Patents

Literature

532results about How to "Meet the requirements of mass production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

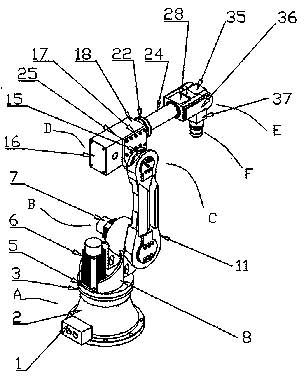

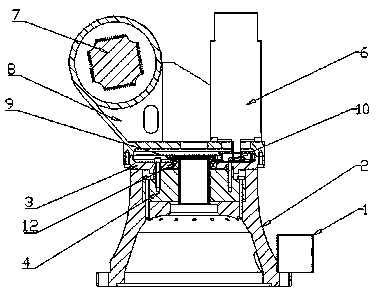

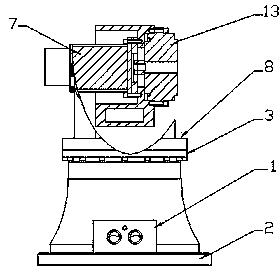

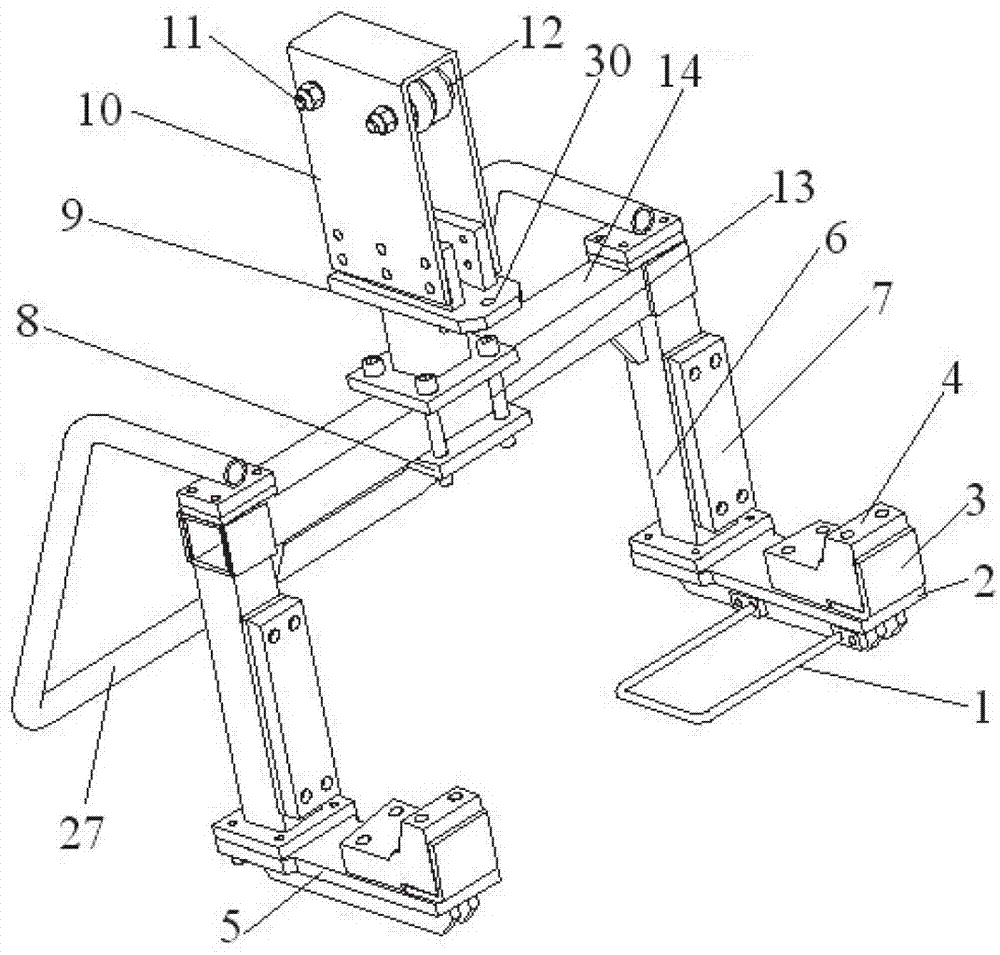

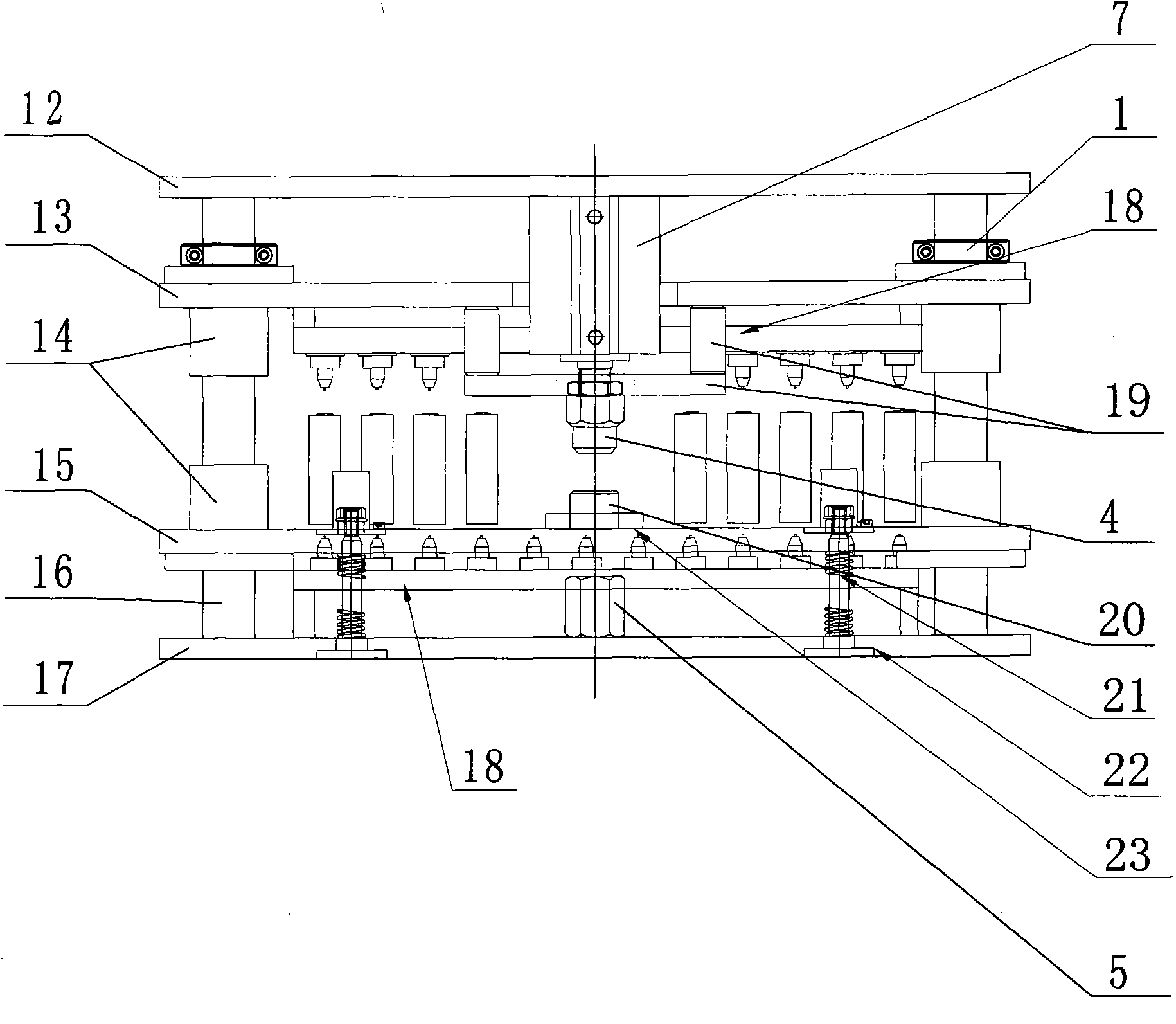

Six-axis degree-of-freedom manipulator

InactiveCN103568002AAvoid jitterCompact structureProgramme-controlled manipulatorControl systemDegrees of freedom

The invention discloses a six-axis degree-of-freedom manipulator. The six-axis degree-of-freedom manipulator comprises a base, wherein the base is in transmission connection with a first transmission mechanism, a second transmission mechanism, a third transmission mechanism, a fourth transmission mechanism, a fifth transmission mechanism and a sixth transmission mechanism in sequence, wherein the six transmission mechanism is in transmission connection with a mechanical palm part. A series of functions such as welding, spraying and handling are combined, the newest servo control system is adopted, and a series of new functions which can meet the industrial production of users are developed on the platform. The conventional complex transmission process is greatly simplified in the aspect of mechanical transmission, and the characteristic that bevel gear mesh type transmission is generally adopted by the conventional six axes is cancelled, so that the manipulator has a compacter structure and higher transmission efficiency, is more accurate in control and can effectively prevent the situation of jitter due to joint movement.

Owner:RIZHAO POLYTECHNIC

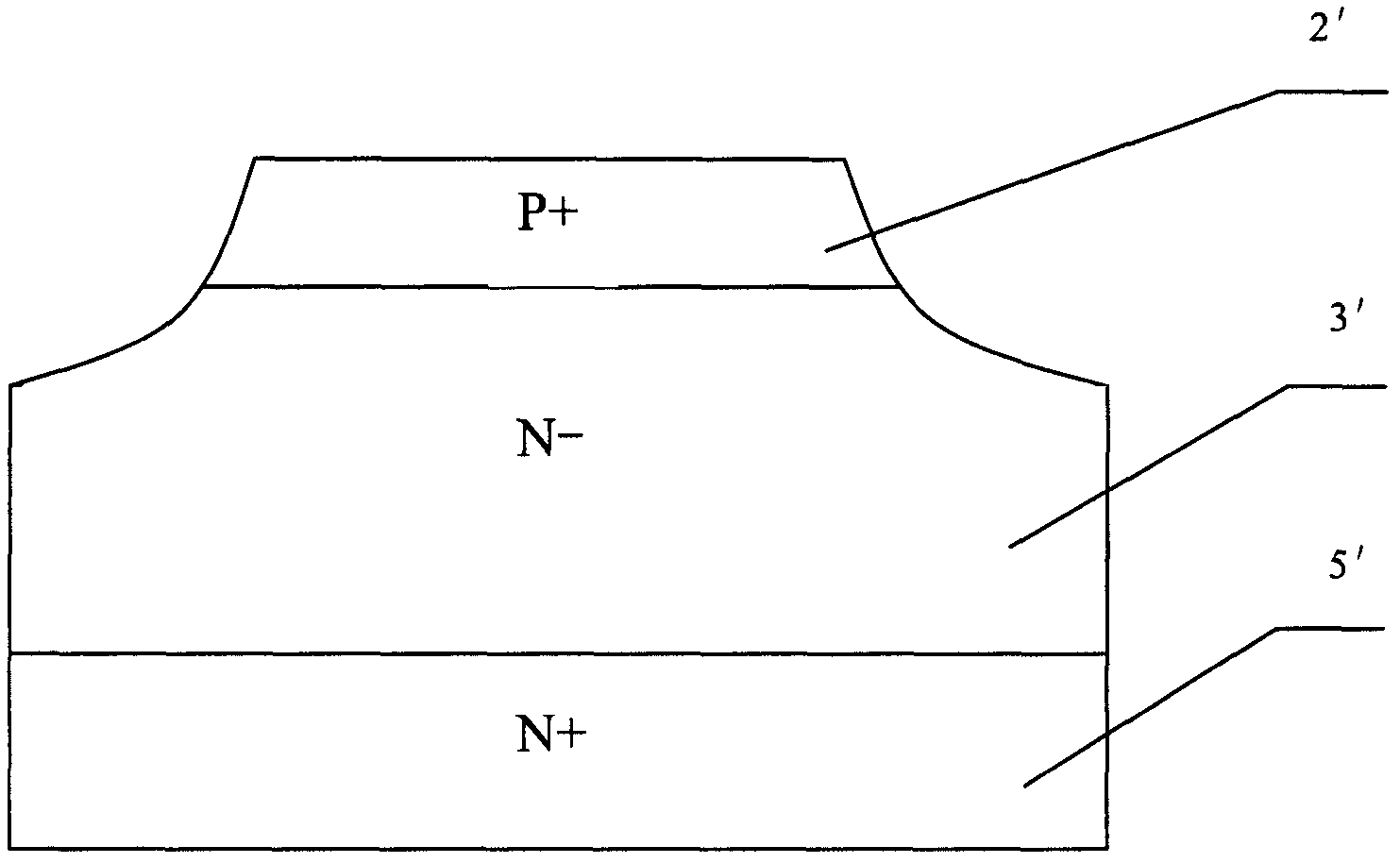

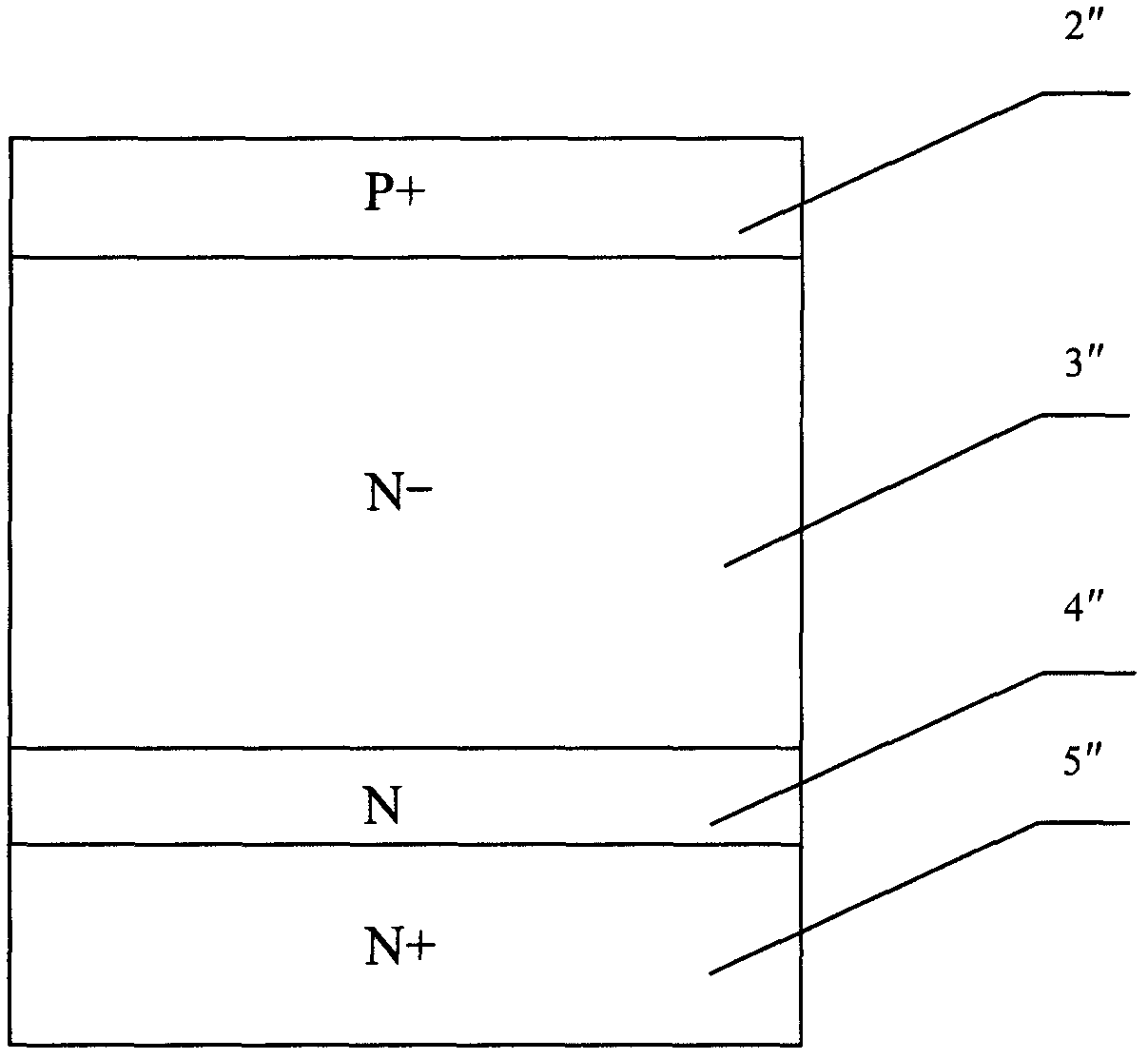

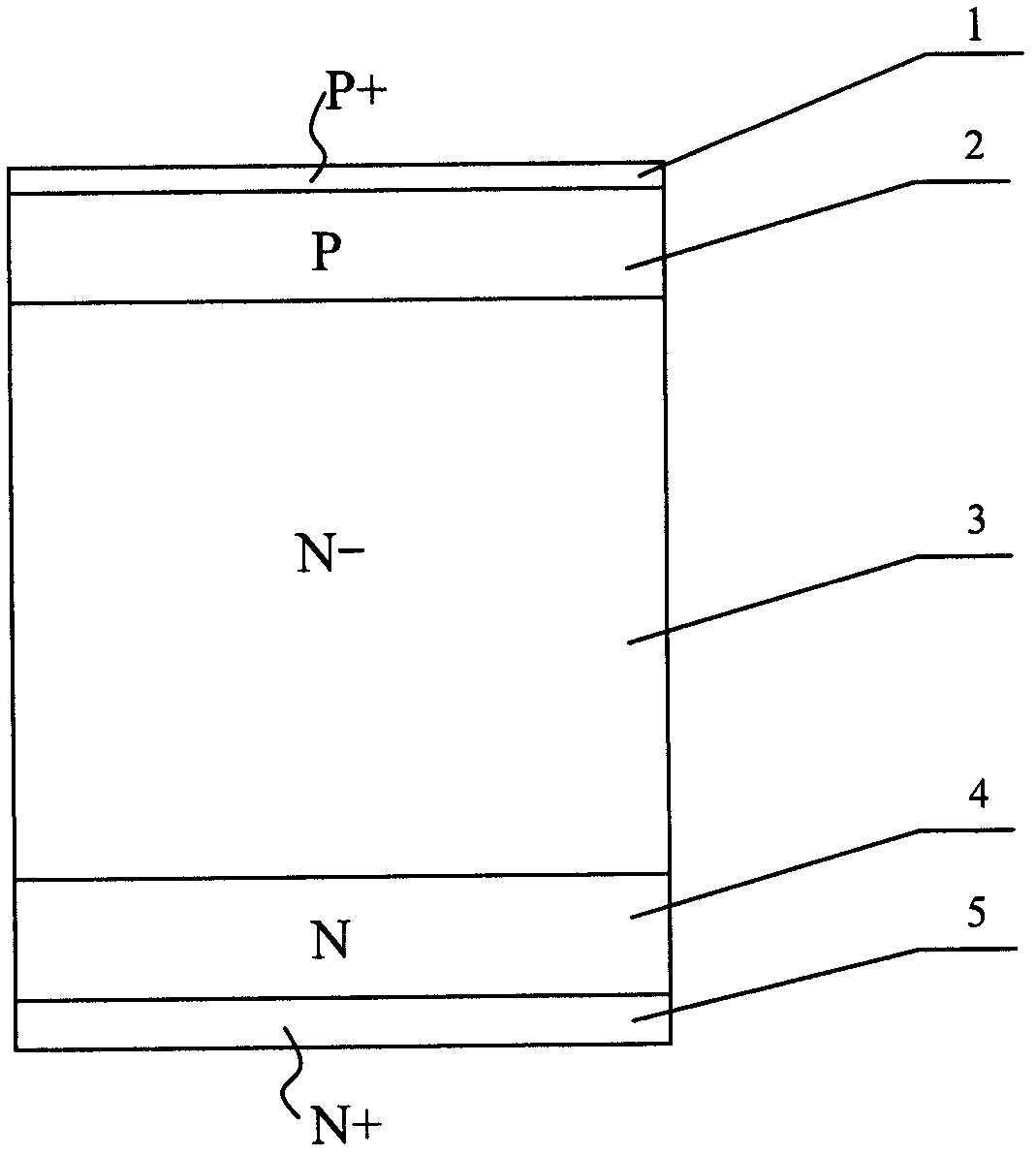

Method for manufacturing planar high-voltage ultrafast soft recovery diode

ActiveCN102569067ALow costMeet the requirements of mass productionSemiconductor/solid-state device manufacturingPlatinumLow leakage

The invention discloses a method for manufacturing a planar high-voltage ultrafast soft recovery diode. The method comprises the following steps of: oxidizing, and photoetching to form an active region and a field limiting ring; doping and pushing; manufacturing a polycrystalline silicon field plate; performing platinum diffusion; thinning; forming an N-type buffer layer; performing contact doping and annealing; and metalizing. The method can be used for manufacturing an ultrafast soft recovery diode chip which is low in cost and short in recovery time and has high-voltage resistance, low leakage current, low forward voltage drop and soft recovery characteristics.

Owner:BEIJING MXTRONICS CORP +1

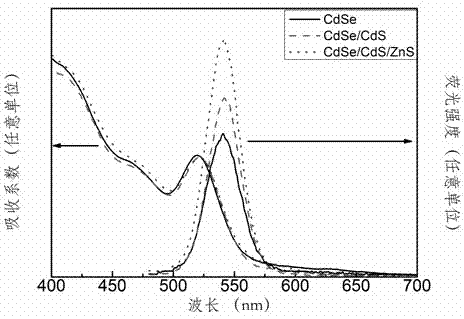

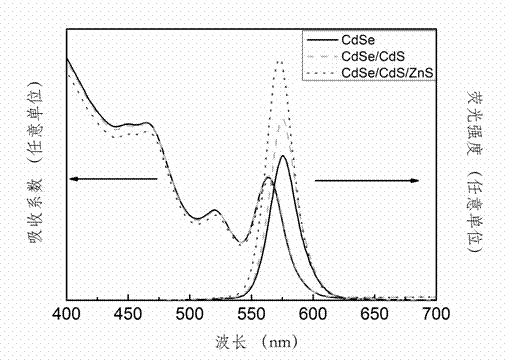

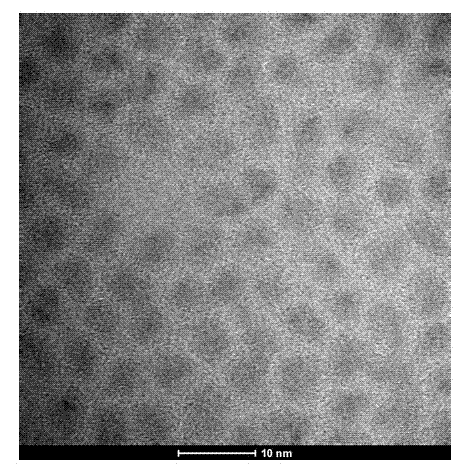

Synthetic method for preparing CdSe/CdS/ZnS core-shell structure quantum dots by acid assistance

InactiveCN104498039ASmall emission wavelength effectCoating method is simpleLuminescent compositionsOrganic acidParaffin oils

The invention discloses a synthetic method for preparing CdSe / CdS / ZnS core-shell structure quantum dots by acid assistance. The synthetic method comprises the following steps: synthesizing a CdSe core quantum dot solution in a paraffin oleic acid system, using cadmium oleate as a precursor of a shell layer CdS, using a sulfur source dissolved in liquid paraffin as a precursor of the shell layers CdS and ZnS, using a zinc source dissolved in the liquid paraffin as a precursor of the shell layer ZnS, adding an organic acid in a precursor of S, and dripping the organic acid into the core quantum dot solution, wherein the organic acid reinforces the activity of the precursors of the shell layers, reduces the surface ligands of the core quantum dot, promotes the growth of the CdS shell layer on the surface of the CdSe core quantum dot and achieves epitaxial coating; dripping the precursor of Zn to wrap the ZnS shell layer to obtain a CdSe / CdS / ZnS core-shell structure quantum dot solution. The synthetic method disclosed by the invention has the advantages that the CdSe / CdS / ZnS core-shell structure quantum dots can be synthesized in the atmosphere under a non-phosphor system, the raw materials are cheap, the reaction temperature is low, the growth of the shell layers is fast, the operation is simple and mass production is suitable.

Owner:HUBEI UNIV

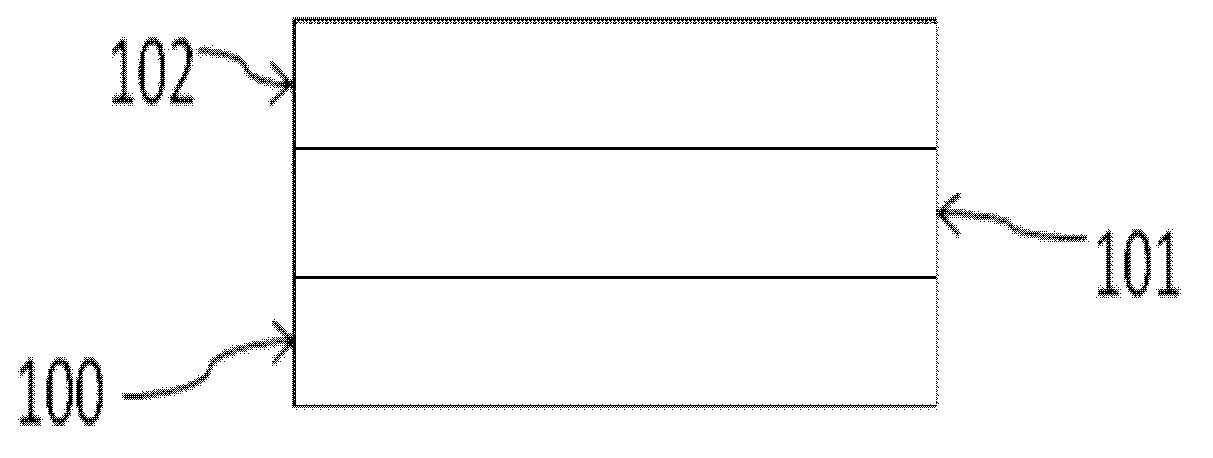

Electrode structure for capacitive touch screens and preparation method thereof

InactiveCN103019493AImprove conductivityImprove adhesionInput/output processes for data processingCorrosionAdhesive

The invention relates to an electrode structure for capacitive touch screens. The electrode structure comprises a substrate, a graphene layer and a conductive metal film layer sequentially from bottom to top, wherein a metal adhesive layer which enhances the adhesion between the graphene layer and the metal film layer is arranged between the conductive metal film layer and the graphene layer. The electrode structure disclosed by the invention has the characteristics of high adhesion, corrosion resistance and good electrical conductivity, moreover, the process of a production method is simple, and the product yield is high.

Owner:无锡力合光电石墨烯应用研发中心有限公司 +1

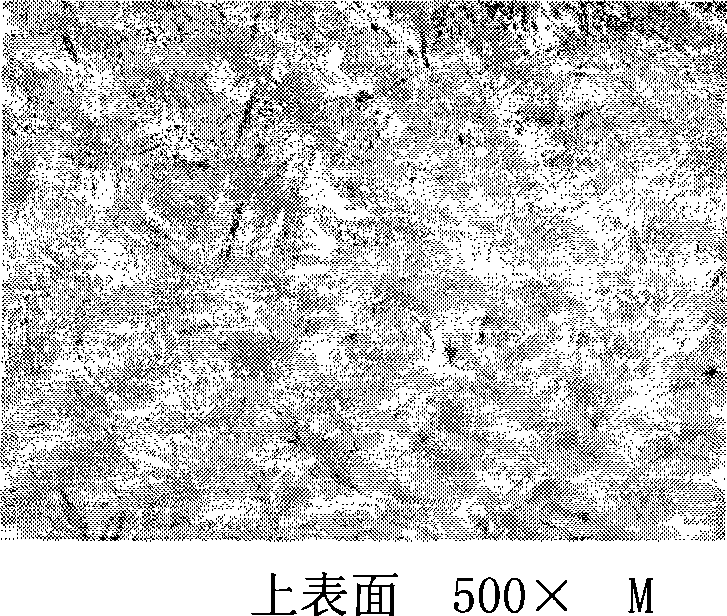

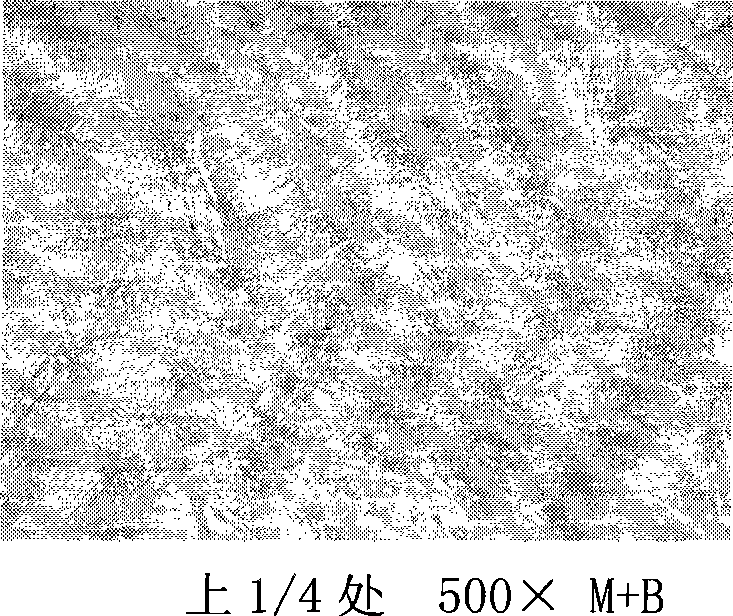

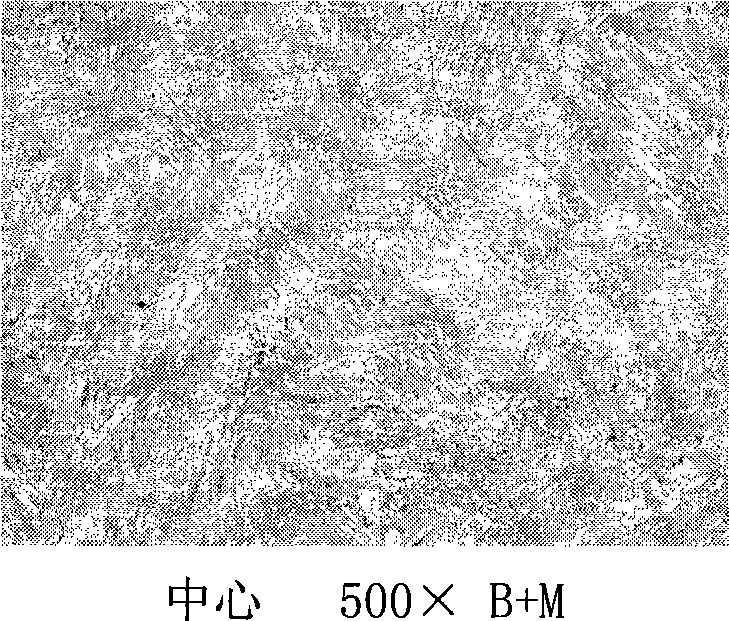

Quenching and tempering type abrasion resistant steel and heat treating method thereof

InactiveCN101451218AReasonable toughness matchingModerate hardnessHeat treatment process controlChemical compositionWear resistant

The invention relates to quenching and tempering type wear resistant steel and a heat treatment method thereof. The steel comprises the following chemical components by weight percentage: less than or equal to 0.22 percent of C, less than or equal to 0.80 percent of Si, less than or equal to 1.60 percent of Mn, less than or equal to 0.025 percent of P, less than or equal to 0.010 percent of S, less than or equal to 0.60 percent of Ni, less than or equal to 1.00 percent of Cr, less than or equal to 0.50 percent of Mo, 0.02 to 0.03 percent of Nb,0.04 to 0.06 percent of V, 0.020 to 0.045 percent of Al, 0.015 to 0.030 percent of Ti, less than or equal to 0.004 percent of B, and the balance being Fe and unavoidable impurities. The steel plate has reasonable obdurability matching, proper hardness, even full-thickness hardness and the mechanical properties reaching the expected design requirements. The steel plate production process has easy operation and high adaptability. The steel plates of various batches have stable and even performance and can reach the requirements for volume production. As the tempering time in a quenching machine is longer, the tempering time can be appropriately shortened in the subsequent production through tests, thereby reducing the cost.

Owner:WUYANG IRON & STEEL

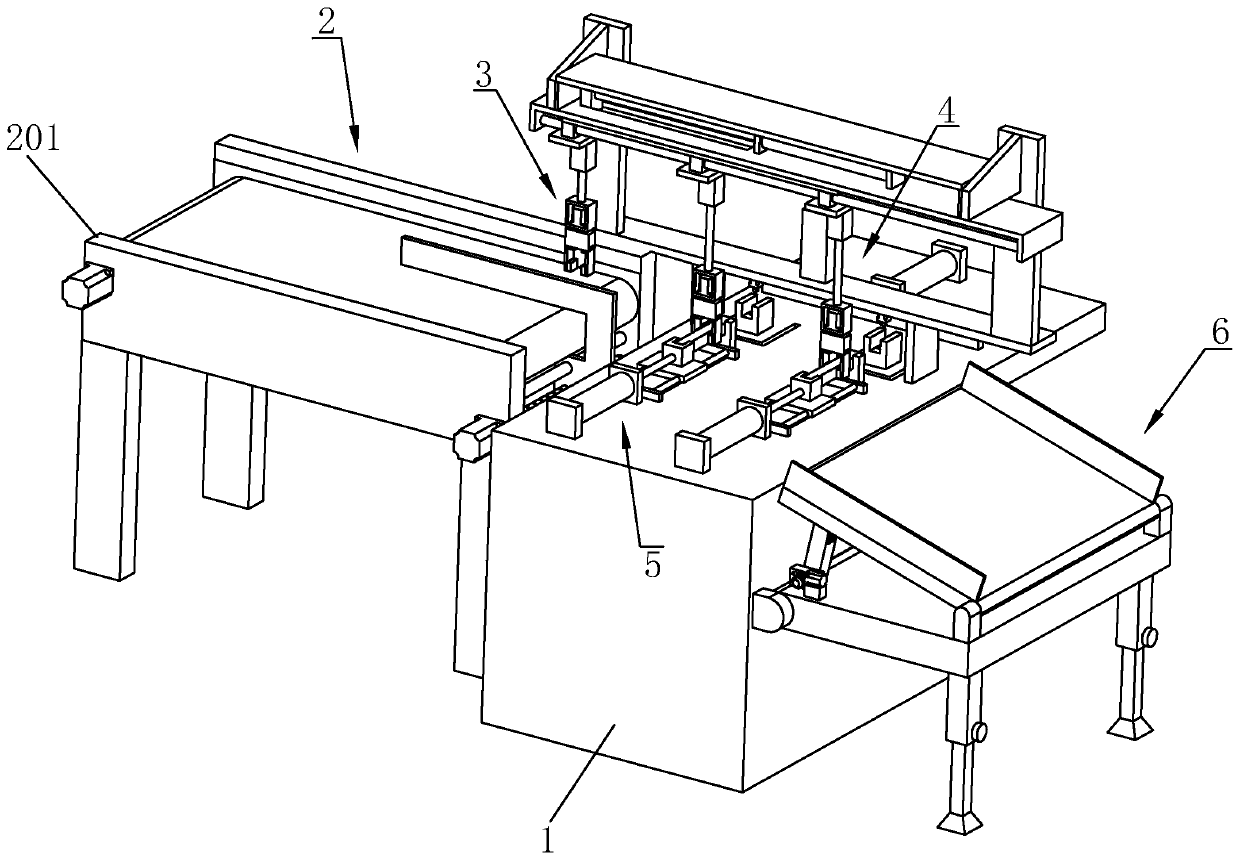

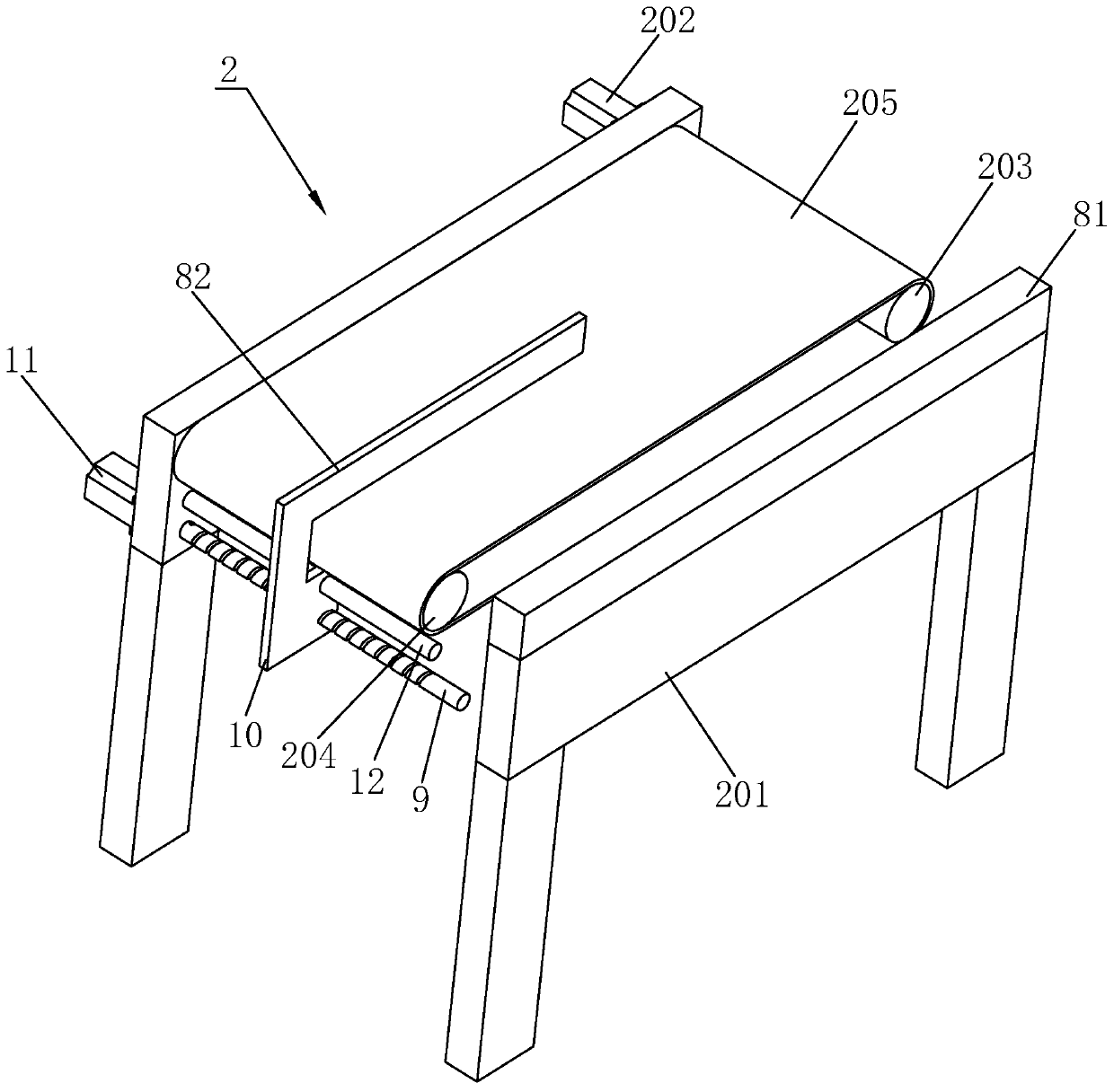

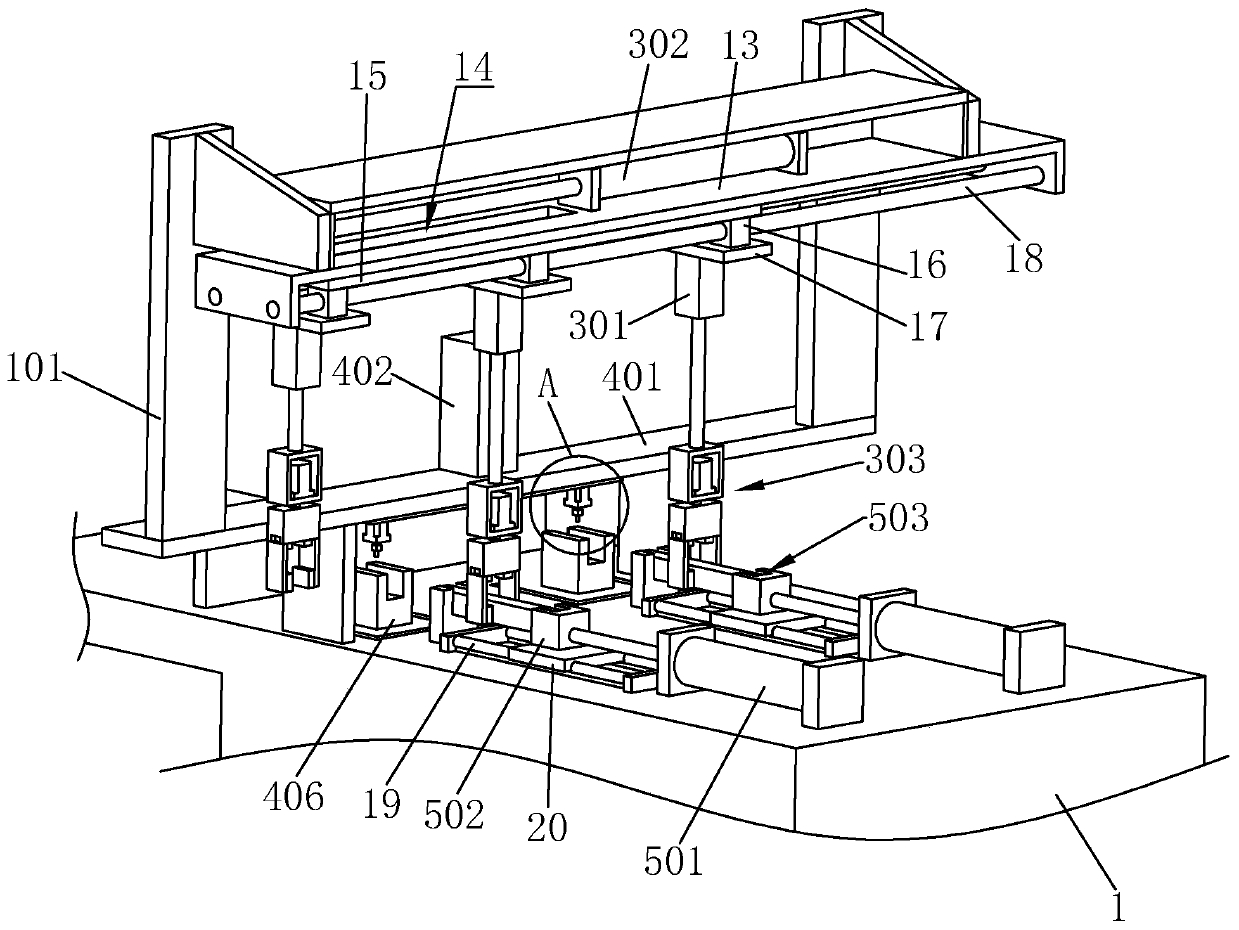

Hardware pipe stock automatic punching machine

ActiveCN110369606AReduce manual operationsIncrease productivityPerforating toolsMetal-working feeding devicesPunchingButt joint

The invention relates to the technical field of pipe stock machining, in particular to a hardware pipe stock automatic punching machine. According to key points of the technical scheme, the hardware pipe stock automatic punching machine comprises a working table, a plurality of feeding mechanisms arranged on the working table, a clamping mechanism for clamping and moving pipe stocks on the feedingmechanism, a forming mechanism, a pushing mechanism, a collecting mechanism and a cleaning mechanism, wherein the forming mechanism is used in cooperation with the clamping mechanism and carries outpunching forming on the pipe stocks, the pushing mechanism pushes the pipe stocks to move to the forming mechanism for machining, the collecting mechanism collects the formed pipe stocks, and the cleaning mechanism collects scraps after punching. A receiving portion for transversely placing the pipe stocks is arranged on the pushing mechanism. The pipe stocks are sequentially arranged on the feeding mechanism to be fed. By means of the clamping mechanism, the pipe stocks are moved to the receiving portion from the feeding mechanism, the pushing mechanism pushes the pipe stocks to the forming mechanism to be punched and formed, and the formed pipe stocks are collected through the collecting mechanism. The punching machine reduces manual operation, the production efficiency is high, the punching machine is applicable to butt joint of an assembly line, and the requirement for batch production is met.

Owner:东莞市天誉箱包配件有限公司

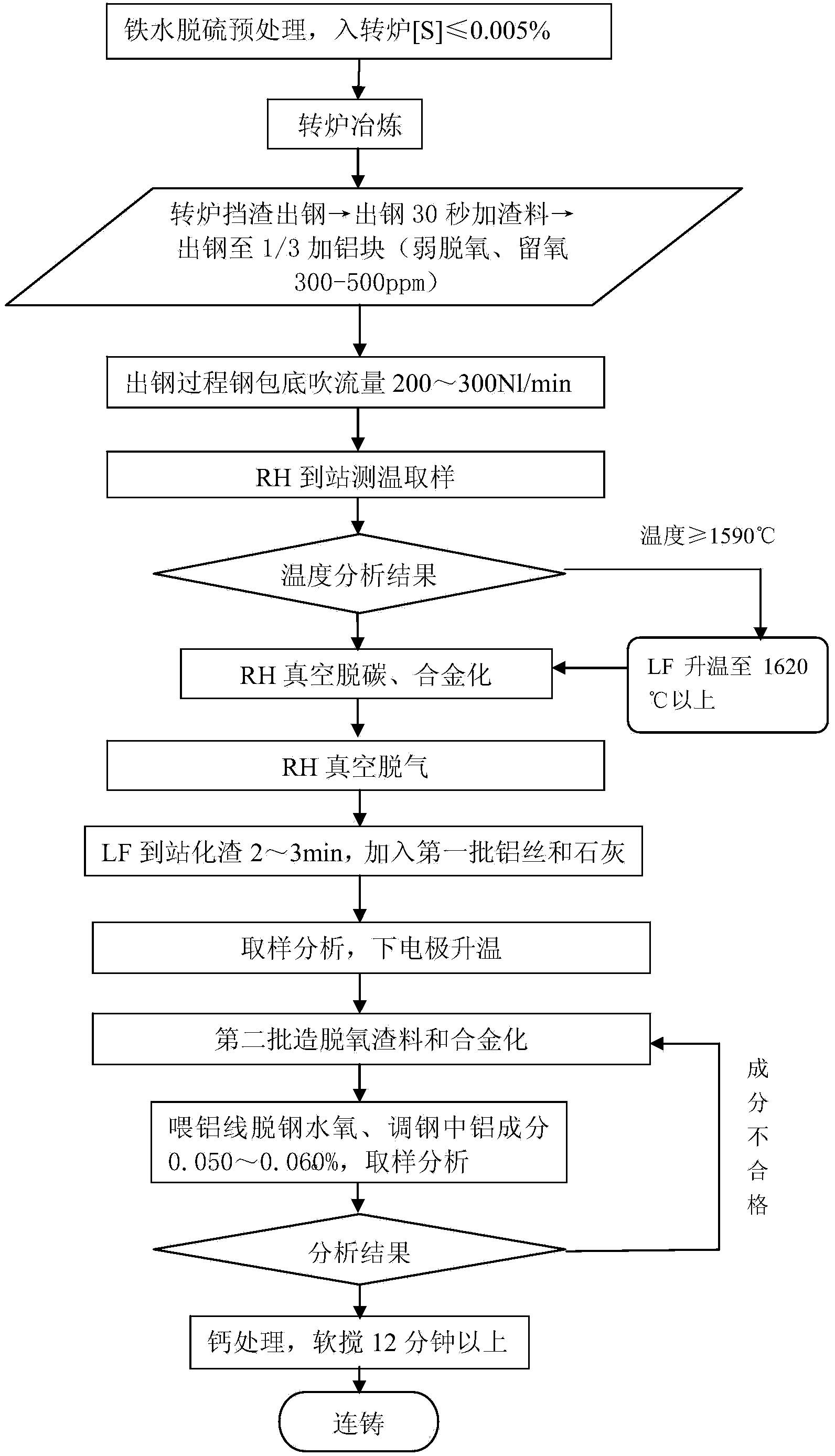

Low-carbon ultra-low sulfur steel smelting method

InactiveCN104232831AThe amount added is accurateStable flaw detection pass rateSteel manufacturing process aspectsManufacturing convertersSmelting processOxygen

The invention discloses a low-carbon ultra-low sulfur steel smelting method. The method comprises the following technological processes: pouring molten iron into a tank, pretreatment of molten iron, oxygen remaining operation of a converter, RH furnace vacuum decarburization, alloying and vacuum degassing in an RH furnace, deoxidization of aluminium yarn / aluminium wire in an LF refining furnace, slagging by using lime and CCM. Through combination of molten iron desulphurization and drossing, optimization of a converter steel tapping and oxygen remaining system and a slagging system, the vacuum decarburization, alloying and degassing control in the RH furnace, and the aluminium wire diffusing deoxidation slagging and aluminium wire sediment deoxidation in the LF furnace, deep decarburization and desulphurization are carried out. With an emphasis on combination of convertor steel tapping and oxygen remaining operations, RH deep decarburization and LF furnace deep desulphurization, technical optimization is carried out; due to reasonable ladle argon bottom blowing control in the smelting process, carbon content control and metallurgical thermodynamics and dynamics conditions of desulphurization are given a full play; the RH furnace decarburization is stable; LF furnace slagging and desulphurization and recarburization control effects are obvious; and low-carbon ultra-low sulfur steel smelting is achieved.

Owner:NANJING IRON & STEEL CO LTD

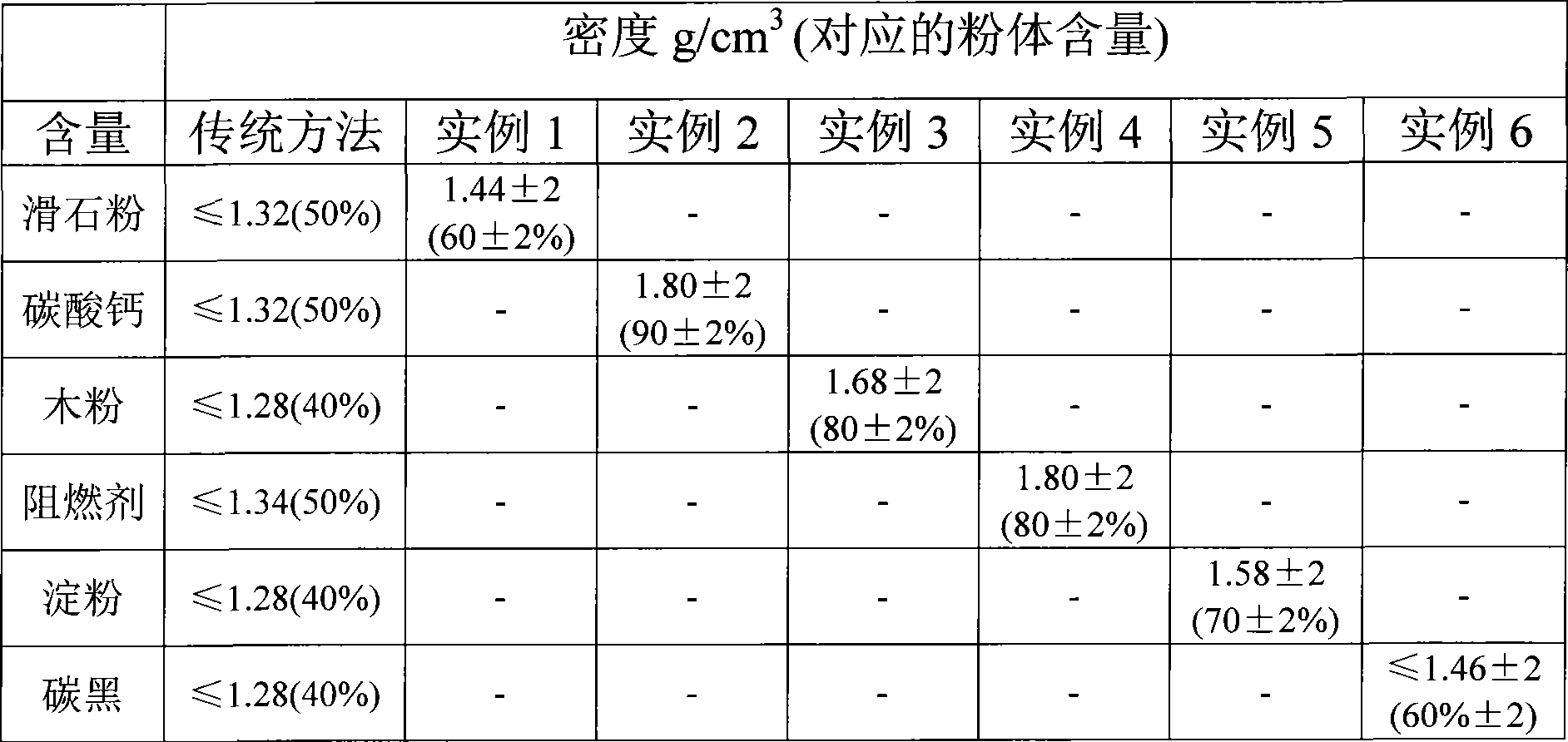

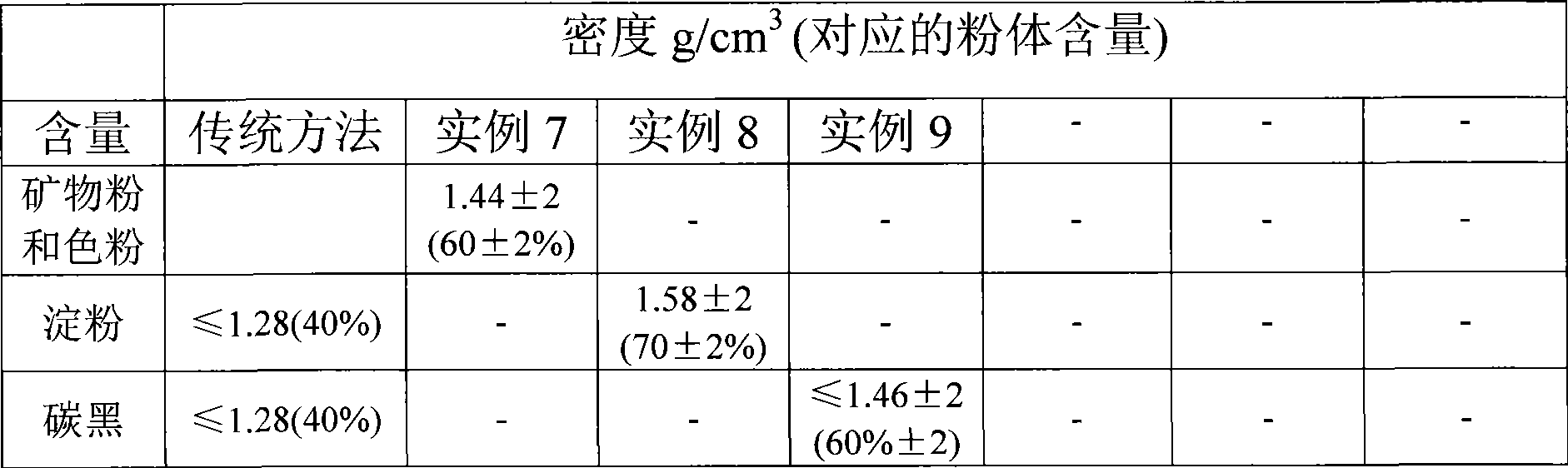

Method for preparing master batch with high-powder content

The invention provides a method for preparing masterbatch with high powder content. The method comprises the following steps: various raw materials are prepared, a Banbury mixer is kept at constant temperature, all the carriers and 50-80 percent of or all powder components, lubricant, dispersing agent and coupling agent are placed in the Banbury mixer for kneading; after the remained functional components are placed in the Banbury mixer for kneading, the Banbury mixer barn is turned over; the materials are decanted into the feeding hopper of a single screw extruder through a transporting receptacle; by the forced feeding of the feeding hopper, the single screw extruder is used to obtain functional masterbatch with high powder content. The method is capable of solving the problem that feeding is difficult during direct production of high powder when blending modified plastics system is filled, and the problem of difficult processing in the modified plastics industry; the masterbatch with high powder content can also meet the requirements of downstream products, and used to produce injection-moulded or extruded products.

Owner:GUANGDONG KINGFA TECH CO LTD

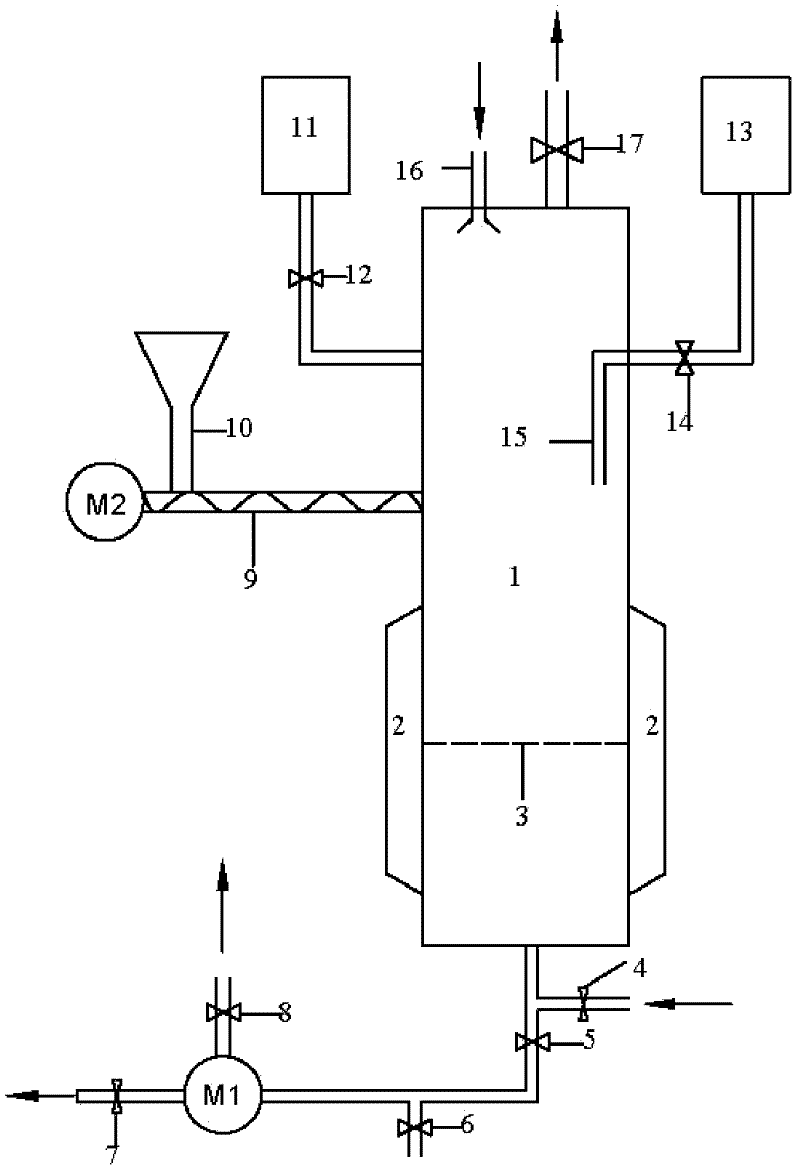

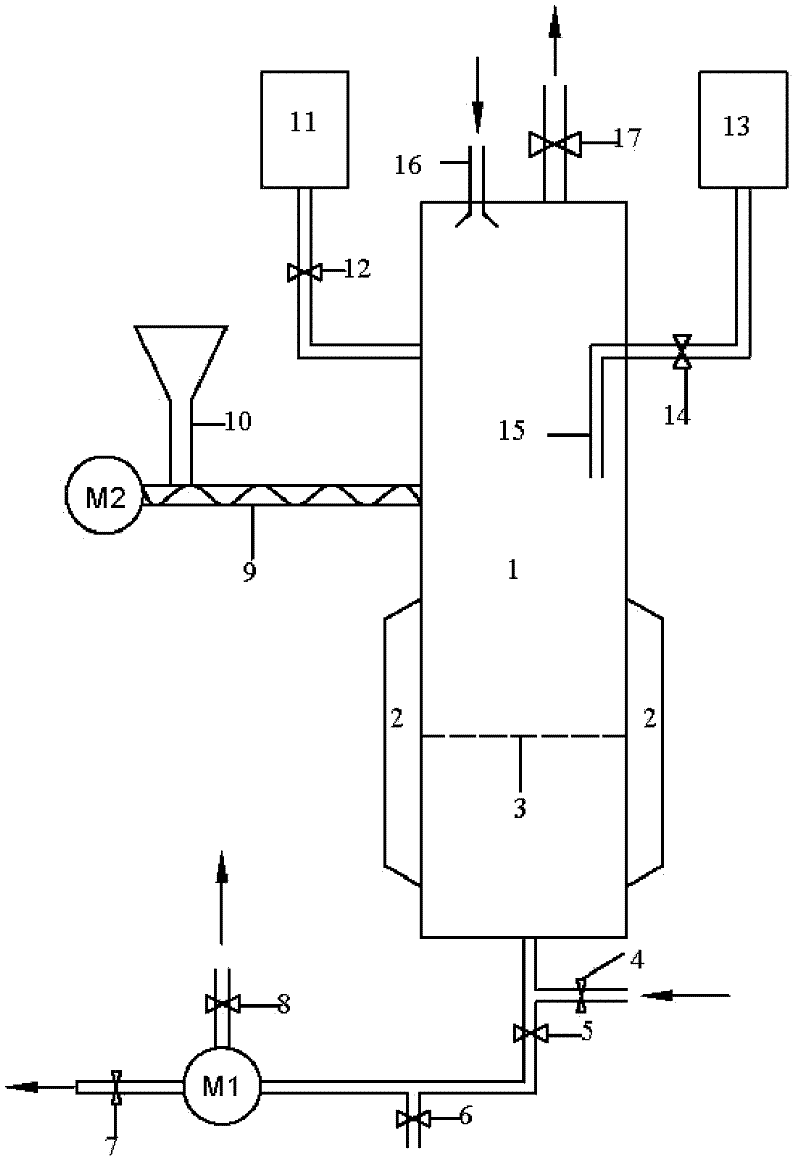

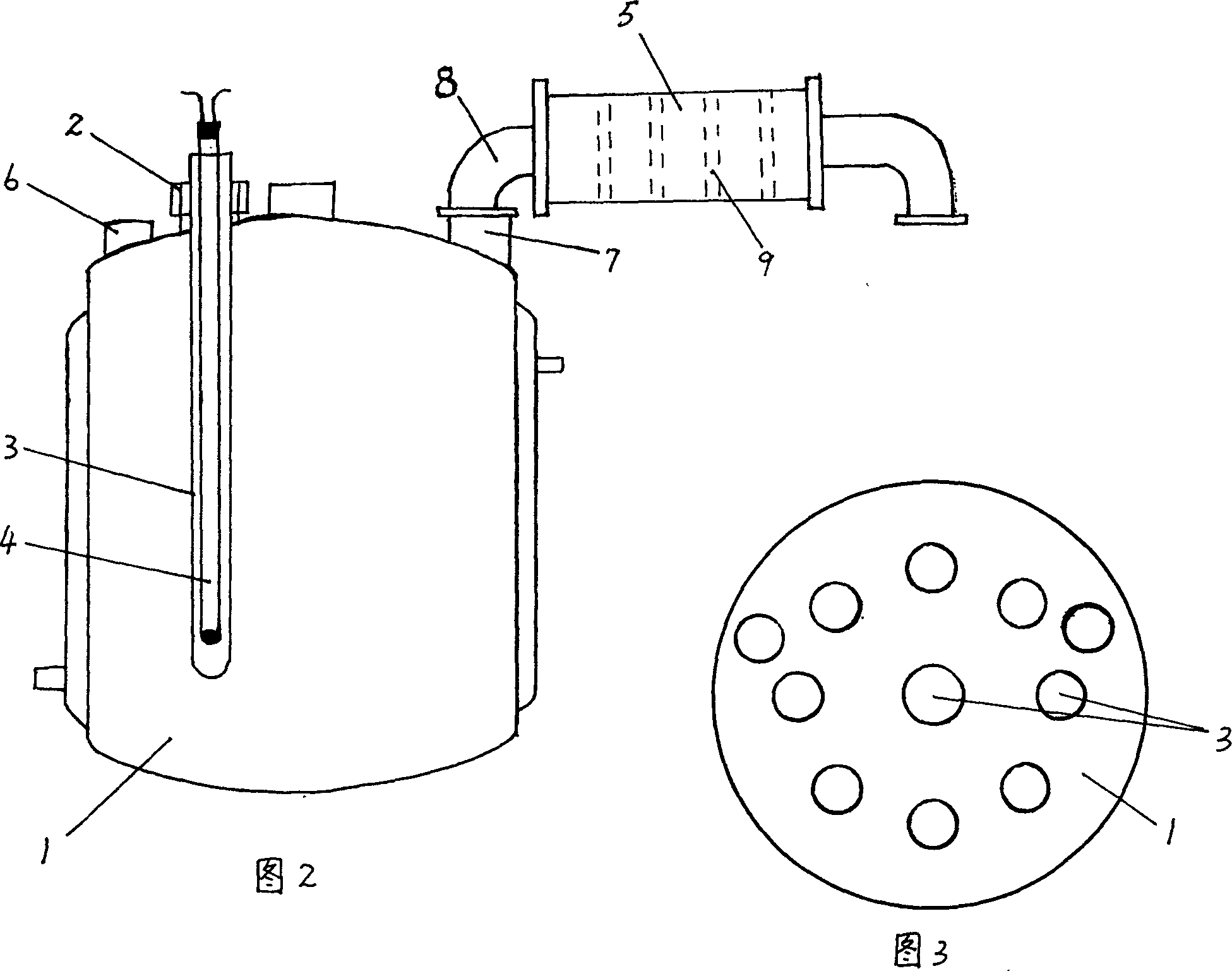

Dissolving system

The invention relates to the technical field of reactant dissolving equipment, in particular to a dissolving system, which comprises a reaction tank, a feeder connected with the reaction tank, a liquid inlet pipeline, a circulation stirring system and an air flow stirring device. The reaction tank is used for storing reactant and providing reaction places, and a discharge pipe for discharging materials is positioned at the bottom of the reaction tank. The circulation stirring device and the air flow stirring device are used for quickening dissolving speed of the reactant in the reaction tank.The feeder and the liquid inlet pipeline are used for adding the reactant. The dissolving system is simple in structure, convenient to operate, large in production and capable of meeting requirementsof large batch production, effectively enabling U3O8 powder to be dissolved quickly and completely and achieving lack acid dissolving to obtain lack acid uranium nitrate solution.

Owner:TSINGHUA UNIV

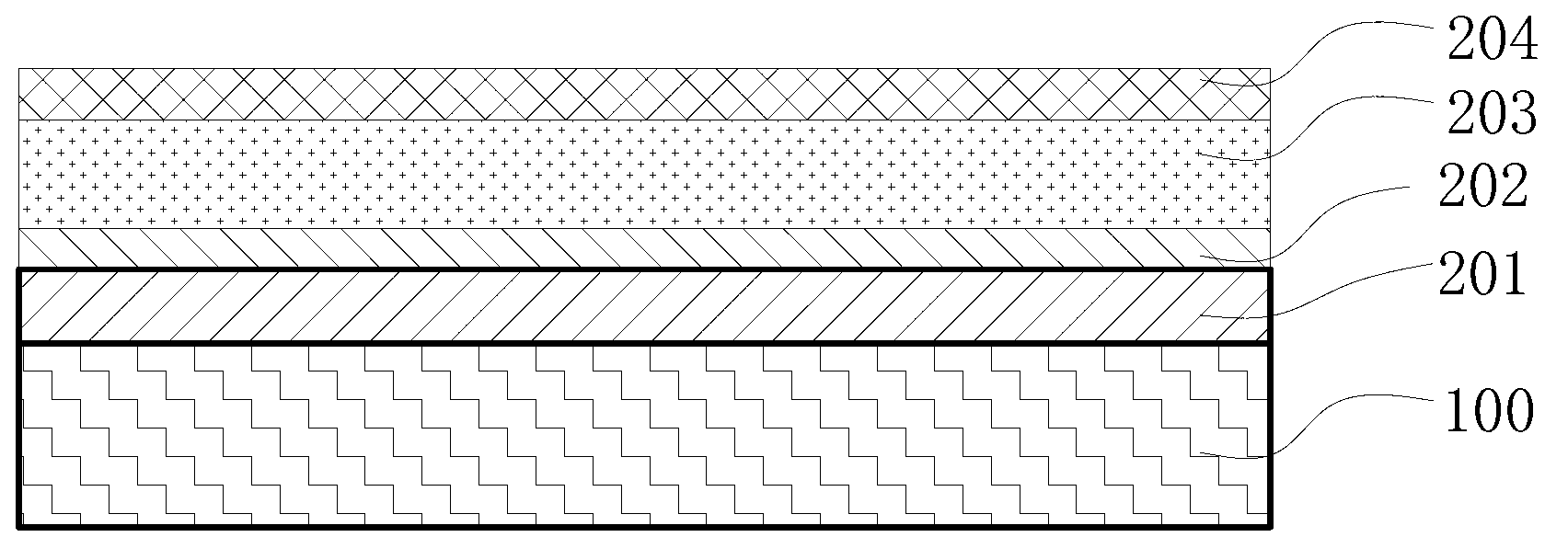

High transmittance conductive glass for touch screen and technique for producing the same

The invention discloses a high-transmissivity conductive glass for a touch screen and a process for producing the same. The high-transmissivity conductive glass for the touch screen comprises a glass substrate; the surface of the glass substrate is sequentially provided with a silicon dioxide film plating layer and a tin indium oxide film plating layer; the silicon dioxide film plating layer is positioned in an inner layer; the tin indium oxide film plating layer is positioned in an outer layer; a niobium pentoxide film plating layer is arranged between the glass substrate and the silicon dioxide film plating layer; a process flow comprises that: the qualified glass substrate is selected and cleaned; the cleaned glass substrate is sent into a film plating machine; the surface of the glass substrate is subjected to film plating processing; a finished product plated with a film is taken out from the film plating machine; the finished product is subjected to performance detection; and the qualified finished product is packaged and enters a warehouse. The high-transmissivity conductive glass utilizes good insulation and stable refractive index of columbium pentoxide and silicon dioxide and can improve the visible light transmittance of the conductive glass to 94 percent above; and a reasonable process course is favorable for improving controllability of operation and stability of product quality and can meet requirement of large-batch production.

Owner:常州津通光电技术有限公司

Method for preparing carbon nano tube thin-film field-effect transistor

InactiveCN101540285AEfficient removalImprove performanceElectrolytic coatingsSemiconductor/solid-state device manufacturingLithographic artistElectrophoresis

The invention relates to a method for preparing a carbon nano tube thin-film field-effect transistor of a nano-electrical appliance, comprising the following steps: producing S / D electrode patterns on silicon chips with surface thereof provided with an insulating barrier by adopting the optical lithography; depositing the carbon nano tubes between S / D electrodes to form the carbon nano tube thin-film by dielectrophoresis in an alternative electric field; then using the method of plasma etching to selectively remove metallic carbon nano tubes in the deposited carbon nano tubes to obtain carbon nano tube thin-film field-effect transistor with fine properties; the other method comprises the following steps: depositing the carbon nano tubes on silicon chips with surface thereof provided with an insulating barrier by means of self-assembly to form the carbon nano tube thin-film; then producing S / D electrode patterns on the carbon nano tube thin-film by the optical lithography; finally using the method of plasma etching to selectively remove metallic carbon nano tubes in the deposited carbon nano tubes to obtain carbon nano tube thin-film field-effect transistor with fine properties.

Owner:SHANGHAI JIAO TONG UNIV

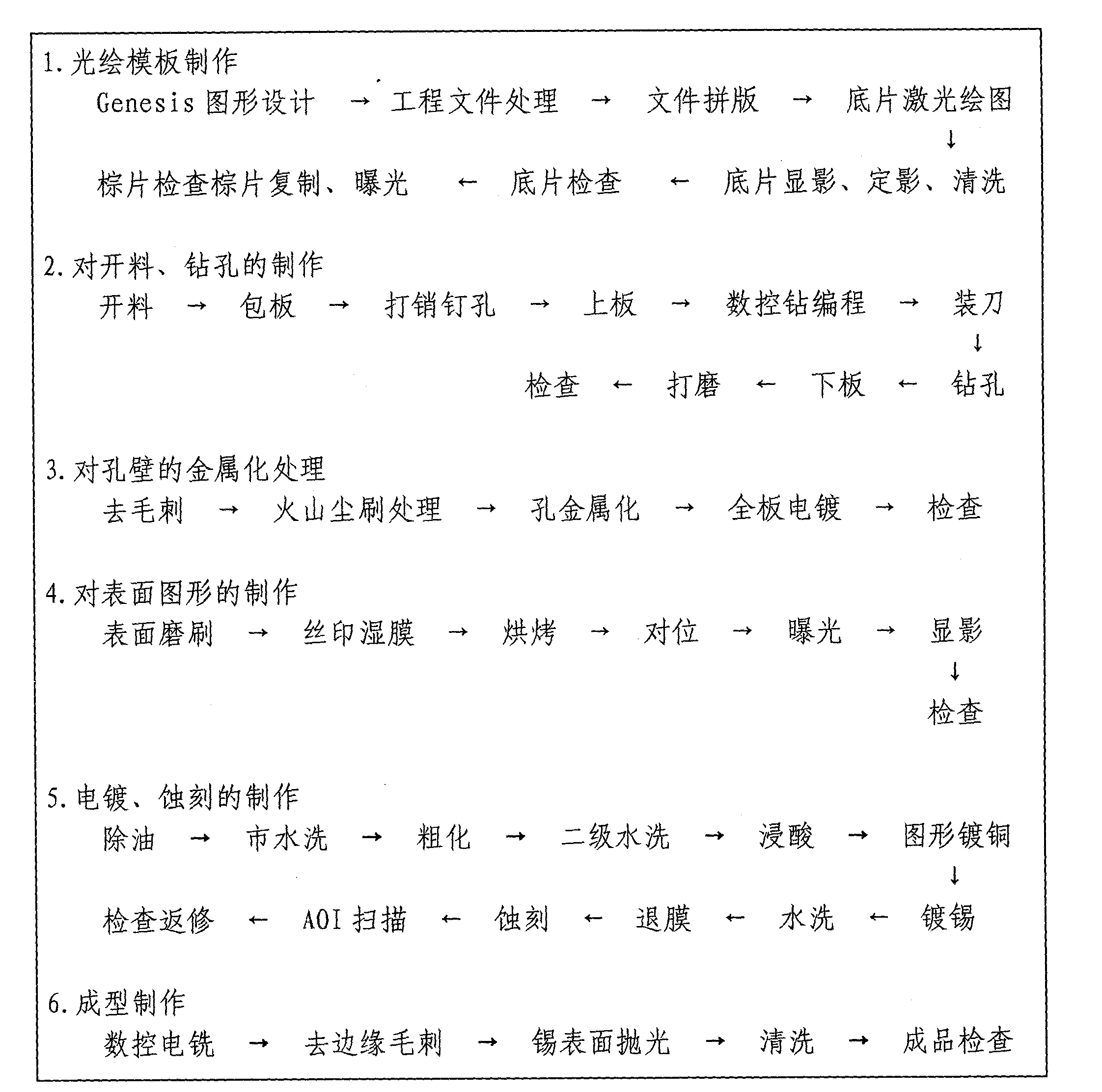

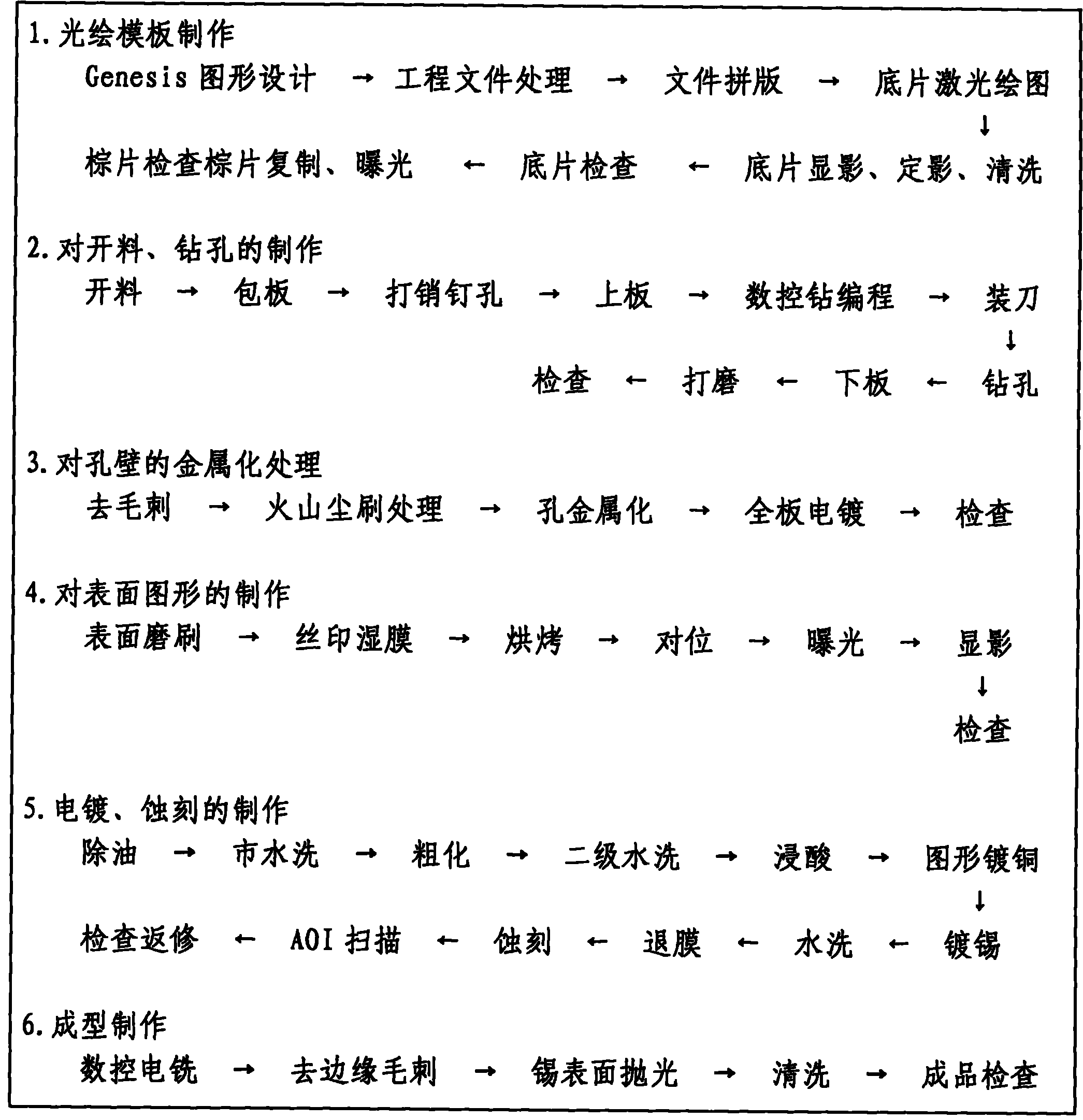

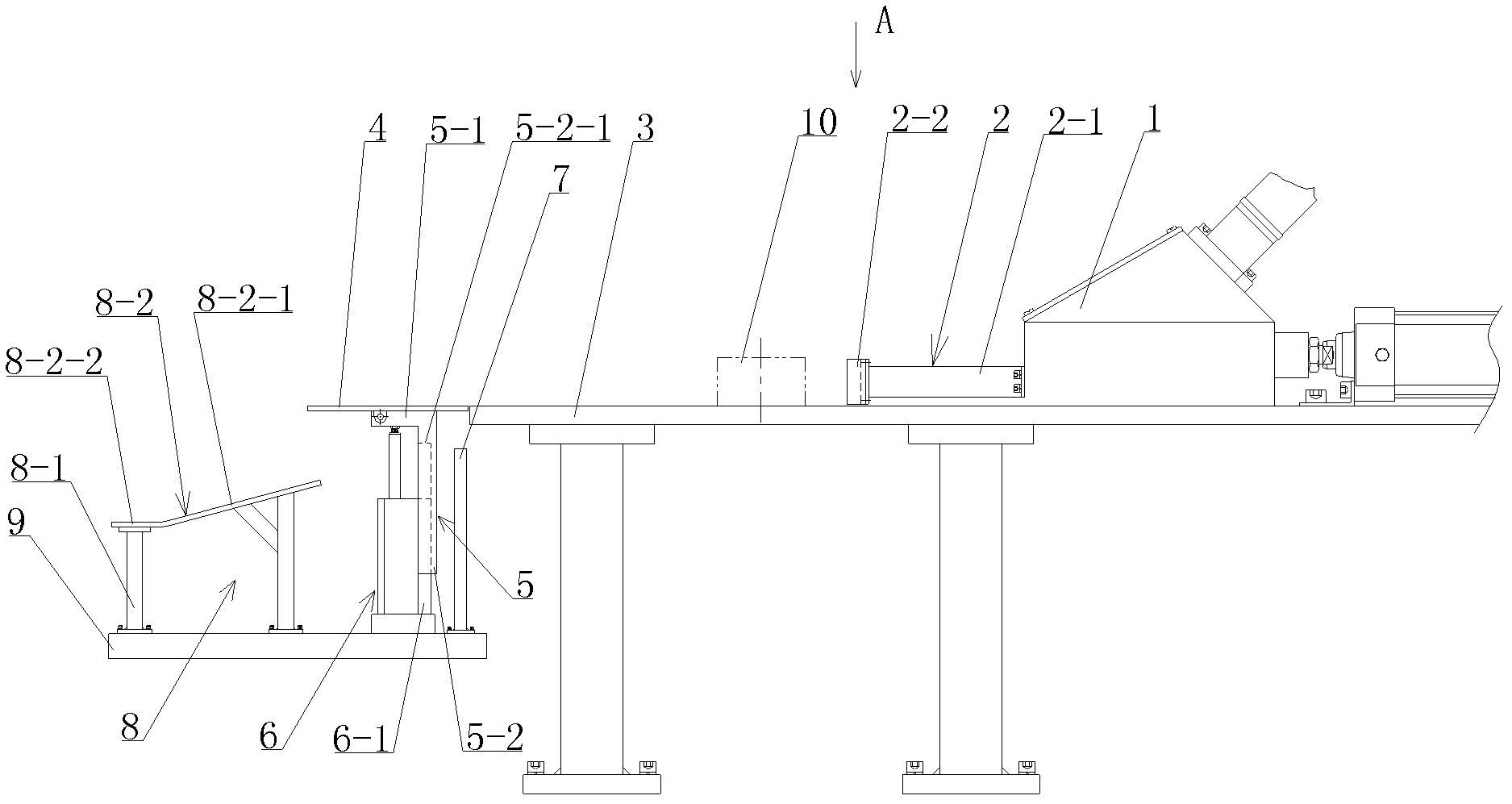

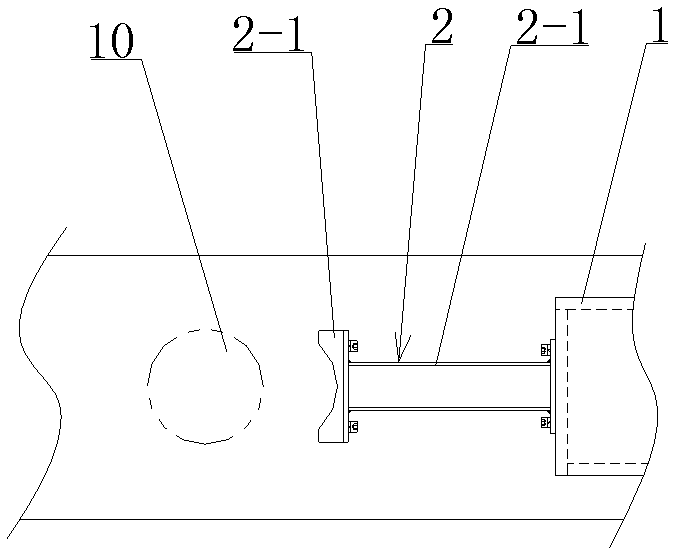

Method for manufacturing ultra-long microwave high-frequency circuit board

InactiveCN101808464AIncrease porosity densityImprove bindingConductive material chemical/electrolytical removalPrinted element electric connection formationMicrowaveEngineering

The invention discloses a method for manufacturing an ultra-long microwave high-frequency circuit board, comprising the following steps: (1) manufacturing a light potting template; (2) shearing to form an ultra-long combination board, and drilling holes on the ultra-long combination board; (3) metallizing the walls of the holes; (4) making patterns on the ultra-long combination board; (5) electroplating and etching the ultra-long combination board; and (6) forming the ultra-long combination board into the ultra-long microwave high-frequency circuit board. The method for manufacturing the ultra-long microwave high-frequency circuit board has high precision, and the ultra-long microwave high-frequency circuit board manufactured with the method has stable performance and can effectively improve the product quality and the work efficiency.

Owner:施吉连

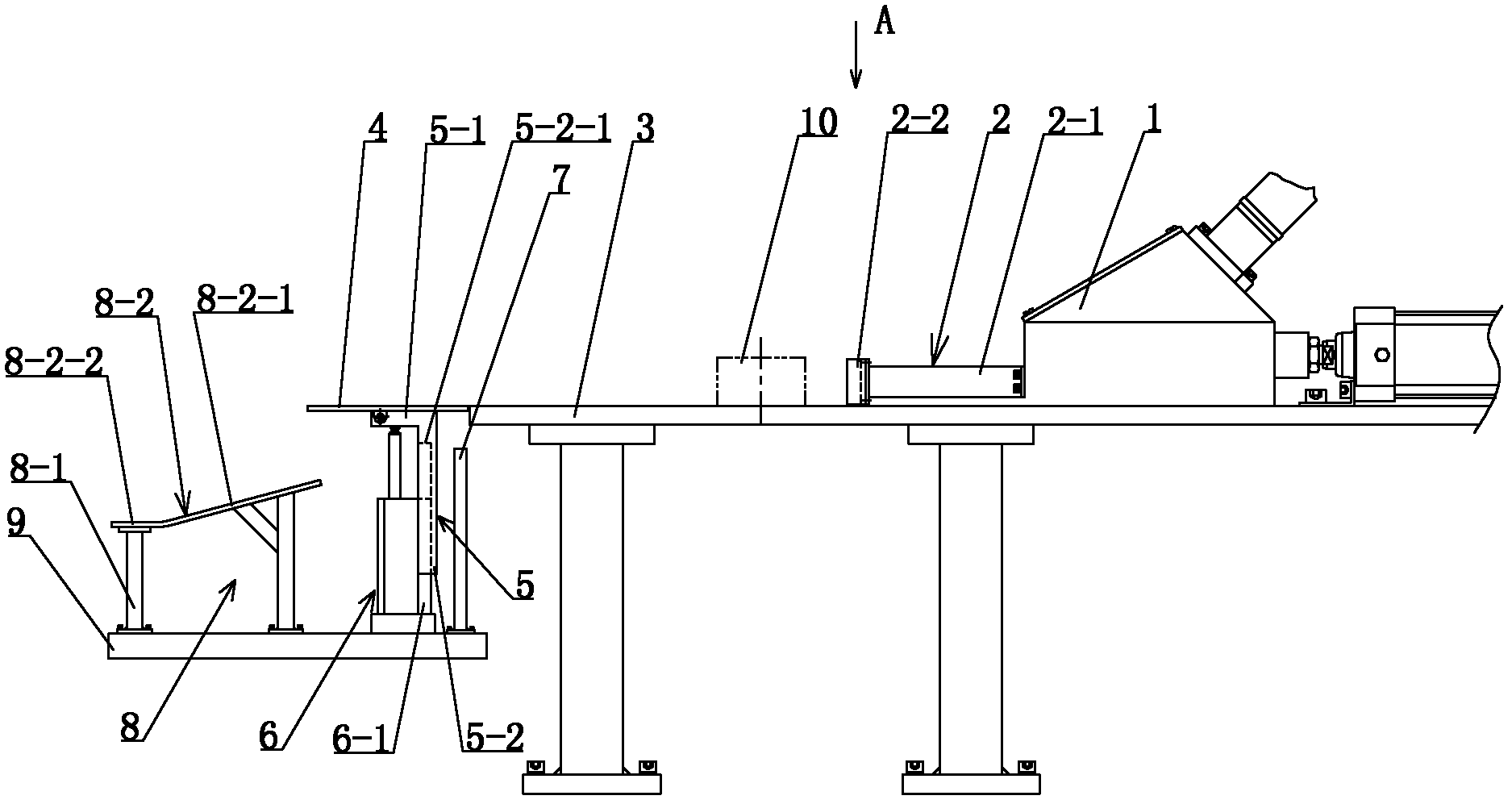

Automatic pushing and receiving device for powder hydraulic press

ActiveCN102274967ASimple structureReduce manufacturing costPressesHigh volume manufacturingManipulator

The invention relates to an automatic pushing and material receiving device for a powder hydraulic machine. The automatic blank pushing and material receiving device is characterized by comprising a push rod fixedly arranged at the front end of a material conveying box and a material receiving device arranged between a product support plate and conveying equipment, wherein the material receiving device comprises a material receiving flat plate, a bent plate which is arranged at the lower end of the material receiving flat plate and hinged with the material receiving flat plate, a driving cylinder arranged at the lower end of the bent plate, and a mandril and a material receiving bracket which are arranged at the lower end of the material receiving flat plate; the push rod end of the driving cylinder is fixedly connected with a horizontal part of the bent plate; a guide structure is arranged between a cylinder barrel of the driving cylinder and a vertical part of the bent plate; the material receiving bracket comprises ground jacks and a material receiving bent plate; and the material receiving bent plate comprises an upward inclined part and a horizontal part. By adopting the structure, a molded product is pushed onto a material conveying flat plate by the push rod during powder conveying; and under the action of the driving cylinder and the mandril, the molded product slides to a material pushing bent plate and finally to the conveying equipment through the bent plate. Compared with a special manipulator, the automatic blank pushing and material receiving device with the structure has a simple structure, is low in manufacturing cost and convenient to operate, guarantees continuous production due to one-to-one correspondence of conveying and pushing and meets the requirement of batch production.

Owner:TIANJIN TIANDUAN PRESS CO LTD

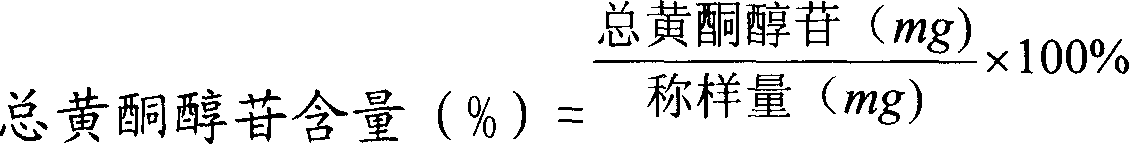

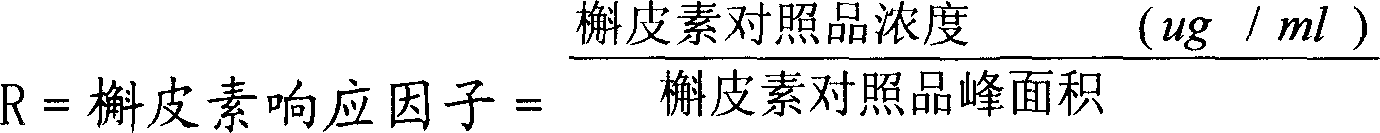

Ginkgo leaf extract and its extracting method

ActiveCN1586548AScientifically feasibleHigh extraction rateUnknown materialsCardiovascular disorderVascular diseaseGinkgo leaf extract

The present invention belongs to the field of Chinese medicine preparing technology. The ginkgo leaf extract has total flavone and total terpene lactone content over 80 %, total flavone content over 70 %, flavonoid glycoside content over 40 % and total terpene lactone content over 10 %. The extraction process includes the following steps: extracting, purifying and separating, concentration, drying, etc. Compared with available technology, the present invention has the advantages of reasonable technological path, being suitable for industrial production, low production cost, high extracting rate of effective components, etc. The present invention also discloses the infusion liquid and powder for injection with the ginkgo leaf extract and their preparation process. The ginkgo leaf extract has wide application in medicine for treating cardiac vascular diseases.

Owner:AOLING BODA MEDICINE SCI & TECH DEV BEIJING

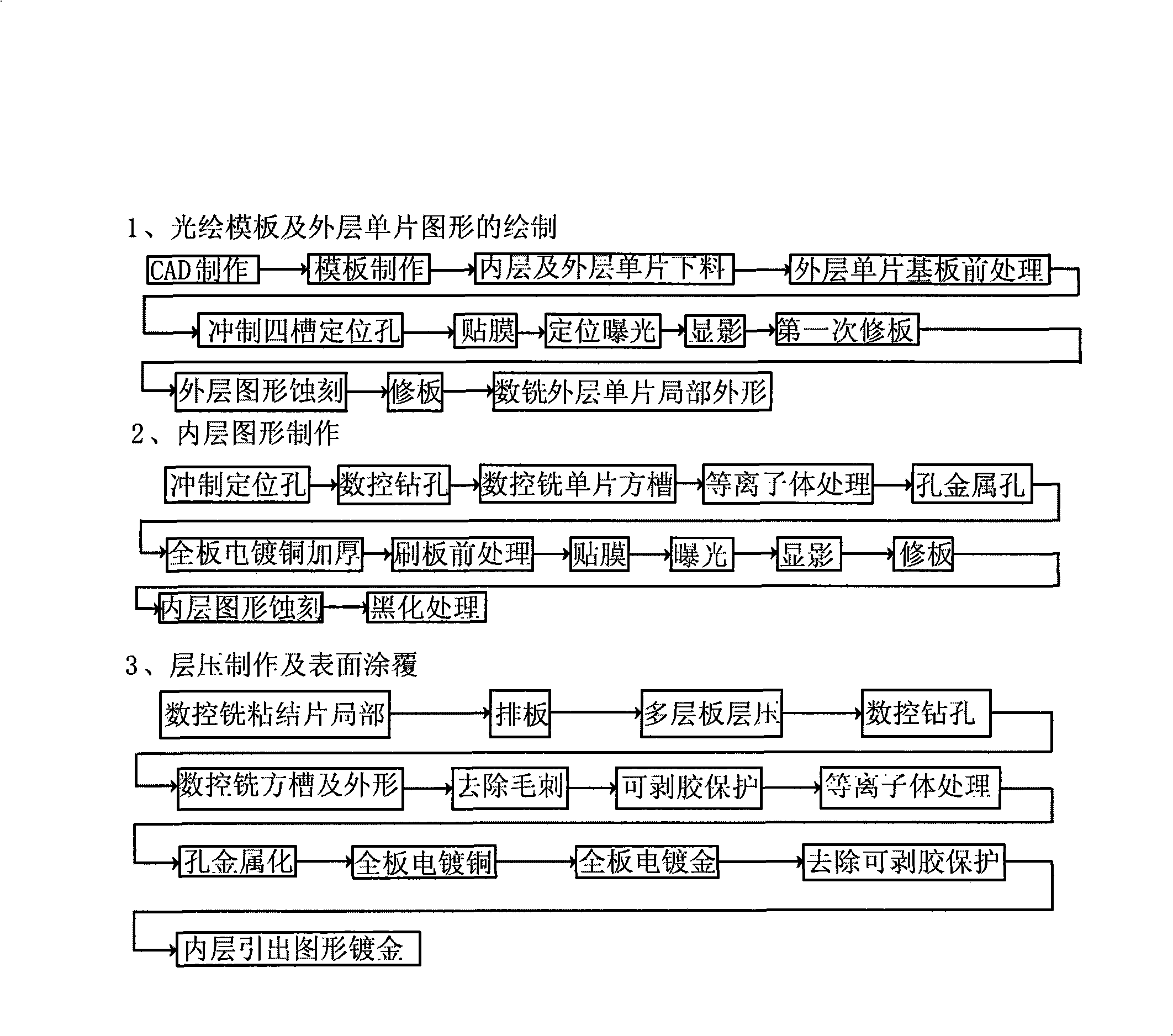

Method for preparing microwave high-frequency multi-layer circuit board

ActiveCN101351093ASatisfy Buried Via RequirementsExcellent dielectric propertiesMultilayer circuit manufactureGraphicsMicrowave

The invention discloses a making method of a microwave and high frequency multilayer circuit board, and the method comprises the following steps: step one, making gerber templates and outer graphics; step two, making inner graphics; step three, laminated making and surface coating. The making method is high in precision and steady in the performance of the made circuit board, and besides dielectric constants are stable and dielectric loss is small.

Owner:TAIZHOU BOTAI ELECTRONICS

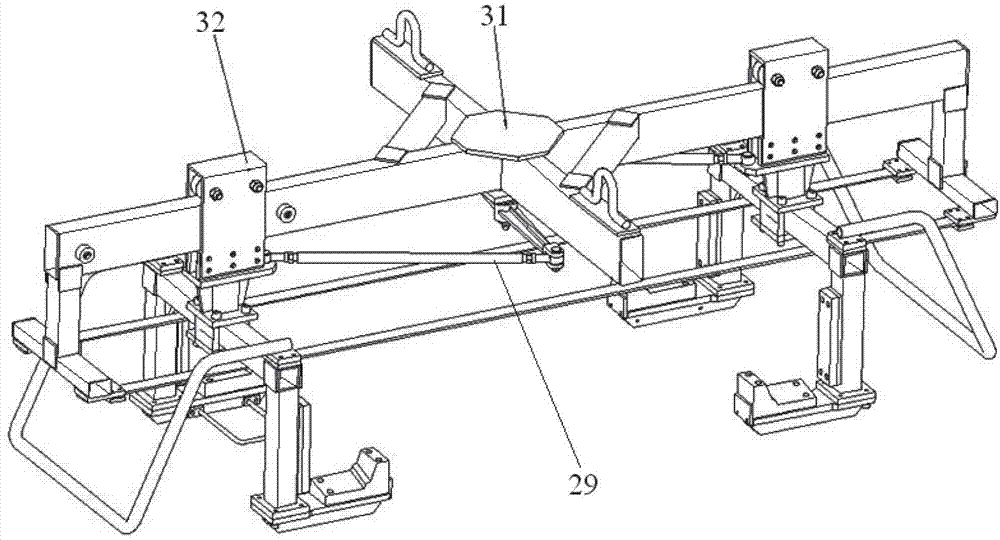

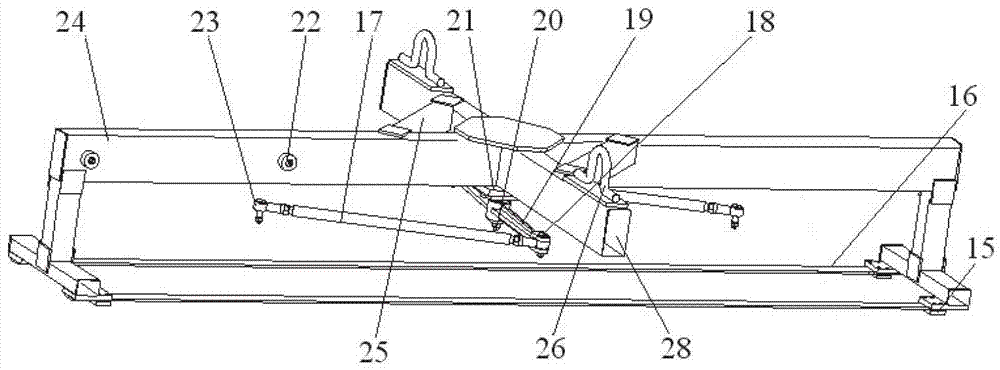

Automobile white body sling structure

ActiveCN102963812AEasy to usePrevent bump deformationLoad-engaging elementsEngineeringFour-bar linkage

The invention discloses an automobile white body sling structure. A sling main body (31) is provided with a horizontal sling main beam (23) and two sliding hooks (32); the sliding hooks (32) are provided with sliding guide structures (10); and the sliding hooks (32) are arranged on the sling main beam (24) through the sliding guide structures (10). According to the technical scheme, a four-bar linkage is used, so that the use of the sling is more convenient, operation can be carried out at one side of the sling during the use, the synchronous advancement of the of the mechanisms at two sides of the sling is ensured, the production beat is accelerated and more stable and the requirement of batch production can be satisfied; the sling is correct in positioning, safe, reliable, high in efficiency and relatively low in cost; the sling can be effectively prevented from colliding with the automobile body to deform so that the automobile body is well protected; and a top beam at the side of the body of a crane is used, so that the automobile body has small possibility of deformation.

Owner:CHERY AUTOMOBILE CO LTD

Hot melting adhesive membrane for adhering ethylene propylene diene monomer

ActiveCN103694909AEasy to produceSimple production processNon-macromolecular adhesive additivesFilm/foil adhesivesPetroleum resinEthylene-propylene-diene-monomer

The invention relates to a hot melting adhesive membrane for adhering ethylene propylene diene monomer (EPDM). The hot melting adhesive membrane comprises the following components in parts by weight: 30-60 parts of modified SEBS (Styrene-Ethylene / Butylene-Styrene) resin, 15-45 parts of maleic anhydride modified petroleum resin, 3-10 parts of functional filler and 1-3 parts of coupling agent, wherein the modified SEBS resin is formed by mixing SEBS and hydrogenated naphthenic oil; and the functional filler is nano SiO2 wrapped with tripolycyanamide-formaldehyde on the surface. When the hot melting adhesive membrane is used, the surface of the EPDM is cleaned without using a solvent and treated without priming glue, and the EDPM is directly compounded and adhered at a high temperature after being directly vulcanized. The hot melting adhesive membrane is simple in wrapping lint, is convenient to produce, and achieves the requirement of large-scale volume production; and the adhesive strength of the hot melting adhesive membrane reaches the industrial standard of automobiles.

Owner:江阴伟韬塑料新材料有限公司

Comprehensive utilization method of straw

InactiveCN103923967AHigh activityLarge specific surface areaBio-organic fraction processingProductsAgricultural engineeringLiquid fuel

The invention discloses a comprehensive utilization method of straw, aiming at solving the problems that the straws are treated by mainly adopting a rot or incineration manner currently so as to seriously pollute environment and air quality, and the rotting and incineration of the straw are resource-wasting. The method disclosed by the invention comprises the steps of preparation of fine straw powder, preparation of a complex microbial inoculant, reaction, posttreatment and the like. According to the invention, the straw can be transformed into multiple products through application of chemical and biological engineering comprehensive manners, and thus the problems that the straw is rotten or burnt so as to cause pollution of environment pollution and wasting of resources are effectively solved, and the prepared product has the advantages of wide application and high economic additional value and has important influence and outstanding progressive meaning. According to the method, ethyl alcohol, activated carbon, liquid fuel, feed, biomass charcoal, fertilizer and the like can be obtained, wastes are turned into wealth, the additional value of the straw is obviously improved, and the comprehensive utilization method has an important meaning on long-time sustainable utilization of the straw.

Owner:SICHUAN MENGYUAN TECH INVESTMENT CO LTD

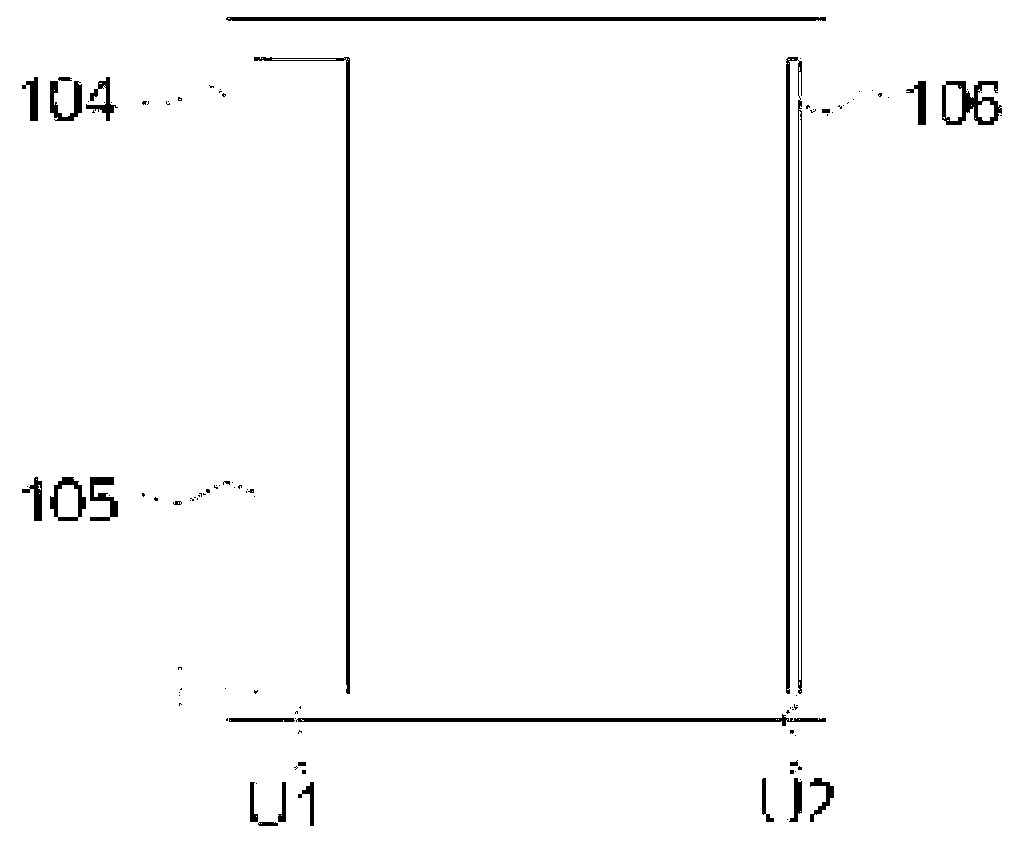

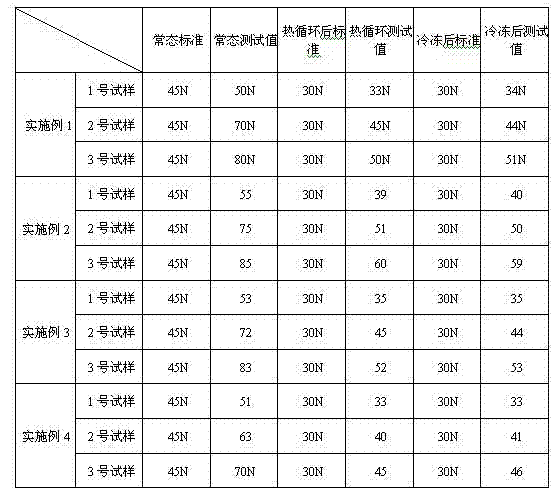

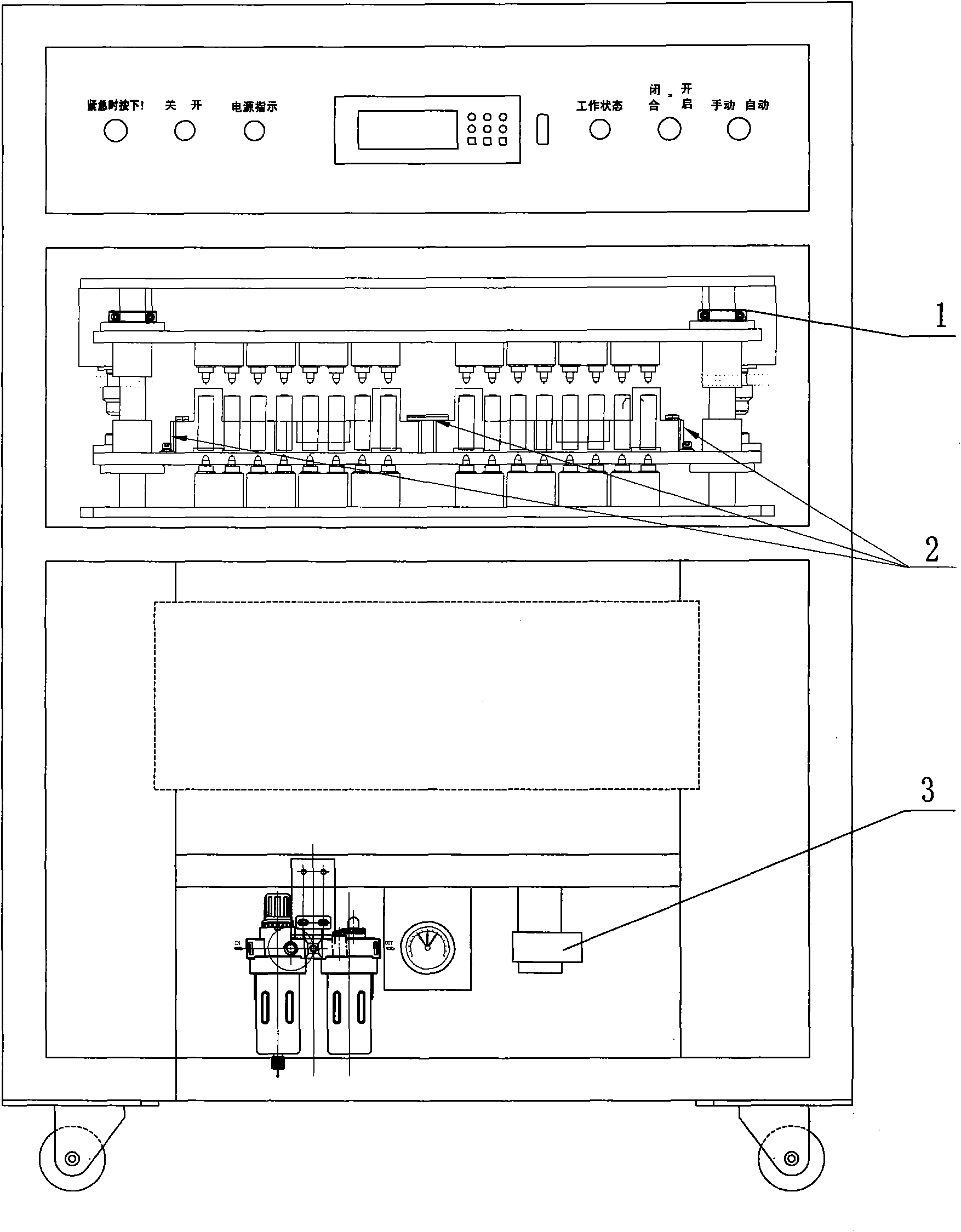

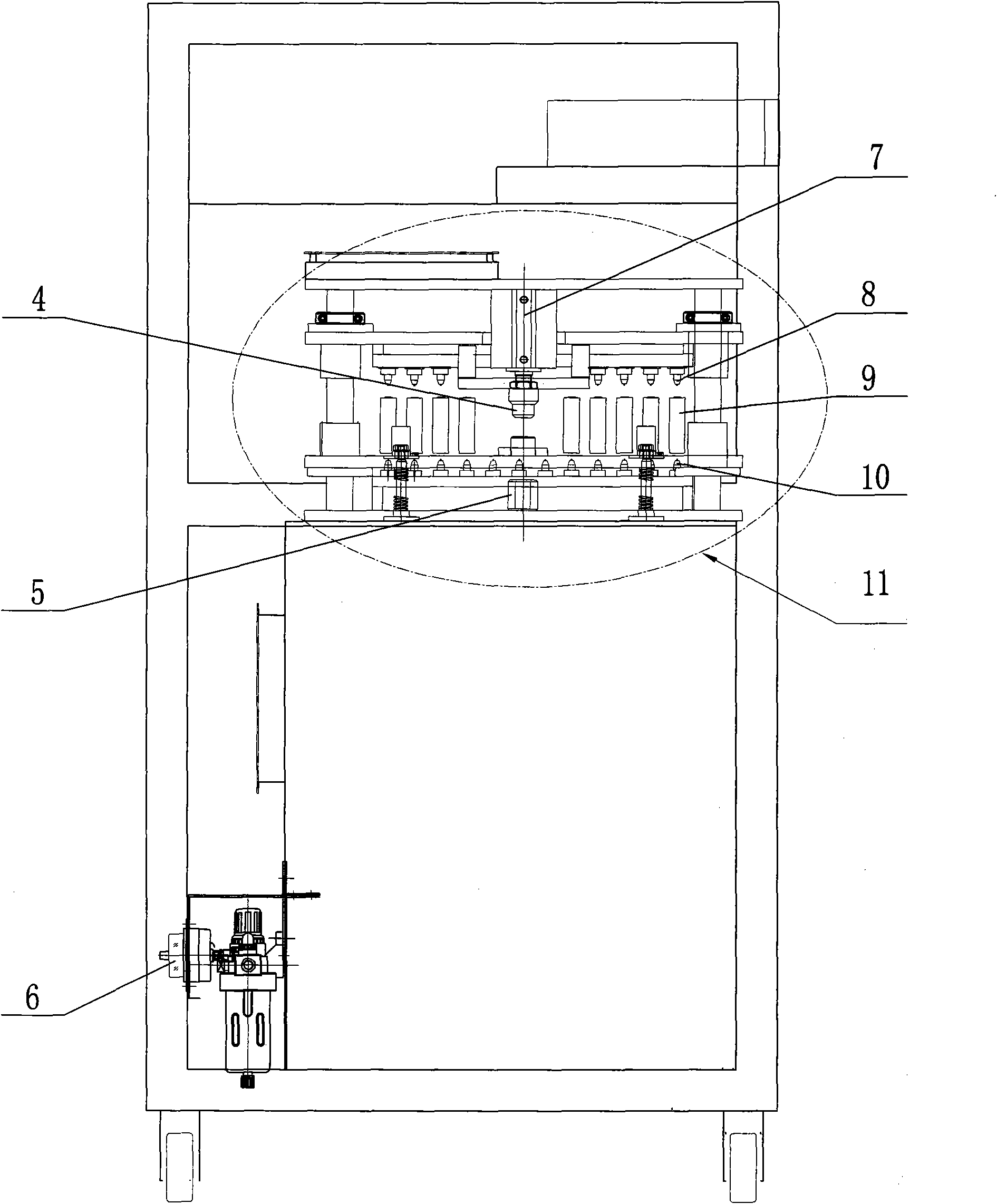

High-precision internal resistance and voltage tester for lithium ion battery

InactiveCN101833071AMeet the requirements of mass productionReduced measurement timeResistance/reactance/impedenceCurrent/voltage measurementObservational errorElectrical battery

The invention relates to a high-precision internal resistance and voltage tester for a lithium ion battery, which not only can eliminate measuring errors generated by manual operation, but also can greatly improve the production efficiency. The tester comprises a cabinet and a press module fixedly mounted on the cabinet, wherein the press module comprises a lower probe plate and a top plate which is arranged above the lower probe plate, a feeding rod is fixedly connected between the top plate and the lower probe plate and slides up and down to be connected with an upper probe plate and a tray plate, the upper probe plate is arranged above the tray plate, a probe-mounting plate is fixedly mounted below the upper probe plate, an upper probe is fixedly mounted below the probe-mounting plate, a probe-mounting plate is fixedly mounted on the lower probe plate, a lower probe is fixedly mounted on the probe-mounting plate and corresponds to the upper probe, an air cylinder is fixedly mounted between the top plate and the upper probe plate, a spring is fixedly mounted between the tray plate and the lower probe plate, and a retaining ring is fixedly connected with the feeding rod and arranged between the top plate and the upper probe plate.

Owner:山东路华电子设备有限公司

Extractive of ginkgo tree leaves, prepn. method and application thereof

ActiveCN1911257AHigh extraction rateNon-irritatingPowder deliveryNervous disorderFreeze-dryingUltrafiltration

A gingko leaf extract used for preparing liquid injection or freeze-dried powder injection is prepared from gingko leaves through breaking, thermal reflux extracting with the aqueous solution of alcohol, vacuum volatilizing of solvent, depositing in ammonia water to remove polyphenol, extracting with n-hexane to remove ginkgolic acid, adsorbing by macroreticular resin, separating, refining, ultrafiltration and spray drying.

Owner:BEIJING SUNHO PHARMA

Preparation method and application of water-soluble carbon fiber sizing agent

The invention discloses a preparation method and application of a water-soluble carbon fiber sizing agent. The water-soluble carbon fiber sizing agent is prepared from the following components in parts by weight: 5-45 parts of a water-soluble polymer, 0.01-1.2 parts of a dispersing agent, 0.08-2 parts of an emulsifying agent, and 62-95 parts of a solvent, wherein the water-soluble polymer is characterized in that a large number of active functional groups exist in molecules. The preparation method comprises the following steps: under temperature of 60-100 DEG C, adding the water-soluble polymer into the solvent, stirring so that the water-soluble polymer can be completely dissolved, adjusting to the proper temperature, adding the dispersing agent and the emulsifying agent into the solution, stirring for dissolving to obtain an integrated solution which is the water-soluble carbon fiber sizing agent. According to the invention, all the raw materials are non-toxic and easily available, are convenient for pulp mixing and sizing, and have good protection effect on carbon fibers; after the carbon fibers are treated by adopting the water-soluble carbon fiber sizing agent, the surfaces of the carbon fibers contain a large number of hydrophilic functional groups, so that the hydrophily and the dispersibility of the surfaces of the carbon fibers can be effectively improved, the carbon fibers can be well adapted to water treatment and other aspects having requirements for good dispersibility of the carbon fibers.

Owner:HANGZHOU INST OF ADVANCED MATERIAL BEIJING UNIV OF CHEM TECH

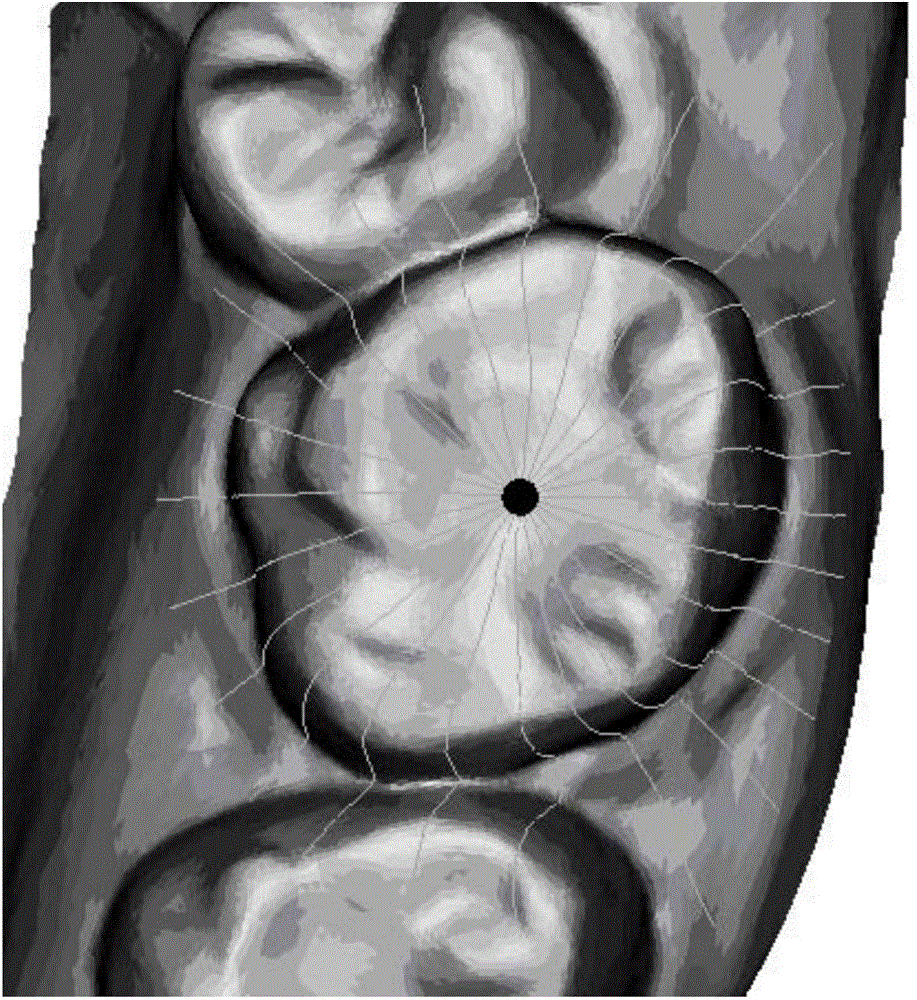

Dental crown data extraction method based on digital model

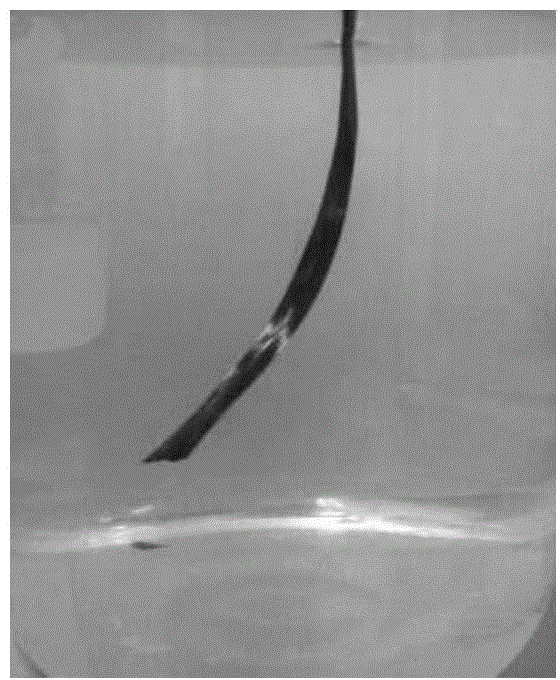

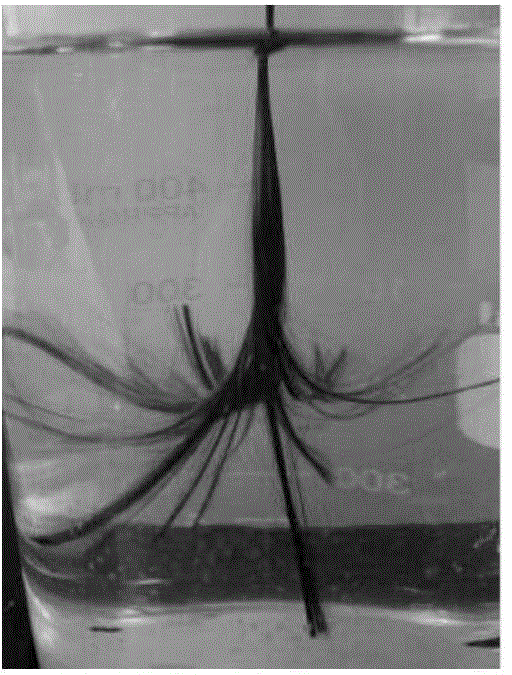

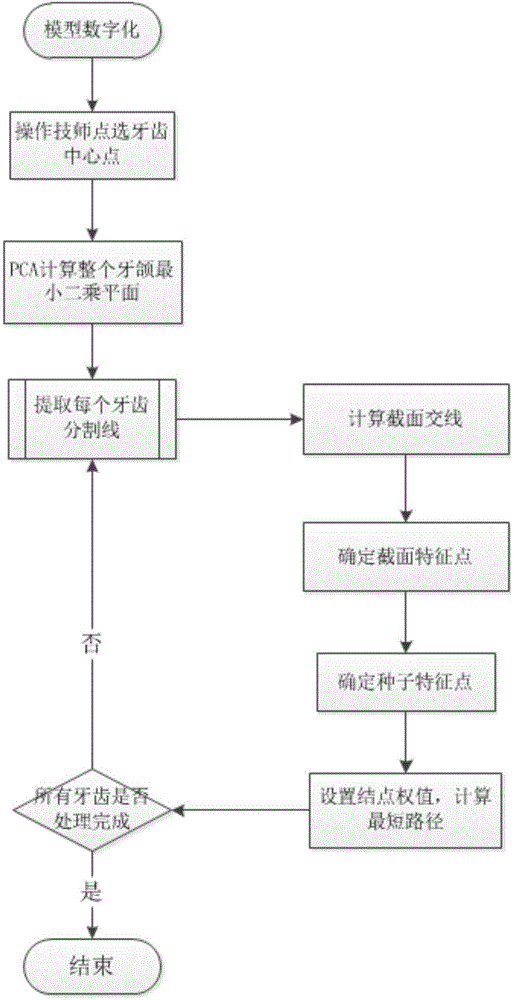

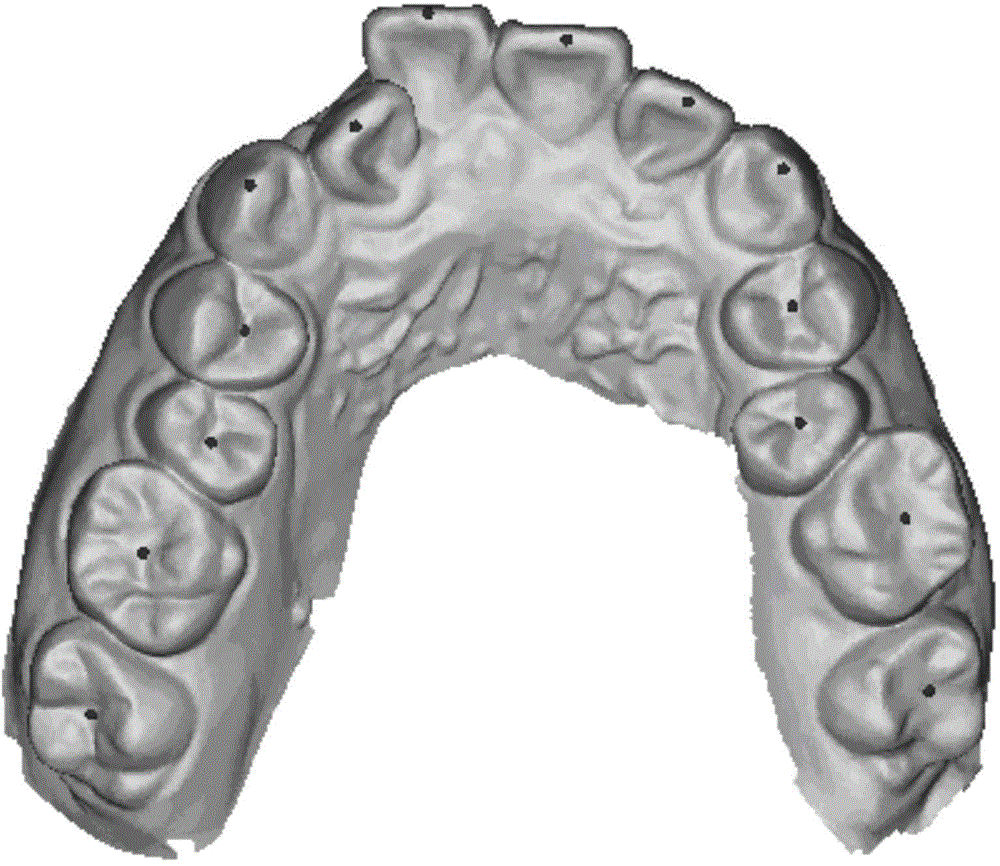

ActiveCN104867131AReduce distractionsLower requirementImage analysis3D modellingIntersection of a polyhedron with a lineReference line

Disclosed is a dental crown data extraction method based on a digital model. The method comprises the following steps: obtaining a digital dental model of a patient; an operator successively performing point-selection on teeth to be segmented on the digital dental model, and taking points clicked by the operator as the centers of currently clicked teeth; obtaining a least square plane of the whole digital dental model and its normal direction; creating a reference plane through the center of each tooth and the normal line of the lease square plane, and taking the normal line of the reference plane as a reference line; rotating the reference line according to an hour hand direction in a stepping mode; obtaining intersection points between a current stepping plane and the digital dental model, wherein these intersection points constitute intersection lines; taking troughs on each intersection line as characteristic points; searching for an intersection line with the least characteristic points as a seed intersection line, wherein the characteristic points on the seed intersection line are taken as seed points; and by taking the seed points as start points and terminal points, searching for a shortest path formed when the seed points surround all the intersection lines by one round. The method has the following advantages: dental crown data and gum data can be accurately segmented, and the segmentation success rate is high.

Owner:杭州一牙数字口腔有限公司

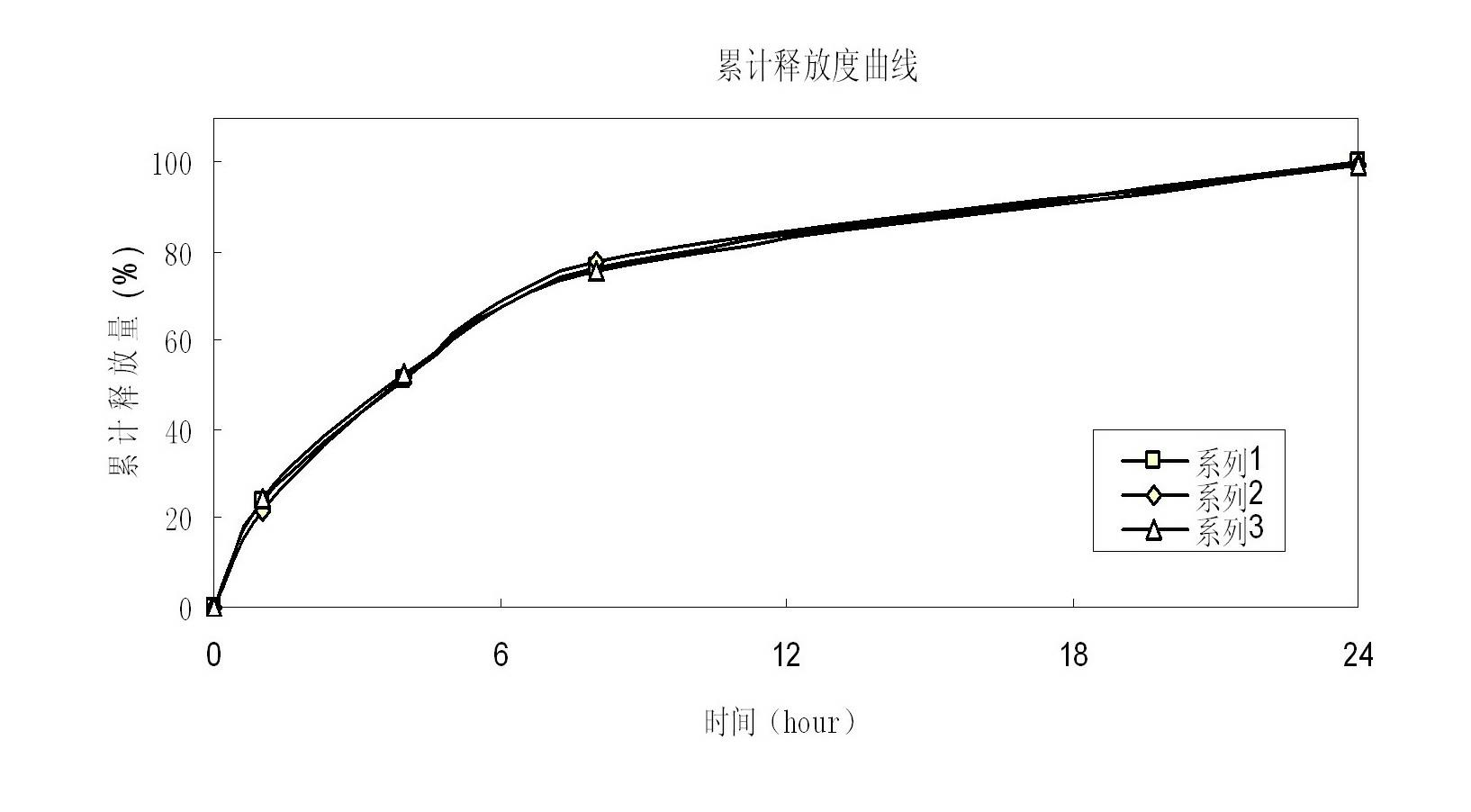

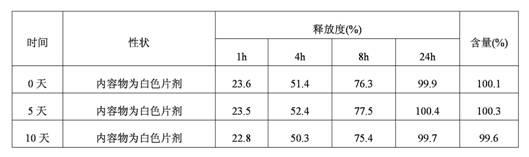

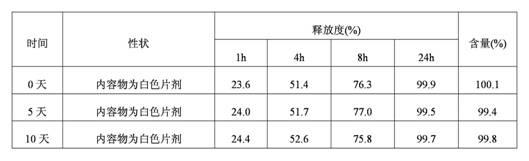

Guanidine hydrochloride sustained release preparation and preparation method thereof

ActiveCN102579381AImprove stabilitySimple manufacturing processOrganic active ingredientsGranular deliveryBlood drug concentrationTableting

The invention discloses guanidine hydrochloride sustained release preparation and a preparation method thereof. The guanidine hydrochloride sustained release preparation is mainly prepared by guanidine hydrochloride, a filling agent, sustained release materials and potential of hydrogen (pH) sensitive materials. The preparation method comprises the steps of firstly preparing all raw materials according to proportion, evenly mixing the guanidine hydrochloride, the filling agent, the sustained release materials and the pH sensitive materials at high speed, granulating and drying the evenly mixed powder, finally adding a flow agent, a lubrication agent and an adhesion agent, tableting according to a general method, and achieving guanidine hydrochloride sustained release tablets. The guanidine hydrochloride sustained release preparation is small in side effect, obviously reduces difference of preparation of different batches, improves stability of samples, is convenient long term curing of patients and improves compliance of medicine. A patient can take the guanidine hydrochloride sustained release tablets once a day, so that effective drug concentration in bodies can be guaranteed for 24 hours, and nervous centralis side reactions caused by the fact that a blood concentration peak value is high due to general preparation is reduced.

Owner:ZHONGSHUAI PHARMA SCI & TECH CO LTD

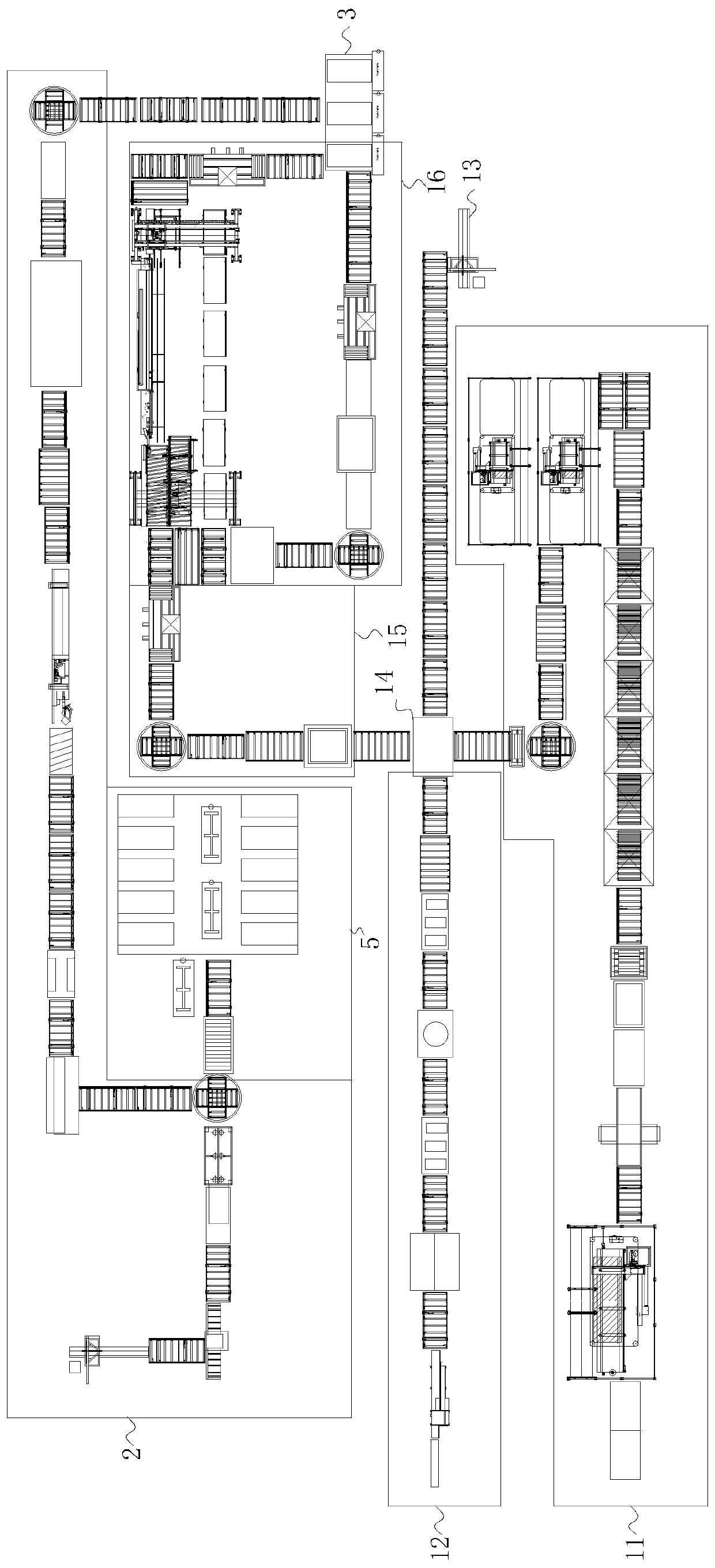

Assembly line of paint-free film-pressing wooden door

PendingCN109702843AReduce labor intensityRealize assembly line productionWood working apparatusProduction lineHigh volume manufacturing

The invention discloses an assembly line of a paint-free film-pressing wooden door. The assembly line comprises a door plate production line, a door face stop strip production line, a combined packaging platform, a conveyor and a master controller. According to the assembly line, the traditional labor division type wooden door production process is replaced, the operation process of equipment is reasonably distributed, the operation working conditions are adjusted, assembly line type production is realized, the production efficiency is greatly improved, the processing cycle is shortened, the requirements of mass production are met, meanwhile, the labor intensity of workers is reduced, and the participation of people on the production process is reduced.

Owner:广东玛格家居有限公司

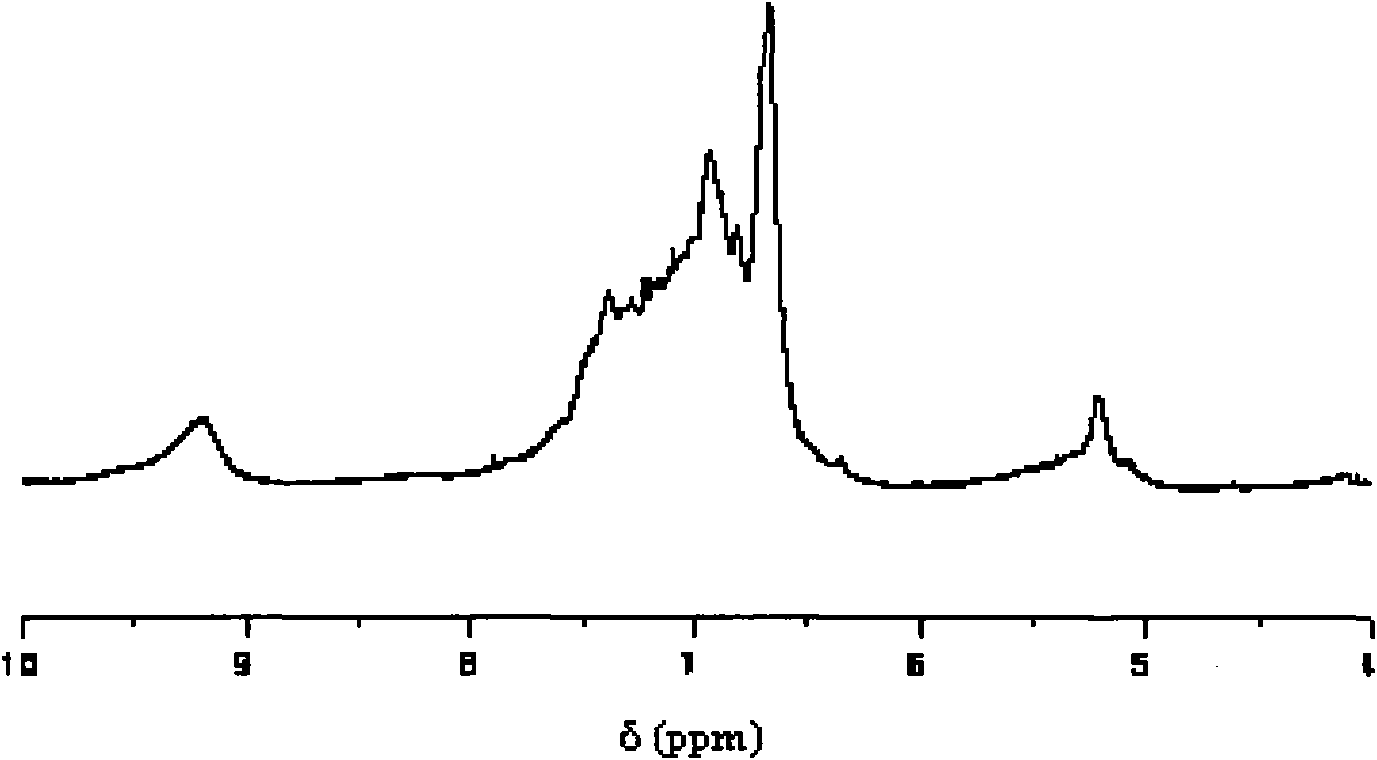

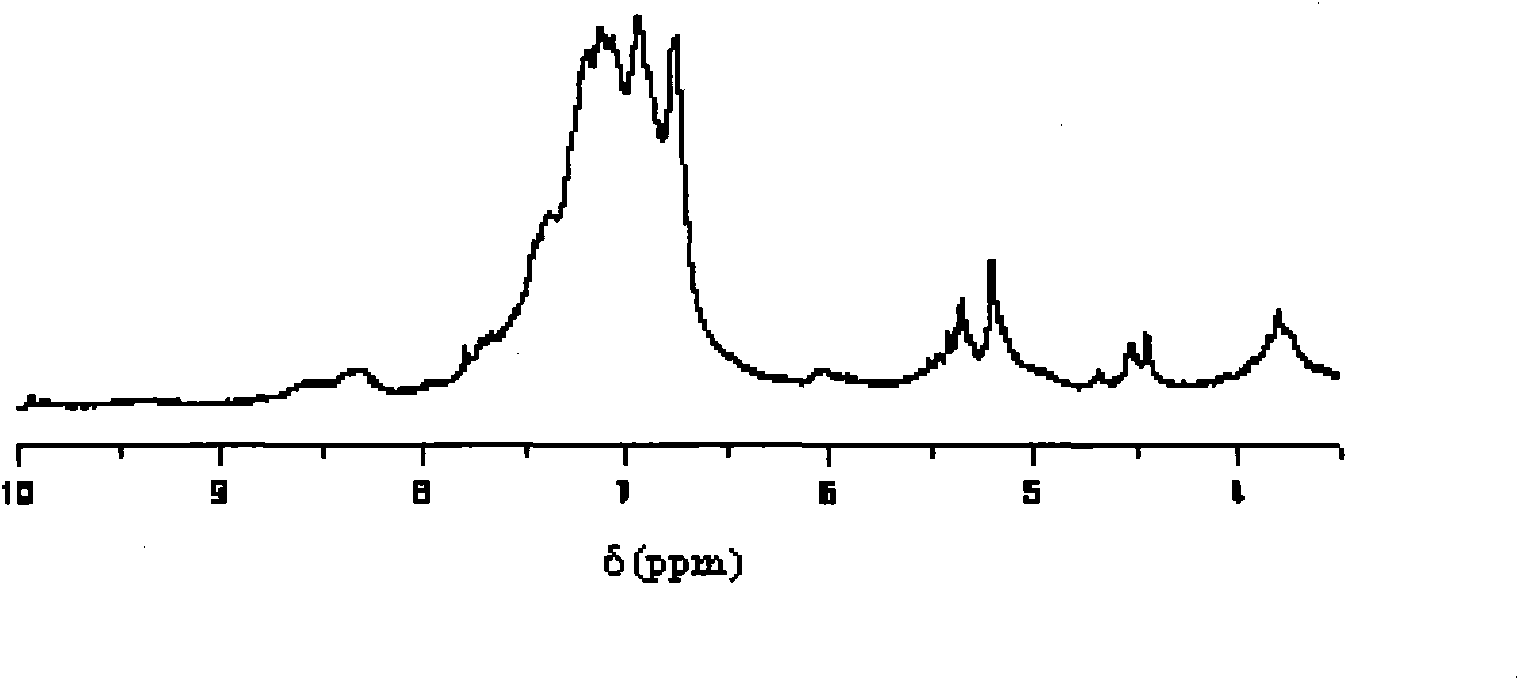

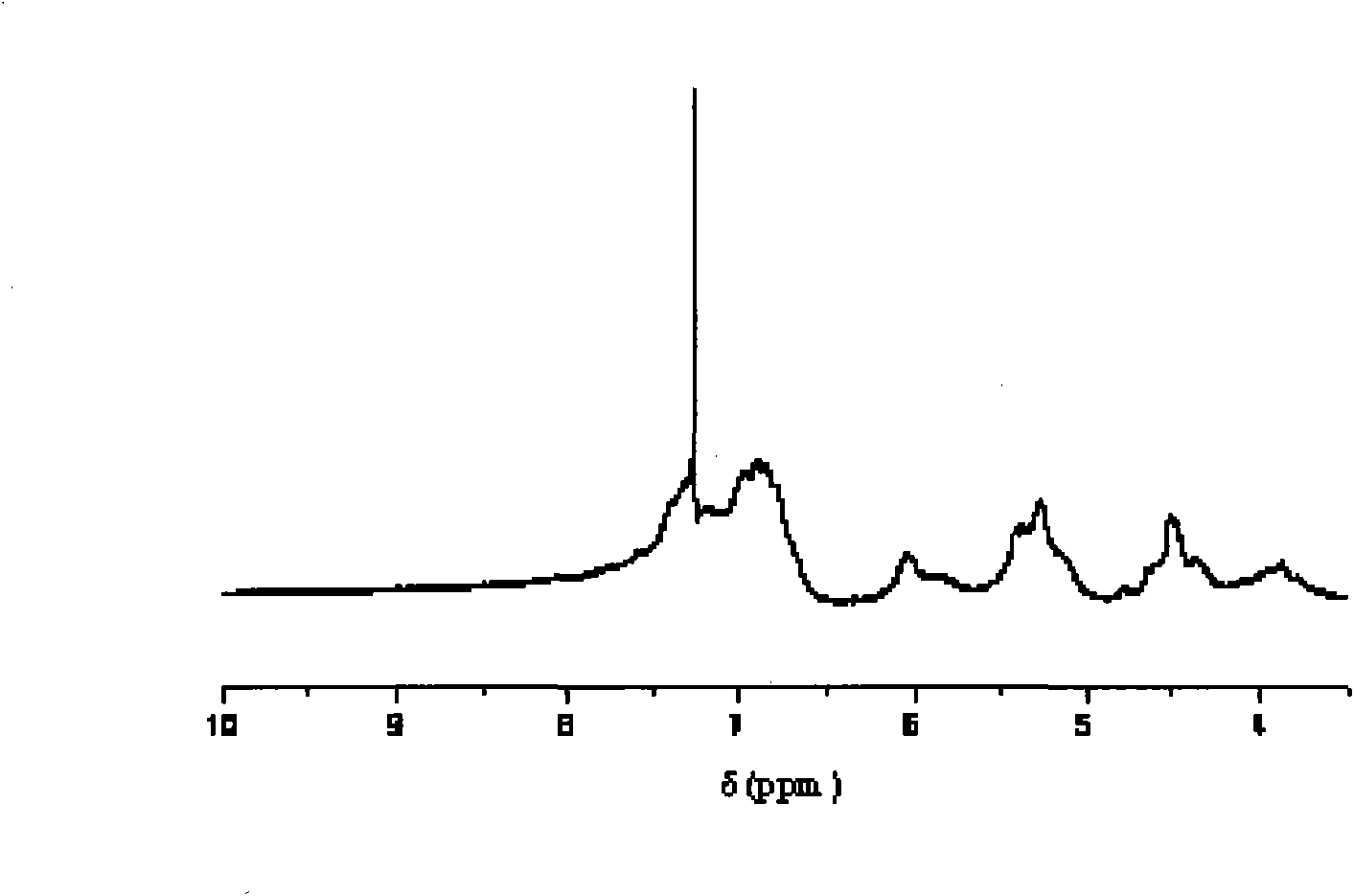

Preparation method of difluoro chloroethane and its production equipment

ActiveCN1556083AImprove conversion rateReduce unit consumptionHalogenated hydrocarbon preparationChemical reactionIt equipment

A process for preparing difluorochloro ethane from difluoroethane and chlorine gas includes proportionally mixing, three-class photo-chemical reaction while regulating light flux for presenting the high-boiling-point substance peaks with different heights, removing acid, alkali washing, compressing, degassing, rectifying and drying. Its equipment is disclosed also. Its advantages are high conversion rate of difluoroethane and high selectivity and purity of product.

Owner:ZHEJIANG AIKESHENG CHEM

Allylation hyperbranched polyphenyl ether modified bismaleimide resin and preparation method thereof

The invention discloses an allylation hyperbranched polyphenyl ether modified bismaleimide resin and a preparation method thereof. The method for preparing the resin comprises the following steps of: according to the molar ratio, stirring 100 parts of bismaleimide and 30 to 85 parts of diallylphenyl compound at the temperature of between 110 and 140 DEG C until the mixture is transparent; adding 1 to 55 parts of allylation hyperbranched polyphenyl ether into the mixture; and reacting for 20 to 100 minutes at the temperature of between 110 and 140 DEG C and cooling so as to obtain the allylation hyperbranched polyphenyl ether modified bismaleimide resin. The method for synthesizing the allylation hyperbranched polyphenyl ether by adopting dimethyl sulfoxide and other weak polar solvents has the advantages of simple process, rich raw materials, high yield, and the capacity of meeting the requirement on mass production. The prepared modified bismaleimide resin has the advantages of excellent toughness, heat resistance, wet resistance and higher dielectrical property (low dielectric constant and dielectric loss). The preparation method for the modified bismaleimide resin also has the characteristics of simple process and easy control.

Owner:SUZHOU UNIV

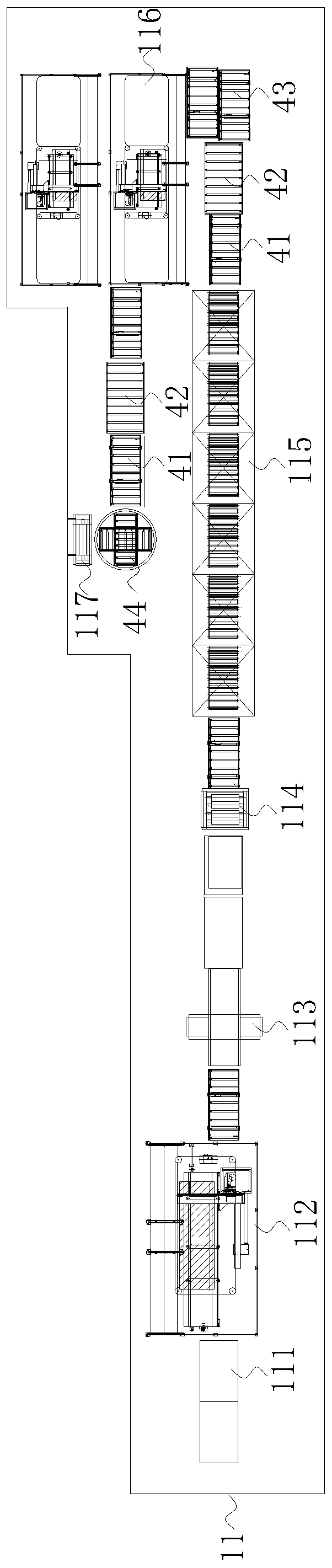

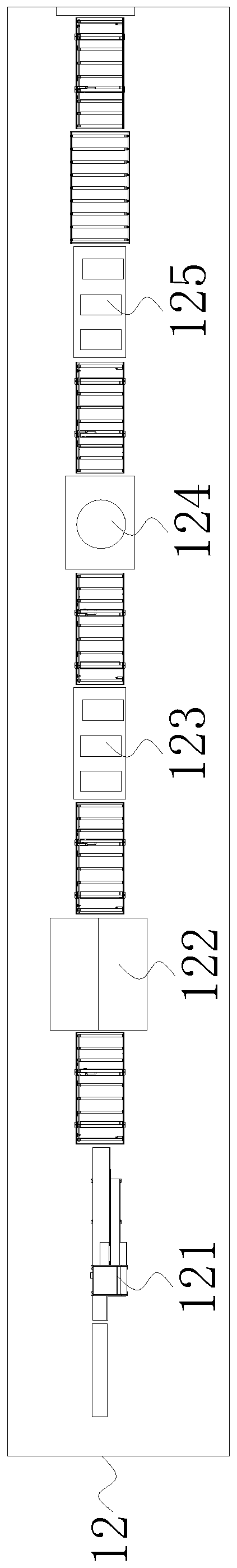

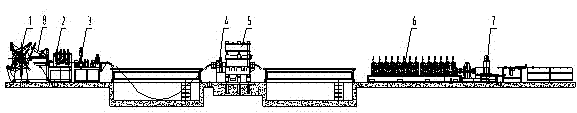

Stainless steel strip forming equipment for steel-aluminum composite contact rail

InactiveCN103612119AImprove performanceQuality improvementOther manufacturing equipments/toolsButt weldingPunching

The invention discloses stainless steel strip forming equipment for a steel-aluminum composite contact rail. The stainless steel strip forming equipment comprises an uncoiler, a material guide leveler, a cutting butt welding platform, a servo feeder, a punching machine, a roll bending and forming unit, and a sizing and cutting machine. The uncoiler is disposed on the front side of the material guide leveler. The cutting butt welding platform is disposed on the rear side of the material guide leveler. The servo feeder is disposed on the front side of the punching machine. The punching machine used for punching holes on two lateral sides of steel strips is connected with the cutting butt welding platform through the servo feeder. The roll bending and forming unit used for bending and forming two lateral sides of the steel strips is disposed on the rear side of the punching machine. The sizing and cutting machine is disposed on the rear side of the roll bending and forming unit. The stainless steel strip forming equipment is reasonable in design, novel in structure, simple in production procedures, capable of forming at one step and continuously and stably producing, and high in efficiency. The produced stainless steel strips are stable in quality and good in performance, and the requirements of batch production of the stainless steel strips for the steel-aluminum composite contact rail can be satisfied completely.

Owner:NANJING JINCHENG RAIL TRANSPORT EQUIP +1

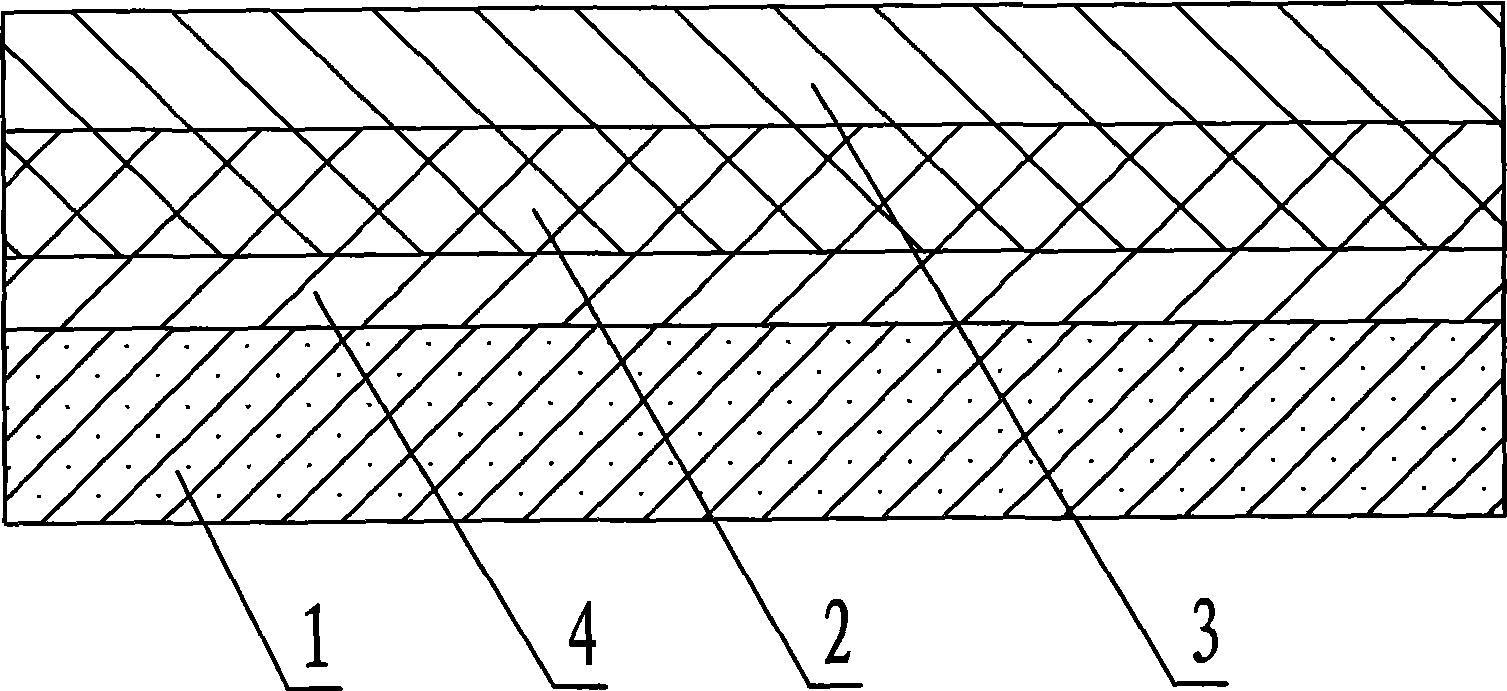

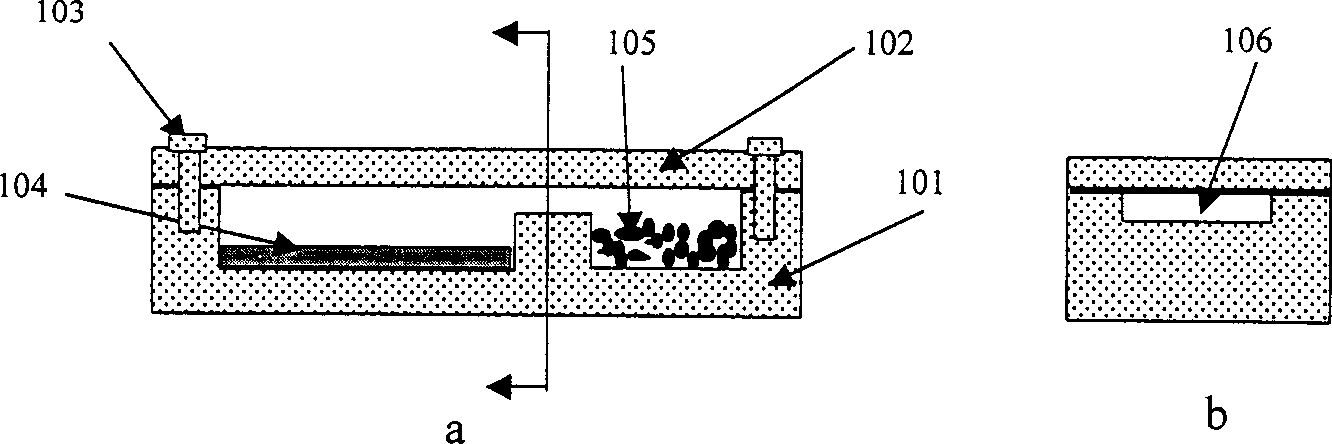

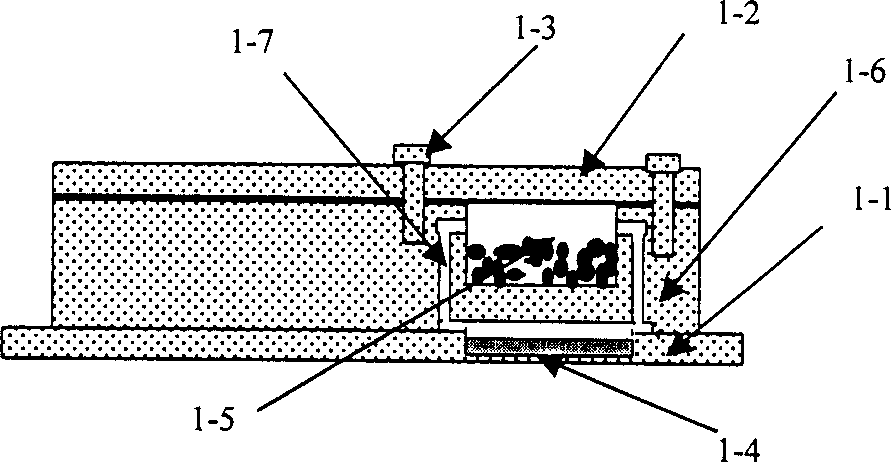

Preparation method of titanium-steel composite plate

ActiveCN107626764AReduce spreadImprove the bonding strength of the interfaceTitaniumMaterials processing

The invention discloses a preparation method of a titanium-steel composite plate, and belongs to the field of material processing. The preparation method of the titanium-steel composite plate comprises the steps that the surfaces of adopted titanium blanks and the surface of an adopted steel blank are treated, and then the surfaces of the titanium blanks are coated with paint and dried at the roomtemperature; the two titanium blanks with the surfaces being treated and coated with paint are aligned and stacked together, the steel blank is placed between the two titanium blanks, and then the blanks are assembled together symmetrically; the periphery of a composite blank is welded and sealed, and vacuumizing treatment is conducted; and the composite blank is placed in a heating furnace so asto be subject to heat treatment, then multi-pass rolling is conducted, the composite blank is air cooled after being rolled, and edge cutting, tension-straightening and flattening are conducted. According to the preparation method of the titanium-steel composite plate, the surfaces of the titanium blanks are coated with protective coatings, so that the titanium blanks are protected, the situationthat the composite performance is affected due to the fact that titanium with active chemical properties is oxidized and forms compounds with other elements is avoided, and the coatings are preparedfrom isolation paint which can prevent oxidization of titanium and prevent diffusion of harmful elements (such as C and N) at high temperatures.

Owner:KUNMING UNIV OF SCI & TECH

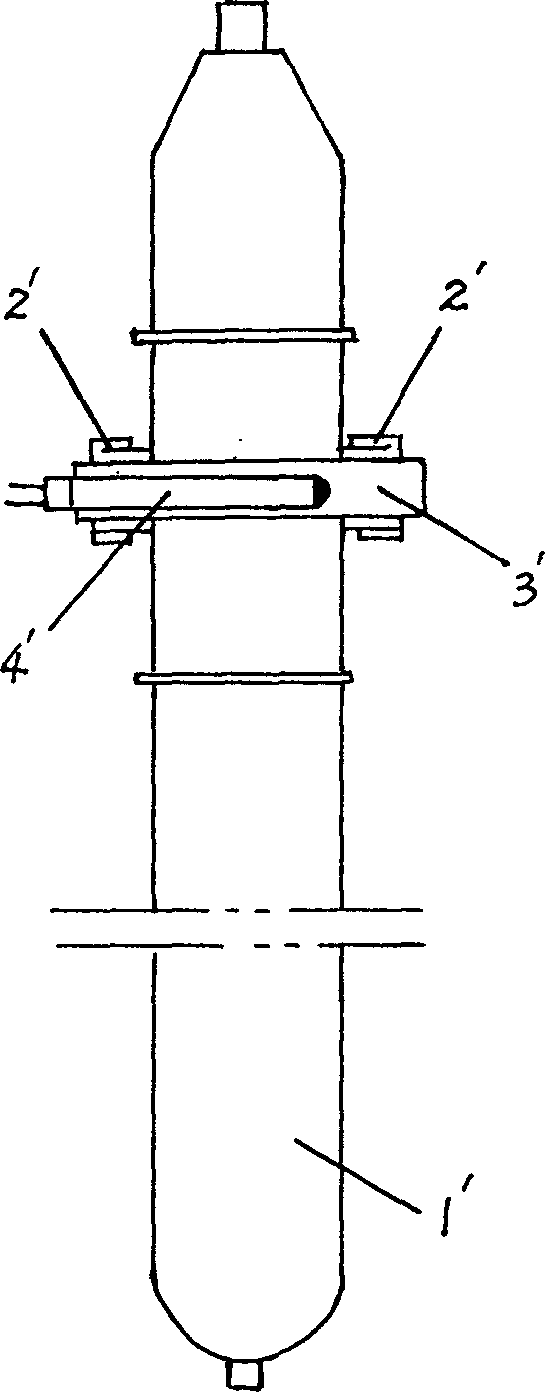

Open pipe tellurium cadmium mercury epitaxial material heat treatment method

InactiveCN1354287AMaintain surface integrityGood surface morphologyAfter-treatment detailsSemiconductor/solid-state device manufacturingDislocationBatch production

The present invention discloses an open tube HgTe source Te-Cd-Hg epitaxial material heat treatment method. The stable mercury steam pressure required for heat treatment is provided by adopting graphite box structure. Said graphite box also can be implemented by utilizing improved liquid-phase epitaxial graphite boat, and its open tube process provides a way for batch production of the part. The success rate of using said process to make hole conduction heat treatment can be up to 100%. The hole density of the material of 77K temp. can be arbitrarily regulated in the range of 5X10 to the power 15 to 5X10 to the power 16 cm (-3). At the same time, the dislocation of material surface in the course of heat treatment does not produce increment effect, and the material composition and appearance form can be better retained.

Owner:SHANGHAI INST OF TECHNICAL PHYSICS - CHINESE ACAD OF SCI

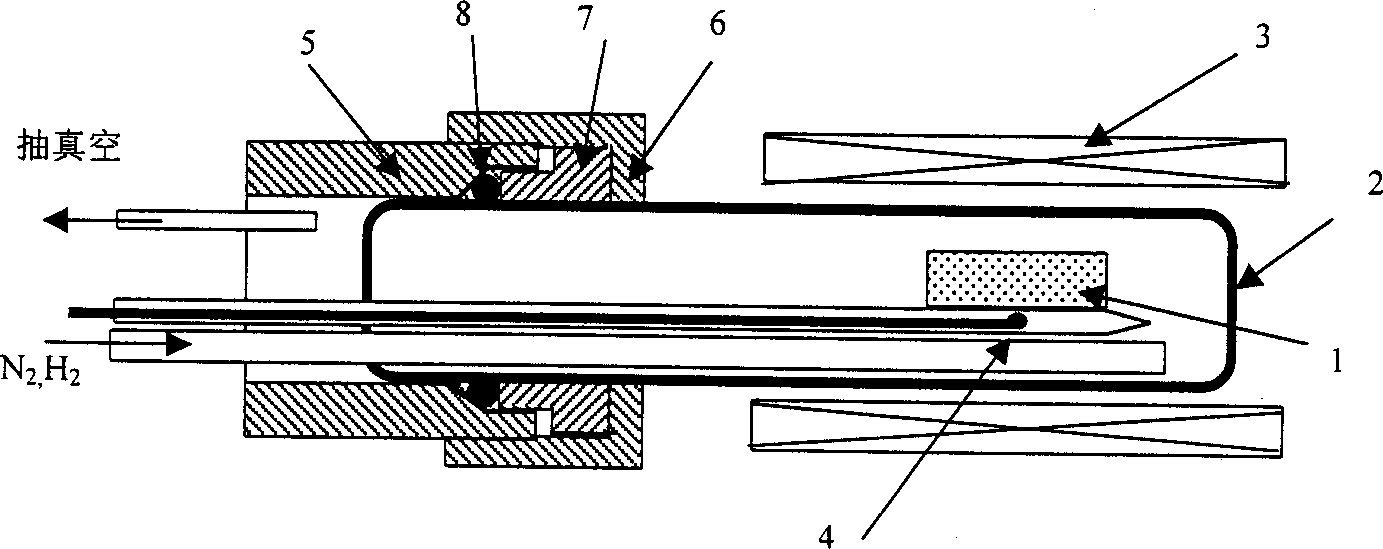

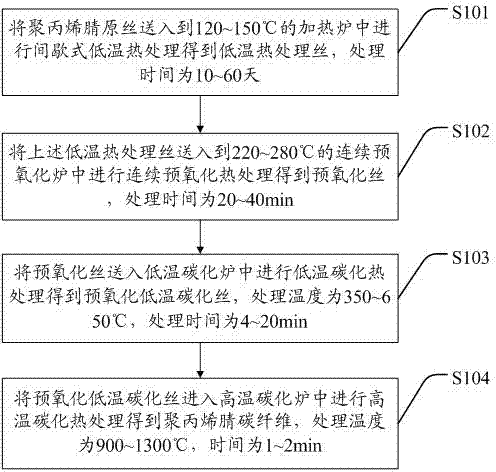

Polyacrylonitrile carbon fiber and preparation method thereof

InactiveCN104233514AReduce manufacturing costSimple production processFibre chemical featuresBatch productionHeating furnace

The invention discloses polyacrylonitrile carbon fiber and a preparation method thereof. The preparation method comprises the following steps: feeding polyacrylonitrile raw silk into a heating furnace with the temperature of 120-150 DEG C, and performing low-temperature heat treatment for 10-60 days to obtain low-temperature heat treated silk; B, feeding the low-temperature heat treated silk into a continuous preoxidation furnace with the temperature of 220-280 DEG C, and performing continuous preoxidation heat treatment for 20-40 minutes to obtain preoxidized silk; C, feeding the preoxidized silk into a low-temperature carbonization furnace, and performing low-temperature carbonization heat treatment at 350-650 DEG C for 4-20 minutes to obtain preoxidized low-temperature carbonized silk; D, feeding the preoxidized low-temperature carbonized silk into a high-temperature carbonization furnace, and performing high-temperature carbonization heat treatment at 900-1,300 DEG C for 1-2 minutes to obtain the polyacrylonitrile carbon fiber. The preparation method is simple in process and convenient and safe to perform and control, and meets the requirements of batch production.

Owner:刘剑洪

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com