Composite catalyst with high specific surface area and application of composite catalyst in preparation of pyromellitic dianhydride through catalytic oxidation

A technology of pyromellitic dianhydride and composite catalyst, applied in the field of catalyst preparation, can solve problems such as low yield of target product, insufficient catalytic activity, small specific surface area, etc., achieve abundant defects, high redox ability, and control calcination conditions , the effect of large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

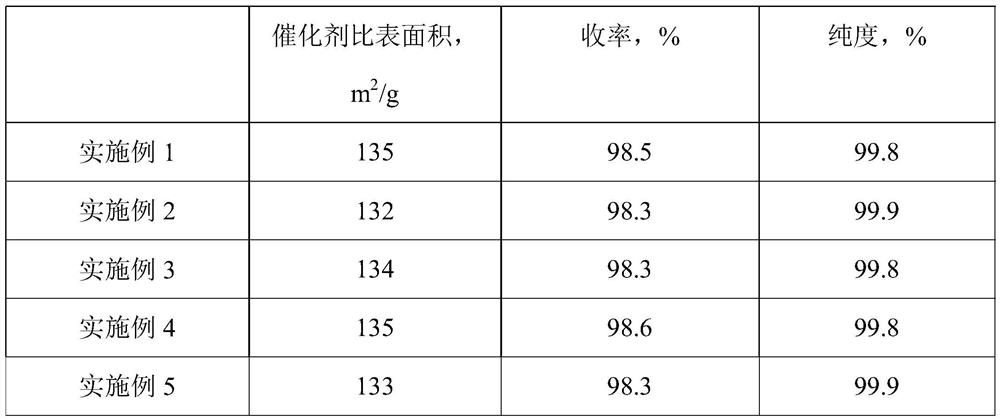

Examples

Embodiment 1

[0025] (1) 5g of boron nitride nanosheets are added to 100ml of 5% sodium hydroxide solution at 100°C for activating treatment with stirring for 1h, filtered, and dried to obtain activated boron nitride nanosheets; Into the mixed solution containing 1mol / L magnesium nitrate and 2mol / L aluminum nitrate, add dropwise 3% sodium citrate solution and 5% sodium hydroxide solution for precipitation treatment for 2 hours, keep the dripping of sodium hydroxide solution The acceleration is 1.5ml / min; after the precipitation is completed, the mixed solution is transferred to a hydrothermal kettle, stirred at high temperature, then cooled to room temperature, filtered, and vacuum-dried. The dried solid is placed in a muffle furnace at 10°C / The temperature was raised to 500°C at a rate of 1 min, and the heat preservation treatment was carried out for 1 hour, and then the temperature was raised to 700°C at a rate of 5°C / min, and the heat preservation treatment was carried out for 2 hours; t...

Embodiment 2

[0028] (1) 5g of boron nitride nanosheets are added to 100ml of 5% sodium hydroxide solution at 100°C for activating treatment with stirring for 3h, filtered, and dried to obtain activated boron nitride nanosheets; Into the mixed solution containing 2mol / L magnesium nitrate and 4mol / L aluminum nitrate, add dropwise 3% sodium citrate solution and sodium hydroxide solution with a mass concentration of 510% respectively for precipitation treatment for 6 hours, and keep the dripping of sodium hydroxide solution The acceleration is 3.5ml / min; after the precipitation is completed, the mixed solution is transferred to a hydrothermal kettle, stirred at high temperature, then cooled to room temperature, filtered, and vacuum-dried. The dried solid is placed in a muffle furnace at 10°C / The temperature was raised to 500°C at a rate of 1 min, and the heat preservation treatment was carried out for 1 hour, and then the temperature was raised to 700°C at a rate of 5°C / min, and the heat prese...

Embodiment 3

[0031] (1) 5g of boron nitride nanosheets are added to 100ml of 5% sodium hydroxide solution at 100°C for activating treatment with stirring for 2h, filtered, and dried to obtain activated boron nitride nanosheets; In the mixed solution that contains 1.5mol / L magnesium nitrate, 3mol / L aluminum nitrate, add dropwise respectively 3% sodium citrate solution and the sodium hydroxide solution that mass concentration is 5% and carry out precipitation treatment 3h, keep the sodium hydroxide solution The rate of addition is 1.5-ml / min; after the precipitation is completed, the mixed solution is transferred to a hydrothermal kettle, stirred at high temperature, cooled to room temperature, filtered, and vacuum-dried. The dried solid is placed in a muffle furnace at first The temperature was raised to 500°C at the rate of ℃ / min, and the heat preservation treatment was carried out for 1h, and then the temperature was raised to 700°C at the rate of 5°C / min, and the heat preservation treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com