Cleaning agent for cleaning of pervious concrete with exposed aggregate

A technology of permeable concrete and cleaning agent, applied in the field of cleaning agent for cleaning exposed aggregate pervious concrete, can solve the problems of affecting the construction quality of exposed aggregate permeable concrete, difficult to control the penetration depth, small ambient temperature range, etc., and achieves the sensitivity of spraying amount fluctuation. Low, good surface exposure, wide temperature range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

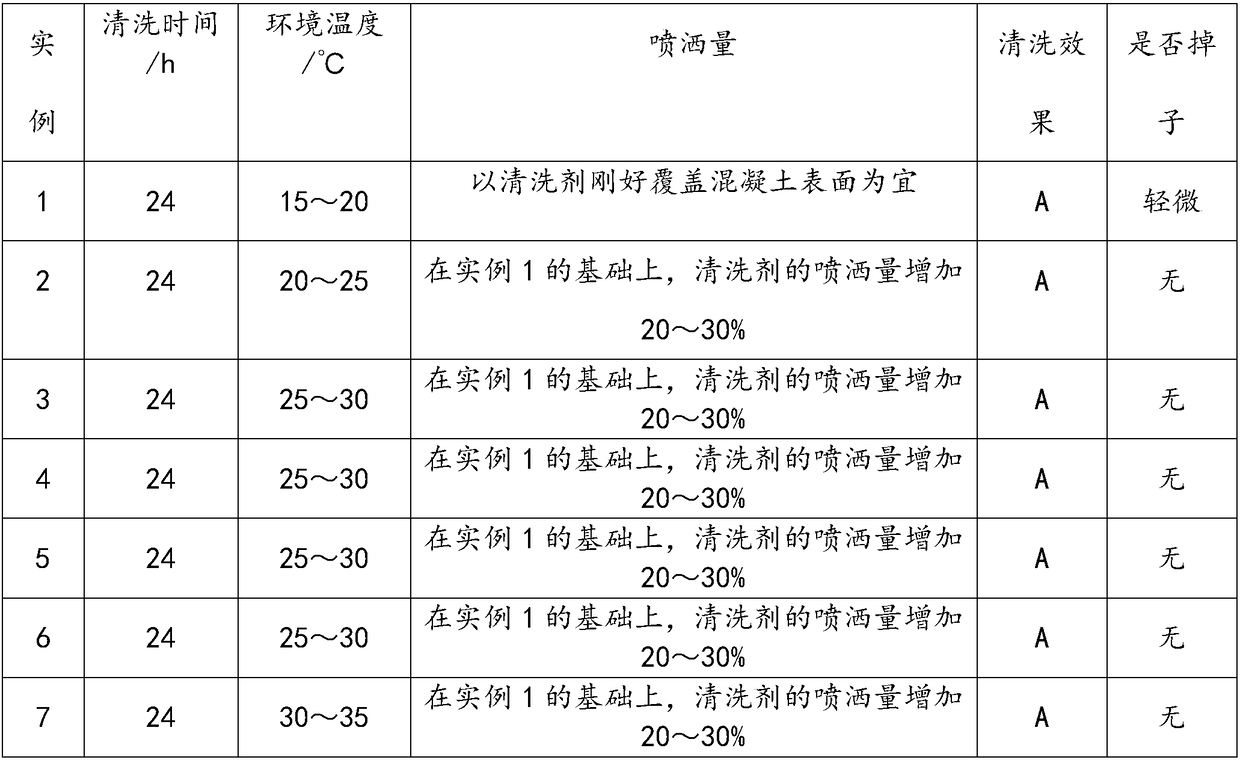

Embodiment 1

[0022] A cleaning agent for cleaning exposed aggregate permeable concrete,

[0023] Its raw materials mainly include sodium gluconate and citric acid according to the mass ratio of 35%: 65% of the retarder 2%, industrial grade hydroxypropyl methylcellulose 0.05%, polyacrylamide 0.01% , iron oxide red 1%, fly ash 85%; the above raw materials are weighed by mass percentage, and added to the preparation vessel and stirred at a speed of 500rpm / min to form a uniformly dispersed mixture; when used, add The mixture is 100% water, and stirred for 1 minute to prepare the aggregate-exposed permeable concrete cleaning agent; immediately after the permeable concrete is poured, the cleaning agent is evenly and comprehensively sprayed on the surface of the permeable concrete, and then immediately covered with a film for curing, after 24 hours Rinse the concrete with a water gun to obtain permeable concrete with exposed aggregates; if the ambient temperature is low (below 25°C), the cleaning...

Embodiment 2

[0025] A cleaning agent for cleaning exposed aggregate permeable concrete,

[0026] Its raw materials mainly include sodium gluconate and citric acid according to the ratio of mass and number of 43%: 57% retarder 4%, industrial grade hydroxypropyl methylcellulose 0.15%, polyacrylamide 0.05% %, iron oxide red 3%, ordinary Portland cement 91%; the above raw materials are weighed according to mass percentage, and added to the preparation vessel and stirred at a speed of 500rpm / min to form a uniformly dispersed mixture; Add water with 150% of the weight of the mixture into the mixture, and stir for 1.5 minutes to prepare the aggregate-exposed permeable concrete cleaning agent; immediately after the permeable concrete is poured, spray the cleaning agent evenly and comprehensively on the surface of the permeable concrete, and then immediately cover the film for curing After 24 hours, rinse the concrete with a water gun to obtain permeable concrete with exposed aggregates; if the amb...

Embodiment 3

[0028] A cleaning agent for cleaning exposed aggregate permeable concrete,

[0029] Its raw materials mainly include sodium gluconate and citric acid according to the ratio of 50% by mass: 50%, 6% of retarder, 0.3% of industrial grade hydroxypropyl methylcellulose, and 0.1% of polyacrylamide , iron oxide red 5%, fly ash and ordinary Portland cement 98%; the above raw materials are weighed by mass percentage, and added to the preparation vessel and stirred at a speed of 500rpm / min to form a uniformly dispersed mixture; during use, Add water with 200% of the mass of the mixture to the obtained mixture, and stir for 2 minutes to prepare the aggregate-exposed permeable concrete cleaning agent; after the permeable concrete is poured, immediately spray the cleaning agent evenly and comprehensively on the surface of the pervious concrete, and then immediately Cover the film for curing, and rinse the concrete with a water gun after 24 hours to obtain permeable concrete with exposed ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com