Patents

Literature

53results about "Ammonium sulfites" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

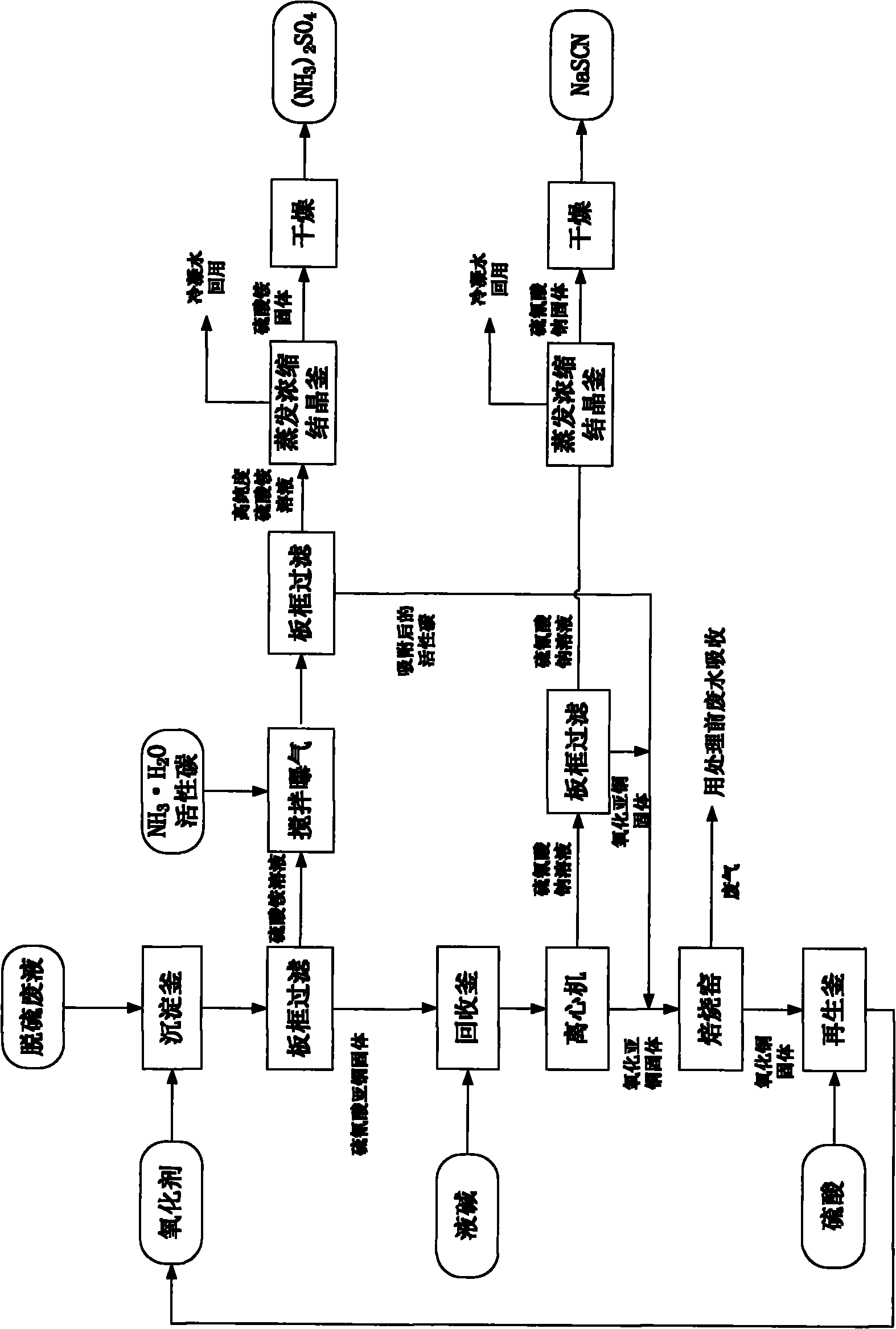

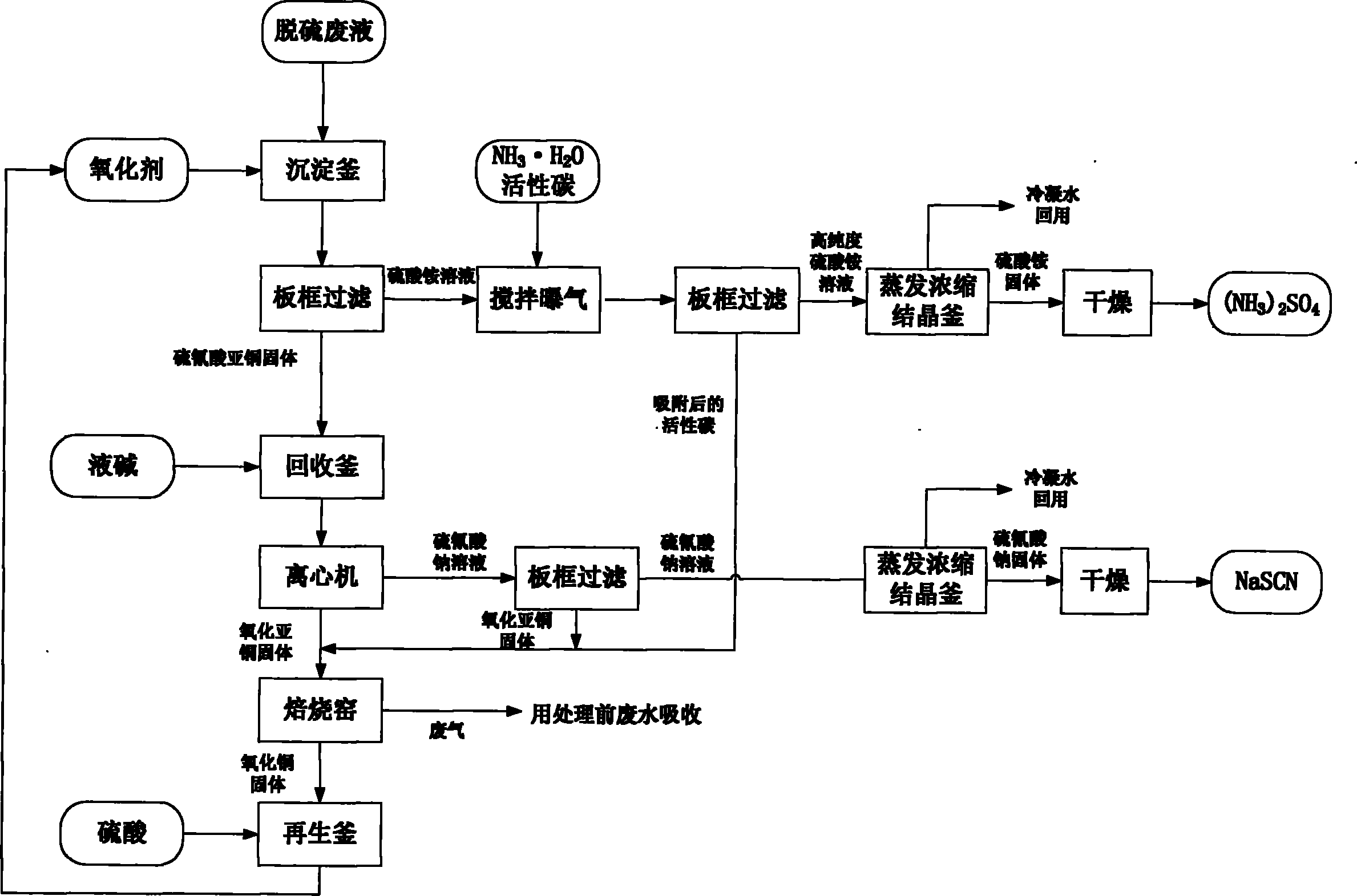

Method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in coking plant

ActiveCN101985359AReduce consumptionReduce lossesThiocyanic acidSulfate preparationActivated carbonSulfate

The invention relates to a method for preparing thiocyanate and sulfate by utilizing desulfuration waste liquor in a coking plant, which comprises the following steps of: preparing saturated solution of copper sulfate, mixing the saturated solution with desulfuration waste liquor, and heating and stirring; performing solid-liquid separation to obtain a solid and sulfate liquid; adding aqueous alkali into the solid, heating at the temperature of between 50 and 98 DEG C, and stirring and reacting for 10 to 120 minutes; performing solid-liquid separation on slurry obtained by heating; concentrating the obtained liquid, and freezing for crystallizing and drying to obtain a high-purity thiocyanate product; calcining the obtained solid, adding solution of sulfuric acid, and stirring to produce the copper sulfate for circular use; adding activated carbon into the sulfate liquid, and aerating and oxidizing to purify sulfate; and concentrating the sulfate, and crystallizing and drying to obtain a high-purity sulfate product. The method solves the problem of pollution of the desulfuration waste liquor to the environment, and simultaneously, pollutants can become value products through the production of the high-purity thiocyanate product and the high-purity sulfate product.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

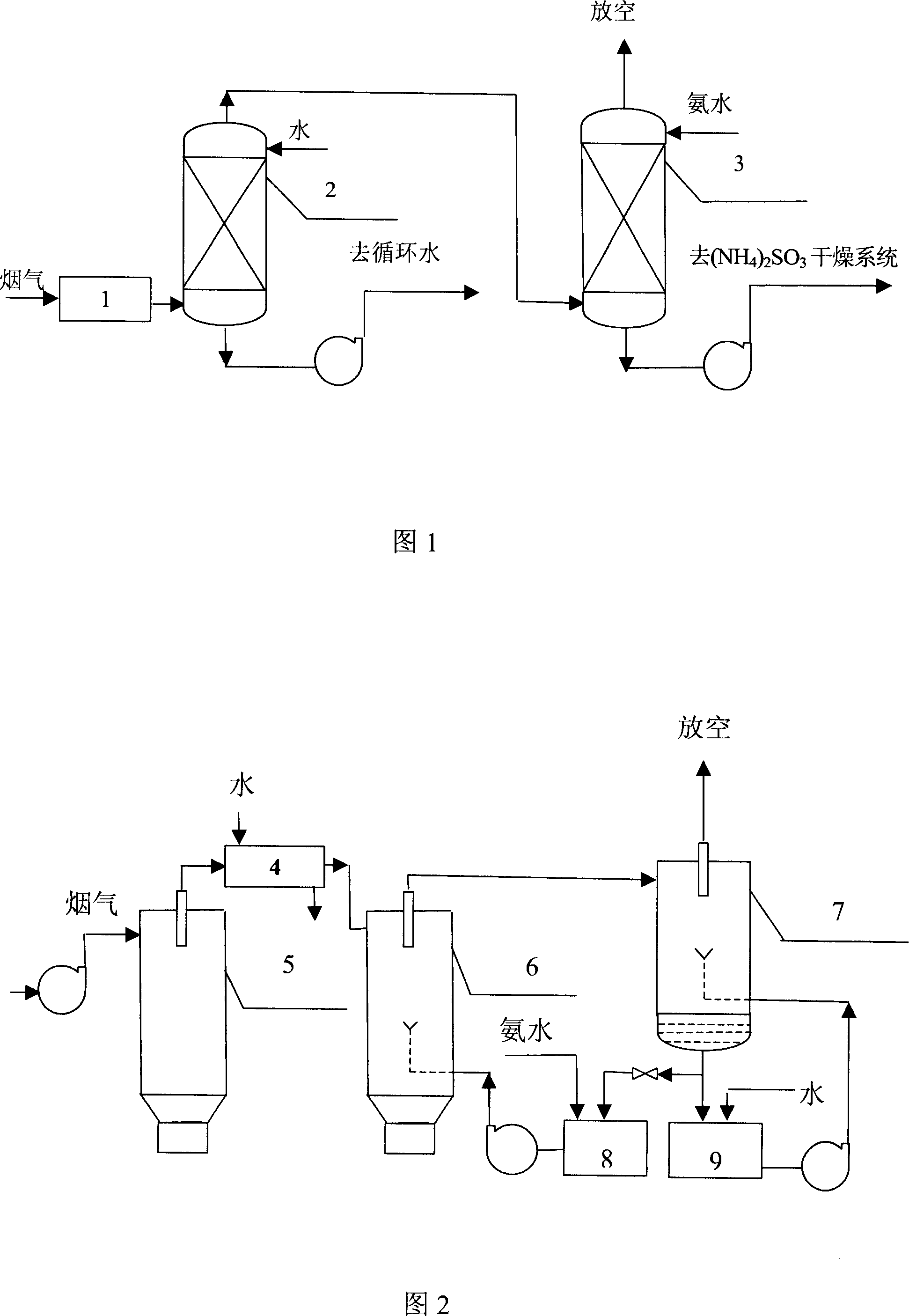

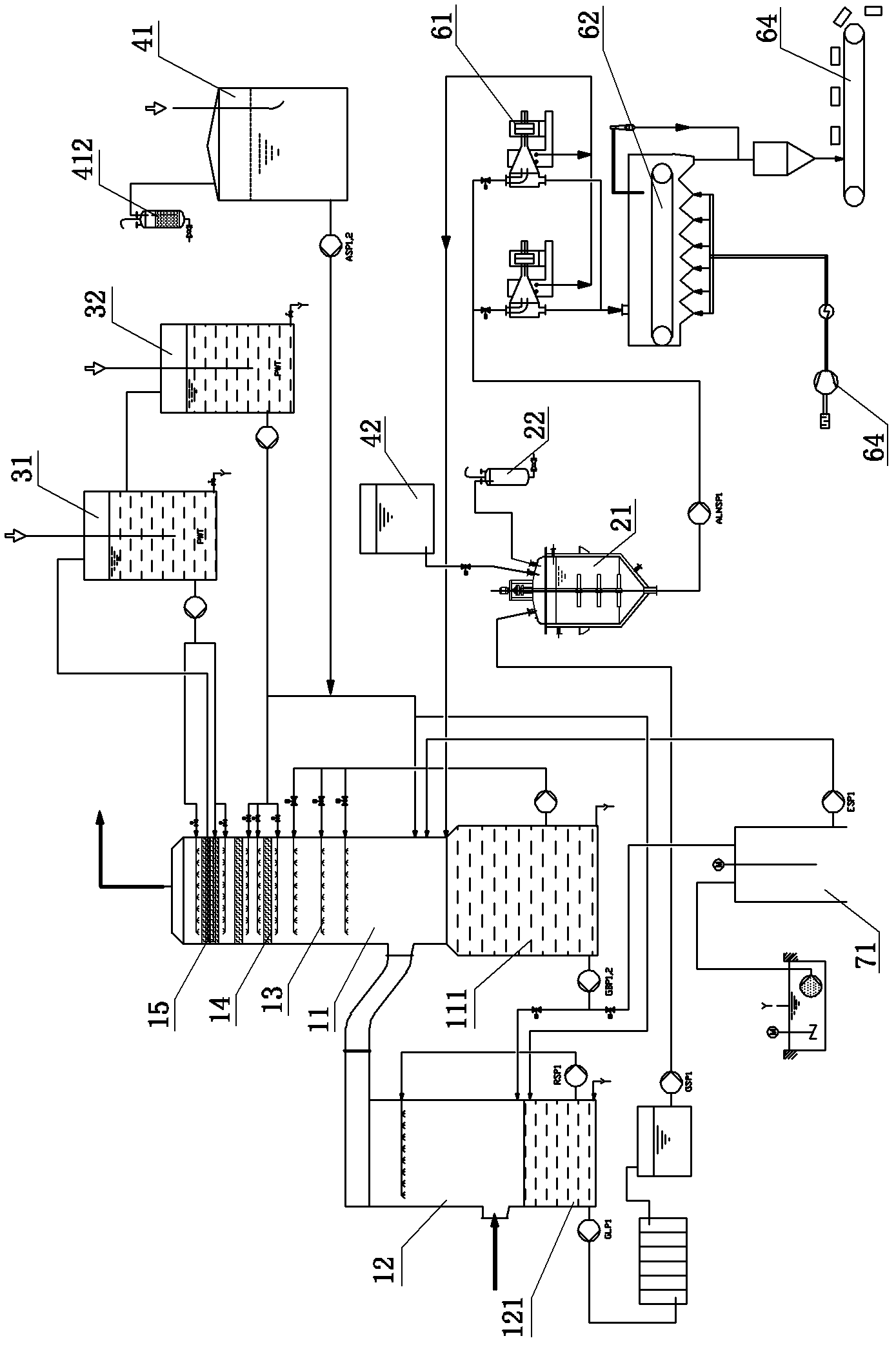

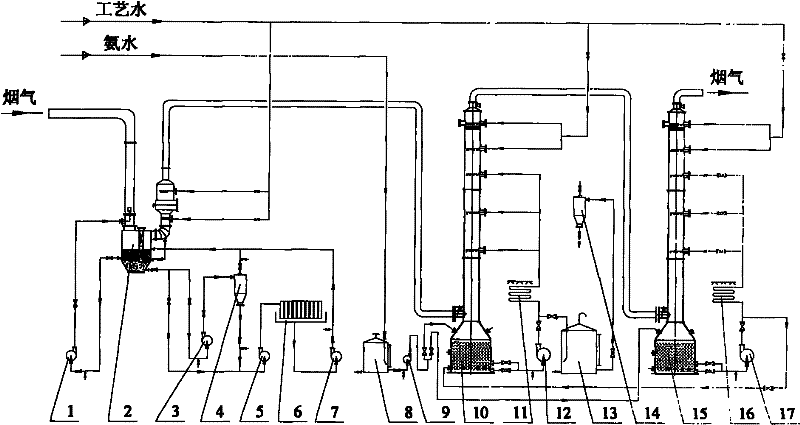

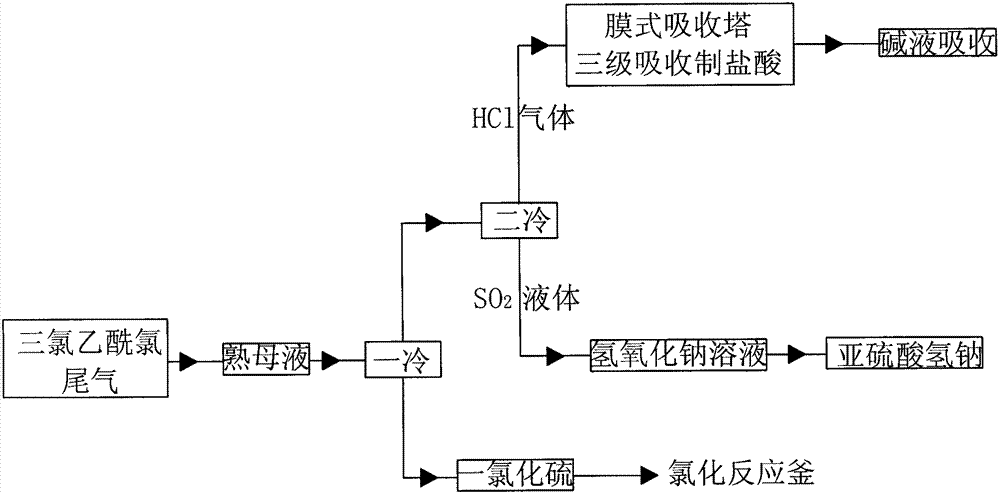

Method for desulfurizing high-sulphur boiler flue gas to prepare high-purity ammonium bisulfite

ActiveCN102755823ASimple processLow investment costCombination devicesAmmonium sulfitesIon exchangeDust control

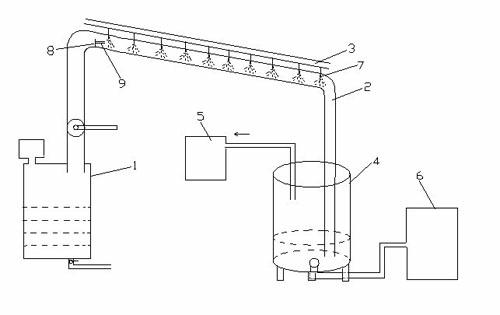

The invention relates to a method for removing and recycling SO2 in high-sulphur boiler flue gas and discloses a method utilizing ammonia water as material and recycling desulfuration to prepare ammonium bisulfite with high SO2 / NH3 value and high purity. The method comprises the steps of (1) performing dry dedusting on high-sulphur boiler flue gas, and cooling through wet dust collection, (2) utilizing ammonia water as absorbents to absorb SO2 in flue gas in a triple tandem desulfurizing absorption tower, controlling the absorbing temperature through an exterior circulation cooling mode, preparing ammonium bisulfite solution with high SO2 / NH3 value, and discharging with standard level after water scrubbing and demisting, (3) removing high chemical valence insoluble heavy metal ions such as ferric iron through microfiltration, and (4) removing heavy metal ions through chelating ion exchange resins to obtain products. According to the method, the concentration of SO2 in flue gas after desulfurization is low, SO2 in high-sulphur boiler flue gas is effectively recycled, and ammonium bisulfite solution with high SO2 / NH3 value and high purity is prepared.

Owner:JIANGSHAN TAIGE CHEM

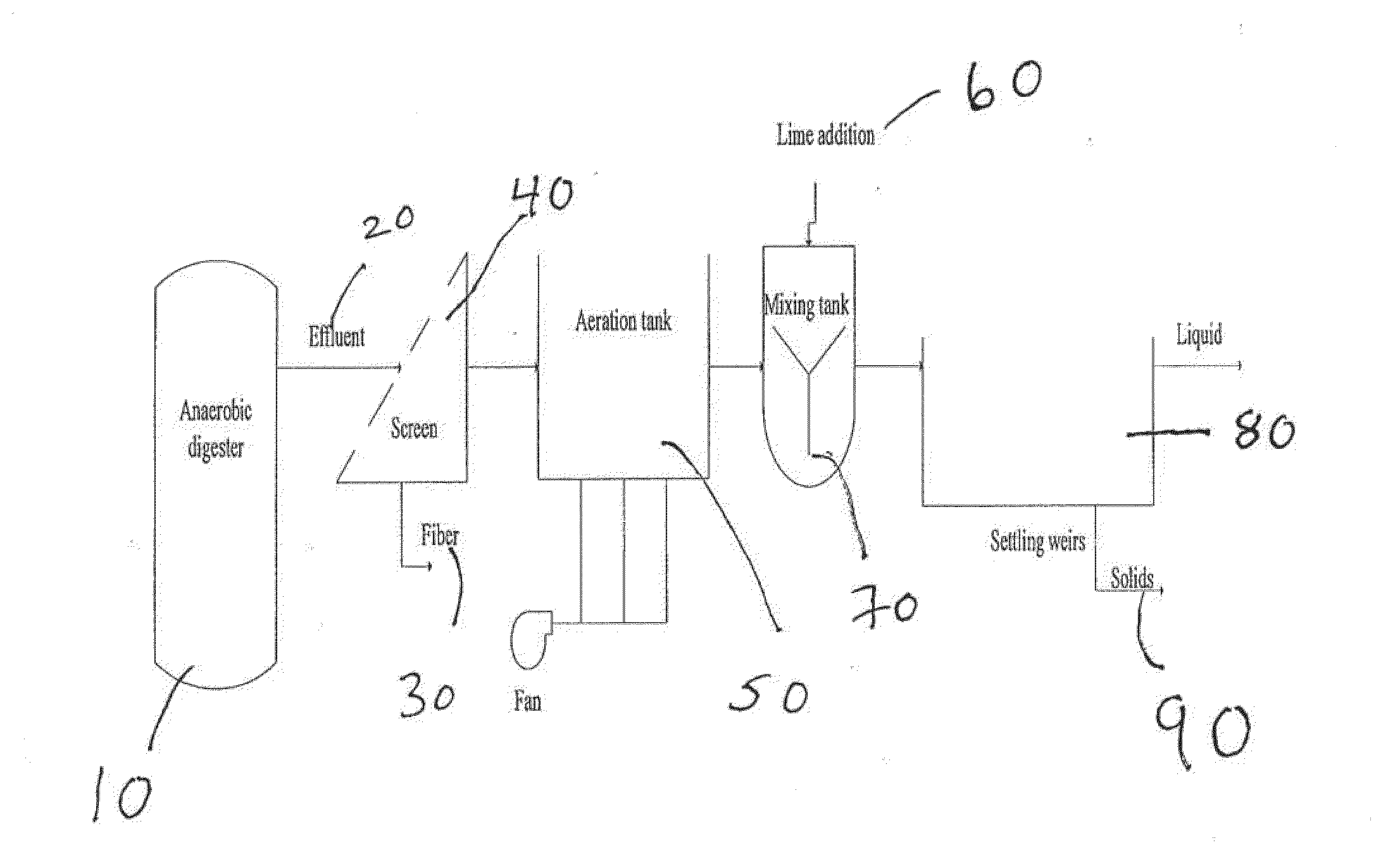

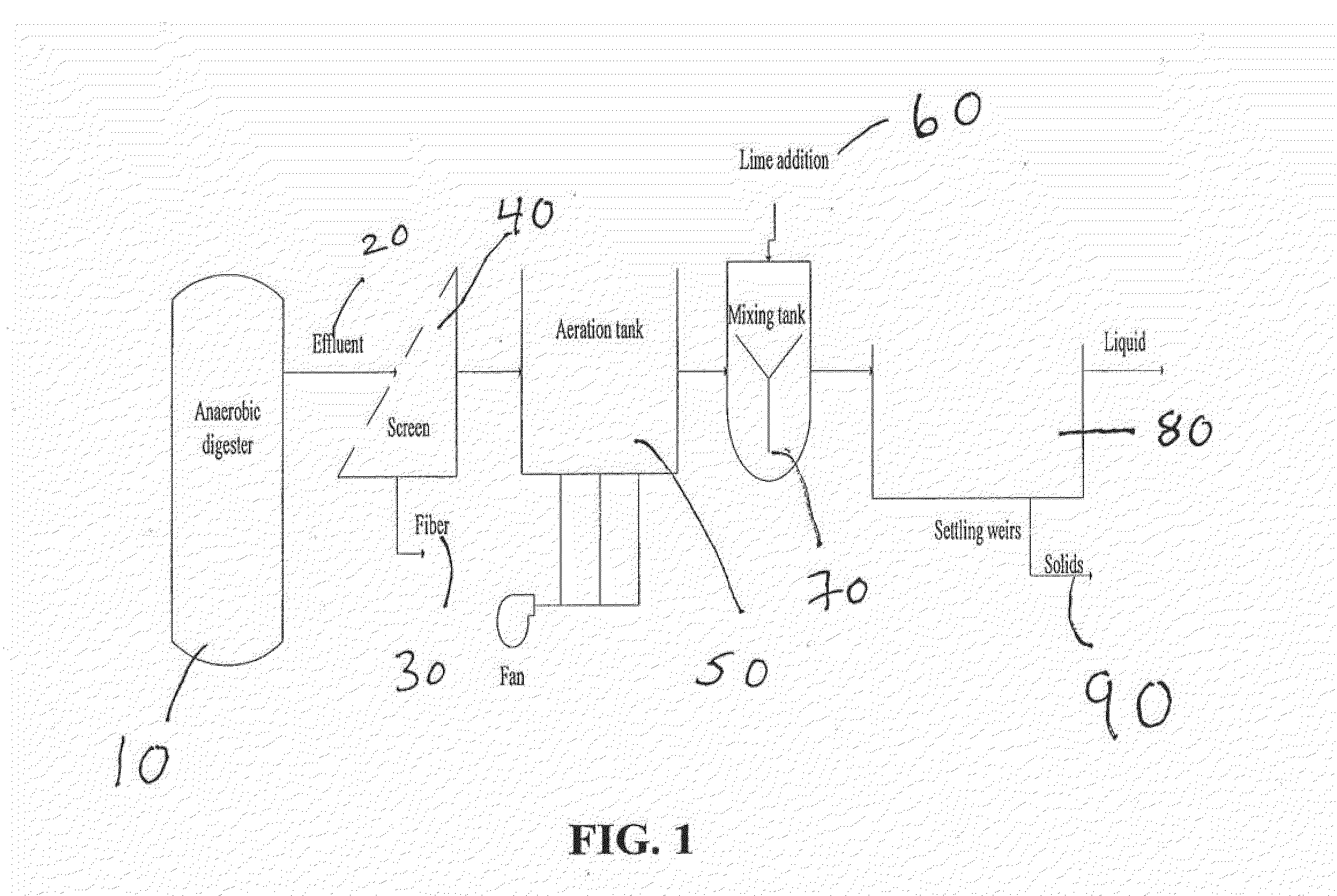

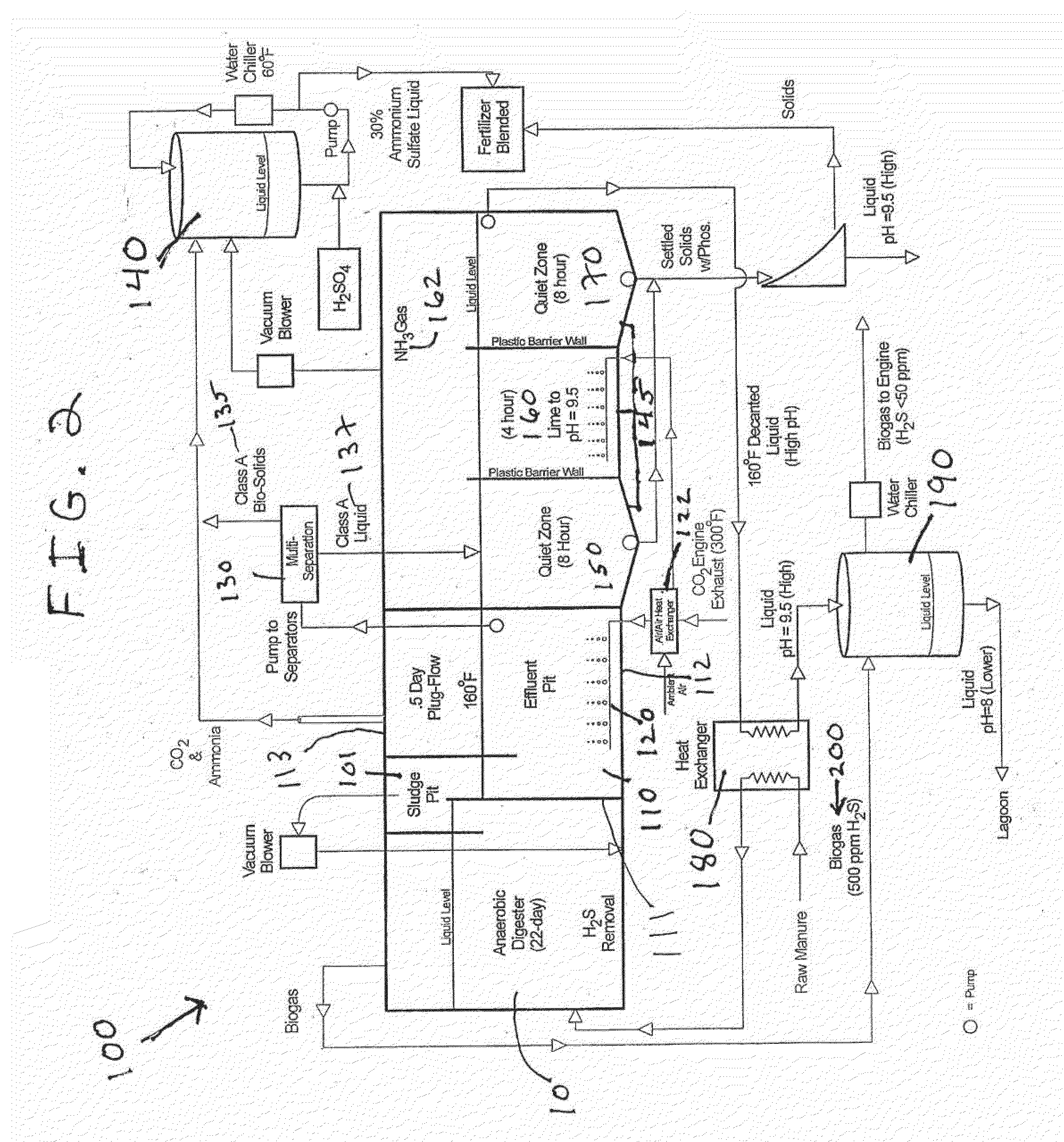

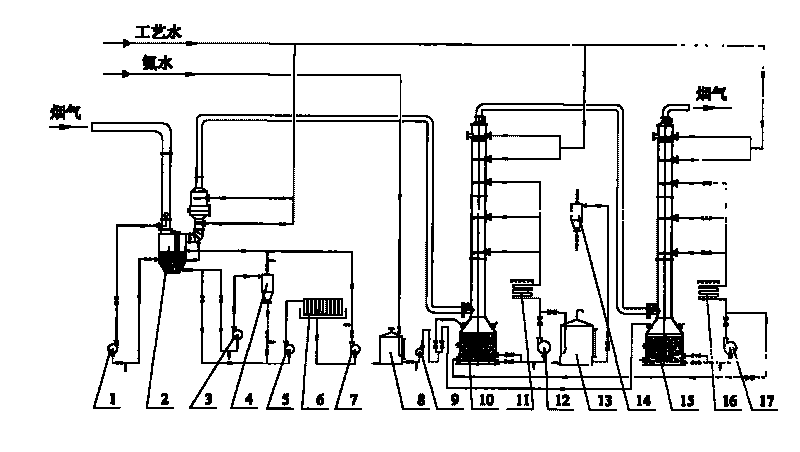

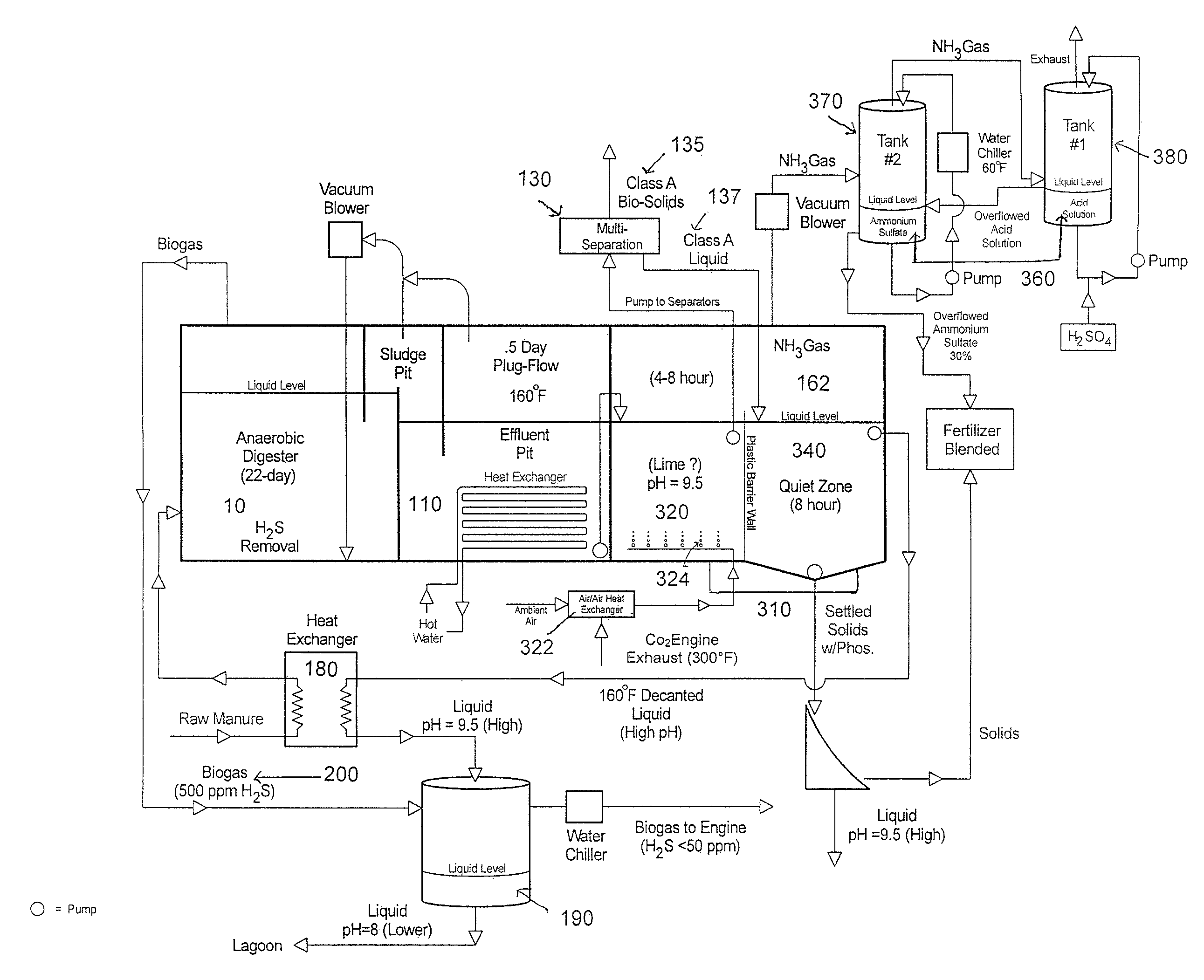

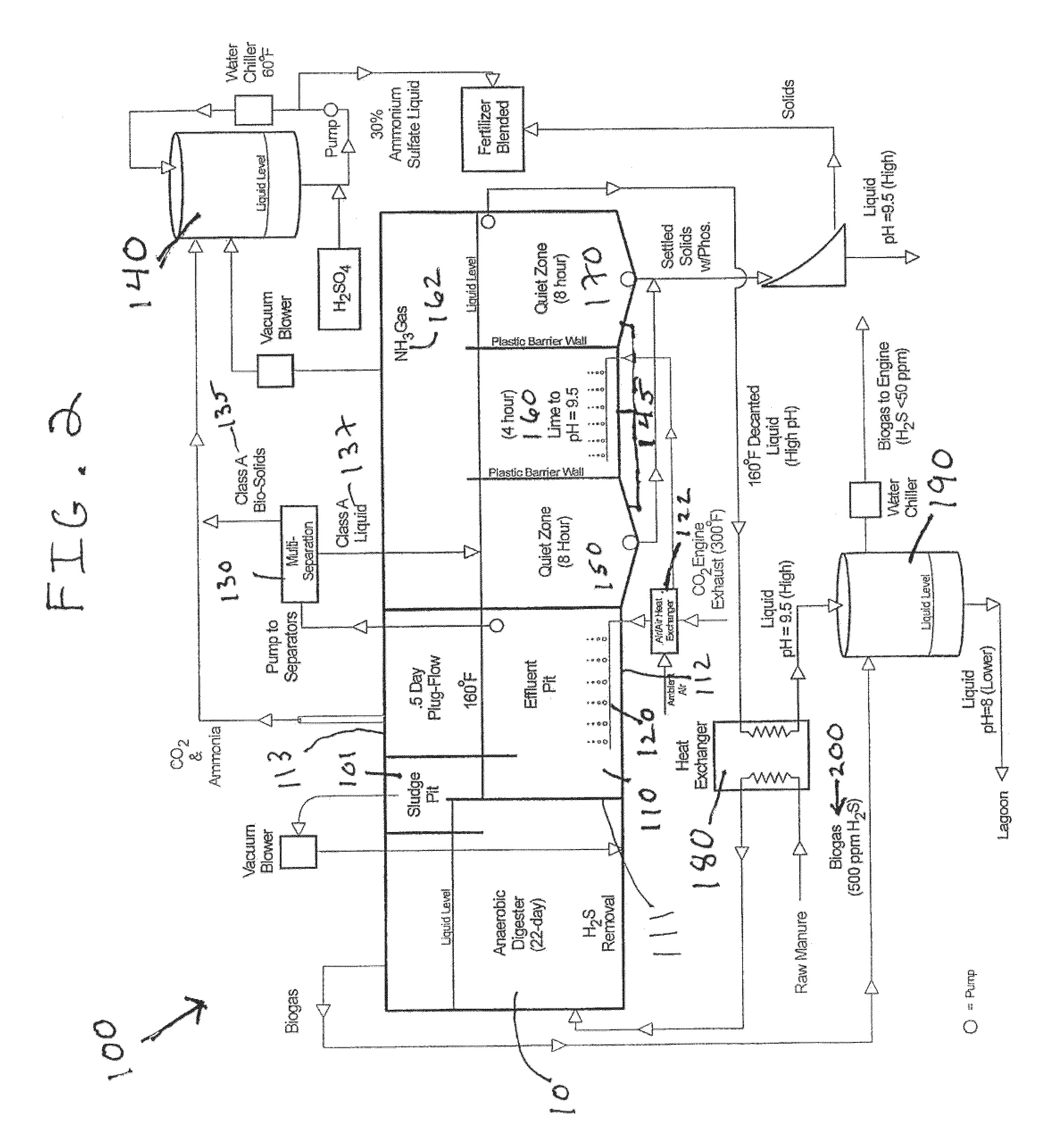

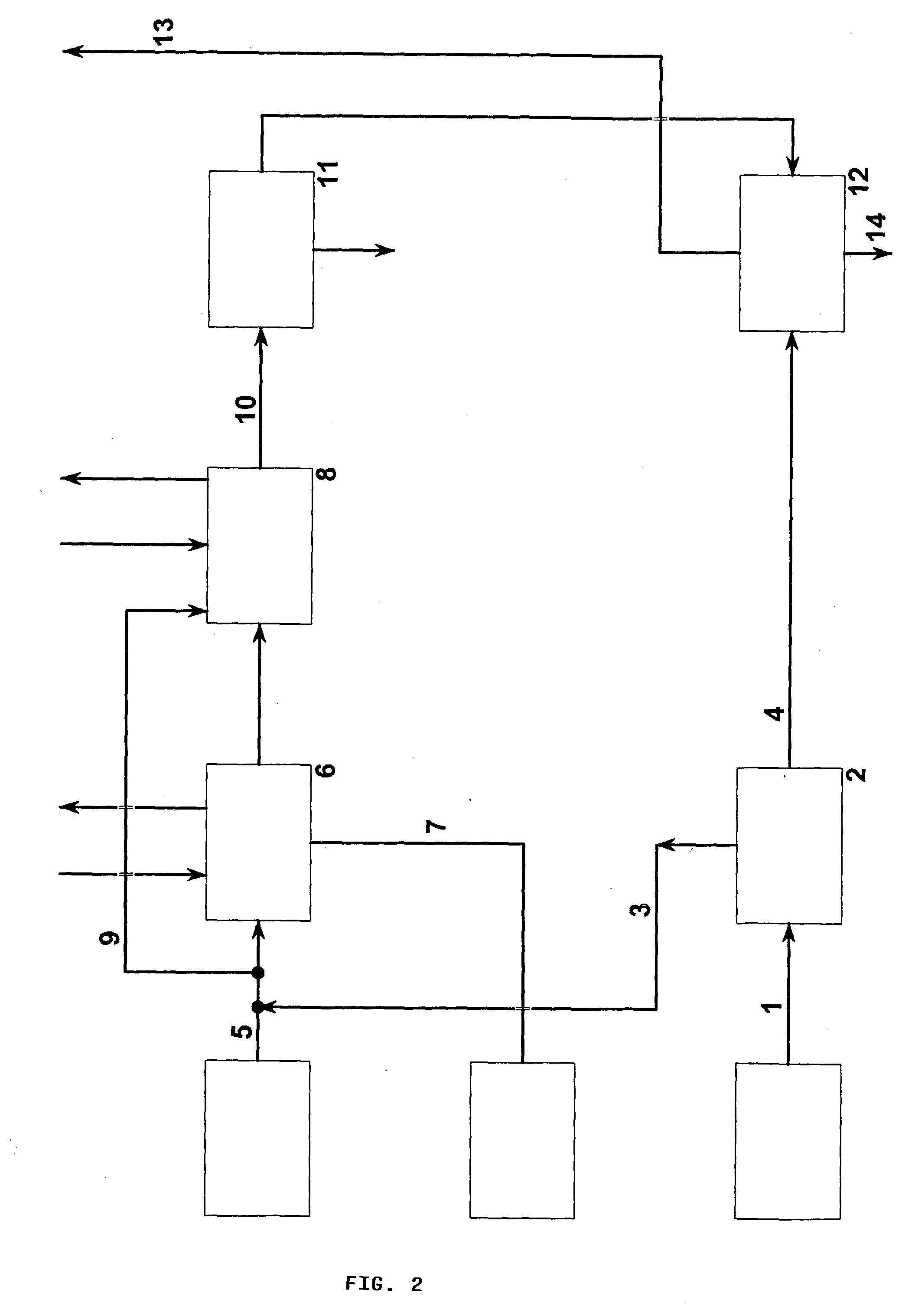

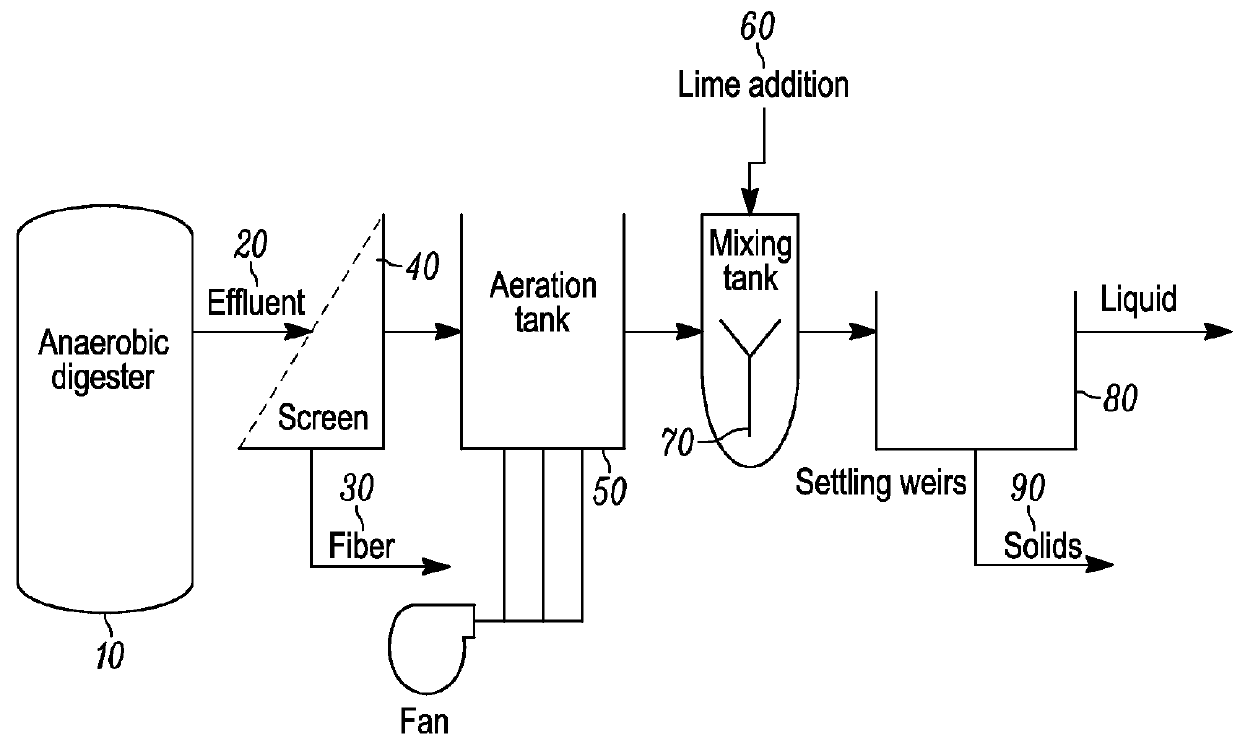

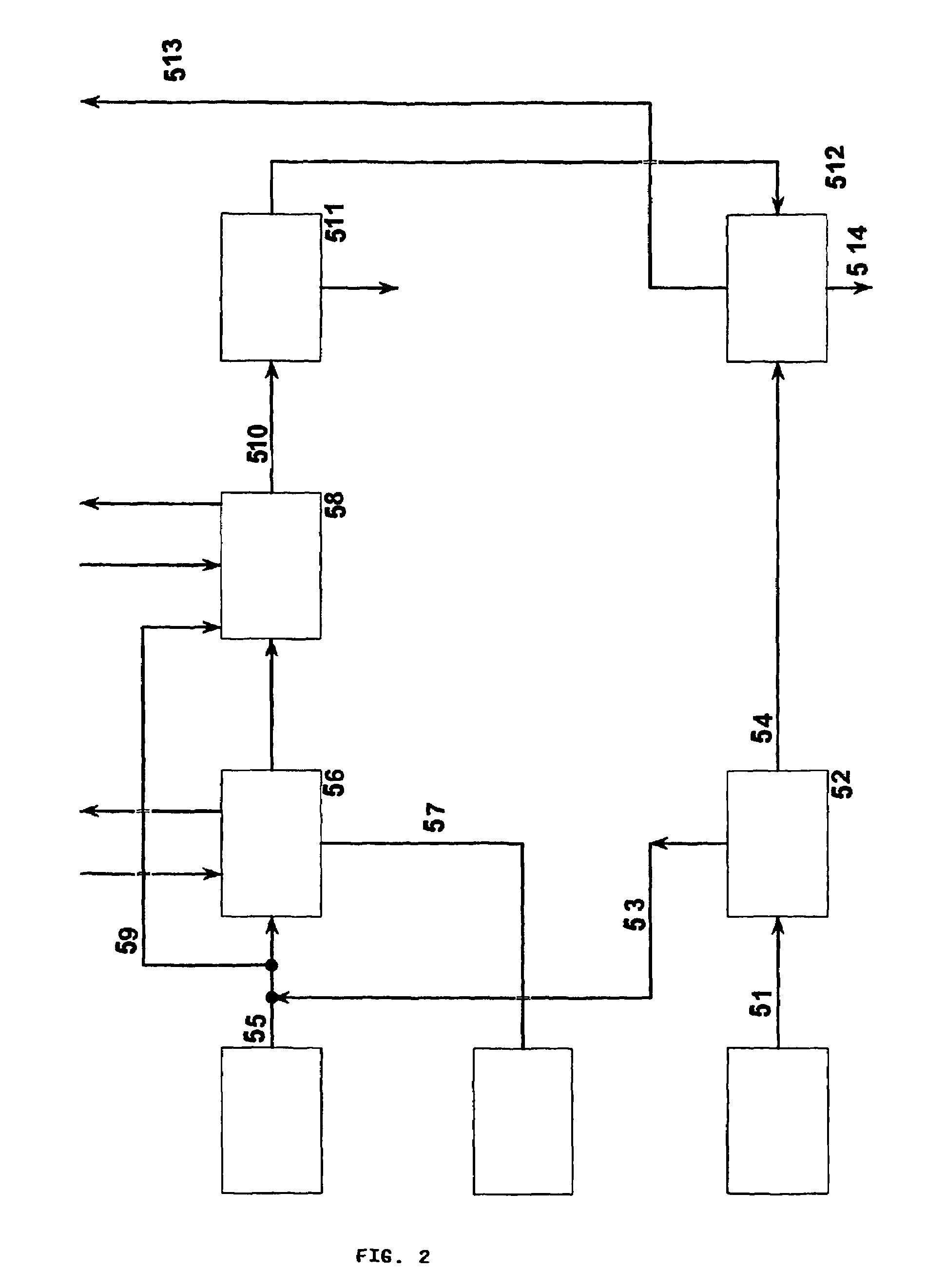

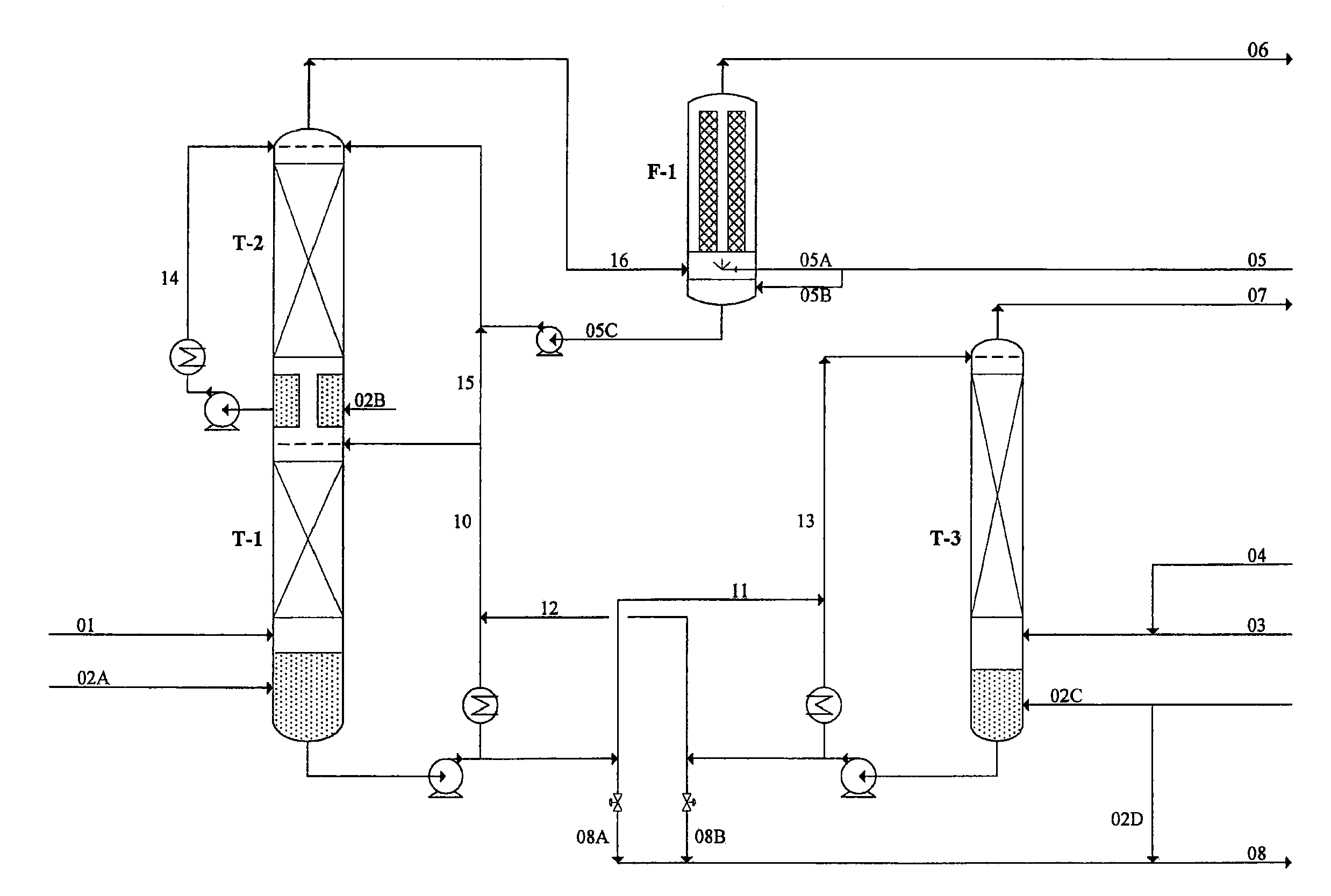

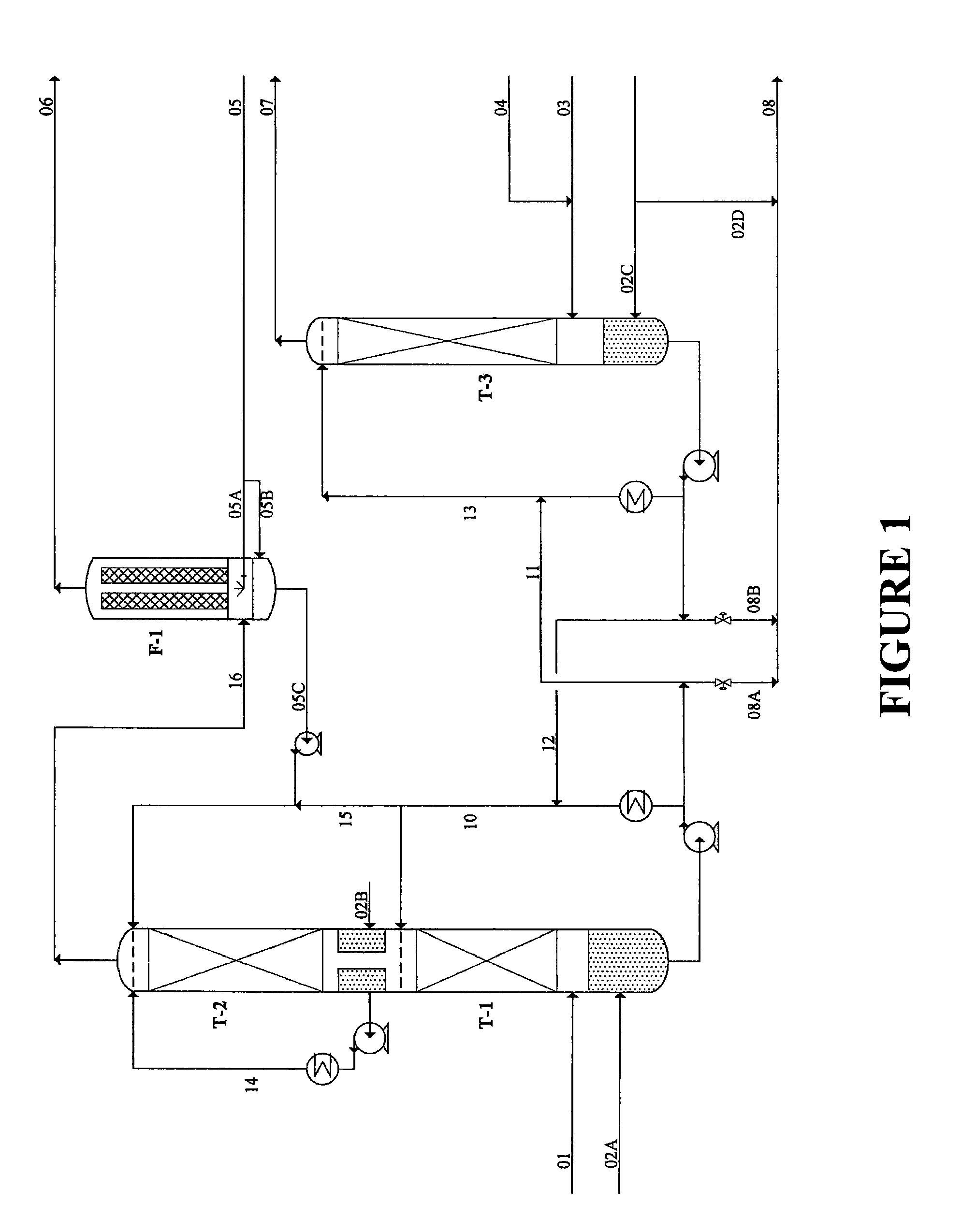

Nutrient recovery systems and methods

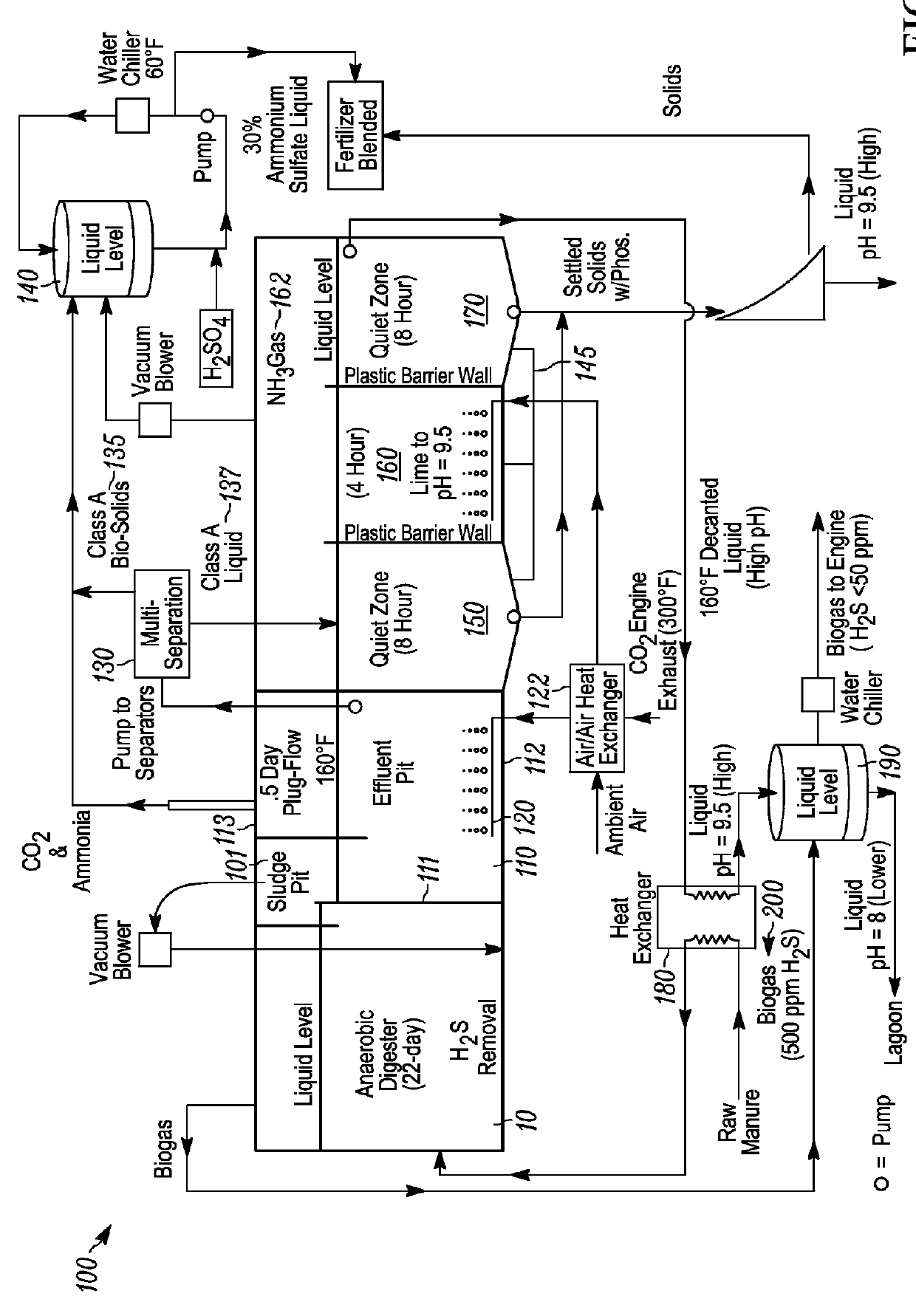

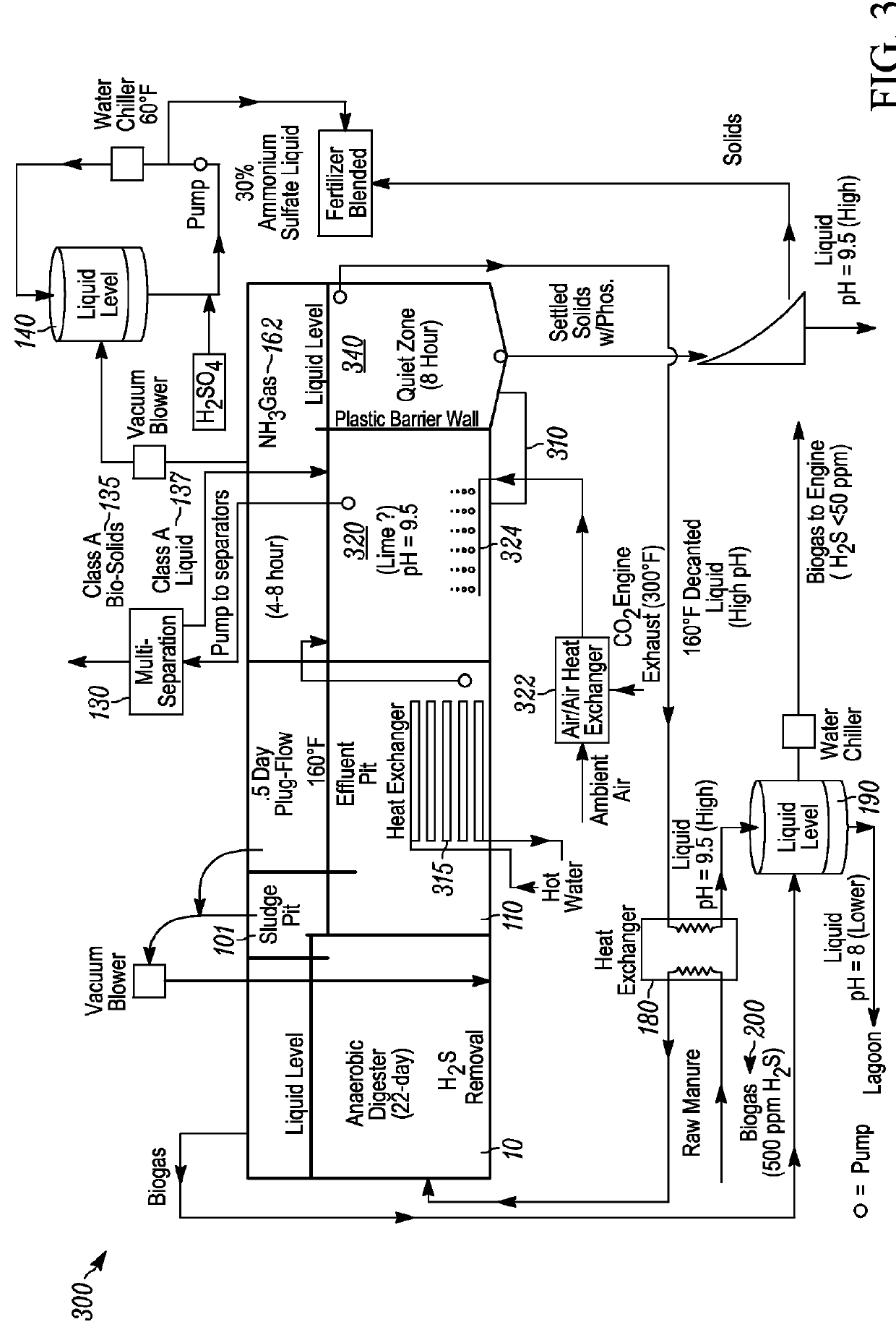

ActiveUS20120118035A1Large levelHigh recovery rateBio-organic fraction processingBioloigcal waste fertilisersAeration rateBiology

Methods, systems, and apparatuses for anaerobic digestion of waste fibrous material and the recovery of nutrients are provided. Methods, systems, and apparatuses disclosed herein provide mechanisms to release dissolved gases from anaerobic digester effluent. Methods, systems and apparatuses disclosed herein can recover one or more nutrients from anaerobic digested effluent using a range of temperatures, aeration rates, aeration times, pH ranges, and settling times.

Owner:DVO +2

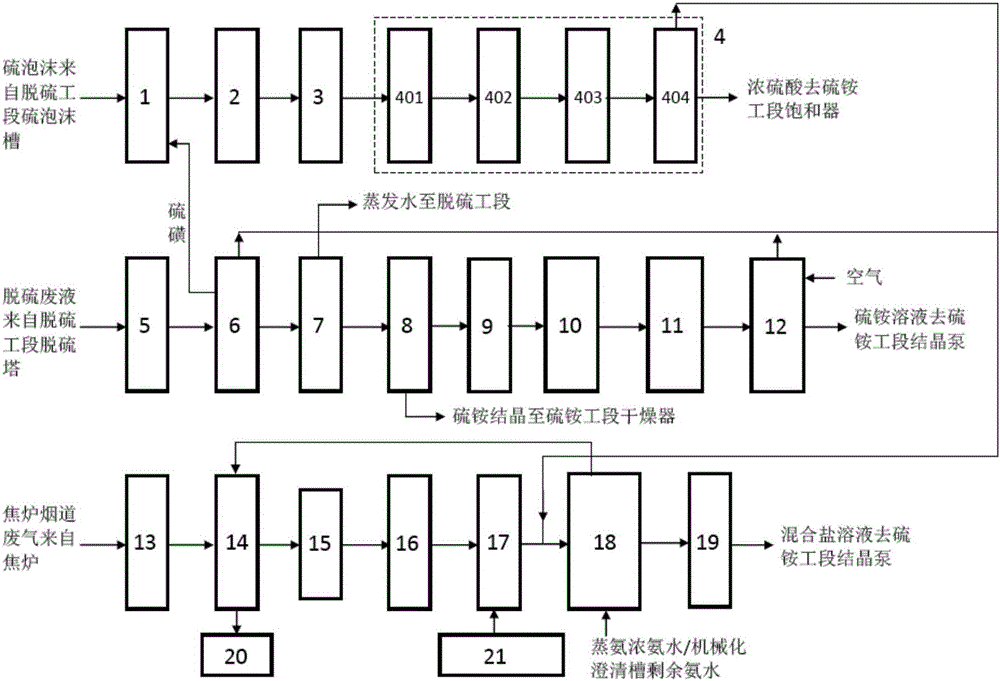

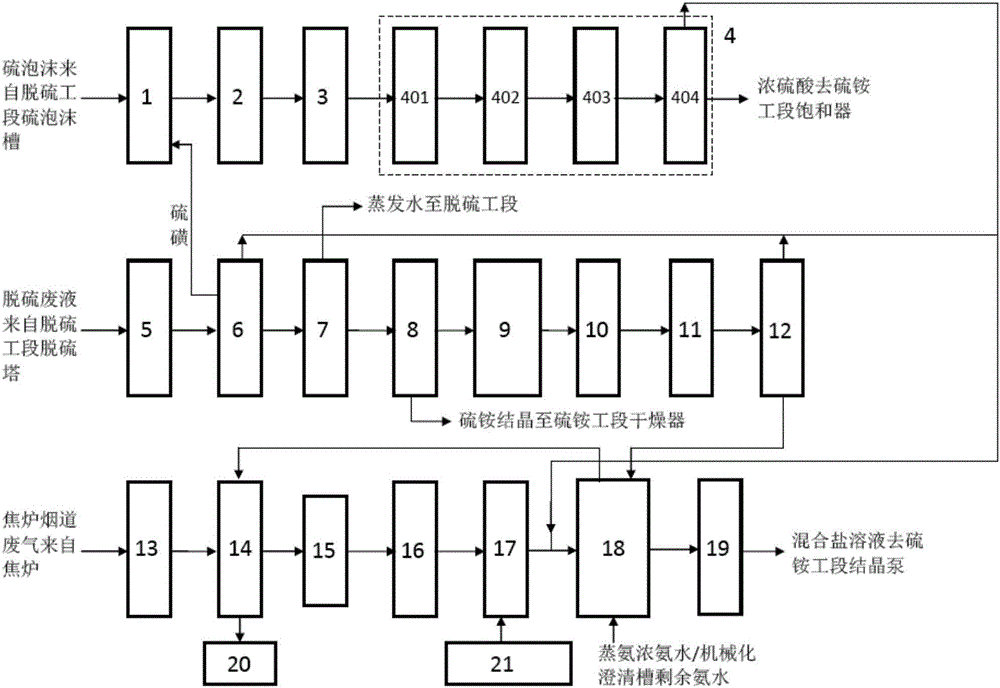

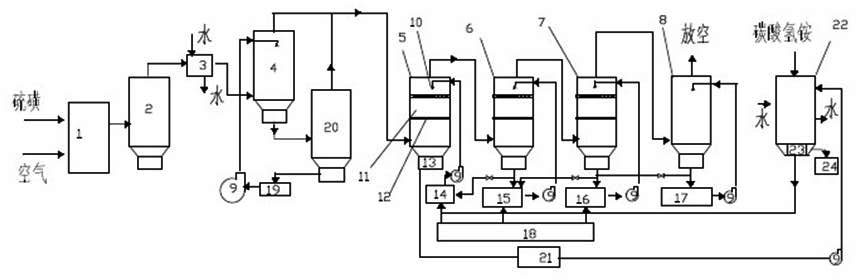

Distributed recycling system and method for sulfur in coking industry

ActiveCN106276973AImprove qualityImprove productivityAmmonium nitratesEnergy inputSelf purificationAmmonium nitrate

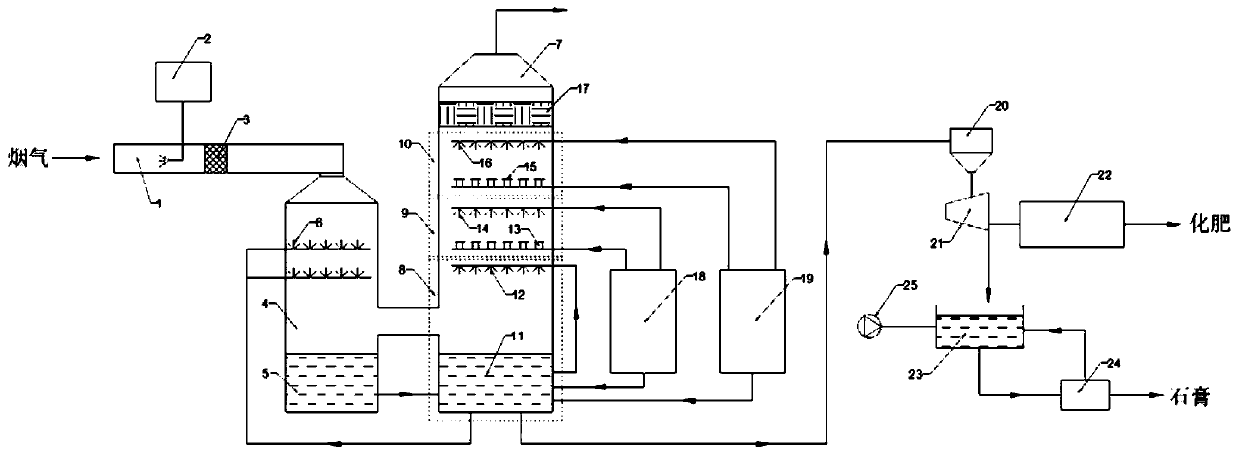

The invention relates to a distributed recycling system and method for sulfur in coking industry. Based on coking flow system resource balance, the self-purification function of coking flows are brought into full play, the system considers coupling treatment of sulfur foams, sulfur-containing waste gas and sulfur-containing waste liquid, waste materials are recycled, and the resource process value is increased. According to the technical scheme, sulfur foams are purified, then, pure sulfur is obtained, incineration is performed to produce acid, and obtained concentrated sulfuric acid absorbs ammonia in coke oven gas to produce ammonium sulfate; the desulfurization waste liquid is subjected to decoloration and then subjected to sulfo-oxidation, sulfur is separated out for incineration to produce acid, after solution crystallization and separation, ammonium sulfate and ammonium thiocyanate mother liquor are obtained, the ammonium thiocyanate mother liquor is incinerated to produce SO2, ammonium hydroxide is used for absorbing the produced ammonium sulfite, the ammonium sulfite is oxidized to produce ammonium sulfate or ammonium sulfite to be adopted as a denitrification agent for flue gas denitrification; waste heat of coke oven flue gas is recycled, the coke oven flue gas is mixed with ozone, some or all NO in the flue gas is oxidized, then, the flue gas and the recycling process tail gas are subjected to desulfurization and denitrification, and finally ammonium sulfate and ammonium nitrate are produced.

Owner:TSINGHUA UNIV

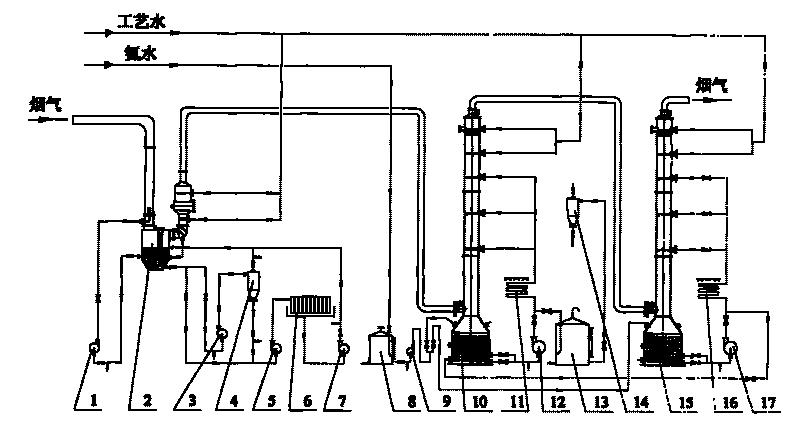

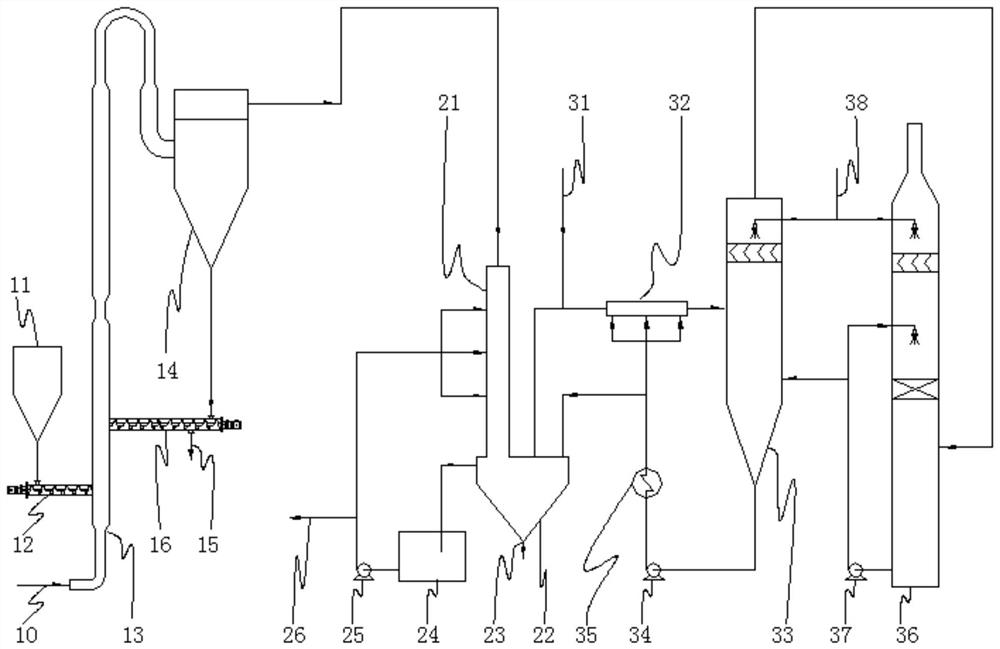

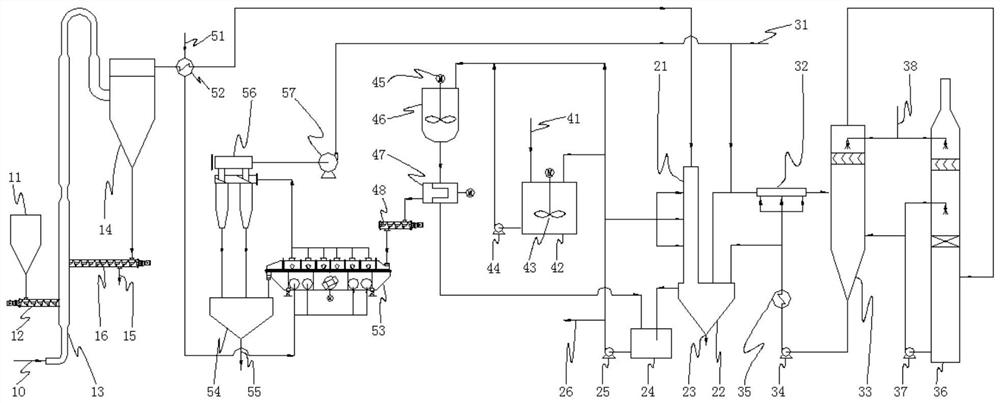

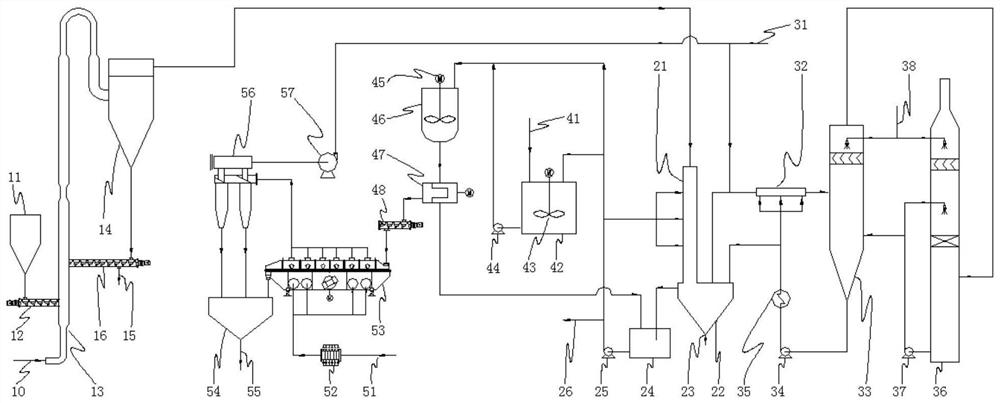

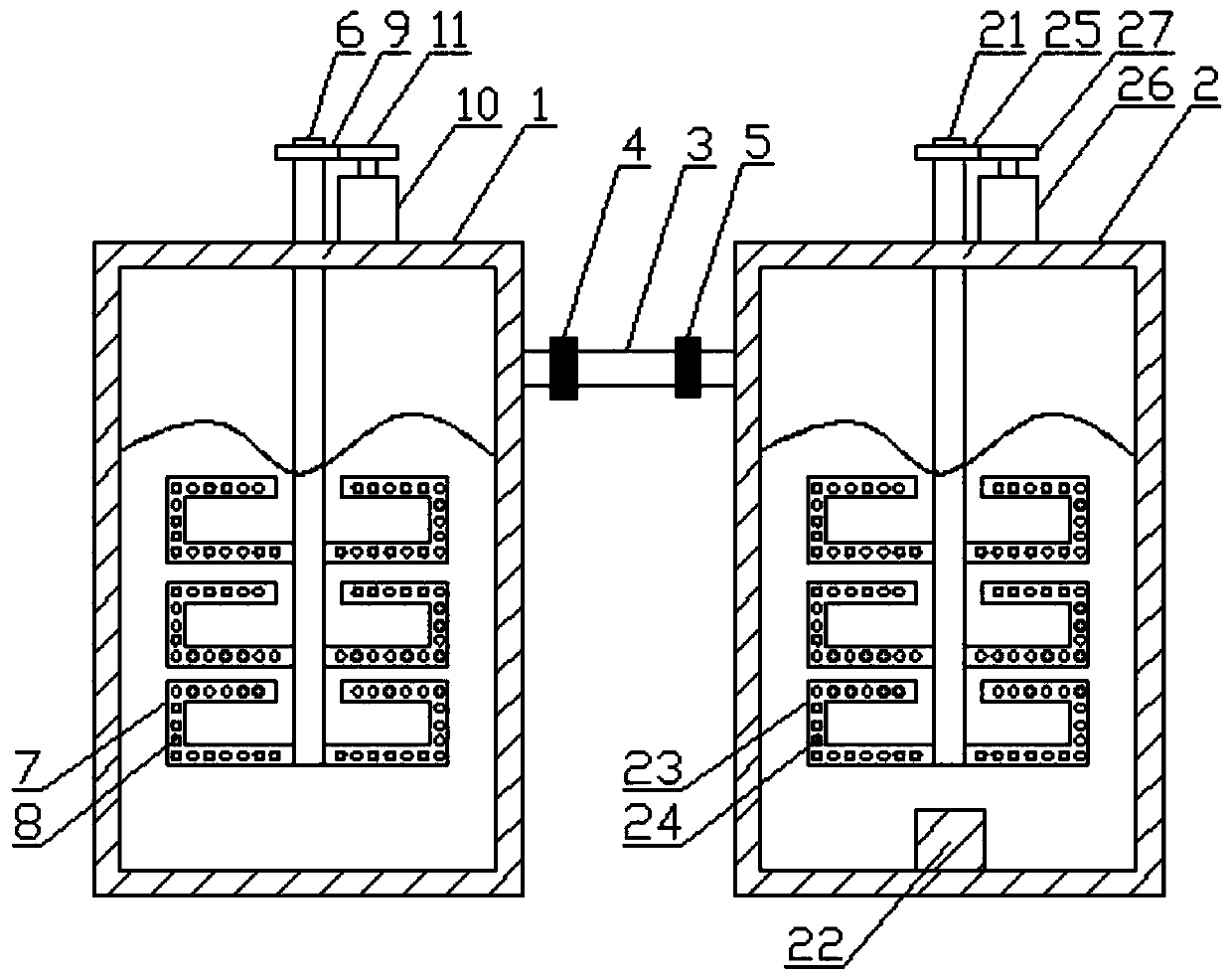

Twin tower type recovering sulfur resource ammonia desulfuration equipment and method

ActiveCN101708412AHigh purityGuaranteed purityUsing liquid separation agentAmmonium sulfitesPollutionBy-product

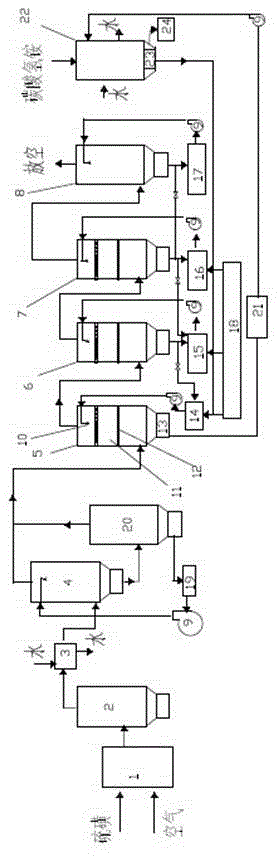

The invention discloses twin tower type recovering sulfur resource ammonia desulfuration equipment and a method. The equipment comprises a dynamic wave washing tower, a primary absorption tower, a secondary absorption tower and the like; the exhaust gas passes through the dynamic wave washing tower to remove ash and passes through a dynamic wave washer to lower the temperature, and then enters the primary absorption tower and the secondary absorption tower in sequence; the primary absorption tower and the secondary absorption tower are both provided with five spraying layers; the lower three spraying layers spraying and absorbing the exhaust gas; the upper two spraying layers are used for preventing ammonia escape; and the exhaust gas is discharged after being sprayed and absorbed by the primary absorption tower and the second absorption tower. The invention has the following advantages: 1) the purity of the by-product is high; 2) the twin tower design can not only obtain higher desulfurization efficiency, but also produce by-product with high purity; 3) the technology takes ammonium acid sulfite as the ultimate by-product, not only saving the technologies of crystallization and drying in the traditional technology, but also improving the additional value of the by-product; and 4) the technology in the invention can be recycled and has no secondary pollution.

Owner:ZHEJIANG UNIV

Nutrient recovery systems and methods

ActiveUS8613894B2High recovery rateLow costBio-organic fraction processingBioloigcal waste fertilisersAeration rateBiology

Methods, systems, and apparatuses for anaerobic digestion of waste fibrous material and the recovery of nutrients are provided. Methods, systems, and apparatuses disclosed herein provide mechanisms to release dissolved gases from anaerobic digester effluent. Methods, systems and apparatuses disclosed herein can recover one or more nutrients from anaerobic digested effluent using a range of temperatures, aeration rates, aeration times, pH ranges, and settling times.

Owner:DVO +2

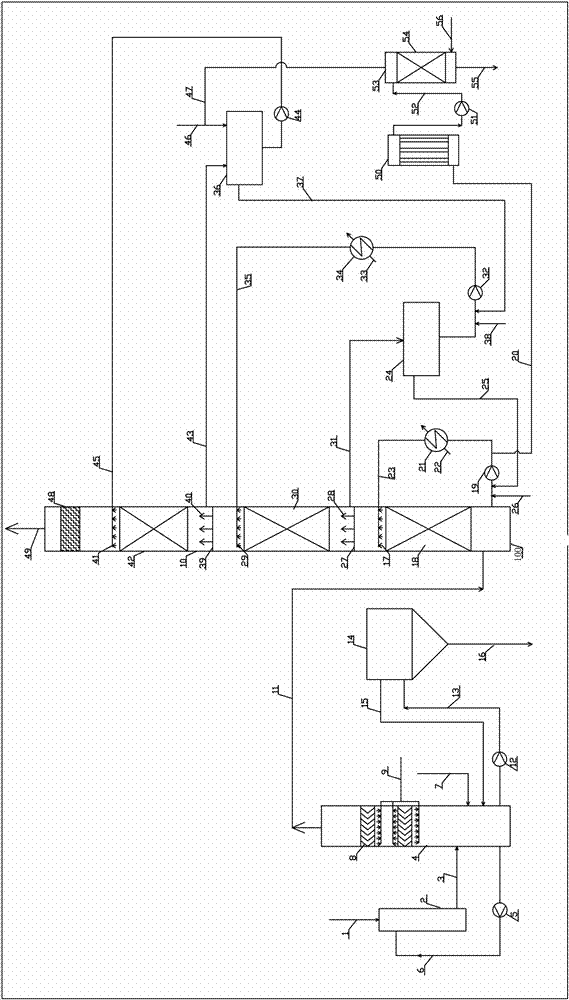

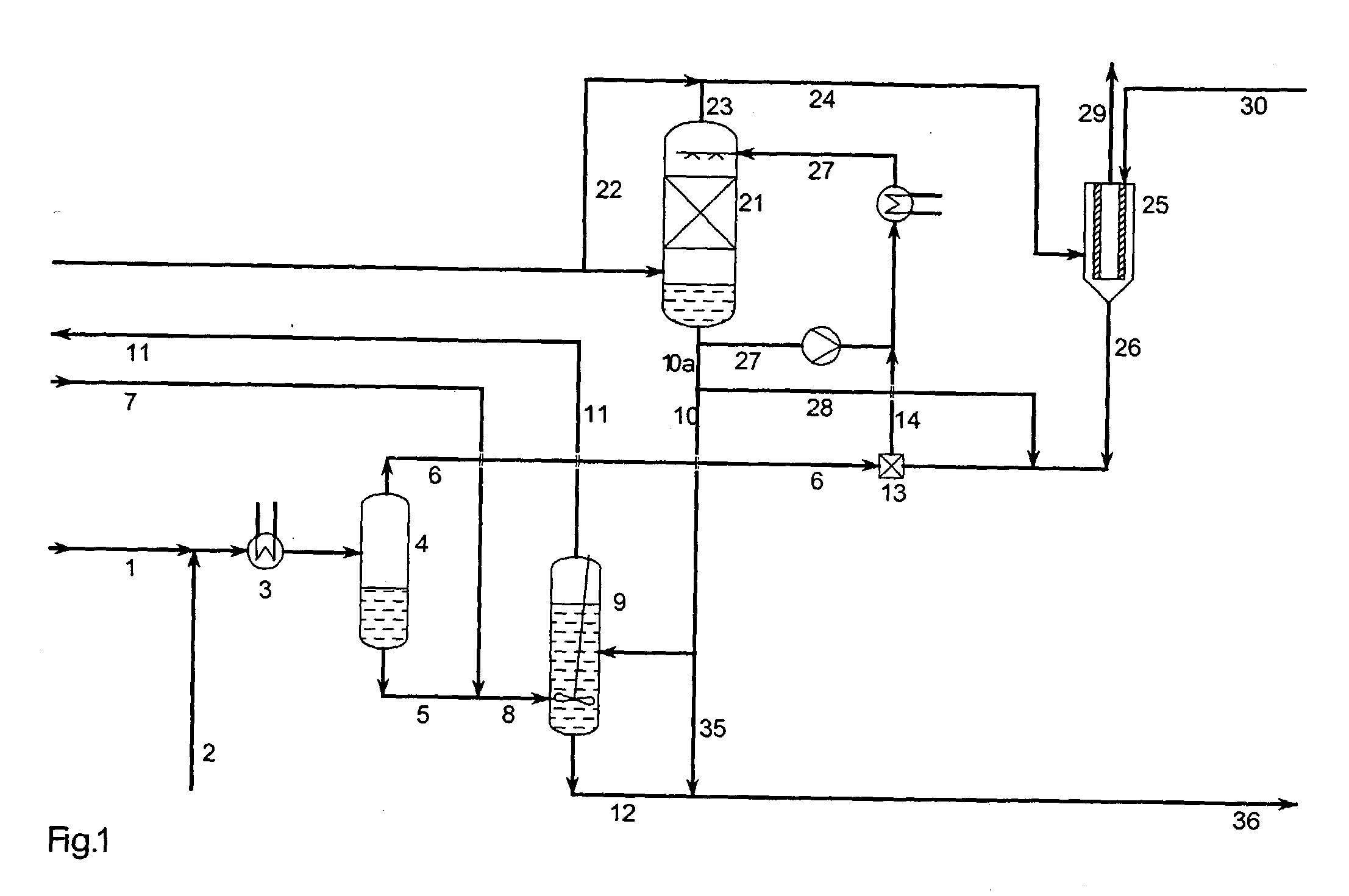

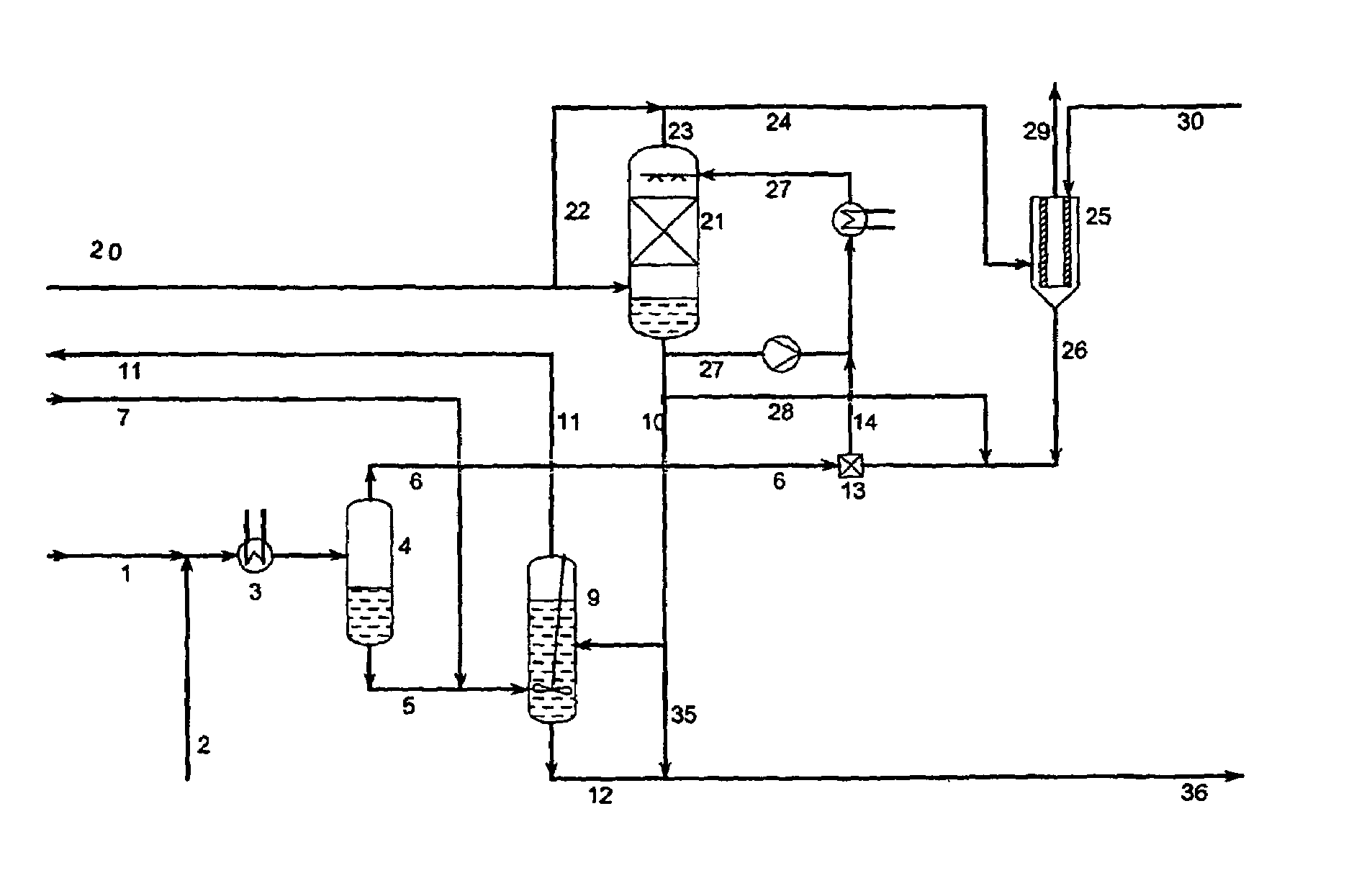

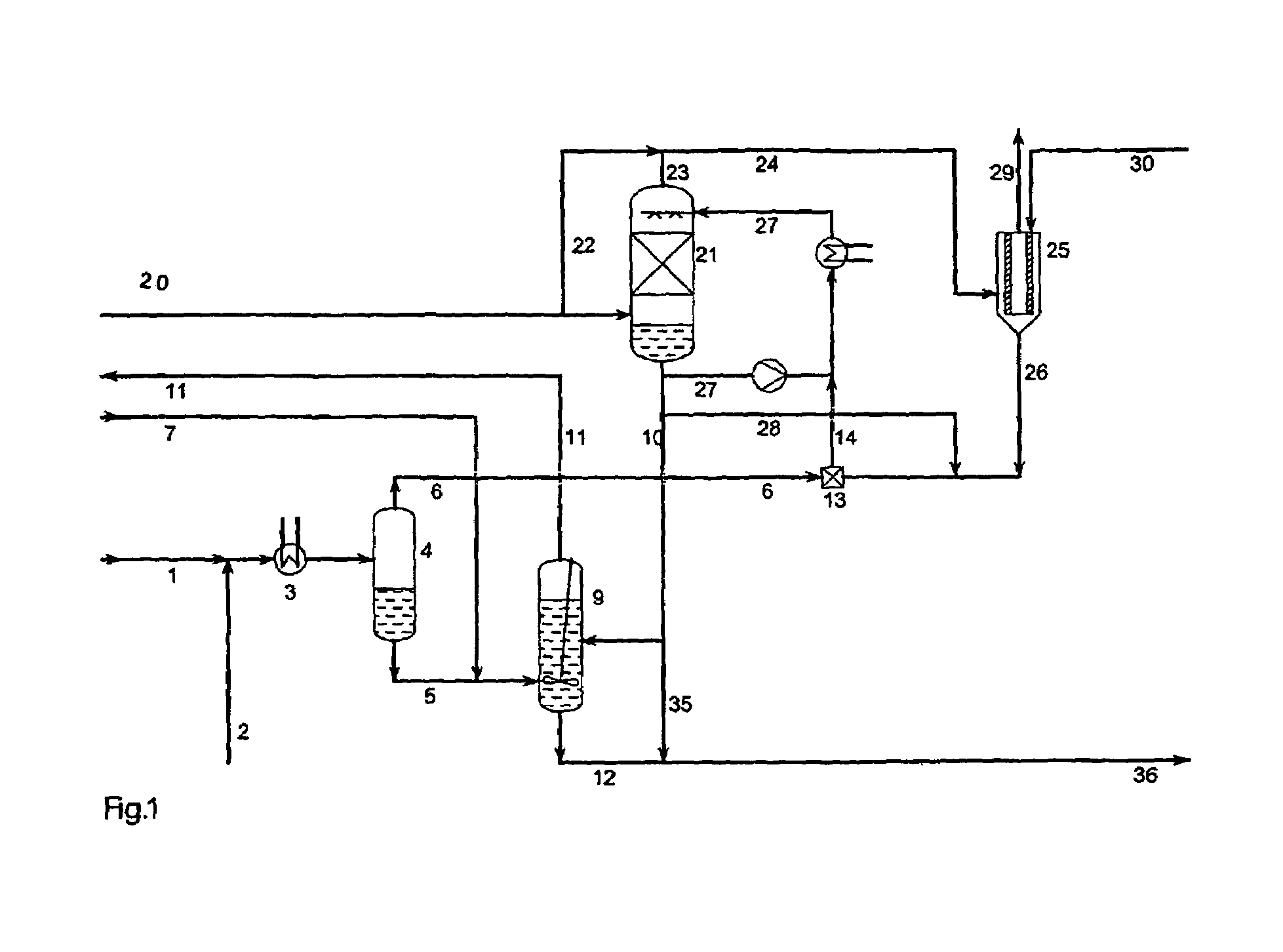

Process for production of ammonium thiosulphate

InactiveUS20030223930A1Speed up the processThiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

A process for continuous production of ammonium thiosulphate, (NH4)2S2O3 (ATS) from NH3, H2S and SO2 comprising steps of: (a) partial condensation in a partial condenser 4 of a first gaseous or partial liquid feed stream comprising H2O, H2S and NH3 with a molar H2S:NH3 ratio <0.4; (b) passing the aqueous condensate comprising NH4HS and NH3 from the partial condenser 4 to a reactor 9 in which said condensate is contacted with a third feed gas stream 7 comprising H2S and with an aqueous solution 10 comprising NH4HSO3 and (NH4)2SO3 under formation of an aqueous solution of (NH4) 2S2O3; (c) passing the gas stream comprising NH3 and H2S from the partial condenser 4 to a mixing device 13 in which said gas stream is completely dissolved in the water drained off from the aerosol filter 25; (d) passing a second feed gas stream 20 comprising approximately 2 / 3 mole SO2 per mole of NH3 contained in the first feed stream to a SO2 absorber 21 and the aerosol filter 25; (e) passing the aqueous solution produced in mixing device 13 to the SO2 absorber 21; (f) passing the off gas from the absorber 21 to the aerosol filter 25 and (g) adding to the aerosol filter 25 a balance amount of water required for obtaining approximately 40-65 wt % (NH4)2S2O3 in the aqueous of solution of (NH4)2S2O3 being withdrawn from the reactor 9.

Owner:HALDOR TOPSOE AS

Stabilized compositions comprising ammonium nitrate

Preferred aspects of the present invention provide ammonium nitrate compositions comprising ammonium nitrate and at least one stabilizing agent, and preferably a third compound. In certain preferred embodiments, the stabilizing agent, together with third compound, is present under conditions and in amounts effective to substantially reduce the detonation sensitivity of the composition and / or to otherwise improve a desired property of the composition.

Owner:ADVANSIX RESINS & CHEM LLC

Dechlorinating tablet and method of manufacture

InactiveUS20050139805A1Decreases friability of tabletProlong dissolution timeOther chemical processesSpecific water treatment objectivesSulfite saltSodium sulfite

A dehalogenating agent is disclosed that is useful for treating aqueous media. The agent contains at least one sulfite salt, such as sodium sulfite. In the agent, the salt is in mixture with a lubricant, an excipient and a saccharide binder. Then a dry, blended mixture of the agent components is directly compressed to form tablets not only of desirable strength and hardness, but also of desirably controlled dissolution rate.

Owner:EXCEL TECH INT CORP

Treatment method for tail gas produced by reaction of sulfonyl chlorination

InactiveCN103071365AReasonable process designSimple and safe operationHydrazine preparationChlorine/hydrogen-chlorideSodium nitriteStorage tank

A treatment method for tail gas produced by reaction of sulfonyl chlorination comprises the following steps: (1), the tail gas produced by the reaction of sulfonyl chlorination is injected into a tertiary series hydrogen chloride falling-film absorption tower, and absorption liquid in a primary hydrogen chloride falling-film absorption tower becomes hydrochloric acid to enter a hydrochloric acid storage tank; (2), tail gas after the hydrogen chloride gas is absorbed by the tertiary hydrogen chloride falling-film absorption tower and then passes through a secondary series aqua ammonia absorption tower, sulfur dioxide gas in the tail gas is absorbed by aqua ammonia in a primary aqua ammonia absorption tower, and the residual tail gas enters a secondary aqua ammonia absorption tower; (3), ammonium sulfite water solution is prepared; (4), parachloroaniline and recovered hydrochloric acid in the primary hydrogen chloride falling-film absorption tower are taken as raw material, and sodium nitrite water solution is added into the raw materials to produce parachlorobenzene diazonium chloride; (5), parachlorobenzene diazonium chloride is dripped into the ammonium sulfite water solution to produce diazonium parachlorobenzene disulfonate; and (6), recovered hydrochloric acid is dripped into the diazonium parachlorobenzene disulfonate to prepare parachlorobenzene hydrazine dihydrochloride. The treatment method effectively separates the tail gas, utilizes hydrochloric acid and ammonium sulfite, which are recovered by the tail gas, to prepare the parachlorobenzene hydrazine dihydrochloride, thereby being environment-friendly and economical.

Owner:天津市天川化工有限公司

Nutrient recovery systems and methods

ActiveUS20140314657A1High recovery rateLow costBioreactor/fermenter combinationsBio-organic fraction processingAeration rateEnvironmental engineering

Methods, systems, and apparatuses for anaerobic digestion of waste fibrous material and the recovery of nutrients are provided. Methods, systems, and apparatuses disclosed herein provide mechanisms to release dissolved gases from anaerobic digester effluent. Methods, systems and apparatuses disclosed herein can recover one or more nutrients from anaerobic digested effluent using a range of temperatures, aeration rates, aeration times, pH ranges, and settling times.

Owner:DVO +2

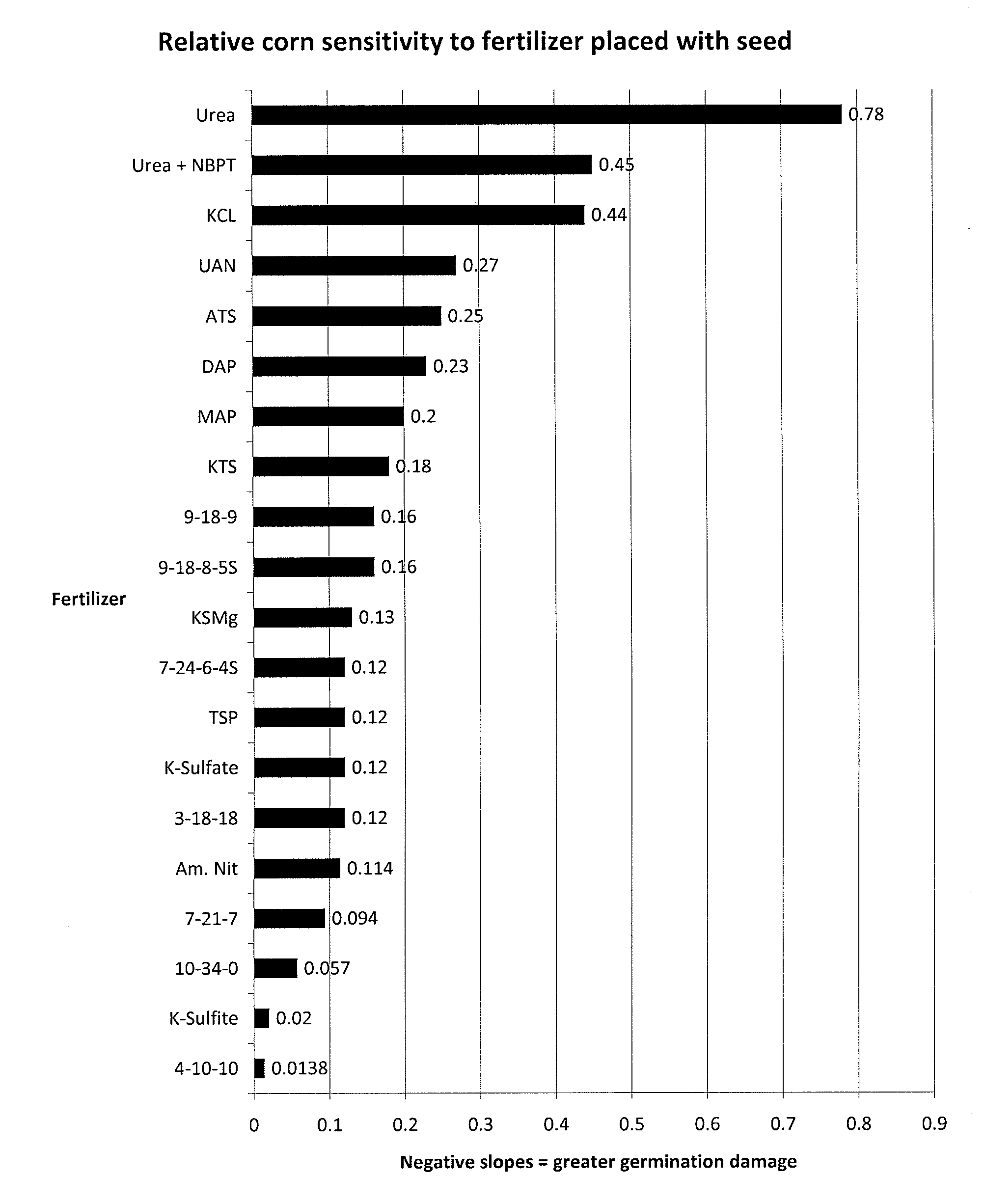

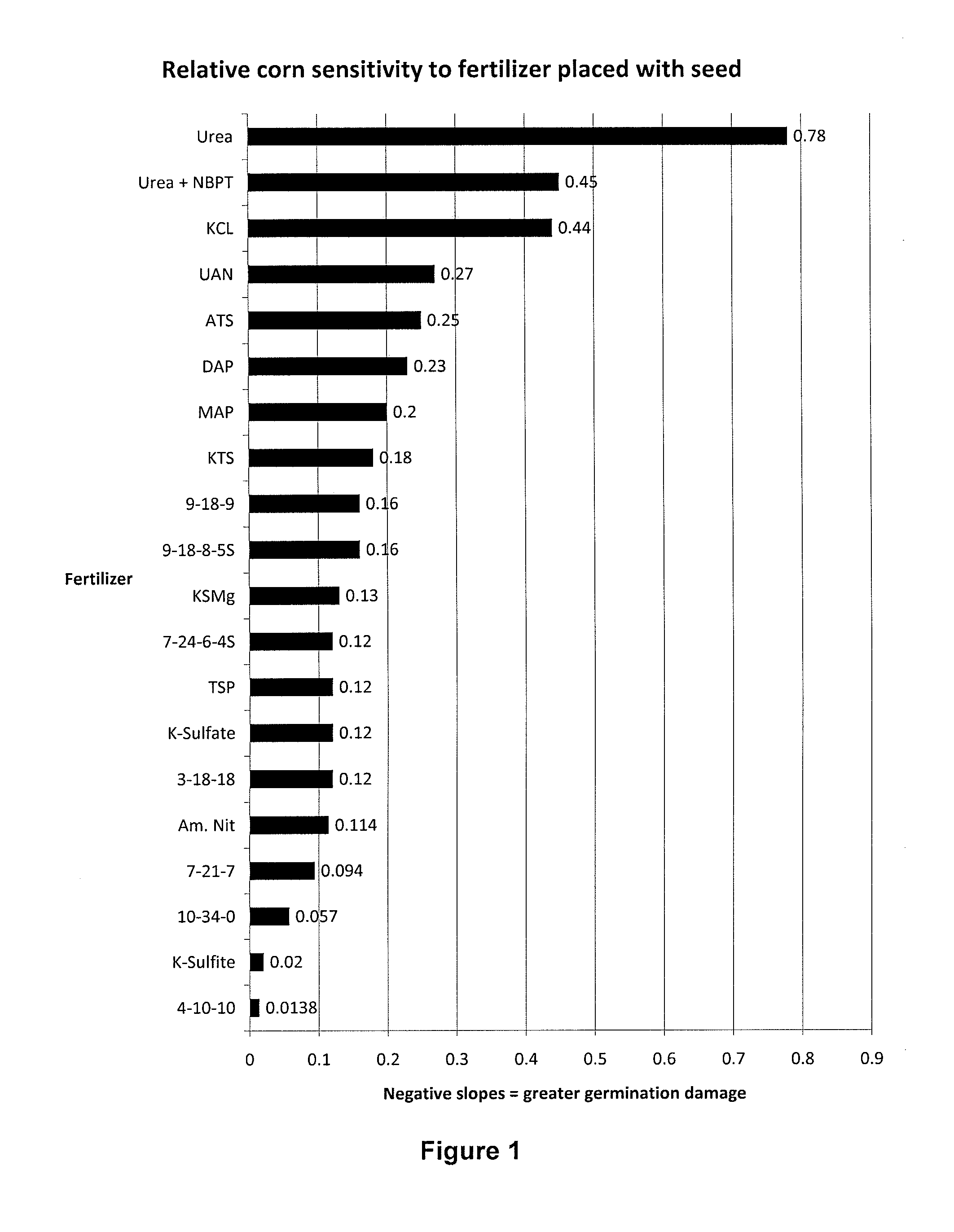

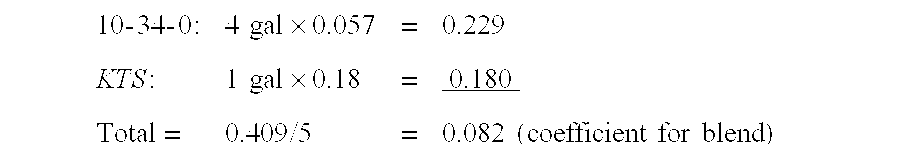

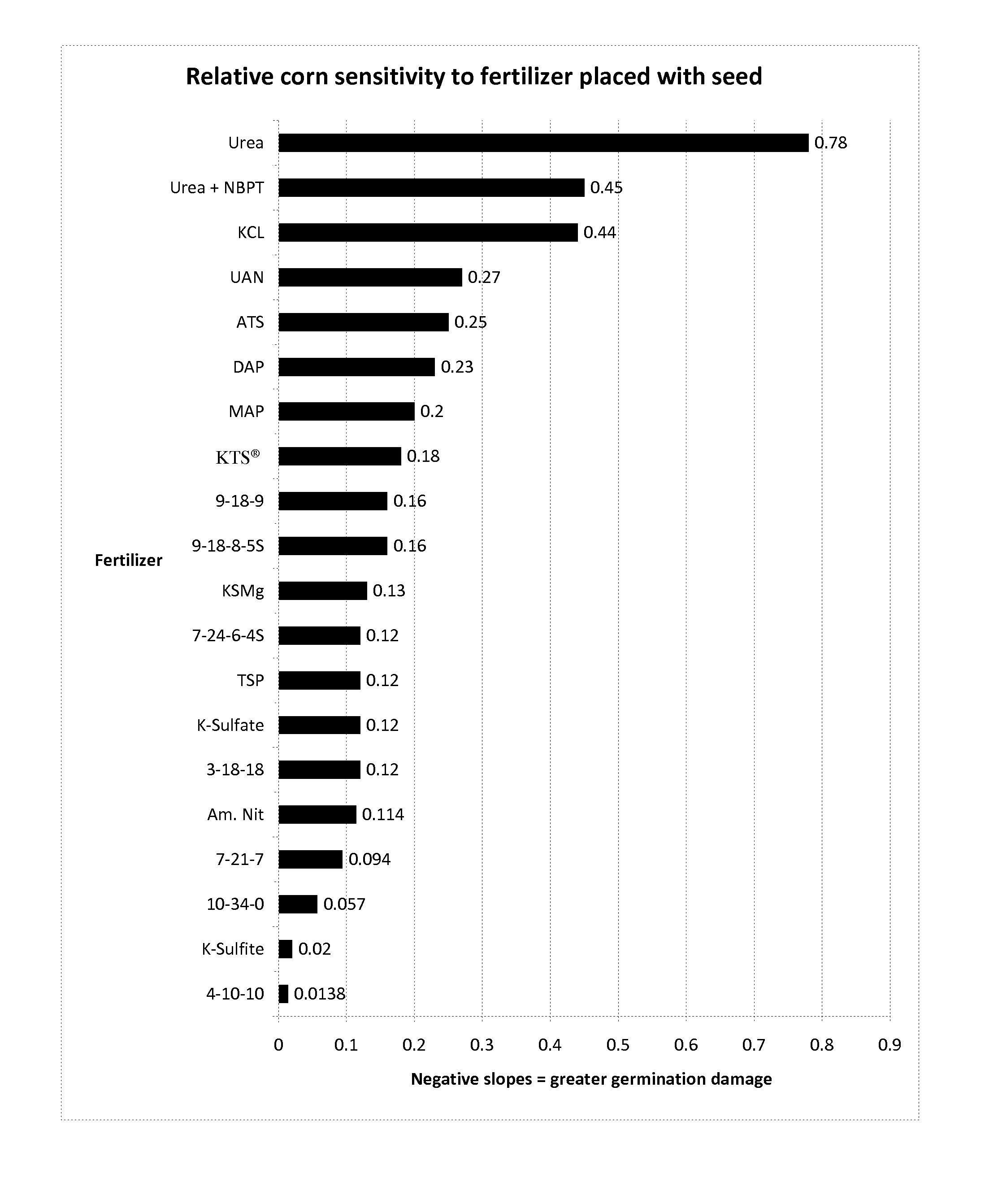

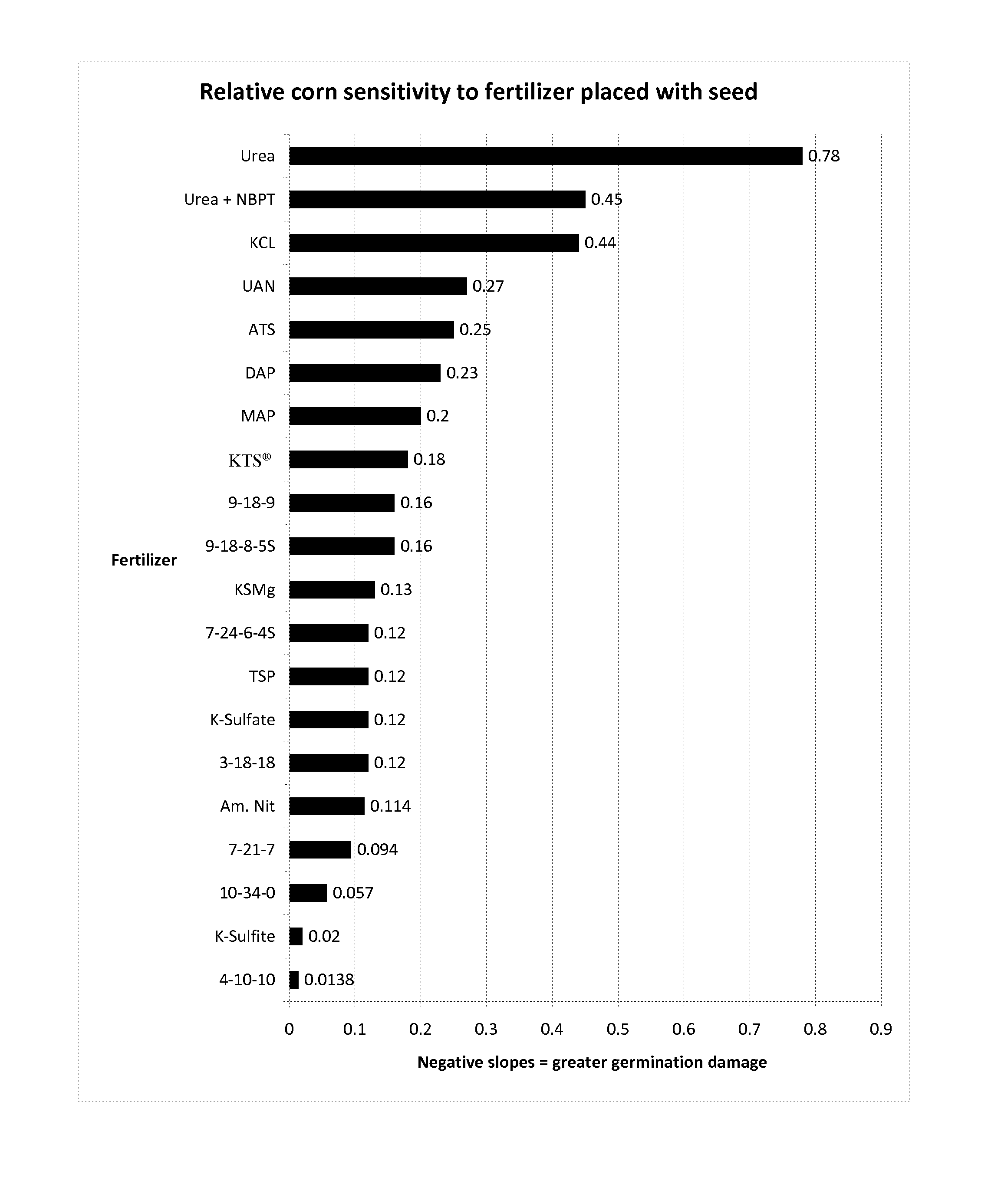

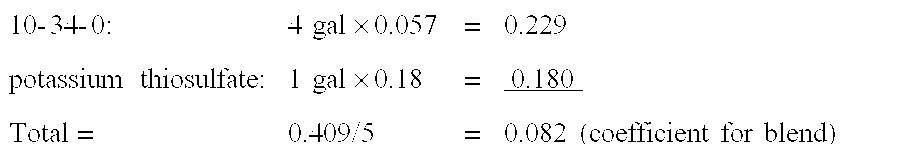

Potassium sulfite/potassium bisulfite (ks/kbs) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

ActiveUS20120255335A1Low indexReduce drug damageBiocideSulfite preparationSulfur productPhytotoxicity

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

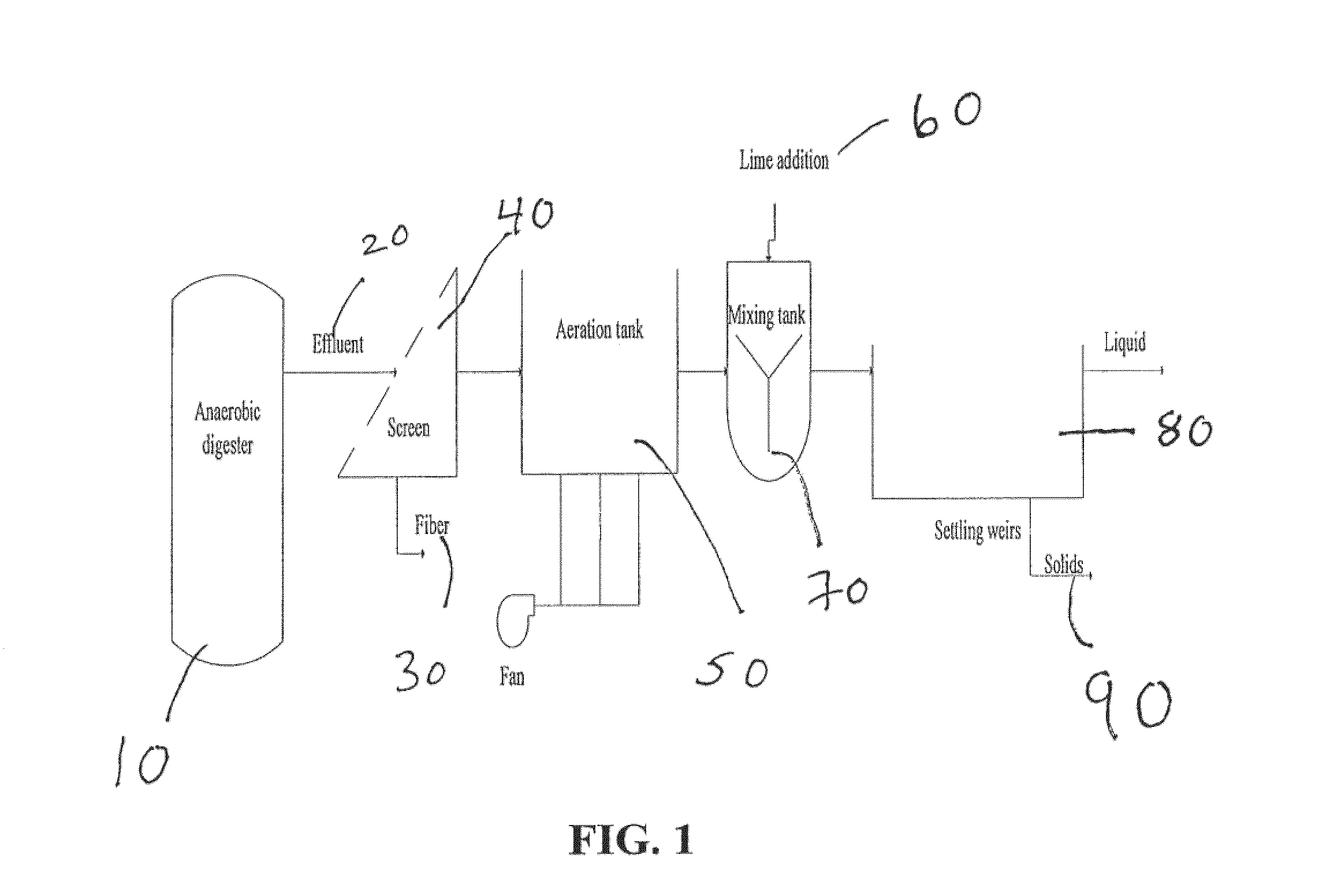

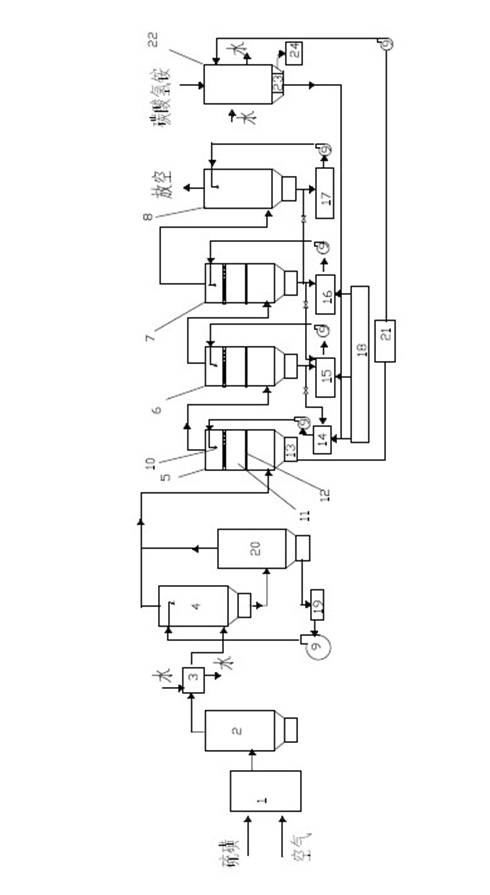

Method for ammonia method desulfurization of flue gas and high-purity solid ammonium sulfite by-producing

ActiveCN102658015AReduce concentrationEmission reductionDispersed particle separationAmmonium sulfitesDust controlPhysical chemistry

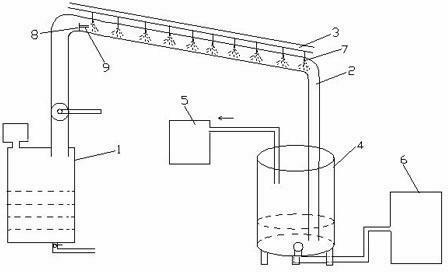

The invention discloses a method for ammonia method desulfurization of flue gas and high-purity solid ammonium sulfite by-producing. The method comprises the following steps that: solid substances rich in sulfur are firstly burnt to generate the flue gas rich in high concentration sulfur dioxide gas; the flue gas enters into a cyclone separator for dedusting, and the dedusted flue gas enters into a heat exchanger for temperature reduction; then the flue gas enters into a washing and purifying tower to be washed; the flue gas respectively enters into a primary absorption tower, a secondary absorption tower and a third absorption tower for absorption, the high concentration ammonium bisulfite solution generated through reaction is taken out from a bottom groove of the primary absorption tower and is neutralized in a neutralization tank after volume and concentration measurement, and the solid ammonium sulfite is separated by a centrifuge in the neutralization tank through cooling crystallization; and the flue gas enters into a washing tower to be discharged after washing. By the method, SO2 and other harmful acidic gas are highly purified; the utilization ratio of an ammonia absorption agent is effectively improved; high-purity solid ammonium sulfite can be obtained; and the ammonium sulfite solution has excellent special industrial use and prospect.

Owner:水泽节(山东)环保科技有限公司

Process for production of ammonium thiosulphate

InactiveUS7052669B2Thiosulfates/dithionites/polythionitesSulfite preparationAqueous solutionAmmonium thiosulfate

Owner:HALDOR TOPSOE AS

Process for ammonia method desulfurization of fume and by-producing ammonium sulfite

ActiveCN1970447APromote absorptionReduce desulfurization efficiencyDispersed particle separationAmmonium sulfitesVolumetric Mass DensitySpray tower

The invention discloses a flue gas desulfurizing method through ammonia process and generating method of by-product ammonium sulfite, which comprises the following steps: making flue gas into cyclone separator and heat exchanger to dedust and cool; atomizing ammonia and (NH4)2SO3 solution in the drying tower; contacting with flue gas to desulfurize; drying; separating; contacting flue gas with (NH4)2SO3 solution in the spray tower; removing residual SO2 and NH3 to lower density; saving ammonia; obtaining by-product (NH4)2SO3.

Owner:PETROCHINA CO LTD

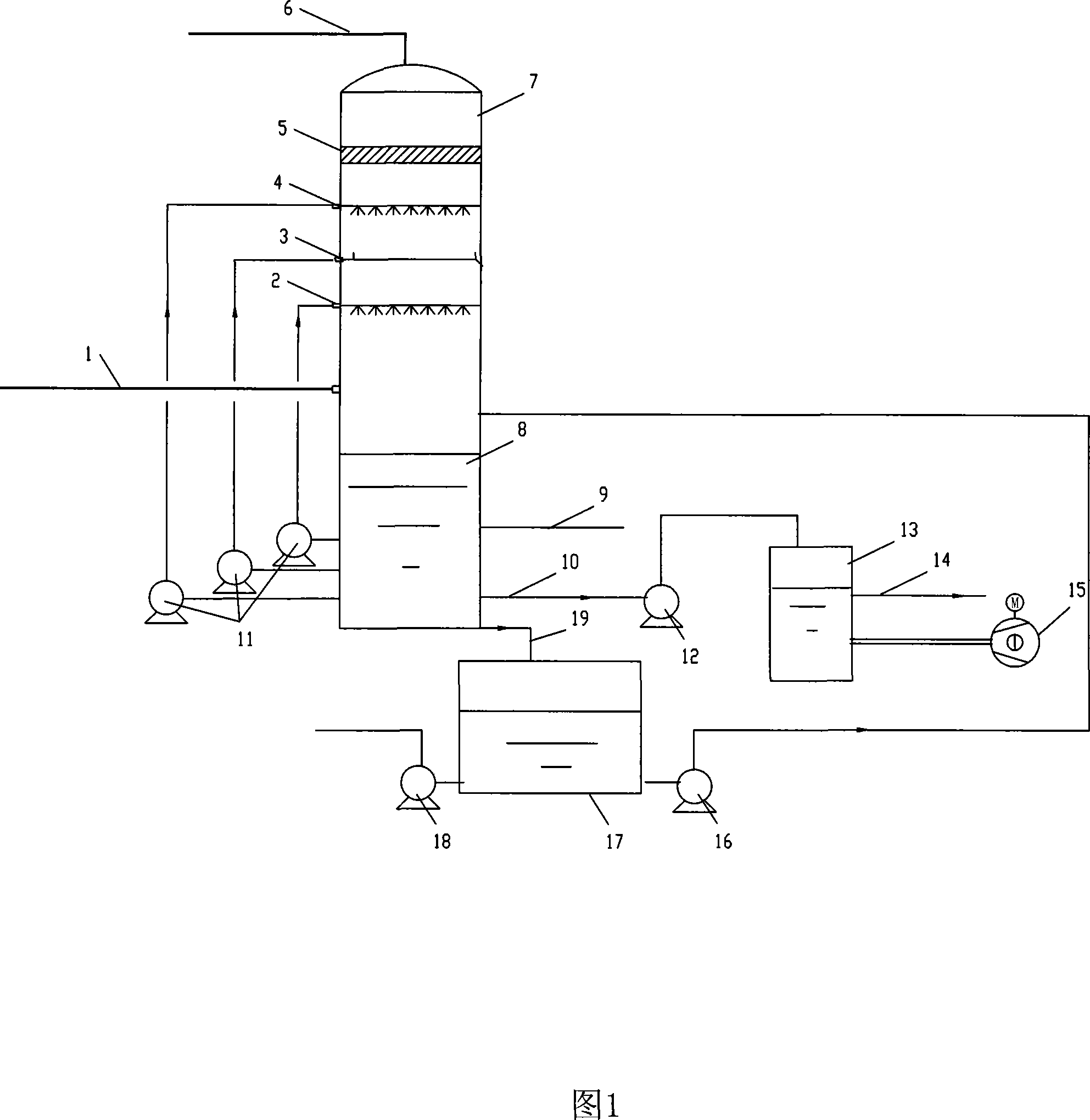

Ammonia method desulfurizing method and device

InactiveCN101053745AReduce contentAbsorptive capacity does not decreaseDispersed particle separationAmmonium sulfitesFlue gasSulfur

The invention disclose a method of ammonium desulfurization and device thereof, and Specifically, the method of the invention utilizes a novel thionizer coupled with the ammonium salt oxidizing tank outer the thionizer to deprive the sulfur oxides and dust in the flue gas step by step via the manner of coupling the sprinkling section with the plate. Using the desulfurization method and device thereof said in the invention, the efficiency is high, the operating trouble is low, and the reconditioning is convenient. The invention also has the advantage of a low content of ammonium and ammiaonia sulfate aerosol, low dust in outgrowth and fine quality.

Owner:中国自控系统工程有限公司

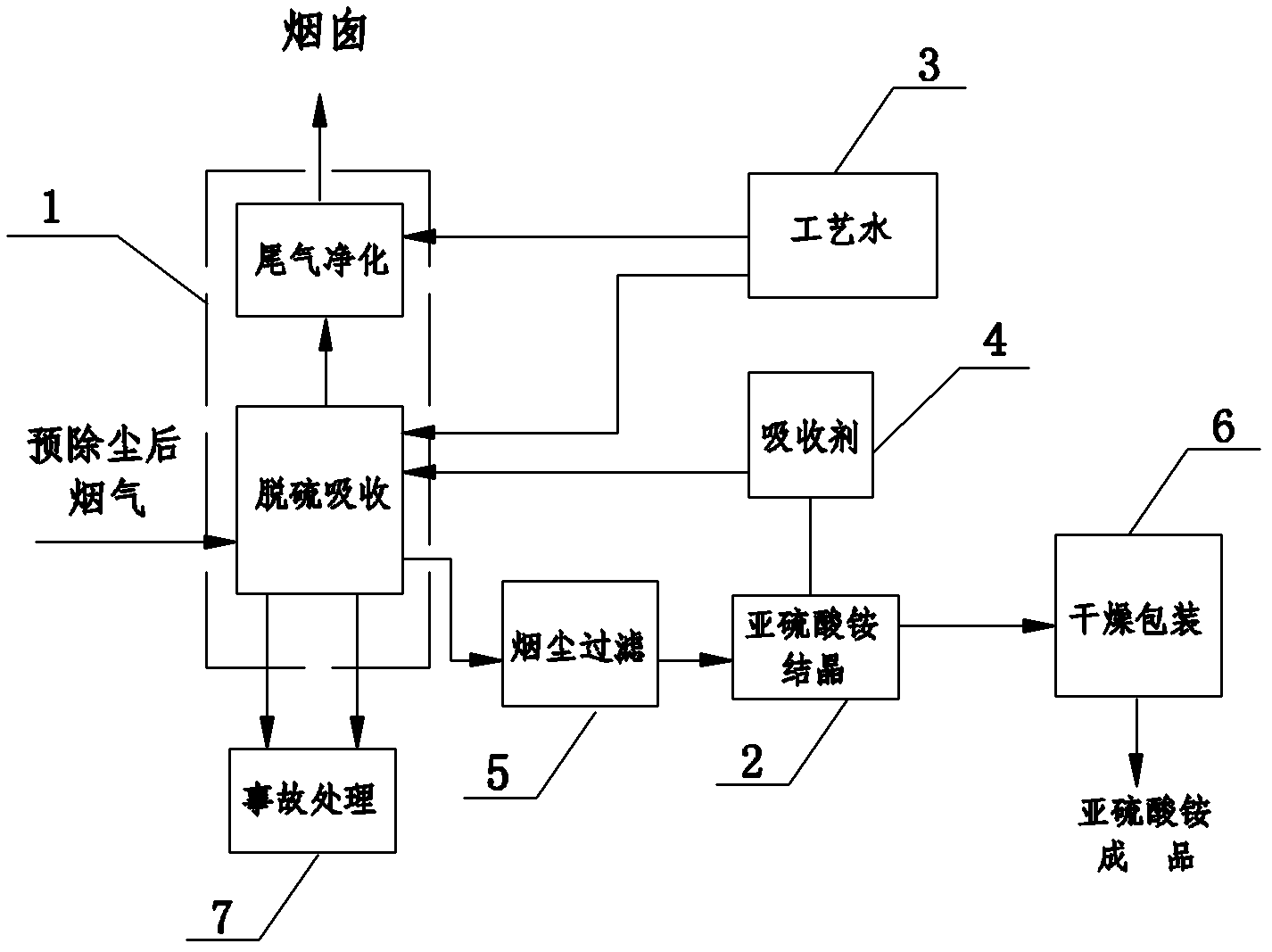

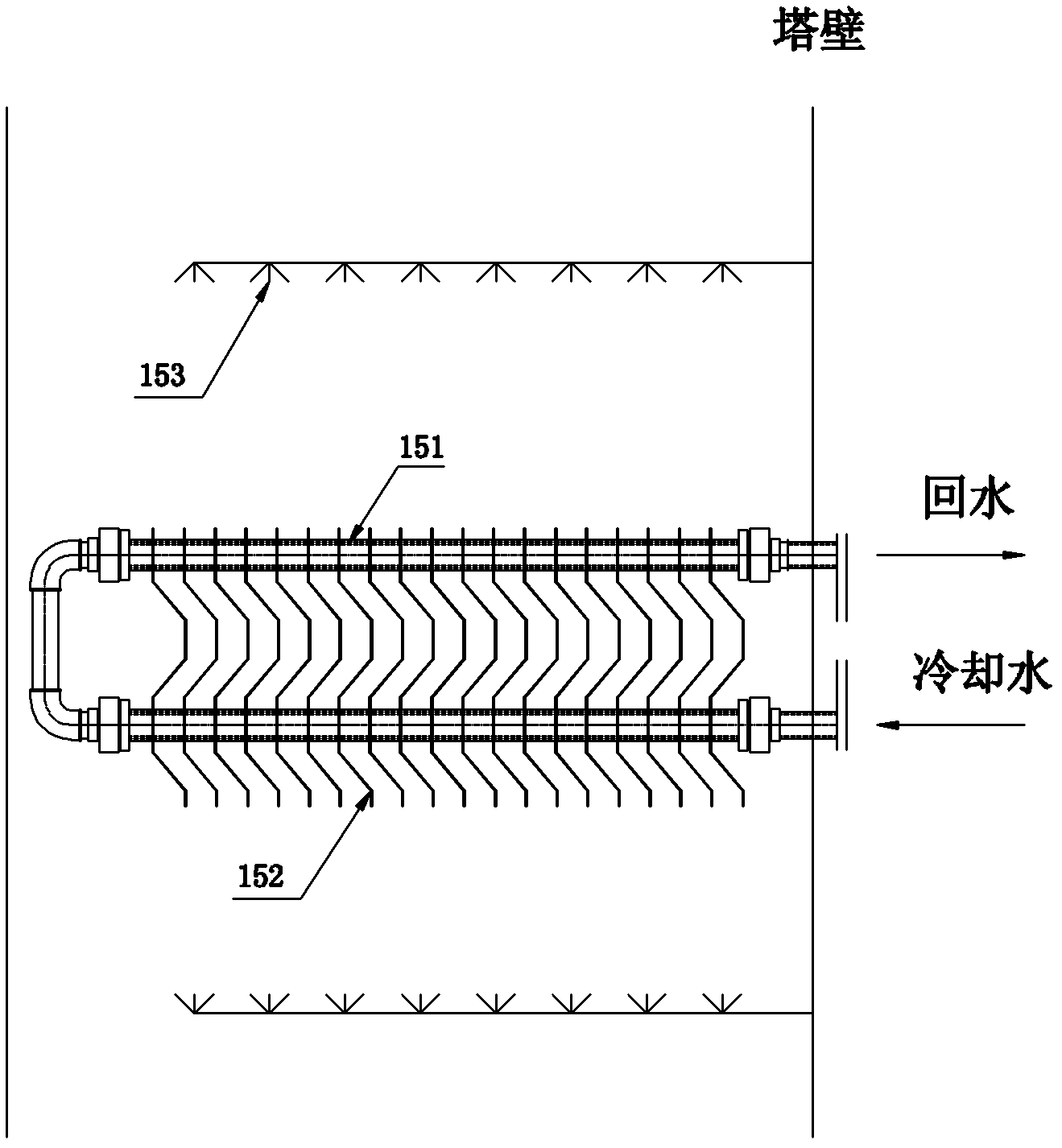

Flue gas desulfurizing device adopting ammonia-ammonium sulfite method

InactiveCN103028317AEfficient removalQuality improvementDispersed particle separationAmmonium sulfitesHandling systemPollution

The invention belongs to the technical field of flue gas desulfurization, and particularly relates to a flue gas desulfurizing device adopting an ammonia-ammonium sulfite method for recycling sulfur resources. The flue gas desulfurizing device comprises a desulfurization absorption system, an ammonium sulfite crystallization system, a process water system, an absorbent system and an emergency treatment system of the desulfurizing device, wherein the ammonium sulfite crystallization system, the process water system and the absorbent system are connected with the desulfurization absorption system. The flue gas desulfurizing device is characterized in that the main body of the desulfurization absorption system is an absorption tower having a double-tower structure or a single-tower double-section structure; a spray device is arranged in the tower; a collision type demister and a desulfurization tail gas purifying device are arranged in sequence above the spray device; an absorption liquid storing groove is formed at the bottom of the tower; the upper section of a single tower is connected with a circulating absorption liquid storing groove arranged outside the tower through a pipeline; and the ammonium sulfite crystallization system comprises a crystallizer provided with a jacket of cooling water. Due to the adoption of the flue gas desulfurizing device, the formation of an aerosol can be suppressed effectively, and secondary pollution is prevented; and compared with the conventional evaporative crystallization, the flue gas desulfurizing device has the advantage that a neutralizing condensation and crystallization way is adopted for ammonium sulfite serving as a side product, so that the energy consumption can be lowered.

Owner:陈有根

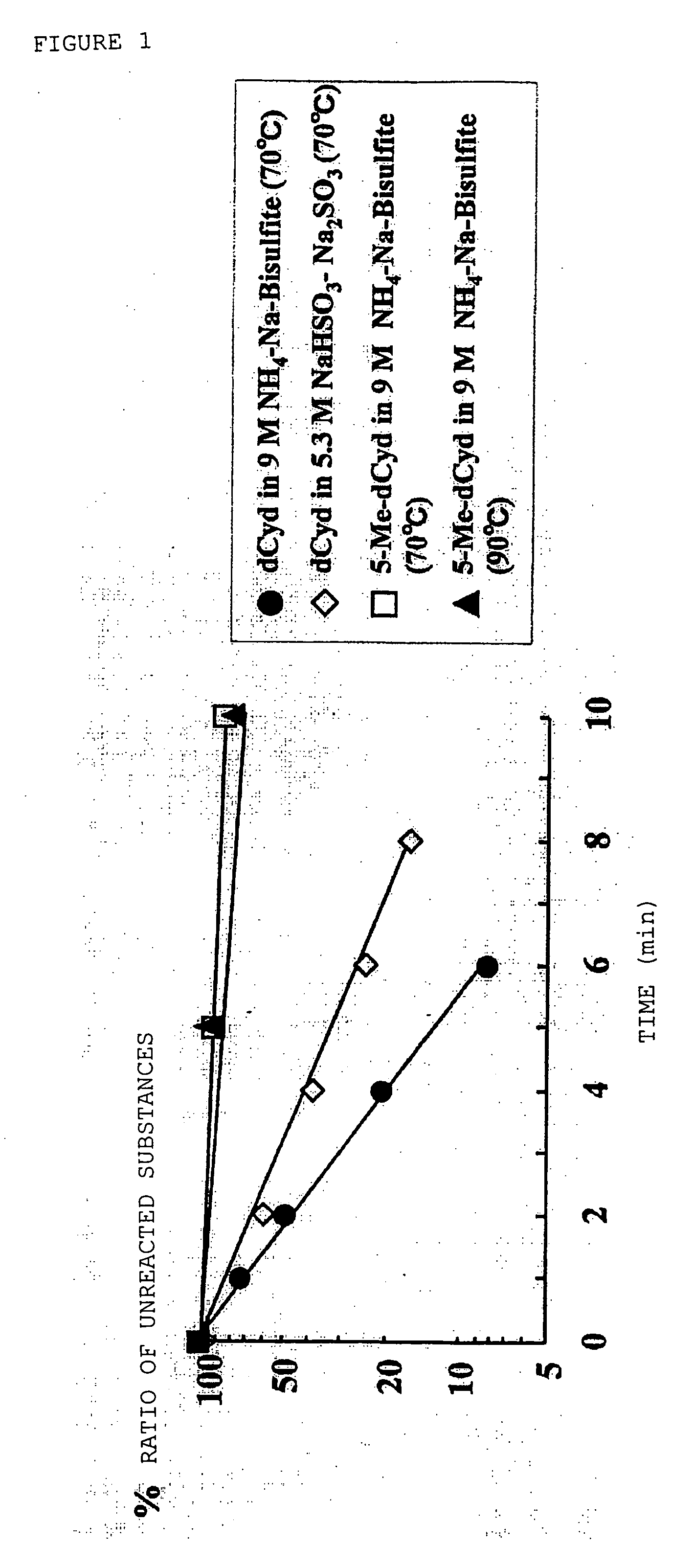

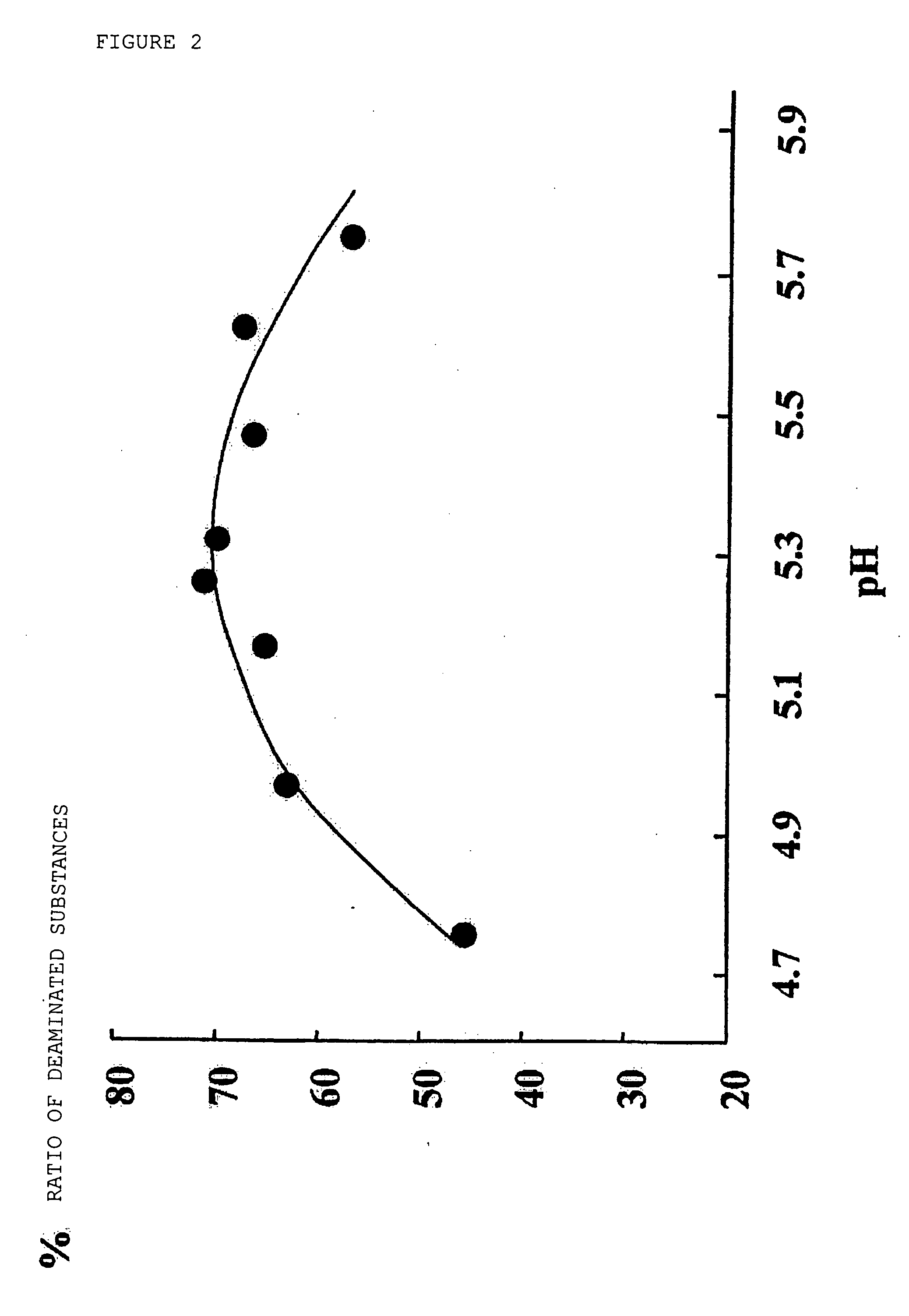

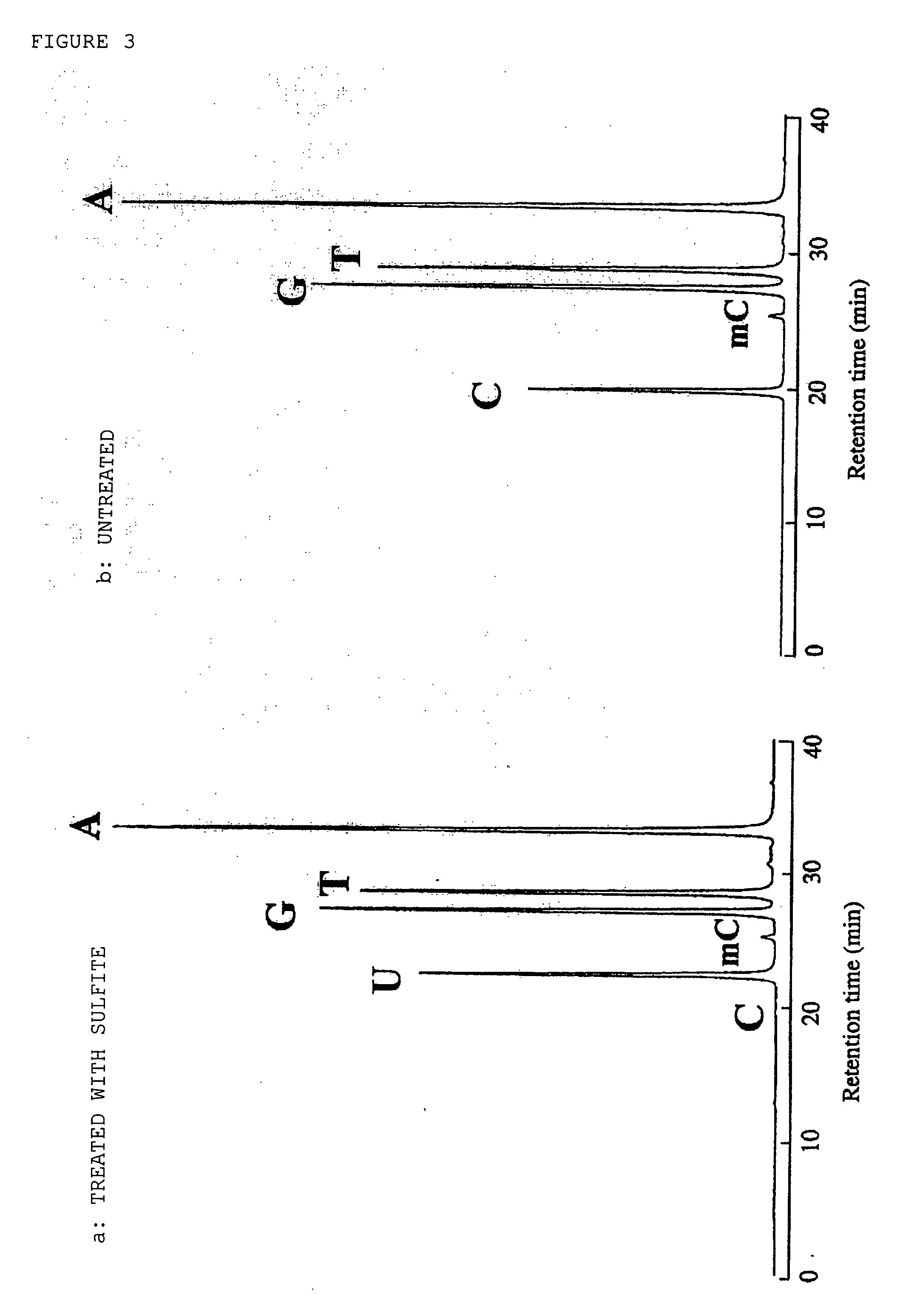

Composition for deaminating dna and method of detecting methylated dna

InactiveUS20070178466A1Short timeAddressing slow performanceSugar derivativesMicrobiological testing/measurementSulfiteDNA

(1) A sulfite composition having a sulfite concentration of more than 6.2 M, (2) a method for deaminating DNA using a sulfite composition described in (1), (3) a method for detecting methylated DNA using a sulfite composition described in (1), (4) a kit for deaminating DNA or for detecting methylated DNA comprising a sulfite composition described in (1).

Owner:TOYOBO CO LTD +1

ATS tail gas treating process for SRU and SWS off gases

ActiveUS7824652B1Promote absorptionMaximize recoveryThiosulfates/dithionites/polythionitesSulfite preparationCombustionExhaust fumes

The present invention relates to a system and process utilizing ammonium thiosulfate solution (ATS) as the primary liquid absorption agent that is re-circulated through an SO2 Contactor / Absorber for high efficiency contacting and absorption of sulfur dioxide, SO2 from a combustion gas stream generated by incineration of a Claus Sulfur Recovery Unit (SRU) off gas stream (often referred to as a Claus tail gas stream) and also additional SO2 generated from incineration of additional sulfur containing streams. ATS is also re-circulated through a separate H2S Contactor / Absorber for absorption of and reaction with a Sour Water Stripper (SWS) off gas stream and additional H2S-Acid Gas (A.G.) streams to produce additional concentrated ATS. The process and equipment also provides the ability to readily switch between using ATS and ABS as the primary absorbent solution for SO2 absorption, depending upon the concentration of SO2 in the off gas feed streams.

Owner:TESSENDERLO KERLEY INC

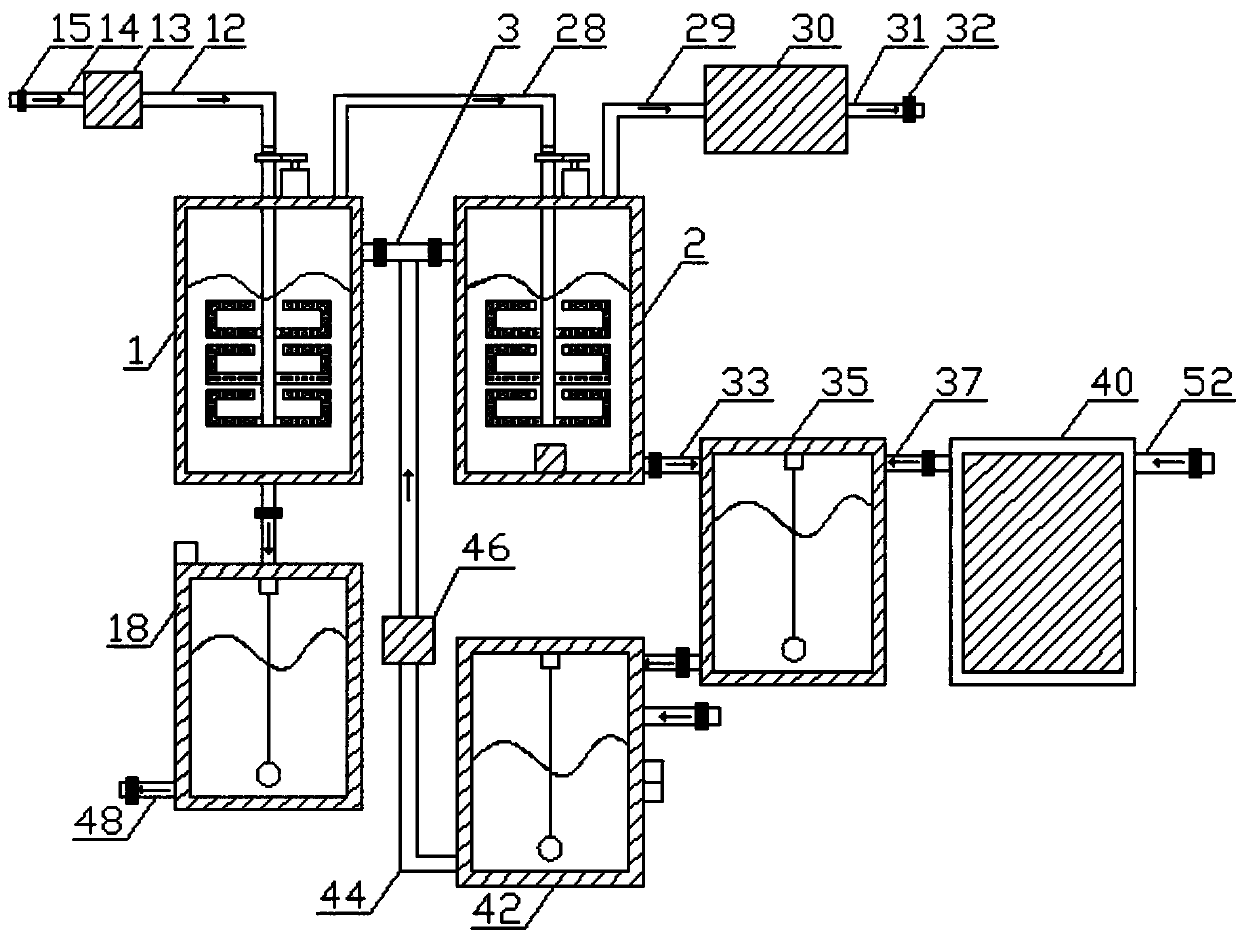

Double-tower ammonia desulfurization device and method for recovering sulfur resources

ActiveCN101708412BHigh purityGuaranteed purityUsing liquid separation agentAmmonium sulfitesFlue gasSulfur

The invention discloses a double-tower ammonia desulfurization device and method for recovering sulfur resources. The device includes a dynamic wave scrubber, a primary absorption tower, a secondary absorption tower, etc. After the flue gas is removed from the ash by the dynamic wave scrubber, the temperature is lowered by the dynamic wave scrubber, and the flue gas enters the primary absorption tower and the secondary absorption tower in turn. , the first-level absorption tower and the second-level absorption tower are equipped with 5 spray layers, the lower three spray layers spray and absorb the flue gas, and the upper two spray layers prevent ammonia from escaping. The absorption tower and the secondary absorption tower are discharged after spraying and absorbing. The present invention has the following advantages: 1) the purity of by-products is high; 2) the double-tower design can not only obtain higher desulfurization efficiency, but also produce high-purity by-products; 3) this process uses ammonium bisulfite as the final The by-product not only omits the process of crystallization and drying in the previous process, but also improves the added value of the by-product; 4) the process of the present invention is all recycled without secondary pollution.

Owner:ZHEJIANG UNIV

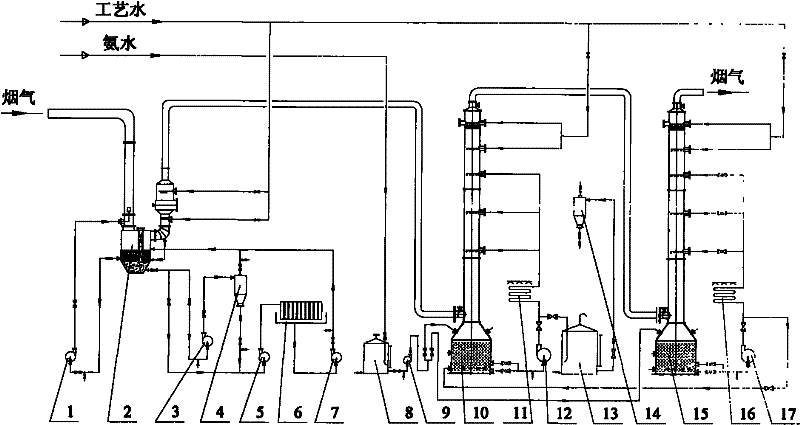

System of producing ammonium sulfite through flue gas desulfurization and method thereof

InactiveCN104971603AIngenious structural designReasonable structural designDispersed particle separationAmmonium sulfitesEnvironmental resistanceLiquid waste

The invention discloses a system of producing ammonium sulfite through flue gas desulfurization, which includes a column body and an out-column conversion system. A flue gas inlet is arranged on the lower section of the column body. A liquid storage section is arranged in the column body at the position corresponding to the lower section of the flue gas inlet. In the column body, a water-washing temperature-reducing section, a primary absorption section, a secondary absorption section, a purifying and water-washing section and a defogging section are arranged corresponding to the upper position of the flue gas inlet in a successively manner from the bottom to the top. An ammonium sulfite conversion system is arranged outside the column and includes an ammonia gas feeding system and a cyclic adjustment system. The system is smart and reasonable in structure design and solves the problem of high operation cost effectively. The system integrates both absorption and production so that the system is free of waste liquid emission and limits escape and emission of ammonia. A method of producing the ammonium sulfite through flue gas desulfurization is simple in process, is energy-saving and environment-protecting, is low in cost, is safe and stable in operations, can turn waste into resources, and is an important development direction of environment-friendly desulfurization.

Owner:张波

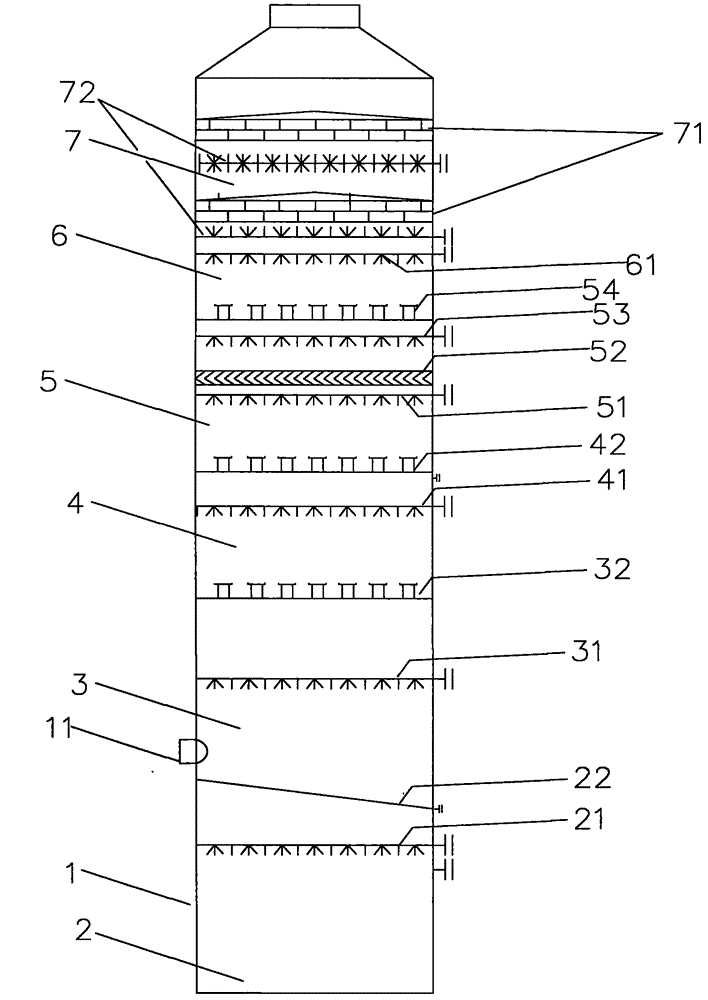

Novel method for absorbing tail gas from trichloro-acetic chloride production through chlorination process

InactiveCN102764572AEfficient separationEfficient recyclingOrganic compound preparationDispersed particle separationDisulfur dichlorideSodium bisulfite

The present invention relates to a novel method for absorbing tail gas from trichloro-acetic chloride production through a chlorination process. The method can realize separation and recovery of hydrogen chloride, sulfur dioxide, sulfur, disulfur dichloride, and chlorine generated in the production process of trichloro-acetic chloride; the method is safe and easily controlled, has no harm to the environment, and generates by-products containing hydrochloric acid with concentration higher than 30% and a sodium bisulfite solution. The invention belongs to the technical field of environmental protection.

Owner:SHANXI SANWEI FENGHAI CHEM

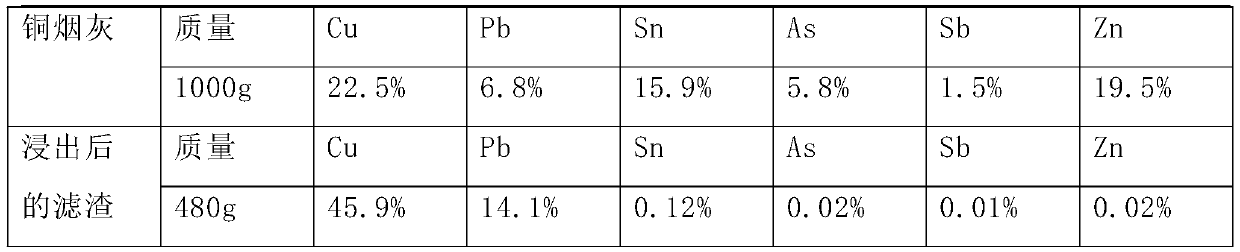

Resourceful treatment method for soot from copper melting furnace

ActiveCN109777963AAchieve separationSimple processAmmonium sulfitesProcess efficiency improvementSootArsenic sulfide

The invention discloses a resourceful treatment method for soot from a copper melting furnace. The method comprises the following steps: separating lead-copper and tin-arsenic-zinc-antimony in soot byhigh-temperature alkaline cooking; introducing hydrogen sulfide into the obtained filtrate to precipitate tin-arsenic-antimony, then continuously introducing hydrogen sulfide to participate zinc, dissolving zinc participates by adding sulfuric acid, and performing concentration and crystallization to obtain industrial pure zinc sulfate; adding lead-copper to a hydrochloric acid solution, then adding sodium chlorate, and cooling the obtained solution to obtain lead chloride filtering residues and copper chloride filtrate; adding tin-arsenic-antimony filtering residues to hydrochloric acid fordissolution so as to obtain an antimony-containing solution, extracting the antimony-containing solution by adding an extraction agent, then performing reverse extraction with p ammonia water, performing concentration and crystallization on the obtained stripping solution to obtain antimony chloride, adding the obtained fifth filtering residues to a sodium sulfide solution for reaction, and then performing filtering so as to obtain tin-containing filtrate arsenic sulfide residues. By adopting the method provided by the invention, the separation and recovery of valuable metals in the soot are achieved, the recovery rate is high and the product finally obtained has high purity; and meanwhile, most of by-products thereof are recovered, the cost is low and the process is short.

Owner:王柯娜

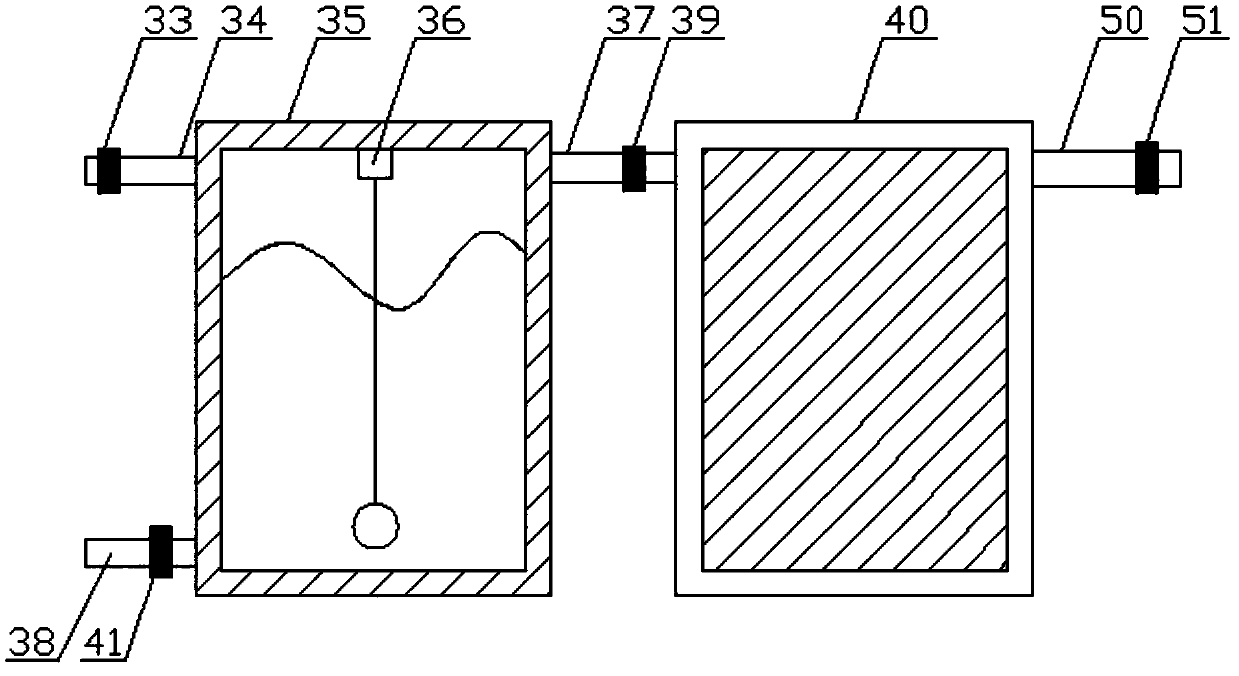

Device and method for preparing sulfite

PendingCN111792651AReduce manufacturing costFull recoveryDispersed particle separationAmmonium sulfitesProcess equipmentFluid phase

The invention discloses a device for preparing sulfite. SO2-containing feed gas passes through a flue gas conditioning unit, then enters an acidic sulfite preparation unit and a basic sulfite slurry preparation and residual SO2 re-absorption unit in sequence, and is discharged out of the system; the synthesized intermediate slurry passes through an acidic sulfite conditioning and target product separating unit and a product drying unit in sequence, and finally a solid-phase target product or a liquid-phase target product is obtained. Ammonia in the feed gas can be fully recycled by the deviceand method, the ammonia consumption of a unit product can be reduced by 1 / 4-1 / 2, and the production cost of a target product is lower. The primary purity of the target product is high, secondary separation and purification are not needed, the loss in a purification step is avoided, and the yield of the target product can be increased by 0.8%-2.3% according to empirical analysis. The primary purityof the target product reaches 98.5-99.3%, one set of process equipment can be used for producing various products, and the market requirements can be better met.

Owner:NANJING LIUYAN ENVIRONMENTAL PROTECTION TECH CO LTD

Industrial tail gas full recycle apparatus

ActiveCN102512934AReduce wasteNo pollutionDispersed particle separationAmmonium carbonates/bicarbonatesIndustrial gasExhaust fumes

The invention reveals an industrial tail gas full recycle apparatus. The apparatus comprises a reaction vessel; one end of a tail gas recovering pipe is connected with the reaction vessel, the tail gas recovering pipe is in a shape of an inverted U, a water pipe is arranged above the tail gas recovering pipe, and the other end of the tail gas recovering pipe extends into a solvent in a stainless steel enclosed pressure container; a pipeline connected with a vacuum pump is arranged in the stainless steel enclosed pressure container and is far away from the solvent in the stainless steel enclosed pressure container, and a condensation kettle communicated with the pipeline is arranged at the bottom of the stainless steel enclosed pressure container. The industrial tail gas full recycle apparatus converts exhaust gas into a variety of concentrates and enables the concentrates to be applied in other fields, which allows the effect of full recycle to be realized, thereby reducing waste of resources and increasing benefits for an enterprise; meanwhile, full recycle of tail gas enables tail gas not to enter into the air, thereby causing no pollution to the air and obtaining a good environmental protection effect.

Owner:JIANGSU YUANYANG PHARMA

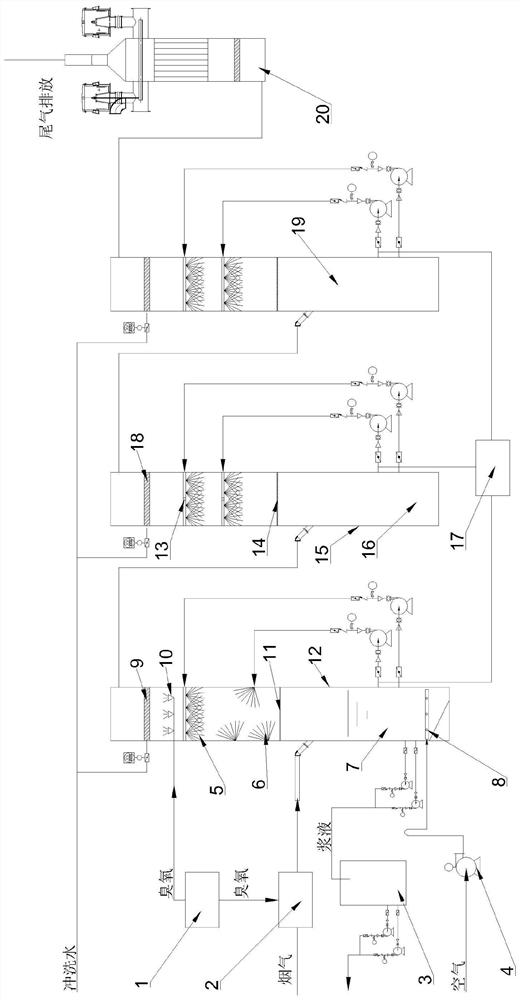

Desulfurization and denitrification system and method by adopting ozone oxidation in cooperation with ammonia method

PendingCN111495160AExtended stayReduce the temperatureAmmonium nitratesGas treatmentFlue gasEnvironmental engineering

The invention provides a desulfurization and denitrification system and method by adopting ozone oxidation in cooperation with an ammonia method. The desulfurization and denitrification system comprises a first absorption device and a second absorption device which are sequentially communicated in the flue gas flow direction. An ozone generation device is connected into an inlet flue of the firstabsorption device; the interior of the second absorption device is sequentially divided into a circulating spraying area and at least two layers of multi-effect spraying areas from bottom to top in the flue gas flowing direction, the circulating spraying area is externally connected with at least two absorbent storage tanks, the absorbent storage tanks are independently connected into the multi-effect spraying areas respectively, and the absorbent storage tanks supply absorbents to the circulating spraying area and the multi-effect spraying areas respectively; and the circulating spraying areais externally connected with a recovery unit. By adopting a double-tower structure for absorption, the retention time of the absorbent in the tower is prolonged, the contact time with flue gas is prolonged, and the desulfurization and denitrification efficiency is improved. A mixed absorbent of ammonia water and a calcium-based absorbent is adopted, and NOx in the flue gas is converted into chemical fertilizer and gypsum with higher additional value.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

A method for flue gas ammonia desulfurization and by-product high-purity solid ammonium sulfite

ActiveCN102658015BReduce concentrationEmission reductionDispersed particle separationAmmonium sulfitesDust controlPhysical chemistry

The invention discloses a method for flue gas ammonia desulfurization and high-purity solid ammonium sulfite as a by-product. Firstly, sulfur-rich solid matter is burned to generate flue gas rich in high-concentration sulfur dioxide gas; the flue gas enters cyclone separation The flue gas after dust removal enters the heat exchanger to cool down; then the flue gas enters the washing and purification tower for washing; the flue gas enters the first-level absorption tower, the second-level absorption tower, and the third-level absorption tower for absorption, and the reaction generated The high-concentration ammonium bisulfite solution is taken out from the bottom tank of the primary absorption tower, and then neutralized in the neutralization tank after measuring the volume and concentration. After cooling and crystallizing, the solid sulfurous acid is separated by the centrifuge in the neutralization tank Ammonium; then the flue gas enters the water washing tower and is washed and discharged. The invention has the characteristics of highly purifying SO2 and other harmful acid gases, effectively improving the utilization rate of ammonia absorbent, etc., and can obtain high-purity solid ammonium sulfite, and has good special industrial applications and prospects.

Owner:水泽节(山东)环保科技有限公司

Flue gas desulfurization and denitrification system device and method adopting ozone oxidation in cooperation with multi-stage spraying

PendingCN112058048AImprove the flow fieldPromote absorptionCombination devicesGas treatmentFlue gasEnvironmental engineering

The invention provides a flue gas desulfurization and denitrification system device and a flue gas desulfurization and denitrification method adopting ozone oxidation in cooperation with multistage spraying. The desulfurization and denitrification system device comprises a mixing device, an oxidation absorption device and a spraying absorption device which are sequentially connected in the flowingdirection of flue gas, the interior of the oxidation absorption device is sequentially divided into an air inlet area, a spraying area, an oxidation area and an exhaust area which are communicated with one another in the air inlet direction, and an inclined spraying module is arranged on the inner wall, where the spraying area is located, of the shell; the mixing device is externally connected with an ozone generating device; and the ozone generating device is also connected to the shell where the oxidation zone of the oxidation absorption device is located. The desulfurization and denitrification method comprises the steps that flue gas and ozone are mixed and oxidized and then sequentially enter a spraying area and an oxidation area of the oxidation absorption device, the flue gas enters the spraying absorption device to be sprayed and absorbed again after being sprayed, absorbed and oxidized, and desulfurization and denitrification of the flue gas are completed. Ozone oxidation iscooperated with multi-stage inclined spraying, so that desulfurization and denitrification treatment can be effectively carried out on flue gas.

Owner:GUANGDONG J TECH ENVIRONMENT SCI CO LTD

Potassium sulfite/potassium bisulfite (KS/KBS) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite and potassium bisulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

Low-temperature dust collection, desulfurization and denitrification system

InactiveCN109092036AEasy to reprocessAvoid emissionsGas treatmentDispersed particle separationWater bathsProduct gas

The invention discloses a low-temperature dust collection, desulfurization and denitrification system. The low-temperature dust collection, desulfurization and denitrification system comprises a desulfurization chamber and a denitrification chamber, wherein the denitrification chamber is formed at one side of the desulfurization chamber; a first connecting pipe is arranged between the desulfurization chamber and the denitrification chamber; a desulfurization charging valve and a denitrification charging valve are arranged on the first connecting pipe; the denitrification charging valve is arranged on one side of the desulfurization charging valve; a first rotating rod is arranged in the desulfurization chamber; first water bath pipes are arranged on two sides of the first rotating rod; first water bath holes are formed in the first water bath pipes; a first ring gear is arranged on the outer side of the end part of the first rotating rod; a first motor is arranged at the top of the desulfurization chamber. Ammonia water is used as a reactant, so that the ammonia water is subjected to a reaction with SO2 and NOx in mixed gas, a purifying effect is realized, sewage treatment is not needed after purification, manpower and money are saved, (NH4)2SO3 capable of being used as fertilizer can be also obtained, and accordingly, the effects of avoiding pollution and using waste are achieved.

Owner:南京瑞宜恒环境科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com