Patents

Literature

85results about How to "Applicable temperature range" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Combined getter

InactiveCN102302923AApplicable temperature rangeHigh reactivityThermal insulationOther chemical processesWater vaporCobalt

The invention relates to a combined getter. The combined getter is characterized in that: an air suction material and an oxidant are put into a carrier to form the combined getter; the air suction material can be a precursor; the oxidant can be one or two oxides selected from iron and nickel, and 5 weight percent of one or more precious metals selected from gold, platinum and palladium can be added into the oxidant to the maximum extent so as to improve the performance of the oxidant; and the oxidant and the precious metals in the oxidant can be prepared by a precipitation method, a coprecipitation method or a mixing method. The invention has the advantages that: when metal oxides of the iron, cobalt, the nickel, copper and the like are used as the oxidant, water absorbed on the surface of the oxidant can seriously influence the reaction activity of the oxidant, but the influences of water vapor can be reduced and the reaction activity of the oxidant can be improved by adding an appropriate amount of Pd into the oxidant. When a trace amount of Au or Pt is added into the oxidant, the influences of the water vapor are greatly reduced; and the metal oxides of the iron and the nickel have higher thermal stability in vacuum, environmental harmful substances can be prevented from being used, and the highest applicable temperature of the conventional combined getter can be expanded.

Owner:NANJING HUADONG ELECTRONICS VACUUM MATERIAL

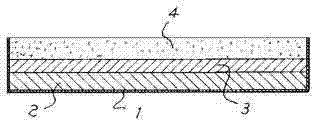

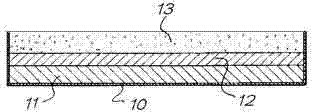

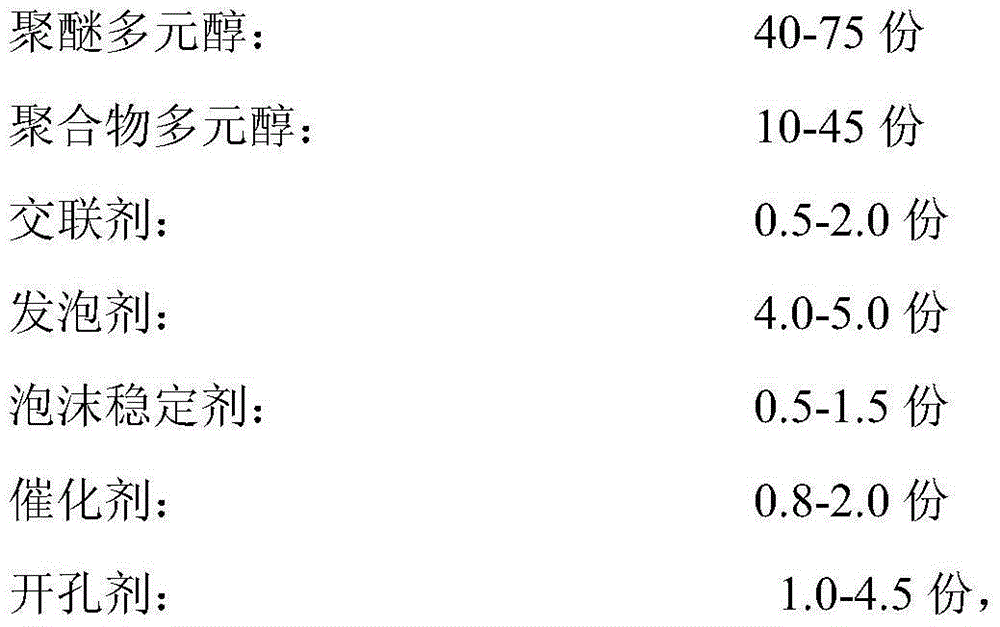

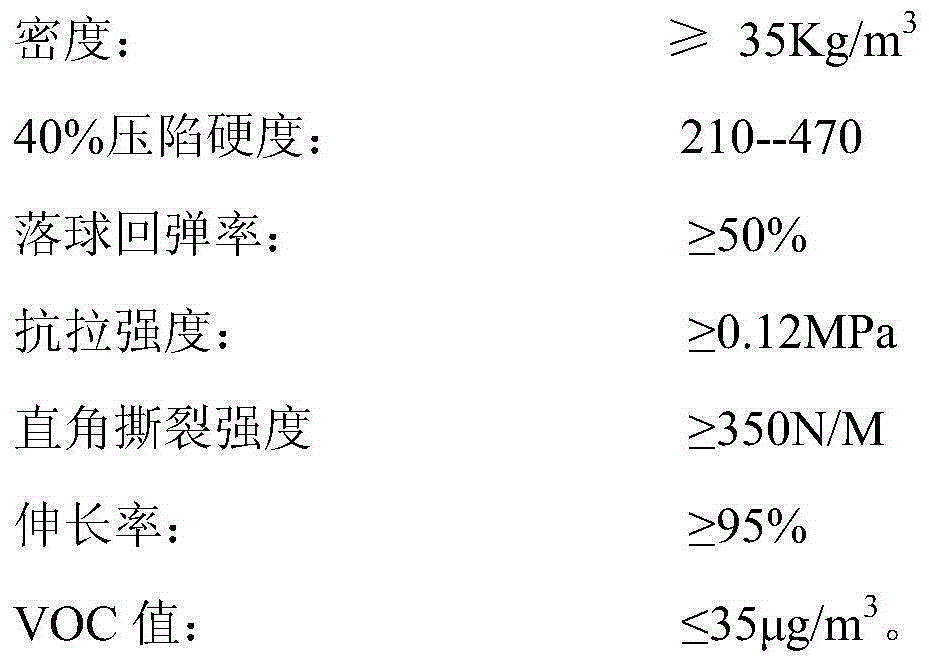

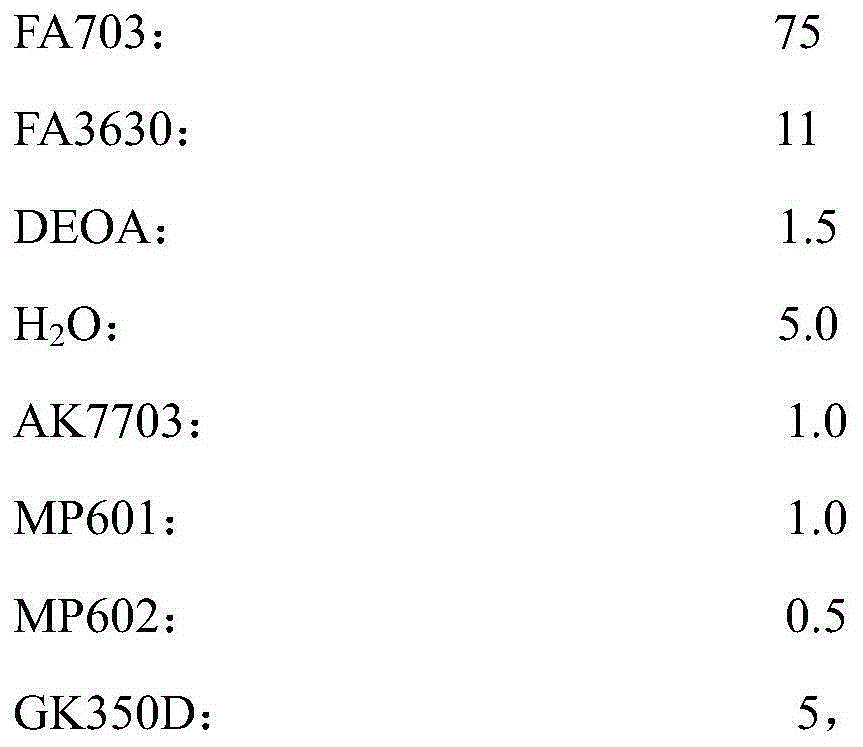

Polyurethane combined material for furniture sponge and preparation method thereof

The invention belongs to the field of polyurethane, and concretely relates to a polyurethane combined material for furniture sponge and a preparation method thereof. The combined material is prepared by mixing a composition A and a composition B, the composition A is prepared from polyether polyol, polymer polyol, a cross-linking agent, a foaming agent, a foam stabilizer , a pore-opening agent and a catalyst, and the composition B is prepared from polyether polyol, an isocyanate and a pore-opening agent. When the combined material is used, the composition A and the composition B are mixed according to the weight ratio of 100:75-110 and injected into a die, so that high-bearing low-density furniture sponge is prepared. The combined material employs low-volatilization low-atomization raw materials, and possesses advantages of low smell, good fluidity, wide applicable temperature scope and the like. The furniture sponge prepared from the combined material possesses the advantages of being basically odorless, safe, nontoxic, free of defects on the surface, good in elasticity, excellent in handfeel, low in density, good in bearing property and the like. The invention also provides a preparation method for the combined material, and the technology is reasonable.

Owner:SHANDONG INOV POLYURETHANE

Eutectic salt cold-storage material

InactiveCN101434830AApplicable temperature rangeReduce cooling efficiencyHeat-exchange elementsCool storageAir conditioning

The invention provides an eutectic-salt cool-storage material, comprising sodium sulfate decahydrate (Na2SO4 question mark 10H2O), ammonium chloride (NH4Cl), sodium borate decahydrate (Na2B4O7 question mark 10H2O), and silica gel (mSiO2 question mark nH2O); the eutectic-salt cool-storage material is characterized in that: according to the mass percentage, the eutectic-salt cool-storage material comprises 72.86 percent of Na2SO4 question mark 10H2O, 12.86 percent of NH4Cl, 2.86 percent of Na2B4O7 question mark 10H2O and 11.42 percent of mSiO2 question mark nH2O. The transformation temperature of the eutectic-salt cool-storage material is 8.47 DEG C, the undercooling degree thereof is 2.41 DEG C and the transformation latent heat thereof is 136.07-182.73Kj / kg. Owning to low transformation temperature and small undercooling degree, the material is the eutectic-salt cool-storage material applicable to cold accumulation air-conditioning systems.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

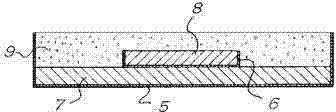

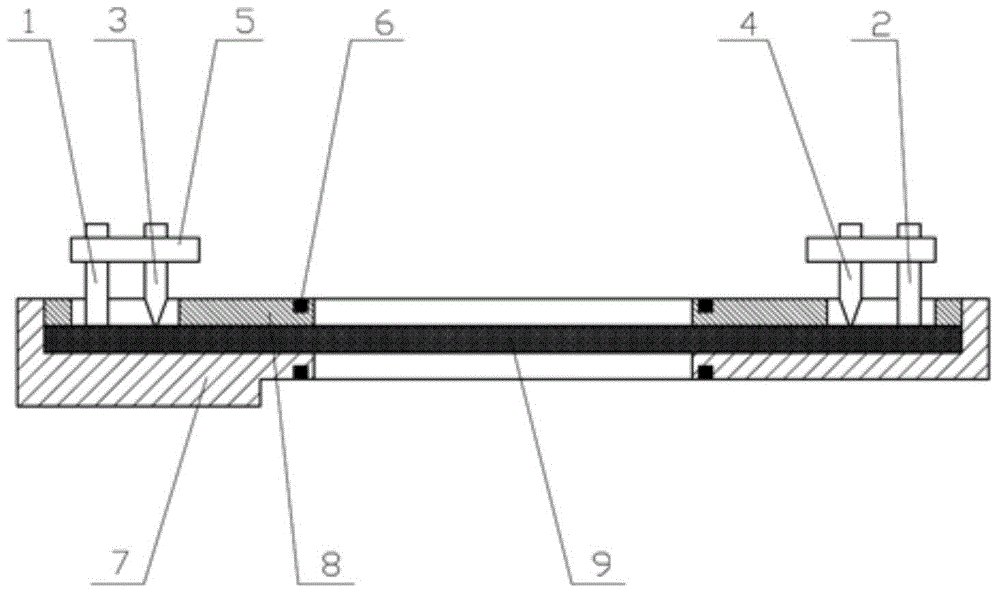

On-line detection sensor for content of ferromagnetic abrasive particles in lubricating oil

The invention relates to an on-line detection sensor for content of ferromagnetic abrasive particles in lubricating oil, and belongs to the technical field of measurement instruments. A filtering sheet is fixed between a lower filtering sheet clamping plate and an upper filtering sheet clamping plate; square holes are respectively formed in the centers of the lower filtering sheet clamping plate and the upper filtering sheet clamping plate, and the sizes of the square holes are equal to that of an oil path channel of the detection sensor; square holes are respectively formed in the left side and the right side of the upper filtering sheet clamping plate. Current input and output electrodes and front and rear detection electrodes are respectively fixed in the square holes of the upper filtering sheet clamping plate through electrode fixing plates. According to the on-line detection sensor, by design of serially connected carbon fiber filtering nets with different apertures, the content of the ferromagnetic abrasive particles with various particle sizes in the liquid can be simultaneously measured on line; furthermore, the analysis speed is high, and the test precision is higher; due to the carbon fiber filtering sheet used in the sensor, the resistivity of carbon fibers is extremely small in temperature change, so that the application temperature range of the sensor is large, and the application field of the sensor is expanded.

Owner:TSINGHUA UNIV

Medicament for fast preventing and controlling malignant aquatic weed and algae and uses thereof

ActiveCN101263829AAvoid photosynthesisReduced normal lifeBiocideEnergy based wastewater treatmentBenzoic acidPropanoic acid

The invention relates to a medicament for fast preventing the malignant float grasses and the water algae and the application thereof, belonging to the pesticide formulation technical field, which is characterized in that the medicament comprises from 40% to 90% of a plant vinegar fluid, from 5% to 35% of an organic acid, and from 1% to 20% of pesticide addition agent, the plant vinegar fluid is either a bamboo vinegar fluid, a wooden vinegar fluid, and (or) grass vinegar fluid, the organic acid is one of or a mixture of more than one of a formic acid, an acetic acid, a propionic acid, a 2-methyl propionic acid, an ethyl acetic acid, a 4-hydroxy ethyl acetic acid, a pentanoic acid, a benzoic acid, a 2,6-hydroxy benzoic acid, a 3-hydroxy-4-methoxy benzoic acid or a 3-methoxy-4-hydroxy benzoic acid. The medicament has the advantages of fast destroying the chlorophyll, stopping the plant to do the photosynthesis, commonly killing the water algae in a half hour and the float grass in three hours by spraying, having low production cost, strong killing capability, wide adaptable temperature range and pH value range. The active component of the invention has the advantages of being the natural-occurring substance, no corrosion, nonirritant, safe use, and reliability, easy biodegradation, and no secondary pollution.

Owner:ZHEJIANG FORESTRY UNIVERSITY

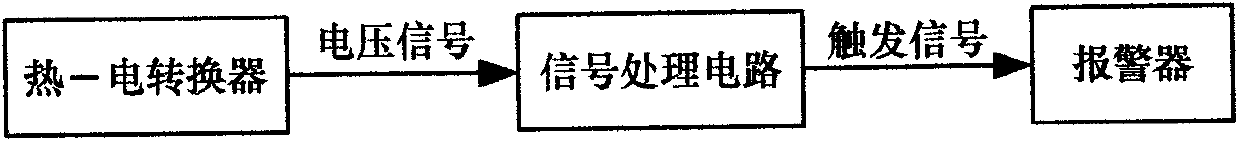

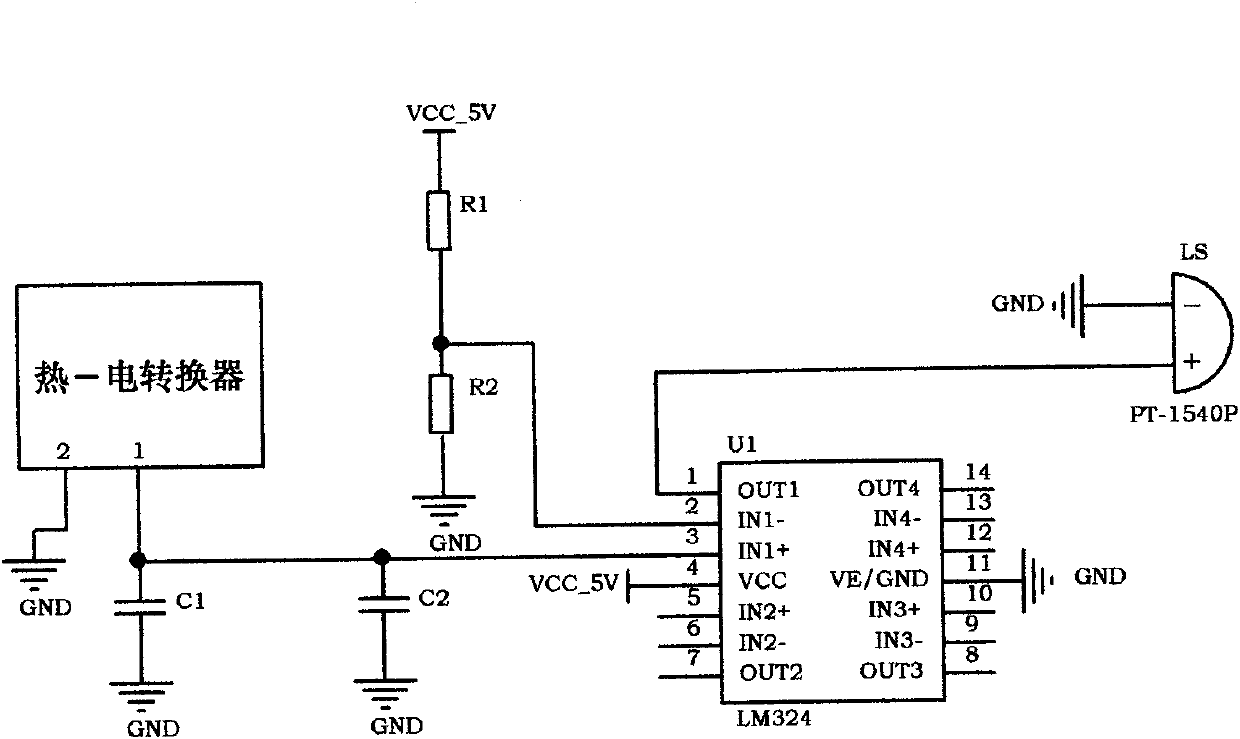

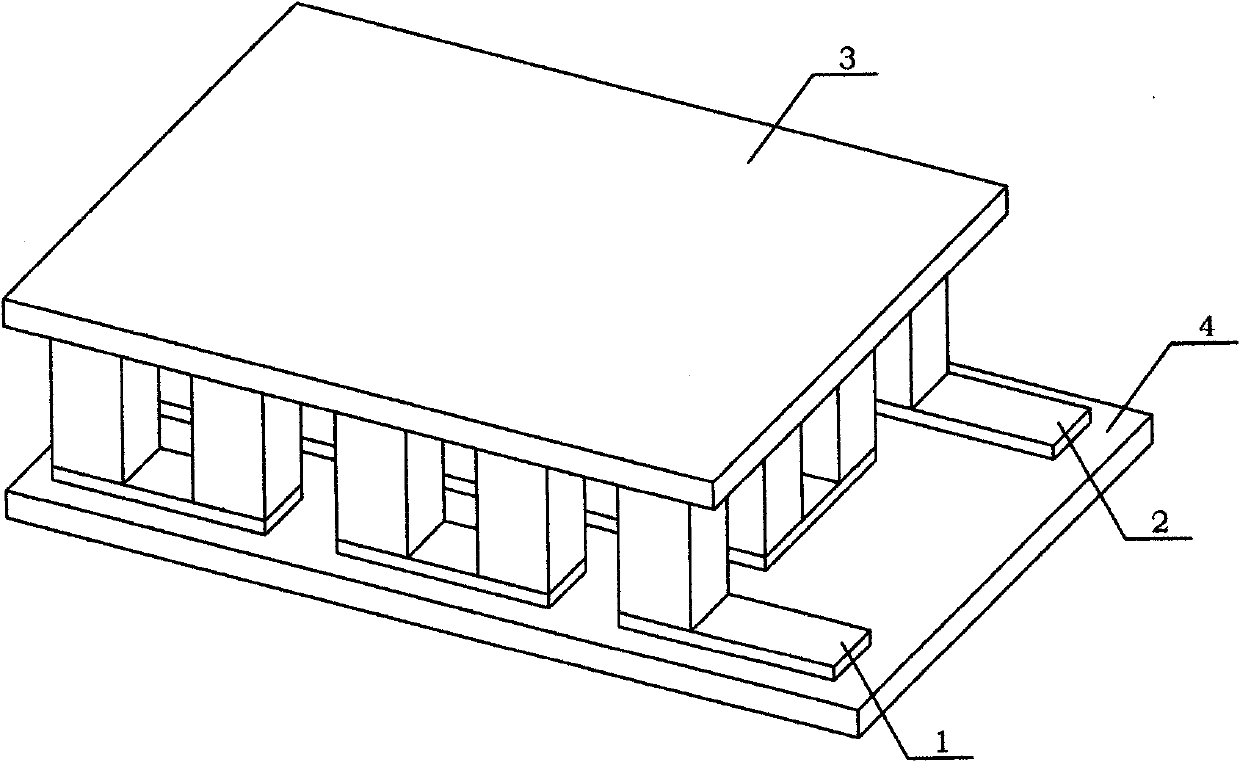

Temperature detecting fire alarm device made of thermoelectric materials

ActiveCN101770678AThe use environment is not limitedFix false positivesThermometers using electric/magnetic elementsUsing electrical meansThermoelectric materialsSignal processing circuits

The invention discloses a temperature detecting fire alarm device made of thermoelectric materials, comprising a thermoelectric converter, a signal processing circuit and an alarm, wherein the thermoelectric converter is used for converting variation of the ambient temperature into voltage signals and outputting the voltage signals to the signal processing circuit; the signal processing circuit is used for filtering and comparing the received voltage signals and then driving the alarm to ring, thus realizing alarm on fire; and the alarm is used for sending out an acousto-optic signal to promote alarm. The thermoelectric converter adopts the structure of concatenated thermoelectric pairs. Each group of thermoelectric pairs 5 is equal to a small power supply and that the output voltage is obtained through repeated addition of the voltage of each small power supply can be known according to the power supply concatenation rule in the circuit, thus the fire alarm device is environmentally friendly, without needing transmission parts, and has small system volume and wide temperature application range.

Owner:BEIHANG UNIV

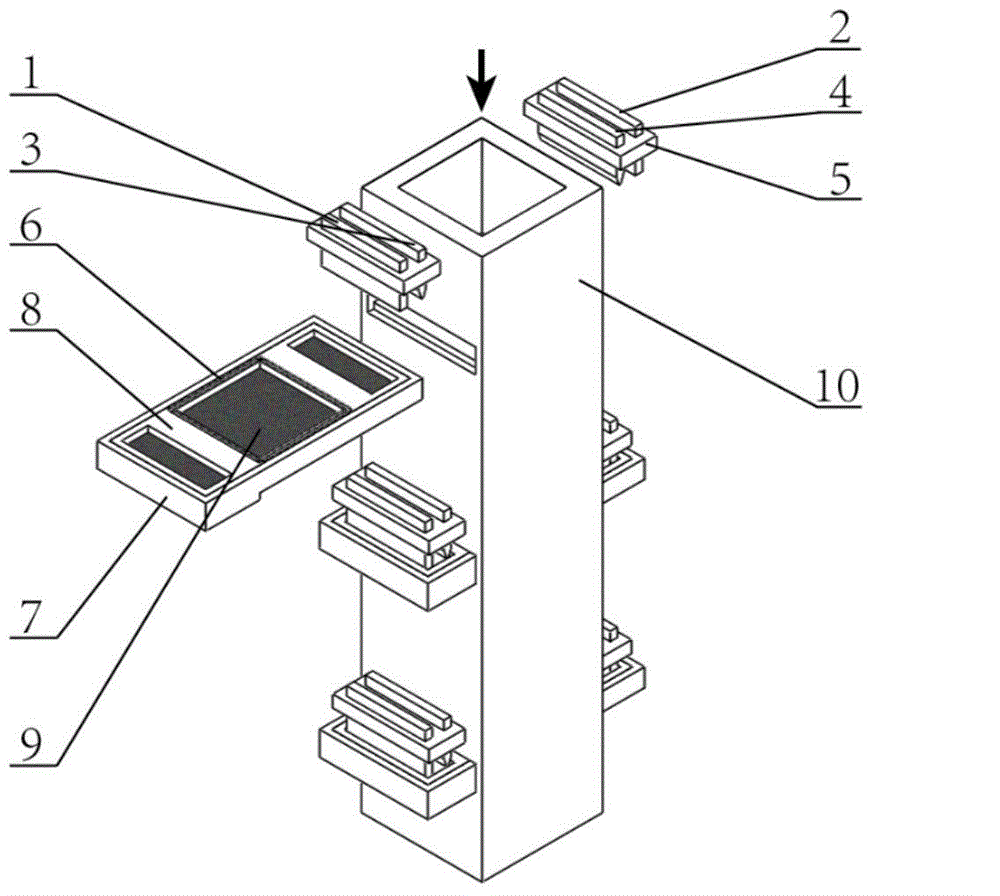

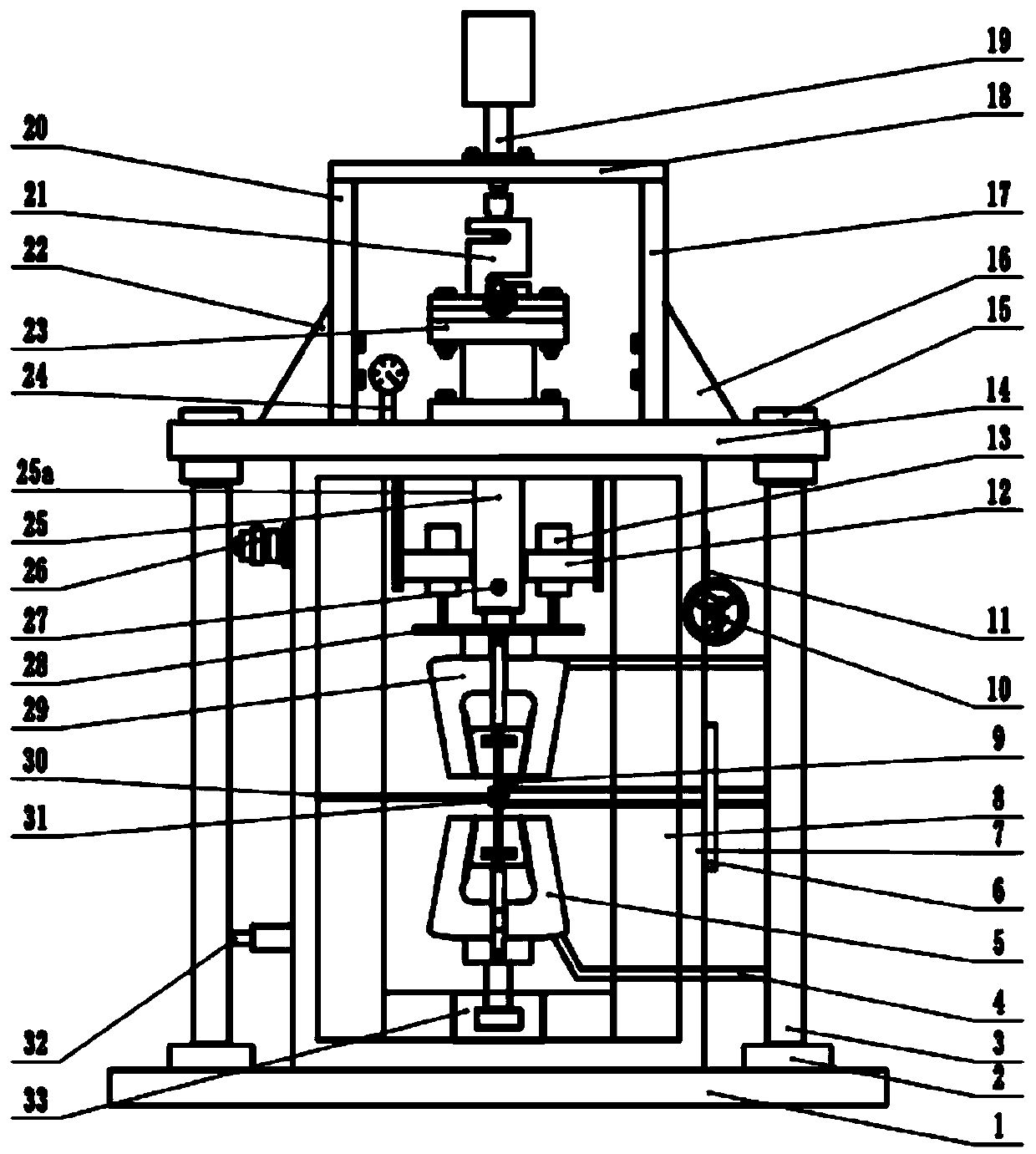

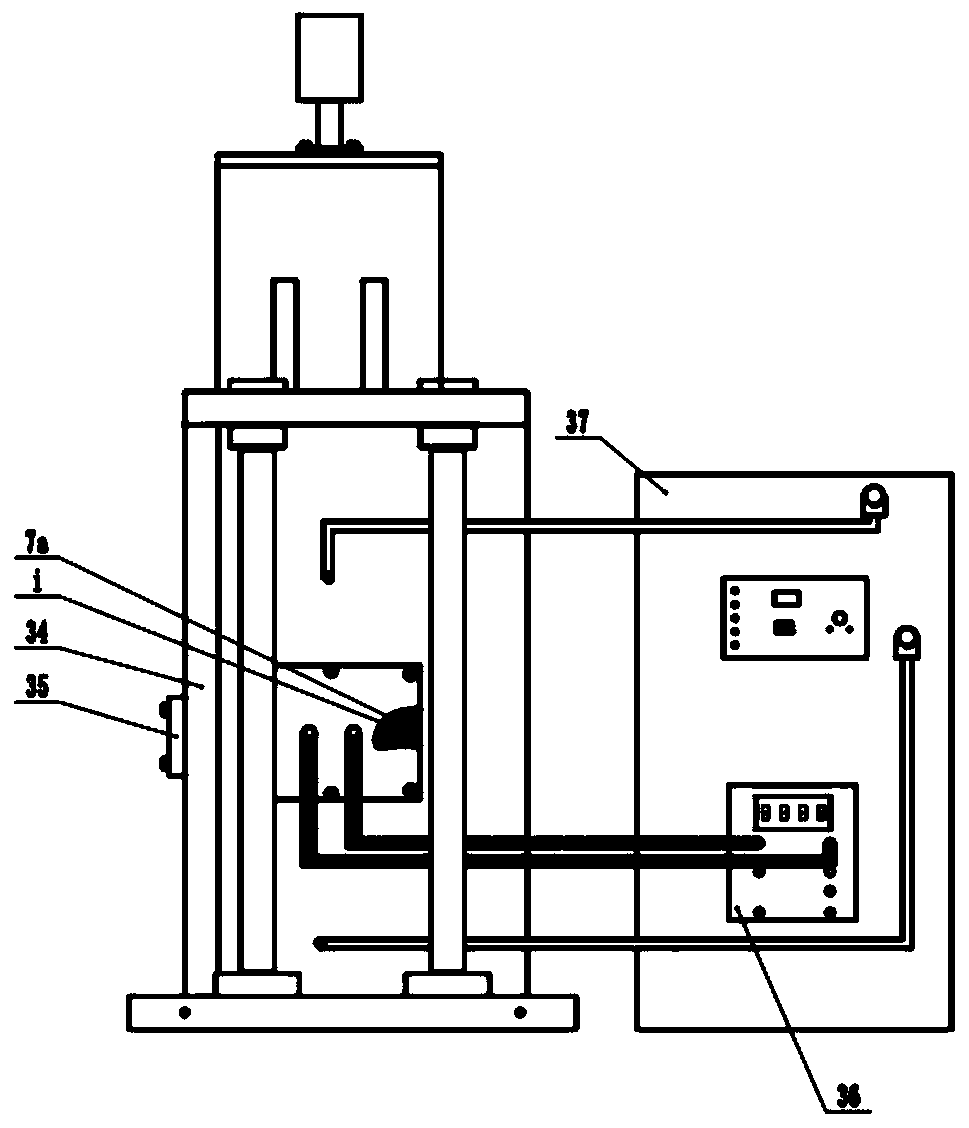

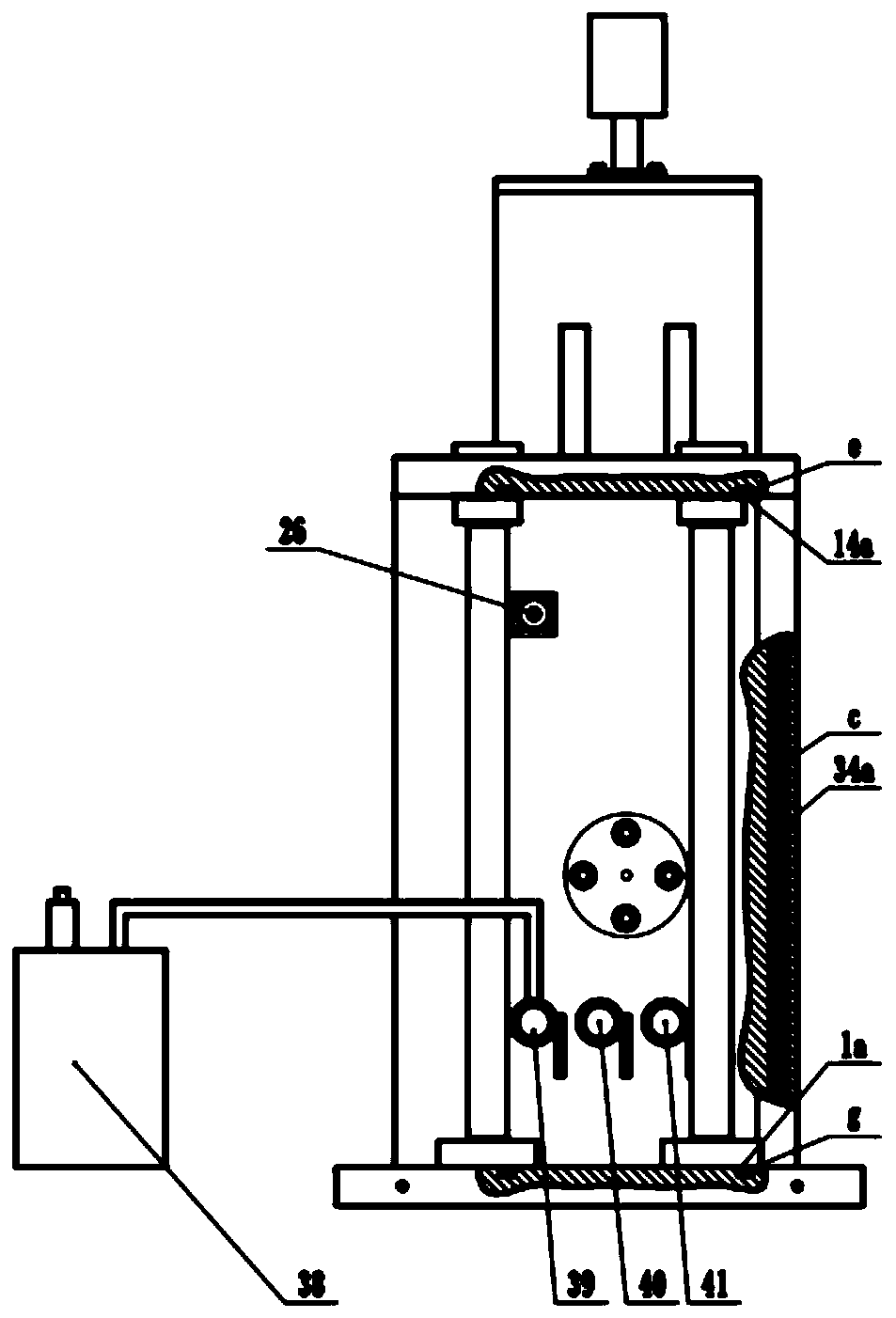

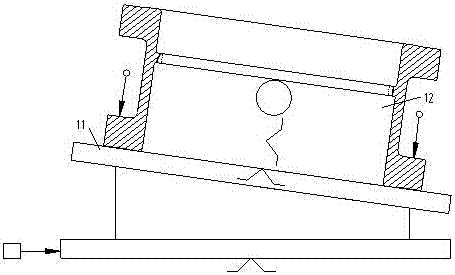

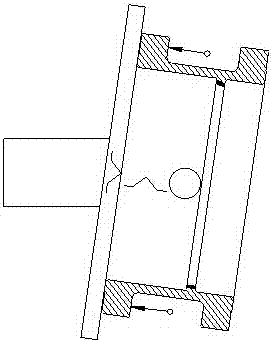

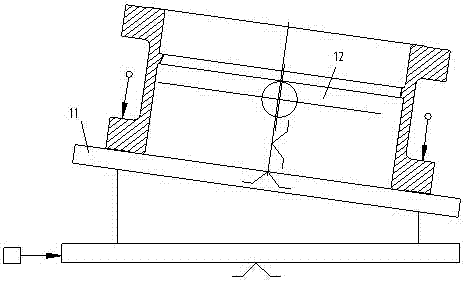

Eddy current heating high temperature mechanical testing device

InactiveCN109932252AHeating up fastApplicable temperature rangeMaterial strength using tensile/compressive forcesHeating efficiencyTraining set

The invention relates to an eddy current heating high temperature mechanical testing device, which belongs to the technical field of mechanical testing and relates to a mechanical testing device for rapidly heating a sample by using an eddy current technique to obtain a high temperature testing environment. The device adopts eddy current rapid heating to meet the requirements of high-rate temperature rise and wide temperature zone heating of the sample in a high temperature mechanical test. An airtight box structure is adopted, and a vacuum pump is used for vacuum pumping to meet vacuum environment requirements. Upper and lower chucks adopt the overall structure, which is good for neutrality and have small measurement errors. The device consists of a clamping unit, a loading unit, a heating and cooling unit, an airtight box, and a reference frame. The device has the characteristics of rapid sample temperature rise, large applicable temperature zone, high heating efficiency, compact structure and simple operation. The device has good neutrality, reduces measurement errors, and has high testing accuracy. An aerospace high temperature thermal shock environment can be accurately simulated, and the mechanical experiments of high temperature materials are completed.

Owner:DALIAN UNIV OF TECH

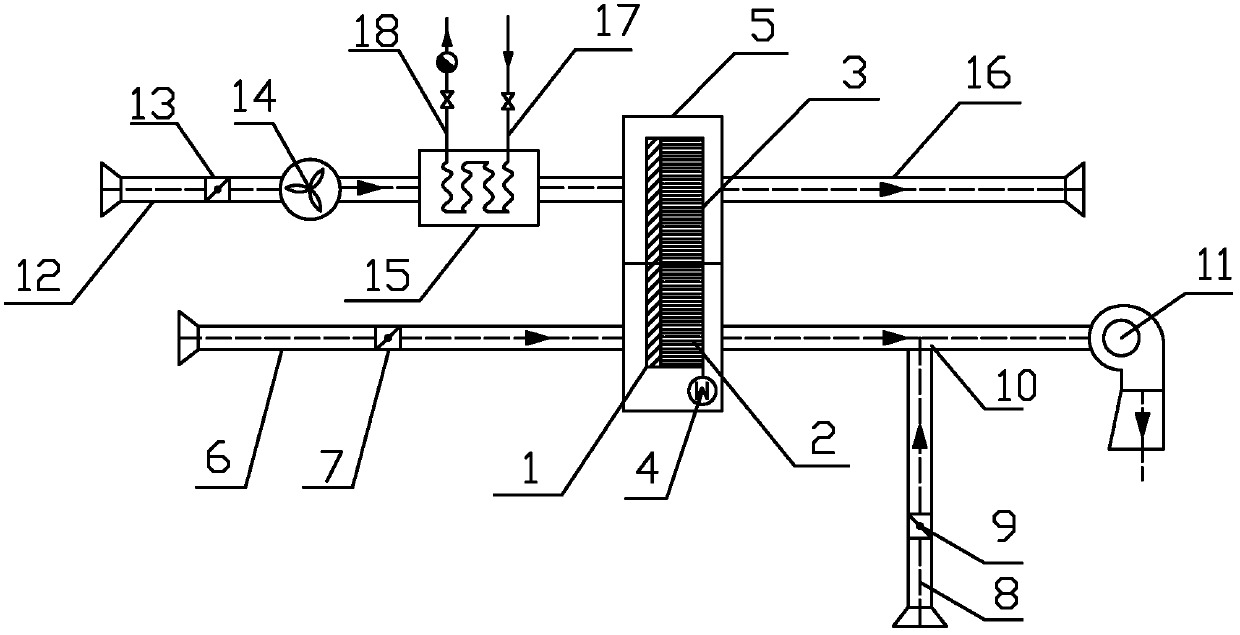

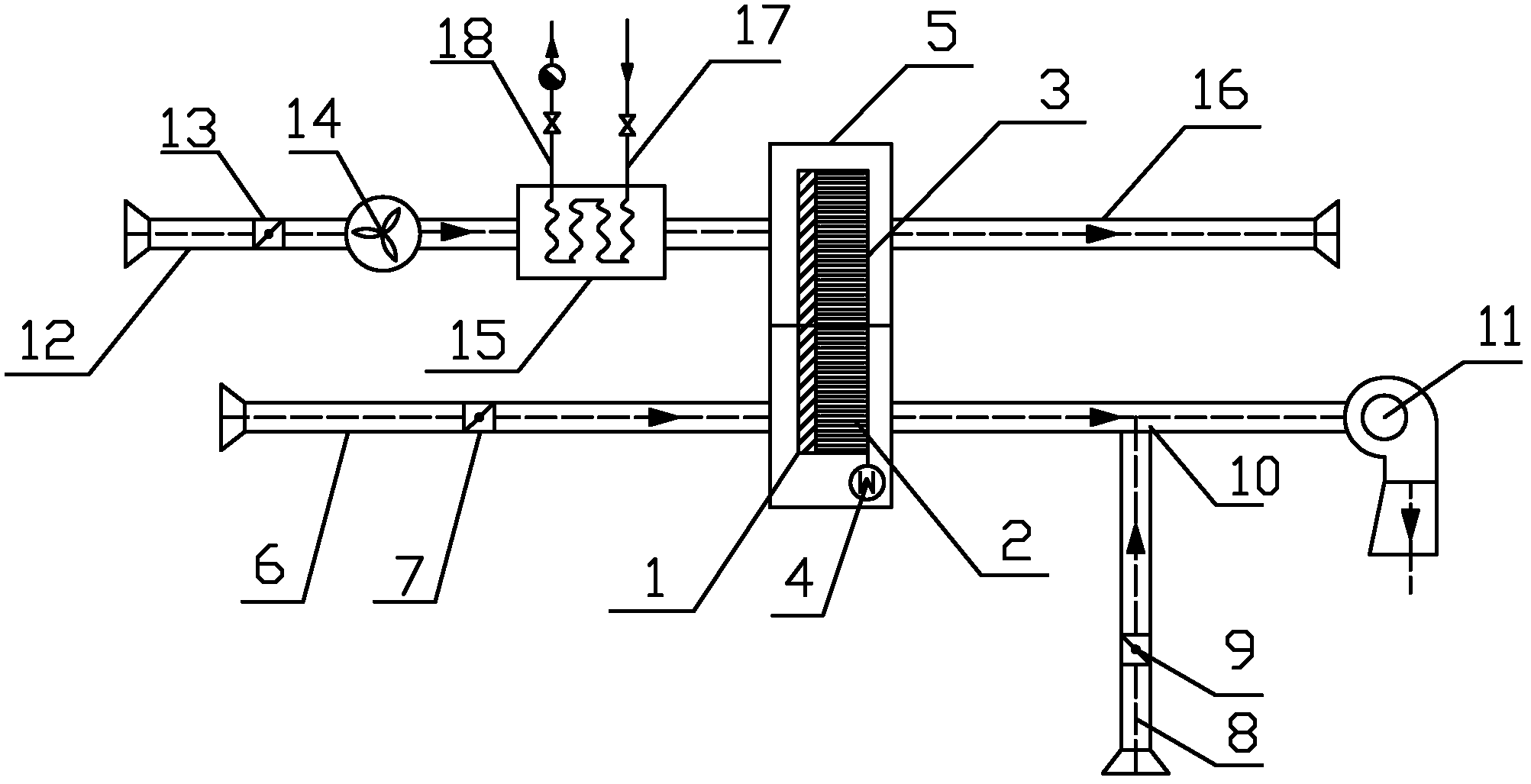

Blast furnace blowing rotary-wheel dehumidification method

InactiveCN102605125ALow running costSave energy for reheatingDispersed particle separationBlast furnace detailsEngineeringEnergy consumption

The invention relates to a blast furnace blowing rotary-wheel dehumidification method, which mainly comprises a rotary wheel dehumidifier which is provided with a rotary wheel dehumidification zone and a rotary wheel regeneration zone and can perform circulating dehumidification and then regeneration. An inlet air pipe and an outlet air pipe are respectively arranged on two sides of the rotary wheel dehumidification zone; a regeneration air inlet air pipe and a regeneration air outlet air pipe are respectively arranged on two sides of the rotary wheel regeneration zone; an inlet air valve is arranged on the inlet air pipe; and the outlet air pipe is connected with a blast blower. The method is characterized in that a heater, a ventilator and a regeneration air valve are sequentially arranged on the regeneration air inlet air pipe; and a heater steam supply pipe and a heater condensation drain pipe are respectively communicated with the heater. After dehumidification is finished by using the method, the air temperature increases by a certain range, the process that air is supercooled firstly and then heated for dehumidification of a surface cooler is avoided, and the reheating energy consumption is saved. The method has the advantages that the efficiency is high, steam is used as a heat source, and the steam resource from metallurgical plants is sufficiently utilized.

Owner:WISDRI ENG & RES INC LTD

Method for preparing nano-structured Zn2SnO4 on stainless steel wires

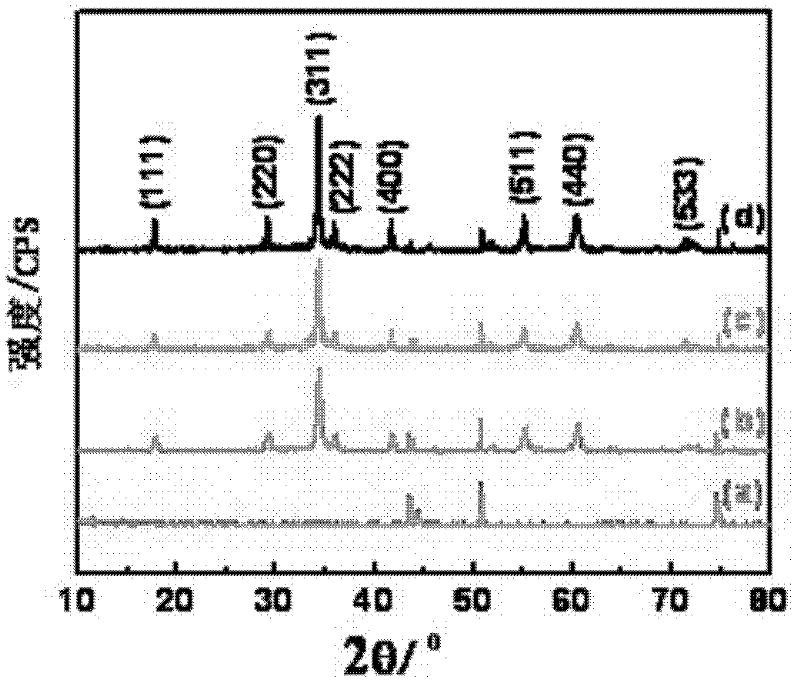

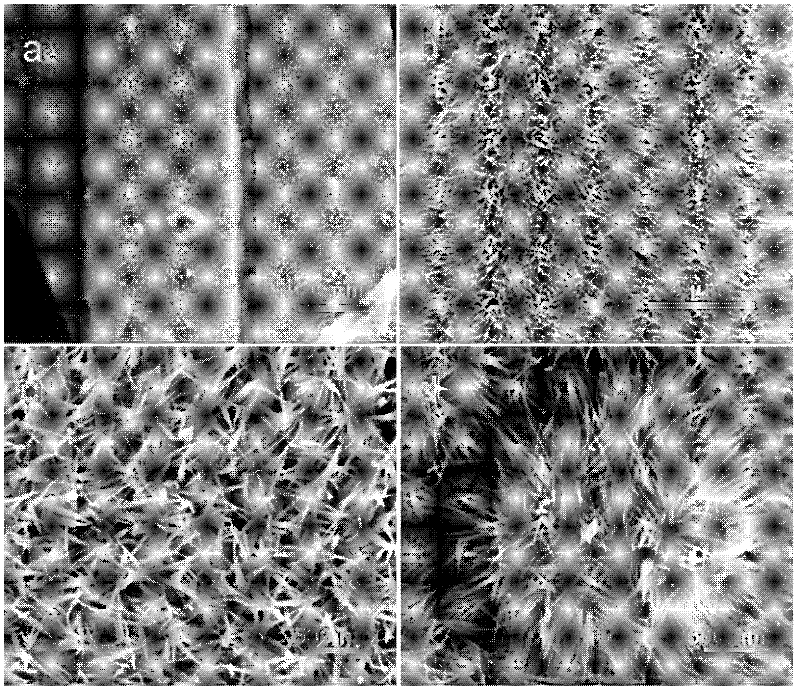

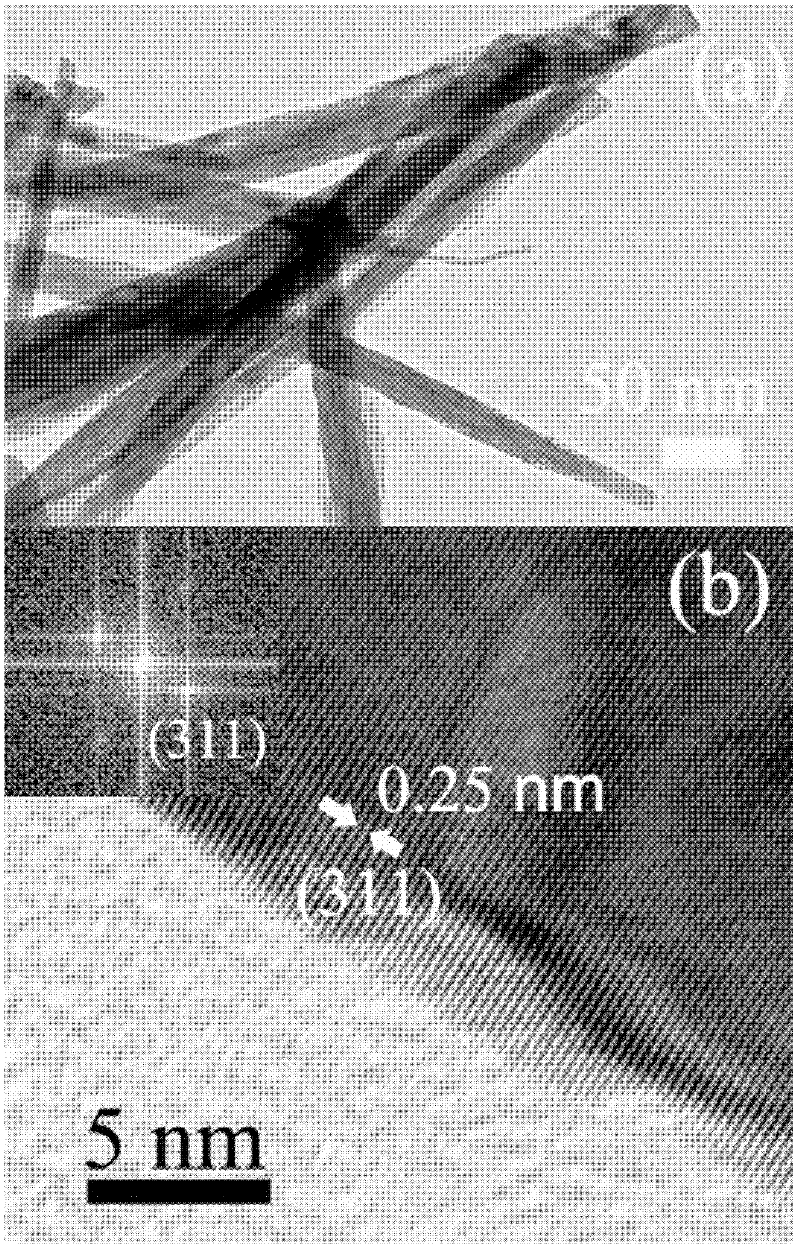

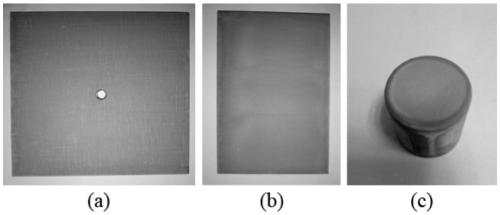

ActiveCN102637530APromote absorptionImprove adaptabilityTin compoundsElectrolytic capacitorsElectronic transmissionTime range

The invention relates to a method for preparing nano-structured Zn2SnO4 on stainless steel wires. The method includes steps: adding tin chloride pentahydrate, zinc acetate dihydrate and sodium hydroxide into ethylenediamine and aqueous liquor, dispersing mixture uniformly and placing the mixture into a cleaned stainless steel wire mesh; leading the stainless steel wire mesh to react at the temperature ranging from 170 DEG C to 200 DEG C and taking out the reacted stainless steel wire mesh; and obtaining two nano-structured Zn2SnO4 products with different shapes by means of regulating the proportion of the ethylenediamine to water. The molar ratio of the tin chloride pentahydrate to the zinc acetate dihydrate to the sodium hydroxide is 1:2:6-1:3:4, the proportion of the ethylenediamine to the water is 30:0-0:30, and the reaction time ranges from 12 hours to 24 hours. The method has the advantages that operation is simple, cost is low, the purity of the products is high, and the like. The nano-structured Zn2SnO4 products with the different shapes are more favorable for electronic transmission; and by the aid of a stainless steel base, on the one hand, absorption of a photoelectrode to scattered light and reflected light is improved, on the other hand, adaptability of a photovoltaic cell to transport environments, installation environments and work environments are greatly enhanced.

Owner:KUSN INNOVATION INST OF NANJING UNIV

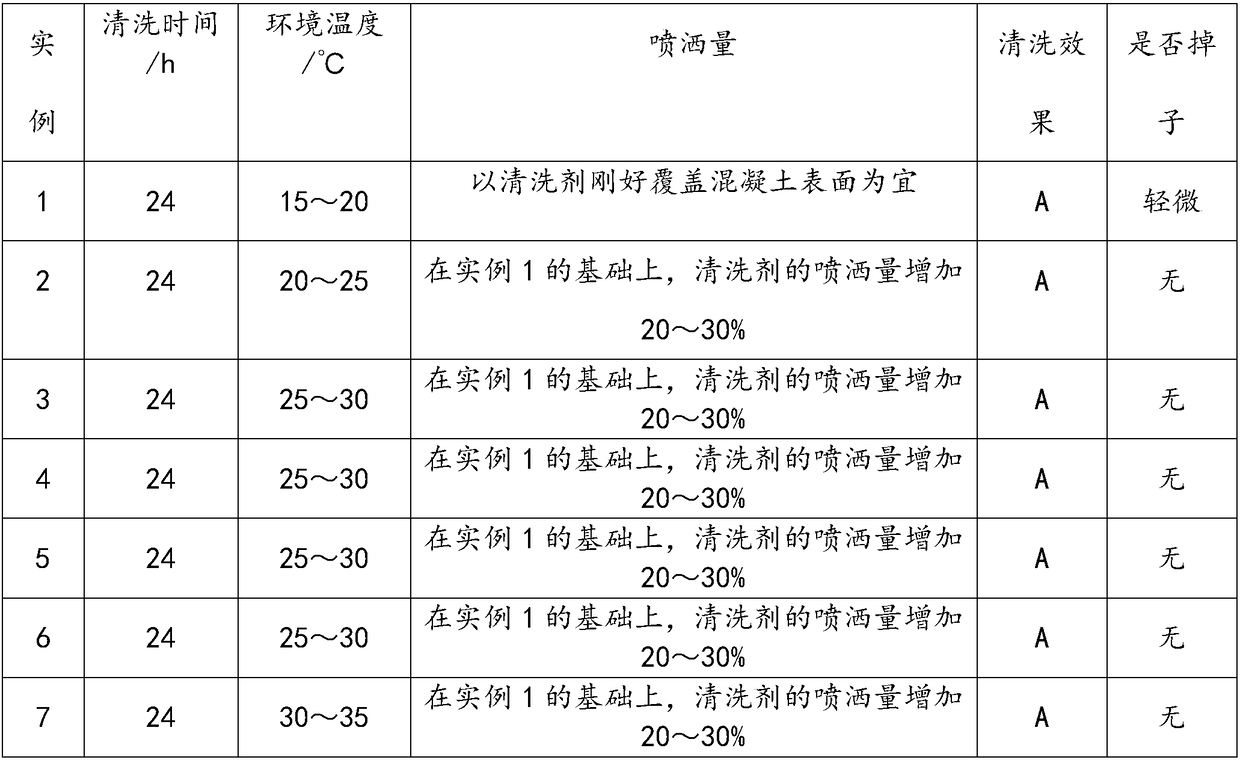

Cleaning agent for cleaning of pervious concrete with exposed aggregate

InactiveCN109020621AApplicable temperature rangeLow sensitivity to spray rate fluctuationsSurface cleaningEngineering

The invention relates to a cleaning agent for cleaning of pervious concrete with exposed aggregate, belonging to the field of surface cleaning of pervious concrete with exposed aggregate. The cleaningagent comprises the following main raw materials by mass: 2-6% of a retarder, 0.05-0.3% of a water retaining agent, 0.01-0.1% of a consistency regulator, 1 to 5% of a coloring agent and 85-98% of a filler. The cleaning agent of the invention is applicable in a wide environmental temperature range, low in spray amount fluctuation sensitivity, easy to color, easily controllable in penetration depthand long in controllable time, and can well realize surface aggregate exposure effect.

Owner:四川聚力建材科技有限公司

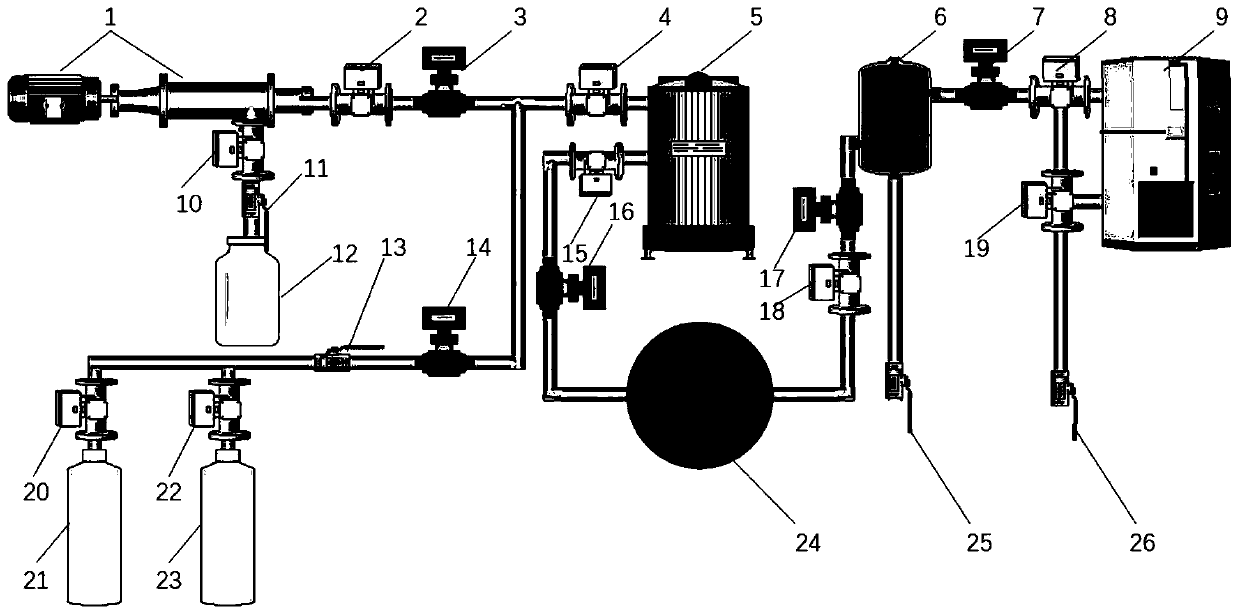

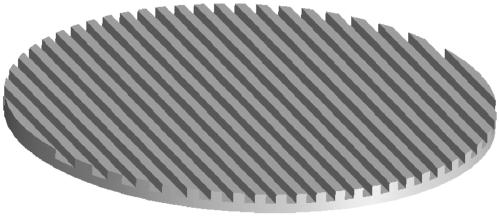

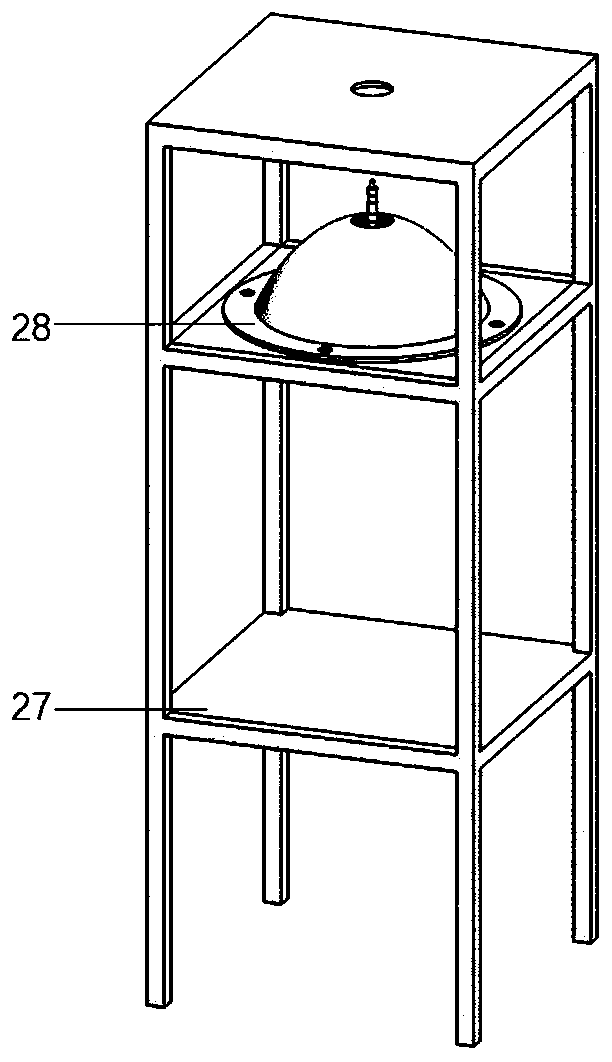

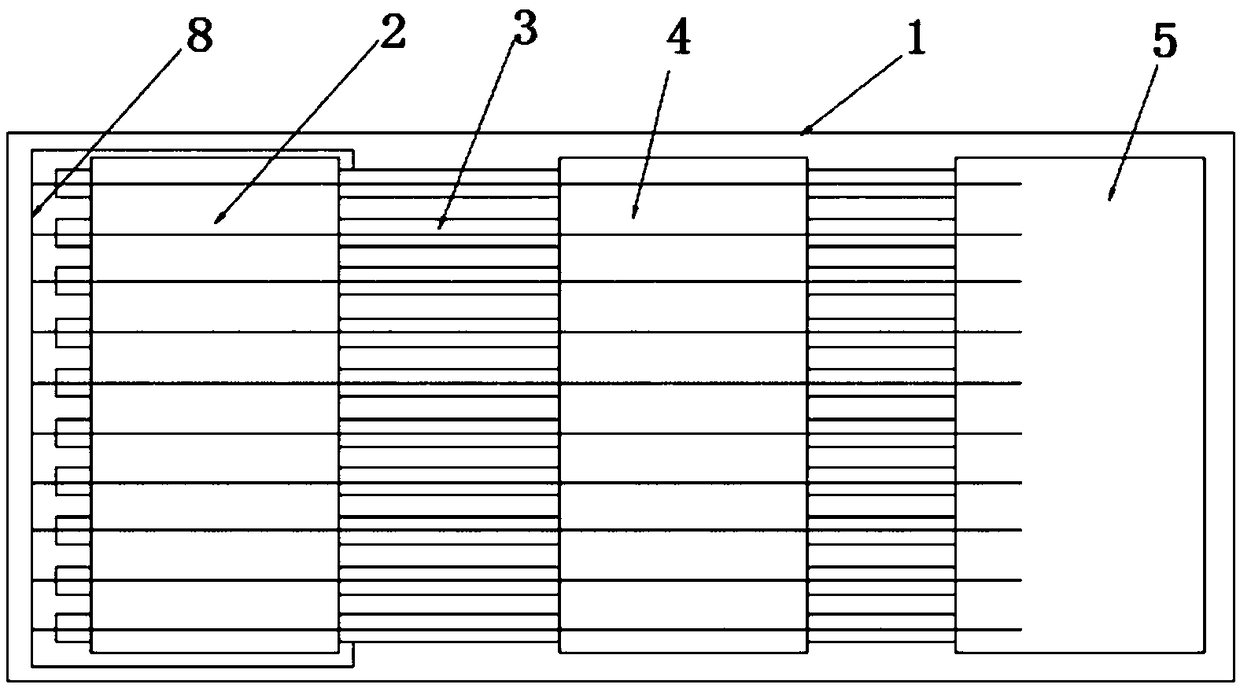

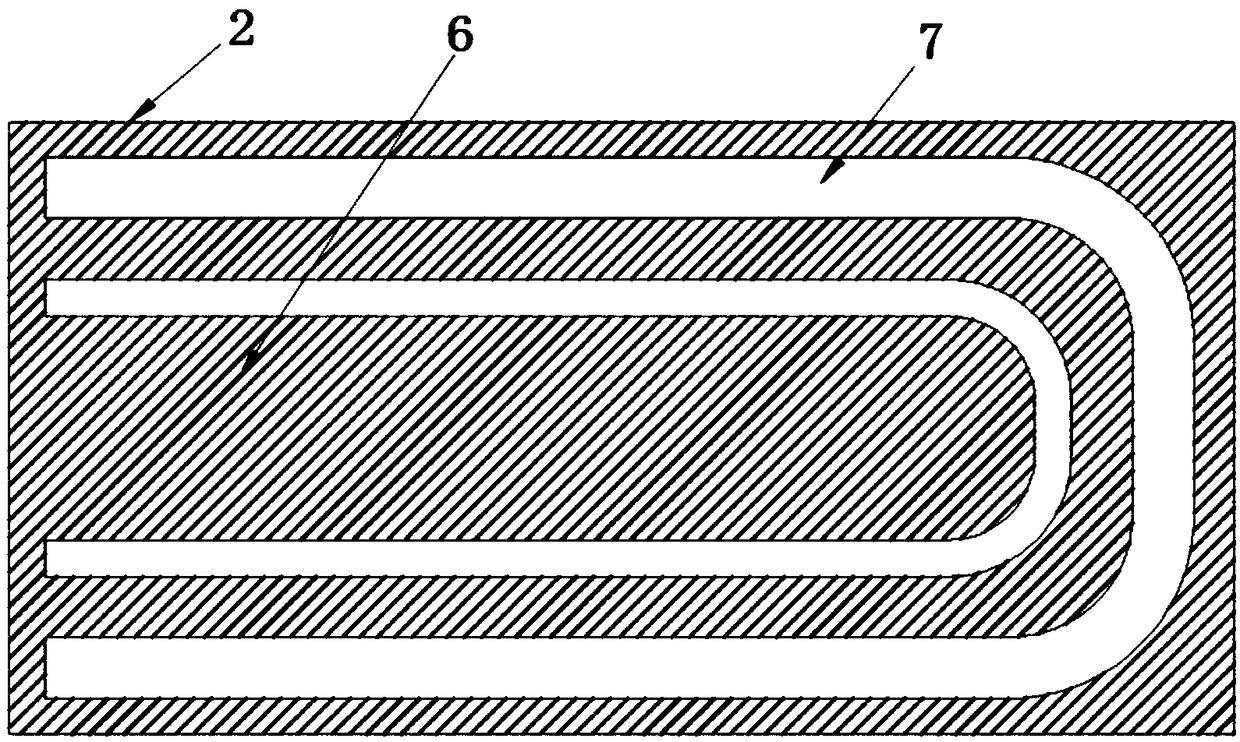

Thermochemical hydrogen production reaction performance evaluation system and thermochemical hydrogen production reaction performance evaluation method based on solar light-concentrating simulator

ActiveCN110407171AApplicable temperature rangeReduce heat absorptionHydrogenComponent separationEvaporatorXenon lamp

The invention relates to a thermochemical hydrogen production reaction performance evaluation system and a thermochemical hydrogen production reaction performance evaluation method based on a solar light-concentrating simulator. The system comprises a raw material input part, an evaporator / pre-heater, a micro multi-channel reactor, a condenser, a chromatograph, a flow pipeline system and a solar light-concentrating simulator, wherein the raw material input part comprises a liquid input part and a gas input part, the liquid input part and the gas input part are converged before the evaporator / pre-heater, the evaporator / pre-heater is a large chamber tank performing heating through electricity or solar energy, and is provided with a spraying device inside, the pre-heater simultaneously performs primary heating on a gas, the micro multi-channel reactor is connected to the evaporator / pre-heater and the condenser through pipelines, the chromatograph is used for detecting the components of the generated mixed gas, and the solar light-concentrating simulator comprises a high-power xenon lamp light source and an elliptical high-reflectivity reflection cover.

Owner:恒基能脉新能源科技有限公司

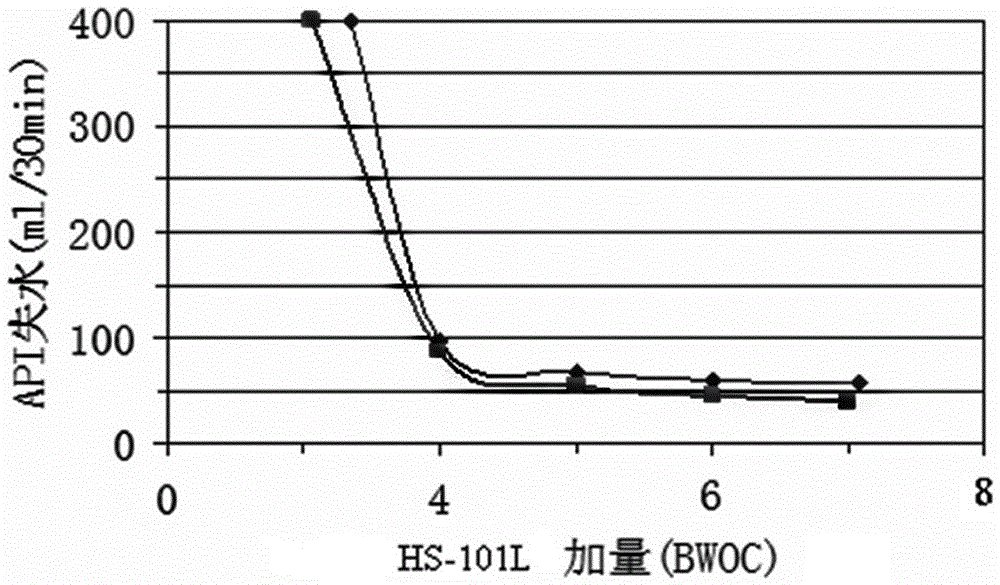

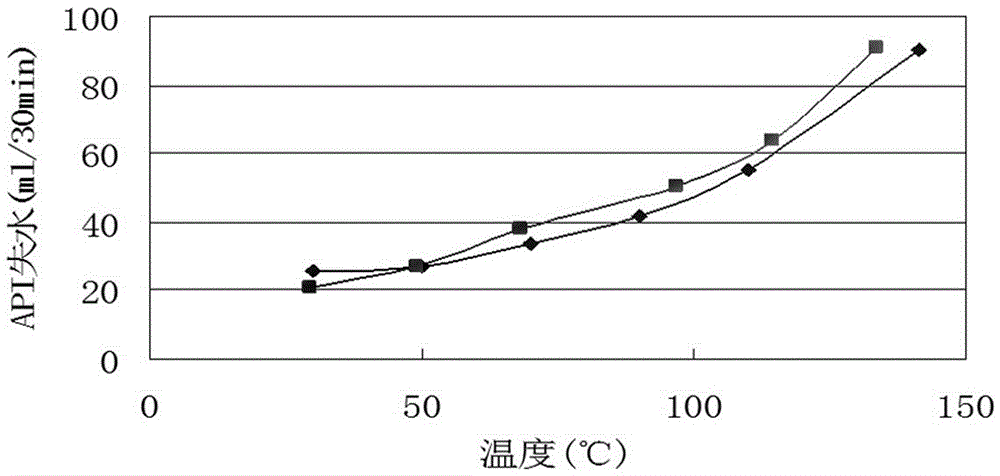

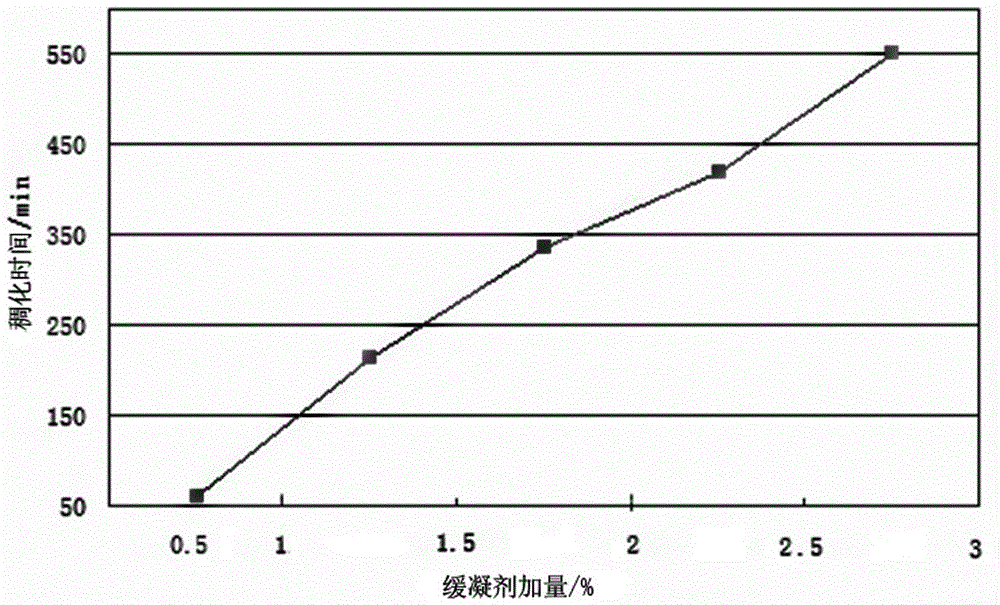

High-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in oil field

ActiveCN105694832AExcellent dehydration performanceGood adaptabilityDrilling compositionSolid phasesSilica fume

The invention relates to high-temperature-resistant and large-temperature-difference-resistant cement grout for well cementation in an oil field. The cement grout is prepared from components of raw materials in parts by weight as follows: 600 parts of G-grade oil well cement, 30-36 parts of an HS101L fluid loss agent, 8-20 parts of an HS201L retarder, 1.8 parts of an HS-301S dispersant, 150 parts of quartz sand, 30 parts of silica fume, 1.8 parts of an HS-XF1S suspension stabilizer, 280-300 parts of water and 1 part of bis(2-ethylhexyl) sulfosuccinate sodium salt, wherein the grain size of the quartz sand is 80-120 meshes, the grain size of the silica fume is 300-400 meshes, and the content of silicon dioxide is 90% or higher. Liquid-phase raw materials are added to a grout mixing container and mixed uniformly; solid-phase substances are added to a solid-phase container and stirred uniformly, the solid-phase mixture is added to the grout mixing container, finally, a defoaming agent is added, and the mixture is stirred uniformly. The cement grout can be used under the condition of 50-180 DEG C, has prominent large-temperature-difference-resistant performance and can effectively avoid a super-retarding phenomenon caused by large temperature difference.

Owner:CHINA PETROCHEMICAL CORP +2

Process liquid for alramenting hardware

InactiveCN1796601AApplicable temperature rangeUniform densityMetallic material coating processesSodium molybdatePhosphate

This invention relates to a surface granosealing liquid for metal components with a specific proportion of raw materials as follows: 170 shares of phosphate acid, 0.4 share of sodium molybdate, 5 shares of potassium carbonate, 0.1 share of molybdenum carbonate, 0.25 share of 0ªð-10, 0.3 share of oxydol and 1000 shares of pure water. This invention has the advantages of: a) wide application. It is applicable in surface granosealing for all kinds of steel products and components with a broad temperature range. Typically it can be employed below 0 and thus can meet the needs from most places in winter. b) Energy economization. Granosealing can be carried out at room temperature so that energy would be saved. c) Rapid filming, uniform film density, strong adhesion and low probability of repetitive rusting.

Owner:天津市怡佳商贸有限公司

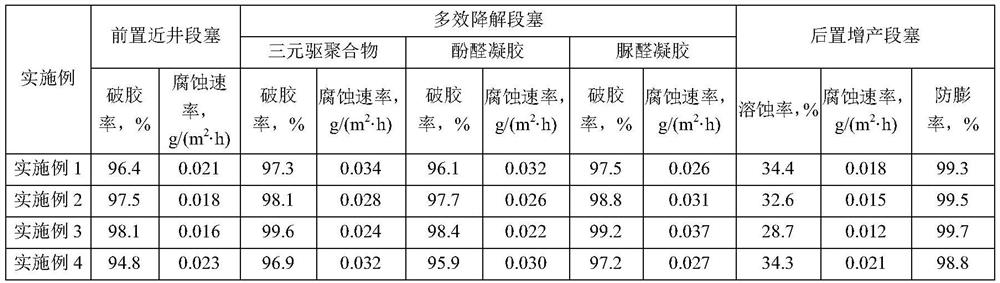

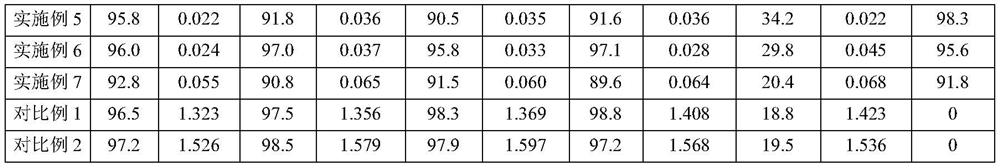

Multi-functional blocking remover and preparation method thereof

The invention discloses a multi-functional blocking remover and a preparation method thereof. The multi-functional blocking remover is composed of functional components with different percentage contents and oilfield produced water, and a front near-well slug blocking remover, a multi-effect degradation slug blocking remover and a rear yield increase slug blocking remover are prepared according to a certain proportion. The multi-functional blocking remover provided by the invention has the advantages of immediate preparation, non-oxidizing property, simple construction process, high gel breaking rate (96.1% or more), wide applicable temperature range (20-120 DEG C), low corrosion rate (lower than 0.04 g / (m<2>. h), good safety and the like, can effectively remove various blockages such as scale, polymers, polymer gel and oil sludge generated in the ASP flooding profile control process, realizes recycling of oilfield produced water, is beneficial to improving the communication capacity between oil-water wells and delaying scale deposition, and can achieve multiple effects of dissolving, plug removal, deposition prevention, low-permeability reservoir pollution reduction, injection increase and pressure reduction and the like during application.

Owner:PETROCHINA CO LTD

Method using plant oil after-cut fraction for production of green lubricating oil

ActiveCN104762121AFix stability issuesSettle the priceFatty-oils/fats separationBase-materialsVegetable oilThermal insulation

The present invention provides a method for using plant oil after-cut fraction for production of green lubricating oil, and the process comprises the following steps: various main components are separated by distillation of plant crude oil, after-cut fraction and a residue accounting for 6-15% of the total tower kettle substrate are heated to about 150 to 200 DEG C in a vacuum distillation tower device for thermal insulation distillation for more than 30-40 hours under the condition of maintaining the vacuum degree in-0.98mpa, wherein the vacuum distillation tower device has the tower height of 7-15m, and the plate number of more than 100, and use a 80-100 mesh stainless steel filler, kettle bottom residual liquid is discharged after cooling, the kettle bottom residual liquid is placed for cooling to 50 DEG C to 60 DEG C, and filter with a 150 mesh filter screen to obtain plant oil distillation kettle bottom polymer, the green lubricating oil is prepared by further addition of composite additives, and the green lubricating oil is similar with mineral base oil in density, viscosity, flash point, pour point and other indexes, and is good in thermal stability, biodegradable, low-cost, and environment friendly.

Owner:统一石油化工有限公司

Epipremnum aureum water culture nutrient solution

InactiveCN104326779AApplicable temperature rangePromote root developmentMagnesium fertilisersOrganic fertilisersNutrientNaCl - Sodium chloride

The invention discloses an Epipremnum aureum water culture nutrient solution which is composed of the following components in parts by weight: 100 parts of water, 40-45 parts of seaweed juice, 20-26 parts of citric acid, 10-17 parts of boric acid, 5-10 parts of potassium dihydrogen phosphate, 0.2-4 parts of zinc sulfate, 0.05-2 parts of magnesium sulfate, 0.05-1 part of copper sulfate, 0.02-1 part of manganese sulfate and 0.02-0.5 part of sodium chloride. The Epipremnum aureum water culture nutrient solution can enable the root of the Epipremnum aureum to develop more quickly, thereby effectively absorbing the nutrients and avoiding the problem of yellow spots of leaves. The Epipremnum aureum water culture nutrient solution has wide temperature application range, and is free from temperature influence.

Owner:LIUZHOU TIANZI HORTICULTURE

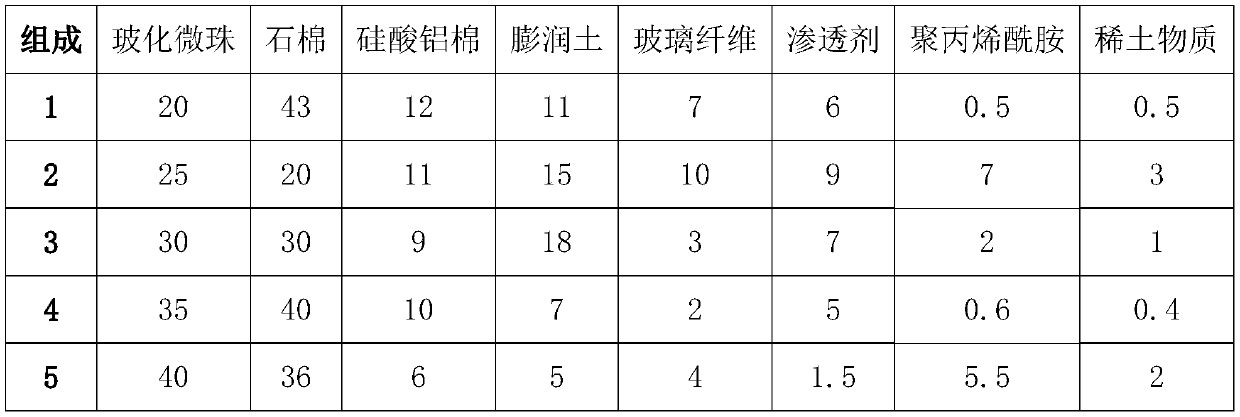

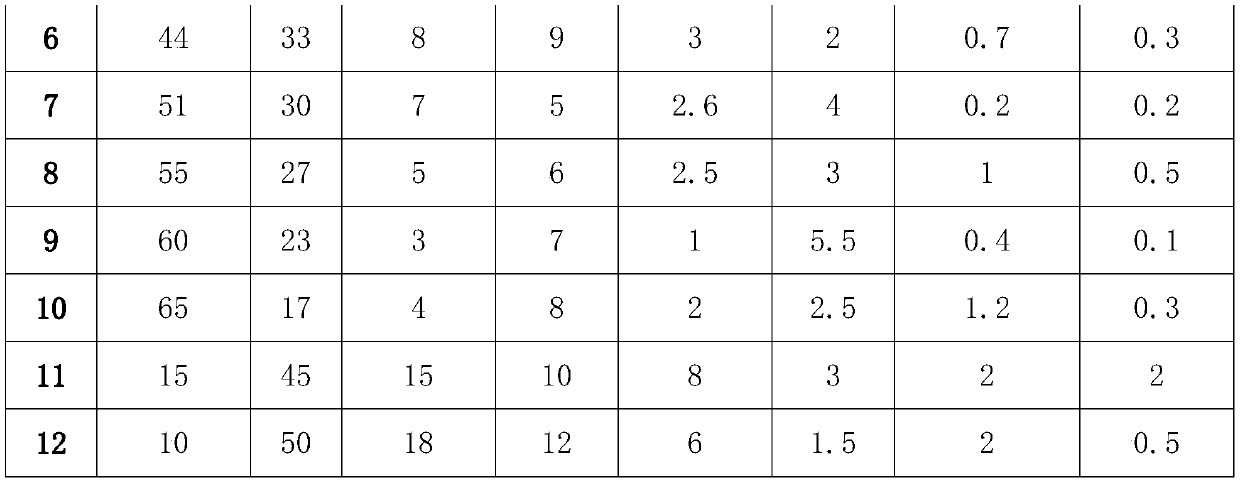

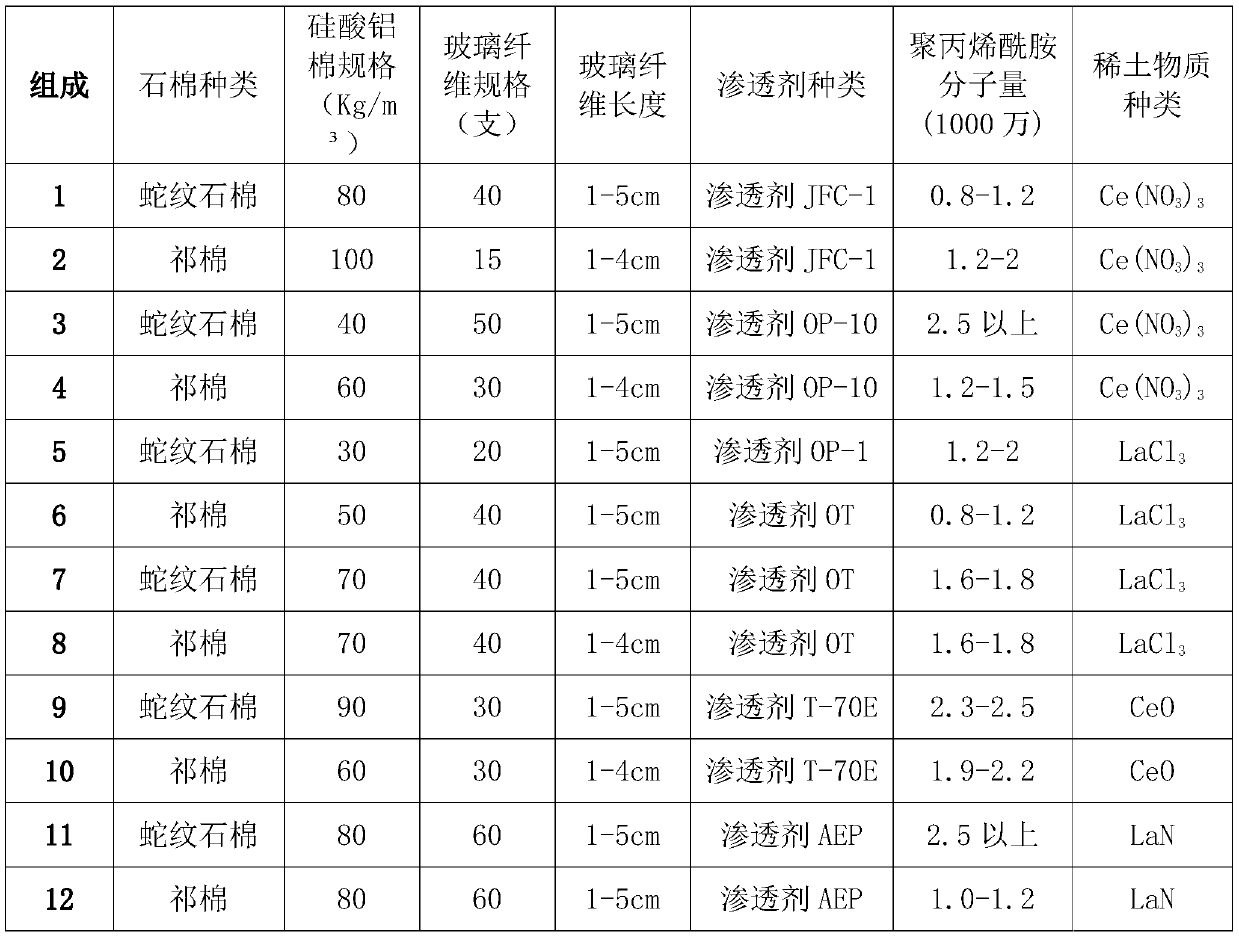

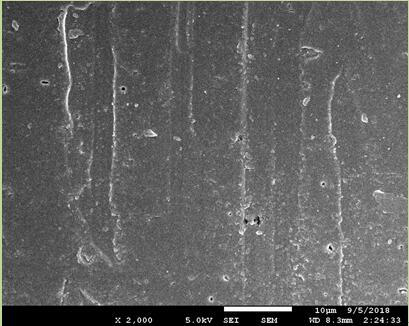

Heat insulation composition

PendingCN110498636AExtended heat conduction pathLow thermal conductivityGlass fiberAluminum silicate

The invention discloses a heat insulation composition with a heat insulation effect. The problem that the volume weight of the heat preservation composition is large when the heat insulation effect isimproved in the prior art is solved. The heat insulation composition comprises 10-65 wt% of vitrified microbeads, 10-50 wt% of asbestos, 1-20 wt% of aluminum silicate wool, 5-20 wt% of bentonite, 1-10 wt% of glass fibers and 1-10 wt% of a penetrant. The heat insulation composition has the advantages of excellent heat insulation performance, low volume weight, reduction of the thickness by 50% orabove under a condition that the surface temperature is same to that of the aluminum silicate wool, and remarkable energy-saving effect due to great reduction of the heat dissipation area, so the adiabatic temperature range is greatly expanded, and the working temperature range can reach -40-1000 DEG C.

Owner:刘永平

Composite material for water lubricated bearing and preparation method thereof

The invention discloses a composite material for a water lubricated bearing, and belongs to the technical field of a polymer composite material. The technical scheme of the invention is that: the composite material comprises the following raw materials in parts by weight: 100 parts of rubber, 2 to 12 parts of active agent, 0.5 to 2 parts of anti-aging agent, 20 to 70 parts of carbon black, 0.5 to2 parts of vulcanizing agent, 0.5 to 1.5 parts of accelerant and 1 to 50 parts of basalt fibers; and the raw materials above are used for preparing according to a special preparation method. The composite material has the beneficial effects that the composite material disclosed by the invention has the advantages of wide applicable temperature, excellent wear resistance, low wear rate and long service life under the water lubricated condition; the composite material uses nitrile rubber, carboxy nitrile rubber and hydrogenated nitrile rubber which are excellent in heat resistance and excellentin wear resistance as base materials; and by adding the basalt fibers and using the special preparation method, wear resistance of the rubber, particularly wear resistance in a water environment at ahigh temperature, is promoted.

Owner:QINGDAO UNIV OF SCI & TECH

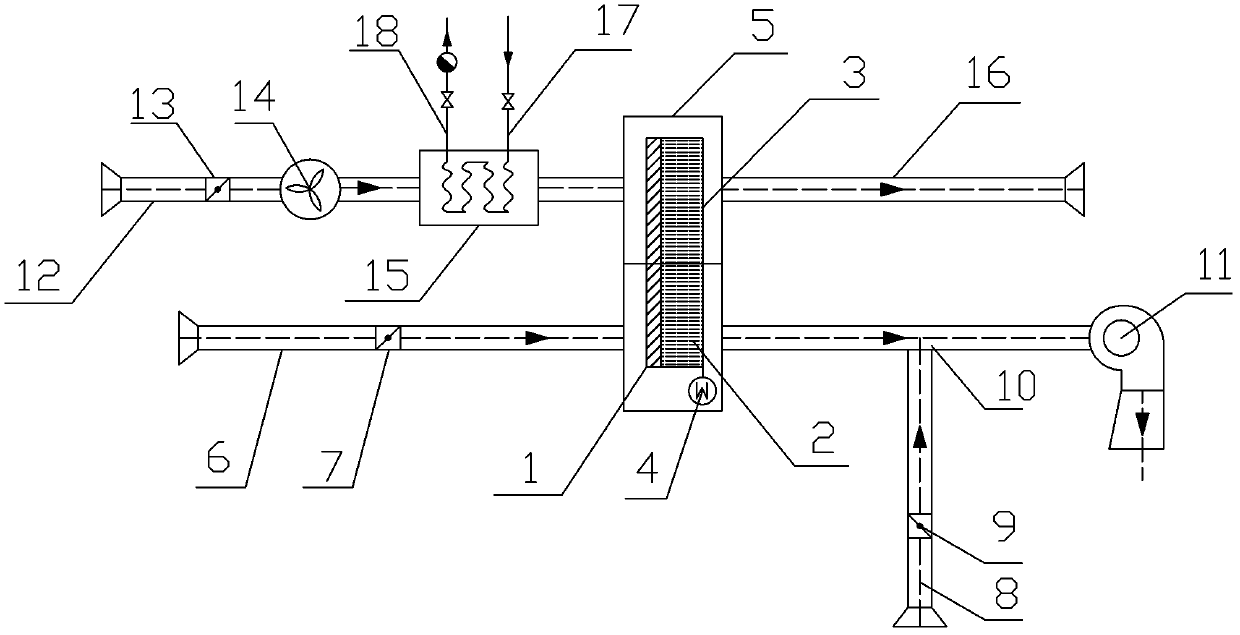

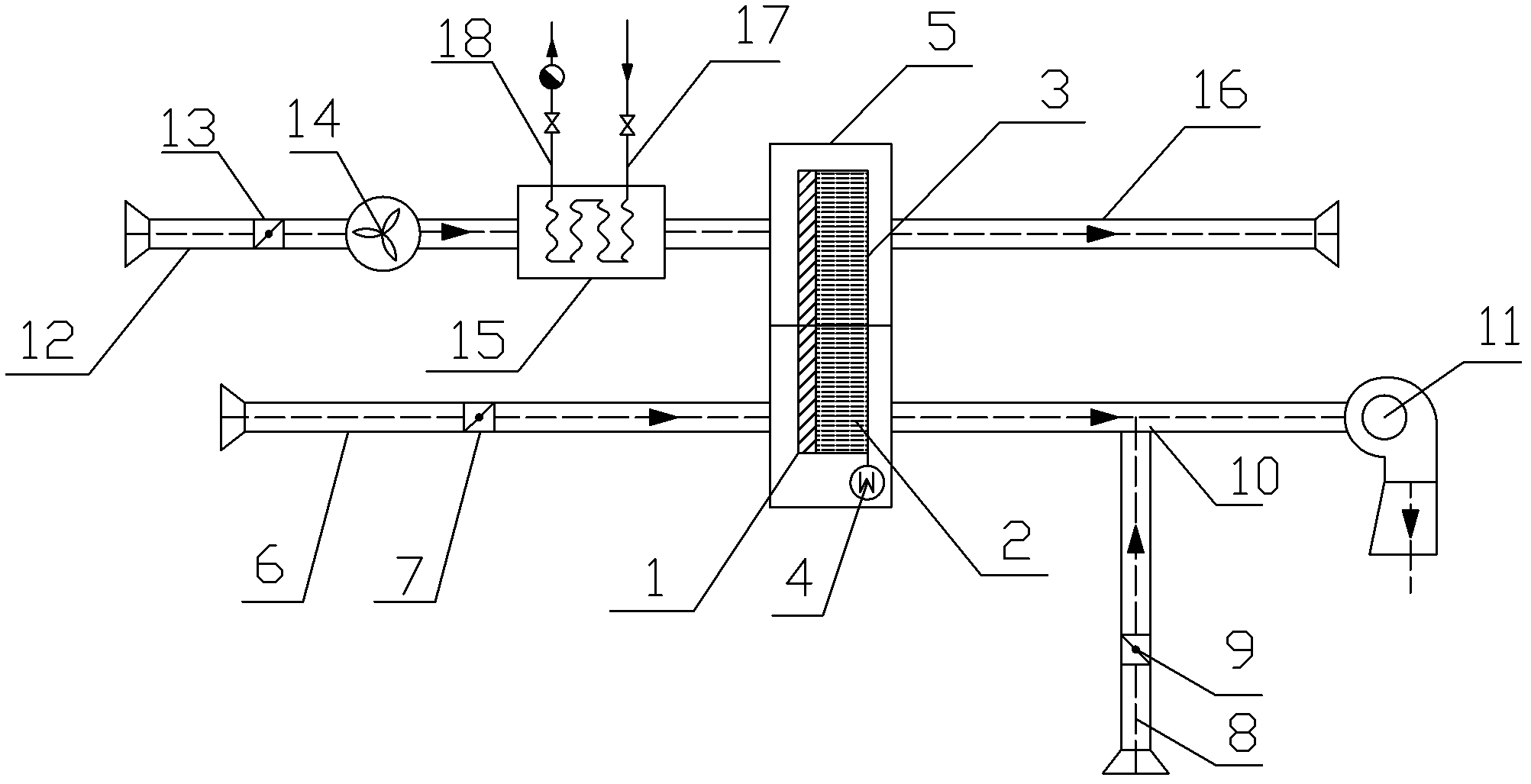

Blast rotary-wheel dehumidification device for blast furnace

InactiveCN102586524ALow running costSave energy for reheatingBlast furnace detailsHeating stovesEngineeringEnergy consumption

The invention relates to a blast rotary-wheel dehumidification device for a blast furnace. The device mainly comprises a rotary-wheel dehumidifier which is provided with a rotary-wheel dehumidification area and a rotary-wheel regeneration area and can perform circulating dehumidification and then perform regeneration, wherein two sides of the rotary-wheel dehumidification area are provided with an inlet air duct and an outlet air duct respectively, and two sides of the rotary-wheel regeneration area are provided with a regenerated-air inlet air duct and a regenerated-air outlet air duct respectively; an inlet valve is arranged on the inlet air duct; and the outlet air duct is connected with a blower. The device is characterized in that: a heater, a ventilator and a regenerated-air air valve are sequentially arranged on a pipeline of the regenerated-air inlet air duct; and a heater steam supply pipe and a heater condensing drain pipe are communicated with the heater respectively. After the air is dehumidified by using the device, the temperature of the air can be raised to a certain degree, so that the process of the dehumidification of a surface cooler, namely the process that the air is required to be super-cooled and then heated is avoided, and the reheating energy consumption is reduced. The device is high in efficiency and compact, takes steam as a heat source, and fully utilizes steam resources of metallurgic plants.

Owner:WISDRI ENG & RES INC LTD

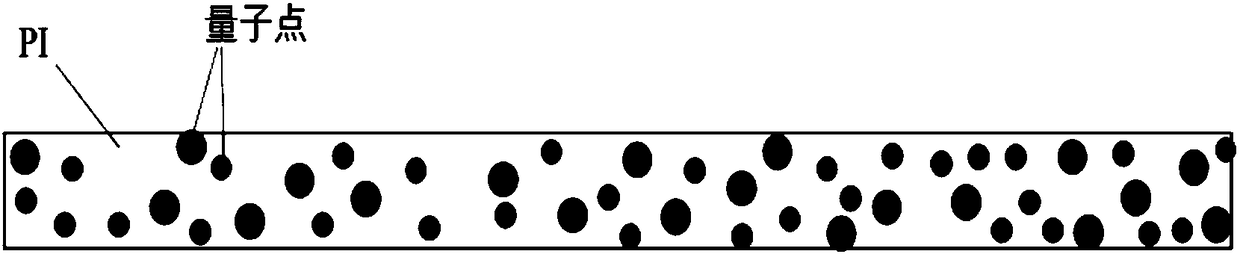

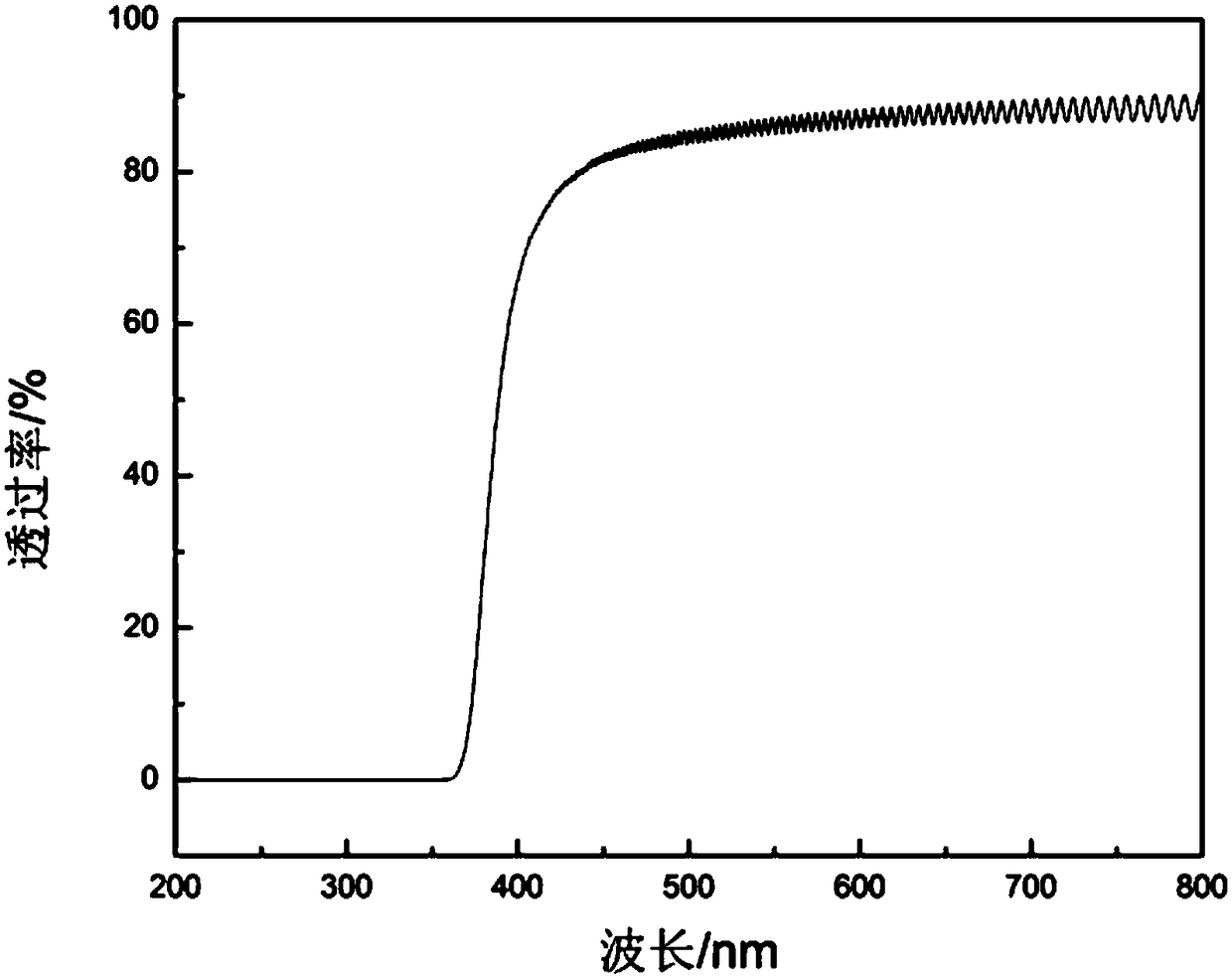

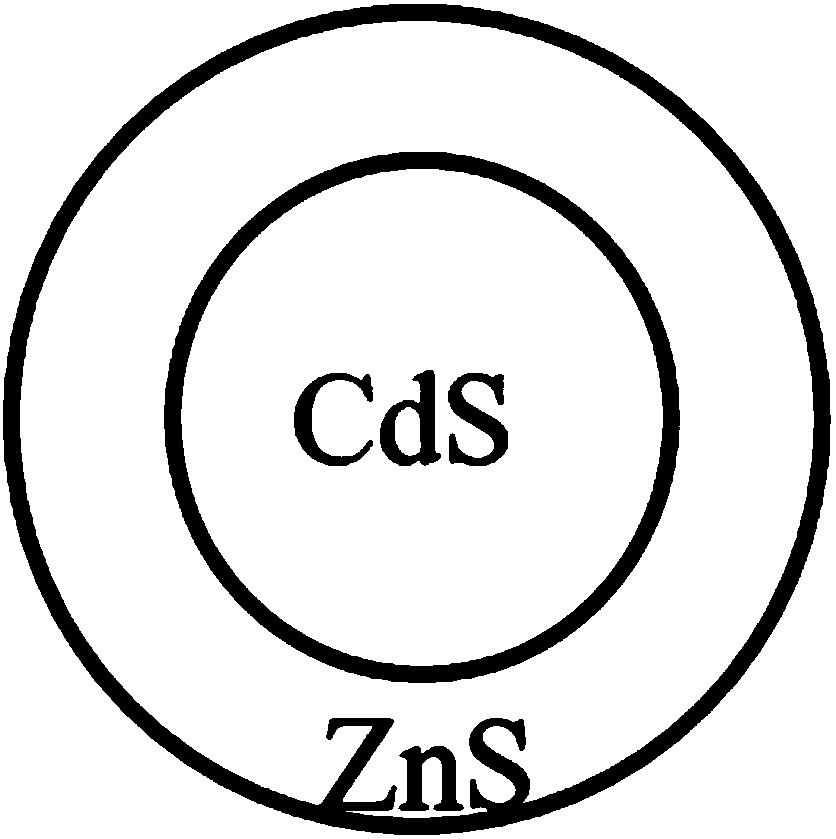

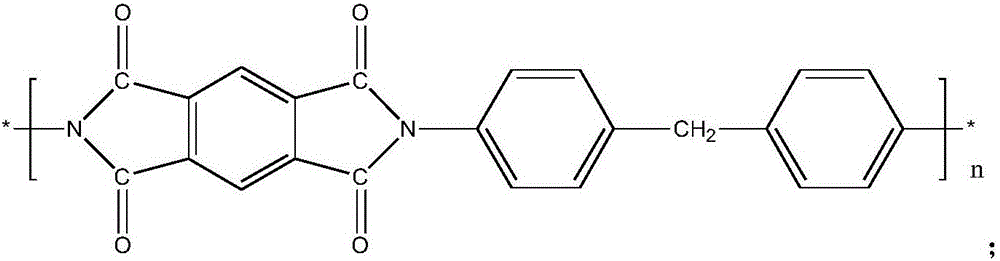

Preparation method of polyimide quantum dot backlight film

InactiveCN108102365AStrong weather resistanceChemically resistantNon-linear opticsOxygenPolymer solution

The invention discloses a preparation method a polyimide quantum dot backlight film. The method comprises the following steps: 1) preparing a transparent polyimide pre-polymer: firstly, carrying out polymerization reaction on dianhydride and diamine in ionic liquid to obtain a polyimide pre-polymer solution; mixing the obtained polyimide pre-polymer solution with a precipitant; after filtering, carrying out drying treatment on sediment to obtain polyimide pre-polymer powder; then dissolving the polyimide pre-polymer powder into a polar solution to obtain polyimide pre-polymer gel; 2) doping quantum dots: adding red and green quantum dots into the polyimide pre-polymer gel and sufficiently stirring and mixing to obtain polyimide gel containing the red and green quantum dots; 3) curing to form a film: spreading the polyimide gel on a substrate and curing through a heating manner to finally form the polyimide quantum dot backlight film. According to the preparation method disclosed by theinvention, polyimide with strong weather resistance is used as a dispersion substrate of the quantum dots, and the light, heat, water and oxygen stability of the quantum dot backlight film can be remarkably improved.

Owner:JIANGHAN UNIVERSITY

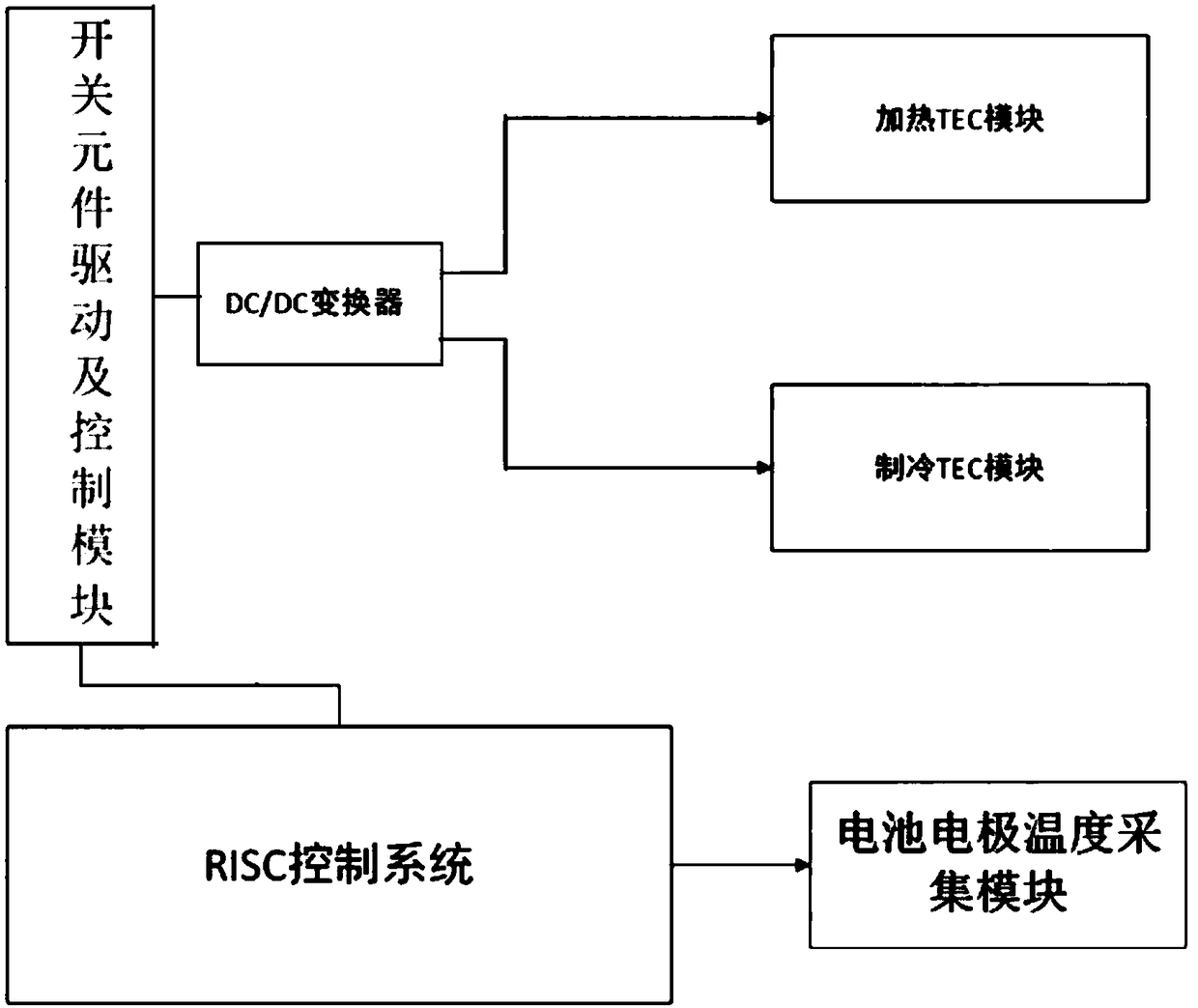

Integrated heat management system for new energy electric vehicle batteries and control method thereof

PendingCN109301368ASealed compact designSimplifies seal designCell temperature controlSecondary cells servicing/maintenanceAutomotive batteryNew energy

The invention relates to an integrated heat management system for new energy electric vehicle batteries and a control method thereof. The output end of a temperature sensor is connected with a batteryelectrode temperature acquisition module; an RISC (reduced instruction set computer) circuit control system is connected with the battery electrode temperature acquisition module and is also connected with a heating TEC (thermoelectric cooler) module and a cooling TEC module; a thermal balance heat pipe is pacakaged in an equalizing plate; the front end of a heat transfer heat pipe is connected with the equalizing plate; the tail end of the heat transfer heat pipe is connected with an energy storage unit; the middle of the heat transfer heat pipe is connected with the heating TEC module and the cooling TEC module; heat is guided out of a battery box via the heat transfer heat pipe, so that the heat dissipation problem of the inner closed space of the battery box is solved; the heating TECmodule is electrified to produce heat to heat up the battery box; the cooling TEC module is electrified to absorb heat so as to cool the battery box. The problem can be solved herein that the prior art has control complexity and poor battery temperature control uniformity.

Owner:瞿志刚 +1

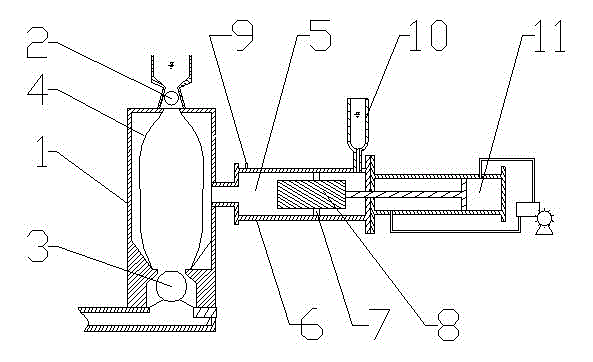

Vertical hydraulic inner tube slurry pump

InactiveCN104612933AExtended service lifeSmooth transmissionPump testingPositive displacement pump componentsReciprocating motionPulp and paper industry

The invention relates to a water conservancy mechanical facility, in particular to a vertical hydraulic inner tube slurry pump. The vertical hydraulic inner tube slurry pump comprises a vertical mortar cylinder, a mortar inner tube is arranged in the mortar cylinder, one-way floating ball valves are arranged in an inlet and an outlet of the mortar cylinder respectively, the mortar cylinder is connected with a plunger type water cylinder, the plunger type water cylinder is connected with a hydraulic oil cylinder, and a heat dissipating position indicator is arranged on the plunger type water cylinder. A plunger in the water cylinder is pushed by the hydraulic oil cylinder to do reciprocating motion to squeeze water in the water cylinder so that mortar in the mortar inner tube can be discharged outwards. The vertical hydraulic inner tube slurry pump has the advantages of being simple in structure, convenient to operate, high in pressure and efficiency, large in lift, environmentally friendly and safe and reliable to operate and consuming little energy, and the mortar conveying flow is large.

Owner:山东国地水利土地勘察设计有限公司

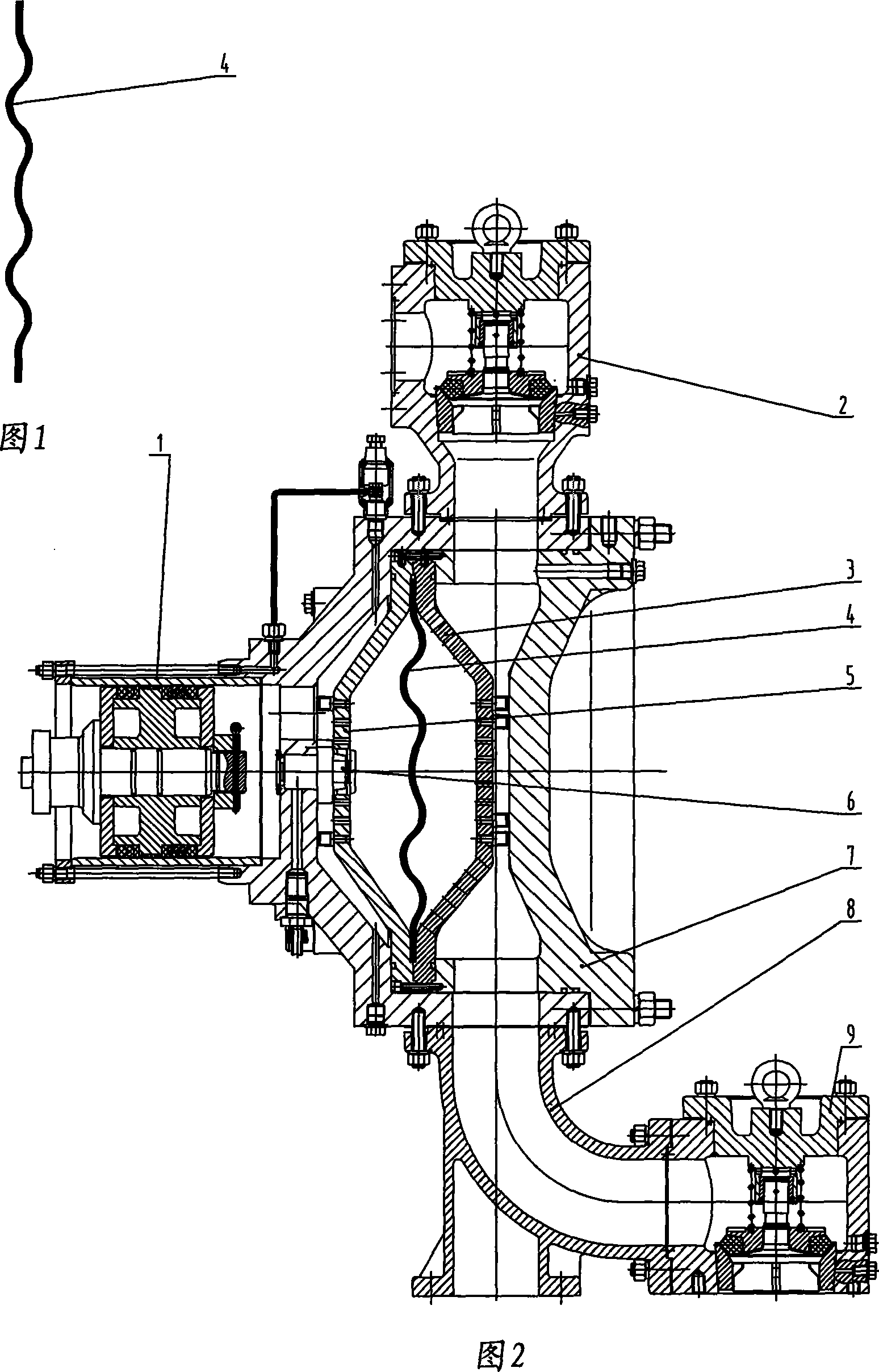

Membrane for reciprocating hydraulic ore slurry membrane pump and manufacturing method thereof

InactiveCN101220812AImprove bearing strengthGuaranteed StrengthPositive displacement pump componentsFlexible member pumpsEngineeringSlurry

The invention discloses a diaphragm used for a reciprocating hydraulic pulp diaphragm pump, which adopts a polytetrafluoroethylene material. The diaphragm is a cirque wave-shape and sequentially gained by the production process of the material preparation, press molding, sintering, quenching, multi-directional rolling, and hot press molding. The invention has higher bearing strength compared with the strength of a rubber, thus ensuring the strength; the invention has better temperature resistance performance and wide applicable range; furthermore, the invention can always keep corrugated structure under the severe working conditions of high temperature and high pressure; the abrasion has small damage sensitiveness to the strength of the polytetrafluoroethylene diaphragm, and the service life of the polytetrafluoroethylene diaphragm can be prolonged in flexible motion.

Owner:重庆水泵厂有限责任公司

Hard alloy composite sealing structure and preparing technology thereof

InactiveCN107269859AReach frictionZero frictionLift valveValve member-seat contactsMachine partsAlloy composite

The invention relates to a hard alloy composite sealing structure and a preparing technology thereof. The hard alloy composite sealing structure comprises a valve seat machining part and a sealing ring machining part. In the valve seat machining part, a casting is fixedly arranged on a valve seat machining clamp inclining by 4-15 degrees, and after the sealing face thickness of 4-8 mm is reserved, a sealing face of the valve seat is roughly turned, and surfacing of a first hard alloy layer is conducted on the sealing face of the valve seat; and in the sealing ring machining part, a sealing ring blank is arranged on a sealing ring machining clamp of a lathe, and after the sealing face of the sealing ring is finely turned, surfacing of a second hard alloy layer is conducted on the sealing face of the sealing ring. According to the hard alloy composite sealing structure and the preparing technology thereof, the machining technology cost is low, the sealing precision is high, the product can achieve zero friction, zero leakage and both-way pressure bearing and achieves real high performance, a sealing pair is all metal, and once after closing is conducted in place, sealing is very reliable, and the application temperature range is wide.

Owner:SHANGHAI LEIFU VALVE MFG CO LTD

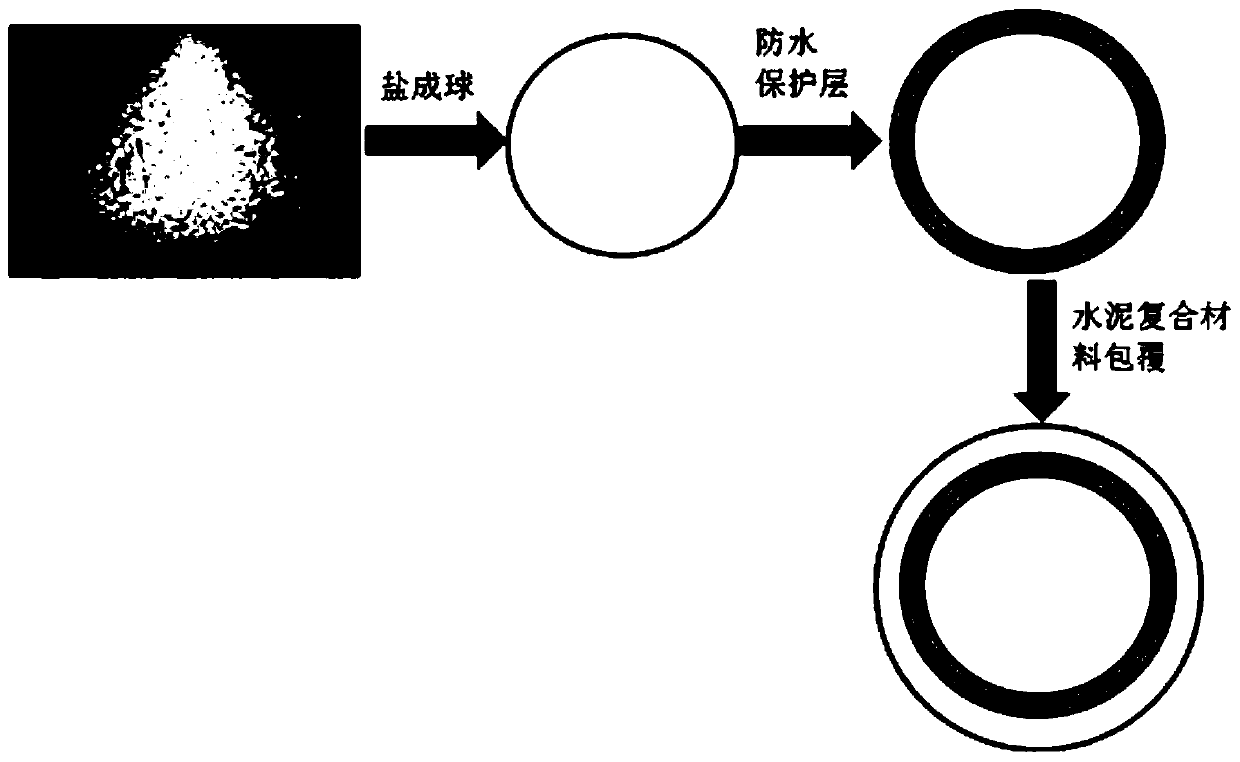

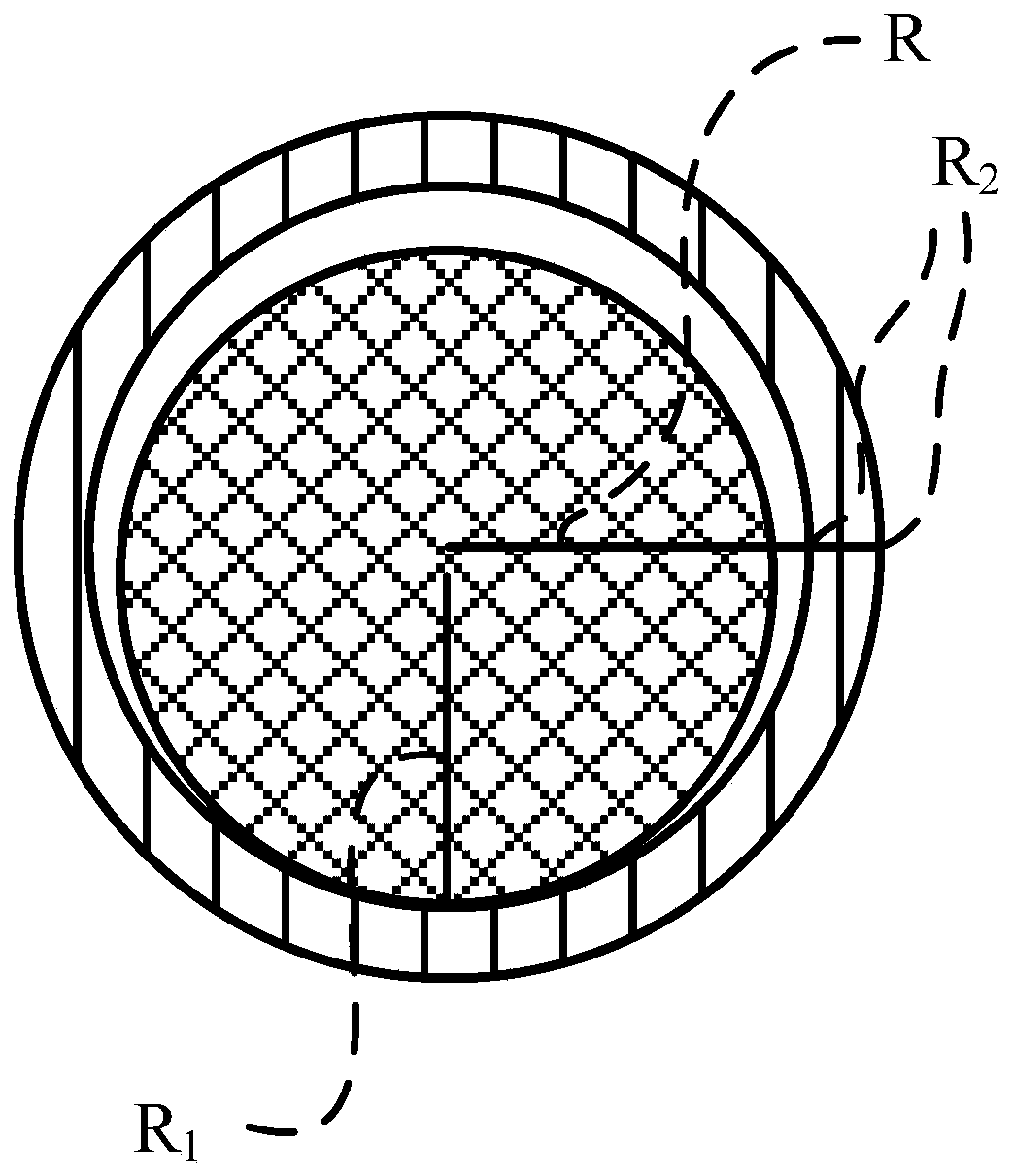

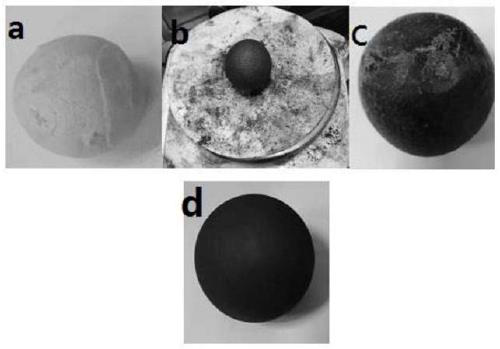

Fused salt phase change heat storage element and preparation method thereof

ActiveCN111334258ALow costImprove thermal conductivityHeat-exchange elementsPhysical chemistryMolten salt

The invention discloses a fused salt phase change heat storage element and a preparation method thereof. The fused salt phase change heat storage element is of a core-shell structure and comprises aninner core and an outer shell. Wherein the inner core is a molten salt ball; the shell is made of a carbon-based heat conduction material and cement; wherein the radius of the fused salt ball accountsfor 29%-90% of the radius of the fused salt phase change heat storage element; the sum of the ratio of the radius of the fused salt ball to the radius of the fused salt phase change heat storage element and the ratio of the thickness of the shell to the radius of the fused salt phase change heat storage element is smaller than 100%; wherein the carbon-based heat conduction material accounts for 1.0-50.0% of the total mass of the carbon-based heat conduction material and the cement. The solid-state phase change heat storage element has the advantages of being low in cost, high in heat conduction, simple and safe in process, convenient to operate and suitable for mass production.

Owner:SHANGHAI INST OF APPLIED PHYSICS - CHINESE ACAD OF SCI

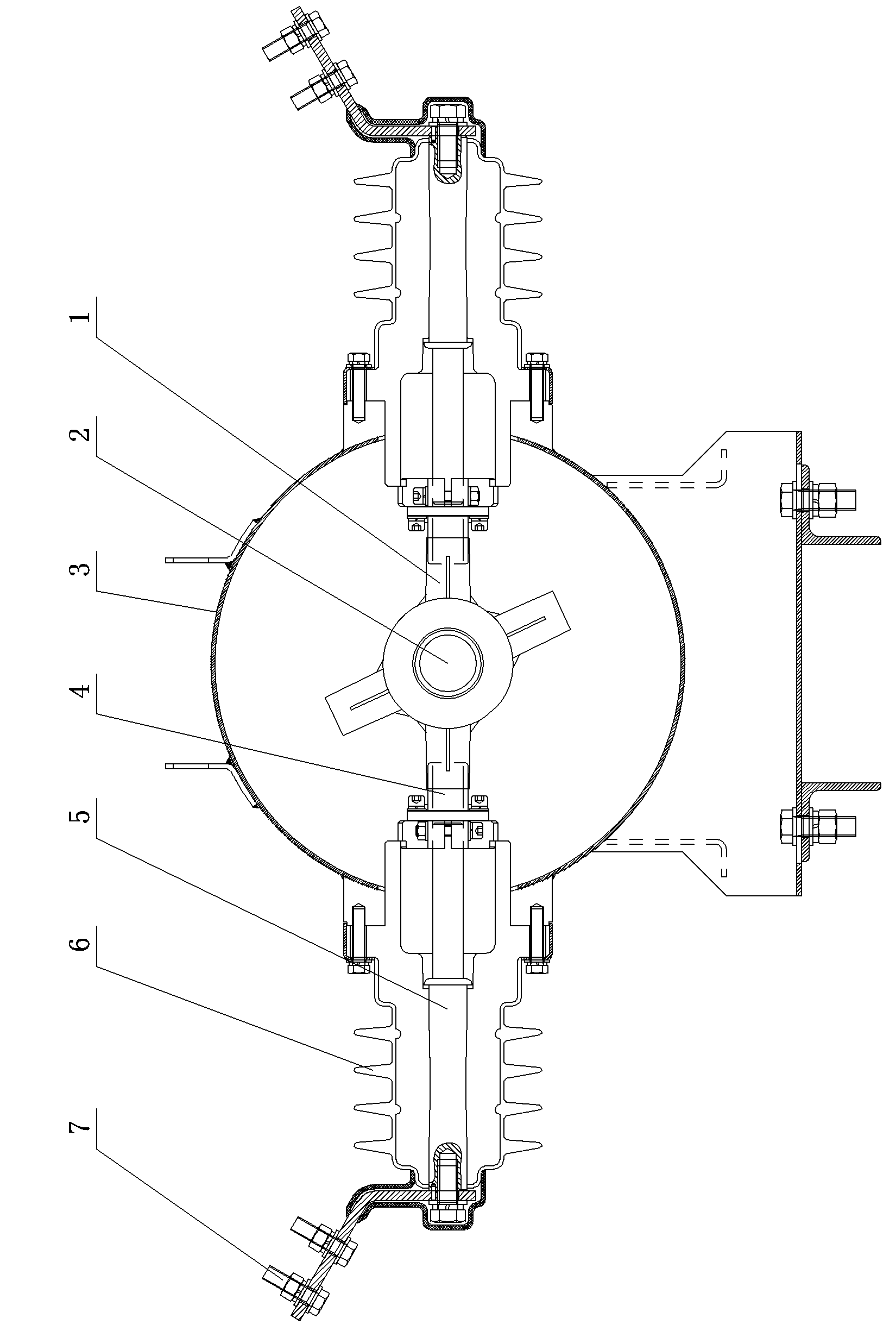

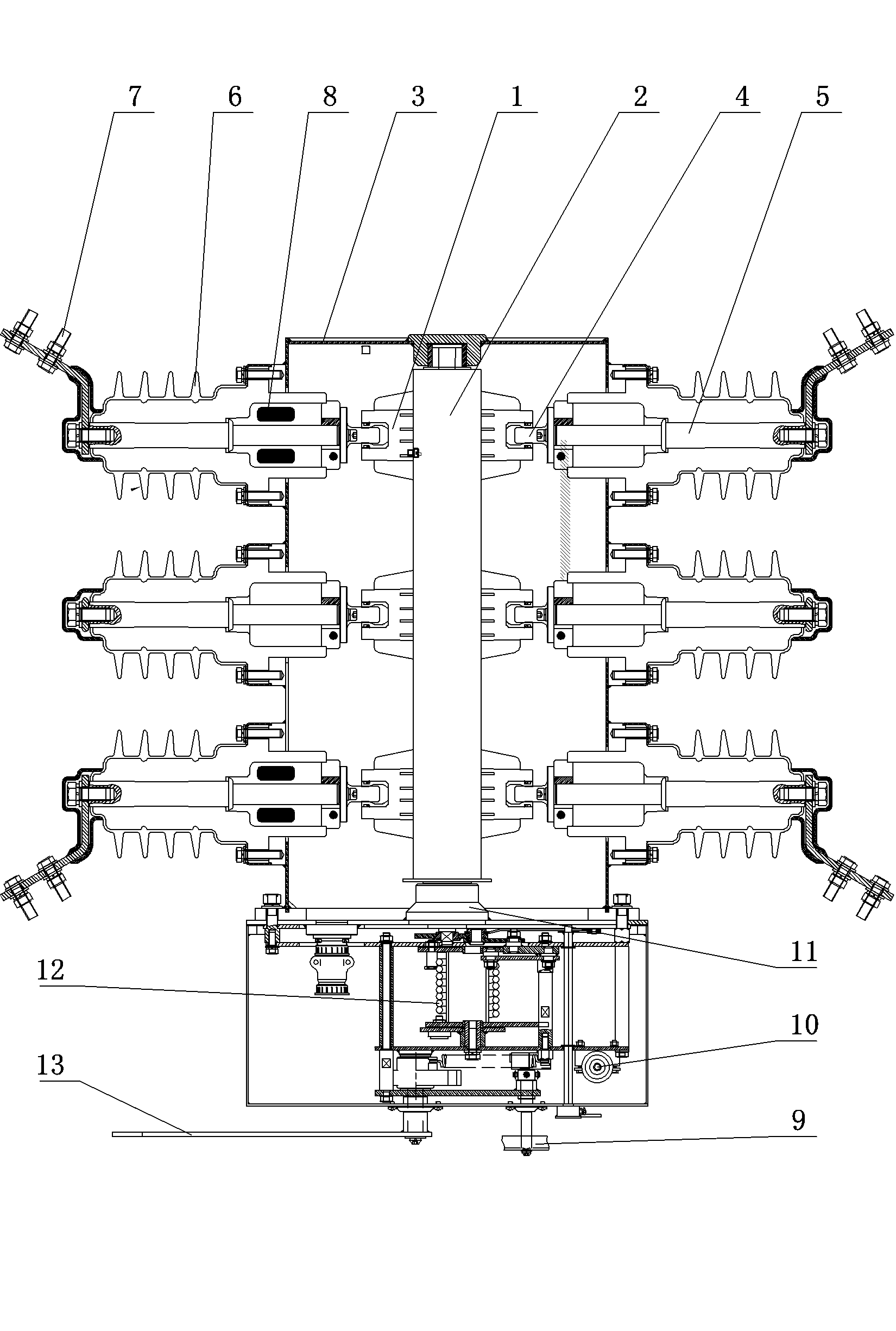

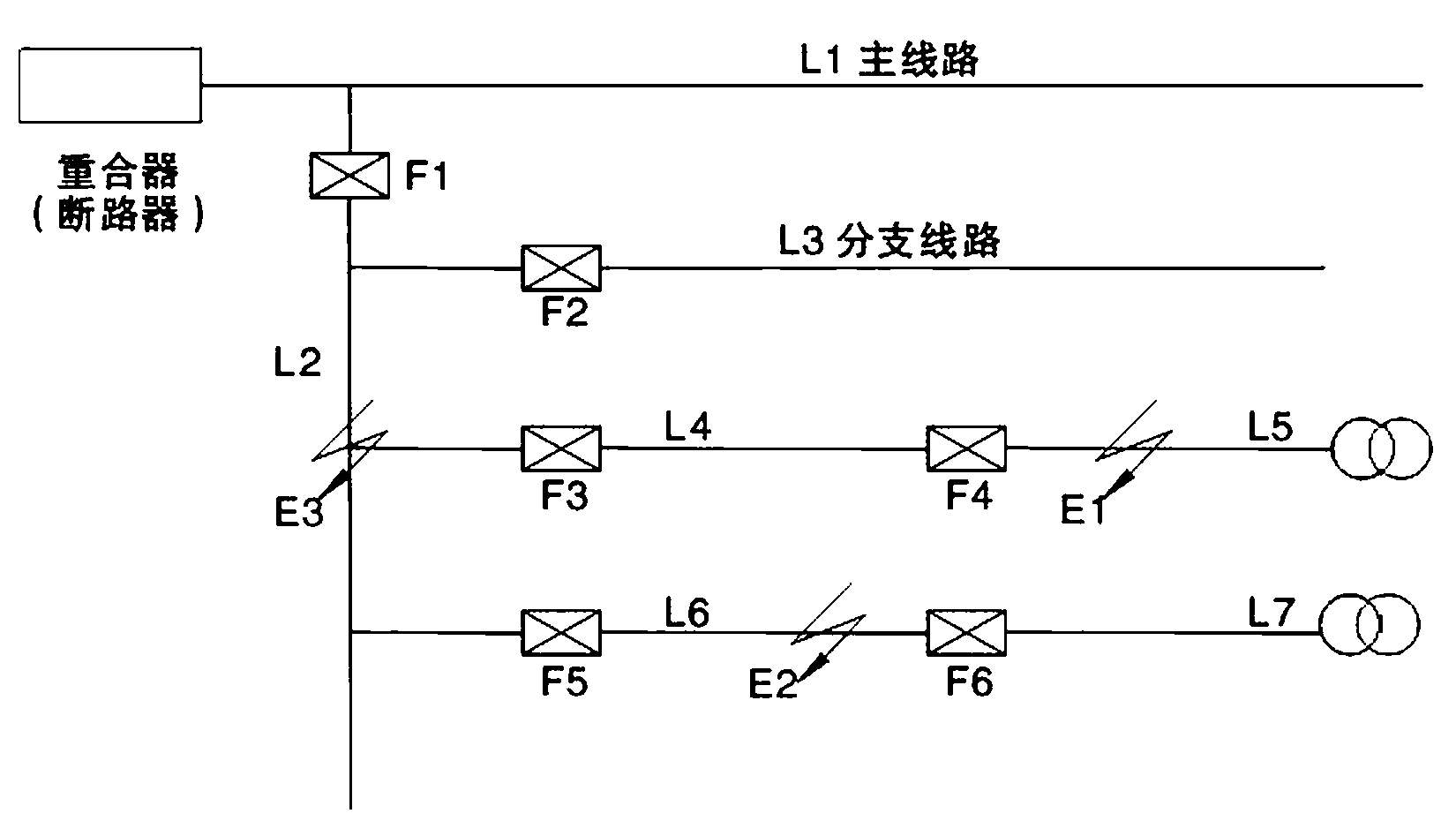

Outdoor alternating current high-voltage SF6 automatic sectionalizer

ActiveCN103065861AApplicable temperature rangeGood differential pressure resistanceHigh-tension/heavy-dress switchesAir-break switchesAlternating currentControl theory

The invention relates to improvement of a sectionalizer structure and provides an outdoor alternating current high-voltage SF6 automatic sectionalizer which is good in sealing property and capable of dividing and shutting a brake timely. The sectionalizer comprises a box body. SF6 gas is filled in the box body. A rotating shaft is arranged in the middle of the box body. A moving contact is arranged on the rotating shaft. An insulator is arranged on the box body. One end of the insulator extends into the box body and a static contact corresponding to the moving contact is arranged at one end of the insulator. A wiring terminal is arranged at the other end of the insulator. The wiring terminal and the static contact are connected through a conducting rod. The sectionalizer is characterized in that one end of the rotating shaft is connected with a spring mechanism driving a rotating shaft outside the box body to rotate through a magnetic fluid sealing shaft head, an energy storage handle and a divide-shut brake electric buckle releasing device which are used for driving the spring mechanism are arranged outside the spring mechanism, a controlled port of the divide-shut brake electric buckle releasing device is connected with an output controlled port of an electronic controller, and the electronic controller detects current intensity in an upper stage line and controls motion of the divide-shut brake electric buckle releasing device.

Owner:沈阳成兴电气有限公司

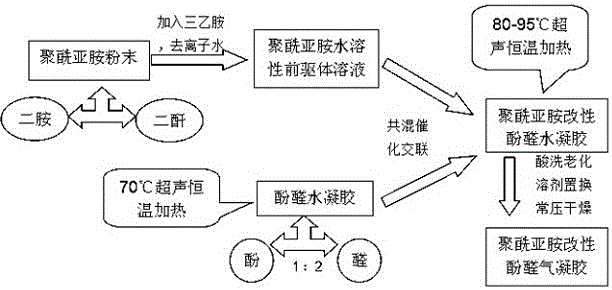

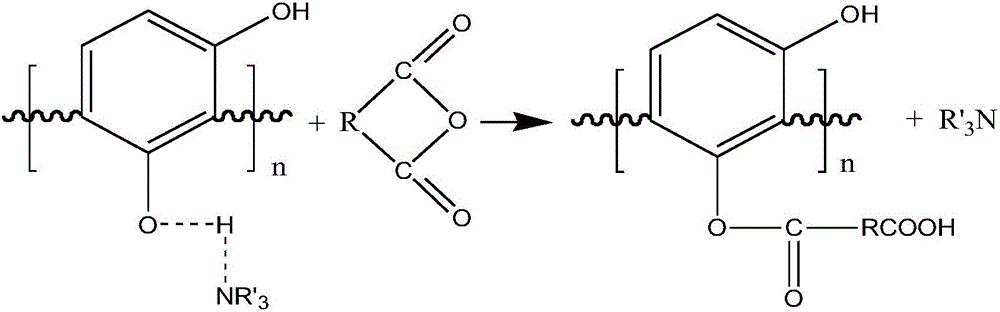

A kind of method for preparing polyimide modified phenolic airgel

The invention discloses a method for preparing polyimide-modified phenolic aerogel. The polyimide modified phenolic aerogel is prepared from the following raw materials in parts by weight: 1 part of polyimide, 1-10 parts of phenol and aldehyde, 85-97 parts of deionized water, 0.5 part of ethylenetriamine, 0.4 part of catalyst A and 0.1 parts of catalyst B. The method comprises the following main steps: preparing a polyimide water-soluble precursor solution firstly; then, preparing phenolic hydrogel; and finally, sequentially carrying out crosslinking, acid pickling and aging on the polyimide water-soluble precursor solution and a network structure in the hydrogel, and carrying out solvent replacement and ambient-pressure drying on the obtained product, so that polyimide-modified phenolic aerogel is obtained finally. The apparent density of the prepared aerogel material is 0.03-0.5 g / cm<3>, the specific surface area is 400-900 m<2> / g, the aperture size of the aerogel is 5-50 nm, the heat conduction coefficient is 0.012-0.025 W / m.k, the temperature resistance range is minus 130-800 DEG C, and the aerogel is good in mechanical and processing properties, excellent in insulating properties, wide in applicable temperature and excellent in thermal insulation performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

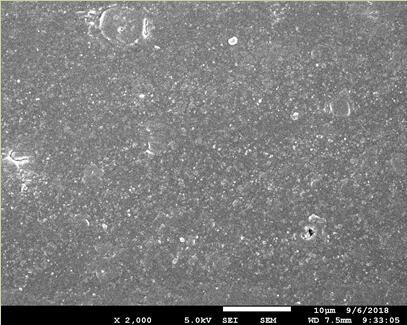

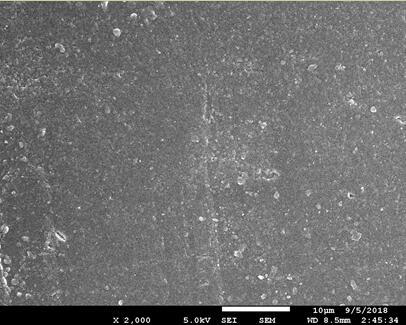

Hole sealing agent for thermal spraying coating and preparation method thereof

PendingCN110230021AHigh hardnessImprove corrosion resistanceMolten spray coatingThermal sprayingPhosphoric acid

The invention discloses a hole sealing agent for a thermal spraying coating. The hole sealing agent is characterized by comprising the following components of, in percentage by mass, 0.1%-1% of graphene and 99%-99.9% of a mixed solution containing boron nitride and aluminum metaphosphate. The thermal spraying coating treated by using the hole sealing agent disclosed by the invention has higher hardness, better corrosion resistance and wear resistance, so that the service life of the thermal spraying coating is prolonged; and moreover, the preparation method of the hole sealing agent for the thermal spraying coating is simple to operate, the maintenance cost is reduced, and the method has a good application prospect.

Owner:SHANGHAI JUSN SURFACE TECH ENG

Method surface protective liquid

InactiveCN1616710AWide range of applicationsApplicable temperature rangeMetallic material coating processesPhosphoric acidChemistry

The metal surface protecting liquid is compounded with phosphoric acid 160 weight portions, potassium molybdate 2 weight portions, tartaric acid 15 weight portions, thiourea 7.5 weight portions, AEO-9 0.2 weight portions, hydrogen peroxide 0.3 weight portions and water 1000 weight portions. The preparation process includes adding phosphoric acid into water via stirring, adding the other components via stirring, and letting stand of 24 hr. The present invention has the advantages of wide application temperature range, no need of heating in use, fast filming and homogeneous film with high adhesion force to prevent rust.

Owner:史秀敏

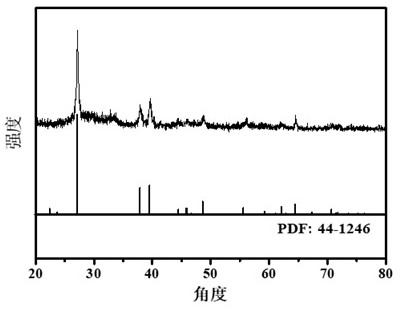

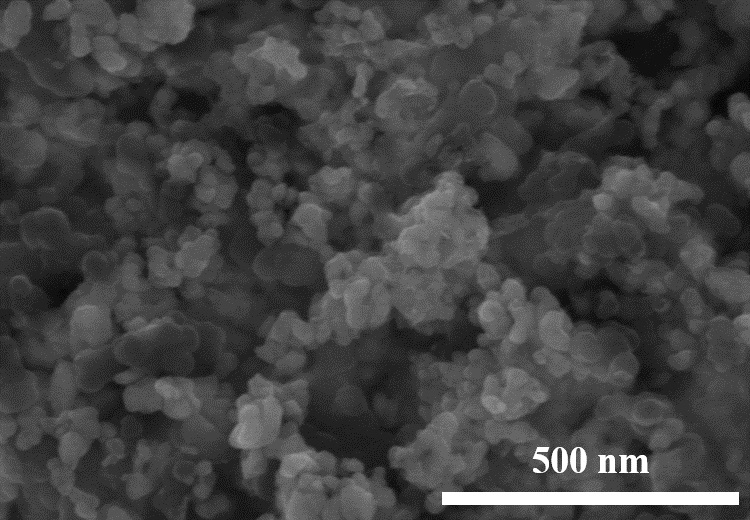

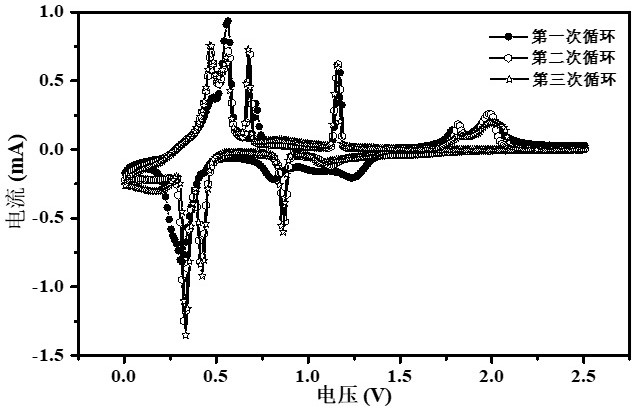

Wide-temperature-range high-performance electrochemical energy storage device based on bismuth-based electrode

ActiveCN112599361AImprove electrochemical performanceImprove cycle stabilityHybrid capacitor electrodesCell electrodesChemical physicsElectrical battery

The invention provides a wide-temperature-range high-performance electrochemical energy storage device based on a bismuth-based electrode. The prepared bismuth electrode is used as a negative electrode material of a potassium ion battery and still shows excellent cycling stability, high reversible capacity and long cycle life under a low-temperature condition. Furthermore, by matching the preparedbismuth electrode with carbon, the bismuth-based potassium ion hybrid supercapacitor with high energy and power density can be obtained at normal / low temperature. The wide-temperature-range high-performance electrochemical energy storage device based on the bismuth-based electrode has excellent electrochemical performance, can simultaneously solve problems of low reversible capacity, short service life and high energy density and power density of a battery at normal / low temperature, is suitable for large-scale production, and has a wide application prospect. And the wide-temperature-range high-performance electrochemical energy storage device is a novel green chemical power supply with a wide application prospect.

Owner:HUNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com