Patents

Literature

107results about How to "Meet the requirements of emission standards" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Waste water treatment system and method for power plant

ActiveCN101891330AAvoid influenceMeet the requirements of emission standardsMultistage water/sewage treatmentEmission standardEvaporation

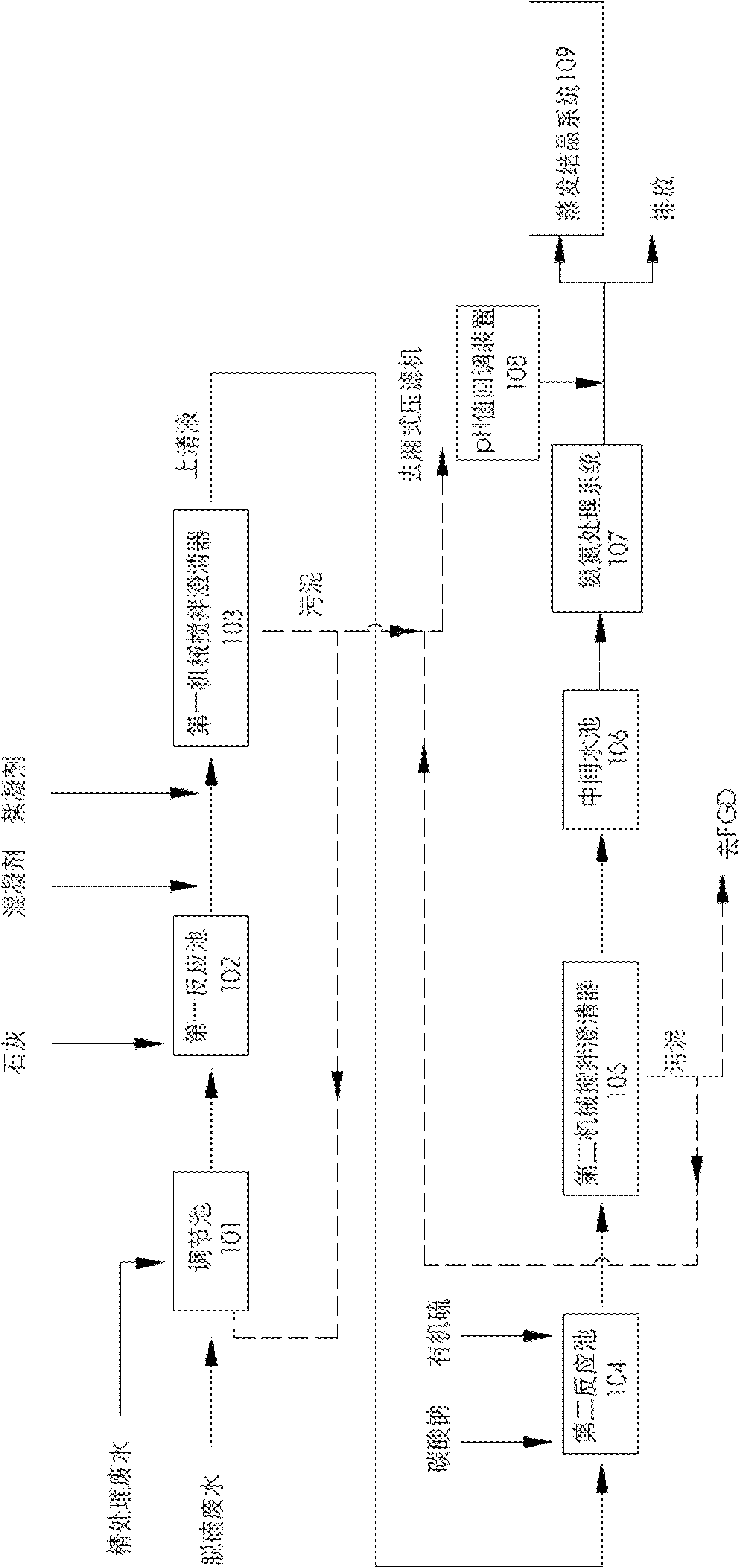

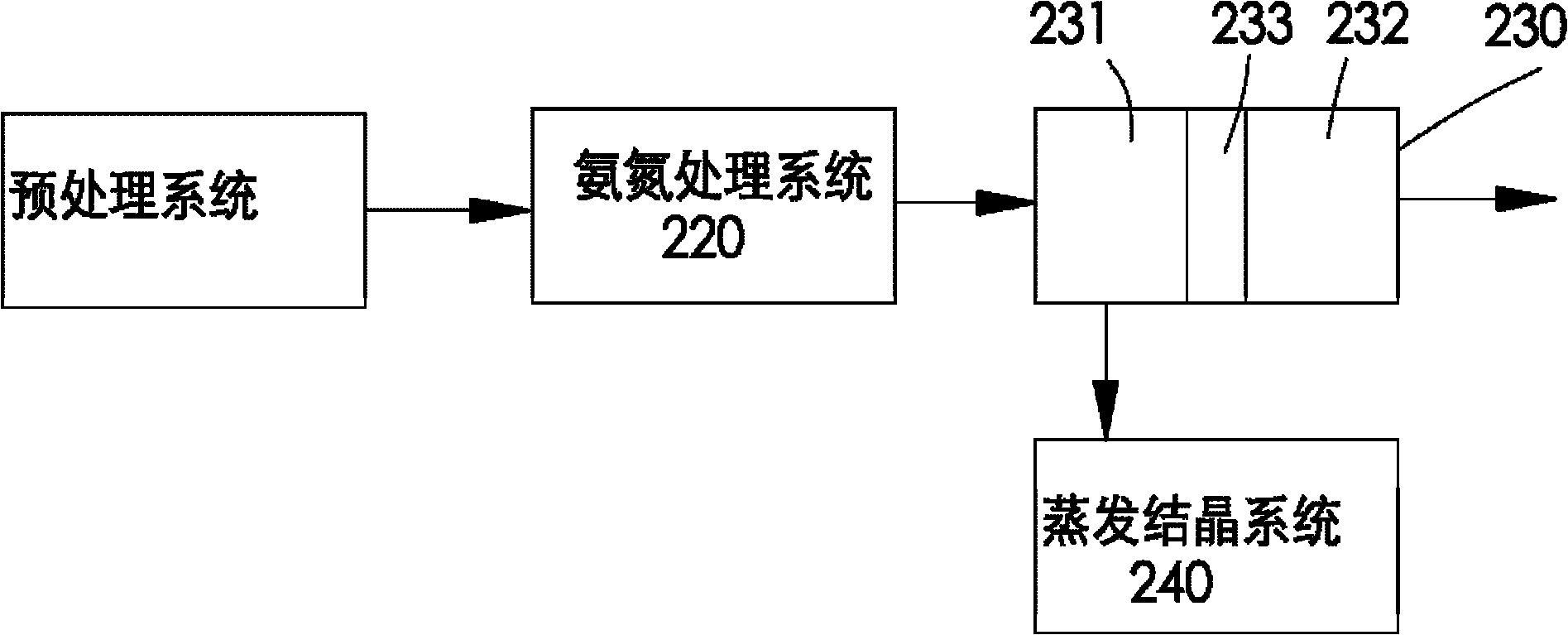

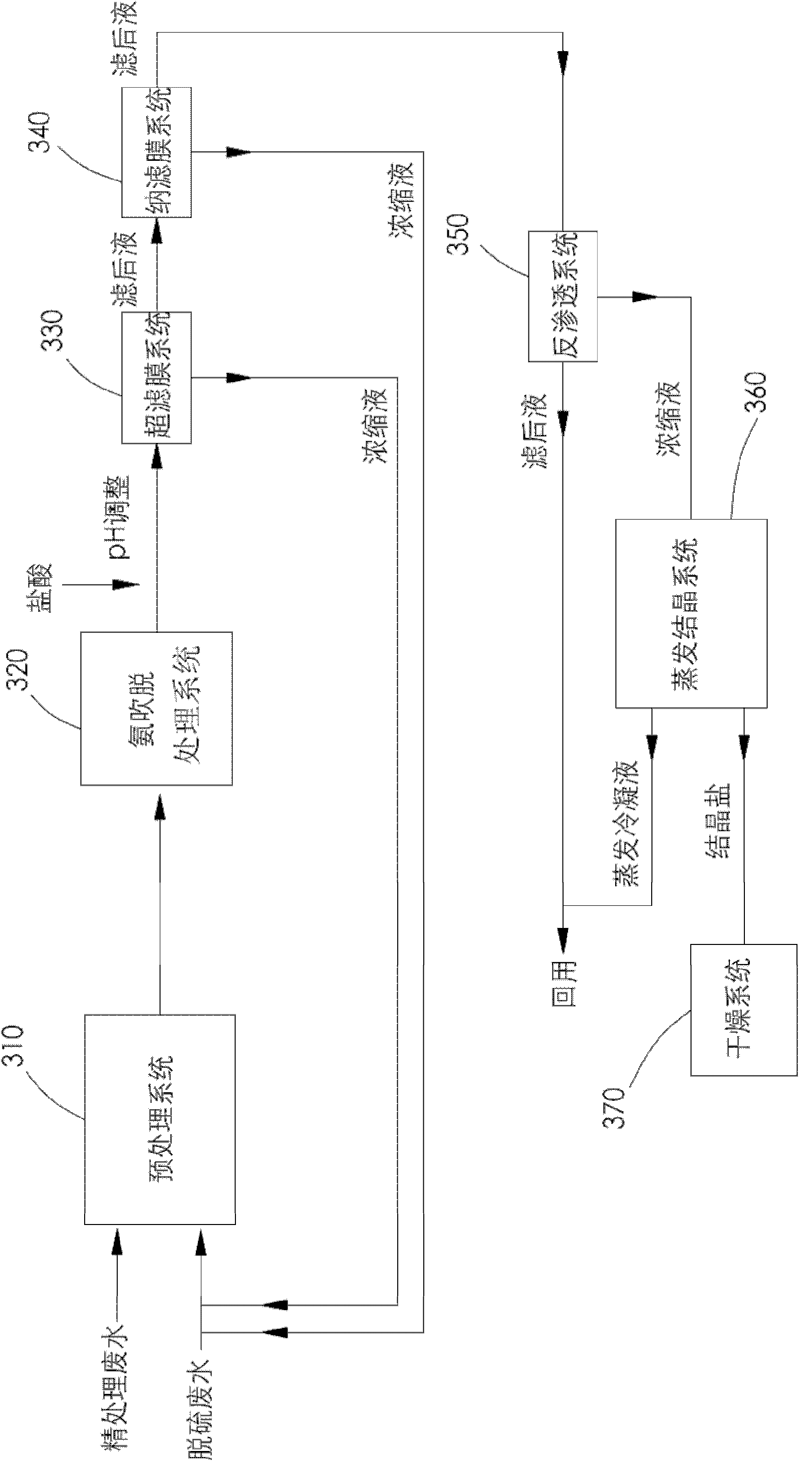

The invention relates to a waste water treatment system and a waste water treatment method for a power plant. The system comprises a pre-treatment system, an evaporation and crystallization system, an ammonia nitrogen treatment system and a membrane condensation and treatment system, wherein the pre-treatment system is connected to waste water of the power plant; the ammonia nitrogen treatment system is connected between the pre-treatment system and the evaporation and crystallization system and connected to waste water treated by the pre-treatment system; and the membrane condensation and treatment system is arranged between the ammonia nitrogen treatment system and the evaporation and crystallization system. A small amount of ammonia nitrogen in system water is removed or the ammonia nitrogen content of the system water is lowered by using the ammonia nitrogen treatment system; the NH3 content of blow-off tail gas produced after blow-off is very low and fully meets the requirement of national atmospheric pollutant emission standard; and the ammonia nitrogen content of water is lowered by a blow-off method (or an oxidation method) so that running cost is lowered. Moreover, the concentration of waste water can be increased by membrane condensation and treatment technology and crystallization can be performed, so that the steam consumption of the evaporation and crystallization system and the running cost are reduced; and the NaCl content of crystal salt is increased so that the crystal salt reaches the quality standard of industrial salt and the aim of recycling waste materials is fulfilled.

Owner:SHENZHEN ENERGY ENVIRONMENT ENG

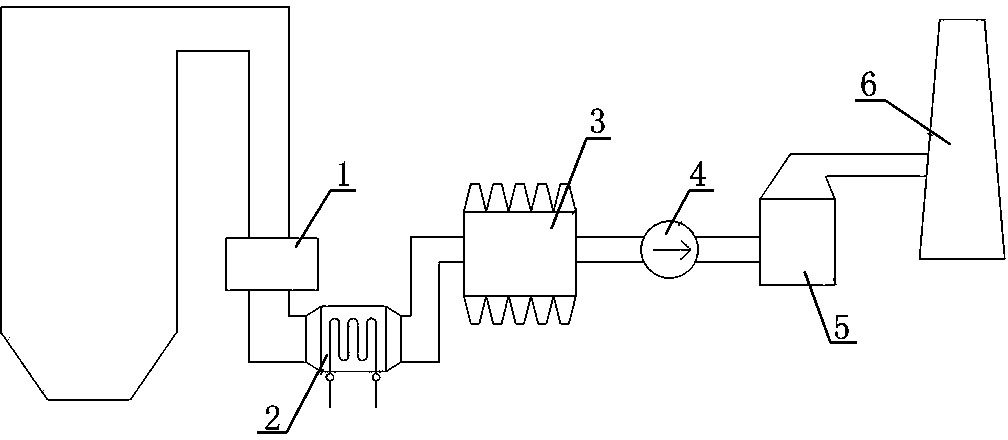

Method for processing paper-making waste water of regenerative paper

InactiveCN101077817AMeet the requirements of emission standardsSS reductionTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentConstructed wetlandFiber

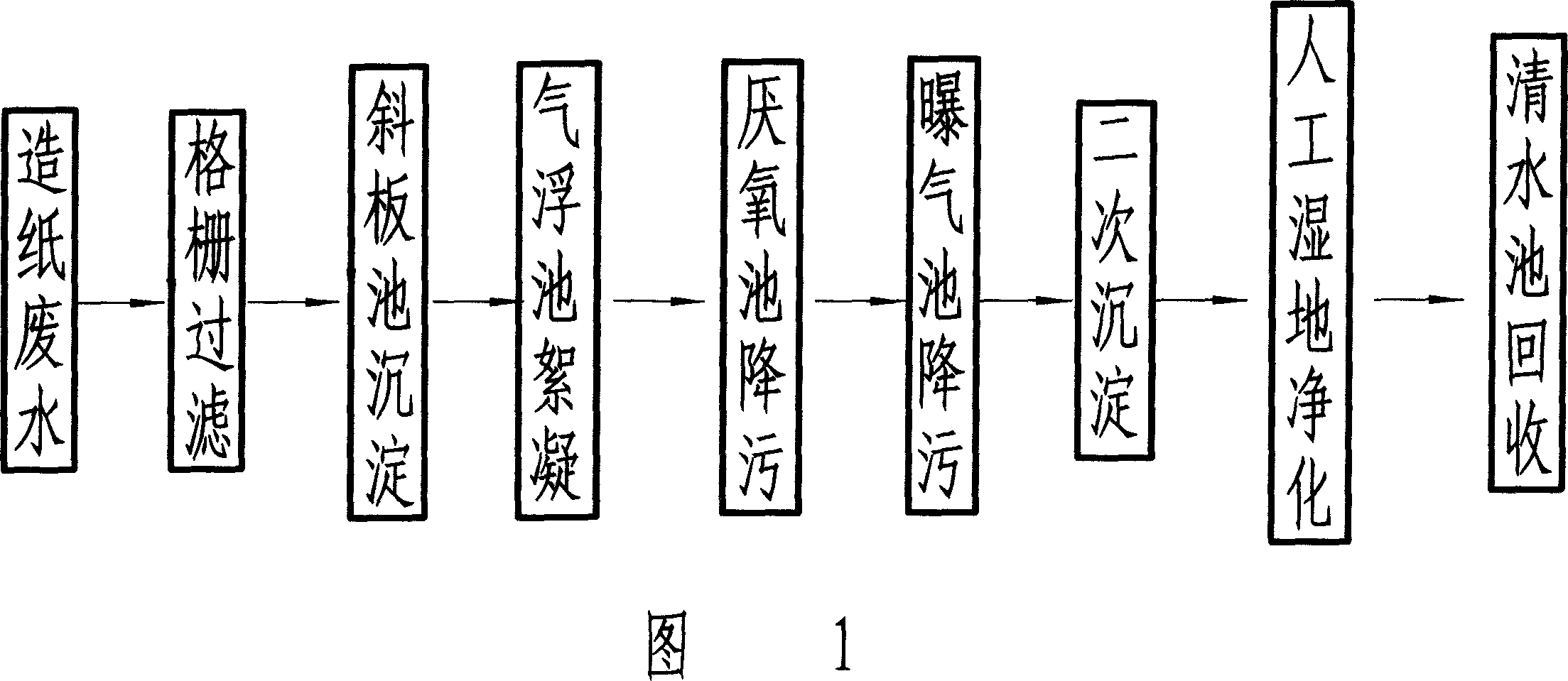

The process of treating effluent from making paper with waste paper belongs to the field of industrial effluent treating technology, and aims at lowering the harmful matter content in the effluent from making paper with waste paper to reach the exhaust standard. The process includes the first passing the effluent through grating to filter out fiber and suspended matter, the subsequent settling in a sloping plate settling tank to eliminate granular impurity, flocculating in an air floating tank with flocculant and fishing out the resultant suspended matter, anaerobic reaction in an anaerobic settling tank, treating with introduced air and active sludge in an aeration tank and eliminating suspended matter and colloidal matter, clarifying in a settling tank, and treating in artificial wetland to eliminate nitrogen and phosphate and obtain clear water. The process can reduce SS, BOD5 and CODcr of the effluent obviously and make the effluent reach draining standard.

Owner:云南恒昌造纸有限责任公司

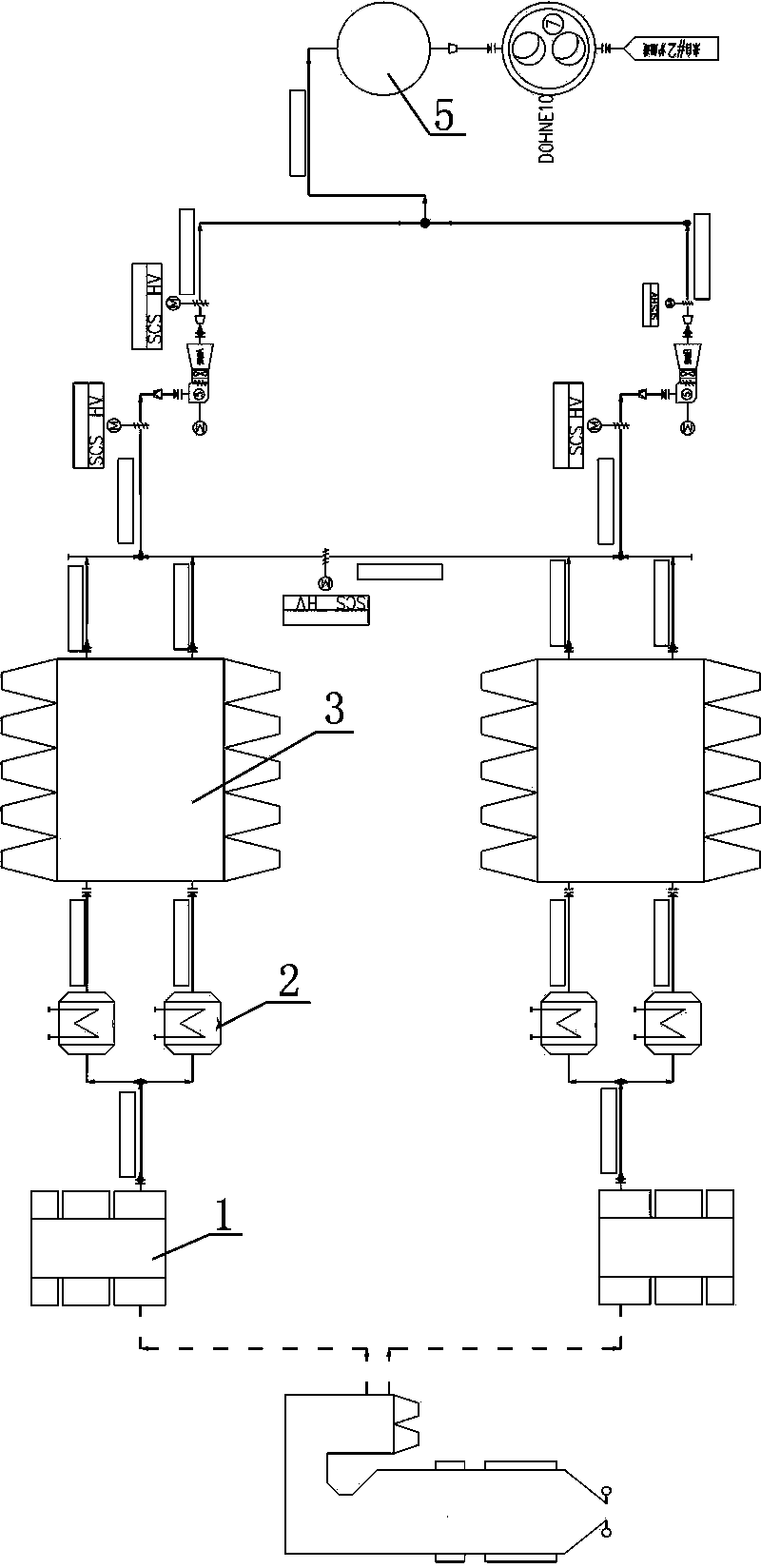

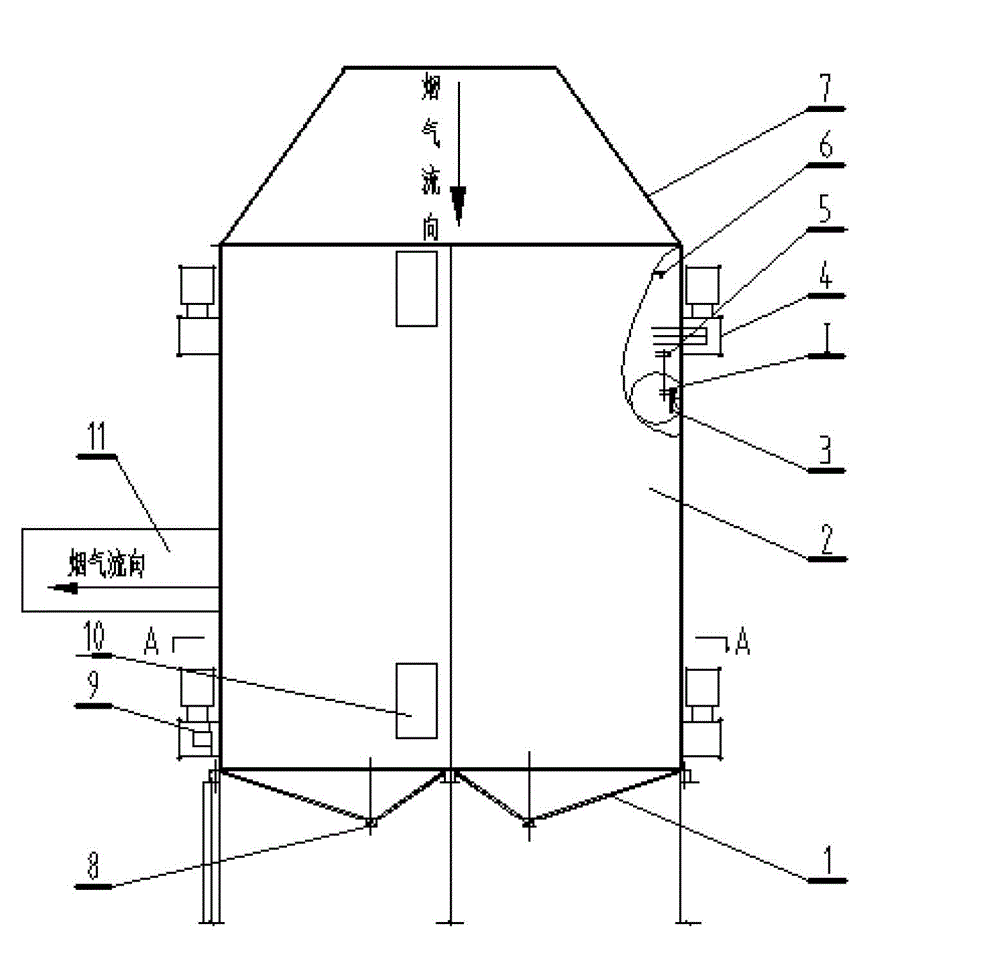

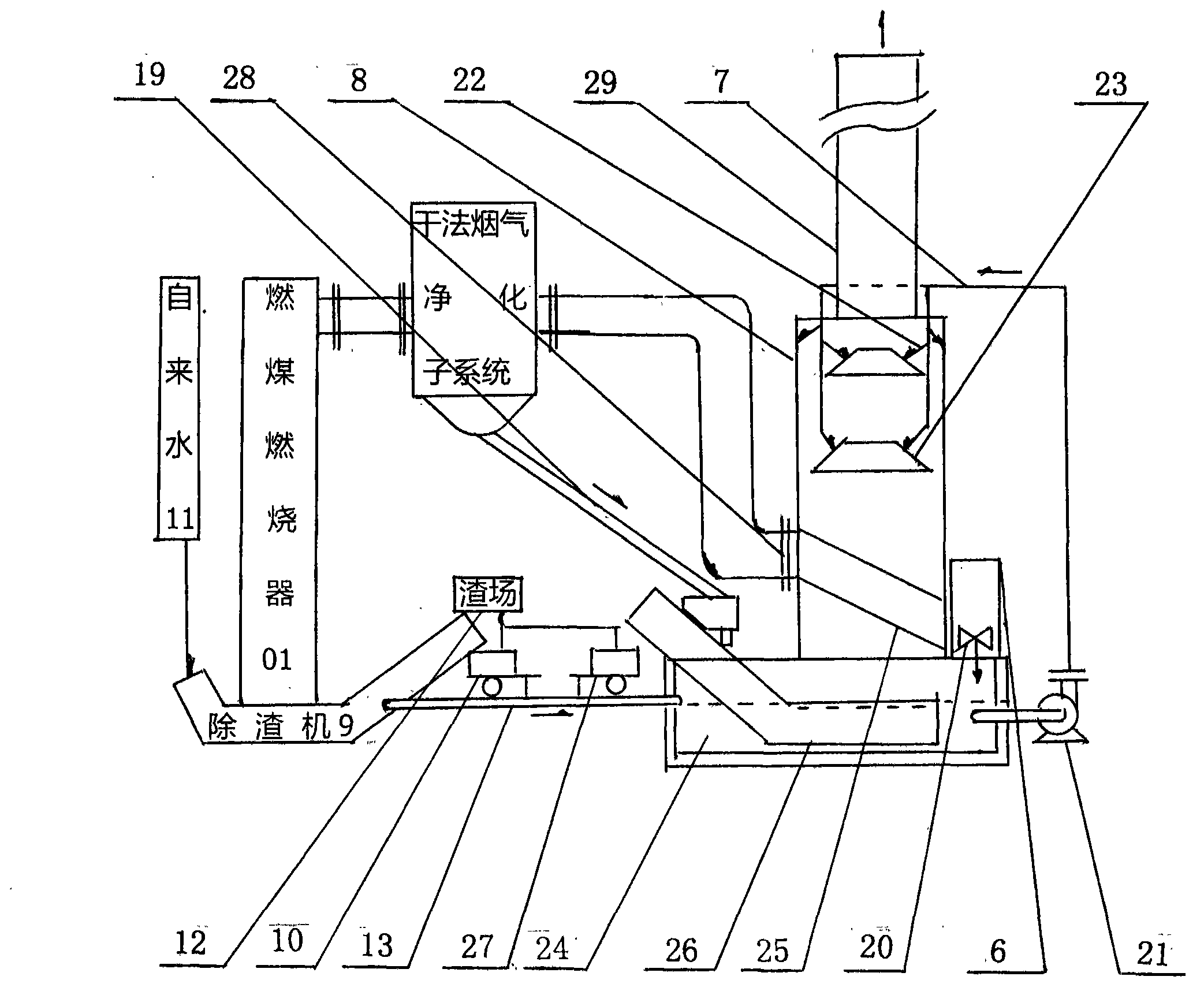

Low temperature electric precipitation system in fuel electric plant

InactiveCN103363536AImprove the dust collection rateMeet the requirements of emission standardsLighting and heating apparatusAir preheaterEnvironmental resistance

A low temperature electric precipitation system in a fuel electric plant comprises at least one air preheater, at least one electric precipitator and connecting pipes for connecting the air preheater and the electric precipitator together, a flue-gas heat exchanger for lowering the flue-gas temperature entering the electric precipitator to enable the flue-gas temperature to reach or be lower than flue-gas dew point at the temperature of 90 DEG C is arranged between the air preheater outlet and the electric precipitator inlet; the electric precipitator is communicated with a desulfuration absorption tower through an induced-draft fan; a chimney is connected with the rear part of the desulfuration absorption tower. The flue-gas heat exchanger adopts a backward flow heat exchange type; a vertical pipe heat exchange flow passage or a horizontal pipe heat exchange flow passage is arranged at the inner part of the flue-gas heat exchanger; the system has the characteristics that the project equipment investment is reduced; the auxiliary power ratio is lowered; the energy is saved; the consumption is reduced; the heat economy of the unit can be improved; the latest environment-friendly emission standard can be satisfied.

Owner:ZHEJIANG ELECTRIC POWER DESIGN INST +1

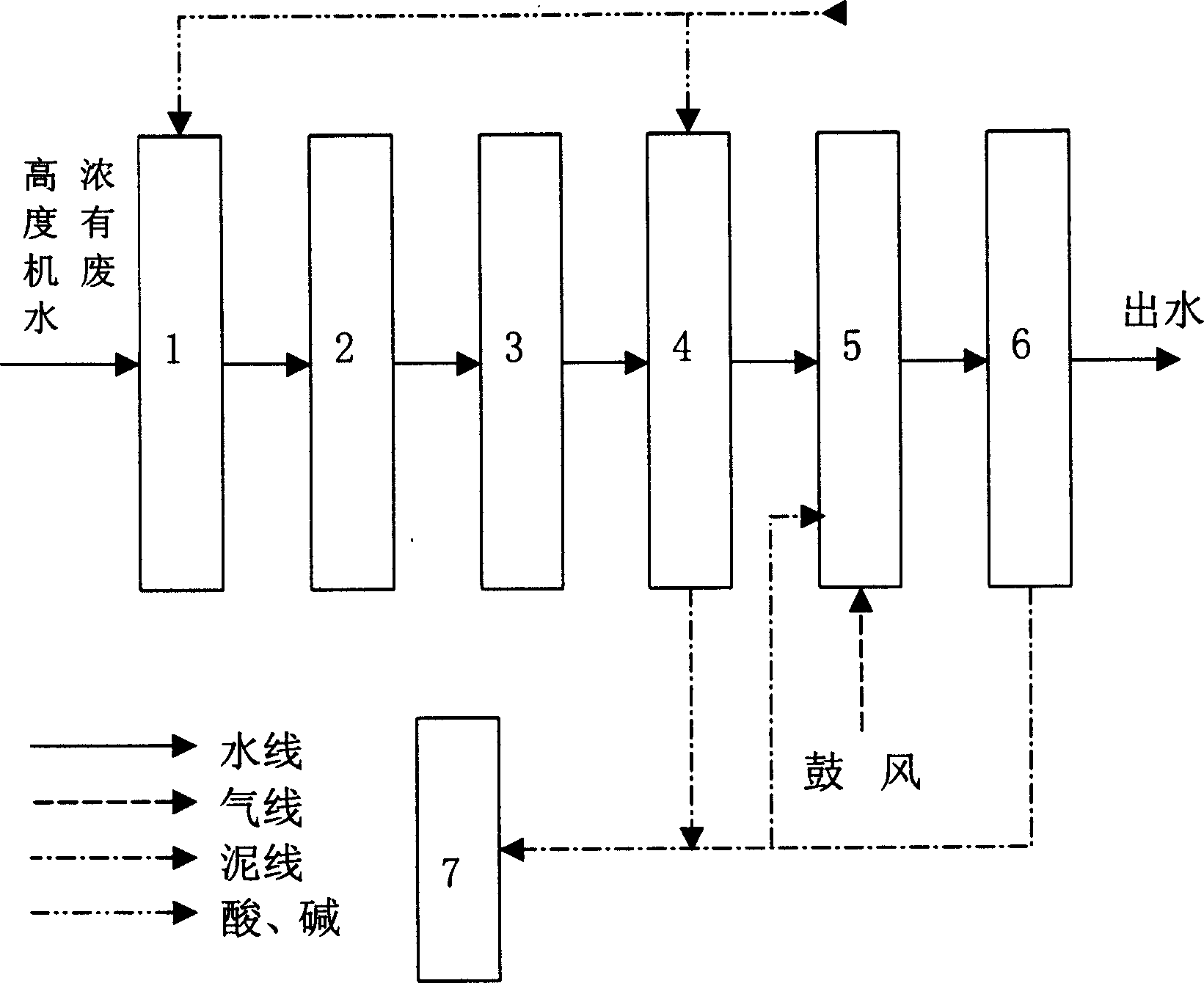

Method for treating or ganic waste water with nigh concentration

ActiveCN1611457AMeet the requirements of emission standardsMultistage water/sewage treatmentHigh concentrationFenton reagent

The invention relates to a kind of treatment method of high concentration organic wastewater. The invention takes anaerobic organism filter tank- Fenton reagent oxidization - contact oxidization method (A-F-O method) as the core. After adjusting PH of high concentration organic wastewater, it runs through bottom of anaerobic organism filter tank (AF), and then overflows into Fenton reagent oxidization reactor from top of AF. After reacting by some time, it runs into neutralization sedimentation tank. When having removed vestigial Fe2+ in the wastewater, it gets into contact oxidization system, then control by regular hour, and last, flux through quadratic sedimentation tank. Treated by this method, COD of high concentration organic wastewater can decline to lower than 80mg / L, so it can achieve national discharge standard. The invention has stable and reliable treating effictiveness, convenient and steerable operation, low running cost, so that it adapts to treat high concentration organic wastewater discharged by petroleum chemical enterprise and other analogous enterprises.

Owner:CHINA PETROLEUM & CHEM CORP +1

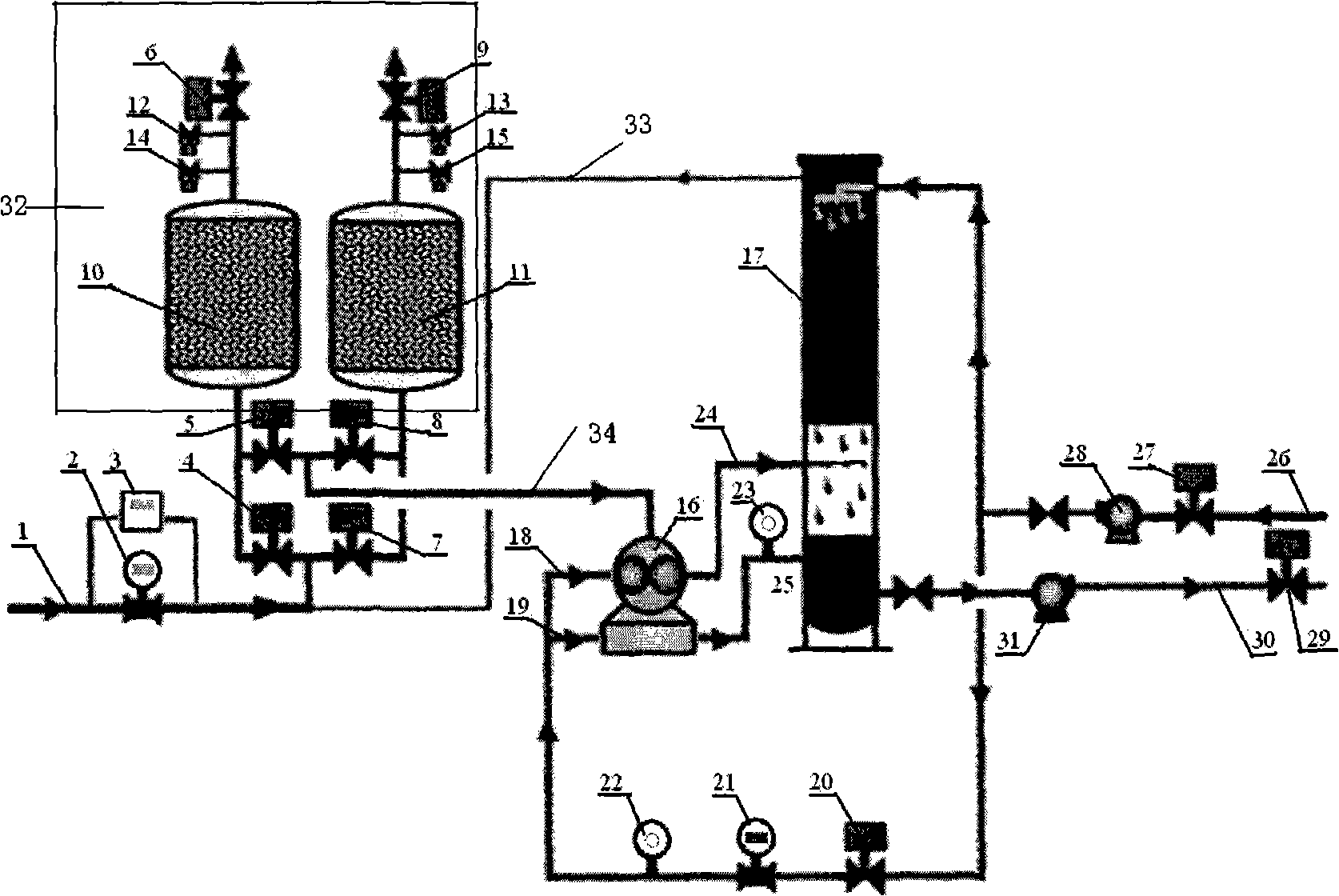

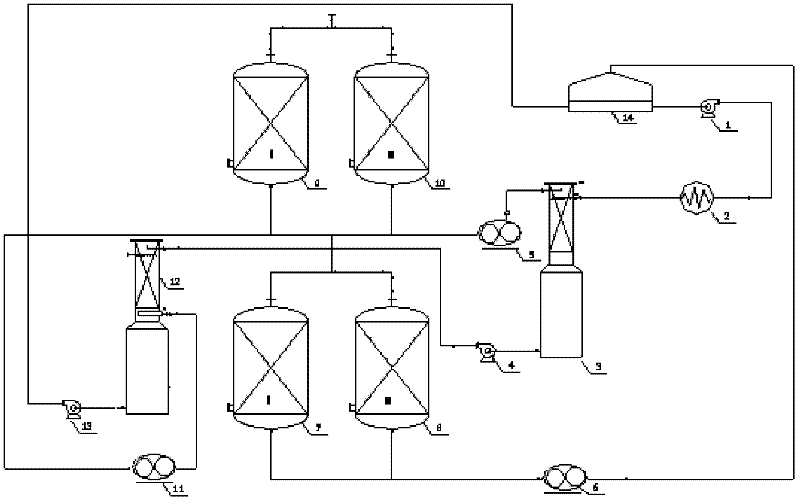

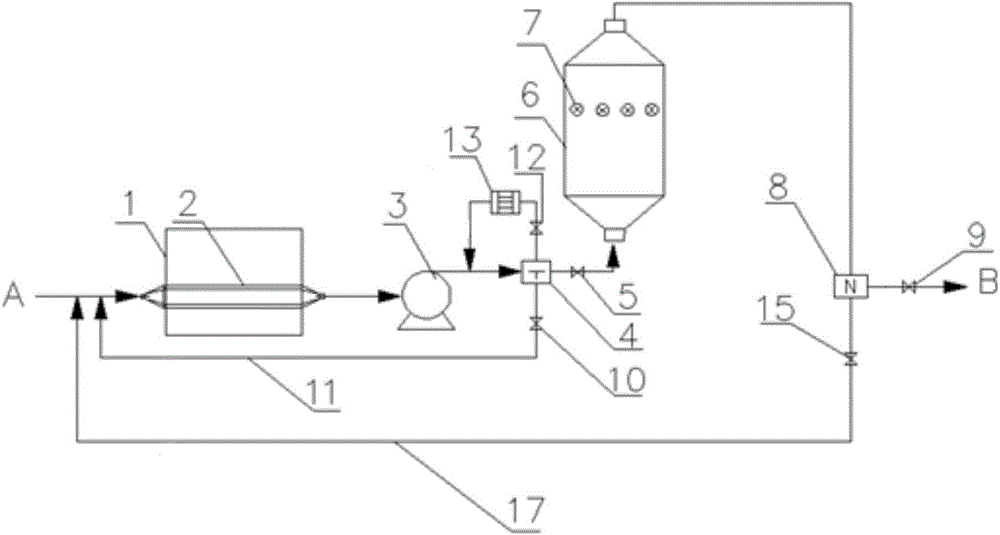

Continuous circulating type oil-gas adsorption recovery method

InactiveCN101259358AEasy to realize fully automatic controlEasy to realize remote monitoringDispersed particle separationHigh concentrationRecovery method

The invention discloses a sustained circulating type method for adsorbing and recycling oil gas , which consists of the following steps: (1) adsorbing and recycling the oil gas by means of an active carbon bed in an adsorption tower; (2) the desorption and regeneration of the adsorption tower saturated is carried out; (3) the oil gas desorbed with high concentration enters a recovery tower to be absorbed by the body of liquid meager gasoline; (4) the tail gas in the recovery tower reenters the adsorption tower to be cycled in a sustaining way, wherein, at least two adsorption tanks in the adsorption tower alternately carry out adsorption and desorption generation, thus leading the oil gas adsorption to be carried out in a sustained circulating way, at the same time, the remote monitoring can be realized by using an automatic control program. The sustained circulating type method for adsorbing and recycling oil gas of the invention is characterized by high efficiency, low energy consumption, convenient operation and safe and reliable running.

Owner:BAY ENVIRONMENTAL TECH BEIJING

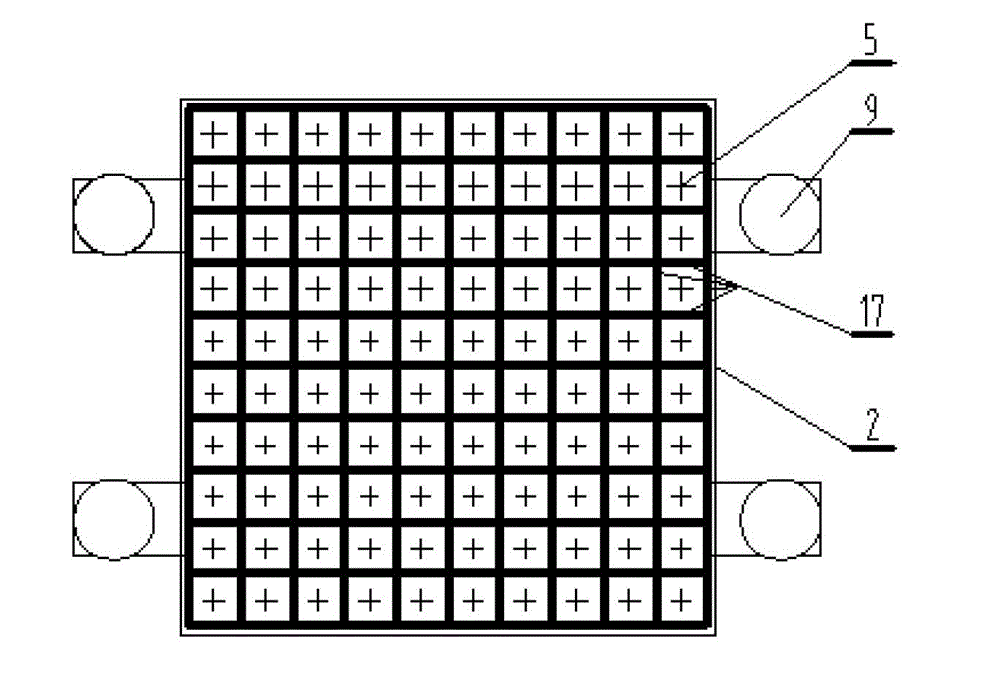

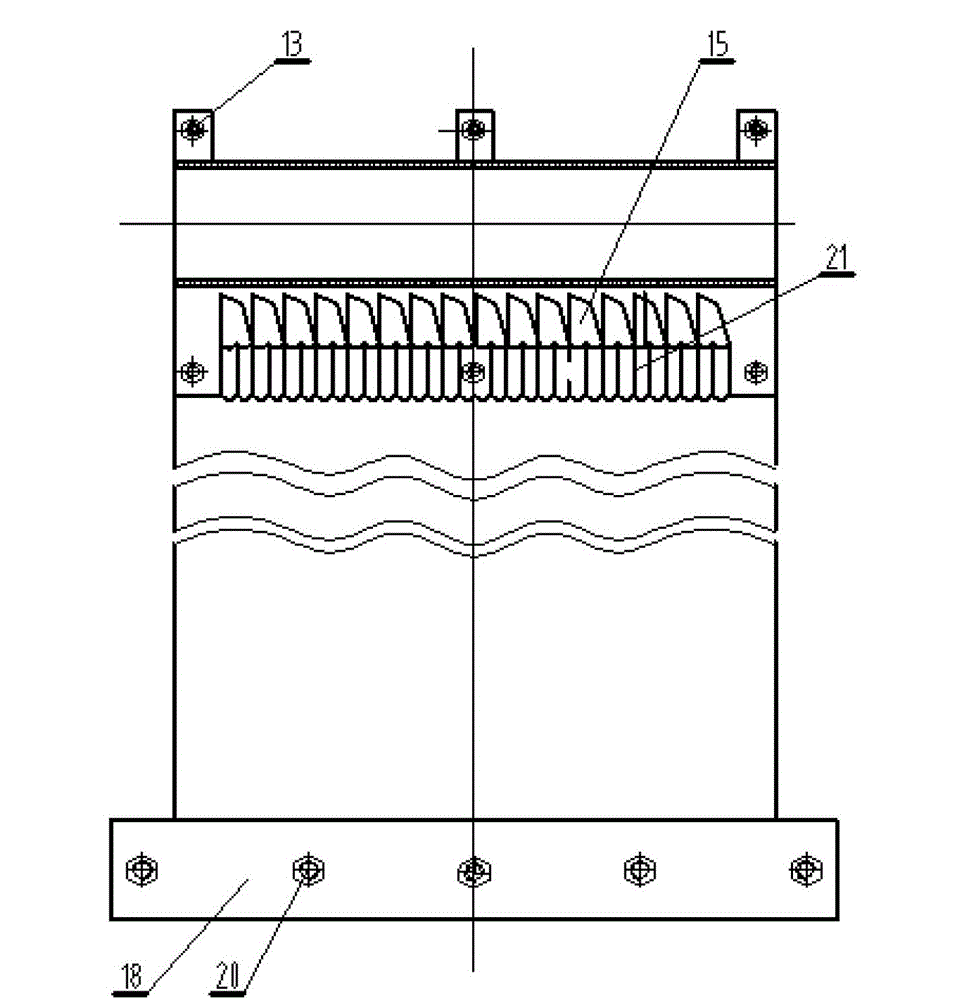

Rigid anode plate surface water film arrangement technology and device

ActiveCN102941158AStable removalEfficient removalExternal electric electrostatic seperatorElectrode constructionsParticulatesEngineering

The invention relates to a solid anode plate surface water film arrangement technology and device for an electrostatic dust collector. The device comprises clamp plate fastening bolts, suspension clamp plates, water distribution pipes, guide vanes, anode plate fastening bolts, anode plates, lower plate part positioning steel plates, lower plate part fixing shafts, and positioning steel plate fastening bolts. The surfaces of the anode plates are subjected to pretreatment of coating by a hydrophilization agent, and the upper parts of the anode plates are connected with the water distributed pipes through suspension clamps and are twisted to form the 45-degree guide vanes; corrugated guide trenches with widths of 5mm-8mm are formed in the front ends of the anode plates; stainless steel pipes are crossed and welded to form a gridding water distribution pipe net, water distribution holes are formed in the lower ends of the water distribution pipes and are connected with an external process water tank, and the quantity of water intake is controlled by a PLC (programmable logic controller); the vertical anode plates with the same width form an electrostatic field channel; upper and lower crossbeams of discharge electrodes are suspended by upper and lower insulating boxes respectively and are insulated from a casing; and ash hoppers are arranged below the anode plates. According to the invention, particulate matters settled on the surfaces of the anode plates can be cleaned away thoroughly in a water-film ash cleaning manner, and thus the smoke emission can reach the standard.

Owner:SHANDONG UNIV +1

A circulating crude oil storage tank oil gas vacuum adsorption recovery system

ActiveCN102295118AEasy to monitor remotelyIncrease contact areaDispersed particle separationLarge containersExhaust gasProcess engineering

The invention provides a circulating type oil-gas vacuum adsorption and recovery system comprising a crude-oil storage tank, comprising the crude-oil storage tank, a vacuum desulfurization device, an adsorption tank, a vacuum pump, an absorbent treating device and an absorption tower, wherein the absorbent treating device treats crude oil pumped from the crude-oil storage tank into lean gasoline;volatile oil gas of the crude-oil storage tank enters the vacuum desulfurization device and then enters the adsorption tank for adsorption and recovery after desorption and desulfurization; standard air is exhausted into atmosphere from the upper end of the adsorption tank, and nonstandard tail gas reenters the adsorption tank for circulating adsorption and recovery; the vacuum pump is used for carrying out vacuum desorption and regeneration on the adsorption tank with saturated adsorption; and desorbed high-concentration oil gas enters the absorption tower, and is absorbed by the lean gasoline body from the absorbent treating device, and the rich gasoline after absorption returns to the crude-oil storage tank. The circulating type oil-gas vacuum adsorption and recovery system is convenient and simple, volatile oil gas is absorbed and recovered by fully utilizing the self characteristic of the crude oil, additional equipment and resources do not need to be added, and the secondary pollution is not caused as well.

Owner:BAY ENVIRONMENTAL TECH BEIJING

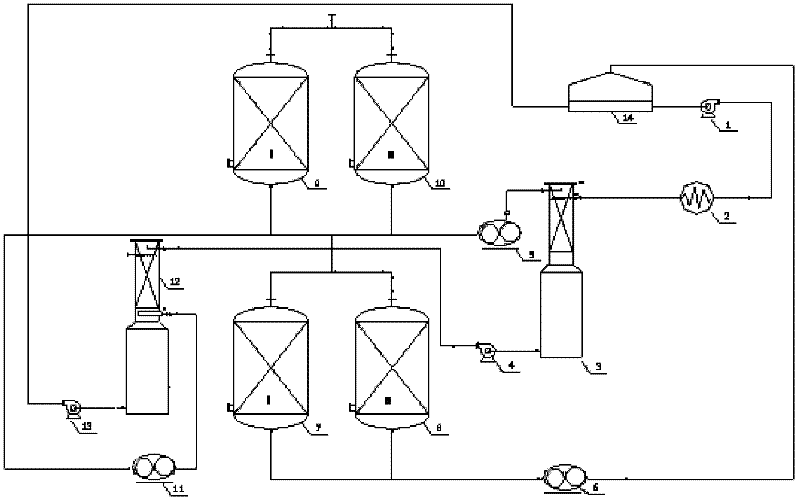

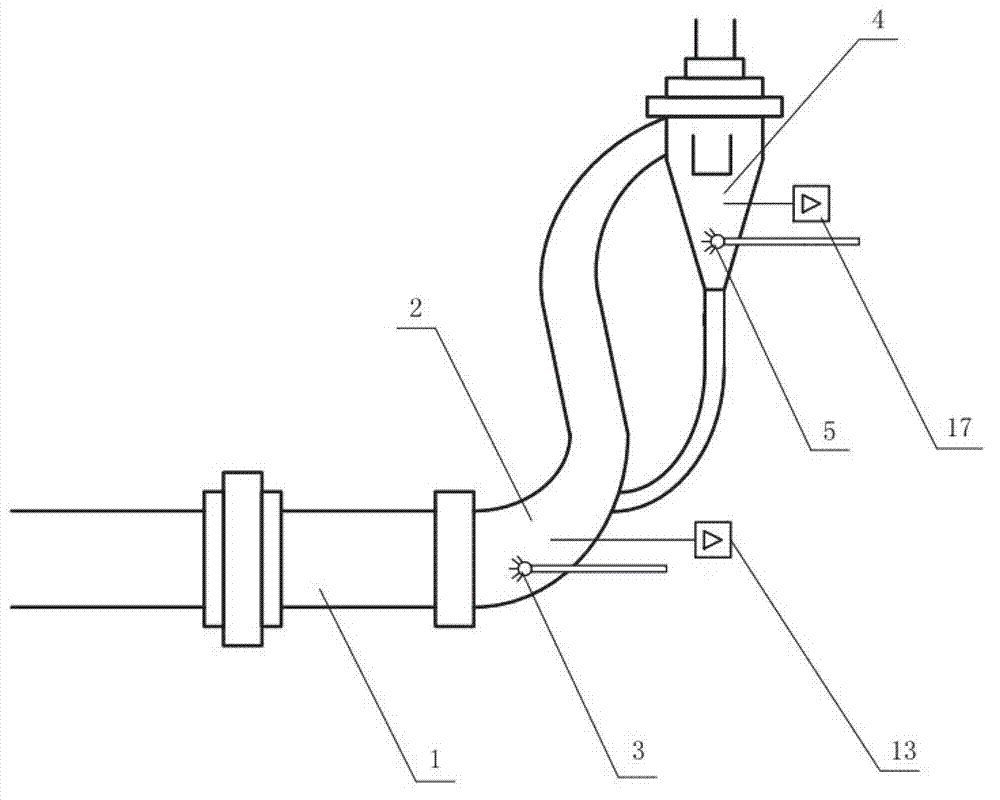

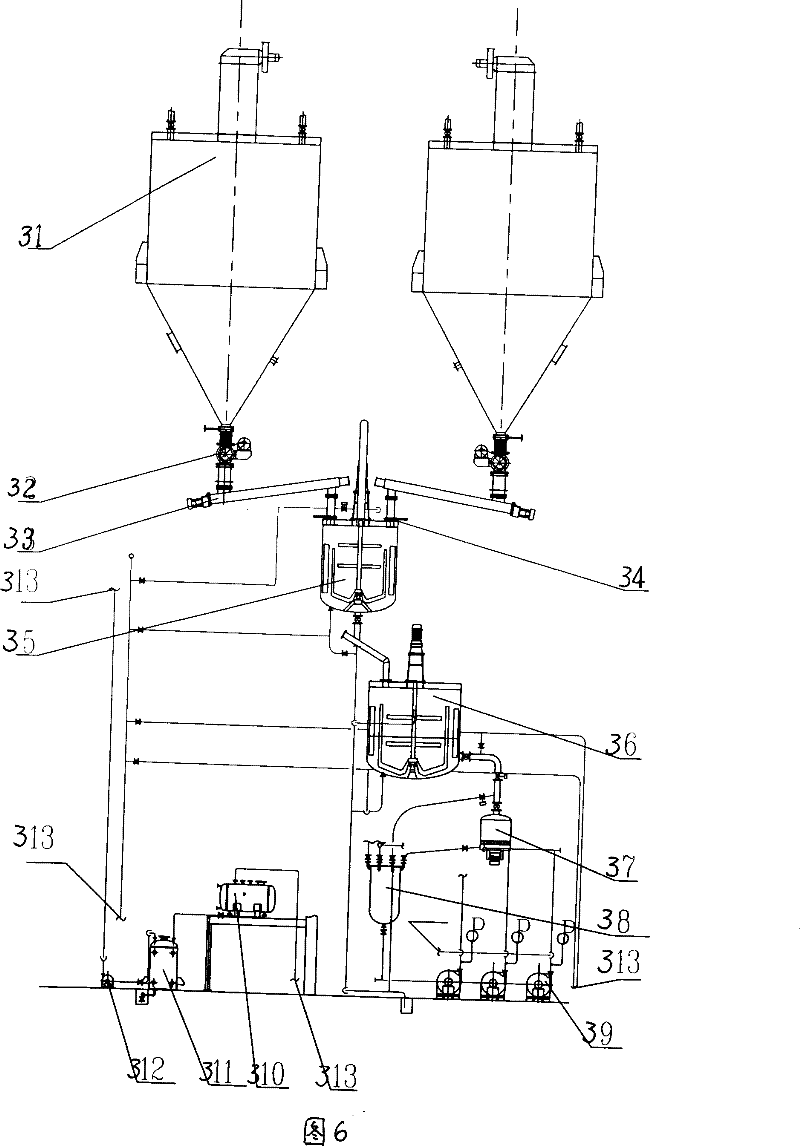

SNCR (selective non-catalytic reduction) denitration device and method for rotary cement kiln

ActiveCN102806003ALow costMeet the requirements of emission standardsDispersed particle separationNitric oxideCement kiln

The invention discloses an SNCR (selective non-catalytic reduction) denitration device and an SNCR denitration method for a rotary cement kiln and belongs to the technical field of rotary cement kiln pollutant discharge control. The device comprises a reducing agent preparation and storage system, a reducing agent transporting system, a reducing agent spraying system and a control system, wherein the reducing agent preparation and storage system consists of a reducing storage tank and a reducing agent dissolving tank, the reducing agent transporting system consists of a conveying pump and a conveying pipeline, the reducing agent spraying system consists of a booster pump and two stages of spray guns, and the control system consists of two flow meters and two flow meter controllers; and the device further comprises NOx on-line detection instruments respectively positioned in a position with the distance being 10 to 20m from the downstream parts of the two-stage spray guns. The method is realized by using the device, ammonia, urea or alkaline industrial waste liquid is used as a reducing agent, the proportion of the quantity of nitric oxide substances in smoke of a decomposing furnace and the quantity of nitrogen element substances in the reducing agent is determined according to the condition of NOx purified by each stage of spray gun, and the reducing agent is sprayed into the decomposing furnace. The SNCR denitration device and the SNCR denitration method have the advantages that economy and environment protection are realized, the operation is simple, the control is flexible, and the denitration performance is high.

Owner:TSINGHUA UNIV

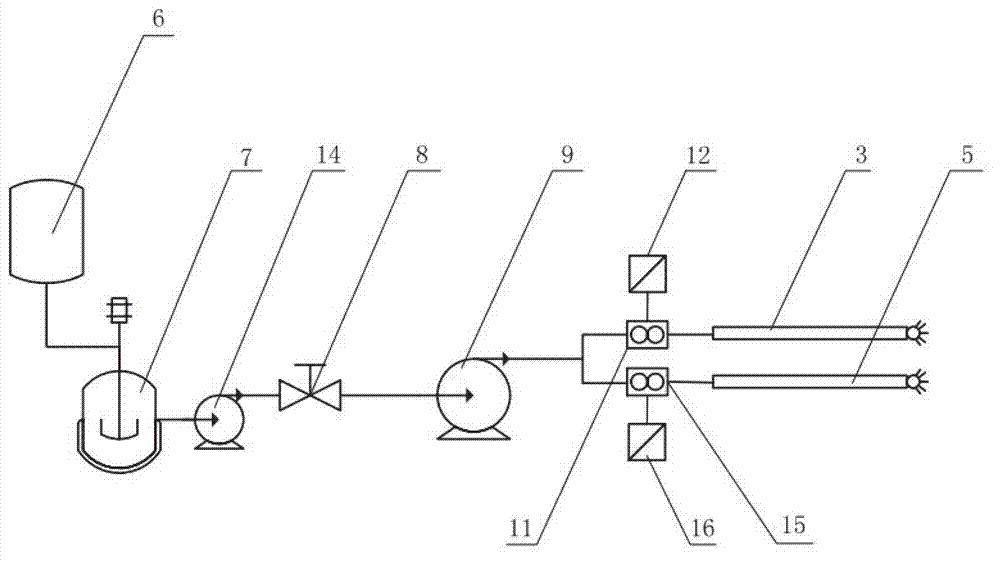

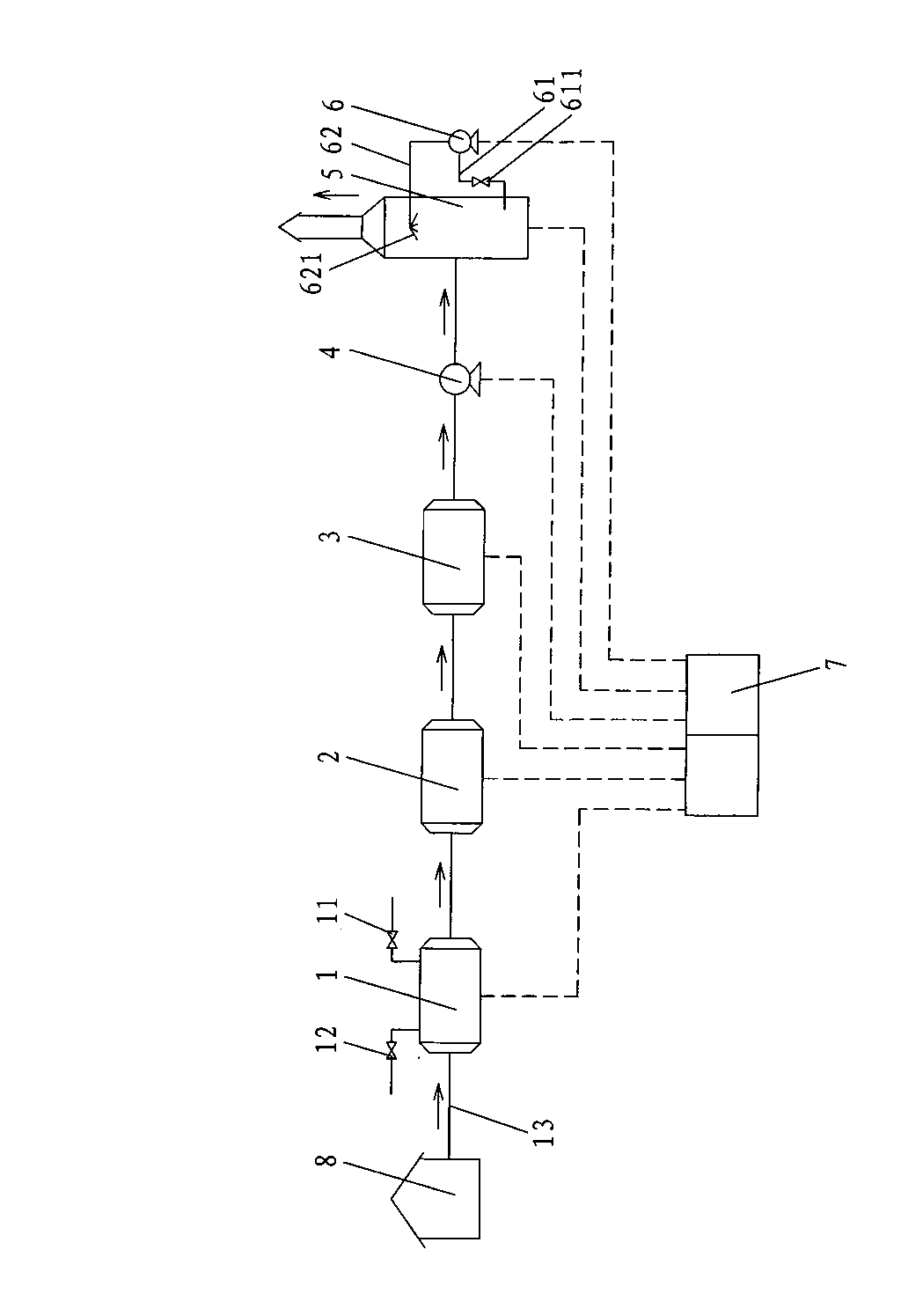

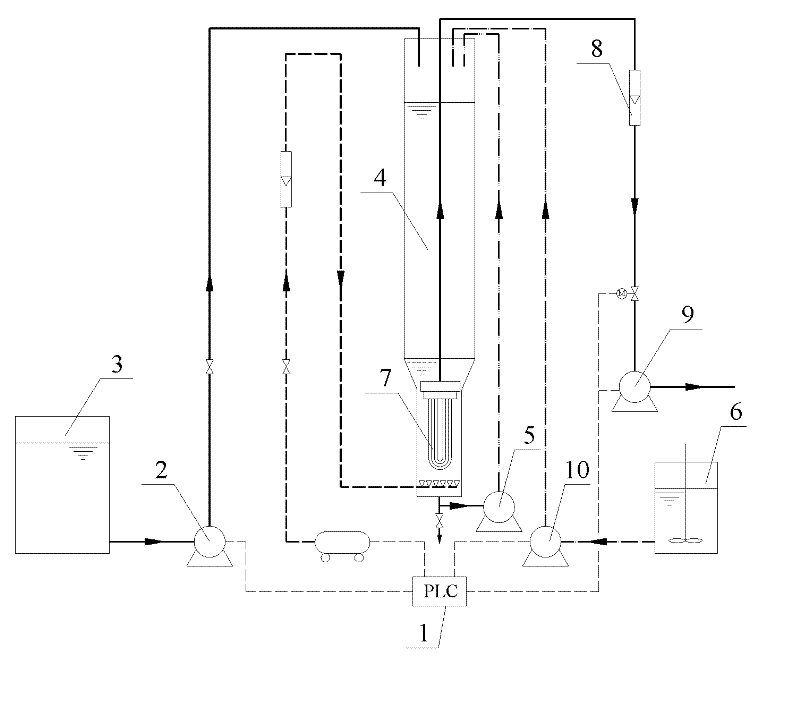

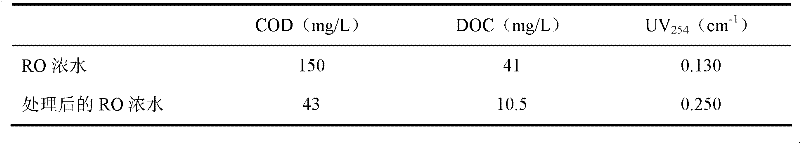

Efficient standard solution production purification system for vehicle urea

ActiveCN104056550AEmission reductionSave electricityDispersed particle separationActivated carbonReverse osmosis

The invention provides an efficient standard solution production purification system for vehicle urea. The system comprises a gravel filtering system (1), an activated carbon filtering system (2), a pressure pump (3), a micro-filtering device (4), an ultra-filtering device (5), a middle water tank (6), a high-pressure pump (7), a primary reverse osmosis device (8), a secondary reverse osmosis device (9) and an EDI system (10). The efficient standard solution production purification system for the vehicle urea can be used for replacing a crystallization method adopted in traditional urea purification, electric energy can be saved, discharging of waste liquid in the crystallization process can be reduced, the efficient urea standard solution production purification system is a new breakthrough in the technical field of the urea for the vehicle, the content of the impurities of the urea for the vehicle can be controlled below 10-20 ppm, the conversion rate of oxynitride can reach up to 95 percent, the requirement for the diesel vehicle exhaust emission standard of the national level 4 and the national level V can be completely met, and important economic value and social value are achieved.

Owner:NANJING JIHONG ENVIRONMENTAL PROTECTION TECH

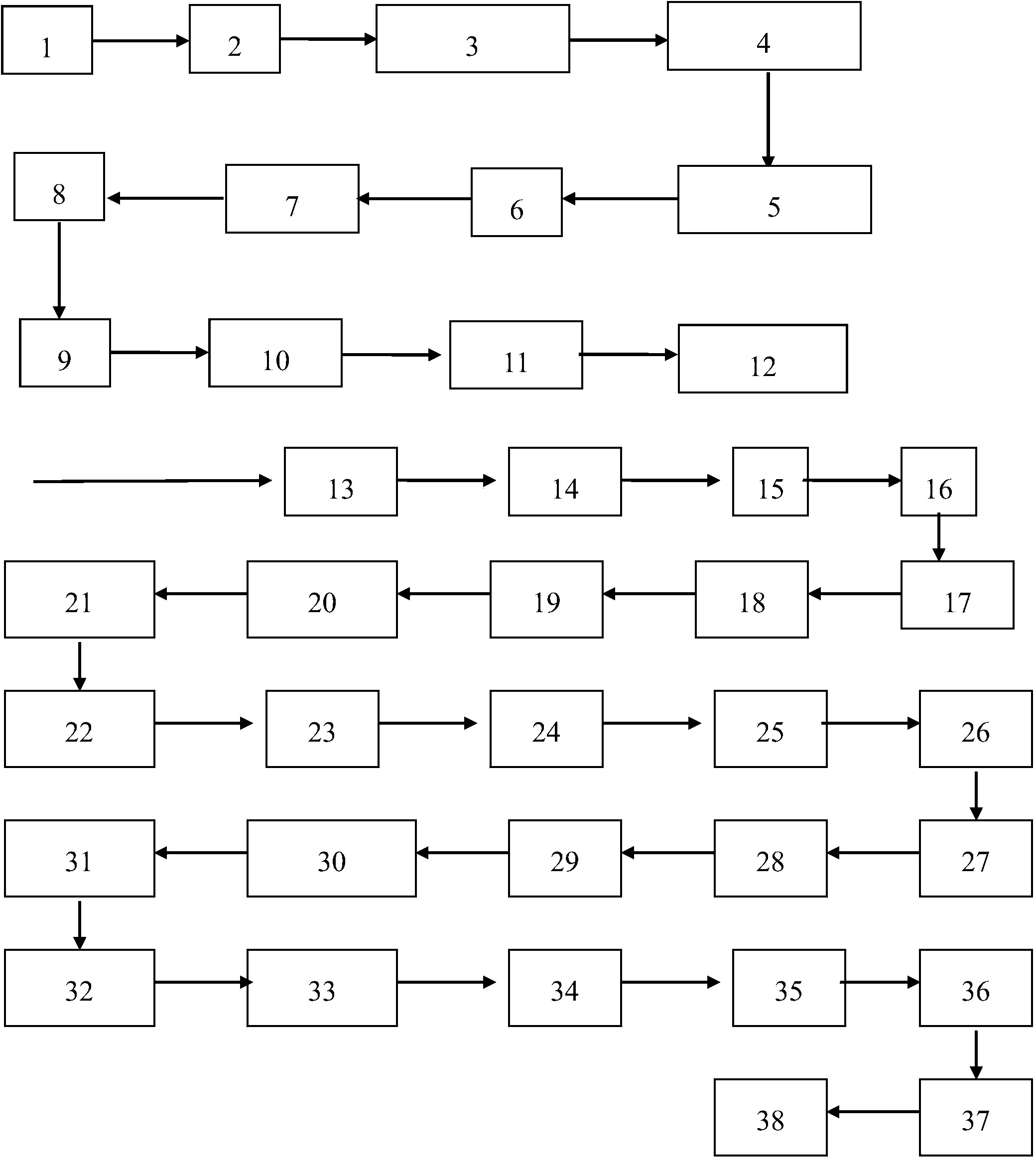

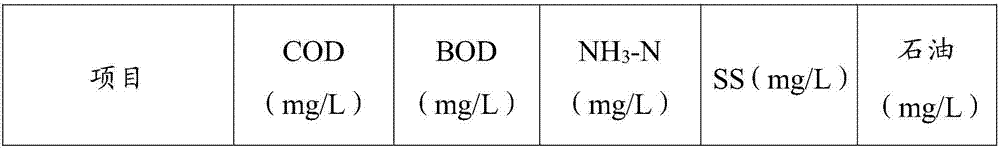

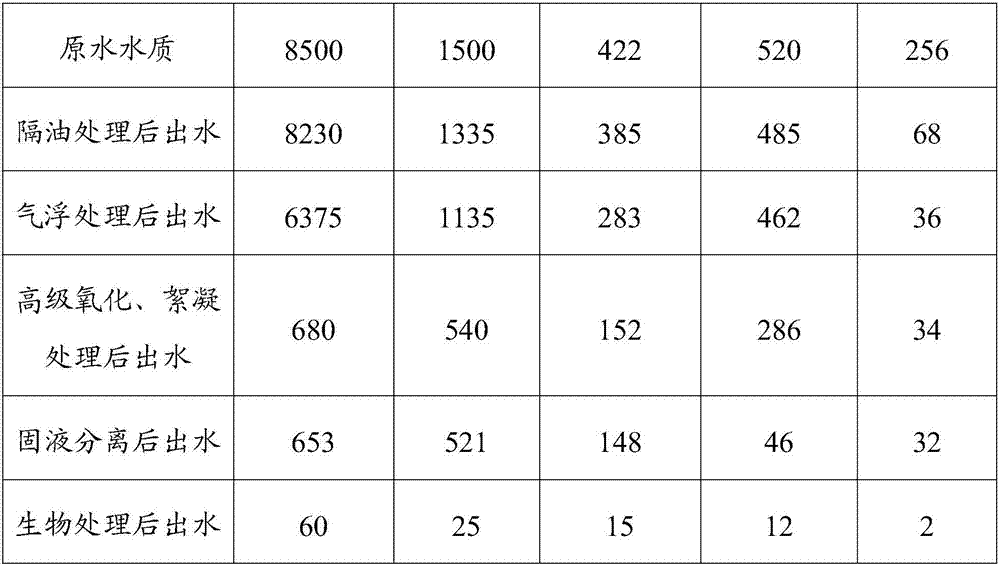

Treatment method of petrochemical wastewater

ActiveCN107117767AReduce usageSmall footprintWaste water treatment from quariesFatty/oily/floating substances removal devicesFlocculationBiological filter

The invention discloses a treatment method of petrochemical wastewater, which comprises the steps of oil separation treatment, air floatation treatment, advanced oxidization, flocculation treatment, solid-liquid separation treatment, biological treatment, and sterilization and disinfection. According to the treatment method of the petrochemical wastewater, most petroleum pollutants in the wastewater are treated by oil separation and air floatation, and then residual petroleum pollutants are removed by petroleum hydrocarbon degrading bacteria loaded on biological porous ceramic powder filled in a biological filter, so that the wastewater meets a discharge standard. In addition, most organic pollutants and partial NH3-N are removed by the advanced oxidization, and then residual NH3-N is removed by aerobic, anoxic and anaerobic regions formed by a biological filler filled in the biological filter, so that the concentration of various pollutants in the wastewater treated by the treatment method meets a standard discharge requirement.

Owner:青海省化工设计研究院有限公司

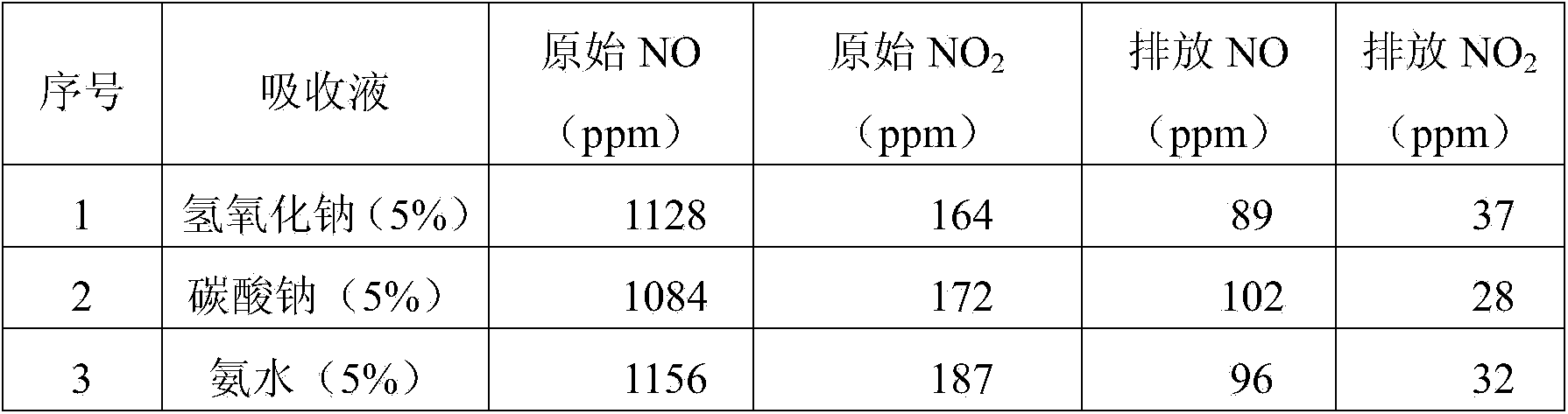

Process and device for treating nitric oxide in tail gas generated in nitric acid and nitrate production

InactiveCN103933848AReduce purchasing costsLow running costDispersed particle separationAlkali metal nitrate preparationNitriteEmission standard

The invention discloses a process and a device for treating nitric oxide in tail gas generated in the nitric acid and nitrate production. The process comprises the following steps: (1) carrying out tempering reaction on the tail gas generated in the the nitric acid and nitrate production by virtue of a 30-68% nitric acid solution, and controlling the volume percentage of NO to NO2 in the tempered tail gas to be 0.95-1.05; and (2) carrying out absorption reaction on the tempered tail gas by virtue of an alkaline absorption liquid, so as to generate nitrate and nitrite. The device comprises an absorption tower which comprises an oxidized-nitric-acid circulating storage tank, a tail gas tempering region, an alkali absorption region and a demisting region from bottom to top, wherein the tail gas tempering region and the alkali absorption region are separated by a tower board, air hoods are uniformly distributed on the tower board, a tail gas inlet is formed in the lower end of the tail gas tempering region, and a tail gas outlet is formed above the demisting region. The process and the device have the advantages that the efficiency is high, the cost is low, the nitric oxide in the tail gas can be recycled, and the tail gas processed by virtue of the process and the device can meet an emission requirement of 'emission standard of pollutants for nitric acid industry'.

Owner:北京中环新锐环保技术有限公司 +1

Waste gas treatment device

InactiveCN103071376AEasy to handleMeet the requirements of emission standardsDispersed particle separationElectrostatic separationLow emissivity

The invention discloses a waste gas treatment device, which belongs to the technical field of organic waste gas treatment facility. The waste gas treatment device comprises an organic waste flue gas heat exchanger, an electrostatic separation purifier, a low-temperature plasma purifier, a centrifugal fan and a spray purification tower, a circulating water pump, and an automatic controller, wherein the organic waste flue gas heat exchanger is connected with an exhaust port pipeline at the production site; the electrostatic separation purifier is connected with an organic waste flue gas heat exchanger pipeline; the low-temperature plasma purifier is connected with an electrostatic separation purifier pipeline; the centrifugal fan is arranged between the low-temperature plasma purifier and the spray purification tower and is used for introducing the flue gas purified by the low-temperature plasma purifier into the spray purification tower and performing spraying treatment by the spray purification tower; the circulating water pump is connected with the spray purification tower; and the automatic controller is electrically connected with the organic waste flue gas heat exchanger, the electrostatic separation purifier, the low-temperature plasma purifier, the centrifugal fan, the spray purification tower and the circulating water pump. The waste gas treatment device has the advantages that ideal treatment on the toxic and harmful organic waste gases produced in the process of producing hydrophilic aluminum foils and producing low-emissivity coated glass is realized, and the emission standards can be met.

Owner:江苏新阪神太阳能有限公司

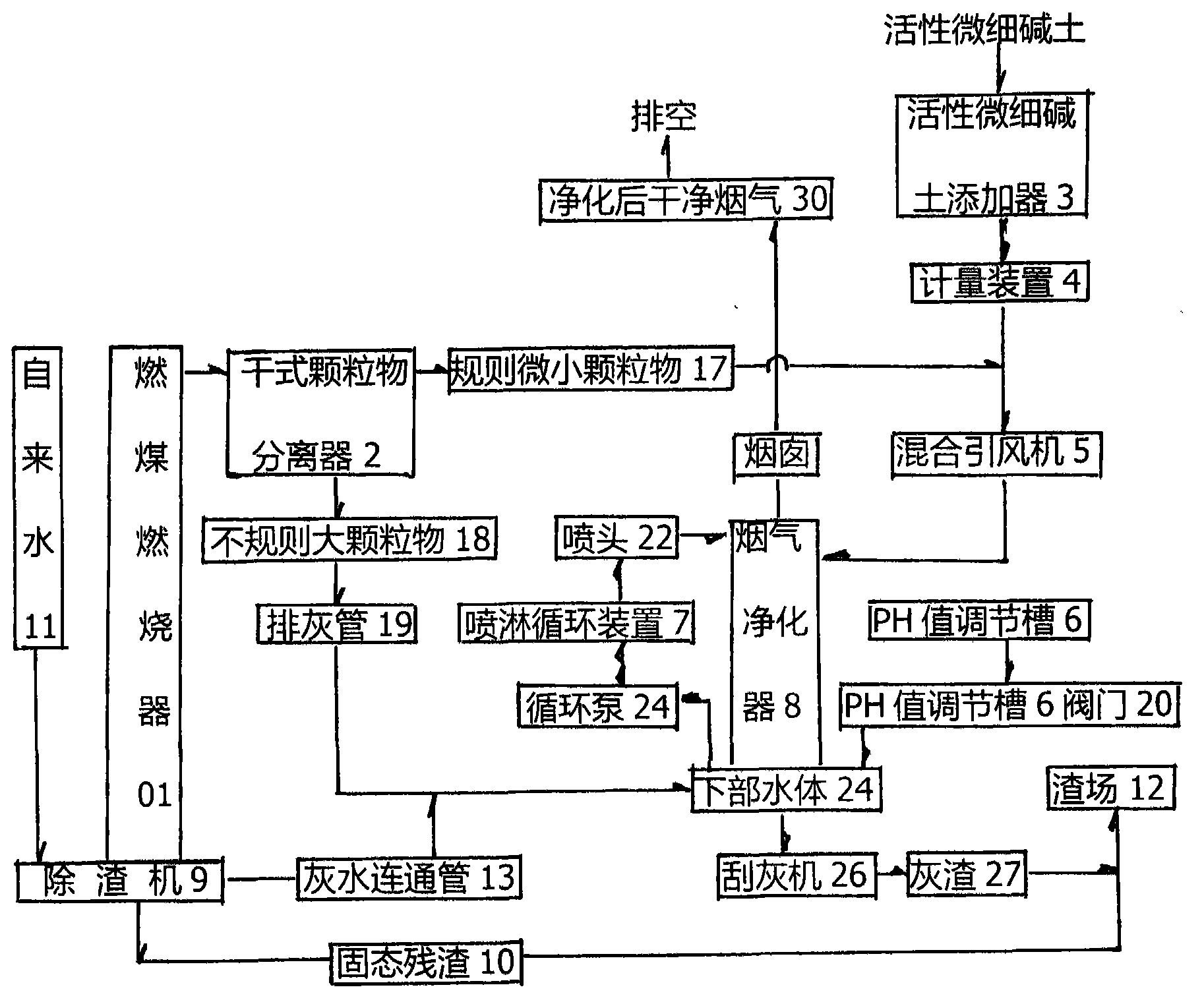

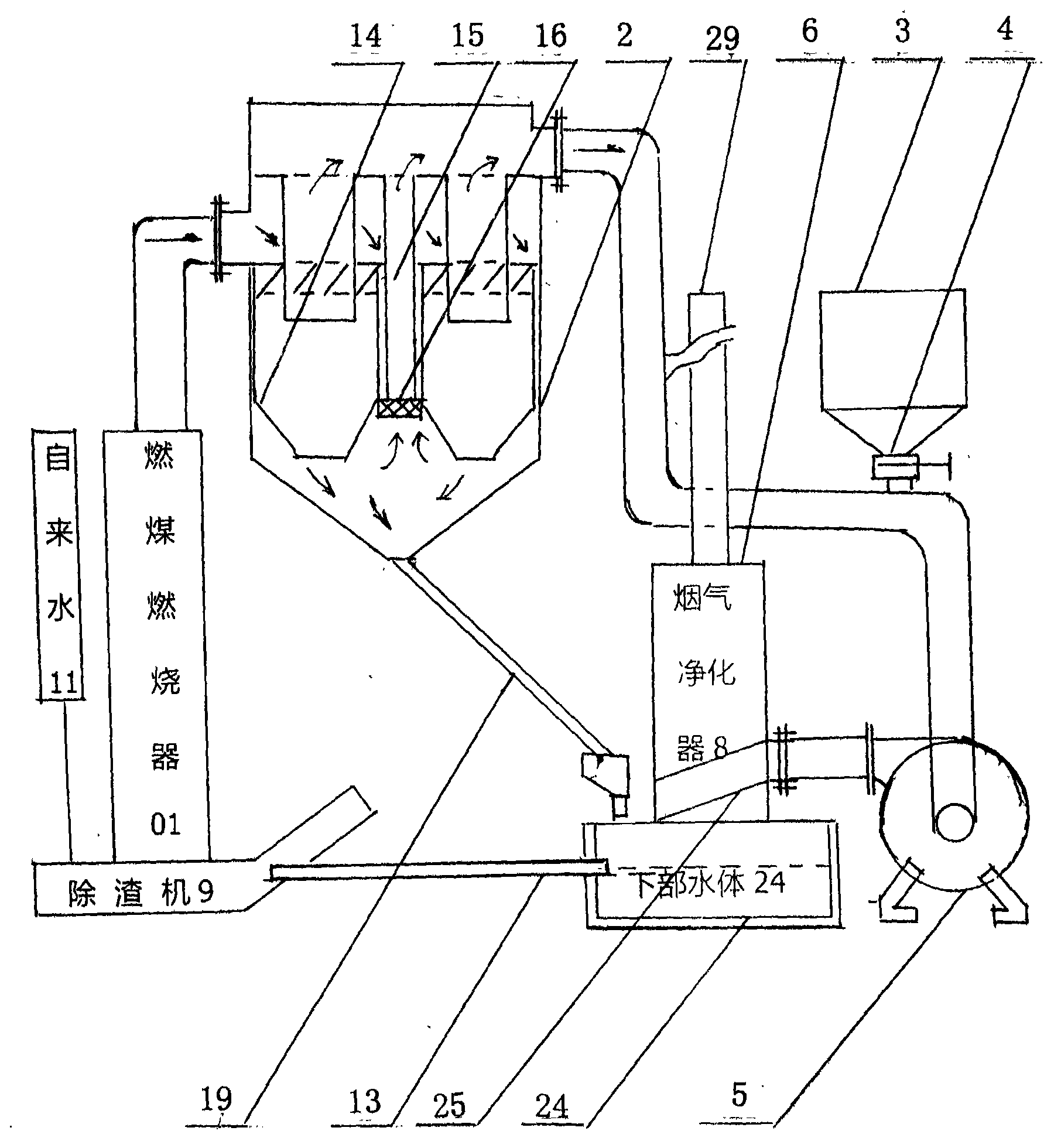

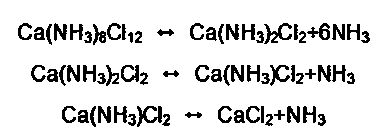

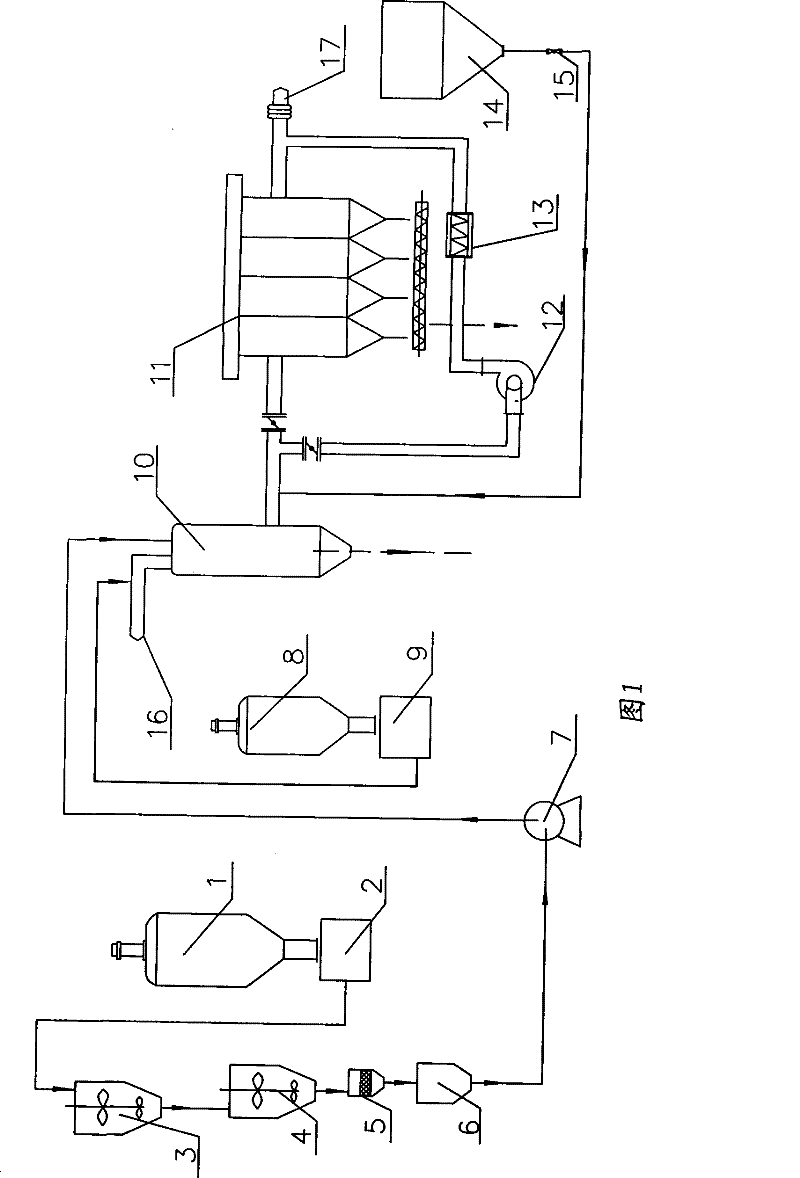

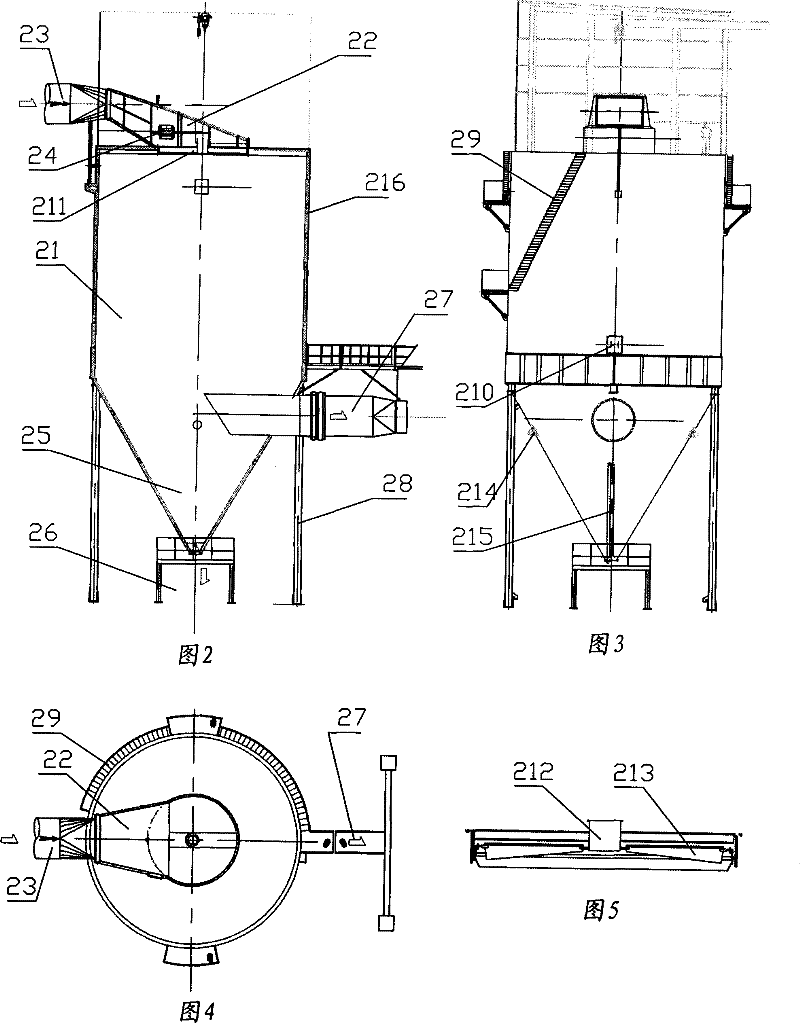

Dry process-wet process combined new method for desulfurization, denitration, decarbonization and dedusting purification of coal-fired flue gas

ActiveCN103877845AMeet the requirements of emission standardsImprove purification effectCombination devicesAir quality improvementCycloneCyclonic separation

Belonging to the field of environmental protection, the invention particularly relates to technologies for smoke prevention and dust control as well as flue gas purification of industrial waste gas and coal-fired flue gas. The invention discloses a dry process-wet process combined new method for desulfurization, denitration, decarbonization and dedusting purification of coal-fired flue gas. A flue gas purification system composed of a fire coal burner, a dry particle separator, an active micro-alkali soil feeder, a mixing draught fan, a pH value adjustment groove, a spraying circulating device and a flue gas purifier forms a complete dry process-wet process combined new technological scheme for desulfurization, denitration, decarbonization and dedusting purification of coal-fired flue gas. The method provided by the invention makes full use of the dry-process cyclone separation dedusting principle, wet-process flue gas spray purification, impact purification and water membrane purification principles, reduces the resistance and operating cost, and at the same time increases the dedusting efficiency of coal-fired flue gas, and also has good purifying effects on SO2, NOx, CO2 and other gaseous pollutants in flue gas, thus fully meeting the national flue gas first-class emission standards or stricter emission standards.

Owner:孙立刚

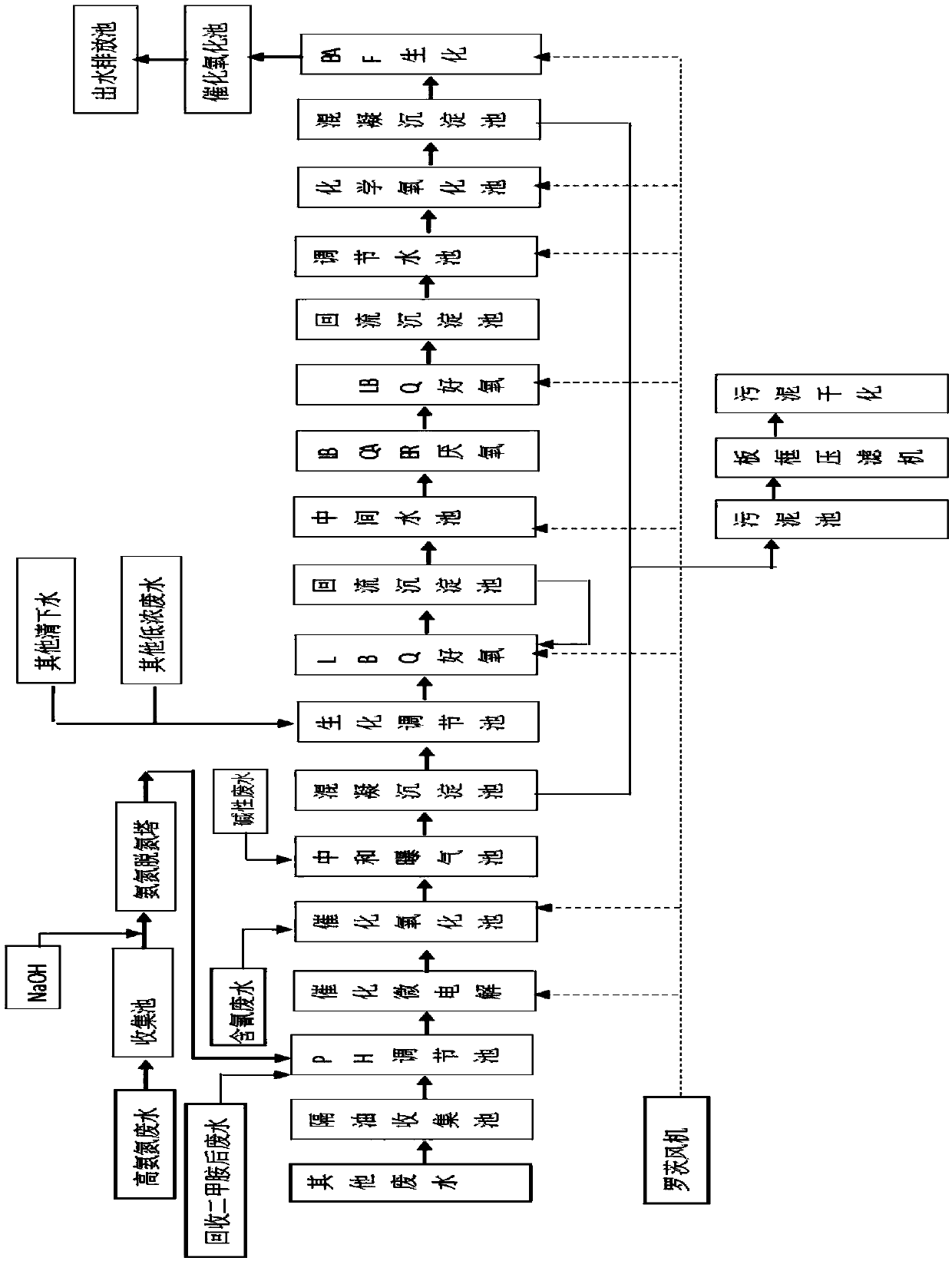

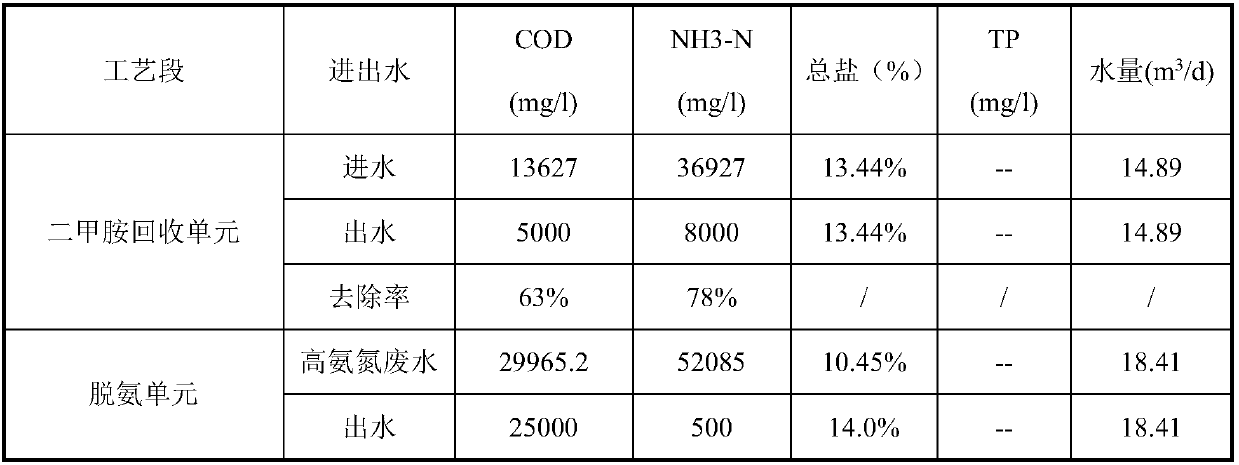

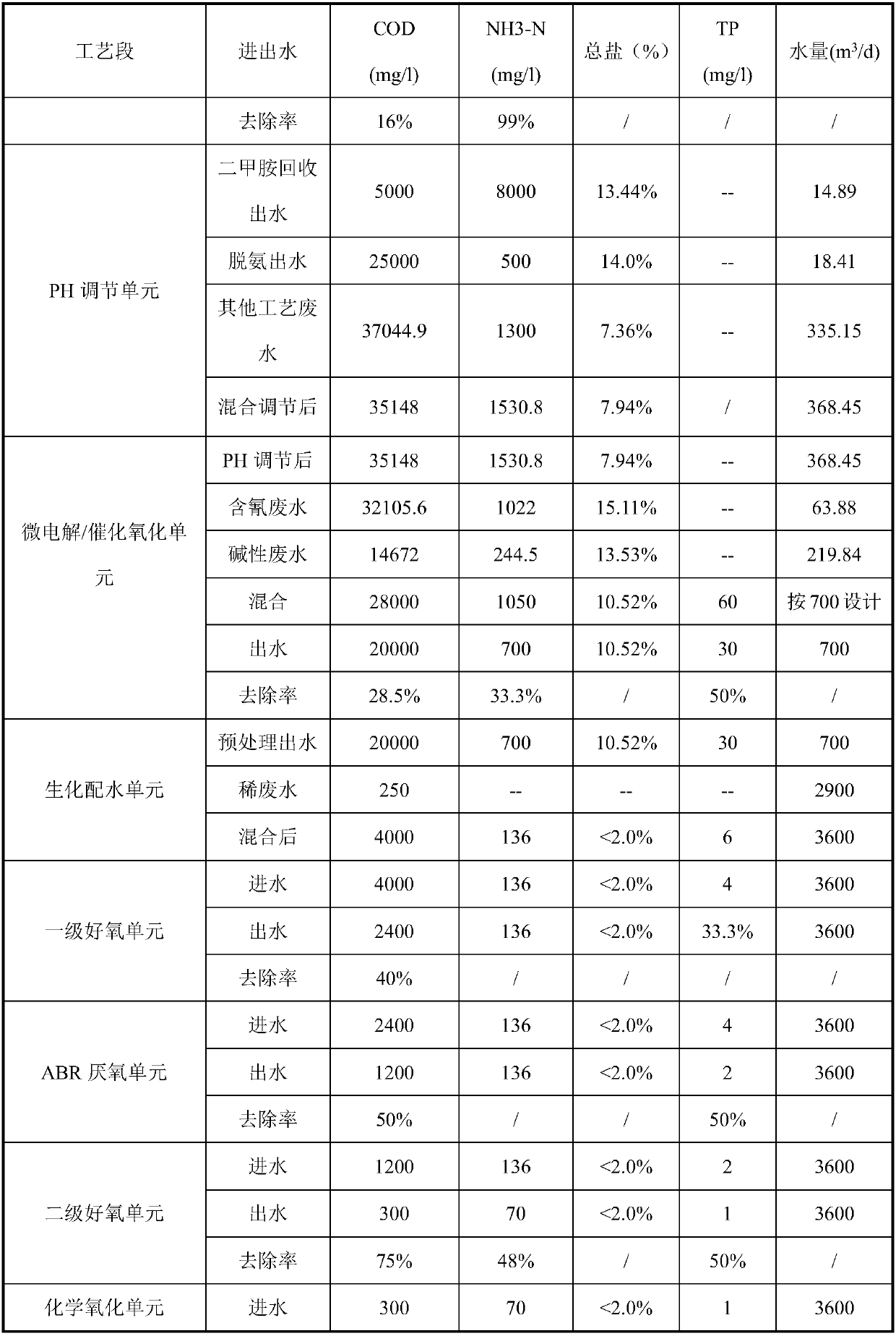

Pesticide chemical wastewater treatment process

ActiveCN107777837AStable and effective removalMeet the requirements of emission standardsWater treatment compoundsMultistage water/sewage treatmentPesticideChemistry

The invention discloses a pesticide chemical wastewater treatment process, and relates to the technical field of wastewater treatment. The pesticide chemical wastewater treatment process includes thesteps: PH (potential of hydrogen) adjustment; micro-electrolysis; catalytic oxidation; LBQ-primary aerobic treatment; LBQ-ABR anaerobic treatment; LBQ-secondary aerobic treatment; AOP; biological aerated filter; deep oxidation. The pesticide chemical wastewater treatment process more effectively, more rapidly and more environmentally treats chemical wastewater, harm of the wastewater to environments and humans is decreased, everything is full of vitality, the process actively responds to the national policy of strict requirements on environmental protection in recent years, and existing wastewater treatment facilities are upgraded and rebuilt. After technological upgrading and rebuilding, a wastewater treatment station can stably and efficiently run, running cost is reduced, and automationdegree is high.

Owner:ANHUI HUAXING CHEM IND CO LTD

Plastic granulating waste gas purifying device

ActiveCN104353307ASimple structureMeet the requirements of emission standardsUsing liquid separation agentPelletizingExhaust fumes

The invention relates to a plastic granulating waste gas purifying device, and belongs to the technical field of waste gas purifying equipment. The waste gas purifying device comprises a gas collecting cover, a vacuum pump, a primary purifying water tank and a secondary purifying water tank, wherein the gas collecting cover is communicated with the primary purifying water tank via a primary communicating pipe; the primary purifying water tank is communicated with the secondary purifying water tank via a secondary communicating pipe; the secondary communicating pipe is provided with the vacuum pump. The waste gas purifying device is simple in structure; when in operation, harmful gases generated in the plastic granulating process are purified completely under the effect of the vacuum pump via full contact with water bodies in the primary purifying water tank and the secondary purifying water tank, and then meet the requirements of emission standard and environment protection; the defects that the existing waste gas purifying device is high in cost and is complex in device structure are solved, and the problems that the treatment effect is not ideal and cannot meet the emission standard and the environment protection requirement are also solved; the plastic granulating waste gas purifying device is particularly suitable for the purification of plastic granulating waste gas.

Owner:湖北三众车桥股份有限公司

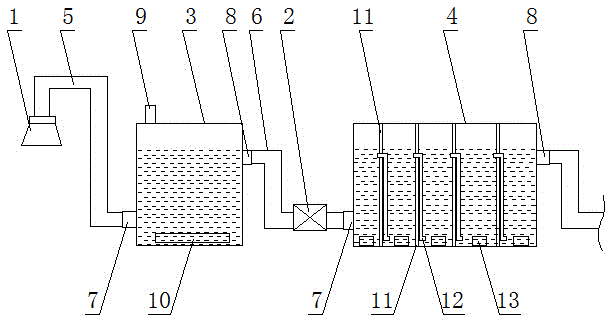

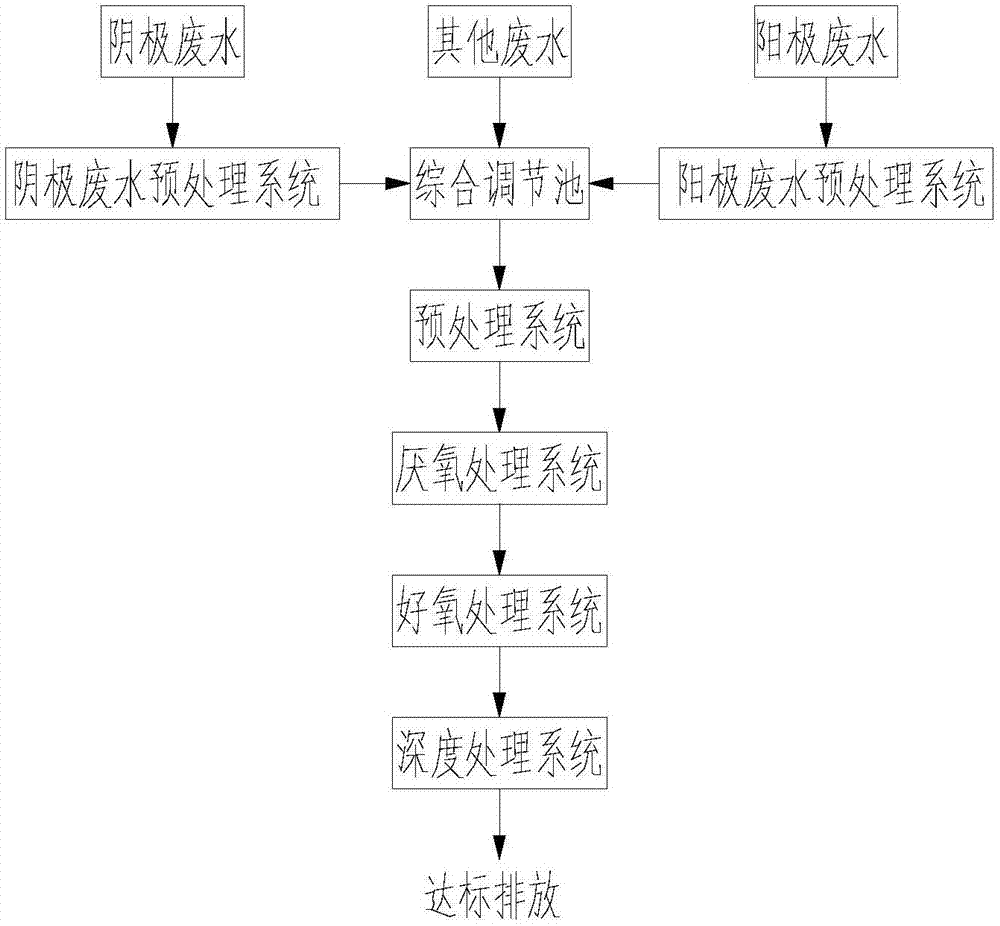

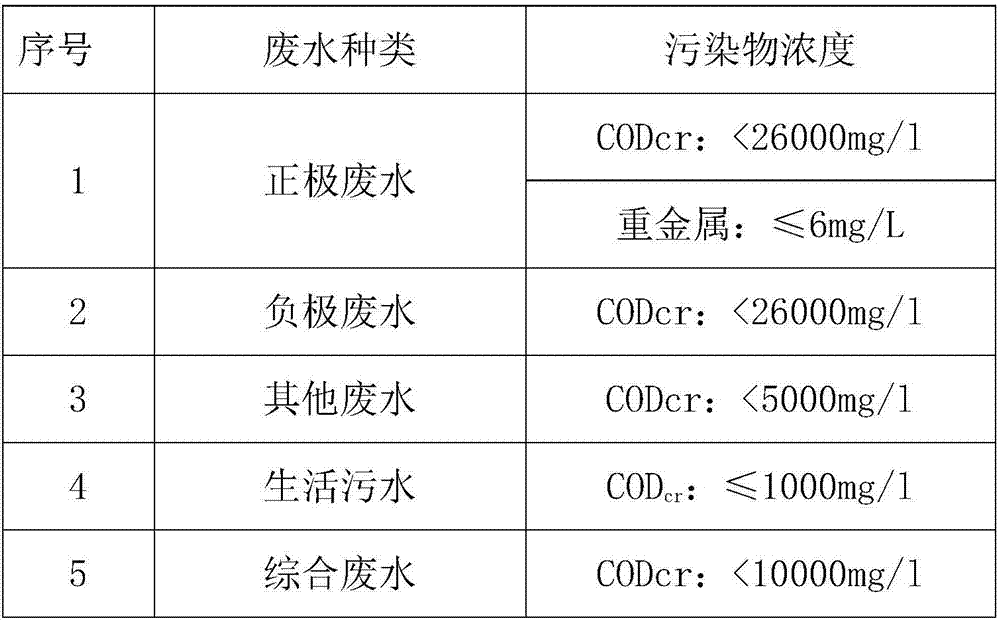

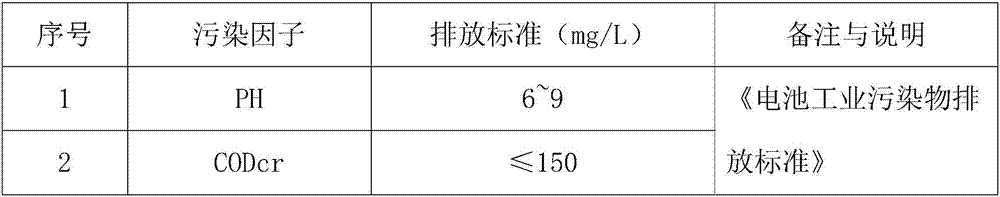

Lithium battery production waste water treatment system

InactiveCN106865896AReduce manufacturing costLess investmentWater contaminantsTreatment with anaerobic digestion processesToxic materialAnaerobic treatment

The invention discloses a lithium battery production waste water treatment system. According to the lithium battery production waste water treatment system, cathode and anode waste water generated in lithium battery production is subjected to cathode and anode pretreatment, and then is mixed with other waste water such as domestic wastewater and workshop washing wastewater at a ratio of 1:1:1-2 in a comprehensive regulating reservoir; an obtained mixed waste water is subjected to pretreatment, anaerobic treatment, aerobic treatment, and deep treatment so as to realize up-to-standard discharge. The water quality and biodegradability of the cathode and anode waste water are adjusted with other waste water; comprehensive building and integrated planning of the lithium battery production waste water treatment system are realized, and investment is reduced; toxic substances are removed, toxicity on microorganisms in subsequent biological treatment is reduced; and treatment effect is improved; recycling of a part of recoverable raw materials is realized, and production cost is reduced; anaerobic treatment are aerobic treatment are combined, occupied area is reduced, and excellent treatment effect is achieved; a subsequent deep treatment system is added flexibly, discharge requirements are satisfied, operation difficulty and operation cost are reduced, and the water quality of discharged water is stable.

Owner:SUZHOU ENV TECH ENVIRONMENTAL PROTECTION ENG

Component of gasoline engine particulate filter and preparation method of component

InactiveCN105060920AHigh reactivityPrevent the aperture from being too smallCeramicwareHydroxypropylmethyl celluloseMethyl cellulose

The invention discloses a component of a gasoline engine particulate filter and a preparation method of the component. The component comprises 35-45 parts of talc powder, 10-15 parts of aluminium hydroxide, 5-15 parts of kaolin, 10-15 parts of silica powder, 5-15 parts of boehmite, 0-4 parts of hydroxypropyl methyl cellulose, 0-10 parts of graphite powder, 5-15 parts of shell powder, 0-10 parts of starch, 10-25 parts of high-molecular plastic particles, 0-2 parts of mineral oil, 0-1 part of stearic acid and 25-35 parts of water. Raw materials, namely, the talc powder, the aluminium hydroxide, the kaolin, the silica powder and the boehmite, are mixed firstly, then a pore-forming agent is added in proportion, finally, a binder is added, cross pore blockage is performed, the gasoline engine particulate filter is prepared through sintering, the porosity of the prepared gasoline engine particulate filter is up to 60%-65%, the pore diameter is up to 20-30 mu m, the porosity of a carrier is greatly increased, the pore diameter is increased, so that the exhaust fluency of the carrier is improved, and blockage is prevented.

Owner:YIXING PRINCE CERAMICS +1

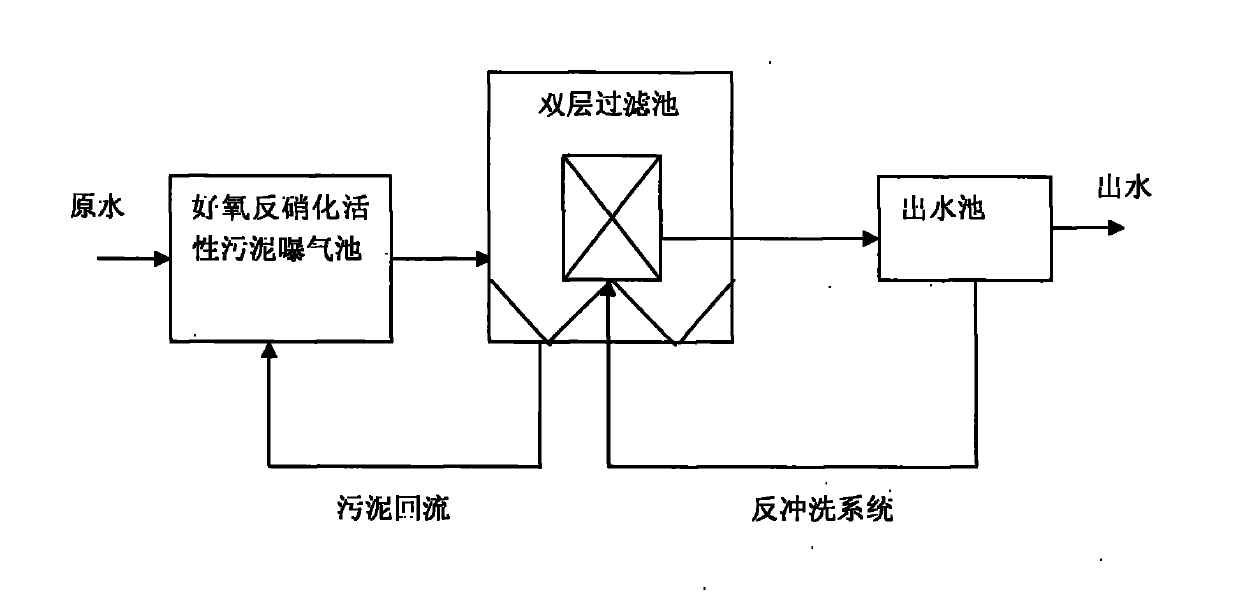

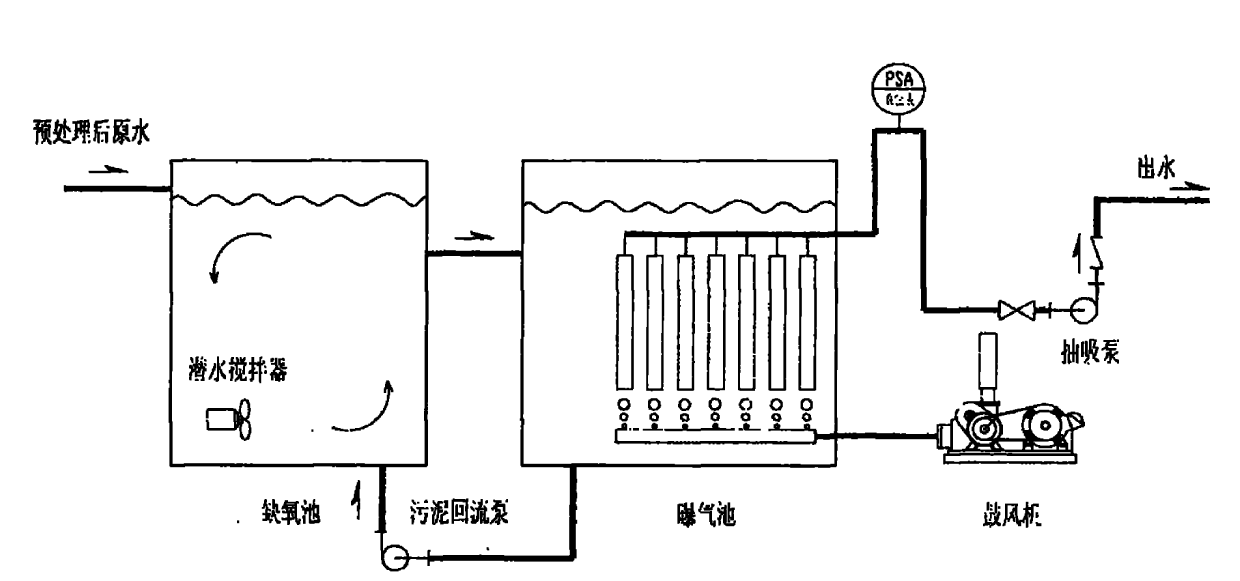

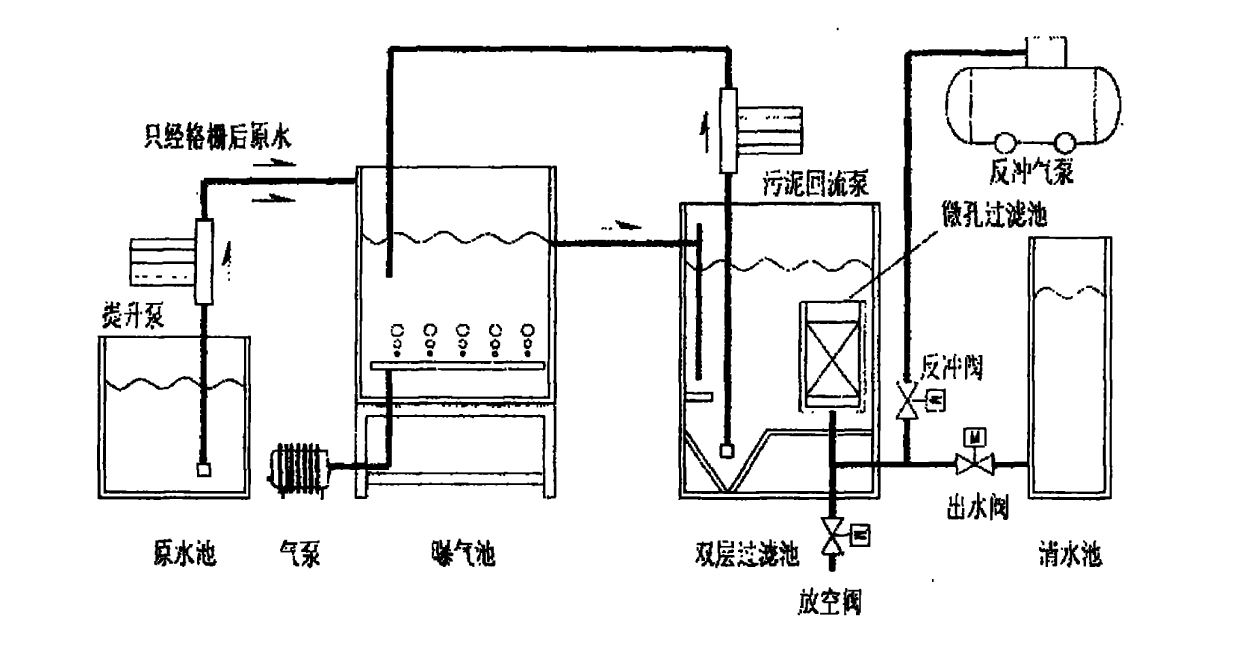

Method for treating municipal sewage by adopting millipore FBR (Filter Bio-reactor)

ActiveCN102070279AMeet the requirements of emission standardsLess investmentMultistage water/sewage treatmentEmission standardMunicipal sewage

The invention discloses a method for treating municipal sewage by adopting a millipore FBR (Filter Bio-reactor), belonging to the technical field of resources and environments. The municipal sewage can be treated by adopting a mode of combining aerobic denitrification with a dual-layer millipore filter tank in the method, thus pollutants, such as NH3-N, TN (Total N), COD, SS, TP (Total Phosphorus) and the like, in the municipal sewage can be greatly effectively reduced, the treated discharge water can reach the national earth surface IV class water standard, wherein CODCr is not more than 30mg / l, NH3-N is not more than 1.5mg / l, the total N (lake, reservoir, in the terms of N) is not more than 1.5mg / l, the total phosphorus (in the terms of P) is not more than 0.3mg / l, and the potassium permanganate index is not more than 10. The discharge water can be directly discharged in an earth surface riverway so as to reduce the environment pollution and meet the requirement on the increasingly improved municipal sewage emission standard. The invention can be applied to building municipal sewage treatment plants and modifying and reconstructing the traditional sewage treatment plants.

Owner:JIANGSU XIANTONG ENVIRONMENT TECH

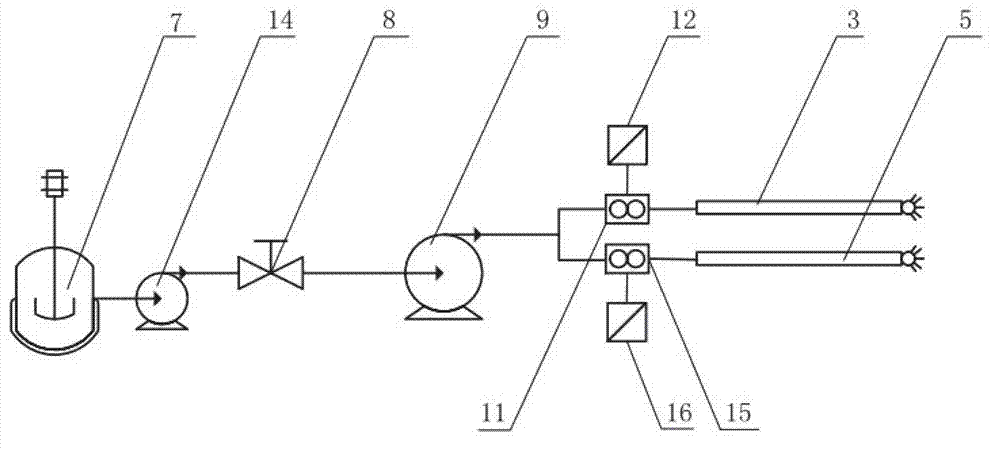

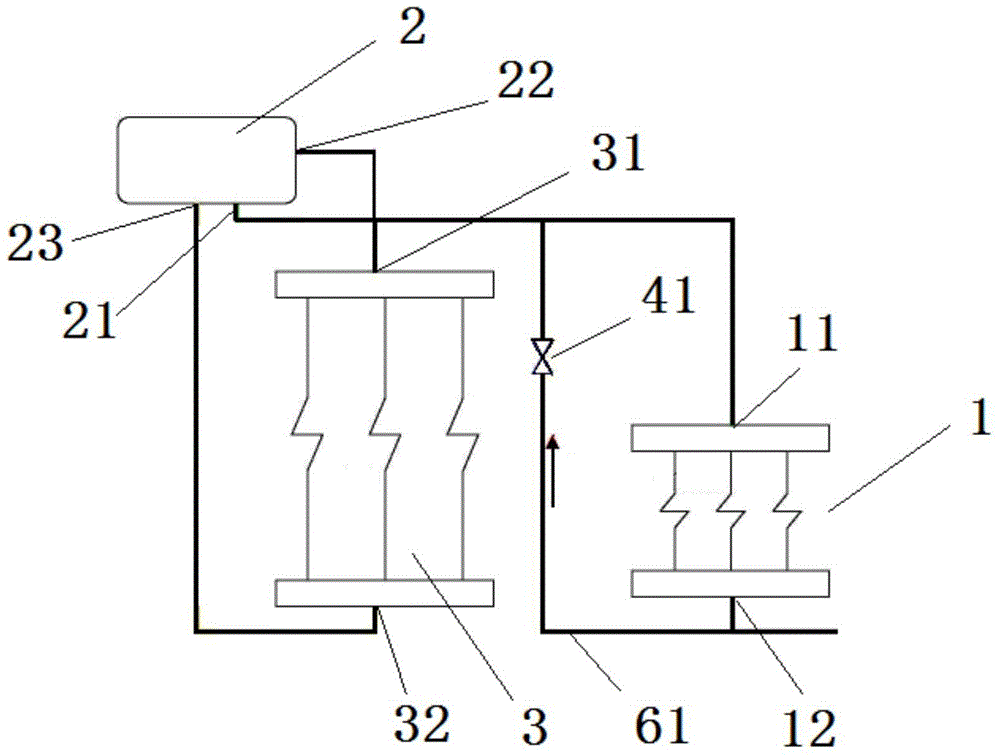

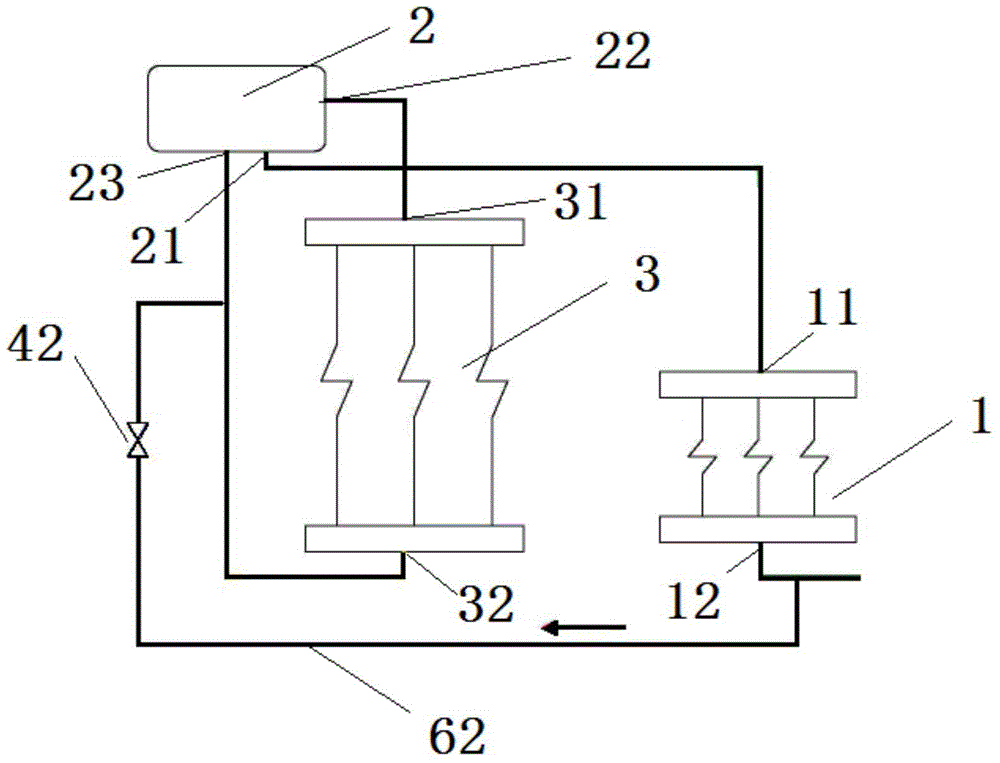

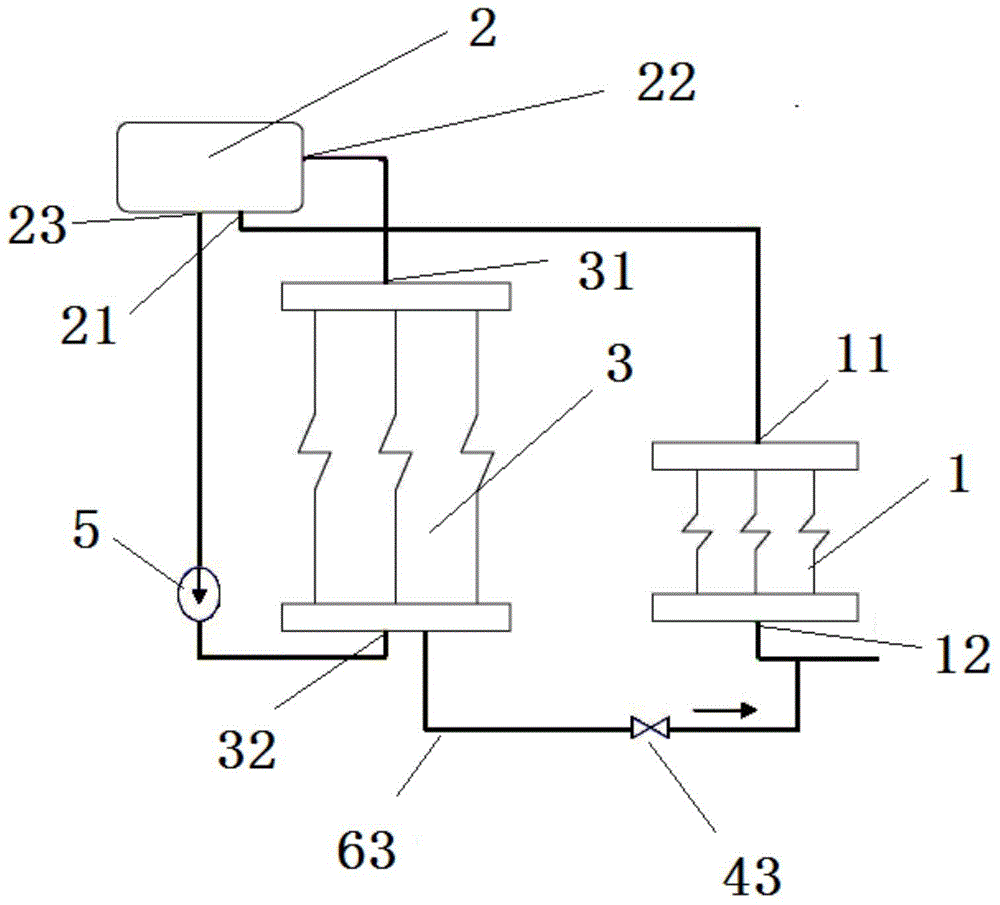

Microwave heating ammonia water reduction and denitrification treatment system and flue gas denitrification method thereof

ActiveCN104437065AAffect stabilityAvoid affecting furnace temperatureDispersed particle separationMicrowaveSolenoid valve

The invention discloses a microwave heating ammonia water reduction and denitrification treatment system and a flue gas denitrification method thereof. The system comprises a microwave tubular furnace, a forced draught blower, a temperature sensor, a denitrification reaction cavity and a concentration sensor, wherein the outlet a chamber of the microwave tubular furnace is connected with the inlet of the forced draught blower by virtue of a pipeline; the outlet of the forced draught blower is connected with the temperature sensor by virtue of a pipeline; the temperature sensor is connected with the bottom inlet of the denitrification reaction cavity by virtue of a pipeline provided with a first solenoid valve; the top outlet of the denitrification reaction cavity is connected with the concentration sensor by virtue of a pipeline; the concentration sensor is connected with the inlet A of the chamber of the tubular furnace by virtue of a second flue gas pipeline provided with a third solenoid valve; and the temperature sensor is connected with the input pipeline A of the chamber of the tubular furnace by virtue of a first flue gas pipeline provided with a second solenoid valve. The system is simple and scientific in denitrification process, the denitrification process is combined with the system, the flue gas emission can effectively meet the requirement on the national flue gas emission standard, and the system can be widely applied to occasions in which denitrification is needed so as to reduce the NOx emission and is wide in application prospects.

Owner:SOUTH CHINA UNIV OF TECH

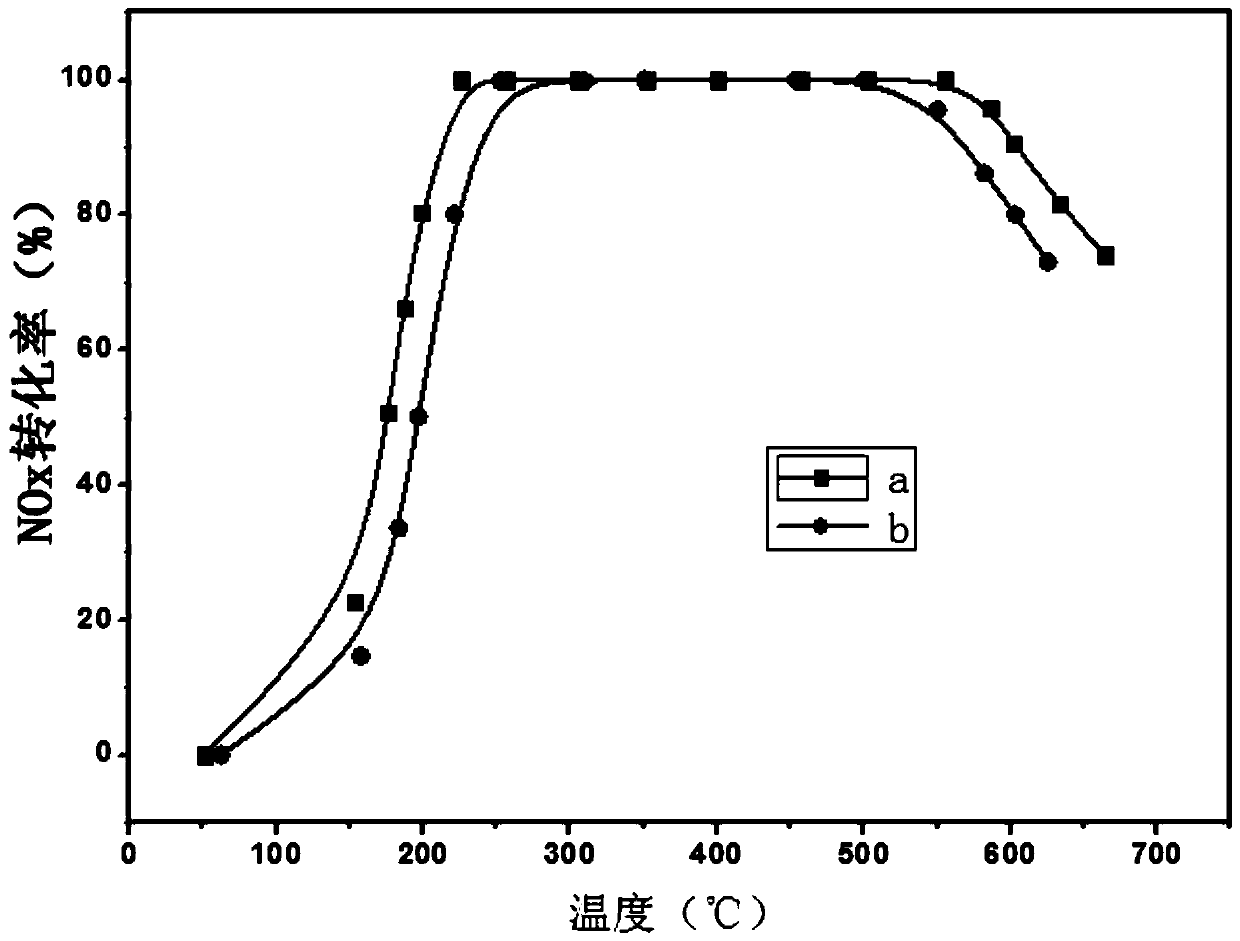

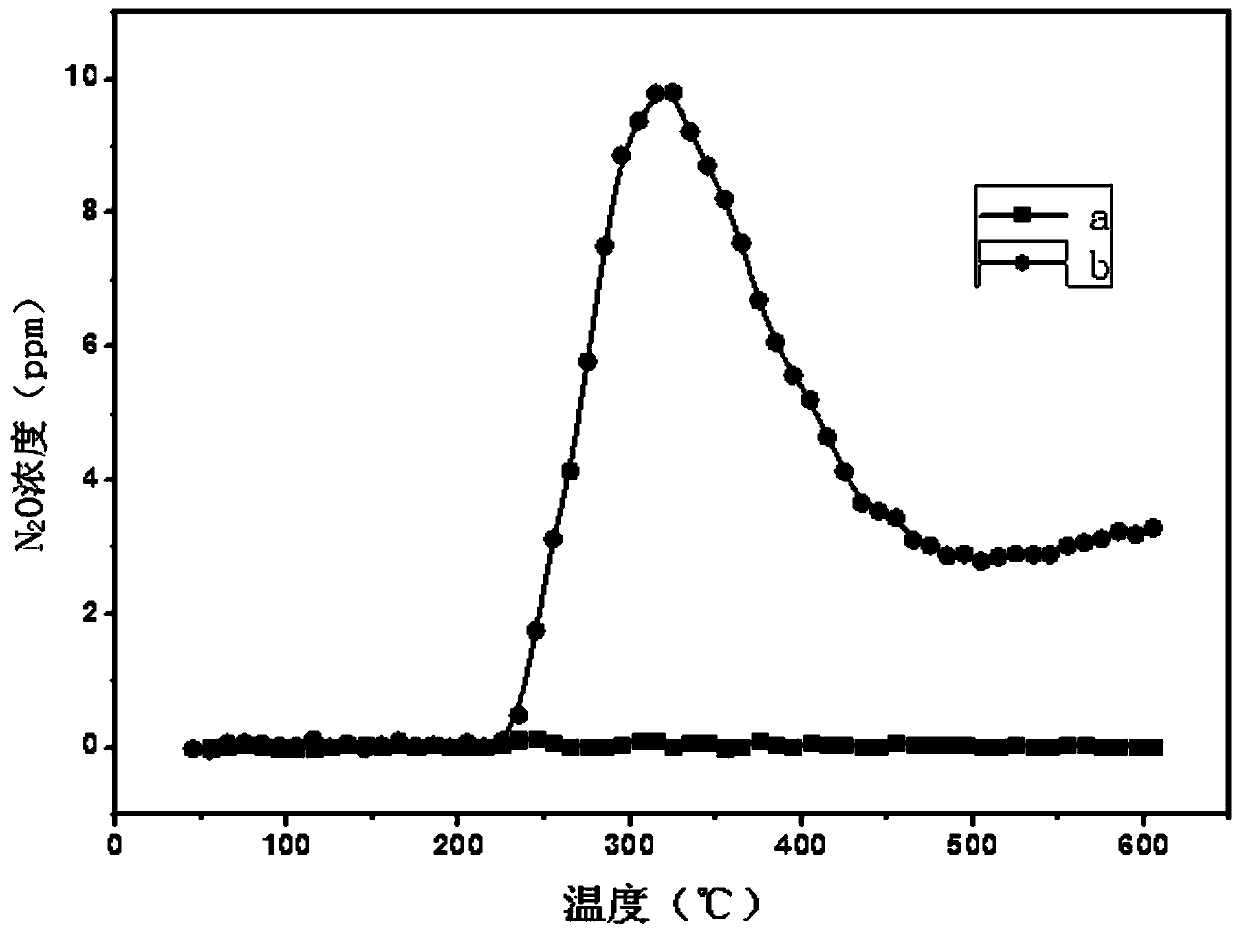

High-temperature-resistant high-activity Cu-based SCR catalyst and preparation method thereof

PendingCN110681412ATroubleshoot MigrationSuppress generationNitrous oxide captureMolecular sieve catalystsMolecular sieveCu2 ions

The invention provides a high-temperature-resistant highly-activity Cu-based SCR catalyst and a preparation method thereof. The preparation method includes the steps that a highly dispersed nano Cu solution is prepared; a Cu-molecular sieve in-situ impregnation solution is prepared; and the Cu-based SCR catalyst using an in-situ impregnation method is prepared. In the method, the Cu molecular sieve SCR is doped with metal salt with an ion radius within 30% of copper ion, by optimizing the preparation process and ratio, a solid solution system is formed, the problem of Cu (II) ion migration issolved, the generation of a by-product N2O is suppressed, the selectivity of N2 is improved, the acid site strength of the catalyst is enhanced, the storage capacity of a catalyst NH3 is improved, a catalytic activity window of the catalyst is widened, and the requirements of national VI emission standards are met. Compared with the prior art, the preparation method is simple, the production costis low, the repeatability is high, the process control is easy to implement, and the practical application requirements can be met well.

Owner:凯龙蓝烽新材料科技有限公司

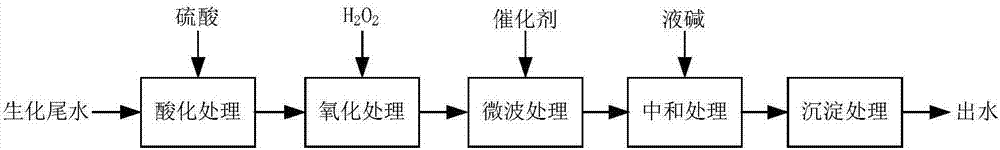

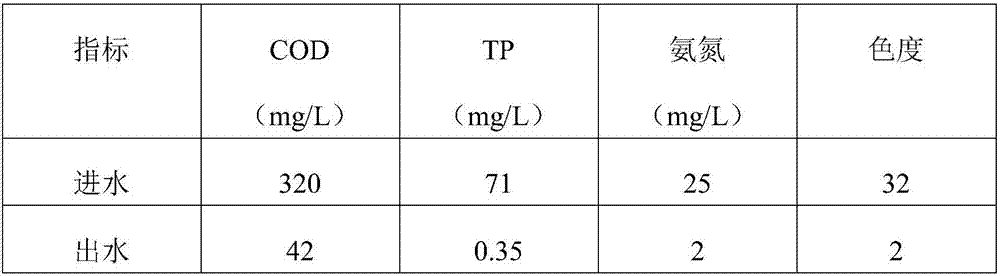

Microwave-assisted catalytic oxidation method for biochemical tail water of brewing wastewater by various metals

ActiveCN107055892AImprove thermal stabilityGood dispersionWater/sewage treatment by irradiationTreatment with anaerobic digestion processesCatalytic oxidationTherapeutic effect

The invention relates to a microwave-assisted catalytic oxidation method for biochemical tail water of brewing wastewater by various metals. Through catalytic oxidation by means of a catalyst compounded by various metals for sulfuric acid acidification, hydrogen peroxide oxidization and microwave assistance, COD, total phosphorus, ammonia nitrogen and chroma in tail water are efficiently removed, and effluent index demands are met efficiently and stably for a long time. The method is high in pertinence, high in reaction speed, stable in treatment effect, high in operability and low in operating cost, and provides a technical support for upgrading and reconstruction and standardized discharge of effluent treatment of breweries.

Owner:NANJING UNIV OF TECH

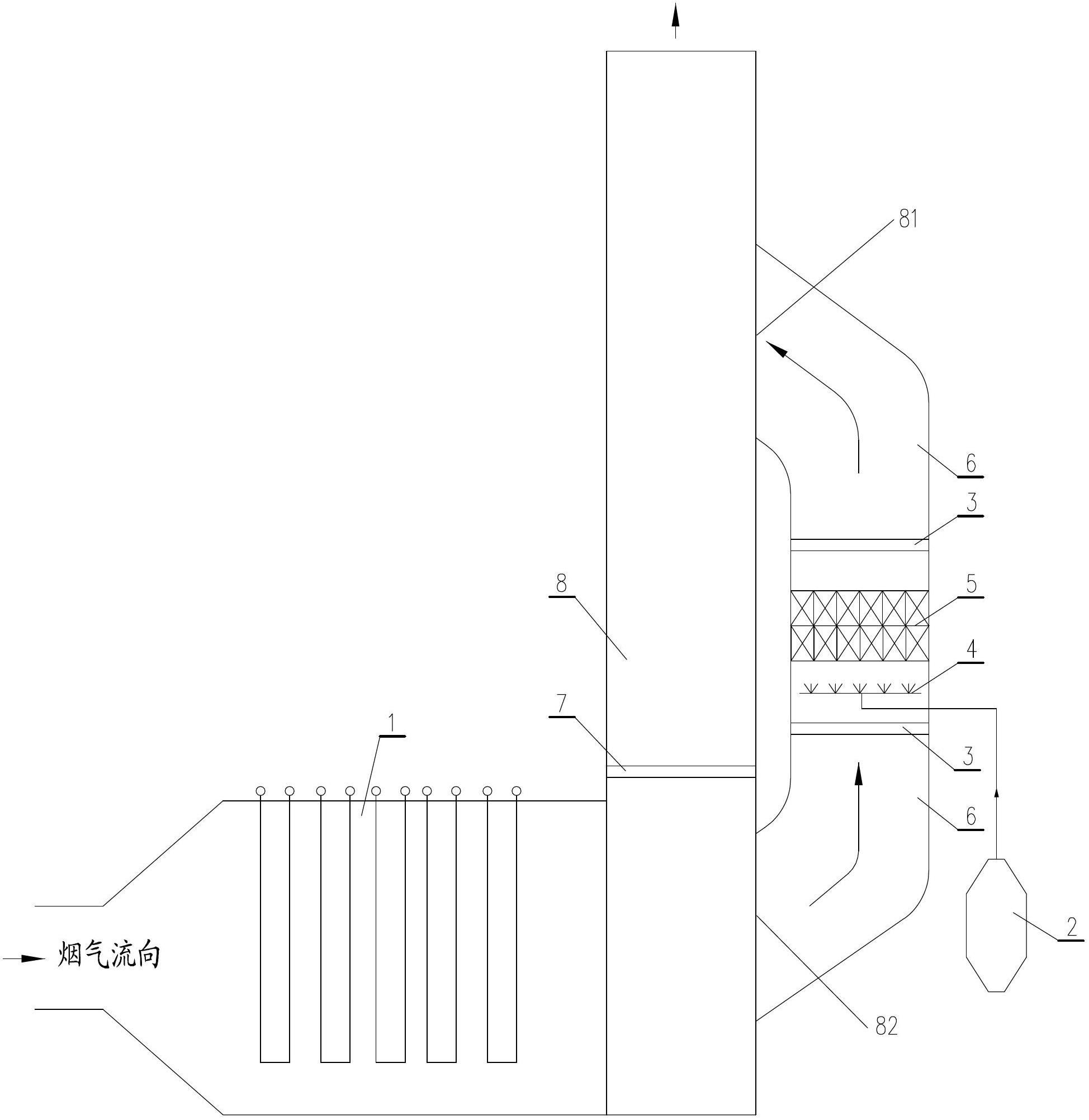

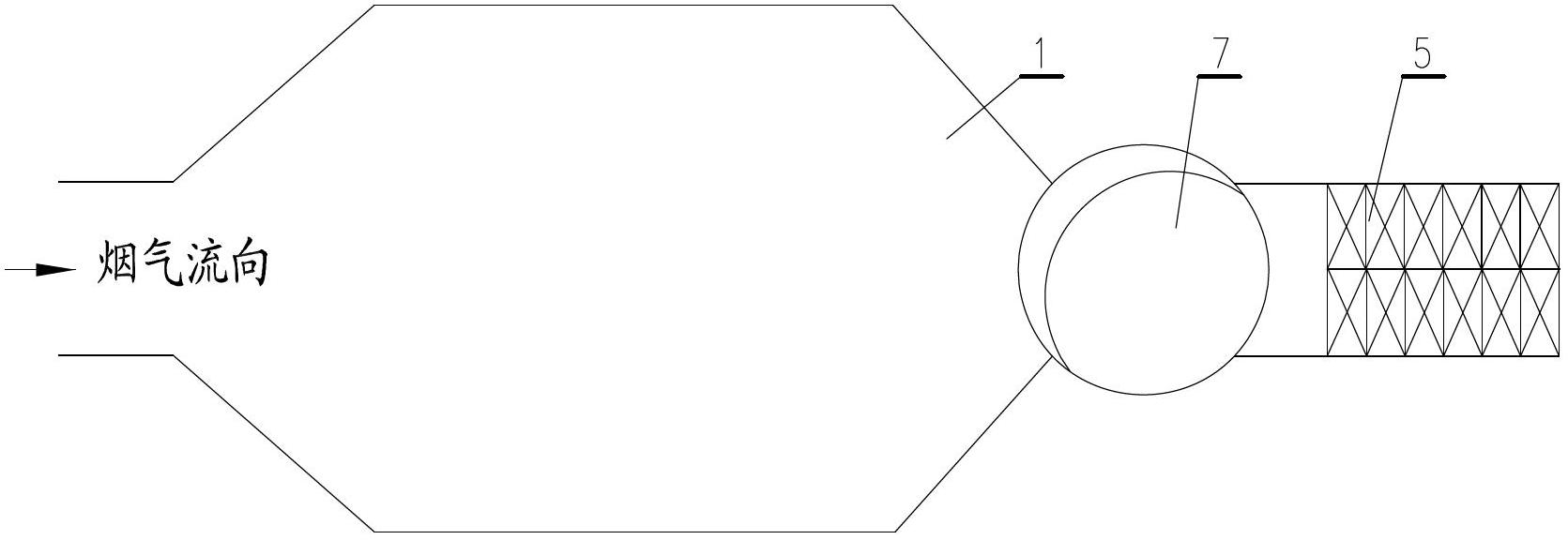

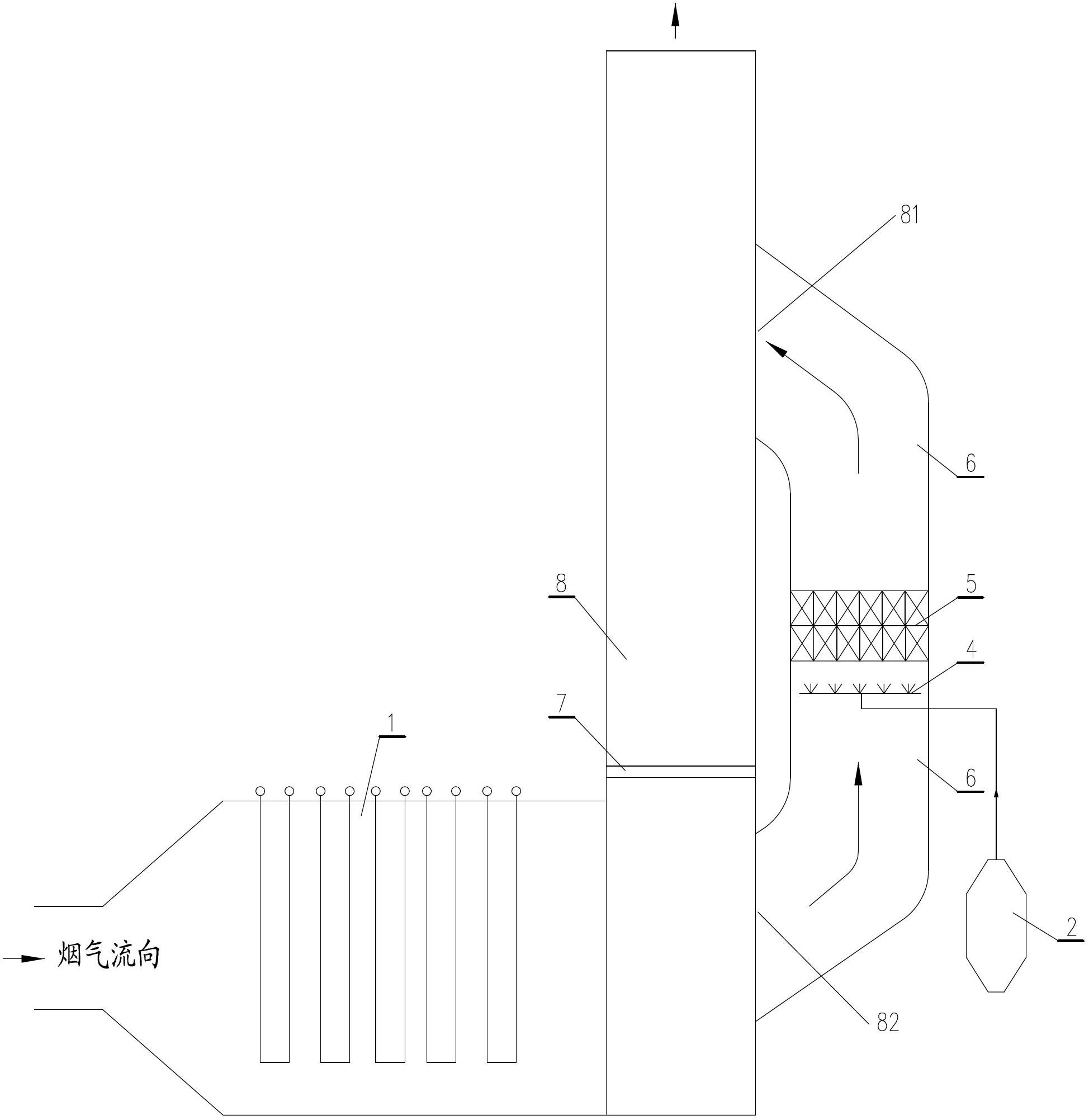

Low-temperature SCR (selective catalytic reduction) fixed bed fume denitration device for horizontal waste heat boiler

InactiveCN102658025ASmall impact on structureSave heatDispersed particle separationFixed bedProcess engineering

The invention relates to a low-temperature SCR (selective catalytic reduction) fixed bed fume denitration device for a horizontal waste heat boiler, which comprises a waste heat boiler and a chimney connected with the waste heat boiler. The invention is structurally characterized in that the outer side of the chimney is provided with a connection flue, an ammonia / air mixer, an ammonia spray mixing device and a low-temperature SCR reactor, wherein the chimney is provided with a lower outlet and an upper inlet, and the connection flue is connected and communicated with the lower outlet and the upper inlet; the ammonia / air mixer is arranged outside the connection flue; the ammonia spray mixing device and the low-temperature SCR reactor are arranged in the connection flue; the ammonia / air mixer is connected with the ammonia spray mixing device; the ammonia spray mixing device is arranged below the low-temperature SCR reactor; a baffle is arranged between the lower outlet and the upper inlet of the chimney; and the low-temperature SCR reactor comprises a denitration reaction space in which a low-temperature catalyst is arranged. The invention is also structurally characterized in that the ammonia spray mixing device and the low-temperature SCR reactor are arranged between the waste heat boiler and the chimney. The low-temperature SCR fixed bed fume denitration device for a horizontal waste heat boiler is obtained according to the two structures.

Owner:NORTH CHINA POWER ENG

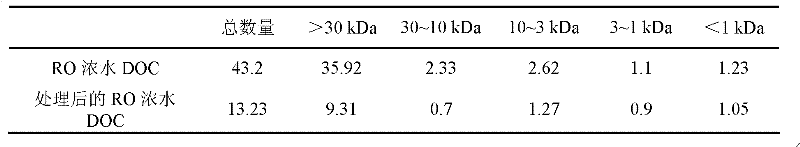

Method for purifying reverse osmosis concentrated water with active carbon-membrane separation countercurrent absorption

InactiveCN102502908ALow costEasy to operateWater/sewage treatment bu osmosis/dialysisWater/sewage treatment by sorptionTherapeutic effectReverse osmosis plant

The invention discloses a method for purifying reverse osmosis concentrated water with an active carbon-membrane separation accumulation countercurrent absorption technology. The method comprises the following steps of: extracting concentrated drain water produced in the running process of a reverse osmosis device, and adding into a membrane reactor for undergoing an adsorption reaction; dissolving powder active carbon (PAC) into the membrane reactor for continually adsorbing, wherein the adding amount of the PAC is determined according to the content of organic matters in the reverse osmosis concentrated water, and the adding amount of the PAC can be added appropriately if a treatment effect is poor; and performing aerated stirring and circulating reflux, adsorbing for 10-15 minutes, uniformly dispersing the PAC, fully mixing with reverse osmosis concentrated water, and discharging purified water with a hollow fiber membrane assembly. PAC accumulation countercurrent absorption and membrane separation are used together, so that cost is low, operation is easy and convenient, and automatic degree is high. Due to the adoption of the method for purifying reverse osmosis concentrated water, the requirements of the Discharge Standard of Pollutants for Municipal Wastewater Treatment Plant are met, and the potential hazard of direct discharge on a water environment is reduced; and the method plays an important role in maintaining the balance of a water ecological system.

Owner:TIANJIN UNIV

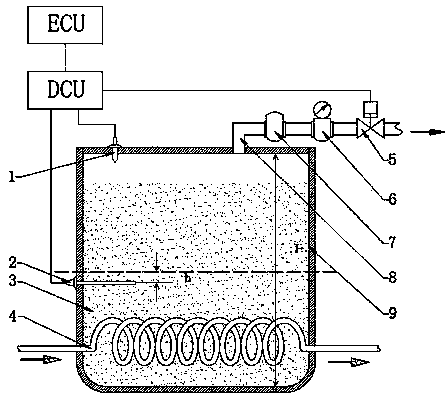

Ammonia gas metering method for solid ammonia storing system

ActiveCN103541796ASolve specific problems in metering usageMeet the requirements of emission standardsInternal combustion piston enginesExhaust apparatusEngineeringProcess engineering

The invention relates to an ammonia gas metering method for a solid ammonia storing system. The method is characterized by including the following steps that 1) a work condition signal of an engine is sent out by an electronic control unit (ECU), a command deceleration control unit (DCU) outputs signals according to system temperature to change the openness of an electromagnetic valve to control ammonia in a solid ammonia storing material to be evenly output; 2) when the DCU acquires analog signal input, the display internal pressure of a pressure sensor is larger than 200kpa, and the display internal temperature of a temperature sensor is larger than 60 DEG C, the 5-electromagnetic valve is opened. The temperature sensor, the pressure sensor, a filter, a stabilizing valve and an electromagnetic valve are combined in use. The method is applicable to silicon catalytic reduction (SCR) utilized by the national fourth discharging standard and above and also applicable to the future FCEV technology. The ammonia gas metering method is ingenious in idea, simple in process, easy to control, low in cost, safe and reliable, easy to maintain, high in accuracy and the like.

Owner:CHINA FIRST AUTOMOBILE

Semi-dry method refuse burning fume cleaning treatment method and system thereof

ActiveCN101310835BEvenly distributedImprove absorption efficiencyDispersed particle separationChemical reactionWater discharge

Owner:DESIGN INST OF CHONGQING IRON & STEEL GRP

Boiler thermodynamic system and boiler

InactiveCN104879743AGuaranteed uptimeMeet the requirements of emission standardsWater feed controlEmission standardEngineering

The invention relates to a boiler thermodynamic system and a boiler. The boiler thermodynamic system comprises an economizer (1). The boiler thermodynamic system further comprises a temperature adjusting device used for adjusting the temperature of smoke at the outlet of the economizer. By means of the technical scheme, the temperature adjusting device of the boiler thermodynamic system can adjust the water temperature or flow in the economizer (1), and therefore the temperature of the smoke at the outlet of the economizer is adjusted. Due to the fact that the outlet of the economizer is communicated with an SCR denitration system, the smoke enters the SCR denitration system through the inlet of the SCR denitration system from the outlet of the economizer, the temperature of the smoke at the outlet of the economizer is adjusted through the temperature adjusting device, then the temperature of the smoke at the inlet of the SCR denitration system is adjusted, and even when the boiler runs in the low-load state, the temperature of the smoke cannot be greatly reduced, in other words, the SCR denitration system can normally run, and the emission of the nitrogen oxide can meet the requirement of the Thermal Power Plant Atmospheric Pollutant Emission Standard.

Owner:CHINA SHENHUA ENERGY CO LTD +2

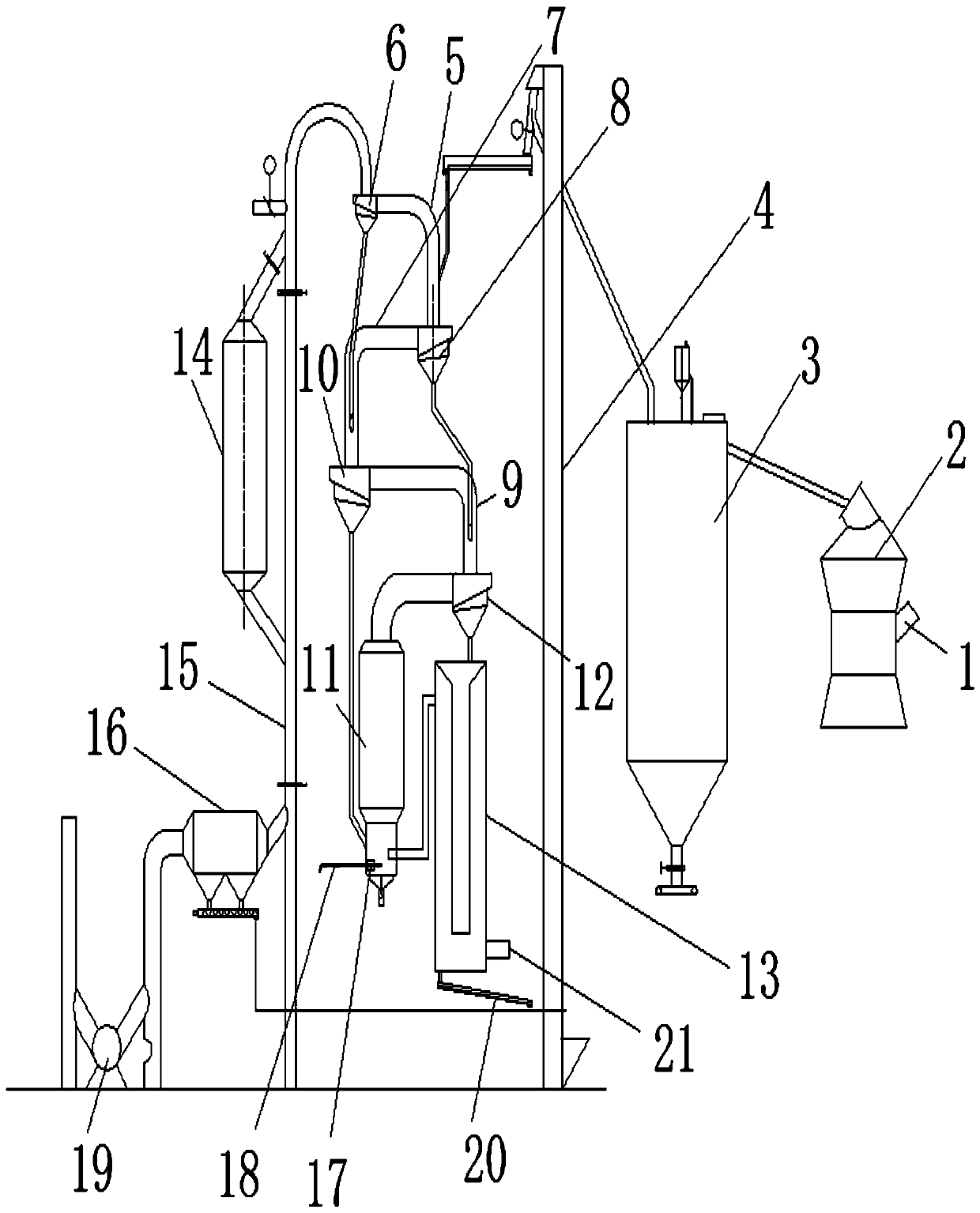

Suspension roasting device of powdery active lime and production technology of suspension roasting device

The invention relates to the technical field of active lime production, in particular to a suspension roasting device of powdery active lime. The upper end of a first cyclone preheater is communicatedwith one end of a discharge flue, the side wall of the discharge flue is communicated with the upper end of a waste heat boiler through a third pipeline, the lower end of a roasting furnace is communicated with a burner, the lower end of the side wall of the burner is connected with a fuel inlet pipeline, the lower end of the side wall of a stepped cooling device is communicated with an air inletpipe, air heated by a cooling system enters the roasting furnace to be used for fuel combustion, waste heat is fully recycled, heat loss is effectively reduced, the resource utilization rate is high,mass production is facilitated, little equipment is used, the floor area is small, operation automation and waste heat recycling are facilitated, the production cost can be reduced, the produced powdery active lime has good activity, the production efficiency is high, the production time is shortened, and the economic benefits of an enterprise can be increased.

Owner:LUOYANG CEMENT ENG DESIGN & RES INST

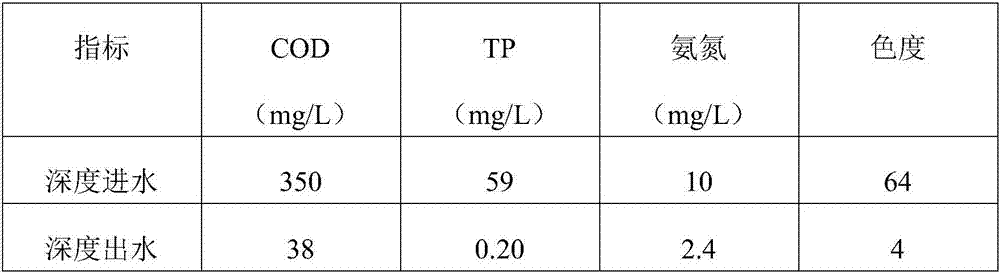

Deep treatment method for landfill leachate

InactiveCN104355463AMeet the requirements of emission standardsWater/sewage treatmentMultistage water/sewage treatmentSequencing batch reactorChemical oxygen demand

The invention relates to a deep treatment method for landfill leachate, and belongs to the field of drinking water treatment methods. The deep treatment method for the landfill leachate comprises steps as follows: the landfill leachate which is treated with an SBR (sequencing batch reactor) method and is not up to the standard and drained is collected, an appropriate amount of sodium chloride is added, the concentration of chloride ions in the leachate is 10,000 mg / L, then the leachate is added into an electrolytic bath for catalytic electrolysis under certain conditions, and the landfill leachate after catalytic electrolysis is up to the standard and drained. According to the deep treatment method for the landfill leachate, the catalytic electrolysis method is adopted to perform catalytic electrolysis on the landfill leachate which is treated with the SBR method and is not up to the standard and drained, so that content of COD (chemical oxygen demand), ammonia nitrogen and BOD5 (biochemical oxygen demand5) in the leachate is reduced, the COD removal rate is higher than 86.5%, the ammonium nitrogen removal rate is nearly 100%, the chroma removal rate is higher than 91%, and the leachate meets requirements of up-to-standard emission.

Owner:XIAN HUALU ENVIRONMENTAL PROTECTION EQUIP

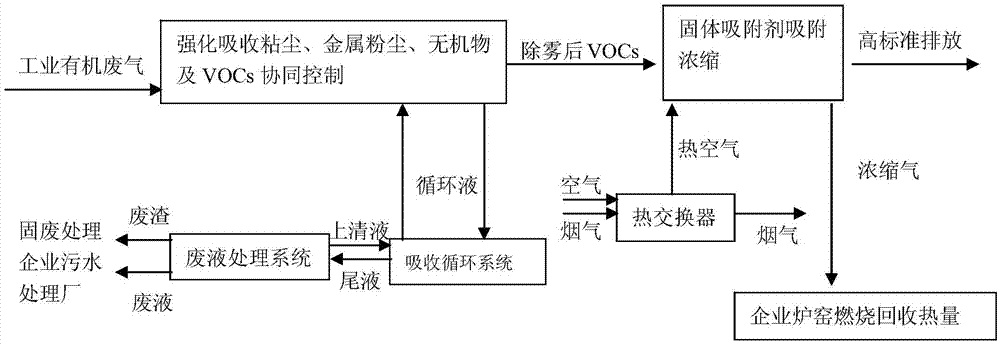

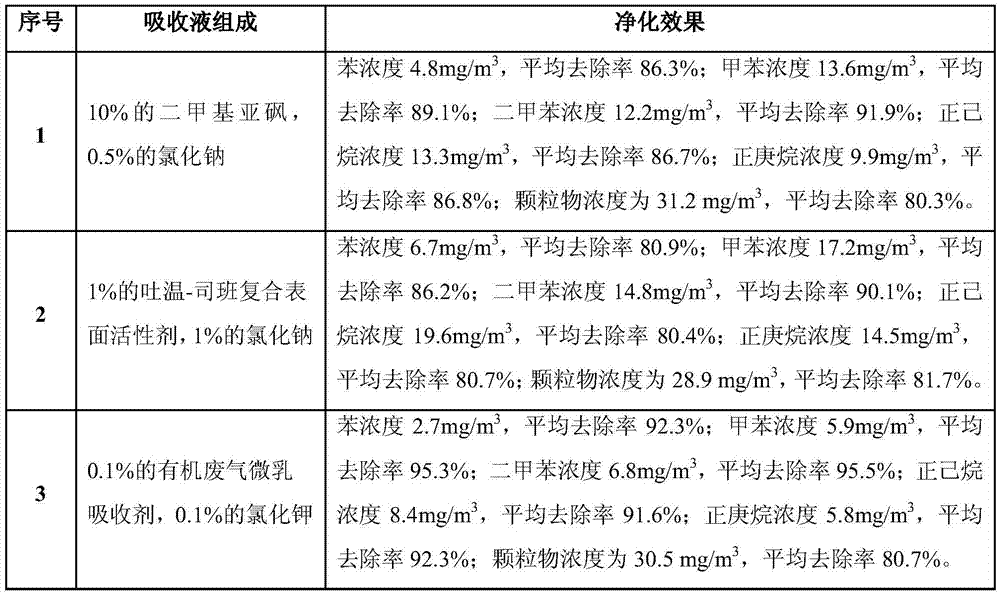

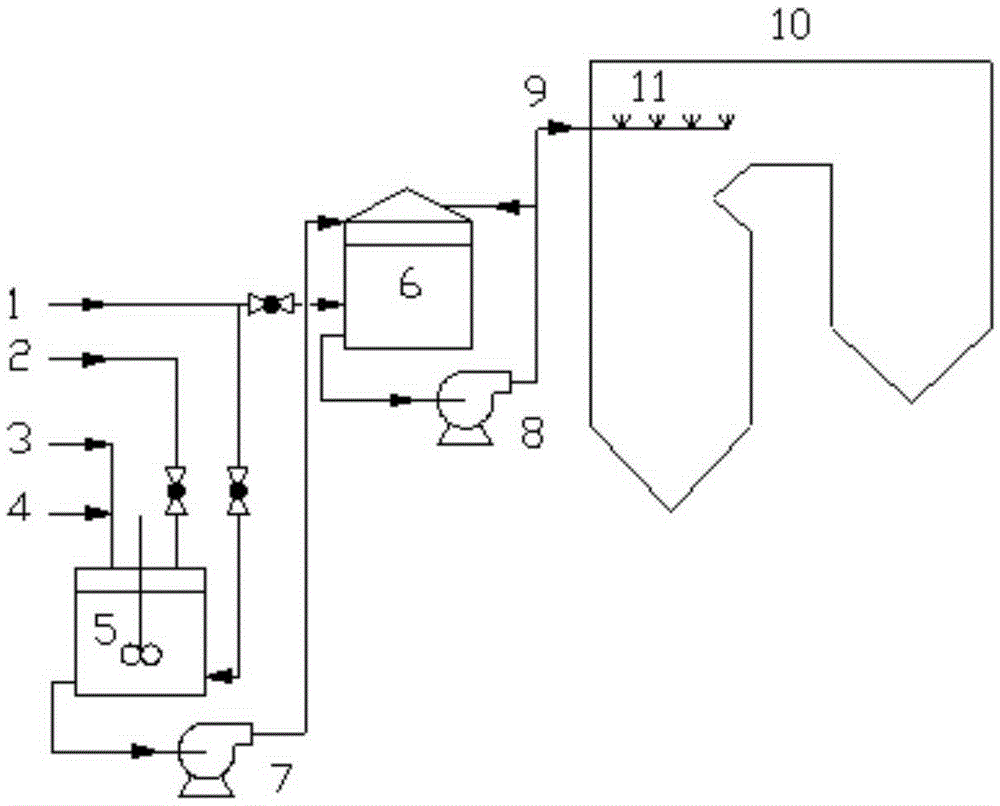

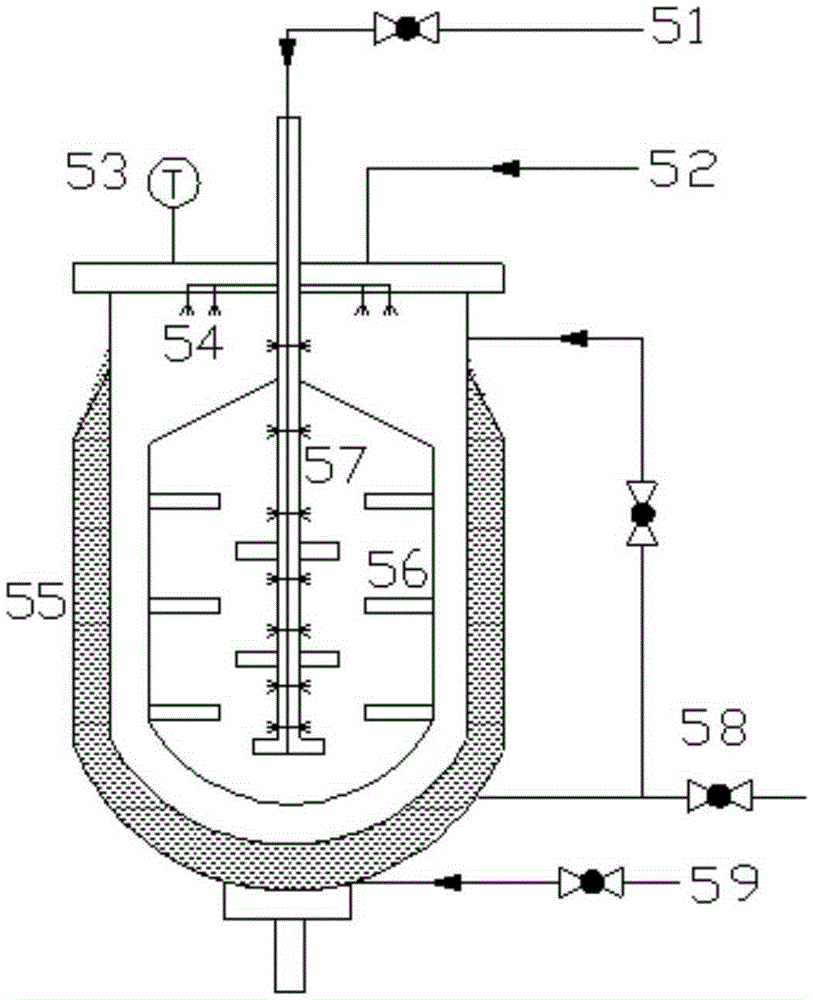

New deep purification process of organic waste gas, and applications of new deep purification process in treatment of industrial organic waste gas

InactiveCN106975334APollution Control and TreatmentLarge specific surface areaGas treatmentDispersed particle separationParticulatesTime efficient

The invention discloses a new deep purification process of organic waste gas, and applications of the new deep purification process in treatment of industrial organic waste gas. According to the present invention, through the integrated innovation of an efficient liquid absorption method and a solid adsorption method, the efficient synergistic purification of particulate matters, VOCs and multiple pollutants is achieved; the concrete principle is that most of the VOCs in waste gas are subjected to absorption removal by using an efficient liquid absorbent through a like dissolves like principle and other principles while the vast majority of particulate matters are removed through washing, most of water is removed from the purified waste gas through a demister, the water removed waste gas enters an adsorption section, and the VOCs in the waste gas is subjected to adsorption removal so as to achieve the standard discharging; and with the previous section absorption process, the bonding and the clogging of the subsequent section adsorption equipment can be prevented, the production load can be reduced, the long-time efficient and stable running can be ensured, and the double efficient synergistic control of the multiple pollutants in the method and between the methods can be achieved; and the new deep purification process has advantages of high VOCs removal efficiency and flexible process selection, and is suitable for the treatment of industrial organic waste gas.

Owner:SOUTH CHINA INST OF ENVIRONMENTAL SCI MEP

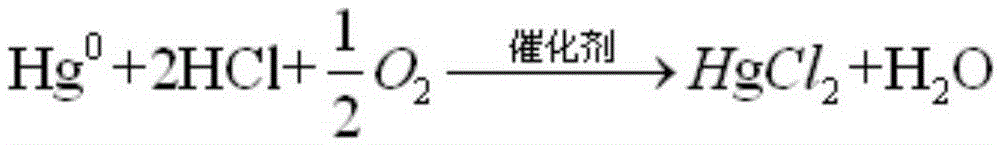

Joint mercury removing method and device based on SNCR

ActiveCN105268300ASimple and economical processReduce initial investment costDispersed particle separationMixersUreaCapital cost

The invention provides a joint mercury removing device based on SNCR. Two kinds of flue gas treatment technologies can be effectively combined, and the purpose of nitrate and mercury removal is achieved while cost is reduced. The device comprises two sets of independent measuring systems, a solution preparing system connected to the output ends of the two sets of measuring systems, a solution conveying system and a solution spraying system, wherein the solution conveying system and the solution spraying system are sequentially connected to the output end of the solution preparing system. The solution spraying system comprises a spraying inlet and a spraying gun. The spraying inlet is formed in a hearth of an SNCR system, and the spraying gun is connected to the spraying inlet and stretches into the hearth. The two sets of measuring systems are used for measuring urea and ammonium chloride solids respectively according to the demanding amount for removing NOx and zero-valent mercury. The mercury removing technology and the SNCR are joined, the advantages of the two technologies are combined, the advanced SNCR technology is developed, additional technological equipment is not added except for the measuring systems based on original facilities, the technology is easier and more convenient to implement and more economical, and capital cost is saved.

Owner:CHINA HUANENG GRP CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com