Process and device for treating nitric oxide in tail gas generated in nitric acid and nitrate production

A nitrogen oxide and tail gas technology, which is applied in the preparation of alkali metal nitrates, chemical instruments and methods, and the separation of dispersed particles, can solve the problems of high investment and low efficiency of absorption methods, and achieve the purpose of making up for operating costs, saving energy, The effect of increasing production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

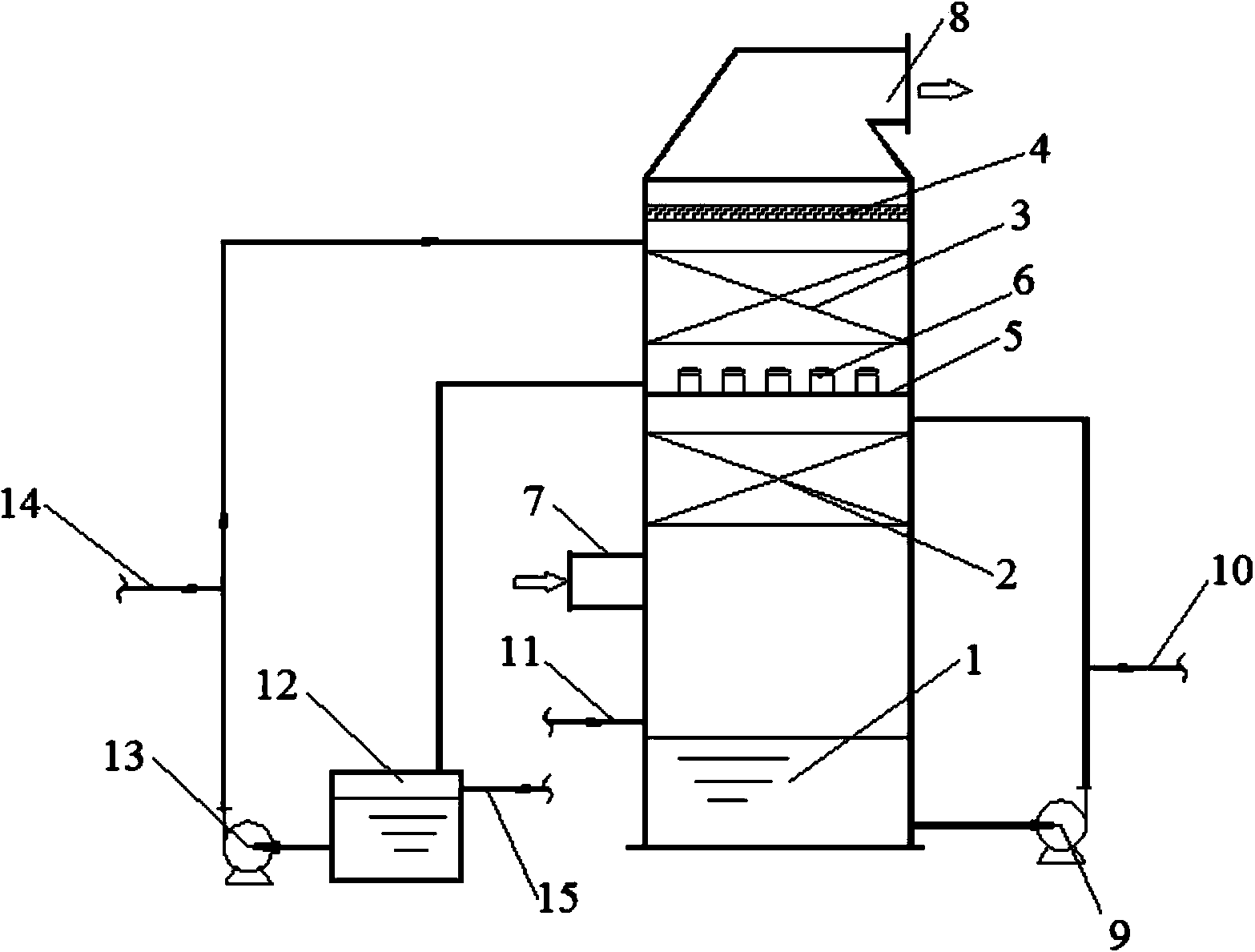

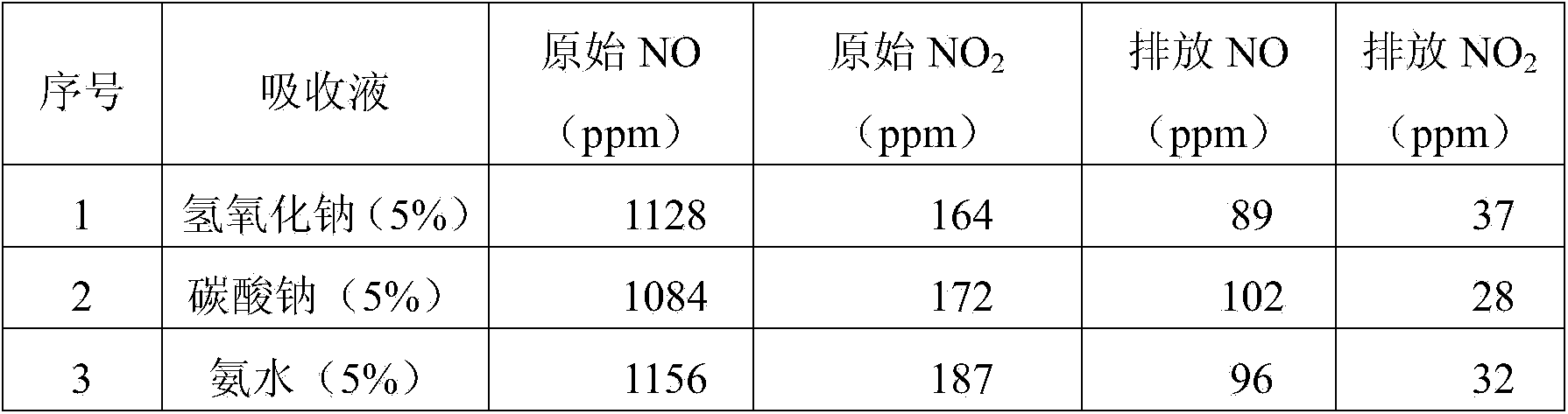

[0039] The device of the present invention is applied to a small nitric acid production device by ammoxidation under atmospheric pressure with a tail gas volume of 18,000 L / h to treat nitrogen oxides in the tail gas. Nitrogen oxides produced after ammonia oxidation at atmospheric pressure, the concentration of nitrogen oxides in the tail gas after acid absorption is about 1200ppm, NO 2 : NO ratio is 1: 6, tail gas conditioning and tempering zone and alkali absorption zone all adopt plate tower form, the mass percentage concentration of nitric acid used for conditioning is 35~68%, and the alkali absorption liquid is sodium hydroxide, which is 5% in mass percentage concentration, Sodium carbonate and ammonia solution.

[0040] When the catalyst is not used, the tail gas conditioning needs to use nitric acid with a concentration of 62-65% by mass to convert NO 2 : NO ratio is adjusted to within the scope of 0.95~1.05; but when adopting catalyst, the mass percent concentration of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com