Patents

Literature

8255 results about "Dichloromethane" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Dichloromethane (DCM or methylene chloride) is an organochlorine compound with the formula CH₂Cl₂. This colorless, volatile liquid with a moderately sweet aroma is widely used as a solvent. Although it is not miscible with water, it is polar, and miscible with many organic solvents.

Process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and such (CO)polymers

A process for preparing a polymer having a 2,5-furandicarboxylate moiety within the polymer backbone and having a number average molecular weight of at least 10,000 (as determined by GPC based on polystyrene standards) includes a first step where a prepolymer is made having the 2,5-furandicarboxylate moiety within the polymer backbone, followed in a second step by a polycondensation reaction. In the first step a 2,5-furandicarboxylate ester is transesterified with a compound or mixture of compounds containing two or more hydroxyl groups, in the presence of a tin(IV) based transesterification catalyst. In the second step at reduced pressure and under melt conditions the prepolymer prepared in the first step is polycondensed in the presence of a tin (II) based polycondensation catalyst until the polymer is obtained. This polymer may then be subjected to Solid State Polycondensation. Polymers so produced may have a 2,5-furandicarboxylate moiety within the polymer backbone, and having a number average molecular weight of at least 20,000 (as determined by GPC based on styrene standards), and an absorbance as a 5 mg / mL solution in a dichloromethane:hexafluoroisopropanol 8:2 at 400 nm of below 0.05.

Owner:FURANIX TECH BV

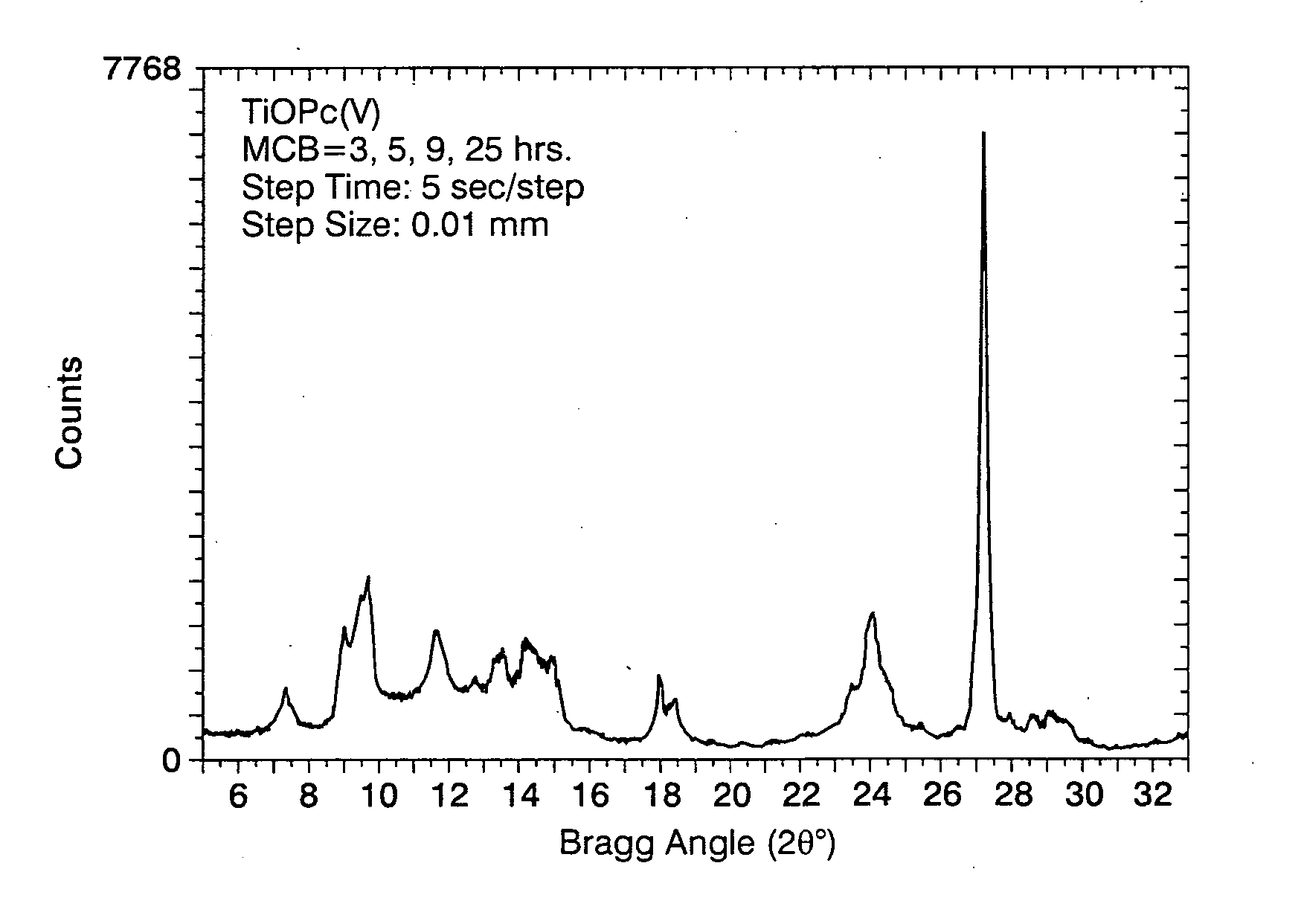

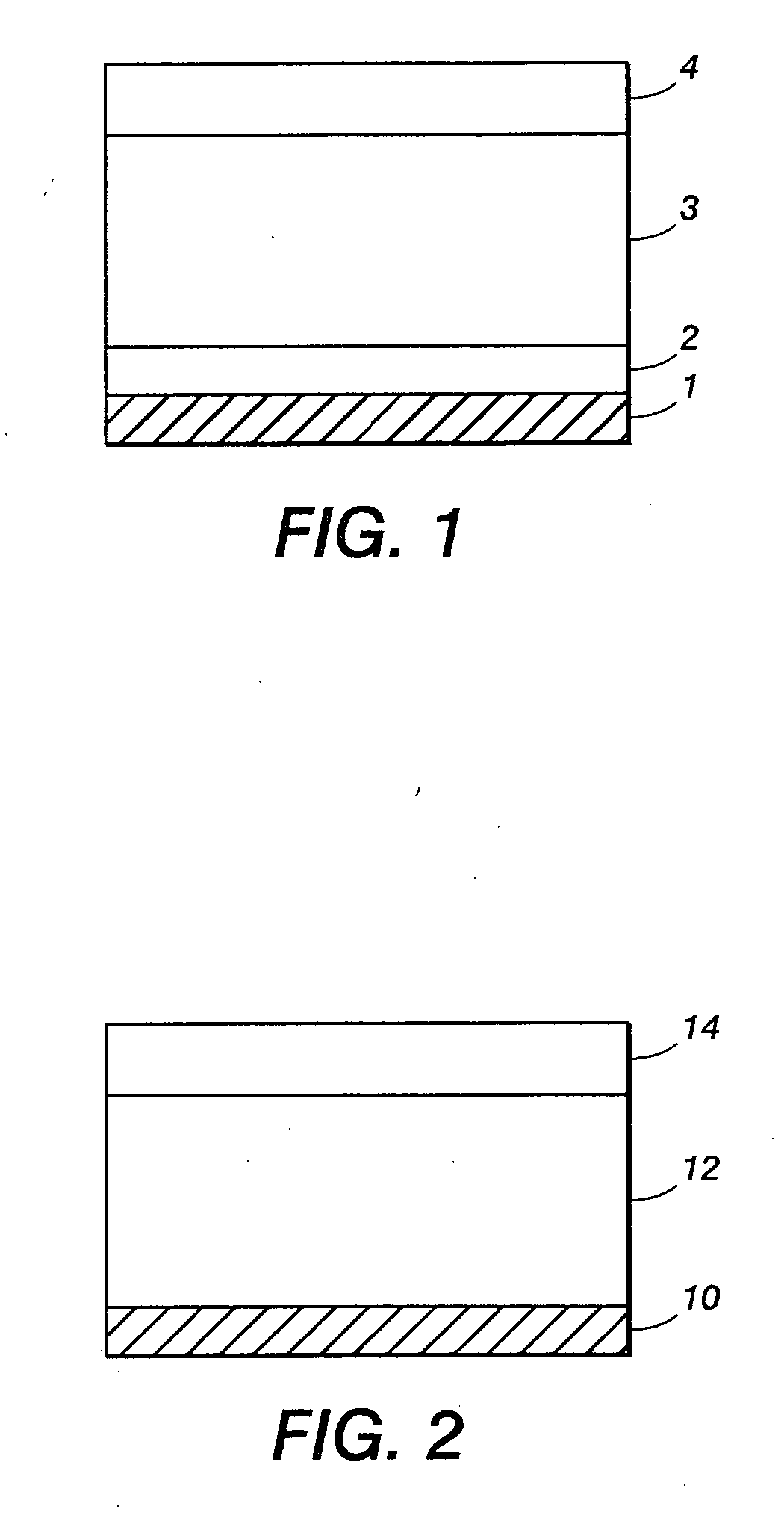

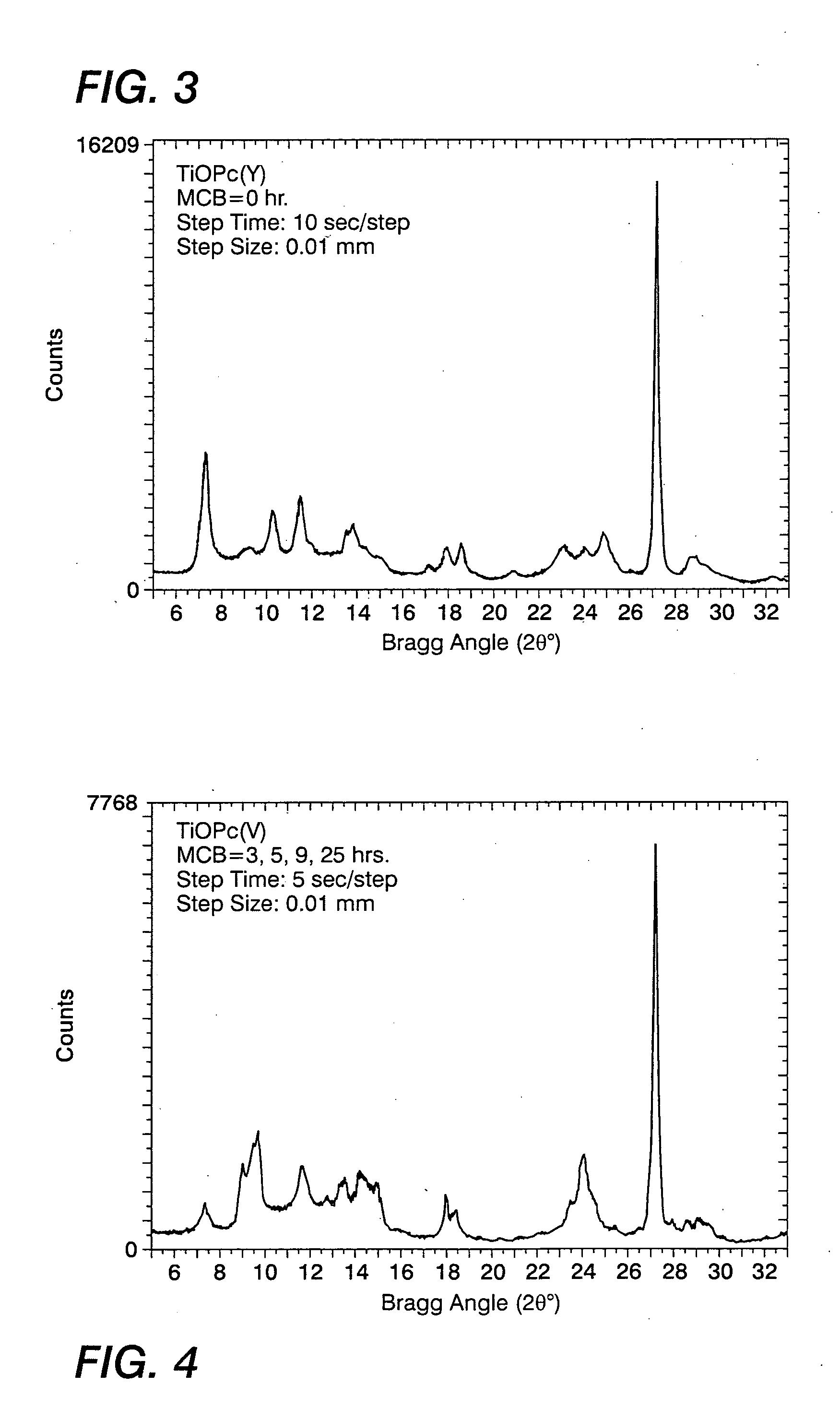

Processes for the preparation of high sensitivity titanium phthalocyanines photogenerating pigments

A process for preparing a high sensitivity titanyl phthalocyanine (TiOPc) pigment includes dissolving a Type I TiOPc in a suitable solvent, precipitating an intermediate TiOPc pigment by quenching the solution comprising the dissolved Type I TiOPc in a solvent system comprising an alcohol and alkylene chloride such as, for example, methylene chloride, and treating the intermediate TiOPc pigment with monochlorobenzene. The resultant TiOPc pigment, which is designated as a Type V TiOPc, is suitable for use as a charge generating material in a photoreceptor of an imaging device.

Owner:XEROX CORP

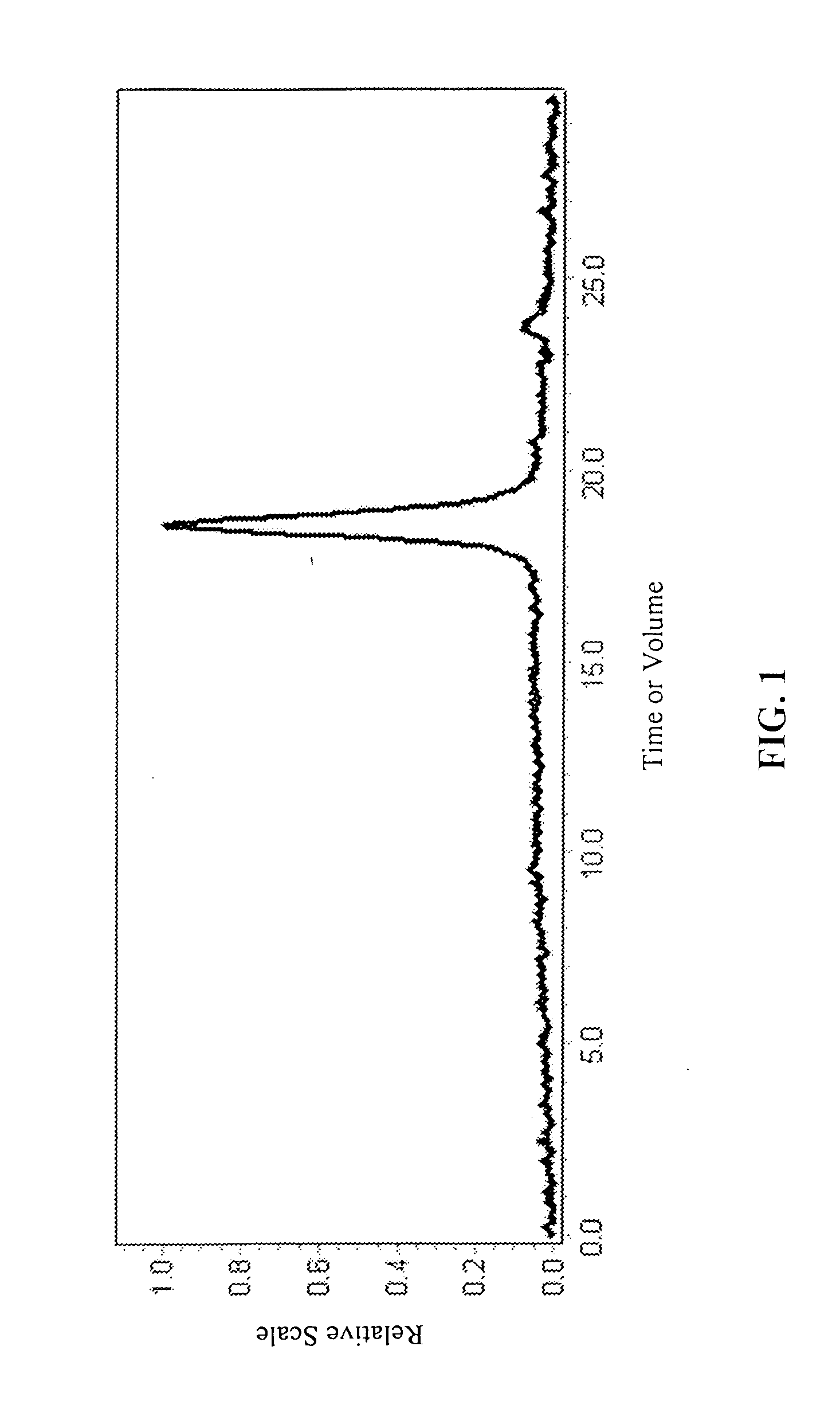

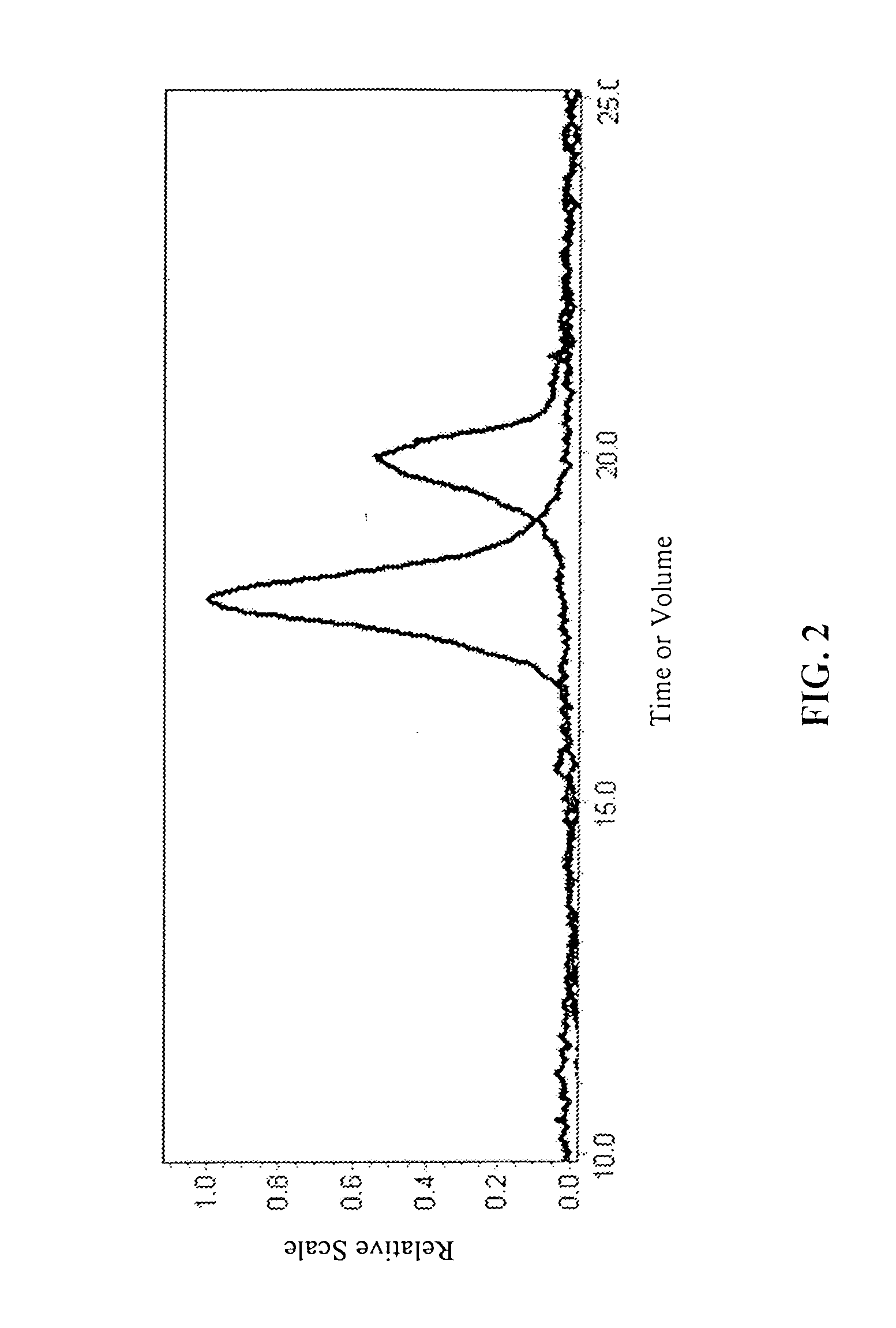

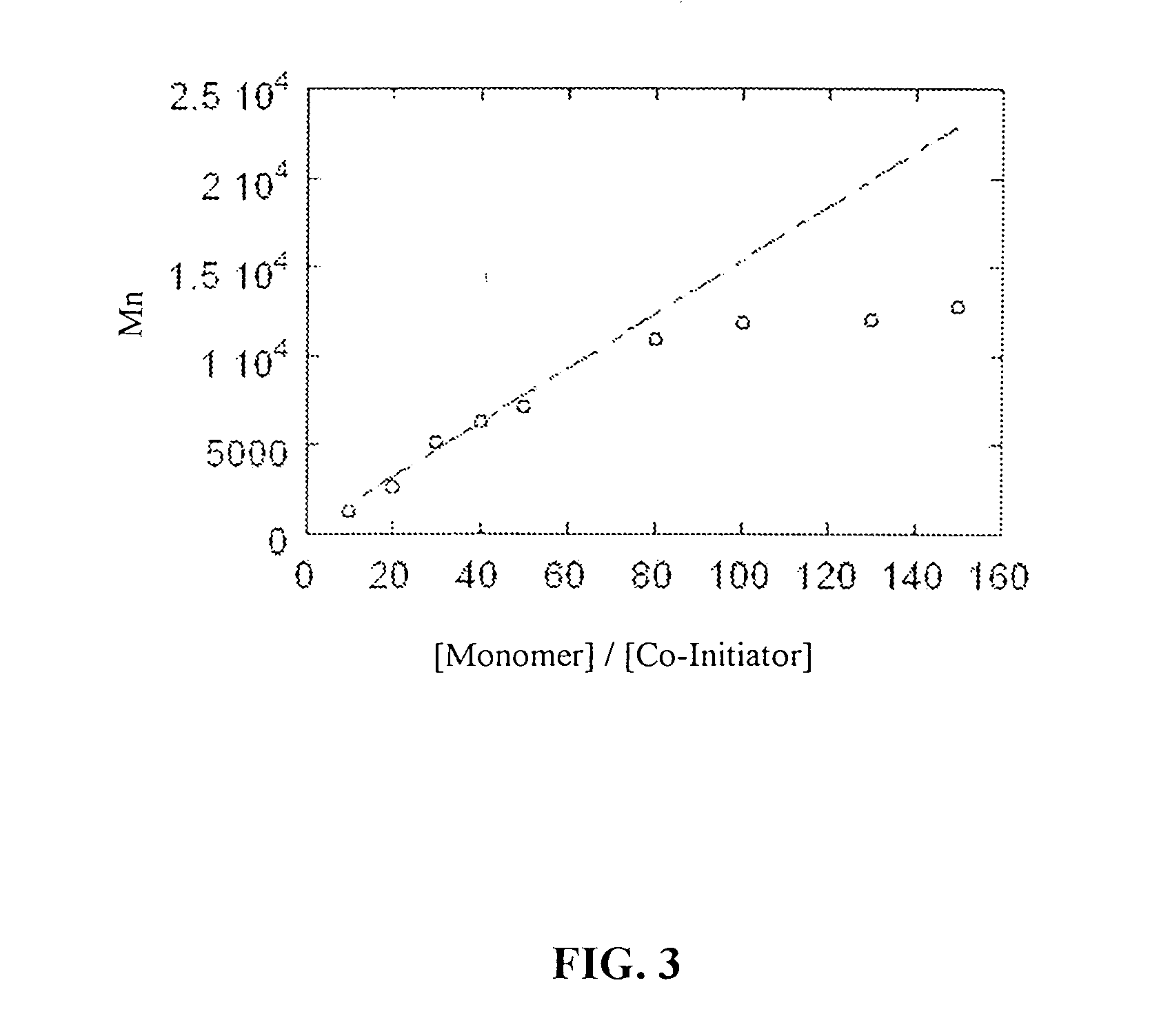

Poly-beta-peptides from functionalized beta-lactam monomers and antibacterial compositions containing same

InactiveUS20070087404A1Control over polymerization conditionLarge molecular weightAntibacterial agentsPeptide/protein ingredientsMonomerTetrahydrofuran

Disclosed is a method of making β-polypeptides. The method includes polymerizing β-lactam-containing monomers in the presence of a base initiator and a co-initiator which is not a metal-containing molecule to yield the product β-polypeptides. Specifically disclosed are methods wherein the base initiator is potassium t-butoxide, lithium bis(trimethylsilyl)amide (LiN(TMS)2), potassium bis(trimethyl-silyl)amide, and sodium ethoxide, and the reaction is carried out in a solvent such as chloroform, dichloromethane, dimethylsulfoxide, or tetrahydrofuran.

Owner:WISCONSIN ALUMNI RES FOUND

Process for preparing 2,3,5,6-Tetrafluoro-para-xylyl alcohol

InactiveCN1458137AOrganic compound preparationHydroxy compound preparationSulfolanePotassium fluoride

The preparation process of 2, 3, 5, 6-tetrafluoro-para-xylyl alcohol with 2, 3, 5, 6-tetrachloro-p-phenyl diformyl chloride as material includes fluorination with potassium fluoride, etc. as fluorination agent, sulfolane, etc. as solvent and calixarene, etc. as catalyst and at 40-230 deg.c; esterification of ester with fatty alcohol or aromatic alcohol as esterifying agent and at 20-120 deg.c; reduction of ester with sodium borohydride, etc. as reductant and sulfolane, etc. as solvent, and at -10 deg.c to 60 deg.c; bromination with HBr acid as brominating agent and dichloromethane as solvent and at 30-160 deg.c; and reduction of bromide with magnesium powder, etc as reductant and fatty alcohol, water, chloride, etc as solvent, and at -10 deg.c to 50 deg.c. The present invention has the advantages of simple process, low production cost, high product yield and purity, and is suitable for industrial production.

Owner:TIANJIN UNIV

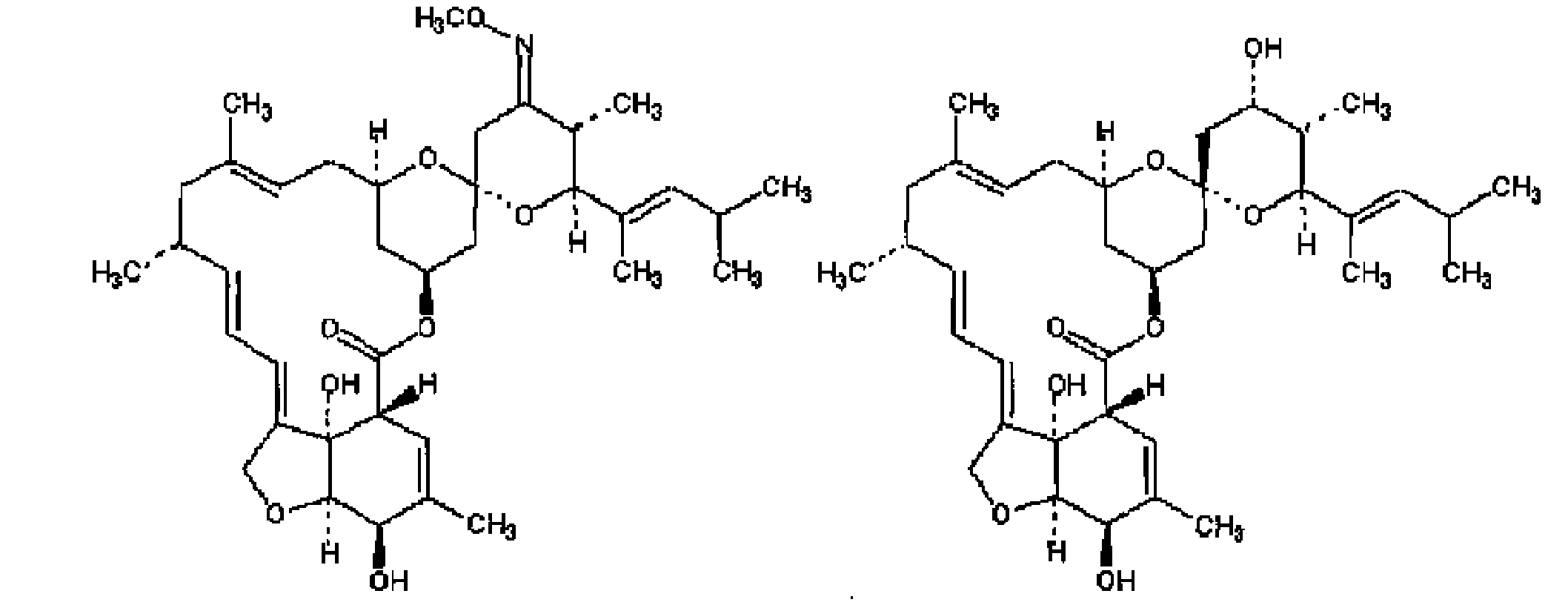

Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process

The present invention relates to a new industrial process for the synthesis of solvate- free 17a-acetoxy-11ss-[4-(N,N-dimethyl-amino)-phenyl]-19-norpregna-4,9-diene-3,20-dione [CDB -2914] of formula (I) which is a strong antiprogestogene and antiglucocorticoid agent. The invention also relates to compounds of formula (VII) and (VIII) used as intermediates in the process. The process according to the invention is the following: i) 3-(ethylene-dioxy)-estra-5(10),9(11)-diene-17-one of formula (X) is reacted with potassium acetilyde formed in situ in dry tetrahydrofuran by known method, ii) the obtained 3-(ethylene-dioxy)-17a-ethynyl-17ss-hydroxy-estra-5(10),9(11)-diene of formula (IX) is reacted with phenylsulfenyl chloride in dichloromethane in the presence of triethylamine and acetic acid, iii) the obtained isomeric mixture of 3-(ethylene-dioxy)-21-(phenyl-sulfinyl)-19-norpregna-5(10),9(11),17(20),20-tetraene of formula (VIII) is reacted first with sodium methoxide in methanol, then with trimethyl phosphite, iv) the obtained 3-(ethylene-dioxy)-17a-hydroxy-20-methoxy-19-norpregna-5(10),9(11),20-triene of formula (VII) is reacted with hydrogen chloride in methanol, then v) the obtained 3-(ethylene-dioxy)-17a-hydroxy-19-norpregna-5(10),9(11l); -diene-20- one of formula (VI) is reacted with ethylene glycol hi dichloromethane in the presence of trimethyl orthoformate and p-toluenesulfonic acid by known method, vi) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-19-norpregna- 5(10),9(11)-diene of formula (V) is reacted with hydrogen peroxide in a mixture of pyridine and dichloromethane in the presence of hexachloroacetone by known method, vii) the obtained 3,3,20,20-bis(ethylene-dioxy)-17a-hydroxy-5,10-epoxy-19-norpregn-9(11)-ene of formula (IV), containing approximately a 1:1 mixture of 5a,10a- and 5ss,10ss-epoxides, is isolated from the solution and reacted with a Grignard reagent obtained from 4-bromo-N,N-dimethyl-aniline in tetrahydrofuran.

Owner:RICHTER GEDEON NYRT

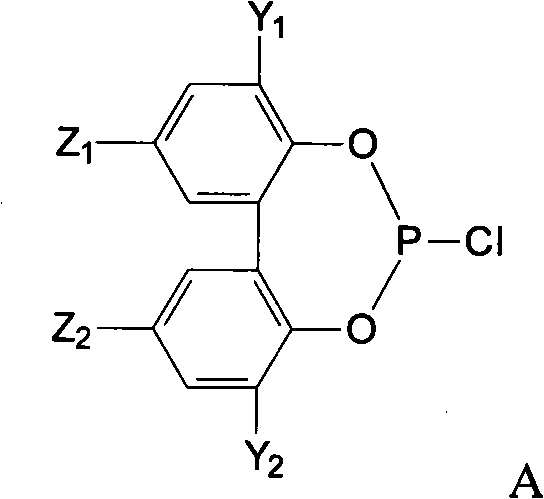

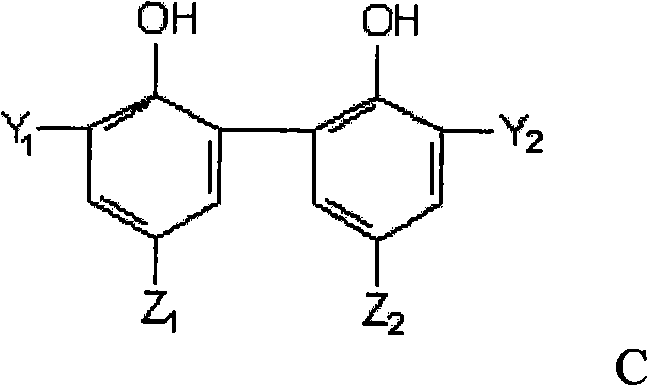

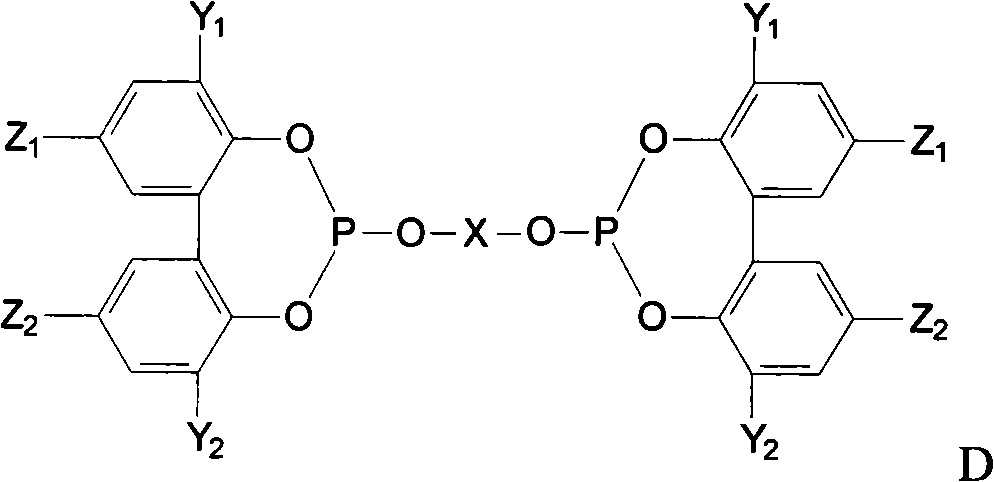

Preparation method of phosphite ester

ActiveCN101684130AEasy to removeReduce Chloride ContentGroup 5/15 element organic compoundsPhosphite esterPhenol

The invention discloses a preparation method of phosphite ester. The method comprises the following steps: dissolving chlorinated phosphite ester in dichloromethane, dissolving phenol in triethylamine or a mixed solution of triethylamine and dichloromethane, mixing the solutions to react and obtain raw product, and purifying the raw product through post-treatment to obtain the desired product. The preparation method of phosphite ester of the invention uses dichloromethane as reaction solvent to synthesize phosphite ester; the preparation process does not have any link with high viscosity material, the product is easy to clean and filtrate, the chlorine ions in the product can be removed conveniently and effectively and the quality of the product can be increased.

Owner:SHANGHAI HUAYI ENERGY CHEM

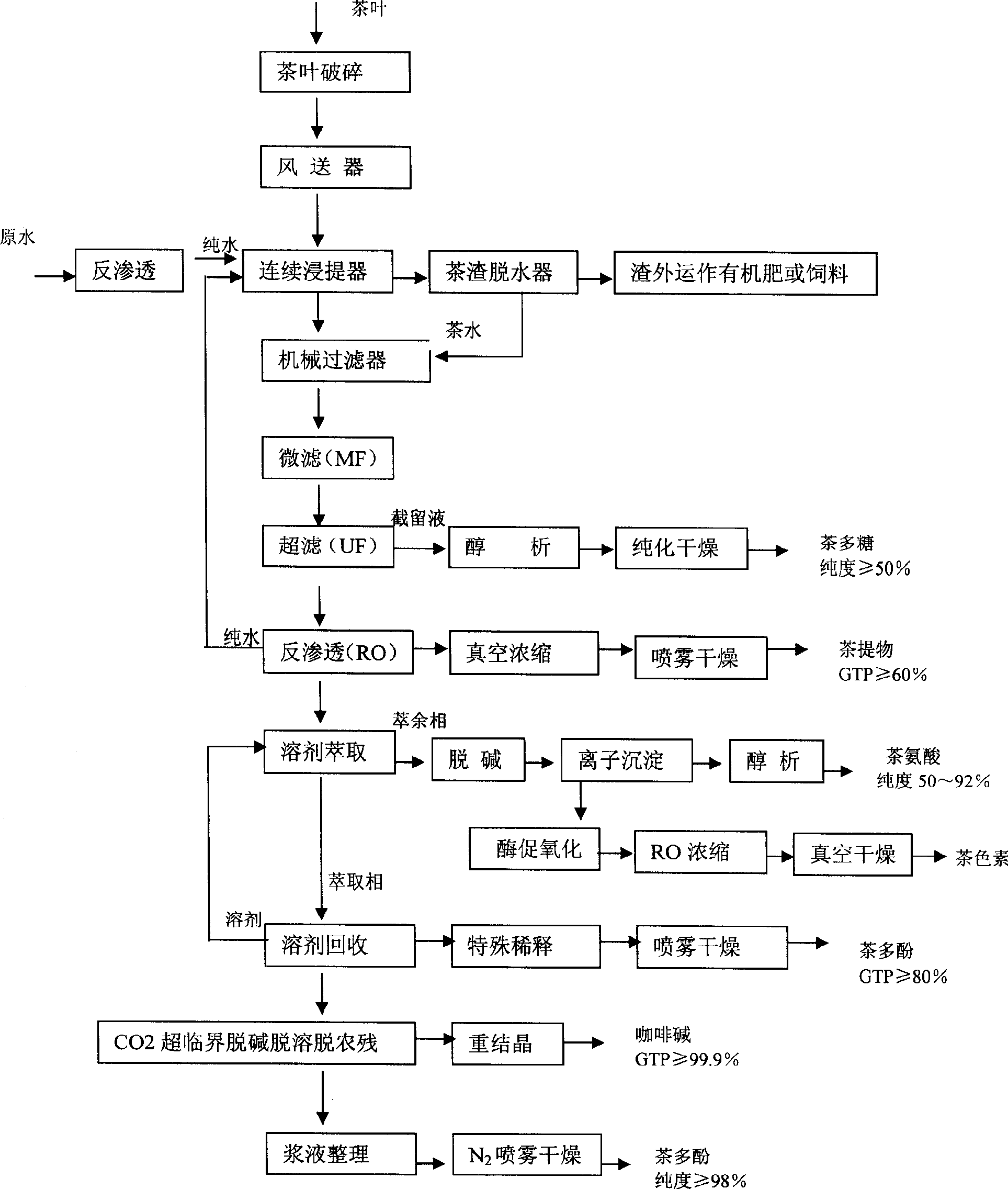

Process for extracting tea polyphenol, theanine, tea polysaccharide and tea pigment from tea

InactiveCN1837201AHigh purityReduce labor intensityCarboxylic acid amide separation/purificationBulk chemical productionForeign matterPhenolic content in tea

The invention discloses an extracting polyphenol, theanine, tea polysaccharide and tea pigment method from tea, which is characterized by the following: using deionized water for lixiviating tea at constant temperature with continuous flow upstream at multi-speed; adopting microstrainer to dislodge the foreign matter of raffinate; using hyperfiltration for putting-off pectin and protein; concentrating by hyperfiltration and dehydration; extracting tea polyphenol by acetic acid ethyl ester and recovering dissolvant; stripping caffeine of extracting extract phase, pesticide residue and dissolvant by CO2 supercritical fluid; getting tea polyphenol by low-temperature nitrogen spray-drying; using alcohol separation and low temperation vacuum drying by hyperfiltration trapped fluid to prepare tea polysaccharide; separating alcohol recrystallization by basic copper carbonate and hydrogen sulfide to get theanine; using enzymatic oxidation and alkaline air to oxygenate remain polyphenols substance of liquid phantom; getting tea pigment by hyperfiltration dehydration compression and vacuum drying; merging caffeine form carbon dioxide above-critical fluid and caffeine from carrene; recovering dissolvent; using deionized water for washing; obtaining caffeine by recrystallization vacuum drying.

Owner:张守政

Dual layer tablet, method of making and use thereof

InactiveUS20050040116A1Easy to optimizeComprehensive treatmentOrganic chemistryOther chemical processesPotassium persulfateLithium hypochlorite

A method for treating a recirculating water system which comprises introducing into said water system a multifunctional, multilayer tablet, wherein the multilayer tablet comprises a fast dissolving layer and a slow dissolving layer, wherein said fast dissolving layer releases a combination of active ingredients including a member selected from the group consisting of lithium hypochlorite, calcium hypochlorite, trichloroisocyanuric acid (TCCA), anhydrous sodium dichloroisocyanurate, sodium persulfate, potassium persulfate, potassium monopersulfate, sodium monopersulfate, and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent, fragrance, or surfactant and, wherein said slow dissolving layer includes a member selected from the group consisting of trichloroisocyanuric acid (TCCA), calcium hypochlorite, 1,3-dichloro-5,5-dimethylhydantoin (DCDMH), 1,3-dibromo-5,5-dimethylhydantoin (DBDMH), 1-bromo-3-chloro-5,5-dimethylhydantoin (BCDMH), 1,3-dichloro-5-ethyl-5-methylhydantoin (DCEMH), 1,3-dibromo-5-ethyl-5-methylhydantoin (DBEMH), 1-bromo-3-chloro-5-methyl-5-ethylhydantoin (BCEMH), and mixtures thereof, and at least one of a clarifier, chelating agent, sequesterant, algaestat, water softener, algaecide, corrosion inhibitor, scale inhibitor, flocculent, disintegrant, dispersant, colorant, dissolution control agent or surfactant.

Owner:BIO LAB

Coated controlled release fertilizer of degradable film prepared by reclaiming thermoplastic resin

ActiveCN1603288ATo achieve the purpose of precise controlled releaseFast agingFertiliser formsFertilizer mixturesPolystyrenePolymer chemistry

This invention relates to an envelope control release fertilizer and its production method that using heating fluidized-bed envelope technology. Exhausted thermoplastic resins are used and many filling materials are added, it is used in quick mass industrialized production. Polystyrene cellular resin and polyethylene pellicle resin are mixed as certain proportion set before, and certain proportion flour, corn powder and rubber powder are mixed and dissolved in mixed liquor perchlorethylene and dichloromethane. The liquor is uniformly sprayed to the pre-heated composite fertilizer, carbamide, lemery salt and other fertilizer particles through twin fluid atomization nozzle in heating fluidized-bed in order to form macromolecule polymer envelope that lubricity and densification and with different capabilities of breaking through of water. The liquor is recovered through special made condensation and compaction recovery plant. This production not only has good nutrition control and releasing capability and the nutrition control and releasing term can reach 1 to 12 months, but also the putamina residue in the soil can be degraded in short time, so it belongs to environment good control and releasing fertilizer.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

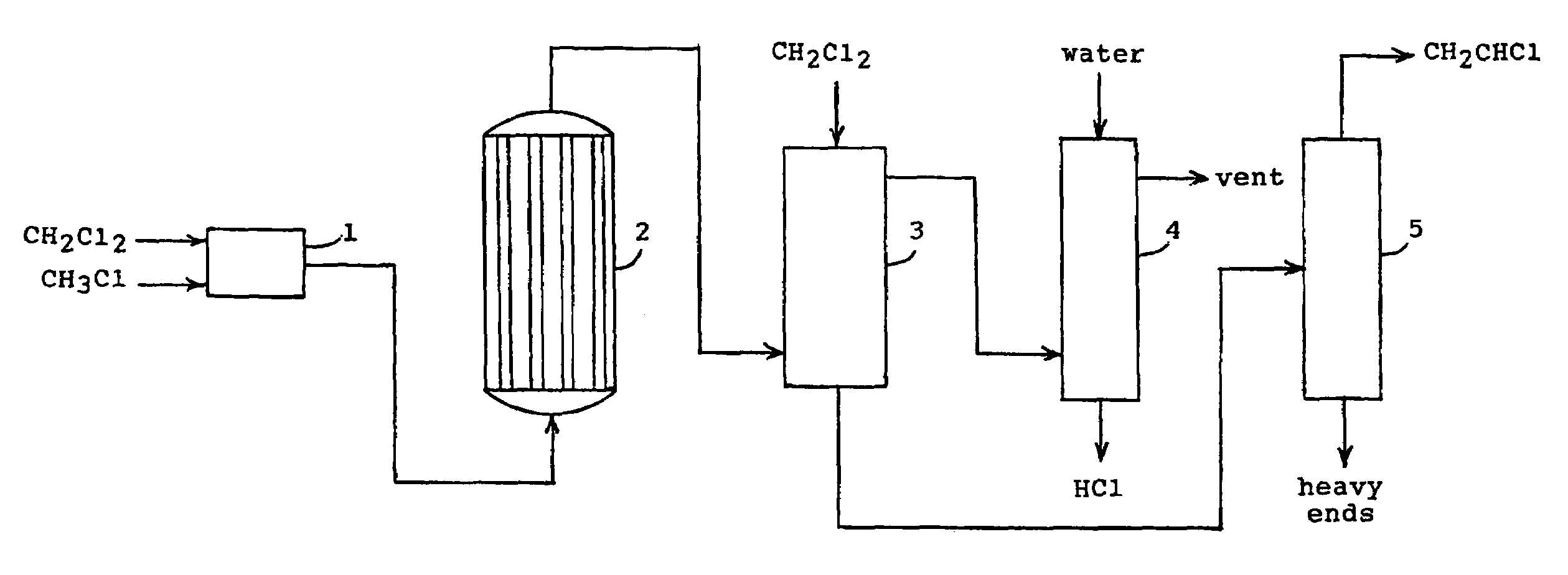

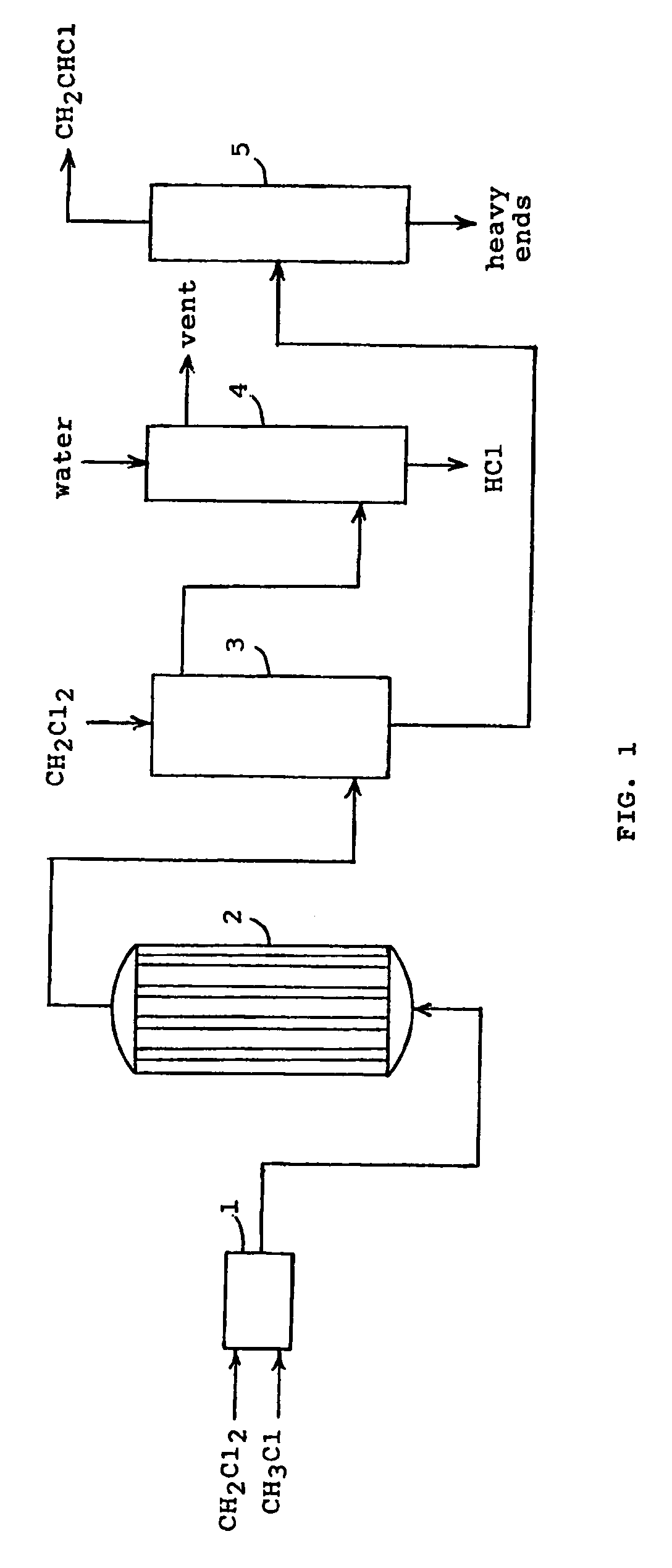

Method for producing vinyl chloride monomer

Owner:STAUFFER VALERIE +1

Method for preparing 4.4-dichlorodiphenyl sulfone by using sulfoxide oxidation

InactiveCN102351757AImprove qualityMild reaction conditionsOrganic chemistryOrganic compound preparationChlorobenzeneDistillation

The invention discloses a method for preparing 4.4-dichlorodiphenyl sulfone by using sulfoxide oxidation. The method comprises the following steps of: (1) performing Frieldel-Crafts reaction at the temperature of 25-35 DEG C by taking AlCl3 as a catalyst and chlorobenzene and thionyl chloride as reaction raw materials; next, hydrolyzing mother liquor after the Frieldel-Crafts reaction is finished; refluxing at the temperature of 95-100 DEG C for 45-60 minutes after hydrolysis is finished; cooling to be below 20 DEG C to divide into an organic phase and a water phase after refluxing is finished; performing reduced pressure distillation and centrifugal washing on the organic phase to be neutral to serve as a product A for later use, wherein a main component in the product A is 4.4-dichlorodiphenyl sulfone; and (2) performing oxidation reaction on the 4.4-dichlorodiphenyl sulfone by taking the product A as the raw material, hydrogen peroxide as a catalyst and dichloromethane as a reaction solvent to synthesize a 4.4-dichlorodiphenyl sulfone rough product. Thus, the method has the advantages of mild reaction conditions, high product quality and low three wastes (waste water, waste gas and industrial residues).

Owner:WUJIANG BEISHE SHENGYUAN TEXTILE PROD AUXILIARIES PLANT

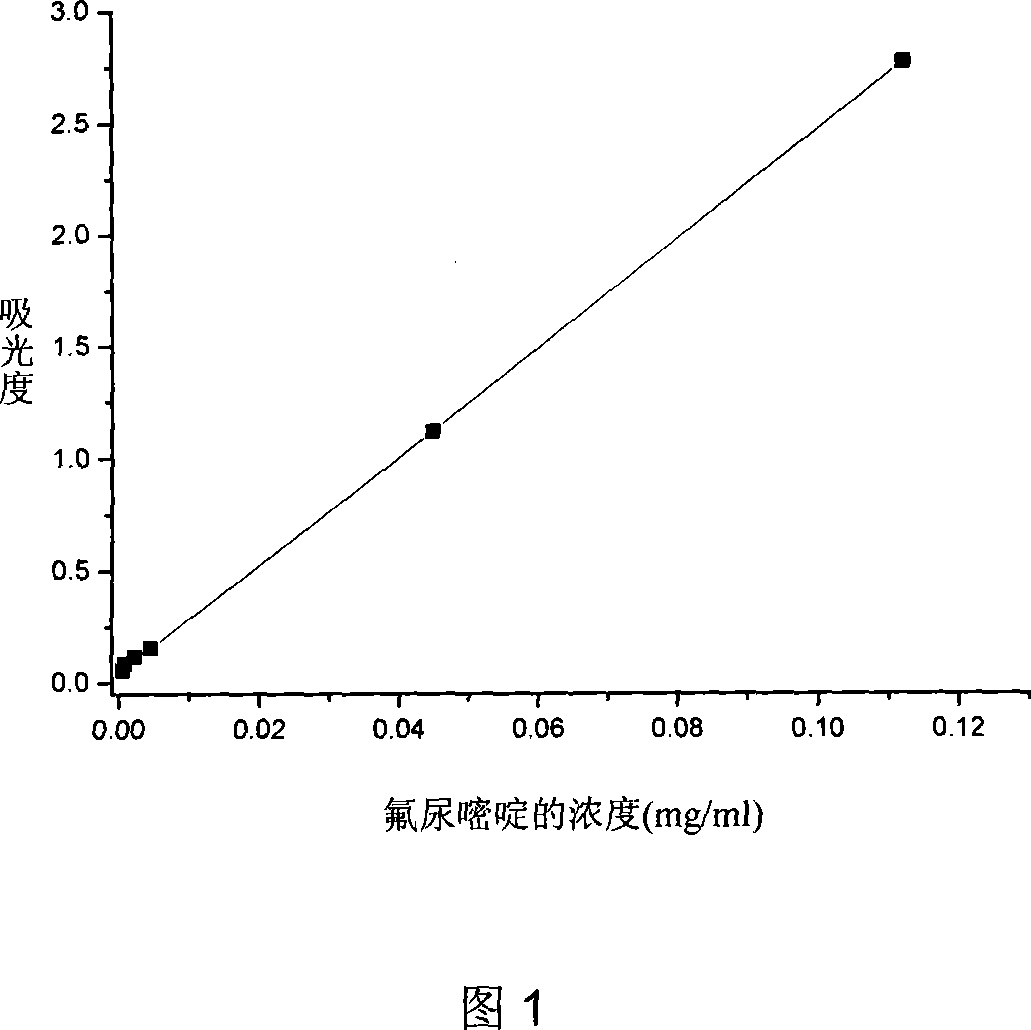

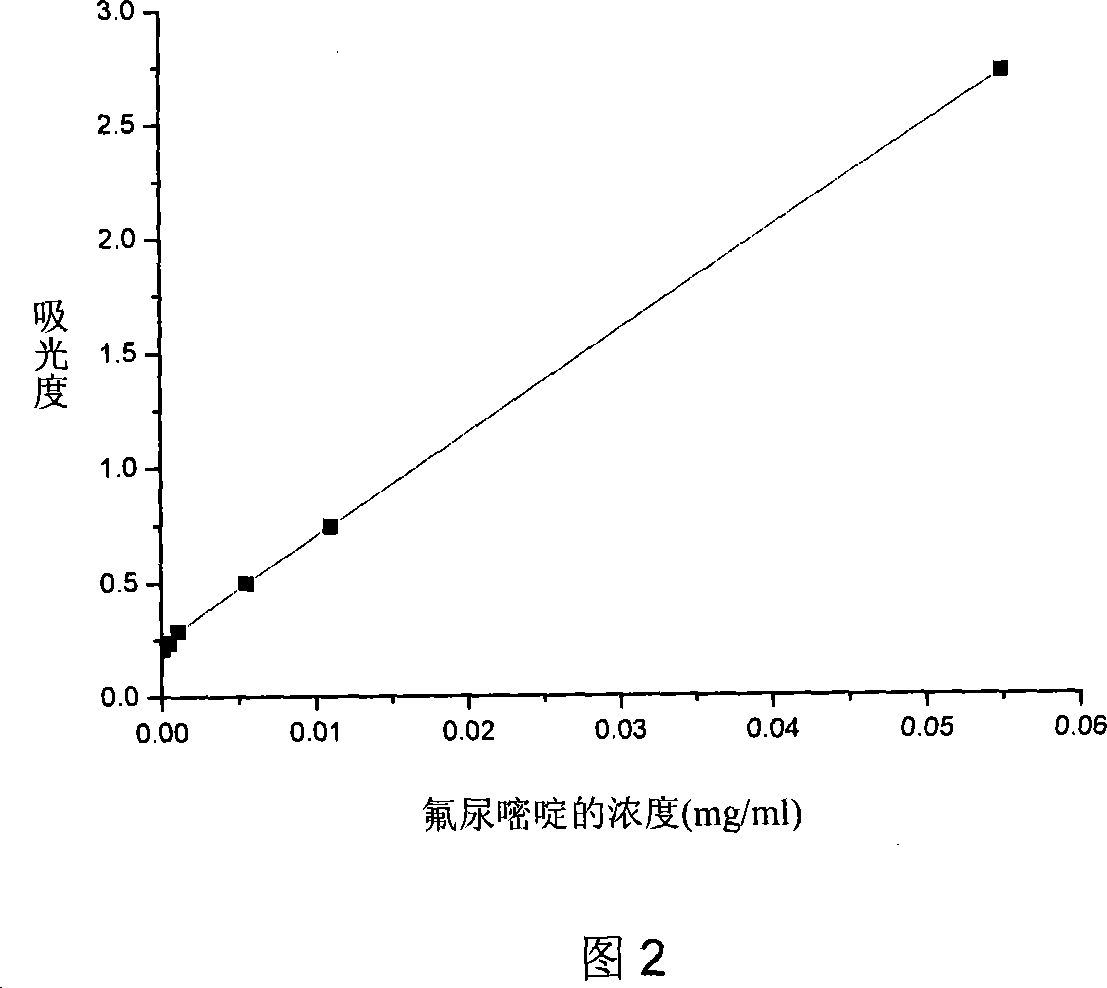

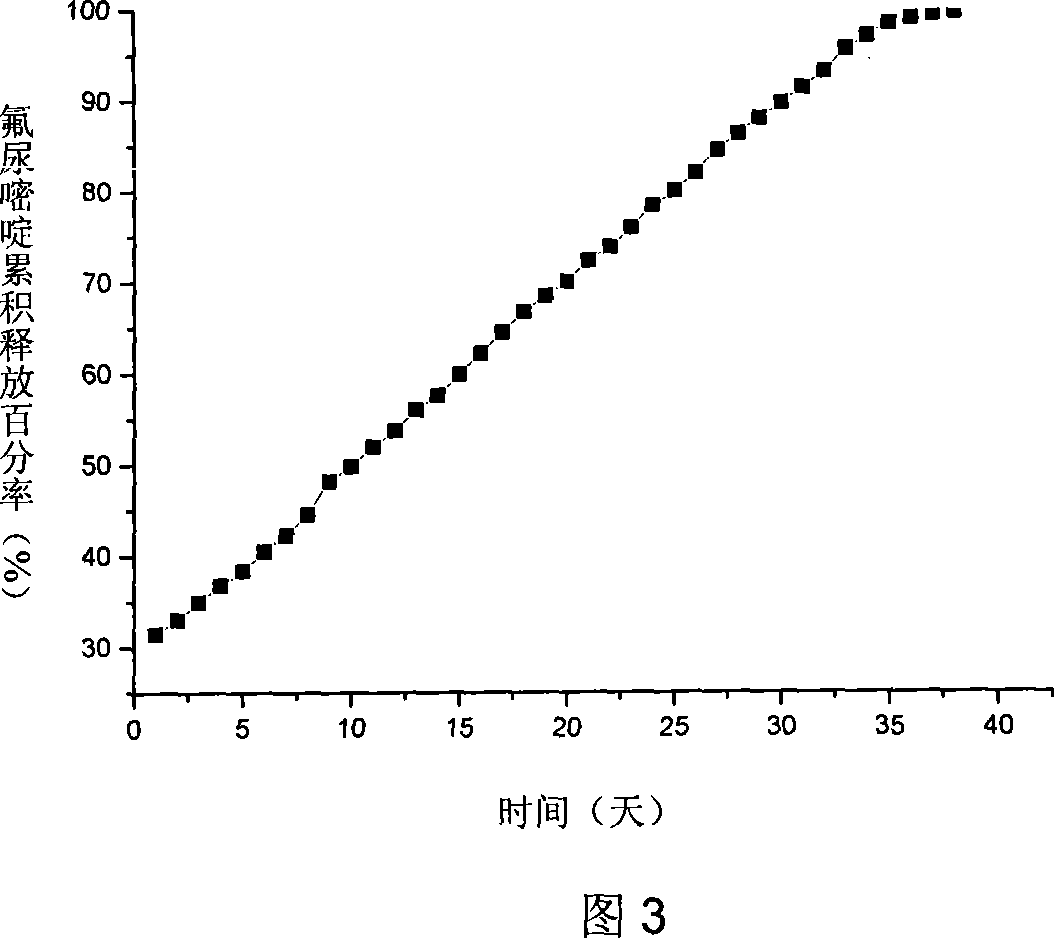

Biodegradable fluorourcacil polyester medicine-carried nanospheres and its preparation method

InactiveCN101053553AHigh drug loadingSmall particle sizeOrganic active ingredientsPowder deliveryPolyesterPolymer science

The invention relates to biodegradable fluorouracil(Fu) polyester drug-bearing manoparticles with a coating material of polylactic acid, polylactic acid-glycolic acid, polylactic acid-polyethylene glycol block copolymer or polylactic acid-glycolic acid-polyethylene glycol block copolymer and the producing method including: firstly, fully dissolving the copolymer in the dichloromethane, under the ultrasonic shock, injecting the fluorouracil NaOH solution in the dichloromethane solution, dispersing uniformly, forming W / O primary latex, and beating up the primary latex and injecting into the fluorouracil saturated water solution containing 5 wt% of polyvinylalcohol (PVA), and storing in the refrigeratory after freeze-dry. The drug-bearing manoparticle has a drug content which is 10-25% of the microparticle mass, and has a smooth surface, an even diameter distribution, a remarkable slow release function and not adhesive. The micropartical size is 100-1000nm.

Owner:JILIN UNIV +1

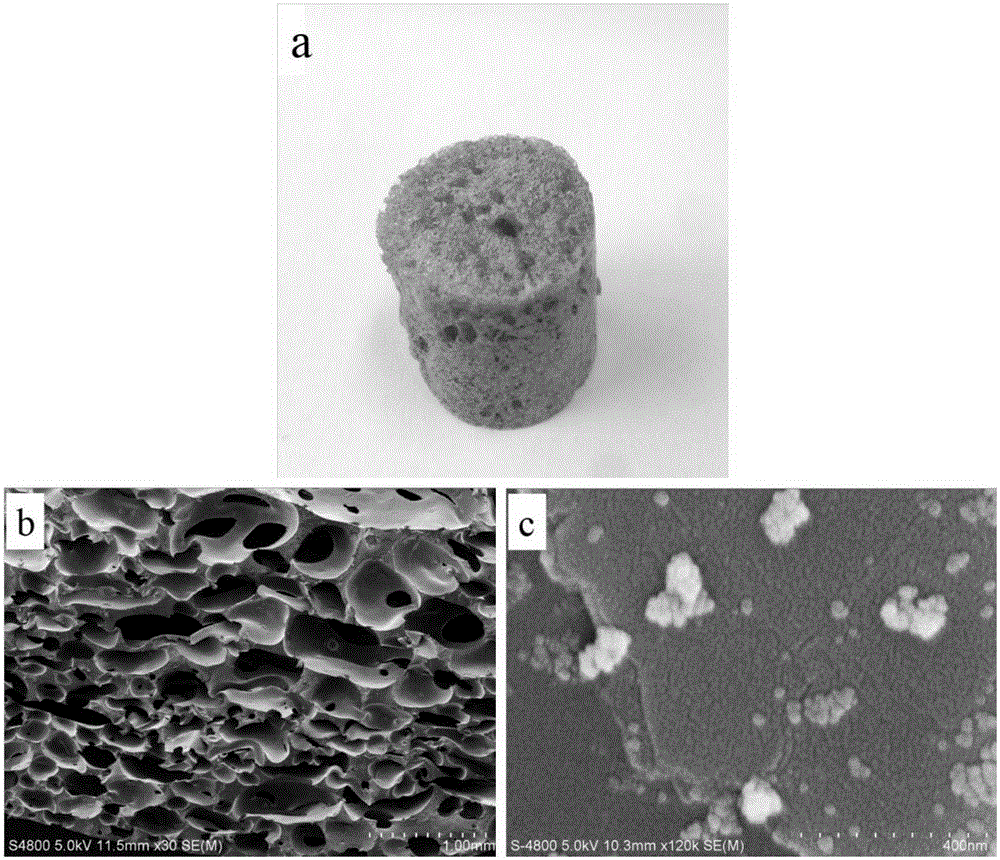

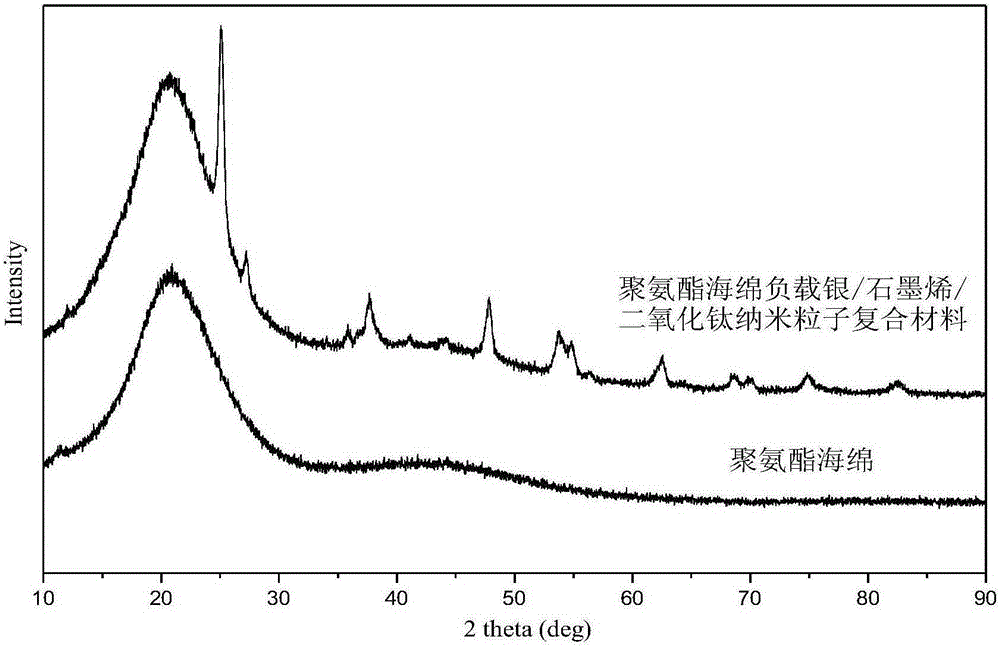

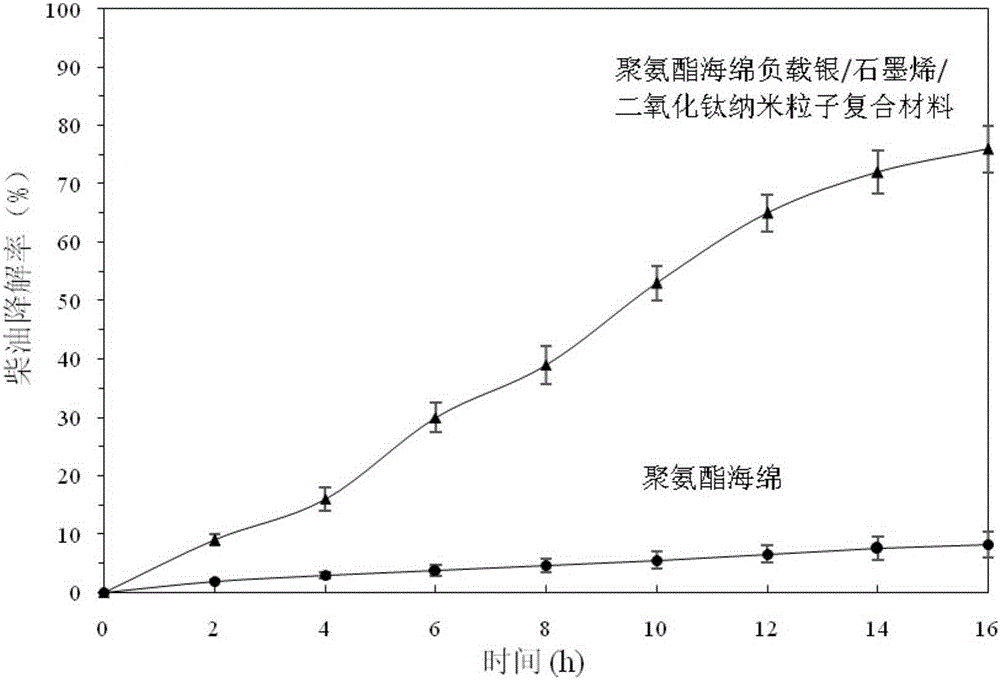

Polyurethane foam supported liver/graphene/ titanium dioxide nano particle composite material, preparation method thereof and application thereof

InactiveCN105170132AStrong persistenceStrong photocatalytic efficiencyWater/sewage treatment by irradiationOther chemical processesSilver ionAdsorption effect

The invention discloses a polyurethane foam supported liver / graphene / titanium dioxide nano particle composite material, a preparation method thereof and an application thereof. The material is a three-dimensional structure which is specifically that sliver / graphene / titanium dioxide ternary nano particles are uniformly loaded in the surface and a base body of the polyurethane foam. The preparation method comprises: preparing graphene / titanium dioxide binary nano particles; adding silver nitrate to carry out silver ion modification, thereby preparing silver / graphene / titanium dioxide ternary nano particles; and finally, quickly mixing and stirring a mixed solution of the silver / graphene / titanium dioxide nano particles and diphenyl methylpropane diisocyanate with a mixed solution of polyether polyol and dichloromethane, thereby preparing the polyurethane foam supported liver / graphene / titanium dioxide ternary nano particle composite material. The material provided by the invention has strong adsorption effect, and can degrade oil pollutants on the surface of a water body under irradiation of visible light, thereby achieving great potential in surface water remediation.

Owner:HOHAI UNIV

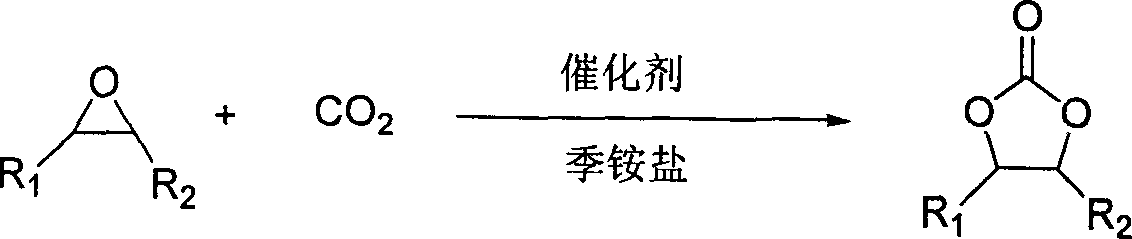

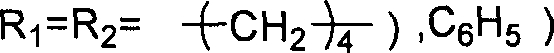

Method for synthesizing cyclic carbonate from carbon dioxide and epoxy compound through reaction of cycloaddition

ActiveCN1796384AMild reaction conditionsSimple processOrganic chemistryChemical recyclingOrganic solventSynthesis methods

This invention relates to a cycloaddition synthesis method for cyclic carbonates from carbon dioxide and epoxides. In this method, both supported catalysts and cocatalysts are adopted and the cycloaddition reaction is kept at a temperature of 50~200 deg.C and a carbon dioxide pressure of 0.1~10MPa for 0.5~10 hours. Qualitative and quantitative analysis with 6890 / 5973 chromatography-MS and NMR shows that the product purity is over 99% and the highest separation yield can be up to 95%. Compared to current methods, no organic solvents are adopted in this invention and therefore it is free from the toxicity of bezene, dichloromethane, and so on.

Owner:江苏华昌新材料技术研究有限公司

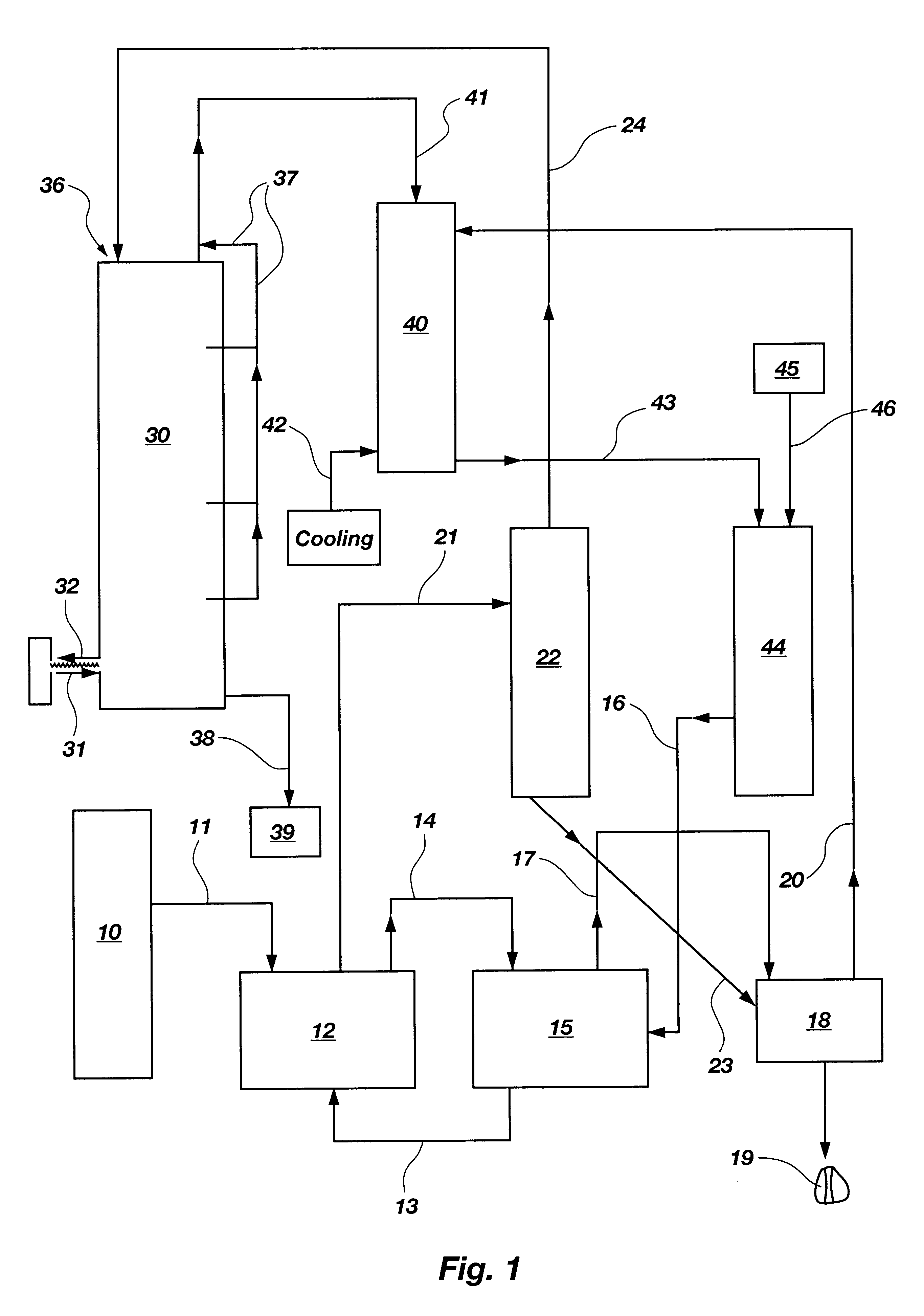

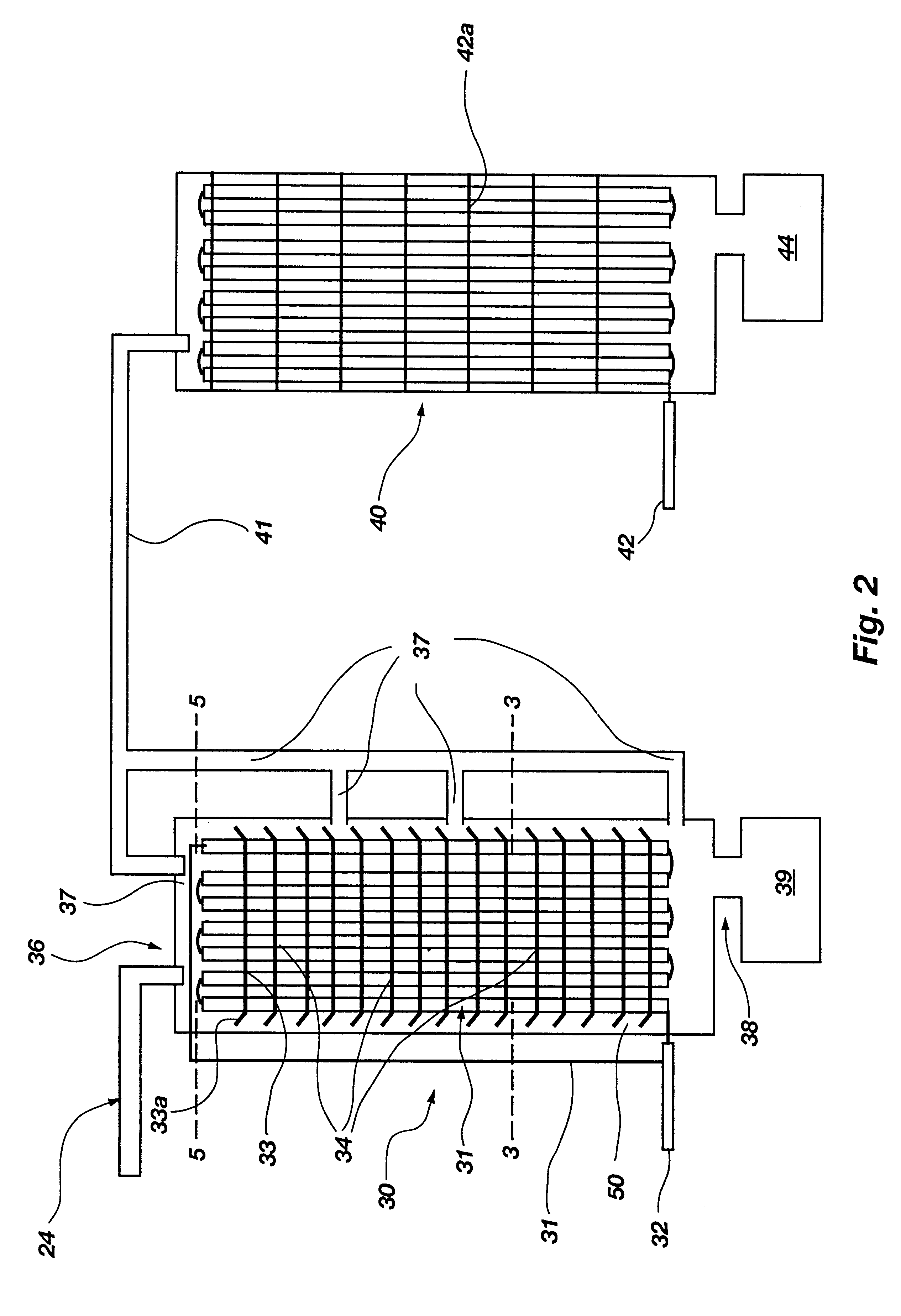

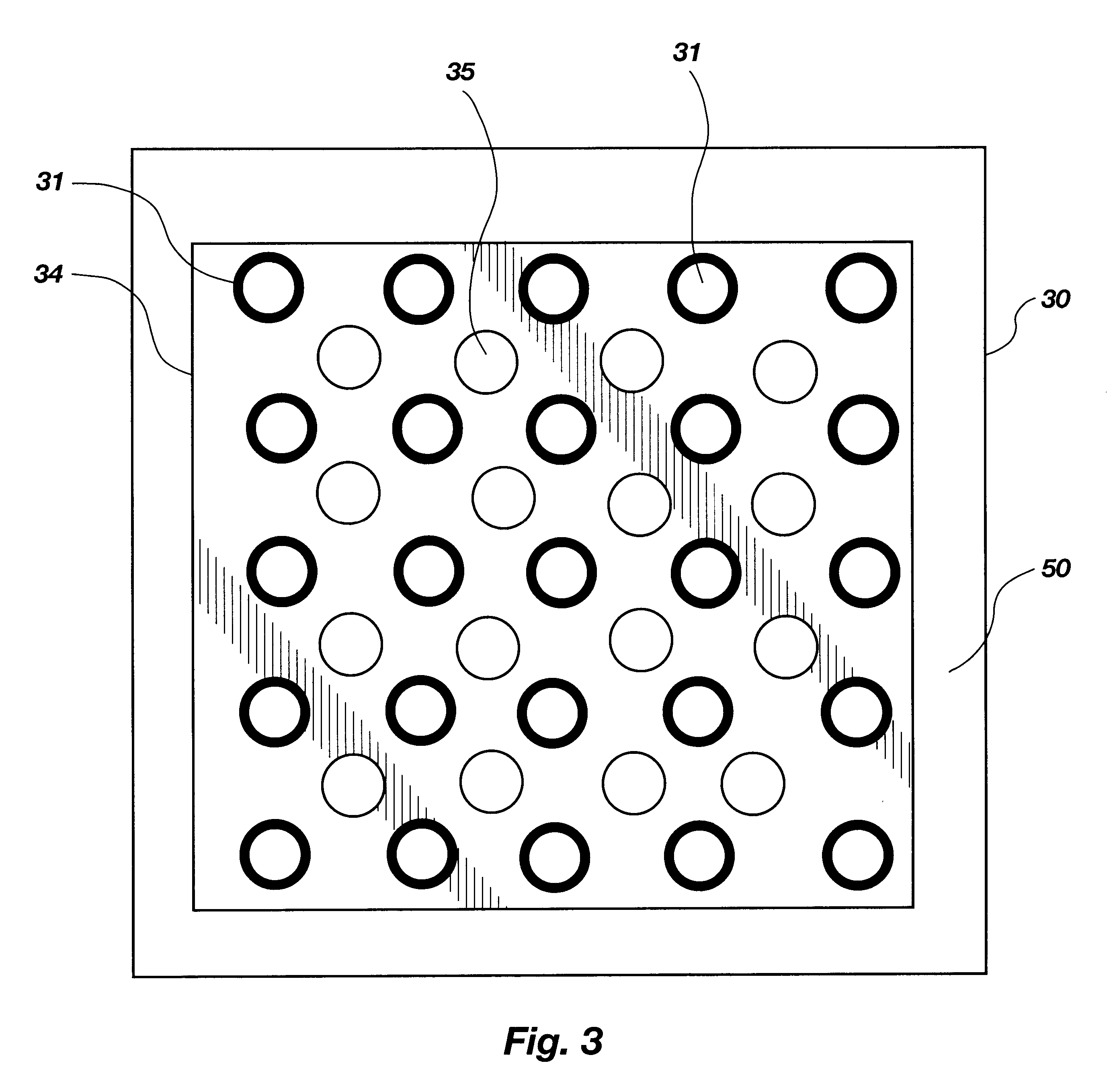

Solvent extraction of hydrocarbons from inorganic materials and solvent recovery from extracted hydrocarbons

InactiveUS6207044B1No pollution to the environmentIncrease surface areaLiquid organic insulatorsWorking-up pitch/asphalt/bitumen by chemical meansHydrocarbon solventsSolvent vapor

A process for the solvent separation of hydrocarbons from tar sand or contaminated soils comprises extracting the hydrocarbons from the sand or soil in a solvent extraction means to form a hydrocarbon rich solvent solution. The rich solvent is separated from the hydrocarbon in a process that utilizes flashing of the solvent in a heated flashing column at ambient pressure. The hydrocarbon is withdrawn from the bottom of the column and the flashed solvent vapors are strategicly withdrawn and passed into a condensation column from which the condensed solvent may be recycled. The flashing column is divided by a series of horizontal, vertically aligned apertured trays. The solution is introduced into the top of the column and the flashing operation is facilitated by the increase in the surface area of the solution as it flows by gravity from tray to tray. The column is maintained at a temperature, preferably above the boiling temperature of the solvent. The process is particularly adapted to the use of chlorinated hydrocarbon solvents and most particularly to the use of methylene chloride.

Owner:LUCENT TECH INC

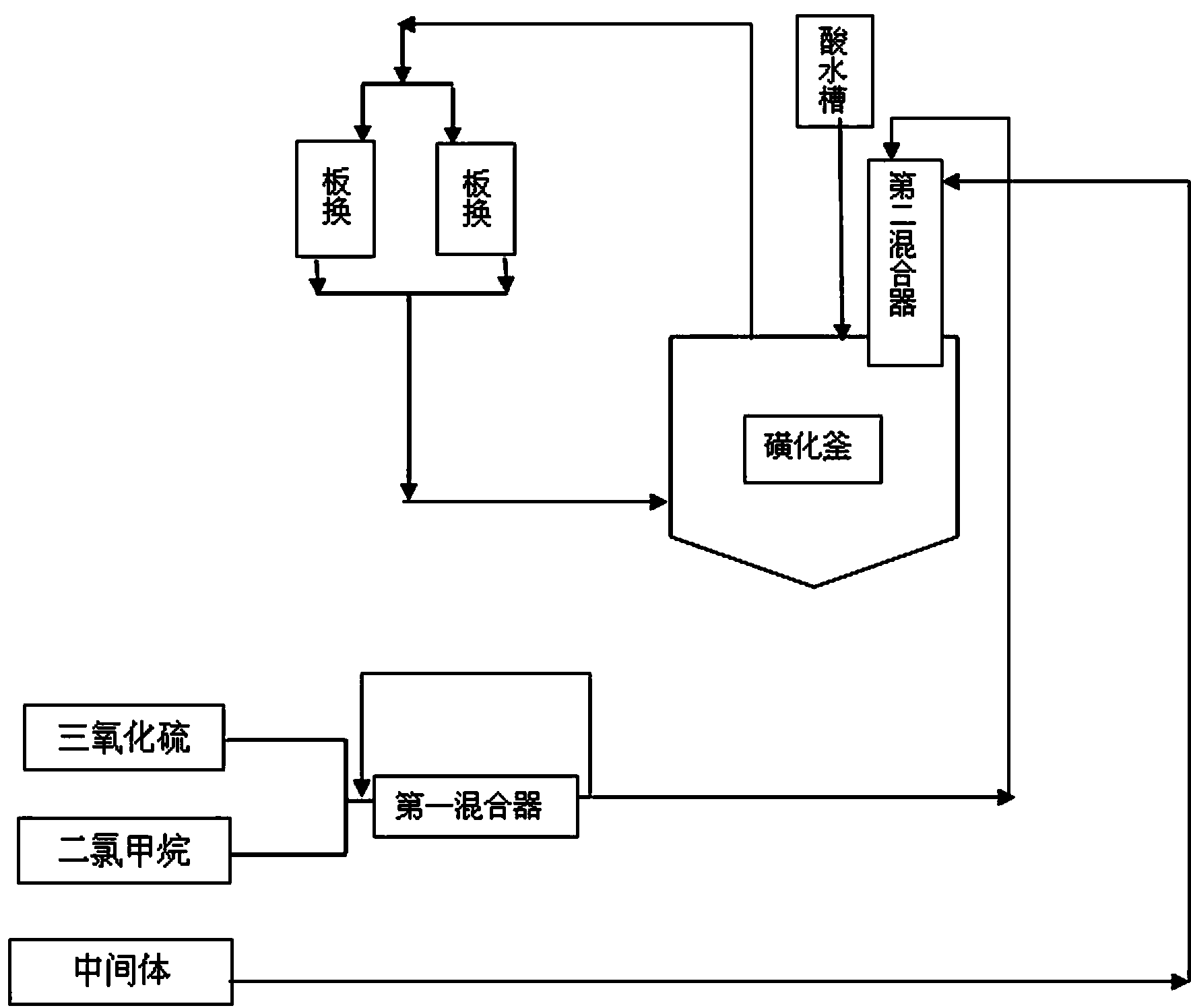

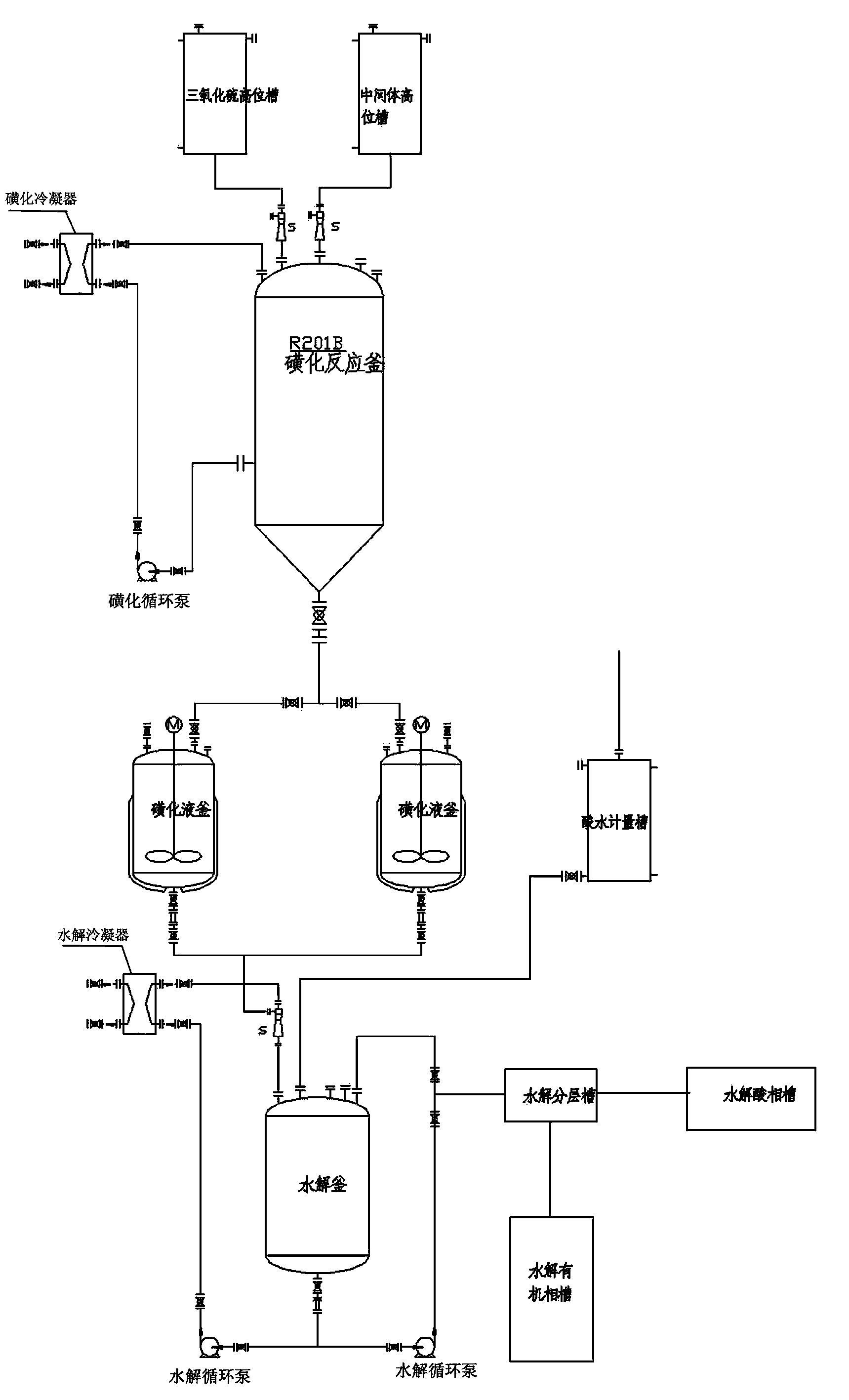

Acesulfame potassium cyclization continuous production method

ActiveCN103613566AImprove continuityReduce labor intensityOrganic chemistryReaction temperatureSulfur trioxide

The invention relates to an acesulfame potassium cyclization continuous production method. The method is characterized in that the sulfonation reaction and hydrolysis reaction comprise the following steps: step a, separately pumping an intermediate generated during a synthesis reaction and sulfur trioxide into a sulfonation reactor in a certain speed, carrying out sulfonation reactions in the sulfonation reactor; step b, gasifying dichloromethane when the concentration of the reactants in the sulfonation reactor reach a certain level, spraying the sulfonation liquid into a hydrolysis reactor; step c, dropwise adding acidic water into the hydrolysis reactor to carry out hydrolysis reactions. The method has the advantages that an cyclization one-step reaction technology is adopted, thus the continuity of production operation is realized, and the work strength of workers is reduced; compared to the conventional intermittent production technology, the one-step reaction method has a higher stability, improves the service life of the reactor, shortens the reaction time, and reduces the side reactions. Furthermore, in the method, the sulfonation reaction temperature is raised, then dichloromethane gasification is utilized to reduce the reaction temperature, so that low temperature production is avoided, and a deep cooling ice machine is stopped, so the production efficient is greatly improved, and the energy consumption is largely reduced.

Owner:ANHUI JINGHE IND

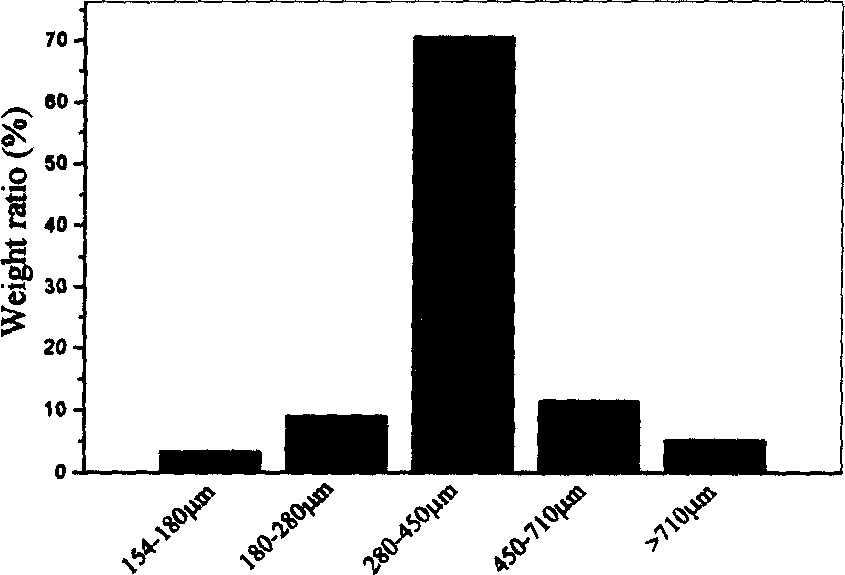

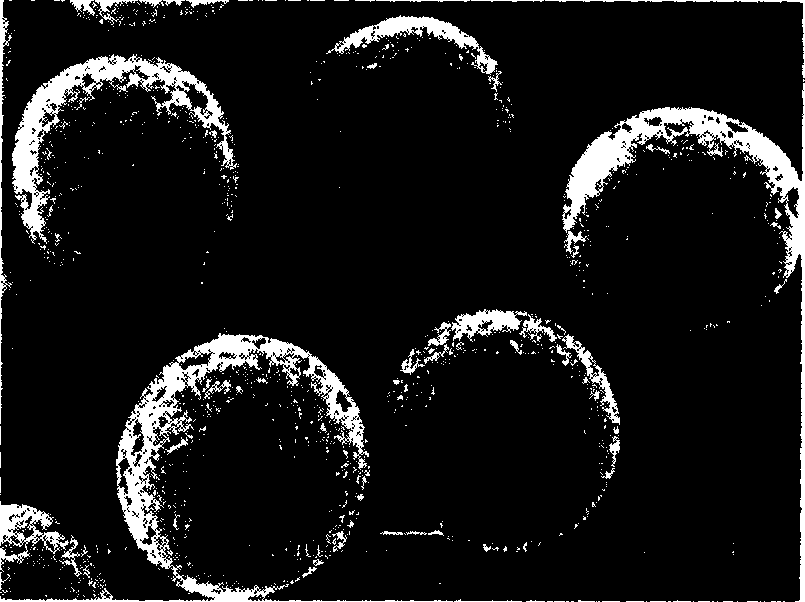

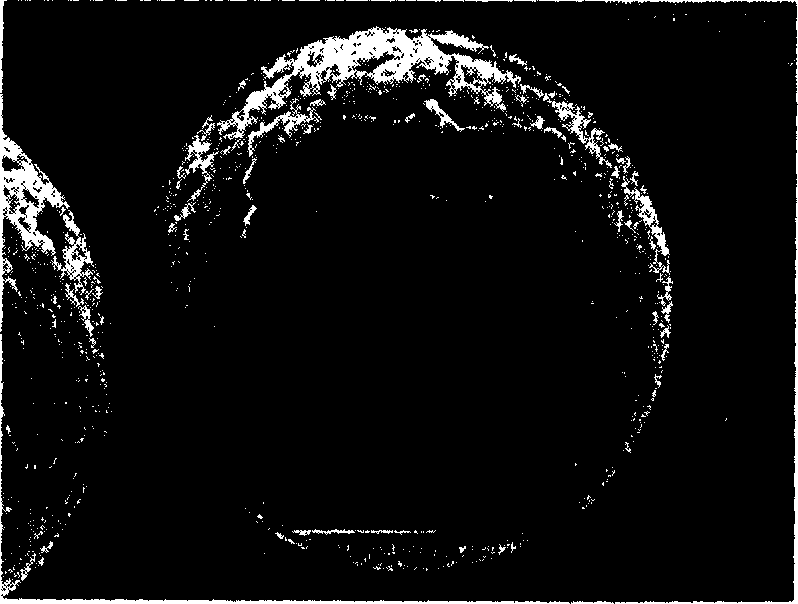

Method for preparing polylactic porous microball

InactiveCN1586704ASimple operation processMild implementation conditionsMicroballoon preparationMicrocapsule preparationOrganic solventPolyvinyl alcohol

The preparation process of porous polylactic acid microball includes the following steps: dissolving polylactic acid in solvent dichloromethane and adding bad solvent via mixing; dissolving PVA in deionized water to prepare solution, and under stirring, pouring the polylactic acid solution into the PVA solution; volatilizing organic solvent, filtering and washing to obtain the porous polylactic acid microball. The said process is simple and has mild condition, and the obtained porous polylactic acid microball may be used widely in controlled medicine releasing system, micro cell carrier in cell engineering and adhered microball rack in tissue engineering.

Owner:ZHEJIANG UNIV

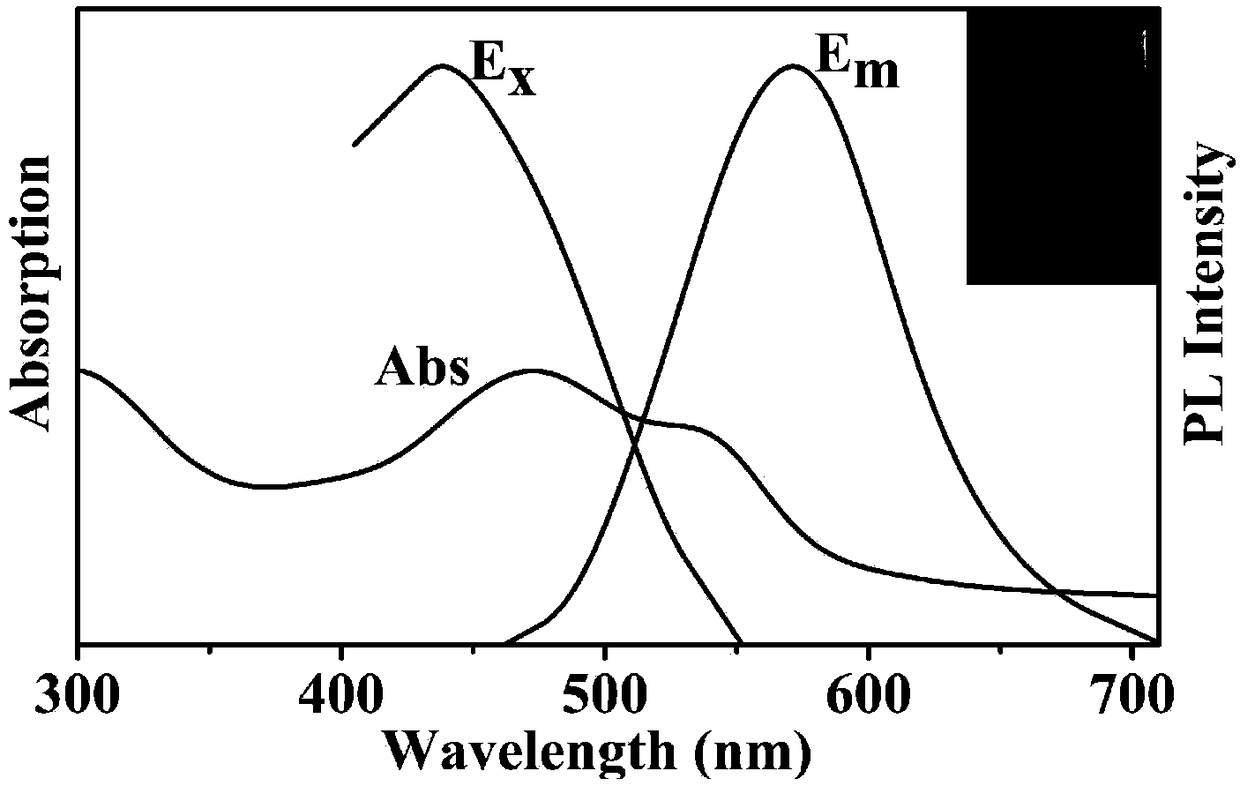

Copper (i) complexes for optoelectronic devices

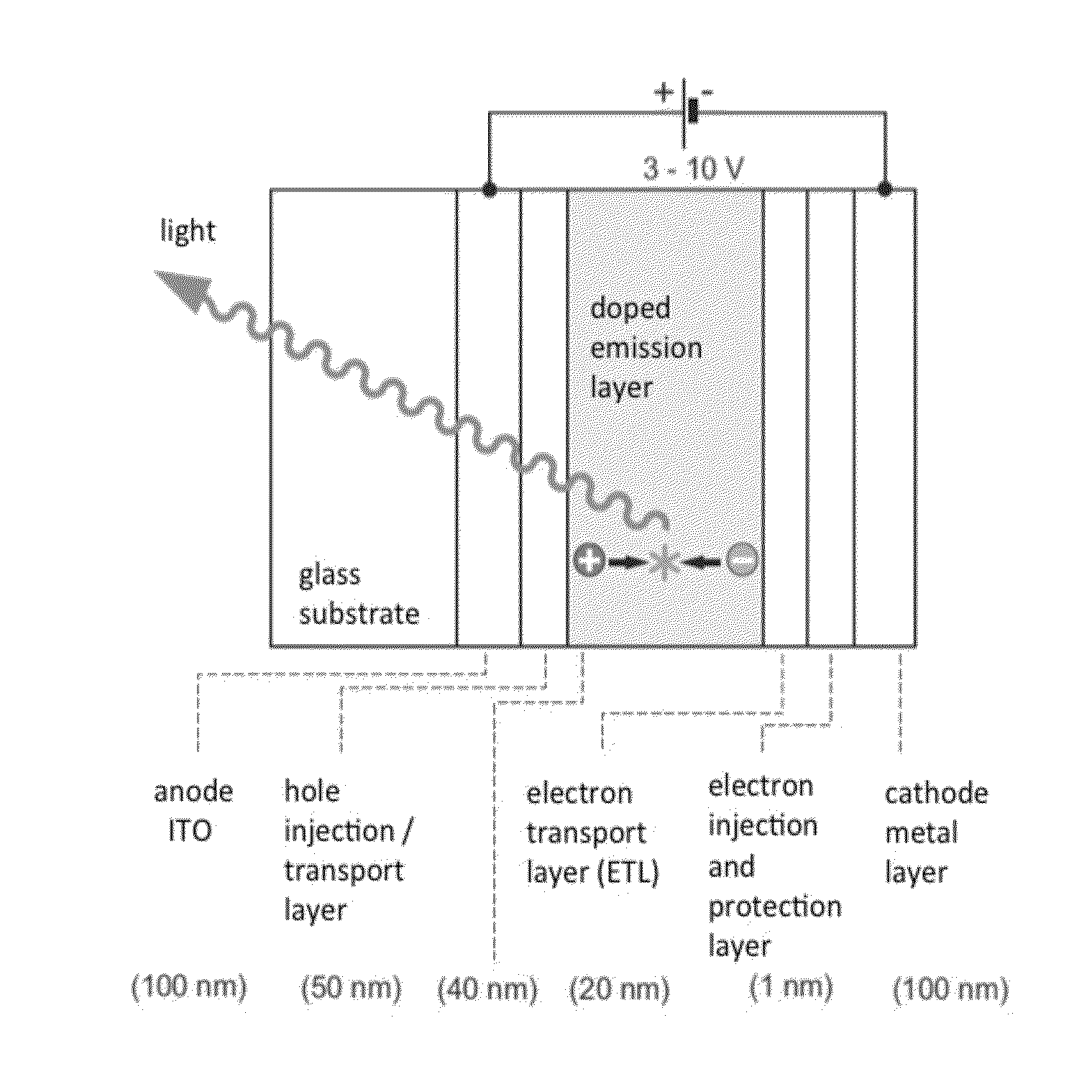

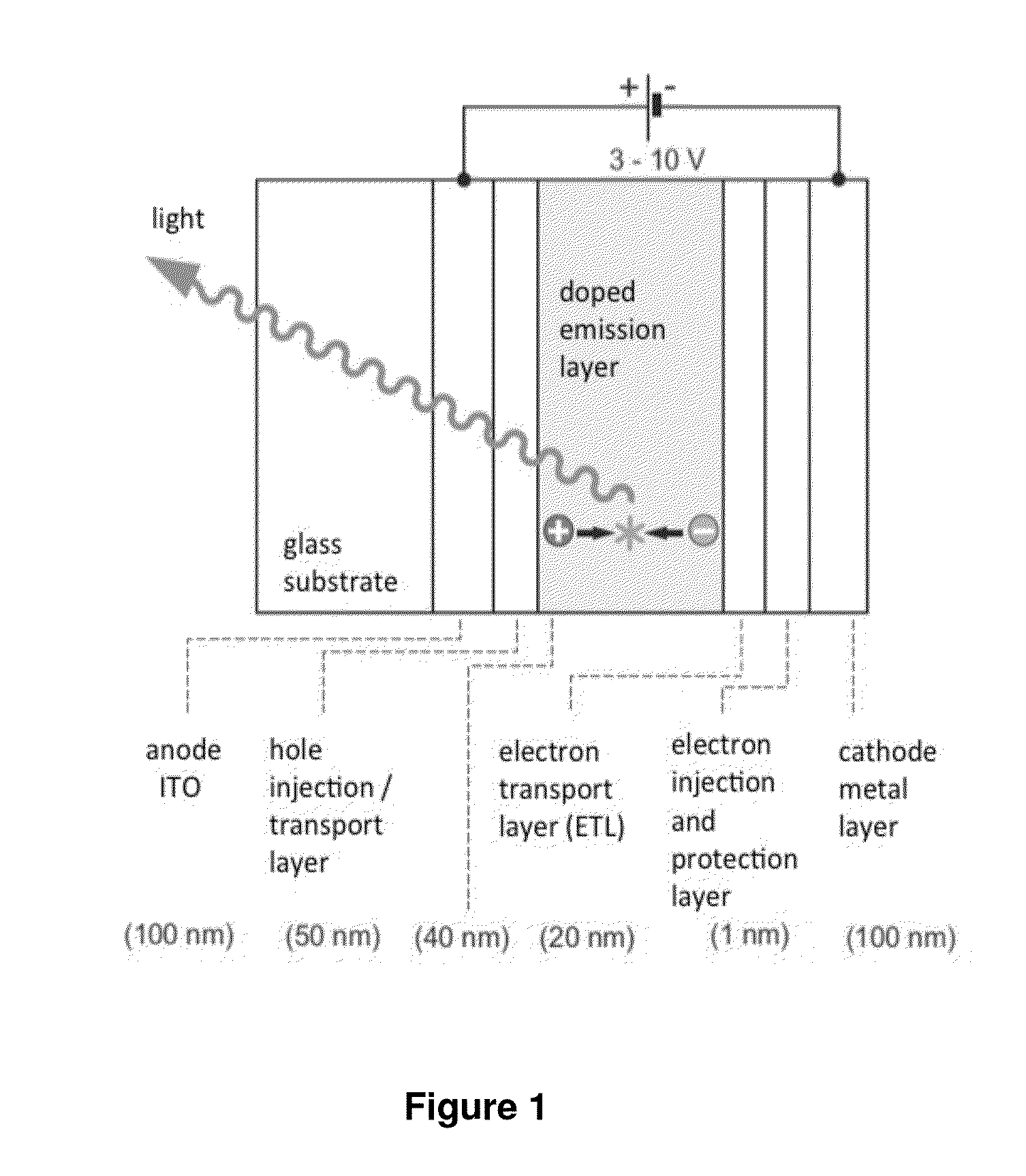

ActiveUS20130150581A1Short possible emission decay timeDiminished roll-off behaviorFinal product manufactureGroup 5/15 element organic compoundsSolubilityChlorobenzene

The invention relates to neutral mononuclear copper (I) complexes for emitting light and with a structure according to formula (A) in which: M represents: Cu(I); L∩L represents: a single, negatively charged, bidentate ligand; N∩N represents: a diimine ligand (substituted with R and FG), in particular a substituted 2,2′-bipyridine derivative (bpy) or a substituted 1,10-phenanthroline derivative (phen); R represents: at least one sterically demanding substituent for preventing the planarisation of the complex in the excited state; FG=functional group, and represents: at least one second substituent for increasing solubility in organic solvents. The substituent can also be used for electron transport or alternatively for hole transport, said functional group being bound to the diimine ligands either directly or by means of suitable bridges; and the copper (I) complex: having a ΔE(S1−T1) value of less than 2500 cm−1 between the lowest excited singlet state (S1) and the triplet state (T1) which lies below; having an emission lifespan of at most 20 μs; having an emission quantum yield of greater than 40%, and a solubility of at least 1 g / L in organic solvents, in particular polar organic hydrocarbons such as acetone, methyl ethyl ketone, benzene, toluene, chlorobenzene, dichlorobenzene, dichloromethane, chloroform, dichloroethane, tetrachloroethylene, alcohols, acetonitrile or water.

Owner:SAMSUNG DISPLAY CO LTD

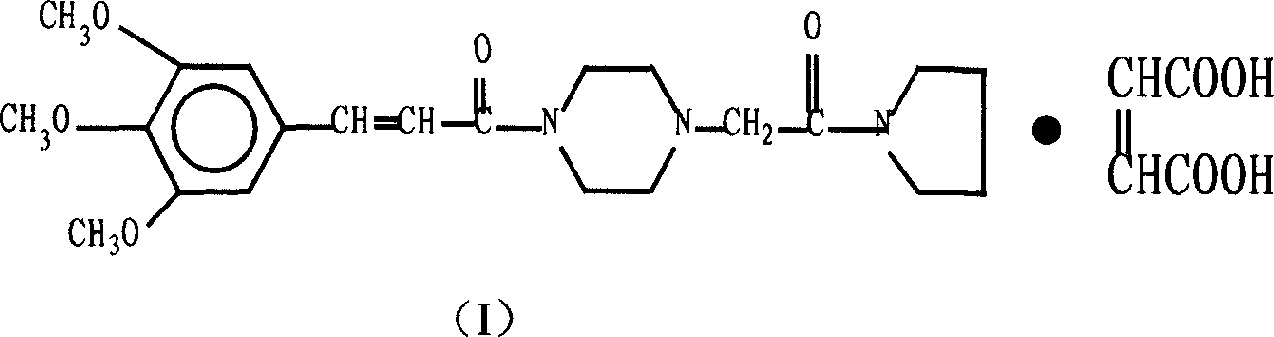

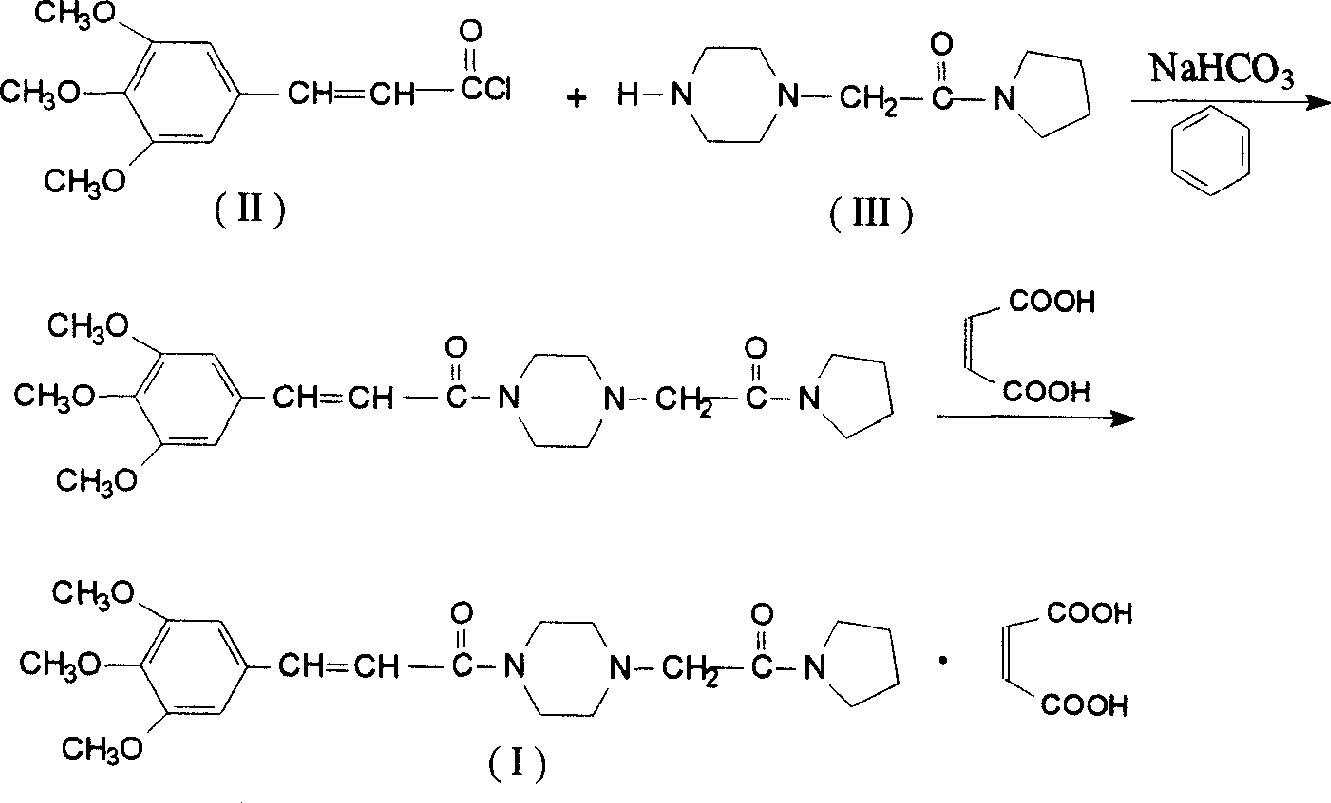

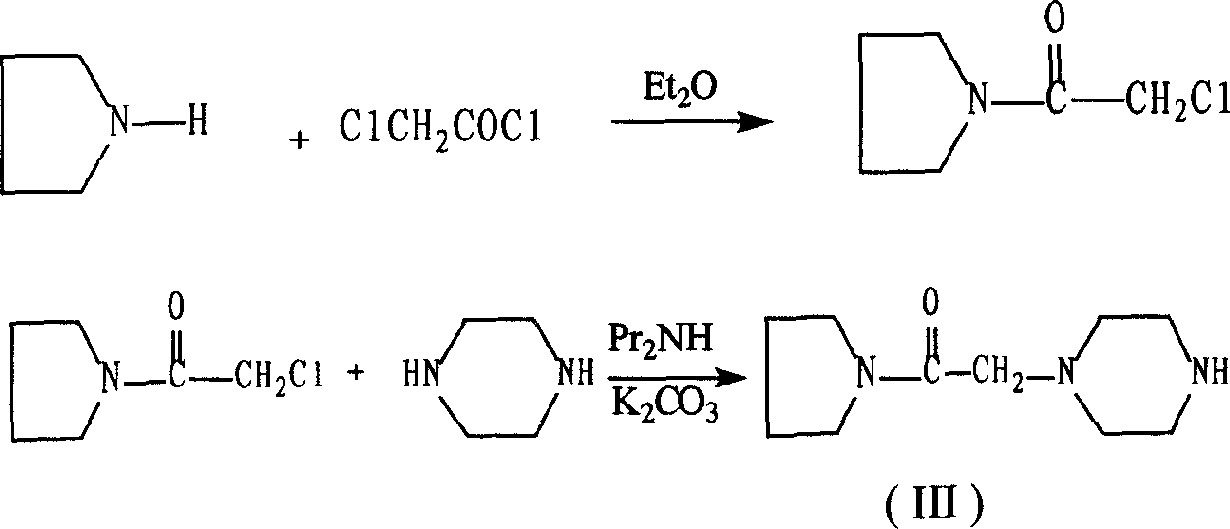

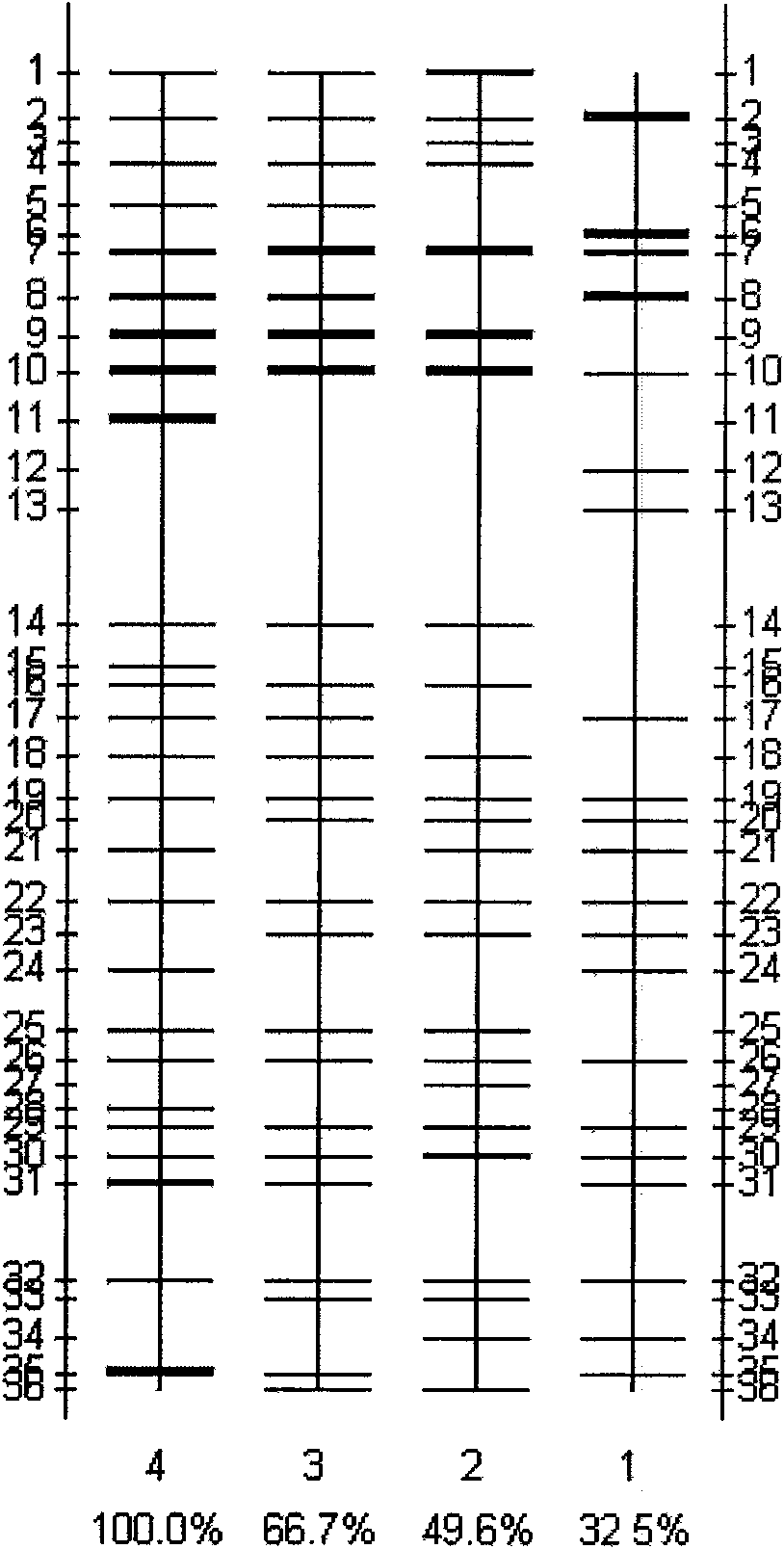

Synthesis method of cinepazide maleate

The invention relates to a method to synthesize maleic acid cinepazide. (2) reacts with 3,4,5- cinnamyl chloride, aquiring free alkali of cinepazide, the solvent is chosen from 5, add 6 and acquire the (7), the method for separating (1) is filtration. The invention uses safe solvent in the synthesis of (2), and the method of filtration and 8, making it suitable for industrialized production. The method uses the solvent with low toxicity and good safety, simplized productive condition and course, has high productivity and low cost.

Owner:BEIJING SIHUAN PHARMA +2

Bacterial preparation for degrading petroleum and restoring petroleum polluted soil ecology and preparation method thereof

InactiveCN101603018ALarge specific surface areaRestoration of polluted soil ecologyFungiBacteriaColony numberBacillus megaterium

The invention relates to a bacterial preparation for degrading petroleum and restoring petroleum polluted soil ecology and a preparation method thereof. The bacterial preparation for degrading the petroleum and restoring the petroleum polluted soil ecology is a composite colony consisting of bacillus megaterium, pseudomonas fluorescens, streptococcus faecalis and candida tropicalis through optimized combination, wherein the matching ratio of the components is 1-2:1:1:0.5-1. The bacterial preparation has the advantage that the bacterial preparation can quickly form a micro-ecological advantage colony after the bacterial preparation is applied to the soil. If 2 to 5 percent of the bacterial preparation is added relative to the weight of surface soil (a cultivation layer of about 15 to 20 centimeters), the oil removal rate in three months is more than or equal to 75 percent (dichloromethane reflux extraction and gravimetric method), and the bacterial preparation has high effective colony number and strong adaptability and has remarkable effect of restoring the petroleum polluted soil ecological environment.

Owner:NANKAI UNIV

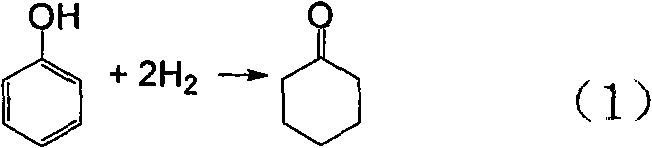

Method and special catalyst for preparing cyclohexanone in one step by phenol hydrogenation

InactiveCN101709027AEasy to makeMild reaction conditionsCatalyst carriersOrganic compound preparationCyclohexanoneHydrogen

The invention discloses a method and a special catalyst for preparing cyclohexanone in one step by phenol hydrogenation. The catalyst for preparing the cyclohexanone in one step by phenol hydrogenation comprises Lewis acid and a loading type metal catalyst, wherein the mole ratio of the Lewis acid to the loading type metal catalyst is 10:1 to 1:10. The method for preparing the cyclohexanone comprises the steps of: using dichloromethane or CO2 as a reaction solvent; and reacting the phenol with hydrogen to generate the cyclohexanone in the presence of the catalyst. The method for preparing the cyclohexanone in one step by phenol hydrogenation has the advantages of simple preparing process, high activity and selectivity, moderate reaction condition, good stability, and the like; in addition, after the reaction is completed, reaction liquid and the catalyst can be separated through filtering and repeatedly used, and catalyzing activity and selectivity are not reduced. Experiments prove that the method for preparing the cyclohexanone can achieve the percent conversion of the phenol more than 99.9 percent and the selectivity of the cyclohexanone more than 95 percent.

Owner:INST OF CHEM CHINESE ACAD OF SCI

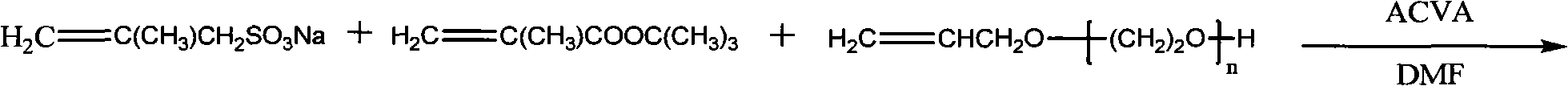

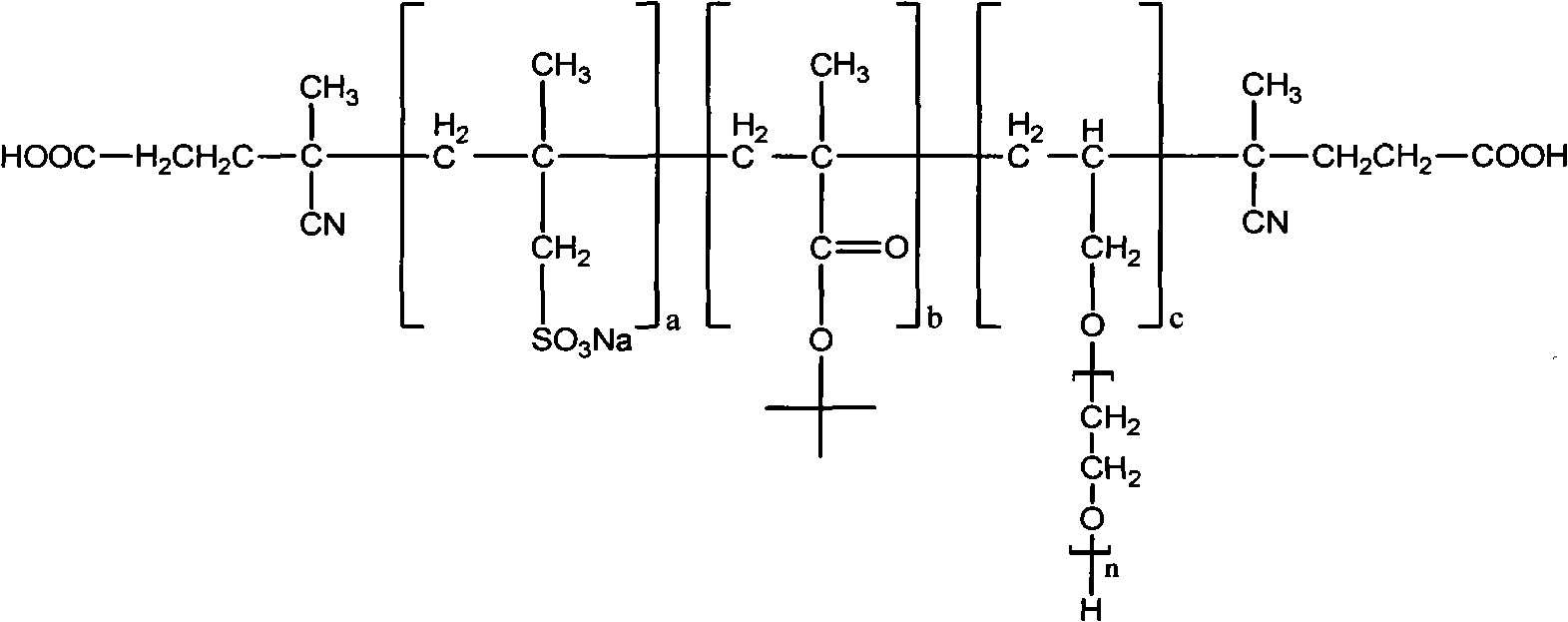

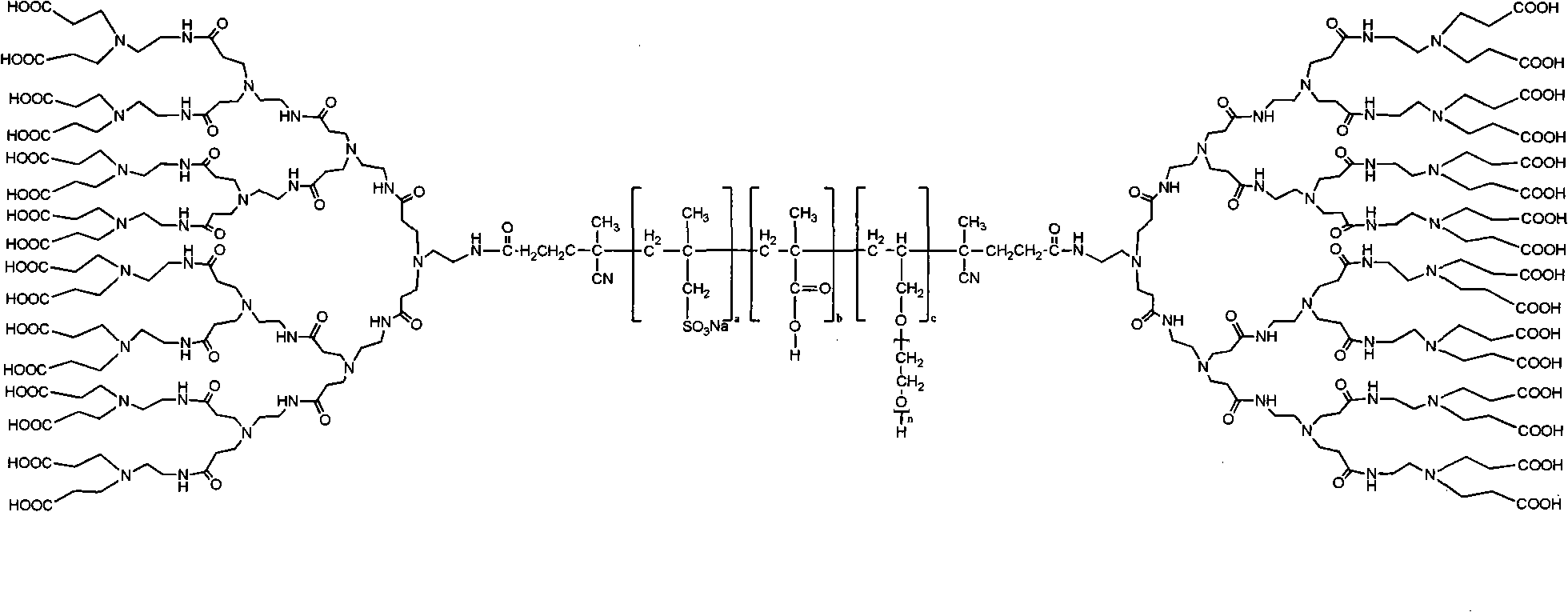

Hyper-branched polycarboxylate high-efficiency water reducing agent and preparation method thereof

The invention relates to a hyper-branched polycarboxylate high-efficiency water reducing agent and a preparation method thereof. The water reducing agent is prepared by polymerizing one of tert-butyl acrylate and methyl tert-butyl acrylate with sodium methyl-acryl sulfonate and allyl polyethenoxy ether to form a copolymer main chain, and then performing condensation polymerization on one of acrylic acid and methacrylic acid with ethylene diamine to form a hyper-branched polyamide structure which is grafted to two ends of the main chain. The preparation method comprises the following steps: (1) preparing the sodium methyl-acryl sulfonate into solution with DMF, and heating the solution in a nitrogen atmosphere; (2) dissolving the other two monomers and an initiating agent into the DMF to prepare mixed solution, and dripping the mixed solution into the step (1) to react for 1 to 20 hours; (3) adding a condensating agent CDI after the reaction and performing condensation reaction by using N-methyl morpholine as an organic base, the ethylene diamine and the acrylic acid as the monomers and the DMF as a solvent; and (4) performing vacuum distillation to remove the residual monomers and the solvent, and refluxing for 2 to 5 hours by using methylene chloride solution of trifluoroacetic acid to obtain the water reducing agent. The hyper-branched polycarboxylate water reducing agent has the advantages of low admixture, high water reducing rate, small slump loss, good compatibility with cement, no corrosivity to steel bars, strong frost resistance and the like.

Owner:厦门路桥翔通建材科技有限公司 +1

Method for preparing high-purity moxidectin

The invention relates to a method for preparing high-purity Moxidectin, which comprises the following steps: (1) macroporous absorption resin chromatography is carried out on Moxidectin solution which is purified in advance, the obtained product is eluted by the mixed solution of polar organic solvent and water; (2) the eluent is extracted by methylene dichloride, and then solvent is removed by conventional concentration; (3) protective reaction is carried out on the condensate to obtain upper protective liquid; (4) macroporous absorption resin chromatography is carried out on the upper protective liquid, and the chromatography is eluted by the mixed solution of the polar organic solvent and the water; (5) the eluted upper protective liquid is oxidized, and then deprotection and oximation reaction are carried out to obtain the reaction liquid of the Moxidectin; (6) macroporous absorption resin chromatography is carried out on the reaction liquid of the Moxidectin, and the chromatography is eluted by the mixed solution of the polar organic solvent and the water, so that the obtained eluent is the high-purity Moxidectin solution; the product can be separated out of the solution by using the conventional concentration and crystallization technology if necessary. As the macroporous absorption resin chromatography is used for separating instead of silica gel chromatography, the method is not only stable and controllable as well as is easy to industrialize, but also improves the product purity, the quality and the yield.

Owner:HISUN PHARMACEUTICAL (HANGZHOU) CO LTD

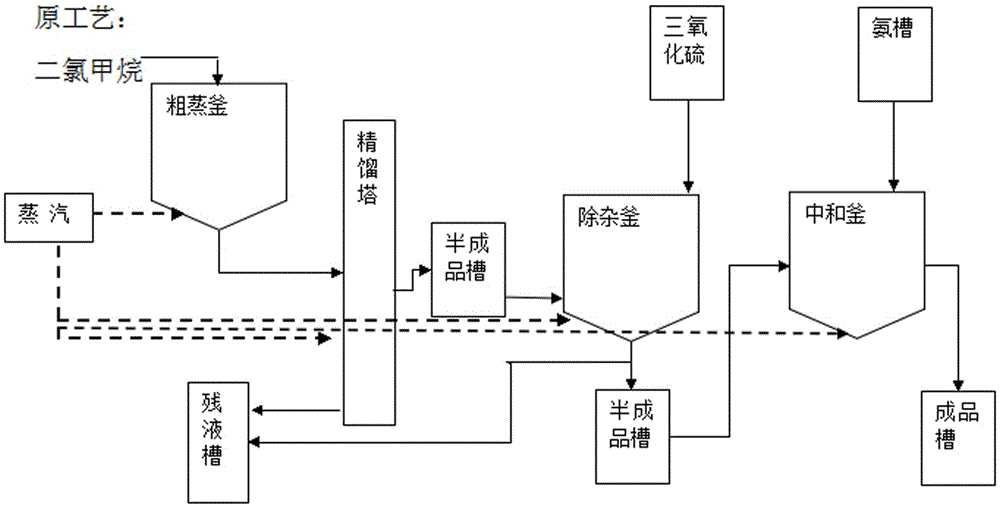

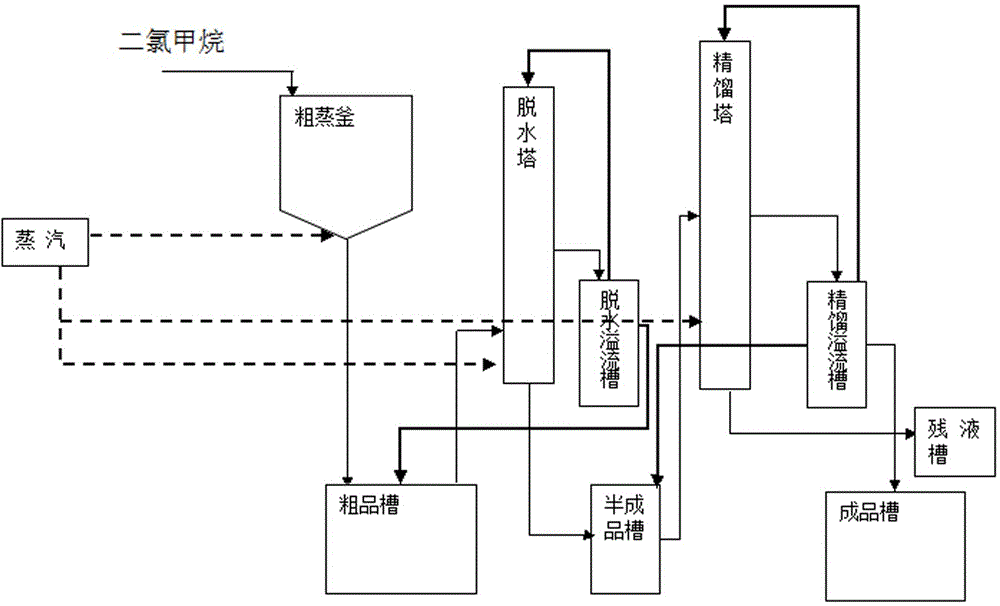

Method for recycling dichloromethane in acesulfame potassium synthesis process

InactiveCN105085160AImprove stabilityImprove product qualityHalogenated hydrocarbon preparationTowerHigh water content

The invention discloses a method for recycling dichloromethane in an acesulfame potassium synthesis process. The method comprises the steps of a, adding roughly distilled dichloromethane into a dehydrating tower, heating, condensing to enable steam of a mixed solution of dichloromethane and water to enter a dehydration overflow tank and dichloromethane containing qualified water at the bottom to enter a semi-finished product tank so as to be used by a rectifying tower; b, enabling dichloromethane containing unqualified water at the bottom of the overflow tank to enter the dehydrating tower again through backflow and dichloromethane with high water content at the top to enter a crude product tank, and regularly discharging layered water in the crude product tank; c, enabling dichloromethane containing qualified water in the semi-finished product tank to enter the rectifying tower, distilling to 45 DEG C, enabling dichloromethane steam to enter the dehydration overflow tank, and sucking dichloromethane with high impurity content at the bottom into a residual solution tank; and d, after detecting dichloromethane in the dehydration overflow tank to be qualified, placing dichloromethane into a finished product tank so as to be used for synthesizing and sulfonating, and enabling the unqualified dichloromethane to enter the rectifying tower so as to be rectified again.

Owner:ANHUI JINGHE IND

Method for preparing iodic liquid embolic agent capable of long-time self-developing

ActiveCN101513542AWith long-term developing functionRelieve painSurgeryX-ray constrast preparationsPolyvinyl alcoholBlood vessel

The invention provides a method for preparing an iodic liquid embolic agent capable of long-time self-developing. Water-soluble polyvinyl alcohol (PVA) is added with pyridine to be stirred and evaporated for removing the pyridine. Residual reactant is dehumidified and dissolved in dimethyl sulphoxide (DMSO) organic solvent and then is added with solution of iodic compound and dichloromethane and added with triethylamine; and an obtained iodic product (I-PVA) is poured into a mixture of butyl ether and acetone to be deposited and separated. The iodic product is washed in water, is dried and then is confected into the liquid embolic agent by the dimethyl sulphoxide or N-methyl-ketopyrrolidine organic solvent. The liquid embolic agent prepared by the invention is injectable and can develop under X-ray for a long time. When contacting with blood, the organic solvent diffuses fast for depositing and separating solid to take embolic effect. The embolic agent can be used for embolotherapy of cerebral arteriovenous malformation, tumour and other vascular disease.

Owner:山东大正医疗器械股份有限公司

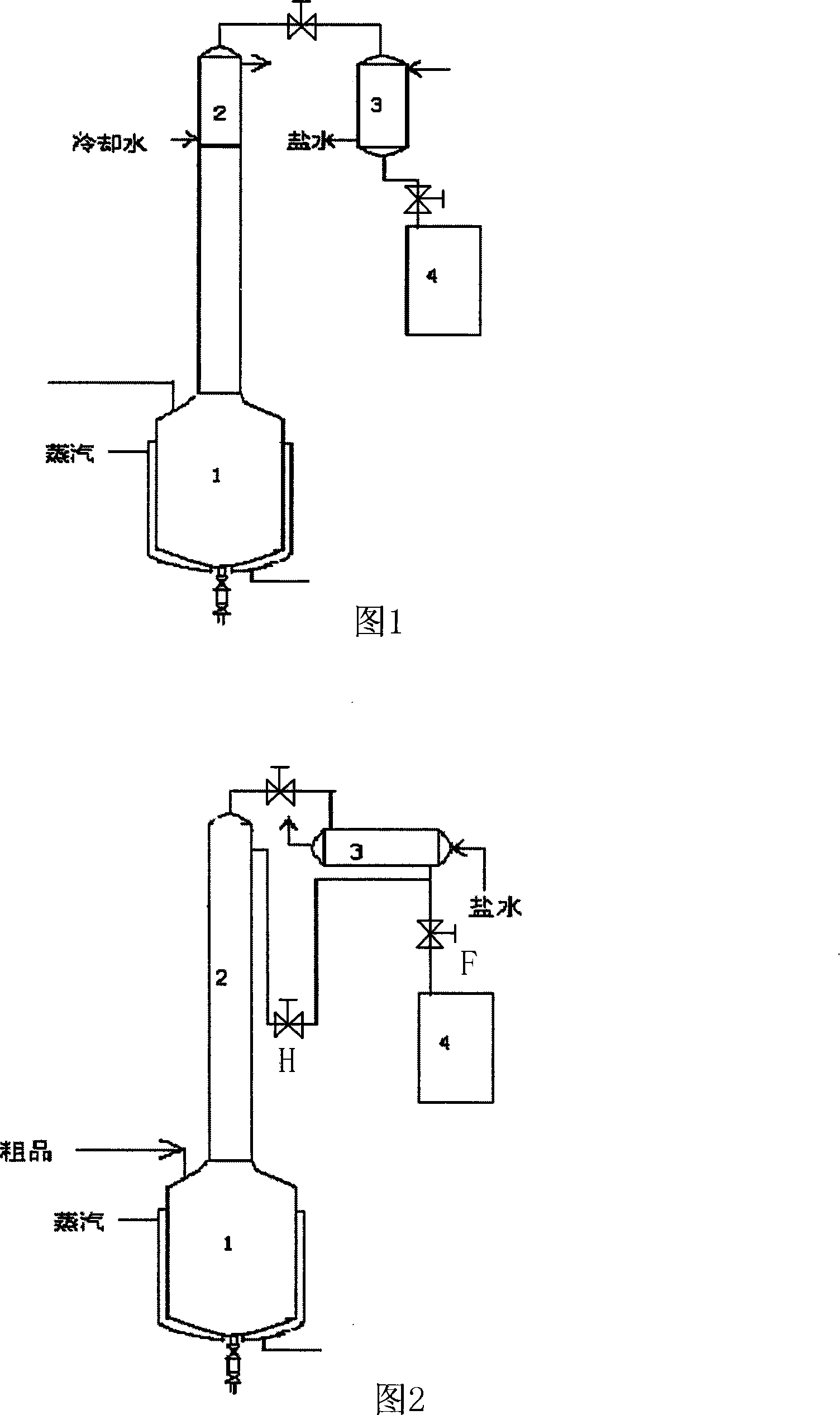

Triethylamine recovery processing method and device for production of acesulfame potassium

ActiveCN101157666AEasy to operateLow costAmino compound purification/separationMolecular sieveBoiling point

The invention relates to a triethylamine reclaim treatment method and the devices in the production of acesulfame-K, which is characterized in that the method includes the following steps: a. the crude triethylamine containing water is put into a distillation kettle (1), which is heated to the temperature of 38 DEG C to 42 DEG C, the time is about 20 to 40 minutes, the dichloromethane and other impurities with the low boiling points which are contained in the crude triethylamine are firstly evaporated, collected and then are condensed and collected by a condenser (3); b. the heating is carried out continually to about 83 DEG C, the temperature is kept for more than 30 minutes, which ensures that the water and triethylamine are placed still for layer separation, a lower layer is water, an upper layer is triethylamine, and triethylamine of the upper layer can be collected after the water is drained completely from the bottom of a kettle. Finally, the collected triethylamine is dried by the solid potassium hydroxide or a molecular screen, so the water content of triethylamine can be lower than 0.1 percent. The invention has the advantages of simple using equipment, convenient operation, safety, reliability, low cost, improved reclaim ratio of the product and significantly reduced operating cost.

Owner:ANHUI JINGHE IND

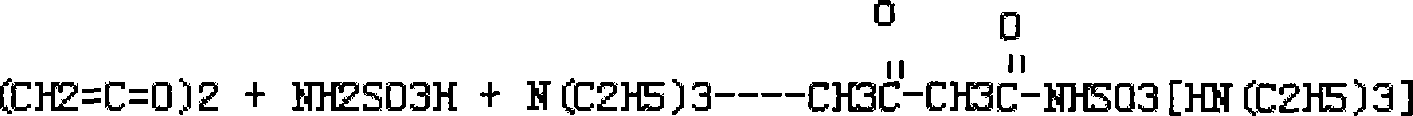

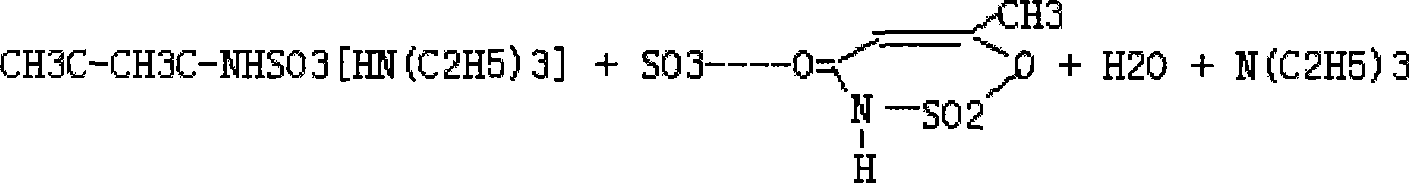

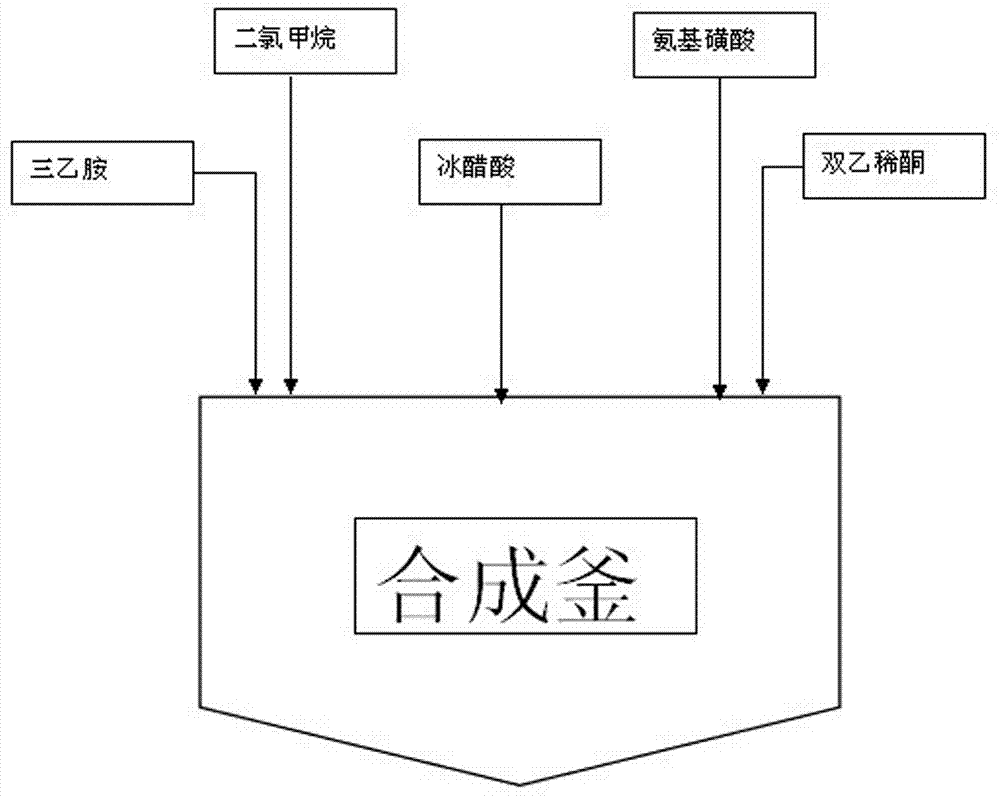

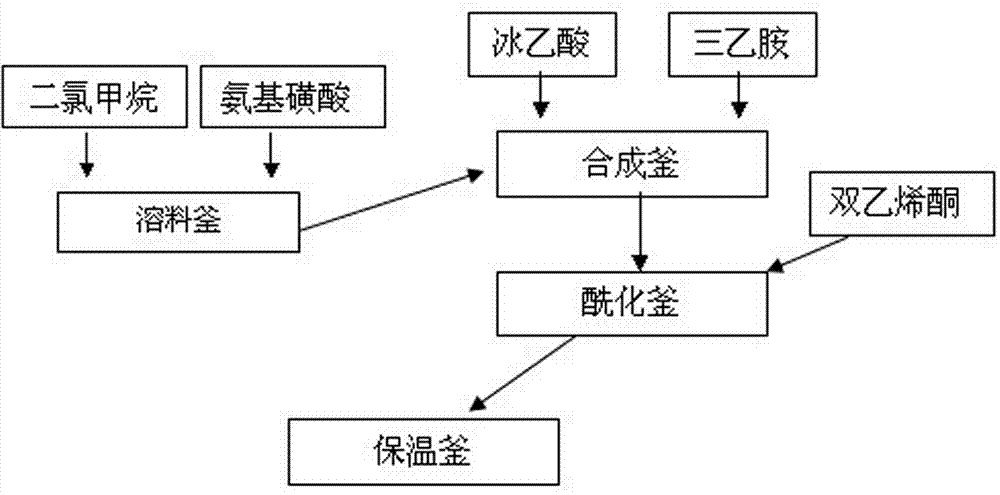

Acesulfame synthesis and acylation production process

InactiveCN103570592AReduce labor intensityImprove continuitySulfuric acid amide preparationAcetic acidEconomic benefits

The invention relates to an acesulfame synthesis and acylation production process, which comprises the following steps of a, putting a sulfamic acid and dichloromethane into a dissolving kettle, and pumping a mixture into a synthesis kettle; b, adding dropwise triethylamine into the synthesis kettle, adding dropwise a glacial acetic acid, and performing natural reaction for 1 hour after the glacial acetic acid is added dropwise; c, placing reactants in the synthesis kettle into an acylation kettle, and adding dropwise diketene for an acylation reaction; and d, after the diketene is added dropwise, circulating a product subjected to the acylation reaction for 1 hour in the acylation kettle, placing into a heat-preservation kettle, performing natural reaction for 1 hour to generate an acetoacetyl-N-sulfonate intermediate, and feeding the acetoacetyl-N-sulfonate intermediate to a sulfonation section for use. The acesulfame synthesis and acylation production process has the advantages that 1, a stepwise reaction mode is adopted, so that compared with a conventional single-kettle production process, the method has the characteristics of production operation continuity and high reaction stability; 2, a multi-kettle stepwise production mode is adopted, so that the production efficiency is greatly improved, the reaction efficiency of the whole production flow is optimized, and the economic benefits of an enterprise are significantly improved.

Owner:ANHUI JINGHE IND

Immobilized carrier of nano-attapulgite clay compounded hydrophilic urethane foam microorganisms

InactiveCN101619310AHigh affinityImprove mass transfer effectImmobilised enzymesSustainable biological treatmentN dimethylformamideRaw material

The invention relates to an immobilized carrier of nano-attapulgite clay compounded hydrophilic urethane foam microorganisms, which consists of the following raw materials in parts by weight: 100 polyether, 36-55 toluene di-isocyanate, 3.1-3.9 polyisocyanate, 0.5-5 nano-attapulgite clay, 0.45-1.2 silicon oil, 0.14-0.25 tertiary amine, 0.14-0.20 organotin, 1.0-2.7 water, 1.6-4.5 methylene dichloride and 0-80 N, N-dimethylformamide. The polyisocyanate and the nano-attapulgite clay are added in the foaming process of common polyether urethane, thereby the common polyether urethane has a water absorbing surface with crosslinked network structure and strong polarity, meanwhile has great adsorption capacity and hydrophilicity of nanomaterials, improves the compatibility and the mass transfer performance of a foam carrier to the microorganism, and simultaneously strengthens the physicochemical performance and the stability of the materials, thereby improving the sewage treatment efficiency.

Owner:LANZHOU JIAOTONG UNIV

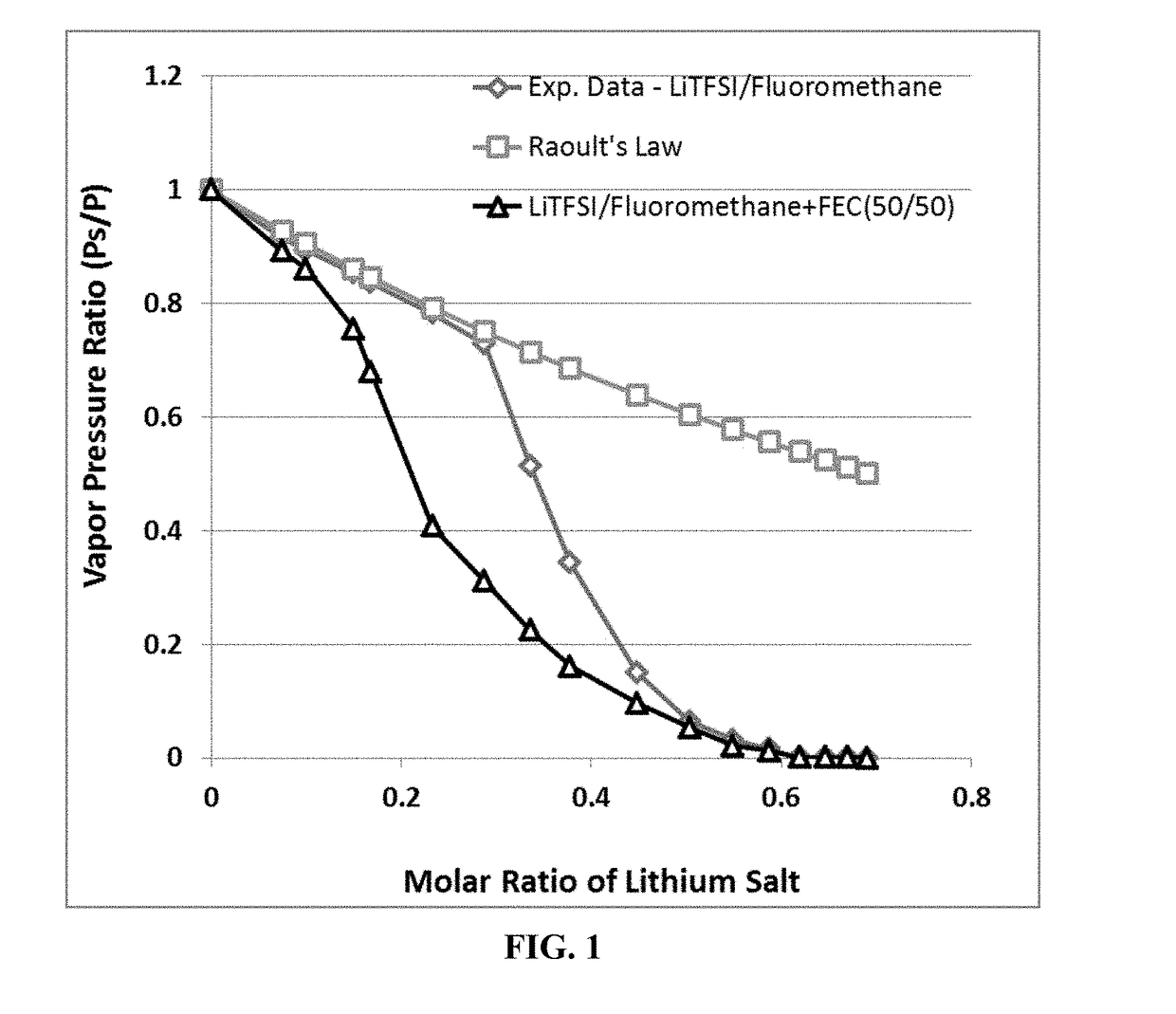

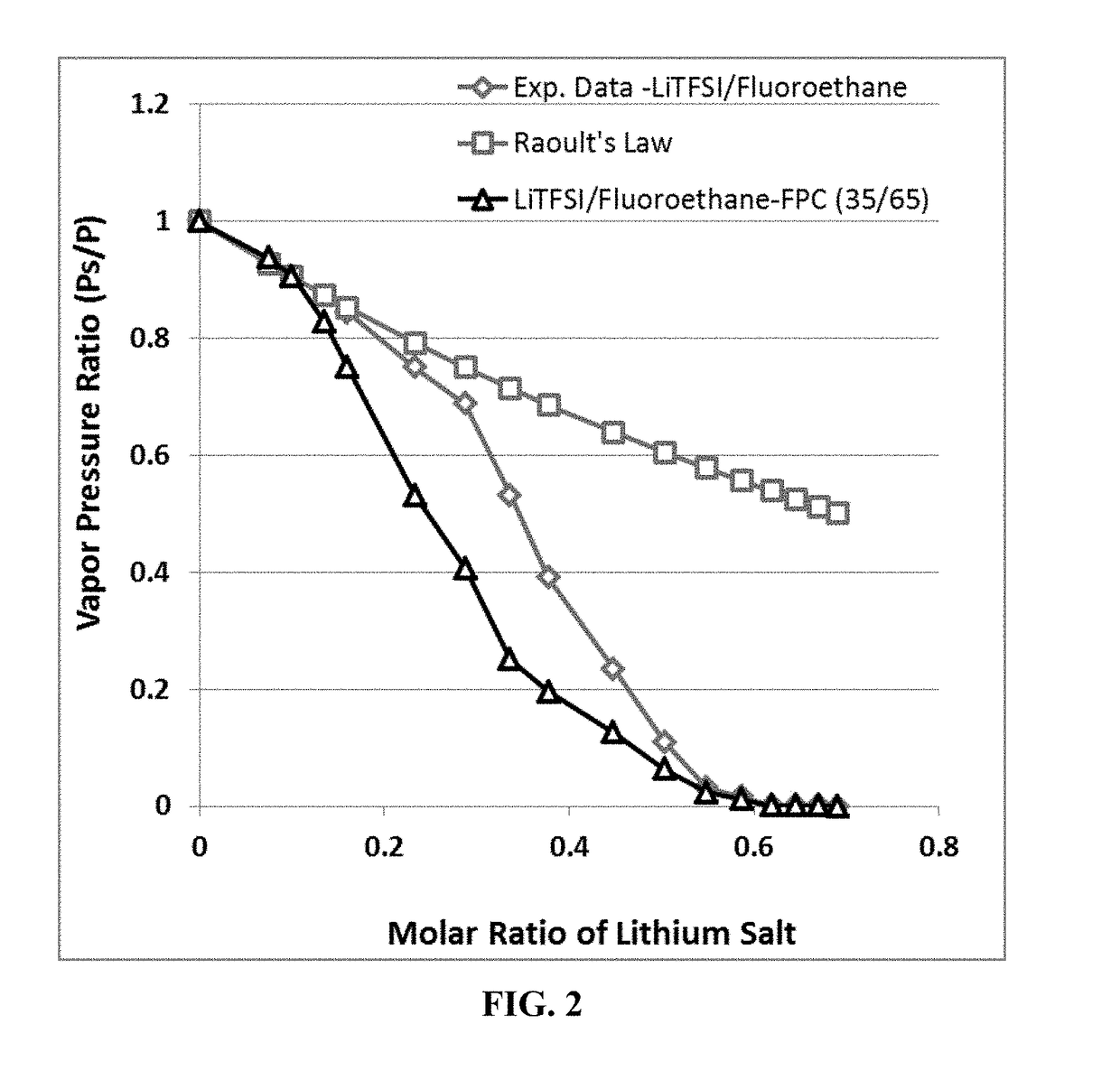

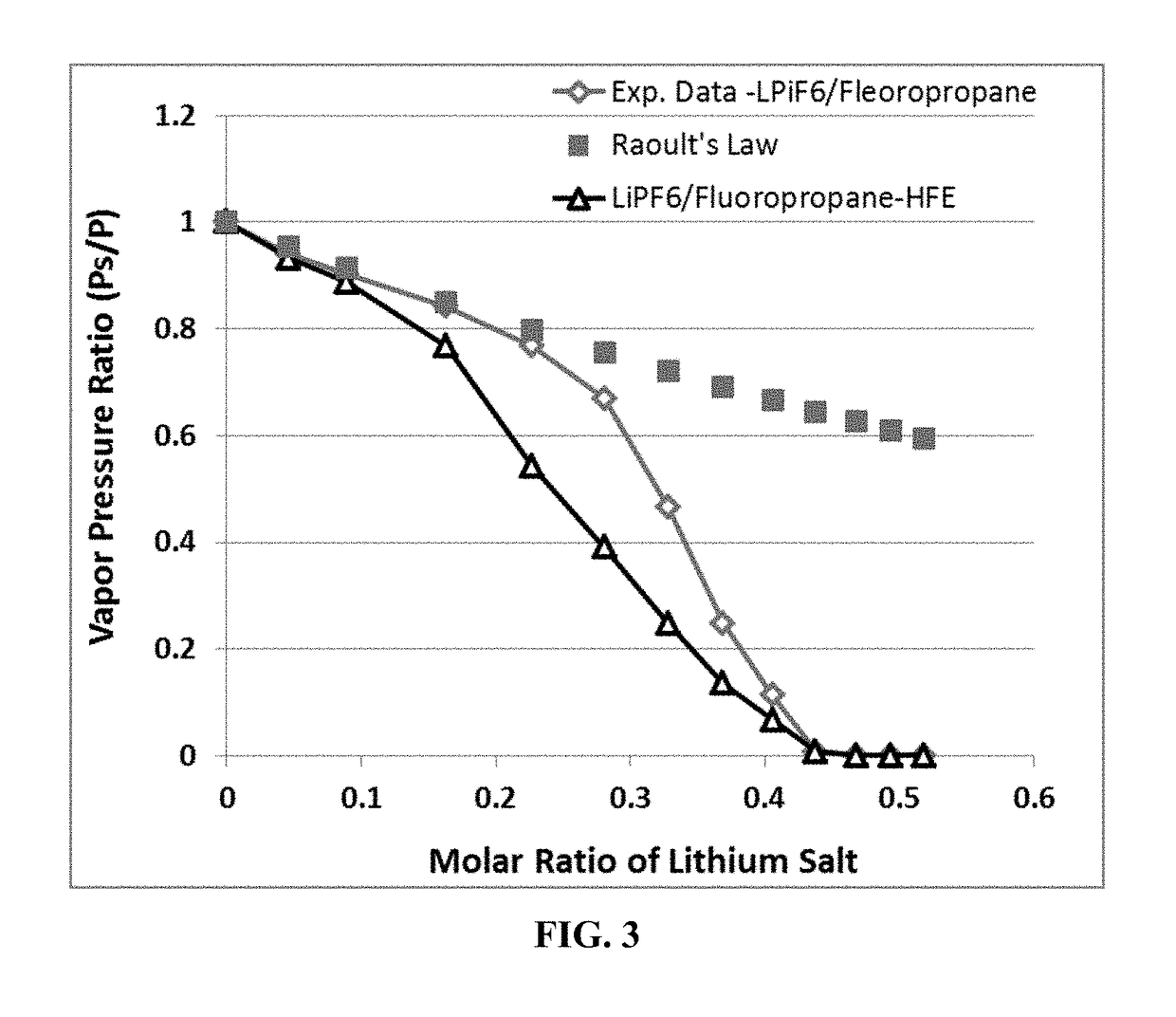

Non-flammable Electrolyte Containing Liquefied Gas and Lithium Secondary Batteries Containing Same

ActiveUS20180375156A1Flammability of any liquefied gas solvent can be effectively suppressedImprove solubilityOrganic chemistryCell electrodesElectrolytic agentDifluoroethyne

A rechargeable lithium cell comprising a cathode, an anode, an optional ion-permeable membrane disposed between the anode and the cathode, a non-flammable salt-retained liquefied gas electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in or mixed with a liquefied gas solvent having a lithium salt concentration greater than 1.0 M so that the electrolyte exhibits a vapor pressure less than 1 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquefied gas solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the liquefied gas solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquefied gas solvent is selected from methane, fluoromethane, difluoromethane, chloromethane, dichloromethane, ethane, fluoroethane, difluoroethane, tetrafluoroethane, chloroethane, dichloroethane, tetrachloroethane, propane, fluoropropane, chloropropane, ethylene, fluoroethylene, chloroethylene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

Preparation method and product of full-color carbon dots for multi-color fluorescent printing

ActiveCN108587615AEmission wavelength red shiftImprove stabilityInksNanoopticsSolubilityColor printing

Owner:JIANGNAN UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00221.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00231.PNG)

![Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process Industrial process for the synthesis of 17a-acetoxy-11ss-[4-(n,n-dimethyl-amino)- phenyl]-19-norpregna-4,9-diene-3,20-dione and new intermediates of the process](https://images-eureka.patsnap.com/patent_img/9a66d1cf-4b54-4dee-bae5-7e40fd7cdedf/A200780021915E00232.PNG)