Method for efficiently removing organic pollutants in industrial wastewater

A technology for organic pollutants and industrial wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problems of many types of pollutants, difficult and difficult removal of organic pollutants, etc. problems, to achieve strong redox ability, increase mineralization rate, and save energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

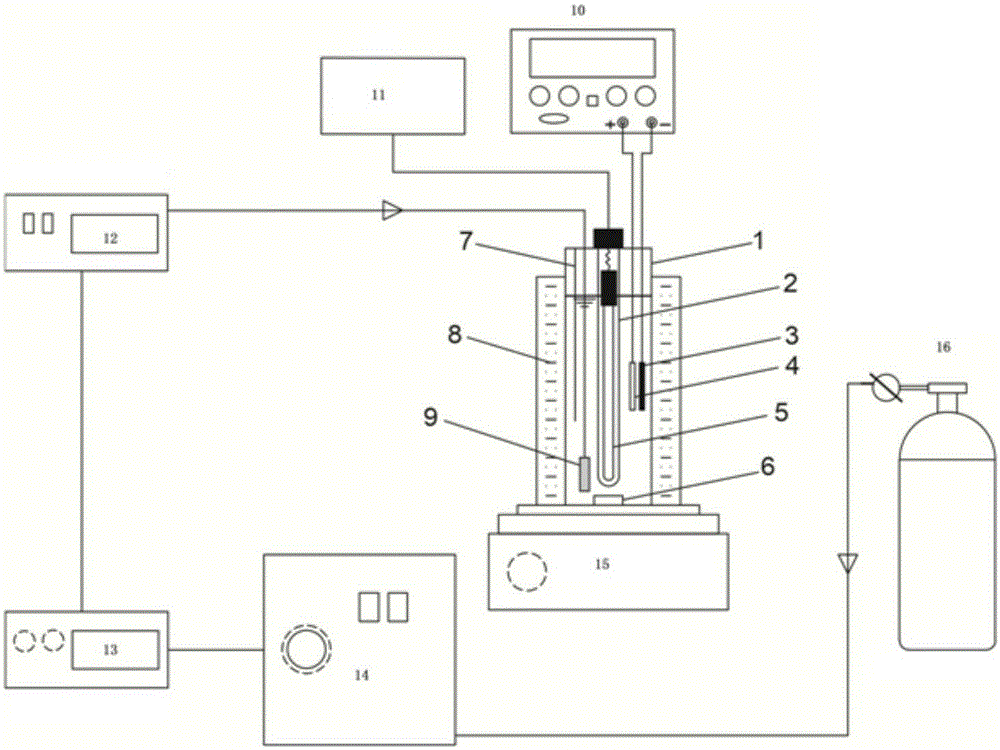

Image

Examples

Embodiment 1

[0030] Proceed as follows:

[0031] Will O 2 into the ozone generator to prepare O 3 10% by volume O 2 and O 3 Mixed gas, the mixed gas is passed into the ozone contactor by adopting the microporous aeration method at the bottom; while the mixed gas is fed into the ozone contactor, the water body to be treated is injected into the ozone contactor, the hydraulic retention time is 15min, and the water body is output immediately, that is, Can;

[0032] The O 3 The ratio of the mass transfer mass to the volume of the water body to be treated is 75mg / L;

[0033] During the first 50% of the hydraulic retention time, a direct current is passed through the two ends of the cathode and anode electrodes located in the ozone contactor, and the current density at the cathode end is 35mA / cm 2 ; After ending the power-on, continue to irradiate the water body with a low-pressure mercury lamp of 10W in the remaining hydraulic retention time.

[0034] After testing, the degradation rate ...

Embodiment 2

[0036] Proceed as follows:

[0037] Will O 2 into the ozone generator to prepare O 3 10% by volume O 2 and O 3 Mixed gas, the mixed gas is passed into the ozone contactor by adopting the microporous aeration method at the bottom; while the mixed gas is fed into the ozone contactor, the water body to be treated is injected into the ozone contactor, the hydraulic retention time is 20min, and the water body is output immediately, that is, Can;

[0038] The O 3 The ratio of mass transfer to the volume of water to be treated is 50mg / L;

[0039] During the first 40% of the hydraulic retention time, a direct current is passed through the two ends of the cathode and anode electrodes located in the ozone contactor, and the current density at the cathode end is 38mA / cm 2 ; After ending the power-on, continue to irradiate the water body with a low-pressure mercury lamp of 10W in the remaining hydraulic retention time.

[0040] After testing, the degradation rate and mineralization...

Embodiment 3

[0042] Proceed as follows:

[0043] Will O 2 into the ozone generator to prepare O 3 10% by volume O 2 and O 3 Mixed gas, the mixed gas is passed into the ozone contactor by adopting the micropore aeration method at the bottom; while the mixed gas is fed into the ozone contactor, the water body to be treated is injected into the ozone contactor, the hydraulic retention time is 10min, and the water body is output immediately, that is, Can;

[0044] The O 3 The ratio of mass transfer to the volume of water to be treated is 100mg / L;

[0045] During the first 60% of the hydraulic retention time, a direct current is passed through the two ends of the cathode and anode electrodes located in the ozone contactor, and the current density at the cathode end is 32mA / cm 2 ; After ending the power-on, continue to irradiate the water body with a low-pressure mercury lamp of 10W in the remaining hydraulic retention time.

[0046] After testing, the degradation rate and mineralization ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com