Patents

Literature

4641 results about "Treated water" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Treated water is any type of hydrogen dioxide H 2O) that undergoes processing to serve a specific end use. The water treatment process involves either the subtraction of components from the water, the addition of components to the water, or both. There is more than one way to produce treated water.

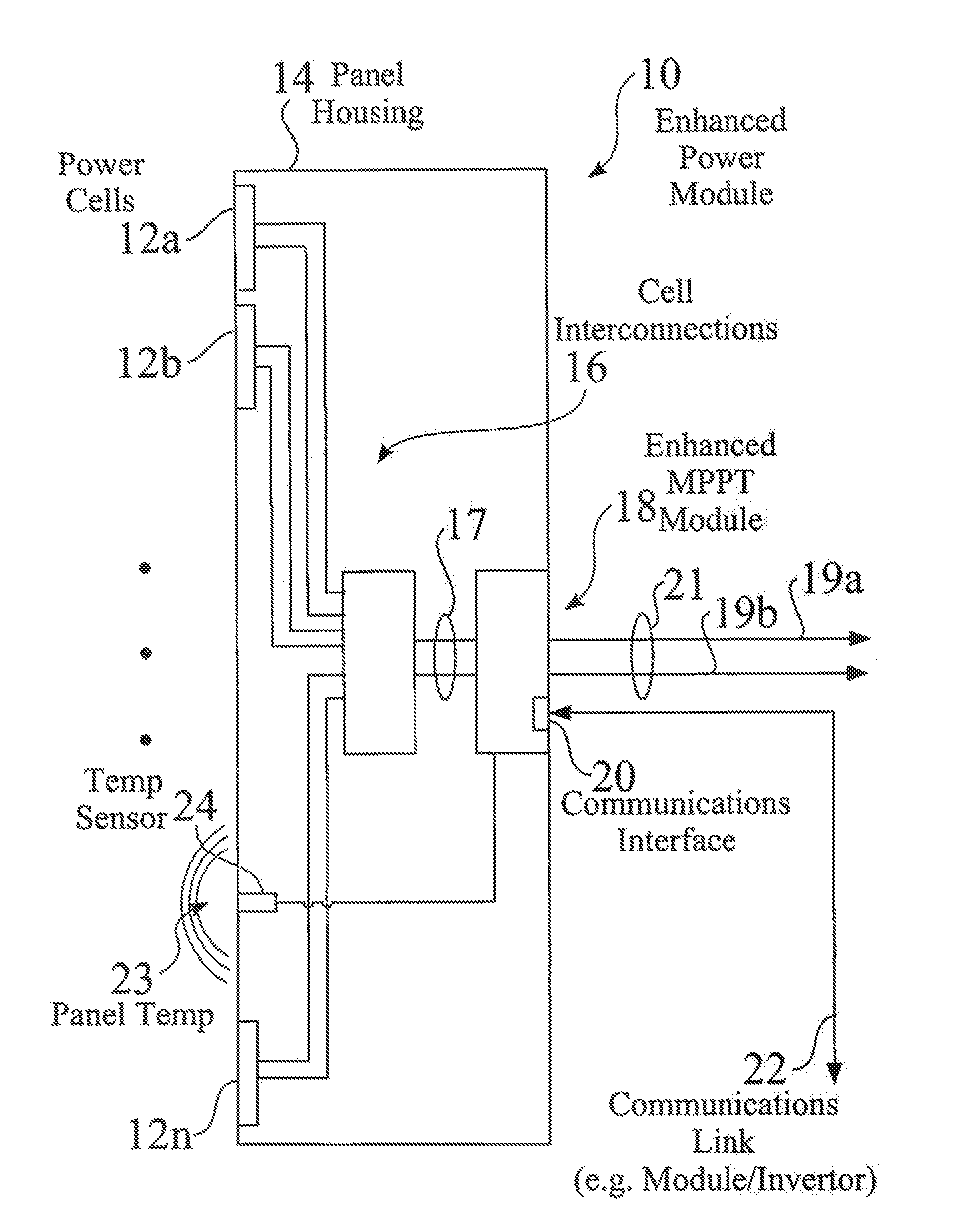

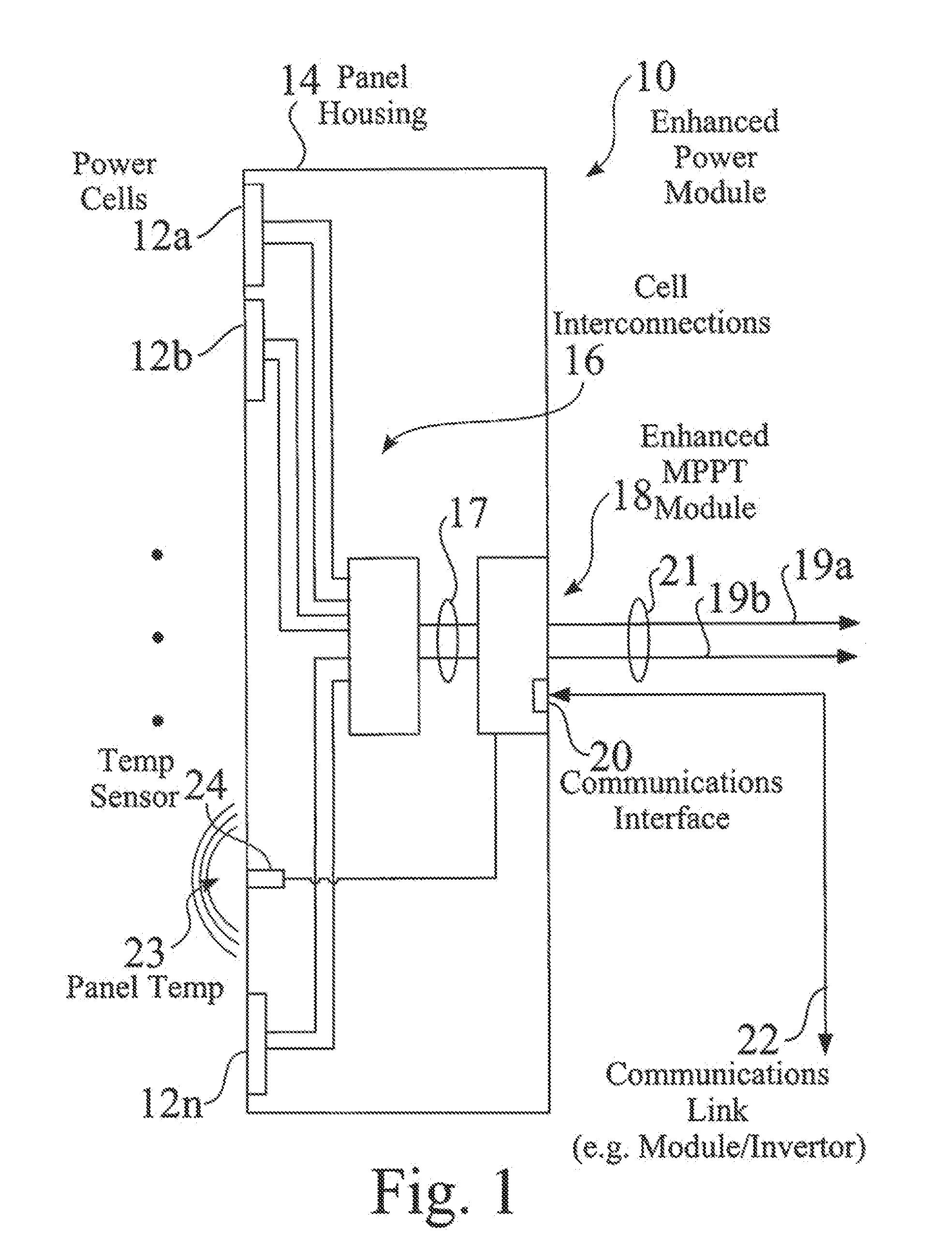

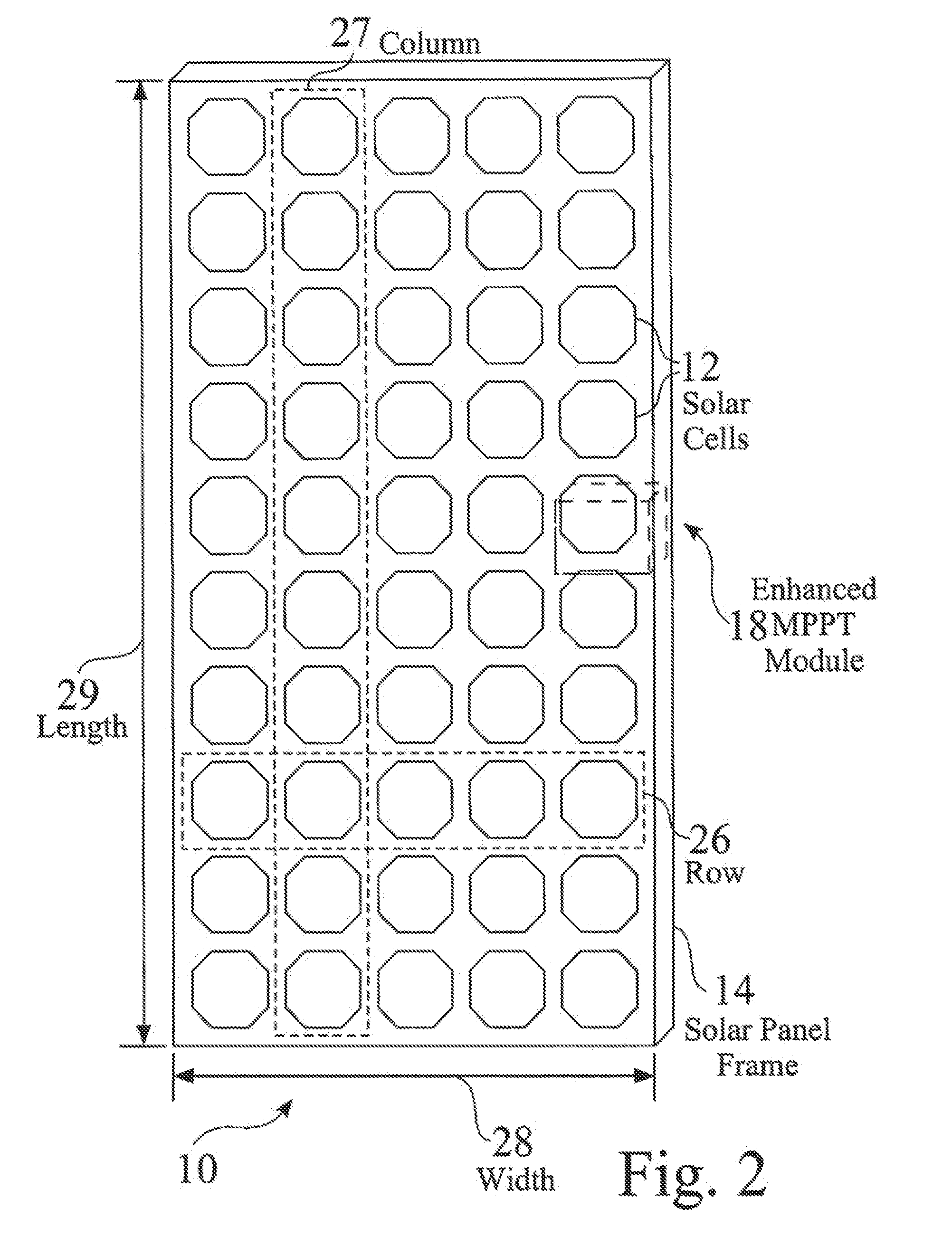

Enhanced solar panels, liquid delivery systems and associated processes for solar energy systems

ActiveUS20120138123A1Avoid accumulationReduce lossesSolar heating energyPhotovoltaic monitoringControl systemFiltration

Fluid delivery systems and related structures and processes are provided, such as for use with water, treated water, and / or a cleaning solution, for any of cleaning, cooling or any combination thereof, for one or more solar panels in a power generation environment. Enhanced coatings are provided for the incident surface of solar panels, such as to avoid build up of dirt, scale, or other contaminants, and / or to improve cleaning performance. Reclamation, filtration, and reuse structures are preferably provided for the delivered fluid, and seal structures may preferably be implemented between adjoining panels, to minimize loss of the delivered water or cleaning solution. The fluid delivery system may preferably be linked to an automated control system, such as but not limited to integrated DMPPT modules and related systems.

Owner:ACCURATE SOLAR POWER LLC

Process for production of steviosides from stevia rebaudiana bertoni

A process for the production of steviosides from Stevia rebaudiana Bertoni includes extraction of comminuted plant material by directly injecting steam into the extractor followed by filtration to get aqueous extract and alkali treatment to remove unwanted compounds in the form of precipitate. The treated aqueous extracted was filtered and the filtrate was first treated with gel or macroporous strong acid cation exchange resin and then with gel or macroporous weak base anion exchange resin. The aqueous eluant containing steviosides was concentrated to obtain purified steviosides.

Owner:COUNCIL OF SCI & IND RES

Water treatment system and method

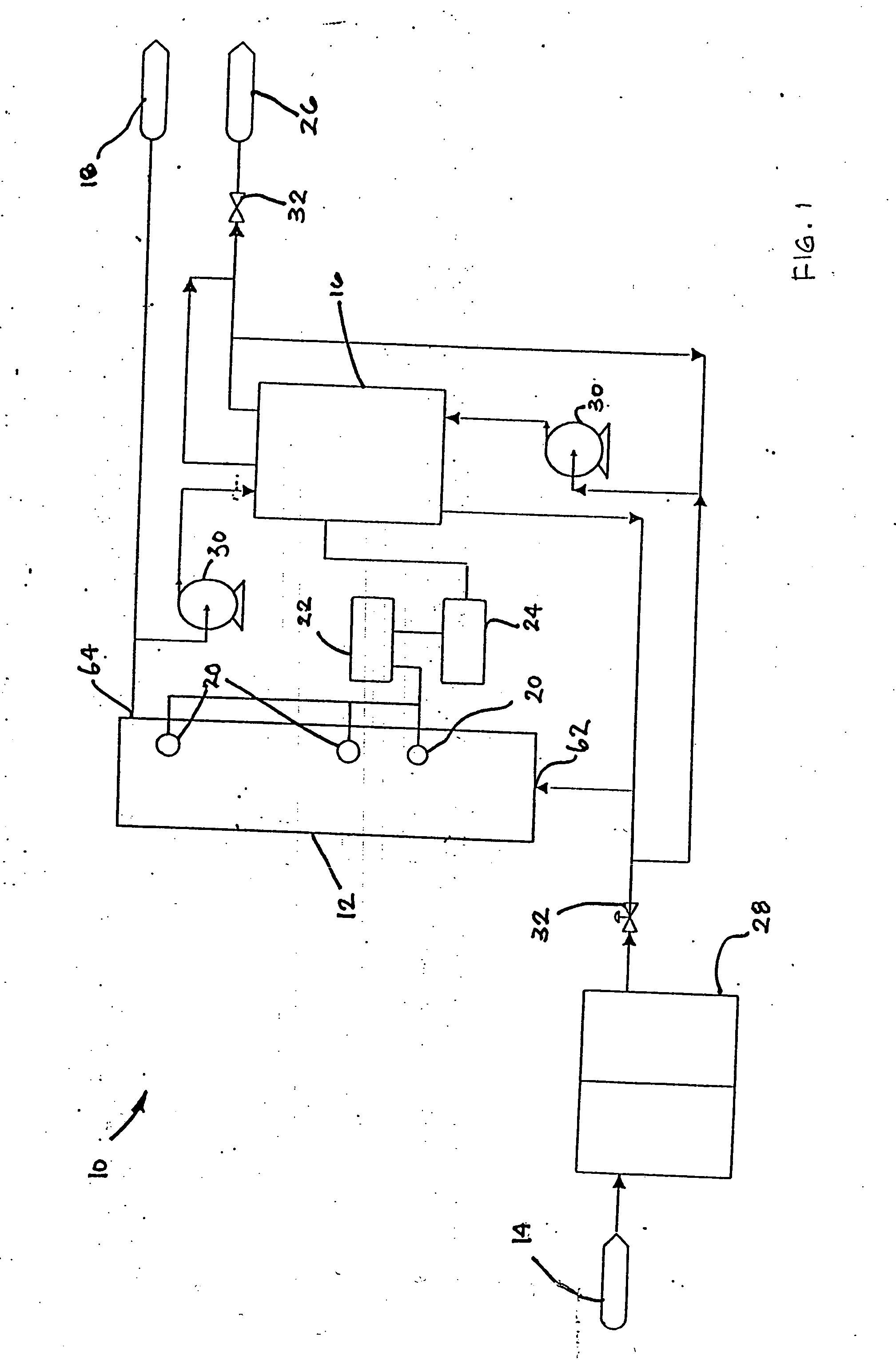

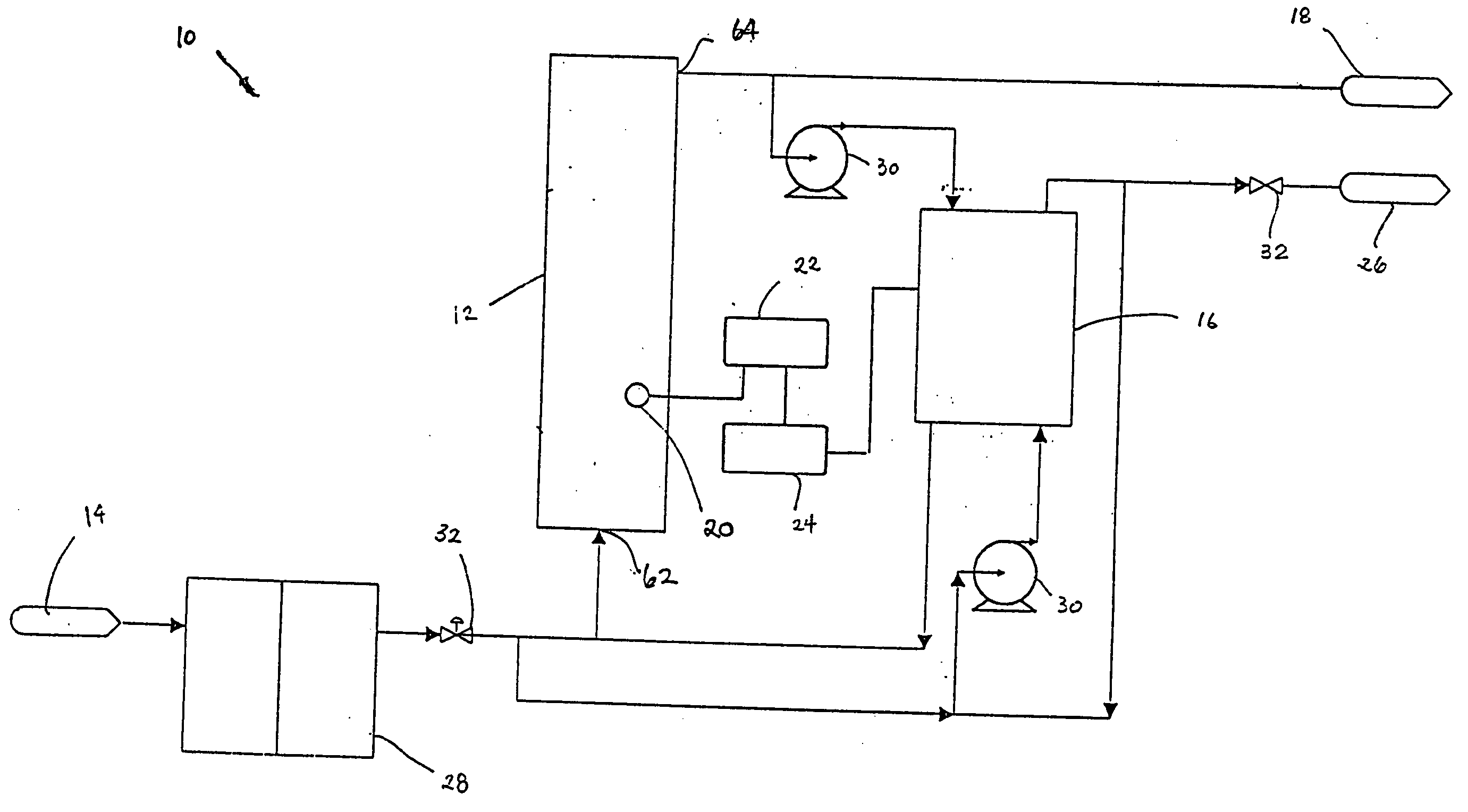

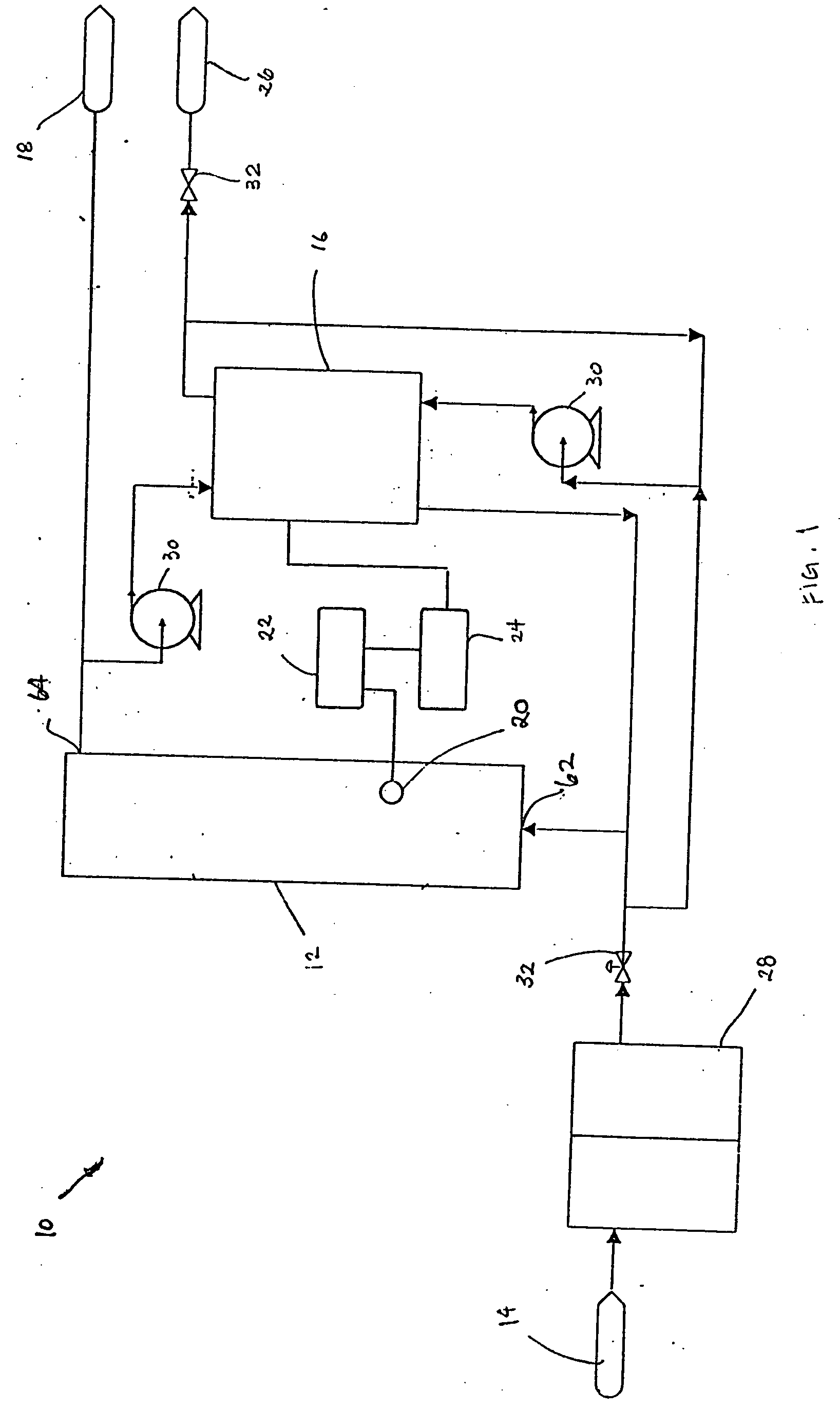

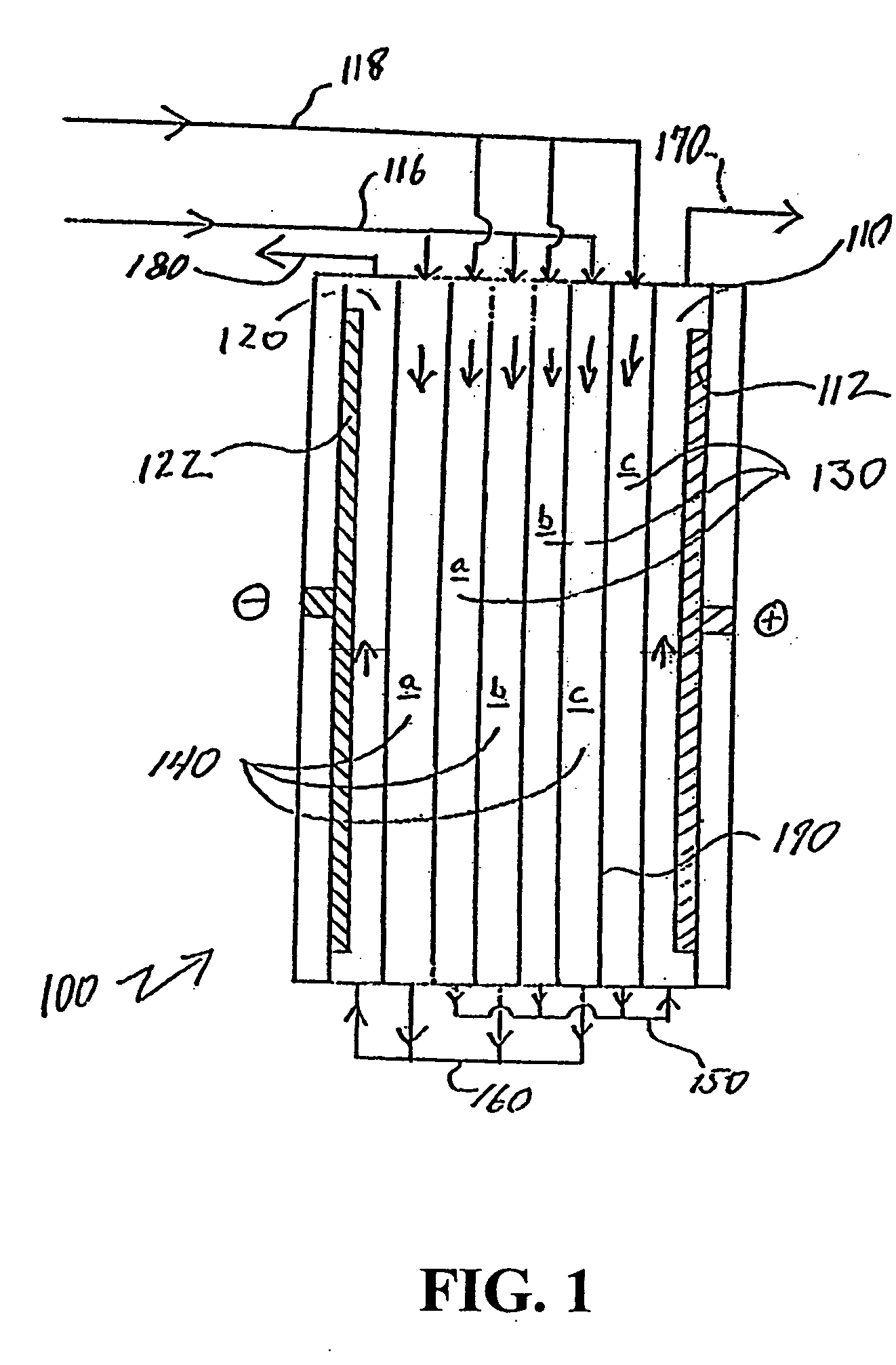

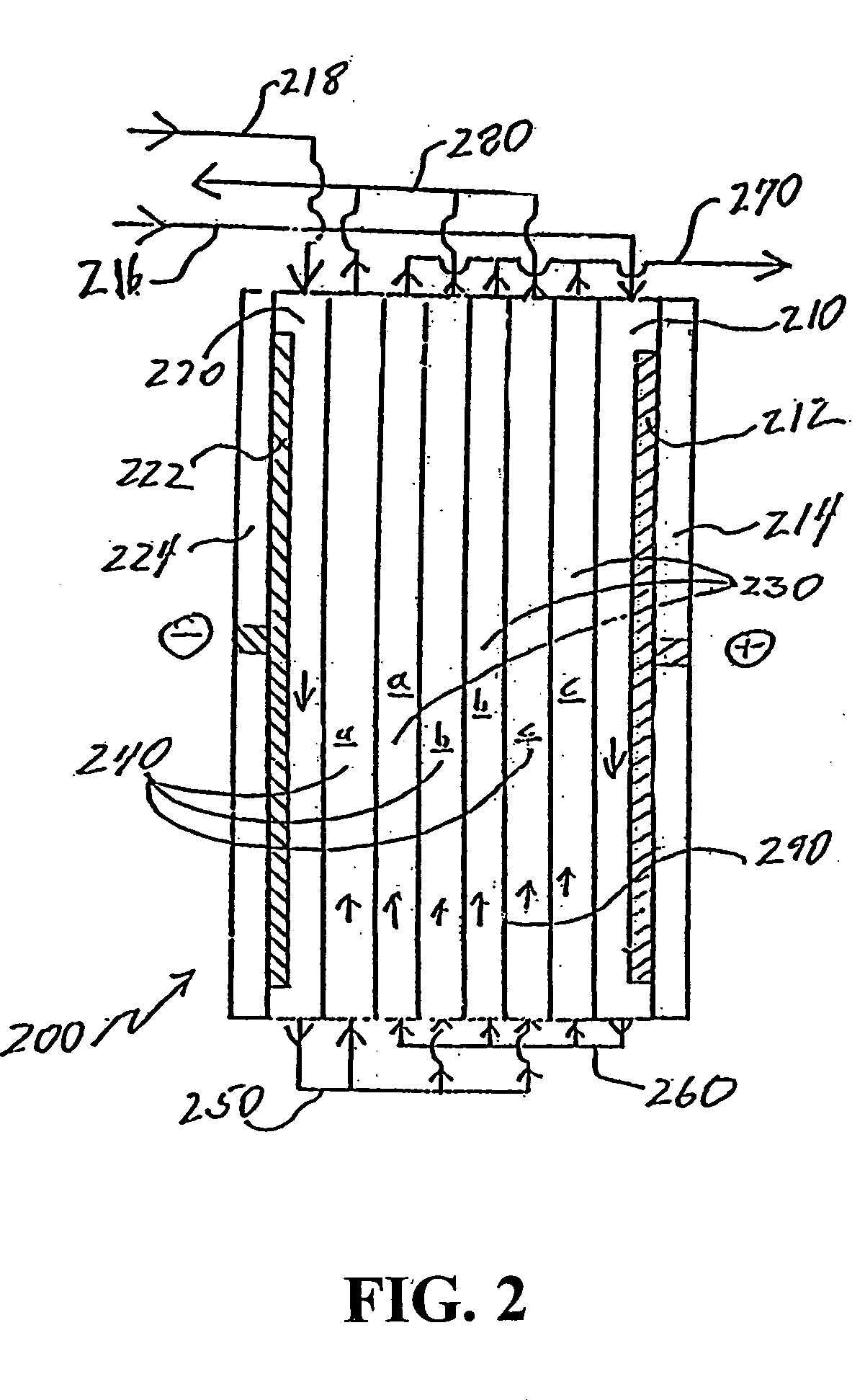

ActiveUS20050103722A1Water treatment parameter controlIon-exchange column/bed processesWater treatment systemWater source

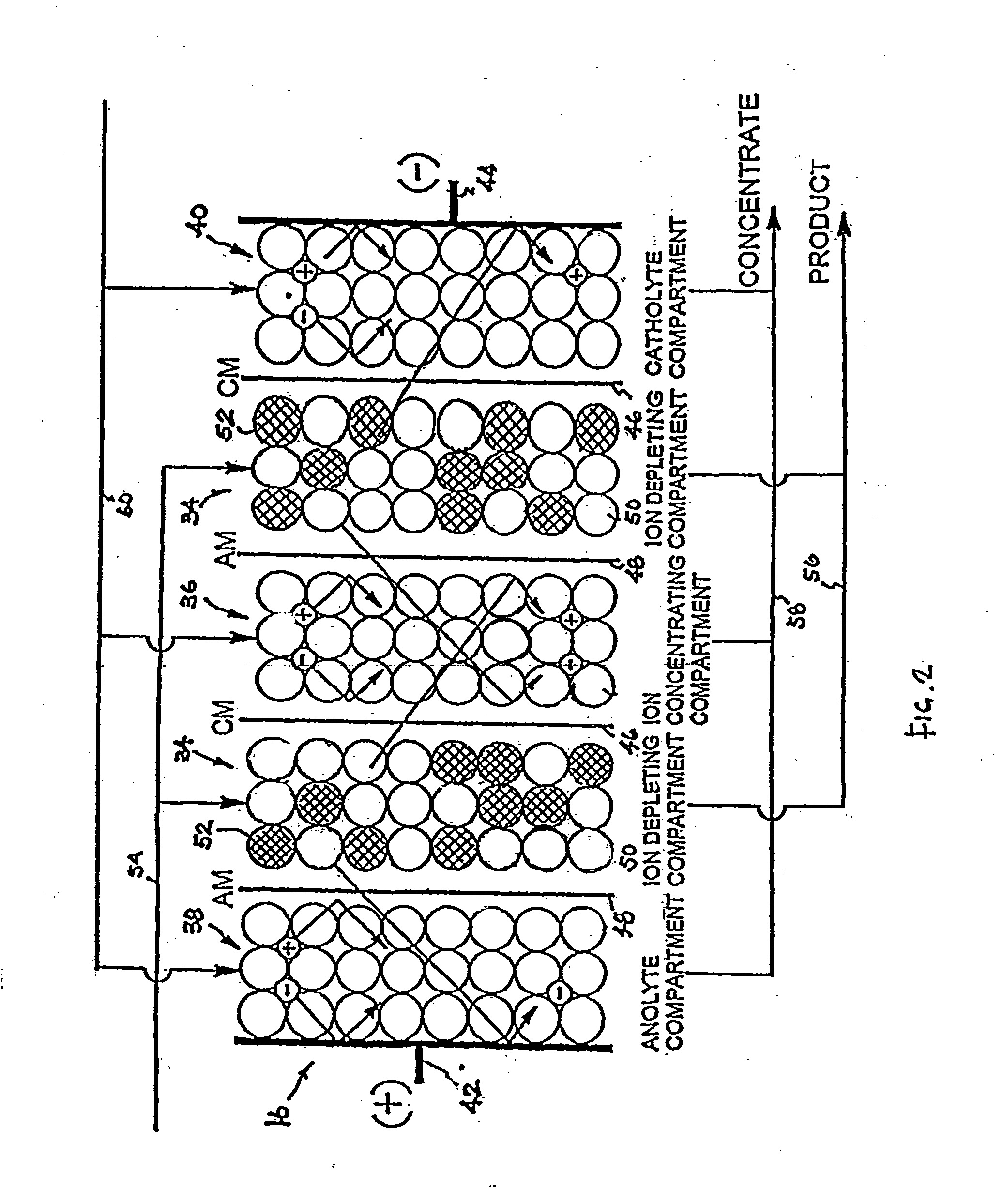

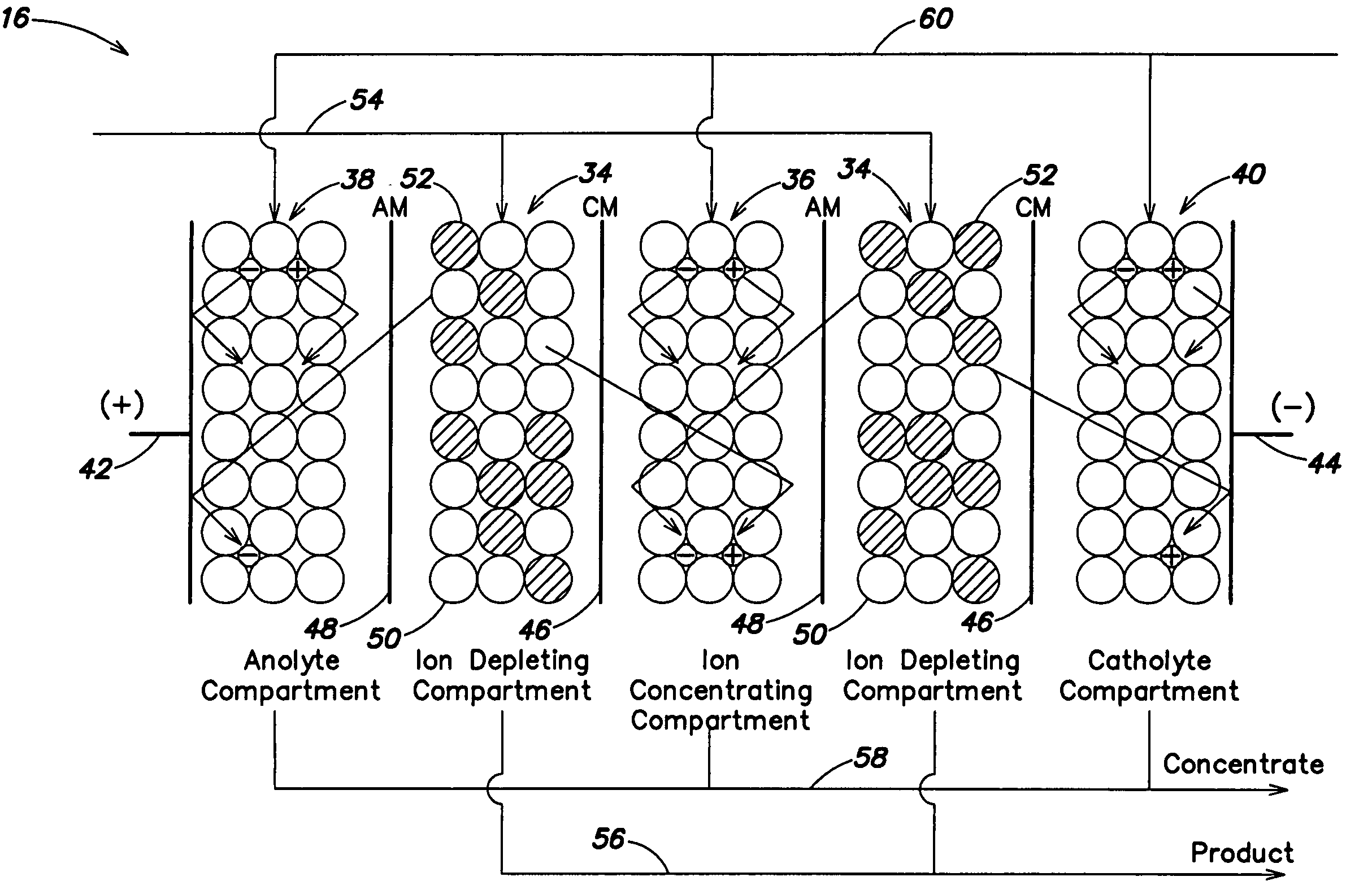

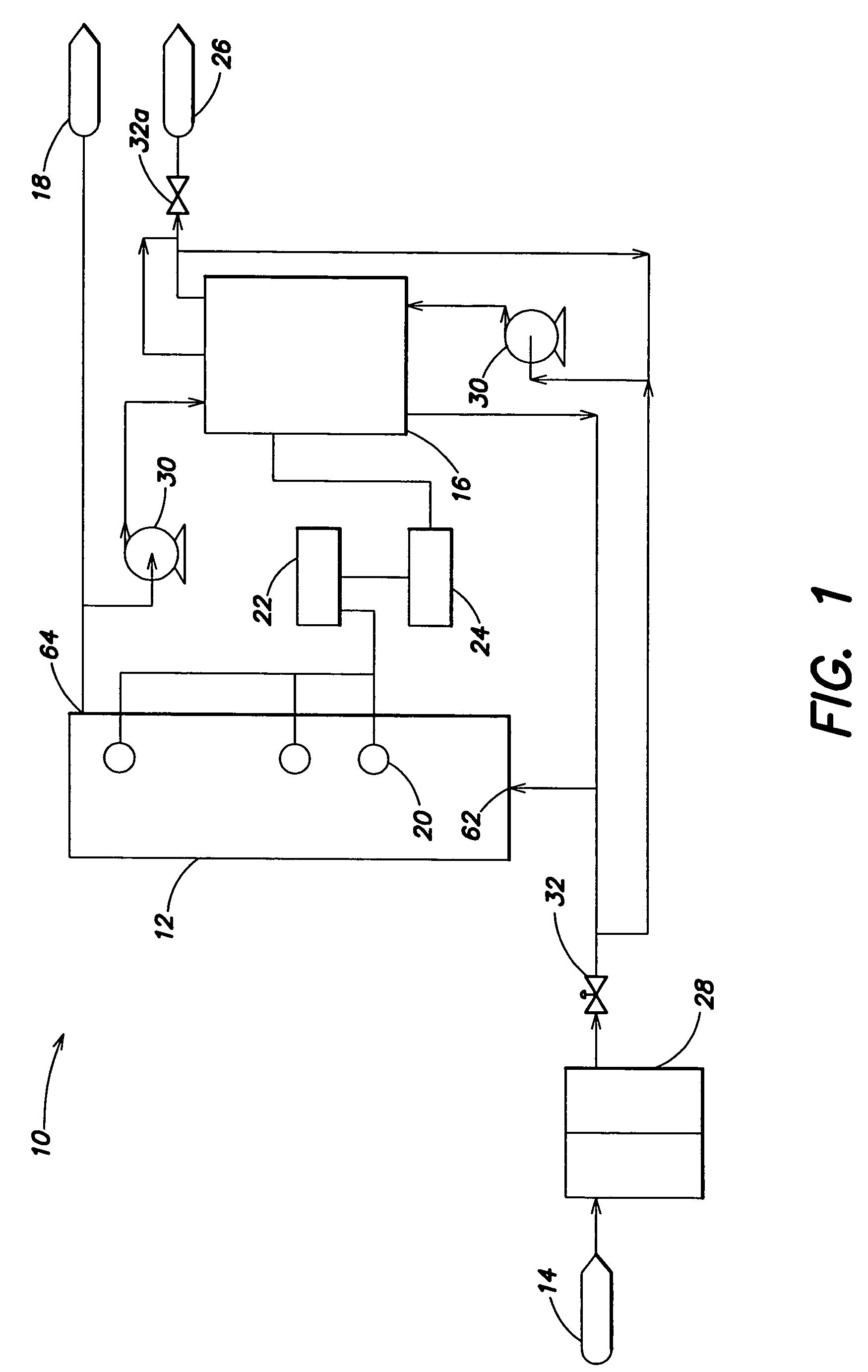

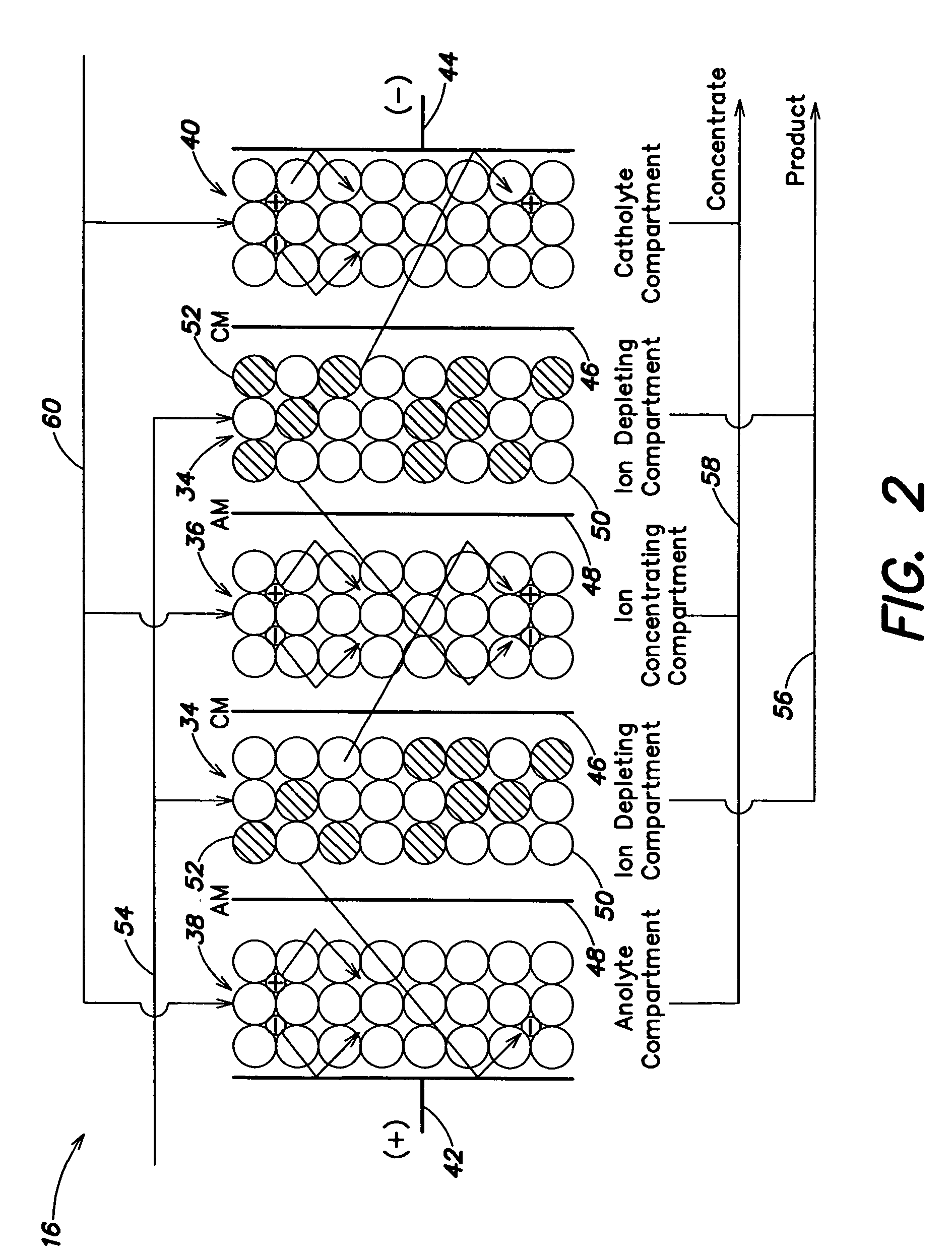

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point of entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system has a sensor or a set of sensors for measuring at least one property of the water or an operating condition of the treatment system. The water treatment system also has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system to supply water tailored to quality requirements.

Owner:EVOQUA WATER TECH LLC

Water treatment system and method

InactiveUS20050103717A1Water treatment parameter controlWater/sewage treatment by electrochemical methodsElectricityWater treatment system

A water treatment system provides treated water to a point of use by removing at least a portion of any hardness-causing species contained in water from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically receives water from the water source or a point of entry and purifies the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a pressurized reservoir system in line with an electrochemical device such as an electrodeionization device. The water treatment system can have a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system.

Owner:SIEMENS WATER TECH HLDG CORP

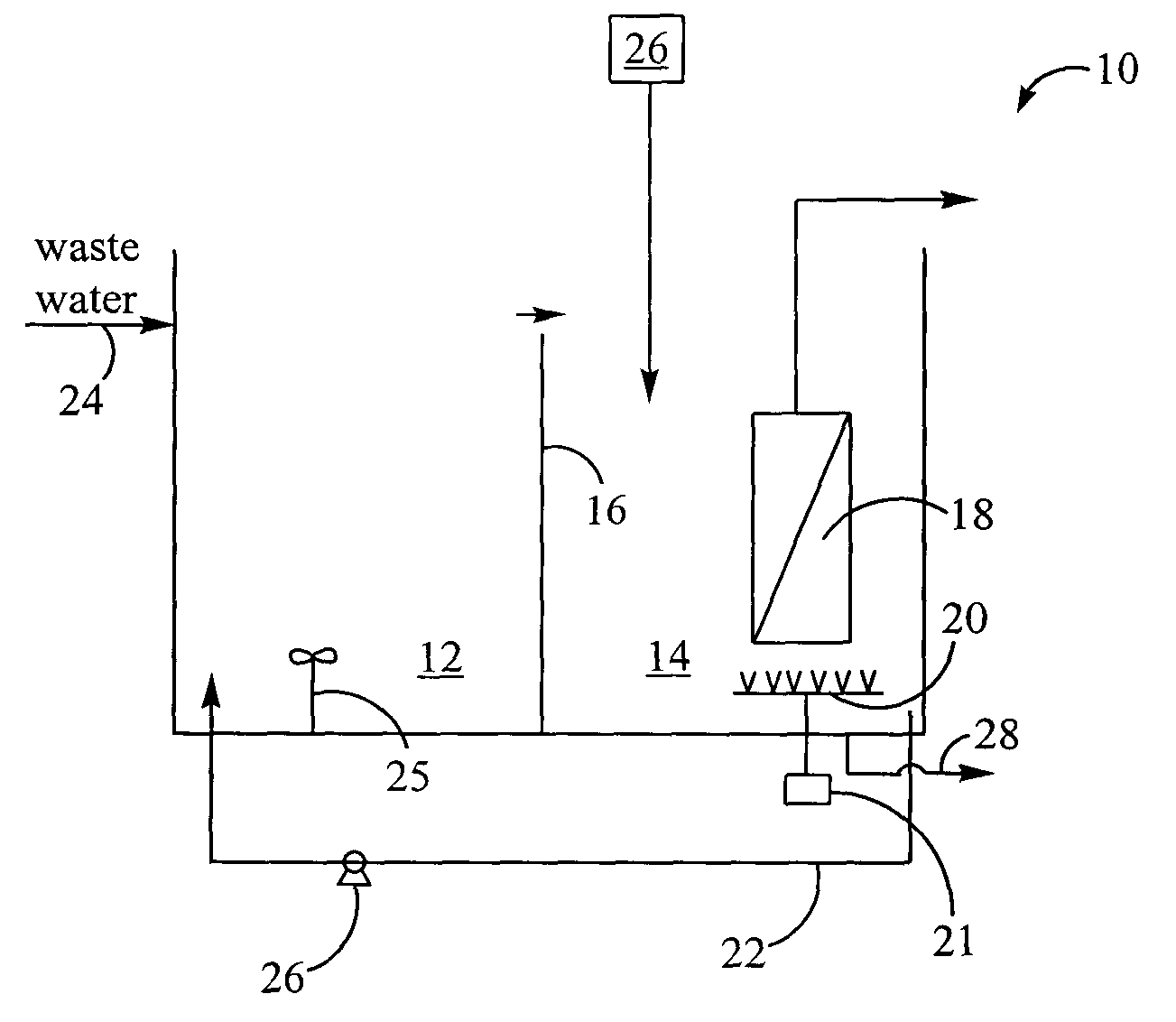

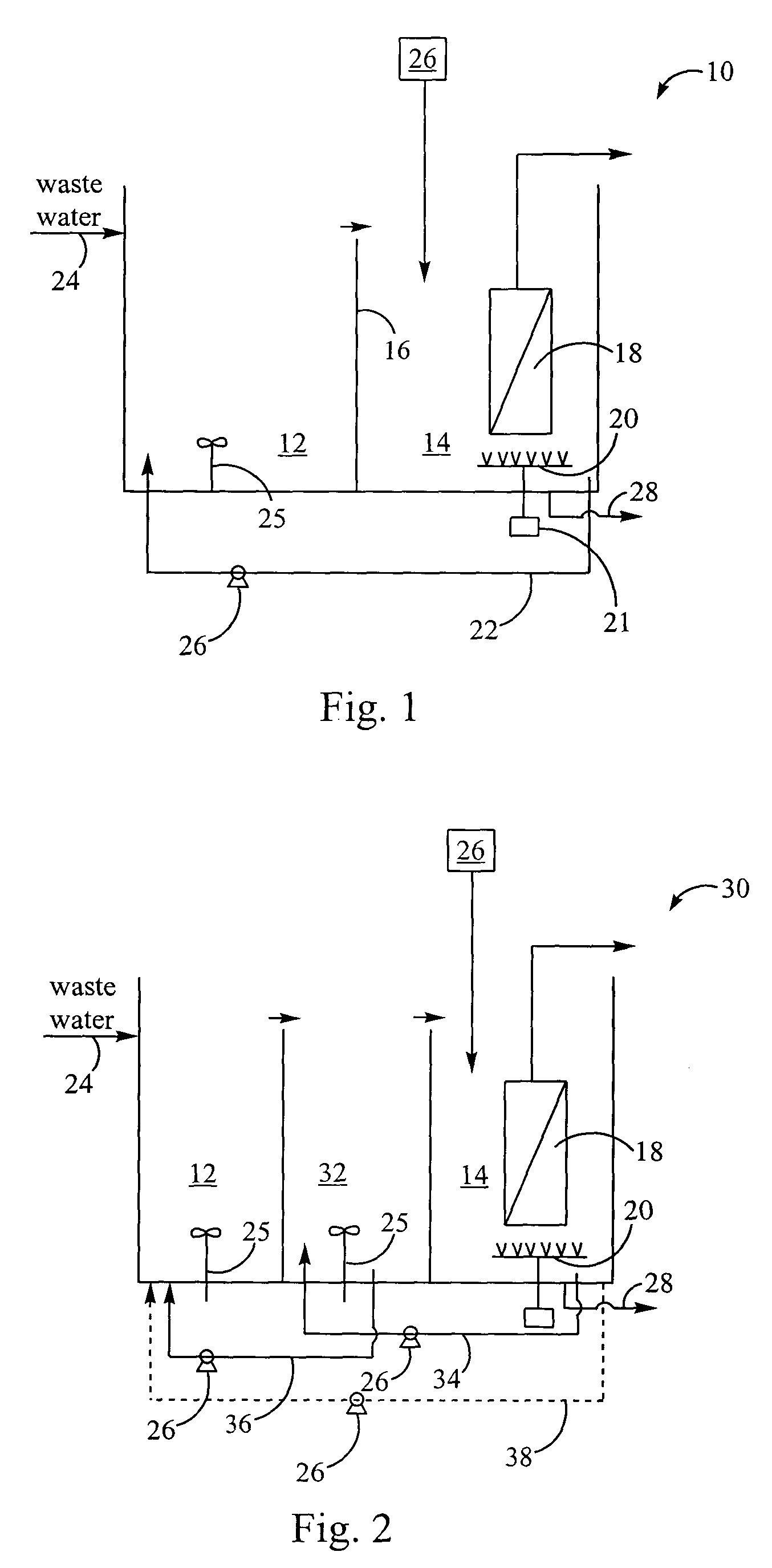

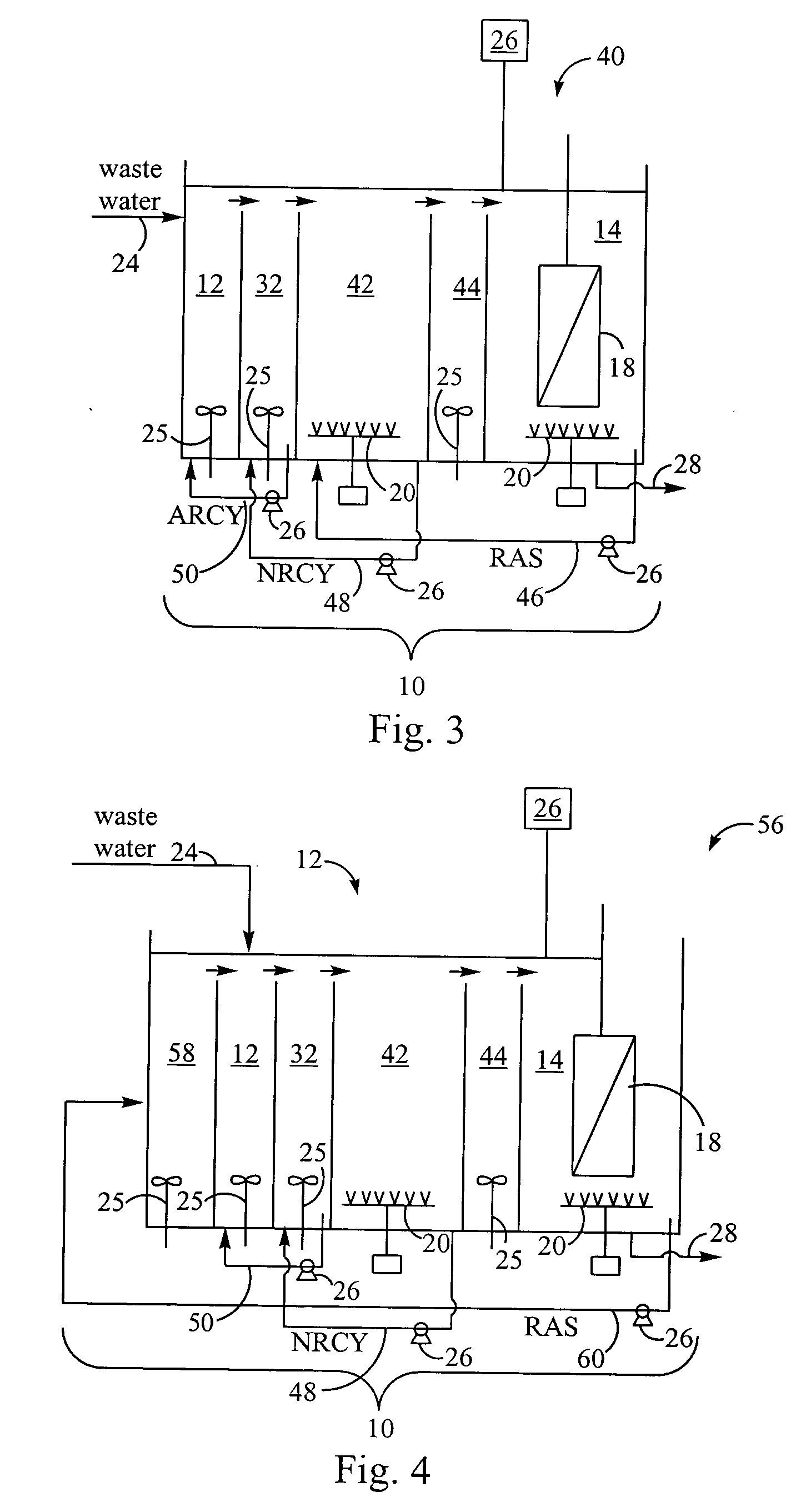

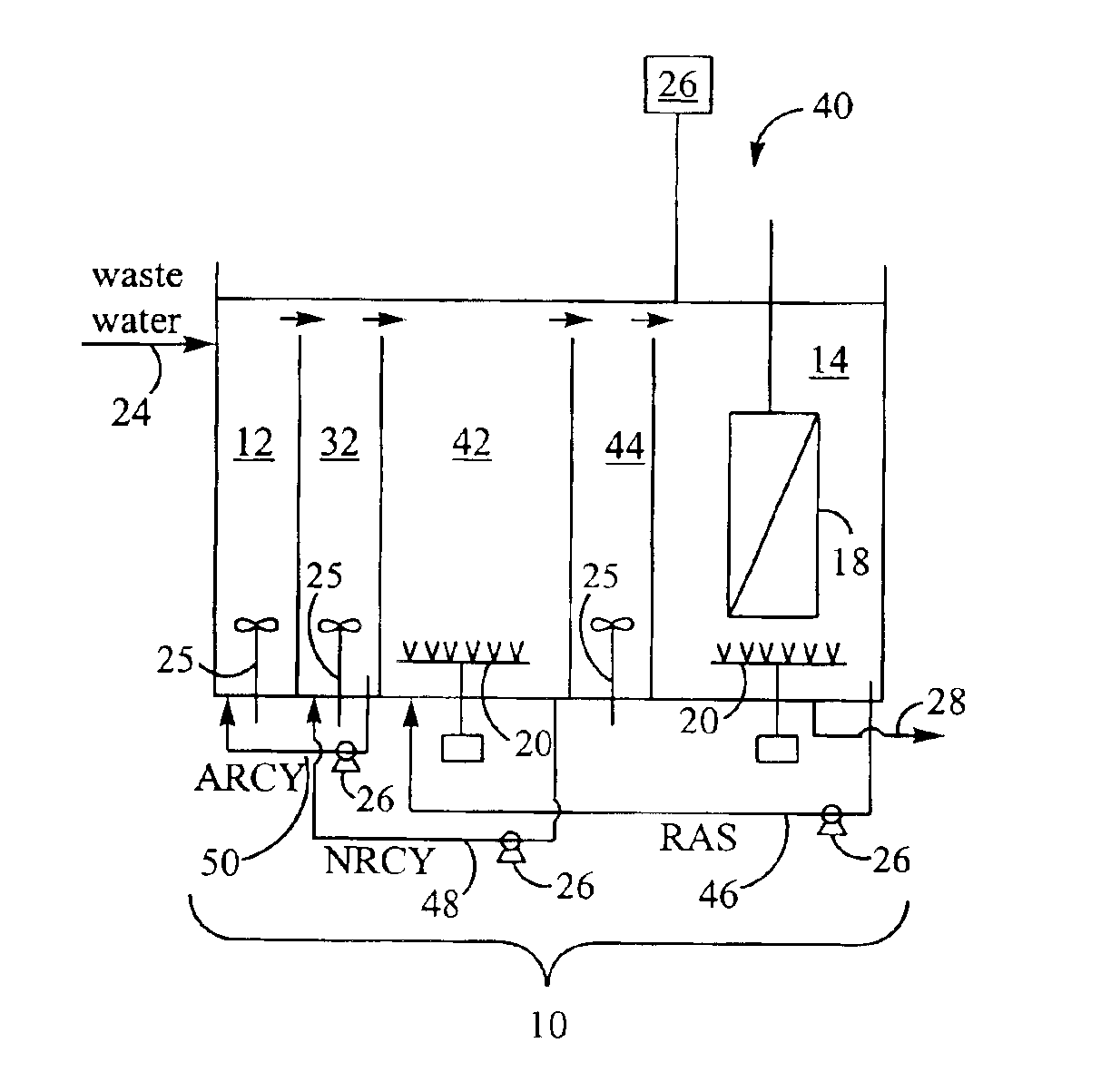

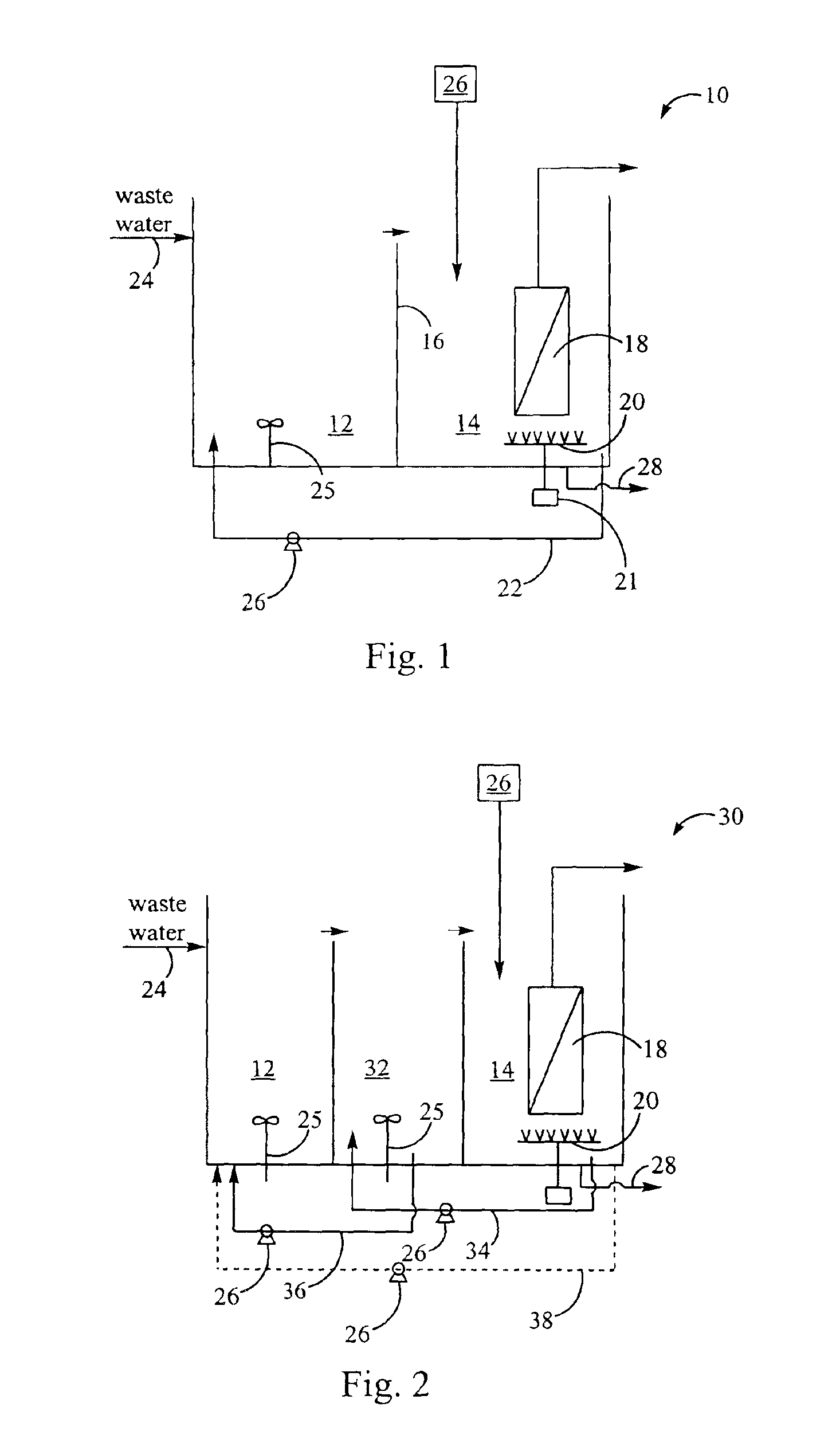

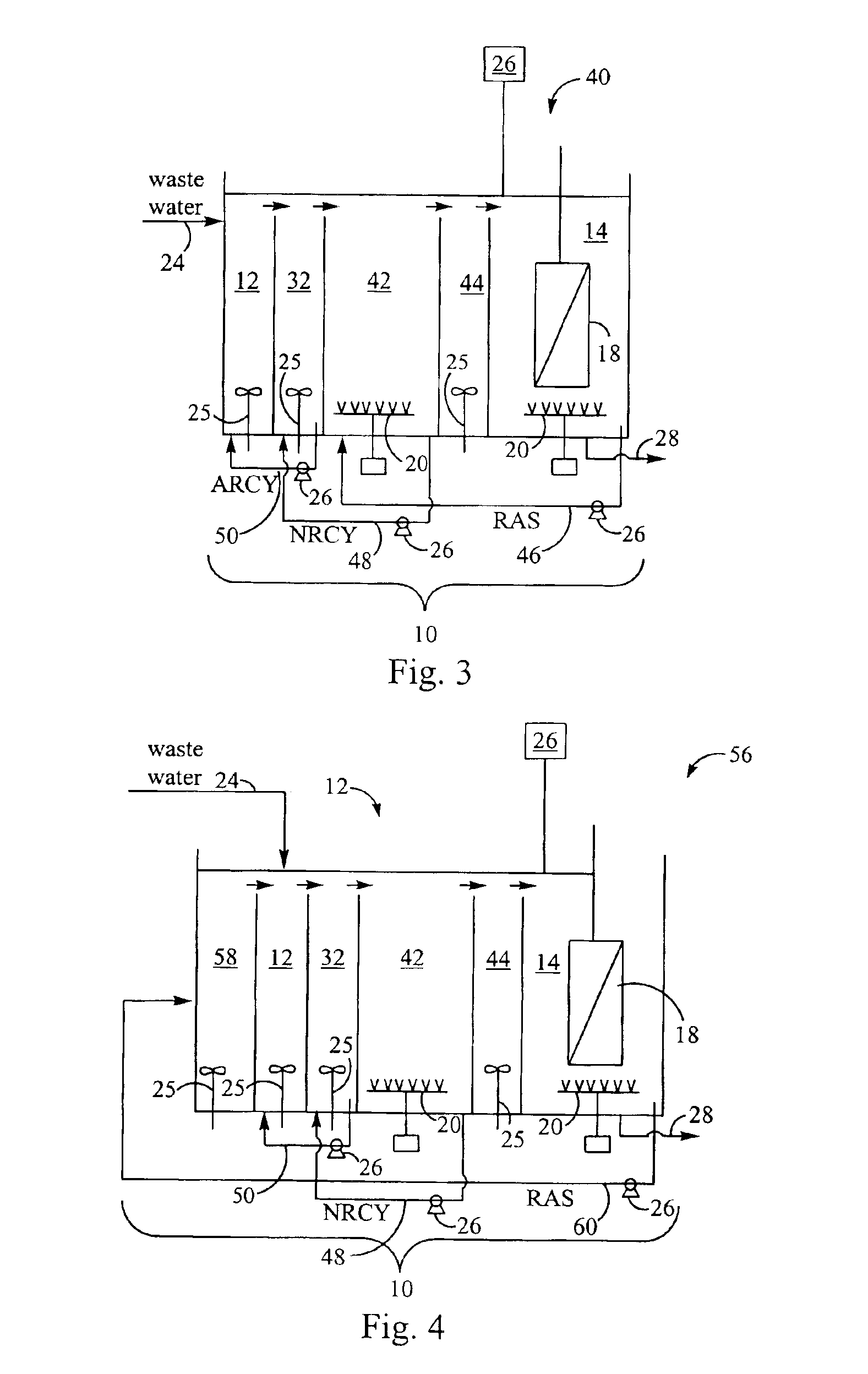

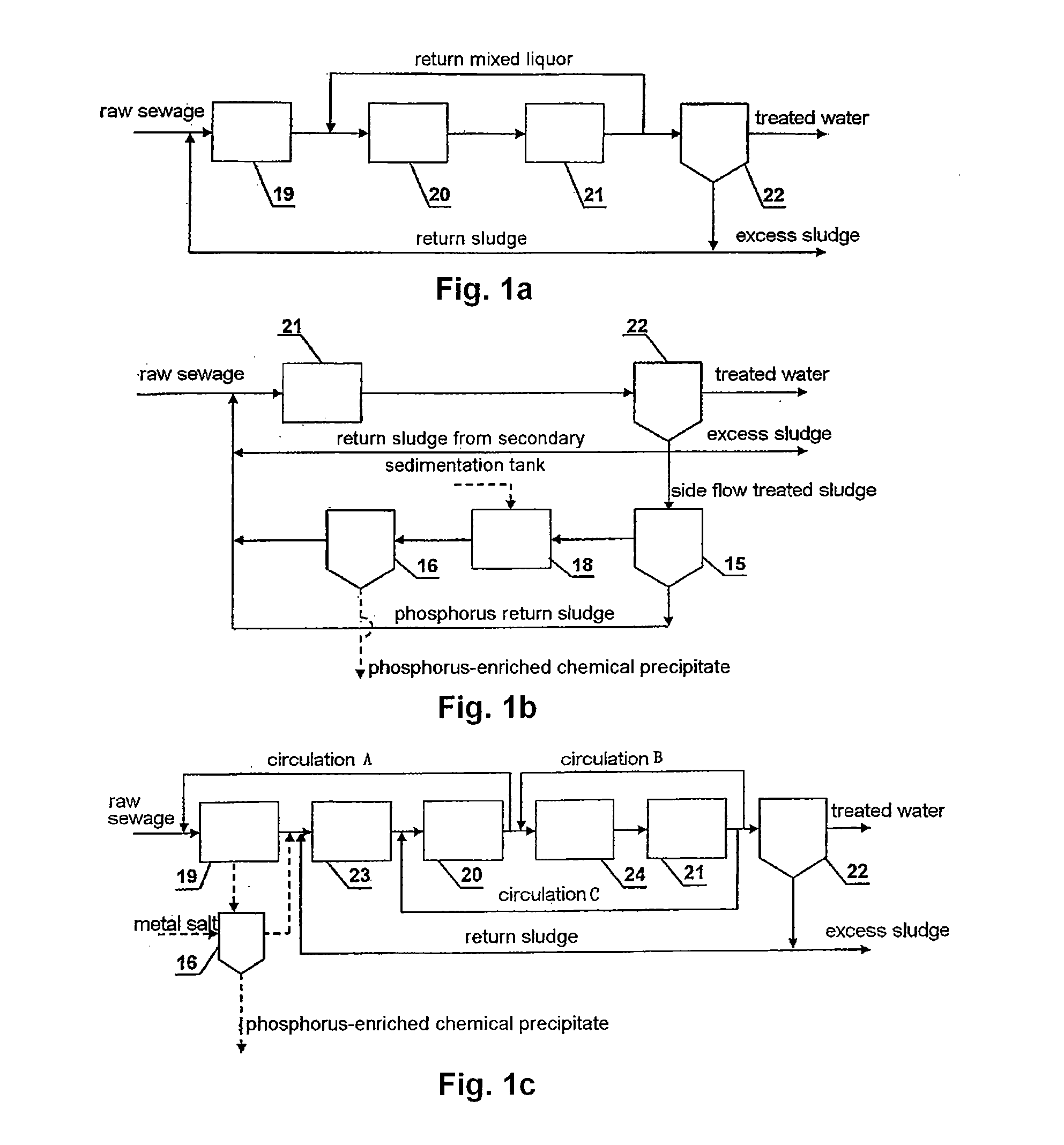

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

ActiveUS20050045557A1Minimizing space requirementMinimizing attendant costTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

Method for treating wastewater in a membrane bioreactor to produce a low phosphorus effluent

InactiveUS6946073B2Reduce outputPromoting robust nutrient uptakeTreatment using aerobic processesOther chemical processesActivated sludgeMembrane bioreactor

Removal of biological nutrients from a wastewater yielding a low phosphorous (e.g., less than 0.25 mg / L) output includes providing a serial multistage bioreactor containing activated sludge having in hydraulic series an anaerobic zone and a downstream aerobic zone, with each zone having an upstream inlet and a downstream outlet. The wastewater is provided to the anaerobic zone inlet. A quantity of chemical sufficient to precipitate soluble and particulate phosphorous is added to the downstream aerobic zone in an amount sufficient to yield a low phosphorous output. Treated water is separated from the activated sludge and precipitated phosphorous and a return activated sludge separated from the treated water is recycled to the anaerobic zone.

Owner:CH2M HILL

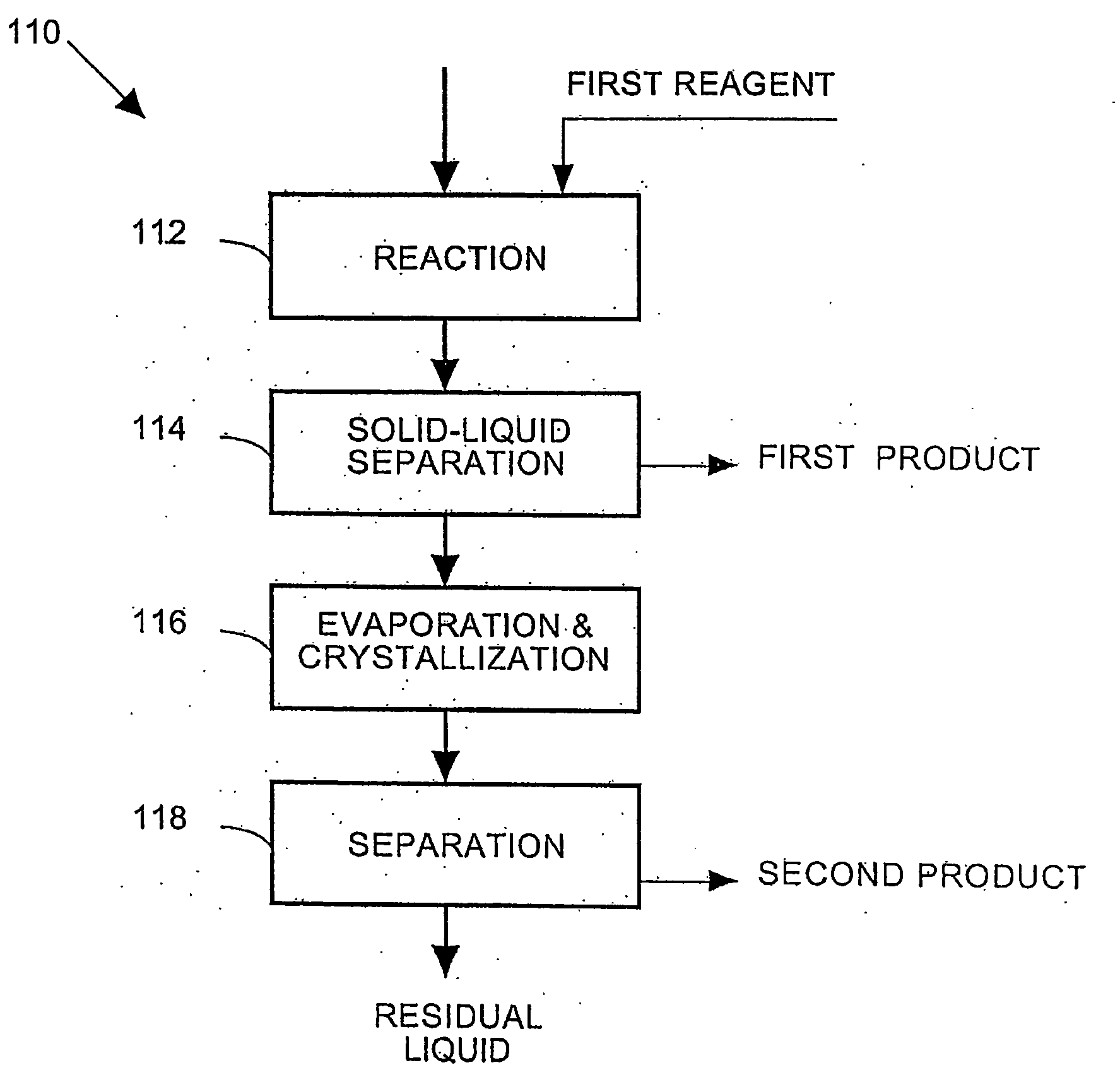

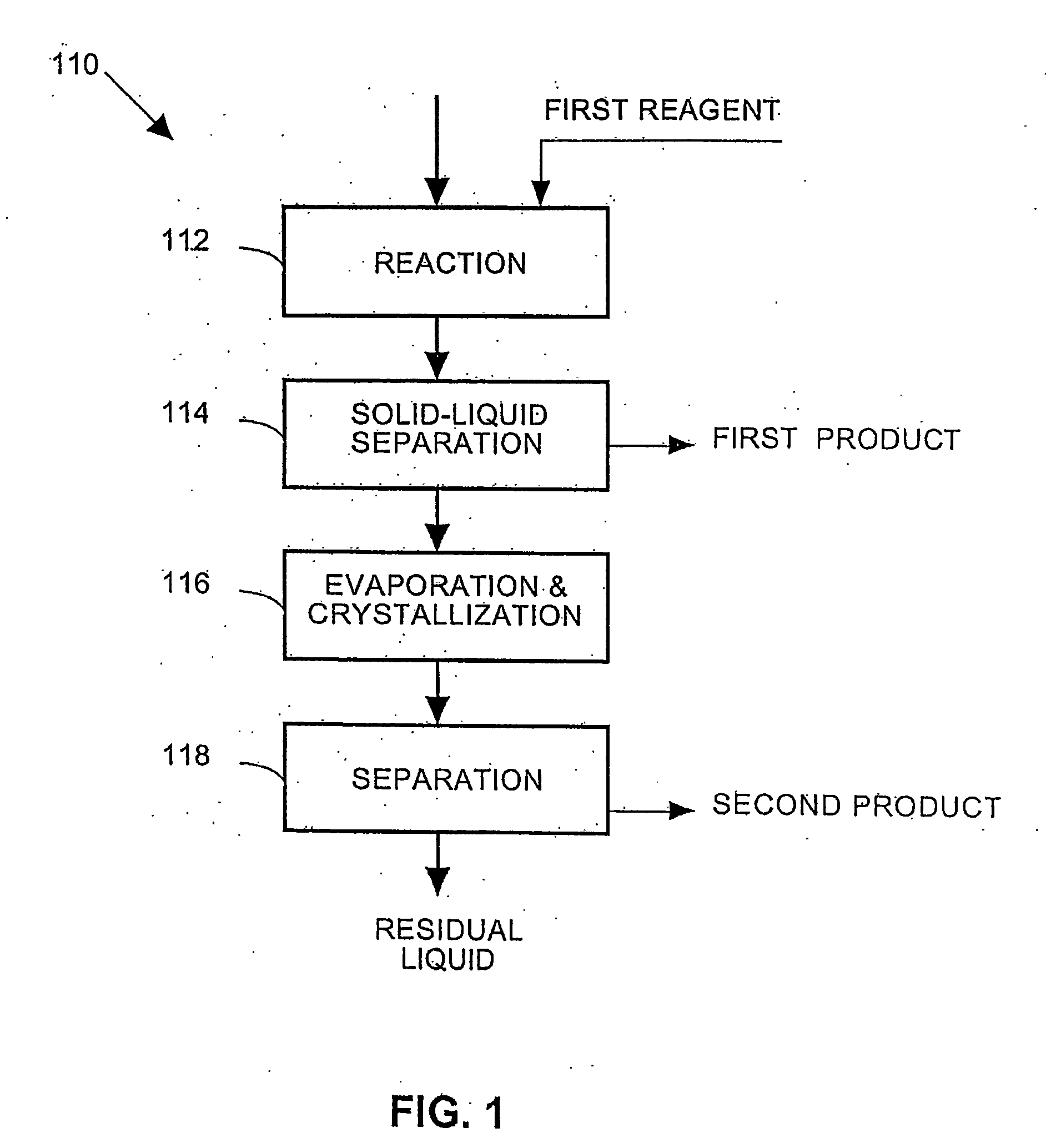

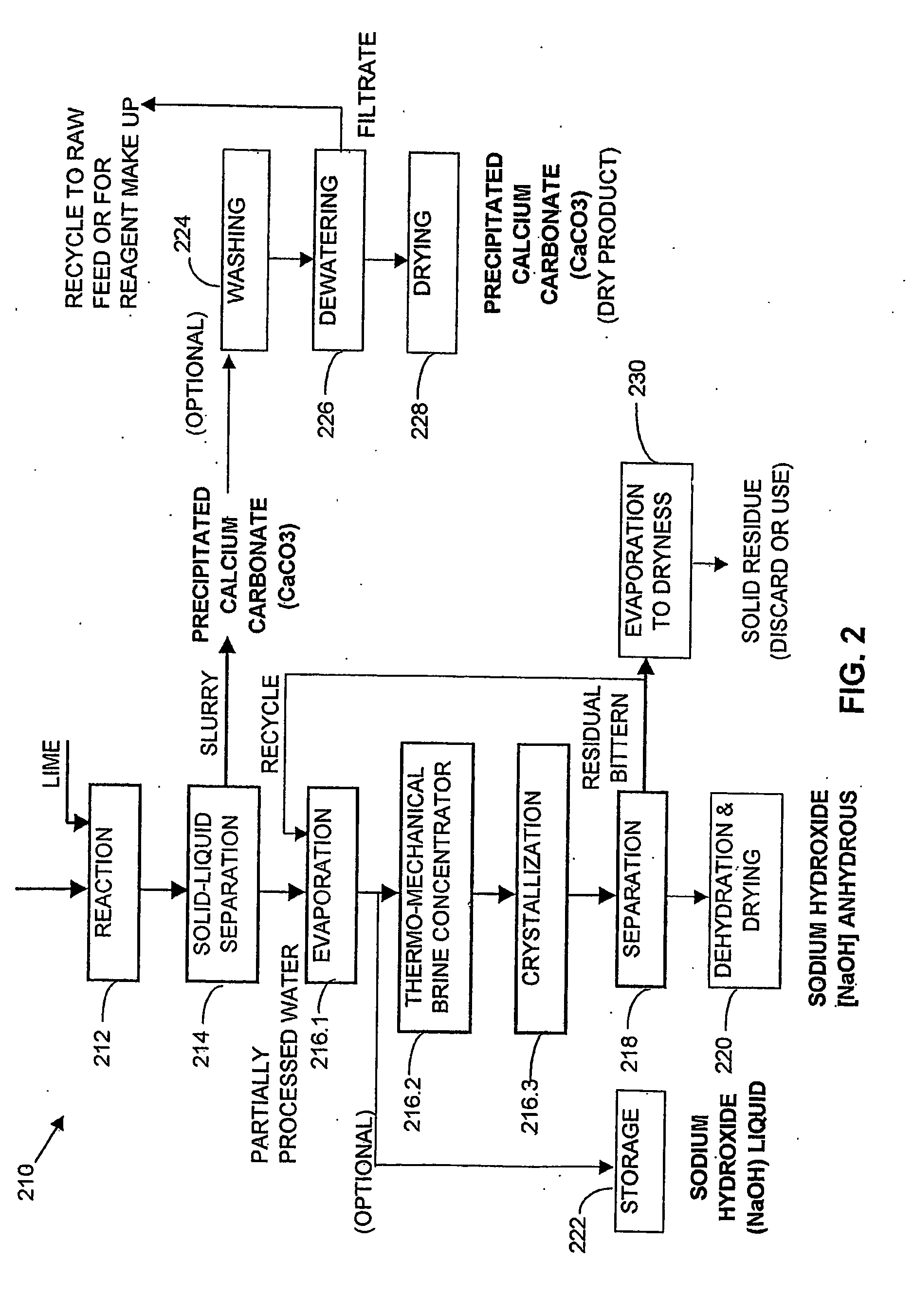

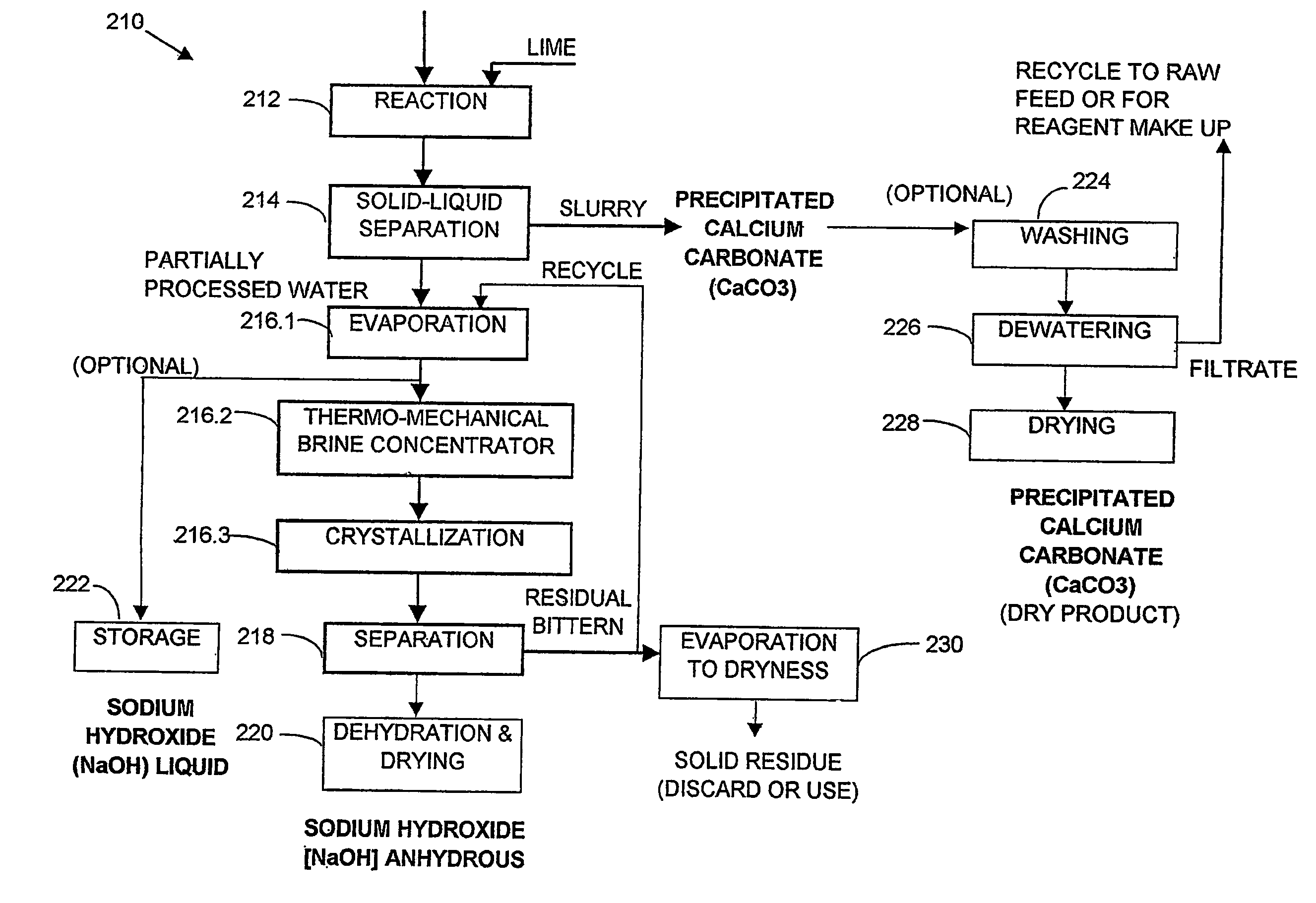

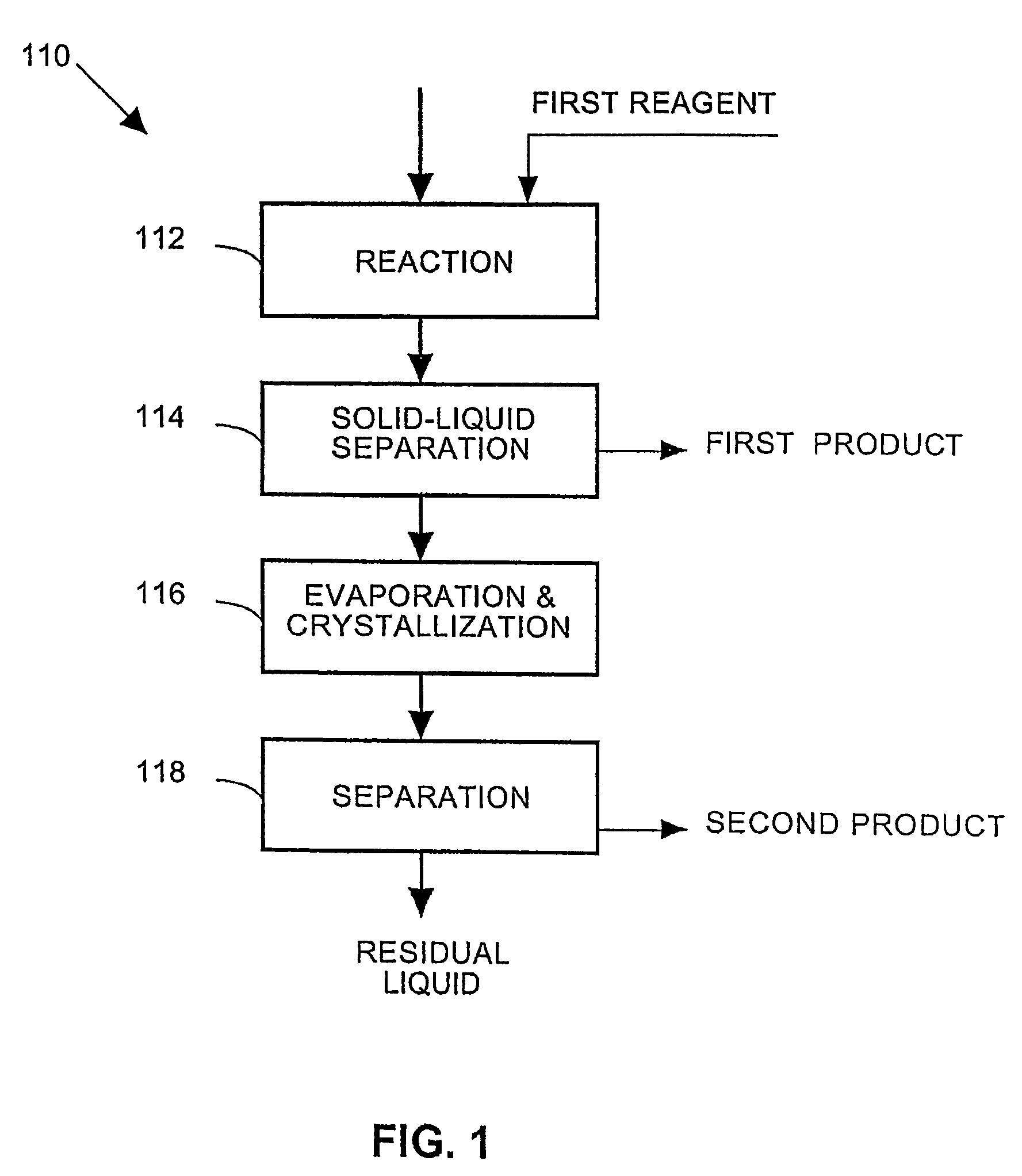

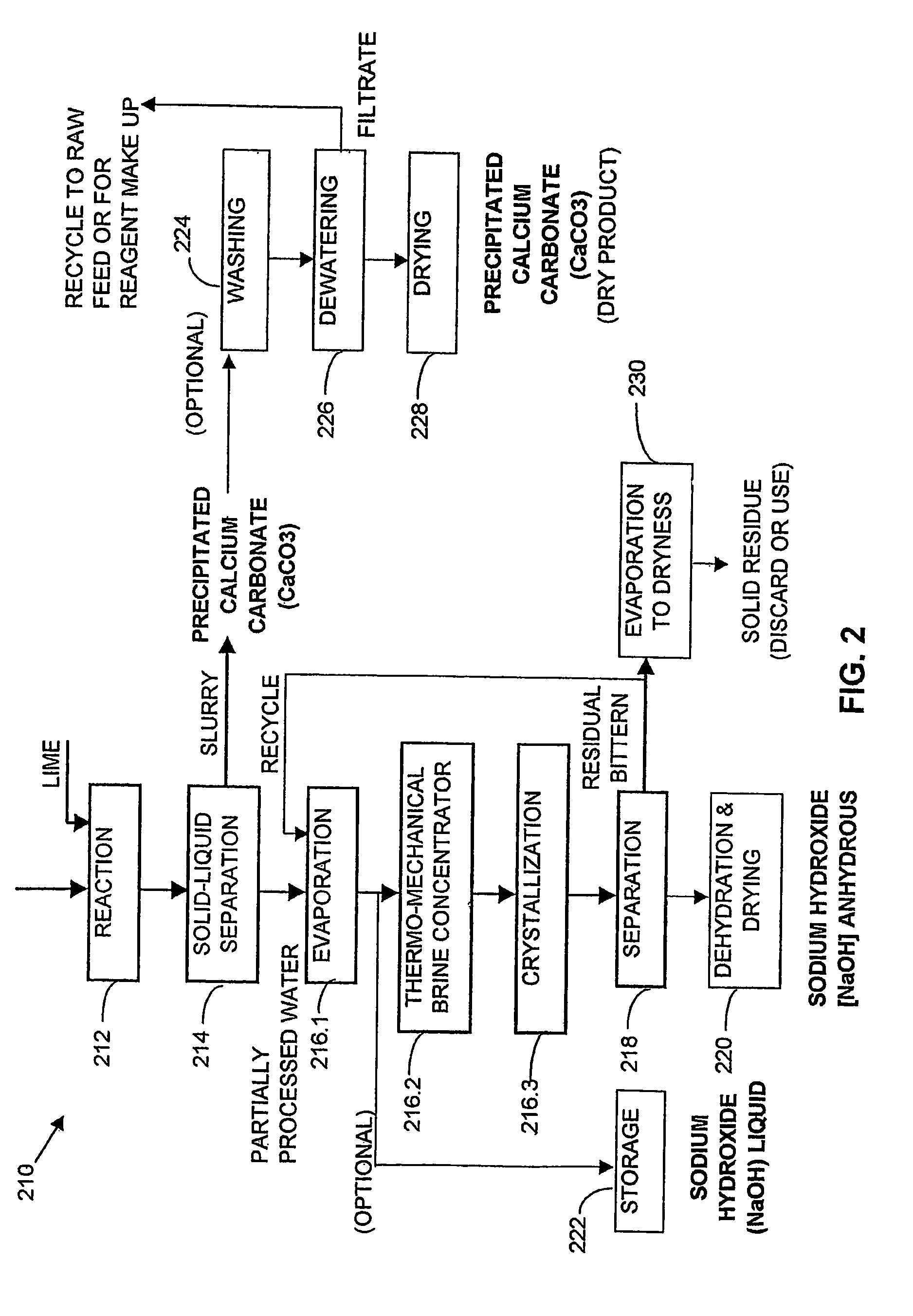

Process and apparatus for the treatment of saline water

InactiveUS20060196836A1Reduce ZLD costReduce loadWaste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

Oxygenated personal care products

InactiveUS20050244354A1Increase oxygen contentImproved body compositionCosmetic preparationsHair removalLotionOxygen

The present invention relates to a personal care composition containing water that has been treated with a combination of ozone and hydrogen peroxide. The personal care composition is further treated with liquid oxygen that is added to the composition prior to packaging. The personal care composition may be in the form of a soap, lotion, cream, balm, stick, foundation, spray, mousse, gel, sanitizer, wash, or towellete, and directed for various uses on the human body. The ozone and hydrogen peroxide is added to the water prior to manufacturing the composition.

Owner:SPERON SAM

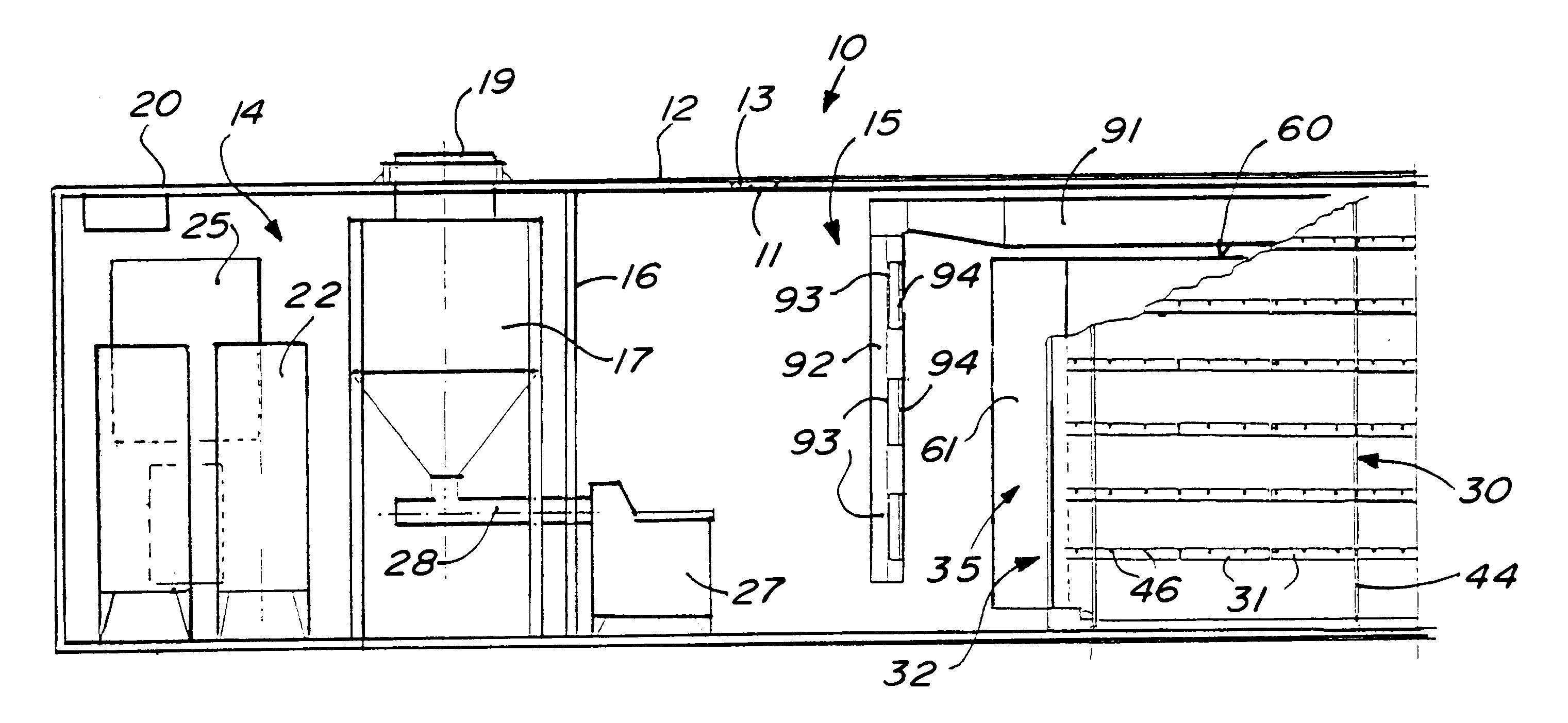

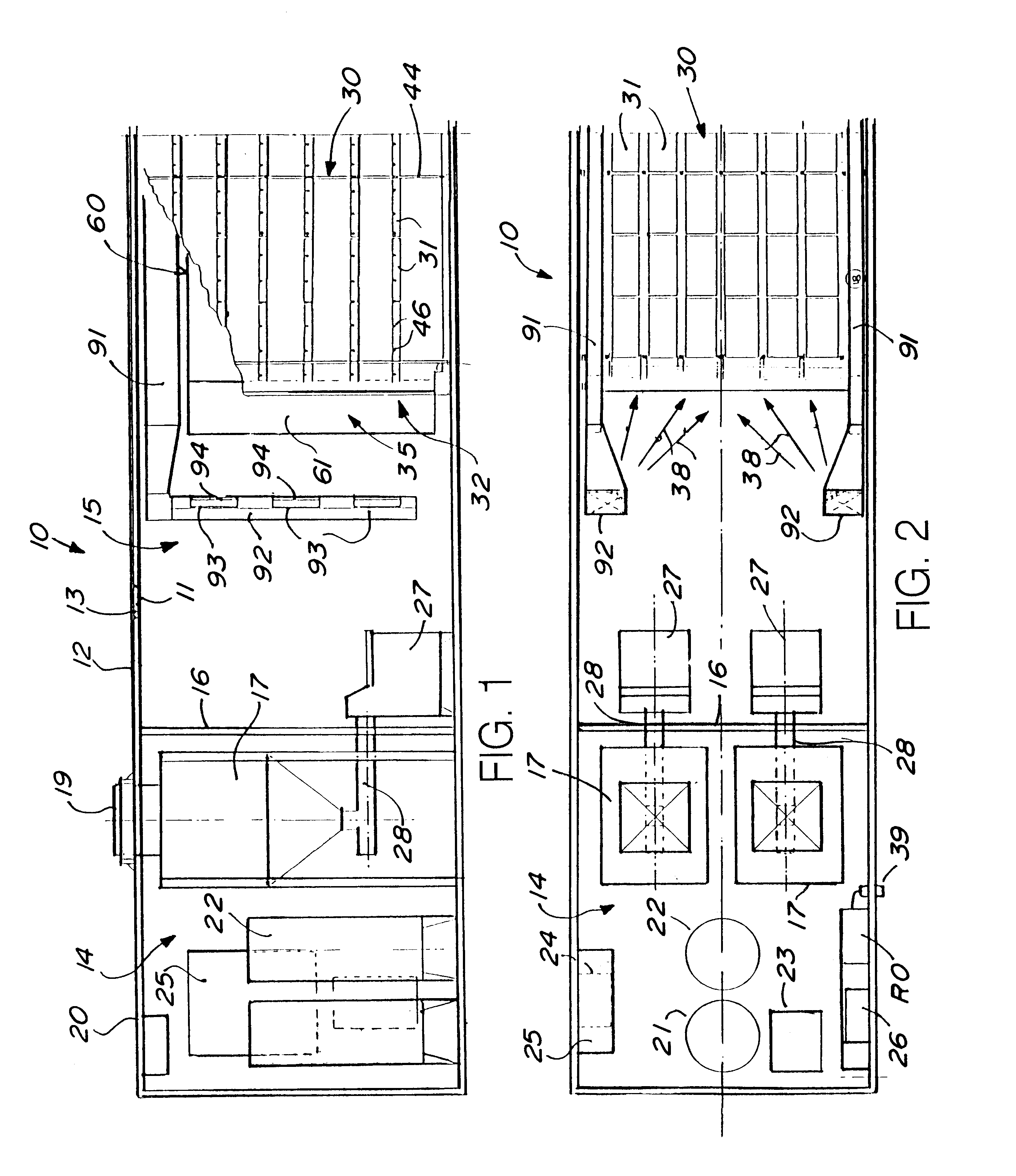

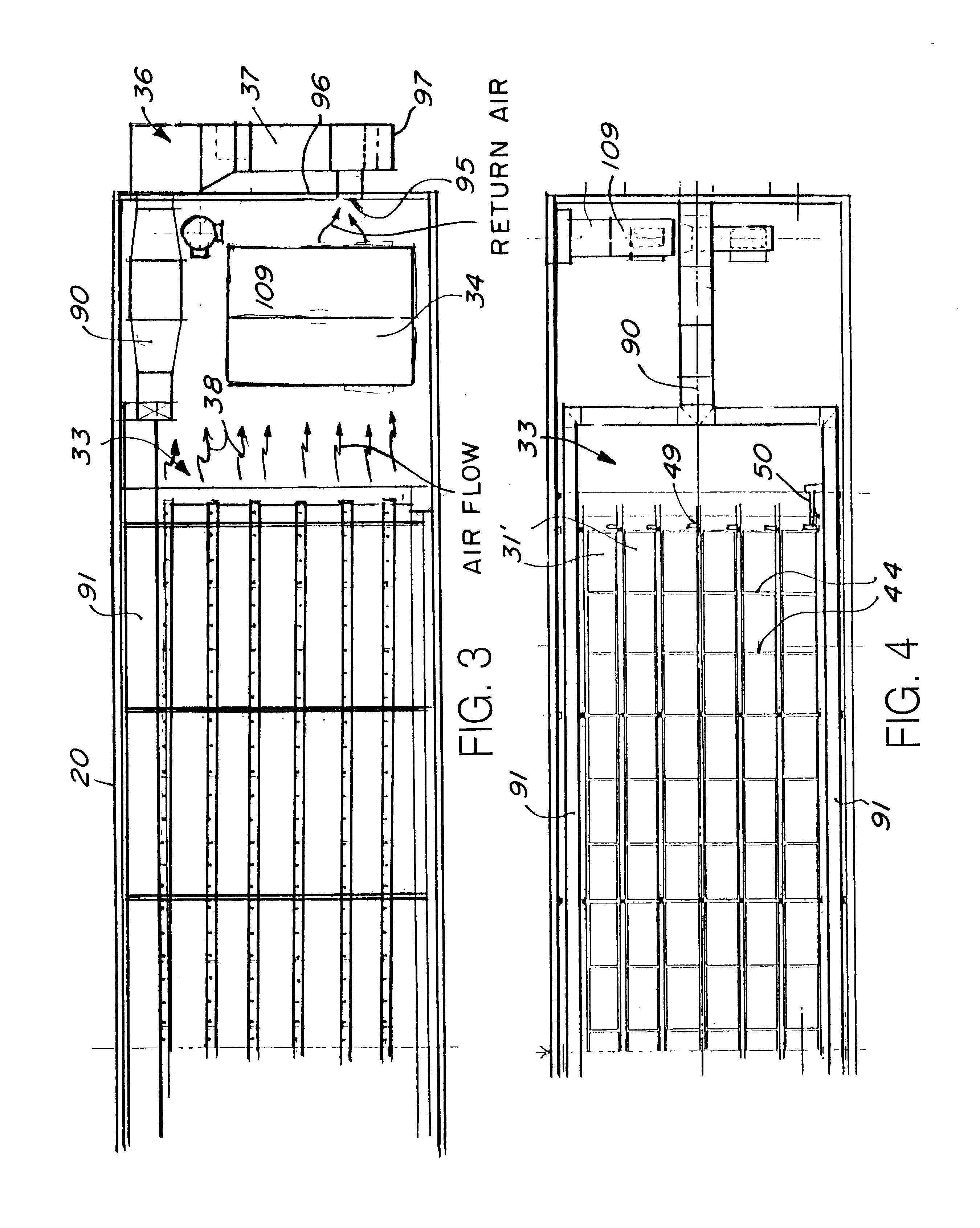

Hydroponic growing enclosure and method for the fabrication of animal feed grass from seed

InactiveUS6578319B1Easy to useAgriculture gas emission reductionCultivating equipmentsSprouted SeedsEngineering

Owner:COLE ROBERT +1

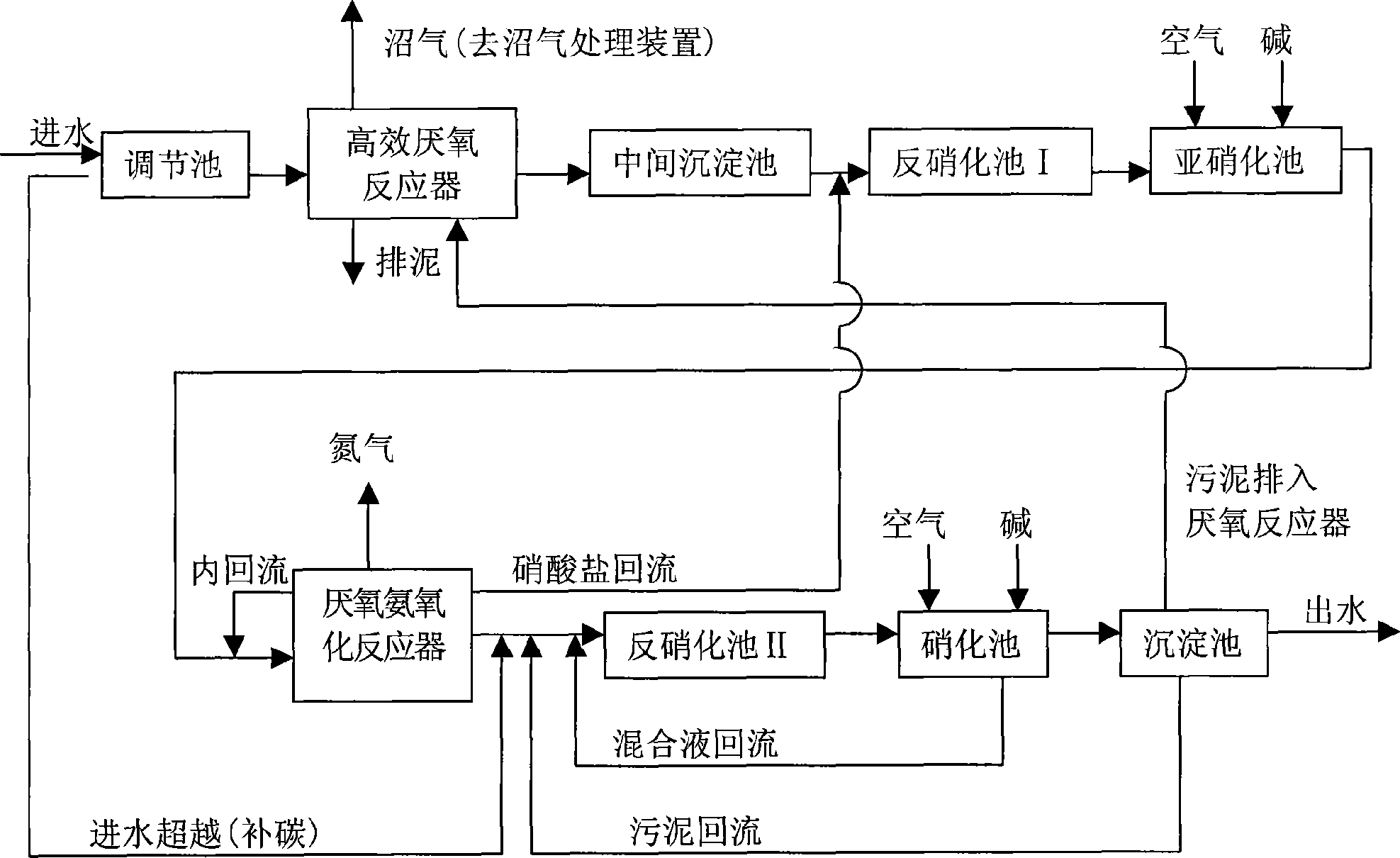

Deepness denitrogenation method for treating organic wastewater in high concentration

ActiveCN101050026AGuaranteed emission standardsThe process route is compactWater contaminantsTreatment with aerobic and anaerobic processesHigh concentrationTotal nitrogen

This invention discloses a method for deep denitrification treatment of high-concentration organic wastewater. The apparatus comprises an anaerobic decarbonization zone, an aerobic nitrosation / anaerobic ammoxidation denitrification zone, and a traditional nitrification / denitrification zone. In the anaerobic decarbonization zone, an anaerobic bioreactor is utilized to perform anaerobic biotreatment on the organic pollutants in raw water to remove the majority of organic matters. In the aerobic nitrosation / anaerobic ammoxidation denitrification zone, ammonia nitrogen and nitrite nitrogen are removed in the form of nitrogen gas. In the traditional nitrification / denitrification zone, nitrate in the water discharged from the aerobic nitrosation / anaerobic ammoxidation denitrification zone is subjected to denitrification and removed in the form of nitrogen gas. Excess organic matters are subjected to aerobic bioreaction and removed. The method can ensure COD; total nitrogen and ammonia nitrogen contents in the treated water are qualified for discharge. The method has such advantages as high decarbonization and denitrification efficiency, low energy consumption, and high running stability.

Owner:BEIJING MUNICIPAL RES INST OF ENVIRONMENT PROTECTION

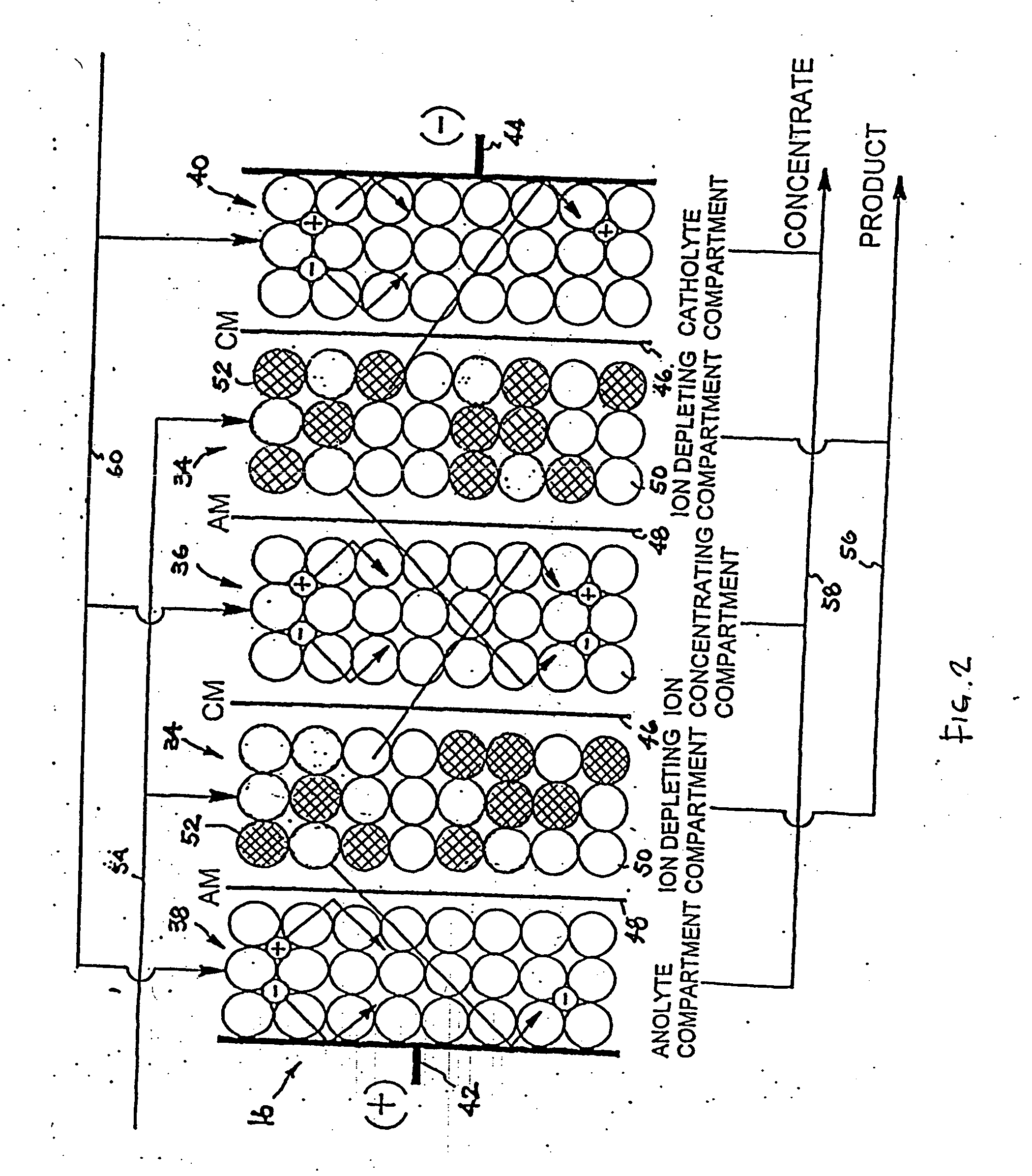

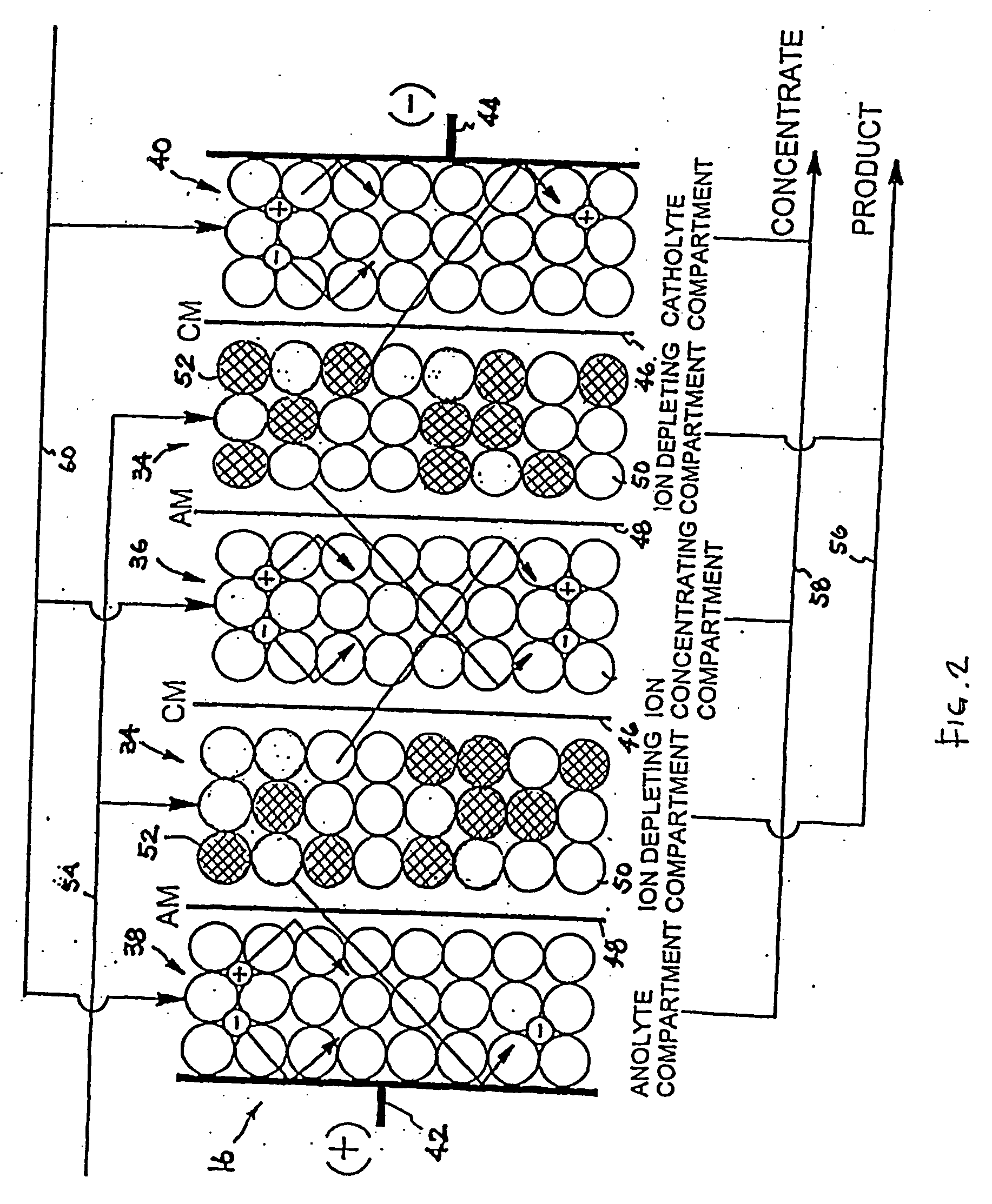

Water treatment system and method

ActiveUS20050103630A1Inhibit migrationPromote migrationSludge treatmentVolume/mass flow measurementWater sourceSoftened water

The present invention is directed to a water treatment or purification system and method for providing treated water in industrial, commercial and residential applications. The treatment system provides treated or softened water to a point of use by removing at least a portion of any hardness-causing species contained in water from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system includes an electrochemical device, such as an electrodeionization device, that can have at least one compartment that generates and traps hydrogen ions which can be used in another compartment of the electrochemical device such as, an electrode compartment, to reduce or at least dissolve any scale. Other applications of the system would be in the treatment and processing of foods and beverages, sugars, various industries such as the chemical, pharmaceutical, waste water treatment and power generating industries.

Owner:EVOQUA WATER TECH LLC

Water treatment system and method

ActiveUS20050103644A1Facilitate water treatmentSludge treatmentVolume/mass flow measurementWater treatment systemWaste stream

A water treatment system provides treated or softened water to a point of use by removing a portion of any hardness-causing species contained in water from a point-of-entry coming from a water source, such as municipal water, well water, brackish water and water containing foulants. The water treatment system typically treats the water containing at least some undesirable species before delivering the treated water to a point of use. The water treatment system has a controller for adjusting or regulating at least one operating parameter of the treatment system or a component of the water treatment system to optimize the operation and performance of the system or components of the system. A flow regulator regulates a waste stream flow to drain and can be operated to recirculate fluid through electrode or concentrating compartments of an electrochemical device and can opened and closed intermittently according to a predetermined schedule or based on an operating parameter of the water treatment system. The flow regulator can also be charged so that ionic species can be generated in the surrounding fluid, which, in turn, can lower the pH of the surrounding fluid.

Owner:EVOQUA WATER TECH LLC

Process for the treatment of saline water

InactiveUS7595001B2Waste water treatment from quariesGeneral water supply conservationTotal dissolved solidsEvaporation

A process and an apparatus are described for treating seven types of saline waters each having a concentration of total dissolved solids exceeding 1 g / L, wherein the concentration of total dissolved solids, the ratio of the chloride ion concentration to the bicarbonate ion concentration and the ratio of the chloride ion concentration to the sulphate ion concentration of each of the water types are as indicated in Table 1. The process includes the steps of contacting the water with a first reagent comprising a source of calcium ions selected from calcium oxide and calcium hydroxide to form a first solid product which is recovered. The process includes a further step of subjecting at least a portion of the partially processed water to at least partial evaporation so as to promote the formation of a precipitate and a mother liquor. The precipitate is recovered as a second product.

Owner:GEO PROCESSORS

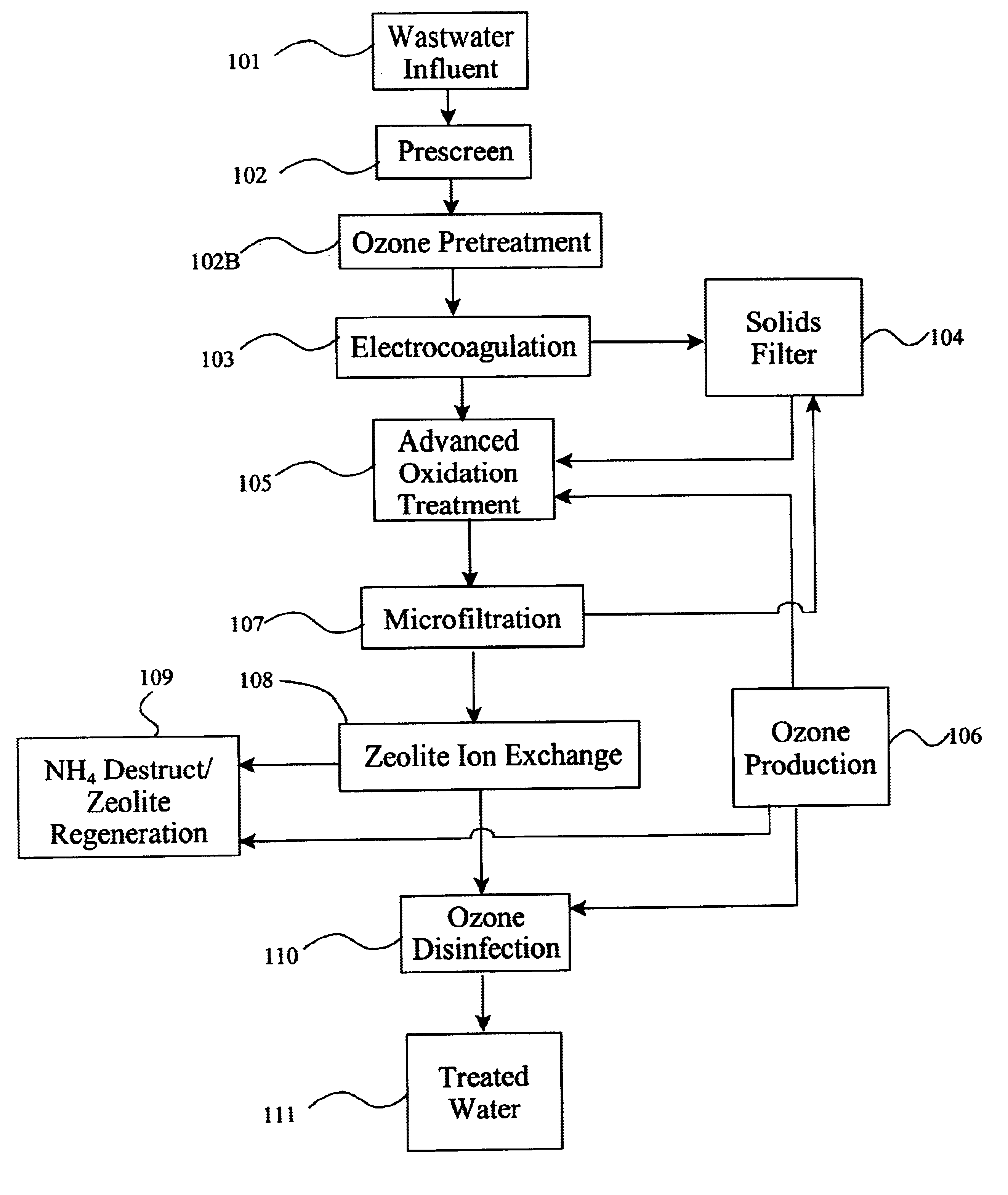

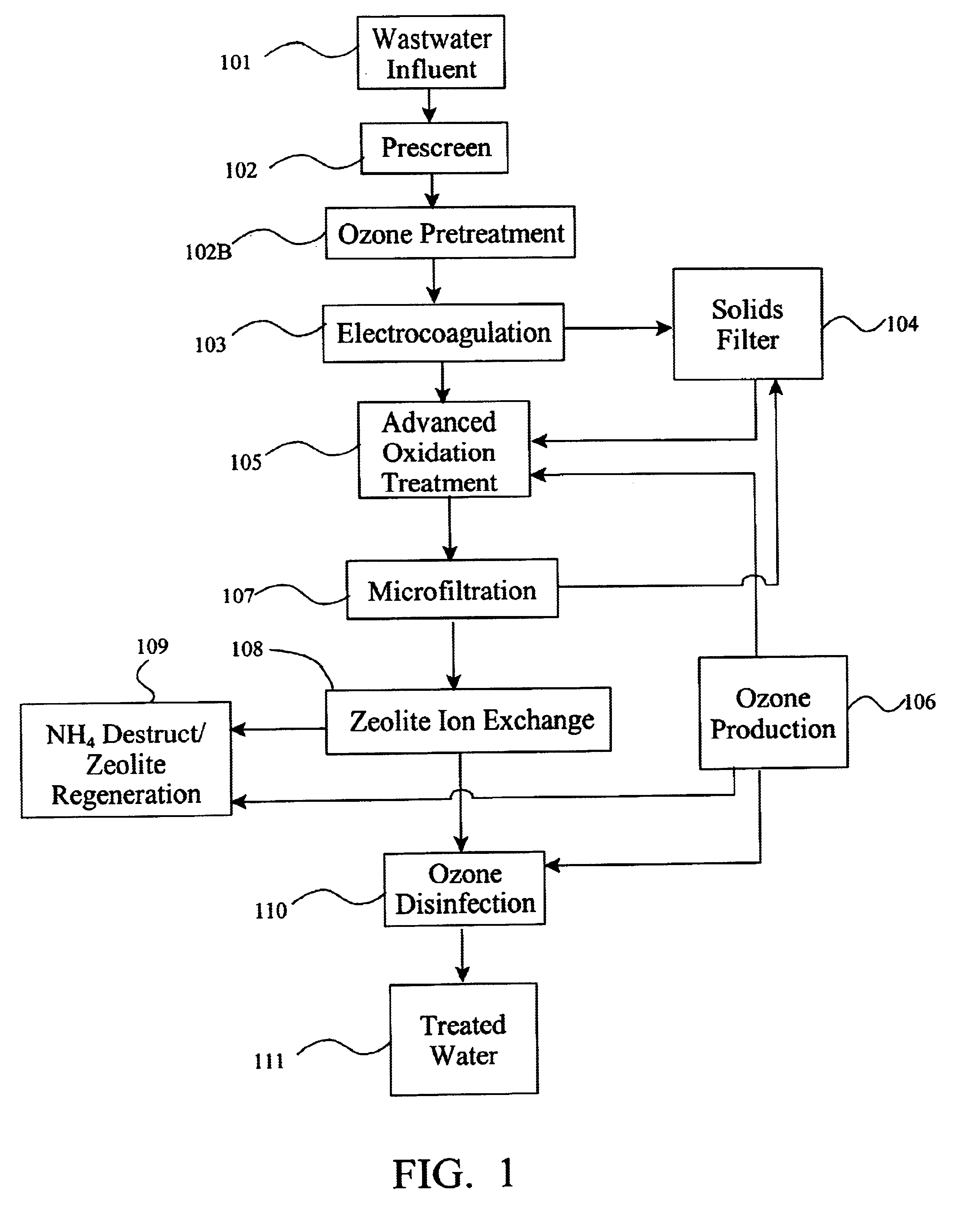

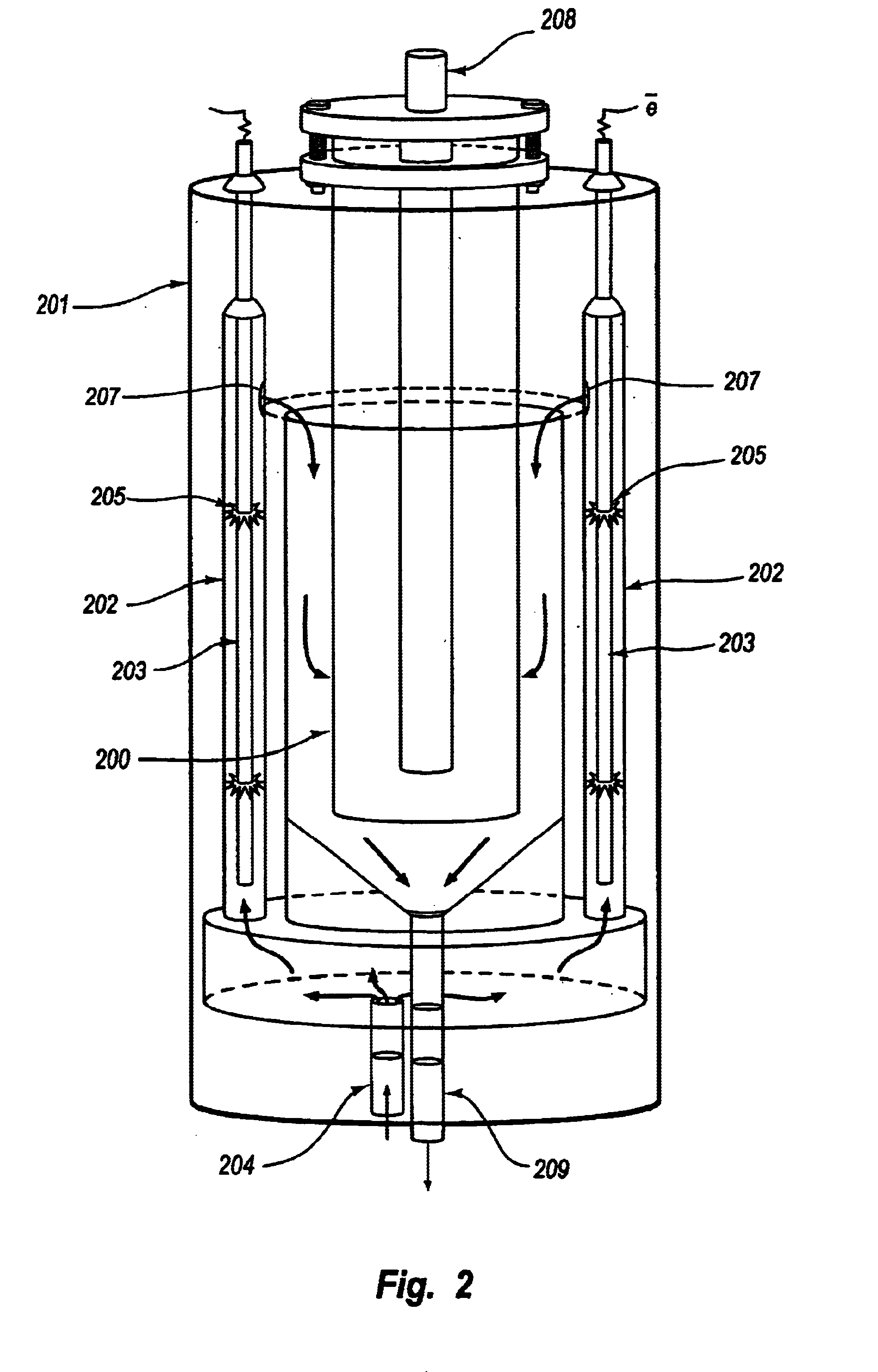

Leachate and wastewater remediation system

InactiveUS6960301B2Effective amount of reactionMany difficultyLiquid separation by electricityFlow mixersAdvanced oxidation processFiltration

A compact portable modular wastewater treatment system which integrates several processing technologies to provide a substantially purified water source. A wastewater stream is sent through an initial filtration step. The filtered wastewater is then subjected to electrocoagulation and then further filtered. The resulting stream containing substantially only organics is then treated in an advanced oxidation process which can include passing an electrical current through the water during the oxidation process. The partially treated water is then passed through ion-exchange columns to polish ammonium and other contaminants. The ion-exchange columns are cycled through regeneration cycles to provide continuous ion-exchange medium. The ammonium rich brine solution used in regeneration is subjected to an ammonium destruct process and then reused in regenerating ion-exchange columns. The water can then be sent through a final disinfection oxidation process to destroy or inactivate pathogens and / or remove any remaining colorants or odor to provide a water source suitable for almost any use.

Owner:NEW EARTH SYST

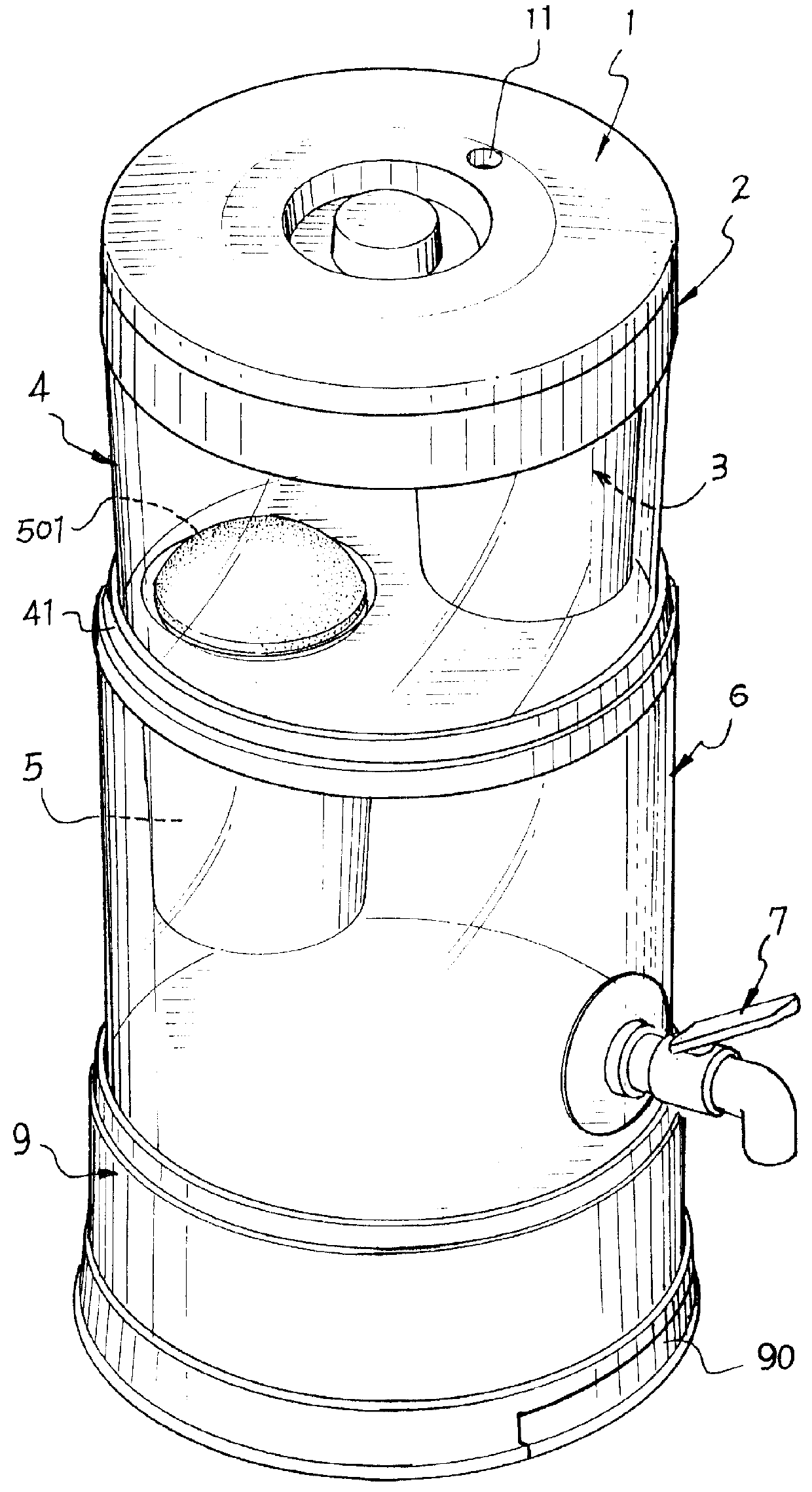

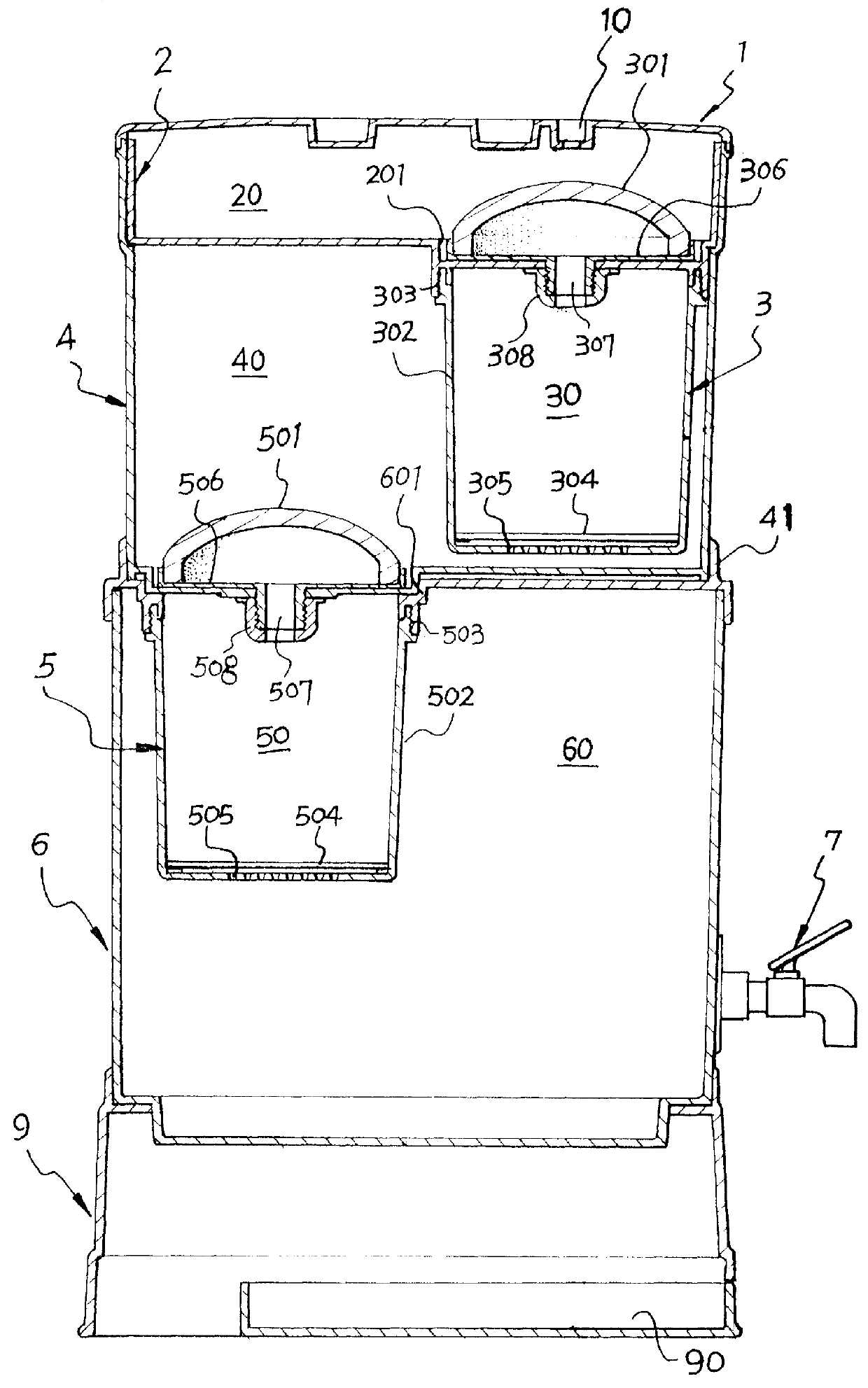

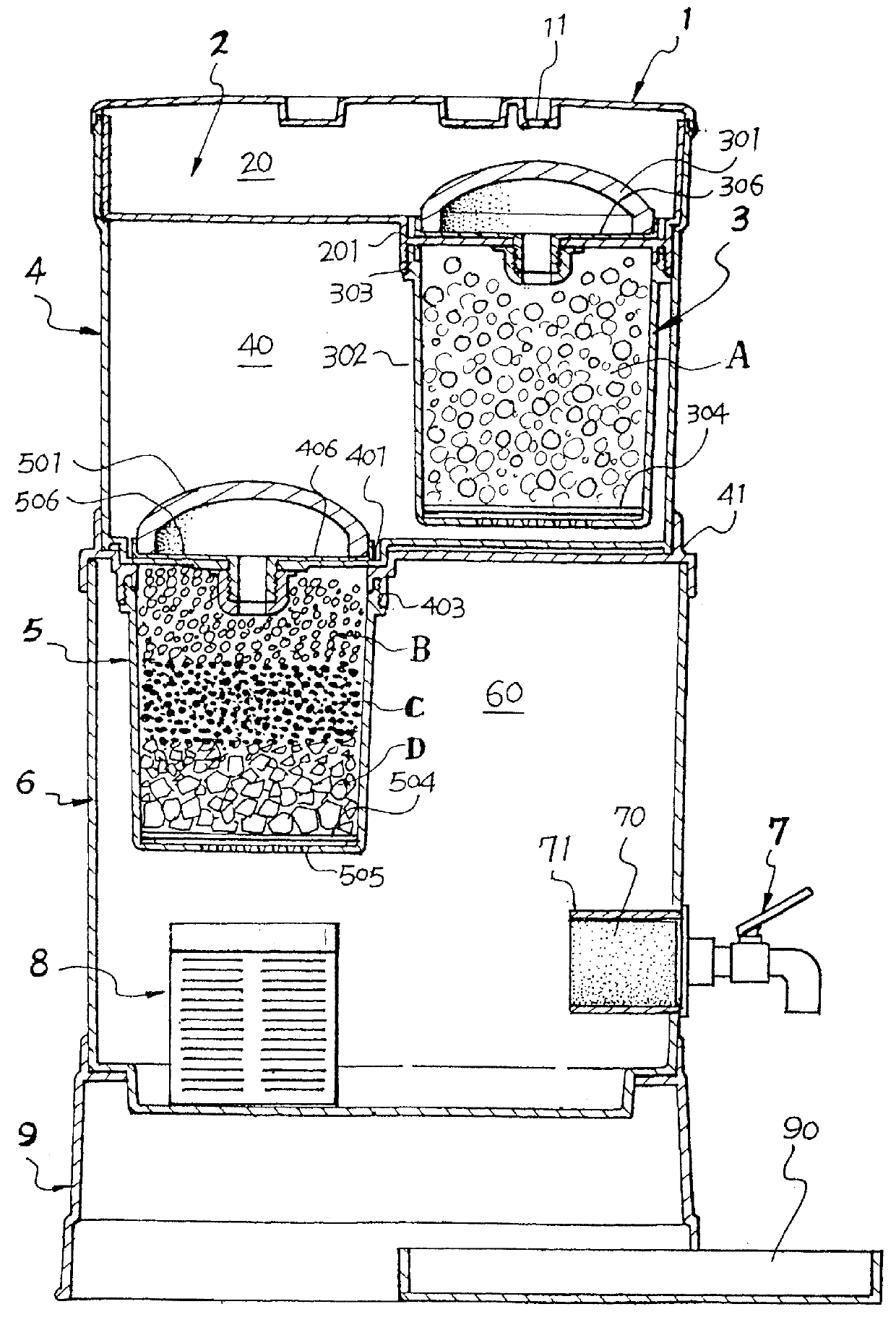

Mineral filtering apparatus

InactiveUS6013180ATreatment involving filtrationLoose filtering material filtersIon exchangeEngineering

The present invention relates to a mineral filtering apparatus in which the raw water is passed through a plurality of filtering processes, such as automatically filtrating without pressure, multiply filtering, ions exchange, sterilization, deodorizing, and releasing mineral substance. The filtering apparatus generally comprises a cover, an inlet water box, a first filtering unit, a filtering box, a second filtering unit, a storing reservoir, a mineral substance barrel that is disposed within the reservoir, an outlet filtering core that is disposed within the reservoir, a spout, a bottom bracket, and a water pan. The storing reservoir is provided with a mineral stone barrel with which the water soluble mineral substance is released. When the raw water flows from top to bottom, it can be treated with filtrating, deodorizing, ions exchange, sterilizing, magnetizing processes such that the treated water is clean and suitable for direct drinking. The treated water contains plentiful mineral substances that are nutritious to human beings.

Owner:WANG WEI RENN

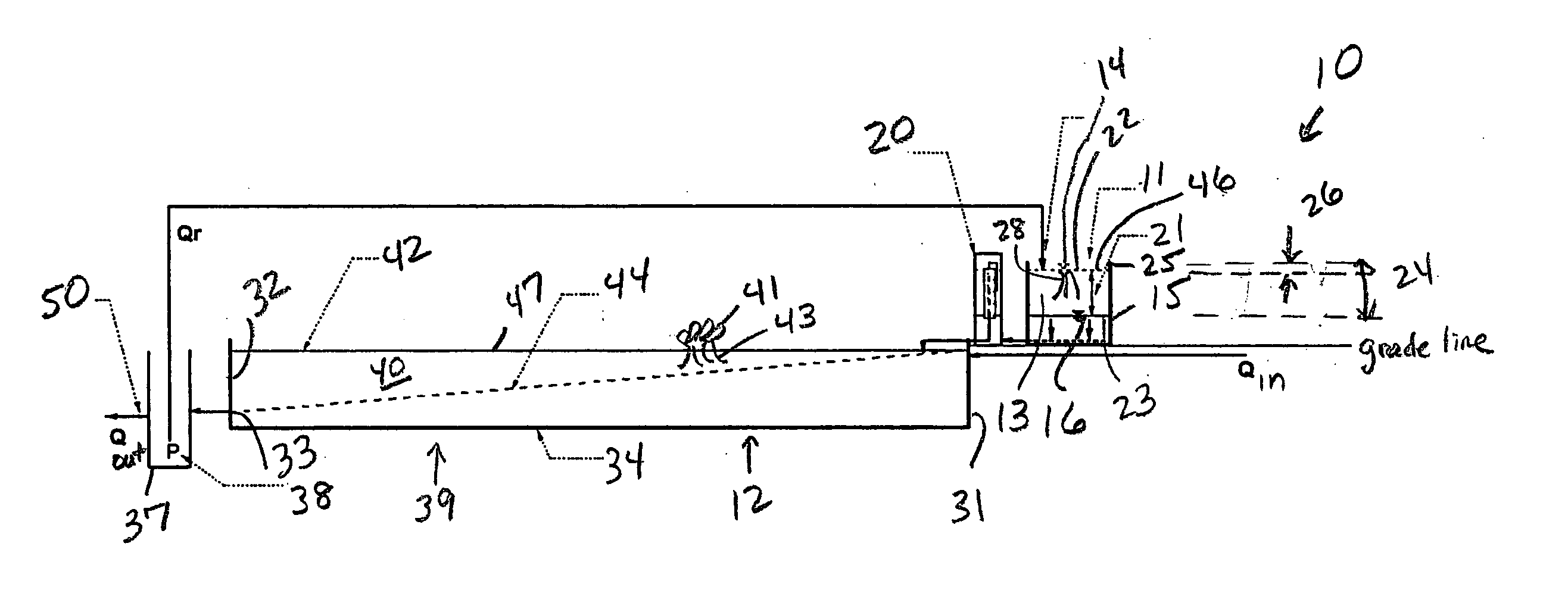

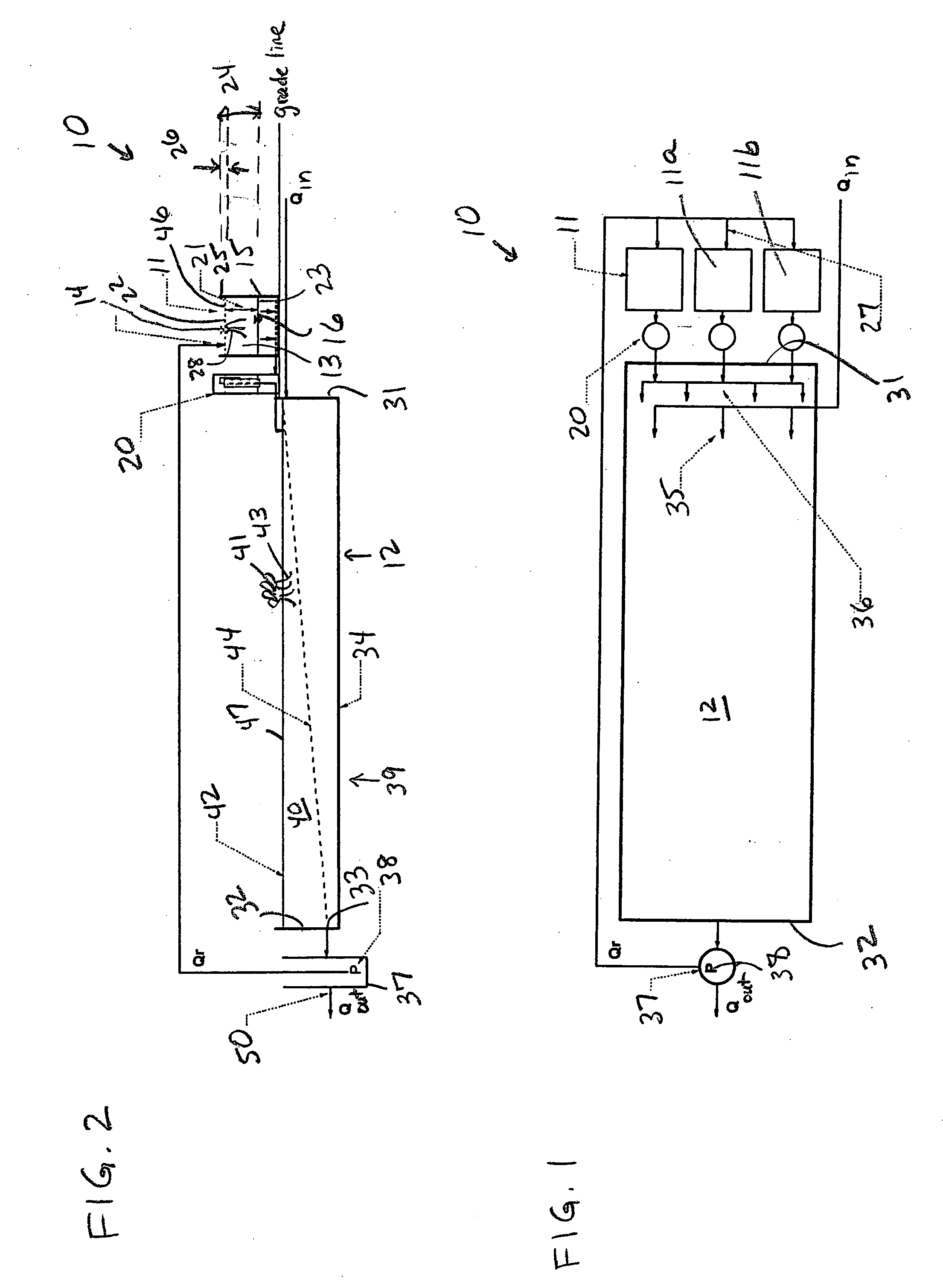

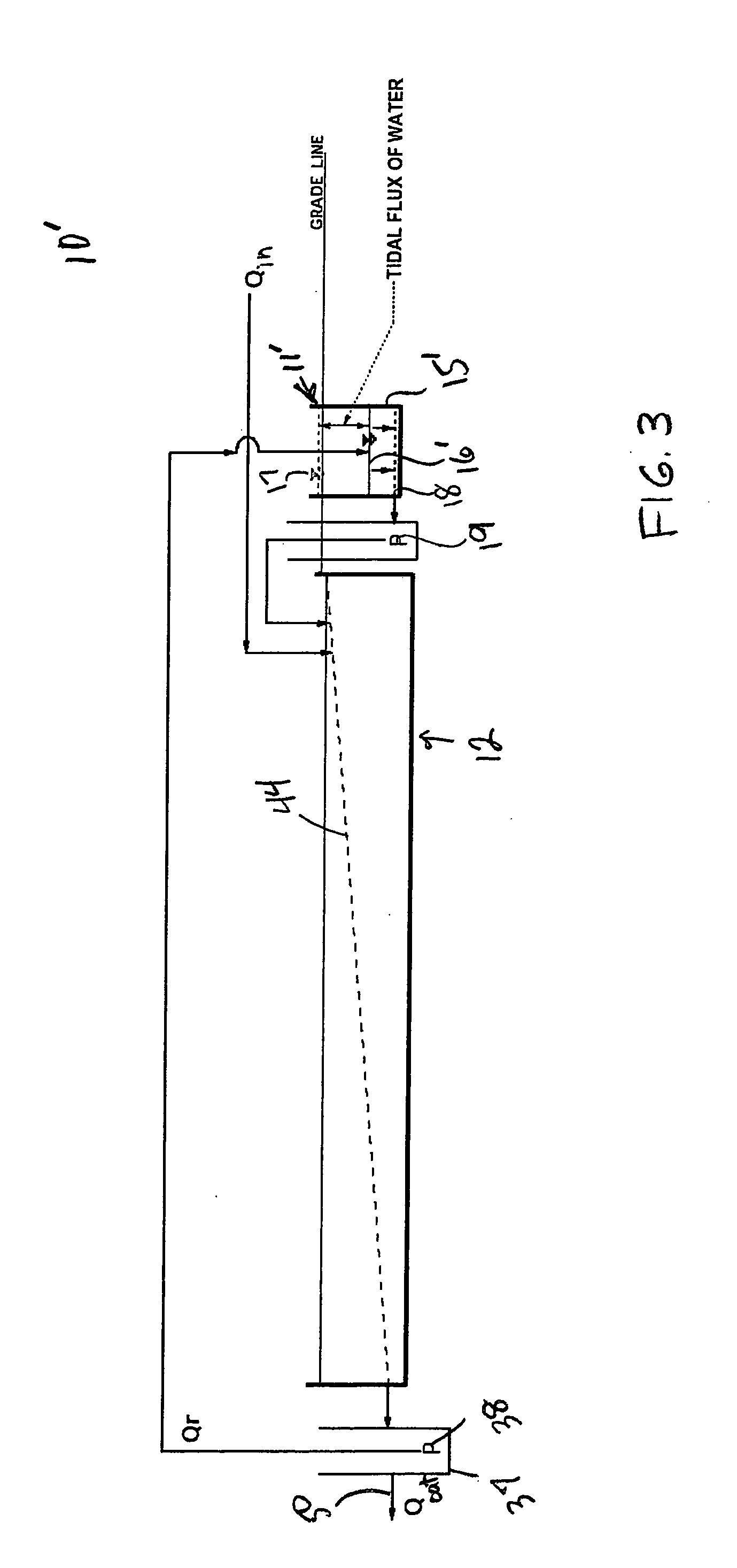

Tidal vertical flow wastewater treatment system and method

InactiveUS20050082222A1Improve performanceIncrease consumptionWater cleaningTreatment using aerobic processesPlant rootsNitrate

A wastewater treatment system includes a vertical flow marsh cell that is adapted to contain media and to support plants having roots extending into the media, the roots and media positioned to contact water flowing downward through the marsh cell during a flooding stage, the media and plant roots providing surfaces to which biofilms can adsorb, the biofilms containing bacteria adapted to adsorb ammonium ions and nitrify ammonium ions to nitrate during an aerated drained phase. The marsh cell is configured to receive water from an outlet of a horizontal wetland that functions essentially anaerobically / anoxically to contain bacteria for transforming nitrate into nitrogen gas. Water to be treated and water exiting the marsh cell outlet are transportable to a wetland inlet, providing dilution of incoming wastewater. Treated water is discharged from the wetland outlet.

Owner:DHARMA IP

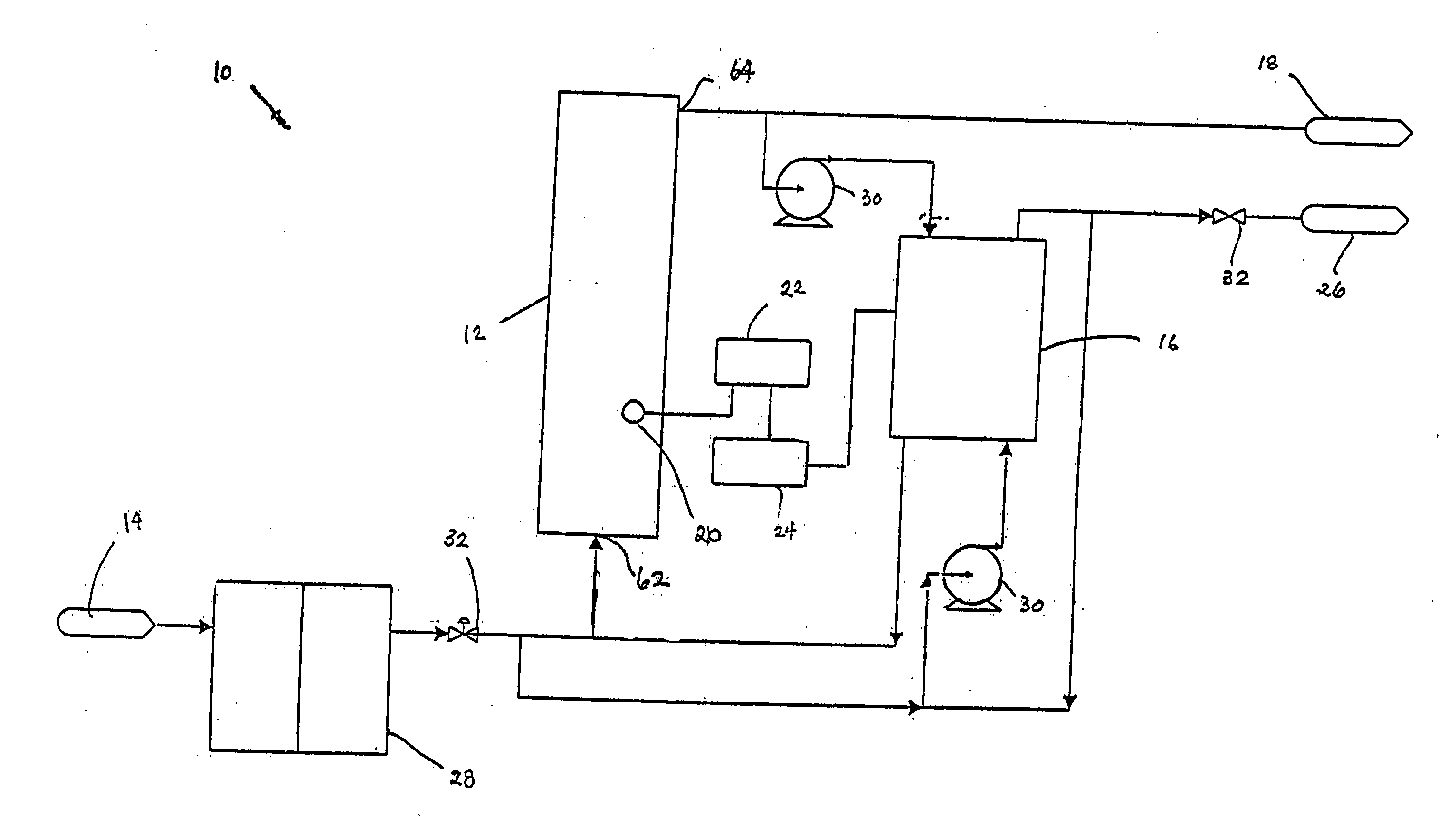

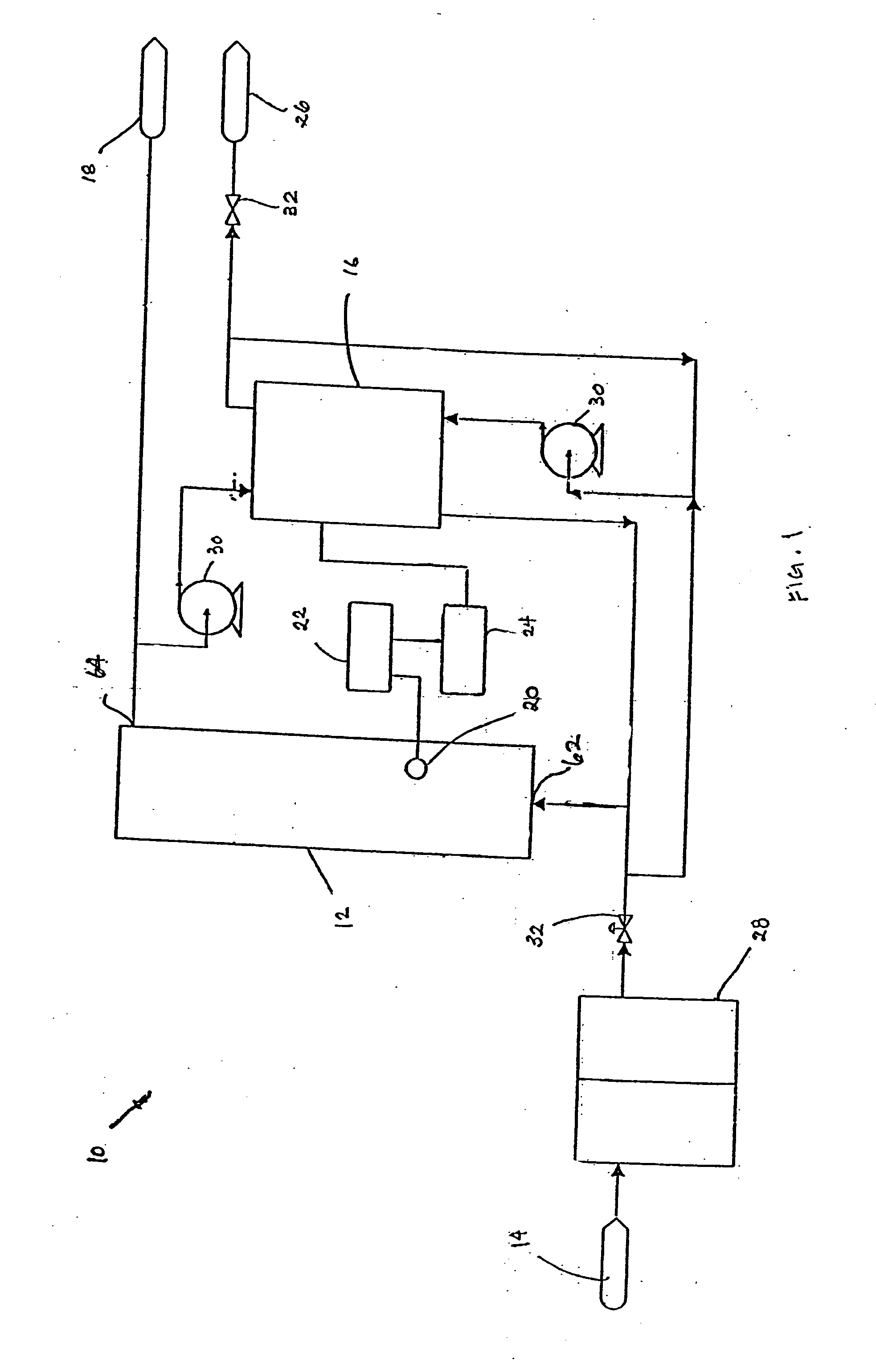

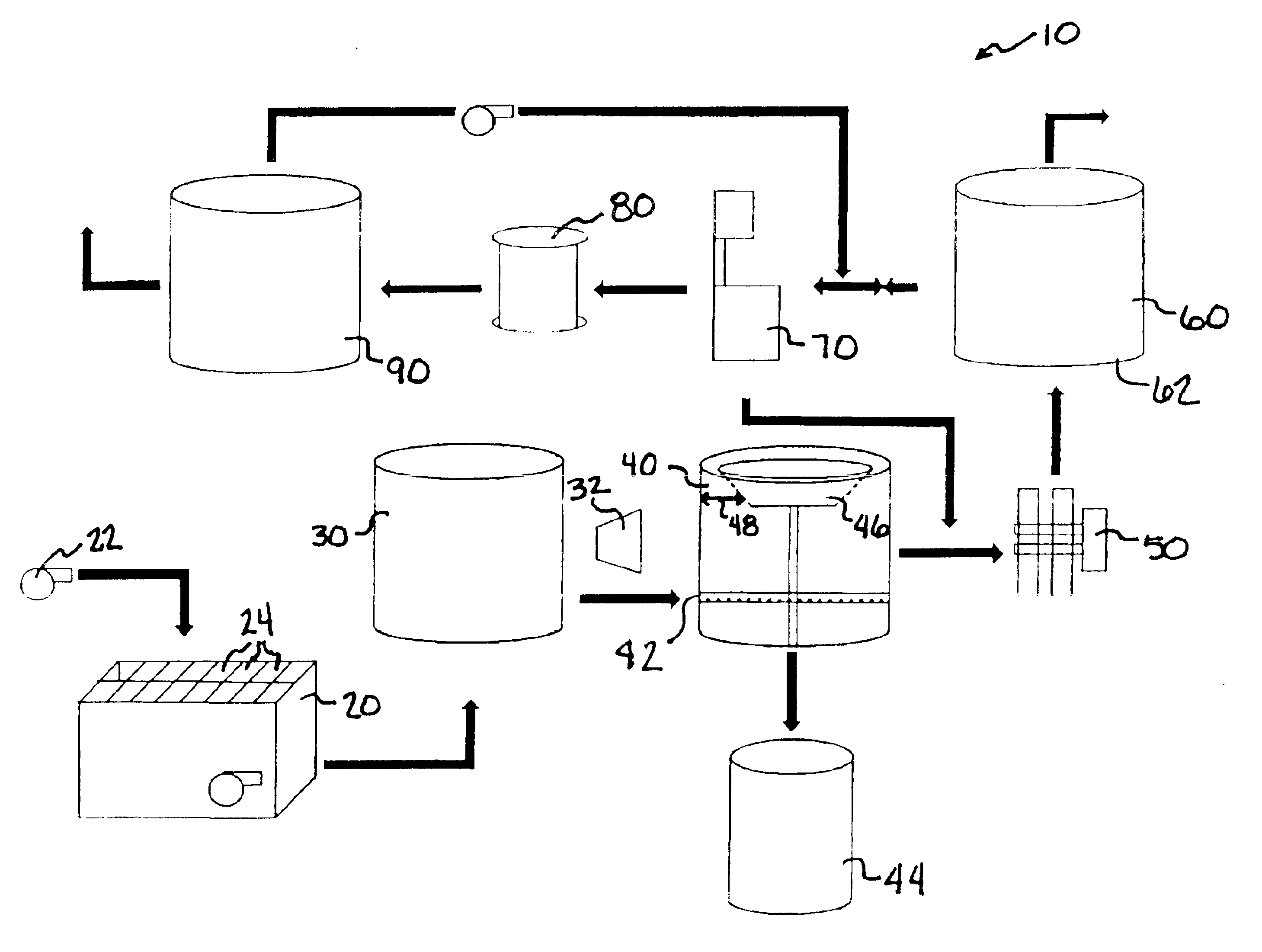

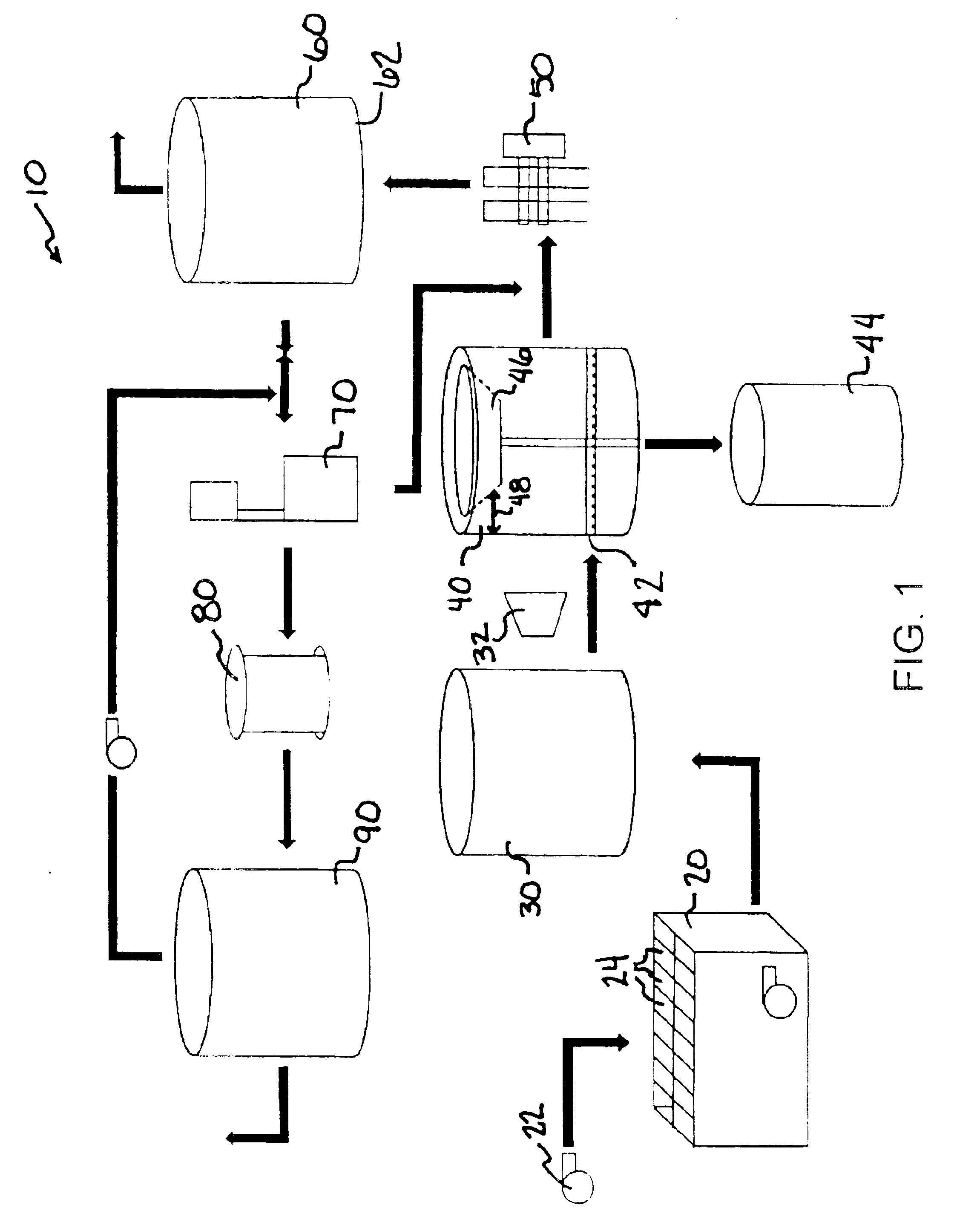

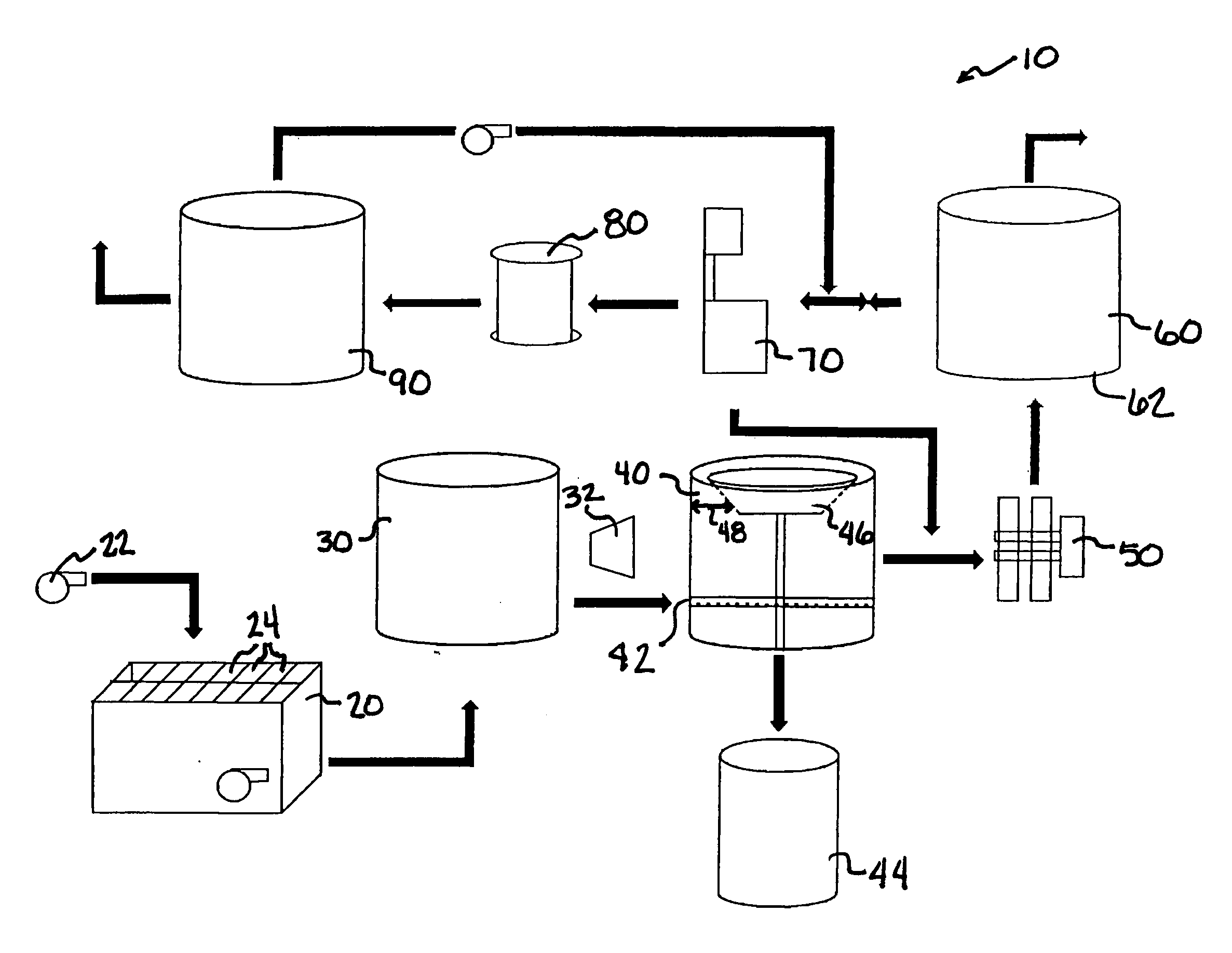

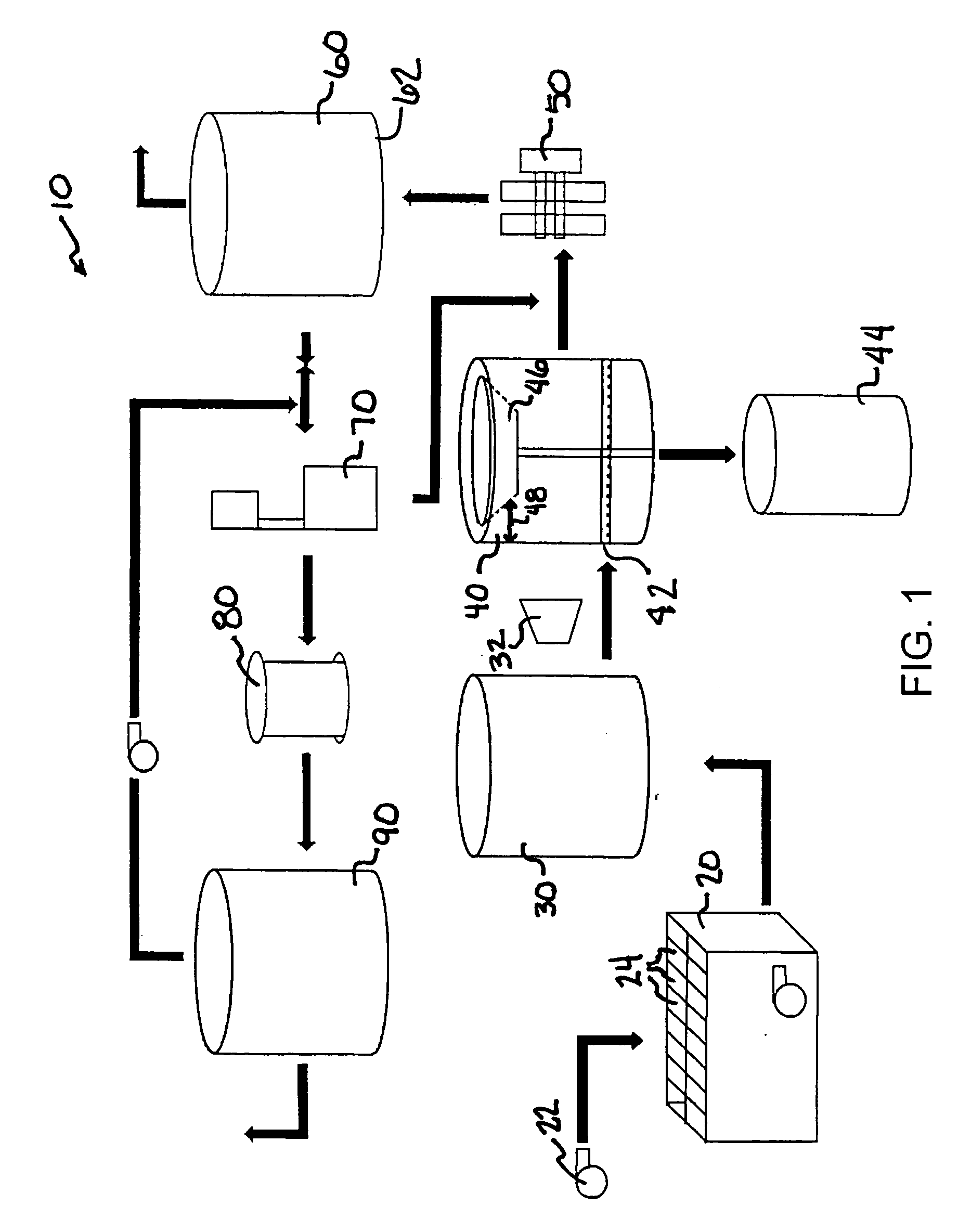

Bilge water reclamation system and process

InactiveUS6902678B2Reduce pollutantsEasy to processLiquid separation by electricityAuxillariesOil retentionBilge

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

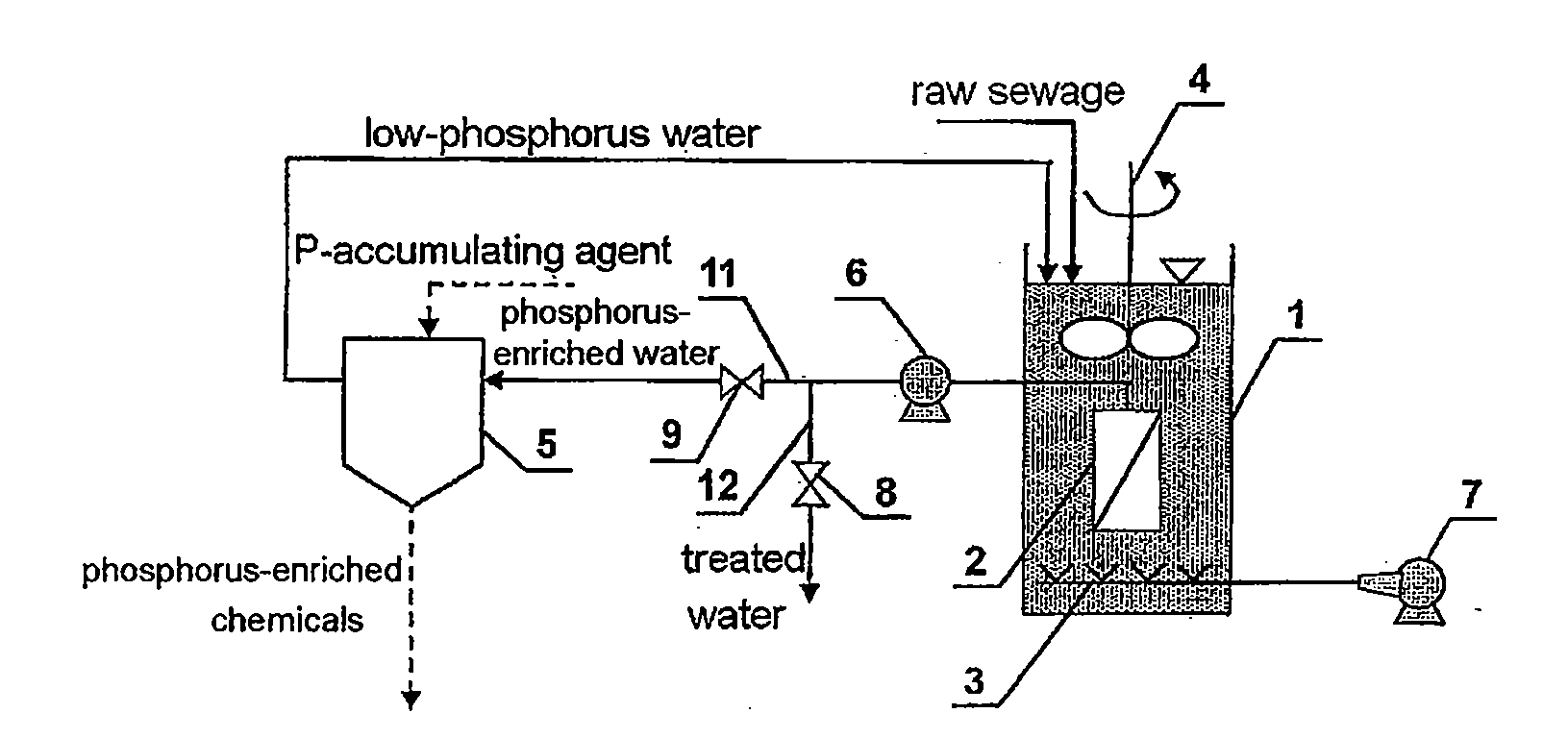

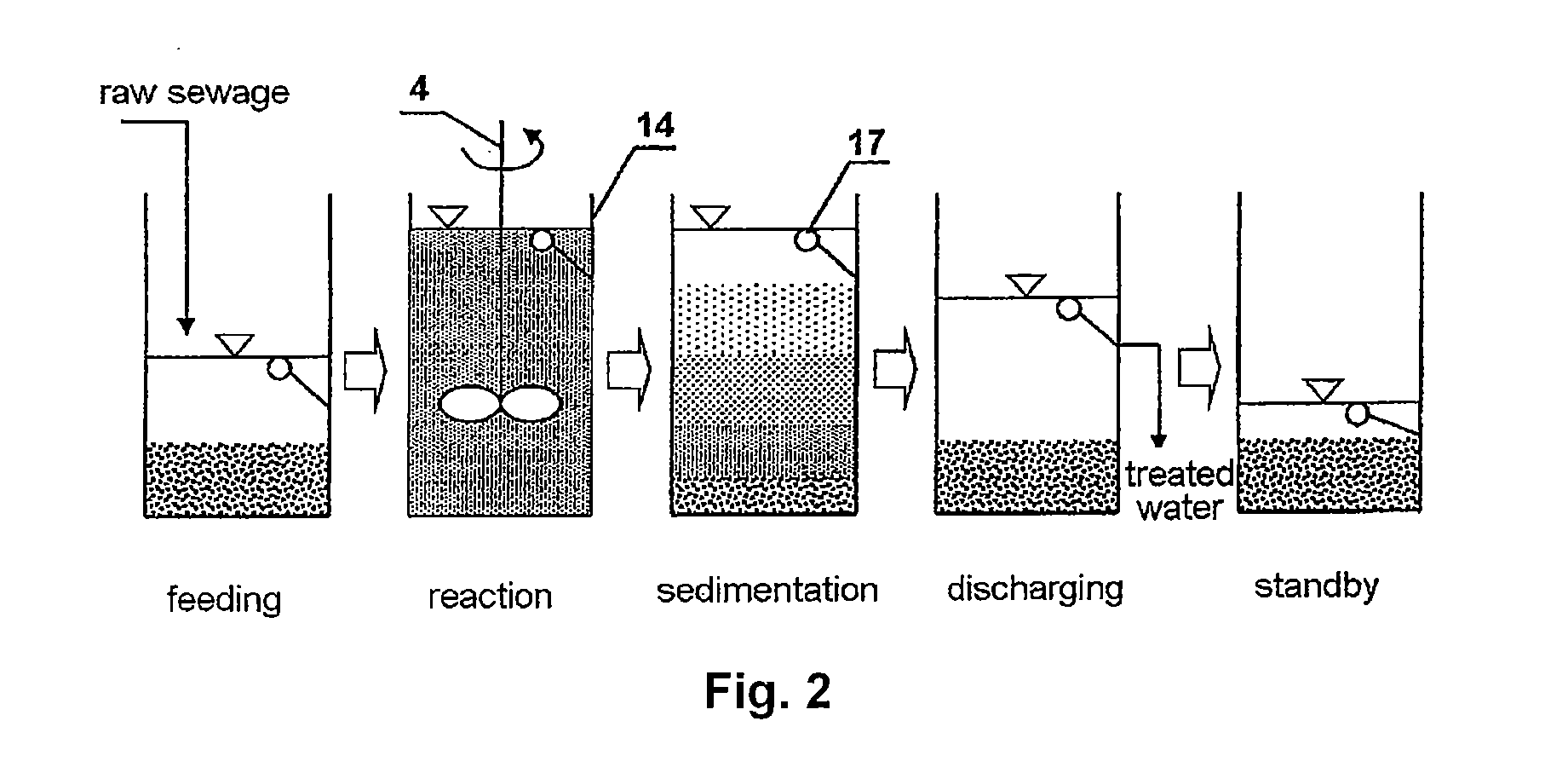

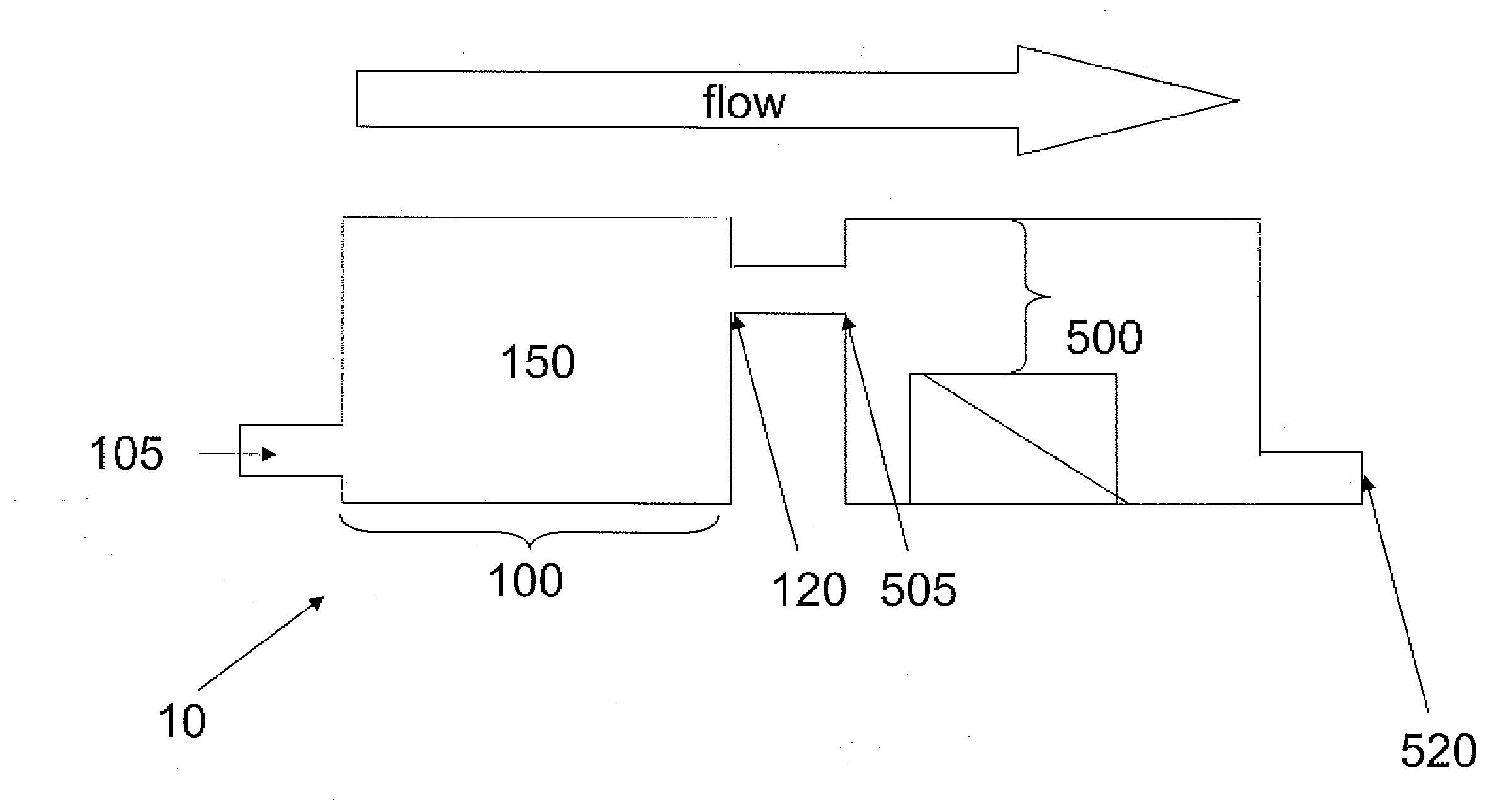

Sewage Treatment Process and System

InactiveUS20120018374A1Reduce space utilizationEfficient removalDialysis systemsTreatment with aerobic and anaerobic processesWater flowSewage

A sewage treatment process is provided, which includes the following steps: a) sewage feeding step, comprising introducing raw sewage into a biological reaction tank (1) to a predetermined time or liquid level; b) reaction step comprising performing aeration and stirring intermittently in the biological reaction tank (1); c) treated water discharging step, comprising performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a first permeate, which is taken as the final treated water; d) standby step comprising stopping aeration in the biological reaction tank (1); and e) phosphorus-enriched water discharging step, comprising keeping anaerobic condition in the biological reaction tank (1) and performing solid-liquid separation of the mixed liquor in the biological reaction tank (1) by a membrane separation device (2) to obtain a second permeate, the second permeate entering inside a phosphorus recycling unit (5) which is set independent from the biological reaction tank (1), the phosphorus recycling unit (5) removing phosphorus from water, the second permeate becoming low-phosphorus water, and the low-phosphorous water flowing back to the biological reaction tank (1); the sewage treatment process runs in cycle by repeating above steps. A corresponding treatment system is also provided.

Owner:SUN YOUFENG

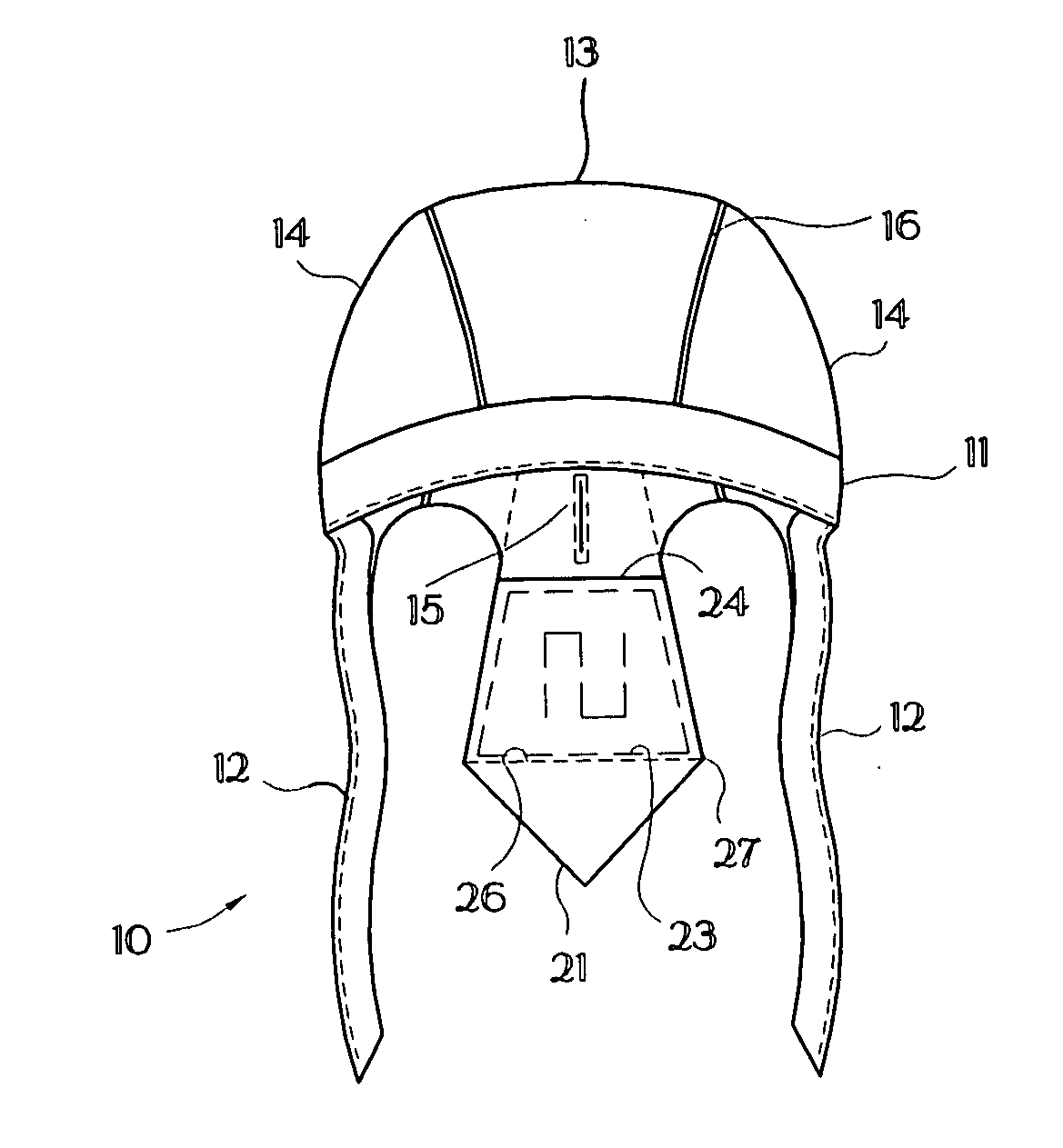

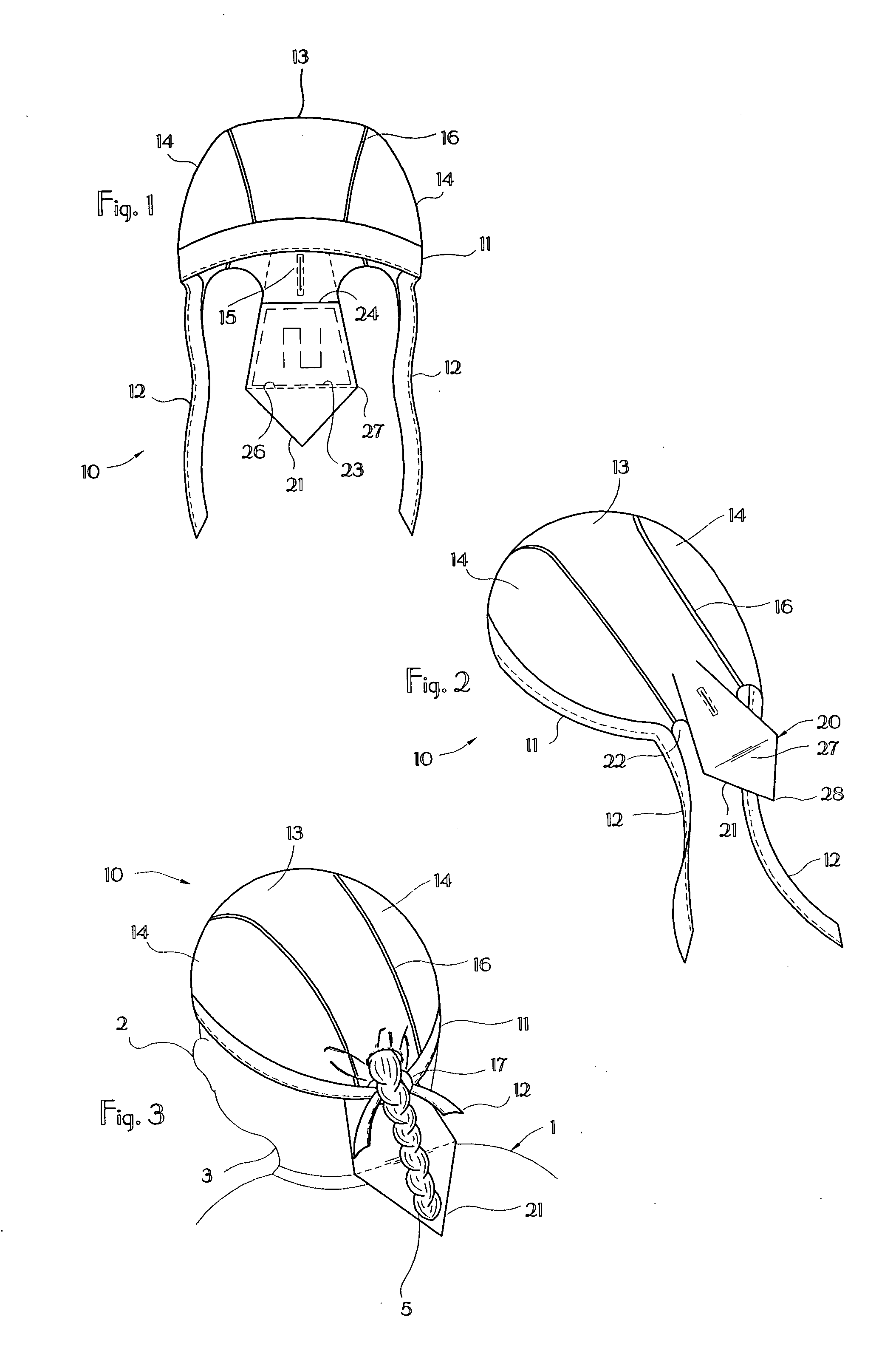

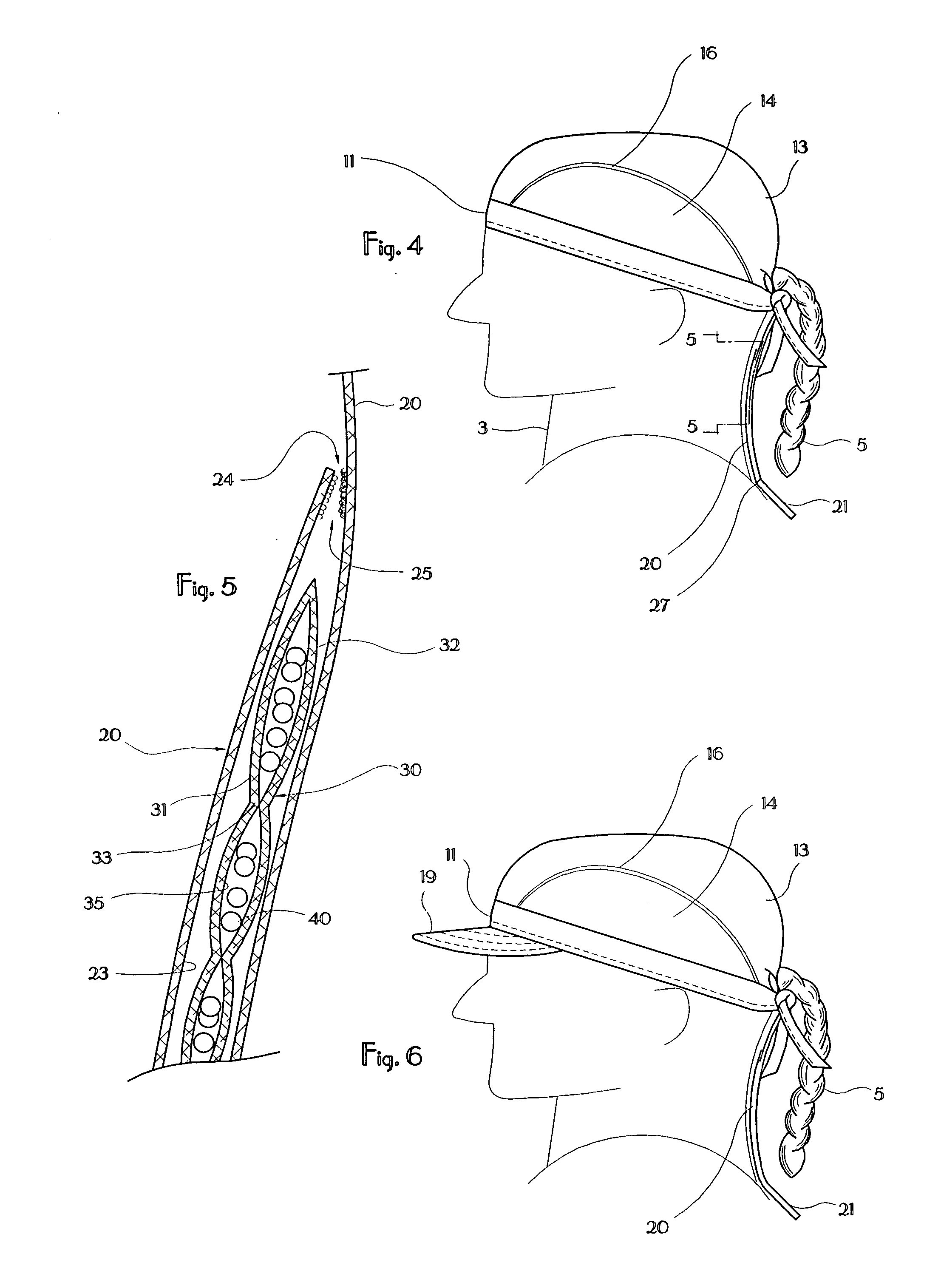

Climate control head cover

InactiveUS20050034215A1Increase rider comfortAvoid interferenceOvergarmentsHatsEvaporationEngineering

A head scarf adapted to be worn typically beneath a motorcycle helmet or other headgear includes an apron depending from its rear beneath its headband. A pocket within the apron holds cooling or warming elements against the wearer's neck to modulate wearer comfort. Thin, baffle-stitched, comfort control packs fit within the pockets, the packs containing water absorption crystals that absorb and thermally treated water without substantial dripping or rapid evaporation. A commercially available warming envelope may be substituted for convenience when appropriate. A triangular tail beneath the pocket helps hold the pocket in place against the neck, and a pony-tail aperture above the pocket prevents a wearer's long hair from interfering with the pocket's juxtaposition on the wearer's neck.

Owner:HARRISON JONE E +1

Multicomponent composite flocculating setting agent and use in arsenic contamination water treatment

ActiveCN101503239AEfficient removalGood arsenic removal effectWater/sewage treatment by flocculation/precipitationArsenic pollutionEarth surface

The invention belongs to the technical field of river water body pollution control and in particular relates to a multiple-element compound flocculating settling agent and the application of the multiple-element compounded flocculating settling agent in arsenic pollution water body treatment. The multiple-element compounded flocculating settling agent is prepared by compounding malysite, aluminium salt, hypermanganate, polyacrylamide and aqueous solution. The multiple-element compounded flocculating settling agent can be applied in the arsenic pollution water body treatment to remove arsenic in the arsenic pollutant water body. The concentration of the arsenic in the treated water can meet or is superior to the specified requirement of three types of water on the arsenic concentration in the national earth surface water environment quality standard (less than 0.05 mg / L). The invention also can be used for removing heavy metals such as copper, chromium, cadmium, lead and the like in water by sedimentation. The multiple-element compounded flocculating settling agent can be used together with a multiple-element compounded metal oxide arsenic removal setting agent in static or flowing arsenic pollution water body treatment for removing the arsenic in the water body polluted by arsenic.

Owner:RES CENT FOR ECO ENVIRONMENTAL SCI THE CHINESE ACAD OF SCI

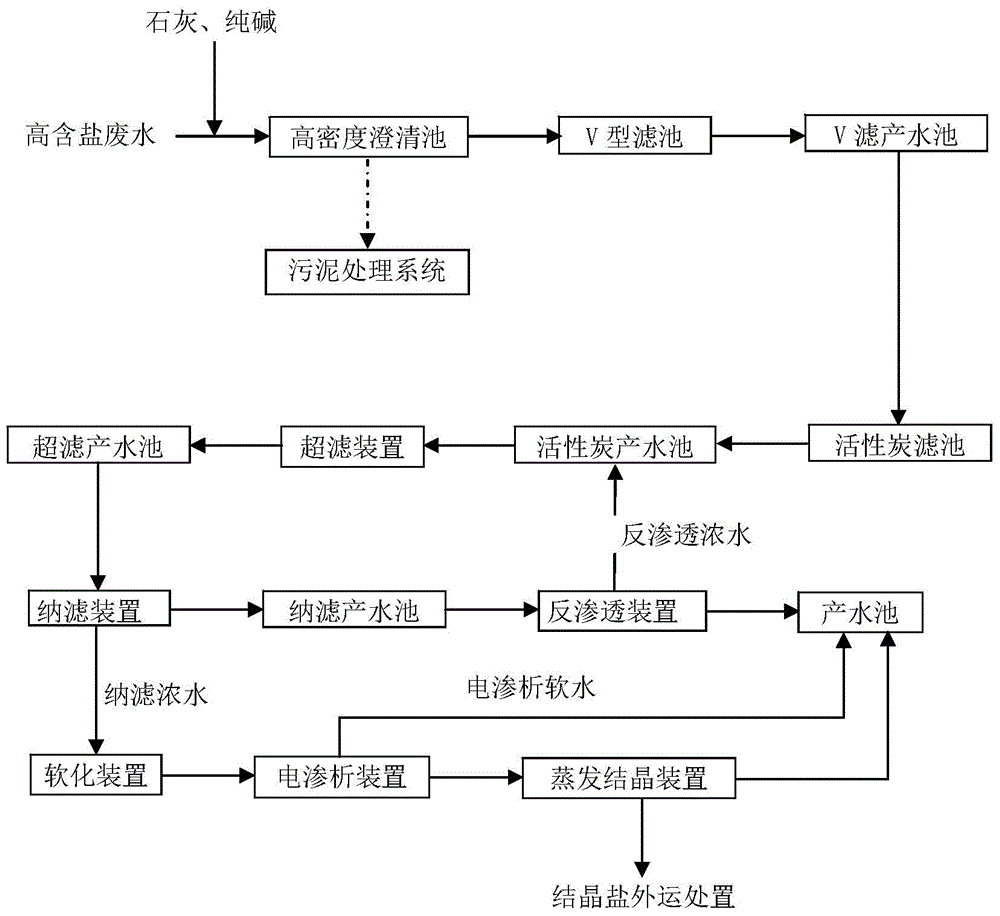

Zero-emission integrated process for treatment and reuse of high-salinity wastewater

ActiveCN104445788AHigh filtration precisionEasy to handleGeneral water supply conservationMultistage water/sewage treatmentSoftened waterEvaporation

The invention discloses a zero-emission integrated process for treatment and reuse of high-salinity wastewater. The invention relates to a softening desalination treatment technology of water and particularly relates to a reuse treatment system for reverse osmosis concentrated water containing low-concentration organic matters which can achieve the requirement of 'zero emission'. The integrated process comprises the following steps: (1) firstly softening and pre-treating the high-salinity wastewater; (2) acquiring pre-treated water by virtue of activated carbon adsorption and an ultrafiltration device; (3) acquiring nanofiltration softened water and nanofiltration concentrated water by virtue of a nanofiltration device; (4) acquiring reverse osmosis softened water and reverse osmosis concentrated water by virtue of a reverse osmosis device; (5) acquiring electrodialysis softened water and electrodialysis concentrated water by virtue of an electrodialysis device; and (6) carrying out evaporation crystallization treatment on the electrodialysis concentrated water by virtue of an evaporation-crystallization device, regularly outwards transporting salts generated by the evaporation crystallization, feeding generated salt into a water-producing tank to enter a reuse system and finally completing the treatment and reuse of high-salinity wastewater. The integrated process is mainly used for the integrated treatment of the high-salinity wastewater.

Owner:XINJIANG DELAND

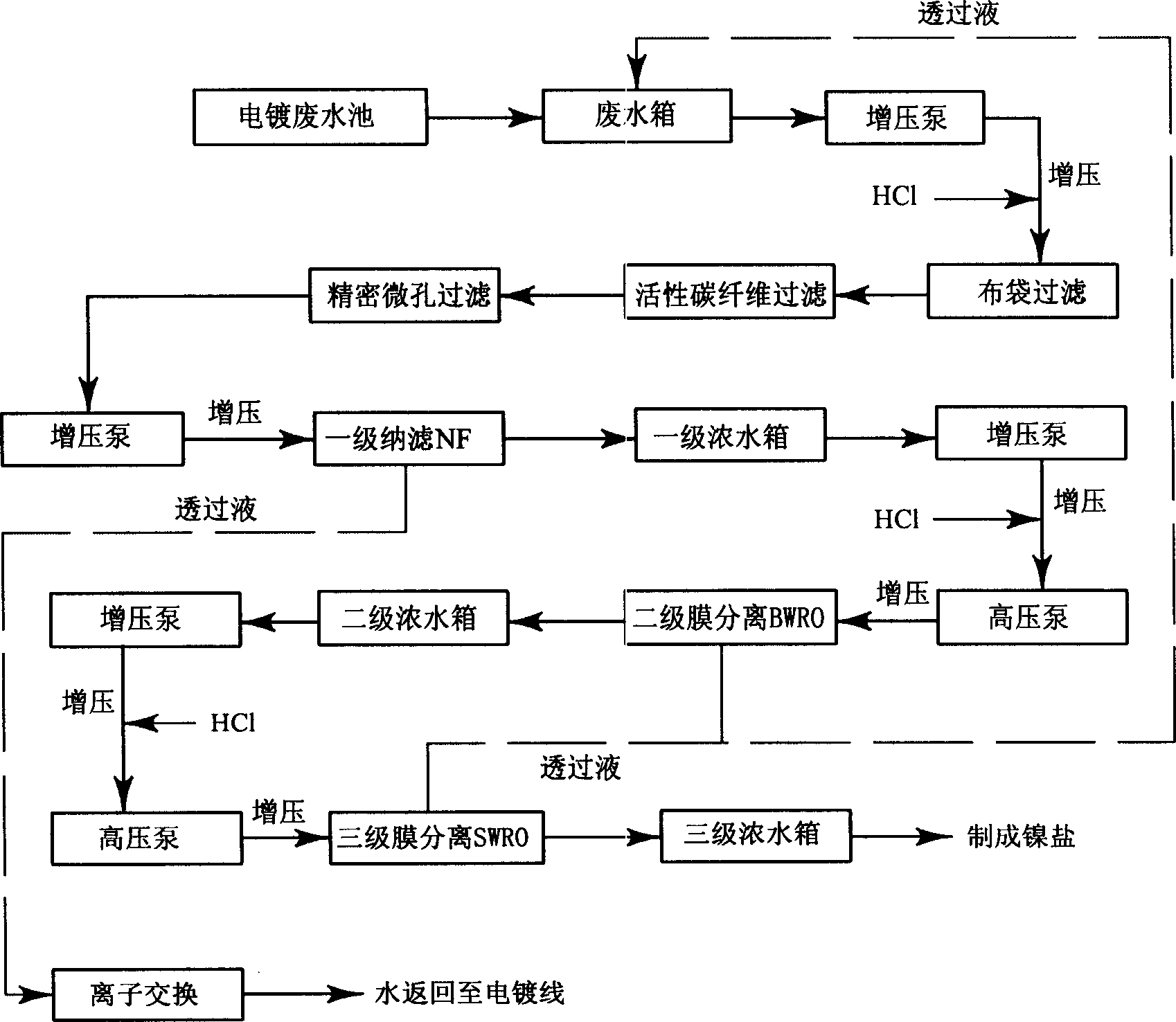

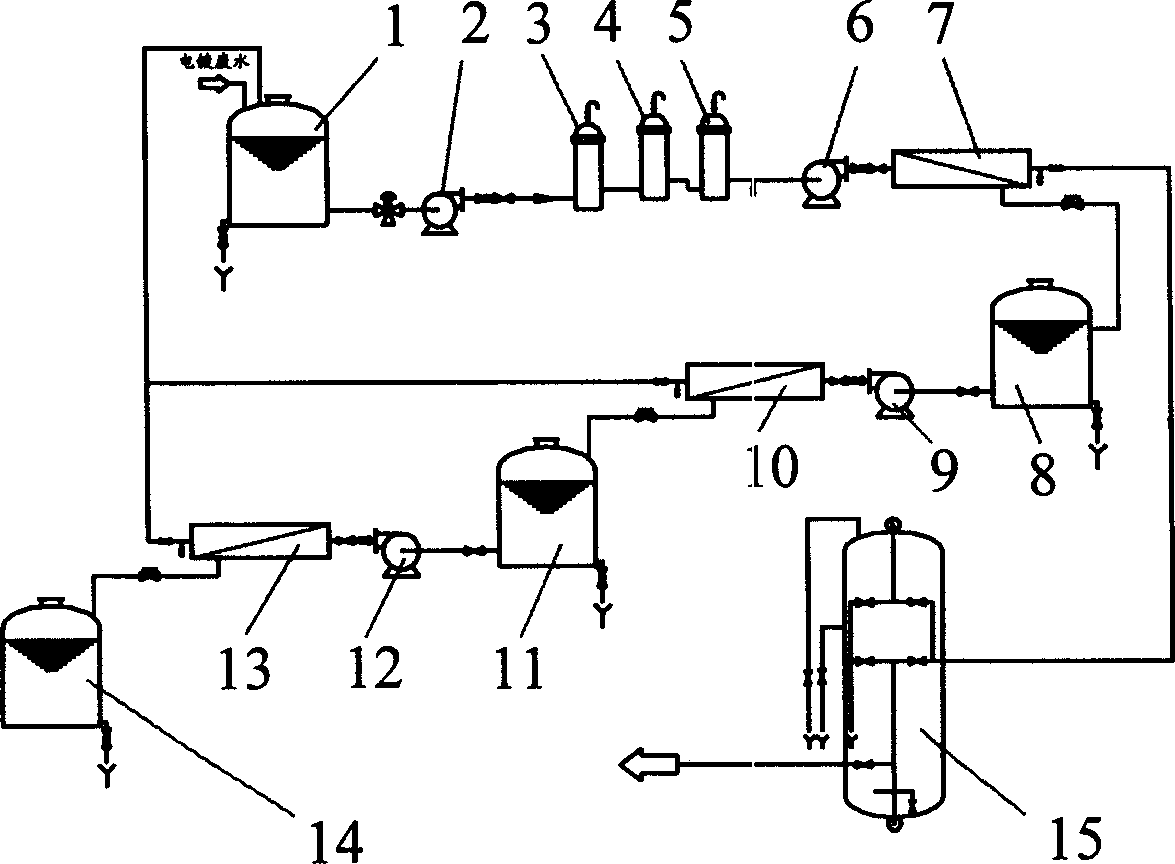

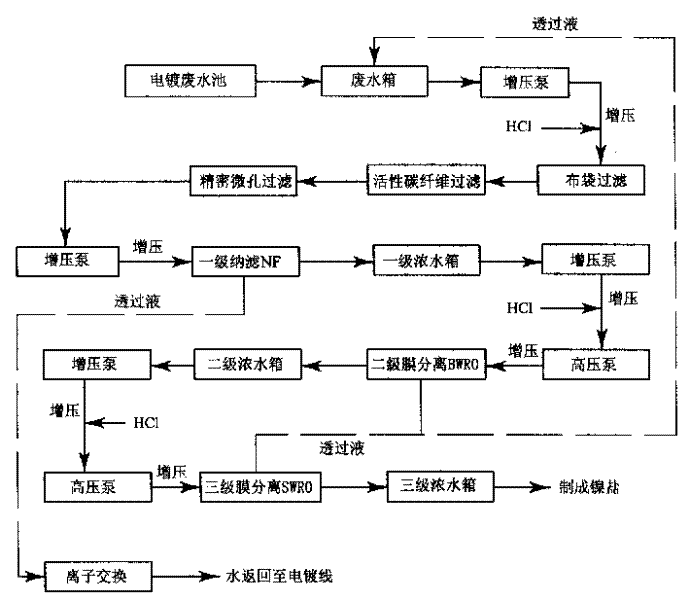

Membrane separation method of zero discharge of electroplating waste water treatment

InactiveCN1590322AAchieving zero emissionsOut of pollutionWater/sewage treatmentMultistage water/sewage treatmentSeparation technologyTreated water

A membrane separation method for reclaiming the electroplating sewage includes liqui material treating, lifting, pressurizing and delivering. It features the 3-class membrane separation to remove impurities, organic substances, fine suspended substances, Na ions, heavy metal ions, inorganic ions, etc. the regulation of pH value to prevent deposition of hydroxide, periodical automatic flushing and reuse of treated water.

Owner:HANGZHOU WATER TREATMENT TECH RES & DEV CENT NAT BUREAU OF OCEANGRAPHY

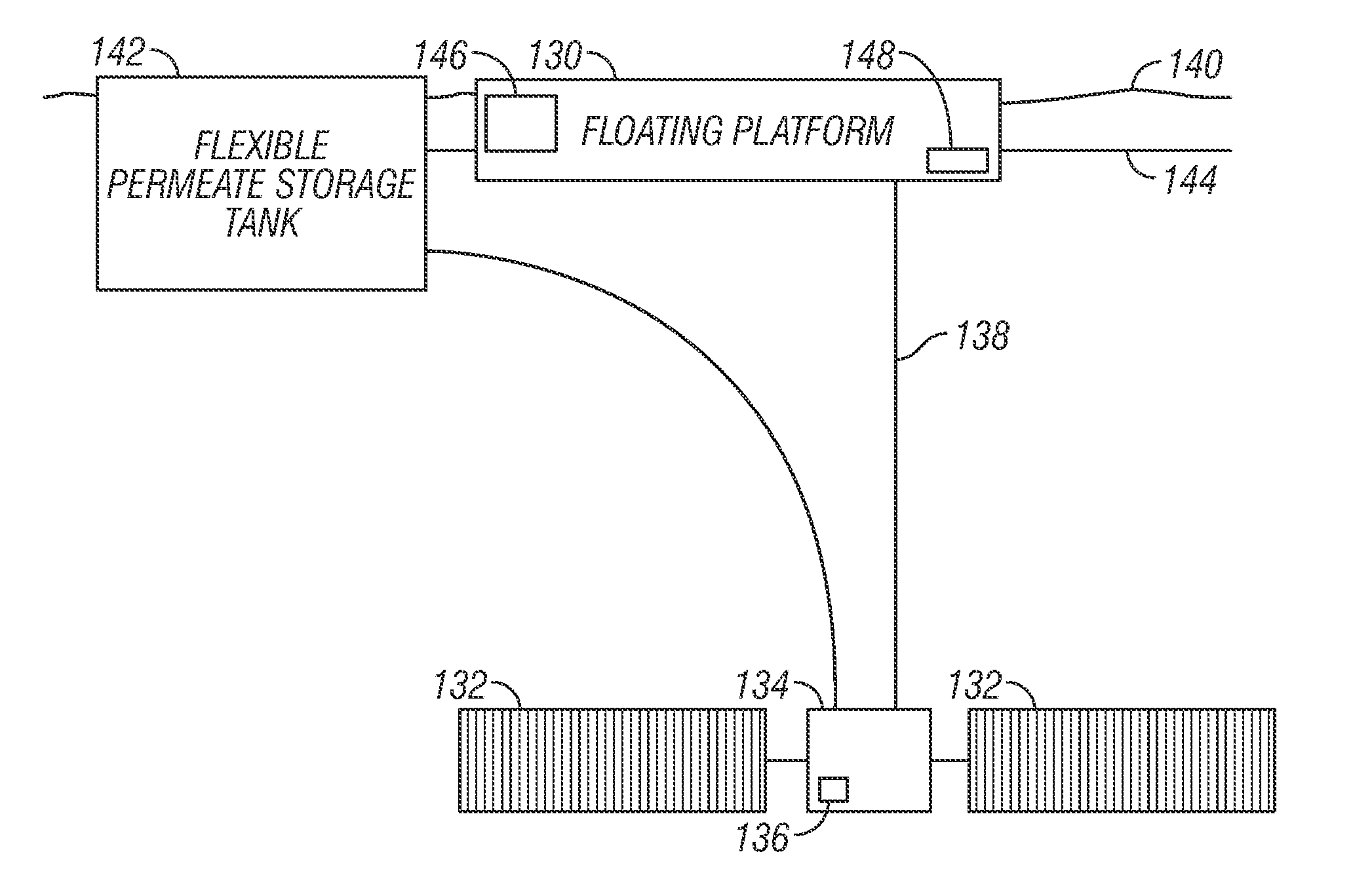

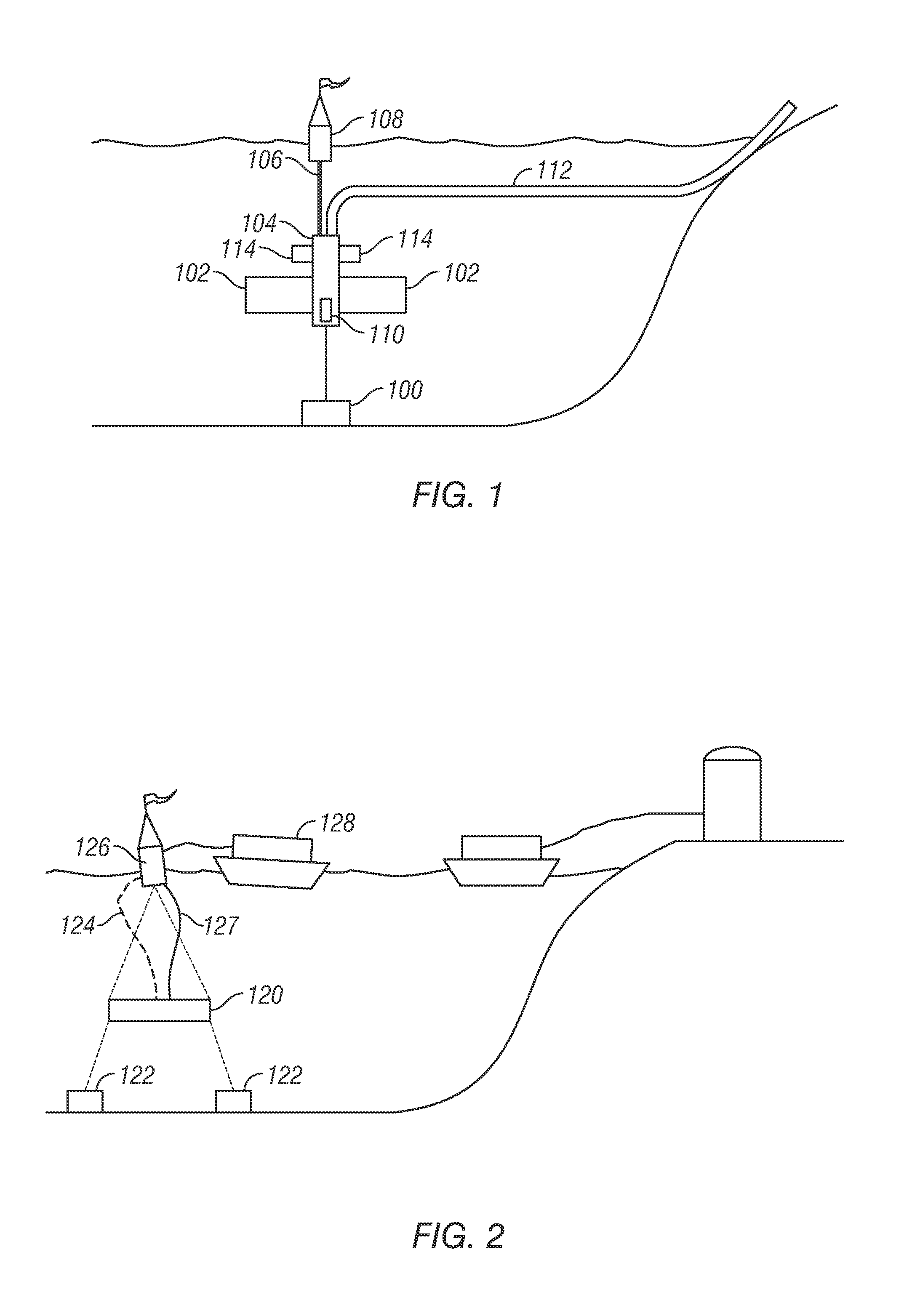

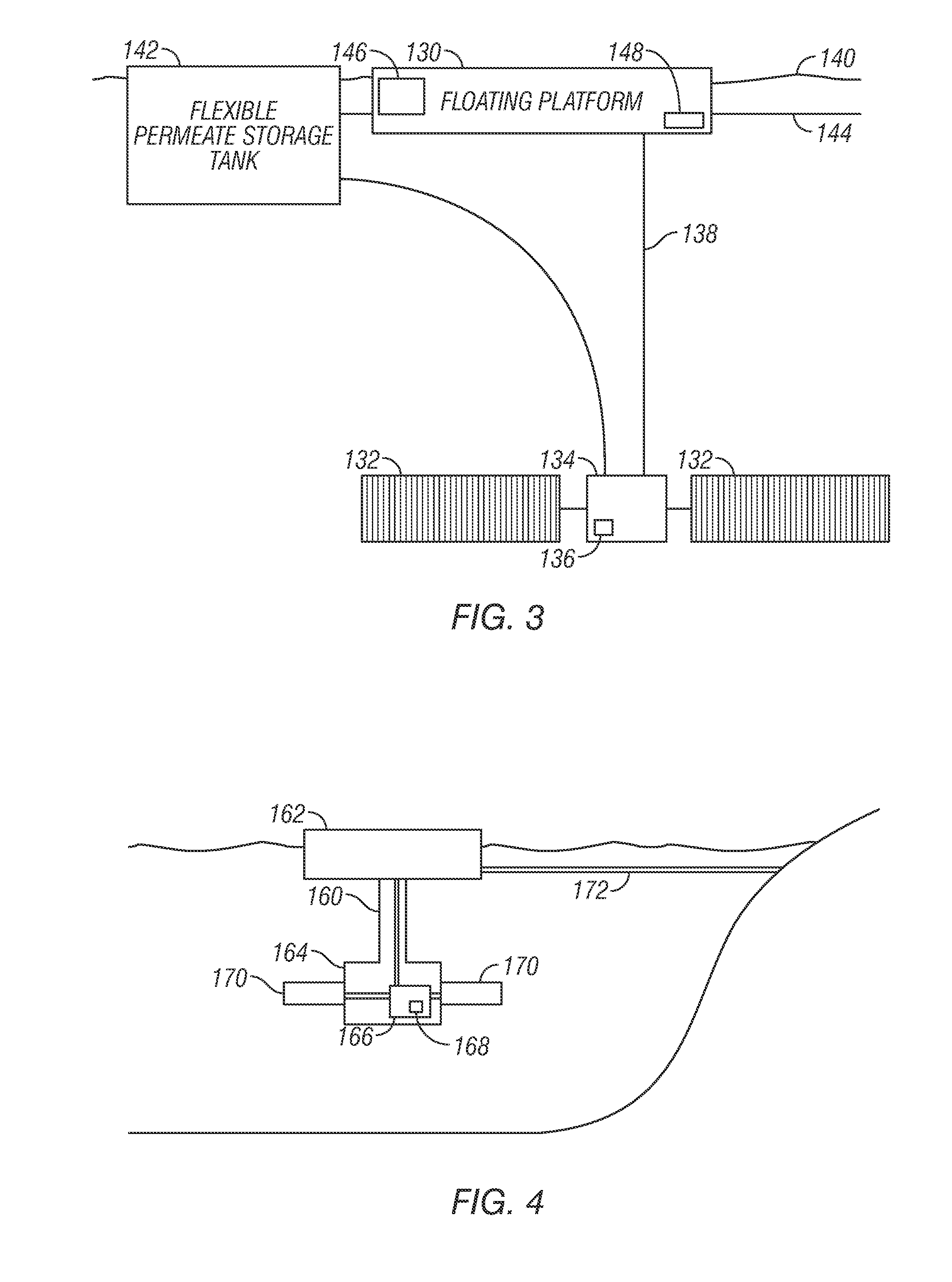

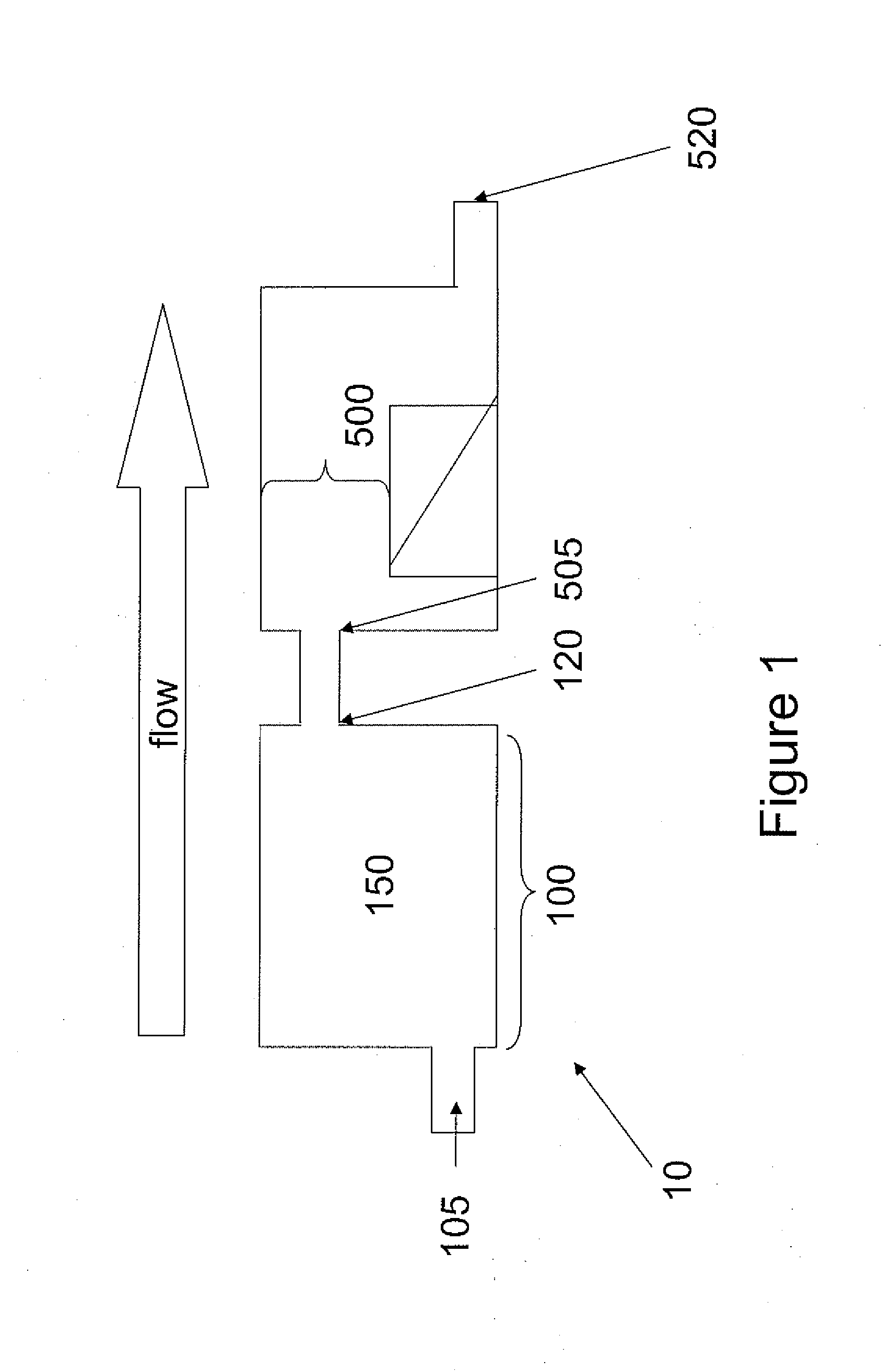

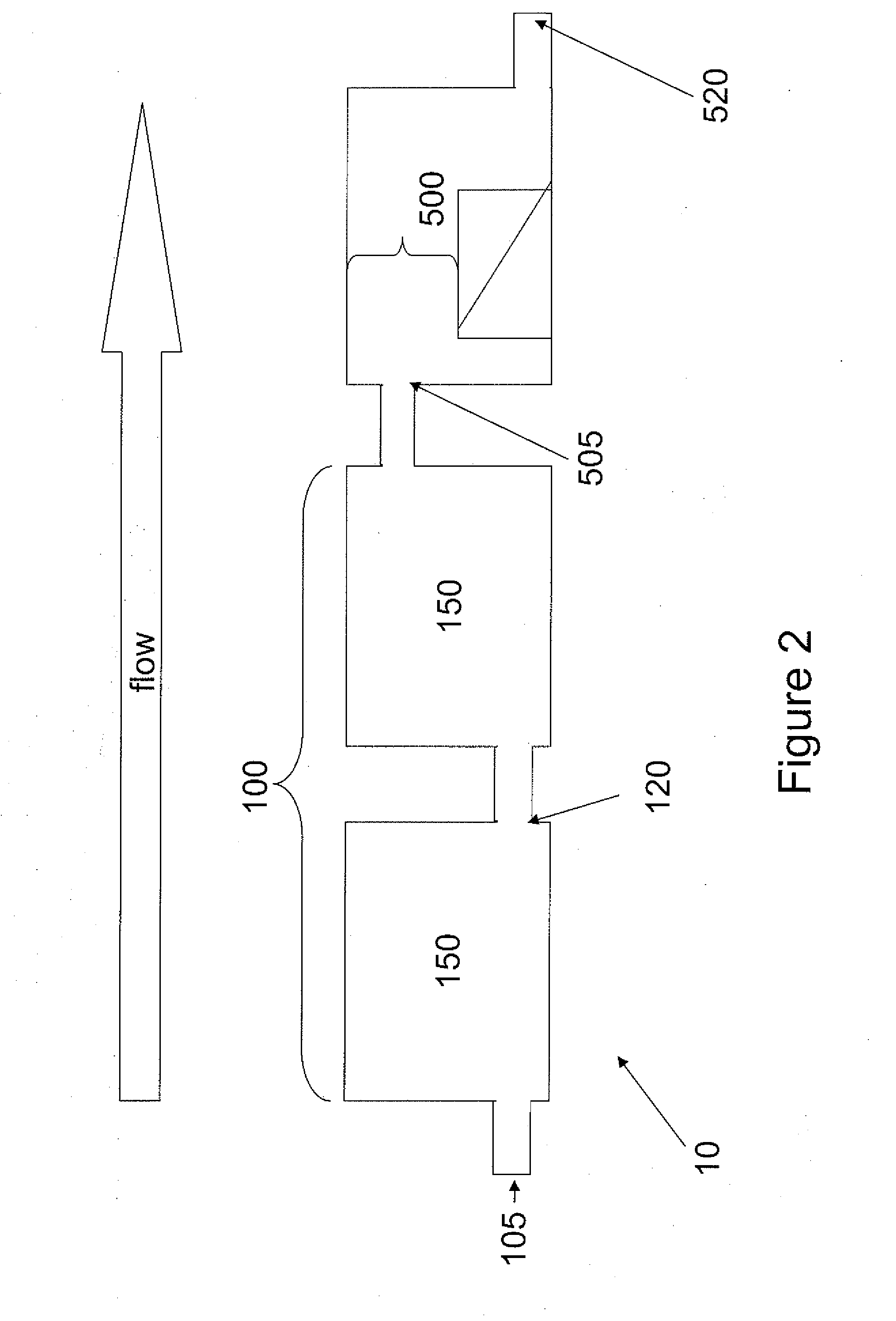

Water treatment systems and methods

InactiveUS20100051546A1Reduce sulfate concentrationReduce concentrationMembranesWater treatment parameter controlWater treatment systemTreated water

A water treatment and conveyance system includes a plurality of substantially planar membrane elements arranged in a stack. Adjacent membrane elements in the stack are spaced apart from one another by element spacers. The element spacers have one or more openings that are in fluid communication with the permeate sides of adjacent membrane elements. The openings are sealed off from the source water sides of the membrane elements by one or more sealing members. The openings in the element spacers cooperate to define a conduit for the filtered permeate. Methods for treating water and conveying treated water are also provided.

Owner:DXV WATER TECH

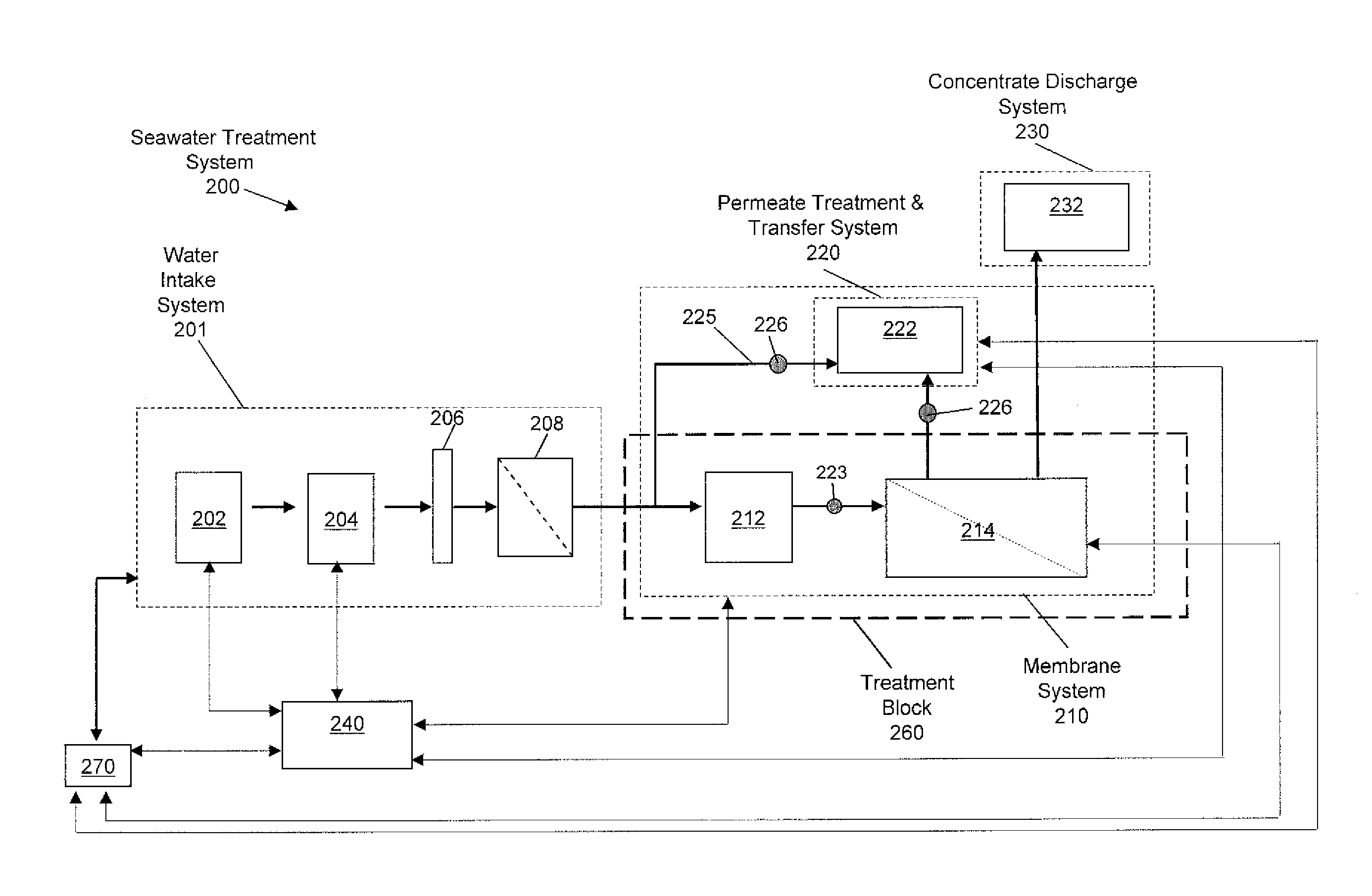

Integrated water processing technology

InactiveUS20100282654A1Quality improvementOptimizes fluxTreatment using aerobic processesWater/sewage treatment by irradiationWater processingTreated water

The invention provides a Bioreactor-Membrane Integrated Technology (B-MIT), comprising an immobilized cellular system bioreactor that initially treats raw water, functionally integrated with a membrane system where the biologically treated water is filtered to generate high quality finished water.

Owner:BLUMETRIC ENVIRONMENTAL

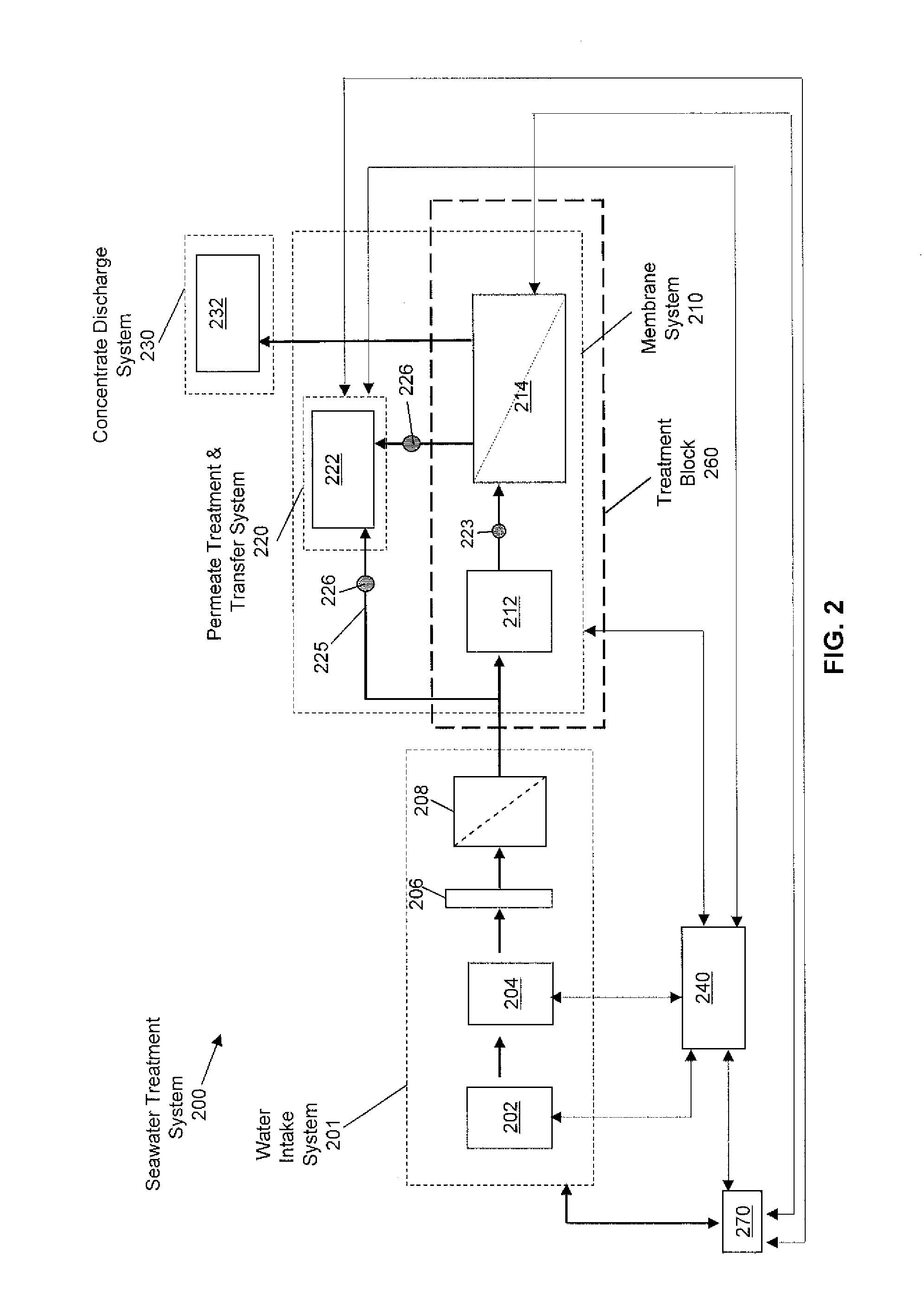

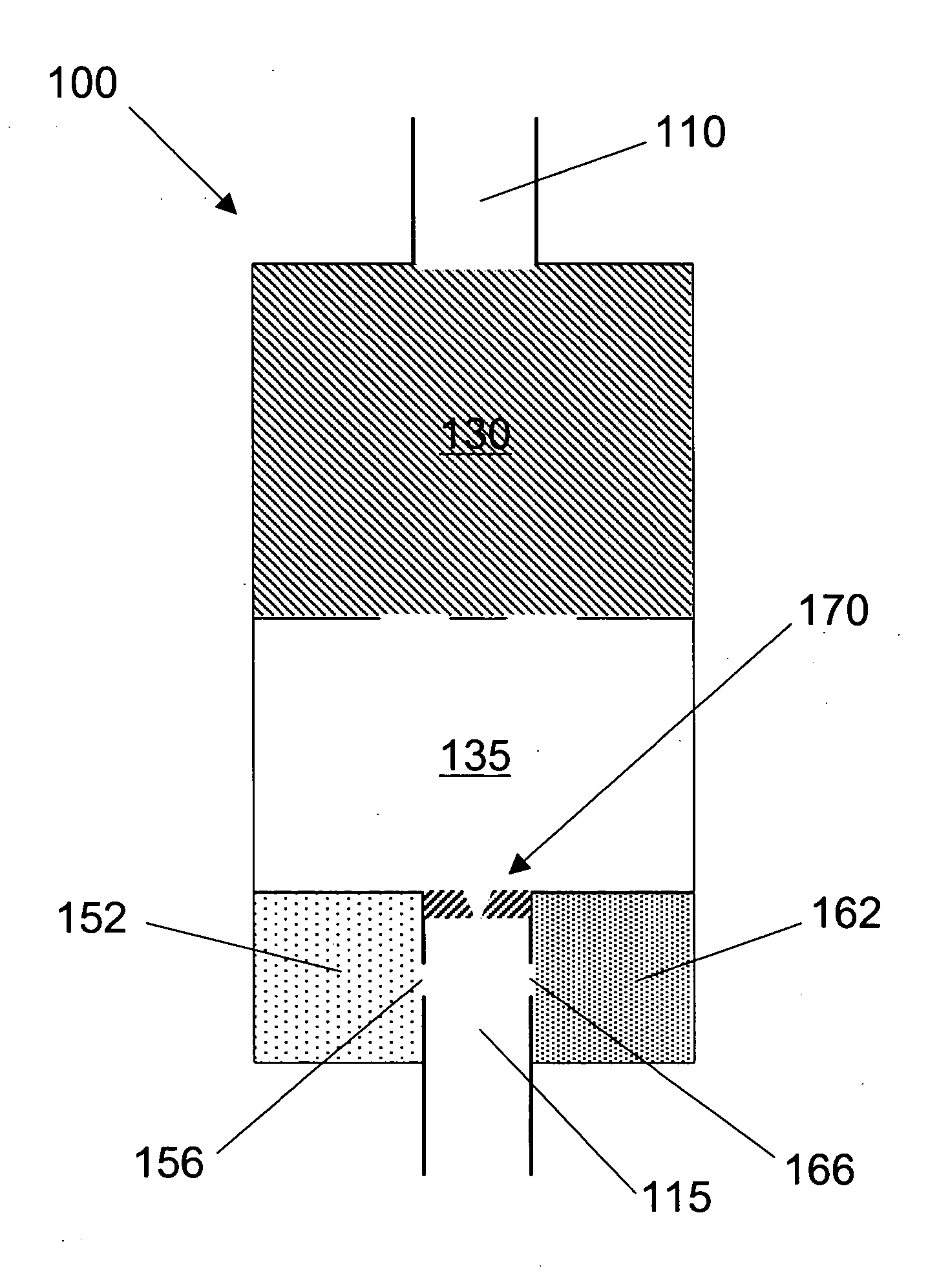

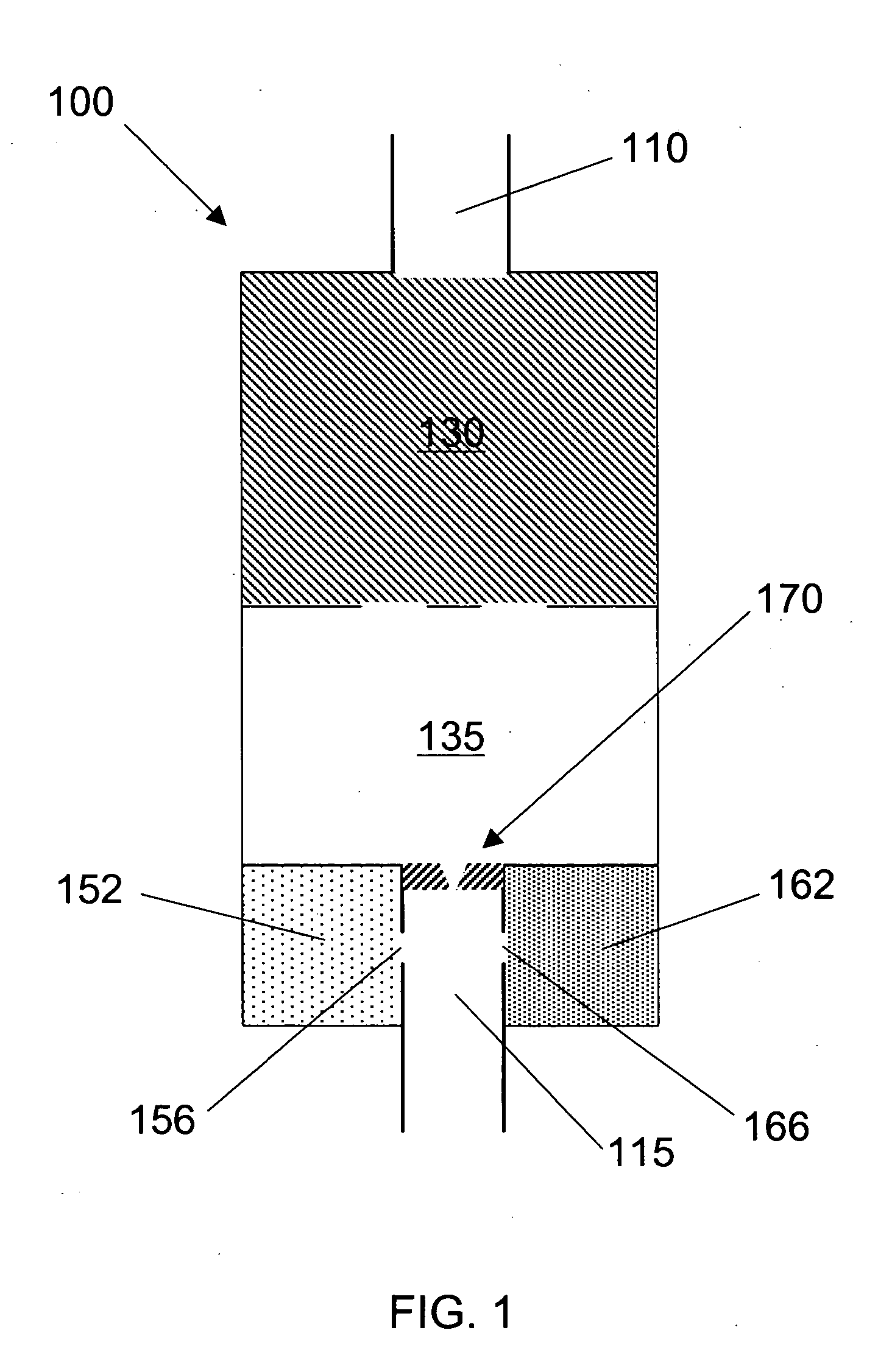

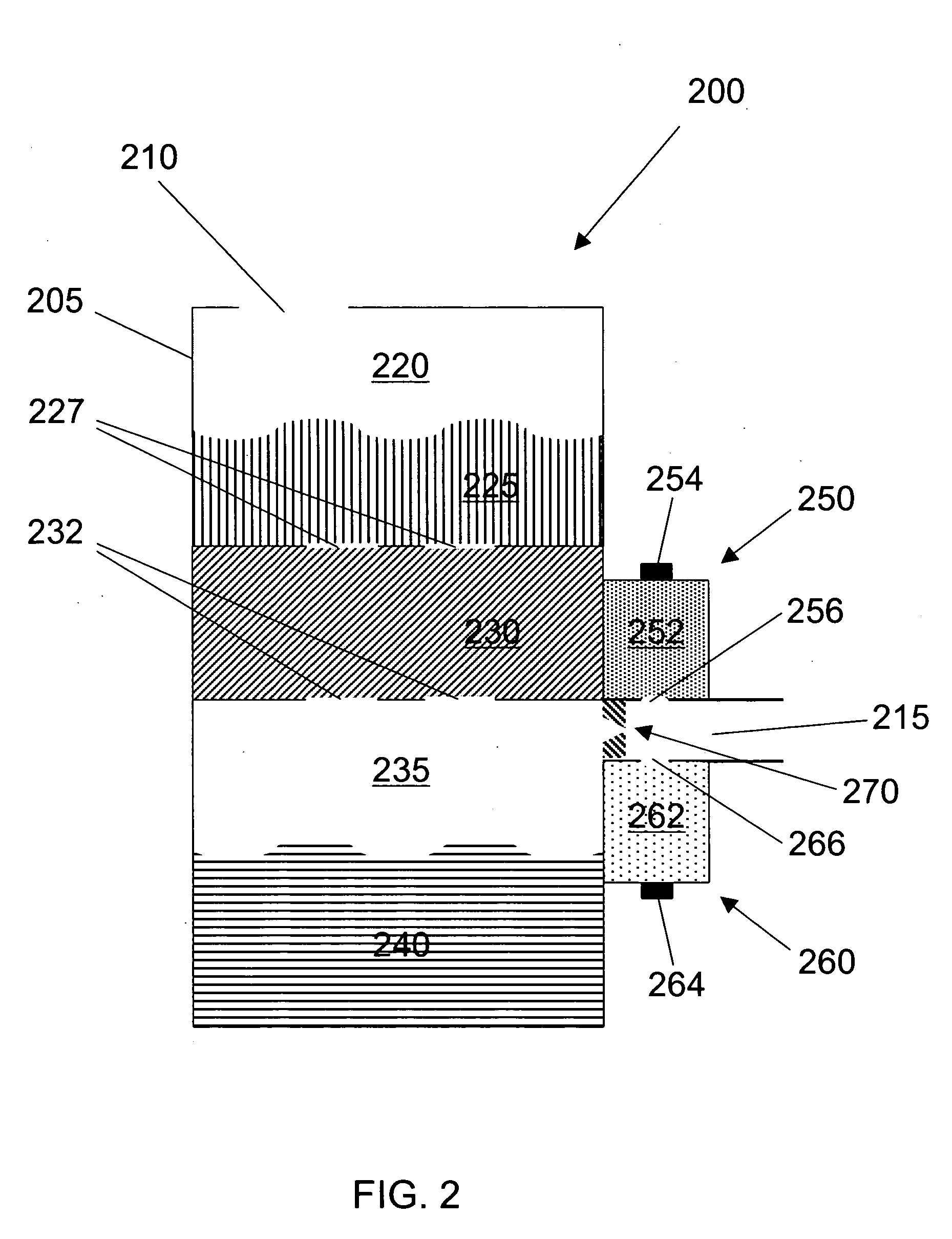

Method and control devices for production of consistent water quality from membrane-based water treatment for use in improved hydrocarbon recovery operations

Owner:CLEAN H2O TECH LLC

Filtered water enhancements

ActiveUS20050133427A1Treatment involving filtrationWater treatment locationHerbal supplementEnvironmental engineering

A system for enhancing water is described. The system includes a housing with an inlet and an outlet, source water at the inlet, which can flow through a filter component in the housing and thus become treated water, and at least one enhancement module that can dispense an enhancement into the treated water as it flows through the outlet. Water can flow through the system only by the force of gravity, pressure in a building's water line, and / or hand pumps. Enhancement that can be used in the system include flavorings, dyes, minerals, vitamins, herbal supplements, nutritional supplements, phytonutrients, probiotics, homoepathic remedies, amino acids, enzymes, hormones, standard prescription medications, and over-the-counter medications, and combinations thereof. A control is also provided, through which a consumer can regulate an amount of enhancement that is added to the treated water.

Owner:THE CLOROX CO

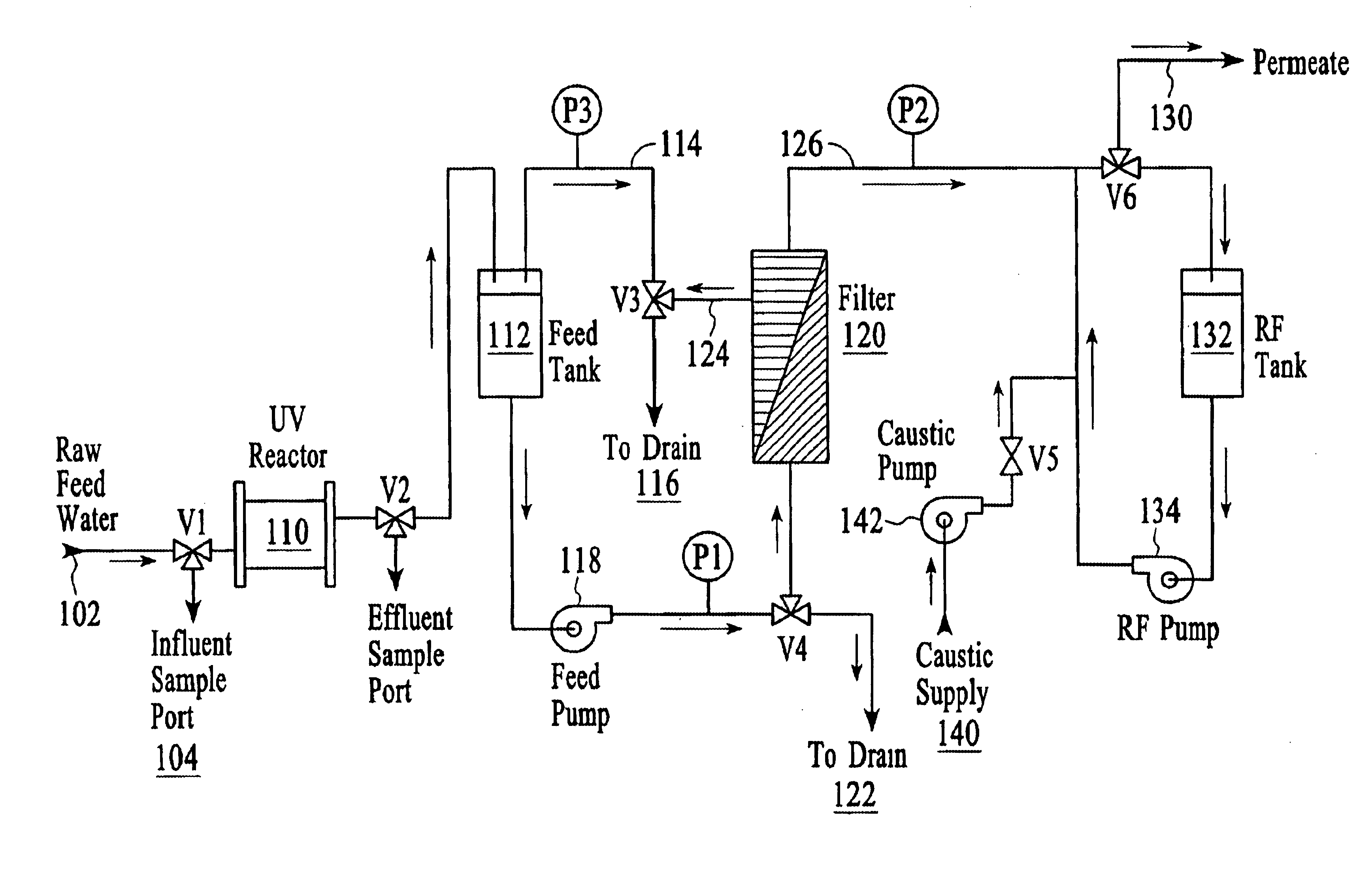

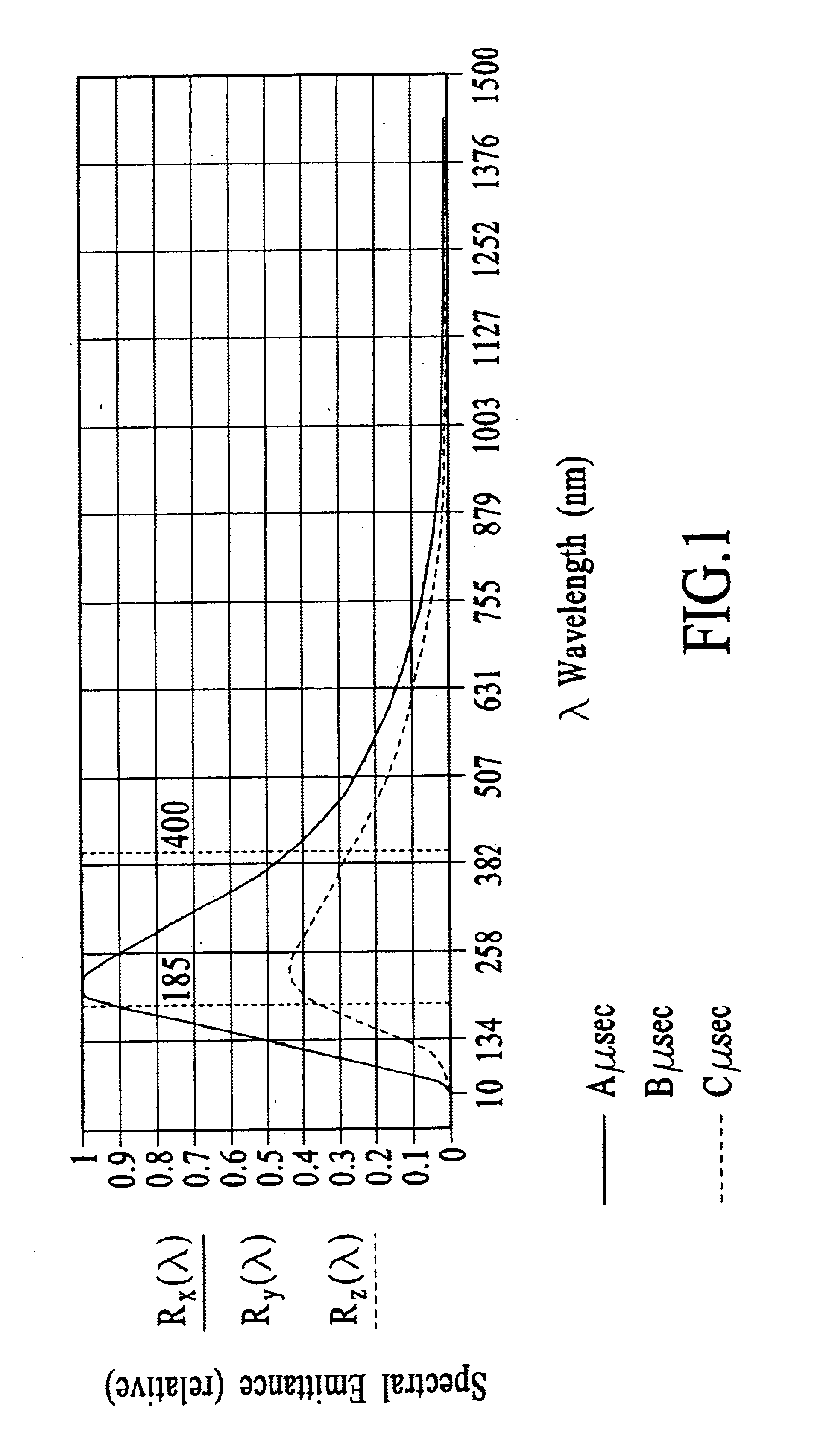

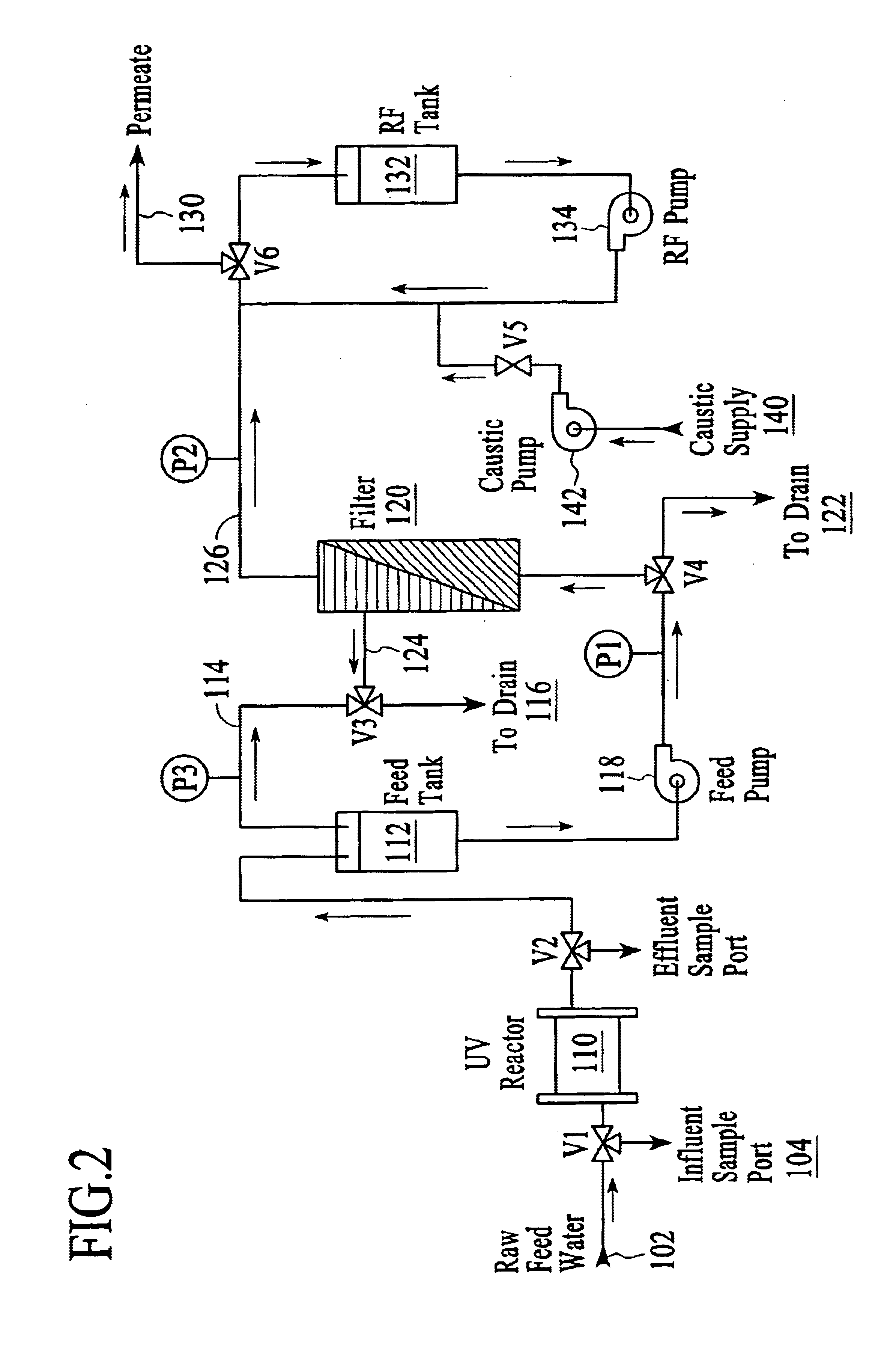

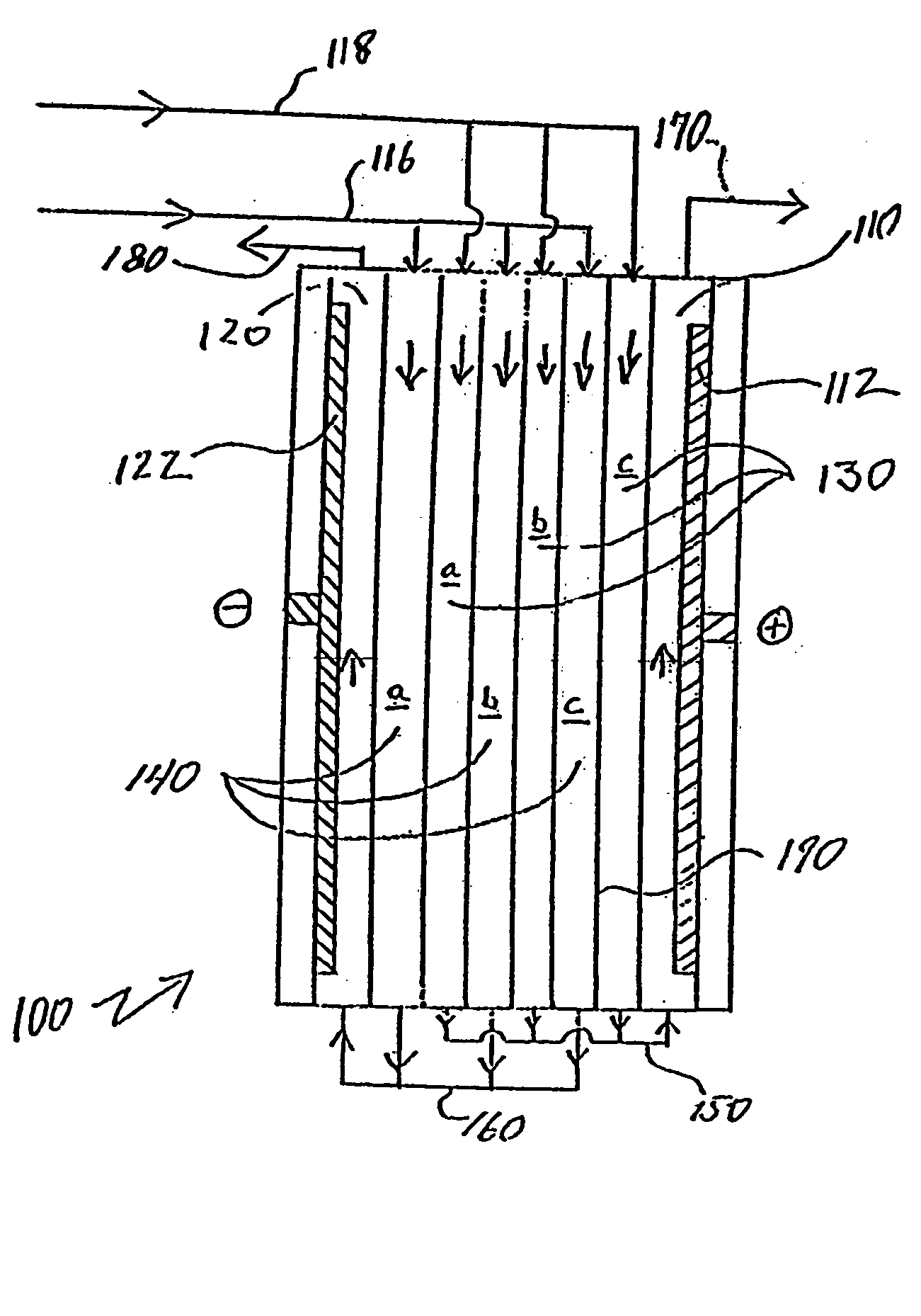

Pulsed blackbody radiation flux enhancement

A system and method for enhancing the flux and separation properties of water filtration membranes by oxidizing raw or processed water constituents with direct photolysis of the water matrix by pulsed blackbody UV, yielding ozone and hydrogen peroxide, hydroxyl radicals and other short lived oxidizing species. The result thereof, causing precipitation of inorganic molecules or organically complexed minerals, partial or complete mineralization of organic molecules and the deactivation or destruction of microbes including: virus, bacteria and protozoa. The system and method comprises a pulsed blackbody, deep-UV reactor having at least one treatment chamber, the reactor having a conveying assembly to convey the water to be treated into the chamber; a filter assembly to screen the UV treated water; a caustic supply means for the post-treatment of water; a recovering assembly recovering the permeate at an outlet of the filtration means. The effect of such UV water treatment is multifaceted. One aspect is the reduction of the transmembrane pressure (TMP), another is the reduction of duration of backwash and caustic cleaning cycles. Also, the oxidation of iron and manganese to insoluble compounds, without the addition of oxidizing agents, does not harm the membranes. Iron and manganese turn into hydroxide crystals trapped by the filtration membrane and separated from the permeate. These effects integrate to enhance the water flux through the filter membrane.

Owner:NEW STAR LASERS

Water treatment system and method

ActiveUS20050103723A1Less corrosiveVolume/mass flow measurementFluid pressure measurement by electric/magnetic elementsWater treatment systemTreated water

A method and apparatus for producing purified water. Treated water may be provided for domestic use wherein the water may be treated by removing selected dissolved species while retaining properties that may improve the properties or aesthetics of the water.

Owner:EVOQUA WATER TECH LLC

Bilge water reclamation system and process

A system and method for treating and removing hydrocarbon and other contaminants in bilge and ballast water, utilizing a multiple progressive process that chemically and electrically treats-and removes contaminants. Wastewater, received by a sump, is transmitted to a holding tank and treated, over a period of time while-influent wastewater continues off loading. The wastewater is pumped to an oil / water separator tank that decants free-floating oil from the wastewater to an oil retention tank. The wastewater then undergoes an electrocoagulation process where emulsions are broken and compounds that further aid treatment are created. The treated water flows to a retention / separation tank where contaminant particles coalesce and separate. Water is decanted and transferred to a clean water holding tank through an ozone injection system and an activated carbon filter. Treated water is recirculated until it exits the system meeting discharge limits for organics and metals allowing release into the environment.

Owner:TIPTON GARY A

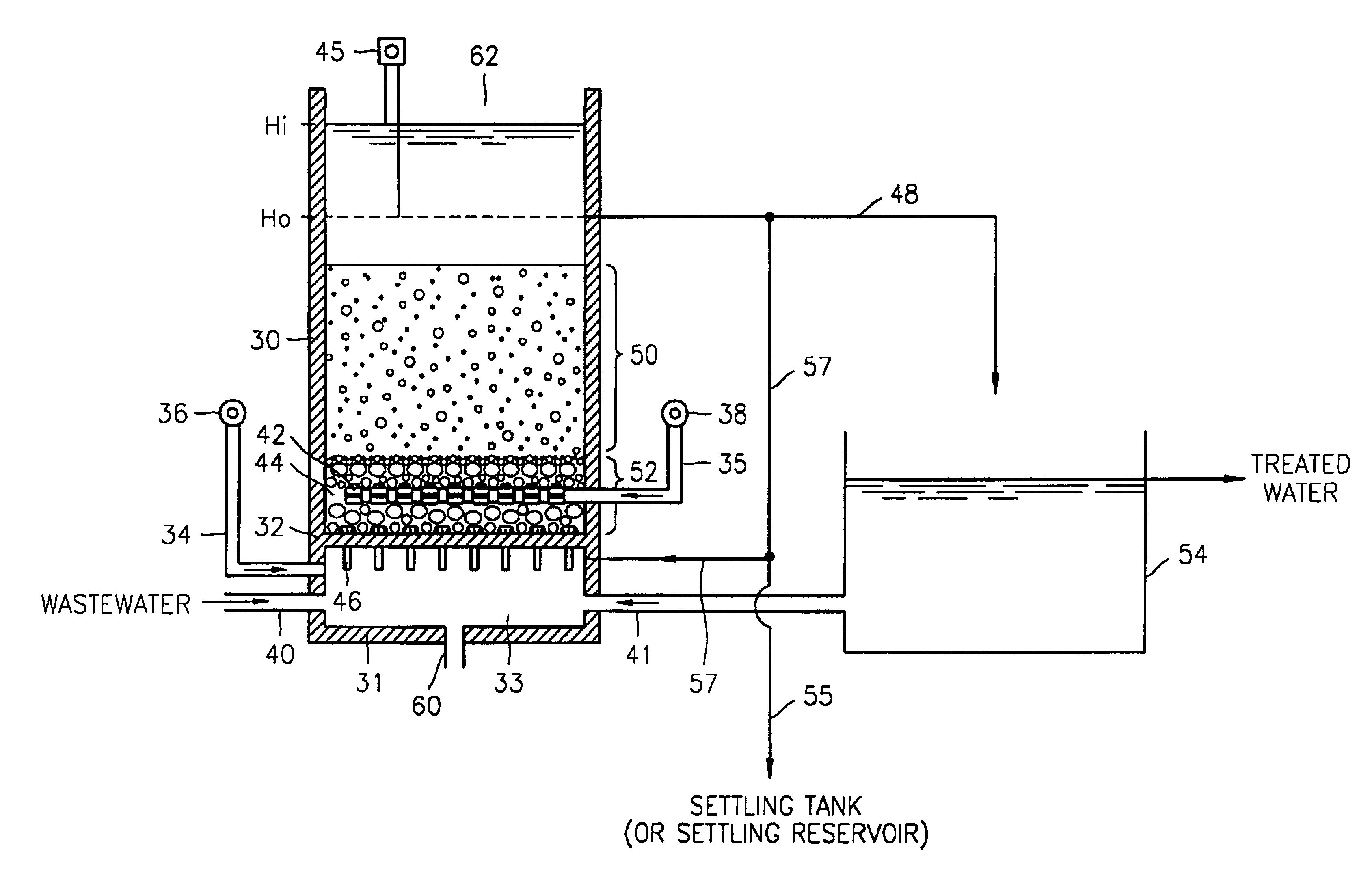

Batch style wastewater treatment apparatus using biological filtering process and wastewater treatment method using the same

InactiveUS6790347B2Simple configurationEasy to operateTreatment using aerobic processesSpecific water treatment objectivesBio filtrationSludge

Provided is a wastewater treatment apparatus including a bottom portion and a plate formed above and spaced apart from the bottom portion to form a lower chamber with the bottom portion, an outlet installed on the bottom portion for drawing off water and sludge in the lower chamber before backwashing, a filter medium layer supported to the upper portion of the plate by the plate, the upper layer of which forms a bottom portion of an upper chamber, a wastewater introducing means connected to the lower chamber, for introducing wastewater to be treated into the lower chamber, a process air introducing means for supplying process air to the filter medium layer formed over the plate, a plurality of aerators formed over and spaced apart a predetermined distance from the plate, and mounted in a plurality of air flow pipes led to the process air introducing means, a backwash air introducing means for supplying backwash air to the lower chamber during backwashing, a backwash water introducing means for supplying backwash water to the lower chamber during backwashing, a plurality of nozzles extending from the lower chamber to the filter medium layer through the plate, a treated water discharging means for discharging the treated water having passed through the filter medium layer, and a returned water introducing means for returning the treated water having passed through the filter medium layer to the lower chamber. A batch style wastewater treatment apparatus utilizing biological filtering process efficiently removes the organic matter, suspended solid matter, nitrogen and phosphorus.

Owner:SAMSUNG ENGINEERING CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com