Patents

Literature

3825results about How to "Improve light extraction efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

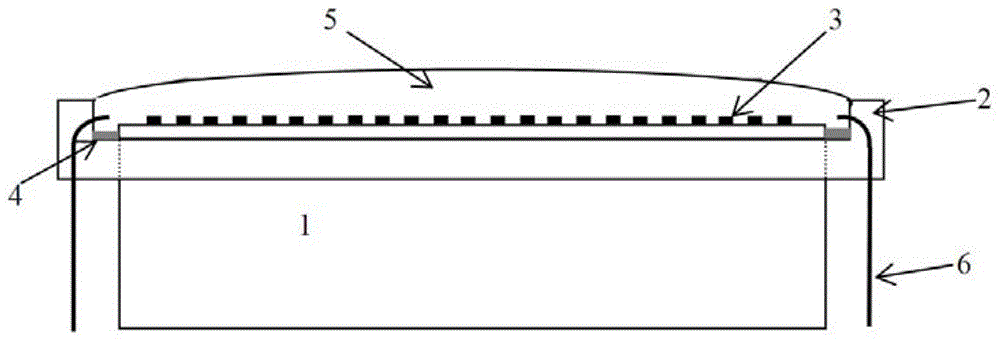

Light emitting unit

InactiveUS20090140271A1Improve light extraction efficiencyEnhancing light light emission rangePlanar light sourcesElongate light sourcesLight-emitting diode

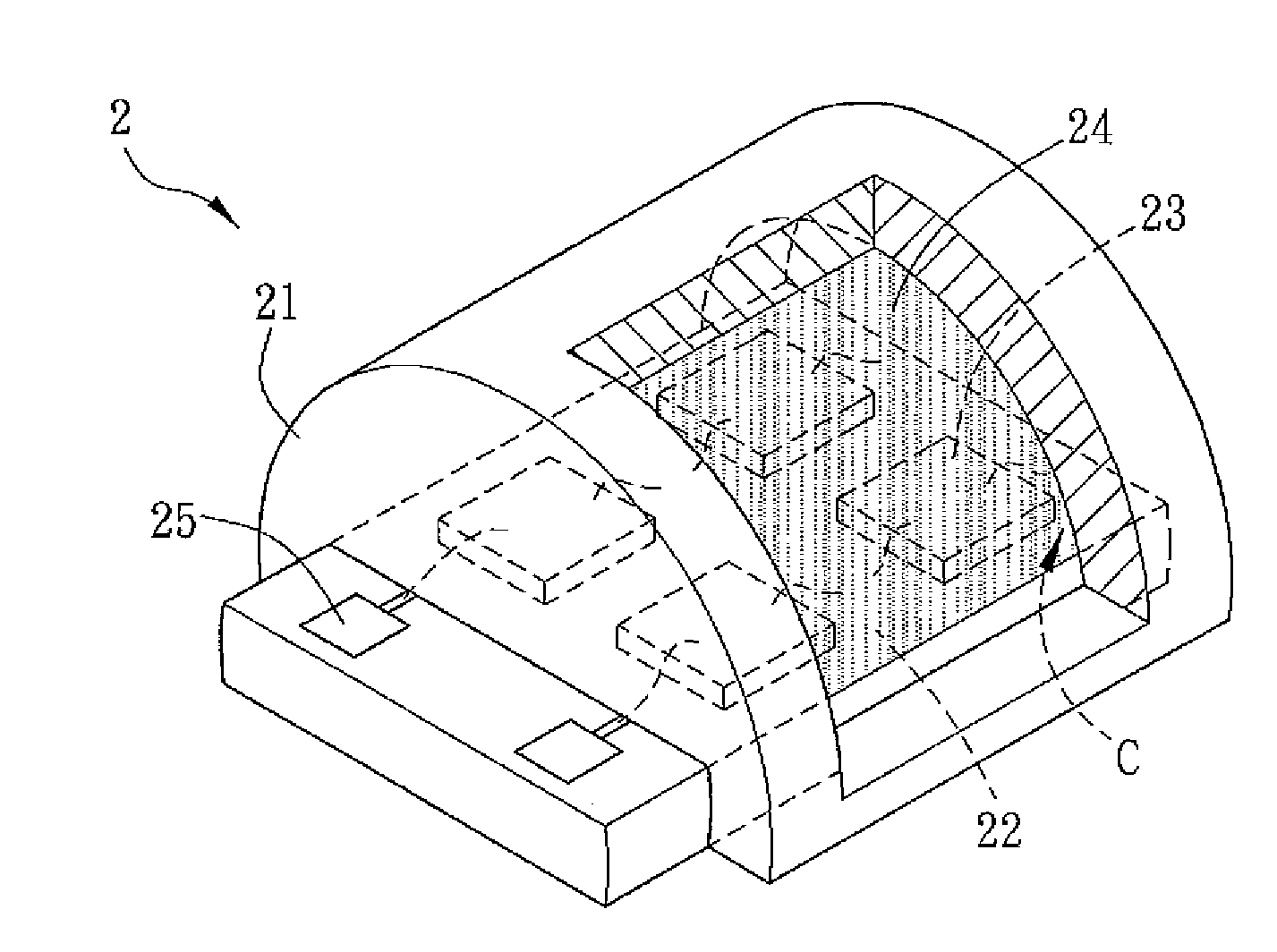

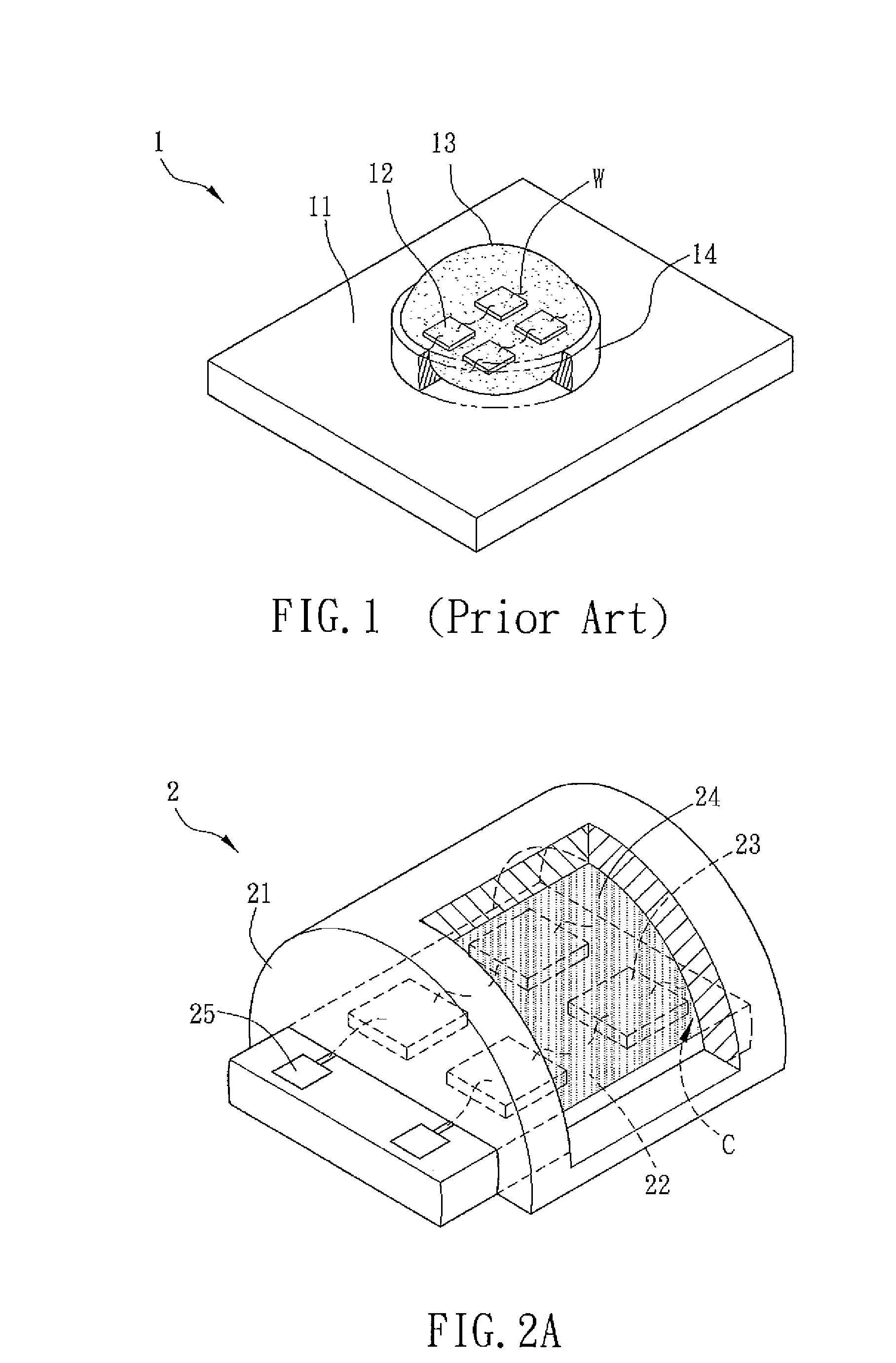

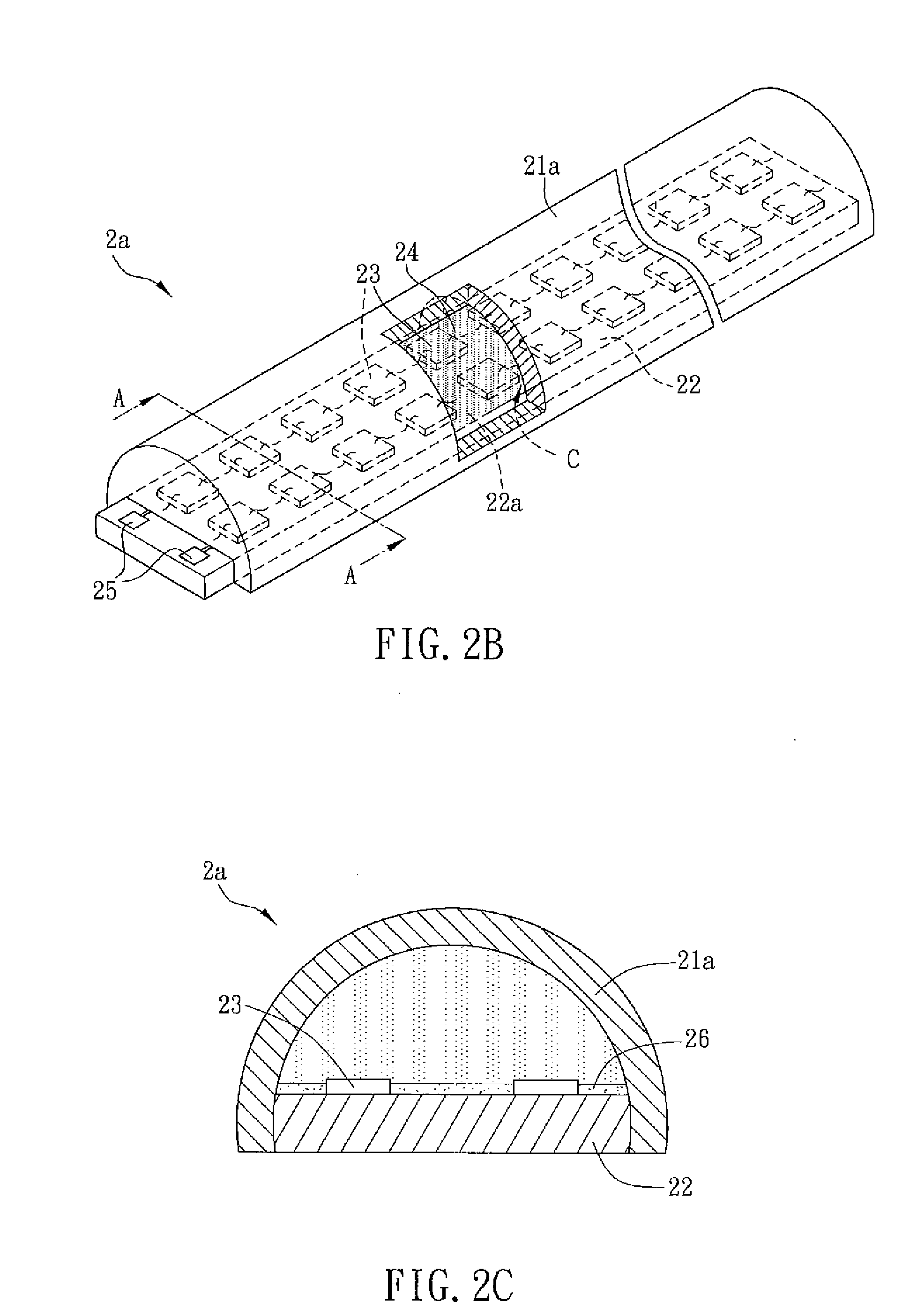

A light emitting unit has a chamber. The light emitting unit includes at least one substrate, a plurality of light emitting diode (LED) dies and a gel or a fluid. The LED dies are disposed on the substrate and in the chamber. At least two LED dies are electrically connected to each other in series or in parallel. The gel or the fluid is filled in the chamber.

Owner:GIGNO TECH CO LTD

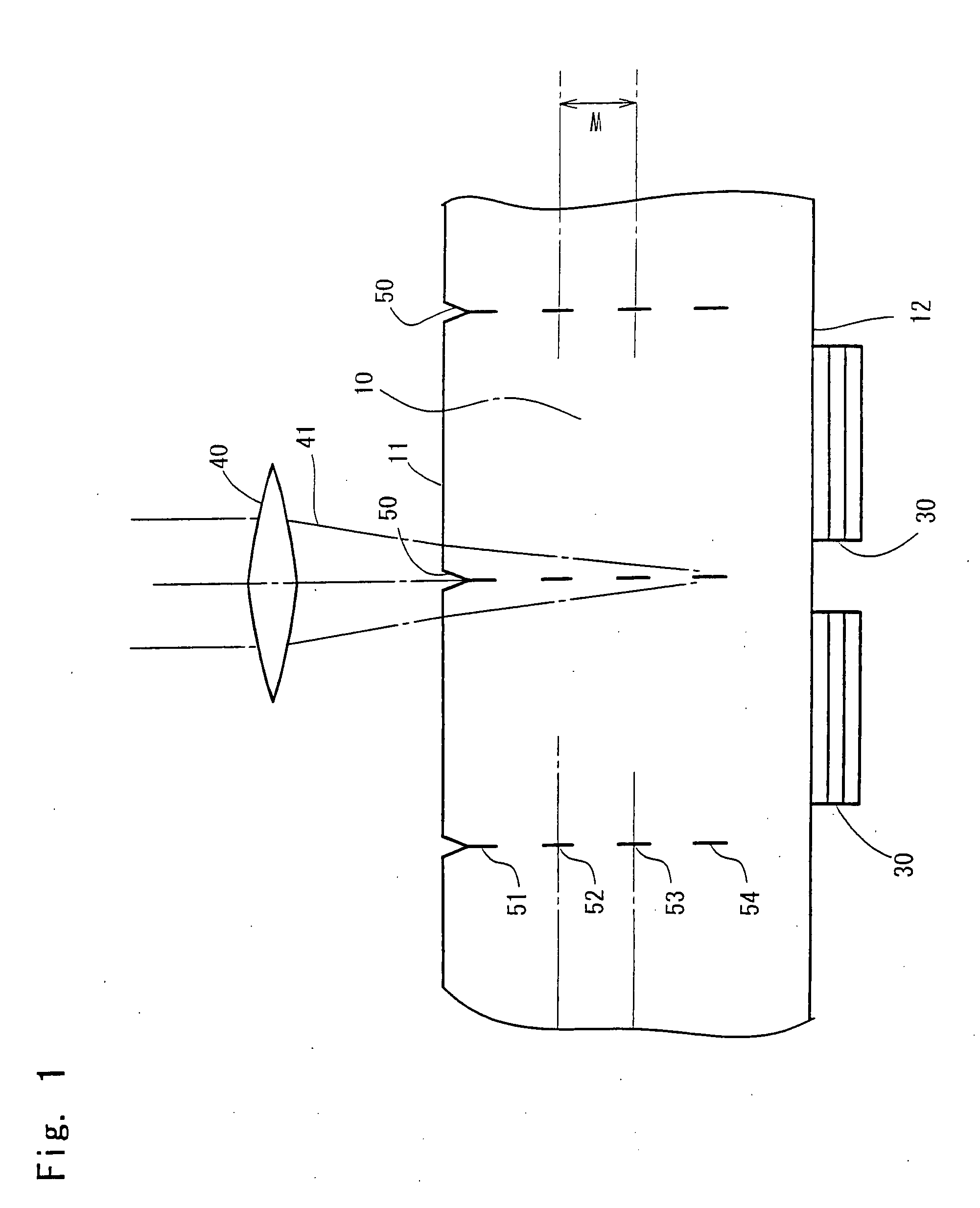

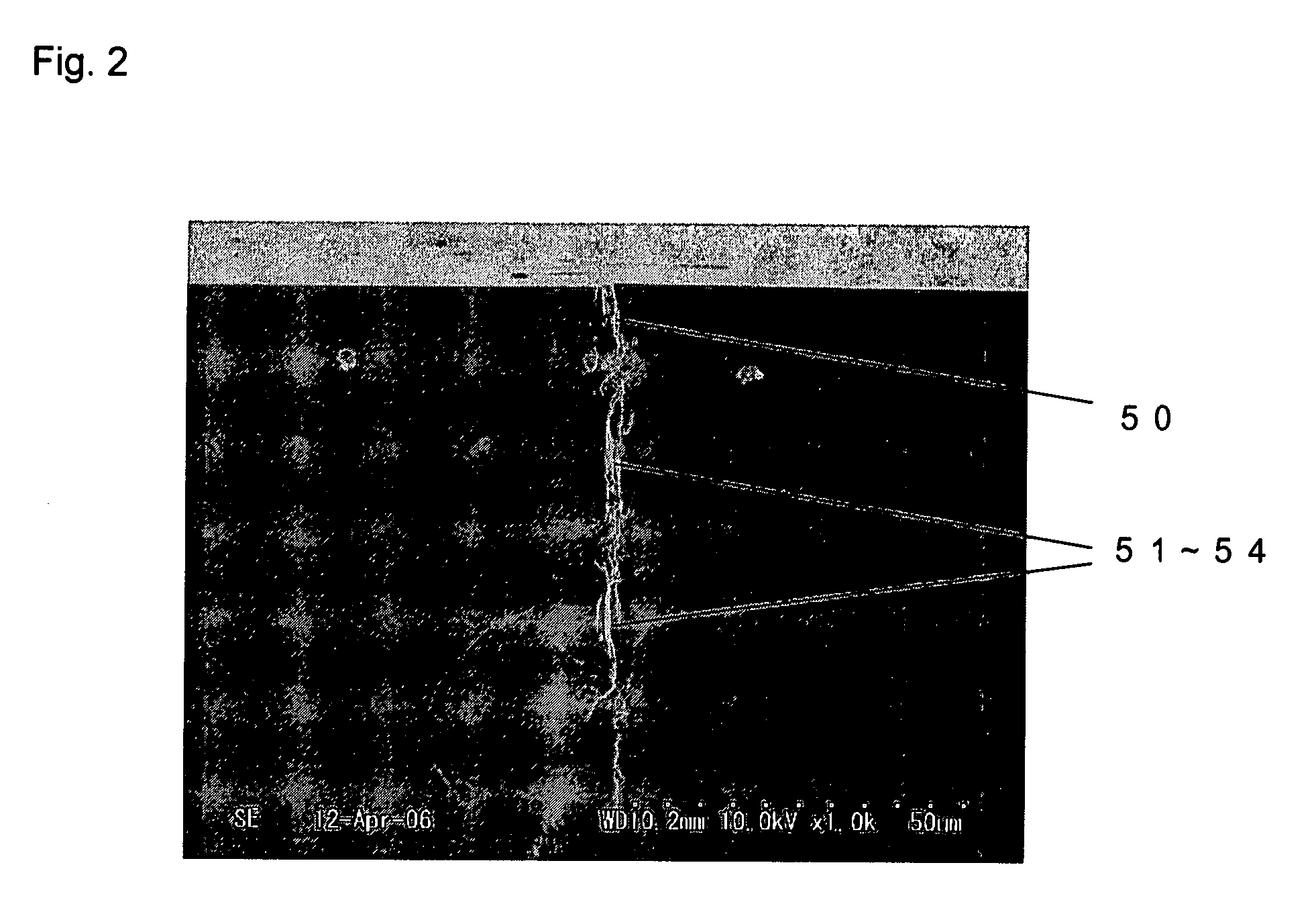

Semiconductor light-emitting device and method for separating semiconductor light-emitting devices

InactiveUS20070298529A1Reliably splitLight absorptionSolid-state devicesSemiconductor/solid-state device manufacturingSplit linesPulsed laser beam

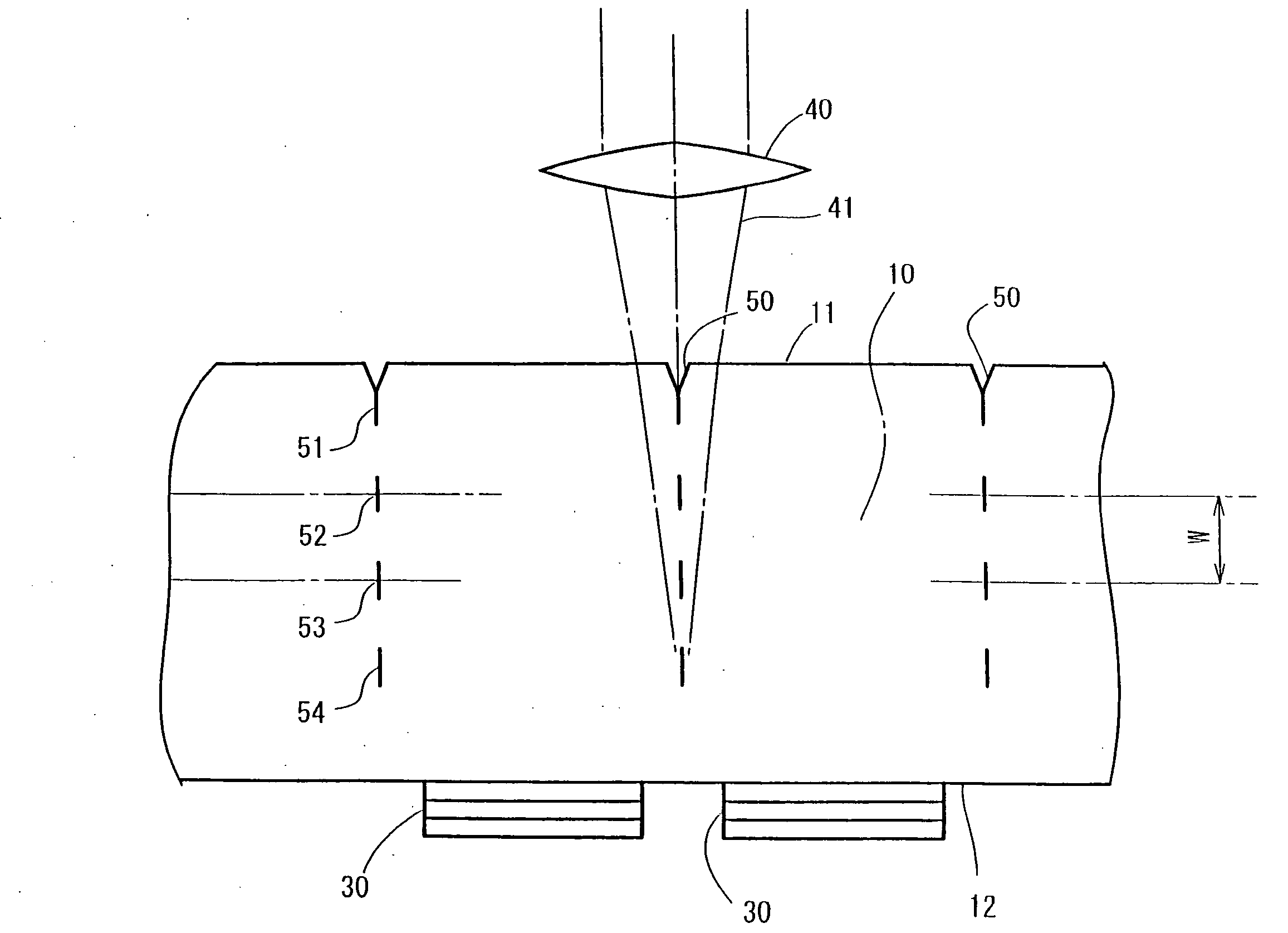

The invention provides a method for separating semiconductor light-emitting devices formed on a substrate. In the method, a pulse laser beam having a pulse width less than 10 ps in a substrate is focused on the substrate, to thereby cause multi-photon absorption in the substrate. Through multi-photon absorption, a groove is formed through the pulse laser beam along a split line predetermined on a surface of the substrate, the groove being substantially continuous in the direction of the predetermined split line. In addition, internal structurally changed portions are formed through the pulse laser beam at a predetermined depth of the substrate on a predetermined split face, the structurally changed portions being discontinuous in the direction of the predetermined split line. Subsequently, an external force is applied to thereby form a split face along the continuous groove and the discontinuous internal structurally changed portions, whereby the semiconductor light-emitting devices are separated from one another

Owner:TOYODA GOSEI CO LTD

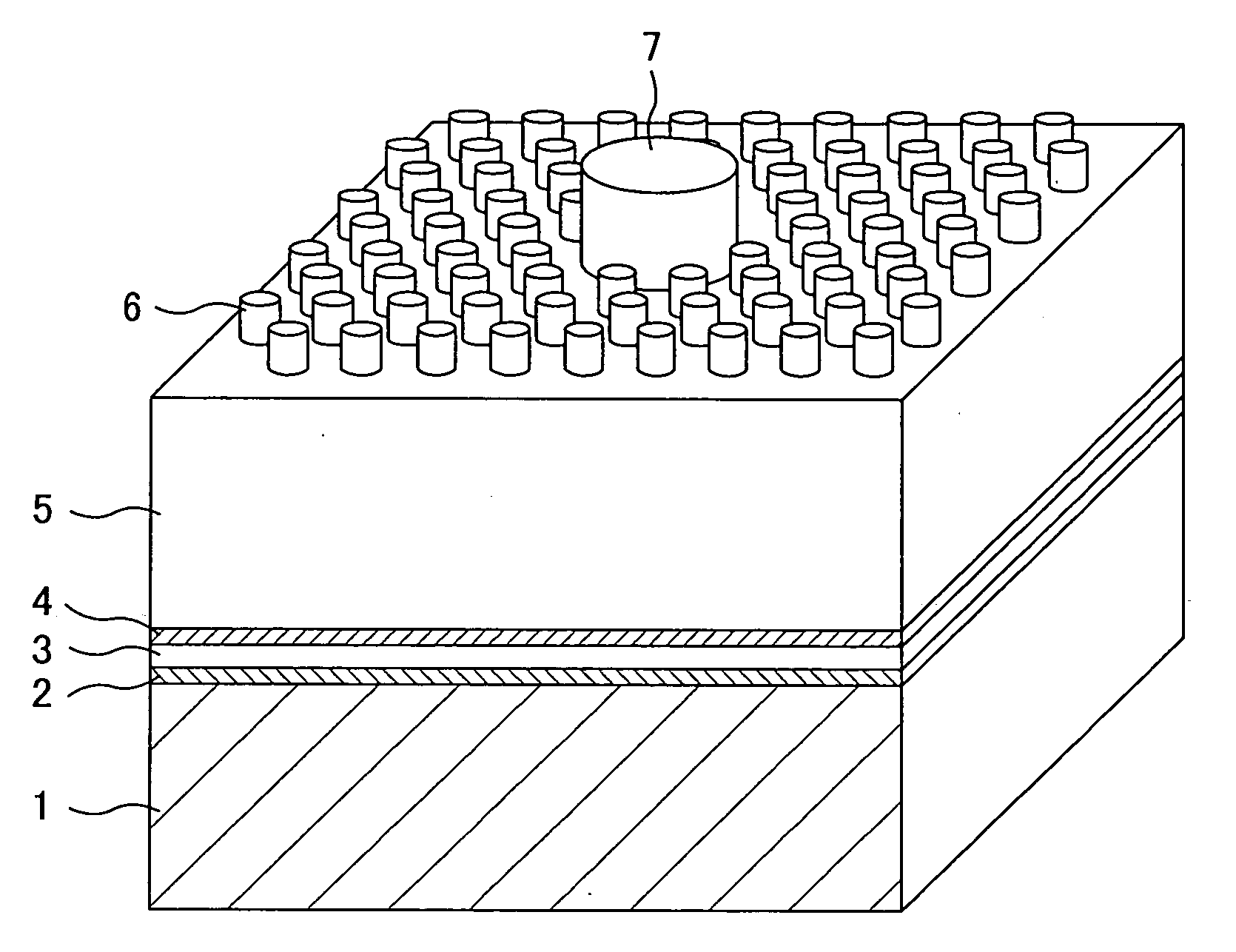

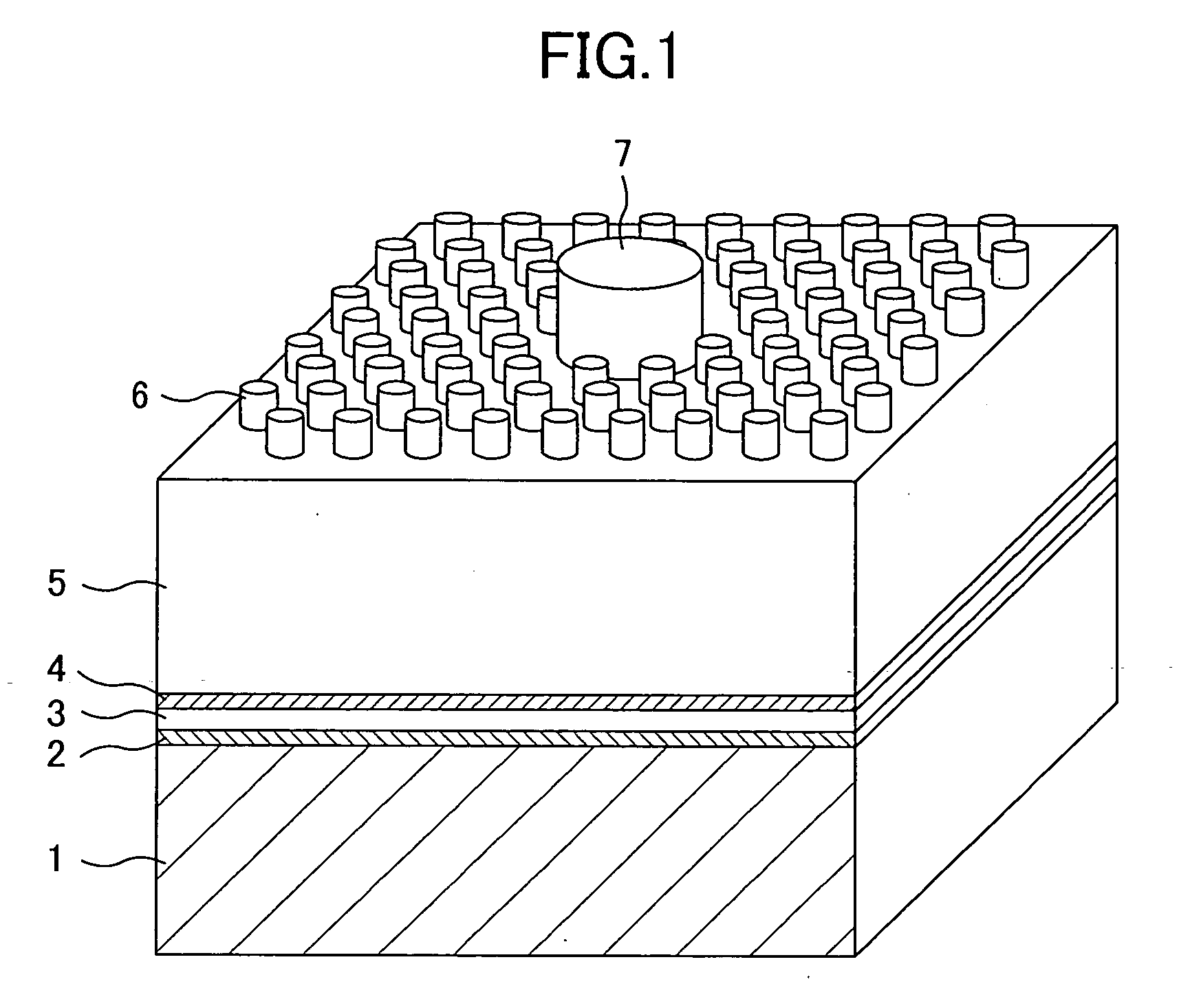

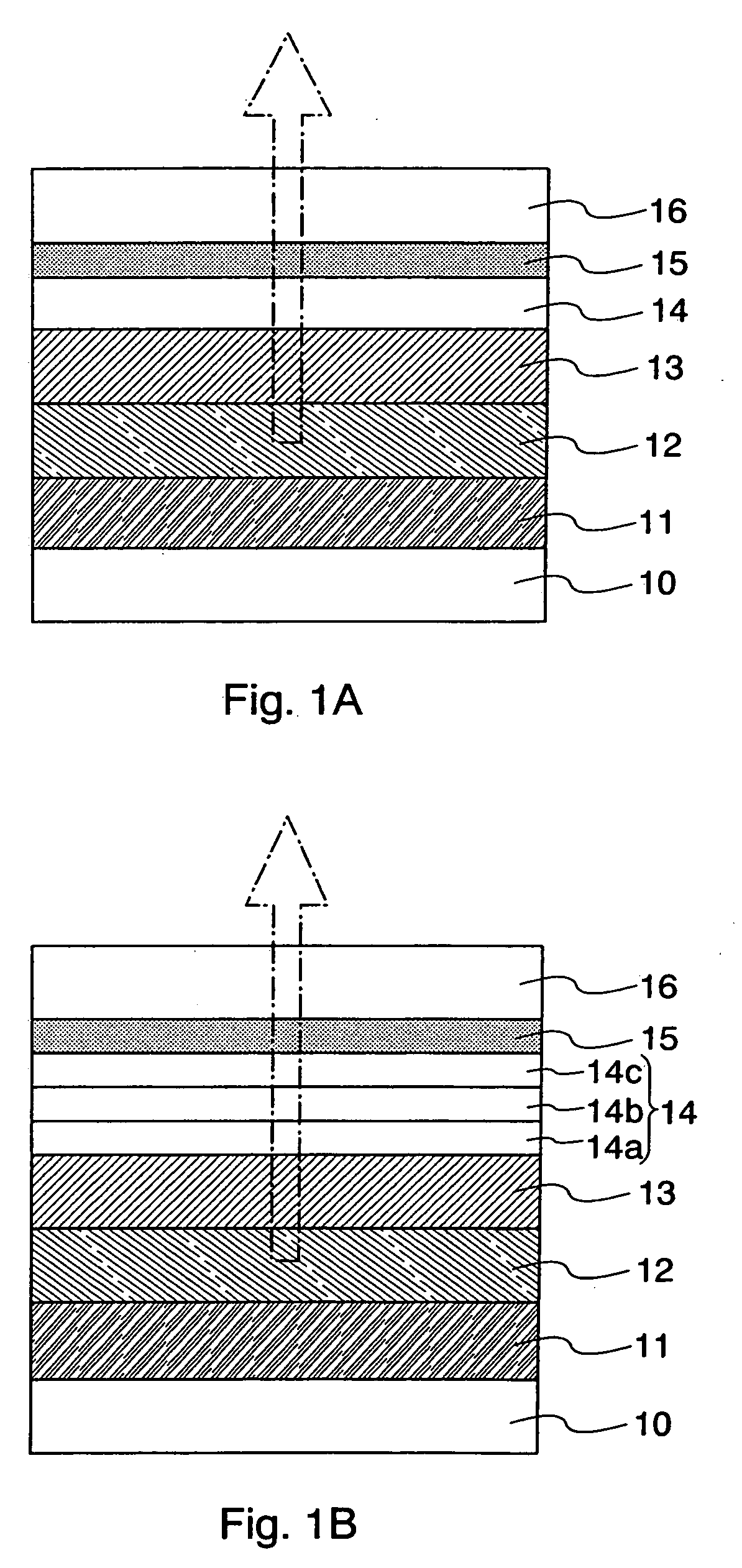

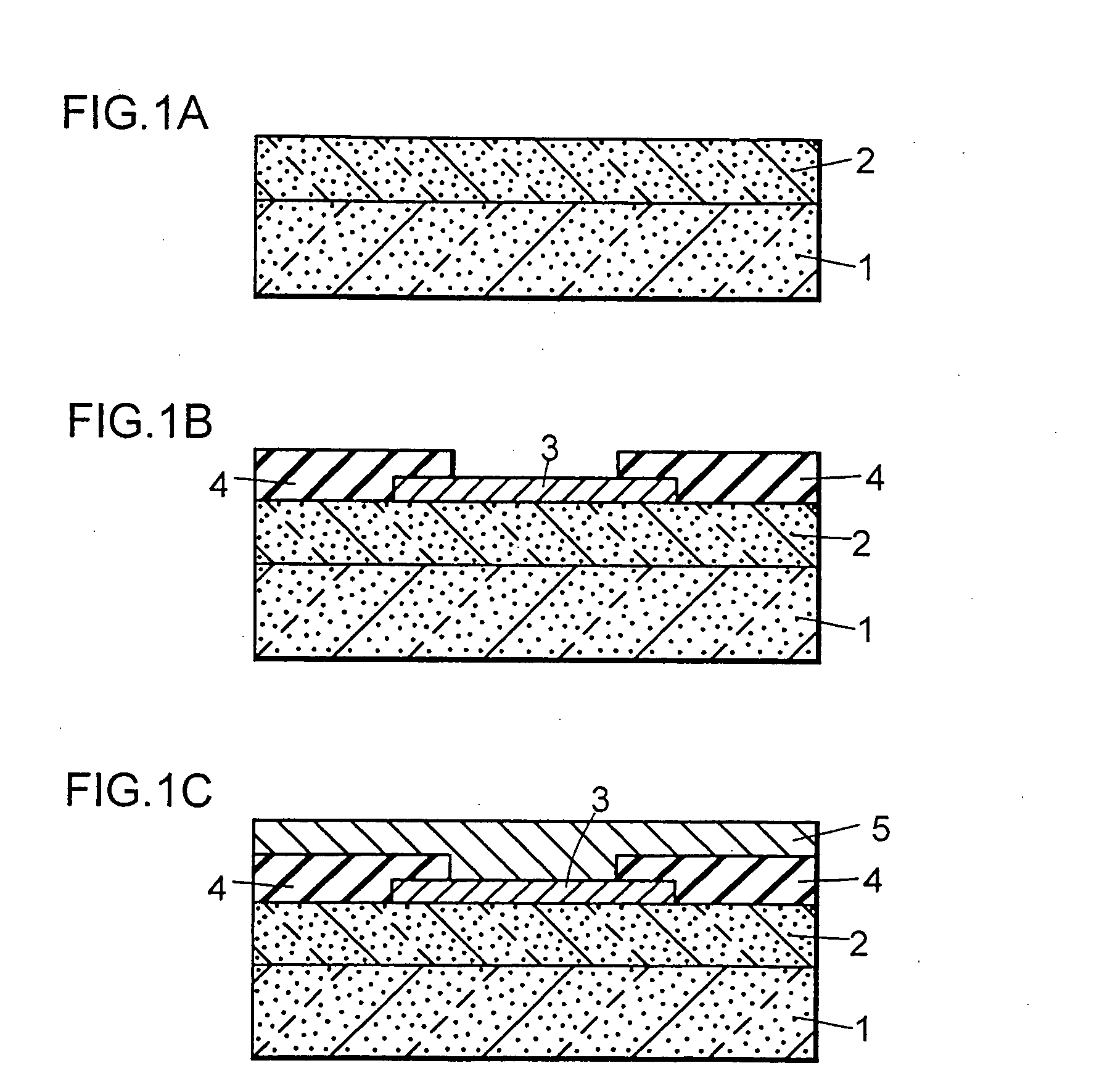

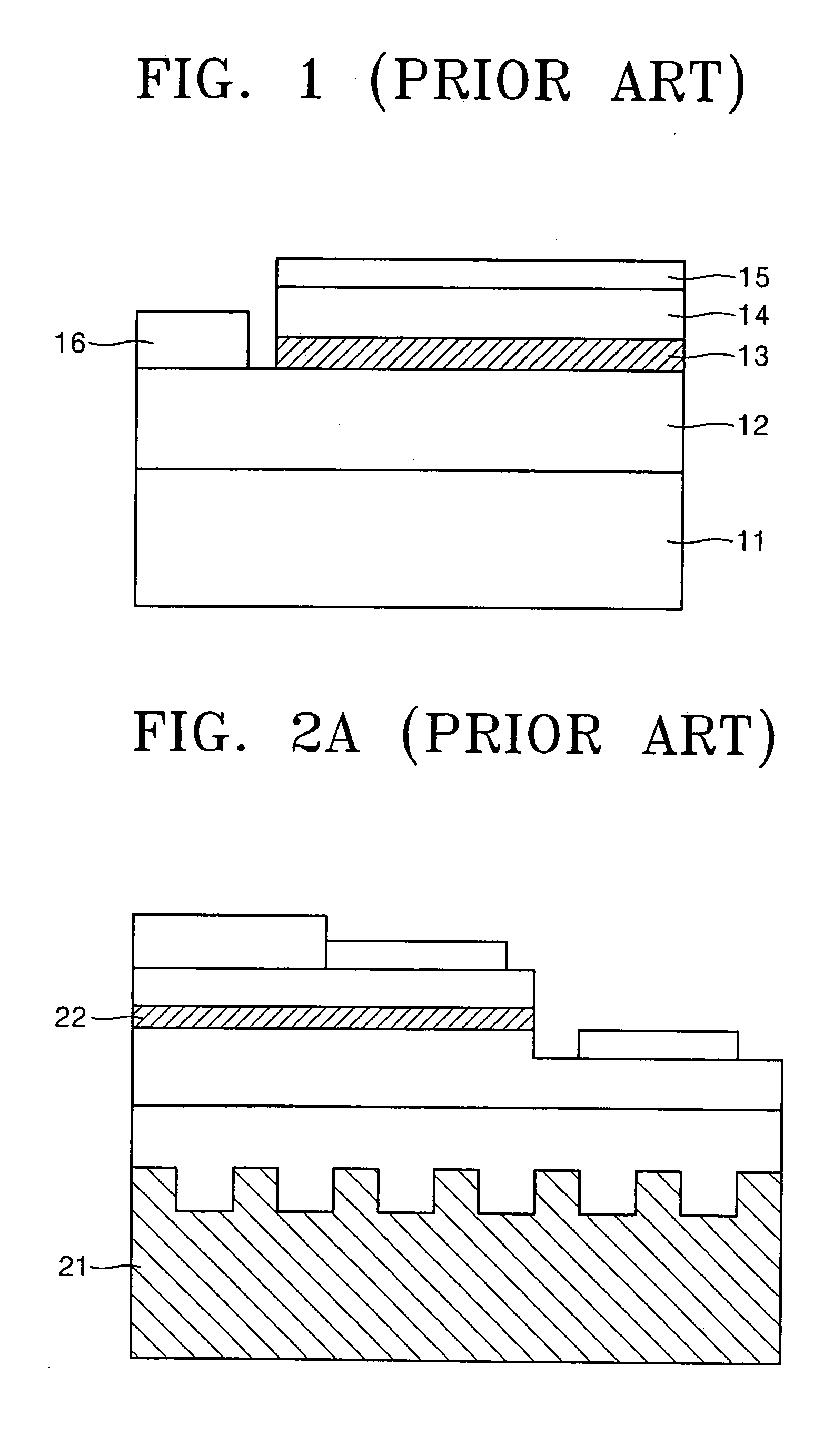

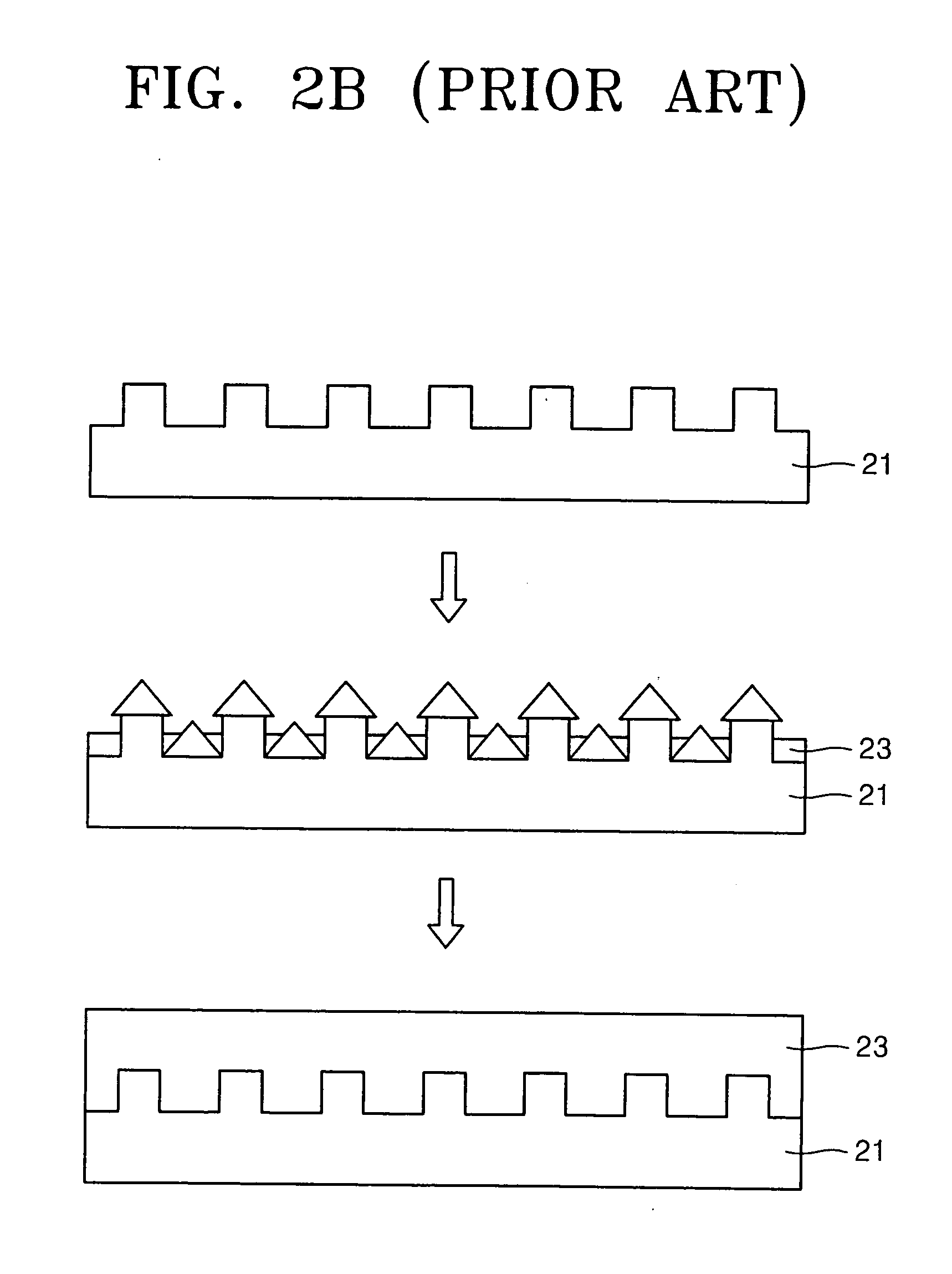

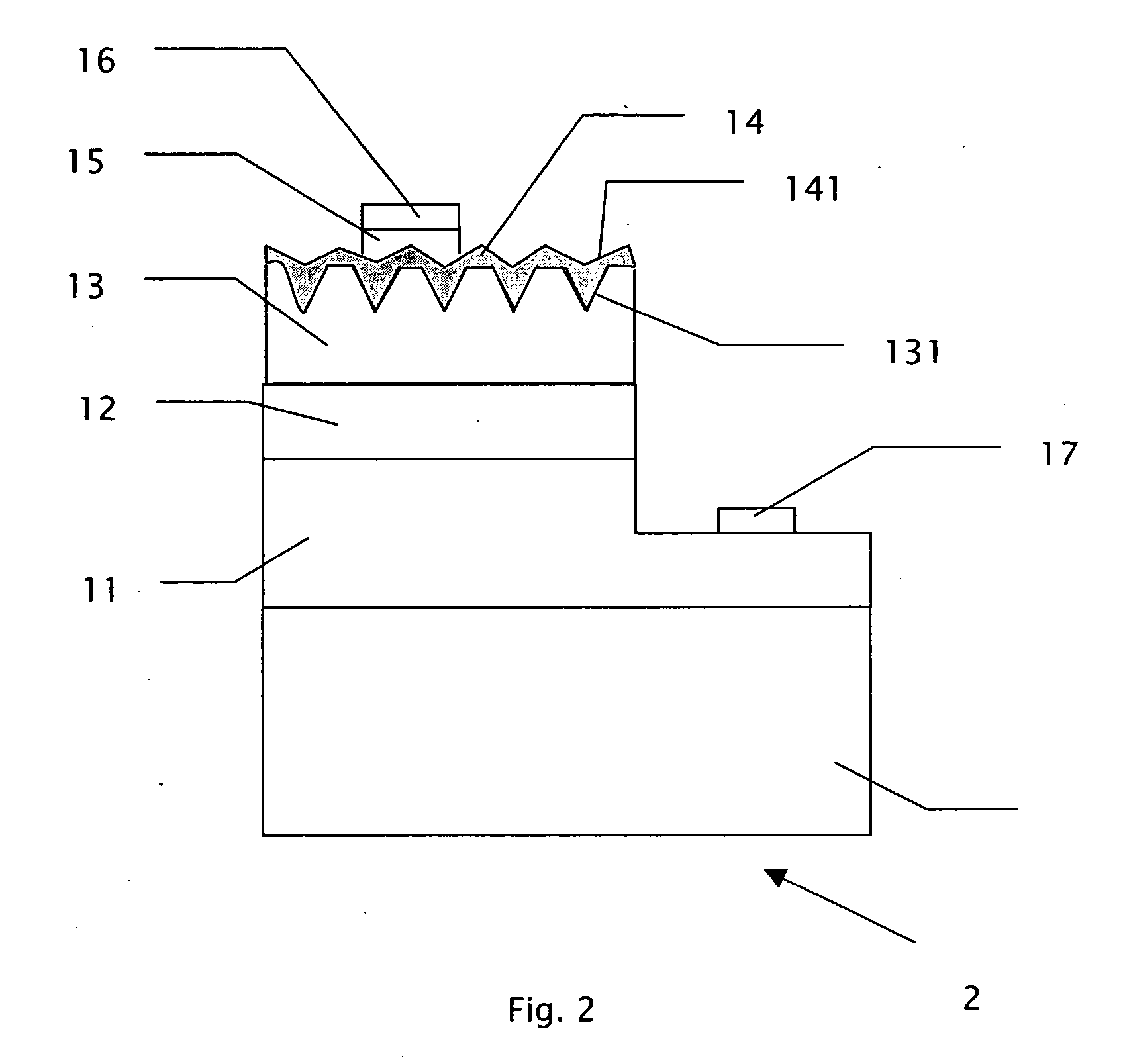

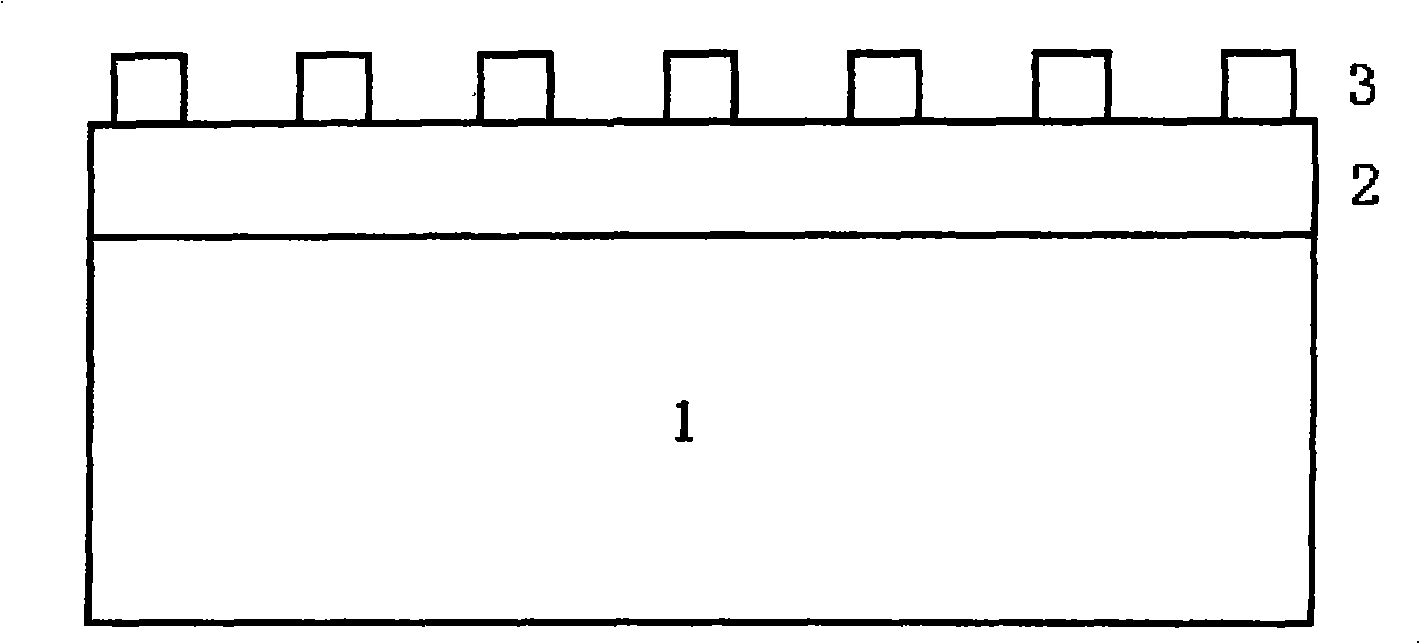

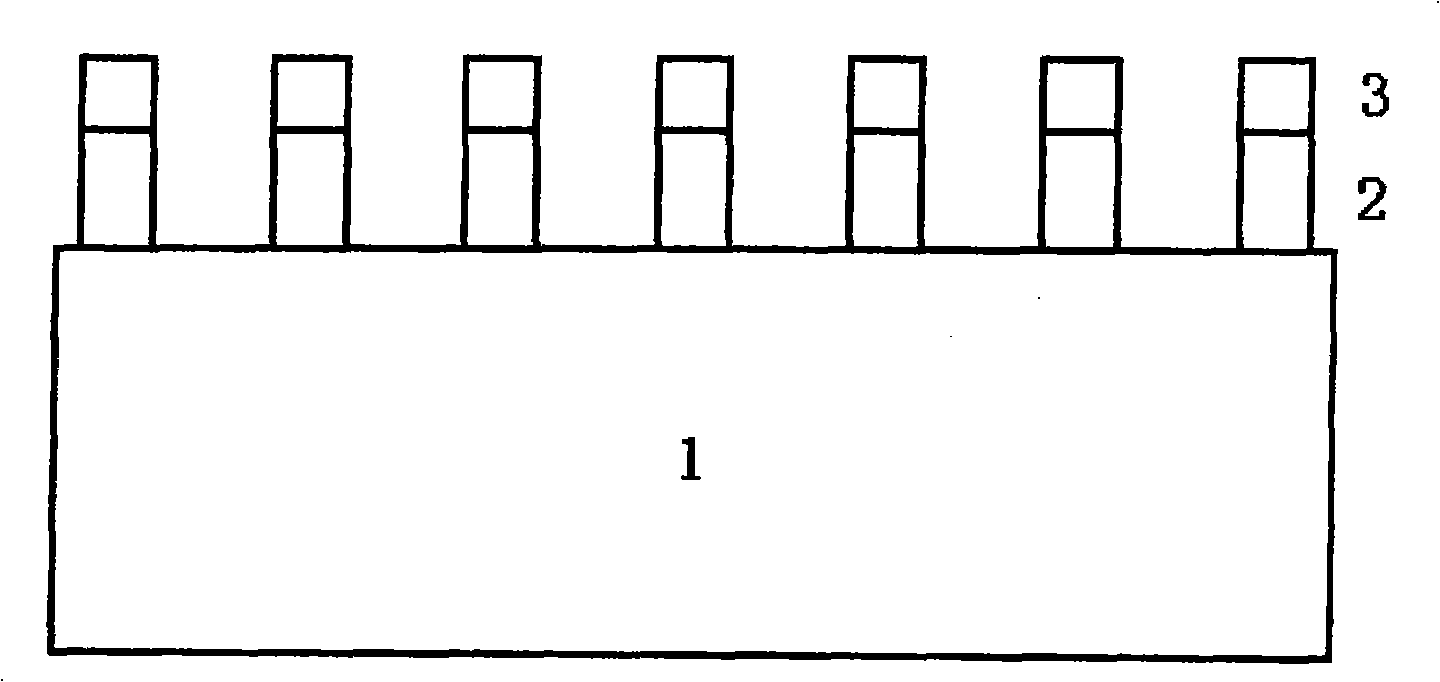

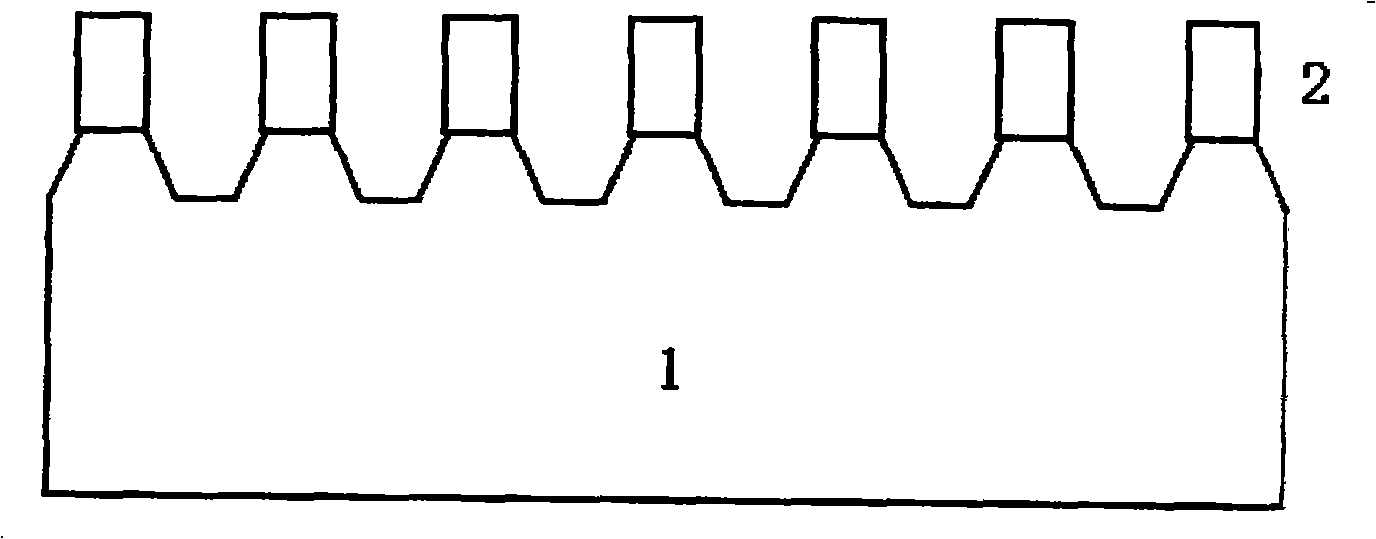

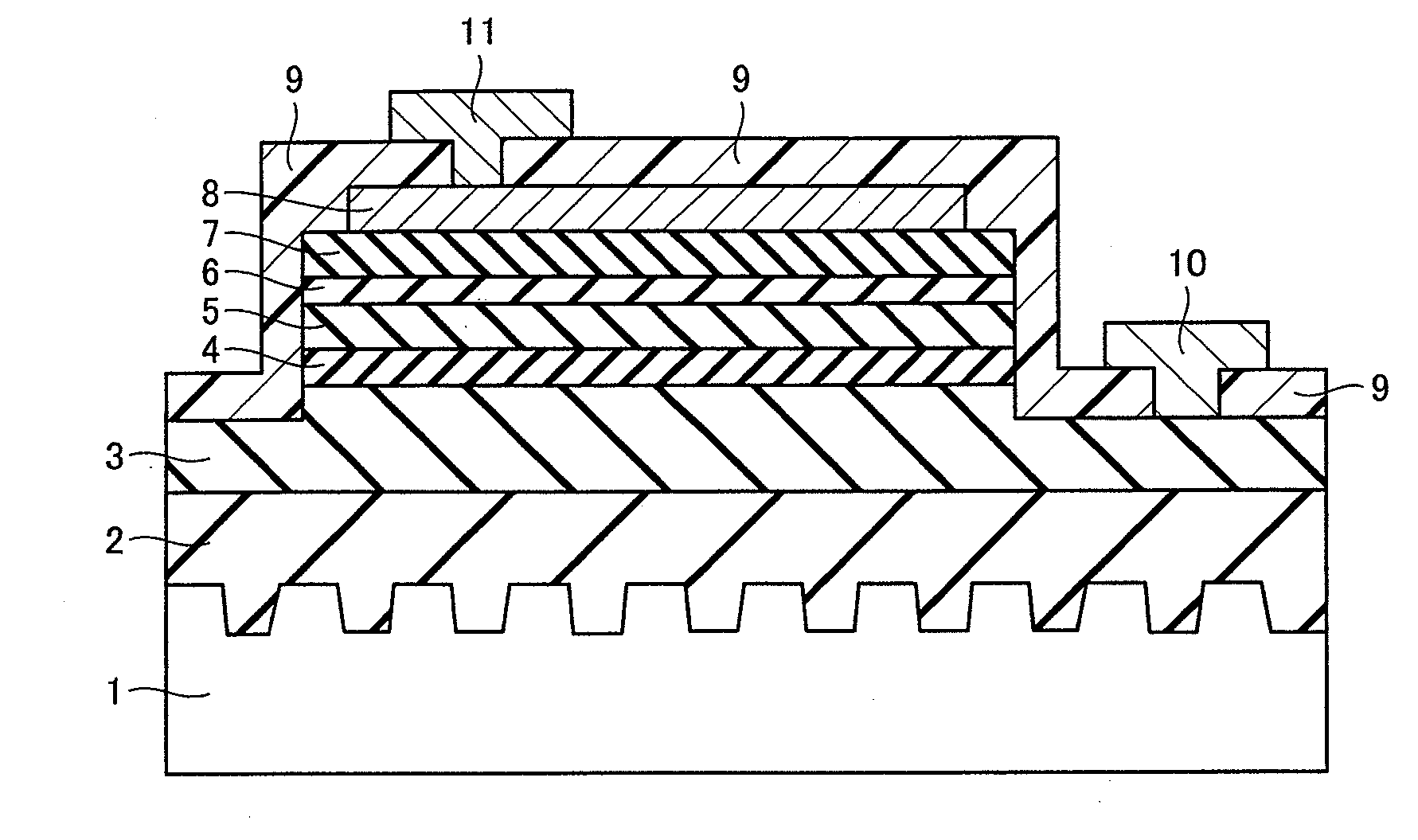

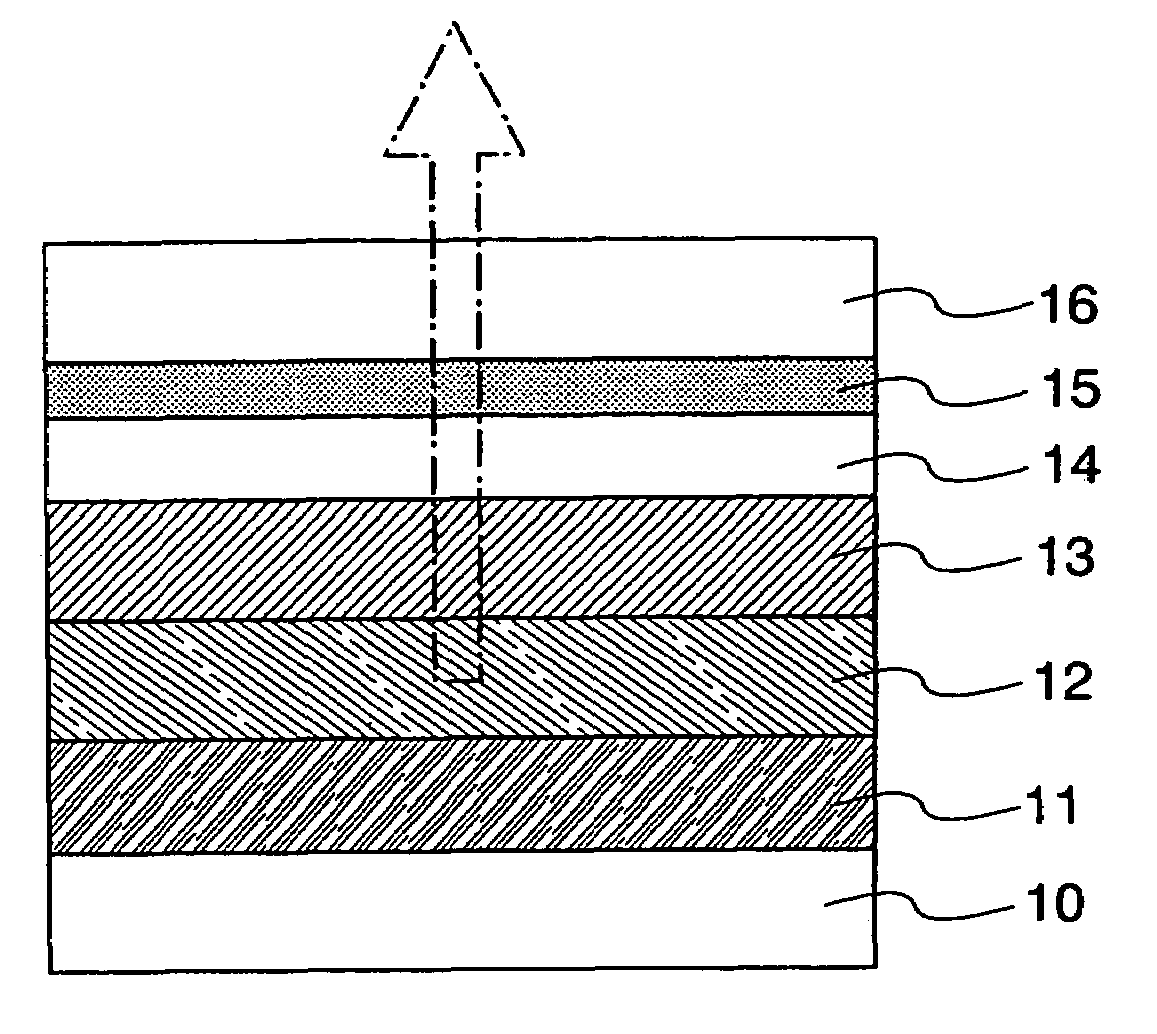

Semiconductor light emitting element, semiconductor light emitting device, and method for fabricating semiconductor light emitting element

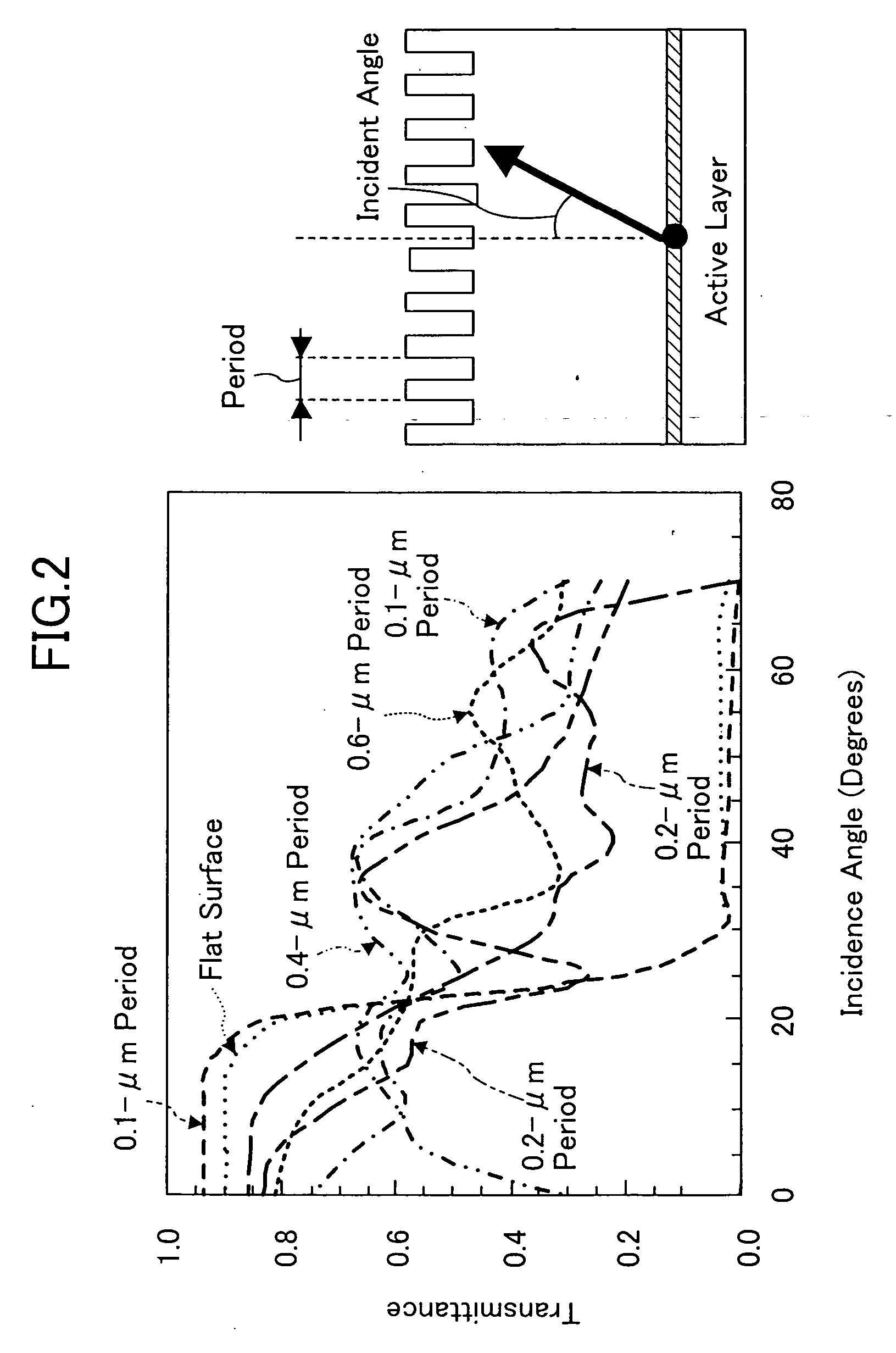

InactiveUS20050285132A1Light extraction efficiencyLow efficiencyNanoopticsOptical light guidesHigh reflectivityMetal electrodes

Projections / depressions forming a two-dimensional periodic structure are formed in a surface of a semiconductor multilayer film opposing the principal surface thereof, while a metal electrode with a high reflectivity is formed on the other surface. By using the diffracting effect of the two-dimensional periodic structure, the efficiency of light extraction from the surface formed with the projections / depressions can be improved. By reflecting light emitted toward the metal electrode to the surface formed with the projections / depressions by using the metal electrode with the high reflectivity, the foregoing effect achieved by the two-dimensional periodic structure can be multiplied.

Owner:PANASONIC CORP

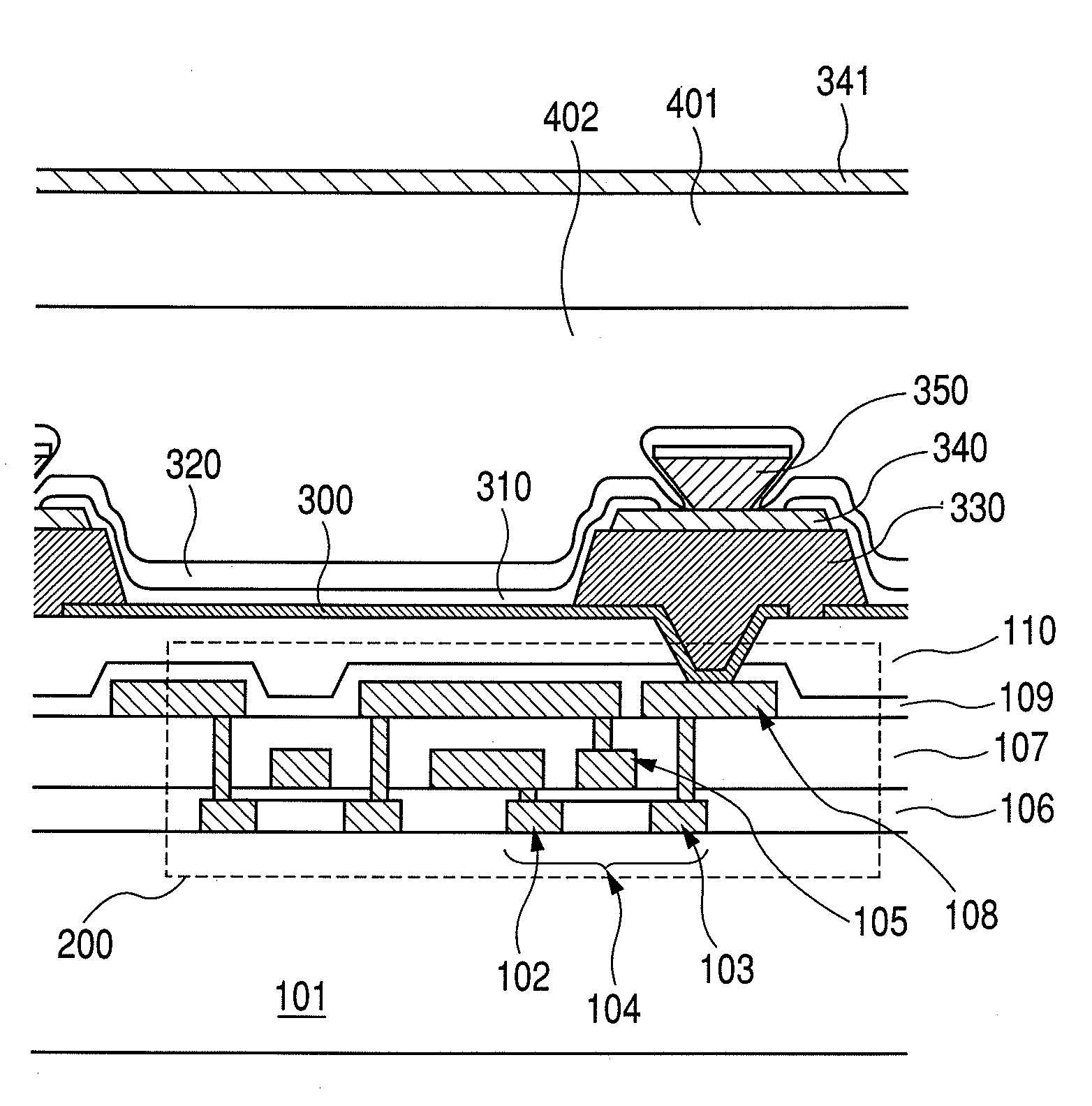

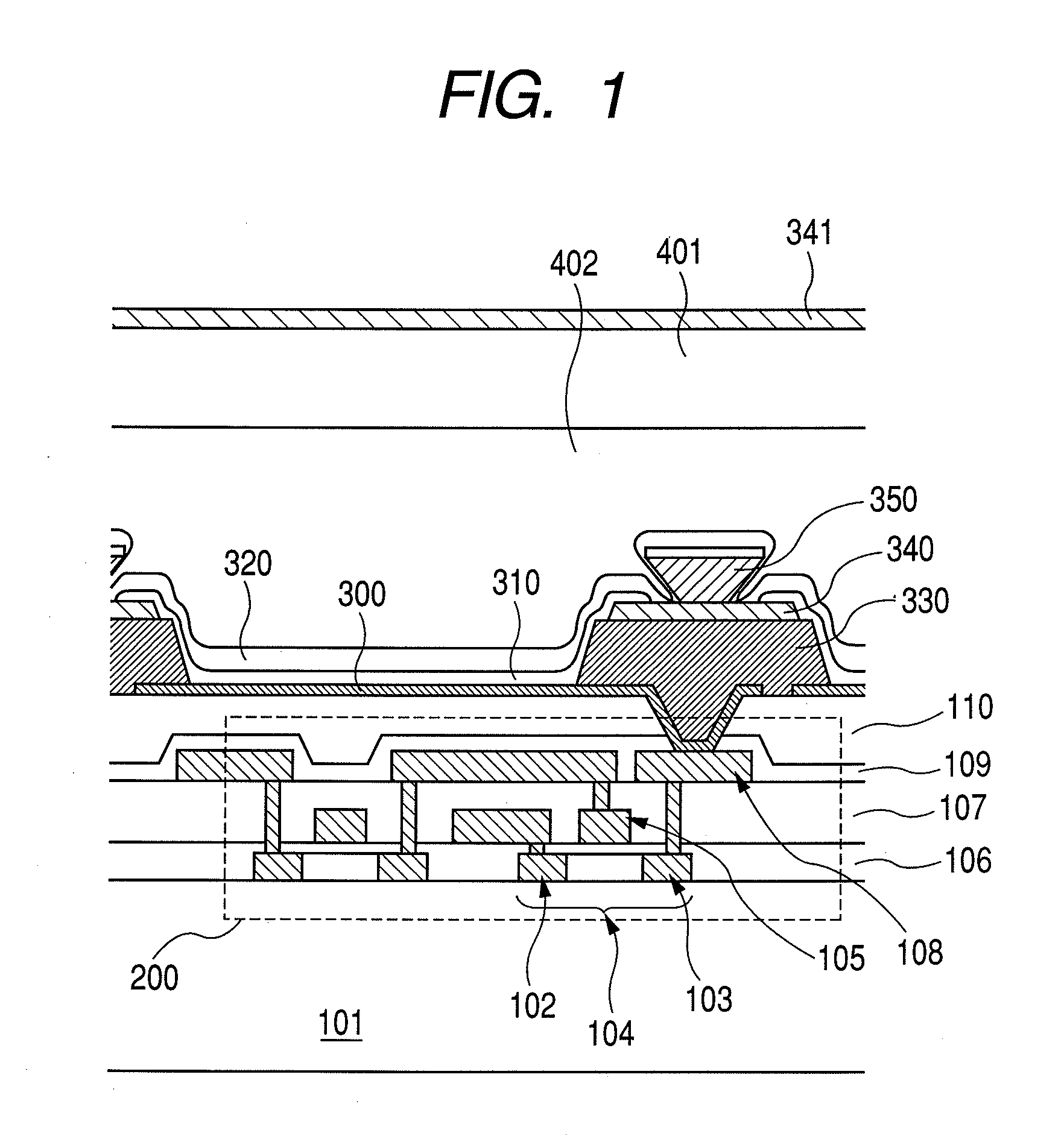

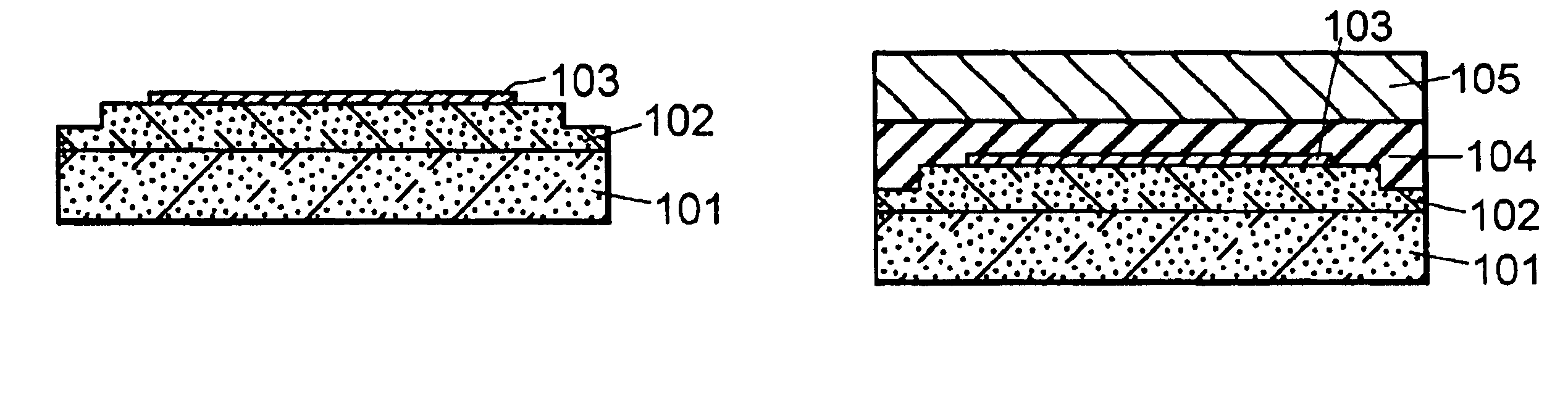

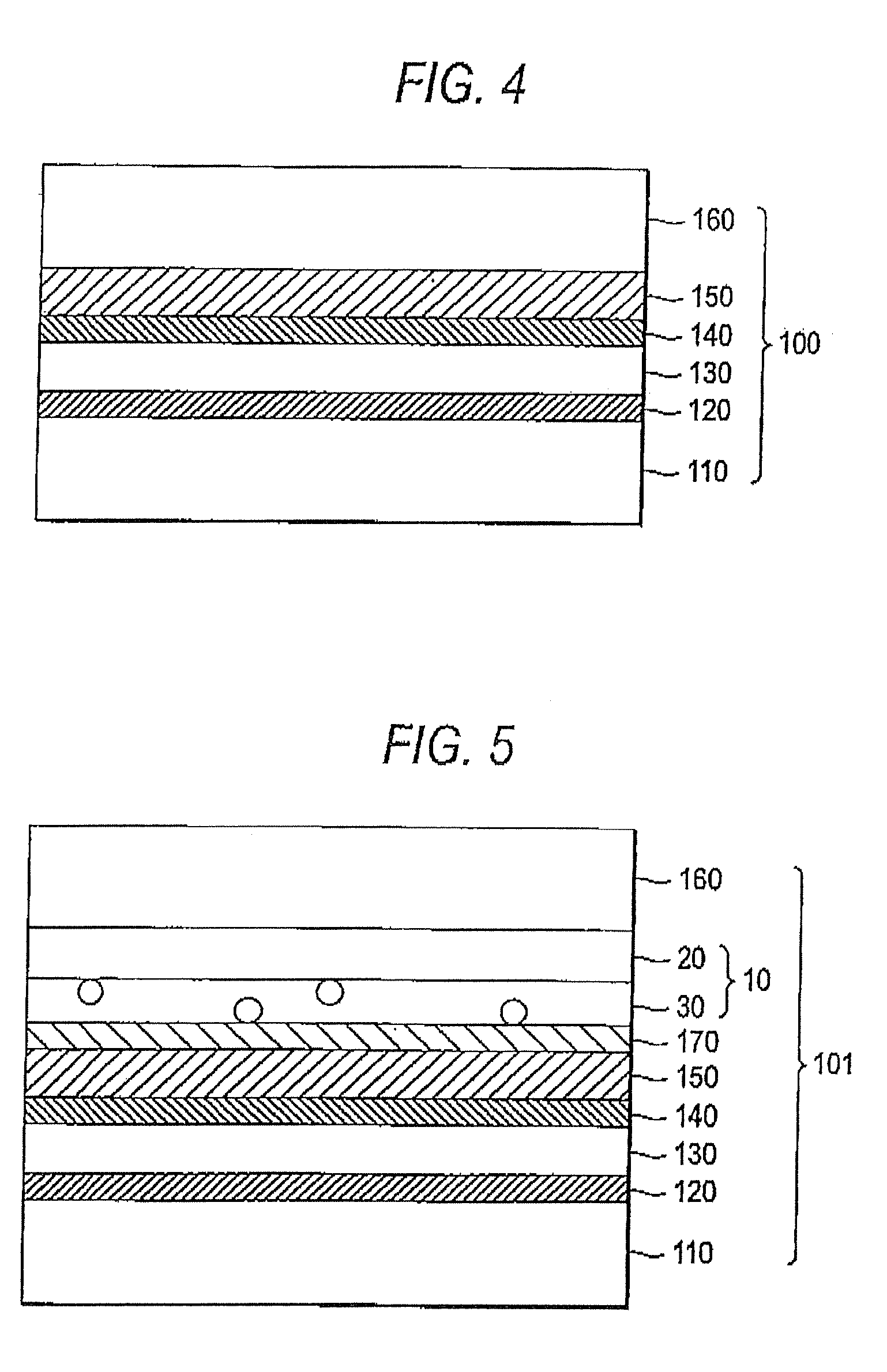

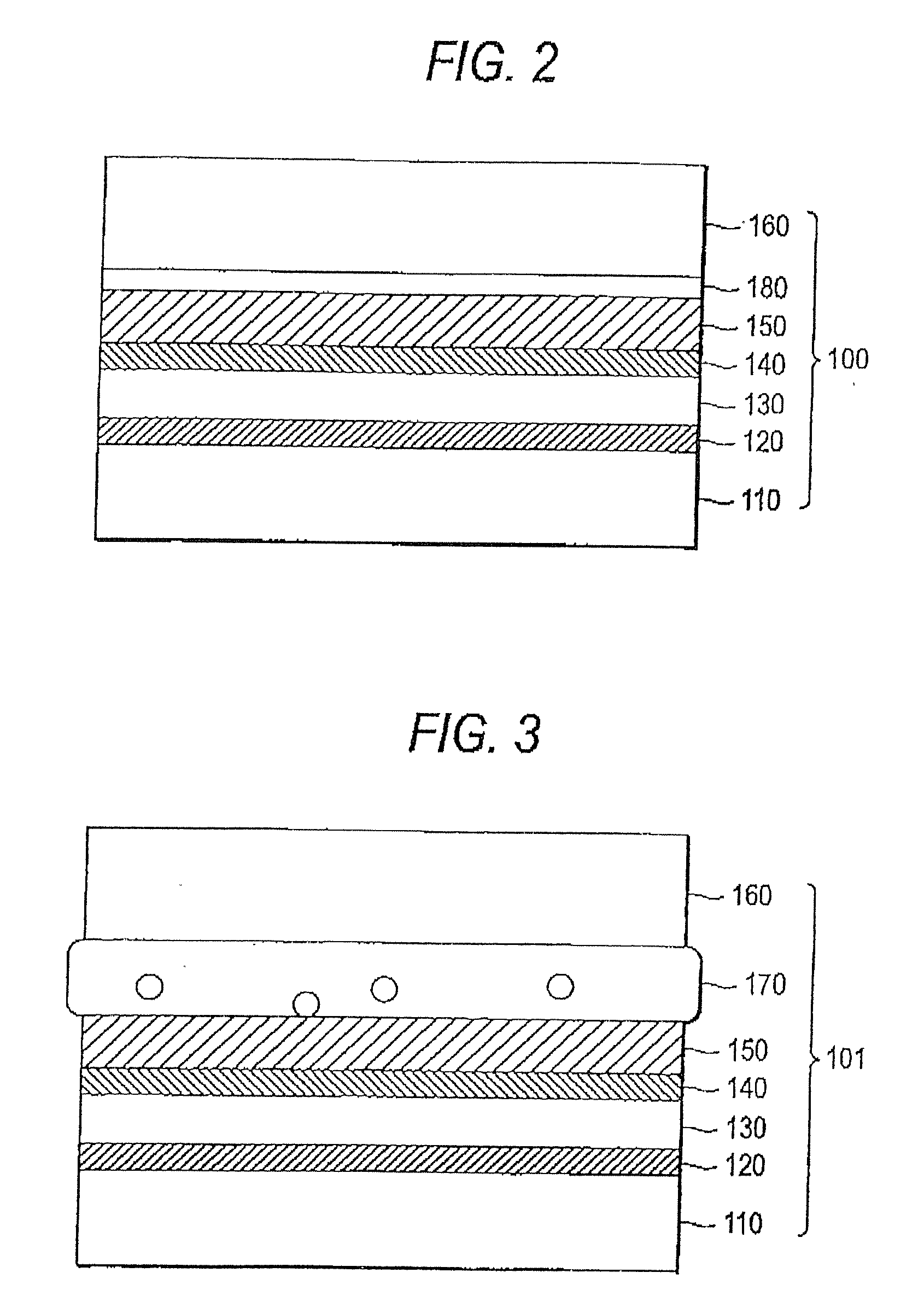

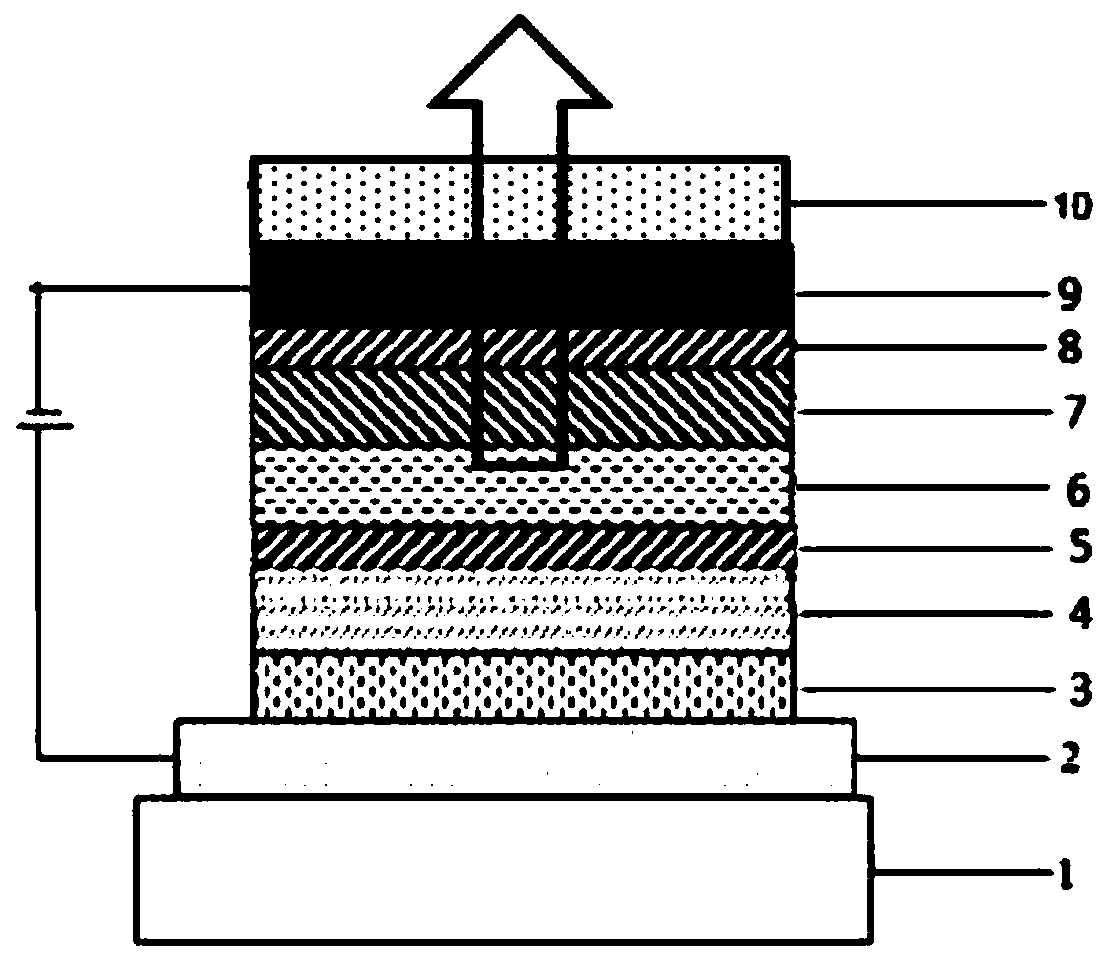

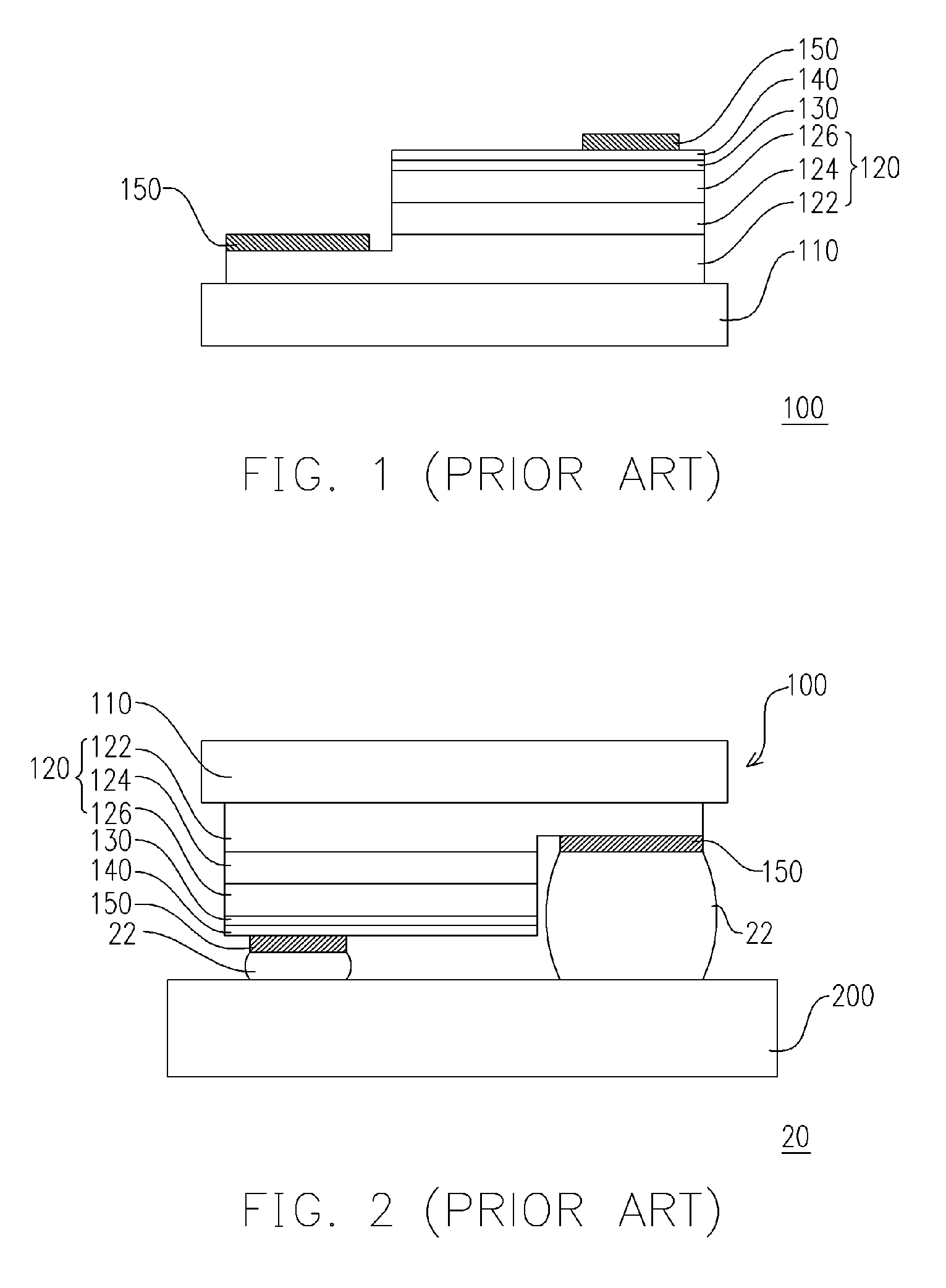

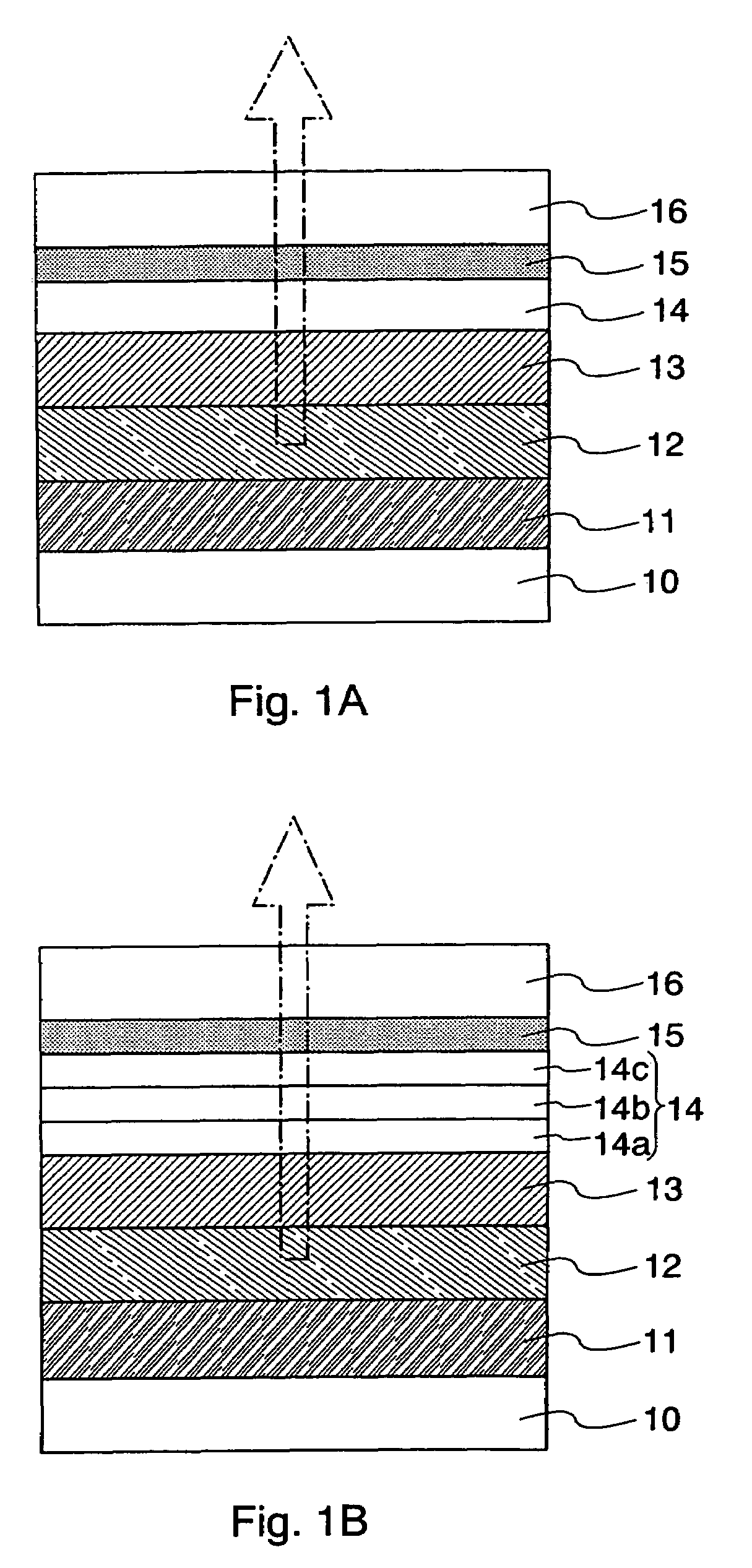

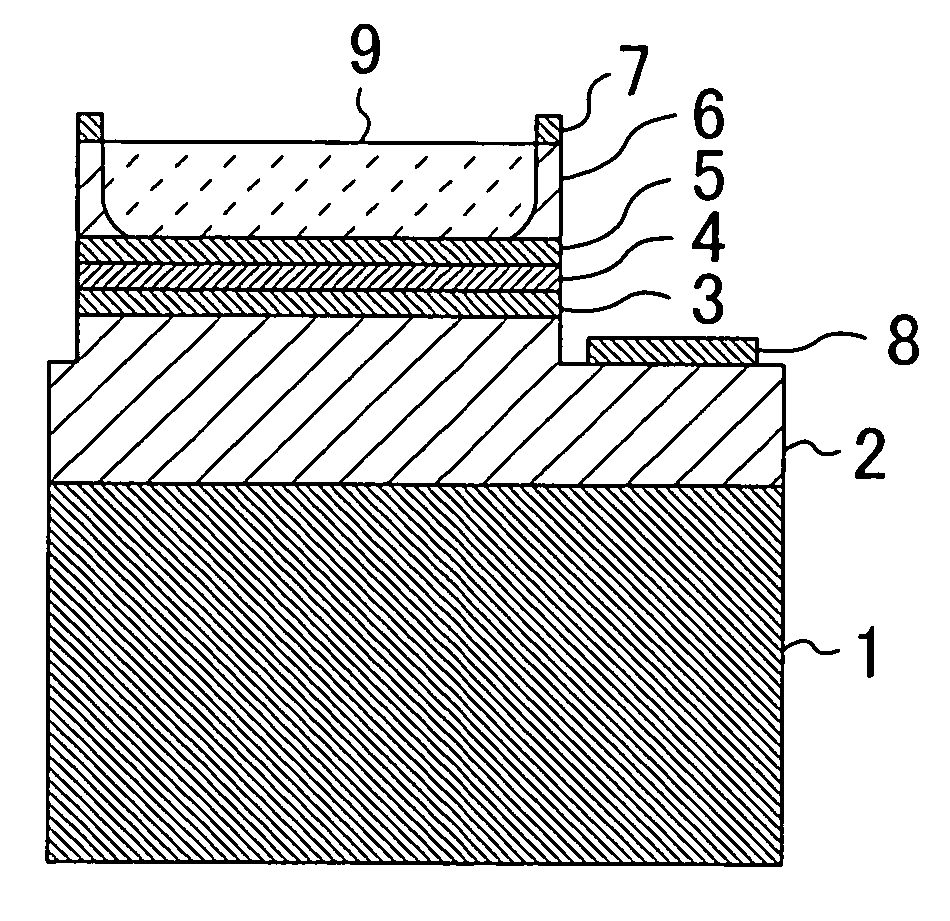

Light-emitting element and display device

InactiveUS20050263775A1Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingRefractive index

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

Organic el display apparatus and method of manufacturing the same

InactiveUS20090009069A1Improve light extraction efficiencyReduce the numberDischarge tube luminescnet screensLamp detailsDevice formOrganic layer

Provided is an organic EL display apparatus including: a substrate; plural organic EL devices formed over the substrate, each of the organic EL devices including a first electrode, an organic layer, and a second electrode which are provided in order from a side of the substrate, the organic layer including at least a light emitting layer; plural pixel isolation films, each of which is an insulating film and formed between the first electrodes located adjacent to each other; plural auxiliary wirings which are formed on the plural pixel isolation films and include a conductive material; and plural partition walls which are formed on the auxiliary wirings and include one of an insulator and a conductor which is reverse-tapered to have reverse-tapered portions, in which the plural auxiliary wirings and the second electrodes are electrically connected with each other in positions directly under the reverse-tapered portions of the plural partition walls.

Owner:CANON KK

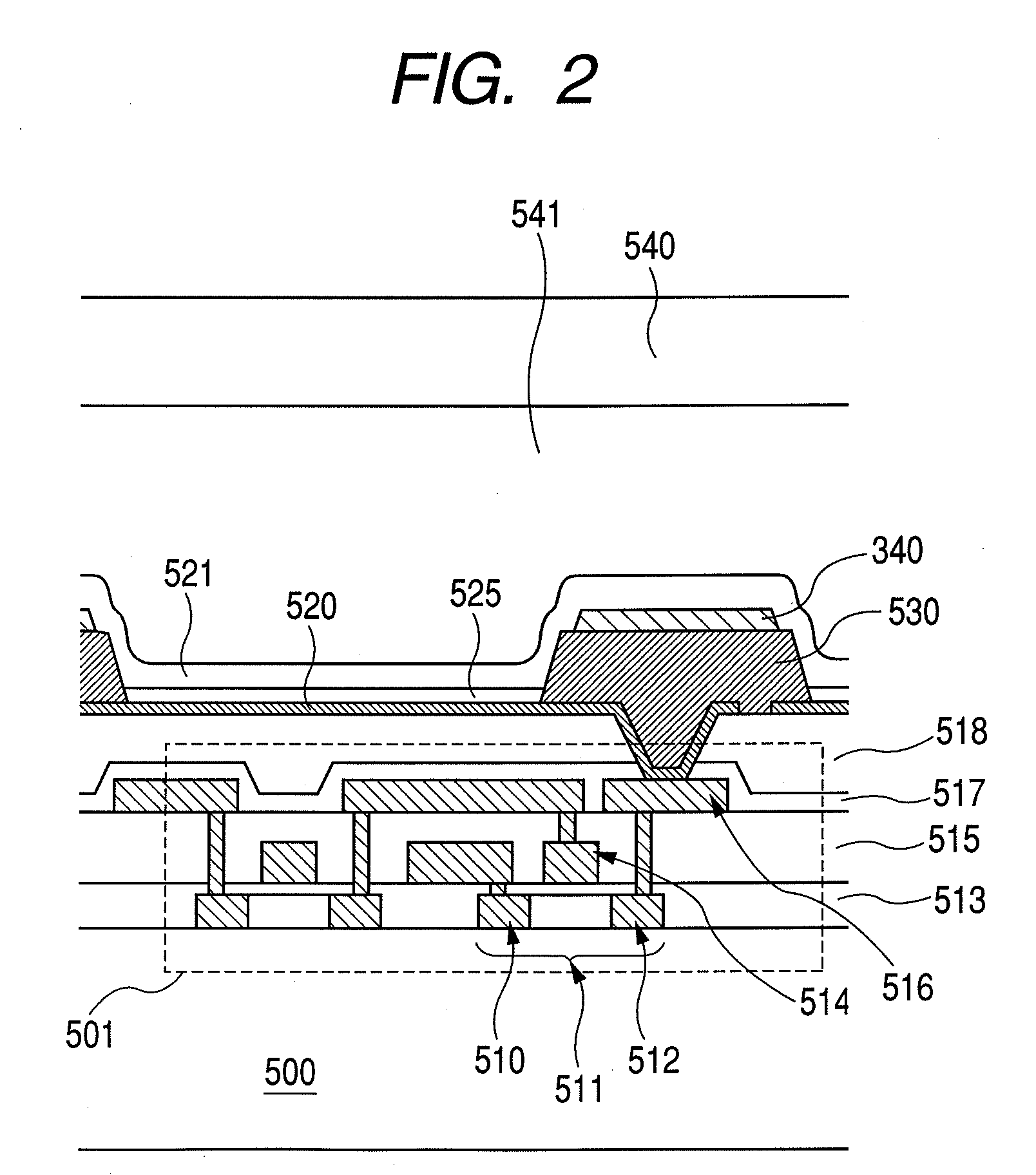

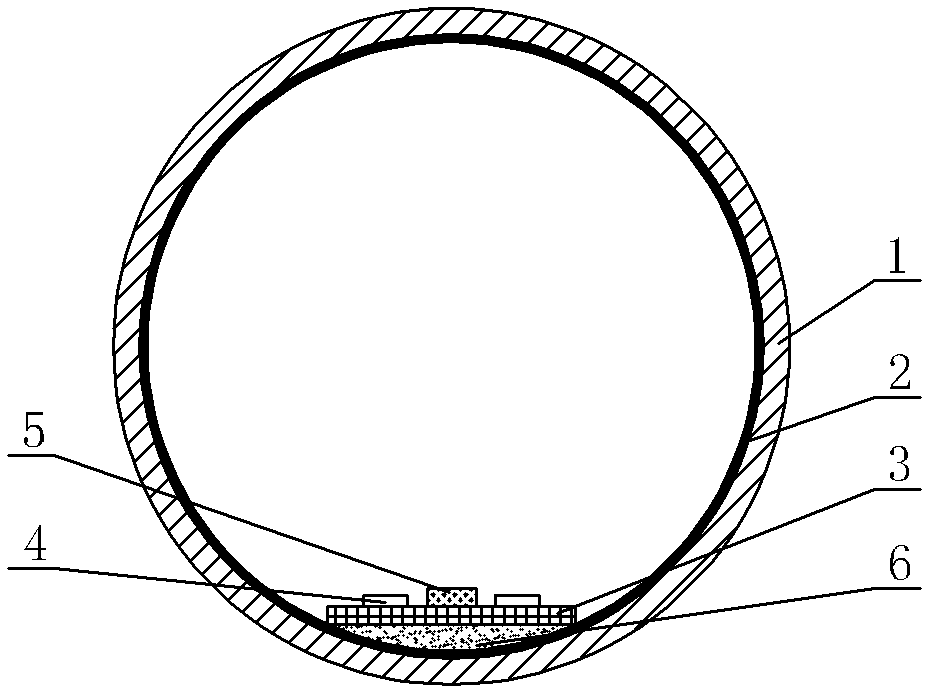

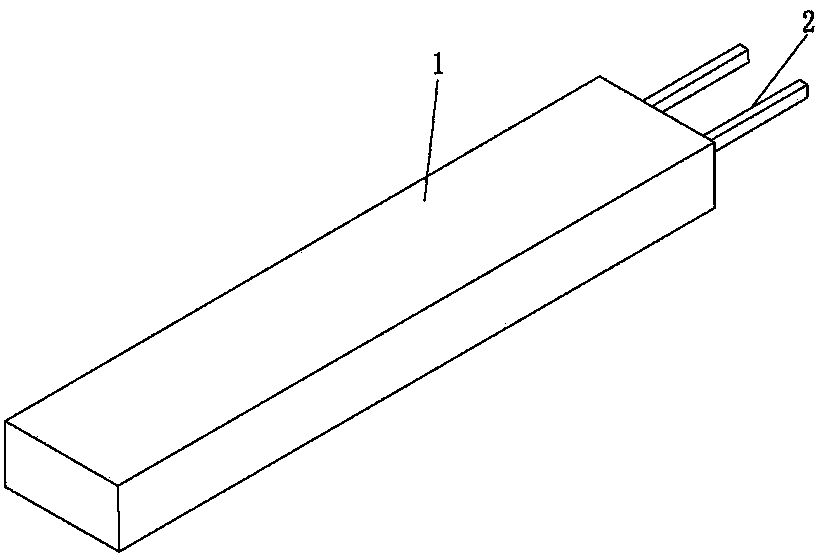

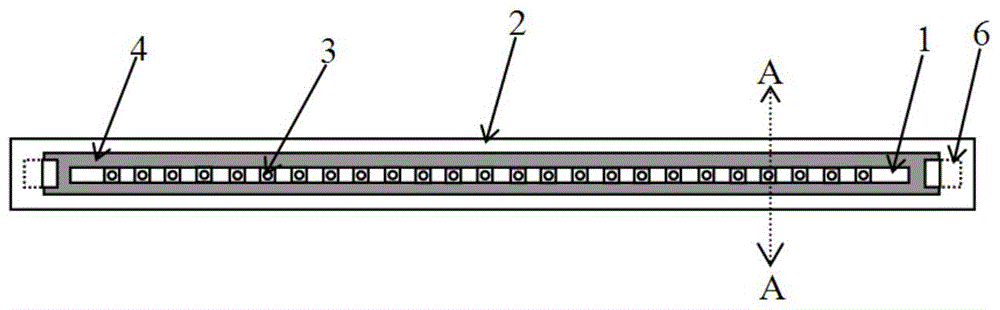

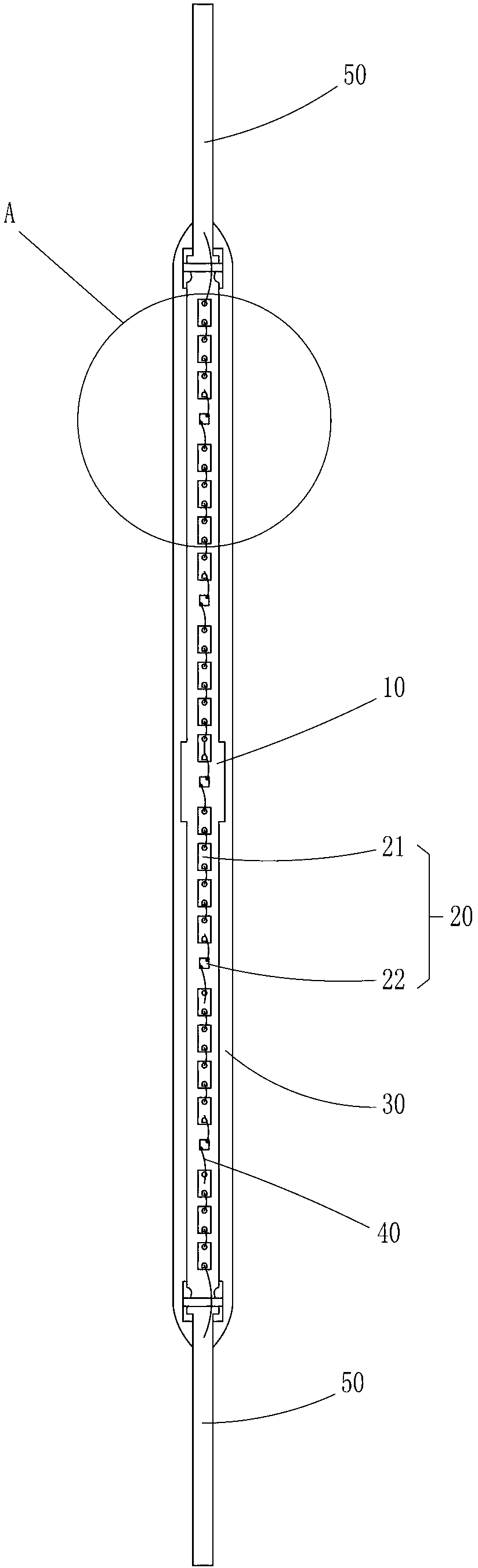

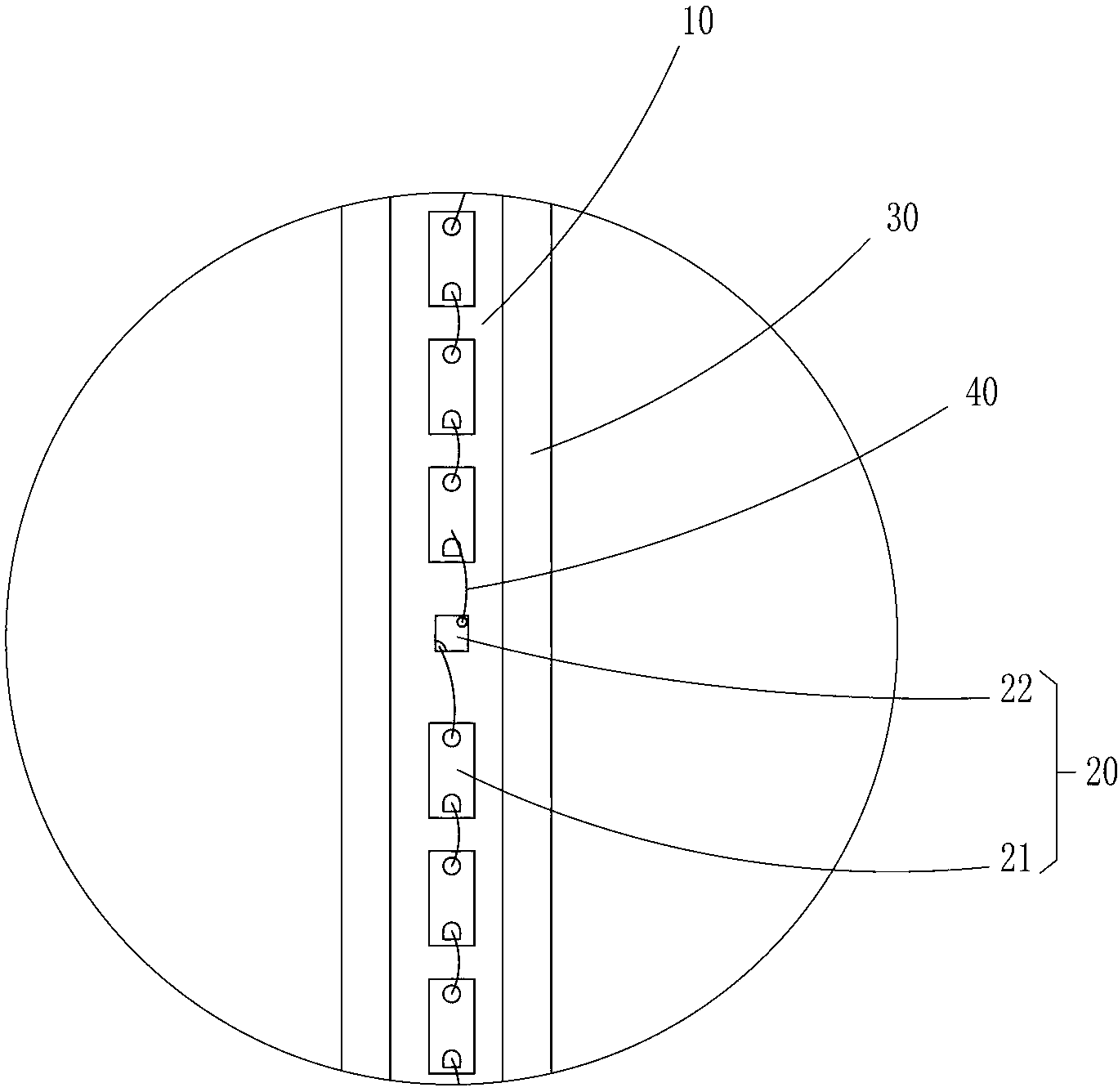

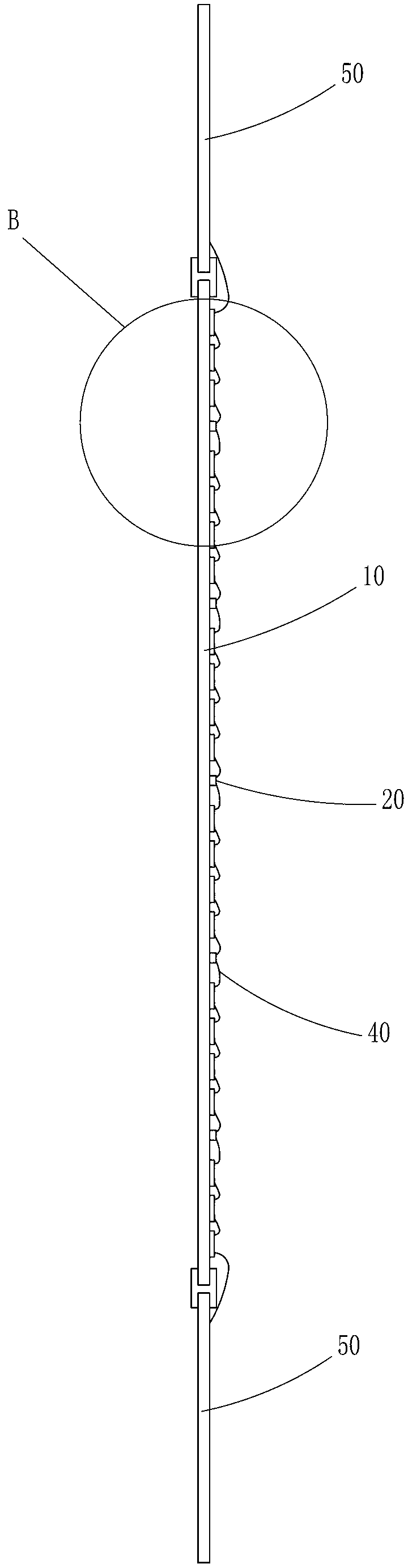

LED (Light Emitting Diode) lamp tube

InactiveCN102518972AHigh light transmittanceHigh refractive indexPoint-like light sourceElongate light sourcesPoint lightAdhesive

The invention discloses an LED (Light Emitting Diode) lamp tube, which comprises a glass tube, lamp caps arranged at two ends of the glass tube as well as an LED lamp strip arranged in the glass tube, wherein the inner wall of the glass tube is coated with a light increasing and heat radiating film; and the LED lamp strip is fixedly adhered to the inner wall of the glass tube through a high heat conduction bonding adhesive. The light increasing and heat radiating film is an aluminum-coated layer, or a frosted heat conduction light increasing adhesive layer or a nano adhesive layer capable of increasing light and radiating heat. The LED lamp strip comprises a substrate, wherein a plurality of LED light sources are welded on the substrate, or an integrated light source consisting of an LED chip is packaged on the substrate; and a driving power supply module is also arranged on the LED lamp strip. According to the LED lamp tube disclosed by the invention, the light emitting efficiency, the light emitting angle and the illumination area of the LED lamp tube are increased; the problems of glare and point light existing in the LED lamp tube are solved; heat generated by an LED is transmitted to the whole glass tube through the substrate of the LED, so that the heat radiating area is greatly increased and the heat increasing speed of the LED lamp tube is increased; the LED lamp tube can be applied to a lamp holder of a traditional fluorescent lamp, and thus the generality of the LED lamp tube is greatly improved; and the replacement and use costs are reduced.

Owner:中山市世耀智能科技有限公司

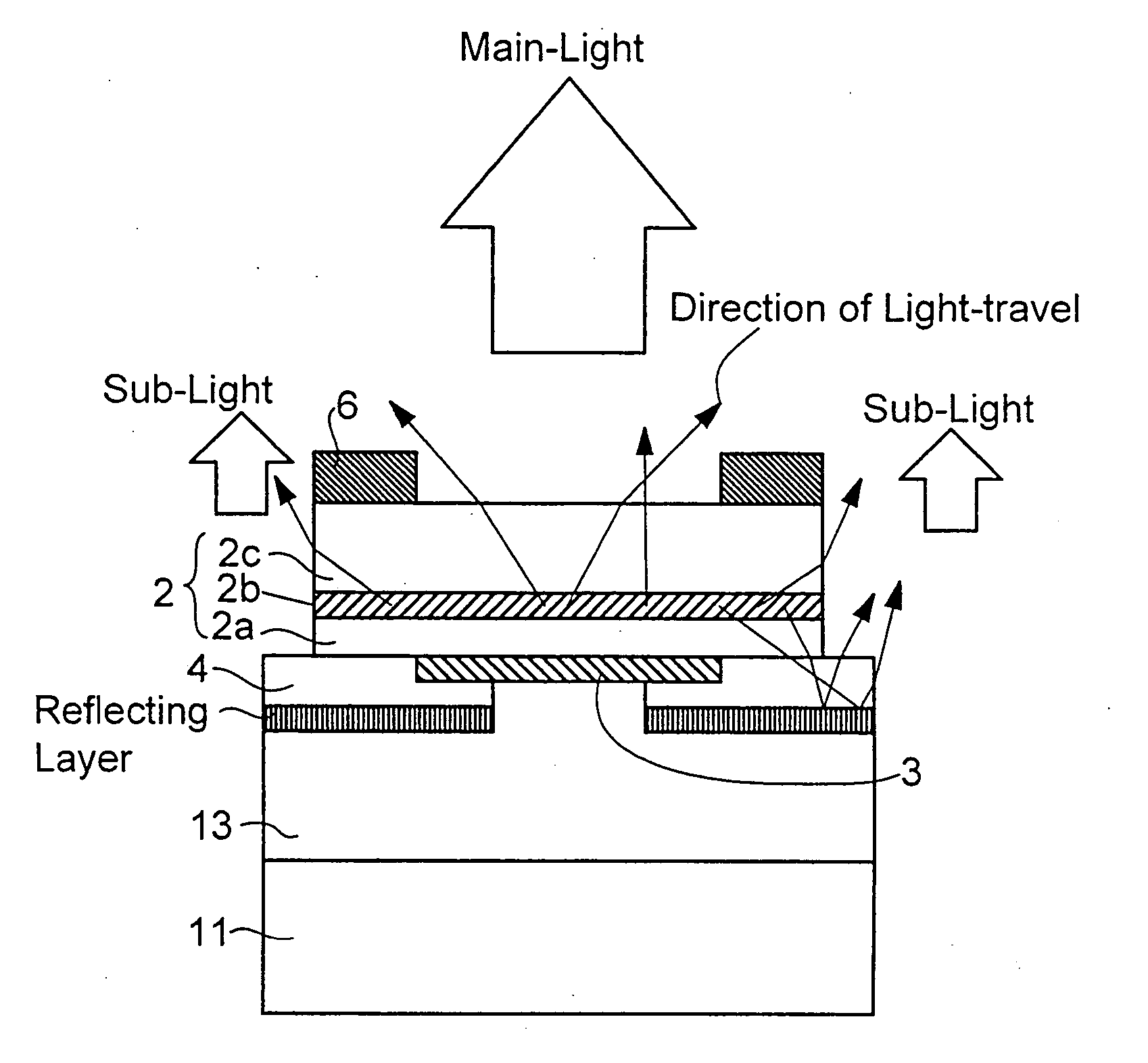

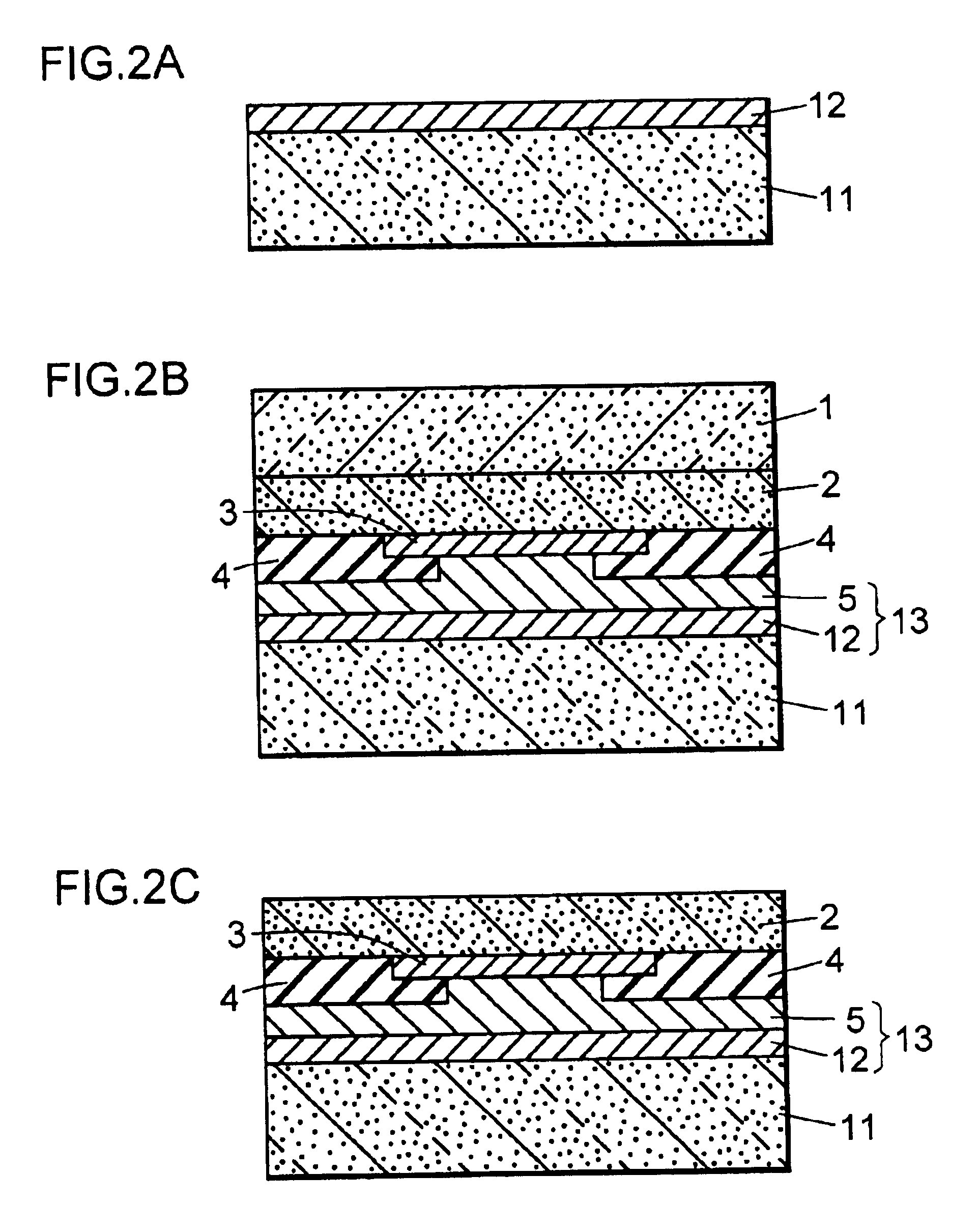

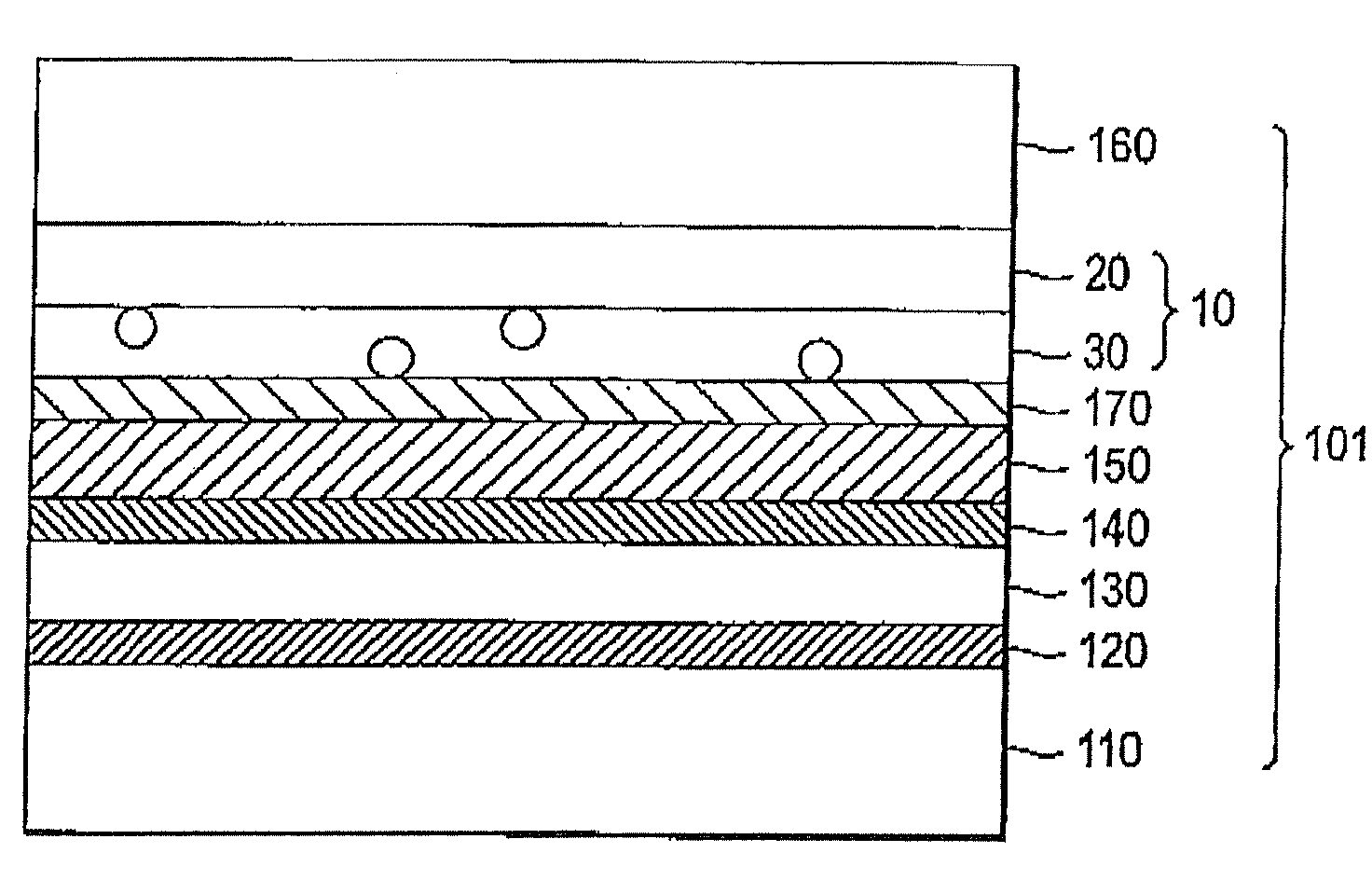

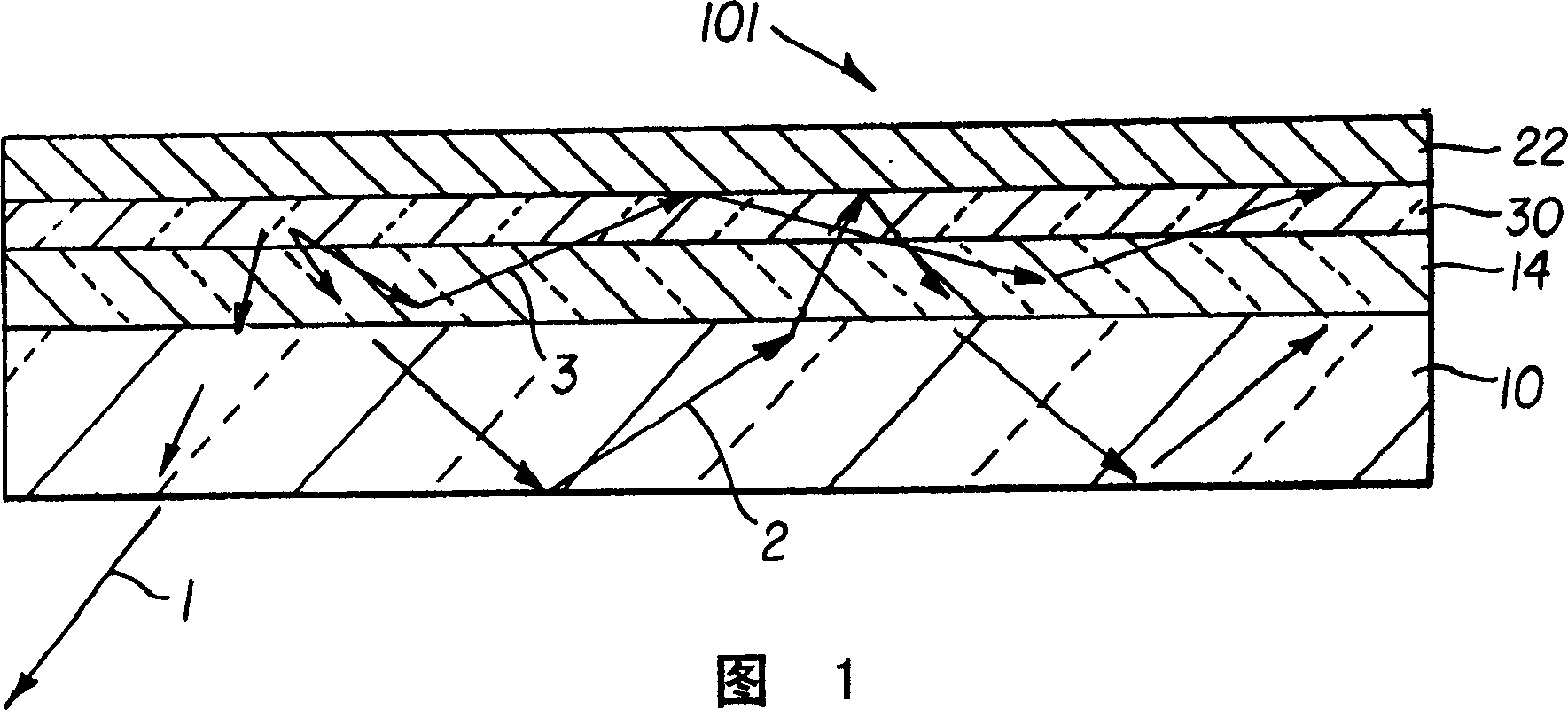

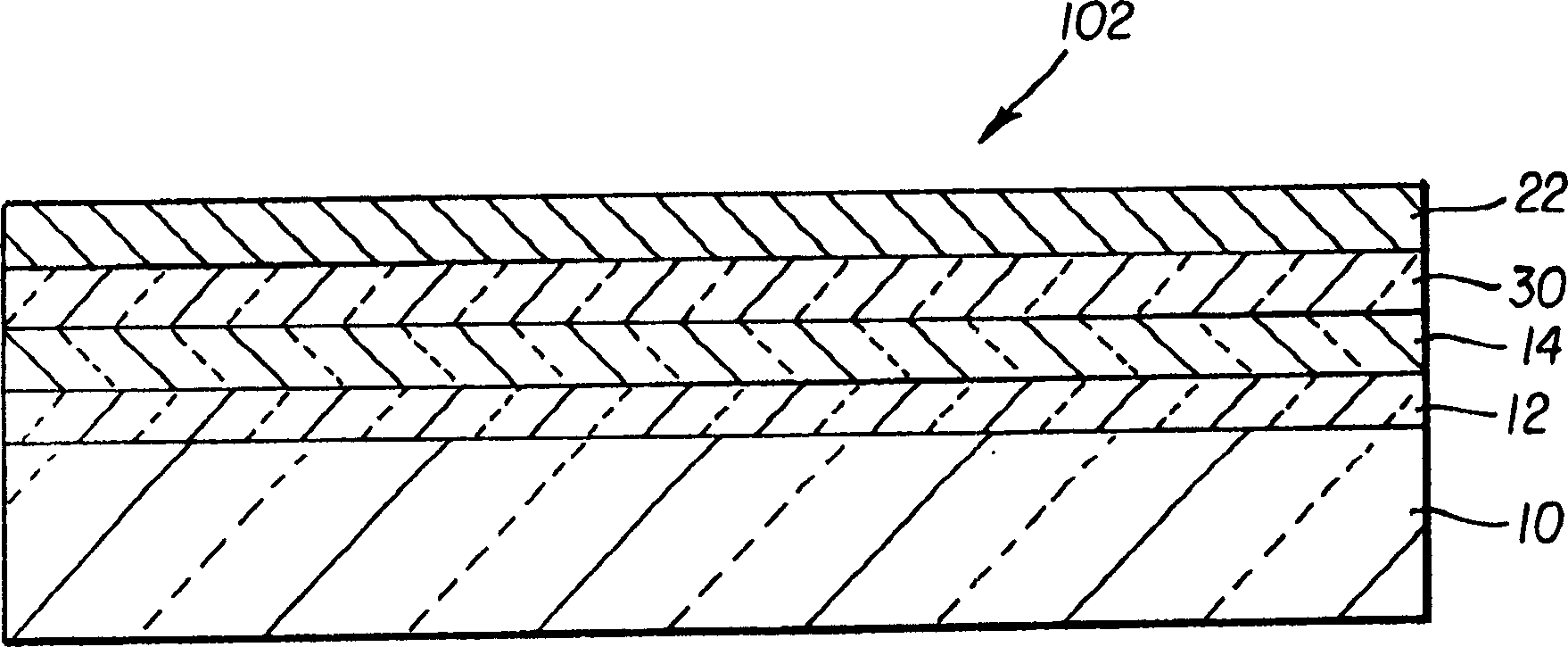

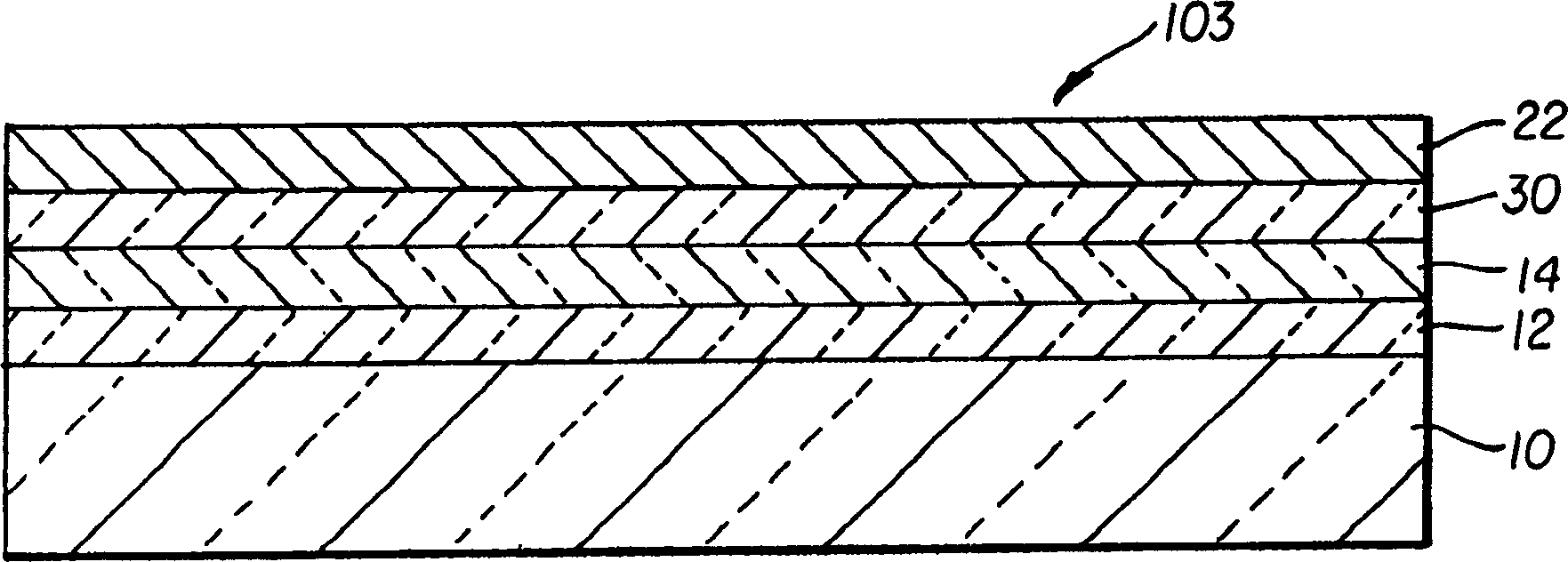

Composite film and semiconductor light emitting device using the same

InactiveUS20110309398A1Improve adhesive propertiesExcellent light extracting efficiencyDecorative surface effectsLayered productsFluorescenceSemiconductor

The present invention relates to a composite film including a wavelength conversion layer and a diffusive reflection resin layer in a laminated state and being used in a semiconductor light emitting device, in which the wavelength conversion layer contains a phosphor material which absorbs a part or all of excitation light and is excited to emit visible light in a wavelength region longer than a wavelength of the excitation light, the diffusive reflection resin layer is selectively formed with patterning on one surface of the wavelength conversion layer, and a region on the one surface of the wavelength conversion layer where the diffusive reflection resin layer is not formed with patterning is a path of the excitation light which excites the phosphor material in the wavelength conversion layer.

Owner:NITTO DENKO CORP

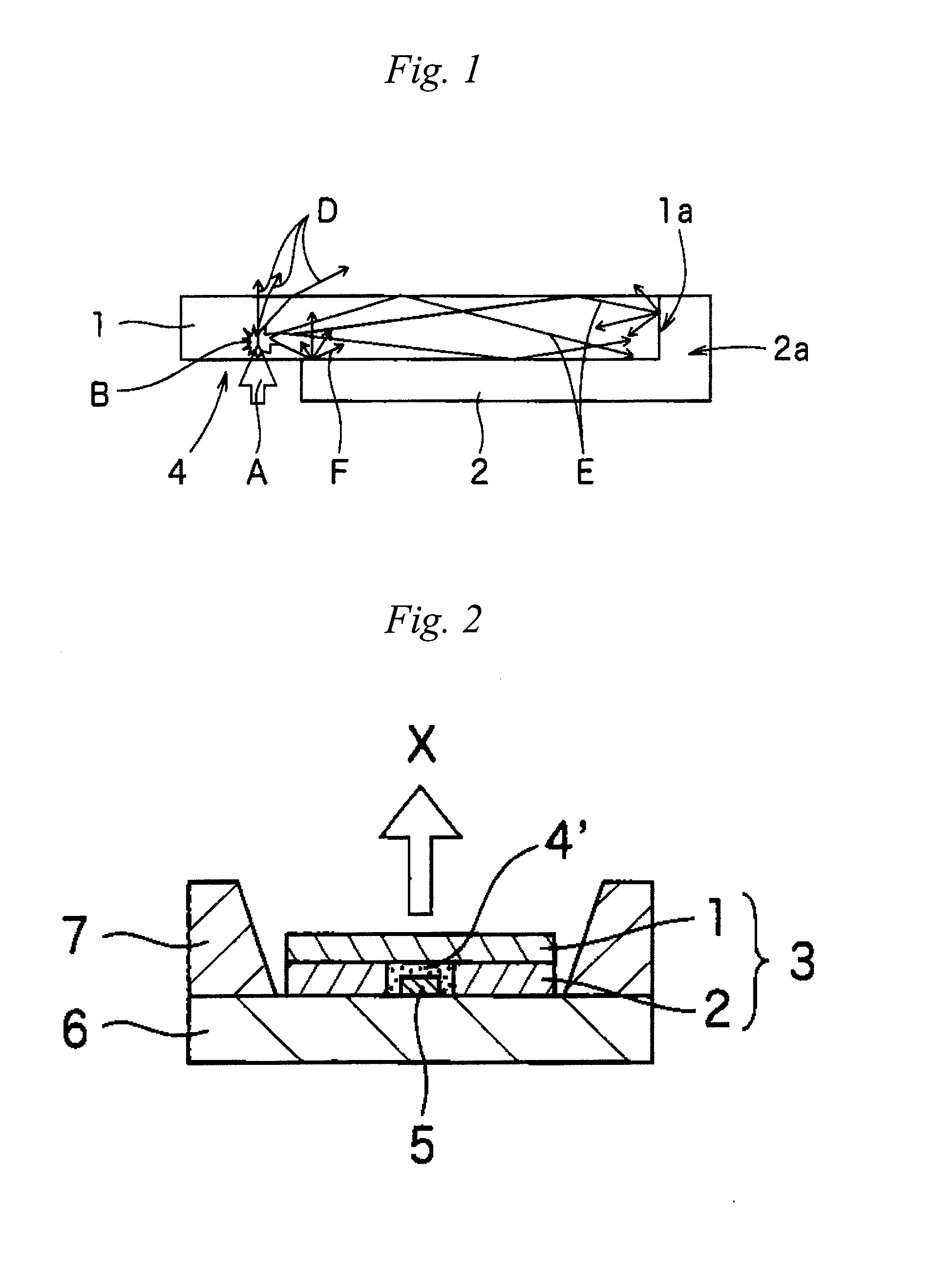

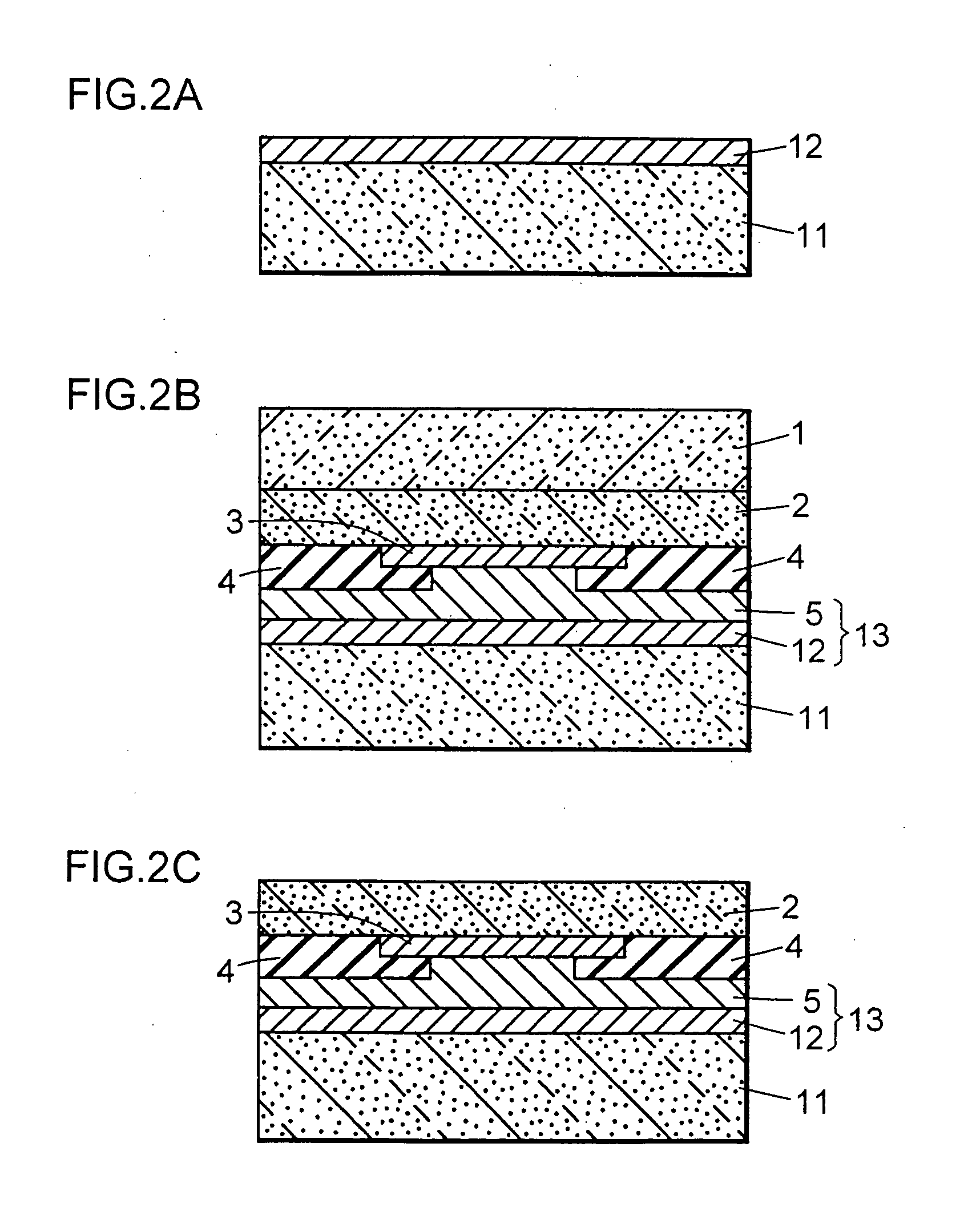

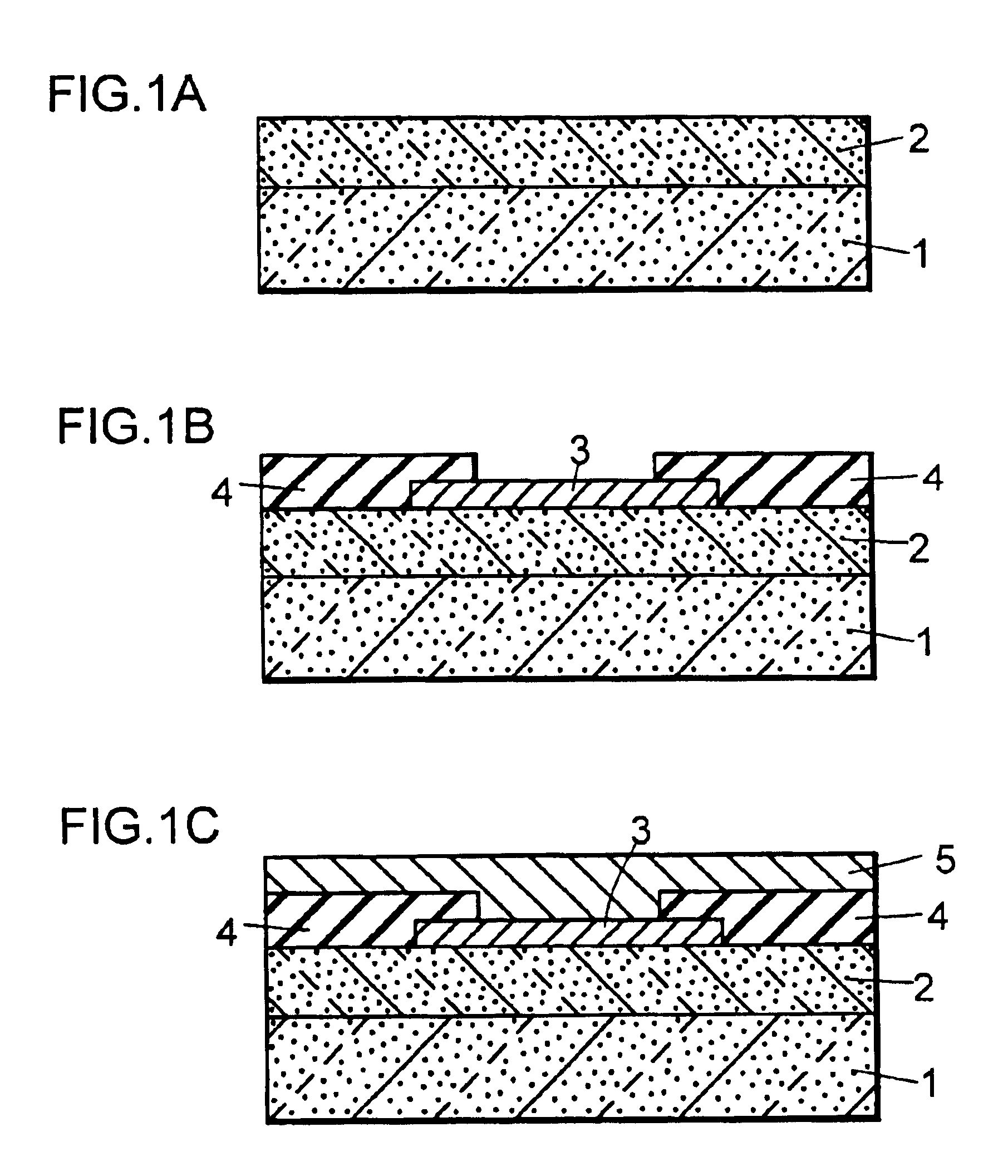

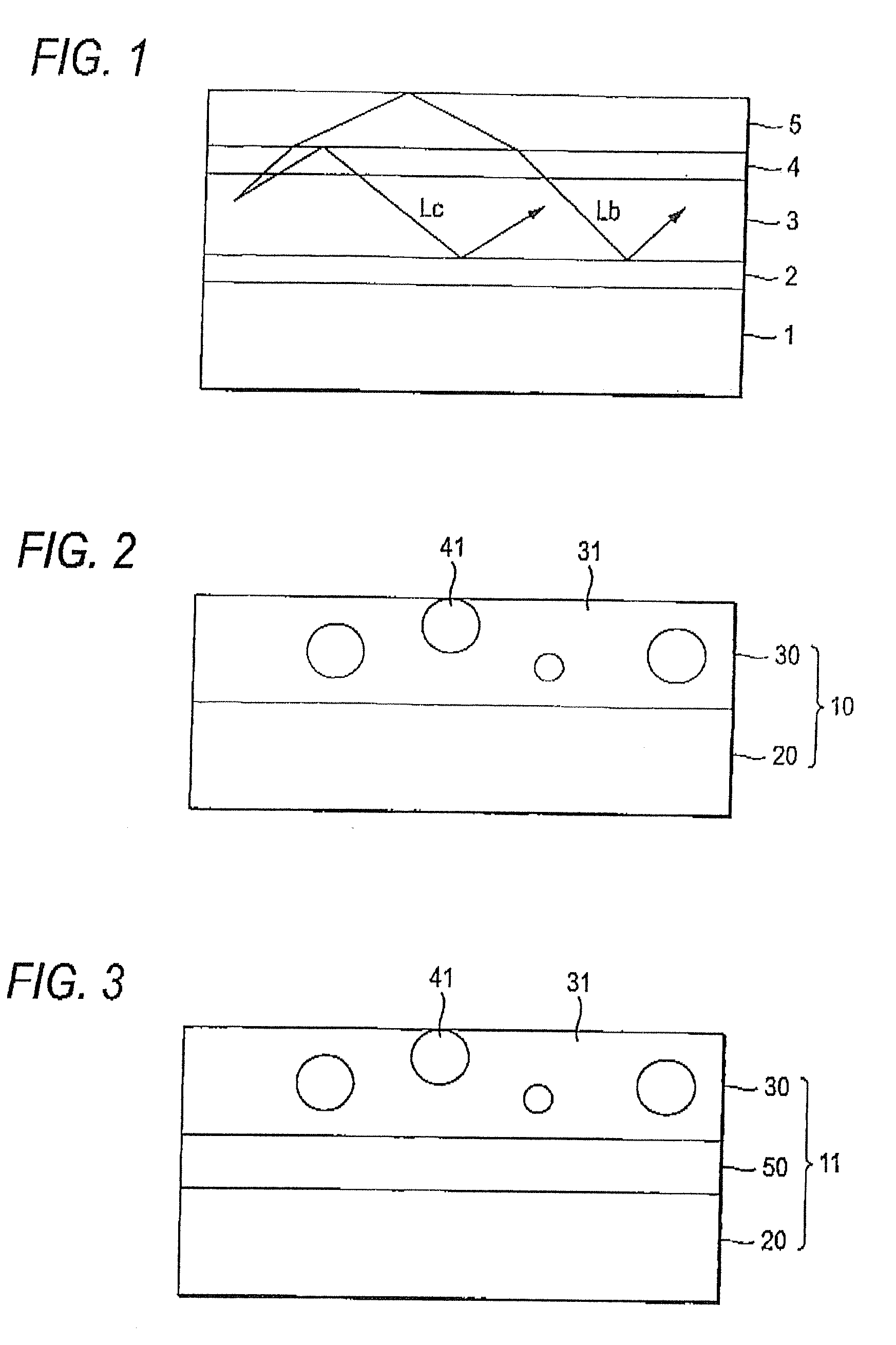

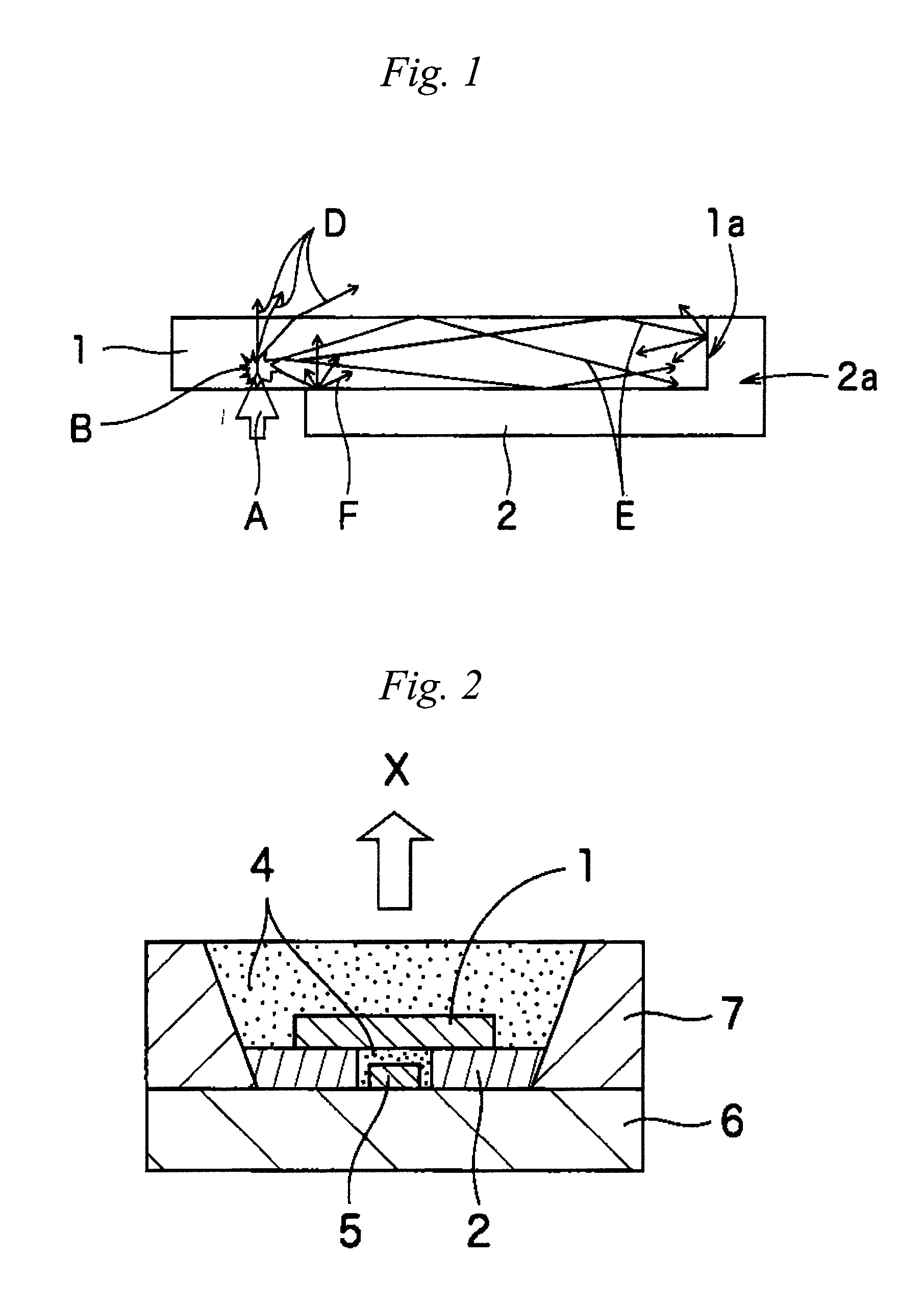

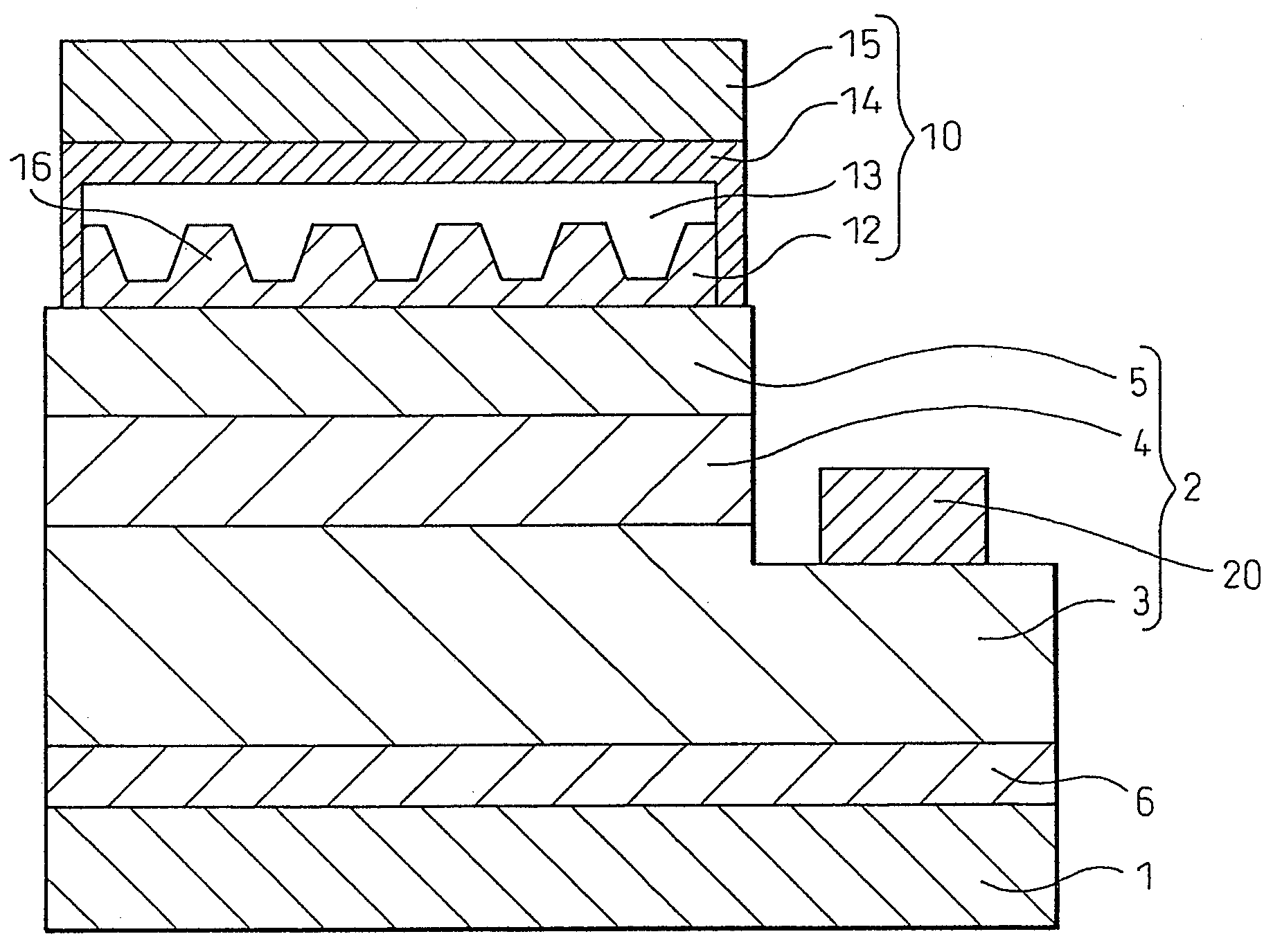

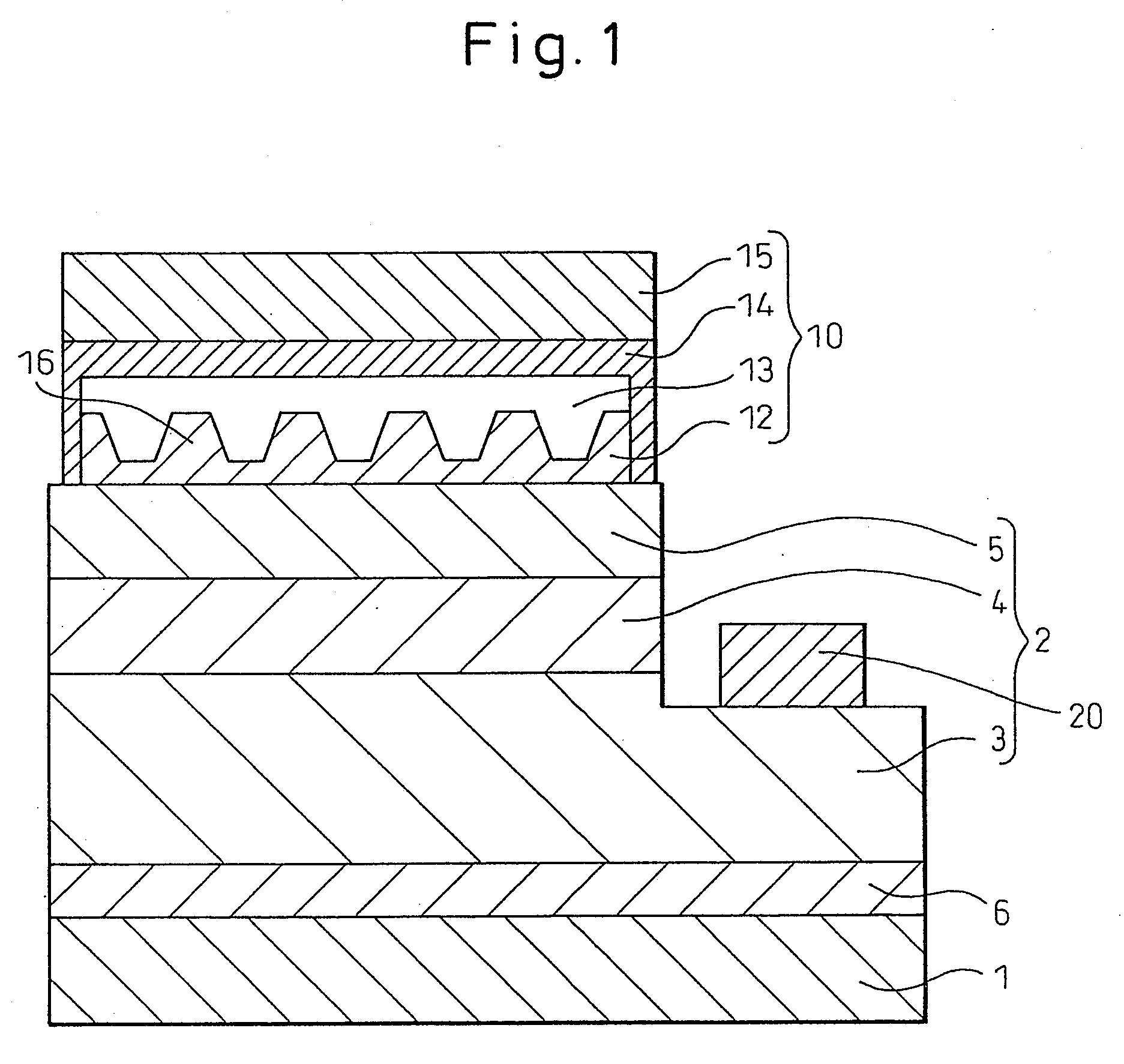

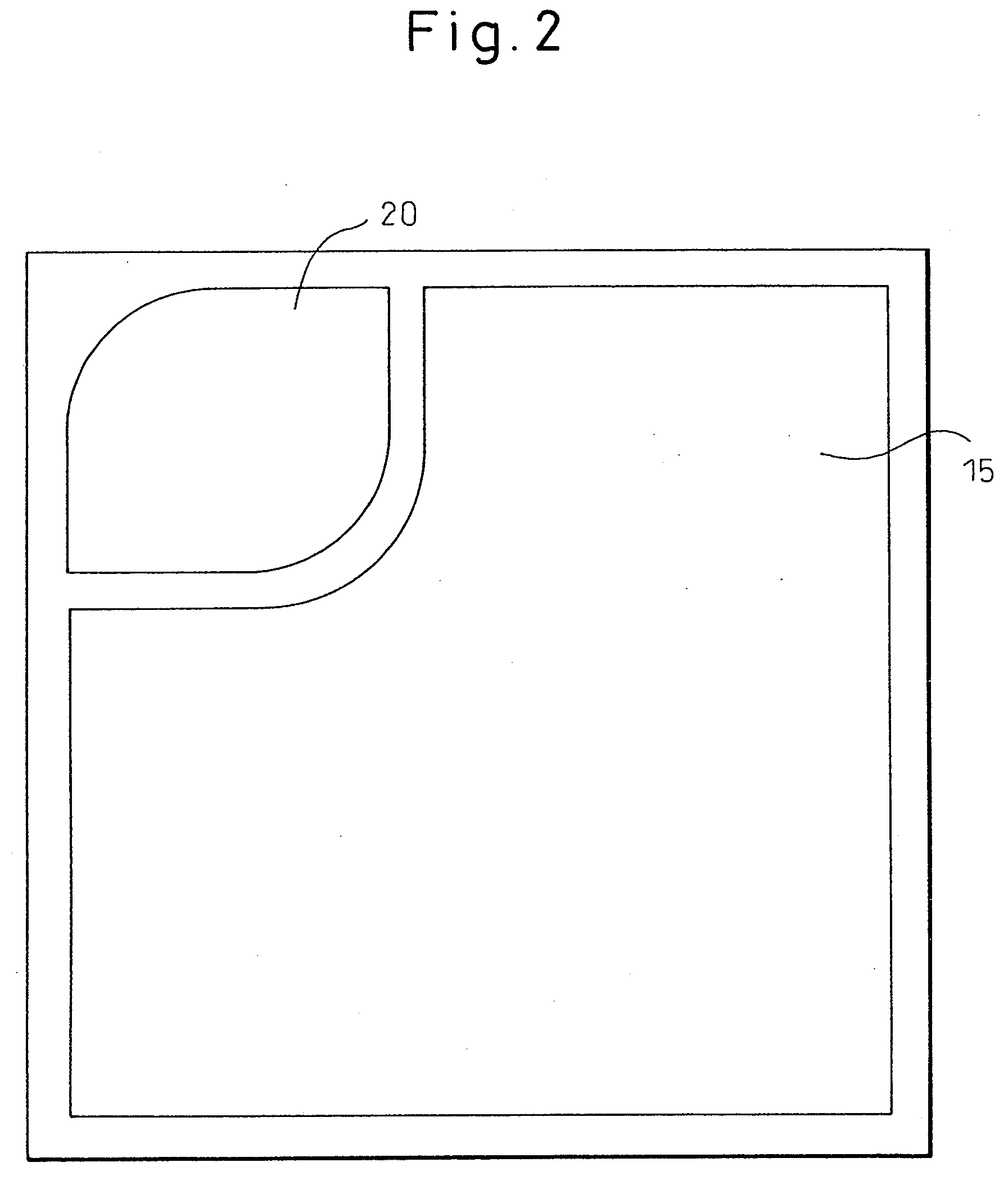

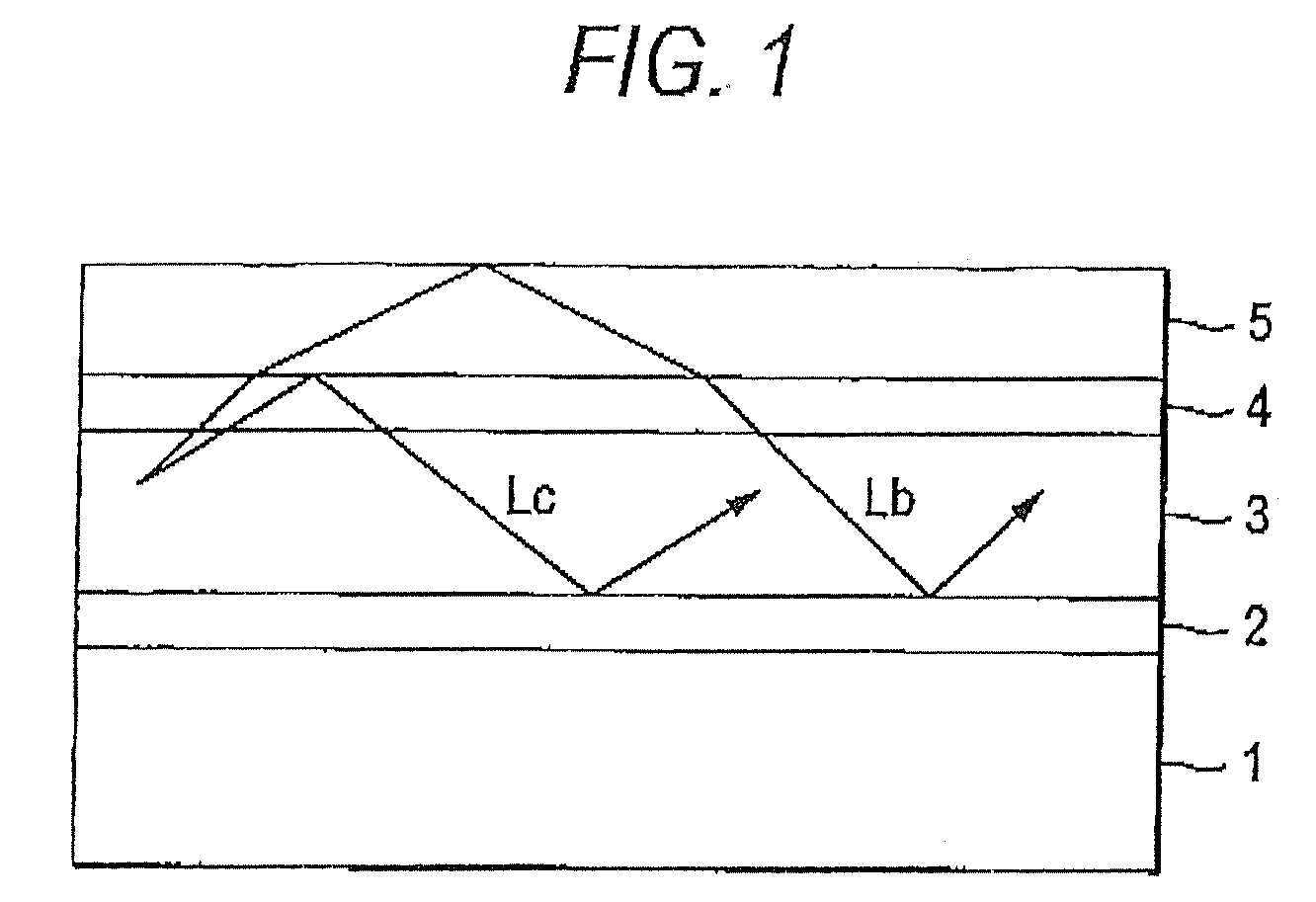

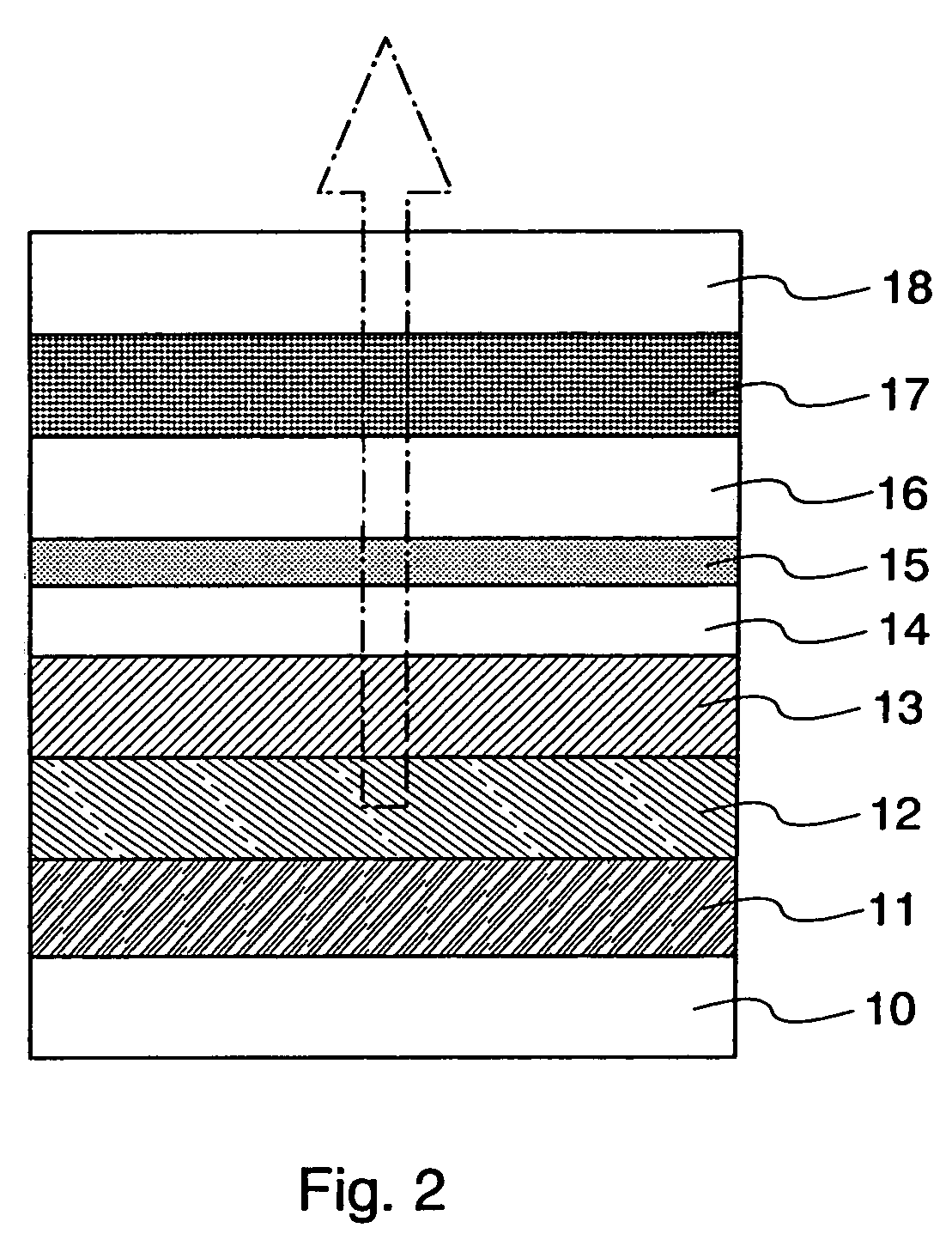

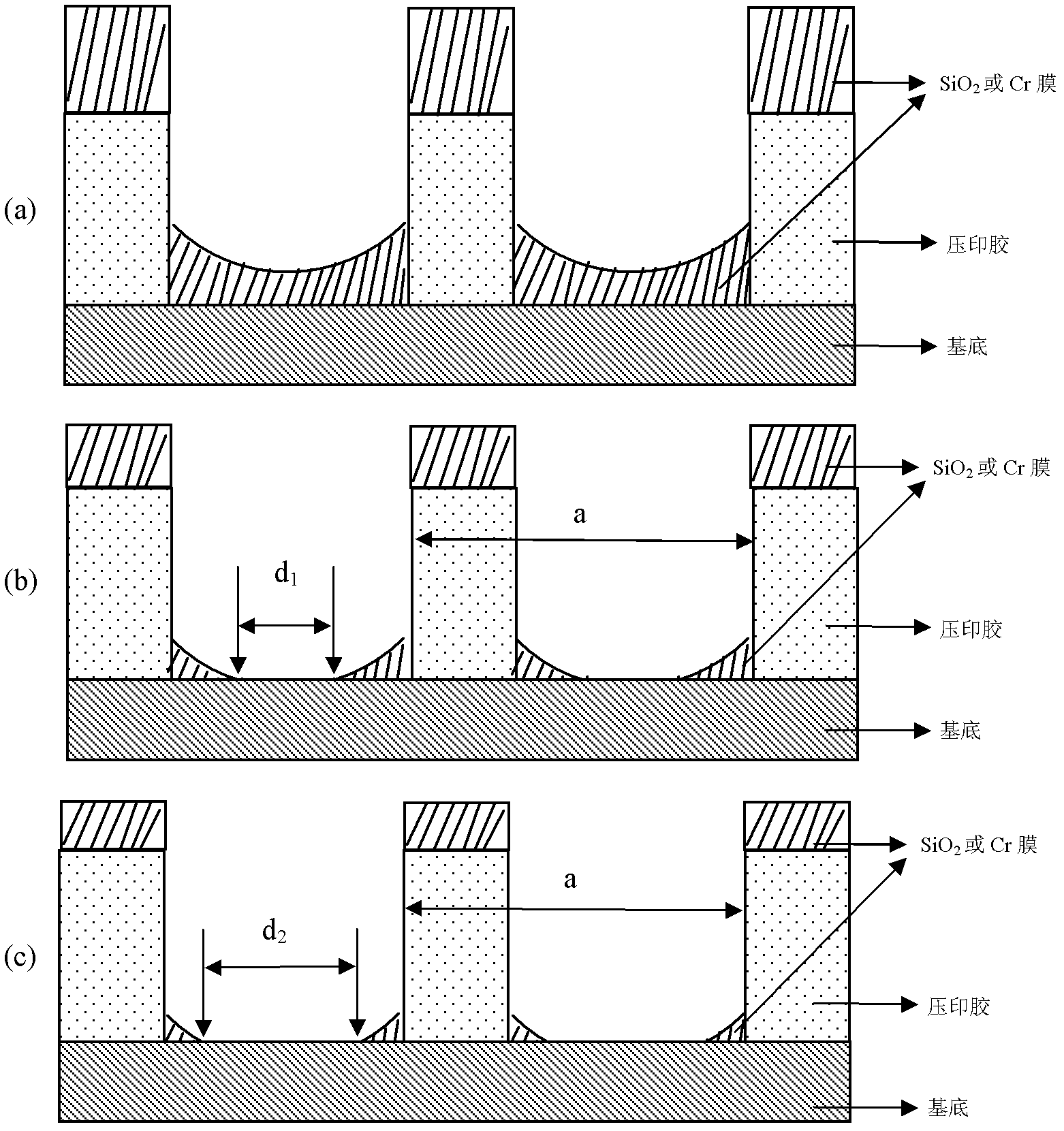

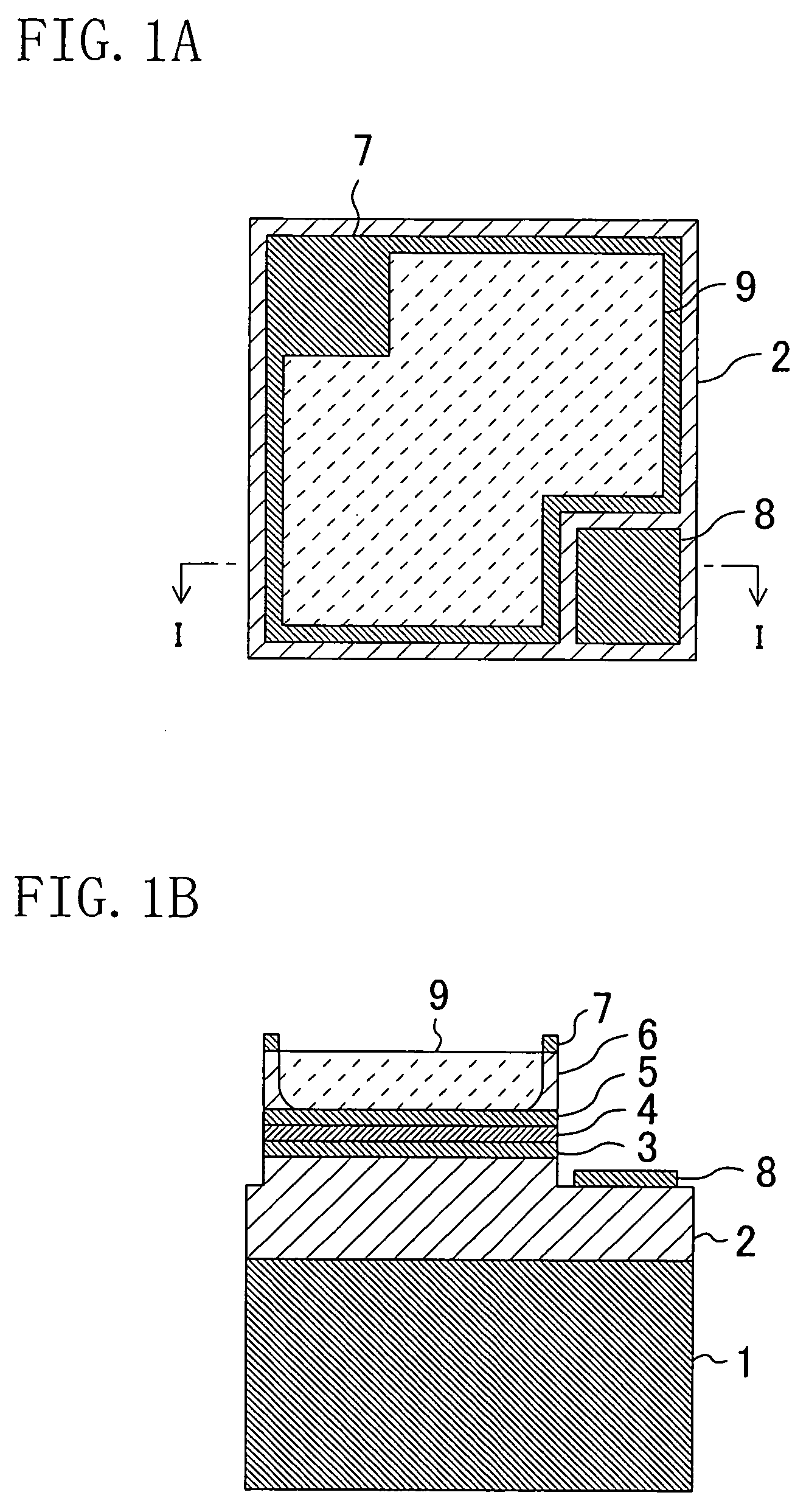

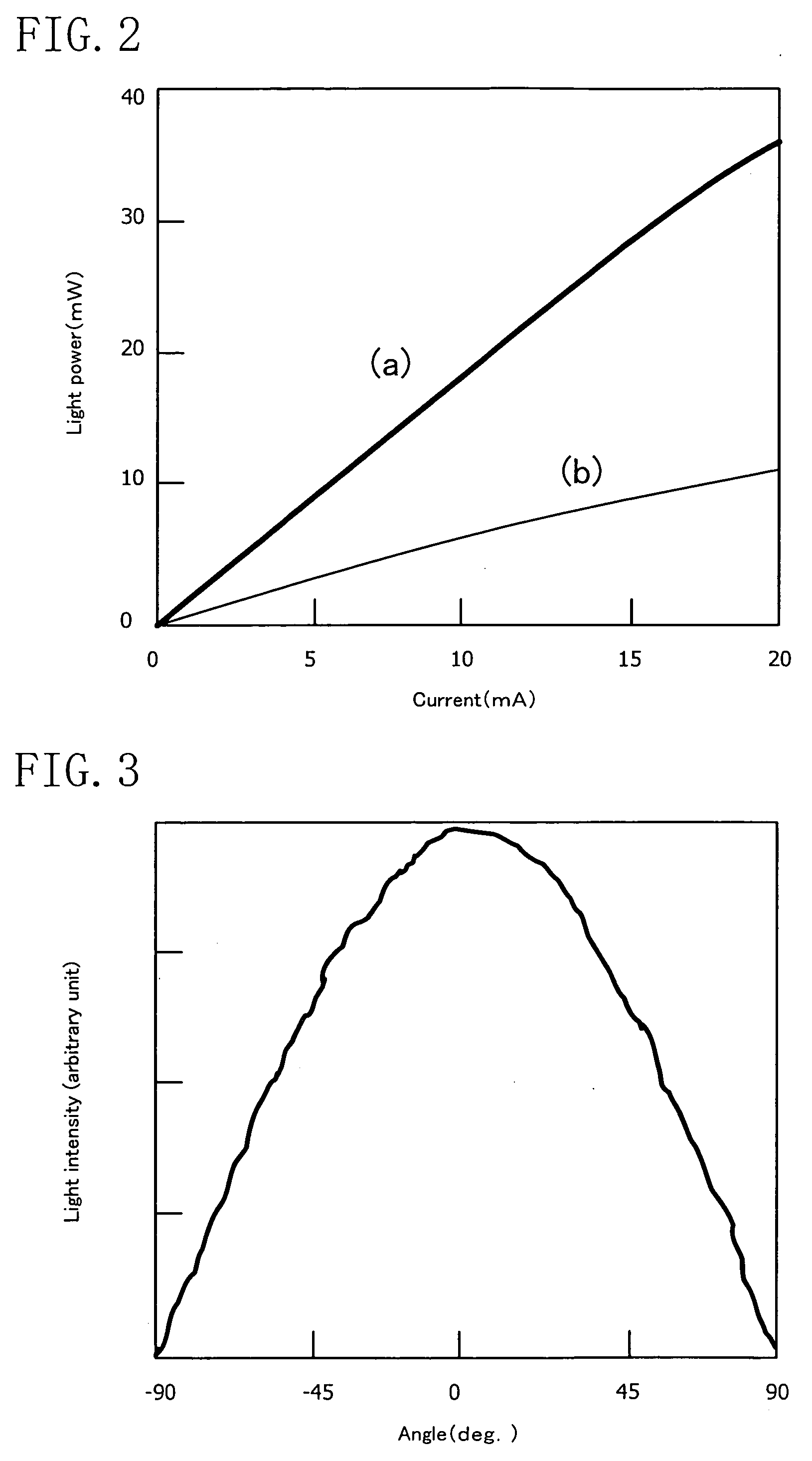

Organic electroluminescent element and lighting device

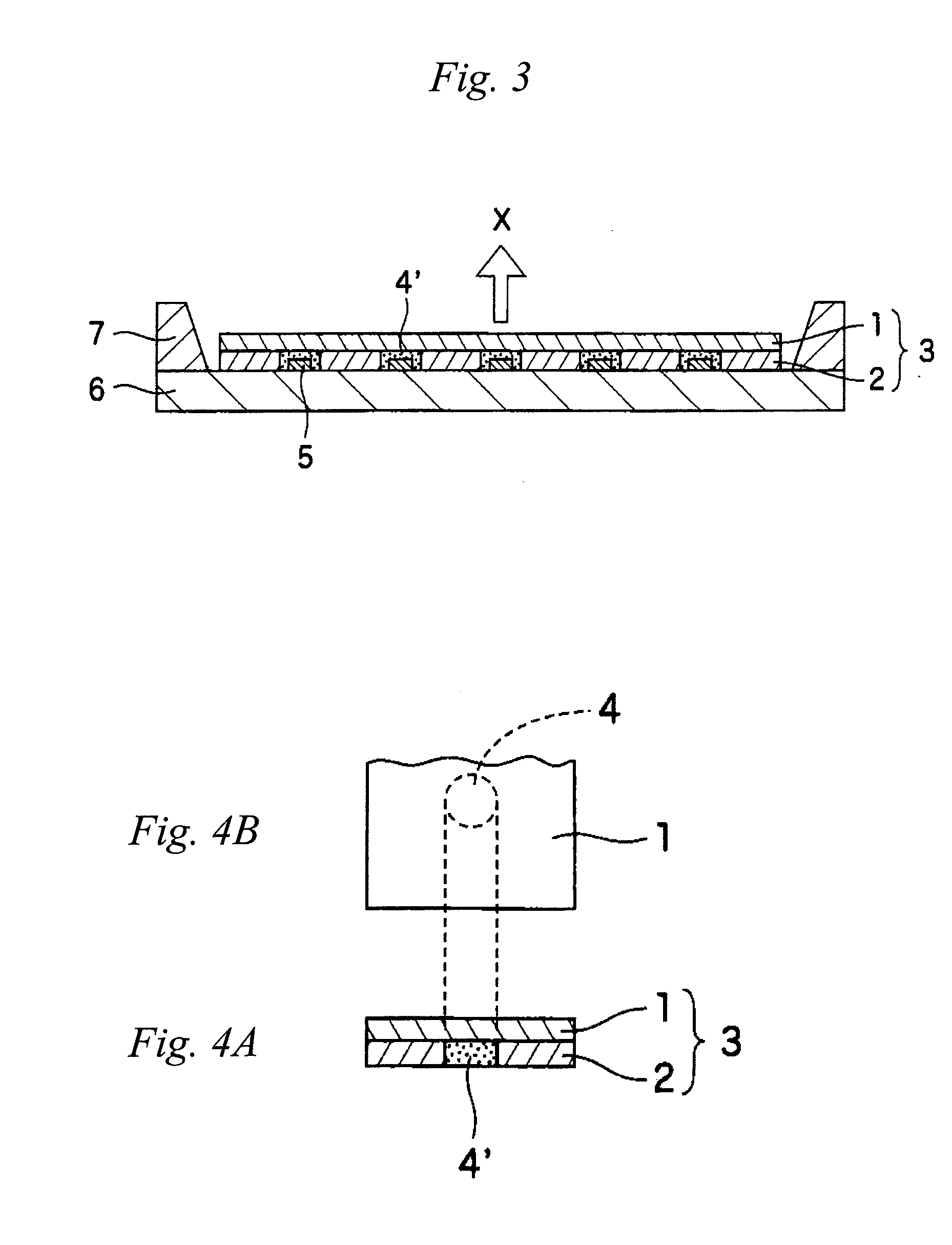

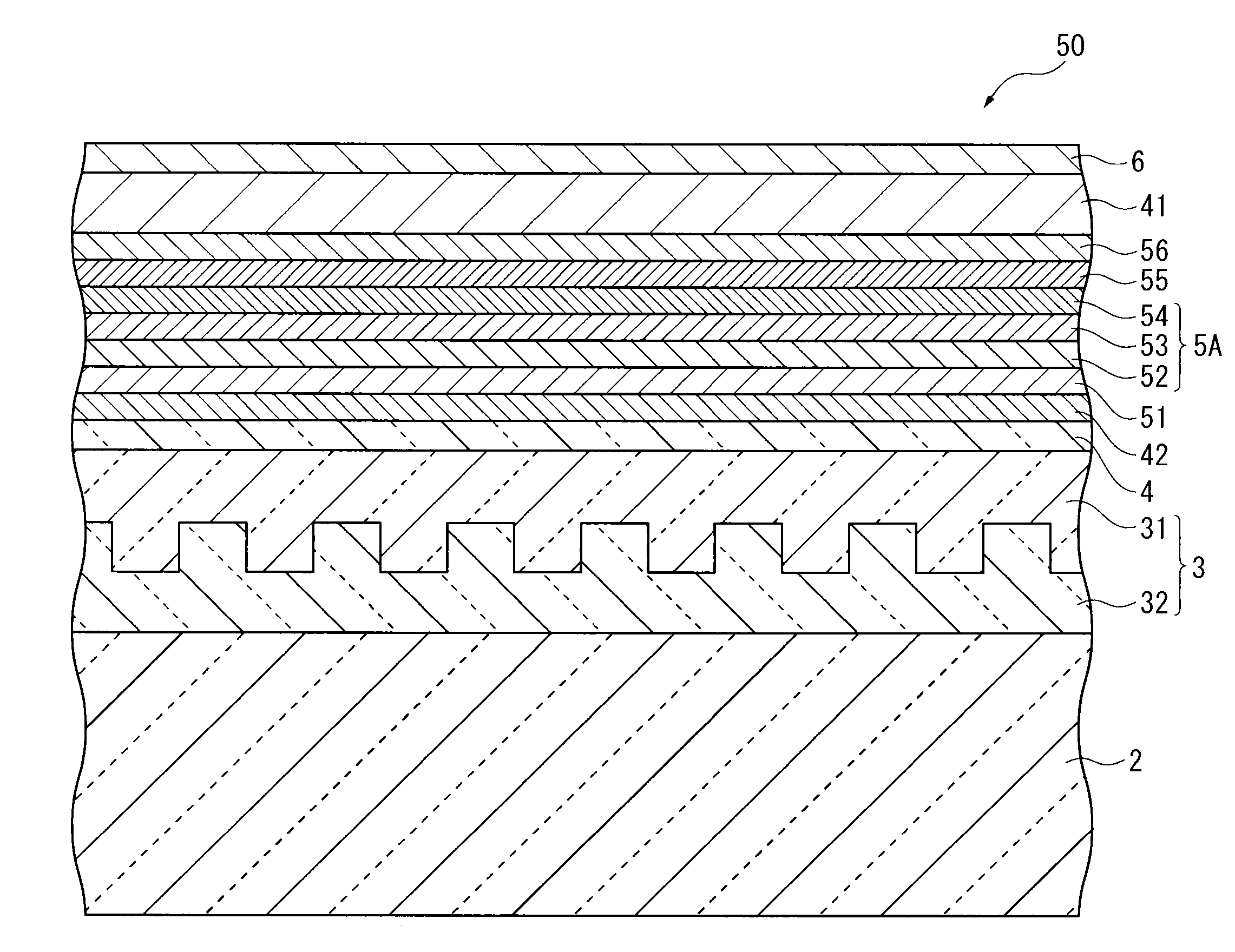

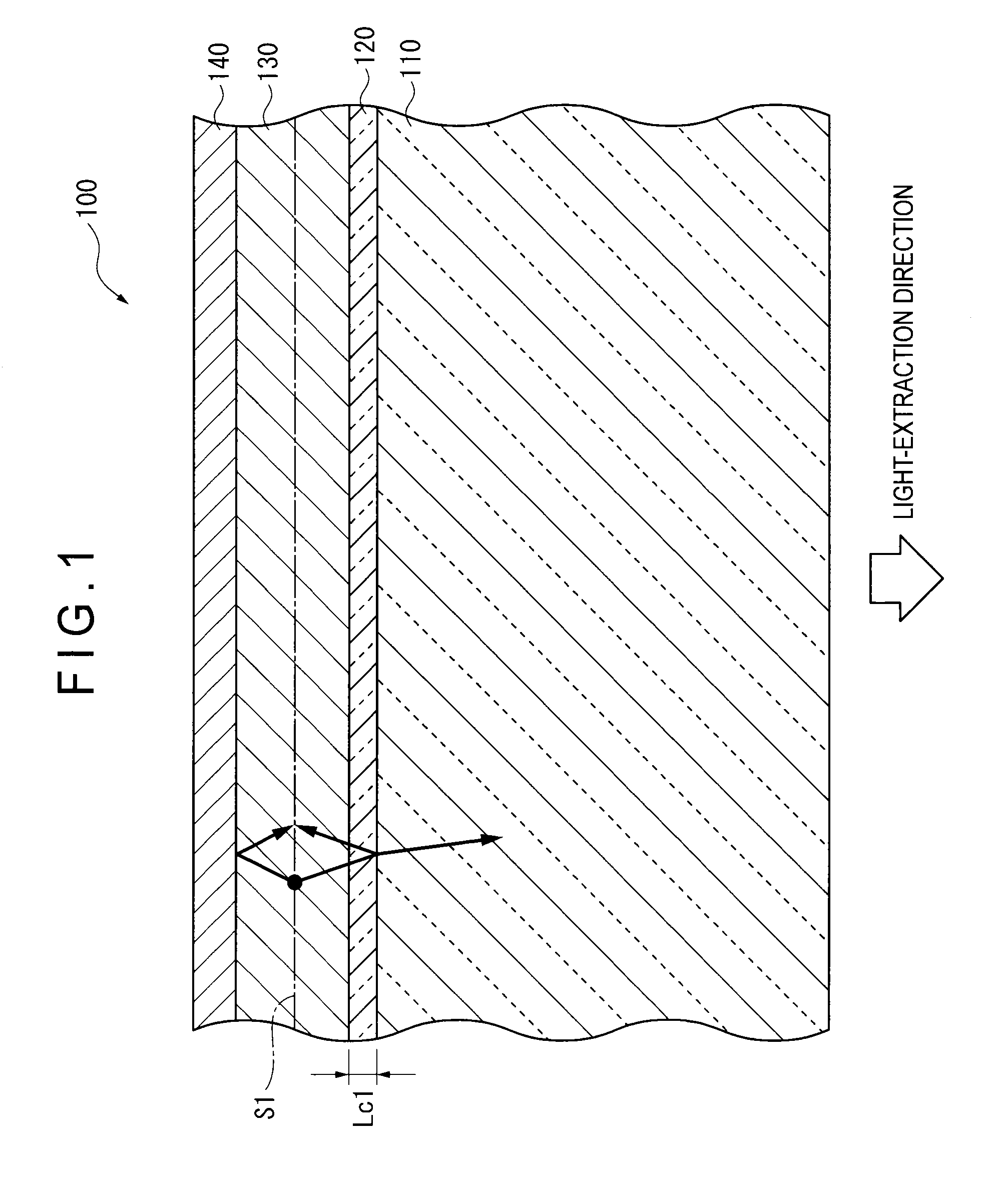

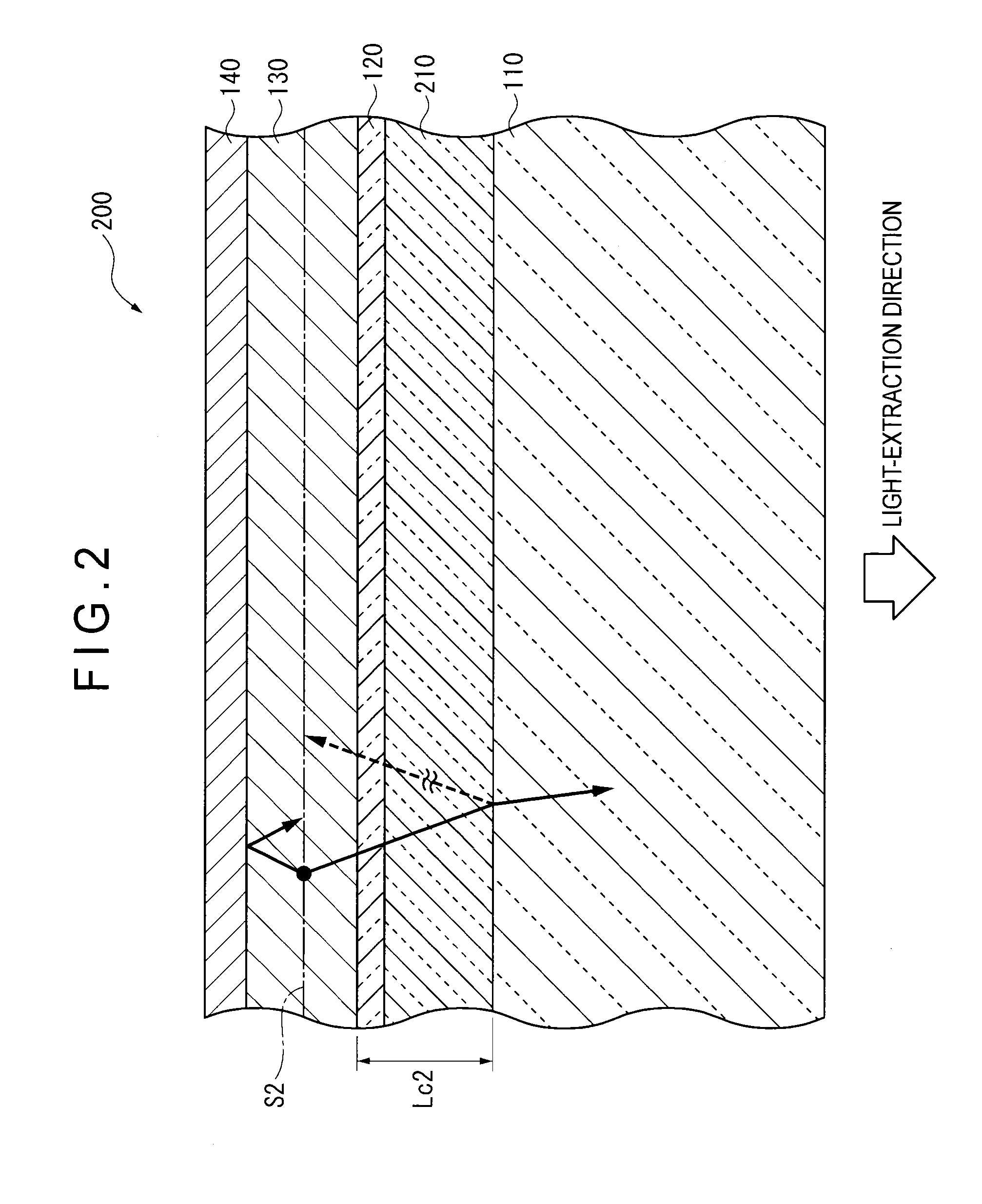

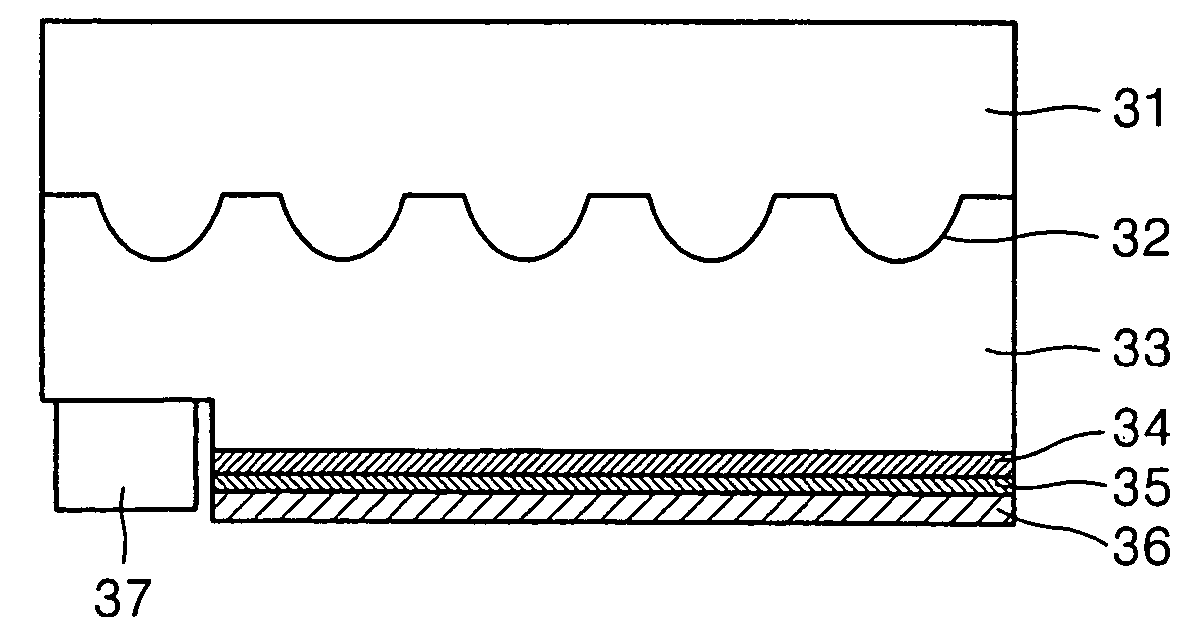

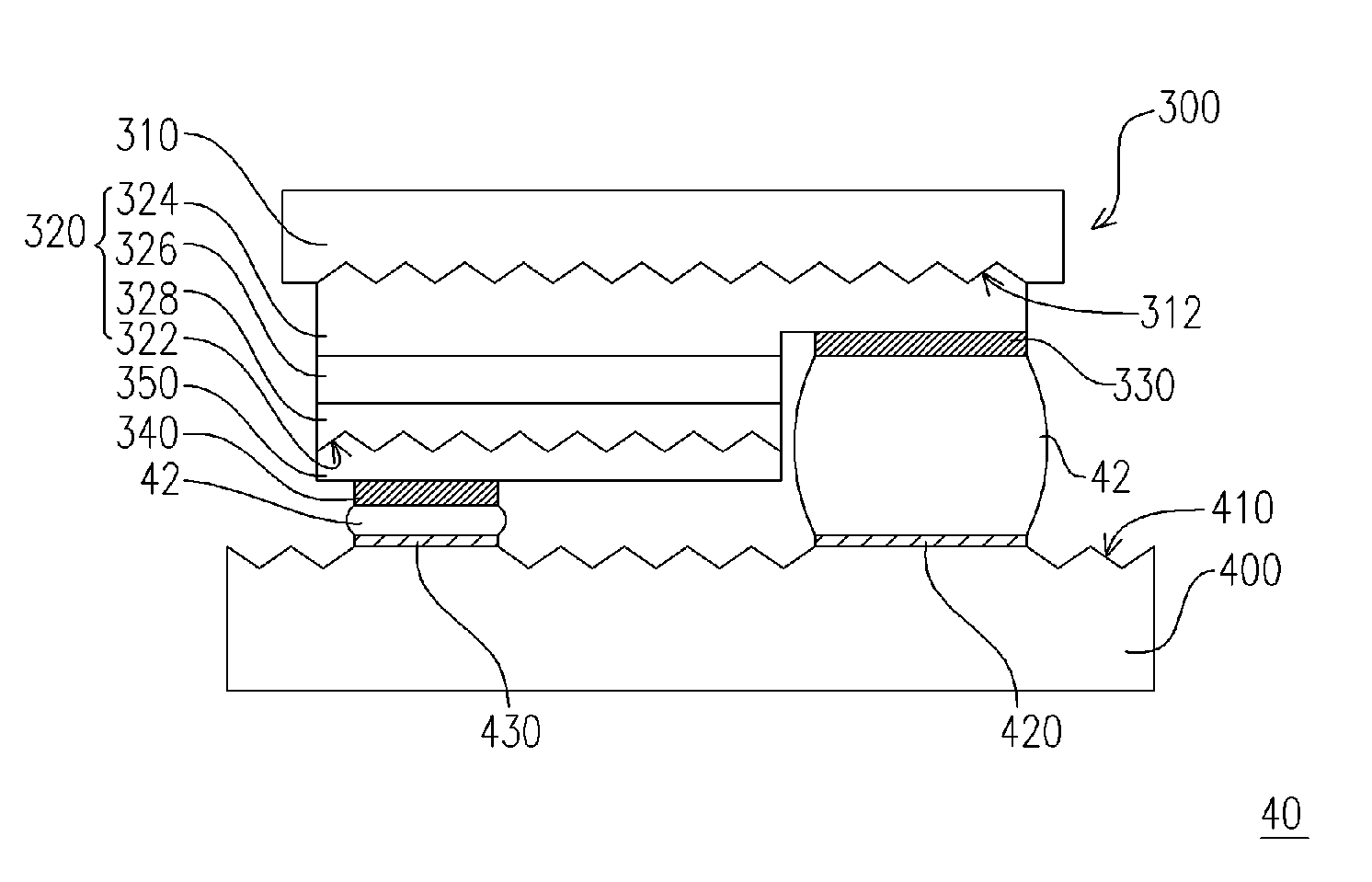

ActiveUS20120286258A1Improve efficiencyIncrease brightnessElectroluminescent light sourcesSolid-state devicesRefractive indexOrganic electroluminescence

An organic EL device (1) comprises: a light-transmissive substrate (2); a transparent electrode (4); an organic emitting layer (5); and an opposing electrode (6). A light-extraction layer (3) provided by layering a high refractive index layer (31) adjoining the transparent electrode (4) and a low refractive index layer (32) adjoining the light-transmissive substrate (2) includes recess-protrusion units (31A) each provided by a protrusion (311) and a recess (312) at an interface between the high refractive index layer (31) and the low refractive index layer (32). In at least one of the recess-protrusion units (31A), a distance d1 from the interface between the high refractive index layer (31) and the low refractive index layer (32) to an interface between the transparent electrode (4) and the high refractive index layer (31) is equal to or more than an optical coherence length and a height d2 of the protrusion (311), a width d3 of the protrusion (311) and a gap d4 between the protrusion (311) and another protrusion (311) adjoining the protrusion across the recess (312) is 1 μm or more.

Owner:IDEMITSU KOSAN CO LTD

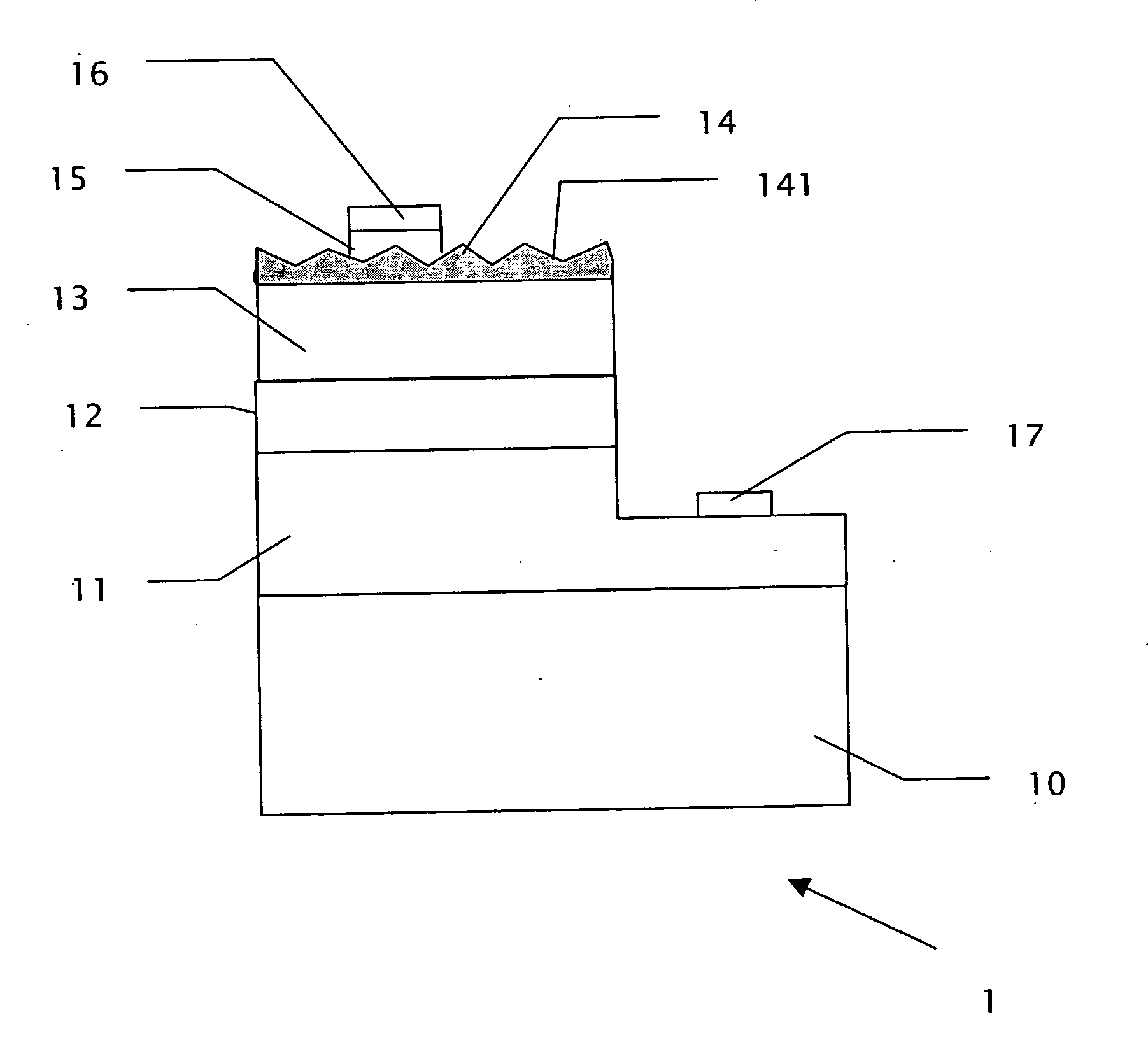

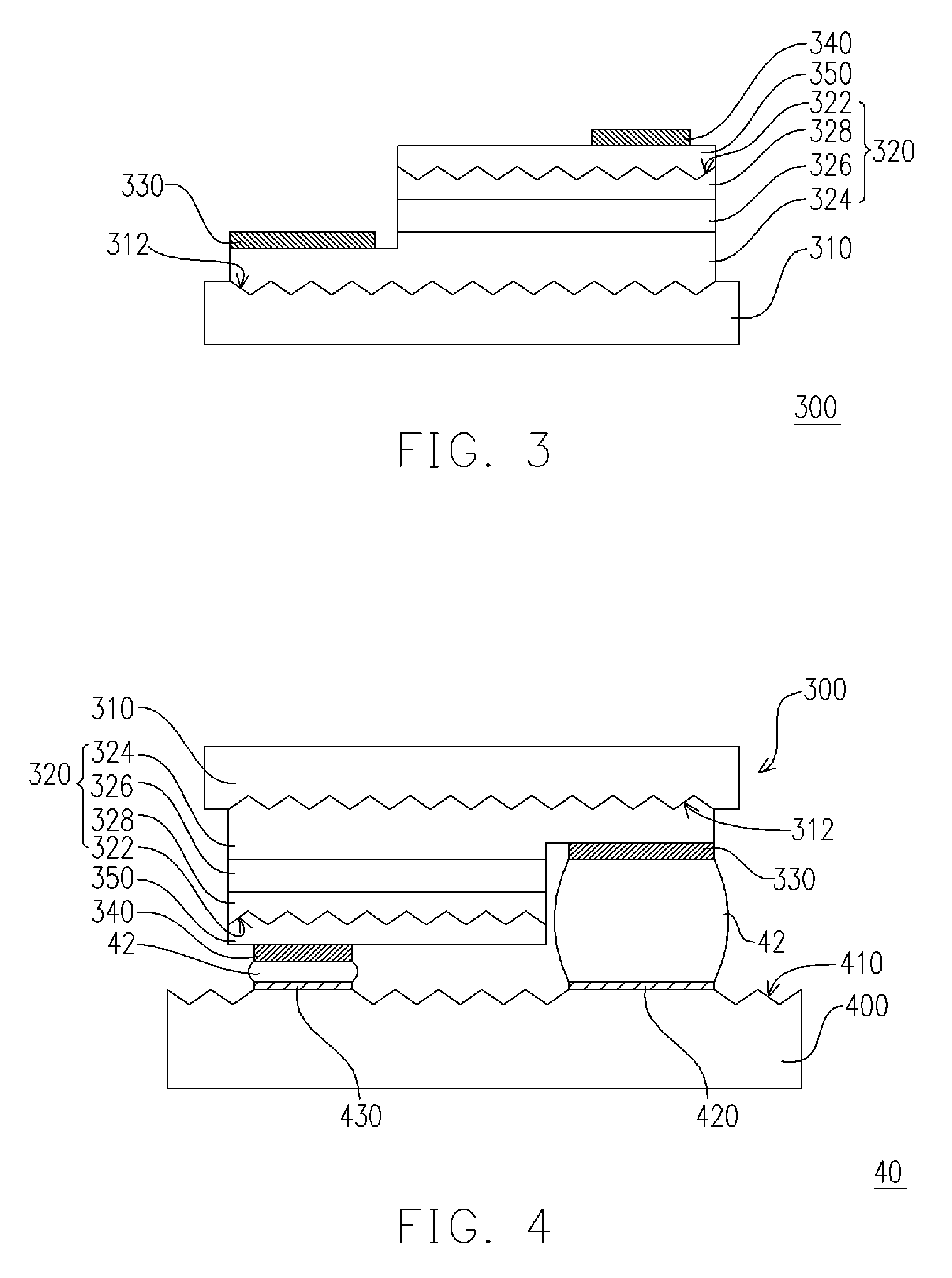

Opposed terminal structure having a nitride semiconductor element

InactiveUS20050035364A1Improve light extraction efficiencyLower resistanceLaser detailsLaser active region structureEngineeringNitride semiconductors

An opposed terminal structure including a supporting substrate, a first terminal, a nitride semiconductor with a light-emitting layer, and a second terminal. The second terminal forms an opposed terminal structure with the first terminal, which can be formed in a variety of patterns.

Owner:NICHIA CORP

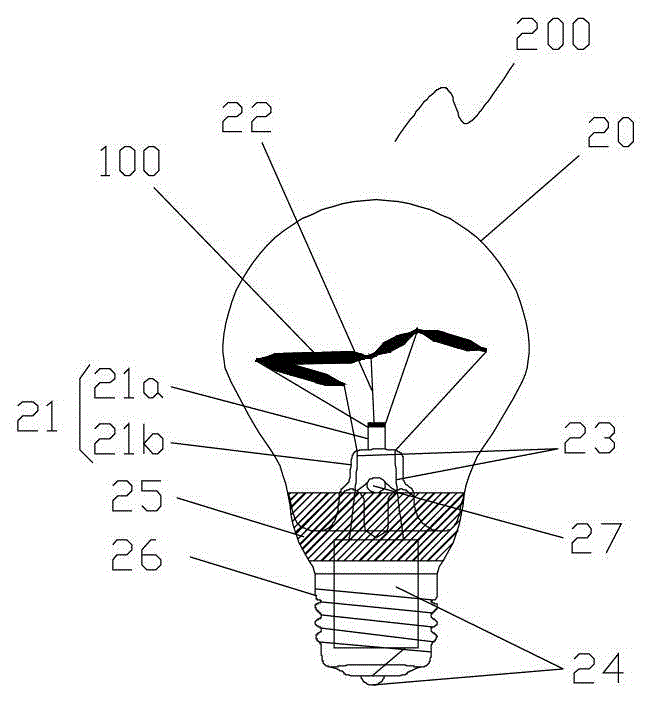

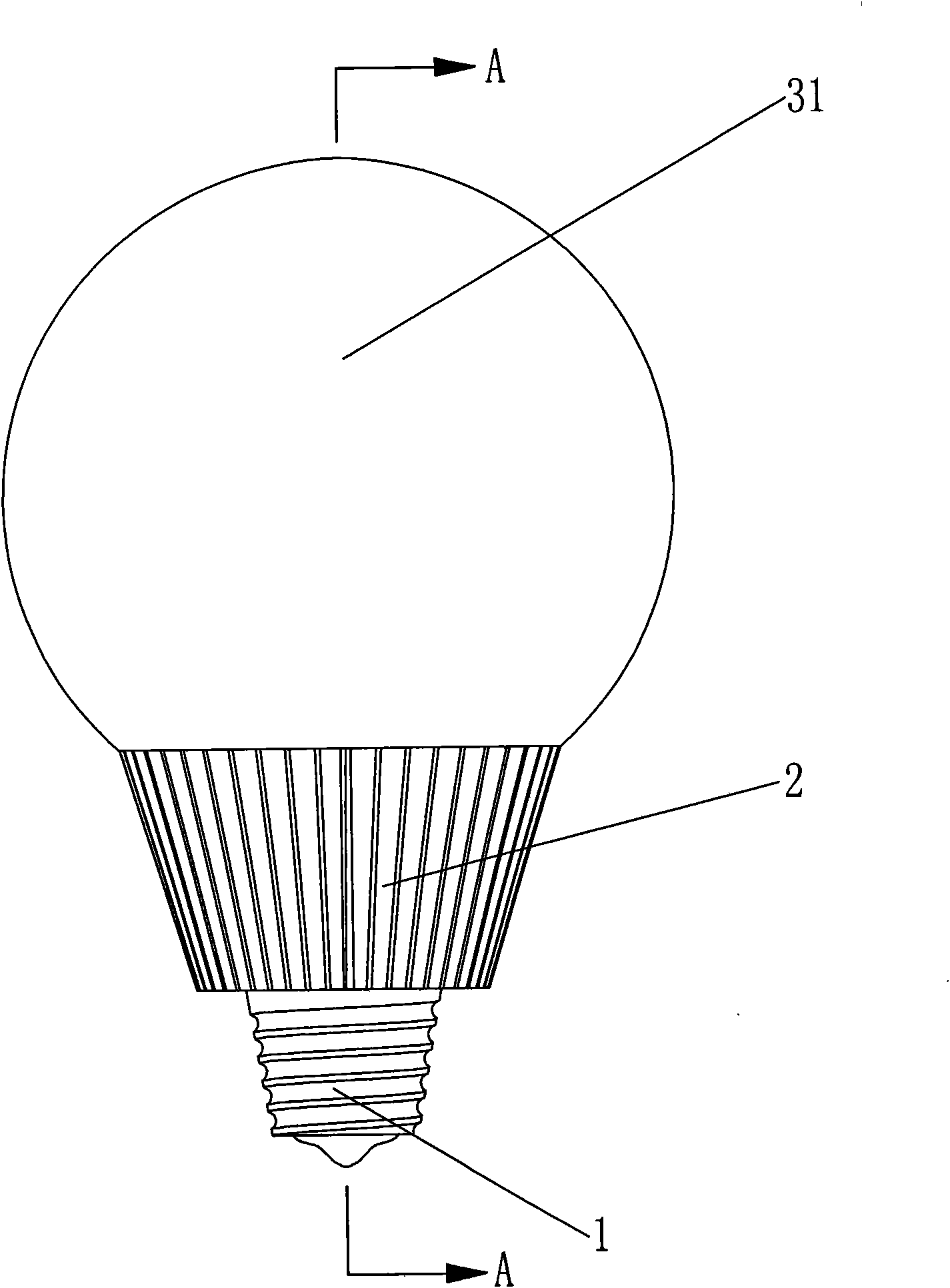

LED lighting device

InactiveCN103939758AImprove aestheticsImprove securityPoint-like light sourceLighting heating/cooling arrangementsEffect lightEngineering

The invention relates to the field of LED lighting, and particularly provides an LED lighting device. The LED lighting device comprises a transparent outer shell, an LED luminescent device and a support, wherein the transparent outer shell and the support form a closed cavity and the LED luminescent device is located inside the cavity and fixed onto the support. The LED lighting device is characterized in that the cavity is filled with inert gas which is used for transmitting heat generated by the LED luminescent device to the outer portion of the transparent outer shell. According to the LED lighting device, through the inert gas arranged in the cavity in a filled mode, the heat generated by the LED luminescent device can be transmitted to the outer portion of the LED lighting device without adopting a heat dissipation body, and therefore the shape, the size and the weight of the LED lighting device cannot be limited by the heat dissipating body. Thus, the attractiveness, the safety and the installation convenience of the LED lighting device can be improved.

Owner:ZHEJIANG ZHONGZHOU LIGHTING TECH

Light-emitting device and method of manufacturing the same

InactiveUS20050082546A1Improve light extraction efficiencyLaser detailsSolid-state devicesStress distributionLight emitting device

Provided is a light-emitting device and a method of manufacturing the same. The light-emitting device includes a substrate having at least one protruded portion with a curved surface in which a consistent defect density and uniform stress distribution can be obtained even when the growth of the semiconductor crystal layer and the forming of the light-emitting device are completed. In addition, the light-emitting device has a high the light extraction efficiency for extracting light generated at an electroluminescense layer externally.

Owner:SAMSUNG ELECTRO MECHANICS CO LTD

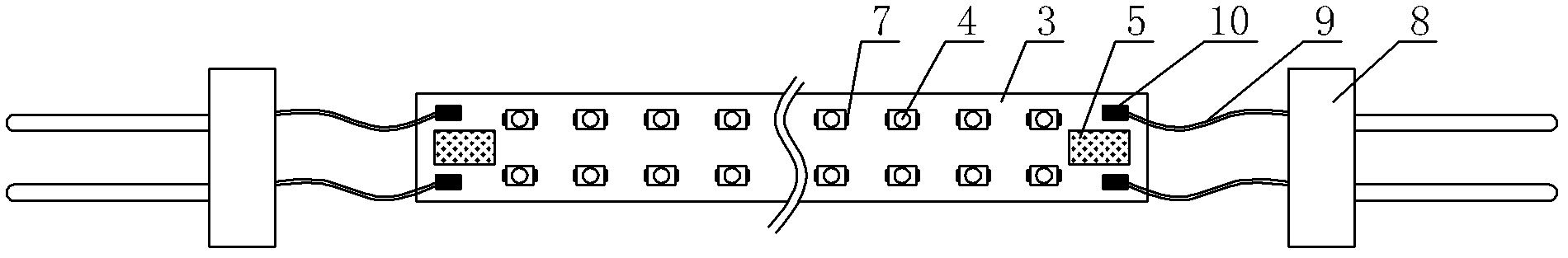

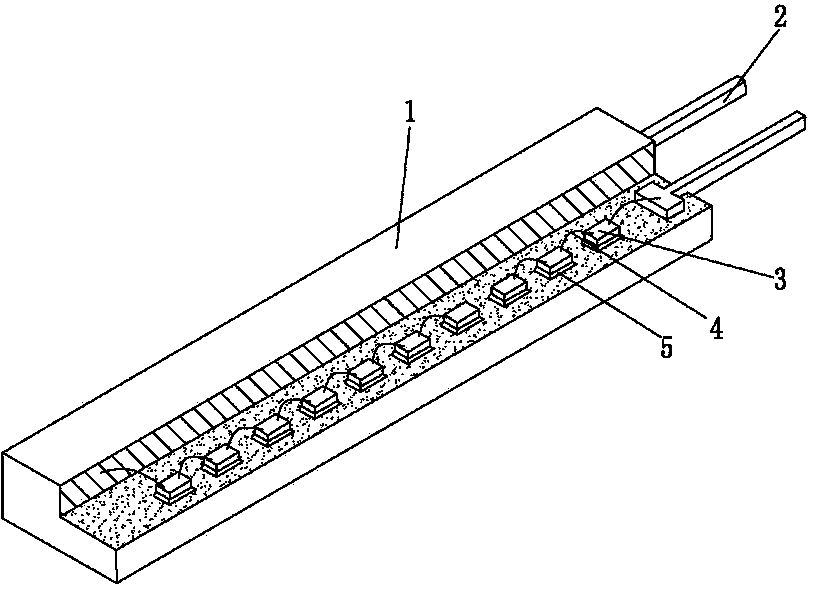

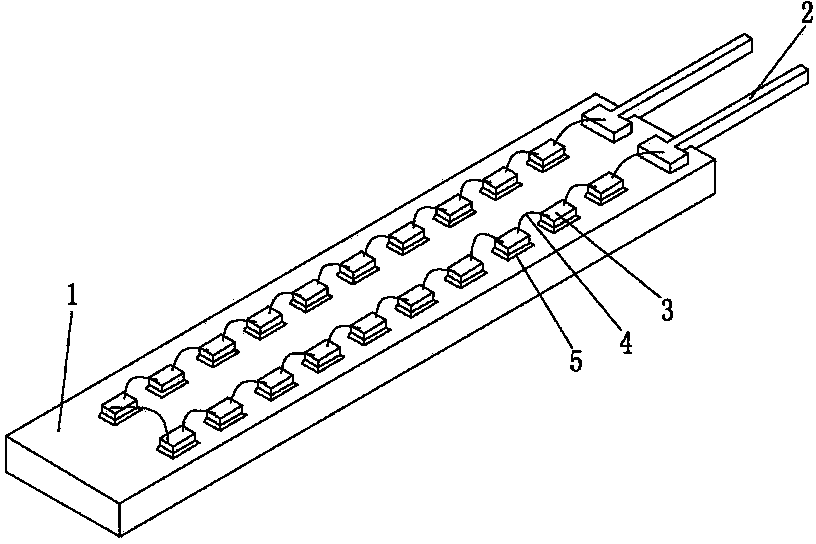

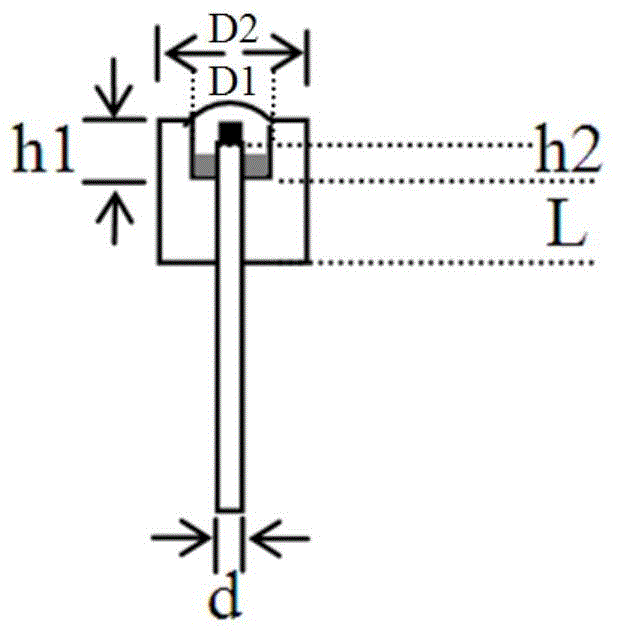

Packaging method of LED filament and LED filament

InactiveCN104319345AEnsure stabilityGuaranteed light transmittanceSemiconductor devicesLED filamentLiquid silicon

The invention discloses a packaging method of an LED filament. The packaging method of the LED filament includes the steps that a liquid silicon resin and fluorescent powder mixture is injected into a mould, and a metal conductive pin is arranged at one end of the silicon resin and fluorescent powder mixture inside the mould; the mould is removed after being heated and solidified, and silicon resin and fluorescent powder colloid with the metal conductive pin at one end is obtained; a plurality of LED chips are installed on the silicon resin and fluorescent powder colloid, and the LED chips are mutually connected through a wire and then connected to the metal conductive pin to form a conductive path; the silicon resin and fluorescent powder colloid with the LED chips is put into the mould, and a liquid silicon resin and fluorescent powder mixture is injected into the mould to cover the LED chips and the wire; the mould is removed after being heated and solidified, and the packaged LED filament finished product with a supporting frame is obtained. The LED filament is packaged without the supporting frame, and the quality problems of low yield, low light transmittance of the supporting frame and the like are resolved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

Method for producing a nitride semiconductor element

InactiveUS6916676B2Improve light extraction efficiencyLower resistanceLaser detailsLaser active region structureNitride semiconductorsMaterials science

Owner:NICHIA CORP

LED (Light Emitting Diode) lamp filament and manufacturing method thereof

ActiveCN104600174AImprove thermal reliabilityMaximum Thermal ReliabilitySemiconductor devicesFluorescenceConductive coating

The invention provides an LED (Light Emitting Diode) lamp filament and a manufacturing method thereof. An LED chip is encapsulated on the edge top surface of a thin and long sheet metal support of the LED filament innovatively, meanwhile the sheet metal is inserted into a preformed transparent plastic model frame to produce a light source, and accordingly the automated continuous production of the LED lamp filament is implemented and the problem of the facing direction strength caused by the too thin and too long metal support is solved due to the transparent plastic model frame; meanwhile the lateral direction strength of the metal support is effectively utilized and accordingly the integral mechanical strength of the LED lamp filament is ensured; the heat dissipation characteristics of the metal is directly utilized, meanwhile the heat dissipation efficiency of the LED chip is maximized through the innovative encapsulation of thermal conductive coatings, and accordingly the problem of a heat dissipation bottleneck of the LED lamp filament is effectively solved, the LED lamp filament can work at the rated power for a long time, and the cost is reduced; the LED light extraction efficiency is improved, the light attenuation is reduced, the high lighting effect and ambient light of lamp filament light emission is implemented, and the market vacancy of the existing LED lamp filament is filled through innovative fluorescence encapsulation materials.

Owner:DONGGUAN RIWEI ELECTRONICS

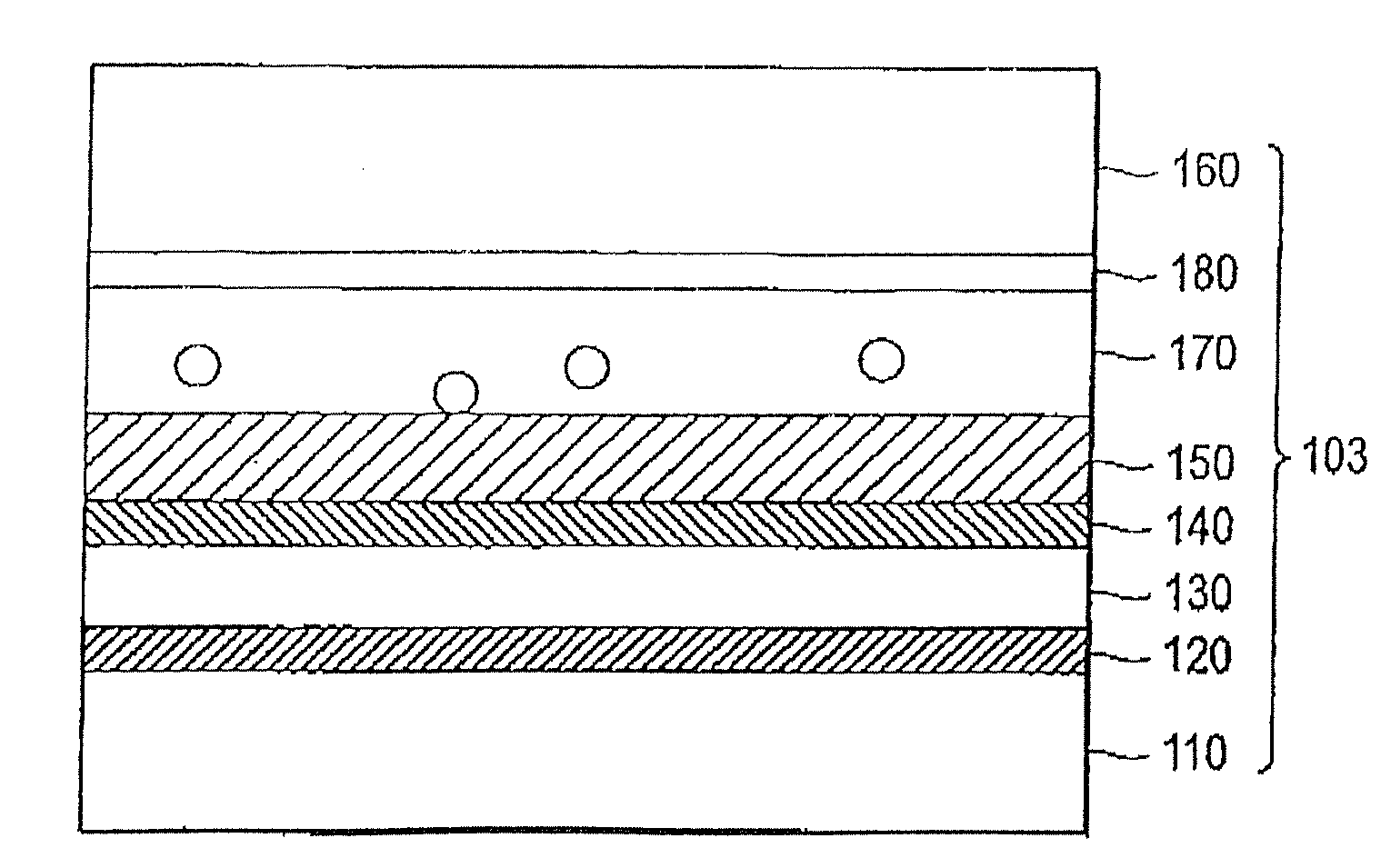

Organic electroluminescent display device having scattering member

InactiveUS20090051278A1Improve light extraction efficiencyReduce image blurDischarge tube luminescnet screensLamp detailsOrganic electroluminescenceMolecular physics

An organic electroluminescent display device includes: a substrate; a lower electrode; an organic electroluminescent layer; and an upper electrode, in this order, wherein the organic electroluminescent display device further comprises a scattering member on or above the upper electrode.

Owner:UDC IRELAND

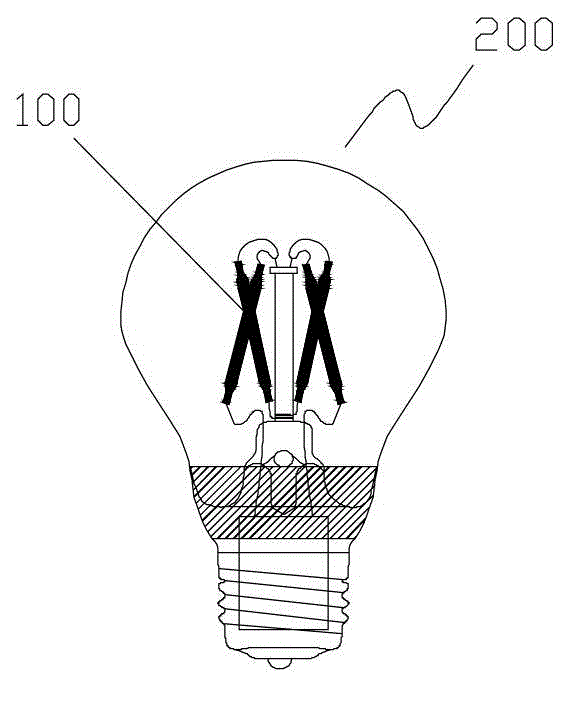

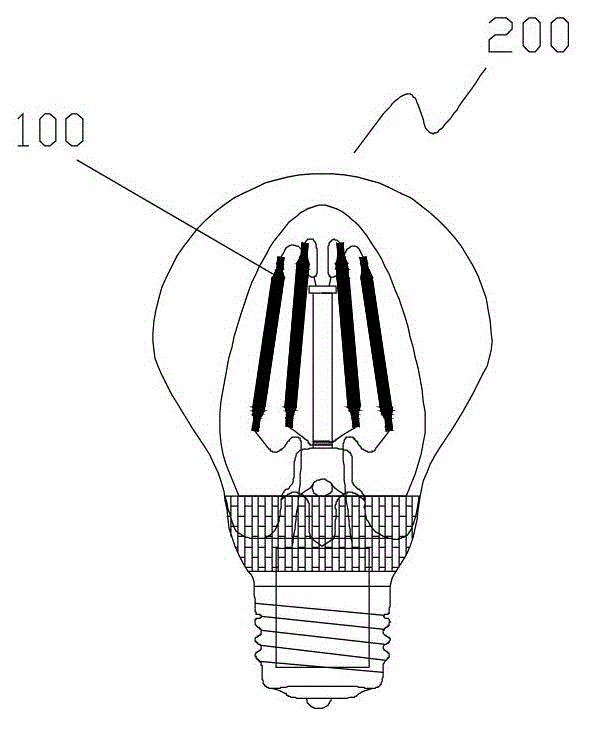

LED (light-emitting diode) lamp and filament thereof

ActiveCN103322525AGood colorIncrease the light output angleLight source combinationsPoint-like light sourceEngineeringSealant

Owner:SHENZHEN RUNLITE TECH

Organic luminescent device with enhanced light extraction efficiency

InactiveCN1498046AImprove light extraction efficiencyPlanar light sourcesPoint-like light sourceOrganic light emitting deviceOrganic layer

An enhanced light extraction OLED device including a transparent substrate; light scattering layer disposed over a first surface of the transparent substrate; a transparent first electrode layer disposed over the light scattering layer; an organic EL element disposed over the transparent first electrode layer and including one or more organic layers but at least one light emitting layer in which light is produced; and a transparent second electrode layer disposed over the organic EL element.

Owner:EASTMAN KODAK CO

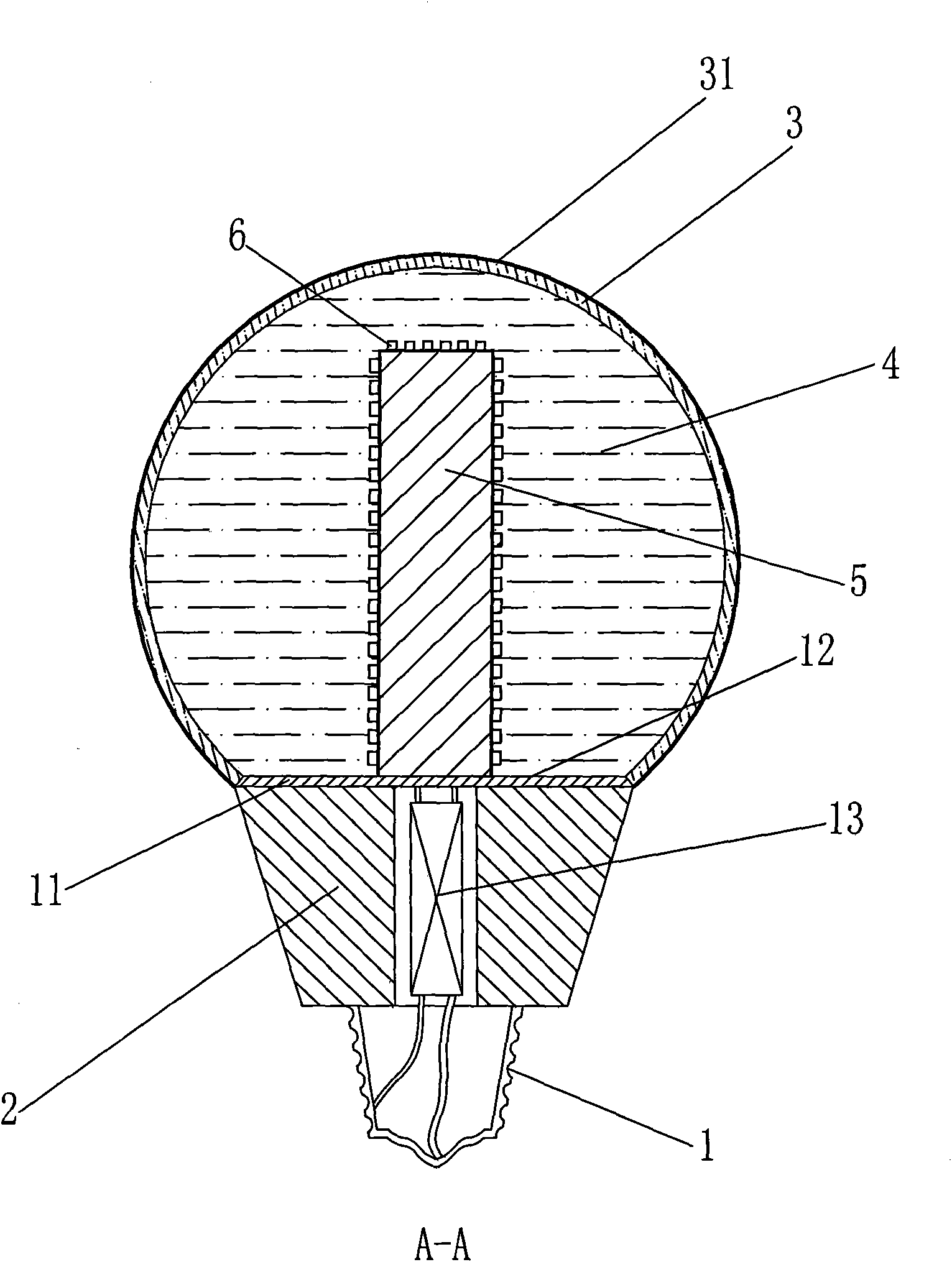

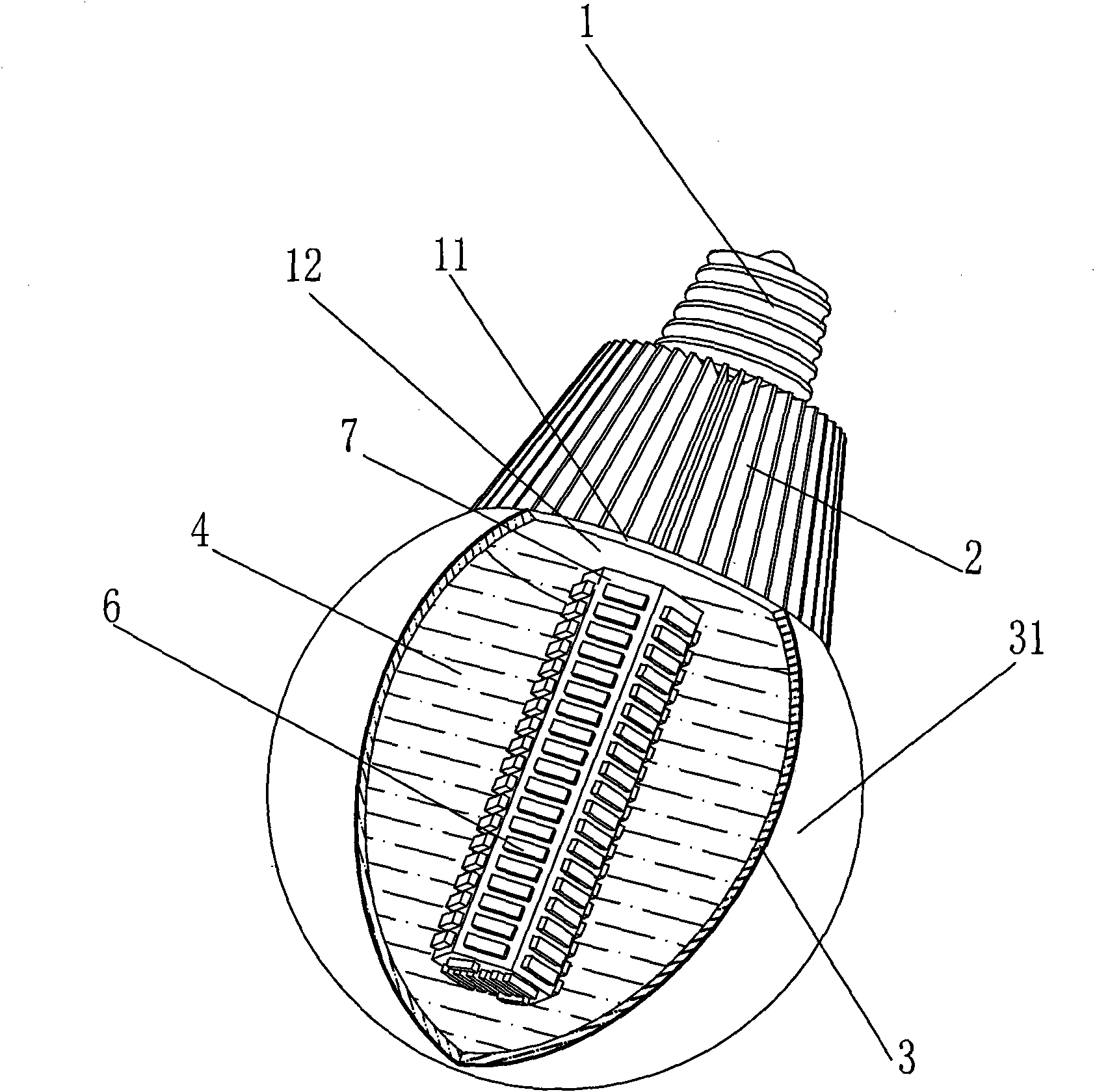

Liquid cooling LED lamp

InactiveCN101666439AReduce heatImprove cooling effectPoint-like light sourceSemiconductor/solid-state device detailsFlexible circuitsHeat conducting

The invention discloses a liquid cooling LED lamp which comprises a lamp seat, a heat abstractor arranged on the lamp seat and a heat conductive column fixed on the heat abstractor, wherein the heat conductive column is wound with a flexible circuit board along the side face and top face thereof, the flexible circuit board is provided with a plurality of LEDs, a transparent outer cover is sheathedat the periphery of the LEDs and fixed on the heat abstractor, and the transparent outer cover and the heat abstractor form a cavity filled with liquid. In the invention, as the cavity formed by thetransparent lamp cover and the heat abstractor is filled with heat conductive liquid, heat generated by the LEDs can be abundantly transmitted to the heat abstractor and the transparent outer cover bythe heat conductive liquid, thus improving the overall radiating effect of the lamp, reducing heat of the LEDs and improving the light emission efficiency. Simultaneously, the LEDs are wound on the side face and the top face of the heat conducting device by the flexible circuit board, thus improving the production efficiency of products and causing the light emission effect of the lamp to be moreeven.

Owner:HE SHAN LIDE ELECTRONICS ENTERPRISE CO LTD

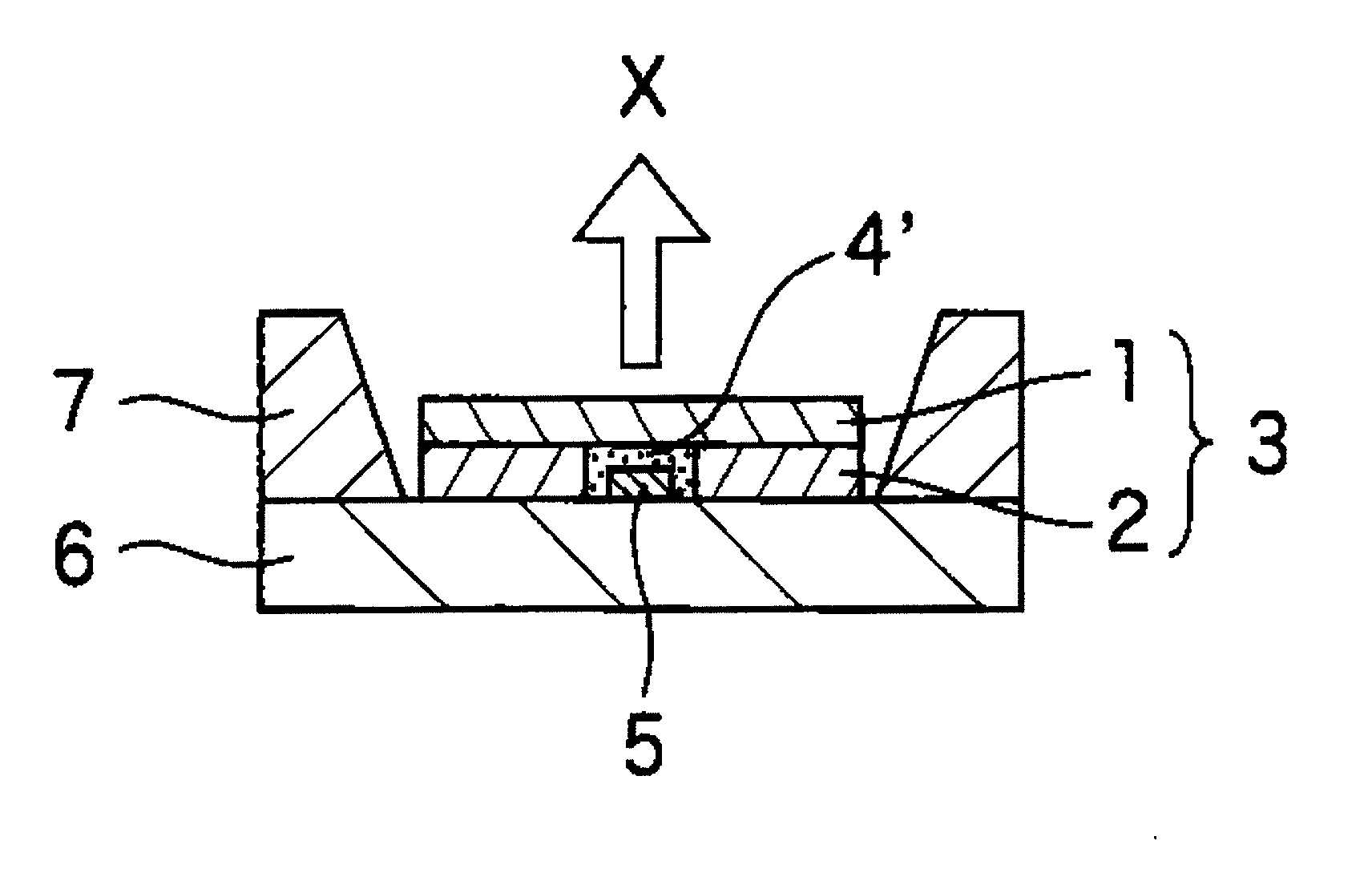

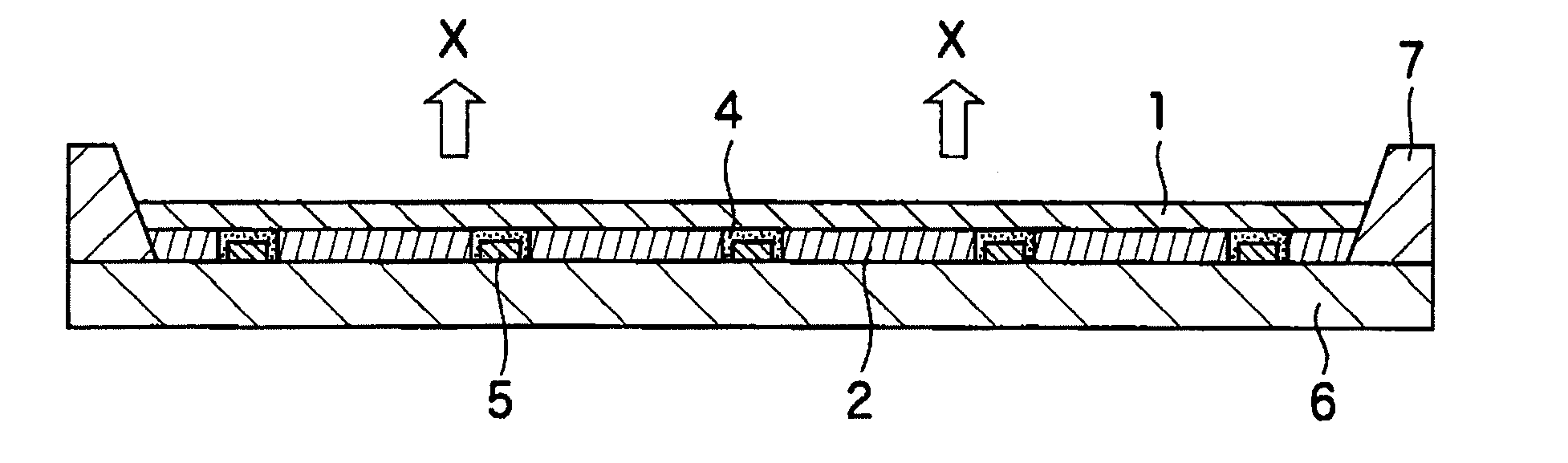

Semiconductor light emitting device

InactiveUS20110309384A1Reduce scatter lightLight extraction efficiency be enhanceSolid-state devicesSemiconductor devicesPhysicsElectricity

The present invention relates to a semiconductor light emitting device including: a substrate for element mounting; a wiring provided on the substrate; an LED element provided on the substrate and electrically connected to the wiring; an encapsulating resin layer for encapsulating the LED element; and a wavelength conversion layer which contains a phosphor material and converts a wavelength of light emitted by the LED element, in which the wavelength conversion layer is provided on an upper side of the LED element, and a diffusive reflection resin layer is provided in a state that side faces of the LED element are surrounded therewith, and an area at the LED element face side of the wavelength conversion layer is at least twice larger by area ratio than an area of light emitting area on an upper surface of the LED element.

Owner:SCHOTT AG

Gallium nitride-based compound semiconductor light-emitting device

ActiveUS20090078951A1Light extraction efficiencyHigh crystallinitySemiconductor devicesGallium nitrideLight emitting device

An object of the present invention is to provide a gallium nitride-based compound semiconductor light-emitting device having a reflective positive electrode configured to achieve excellent light extraction efficiency.The inventive gallium nitride-based compound semiconductor light-emitting device has a gallium nitride-based compound semiconductor layer structure comprising an n-type semiconductor layer, a light-emitting layer and a p-type semiconductor layer, on a substrate, wherein a positive electrode provided on the p-type semiconductor layer is a reflective positive electrode comprising a transparent material layer and a reflective metal layer formed on the transparent material layer.

Owner:TOYODA GOSEI CO LTD

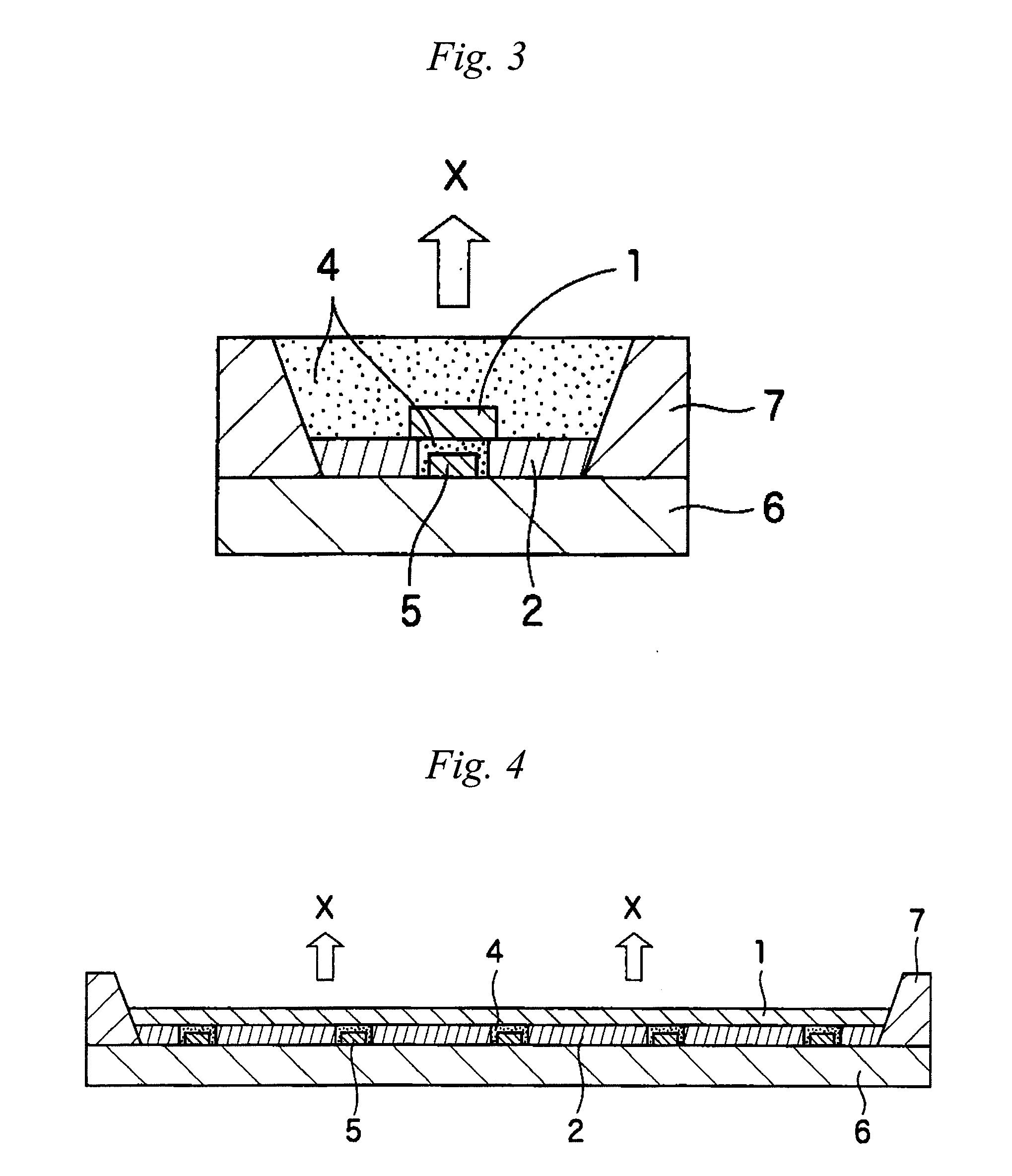

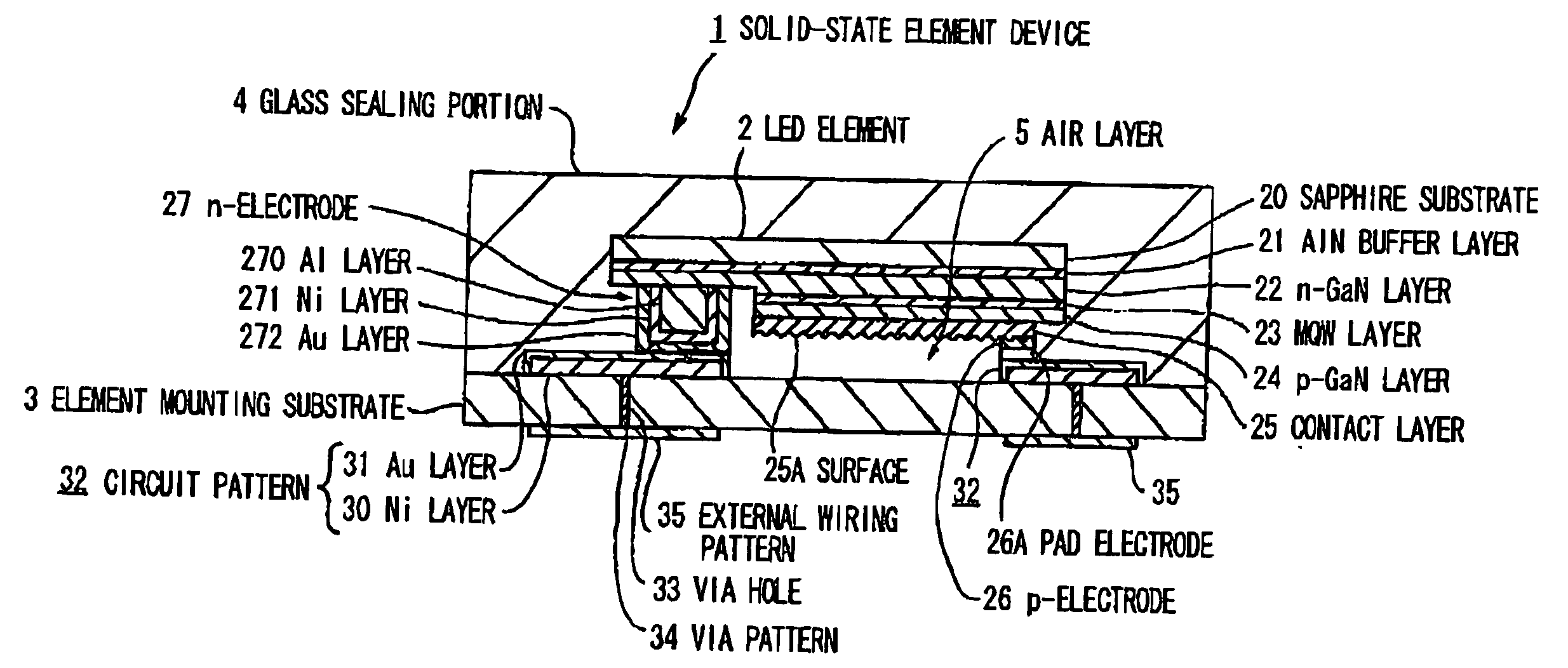

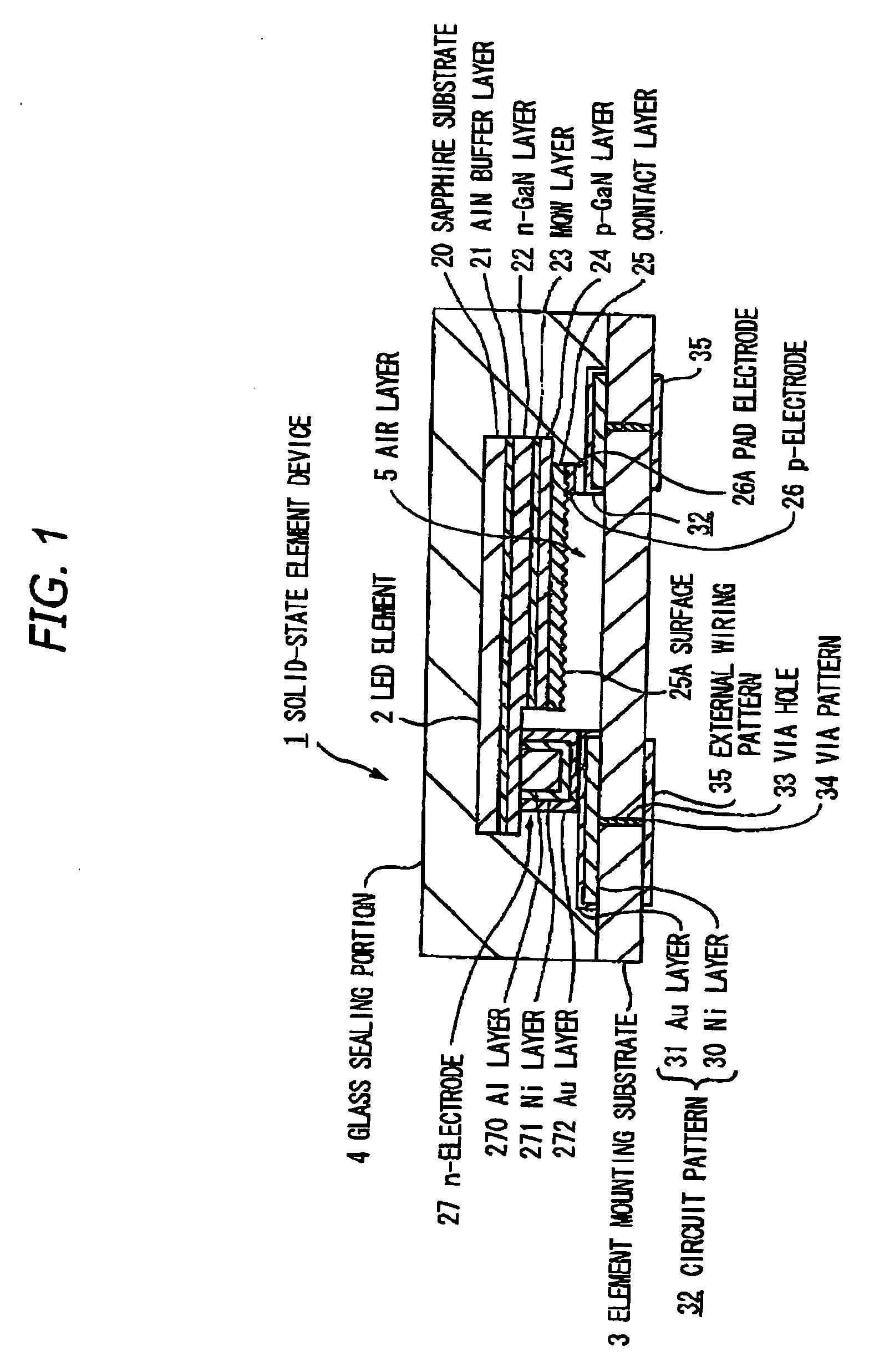

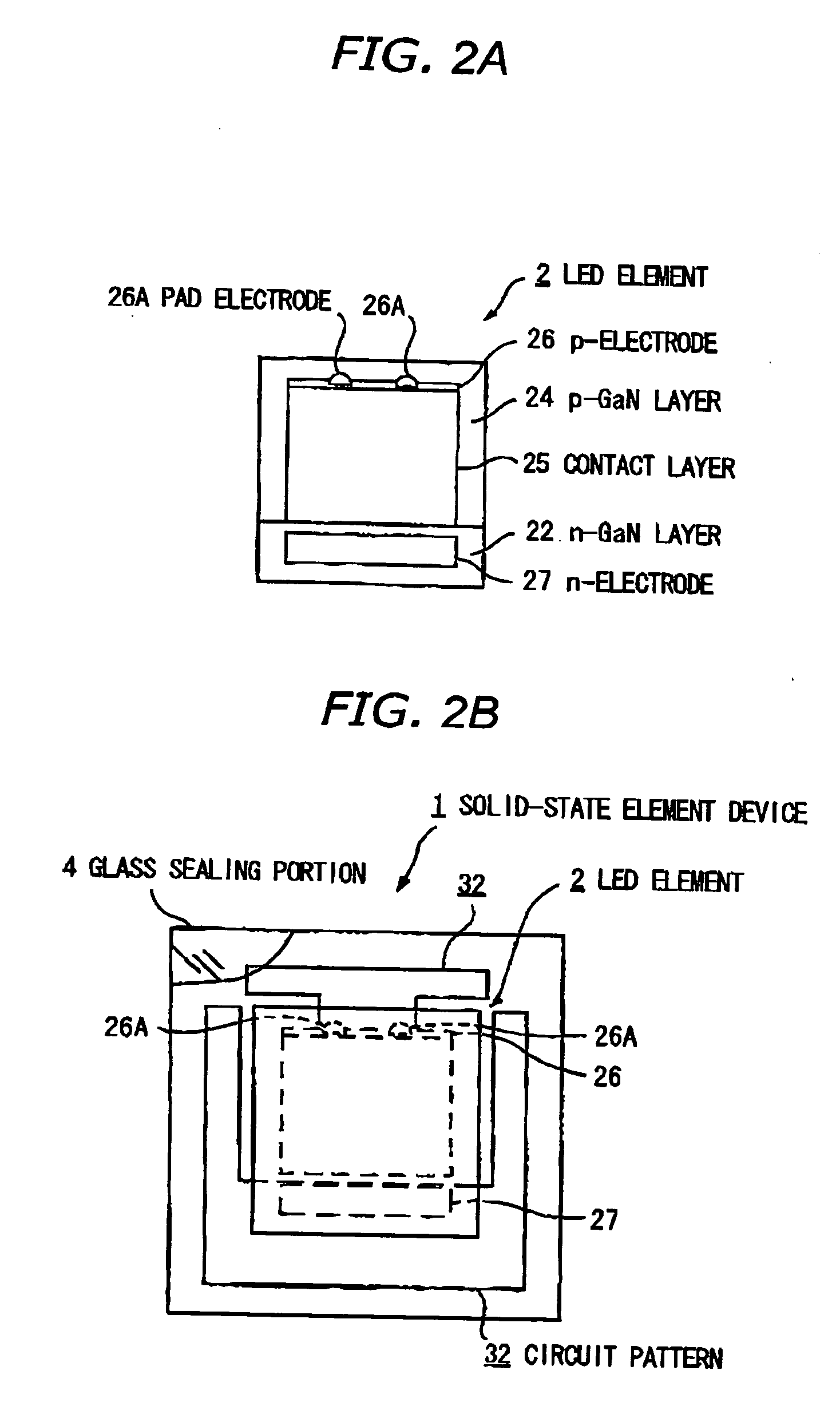

Solid-state element device

ActiveUS20070058059A1Avoid separationImprove light extraction efficiencyTelevision system detailsTelevision system scanning detailsElectric forceEngineering

A solid-state element device having: a solid-state element having a pad electrode smaller than a contact electrode, the solid-state element being flip-mounted; a power receiving / supplying portion for receiving / supplying a power, the power receiving / supplying portion being bonded to the solid-state element such that an element mounting surface thereof is nearly flush with a mounting surface of the solid-state element; and an inorganic sealing portion for sealing the solid-state element formed of an inorganic sealing material and a thermal expansion coefficient equal to that of the power receiving / supplying portion. The inorganic sealing portion defines an air layer between the solid-state element and the power receiving / supplying portion.

Owner:TOYODA GOSEI CO LTD

Light-emitting apparatus

InactiveUS20070200493A1Improve light extraction efficiencyReduce light areaDischarge tube luminescnet screensLamp detailsAdhesion strengthLight emitting device

The light-emitting apparatus comprises a substrate, a first semiconductor layer formed on the substrate, a light-emitting layer formed on the first semiconductor layer, a second semiconductor layer formed on the light-emitting layer, a first transparent conductive oxide layer formed on the second semiconductor layer, a reflective metal layer form on the transparent conductive oxide layer, and a first electrode formed on the reflective metal layer; characterized in that the first transparent conductive oxide layer is formed with a plurality of cavities on the interface between the first transparent conductive oxide layer and the reflective metal layer for improving the adhesion strength therebetween.

Owner:EPISTAR CORP

Scattering member and organic electroluminescent display device using the same

InactiveUS20090052195A1Improve light extraction efficiencyReduce image blurDischarge tube luminescnet screensSemiconductor/solid-state device testing/measurementOrganic electroluminescenceMolecular physics

A scattering member includes: a binder; and a light scattering particle, wherein the scattering member is used for an organic electroluminescent display device; and an organic electroluminescent display device uses the scattering member.

Owner:FUJIFILM CORP

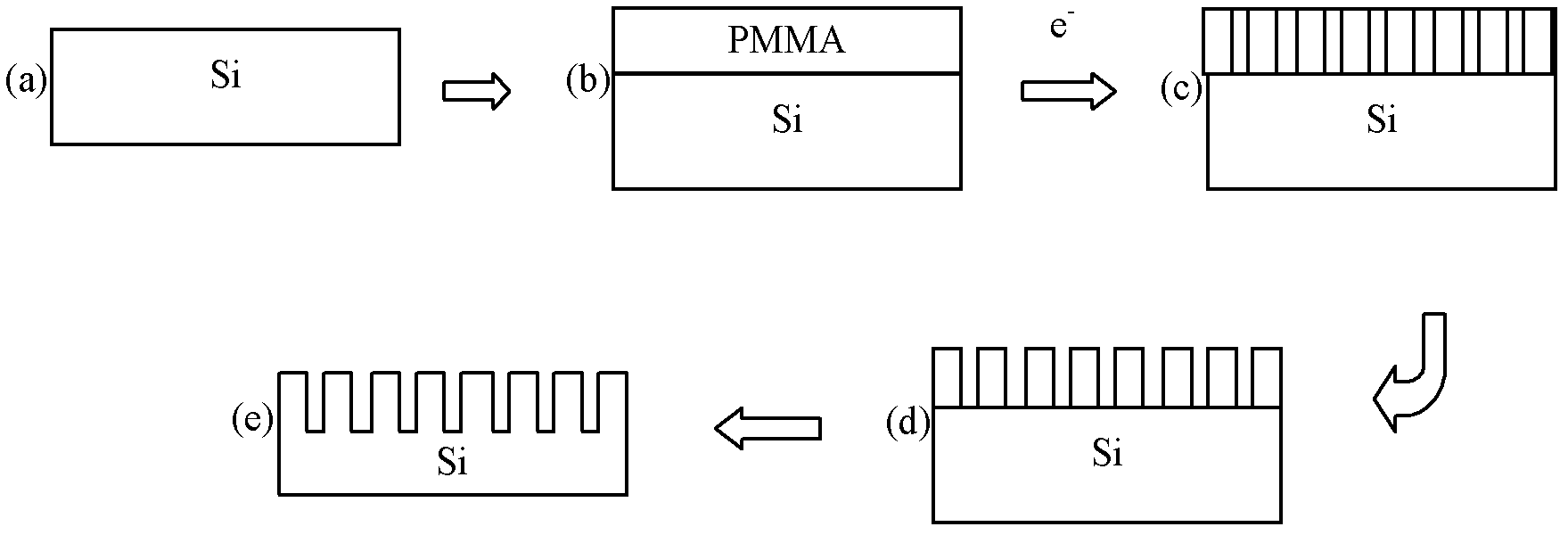

Method for improving luminous efficiency of GaN based LED by using graphic underlay

InactiveCN101345274AImprove luminous efficiencyQuality improvementSemiconductor devicesGraphicsNucleation

The invention provides a method which uses a graphic substrate to improve the illumination efficiency of a GaN-based efficiency, comprising the steps as follows: a silicon dioxide film is deposited on a sapphire substrate; a photoresist graphic array is optically etched; the photoresist graphic array is taken as a mask so as to etch the silicon dioxide film with the graphic structure; the silicon dioxide film with the graphic structure is taken as a mask so as to etch the sapphire substrate and the graphics is etched onto the sapphire substrate; the sapphire substrate is thoroughly cleaned so as to form a pyramid structure with triangular sections; a low-temperature nucleation layer grows on the graphic sapphire substrate; temperature is continuously increased on the low-temperature nucleation layer so as to grow an n-typed mixed GaN layer and an array structure which has low dislocation density and V-shaped holes on the surface; a multiple quantum well layer and a p-typed material layer required when the LED structure material grows continue to grow; furthermore, the final surface is led to still have the array structure with V-shaped holes.

Owner:YANGZHOU ZHONGKE SEMICON LIGHTING

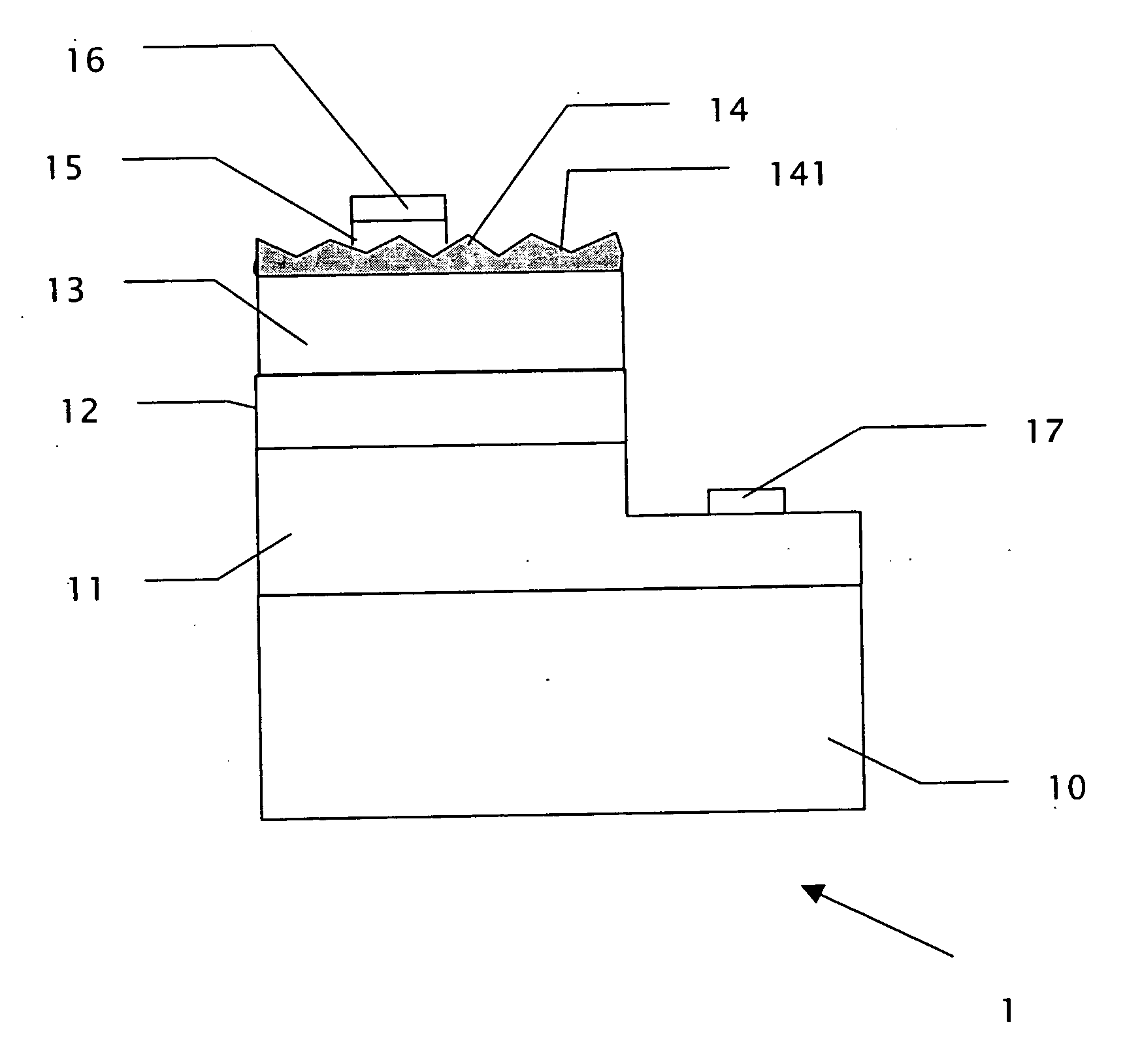

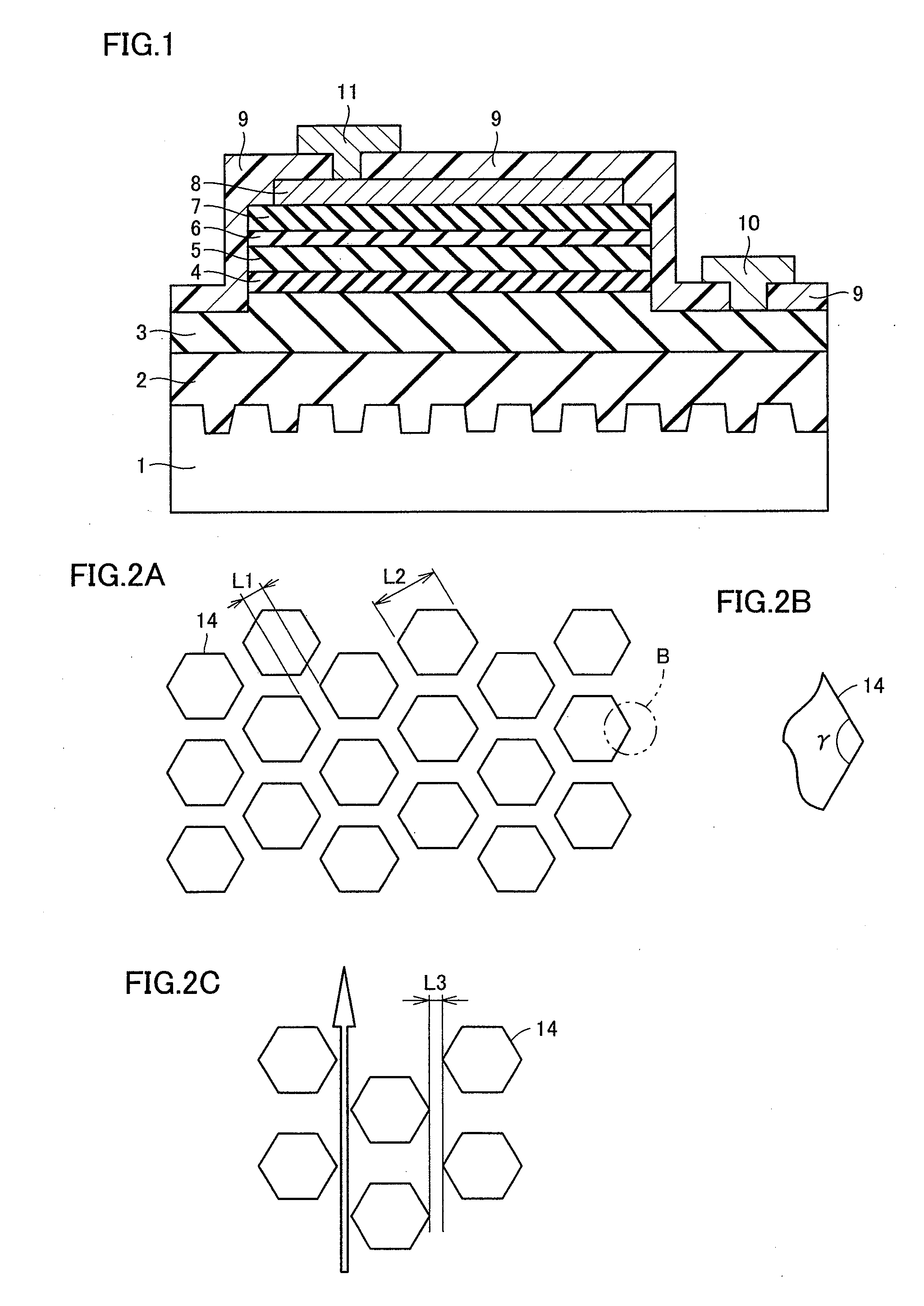

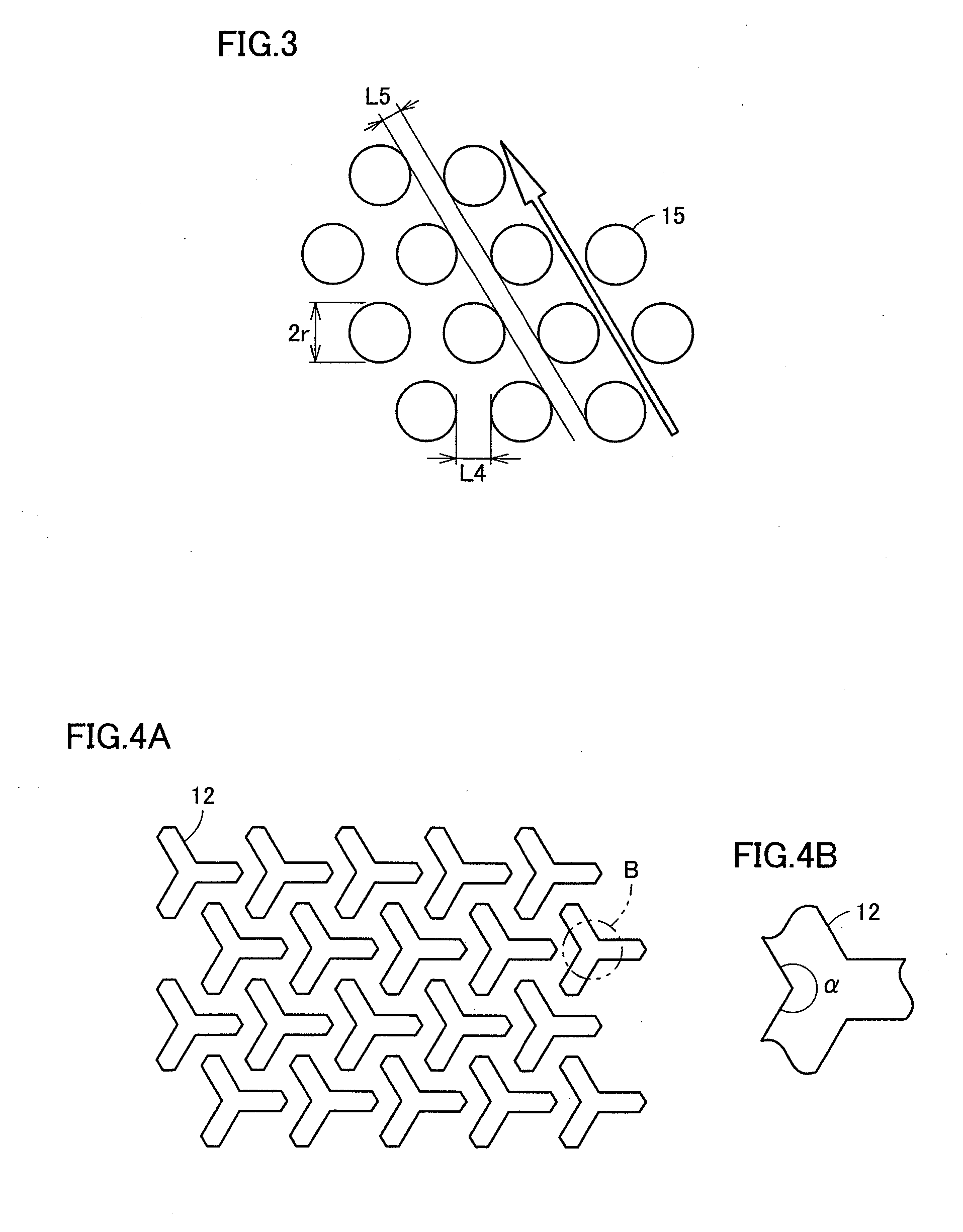

Nitride semiconductor light emitting element

ActiveUS20100163901A1High densityImprove extraction efficiencySemiconductor/solid-state device manufacturingSemiconductor devicesNitride semiconductors

In a nitride semiconductor light emitting element, a light transmitting substrate has an upper surface on which a nitride semiconductor layer including at least a light emitting layer is formed. On the upper surface of the light transmitting substrate, recess regions and rise regions are formed. One of each of the recess regions and each of the rise regions is formed by a polygon having at least one apex having an interior angle of 180° or greater when viewed in a planar view. The other of each of the recess regions and each of the rise regions is formed not to be connected to one another in a straight line when viewed in a planar view. A nitride semiconductor light emitting element having such a configuration has excellent light extraction efficiency and can be manufactured at a moderate cost.

Owner:SHARP KK

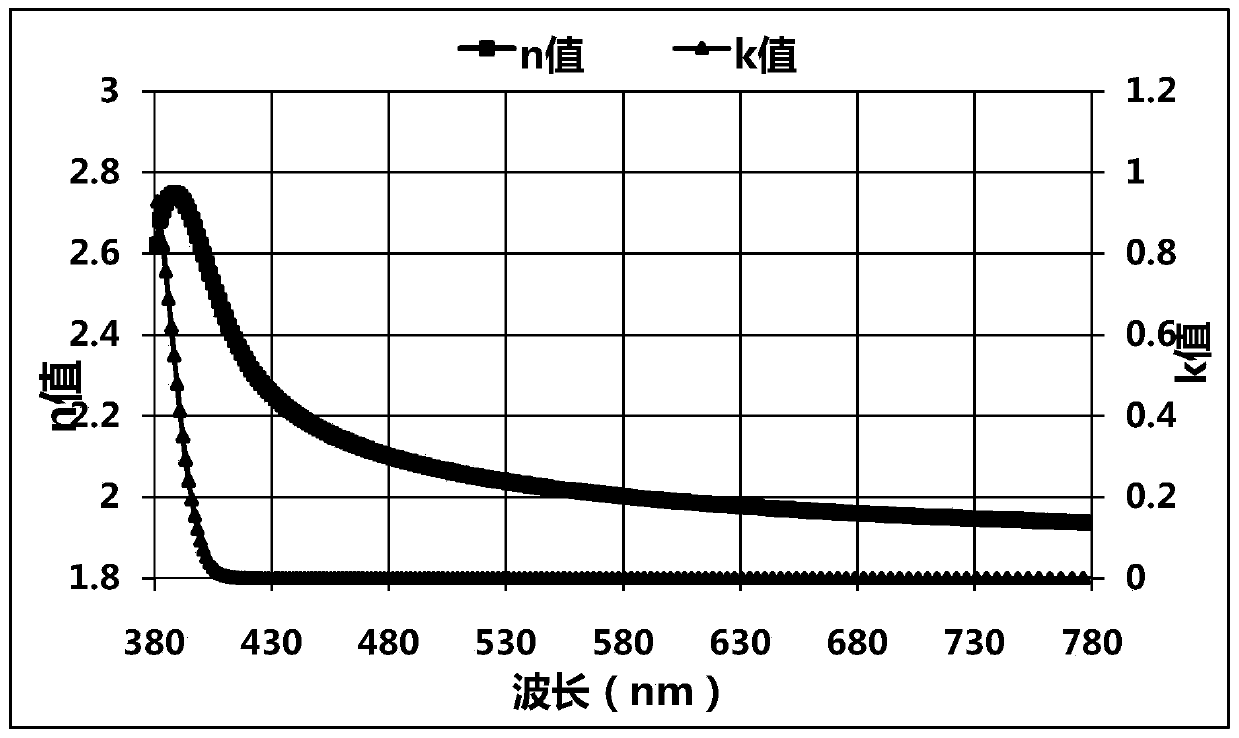

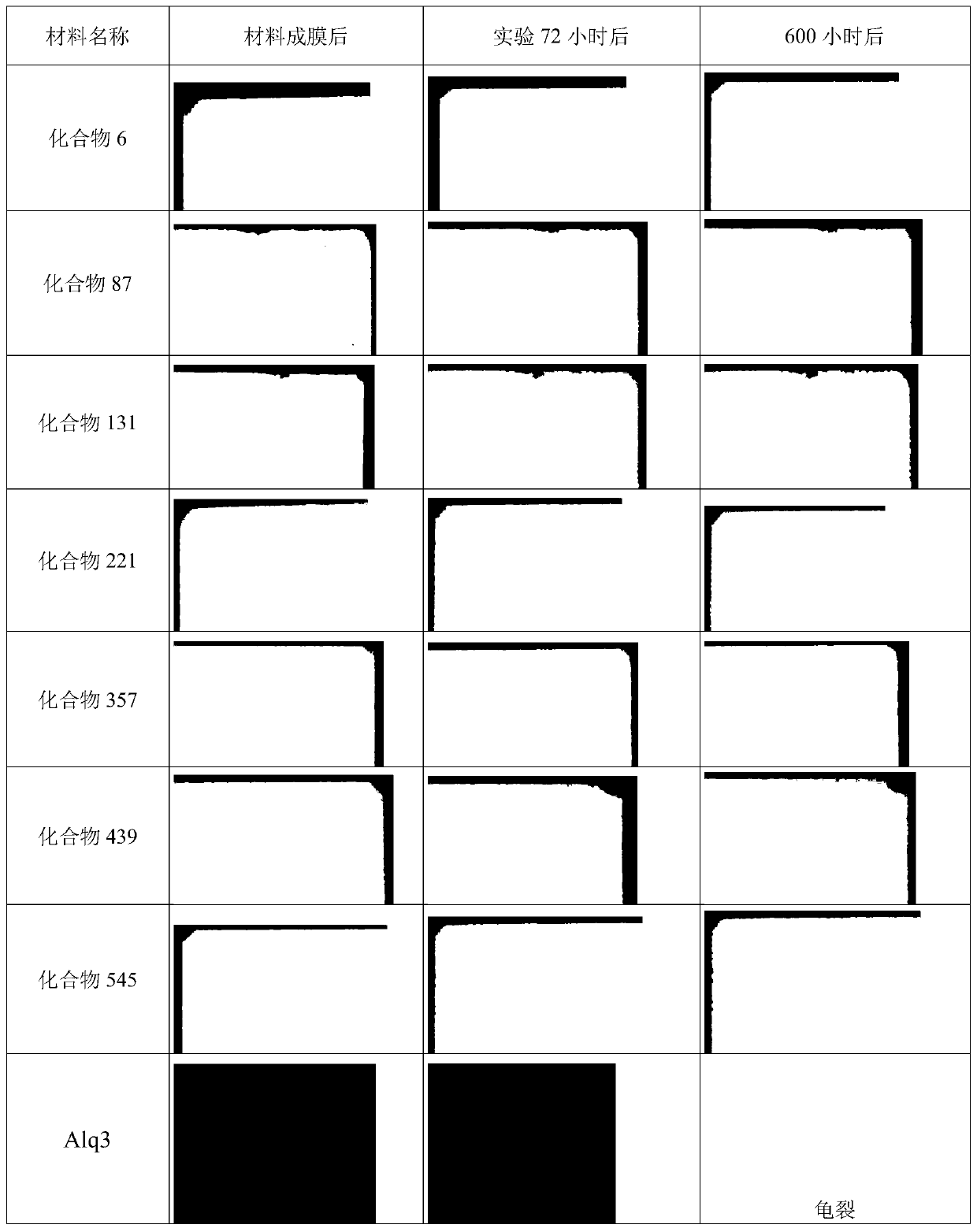

Organic compound based on heteroaryl amine structure and application thereof to OLED (Organic Light Emitting Diode)

ActiveCN109761967AImprove stabilityHigh refractive indexOrganic chemistrySolid-state devicesFlexible organic light-emitting diodeAryl

The invention discloses an organic compound based on heteroaryl amine structure and application thereof to an OLED (Organic Light Emitting Diode). The compound structurally contains heteroaryl and benzo-heteroaryl amine structures at the same time, has relatively shallow LUMO energy stage, relatively high glass transition temperature and molecular thermal stability; the absorption in the visible light field is low; the refractive index is high; after the organic compound is applied to the CPL layer of the OLED device, the light extraction efficiency of the OLED device can be effectively improved.

Owner:JIANGSU SUNERA TECH CO LTD

Light-emitting diode package

InactiveUS20070272930A1Improve light extraction efficiencyEffective lightingSolid-state devicesSemiconductor devicesRough surfaceContact pad

A light-emitting diode package (LED package) includes a LED and a carrier. The LED includes a substrate, a semiconductor layer, a first electrode and a second electrode. The semiconductor layer is located on a surface of the substrate and has a rough surface. The semiconductor layer includes a first-type doped semiconductor layer, a second-type doped semiconductor layer and a light-emitting layer disposed between the two doped semiconductor layers. The first electrode and the second electrode are disposed on and electrically coupled the first-type doped semiconductor layer and the second-type doped semiconductor layer, respectively. The carrier has a rough carrying surface and includes a first contact pad and a second contact pad disposed on the rough carrying surface. The first electrode and the second electrode of the LED face the carrier and are electrically coupled to the first contact pad and a second contact pad, respectively.

Owner:EPISTAR CORP

Light-emitting element and display device

InactiveUS7202504B2Improve reliabilityImprove light extraction efficiencyStatic indicating devicesElectroluminescent light sourcesStress relievingDisplay device

There has been a problem that difference in refractive index between an opposite substrate or a moisture barrier layer (passivation film) such as SiN provided thereover, and air is maintained large, and light extraction efficiency is low. Further, there has been a problem that peeling or cracking due to the moisture barrier layer is easily generated, which leads to deteriorate the reliability and lifetime of a light-emitting element. According to the present invention, a light-emitting element comprises a pixel electrode, an electroluminescent layer, a transparent electrode, a passivation film, a stress relieving layer, and a low refractive index layer, all of which are stacked sequentially. The stress relieving layer serves to prevent peeling of the passivation film. The low refractive index layer serves to reduce reflectivity of light generated in the electroluminescent layer in emitting to air. Therefore, a light-emitting element with high reliability and long lifetime and a display device using the light-emitting element can be provided.

Owner:SEMICON ENERGY LAB CO LTD

Method for preparing two-dimensional photonic crystal structure GaN (gallium nitride) based LED (light emitting diode)

InactiveCN102214742AEasy transferImprove etch selectivityPhotomechanical apparatusSemiconductor devicesResistUltraviolet

The invention discloses a method for preparing a two-dimensional photonic crystal structure GaN (gallium nitride) based LED (light emitting diode). The method comprises: firstly, spinning a layer of ultraviolet optical resist on a target; copying the two-dimensional photonic crystal structure of a template to the surface of the optical resist by utilizing ultraviolet soft nanoimprinting, and etching to remove the residual resist; evaporating a layer of SiO2 or Cr film on a photonic crystal ultraviolet resist, thus a photonic crystal image is obtained on a target sheet through etching; and theobtained GaN is subjected to removing of photoresist, cleaning and drying, thus a photonic crystal target sheet is obtained, and carrying out subsequent process treatment on the obtained target sheet, thus the manufacturing of a device is finished, and the photonic crystal GaN based LED with high light extracting efficiency is obtained. Through the method provided by the invention, the selection ratio of etching can be improved, the duty ratio of the photonic crystal can be regulated in a certain range, the uneven problem of the surface of the LED chip can be overcome, the photonic crystal image can be prepared better through the nanoimprinting technology, and the method is suitable for the preparation of the GaN based photonic crystal LED in industrial production.

Owner:HUAZHONG UNIV OF SCI & TECH

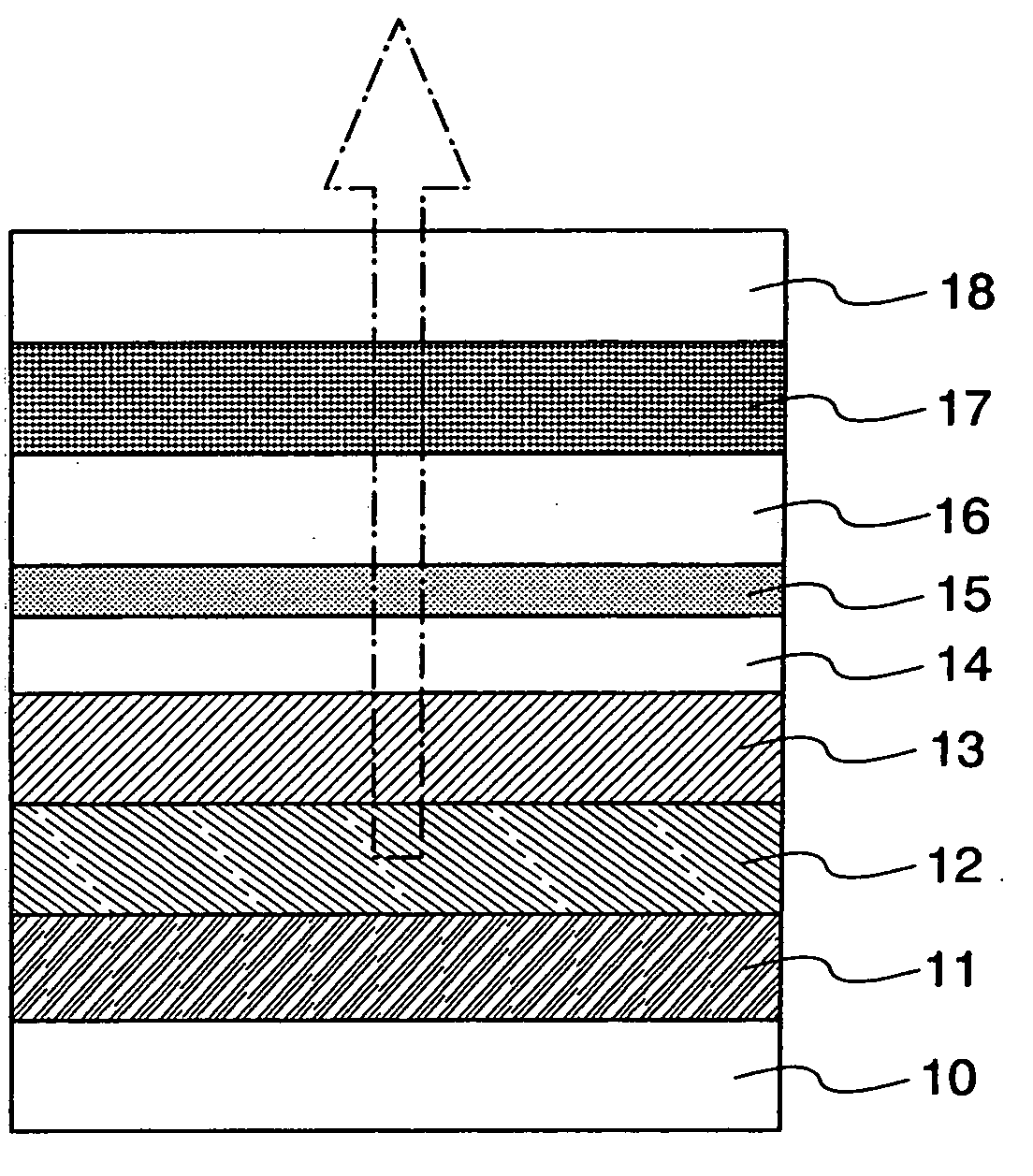

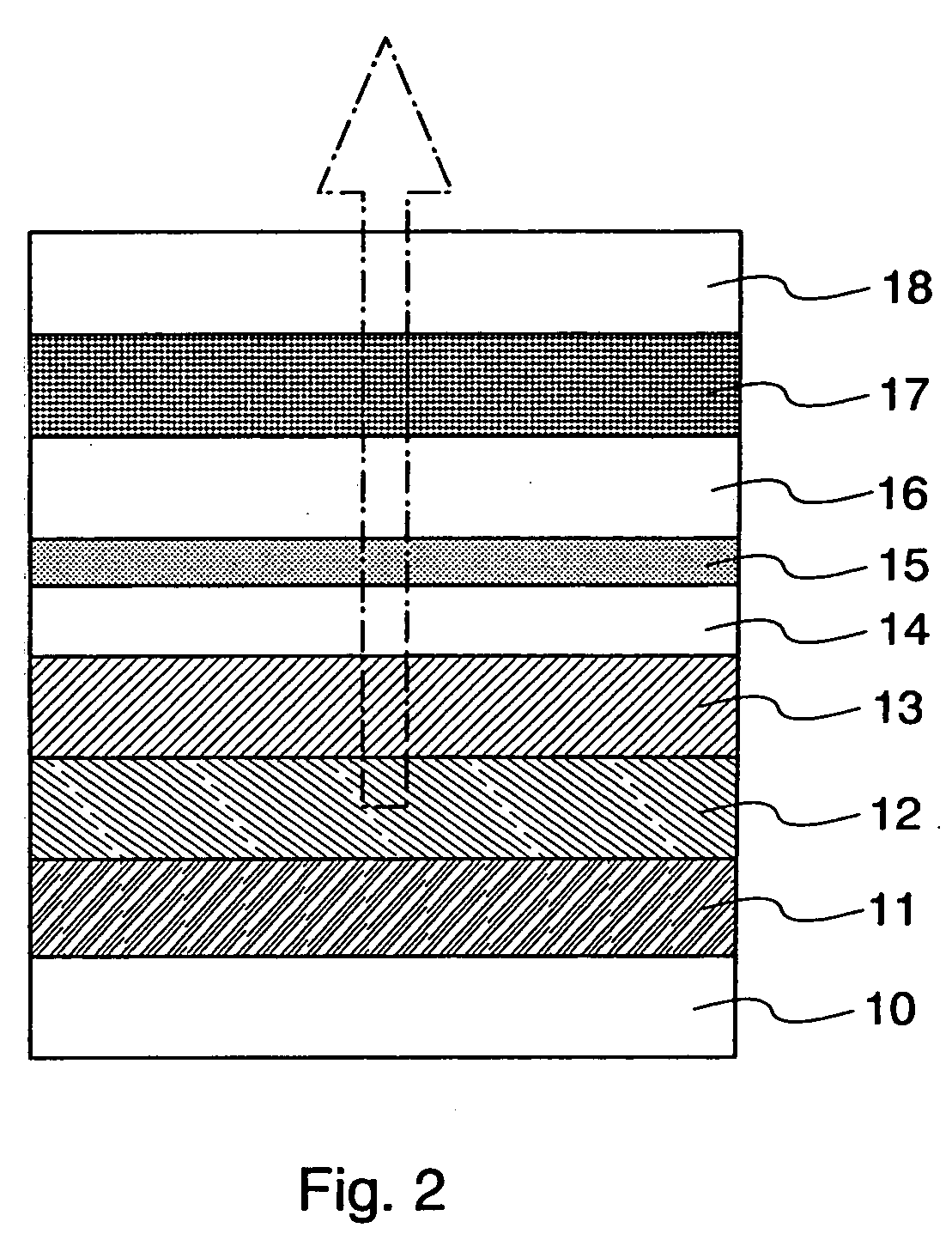

Semiconductor light-emitting device and method for fabricating the same

InactiveUS20050161696A1Improve light extraction efficiencyImproved radiation patternSemiconductor/solid-state device manufacturingSemiconductor devicesDevice formSemiconductor package

In a semiconductor light-emitting device formed by stacking a plurality of semiconductor layers including an active layer, at least a portion of a semiconductor layer of the plurality of semiconductor layers is made porous. The semiconductor layer made porous has a surface serving as a light-extraction surface for extracting light emitted from the active layer.

Owner:PANASONIC CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com