Preparation method of difluoro chloroethane and its production equipment

A technology for difluoromonochloroethane and production equipment, which is applied in the preparation of halogenated hydrocarbons, chemical instruments and methods, organic chemistry, etc., can solve the problems of low conversion rate, low conversion rate and selectivity, low conversion rate and the like, Achieve the effect of satisfying mass production, convenient luminous flux control, and low unit consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

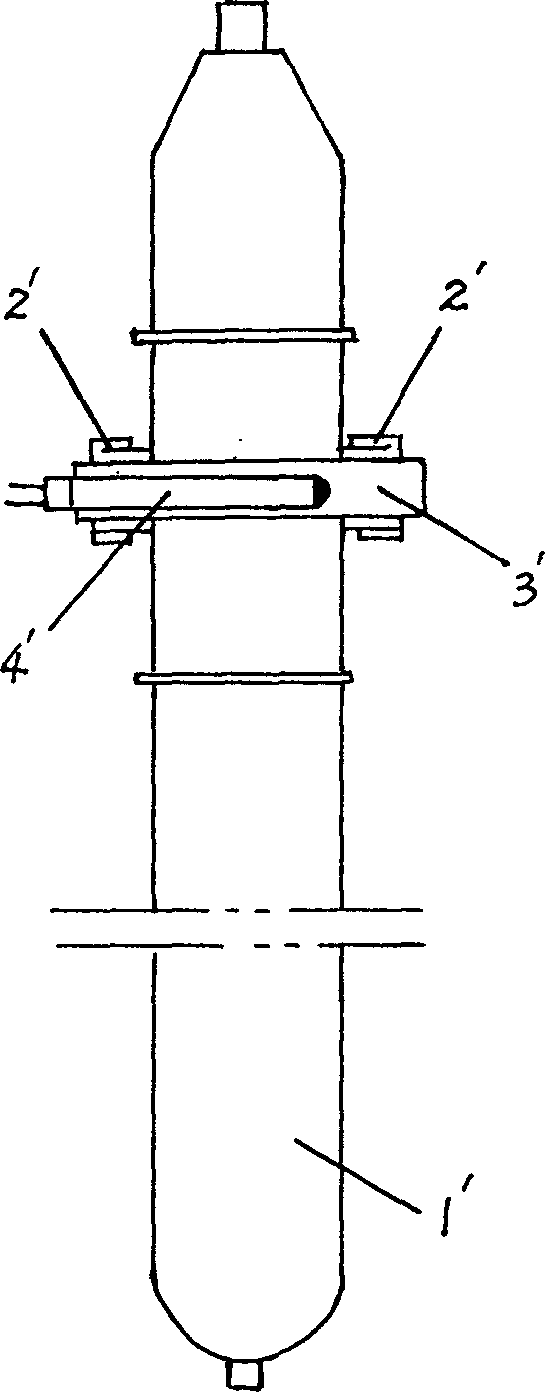

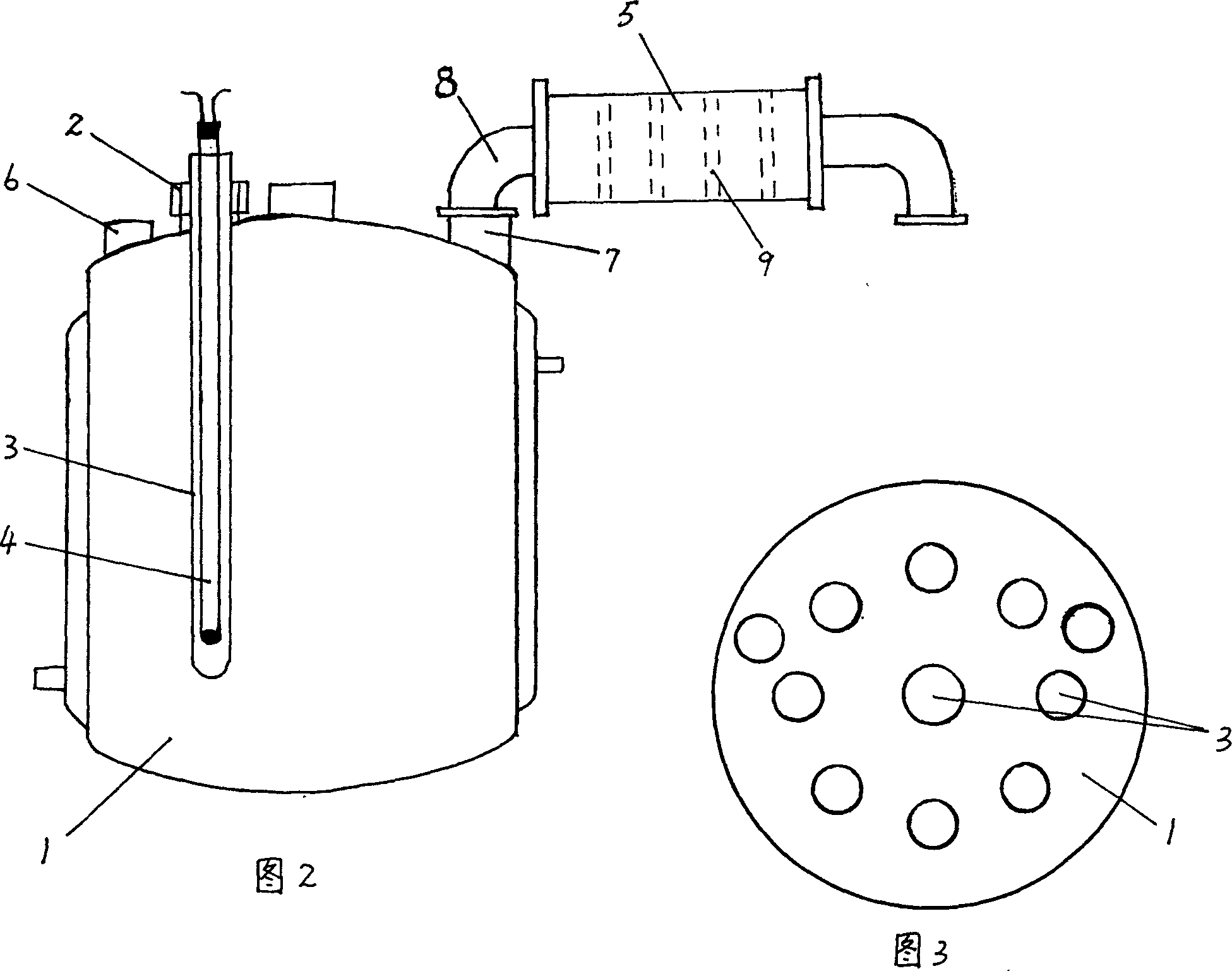

[0031] In this embodiment, the tank-type multi-stage reactor adopts a three-stage reactor. Its technological process is:

[0032] A. Mix difluoroethane and chlorine gas at a weight ratio of 85:75Kg and then add them to the primary photochemical reactor. The temperature of the reactor is controlled at 55°C, and the reaction residence time is 40 seconds; adjust the luminous flux to make the sample appear on the chromatogram A high boiler peak with a peak height of 0-2 mm appears;

[0033] B. Import the materials of the above-mentioned primary reactor into the secondary reactor through the connecting pipe, add 10Kg of chlorine gas, control the temperature of the reactor at 55°C, and the reaction residence time is 40 seconds; adjust the luminous flux so that the sample appears on the chromatogram 2-4mm high boiler peak;

[0034] C. Import the materials of the above-mentioned secondary reactor into the tertiary reactor through the connecting pipe, add 5Kg of chlorine gas, control...

Embodiment 2

[0043] In this embodiment, the kettle-type multi-stage reactor adopts a two-stage reactor. Its technological process is:

[0044] A. Mix difluoroethane and chlorine gas in a weight ratio of 65:60Kg and add them to the primary photochemical reactor. The temperature of the reactor is controlled at 50°C, and the reaction residence time is 50 seconds; adjust the luminous flux to make the sample appear in the chromatogram. A high boiler peak with a peak height of 0-2 mm appears on the top;

[0045] B. Import the material of the above-mentioned primary reactor into the secondary reactor through the connecting pipe, add 10Kg of chlorine gas, control the temperature of the reactor at 50°C, and the reaction residence time is 50 seconds; adjust the luminous flux to make the chromatogram of the sample appear 4mm peak;

[0046] C. Separation treatment:

[0047] a Removal of HCL: The material in the three-stage reactor is absorbed by the graphite absorption tower, and the water spray vol...

Embodiment 3

[0054] In this embodiment, the tank-type multi-stage reactor adopts a three-stage reactor. Its technological process is:

[0055] A. Mix difluoroethane and chlorine gas at a weight ratio of 60:50Kg and then add them to the primary photochemical reactor. The temperature of the reactor is controlled at 45°C, and the reaction residence time is 60 seconds; adjust the luminous flux to make the sample appear in the chromatogram. A high boiler peak with a peak height of 0-2 mm appears on the top;

[0056] B. Import the materials of the above-mentioned primary reactor into the secondary reactor through the connecting pipe, add 10Kg of chlorine gas, control the temperature of the reactor at 45°C, and the reaction residence time is 60 seconds; adjust the luminous flux so that the sample appears on the chromatogram 2-4mm high boiler peak;

[0057] C. Import the materials of the above-mentioned secondary reactor into the tertiary reactor through the connecting pipe, add 4Kg of chlorine ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com