Patents

Literature

74 results about "Potassium bisulfite" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium hydrogen sulfite or potassium bisulfite is a chemical compound with the chemical formula KHSO₃. It is used during the production of alcoholic beverages as a sterilising agent. This additive is classified as E number E228 under the current EU approved food additive.

Animal hair solvent and preparation method and use of keratin solution

InactiveCN101979428AHigh molecular contentGuaranteed stabilityFibre treatmentAdditive ingredientSulfite salt

The invention discloses an animal hair solvent and the preparation method and use of keratin solution. The solvent is characterized in that tris(2-carboxyethyl)phosphine hydrochloride, tris(2-cyanoethyl)phosphine or trisphosphine is used as a main ingredient and is mixed with 1 to 8 percent of assistant which may be at least one of mercaptoacetic acid, mercaptoethanol, sodium hydrogensulfite, potassium bisulfate, sodium sulfite, potassium sulfite, sodium hypophosphite, ethanol, methanol and urea. The preparation method adopts the following processes: 1, preparing animal hair solution by using the animal hair solvent of the invention; 2, dissolving animal hair in the solution to prepare keratin solution; and 3, adding a proper amount of acid to perform the post-treatment of the keratin solution. The use is to use the keratin solution as textile finishing liquor or the main functional ingredient of the textile finishing liquor.

Owner:TIANJIN POLYTECHNIC UNIV +1

Cyclopropene preservative with double functions of anticorrosion and keeping freshness

The cyclopropene consists of: 1-methyl cyclopropene 0.3-4 weight portions, preservative 5-40 weight portions, stabilizer 60-90 weight portions, slow releasing agent 0-20 weight portions and excipient 0-5 weight portions. The preservative is one or several of 2-aminobutane, phosphate of 2-aminobutane, hydrochloride of 2-aminobutane, sulfate of 2-aminobutane, lactate of 2-aminobutane, sodium pyrosulfite, potassium pyrosulfite, sodium bisulfite, potassium bisulfite and propyl isothiocyanate; the release controlling agent is one or several of lime, sodium bicarbonate, soda lime, reductive microcrystal alditol acid lignin polyacrylamide; and the stabilizer is one or several of cyclodextrin, rosin, silica gel and lac. The slow releaseing preservative has obvious functions of resisting rot and keeping freshness.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Fruit and vegetable preserving backing

InactiveCN1505935AReduce mechanical damageSuppresses aging symptomsFruit and vegetables preservationChlorine dioxidePotassium

The fruit and vegetable preserving backing consists of preferably: preservative 4-40 weight portions, physiological regulator 0-30 weight portions and gas regulator 0-30 weight portions. The preservative is one or two of 2-aminobutane, hydrochloride of 2-aminobutane, sulfate of 2-aminobutane, sodium pyrosulfite, potassium pyrosulfite, sodium bisulfite, potassium bisulfite, stable chlorine dioxide, propyl isothiocyanate, cinamic aldehyde and acetyldehyde; the physiological regulator is potassium permanganate and / or potassium bromate; and the gas regulator one or several of soda lime, sodium hydroxide, lime and active carbon. The present invention has the functions of reducing mechanical damage of fruits and vegetables, suppressing softening, yellowing and other senility symptoms of fruits and vegetables during storage and transportation, reducing rot of fruits and vegetables during transportation caused by vibration and pressure and regulating humidity inside the package.

Owner:NAT ENG AN TECH RES CENT FOR PRESERVATION OF AGRI PROD TIANJIN

Method for producing fertilizer by utilizing mud and plant straws

InactiveCN101659572AAchieve disposalRealize comprehensive utilizationClimate change adaptationSewage/sludge fertilisersDry weightSludge

The invention discloses a method for producing a fertilizer by utilizing mud and plant straws, mainly comprising the following steps with the mixture of concentrated mud and plant straw powders as theraw material and one or a plurality of ammonium sulfite, sodium sulfite and potassium hydrogen sulfite as the stewing decay agent: the stewing decay agent accounting for 8-15 percent of the reduced dry weight of the raw material and the raw material are mixed uniformly, and are stewed at the temperature of 125-170 DEG C for 2-7 hours to obtain the semi-finished product of slurry organic fertilizer which can be directly prepared into commercial organic fertilizer; or appropriate amount of chemical fertilizers such as nitrogen, phosphor, kalium and trace elements are added into the semi-finished product to prepare organic-inorganic composite fertilizer; or the semi-finished product is separated to prepare an organic kalium liquid fertilizer and an organic ammonium liquid fertilizer. The method has simple technology, the decay conversion speed of raw materials is fast, and the purposes of sterilizing, decontaminating and deodorizing the raw material can be realized with the method; the product has high organic content and humic acid content, is sulfur-bearing, and has high fertilizer efficiency; and with the method, the large-scale and low-cost fertilizer utilization of the mud and plant straw waste is realized.

Owner:HEBEI NORMAL UNIV

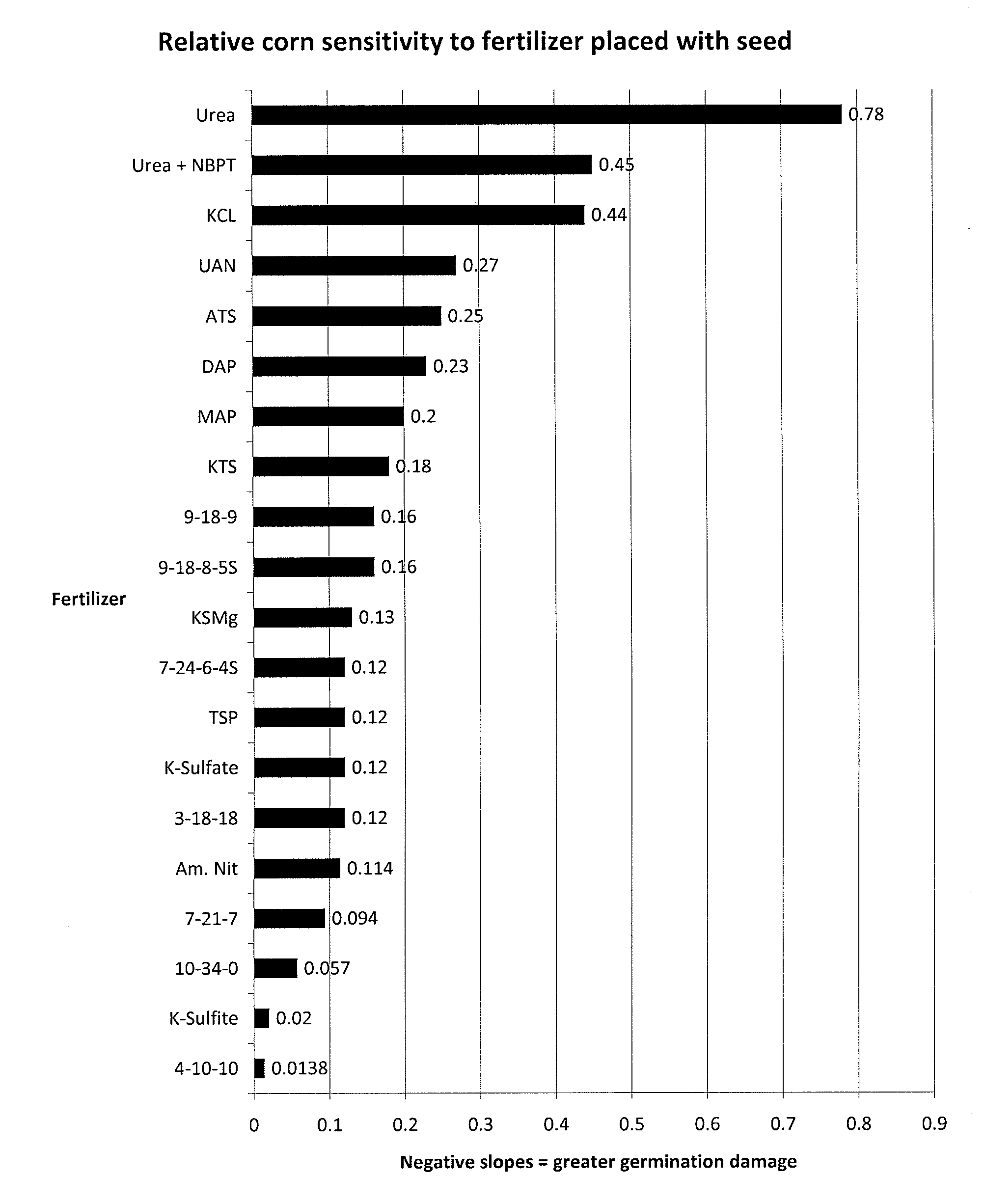

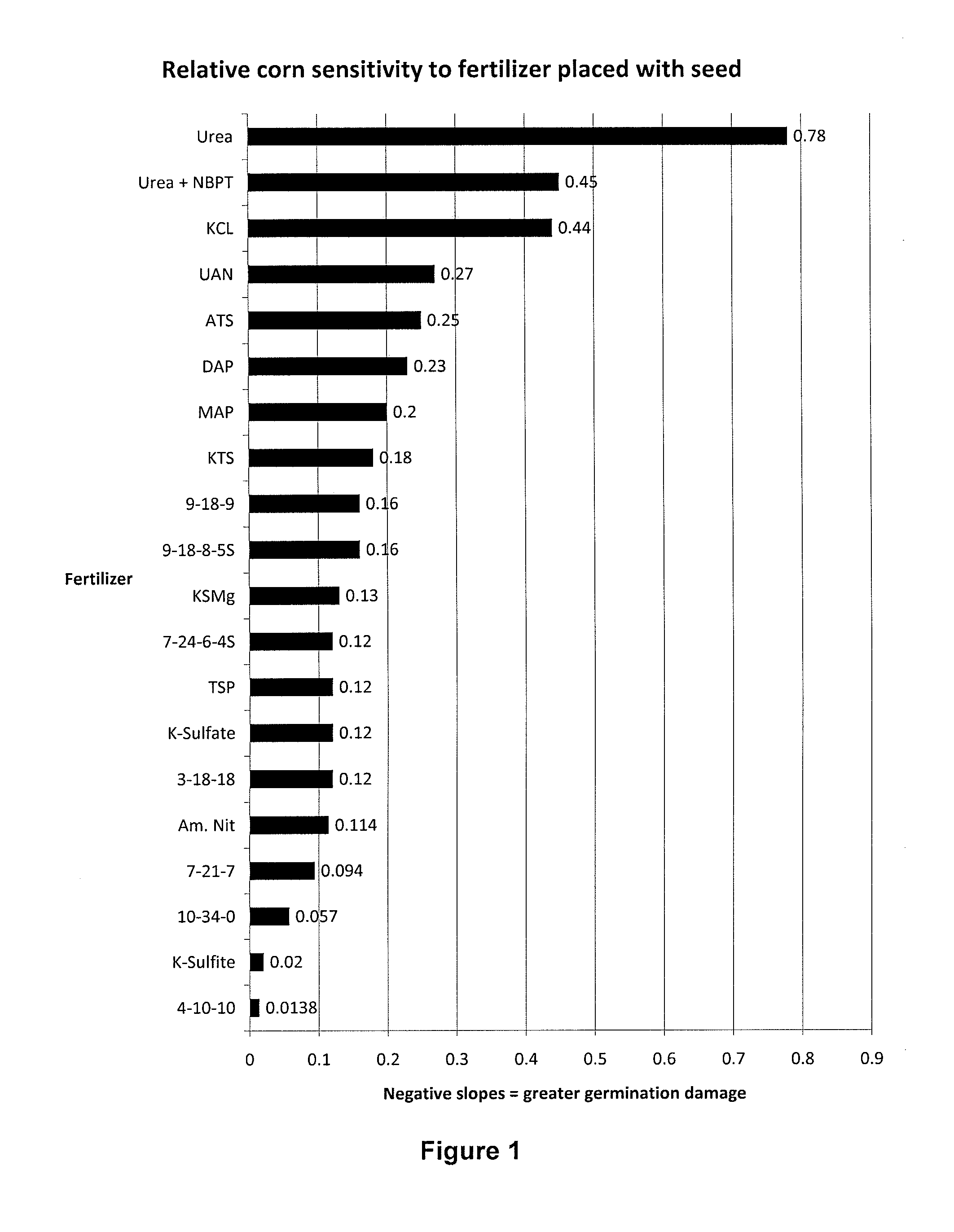

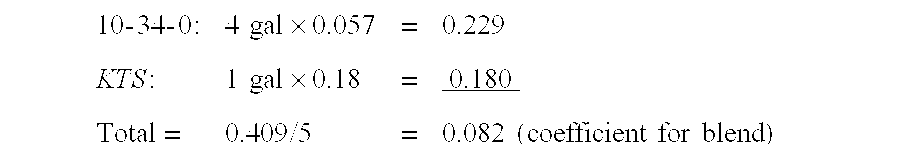

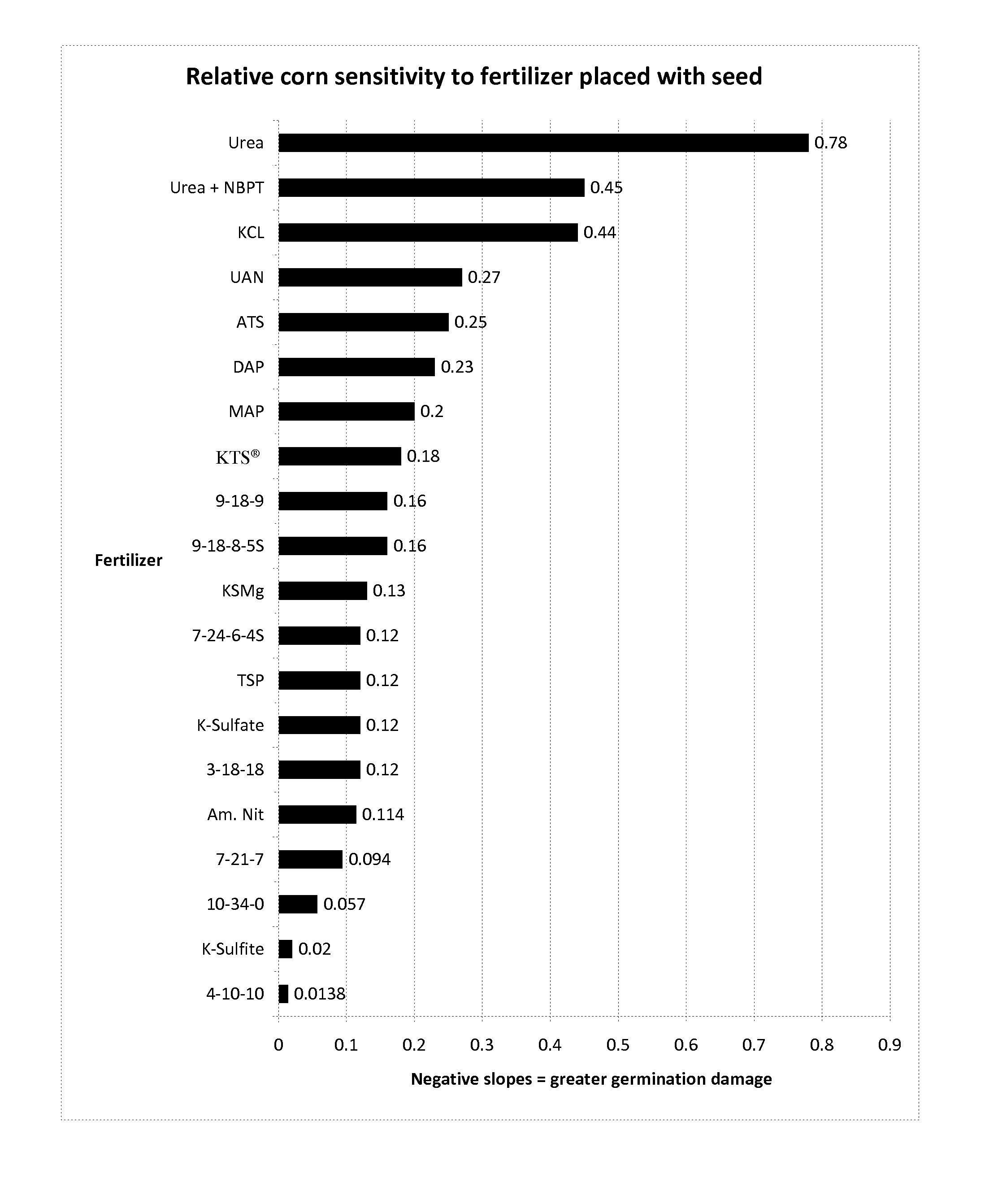

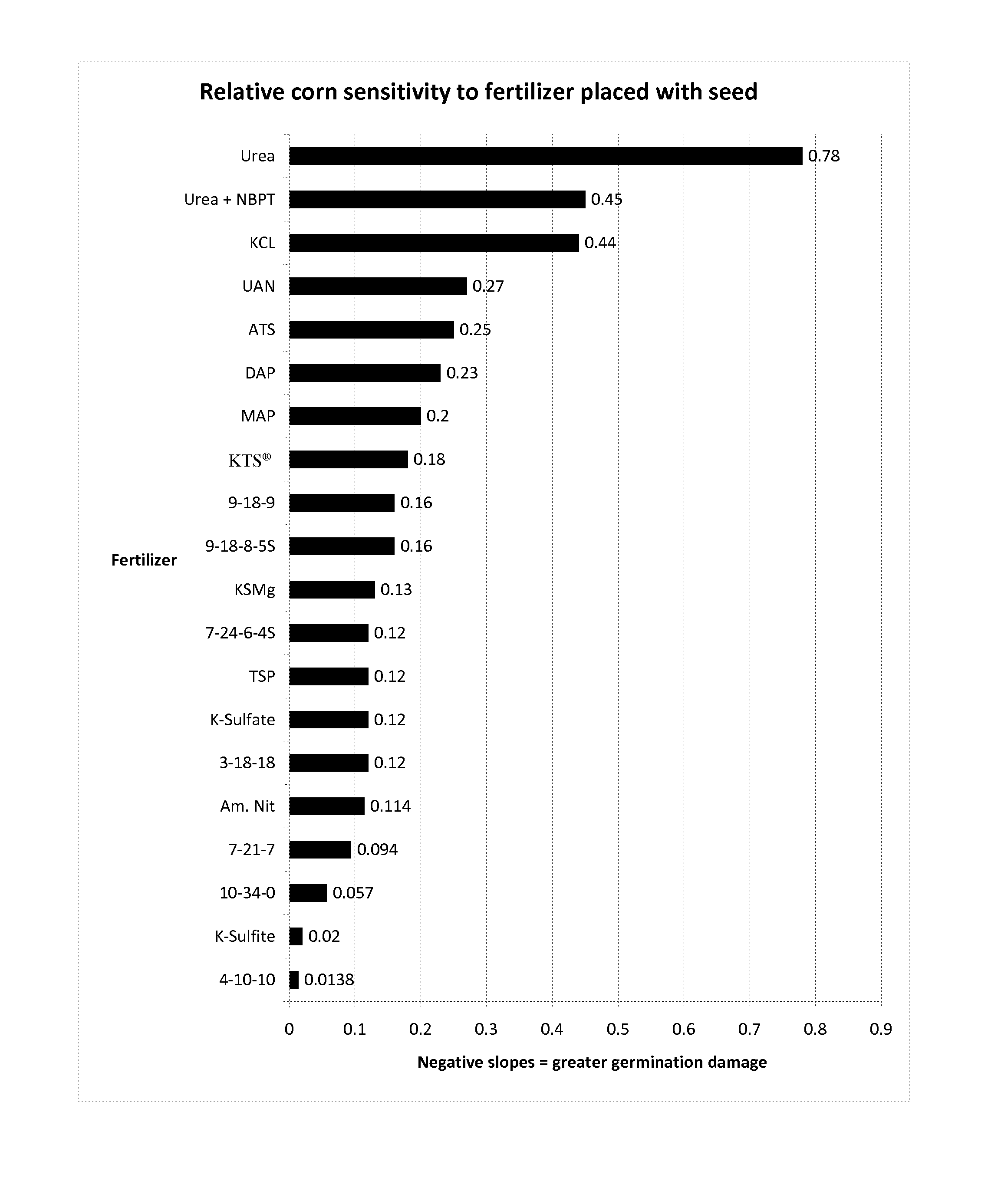

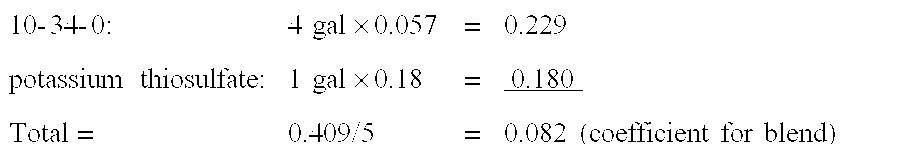

Potassium sulfite/potassium bisulfite (ks/kbs) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

ActiveUS20120255335A1Low indexReduce drug damageBiocideSulfite preparationSulfur productPhytotoxicity

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

Andrographolidi natrii bisulfis and preparation method thereof

ActiveCN101148441ALess impuritiesHigh purityAntibacterial agentsOrganic active ingredientsPotassium bisulfiteSodium bisulfate

The present invention provides one kind of sodium bisulfite andrographolide, which is prepared through adding water solution of sodium bisulfite into alcohol solution of andrographolide, heating to reflux, recovering alcohol, cooling, extracting with chloroform for several times, filtering, vacuum concentrating the filtrate, crystallizing the concentrated solution, suction filtering, and vacuum drying the filter cake to obtain the white sodium bisulfite andrographolide addition compound. The sodium bisulfite andrographolide product has high purity, high stability, high curative effect and wide use.

Owner:吉林省长源药业有限公司

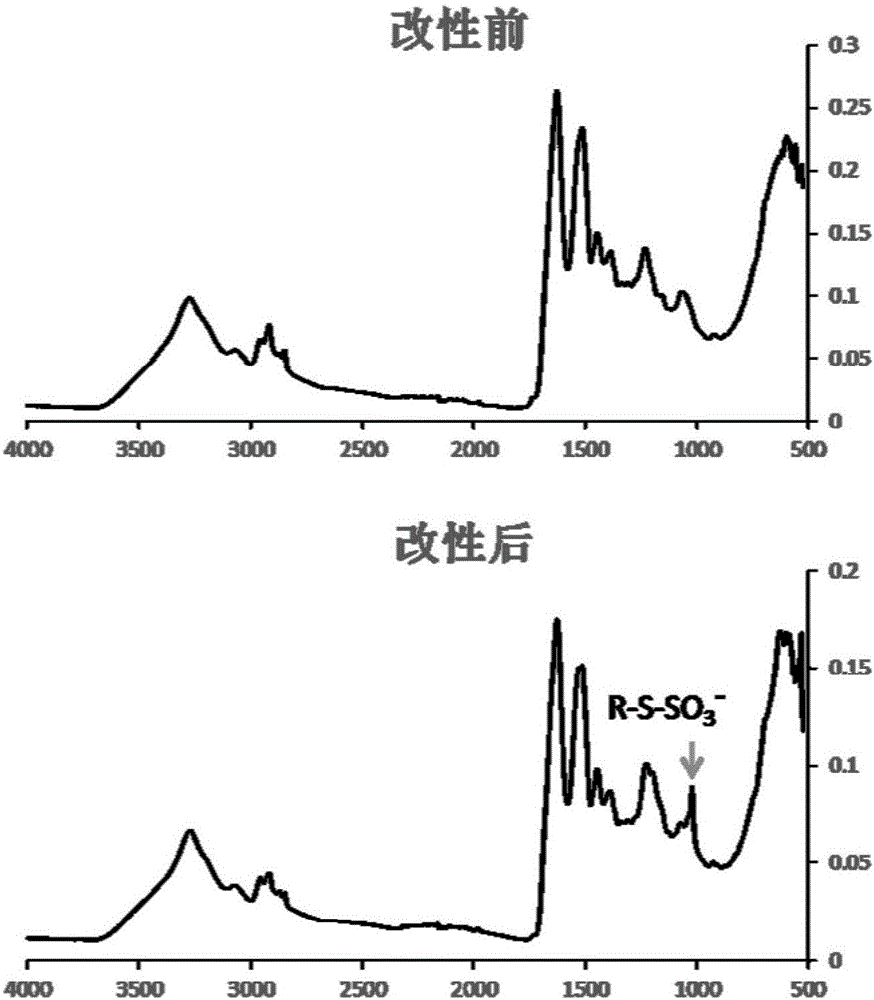

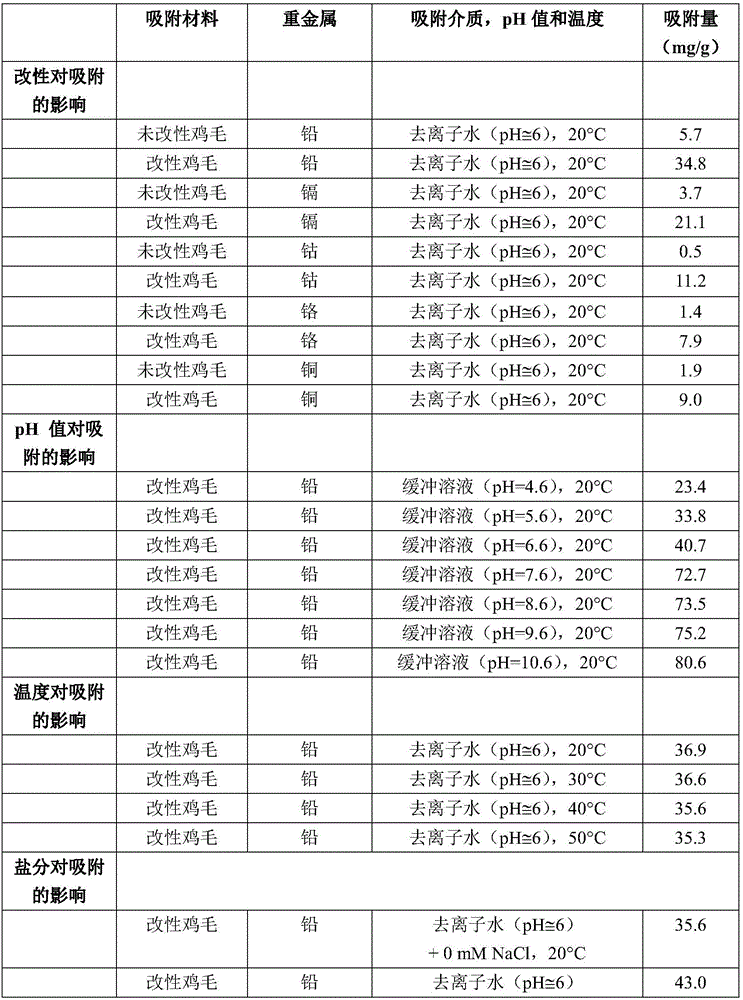

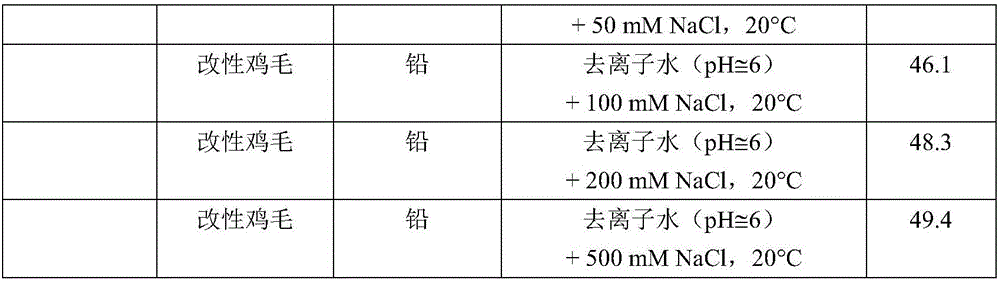

Keratin heavy metal adsorbent and preparation method thereof

InactiveCN106799212ADistinctive featuresLow priceOther chemical processesWater contaminantsSulfite saltSorbent

The invention provides a preparation method of a keratin heavy metal adsorbent. The preparation method comprises the following steps: step I, cleaning and smashing a keratin raw material; step II, carrying out oxidation reaction on the ready keratin raw material: taking the keratin raw material, and putting the keratin raw material in an oxidant aqueous solution to carry out oxidation reaction, wherein an oxidant is a potassium monopersulfate composite salt or a sodium monopersulfate composite salt; and step III, carrying out reduction reaction on the oxidized keratin material: taking the oxidized keratin material, putting the oxidized keratin material in an aqueous solution containing a reducing agent to carry out reaction, and drying the obtained keratin material to obtain the keratin heavy metal adsorbent, wherein the reducing agent is one of sodium sulfite, sodium metasulfite, sodium bisulfite, potassium sulfite, potassium metasulfite and potassium bisulfate. The prepared heavy metal adsorbent has certain selectivity, is high in adsorption efficiency, low in cost, simple and convenient to operate, mild in required condition and does not generate secondary pollution.

Owner:由永峰

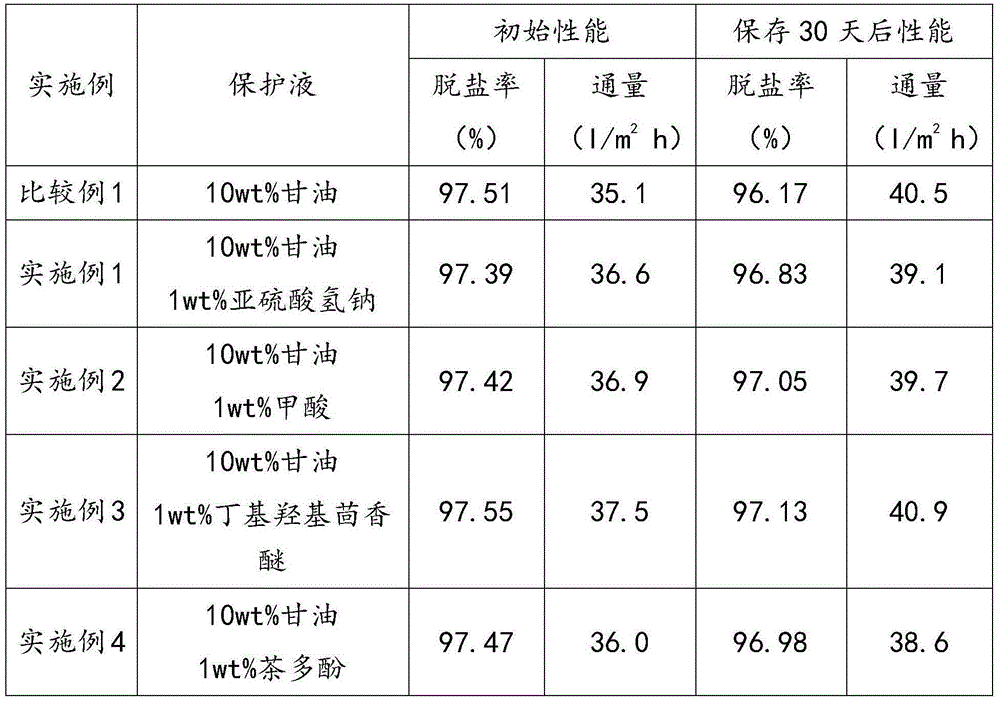

Preparation method for dried reverse osmosis composite membrane

ActiveCN105148742ASolve the problem of separation performance degradationReverse osmosisReverse osmosisPotassium

The invention relates to a preparation method for a dried reverse osmosis composite membrane. The preparation method comprises the following steps: soaking a conventional reverse osmosis composite membrane in a protector-containing aqueous solution, wherein the soaking temperature is 10-50 DEG C and the soaking time is 1-10 minutes; and then carrying out thermal treatment for 8-12 minutes in an oven at 80-100 DEG C, wherein the protector is one or a mixture of more of sodium hydrogen sulfite, potassium hydrogen sulfite, ammonium hydrogen sulfite, formic acid, oxalic acid, citric acid, dipotassium glycyrrhizate, butylated hydroxyanisole, butylated hydroxytoluene, propylgallate, tert-butylhydroquinone, tea polyphenol, 3,4,5,7-tetrahydroxy flavone and a glycyrrhisoflavone solution. The preparation method provided by the invention not only can be used for realizing dry state storage of the reverse osmosis composite membrane, but also can effectively solve the problem that the dried reverse osmosis composite membrane is attenuated in performance in a long-term storage process.

Owner:HANGZHOU FANGRAN MEMBRANE TECH

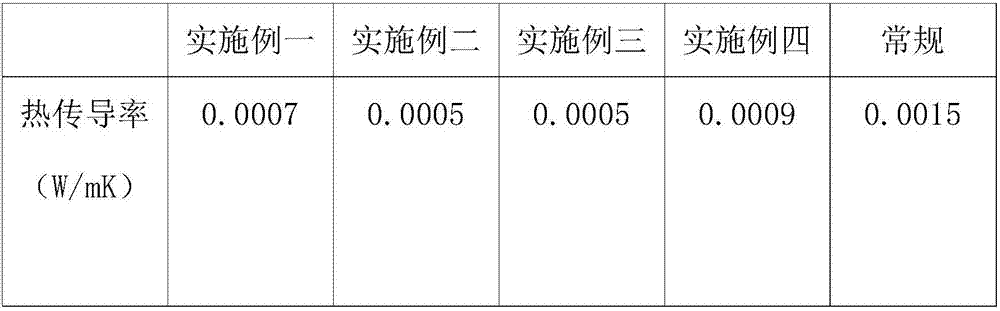

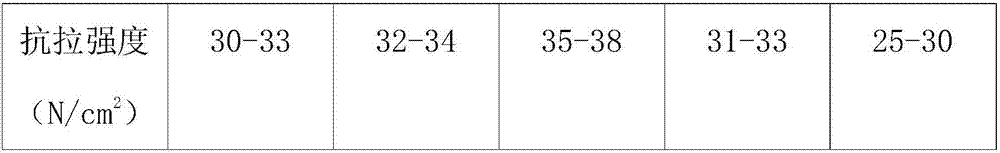

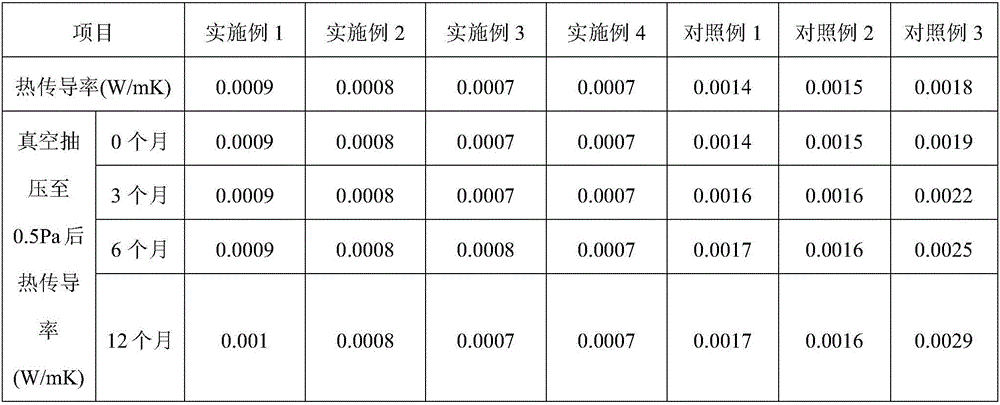

Vacuum thermal-insulation plate core material for building

InactiveCN106946535AImprove stabilityReduce manufacturing costClimate change adaptationInsulation improvementSodium BentonitePolyvinyl alcohol

The invention belongs to the field of vacuum thermal-insulation plates, and particularly relates to a vacuum thermal-insulation plate core material for building. In the prior art, the existing core material does not have excellent pressure-resistant stability and excellent thermal-insulation stability, and has disadvantages of high heat thermal conductivity, high cost and difficult processing, and the heat inertness and the thermal insulation do not meet the stringent requirements. A purpose of the present invention is to solve the problems in the prior art. The technical scheme of the present invention is that the raw materials comprise, by weight, 20-25 parts of stone wool fibers, 18-22 parts of glass fibers, 23-26 parts of mineral wool, 22-26 parts of silicon dioxide, 14-18 parts of calcium chloride hexahydrate, 8-12 parts of quicklime, 6-9 parts of acrylic acid, 7-11 parts of polyvinyl alcohol, 4-8 parts of potassium bisulfite, 13-16 parts of bentonite, 11-14 parts of quartz sand, 9-13 parts of magnesium oxide, 5-8 parts of zinc oxide, and 30-35 parts of deionized water. The preparation method comprises: S1, adding acrylic acid and deionized water to a reaction kettle. According to the present invention, the vacuum thermal-insulation plate core material has advantages of excellent pressure-resistant stability, excellent thermal-insulation stability, low thermal conductivity, high hardness, excellent heat inertness, excellent heat insulation effect, low production cost, and convenient processing.

Owner:HUANGHE S & T COLLEGE

Reduced irritant enema for treatment of inflammatory bowel disease (IBD)

ActiveUS7645801B2Little or no shelf lifeExtended shelf lifeBiocidePeptide/protein ingredientsIrritationMedicine

The present invention comprises packaged enemas for the treatment of Inflammatory Bowel Disease (IBD), having substantially pure 5-ASA as the active ingredient, with a liquid carrier medium having a material avoidance of bowel irritant substances, such as anti-oxidants for the 5-ASA active ingredient, including such sulfites as potassium metabisulfite, for example, and contained within a sealed and substantially oxygen-free barrier package, which may preferably be formed of a foil / polymer laminate, and which package contains or otherwise includes an oxygen scavenger, such as a an oxygen scavenging sachet.

Owner:ALAVEN PHARMA

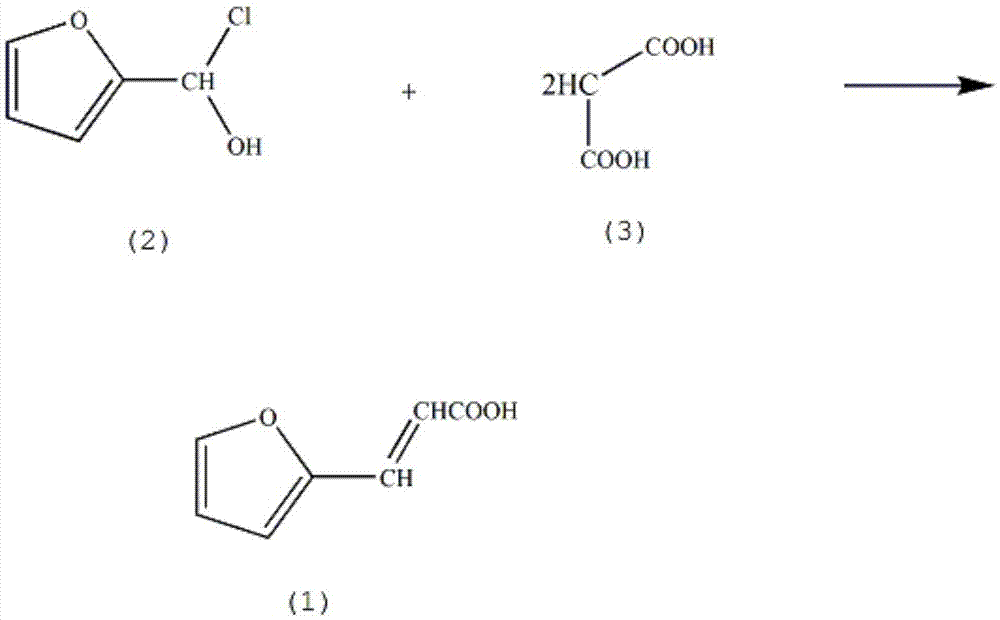

Synthesis method of furapromide drug intermediate 2-furfuracrylic acid

InactiveCN105439996AReduce intermediate linksLow reaction temperatureOrganic chemistryEthylenediamineSynthesis methods

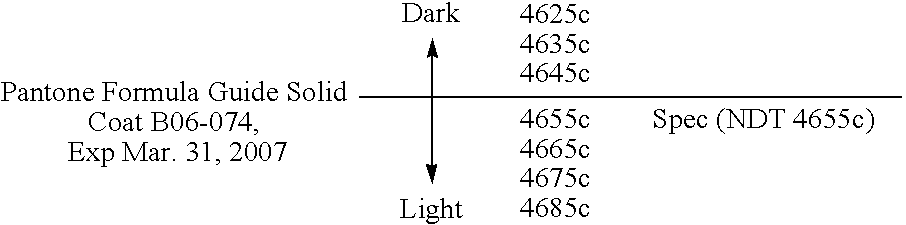

The invention relates to a synthesis method of a furapromide drug intermediate 2-furfuracrylic acid, which comprises the following steps: adding 3.1mol of 2-furylchloromethanol solution (2), 3.6-3.9mol of malonic acid solution (3) and 300ml of nitroethane into a reaction vessel which is provided with a stirrer and a reflux condenser, controlling the stirring rate at 130-170 rpm, heating the solution to 70-75 DEG C, refluxing for 5-8 hours, lowering the temperature of the solution to 8-13 DEG C, adding 310ml of sodium bromide solution and 200ml of potassium bisulfite solution, reacting for 90-120 minutes, standing for 3-6 hours, precipitating a solid, filtering, washing with a salt solution, washing with toluene, washing with ethylenediamine, dehydrating with a dehydrating agent, and recrystallizing in propionitrile to obtain the crystal 2-furfuracrylic acid.

Owner:CHENGDU ZHONGHENG HUATIE TECH CO LTD

Core material for vacuum heat-insulating board and preparation method thereof

The invention discloses a core material for a vacuum heat-insulating board and a preparation method thereof. The core material comprises the following raw material components: acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethyl ammonium chloride, stearic acid, potassium bisulfite, glass fiber, silicon dioxide, polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate glycol, a silane coupling agent, pentamethyldiethylene triamine, bentonite, a chain extender and Tween 20. The preparation method comprises the following steps: successively subjecting acrylic acid, calcium oxide, polyvinyl alcohol, methacryloylpropyltrimethyl ammonium chloride, stearic acid and potassium bisulfite to reacting so as to obtain a reactant; then carrying out shearing granulation, and carrying out drying so as to obtain a material 1; and subjecting glass fiber, silicon dioxide, polyester fiber, 1,4-cyclohexane diisocyanate, polyethylene adipate glycol, the material 1 and the remained components to a certain reaction so as to obtain the core material for the vacuum heat-insulating board. The core material obtained by using the method provided by the invention has good heat-insulating performance and vacuum compression use stability.

Owner:JIANGSU JINGWEI INTELLECTUAL PROPERTY OPERATION CO LTD

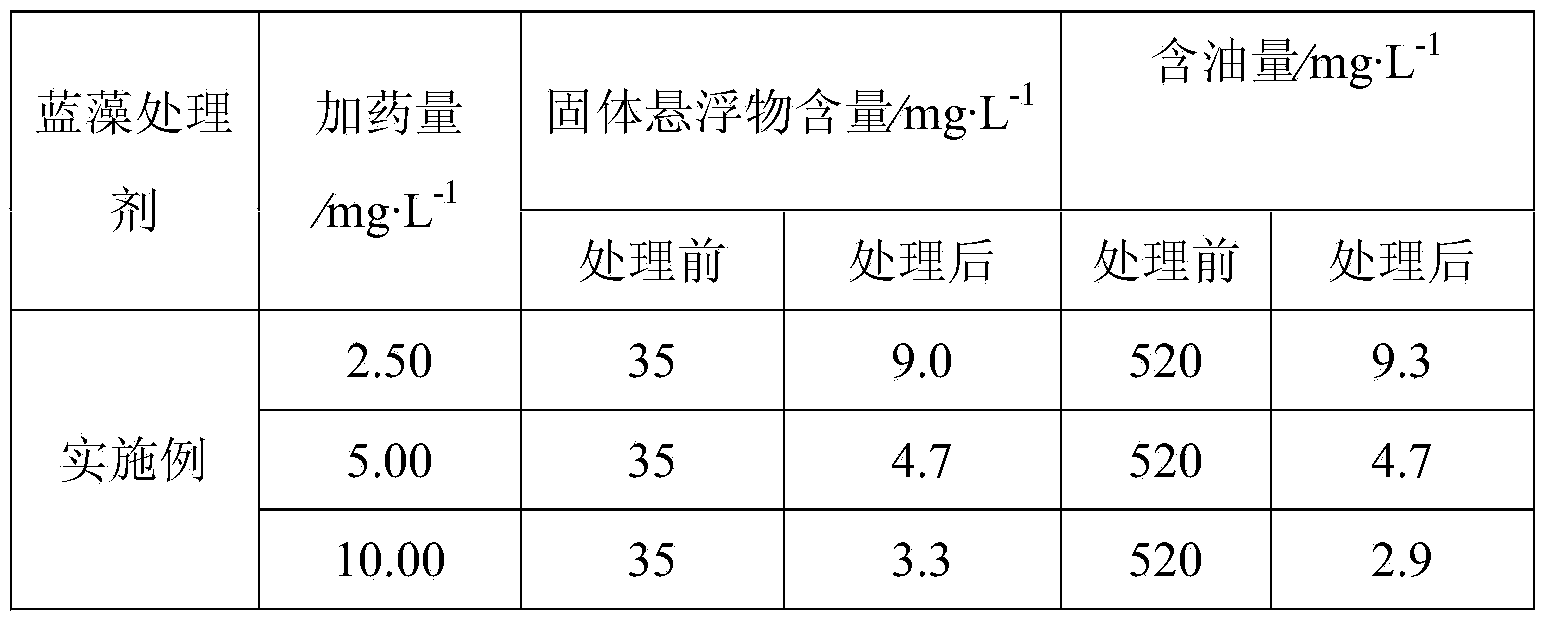

Deodorizing powdery blue algae treating agent and production method thereof

ActiveCN103936122AGood deodorizing effectStrong flocculation and purificationWater/sewage treatment by flocculation/precipitationPotassium bisulfiteBiology

The invention discloses a deodorizing powdery blue algae treating agent. The deodorizing powdery blue algae treating agent is characterized by being prepared from the following raw materials in parts by weight: 26-29 parts of TiO2 pillared montmorillonite, 18-22 parts of pumice, 17-19 parts of urea, 19-20 parts of potassium bisulfite, 20-22 parts of potassium sulfite, 16-18 parts of manganese sulfate, 1-3 parts of garden burnet, 2-4 parts of honeysuckle, 2-5 parts of red paeony root and 4-7 parts of trigone. The deodorizing powdery blue algae treating agent is good in deodorization effect, high in flocculation and purification capacity, convenient to use, low in cost and strong in adaptability, can take effect quickly and has smaller erosion and corrosion effects of alkalisation on equipment than other aluminum salts and ferric salts, and thus can be widely applied to various blue algae polluted water areas.

Owner:WUHU KAIAOER ENVIRONMENTAL PROTECTION TECH

Electrolyte for medium and low voltage of electrolytic capacitor and preparation method of electrolyte

InactiveCN104538182AEasy to useImprove conductivityElectrolytic capacitorsElectrolysisAcetic anhydride

The invention discloses an electrolyte for the medium and low voltage of an electrolytic capacitor and a preparation method of the electrolyte. The electrolyte includes, by weight, 5 to 10 parts of chloroactic acid, 1 to 4 parts of polyethylene glycol, 10 to 20 parts of ethyl alcohol, 3 to 7 parts of acetic anhydride, 5 to 10 parts of phthalic acid, 1 to 3 parts of potassium biphthalate, 2 to 6 parts of maleic anhydride, 1 to 5 parts of vinyl cyanide, 0.5 to 1 part of potassium bisulfite, 0.3 to 0.8 part of nitrophenol, 0.1 to 0.5 part of ammonium persulfate, 1 to 4 parts of acrylamide and 3 to 8 parts of sebacic acid. The preparation method includes the steps that all constituents are mixed, so that mixed liquid is acquired, inert gas is blown into the mixed liquid, oxygen in the mixed liquid is exhausted, the temperature is increased for conducting a reaction, the temperature is then decreased to indoor temperature, and therefore the electrolyte is acquired. The electrolyte is suitable for the medium and low voltage conditions, good in electricity conductive performance and long in service life.

Owner:NANTONG RUIDA ELECTRONICS MATERIAL

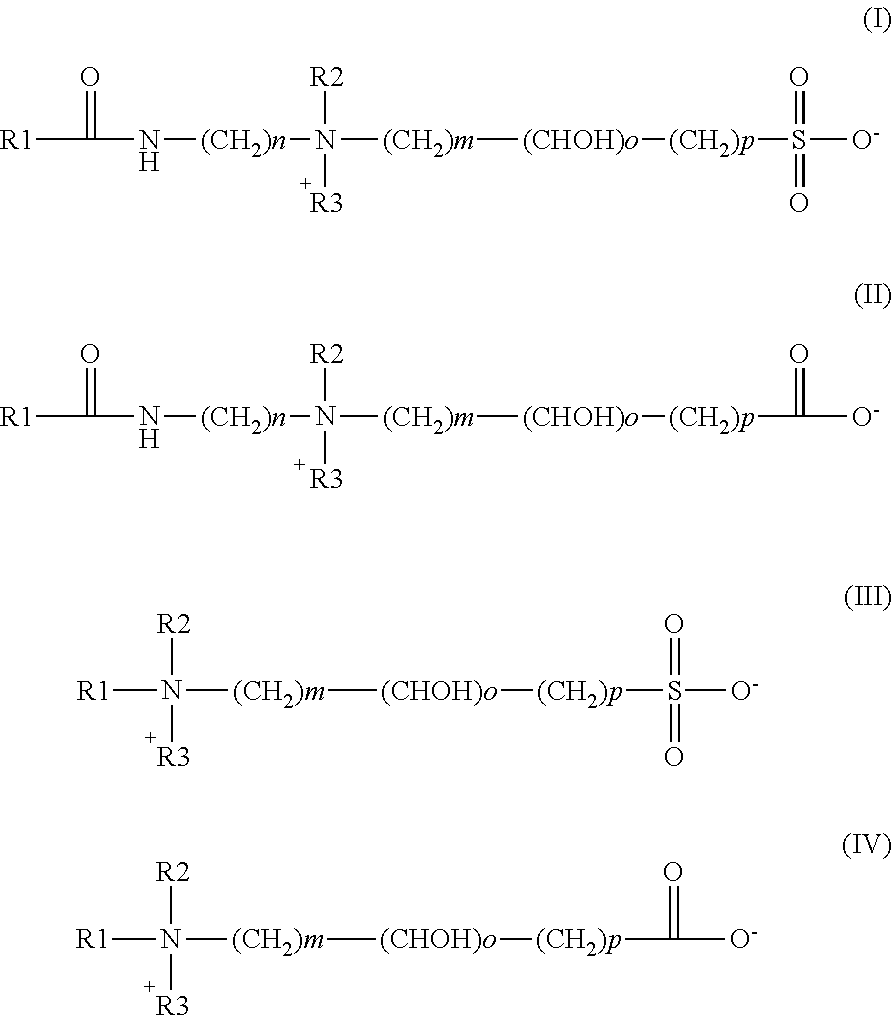

Decolorization of colored keratinic fibers

ActiveUS10456606B2Good decolorization effectCosmetic preparationsHair cosmeticsPotassium bisulfiteSodium sulfate

A multi-component packaging unit and related method for the reductive decolorization of colored keratinic fibers comprising, packaged separately from one another,(I) a container (A) containing a cosmetic agent (a),(II) a container (B) containing a cosmetic agent (b), and(III) a container (C) containing a cosmetic, aqueous agent (c), withthe agent (b) in container (B) containing(a1) one or more reducing agents from the group of sodium dithionite, zinc dithionite, potassium dithionite, sodium sulfite, sodium hydrogen sulfite, potassium sulfite, potassium hydrogen sulfite, ammonium sulfite, sodium thiosulfate, potassium thio sulfate, ammonium thio sulfate, hydroxymethane sulfinic acid, aminomethane sulfinic acid, cysteine, thiolactic acid, sulfanylacetic acid (thioglycolic acid) and / or ascorbic acid, andagent (c) in container (C) including(c1) one or more acids from the group of the inorganic and / or organic acids and(c2) one or more zwitterionic and / or amphoteric surfactants.

Owner:HENKEL KGAA

Deodorant refrigerator disinfectant

InactiveCN104824049AImprove the bactericidal effectImprove deodorization abilityBiocideFungicidesBiotechnologyDisinfectant

The invention discloses a deodorant refrigerator disinfectant, which is prepared from the following raw materials in parts by weight: 6-10 parts of chinaberry, 4-7 parts of crowndaisy chrysanthemum, 9-13 parts of folium syringae, 6-9 parts of thesium chinense, 4-7 parts of eclipta alba, 5-10 parts of radix bupleuri, 2-3 parts of atractylis oil, 3-6 parts of glycerin, 4-7 parts of citric acid, 3-4 parts of triethylene glycol, 5-8 parts of ammonium bisulfate, 4-6 parts of potassium metabisulfite and 5-7 parts of fatty alcohol-polyoxyethylene ether. The deodorant refrigerator disinfectant disclosed by the invention has the beneficial effects of having extremely high bactericidal power and deodorizing property, and being capable of effectively removing odor and harmful bacteria in a refrigerator and prolonging the preservation time of fresh meat, fruits and vegetables.

Owner:青岛百千川海洋生态科技有限公司

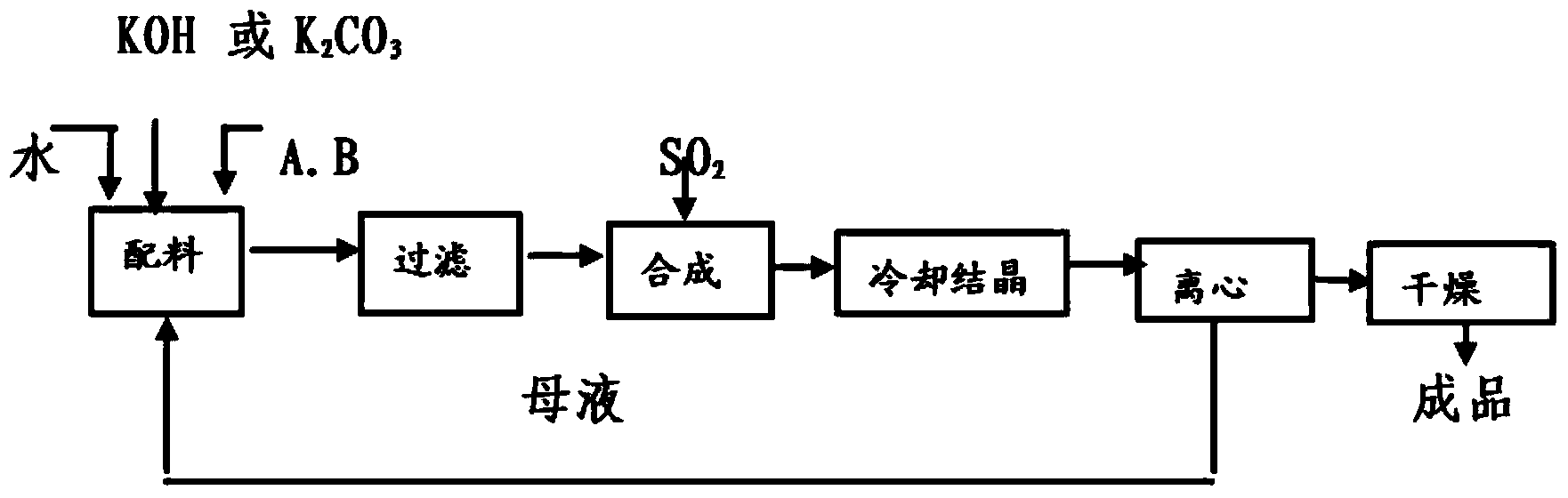

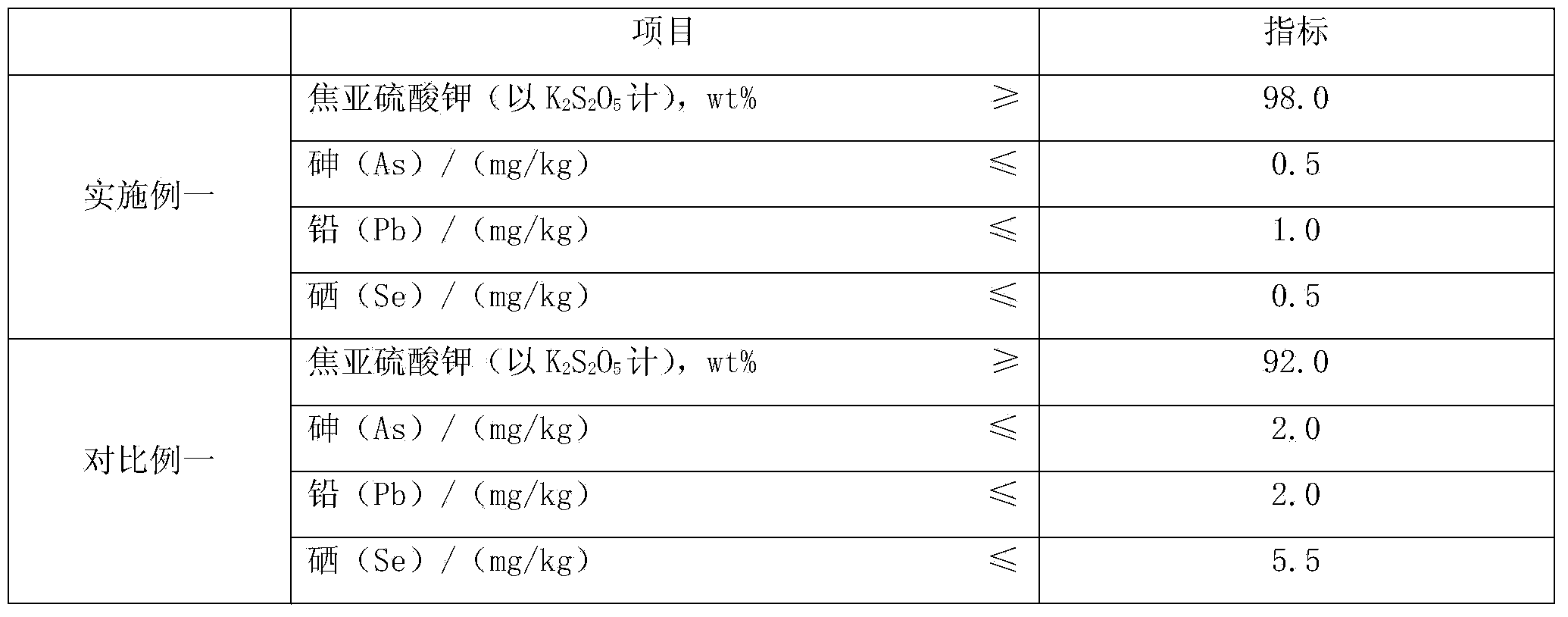

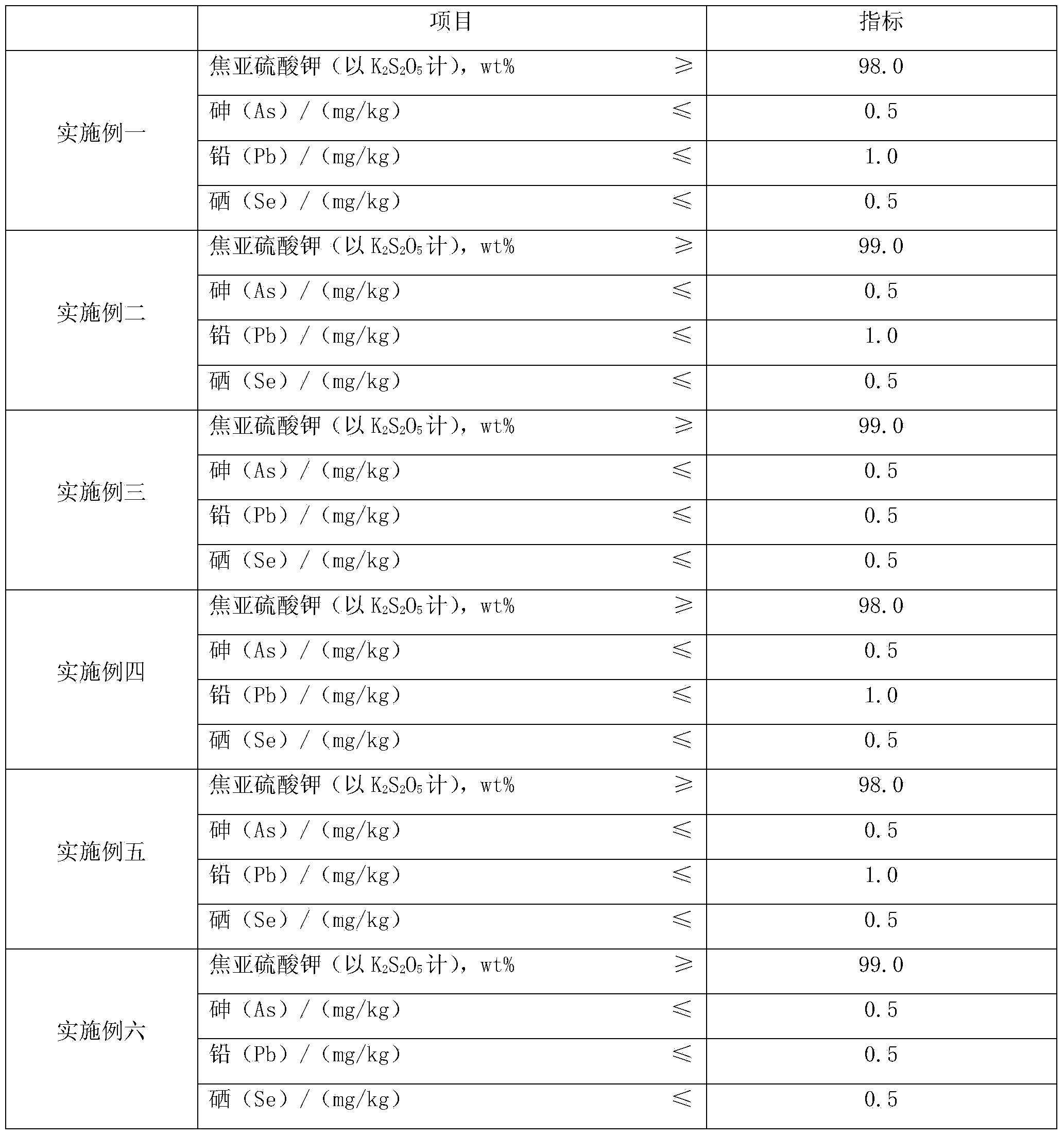

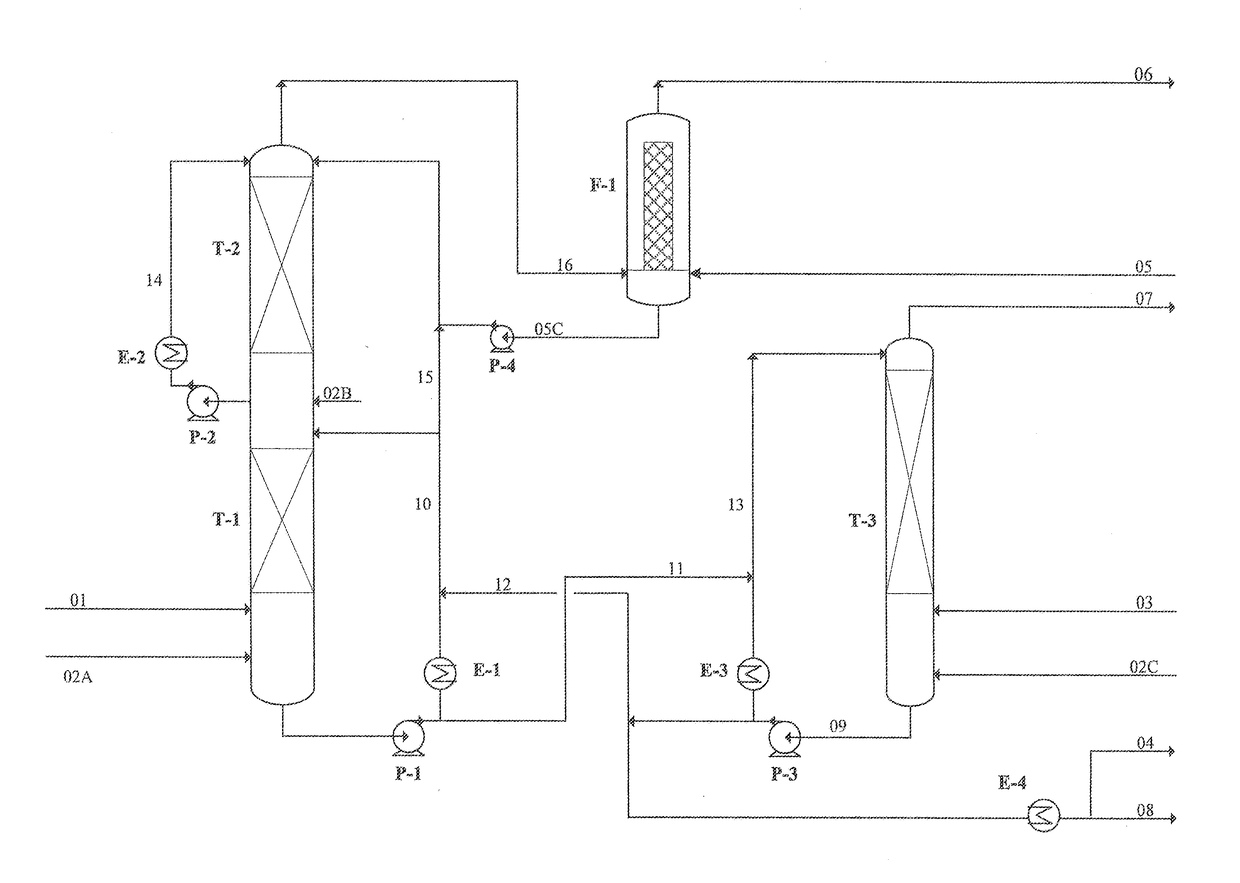

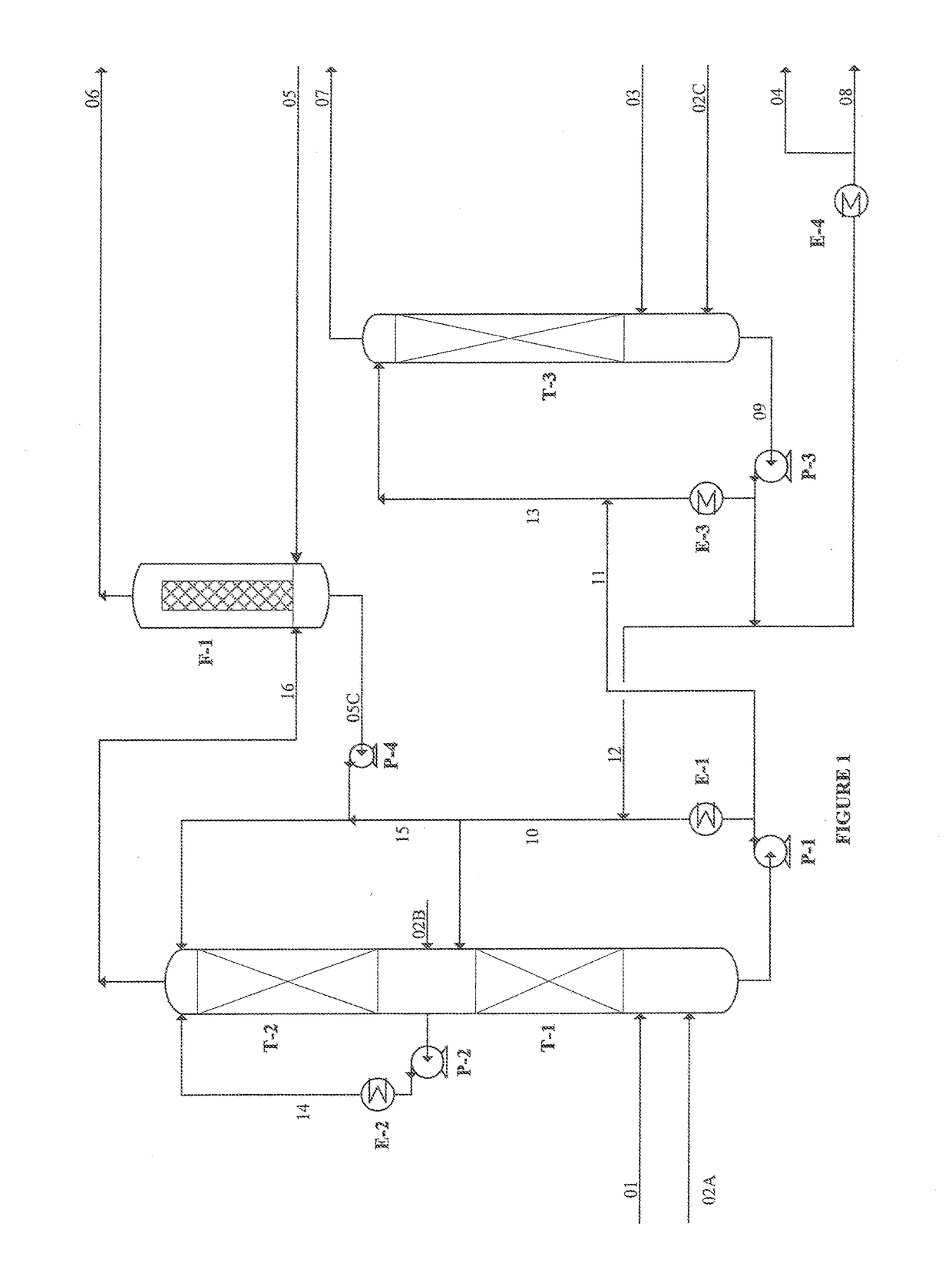

Production method for food-grade potassium metabisulfite

InactiveCN104071809ALow clarityControllable formation speedAlkali metal sulfite preparationMicropore FilterFiltration

The invention discloses a production method for food-grade potassium metabisulfite. The production method comprises the following steps: (1) conducting batching on tap water, purified water or potassium metabisulfite mother liquid and potassium hydroxide or potassium carbonate to form a solution, wherein the solution contains K<+> by 100-400 g / L; then adding an edulcoration agent A and an additive B; (2) carrying out filtration by a micropore filtering device of which the pore diameter is 0.1-10 <Mu>m to obtain a clarified solution; (3) pumping in gas or introducing SO2 liquid until the PH value is 2.5-5.0; reacting to generate a potassium bisulfite solution; (4) cooling and stirring the solution, and enabling the content of the potassium bisulfite in the solution to reach to supersaturated density; separating potassium metabisulfite crystal; conducting seriflux on the separated potassium metabisulfite crystal; obtaining a potassium metabisulfite crystal wet material and the mother liquid after solid-liquid separation, wherein the mother liquid can be used for batching with the potassium hydroxide or the potassium carbonate in the step (1) over again to form the solution; (5) conducting microwave drying on the potassium metabisulfite crystal wet material in the step (4) to obtain the food-grade potassium metabisulfite product.

Owner:徐德良 +4

Saving type crop multi-way yield increasing regulator

InactiveCN101061805APromote photosynthesisReduce respiratory consumptionPlant growth regulatorsBiocidePhosphateSulfate

The invention discloses a saving type farm crop multiaspect increase production modifier as lifting agent and fruit expanding agent, which is characterized by the following: allocating the lifting agent with glycerine, zinc sulfate, boric acid, yellow erode acid salt, manganese sulfate, ferrous sulfate, potassium sulfate, magnesium sulfate, double super phosphate of lime, ammonium molybdate, copper sulfate, aquacare, potassium bisulfite, carbendazol wettable powder, detergent, water and edible vinegar; replacing the carbendazol wettable powder with multiple-effect azoles as the raw material of the fruit expanding agent. This product can intensify photosynthetic activity and increase crop stress.

Owner:曹先兵

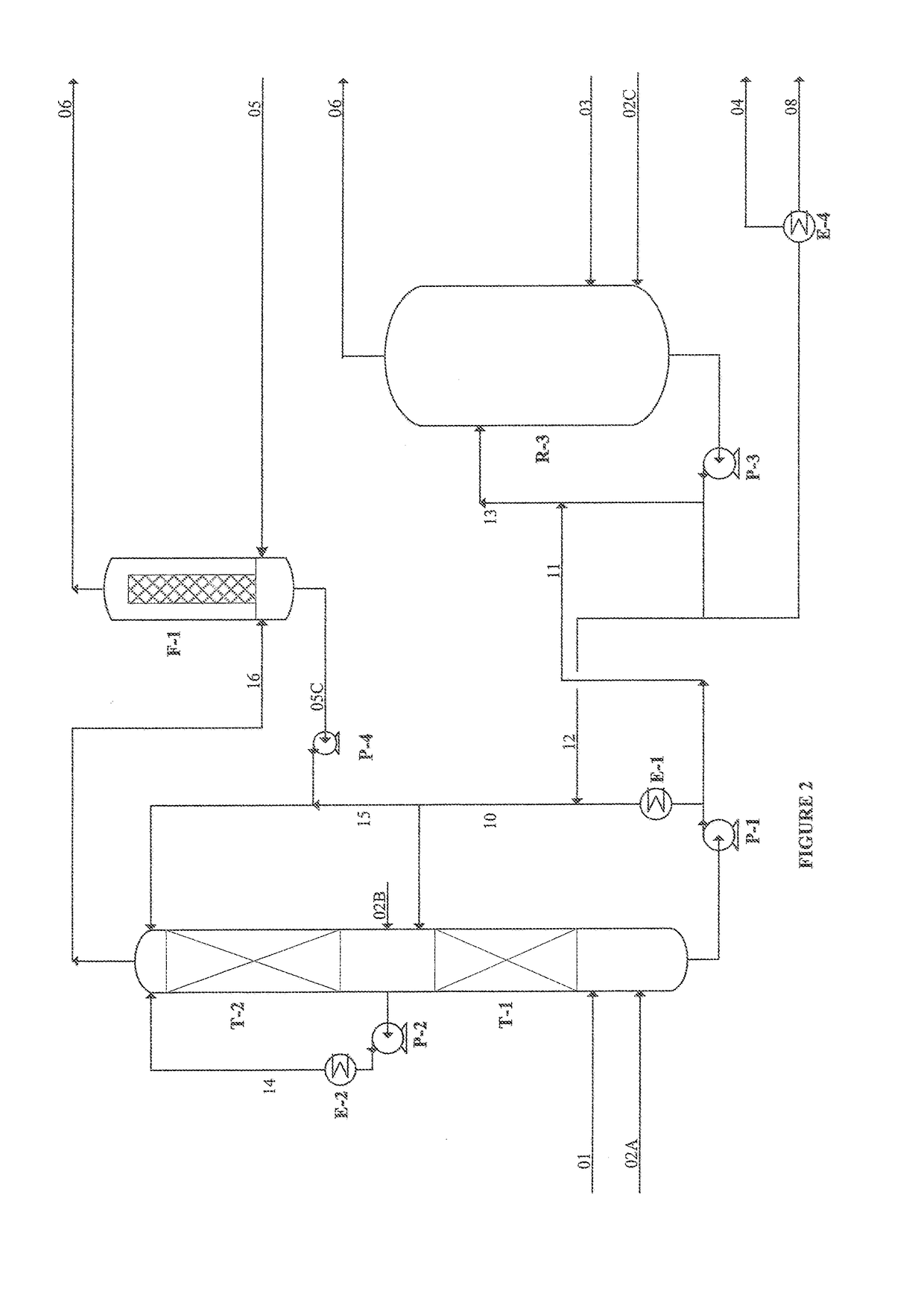

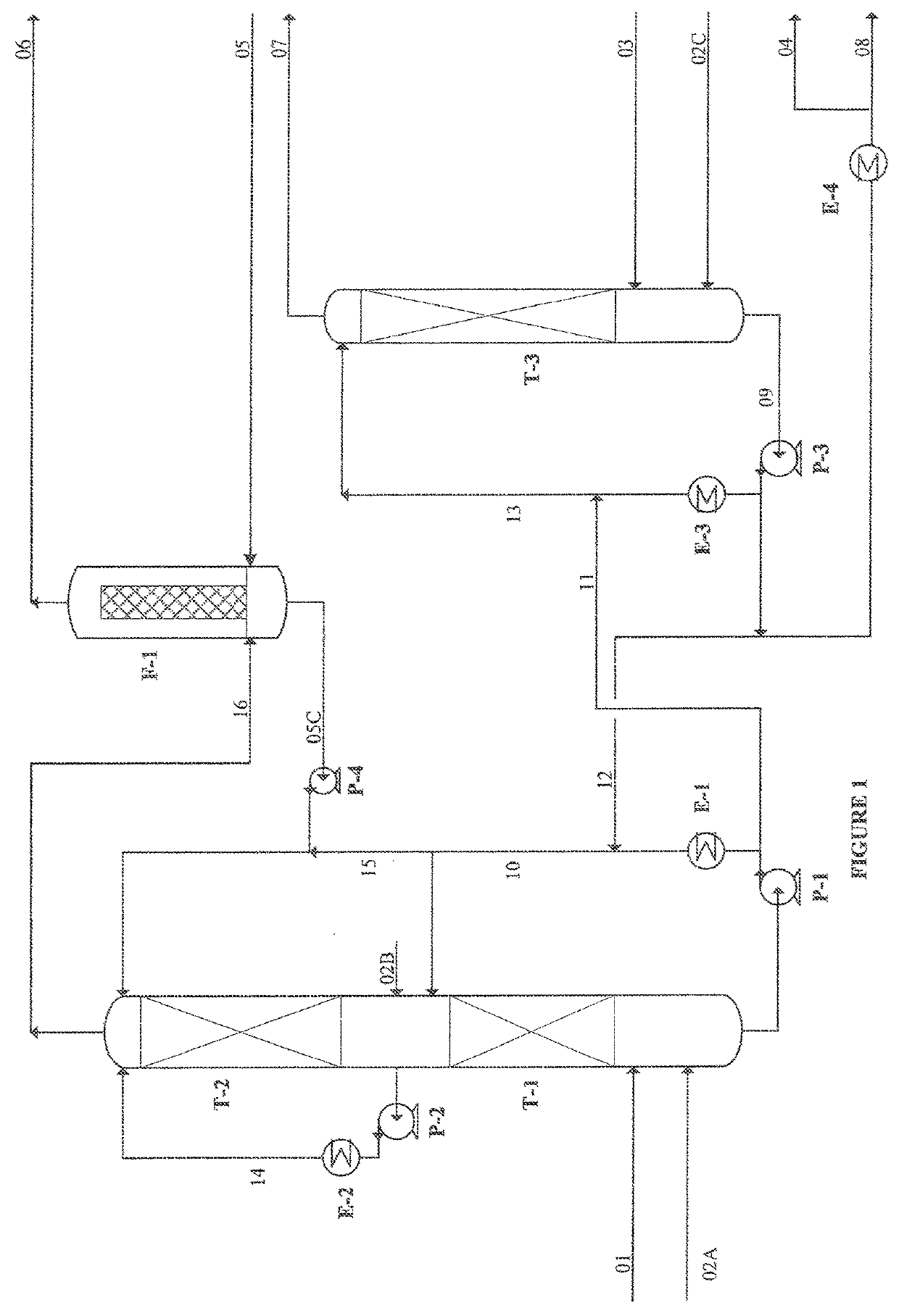

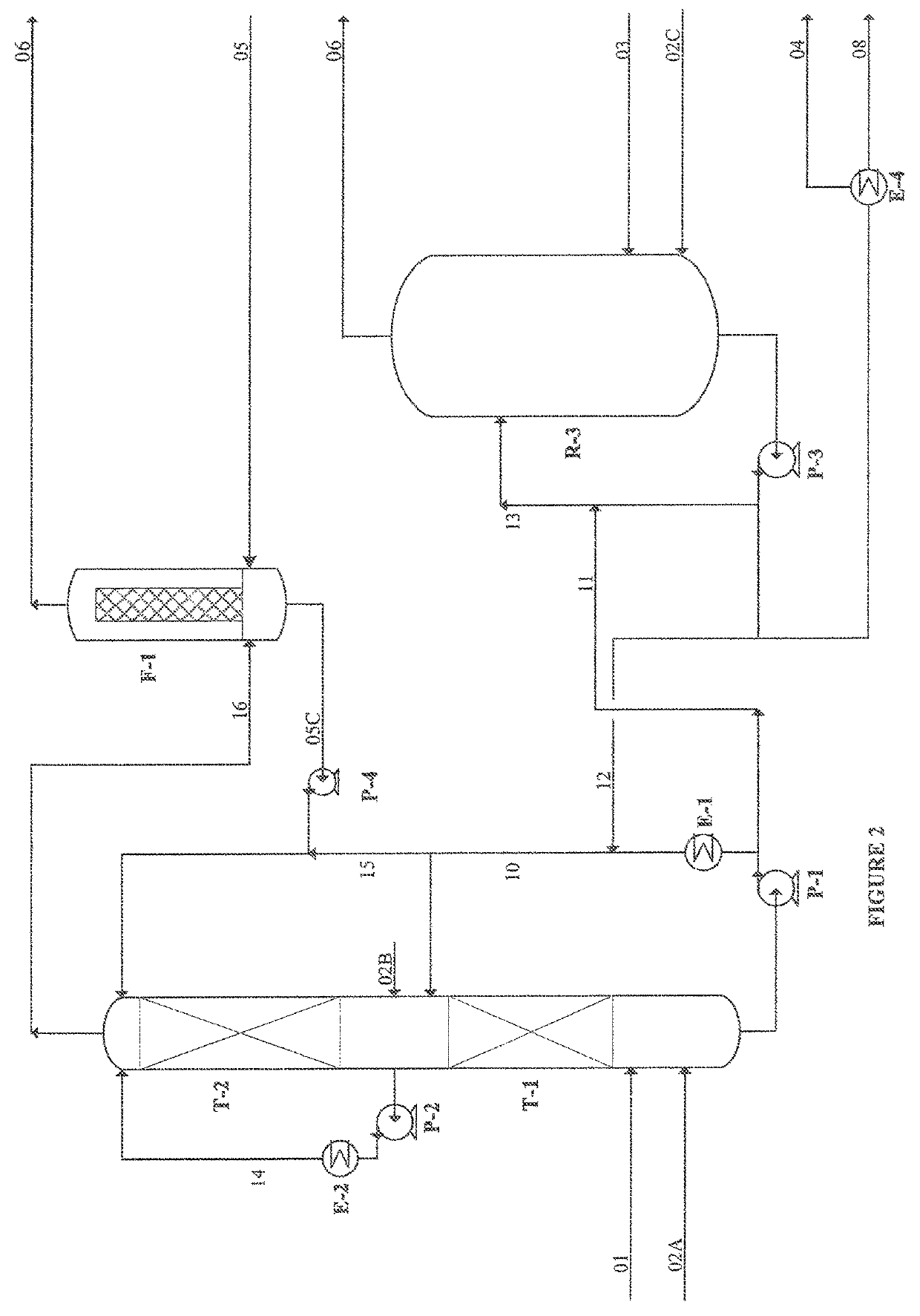

Sulfur dioxide scrubbing system and process for producing potassium products

ActiveUS20170190575A1Gas treatmentThiosulfates/dithionites/polythionitesPotassium peroxideOxidation state

The invention relates to a process for preparing potassium thiosulfate, potassium sulfite or potassium bisulfite comprising the following steps:Step (1a): providing a potassium hydroxide or potassium carbonate solution for neutralizing acid forming components such as dissolving SO2 or H2S;Step (1b): providing an SO2 contacting solution, containing at least some potassium sulfite or potassium bisulfite or potassium thiosulfate;Step (2): providing SO2 gas;Step (3): reacting these to absorb the SO2 gas and to form an intermediate reaction mixture comprising potassium sulfite, or potassium bisulfite or a mixture thereof, and optionally recovering the potassium sulfite, or potassium bisulfite or a mixture thereof, and / or optionally using steps 4 and 5;Step (4): adding sulfur or sulfide containing compound containing sulfur having the oxidation state of 0, −2 or of between 0 and −2 to the reaction mixture and optionally potassium hydroxide or potassium carbonate, and reacting the mixture under suitable conditions to form potassium thiosulfate; andStep (5): recovering the potassium thiosulfate, and optionally concentrating the potassium thiosulfate.

Owner:TESSENDERLO KERLEY INC

Electroless gold plating solution

ActiveUS7396394B2High strengthLow toxicityAnti-corrosive paintsLiquid/solution decomposition chemical coatingCyanidePotassium

The invention provides a displacement electroless gold plating solution that is low in toxicity, can be used at a pH near to neutrality, and affords good solder adhesion and film adhesion. The displacement electroless gold plating solution contains a non-cyanide water-soluble gold compound and a hydrogensulfite compound. Preferably, the plating solution further contains a thiosulfuric acid compound or an aminocarboxylic acid compound. Sodium hydrogensulfite, potassium hydrogensulfite, ammonium hydrogensulfite or the like can be used as the hydrogensulfite compound.

Owner:JX NIPPON MINING & METALS CORP

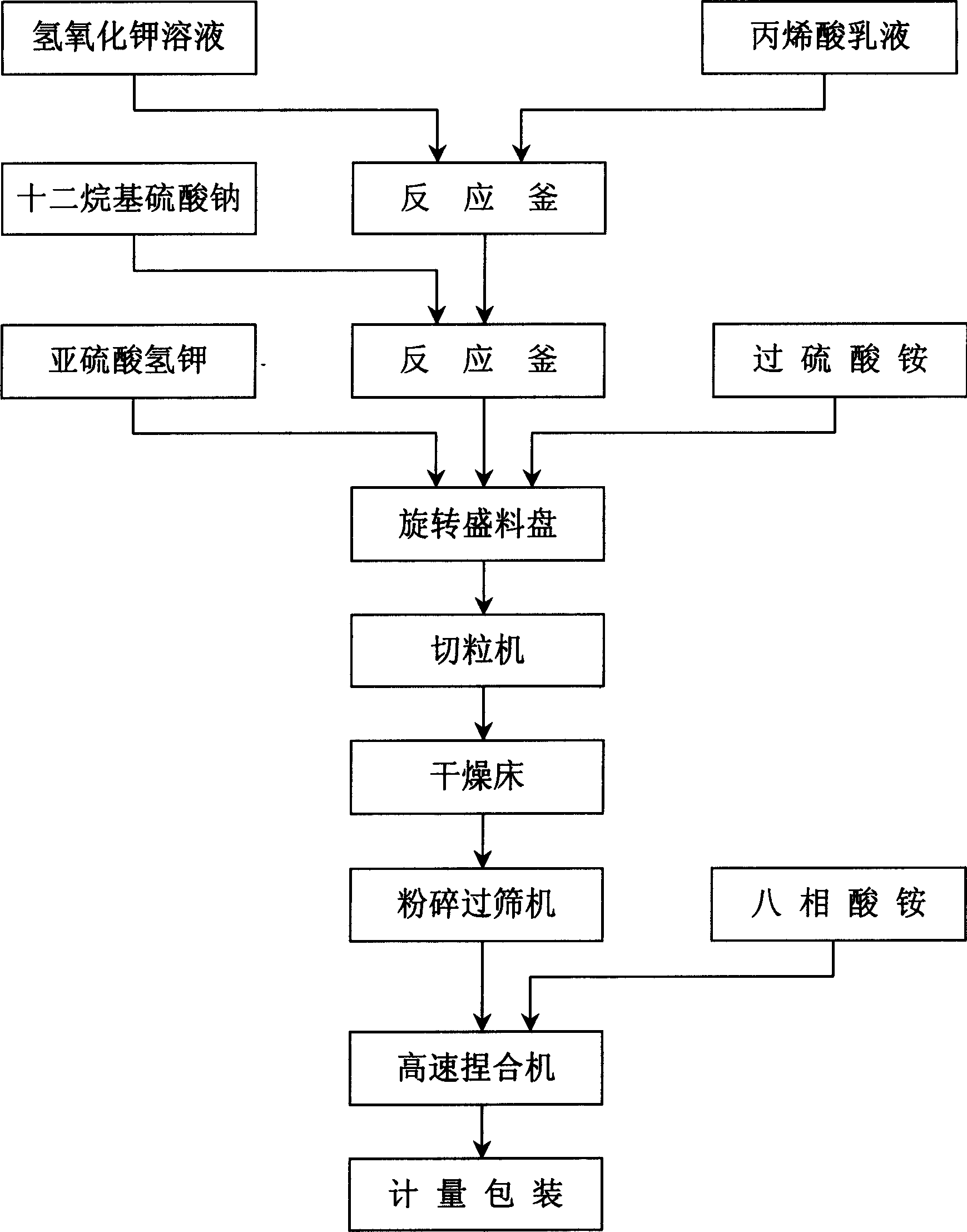

Method for preparing compound fire-extinguishing particulate material

InactiveCN1736516ASmoke suppressionReduce the temperatureFire extinguisherPotassium hydroxidePotassium bisulfite

The invention relates to a making method of composite fire-extinguishing particle material in new fire-extinguishing material domain, which is characterized by the following: adapting the potassium hydroxide and acrylic emulsion as the basic raw material; adding sodium lauryl sulfate, potassium bisulfite, ammonium peroxodisulfate and eight looks acid ammonium into the raw material; making the composite fire-extinguishing particle material by neutralization reaction, initiating crosslinking polymerization, dicing, drying, disintegrating, sifting, modifying property compound, measuring and packing. The composite particle material ejects the gelatin with 1:300 qualities mixing to the ignition area, which reduces the temperature of ignition area to inhibit the smog and reaches the goal of quick fire-extinguishing and flame-proof by forming a heat-proof layer and oxygen-proof gelatination layer.

Owner:FUJIAN NORMAL UNIV

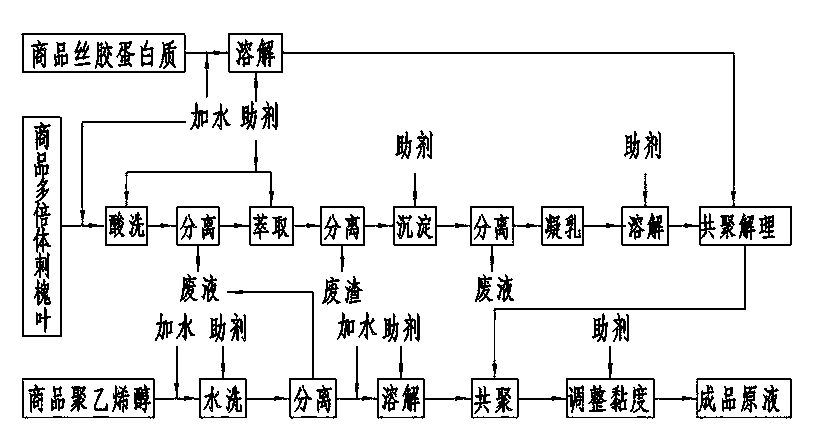

Protein regeneration composite fiber spinning solution and production method thereof

InactiveCN103388194AStrong color fastnessLow priceConjugated cellulose/protein artificial filamentsConjugated synthetic polymer artificial filamentsPolyvinyl alcoholPotassium bisulfite

The invention relates to a regeneration animal-plant double-protein composite fiber spinning solution and a production method thereof. The protein regeneration composite fiber spinning solution includes an animal protein and / or a plant protein, the animal protein is sericin protein obtained by processing of reeling silk leftovers, and the plant protein is a protein obtained by extraction of multiploid locust leaves. The protein regeneration composite fiber spinning solution also includes the following components by weight: 0-40 parts of the animal sericin protein, 0-40 parts of the plant polyploid locust leaf protein, 58.6-74.4 parts of polyvinyl alcohol, 0.3-0.8 part of potassium sulfite or potassium bisulfite and 0.3-0.8 part of hydrogen peroxide, performic acid or peracetic acid; and then the composite spinning solution with the viscosity of 800-1200 centipoises is obtained by adding water and sodium hydroxide for copolymerization. According to the regeneration animal-plant double-protein composite fiber spinning solution and the production method thereof, the cost of fiber is reduced, the quality of products is improved, and the problems of chromaticity, color fastness, resistance to hot water and boiling water shrinkage of the fiber are solved.

Owner:郭洁清 +1

Potassium sulfite/potassium bisulfite (KS/KBS) liquid as starter, side-dress, broadcast, foliar and fertigation fertilizers

The present invention provides a new liquid fertilizer comprised of potassium sulfite and potassium bisulfite, with neutral to slightly alkaline pH, relatively lower salt index and potentially lower phytotoxicity damage compared to other sources of potassium and sulfur products applied in equal amounts as a starter fertilizer. More specifically, the present invention further relates to methods for fertilizing using a composition of potassium sulfite and potassium bisulfite, particularly as a starter fertilizer, in-furrow fertilizer, side dress fertilizer, and for foliar, broadcast, soil injection and fertigation applications. The fertilizer composition is comprised primarily of potassium sulfite and potassium bisulfite (with the fertilizer grade of 0-0-23-8S).

Owner:TESSENDERLO KERLEY INC

Preparation method of polyacrylate flocculant

InactiveCN105086309AHigh molecular weightLow residual monomer contentSodium bicarbonateSodium stearate

A preparation method of a polyacrylate flocculant comprises the following steps: (1) preparation of an acrylate solution I: controlling system temperature to be lower than 35 DEG C and mixing alkali at the weight percent concentration of 22.6% and acrylic acid according to the molar ratio of 1:1 so as to obtain the acrylate solution I; (2) preparation of a polymerization additive liquid II: dissolving 0.5-4 parts by weight of an anti-cross-linking agent, 0.1-0.5 part by weight of an anti-agglomeration agent and 0.16-0.46 part by weight of an initiator in 10-30 parts by weight of water and uniformly mixing the above components so as to obtain the polymerization additive liquid II; (3) adjusting pH value of 346 parts by weight of the acrylate solution I to 12-12.5 by the use of alkali, adding the polymerization additive liquid II, stirring and uniformly mixing, and standing at normal temperature for 3-10 h; (4) smashing, drying and crushing. The alkali for neutralizing acrylic acid and the alkali for adjusting pH value of the system are sodium hydroxide, potassium hydroxide, sodium bicarbonate or sodium carbonate. The initiator is sodium persulfate or potassium persulfate and sodium sulfite, sodium hydrogen sulfite or a potassium bisulfate compound. The anti-cross-linking agent is urea or EDTA. The anti-agglomeration agent is soap base or sodium stearate.

Owner:谈丽娜

Method for synthesizing diacetone acryloamide and acrylic amide copolymer

ActiveCN108314750AChange solubilityAvoid pollutionBulk chemical productionPotassium persulfatePersulfate

The invention discloses a method for synthesizing a diacetone acryloamide and acrylic amide copolymer. A diacetone acryloamide and acrylic amide comonomer is subjected to precipitation polymerizationunder the critical temperature and pressure of carbon dioxide by taking the carbon dioxide as a medium and a persulfate and hydrosulphite redox system as an initiator to obtain the diacetone acryloamide and acrylic amide copolymer. The initial use amount concentration of the initiator is 0.05 to 0.5 mol / l; the total monomer concentration of the diacetone acryloamide and the acrylic amide is 1 to 8mol / l; in the initiator, the persulfate is one of potassium persulfate, sodium persulfate or ammonium persulfate, and the hydrosulphite is one of potassium hydrosulphite, sodium hydrosulphite or ammonium hydrosulphite. The organic solvent is replaced by the non-toxic and pollution-free medium supercritical carbon dioxide, so environmental pollution caused by use of toxic, harmful, volatile and combustible organic solvents is avoided, and the effects of environmental friendliness, energy conservation and resource conservation can be realized.

Owner:福建省智野实业有限公司

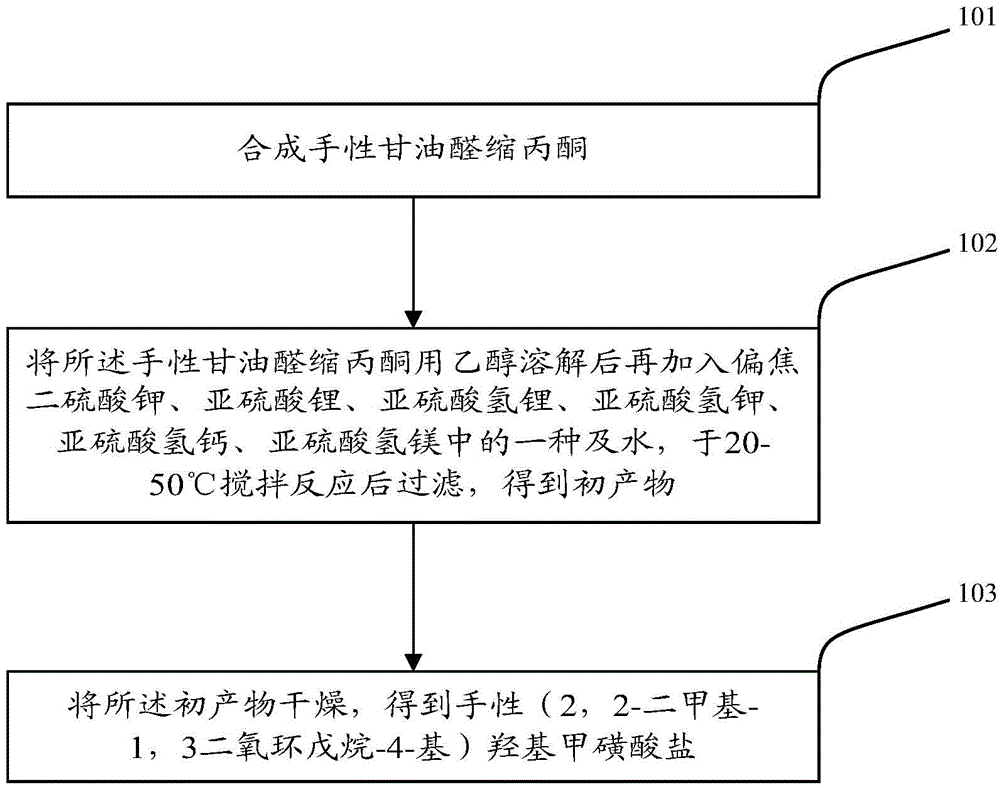

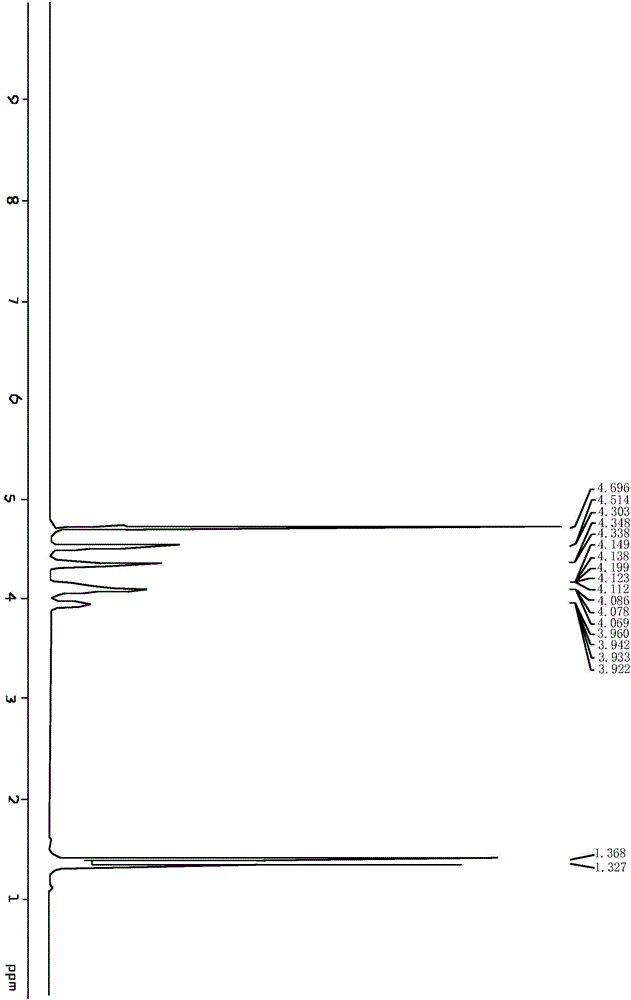

Chiral (2,2-dimethyl-1,3-dioxolane-4-yl)hydroxy mesylates, and preparing method and applications thereof

ActiveCN104788419AStable structureAchieve preparationOrganic chemistryMagnesium bisulfitePotassium bisulfite

The invention provides chiral (2,2-dimethyl-1,3-dioxolane-4-yl)hydroxy mesylates, and a preparing method and applications thereof, and relates to the fields of fine chemicals and medical intermediates. The preparing method includes synthesizing chiral glyceraldehyde acetonide, dissolving the chiral glyceraldehyde acetonide with ethanol, adding water and one of potassium metabisulfite, lithium sulfite, lithium bisulfite, potassium bisulfite, calcium bisulfite or magnesium bisulfite, stirring and reacting at 20-50 DEG C, filtering to obtain a head product, and drying the head product to obtain the chiral (2,2-dimethyl-1,3-dioxolane-4-yl)hydroxy mesylates. The chiral (2,2-dimethyl-1,3-dioxolane-4-yl)hydroxy mesylates can participate Wittig reactions, in place of the chiral glyceraldehyde acetonide.

Owner:宜宾市南溪区红光制药有限公司

Sulfur dioxide scrubbing system and process for producing potassium products

ActiveUS10005667B2Gas treatmentThiosulfates/dithionites/polythionitesOxidation statePotassium hydroxide

The invention relates to a process for preparing potassium thiosulfate, potassium sulfite or potassium bisulfite comprising the following steps:Step (1a): providing a potassium hydroxide or potassium carbonate solution for neutralizing acid forming components such as dissolving SO2 or H2S;Step (1b): providing an SO2 contacting solution, containing at least some potassium sulfite or potassium bisulfite or potassium thiosulfate;Step (2): providing SO2 gas;Step (3): reacting these to absorb the SO2 gas and to form an intermediate reaction mixture comprising potassium sulfite, or potassium bisulfite or a mixture thereof, and optionally recovering the potassium sulfite, or potassium bisulfite or a mixture thereof, and / or optionally using steps 4 and 5;Step (4): adding sulfur or sulfide containing compound containing sulfur having the oxidation state of 0, −2 or of between 0 and −2 to the reaction mixture and optionally potassium hydroxide or potassium carbonate, and reacting the mixture under suitable conditions to form potassium thiosulfate; andStep (5): recovering the potassium thiosulfate, and optionally concentrating the potassium thiosulfate.

Owner:TESSENDERLO KERLEY INC

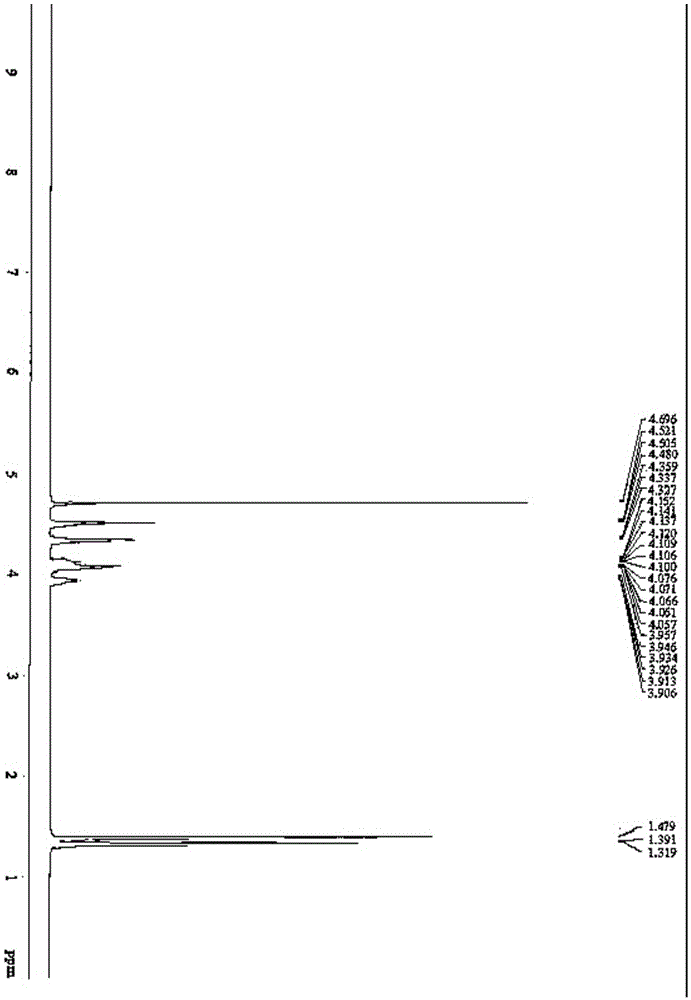

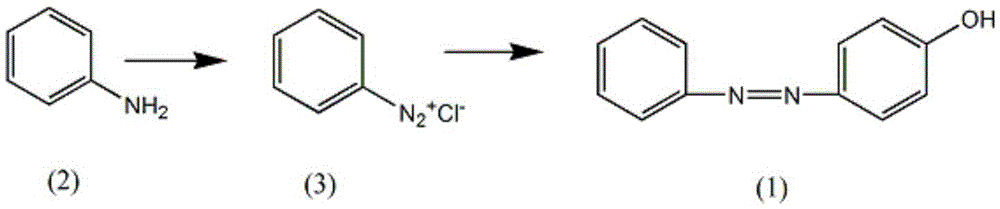

Synthetic method for oxyphenbutazone drug intermediate-4-hydroxyazobenzene

InactiveCN105601534AReduce intermediate linksLow reaction temperatureOrganic chemistryFiltrationPotassium

The invention discloses a synthetic method for an oxyphenbutazone drug intermediate-4-hydroxyazobenzene. The method comprises the following steps: (i) adding 300ml of a sulfuric acid solution with a certain concentration into a reaction container equipped with a stirrer, a temperature meter and a drop funnel, controlling the stirring speed to be 100-200rpm, slowly adding 1.2mol of phenylamine, after phenylamine is completely dissolved, cooling the solution to 6-9 DEG C, dropwise adding 1.1mol of potassium bisulfite, performing dissolution in 200-230ml of water to prepare a solution, testing a reaction termination point by using potassium iodide test paper, and generating diazonium salt (3); and (ii) adding 2-2.3L of a potassium carbonate solution with a certain concentration and 1.2mol of phenol into the other container to prepare a potassium phenate solution, slowly adding a diazotization solution obtained in the step (i) at the stirring speed of 100-160rpm, controlling the temperature of the solution to be 16-20 DEG C, after the addition is finished, continuing to react for 30-40 minutes, adding an adjusting solution for maintaining the pH value of the solution to be 8-9, then adding an oxalic acid solution for reducing the pH value to be 2-3, keeping the reaction for 40-50 minutes, performing suction filtration, adding a washing solution, and performing dewatering with a dewatering agent to obtain 4-hydroxyazobenzene.

Owner:CHENGDU ZHONGHENG HUATIE TECH CO LTD

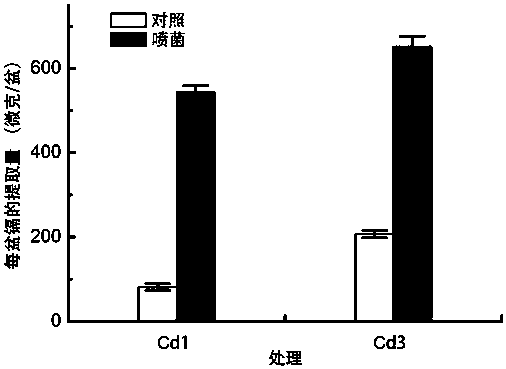

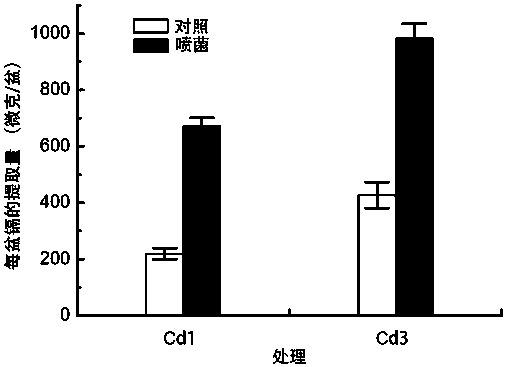

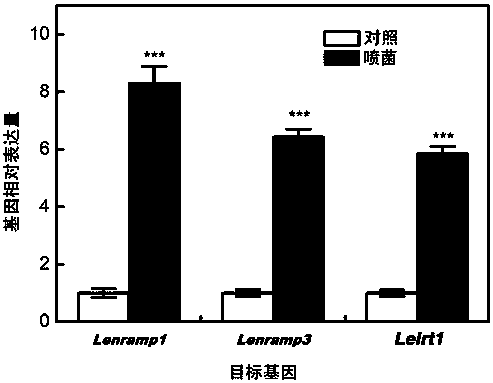

Manufacturing method for plant heavy metal enrichment accelerant based on pseudomonas syringae

InactiveCN107931326AReduce investmentImprove efficiencyBacteriaContaminated soil reclamationNicotiana tabacumPotassium bisulfate

The invention relates to a manufacturing method for a plant heavy metal enrichment accelerant based on pseudomonas syringae. The method is characterized in that the plant heavy metal enrichment accelerant comprises the pseudomonas syringae, potassium bisulfate and a surface active agent. A preliminary test is conducted on tomatoes and tobaccos. Results show that (1) the accelerant can remarkably promote the enrichment effect of plants on Cd, Pb and Cu, and the enrichment capacity of the tested plants can be improved by at least two times; and (2) the accelerant can remarkably promote improvement of expression of heavy metal transfer related protein genes, including LeNRAMP1, LeNRAMP3 and LeIRT1, in the tomatoes. In conclusion, the plant heavy metal enrichment accelerant based on the pseudomonas syringae is a new efficeint agent for promoting heavy metal enrichment of the plants and has broad application prospects.

Owner:EASTERN GANSU UNIVERSITY

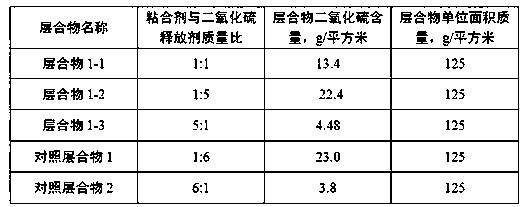

Sulfur dioxide fresh-keeping laminate, preparation method and application

InactiveCN110447710ASimple production processImprove quality controlFruit and vegetables preservationSynthetic resin layered productsHydrogenAdhesive

The invention provides a sulfur dioxide fresh-keeping laminate. The laminate at least comprises a first base material, a second base material, an adhesive and a sulfur dioxide releasing agent, whereina mixture of the adhesive and the sulfur dioxide releasing agent is uniformly distributed between the first base material and the second base material, the first base material and the second base material tightly adhere to each other under the action of the adhesive through heating and pressurizing, and the sulfur dioxide releasing agent tightly adheres to the adhesive through heating and pressurizing; the first base material is a breathable material; the sulfur dioxide releasing agent comprises one or more of sodium pyrosulfite, potassium metabisulfite, sodium hydrogen sulfite and potassiumhydrogen sulfite; the amount of sulfur dioxide in the laminate is 3-40 g per square meter. The laminate has is simple in process, the quality is easy to control, continuous production can be achieved,the production efficiency is high, the labor consumption is low, and the production cost is low.

Owner:山东营养源食品科技有限公司

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com