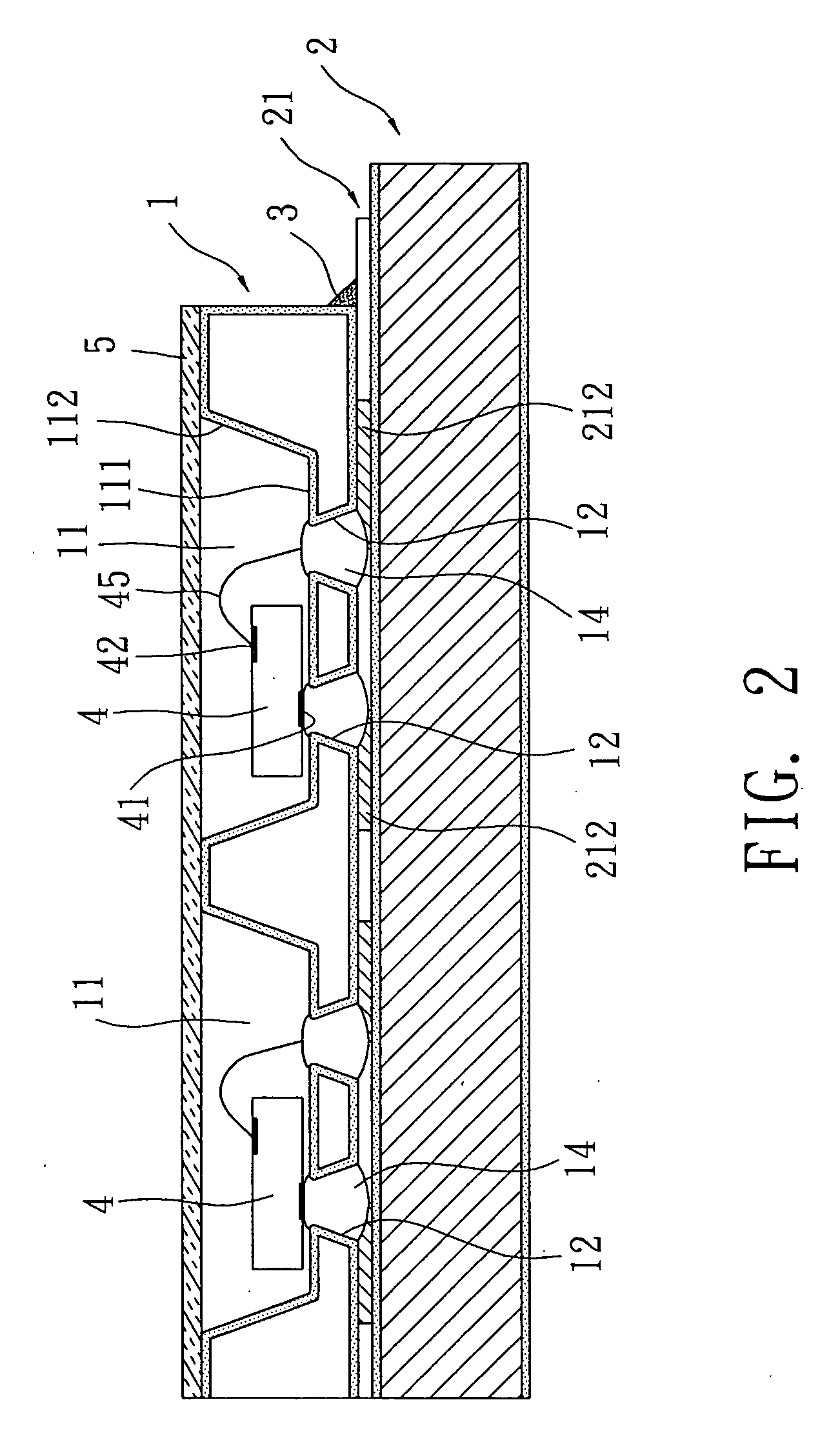

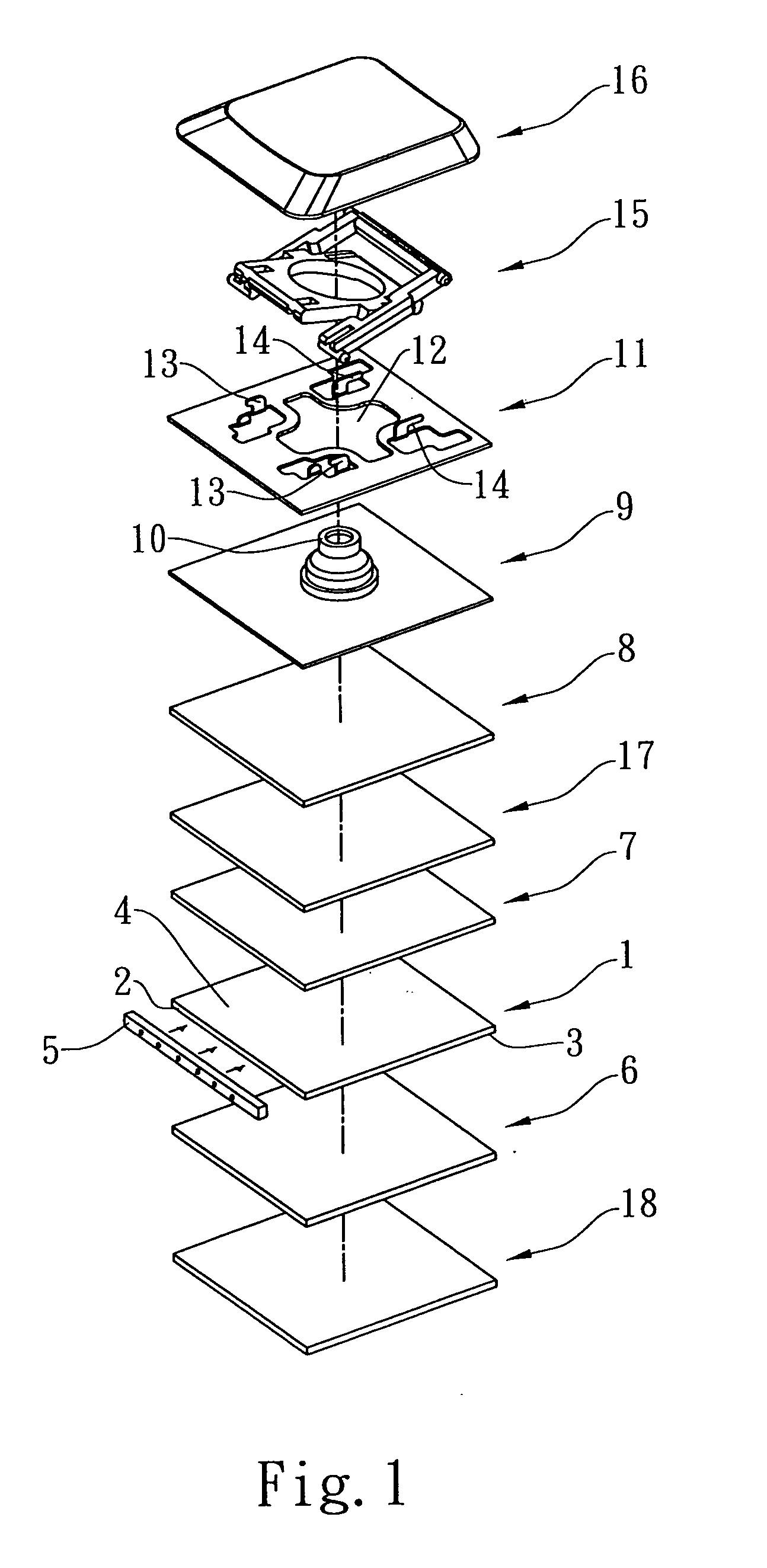

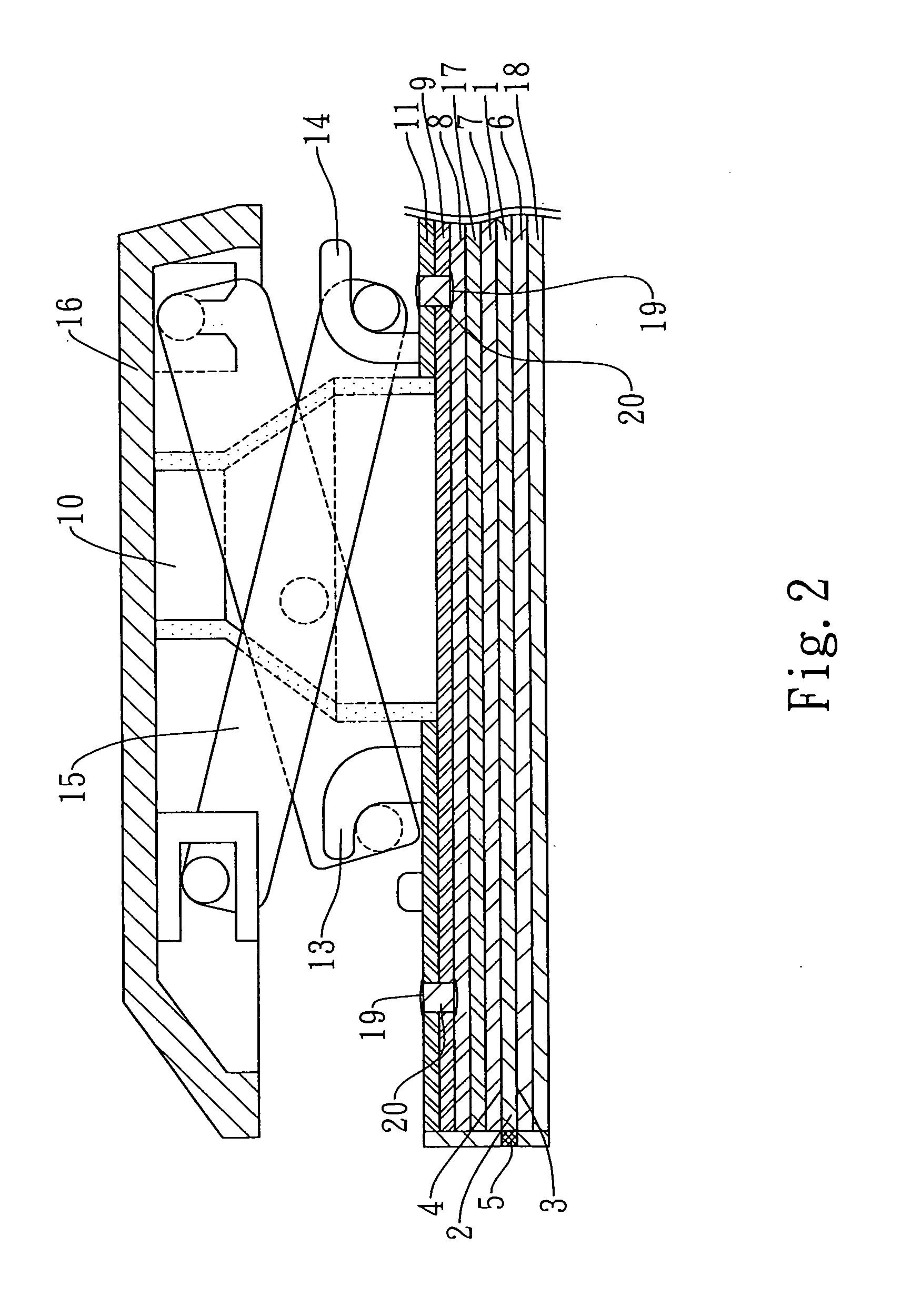

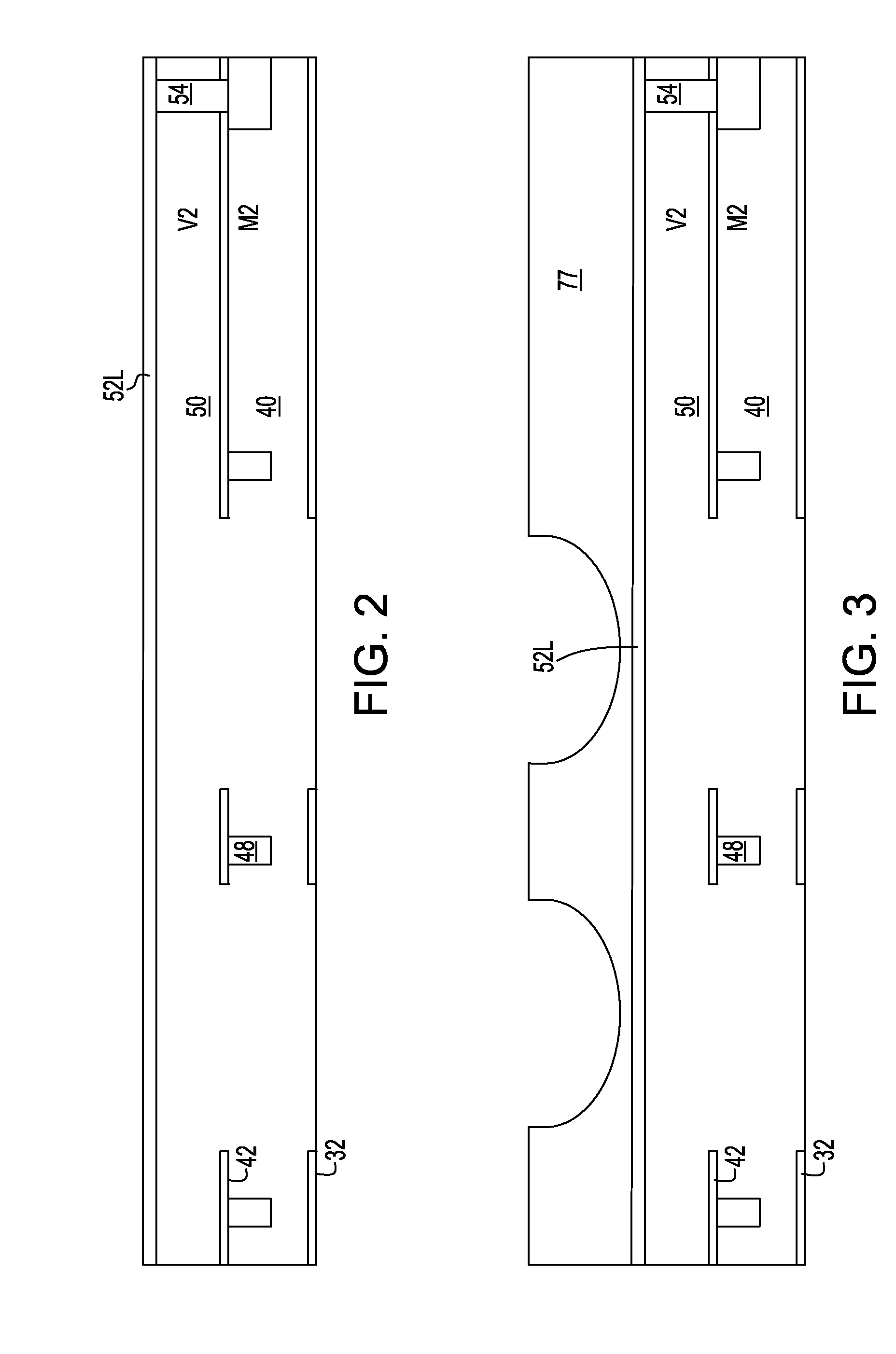

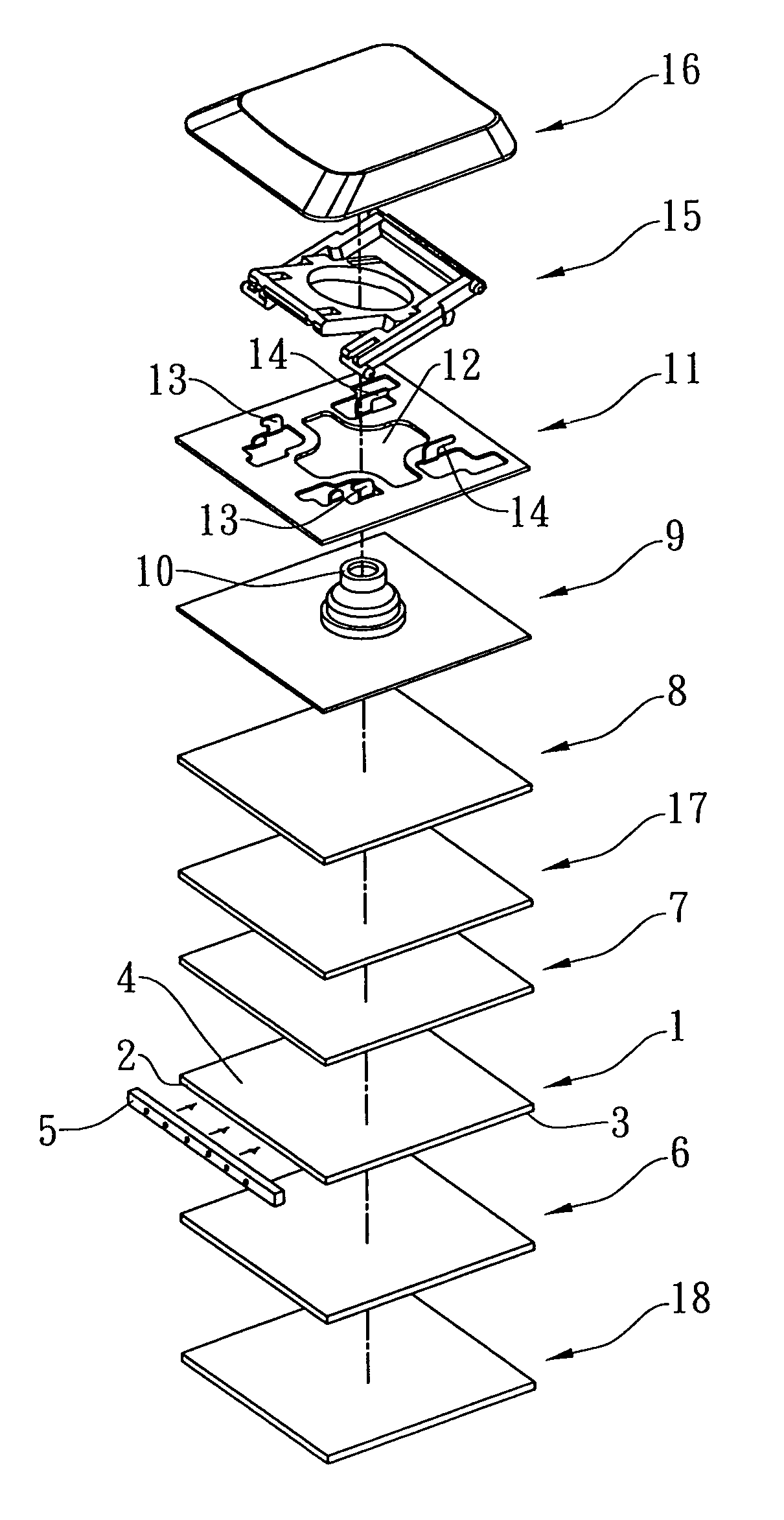

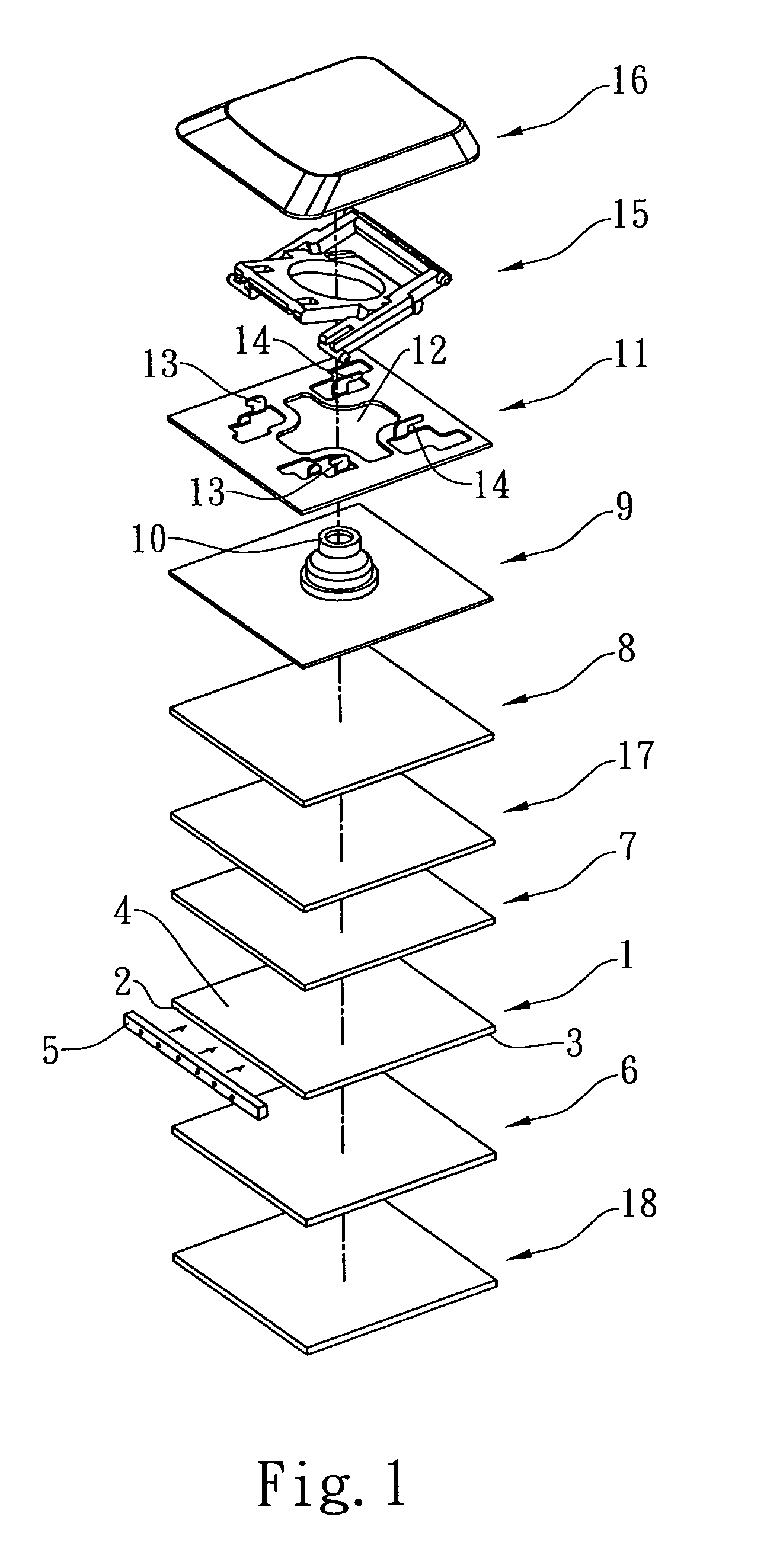

Light mixer and backlight module having the same

ActiveUS20080137335A1Conveniently fabricatedSimple and convenient to maintainNon-electric lightingPoint-like light sourceSpecial designOptoelectronics

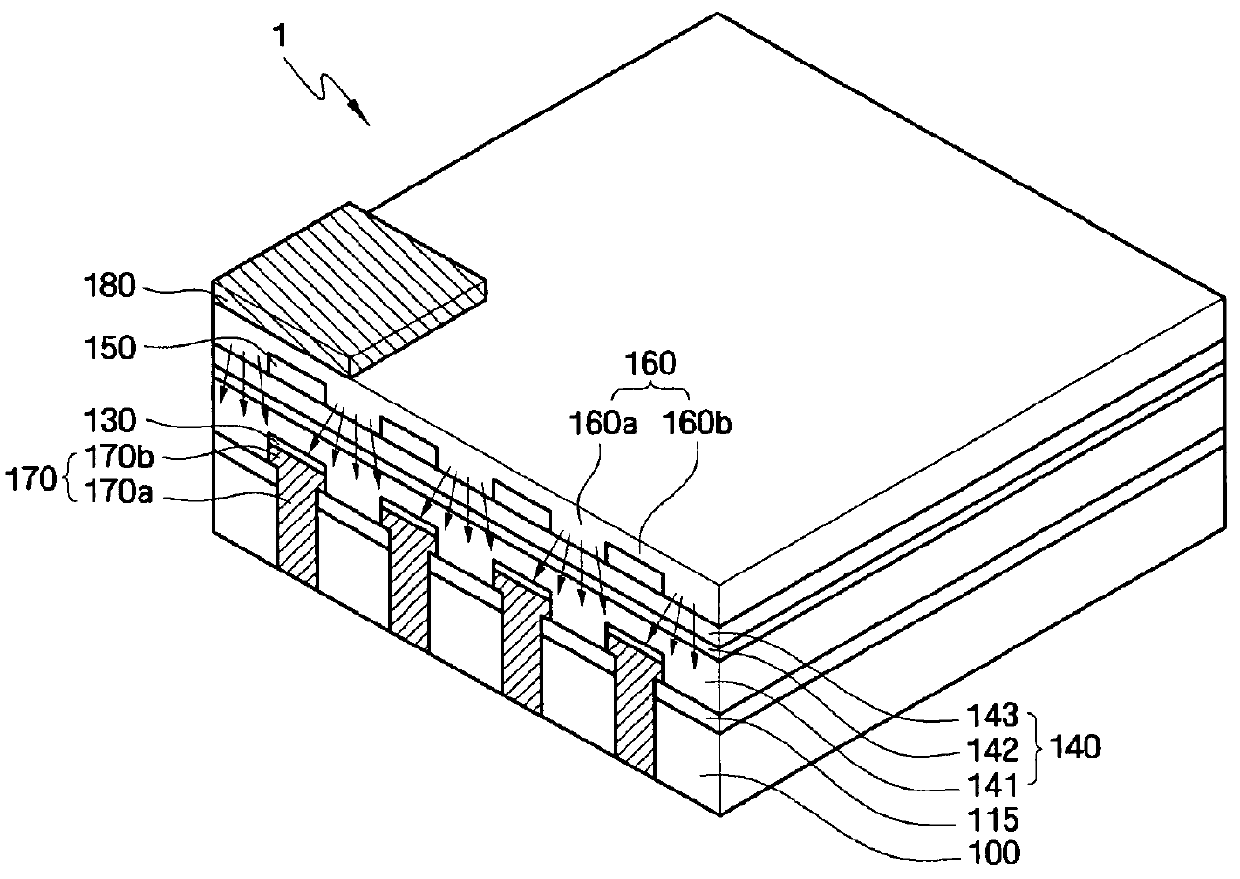

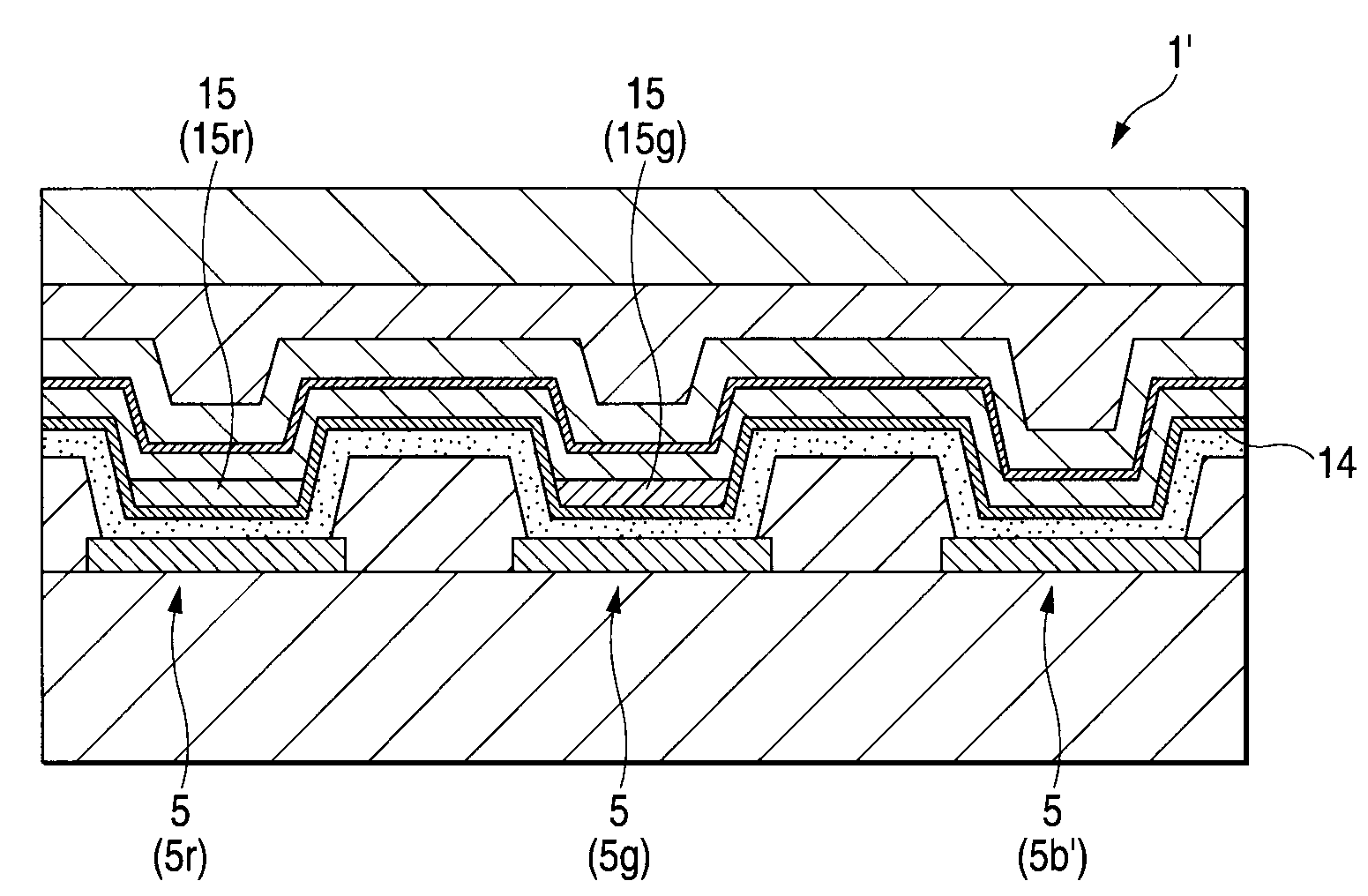

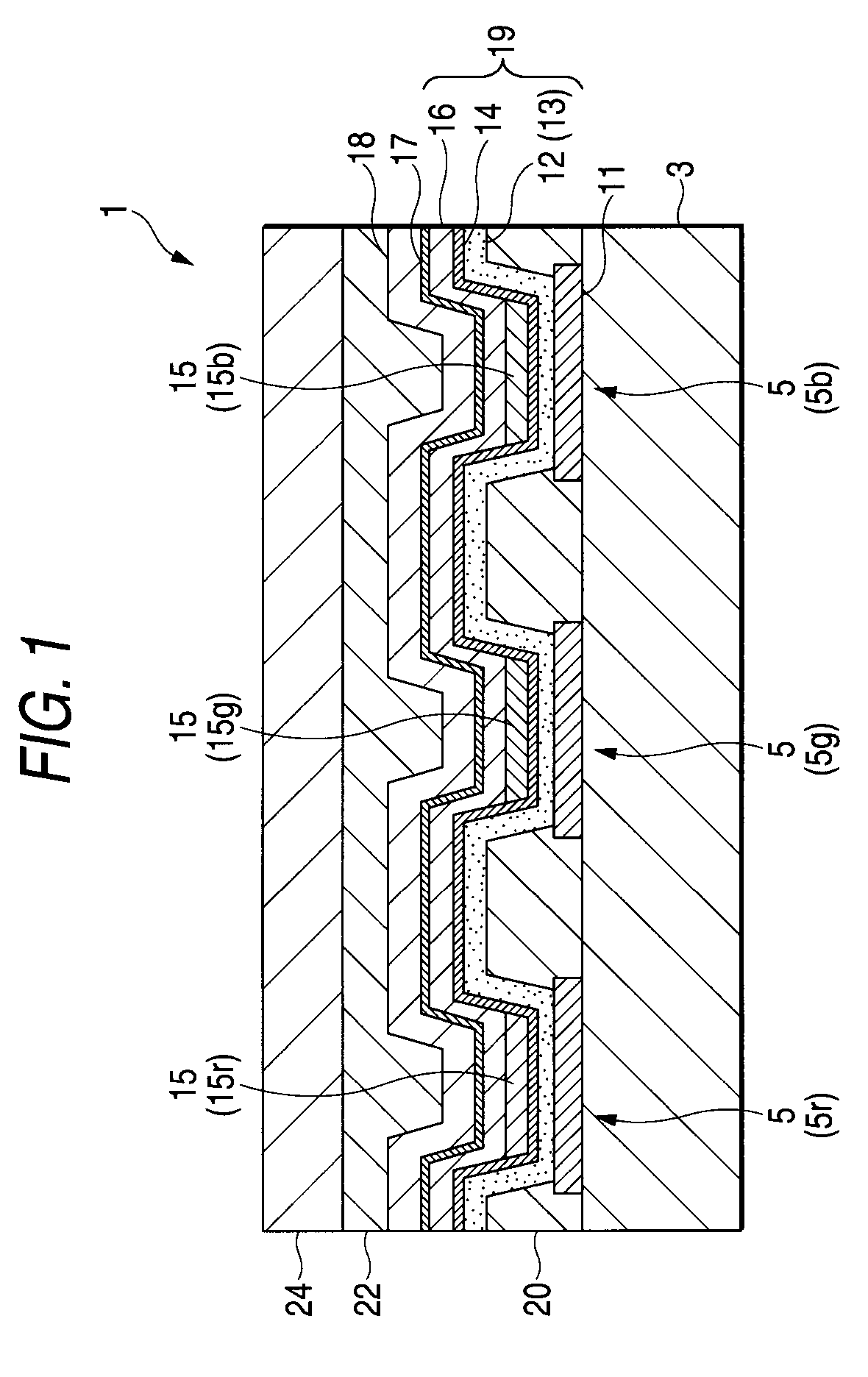

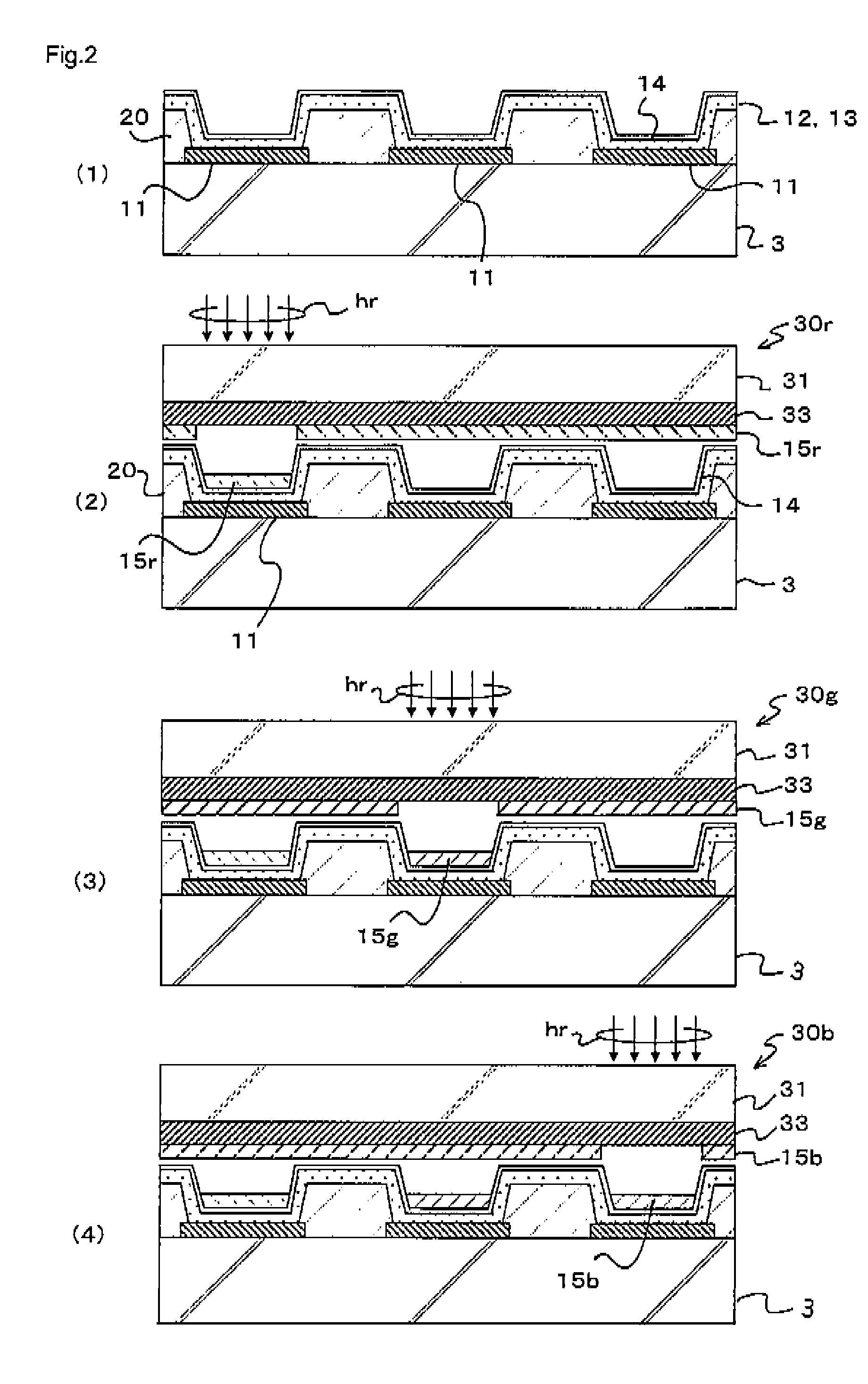

A light mixer and a backlight module having the light mixer are provided. The backlight module includes a plurality of light mixers and a diffuser. The light mixers are arranged on a plane in an array. Each light mixer includes a light mixing plate, a plurality of light sources, a plurality of upper reflecting layers, a lower reflecting layer, and a semi-permeable layer. The light mixing plate has an upper surface, a lower surface, a peripheral surface, and a plurality of receiving holes. The light sources are respectively located in the receiving holes. The upper reflecting layers are respectively located right above the light sources. The lower reflecting layer is located on the lower surface of the light mixing plate. The semi-permeable layer wraps the peripheral surface of the light mixing plate. The diffuser is located above the light mixers. Therefore, the fabricating process of the backlight module is relatively simple, the fabricating cost is relatively low, and it is simple and convenient to maintain. Furthermore, the special design of the light mixers enhances the light mixing efficiency and the luminance.

Owner:HKC CORP LTD

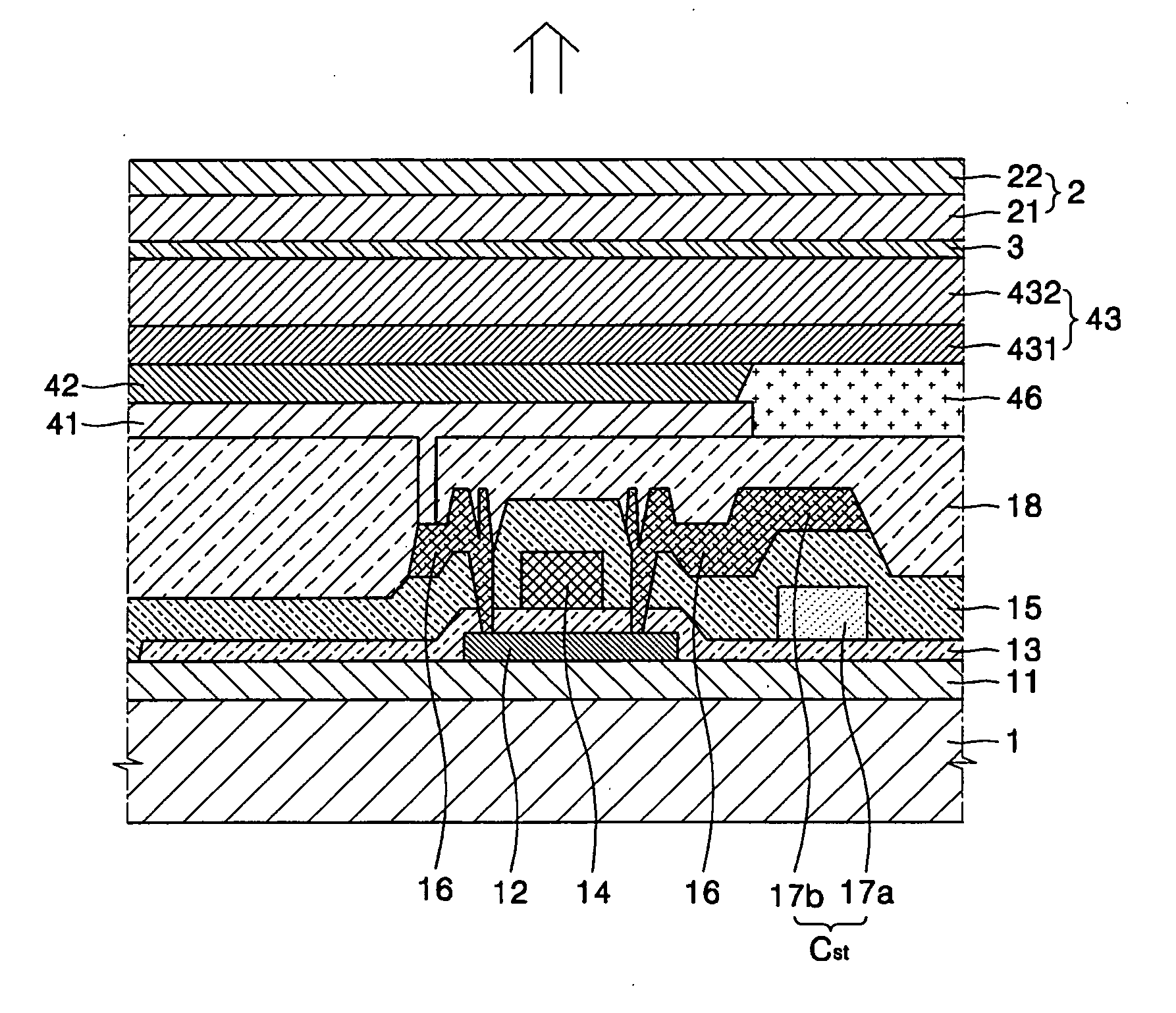

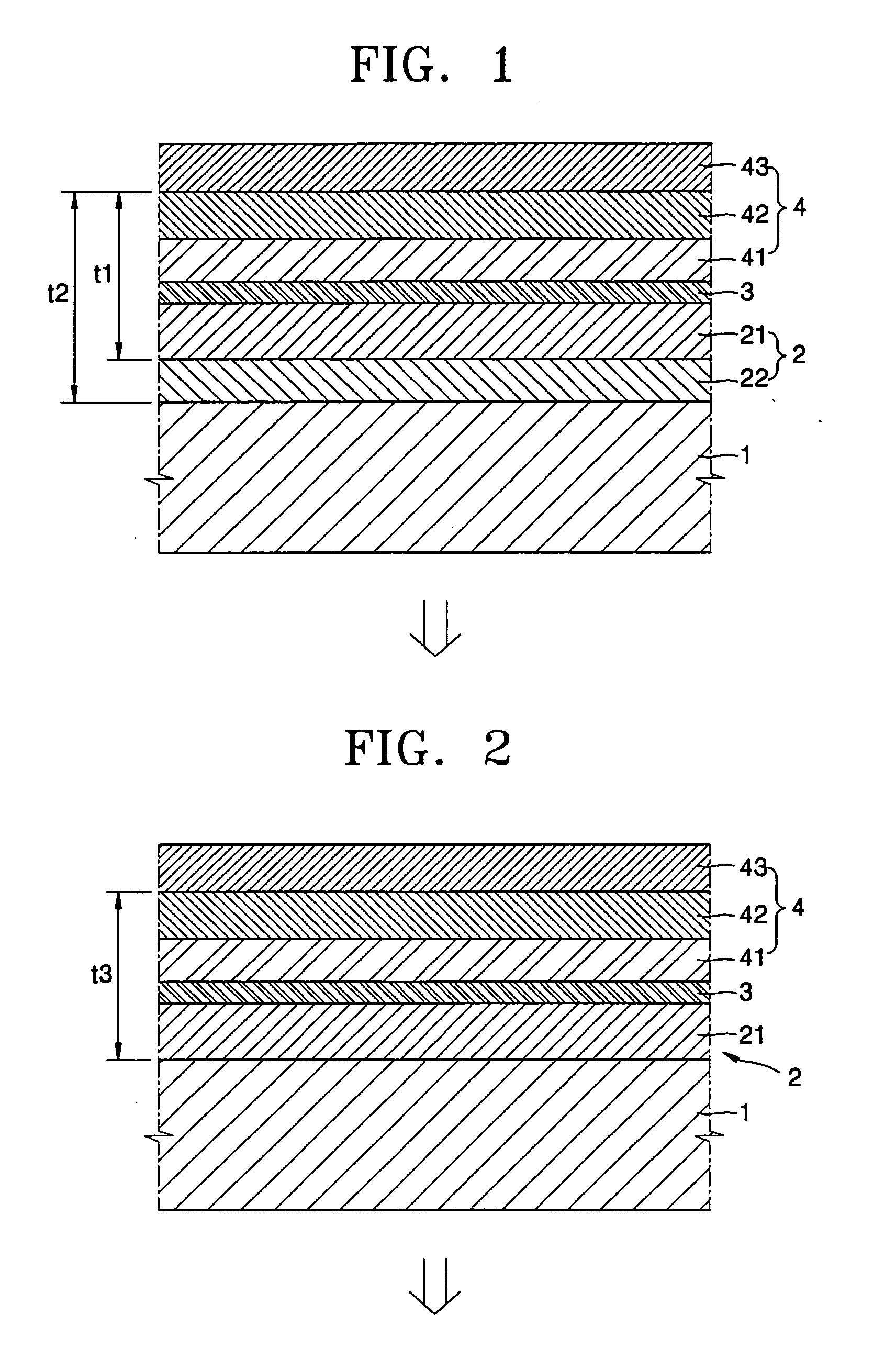

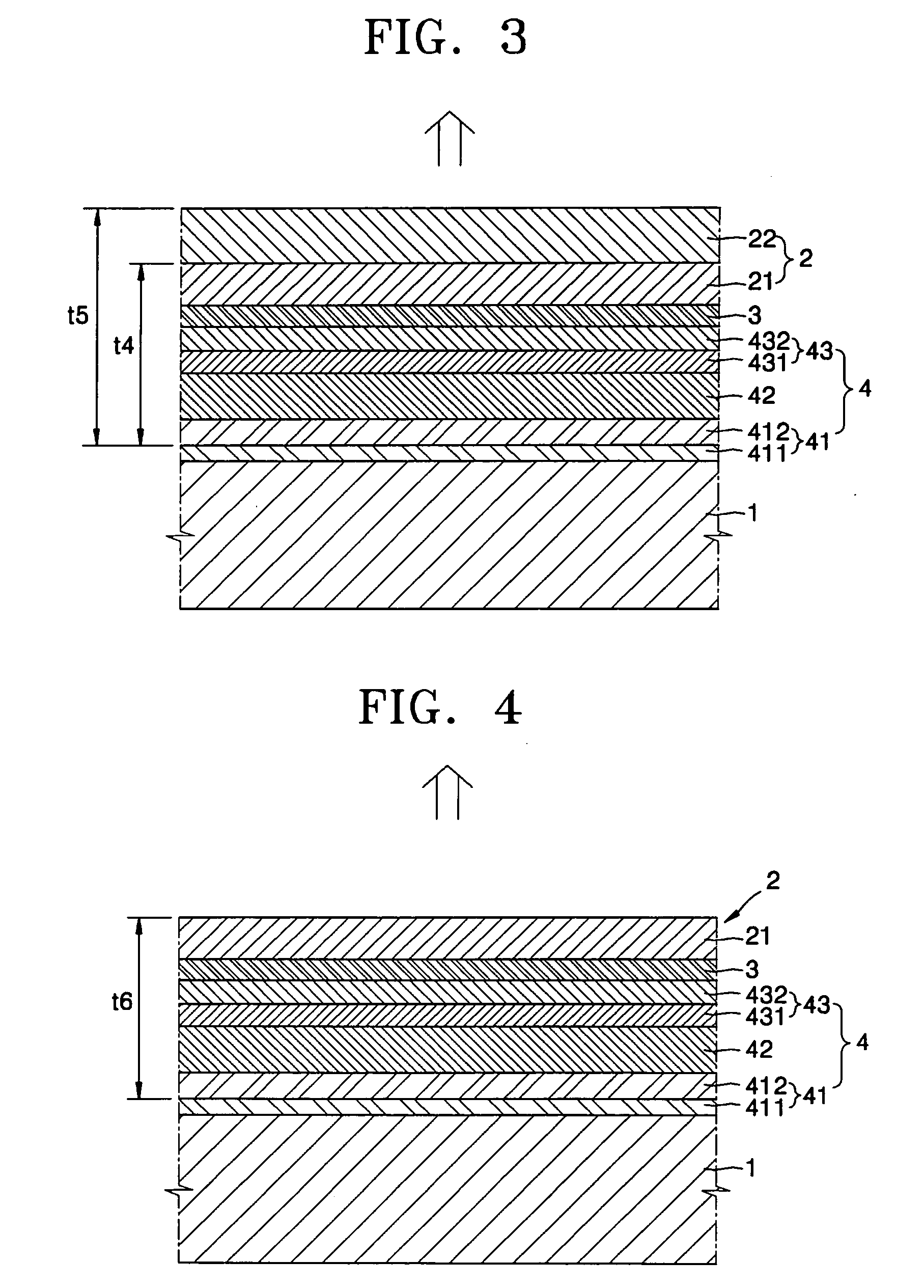

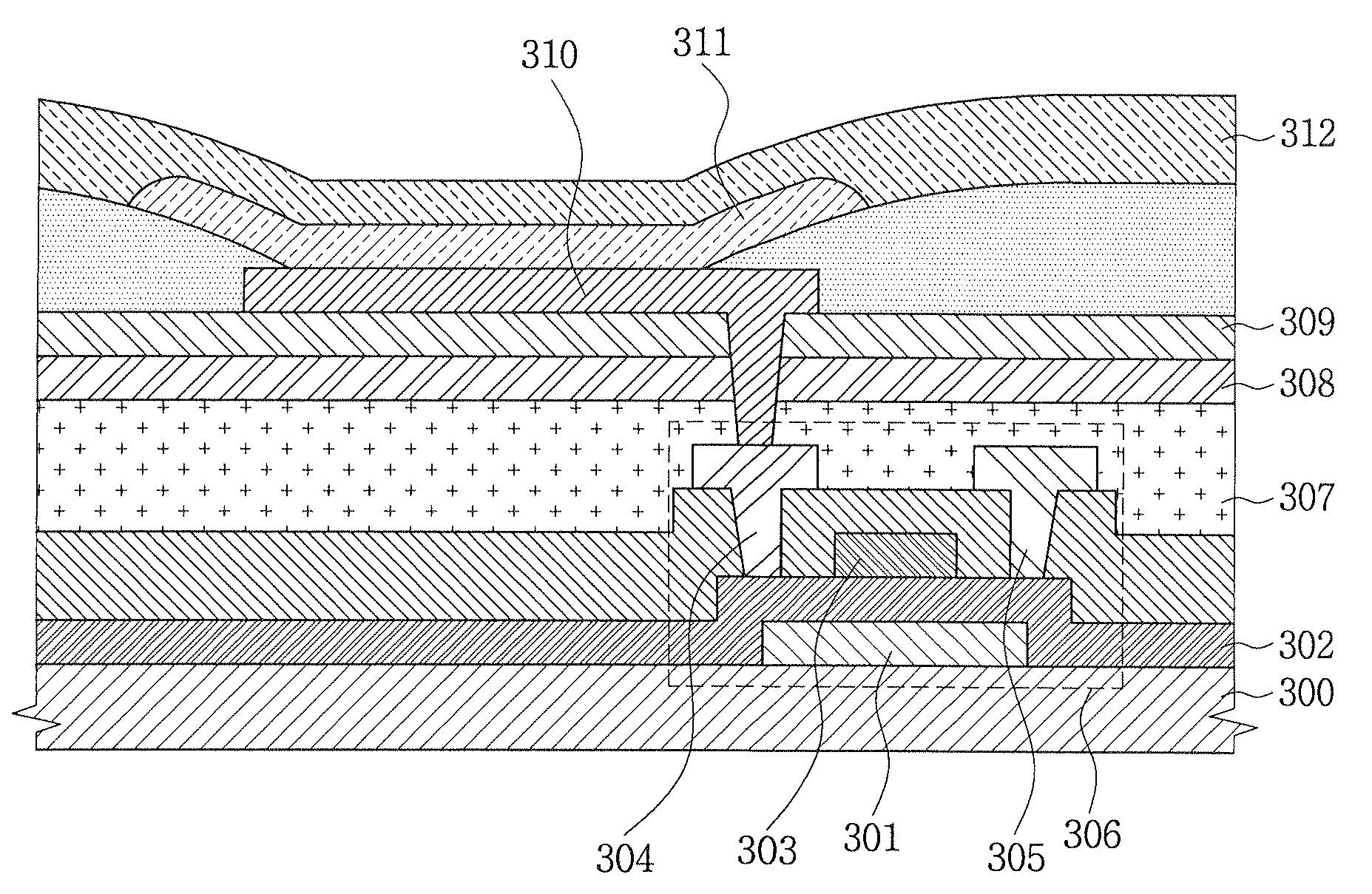

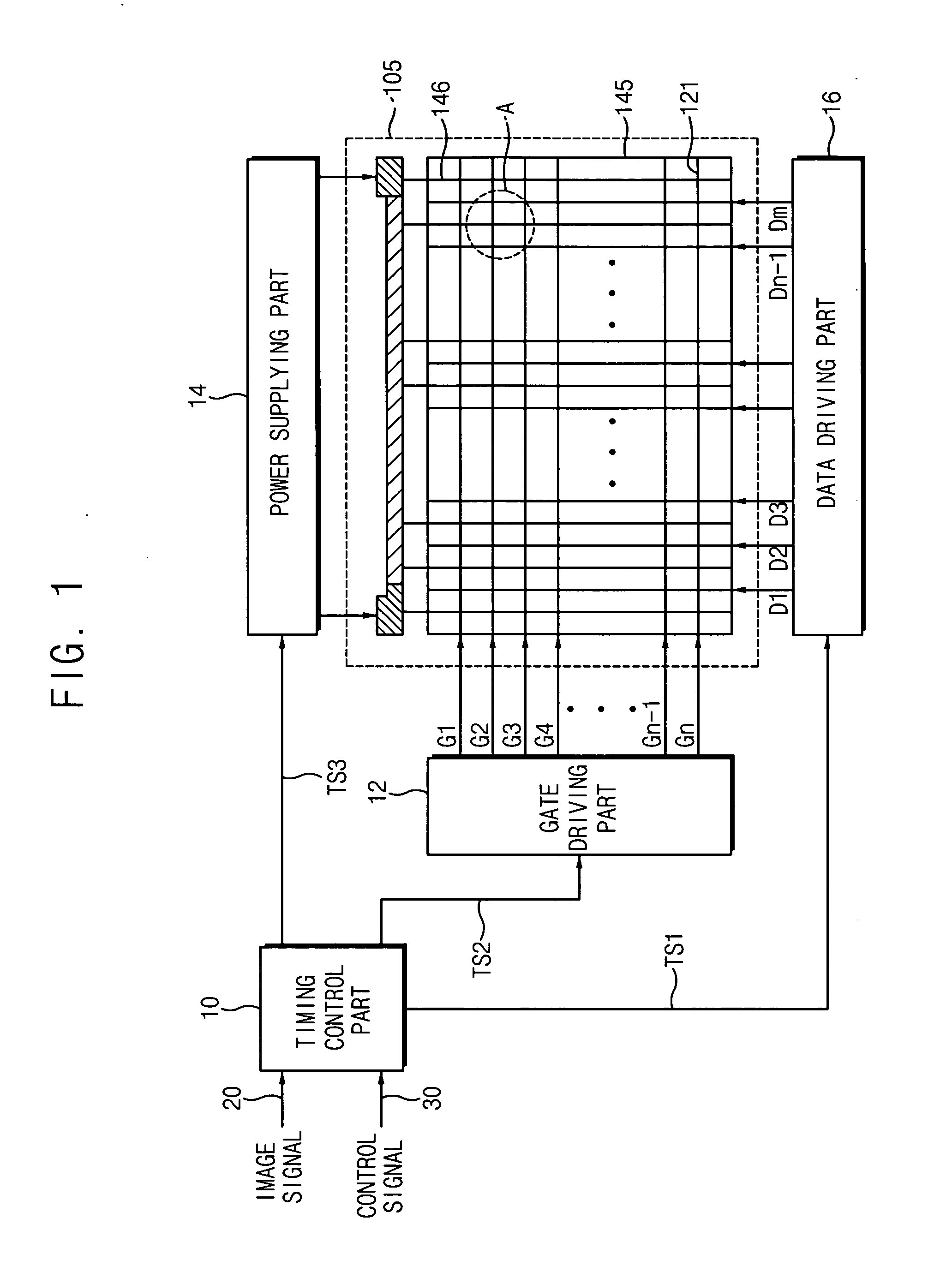

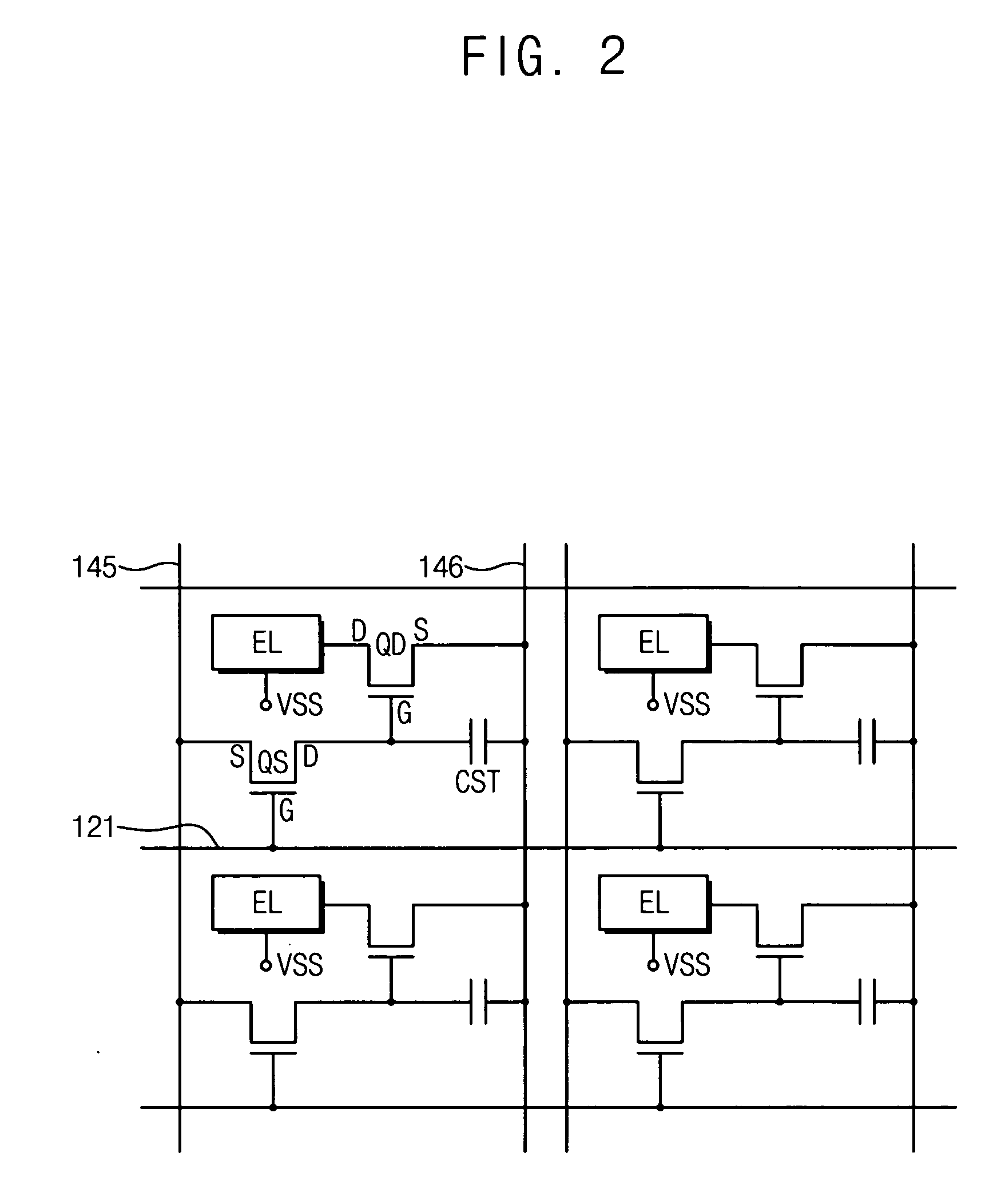

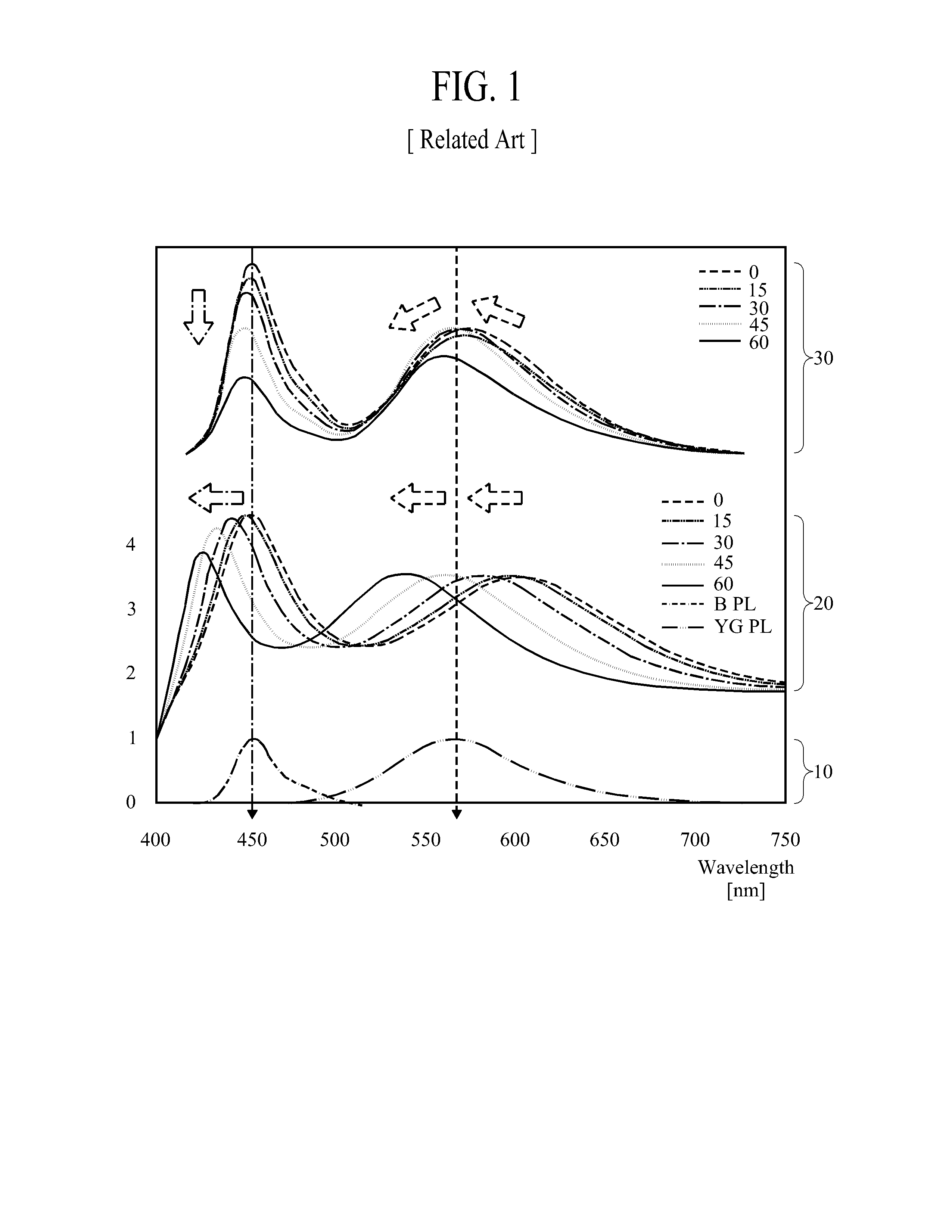

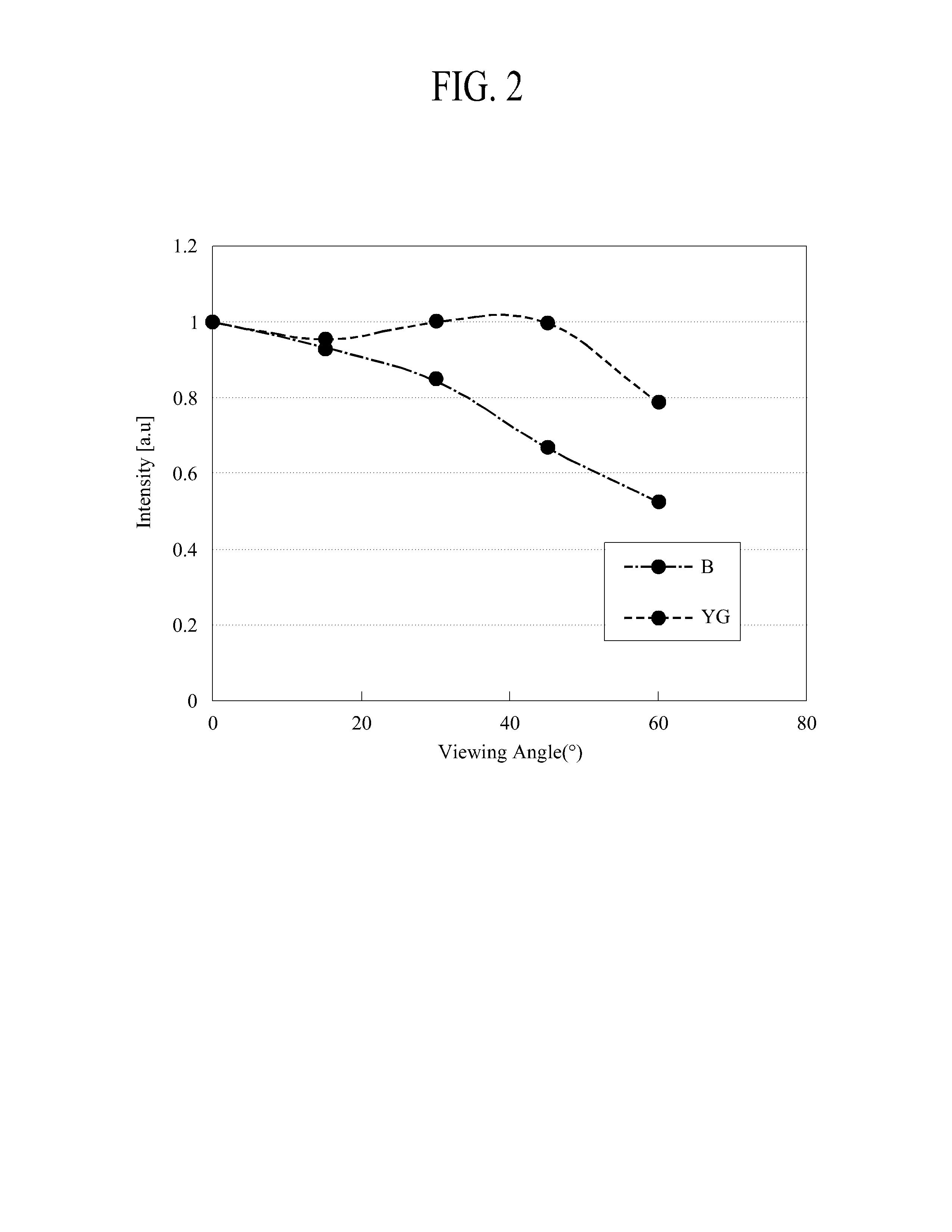

Organic light emitting diode display device

ActiveUS20090302750A1Increase brightnessImprove color coordinate characteristicDischarge tube luminescnet screensSemiconductor/solid-state device testing/measurementOrganic layerRefractive index

Provided is an organic light emitting diode display device which can improve brightness and color coordinate characteristics in all emission wavelength ranges, and thus can enhance light extraction efficiency and color reproducibility. The organic light emitting diode display device includes a substrate, a first electrode disposed on the substrate, an organic layer disposed on the first electrode and having an emission layer, a second electrode disposed on the organic layer, and first and second refraction layers. A stack of the first and second refraction layers is disposed either between the first electrode and the substrate or on the second electrode. A refractive index of the first refraction layer is smaller than a refractive index of the second refraction layer. A thickness of the first refraction layer is no greater than 100 nm.

Owner:SAMSUNG DISPLAY CO LTD

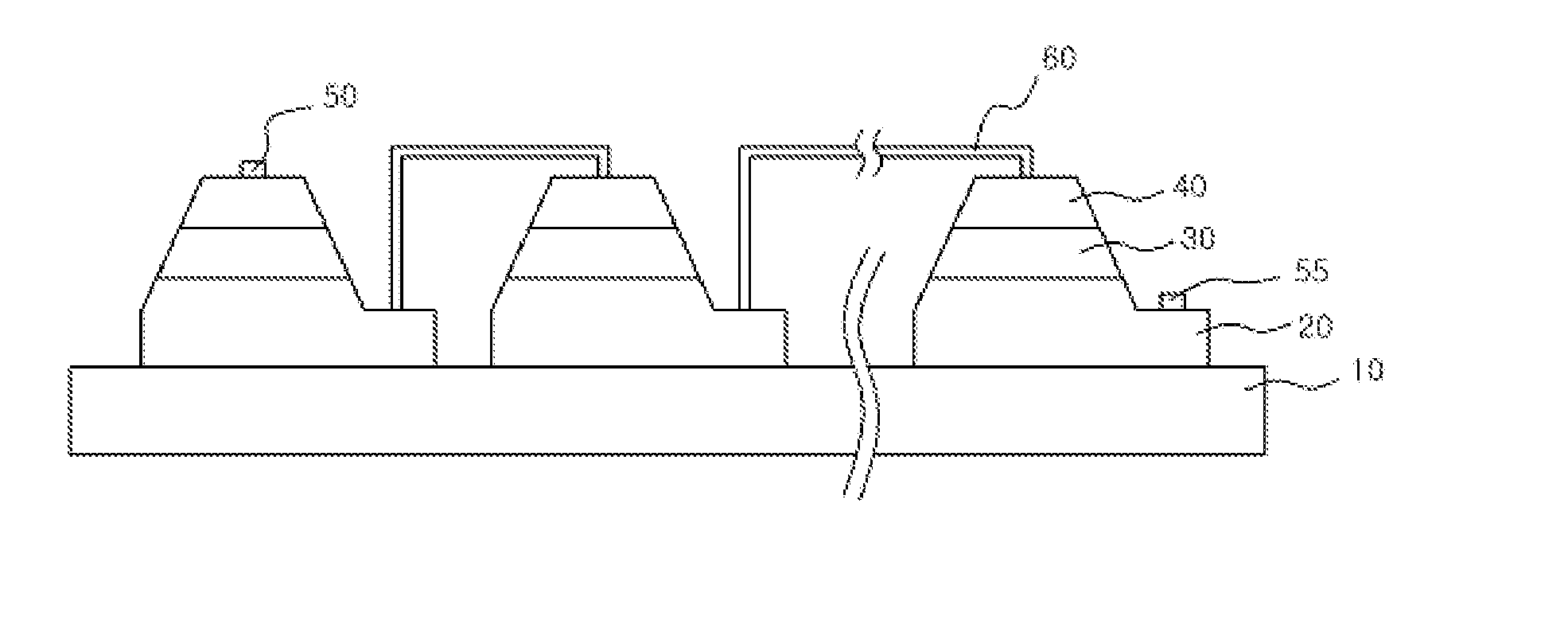

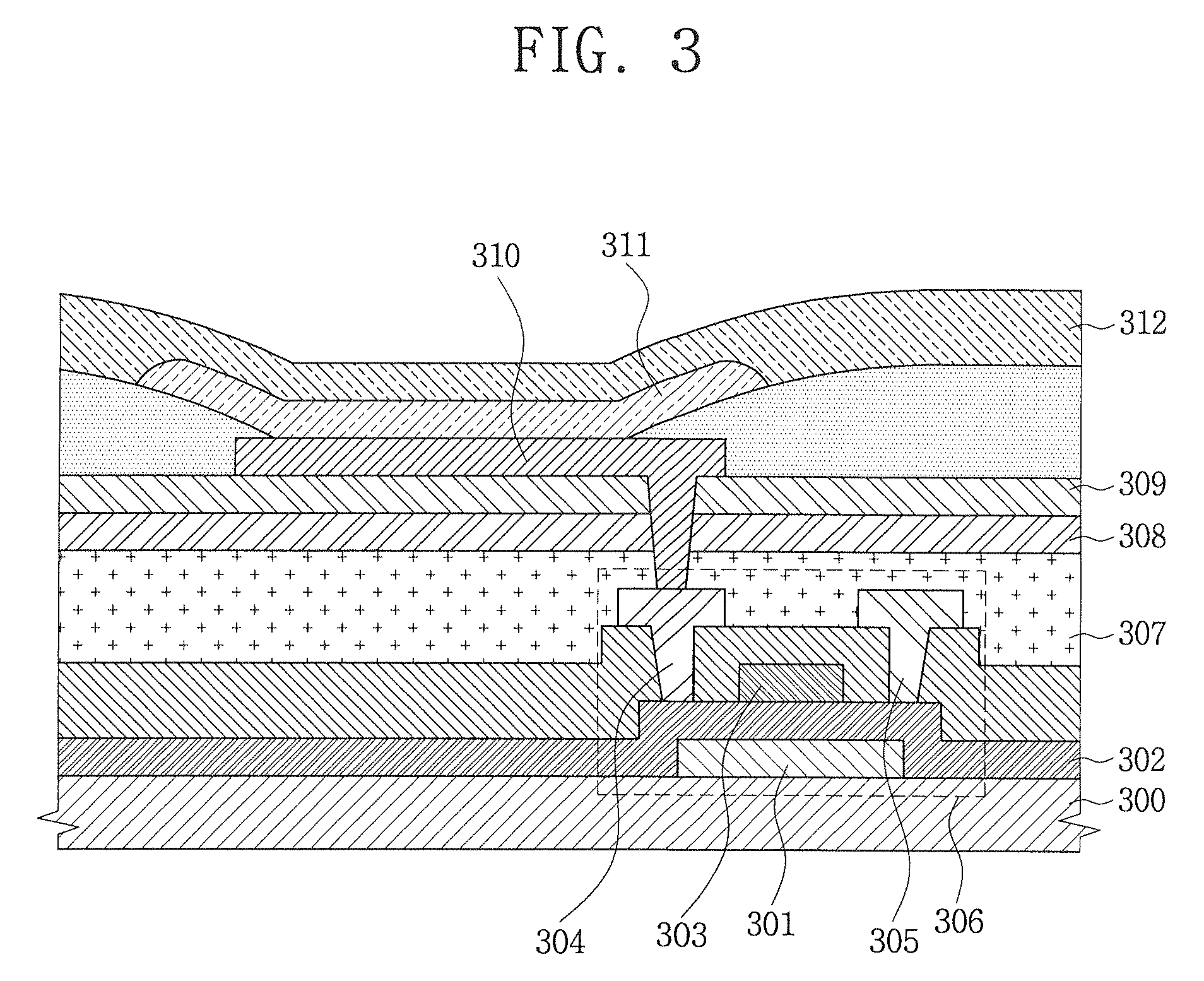

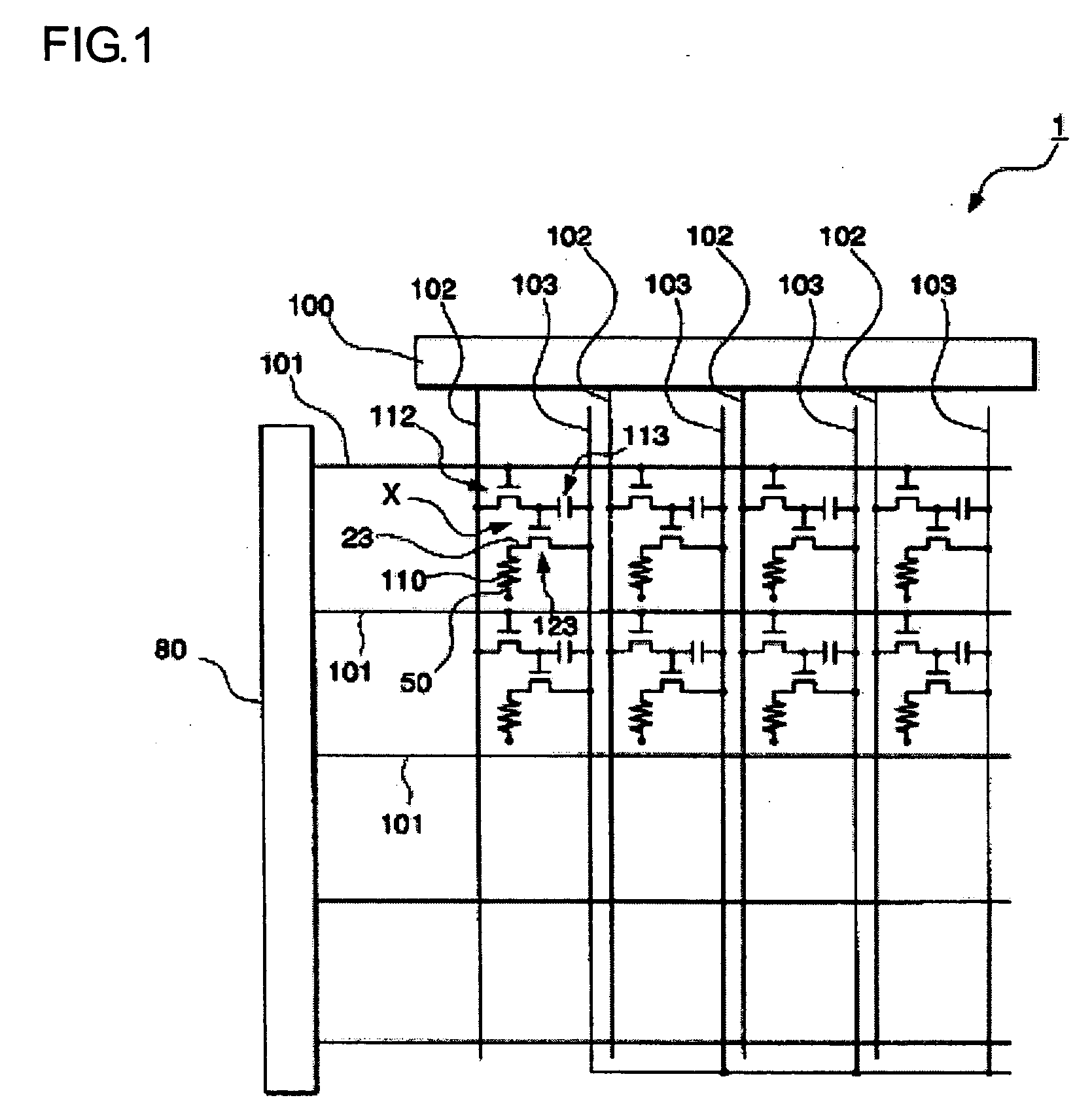

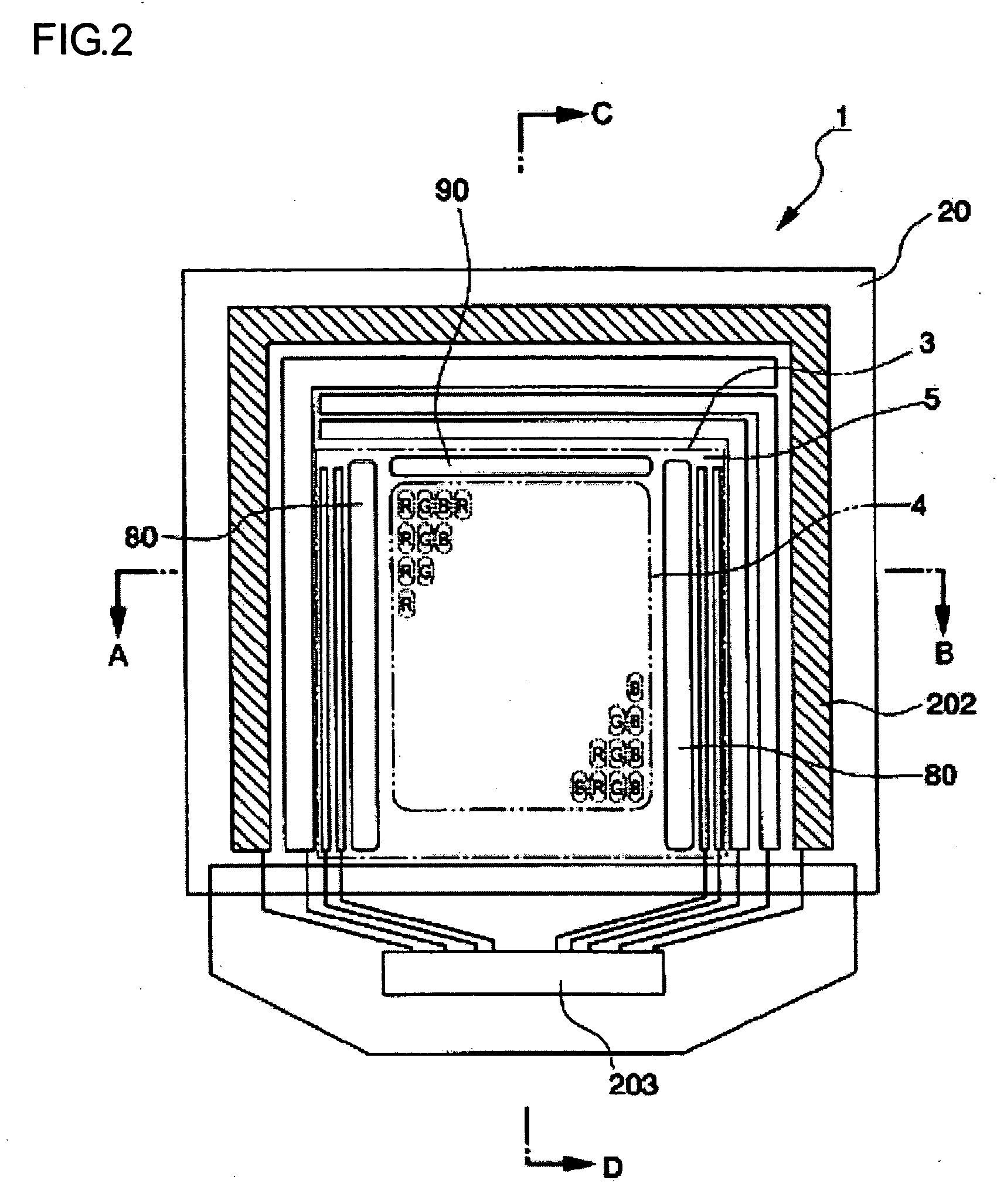

Color filter panel, organic light emitting display apparatus and method of manufacturing the same

ActiveUS20050269942A1Increase brightnessIncrease opening ratioDischarge tube luminescnet screensStatic indicating devicesScan lineData signal

An OLED apparatus includes a substrate, a TFT, a scan line, a data line, a power supply line, a color filter, a pixel electrode, a light emitting layer and a counter electrode. The TFT is formed on the substrate. The scan line transmits a scan signal to a control electrode of the TFT. The data line transmits a data signal to the TFT. Bias voltages are applied to the TFT through the power supply line. The color filter overlaps with one or more of the scan line, the data line and the power supply line. The pixel electrode overlaps with one or more of the scan line, the data line and the power supply line. The light-emitting layer is formed on the pixel electrode. The counter electrode is formed on the light-emitting layer. Therefore, cross talk may be reduced and the opening ratio increased to enhance luminance.

Owner:SAMSUNG DISPLAY CO LTD

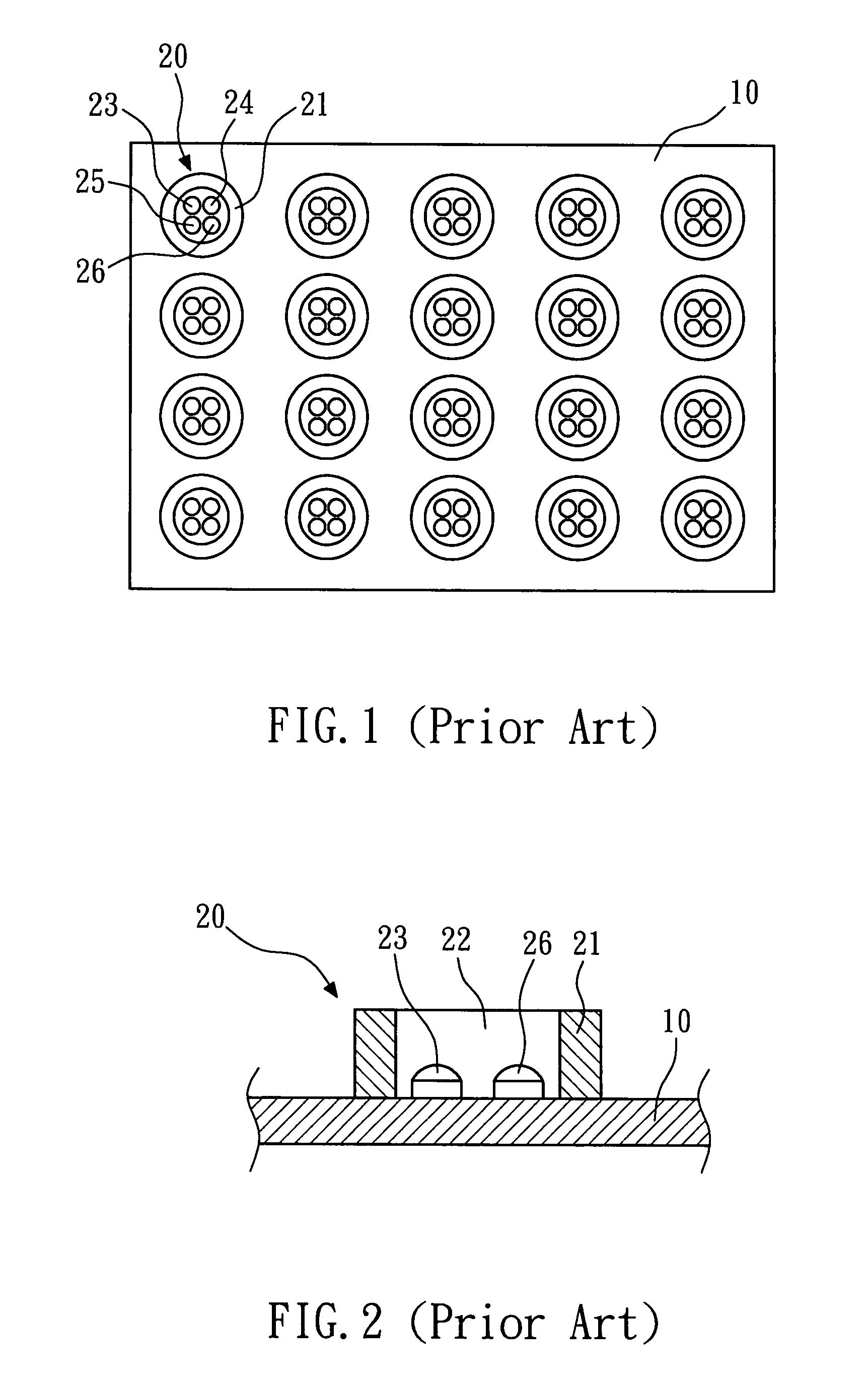

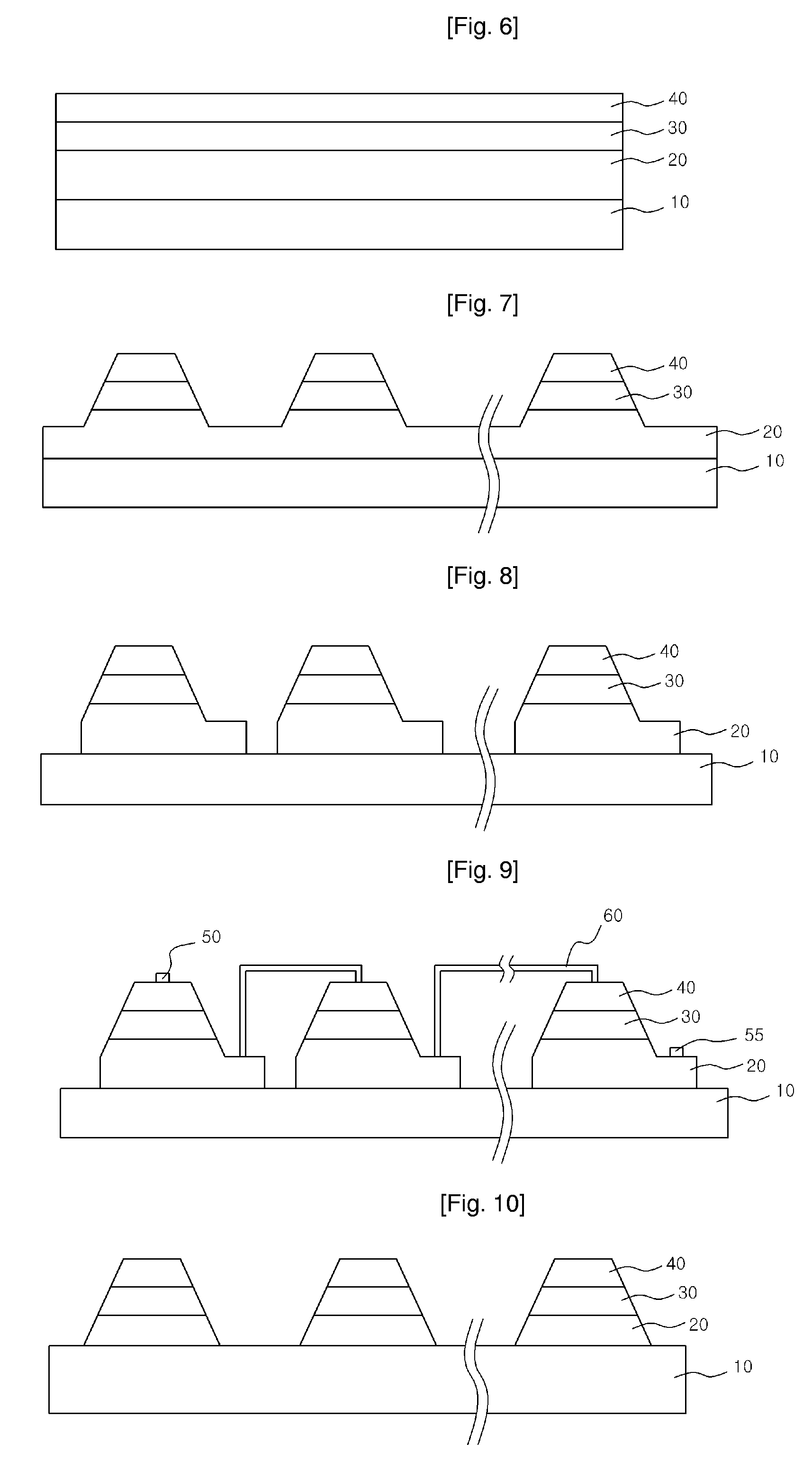

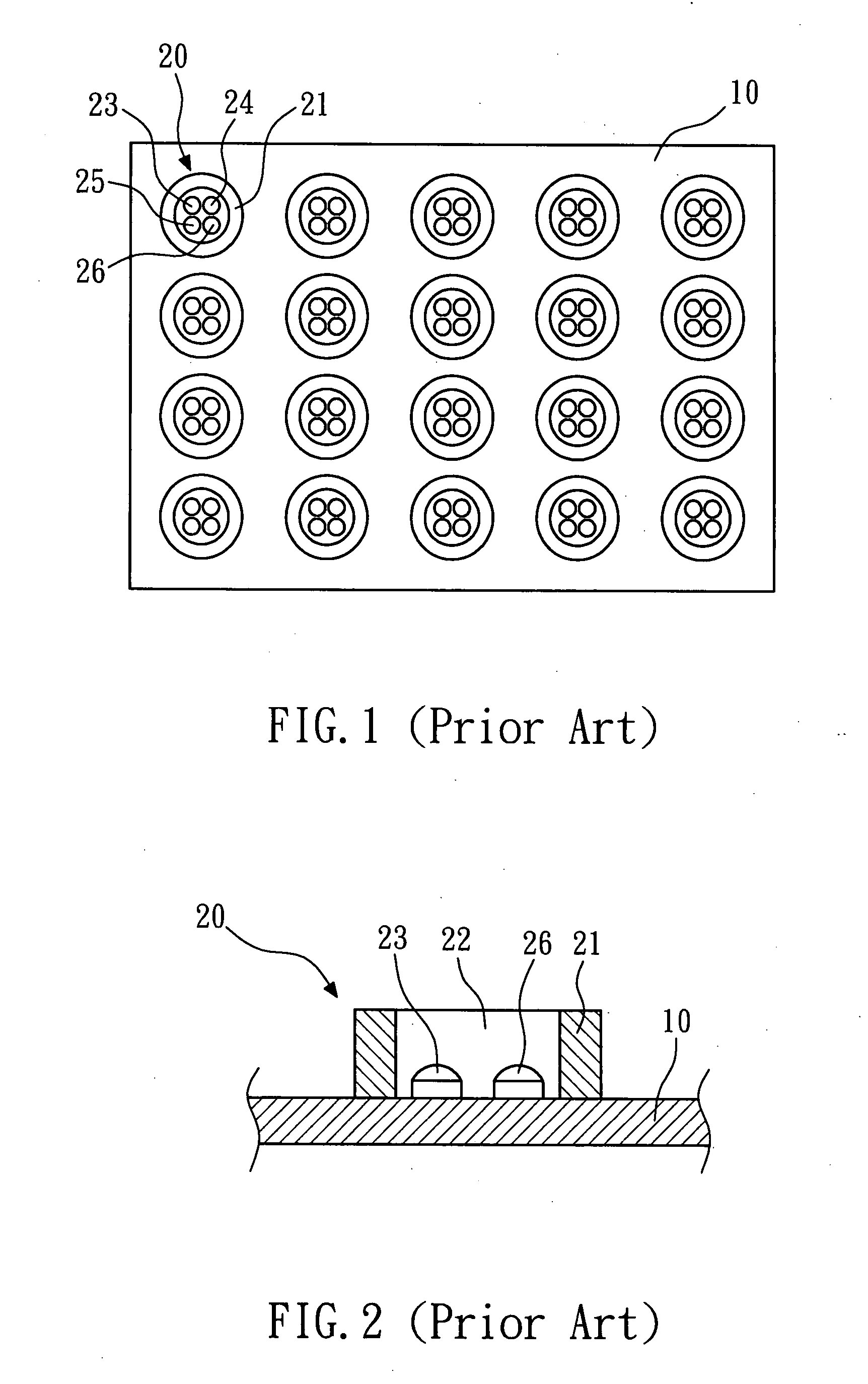

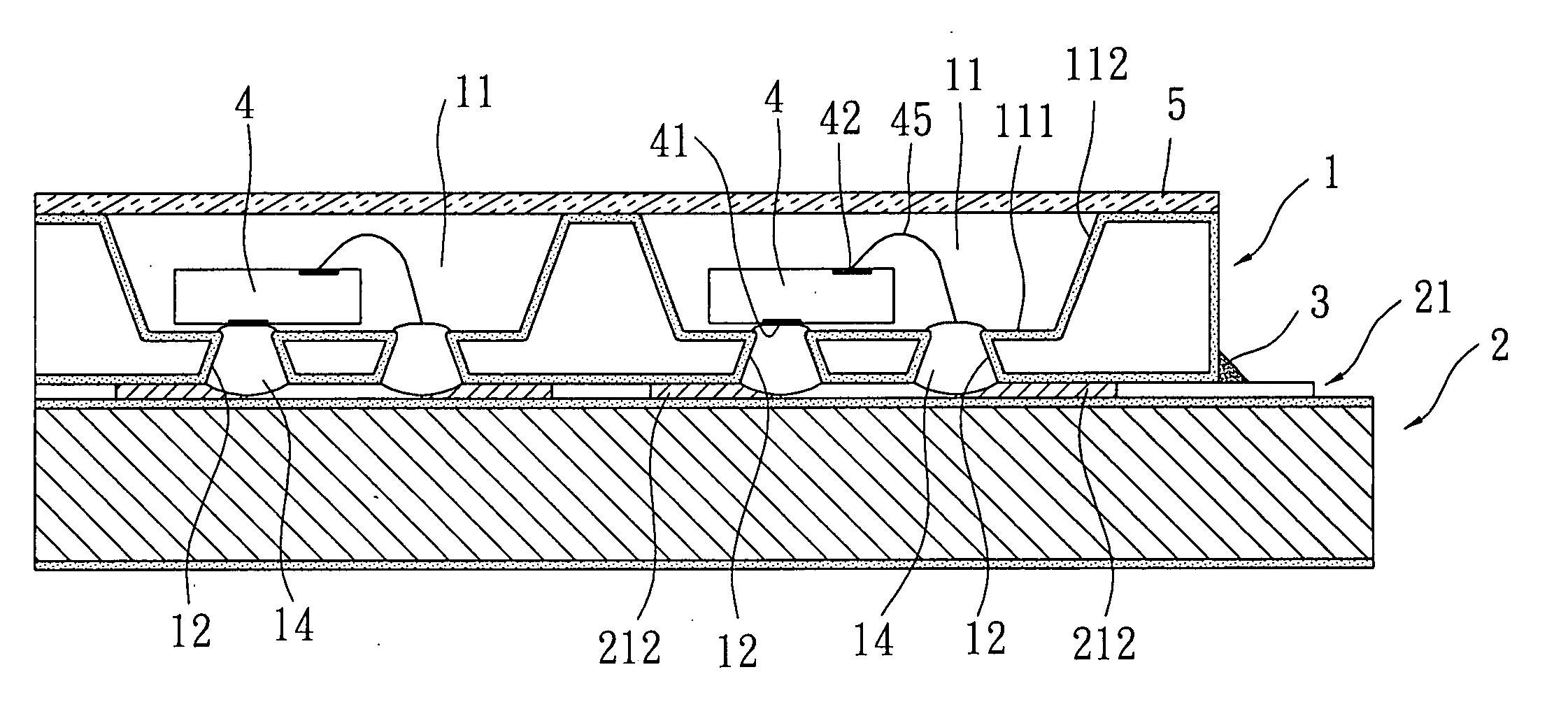

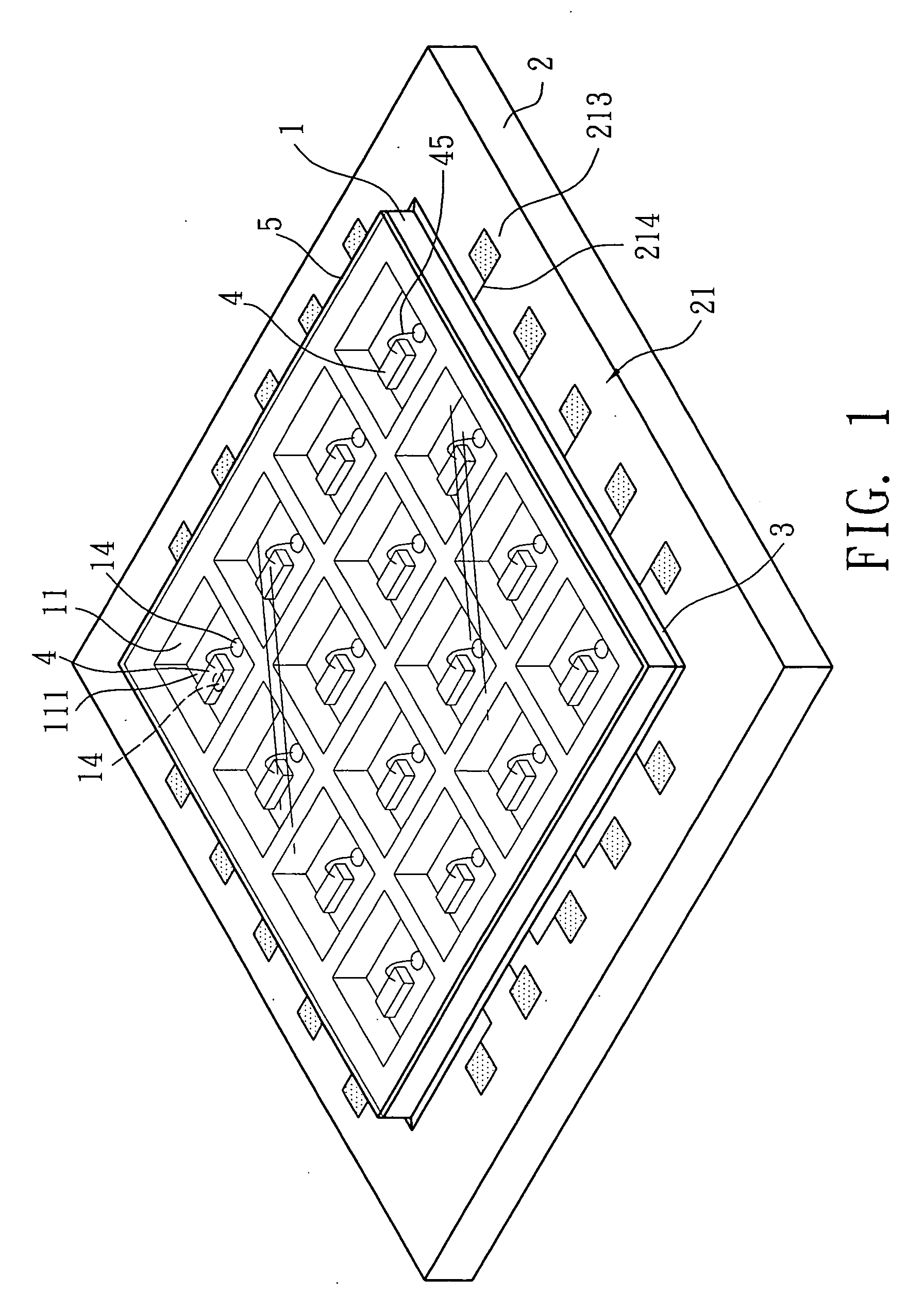

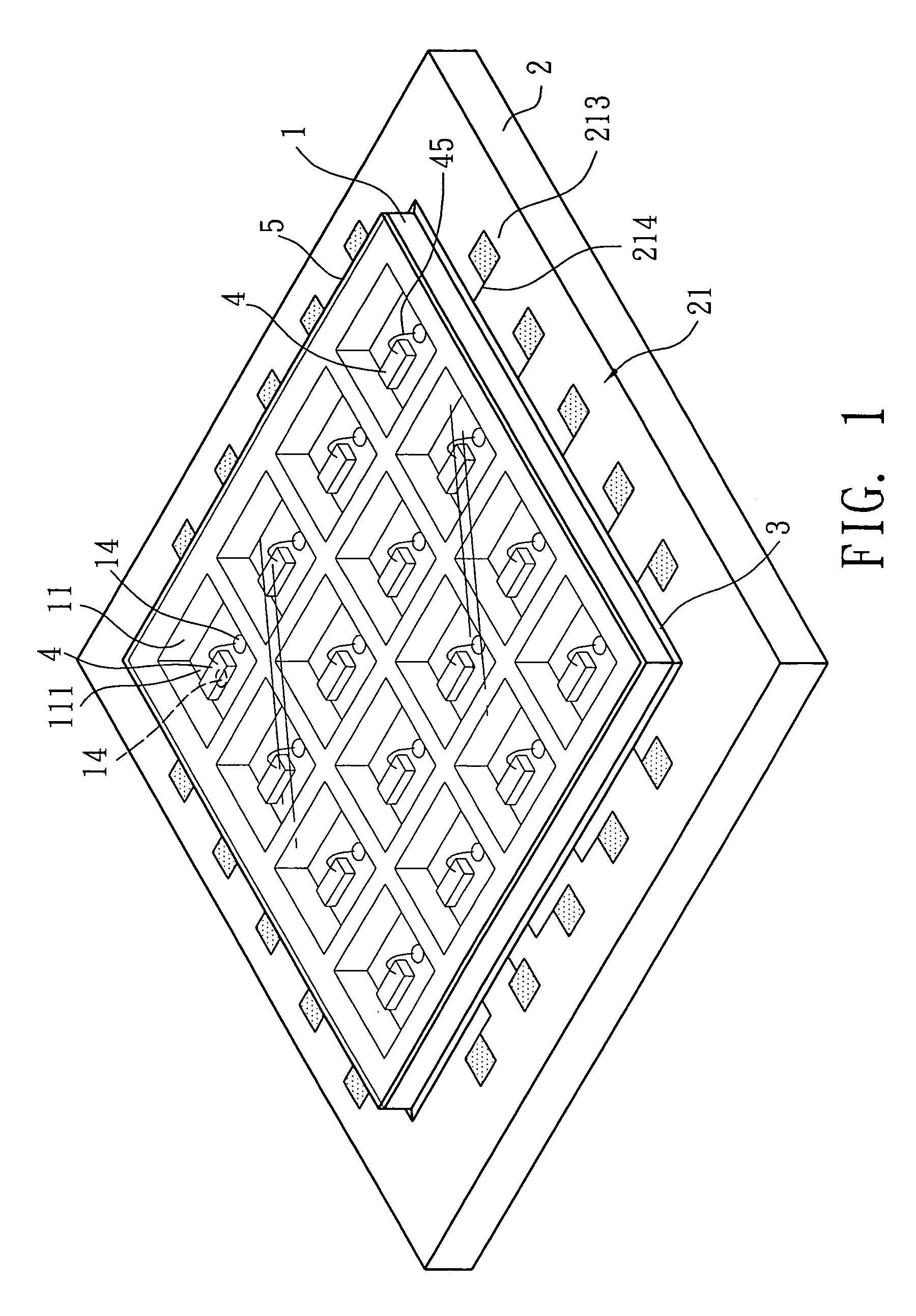

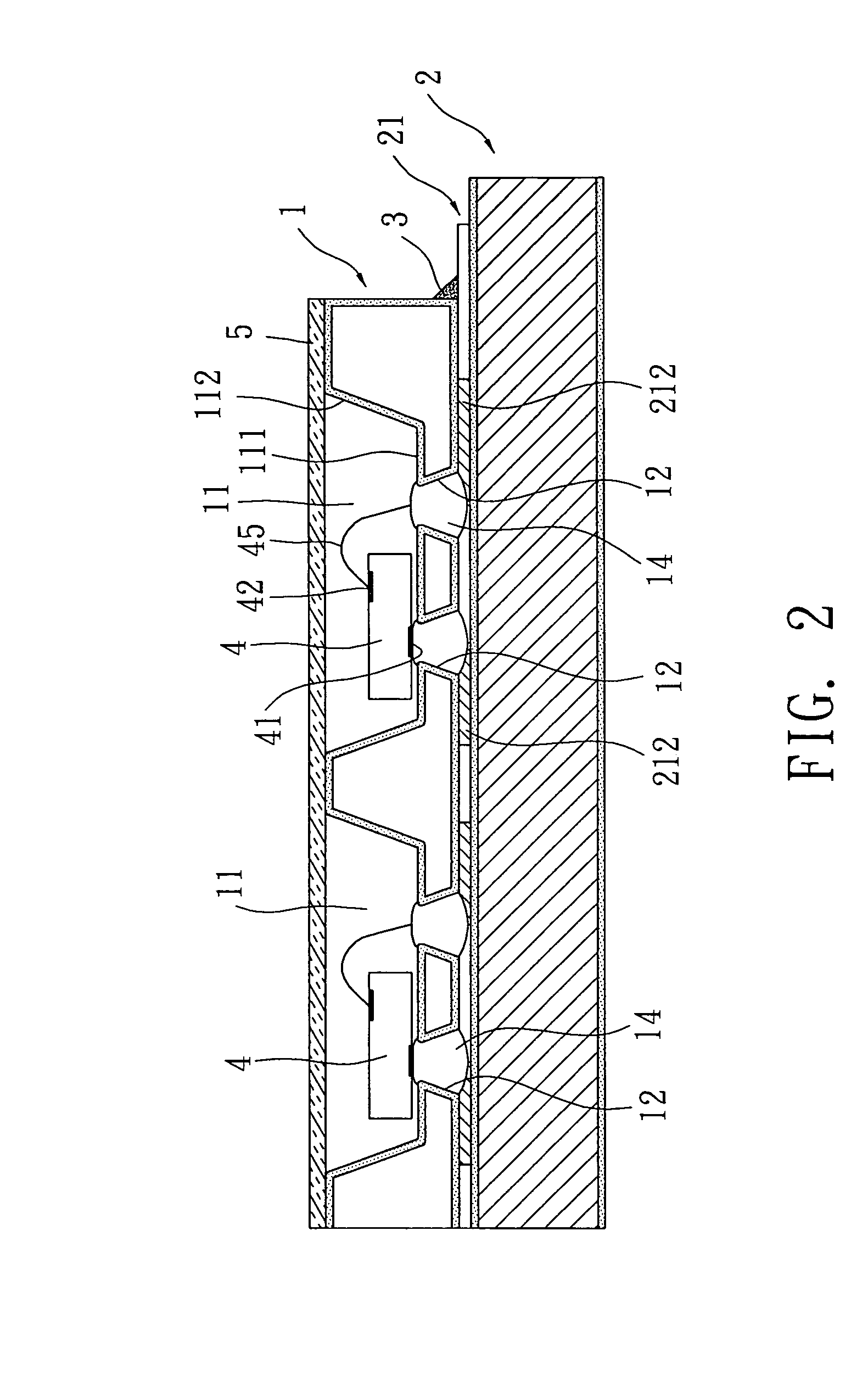

Array-type modularized light-emitting diode structure and a method for packaging the structure

InactiveUS20060261357A1High heat conductivityGood effectSemiconductor/solid-state device detailsSolid-state devicesLight-emitting diodeContact electrode

An array-type modularized light-emitting diode structure and a method for packaging the structure. The array-type modularized light-emitting diode structure includes a lower substrate and an upper substrate fixed on the lower substrate. A material with high heat conductivity is selected as the material of the upper substrate. The upper substrate is formed with multiple arrayed dents and through holes on the bottom of each dent. A material with high heat conductivity is selected as the material of the lower substrate. The surface of the lower substrate is formed with a predetermined circuit layout card. The bottom face of the upper substrate is placed on the upper face of the lower substrate with the through holes of the dents respectively corresponding to the contact electrodes of the circuit layout card of the lower substrate. Multiple light-emitting diode crystallites are respectively fixed on the bottoms of the dents. Via the through holes, the electrodes of the light-emitting diode crystallites are electrically connected with the contact electrodes. Then the dents of the upper substrate are sealed to prevent the light-emitting diode crystallites from being oxidized.

Owner:TSOU CHING FU +2

Light-Emitting Devices

ActiveUS20100244083A1Light efficiencyLight heatSolid-state devicesSemiconductor devicesAdemetionineEngineering

Owner:SAMSUNG ELECTRONICS CO LTD

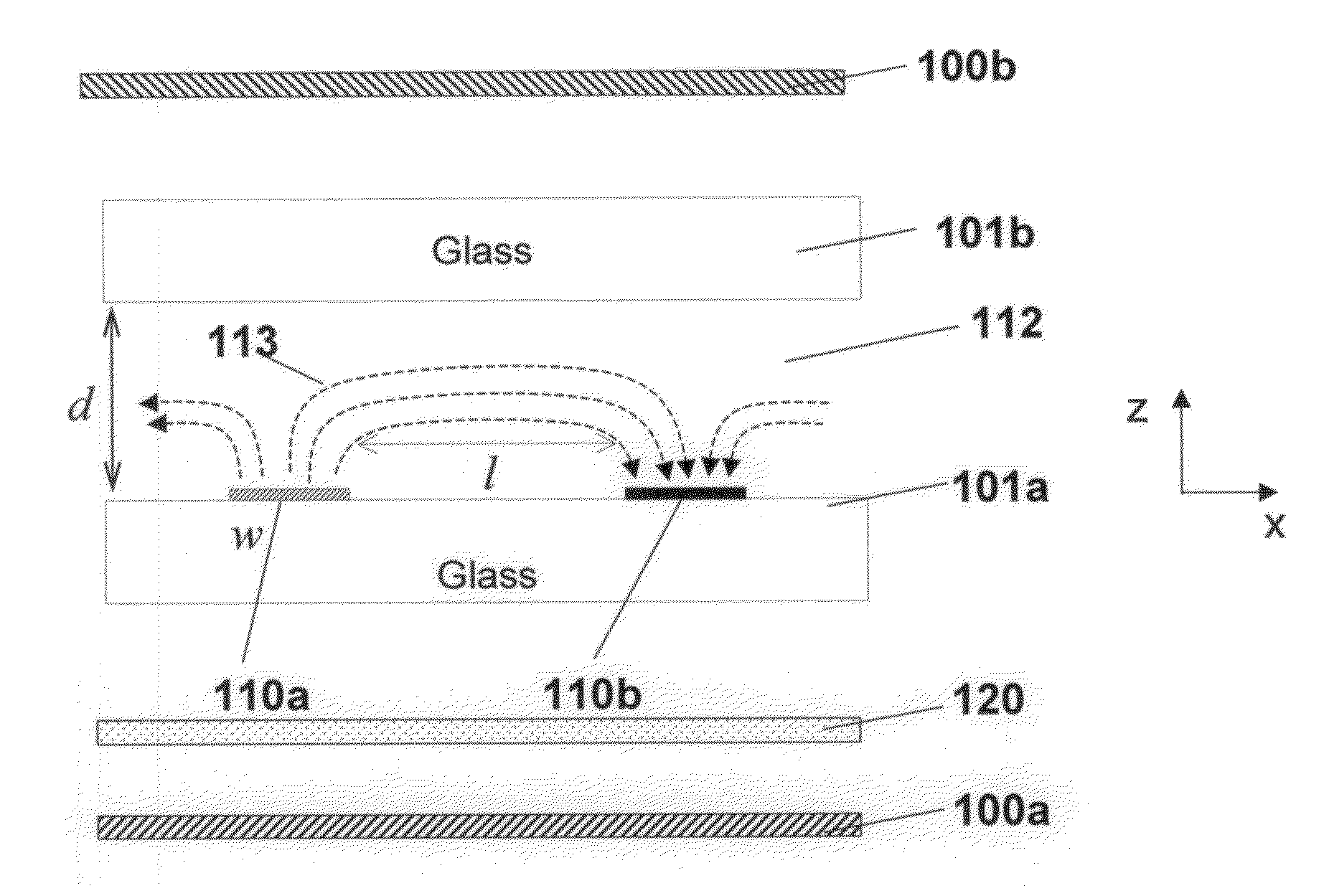

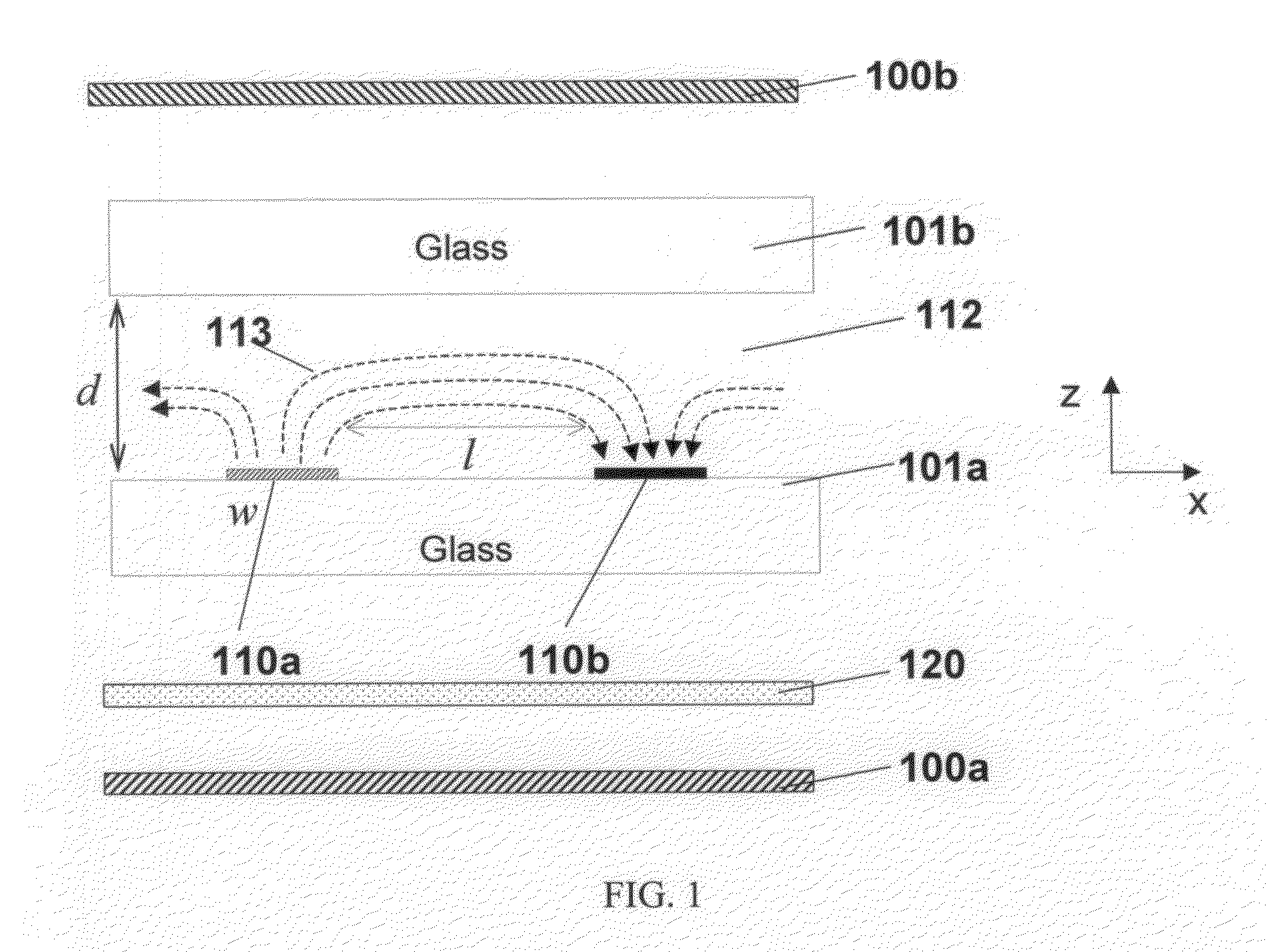

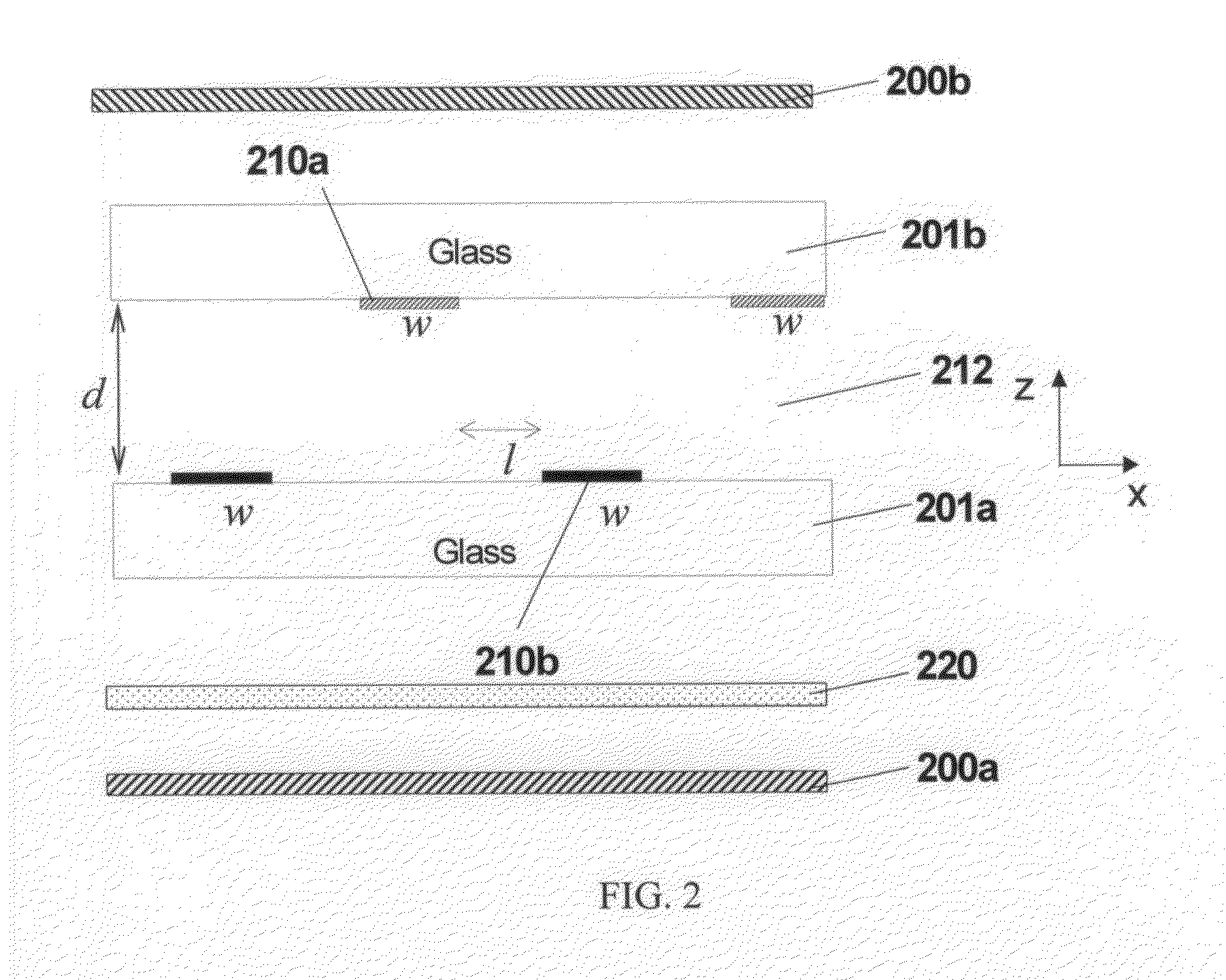

Liquid Crystals Composition and Liquid Crystal Display with Patterned Electrodes

InactiveUS20110075074A1High light efficiencyProcess stabilityLiquid crystal compositionsThin material handlingCrystallographyDisplay device

A blue phase liquid crystal composition and a LC display using the composition. The liquid crystal composition includes a first class including a highly polar compound and a second class including a highly conjugated liquid crystal compound. The blue phase liquid crystal display device includes first and second substrates each with polarizer on the exterior surface and the blue phase liquid crystal composition sandwiched therebetween with and patterned electrodes on one of the substrates or both substrates. The patterned electrodes can be T-shaped, chevron or v-shaped, thin comb like shape and can also be flat or trapezoidal. The device outputs different light transmissions from the electrically controllable induced birefringence of the blue phase LC material for a low driving voltage, high transmittance blue phase liquid crystal display device.

Owner:UNIV OF CENT FLORIDA RES FOUND INC +1

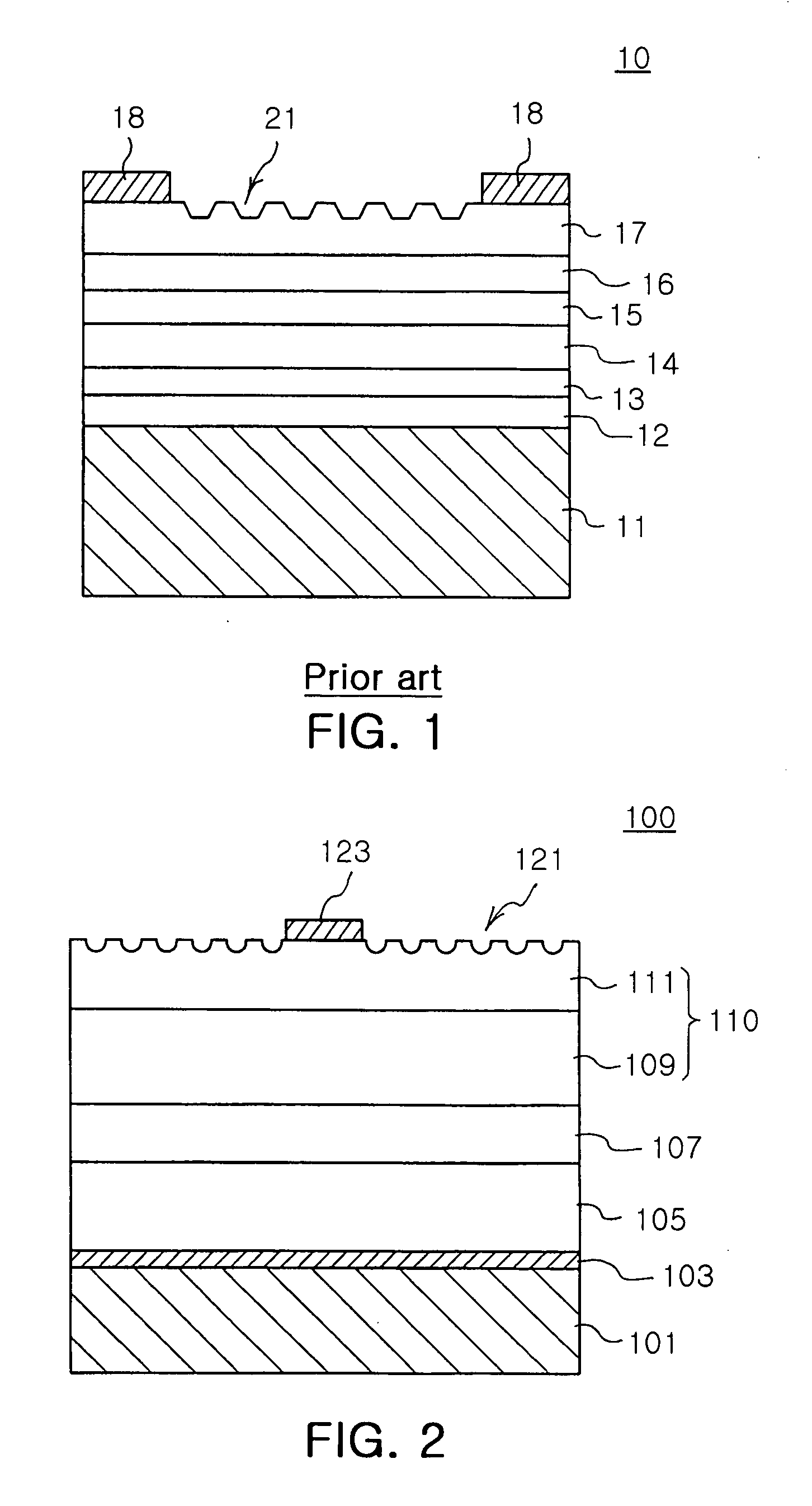

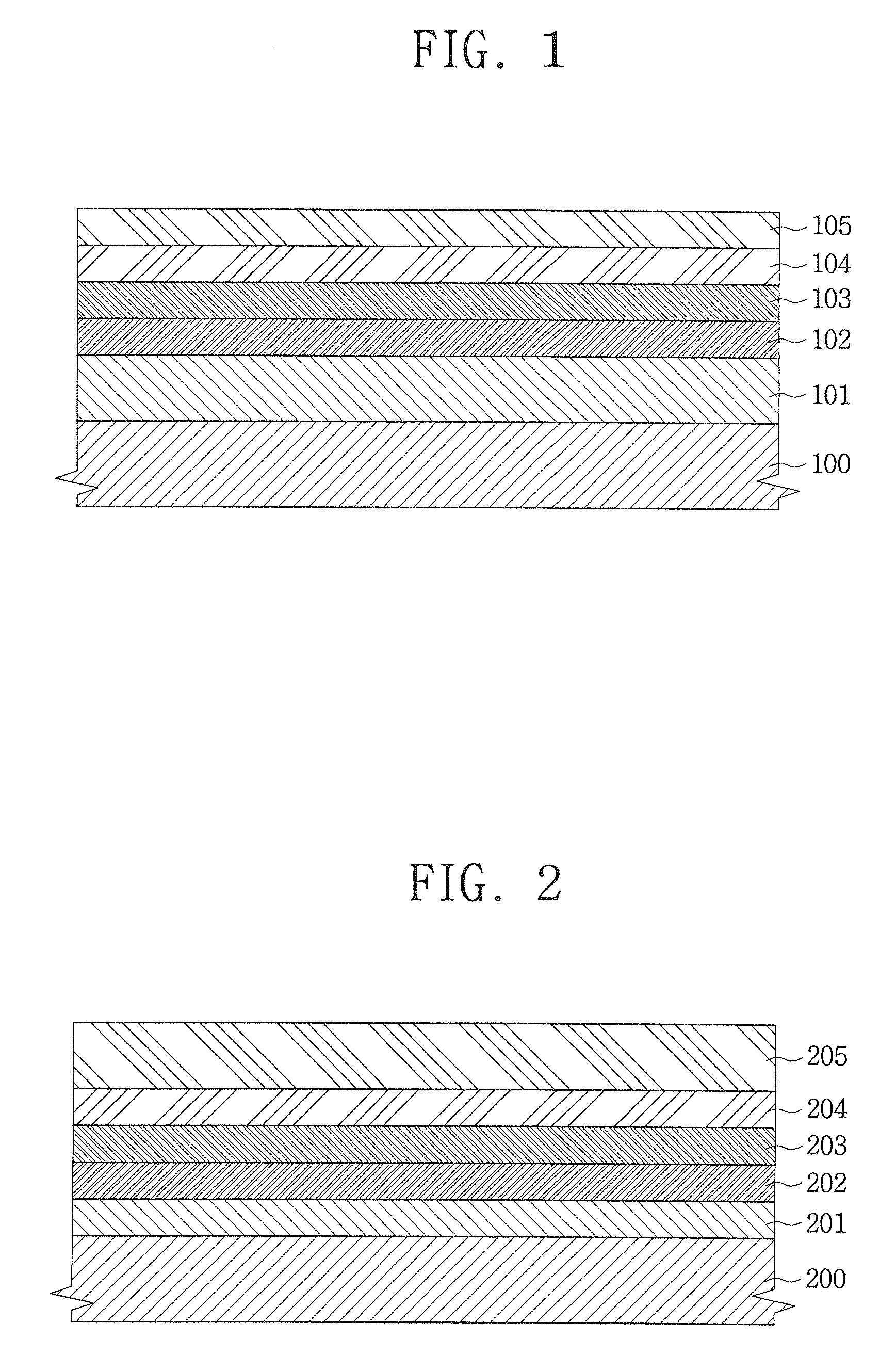

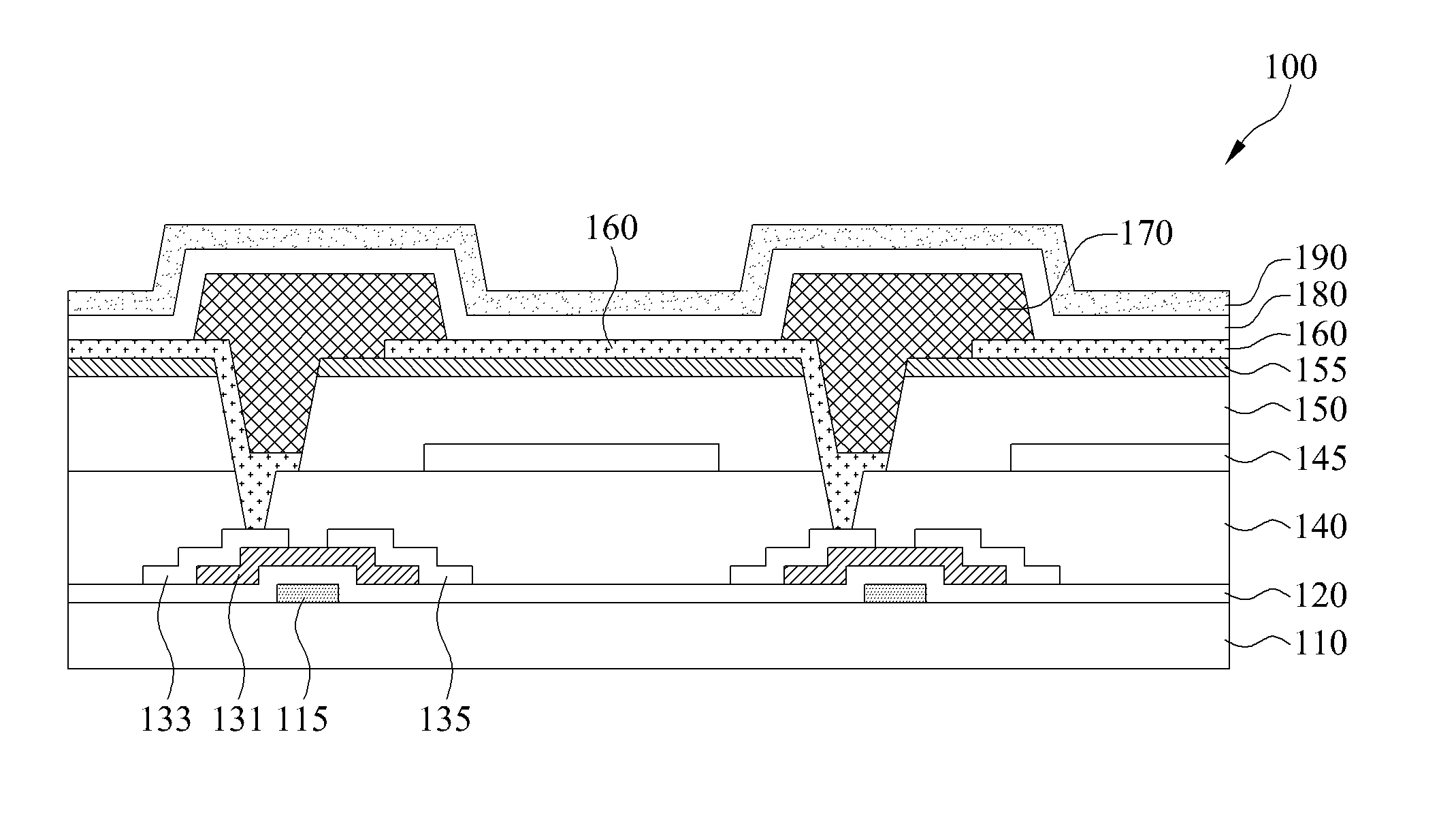

Light-emitting diode and method for manufacturing the same

InactiveUS20110073894A1Light extraction efficiencyStability of wiring lightSemiconductor/solid-state device manufacturingSemiconductor devicesRough surfaceLight-emitting diode

In one aspect of the invention, an LED includes a substrate, an n-type semiconductor layer, a light emitting layer, a p-type semiconductor layer and a transparent conductive layer sequentially stacked on the substrate, and p-type and n-type electrodes. The p-type semiconductor layer has a rough surface region and at least one flat surface region. The transparent conductive layer has a rough surface region and a flat surface region corresponding to the rough surface region and the at least one flat surface region of the p-type semiconductor layer, respectively. The p-type electrode is disposed on the flat surface region of the transparent conductive layer. The n-type electrode is electrically couple to the n-type semiconductor layer.

Owner:CHI MEI LIGHTING TECH

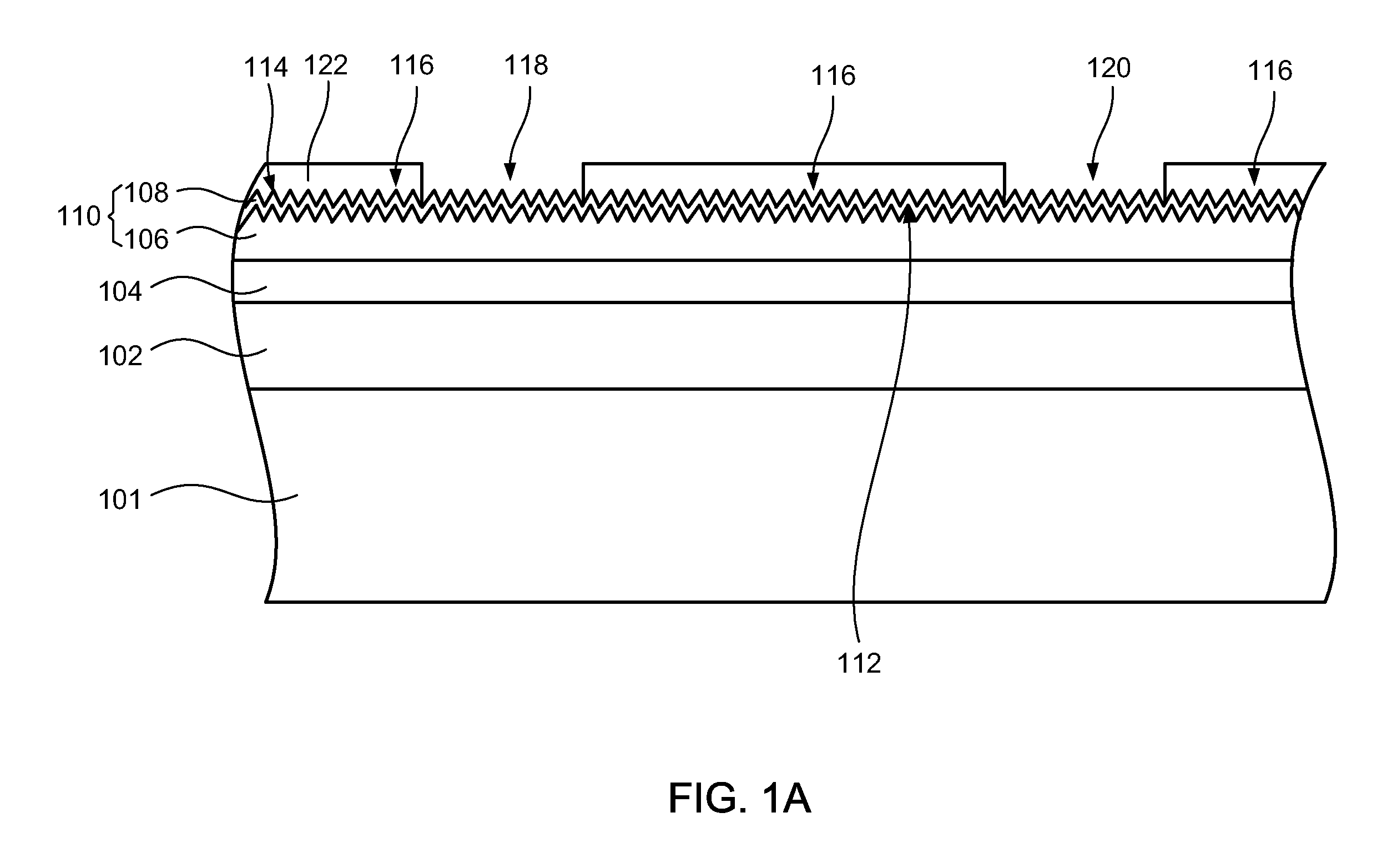

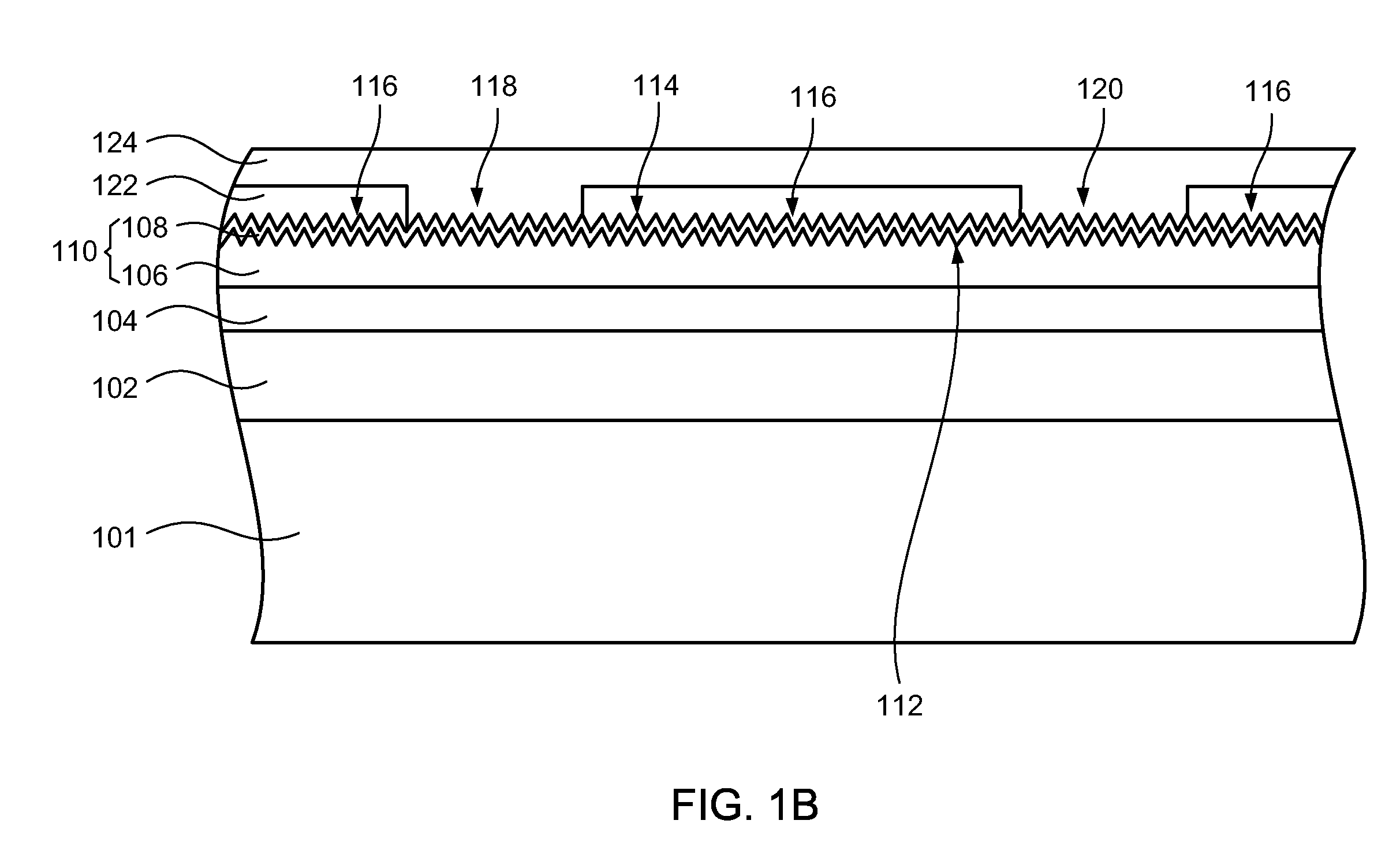

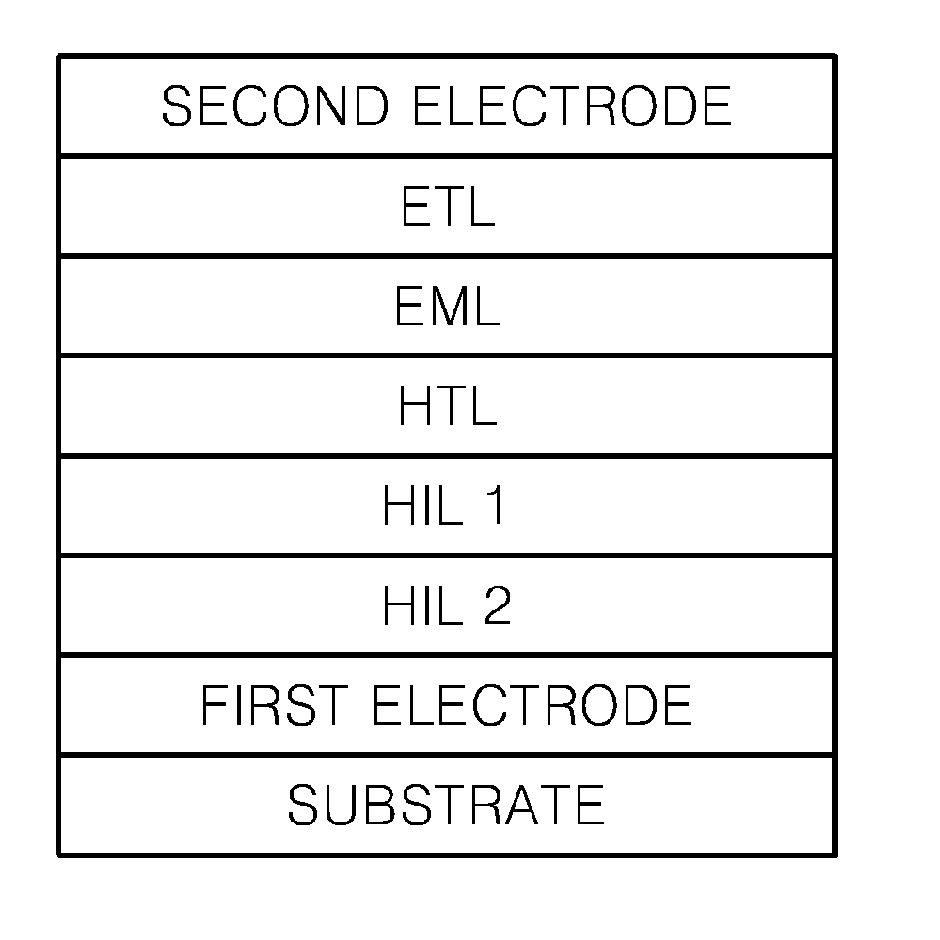

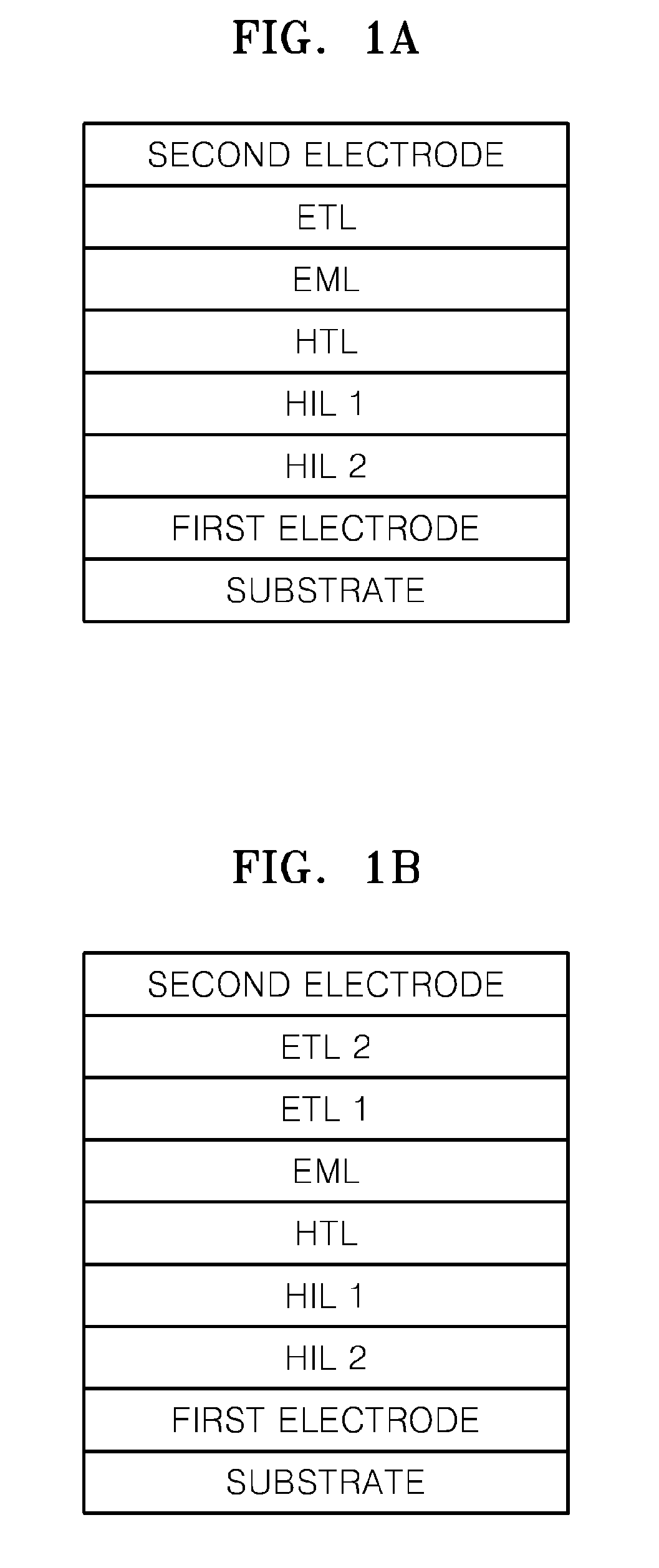

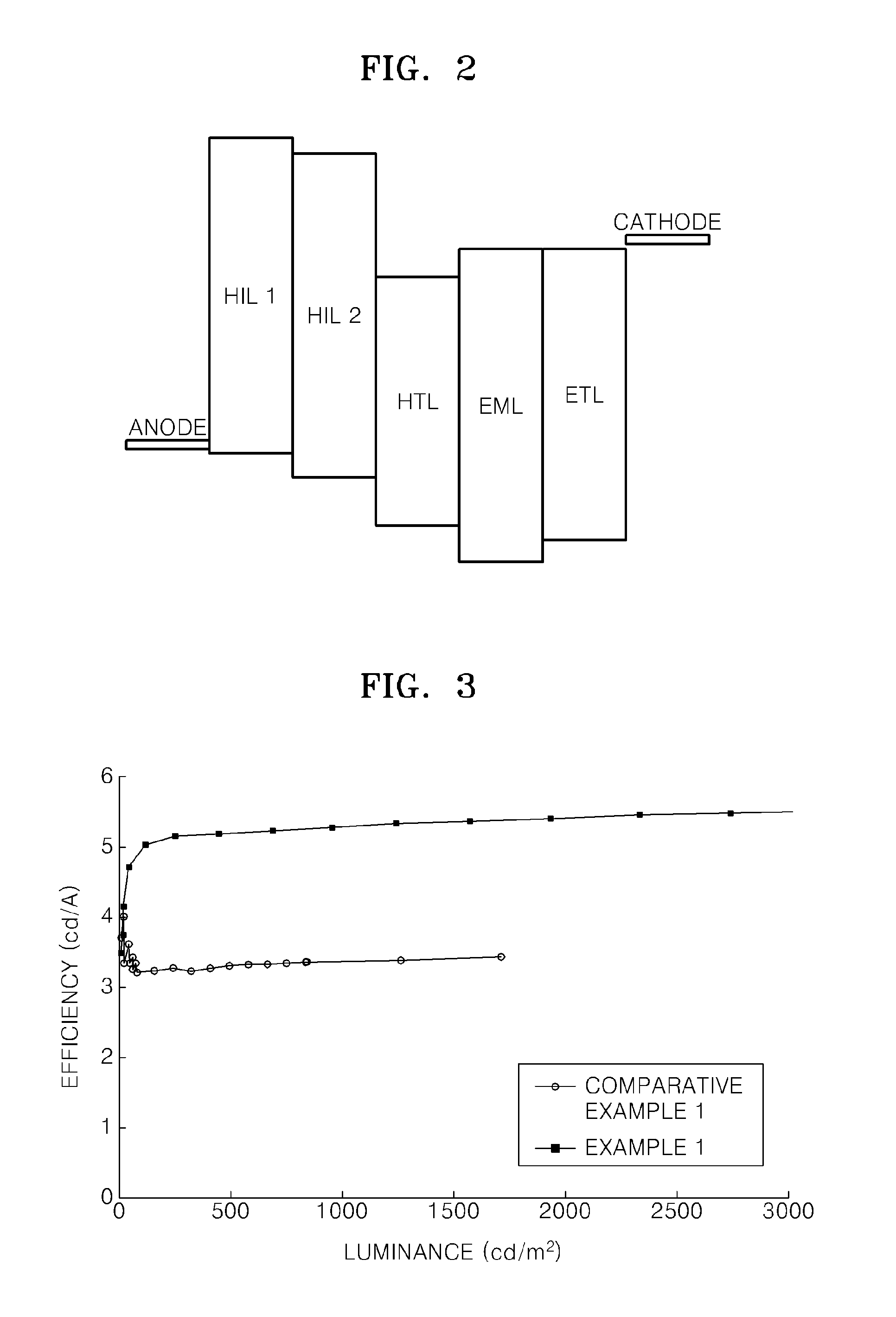

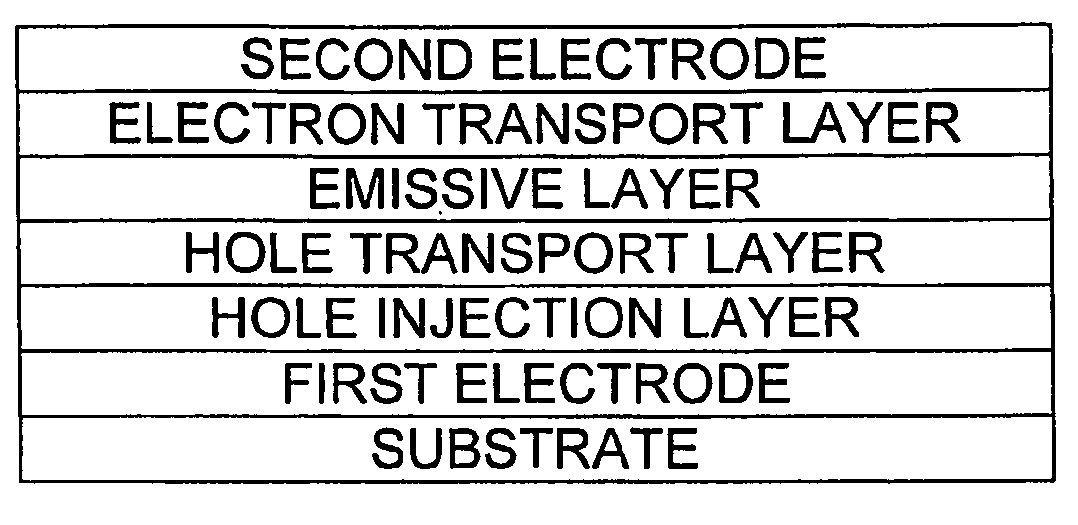

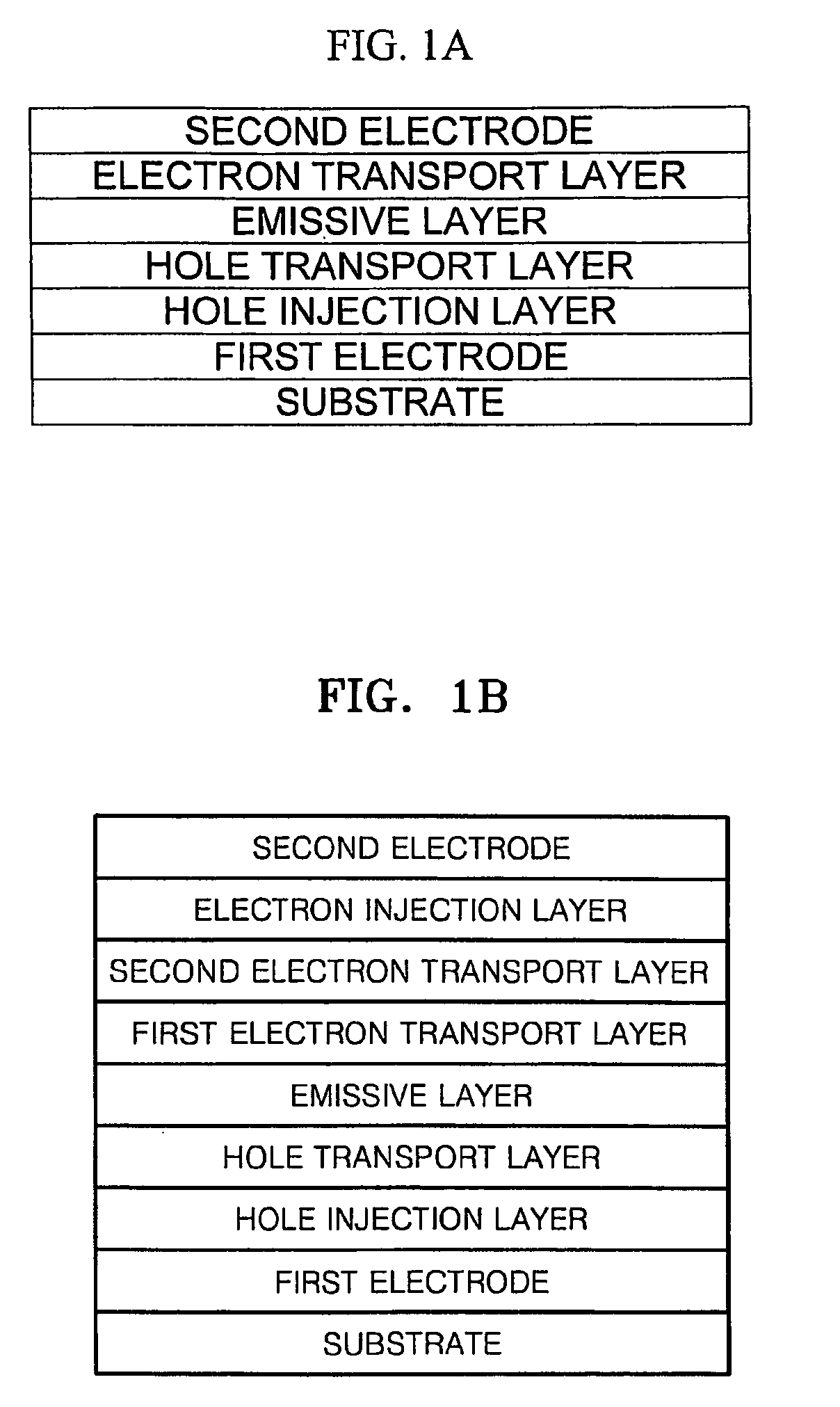

Organic light-emitting device

InactiveUS20090218934A1Easily chargeDecrease voltage and power consumptionDischarge tube luminescnet screensElectroluminescent light sourcesHole injection layerElectron transport layer

An organic light-emitting device comprising: a first electrode; a second electrode; an emissive layer; a first hole injecting layer disposed between the first electrode and the emissive layer; a second hole injecting layer disposed between the first electrode and the emissive layer; and an electron transporting layer disposed between the emissive layer and the second electrode, wherein the first hole injecting layer comprises a metal fluoride, the second hole injecting layer comprises molybdenum oxide, and the electron transporting layer comprises a metal compound represented by Formula 1 below:XaYb <Formula 1>X is one of an alkaline metal, an alkaline earth metal, and a transition metal,Y is one of a Group 7 element and a C1-C20 organic group,a is 1 to 3, andb is 1 to 3.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

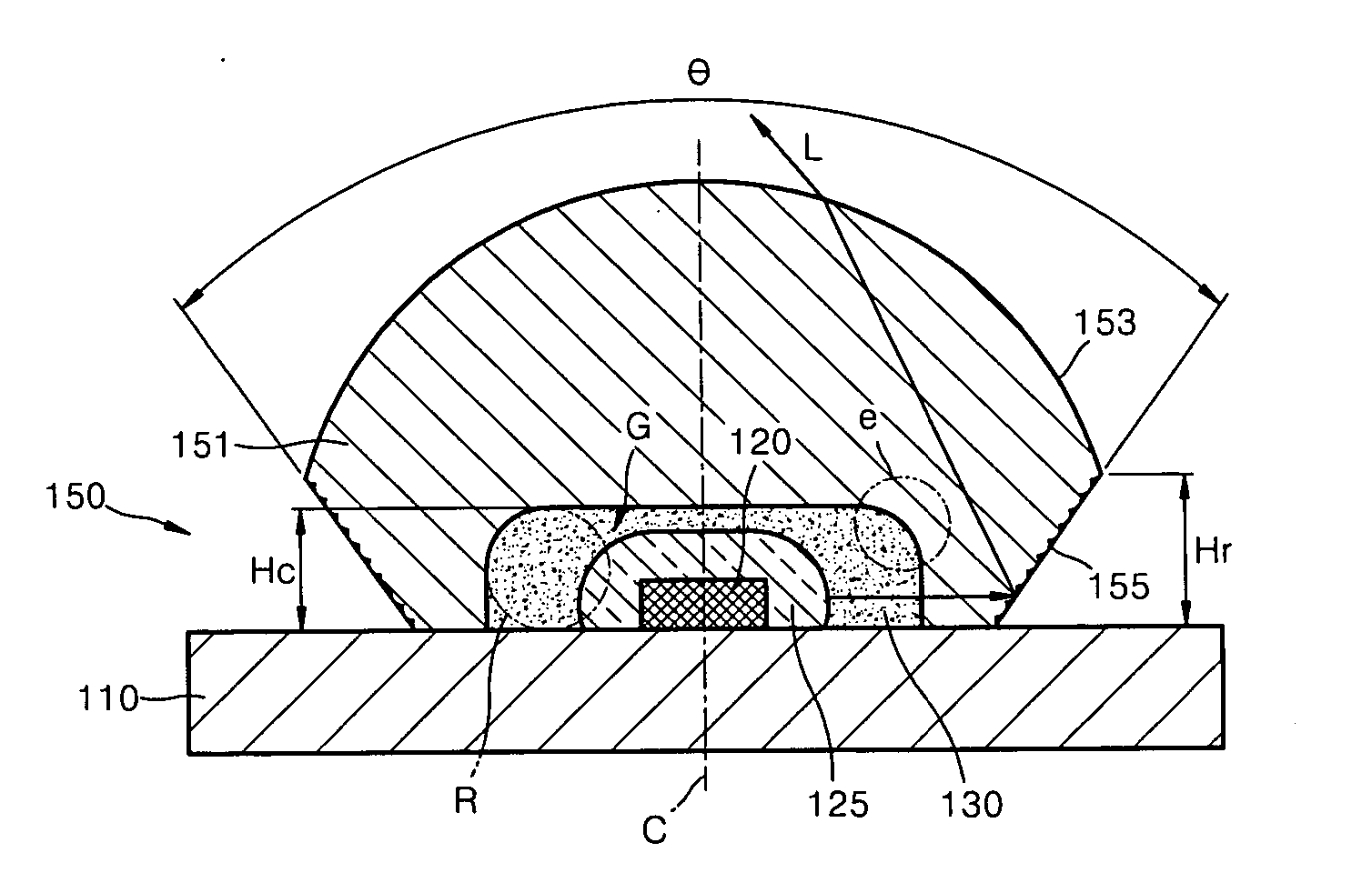

Lens-equipped light-emitting diode device and method of manufacturing the same

InactiveUS20070145255A1Light extraction efficiencyLight reliabilityBeam/ray focussing/reflecting arrangementsSolid-state devicesEngineeringLead frame

A lens-equipped light-emitting diode device of the present invention includes a lead frame in which an electrode is formed, a light-emitting diode which is mounted on the electrode of the lead frame, an outer peripheral unit which is made of a first resin, which is provided on the lead frame, and in which a hollow portion is formed while an area including at least the light-emitting diode is exposed in the outer peripheral unit, a sealing portion which is made of a second resin filled in the lead frame of the hollow portion of the outer peripheral unit, and which seals the light-emitting diode, and a lens unit made of a third resin laminated and filled in the sealing portion.

Owner:KK TOSHIBA

Light-Emitting Device

The invention provides a light-emitting device, comprising a light-emitting element and a surface plasmon coupling element connected to the light-emitting element. In an embodiment of the invention, the surface plasmon coupling element comprises a dielectric layer connected to the light-emitting element and a metal layer on the dielectric layer. In another embodiment of the invention, the light-emitting device is a light-emitting diode, comprising an active layer between an n-type semiconductor layer and a p-type semiconductor layer, and a surface plasmon coupling element adjacent to the n-type semiconductor layer. In a further embodiment of the invention, a current spreading layer on a second type semiconductor layer of the light-emitting device includes a plurality of strip-shaped structures, and the surface plasmon coupling element is disposed on the current spreading layer and filled into the gap between the strip-shaped structures of the current spreading layer.

Owner:NAT TAIWAN UNIV

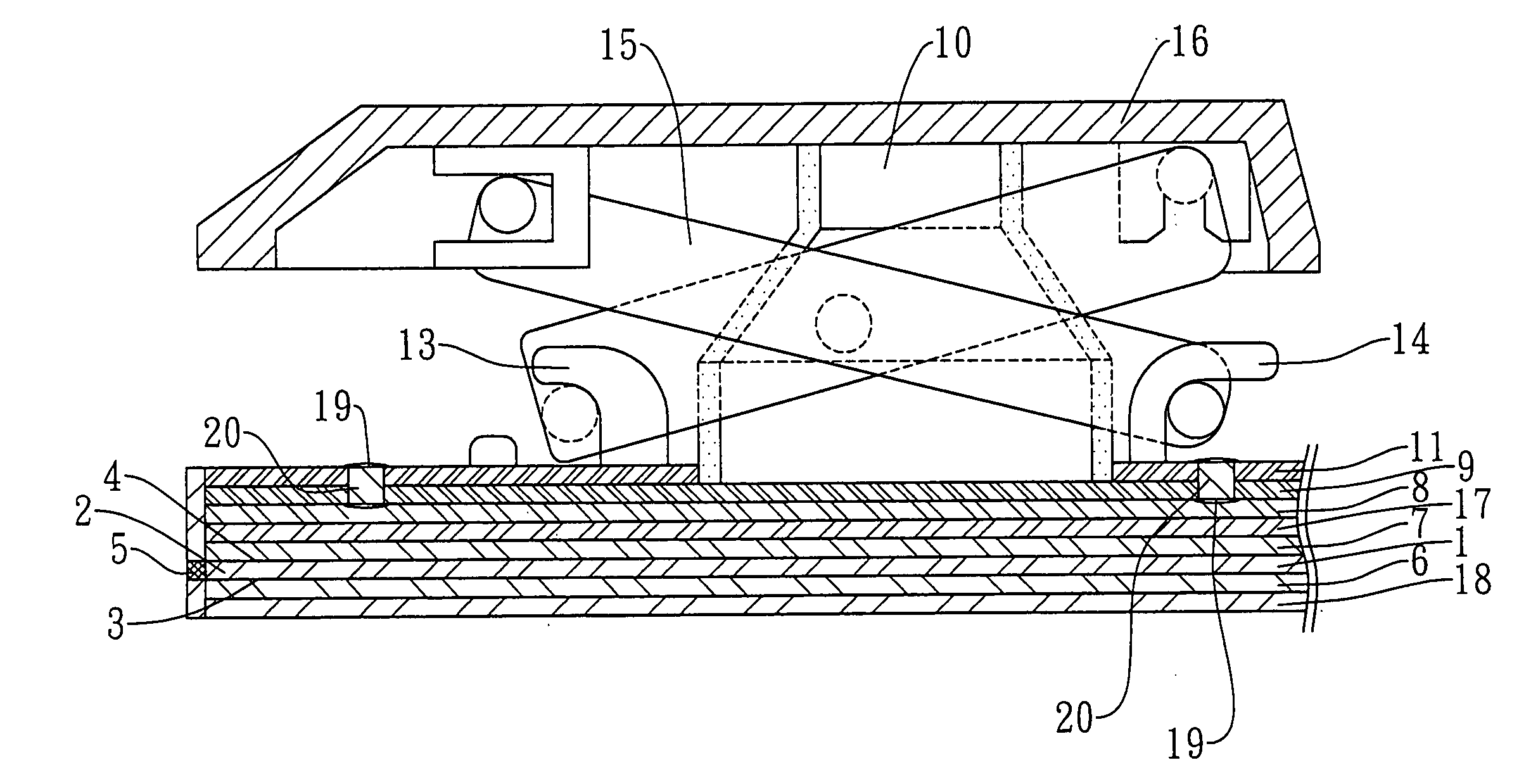

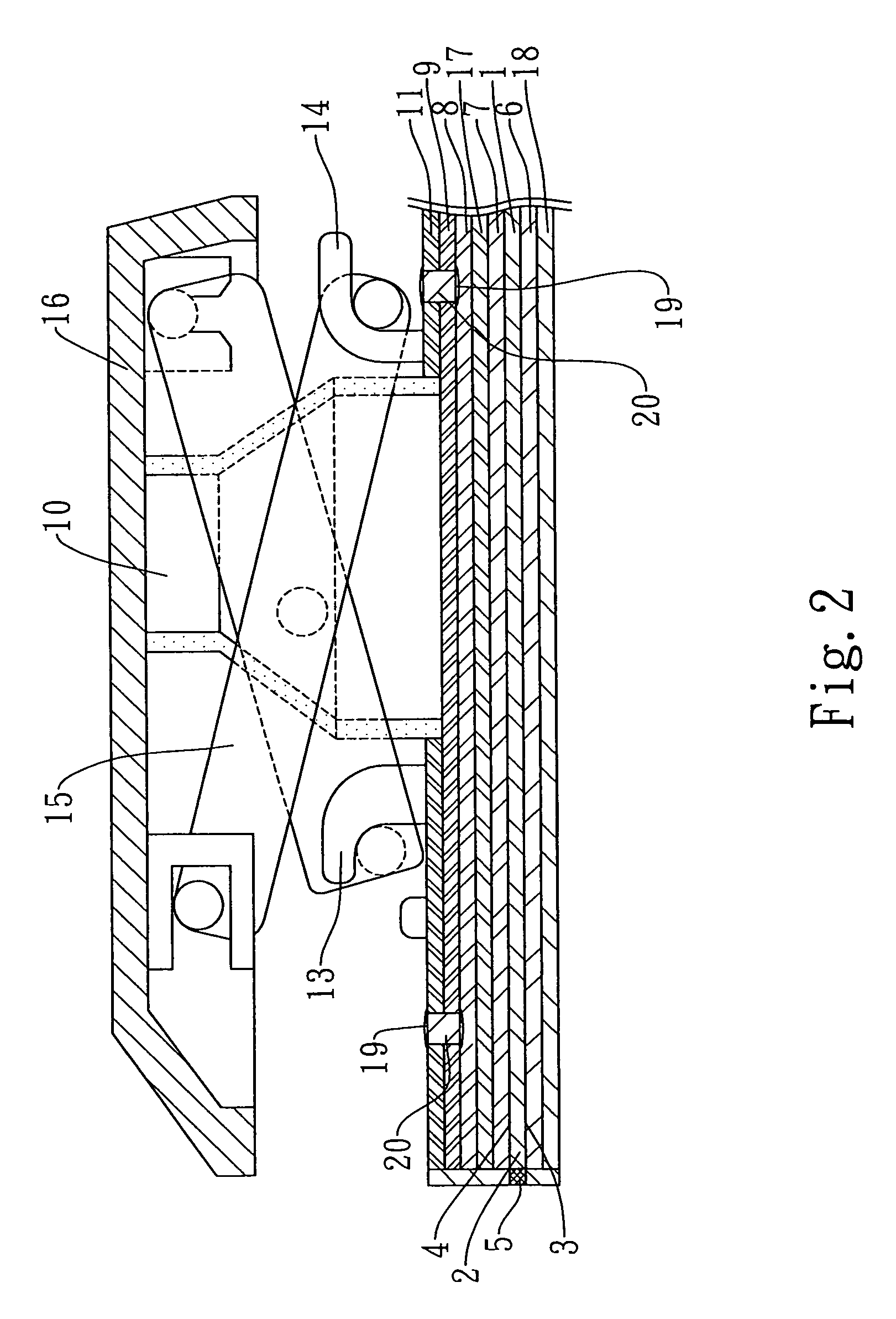

Light-emitting keyboard

InactiveUS20090283393A1Reduce complexityLow costElectric switchesInput/output processes for data processingLight guideOptoelectronics

The present invention is related to a light-emitting keyboard, comprising: a light guide having a light entrance surface, a bottom surface and a light exit surface; a light source provided adjacent to the light entrance surface of the light guide; a first reflector disposed underneath the bottom surface of the light guide to reflect the light originated from the light source to enter into said light guide; a second reflector disposed on top of said light exit surface of the light guide; a membrane circuit board disposed on top of said second reflector, said membrane circuit board being provided with an elastic member; a supporting plate disposed on top of the membrane circuit board; a scissor assembly engaged with said supporting plate and provided thereon; and a keycap supported by said scissor assembly.

Owner:CHICONY ELECTRONICS

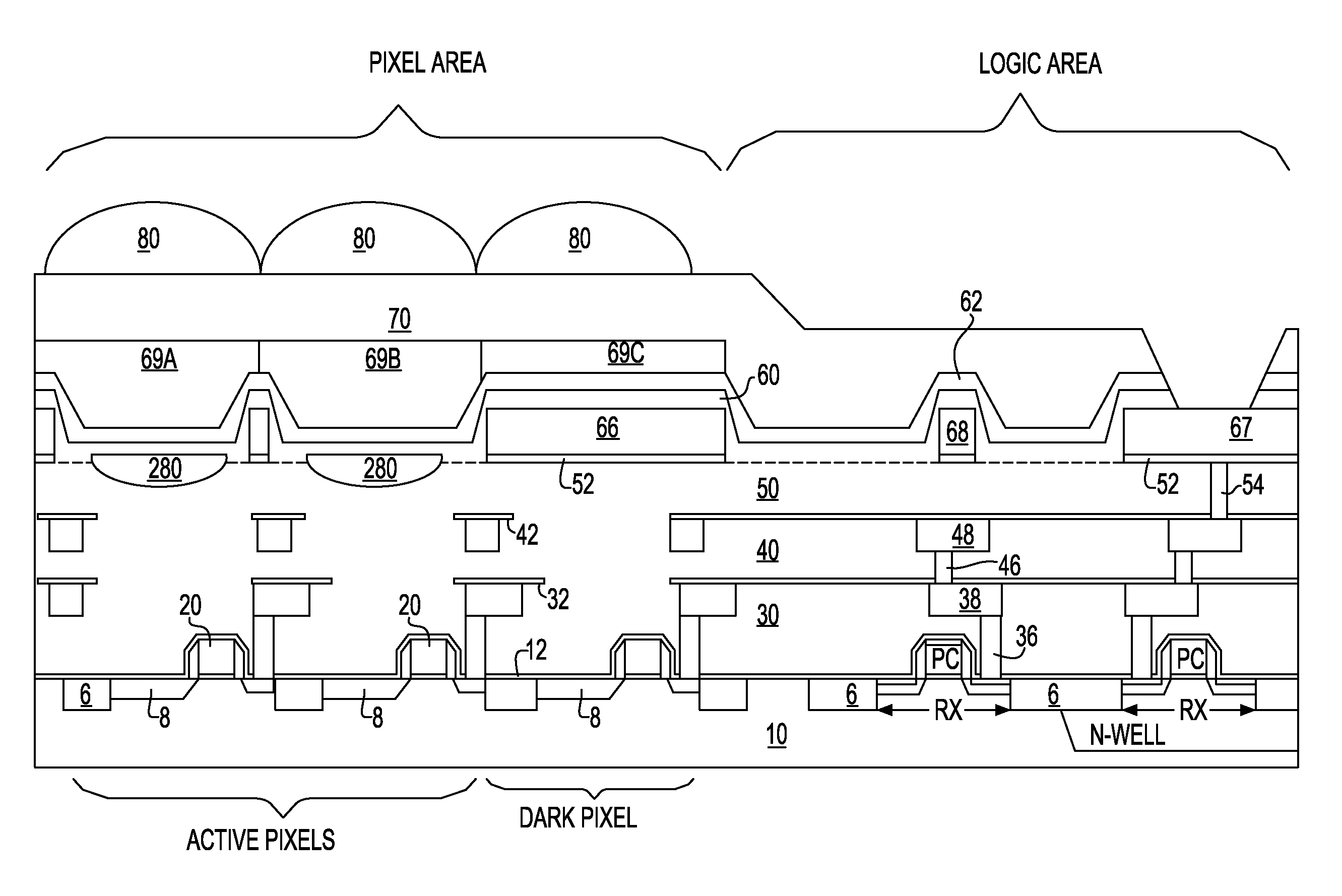

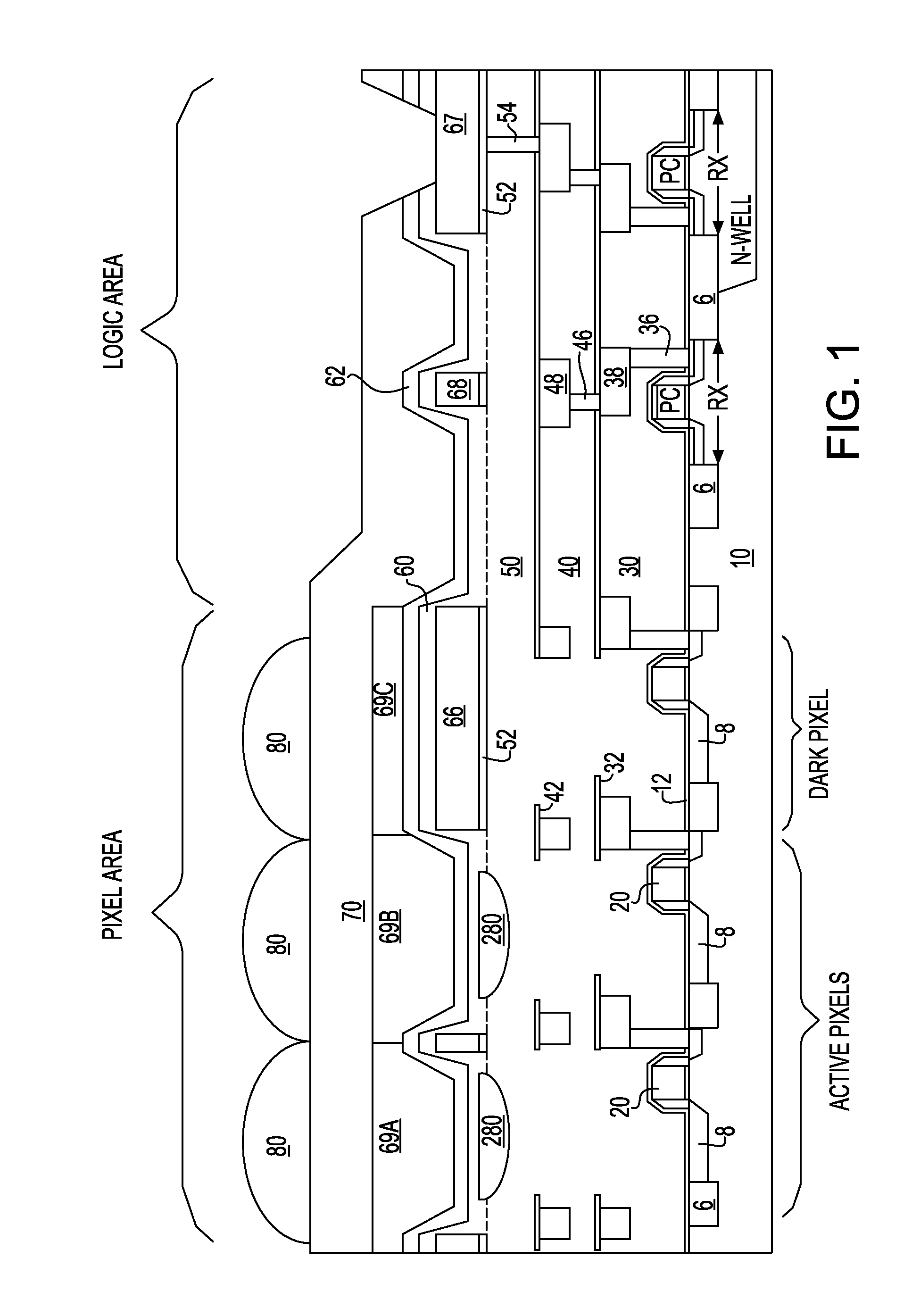

Method of forming an inverted lens in a semiconductor structure

InactiveUS20090242948A1Light capacityLight efficiencySolid-state devicesSemiconductor/solid-state device manufacturingSemiconductor structureRefractive index

A flat-top convex-bottom lower lens is formed by first applying a positive tone photoresist over a silicon oxide layer and an optional metallic barrier layer thereupon in a back-end-of-line (BEOL) metallization structure. The positive tone photoresist is exposed under defocused illumination conditions and / or employing a half-tone mask so that a cross-sectional profile of the positive tone photoresist after exposure contains a continuous and smooth concave profile, which is transferred into the underlying silicon oxide layer to form a concave cavity therein. After removing the photoresist, the cavity is filled with a high refractive index material such as silicon nitride, and planarized to form a flat-top convex-bottom lower lens. Various aluminum metal structures, a color filter, and a convex-top flat-bottom upper lens are thereafter formed so that the upper lens and the lower lens constitute a composite lens system.

Owner:IBM CORP

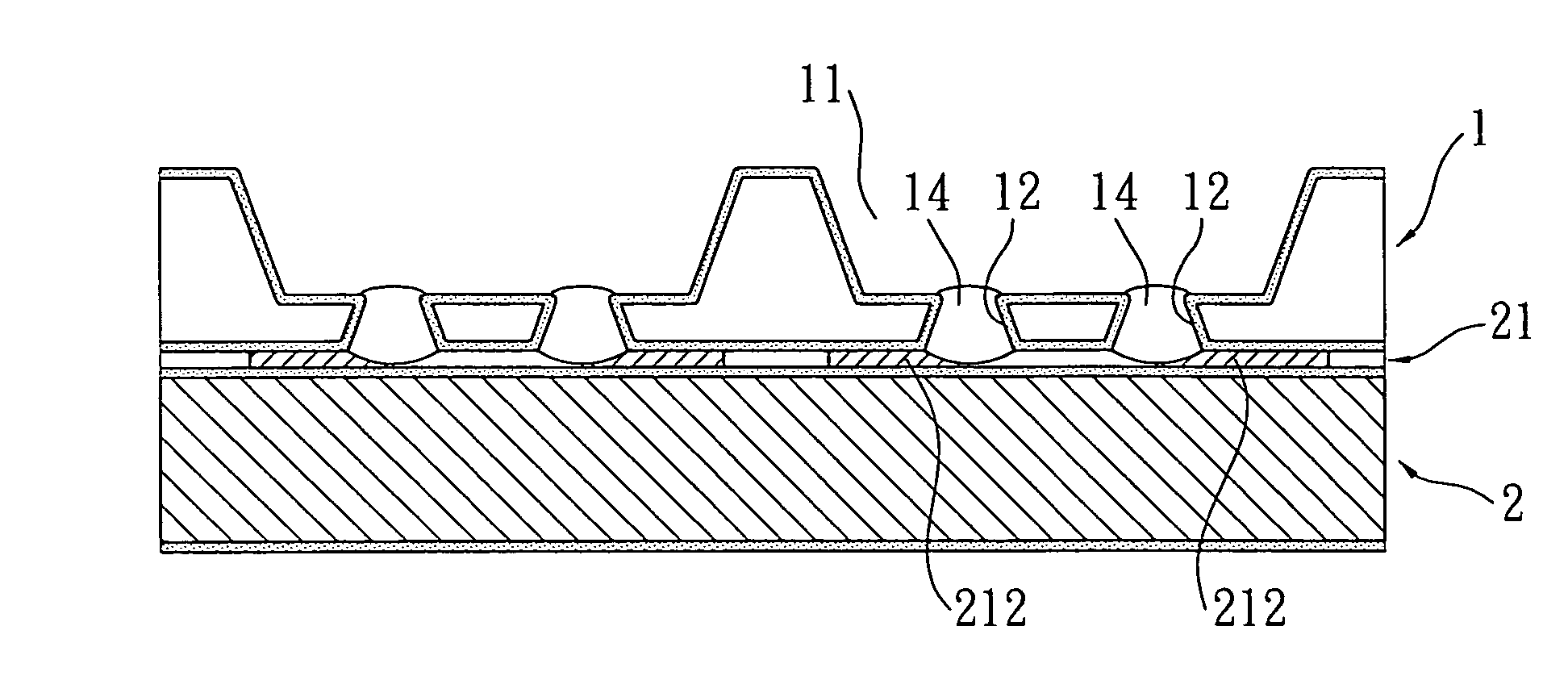

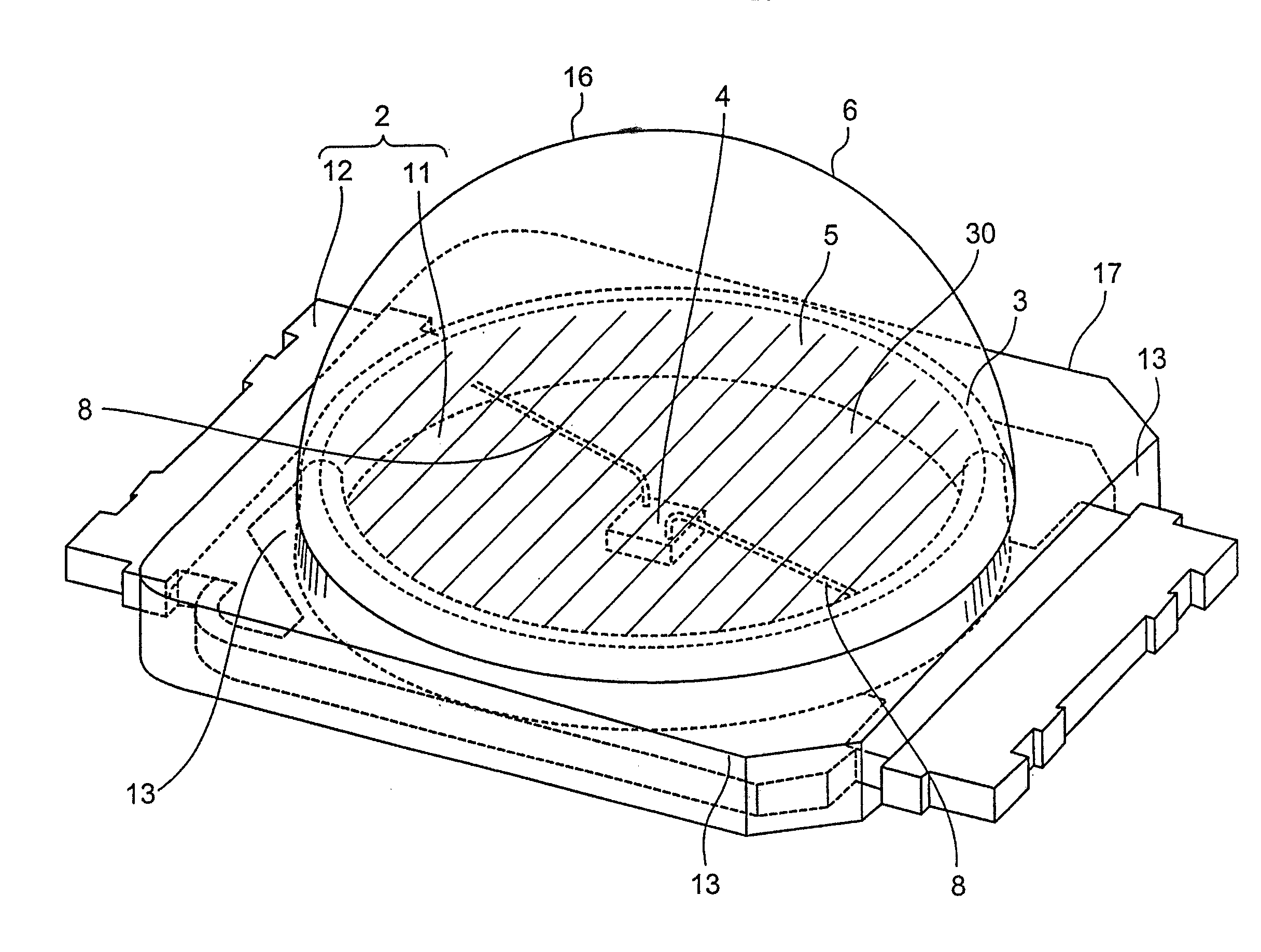

Array-type modularized light-emitting diode structure and a method for packaging the structure

InactiveUS7329942B2Improve conductivityGood effectSemiconductor/solid-state device detailsSolid-state devicesLight-emitting diodeContact electrode

An array-type modularized light-emitting diode structure and a method for packaging the structure. The array-type modularized light-emitting diode structure includes a lower substrate and an upper substrate fixed on the lower substrate. A material with high heat conductivity is selected as the material of the upper substrate. The upper substrate is formed with multiple arrayed dents and through holes on the bottom of each dent. A material with high heat conductivity is selected as the material of the lower substrate. The surface of the lower substrate is formed with a predetermined circuit layout card. The bottom face of the upper substrate is placed on the upper face of the lower substrate with the through holes of the dents respectively corresponding to the contact electrodes of the circuit layout card of the lower substrate. Multiple light-emitting diode crystallites are respectively fixed on the bottoms of the dents. Via the through holes, the electrodes of the light-emitting diode crystallites are electrically connected with the contact electrodes. Then the dents of the upper substrate are sealed to prevent the light-emitting diode crystallites from being oxidized.

Owner:TSOU CHING FU +2

Light-emitting keyboard

InactiveUS7709760B2Reduce complexityLow costElectric switchesInput/output processes for data processingLight guideOptoelectronics

The present invention is related to a light-emitting keyboard, comprising: a light guide having a light entrance surface, a bottom surface and a light exit surface; a light source provided adjacent to the light entrance surface of the light guide; a first reflector disposed underneath the bottom surface of the light guide to reflect the light originated from the light source to enter into said light guide; a second reflector disposed on top of said light exit surface of the light guide; a membrane circuit board disposed on top of said second reflector, said membrane circuit board being provided with an elastic member; a supporting plate disposed on top of the membrane circuit board; a scissor assembly engaged with said supporting plate and provided thereon; and a keycap supported by said scissor assembly.

Owner:CHICONY ELECTRONICS

Organic light emitting device

InactiveUS20090167159A1Reduce power consumptionIncrease the driving voltageDischarge tube luminescnet screensElectroluminescent light sourcesElectron holeHole injection layer

An organic light emitting device includes a first electrode; a second electrode; an emissive layer disposed between the first electrode and the second electrode; a first hole injection layer disposed between the first electrode and the emissive layer; and a first electron transport layer disposed between the emissive layer and the second electrode. The hole injection layer includes a hole injecting material and a first compound made up of an element selected from the group consisting of Mo, Li, Na, K, Rb, Cs, Be, Mg, Ca, Sr, Ba, and B and an element selected from the group consisting of O, F, S, Cl, Se, Br, and I. The electron transport layer comprises an electron transporting material and a second compound, which is Li2O, MoO3, BaO, or B2O3.

Owner:SAMSUNG MOBILE DISPLAY CO LTD

Light-emitting devices

ActiveUS8183591B2Light efficiencyLight heatSolid-state devicesSemiconductor devicesEngineeringAdemetionine

Owner:SAMSUNG ELECTRONICS CO LTD

Display device and a method of manufacturing the same

InactiveUS7723735B2Reduced luminous efficiencyShort lifeElectroluminescent light sourcesSolid-state devicesOrganic layerDisplay device

Owner:JOLED INC

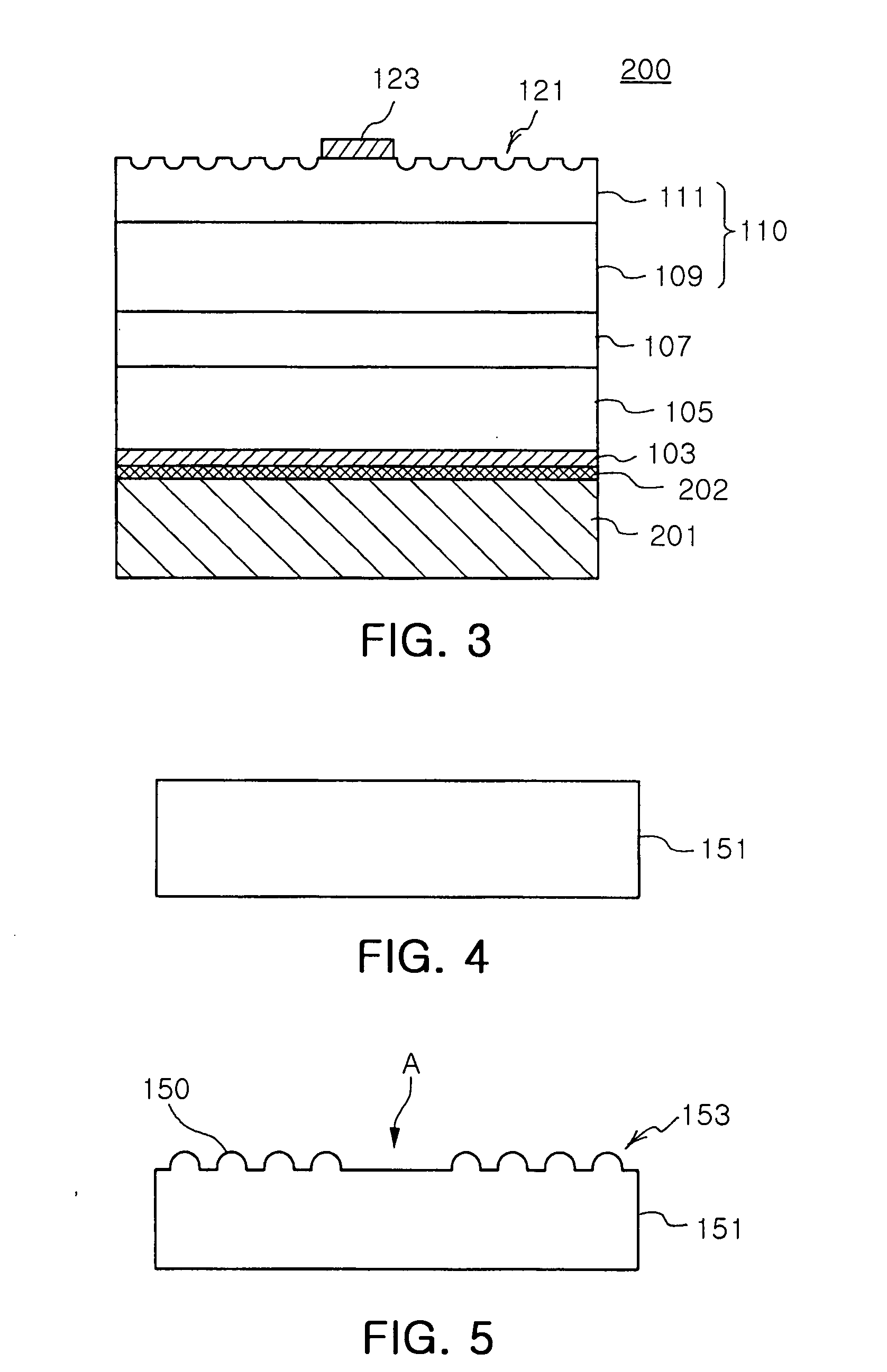

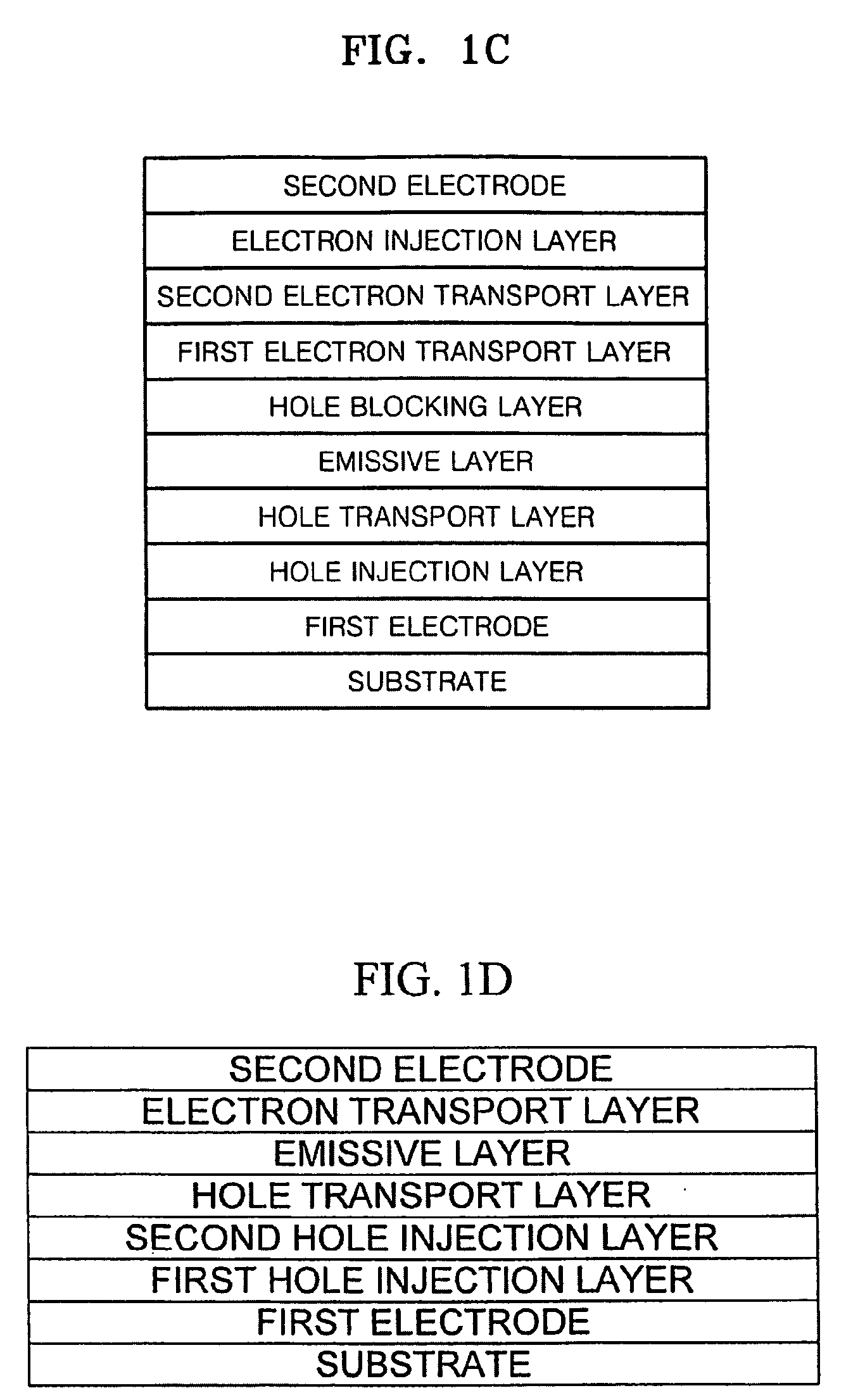

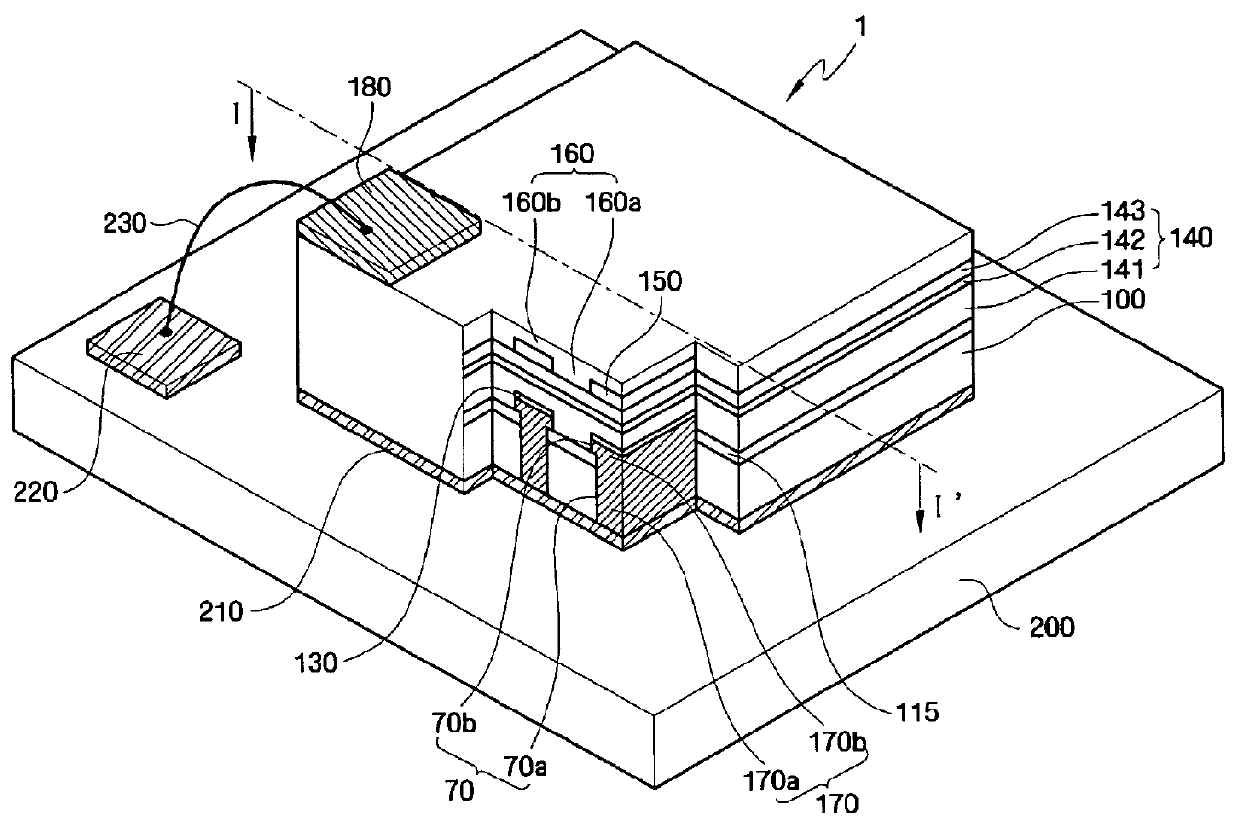

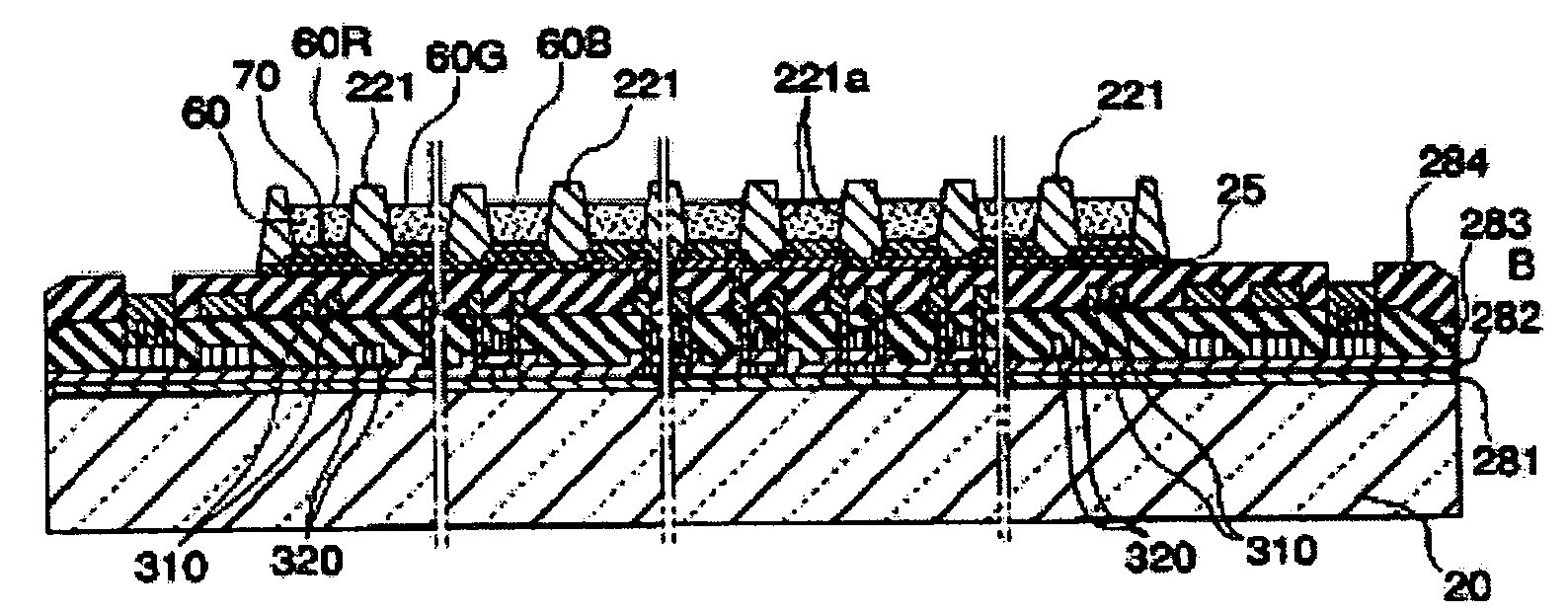

Electro-optical device, manufacturing method of the same, and electronic apparatus

ActiveUS20050084214A1Easily uniformLight efficiencyMaterial nanotechnologyElectroluminescent light sourcesEngineeringVolume change

To provide an electro-optical device in which the fluidity of a material for forming the underlying layer of a gas barrier layer is controlled, and the volume-change of the underlying layer is suppressed, so that stress-concentration on the gas barrier layer is relaxed, and to provide a method of producing the same and an electronic apparatus. In an electro-optical device 1 having, on a substrate 200, a plurality of first electrodes 23, a bank structure 221 having a plurality of openings 221 a positioned correspondingly to the formed first electrodes 23, electro-optical layers 60 arranged in the respective openings, and a second electrode 50 covering the bank structure 221 and the electro-optical layers 60, the device 1 includes a buffer layer 210 formed so as to cover the second electrode 50 and have a substantially flat upper surface, and a gas barrier layer 30 covering the buffer layer 210.

Owner:INTELLECTUAL KEYSTONE TECH LLC

Organic Light Emitting Display Device

ActiveUS20130175512A1High color reproductionCharacteristic lightSolid-state devicesSemiconductor/solid-state device manufacturingDisplay deviceCharge generation

Disclosed is an organic light emitting display device. The organic light emitting display device includes a substrate, a thin film transistor formed on the substrate, a first electrode formed on the thin film transistor, an organic emission layer, and a second electrode formed on the organic emission layer. The organic emission layer includes a first stack that includes a first emission layer formed on the first electrode to emit first color light, a second stack that includes a second emission layer formed on the first electrode to emit second color light, and a charge generation layer formed between the first and second stacks.

Owner:LG DISPLAY CO LTD

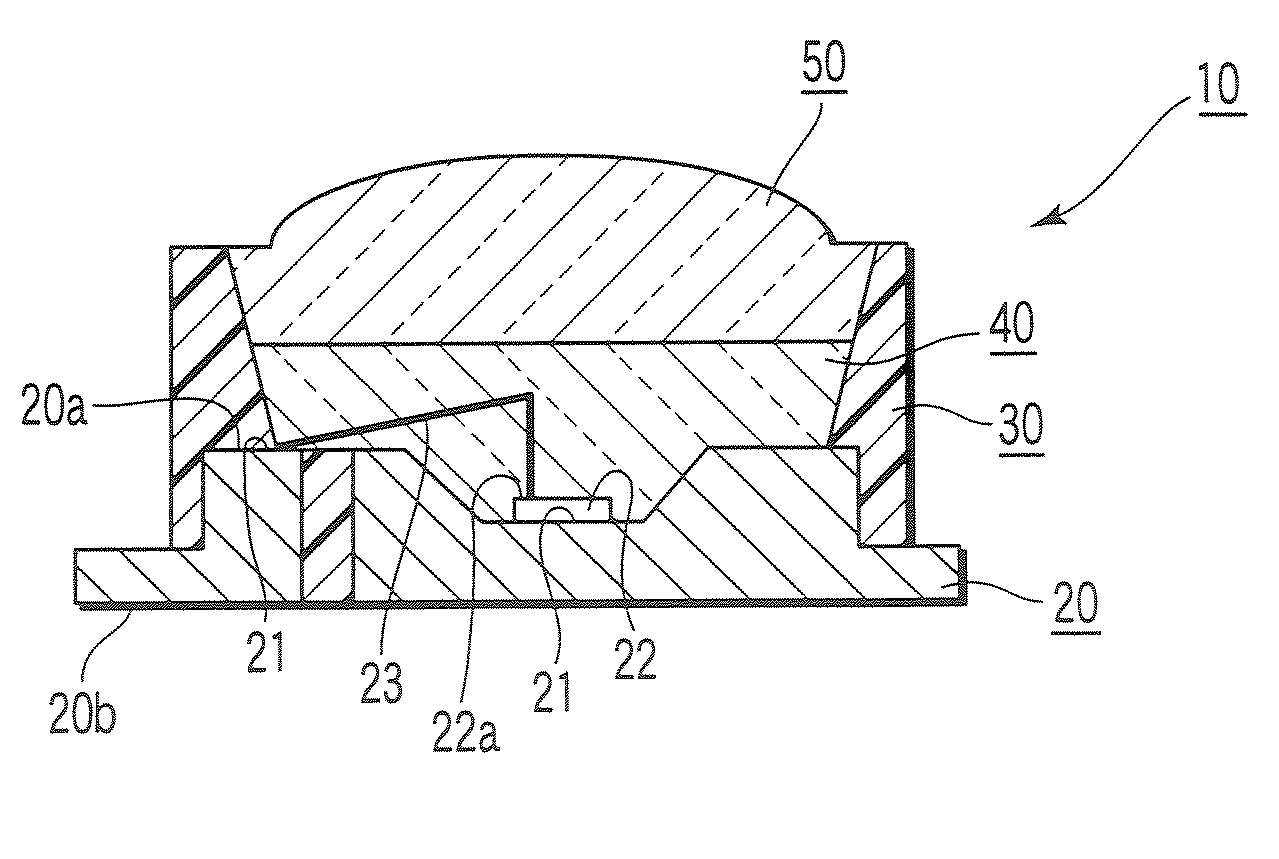

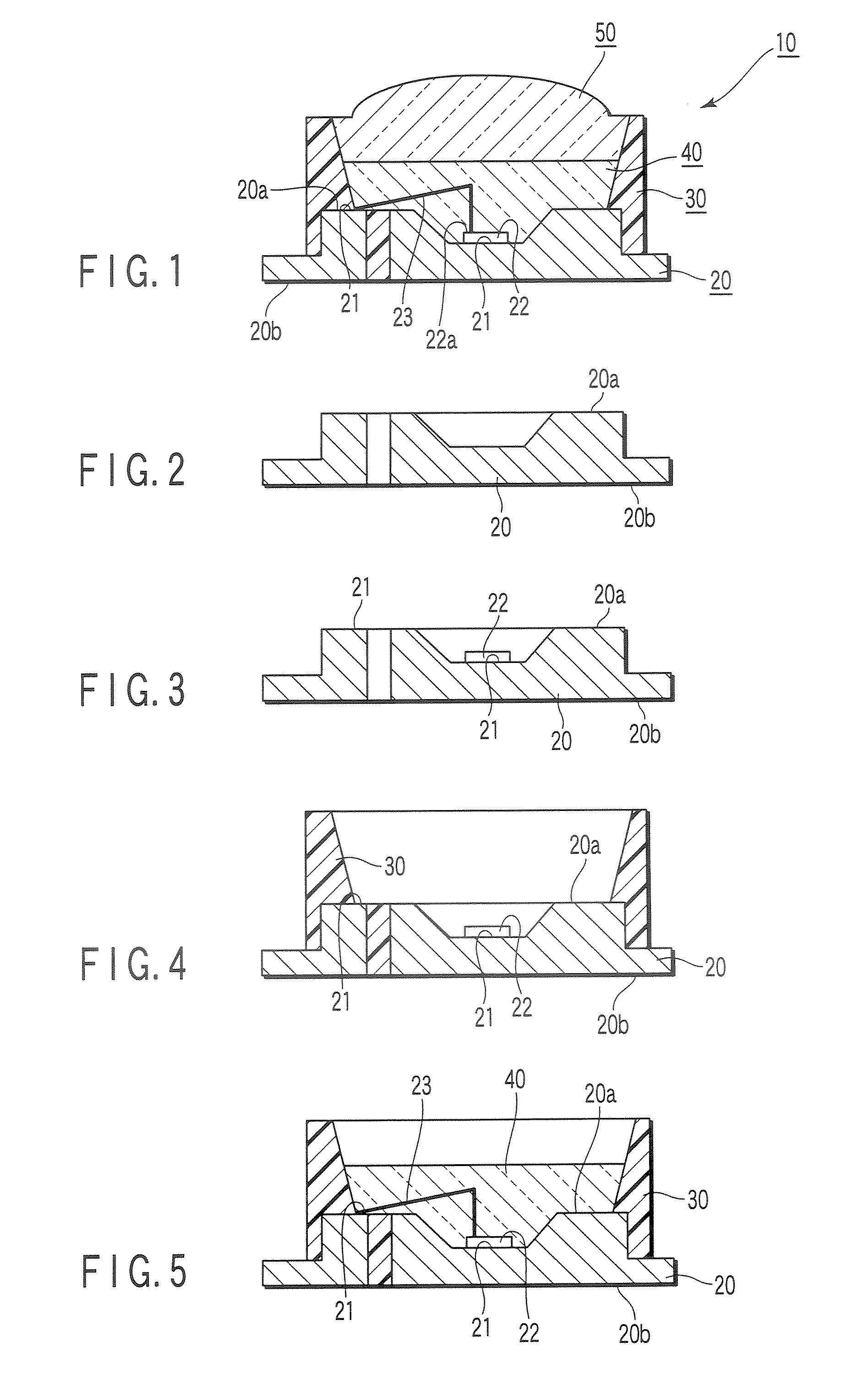

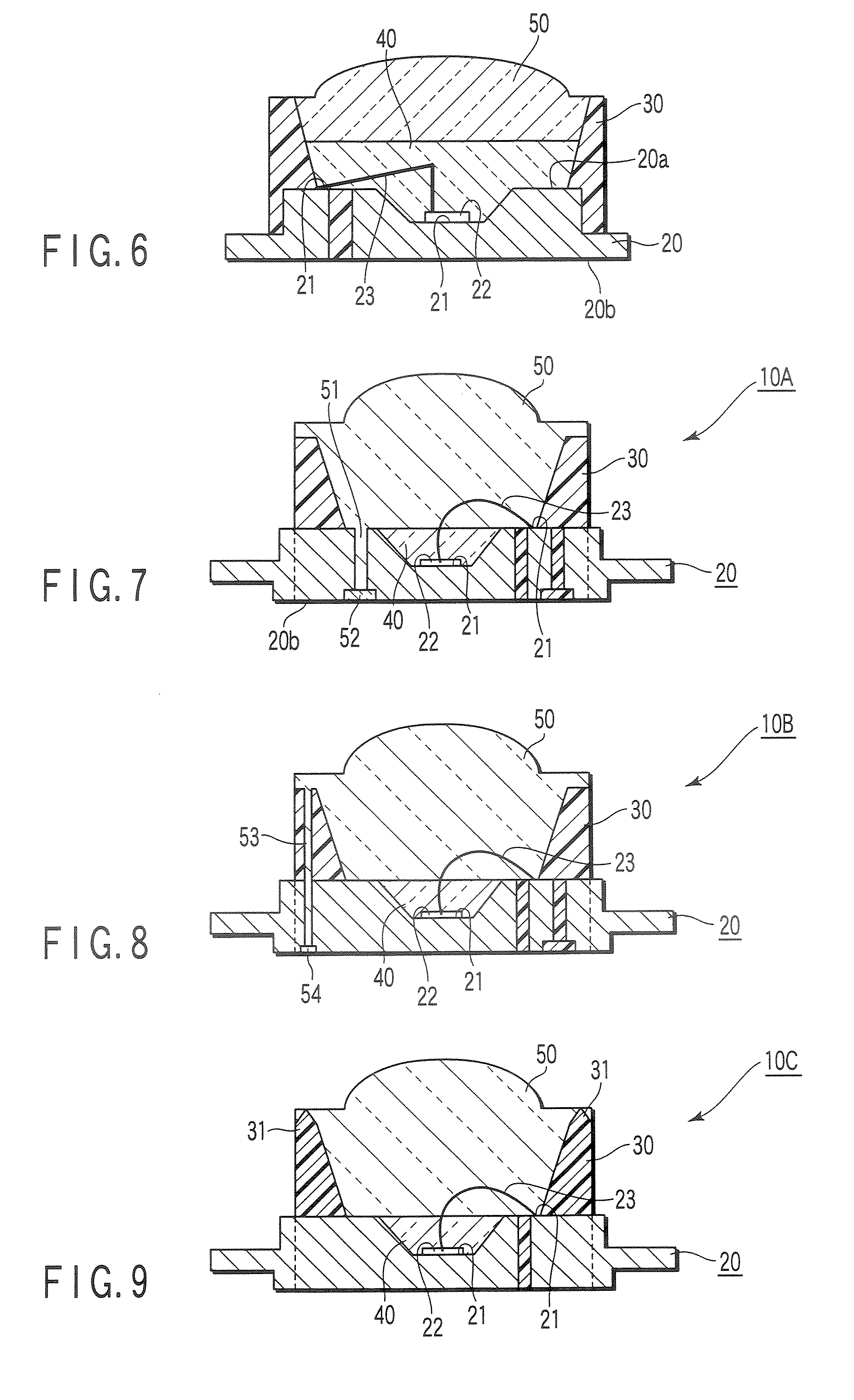

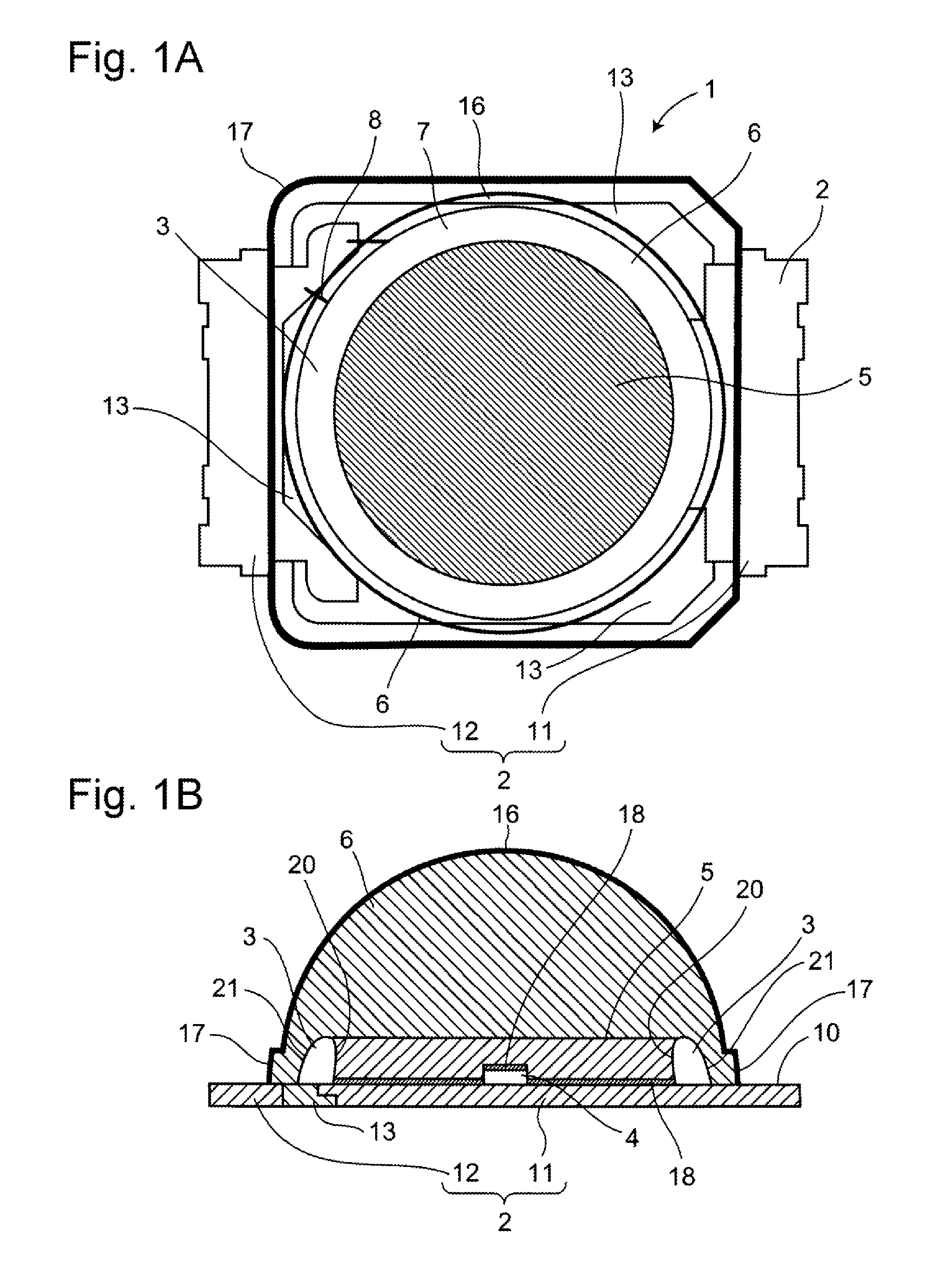

Light emitting device and method of manufacturing the same

ActiveUS20140291716A1Improve light extraction efficiencyHigh heat releasing propertySolid-state devicesSemiconductor/solid-state device manufacturingLead frameLight emitting device

Provided is a light emitting device with improved light extracting efficiency and further higher heat releasing performance. A light emitting device includes a planar lead frame having a first lead and a second lead, and includes a light emitting element mounted on the first lead, a resin frame surrounding a periphery of the light emitting element, a first sealing resin filled in the inner side of the resin frame and sealing the light emitting element, and a second sealing resin covering the resin frame and the first sealing resin. Lower end of inner surface of the resin frame is arranged only on the first lead, and at an outside of the resin frame, and the second resin member covers at least a part of the first lead and the second lead. Of the back-surface of the first lead, a region directly under the blight emitting element is exposed.

Owner:NICHIA CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com