Patents

Literature

66results about How to "Enhanced skeleton structure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat-resisting silica aerogel material and preparation method thereof

The invention relates to a heat-resisting silica aerogel material and a preparation method thereof. SiO2 sol is prepared by adopting a sol-gel method, modified liquid is innovatively led to a supercritical drying process by ageing and solvent replacement through adopting a supercritical modification process, so as to obtain bulk aerogel which is high in mechanical strength and easy to process, and then the SiO2 aerogel of which linear contraction just is 5%, and the specific surface area can be up to 530m<2> / g after high-temperature treatment at 1000 DEG C can be obtained by high-temperature pretreatment at 800 DEG C and gas-phase modification of hexamethyldisilazane. By adopting the synthetic method, application of the SiO2 aerogel in high-temperature fields such as high-temperature catalysis, a catalyst carrier and high-temperature heat preservation and insulation is greatly facilitated.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Making method for charcoal electrode of liquid flow type electroadsorption desalinization device

InactiveCN1544116AImprove conductivityHigh strengthIon-exchange process apparatusIon-exchanger regenerationFiberPorosity

The invention relates to a method of making carbon electrode of fluid electric-absorption desalter. It mainly mixes high specific surface area electrode carbon, nano carbon tube absorption material, carbon fiber, and nano carbon tube conductive material as well as adhesive polytetrafluoroethylene in a certain proportion and in a certain mode to make cold press molding and makes them into a double-faced electrode with a collector interlaid; the carbon electrode has good electric conductivity, small resistance, large electric capacity and low energy consumption; in addition, the modified carbon electrode has larger specific surface area and mesoporous porosity, therefore able to increase the absorption quantity of electrode to salt ions. The carbon electrode is especially applied to the fluid electric-absorption desalter and has higher desalting efficiency.

Owner:上海维安新材料研究中心有限公司 +1

Method for preparing zirconium boride-tungsten titanium carbide self-lubricating composite ceramic material

The invention relates to a method for preparing a zirconium boride-tungsten titanium carbide self-lubricating composite ceramic material. The material is prepared by adding (W, Ti) C solid solution and ZrO2 powder into a ZrB2 matrix, taking MgO as a sintering aid and performing hot pressing sintering on the materials under the vacuum environment. Matrix phase ZrB2 and enhanced phase (W, Ti) C form a good framework structure by introducing (W, Ti) C solid solution; and the ZrO2 is added so as to improve the toughness of the composite ceramic material by means of the phase change characteristic. The sintering temperature of the ZrB2 is reduced by adding the MgO sintering aid, so that a material with higher compactness is obtained. Self-lubricating function of the zirconium boride-tungsten titanium carbide self-lubricating composite ceramic material can be realized by using the chemical reaction of the composite material under the action of high temperature friction. The method has the characteristics of high hardness, high bending strength, high fracture toughness and the like and is suitable for preparing metal cutting tools, modules, nozzles and the like.

Owner:SHANDONG UNIV

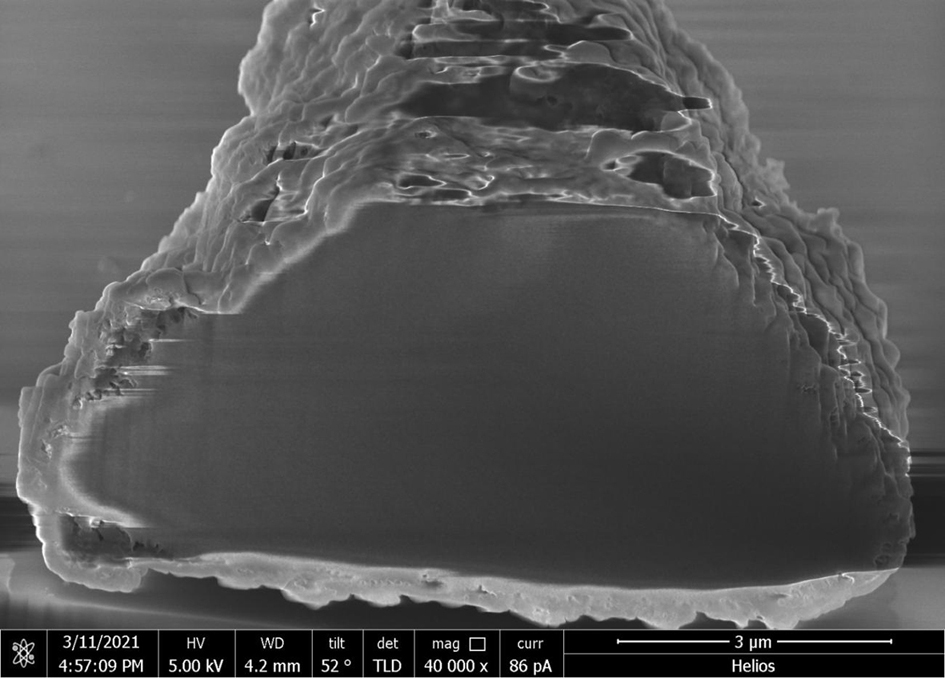

Diaphragm of electrochemical power supply and preparation method thereof

InactiveCN103579559AEnhanced skeleton structureHigh heat resistanceHybrid capacitor separatorsElectrolytic capacitorsPolyolefinAluminium hydroxide

The invention belongs to the technical field of electrochemical power supply, and discloses a diaphragm of an electrochemical power supply and a preparation method thereof. The diaphragm of an electrochemical power supply comprises a diaphragm substrate formed by polyolefin, and a fire-retardant layer which is coated on the diaphragm substrate and contains inorganic powder, wherein the inorganic powder is composed of boehmite and / or aluminium hydroxide. The preparation method comprises the following steps: preparing coating suspension containing the inorganic powder mentioned above, then evenly coating the suspension on two sides of a diaphragm substrate formed by polyolefin, and drying the diaphragm substrate by baking to form a fire-retardant layer on the surface of the diaphragm substrate so as to obtain the diaphragm of electrochemical power supply. The fire-retardant inorganic powder coated on the surface of the diaphragm substrate not only can improve the heat resistant temperature of the diaphragm, but also enables the diaphragm to have a fire-retardant effect, and provides a double safety guarantees for an electrochemical power supply. The diaphragm of an electrochemical power supply has the advantages of simple and practicable preparation technology, low-cost and available raw material, and convenient promotion and application in the field of power supply production.

Owner:OCEANS KING LIGHTING SCI&TECH CO LTD +1

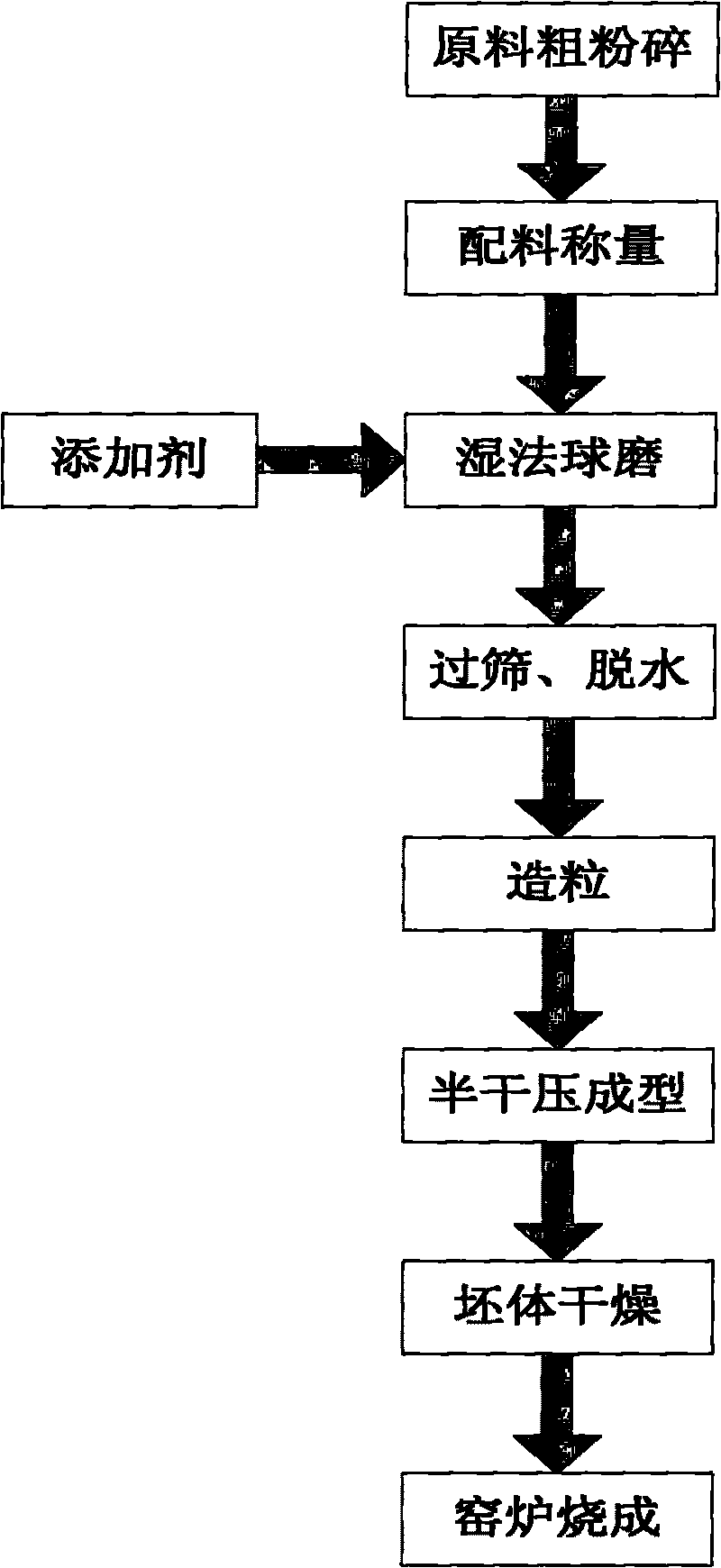

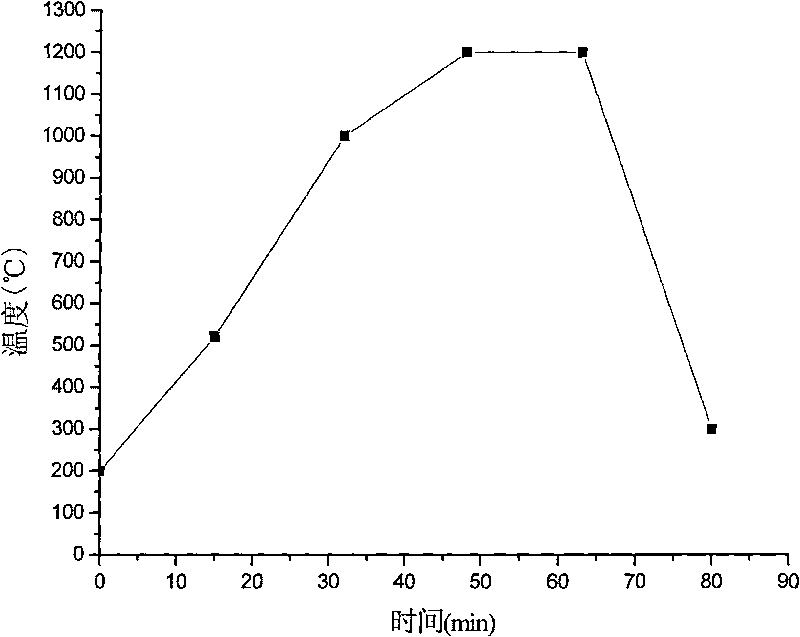

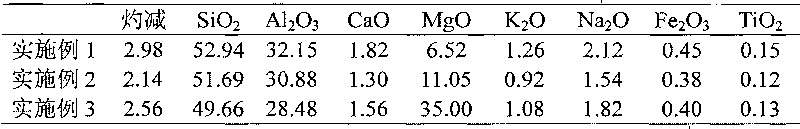

Lithium mine tailing lightweight ceramic sheet material manufacturing method

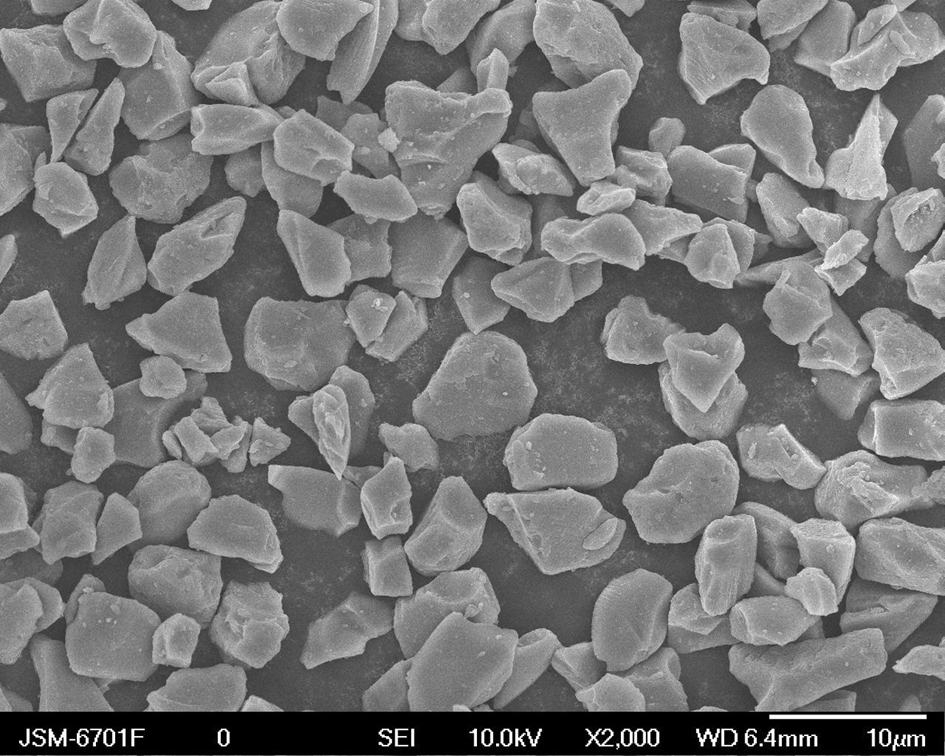

InactiveCN108911778AReduce consumptionLower firing temperatureCeramic materials productionCeramicwareLithiumPrill

The invention relates to a lithium mine tailing lightweight ceramic sheet material manufacturing method. The sheet material comprises the following raw materials: 30 to 85 wt% of lithium mine tailing,10 to 60 wt% of kaolin, 3 to 10 wt% of powdered steatile, and 0.2 to 3 wt% of a foaming agent; the manufacturing method comprises the following steps: 1) taking raw materials for dry-method pulverizing, mixing the raw materials in proportion to obtain a mixture; 2) adding water to the mixture, and performing steps of stirring, granulating, drying, and sieving to obtain a pellet; and 3) placing the pellet in a crucible, sintering the pellet after spreading, and cooling the pellet to obtain the lightweight ceramic sheet material. The method utilizes lithium mine tailing to produce the lightweight ceramic sheet material, the lithium mine tailing contains a certain amount of lithium and iron elements, the sintering temperature is significantly reduced, the sintering cycle is shortened, energyconsumption can be saved, and production cost can be greatly reduced.

Owner:江西庾岭晶硕新材料有限公司

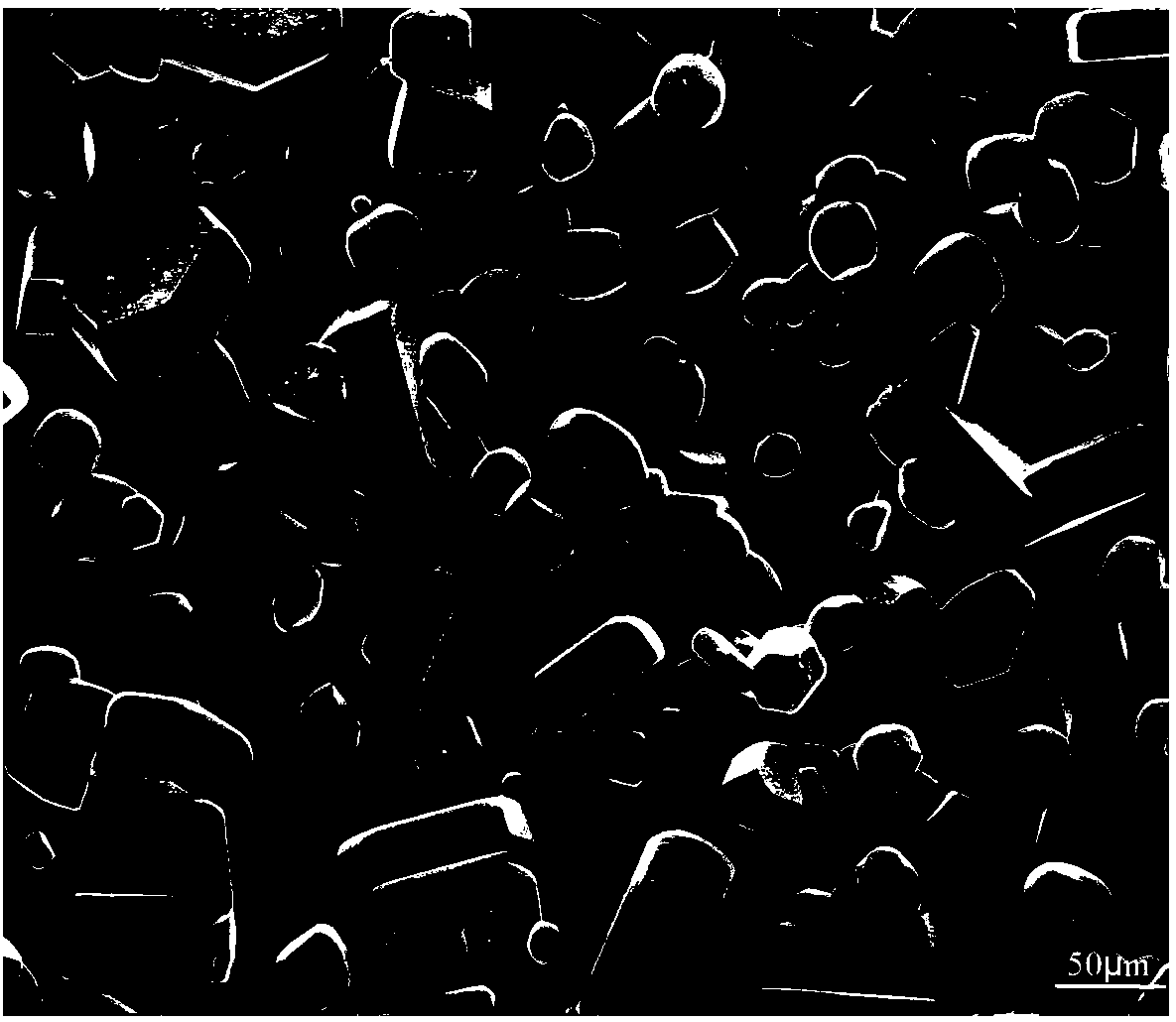

Method for firing porous filtering ceramic tiles with ceramic polishing scrap

InactiveCN101709001AIncrease contentIncrease the number ofSolid waste disposalCeramicwareCordieriteMaterials processing

The invention discloses a method for firing porous filtering ceramic tiles with ceramics polishing scrap. The method is implemented through raw materials processing, powder preparation, pressing molding, sintering and other processes performed on 50 to 70 percent of building ceramics polishing scrap mixed with 18 to 22 percent of calcined alumina, 0 to 10 percent of fired talc and 28 to 35 percent of light magnesium oxide. The porous filtering ceramic tiles prepared by the method not only have the function of protecting and purifying environment, but also have high modulus of rupture and good filtration performance. The method can effectively solve the problem of dealing with the building ceramics polishing scrap, can save natural ceramic raw materials, is simple in technological process of utilizing the ceramics polishing scrap to fire cordierite porous filtering ceramic tiles and low in cost, and has good application prospects in the fields of liquid pollution treatment, precise filtration and the like.

Owner:SOUTH CHINA UNIV OF TECH

Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic and preparation method thereof

The invention discloses a preparation method of Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. The preparation method comprises the following steps: taking silicon carbidepowder A, silicon carbide powder B, Al<4>SiC<4> and Al powder as main materials, adding a metal oxide accounting for 5-15 wt% of the main materials as a sintering aid, on the basis of the mass of themain material, dissolving 7.5wt% of cellulose, 3-5 wt% of a surfactant, 1.5-3.5 wt% of vegetable oil and 1-4 wt% of glycerol in equal mass of water to obtain a binding agent, mixing the main materials, the sintering aid and the binding agent uniformly, so as to obtain a mixture; pouring the mixture into a vacuum extruder for forming, performing drying, so as to obtain a honeycomb ceramic green body; heating the honeycomb ceramic green body to 2000-2200 DEG C under an argon atmosphere condition, preserving heat for 1-3 hours; and performing natural cooling, so as to obtain the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic. According to the Al<4>SiC<4> and Al composite reinforced silicon carbide honeycomb ceramic prepared by the method, raw material utilization rate is high, the production efficiency is high, the structure of the product is wall-flow type, the purification capacity on the waste gas is improved, the microstructure is good, the micropore distribution is uniform, and the mechanical strength is high.

Owner:NANJING KERUI SPECIAL CERAMICS

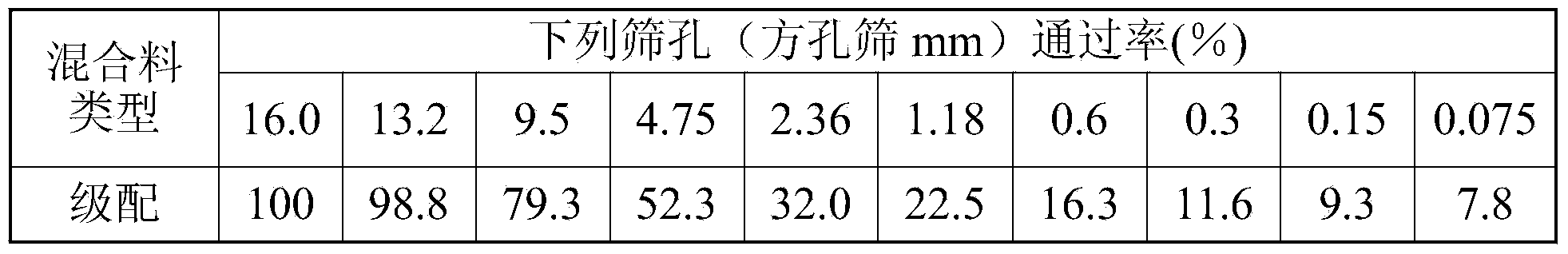

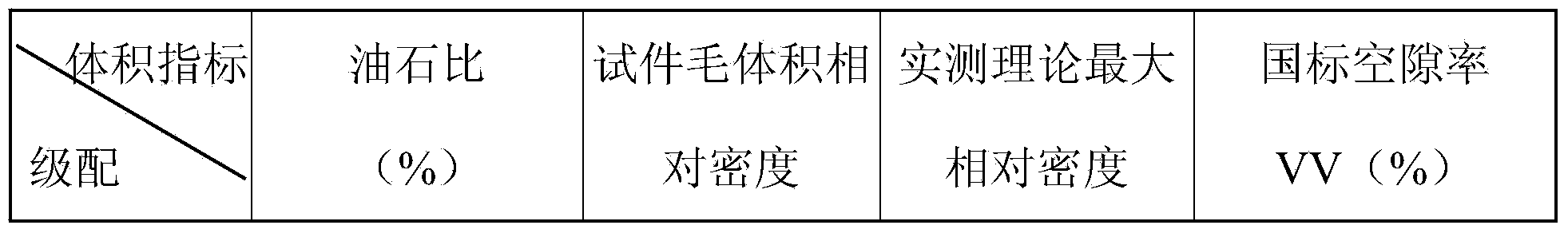

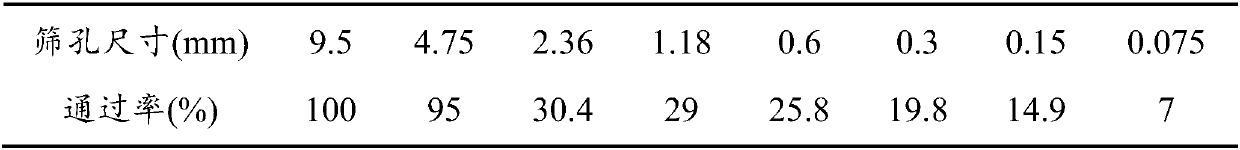

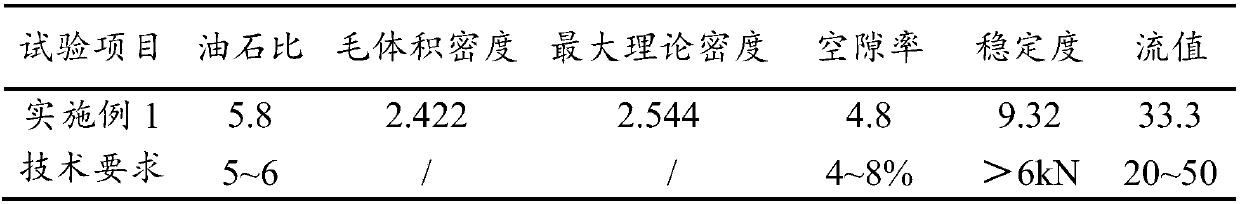

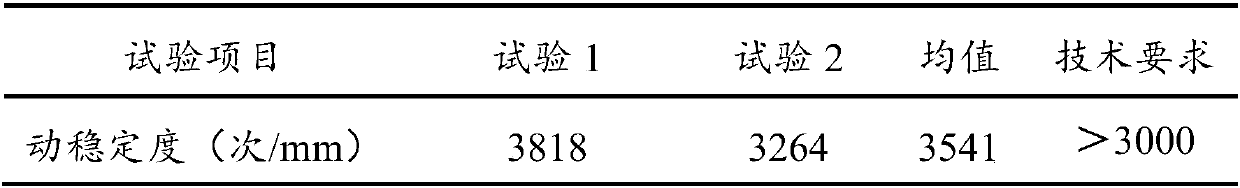

Durable high-modulus asphalt mixture based on hard asphalt particles

InactiveCN103588424AImprove high temperature performanceImprove shear resistanceAdhesive cementRoad surface

The invention discloses a durable high-modulus asphalt mixture based on hard asphalt particles. The asphalt mixture comprises 100 parts by mass of mineral aggregate and 5.3-5.7 parts by mass of asphalt, wherein the mineral aggregate comprises a limestone aggregate accounting for 96-98% of the total mass of the mineral aggregate, and limestone mineral powder accounting for 2-4% of the total mass of the mineral aggregate; and the asphalt is a compound of number 70 road petroleum asphalt and the hard asphalt particles. The asphalt mixture improves the gradation of the mineral aggregate, so that a coarse aggregate forms a good skeleton structure, and the shear property and the compressive property of the mixture are improved; and the property of asphalt adhesive cement in the mixture is improved by adding an appropriate amount of mineral powder, so that the surface of the mineral aggregate has appropriate asphalt membrane thickness. Therefore, the mixture is good in high temperature property, easy to compact, and excellent in fatigue resistance and durability; the capacity of a pavement for resisting damage of a track and the like can be improved if the mixture is used in a road middle surface course; the construction cost can be lowered; and the service life and the maintenance cycle of the pavement can be prolonged.

Owner:JIANGSU TRANSPORTATION RES INST CO LTD

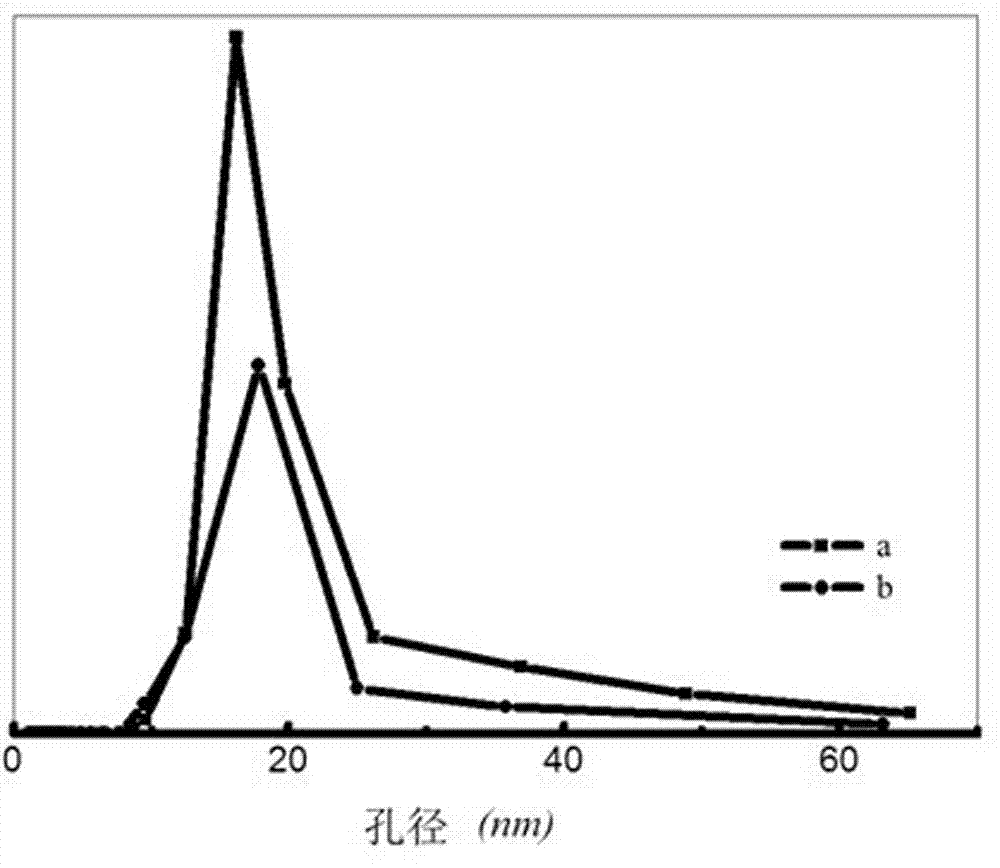

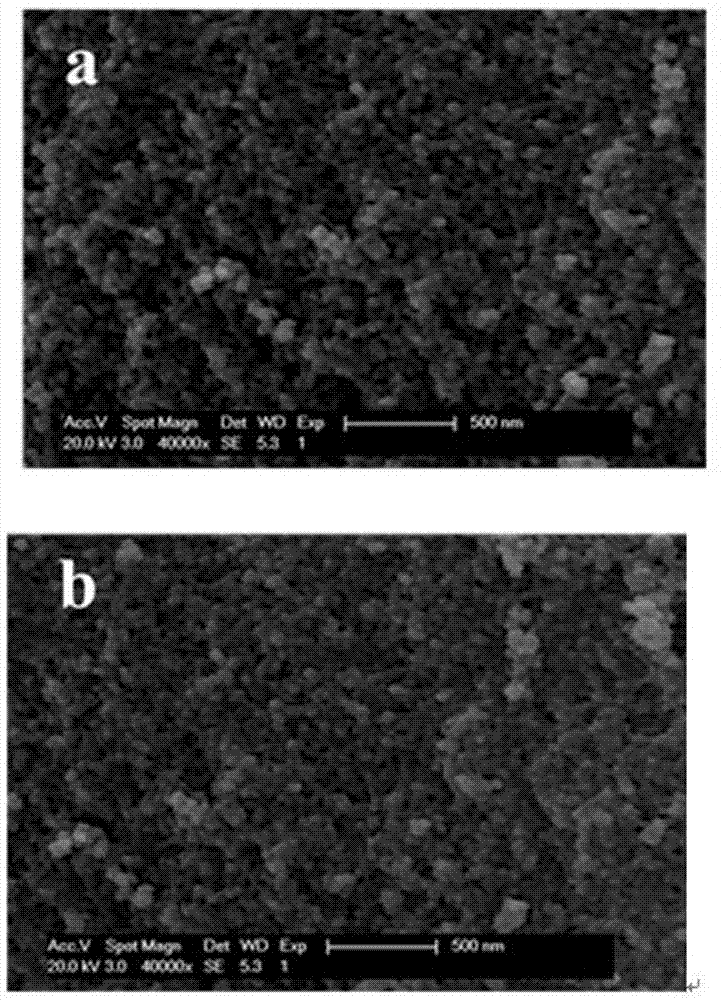

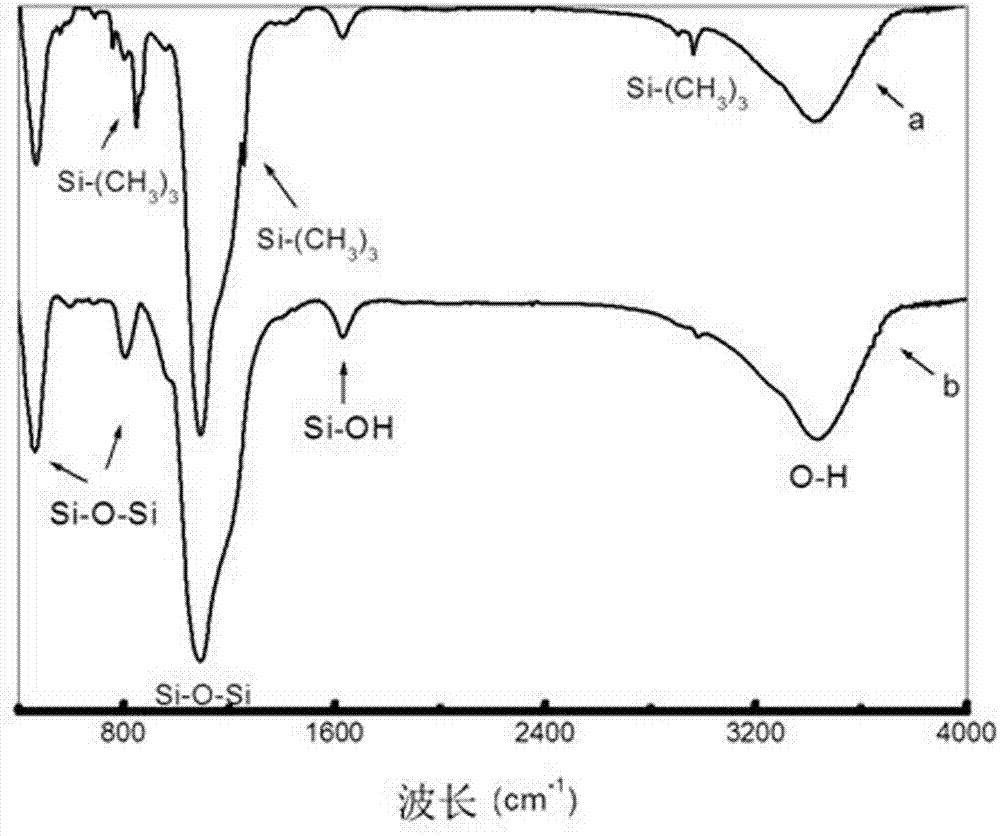

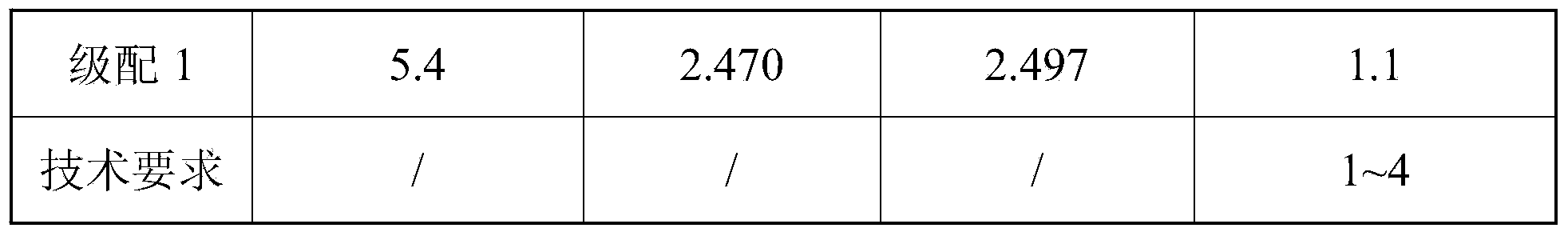

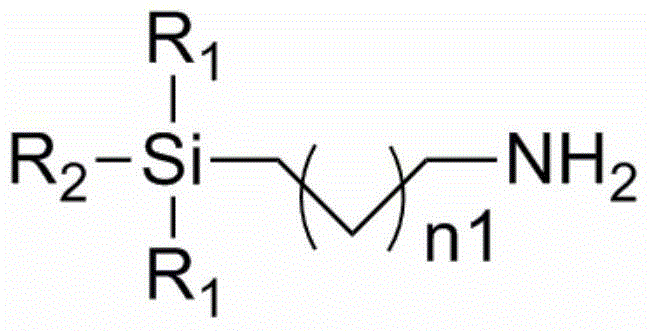

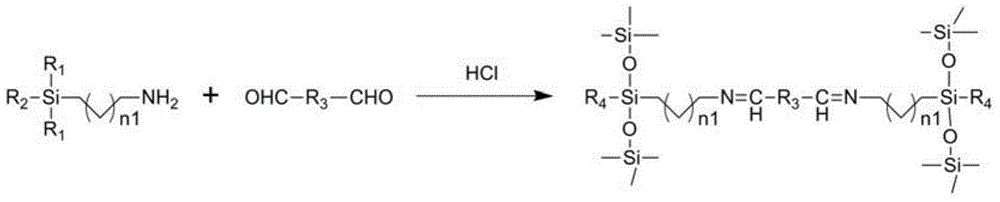

Organic modified nanoporous silica aerogel and preparation method thereof

The invention discloses organic modified nanoporous silica aerogel and a preparation method thereof. The preparation method comprises the following specific steps: by using amino-containing siloxane as a starting silicon source and only using ethanol as a solvent, performing function compounding and chemical modification through an aldehyde group-containing organic function body, improving the intensity of an aerogel network, obtaining wet gel with hydrophobic properties, and finally performing atmospheric drying, thereby obtaining the modified nanoporous silica aerogel with good mechanical properties. The organic modified nanoporous silica aerogel provided by the invention has the advantages of simple preparation method and process, short flow, atmospheric drying technology, and great reduction in preparation cost of aerogel, and is favorable for realizing large-scale production and promoting the actual application.

Owner:UNIV OF SCI & TECH BEIJING

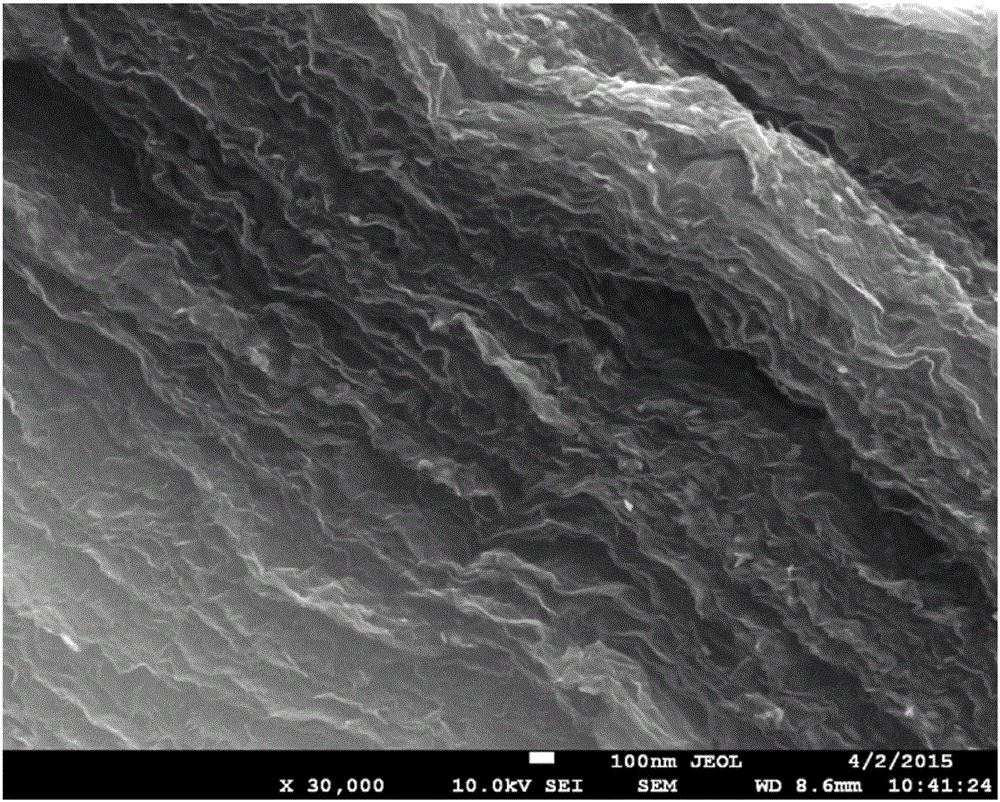

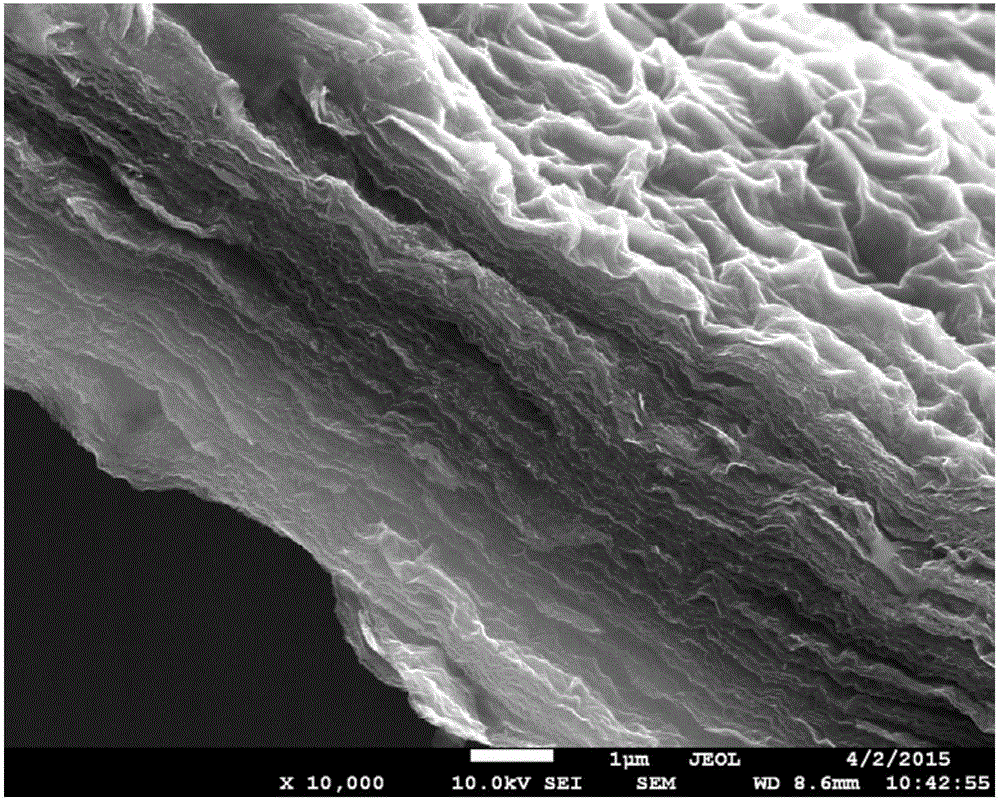

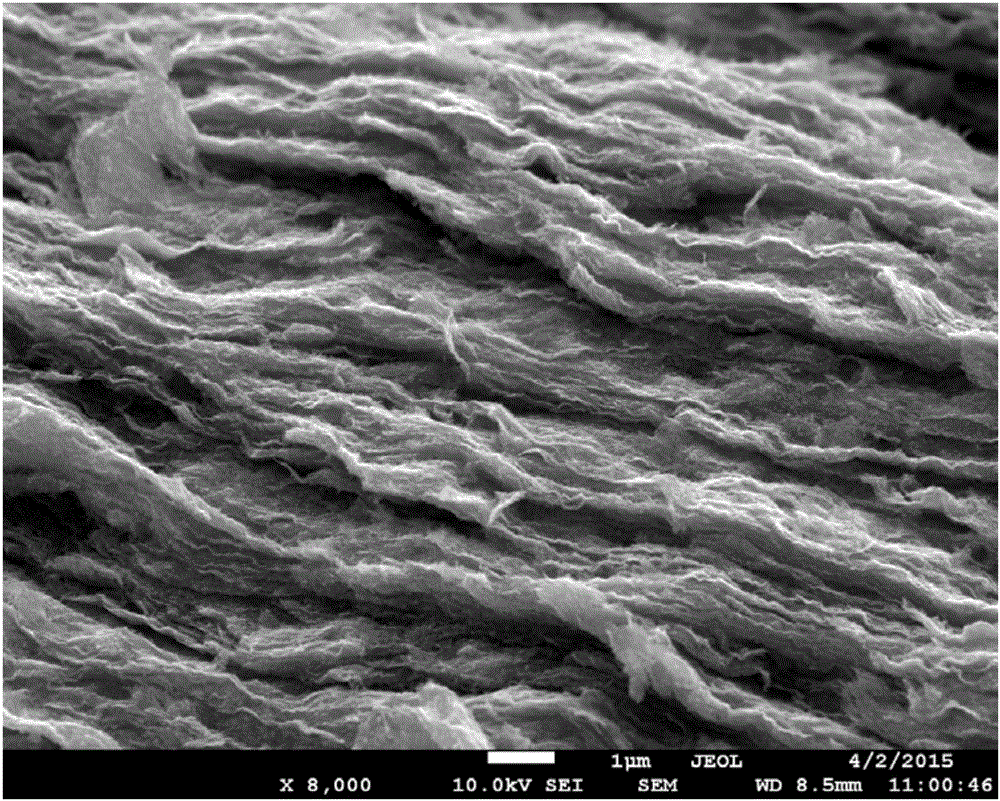

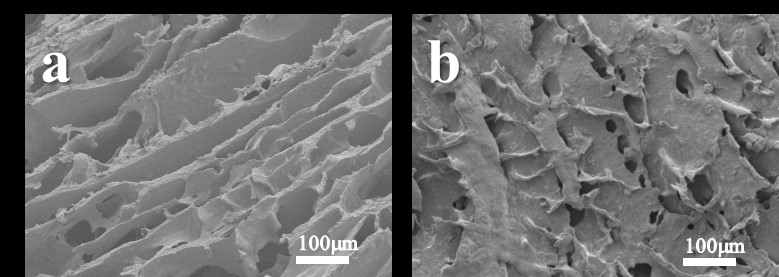

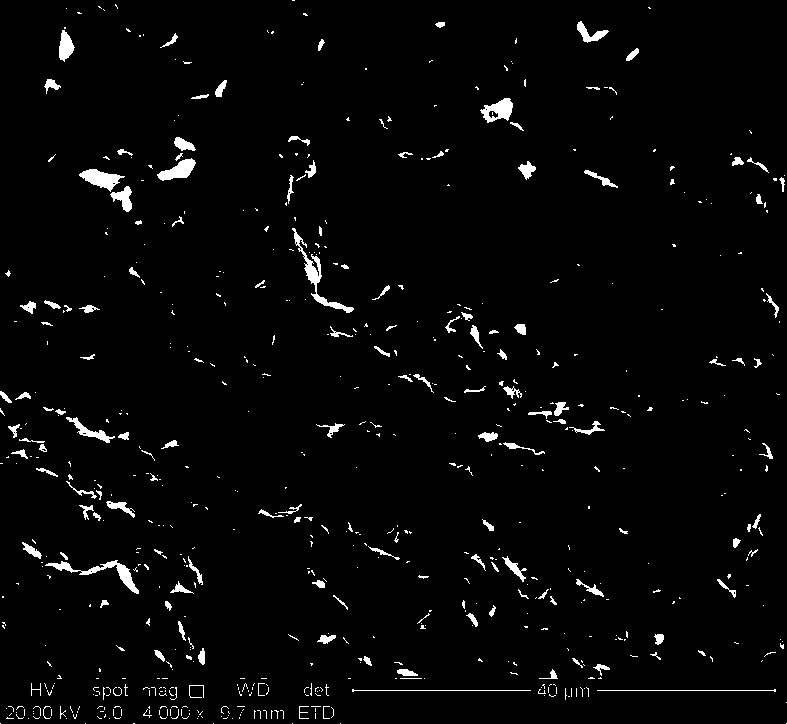

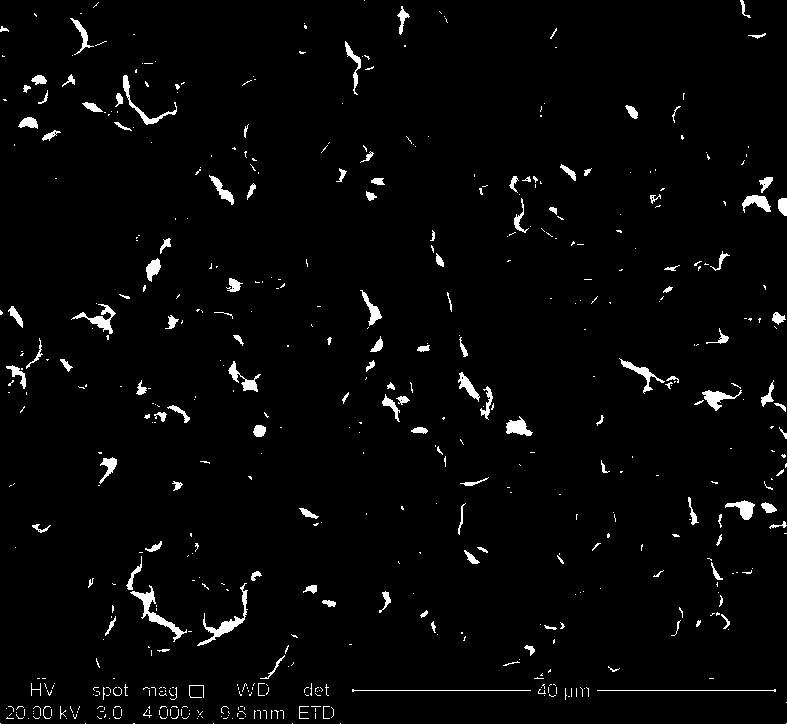

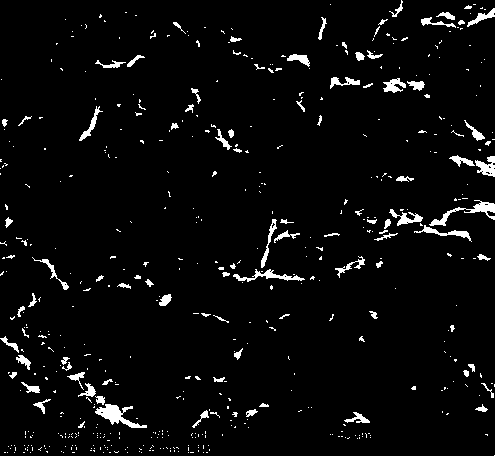

Highly folded grapheme material and preparation method thereof

ActiveCN106252090ALarge specific surface areaIncrease migration channelHybrid capacitor electrodesHybrid/EDL manufactureCapacitanceIon migration

The invention relates to a highly folded grapheme material and a preparation method thereof, belonging to the technical field of energy storage device electrode materials. The preparation method comprises the steps of carrying out pickling of a Fe3O4 / grapheme composite material, and drying the material to obtain the highly folded grapheme material. According to the preparation method, an iron oxide is selected as a template agent to construct highly folded grapheme, the redox reaction between the iron oxide and a carbon material can be used, a hole is etched at the surface of the grapheme, the specific surface area of grapheme is increased, more importantly, the channels of ion migration are increased, and the good super capacitor energy storage performance is realized.

Owner:ZHENGZHOU UNIVERSITY OF LIGHT INDUSTRY

Mochi bread premix powder with good freeze thawing stability, mochi bread and production thereof

InactiveCN104012591AIncrease productionAvoid odorDough treatmentBakery productsMaltodextrinRice flour

Owner:GUANGZHOU FOOD IND RES INST

Preparation method of high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material

PendingCN113831103AImprove mechanical propertiesEnhanced skeleton structureCeramicwareFiberOxide composite

The invention discloses a preparation method of a high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material, wherein the preparation method comprises the following steps: (1) sufficiently dispersing and mixing nano aluminum oxide powder, micron aluminum oxide powder, an infrared opacifying agent and short fibers to obtain a mixture A; (2) performing compression molding on the mixture A to obtain an aluminum oxide composite material; (3) uniformly mixing a silicon source, ethanol and water to obtain silicon dioxide sol; (4) dipping the aluminum oxide composite material by adopting silicon dioxide sol; and (5) performing drying treatment to obtain the high-temperature-resistant aluminum oxide-silicon oxide aerogel composite material. According to the preparation method disclosed by the invention, compounding of aluminum oxide and silicon oxide aerogel is realized through impregnation, a complex preparation process is avoided, the preparation period is shortened, the silicon oxide aerogel is fixed in the aluminum oxide composite material, the compactness of the aluminum oxide composite material is further increased, the composite material has relatively good mechanical properties, and great shrinkage of the aluminum oxide composite material at high temperature is avoided.

Owner:GONG YI VAN-RES INNOVATION COMPOSITE MATERIAL CO LTD

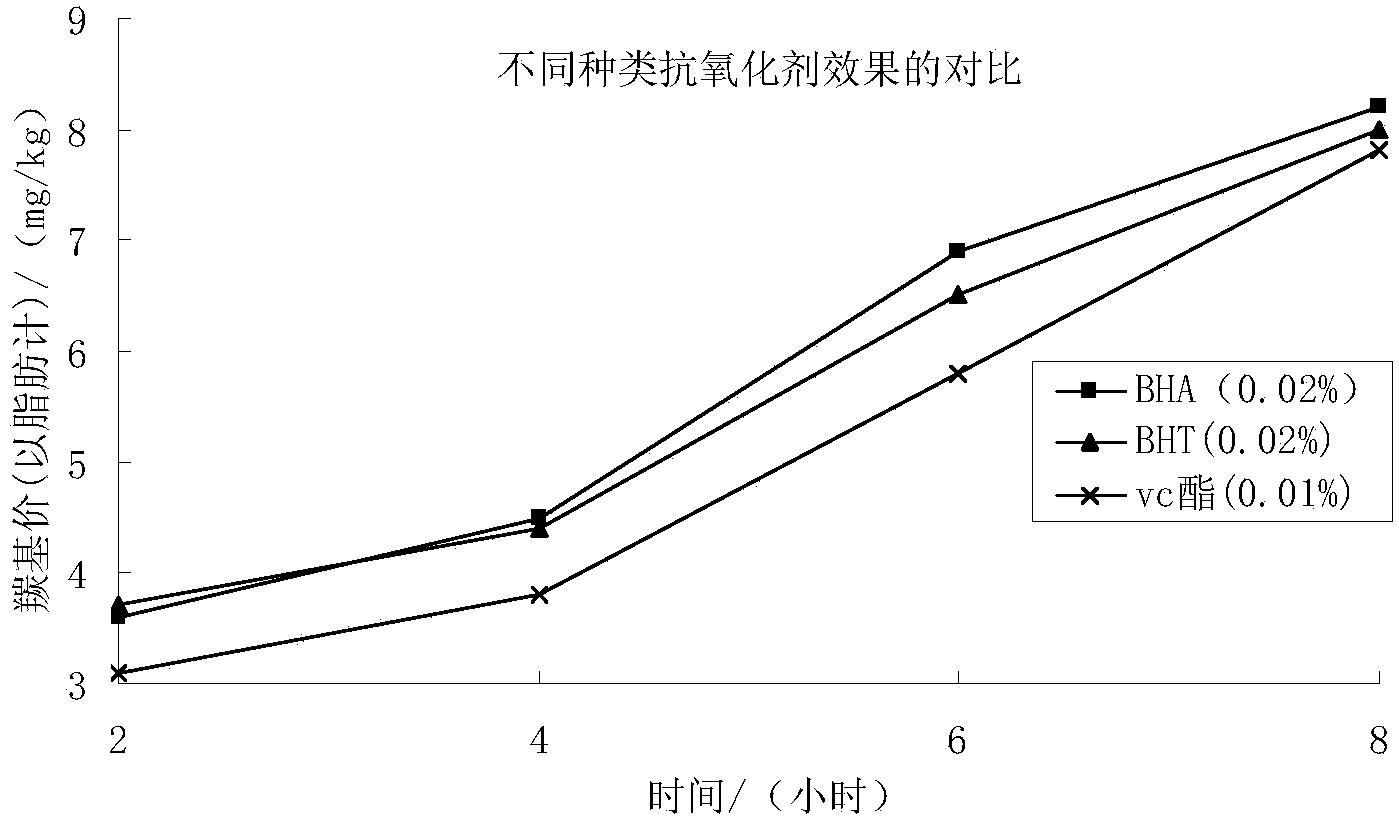

Positive lead cream of valve-controlled sealed plumbous acid accumulator for starting vehicle and production thereof

InactiveCN1747204AIncreased rechargeabilityImprove crystal structureElectrode manufacturing processesFiberLow voltage

The lead plaster for use in battery anode comprises 100 proportion lead powder, 0.05-0.06 proportion fabric and 0.1-0.3 proportion high purity natural graphite powder. The oxidation-proof anode ingredient is selected to improve charging property at low voltage and attain more cycling times.

Owner:中国船舶重工集团动力股份有限公司

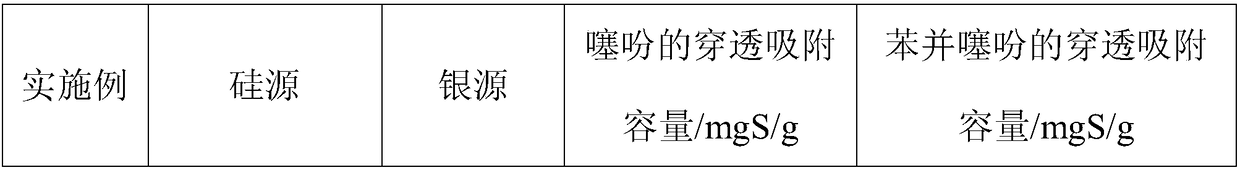

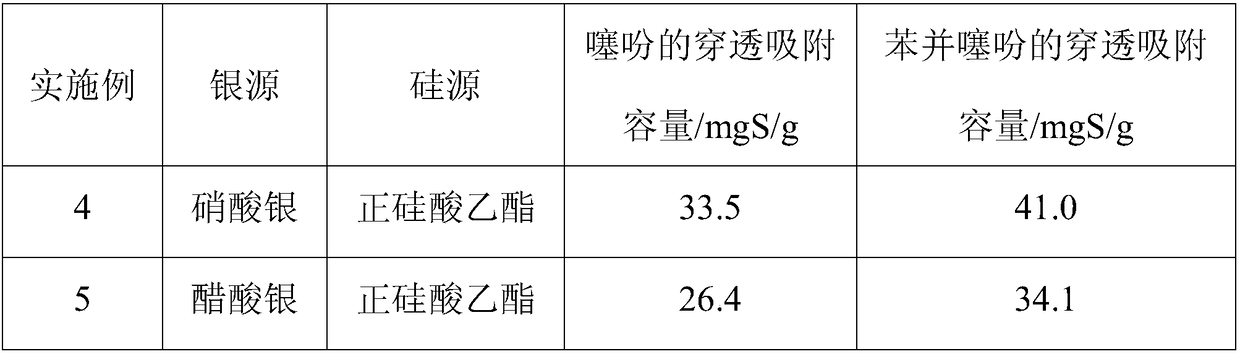

Method for removing thiophenic sulfur in fuel oil by using Ag2O/SiO2-graphene oxide composite aerogel as adsorbent

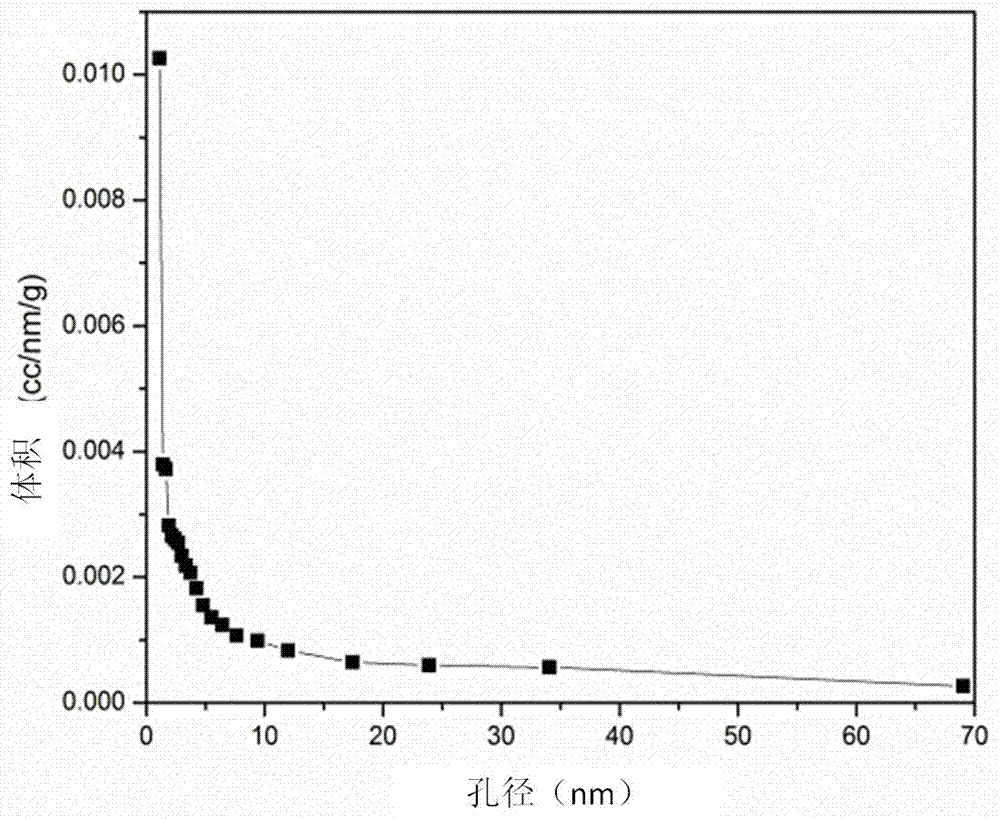

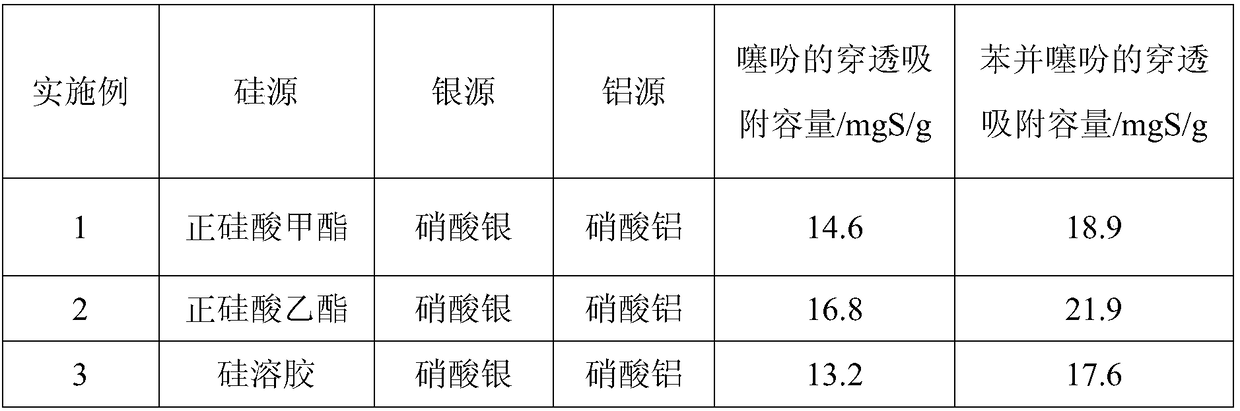

InactiveCN108342217ATypical mesoporous featuresThe amount can be adjustedOther chemical processesHydrocarbon oils refiningSorbentFixed bed

The invention relates to a method for removing thiophenic sulfur in fuel oil by using an Ag2O / SiO2-graphene oxide composite aerogel as an adsorbent, and belongs to the technical field of fuel oil processing. According to the method, methyl orthosilicate, tetraethyl orthosilicate, silica sol, water glass and the like are used as a silicon source, silver acetate, silver nitrate and the like are usedas a silver source, and the Ag2O / SiO2-graphene oxide composite aerogel is obtained by a sol-gel-normal pressure drying method. The Ag2O / SiO2-graphene oxide composite aerogel is quantitatively filledin a fixed bed adsorption device, simulated gasoline containing the thiophenic sulfur is injected into the adsorbed simulated gasoline at a certain temperature and space velocity into the fixed bed adsorption device, and the adsorbed simulated gasoline is collected at the lower end outlet of the device for chromatographic analysis. Results show that the Ag2O / SiO2-graphene oxide composite aerogel has good adsorption properties for the thiophenic sulfur. The preparation method of the Ag2O / SiO2-graphene oxide composite aerogel adsorben is simple and low in cost, and the adsorbent can be repeatedly used, has high economic efficiency, is environmentally friendly, and has mild adsorption conditions and low requirements on adsorption equipment.

Owner:ZHEJIANG UNIV OF TECH

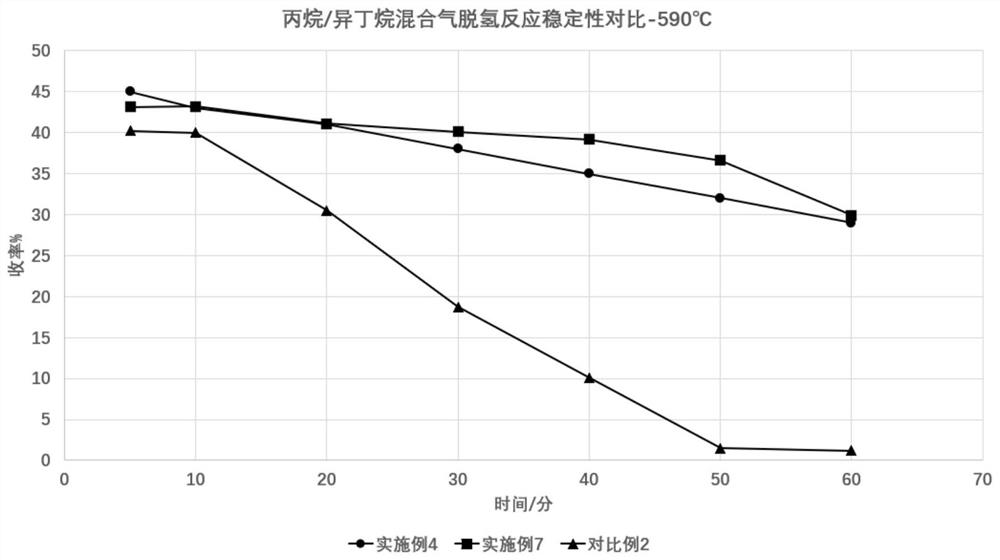

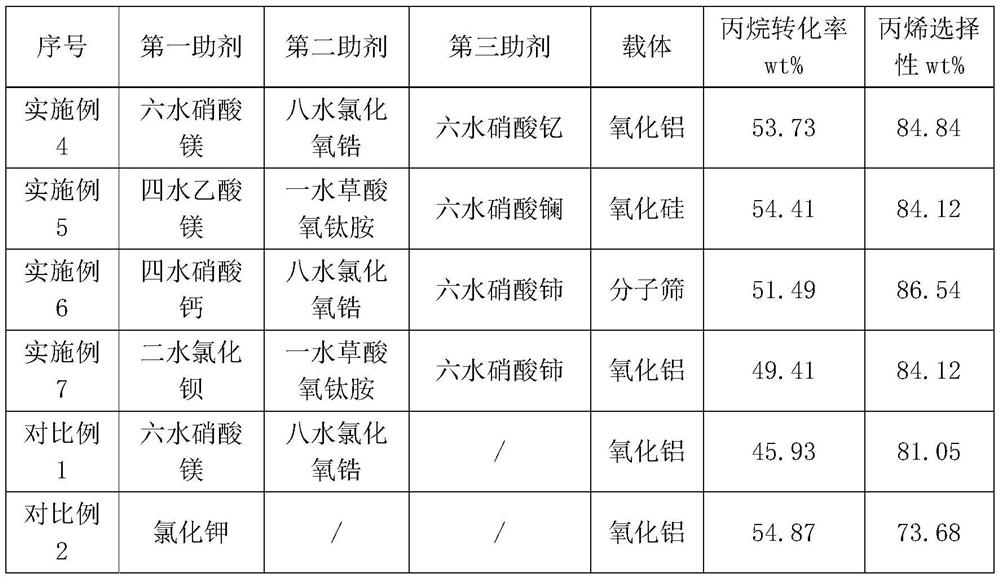

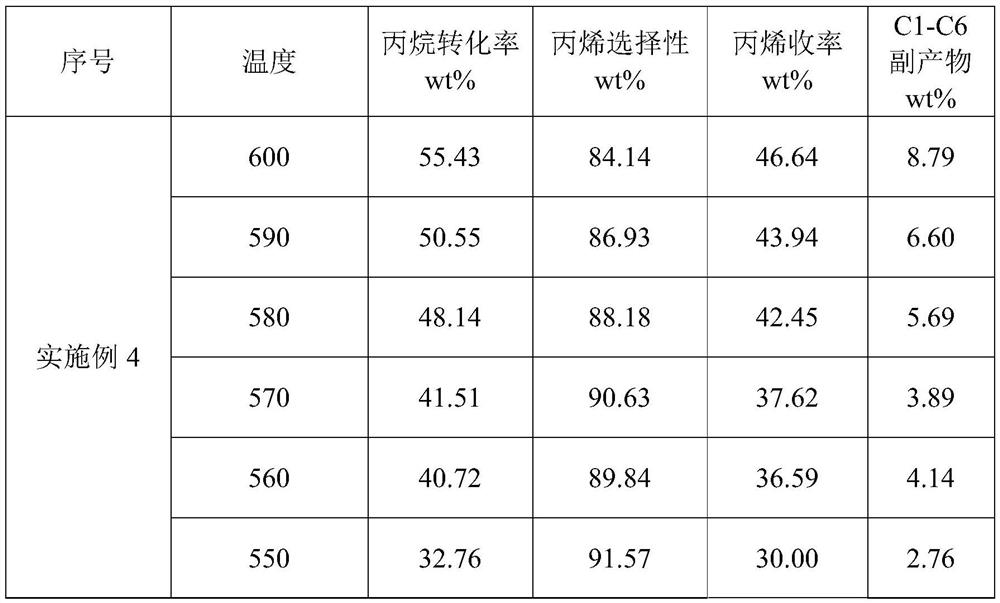

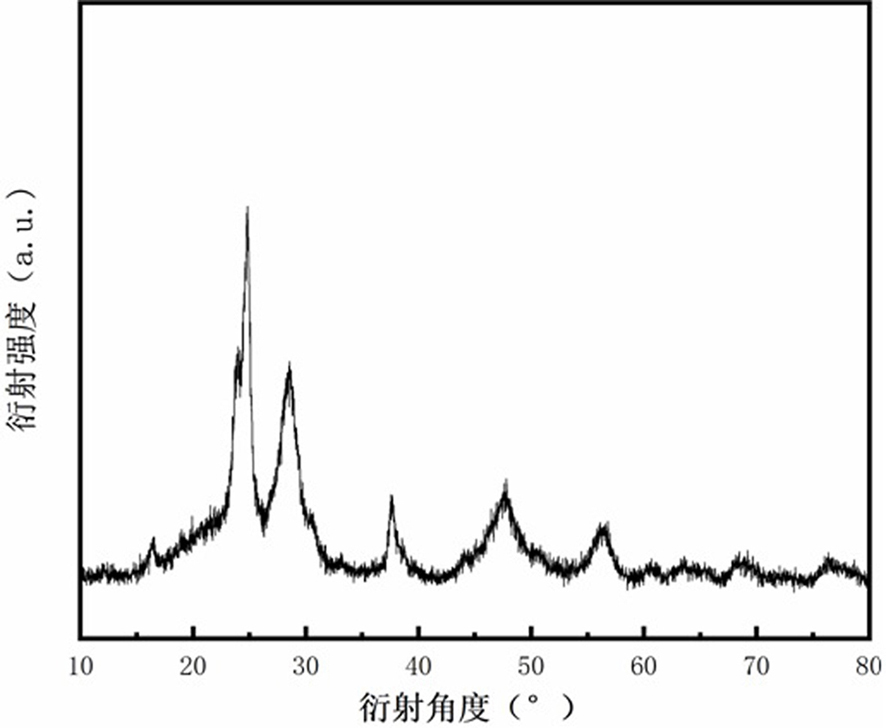

Low-carbon alkane chromium dehydrogenation catalyst containing a spinel structure and preparation method thereof

ActiveCN112246236AImprove stabilityWell formedMolecular sieve catalystsMolecular sieve catalystAlkanePtru catalyst

The invention discloses a low-carbon alkane chromium dehydrogenation catalyst containing a spinel structure and a preparation method thereof. The low-carbon alkane chromium dehydrogenation catalyst isused in a fixed bed, the reaction pressure is 0.01-1 MPa, the temperature is 530-660 DEG C, and the mass space velocity is 0.3-8 h<-1>. The low-carbon alkane chromium dehydrogenation catalyst comprises the following components in percentage by mass based on the total mass of a dry base of the low-carbon alkane chromium dehydrogenation catalyst: 0.1-30% of chromium oxide, 0.1-10% of a first auxiliary agent, 0.1-10% of a second auxiliary agent, 0.1-10% of a third auxiliary agent and the balance of a fixed bed carrier. The third additive is one or a mixture of more of rare earth elements. The catalyst has good acidity, so that the catalyst has higher target product selectivity, and acidic cracking is avoided to the greatest extent; the catalyst has a stable spinel structure, the strength andstability of the catalyst are remarkably enhanced, the catalyst has longer service life and excellent selectivity and stability, and the carbon deposition resistance of the catalyst in the light alkane reaction process is remarkably enhanced.

Owner:REZEL CATALYSTS CO LTD

Silicon-based negative electrode material for inhibiting crack formation in lithium intercalation and deintercalation process and preparation method of silicon-based negative electrode material

InactiveCN113394384AFast transmissionImprove the first Coulombic efficiencyNegative electrodesSecondary cellsCarbon coatingPerovskite (structure)

The invention discloses a silicon-based negative electrode material for inhibiting crack formation in a lithium intercalation and deintercalation process and a preparation method of the silicon-based negative electrode material, the silicon-based negative electrode material is of a three-layer composite structure which sequentially comprises a silicon-based material layer, a perovskite coating layer and an amorphous carbon coating layer from inside to outside; the silicon-based material layer is doped with at least one element selected from B, P, Al, Zr, Ti and Mg; and the perovskite is LaMO3, and M = Co and / or Fe. According to the invention, the method of high-temperature sintering element doping, perovskite coating layer coating and carbon coating is adopted to inhibit the formation of cracks in the lithium intercalation and deintercalation process of the silicon-based negative electrode material, so that the huge stress change of the silicon-based negative electrode material in the lithium intercalation and deintercalation process is effectively relieved, and the formation of cracks in particles is inhibited; and relatively high first coulombic efficiency and excellent cycling stability are shown.

Owner:BEIJING IAMETAL NEW ENERGY TECH CO LTD

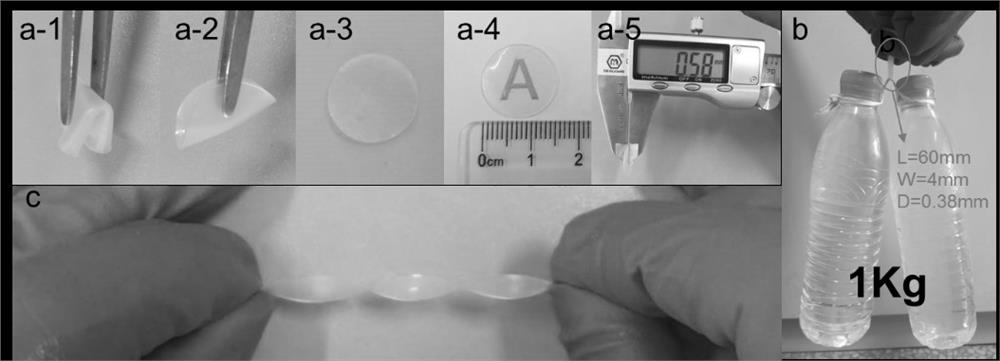

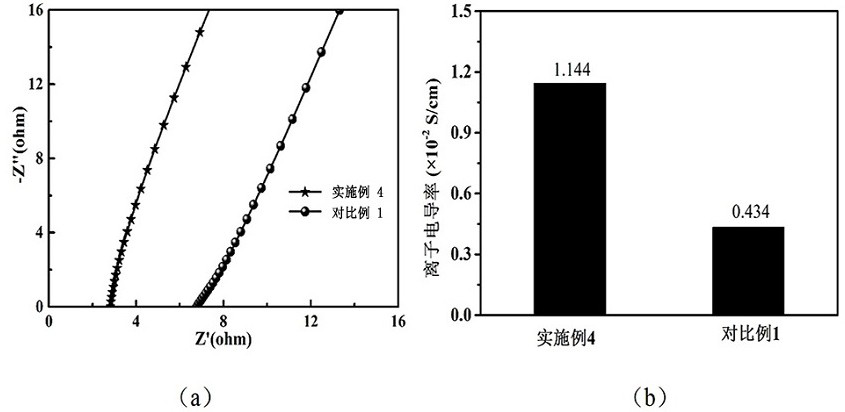

Gel electrolyte of zinc-based battery and preparation and application thereof

PendingCN112510255ASimple preparation processRaw materials are easy to getLi-accumulatorsElectrolyte immobilisation/gelificationTetraethyl orthosilicatePTFE - Polytetrafluoroethylene

The invention discloses a gel electrolyte of a zinc-based battery and preparation and application thereof. The invention aims to improve the mechanical strength and the ionic conductivity of the gel electrolyte through the synergistic effect of the sodium alginate and the tetraethyl silicate hydrolysate. The preparation method comprises the following steps: (1) dissolving sodium alginate in waterunder a heating condition, sequentially adding tetraethyl orthosilicate, glycerol and an acid solution, adjusting the pH value, stirring for dissolving, and carrying out a reaction for a certain timeat a certain temperature to obtain a uniform mixture; (2) injecting the obtained mixture into a polytetrafluoroethylene mold, and standing for a certain time at room temperature to obtain alginic acidpolysilicic acid hydrogel; (3) dissolving a zinc salt and a lithium salt into water to obtain a water electrolyte; and (4) immersing the hydrogel obtained by standing into a water electrolyte, and obtaining the gel electrolyte at a certain temperature after a certain period of time. According to the invention, the problems of few types of solid gel electrolytes, complex preparation process, low ionic conductivity and low mechanical strength in the prior art are overcome.

Owner:CHANGCHUN UNIV OF TECH

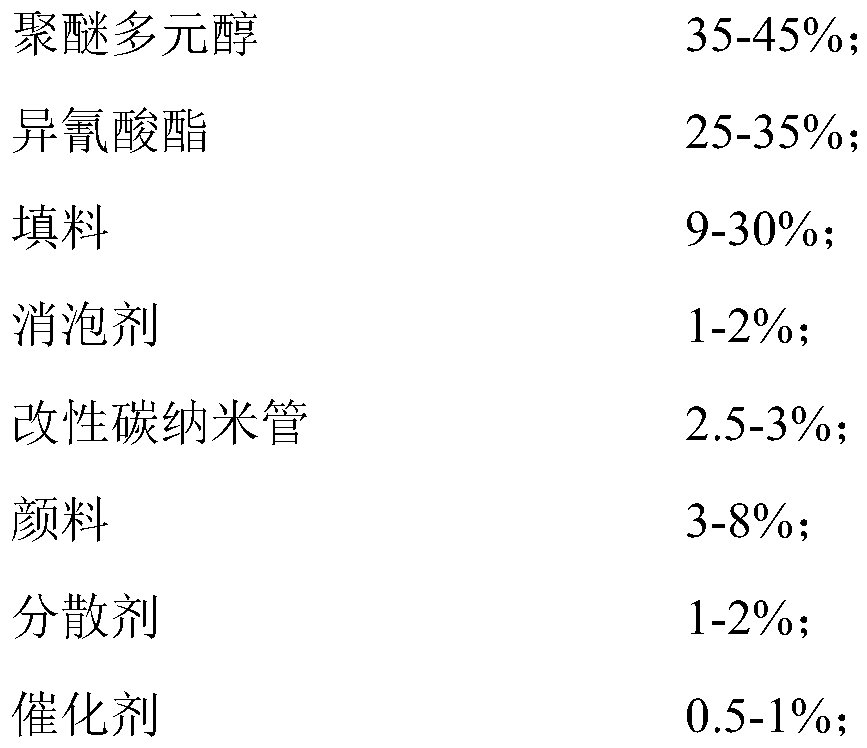

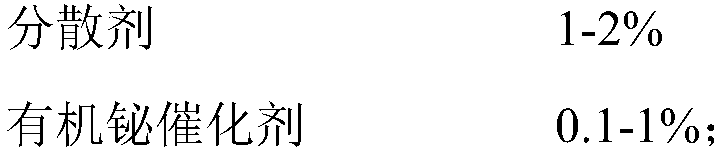

High-wear-resistance and high-strength polyurethane court material, and preparation method and using method thereof

InactiveCN110643015AImprove skeleton structureHigh tensile strengthPaving detailsGround pavingsIsocyanateDefoaming Agents

The invention relates to the technical field of polyurethane, and concretely relates to a high-wear-resistance and high-strength polyurethane court material, and a preparation method and a using method thereof. The high-wear-resistance and high-strength polyurethane court material comprises a component A and a component B, a mass ratio of the component A to the component B is (28-82):100, and thecomponent A is a liquid formed by mixing polyether polyol with a crosslinking chain extender according to a mass ratio of (2-4):1; the component B comprises polyether polyol, isocyanate, a filler, a defoaming agent, modified carbon nanotubes, a pigment, a dispersant and a catalyst; and the polyether polyol is polyether polyol with a number-average molecular weight of 3000-6000 and a functionalityof 2-3. The high-wear-resistance and high-strength polyurethane court material get rids of a finish paint, so the delaminating phenomenon of an elastic layer and a finish paint layer is thoroughly avoided, the finish paint material is saved, a large amount of the construction cost is saved, and the construction period is shortened. The invention also provides the preparation method and the using method of the high-wear-resistance and high-strength polyurethane court material.

Owner:SHANDONG INOV POLYURETHANE

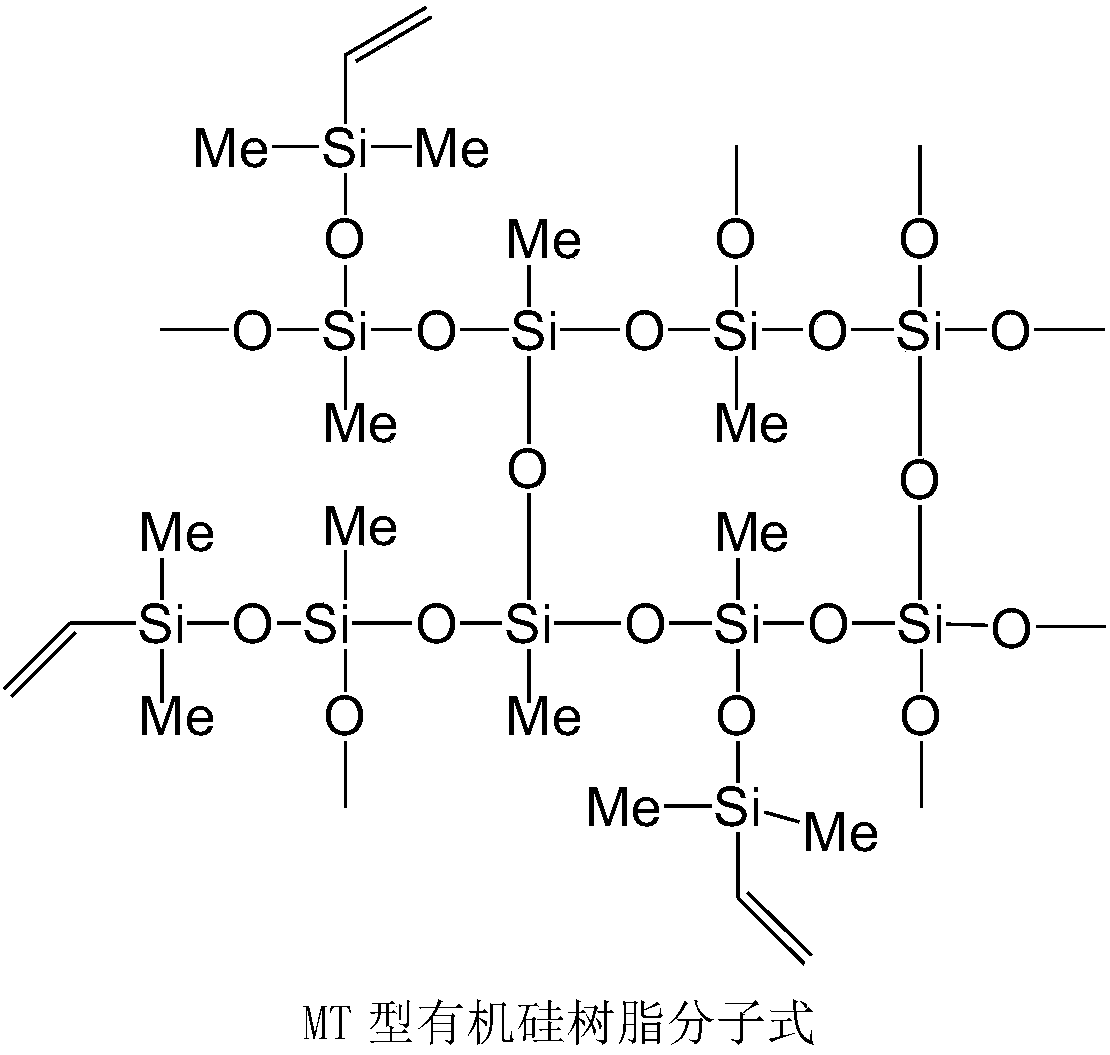

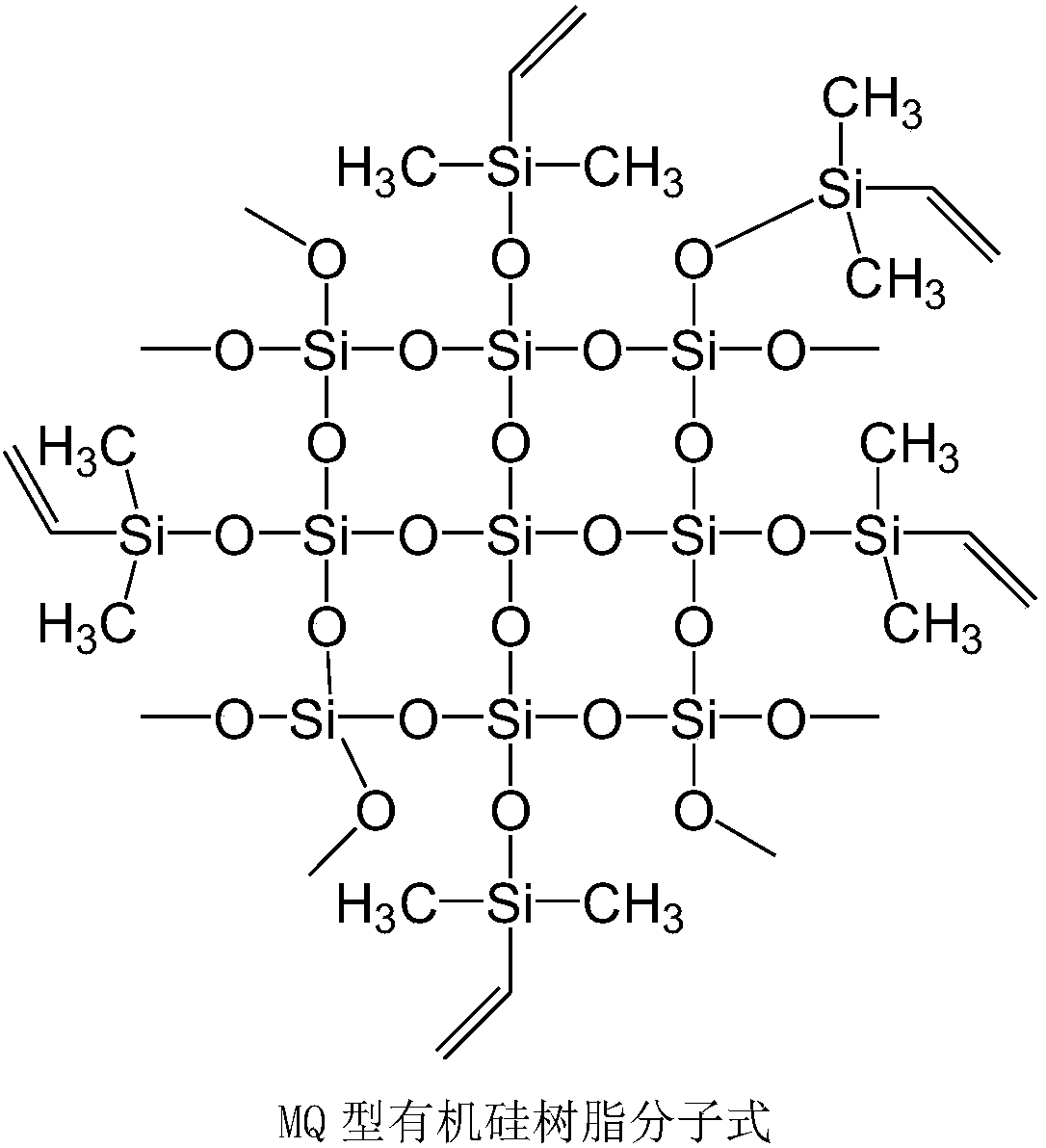

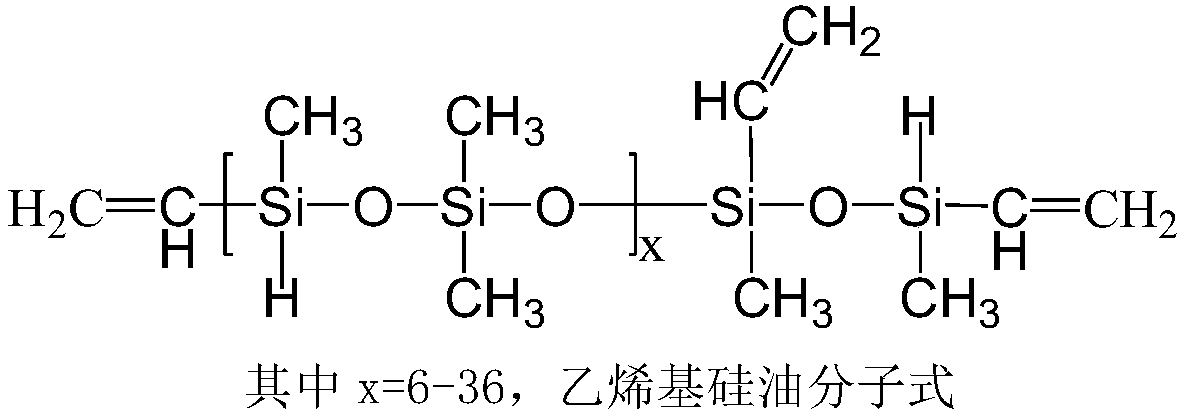

LED chip silicone die bond adhesive

InactiveCN109294514AIncrease crosslink densityEnhanced skeleton structureMacromolecular adhesive additivesSilicone resinPolymer chemistry

An LED chip silicone die bond adhesive comprises, by weight, 20-40 parts of MT type silicone resin, 20-40 parts of MQ type silicone resin, 15-45 parts of silicone oil, 5-10 parts of a crosslinking agent, 2-10 parts of a special filler, 0.1-0.5 part of a catalyst, 1-10 parts of a binder and 0.3-0.6 part of an inhibitor. The silicone die bond adhesive prepared in the invention has the advantages ofconsideration of the hydroxyl content in the adhesive, good high-temperature bonding performance, control of the content of a Pt-based catalyst, ensuring of the catalytic degree of Si-H and vinyl groups in the silicone die bond adhesive, and ensuring of the high-temperature yellowing resistance.

Owner:YANTAI DARBOND TECH

Preparation method of manganese-doped sodium-ion battery positive electrode material

PendingCN114229900AEnhanced skeleton structureInhibition of phase transitionSecondary cellsPositive electrodesElectrical batteryManganese

The invention discloses a preparation method of a manganese-doped sodium-ion battery positive electrode material, which comprises the following steps: dissolving one or two of antimony trioxide and bismuth trioxide with acid, adding a divalent manganese salt to prepare a mixed metal salt solution, adding the mixed metal salt solution into an alkaline oxidant solution, and reacting to obtain the manganese-doped sodium-ion battery positive electrode material. And carrying out solid-liquid separation to obtain a solid material, drying the solid material, mixing the solid material with a sodium source, and sintering to obtain the manganese-doped sodium ion battery positive electrode material. The antimony or bismuth element is doped, the skeleton structure of the material is enhanced, the phase change of the material in the charge-discharge process is inhibited, the specific capacity, the cycle performance and the rate capability of the material can be obviously improved, the mixed metal salt solution is dropwise added into the excessive alkaline oxidant solution, manganese ions are oxidized into manganese dioxide, and the specific capacity, the cycle performance and the rate capability of the material are improved. Antimony and bismuth are co-precipitated with manganese dioxide in the form of hexahydroxy sodium antimonate or sodium bismuthate, so that the uniformity of doped elements of the material is ensured, and atomic-scale mixing of the elements is realized.

Owner:GUANGDONG BRUNP RECYCLING TECH +2

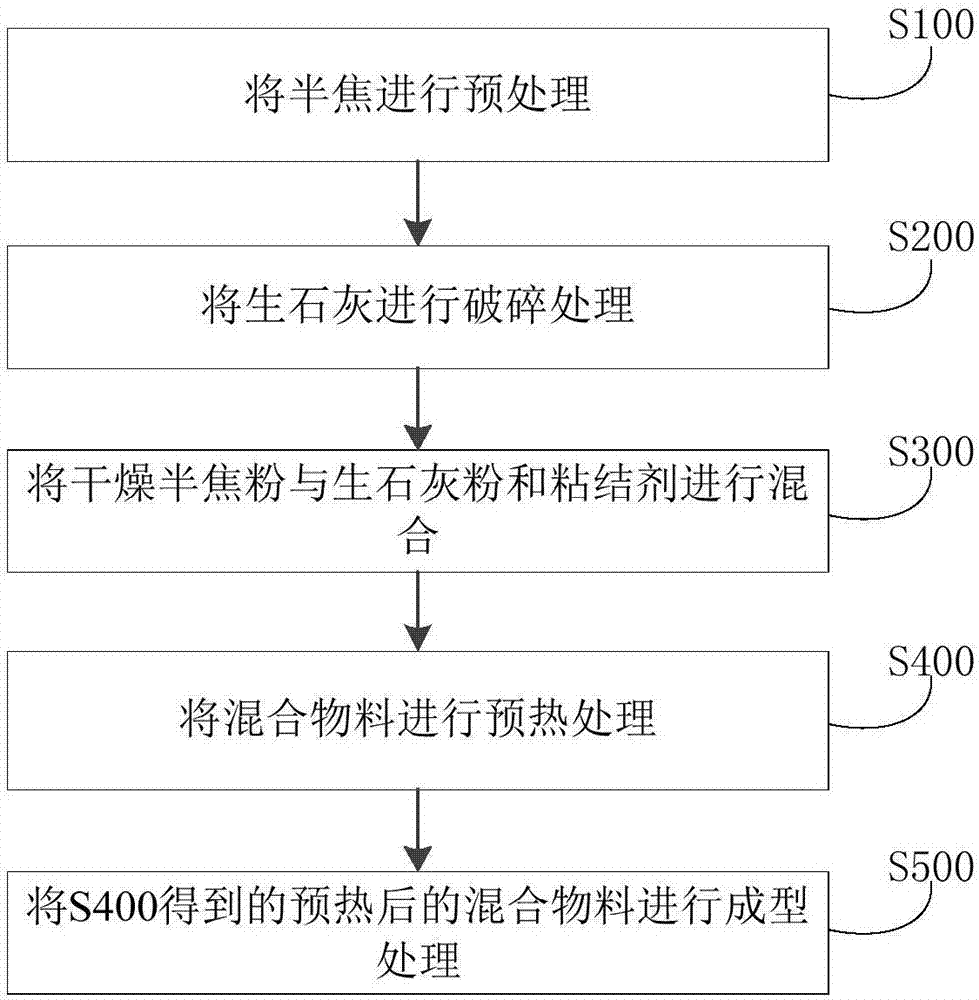

Compound binder and method of preparing mixed pellets for producing calcium carbide

InactiveCN107129792AHigh softening pointImprove adhesionBituminous material adhesivesCalcium carbidePolyethylene glycolAsphalt

The invention discloses a composite binder and a method for preparing mixed pellets for calcium carbide. The composite binder includes asphalt, rubber powder and polyethylene glycol, and the asphalt, the rubber powder and the The mass ratio of polyethylene glycol is 100:(10-30):(5-10). The composite binder can guarantee the requirements of the production of calcium carbide for raw material pellets into the furnace and the requirements of heat intensity during the production process.

Owner:SHENWU ENVIRONMENTAL TECH CO LTD

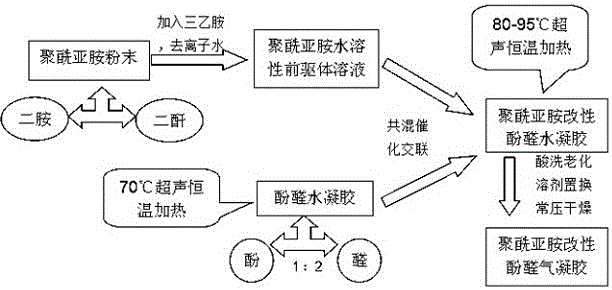

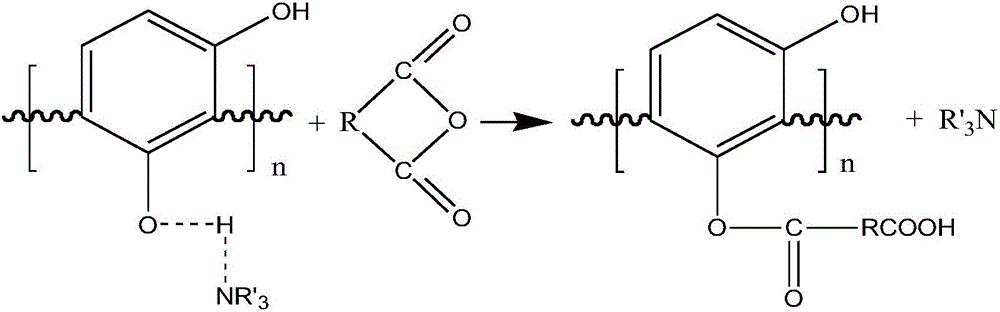

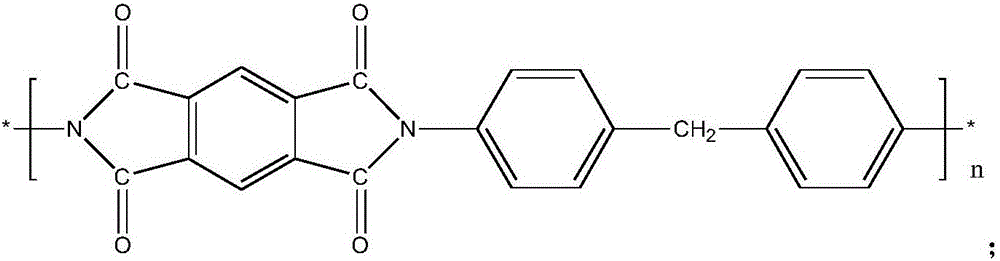

A kind of method for preparing polyimide modified phenolic airgel

The invention discloses a method for preparing polyimide-modified phenolic aerogel. The polyimide modified phenolic aerogel is prepared from the following raw materials in parts by weight: 1 part of polyimide, 1-10 parts of phenol and aldehyde, 85-97 parts of deionized water, 0.5 part of ethylenetriamine, 0.4 part of catalyst A and 0.1 parts of catalyst B. The method comprises the following main steps: preparing a polyimide water-soluble precursor solution firstly; then, preparing phenolic hydrogel; and finally, sequentially carrying out crosslinking, acid pickling and aging on the polyimide water-soluble precursor solution and a network structure in the hydrogel, and carrying out solvent replacement and ambient-pressure drying on the obtained product, so that polyimide-modified phenolic aerogel is obtained finally. The apparent density of the prepared aerogel material is 0.03-0.5 g / cm<3>, the specific surface area is 400-900 m<2> / g, the aperture size of the aerogel is 5-50 nm, the heat conduction coefficient is 0.012-0.025 W / m.k, the temperature resistance range is minus 130-800 DEG C, and the aerogel is good in mechanical and processing properties, excellent in insulating properties, wide in applicable temperature and excellent in thermal insulation performance.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material and preparation method thereof

The invention belongs to the technical field of engineering materials and particularly relates to a titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material and a preparation method thereof. Powdery TiB2 is used as the matrix material of the ceramic material, ZrB2 is used as a strengthening phase, SiC is used as a toughening phase ingredient, wherein the percents by volume of the ingredients are as follows: 55.0-85.0% of TiB2, 10.0-40.0% of ZrB2 and 5.0% of SiC. According to the preparation method provided by the invention, a reaction film with a lubrication function is formed on the material surface through the chemical reaction of the titanium boride-zirconium boride-silicon carbide self-lubricating composite ceramic material under the action of high-temperature friction, thus realizing self lubrication; and the composite ceramic material of the invention has the advantages of high strength, high bending strength, high fracture toughness and the like and can be used for the preparation of metal cutting tools, bearings, nozzles, etc.

Owner:LUOYANG INST OF SCI & TECH

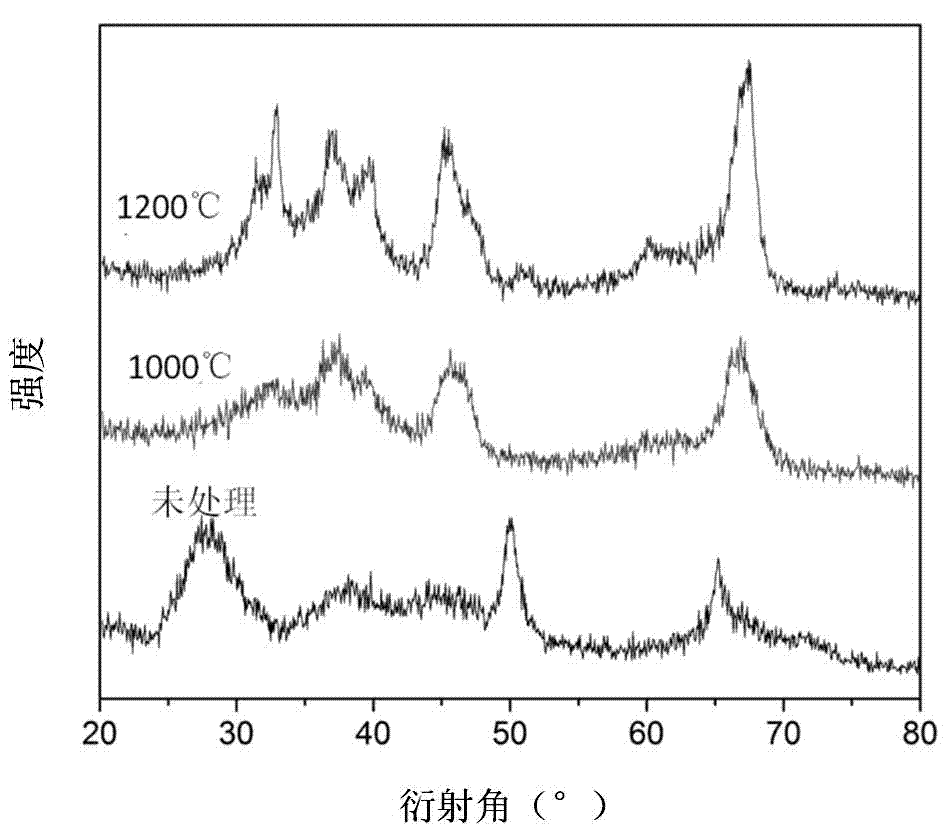

Preparation method of high temperature-resistant alumina aerogel material

The invention relates to a preparation method of a high temperature-resistant alumina aerogel material. The technology comprises the processes of: preparing alumina sol by adopting an in situ generation method; innovatively leading in a modified liquid in a supercritical drying process by adopting the originated supercritical modifying technology in manners of ageing and solvent substitution, so as to obtain block aerogel which is high in mechanical strength and easy to process; carrying out pretreatment at high temperature of 1000 DEG C, and carrying out gas-phase modification of hexamethyl disilazane, so as to prepare the alumina aerogel of which the linear contraction is just 5% and the specific surface area can be up to 280 m<2> / g after high-temperature treatment at 1200 DEG C. By adopting the synthesis method, application of the alumina aerogel in high-temperature fields such as high-temperature catalysis, catalyst carriers and high-temperature heat insulation is greatly facilitated.

Owner:IBIH ADVANCED MATERIALS CO LTD

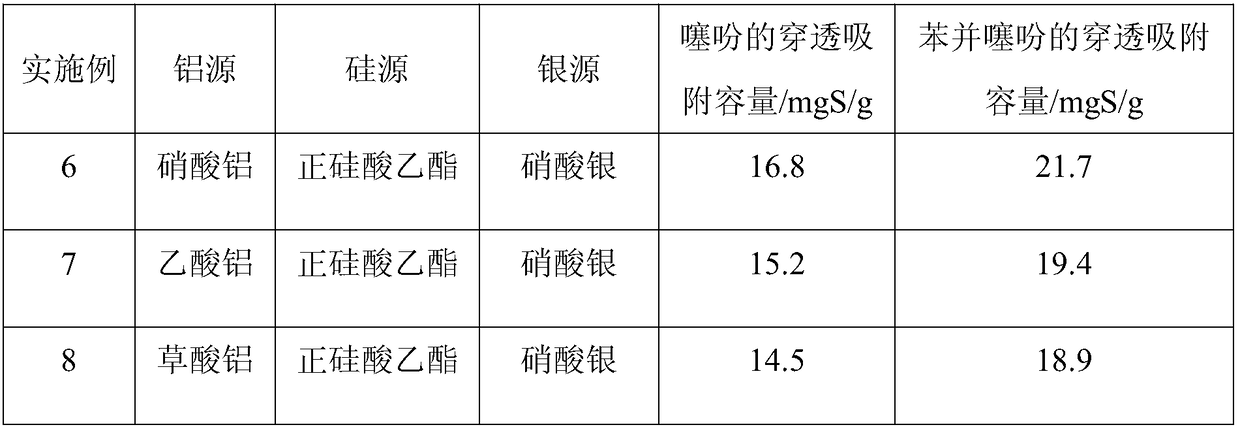

Method of removing thiophene sulfur from fuel oil by Ag2O/SiO2-Al2O3-graphene oxide composite aerogel

InactiveCN108311099AImprove adsorption performanceEnhanced skeleton structureOther chemical processesHydrocarbon oils refiningTetraethyl orthosilicateSol-gel

The invention relates to a method for removing thiophene sulfur from fuel oil by Ag2O / SiO2-Al2O3-graphene oxide composite aerogel and belongs to the technical field of fuel oil processing. The methodis characterized in that the Ag2O / SiO2-Al2O3-graphene oxide composite aerogel is prepared by taking silicon orthosilicate, tetraethyl orthosilicate, silica sol, water glass and the like as silicon sources, taking silver acetate, silver nitrate and the like as silver sources and taking aluminum nitrate, aluminum acetate and aluminum oxalate as aluminum sources and adopting a sol-gel and atmosphericpressure drying method. The Ag2O / SiO2-Al2O3-graphene oxide composite aerogel is quantitatively packed in a fixed bed adsorption device, simulated gasoline containing the thiophene sulfur is injectedat a certain temperature and airspeed, and the simulated gasoline after absorption is collected at an outlet in the lower end of a reaction device for chromatographic analysis. Results show that the Ag2O / SiO2-Al2O3-graphene oxide composite aerogel has good adsorption properties for the thiophene sulfur. The Ag2O / SiO2-Al2O3-graphene oxide composite aerogel absorbent in the method provided by the invention is simple in preparation method, low in cost, capable of reuse for many times, high in economic benefits, environmentally friendly, mild in absorption conditions and low in requirements for absorption equipment.

Owner:ZHEJIANG UNIV OF TECH

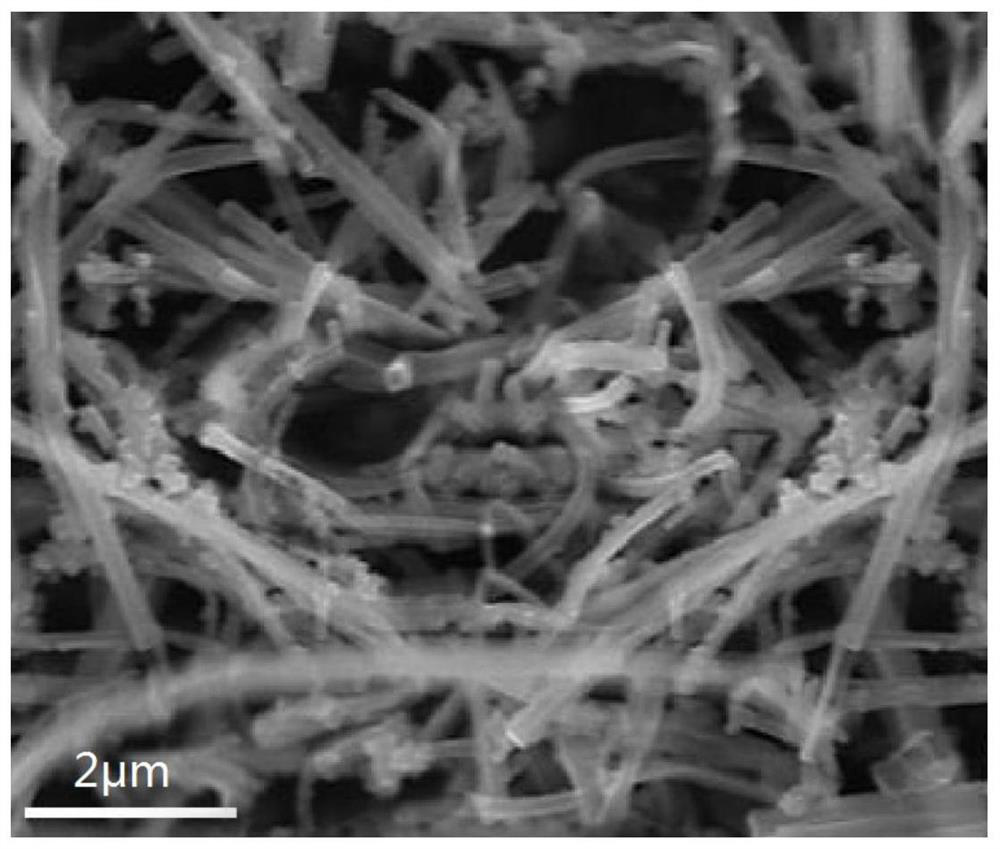

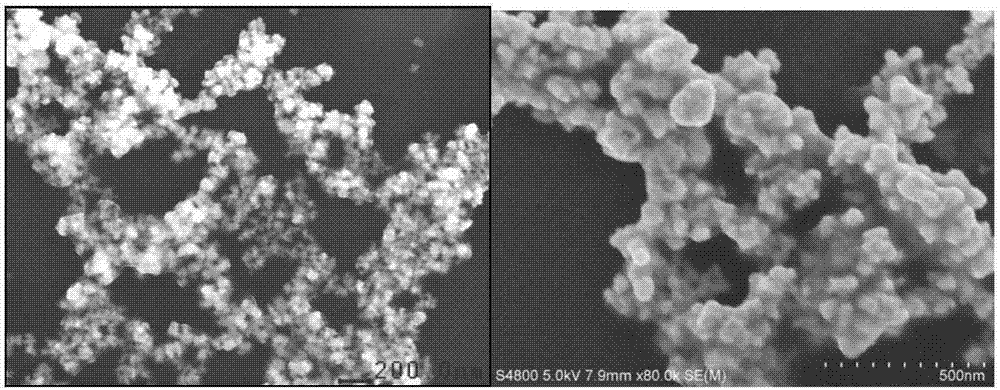

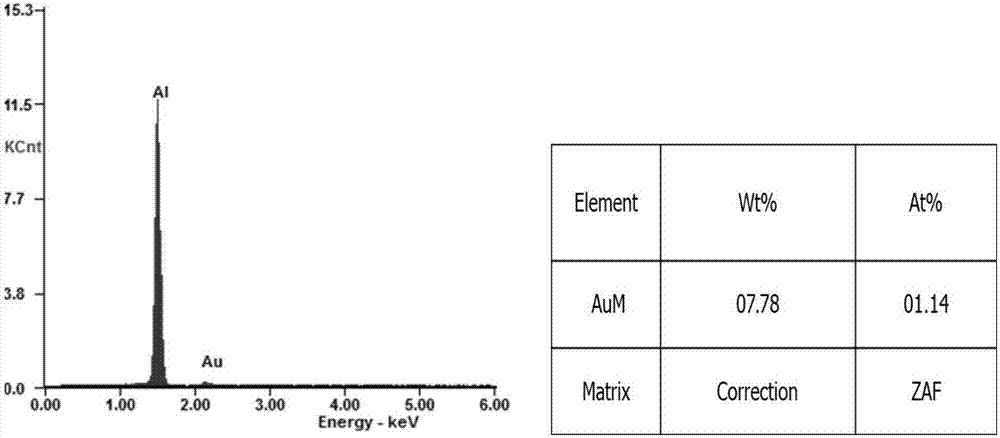

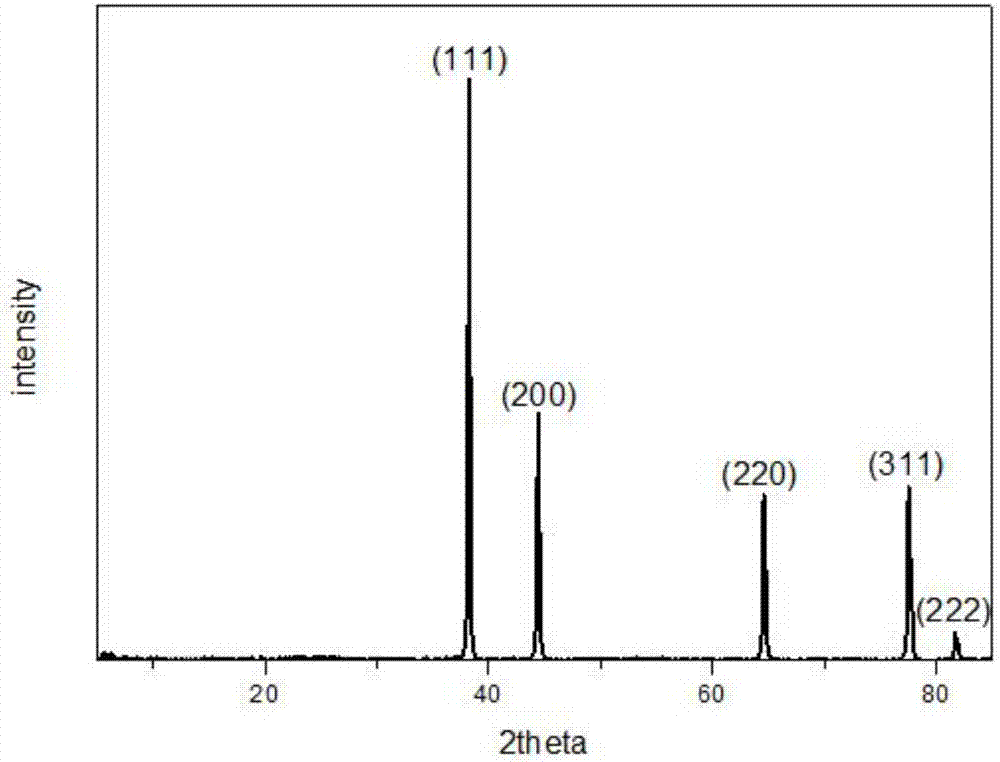

Porous nano-gold carbon nanotube composite material and preparation method thereof

InactiveCN107046136AMild reaction conditionsSimple stepsMaterial nanotechnologyCell electrodesCarbon nanotubeSolvent

The invention relates to a porous nano-gold carbon nanotube composite material and a preparation method thereof. The porous nano-gold carbon nanotube composite material is characterized in that nano-gold particles with large size are accumulated to form a tunnel, the carbon nanotube is interpenetrated in the tunnel, and nano-gold particles with small size is attached on the surface of the carbon nanotube. The nano-gold carbon nanotube composite material with the porous structure is obtained by crystallization of nano-gold seed crystal with the crystal grain size of 20-30 nm by taking toluene as a solvent through a solvothermal method. Compared with the traditional porous gold material, the method provided by the invention use a self-assembly solvothermal method, does not use a strong corrosive substance, reaction condition is mild, steps are simple, and the used reagent is mild.

Owner:WUHAN UNIV OF TECH

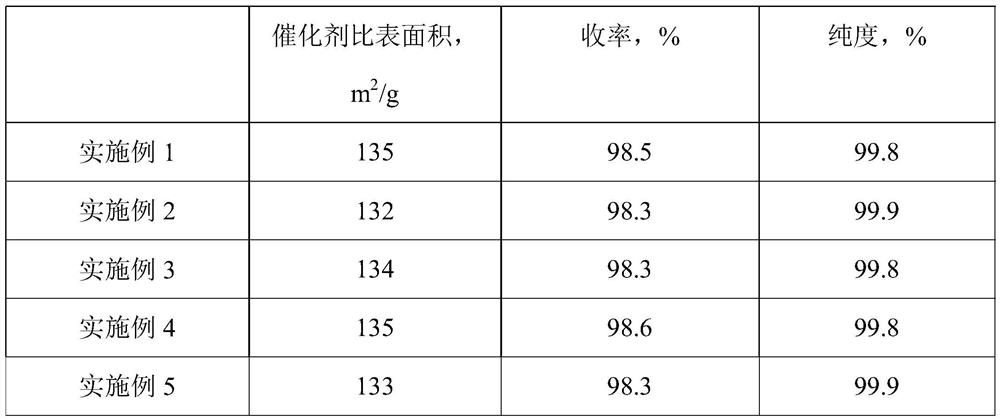

Composite catalyst with high specific surface area and application of composite catalyst in preparation of pyromellitic dianhydride through catalytic oxidation

ActiveCN111841613AImprove redox abilityHigh yieldPhysical/chemical process catalystsOrganic chemistryPtru catalystCatalytic oxidation

The invention discloses a composite catalyst with a high specific surface area, which is characterized in that the composite catalyst comprises a magnesium aluminate spinel / boron nitride composite material prepared by taking boron nitride nanosheets as a guiding agent, and vanadium, titanium and molybdenum composite oxides growing on the magnesium aluminate spinel / boron nitride composite materialin situ, the invention also discloses the composite catalyst and application of the composite catalyst in preparation of pyromellitic dianhydride through catalytic oxidation. The composite catalyst provided by the invention is good in dispersity, large in specific surface area, high in catalytic activity and long in service life; when the catalyst is used for preparing pyromellitic dianhydride, the yield of the product can be effectively improved.

Owner:连云港鹏辰特种新材料有限公司

Asphalt mixture with ultra-thin overlay

The invention discloses an asphalt mixture with an ultra-thin overlay. The asphalt mixture comprises the following preparation raw materials in percentages by weight: 88.5%-91% of stone materials, 4.5%-5.0% of mineral powder, 5-6% of asphalt, and 0.3-0.5% of fibers; and the stone materials includes a stone material with a particle size of 0-3mm and a stone material with a particle size of 3-5mm, wherein the weight content of the stone material with the particle size of 0-3mm is 23-27% in the stone materials, and the weight content of the stone material with the particle size of 3-5mm is 73-77%in the stone materials. The asphalt mixture with the ultra-thin overlay disclosed by the invention belongs to skeleton dense types, and has a better skeleton structure, so that the asphalt mixture with the ultra-thin overlay prepared in a reasonable ratio has stronger deformation and rutting resistant ability, has a good structure depth, and meets the anti-slip requirements for road surface acceptance; and the asphalt mixture has good high-temperature, low-temperature, and water-stable properties, and has positive effects on effective prevention of early damage to the road surface.

Owner:GUANGZHOU UNIVERSITY

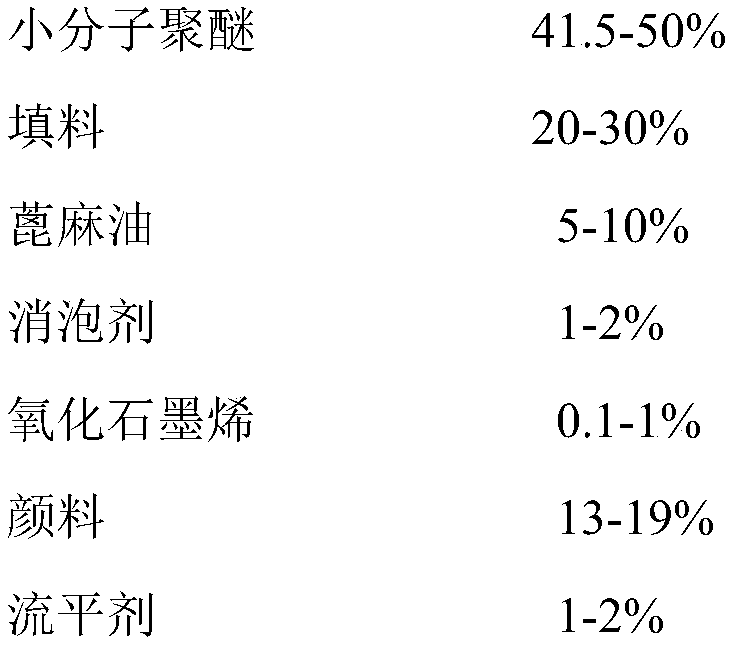

Graphene oxide modified environmentally-friendly polyurethane oily topcoat and preparation method thereof

ActiveCN109266202ASolve construction problemsSolve productivityPolyurea/polyurethane coatingsSolventDefoamer

The invention belongs to the technical field of polyurethane materials, and particularly relates to a graphene oxide modified environmentally-friendly polyurethane oily topcoat and a preparation method thereof. The graphene oxide modified environmentally-friendly polyurethane oily topcoat comprises a component A and a component B, wherein the component A comprises small molecule polyether, a filler, castor oil, a defoamer, graphene oxide, a pigment, a leveling agent, a dispersant and an organic bismuth catalyst, the component B is a prepolymer, and the prepolymer is made of polyether with a molecular weight of 3000-6000 and functionality of 2-3 and 4,4'-dicyclohexylmethane diisocyanate. According to the present invention, the use of the solvent is eliminated during the production and the use, and the product has characteristics of excellent aging resistance, high toughness, super strength and wear resistance.

Owner:SHANDONG INOV POLYURETHANE

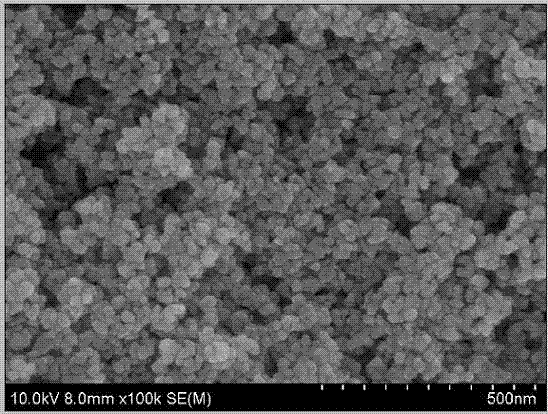

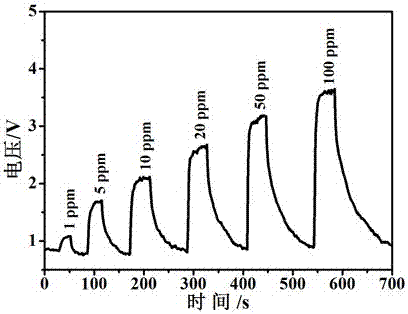

Preparation method of hydrogen sulfide gas sensor material with biomass-loaded inorganic particles as well as product and application thereof

ActiveCN107880318AEnhanced skeleton structureImprove conductivityMaterial nanotechnologyGas treatmentOrganic filmIron salts

The invention discloses a preparation method of a hydrogen sulfide gas sensor material with biomass-loaded inorganic particles as well as a product and application thereof. According to the preparation method, an iron salt and a cobalt salt which are water-soluble are used as precursors, and an OH-containing precipitation agent is added, and the solution is centrifuged and spinel structure CoFe2O4inorganic nanometer particles are collected; biodegradable starch is dissolved in water and mixed with the inorganic particles to form an organic film embedded with inorganic particles; and the organic material has a porous structure, and can realize capture of a large amount of hydrogen sulfide gas, and then the gas sensitive reaction of adsorption and desorption is performed on the CoFe2O4. According to the preparation method of the hydrogen sulfide gas sensor material with the biomass-loaded inorganic particles, a flexible gas-sensitive thin film can be prepared, the operation is simple, and the controllability is high; and the flexible gas-sensitive thin film is used for hydrogen sulfide gas detection.

Owner:SHANGHAI NAT ENG RES CENT FORNANOTECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com