Patents

Literature

1059 results about "Ammoxidation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

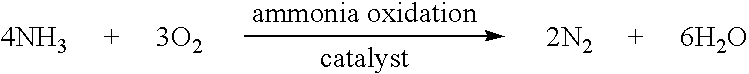

In chemistry, ammoxidation is an industrial process for the production of nitriles using ammonia and oxygen. The usual substrates are alkenes. It is sometimes called the Sohio process, acknowledging that ammoxidation was first discovered by Standard Oil of Ohio in 1957.

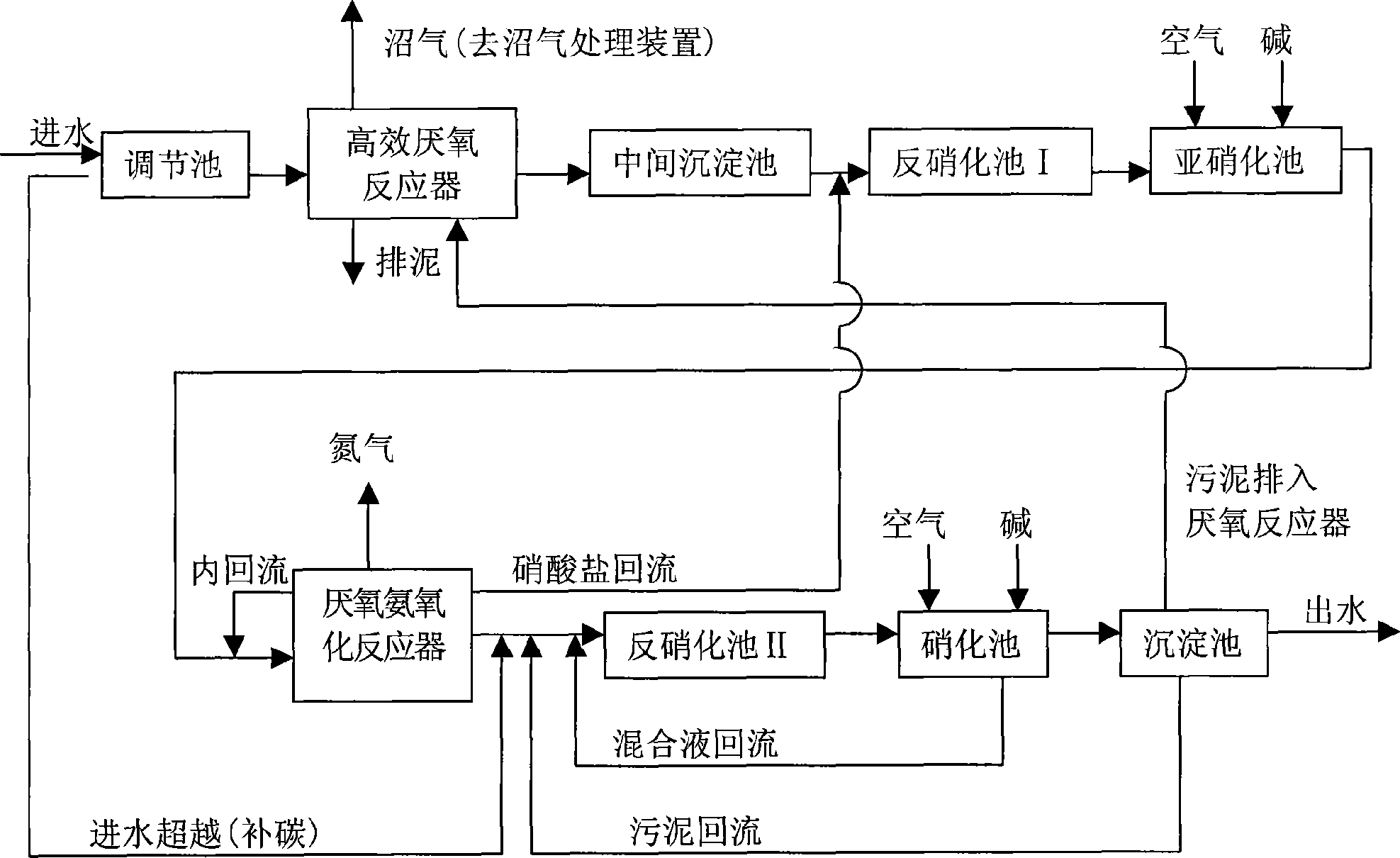

Deepness denitrogenation method for treating organic wastewater in high concentration

ActiveCN101050026AGuaranteed emission standardsThe process route is compactWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationTotal nitrogen

This invention discloses a method for deep denitrification treatment of high-concentration organic wastewater. The apparatus comprises an anaerobic decarbonization zone, an aerobic nitrosation / anaerobic ammoxidation denitrification zone, and a traditional nitrification / denitrification zone. In the anaerobic decarbonization zone, an anaerobic bioreactor is utilized to perform anaerobic biotreatment on the organic pollutants in raw water to remove the majority of organic matters. In the aerobic nitrosation / anaerobic ammoxidation denitrification zone, ammonia nitrogen and nitrite nitrogen are removed in the form of nitrogen gas. In the traditional nitrification / denitrification zone, nitrate in the water discharged from the aerobic nitrosation / anaerobic ammoxidation denitrification zone is subjected to denitrification and removed in the form of nitrogen gas. Excess organic matters are subjected to aerobic bioreaction and removed. The method can ensure COD; total nitrogen and ammonia nitrogen contents in the treated water are qualified for discharge. The method has such advantages as high decarbonization and denitrification efficiency, low energy consumption, and high running stability.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

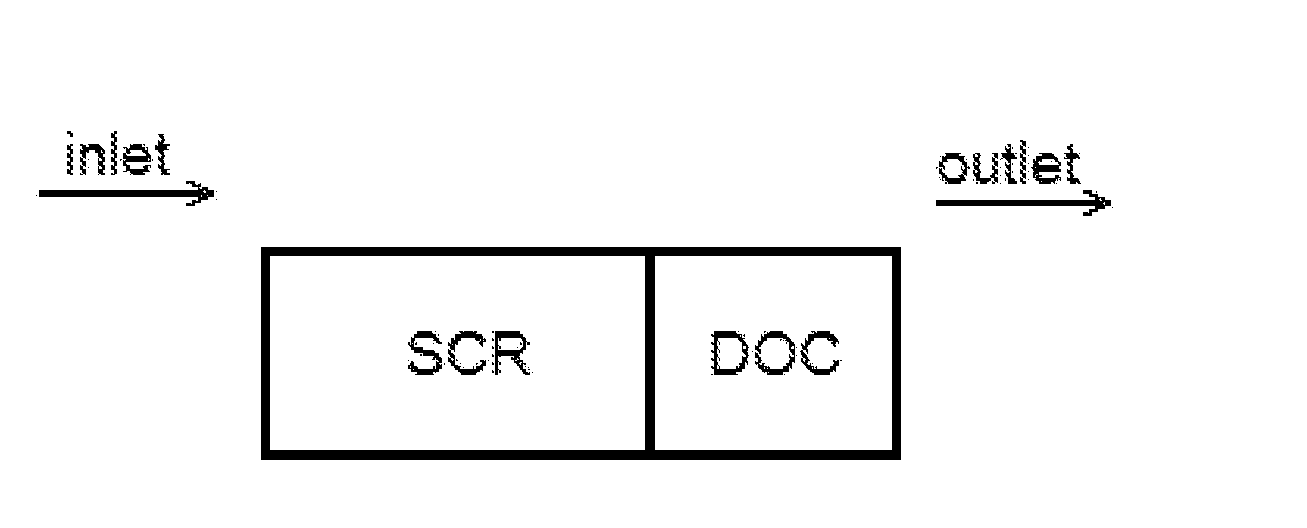

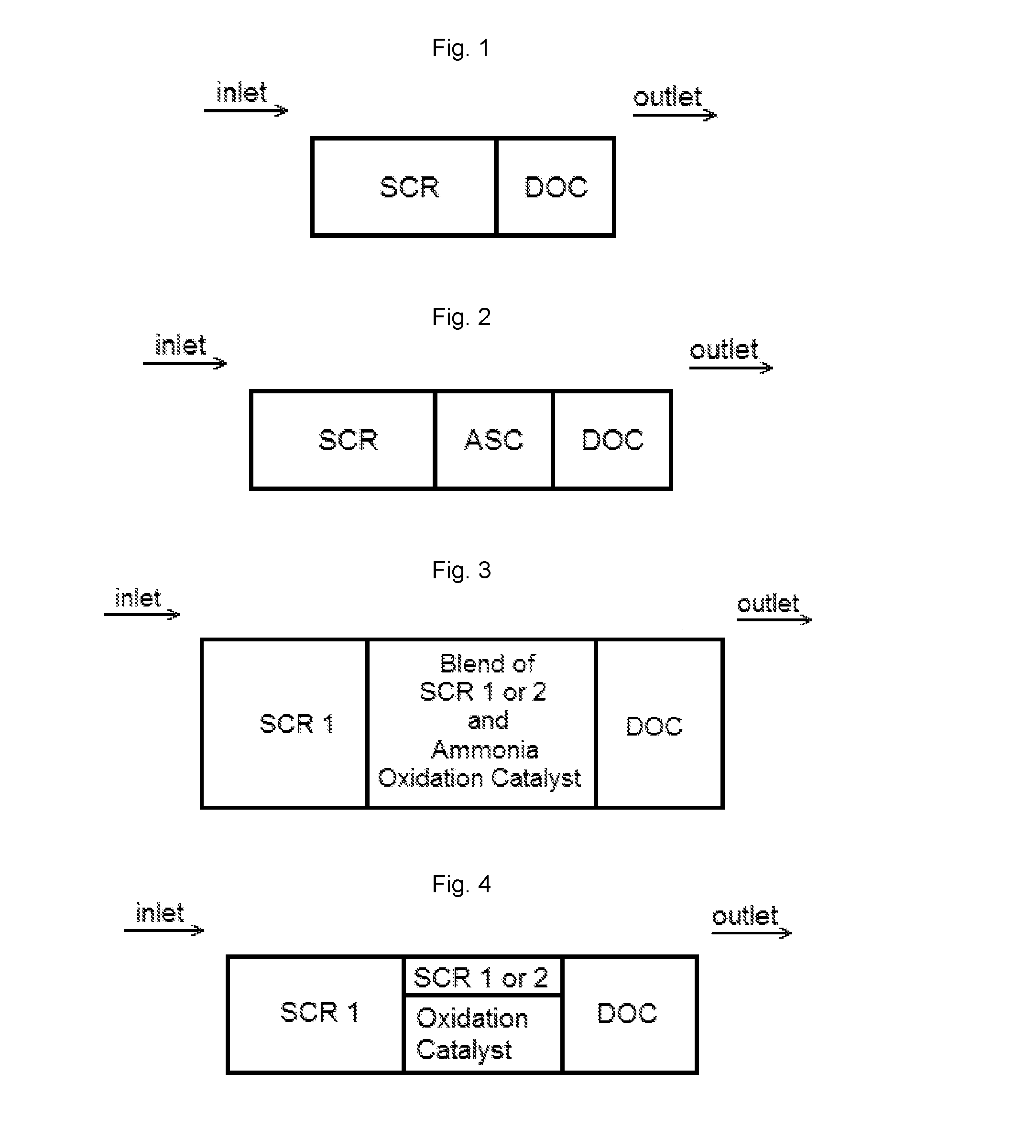

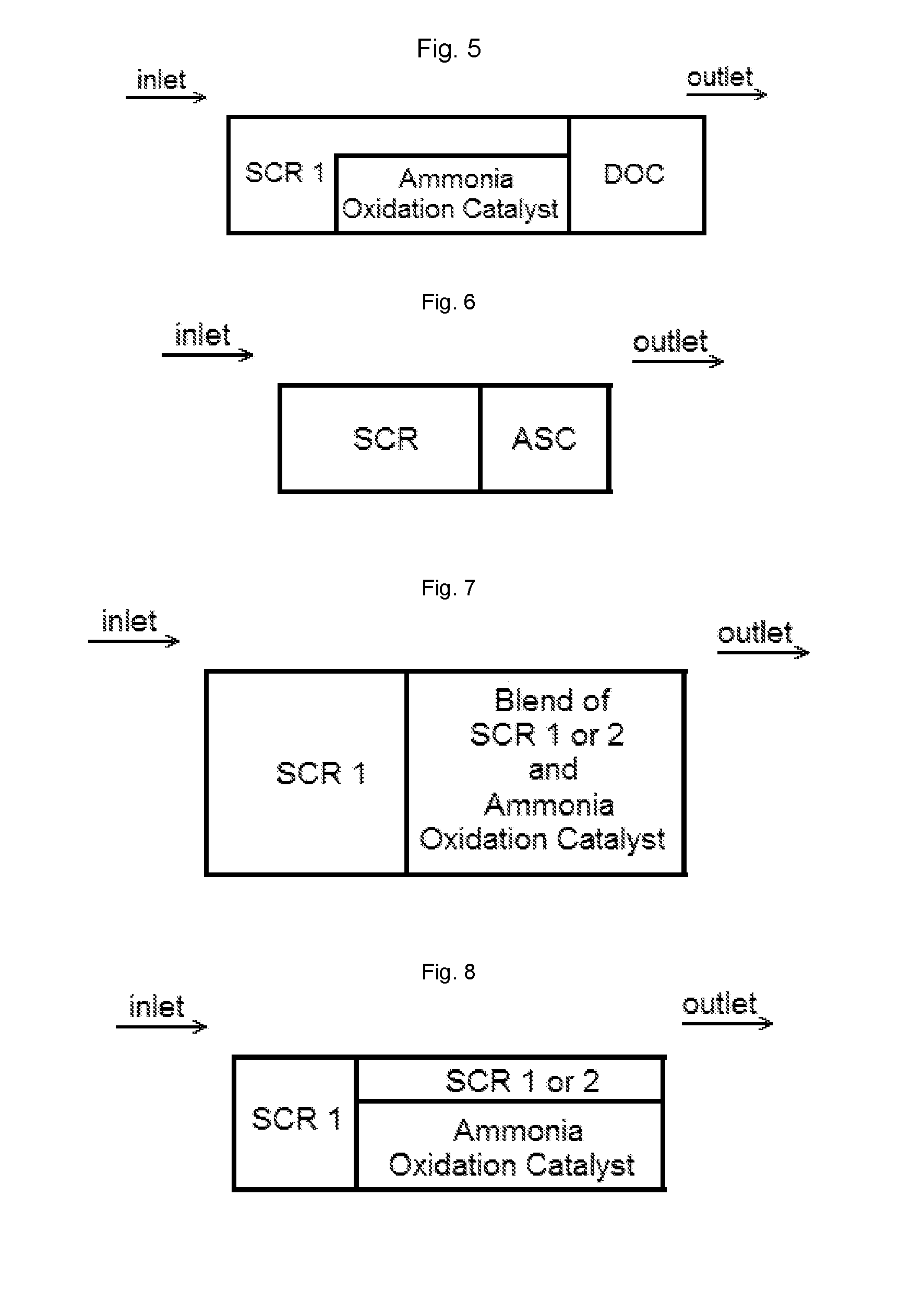

Zoned Exhaust System

ActiveUS20160367941A1Rapid responseQuick responseInternal combustion piston enginesDispersed particle separationPtru catalystPhysical chemistry

A catalytic article having a flow-through substrate having an inlet, an outlet, and an axial length; an SCR zone containing a first SCR catalyst; and an oxidation zone containing (a) an ASC zone and a DOC zone or (b) a mixed ASC and DOC zone, where the oxidation zone contains an ammonia oxidation catalyst and a DOC catalyst, the SCR zone is positioned on the substrate from the inlet end and extends less than the axial length of the substrate from the inlet, the DOC zone or the mixed ASC and DOC zone is position on the substrate from the outlet end, and when the DOC zone is present, the ASC zone is located between the SCR zone and the DOC zone. In other catalytic articles, the ASC zone further comprises a DEC catalyst. Methods of using the catalytic articles in an SCR process, where the amount of ammonia slip is reduced, are also described.

Owner:JOHNSON MATTHEY PLC

Fluid bed catalyst in use for oxidizing reaction of olefin ammonia

InactiveCN1600422AImprove wear resistanceHigh activityPreparation by hydrocarbon ammoxidationMetal/metal-oxides/metal-hydroxide catalystsFluidized bedActive component

A fluidized-bed catalyst for the ammoxidation reaction of olefin is composed of the carrier consisting of nano-SiO2 and silica sol, and the active component Mo(12-g)BiaFebNicXdZfOgOx, where X is chosen from Mg, Co, Ca, Be, Cu, Zn, Pb, Sb, Mn and Cr, Y is chosen from La, Ce and Sm, Z is chosen from Li, K, Rb, Na and Cs, Q is chosen from B, W, P and V, a=0.1-6, b=0.01-10, c=0.01-10, d=0.01-10, e=0.01-10, g=0-2 and f is more than (0-0.5).

Owner:CHINA PETROLEUM & CHEM CORP

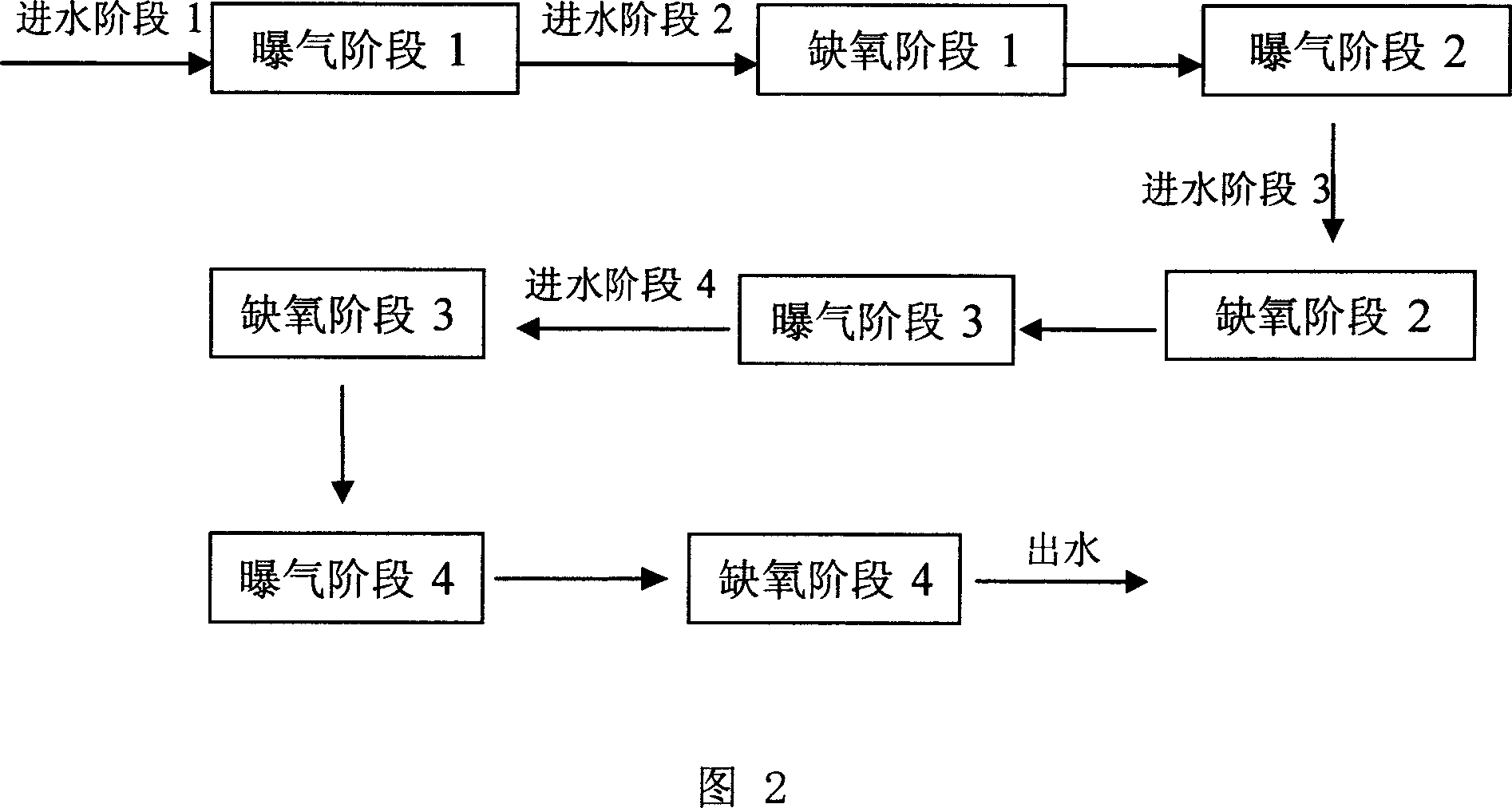

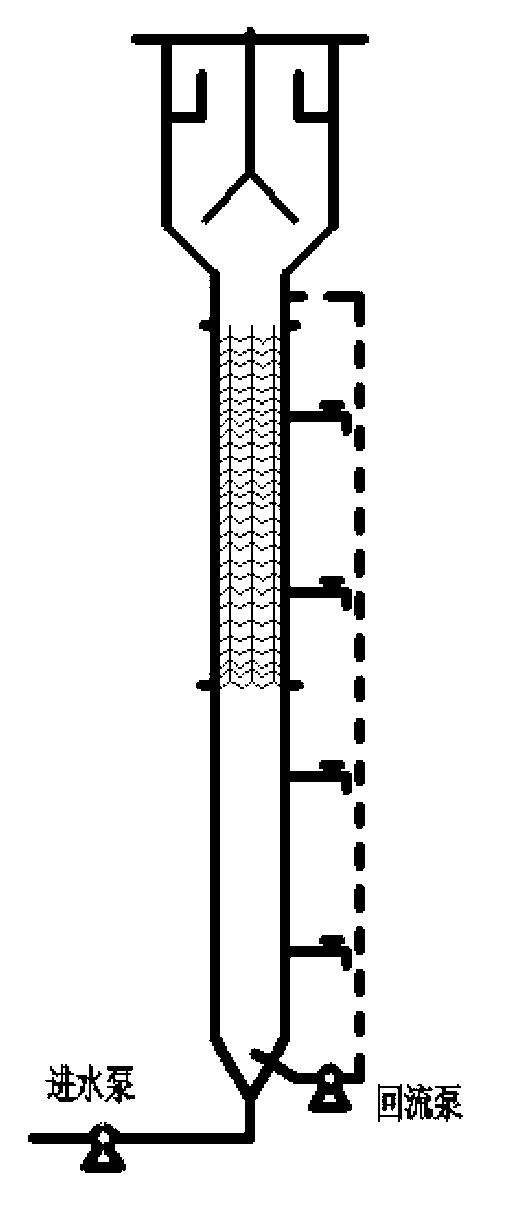

Operation mode and apparatus of short distance nitration-anaerobic ammoxidation batched biomembrane denitrogenation

InactiveCN1927739AToxic reductionControl the maximum cumulative concentrationTreatment with aerobic and anaerobic processesSludgeElectron donor

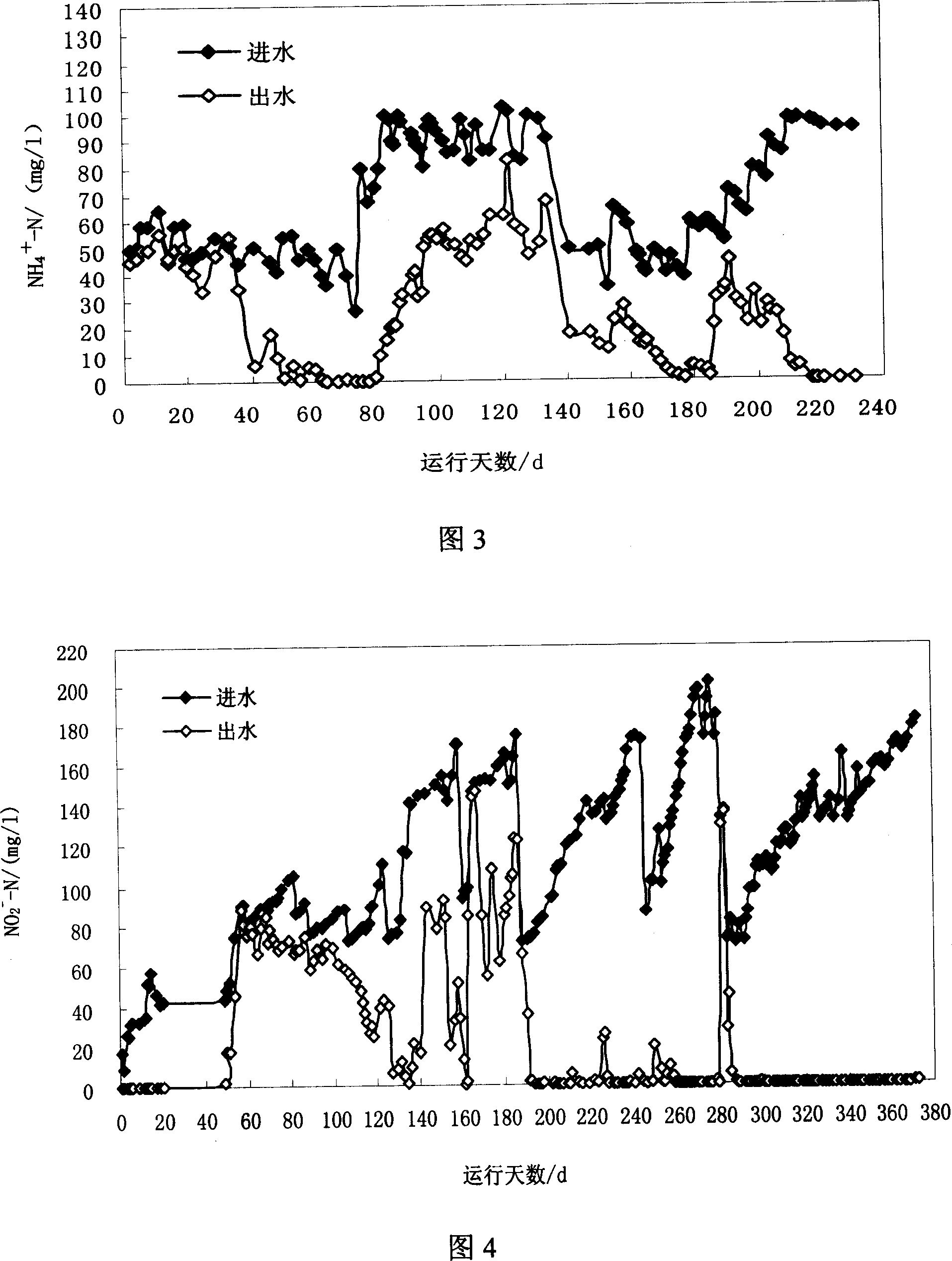

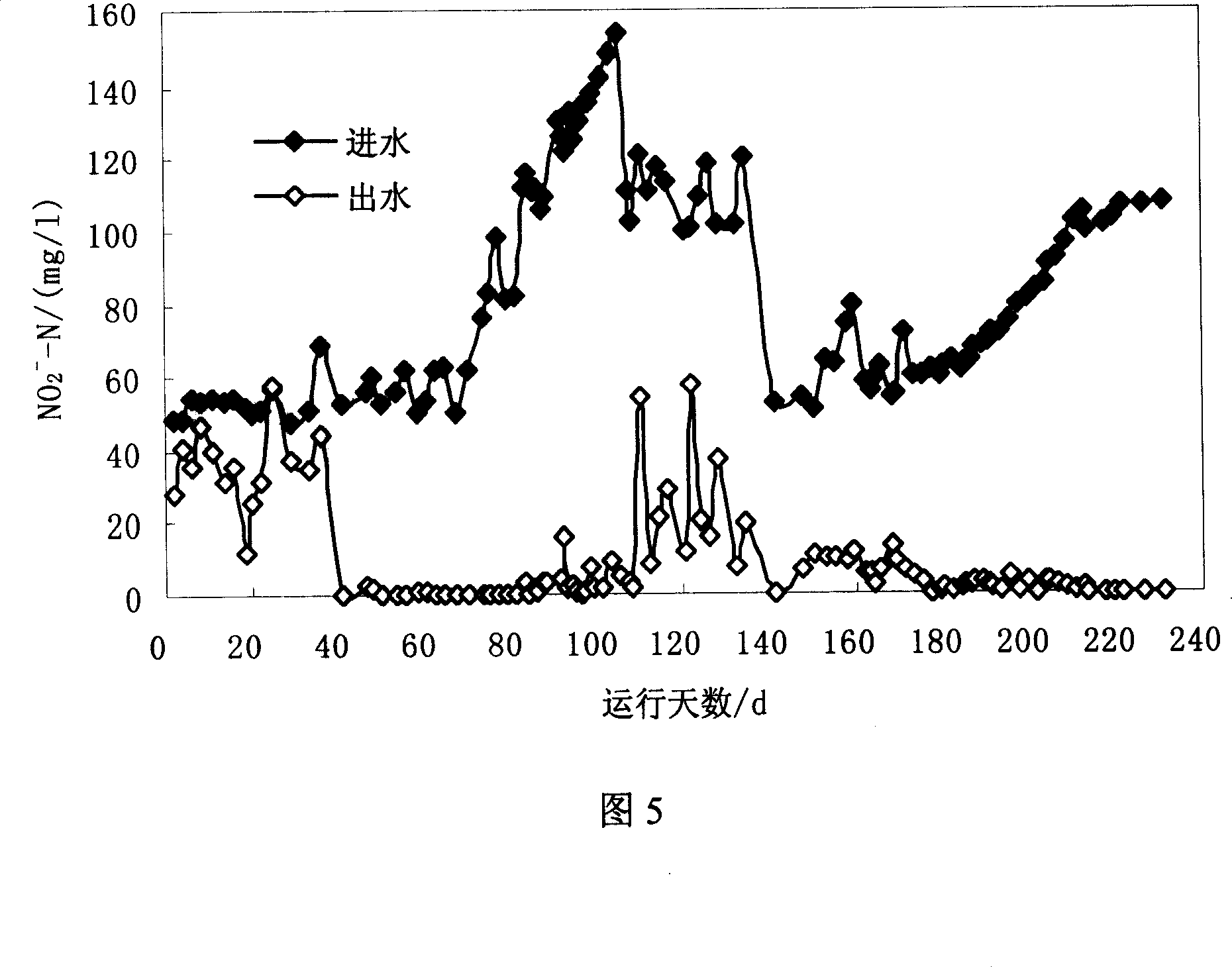

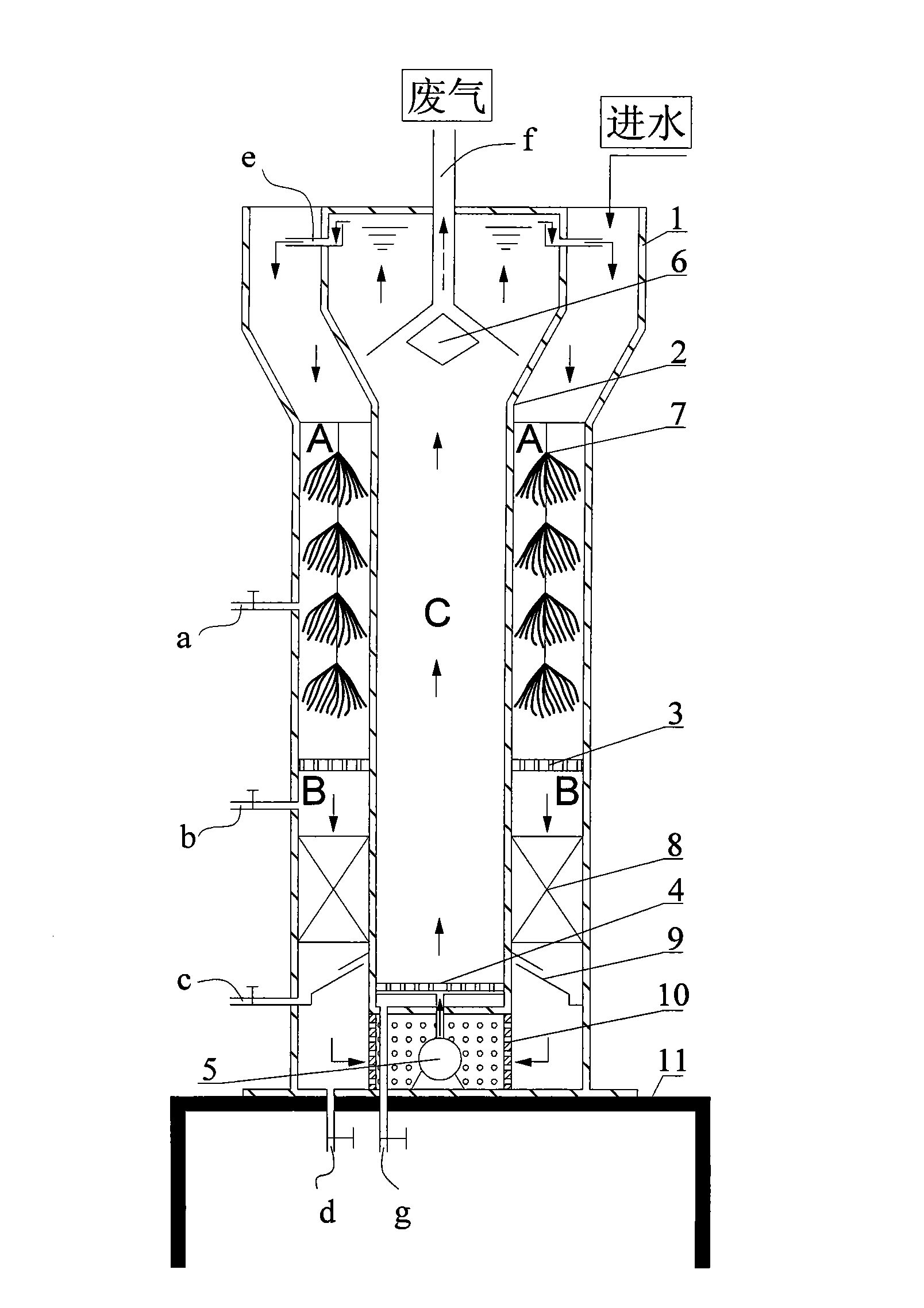

One kind of short range nitrifying-anaerobic aminoxidizing sequencing batch type denitrifying biomembrane mode and plant is disclosed. The limited aerating mode with real-time control of the sewage temperature inside the reactor and high frequency alternation between aeration and anaeration can inhibit the growth of nitrite oxidizing bacteria and denitrifying bacteria so that the aminoxidizing bacteria and the anaerobic aminoxidizing bacteria become the dominant bacteria in the nitrifying and denitrifying stages. In the nitrifying stage, nitrification is stopped in the nitrite step; and in the denitrifying stage, ammonia nitrogen acts as the direct electron donor to reduce nitrite. The plant is provided with fixed spherical composite stuffing with spherical shell of polypropylene and filled inside biological composite material. Sectional discrete water feeding mode is adopted to feed the sewage to be treated in four stages into the reactor.

Owner:HUNAN UNIV

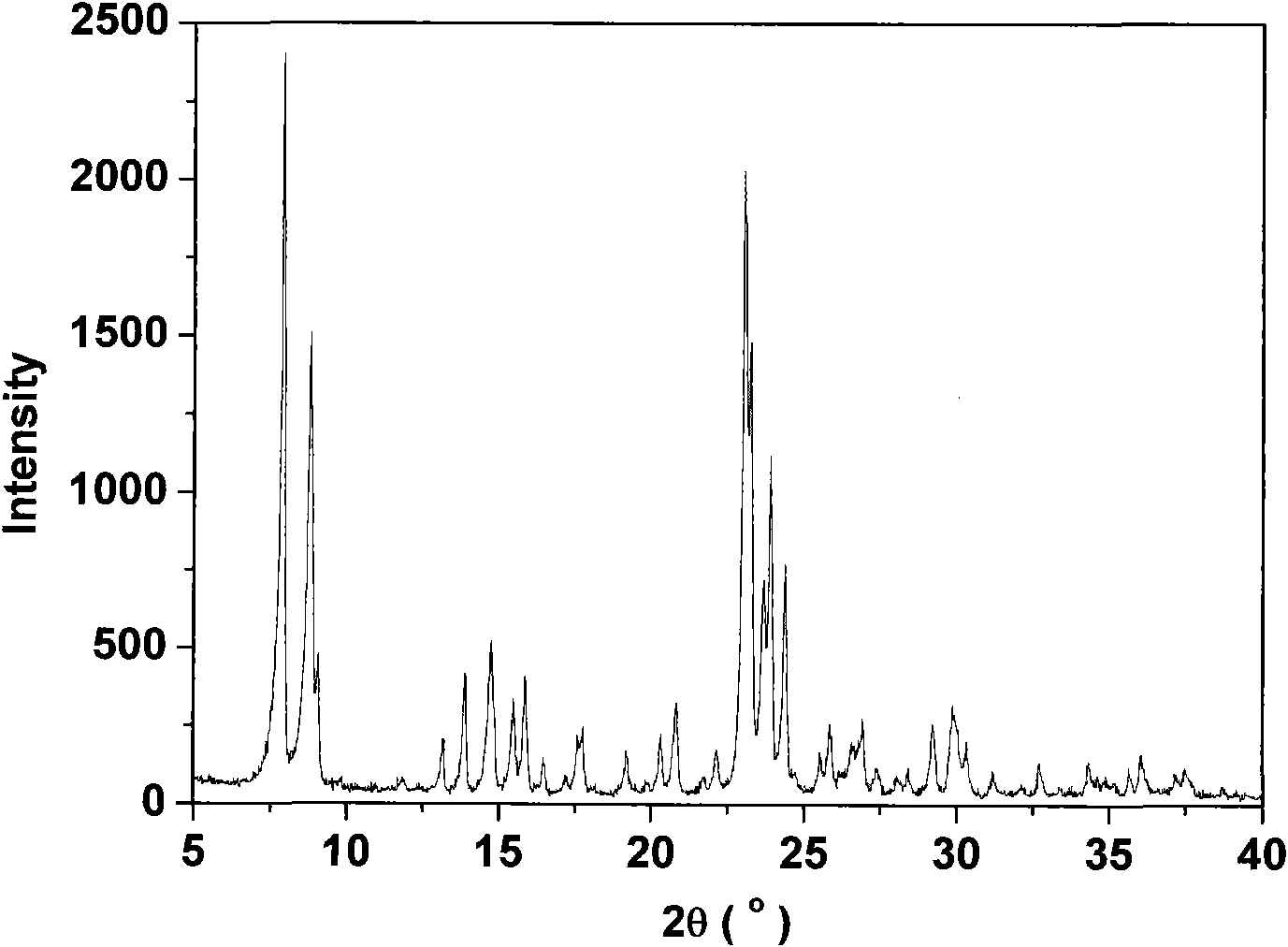

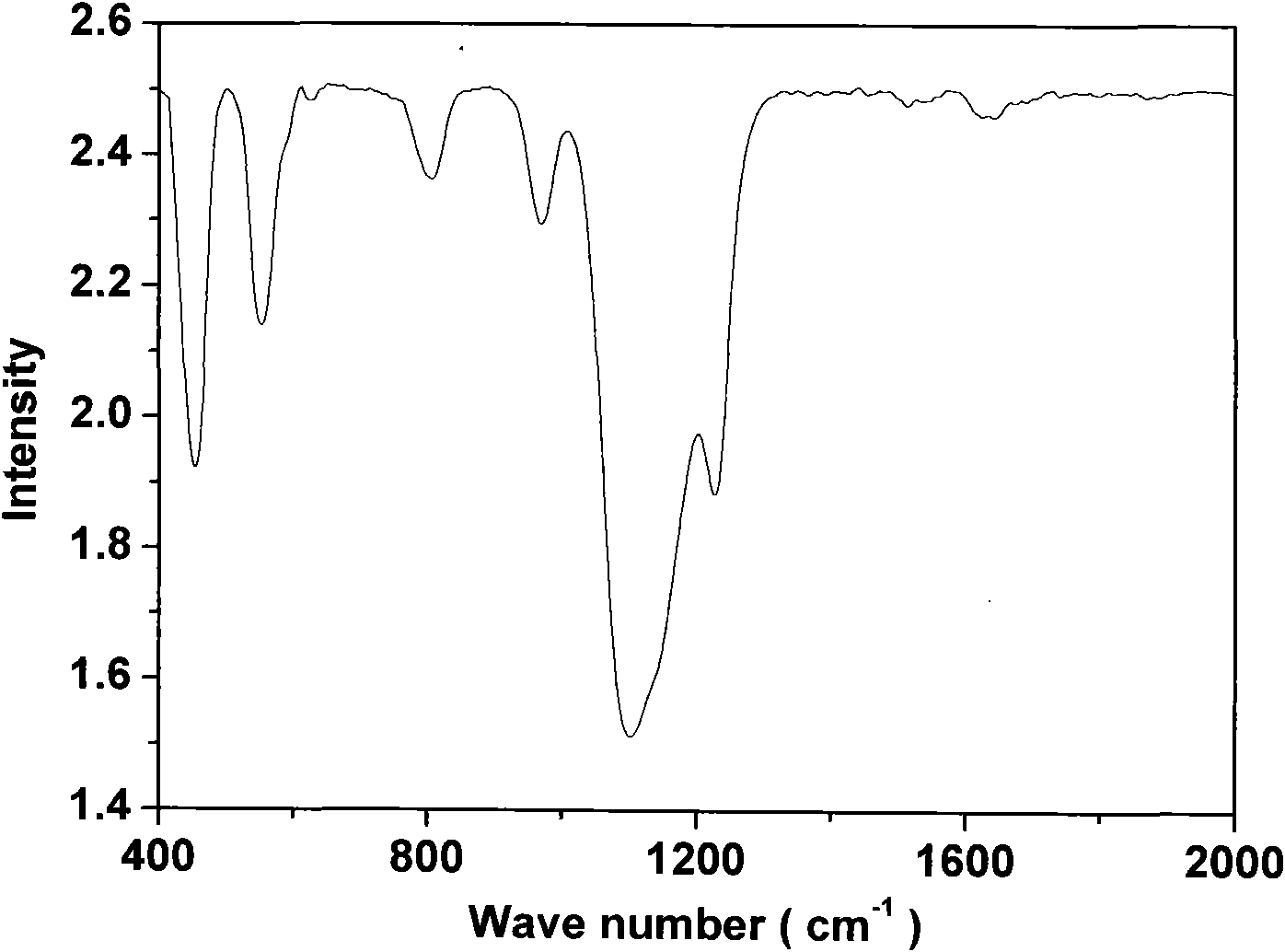

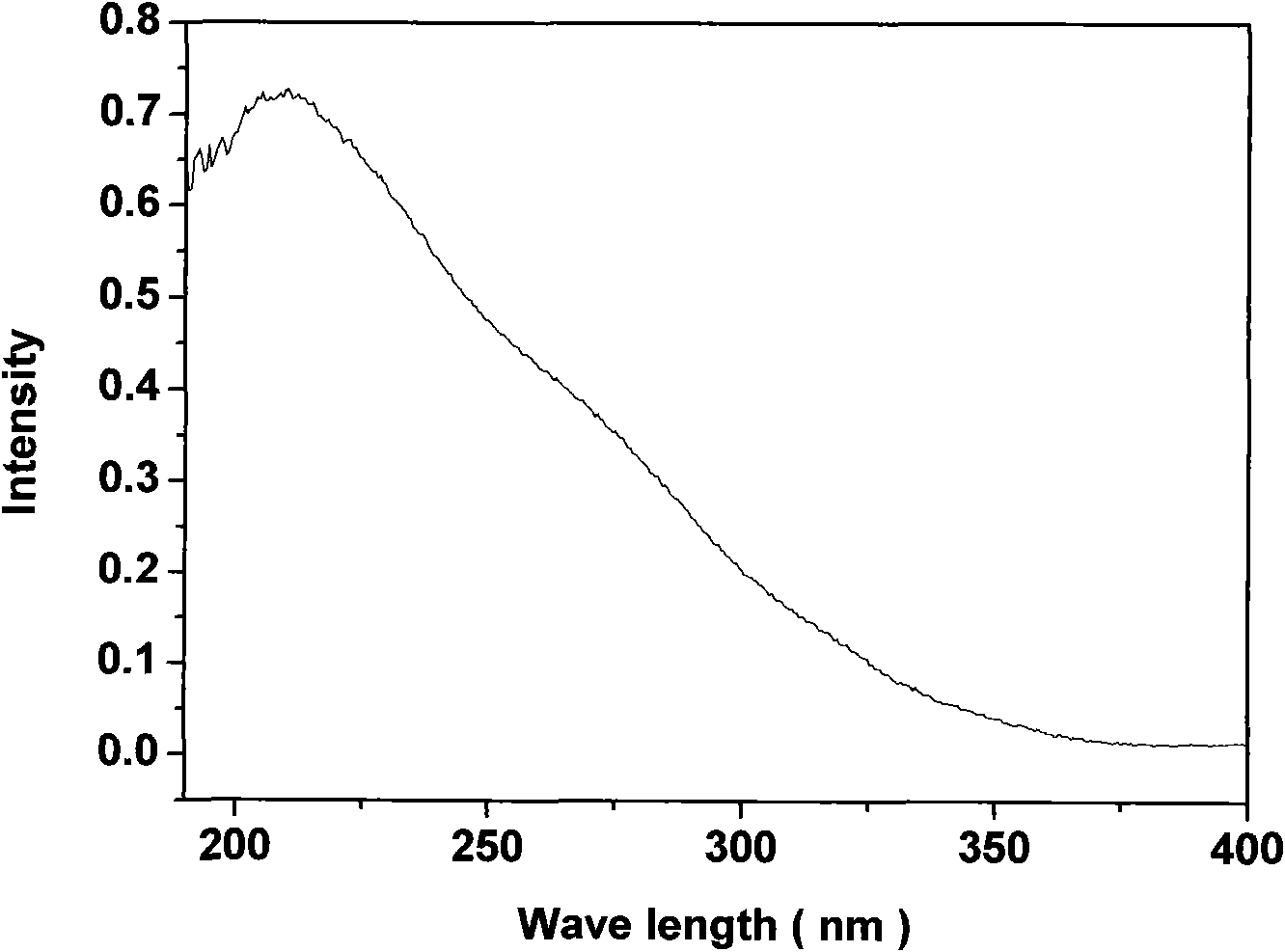

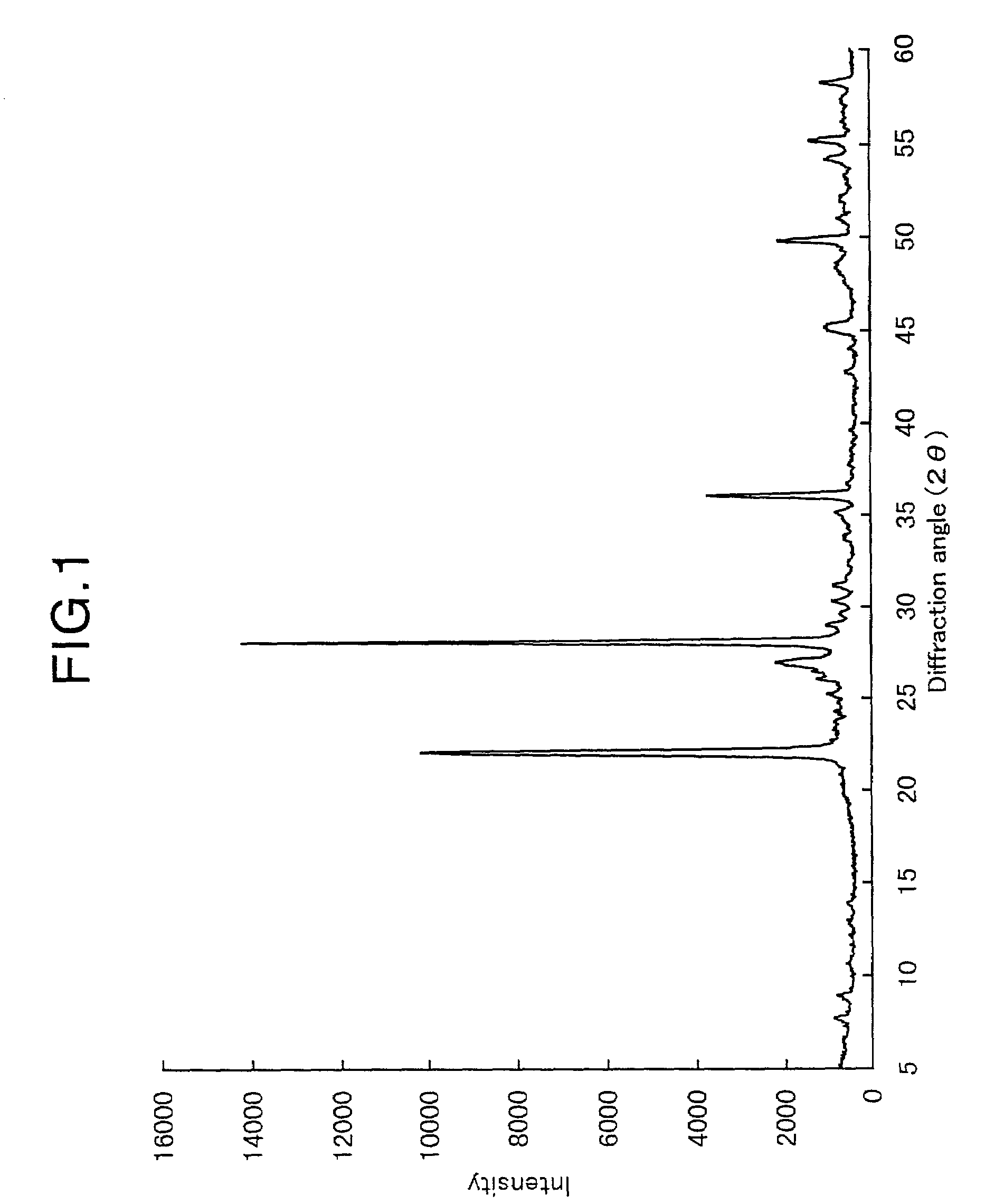

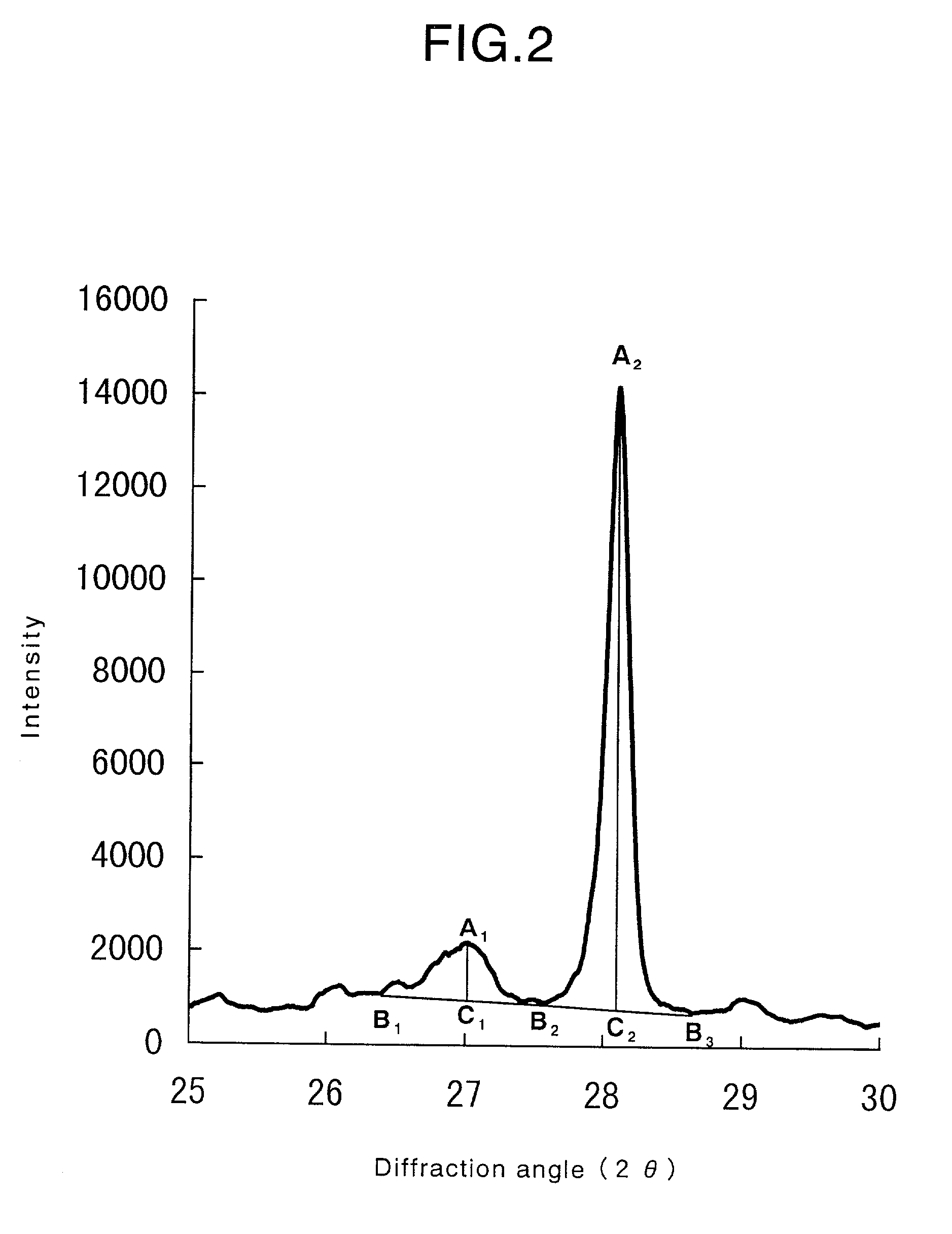

Method for quickly synthesizing small-crystallite titanium-silicon molecular sieve in cheap system

ActiveCN101913620ALower synthesis costFast crystallization rateCrystalline aluminosilicate zeolitesCyclohexanoneHigh activity

The invention provides a method for preparing a small-crystallite titanium-silicon molecular sieve in a cheap system by changing the adding mode of seed crystals and by a hydrothermal process. The titanium-silicon molecular sieve is prepared by using silicon sol as a silicon source, titanium tetrachloride or tetrabutyl titanate as a titanium source, tetrapropylammonium bromide ( TPABr) as a template agent, organic amine as an alkali source and unseparated nanoscale TS-1 mother liquor as seed crystals directly and by the hydrothermal process. The grain size of the titanium-silicon molecular sieve is less than 1 micrometer, and the titanium-silicon molecular sieve has high activity for selective oxidization reactions using hydrogen peroxide as an oxidant, such as epoxidation of olefins, hydroxylation of phenol, ammoxidation of cyclohexanone and the like. The method simplifies the synthesis process of small crystallite TS-1 in the cheap system and reduces synthesis time and cost.

Owner:DALIAN UNIV OF TECH

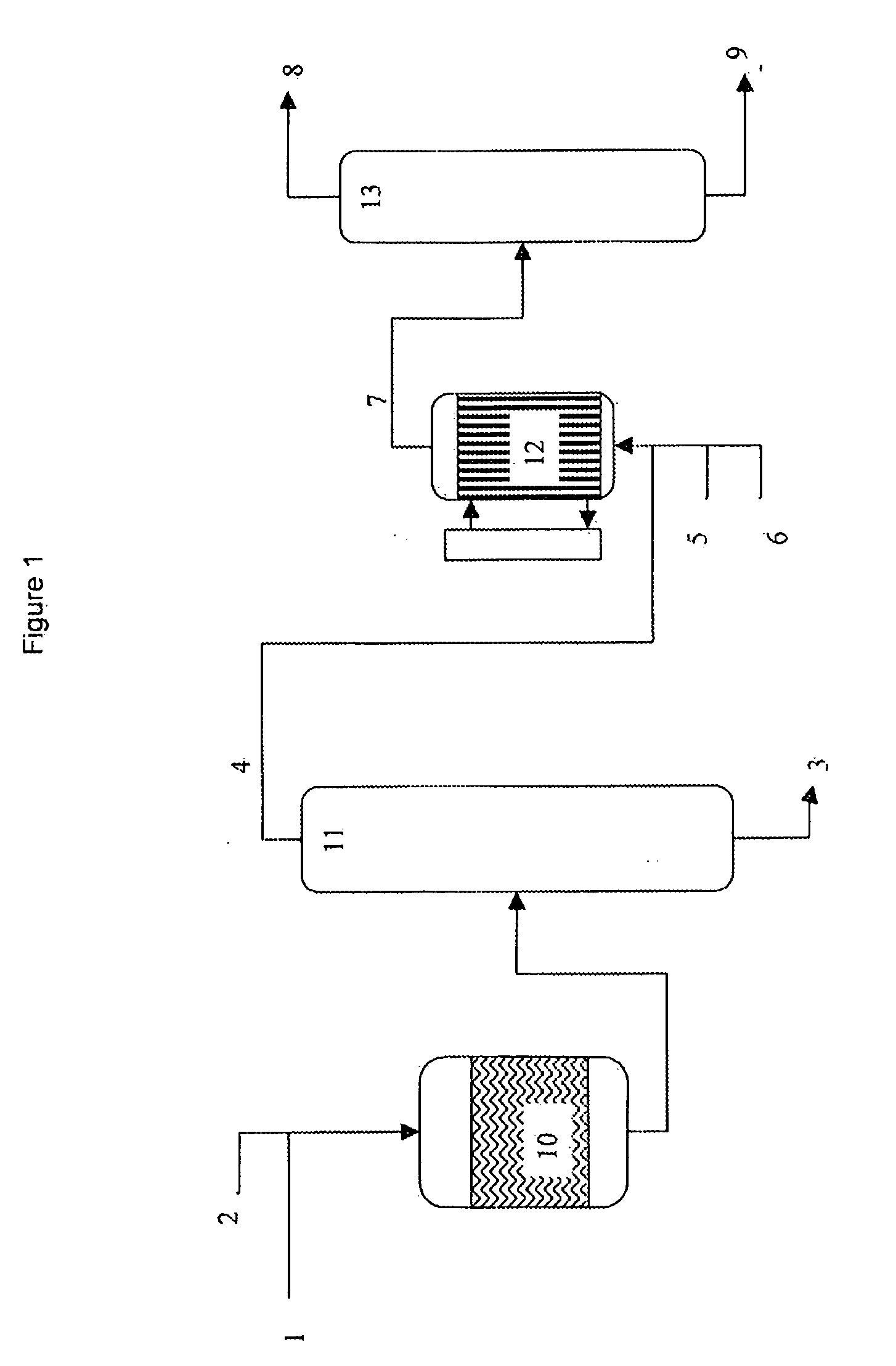

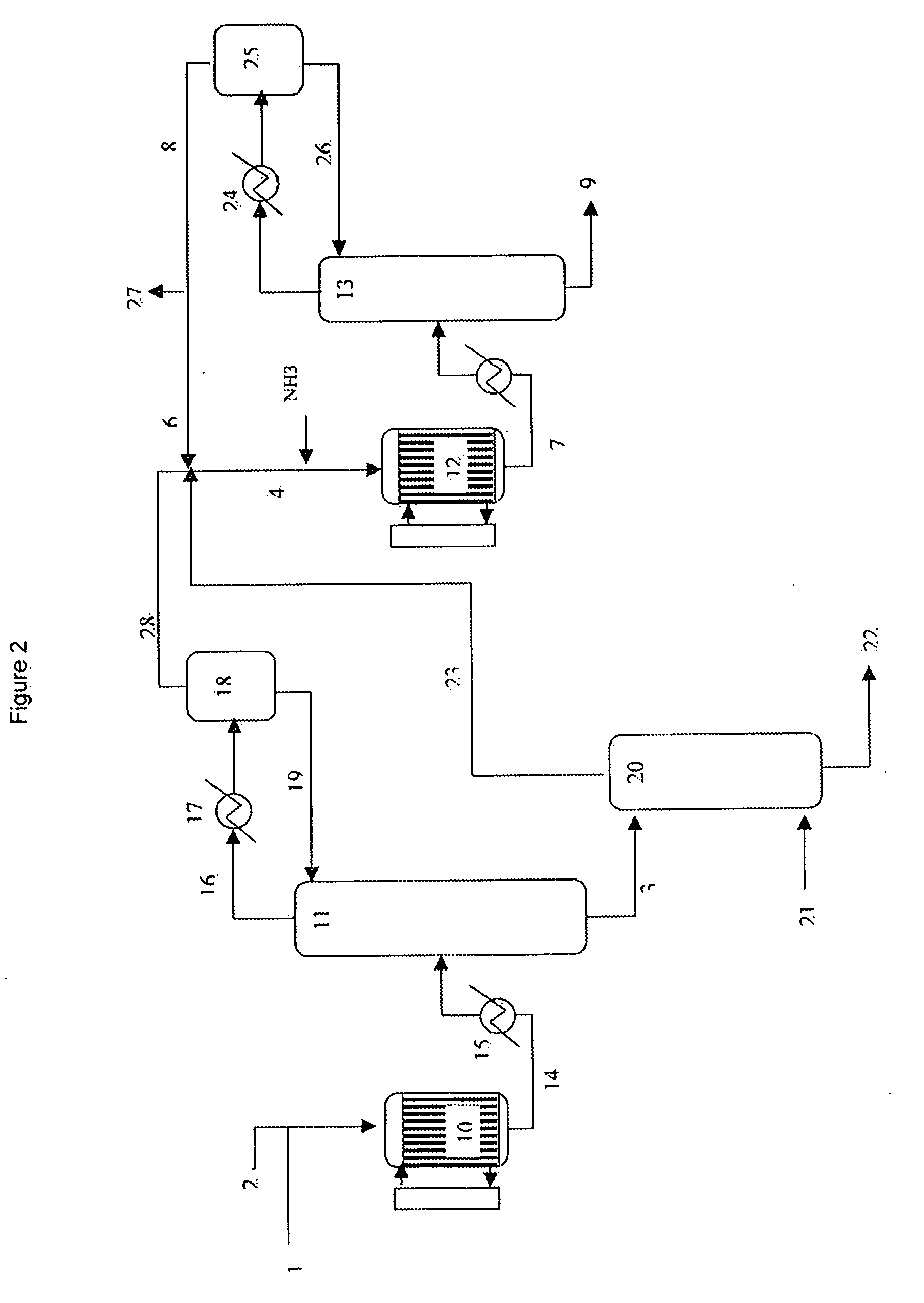

Method for the synthesis of acrylonitrile from glycerol

InactiveUS20100048850A1Less heat releaseIncrease partial pressureOrganic compound preparationPreparation by hydrocarbon ammoxidationGas phaseGlycerol

The invention relates to a novel way to synthesize acrylonitrile from a renewable raw material and more particularly relates to a method for producing acrylonitrile by the ammoxidation of glycerol in gaseous phase. The method can be implemented in a single step, or the glycerol can be previously submitted to a dehydration step. The acrylonitrile thus obtained meets the requirements of green chemistry.

Owner:ARKEMA FRANCE SA

Fluidized-bed catalyst for ammoxidation of propylene or isobutylene

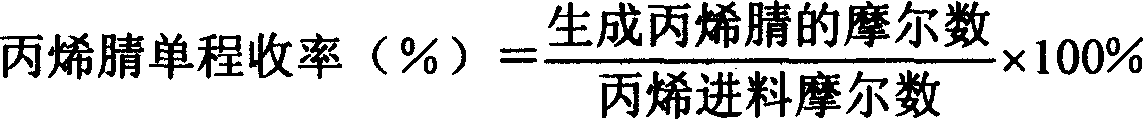

InactiveCN1736592AEasy loadingIncrease reaction pressurePreparation by ammonia-carboxylic acid reactionMetal/metal-oxides/metal-hydroxide catalystsReaction temperatureHigh load

The invention provides a fluid-bed catalyst, which can withstand high voltage and high load, contains non corrosive halide, and has a high single-pass yield. The catalyst comprises metal oxide containing multi active component of Mo, Bi, Fe, Ni and Sm, and a carrier of SiO2, Al2O3 or the mixture. It can be used to prepare the high selective acrylic with propone. Comparing with the prior technique, in the condition of keeping the single- pass yield of acrylic, with the invented catalyst, production capacity of fluid-bed reactor can be improved by 20- 30%, and the usage of the catalyst can decreases by 35%.

Owner:YINGKOU XIANGYANG CATALYST

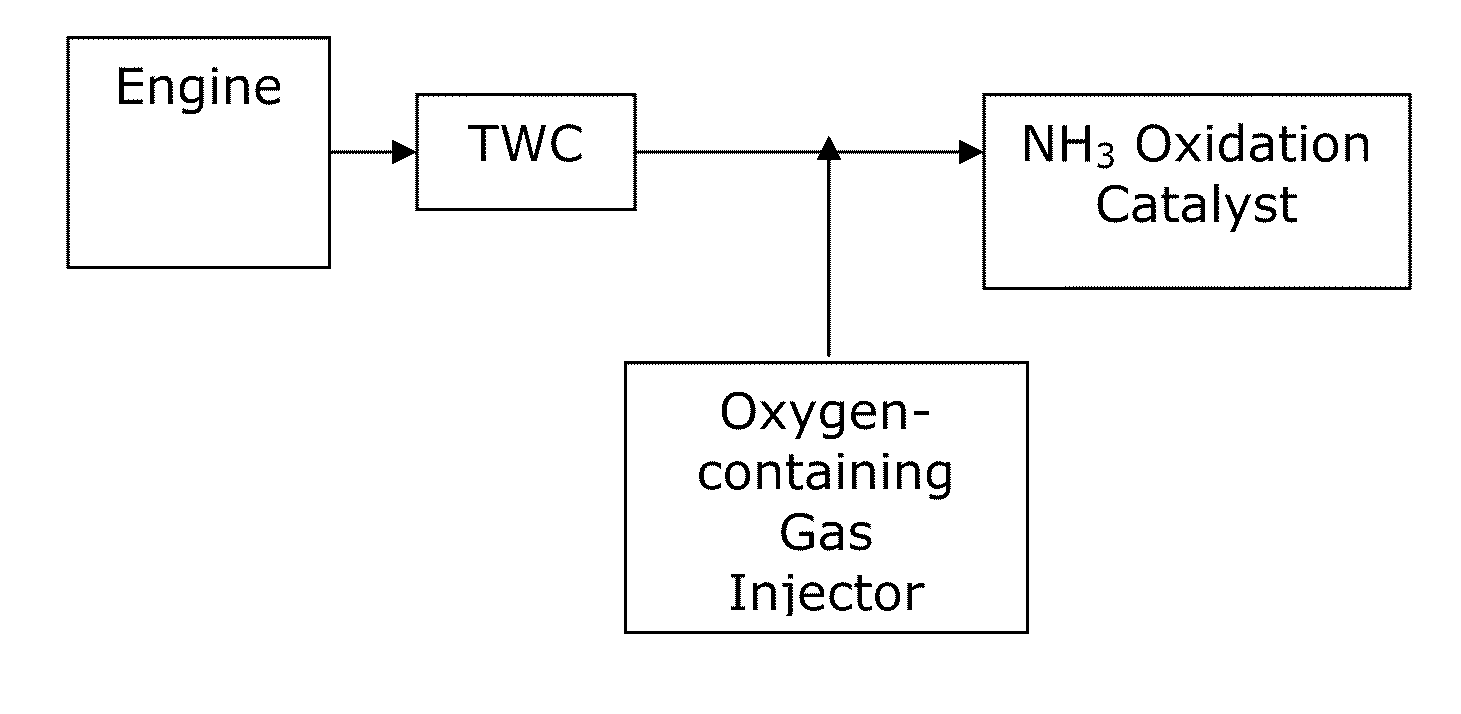

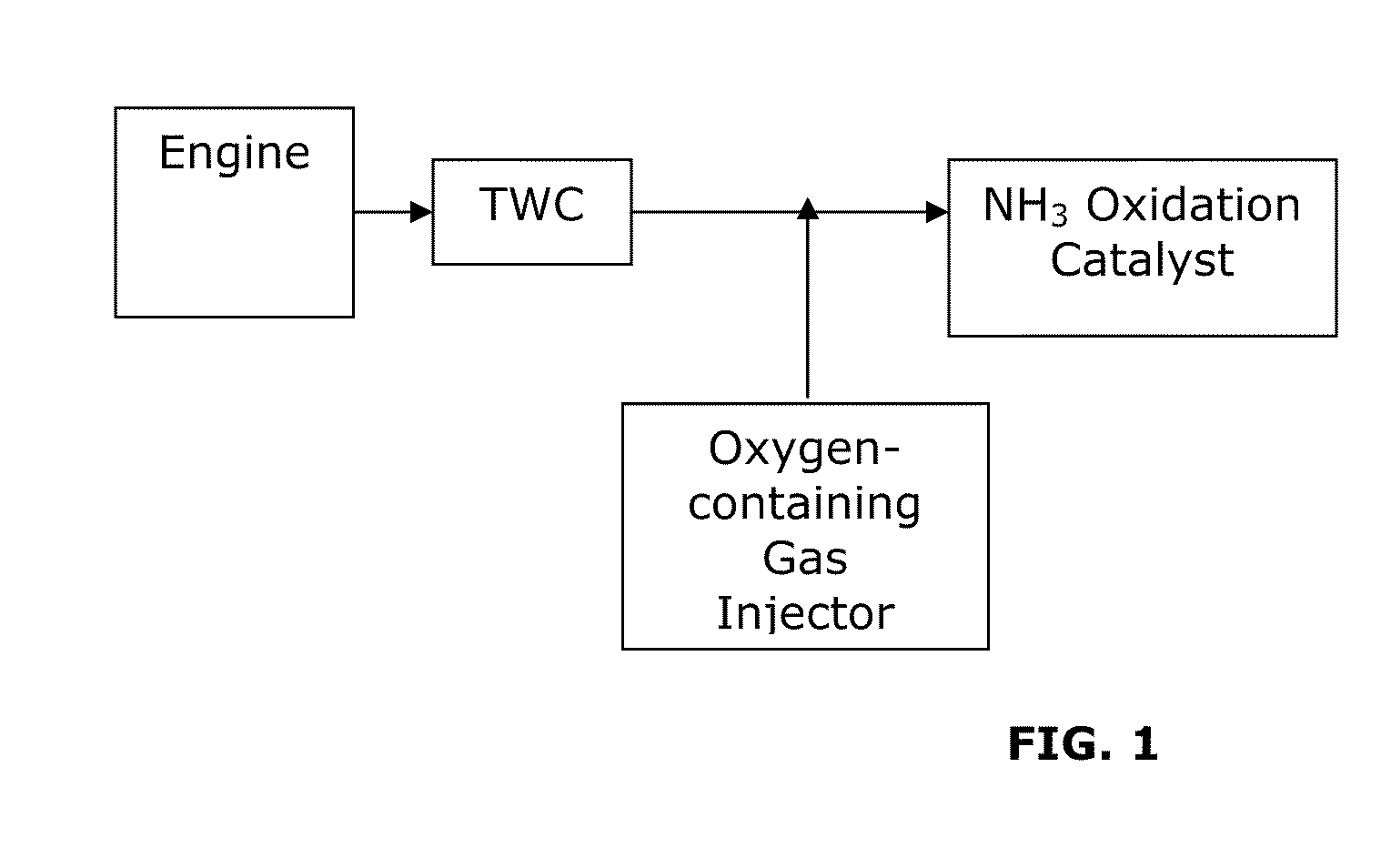

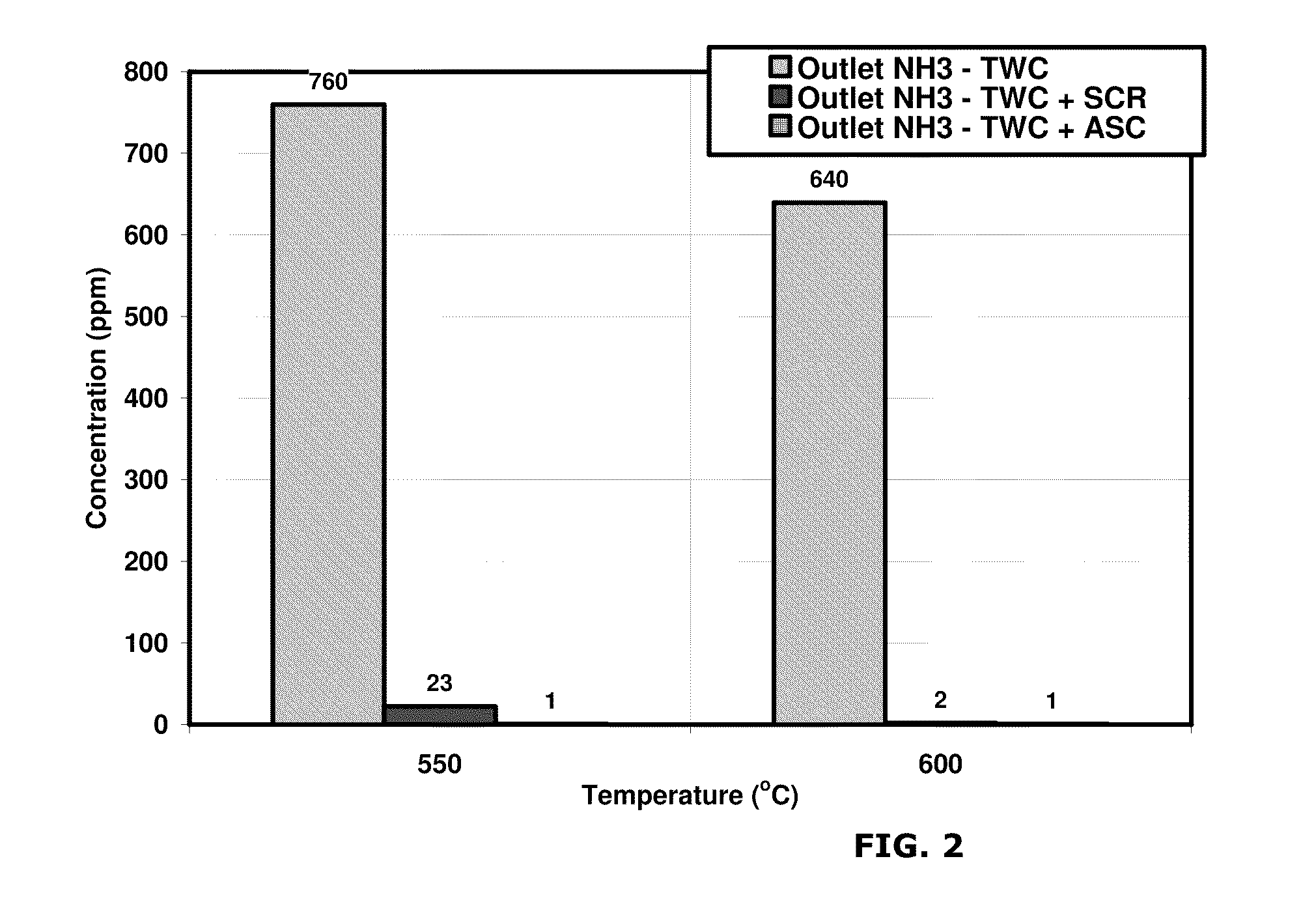

Catalysts for the reduction of ammonia emission from rich-burn exhaust

ActiveUS20110182791A1High selectivityEmission reductionCombination devicesCyanogen compoundsMolecular sievePtru catalyst

A system for reducing ammonia (NH3) emissions includes (a) a first component comprising a first substrate containing a three-way catalyst, wherein the first component is disposed upstream of a second component comprising a second substrate containing an ammonia oxidation catalyst, wherein said ammonia oxidation catalyst comprises a small pore molecular sieve supporting at least one transition metal; and (b) an oxygen-containing gas input disposed between the components. For example, a CHA Framework Type small pore molecular sieve may be used. A method for reducing NH3 emission includes introducing an oxygen-containing gas into a gas stream to produce an oxygenated gas stream; and exposing the oxygenated gas stream to an NH3 oxidation catalyst to selectively oxidize at least a portion of the NH3 to N2. The method may further include the step of exposing a rich burn exhaust gas to a three-way catalyst to produce the gas stream comprising NH3.

Owner:JOHNSON MATTHEY PLC

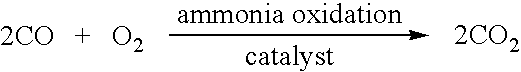

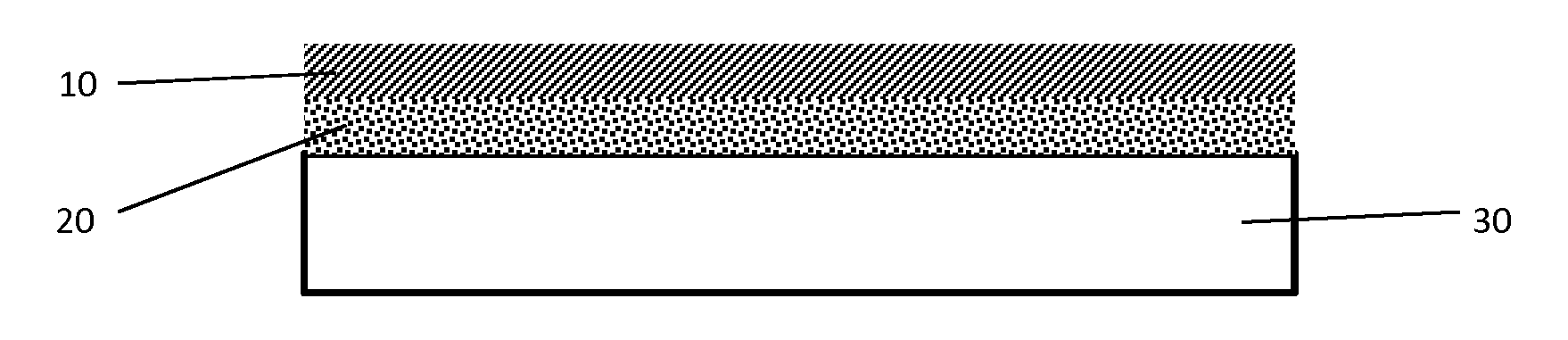

Layered ammonia oxidation catalyst

The invention pertains to a layered ammonia oxidation catalyst. The layered catalyst causes ammonia to be selectively oxidized in the presence of an oxidant such as air, while minimizing the formation of nitrogen oxides (NOx). The layered catalyst comprises a refractory oxide support such as gamma alumina upon which a platinum component is deposited and a vanadia component is deposited on the platinum. The catalyst is preferably disposed on a substrate such as a metal foil whose surface contains a “herringbone” pattern.

Owner:BASF CATALYSTS LLC

Denitrogenation method for nitrosation-anaerobic ammoxidation single stage organism

ActiveCN101054236ARealize the biological denitrification reactionReduce mass transfer resistanceWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationSludge

The invention discloses a nitrosation-anaerobic ammonoxidation single-stage biological denitrification method, the technology utilizes nitrosation flora with intensified active carbon as core after adding powdery active carbon and anaerobic ammonoxidation flora to generate composite granule sludge, and couples two reactions of nitrosation reaction and anaerobic ammonoxidation reaction, realizes biological denitrification reaction for transforming ammonia nitrogen into nitrogen in macrography. The invention is operated in one reactor at normal temperature without need of heating preprocessing waste water, saves energy, needs small accommodation area and reduces free nitrous cumulant of free nitrite to resist ammonia nitrogen with higher concentration. The invention adds powdery active carbon to form intensified granule sludge and self-cultures suspended sludge, thereby simplifying startup and running of the technology.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

Ammonia oxidation catalyst

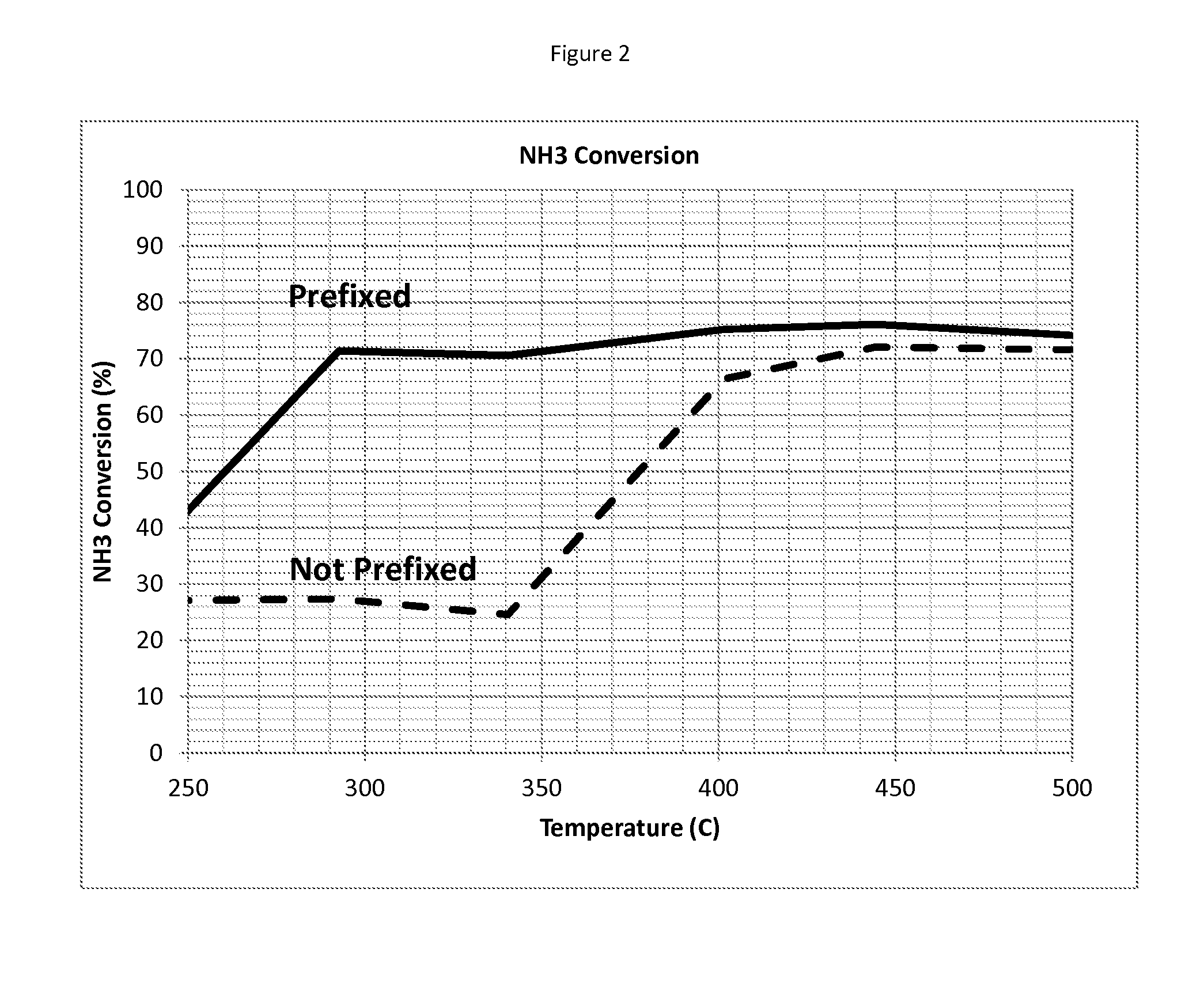

ActiveUS20140154163A1High catalytic activityImproving low temperature ammonia conversionCombination devicesCyanogen compoundsPtru catalystSilicon oxide

Provided is a catalyst article for treating an emission gas comprising (a) a noble metal catalyst layer comprising one or more noble metals disposed on a first refractory metal oxide support; and (b) a vanadium catalyst layer comprising vanadium pre-fixed on a second refractory metal oxide support selected from alumina, titania, zirconia, ceria, silica, and mixtures of these, wherein the first catalyst layer is in physical contact with said second catalyst layer. Also provided is a method for making such a catalyst article, a method for treating gas emissions using such an article, and an emission gas treatment system incorporating such an article.

Owner:JOHNSON MATTHEY PLC

Waste water biological treatment method for realizing anaerobic ammoxidation and methanation denitrification coupling

InactiveCN101058463ASave energySave organic carbon sourcesTreatment with aerobic and anaerobic processesIndustrial effluentMethanation

The invention discloses a biological disposing method of waste water through coupling the anaerobic ammonoxidation and methanation denitrification, which is characterized by the following: inoculating the particle sludge with methanation, denitrification and anaerobic ammonoxidation activity in the expansion grain sludge bed (EGSB); inoculating aerobic ammonoxidation bacteria in the biological aerating filter (BAF) or SHARON technique or SBR reactor; connecting the EGSB reactor and BAF or SHARON technique or SBR reactor; realizing the biological disposal of waste water through controlling pH value, temperature, dissolved oxygen, external reflow rate, load velocity, oxidizing reducing potential and organic COD density, ammonia nitrogen density.

Owner:CHONGQING UNIV

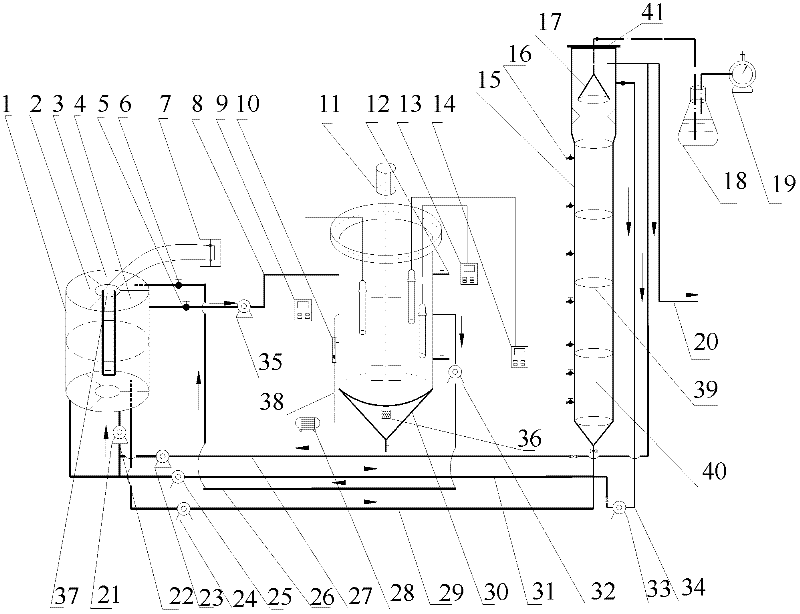

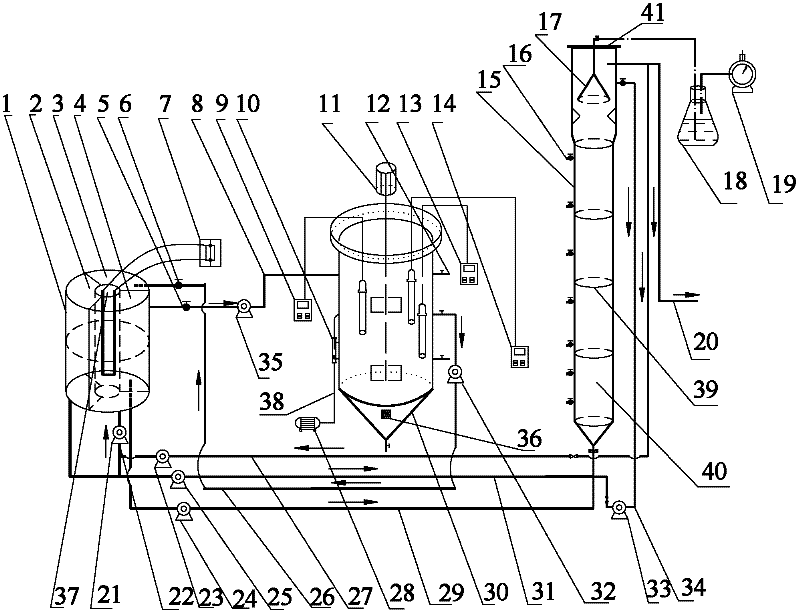

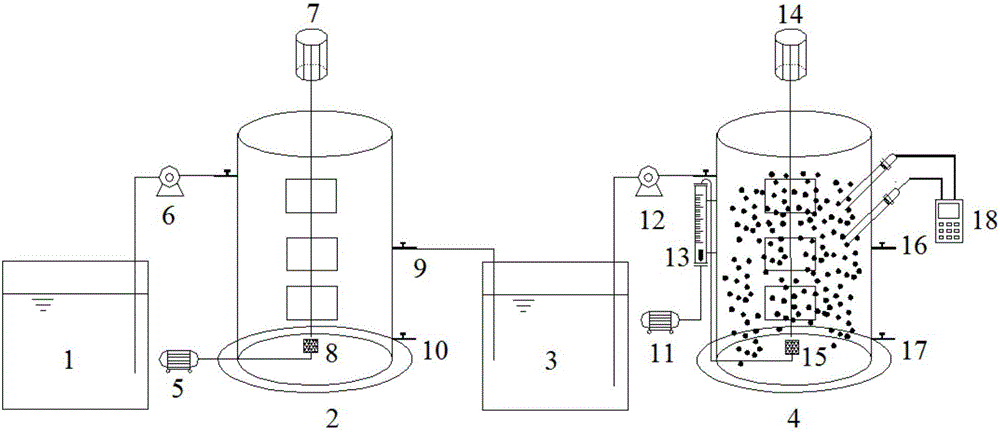

Apparatus and method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation

ActiveCN102515350AEfficient biological denitrificationLow running costTreatment with aerobic and anaerobic processesPeristaltic pumpNitrogen removal

The invention relates to an apparatus and a method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation, which belongs to the low carbon nitrogen (CN) ratio high density ammonia nitrogen garbage leachate biological denitrogenation technical field. The apparatus comprises an integrated water tank, a SBR short distance nitrated reactor and an anaerobic ammoxidation reactor; a preposition water tank and a postposition water tank in the integrated water tank are communicated with a peristaltic pump and the SBR short distance nitrated reactor, the postposition water tank is connected with the bottom of the anaerobic ammoxidation reactor through the outlet pipe and the peristaltic pump, an self-circulation pipeline is provided on the anaerobic ammoxidation reactor, and is connected with the SBR preposition water tank through the outlet pipe and the peristaltic pump. The method comprise the following steps starting the SBR short distance nitrated reactor, starting the anaerobic ammoxidation reactor, and an operation is in series of the SBR short distance nitrated reactor and the anaerobic ammoxidation reactor is carried out. The apparatus of the present invention is suitable for organic matter removal and short distance nitrogen removal of the garbage leachate at late period in the garbage landfill, the process is advanced, and the advantages of energy saving and consumption reduction is obvious.

Owner:BEIJING UNIV OF TECH

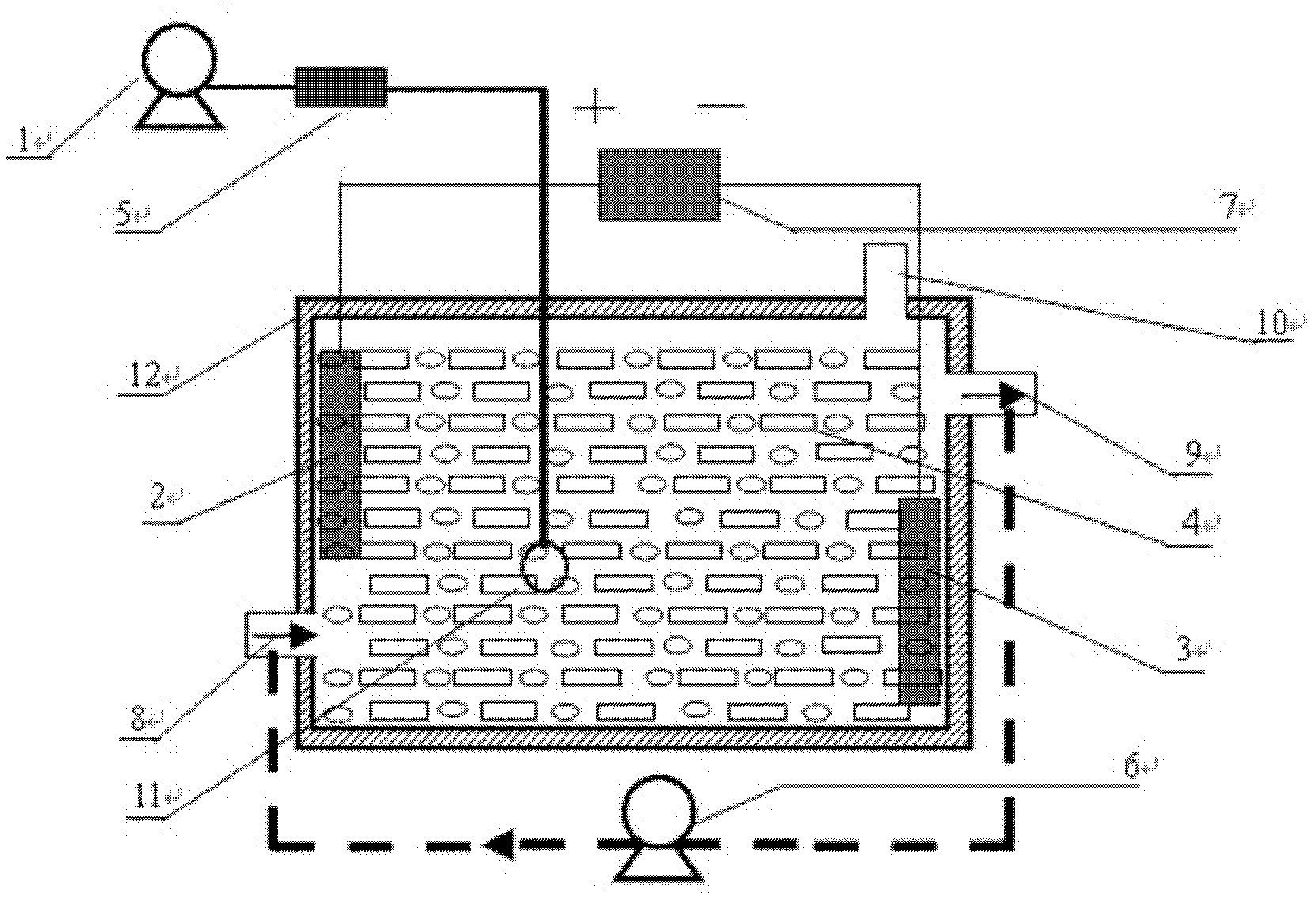

Bioelectrochemical denitriding reactor and application method thereof

ActiveCN102351312ALittle pH fluctuationLow applied voltageTreatment with aerobic and anaerobic processesTreatment effectEngineering

The invention belongs to the technical field of biological wastewater treatment, and particularly relates to a bioelectrochemical synchronous nitrification / denitrification denitriding reactor and an application method thereof. The reactor comprises a bed, a biological anode, a biological cathode, a filler, a gas flowmeter, an aerator, an aeration head, a circulating pump and a direct-current stabilized-voltage power supply, wherein the biological cathode and the biological anode are respectively arranged at both sides in the reactor and are respectively connected with the negative pole and the positive pole of the direct-current power supply; the filler is filled in the bed; the aeration head is arranged at the middle upper part of the bed; both ends of the bed are respectively provided with a water inlet and a water outlet and are connected with a circulating pipeline for internal circulation through the circulating pump; and the top of the reactor is provided with a gas outlet through which the reactor is communicated with the outside. The application method of the reactor comprises the following steps: forming an anode ammoxidation biological film and a cathode denitrification biological film, and starting the reactor after the films are successfully formed; carrying out nitrification and denitrification reaction under the condition of 0.2-1.0mg / L of dissolved oxygen; and carrying out denitriding reaction while applying a micro voltage of 0.2-0.5V and keeping a cathode potential of (-100)-(-250)mV. The invention has the advantages of good treatment effect, energy saving, environment friendliness, high start speed, convenient operation process and the like.

Owner:CHENGDU INST OF BIOLOGY CHINESE ACAD OF S

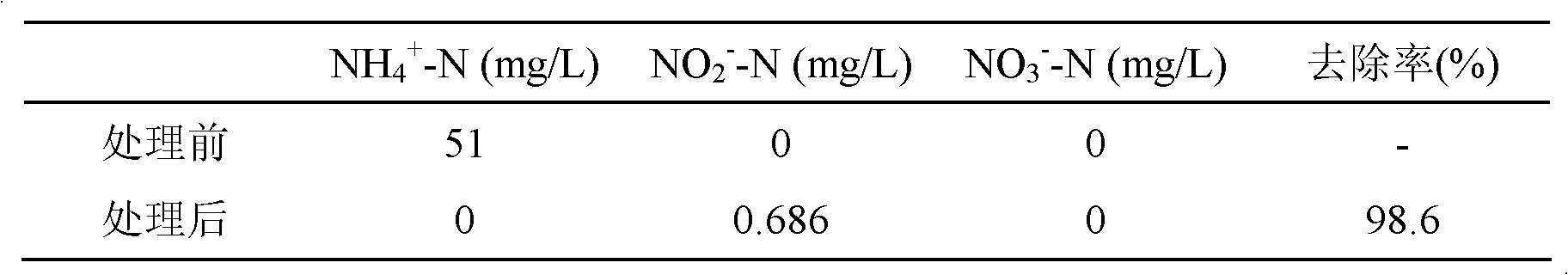

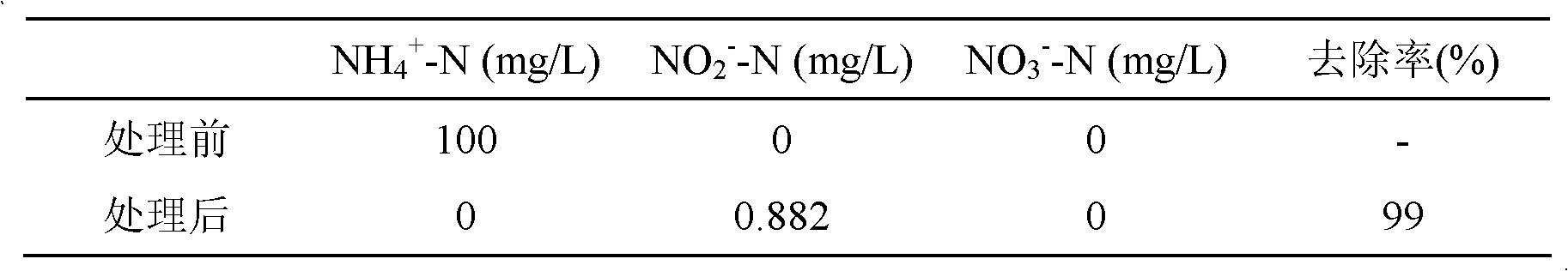

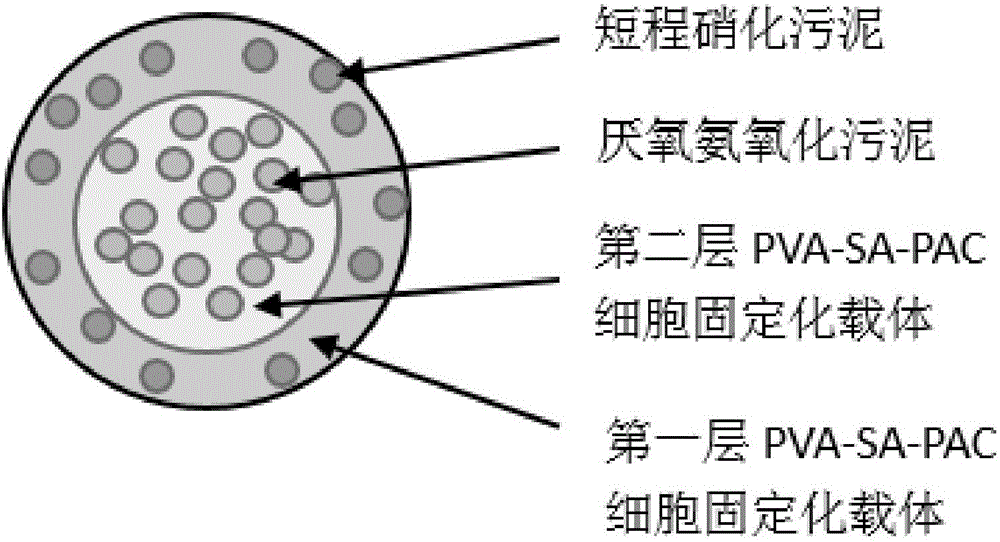

Method for co-immobilizing anaerobic ammoxidation bacteria-short-cut nitrobacteria and application thereof

InactiveCN105861479AAchieve coordinated operationStable enrichmentTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentPolyvinyl alcoholSludge

A method for co-immobilizing anammox bacteria-short-range nitrifying bacteria and its application belong to the technical field of sewage treatment, using polyvinyl alcohol, sodium alginate and activated carbon as embedding agents to anaerobic ammonium oxidizing bacteria and short-range nitrifying bacteria Layered embedding and fixation, firstly mix equal volumes of anammox sludge and embedding agent uniformly, get anaerobic ammonium oxidation gel pellets after fixation, and then put them into the mixed solution of short-range nitrifying bacteria and embedding agent In the process, anammox-short-range nitrifying bacteria gel pellets were obtained after fixation, and were directly added to the autotrophic denitrification reactor after activation. The present invention uses immobilized microbial technology to co-immobilize anammox bacteria and short-range nitrification bacteria on the same carrier, and stably enrich high-activity anammox and short-range nitrification sludge, so that the biological efficacy of the two bacteria can be coordinated. , to realize the coordinated operation of short-range nitrification reaction and anammox reaction.

Owner:BEIJING UNIV OF TECH

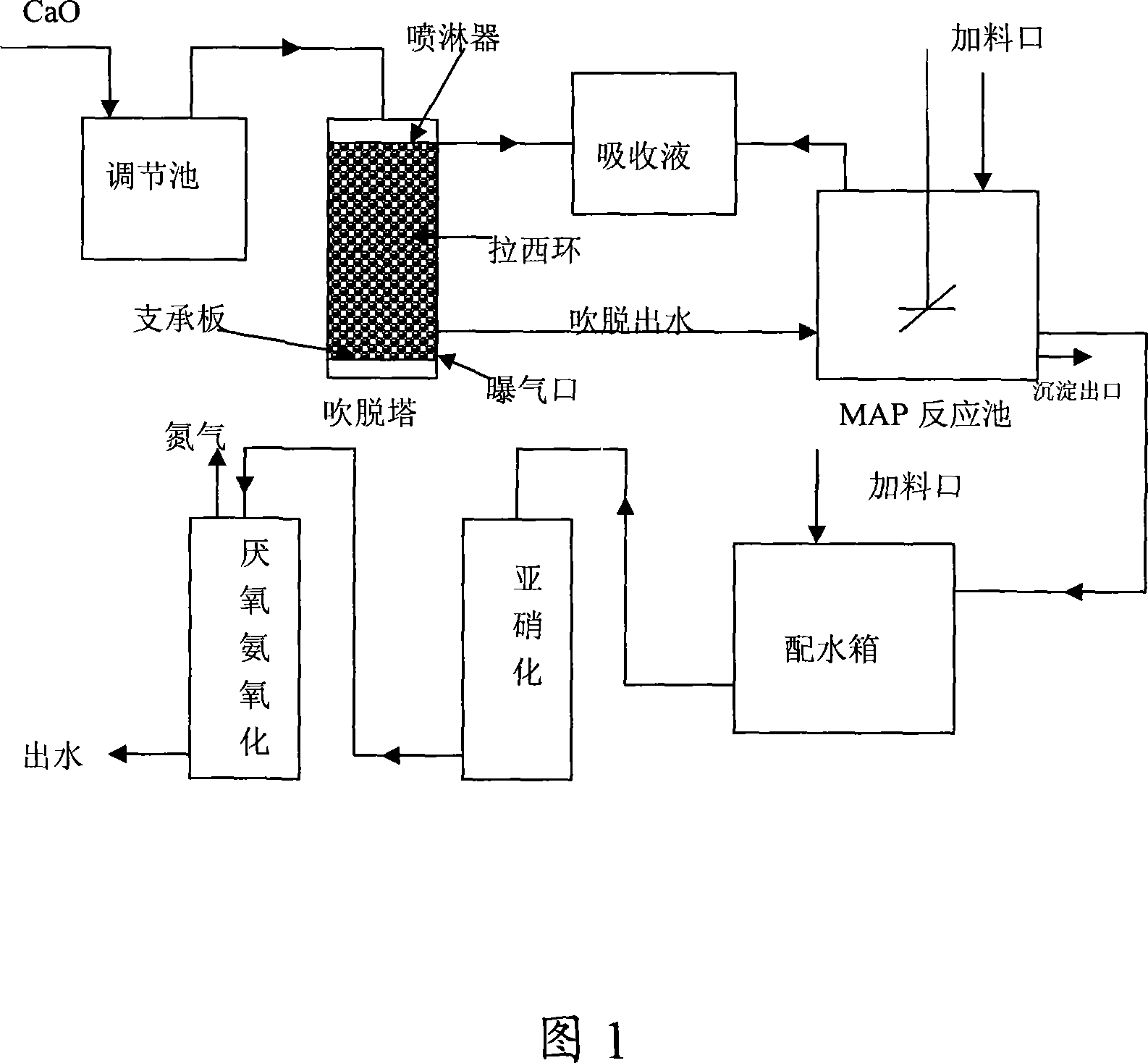

Combined treatment process for high-concentration ammonia nitrogen waste water

InactiveCN101066822AHigh total removal rateReduce energy consumptionTreatment with anaerobic digestion processesMultistage water/sewage treatmentHigh concentrationMagnesium ammonium phosphate

The combined treatment process of high concentration ammonia nitrogen waste water belongs to the field of waste water treating technology. The combined treatment process of high concentration ammonia nitrogen waste water features the combination of blow-off method, MAP method and nitrosation-anaerobic ammoxidation biological method. The treating process of the present invention includes the steps of: adding lime into the waste water in a regulating tank to reach pH of 11-12; blow-off and aerating in a blow-off tank, with the blow-off tail gas entering to an absorbing tank and the blow-off water entering to a MAP reaction tank; treating the blow-off effluent in the MAP reaction tank with thrown disodium hydrogen phosphate and magnesia to produce magnesium ammonium phosphate precipitate exhausted; and the final nitrosation-anaerobic ammoxidation biological treatment. The process has low power consumption and other advantages.

Owner:SHANGHAI UNIV

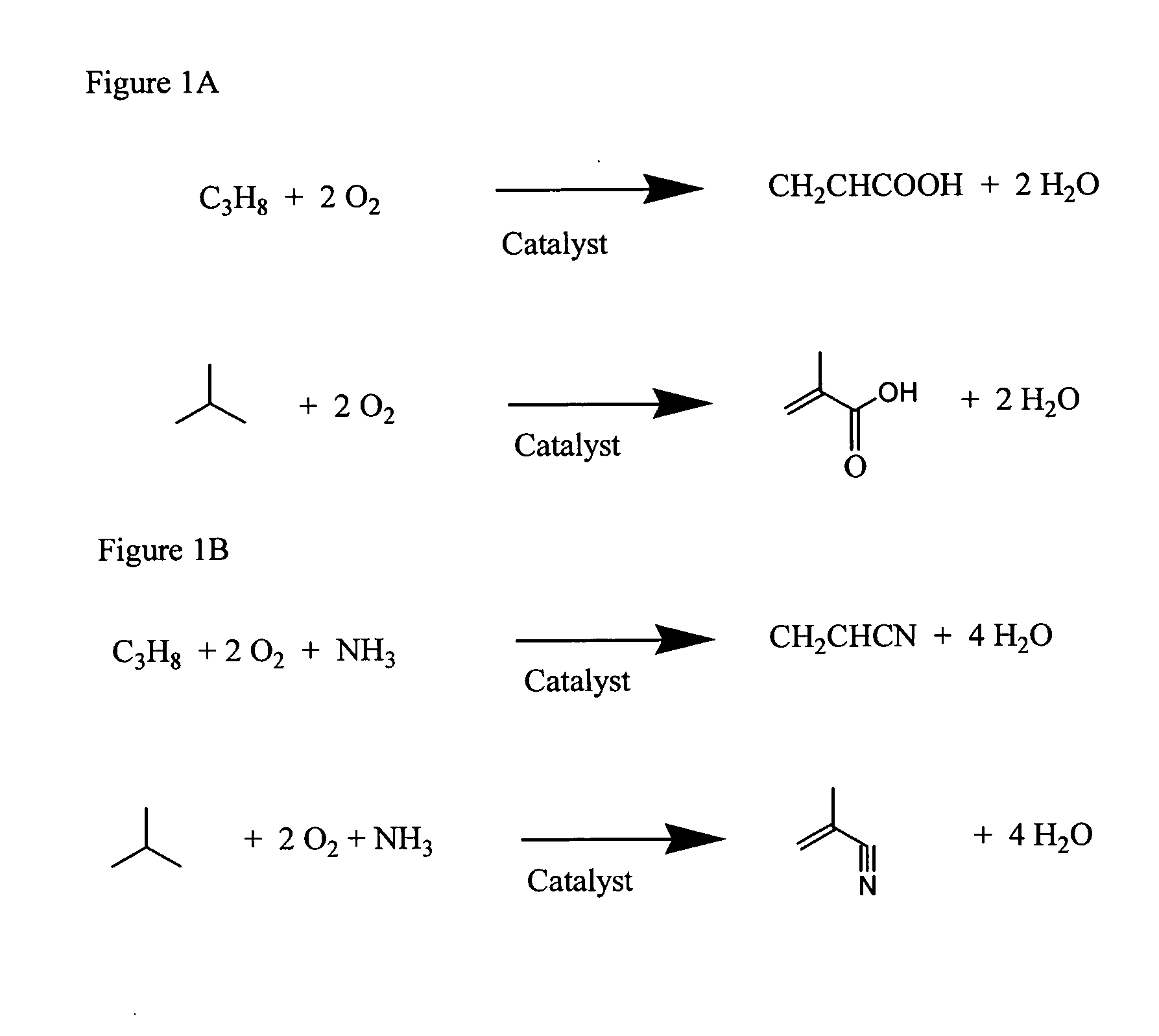

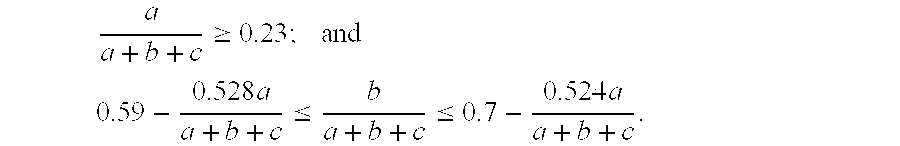

Process for producing acrylonitrile or methacrylonitrile from propane or isobutane by ammoxidation

Owner:ASAHI KASEI KK

Mixed metal oxide catalysts for propane and isobutane oxidation and ammoxidation, and methods of preparing same

InactiveUS20050054869A1Increase productionOrganic compound preparationHeterogenous catalyst chemical elementsNiobiumGas phase

Compositions of matter and catalyst compositions effective for gas-phase conversion of propane to acrylic acid (via oxidation) or to acrylonitrile (via ammoxidation) and isobutane to methacrylic acid (via oxidation) and isobutane to methacrylonitrile (via ammoxidation) are disclosed. Preferred catalyst compositions comprise molybdenum, vanadium, niobium, antimony and germanium and molybdenum, vanadium, tantalum, antimony, and germanium. Methods of preparing such compositions and related compositions, including hydrothermal synthesis methods are also disclosed. The preferred catalysts convert propane to acrylic acid and / or to acrylonitrile and isobutane to methacrylic acid / methacrylonitrile with a yield of at least about 50%.

Owner:INEOS USA LLC

Catalyst for producing unsaturated nitrile

InactiveUS6479691B1High selectivityGood physical propertiesCarboxylic acid nitrile preparationOrganic compound preparationAtomic groupCerium

A catalyst composition represented by the following empirical formula which is useful in production of unsaturated nitrites by ammoxidation:wherein F represents at least one element selected from the group consisting of zirconium, lanthanum and cerium, G represents at least one element selected from the group consisting of magnesium, cobalt, manganese and zinc, H represents at least one element selected from the group consisting of vanadium, niobium, tantalum and tungsten, x represents at least one element selected from the group consisting of phosphorus, boron, and tellurium, Y represents at least one element selected from the group consisting of lithium, sodium, rubidium and cesium, the suffixes a-k, x and y represent a ratio of atoms or atomic groups, and a=0.1-3, b=0.3-15, c=0-20, d=3-8, e=0.2-2, f=0.05-1, e / f>1, g=0-5, h=0-3, k=0.1-1, x=0-3, y=0-1, i is the number of oxygen produced by bonding of the above respective components, and j=0-100.

Owner:MITSUBISHI CHEM CORP

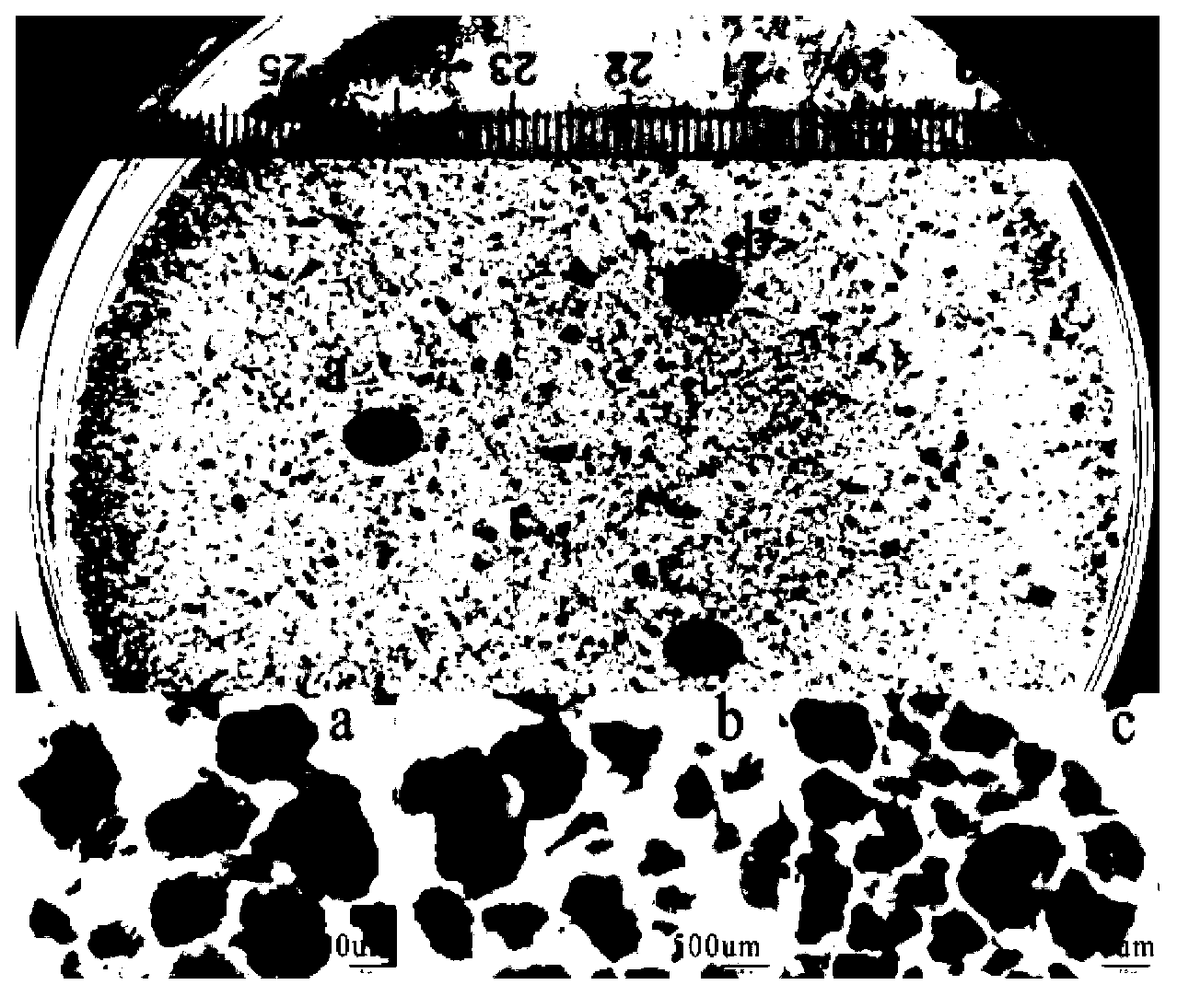

Particulate porous ammoxidation catalyst

ActiveUS7473666B2High yieldIncrease productionOrganic compound preparationHeterogenous catalyst chemical elementsPore distributionNiobium

A particulate porous ammoxidation catalyst for use in producing acrylonitrile or methacrylonitrile by reacting propylene, isobutene or tert-butyl alcohol with molecular oxygen and ammonia in a fluidized-bed reactor, the catalyst comprising a metal oxide and a silica carrier having supported thereon the metal oxide, wherein the metal oxide contains at least two elements selected from the group consisting of molybdenum, bismuth, iron, vanadium, antimony, tellurium and niobium, and the catalyst having a particle diameter distribution wherein the amount of catalyst particles having a particle diameter of from 5 to 200 μm is from 90 to 100% by weight, based on the weight of the catalyst, and having a pore distribution wherein the cumulative pore volume of pores having a pore diameter of 80 Å or less is not more than 20%, based on the total pore volume of the catalyst and wherein the cumulative pore volume of pores having a pore diameter of 1,000 Å or more is not more than 20%, based on the total pore volume of the catalyst. A method for efficiently producing this catalyst.

Owner:ASAHI KASEI CHEM CORP

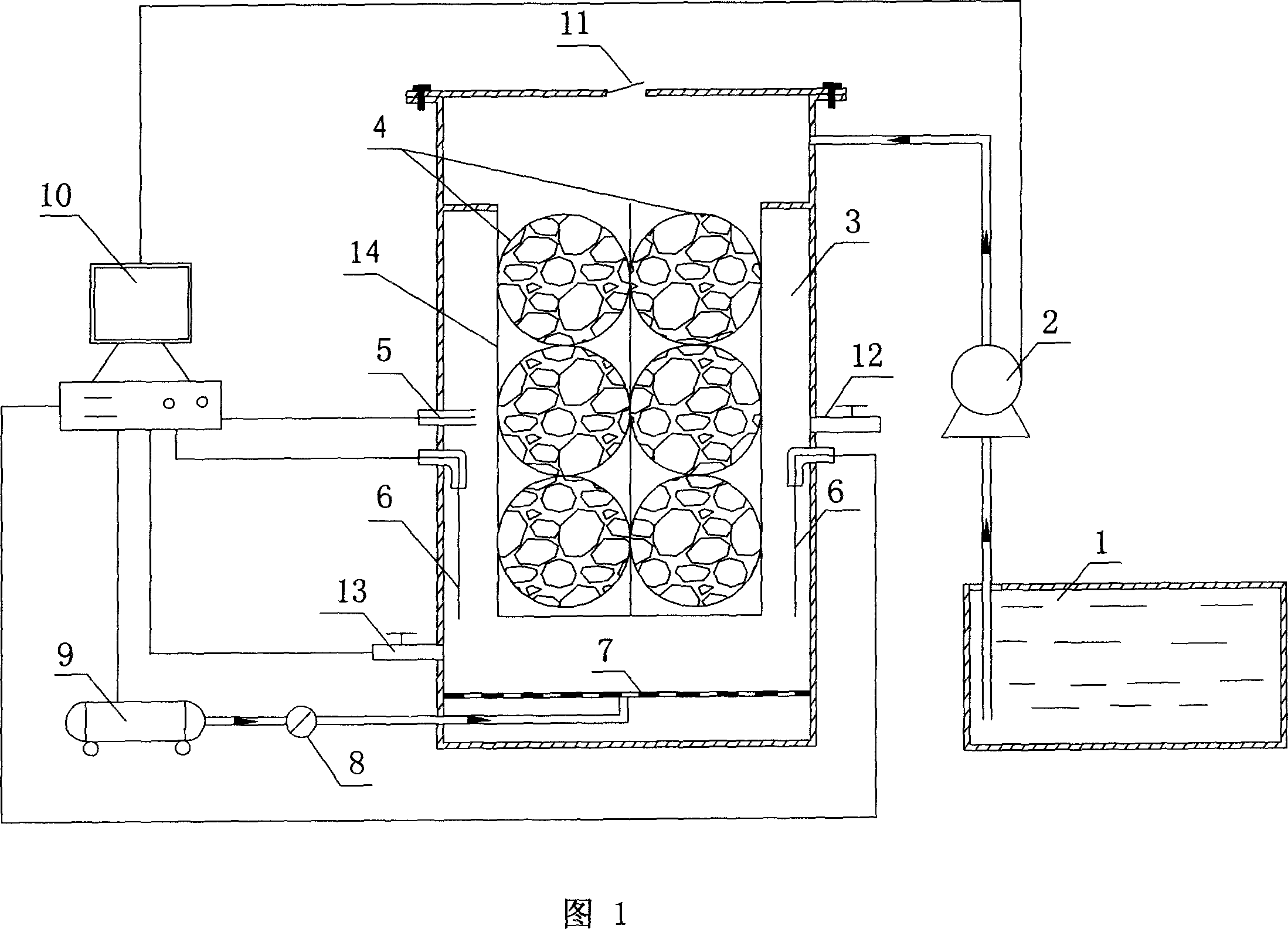

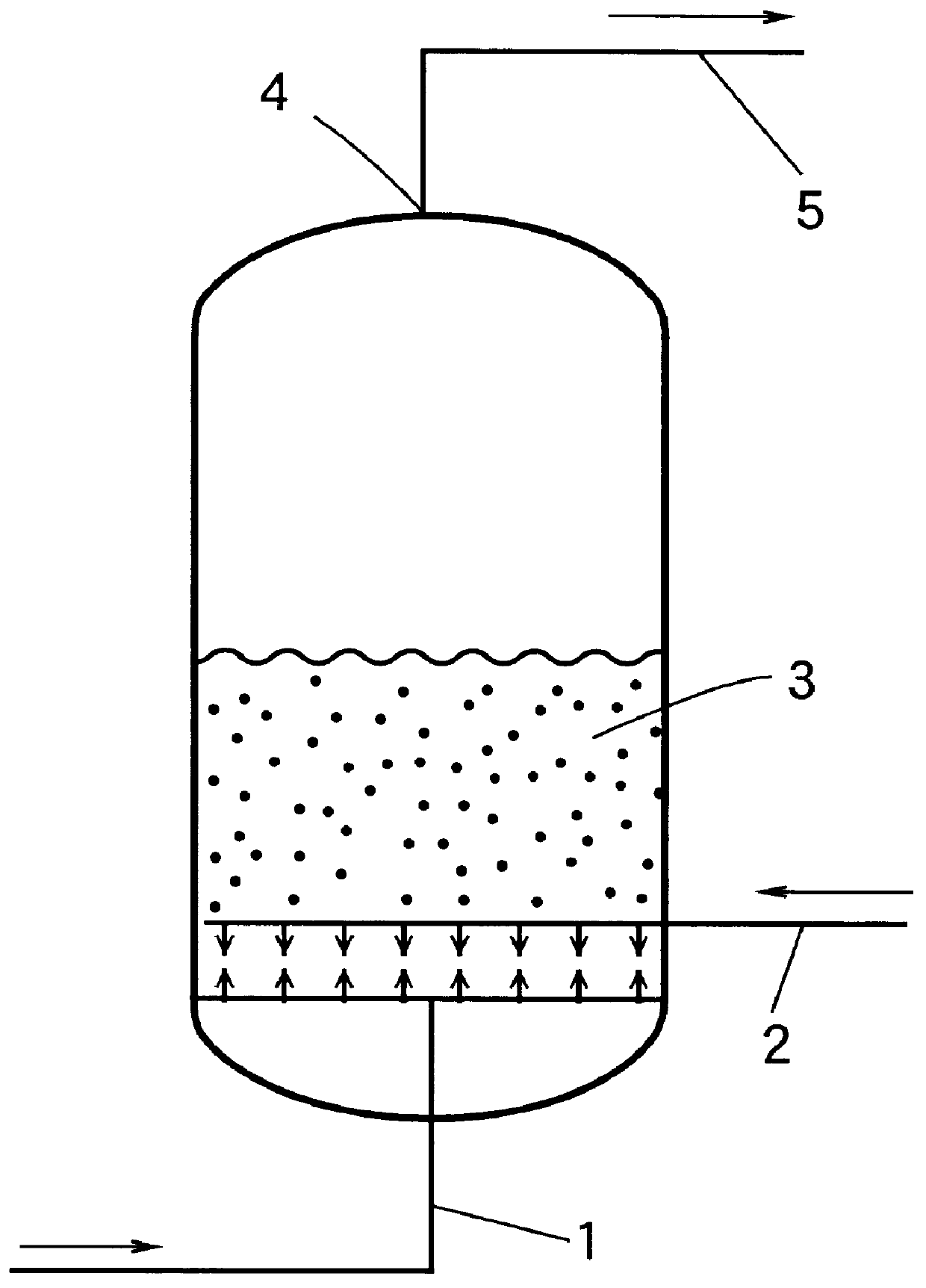

Temperature controlled USAB anaerobic ammoxidation strain denitrogenation method and its apparatus

InactiveCN101007678AGood removal effectEasy to handleTreatment with anaerobic digestion processesTemperature controlNitrogen

The invention discloses a temperature-control UASB anaerobic ammoxygen denitrifying method and equipment, which comprises the following parts: cylinder (1) of UASB biological reactor, anaerobic sludge bed (2) on the lower part of cylinder (1), three-phased separator (3) on the top, temperature-control system (4) on the exterior of anaerobic sludge bed (2), wherein the anaerobic sludge bed (2) is active sludge after aerobic and anaerobic disposal in the SBR reactor, which cultures anaerobic ammoxygen strain tamed by microbe rapidly.

Owner:SOUTH CHINA UNIV OF TECH

Sequencing batch internal circulation biological denitrification process and device thereof

InactiveCN101514064AHigh volume loadLow toxicityTreatment with aerobic and anaerobic processesMultistage water/sewage treatmentTherapeutic effectOxidative treatment

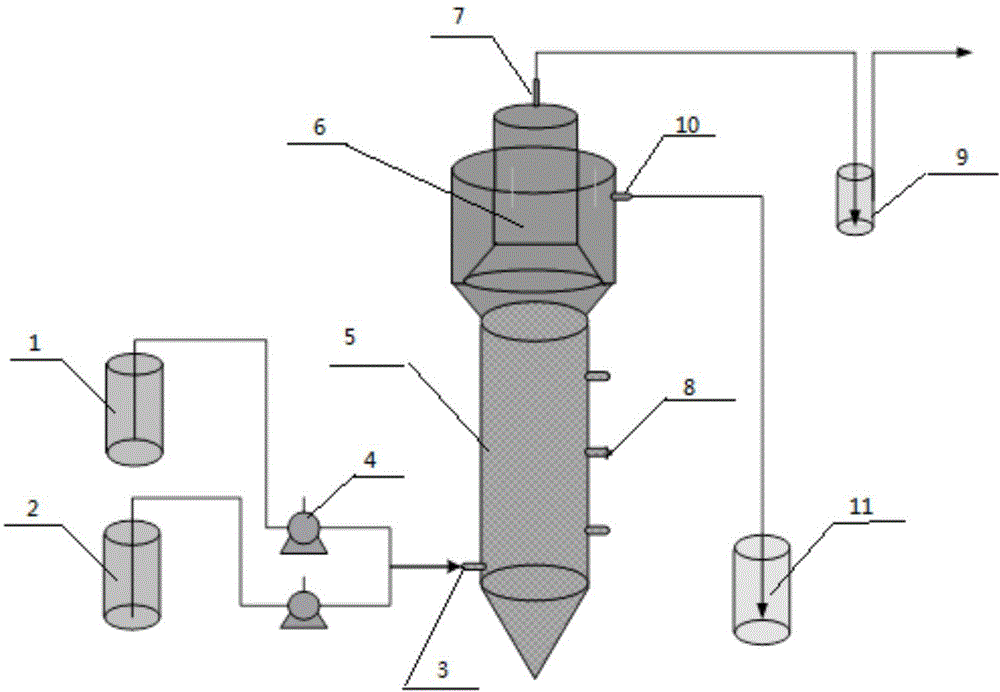

The invention discloses a sequencing batch internal circulation biological denitrification process. The process mainly comprises four steps of water feeding, biological denitrification reaction, precipitation and water and mud discharge. The biological denitrification reaction comprises an internal circulation reaction from short-cut nitrificaition treatment to deoxidation treatment, anaerobic ammoxidation treatment and to the short-cut nitrificaition treatment, and the short-cut nitrificaition treatment, the deoxidation treatment and the anaerobic ammoxidation treatment are carried out in three intercommunicated different reaction areas of one reactor. The invention further discloses a biological denitrification device. The device is separated into three intercommunicated reaction areas, that is, a short-cut nitrificaition treatment reaction area, a deoxidation treatment reaction area and an anaerobic ammoxidation treatment reaction area. The device is further equipped with an aerating device, an internal circulation pump, a water distributor and the like. The process has the advantages of convenient operation management, low energy consumption, high denitrification efficiency and stable treatment effect, and the device matching the process has the advantages of compact structure, convenient use, low cost and the like.

Owner:HUNAN UNIV

Rapid culture method of simultaneous desulfidation and denitrogenation granular sludge

ActiveCN104891650AGood granularityStrong impact resistanceWaste based fuelTreatment with anaerobic digestion processesSulfideChemistry

The invention discloses a rapid culture method of simultaneous desulfidation and denitrogenation granular sludge. The method is characterized in that an upflow anaerobic sludge bed reactor is adopted, anaerobic ammoxidation granular sludge and methanogenesis granular sludge are adopted as inoculation sludge, model wastewater containing ammonia nitrogen and nitrite nitrogen is adopted as inlet water, and the method comprises the following steps: adding sulfide into the model wastewater, adding inorganic salts and trace elements for maintaining the growth of microbes, gradually improving the concentrations of matrixes in the inlet water and / or shortening the hydraulic retention time in order to adjust the running of the reactor, and culturing under anaerobic and shady conditions at 30-37DEG C under the pH value of the inlet water of 7.5-8.0. The sludge obtained in the invention has the advantages of obvious granularity, strong impact resistance, high processing efficiency, saving of the occupied are through cooperating with a UASB reactor, simplification of the desulfidation and denitrogenation process, and low investment and running cost, and is suitable for treating wastewater containing ammonia nitrogen, nitrite nitrogen and sulfides of the light industry, the pharmacy industry, the oil refining industry and the leather making industry.

Owner:HANGZHOU NORMAL UNIVERSITY

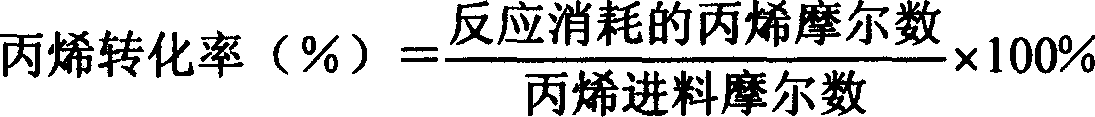

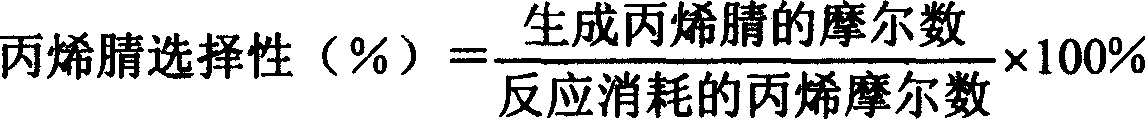

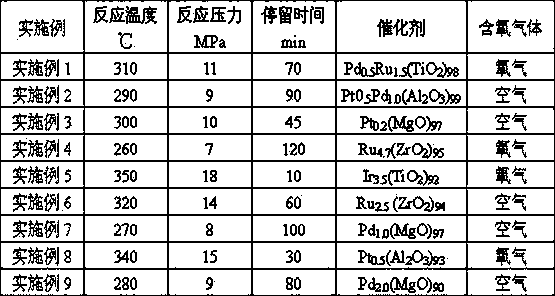

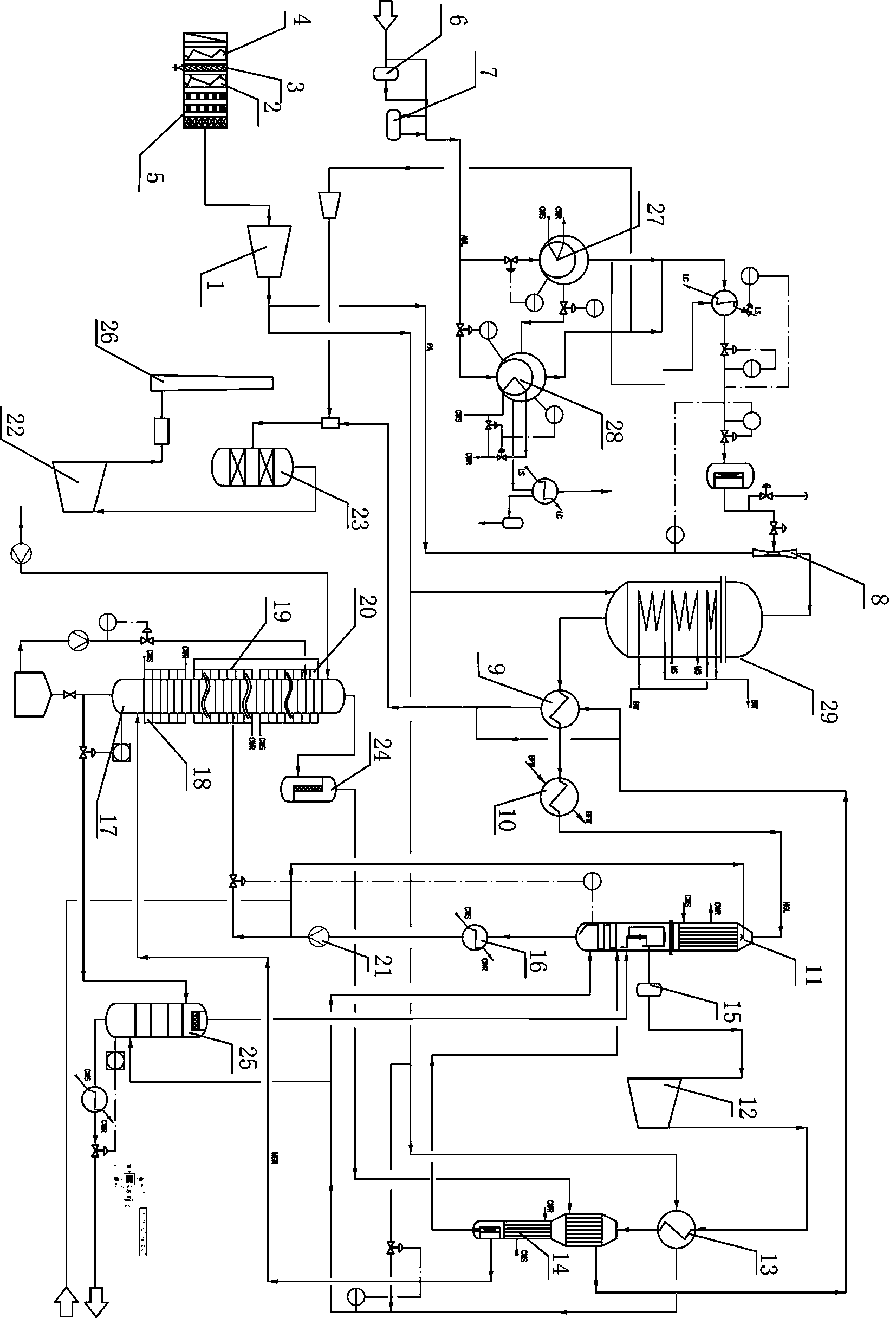

Processing method of wastewater of acrylonitrile production refining process

ActiveCN103420473ASimple processRemove completelyNature of treatment waterWater/sewage treatment by oxidationOxygenOrganic matter

The invention relates to a processing method of wastewater of an acrylonitrile production refining process. The processing of the wastewater of an acrylonitrile production refining system has the problems of complex processing technology and high operation cost. Through use of a technical scheme of the processing method of the wastewater of the acrylonitrile production refining process, the problems are well solved, and the processing method can be used for processing of the wastewater of the acrylonitrile production refining process. The technical scheme is shown as follows: the wastewater produced in the acrylonitrile refining process of the acrylonitrile production by ammoxidation of propylene and propane is mixed with an element-oxygen-containing gas to pass through a wet oxidation reactor to remove organic matters in the wastewater to enable the COD value of the wastewater to be less than 500 mg / L.

Owner:CHINA PETROLEUM & CHEM CORP +1

Oxide catalyst for oxidation or ammoxidation

InactiveUS7109144B2High selectivityEasy to useOrganic compound preparationOrganic chemistry methodsAlkaline earth metalIndium

Disclosed is an oxide catalyst for use in catalytic oxidation or ammoxidation of propane or isobutane in the gaseous phase, which comprises a composition represented by the Mo1VaSbbNbcZdOn (wherein: Z is at least one element selected from the group consisting of tungsten, chromium, titanium, aluminum, tantalum, zirconium, hafnium, manganese, iron, ruthenium, cobalt, rhodium, nickel, palladium, platinum, zinc, boron, indium, germanium, tin, lead, bismuth, yttrium, gallium, rare earth elements and alkaline earth metals: and a, b, c, d, and n are, respectively, the atomic ratios of V, Sb, Nb, Z and O, relative to Mo), wherein 0.1≦a<0.4, 0.1<b≦0.4, 0.01≦c≦0.3, 0≦d≦1, with the proviso that a<b, and n is a number determined by and consistent with the valence requirements of the other elements present. Also disclosed is a process for producing an unsaturated carboxylic acid or an unsaturated nitrile by using the above-mentioned oxide catalyst.

Owner:ASAHI KASEI KK

Method for regenerating molybdenum-containing oxide fluidized-bed catalyst

InactiveUS6559085B1Improve catalytic performanceOther chemical processesCatalyst regeneration/reactivationCeriumLanthanum

A method for regeneration of a molybdenum-containing oxide fluidized bed catalyst which comprises impregnating a fluidized catalyst of a metal oxide containing molybdenum, bismuth and iron which has been deteriorated by being used for a reaction in production of acrylonitrile by ammoxidation of propylene, with a solution of a molybdenum compound and a solution of at least one compound containing at least one element selected from the group consisting of iron, chromium, lanthanum and cerium which are prepared separately or with a previously prepared mixed solution of the above compounds, drying the resulting catalyst and, then, firing the catalyst at a temperature of 500-700° C.

Owner:MITSUBISHI CHEM CORP

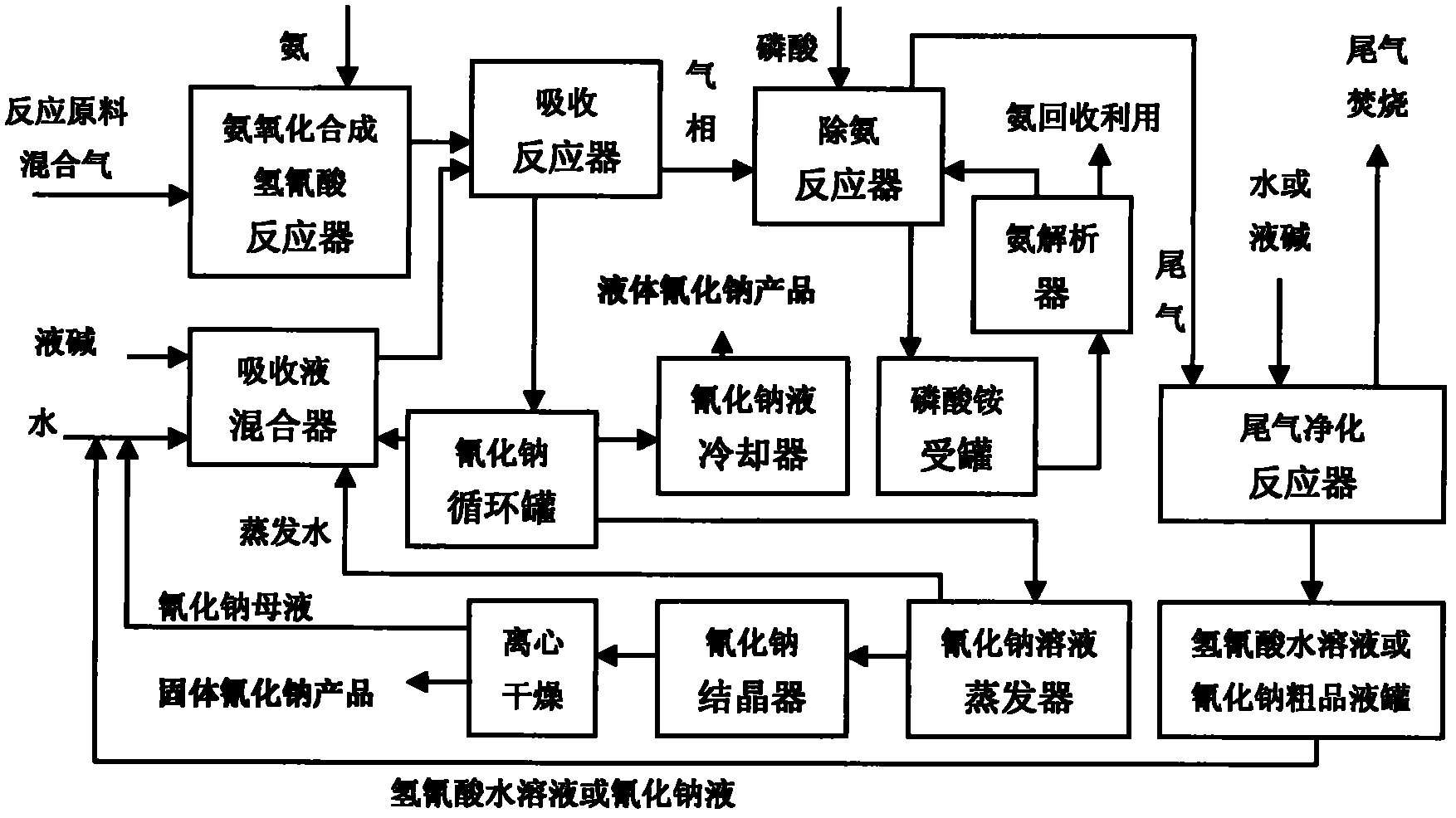

Environment-friendly clean production method for high purity sodium cyanide

InactiveCN103073027ARealize recyclingAchieving a circular economy modelAlkali metal cyanidesPhosphoric acidSodium cyanide

The invention provides an environment-friendly clean production method for high purity sodium cyanide. The production method comprises the following steps that: without removal of ammonia, hydrocyanic acid synthetic gas synthesized through ammoxidation is directly absorbed by and reacts with an aqueous sodium hydroxide solution to obtain a high purity aqueous sodium cyanide solution, and free ammonia remains in tail gas; the aqueous sodium cyanide solution is cooled and blended to obtain a high purity liquid sodium cyanide product, the high purity liquid sodium cyanide product undergoes condensation, crystallization and centrifugation to obtain a high purity solid sodium cyanide product, and mother liquor is indiscriminately used in liquid alkali absorption liquor; phosphoric acid or ammonium biphosphate is employed as a carrier for repeated cyclic indiscriminate application of ammonia so as to recover ammonia in the tail gas; and after recovery of ammonia, the tail gas is purified and absorbed with water or the aqueous sodium hydroxide solution, a small amount of the aqueous hydrocyanic acid solution or a crude aqueous sodium cyanide solution product is obtained while the tail gas is purified, the purified tail gas is burned with a tail gas boiler, and the aqueous hydrocyanic acid solution or the crude aqueous sodium cyanide solution product is indiscriminately used in the liquid alkali absorption liquor.

Owner:龙智

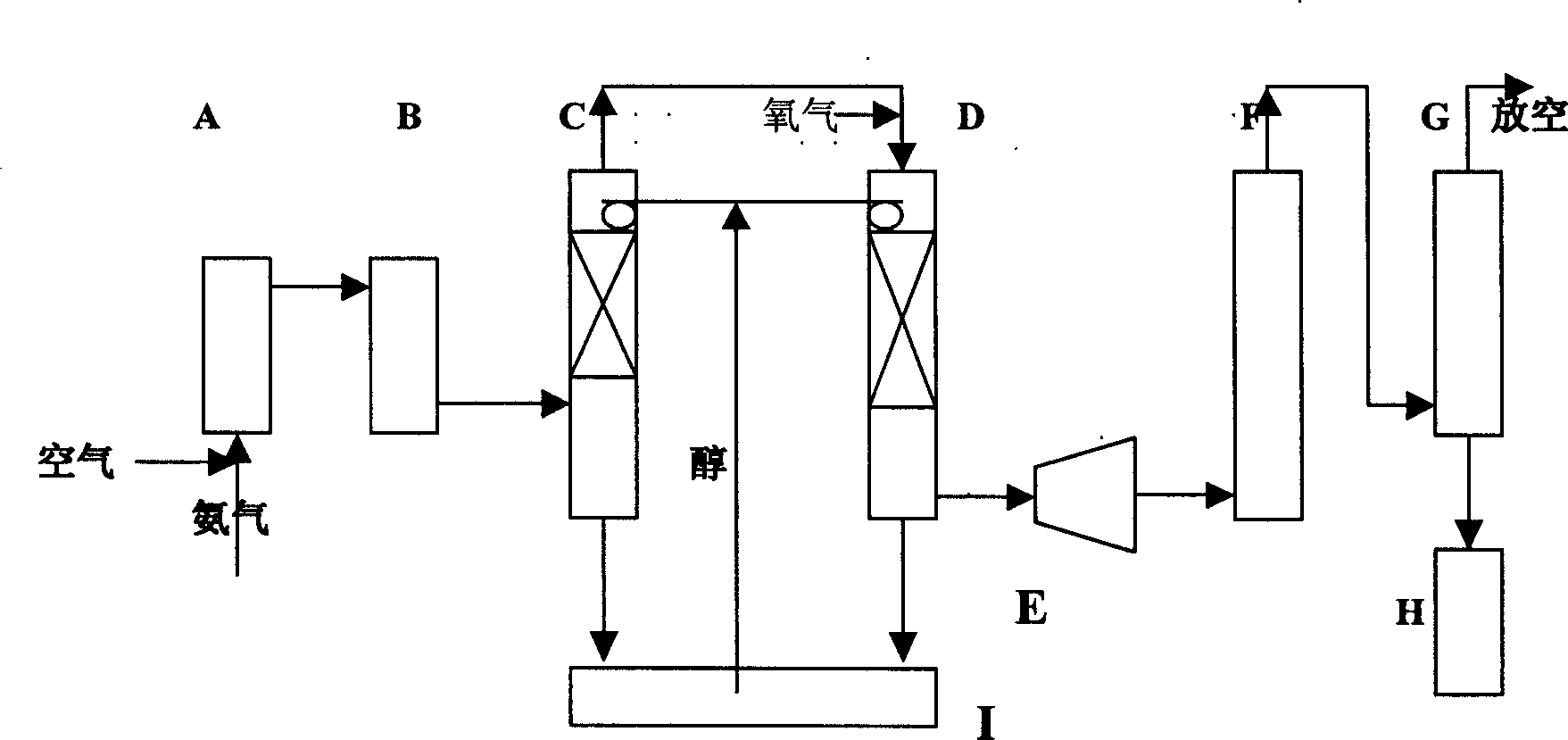

Production process of No gas for synthesizing oxalate

The production process of NO gas for synthesizing oxalate belongs to the field of chemical and environment protection technology. The production process includes ammoxidation of air to produce NOx as the NO gas for synthesizing oxalate, or utilizing the NOx in nitric acid producing tail gas as the NO gas for synthesizing oxalate, absorbing nitrite with alcohols and compression and condensation to recover alcohols and nitrite from the tail gas. The production process has liquid ammonia or gaseous ammonia of concentration 1-30 vol%, oxygen of concentration 1-30 vol%, alcohol concentration of 50-100 wt%, pressure of 0.1-10 MPa, and condensation temperature of ¿C20 to 100 deg.c. The present invention has high economic utility and social utility.

Owner:TONGLIAO GOLD COAL CHEM

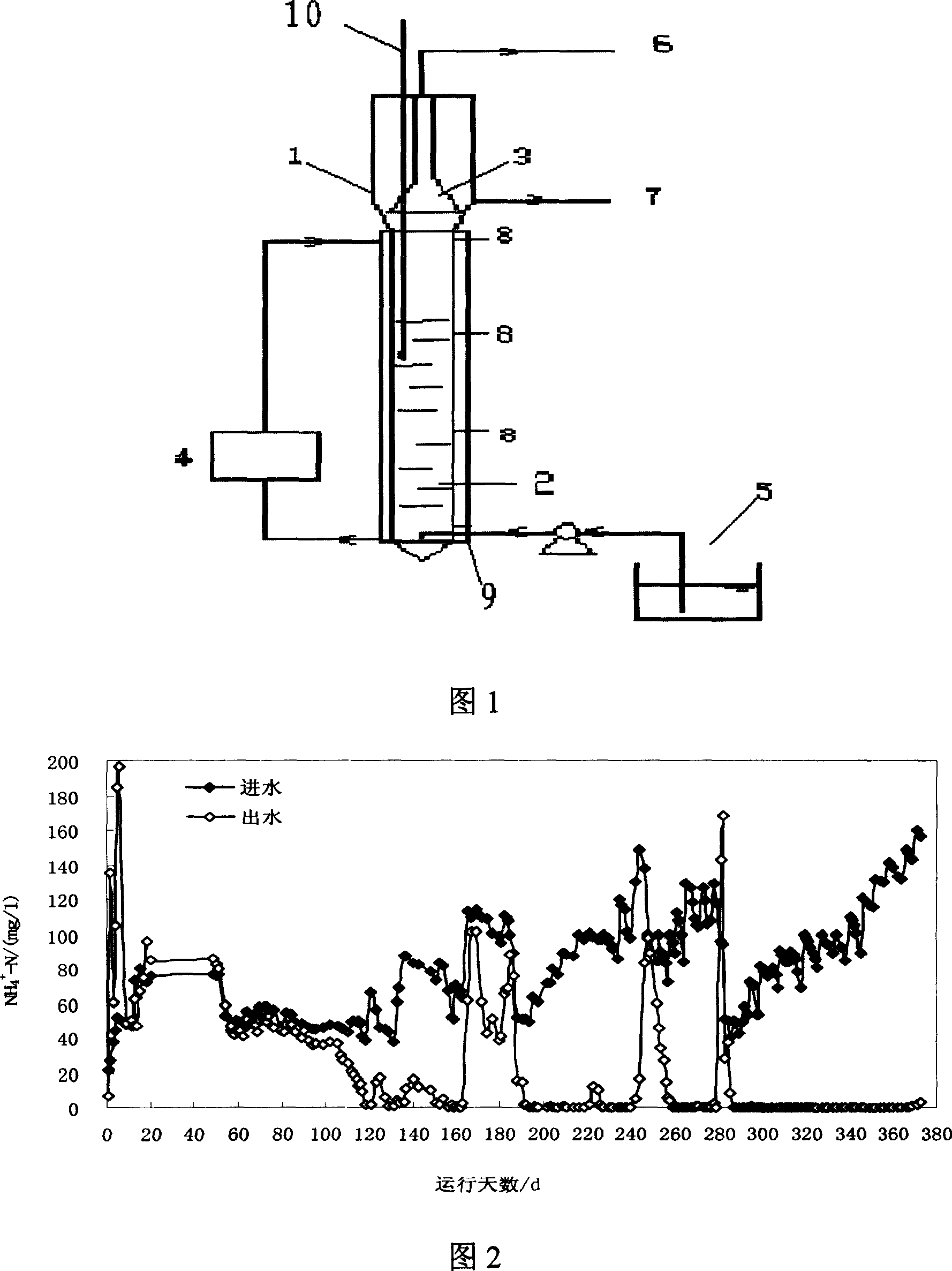

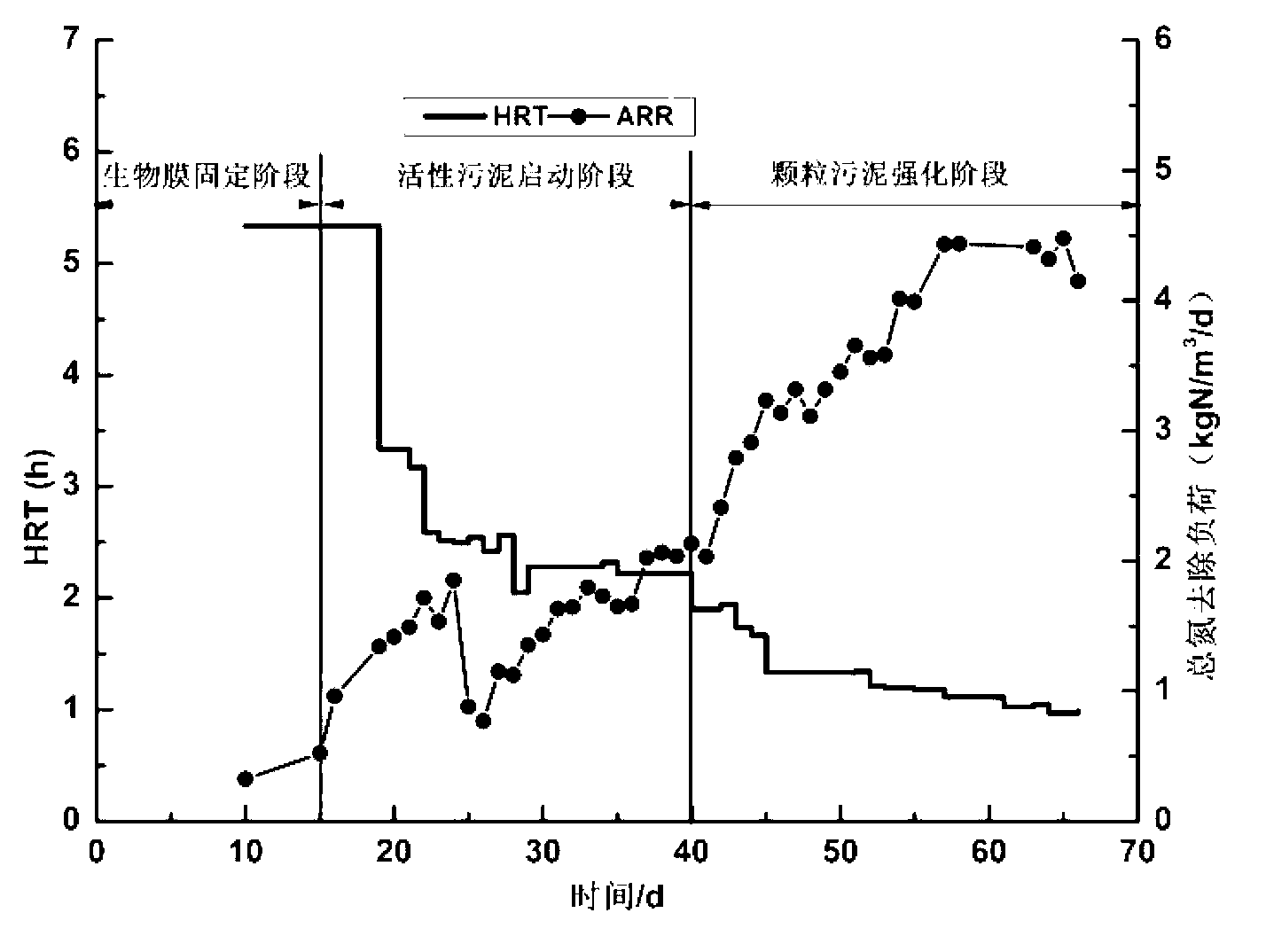

Method for rapid starting of anaerobic ammonium oxidation granular sludge by using UASB

ActiveCN102976483AGranularizeImprove living conditionsWater contaminantsTreatment with anaerobic digestion processesActivated sludgeReaction zone

The invention provides a method for rapid starting of anaerobic ammonium oxidation granular sludge by using UASB, which belongs to the field of treatment and regeneration of municipal sewage. According to the invention, a UASB reactor is used, wherein the upper part of the UASB reactor is filled with a filling material and used as a biomembrane reaction zone, and the lower part of the UASB reactor is an activated sludge zone; the stages of immobilization of a biomembrane, starting of the activated sludge and reinforcement of the granular sludge are carried out; thus, in 66 days, overall nitrogen removal load reaches 4.34 kgN / m<3> / d, an average particle size of the sludge is 1.0 mm, SV2 is equal to SV10, and the anaerobic ammonium oxidation granular sludge is successfully started; and compared to a method of culturing the anaerobic ammonium oxidation granular sludge by using an SBR reactor advocated by Zhihong Zhao and the like (2007), the method provided by the invention has the advantages that time for starting of the granular sludge is reduced by 25 d and overall nitrogen removal load is 4.3 kgN / m<3> / d higher.

Owner:BEIJING UNIV OF TECH

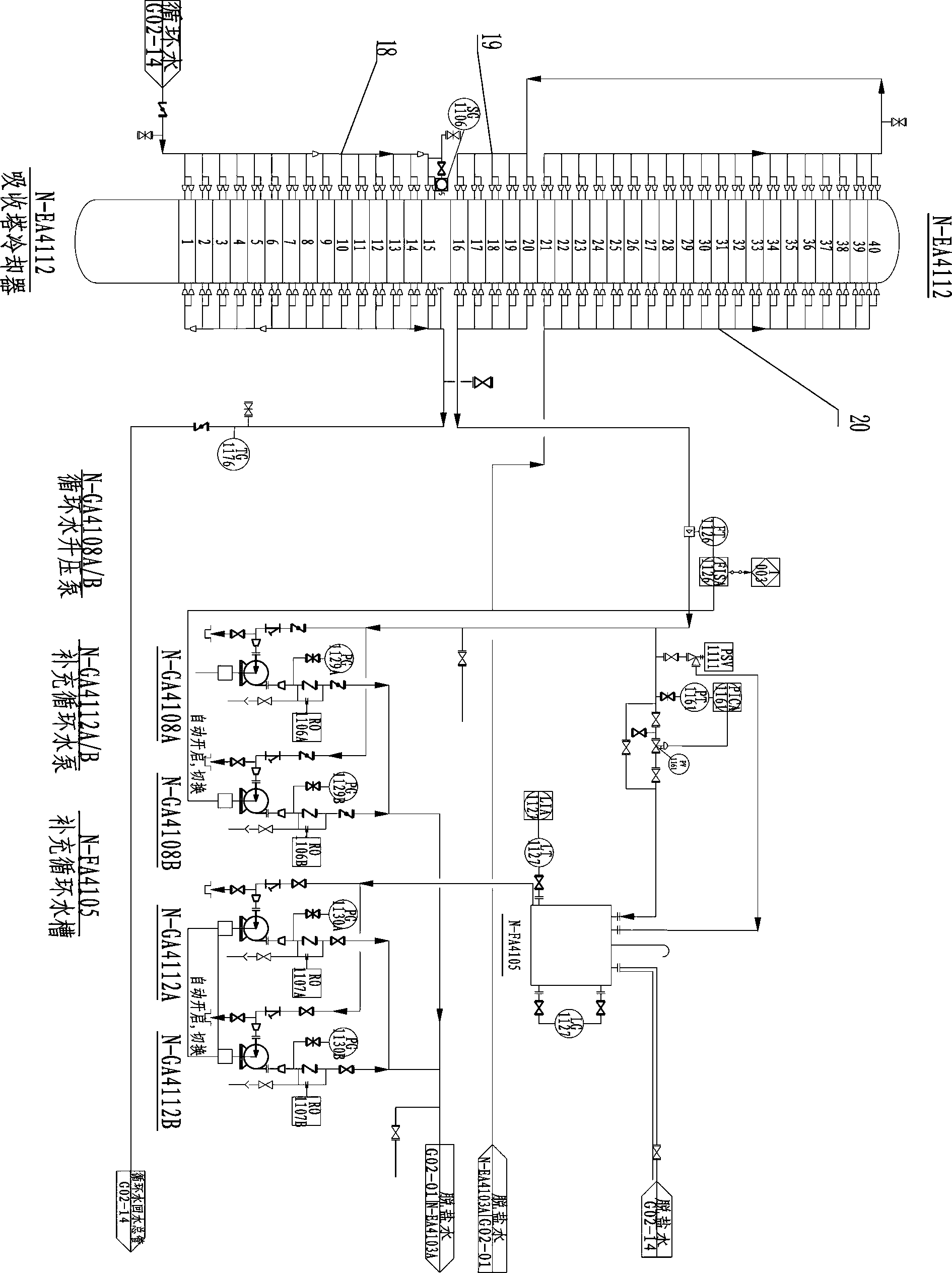

Method and device for preparing high-concentration dilute nitric acid

The invention discloses a method and device for preparing high-concentration dilute nitric acid. The method comprises the following steps: carrying out ammonia-air mixing, ammoxidation, condensation separation and fine separation on air subjected to impurity removal and dehumidification and liquid ammonia subjected to impurity removal, oil removal and evaporation, absorbing in an absorption tower in which 40 tower plates are arranged, meanwhile, carrying out cooling heat exchange by a three-stage water circulation technique to obtain the high-concentration dilute nitric acid of which the concentration is not lower than 68-70%. The method and device effectively enhance the nitric acid absorption efficiency, enhance the concentration of the dilute nitric acid, and can better satisfy the demands of modern industry for high-concentration dilute nitric acid.

Owner:TIANJI COAL CHEM IND GROUP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com