Patents

Literature

1954 results about "Industrial effluent" patented technology

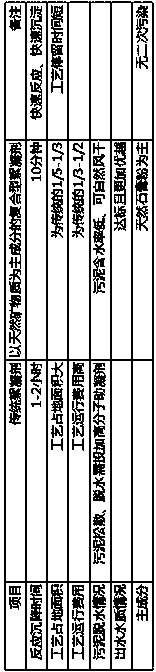

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Industrial effluent is any wastewater that is produced by various industrial activities. The quality of industrial effluent/wastewater varies from one industry to another is responsible for the degradation of receiving water sources. In other words, treating all kinds of effluents originating...

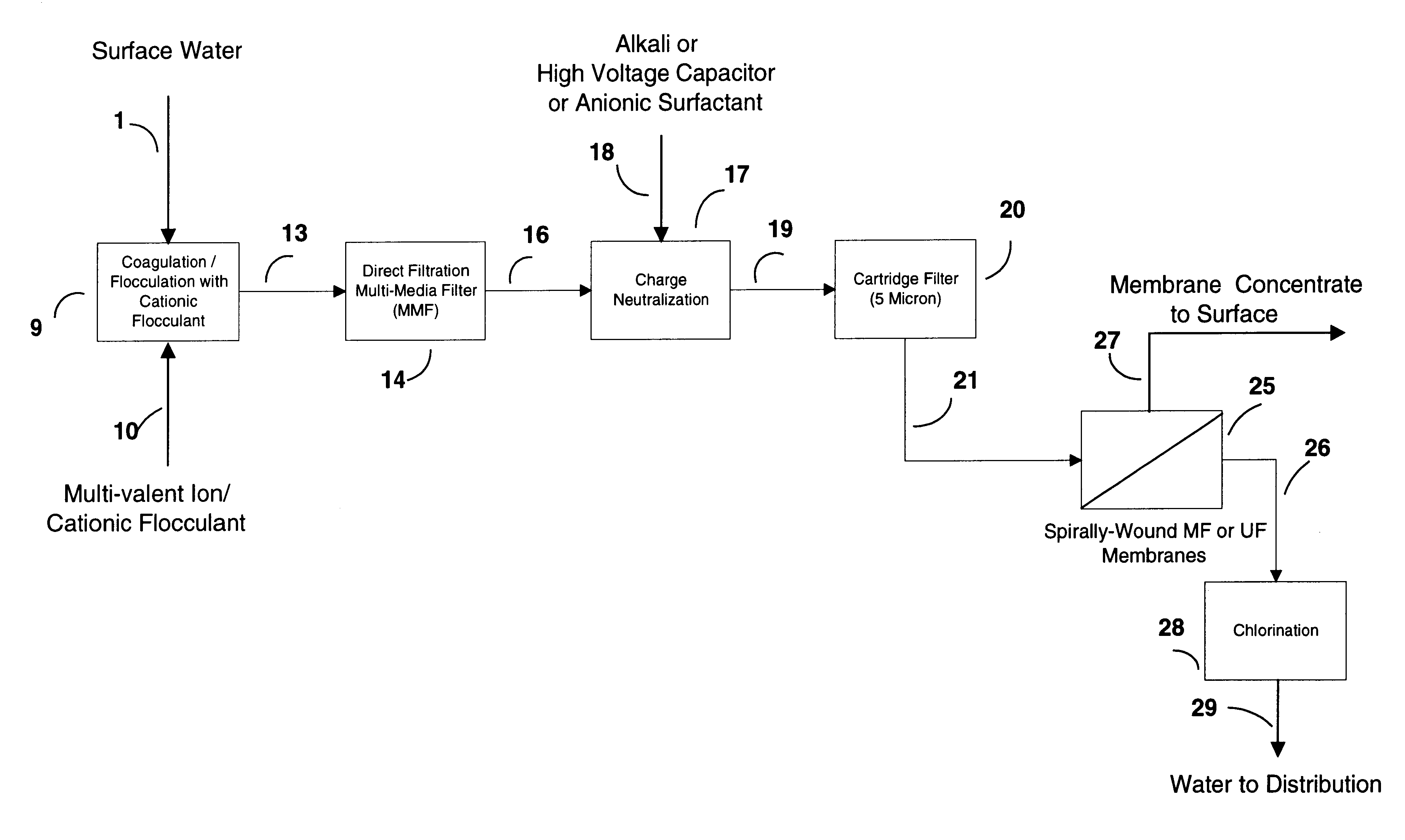

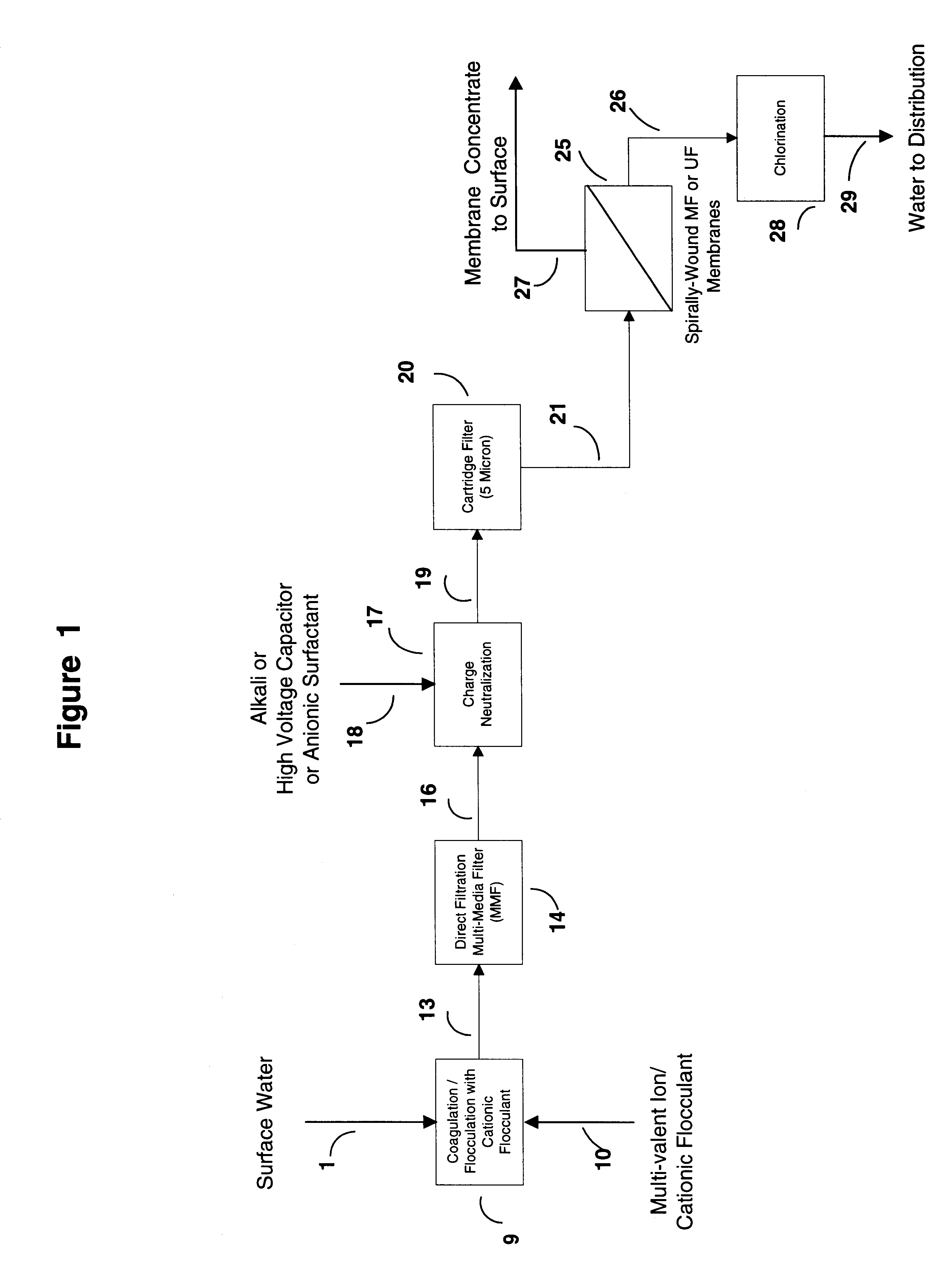

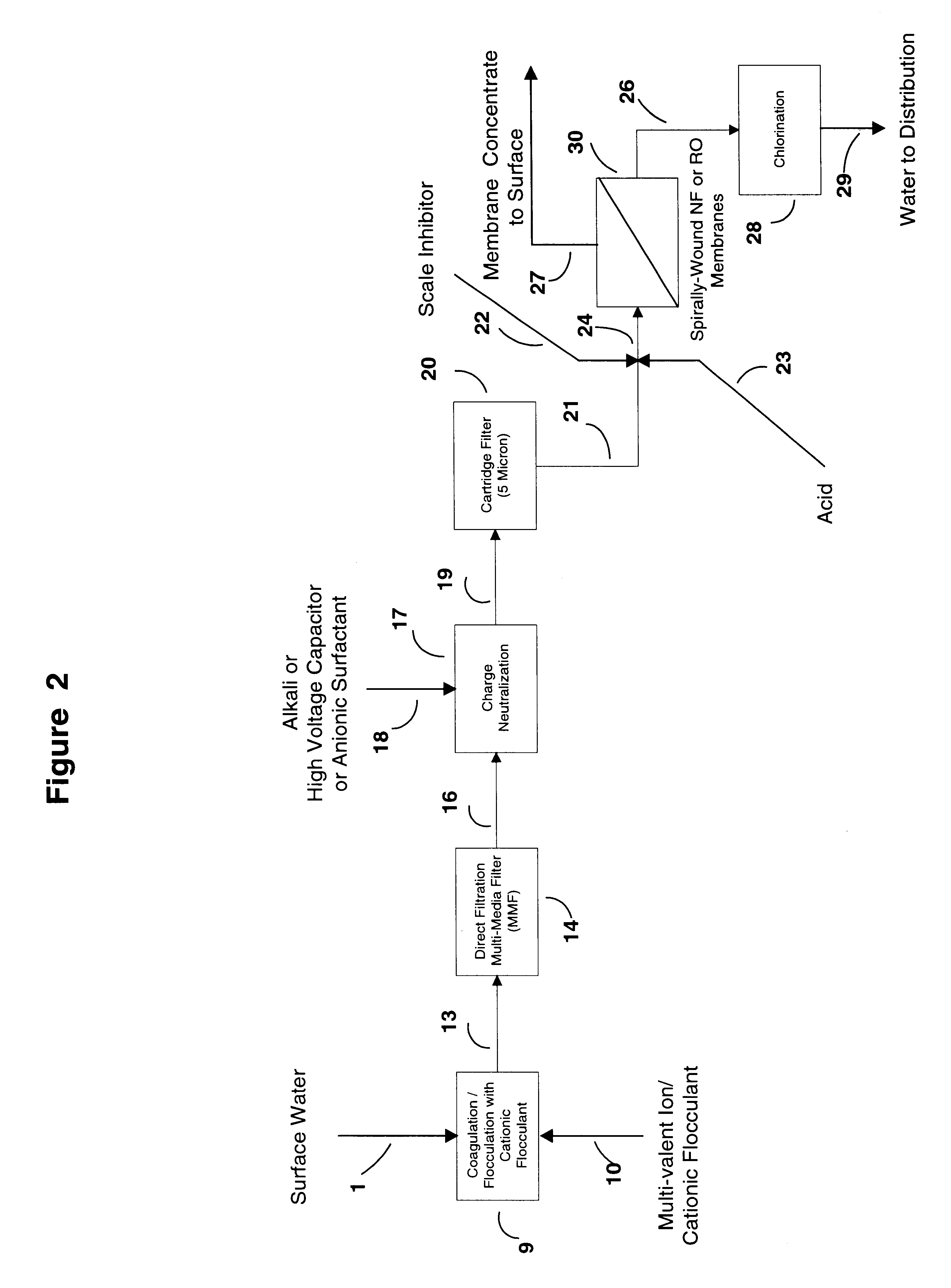

Water treatment process for membranes

InactiveUS6416668B1Effective and safe and reliable to produceCapital and operating costMembranesUltrafiltrationZeta potentialFiltration

This invention discloses a cost-effective process for separating contaminants and a wide-range of fouling material from surface water, ground water and from industrial effluents. Having undergone effective pre-treatment, the water can be purified further by using high-surface area spirally wound micro-filtration (MF), ultra-filtration (UF), nano-filtration (NF) or reverse osmosis (RO) membranes. High-quality potable water free from pathogen and other contaminants is thus produced at low-cost from the pre-treated surface water and ground-water. Conversely, pre-treated industrial effluents are further purified at a relatively low-cost using NF or RO membranes, thus producing water suitable for recycle or surface discharge. The process of this invention uses cationic inorganic and / or polymeric flocculants to coagulate and flocculate the water-borne colloidal matter (e.g. clays, iron hydroxides, naturally occurring matter (NOM's), etc.), followed by filtration using a multi-media filter, charge neutralization and reversal and final filtration using a 5-micron cartridge filter. These pre-treatment steps provides a good quality water having a low Silt Density Index and a significant negative zeta potential, thereby ensuring against irreversible chemical fouling of the spirally-wound membranes.

Owner:AL SAMADI RIAD A

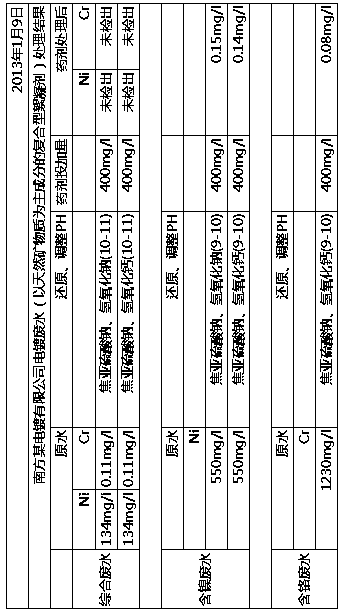

Compound flocculant taking natural minerals as main components

InactiveCN104229957AEfficient removalApplicable to a wide range of PHWater resource protectionWater/sewage treatment by flocculation/precipitationDry weightNatural mineral

The invention discloses a compound flocculant taking natural minerals as main components. The compound flocculant is mainly prepared from the following components by weight percent: 60%-85% of natural minerals, 8%-38% traditional inorganic flocculant and 3%-10% of organic polymer flocculant. According to the invention, key points are as follows: in the compound flocculant taking natural minerals as main components, the weight of the natural minerals, the inorganic flocculant and the organic polymer flocculant is dry weight; and the compound flocculant is implemented to purification of civil engineering wastewater, natural water, industrial wastewater, oily wastewater, fluoride wastewater, food processing wastewater, auto parts processing wastewater, colored wastewater, clean wastewater, semiconductor processing wastewater, restaurant waste water, mine water, slaughter wastewater, grinding wastewater, sewage effluent and the like.

Owner:张家领

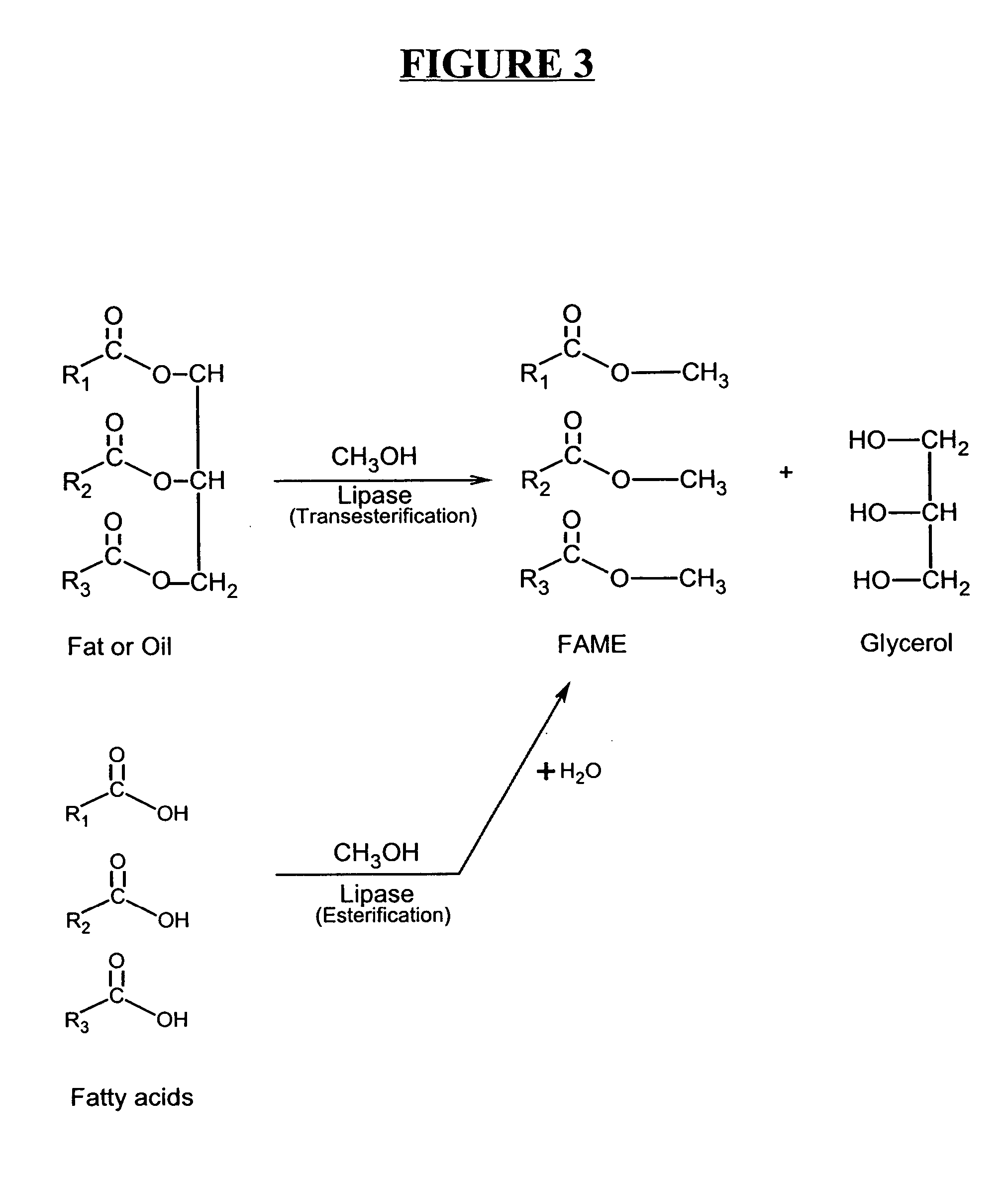

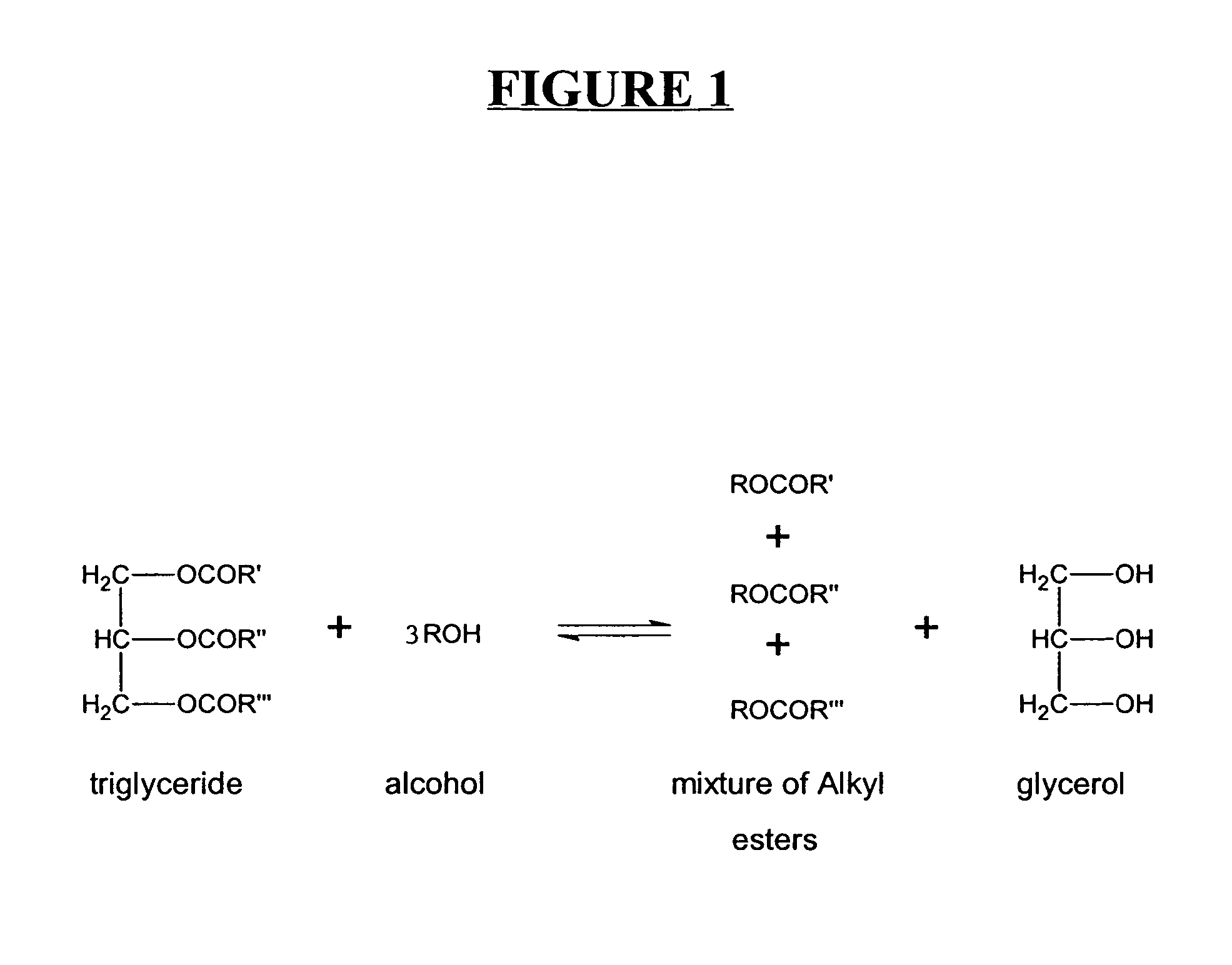

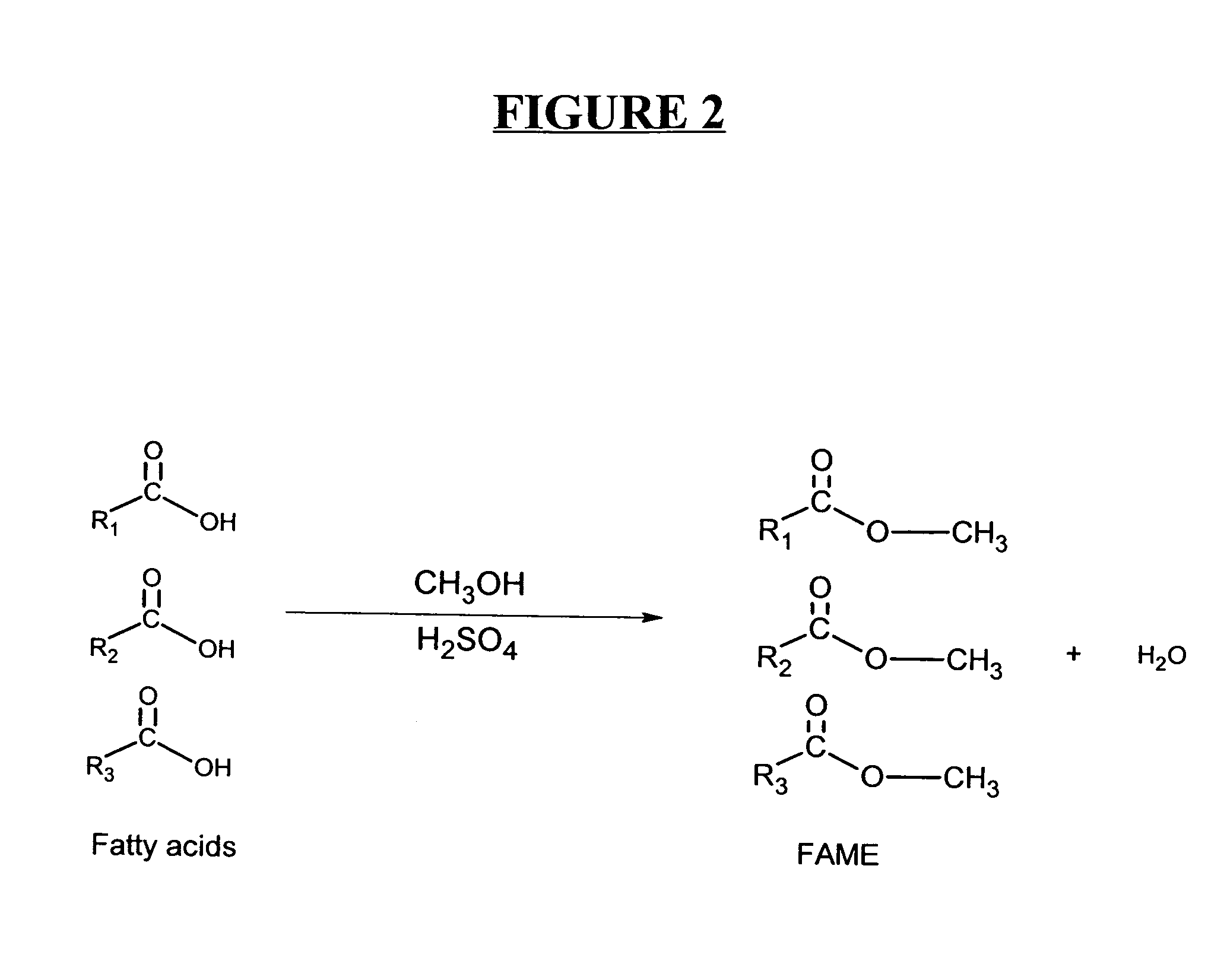

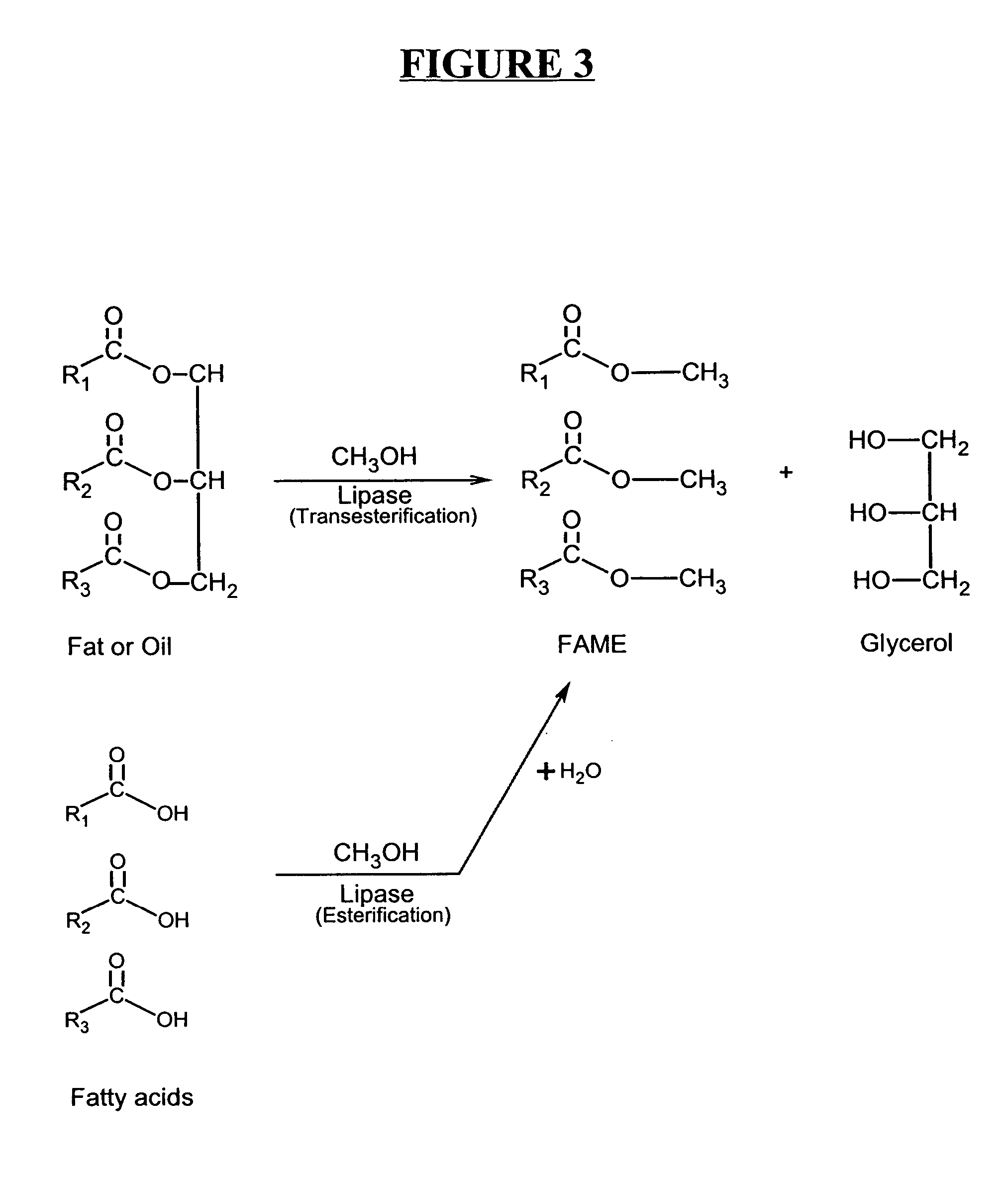

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

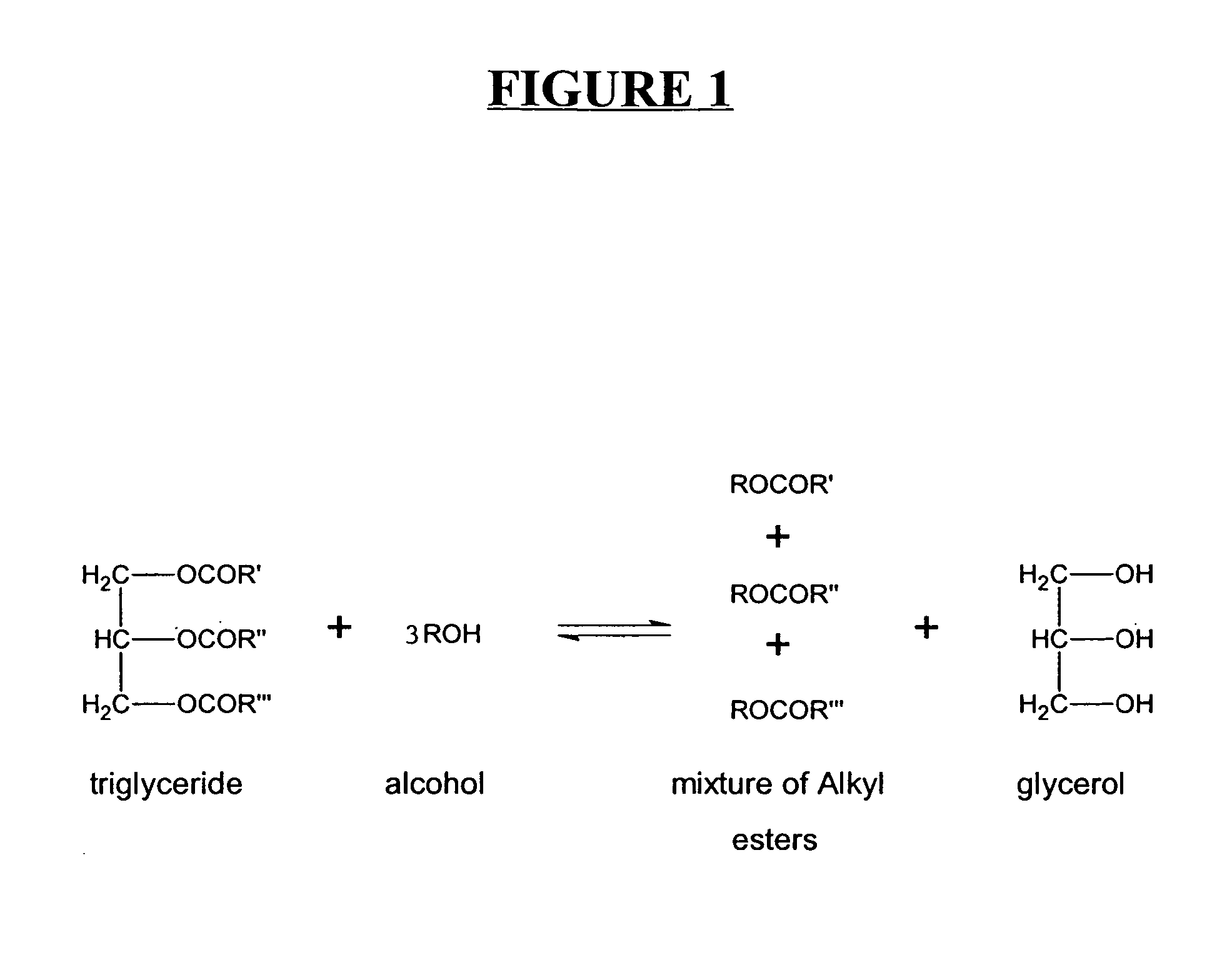

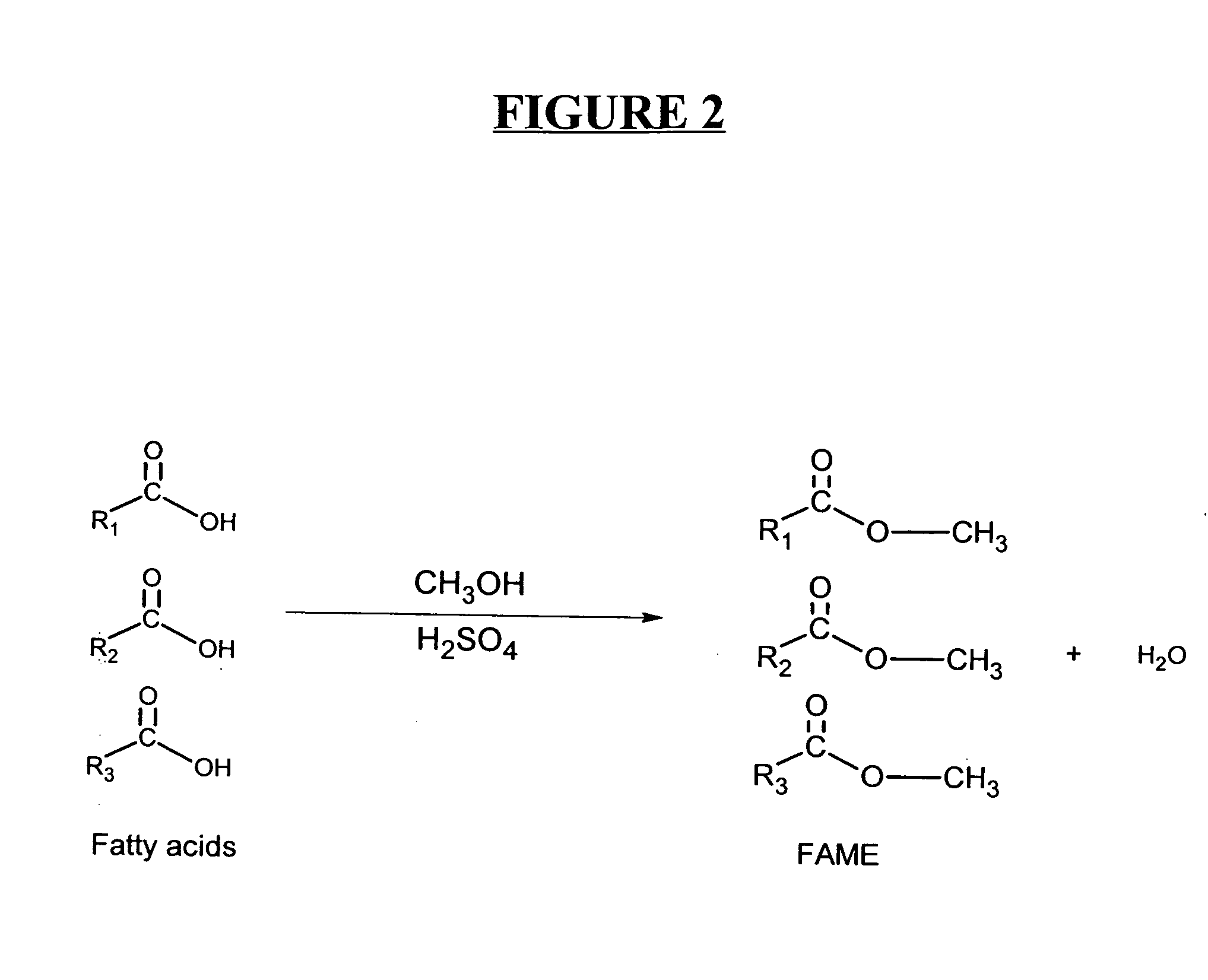

ActiveUS20050112735A1Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationLipid formationSludge

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

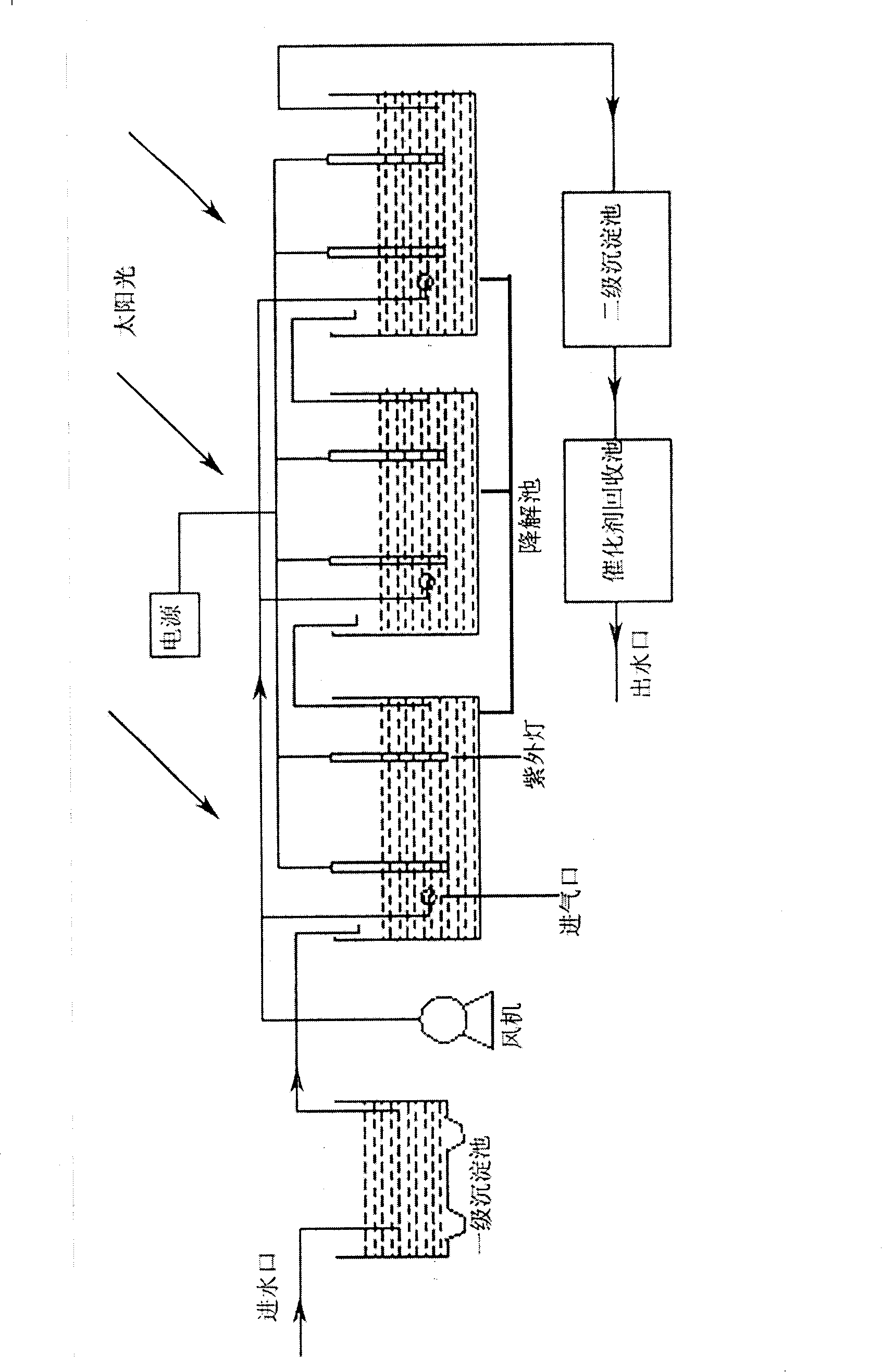

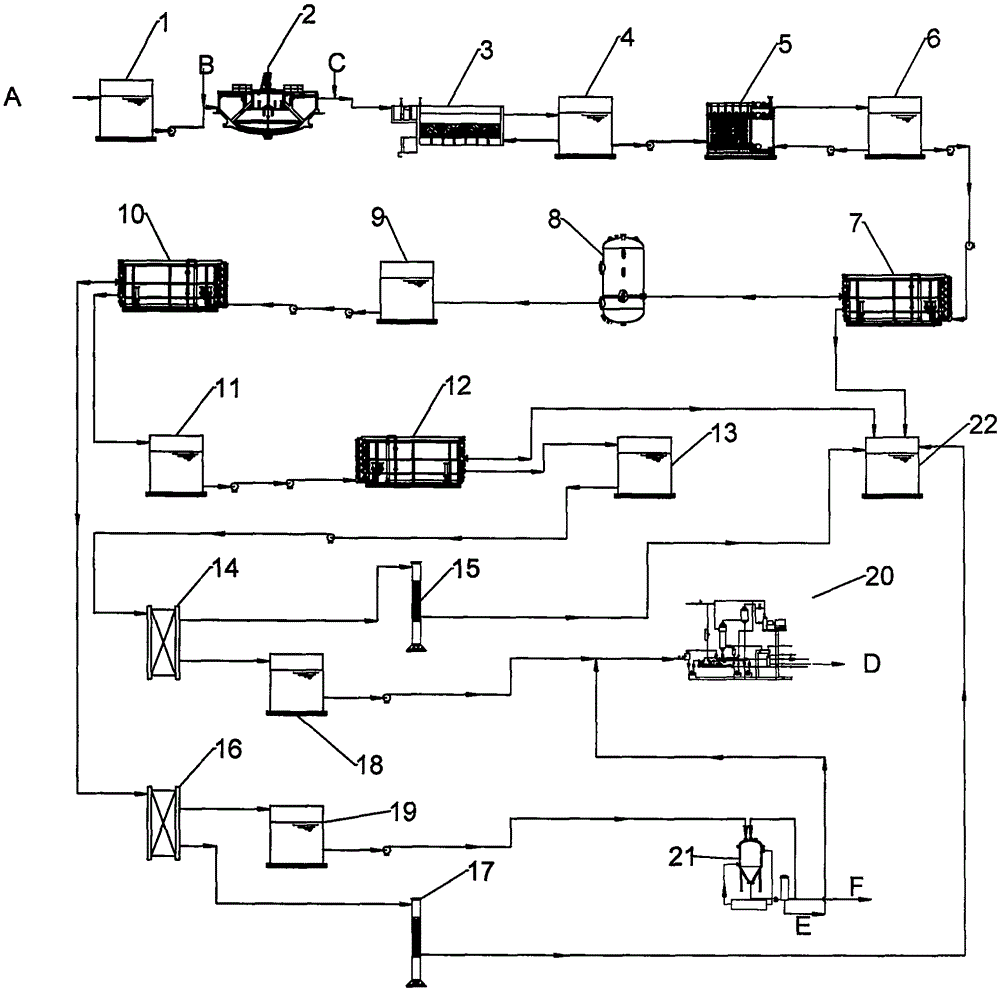

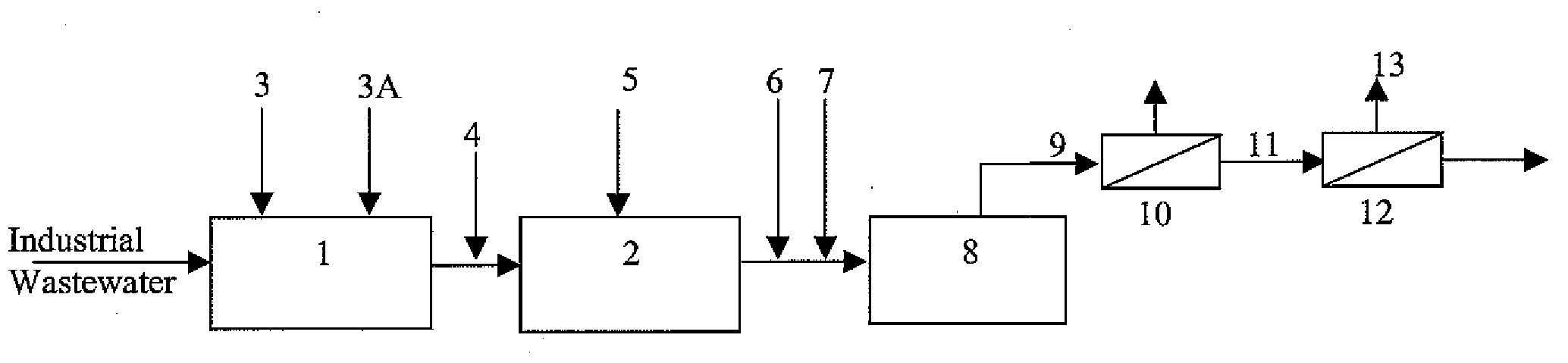

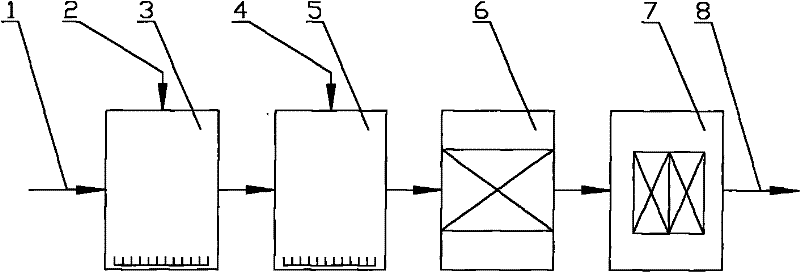

Photocatalysis oxidation treated high concentration organic trade waste

InactiveCN101219371AHigh activityImprove stabilityCatalyst carriersEnergy based wastewater treatmentHigh concentrationEmission standard

The invention relates to a modified loading nano composite photocatalyst which takes titanium dioxide as main part and adopts new reaction technique to degraded the organic industrial wastewater in a water processing system (see attached drawing 1 in Instruction). The main point on preparing the catalyst lies in that titanium dioxide active compounds loaded on different carriers are employed to prepare a loading photocatalyst with grain diameter of 5-40nm; meanwhile, different elements are mixed into the loading photocatalyst to reduce the composition between photoproduciton electron and cavity, which enables the catalyst to move the light absorbing wavelength thereof towards the visible regions, thus effectively improving the degradation rate of organic pollutants as a new environmental-friendly catalyst. As to the new technique of processing the organic industrial wastewater, the invention overcomes the defects that the present photocatalysts are only used for degrading the organic industrial wastewater with low concentration. The catalyst being irradiated respectively or simultaneously under sunbeam and ultraviolet light can decrease COD values of high-concentration organic industrial wastewater from 10000-40000mg / L to less than 100mg / L in short time, thus meeting the national emission standard.

Owner:BEIJING UNIV OF CHEM TECH

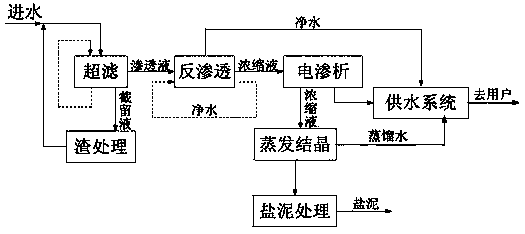

Membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater

ActiveCN103508602AAchieving zero emissionsReduce energy consumptionDispersed particle separationWater/sewage treatment bu osmosis/dialysisFiltrationUltrafiltration

The invention relates to a membrane and evaporation crystallization integrated process with zero discharge of high-salinity industrial wastewater. The process is as below: carrying out ultrafiltration pretreatment on industrial wastewater and sending the wastewater to a reverse osmosis process through a high-pressure pump; reusing lateral infiltration water; conducting electrodialysis treatment on a concentrate subjected to several times of filtration; evaporating and crystallizing the materials obtained from electrodialysis concentration to obtain salt slurry and water; carry outing posttreatment on the salt slurry; and reusing condensed water. The process provided by the invention couples membrane and evaporation crystallization, not only can recover high quality purified water from industrial wastewater with high salinity but also can realize zero discharge of wastewater with high salinity, and has the characteristics of low energy consumption, low production cost and advanced process.

Owner:NANJING JIUSI HIGH TECH +1

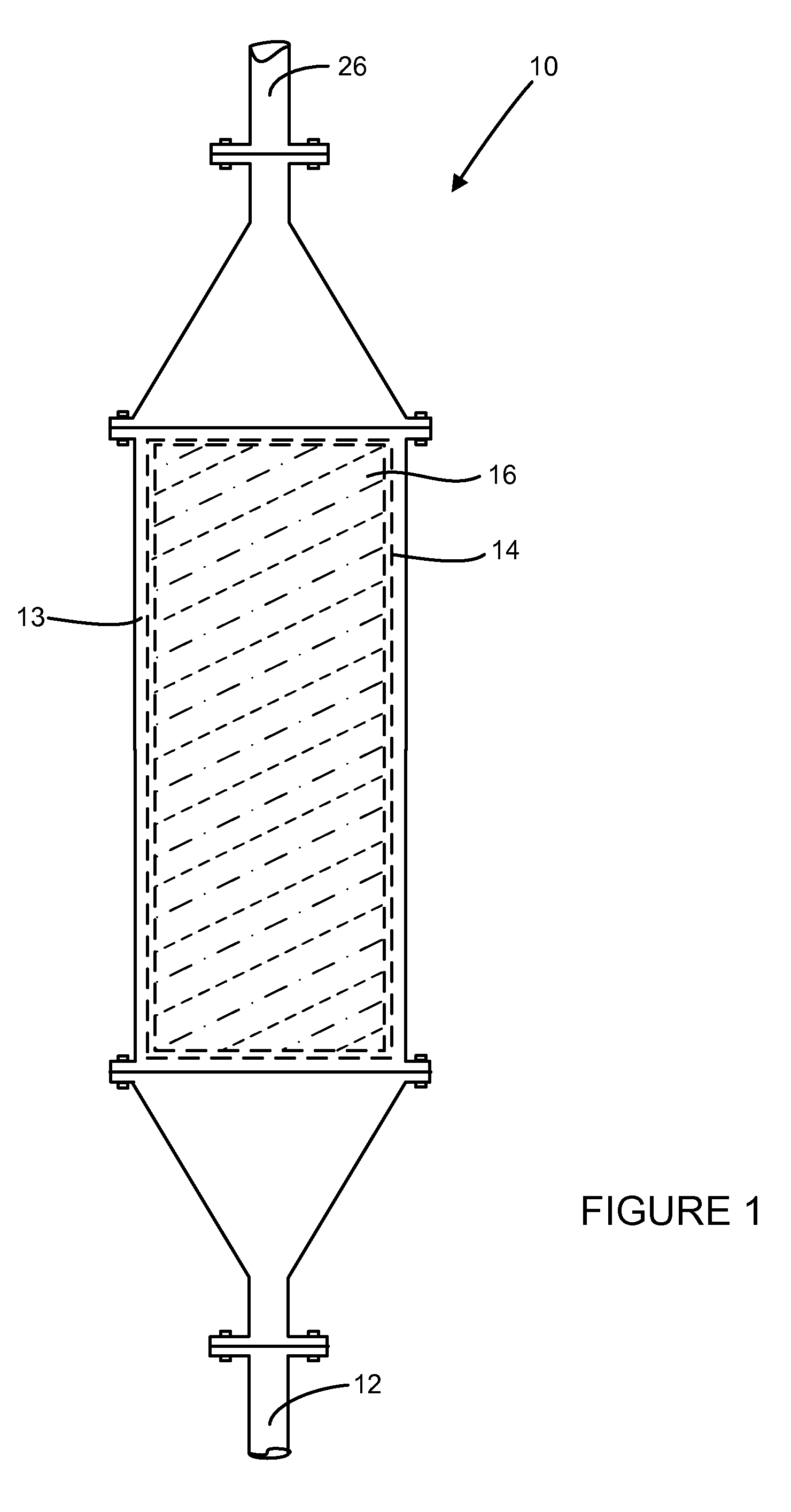

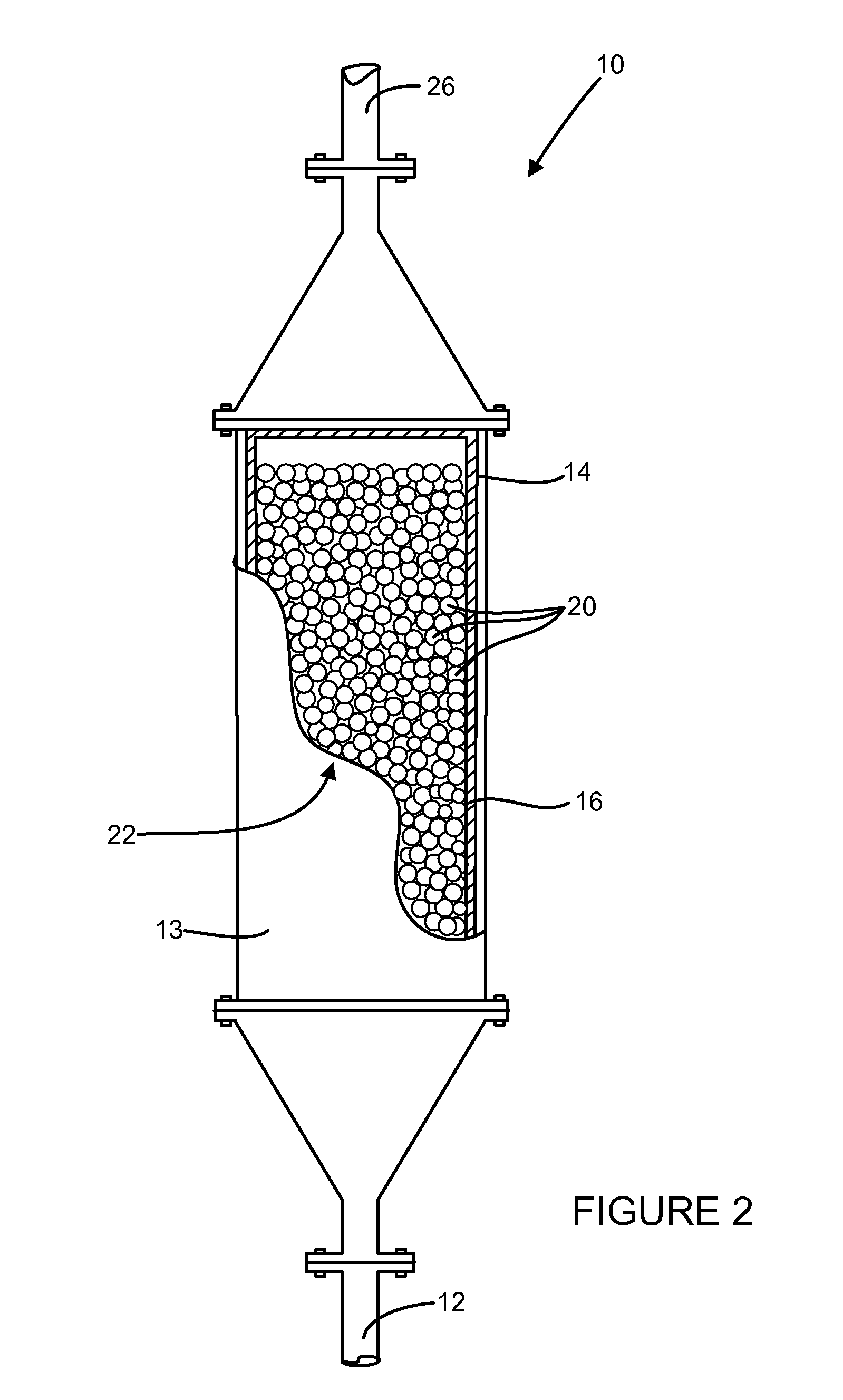

Methods and devices for reducing hazardous air pollutants

ActiveUS20090081093A1Reduce pollutionReduce the amount requiredCombination devicesCyanogen compoundsSlagSolid particle

The disclosure provides methods and systems for sequestering and / or reducing sulfur oxides, nitrogen oxides and / or carbon dioxide present in industrial effluent fluid streams. A solid particulate material comprising a slag component, a binder component (distinct from the slag component), and optionally water is formed and then contacted with the effluent fluid stream to reduce at least one of the sulfur oxides, nitrogen oxides, and / or carbon dioxide. The contacting of the effluent stream may occur in a packed bed reactor with the solid dry particulate material. Methods of reducing pollutants from exhaust generated by combustion sources, lime and / or cement kilns, iron and / or steel furnaces, and the like are provided.

Owner:C QUEST TECH

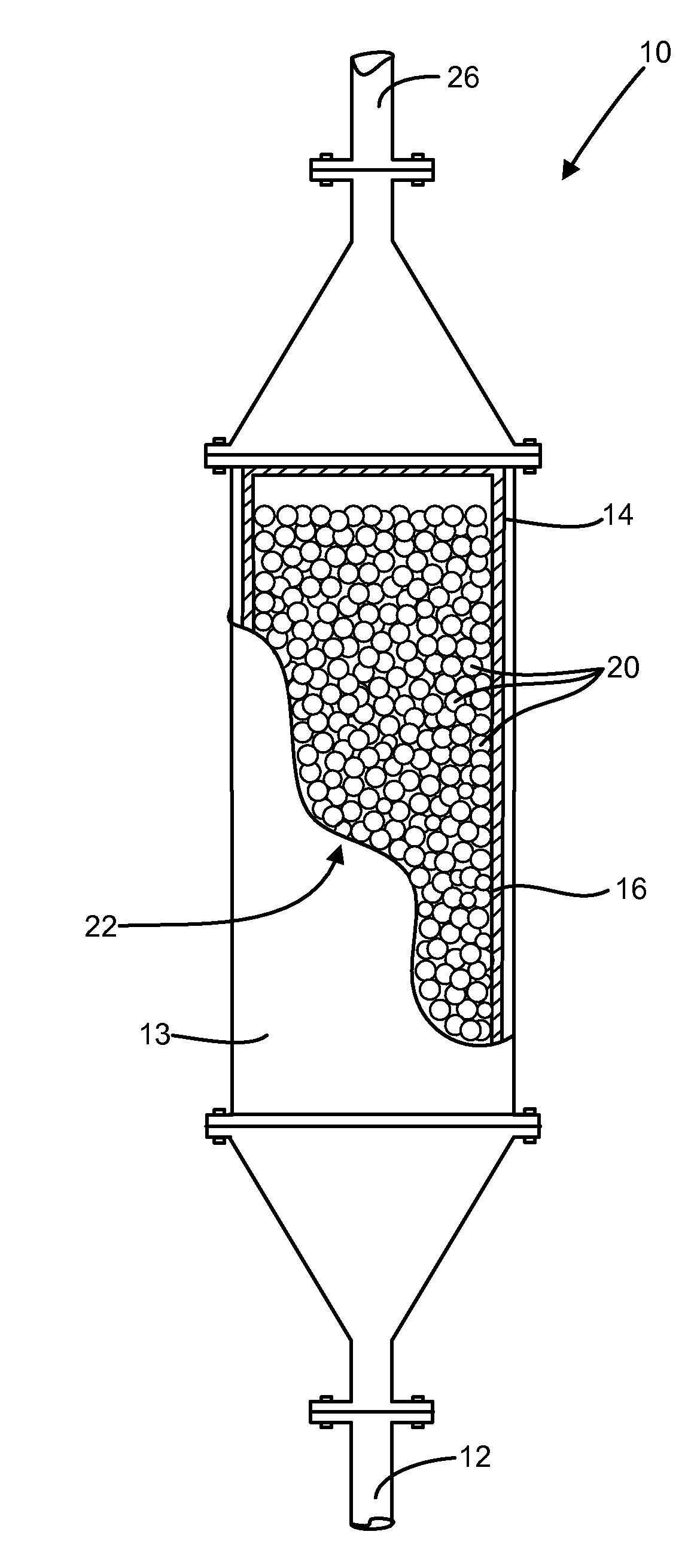

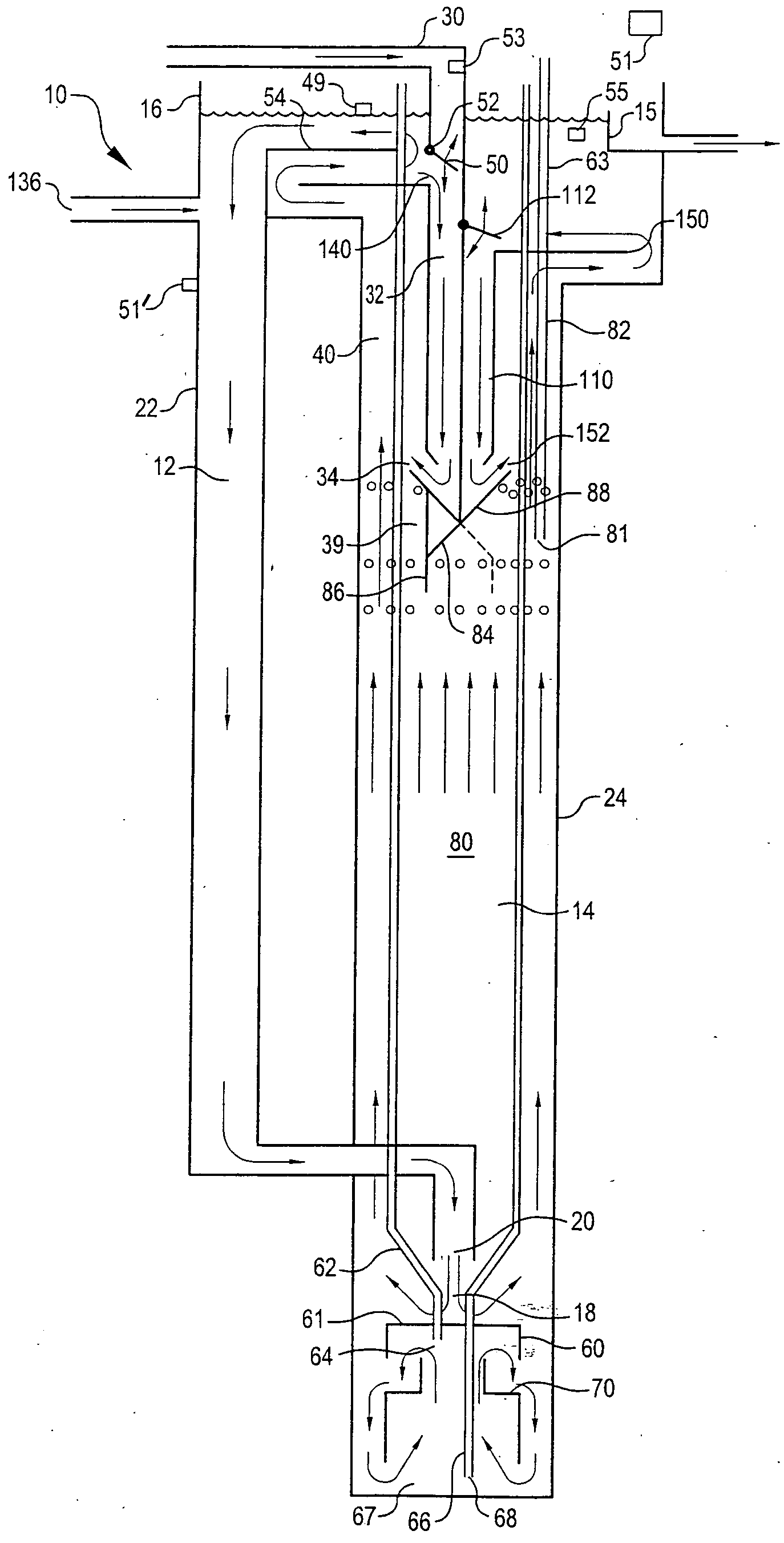

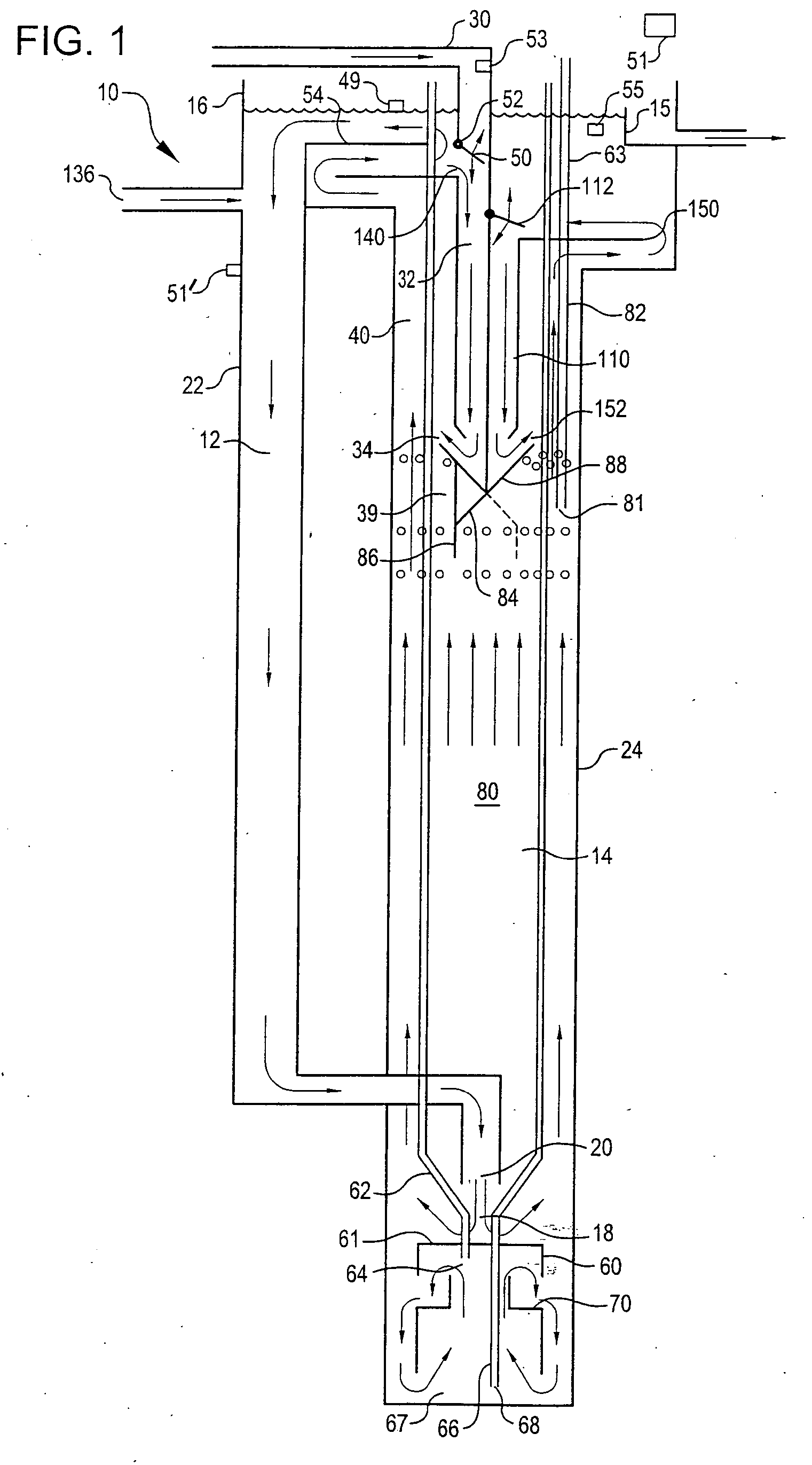

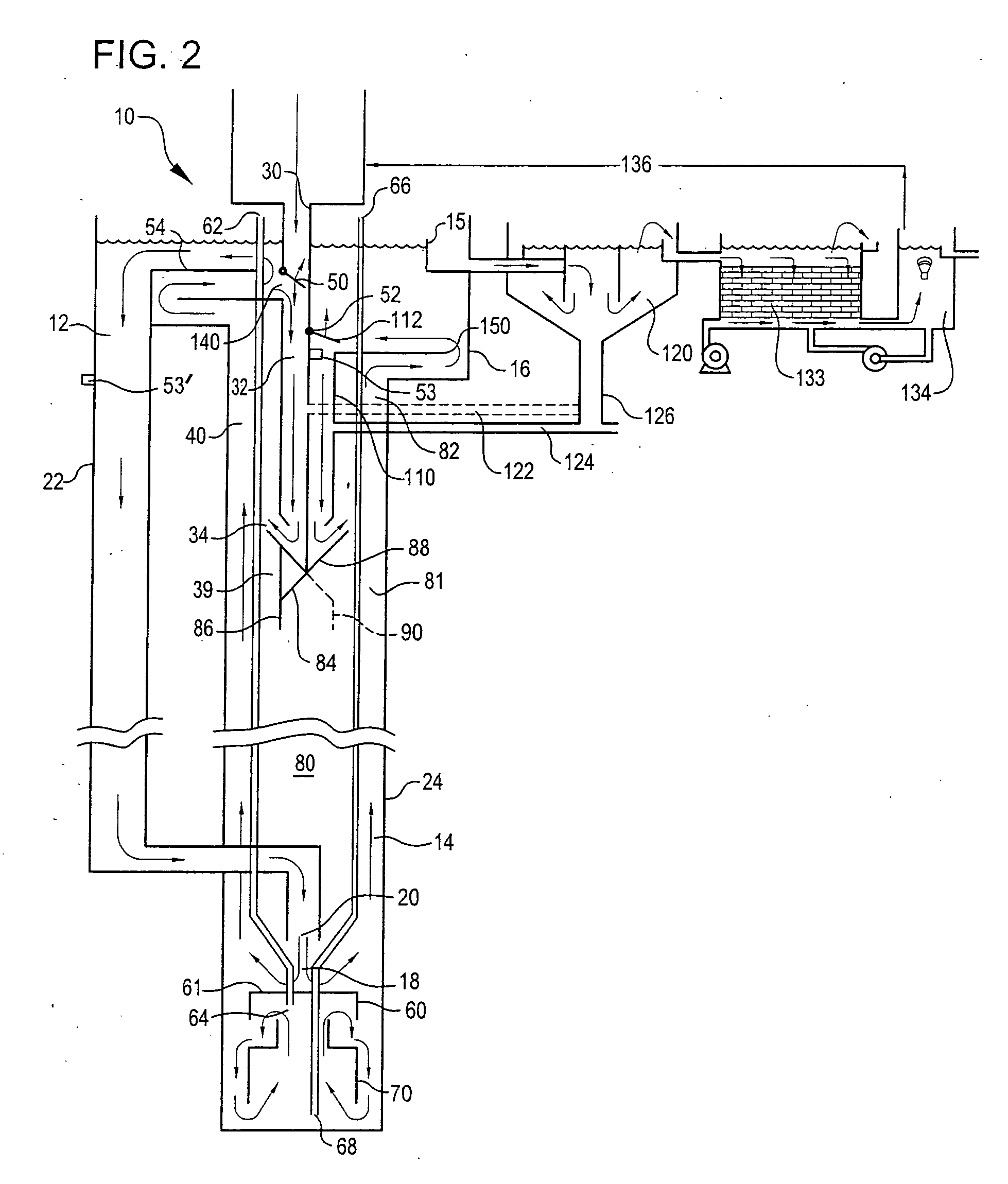

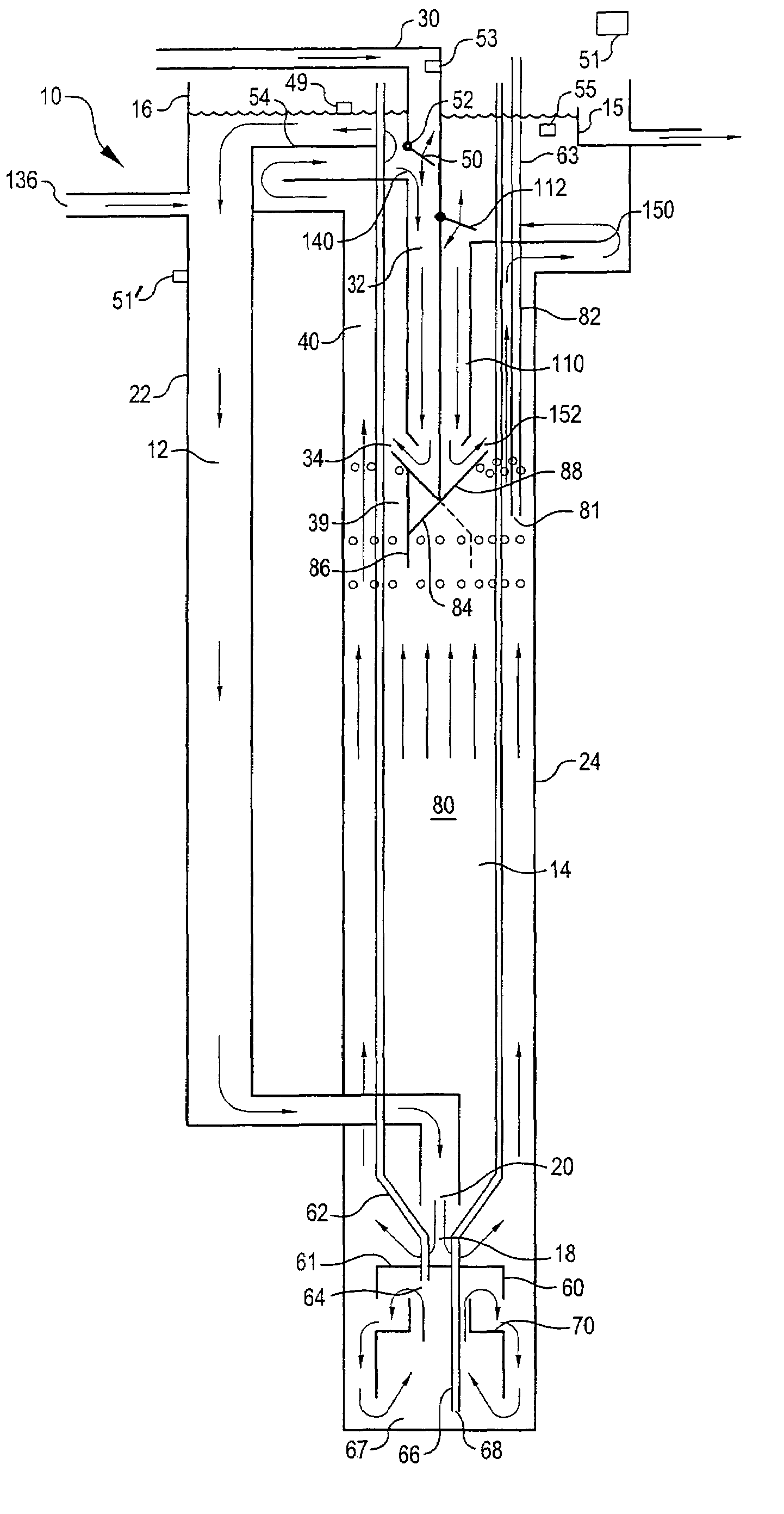

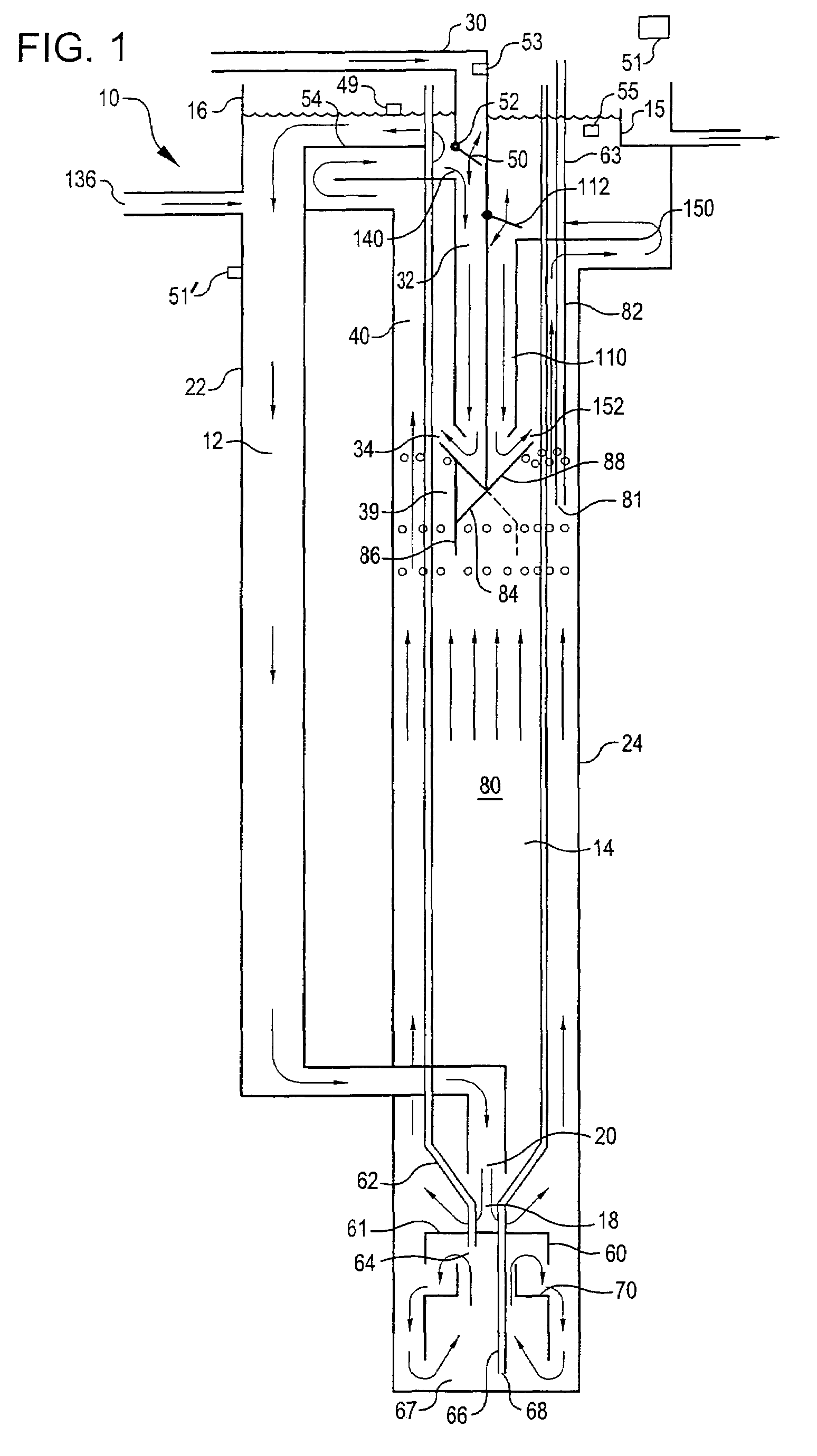

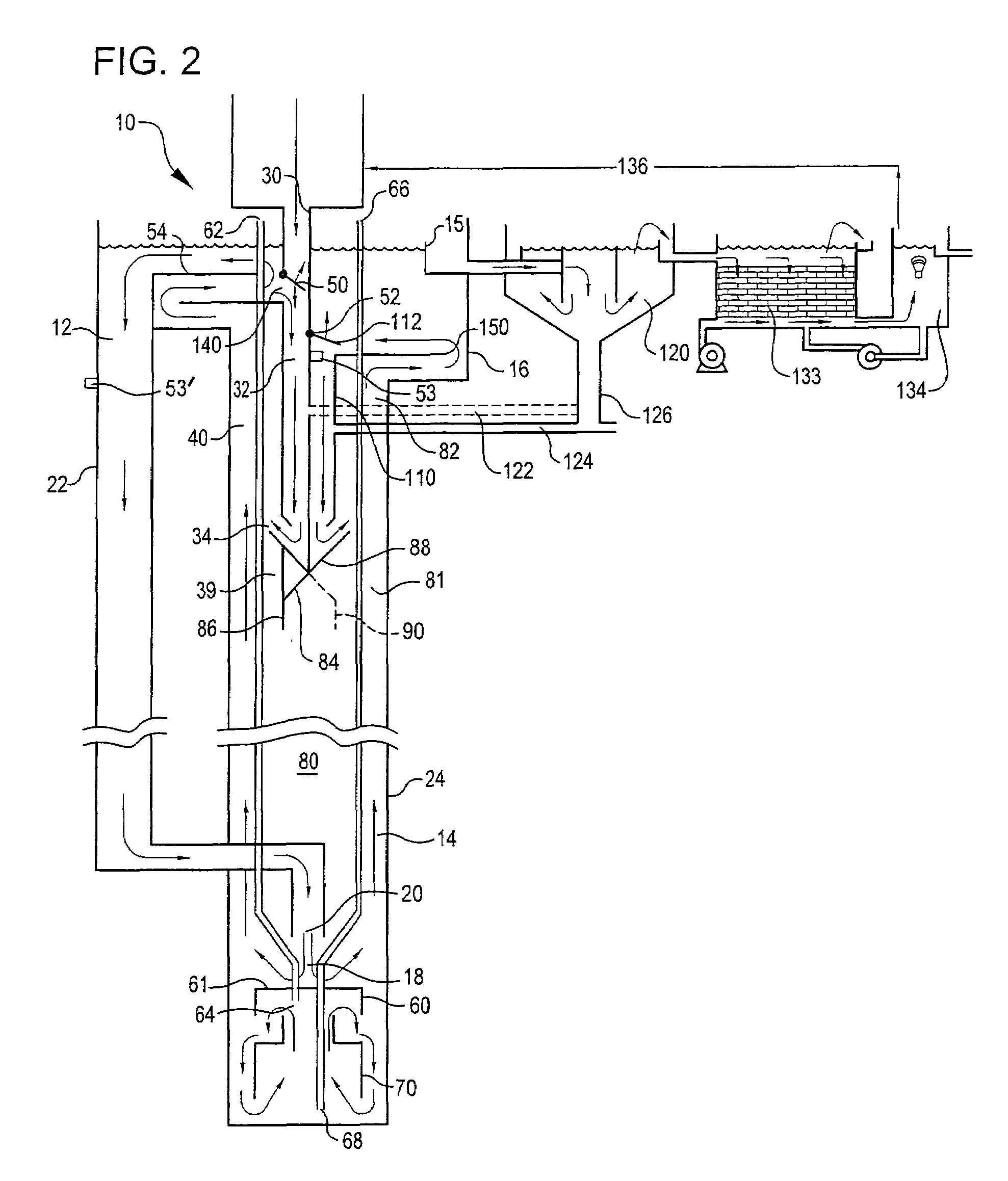

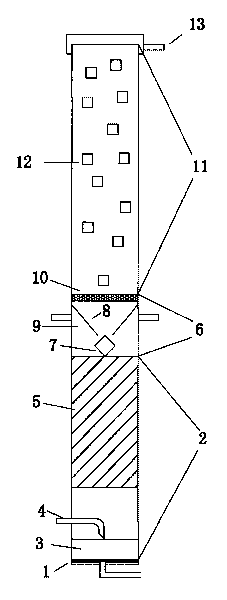

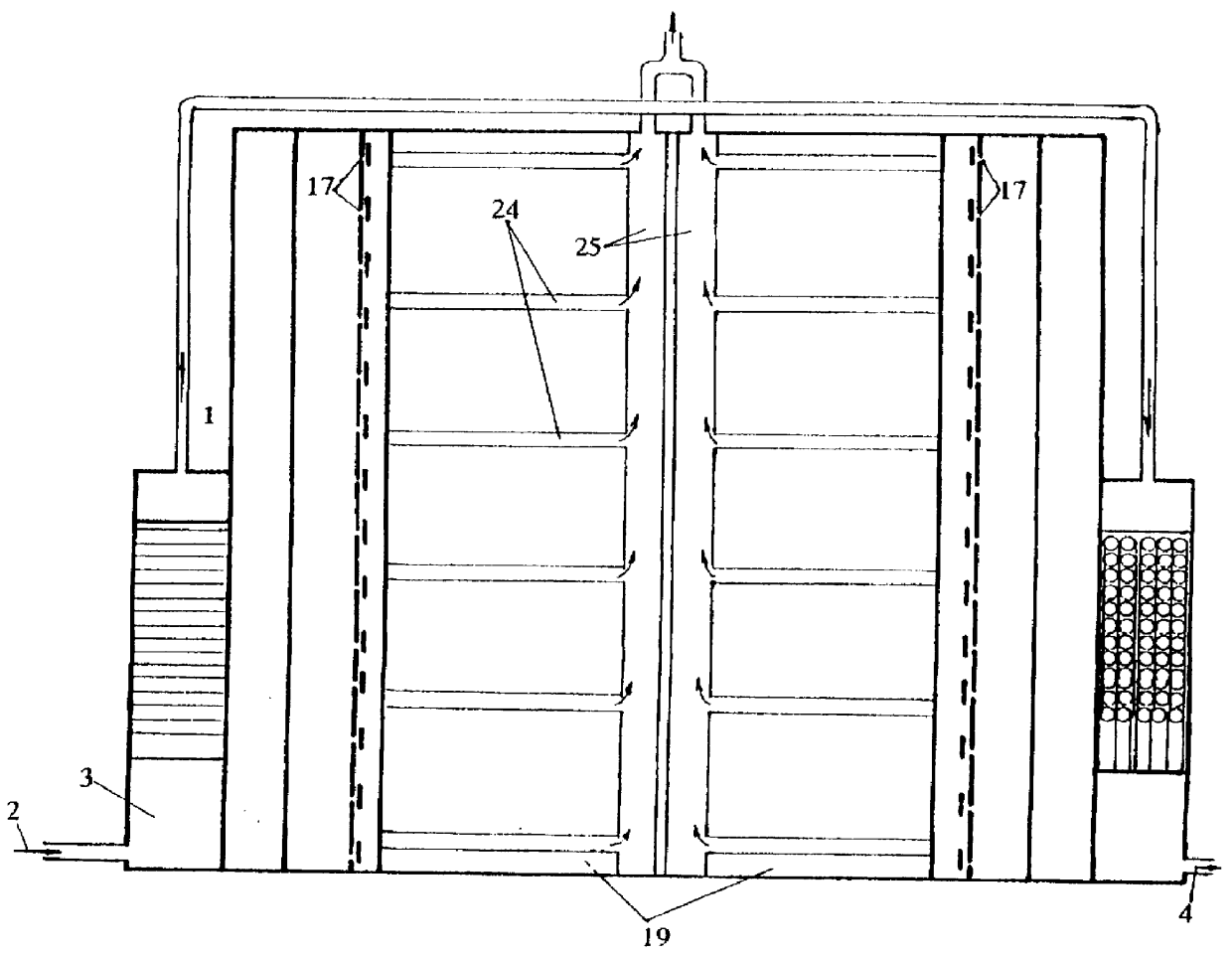

Methods and apparatus for biological treatment of waste waters

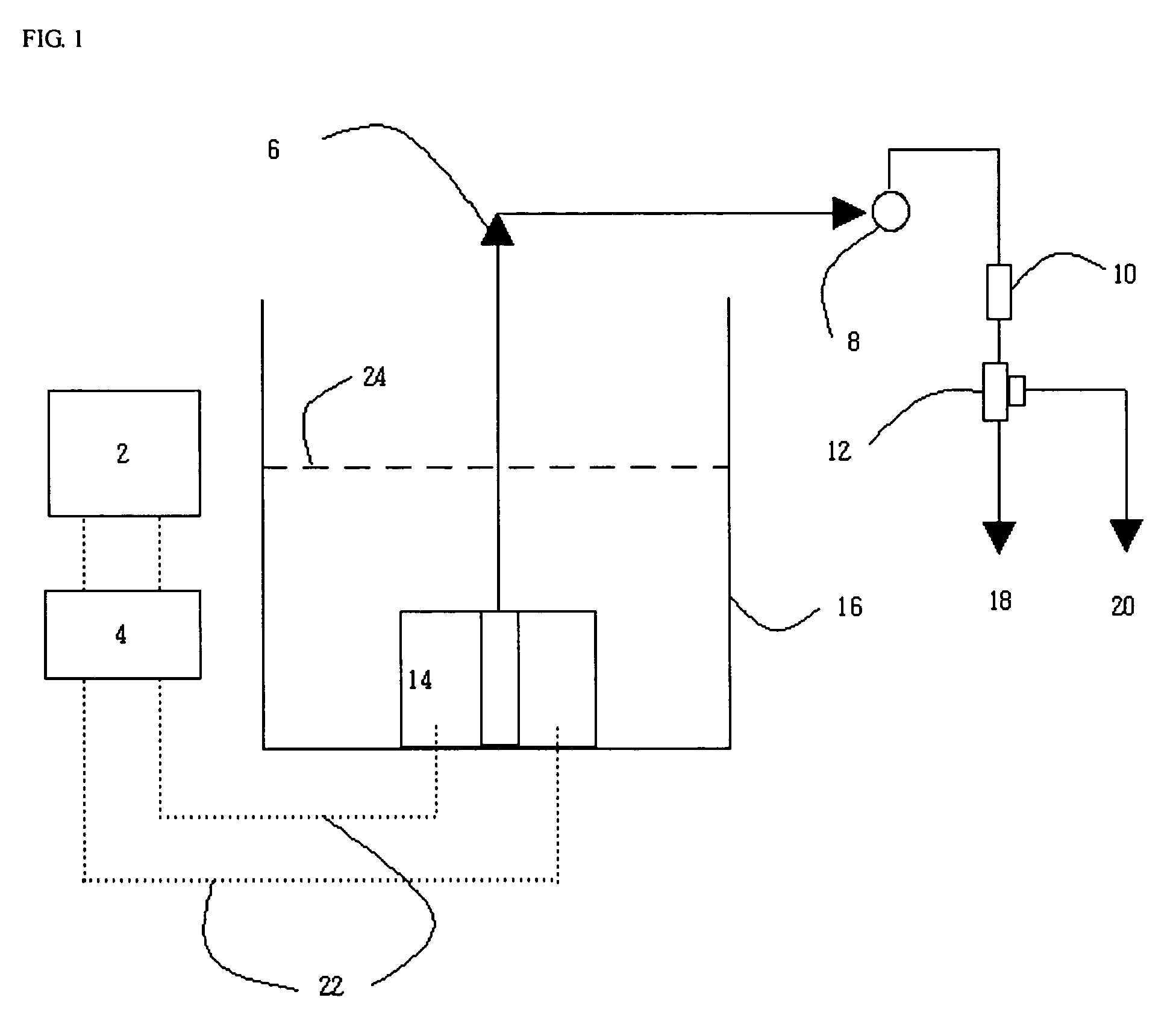

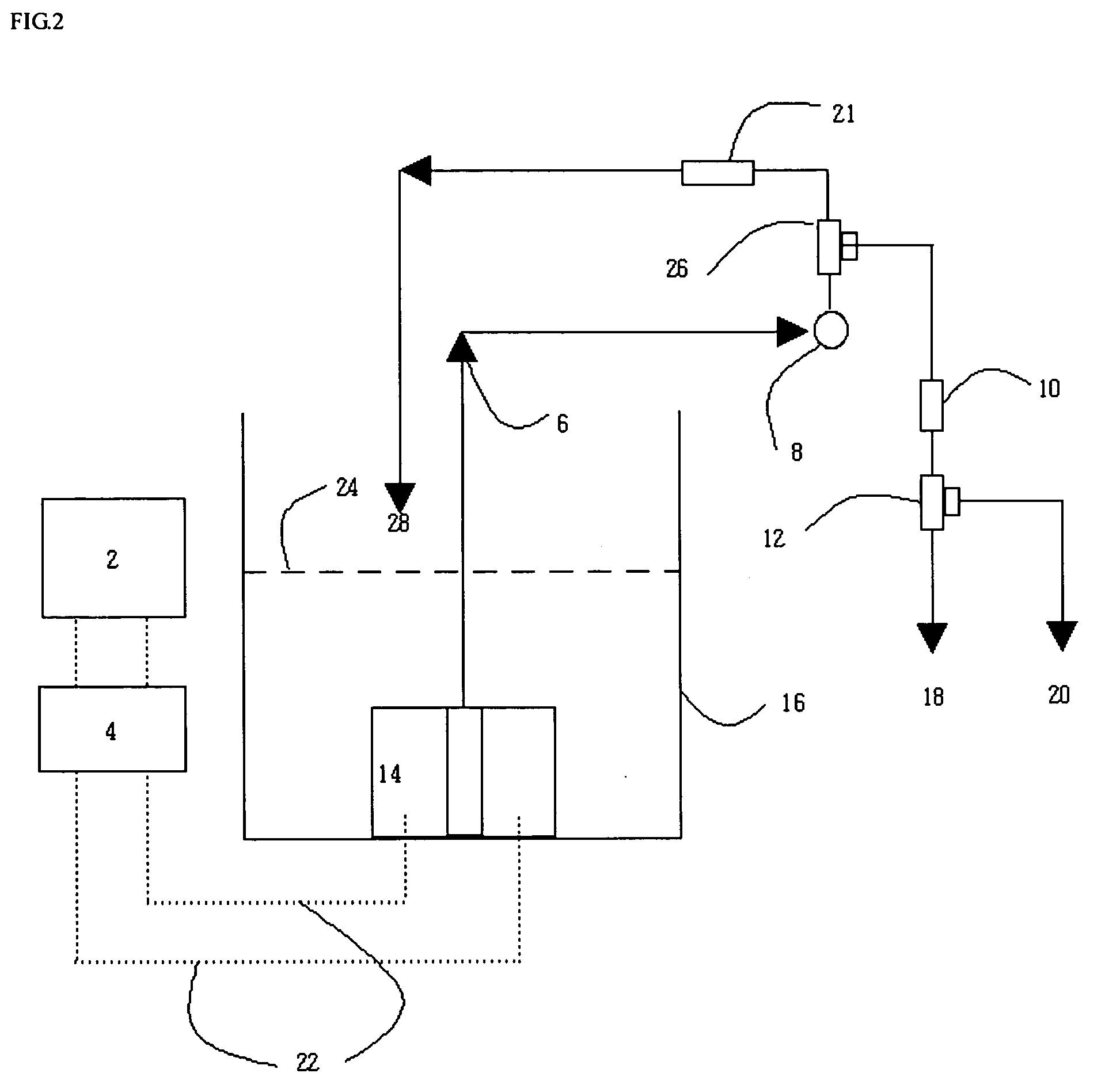

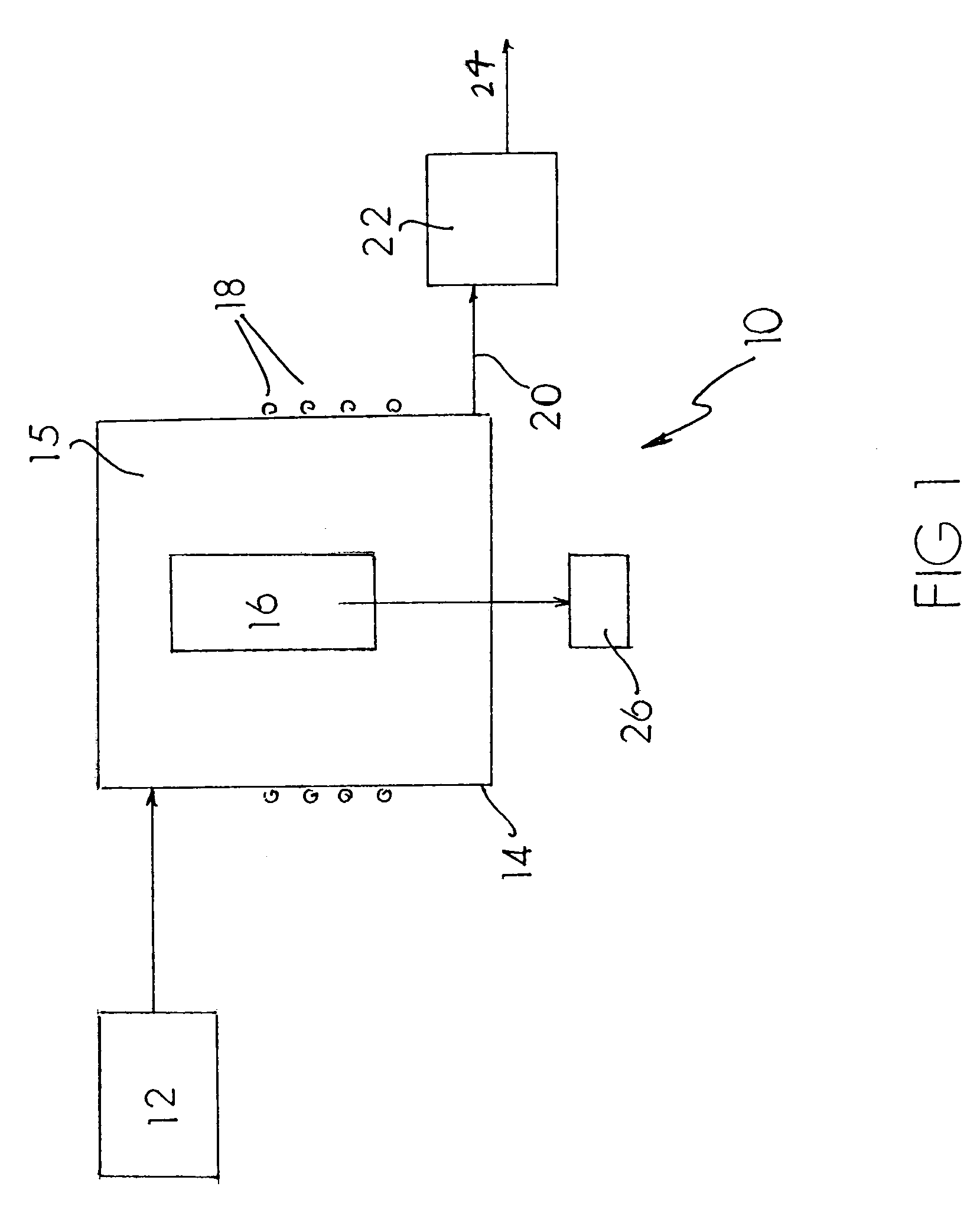

InactiveUS20050115880A1Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

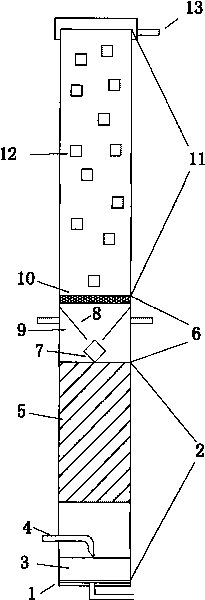

Apparatus for biological treatment of waste waters

InactiveUS7018530B2Liquid degasificationTreatment using aerobic processesIndustrial effluentPasteurization

In a vertical shaft bioreactor, improved devices and methods are provided for enhanced secondary and / or tertiary treatment of wastewater, including residential, municipal and industrial wastewater. The devices and methods of the invention are useful for enhanced secondary wastewater treatment, including BOD and TSS removal. Tertiary treatment can alternately or additionally be achieved in the bioreactor with nitrification of ammonia, with nitrification and denitrification, and with nitrification, denitrification, and chemical phosphorus removal. A vertical shaft bioreactor is also provided which achieves thermophilic aerobic digestion and pasteurization of sewage sludges, optionally to produce class A biosolids.

Owner:VOST ENVIRONMENTAL TECH

Method for comprehensively treating high salt content organic industrial wastewater

ActiveCN101585620AUnique methodSimple processMultistage water/sewage treatmentWater/sewage treatment by neutralisationSocial benefitsIndustrial effluent

The present invention provides a method for comprehensively treating high salt content organic industrial wastewater, and relates to the field of the organic material preparing technique. The method of the invention mainly comprises the following steps: executing acid-alkali adjustment to the organic wastewater until pH=7-9, preheating to 30-60 DEG C; introducing the wastewater into a triple effect evaporator for executing triple effect evaporation, executing salting out to the evaporated wastewater which is condensed to a certain degree so that the solid and liquid are separated; separating the concentrated liquid for continuing the condensation; when the separated liquid satisfies a certain requirement, atomizing into an incinerator for incinerating and discharging according to the standard, and introducing the triple effect evaporation condensation water into a biochemical treating system. The method of the invention can totally dispose and remove the organic matter in the high salt content organic industrial wastewater so that the high salt content organic industrial wastewater can be charged according to the standard. The method of the invention has the advantages of unique method, simple technical process, easy operation, low operation cost, large treating capacity, low regeneration energy consumption, no easy forming of secondary pollution after abandon, better economic and social benefit, and wide application range. The method of the invention can be widely applied for the treating of the high salt content organic wastewaters of garbage penetrating fluid, dye intermediate wastewater, etc.

Owner:HEBEI JIANXIN CHEM IND CO LTD

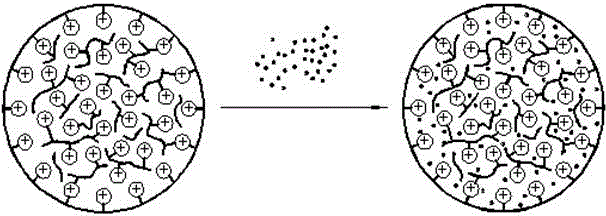

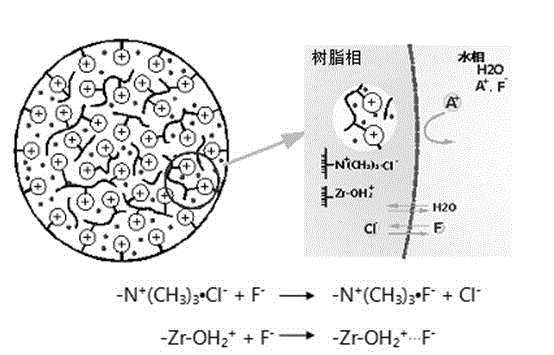

Novel polymer-based composite material and preparation method of composite material as well as method for deep fluorine removal of water body

ActiveCN102942239AHigh adsorption capacityHigh removal rateOther chemical processesAlkali metal oxides/hydroxidesIndustrial effluentDivinylbenzene

The invention discloses a novel polymer-based composite and a preparation method of the composite material as well as a method for deep fluorine removal of a water body, belonging to the fields of drinking water and industrial wastewater treatment, and environment function materials. The substrate of the composite is styrene-divinylbenzene copolymerized spheres, and nanometre zirconia hydrate particles are uniformly distributed in the holes of the spheres. The method for deep fluorine removal of the water body comprises the following steps of: (a) filtering fluorine-containing wastewater, and adjusting the pH of a filtrate to 3.0-8.0; (b) passing the filtrate through an adsorption tower in which a novel polymer-based composite material is filled; and (c) stopping adsorption in the case that the concentration of fluorine ions in effluent achieves a leakage point, performing adsorption regeneration on the novel polymer-based composite material in the adsorption tower by virtue of a NaOH-NaCl mixed solution, and then standing for recycling after regeneration. According to the invention, the pre-concentration effect of a polymer substrate and the selective fluorine removal performance of nanometre zirconia hydrate are organically combined, thus the adsorption capacity and the selectivity of the material on fluorine ions are effectively improved.

Owner:NANJING UNIV

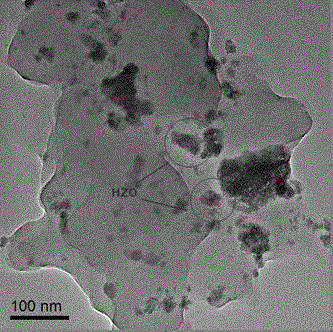

Submerged-type electrosorption-based water purification apparatus and method thereof

ActiveUS20070284313A1Improve efficiencyPromote recoverySeawater treatmentCell electrodesElectricityIndustrial effluent

Provided is a submerged-type, electrosorption-based desalination apparatus for water purification and method, comprising applying a DC voltage of 0.1 to 2.0 volts to a carbon electrode of the reactor to thereby adsorb inorganic ions on the carbon electrode, and reversely applying the same DC voltage having opposite polarity to recycle regeneration solution to the outside of the apparatus or into the treatment tank, thereby enhancing a recovery rate. In addition, in order to improve desalination efficiency, the reactor used in the desalination apparatus may be embodied in various forms of T-shaped, linear type, single, composite, and ion exchange membrane electrodes. Therefore, the present invention may be applied to remove inorganic ions from industrial wastewater, sea water, and brackish water, which contain large amounts of inorganic ions.

Owner:KOREA ELECTRIC POWER CORP

Production of biodiesel and other valuable chemicals from wastewater treatment plant sludges

ActiveUS7638314B2Reduce the environmentPromote digestionBio-organic fraction processingByproduct vaporizationSludgeFree protein

A process for producing biodiesel has been invented by first extracting lipids from the sludges generated during primary and / or biological treatment of municipal, agricultural, and industrial wastewaters using primary, secondary, and tertiary treatments followed by the transesterification of the extracted lipids using transesterification conversion into alcohol-based esters. The resulting products from this process include biodiesel, glycerol, lipid-free proteins, various other useful chemicals and an aqueous-based substrate well suited for optimized digestion within subsequent biological digestion (either aerobic or anaerobic). The lipids extracted from the sludges containing high levels of microorganisms are phospholipids which can also be directly used as lecithin. The extraction of the lipids from the sludges will be performed using chemical extraction techniques with the transesterification of the extracted lipids accomplished using basic, acidic, and / or a combination of the two transesterification techniques.

Owner:MISSISSPPI STATE UNIV RES & TECH

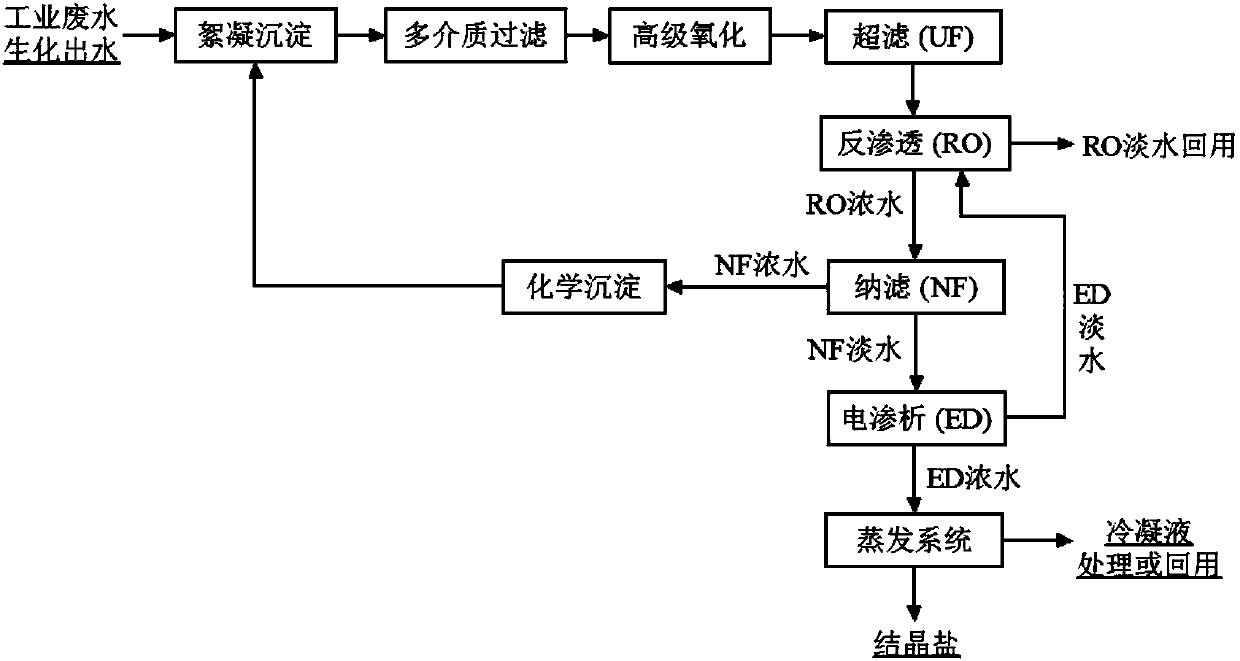

Treatment system and treatment method for biochemical effluent of industrial wastewater

InactiveCN107651794AEfficient removalHigh recovery rate of fresh waterGeneral water supply conservationTreatment involving filtrationHigh concentrationFiltration

The invention provides a treatment system and treatment method for biochemical effluent of industrial wastewater. The treatment system comprises a flocculation sedimentation unit, a filtration unit, an advanced oxidation unit, an ultrafiltration unit, a reverse osmosis unit, a nanofiltration unit, an electrodialysis unit and an evaporation unit which are sequentially connected; and the water production outlet of the ultrafiltration unit is connected with the water inlet tank of the reverse osmosis unit, and the concentrated-water outlet of the reverse osmosis unit is connected with the water inlet of the nanofiltration unit. According to the invention, the treatment system and the treatment method utilize the coupling and synergistic effects of a physical-chemical method and a membrane technology to overcome the limitation of using a single technology, and the advanced treatment and desalination reuse of the industrial wastewater are realized; and the treatment system and the treatmentmethod have the advantages of strong adaptability to raw water, a high recovery rate of fresh water, a high concentration multiple of concentrated water, low energy consumption of evaporation and crystallization and the like, greatly improve the reuse rate of the industrial wastewater, reduce the amount of wastewater discharging, can be applied to the deep treatment and desalination reuse of various effluent wastewater, and promote the promotion and application of the technology in related industries.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

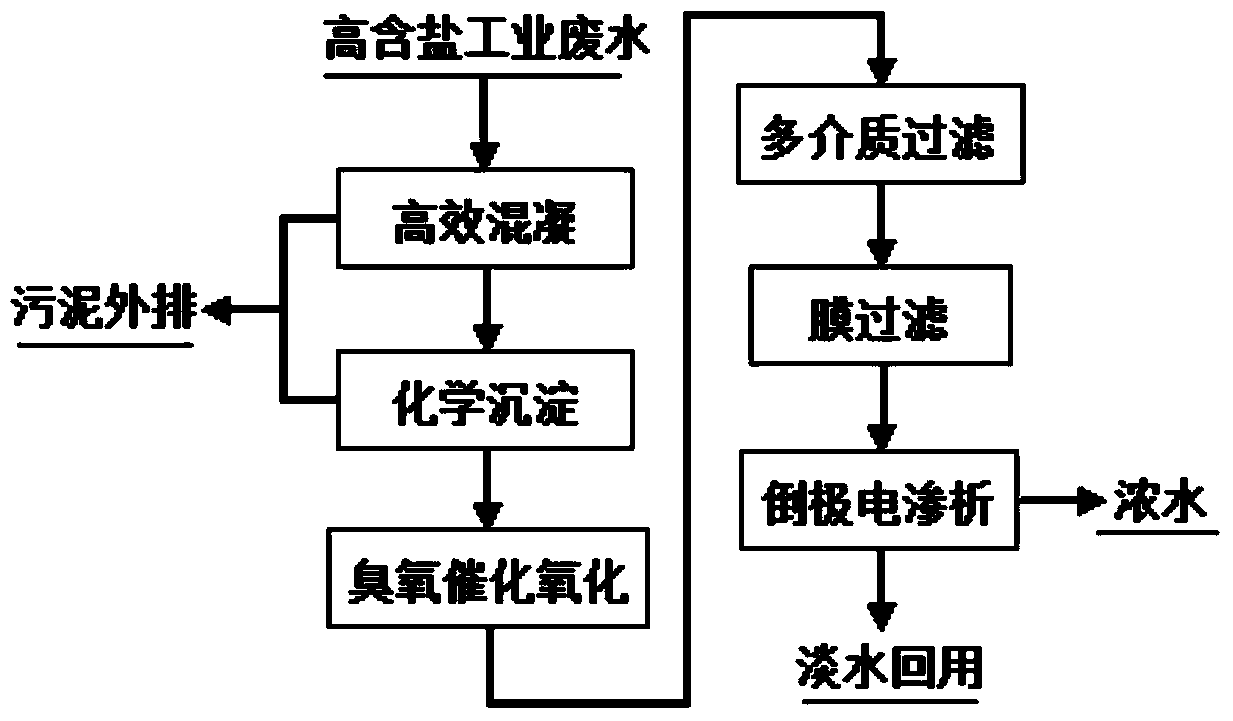

Method for deeply treating, desalting and recycling industrial wastewater with high salt content

ActiveCN104016530AImprove catalytic oxidation efficiencyGood removal effectMultistage water/sewage treatmentSuspended particlesFiltration

The invention relates to the field of industrial wastewater treatment processes and provides a method for deeply treating, desalting and recycling industrial wastewater with high salt content. The method comprises the following steps: 1) carrying out efficient coagulation treatment on the industrial wastewater with high salt content to obtain supernatant; 2) carrying out chemical precipitation on the supernatant obtained in the step 1) to remove high valence ions with valence higher than bivalence in the wastewater; 3) carrying out catalytic ozonation treatment on the supernatant subjected to chemical precipitation in the step 2); 4) carrying out multi-media filtration, precise filtration and membrane filtration treatment on the wastewater subjected to catalytic ozonation in the step 3) in sequence; and 5) carrying out electrodialysis reversal treatment on the effluent obtained after membrane filtration in the step 4). By adopting the method, organic matters, bacteria, colloids, suspended particles, Ca<2+>, Mg<2+> and high valence ions, other soluble inorganic salts and the like in the industrial wastewater with high salt content are removed by utilizing the coupling and synergistic effects of different unit technologies, thus achieving deep treatment, desalting and recycling of the industrial wastewater with high salt content.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

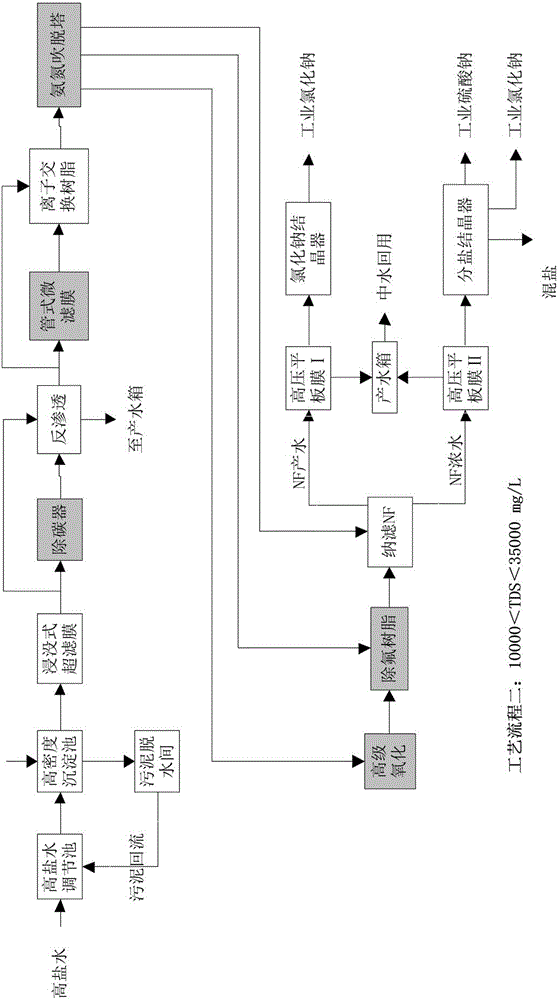

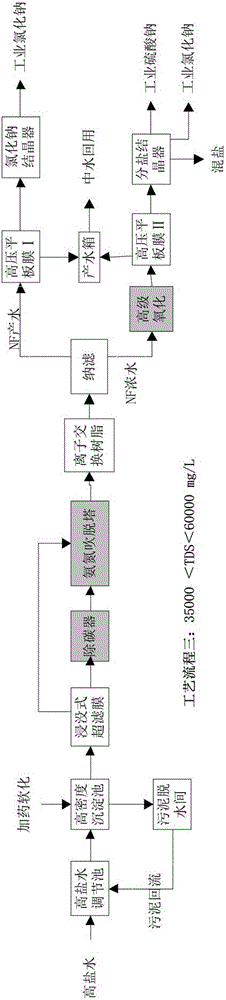

Intensified deep concentration system for high-salt-content industrial wastewater and technology thereof

InactiveCN105565569ARemove hardnessAlkalinity removalTreatment involving filtrationWater/sewage treatment by ion-exchangeHigh pressureIon-exchange resin

The invention discloses an intensified deep concentration system for high-salt-content industrial wastewater and a technology thereof and belongs to the field of water treatment. The high-salt-content industrial wastewater is adjusted through an adjusting tank, settled through a softening settling pond, filtered through a V-type filter tank, filtered through an ultrafiltration device in an intensified mode and concentrated through a first-stage reverse osmosis device, then the hardness is removed through an ion exchange resin device, and salt separation is performed through a nanofiltration device; thick water of the nanofiltration device is concentrated through a frequent electrode transfer electrodialysis device, produced water is oxidized through an advanced oxidization device and then enters a general produced water tank, and thick water is crystallized through a freezing crystallization system and crystallized with sodium sulfate; produced water of the nanofiltration device is concentrated through a second-stage reverse osmosis device and concentrated again through the frequent electrode transfer electrodialysis device, produced water is oxidized through the advanced oxidization device and enters the general produced water tank, and thick water is crystallized through an MVR evaporative crystallization device and crystallized with sodium chloride. The intensified deep concentration system has the advantages that potential safety hazards caused by high-pressure operation are effectively reduced; the problem that the COD content is high after thick salt water is highly concentrated is effectively solved, the purity of crystallized salt is improved, and the using value of the crystallized salt is improved; the system is high in automation degree, easy to operate, low in operation pressure, stable in operation, high in purity of the crystallized salt, low in operation cost and the like.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

Waste water biological treatment method for realizing anaerobic ammoxidation and methanation denitrification coupling

InactiveCN101058463ASave energySave organic carbon sourcesTreatment with aerobic and anaerobic processesIndustrial effluentMethanation

The invention discloses a biological disposing method of waste water through coupling the anaerobic ammonoxidation and methanation denitrification, which is characterized by the following: inoculating the particle sludge with methanation, denitrification and anaerobic ammonoxidation activity in the expansion grain sludge bed (EGSB); inoculating aerobic ammonoxidation bacteria in the biological aerating filter (BAF) or SHARON technique or SBR reactor; connecting the EGSB reactor and BAF or SHARON technique or SBR reactor; realizing the biological disposal of waste water through controlling pH value, temperature, dissolved oxygen, external reflow rate, load velocity, oxidizing reducing potential and organic COD density, ammonia nitrogen density.

Owner:CHONGQING UNIV

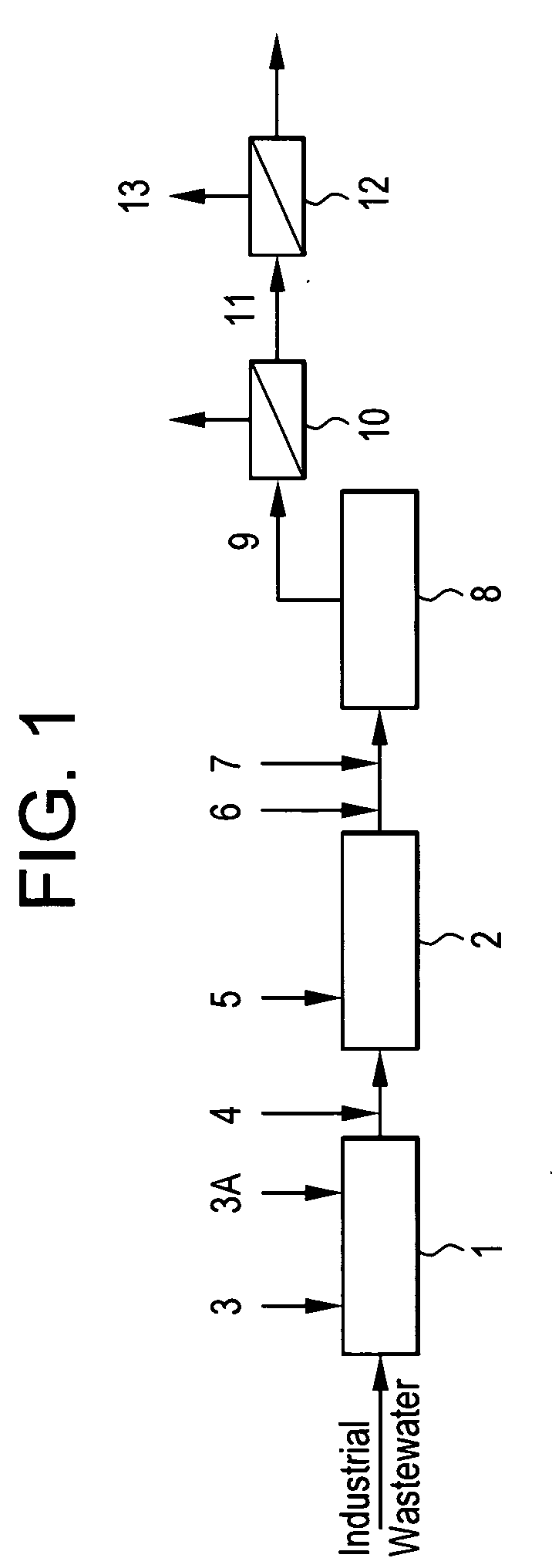

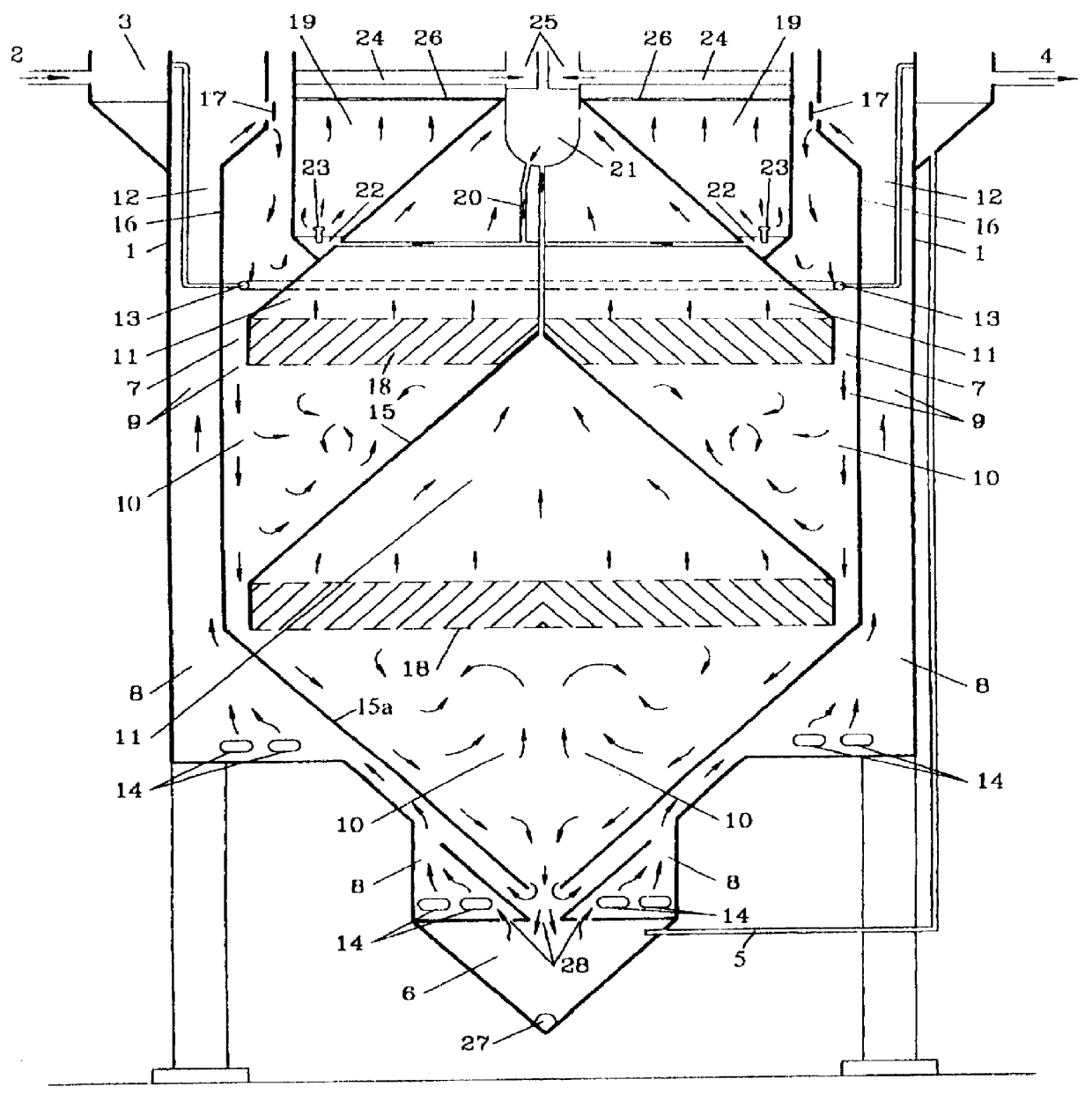

Integrated up-flow reactor and advanced treatment method of fermentation industrial effluent

InactiveCN101698555AImprove biodegradabilityPromote degradationTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentRetention timeTreatment field

The invention discloses an integrated up-flow reactor and an advanced treatment method of fermentation industrial effluent, belonging to effluent treatment field. The upper part of the reactor is an aerobic fluidized bed system, the lower part is an anaerobic filter system, the intermediate transition zone is designed to be a connecting part which has a tri-phase separation function and organically combines the upper part and the lower part together. In the reactor, the concentration of biological solid is high and the retention time of biological solid is long, therefore the reactor is suitable for treating secondary biochemical treatment effluent of fermentation industrial effluent which has high salinity and is difficult to be biodegraded; sludge output of each system is low, and the residual sludge generated in the aerobic zone enters to the transition zone and the anaerobic zone to be further treated, the overall sludge output of the reactor is low, and simultaneously, the reactor contains rich biological species which act on organics difficult to be degraded jointly and promote the degradation thereof. The integrated reactor has low energy consumption, less land occupation, convenient operation, load impact resistance and high treatment efficiency, thereby being applicable to the advanced treatment of fermentation industrial effluent.

Owner:NANJING UNIV

Removing mercury and other heavy metals from industrial wastewater

InactiveUS20080197075A1Sludge treatment by de-watering/drying/thickeningMembranesIndustrial effluentFiltration

A method of removing one or more heavy metals including mercury from industrial wastewater by use of a filtration and / or a solid-liquid separation system by use of a water soluble ethylene dichloride ammonia polymer.

Owner:ECOLAB USA INC

Using knowledge pattern search and learning for selecting microorganisms

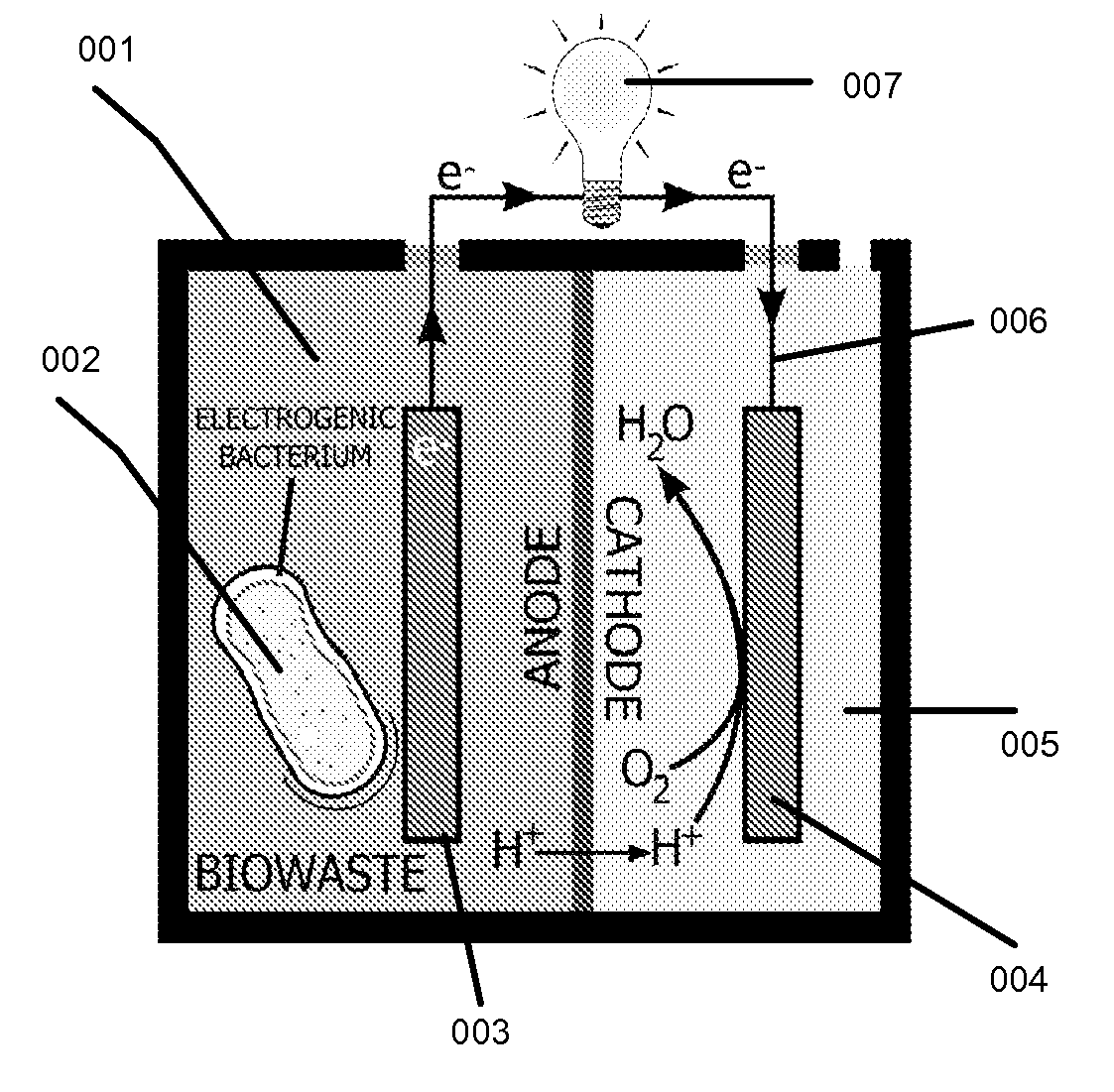

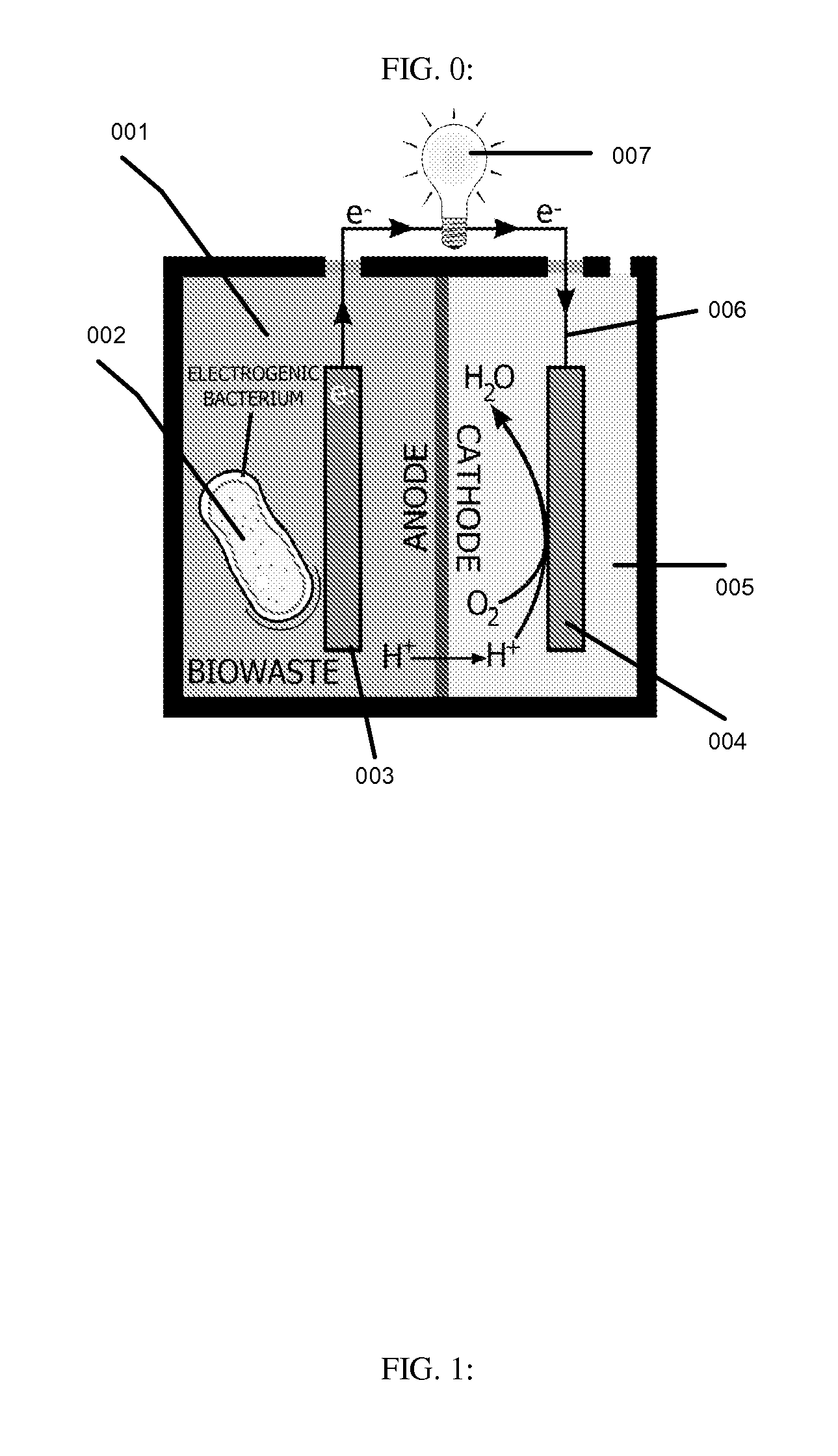

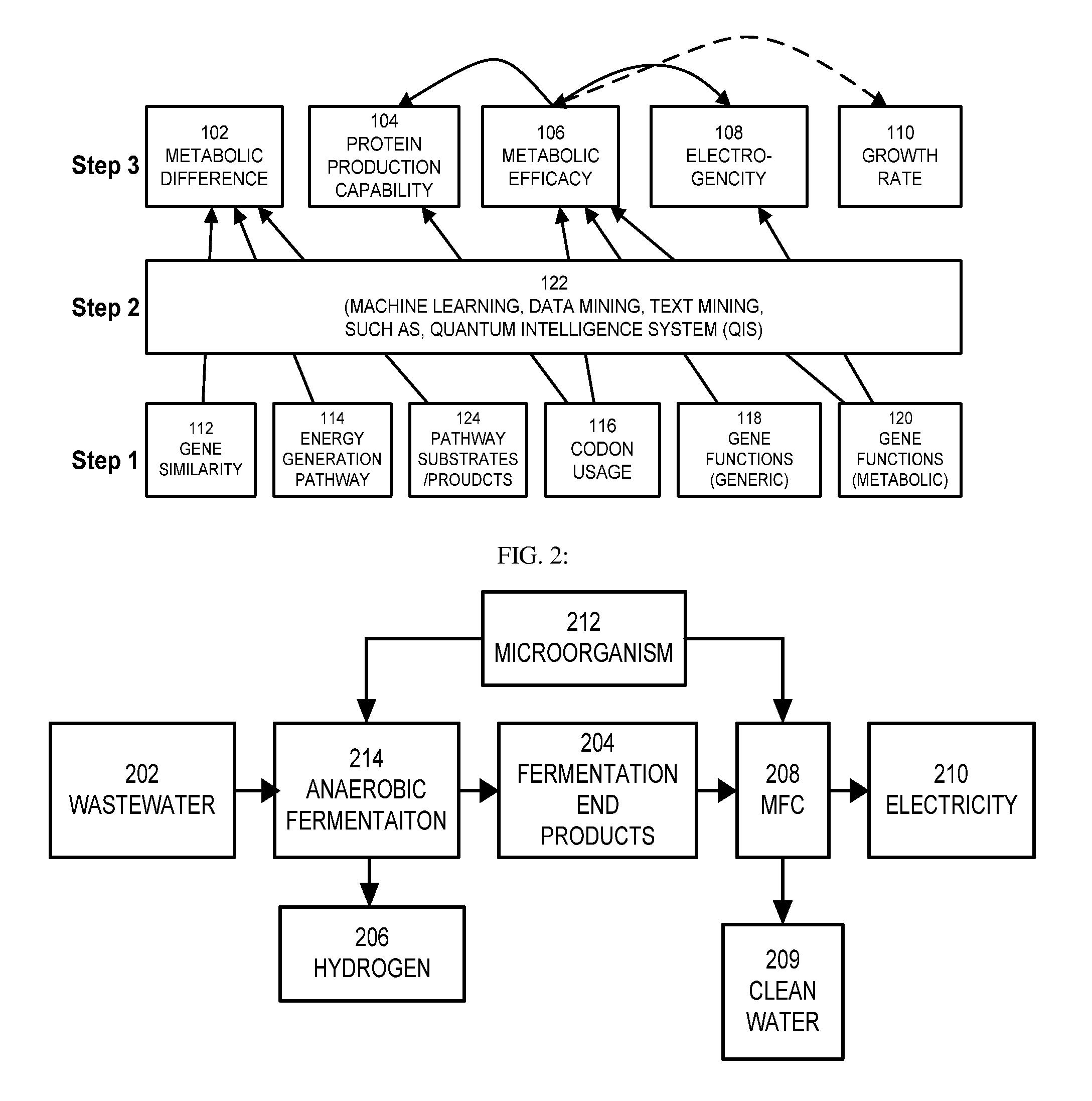

InactiveUS20080090736A1Recover clean energyMost efficientMicrobiological testing/measurementLibrary screeningScreening methodClean energy

This invention is to use knowledge pattern learning and search system for selecting microorganisms to produce useful materials and to generate clean energy from wastes, wastewaters, biomass or from other inexpensive sources. The method starts with an in silico screening platform which involves multiple steps. First, the organisms' profiles are compiled by linking the massive genetic and chemical fingerprints in the metabolic and energy-generating biological pathways (e.g. codon usages, gene distributions in function categories, etc.) to the organisms' biological behaviors. Second, a machine learning and pattern recognition system is used to group the organism population into characteristic groups based on the profiles. Lastly, one or a group of microorganisms are selected based on profile match scores calculated from a defined metabolic efficiency measure, which, in term, is a prediction of a desired capability in real life based on an organism's profile. In the example of recovering clean energy from treating wastewaters from food process industries, domestic or municipal wastes, animal or meat-packing wastes, microorganisms' metabolic capabilities to digest organic matter and generate clean energy are assessed using the invention, and the most effective organisms in terms of waste reduction and energy generation are selected based on the content of a biowaste input and a desired clean energy output. By selecting a microorganism or consortia of multiply microorganisms using this method, one can clean the water and also directly generate electricity from Microbial Fuel Cells (MFC), or hydrogen, methane or other biogases from microorganism fermentation. In addition, using similar screening method, clean hydrogen can be recovered first from an anaerobic fermentation process accompanying the wastewater treatment, and the end products from the fermentation process can be fed into a Microbial Fuel Cell (MFC) process to generate clean electricity and at the same time treat the wastewater. The invention can be used to first select the hydrogenic microorganisms to efficiently generate hydrogen and to select electrogenic organisms to convert the wastes into electricity. This method can be used for converting wastes to one or more forms of renewable energies.

Owner:QUANTUM INTELLIGENCE

Method for high temperature mercury capture from gas streams

ActiveUS7033419B1Maintain thermal efficiencyIncrease temperatureGas treatmentOther chemical processesIridiumSorbent

A process to facilitate mercury extraction from high temperature flue / fuel gas via the use of metal sorbents which capture mercury at ambient and high temperatures. The spent sorbents can be regenerated after exposure to mercury. The metal sorbents can be used as pure metals (or combinations of metals) or dispersed on an inert support to increase surface area per gram of metal sorbent. Iridium and ruthenium are effective for mercury removal from flue and smelter gases. Palladium and platinum are effective for mercury removal from fuel gas (syngas). An iridium-platinum alloy is suitable for metal capture in many industrial effluent gas streams including highly corrosive gas streams.

Owner:THE UNITED STATES AS REPRESENTED BY THE DEPARTMENT OF ENERGY

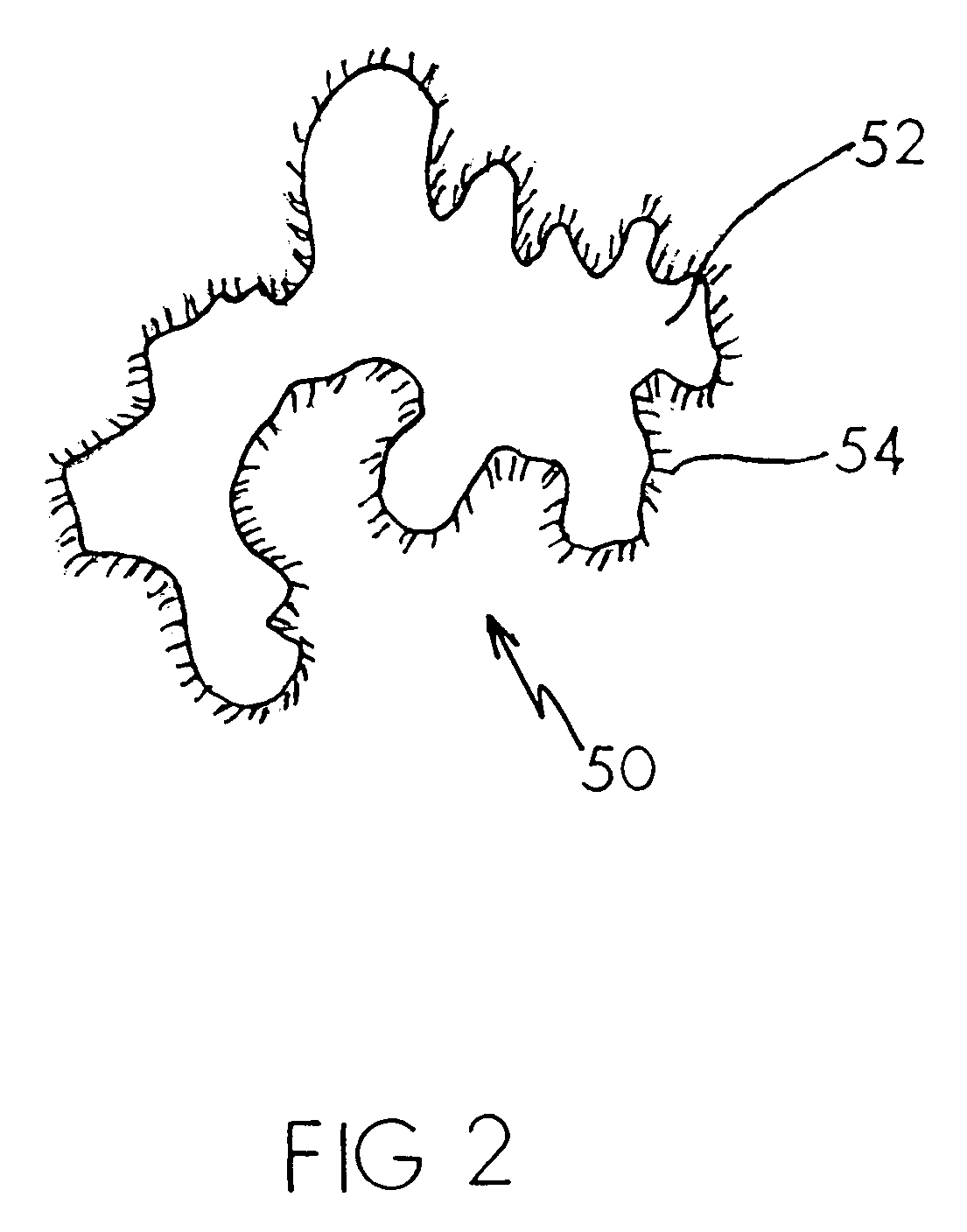

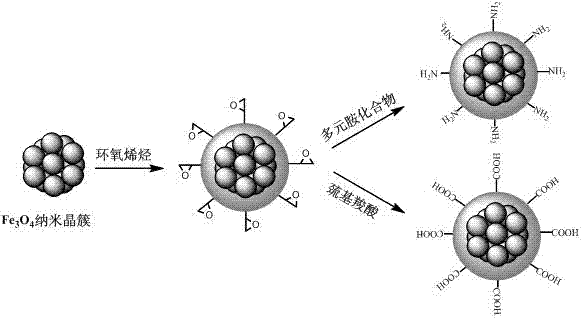

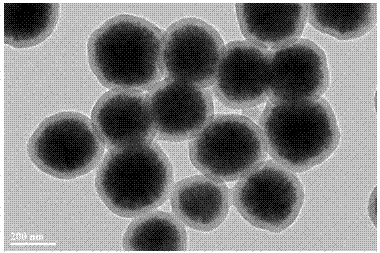

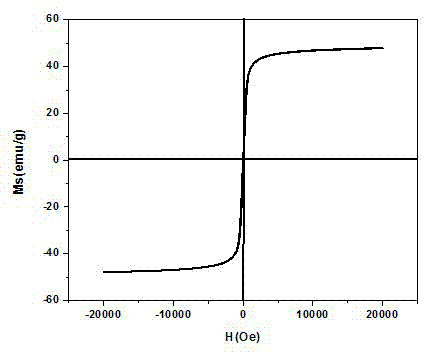

Preparation method of functional magnetic absorbent used for treating industrial wastewater

InactiveCN103285838AMagnetic content controllableUniform structureOther chemical processesAlkali metal oxides/hydroxidesEpoxyMicrosphere

The invention discloses a preparation method of a functional magnetic absorbent used for treating industrial wastewater. The method comprises the following four steps of: (1) preparing a ferroferric oxide nanocluster with a high magnetic saturation value by solvothermal synthesis; (2) modifying the ferroferric oxide nanocluster surface into a double-bond functional group by adopting a sol-gel process; (3) wrapping the ferroferric oxide nanocluster surface with a polymer shell containing an epoxy functional group in a distilling, precipitating and polymerizing manner; and (4) modifying a microsphere surface into an amino group or a carboxyl group through a ring-opening reaction of the epoxy group. The magnetic absorbent is high in functional group content, fast in magnetic responsiveness, easy for magnetic separation, regular in structure, stable in chemical and physical performances and high in dispersion stability in an aqueous solution; and the surface-modified amino and carboxyl functional groups can efficiently adsorb a plurality of heavy metals or organic pollutants, so that the magnetic absorbent can be applied to the field of industrial wastewater treatment. The preparation method is simple to operate and controllable in process and has a good application prospect.

Owner:JINGDEZHEN CERAMIC INSTITUTE

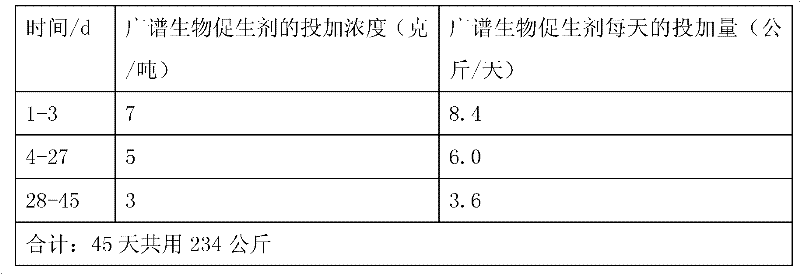

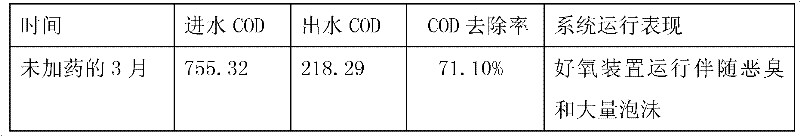

Broad-spectrum bio-energizer for industrial wastewater treatment and preparation method thereof

ActiveCN102515364AReduce processing costsPromote growthBiological water/sewage treatmentDecompositionWater quality

The invention relates to the technical field of industrial wastewater biochemical treatment and discloses a broad-spectrum bio-energizer for industrial wastewater treatment. The broad-spectrum bio-energizer contains the following components of: by weight, 1 part of enzyme, 0.15-0.4 part of a micro-element nutrition, 0.15-0.4 part of hormone, 1.5-2.5 parts of organic acid, 2.5-3 parts of a nitrogen nutrition and 0.8-1.2 parts of a phosphorus nutrition. The broad-spectrum bio-energizer can be used to promote rapid growth of various bacteria and fungi in a complex environment, promote the pollutant decomposition ability of microorganisms, raise an industrial wastewater biochemical treatment system's capability of recovering fluctuation of water quality and quantity and improve treatment efficiency of the system.

Owner:普罗生物技术(上海)有限公司

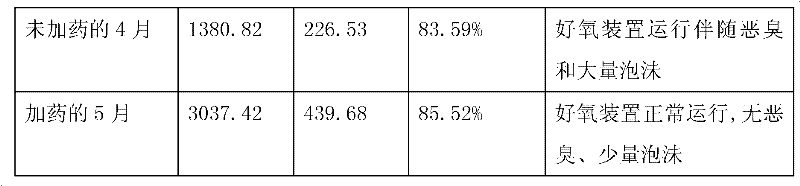

Method and device for treating high-salt refractory organic wastewater

PendingCN106495386AHigh thermal efficiencyReduce energy consumptionWater contaminantsMultistage water/sewage treatmentHigh concentrationVapor liquid

The invention discloses a method and a device for treating high-salt refractory organic wastewater, and particularly relates to a method and a device for treating high-concentration refractory COD and high-salt industrial wastewater by coupling the catalytic wet oxidation and MVR evaporation and concentration crystallization technology. The device comprises a vapor-liquid heat exchanger, a liquid-liquid exchanger, a booster pump (or a circulating pump), a compression fan, an oxidant dosing device, a wet catalytic oxidation reactor (WAO), an evaporator, a vapor compressor and a vapor-water separator. Raw water is subjected to air catalytic wet oxidation in the WAO reactor after two-stage preheating through the vapor-liquid heat exchanger and the liquid-liquid exchanger; the oxidized wastewater is evaporated and concentrated by an evaporator to obtain crystalline salt and the distilled water. The method and the device provided by the invention combine advantages of a wet oxidation technology and an MVR technology, effectively degrade organic matters, improve biodegradability of wastewater, and realize effective utilization of heat energy generated by WAO oxidation reaction and secondary vapor of the evaporator.

Owner:HUNAN PINGAN ENVIRONMENT PROTECTION

Method and apparatus for treating contaminated water

InactiveUS6159365AHigh purityIncrease mass concentrationTreatment using aerobic processesWater contaminantsIndustrial effluentNatural water

A method and apparatus for treating contaminated water are described wherein contaminated natural water or industrial wastewater is treated to remove contaminants in a packaged modular treatment unit.

Owner:AMERICAN ENVIROCARE

Method of deep desalting and recycling of industrial effluent

ActiveCN102452751AGuaranteed uptimeAvoid the problem of susceptibility to incoming water organic contaminationGeneral water supply conservationMultistage water/sewage treatmentElectricityIndustrial effluent

The invention provides a method of deep desalting and recycling of industrial effluent. The method is characterized in that industrial effluent to be treated is treated with a hardness reducing operating unit, an efficient filtering operating unit and an electro-adsorption desalting operating unit to reach a standard of recycling water. The method comprises specific steps of: a. hardness reduction, precipitation and neutralization; b. efficient filtering; and c. electro-adsorption desalting. The provided method of deep desalting and recycling of industrial effluent requires no equipment of electroosmosis or reverse osmosis membrane, or ion exchange resin, keeps stable operation of the system under a condition of water quality conductivity higher than 2500 muS / cm and does not scale; and an outlet water quality satisfies water quality requirements on recycling water replenishment. Discharge secondary industrial effluent with water quality conductivity lower than 4500 muS / cm can be treated to reach water replenishment requirements of an industrial recycling water system. The method is suitable for chemical effluent, printing and dyeing effluent, spinning effluent and oil refining effluent and has wide water quality scope of application, stable technology operation and high desalting efficiency.

Owner:CHINA PETROLEUM & CHEM CORP

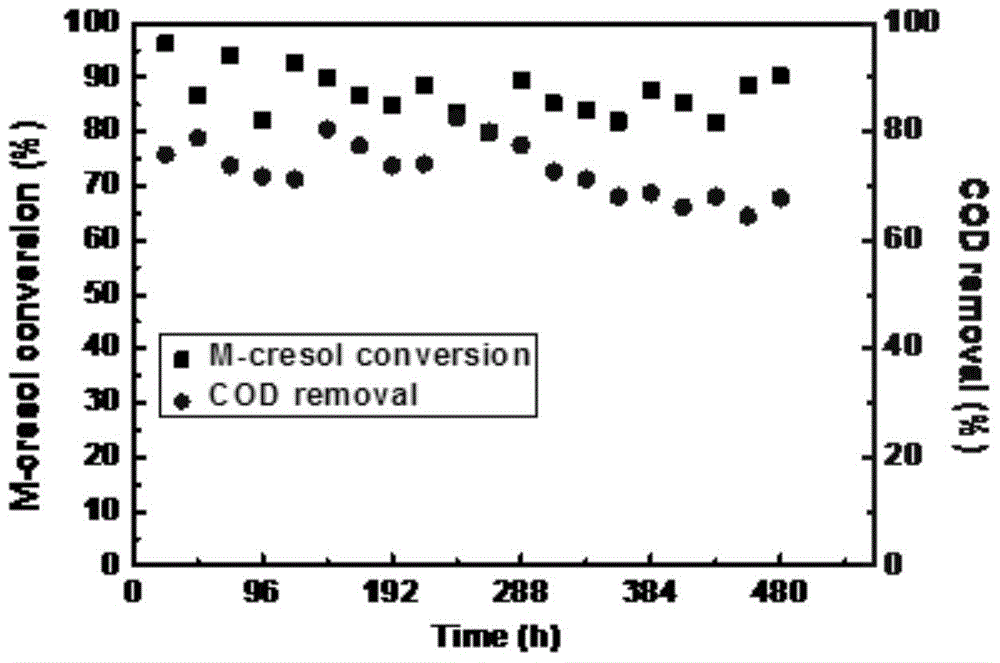

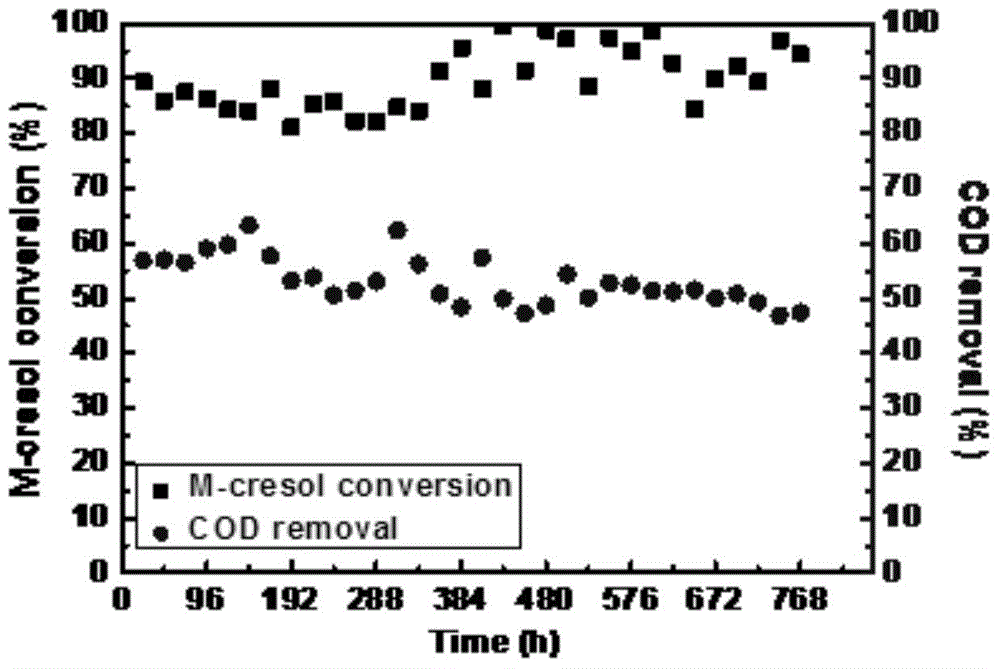

Activated carbon catalyst used for Fenton-like technology, and preparation and application thereof

InactiveCN104923229ALow priceEfficient degradationWater contaminantsMetal/metal-oxides/metal-hydroxide catalystsRare-earth elementActivated carbon

The invention relates to an activated carbon catalyst used for treating refractory organic wastewater with a Fenton-like technology, and preparation and application thereof. The catalyst is prepared by using an isopyknic impregnation method with transition metals - Cu, Fe, Ni and Mn or rare earth elements as active components and formed activated carbon as a carrier; and the catalyst is mainly used for treating refractory organic wastewater, or wastewater failing to achieve standards after treated by using a biochemical method. The activated carbon catalyst provided by the invention treats the wastewater at room temperature without adjustment of the pH value of the wastewater, wherein the concentration ratio of H2O2 (mg / L) to COD (mg / L) is 0.3 to 1.5, and airspeed is 0.5 to 2.0 h<-1>. According to the invention, COD removal rate is greater than 50%; BOD5 / COD indexes of the wastewater before and after treatment is significantly enhanced; biodegradability of the wastewater is improved; and the catalyst is capable of continuously operating for more than 700 hours with unchanged catalytic activity, and can be popularized in industrial application of treating industrial wastewater, specifically the refractory organic wastewater, by using the Fenton-like method.

Owner:DALIAN INST OF CHEM PHYSICS CHINESE ACAD OF SCI

Technological process and apparatus for advanced oxidation degradation of nitrobenzene wastewater

ActiveCN101462788AReduce processing costsBiochemical effectWater contaminantsWater/sewage treatment with mechanical oscillationsDetonatorElectrolysis

The invention belongs to the technical field of nitrobenzene class wastewater treatment and in particular relates to a process method for advanced oxidation and degradation of nitrobenzene class wastewater. The invention solves the problem that the prior method for degrading nitrobenzene class wastewater has long time consumption and high cost. The method comprises that: wastewater and ozone undergo full haptoreaction in gas-liquid mass transfer equipment; after the haptoreaction, the wastewater enters a coupling reactor consisting of an ultrasonic wave field and an electrolysis field; and nitrobenzene class substances in the wastewater are degraded under the synergistic action of ultrasonic wave and micro-electrolysis. The device comprises the gas-liquid mass transfer equipment; a gas inlet of the gas-liquid mass transfer equipment is connected with an ozone generator; a liquid inlet of the gas-liquid mass transfer equipment is connected with a nitrobenzene class wastewater pool; a liquid outlet of the gas-liquid mass transfer equipment is connected with the wastewater coupling reactor; and the bottom of the wastewater coupling reactor is provided with an ultrasonic wave generator. The process method has the following advantages: the process method has simple process flow and convenient operation, farthest reduces treatment cost and can be applied to various organic industrial wastewater such as phenol-containing wastewater, detonator wastewater, dye wastewater, wastewater in a petrochemical enterprise, detergent wastewater and the like.

Owner:ZHONGBEI UNIV

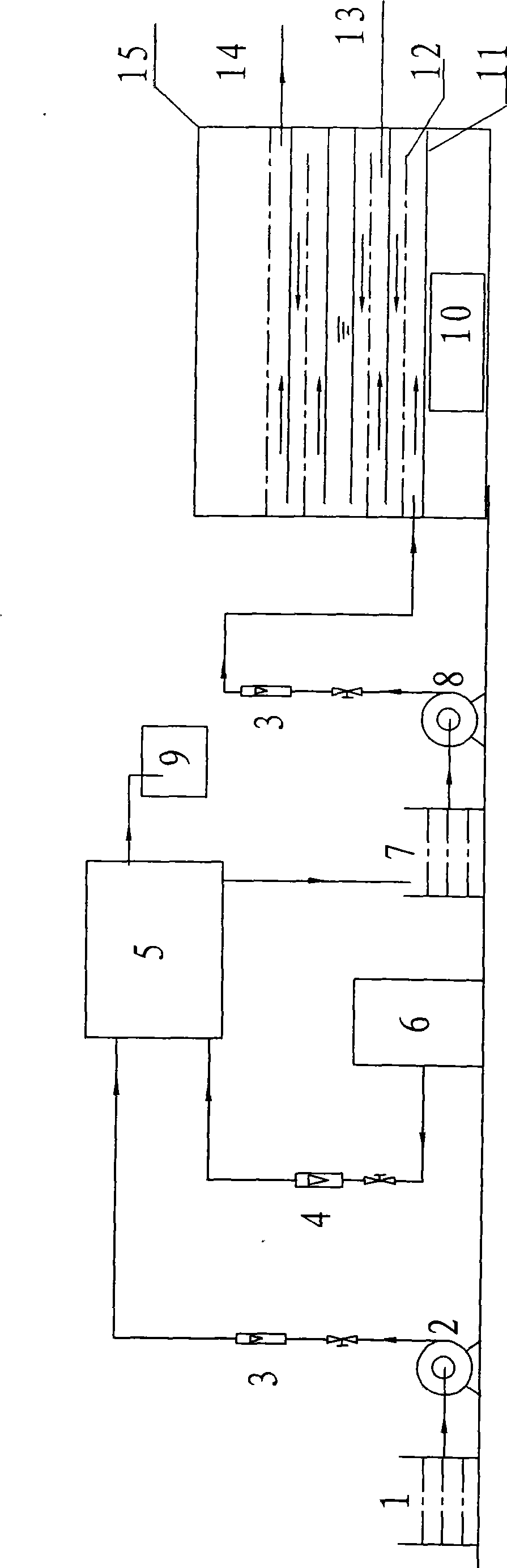

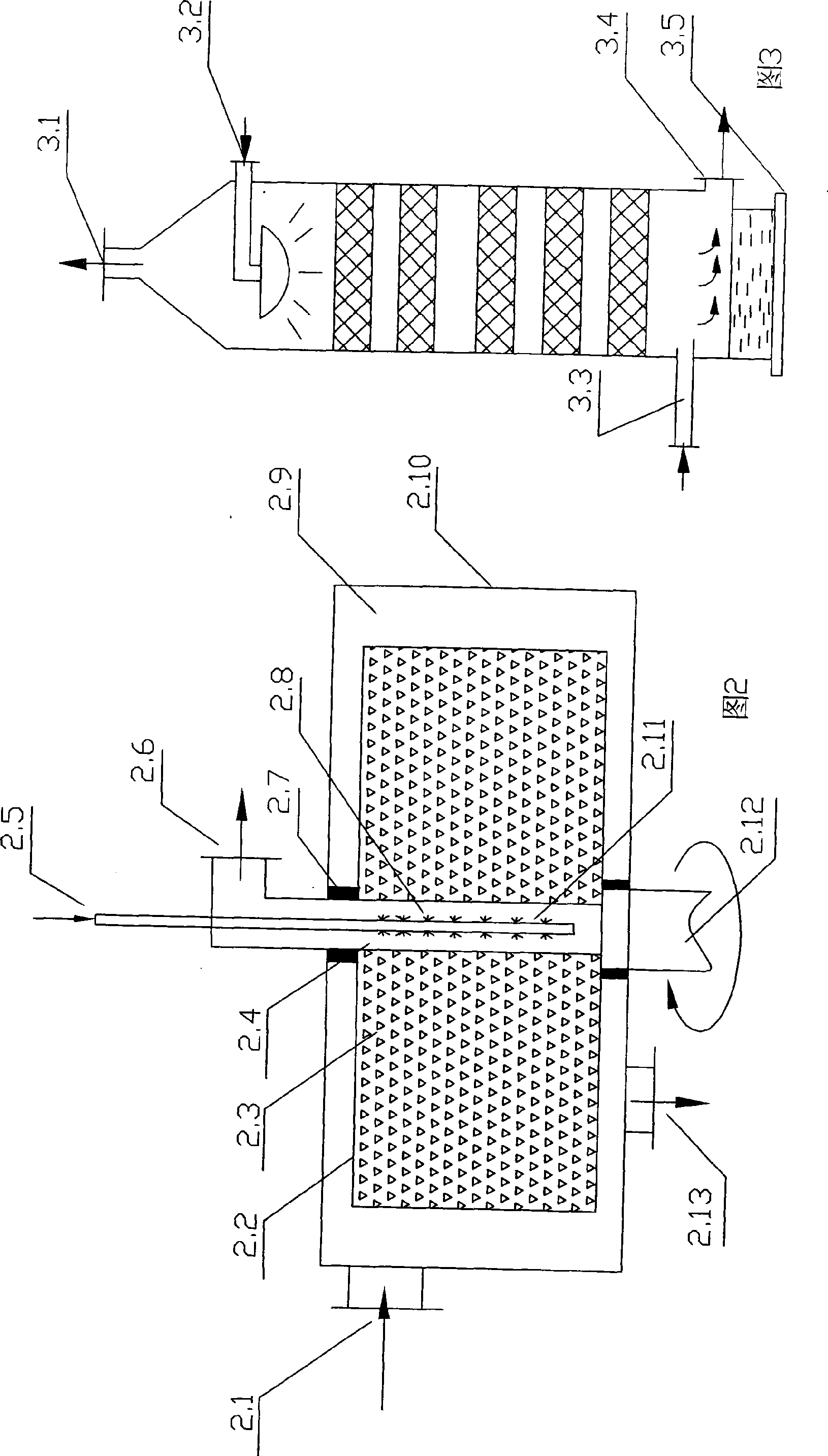

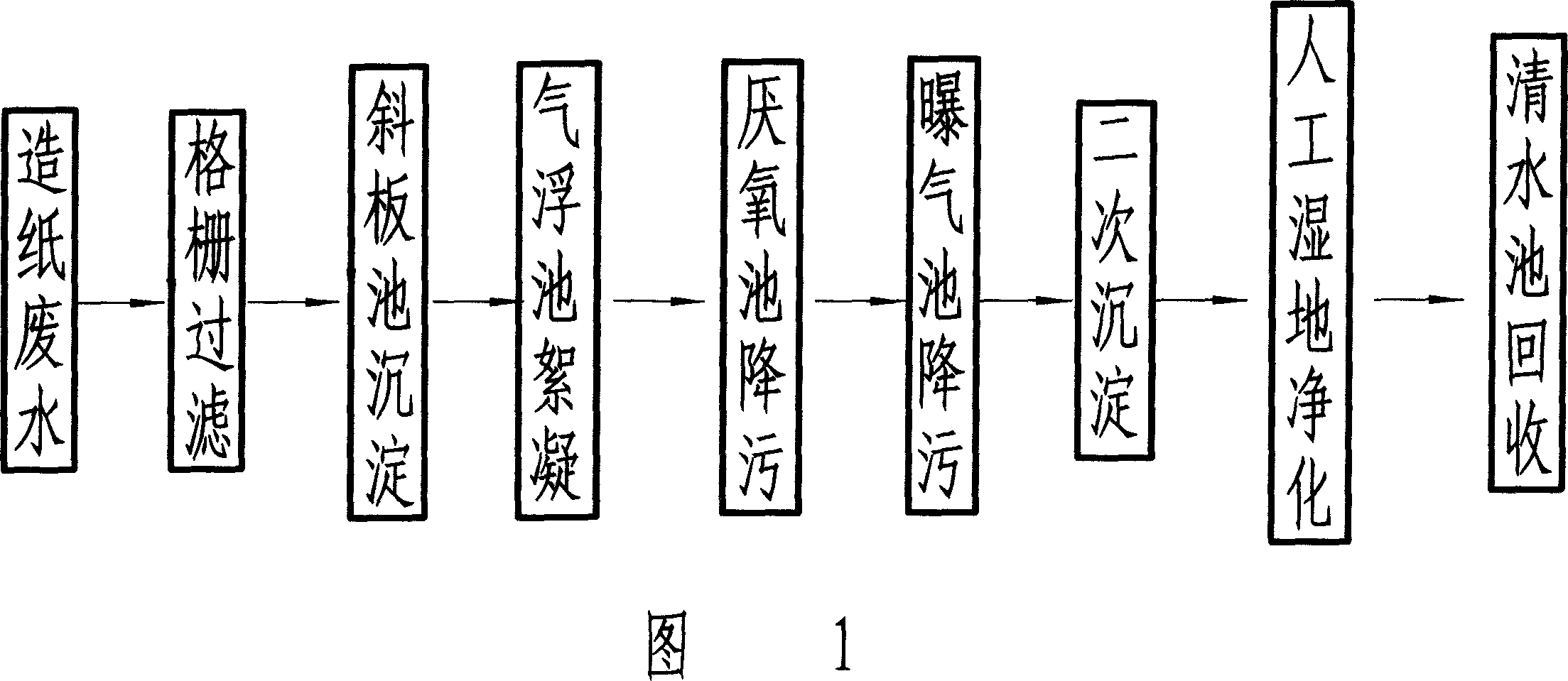

Method for processing paper-making waste water of regenerative paper

InactiveCN101077817AMeet the requirements of emission standardsSS reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandFiber

The process of treating effluent from making paper with waste paper belongs to the field of industrial effluent treating technology, and aims at lowering the harmful matter content in the effluent from making paper with waste paper to reach the exhaust standard. The process includes the first passing the effluent through grating to filter out fiber and suspended matter, the subsequent settling in a sloping plate settling tank to eliminate granular impurity, flocculating in an air floating tank with flocculant and fishing out the resultant suspended matter, anaerobic reaction in an anaerobic settling tank, treating with introduced air and active sludge in an aeration tank and eliminating suspended matter and colloidal matter, clarifying in a settling tank, and treating in artificial wetland to eliminate nitrogen and phosphate and obtain clear water. The process can reduce SS, BOD5 and CODcr of the effluent obviously and make the effluent reach draining standard.

Owner:云南恒昌造纸有限责任公司

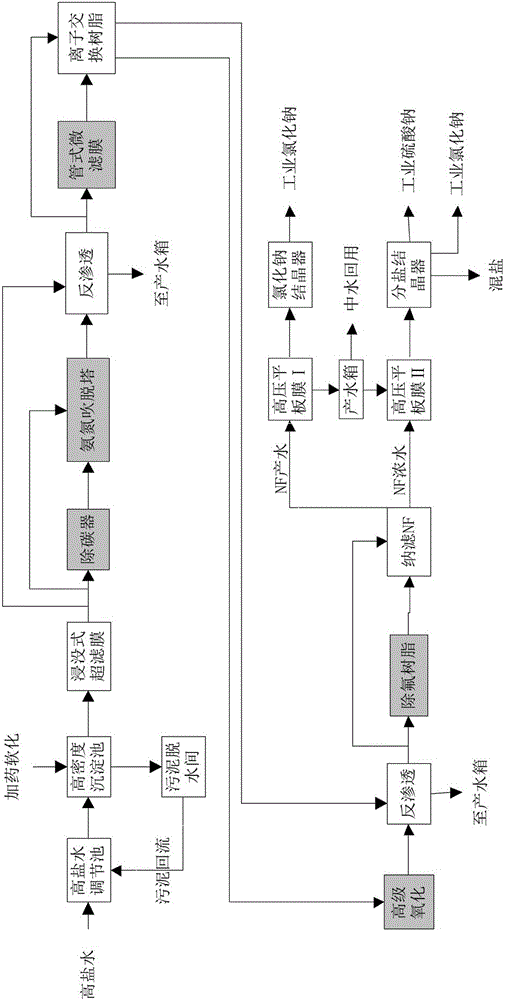

Device and method for treating industrial wastewater with high salt content

InactiveCN106396228AHigh recovery rateAchieving zero emissionsGeneral water supply conservationWater/sewage treatment by ion-exchangeFiltrationIon exchange

The invention provides a method for treating industrial wastewater with a high salt content. The method includes steps of pretreating the industrial wastewater with the high salt content, to be more specific, regulating and homogenizing the industrial wastewater with the high salt content by the aid of a high-salinity water regulating tank, then feeding the industrial wastewater into a high-density sedimentation tank, carrying out chemical softening treatment and flocculation sedimentation on the industrial wastewater, simultaneously removing most silicon dioxide and suspended matters, feeding water treated by the high-density sedimentation tank into an immersed ultra-filtration tank and further removing suspended matters and colloidal impurities in the water; carrying out separation and concentration, to be more specific, concentrating and separating the industrial wastewater with the high salt content after the industrial wastewater is pretreated at the pretreatment step, or carrying out ion exchange treatment on the industrial wastewater; recycling crystals, and to be more specific, separating the sodium chloride crystals and the sodium sulfate crystals from the water by the aid of crystallizers. The invention further provides a device for treating the industrial wastewater with the high salt content.

Owner:INNER MONGOLIA JIUKE KANGRUI ENVIRONMENTAL TECH

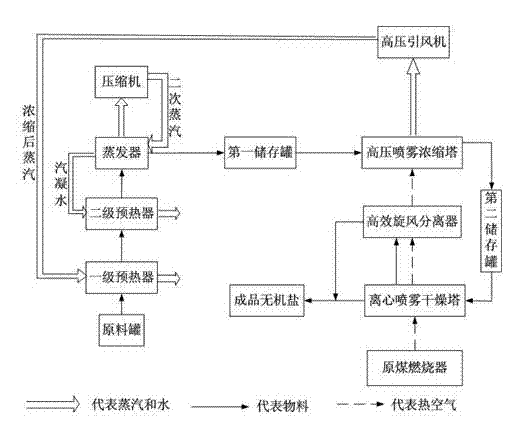

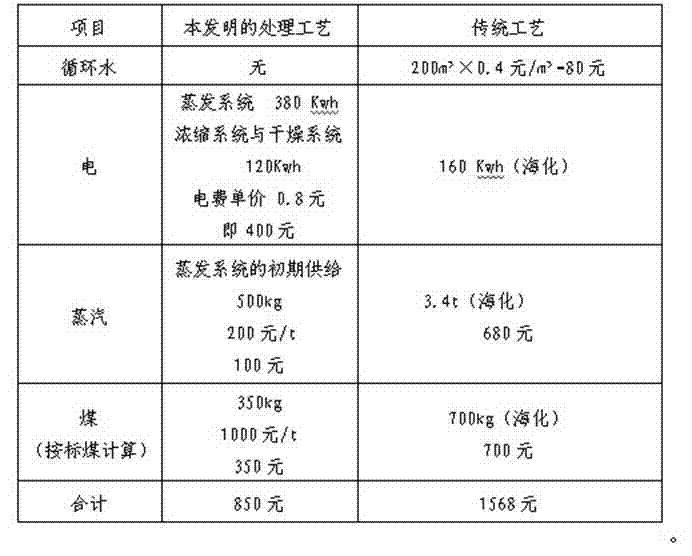

Energy-saving evaporation treatment process of high-salinity wastewater

ActiveCN102964019AStrong adsorption and removal abilityHigh purityCalcium/strontium/barium chloridesMultistage water/sewage treatmentInorganic saltsIndustrial effluent

The invention provides an energy-saving evaporation treatment process of high-salinity wastewater. The energy-saving evaporation treatment process comprises an evaporating system, a concentrating system, a drying system and a heat circulating system. Grading preheating, heating evaporation, adsorption purification, concentration, adsorption purification and high-temperature drying are successively carried out on the high-salinity wastewater treated by a wastewater treatment system to obtain the finished product of inorganic salt, heat exhausted in the evaporation, concentration and drying processes is recycled, and wastewater is discharged. By adopting the technical scheme, wastewater discharged finally meets the national industrial wastewater discharge standard, the purity of the obtained inorganic salt is as high as 99.3%, and the energy-saving effect is remarkable.

Owner:山东大明消毒科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com