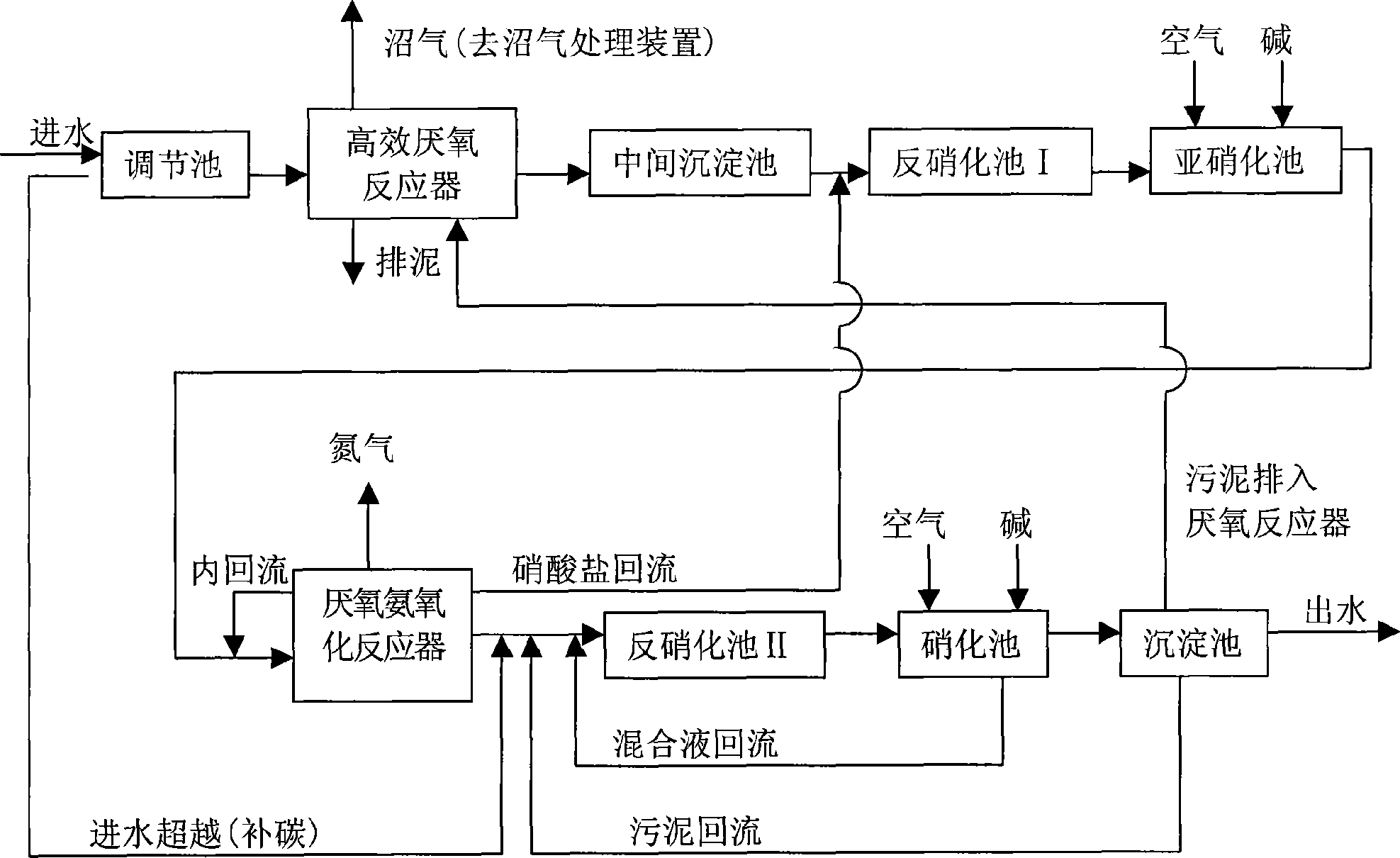

Deepness denitrogenation method for treating organic wastewater in high concentration

A technology for deep denitrification of organic wastewater, applied in energy wastewater treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of limited denitrification effect, high nitrogen content, large power consumption, etc. Achieve the effects of easy and stable realization, high-efficiency carbon and nitrogen removal, and less control conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] (1) Start-up phase:

[0039] In order to achieve a faster start-up speed and shorten the start-up time, anaerobic granular sludge, highly active nitrosative sludge and anaerobic ammonium oxidation sludge can be used. Before each process is connected in series, better biological activity is achieved respectively.

[0040] First start the anaerobic carbon removal bioreactor, anaerobic microorganisms hydrolyze and acidify the organic matter in the raw water, hydrolyze the more complex organic matter into simpler small molecule organic matter, and produce simple organic acids, and then the methanogens use the organic The acid undergoes a methanogenic reaction to generate biogas, and the organic matter is degraded. In the process of starting the power, the load of organic matter should be gradually increased, and the mixed solution in the reactor should be kept at a medium temperature (35~40°C) to react. When the activity of the reaction reaches a normal level, the suspend...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com