Patents

Literature

7102results about How to "Reduce output" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

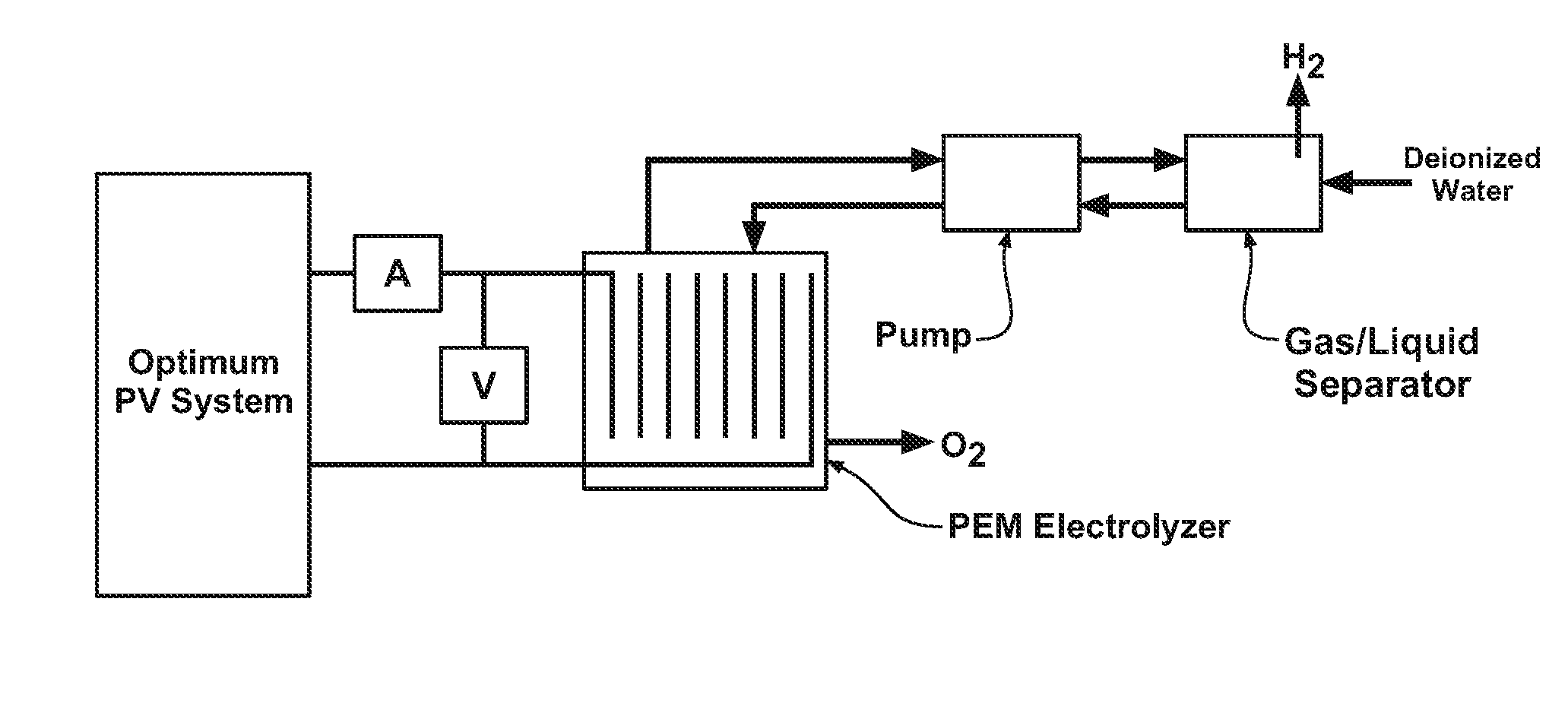

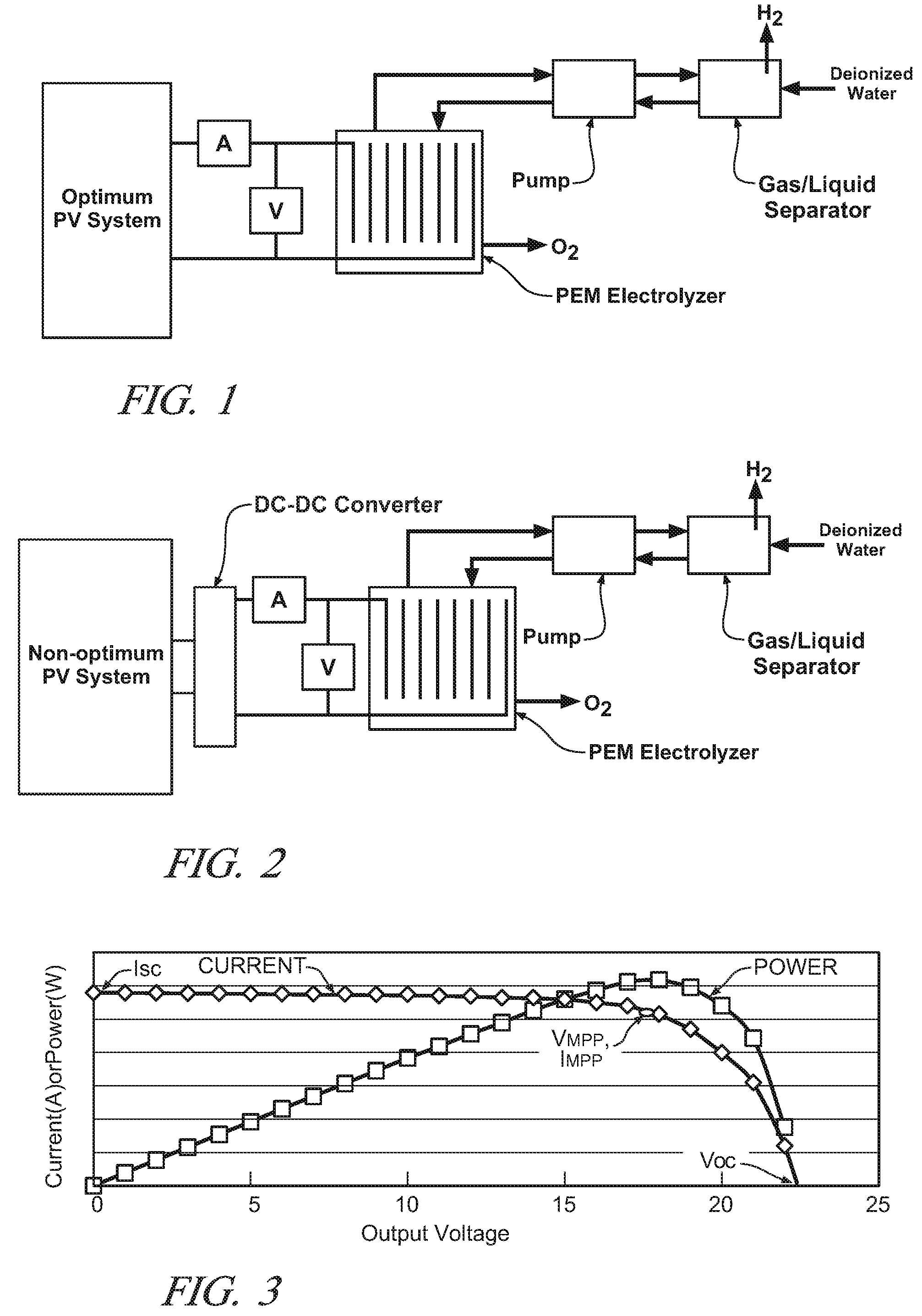

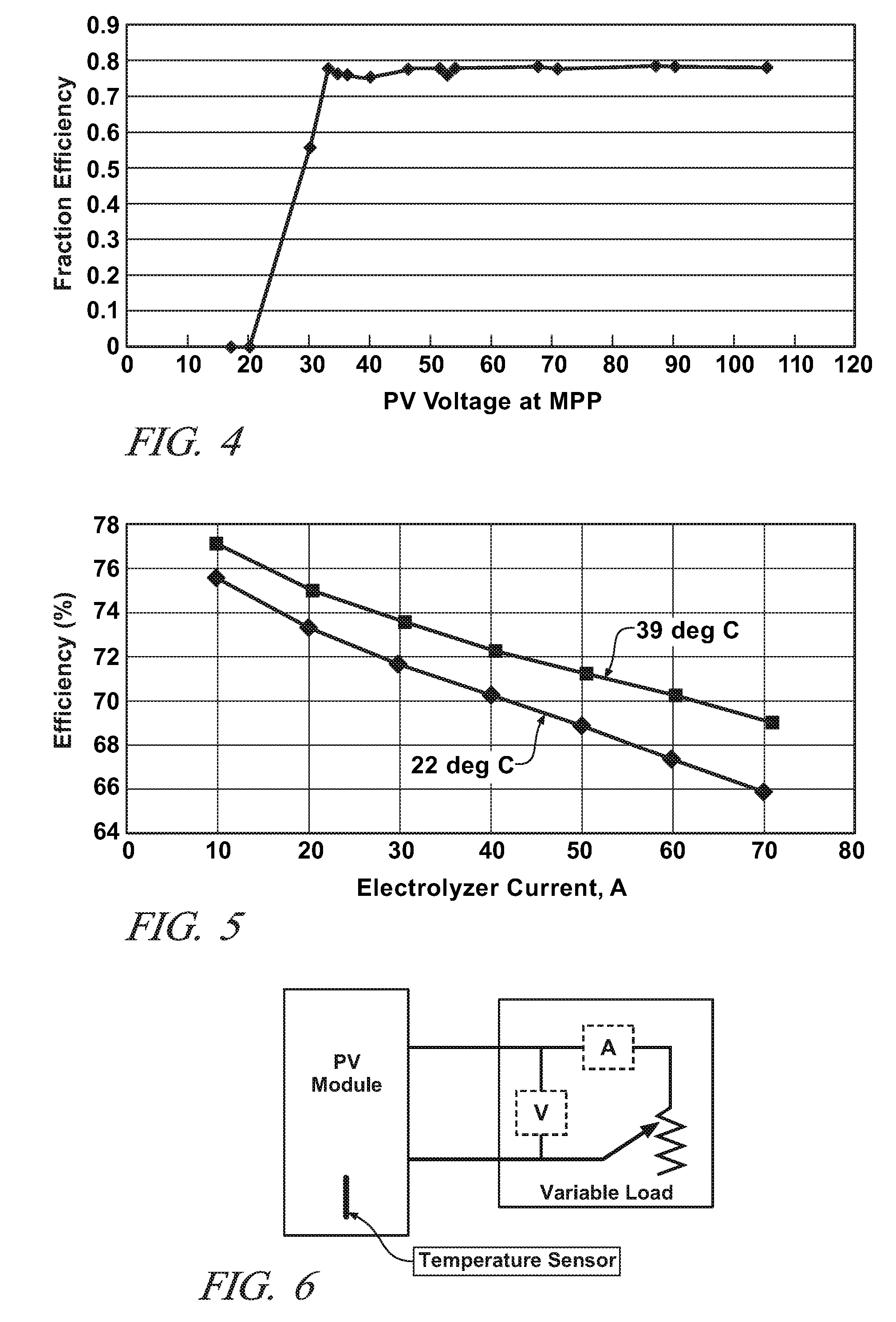

Optimizing photovoltaic-electrolyzer efficiency

InactiveUS20070119718A1Efficient productionEasy to operatePhotography auxillary processesElectrolysis componentsElectrolysisHydrogen

Owner:GM GLOBAL TECH OPERATIONS LLC

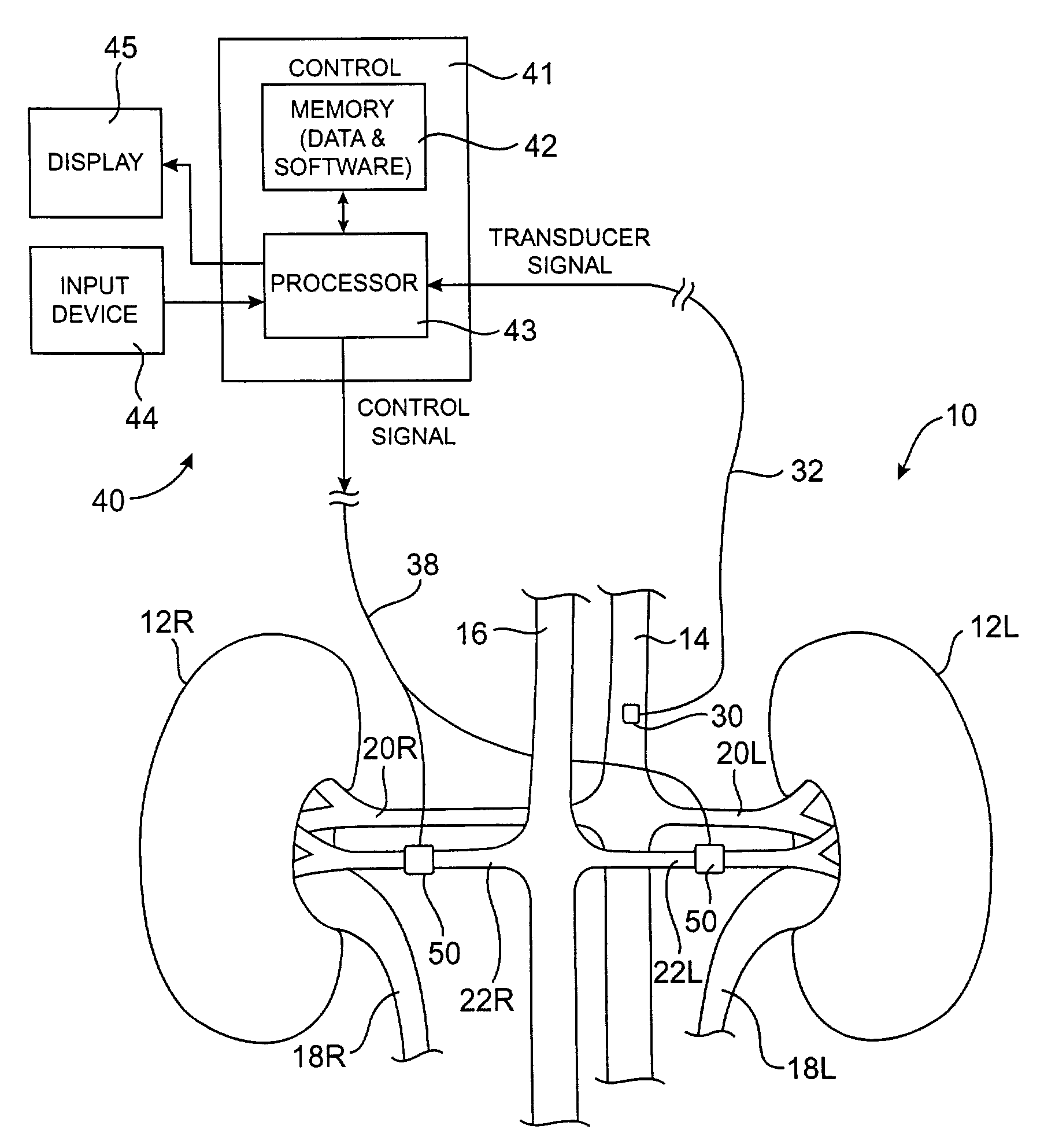

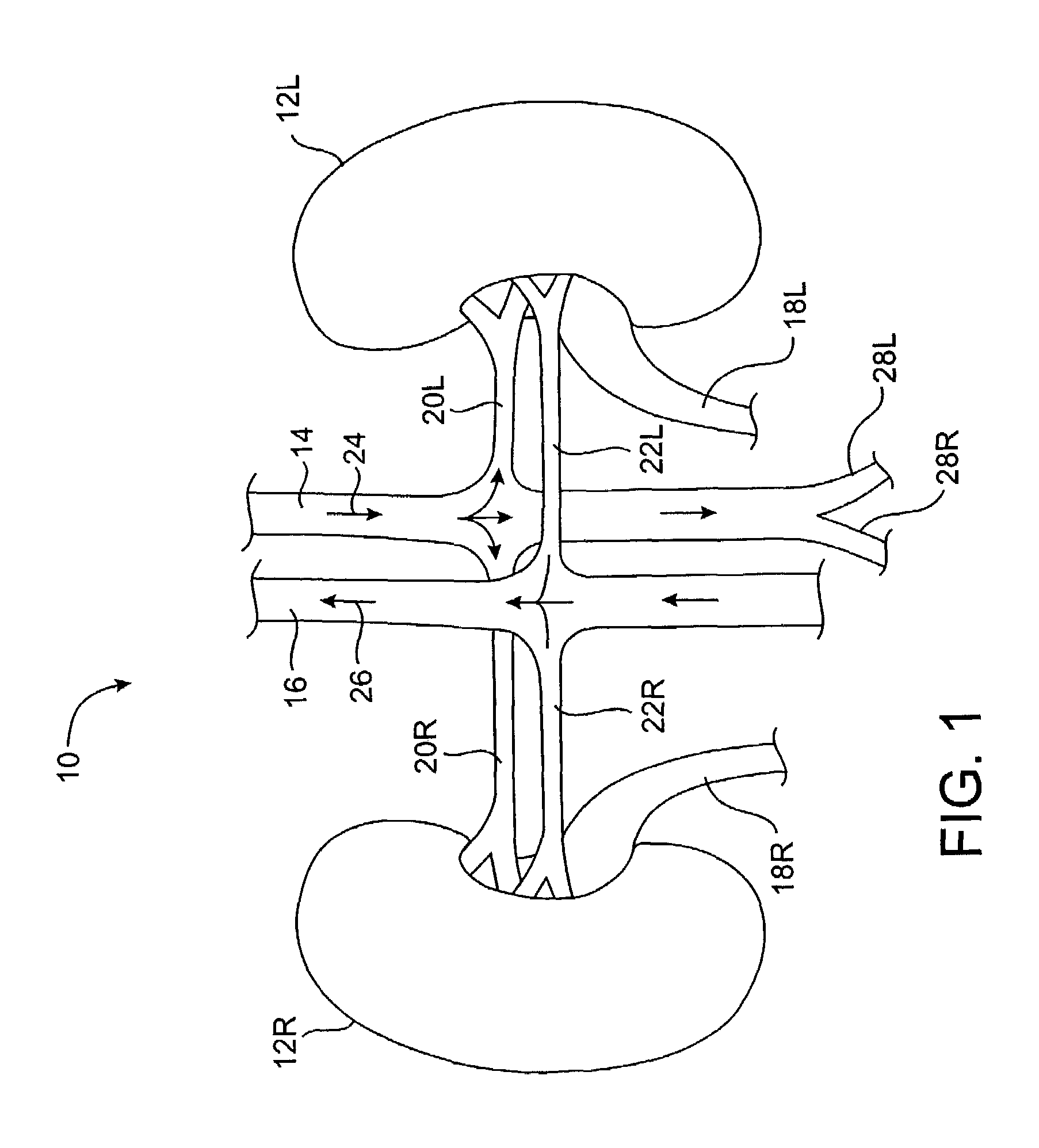

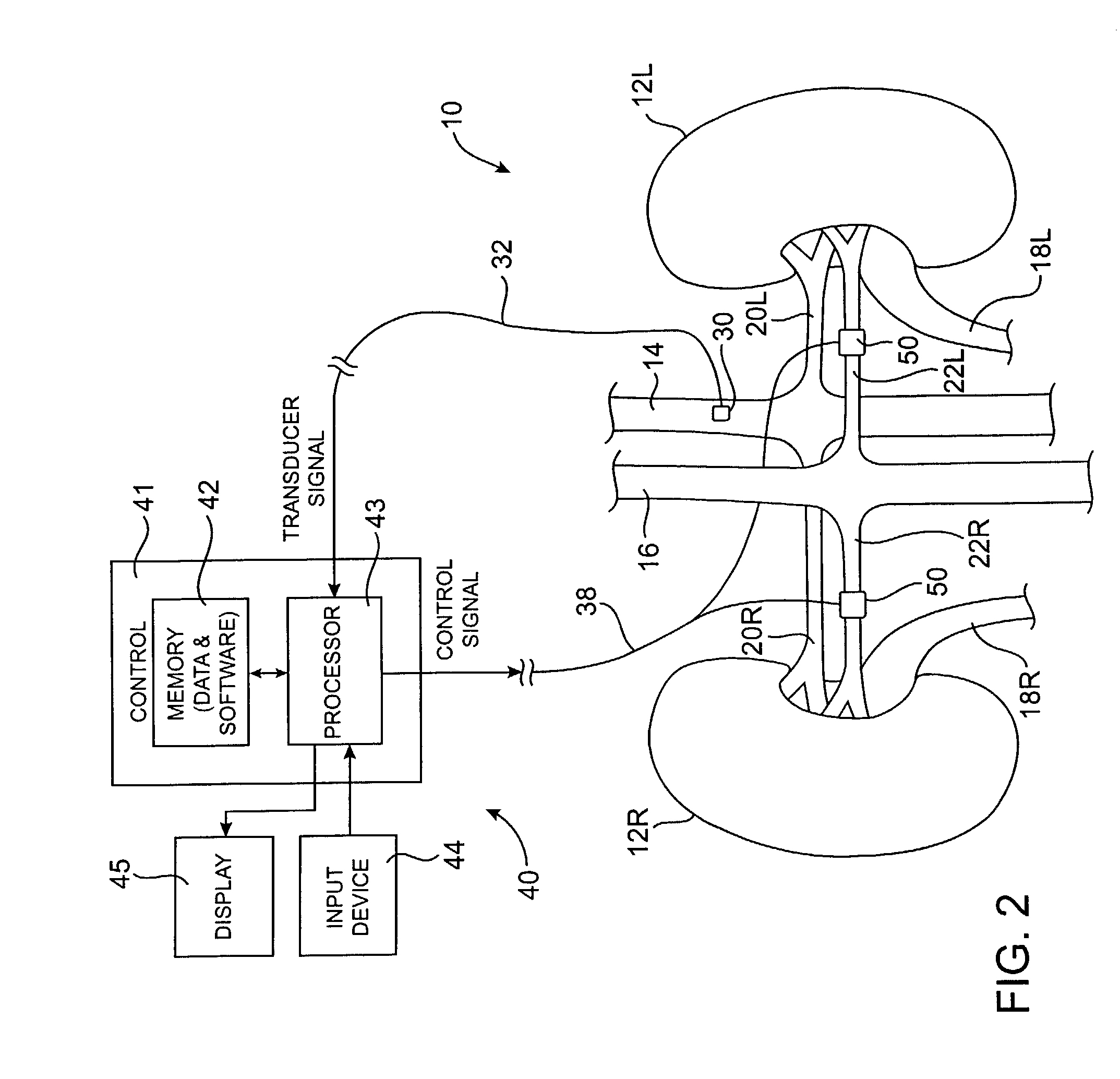

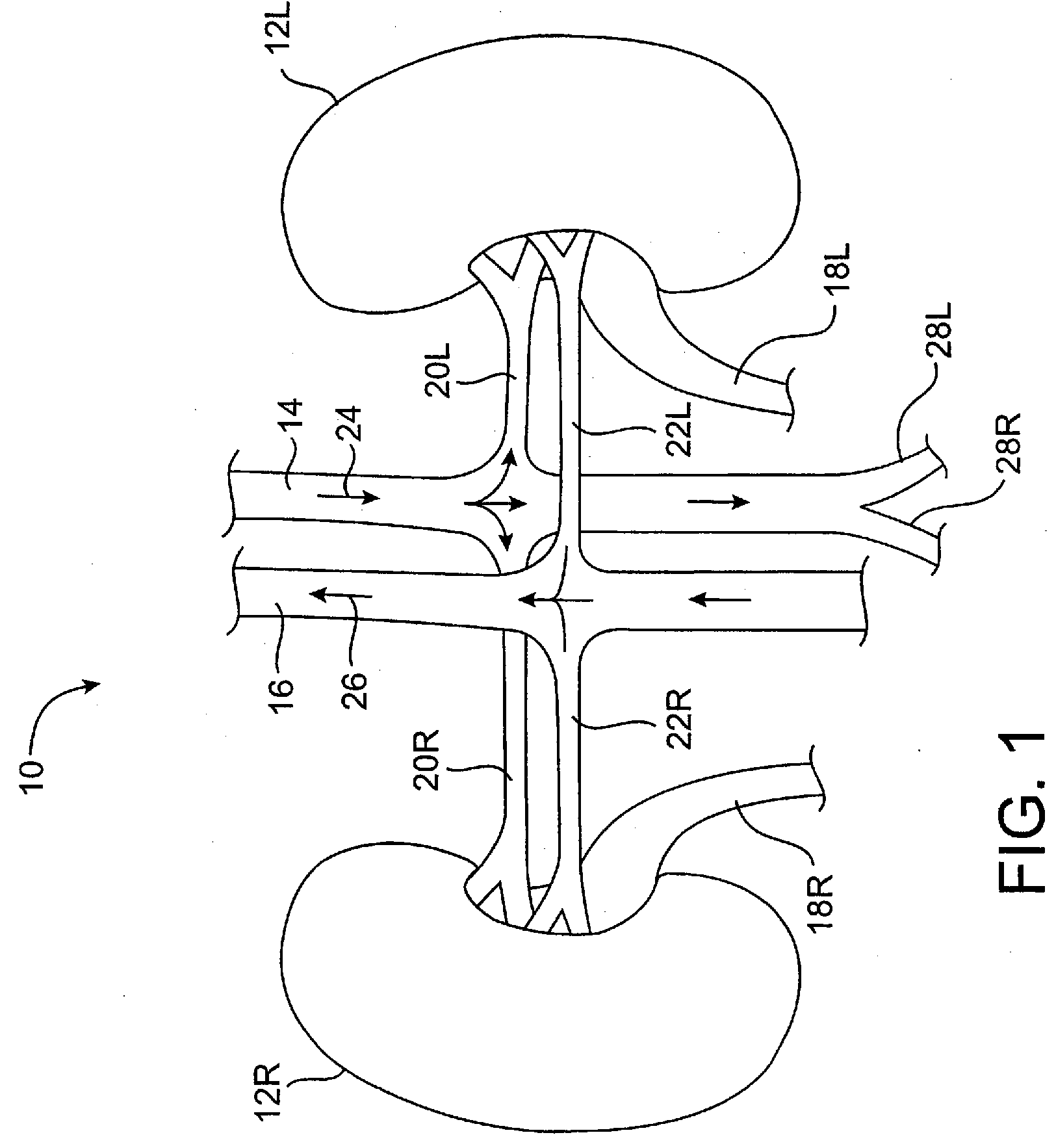

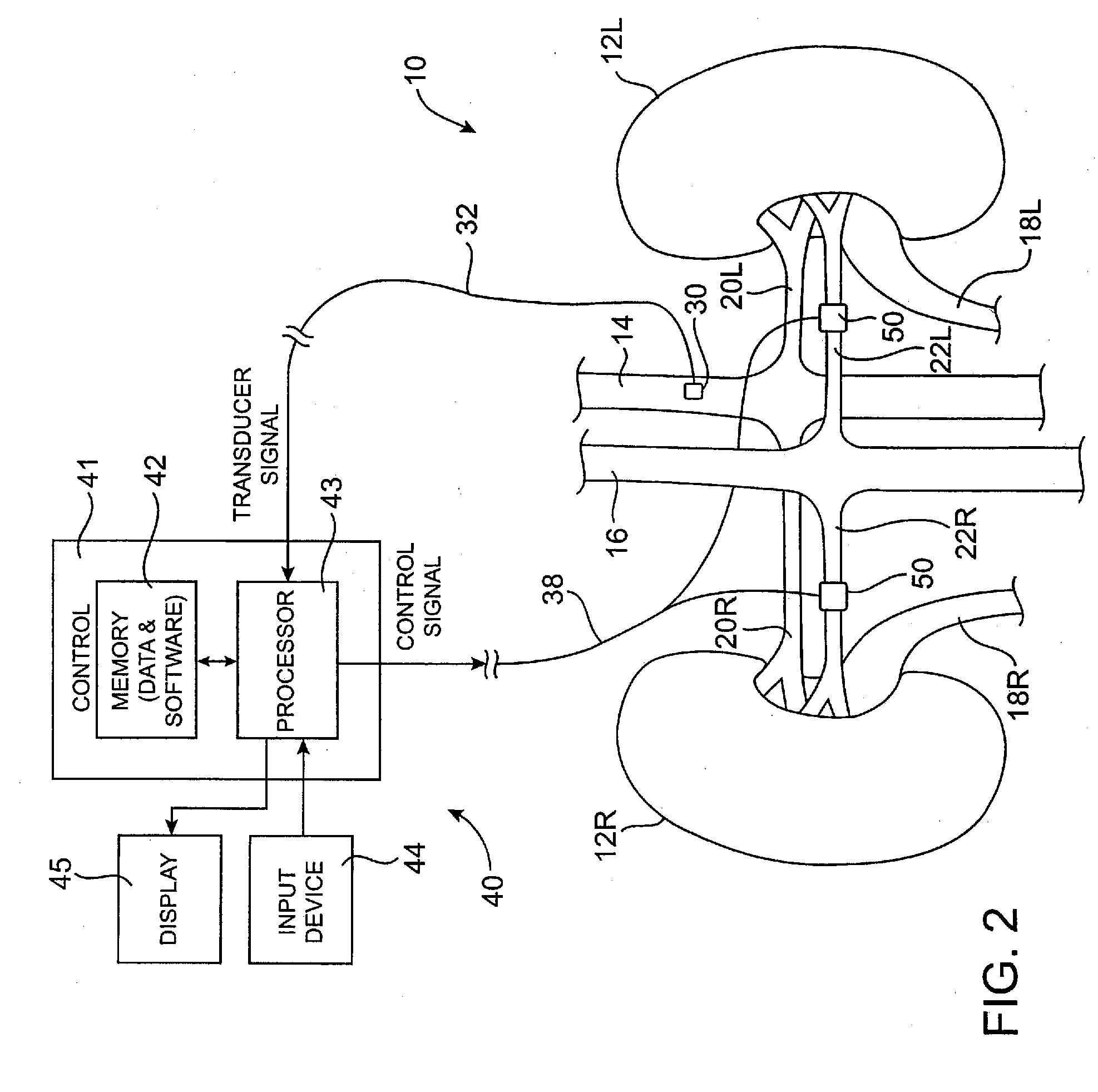

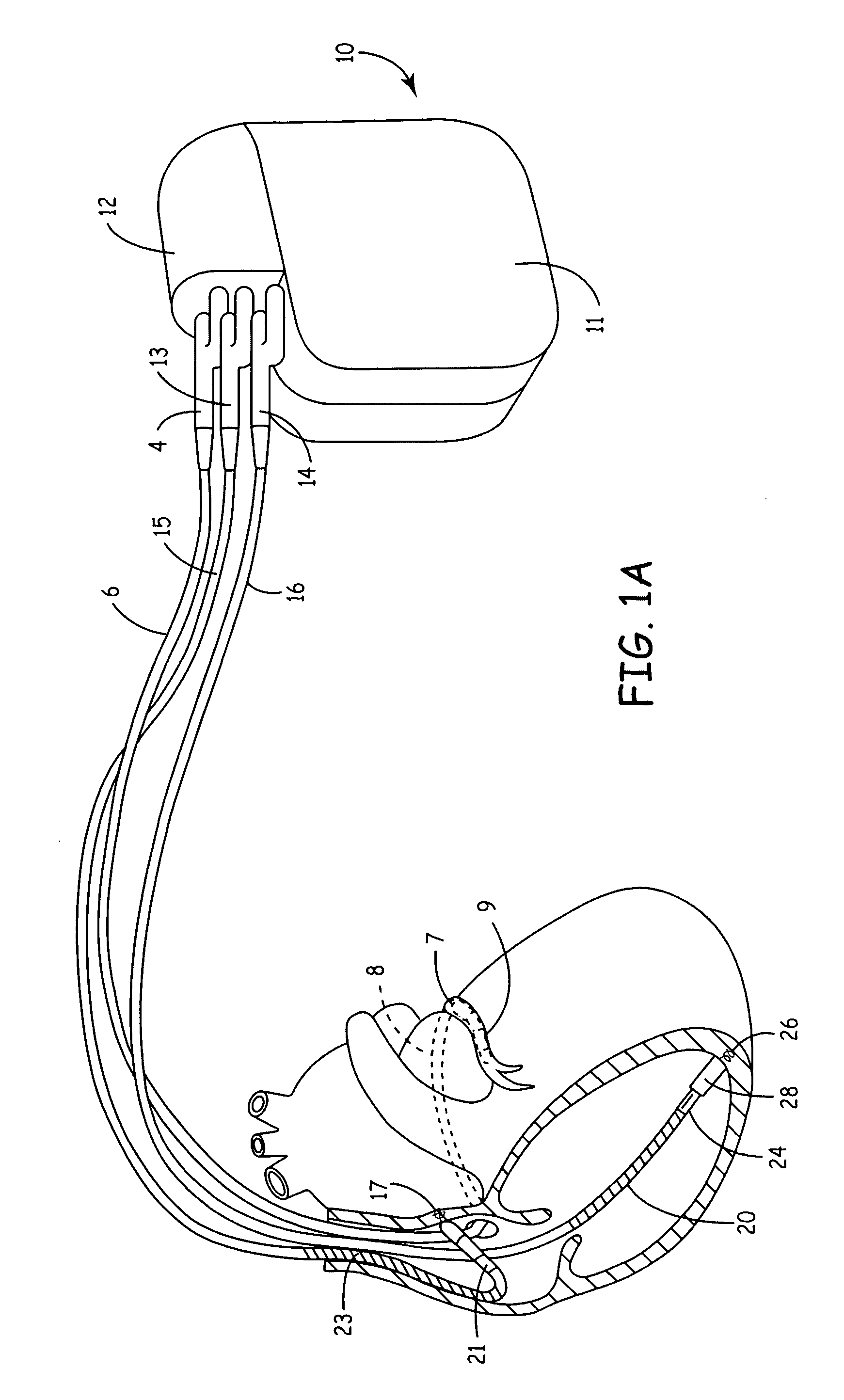

Systems and methods for controlling renovascular perfusion

InactiveUS7485104B2Reduced perfusionReduces and reverses neurohormonal activationOther blood circulation devicesMedical devicesHormoneRenovascular hypertension

Devices, systems and methods by which the real or apparent renovascular perfusion and intrarenal pressure may be selectively and controllably increased. By selectively and controllably increasing renovascular perfusion and interstitial hydrostatic pressure when the heart is unable to pump sufficient blood or when renal perfusion is suboptimal, the present invention reduces or reverses neurohormonal activation and fluid retention, and thereby minimizes their deleterious effects on the heart, vasculature, kidneys and other body systems.

Owner:CVRX

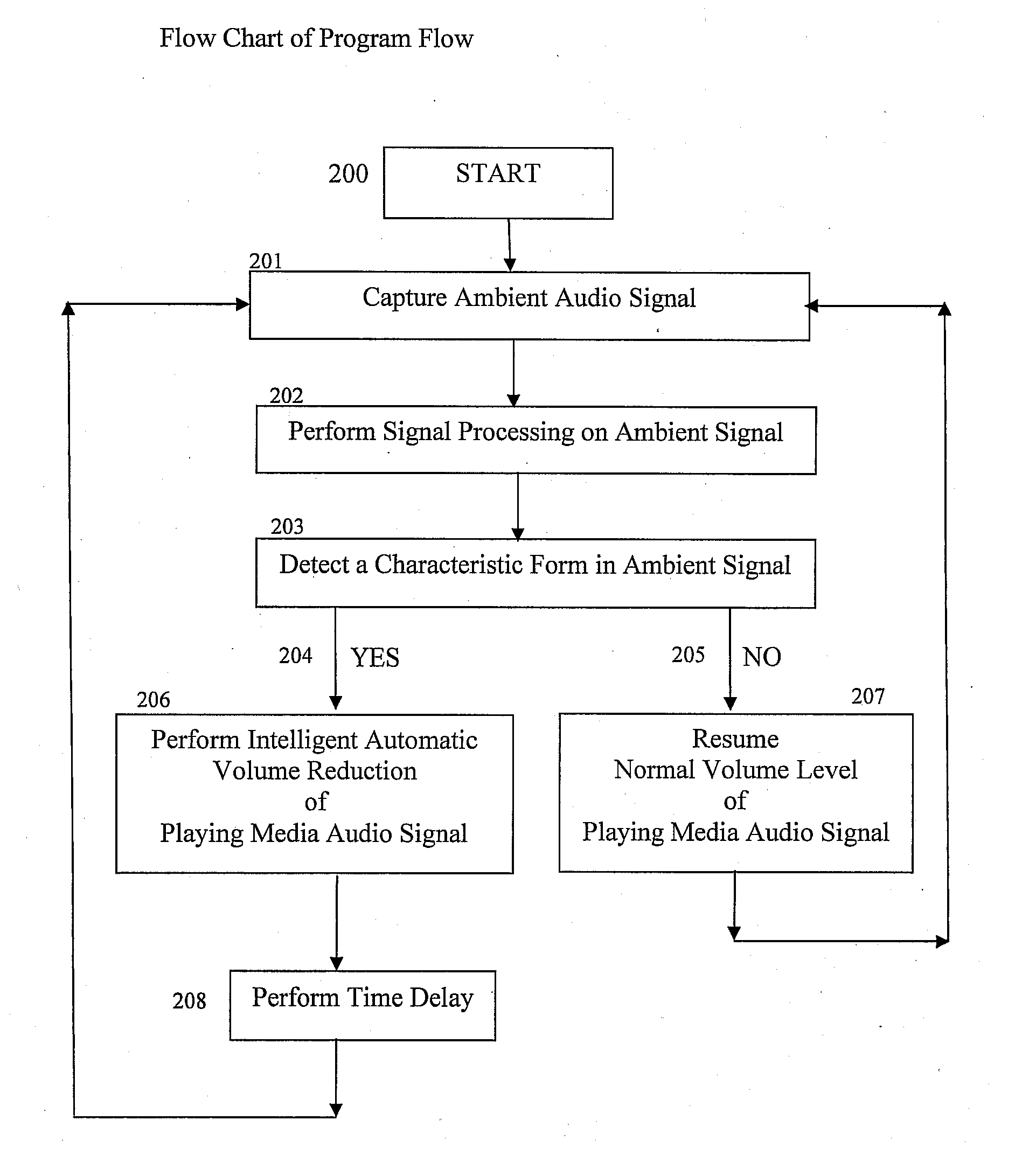

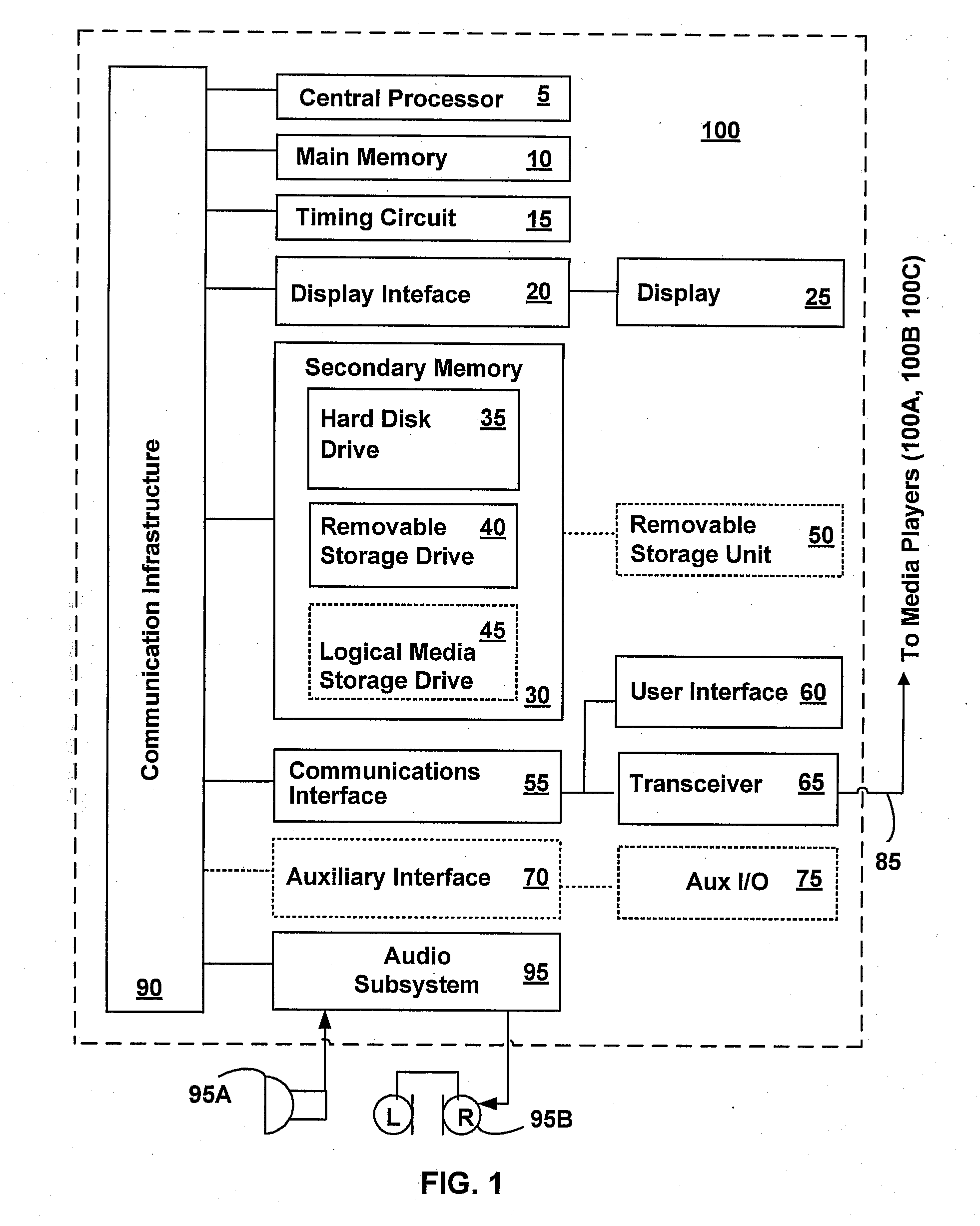

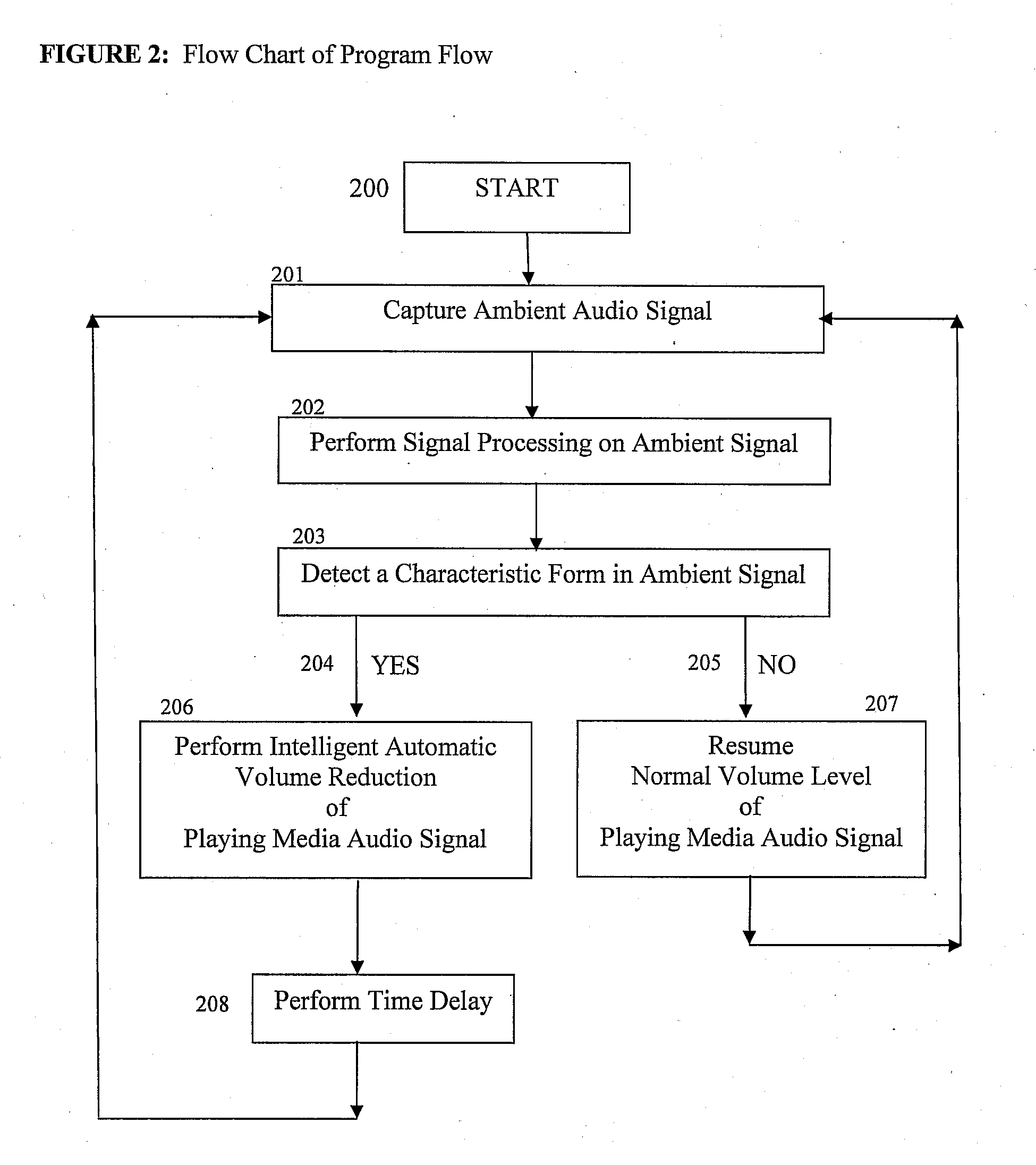

Ambient sound responsive media player

InactiveUS20070189544A1Reduce outputRecording carrier detailsGain controlComputer scienceAudio frequency

Some embodiments of the present invention provide a method of adjusting an output of a media player comprising capturing an ambient audio signal; processing the ambient audio signal to determine whether one or more characteristic forms are present within the ambient audio signal; and reducing an output of a media player from a first volume to a second volume if the one or more characteristic forms are present within the ambient audio signal. The characteristic forms may be, for example, a name or personal identifier of a user of the media player, the voice of a user of the media player, or an alarm or siren.

Owner:GOOGLE LLC

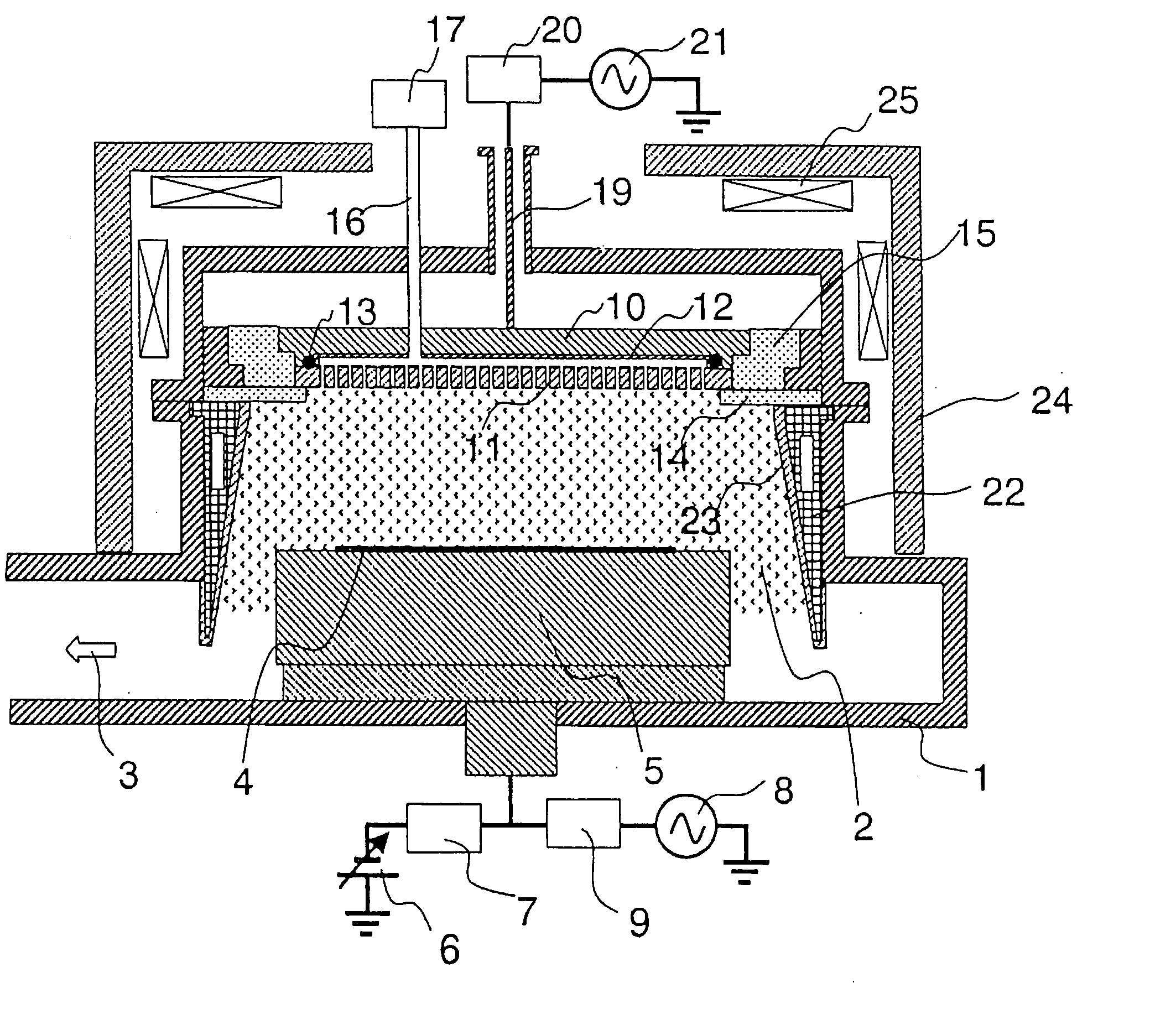

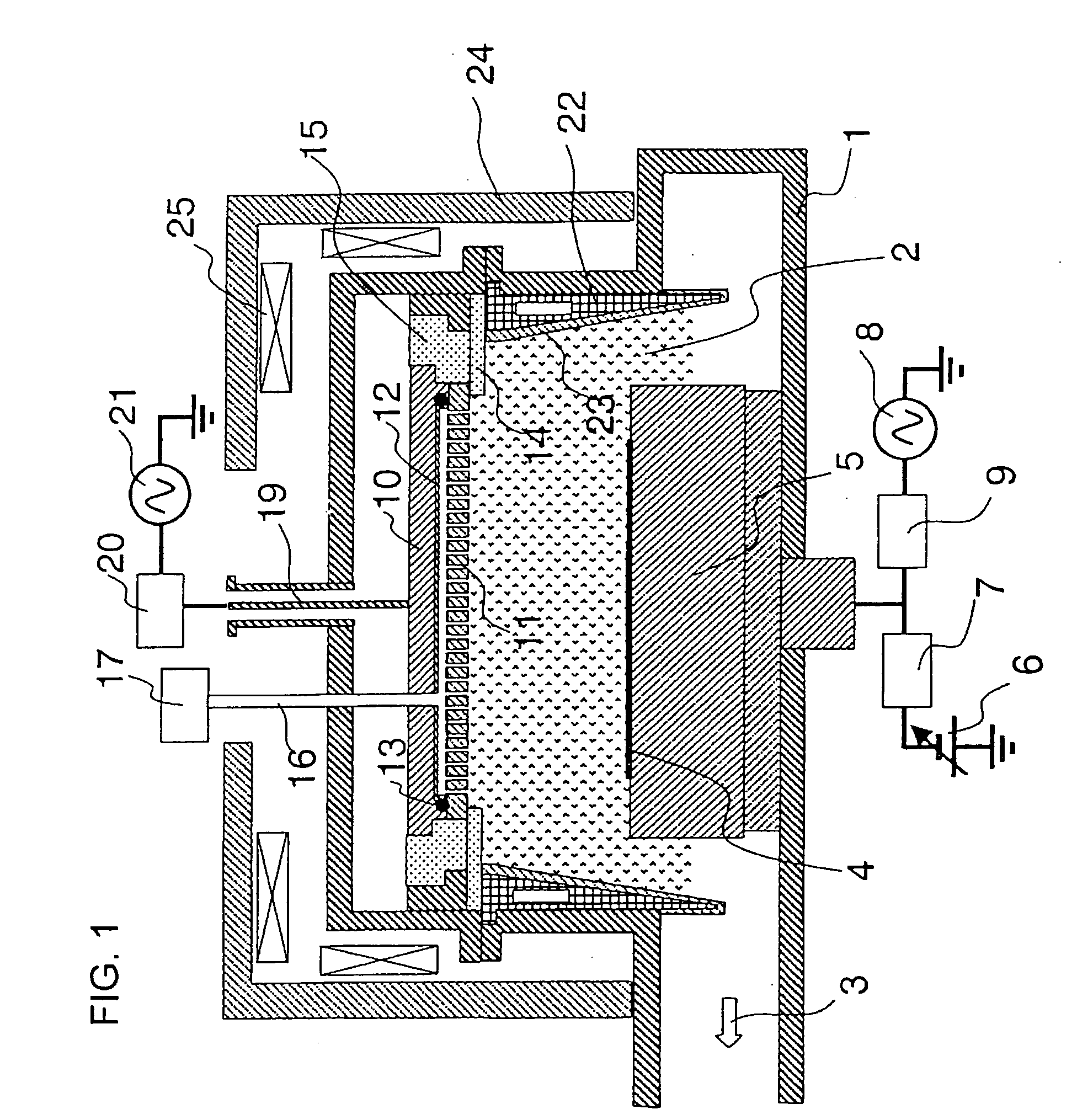

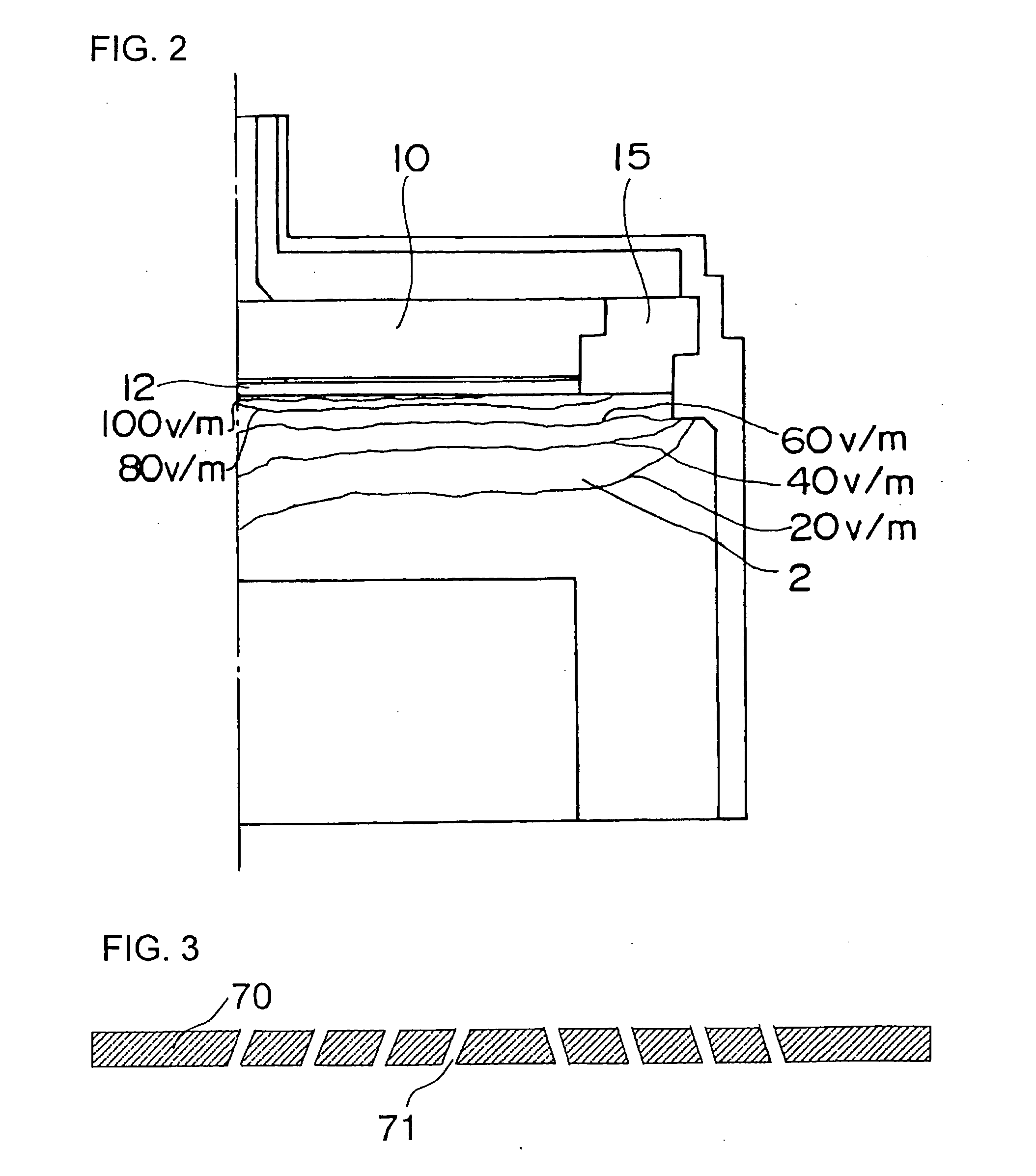

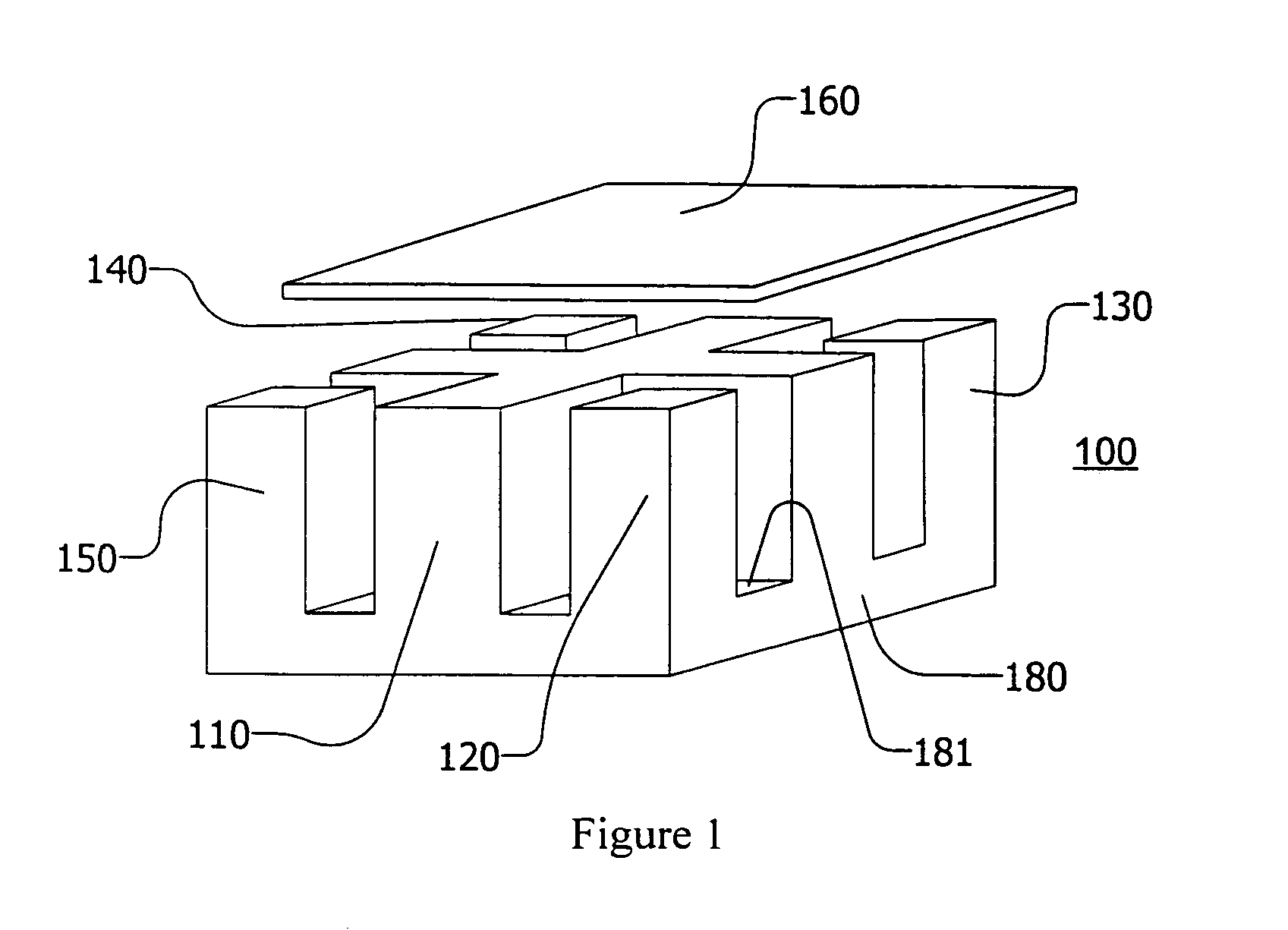

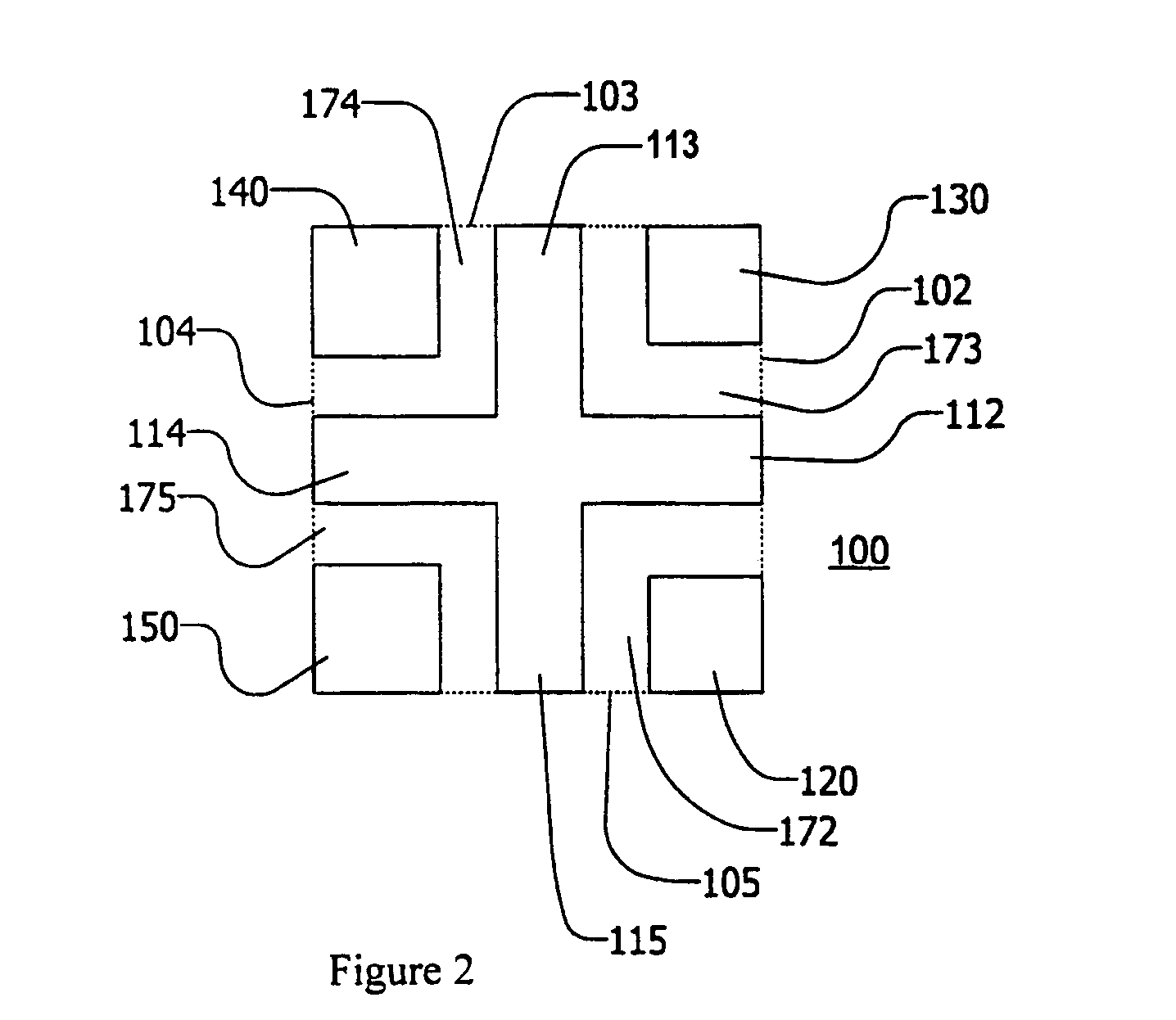

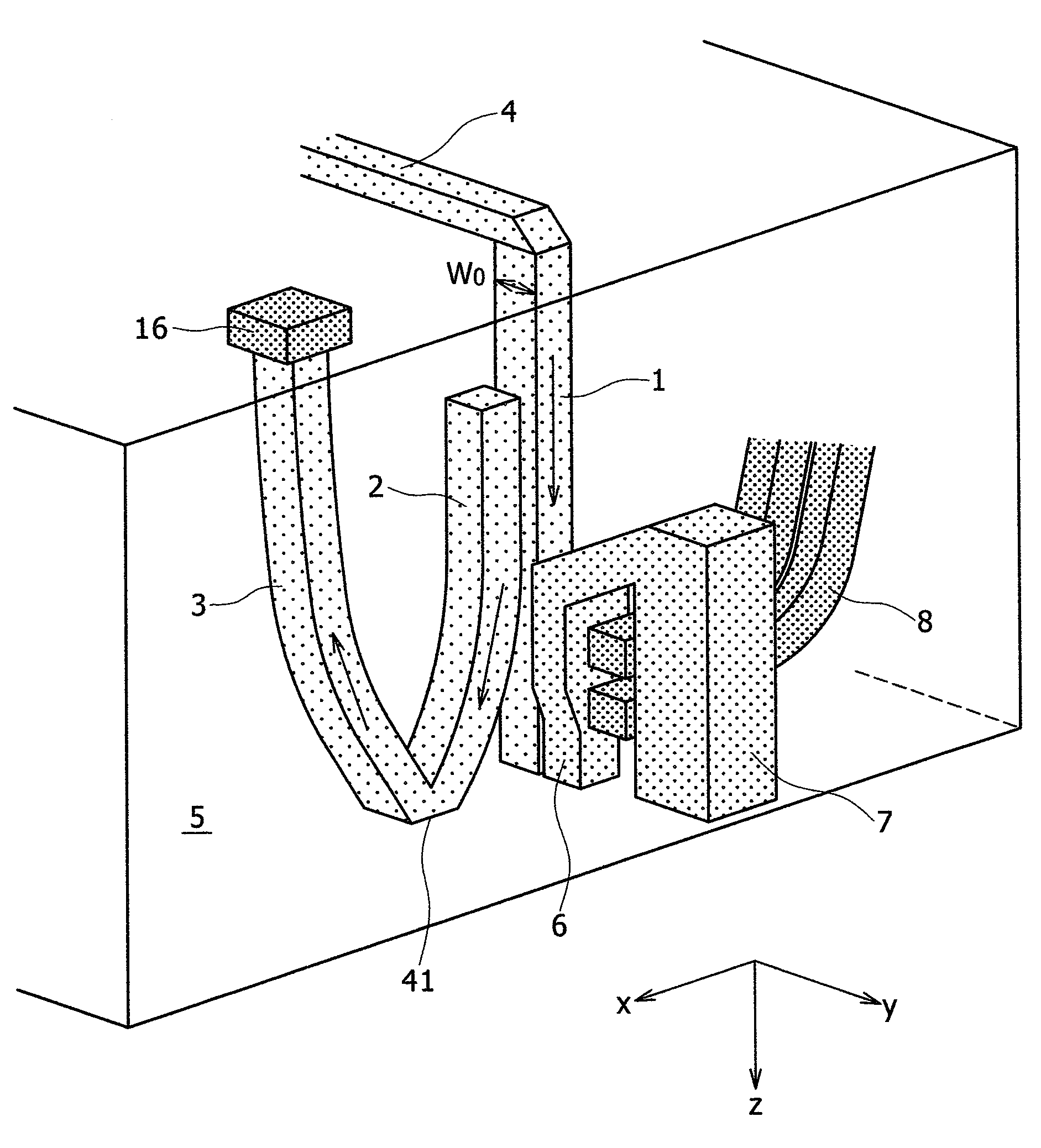

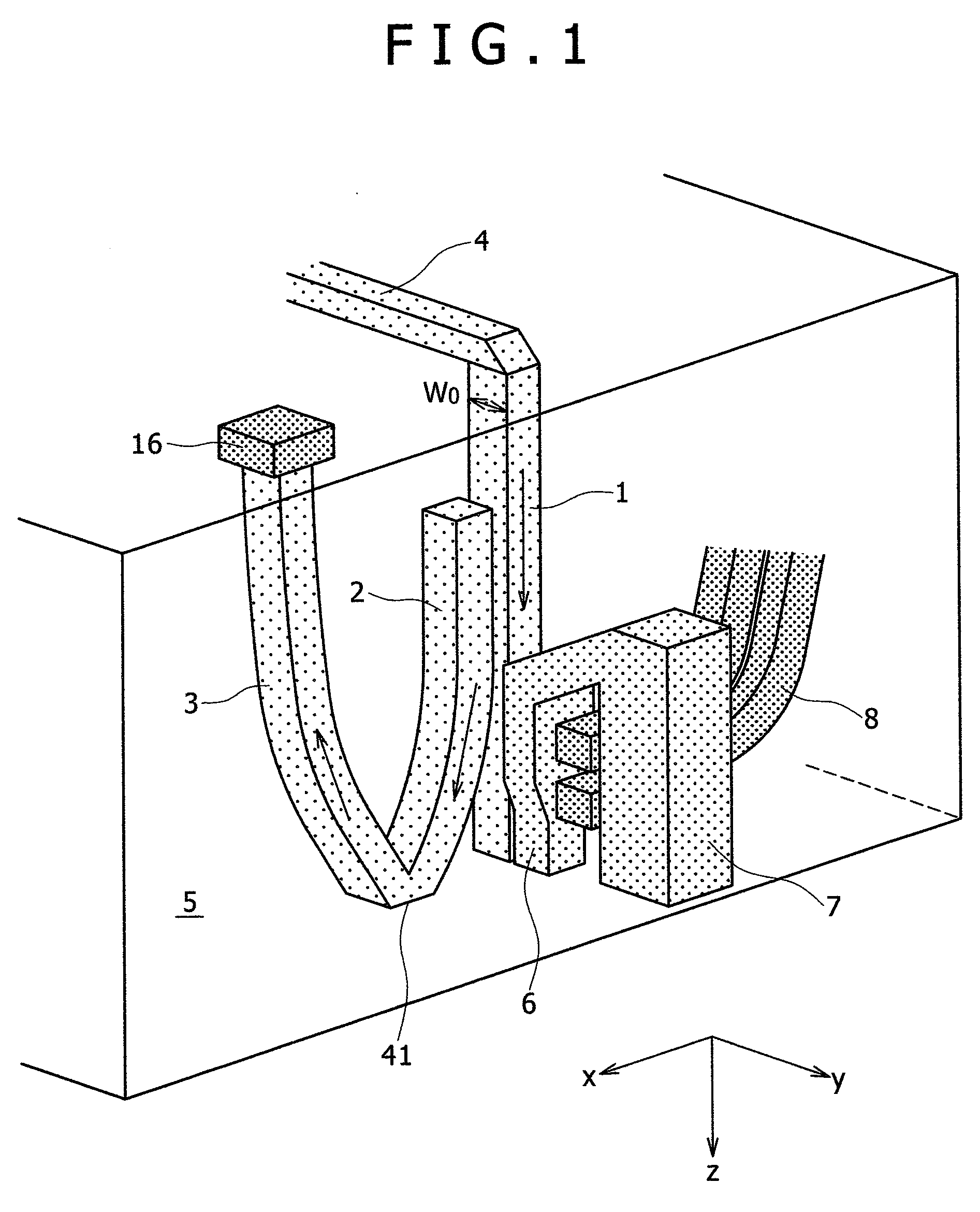

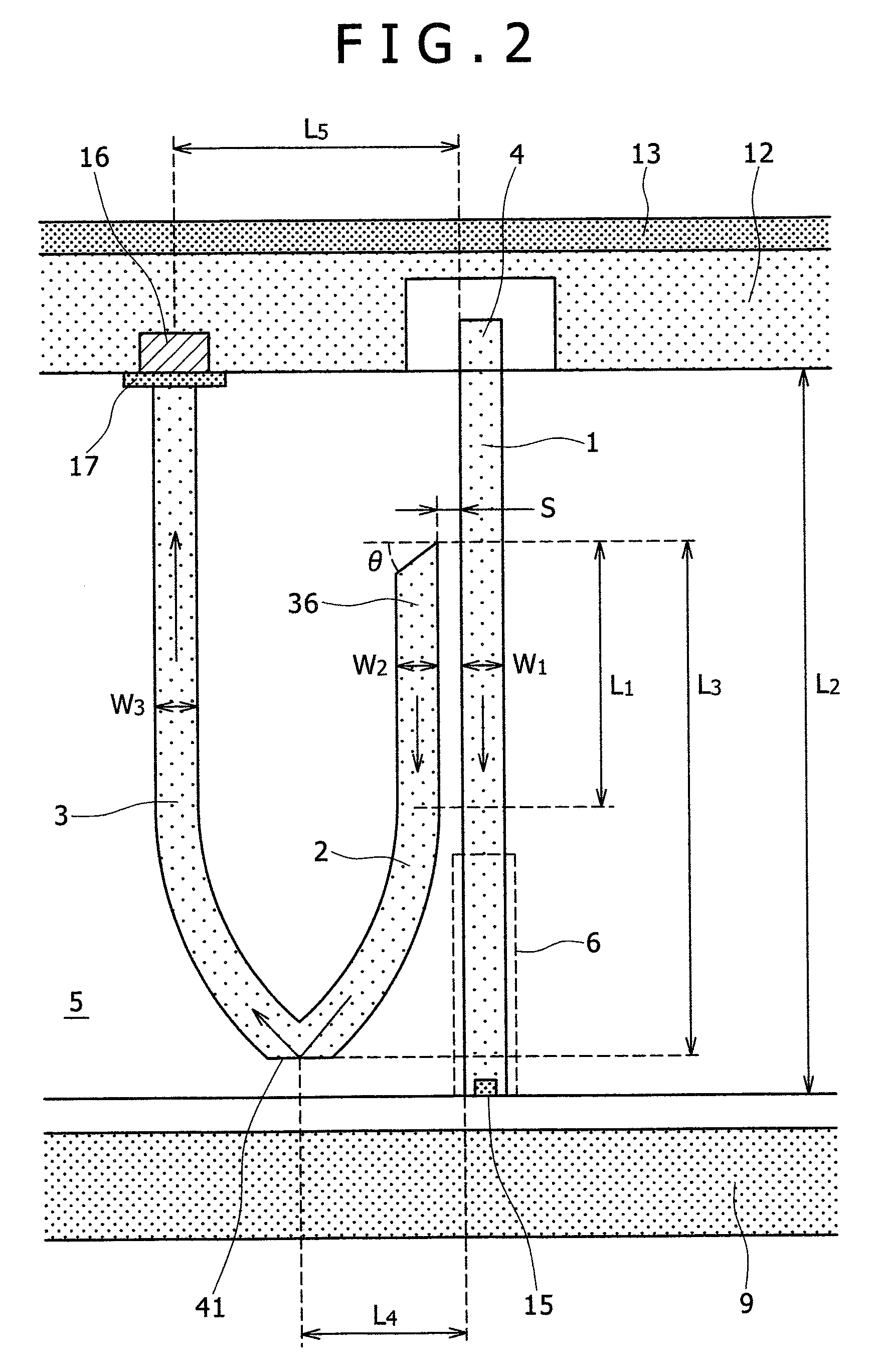

Plasma processing apparatus

ActiveUS20070044716A1Free from pollutionAvoid damageElectric discharge tubesChemical vapor deposition coatingTectorial membraneElectrical conductor

The invention provides a plasma processing apparatus aimed at suppressing the corrosion caused by reactive gas and heavy-metal contamination caused by plasma damage of components constituting the high-frequency electrode and gas supply unit. The plasma processing apparatus comprises a processing chamber 1 for subjecting a processing substrate 4 to plasma processing, gas supply means 17, 16 and 11 for feeding gas to the processing chamber 1, and an antenna electrode 10 for supplying high-frequency radiation for discharging the gas to generate plasma, wherein the gas supply means includes a gas shower plate 11 having gas discharge holes on the surface exposed to plasma, and a portion of or a whole surface of the conductor 10 exposed to gas constituting the antenna-electrode side of the gas supply means is subjected to ceramic spraying containing no heavy metal to form a protecting film 12.

Owner:HITACHI HIGH-TECH CORP

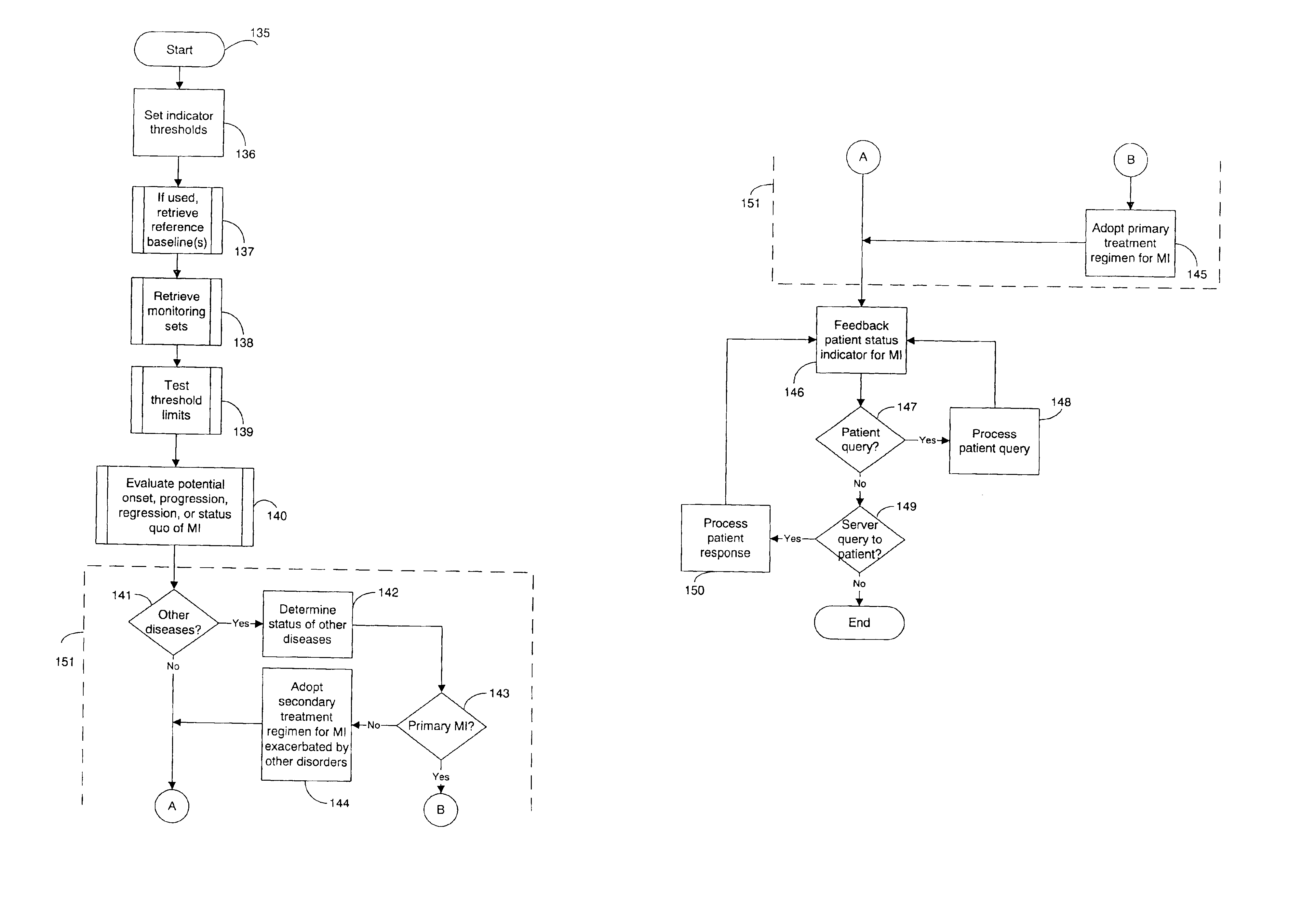

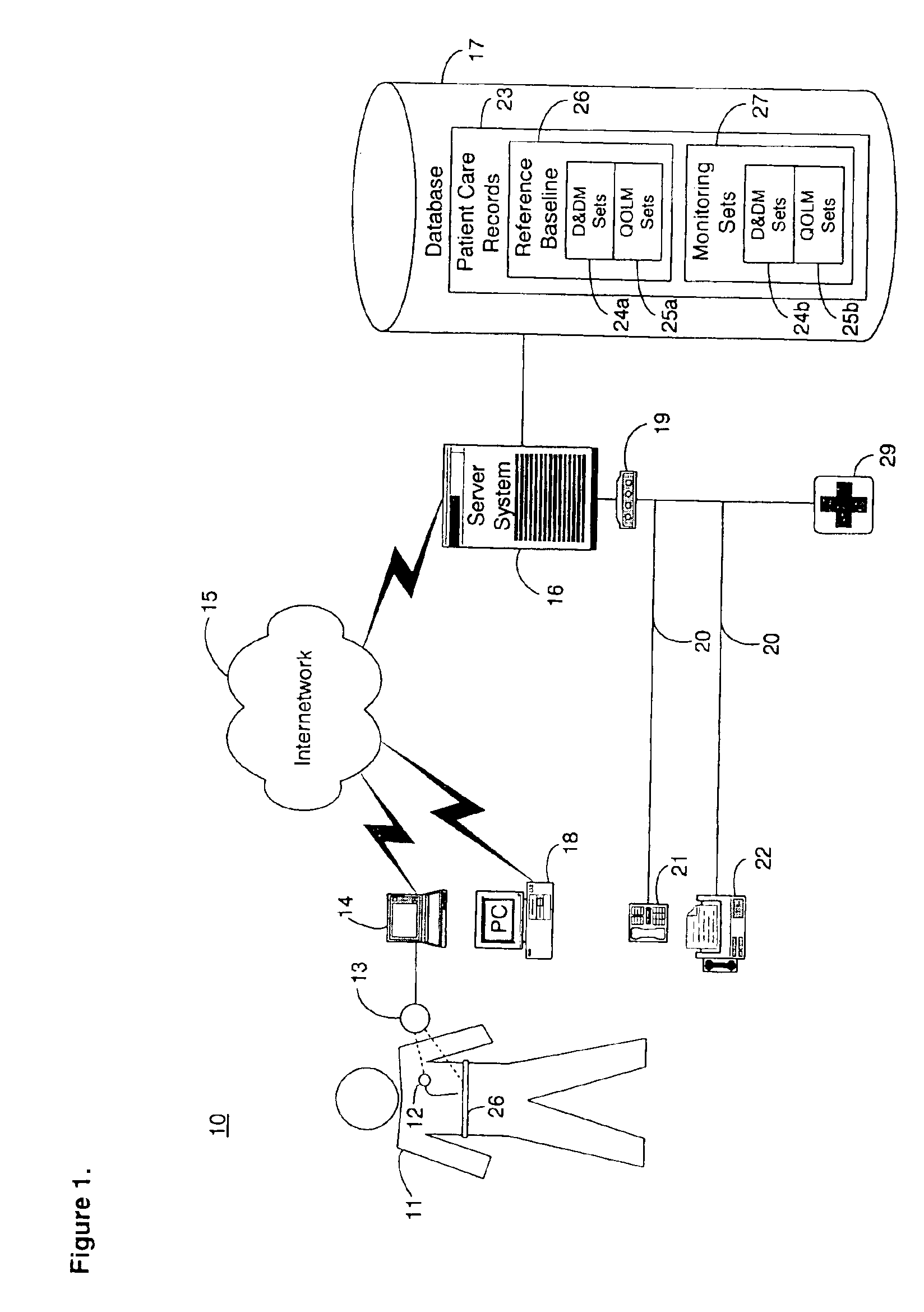

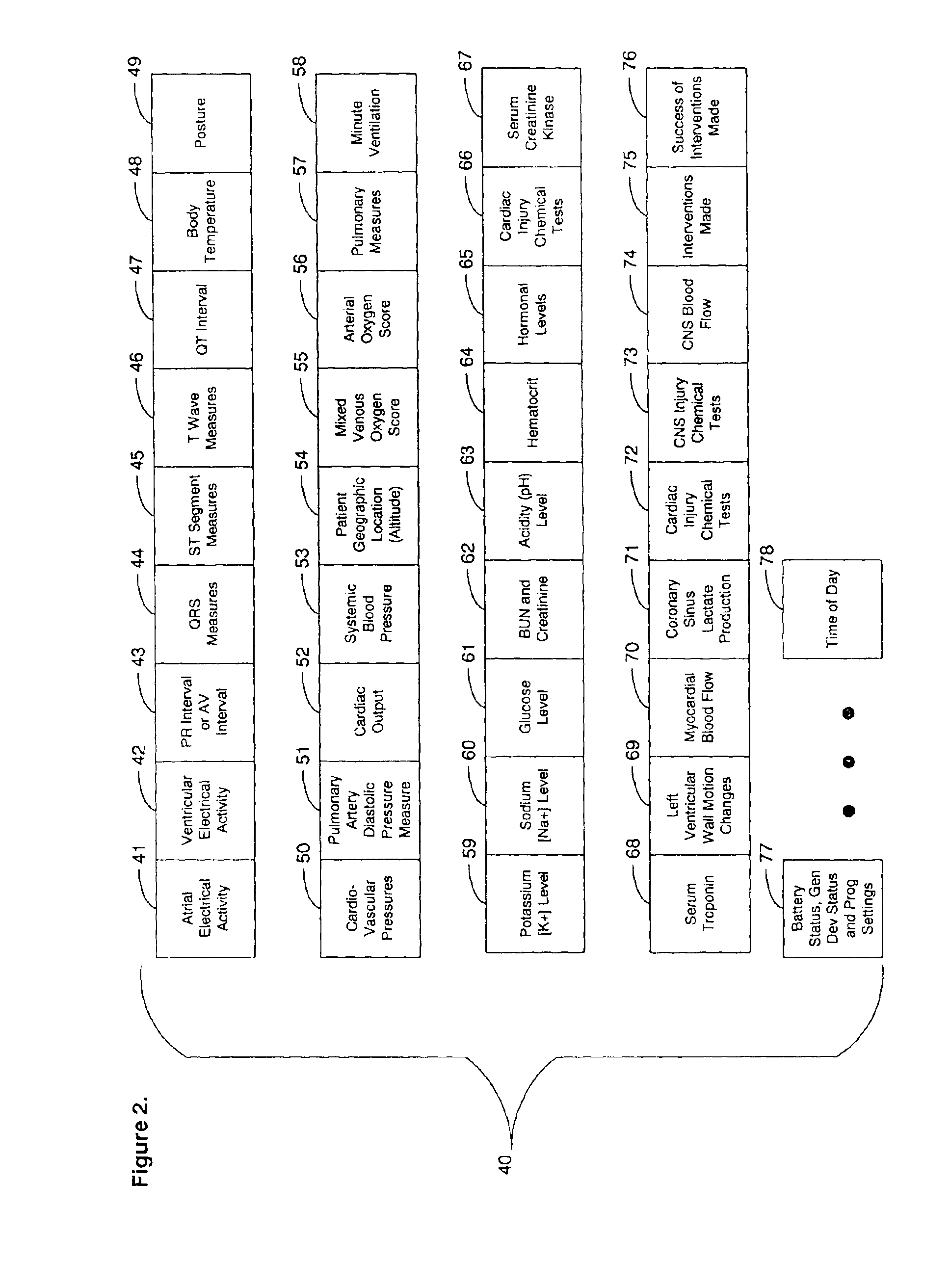

System and method for diagnosing and monitoring myocardial ischemia for automated remote patient care

InactiveUS6913577B2Increase productionIncreased serum creatinine kinaseElectrotherapyMechanical/radiation/invasive therapiesHysteresisHeart muscle extract

A system for diagnosing and monitoring myocardial ischemia for automated remote patient care is presented. A database stores monitoring sets containing recorded measures relating to patient information recorded on a substantially continuous basis. A server retrieving and processing the monitoring sets includes a comparison module determining a patient status change by comparing recorded measures and time from each of the monitoring sets to other recorded measures and time from another monitoring set with both recorded measures relating to a same type of patient information recorded at different times, and an analysis module testing each patient status change for, an onset, a progression, a regression, and a status quo of myocardial ischemia against a predetermined indicator threshold, including hysteresis threshold, corresponding to same type of patient information as the compared recorded measures.

Owner:CARDIAC INTELLIGENCE

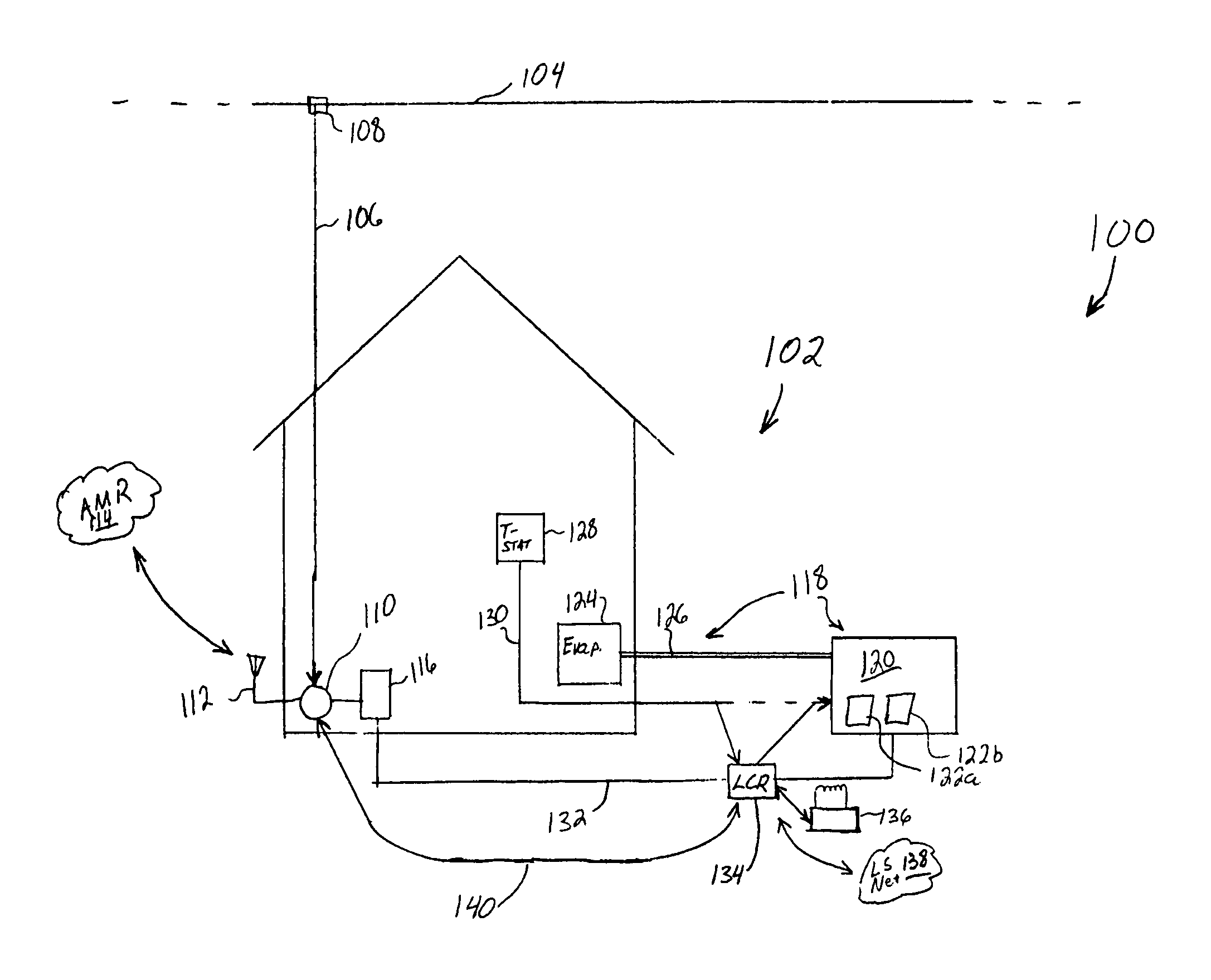

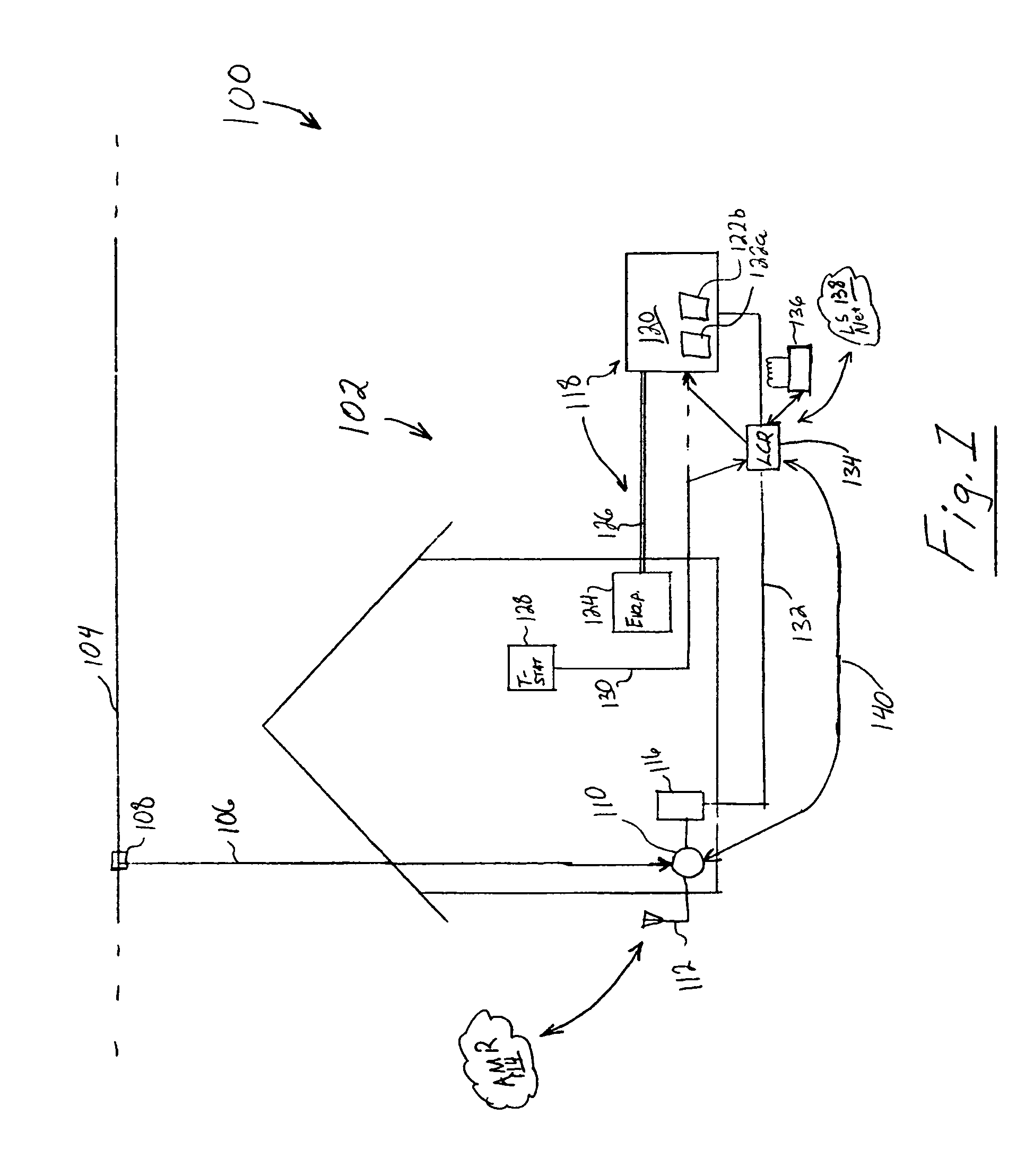

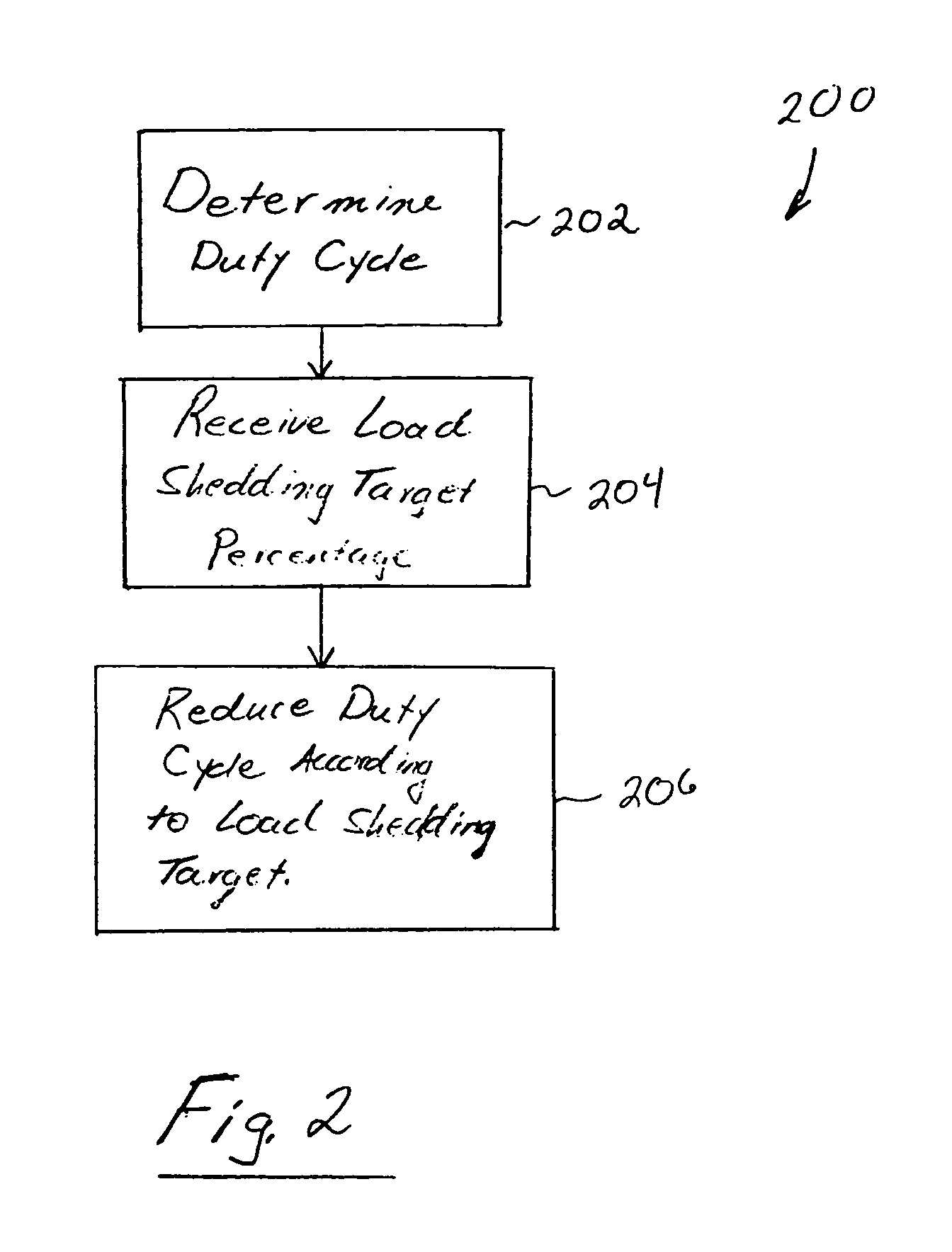

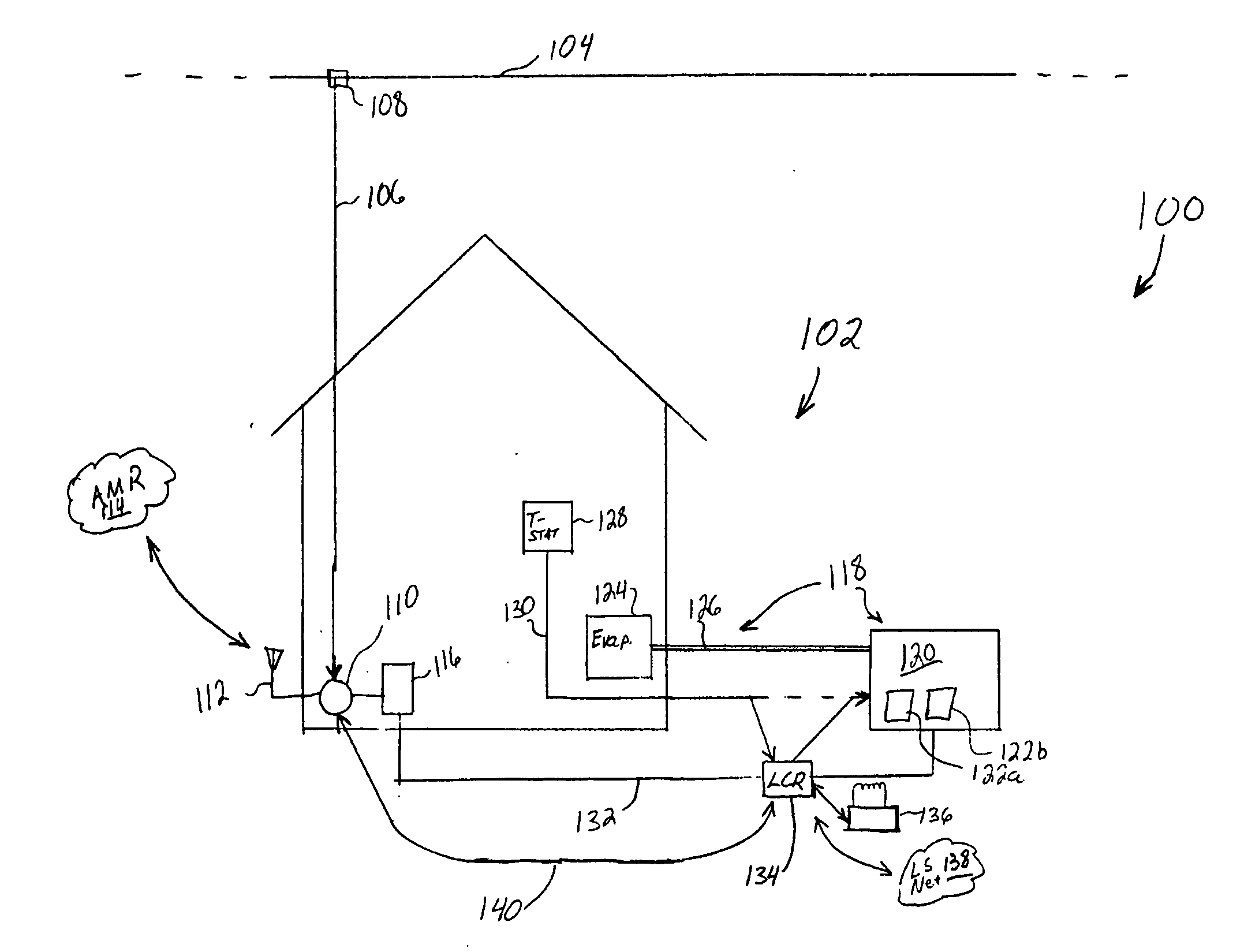

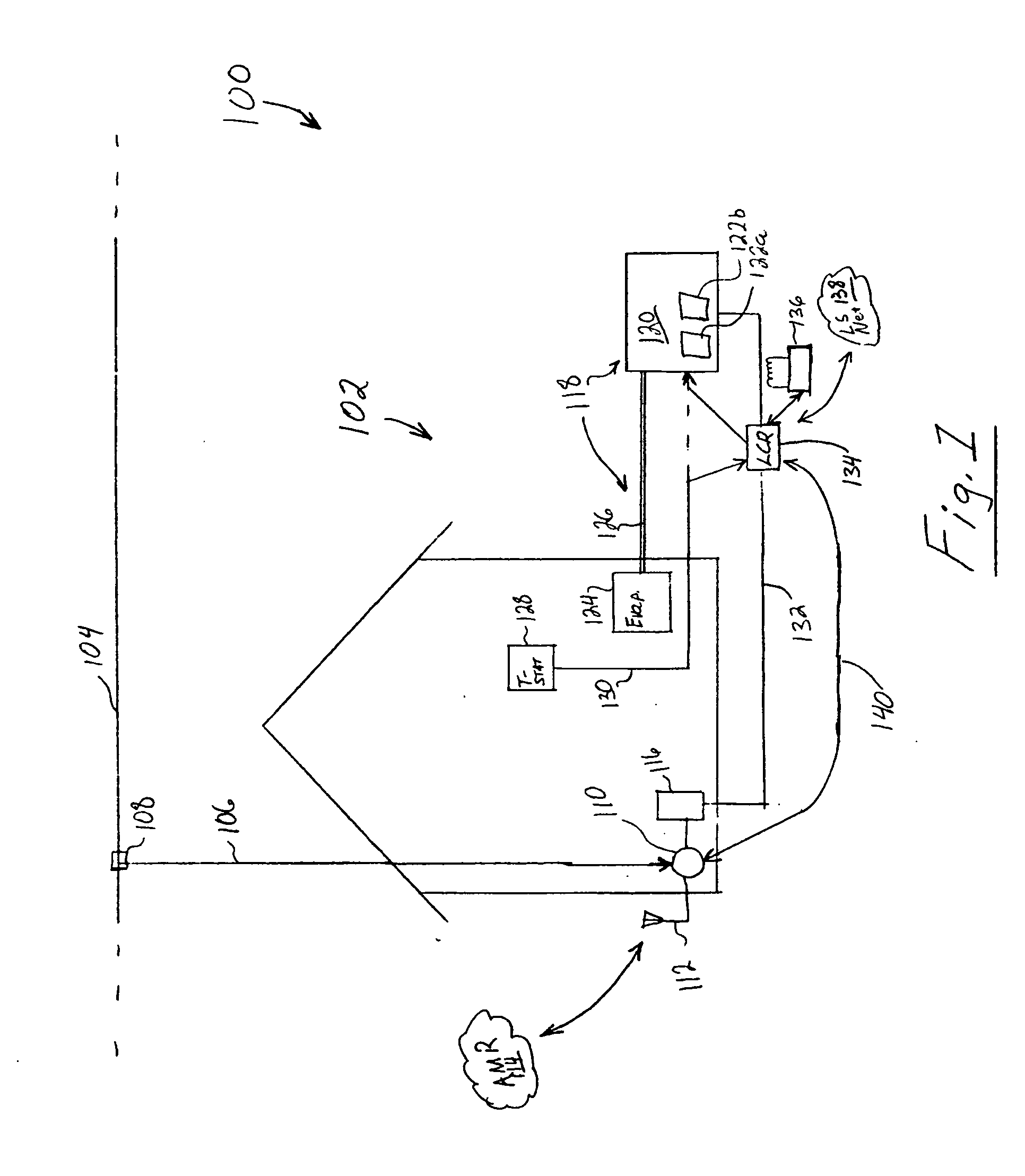

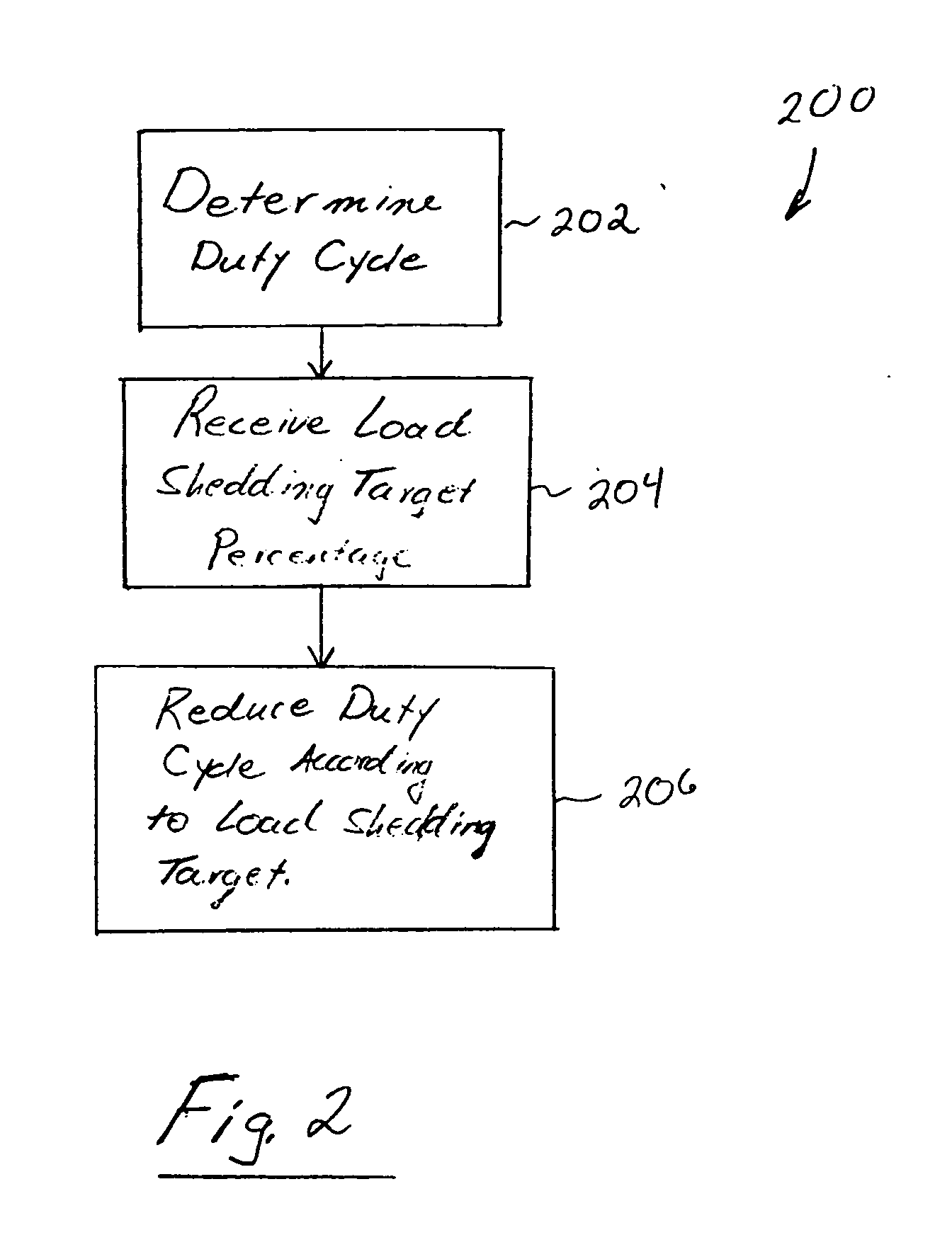

Load shedding control for cycled or variable load appliances

ActiveUS7528503B2Reduce outputReduce cycle frequencyBatteries circuit arrangementsDiscounts/incentivesLoad SheddingControl engineering

Control of a variable output appliance of a small energy consumer participating in an electrical load shedding program. A baseline operating characteristic of the appliance is determined for ordinary operation (such as in an absence of any load shedding requirements). An amount by which to reduce output of the appliance is determined in accordance with the load shedding program. Operation of the appliance is controlled to achieve the output reduction in accordance with the load shedding. This approach enables providing incentive for the small energy consumer to participate in the load shedding program, the incentive being based on the amount by which output is reduced, thereby representing a reduction of actual energy consumption for that small energy consumer.

Owner:EATON INTELLIGENT POWER LTD

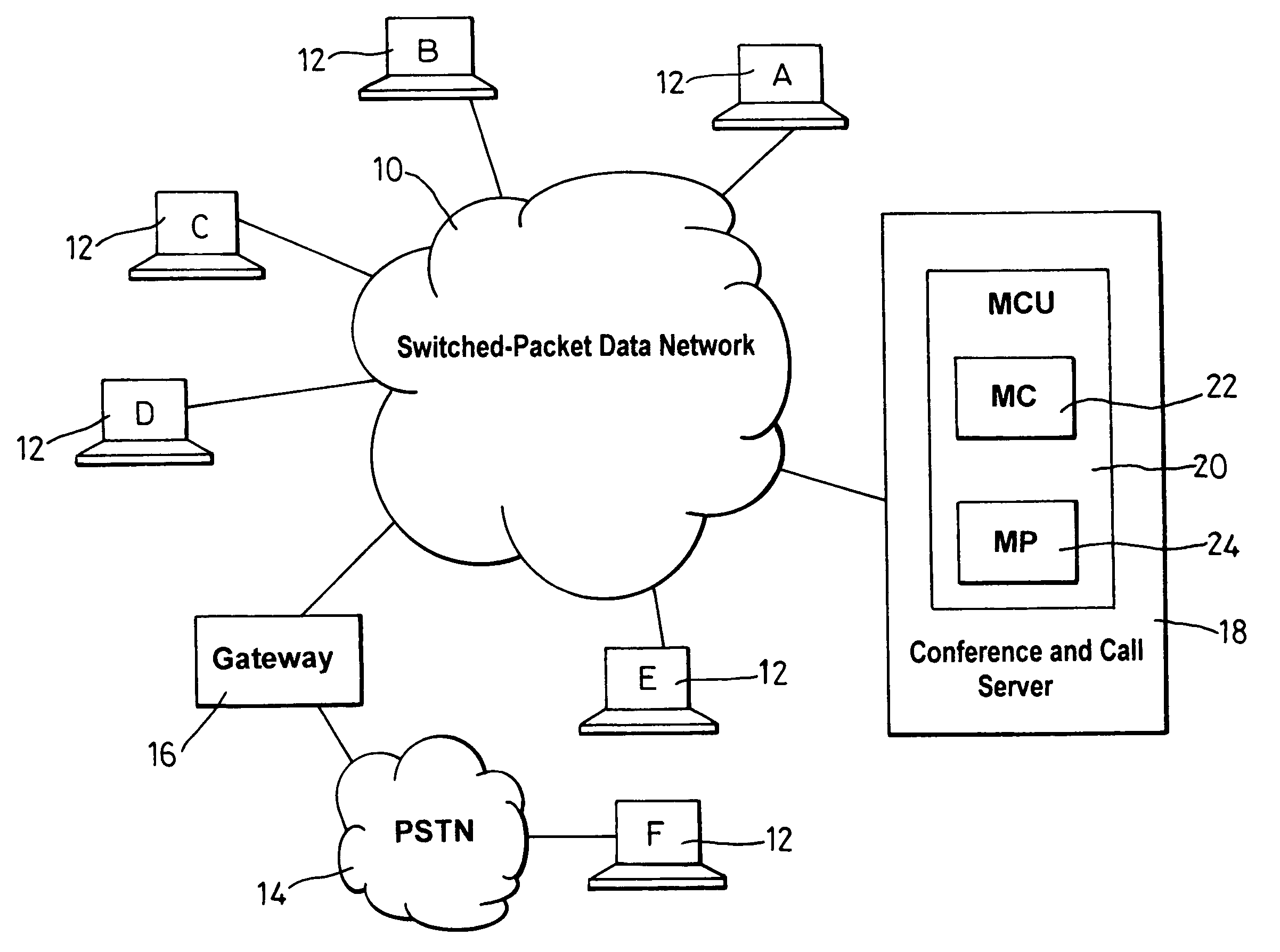

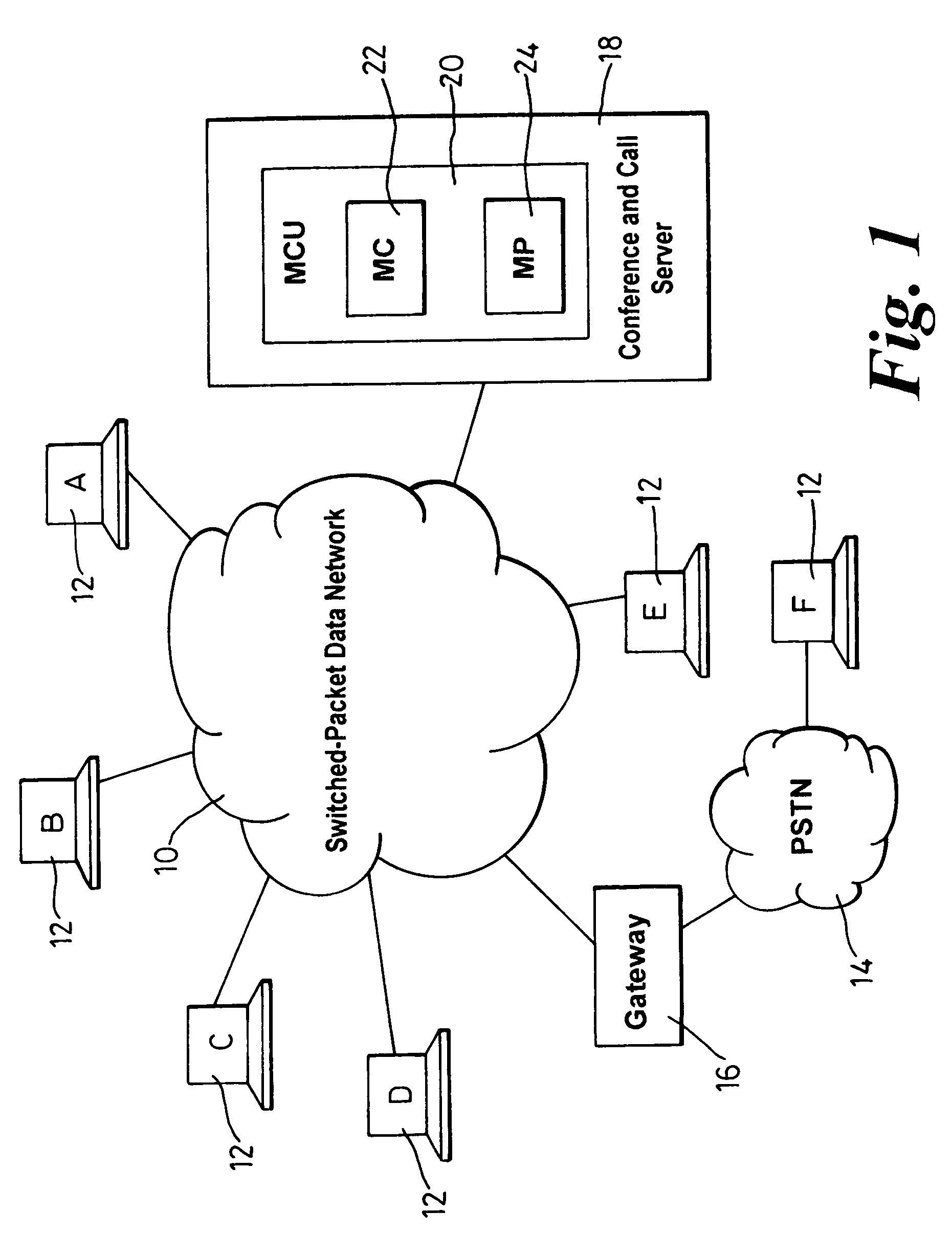

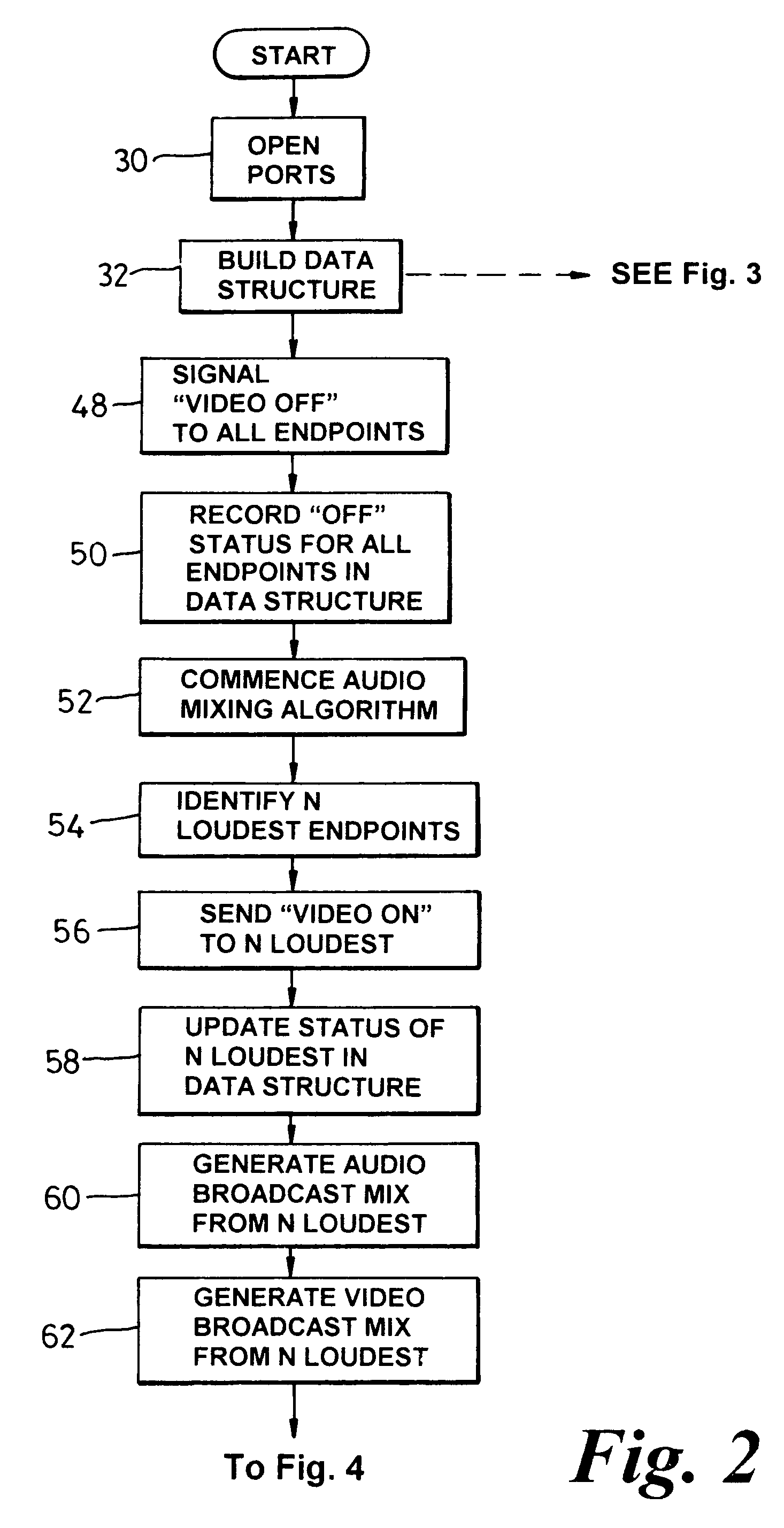

Methods of controlling video signals in a video conference

InactiveUS7007098B1Reduce rateReduce resolutionMultiple digital computer combinationsTelevision systemsBandwidth requirementBroadcasting

A method of controlling video signals in a multi-participant video conference involves assessing the level of video signal required from each participant to mix the desired broadcast video signals, and using the result of this assessment to dynamically control the video output from the endpoints of the conference participants. The assessment of the required level of video signal preferably utilizes an audio mixing algorithm, such that the video outputs of those participants whose audio signals are currently being discarded in the audio mixing process are switched off at the endpoints, or are transmitted in a lower bandwidth format, thereby reducing the overall bandwidth requirements of the conference and reducing processor resources to mix the broadcast video signals.

Owner:RPX CLEARINGHOUSE

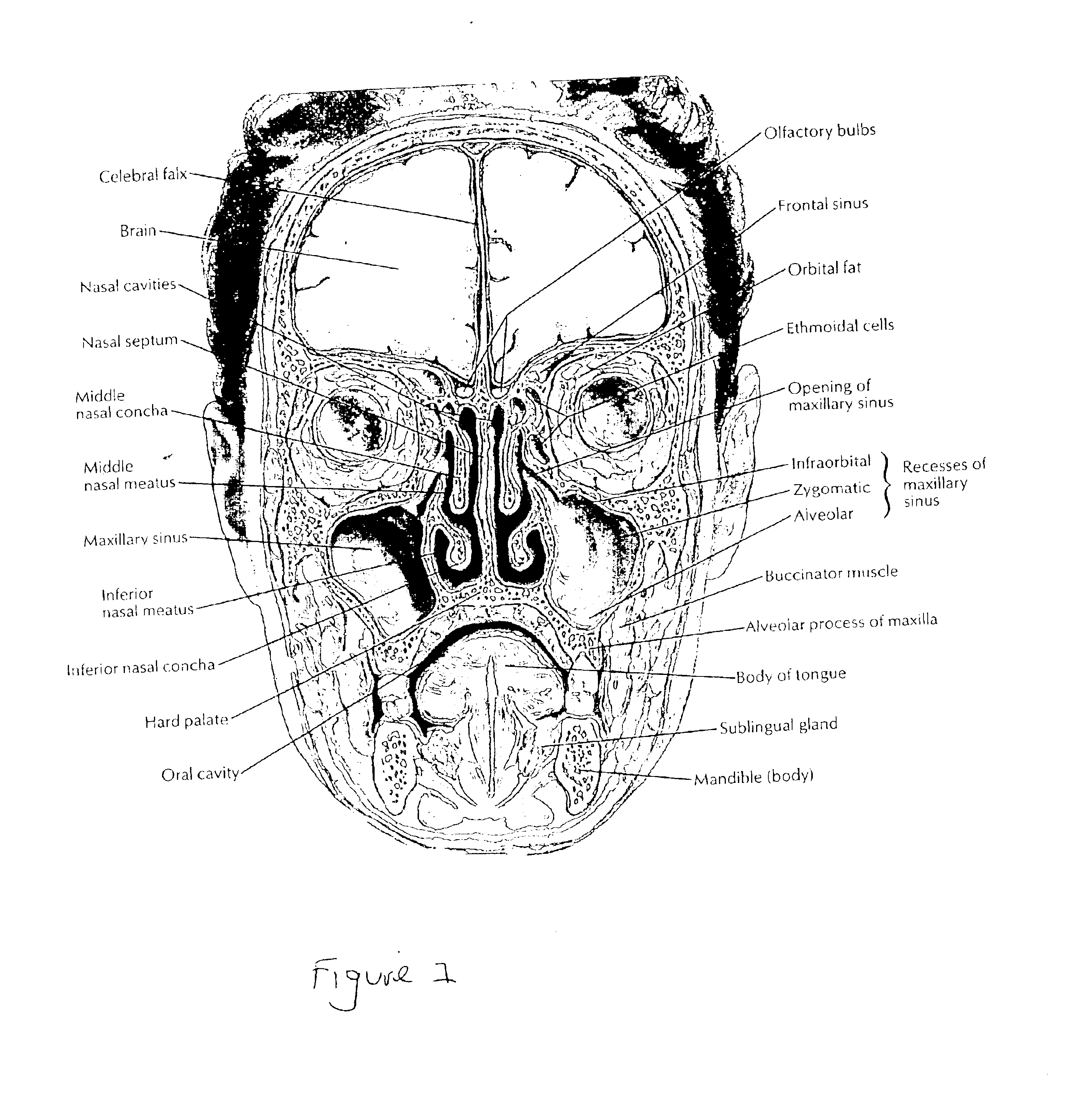

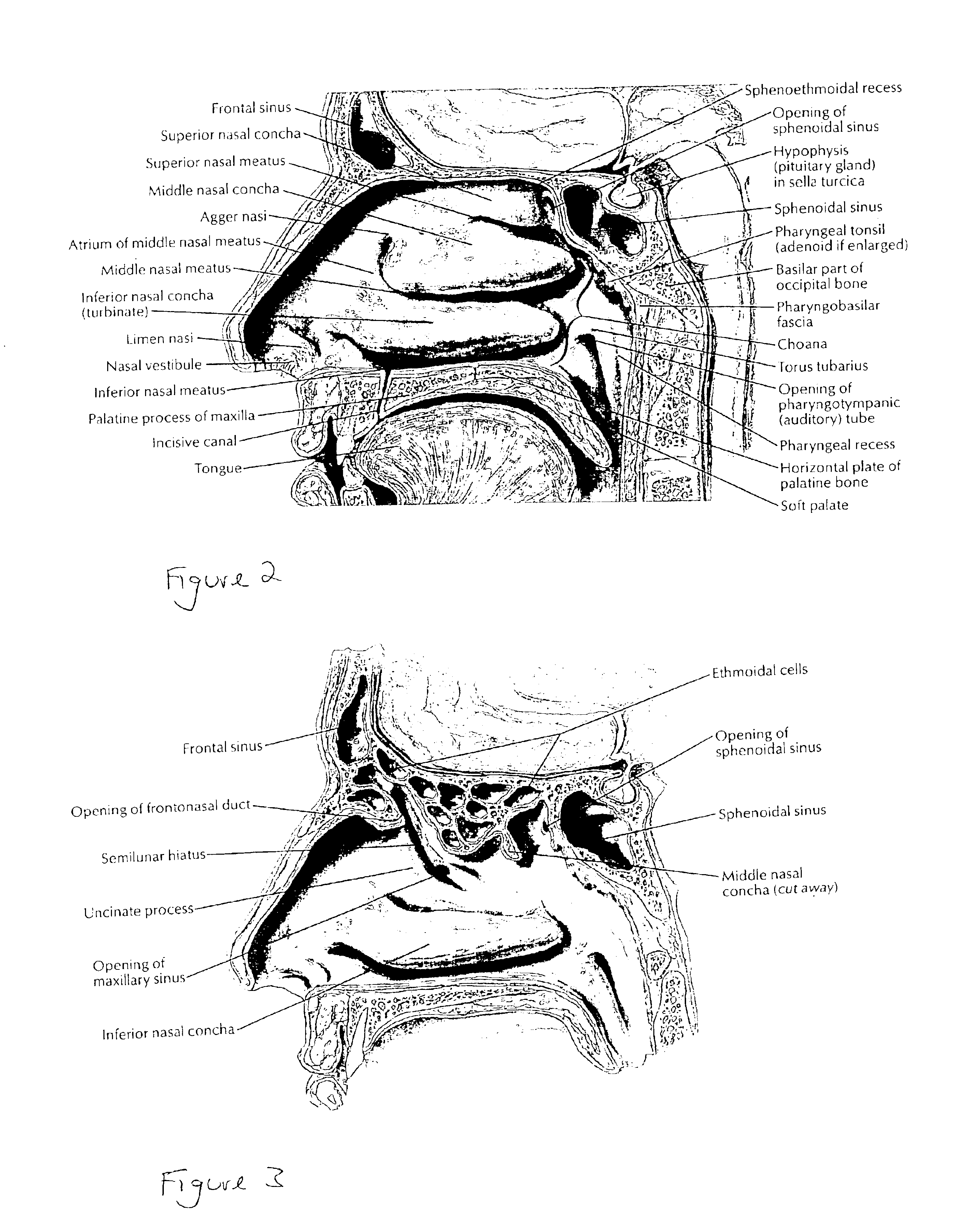

Methods for treating sinus headache

InactiveUS6838434B2Effective treatmentReduce and inhibit and eliminateAntibacterial agentsBiocideToxin typesSurgery

A sinus headache can be treated by administration of a botulinum toxin to a patient. The botulinum toxin can be botulinum toxin type A and the botulinum toxin can be administered to or to the vicinity of a sinus membrane of a patient with a sinus headache.

Owner:ALLERGAN INC

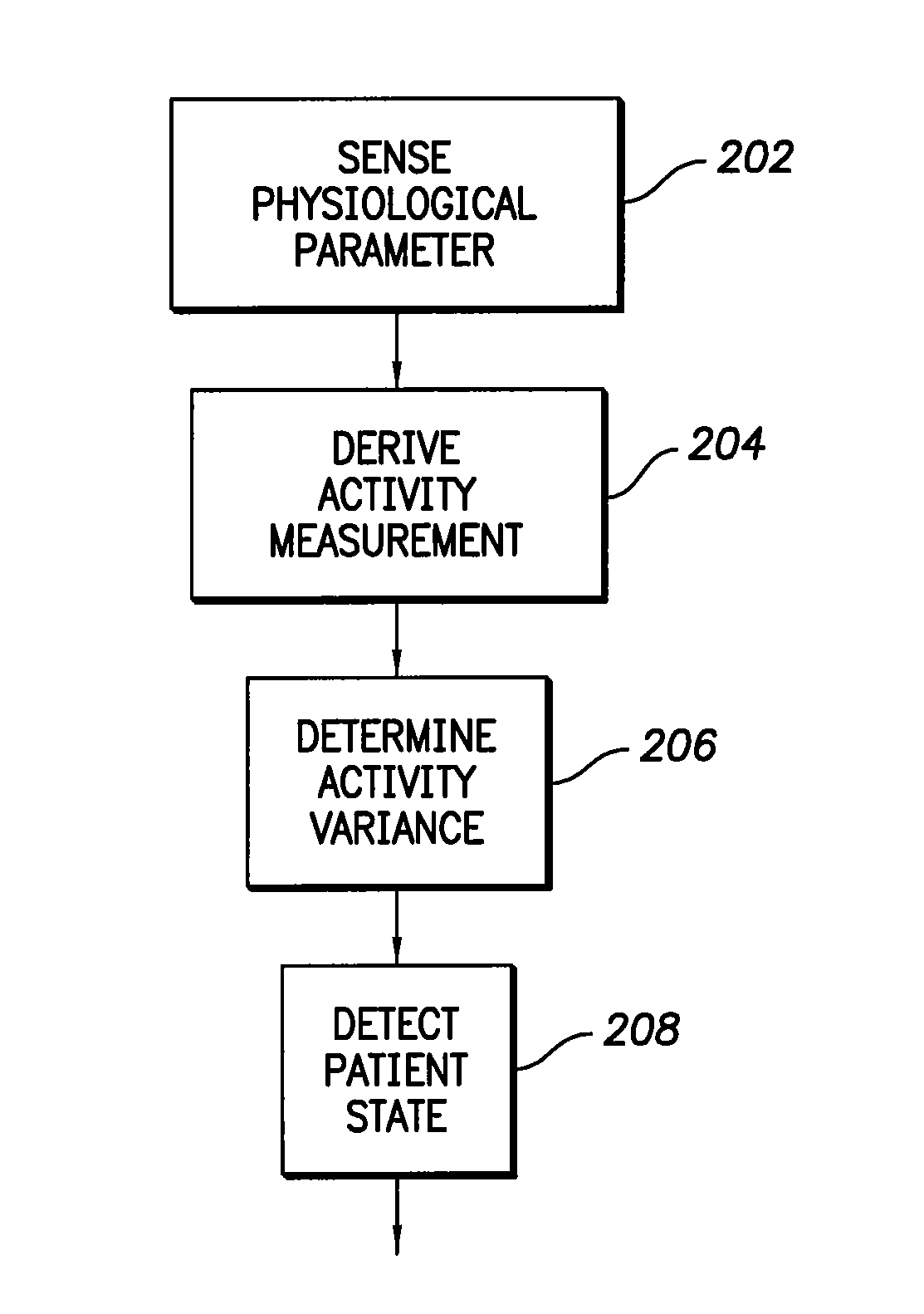

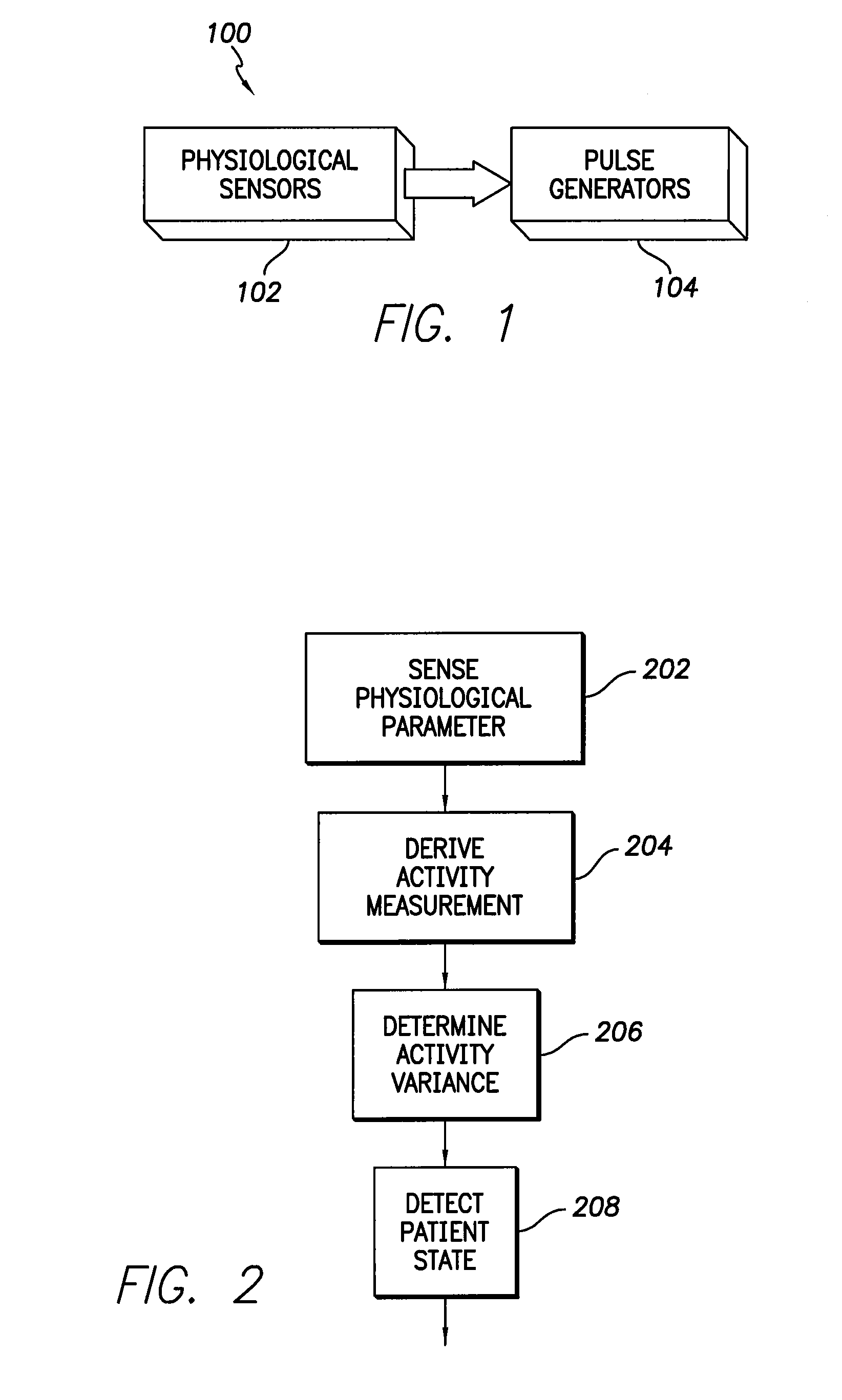

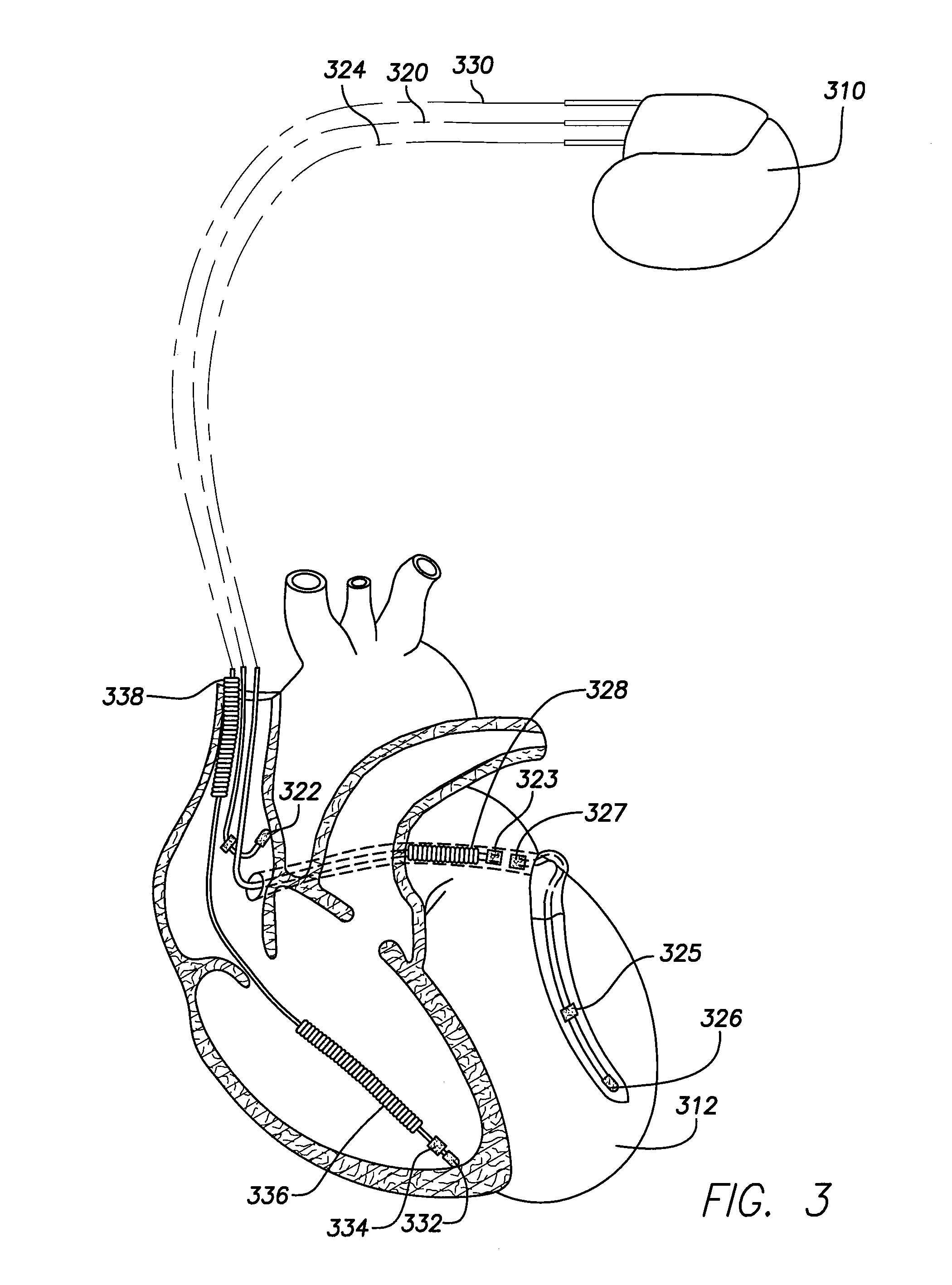

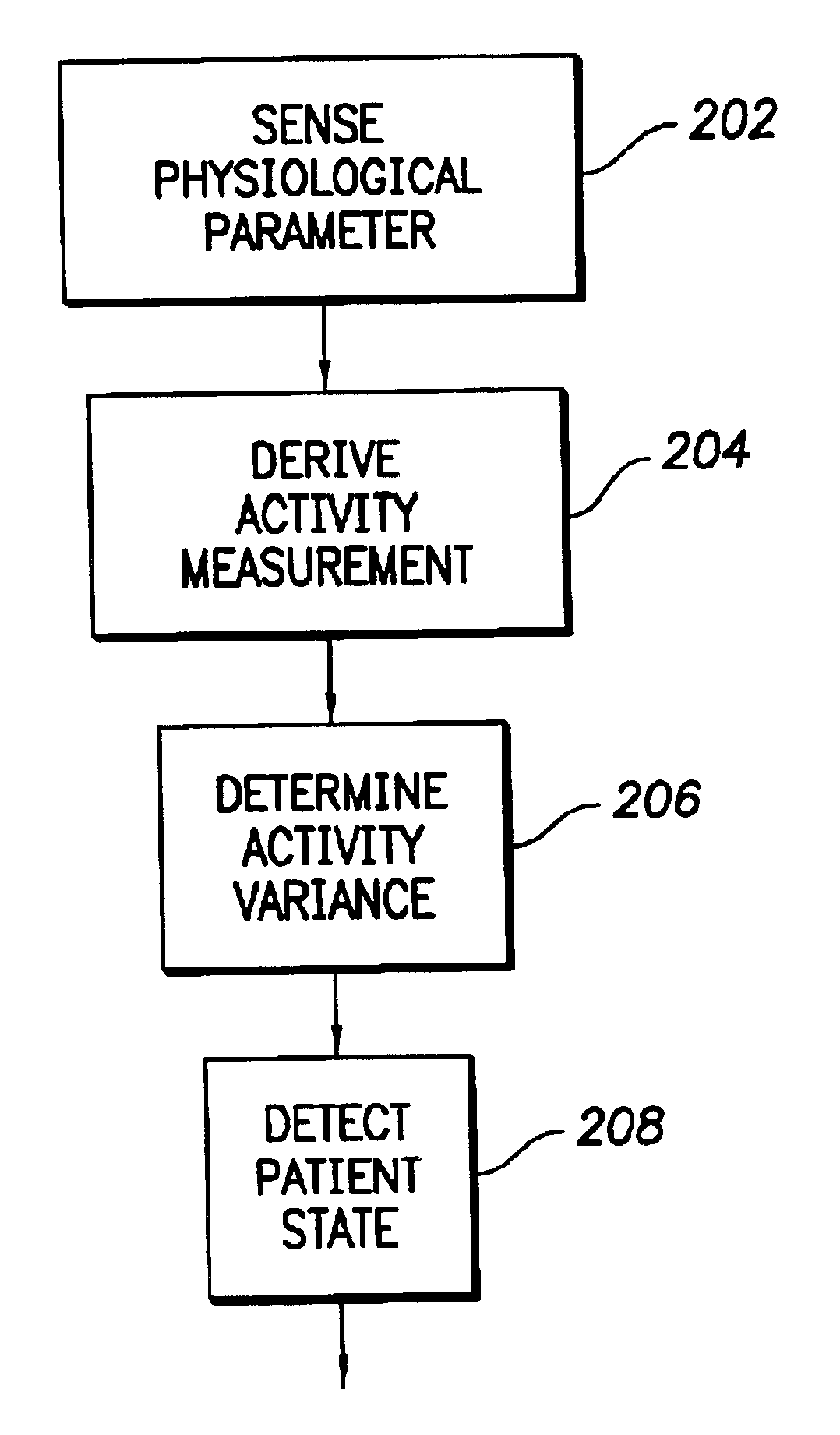

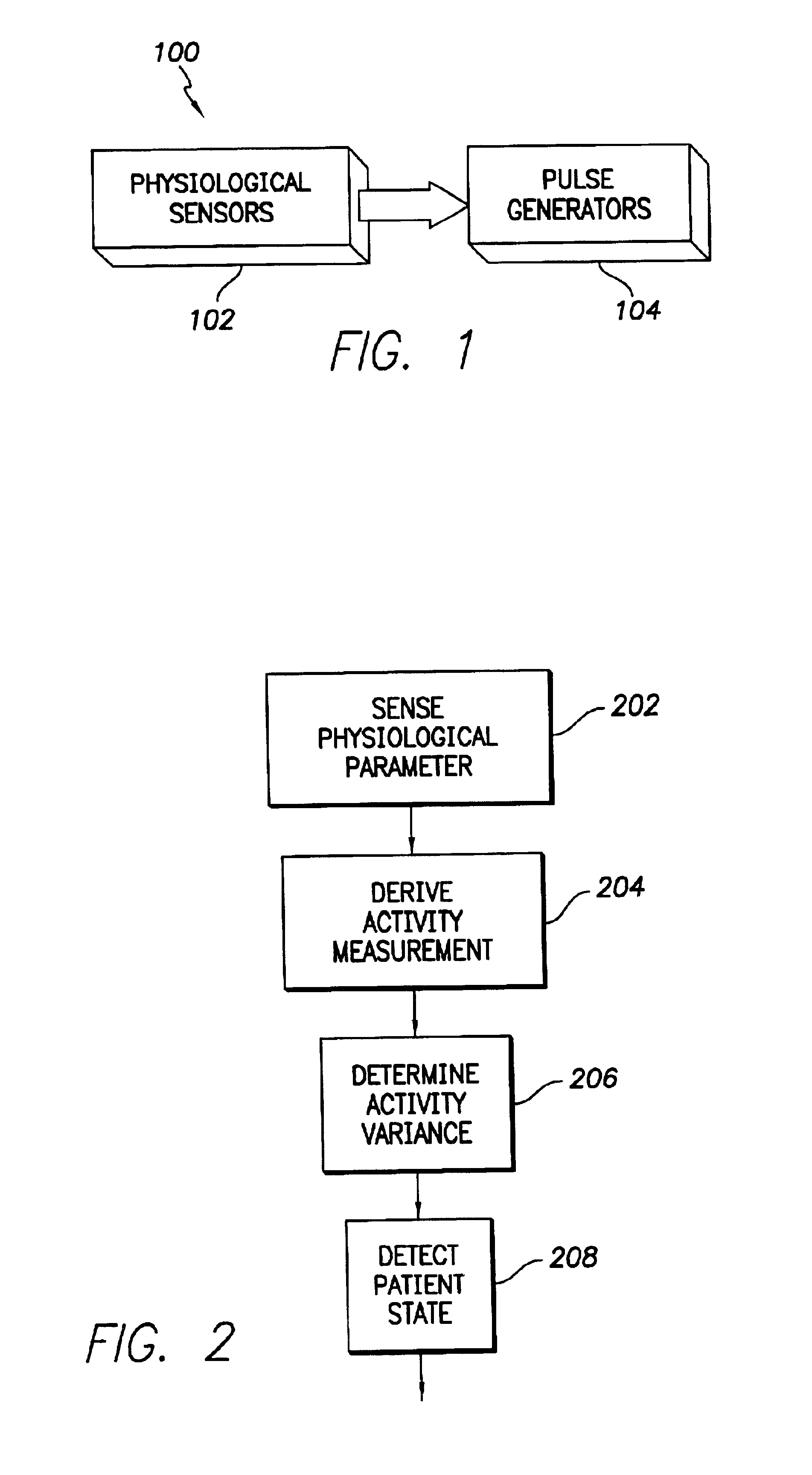

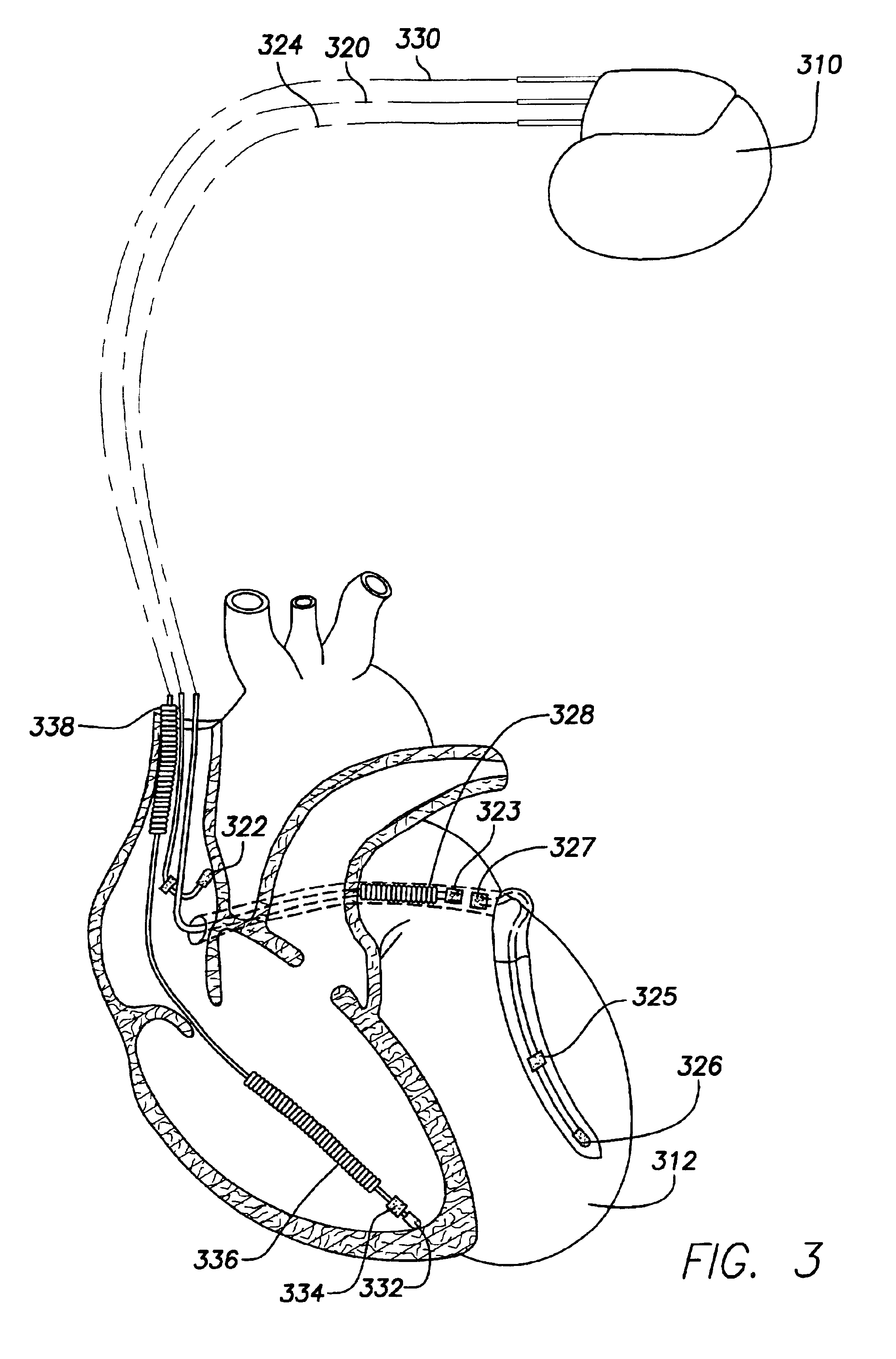

Cardiac stimulation device including sleep apnea prevention and treatment

InactiveUS7212862B2Prevents sleep apneaReduce outputHeart stimulatorsArtificial respirationTreatment sleepPulse rate

An implantable cardiac stimulation device comprises a physiologic sensor and one or more pulse generators. The physiologic sensor is capable of sensing a physiologic parameter. The pulse generators can generate cardiac pacing pulses with a timing based on the physiologic parameter. The timed cardiac pacing pulses can prevent a sleep apnea condition. In one example, a cardiac stimulation device has a physiologic sensor and can be configured to pace a patient's heart according to a rest mode of operation. The cardiac stimulation device uses measurements from the physiologic sensor to prevent and treat sleep apnea using a revised rest mode of operation. The revised rest mode operates under a presumption that sleep apnea is primary to a reduced heart rate, rather than secondary, so that pacing at a rate higher than the natural cardiac rate during sleep will prevent sleep apnea.

Owner:PACESETTER INC

Cardiac stimulation device including sleep apnea prevention and treatment

InactiveUS6999817B2Prevents sleep apneaAvoid adjustmentHeart stimulatorsArtificial respirationTreatment sleepPulse rate

An implantable cardiac stimulation device comprises a physiologic sensor and one or more pulse generators. The physiologic sensor is capable of sensing a physiologic parameter. The pulse generators can generate cardiac pacing pulses with a timing based on the physiologic parameter. The timed cardiac pacing pulses can prevent a sleep apnea condition. In one example, a cardiac stimulation device has a physiologic sensor and can be configured to pace a patient's heart according to a rest mode of operation. The cardiac stimulation device uses measurements from the physiologic sensor to prevent and treat sleep apnea using a revised rest mode of operation. The revised rest mode operates under a presumption that sleep apnea is primary to a reduced heart rate, rather than secondary, so that pacing at a rate higher than the natural cardiac rate during sleep will prevent sleep apnea.

Owner:PACESETTER INC

Load shedding control for cycled or variable load appliances

ActiveUS20070021874A1Reduce outputReduce cycle frequencyMechanical power/torque controlLevel controlLoad SheddingProgram planning

Control of a variable output appliance of a small energy consumer participating in an electrical load shedding program. A baseline operating characteristic of the appliance is determined for ordinary operation (such as in an absence of any load shedding requirements). An amount by which to reduce output of the appliance is determined in accordance with the load shedding program. Operation of the appliance is controlled to achieve the output reduction in accordance with the load shedding. This approach enables providing incentive for the small energy consumer to participate in the load shedding program, the incentive being based on the amount by which output is reduced, thereby representing a reduction of actual energy consumption for that small energy consumer.

Owner:EATON INTELLIGENT POWER LTD

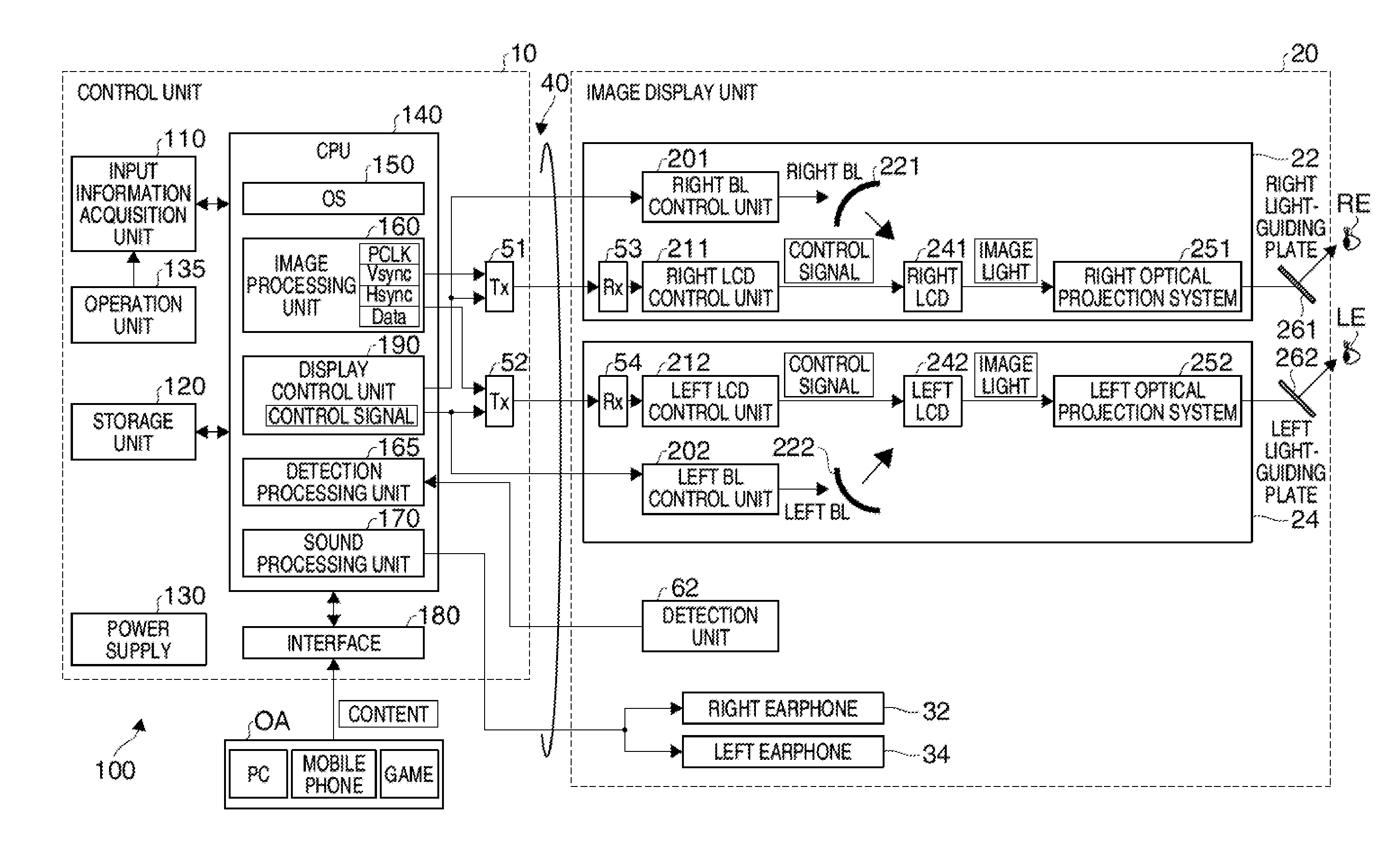

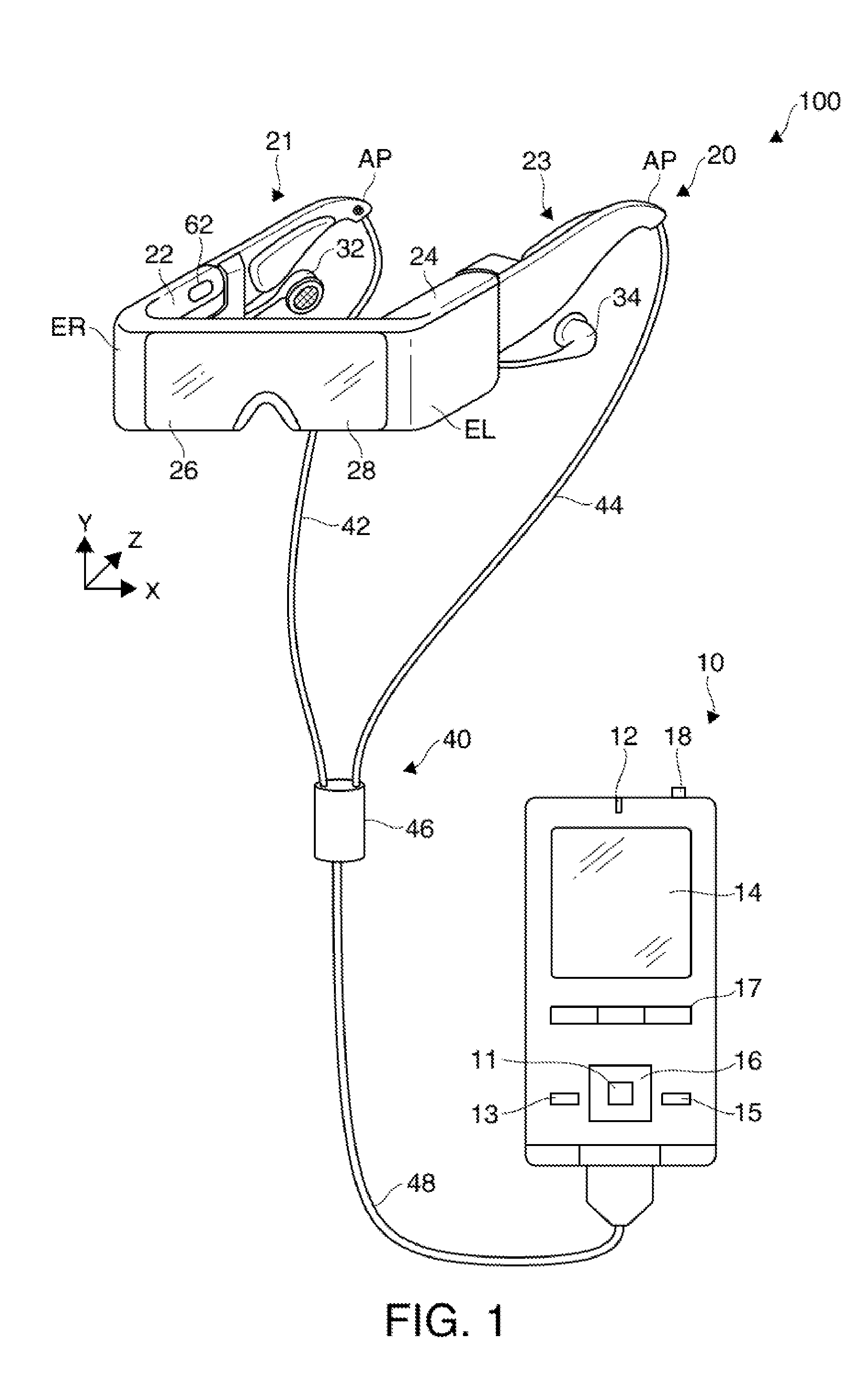

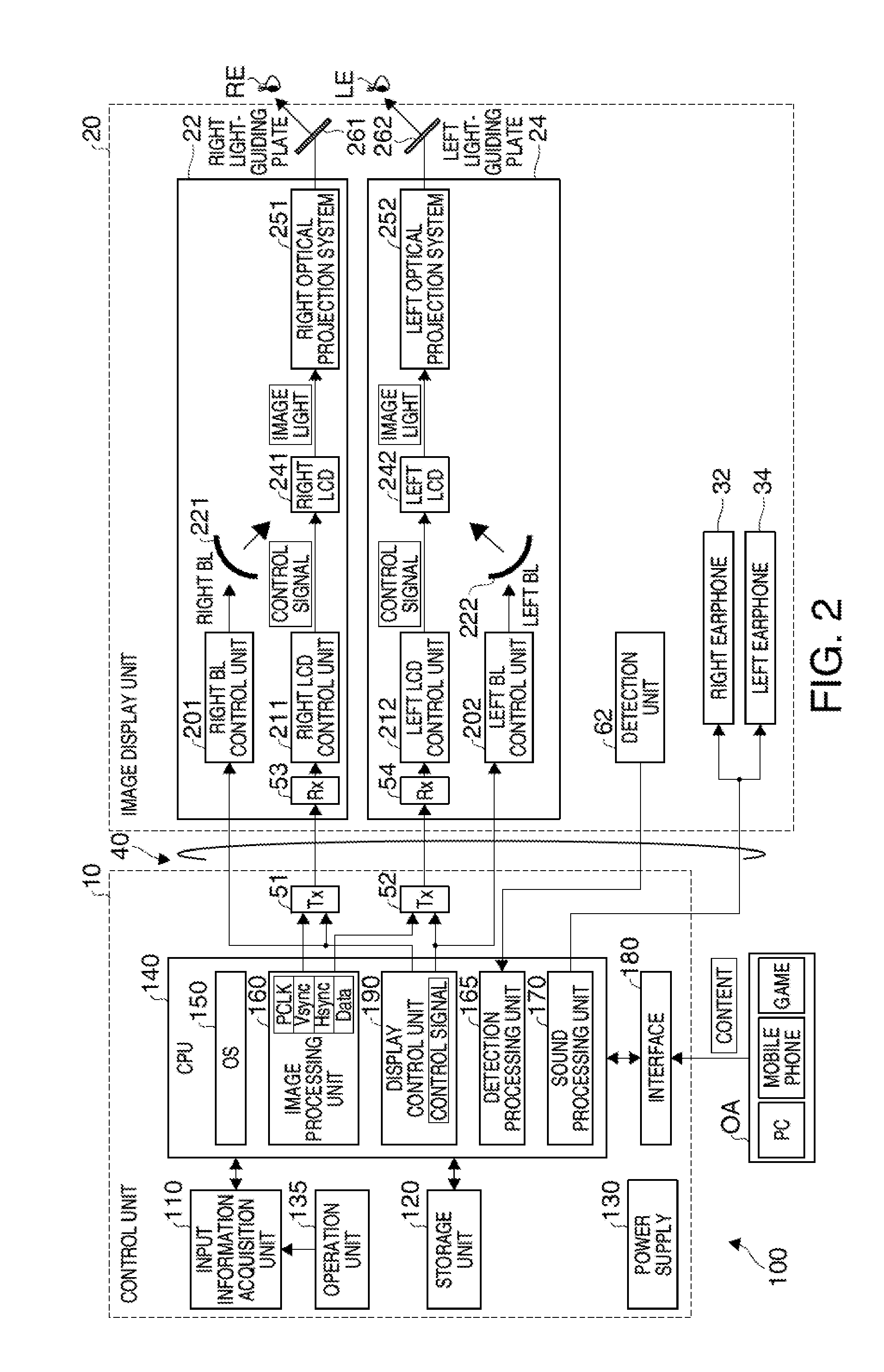

Head mounted display apparatus and method of controlling head mounted display apparatus

ActiveUS20130241948A1Increase awarenessLower Level RequirementsCathode-ray tube indicatorsSteroscopic systemsRadiologyImaging data

An optical transmission-type head mounted display apparatus includes an acquisition unit that acquires image data; an image display unit that generates image light based on the image data, and outputs the image light in order to cause a user to see the image light as a virtual image; and a control unit that performs control so as to reduces an output level of the image light corresponding to a part of regions of the virtual image from among the image light to a level at which the user cannot see the virtual image in a specific condition.

Owner:SEIKO EPSON CORP

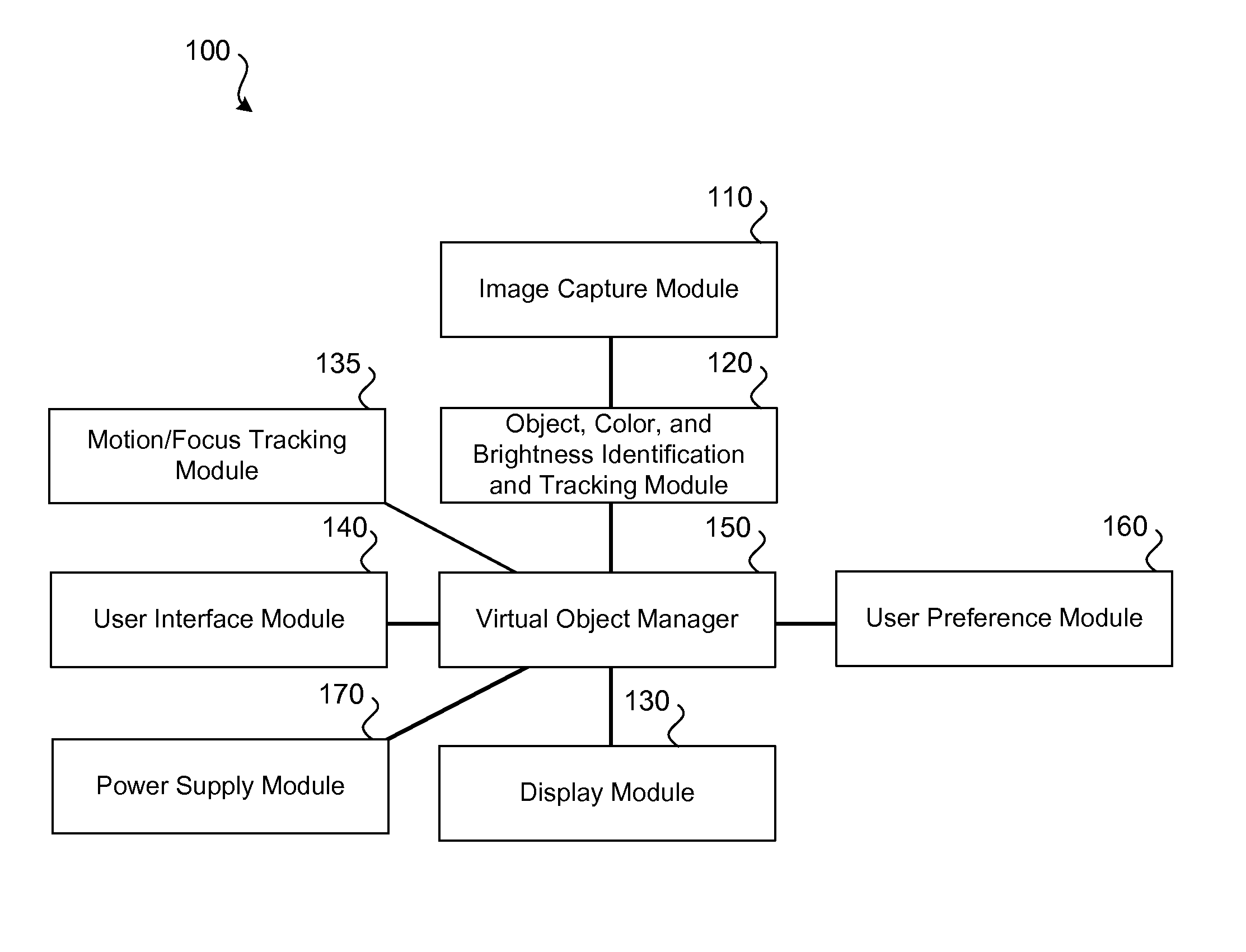

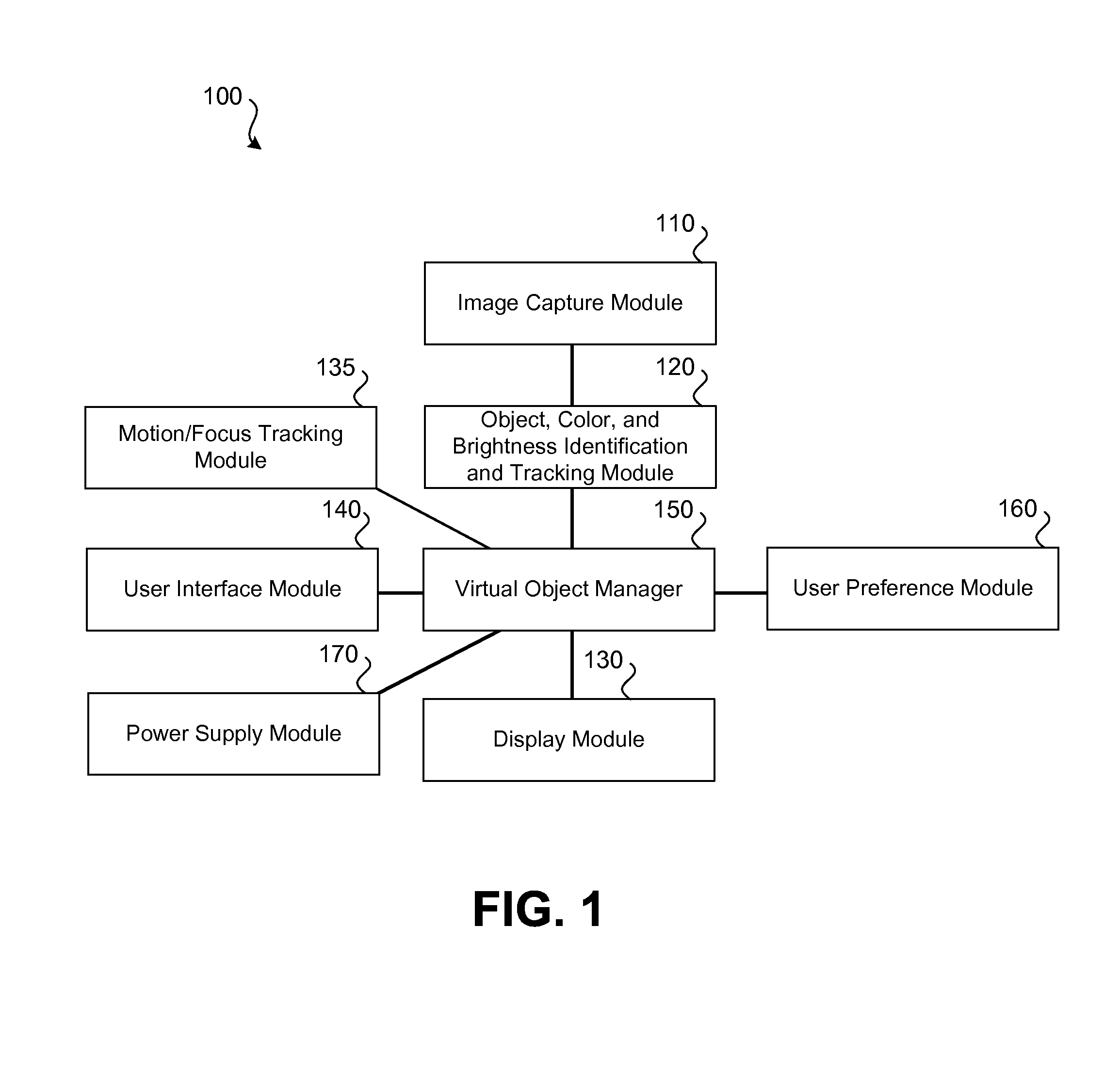

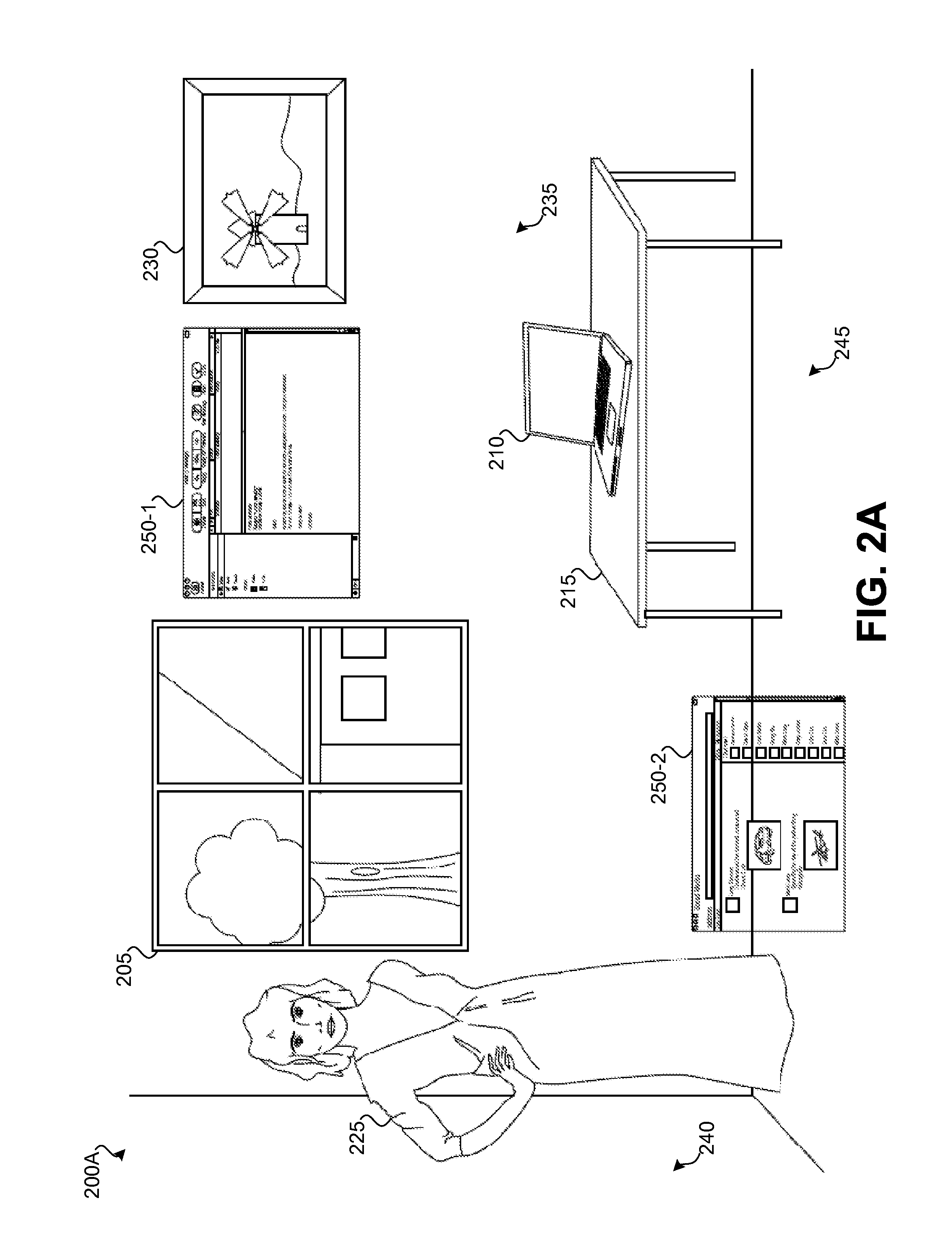

Modifying virtual object display properties to increase power performance of augmented reality devices

ActiveUS20140132484A1Lumen output decreaseReduce outputTexturing/coloringCathode-ray tube indicatorsVirtual fieldDisplay device

Various arrangements for controlling a head-mounted display of an augmented reality display are presented. A head-mounted display may be provided and may be configured to present a virtual field of view comprising a virtual object superimposed on a real-world scene. A controller may be provided and configured to modify display of the virtual object by the head-mounted display based on a first color of a real-world object in the real-world scene. The virtual object in the virtual field of view may be superimposed over the real-world object. A lumen output of the head-mounted display for displaying the virtual object may be decreased.

Owner:QUALCOMM INC

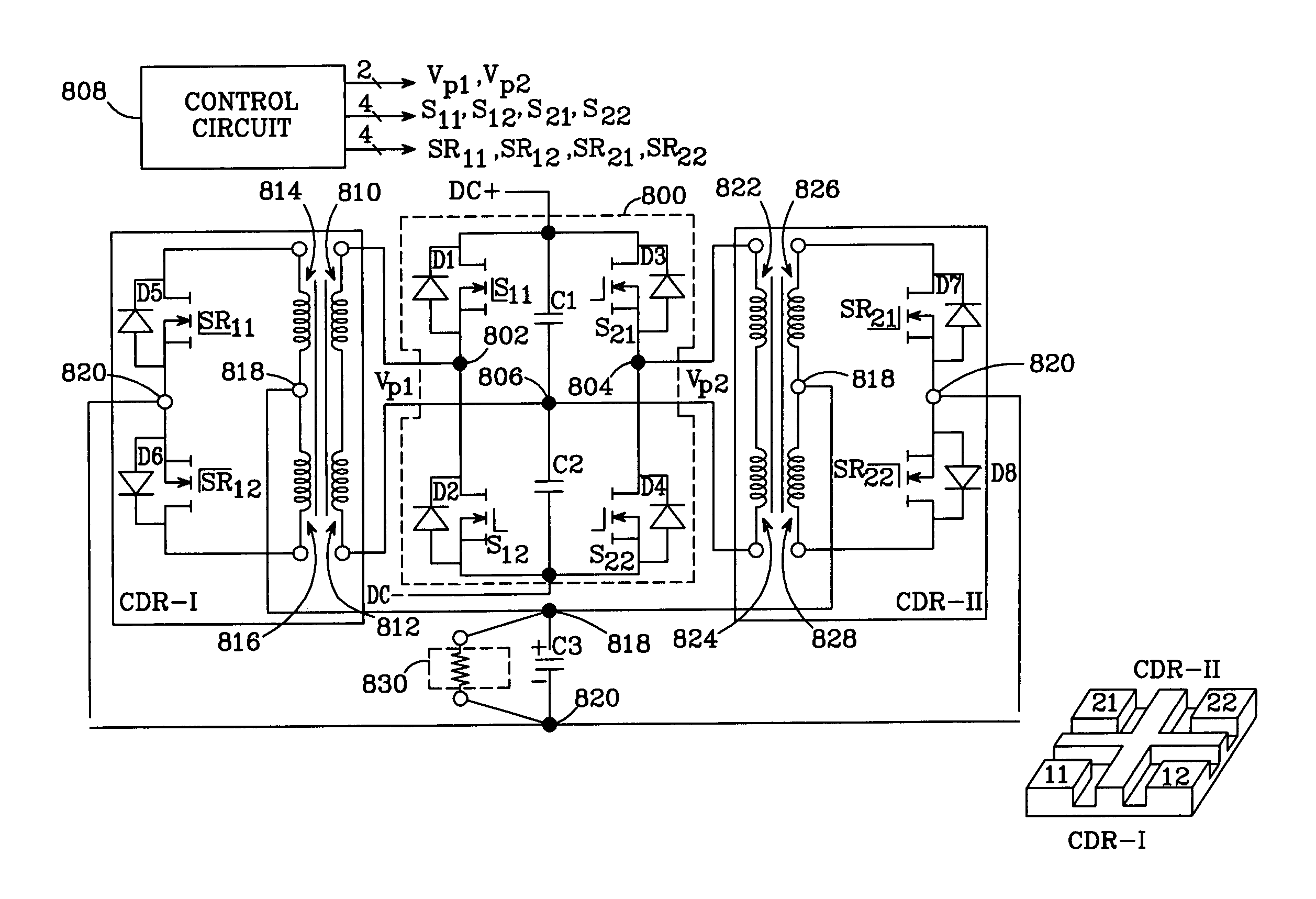

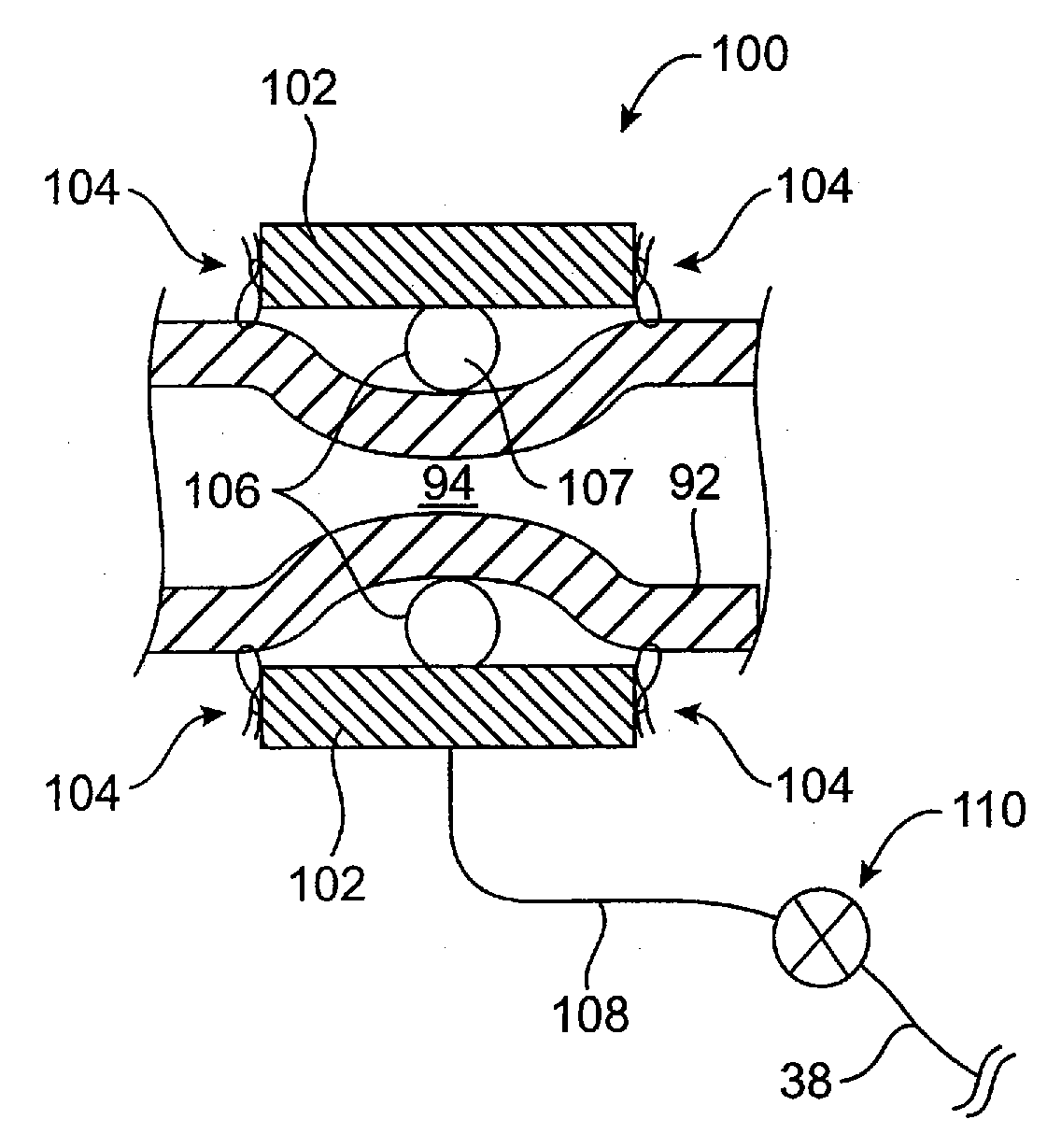

Core structure and interleaved DC-DC converter topology

ActiveUS7046523B2Reduced output voltage rippleReduce outputAc-dc conversion without reversalConversion with intermediate conversion to dcDc dc converterPhase shifted

There is disclosed a core structure with a very low profile, high power density and lower losses. The disclosed design allows for a larger core area where the DC fluxes are added, thereby reducing the air-gap requirements in the cores derived from low saturation density materials such as ferrites. The cellular nature of the design can be effectively employed in vertically packaged power converters and modules. Also disclosed is a DC-DC converter topology which preferably employs the disclosed core. N AC drive voltages drive N current doubler rectifiers (CDRs) in accordance with the symmetric modulation scheme; each CDR provides two rectified output currents to an output node. Each AC drive voltage has a switching period Ts. The drive voltages are phase-shifted by Ts / (2*N), such that the rectified output currents of the CDRs are interleaved, thereby reducing output voltage ripple.

Owner:MYPAQ HLDG LTD

Systems and methods for controlling renovascular perfusion

InactiveUS20090105631A1Reduced perfusionReduce activationOther blood circulation devicesMedical devicesHydrostatic pressureBiological activation

Devices, systems and methods by which the real or apparent renovascular perfusion and intrarenal pressure may be selectively and controllably increased. By selectively and controllably increasing renovascular perfusion and interstitial hydrostatic pressure when the heart is unable to pump sufficient blood or when renal perfusion is suboptimal, the present invention reduces or reverses neurohormonal activation and fluid retention, and thereby minimizes their deleterious effects on the heart, vasculature, kidneys and other body systems.

Owner:CVRX

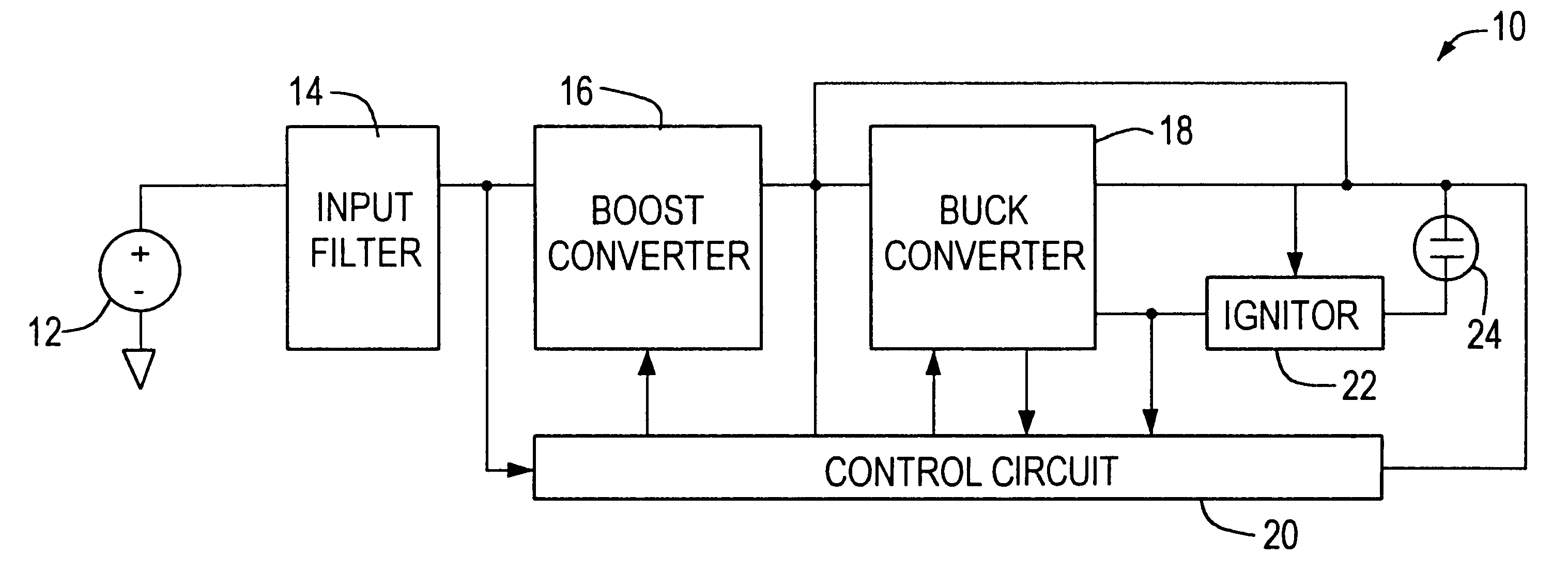

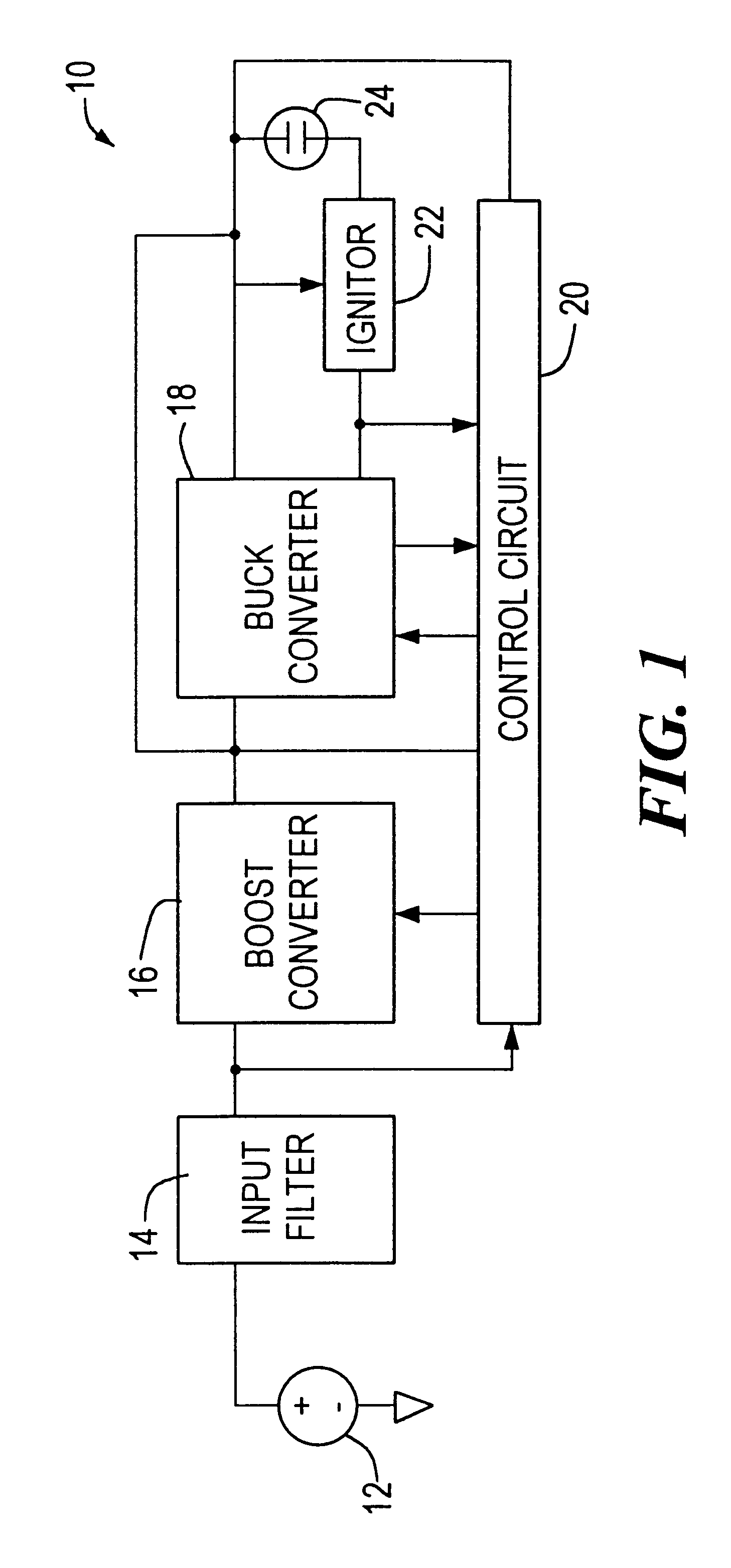

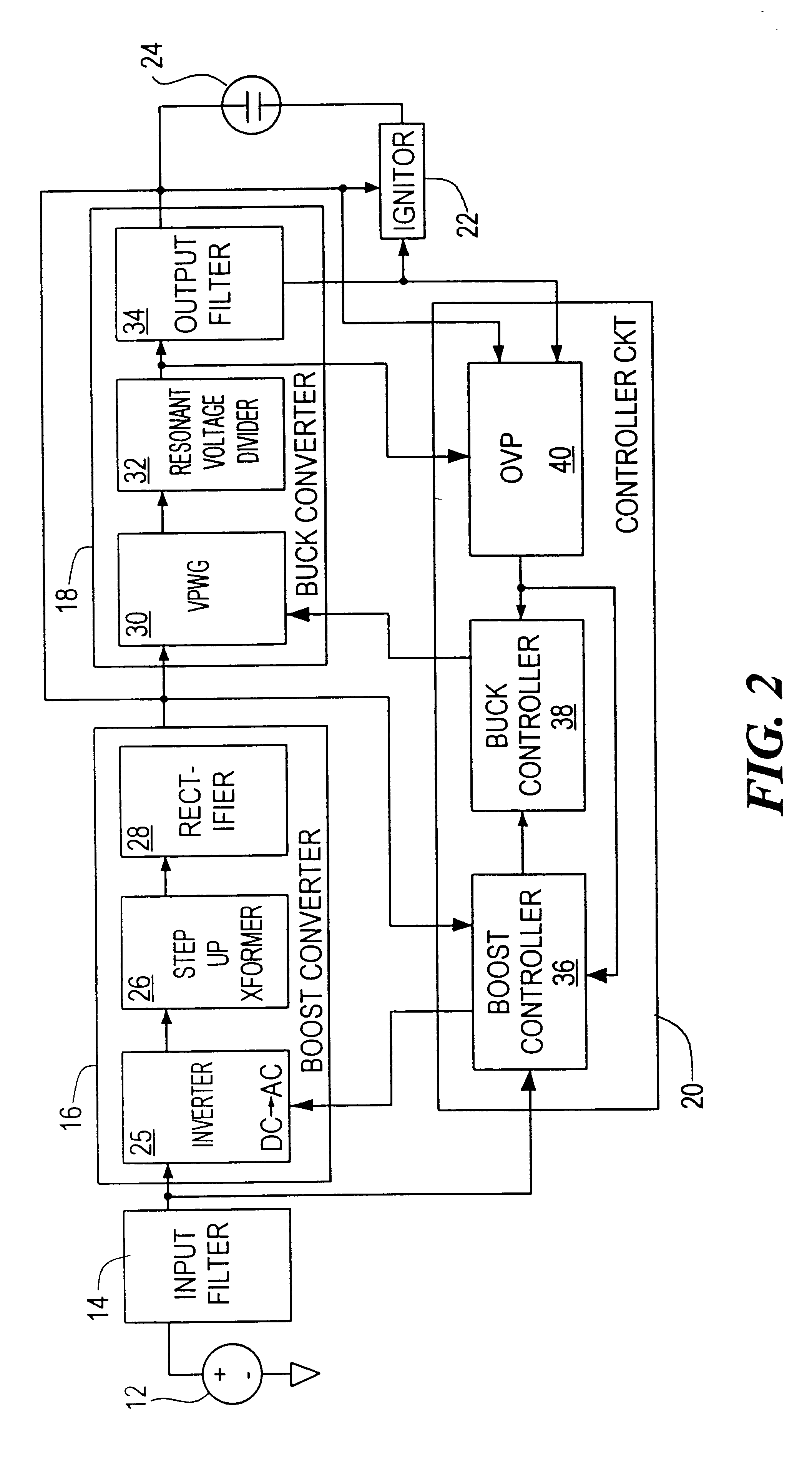

Ballast circuit for high intensity discharge lamps

InactiveUS6181084B1Eliminate flickeringMinimises levelAc-dc conversion without reversalConversion with intermediate conversion to dcBuck converterBoost controller

A ballast circuit for a high intensity discharge lamp includes a boost converter, responsive to a dc input voltage, for providing a boosted dc output voltage; a boost controller, responsive to the boosted dc output voltage, for driving the boost converter to maintain the boosted output voltage at a predetermined level; a buck converter, responsive to the boosted dc output voltage, for providing a reduced dc output voltage; and a buck controller, responsive to the reduced output voltage, for driving the buck converter to operate the discharge lamp in a transition mode and maintaining the reduced dc output voltage at a preselected level for operating the discharge lamp in a steady state mode.

Owner:EXCELITAS TECH

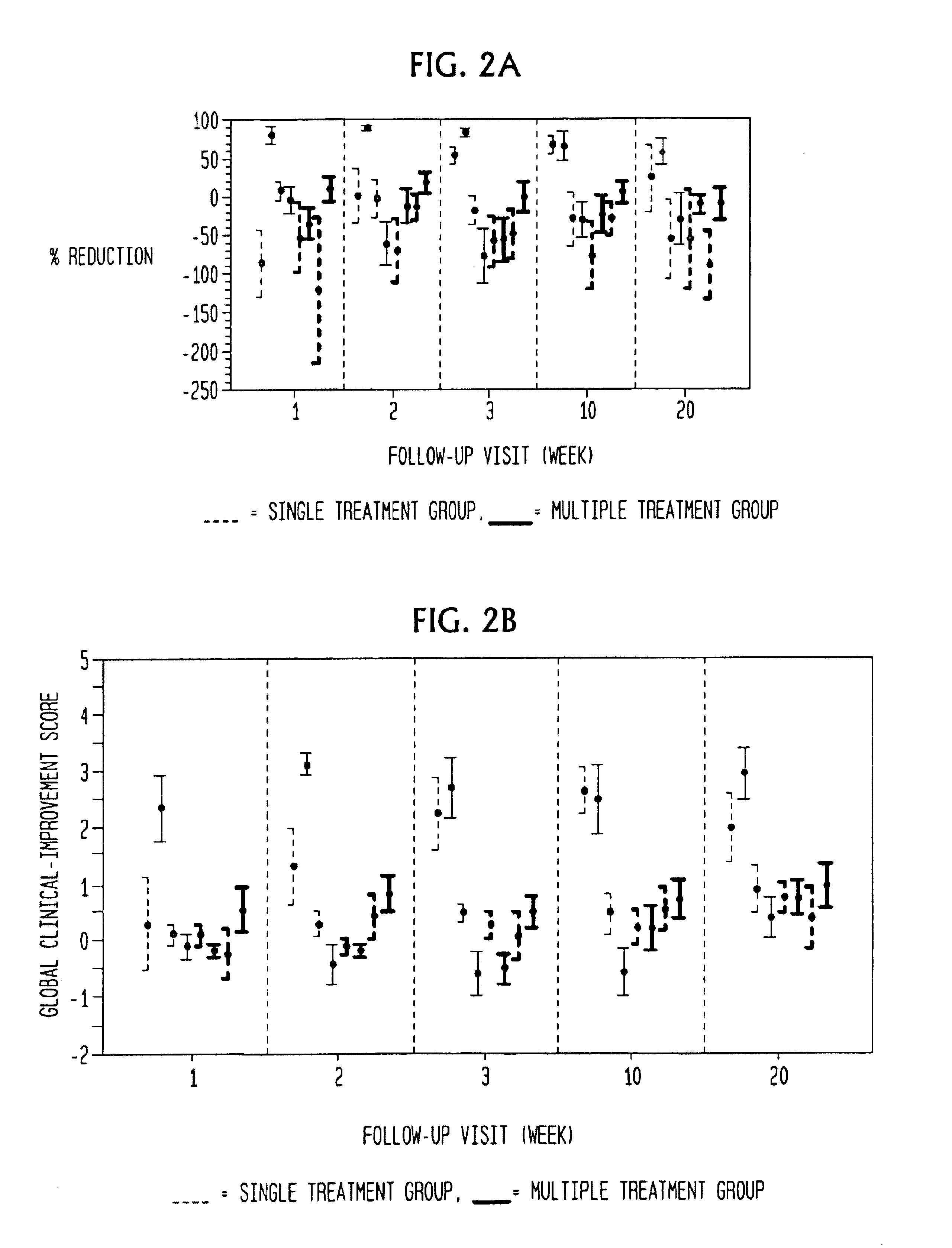

Topical aminolevulinic acid-photodynamic therapy for the treatment of acne vulgaris

InactiveUS6897238B2Reduce sebum productionSmall sizeBiocideOrganic active ingredientsBacteroidesDisease

Light treatments of sebaceous gland disorders with 5-aminolevulinic acid and photodynamic therapy are disclosed. A preferred treatment includes topical application of 5-aminolevulinic acid to the skin followed by light exposures with repeated treatment at various intervals. At low doses of ALA and photodynamic therapy (PDT) in single or multiple treatments, improvement in the sebaceous gland disorder, e.g., acne, provides the discovery that diminishment in sebum secretion and the eradication of bacteria occurs. At high doses of ALA and a single high energy PDT treatment, permanent changes to the sebaceous gland and sebum secretion have been discovered.

Owner:THE GENERAL HOSPITAL CORP

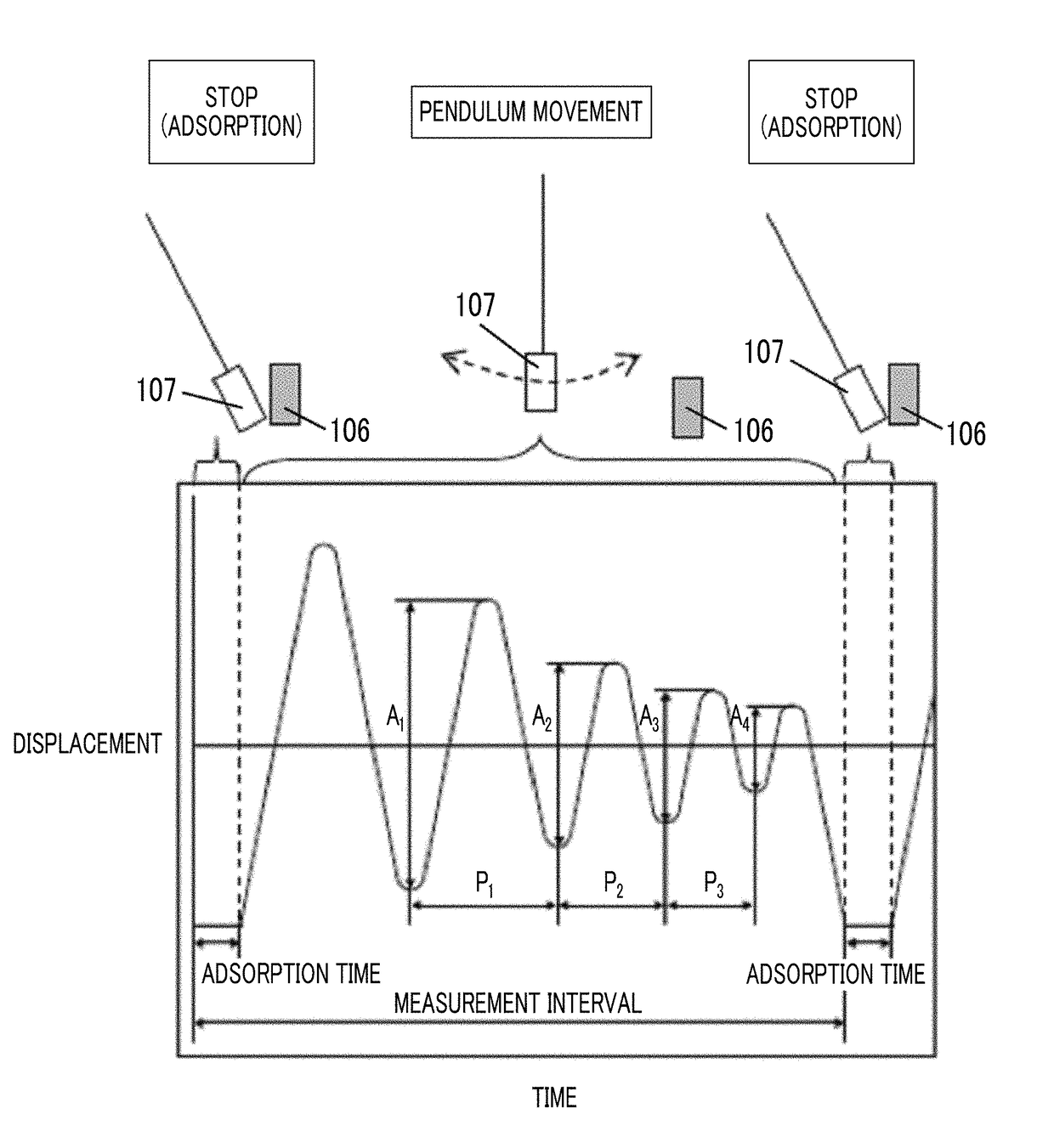

Magnetic tape

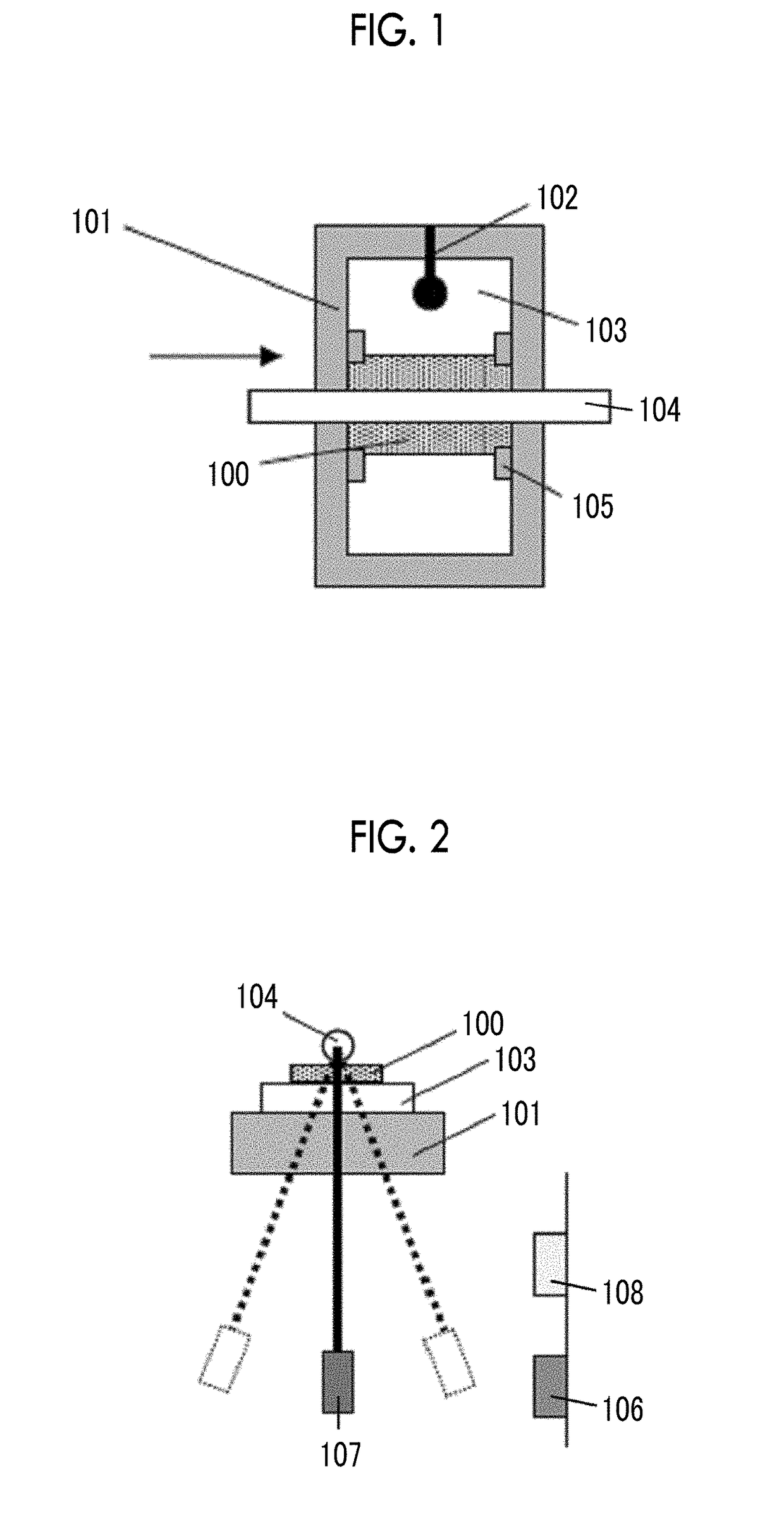

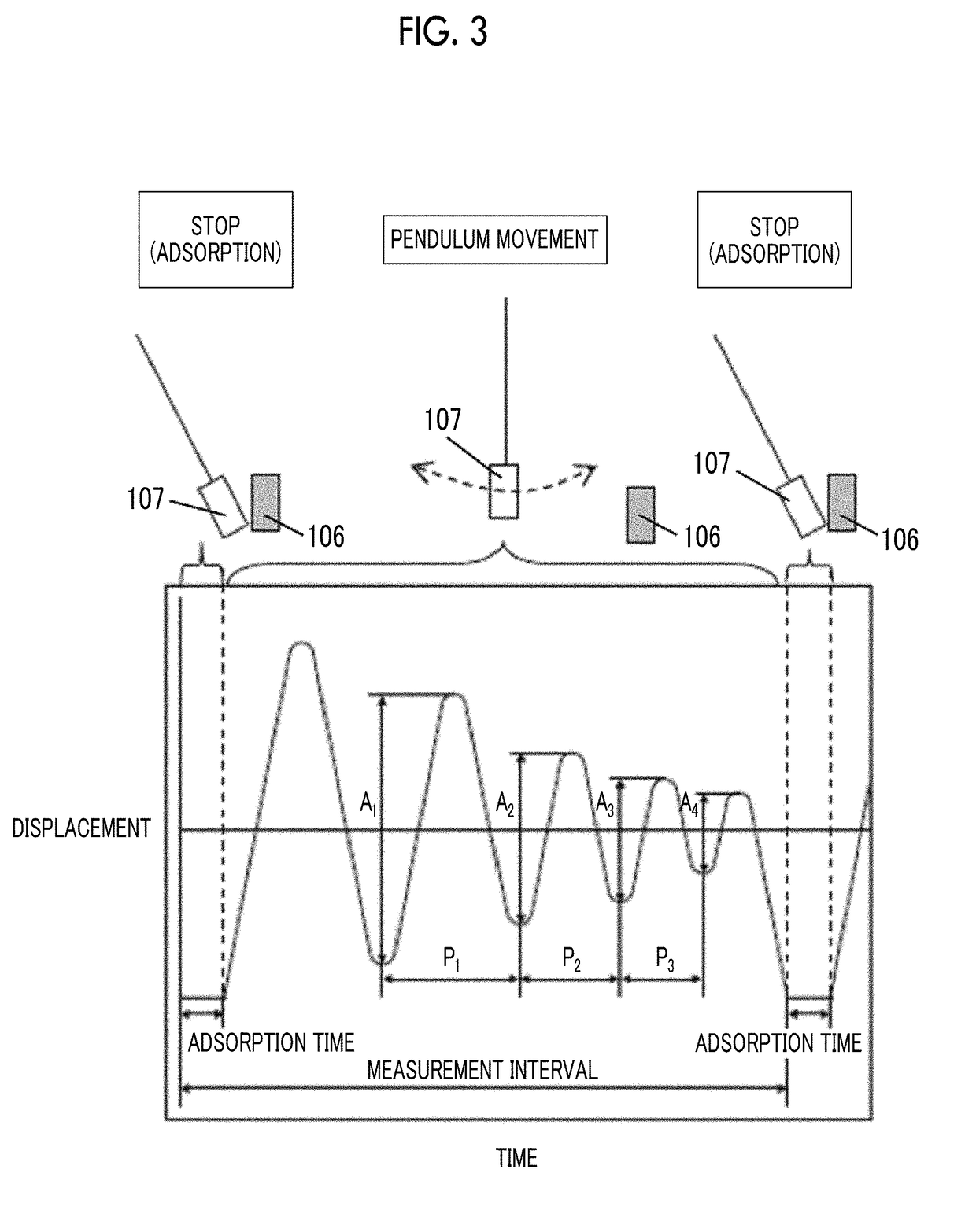

ActiveUS20180240493A1Improve surface smoothnessPrevent decrease in reproduction outputMaterials with ironRecord information storageMagnetic tapeSurface roughness

The magnetic tape includes a non-magnetic support; and a magnetic layer including ferromagnetic powder and a binding agent on the non-magnetic support, in which a center line average surface roughness Ra measured regarding a surface of the magnetic layer is equal to or smaller than 1.8 nm, a logarithmic decrement acquired by a pendulum viscoelasticity test performed regarding the surface of the magnetic layer is equal to or smaller than 0.050, and ΔSFD in a longitudinal direction of the magnetic tape calculated by Expression 1: ΔSFD=SFD25° C.−SFD−190° C. is equal to or greater than 0.35. In Expression 1, the SFD25° C. is a switching field distribution SFD measured in a longitudinal direction of the magnetic tape at a temperature of 25° C., and the SFD−190° C. is a switching field distribution SFD measured in a longitudinal direction of the magnetic tape at a temperature of −190° C.

Owner:FUJIFILM CORP

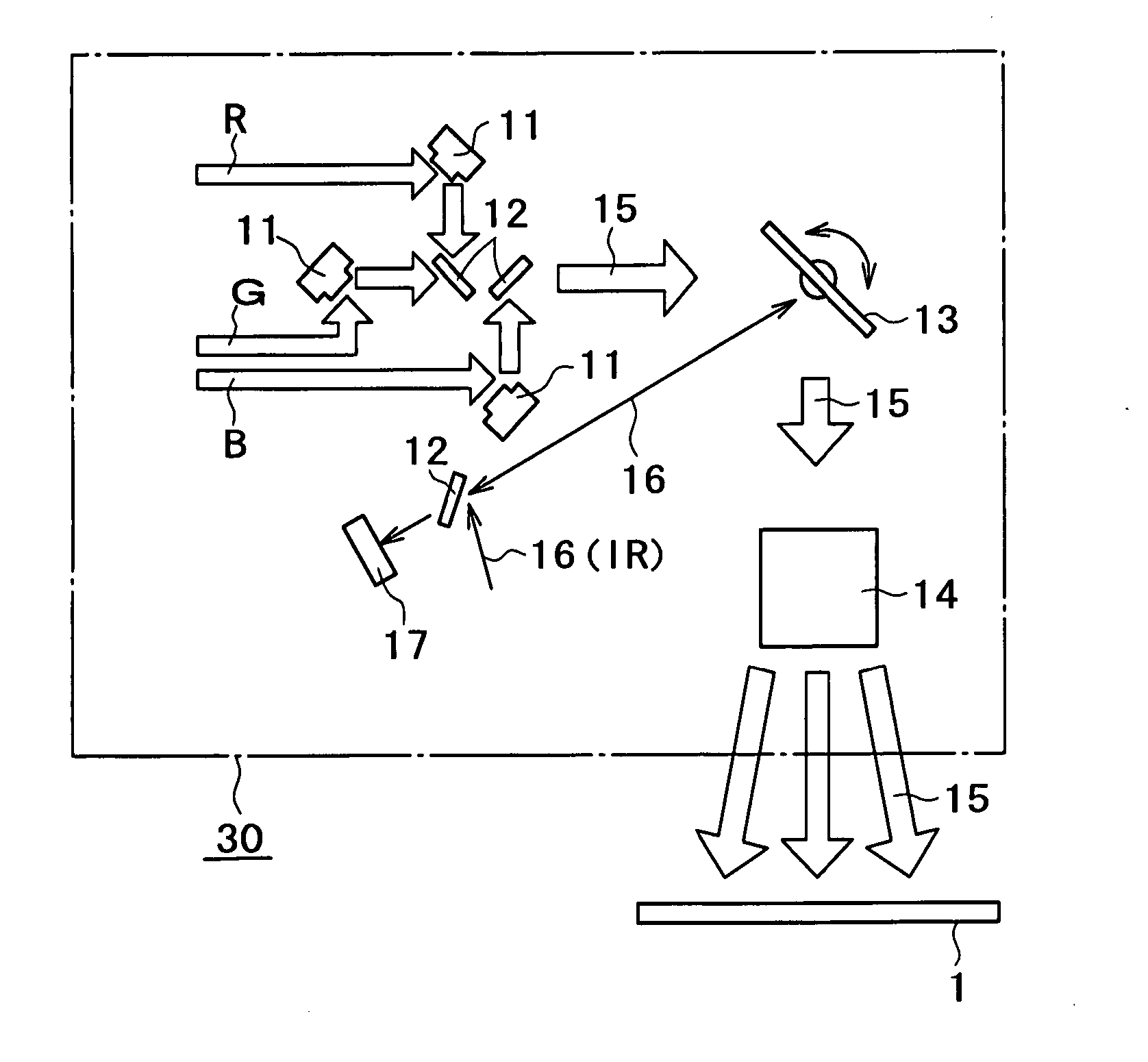

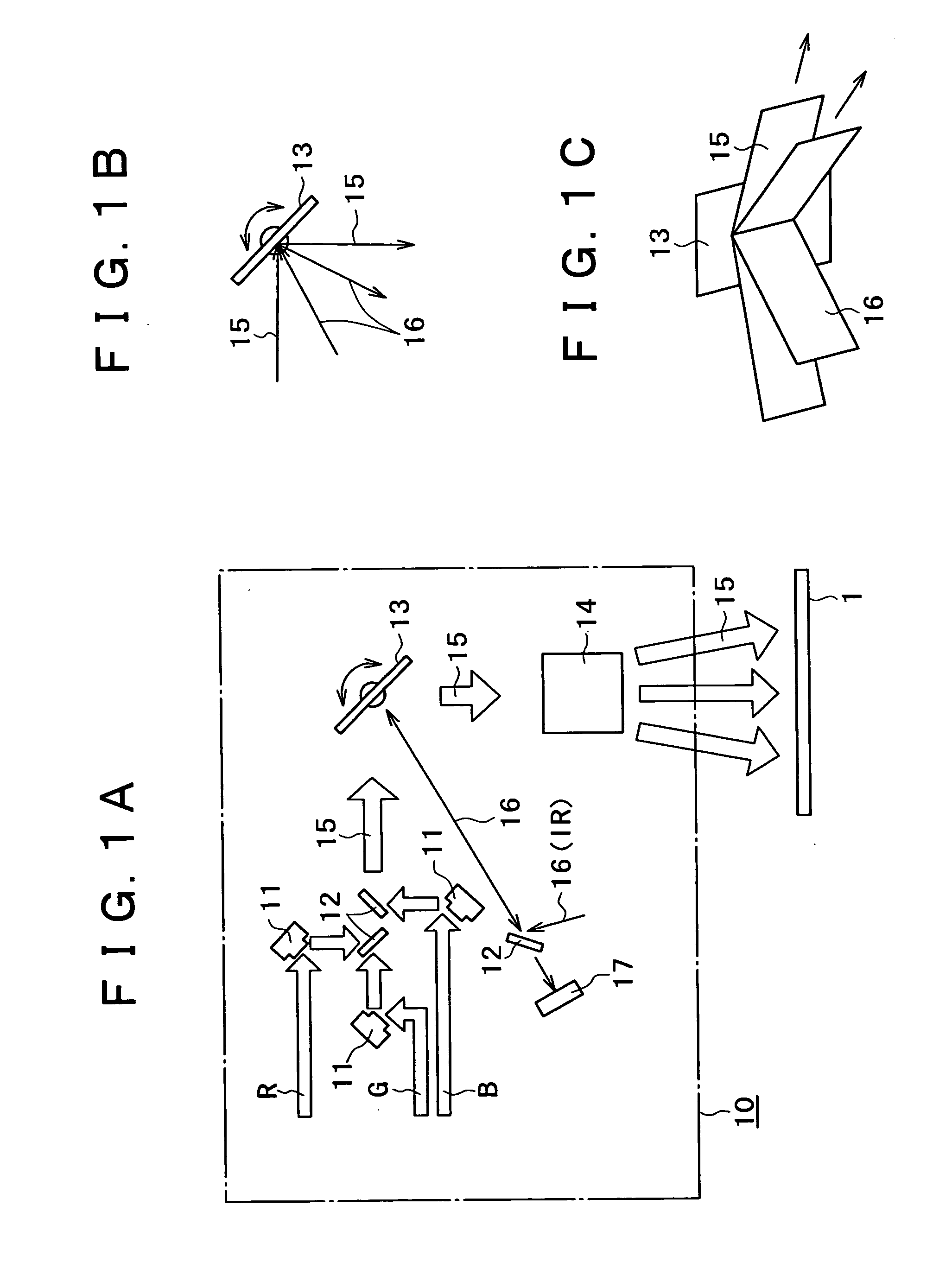

Projection type image display apparatus

InactiveUS20050035943A1Quick checkAvoid influenceTelevision system detailsLaser detailsLaser beamsPhysics

Disclosed herein is a projection type image display apparatus comprising projection means for projecting an image on an image-displaying screen by scanning with a laser beam, and detection means for detecting the presence or absence of an intruding object between the projection means and the screen, wherein detection by the detection means is conducted relative to a position preceding the laser beam in the scan direction of the laser beam.

Owner:SONY CORP

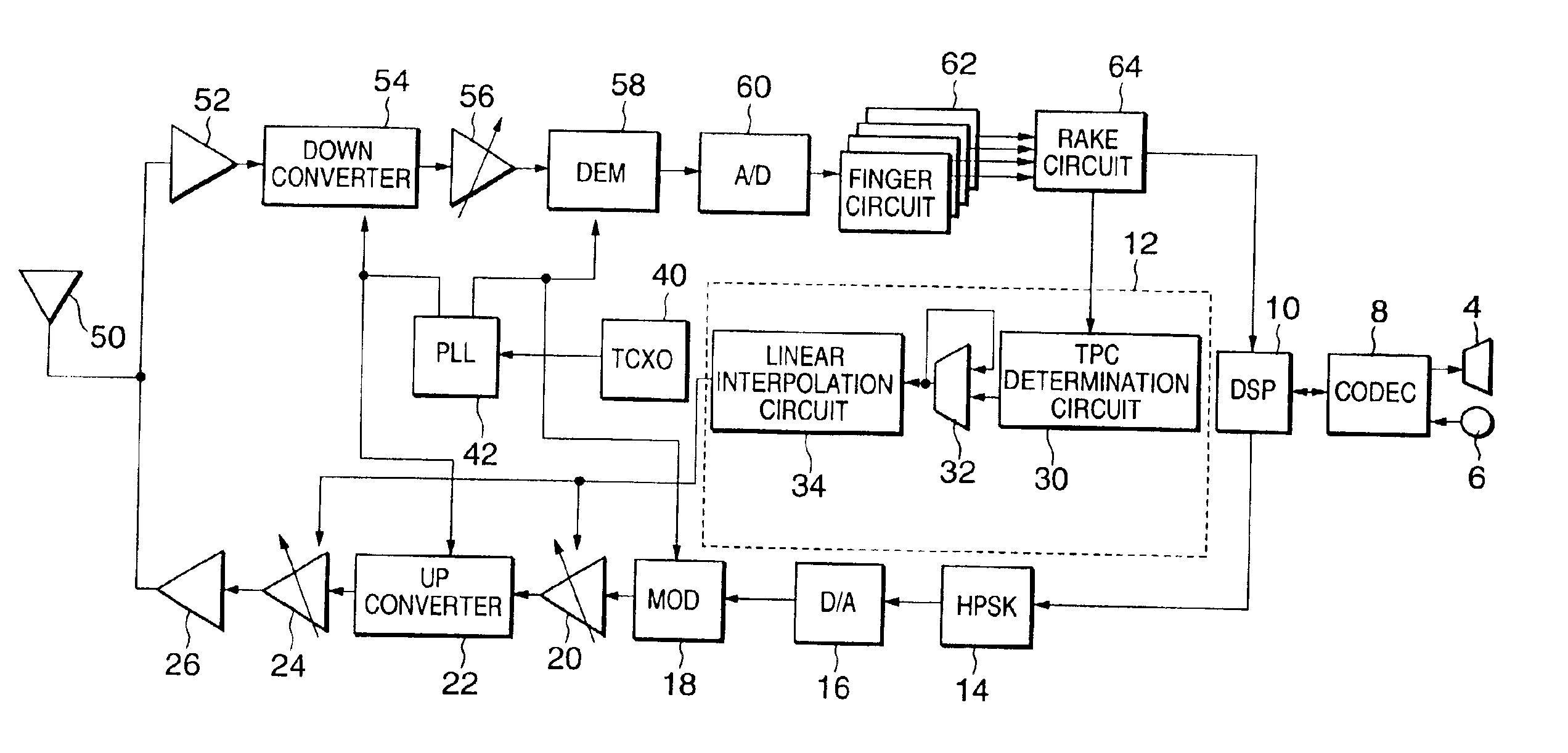

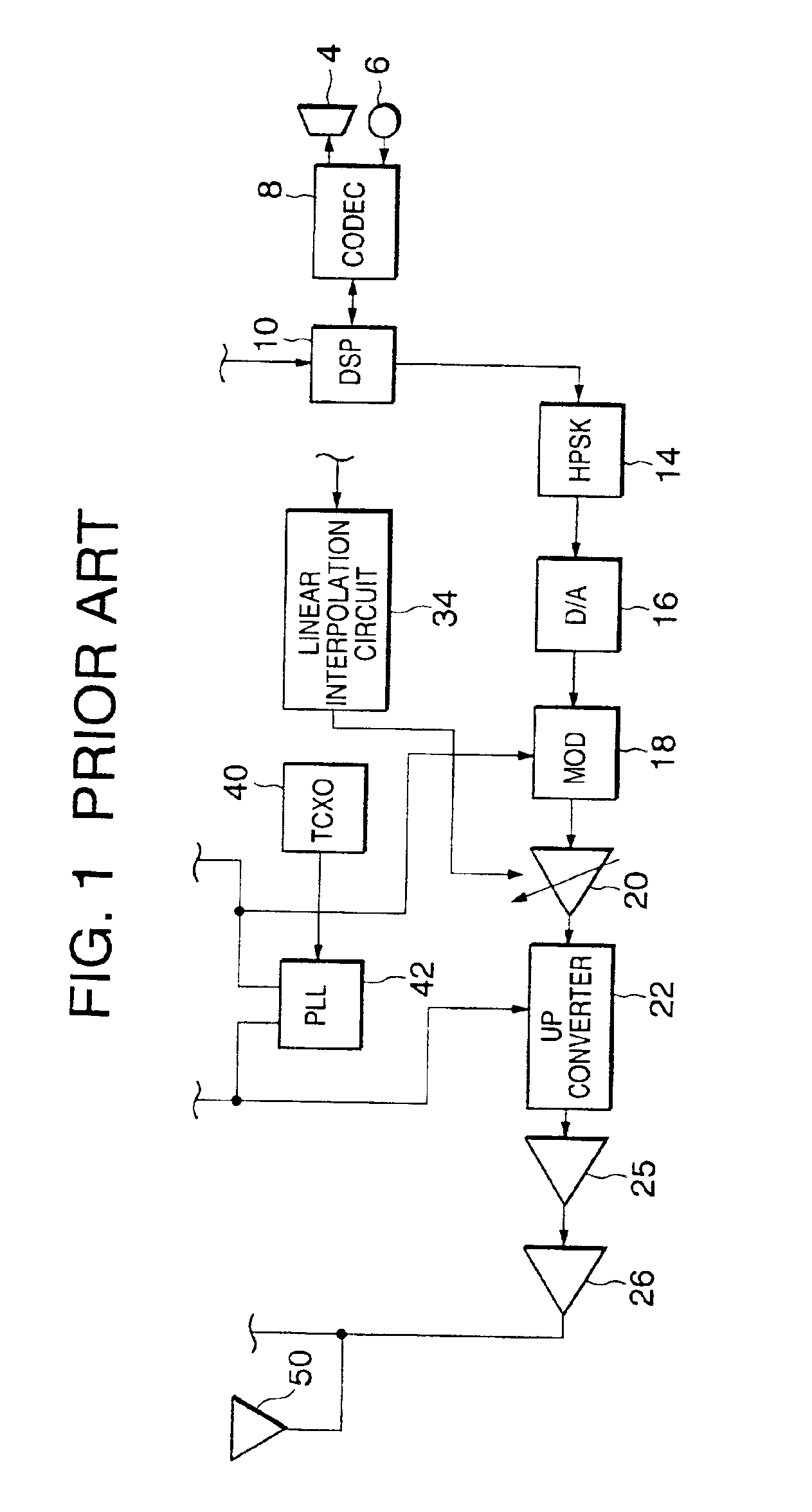

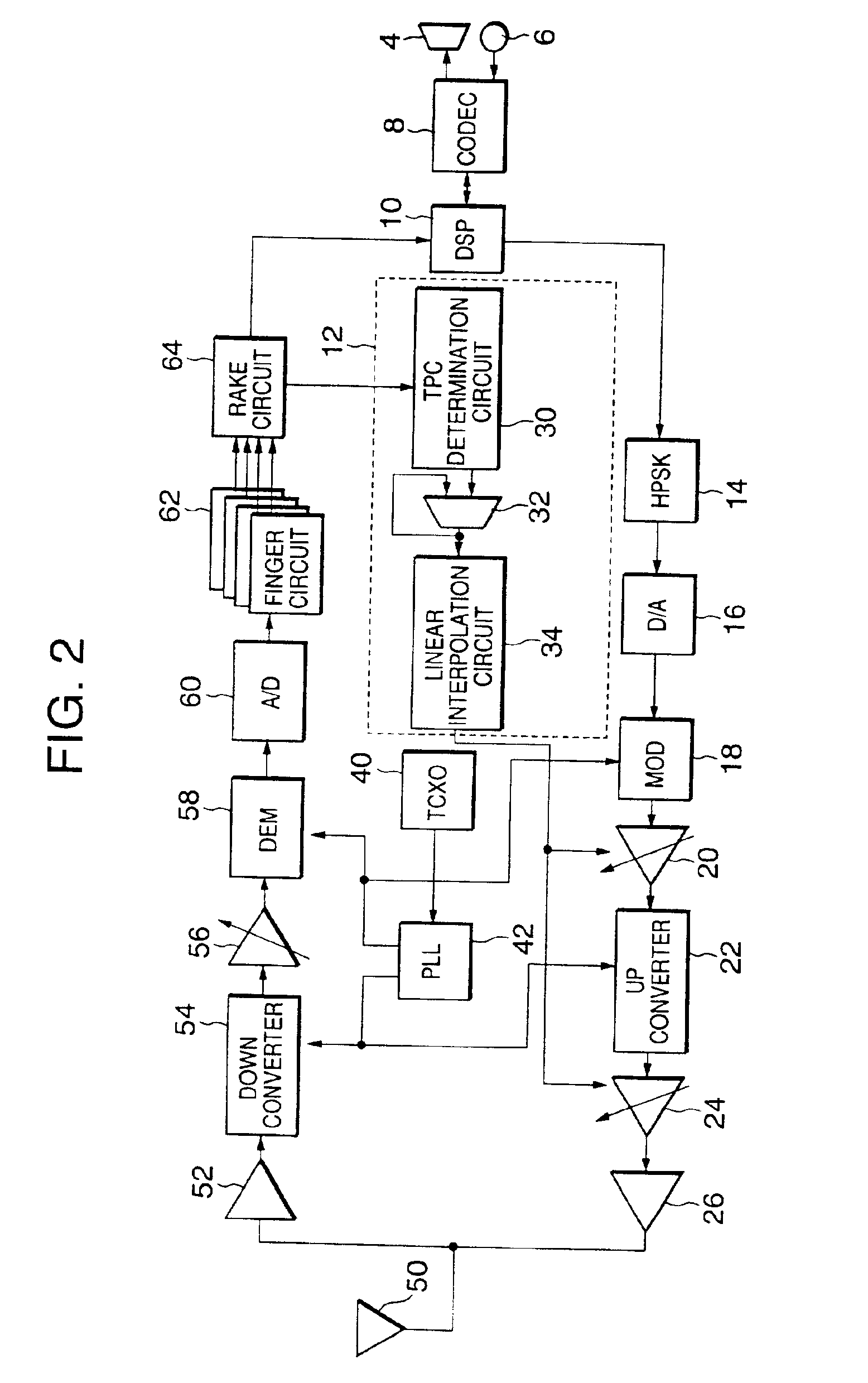

Gain control amplification circuit and terminal equipment having the same

InactiveUS6941112B2Linear characteristicSuppress noiseResonant long antennasManually-operated gain controlEngineeringAudio power amplifier

A gain control amplification circuit of this invention has a gain control amplification section which has at least two stages and is arranged in the transmission circuit of a terminal equipment for communicating with a base station. The gain control amplification section includes gain control amplifiers of IF-GCA and RF-GCA arranged on the input side (former stage) and output side (latter stage) of an up converter in the transmission circuit. The gains of the gain control amplifiers are individually controlled by a control section.

Owner:LENOVO INNOVATIONS LTD HONG KONG

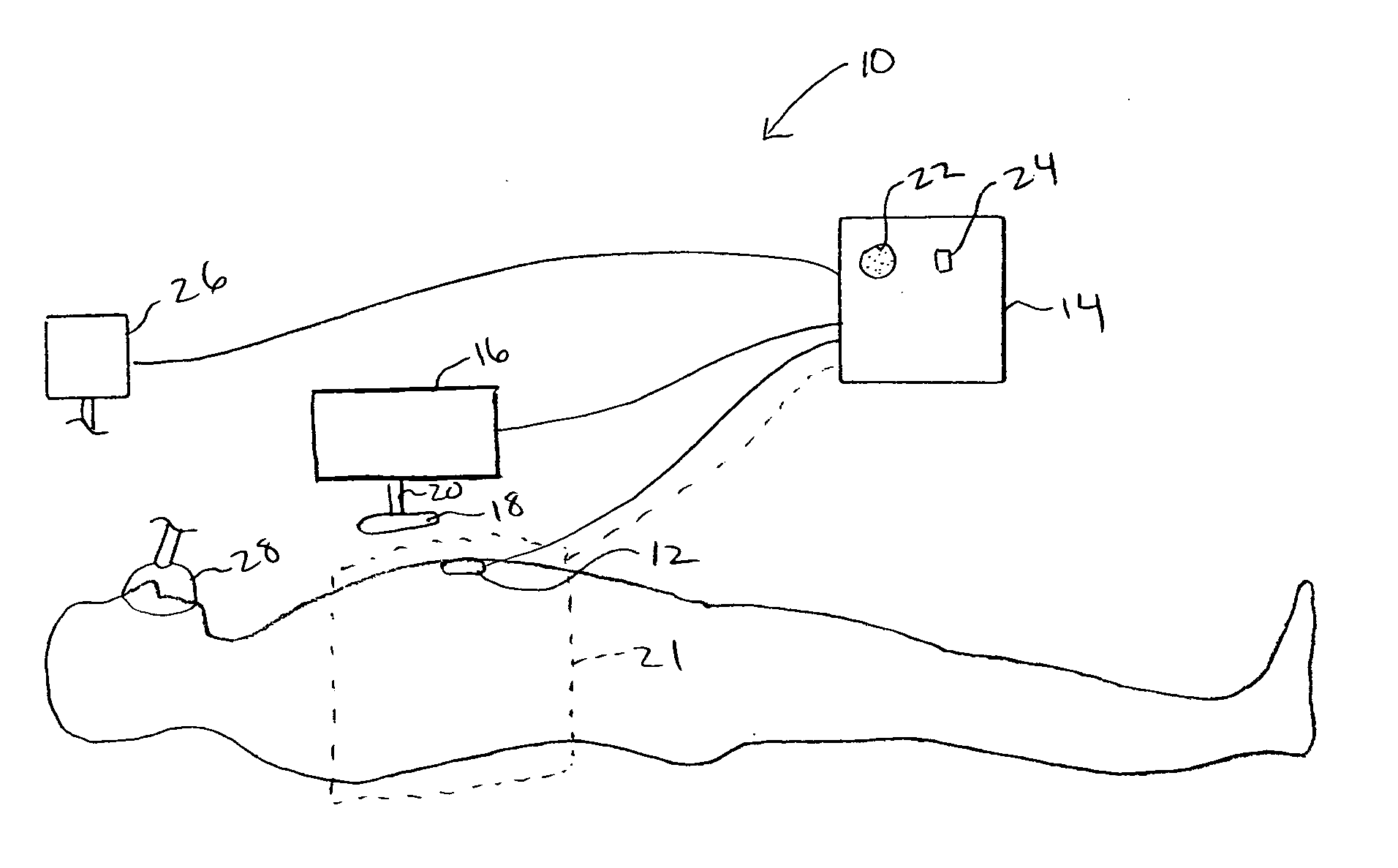

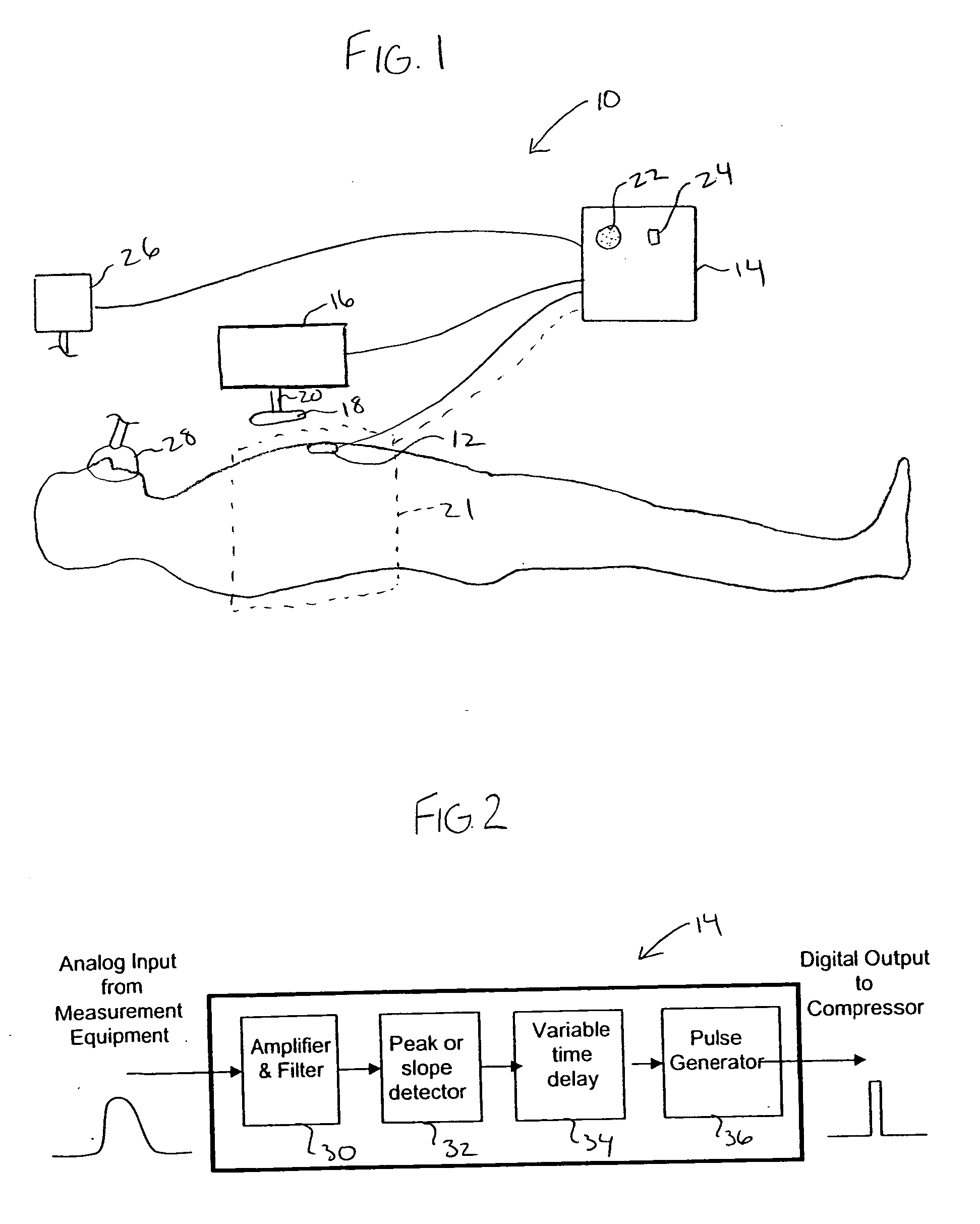

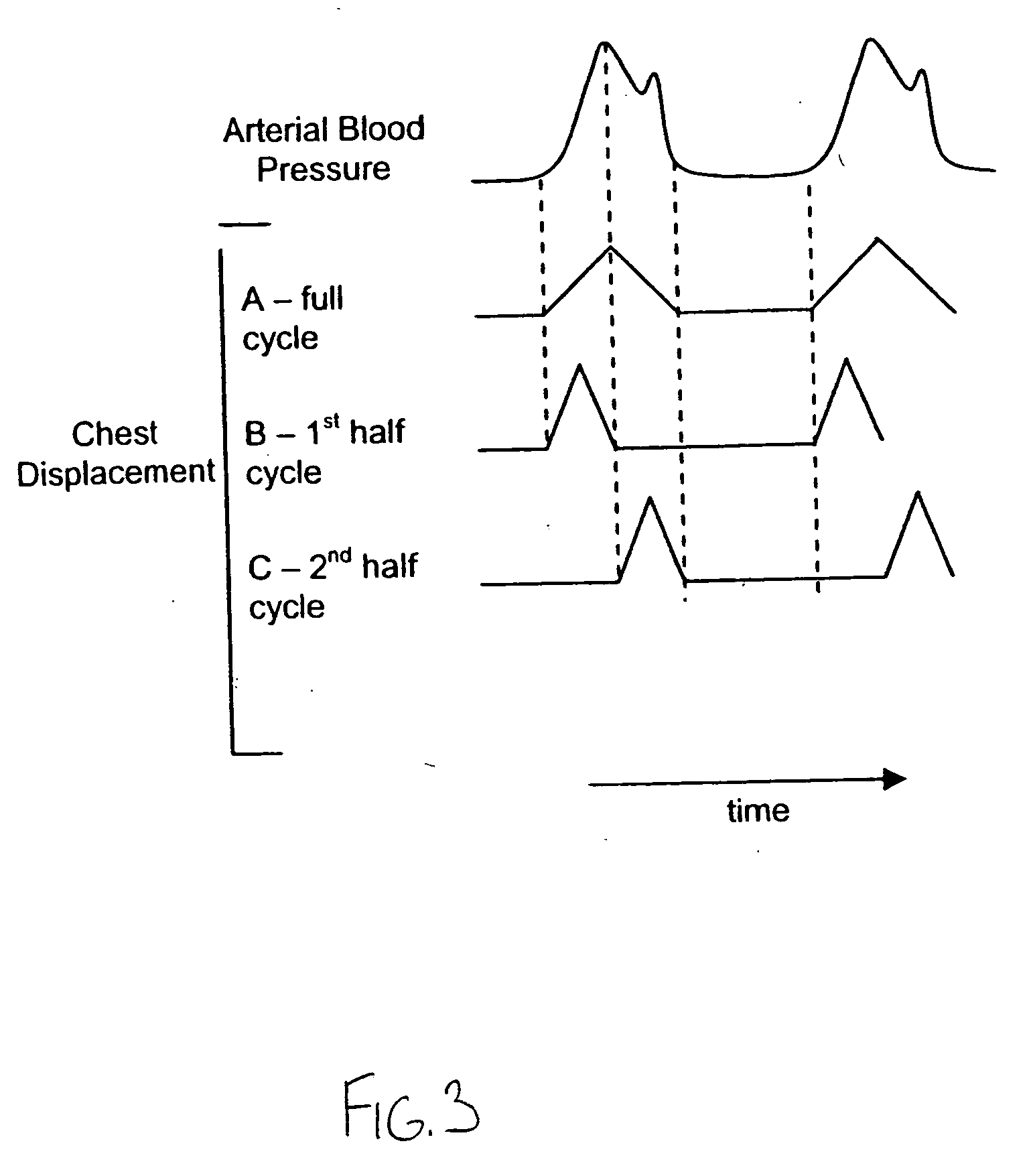

Non-invasive device for synchronizing chest compression and ventilation parameters to residual myocardial activity during cardiopulmonary resuscitation

ActiveUS20060089574A1Promote recoveryDecreased cardiac outputRespiratorsElectrotherapyPulseless electrical activityLeft ventricular size

In one embodiment, a method for improving the cardiac output of a patient who is suffering from pulseless electrical activity or shock and yet still displays some myocardial wall motion comprises sensing myocardial activity to determine the presence of residual left ventricular pump function having a contraction or ejection phase and a filling or relaxation phase. In such cases, a compressive force is repeatedly applied to the chest based on the sensed myocardial activity such that the compressive force is applied during at least some of the ejection phases and is ceased during at least some of the relaxation phases to permit residual cardiac filling, thereby enhancing cardiac output and organ perfusion. Also incorporated may be a logic circuit capable of utilizing multiple sensing modalities and optimizing the synchronization pattern between multiple phasic therapeutic modalities and myocardial residual mechanical function.

Owner:ZOLL MEDICAL CORPORATION

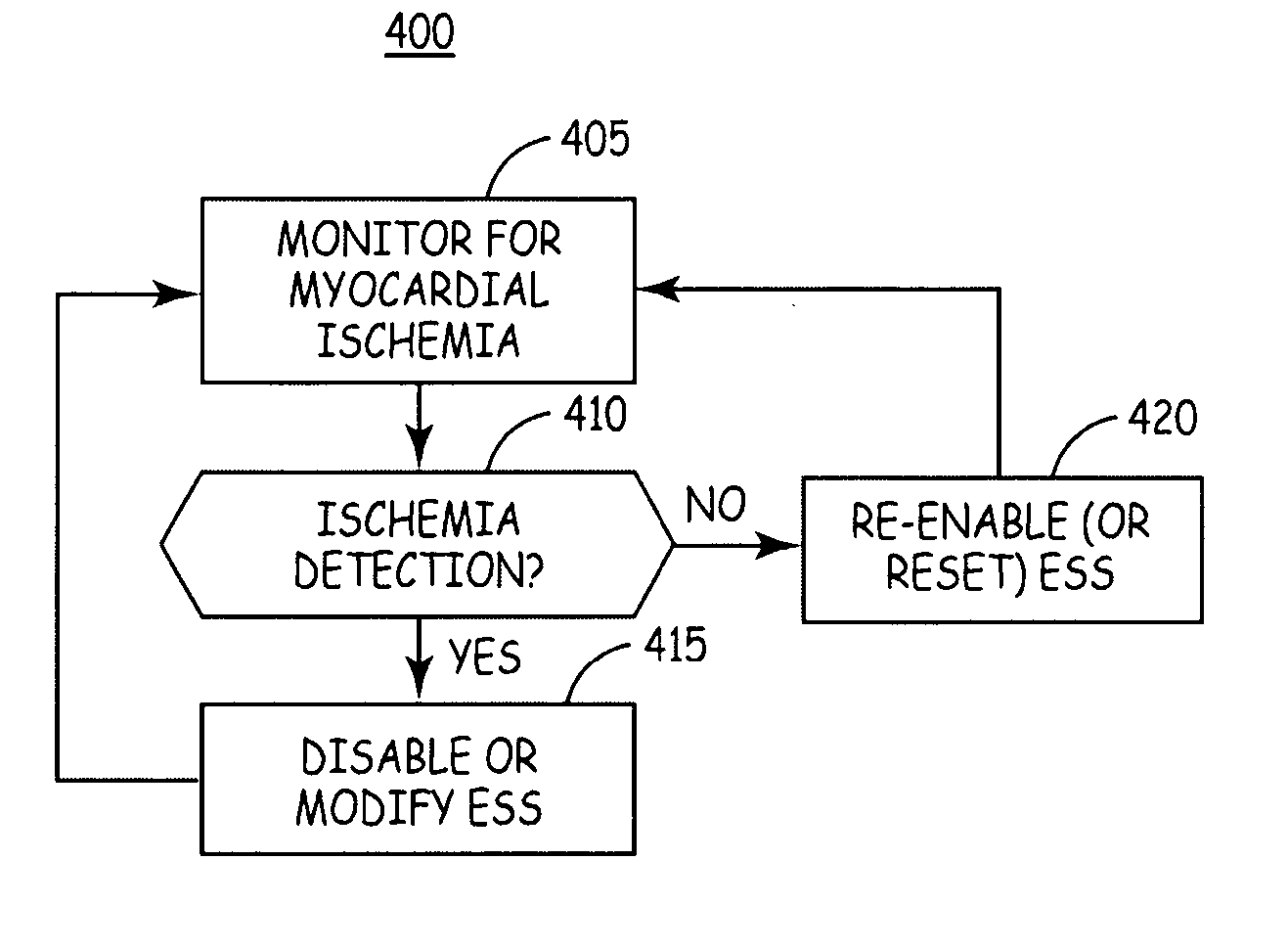

Method and apparatus for controlling extra-systolic stimulation (ESS) therapy using ischemia detection

InactiveUS20050075673A1Achieve effectRisk is exacerbatedHeart stimulatorsCardiac muscleMyocardial ischemia

An implantable cardiac stimulation device capable of delivering ESS, monitoring for myocardial ischemia and responding to the detection of myocardial ischemia by modifying the delivery of ESS. Modification of ESS delivery may include disabling ESS, initiating ESS, and / or modifying ESS control parameters.

Owner:MEDTRONIC INC

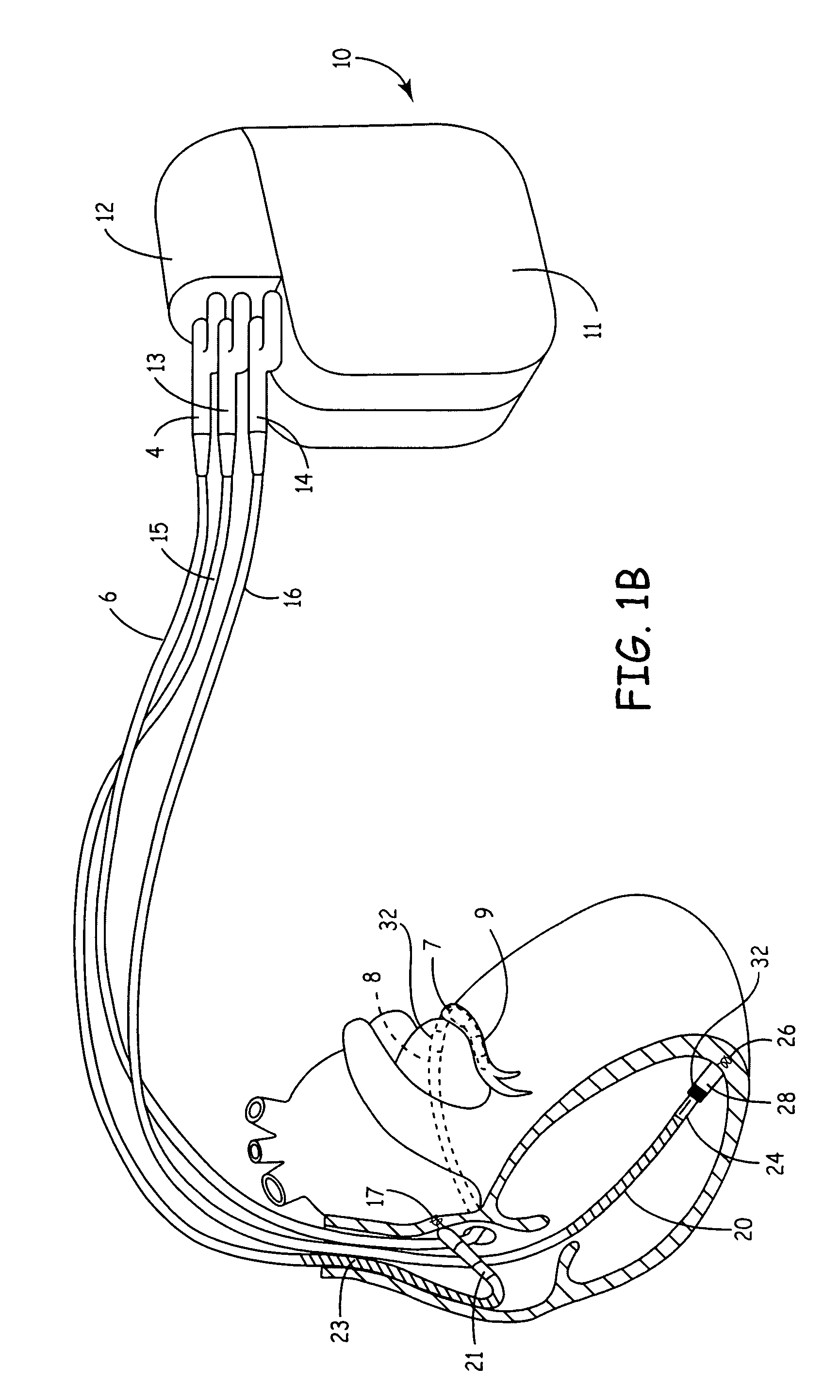

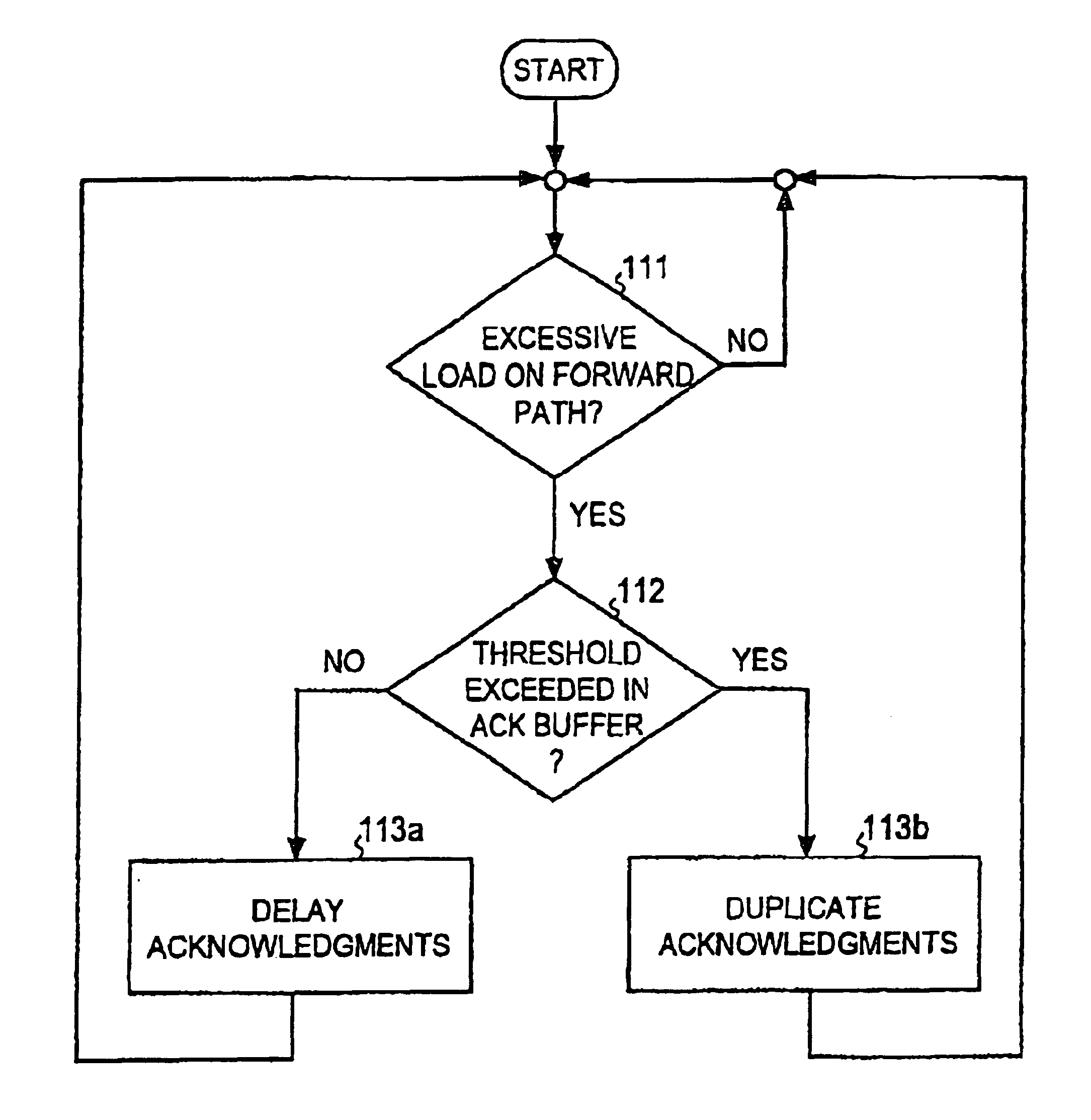

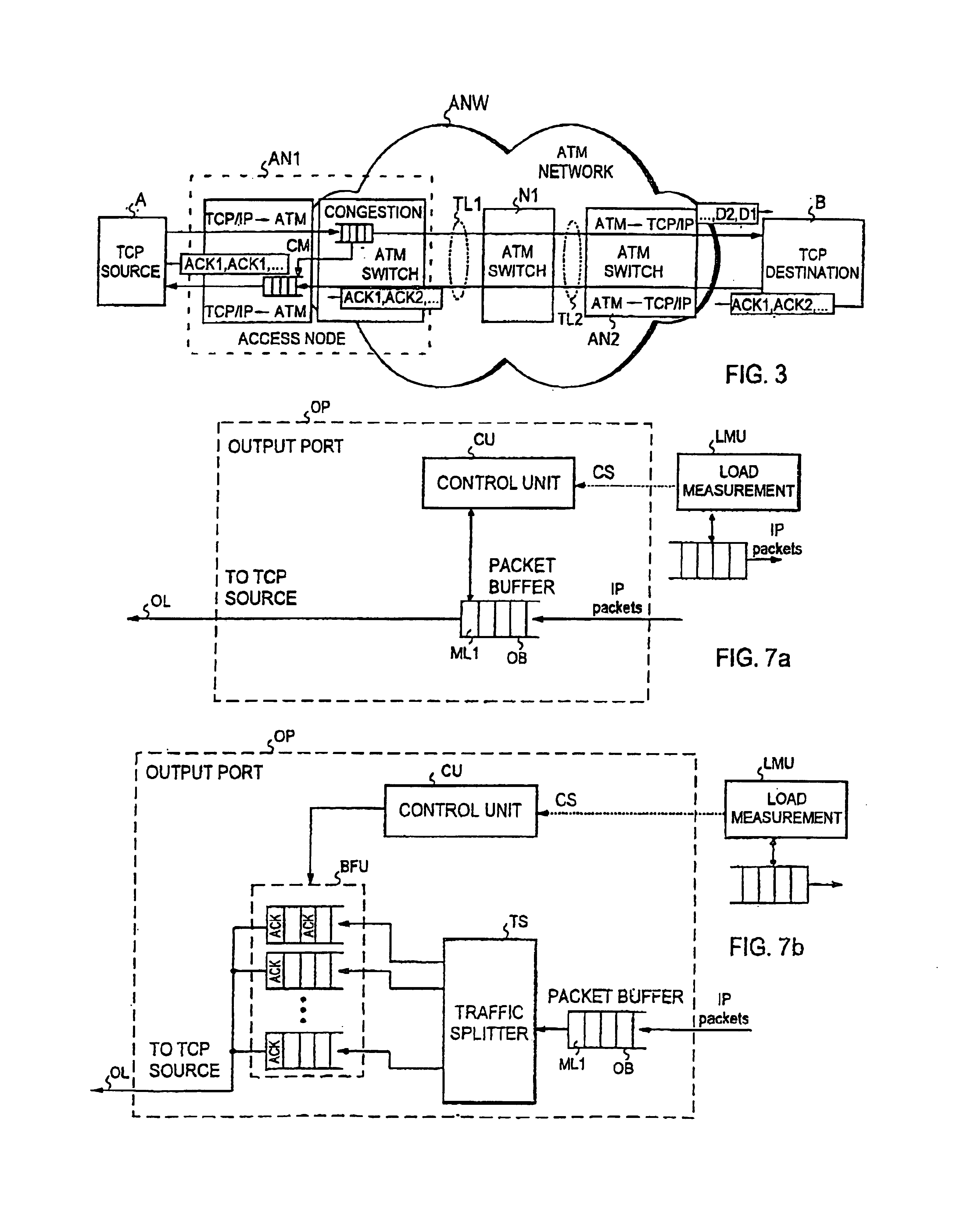

Congestion and overload control in a packet switched network

InactiveUS6882624B1Firmly connectedImprove performanceError preventionTransmission systemsTransport layerOverload control

The invention relates to a method for controlling overload in a packet switched network, especially in a network where Transmission Control Protocol (TCP) is used as the transport layer protocol. In order to inform the traffic source at a very early stage that the network is getting overloaded or congested, duplicate acknowledgments are transmitted towards the traffic source when the measured load level exceeds a predetermined threshold.

Owner:WSOU INVESTMENTS LLC

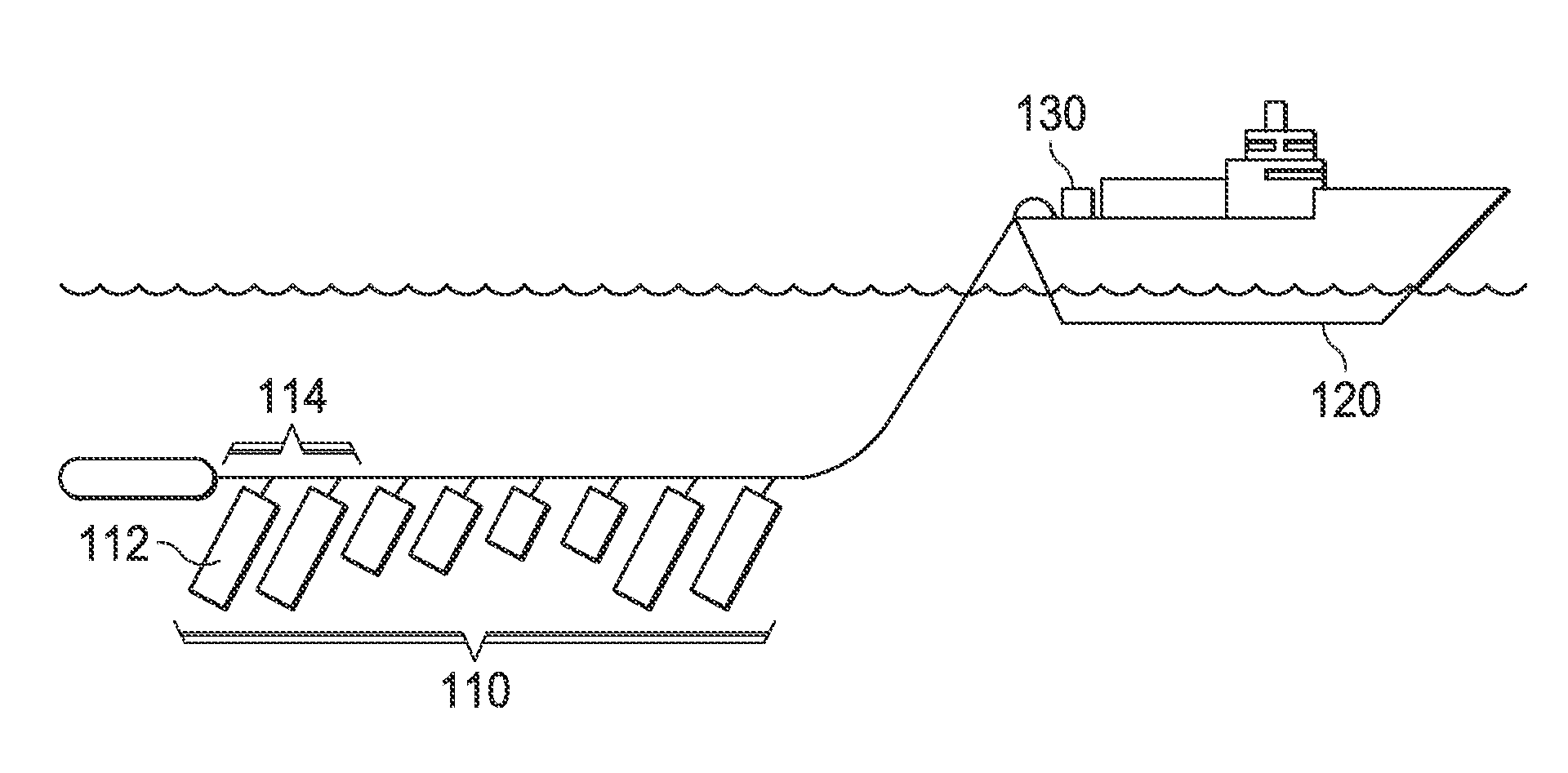

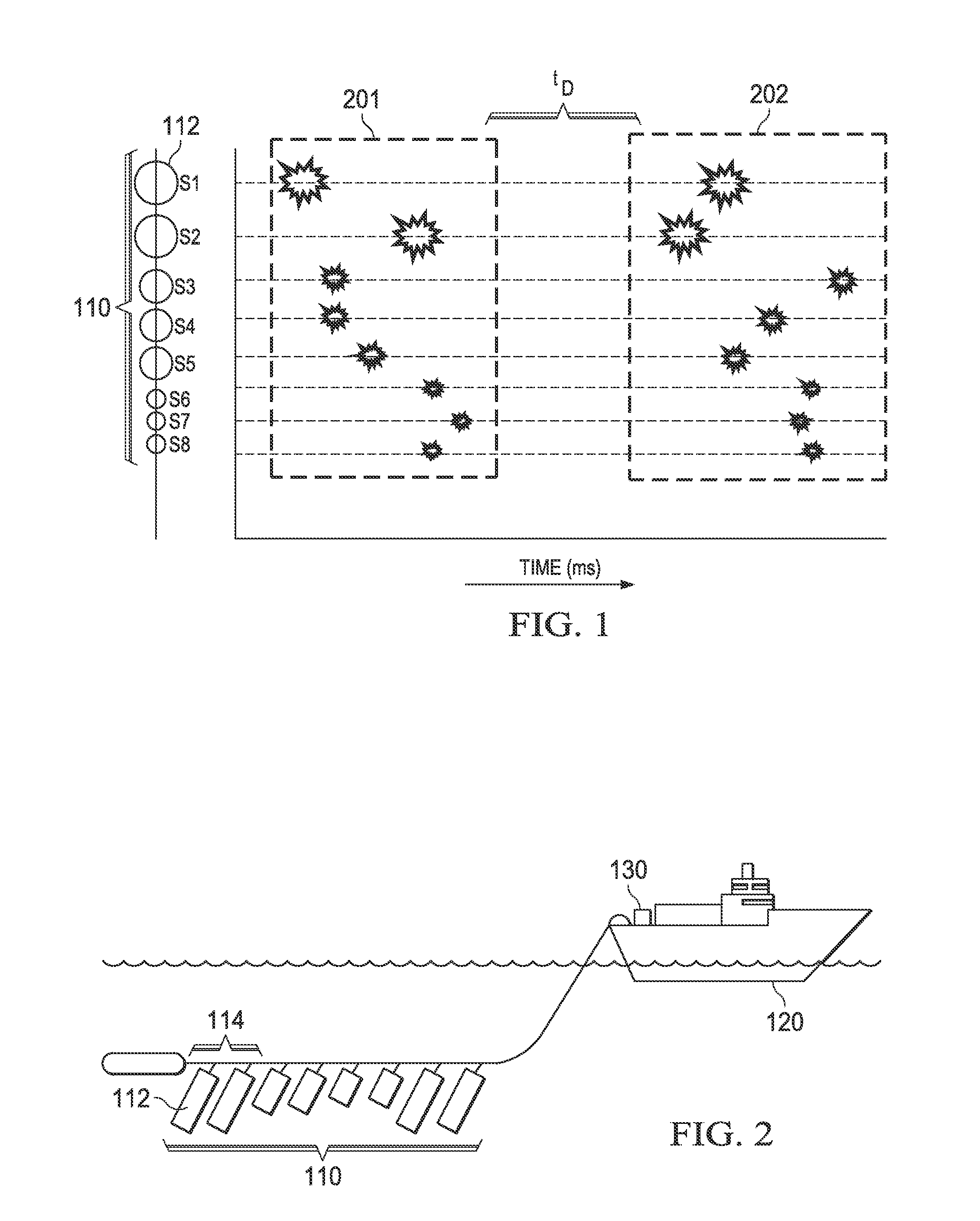

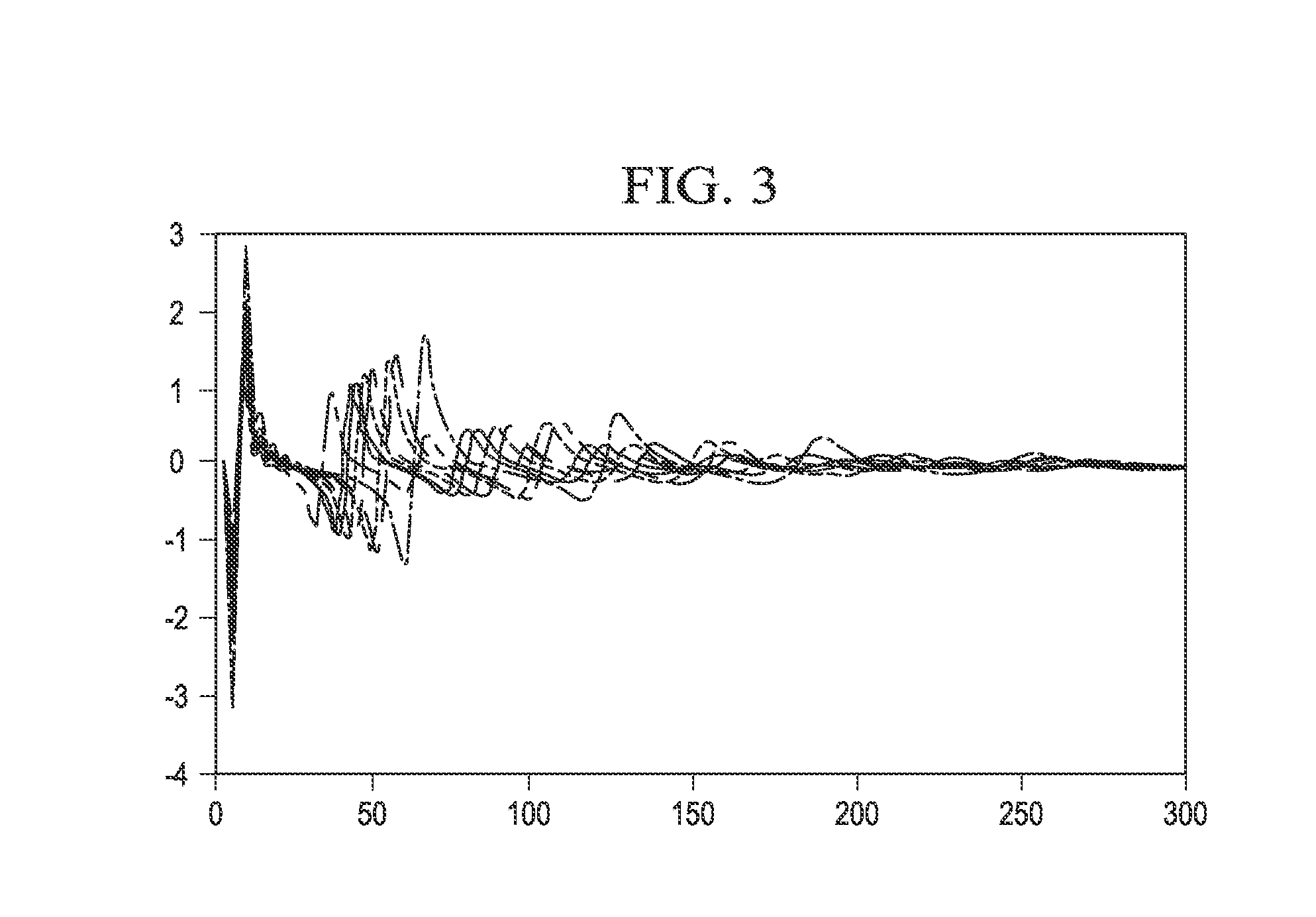

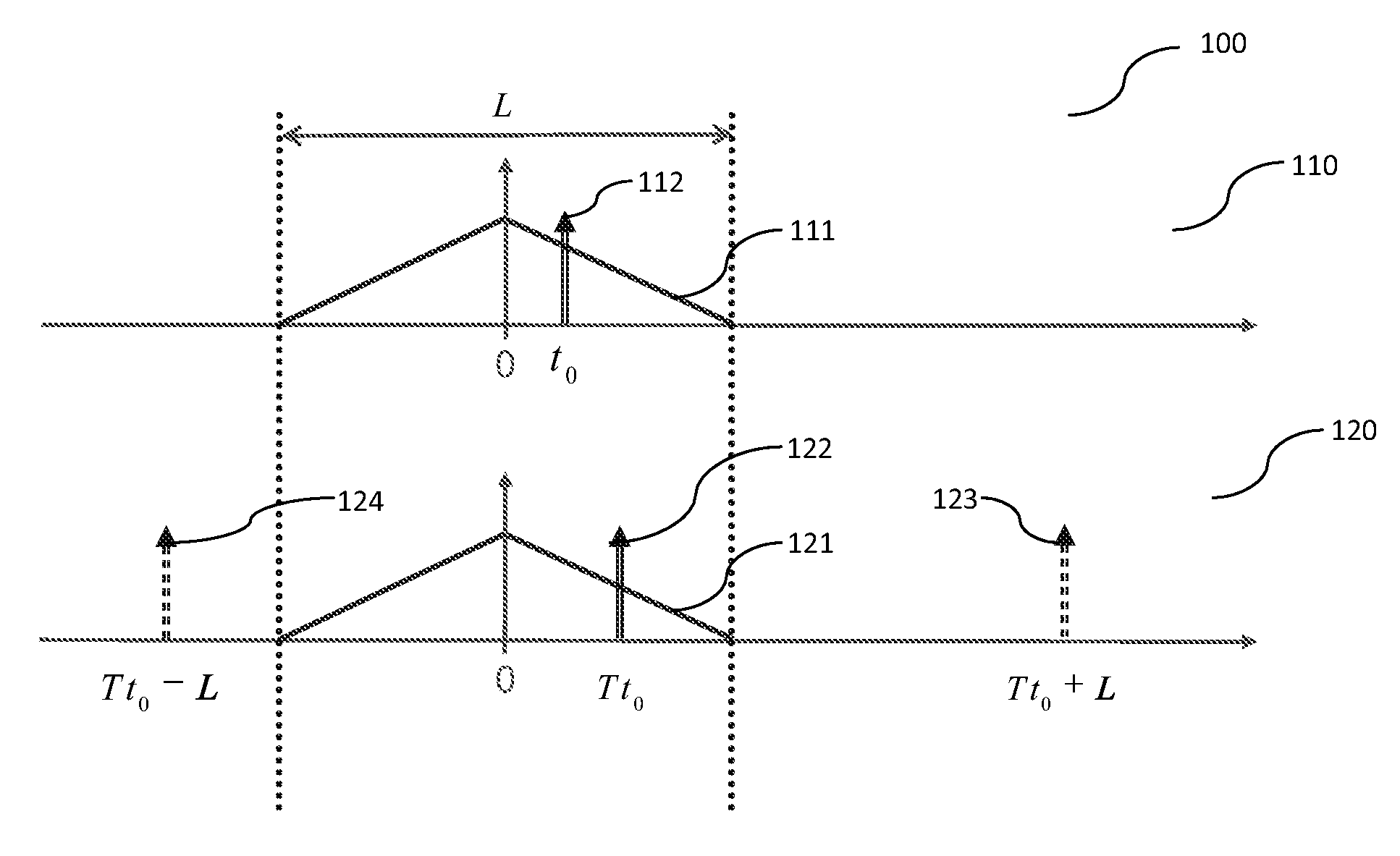

Seismic acquisition method and system

ActiveUS20120147701A1Reduce impactReduce outputSeismic data acquisitionSeismic energy generationImaging qualityBiological activation

The maximum output of a seismic source array may be reduced by activating the individual seismic sources within these seismic source array in a pattern that is extended in time rather than by the presently employed conventional simultaneous activation of a large number of individual seismic sources. Methods are disclosed which take data shot with patterned sources and may use a sparse inversion method to create data with the about same image quality as that of conventional sources. In this manner the output of the maximum impulse of a seismic source array may be reduced by an amplitude factor of about 10 in the examples shown here, corresponding to a reduction of about 20 dB while maintaining virtually the same seismic image quality. The disclosed methods may be used in combination with any simultaneous sourcing technique. In addition, the disclosed methods may be used with a plurality of source arrays.

Owner:BP CORP NORTH AMERICA INC

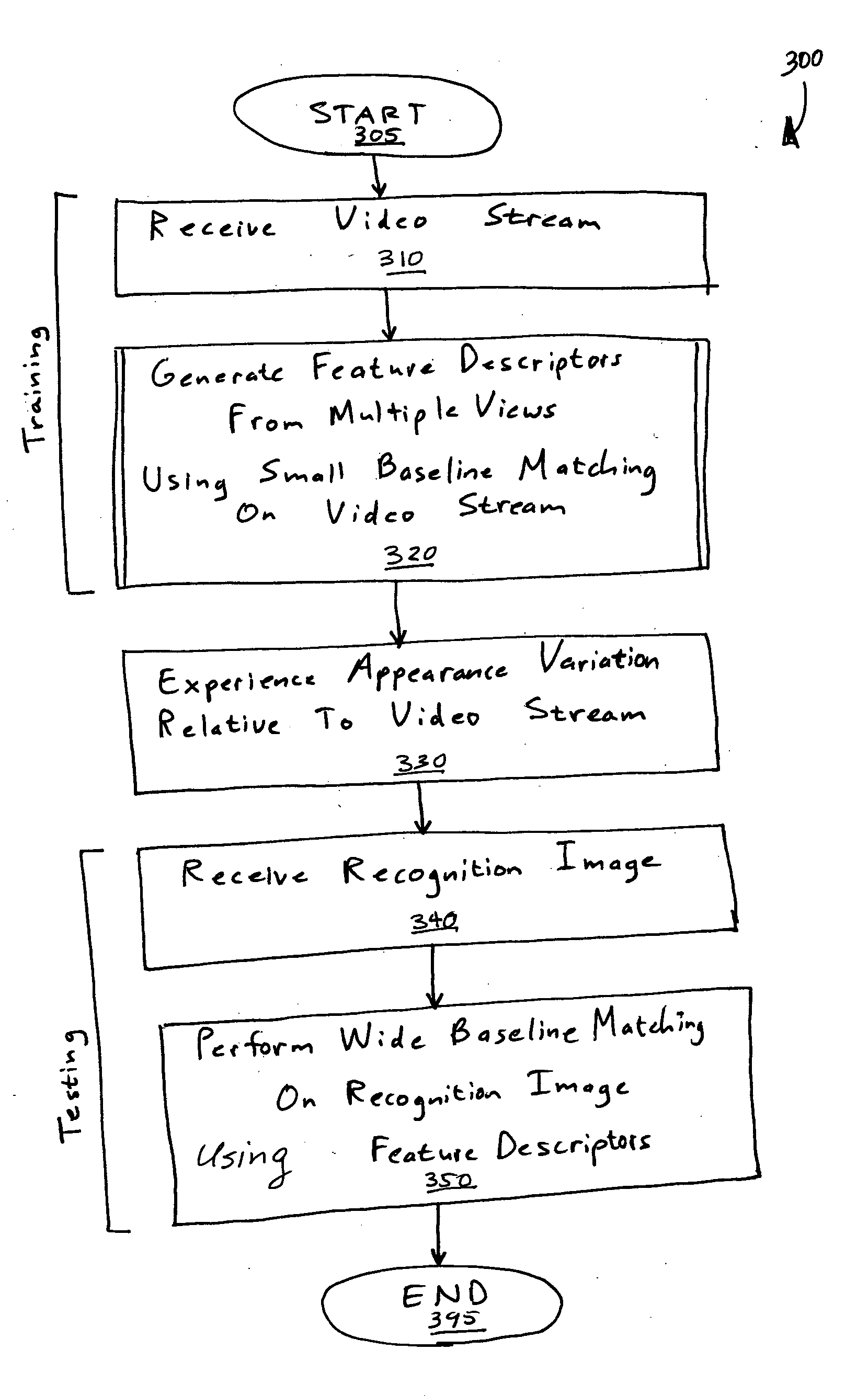

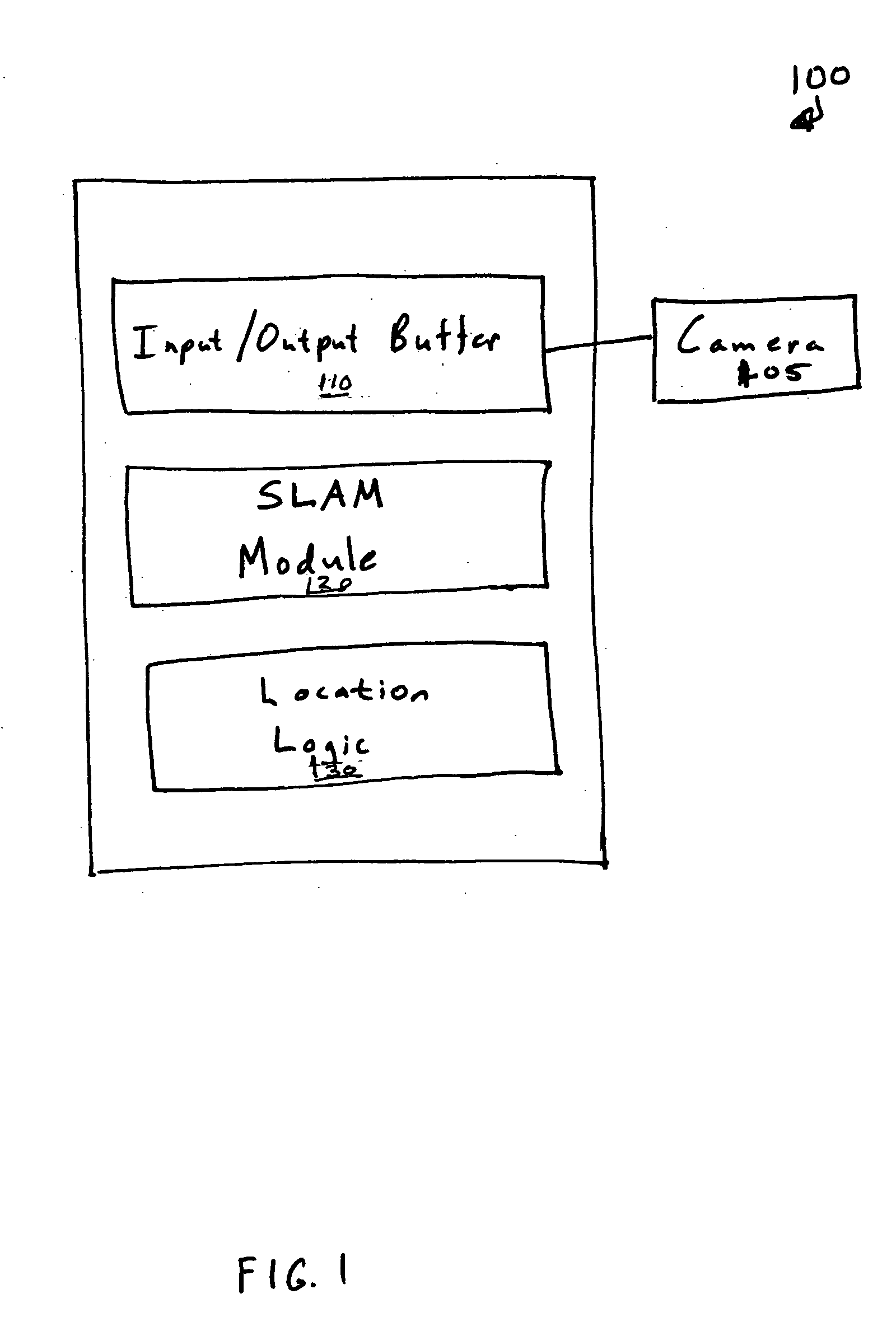

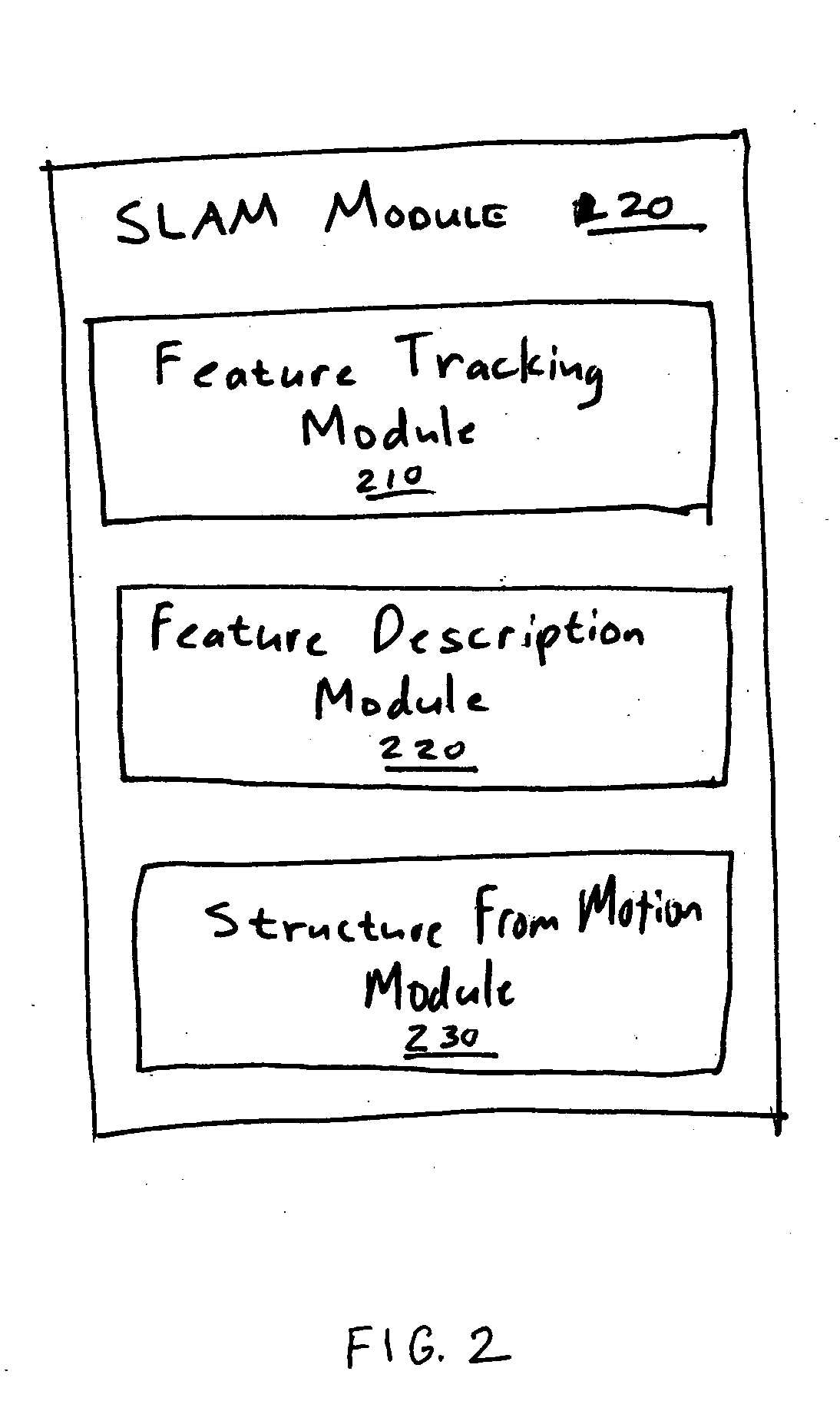

Simultaneous localization and mapping using multiple view feature descriptors

InactiveUS20050238200A1Efficiently build necessary feature descriptorReliable correspondenceThree-dimensional object recognitionKaiman filterKernel principal component analysis

Simultaneous localization and mapping (SLAM) utilizes multiple view feature descriptors to robustly determine location despite appearance changes that would stifle conventional systems. A SLAM algorithm generates a feature descriptor for a scene from different perspectives using kernel principal component analysis (KPCA). When the SLAM module subsequently receives a recognition image after a wide baseline change, it can refer to correspondences from the feature descriptor to continue map building and / or determine location. Appearance variations can result from, for example, a change in illumination, partial occlusion, a change in scale, a change in orientation, change in distance, warping, and the like. After an appearance variation, a structure-from-motion module uses feature descriptors to reorient itself and continue map building using an extended Kalman Filter. Through the use of a database of comprehensive feature descriptors, the SLAM module is also able to refine a position estimation despite appearance variations.

Owner:HONDA MOTOR CO LTD

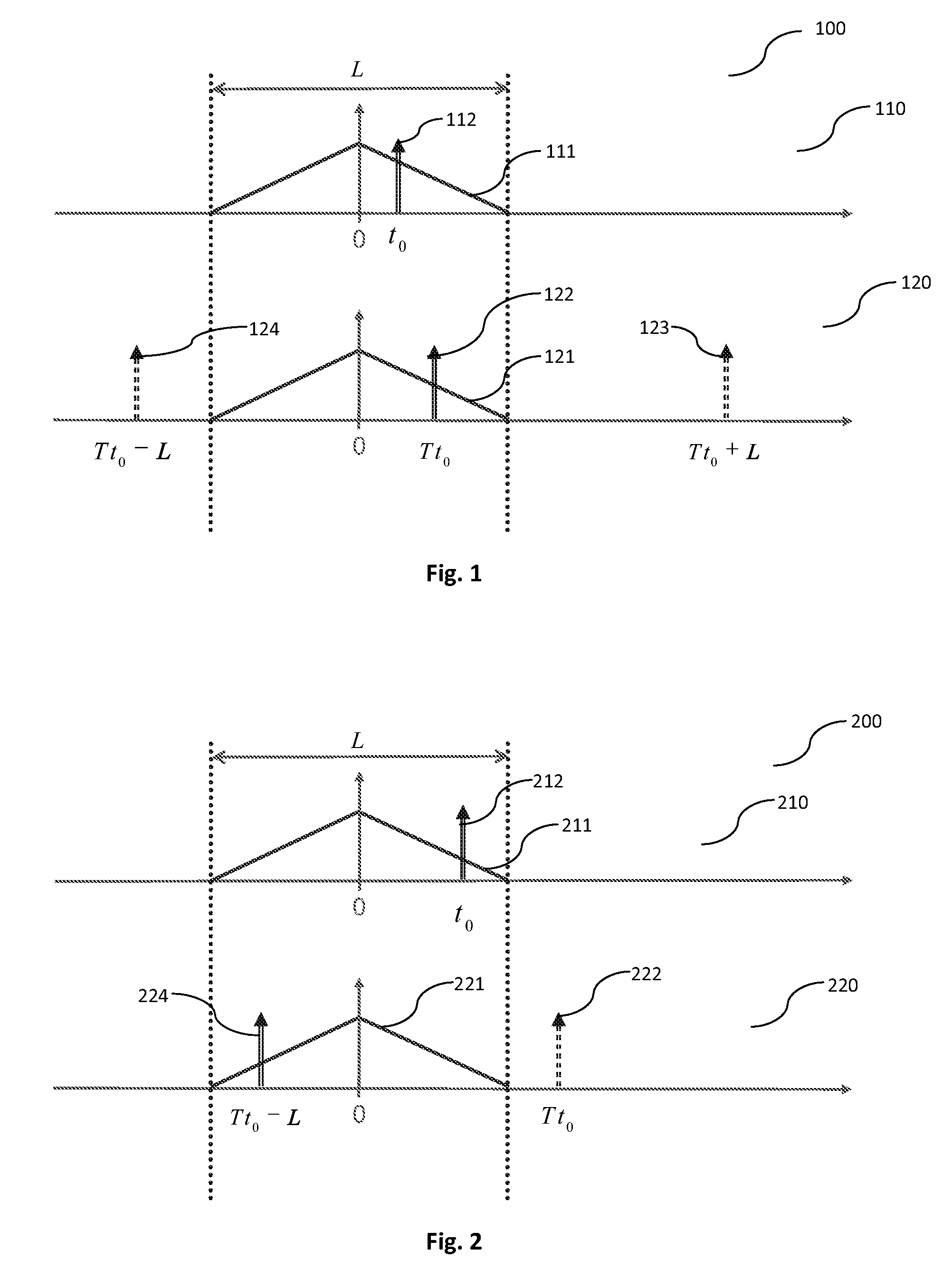

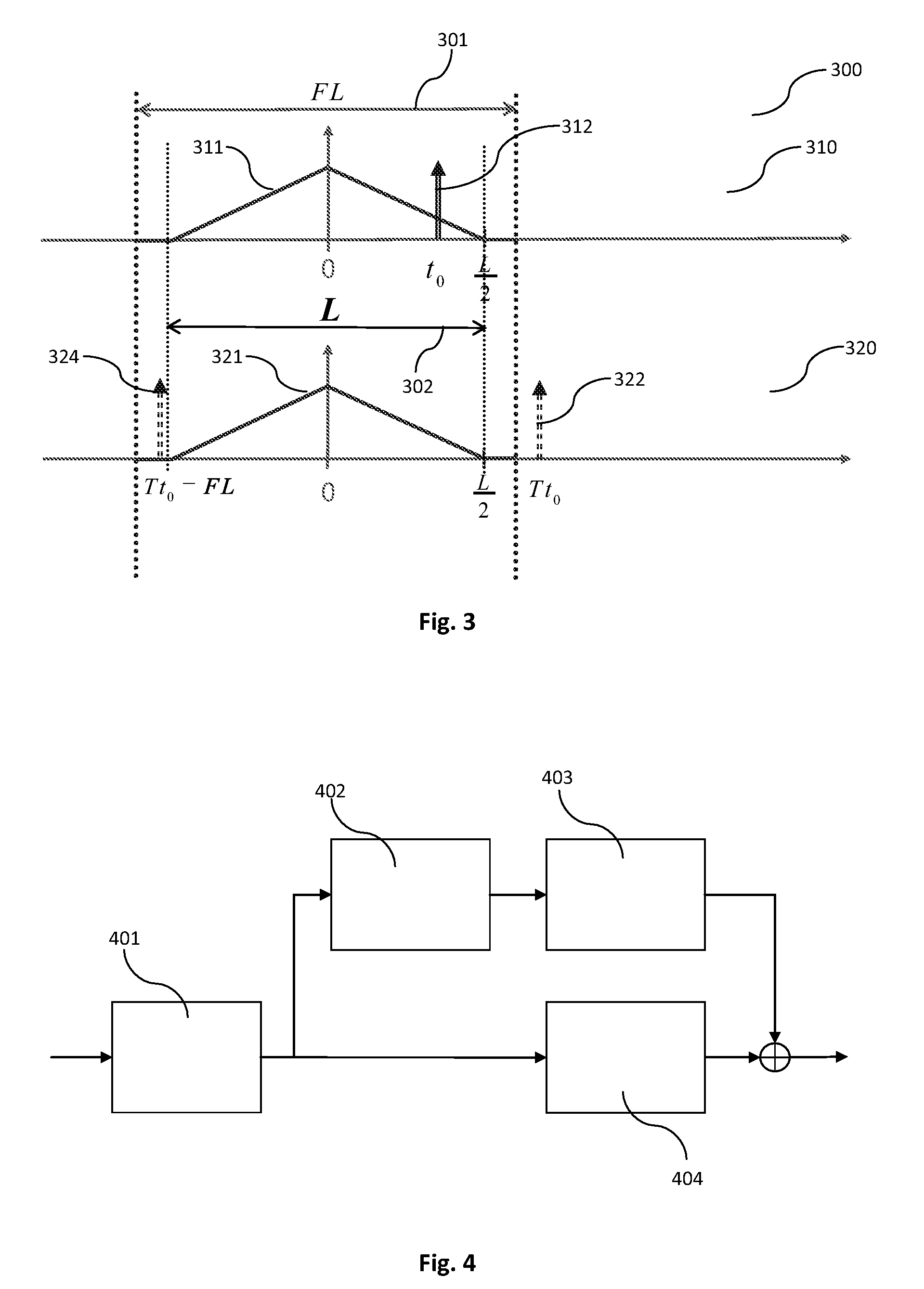

Harmonic transposition

ActiveUS20110004479A1Improved transient performanceReduce outputSpeech analysisAudio signalFrequency domain

Owner:DOLBY INT AB

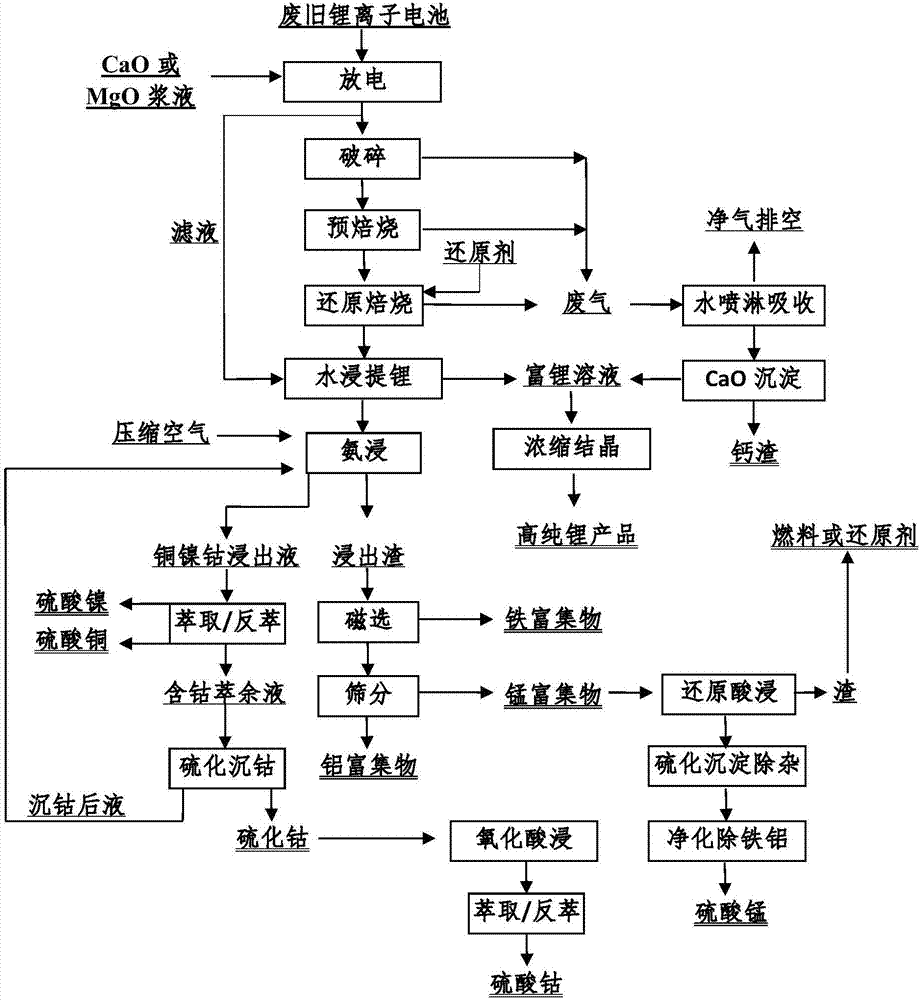

Method for comprehensively recycling valuable metals from spent lithium ion battery

ActiveCN107017443AThe pre-processing process is simpleHigh recovery rateWaste accumulators reclaimingProcess efficiency improvementVulcanizationSlag

The invention discloses a method for comprehensively recycling valuable metals from a spent lithium ion battery. The method comprises the following steps: carrying out electric discharge treatment on a spent battery, crushing, pre-roasting at 300-400 DEG C, adding a reducing agent, and carrying out reduction roasting at 450-700 DEG C; carrying out water extraction and evaporative crystallization on fine aggregates obtained through the reduction roasting, so as to obtain a high-purity lithium product, leaching copper, nickel and cobalt from leached slag and roasted lump materials by virtue of ammonia oxide, carrying out magnetic separation and sieving on ammonia leaching slag so as to obtain iron and aluminum enriched products, and carrying out reduction acid leaching, purification and edulcoration on sieved products, so as to obtain a high-purity manganese sulfate solution; and carrying out extraction and selective reverse extraction on ammonia leaching liquid, so as to obtain a high-purity nickel sulfate solution and a high-purity copper sulfate solution, and carrying out vulcanization cobalt precipitation, oxidation acid leaching and extraction purification on raffinate, so as to obtain a high-purity cobalt sulfate solution. The method is high in extraction rate of valuable metals and applicable to the treatment of multiple waste lithium ion battery raw materials and efficient utilization of multiple elements, and sorting is not required.

Owner:GUANGDONG GUANGHUA SCI TECH

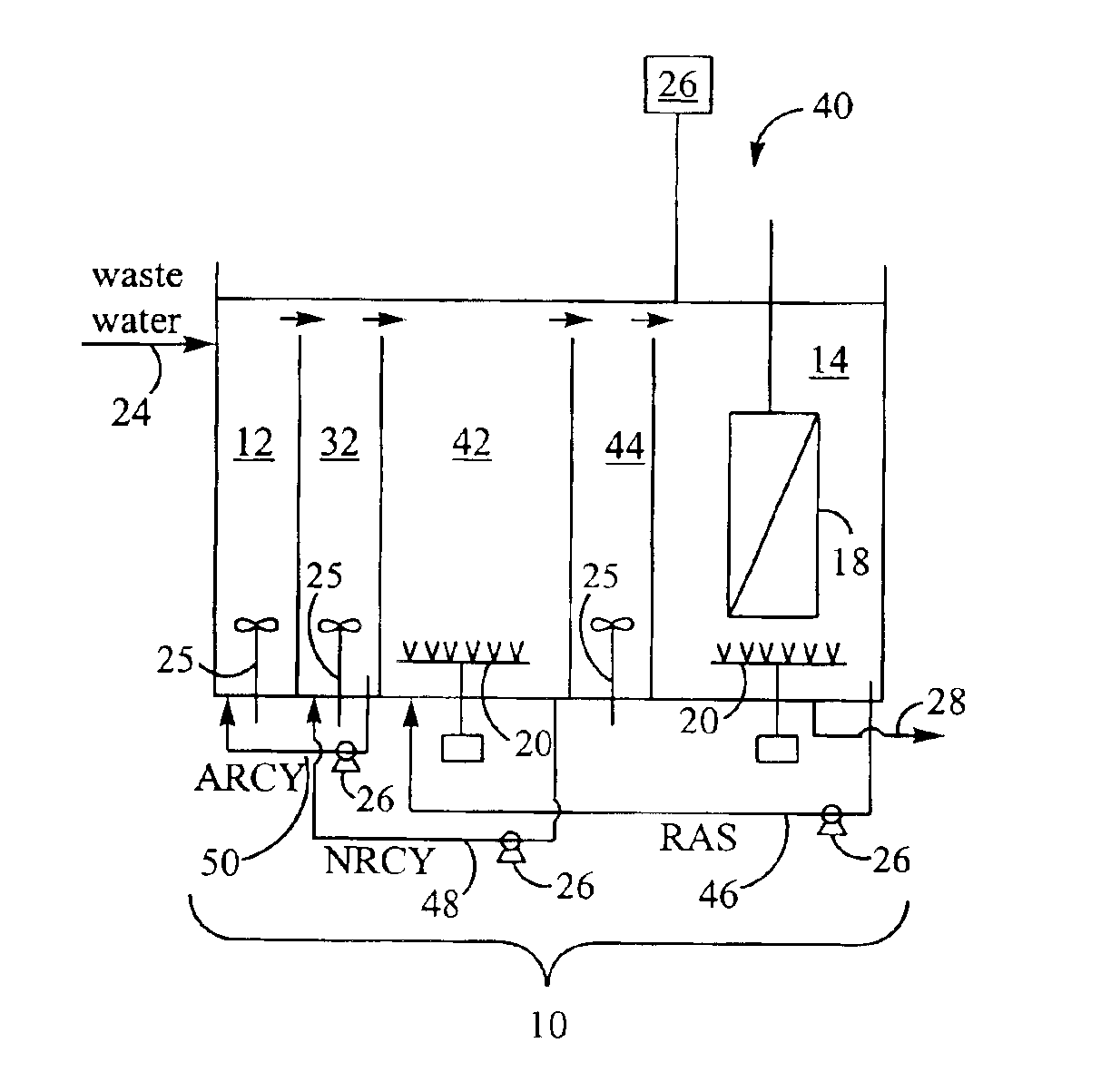

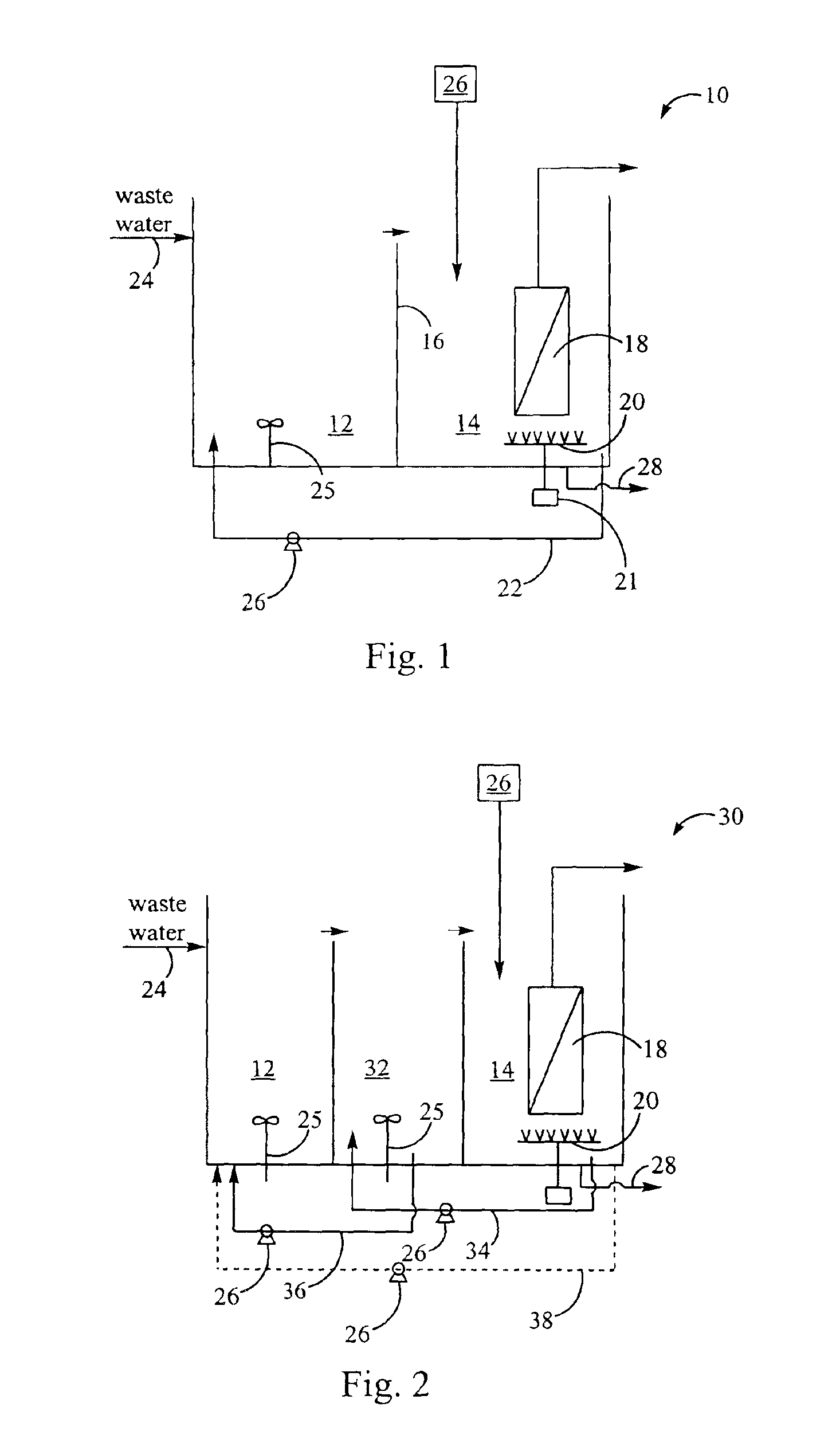

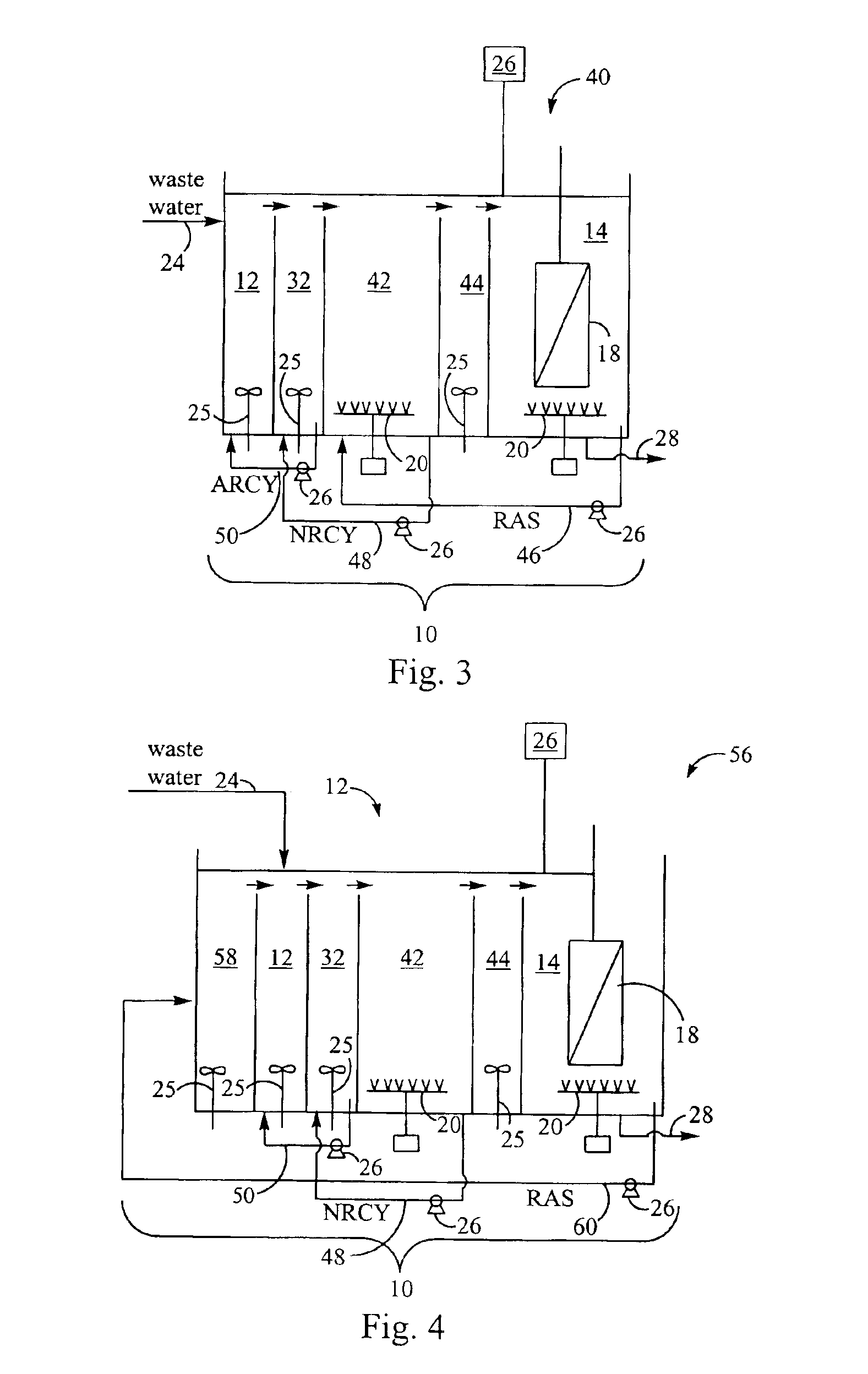

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

InactiveUS6946073B2Reduce outputPromoting robust nutrient uptakeTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

Thermally assisted magnetic recording head and magnetic recording apparatus

InactiveUS20080204916A1Coupling efficiency is improvedOptical power in fluctuatesDriving/moving recording headsRecord information storageHeat-assisted magnetic recordingPhotodetector

A second waveguide is formed near a first waveguide for guiding light to the vicinity of a main pole of a thermally assisted magnetic recording head, and a portion of light propagated through the waveguide 1 is branched to the second waveguide. The light transmitting in the second waveguide is detected by a photodetector to detect an intensity of the light propagated through the first waveguide. In the magnetic recording apparatus, an intensity of a semiconductor laser is decreased when an amount of light incident to the photodetector is large and the intensity of the semiconductor laser is increased when the amount of light incident to the photodetector is small. By constituting a feedback loop as described above, the intensity of the light propagated through the first waveguide is kept constant.

Owner:HITACHI LTD

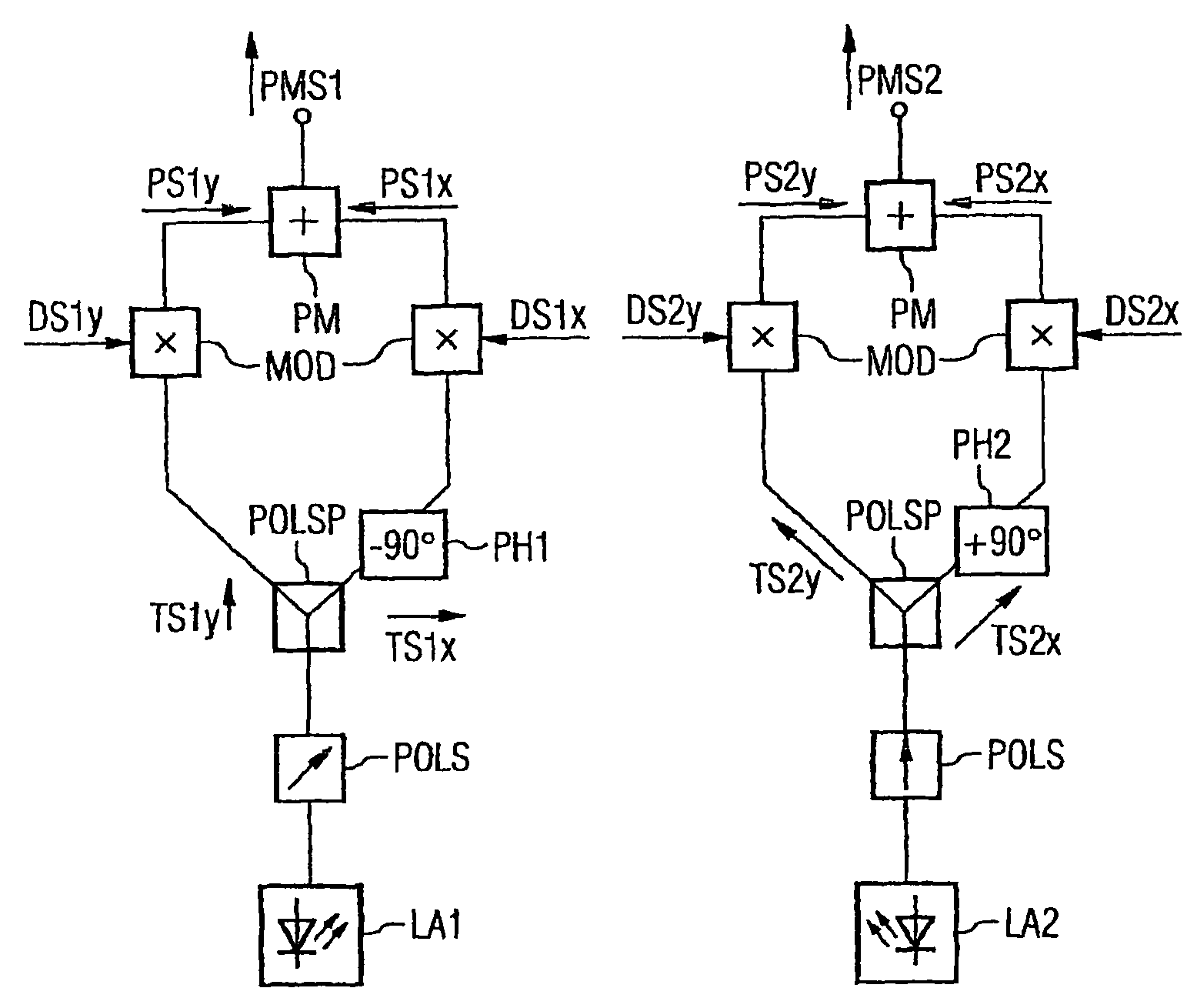

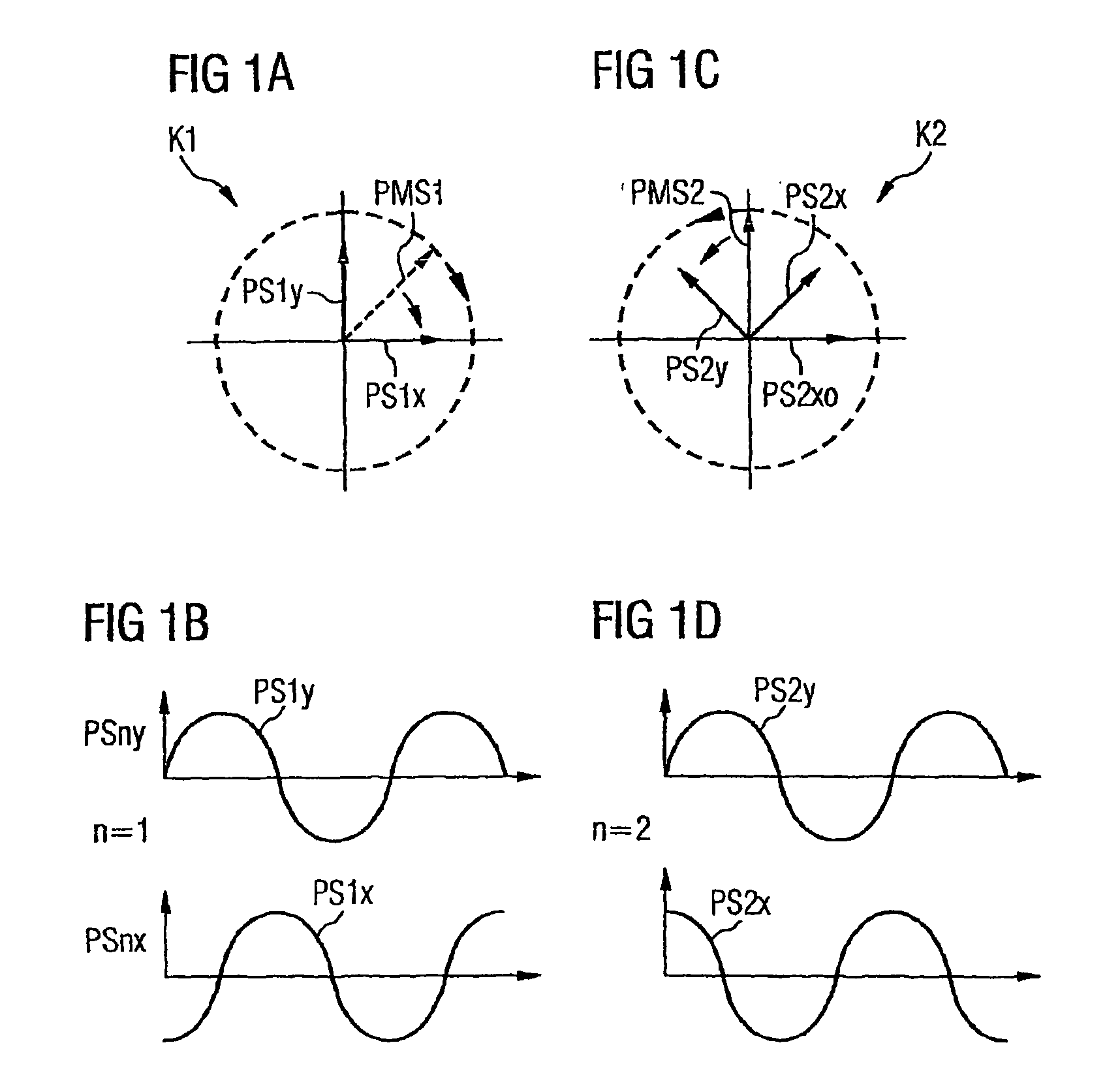

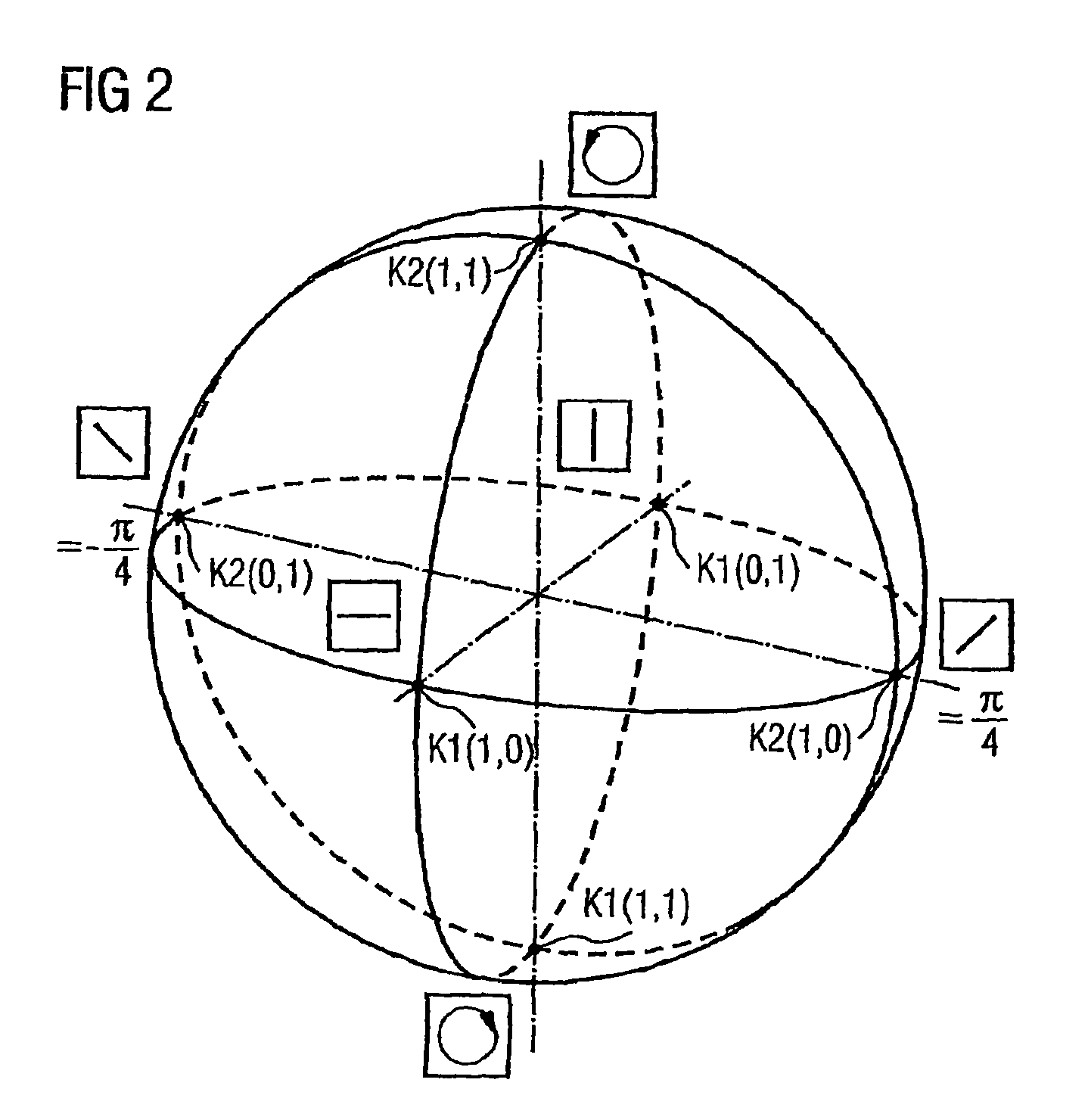

Methods for the optical transmission of polarization multiplex signals

InactiveUS7865080B2Reduce interactionStrong mutual interferencePolarisation multiplex systemsWavelength-division multiplex systemsPhysicsPolarization plane

In order to reduce mutual interferences between POLMUX and signals, the signals are transmitted with differed to each other carrying signals, thereby making it possible to obtain the circular polarization of each resulting POLMUX signal. Each second POLMUX signal is transmissible with an opposite circular polarization. In order to reduce also interferences when only one modulated data signal is transmitted through a POLMUX channel, a polarization plane of modulated data signals of each second POLMUX channel is turned at 45°. In a variant, polarization multiplex signals are produces and the resulting polarizations thereof in adjacent channels are perpendicular to each other.

Owner:XIEON NETWORKS SARL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com