Patents

Literature

713 results about "Liquid silicon" patented technology

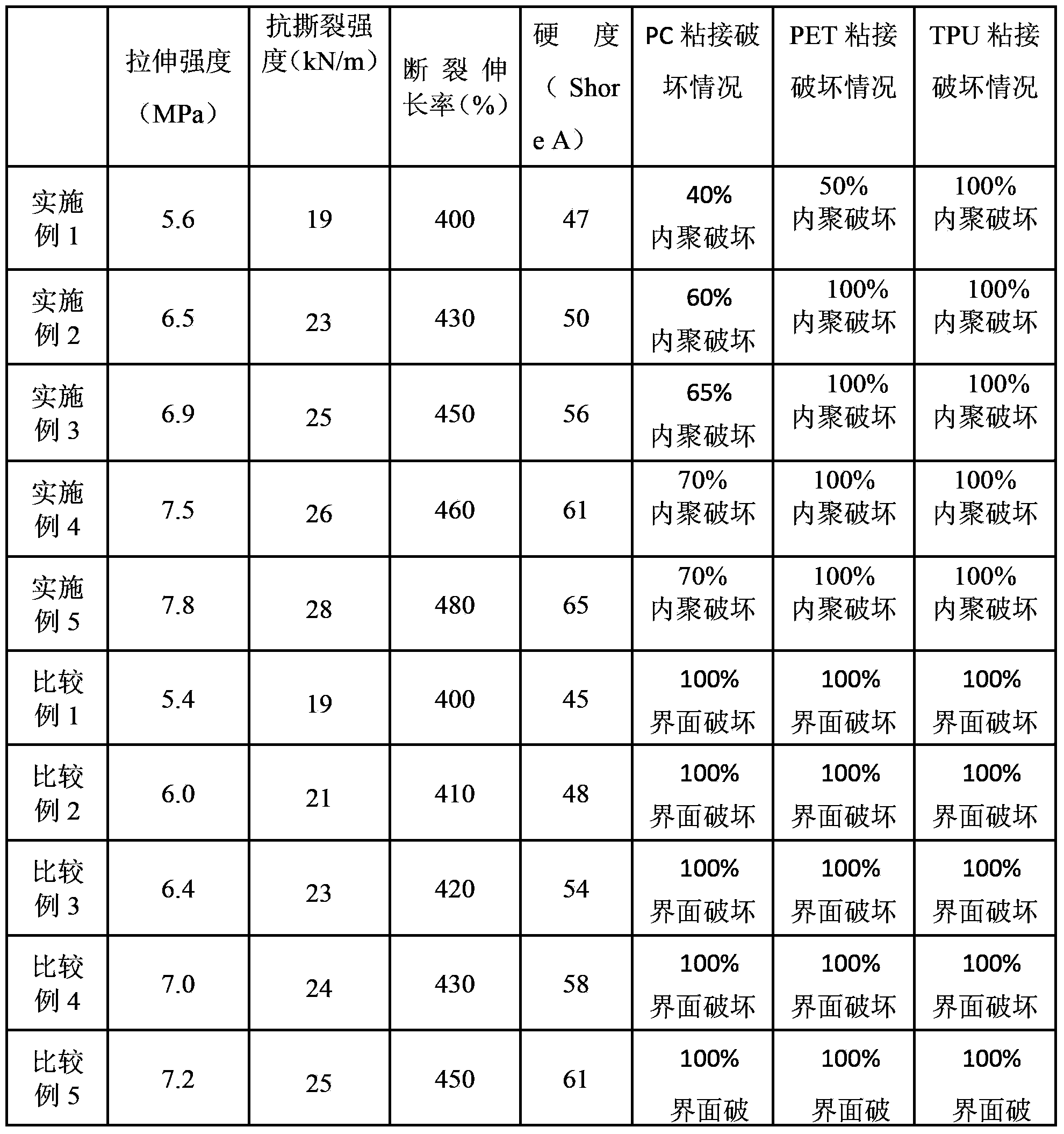

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Liquid Silicon is one of the various liquids added by GregTech 4. It is a form in which Silicon can be stored, usually in bulk. It is created by placing a Silicon Cell in a Liquid Transposer.

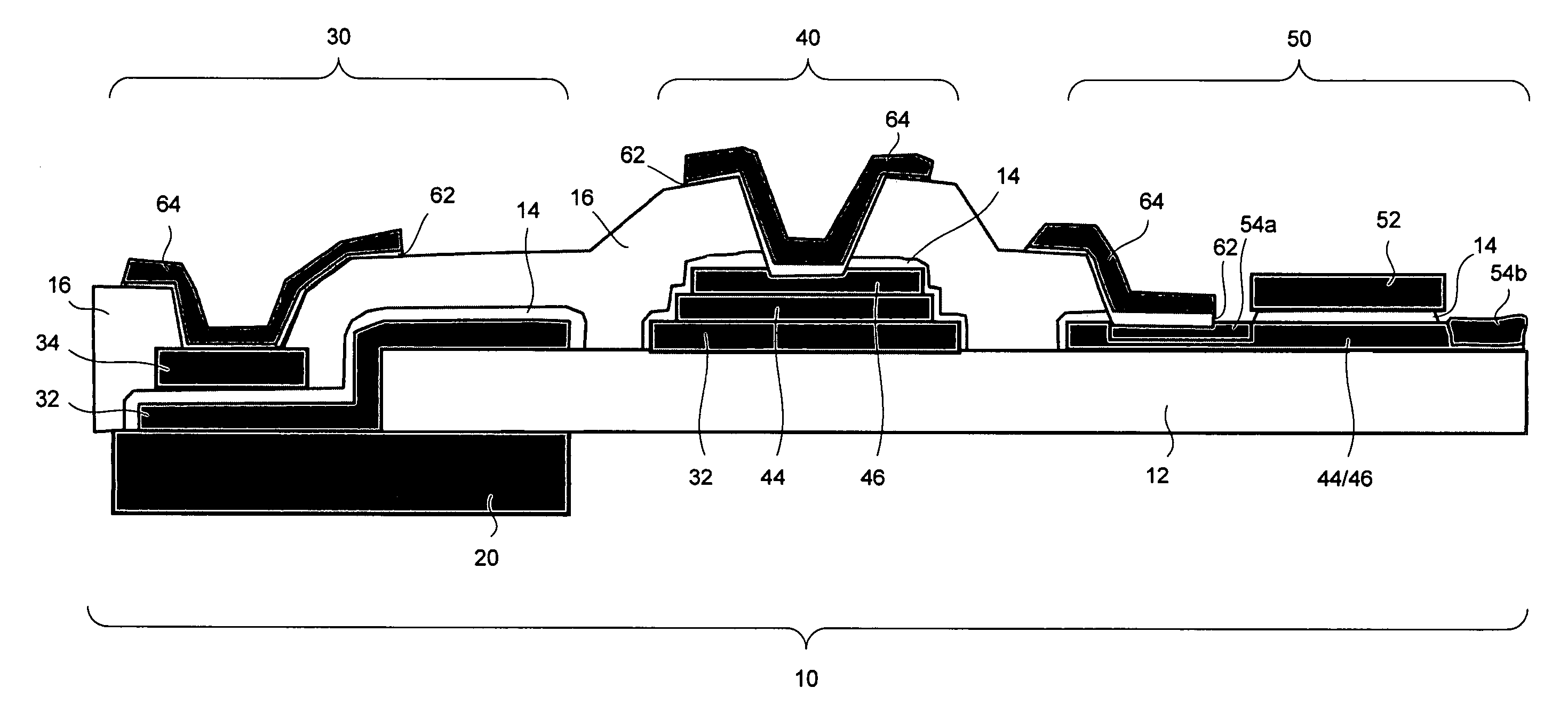

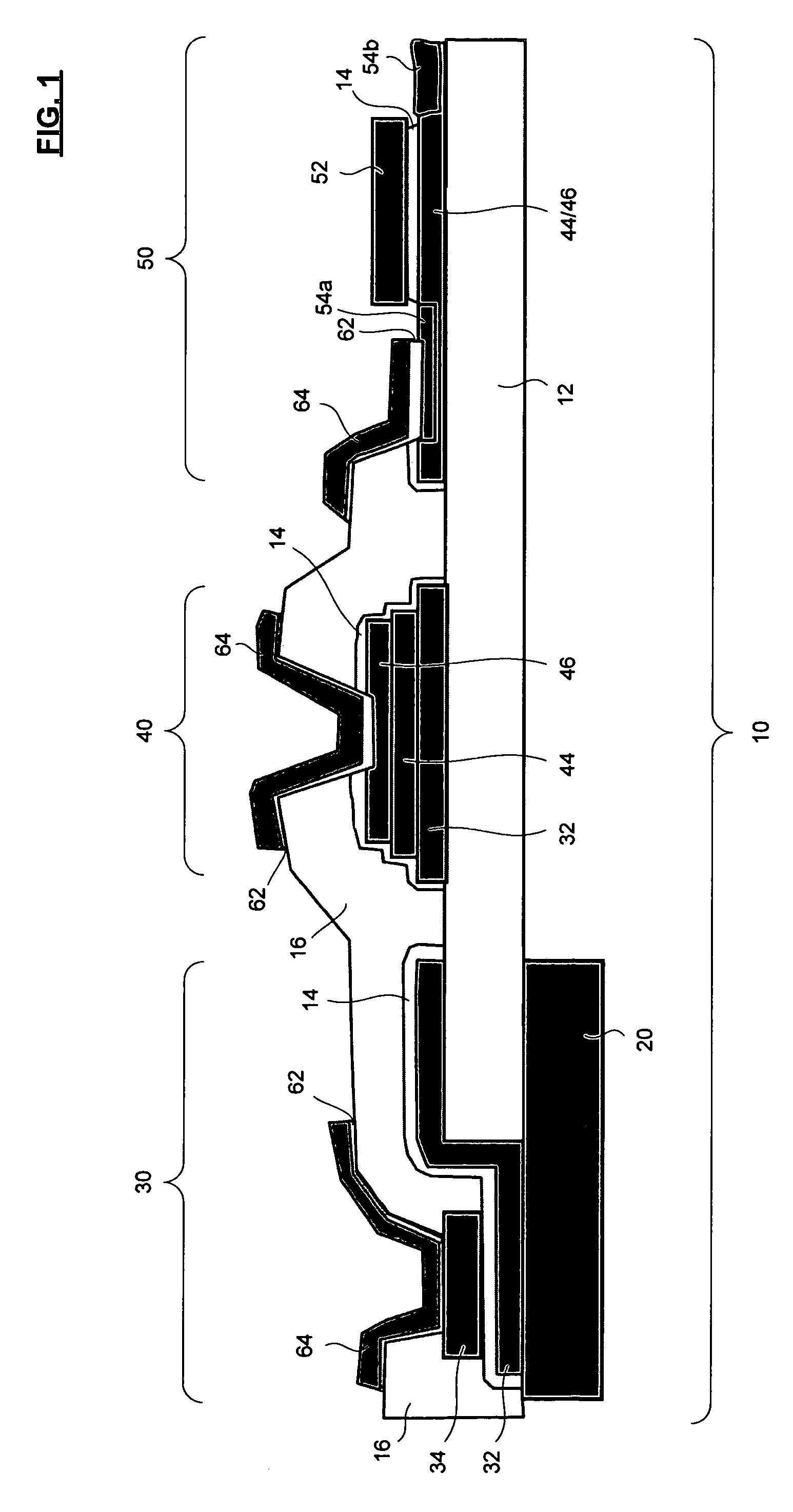

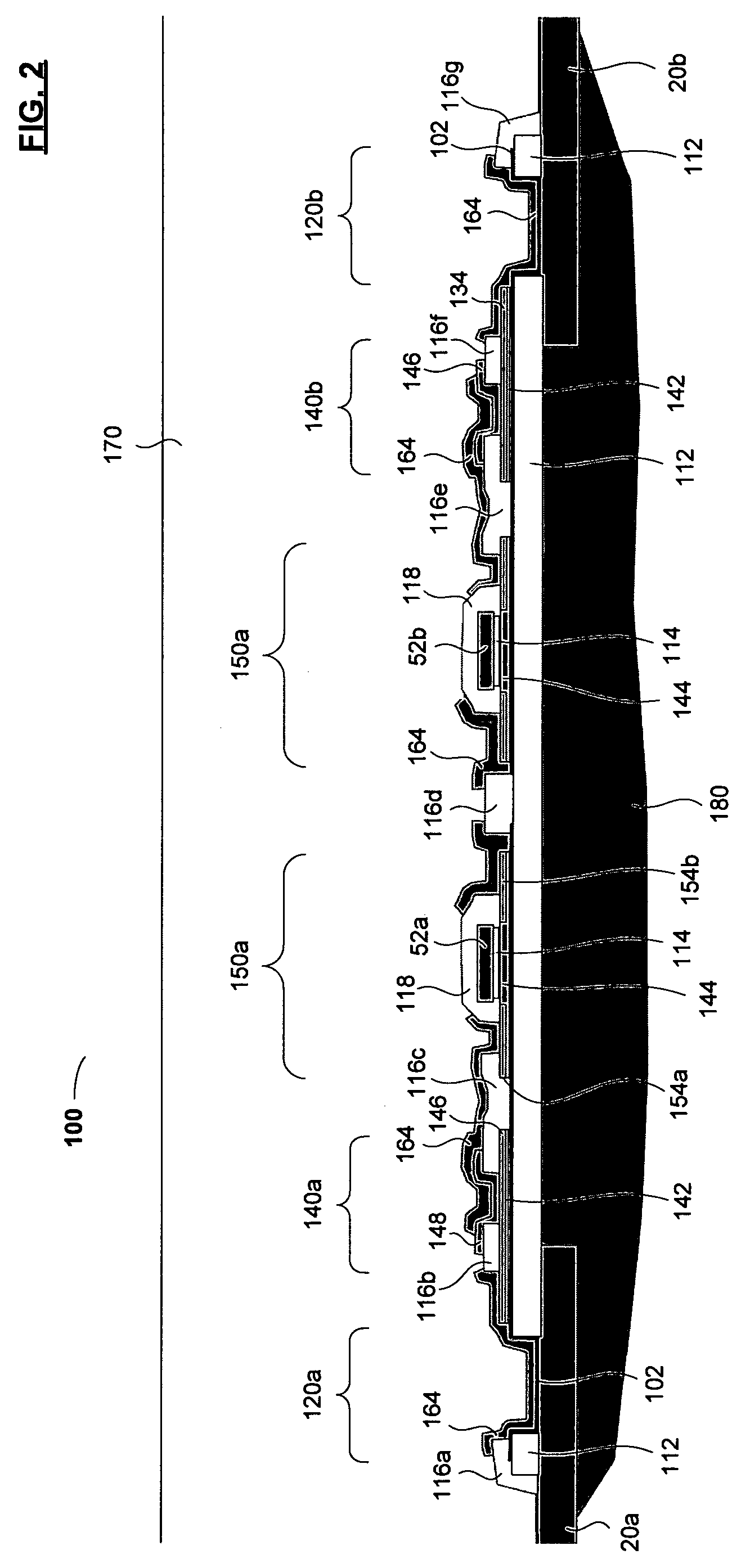

Methods for manufacturing RFID tags and structures formed therefrom

ActiveUS20070007342A1Low costLarge dieSemiconductor/solid-state device detailsSolid-state devicesManufacturing technologyEngineering

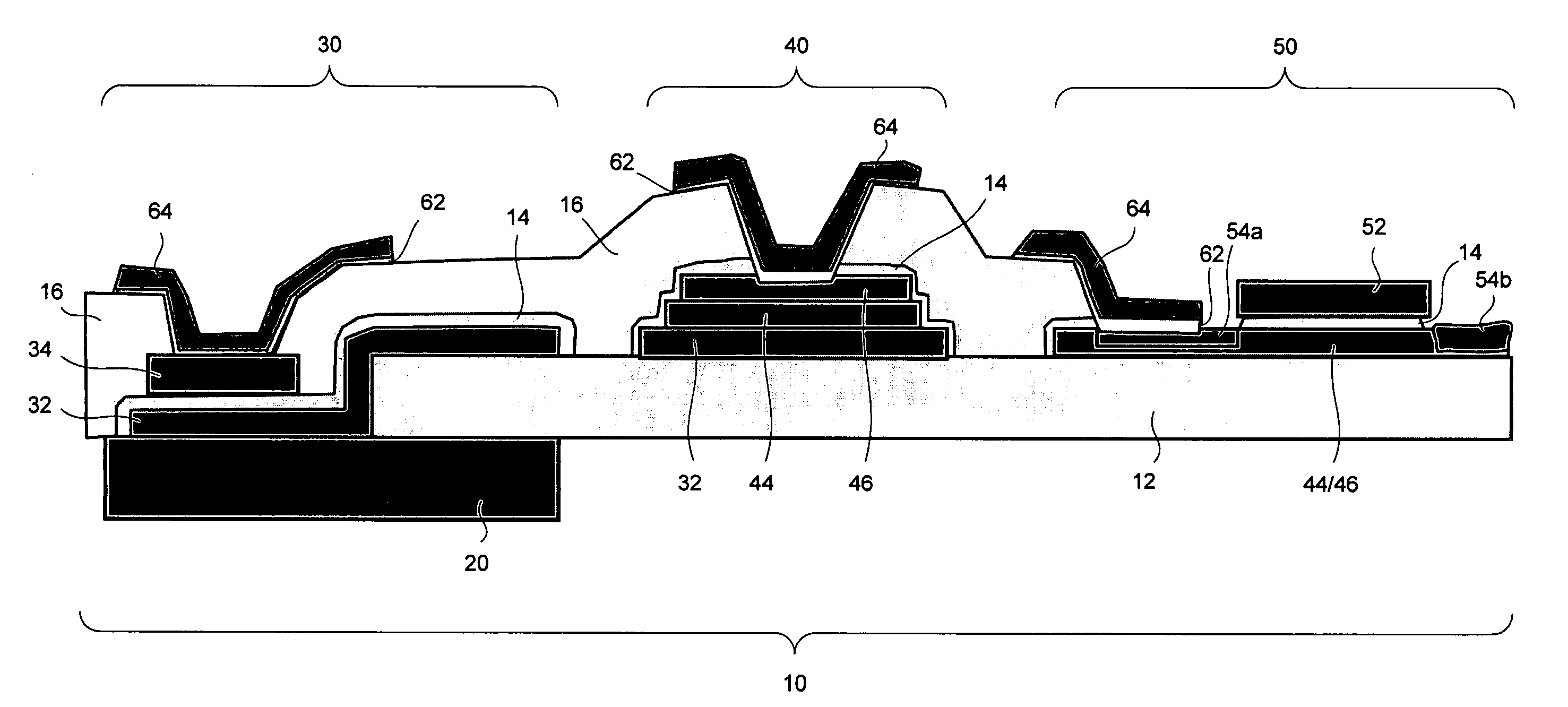

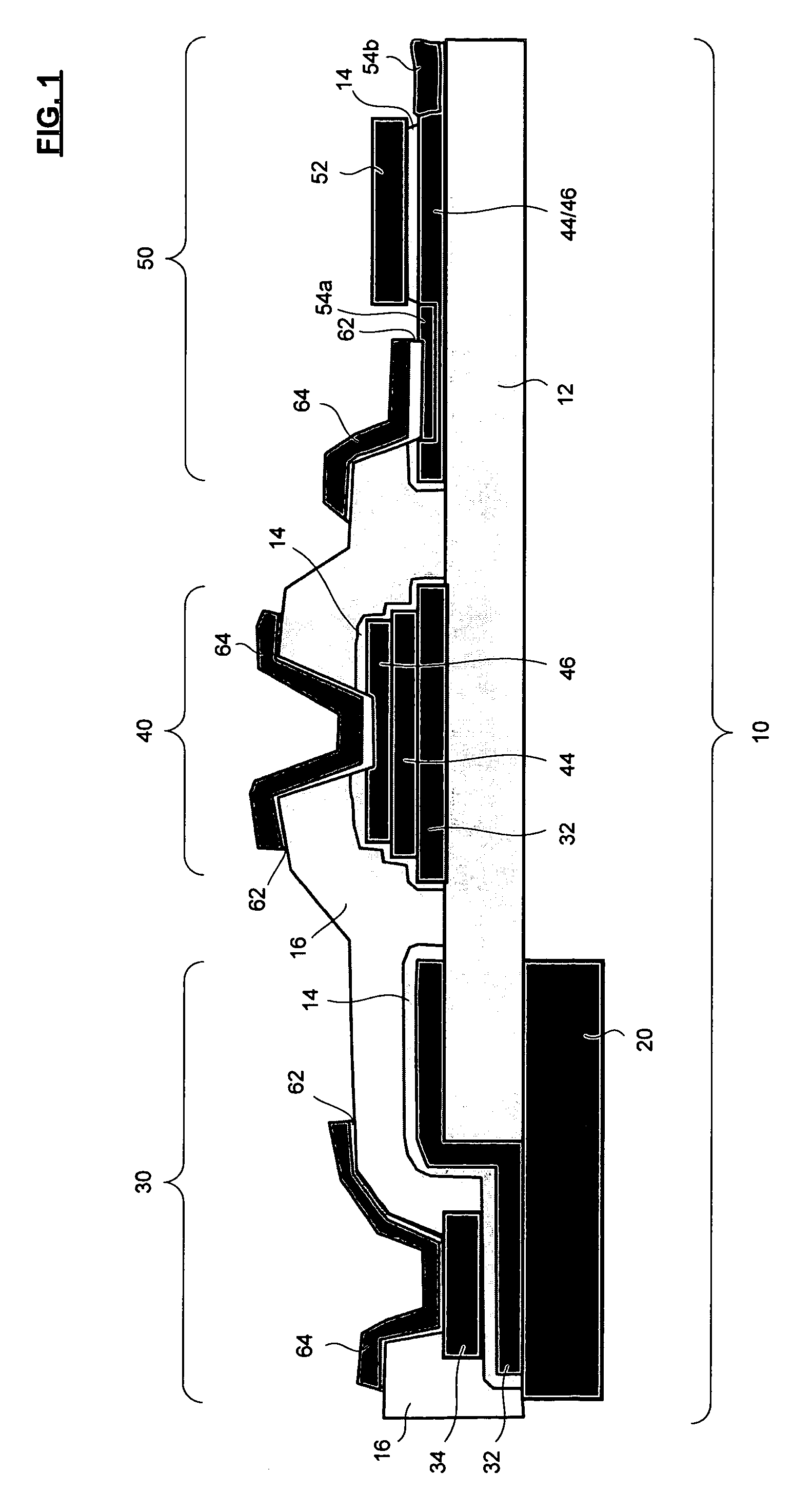

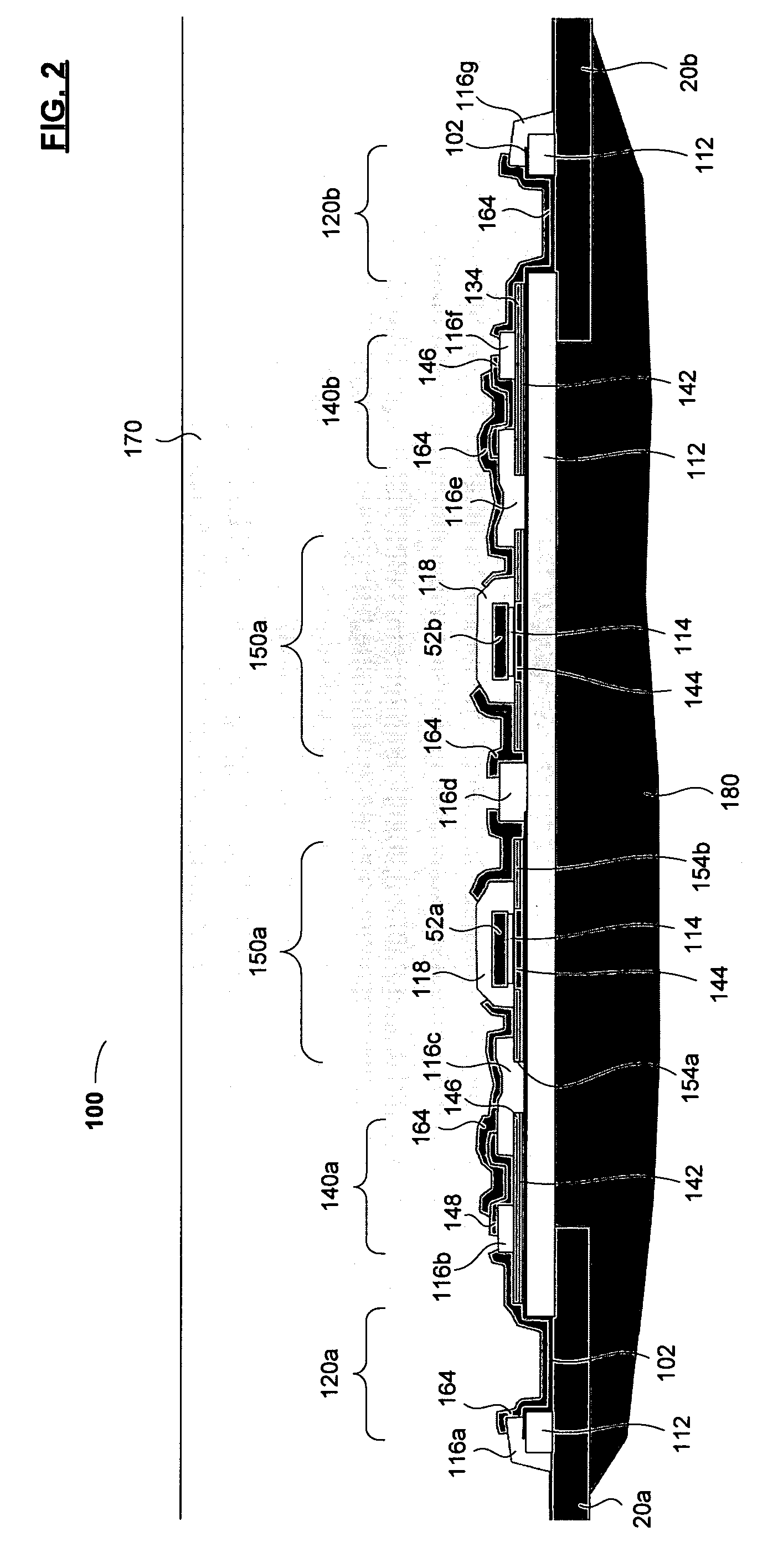

Radio frequency identification (RFID) tags and processes for manufacturing the same. The RFID device generally includes (1) a metal antenna and / or inductor; (2) a dielectric layer thereon, to support and insulate integrated circuitry from the metal antenna and / or inductor; (3) a plurality of diodes and a plurality of transistors on the dielectric layer, the diodes having at least one layer in common with the transistors; and (4) a plurality of capacitors in electrical communication with the metal antenna and / or inductor and at least some of the diodes, the plurality of capacitors having at least one layer in common with the plurality of diodes and / or with contacts to the diodes and transistors. The method preferably integrates liquid silicon-containing ink deposition into a cost effective, integrated manufacturing process for the manufacture of RFID circuits. Furthermore, the present RFID tags generally provide higher performance (e.g., improved electrical characteristics) as compared to tags containing organic electronic devices.

Owner:ENSURGE MICROPOWER ASA

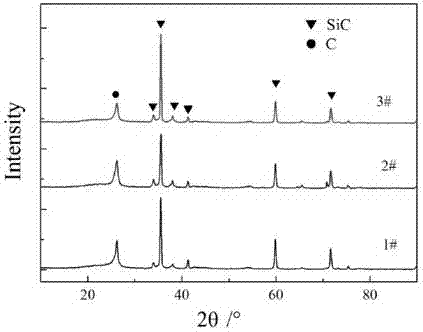

Preparation method for fiber reinforced carbon-silicon carbide-zirconium carbide-based composite material

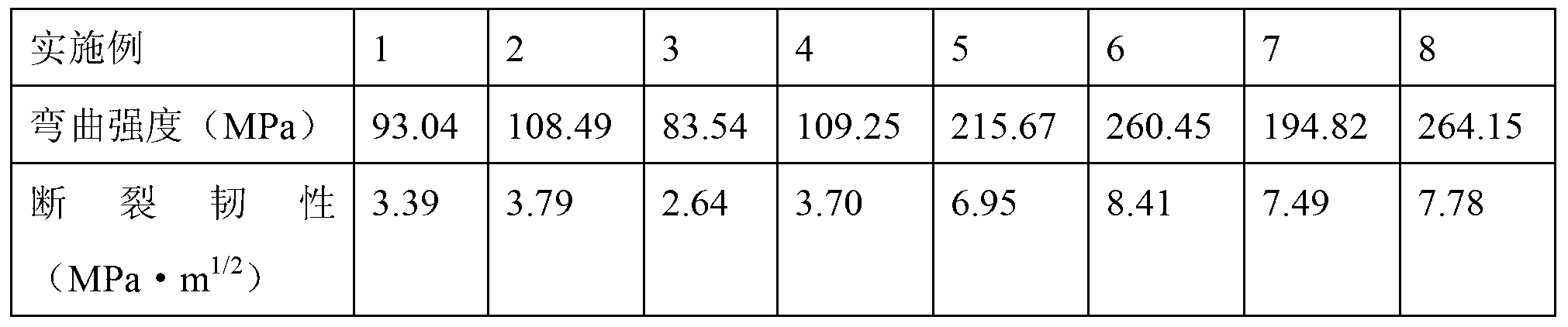

The invention discloses a preparation method for a fiber reinforced carbon-silicon carbide-zirconium carbide-based (C / C-SiC-ZrC) composite material. The preparation method comprises the following steps of: (a) evenly dispersing ZrC nanopowder in absolute ethyl alcohol; (b) mixing phenolic resin and ZrC dispersion liquid to form slurry; (c) immersing a two-dimensional carbon fiber sheet into the slurry for dipping and drying, then carrying out continuous superposition paving on the two-dimensional carbon fiber sheet, and carrying out curing and post-curing treatment to prepare a fiber-reinforced sintered body; (d) cracking the fiber-reinforced sintered body to obtain a porous C / C prefabricate; (e) placing silicon powder into a graphite crucible, burying the porous C / C prefabricate into the silicon powder, heating to 1,500-1,650 DEG C, and preserving heat for preset time so as to carry out liquid silicon permeation. The method can be used for improving the high-temperature oxidizing property and ablation property of the carbon fiber reinforced ceramic (C / C-SiC) composite material.

Owner:DALIAN UNIV OF TECH

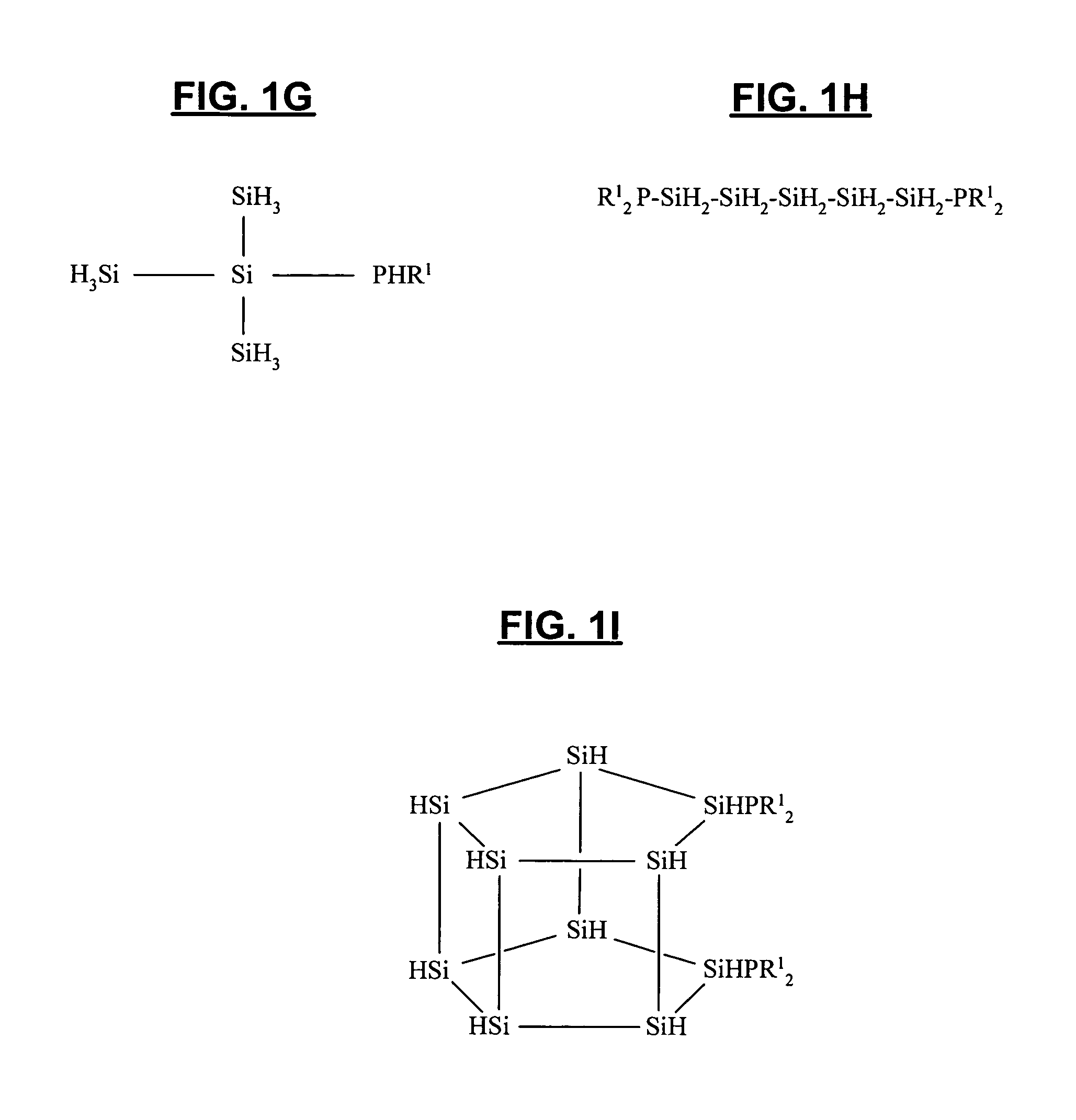

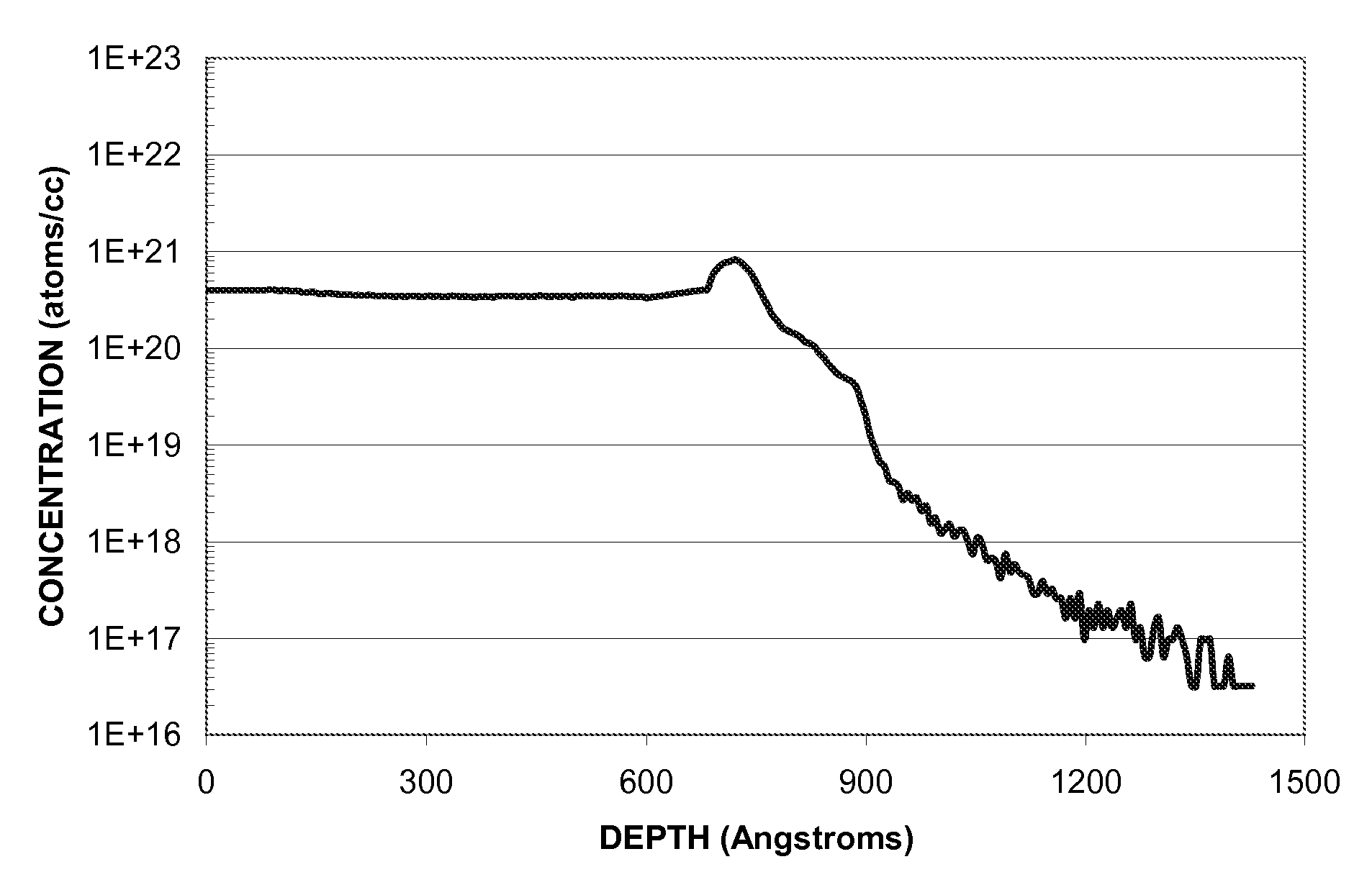

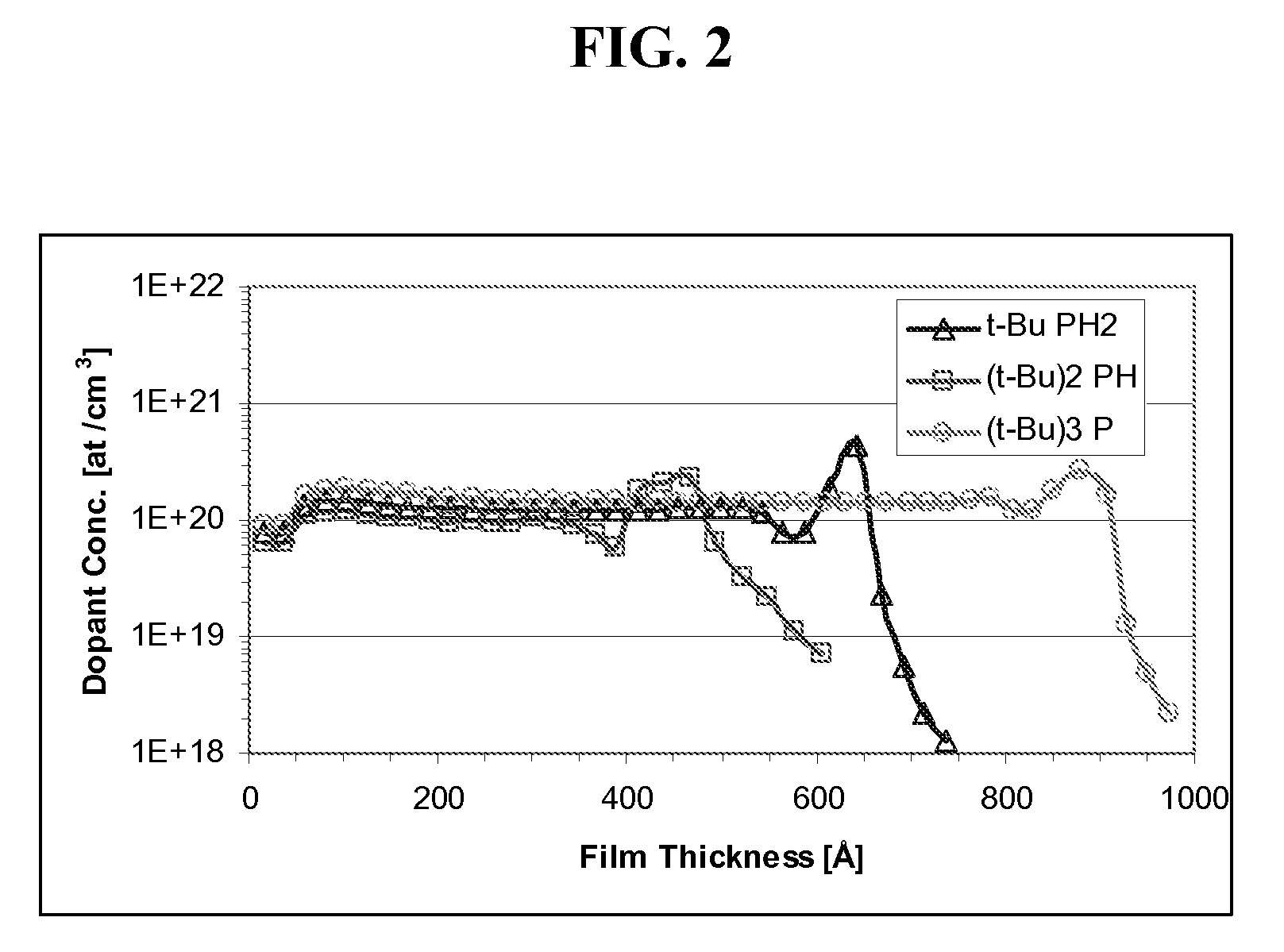

Methods of forming a doped semiconductor thin film, doped semiconductor thin film structures, doped silane compositions, and methods of making such compositions

ActiveUS7314513B1Reduce volatilityHigh molecular weightOther chemical processesSemiconductor/solid-state device manufacturingIsomerizationElectron

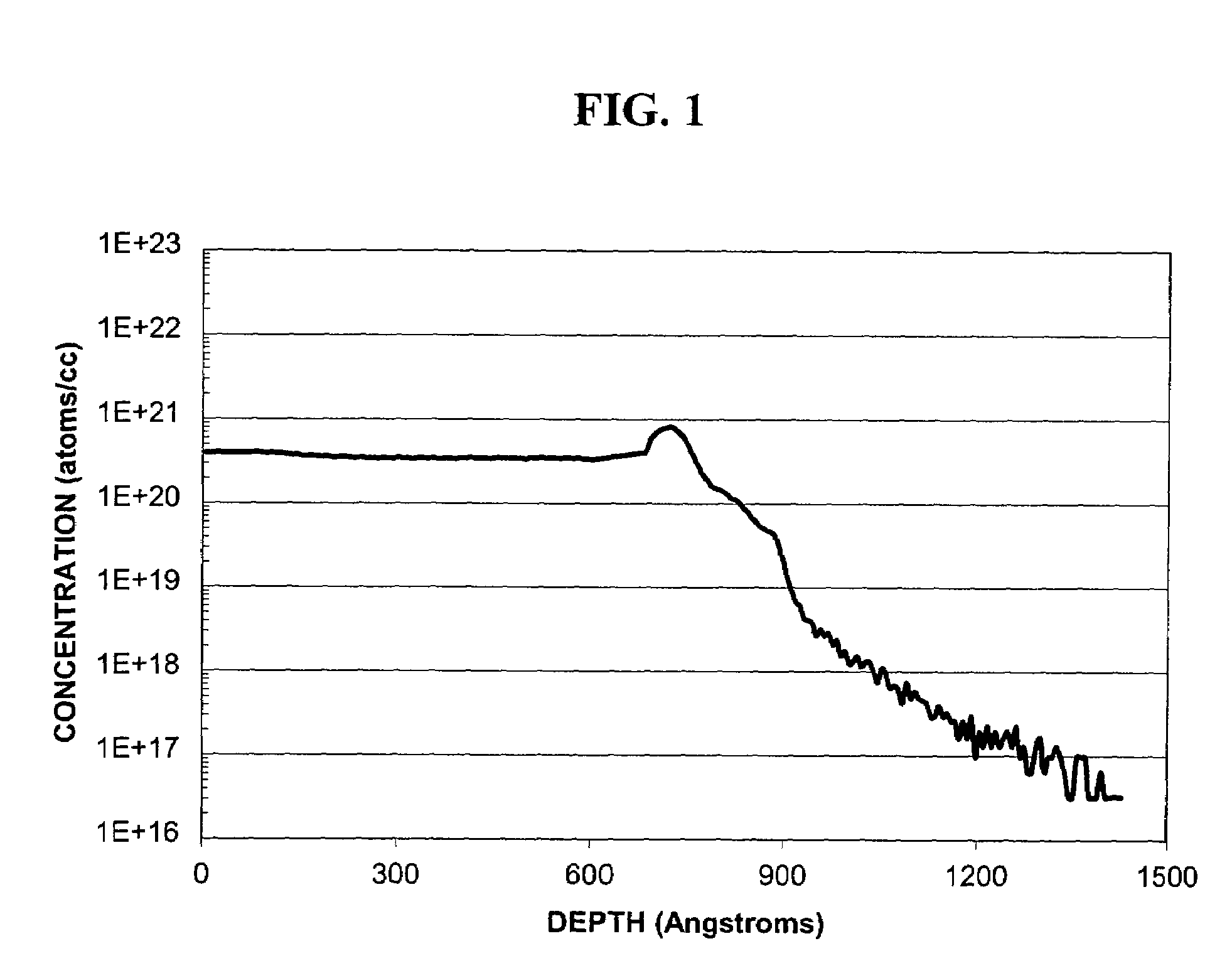

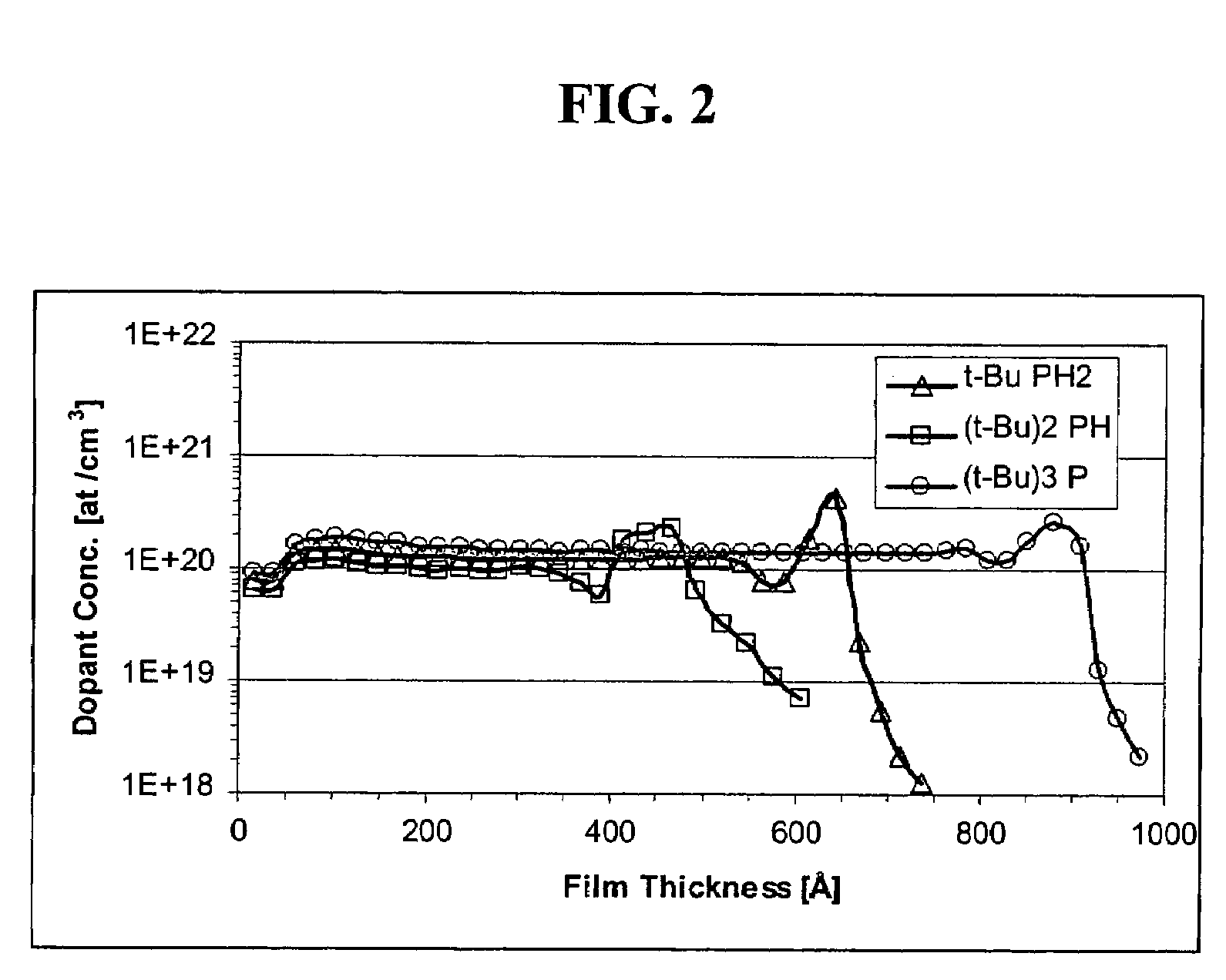

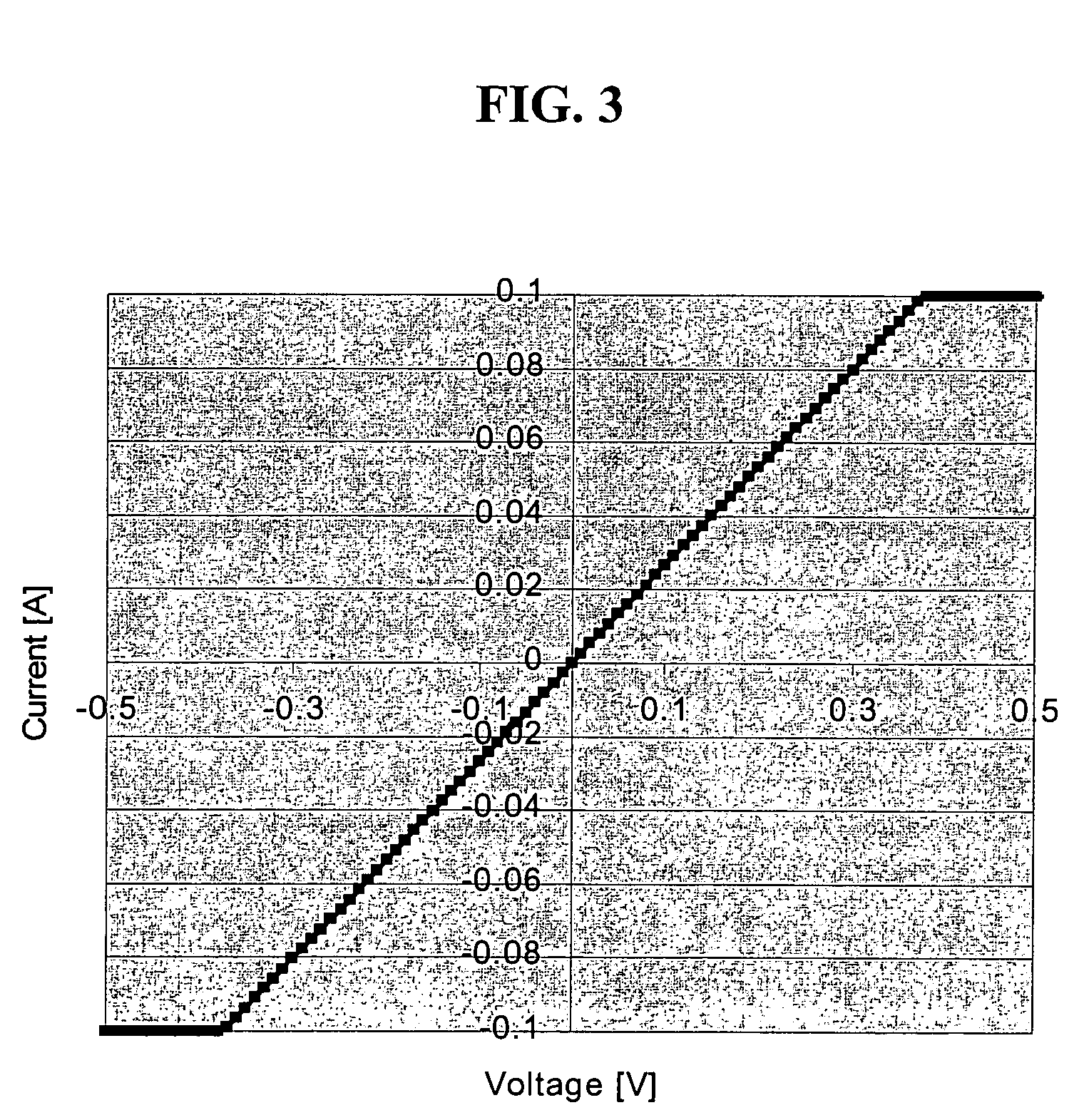

Methods for forming doped silane and / or semiconductor thin films, doped liquid phase silane compositions useful in such methods, and doped semiconductor thin films and structures. The composition is generally liquid at ambient temperatures and includes a Group IVA atom source and a dopant source. By irradiating a doped liquid silane during at least part of its deposition, a thin, substantially uniform doped oligomerized / polymerized silane film may be formed on a substrate. Such irradiation is believed to convert the doped silane film into a relatively high-molecular weight species with relatively high viscosity and relatively low volatility, typically by cross-linking, isomerization, oligomerization and / or polymerization. A film formed by the irradiation of doped liquid silanes can later be converted (generally by heating and annealing / recrystallization) into a doped, hydrogenated, amorphous silicon film or a doped, at least partially polycrystalline silicon film suitable for electronic devices. Thus, the present invention enables use of high throughput, low cost equipment and techniques for making doped semiconductor films of commercial quality and quantity from doped “liquid silicon.”

Owner:ENSURGE MICROPOWER ASA

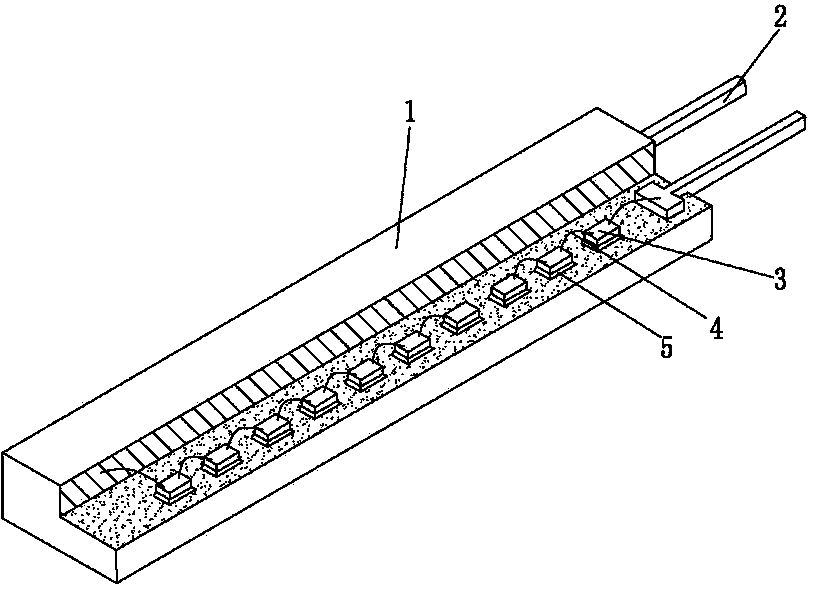

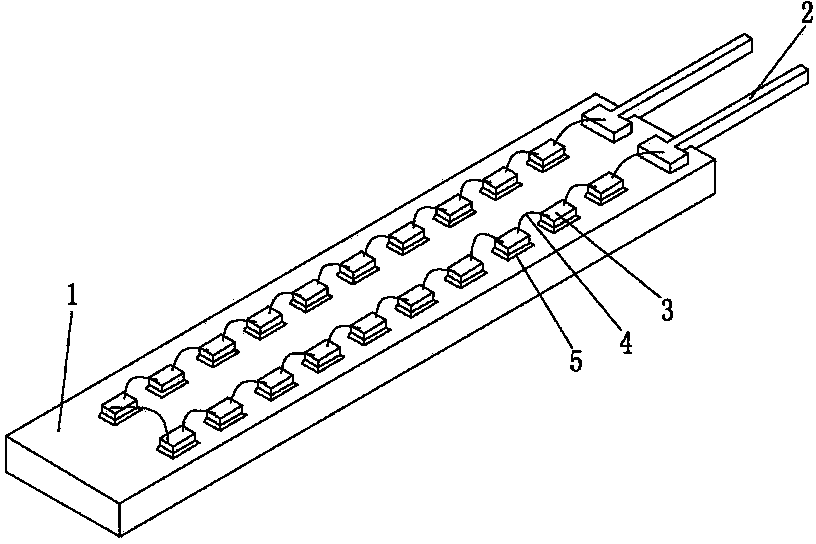

Packaging method of LED filament and LED filament

InactiveCN104319345AEnsure stabilityGuaranteed light transmittanceSemiconductor devicesLED filamentLiquid silicon

The invention discloses a packaging method of an LED filament. The packaging method of the LED filament includes the steps that a liquid silicon resin and fluorescent powder mixture is injected into a mould, and a metal conductive pin is arranged at one end of the silicon resin and fluorescent powder mixture inside the mould; the mould is removed after being heated and solidified, and silicon resin and fluorescent powder colloid with the metal conductive pin at one end is obtained; a plurality of LED chips are installed on the silicon resin and fluorescent powder colloid, and the LED chips are mutually connected through a wire and then connected to the metal conductive pin to form a conductive path; the silicon resin and fluorescent powder colloid with the LED chips is put into the mould, and a liquid silicon resin and fluorescent powder mixture is injected into the mould to cover the LED chips and the wire; the mould is removed after being heated and solidified, and the packaged LED filament finished product with a supporting frame is obtained. The LED filament is packaged without the supporting frame, and the quality problems of low yield, low light transmittance of the supporting frame and the like are resolved.

Owner:DONGGUAN INST OF OPTO ELECTRONICS PEKING UNIV +1

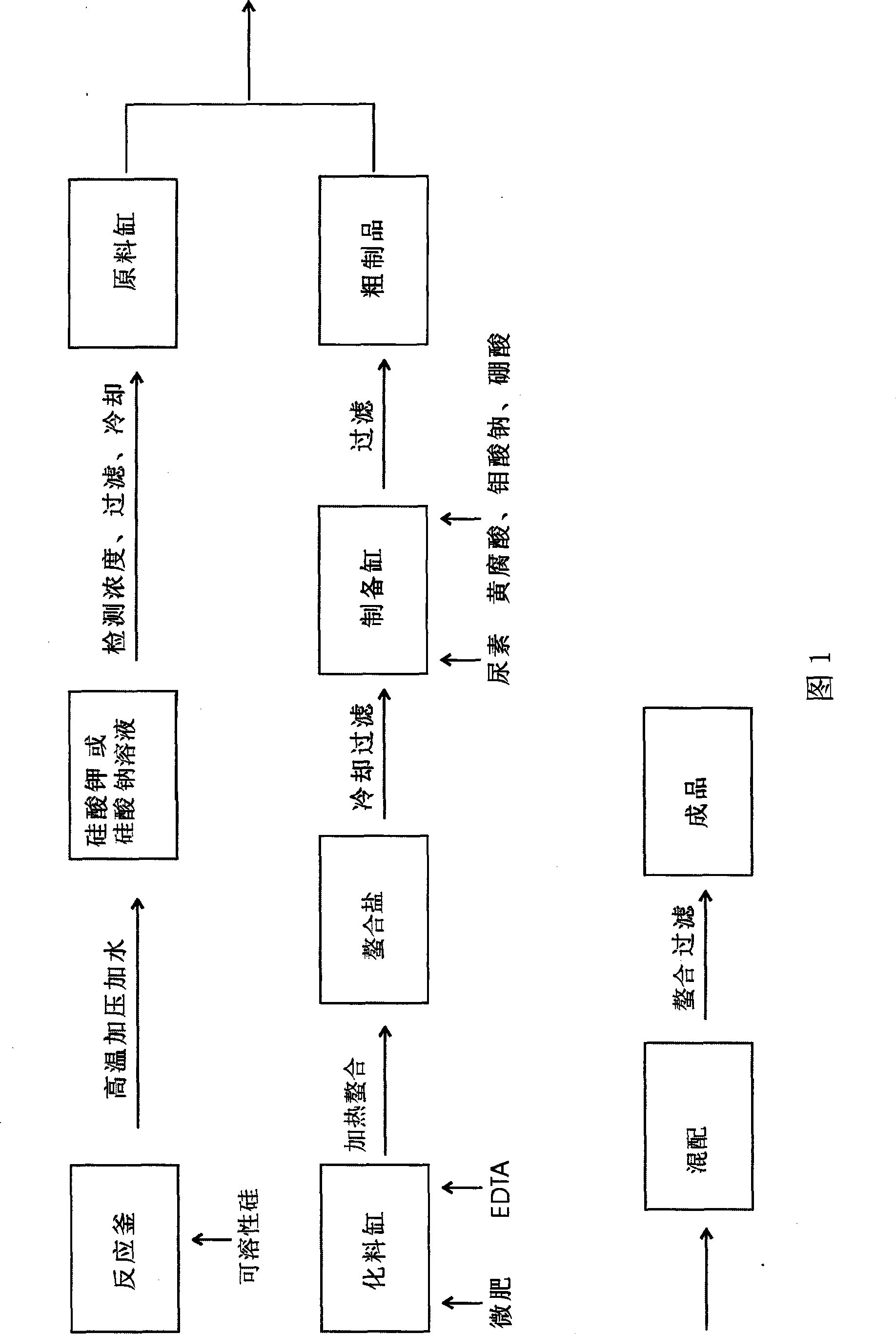

Liquid silicon fertilizer and technique for producing the same

InactiveCN101440001APromote growthIncrease resistanceOrganic fertilisersUrea compound fertilisersMetasilicateSilicic acid

The invention relates to a liquid silicon fertilizer and a production technique thereof, and belongs to the technical field of fertilizer. The liquid silicon fertilizer is characterized in that raw materials comprise soluble silicon, urea, trace elements, chelate and fulvic acid, which are prepared into the balanced compound fertilizer. The production technique comprises the following steps: 1, dissolving solid potassium metasilicate; 2, dissolving sulfate of the trace elements in water, and adding EDTA into the mixture to obtain the chelate of the EDTA trace elements; and adding boric acid, ammonium molybdate, the urea and the fulvic acid into the mixture after cooling and filtration; and 3, blending the chelate into the mixture to obtain the liquid silicon fertilizer. The production technique is characterized in that (1) the production technique uses water glass and the fulvic acid chelate, has better buffer action for alkali, and can effectively improve stability of SiO3; and (2) the trace elements are chelated twice by using the EDTA and the fulvic acid to form chelated metal ions, so as to prevent silicic acid radicals and the metal ions reacting to form silicate difficult to be dissolved in water, and influence utilization rate of silicon element. The production technique uses the liquid potassium metasilicate and large amount of elements, trace elements and organic substances to establish a balanced compound system, and can effectively improve utilization rate of the silicon element and various nutrient elements for the crops.

Owner:于春开

Method for preparing carbon/carbon-silicon carbide composite material for bearings

The invention discloses a method for preparing a carbon / carbon-silicon carbide composite material for bearings. The preparation method comprises the following steps: preparing a carbon fiber integral felt of 0.15-0.30g / cm<3> from polyacrylonitrile preoxidized fibers through puncture carbonization, or preparing a non-woven cloth carbon fiber integral felt of 0.4-0.6g / cm<3> from non-woven cloth and a mesh tyre through puncture carbonization in an alternating lamination manner; preparing C / C porous preform with density of 1.35-1.75g / cm<3> by adopting a chemical vapor infiltration (CVI) and resin precursor infiltration and pyrolysis (PIP) comprehensive process, and performing a high-temperature treatment at 2,250-2,600 DEG C in the Ar gas protective atmosphere; and vacuumizing, then introducing Ar gas, heating to 2,200-2,350 DEG C to perform liquid silicon infiltration, and preserving heat for 1.5 hours. The method is a preparation method of the carbon / carbon-silicon carbide (C / C-SiC) composite material with little residual silicon and low abrasion rate for bearings.

Owner:SHANGHAI UNIV +2

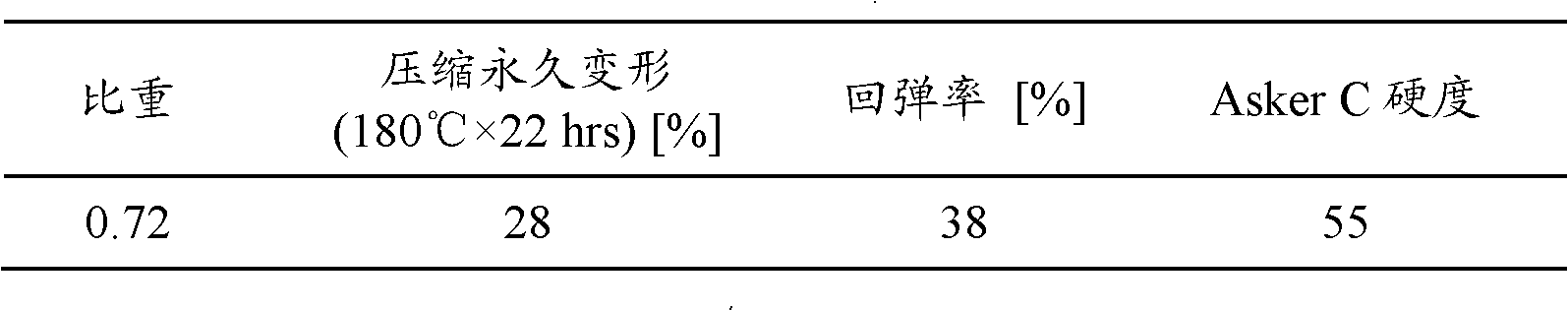

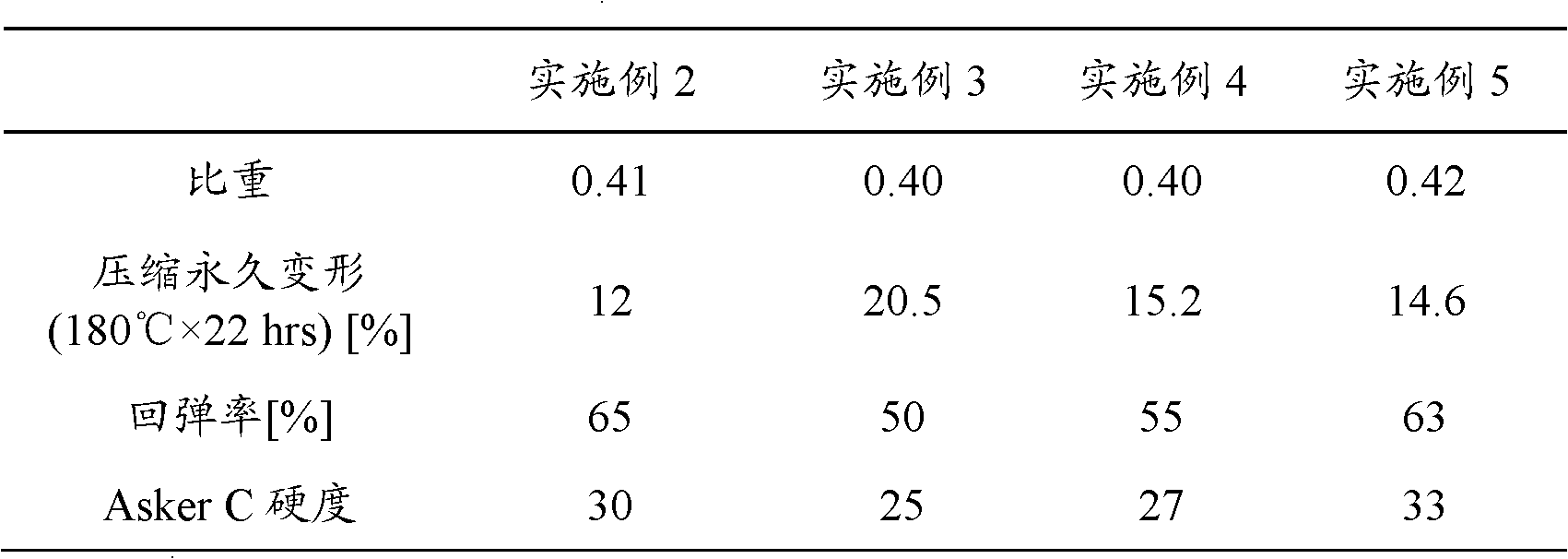

Liquid silicon rubber composition and preparation method thereof

The invention relates to a liquid silicon rubber composition which comprises the following components in parts by mass: 100 parts of polydimethylsiloxane with vinyl as an end group, 1-400 parts of inorganic reinforcing agent, 1-20 parts of low-viscosity polydimethylsiloxane with a vinyl-containing side group, 0.01-10 parts of cross-linking agent, 1-30 parts of polydimethylsiloxane with hydroxyl as an end group, and a platinum catalyst capable of curing the liquid silicon rubber composition. The invention further relates to a preparation method of the liquid silicon rubber composition. The liquid silicon rubber composition has low viscosity and good fluidity before being cured and is applicable to injection molding; and the composition has excellent resilience and low compression deformation ratio after being cured. The liquid silicon rubber composition can be applied to an elastomer, a pressure roll and an image heating and fixing device in a copier and a laser printer as well as certain silicon rubber products in need of the properties.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

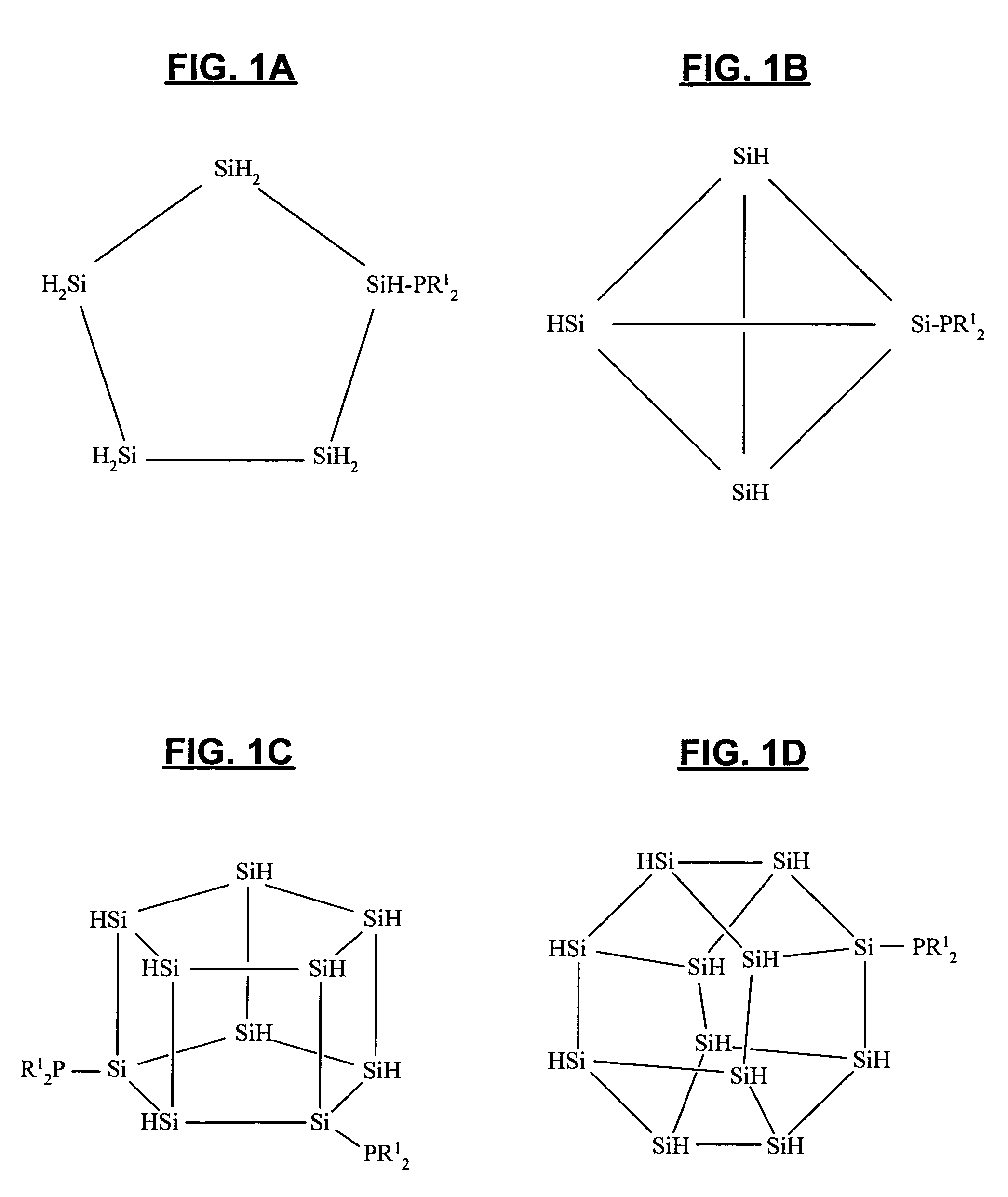

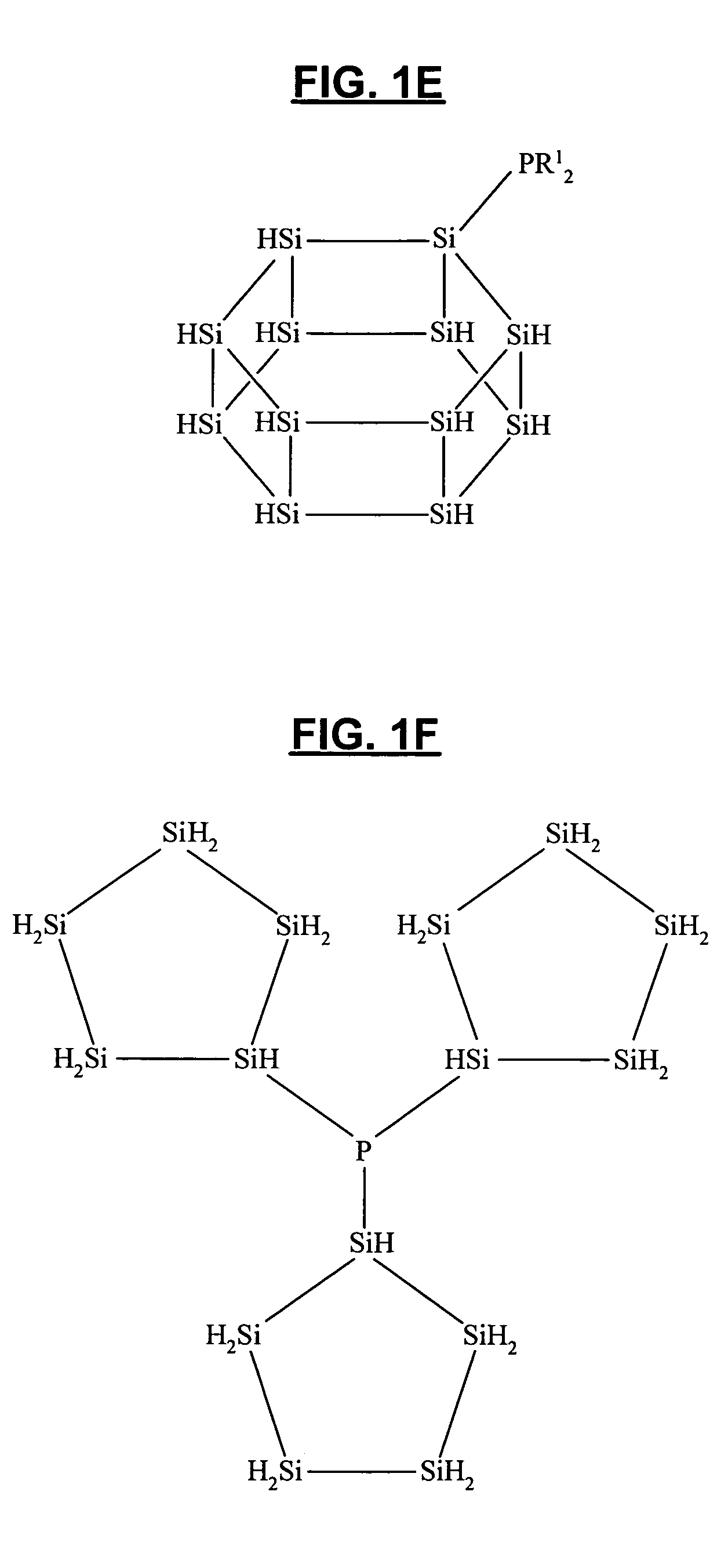

Dopant group-substituted semiconductor precursor compounds, compositions containing the same, and methods of making such compounds and compositions

ActiveUS7674926B1Readily apparentSilicon organic compoundsGroup 3/13 element organic compoundsSilane compoundsDopant

Dopant-group substituted (cyclo)silane compounds, liquid-phase compositions containing such compounds, and methods for making the same. Such compounds (and / or ink compositions containing the same) are useful for printing or spin coating a doped silane film onto a substrate that can easily be converted into a doped amorphous or polycrystalline silicon film suitable for electronic devices. Thus, the present invention advantageously provides commercial qualities and quantities of doped semiconductor films from a doped “liquid silicon” composition.

Owner:ENSURGE MICROPOWER ASA

Methods of forming a doped semiconductor thin film, doped semiconductor thin film structures, doped silane compositions, and methods of making such compositions

InactiveUS20080022897A1Reduce volatilityHigh molecular weightSemiconductor/solid-state device manufacturingCoatingsIsomerizationElectron

Methods for forming doped silane and / or semiconductor thin films, doped liquid phase silane compositions useful in such methods, and doped semiconductor thin films and structures. The composition is generally liquid at ambient temperatures and includes a Group IVA atom source and a dopant source. By irradiating a doped liquid silane during at least part of its deposition, a thin, substantially uniform doped oligomerized / polymerized silane film may be formed on a substrate. Such irradiation is believed to convert the doped silane film into a relatively high-molecular weight species with relatively high viscosity and relatively low volatility, typically by cross-linking, isomerization, oligomerization and / or polymerization. A film formed by the irradiation of doped liquid silanes can later be converted (generally by heating and annealing / recrystallization) into a doped, hydrogenated, amorphous silicon film or a doped, at least partially polycrystalline silicon film suitable for electronic devices. Thus, the present invention enables use of high throughput, low cost equipment and techniques for making doped semiconductor films of commercial quality and quantity from doped “liquid silicon.”

Owner:ZURCHER FABIO +6

Honeycomb composite silicon carbide mirrors and structures

Owner:FANTOM MATERIALS INC

Medium purity metallurgical silicon and method for preparing same

The invention concerns a method for producing a medium purity silicon comprising: preparing, by carbothermic reduction of silica in a submerged arc-furnace a silicon with low boron content; refining the liquid silicon with oxygen or chlorine; treating the refined silicon under reduced pressure from 10 to 100 Pa with neutral gas injection; segregated solidification. The invention also concerns a medium purity silicon designed to serve as raw material for making silicon of electronic or voltaic quality, and having (in weight fractions): a total of impurities ranging between 100 and 400 ppm, with the content in metallic elements ranging between 30 and 300 ppm; a boron content from 1 to 10 ppm; a phosphorus / boron ratio ranging between 0.5 and 1.5.

Owner:FERROPEM SAS

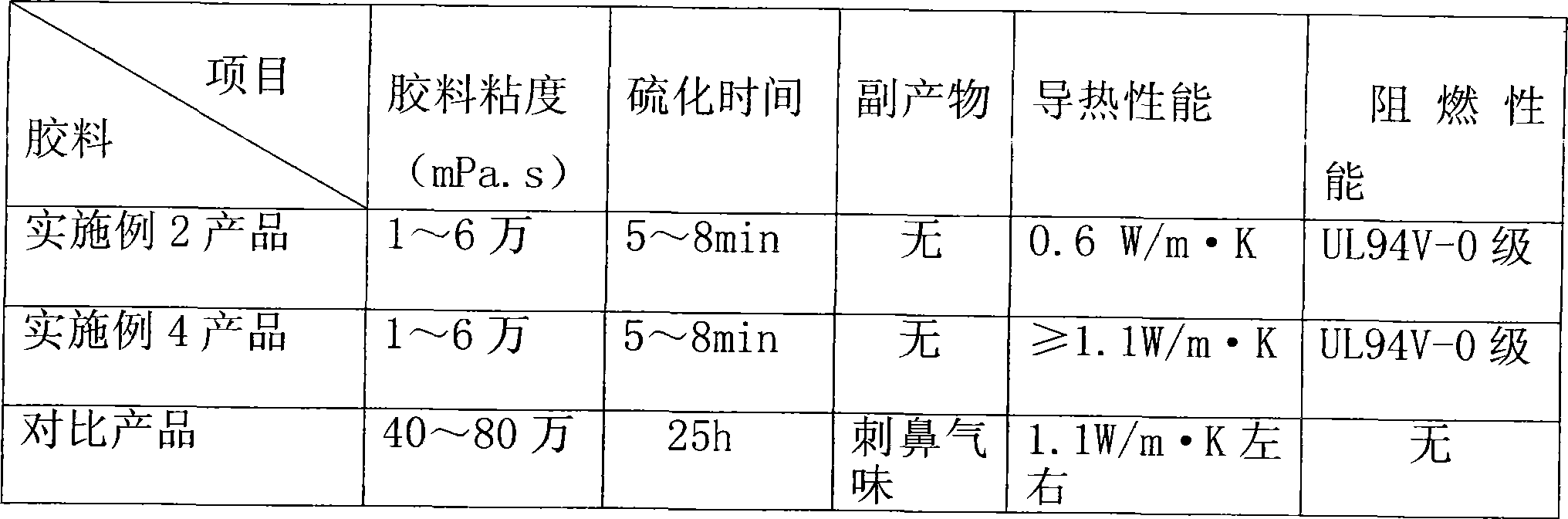

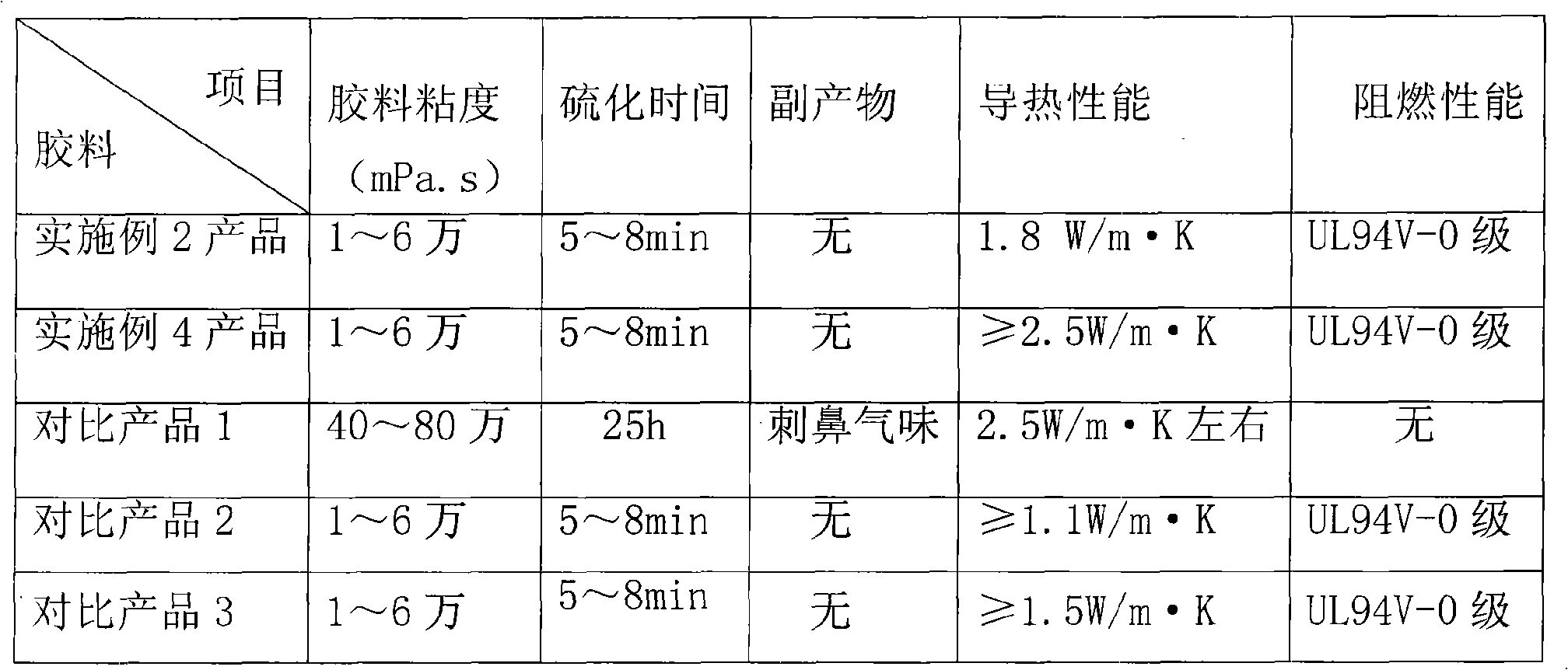

Heat-conducting anti-flaming liquid silicon rubber and preparation method thereof

InactiveCN101168620AReduce consumptionIncrease demandHeat-exchange elementsVulcanizationHeat conducting

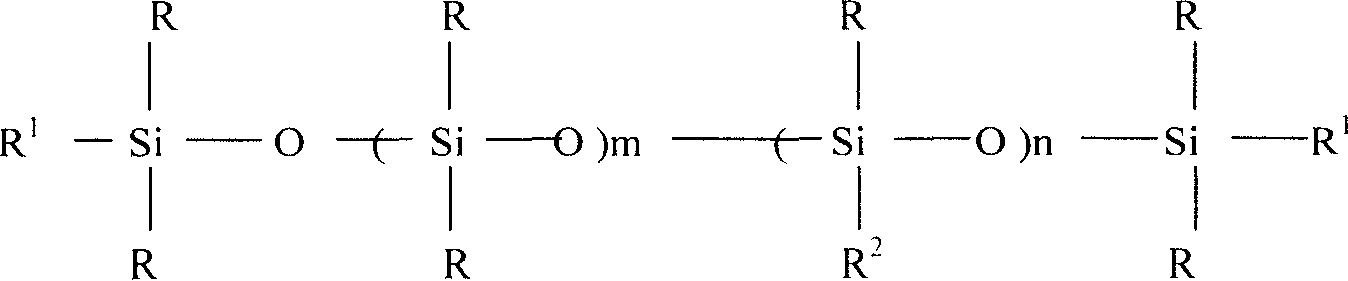

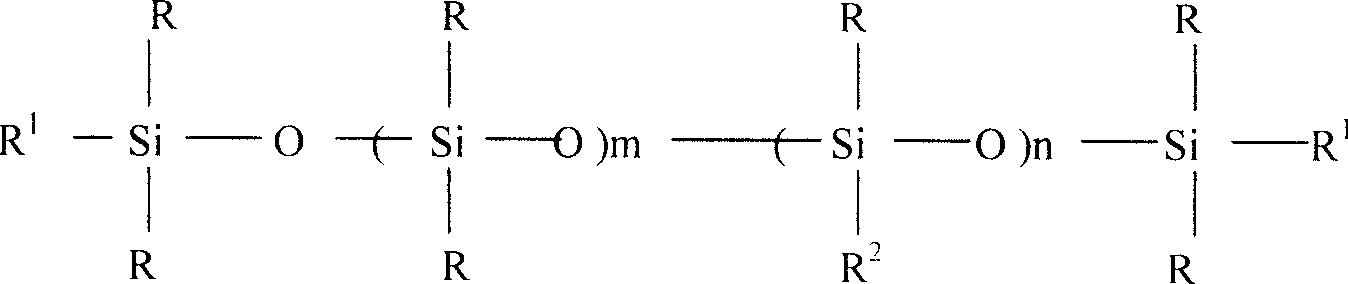

The invention discloses heat conduction flame retardant liquid silica gel, which comprises components with the following parts by weight: 10 to 40 parts of vinyl end organopolysiloxane with 500 to 5000 mPa.s polymeric viscosity in 25 DEG C, 10 to 40 parts of vinyl end organopolysiloxane with 10000 to 50000 mPa.s in 25 DEG C, and 1 to 5 parts of hydrogen-containing polymethylsiloxane, 2 to 8 parts of alkyl disilazane, 20 to 50 parts of surface hydrophobicity Al2O3 powder with average particle diameter of 5 to 20 microns, 10 to 50 parts of Al(OH)3 powder with average particle diameter of 5 to 20 microns, 0.3 to 2 parts of addition solidification catalyst, 0.01 to 0.06 part of alkynol depressant and 0.5 to 2 parts of distilled water, wherein, R is methyl, ethyl, propyl or butyl. The invention is prepared by the way of addition type heat vulcanization, toxic substance or irritant gas is not produced in the production process, the vulcanization rate is quick, and the energy saving, the consumption decreasing and the environmental protection requirements are conformed. The storage stability of the product is good, the viscosity is moderate, the operability is good, the product integrates the heat conduction, insulation and flame retardant performances into a whole, and the performance-price ratio is high.

Owner:兆舜科技(广东)有限公司

Preparation method of micro-nanometer mixed stuffing/liquid silicon rubber heat-conductive composite material

InactiveCN103013122AThermal conductivity anisotropyHigh thermal conductivityHeat-exchange elementsDiameter ratioNanofiber

The invention discloses a preparation method of a micro-nanometer mixed stuffing / liquid silicon rubber heat-conductive composite material. The preparation method is characterized in that the solidified two-component liquid silicon rubber is taken as a substrate; micro-scale heating conductive particles are taken as connecting points; under an external electric field action, the nanofiber heat conductive stuffing with high length-diameter ratio is oriented to a connecting line, so that the effective heat conductive chain is formed in the silicon rubber substrate, and the heat conductive silicon rubber composite material with anisotropic heat conduction is prepared. The high heat-conductive composite material is excellent in the heat-conductive performance, low in the heat-conductive stuffing dosage, good in mechanical property, simple in the preparation technology and low in cost.

Owner:JIANGSU UNIV

Conductive liquid silicon rubber-based adhesive and preparation method for composition thereof

ActiveCN102010600AModerate viscosityExcellent long-term storage stabilityNon-conductive material with dispersed conductive materialAliphatic unsaturated hydrocarbonAdhesive

The invention discloses a conductive liquid silicon rubber-based adhesive (A), which comprises 100 to 200 mass parts of aliphatic unsaturated hydrocarbon-terminated organic polybisiloxane (a), 10 to 60 mass parts of silica reinforcing filler (b), 10 to 60 mass parts of conductive filler (c) and 5 to 25 mass parts of structural controller (d). In addition, the invention also discloses a conductiveliquid silicon rubber composition, which consists of the component (A) and a component (B) according to a mass ratio of 1:1. The component (A) comprises 100 mass parts of the conductive liquid silicon rubber-based adhesive and 0.05 to 0.5 mass part of addition reaction catalyst; and the component (B) comprises 100 mass parts of the conductive liquid silicon rubber-based adhesive, 2 to 10 mass parts of crosslinking agent (h), 0.04 to 0.5 mass part of addition reaction inhibitor (i) and 0.03 to 2.0 mass parts of pigment (j). The invention also discloses preparation methods and use of the adhesive and the composition.

Owner:GUANGZHOU TINCI MATERIALS TECH

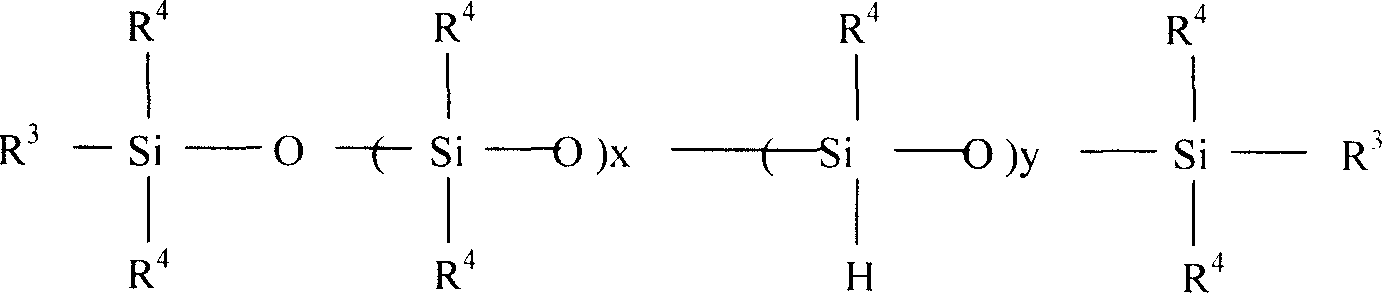

Liquid silicon rubber sizing, liquid silicon rubber material and their preparation method

The invention discloses a liquid silicon rubber base glue stock comprising 100 weight parts of HO[(CH3)2SiO]nH, 30-70 weight parts of reinforcement filling material, and 1-20 weight parts of structured control agent. The invention also discloses the process for preparing the liquid silicon rubber base glue stock, liquid silicon rubber material containing the liquid silicon rubber base glue stock and its preparing process, wherein the material comprises component (A) and component (B) by the mass ratio of 1:1, wherein the component (A) comprises 100 weight parts of liquid silicon rubber base glue stock, 0.05-0.5 weight parts of addition reaction catalyst, and the component (B) comprises 100 mass parts of liquid silicon rubber base glue stock, 2-10 weight parts of cross linking agent, 0.04-0.5 weight parts of addition reaction depressant and 0.03-0.5 wt% of pigment.

Owner:GUANGZHOU TINCI MATERIALS TECH

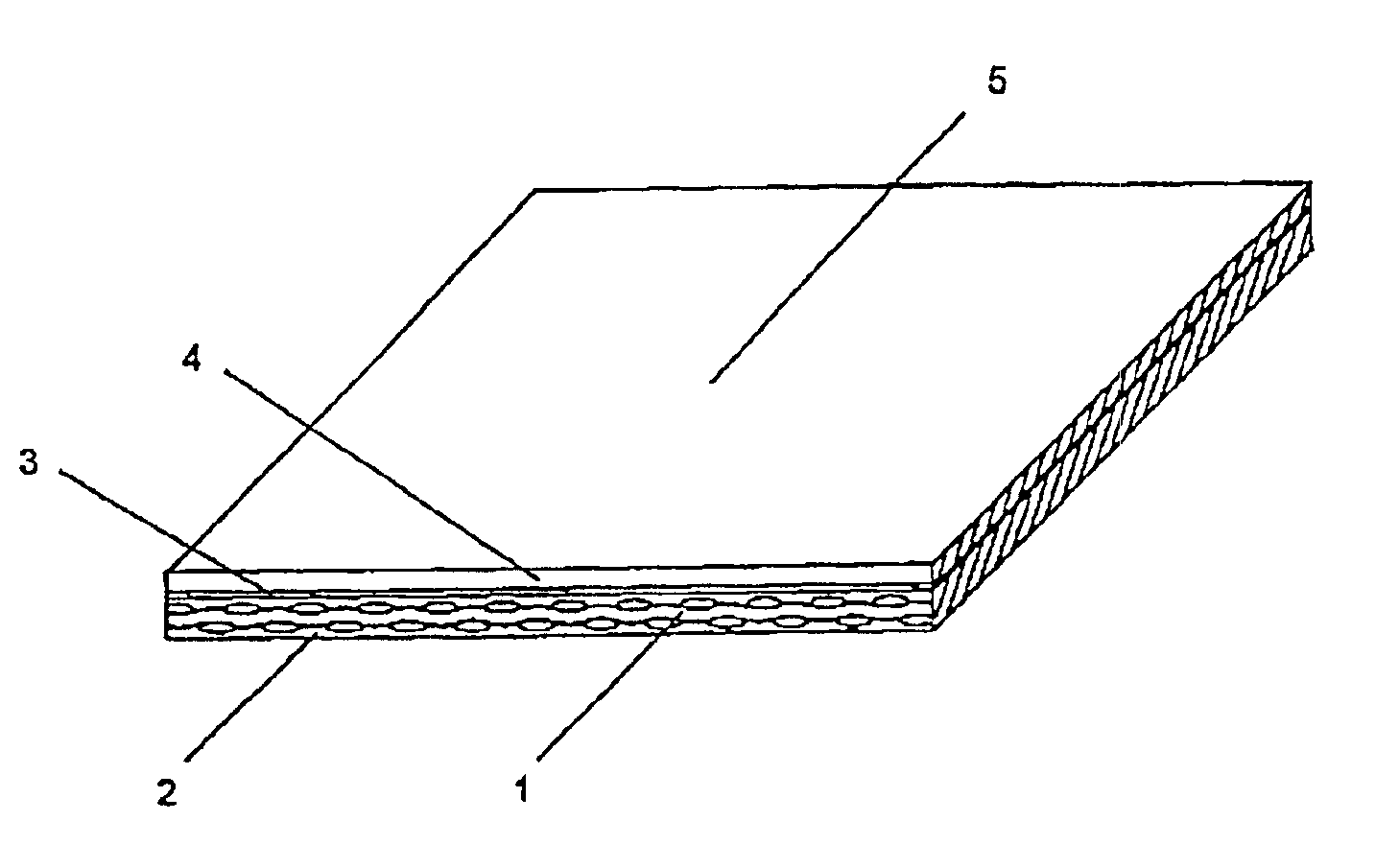

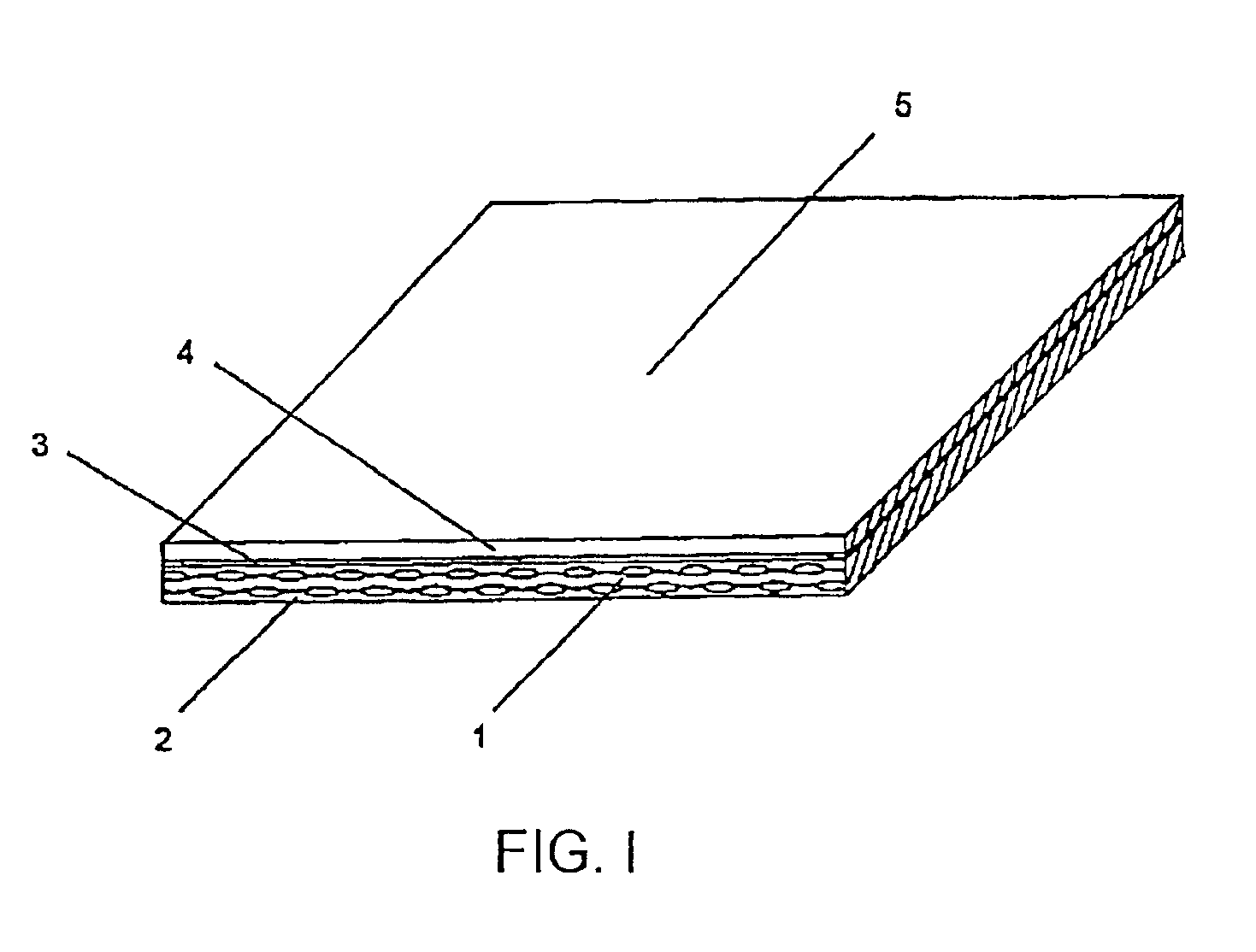

Non-curling reinforced composite membranes with differing opposed faces, methods for producing and their use in varied applications

InactiveUS6930063B2Improve performanceConveyorsSynthetic resin layered productsGlass compositesPolymer science

A double-faced PTFE-silicone rubber reinforced composite with curling tendency controlled is achieved by coating one side of a balanced PTFE / glass composite with liquid silicone rubber. Each face of the composite can perform independent functions in a single application, thereby optimizing performance.

Owner:SAINT GOBAIN PERFORMANCE PLASTICS CORP

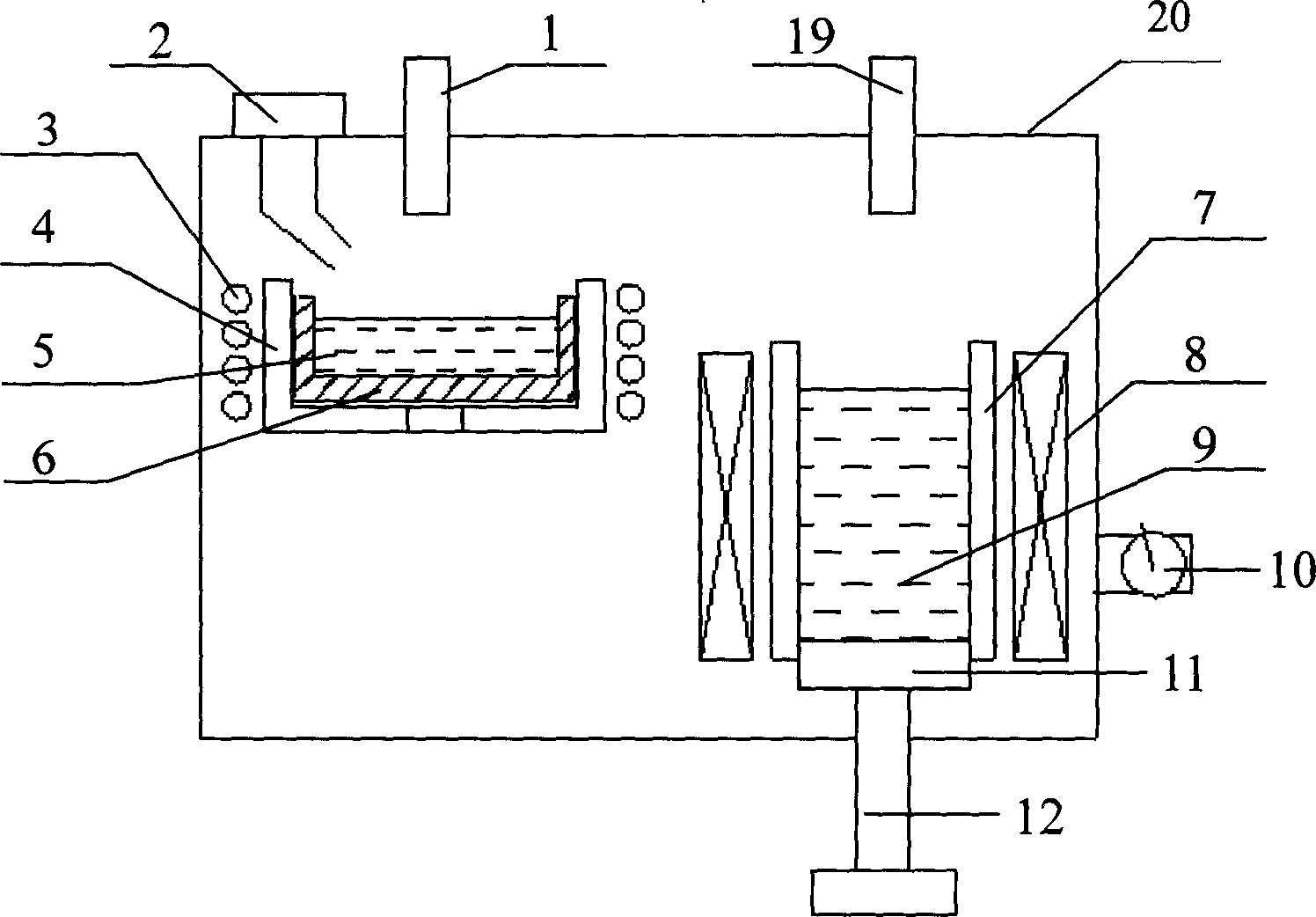

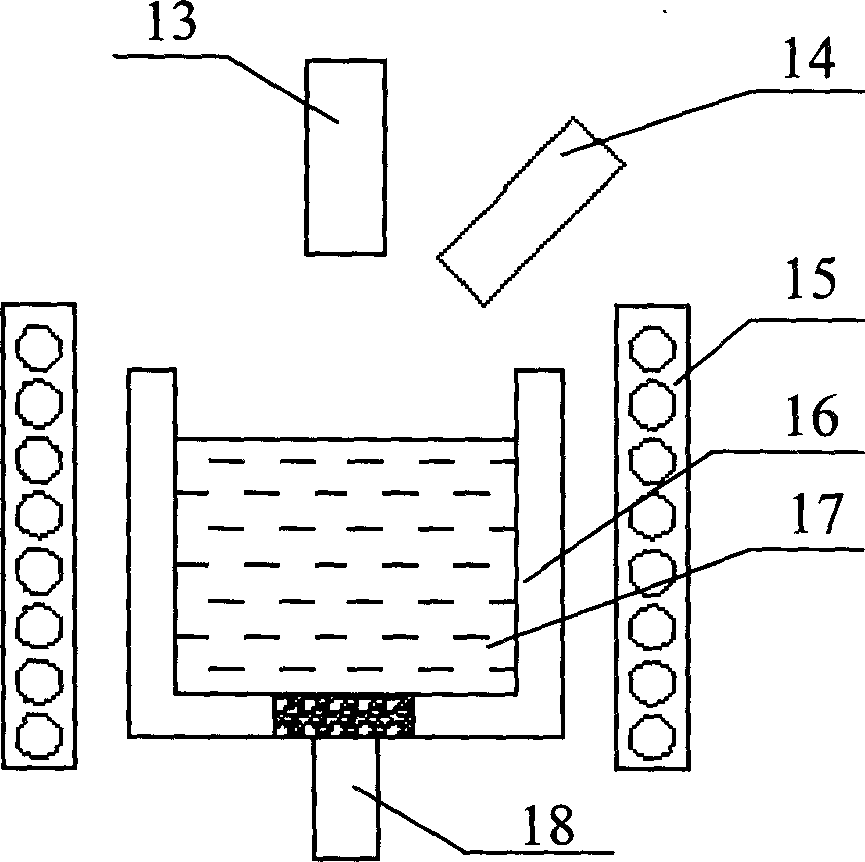

Method for preparing polysilicon in high purity in use for solar cell

InactiveCN1873062ANo crackNo segregationPolycrystalline material growthSingle crystal growth detailsSemiconductor materialsElectromagnetic theory

This invention discloses method and device for preparing high purity polycrystalline silicon for solar cells. This invention combines vacuum electromagnetic induction smelting, plasma oxidation and purification, and oriented-solidification to prepare high purity silicon ingots for solar cells. The method comprises: (1) applying an alternative electromagnetic field (Q is J2 / sigma) at the outer side of solid silicon according to electromagnetic theory; (2) smelting to remove impurities such as P in liquid silicon according to chemical equilibrium theory; (3) performing oriented-solidification according to metal solidification theory that the elements whose equilibrium distribution coefficients are less than 1 can be enriched at the last solidification site, and thus discharged from the liquid. This invention has such advantages as simple equipment, rapid and convenient smelting and purification, uniform solidification, no cracking, no segregation.

Owner:DALIAN UNIV OF TECH

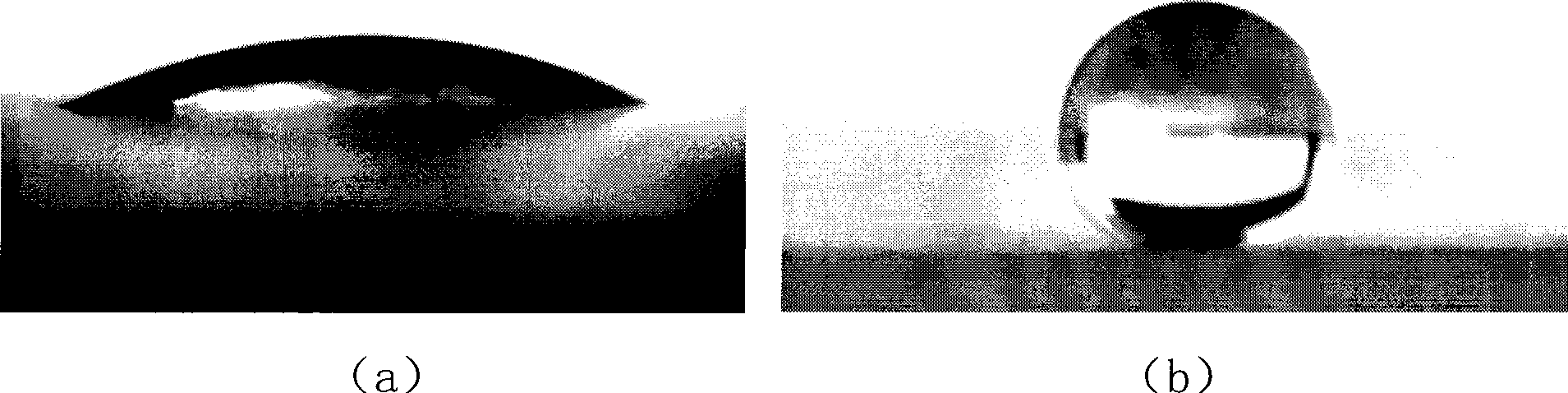

Method for preparing porcelain insulator surface super-hydrophobic coating

The invention discloses a method for preparing a porcelain insulator surface super-hydrophobic coating, which takes ethyl orthosilicate as a presoma and absolute ethyl alcohol as flux, and comprises the following steps: preparing silicon dioxide sol through alkaline catalysis, and adding a silane coupling agent to perform the modification treatment; after the porcelain insulator surface is subjected to the cleaning treatment, dipping in the modified silicon dioxide sol for film coating through the czochralski method to form a primary coating and to obtain a micro-nanometer grade coarse structure which is similar to taro leaf; after drying, dipping in addition type liquid silicon rubber sol for secondary film coating through the czochralski method, and then placing into an oven for heat treatment at a temperature of 100-120 DEG C; and obtaining a transparent super-hydrophobic coating after subjecting the primary coating with the micro-nanometer coarse structure to the secondary film coating modification by the liquid silicon rubber with low surface energy.

Owner:XI AN JIAOTONG UNIV

Methods for manufacturing RFID tags and structures formed therefrom

ActiveUS7687327B2Improve performanceCost effectiveSemiconductor/solid-state device detailsSolid-state devicesHemt circuitsRadio frequency

Radio frequency identification (RFID) tags and processes for manufacturing the same. The RFID device generally includes (1) a metal antenna and / or inductor; (2) a dielectric layer thereon, to support and insulate integrated circuitry from the metal antenna and / or inductor; (3) a plurality of diodes and a plurality of transistors on the dielectric layer, the diodes having at least one layer in common with the transistors; and (4) a plurality of capacitors in electrical communication with the metal antenna and / or inductor and at least some of the diodes, the plurality of capacitors having at least one layer in common with the plurality of diodes and / or with contacts to the diodes and transistors. The method preferably integrates liquid silicon-containing ink deposition into a cost effective, integrated manufacturing process for the manufacture of RFID circuits. Furthermore, the present RFID tags generally provide higher performance (e.g., improved electrical characteristics) as compared to tags containing organic electronic devices.

Owner:ENSURGE MICROPOWER ASA

Heat conduction flame-proof liquid silicon rubber for electron and method of producing the same

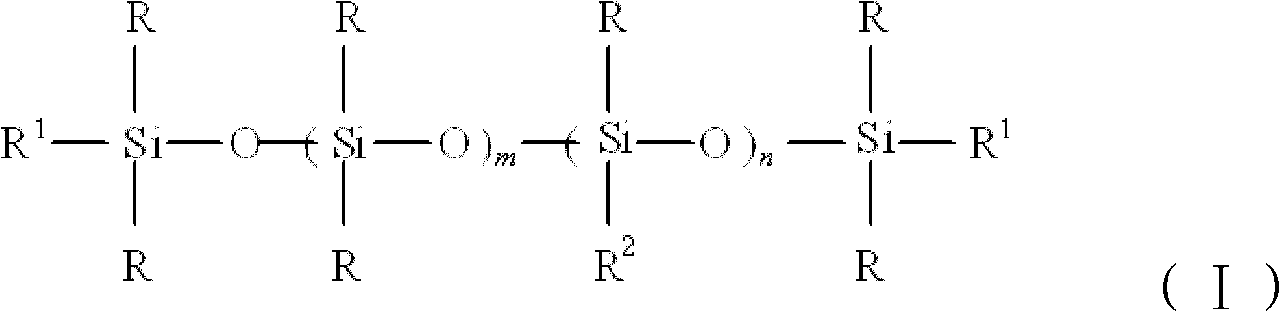

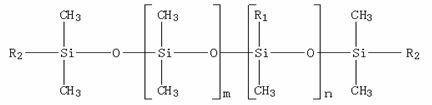

The invention discloses a heat-conductive anti-flaming liquid silicone rubber used for electrons, which comprises the components with the following parts by weight: ethylene group dead-end organic polysiloxane which has polymer viscosity of 500 to 5000mPa.s and 10000 to 50000mPa.s when reaching 25 DEG C and has a general formula R2SiO(SiRR'O)nSiR2; hydric polysiloxane which has a general formula R'R2SiO(SiR HO)nSiR2R'; alkyldisilazane which has a general formula R3SiNHSiR3; a mixed-powder of Al2O3 and MgO with the surface hydrophobic particle size being respectively 5 Mum and 2 Mum and with the ratio of 4:1between Al2O3 and MgO; an Al(OH)3 powder which has an average particle size of 2 to 10 Mum; an additive solidified catalyst; an alkynol solidified inhibitor; and distilled water. The silicone rubber generates no toxic substance or irritative gas and has no side product and high efficiency; the product obtained is characterized by high thermal conductivity, good storage stability, moderate viscosity and good operability, and can integrate heat conduction, insulation and anti-flaming properties together, thereby meeting higher requirements of electrical appliances industry and having high cost performance.

Owner:兆舜科技(广东)有限公司

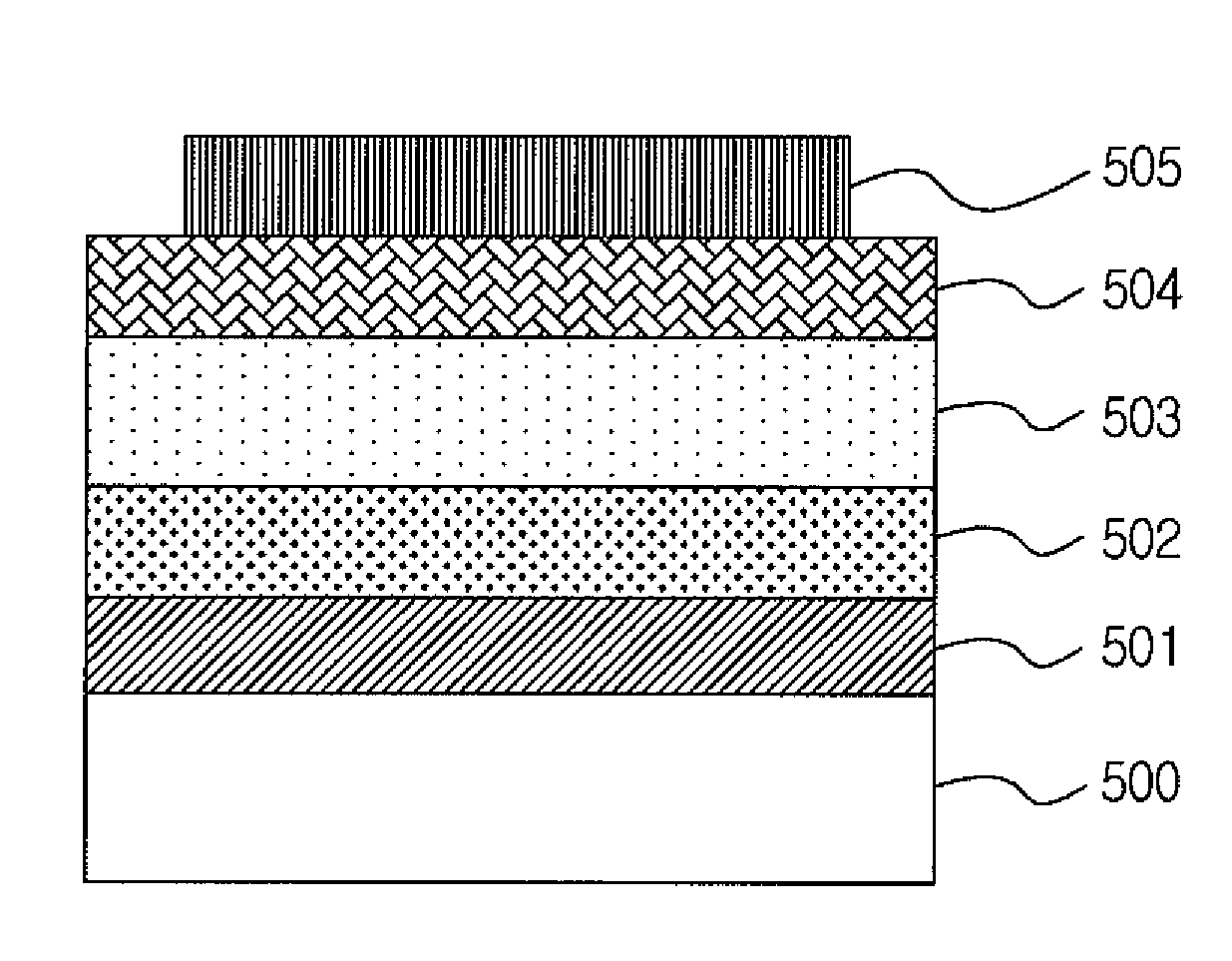

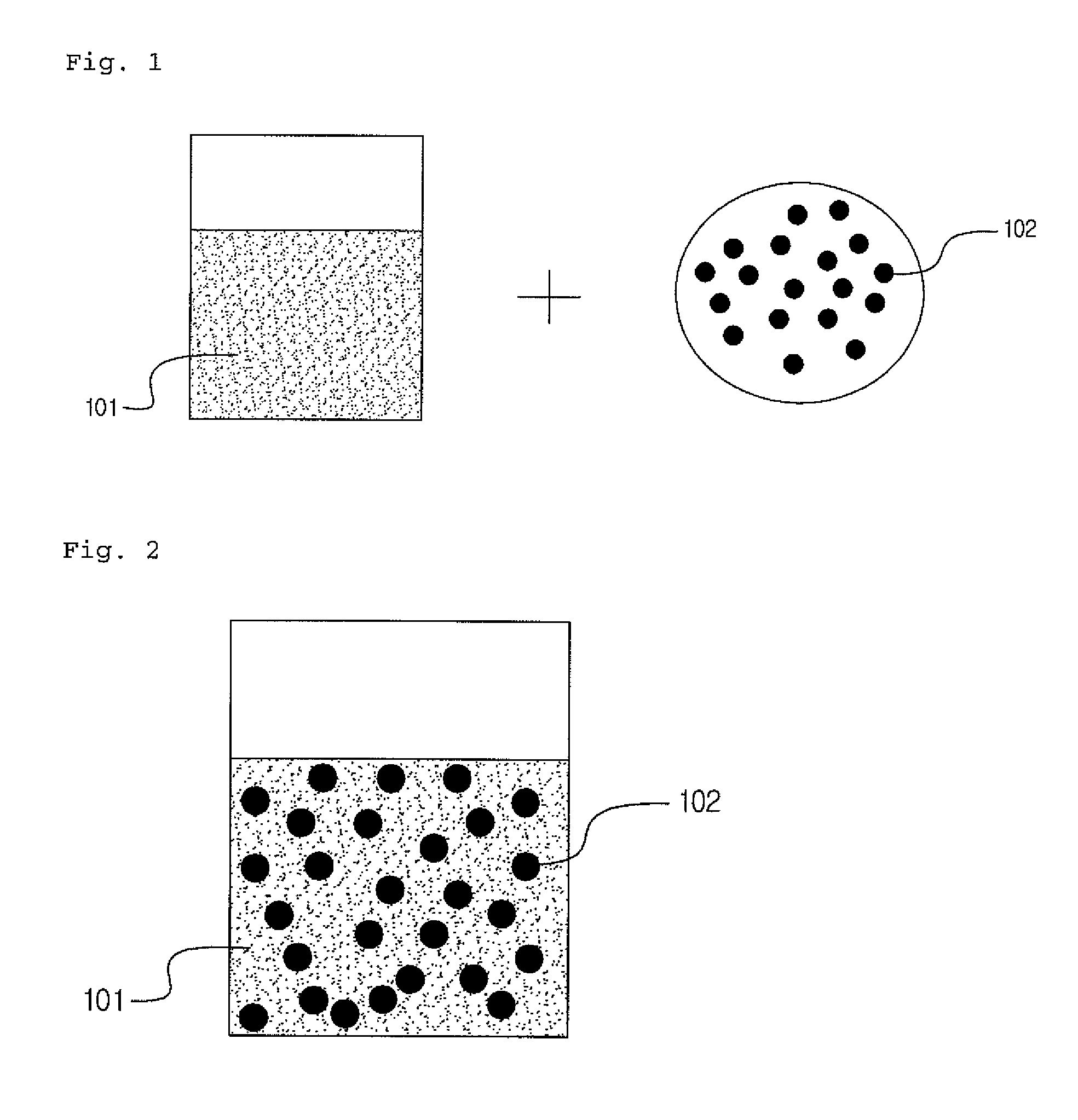

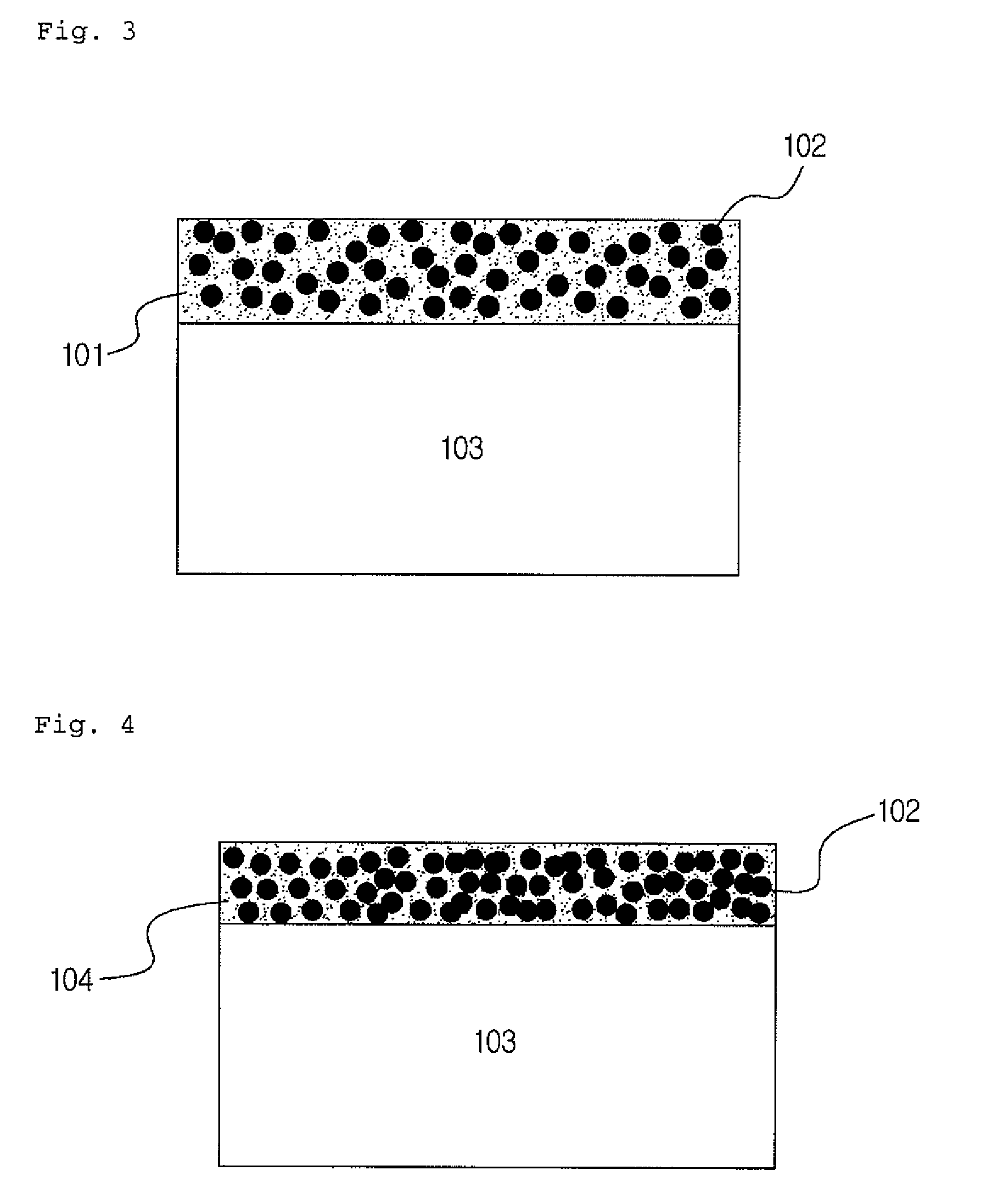

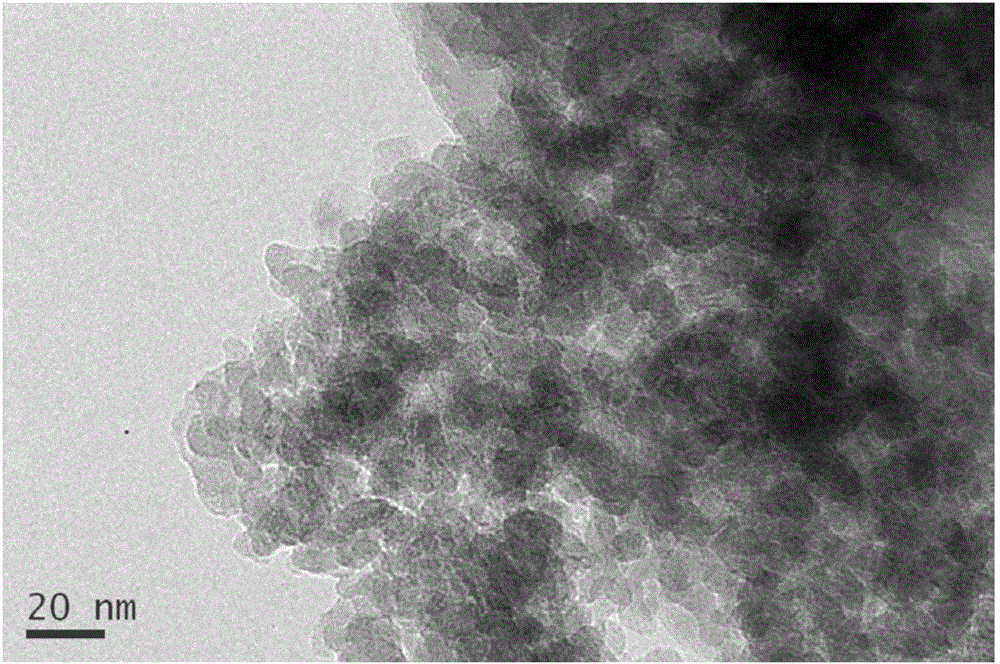

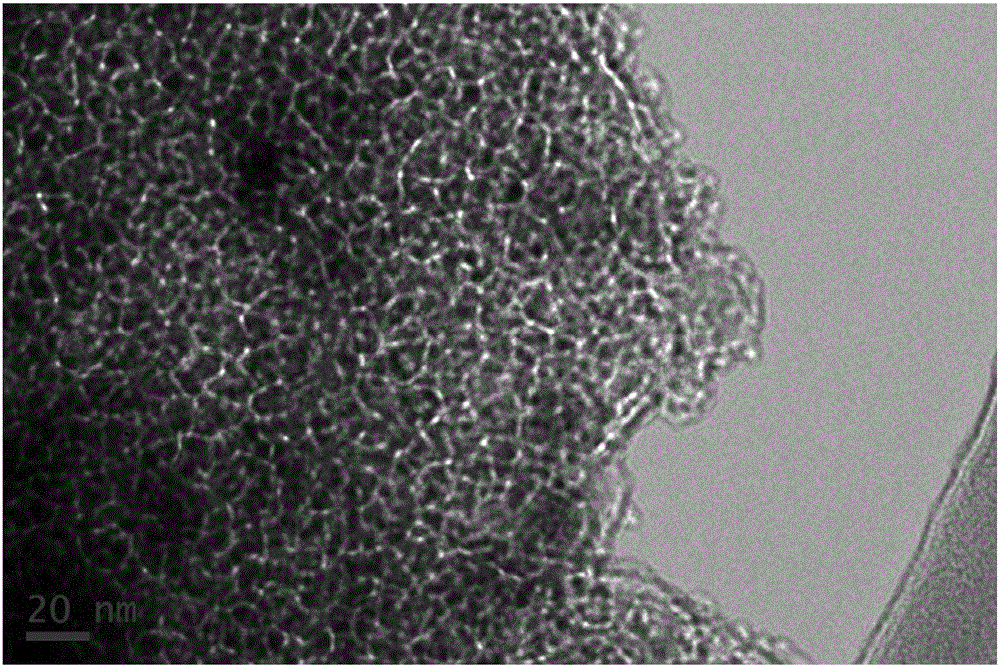

Solar cell manufactured using amorphous and nanocrystalline silicon composite thin film, and process for manufacturing the same

InactiveUS20090071539A1Improve photoelectric conversion efficiencyReduce defectsMaterial nanotechnologyFinal product manufactureComposite filmNanoparticle

Disclosed are a solar cell manufactured using a composite thin film comprising amorphous silicon and nanocrystalline silicon, a method of manufacturing the solar cell, and a composition for the composite thin film used in manufacturing the solar cell. More particularly, a silicon semiconductor layer in the solar cell is fabricated by using the composite thin film comprising the amorphous silicon and the nanocrystalline silicon, the composite thin film being formed by dispersing nanoparticles of the crystalline silicon in a liquid silicon precursor and modifying them.The solar cell of the present invention is manufactured by dispersing the crystalline silicon nanoparticles in the liquid silicon precursor, coating the dispersion on a substrate or printing the substrate with the dispersion, and heating the coated or printed substrate to modify the liquid silicon precursor into the amorphous silicon.According to the present invention, any expensive equipment requiring alternative complicated installations is not needed to form a composite thin film comprising both of amorphous silicon and crystalline silicon. In addition, it is possible to form a composite thin film comprising plural materials with different band gap energy which can remarkably improve conversion efficiency of a solar cell by using a liquid precursor and nanocrystalline particles in a solution process with low production cost.

Owner:LG ELECTRONICS INC

Addition type liquid silicone rubber bonding accelerant and preparation method and application thereof

The invention discloses an addition type liquid silicone rubber bonding accelerant and a preparation method and application thereof. The preparation method comprises the steps as follows: mixing an acrylic ester compound and a platinum catalyst solution, and preheating the mixed solution for 20-60 minutes at the temperature of 30-60 DEG C for later use; adding silicon hydrogen bond, hydrogen-containing silicone oil, methylbenzene and para-hydroxybenzaldehyde into a reactor; stirring while heating; when the temperature in the reactor achieves 30-80 DEG C, dripping the mixture of the acrylic ester compound and the platinum catalyst which are primarily heated to 30-60 DEG C into the reactor, for 0.5-3 hours; after dripping, controlling the reaction temperature within 50-90 DEG C and reacting for 0.5-4 hours; adding activated carbon for adsorption, and then performing suction filtering and rotary evaporation to the solution after reaction so as to obtain the bonding accelerant. The bonding accelerant prepared through the method can remarkably improve the adhesive property of the addition type liquid silicon rubber, the preparation process is simple and convenient, the raw materials are cheap and easy to obtain, and the industrialized production is facilitated.

Owner:东莞市贝特利新材料有限公司

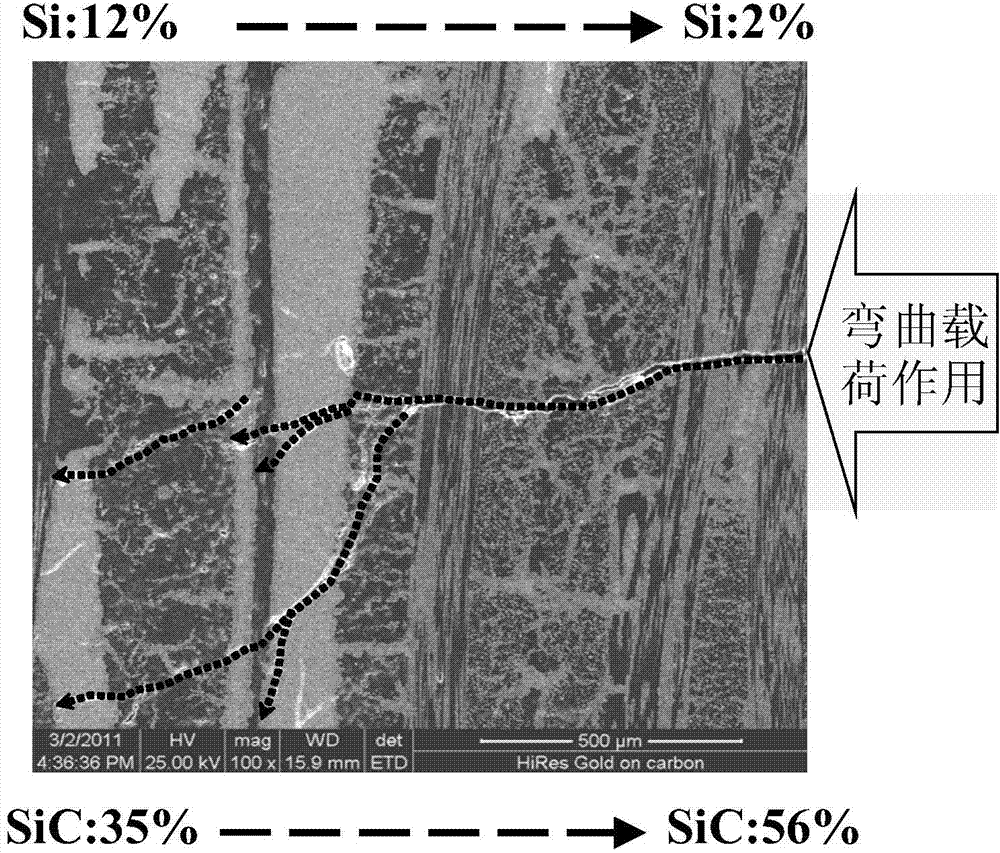

Preparation method of carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material

The invention discloses a preparation method of a carbon fiber reinforced carbon-silicon carbide dual-ceramic based gradient composite material. The preparation method is characterized by comprising the following steps: (a), carrying out thermal treatment onto the fibers by adopting different temperatures; (b), dipping the fibers which are not subjected to thermal treatment and the thermally-treated fibers obtained in the step (a) in resin glue liquor, drying, continuously superposing and laying up, applying a certain pressure after laying up, and carrying out curing and post-curing treatment in sequence to prepare a composite material biscuit body with fiber / base body interface adhesive strength in gradient change; (c), carrying out high-temperature pyrolysis onto the composite material biscuit body obtained in the step (b) to obtain a carbon / carbon porous body with porosity in gradient change; (d), carrying out liquid silicon permeation onto the carbon / carbon porous body obtained in the step (c) under a high temperature to obtain the C / C-SiC composite material with SiC ceramic base body content in gradient change. The preparation method disclosed by the invention is simple in process, short in preparation period, low in cost and capable of preparing a large workpiece with a complex shape.

Owner:DALIAN UNIV OF TECH

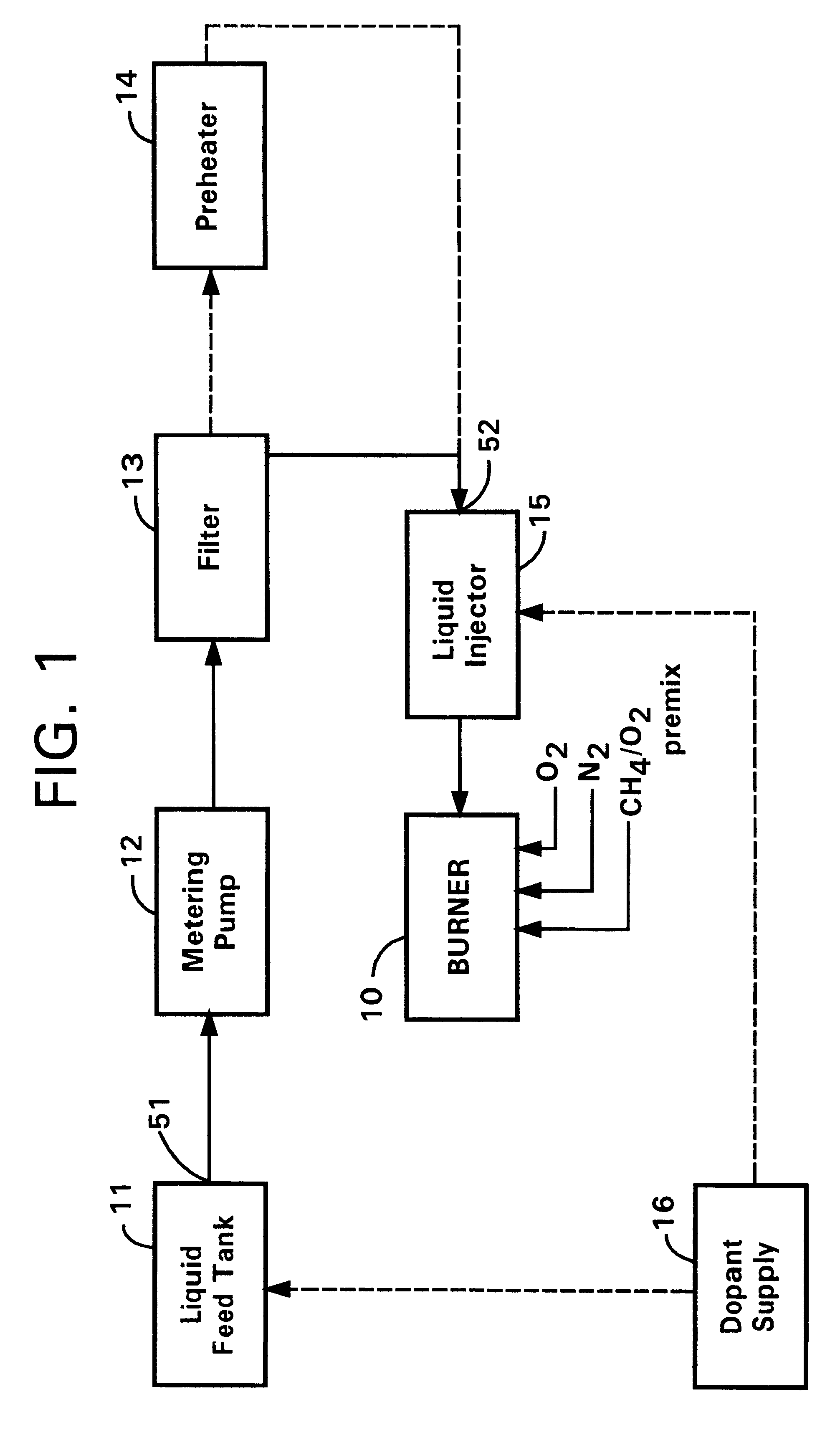

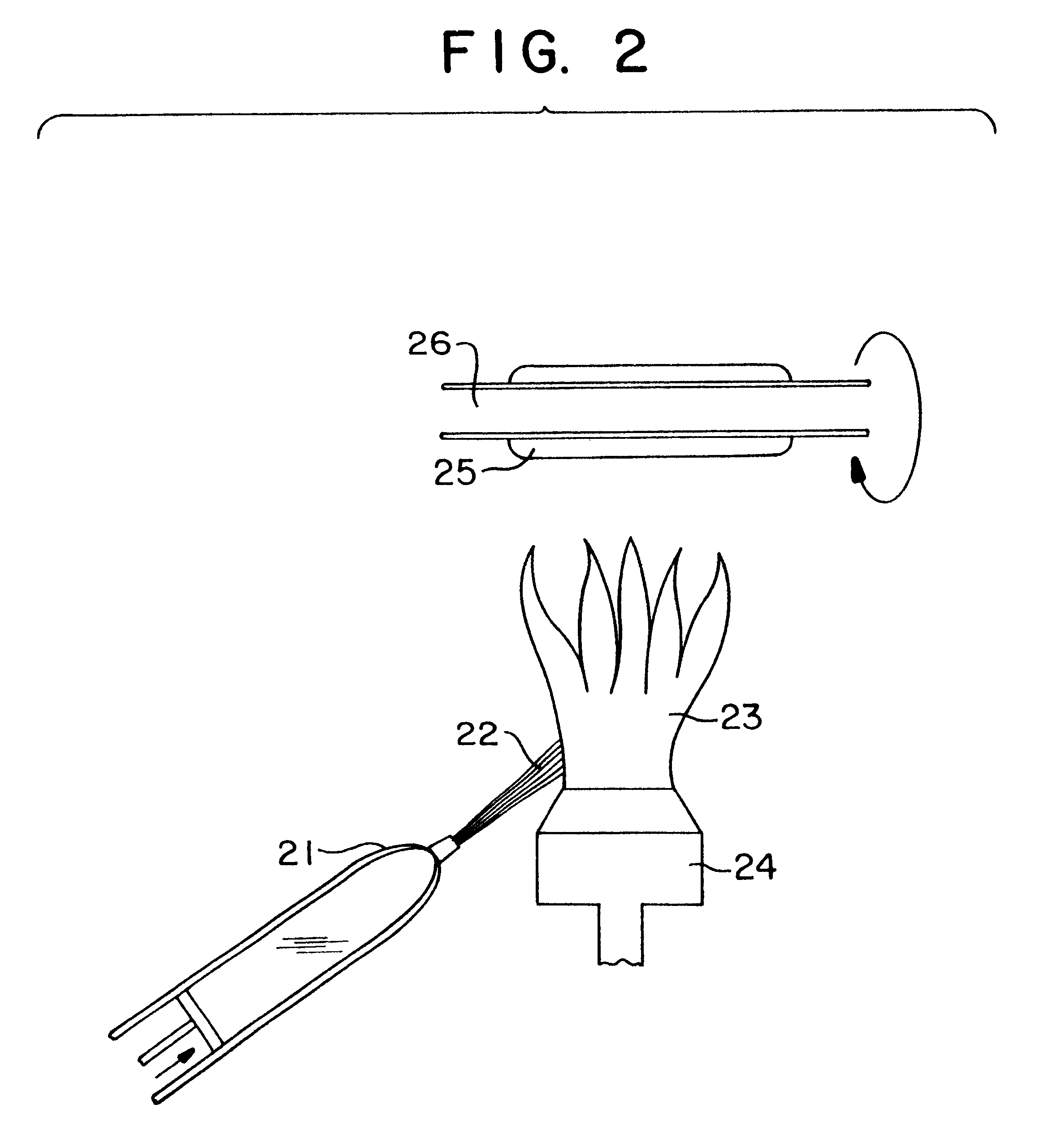

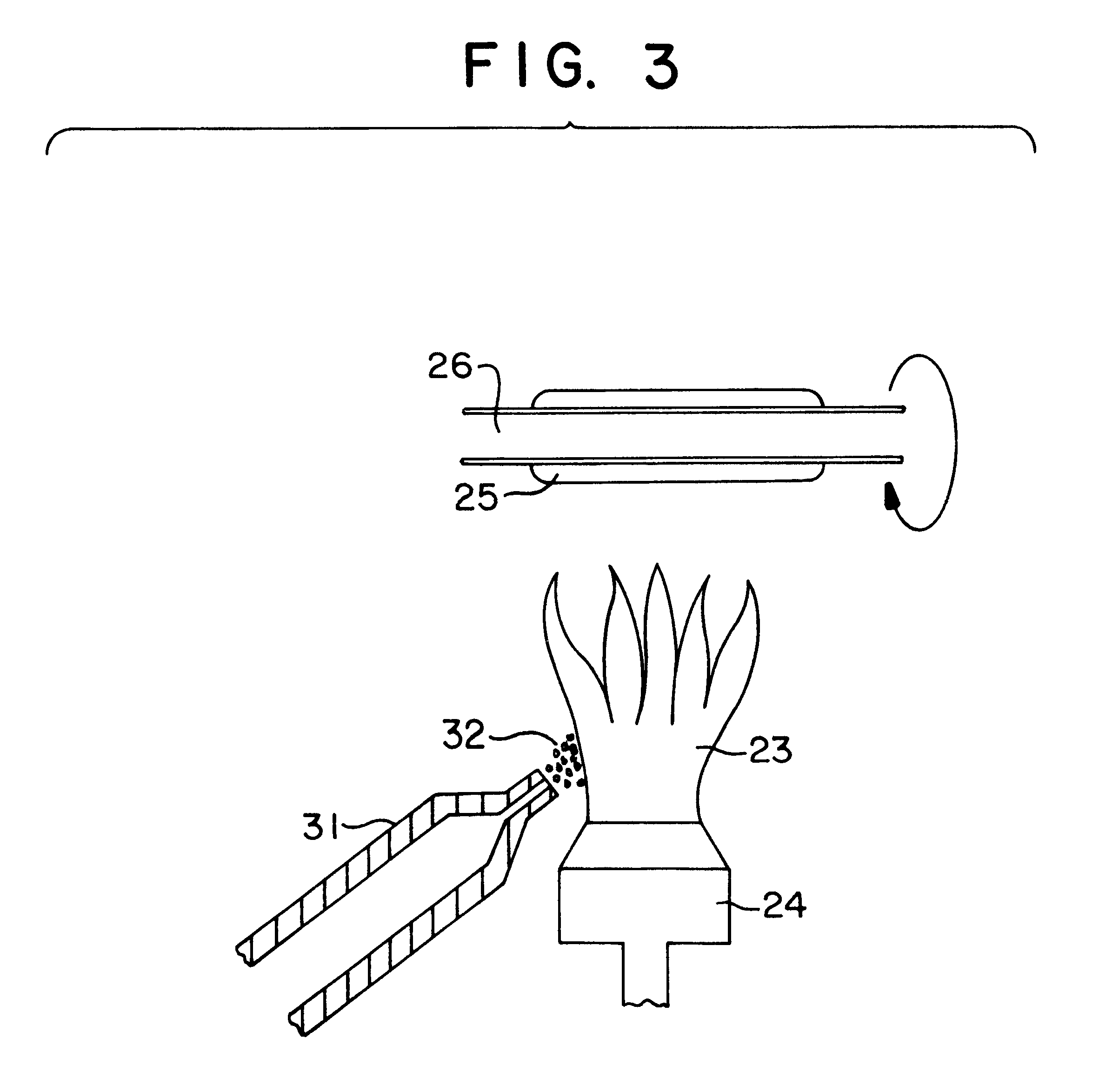

Method and apparatus for forming fused silica by combustion of liquid reactants

InactiveUS6565823B1High concentricityPrevents burner buildupSilicaSpray nozzlesCombustorDecomposition

The present invention is directed to a method for making fused silica glass. A liquid, preferably halide-free, silicon-containing compound capable of being converted by thermal oxidative decomposition to SiO2 is provided and introduced directly into the flame of a combustion burner, thereby forming finely divided amorphous soot. The amorphous soot is deposited on a receptor surface where, either substantially simultaneously with or subsequently to its deposition, the soot is consolidated into a body of fused silica glass. The invention further relates to an apparatus for forming fused silica from liquid, preferably halide-free, silicon-containing reactants which includes: a combustion burner which, in operation, generates a flame; an injector for supplying a liquid silicon-containing compound to the flame to convert the compound by thermal oxidative decomposition to a finely divided amorphous soot; and a receptor surface on which the soot is deposited.

Owner:CORNING INC

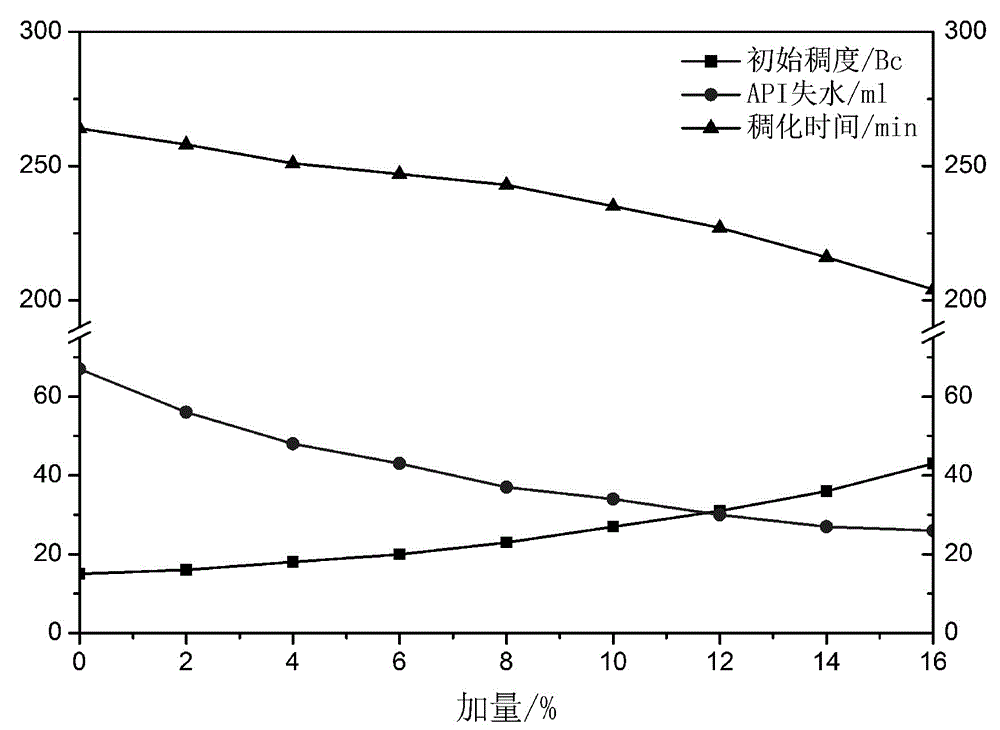

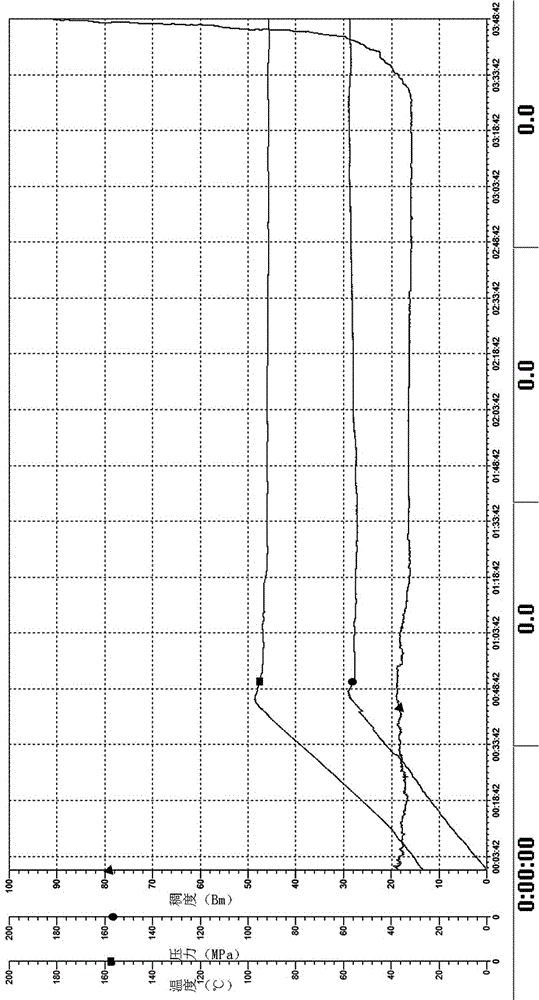

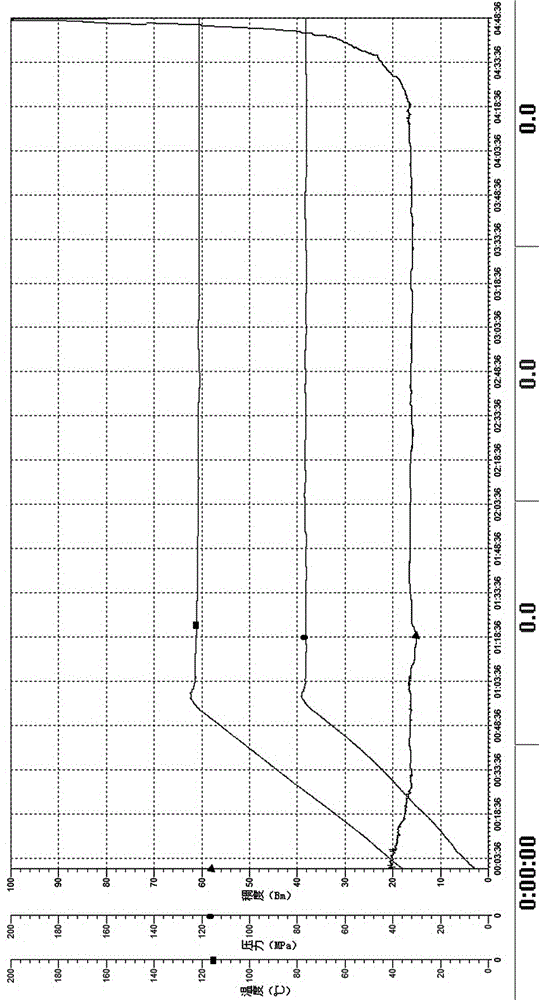

Novel liquid silicon anti-channeling cement slurry used in well cementation

InactiveCN105038745AApplicable temperature rangeHigh densityDrilling compositionPorosityWell cementing

The invention discloses a novel liquid silicon anti-channeling cement slurry used in well cementation, which includes following raw materials, by weight, 95-105 parts of G-grade cement, 10-35 parts of a strength stabilizer, 0.5-4 parts of a retarder, 0.1-0.2 parts of a defoaming agent, 5-15 parts of a filling agent, 0.5-2 parts of a dispersing agent, 100 parts of water, 5-15 parts of an anti-gas channeling agent, 5-10 parts of a fluid loss agent and also a density adjusting agent. The raw materials are mixed and stirred uniformly to prepare the novel liquid silicon anti-channeling cement slurry. The anti-channeling cement slurry is low in water loss, is good in stability, is short in static gelatinization transition time, is strong in anti-gas channeling performance, is quick in early strength development at a low temperature and resists corrosion of acidic mediums. Set cement slurry is slight in expansion, is less in porosity, is high in compactness and low in permeability, and can satisfy requirements in various well cementation situations.

Owner:成都欧美克石油科技股份有限公司

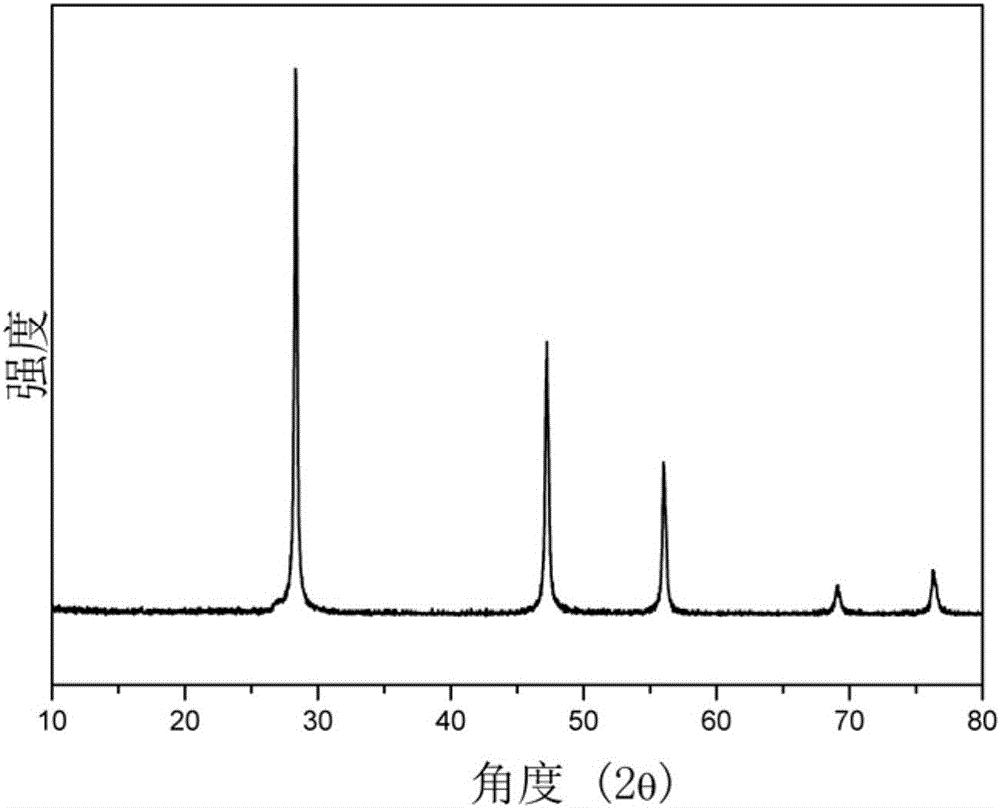

Method for preparing nanometer silicon based on introduction of metal into metallothermic reduction

ActiveCN106495161AUniform shapeExcellent cycle performanceCell electrodesSilicon compoundsLithium-ion batterySilicon particle

The invention discloses a method for preparing nanometer silicon based on introduction of metal into metallothermic reduction. The method comprises the steps of utilizing a metal ion solution and a liquid silicon source as raw materials, obtaining nano silica-metal oxide precursor through co-deposition, then mixing the precursor and a metallothermic reduction reducing agent, controlling reaction conditions, and removing introduced metal after the metallothermic reduction so as to prepare nanometer silicon particles with various shapes and appearances. Because of the porous structure of the precursor, infiltration of reducing agent metal in the reduction process is promoted, and thus the reaction can be conducted more evenly. The microstructure of the reaction product can be adjusted by adjusting types and quantities of metal. Therefore, the nanometer silicon particles has the advantages of being uniform in appearance and shape, homogeneous in aperture distribution, high in specific surface area and low in preparing cost. According to the method, silicon sources of water glass and the like are metal slat are adopted as raw materials, the method is low in cost, amplifying production is easily achieved, and the method has a wide application prospect in the fields of lithium ion battery materials and the like.

Owner:湖南宸宇富基新能源科技有限公司

Full-transparent liquid silicone rubber composition and preparation method thereof

The invention relates to a full-transparent liquid silicone rubber composition, which comprises the following components in mass part: 100 parts of vinyl polydimethylsiloxane, 10-80 parts of vinyl MQ silicon resin, 10-80 parts of methyl hydride MQ silicon resin, 0.01-10 parts of cross-linking agent, 0.001-1 part of inhibitor and 0.01-2 parts of platinum catalyst. The invention further relates to a preparation method for the full-transparent liquid silicone rubber composition. According to the invention, by utilizing the compatibility of the vinyl MQ silicon resin and the methyl hydride MQ silicon resin, the full-transparent liquid silicon rubber with more than 95% light transmittance can be prepared, and the full-transparent liquid silicon rubber with different intensity can be provided through the hard segment structural design of the silicon rubber provided by the invention.

Owner:SHENZHEN CITY SQUARE SILICONE MATERIALS

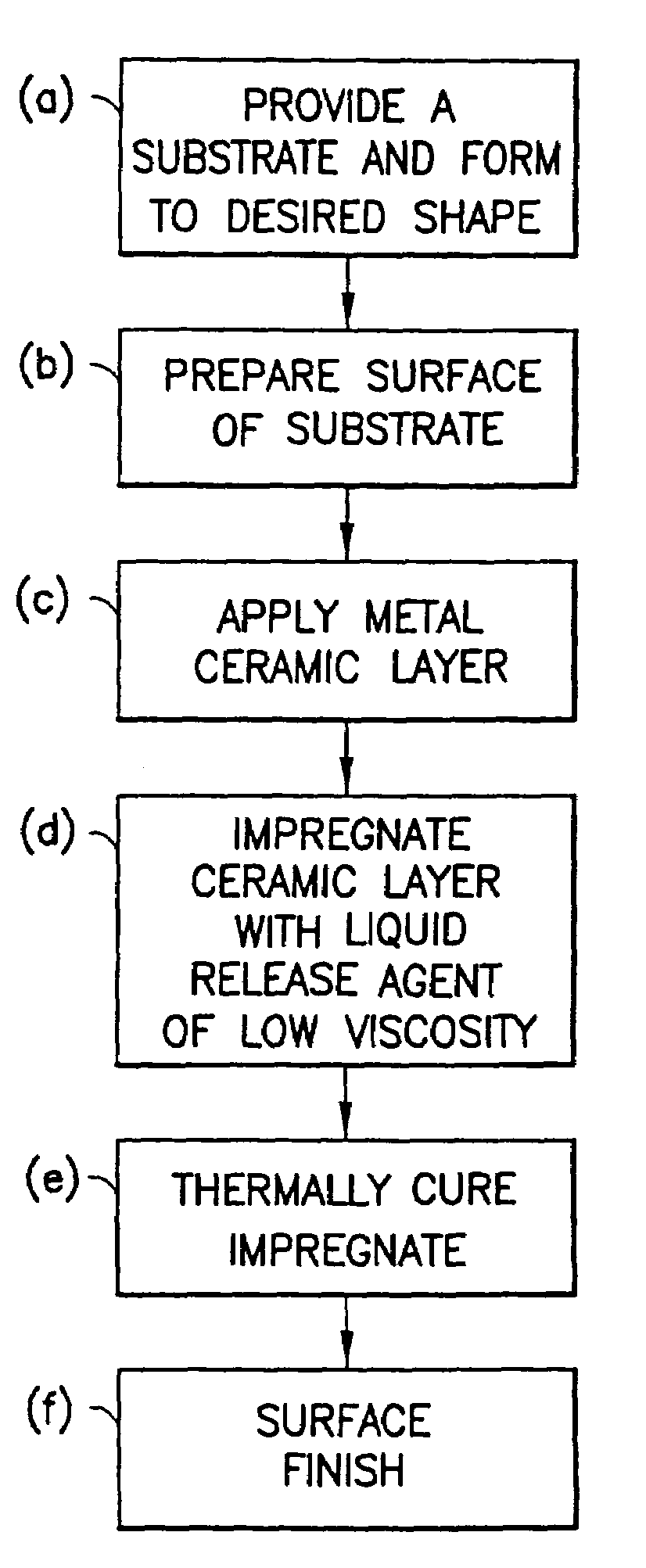

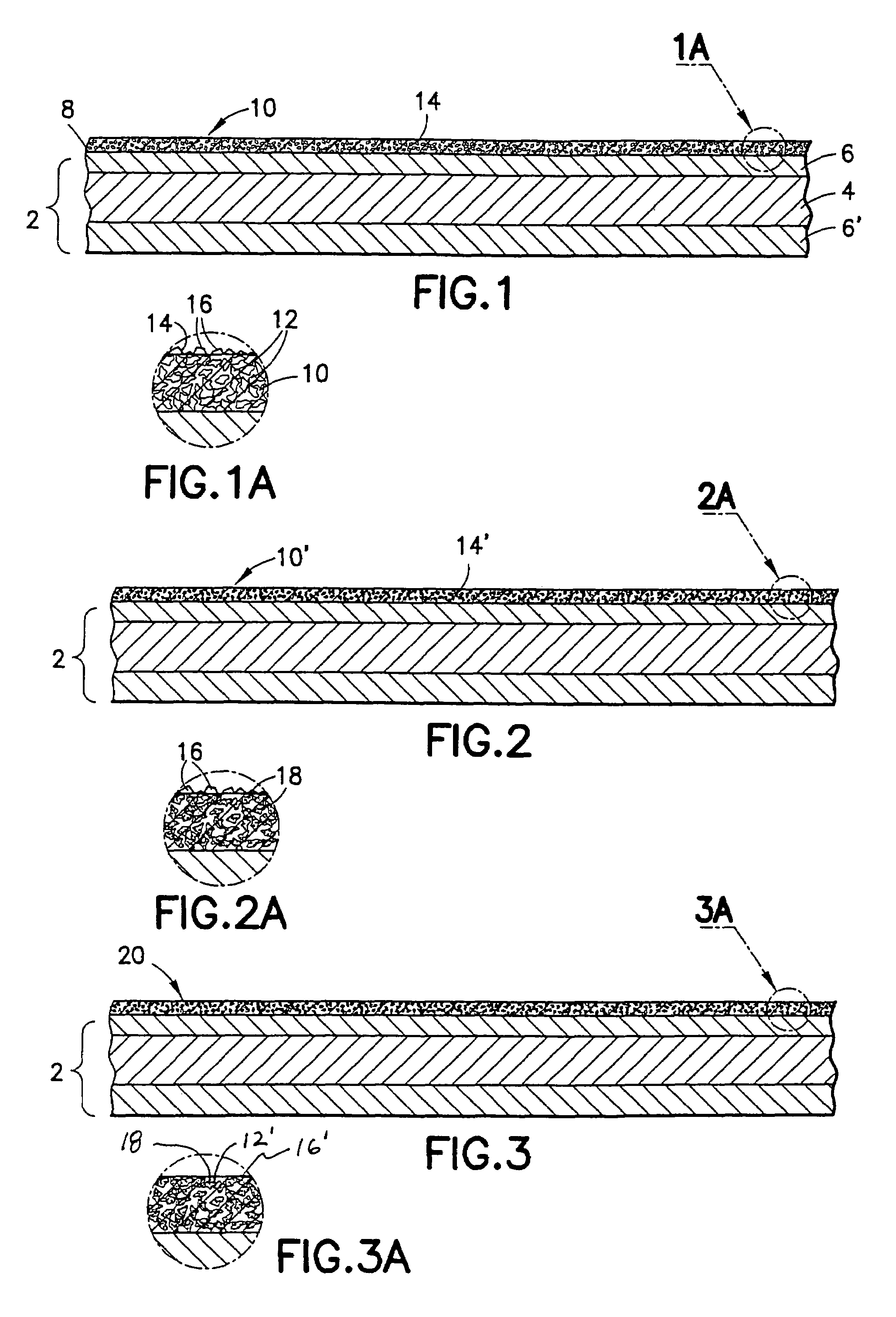

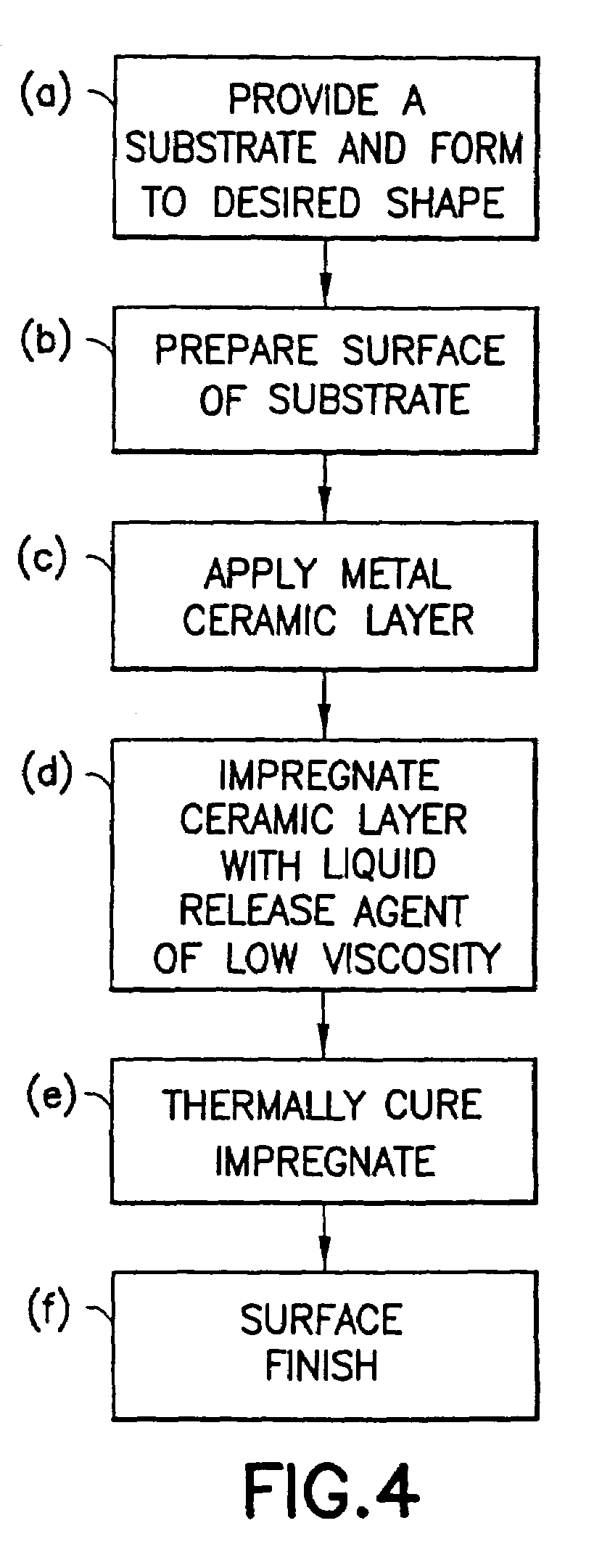

Method of making non-stick cookware

InactiveUS7488515B2Improve adhesionLow viscosityCooking-vessel materialsMolten spray coatingCeramic coatingHard metal

A non-stick surface comprising a porous, hard metal-ceramic coating such as chromium oxide applied to the cook surface of a cooking utensil by arc or plasma spraying. The pores of the coating are impregnated under vacuum with an inert release agent of low viscosity such as food grade liquid silicon resin. After vacuum impregnation, the impregnate is thermally cured and the cook surface is mechanically abraded / polished to remove the protruding peaks of metal-ceramic material to expose flattened bare metal portions interspersed between and substantially co-planar with the surfaces of the impregnated release agent residing in the valleys / pores.

Owner:CLAD METALS

Method for preparing alcohol permselective silicon rubber composite membrane

The invention relates to a method for preparing an alcohol permselective silicon rubber composite membrane, comprising the following steps of: firstly preparing a PVDF (polyvinylidene fluoride) porous base membrane, dissolving PVDF in an organic solvent to prepare a PVDF solution, stirring to be uniform, filtering, defoaming, wiping a membrane on a polyester non-woven fabric, carrying out a gel bath with water, obtaining a non-woven fabric supported PVDF porous base membrane by adopting an immersion sedimentation phase inversion method, and drying in the air after solution exchange is complete; then preparing a silicon rubber membrane solution, namely mixing liquid silicon rubber containing vinyl, silicon oil containing hydrogen, MQ silicon resins, a chloroplatinic acid solution, nano silicon dioxide and a solvent, stirring to be uniform, filtering and defoaming; and finally preparing the silicon rubber composite membrane, namely coating the membrane solution on the PVDF porous supported base membrane, and carrying out deep crosslinking to obtain an addition-type silicon rubber composite membrane. The composite membrane provided by the invention breaks through the optimal separating property of the traditional pure silicon rubber membrane, has an excellent pervaporation alcohol permselective effect and also has a large-scale industrial application prospect.

Owner:TSINGHUA UNIV

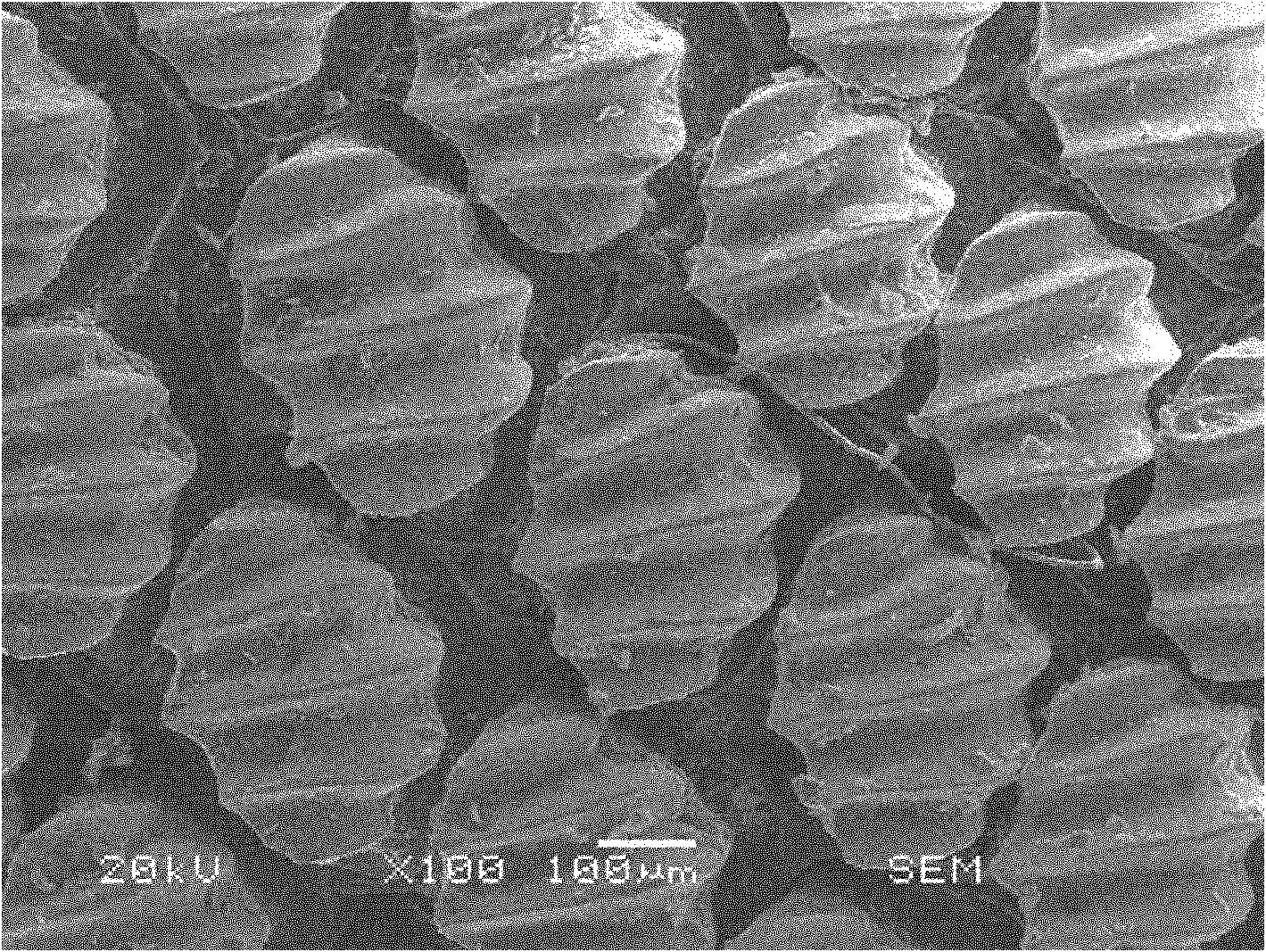

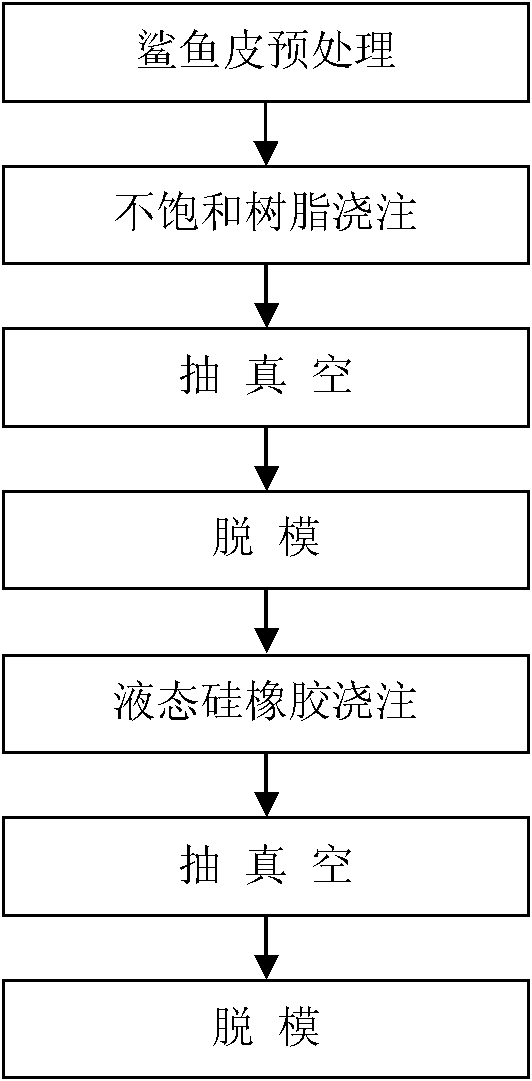

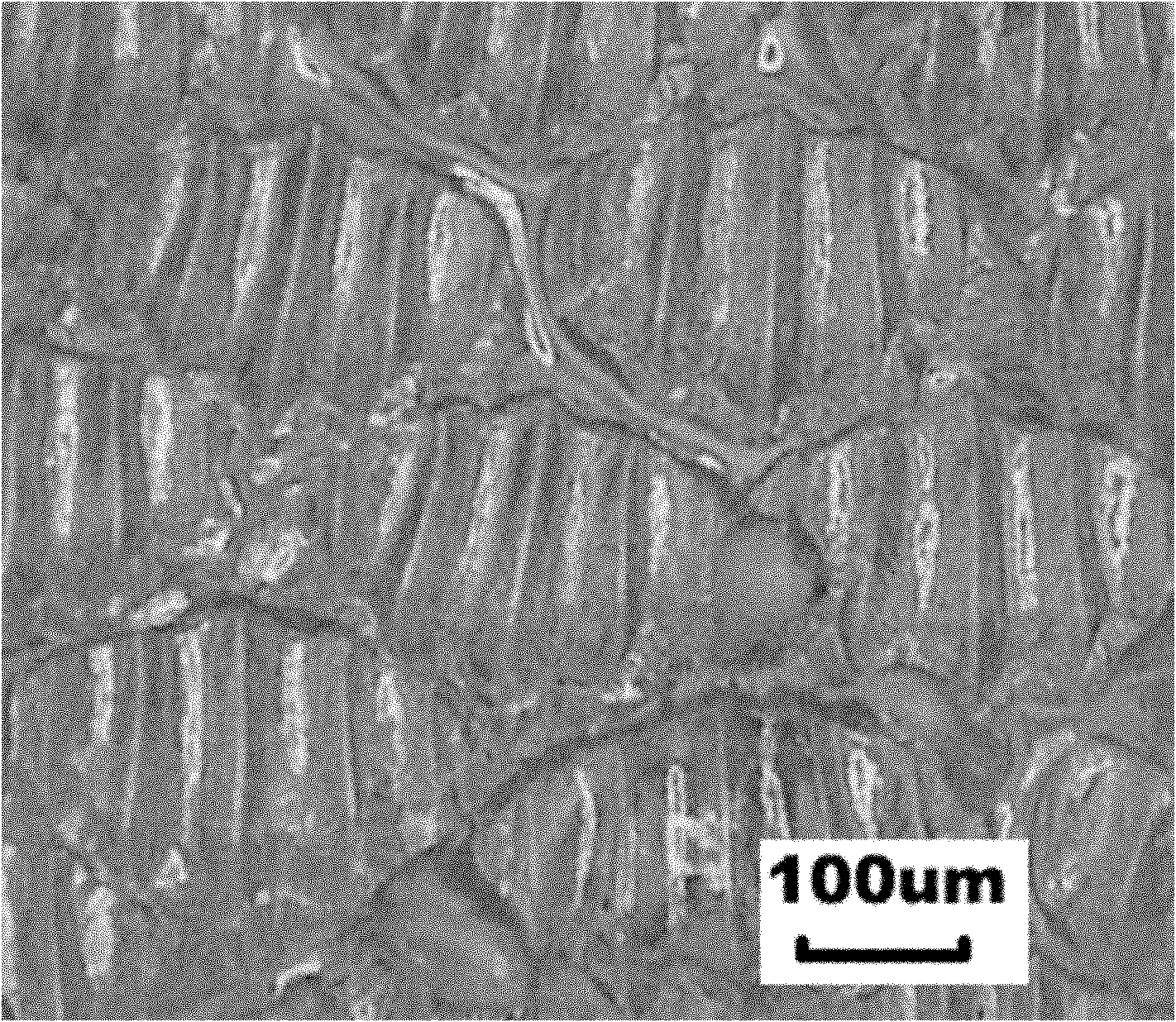

Method for copying sharkskin surface micro groove structure

InactiveCN101966753ASolve the accuracy problemSolve the difficulty of strippingReplication methodSharkskin

The invention discloses a method for copying a sharkskin surface micro groove structure and belongs to the technical field of biological constraint molding. The method is characterized by comprising the following implementation steps: pretreating sharkskin; blowing mold release agent; pouring unsaturated resin; vacuumizing; releasing the unsaturated resin from a mold; blowing mold release agent; pouring liquid silicon rubber; vacuumizing; and releasing the liquid silicon rubber from a mold. The silicon rubber simulation sharkskin thin film obtained by the steps can copy the surface with a riblet micro groove structure of a shark completely and clearly and can be widely used in fields of resistance reduction in aircraft, ship and oil pipe projects and other projects.

Owner:DALIAN UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com