Apparatus and method for nitrogen removal by combining garbage leachate SBR and anaerobic ammoxidation

An anaerobic ammonia oxidation and landfill leachate technology, which is applied in the field of biological denitrification of low-carbon-nitrogen ratio and high-concentration ammonia-nitrogen wastewater, can solve problems such as insufficient organic carbon sources, and achieve the goals of reducing sludge production, improving efficiency and saving energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

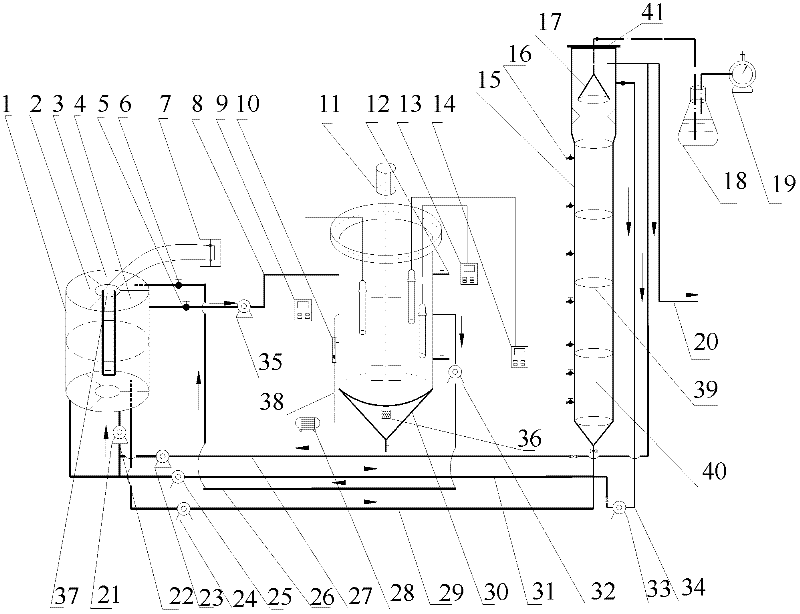

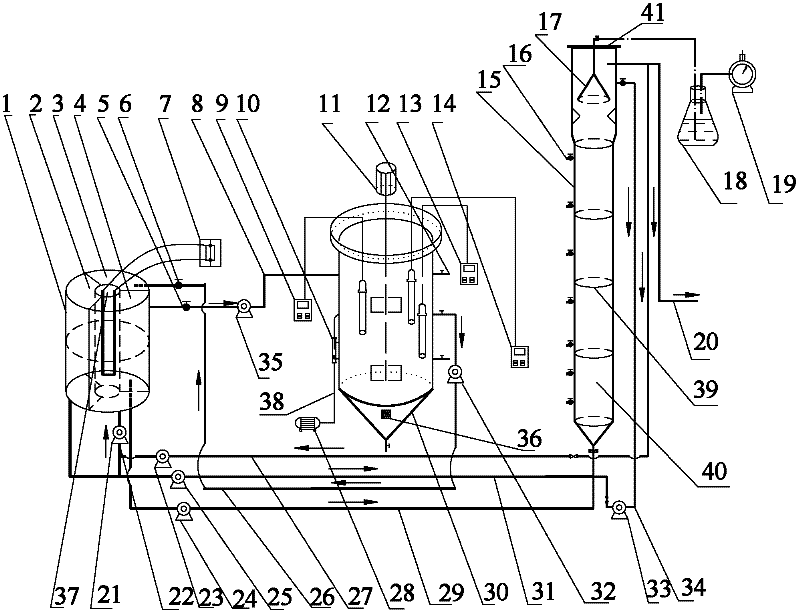

[0024] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

[0025] Such as figure 1 As shown, the landfill leachate SBR and anammox combination denitrification device of the present invention includes an integrated water tank 1, an SBR short-range nitrification reactor 30, and anammox reactor 15; the integrated water tank includes a raw water tank 2, a rear The water tank 3, the front water tank 4 and the heating water tank 37 placed between the original water tank 2, the rear water tank 3 and the front water tank 4 are provided with a temperature control heating device 7; the original water tank 2 passes through the first water inlet pipe 22 The first peristaltic pump 21 is connected with the front water tank 4, and the raw water tank 2 is connected with the anaerobic ammonium oxidation reactor 15 through the fourth water inlet pipe 31 and the seventh peristaltic pump 25; the front water tank 4 in the integrated wate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com