Patents

Literature

108 results about "Difluoroethyne" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Non-flammable Electrolyte Containing Liquefied Gas and Lithium Secondary Batteries Containing Same

ActiveUS20180375156A1Flammability of any liquefied gas solvent can be effectively suppressedImprove solubilityOrganic chemistryCell electrodesElectrolytic agentDifluoroethyne

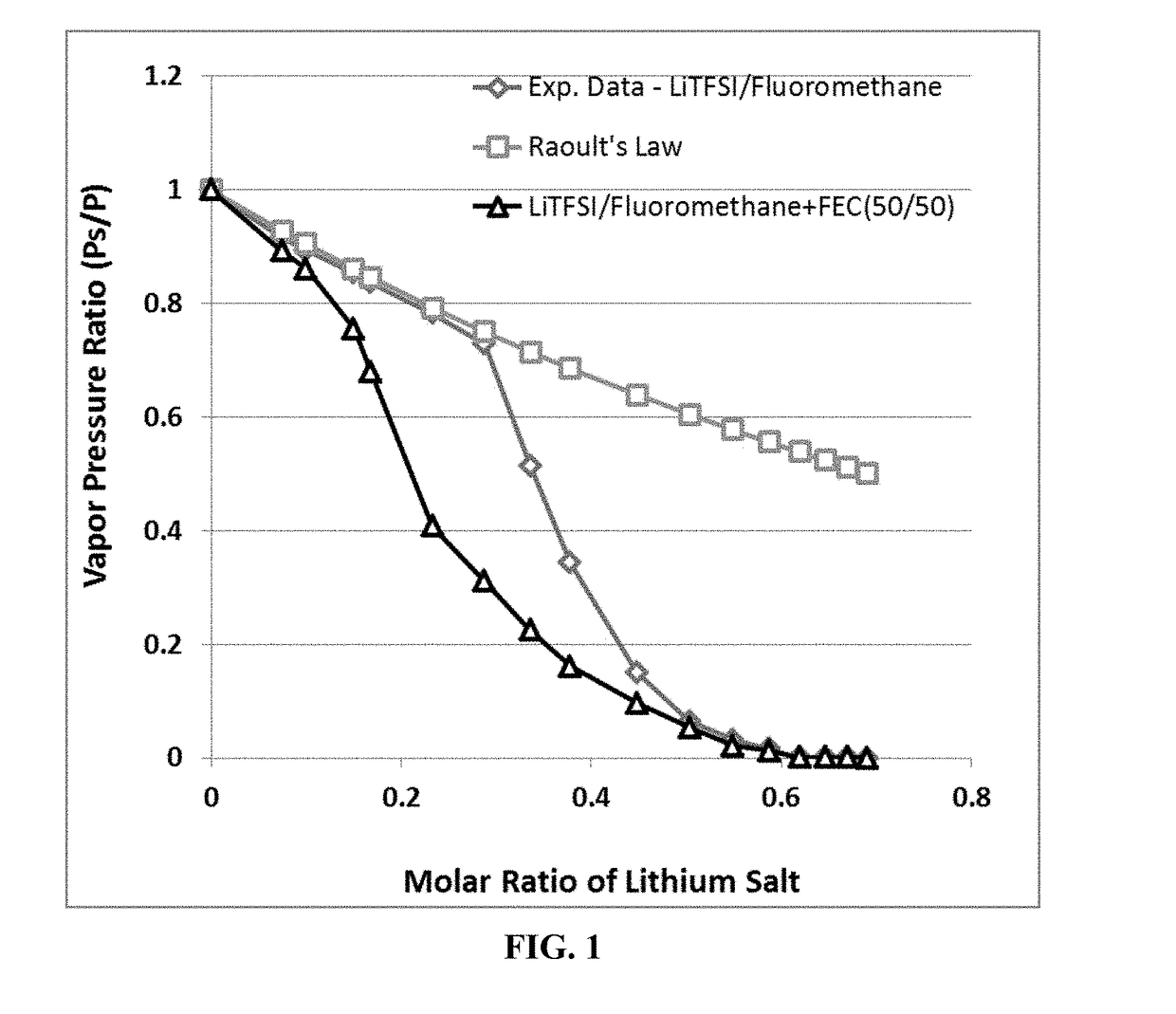

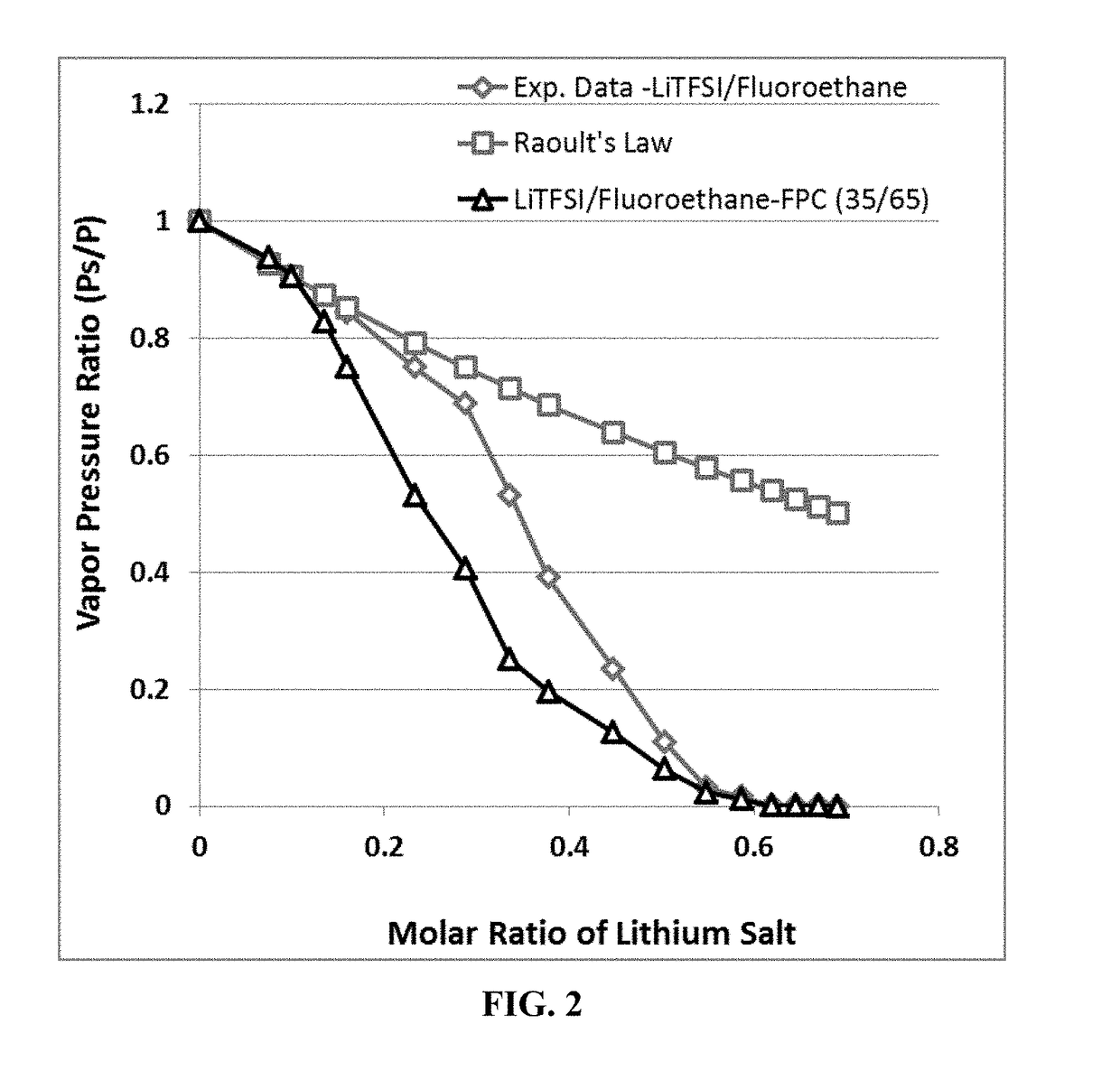

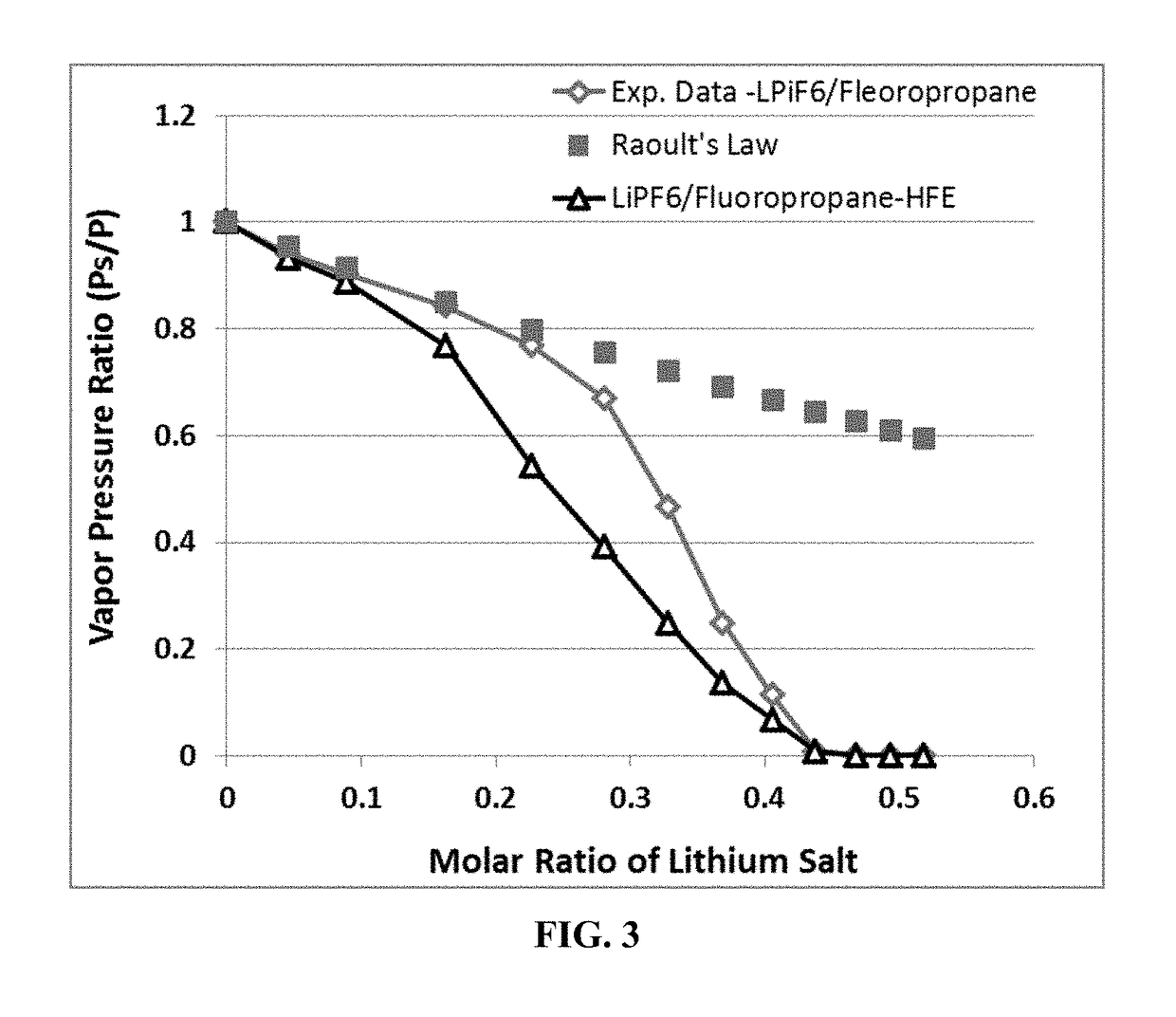

A rechargeable lithium cell comprising a cathode, an anode, an optional ion-permeable membrane disposed between the anode and the cathode, a non-flammable salt-retained liquefied gas electrolyte in contact with the cathode and the anode, wherein the electrolyte contains a lithium salt dissolved in or mixed with a liquefied gas solvent having a lithium salt concentration greater than 1.0 M so that the electrolyte exhibits a vapor pressure less than 1 kPa when measured at 20° C., a vapor pressure less than 60% of the vapor pressure of the liquefied gas solvent alone, a flash point at least 20 degrees Celsius higher than a flash point of the liquefied gas solvent alone, a flash point higher than 150° C., or no flash point, wherein the liquefied gas solvent is selected from methane, fluoromethane, difluoromethane, chloromethane, dichloromethane, ethane, fluoroethane, difluoroethane, tetrafluoroethane, chloroethane, dichloroethane, tetrachloroethane, propane, fluoropropane, chloropropane, ethylene, fluoroethylene, chloroethylene, or a combination thereof.

Owner:GLOBAL GRAPHENE GRP INC

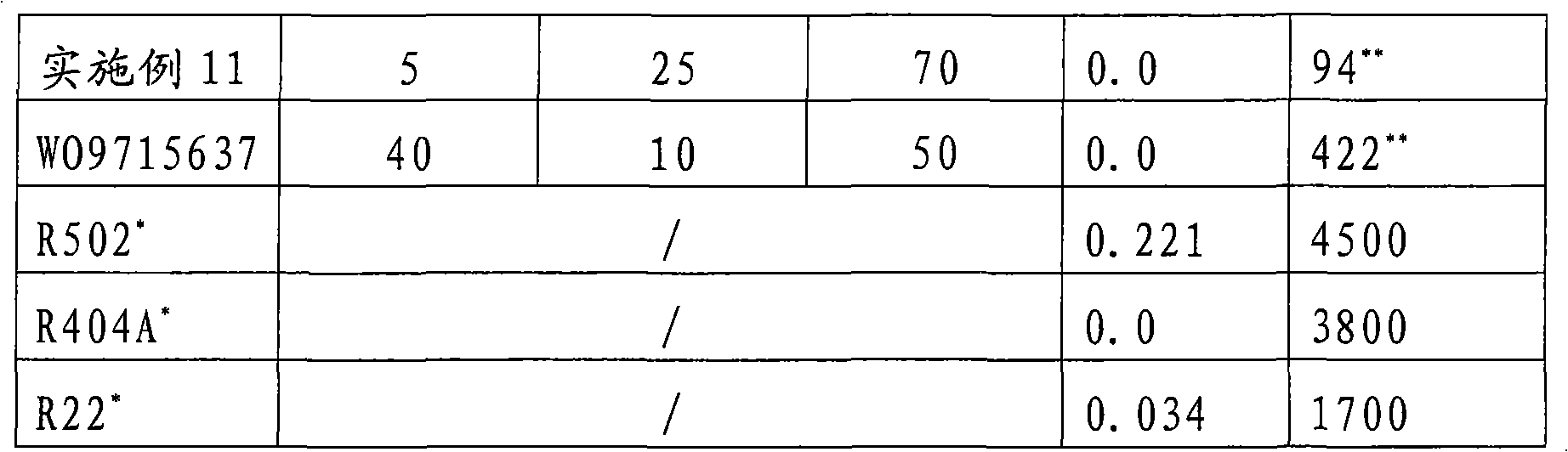

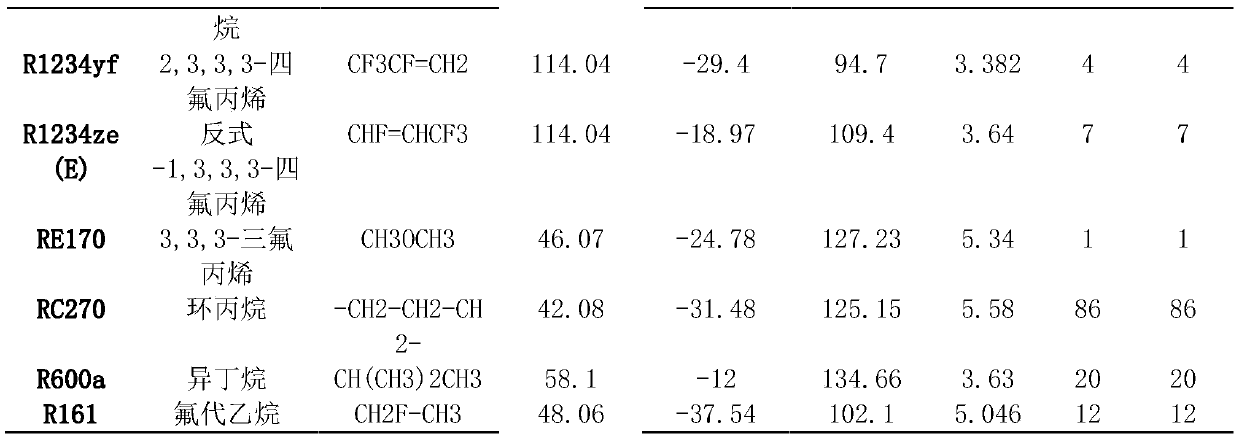

Refrigerant composition

InactiveUS20030001132A1Domestic cooling apparatusLighting and heating apparatus1,1-DifluoroethaneButane

The present invention relates to a refrigerant composition of four-constituent system, comprising: (a) a first constituent of difluoromethane, (b) a second constituent of 1,1,1,2,3,3,3-heptafluoropropane, (c) a third constituent selected from the group consisting of 1,1,1,2-tetrafluoroethane and 1,1-difluoroethane and (d) a for the constituent selected from the group consisting of isobutane, 1,1,1,2,3,3,-hexafluoropropane and butane, useful as a substitute for chlorodifluoromethane (HCFC-22).

Owner:KOREA INST OF SCI & TECH

Environmental protection type refrigerant for replacement of CFC-12

ActiveCN1285699CEnvironmentally friendlyMeet environmental protection requirementsHeat-exchange elementsThermodynamicsDifluoroethyne

Owner:SINOCHEM LANTIAN +1

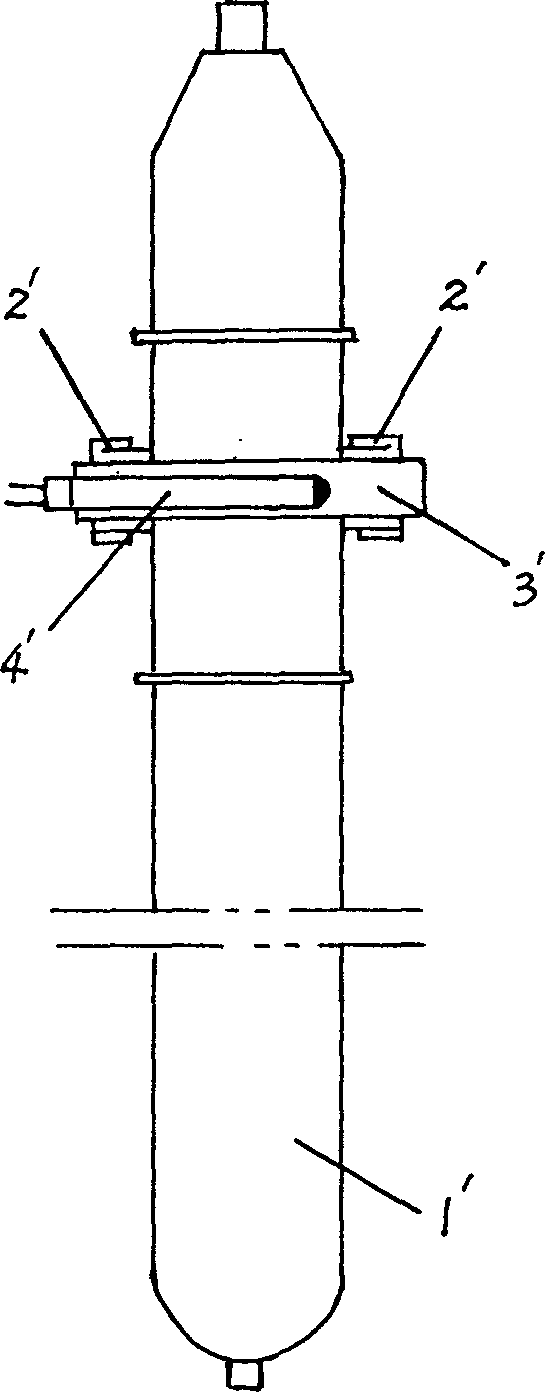

Preparation method of difluoro chloroethane and its production equipment

ActiveCN1556083AImprove conversion rateReduce unit consumptionHalogenated hydrocarbon preparationChemical reactionIt equipment

A process for preparing difluorochloro ethane from difluoroethane and chlorine gas includes proportionally mixing, three-class photo-chemical reaction while regulating light flux for presenting the high-boiling-point substance peaks with different heights, removing acid, alkali washing, compressing, degassing, rectifying and drying. Its equipment is disclosed also. Its advantages are high conversion rate of difluoroethane and high selectivity and purity of product.

Owner:ZHEJIANG AIKESHENG CHEM

Composition of refrigerant mixtures for high back pressure condition

InactiveUS20040021124A1Excellent coefficientImprove securityFire rescueHeat-exchange elements1,1-DifluoroethaneIodide

There is provided a composition of refrigerant mixtures for high back pressure condition, comprising propane, propylene or 1,1-difluoroethane and, optionally, additive selected from the group consisting of carbon dioxide, trifluoromethyl iodide and mixture thereof. The composition according to the present invention is environment-friendly and can be directly drop in the conventional refrigerator system adopting HCFC-22 refrigerant without any systemic change.

Owner:ACM TECH

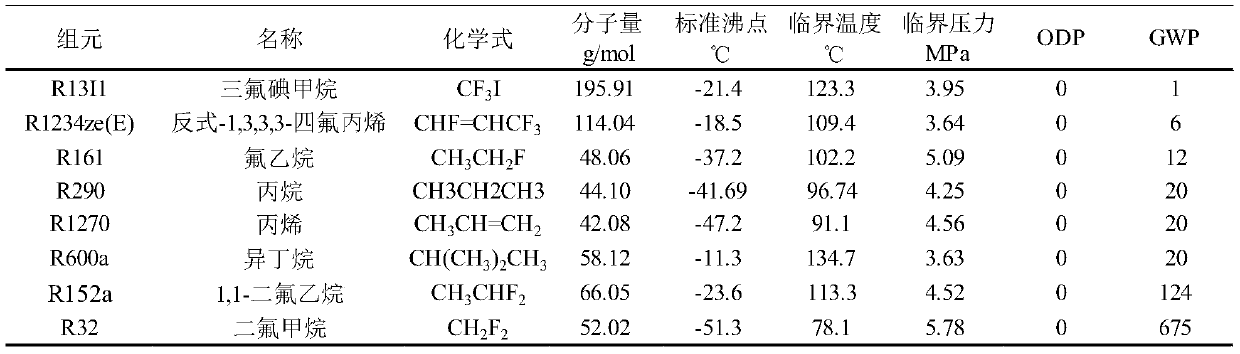

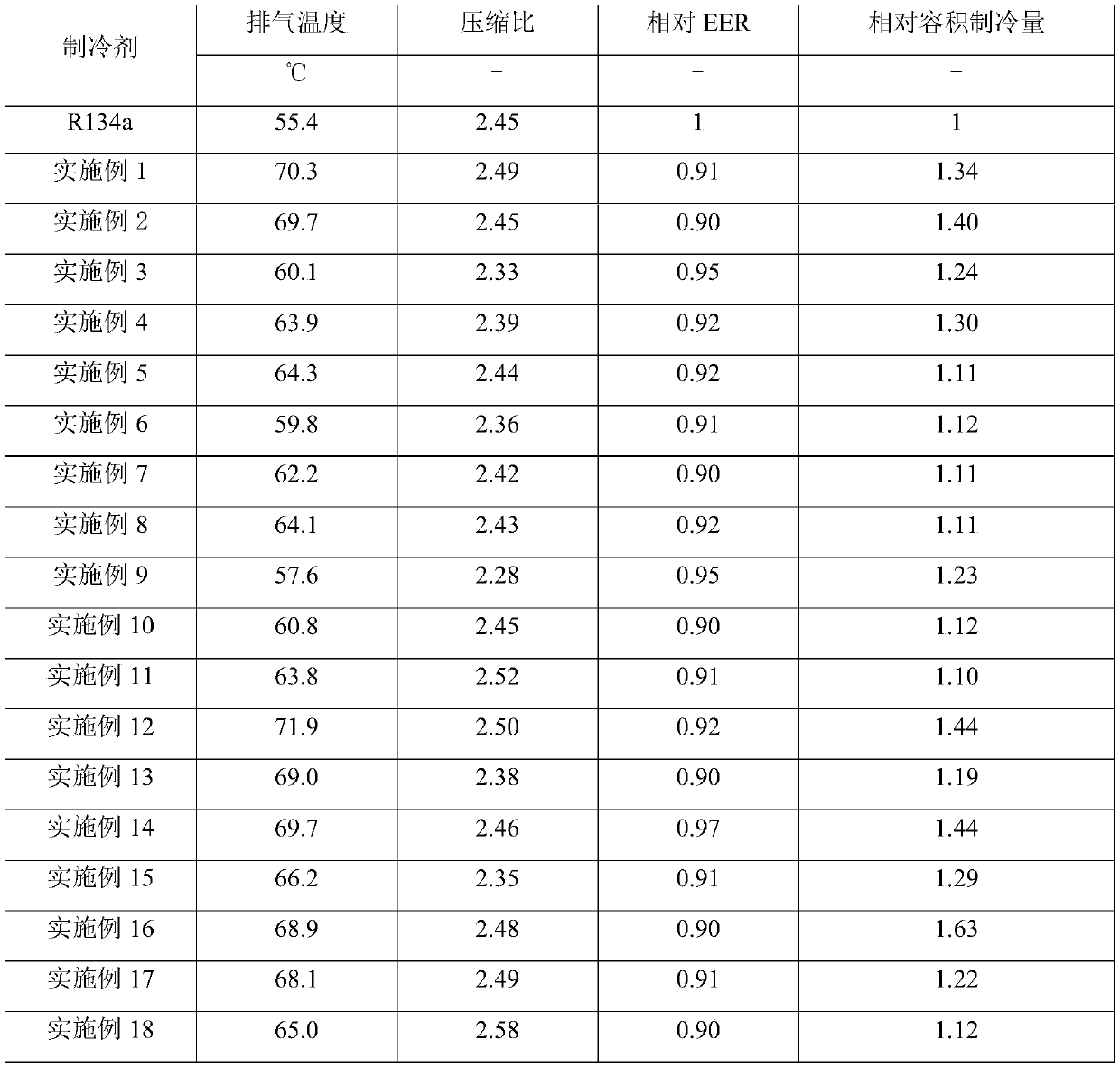

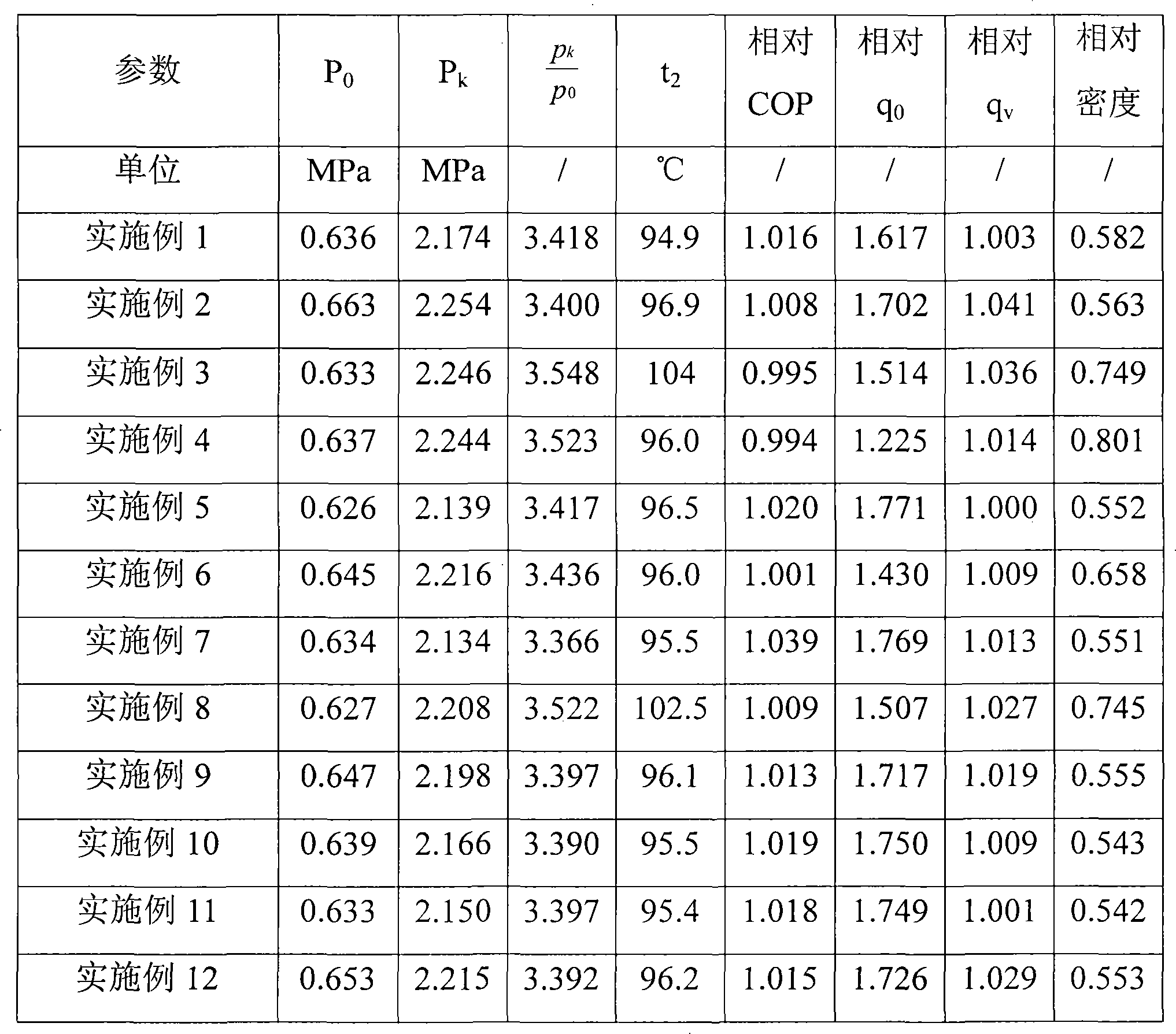

Environment-friendly mixed refrigerant

ActiveCN110699043AEnvironmentally friendlyLow GWP valueHeat-exchange elementsDifluoroethyneEngineering

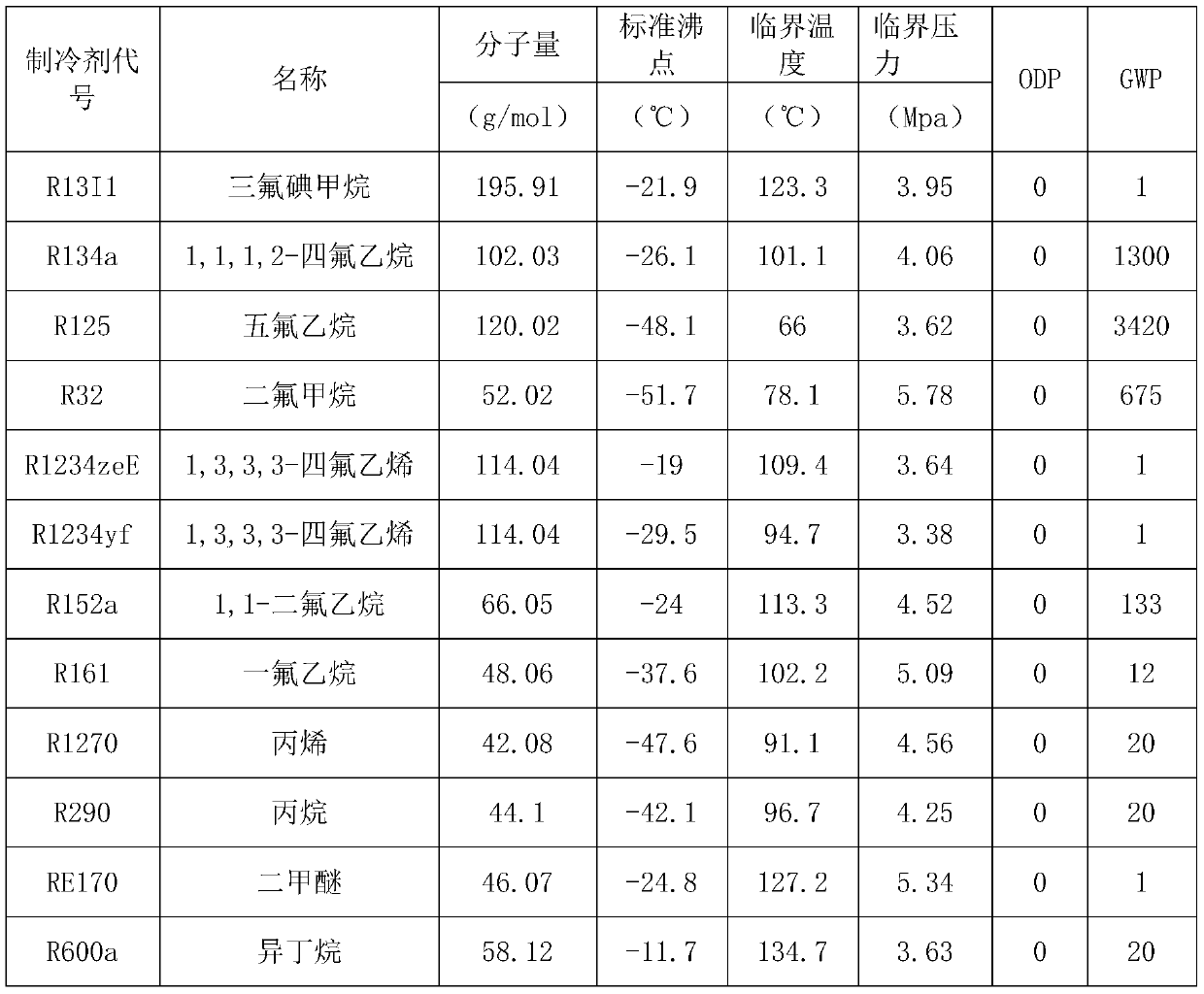

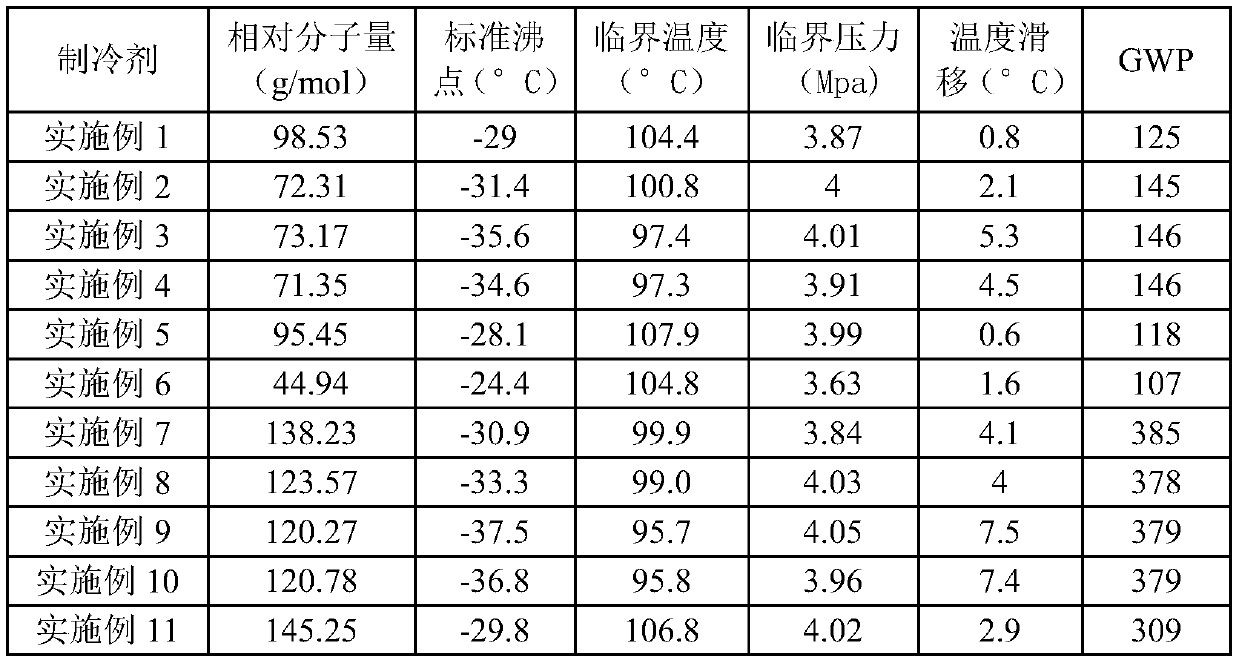

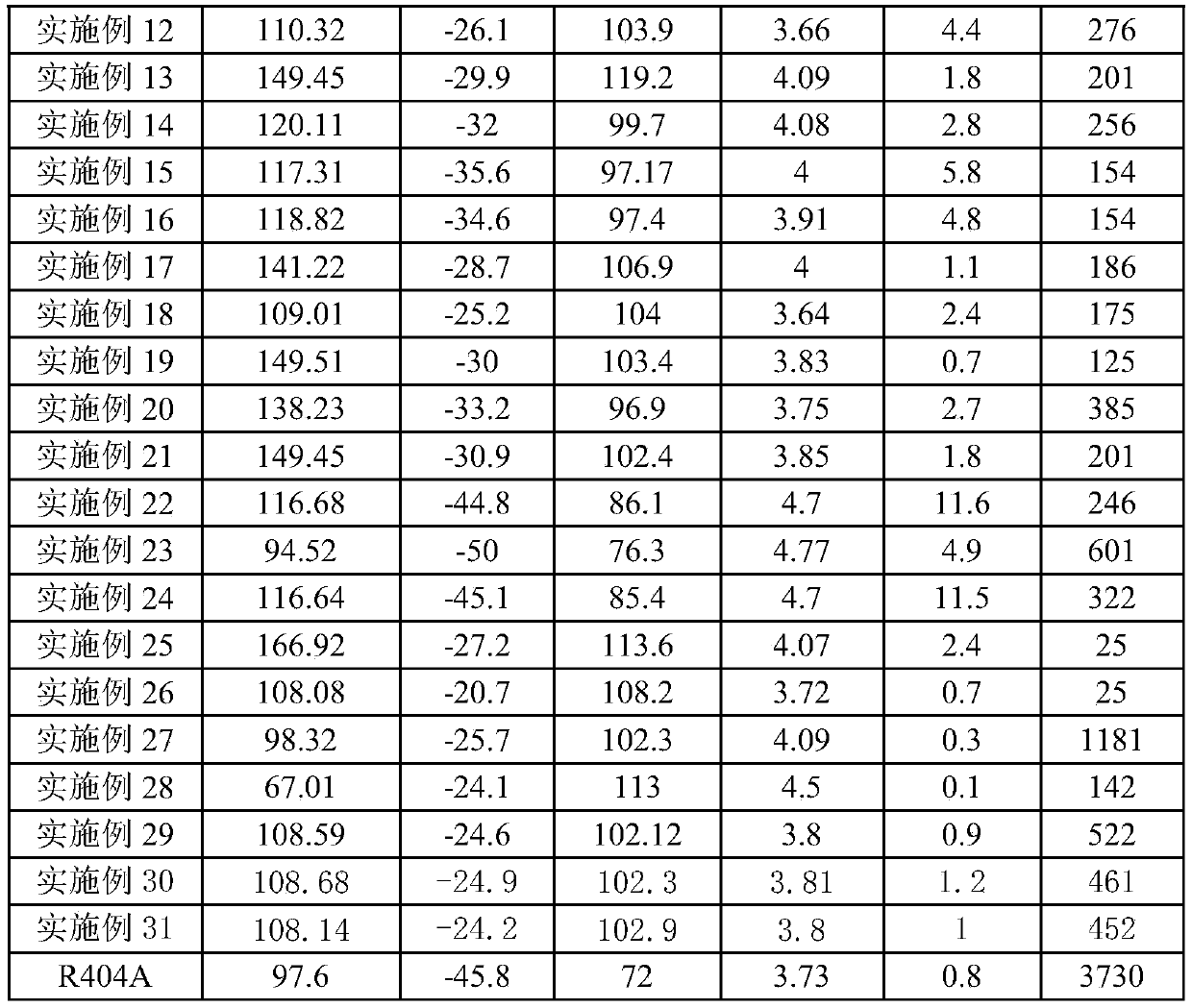

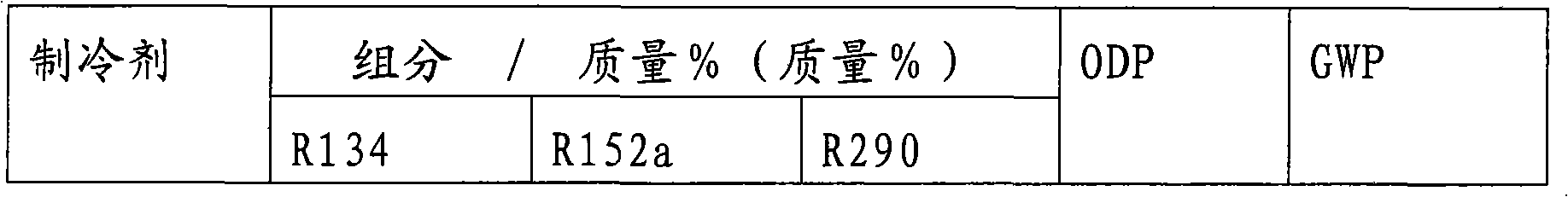

The invention discloses an environment-friendly mixed refrigerant. The refrigerant comprises the following components, in percentages by mass: 1%-90% of a first component, 1%-90% of a second component, 1%-90% of a third component and 1%-97% of a fourth component, wherein the first component is trifluoroiodomethane, the second component is at least one selected from 1,1,1,2-tetrafluoroethane and pentafluoroethane, the third component is at least one selected from trans-1,3,3,3-tetrafluoropropene, 2,3,3,3-tetrafluoropropene and difluoromethane, and the fourth component is at least selected from1,1-difluoroethane, monofluoroethane, propylene, propane, dimethyl ether and isobutane. The GWP value of the mixed refrigerant provided by the invention is greatly reduced relative to R404A, the ODP is 0, and the environmental performance is better than that of the R404A.

Owner:TIANJIN UNIV

Mix refrigerant, preparing method and uses thereof

ActiveCN101270275ASmall temperature glideImprove thermal cycle efficiencyHeat-exchange elementsDischarge rateRefrigerant

The invention provides a ternary near azeotropic refrigerant, which comprises tertiary mixture consisting of 1, 1, 2, 2-tetra fluoro ethane, 1, 1-difluoroethane and propane. The total of the mass percent concentration of all components of the mixed refrigerant is 100 percent, including 1, 1, 2, 2-tetra fluoro ethane with the condensation of 1 percent to 20 percent, dimethyl ether with the condensation of 1 percent to 50 percent, and propane with the condensation of 30 percent to 90 percent. The invention further provides a method for preparing the mixed refrigerant and a use of the mixed refrigerant. The mixed refrigerant has high efficiency and high evaporating pressure with large refrigerating capacity when the compressor discharge rate is the same; the ODP is zero, and compared with R502 and R404A, the GWP of the refrigerant is significantly reduced.

Owner:青岛中科未来健康研究院有限公司

Environment-friendly mixed working medium

ActiveCN110484209AGood physical propertiesNo toxicityHeat-exchange elementsButylated hydroxytolueneEngineering

The invention relates to an environment-friendly mixed working medium, a preparation method thereof and a device comprising the environment-friendly mixed working medium. The mixed working medium comprises a first component trifluoroiodomethane (R13I1), a second component 1, 1-difluoroethane (R152a), a third component isobutane (R600a) and a fourth component, wherein the fourth component is one ofthe propane (R290) or propylene (R1270); or the mixed working medium comprises the first component trifluoroiodomethane (R13I1), the second component fluoroethane (R161), the third component difluoromethane (R32) and the fourth component, wherein the fourth component is one of trans-1, 3, 3, 3-tetrafluoropropene (R1234ze (E)) or propylene (R1270). According to the present invention, the preferredlubricant polyalkylene glycol, stabilizer butylated hydroxytoluene and extreme pressure agent zinc dialkyl dithiophosphate can be added into the environment-friendly mixed working medium, so that theperformance and stability of the mixed working medium are enhanced. Meanwhile, the mixed working medium is good in environment performance, has the GWP lower than 100, enables the volume refrigerating capacity and the volume heating capacity to be greatly improved by 30% or above, and has the smaller temperature slippage.

Owner:GREE ELECTRIC APPLIANCES INC

Environmental protection type refrigerant

ActiveCN101235275AEnvironmentally friendlyMeet environmental protection requirementsChemical industryHeat-exchange elementsButeneAtmospheric ozone

The invention discloses a novel environment-friendly refrigerant, which is formed by a first component, difluoromethane, penta-fluoroethane and hydrocarbon component, wherein the first component is one of fluoroethane and 1, 1-difluoroethane, hydrocarbon component is the combination of one or more than one of isobutene, normal butene, propane and propylene. The refrigerant whose ODP is zero, which does not damage atmospheric ozone layer, and largely reduces GWP value compared with HCFC-22 and current substitutes R407 C and R410A, and has excellent environment-friendly property. The refrigerant whose thermal property is equivalent to HCFC-22 can be directly used in a system which originally uses HCFC-22, can reduce charge amount and increase energy effect ratio, and has the advantages of saving resources and energy. The refrigerant can be used as long-term substitute of HCFC-22, which provides a reliable technology which is easy to be popularized and applied and can take effect rapidlyfor the global to cope with climate warming.

Owner:SINOCHEM LANTIAN +1

Green mixed refrigerant

InactiveCN102516946ALow ODPImprove thermal performanceHeat-exchange elementsDifluoroethyneEngineering

The invention discloses a green mixed refrigerant, comprising 20-60 wt% of 2,3,3,3-tetrafluoro propylene or trans-1,3,3,3-tetrafluoro propylene, 5-30 wt% of 1,1-difluoroethane or 1,1,1,2-tetrafluoro ethane, and 35-60 wt% of difluoromethane. The preparation method is characterized by physically mixing the above ingredients according to corresponding ratio at normal temperature. According to the invention, because the volume refrigerating capacity of the green mixed refrigerant is very close to that of HCFC-22 and the condensation pressure of the green mixed refrigerant is lower than that of R410A, the green mixed refrigerant can be directly filled in existing refrigeration, air-conditioning or heat pump sets which use HCFC-22; and when HCFC-22 is replaced, the components and pipeline of the system have no need of redesigning. The green mixed refrigerant can be an alternative refrigerant to HCFC-22 and R410A.

Owner:JIMEI UNIV

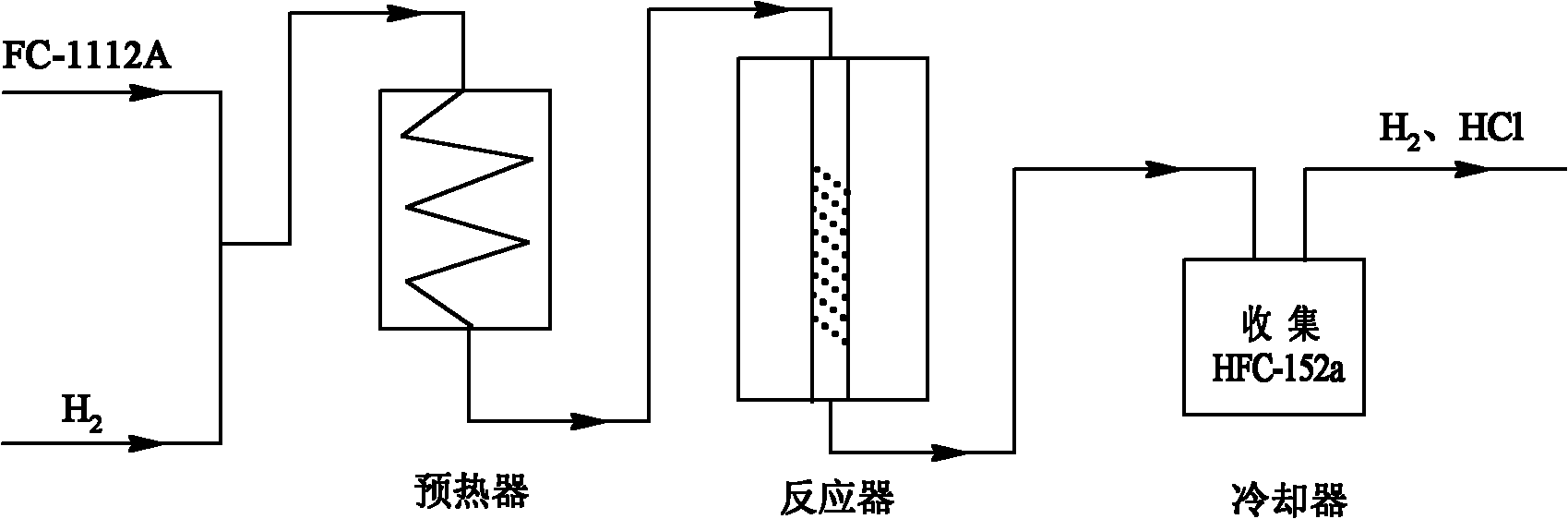

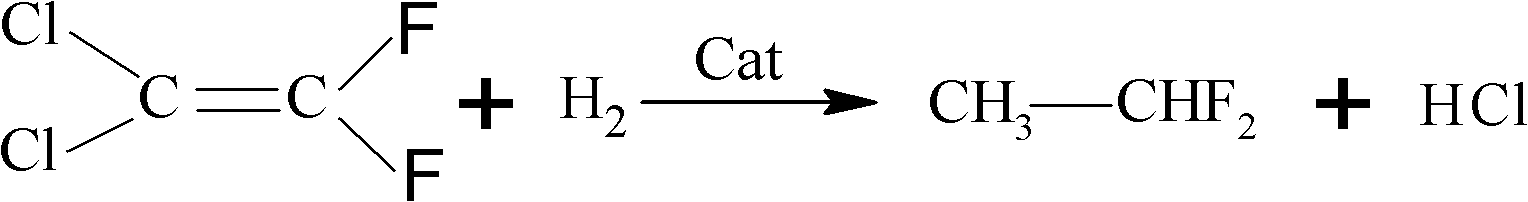

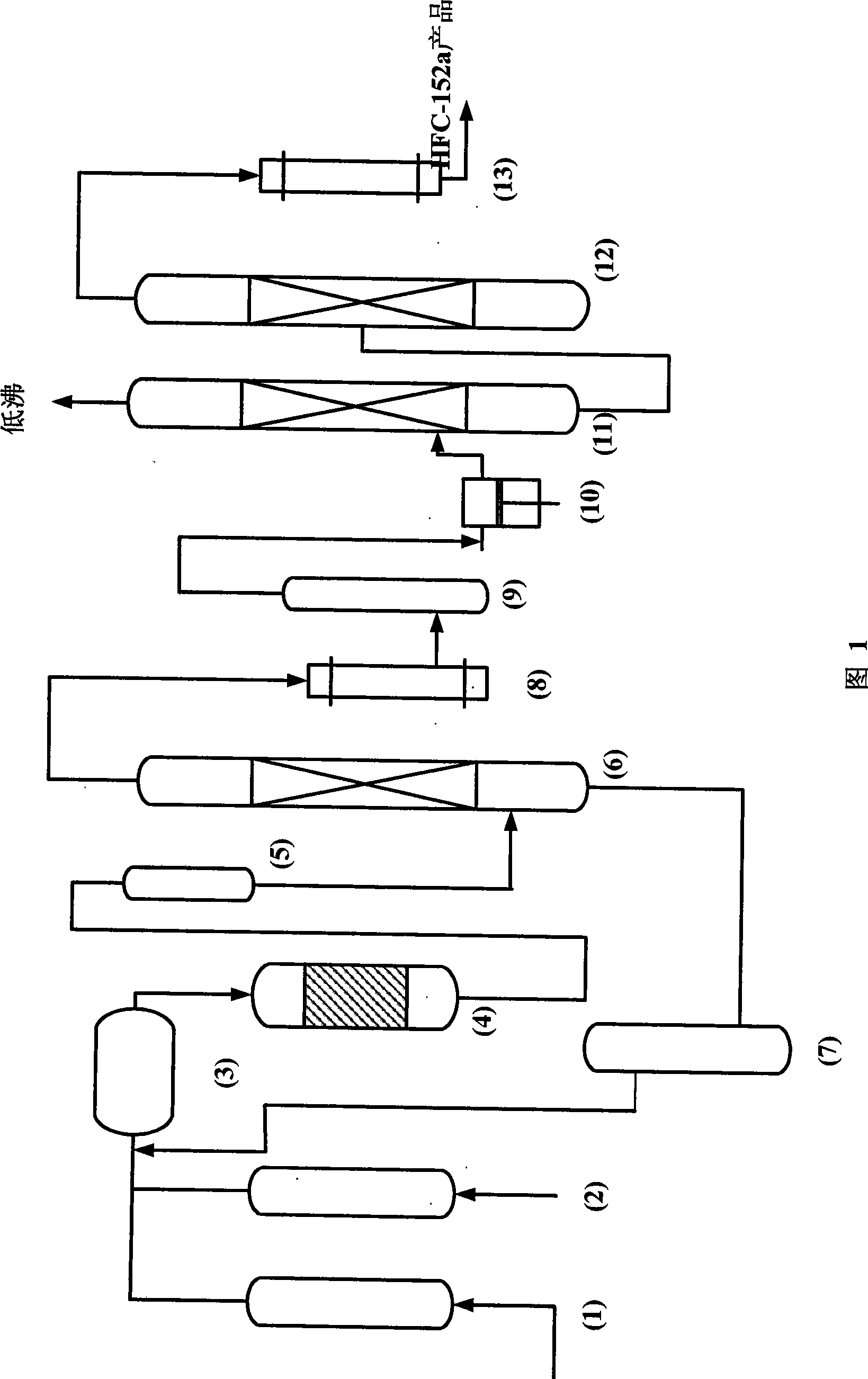

Preparation method of 1,1-difluoroethane

ActiveCN102838446ASimple post-processingMild conditionsPreparation by dehalogenationMetal/metal-oxides/metal-hydroxide catalysts1,1-DifluoroethaneHydrogen

The invention discloses a preparation method of 1,1-difluoroethane. Under the existence of a catalyst, difluoro dichloroethylene and hydrogen are subjected to a hydrodechlorination reaction, such that 1,1-difluoroethane is prepared. The catalyst is composed of a main catalyst, an auxiliary agent, and a carrier. The main catalyst is Pd, the auxiliary agent is one or more selected from La, Ce, Cu, Zn or Ni, and the caralyst is loaded on the carrier. The preparation method disclosed by the invention has the advantages of novel raw material route, mild reaction conditions, simple product post-treatment, high catalyst efficiency, and the like. A conversion rate upon a raw material FC-1112A can be higher than 90%, and a selectivity of HFC-152a can be higher than 90%.

Owner:SINOCHEM LANTIAN +1

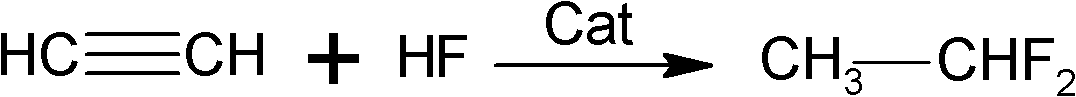

Preparation of 1,1-difluoroethane and fluorating catalyst

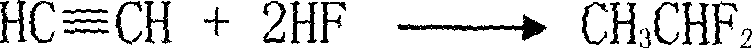

ActiveCN101412654AProper control of process conditionsEasy to controlPhysical/chemical process catalystsPreparation by halogen halide additionHydrofluoric acidGas phase

The invention discloses a method for preparing 1, 1-difluoroethane and a fluorination catalyst using the method. The method is characterized in that in the presence of a chromium-based fluorination catalyst, ethyne and anhydrous hydrofluoric acid are gasified and mixed to undergo gas-phase fluorination reaction so as to generate 1,1- difluoroethane HFC-152a(C2H4F2); the reaction temperature is between 140 and 380 DEG C; the pressure is between 0.3 and 1.8 MPa; under the standard condition, air speed of a reactor is between 300 and 2,200 h<-1>; the mixture ratio of the reaction materials of the anhydrous hydrofluoric acid to the ethyne is 4 to 1-30 to 1; the transformation rate of the ethyne in an outlet of the reactor reaches over 75 percent; and the selectivity of HFC-152a reaches over 90 percent.

Owner:ZHEJIANG QUHUA FLUOR CHEM

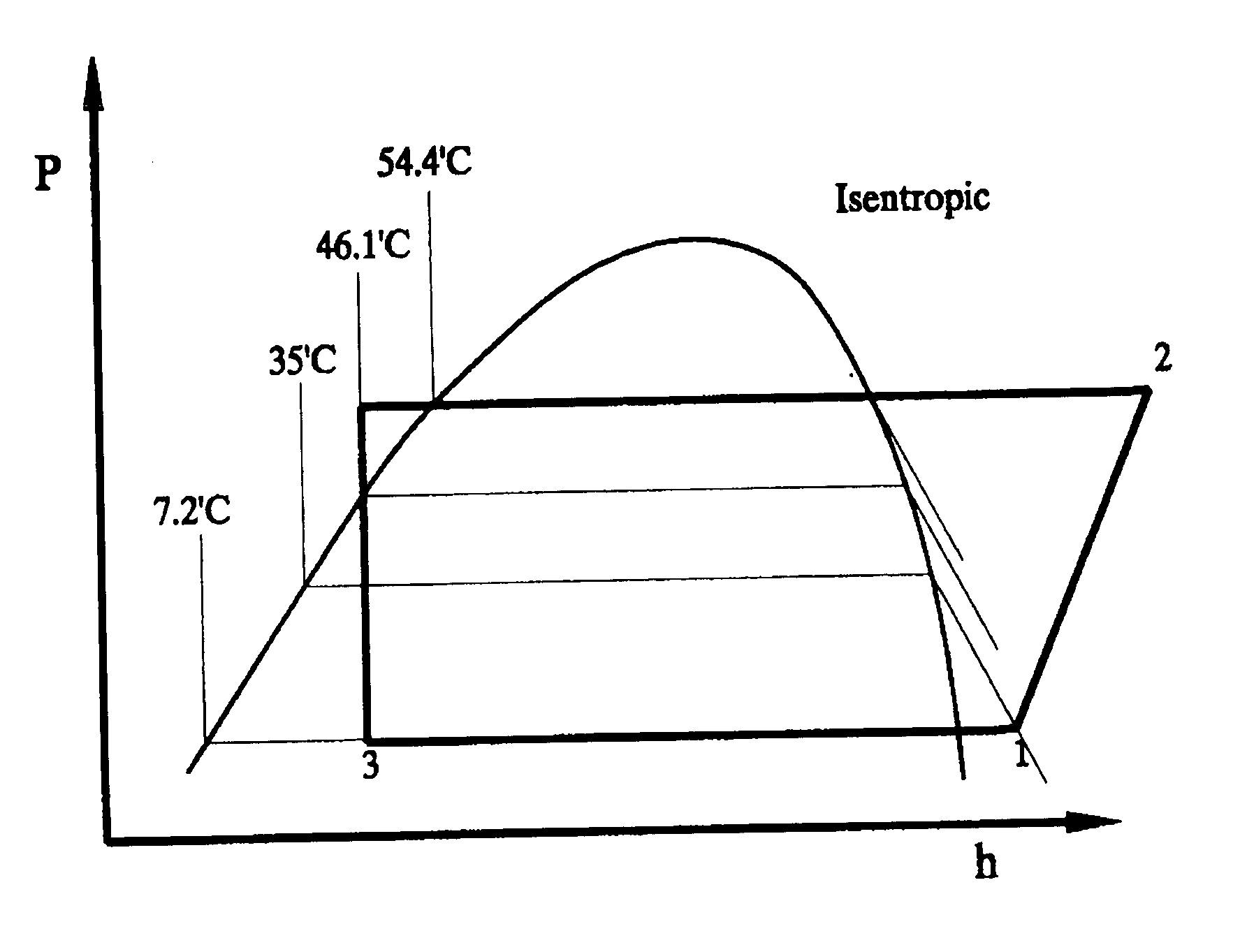

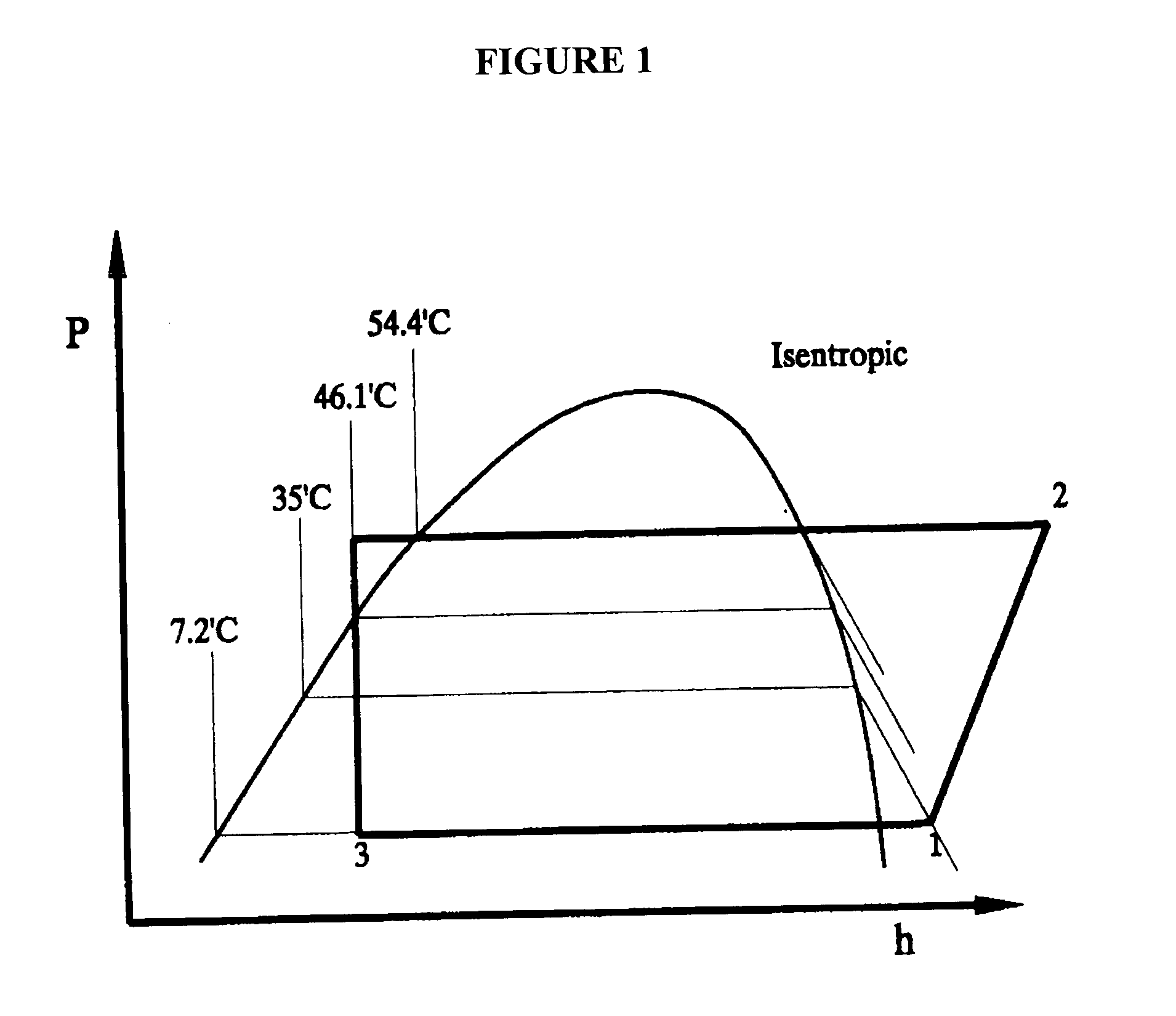

Environmentally safer replacement refrigerant for freon 12-based refrigeration systems

InactiveUS6565766B1Low vapor pressureAvoid damageCompression machines with non-reversible cycleHeat-exchange elementsDichlorodifluoromethaneEngineering

An apparatus and method wherein ozone layer-damaging dichlorodifluoromethane is substituted with a mix of less environmentally damaging refrigerants chlorodifluoroethane and tetrafluoroethane in dichlorodifluoromethane-based air-cooling systems. While less environmentally damaging than dichlorodifluoromethane, the substitute refrigerant has a temperature-pressure relationship similar to that of dichlorodifluoromethane, making the substitute refrigerant suitable for use with dichlorodifluoromethane-based air-cooling systems. The substitute refrigerant can be used alone or in combination with dichlorodifluoromethane. In either event, it is mixed with a relatively small percentage of a hydrophobic lubricating oil which is compatible with both the substitute refrigerant and with dichlorodifluoromethane.

Owner:KENNETH B RUELLO

Method for preparing fluorine-containing ethylene by catalytic cracking of 2-chloro-1,1-difluoroethane

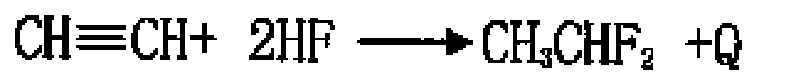

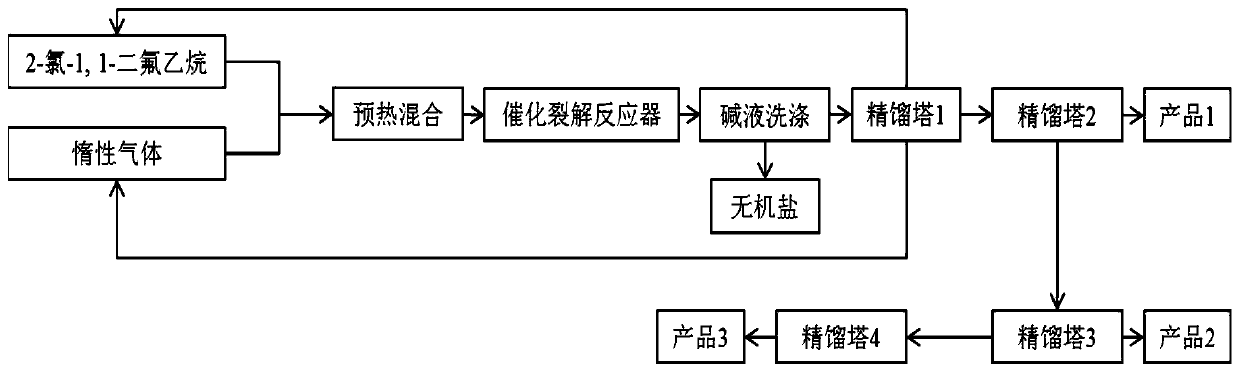

ActiveCN110776394AImprove conversion ratePreparation by hydrogen halide split-offDifluoroethynePtru catalyst

The invention disclose a method for preparing fluorine-containing ethylene by catalytic cracking of 2-chloro-1,1-difluoroethane. The method comprises the following steps that (i), a catalytic crackingcatalyst is provided, wherein the catalyst comprises fluoride carried on active carbon, the weight ratio of the active carbon to the fluoride is 1 to (0.01-0.5), and the fluoride is selected from aluminum fluoride, chromium fluoride, potassium fluoride, magnesium fluoride, calcium fluoride, or a mixture of two or more of the aluminum fluoride, chromium fluoride, potassium fluoride, magnesium fluoride and calcium fluoride; (ii), the catalyst is loaded into a catalytic cracking reactor, a mixture of preheated inert gas and the 2-chloro-1,1-difluoroethane is introduced, and the catalyst is activated; and (iii), the mixture of preheated 2-chloro-1,1-difluoroethane and inert gas is introduced, the reaction temperature is 400-700 DEG C, space velocity is 200-3000h<-1>, pressure is 0.1-1.0Mpa, and 1,1-dichloroethylene is obtained.

Owner:SHANGHAI 3F NEW MATERIAL TECH CO LTD +1

Method of making difluoromethane, 1,1,1-trifluoroethane and 1,1-difluoroethane

ActiveUS20050222472A1Preparation by halogen halide additionPreparation by halogen replacementVinyl chlorideChlorofluoromethane

A process for the production of difluoromethane (HFC-32), 1,1,1-trifluoroethane (HFC-143a) and 1,1-difluoroethane (HFC-152a). In the process the following steps are employed: (a) providing a reaction vessel, (b) providing in the reaction vessel activated carbon impregnated with a strong Lewis acid fluorination catalys selected from halides of As, Sb, Al, TI, In, V, Nb, Ta, Ti, Zr and Hf, (c) activating the catalyst by passing through the activated carbon impregnated with a strong Lewis acid fluorination catalyst anhydrous hydrogen fluoride gas and chlorine gas, (d) contacting, in a vapor state in the reaction vessel containing the activated catalyst, hydrogen fluoride and one or more halogenated hydrocarbons selected from chlorofluoromethane, dichloromethane, 1,1,1-trichloroethane, vinyl chloride, 1,1-dichloroethylene, 1.2-dichloroethylene, 1,2-dichloroethane, and 1,1-dichloroethane for a time and at a temperature to produce a product stream comprising hydrofluorocarbon product(s) corresponding to the chlorinated hydrocarbon reactant(s), and one or more of hydrogen chloride, unreactacted chlorinated hydrocarbon reactant(s), under-fluorinated intermediates, and unreacted hydrogen fluoride, and (e) separating the hydrofluorocarbon product(s) from the product stream.

Owner:HONEYWELL INT INC

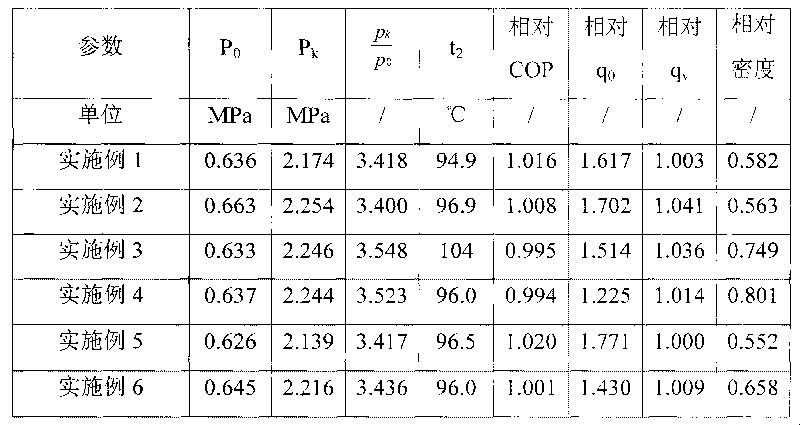

Refrigerant containing trifluoroiodomethane, mixture containing refrigerant and heat exchange system containing refrigerant

ActiveCN110878195ALow GWP valueMeet the requirementsChemical industryHeat-exchange elementsDifluoroethyneMeth-

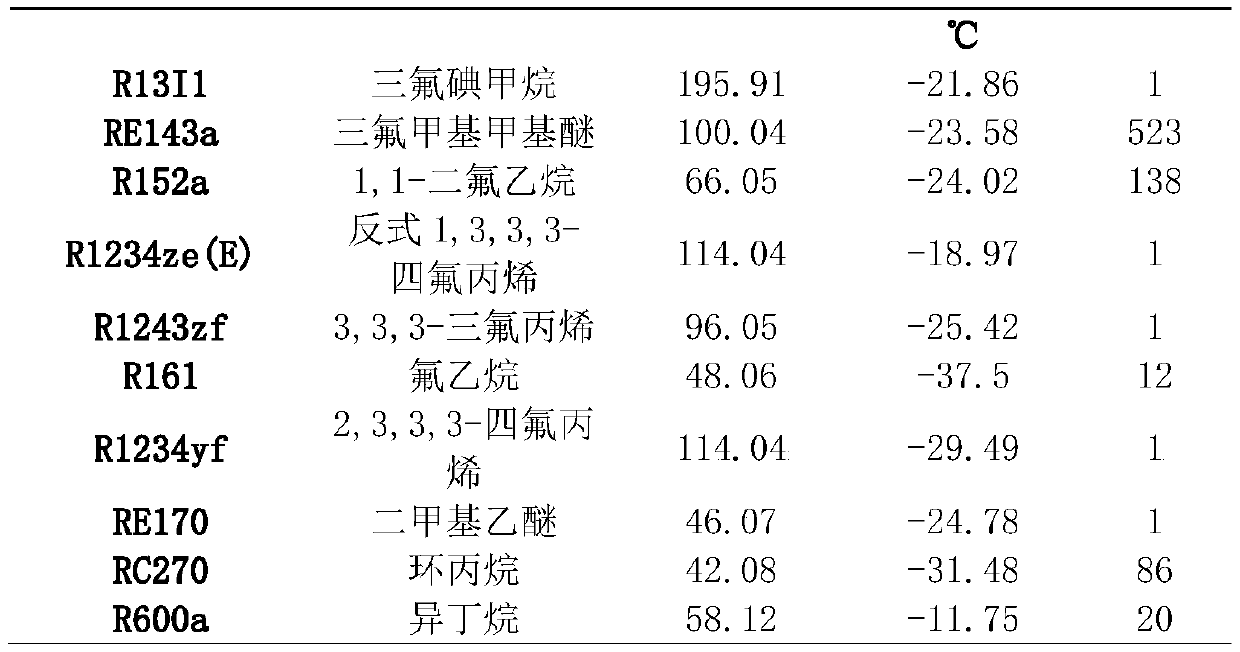

The invention provides a refrigerant containing trifluoroiodomethane. The refrigerant comprises the following three components in percentage by mass: 36%-80% of a first component, 8%-60% of a second component and 4%-24% of a third component, wherein the mass ratio is based on the total mass of the refrigerant substance; the first component is trifluoroiodomethane (R13I1); the second component is amixture of any two components selected from trifluoromethyl methyl ether (RE143a), 1, 1-difluoroethane (R152a), trans-1, 3, 3-tetrafluoropropene (R1234ze (E)), 3, 3, 3-trifluoropropene (R1243zf), 2,3, 3, 3-tetrafluoropropene (R1234yf), isobutane (R600a), dimethyl ether (RE170) and fluoroethane (R161); the third component is one of dimethyl ether (RE170) and cyclopropane (RC270); and the GWP of the refrigerant is less than or equal to 150. According to the refrigerant, the problems that the refrigerant GWP replacing R134a in an existing automobile air conditioning system is high in GWP and low in the refrigerating capacity can be solved, and meanwhile the problem that the heat exchange efficiency is low due to large temperature slippage is solved.

Owner:GREE ELECTRIC APPLIANCES INC

Novel environment friendly refrigerating fluid

ActiveCN101735772AEnvironmentally friendlyMeet environmental protection requirementsChemical industryHeat-exchange elementsBusiness efficiencyHydrogen

The invention relates to a novel environment friendly refrigerating fluid which is prepared by 1,1-difluoroethane, difluoromethane, pentafluoroethane and carbureted hydrogen component, the carbureted hydrogen component is formed by choosing one or more than one of iso-butane, n-butane, dimethylmethane and propene with arbitrary proportion, and all components are as follows by mass percent: 5-98 percent of 1,1-difluoroethane, 1-60 percent of difluoromethane, 0-30 percent of pentafluoroethane, and 1-20 percent of the carbureted hydrogen component; the ODP value of the refrigerating fluid is zero without damaging atmospheric ozone layer, and compared with HCFC-22 and the existing substitution R407 and R410A, the GWP value is greatly reduced and the environment protecting performance is better; in addition, the charging amount is reduced, the energy efficiency ratio is improved, resource is saved, the novel environment friendly refrigerating fluid can be used as long-term substituent for HCFC-22.

Owner:ZHEJIANG LANTIAN ENVIRONMENTAL PROTECTION HI TECH

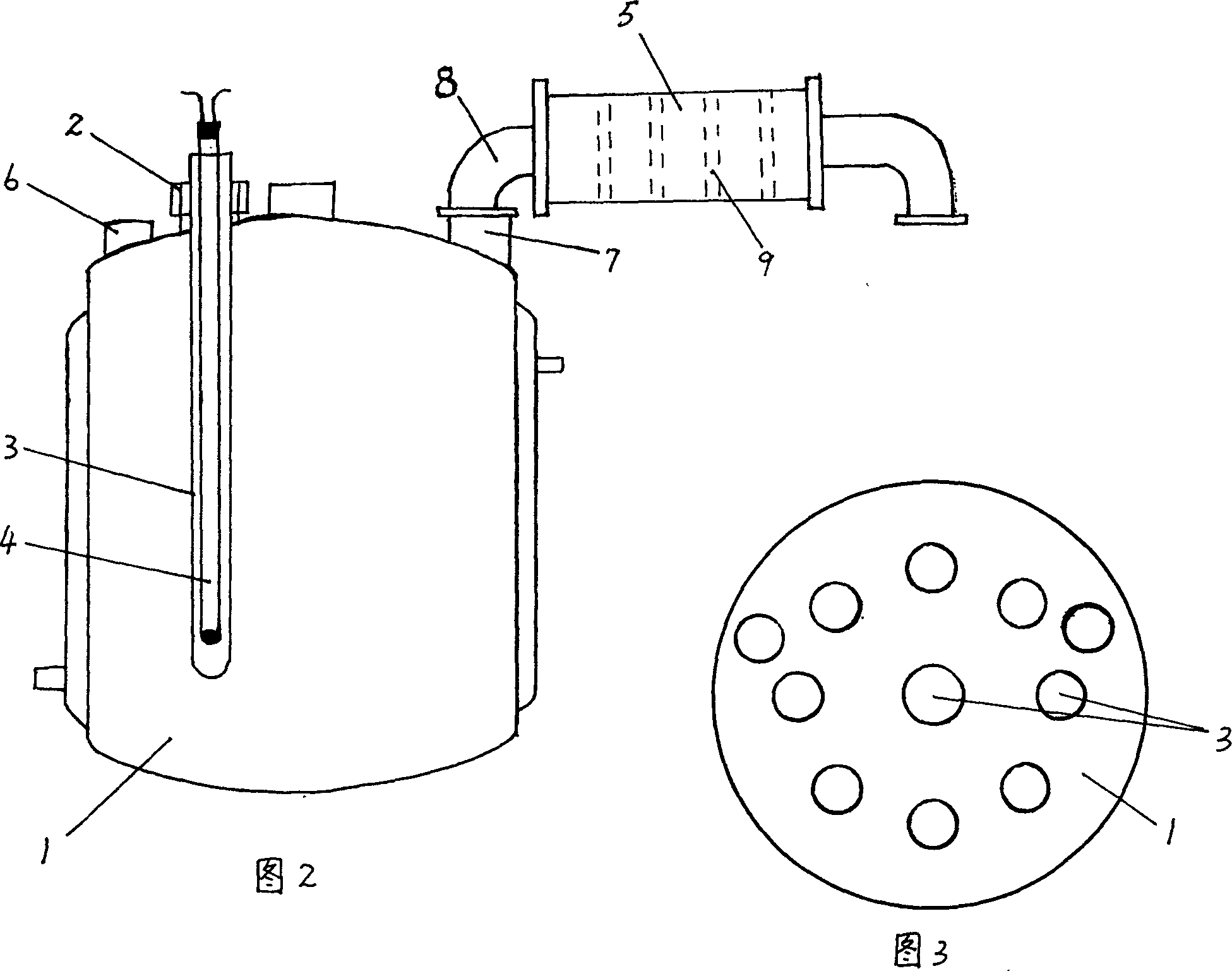

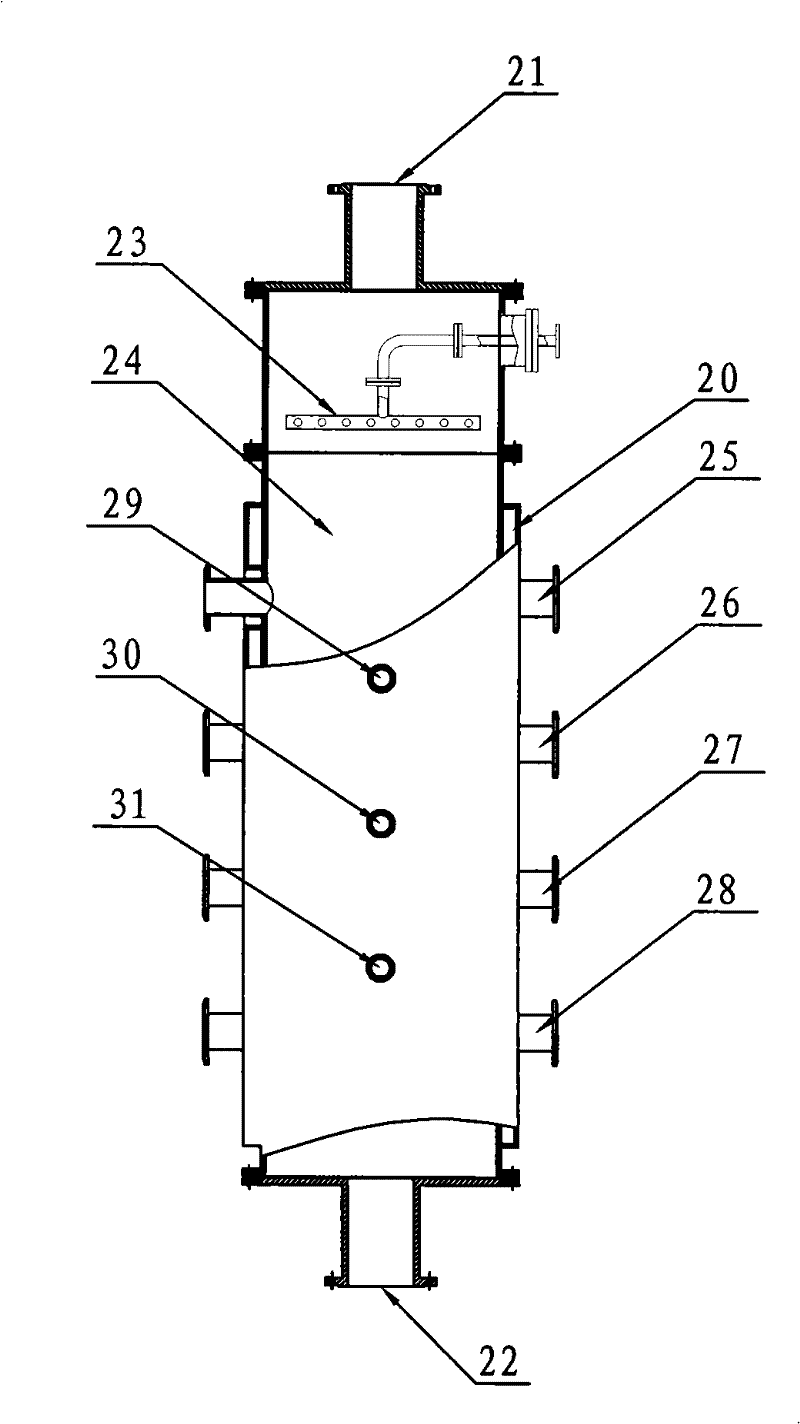

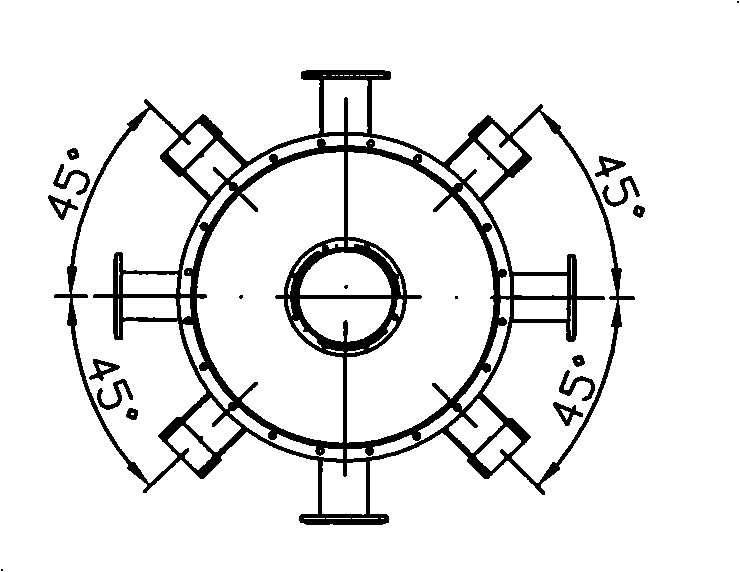

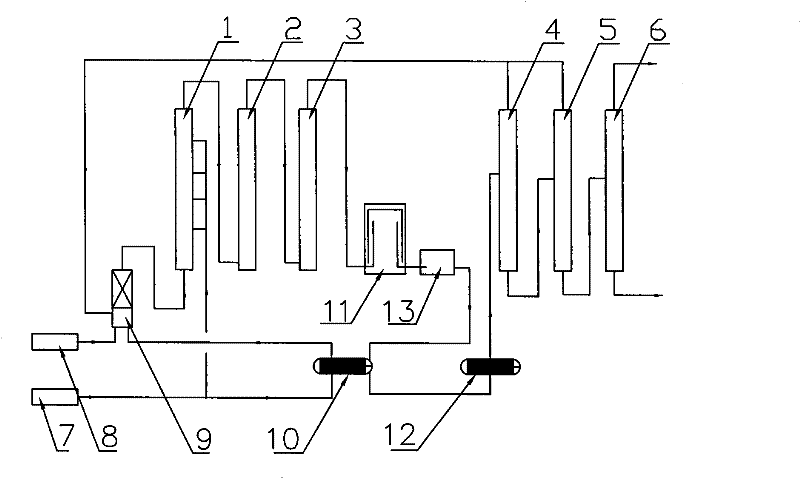

Method and equipment for preparing difluoromonochloroethane by photochemical catalyst

The invention discloses a method for preparing difluoro monochloro ethane in a photocatalytic reactor, which comprises: firstly, chlorine gas and difluoroethane are mixed and enter the photocatalytic reactor for reaction to generate a difluoro monochloro ethane crude product; and secondly, the difluoro monochloro ethane crude product is subjected to water washing, alkaline washing, deaeration, rectification and drying to obtain the difluoro monochloro ethane finished product. The photocatalytic reactor adopted during reaction comprises a cylinder body, wherein the outer wall of the cylinder body is provided with a heat exchange jacket, and the inner wall of the cylinder body is lined with anticorrosive materials; material openings are arranged on the top and the bottom of the cylinder body; a spray device is arranged on the top of the inside of the cylinder body; the part below the spray device is formed by communicating and assembling four tower sections up and down; and each tower section is provided with four ultraviolet lamps which are arranged up and down, three temperature measurement openings which are arranged up and down, and a liquid difluoroethane feed opening. The method has high once-through conversion and less byproducts; and the selectivity during reaction is higher than 95 percent. Moreover, the photocatalytic reactor has small floor occupation and a compact structure, and less backmixing of materials.

Owner:TAIXING MEILAN CHEM

Refrigerant composition

Owner:KOREA INST OF SCI & TECH

Method for purification of 1,1-dichloroethane and process for production of 1,1-difluroethane using this method

InactiveUS20070197843A1Efficient removalSimple methodPreparation by halogen replacementHalogenated hydrocarbon separation/purificationOrganic chemistryLiquid phase

1,1-dichloroethane containing a compound having a nitro group and / or a hydroxyl group as a stabilizer is brought into contact with zeolite having an average pore size of 3.4 to 11 Å and / or a carbonaceous adsorbent having an average pore size of 3.4 to 11 Å in a liquid phase. A stabilizer contained in 1,1-dichloroethane is efficiently removed by a simple and convenient method and 1,1-difluoroethane can be economically produced.

Owner:SHOWA DENKO KK

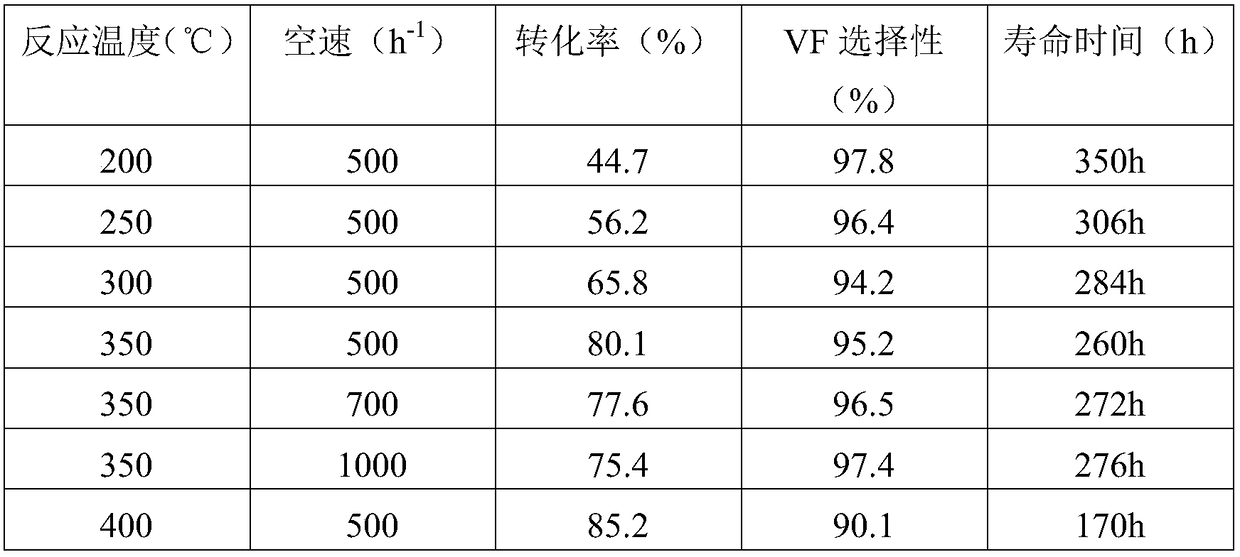

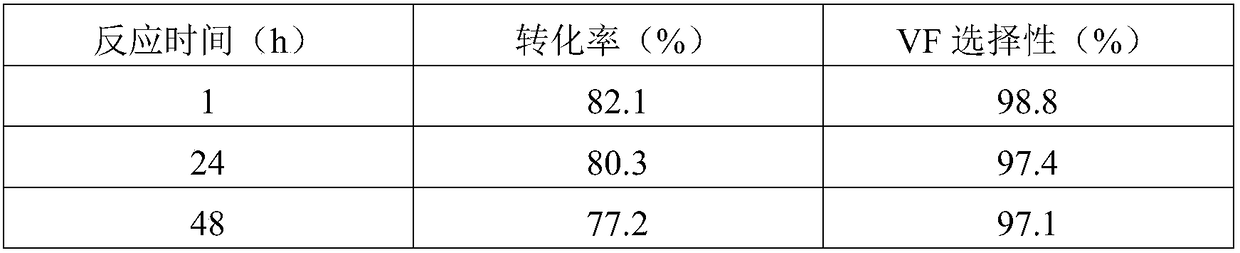

Catalyst for preparing vinyl fluoride through gas phase removal of HF by virtue of 1,1-difluoroethane as well as preparation method and application of catalyst

ActiveCN109174139AChange active siteImprove anti-carbon performancePhysical/chemical process catalystsPreparation by hydrogen halide split-offActivated carbonMetal chloride

The invention provides a catalyst for preparing vinyl fluoride through gas phase removal of HF by virtue of 1,1-difluoroethane as well as a preparation method and application of the catalyst. The catalyst is prepared by the steps of preparing a precursor from a carrier and an active component, and carrying out roasting and trifluoromethane fluorination, wherein the carrier is activated carbon, andthe active component is metal chloride or metal nitrate. The prepared catalyst is applied to the preparation of vinyl fluoride by virtue of 1,1-difluoroethane, the anti-carbon performance of the catalyst is remarkably improved, and the service life of the catalyst is prolonged; and meanwhile, the selectivity of reaction for preparing vinyl fluoride from 1,1-difluoroethane at low temperature and the conversion rate of 1,1-difluoroethane(R152a) are relatively high.

Owner:SHANDONG DONGYUE CHEM

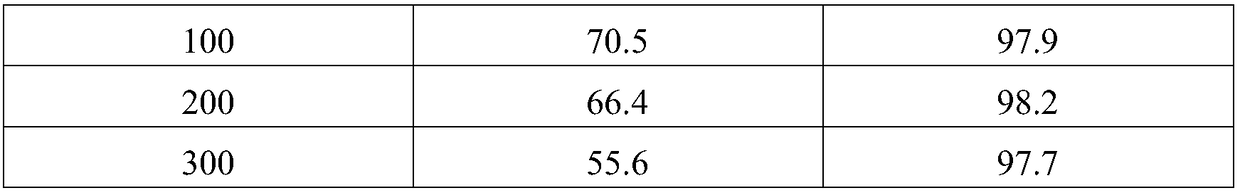

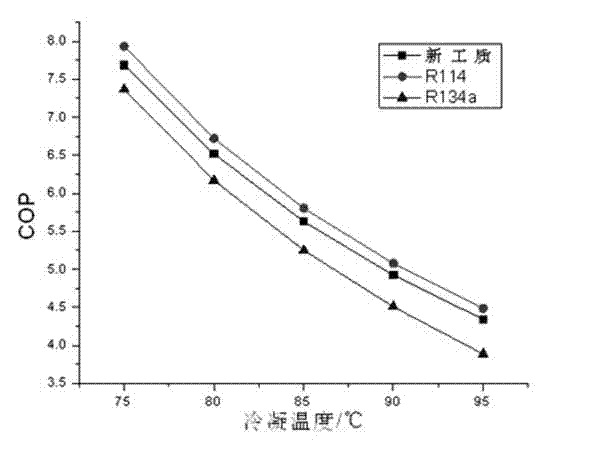

Environment-friendly medium-high temperature heat pump working medium containing dimethyl ether and iodotrifluoromethane

InactiveCN103045174AComply with protectionImprove protectionHeat-exchange elementsDifluoroethyneThermodynamics

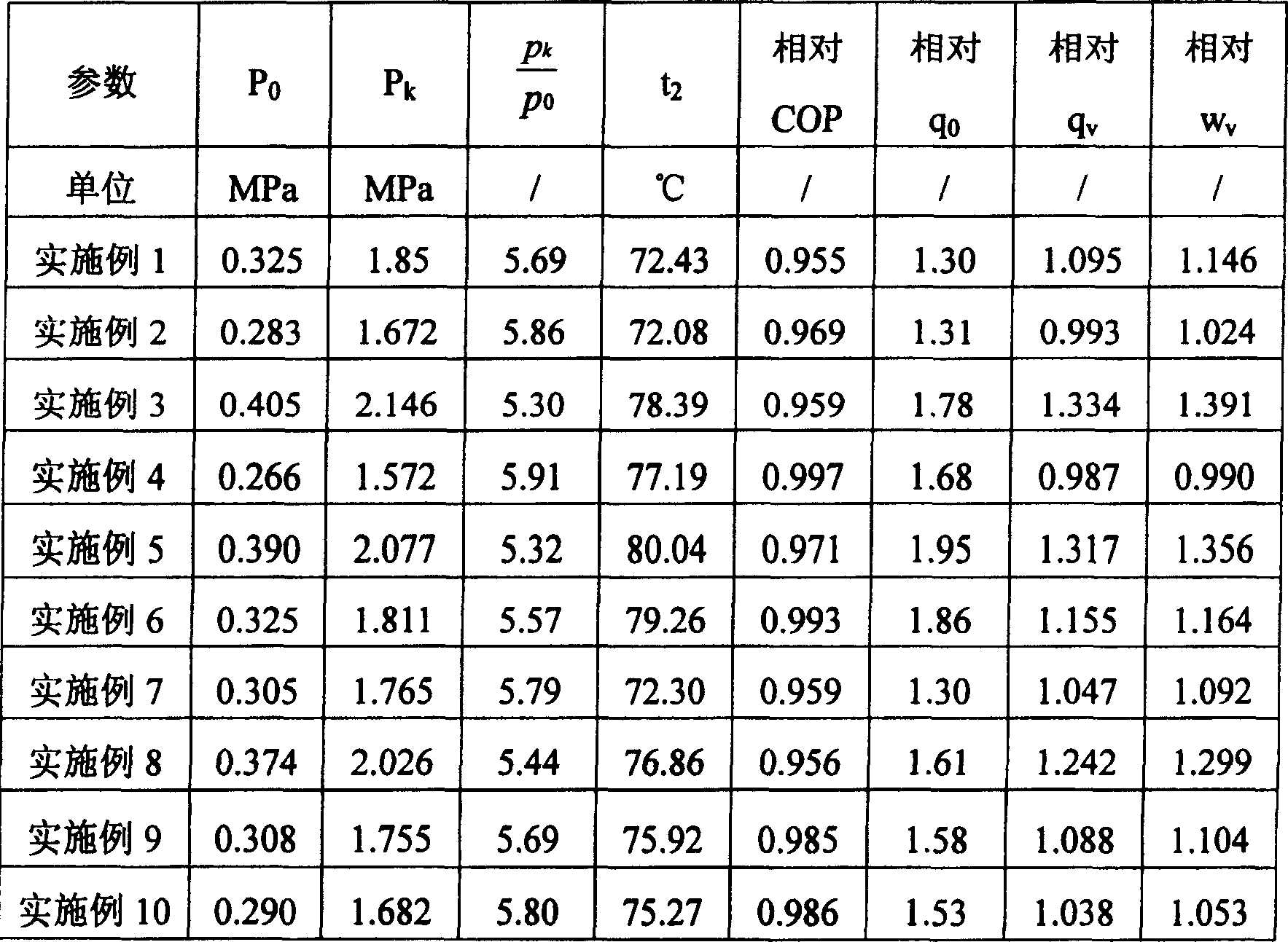

The invention relates to an environment-friendly mixing working medium suitable for compression type medium-high temperature heat pump unit. The working medium comprises three components in percentage by weight as follows: 25%-75% of DME (dimethyl ether), 15%-45% of R13I1 (iodotrifluoromethane) and 10%-50% of R152a (difluoroethane). A preparation method comprises the step that the components are subjected to fluent physical mixing at the normal temperature in a designated proportion. The working medium has the advantages that the ODP (ozone depletion potential) of the working medium is zero, the GWP (global warming potential) is very low, and the mixing working medium is environment-friendly; the cycle performance is excellent, the performance of the medium-high temperature variable working condition is better, and the slippage temperature is very low; and the working medium can be directly used in the R134a heat pump unit, so that the compressor and main parts in the system are not required to be changed. The heat pump unit employing the mixing working medium can provide a medium-high temperature heat source in a range from 70 DEG C to 90 DEG C.

Owner:GUANGZHOU HKUST FOK YING TUNG RES INST

Ternary refrigeration composition and refrigeration device comprising same

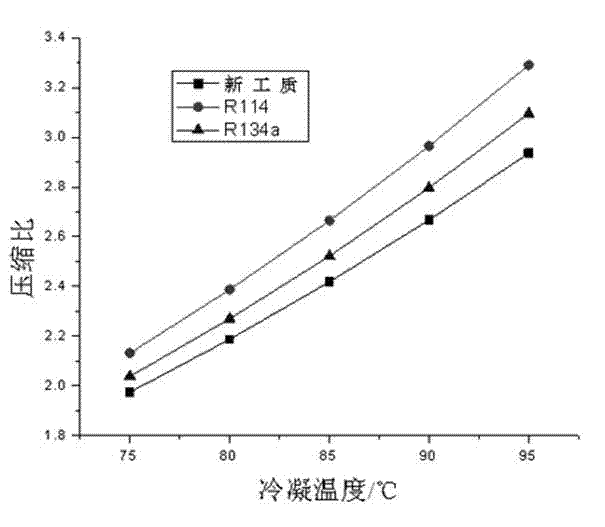

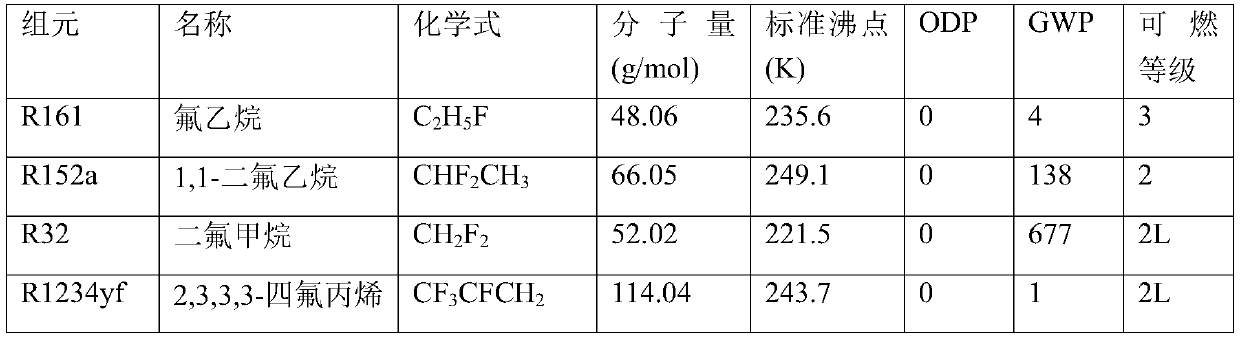

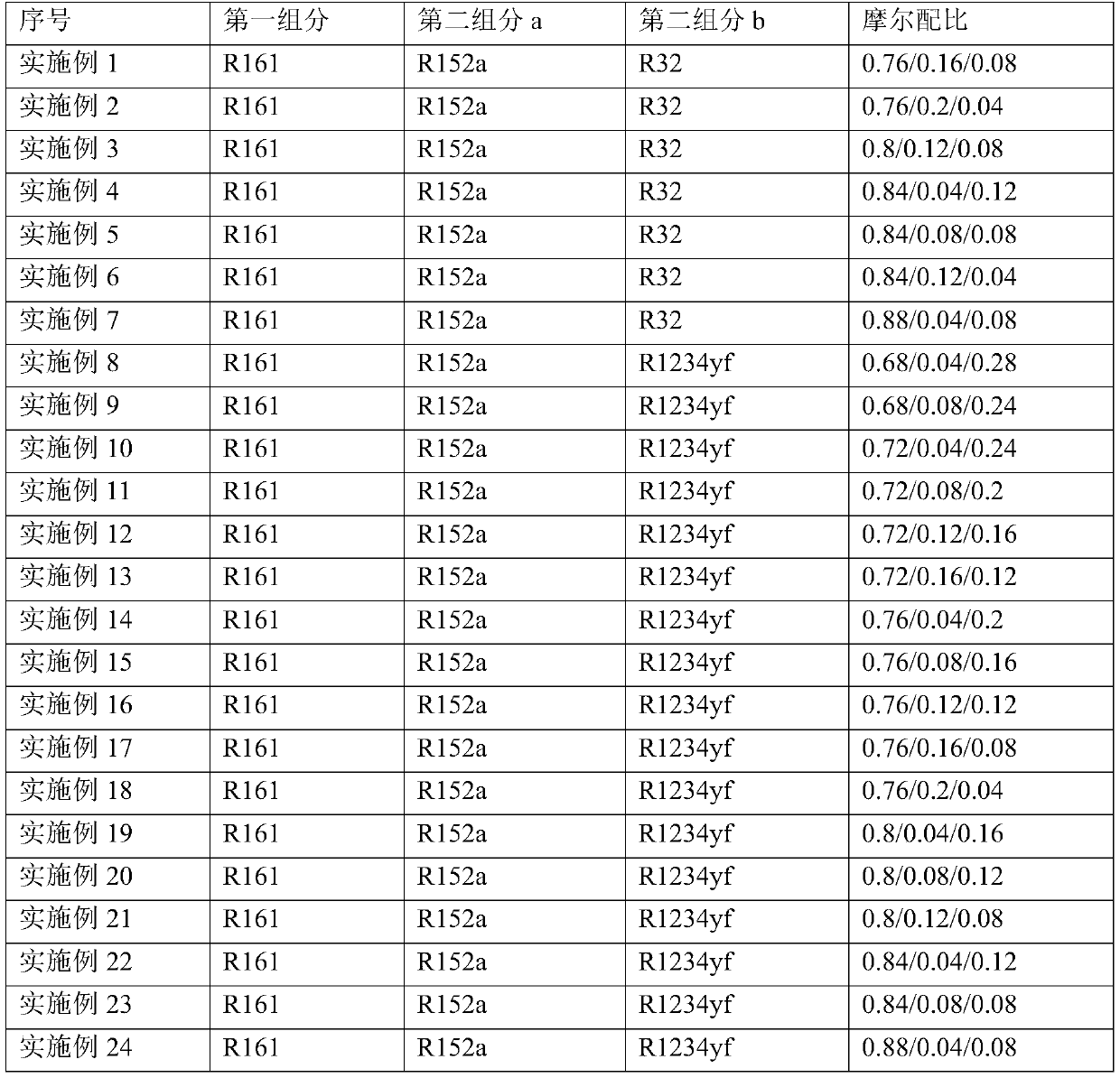

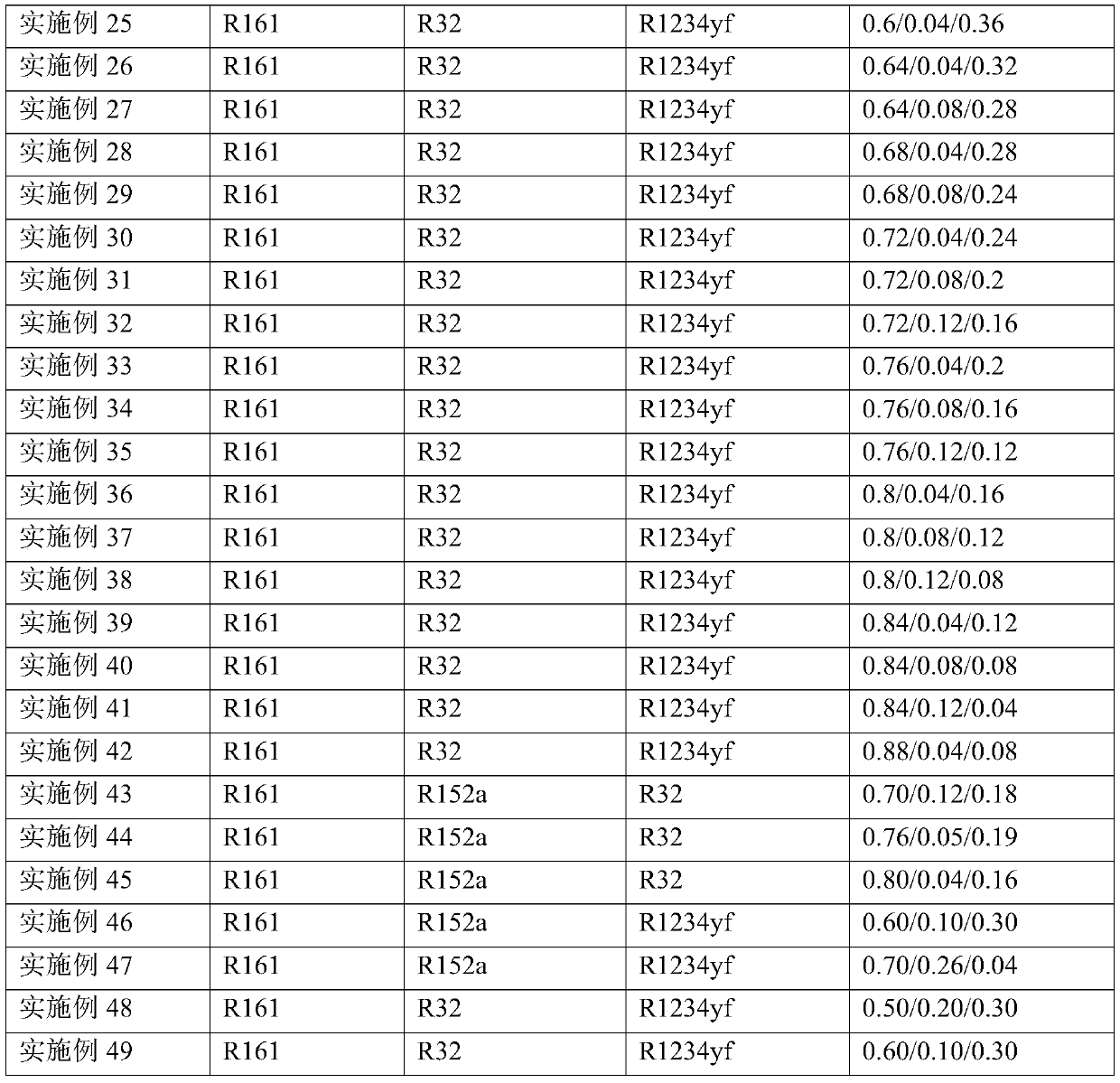

ActiveCN111423852ALow GWPLow flammability ratingCompression machines with non-reversible cycleChemical industryDifluoroethyneRefrigeration

The invention provides a ternary refrigeration composition and a refrigeration device comprising the same. The ternary refrigeration composition is composed of a first component and a second component, the first component is fluoroethane, and the second component is selected from any two of 1, 1-difluoroethane, difluoromethane and 2, 3, 3, 3-tetrafluoropropene. According to the present invention,the environmental protection property and the thermodynamic property of fluoroethane are similar to those of R290 while the combustibility of fluoroethane is lower than R290, and fluoroethane and thesecond component with the combustibility of class 2 or 2L are used together, so that the refrigeration composition can have characteristics of low GWP, good thermodynamic property and low combustibility grade, and the use safety is improved; the ternary refrigeration composition has an ODP value of zero, and does not cause damage to the ozone layer even after long-term use. Therefore, the ternaryrefrigeration composition has lower GWP, ODP is 0, the combustibility is 2 types, and the capacity and the energy efficiency of a unit are equivalent to those of a unit using an R290 refrigerant whenthe ternary refrigeration composition is applied.

Owner:GREE ELECTRIC APPLIANCES INC

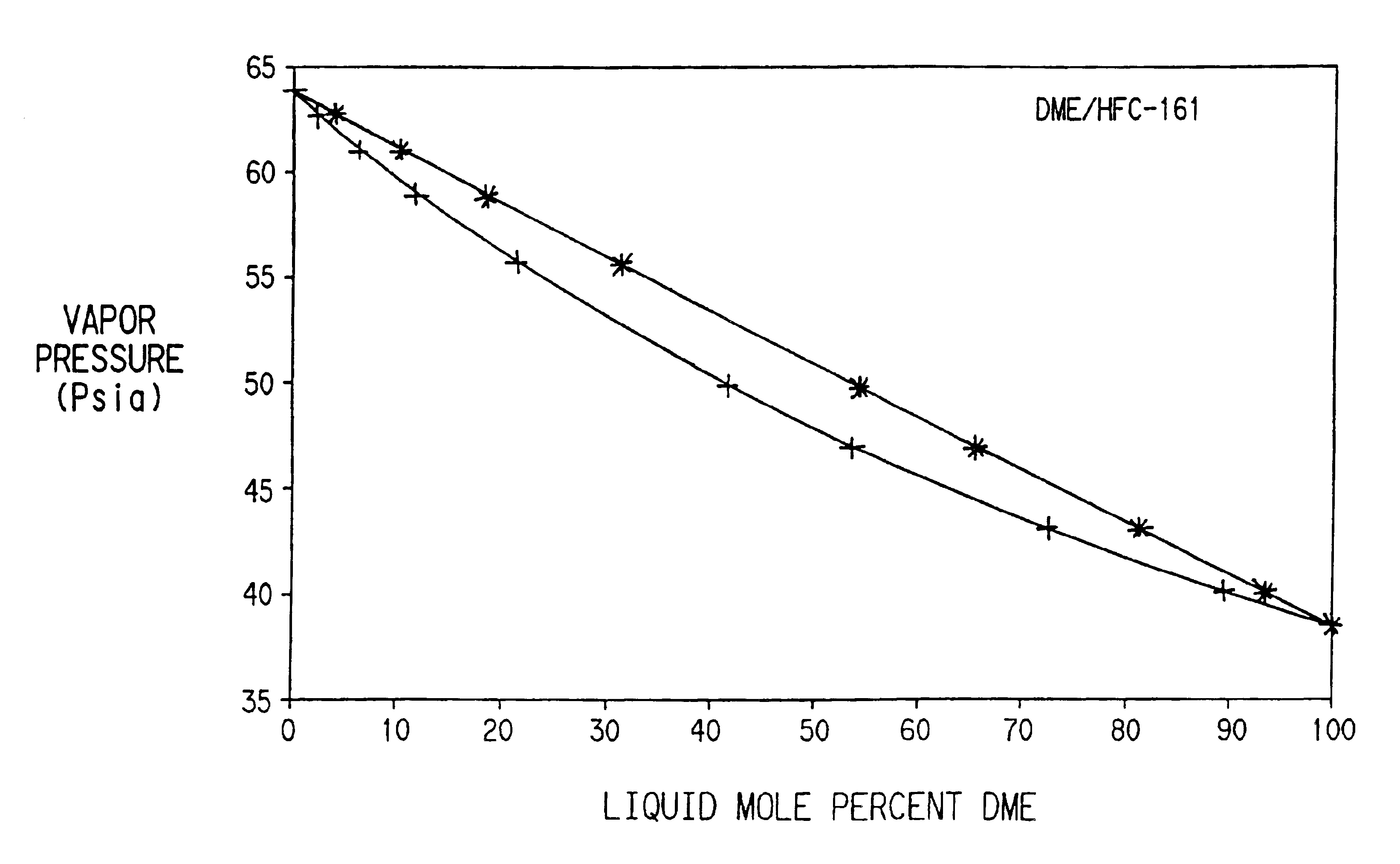

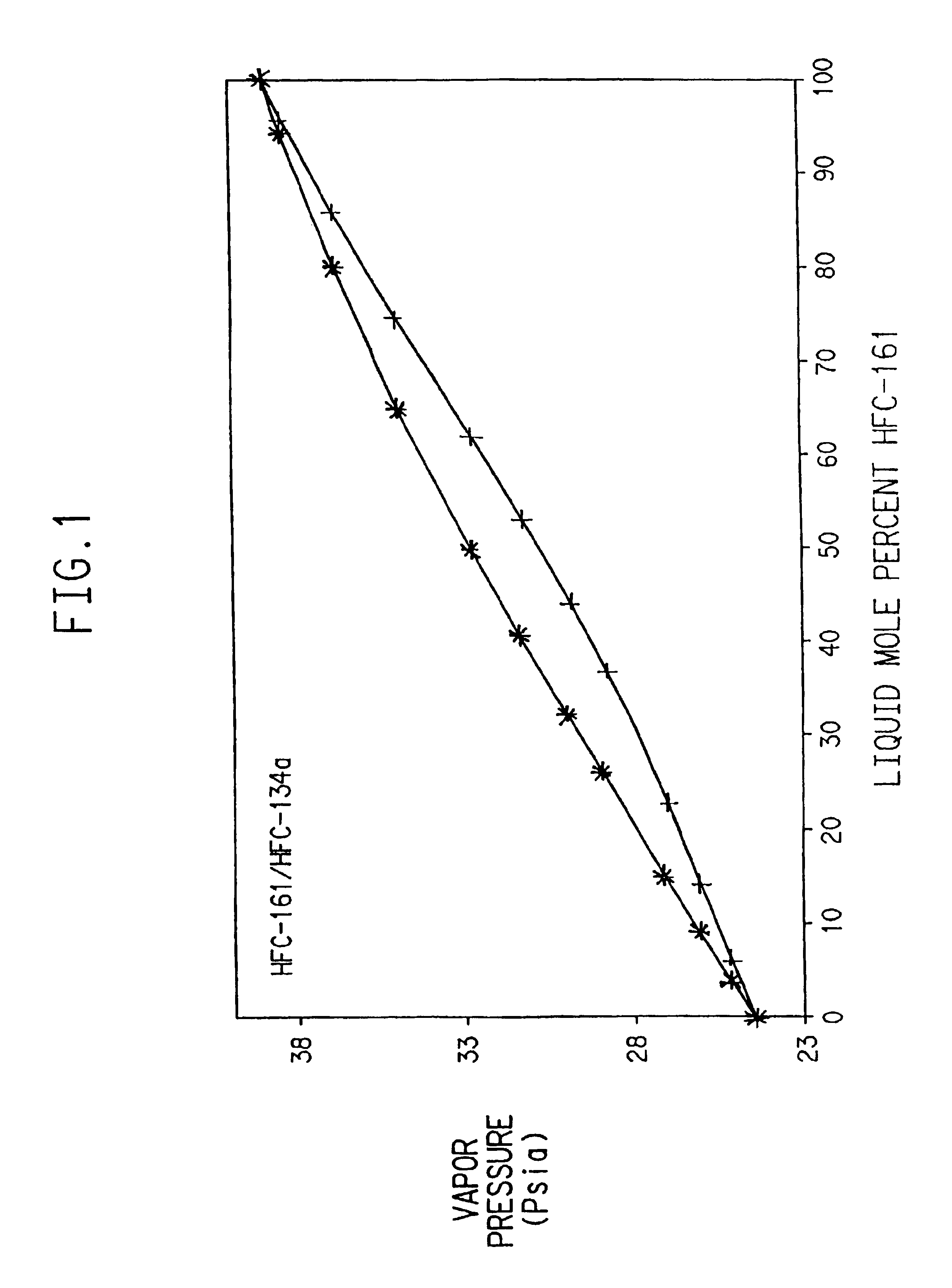

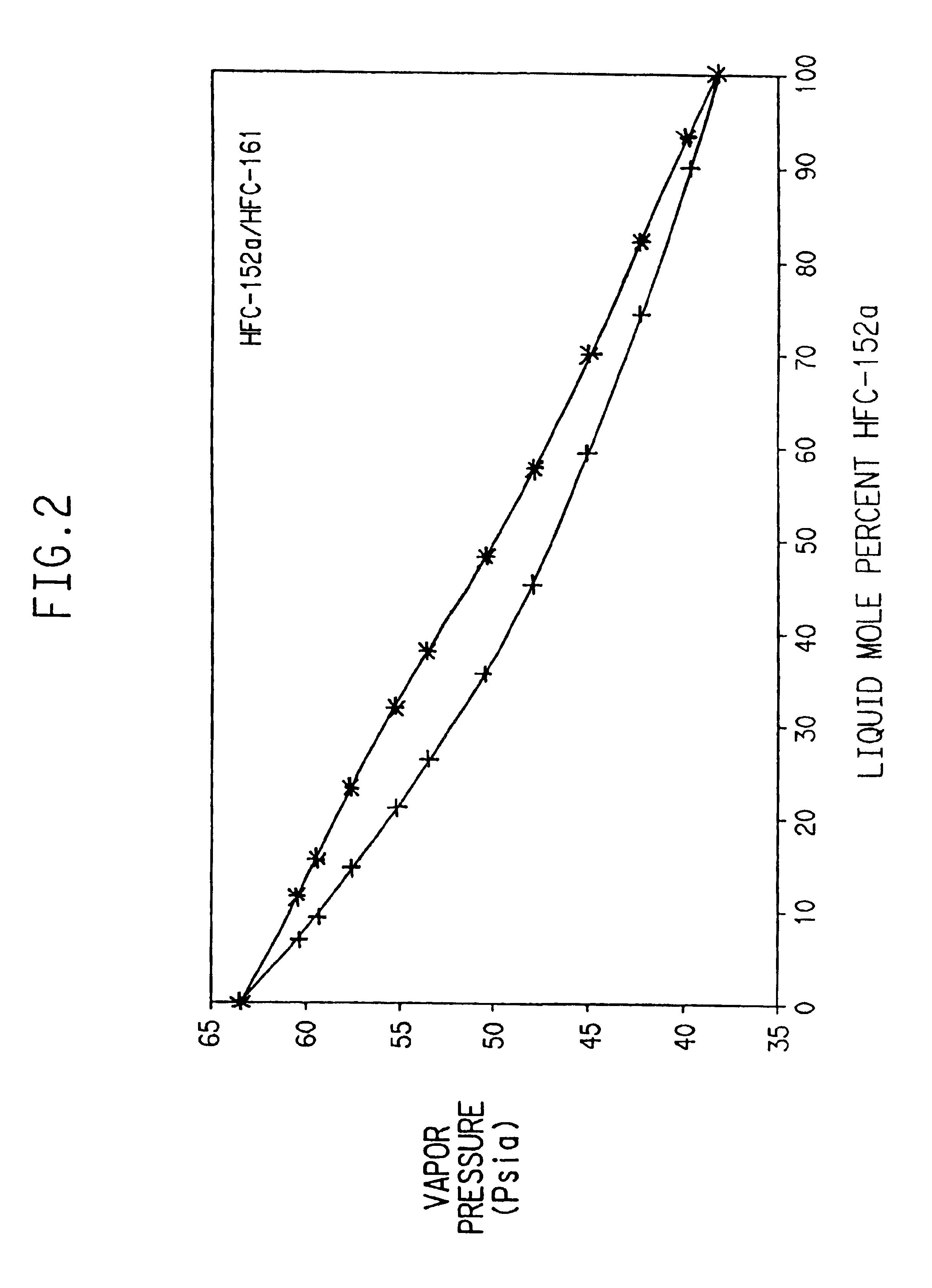

Azeotrope-like compositions containing fluoroethane

The present invention relates to the discovery of compositions which include fluoroethane, 2-fluoropropane or tert-butylfluoride. These compositions are useful as pure components or with at least one of tetrafluoroethane, difluoroethane, hexafluoropropane, a hydrocarbon or dimethylether.These compositions are useful as aerosol propellants, refrigerants, cleaning agents, expansion agents for polyolefins and polyurethanes, refrigerants, heat transfer media, gaseous dielectrics, fire extinguishing agents, power cycle working fluids, polymerization media, particulate removal fluids, carrier fluids, buffing abrasive agents, and displacement drying agents.

Owner:EI DU PONT DE NEMOURS & CO

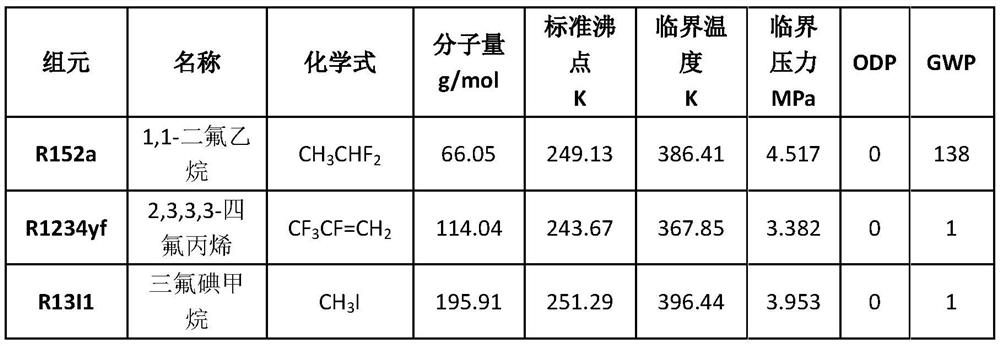

Ternary environment-friendly mixed refrigerant, preparation method thereof and refrigerating system

ActiveCN112409992ALow environmental characteristicsImprove flammabilityHeat-exchange elementsDifluoroethyneFluid phase

The invention relates to the technical field of refrigerants, in particular to a ternary environment-friendly mixed refrigerant, a preparation method of the ternary environment-friendly mixed refrigerant and a refrigerating system. The ternary environment-friendly mixed refrigerant comprises 1, 1-difluoroethane, 2, 3, 3, 3-tetrafluoropropene and trifluoroiodomethane, the GWP value of the ternary environment-friendly mixed refrigerant is smaller than 150, and the ODP value of the ternary environment-friendly mixed refrigerant is 0. The ternary environment-friendly mixed refrigerant is preparedfrom the following components in percentage by mole: 40-80 percent of 1, 1-difluoroethane, 4-64 percent of 2, 3, 3, 3-tetrafluoropropene and 4-52 percent of trifluoroiodomethane. The preparation method of the ternary environment-friendly mixed refrigerant comprises the following steps: mixing and stirring the components of the ternary environment-friendly mixed refrigerant at room temperature in aliquid phase state to obtain the ternary environment-friendly mixed refrigerant. The ternary environment-friendly mixing system provided by the invention has the environment-friendly characteristic of low GWP, the refrigerating capacity per unit volume and the system performance coefficient are close to those of R152a, the combustibility is greatly improved, and an R152a refrigerant can be well replaced.

Owner:GREE ELECTRIC APPLIANCES INC

Environment-friendly energy-saving refrigerant composition as well as preparation method and application thereof

ActiveCN114045155AReduce irreversible lossImprove energy efficiencyChemical industryCompression machinesDifluoroethyneProcess engineering

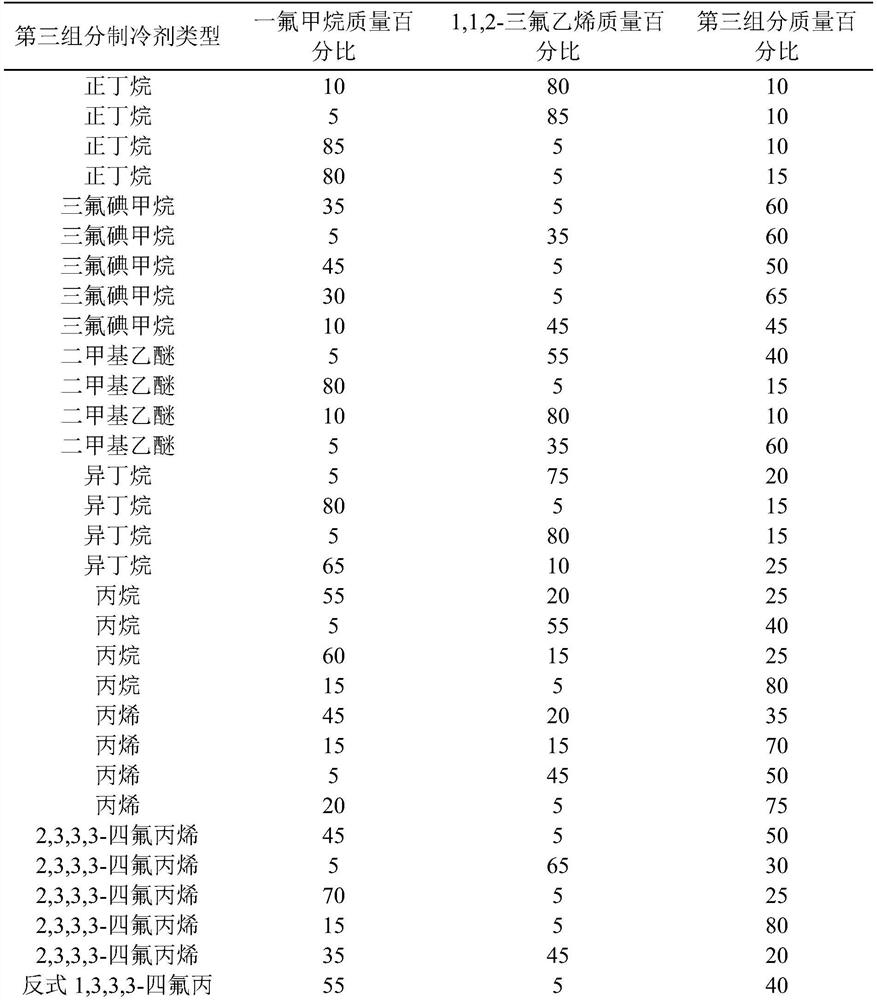

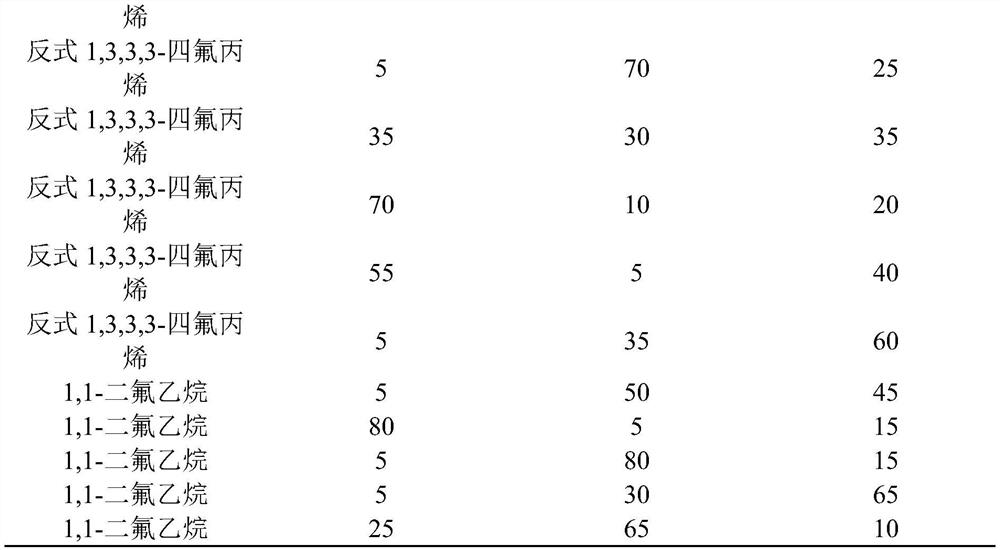

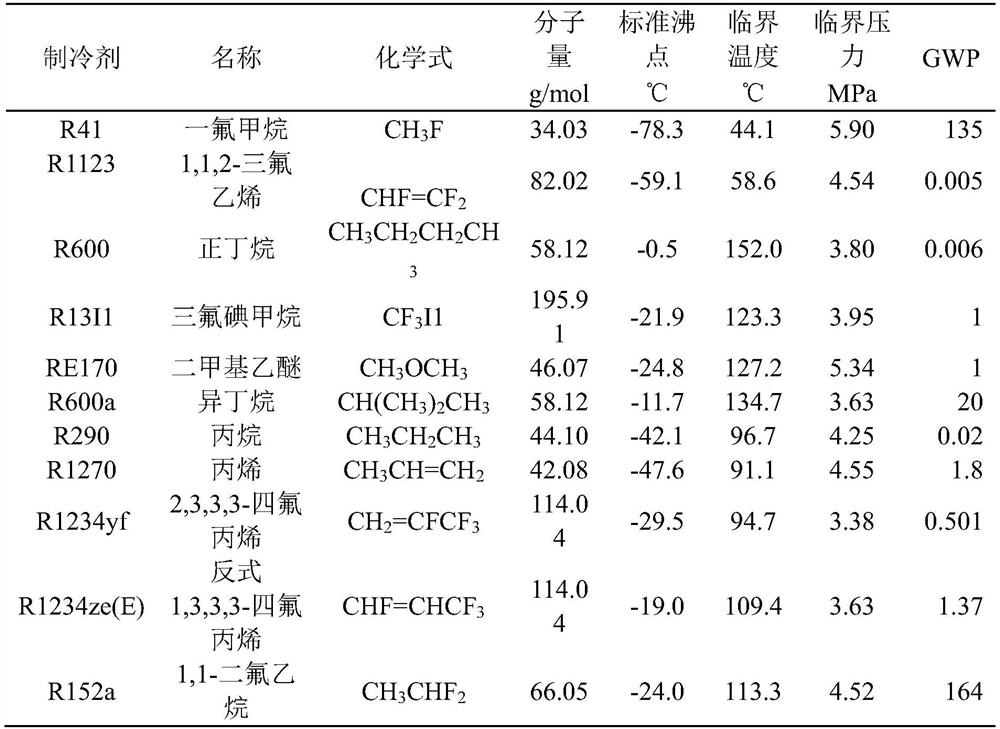

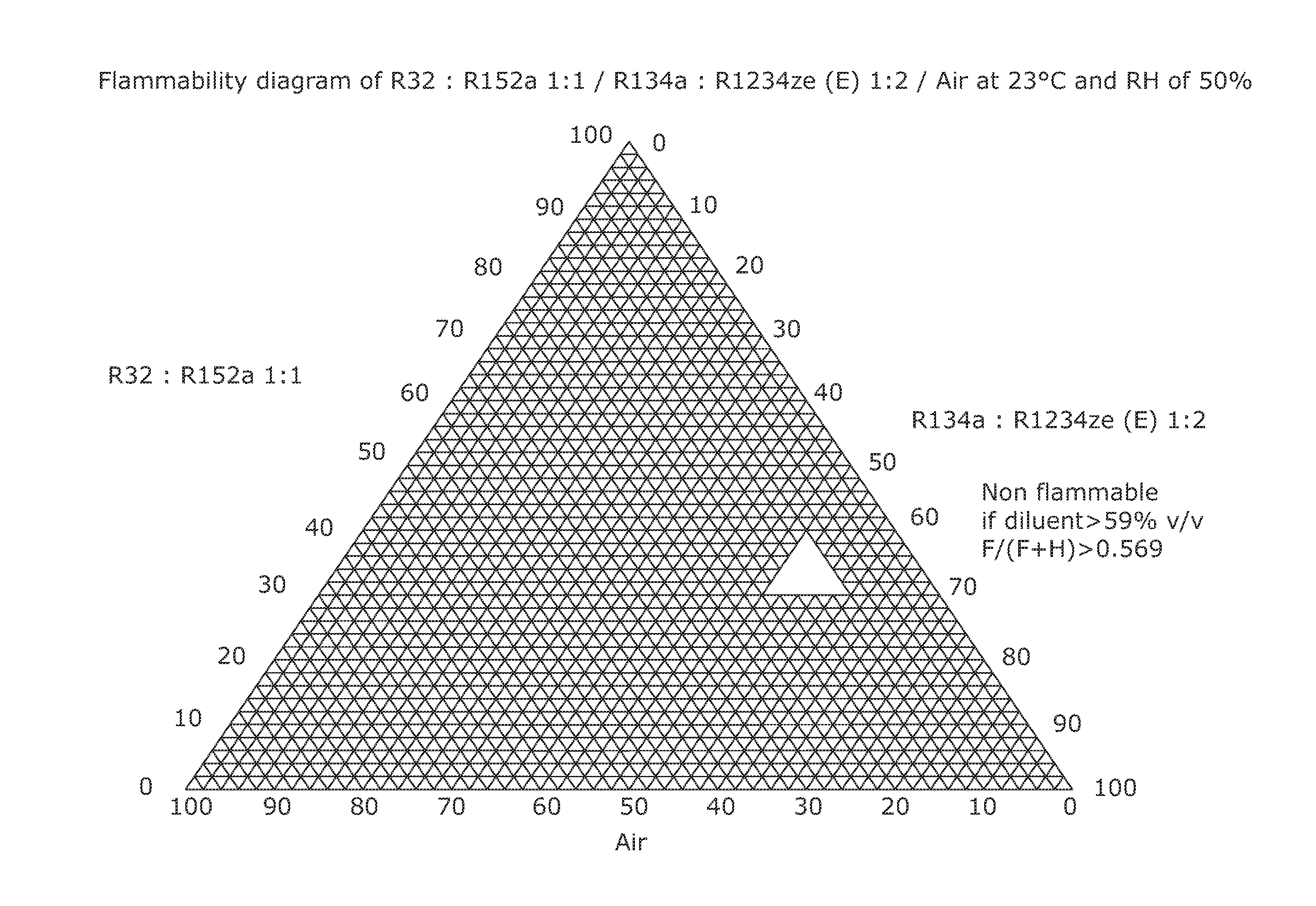

The invention relates to the technical field of refrigeration, and discloses an environment-friendly energy-saving refrigerant composition as well as a preparation method and application thereof. The refrigerant composition comprises a first component, a second component and a third component, wherein the first component is monofluoromethane, the second component is 1,1,2-trifluoroethylene, and the third component is n-butane, trifluoroiodomethane, dimethyl ether, isobutane, propane, propylene, 2,3,3,3-tetrafluoropropene, trans-1,3,3,3-tetrafluoropropene or 1,1-difluoroethane. Based on the temperature slippage characteristic of the non-azeotropic refrigerant, the environment-friendly energy-saving refrigerant composition with low GWP and high system energy efficiency is provided by weighing the respective characteristics of different refrigerants; the refrigerant composition has good environmental performance, and the GWP of the refrigerant composition is lower than 140 while the GWP of most refrigerant compositions is lower than 100; and meanwhile, the refrigerant composition can remarkably improve the operation energy efficiency of refrigeration equipment, and the purpose of saving energy is achieved.

Owner:GREE ELECTRIC APPLIANCES INC

Heat Transfer Compositions

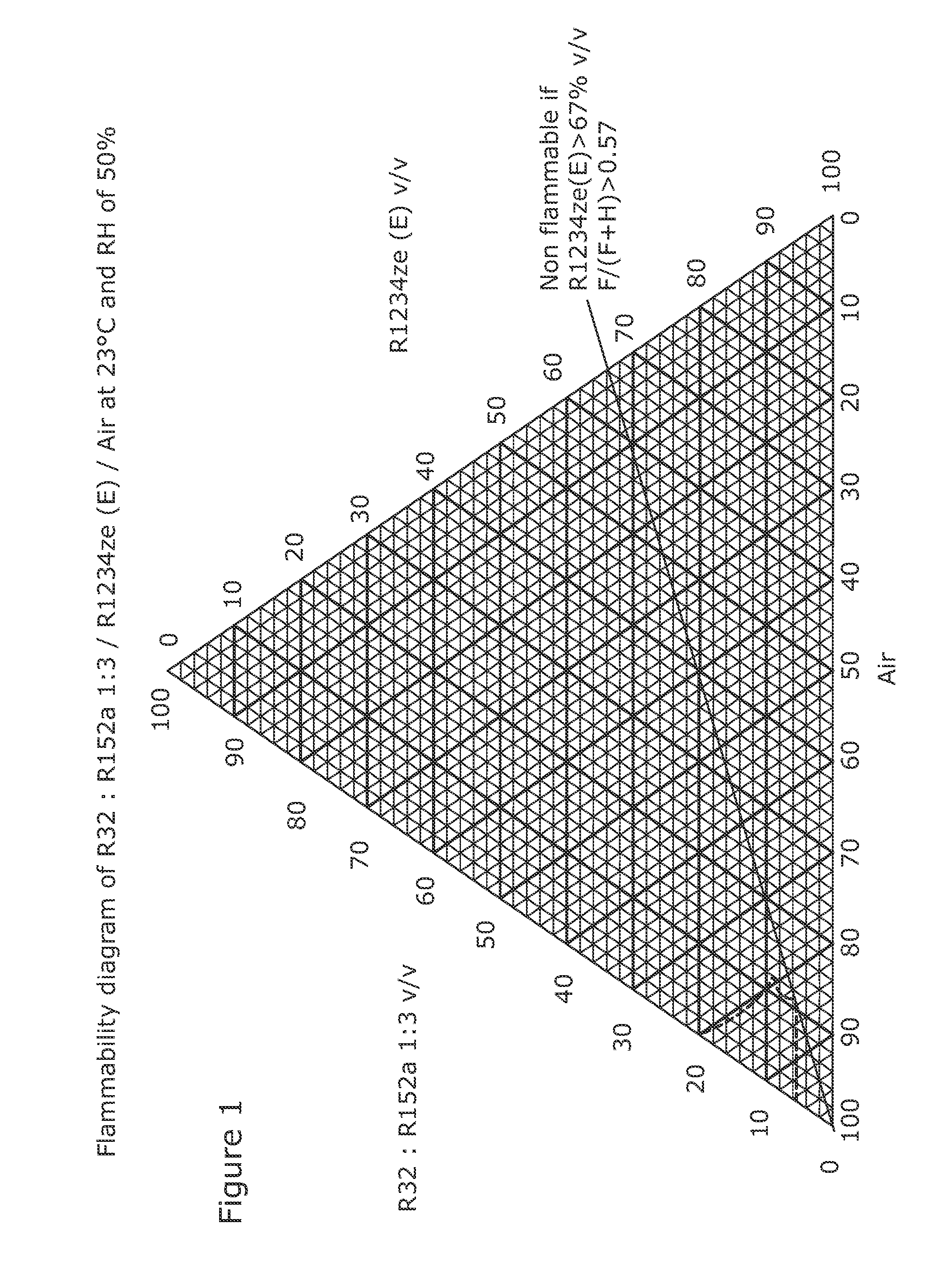

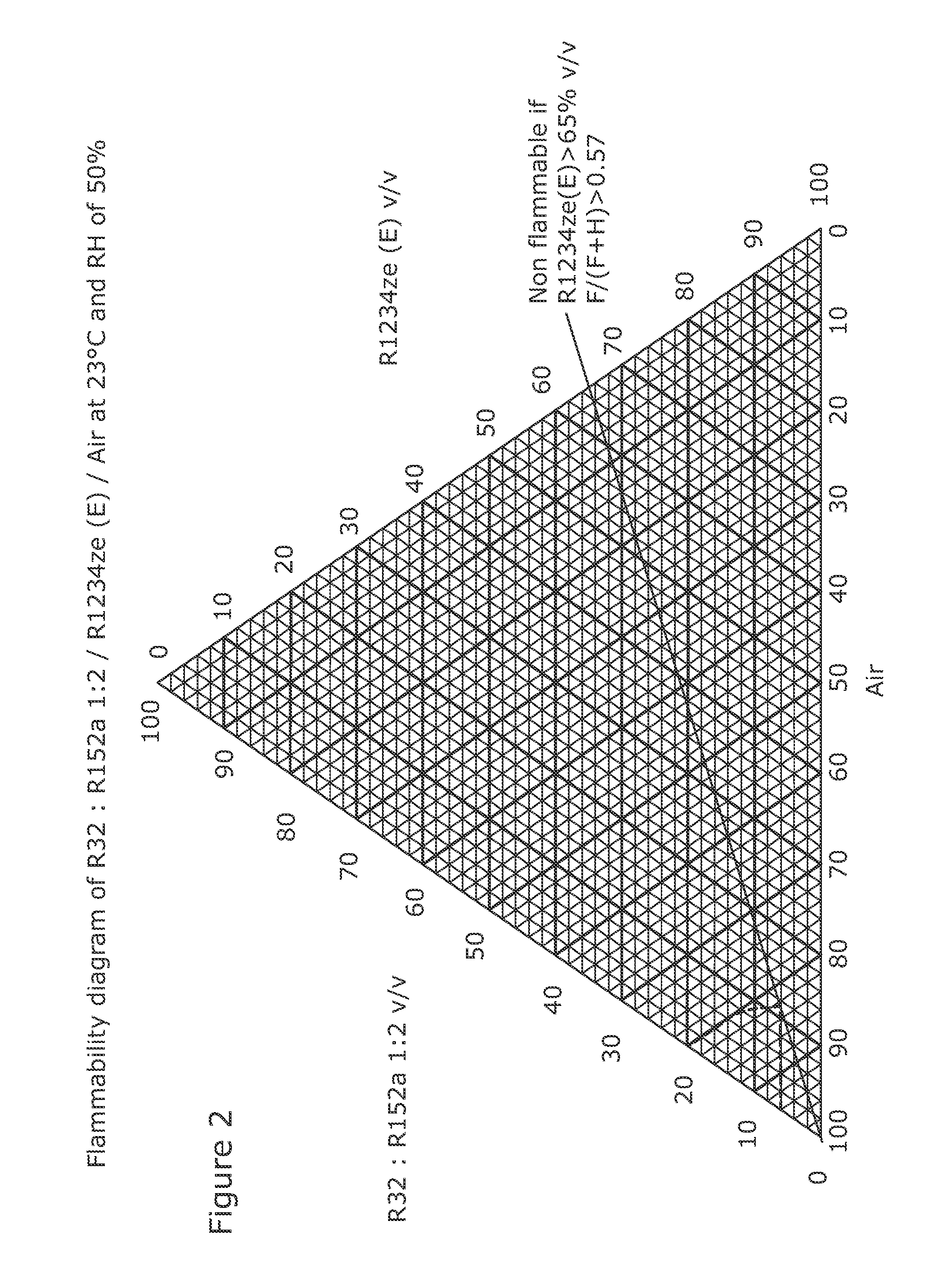

ActiveUS20130325732A1Reduced GWPLow toxicityDomestic cooling apparatusSolvent extractionThermodynamicsDifluoroethyne

A heat transfer composition comprising trans-1,3,3,3-tetrafluoropropene (R-1234ze(E)), difiuoromethane (R-32) and 1,1-difluoroethane (R-152a).

Owner:MEXICHEM AMANCO HLDG DE C V

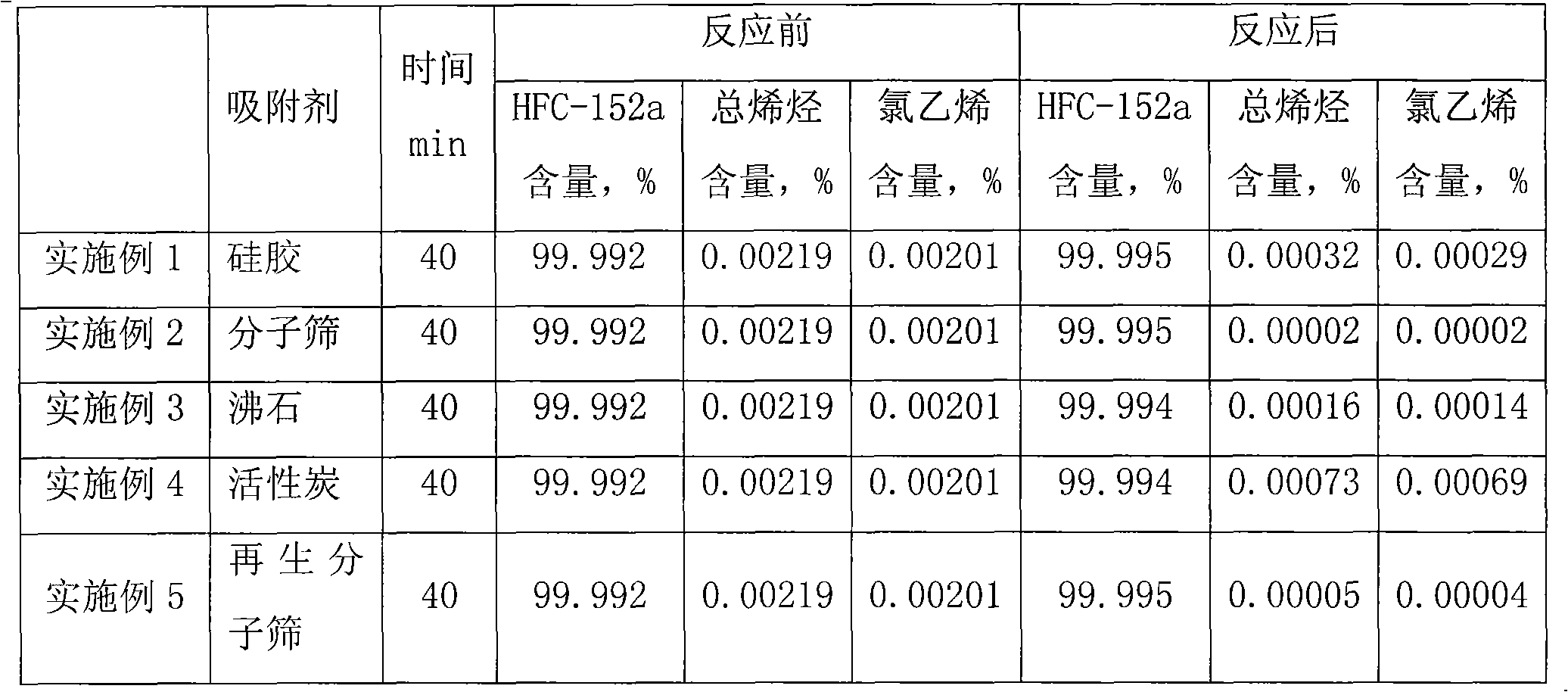

Liquid phase purification method for 1,1- difluoroethane

InactiveCN102101822AReduce contentTotal olefin contentCombustible gas purificationHalogenated hydrocarbon preparationMagnesiumSingle point

The invention relates to a method for purifying 1,1-difluoroethane through liquid phase adsorptive separation. An adsorbent which is one or a combination of more of silica gel, activated aluminium oxide, activated magnesium oxide and aluminosilicate absorbents and a carbon-based adsorbent is used, and an adsorbent, which has the BET surface area of more than or equal to 400m<2> / g and the single-point average pore size of about 5 and is capable of reducing the content of total olefins in crude chloroethylene-containing 1,1-difluoroethane to below 10ppm and reducing the content of chloroethylene to below several ppm and even below 1 ppm, is preferred. The 1,1-difluoroethane can be independently used, and also can be mixed with other materials to serve as a low temperature refrigerant, a foaming agent, a propellant, an etching gas, a cleaning agent or an intermediate of other fluorocarbon compounds.

Owner:SINOCHEM LANTIAN

Trifluoroethylene-based compositions and uses thereof

The present invention relates to a composition comprising:trifluoroethylene;pentafluoroethane; andat least one compound C chosen from the group constituted by difluoromethane, 1,1,1-trifluoropropene, trifluoroethane, 1,1,1,2-tetrafluoroethane, monofluoroethane, 1,1,1,4,4,4-hexafluorobut-2-ene, 3,3,4,4,4-pentafluorobut-1-ene, 2,4,4,4-tetrafluorobut-1-ene, 1,1,1,3,3-pentafluoropropane, 2,3,3,3-tetrafluoropropene, 1,1,2,2-tetrafluoroethane, 1,1-difluoroethane, 1,1,1,3,3-pentafluorobutane, butane, 1,1,1,2,3,3,3-heptafluoropropane, 1-chlorotrifluoropropene, 2-methylbutane, pentane, propane, and mixtures thereof.The present invention also relates to the uses thereof in refrigeration, air conditioning and heat pumps.

Owner:ARKEMA FRANCE SA

Heat transfer medium, and heat transfer medium composition suitable for applications in coolers

ActiveCN110845997AImprove securityReduce flammabilityHeat-exchange elementsLubricant compositionThermodynamicsDifluoroethyne

Owner:GREE ELECTRIC APPLIANCES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com