Patents

Literature

375 results about "Propionitrile" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Propionitrile, also known as ethyl cyanide and propanenitrile, is an organic compound with the formula CH₃CH₂CN. It is a simple aliphatic nitrile. The compound is a colourless, water-soluble liquid. It is used as a solvent and a precursor to other organic compounds.

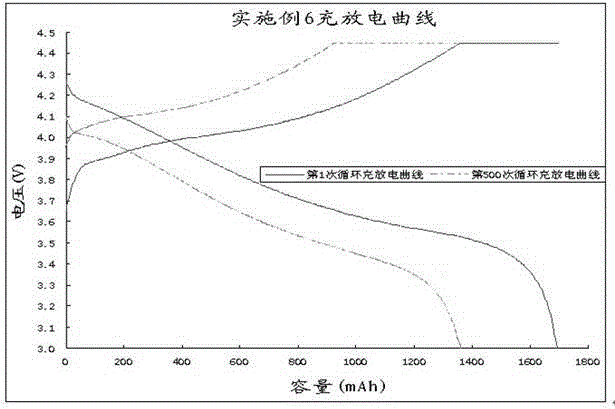

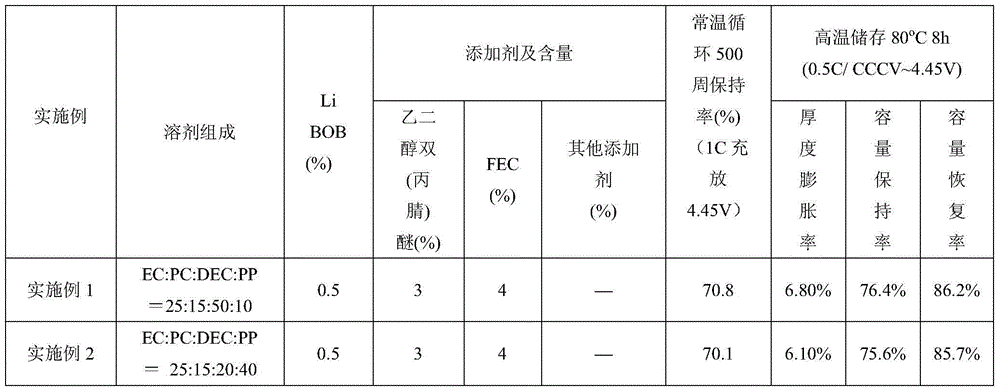

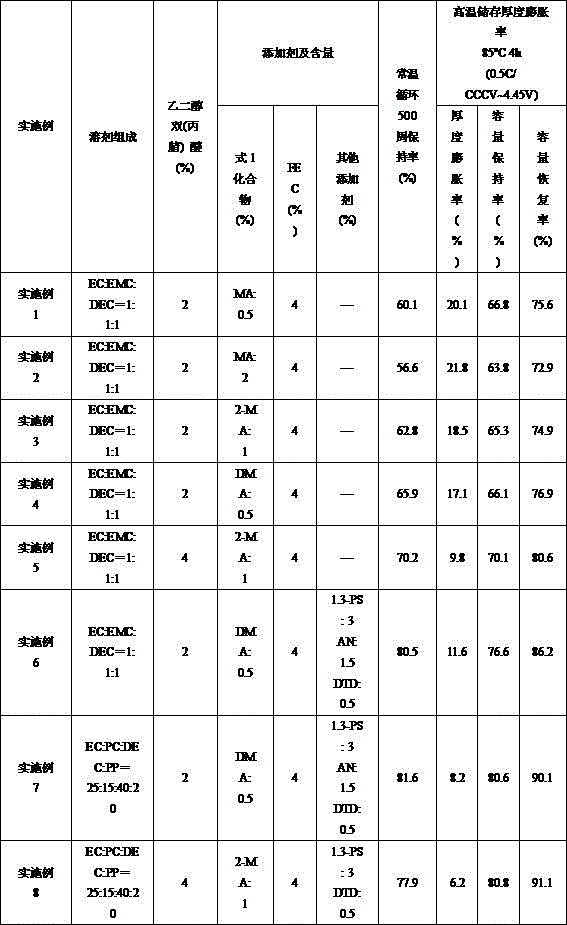

High-voltage electrolyte and lithium ion battery using electrolyte

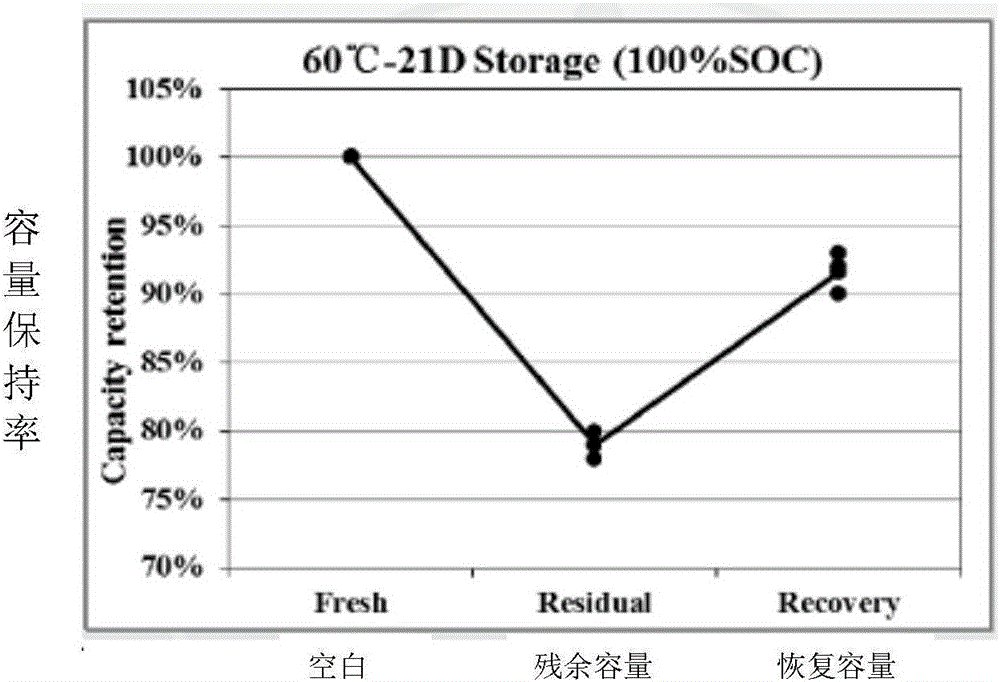

InactiveCN104979589APromote circulationHigh decomposition voltageSecondary cellsHigh temperature storageEthylene glycol bis

The invention discloses high-voltage electrolyte and a lithium ion battery using the electrolyte. The invention is realized by the following technical scheme: the high-voltage electrolyte comprises a non-aqueous solvent, lithium salt and an additive, wherein the non-aqueous solvent is a carboxylic ester compound which accounts for 1-40% by mass of the high-voltage electrolyte; the additive is any one or more of lithium bis(oxalate)borate (Li BOB), fluoroethylene carbonate (FEC) and ethylene glycol bis(propionitrile) ether. The high-voltage electrolyte contains carboxylic ester solvents capable of improving an electrode / electrolyte interface, and through optimized combination of the carboxylic ester solvents, Li BOB, FEC, ethylene glycol bis(propionitrile) ether and other various additives, the good cycle performance of a high-voltage battery can be ensured, meanwhile, the high-temperature storage performance of the high-voltage battery can be effectively improved, and gas generation of the battery under high-voltage high-temperature storage condition can be obviously inhibited.

Owner:DONGUAN KAIXIN BATTERY MATERIAL

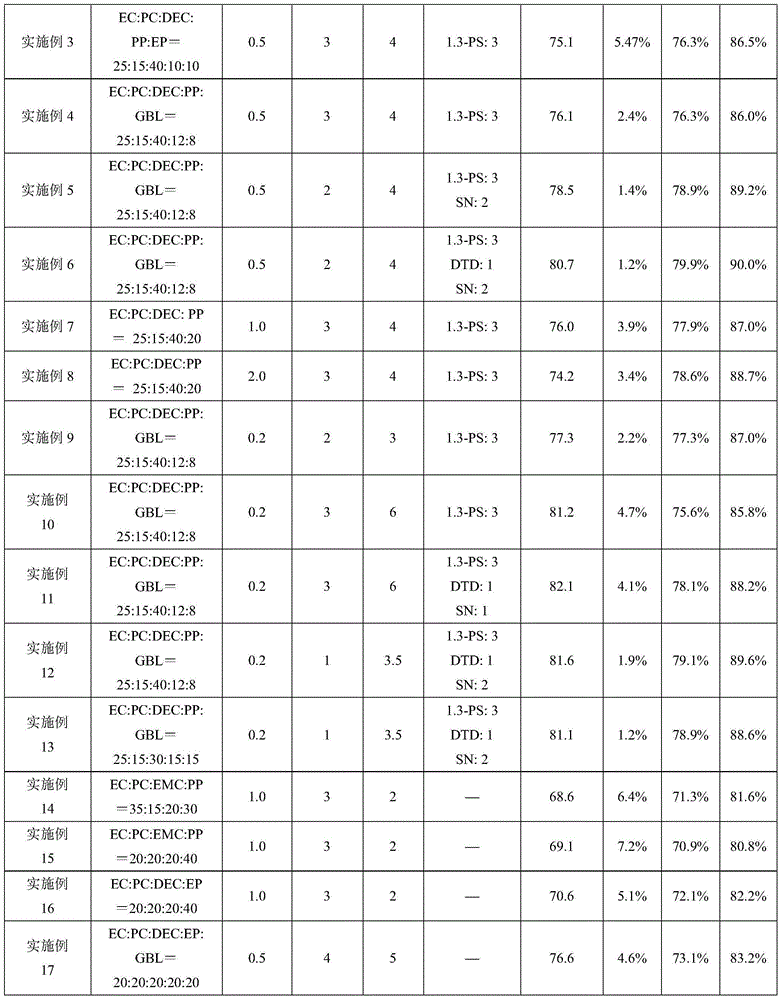

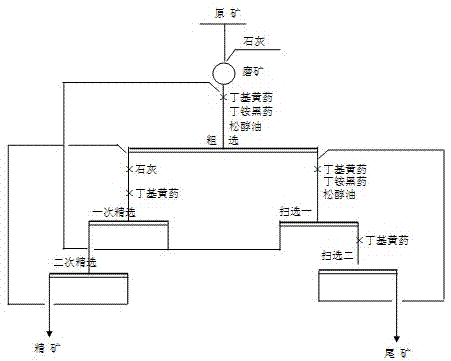

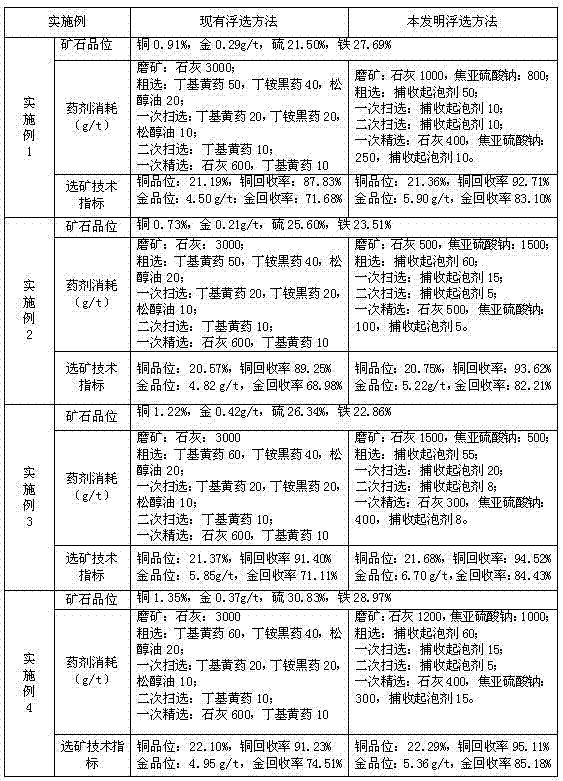

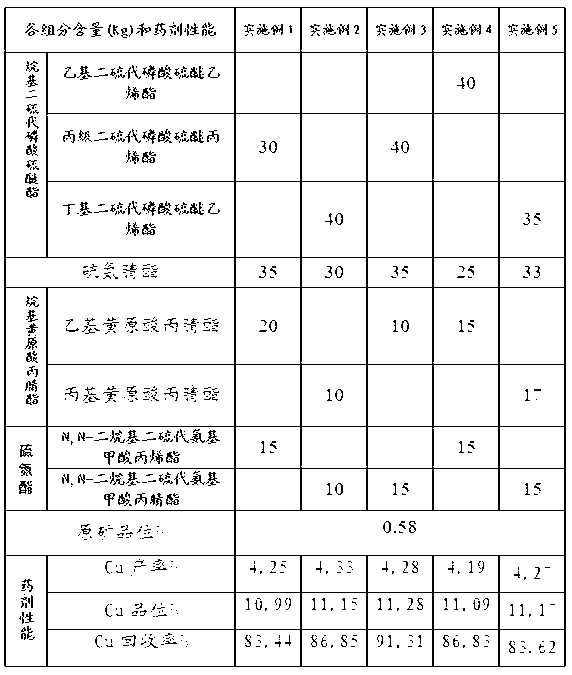

Method for floating high-sulfur gold-bearing copper ore

ActiveCN103691569AEnhanced inhibitory effectImprove beneficiation indexFlotationPropionitrileEthyl group

The invention discloses a method for floating high-sulfur gold-bearing copper ore, which aims at solving the problems that the existing beneficiation method is lower in copper and gold recovery rate under high-alkali condition, and problems that xanthate and black powder are adopted as high-sulfur gold-bearing copper ore collecting agents, the collecting power is stronger, the selectivity is poor, the separation difficulty of copper and sulfur can be aggravated and the consumption of inhibitors is increased. The method comprises the steps of by adopting lime and sodium metabisulfite as an ore pulp pH regulator and a pyrite inhibitor, and the mixture of isopropyl xanthogen propionitrile ester, black powder acid and ethyl dithiocarboxyl propionitrile ester according to certain proportion as a collecting foaming agent, carrying out ore grinding, rough concentration, primary scavenging, secondary scavenging, primary concentration, and secondary concentration on a crude ore, thus realizing the high-efficiency recovery on copper and gold in the high-sulfur gold-bearing copper ore. According to the method, through reasonable combination and addition of medicaments, the selective adsorption of the collecting agent on target mineral-copper pyrite and other copper sulfide minerals and gold minerals can be reinforced, and the copper recovery rate and the gold recovery rate can be improved.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

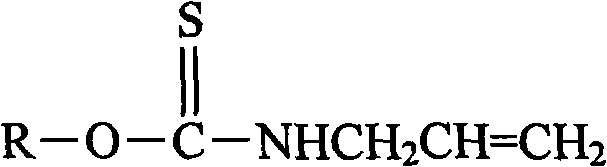

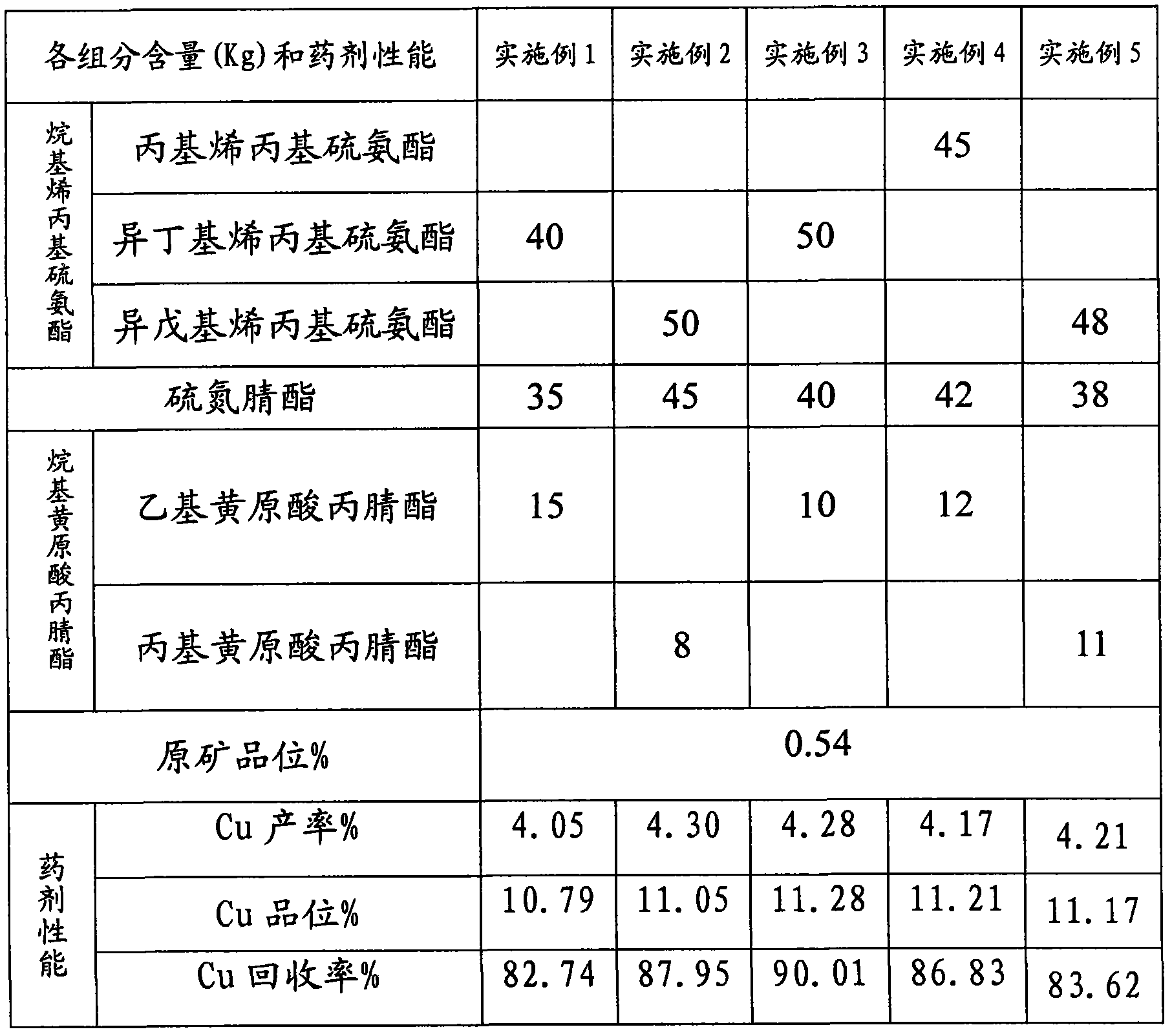

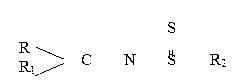

High sulfur copper ore collecting agent

The invention relates to a high sulfur copper ore collecting agent, which is characterized by consisting of the following materials in part by weight: 40 to 50 parts of alkyl allyl thionocarbamate, 35 to 45 parts of sulfur nitrogen nitrile ester and 8 to 15 parts of alkyl xanthonic acid propionitrile ester. The collecting agent has double properties of collecting and foaming, high selectivity and high collecting capacity, can realize high-efficiency separation of copper and sulfur when the pH value is in a range from 7 to 10, can effectively improve the concentrate grade and the recovery rate, and has a wider application range.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

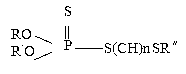

Collecting agent for high-sulfur copper mine

The invention relates to a flotation agent for a copper mine and discloses a high-efficiency collecting agent for a high-sulfur copper mine. The collecting agent comprises the following materials in parts by weight: 30-40 parts of alkyl phosphorodithioic acid thioether ester, 25-35 parts of cyanoethyl diethyl dithionocarbamate, 10-20 parts of alkyl xanthic acid propionitrile ester and 10-15 parts of sulfur-nitrogen ester. The collecting agent for the high-sulfur copper mine has double functions of collecting and foaming, is good in selectivity and high in collecting ability, can realize high-efficiency separation of copper from sulfur in a low pH value (approximately 5) range, can effectively reduce the consumption of lime in the floatation process, can effectively increase the grade and recovery rate of concentrate, and has a wider application scope.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

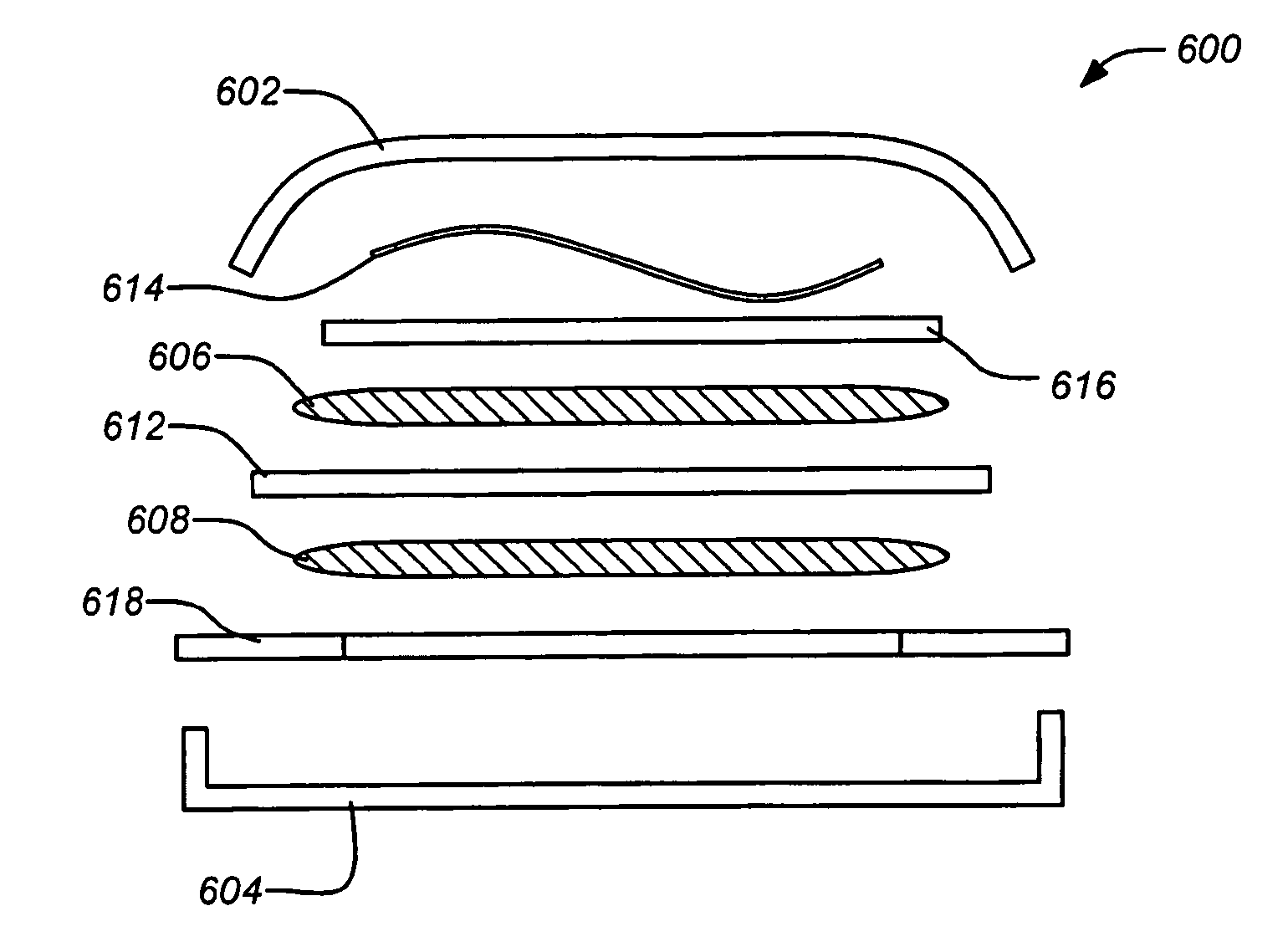

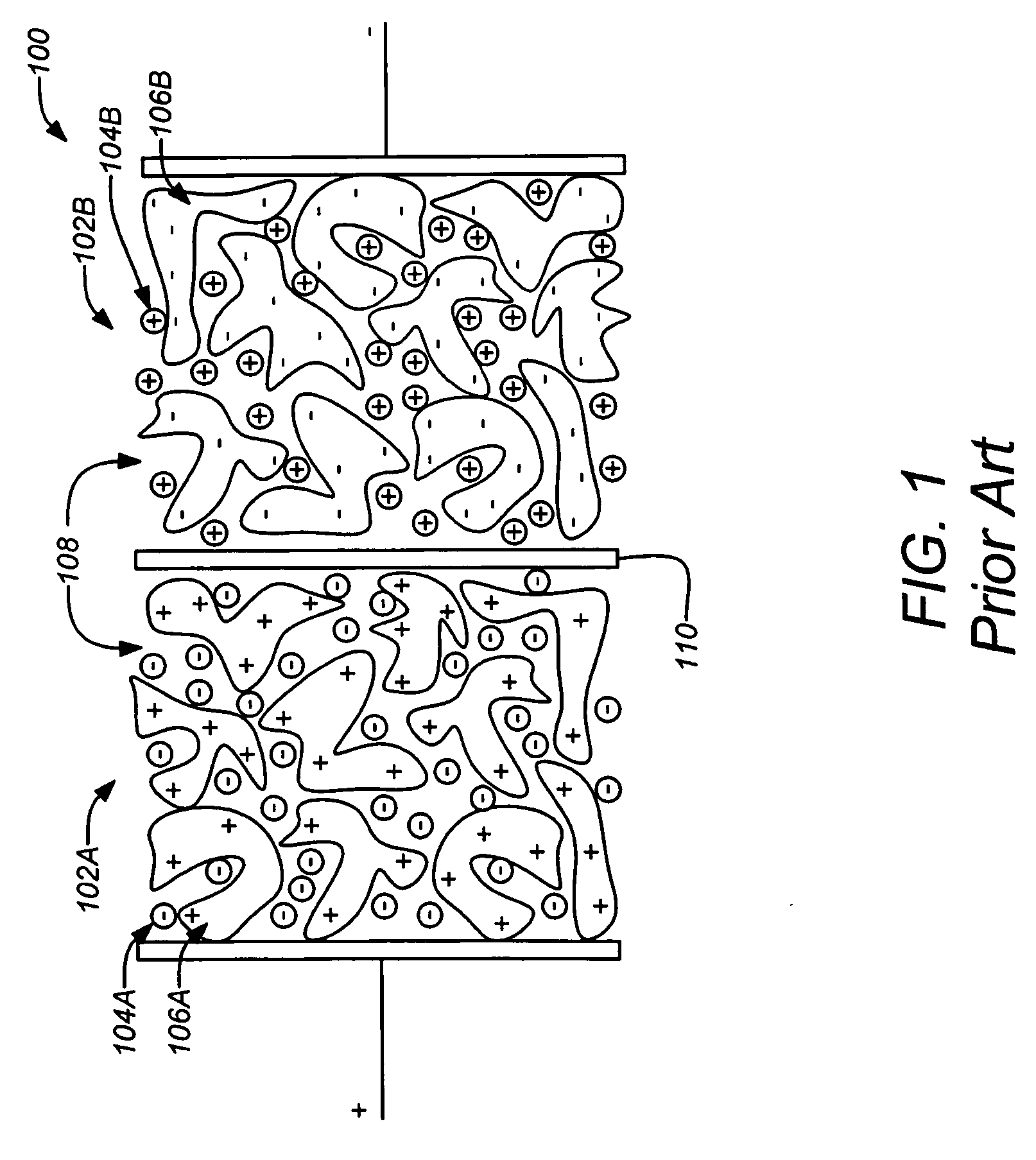

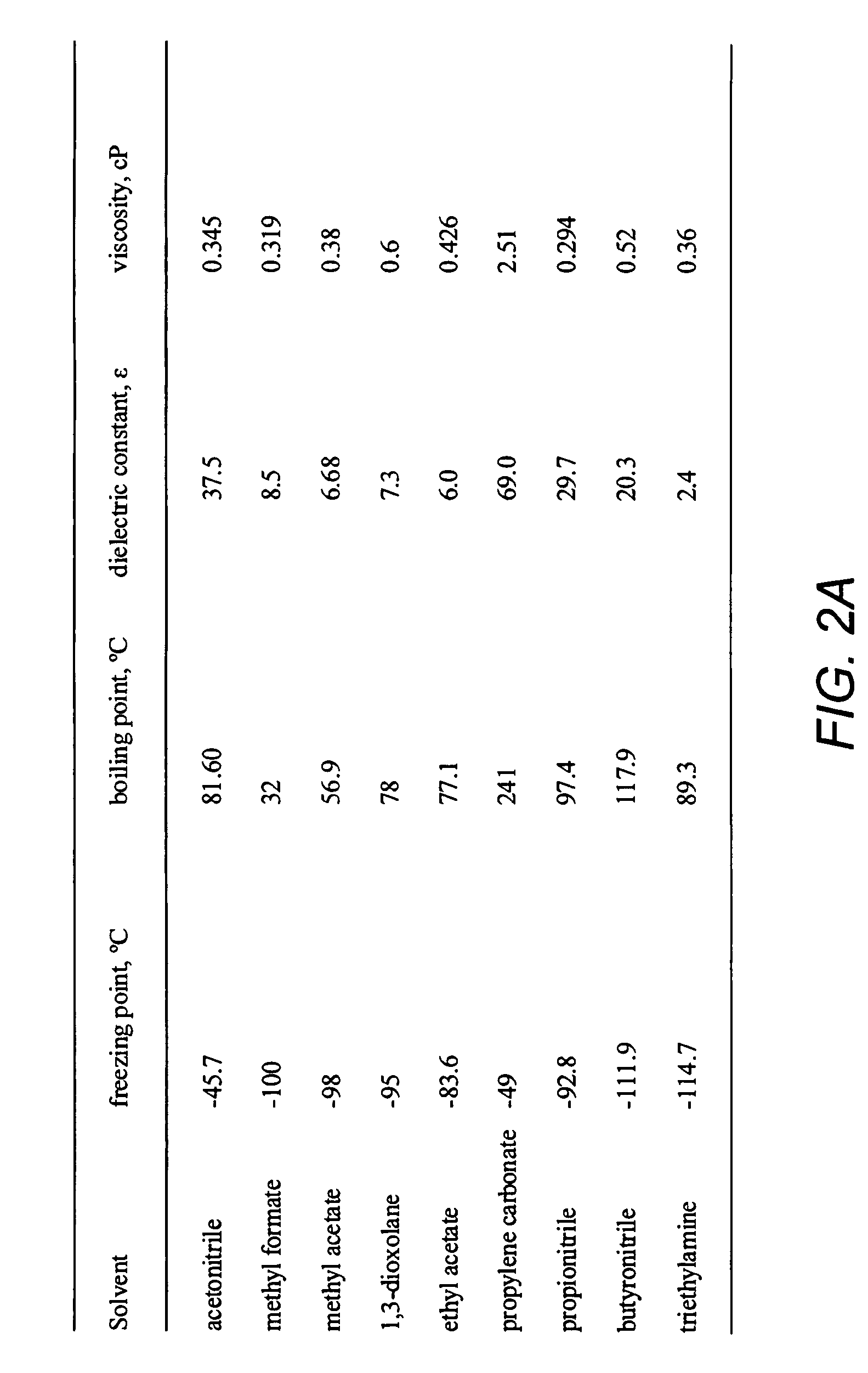

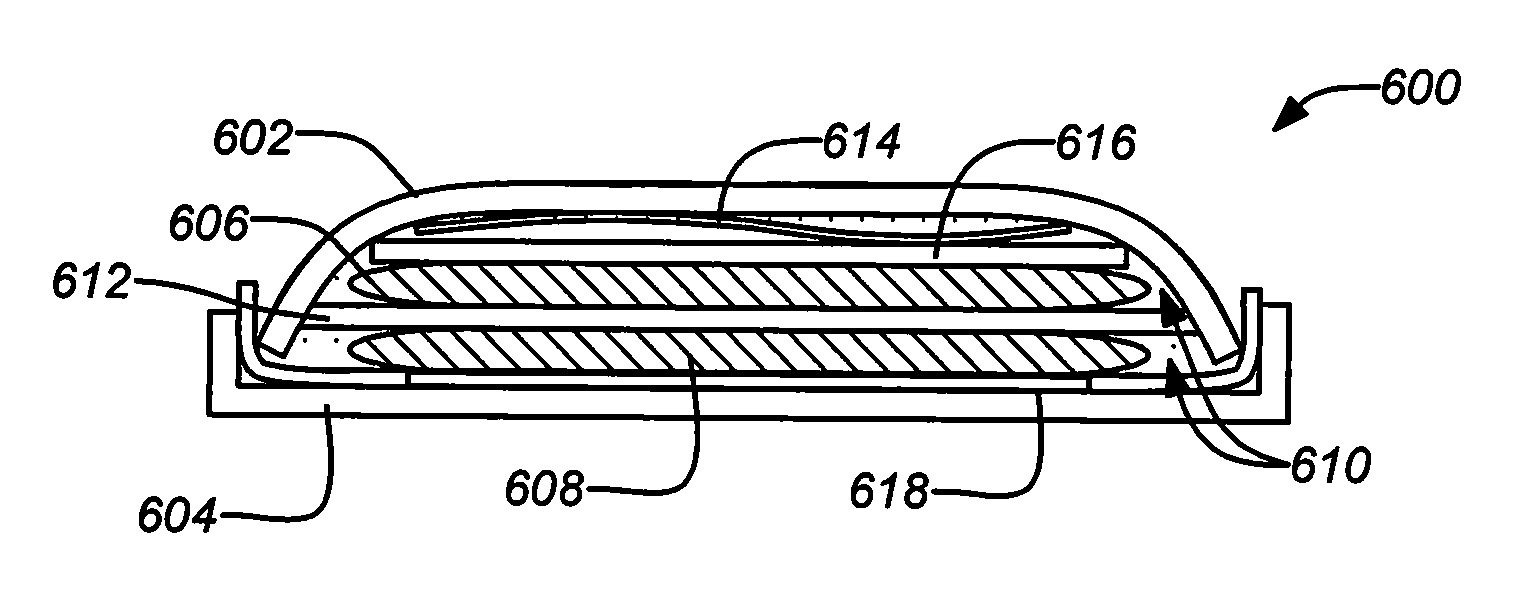

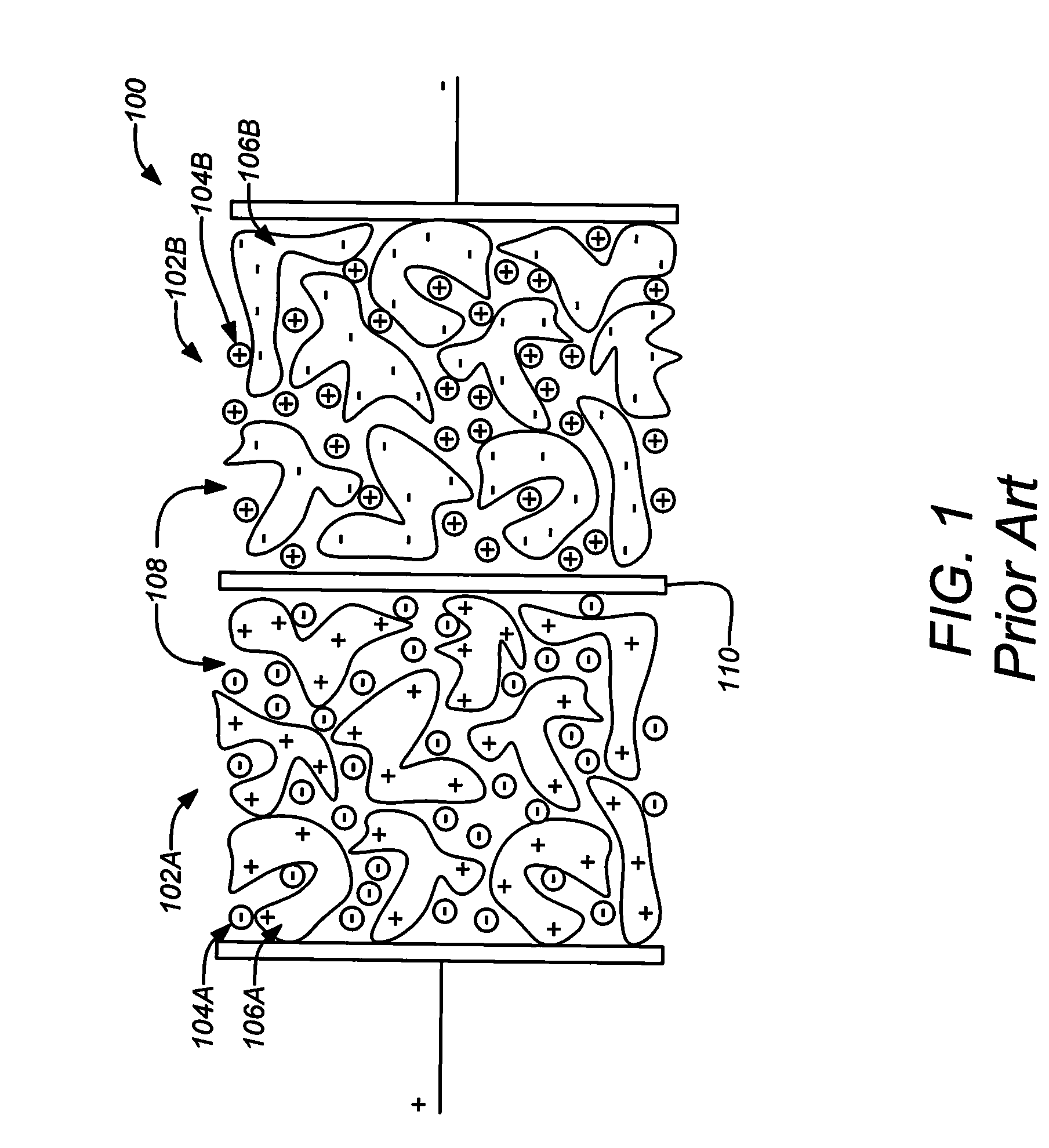

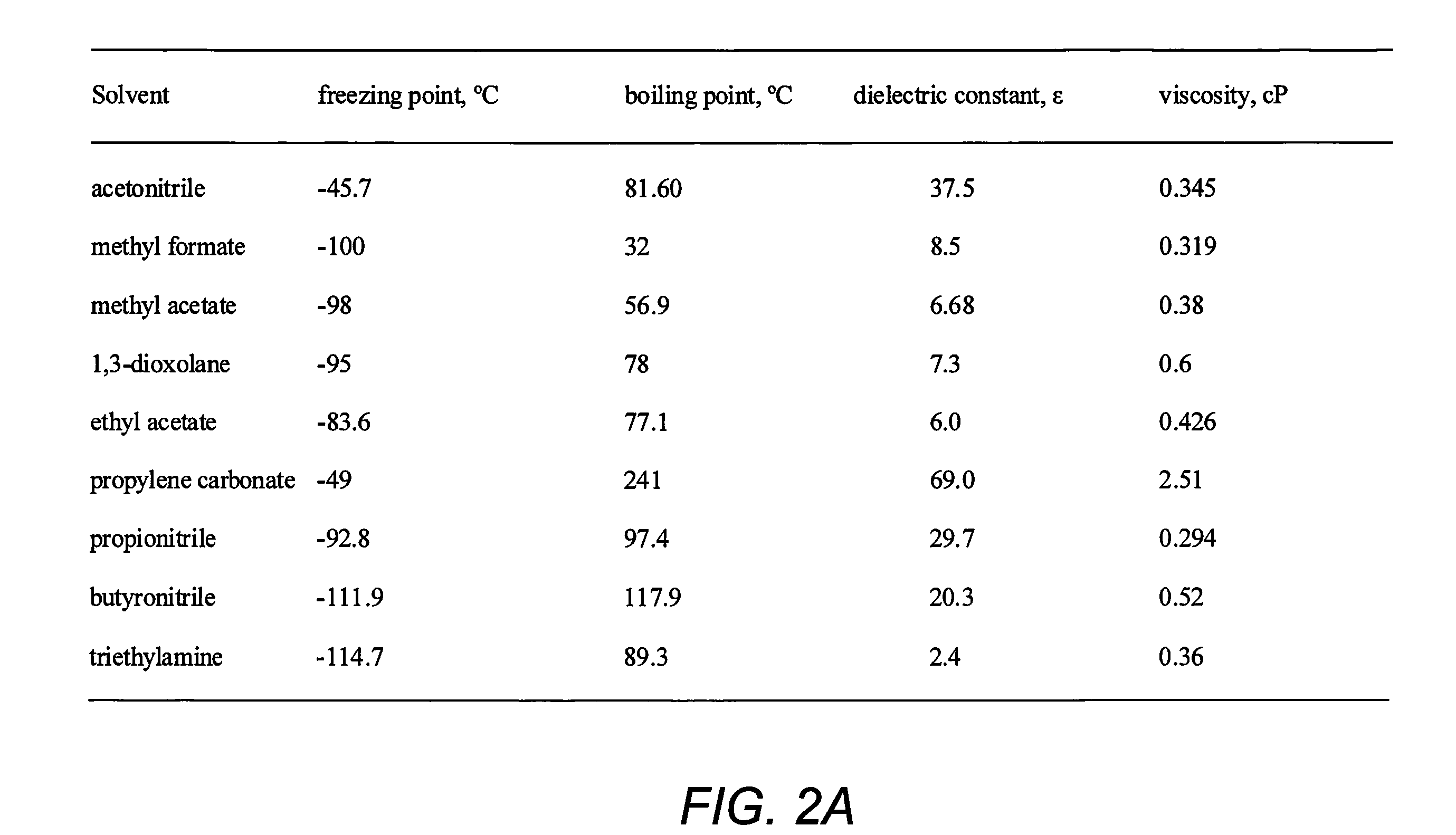

Low temperature double-layer capacitors

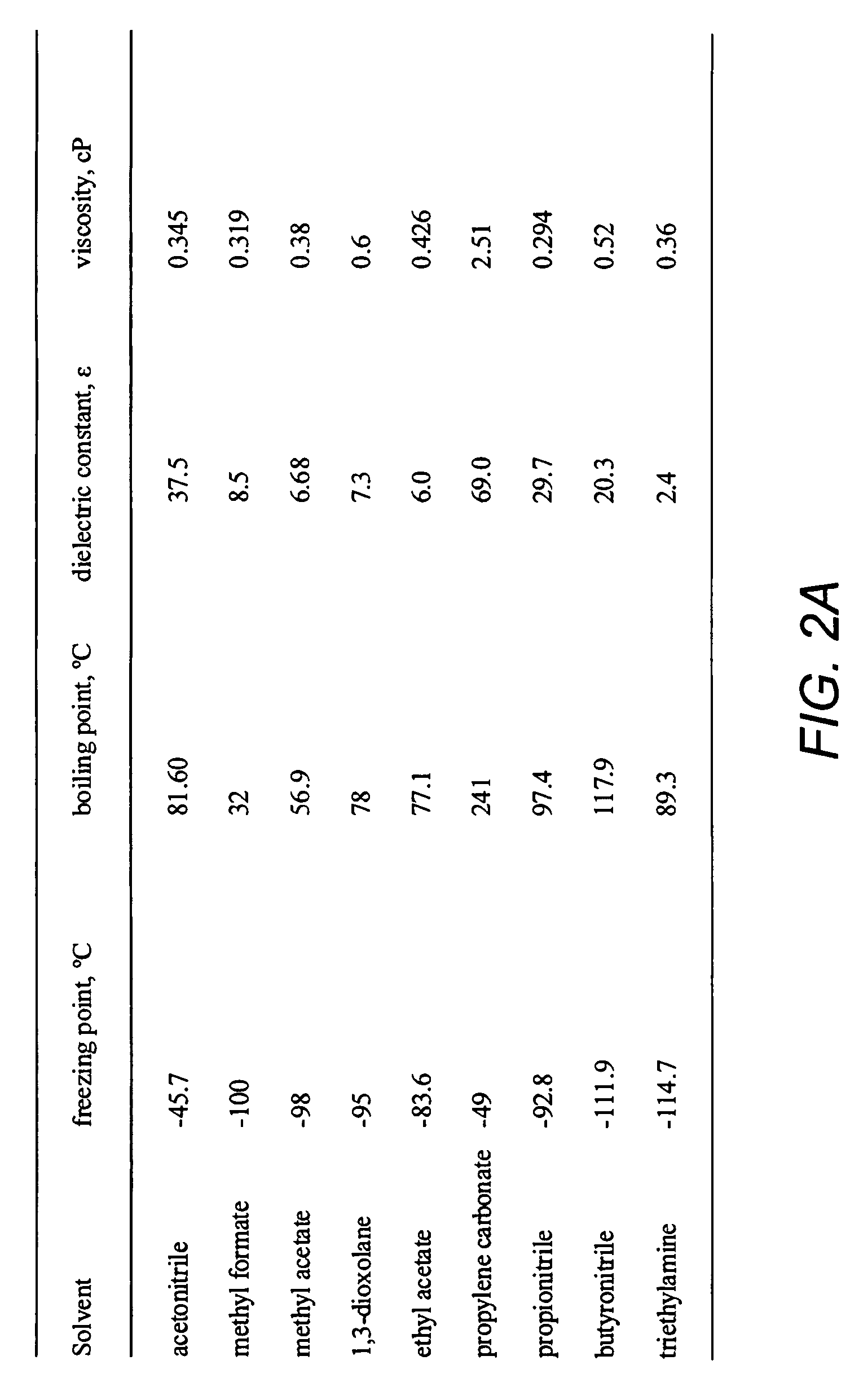

ActiveUS20080304207A1Low melting pointHybrid capacitor electrolytesClosuresTetrafluoroborateDevice form

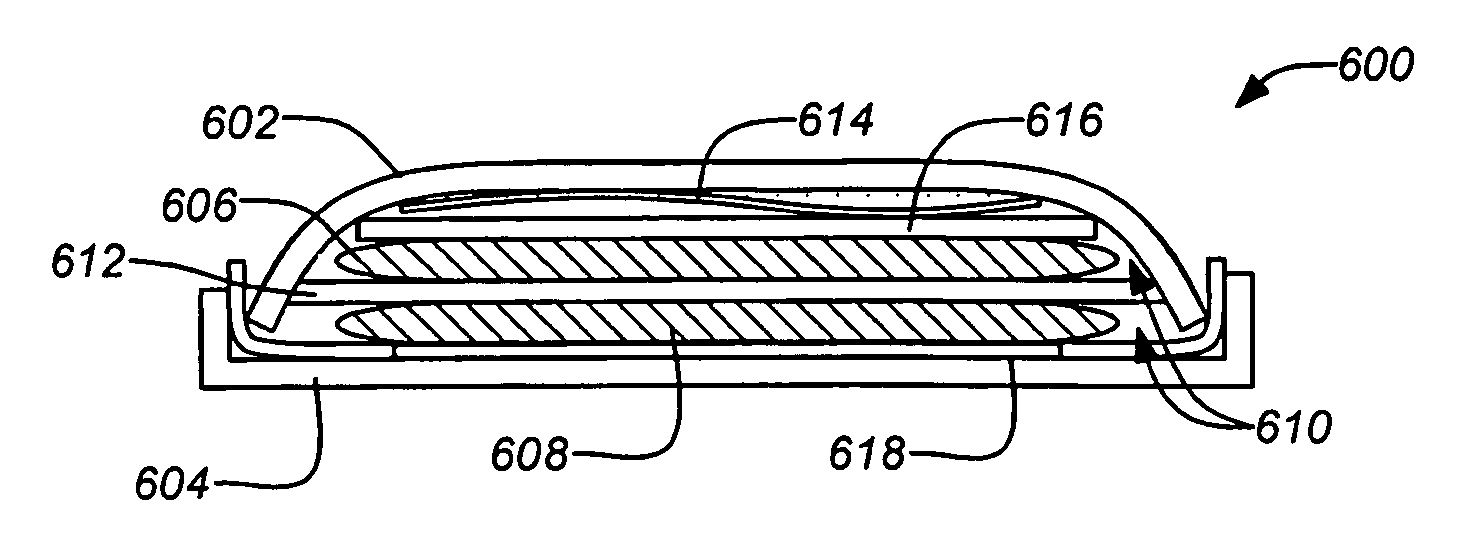

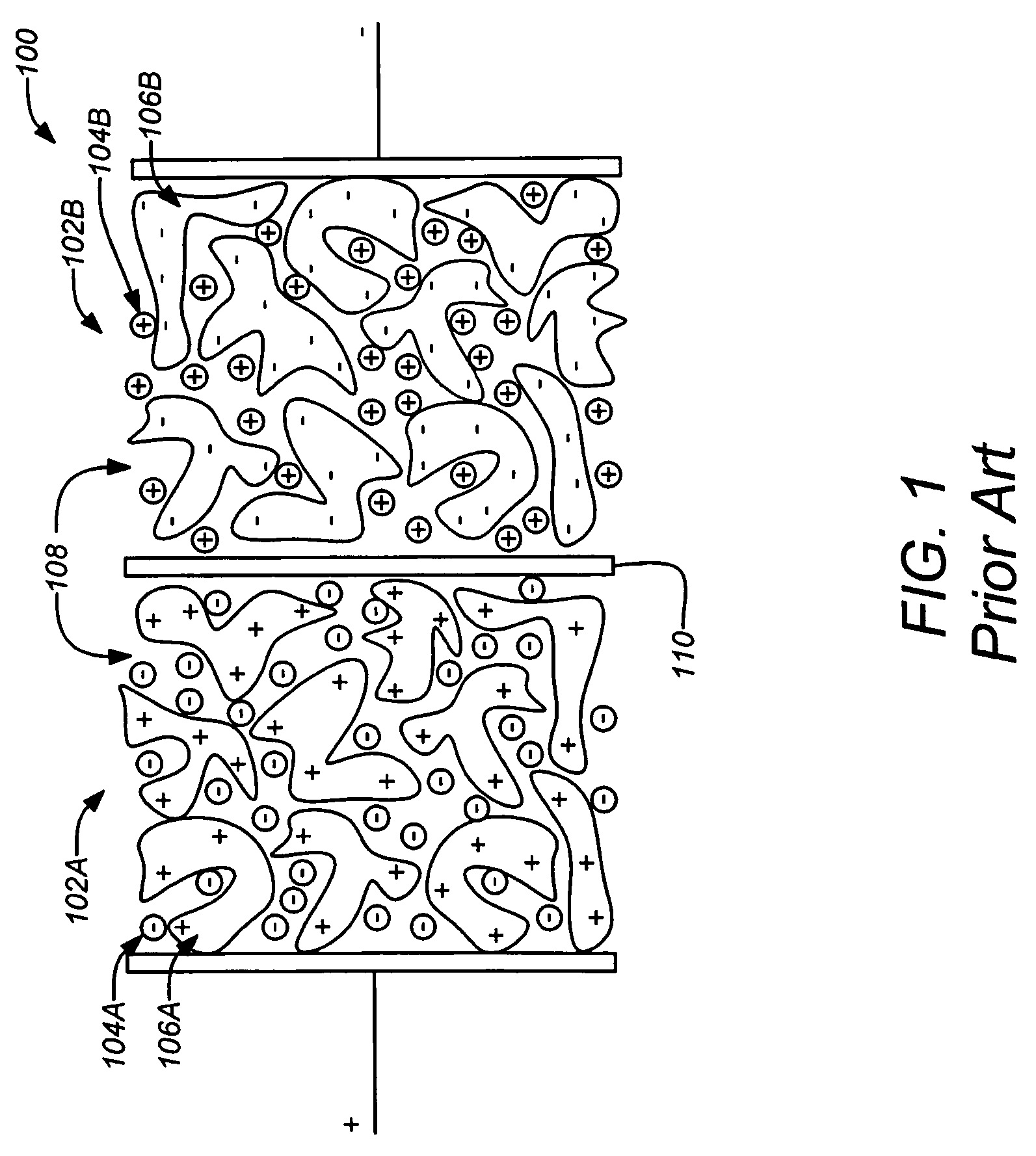

Double-layer capacitors capable of operating at extremely low temperatures (e.g., as low as −75° C.) are disclosed. Electrolyte solutions combining a base solvent (e.g., acetonitrile) and a cosolvent are employed to lower the melting point of the base electrolyte. Example cosolvents include methyl formate, ethyl acetate, methyl acetate, propionitrile, butyronitrile, and 1,3-dioxolane. An optimized concentration (e.g., 0.10 M to 0.75 M) of salt, such as tetraethylammonium tetrafluoroborate, is disolved into the electrolyte solution. In some cases (e.g., 1,3-dioxolane cosolvent) additives, such as 2% by volume triethylamine, may be included in the solvent mixture to prevent polymerization of the solution. Conventional device form factors and structural elements (e.g., porous carbon electrodes and a polyethylene separator) may be employed.

Owner:CALIFORNIA INST OF TECH

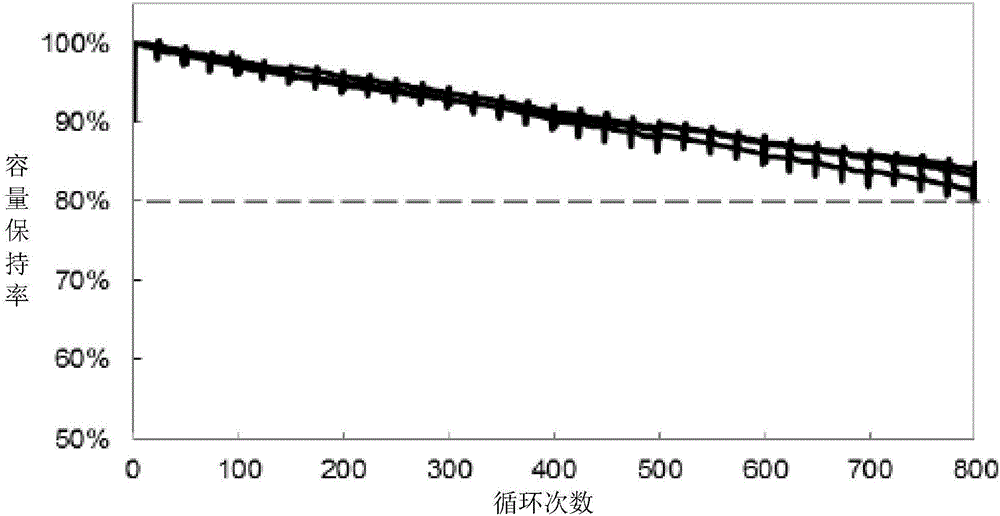

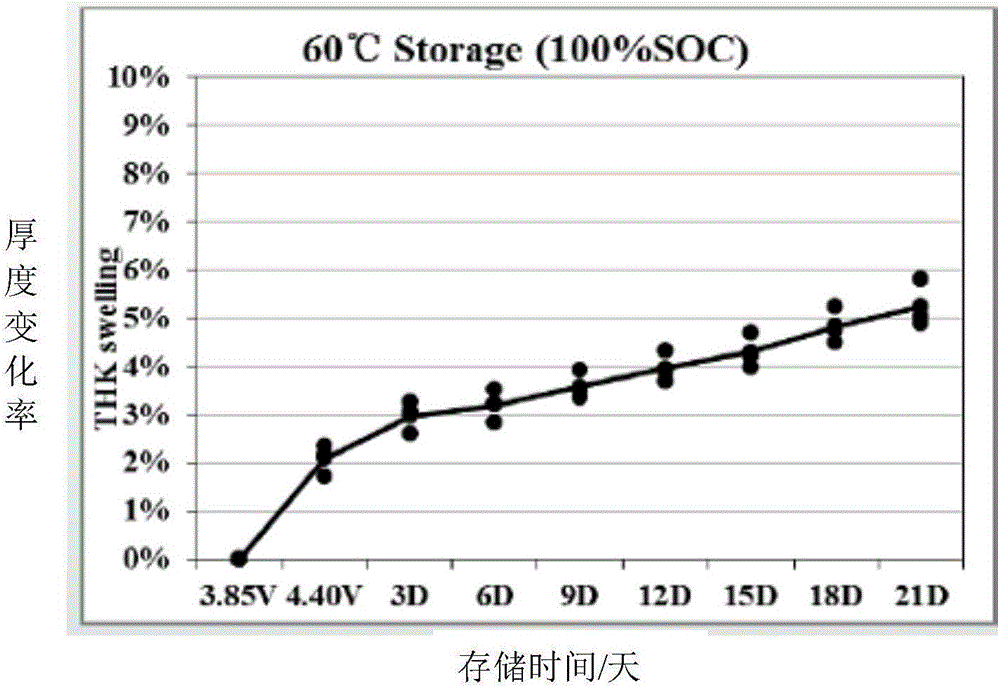

Lithium-ion battery electrolyte, lithium-ion battery and electronic instrument

The invention provides a lithium-ion battery electrolyte, comprising a solvent and an additive, wherein the solvent comprises propyl propionate and two or three selected from a group consisting of vinyl carbonate, diethyl carbonate and propylene carbonate, and the additive comprises vinyl sulfate, fluoroethylene carbonate, adiponitrile, glycol bis(propionitrile) ether, 1,3-propanesultone and fluorobenzene. A lithium-ion battery prepared from the lithium-ion battery electrolyte has stable usability under the condition of 4.40 V or 4.45 V, has energy density of 750 Wh / L or above, cycle life of 800 times or above and a capacity retention ratio of 80% or above, so the service life of a novel high-voltage high-energy-density polymer lithium-ion battery is substantially improved.

Owner:LENOVO (BEIJING) CO LTD

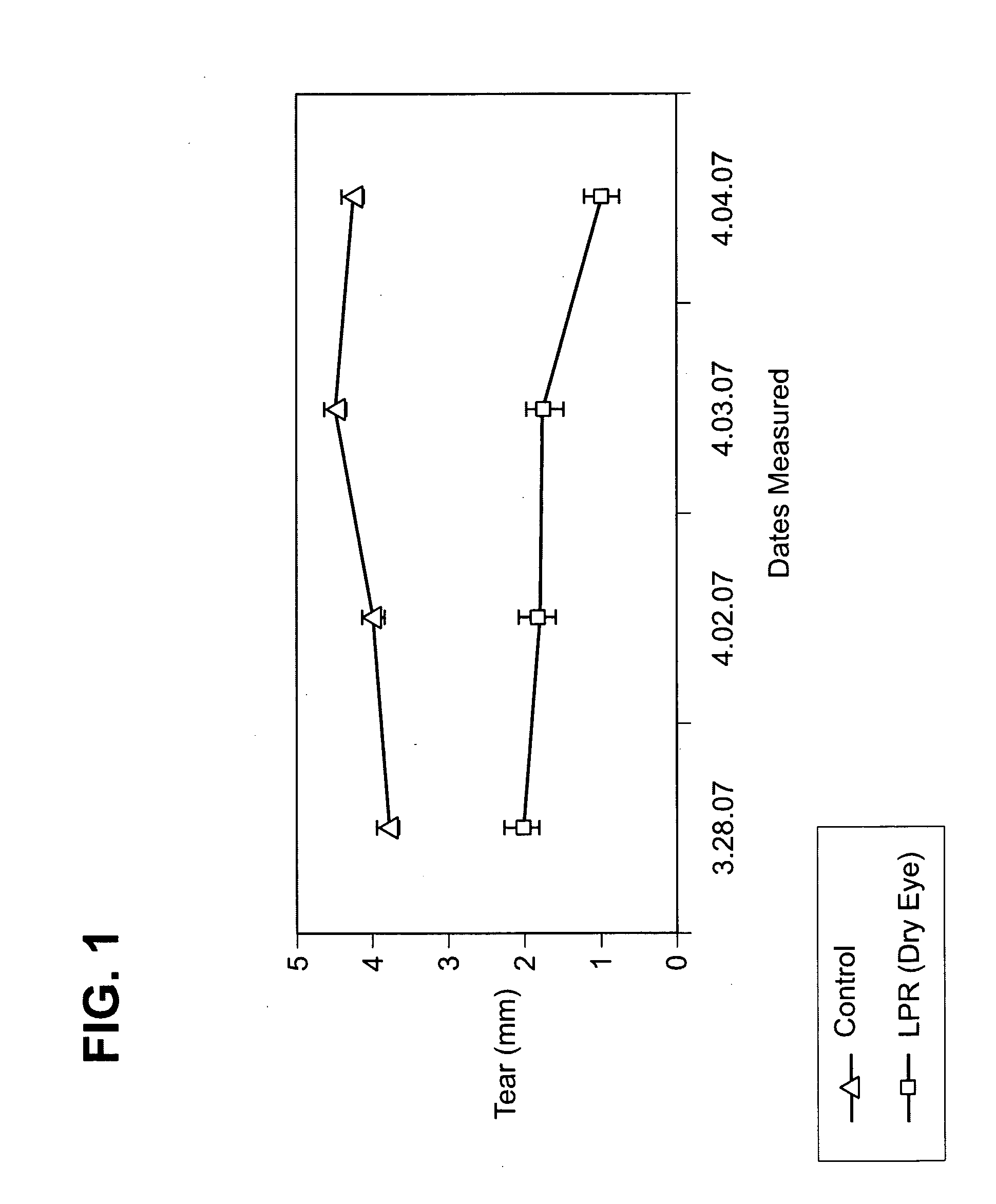

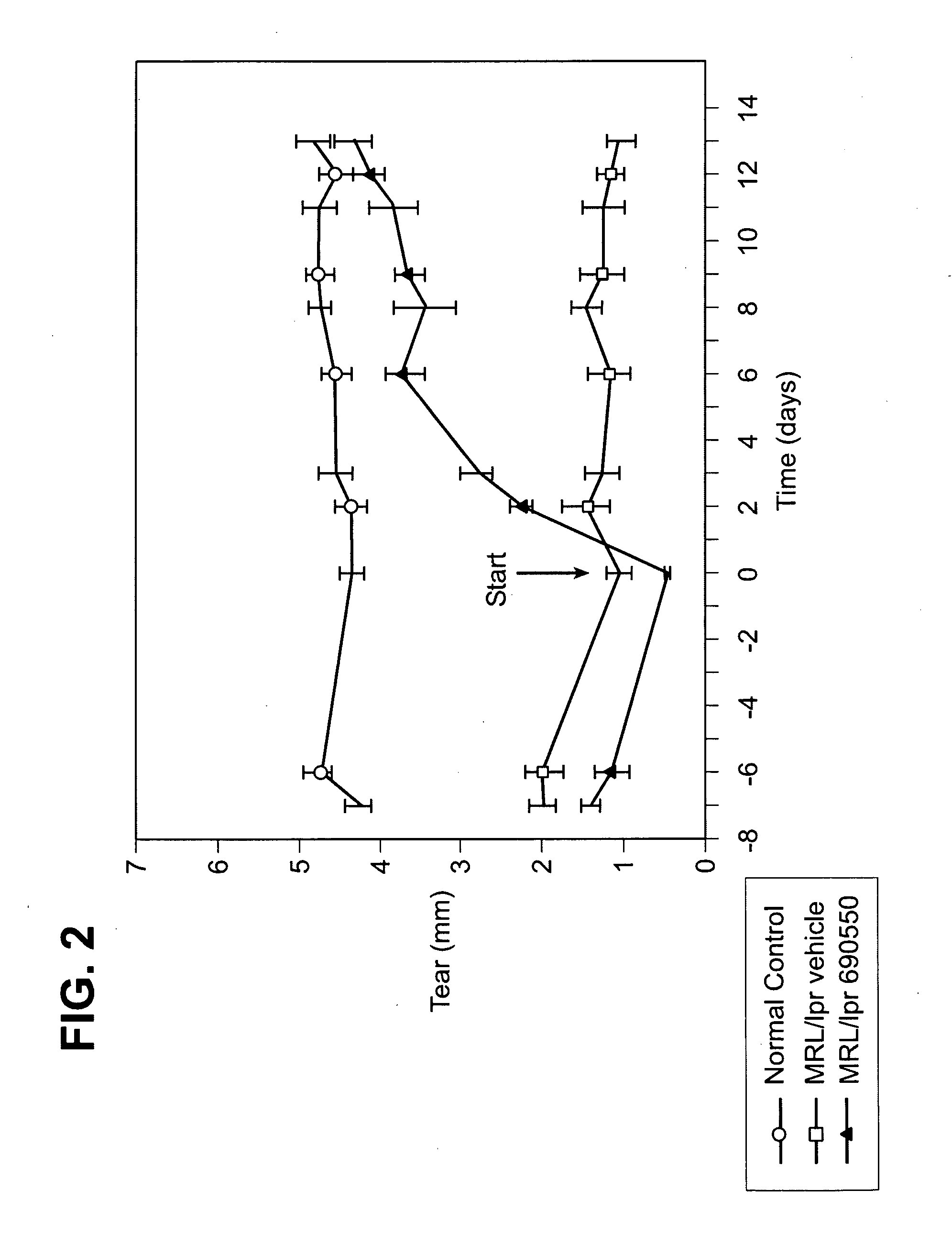

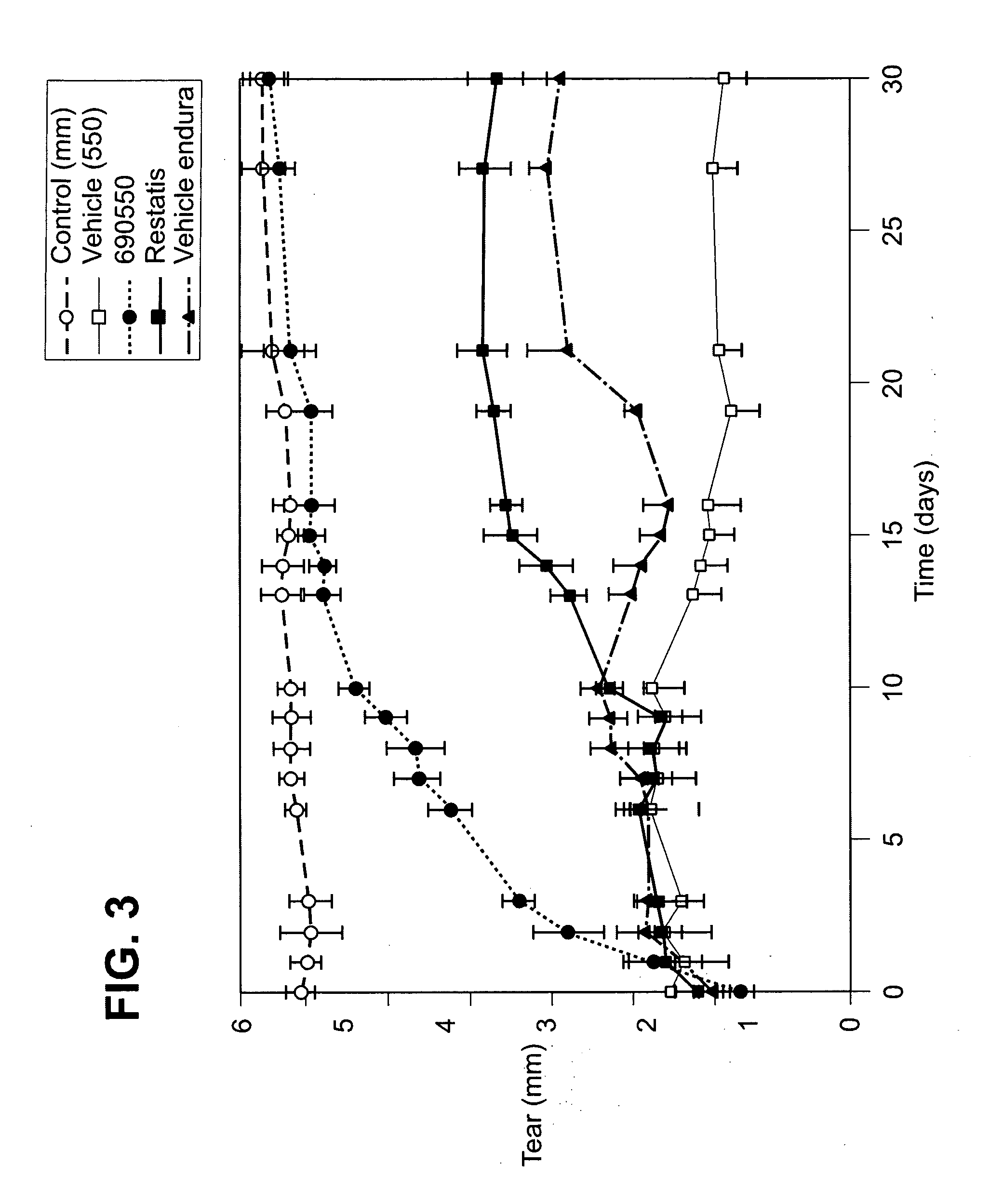

Pharmaceutical compositions and methods of treating dry eye disorders

InactiveUS20100267751A1Increase tear production volumeIncrease volumeBiocideOrganic active ingredientsDiseaseOphthalmology

Inhibitors of Janus kinase-3 (“Jak3”) are useful for treating dry eye disorders and other disorders requiring the wetting of the eye. Jak3 inhibitors useful for treating eye disorders include the compound 3-{(3R,4R)-4-Methyl-3-[methyl-(7H-pyrrolo [2,3-d]pyrimidin-4-yl)-amino]-piperidin-1-yl}-3-oxo-propionitrile.

Owner:PFIZER INC

Chemical method used for preparing aromatic cyclopropanecarbonitrile and cyclopropylamine

The invention relates to a method for preparing trans-aryl cyclopropanecarbonitrile with a structure shown in a formula (IV) in the specification through reaction between aryl substituted ethylene oxide and cyan substituted phosphate and further relates to a method for preparing cyclopropylamine from trans-aryl cyclopropanecarbonitrile. Trans-aryl cyclopropanecarbonitrile and cyclopropylamine are used for preparing drugs, especially ticagrelor.

Owner:BRIGHTGENE BIO MEDICAL TECH (SUZHOU) CO LTD

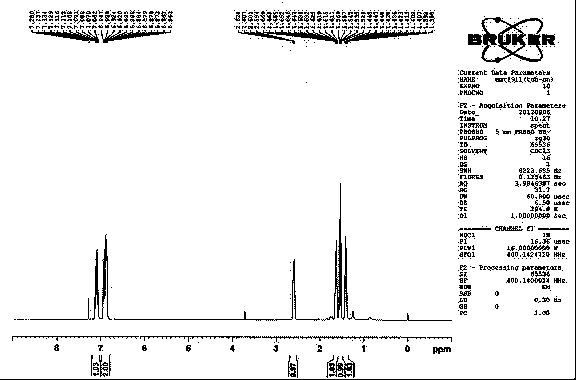

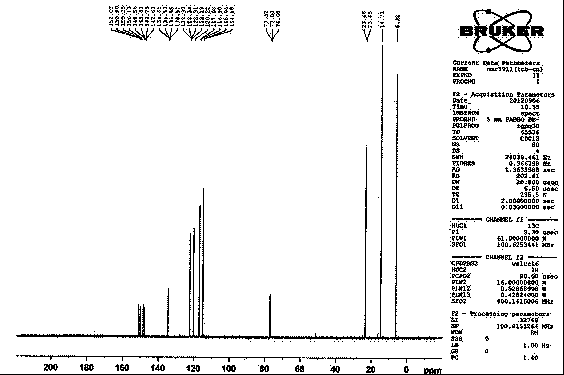

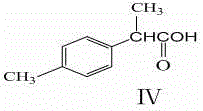

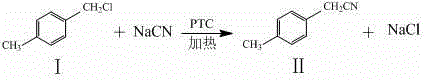

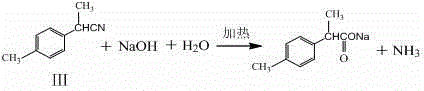

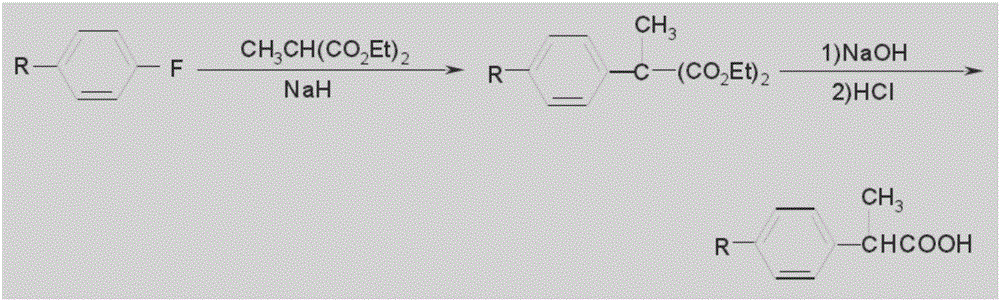

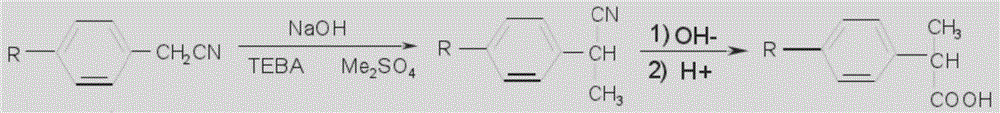

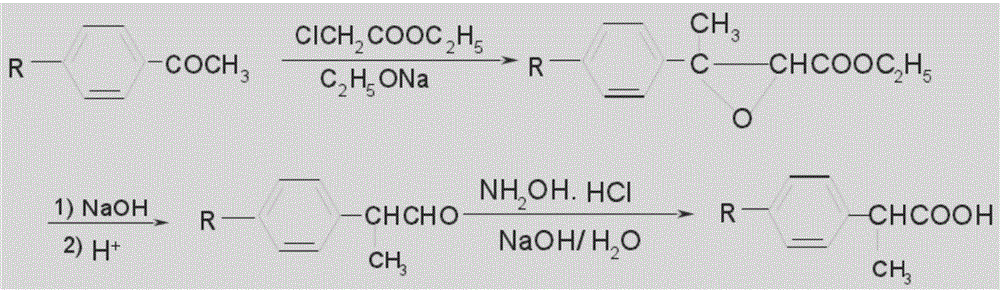

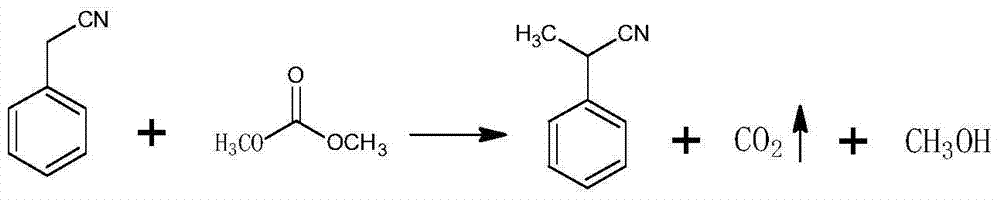

2-(4-methylphenyl)propionic acid syntehsis method

ActiveCN104402698AShort process routeReduce the discharge of three wastesPreparation from carboxylic acid saltsOrganic compound preparationPropanoic acidPropionitrile

The invention relates to a synthesis method of a fine chemical product 2-(4-methylphenyl)propionic acid. According to the method, para-xylene is adopted as a raw material, and a chlorination reaction is carried out, such that a compound I which is p-methylbenzyl chloride is obtained; p-methylbenzyl chloride is subjected to a nitrilation reaction, such that a compound II which is p-methylbenzyl cyanide is adopted; p-methylbenzyl cyanide is subjected to methylation, such that a compound III which is 2-(4-methylphenyl)propionitrile is obtained; and 2-(4-methylphenyl)propionitrile is subjected to hydrolysis acidification, such that a compound IV which is 2-(4-methylphenyl)propionic acid is obtained. The method provided by the invention has the advantages of short process route, low three-waste discharge, low environment pollution, no solid waste production during reaction processes, relatively low production cost, less chemical substances used during reaction processes, less raw material types, easy-to-obtain raw materials, simple operation, high yield, relatively mild process conditions, and the like.

Owner:柳州丰康泰科技有限公司 +2

High-purity acetonitrile and process for producing the same

ActiveCN101171233AReduce contentLow absorbanceCarboxylic acid nitrile purification/separationDistillationPropionitrile

The present invention relates to high-purity acetonitrile and its production method. The object of the present invention is to provide a kind of method of manufacturing high-purity acetonitrile, wherein, the absorbance of high-purity acetonitrile under the wavelength 200nm is low, and this method is that the used energy of purification is few and the technique of purification operation is simple, obviously reduces the content in acetonitrile of propionitrile. The invention relates to a method for producing high-purity acetonitrile, which is characterized in that the crude acetonitrile with water is mixed with an alkali, separated into an acetonitrile phase and a water phase, and then the water phase is removed, and the obtained acetonitrile phase is subjected to a distillation process to obtain purified acetonitrile, The resulting purified acetonitrile is passed through a cation exchange resin to obtain high-purity acetonitrile.

Owner:ASAHI KASEI KK

Low temperature double-layer capacitors using asymmetric and spiro-type quaternary ammonium salts

InactiveUS20110170237A1Improve performanceHybrid capacitor electrolytesHybrid capacitor electrodesTetrafluoroborateQuaternary ammonium cation

Double-layer capacitors capable of operating at extremely low temperatures (e.g., as low as −80° C.) are disclosed. Electrolyte solutions combining a base solvent (e.g., acetonitrile) and a cosolvent are employed to lower the melting point of the base electrolyte. Example cosolvents include methyl formate, ethyl acetate, methyl acetate, propionitrile, butyronitrile, and 1,3-dioxolane. A quaternary ammonium salt including at least one of triethylmethylammonium tetrafluoroborate (TEMATFB) and spiro-(1,1′)-bipyrrolidium tetrafluoroborate (SBPBF4), is used in an optimized concentration (e.g., 0.10 M to 0.75 M), dissolved into the electrolyte solution. Conventional device form factors and structural elements (e.g., porous carbon electrodes and a polyethylene separator) may be employed.

Owner:CALIFORNIA INST OF TECH

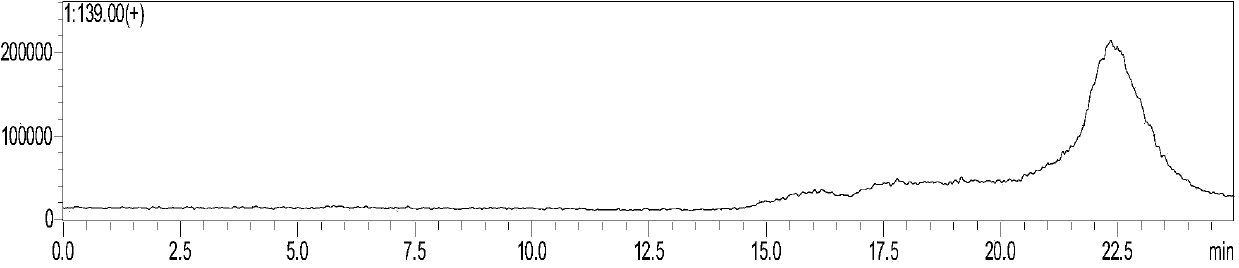

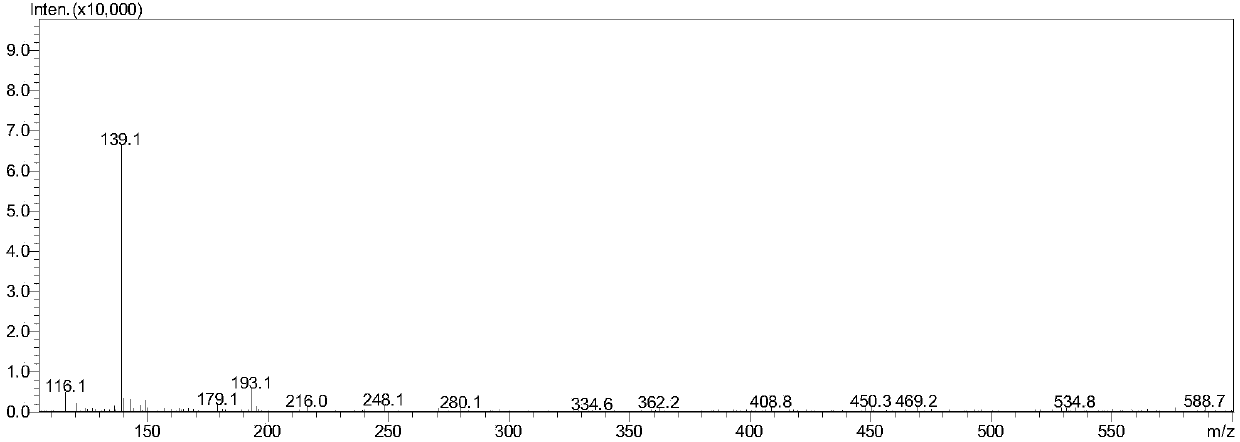

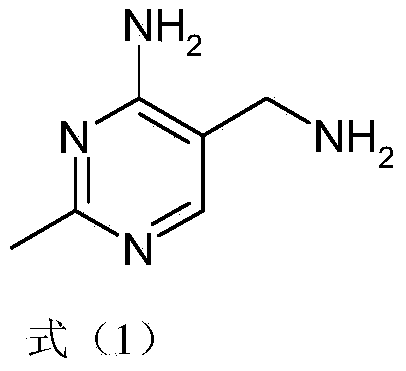

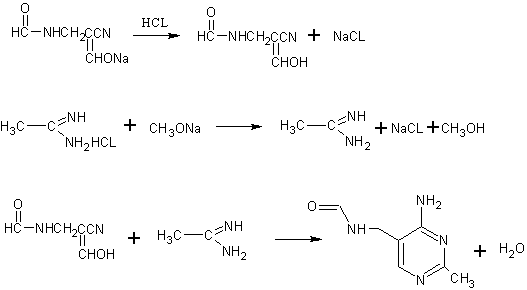

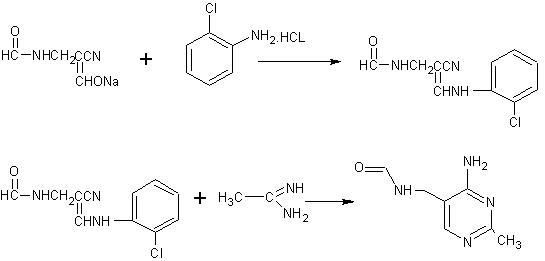

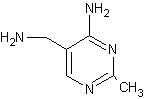

Simple and quick method for synthesizing improved vitamin B1 intermediate 2-methyl-4-amino-5-aminomethylpyrimidine

ActiveCN103435556AReduce concentrationReduce decompositionOrganic chemistryAminopropionitrilePropionitrile

The invention relates to a simple and quick method for synthesizing an improved vitamin B1 intermediate 2-methyl-4-amino-5-aminomethylpyrimidine. The method comprises the following steps: condensing 3-alkyl (aryl) formamido-propionitrile serving as a raw material with acetamidine in the catalytic action of lewis acid; cyclizing with trimethyl orthoformate, and hydrolyzing under an alkaline condition to prepare the vitamin B1 key intermediate 2-methyl-4-amino-5-aminomethylpyrimidine. The four reacting processes are performed in sequence by a one-pot reaction, and the product in each step does not need to be separated and purified. According to the method, highly carcinogenic o-chloroaniline or other small molecular aniline compounds are not used, residues of o-chloroaniline compounds in the vitamin B1 product can be eliminated. Furthermore, the preparation process is short and convenient in flow, small in wastewater amount and high in yield.

Owner:XINFA PHARMA

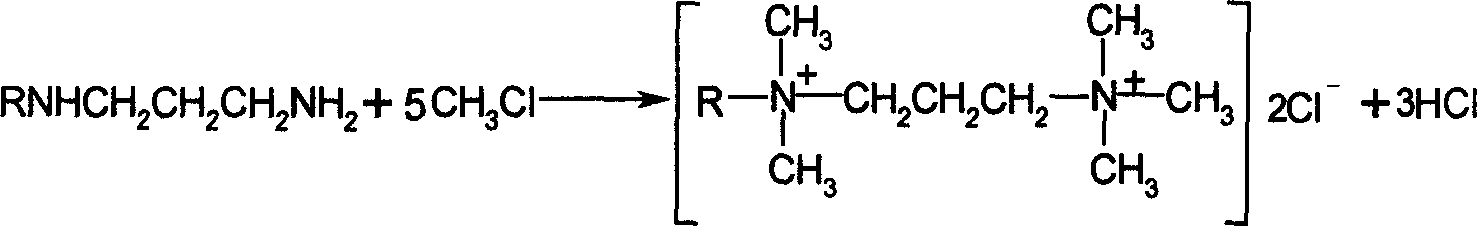

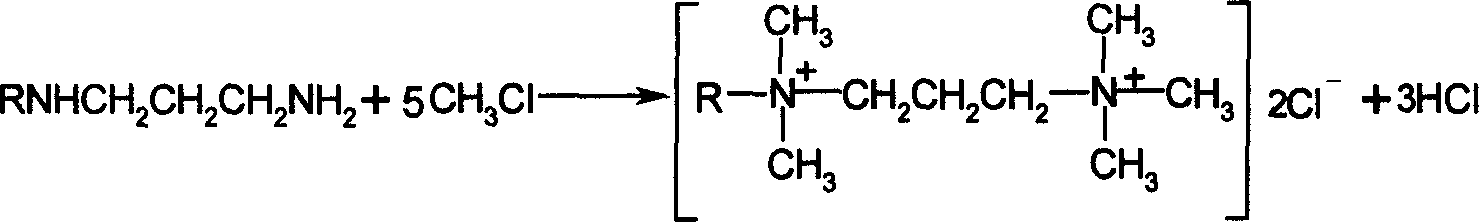

High temp. thicking oil viscosity reducing agent and preparation process thereof

The invention provides a higher-temperature resistant crude oil viscosity reductant and its preparing method, and it is N-alkyl-gama-di-quaternary cation surfactant, and its preparing method includes three steps: (1) taking aliphatic amine and catalyst in a three-mouthed bottle, dropping in acrylic nitricle at 30-60 deg.C and reacting for 4-8 hours, makeing N-alkyl-beta- amino-propionitrile; (2) adding the N-alkyl-beta-amino-propionitrile and solvent in a high-pressure kettle, displacing the air in the kettle with nitrogen gas, charging in hydrogen gas and chlorine gas and reacting for 1-2 hours at 80-90 deg.C, preparing N-alkyl trimethylene diamine; (3) adding N-alkyl trimethylene diamine and catalyst in the kettle, using nitrogen gas to displace the air in the kettle, raising temperature to 60 deg.C and charging in chloromethane, reacting at 80-90 deg.C at 0.49-0.59 MPa for 2-6 hours to prepare the surfactant, which is prepared into 25-30% water solution, obtaining the viscosity reductant. It need not mix with the alkali and has better viscosity-reducing effect on different crude oils at lower concentration.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Synthetic method of vitamin B1 intermediate

The invention relates to an improvement of a synthetic method of an important vitamin B1 intermediate 2-methyl-4-amino-5-formyl ammonium methyl pyridine. According to the method provided by the invention, the raw material o-chloroaniline in the prior synthetic process is omitted, the 2-methyl-4-amino-5-formyl ammonium methyl pyridine is synthesized directly by alpha-sodium substituted formyl-beta-formyl amine propionitrile and ethanamidine, so that the middle process is reduced.

Owner:HUAZHONG PHARMA

Method for treating wastewater of dilute thiamine containing acrylonitrile

ActiveCN101092266AImprove recycling qualityQuality improvementWater/sewage treatment by neutralisationWater/sewage treatment by heatingPropionitrileAcrylonitrile

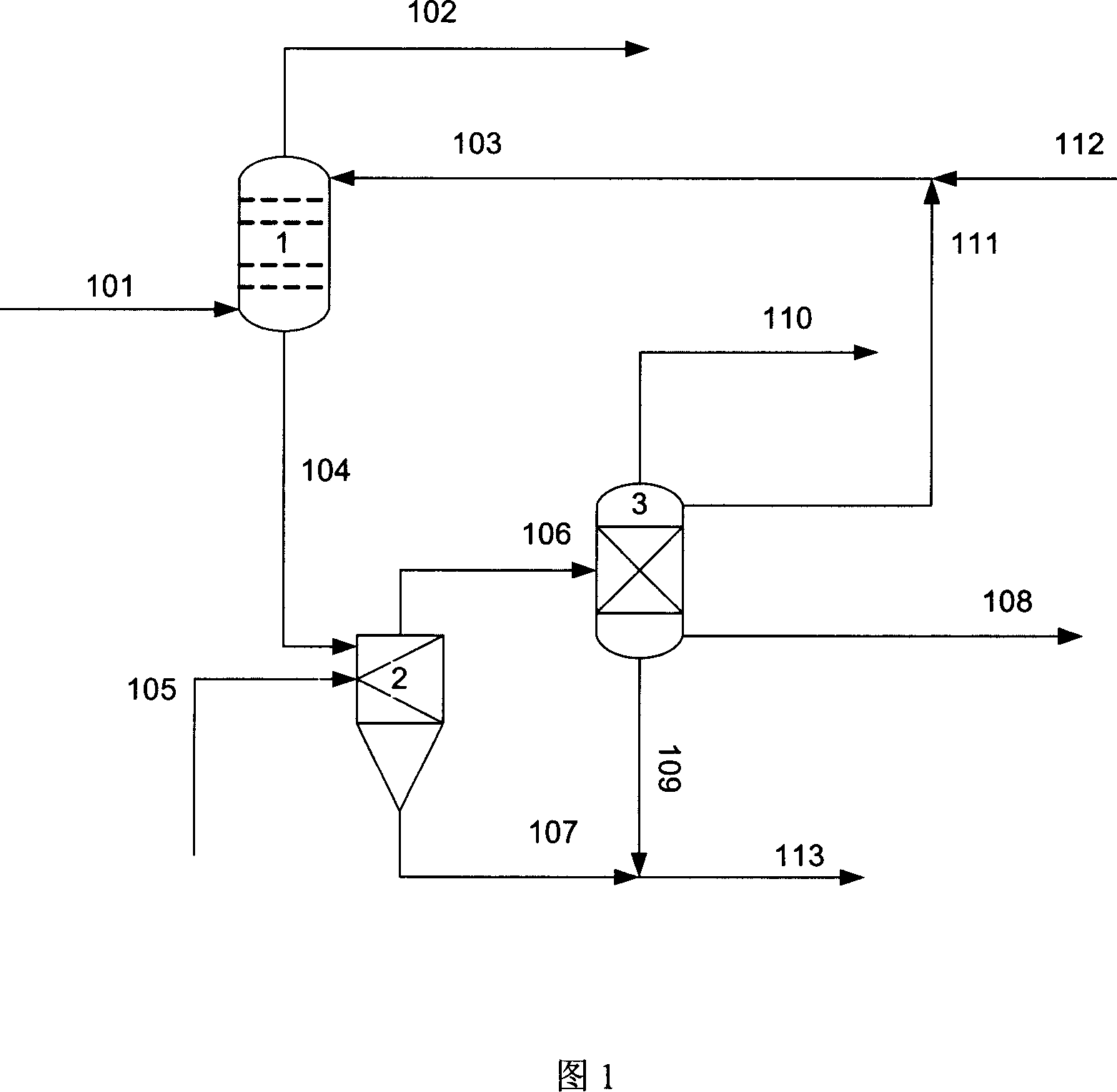

This invention relates to a method for treating diluted ammonium sulfate wastewater containing propionitrile. The method solves the problems of high solid waste and organic nitrile impurity contents, low ammonium sulfate concentration, difficult ammonium sulfate recovery, and low recovered ammonium sulfate quality. The method comprises: (1) removing solid impurities from diluted ammonium sulfate wastewater containing propionitrile, and adjusting the pH value to 6.5-7.5 to obtain material flow 1; (2) sending material flow 1 into a liquid-gas separator, and performing stripping or rectification; (3) removing lightweight organic fractions at the overhead of the liquid-gas separator, collecting polymer fractions at the bottom, extracting the rest wastewater at 1st-5th theoretical plates from the overhead to obtain material flow 2, extracting water free of solids and organic matters from 1st-10th theoretical plates from the bottom to obtain material flow 3, mixing material flow 3 with water added by the quenching system and diluted acid, circulating to the quenching column, and recovering ammonium sulfate from material flow 2.

Owner:CHINA PETROLEUM & CHEM CORP +1

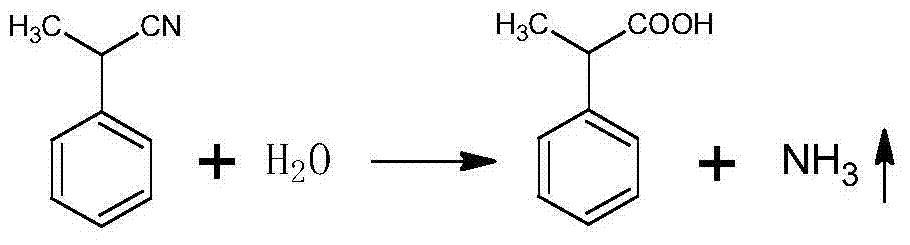

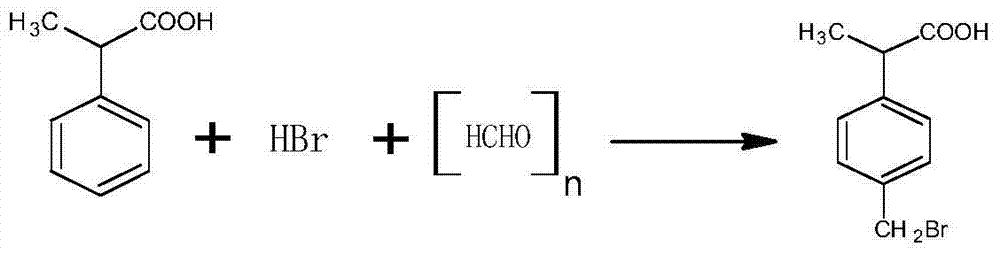

Method for preparing loxoprofen intermediate

InactiveCN105753685AAvoid bringing inHigh selectivityCarboxylic acid nitrile preparationOrganic compound preparationPropanoic acidPropionitrile

A method for preparing a loxoprofen intermediate comprises the following steps that 1, on the presence of sodium alkoxide, benzyl cyanide and dimethyl carbonate are subjected to methylation in an organic solvent, and 2-(phenyl cyano) sodium propionate is obtained; 2, 2-(phenyl cyano) sodium propionate and dimethyl sulfate react in an organic solvent to obtain 2-(phenyl cyano) methyl propionate; 4, 2-(phenyl cyano) methyl propionate reacts under the alkaline condition to obtain 2-phenyl propionitrile; 4, 2-phenyl propionitrile is hydrolyzed under the alkaline condition, acid is added for acidizing after the reaction to obtain 2-phenylpropionic acid; 5, 2-phenylpropionic acid, hydrobromic acid and paraformaldehyde are mixed and subjected to a bromine methylation reaction under the acidic condition, and 2-(4-tribromomethyl phenyl) propionic acid is obtained.According to the method, a new synthesis route is designed, product selectivity is good, the purity is high, the conversion rate is high, and few by-products are generated; the raw materials are simple and easy to obtain, the production conditions are mild, the process is simple, production cost is low, and pollution is small.

Owner:UPCHEM CHINA

Preparation method of 2-(4-bromomethylphenyl) propionic acid

ActiveCN104744237AHigh purityHigh yieldCarboxylic acid nitrile preparationOrganic compound preparationPropanoic acidMethyl carbonate

The invention discloses a preparation method of 2-(4-bromomethylphenyl) propionic acid. The preparation method is characterized by comprising a preparation stage of 2-phenyl propionitrile, a preparation stage of 2-phenyl propionic acid and a preparation stage of 2-(4-bromomethylphenyl) propionic acid. The preparation stage of 2-phenyl propionitrile comprises the following steps: mixing benzyl cyanide, dimethyl carbonate and potassium carbonate; heating to 100-300 DEG C and carrying out thermal reaction for 5-50h under the pressure of 0.5-6MPa; and by the end of the reaction, carrying out filter pressing and rinsing to be neutral; distilling to removal excessive dimethyl carbonate; and carrying out high-vacuum rectification to obtain 2-phenyl propionitrile. Compared with the prior art, the preparation method disclosed by the invention has the following advantages and effects that the main raw material is benzyl cyanide which is subjected to methylation, hydrolysis reaction and bromomethylation to finally obtain the finished product; the purity of the finished product is high and the yield is up to 90% or above; and in addition, the preparation method has the advantages of simple production process, low production cost and low environment pollution.

Owner:ZHEJIANG BOJU NEW MATERIALS CO LTD

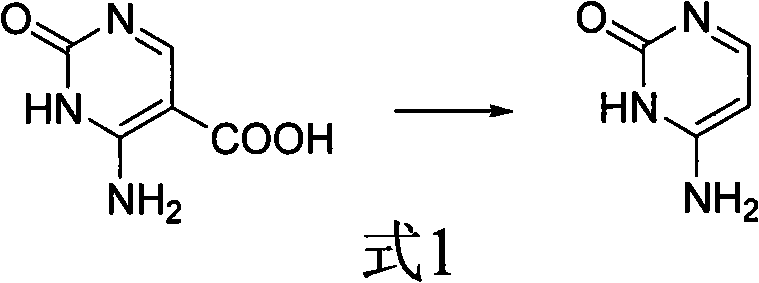

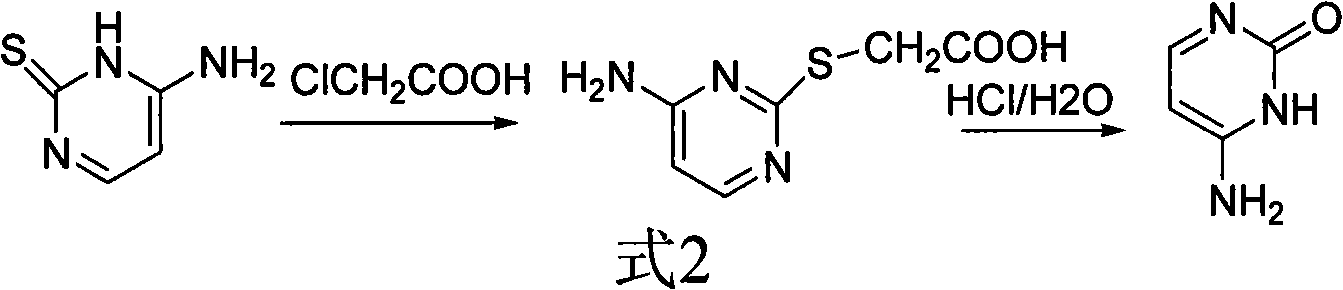

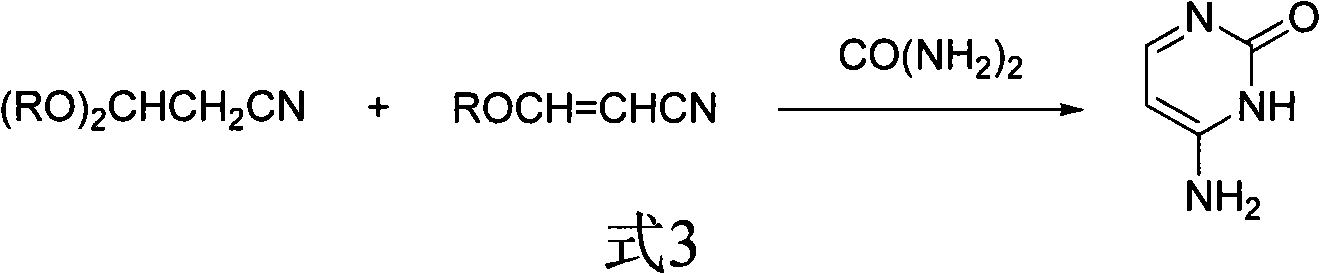

Method for synthesizing cytimidine

The invention discloses a method for synthesizing cytimidine, which comprises the following steps: performing a reaction of a reactant (1) and a reactant (2) to acquire cytimidine under the action of sodium methoxide, wherein the reactant (1) is 3-alkoxy acrylonitrile and / or 3, 3-alkoxy propionitrile, and the reactant (2) is carbamide. The method is characterized in that a solid catalyst is added in the reaction. The catalyst is the solid catalyst, such as one or more of acidic alumina, solid super acid, zinc oxide and a molecular sieve. The method can achieve the effects of shortening the reaction time, improving the yield and reducing the price of raw materials.

Owner:上海普渡生化科技有限公司

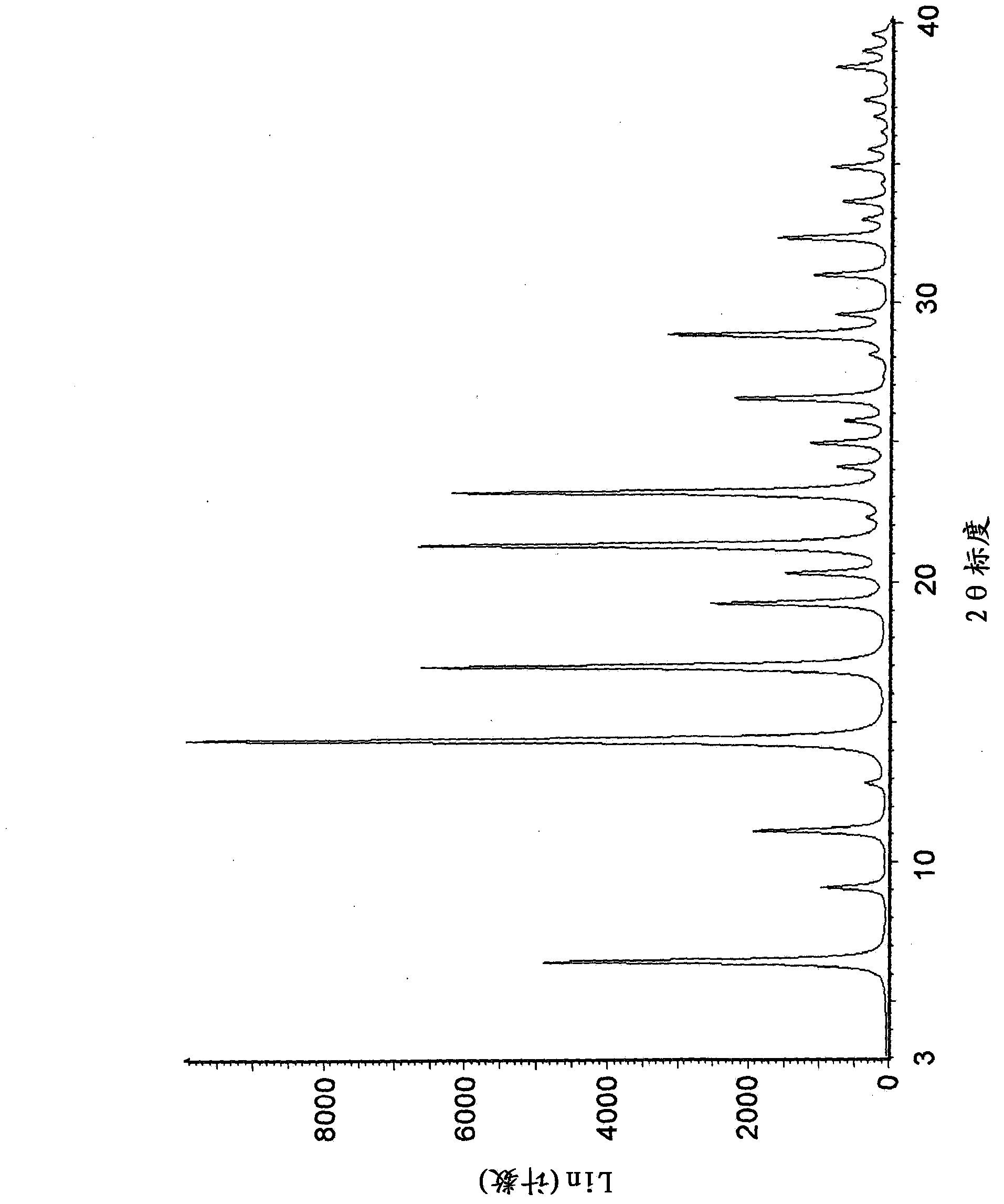

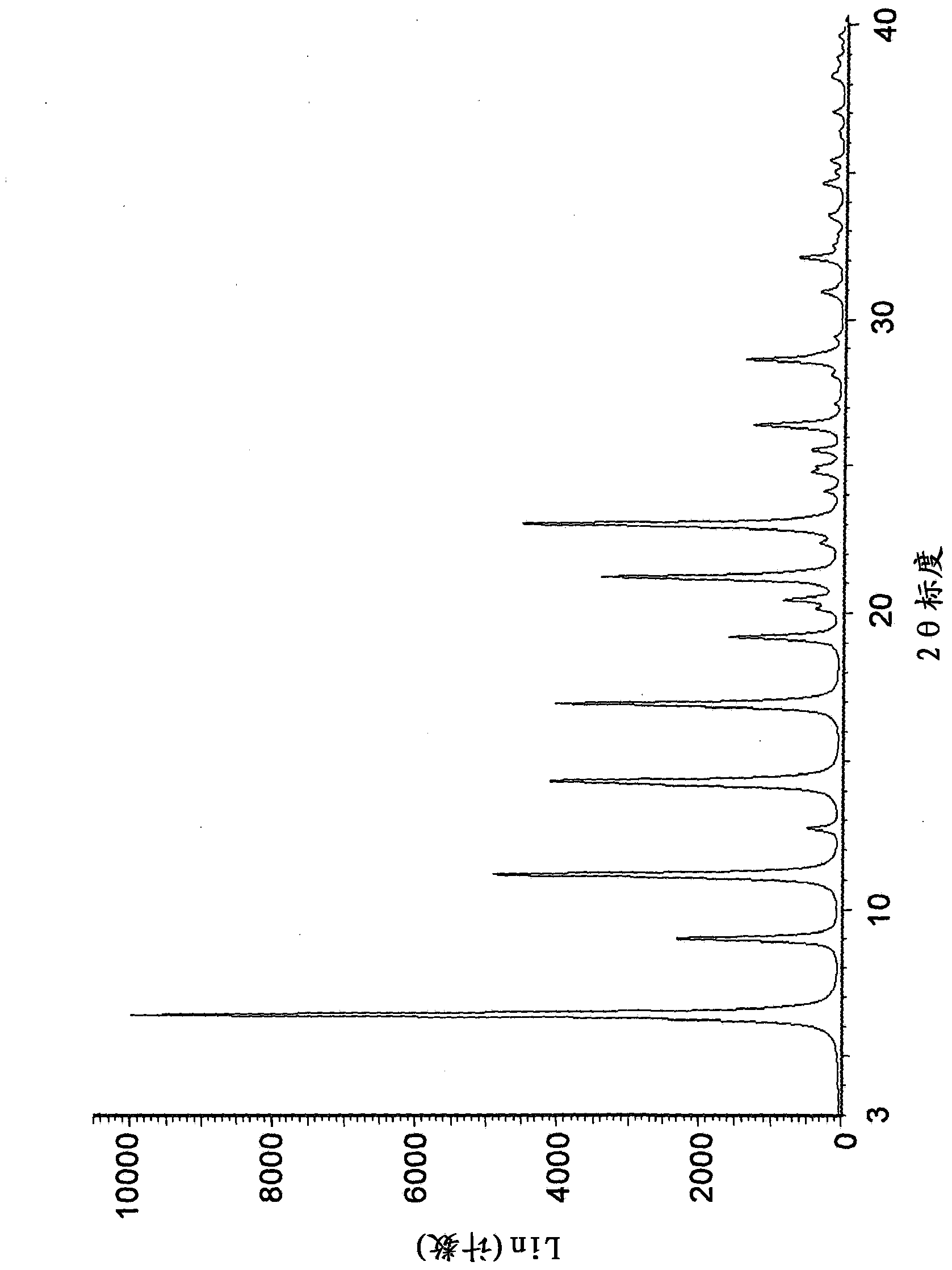

Crystalline and non-crystalline forms of tofacitinib, and a pharmaceutical composition comprising tofacitinib and a penetration enhancer

Owner:PFIZER INC

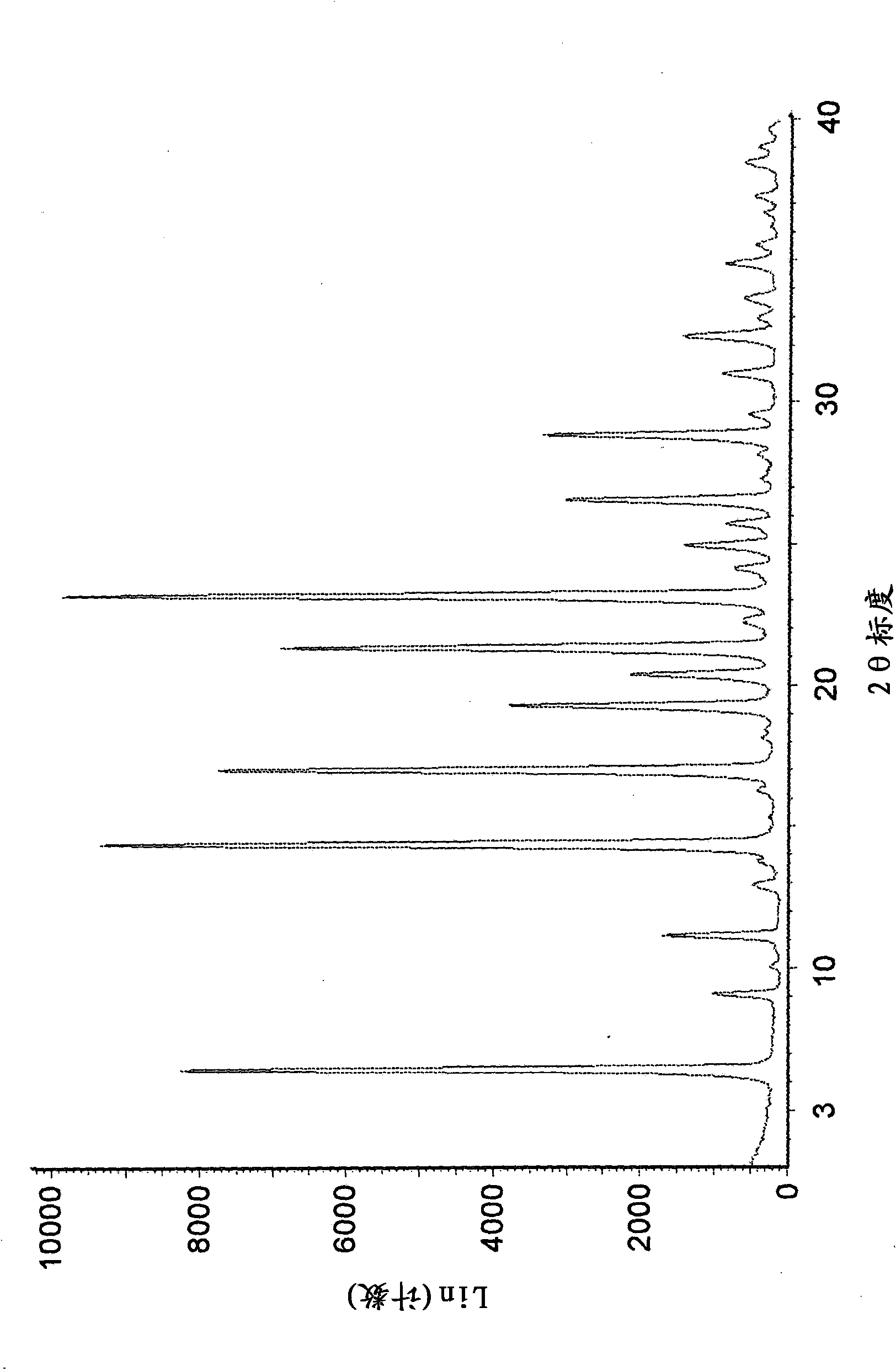

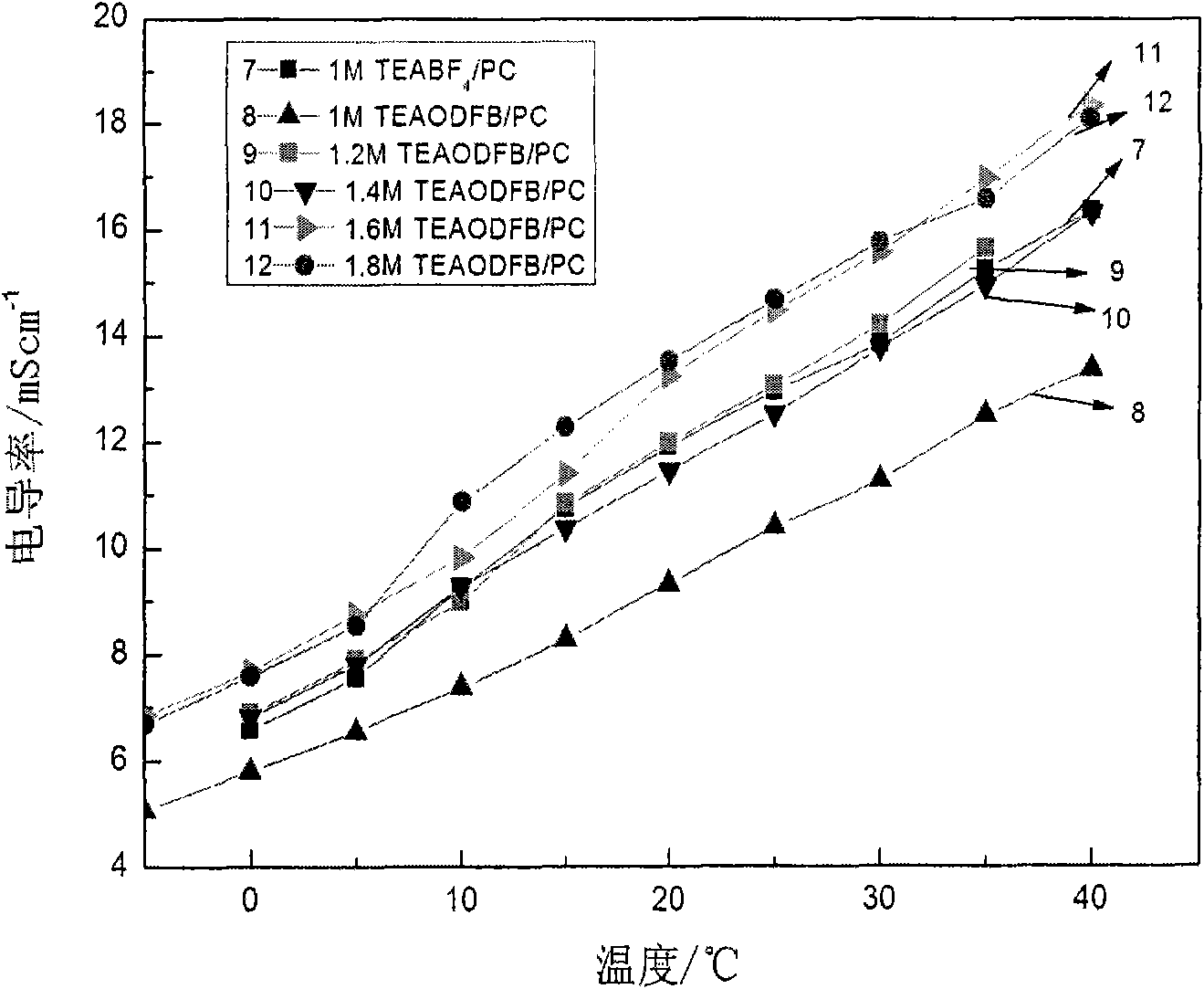

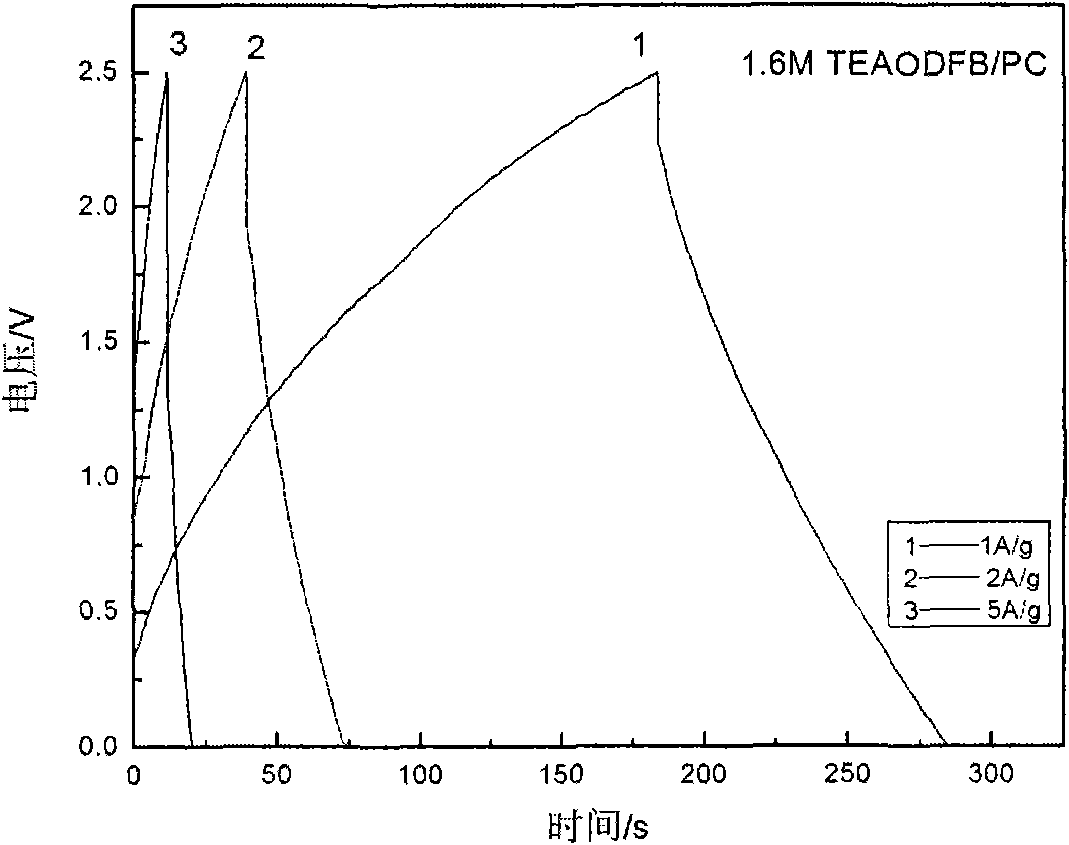

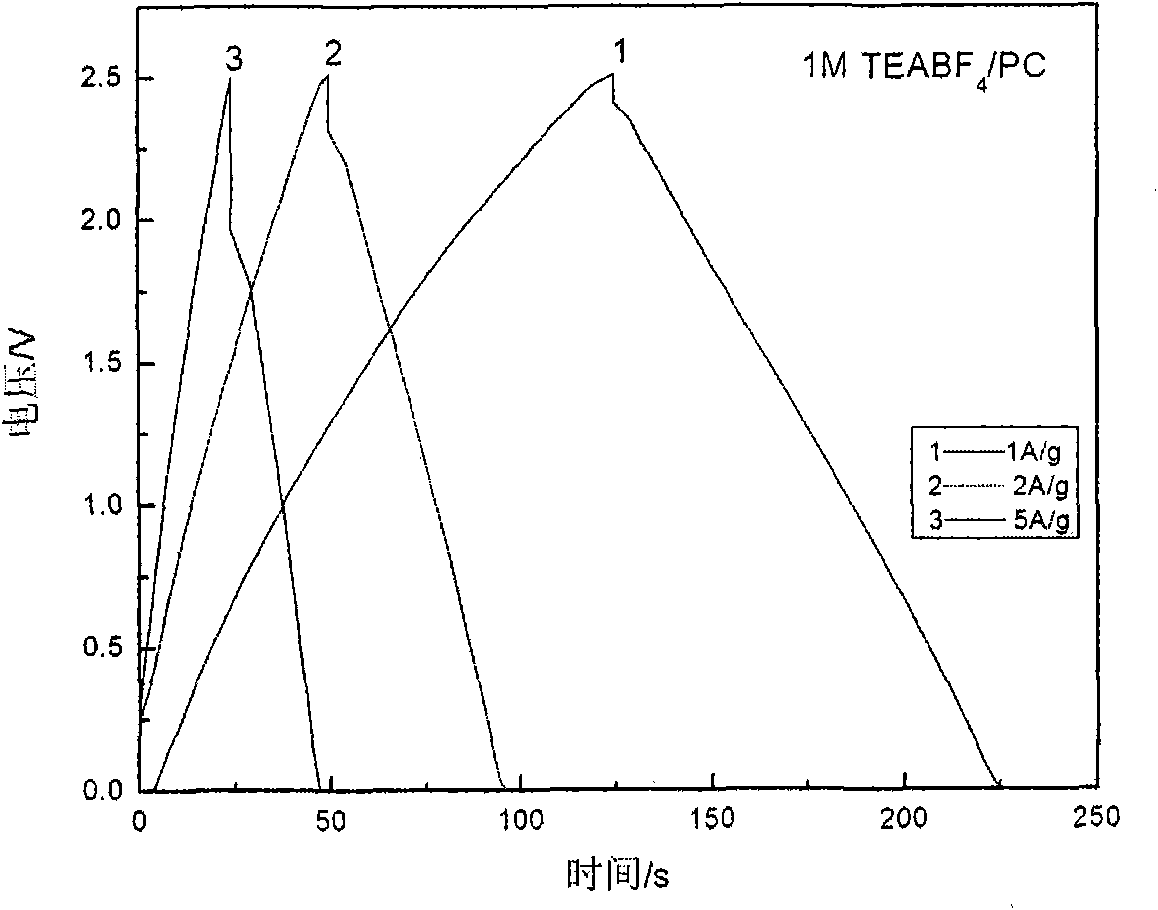

Low-temperature electrolyte for supercapacitor and preparation method thereof

InactiveCN101593625ALow melting pointImprove solubilityElectrolytic capacitorsSulfolanePropionitrile

The invention discloses low-temperature electrolyte for a supercapacitor and a preparation method thereof. The electrolyte comprises solute and non-aqueous organic solvent. The solute is ionic liquid tetraethylammonium-oxalate-difluoro-borate (TEAODFB) which is battery-grade TEAODFB obtained by purifying a product of reaction of a chlorine-containing compound, an oxalate-containing compound and a fluoroboric acid containing compound in acetonitrile or carbonic ester medium by adopting a method of reduced pressure evaporation or low-temperature recrystallization. The non-aqueous organic solvent is one or the combination of acetonitrile, propionitrile, methoxy propionitrile, ethylene carbonate, propylene carbonate, dimethyl carbonate, diethyl carbonate, methyl ethyl carbonate, gamma-butyrolactone, N,N-dimetbylformamide, tetrahydrofuran and sulfolane. The concentration of the adopted electrolyte is 0.8 to 2mol / L. The obtained low-temperature electrolyte has high specific capacity and charge / discharge cyclic life at the temperature of 30 DEG C below zero.

Owner:CENT SOUTH UNIV +1

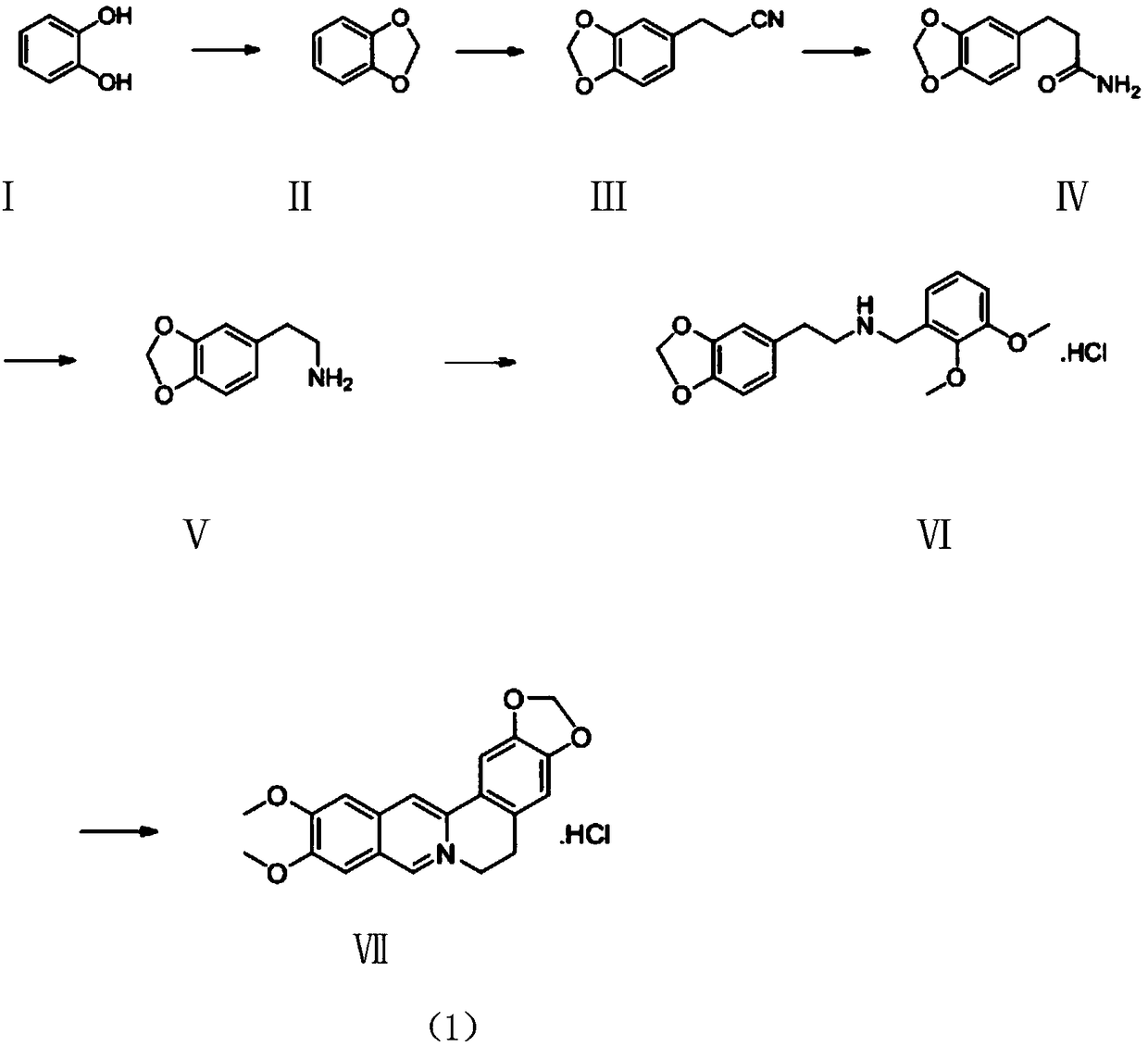

Green synthesis process of berberine

InactiveCN108358912AReduce usageReduce formationOrganic chemistryChemical synthesisN dimethylformamide

The invention discloses a green synthesis process of berberine. The synthesis process comprises the following steps: firstly, introducing dichloromethane into N,N-dimethylformamide by adopting catechol under the alkaline condition and reacting to synthesize benzodioxole; secondly, preparing pepper propionitrile by utilizing the obtained benzodioxole, preparing pepper propionamide by utilizing obtained pepper propionitrile, preparing homopiperony lamine by utilizing pepper propionamide and then synthesizing N-2,3-dimethoxybenzyl homopiperony lamine hydrochloride; finally, synthesizing berberinehydrochloride by utilizing the N-2,3-dimethoxybenzyl homopiperony lamine hydrochloride under the condition of glyoxal, formic acid and copper sulfate. The green synthesis process of the berberine, disclosed by the invention, has the advantages that the formation of black polymers is reduced, the reaction yield is improved, the problem that environmental pollution caused by a large amount of the black polymers produced in the original process production is solved and the requirements of green chemical synthesis required by China are met.

Owner:SICHUAN YIKE PHARMA CO LTD

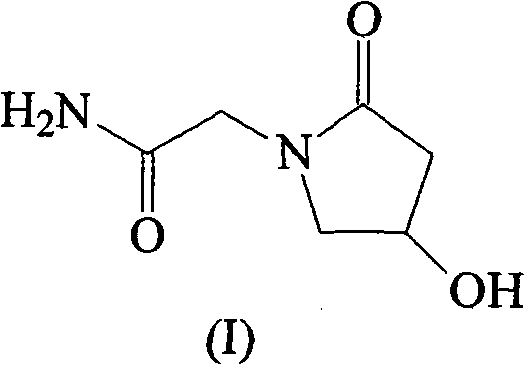

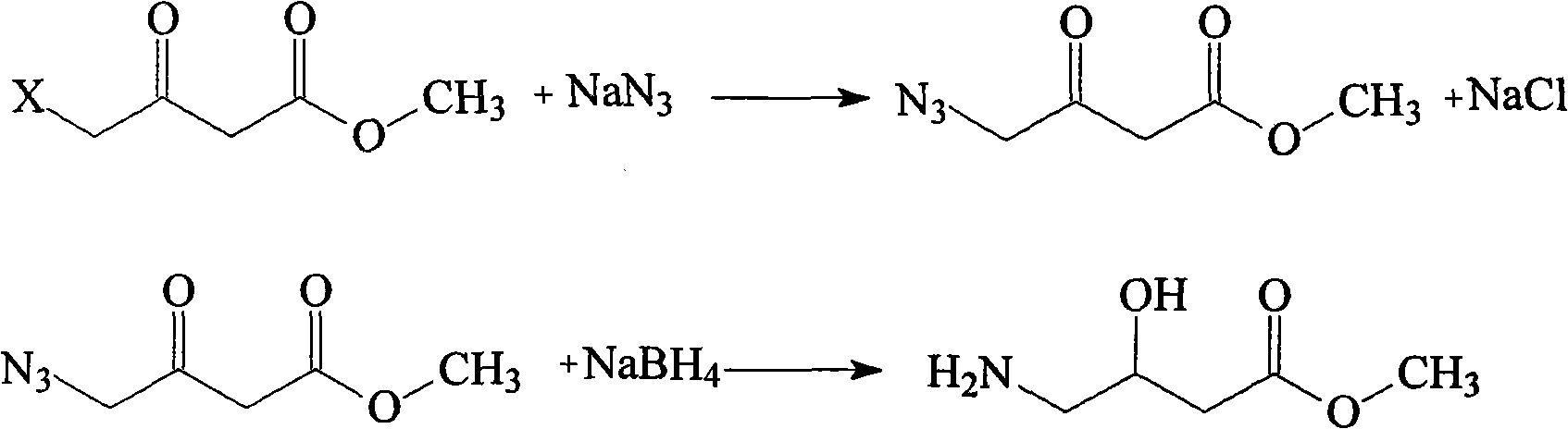

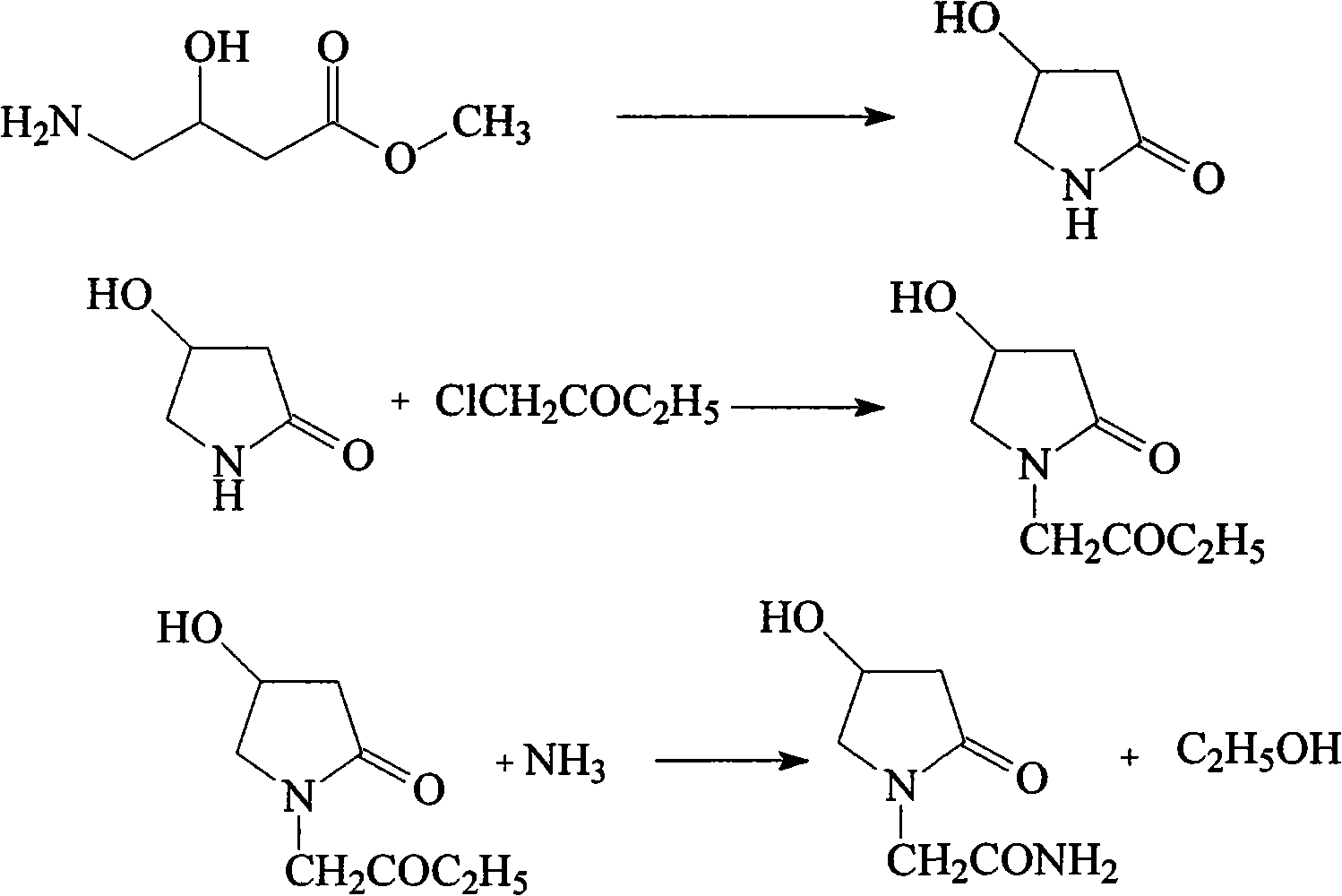

Oxiracetam compound and new method thereof

The invention relates to an oxiracetam compound and a new method thereof. In the method, 3-chloro-2-hydroxy propionitrile is used as an initial raw material. The method comprises the following steps of: synthesizing 4-hydroxyl-2-pyrrolidone through 4-chloro-3-hydroxyl-butylamide; and then synthesizing oxiracetam. The invention overcomes the defects of complicated preparation process, trouble steps, high cost, low product purity and difficult purification of the prior art.

Owner:HAINAN LINGKANG PHARMA CO LTD

Copper-nickel sulphide ore catching agent

ActiveCN102716809AGive full play to the synergistic effectRaise the gradeFlotationPropionitrileCopper

The invention relates to a copper-nickel sulphide ore catching agent, namely a J622 catching agent. The copper-nickel sulphide ore catching agent is prepared by the following raw materials in parts by weight: 30-60 parts of alkyl xanthate propionitrile ester, 10-30 parts of oil No.2, 10-20 parts of black catching agent No.25, 5-15 parts of amino propionitrile, and 5-15 parts of black catching agent acid. The raw materials are mixed fully and stirred uniformly to prepare the copper-nickel sulphide ore catching agent. The copper-nickel sulphide ore catching agent has catching and foaming doubleattributes, and is good in selectivity, high in catching capability and ore flotation speed, and stable in flotation foam, so that the grade and the recovery rate of the concentrate can be effectively improved; and therefore, the copper-nickel sulphide ore catching agent is a very ideal selective catching agent for copper-nickel ores.

Owner:NORTHWEST RES INST OF MINING & METALLURGY INST

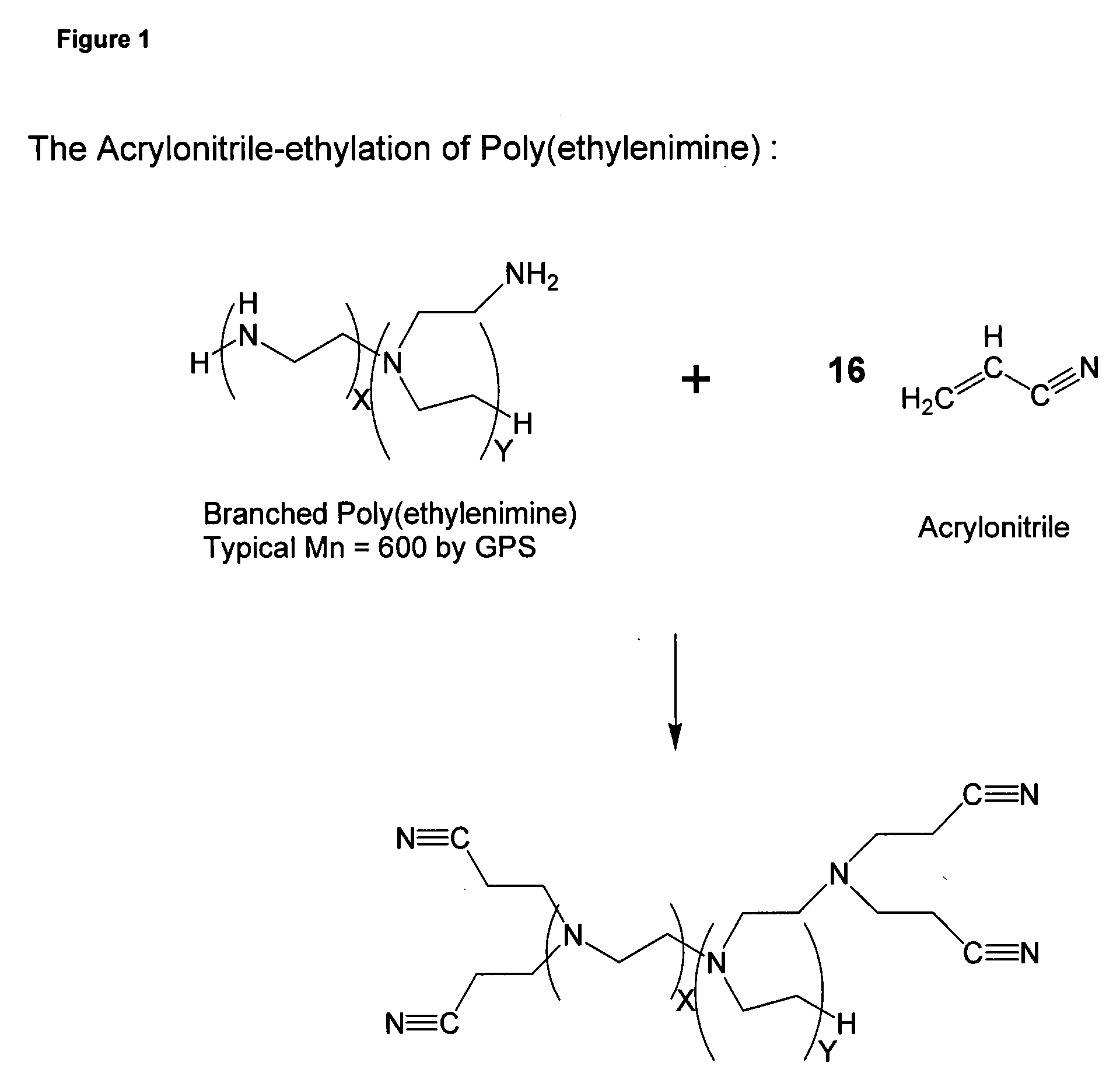

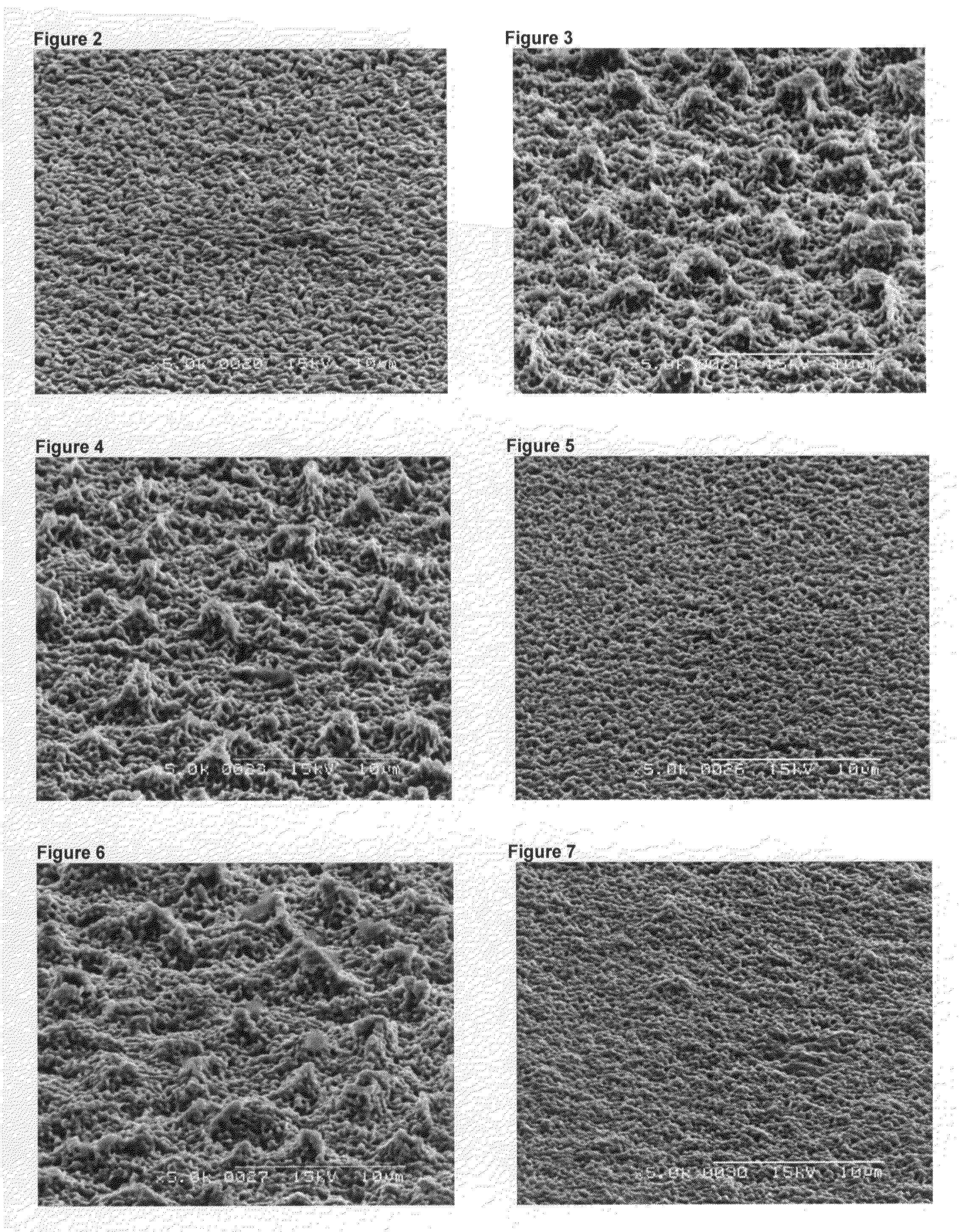

Metal surface treatment composition

ActiveUS20080264900A1Improve adhesionControl of characteristicDecorative surface effectsAdhesive processes with surface pretreatmentPropionitrileThermal stability

A process is described for treating metal surfaces with roughening compositions that use poly(ethyleneamino propionitrile)polymer as an additive in the composition to improve adhesion of polymeric materials to the metal surfaces and to improve peel strength for thermal stability. The polymer of the invention may be added to compositions containing for example, cupric chloride and hydrochloric acid and is also usable in compositions containing an oxidizer / acid / azole mixture. Other additives, such as adiponitrile may also be beneficially added to compositions of the invention.

Owner:MACDERMID ACUMEN INC

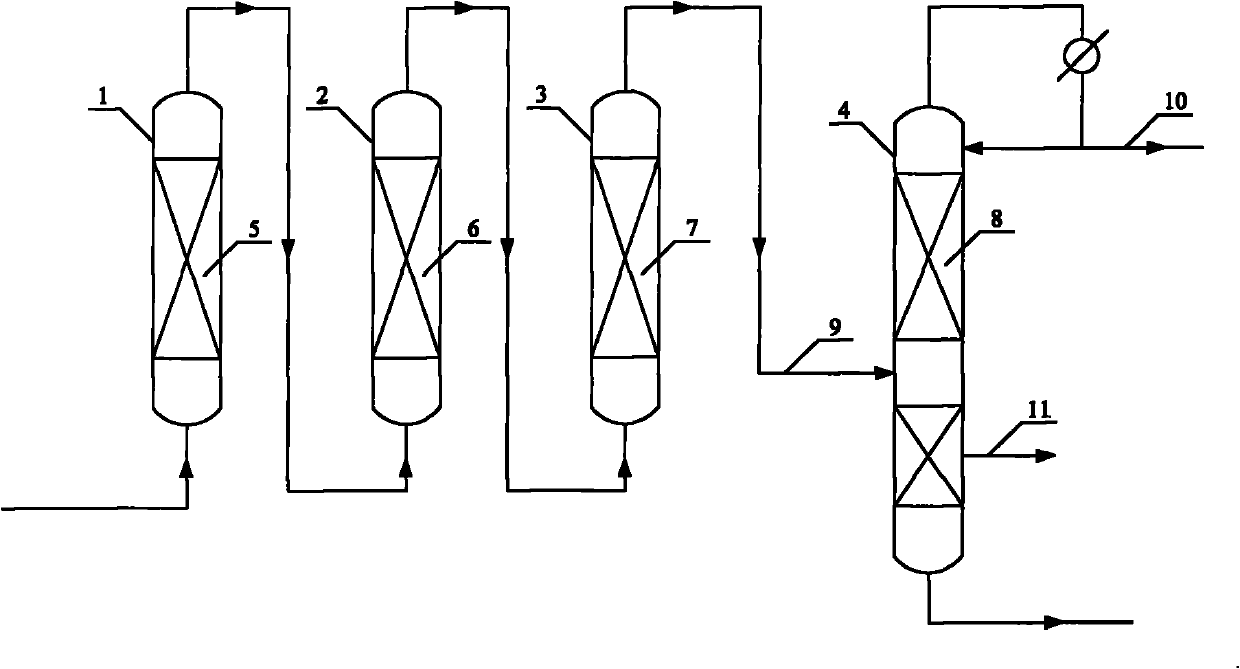

Method for preparing high-purity acrylonitrile

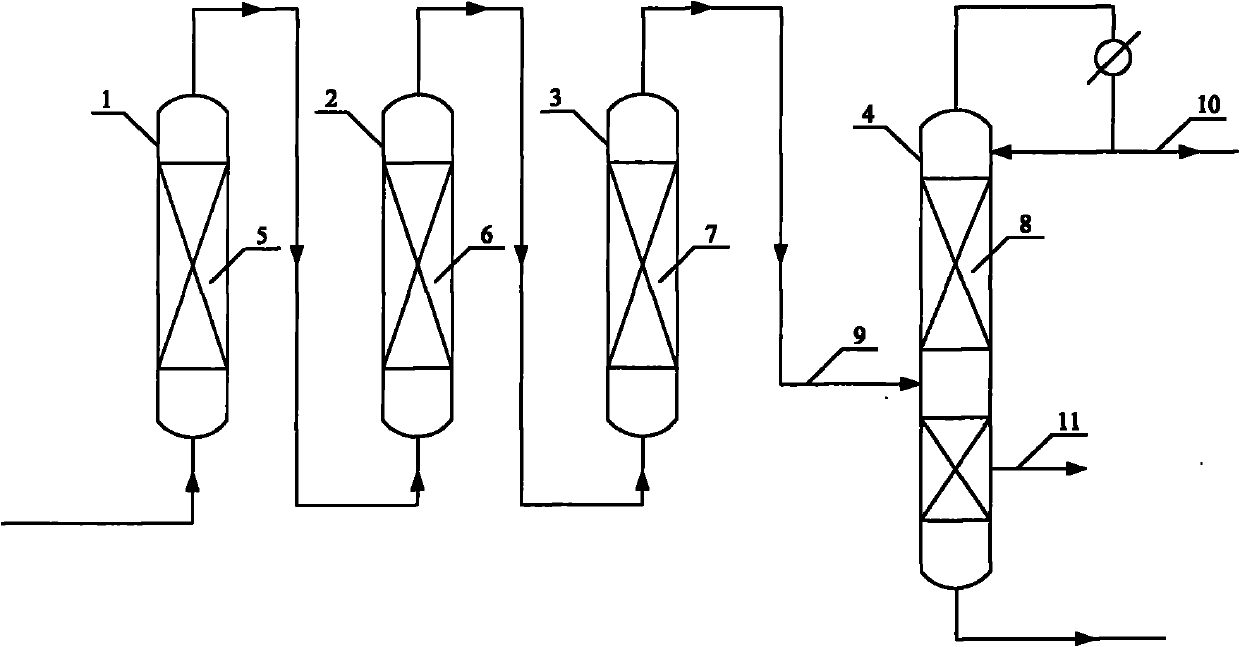

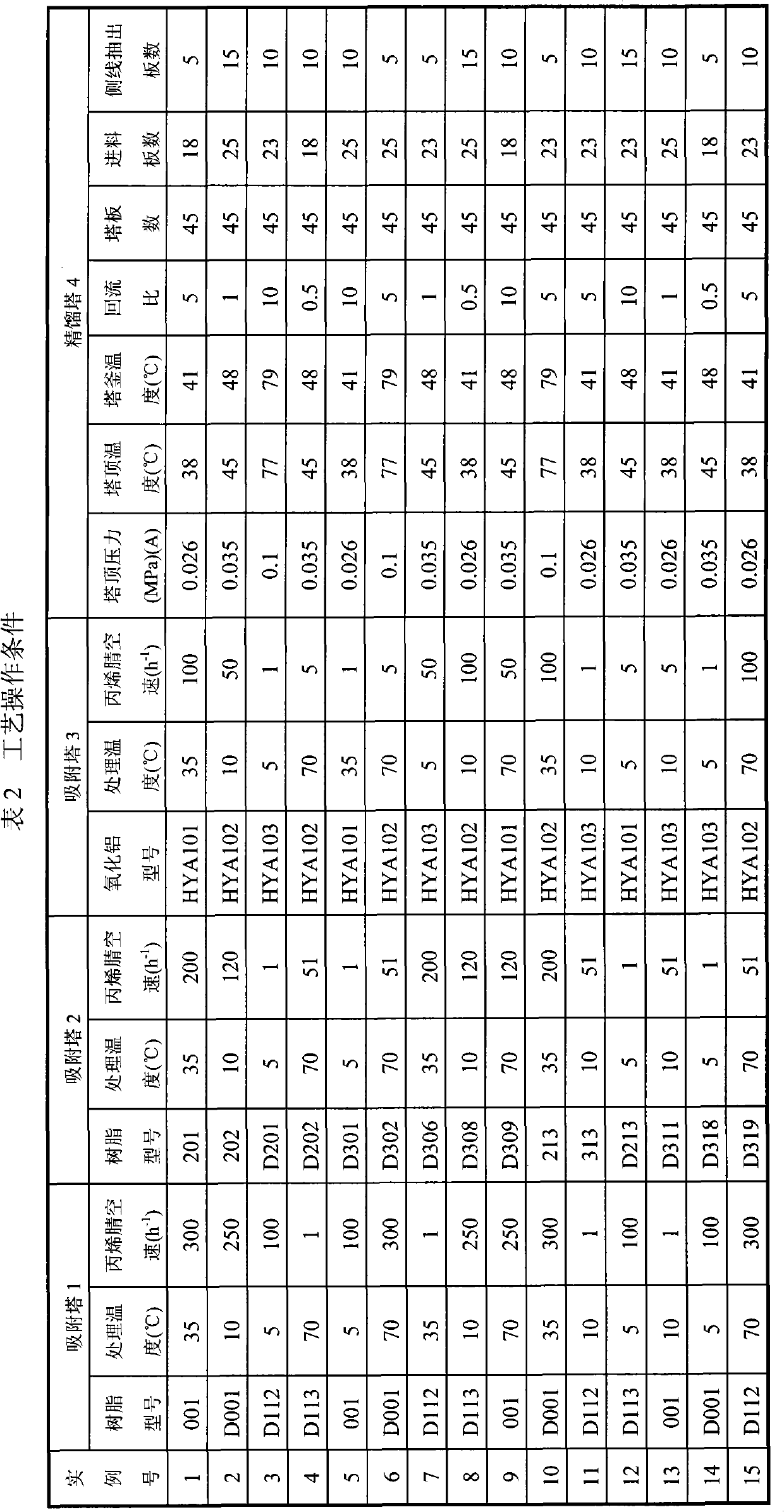

The invention relates to a method for preparing high-purity acrylonitrile, which mainly solves the problems that acrylonitrile raw material treatment capacity is low in the process of removing aldehyde, hydrocyanic acid, acetone, acrolein, methacrylonitrile, oxazole, propionitrile, butene nitrile, a polymerization inhibitor, peroxide, iron ions and other trace impurities from the acrylonitrile raw material, or new compounds are introduced and new impurities of the acrylonitrile raw material are increased but a method for simultaneously removing various trace impurities from the acrylonitrile raw material is absent, and the like in the prior art. The method comprises the following steps of: a) contacting the acrylonitrile raw material with cation exchange resin to obtain a material flow I from which the oxazole is removed; b) contacting the material flow I with anion exchange resin to obtain a material flow II from which the acrolein is removed; c) contacting the material flow II with alumina to obtain a material flow III from which the peroxide and water are removed; and d) rectifying the material flow III by using a rectifying tower, and performing side stream gas phase production at a position of 5-15 plates of the rectifying tower (counted from bottom to top) to obtain the high-purity acrylonitrile which has the purity of 99.99 percent and from which the aldehyde, the hydrocyanic acid, the acetone, the acrolein, the methacrylonitrile, the oxazole, the propionitrile, the butene nitrile, the polymerization inhibitor, the peroxide and the iron ions are removed. The technical scheme solves the problems; and the method can be applied to industrial production of purification treatment of high performance polyacrylonitrile-based carbon fiber materials.

Owner:CHINA PETROLEUM & CHEM CORP +1

Low temperature double-layer capacitors

Owner:CALIFORNIA INST OF TECH

Electrolyte for high-voltage lithium ion battery and high-voltage lithium ion battery

InactiveCN106410272APromote circulationImprove high temperature storage performanceSecondary cellsOrganic electrolytesHigh temperature storageEthylene glycol bis

The invention discloses an electrolyte for a high-voltage lithium ion battery and the high-voltage lithium ion battery. Additives of the electrolyte comprise ethylene glycol bis(propionitrile) ether and cyclic anhydride containing unsaturated double bonds; the electrolyte is used for the lithium ion battery, and can enable the lithium ion battery to maintain good cycle performance and high-temperature storage characteristic at high voltage.

Owner:GUANGZHOU TINCI MATERIALS TECH

Lithium ion battery with adoption of secondary electrolyte injection

ActiveCN102255105AImprove conductivityReduce restrictionsSecondary cellsCell component detailsPropionitrileEthyl propionate

The invention discloses a lithium ion battery with adoption of secondary electrolyte injection, comprising a positive pole, a negative pole, a diaphragm, an electrolyte and an outer package. In the process of manufacturing the battery, the secondary electrolyte injection is adopted; the electrolyte solvent in the first electrolyte injection is one or a combination of more than one of EC (ethylene carbonate), PC (propylene carbonate), DMC (dimethyl carbonate), DEC (diethyl carbonate), EMC (ethyl methyl carbonate), Gamma-BL (butyrolactone), MF (methyl formate), MA (methyl acetate), EP (ethyl propionate) and THF (tetrahydrofuran) and does not contain acetonitrile and propionitrile; the secondary electrolyte injection is conducted after the formation; and the used electrolyte in the secondary electrolyte injection contains at least one of the acetonitrile and the propionitrile. The electrolyte containing the at least one of the acetonitrile and the propionitrile has the advantage of high normal-temperature conductivity (10-50mS / cm) and low-temperature conductivity (4-20mS / cm at the temperature of -20 DEG C), thereby exceeding the level of an existing electrolyte.

Owner:DONGGUAN AMPEREX TECH +1

Electrolytic solution used in electrolysis of acrylonitrile for preparing adiponitrile and method

InactiveCN105543888AReduce consumptionElectrode corrosion is smallElectrolysis componentsElectrolytic organic productionPhosphateAcrylonitrile

The invention discloses an electrolytic solution used in electrolysis of acrylonitrile for preparing adiponitrile and a method. The electrolytic solution consists of the following components in percentage by mass: 1%-5% of acrylonitrile, 0-10% of adiponitrile, 8%-15% of phosphate, 0.1%-2% of EDTA or EDTA salt, 1%-10% of borax, 0.1%-5% of biquaternary ammonium salt and the balance of water. The electrolytic solution is added into a non-membrane electrolytic cell, so that the adiponitrile is prepared by electrolysis. The biquaternary ammonium salt and the borax are added into the electrolytic solution, so that electrode corrosion during electrolysis is reduced, and the selectivity and the current efficiency of the acrylonitrile are higher than 90%; and moreover, the consumption of the biquaternary ammonium salt is reduced, so that the content of the propionitrile is kept at a relatively low level while the propionitrile is continuously used for 400 hours without being supplemented.

Owner:CHONGQING UNISPLENDOUR INT CHEM

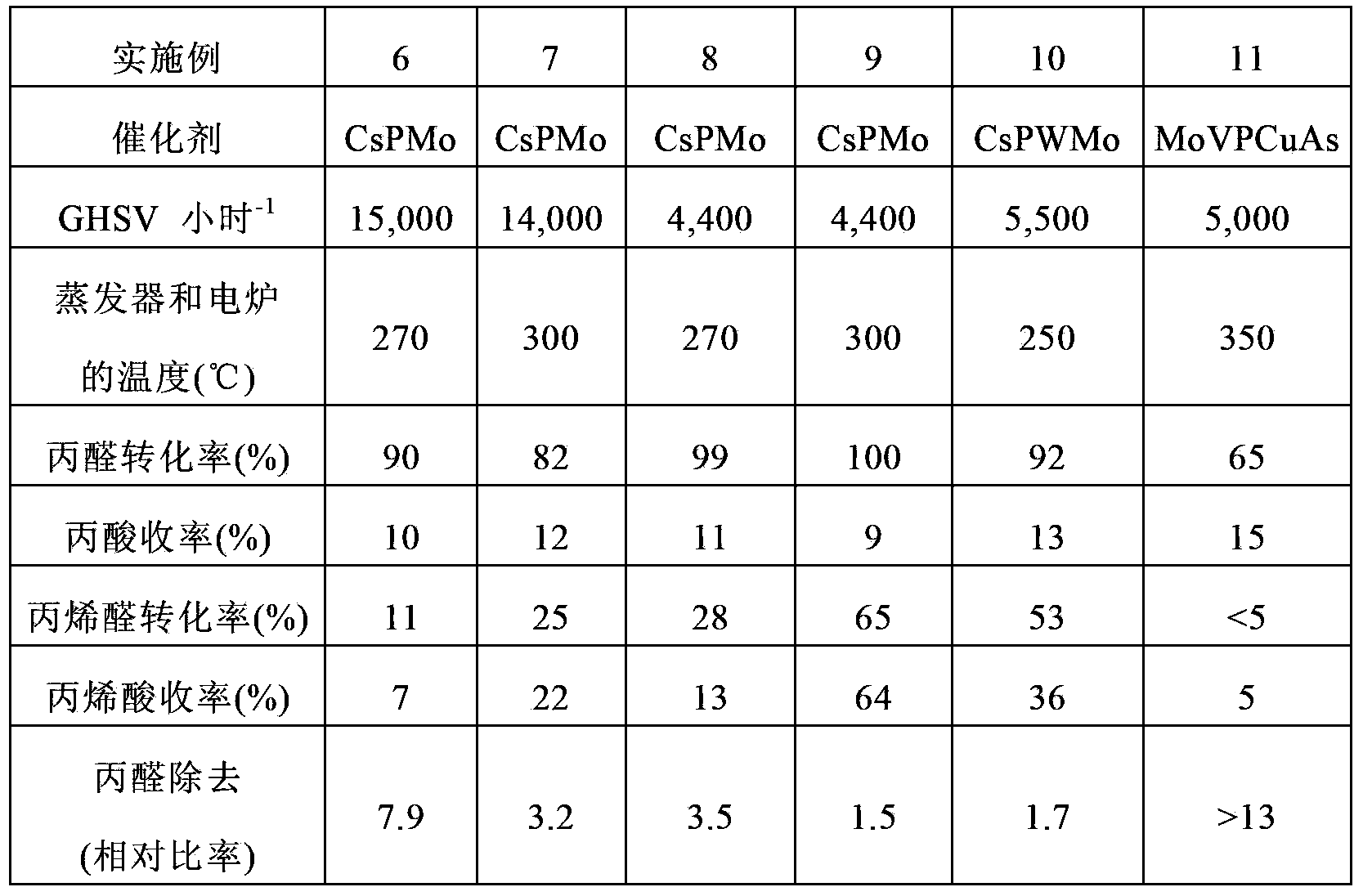

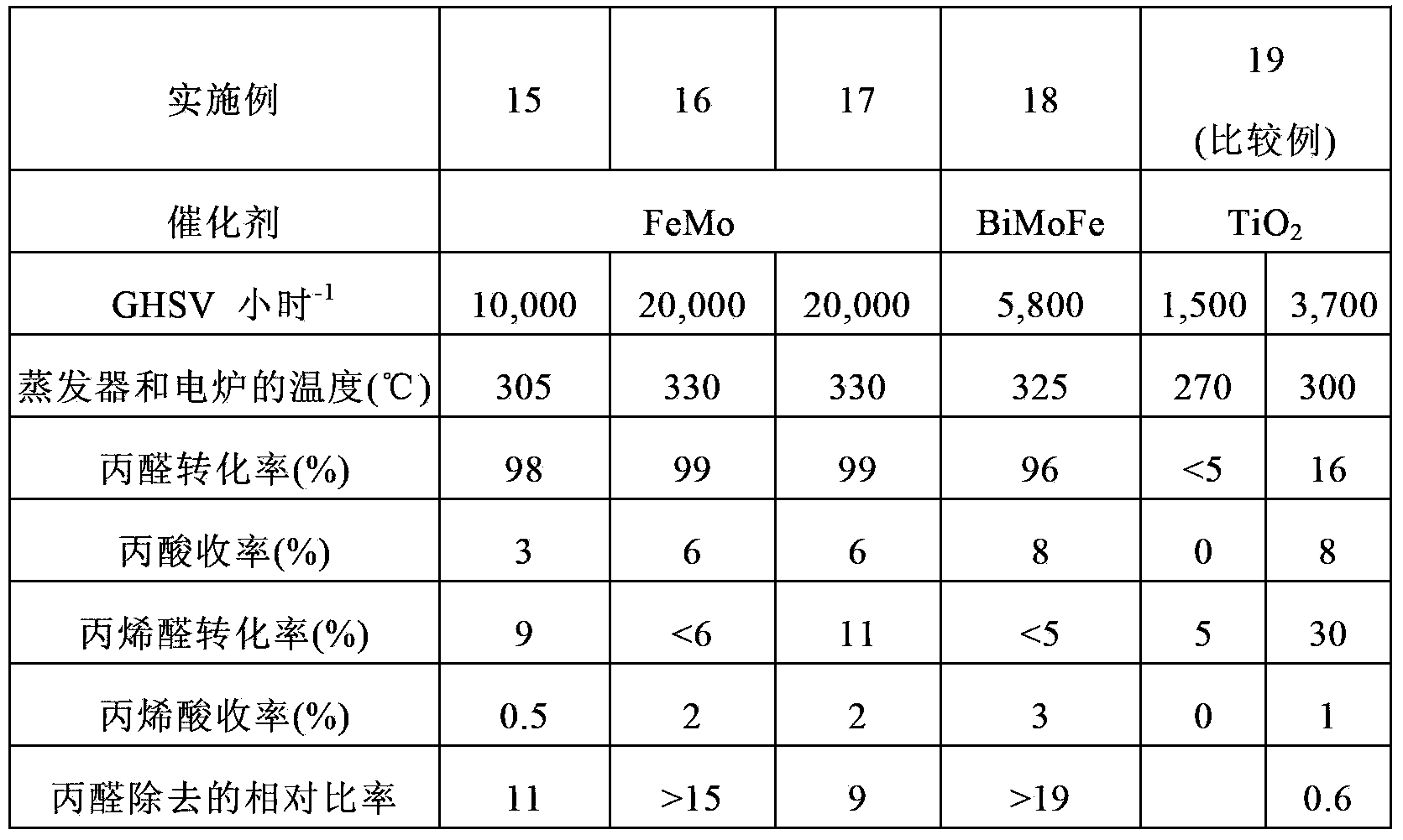

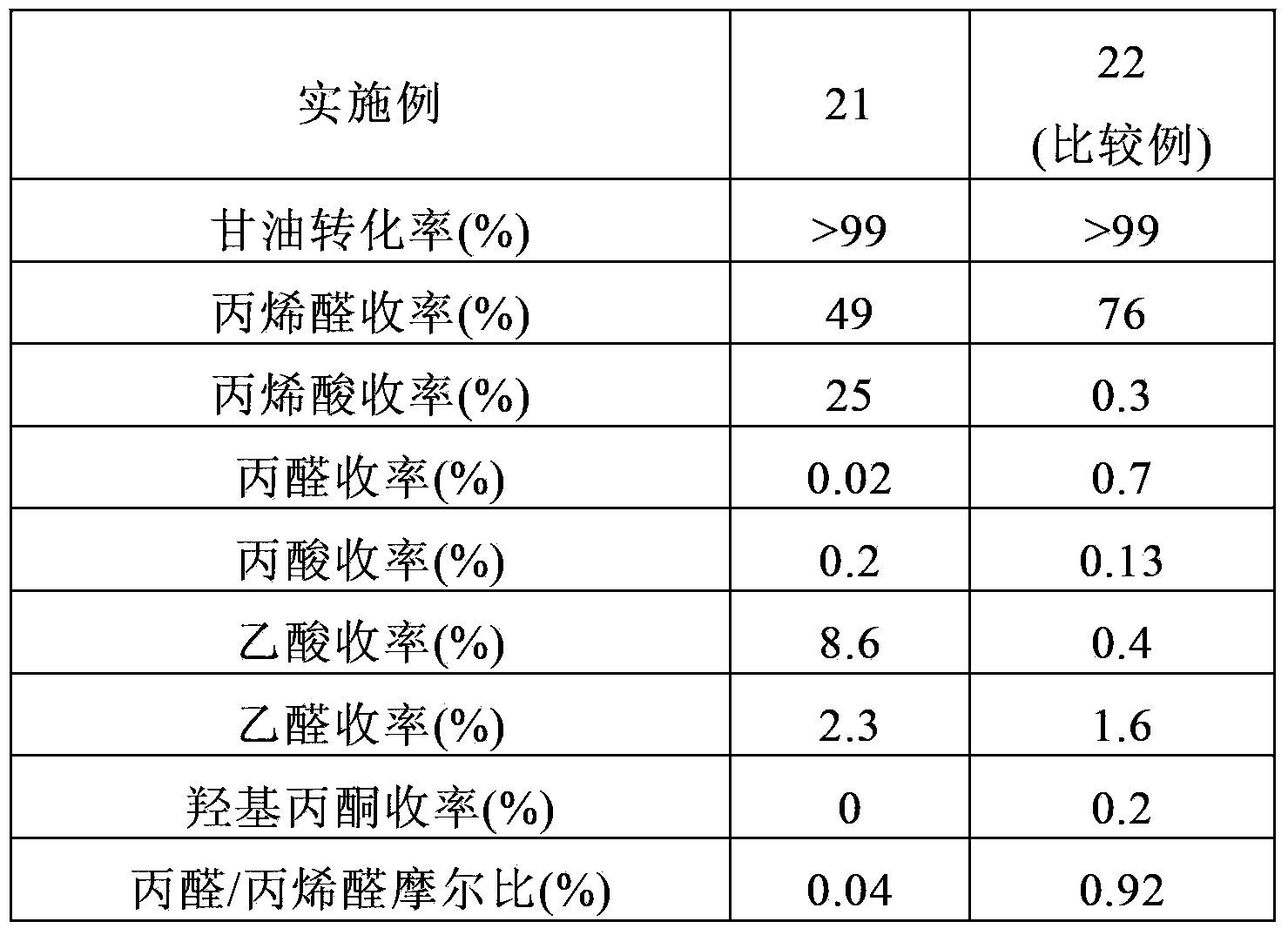

Catalyst for selectively reducing saturated aldehyde, and production method thereof

InactiveCN103648641AReduce propionaldehyde contentImprove qualityCarbonyl compound separation/purificationMetal/metal-oxides/metal-hydroxide catalystsPropanoic acidPtru catalyst

[Problem] To provide a novel catalyst for selectively reducing propionaldehyde from a starting-material acrolein in order to produce an acrolein and / or acrylic acid and / or acrylonitrile and / or methylmercaptopropionaldehyde that has a low-concentration of propionaldehyde and / or propionic acid and / or propionitrile. In particular, to provide a catalyst used to selectively reduce propionaldehyde-containing acrolein. [Solution] A catalyst used for selectively reducing propionaldehyde from propionaldehyde-containing acrolein, said catalyst including Mo as the essential component, and further containing at least one element selected from P, Si, W, Ti, Zr, V, Nb, Ta, Cr, Mn, Fe, Co, Ni, Cu, Zn, Ga, In, Tl, Sn, Ag, As, Ge, B, Bi, La, Ba, Sb, Te, Ce, Pb, Mg, K, Rb, Cs and Al, and preferably from P, Si, W, Ti, Cr, Mn, Fe, Co, Ni, Zn, Sn, Bi, Sb, Ce, Mg, Cs and K.

Owner:NIPPON KAYAKU CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com