Patents

Literature

101results about How to "Realize assembly line production" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

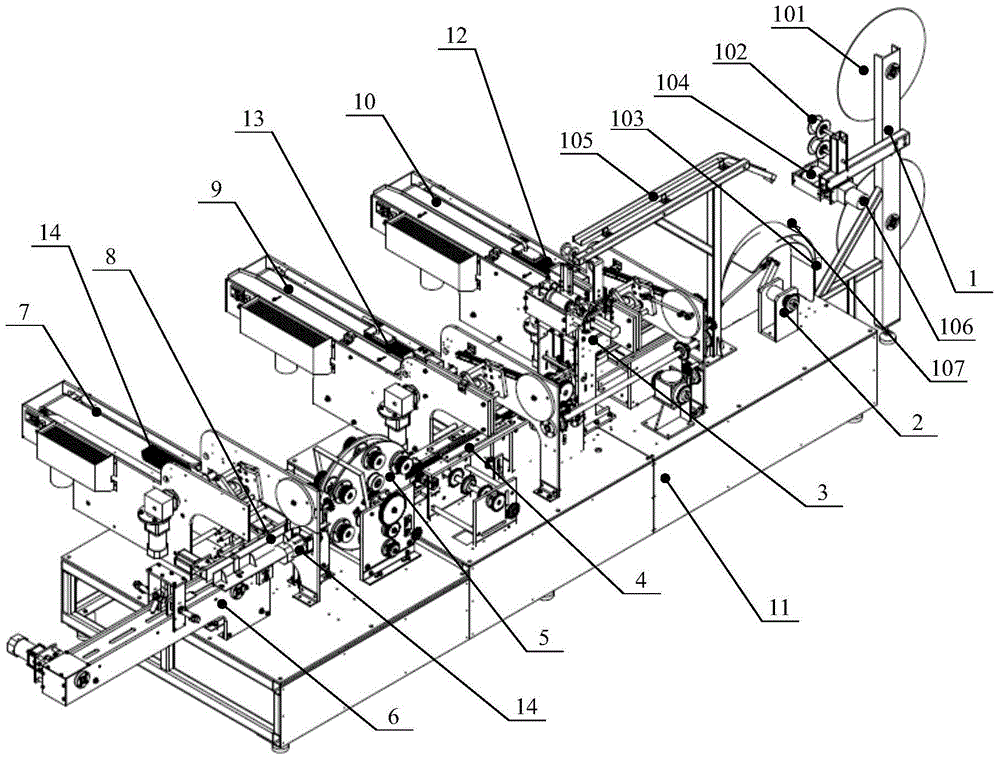

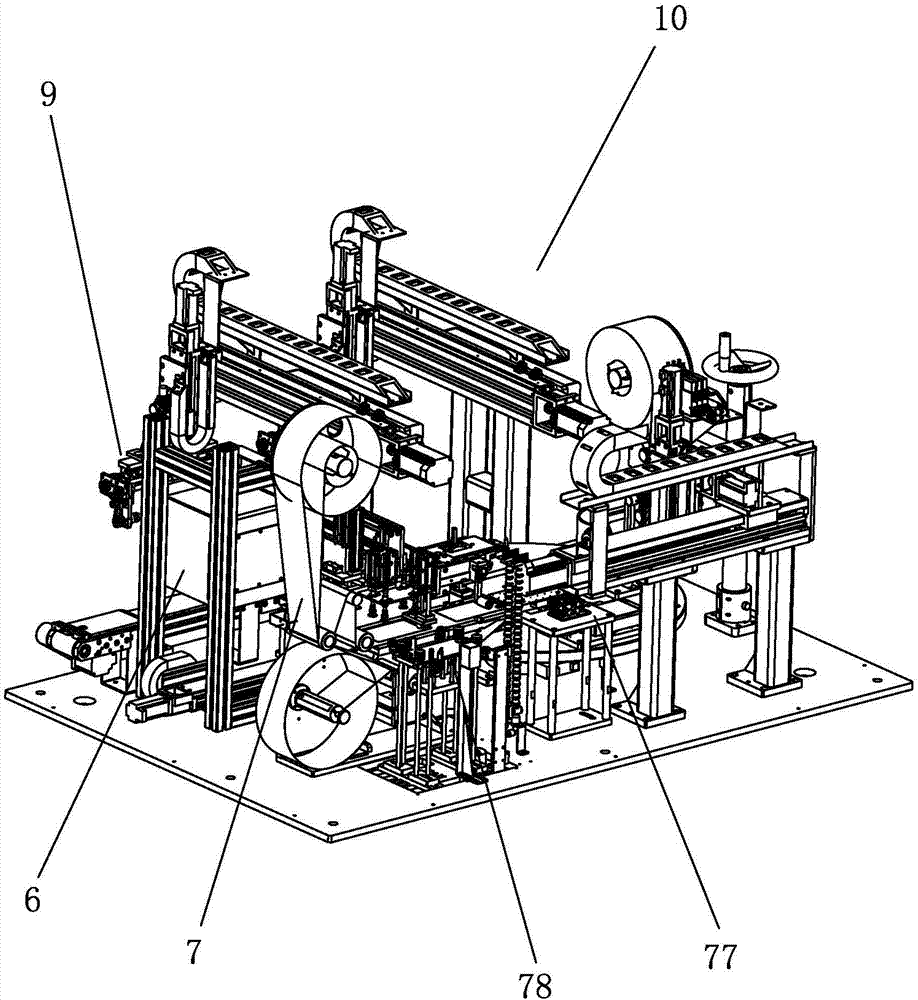

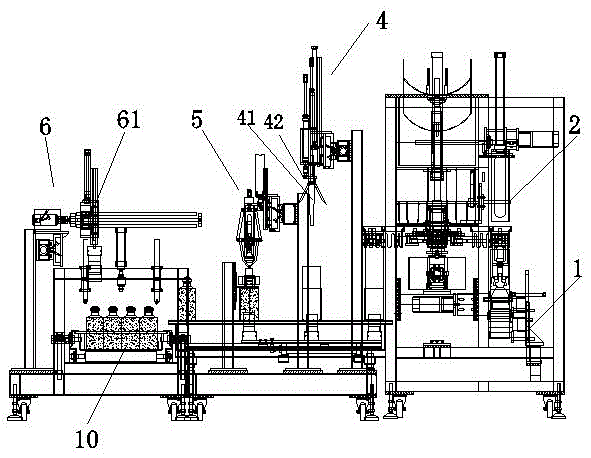

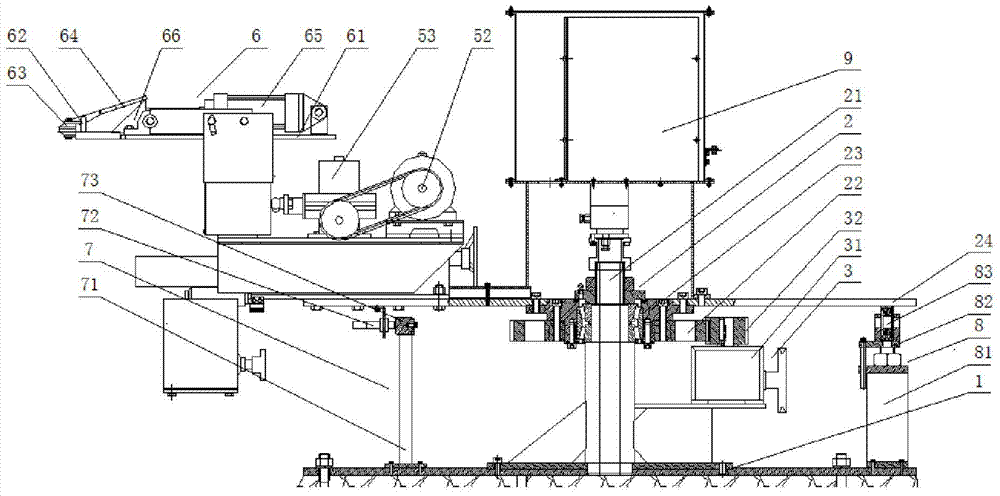

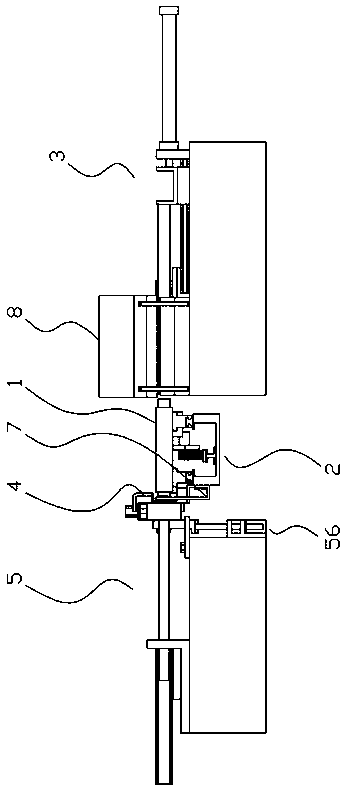

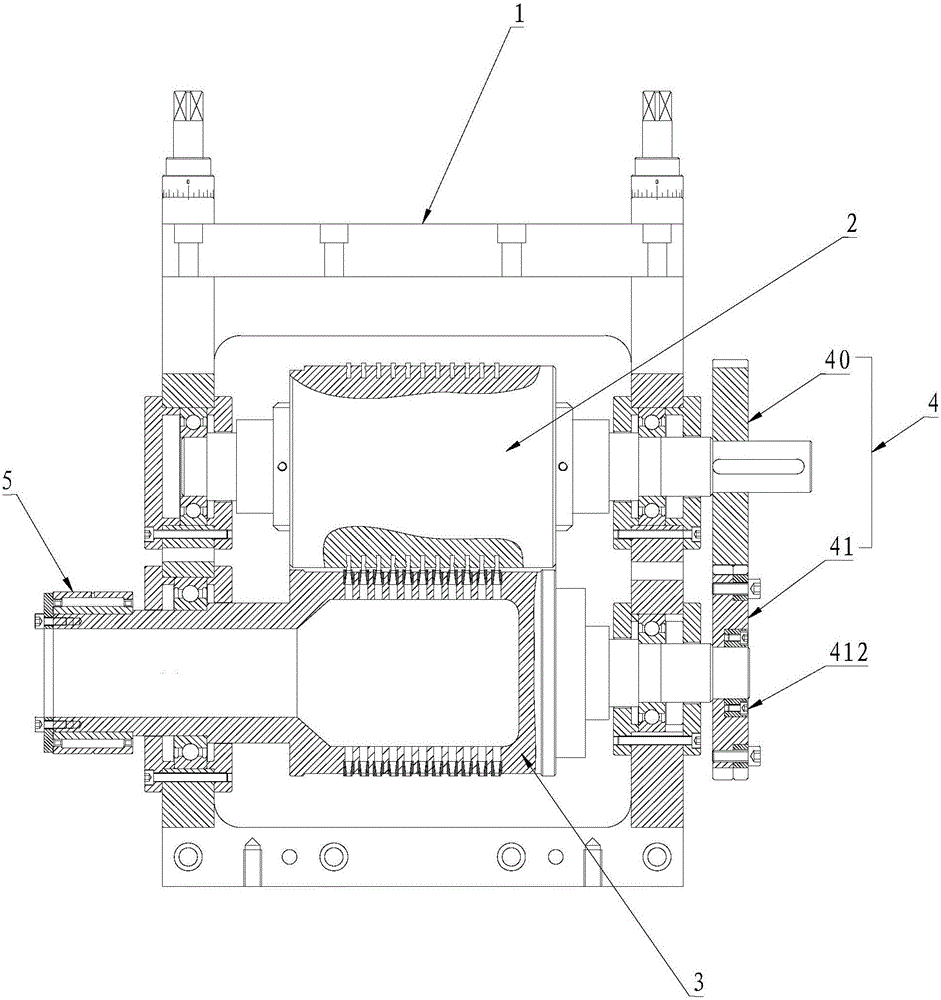

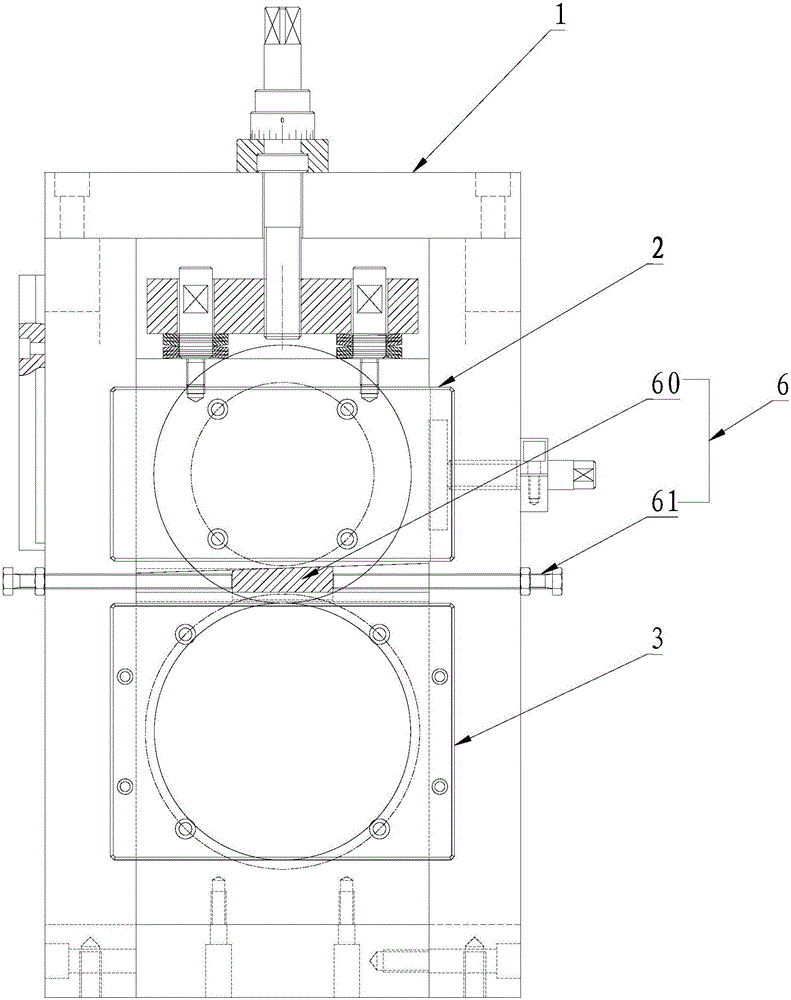

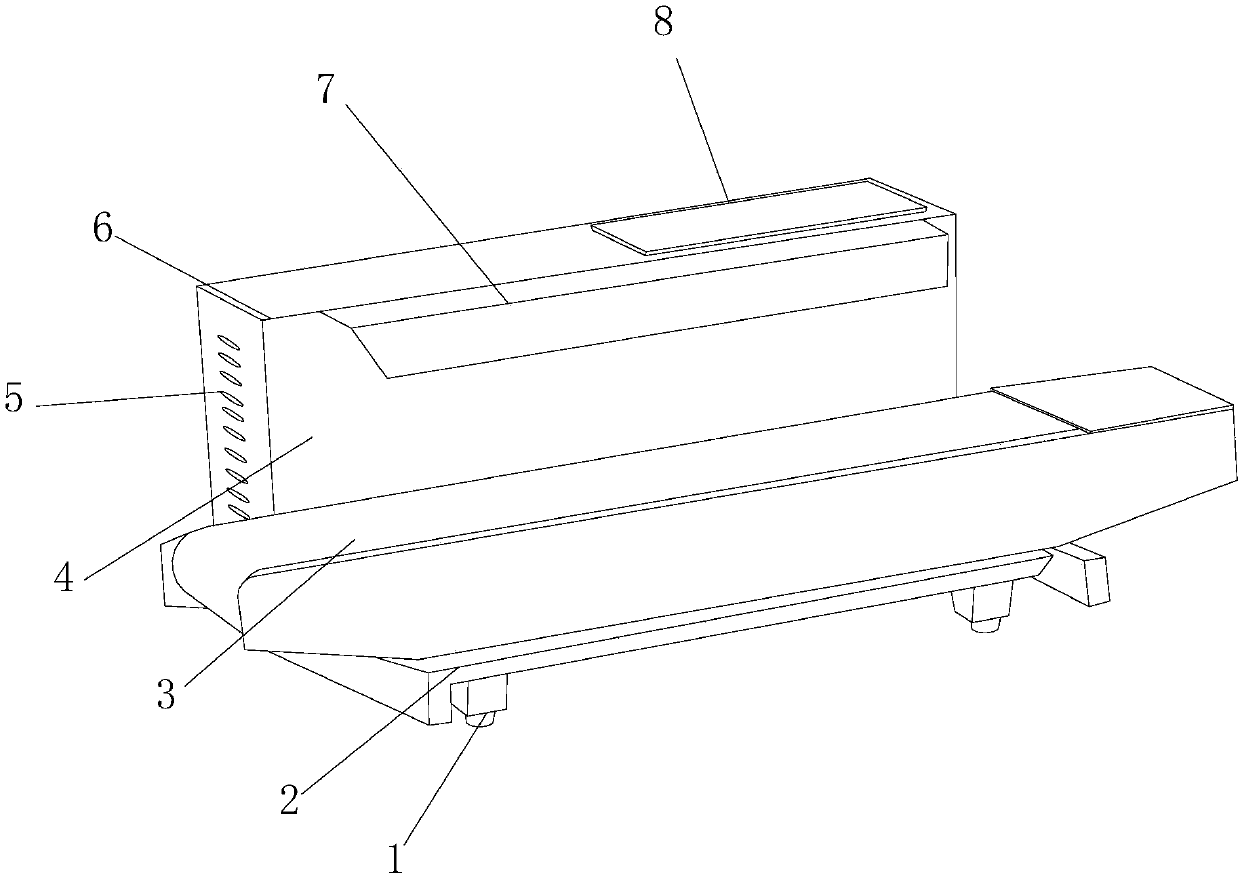

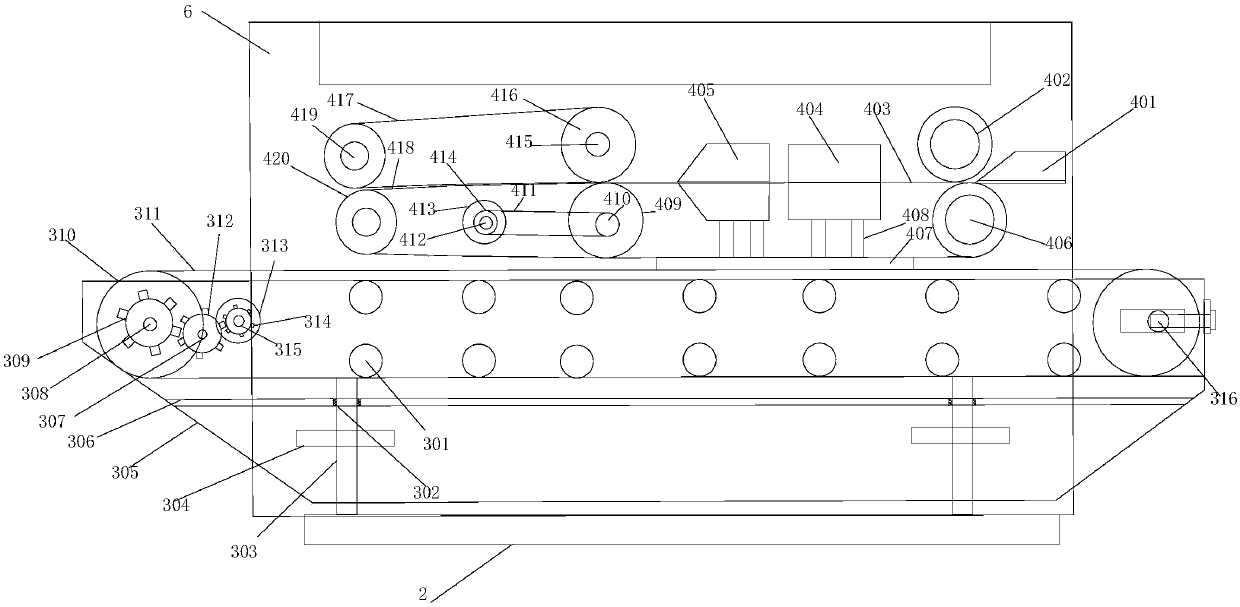

Full-automatic storage battery piece wrapping distribution machine

ActiveCN104681882ACompact structureReasonable structureFinal product manufactureLead-acid accumulators constructionPole pieceAssembly line

The invention provides a full-automatic storage battery piece wrapping distribution machine which comprises a paper cutting and wrapping piece mechanism, a rotary battery plate group piece laminating mechanism, a pole piece underfloor mechanism, a first feeding mechanism, a piece pushing mechanism, a partition paper transfer mechanism, a wrapping piece transfer mechanism, a second feeding mechanism, a pneumatic piece pushing mechanism, a third feeding mechanism and a frame, wherein the partition paper transfer mechanism, the piece pushing mechanism, the firs feeding mechanism, the paper cutting wrapping piece mechanism, the second feeding mechanism, the wrapping piece transfer mechanism, the rotary battery plate group piece laminating mechanism, the third feeding mechanism, the pneumatic piece pushing mechanism and the pole piece underfloor mechanism are sequentially arranged on the frame. The distribution machine provided by the invention can be used for achieving assembly line type production of wrapping pole pieces and automatically feeding, wrapping, laminating and discharging the pole pieces, so that the harm of lead dust is greatly reduced, the labor cost is lowered, the efficiency is improved, and the distribution machine is convenient to operate.

Owner:FUJIAN JIANYANG YAHENG MACHINERY MFG

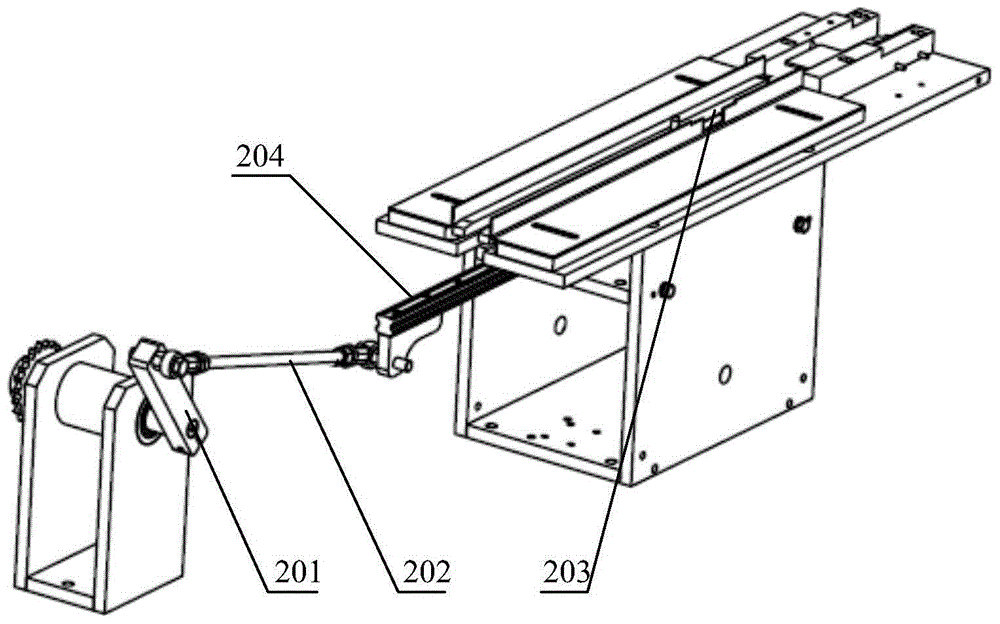

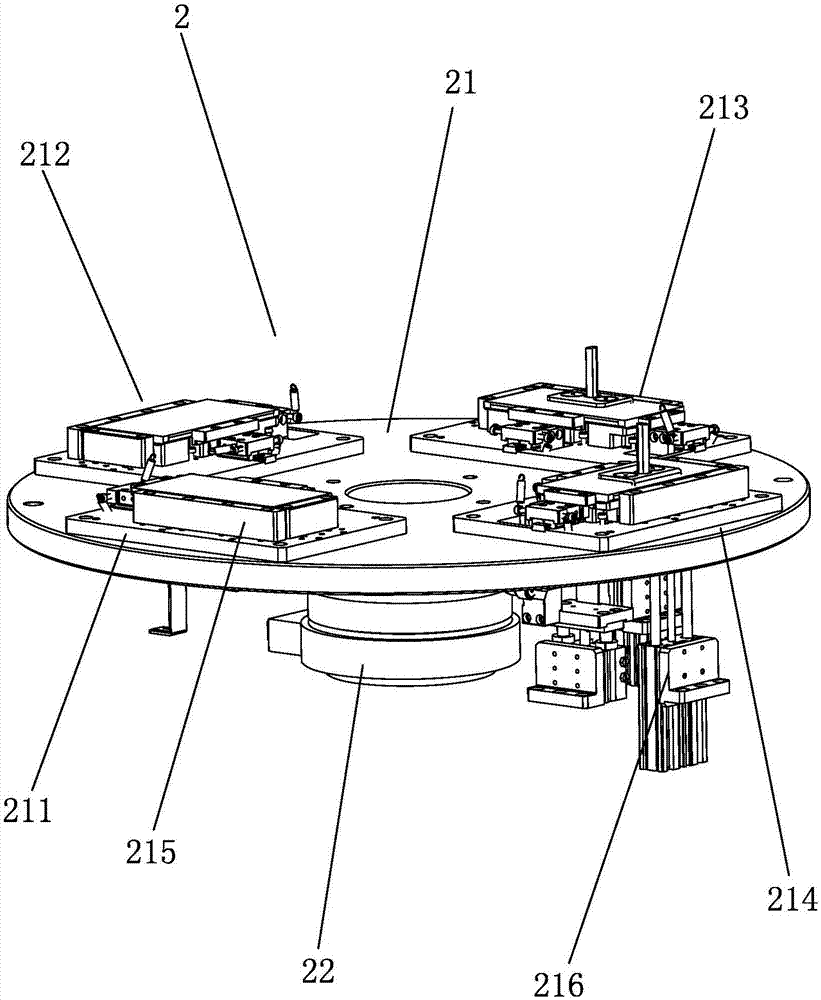

Film pasting equipment for mobile phone screen and film pasting method for mobile phone screen

ActiveCN107336865ASmall footprintReduce labor costsPlastic recyclingPackaging automatic controlProduction rateSmall footprint

The invention relates to film pasting equipment for a mobile phone screen and a film pasting method for the mobile phone screen. The film pasting equipment for the mobile screen comprises a base, a conveying device arranged on the base, a first feeding device arranged on one side of a feeding station, a cleaning device arranged on one side of a cleaning station, a film pasting device arranged on one side of a film pasting station and a detection device arranged on one side of a detection station, wherein the feeding station, the cleaning station, the film pasting station, the detection station and clamps for clamping mobile phones are arranged on the conveying device. The film pasting equipment for the mobile phone screen further comprises a film tearing device arranged on one side of the film pasting device. The whole equipment is small in occupied space, the automatic control is adopted in the full process, the labor cost is saved, the stability of mobile phone film pasting is high, and the efficiency is high; and due to the fact that the mobile phones pasted with films are detected by the detection device, the reject ratio during production can be reduced.

Owner:SHENZHEN GDLASER TECH CO LTD

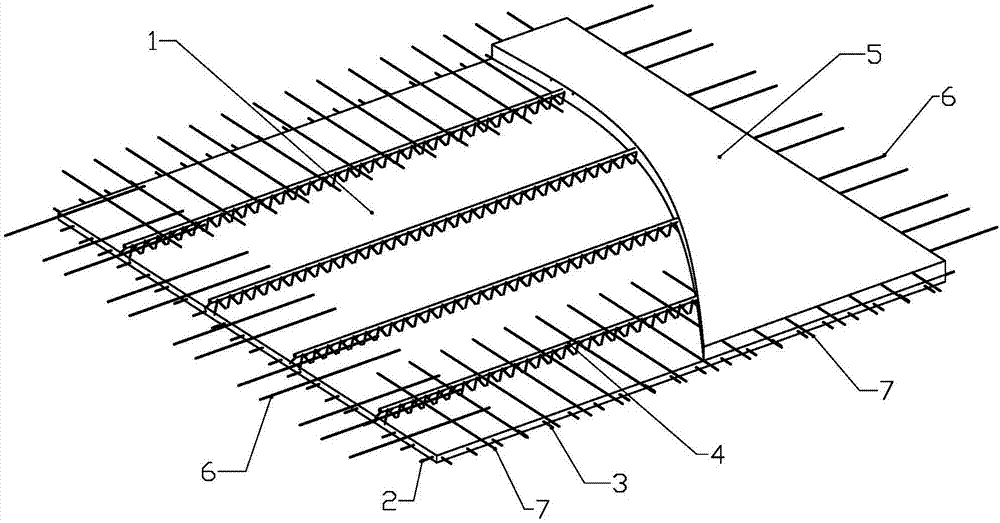

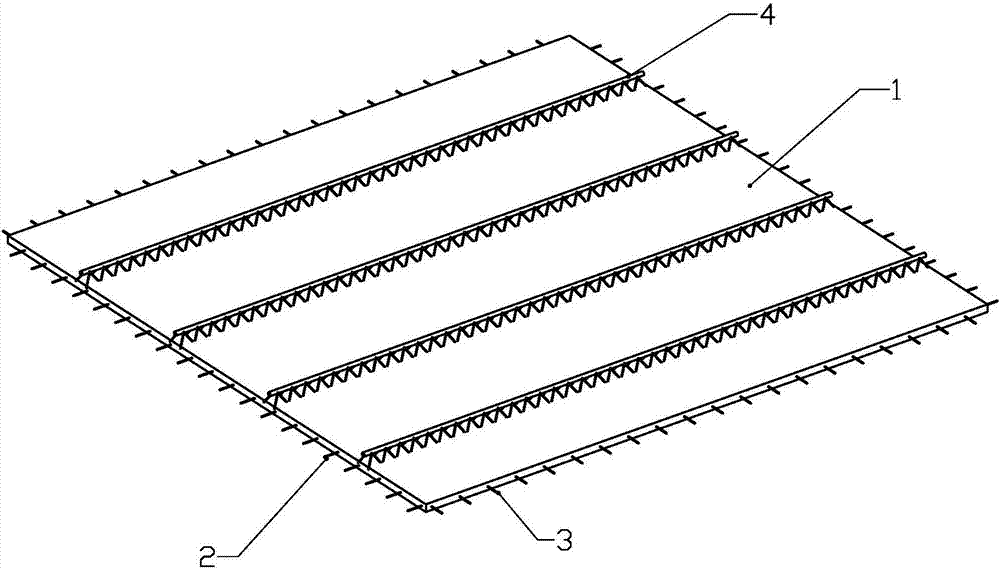

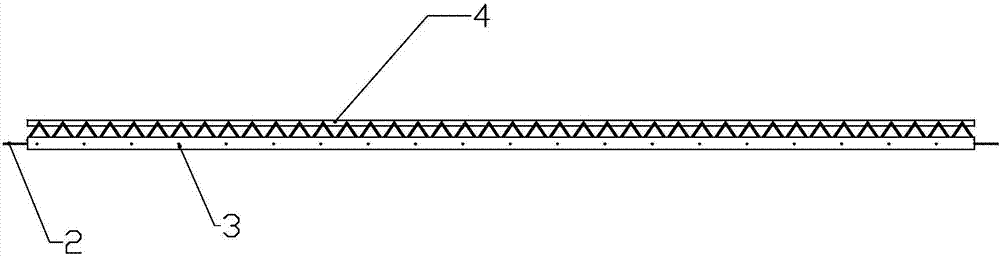

Prestressed concrete bidirectional laminated slab and manufacturing method

InactiveCN107542196AReduce support and formwork usageImprove construction efficiencyFloorsBuilding material handlingRebarPre stress

The invention discloses a prestressed concrete two-way laminated slab and a manufacturing method thereof, which belong to the technical field of construction engineering. Its structure includes a prefabricated bottom plate, a laminated layer and a steel truss. The trusses are connected, and the laminated layer transverse steel bars and laminated layer longitudinal steel bars are arranged inside the laminated layer. The laminated layer longitudinal steel bars are fixed on the upper surface of the steel truss. The transverse prestressed reinforcement is arranged at equal intervals, the longitudinal prestressed reinforcement is arranged at equal intervals along the length direction, the longitudinal prestressed reinforcement is located above the transverse prestressed reinforcement, and multiple steel trusses are arranged at equal intervals along the width direction on the upper part of the prefabricated floor. The invention also discloses a manufacturing method of the laminated board. The invention has the characteristics of high overall rigidity of the laminated slab, good force bearing performance, two-way force transmission mechanism, no joints on the prefabricated bottom plate, reduced on-site support and formwork consumption, and improved construction speed and the like.

Owner:SHANDONG PROVINCIAL ACAD OF BUILDING RES

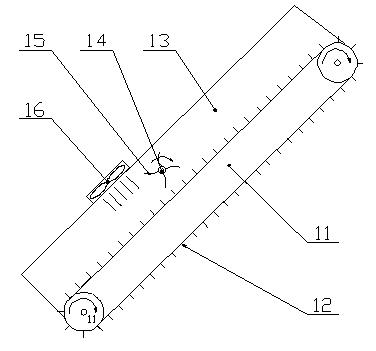

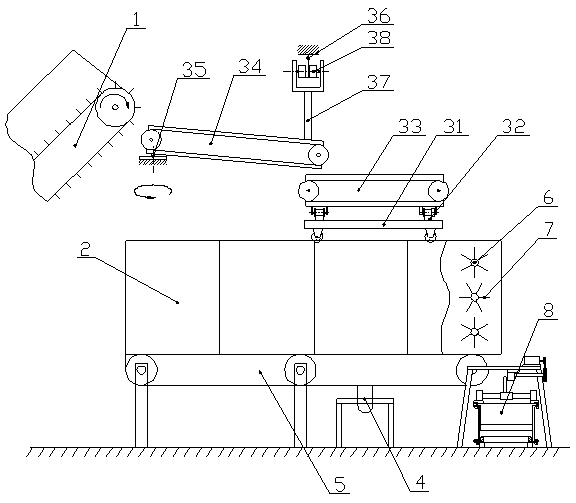

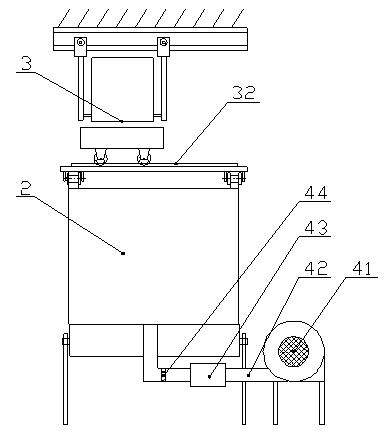

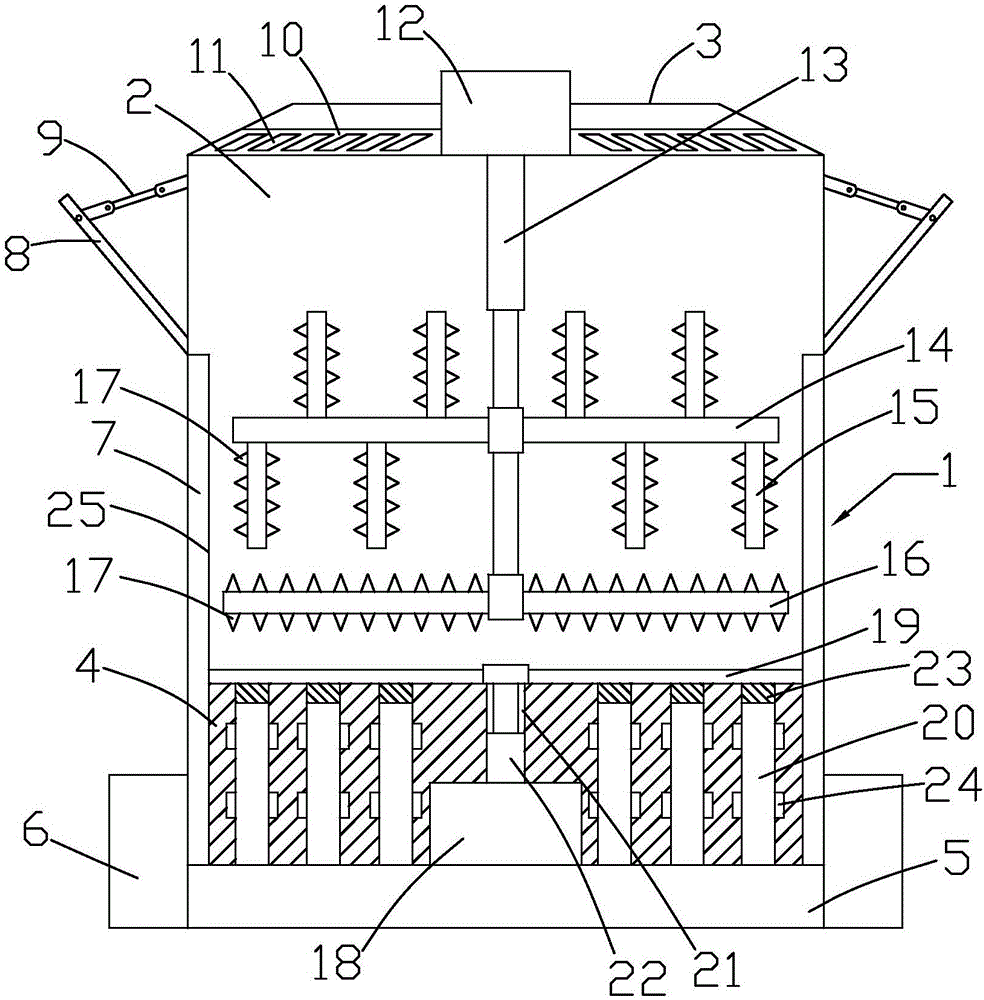

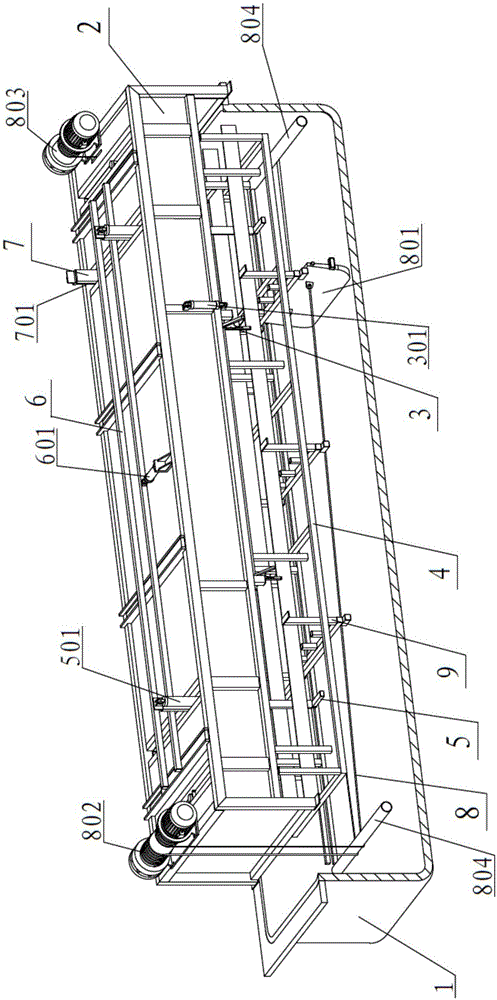

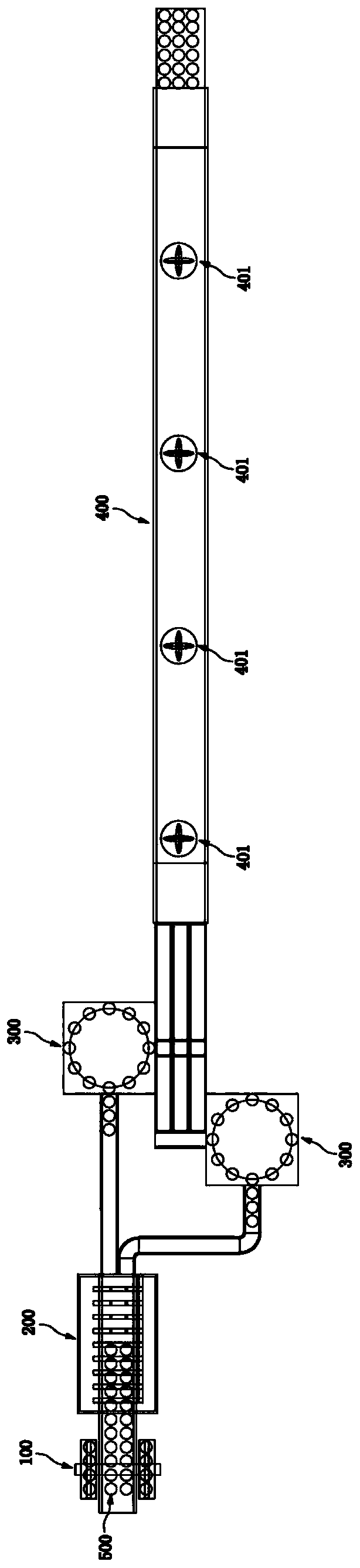

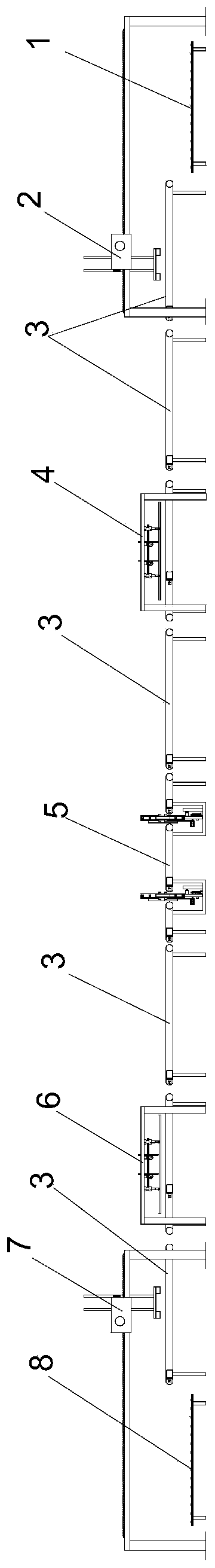

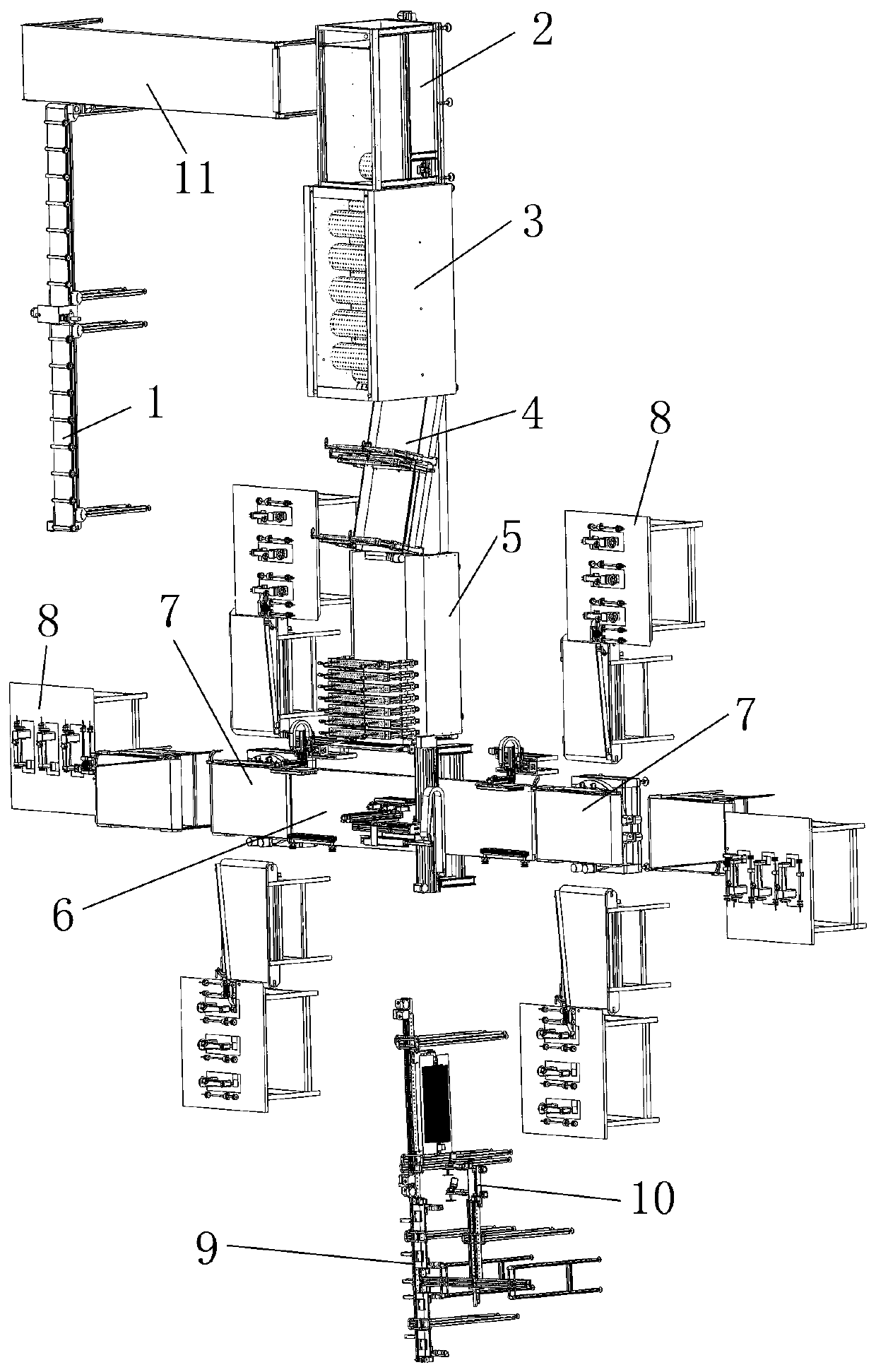

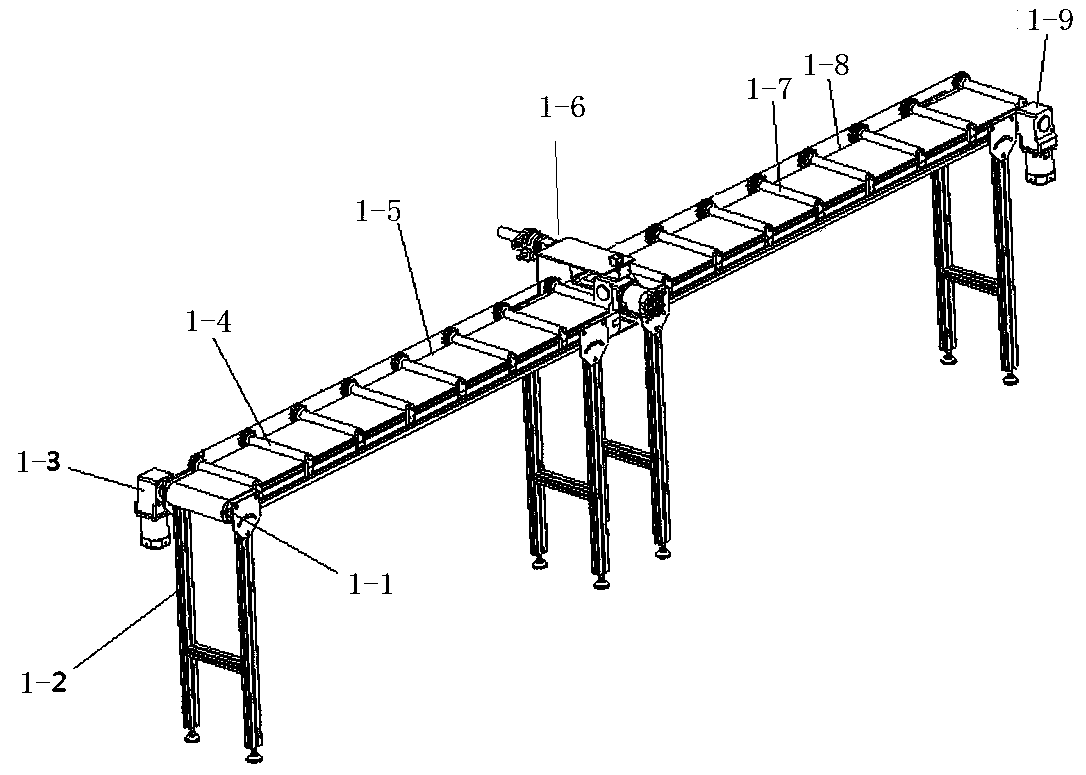

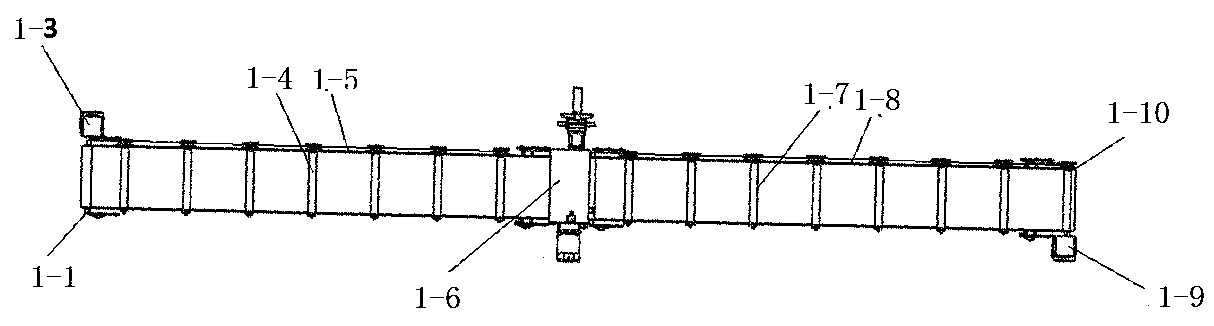

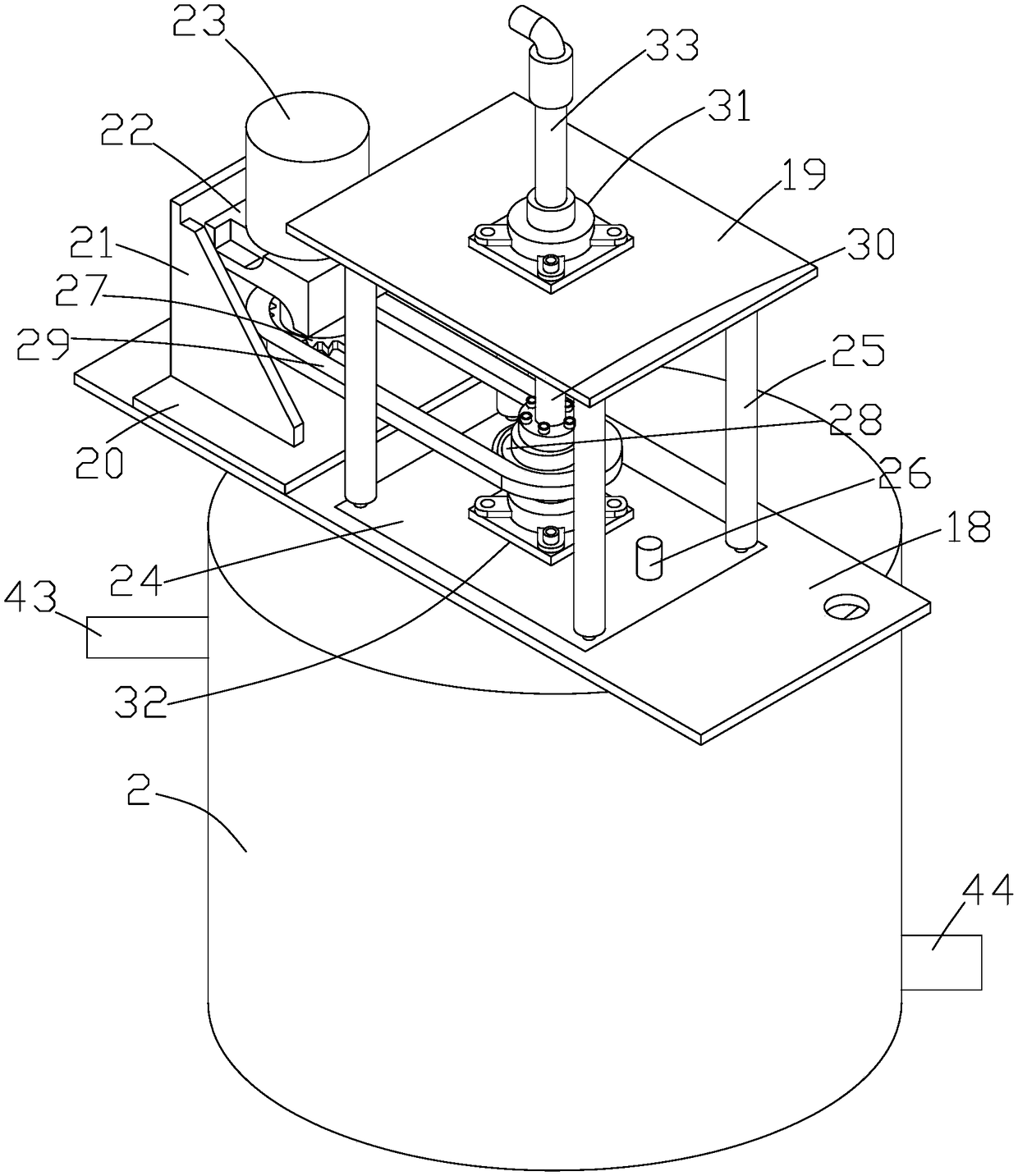

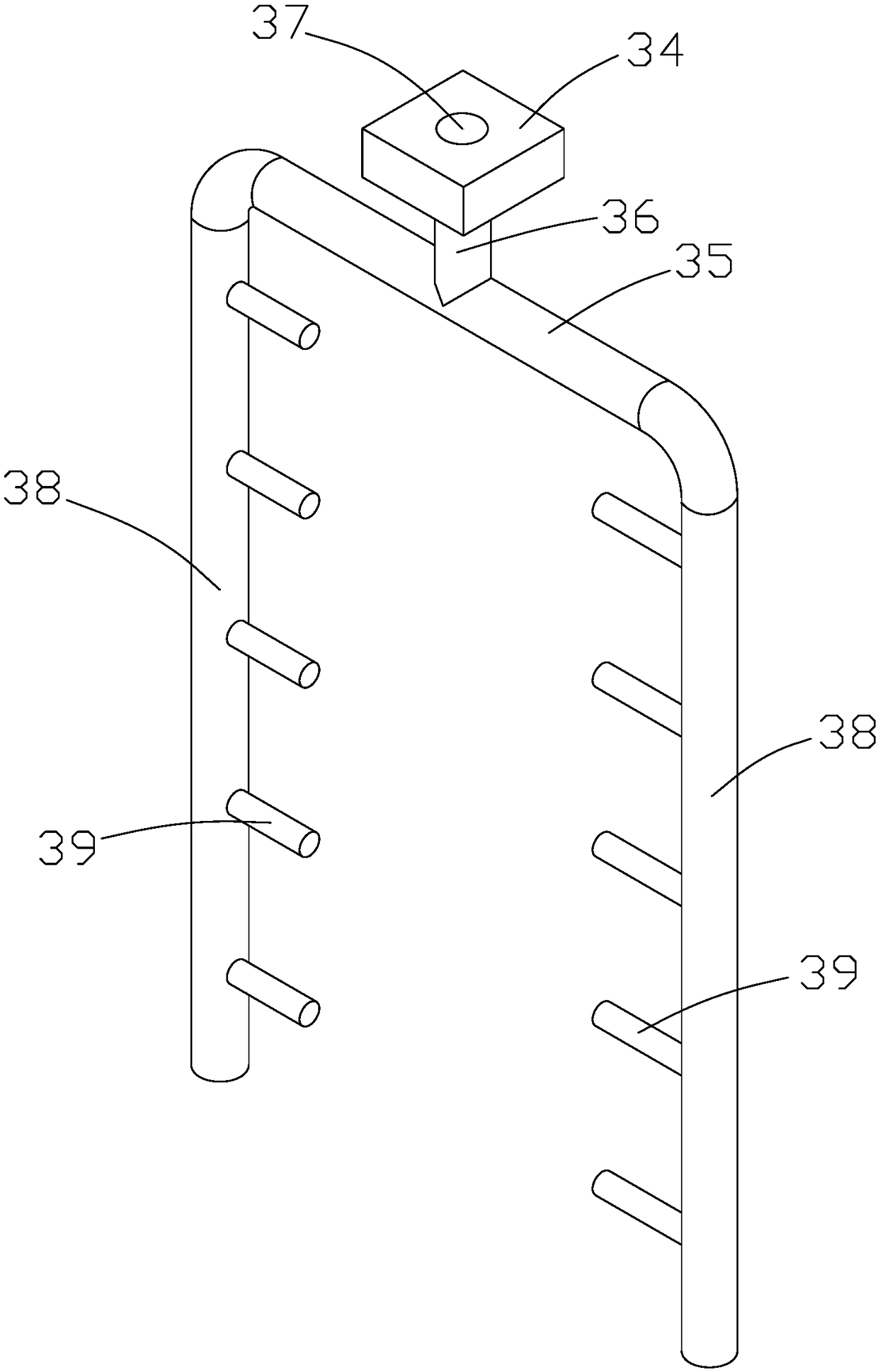

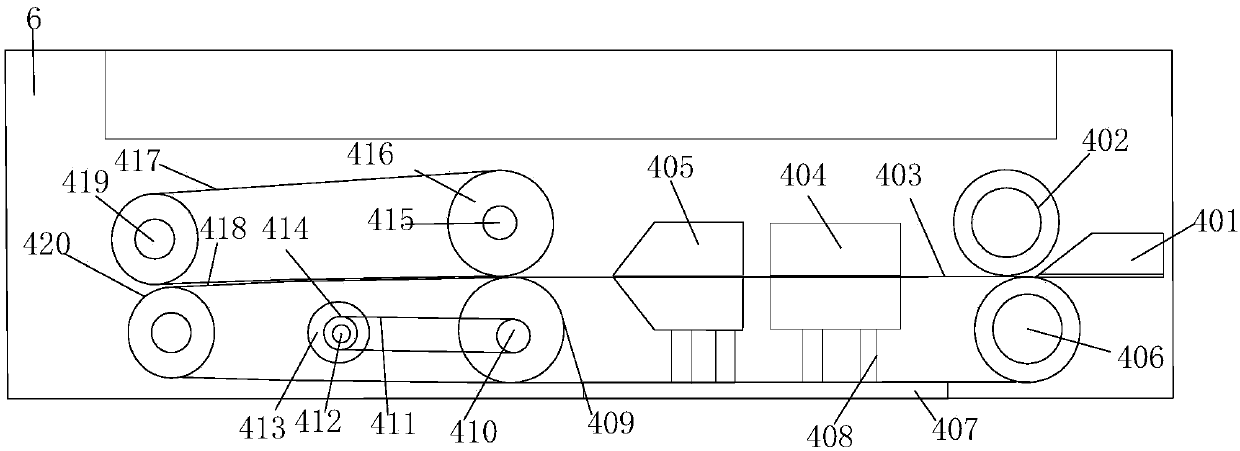

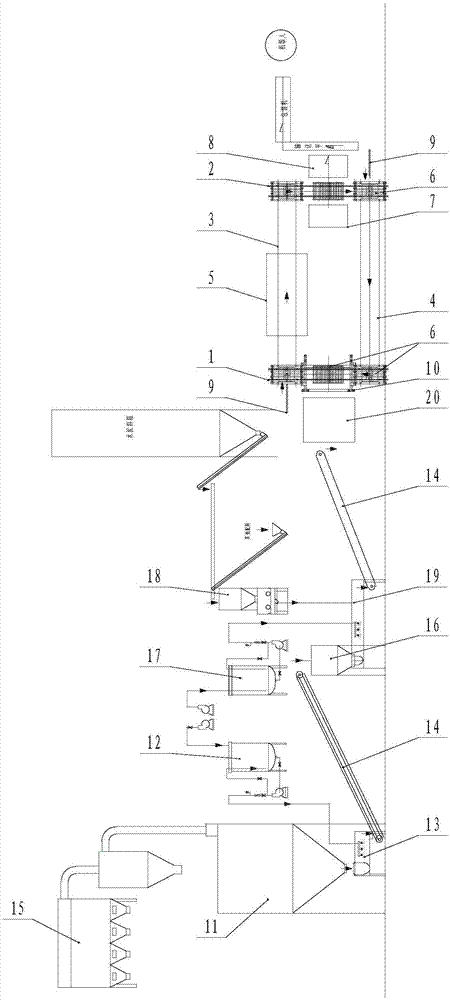

Automatic green tea leaf storing and withering production line

ActiveCN102524445ASimple structureLow costPre-extraction tea treatmentProduction lineEconomic benefits

The invention relates to an automatic green tea leaf storing and withering production line. the production line is characterized by comprising a green tea leaf lifting and conveying mechanism for feeding material at a start end, wherein the upper end of the green tea leaf lifting and conveying mechanism leads to a green tea leaf storage box blanking mechanism arranged above a green tea leaf storage box, a humidifying device is arranged beside the green tea leaf storage box and leads to the inner cavity of the box from the bottom of the green tea leaf storage box, a conveyor belt is arranged at the bottom of the green tea leaf storage box, a plurality of rotating shafts are arranged vertically side by side on one side of the discharge end of the green tea leaf storage box, a shifting rod for spreading green tea leaves is arranged on each rotating shaft, a green tea leaf vibrating conveying mechanism is arranged below the discharge end side of the green tea leaf storage box, the discharge end of the green tea leaf vibrating conveying mechanism leads to an energy-saving green tea leaf withering device through a lifter to perform withering and cooling. The production line is simple inwhole structure, low in manufacturing cost, can implement flow line production of tea leaves, can improve the automation degree of early-state processing of tea leaves and can reduce workload and improve production capacity on the condition that the quality of tea leaves is ensured; therefore, higher economic benefit is created for enterprises.

Owner:DABUTONG TEA IND FUJIAN

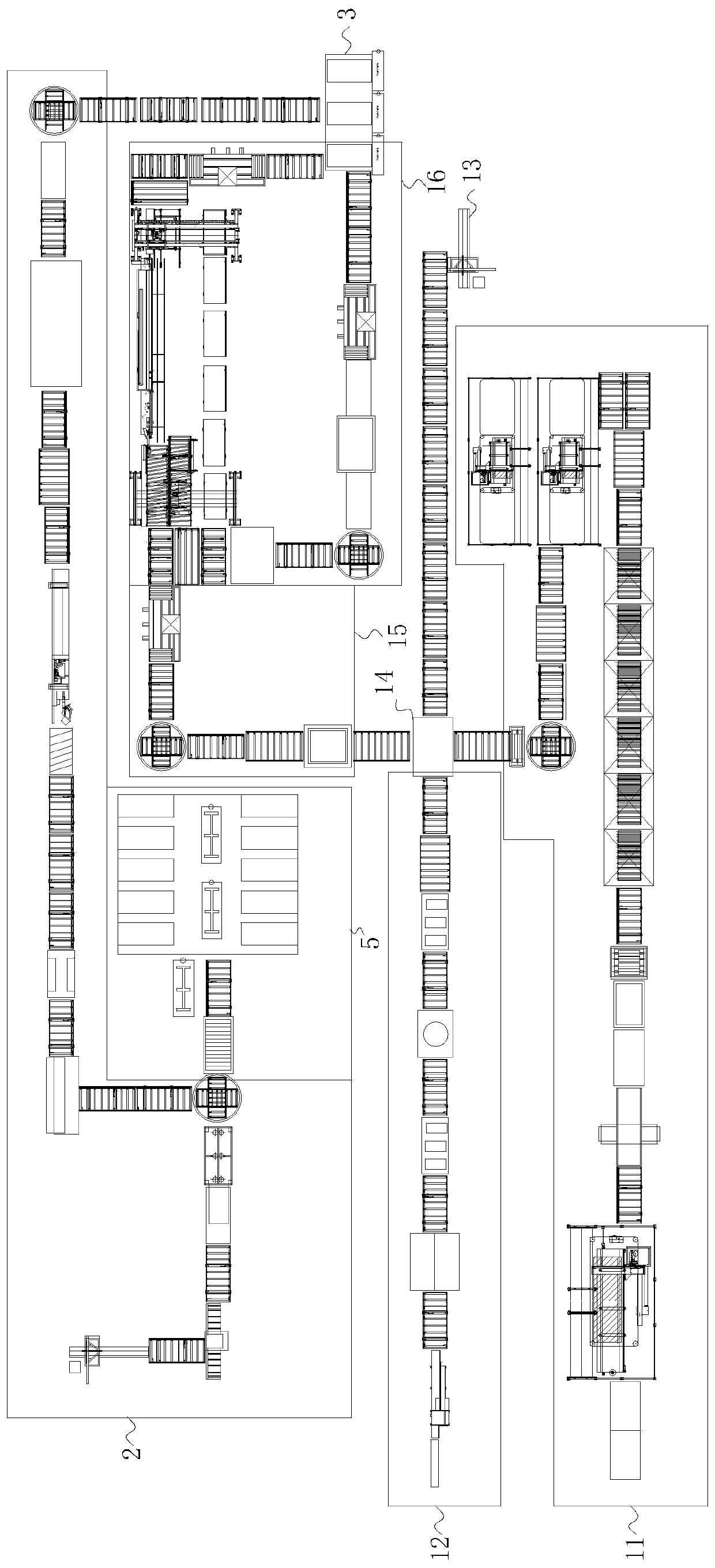

Assembly line of paint-free film-pressing wooden door

PendingCN109702843AReduce labor intensityRealize assembly line productionWood working apparatusProduction lineHigh volume manufacturing

The invention discloses an assembly line of a paint-free film-pressing wooden door. The assembly line comprises a door plate production line, a door face stop strip production line, a combined packaging platform, a conveyor and a master controller. According to the assembly line, the traditional labor division type wooden door production process is replaced, the operation process of equipment is reasonably distributed, the operation working conditions are adjusted, assembly line type production is realized, the production efficiency is greatly improved, the processing cycle is shortened, the requirements of mass production are met, meanwhile, the labor intensity of workers is reduced, and the participation of people on the production process is reduced.

Owner:广东玛格家居有限公司

Full-automatic fungus bag production line for edible fungi

ActiveCN105564688AFully automatic production processRealize preliminary productionSuccessive articlesPulp and paper industryManufacturing line

The invention relates to a full-automatic fungus bag production line for edible fungi. The full-automatic fungus bag production line comprises a bag feeding device, a bag manufacturing device, a shaping device, a ring sleeving device, a cover pressing device and a basket loading device. According to the full-automatic fungus bag production line for the edible fungi, the full-automatic fungus bag manufacturing process can be achieved; the bag taking and fixing process is completed from bag manufacturing, bag taking and bag clamping; initial manufacturing of fungus bags is achieved through discharging, shaping and compaction; the bag opening packaging process is carried out through ring sleeving and cover pressing; and finally basket loading is carried out. Full automation is achieved, and the labor force is greatly saved; errors are not likely to be made; and in addition, the looseness degree of the fungus bags is the same, the weight of the fungus bags is the same, and therefore the production quality of the fungus bags is greatly improved.

Owner:厦门祺安达自动化设备有限公司

Anti-corrosive intelligent kitchen garbage barrel and manufacturing method thereof

ActiveCN106335723AEffective absorption and filtrationEffective shreddingRefuse receptaclesWastewaterSewage

The invention discloses an anti-corrosive intelligent kitchen garbage barrel and a manufacturing method thereof. The anti-corrosive intelligent kitchen garbage barrel comprises a barrel box, an end cover and a wastewater purifying device, wherein a stirring cavity, a cylinder body, a forming plate and a storage cavity are arranged inside the barrel body; a crushing mechanism is arranged in the stirring cavity; feeding mechanisms are symmetrically arranged on the outer side surface of the barrel boxy; the forming plate is positioned between the cylinder body and the storage cavity; a forming extrusion mechanism is arranged above the forming plate; and the wastewater purifying device is positioned on the bottom side surface of the barrel body. The manufacturing method comprises the following steps: (1) mounting of the storage cavity; (2) mounting of the forming plate and the forming extrusion mechanism; (3) mounting of the crushing mechanism; (4) mounting of the wastewater purifying device; (5) mounting of the feeding mechanisms; and (6) preliminary running debugging. The anti-corrosive intelligent kitchen garbage barrel disclosed by the invention is simple in structure and high in practicability; not only can kitchen garbage be crushed, but also the crushed kitchen garbage can be used for fish and poultry feeding; the garbage recovery efficiency is improved; and the environmental pollution caused by corrosion of the kitchen garbage is effectively prevented.

Owner:浙江融家科技有限公司

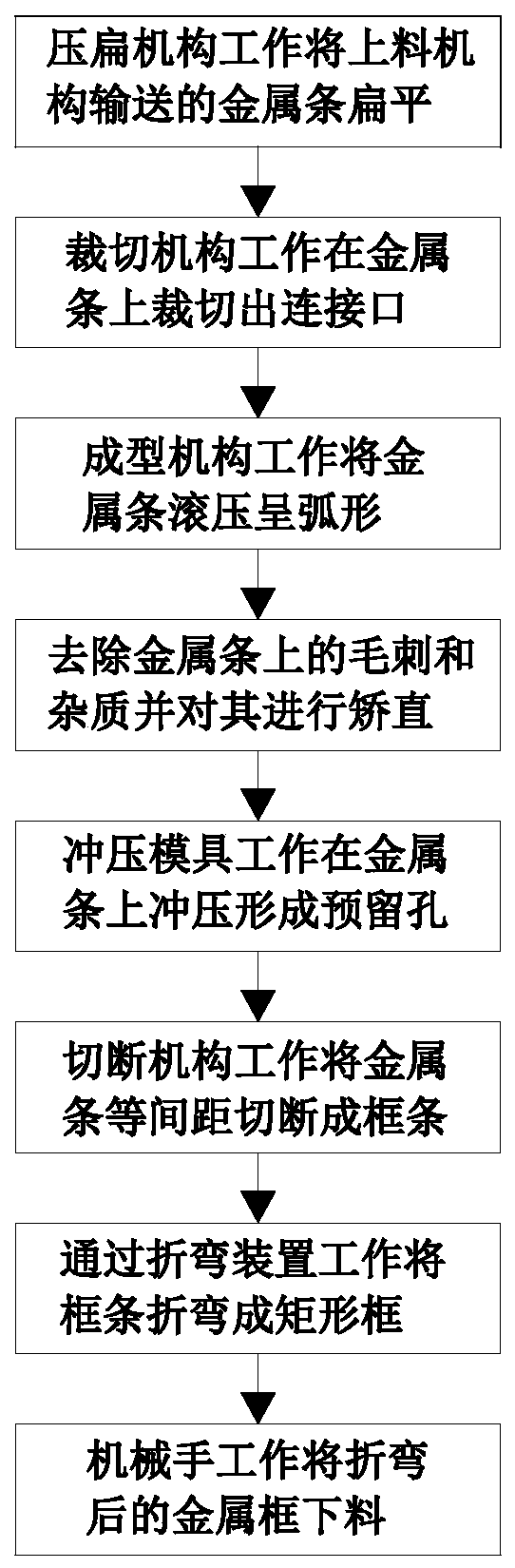

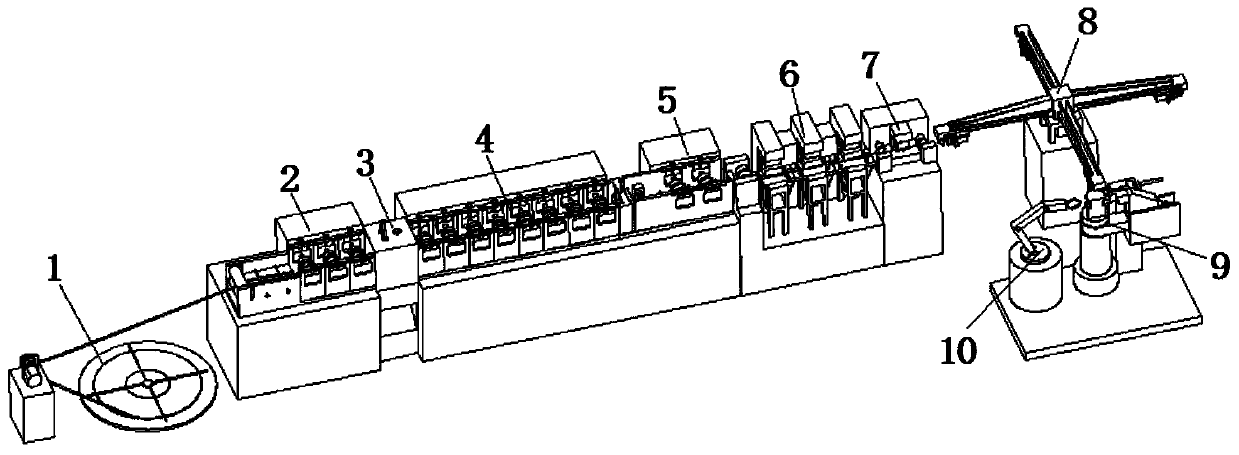

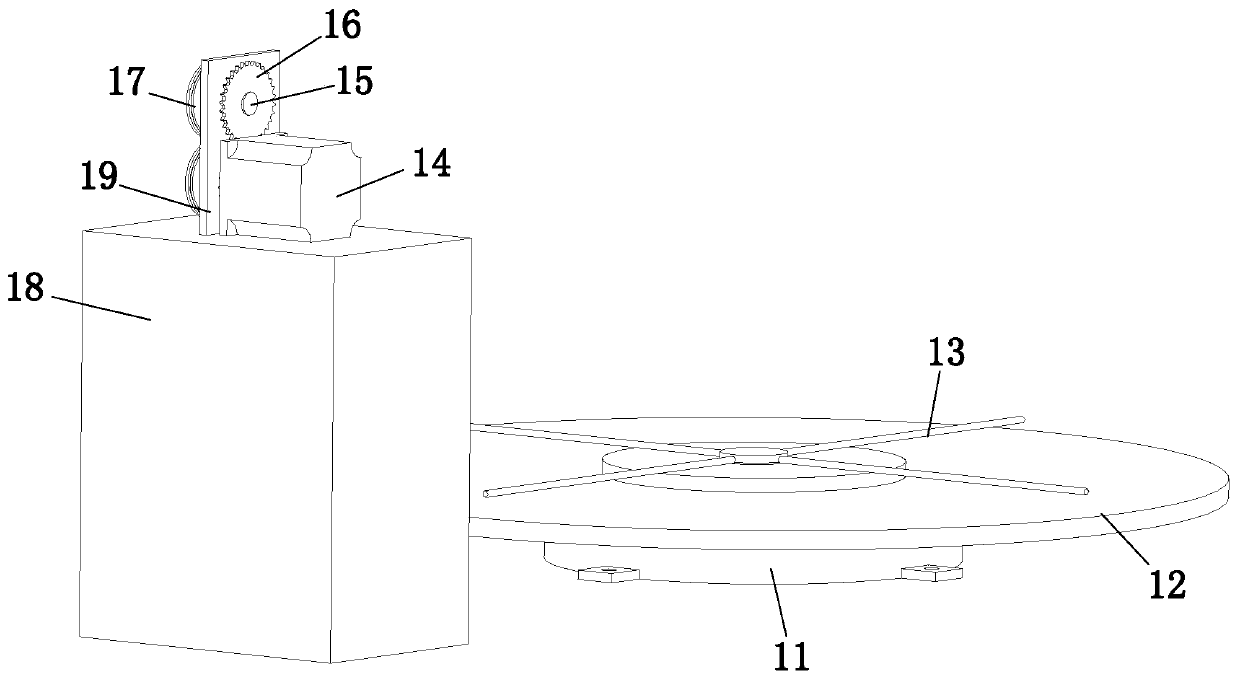

Automatic production process for mobile phone frame

ActiveCN110355536ASimplify production stepsIncrease productivityTelephone set constructionsMetal stripsProduction line

The invention discloses an automatic production process for a mobile phone frame, and belongs to the technical field of mobile phone frame processing processes. The automatic production process comprises the steps of 1, rolling, specifically, a metal strip is subjected to continuous rolling and flattening; 2, cutting a connecting port, specifically, upper cutting notches and lower cutting notchesare cut on the upper end and the lower end of the metal strip in a staggered mode; 3, forming, specifically, the metal strip is processed into an arc-shaped structure through rolling; 4, punching, punching is carried out between each adjacent upper cutting notch and the corresponding lower cutting notch to form a hole; 5, cutting, specifically, cutting is carried out on each upper cutting notch and the corresponding lower cutting notch; and 6, bending, specifically, bending is carried out on each section of frame strip to form a rectangular frame structure. The process steps in the invention simplifies the production steps of the mobile phone metal frame, improves the production efficiency, realizes flow line production of the mobile phone metal frame through the matching work of the matched production line, further improves the production efficiency of the mobile phone metal frame, does not need manual operation in the production process, and eliminates potential safety hazards.

Owner:惠州市高艺科技有限公司

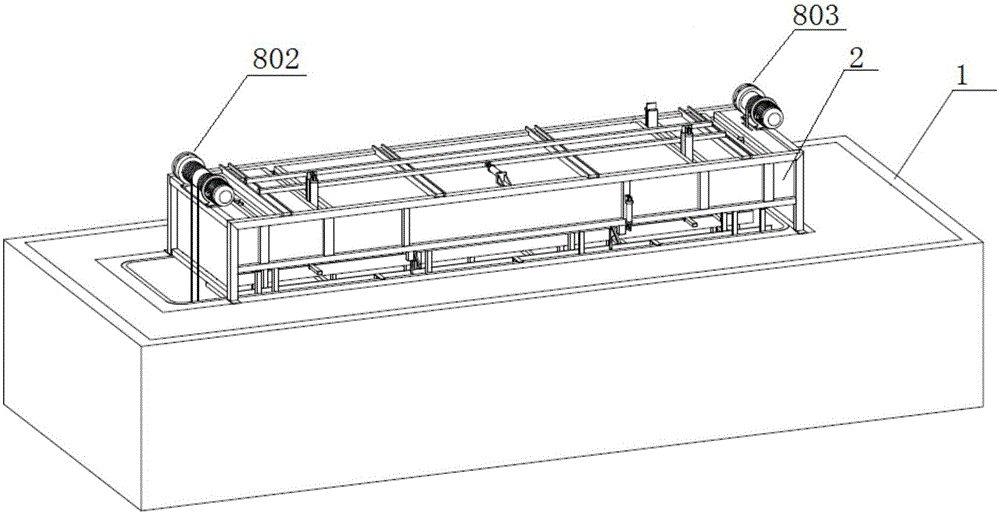

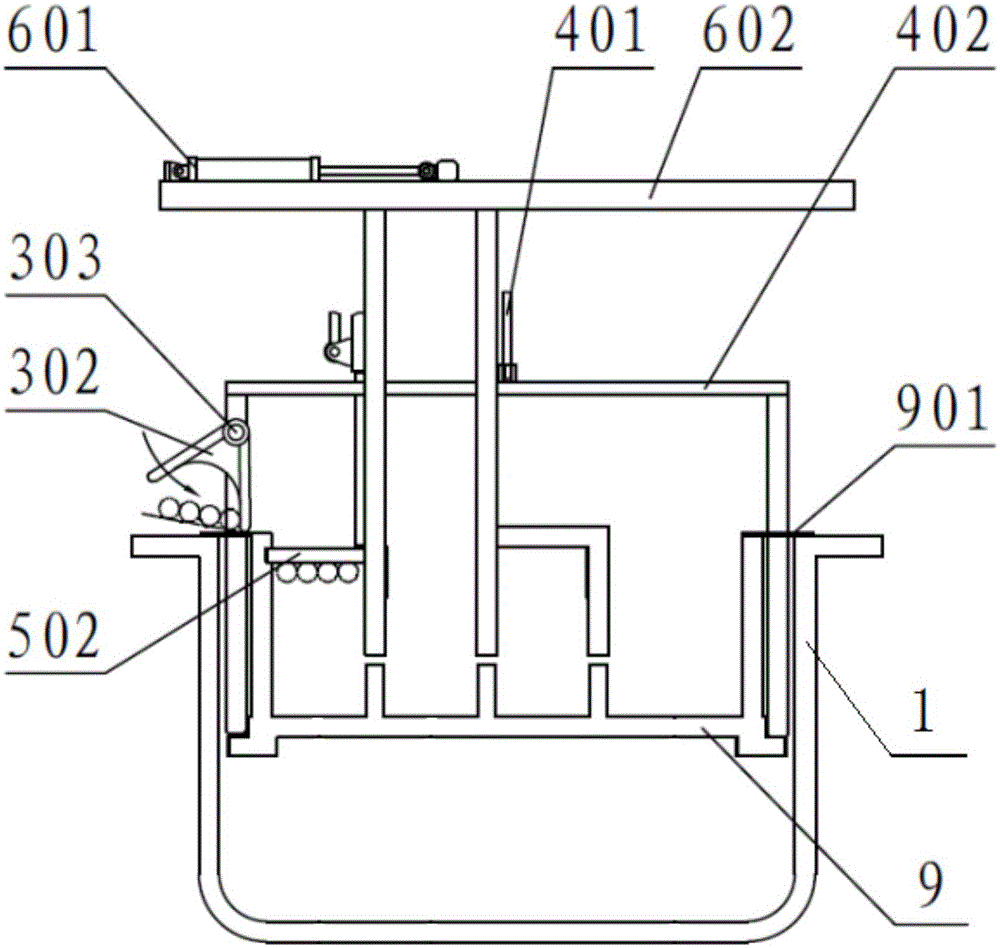

Hot galvanizing system and hot galvanizing method

InactiveCN105039888ARealize assembly line productionImprove automationHot-dipping/immersion processesAssembly lineZinc

The invention discloses a hot galvanizing system and a hot galvanizing method. The hot galvanizing system comprises a zinc pot (1) used for accommodating molten zinc, a feeding end and a discharging end. The hot galvanizing system is characterized in that a fixing support (9) is arranged in the zinc pot (1) and divides the interior of the zinc pot (1) into multiple stations which are sequentially arranged from the feeding end to the discharging end; the hot galvanizing system further comprises a lifting device (4) used for lifting metal parts corresponding to all the stations and a pushing device (6) used for moving the metal parts between the stations. By means of the technical scheme, the pushing device and the lifting device coordinate to enable the to-be-galvanized metal parts to be galvanized in a stepping mode, so that assembly line type production is achieved, automation is improved, operation is simplified, and the production efficiency is improved.

Owner:北京钢研新冶环科科技有限公司

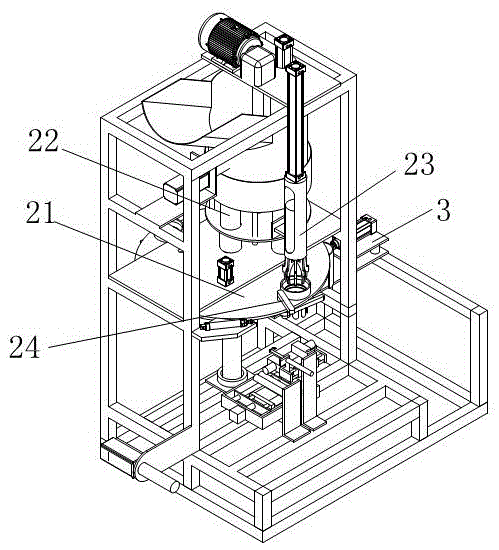

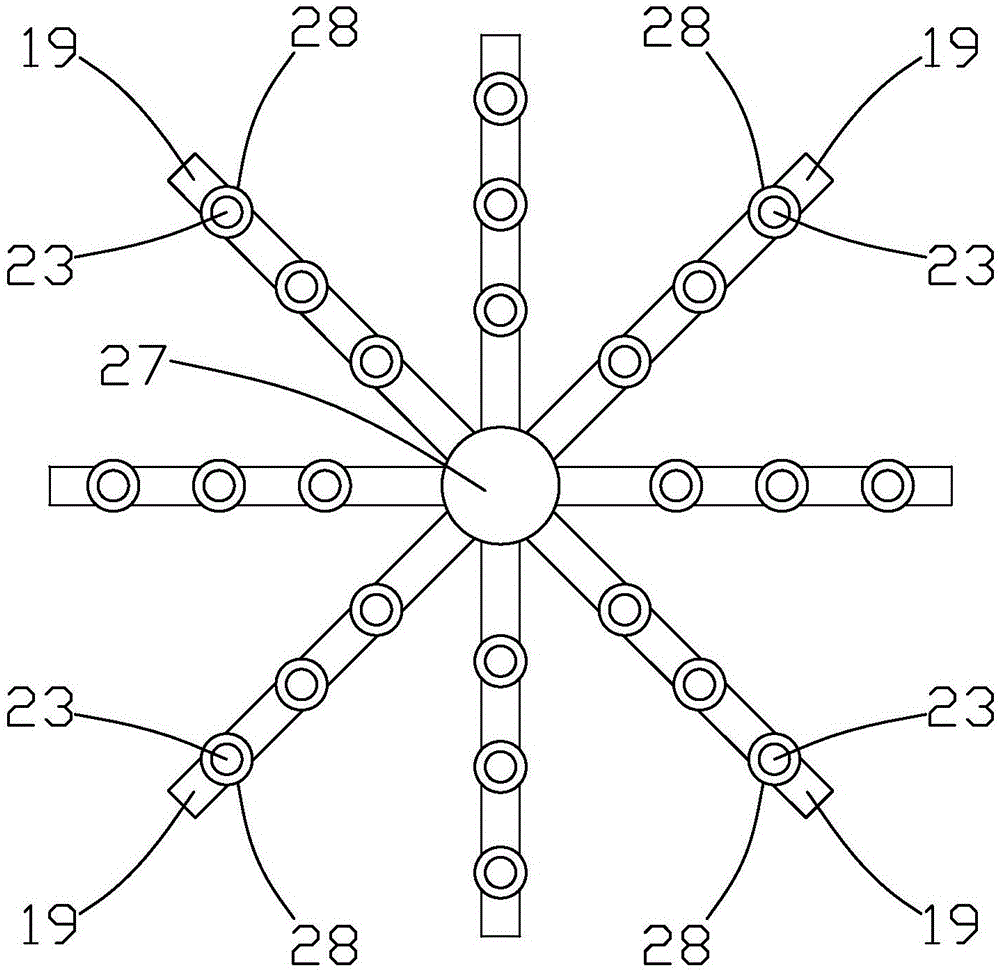

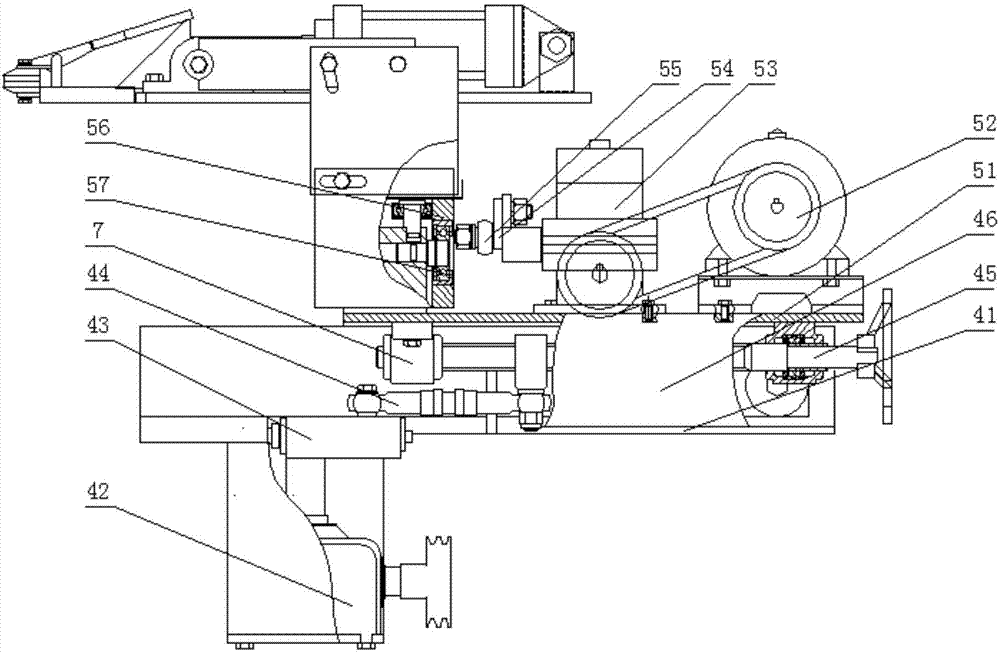

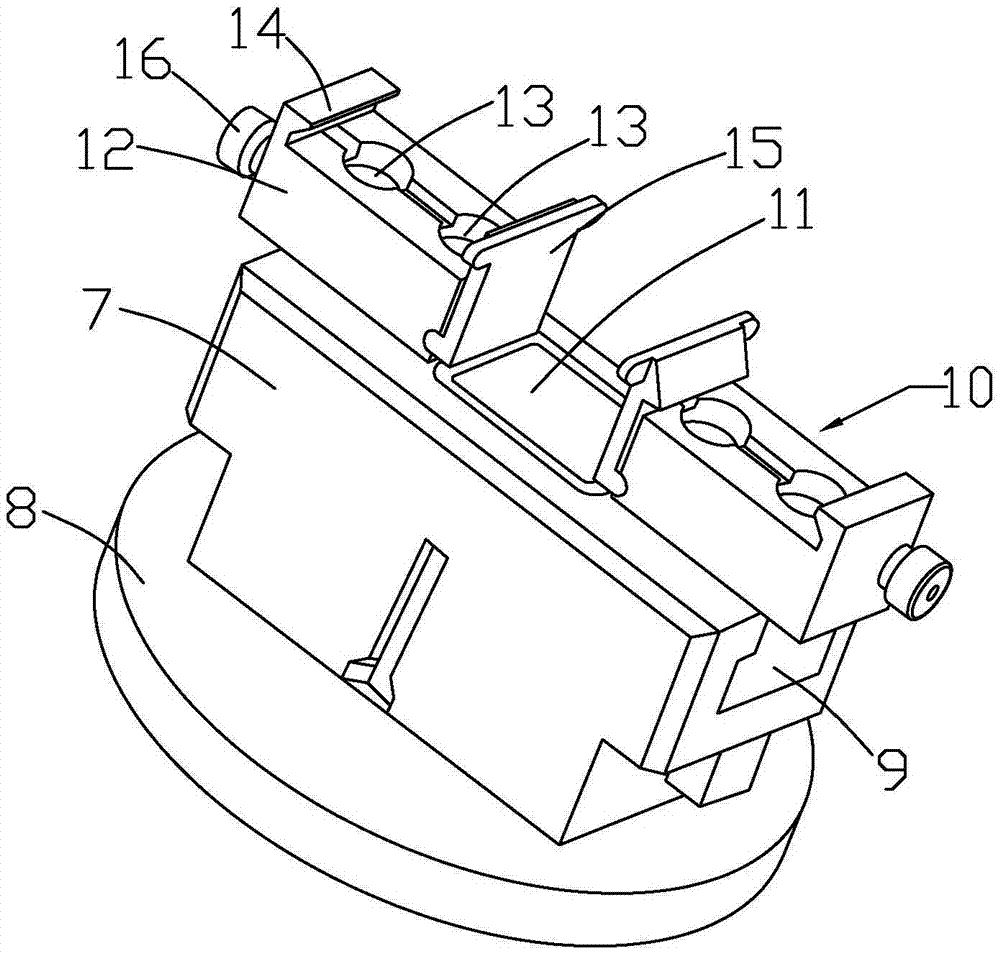

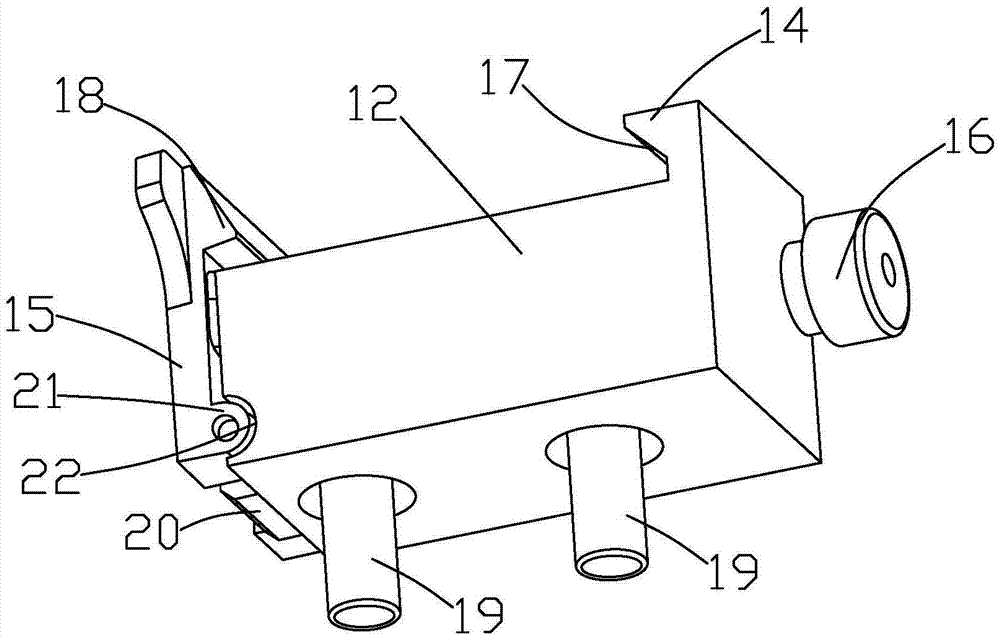

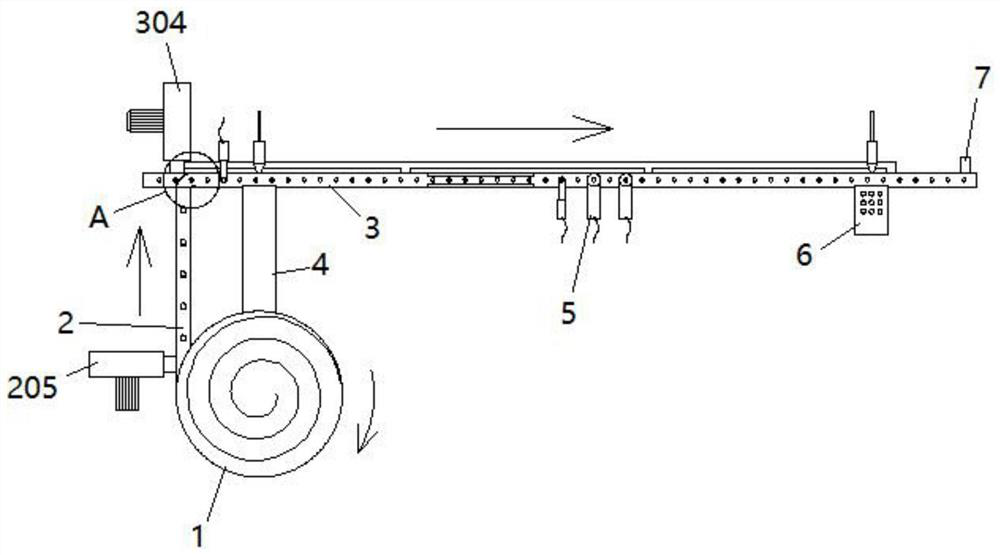

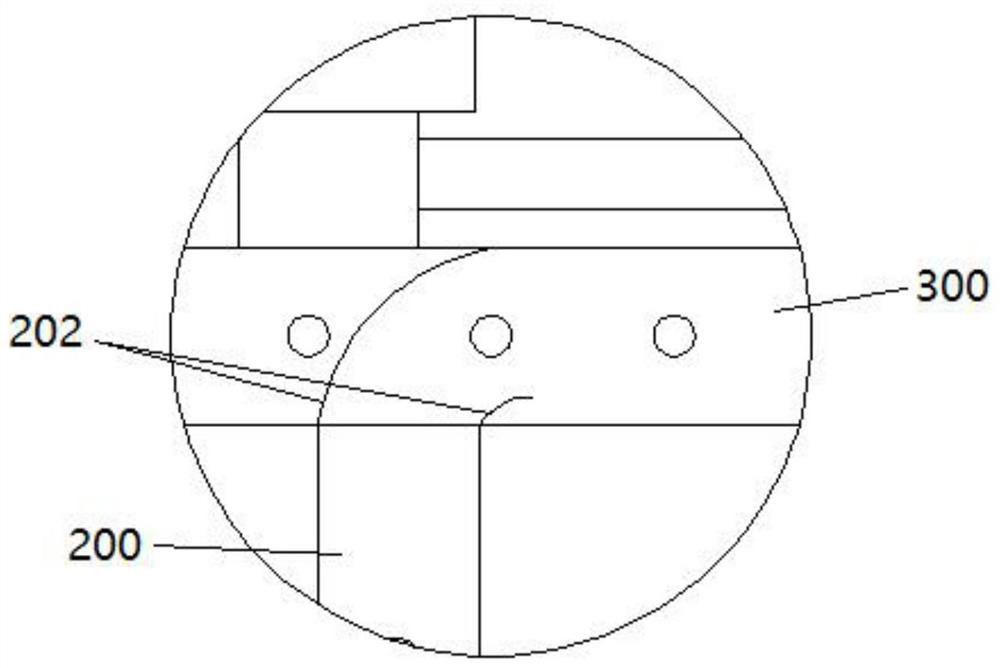

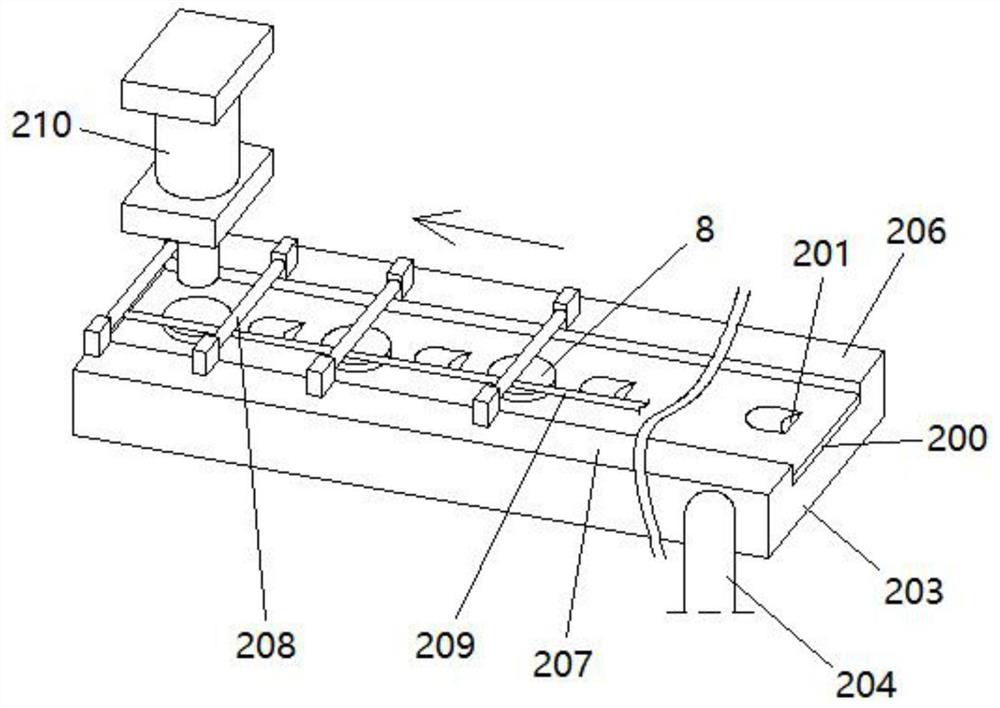

Disc-type automatic feeding system for tableware polishing

InactiveCN104493698ARealize assembly line productionReduce labor intensityGrinding feedersGrinding work supportsEngineeringUltimate tensile strength

The invention provides a disc-type automatic feeding system for tableware polishing and belongs to the technical field of polishing equipment. The disc-type automatic feeding system comprises an underpan, a turnplate rotating device, a driving device, multiple mobile clamping devices, a longitudinal swing device, a transverse swing device and a rotating control box, and the rotating control box controls the longitudinal swing device and the transverse swing device to swing on the turnplate rotating device to polish tableware. The disc-type automatic feeding system has the advantages that a mode that multiple persons operate multiple devices is replaced by a mode that one person operates multiple devices; circular polishing is realized through a turnplate, streamline production is realized until finished products are formed by polishing, operating personnel is reduced, labor intensity is reduced, and safety guarantee is improved.

Owner:天津市宏强不锈钢制品有限公司

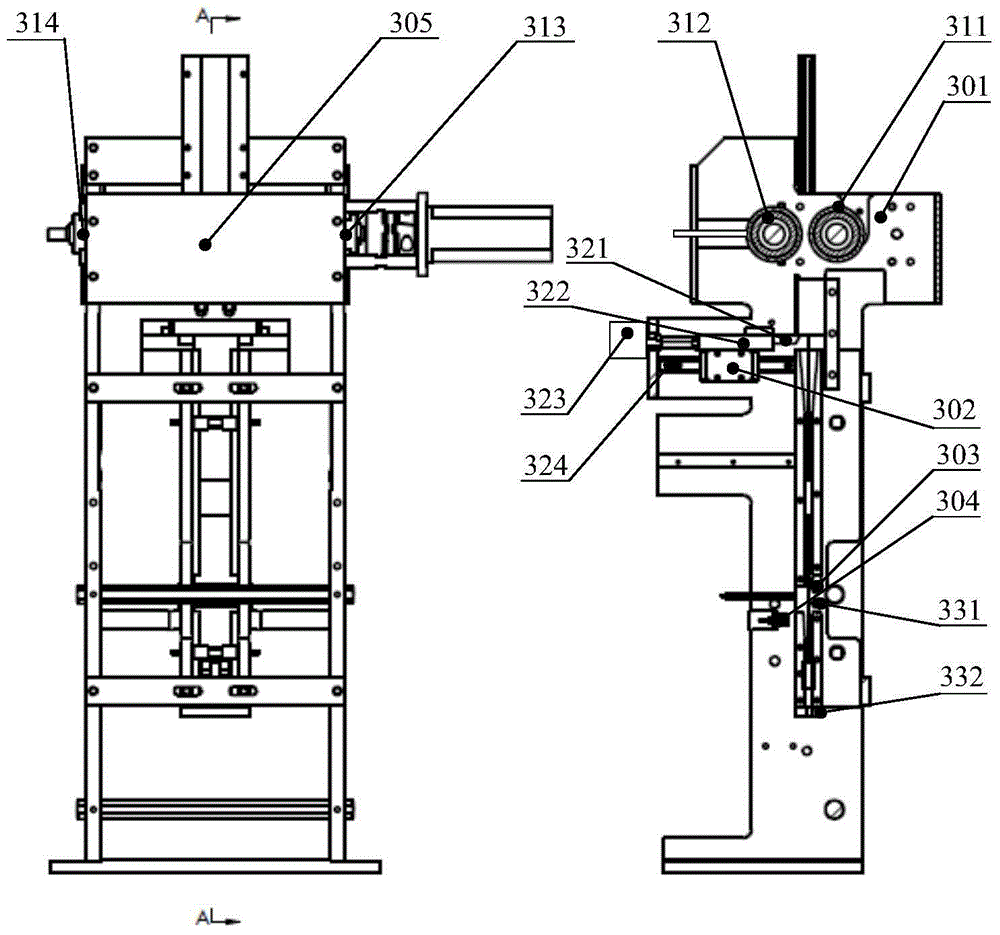

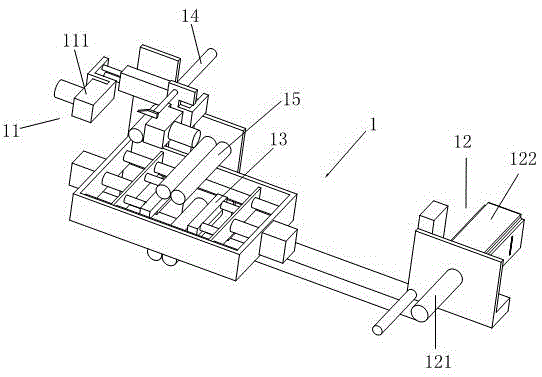

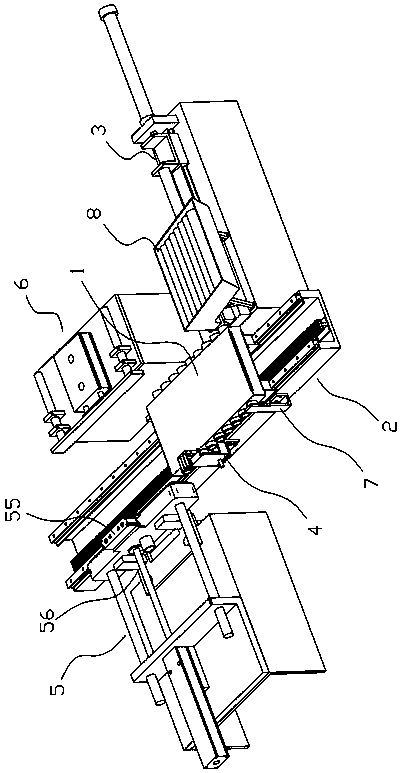

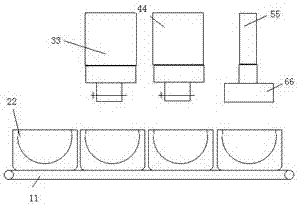

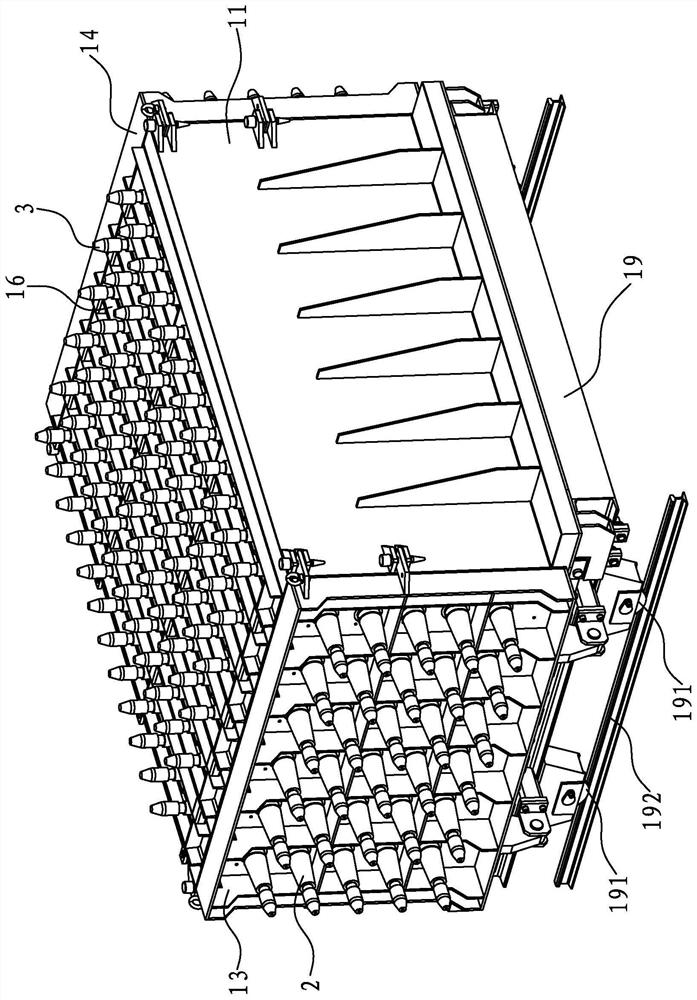

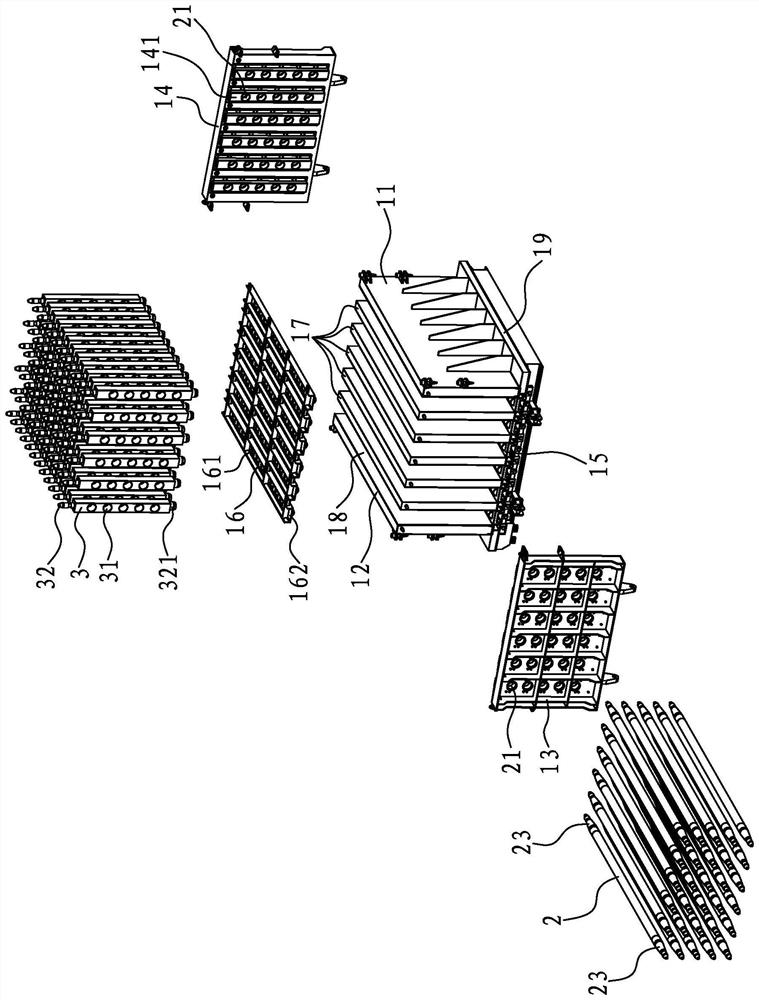

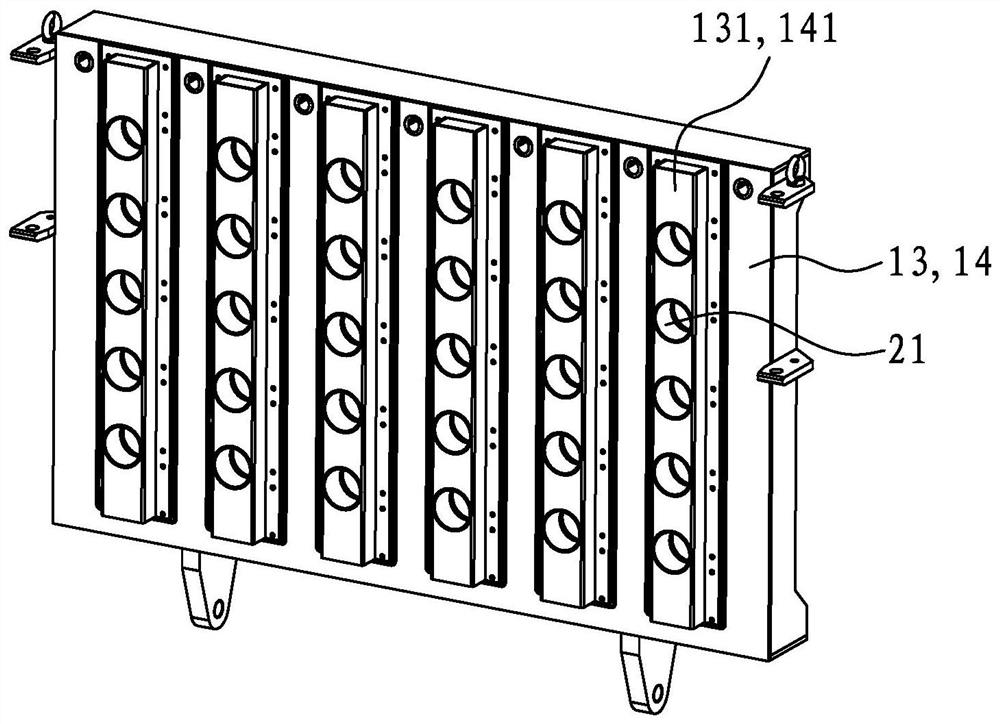

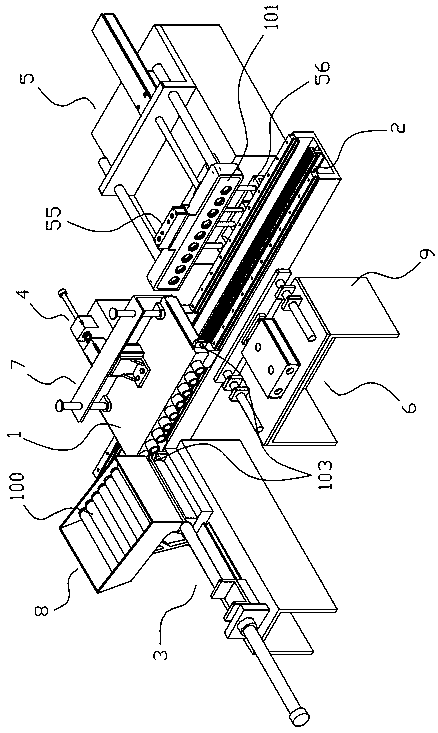

Automatic assembling production line of heat pipe radiator for 5G communication base station

ActiveCN111390457ARealize assembly line productionHigh degree of automationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineThermodynamics

The invention discloses an automatic assembly production line of a heat pipe radiator for a 5G communication base station, and relates to the technical field of communication equipment processing. Theautomatic assembly production line comprises a fixing tool, a conveying platform, a heat pipe feeding mechanism, a solder spraying mechanism, a substrate feeding mechanism, and a pressing mechanism.The fixing tool is used for horizontally positioning and intensively collecting heat pipes together. The fixing tool is installed on the conveying platform and used for achieving horizontal conveyingof the fixing tool. The heat pipe feeding mechanism is located on the left side of the conveying platform and used for conveying the heat pipes into the fixing tool. The solder spraying mechanism is located on the right side of the conveying platform and used for spraying solder to the assembling ends of the heat pipes. The substrate feeding mechanism is located on the right side of the conveyingplatform and used for clamping a substrate and then conveying the substrate to an assembling station. The pressing mechanism is located on the left side of the conveying platform and used for pressingthe heat pipes on the fixing tool into the substrate. According to the automatic assembly production line, the feeding of the heat pipes, the spraying of the solder, the feeding of the substrate andthe overall pressing are completed on one conveying platform, assembly line type production is achieved, the overall automation degree is high, and the assembly efficiency is obviously improved.

Owner:CHAOHU POWER SUPPLY CO STATE GRID ANHUI PROVINCE ELECTRIC POWER CO LTD +1

Production process of shuttlecock heads

ActiveCN107283705AGuaranteed uniformityRealize assembly line productionDomestic articlesAssembly linePolyurethane elastomer

The invention belongs to the field of shuttlecock equipment and the field of shuttlecock head production devices, and particularly relates to a production process of shuttlecock heads. The production process comprises the following steps that firstly, the inner surfaces of shuttlecock head molds are coated with a lubricating agent, and a heating device is adopted for preheating the shuttlecock head molds; secondly, the multiple preheated shuttlecock head molds are put on a vibration conveyor at equal intervals; thirdly, a wood block feeder is started, and wood blocks are fed into the shuttlecock head molds; fourthly, a polyurethane particle feeder is started; fifthly; a compression cylinder does lifting and contraction motion, and the wood blocks and polyurethane elastomer particles in the molds are compressed through a compaction block; and sixthly, a glue injection machine is started, glue injection is firstly carried out on the wood blocks and the polyurethane elastomer particles along the inner walls of the shuttlecock head molds, and then glue injection is carried out on the surfaces of the wood blocks and the surfaces of the polyurethane elastomer particles. According to the production process, streamline production can be carried out on the shuttlecock heads, and the stability of the quality of the shuttlecock heads produced on an assembly line can be guaranteed.

Owner:安徽明亮面业股份有限公司

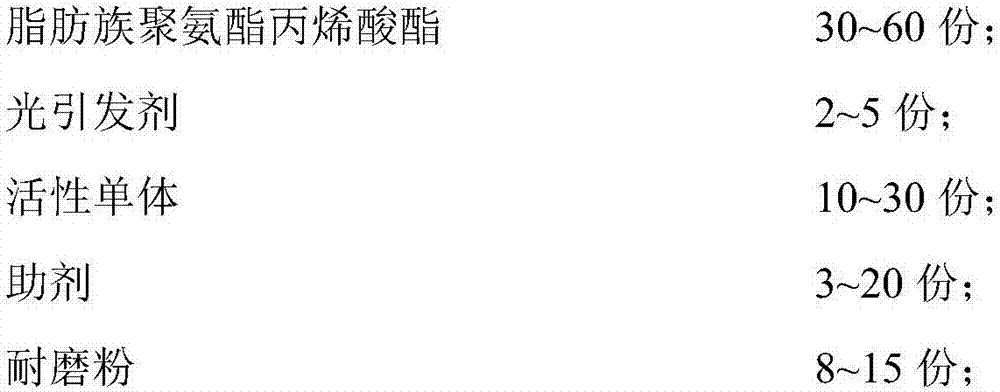

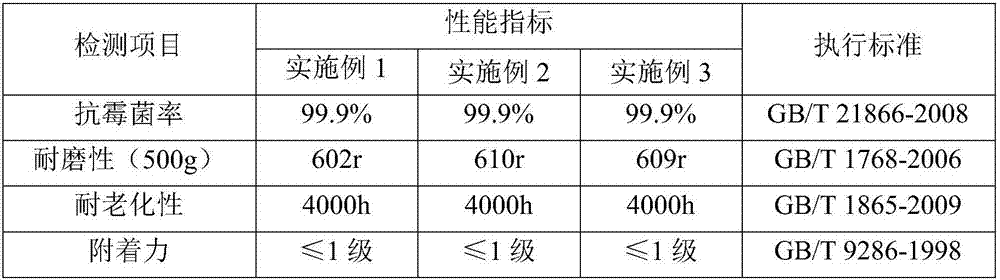

Outdoor heavy bamboo and wood floorboard and preparation method thereof

ActiveCN107384182AGood weather resistanceImprove the decorative effectAntifouling/underwater paintsPretreated surfacesWeather resistanceUV curing

The invention discloses an outdoor heavy bamboo and wood floorboard and a preparation method thereof. The outdoor heavy bamboo and wood floorboard comprises a heavy bamboo and wood floorboard substrate, wherein a sealed bottom layer, an attached primer layer, a first finish paint layer and a second finish paint layer are sequentially coated on the heavy bamboo and wood floorboard substrate from inside to outside; each of the first finish paint layer and the second finish paint layer is UV finish paint; the attached primer layer is UV attached primer; the sealed bottom layer is waterborne UV sealed bottom. The preparation method of the floorboard comprises the following steps that the waterborne UV sealed bottom is coated on each surface of the heavy bamboo and wood floorboard substrate; infrared levelling is implemented; primary UV curing is performed; the UV attached primer is coated on the upper surface of a board material; secondary UV curing is performed; the UV finish paint is coated on the upper surface of the board material once, and UV curing is performed; the UV finish paint is coated again, and the UV curing is performed; the outdoor heavy bamboo and wood floorboard is obtained. The outdoor heavy bamboo and wood floorboard has the advantages that the antifungal rate is high; the wearing resistant performance is good; the weather resistance is good; the production efficiency is high; the environmental protection performance is good.

Owner:HUNAN BANFERT NEW MATERIALS TECH

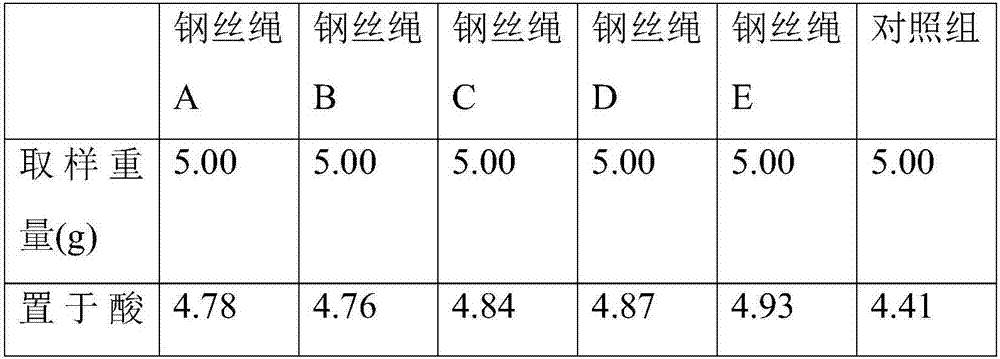

Stainless steel wire rope, production technology and application thereof

InactiveCN106967933ASimple production processImprove high temperature resistanceCoatingsTextile cablesManufacturing technologyAssembly line

The invention provides a stainless steel wire rope. According to the chemical components, the stainless steel wire rope comprises, by mass percentage, 0.012%-0.025% of C, 0.06%-0.075% of Si, smaller than 0.03% of P, 10.0%-13.0% of Cr, 21.0%-24.0% of Ni, 2.50%-5.00% of Mn, smaller than 0.02% of S, smaller than 0.1% of Cu, smaller than 0.01% of N, smaller than 0.02% of Ti and the balance Fe and inevitable impurities. The invention further provides a manufacturing technology and application of the stainless steel wire rope. The production technology of the stainless steel wire rope is simple, assembly line production can be achieved, the stainless steel wire rope is high in high temperature resistance, acid resistance and tensile strength, and metal interior crystals are uniformly distributed.

Owner:桥运精密部件(苏州)有限公司

Casting process for high-strength and low-alloy chilling spheroidal graphite cast iron camshaft blanks

The invention discloses a casting process for high-strength and low-alloy chilling spheroidal graphite cast iron camshaft blanks. The casting process is characterized by including the following steps that a, camshaft shells are manufactured according to the specification; b, iron boxes are manufactured, the shells manufactured in the step a are placed in the iron boxes, each iron box contains 4 to 6 shells, and gaps are formed between each shell and the inner wall of the adjacent iron box and between the shells respectively; c, the gaps are filled with iron pills, the shells are completely covered, and casting ports of the shells are exposed outside so that molten iron can be cast conveniently; d, the molten iron is cast through the casting ports, cavities of the shells are filled with the molten iron, and casting operation is finished; and e, the temperature is kept for 3 to 5 hours, the iron pills in the iron boxes are removed, camshaft castings are taken out, and therefore the camshaft blanks are obtained. By the adoption of the casting process for the camshaft blanks, the stress of the camshaft blanks can be eliminated, the thermal treatment process can be omitted, and the process is simple.

Owner:CHANGSHA YOUCHENG CAMSHAFTS MFR

Paper-plastic tableware spraying device and technology

PendingCN110899030AMaximize production efficiencyPrevent splash/fogLiquid surface applicatorsCoatingsProcess engineeringTransfer mechanism

The invention discloses a paper-plastic tableware spraying device and technology. The spraying device comprises a feeding module, a spray module and a spinning module which are connected through a transfer mechanism from left to right in sequence, wherein the feeding module is used for conveying to-be-processed paper-plastic tableware to the spray module; the spray module is used for spraying water-proof and oil-proof paint to the paper-plastic tableware conveyed from the feeding module from top to bottom; the spinning module is used for spinning the paint accumulated on the surface of the paper-plastic tableware to be uniform, and recycling the paint which are thrown out. According to the spraying device, the extra accumulated paint is thrown out through the spinning module, the paint layer on the surface of the product is smooth and even, the situation that a lot of paint spatters or produces fog in air during spraying can be prevented, the paint can be recycled, and the paint utilization rate is increased. The extra paint is recycled through a recycling water tank arranged on the bottom of a conveying belt, little cost is increased, the recycled extra paint can be reused, and pipelined production can be achieved, and the spraying device has the advantages of being high in production and production rate, and the like.

Owner:广州愈扬实业有限公司

Roller pressing punching device

ActiveCN105751299AHigh dimensional accuracyRealize assembly line productionMetal working apparatusPunchingAssembly line

The invention relates to a roller pressing punching device. The device comprises a machine frame, a male die roller and a female die roller. The male die roller and the female die roller are rotationally arranged on the machine frame in parallel. The gap between the male die roller and the female die roller is adjustable, the male die roller and the female die roller synchronously rotate in opposite directions, a male die is arranged on the male die roller, a female die is arranged on the female die roller, a waste hole is formed in the bottom of a cavity of the female die, a waste channel is formed in the female die roller, at least one end face of a roller shaft of the female die roller is provided with a discharge opening, the discharge opening is provided with a connector assembly used for being connected with a suction device, and the waste hole and the discharge opening are communicated with the waste channel. Assembly line production of flexible material punching can be achieved, requirements of manpower are reduced, and the device has the advantages of being efficient, safe and capable of saving energy and reducing consumption. Holes in different shapes can be punched. Besides, size precision of the machined holes is high, and no burrs exist.

Owner:三明市普诺维机械有限公司

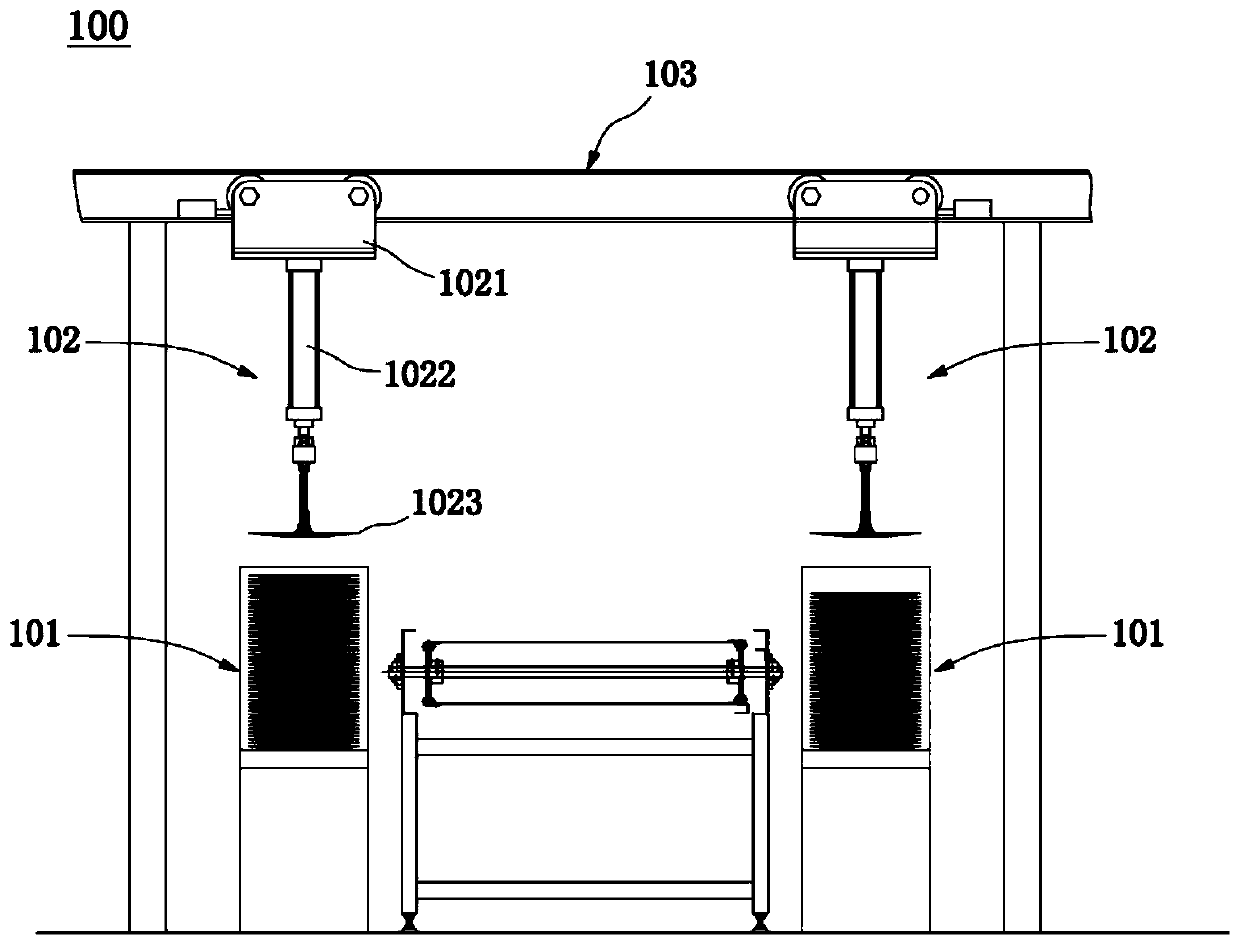

Line pressing door assembling production line

PendingCN110405891ASave energyRealize assembly line productionMulti-purpose machinesProduction lineEngineering

The invention belongs to the technical field of door panel assembling, machining and producing, and particularly relates to a line pressing door assembling production line. A suction cup type automatic feeder, a pneumatic press machine I, an overturning machine, a pneumatic press machine II and a suction cup type automatic discharger are included and sequentially arranged in the conveying direction of a conveying line. The suction cup type automatic feeder is used for conveying door panels which are about to be subjected to line pressing to the conveying line. The door panels which are about to be subjected to line pressing are conveyed to various stations through the conveying line. The pneumatic press machine I is used for conducting line pressing on one side faces of the door panels which are about to be subjected to line pressing and conveyed to the first pressing-assembling station, and the overturning machine is used for 180-degree overturning of the door panels which are conveyed to the overturning station. The pneumatic press machine II is used for conducting line pressing on the other side faces of the door panels which are conveyed to the second pressing-assembling station. The suction cup type automatic discharger is used for taking the door panels obtained after line pressing from the conveying line. Automatic equipment is used for carrying and overturning, and thephysical power of workers is reduced. Meanwhile, workers work according to procedures based on beats, the labor efficiency is greatly improved, and the labor cost is saved.

Owner:沈阳盛西尔科技发展有限公司

Automatic production method for prefabricated reinforced concrete hollow formwork

ActiveCN111618991ARealize assembly line productionIncrease productivityDischarging arrangementMouldsReinforced concreteMesh reinforcement

The invention discloses an automatic production method for prefabricated reinforced concrete hollow formwork. The automatic production method comprises the following steps: (1) preparing a concrete raw material and a bundled reinforcement net rack; (2) assembling a front side plate, a rear side plate, a left side plate, a right side plate, a bottom side plate and a partition plate at a mould closing station, and dividing the mould into multiple sub cavities; (3) moving the mould to a mandrel core-penetrating or core-withdrawing station for inserting a mandrel into the mould; (4) moving the mould to a mould pouring station, and pouring the concrete raw material; (5) after pouring is accomplished, moving the mould to a mould top side plate covering station, and covering a top side plate to amould cavity opening; (6) moving the mould to a first curing station to preliminarily cure and form; (7) moving the mould to the mandrel core-penetrating or core-withdrawing station for withdrawing the mandrel out of the mould; (8) moving the mould to a second curing station for steam-curing and forming; and (9) moving the mould to a mould de-moulding station for dismounting the top side plate, the left side plate and the right side plate, and de-moulding a finished product. The mould is sequentially transferred to each station to form circulating type production which is performed in a prefabricated component production process, so that production efficiency is improved.

Owner:FUJIAN QUNFENG MACHINERY

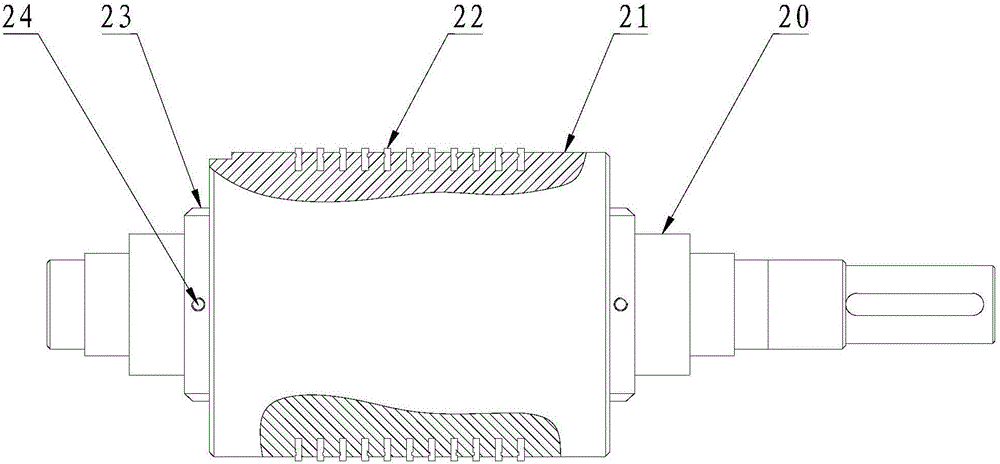

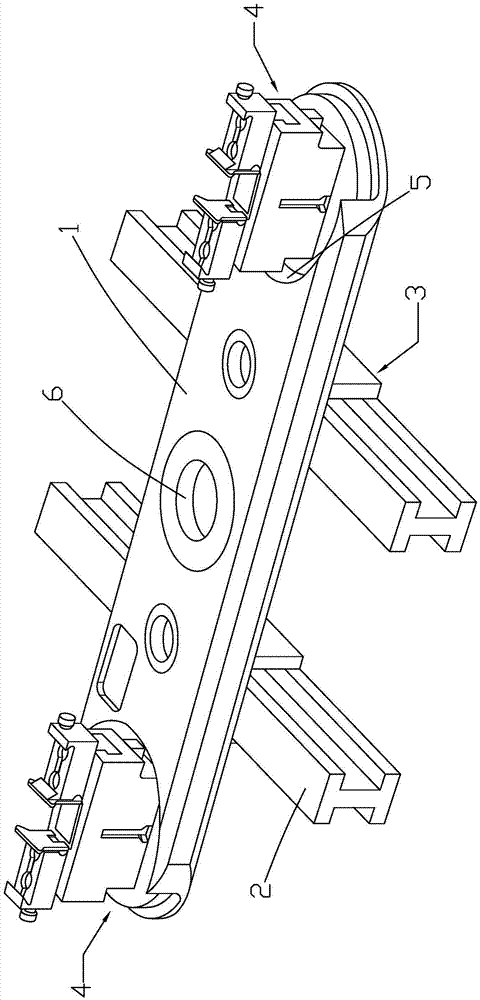

Locking device for machining mechanical parts

InactiveCN105436942AIncrease flexibilityReduce processing timePositioning apparatusMetal-working holdersLocking mechanismEngineering

The invention discloses a locking device for machining mechanical parts. The locking device for machining mechanical parts comprises a supporting and positioning plate, an H-shaped guide track, a sliding mechanism and a locking system, wherein the supporting and positioning plate is movably connected to the H-shaped guide track through the sliding mechanism; a positioning hole and annular slots are formed in the supporting and positioning plate; the annular slots are symmetrically distributed in two sides of the positioning hole; the locking system comprises rotating chucks, positioning bases and locking mechanisms; each rotating chuck is rotatably connected to the inside of the corresponding annular slot; each positioning base is fixedly connected to the corresponding rotating chuck; a chute is formed in the top surface of each positioning base; and each locking mechanism is movably connected to the corresponding positioning base through a boosting plate. The locking device for machining mechanical parts is simple in structure and high in practicality; the distance between the two locking mechanisms can be adjusted to lock a mechanical part, and furthermore, the mechanical part can be locked by the independent locking mechanisms; locking machining of mechanical parts with different sizes and specifications can be implemented; and operability of the locking device is improved.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

Hair product production line

ActiveCN111227403ARealize assembly line productionSuitable for modernizationWigsBundling machine detailsProcess engineeringHair-pulling

The invention relates to a hair product production line. The hair product production line comprises fixed-length cutting machines which are sequentially arranged and used for cutting hair, the material preparation machine is used for supplying cut hair; the carding conveyor is used for carding and conveying hair; the intermittent conveyor is used for intermittently conveying hair; wherein the hairpulling pressing machine is used for pressing hair, the hair pulling conveying machine is used for tidying and conveying the hair, the conveying device is used for conveying the hair, the sewing three-in-one machine is used for manufacturing a wig curtain, the wig curtain folding machine is used for folding the wig curtain into combined parts, and the bundling packaging machine is used for bundling the combined parts. According to the invention, a device for replacing manual operation is correspondingly arranged in each step of hair product production. According to the invention, the production line type production of hair products is realized, the labor cost is reduced, the efficiency is effectively improved, the processing quality can be effectively controlled, the production purposes of higher production efficiency and excellent product quality can be achieved with the minimum labor cost, and the production line is very suitable for modernization transformation of the hair productindustry.

Owner:陈熙

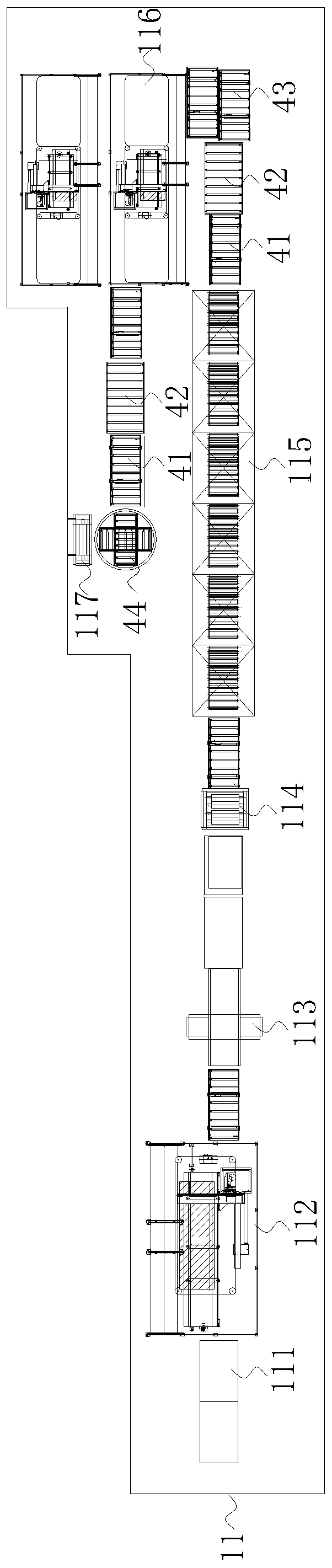

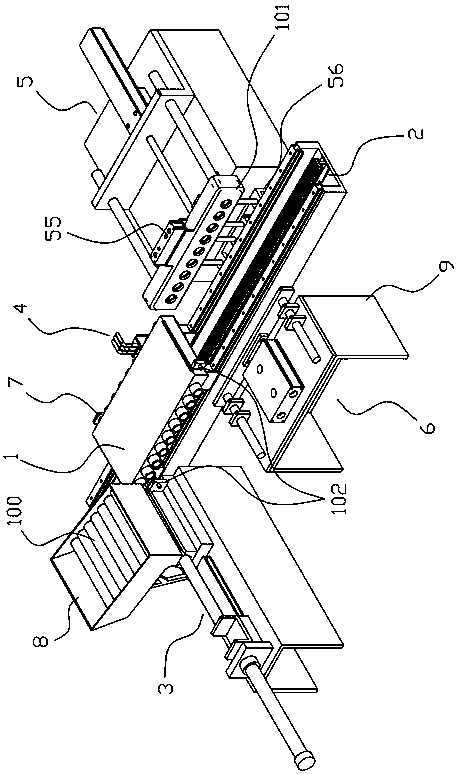

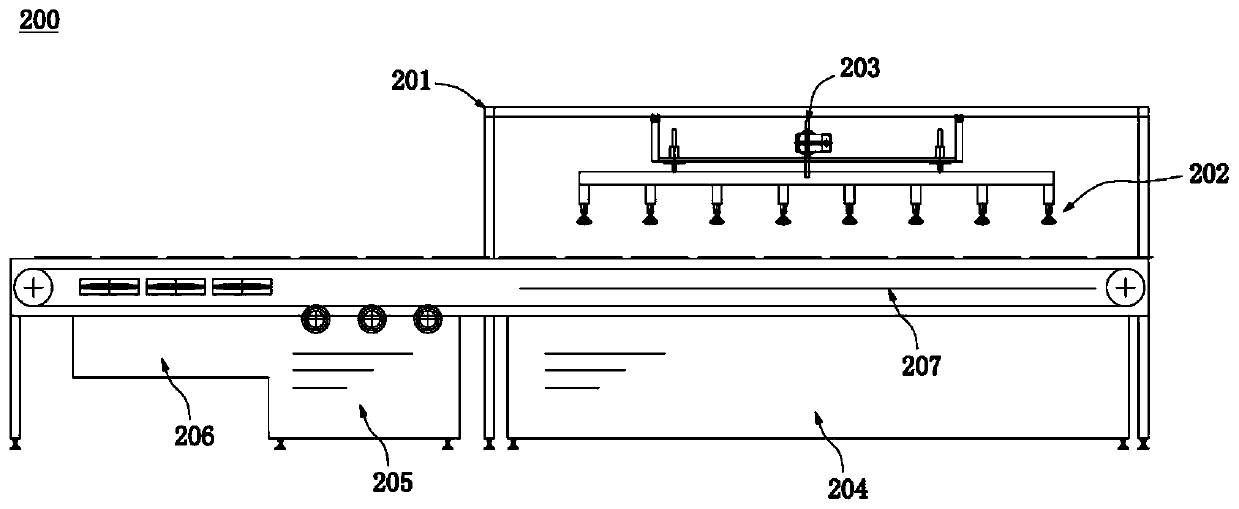

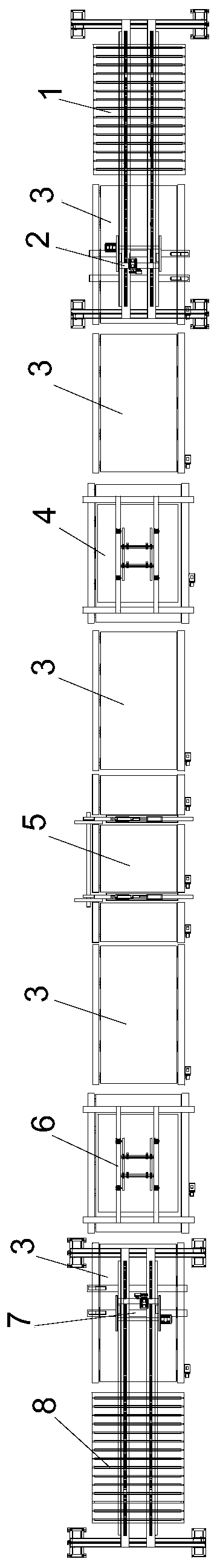

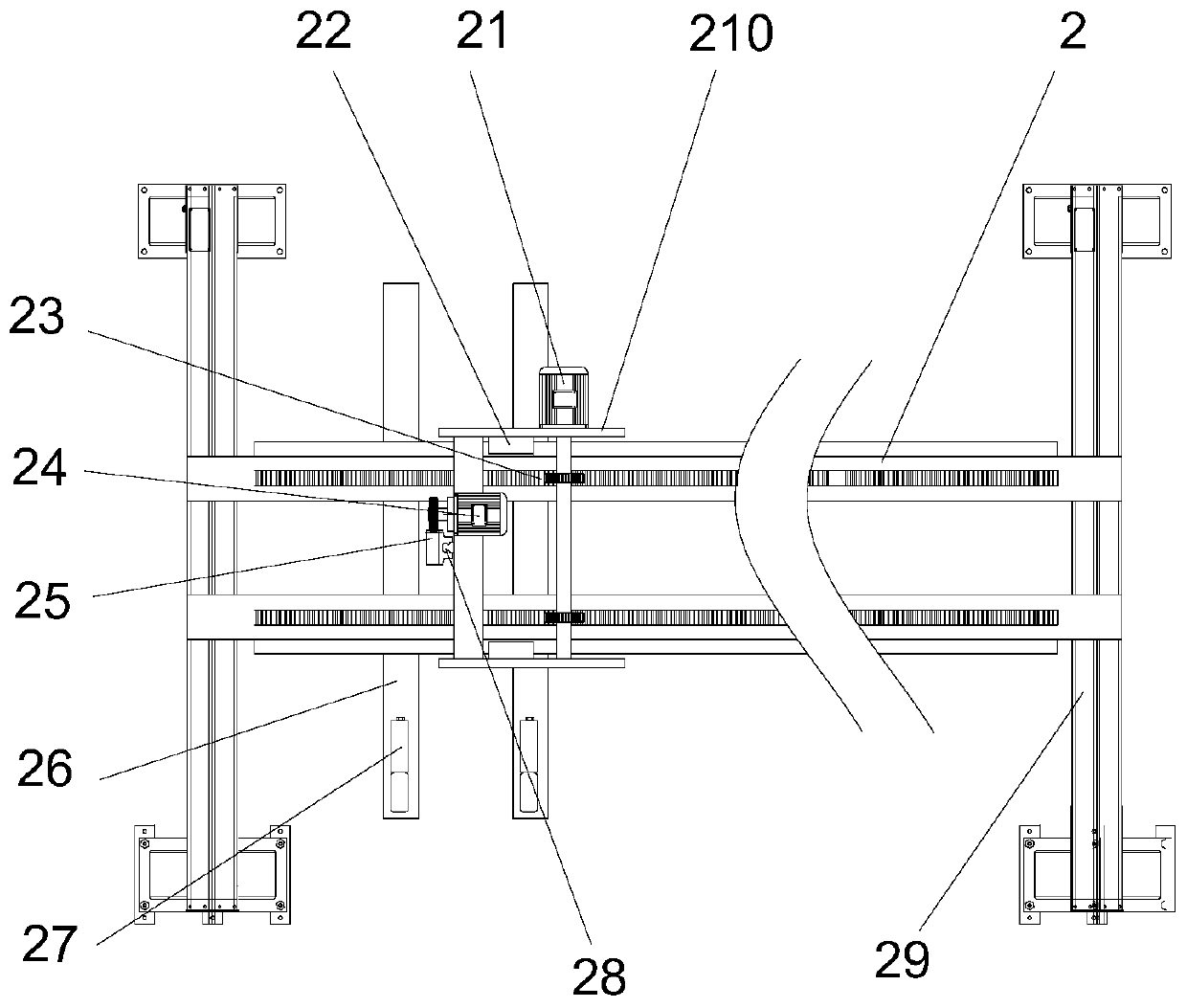

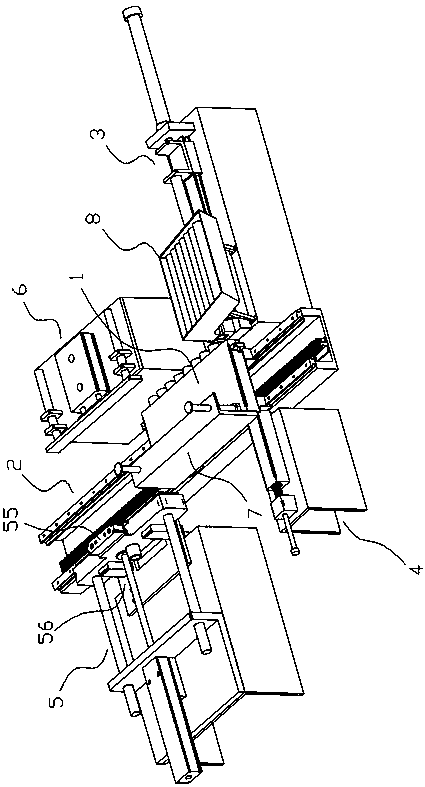

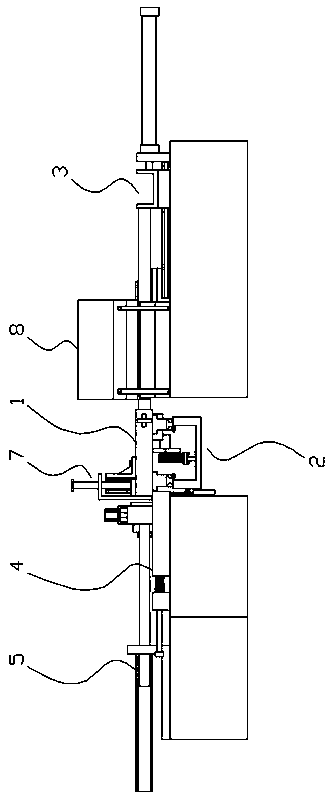

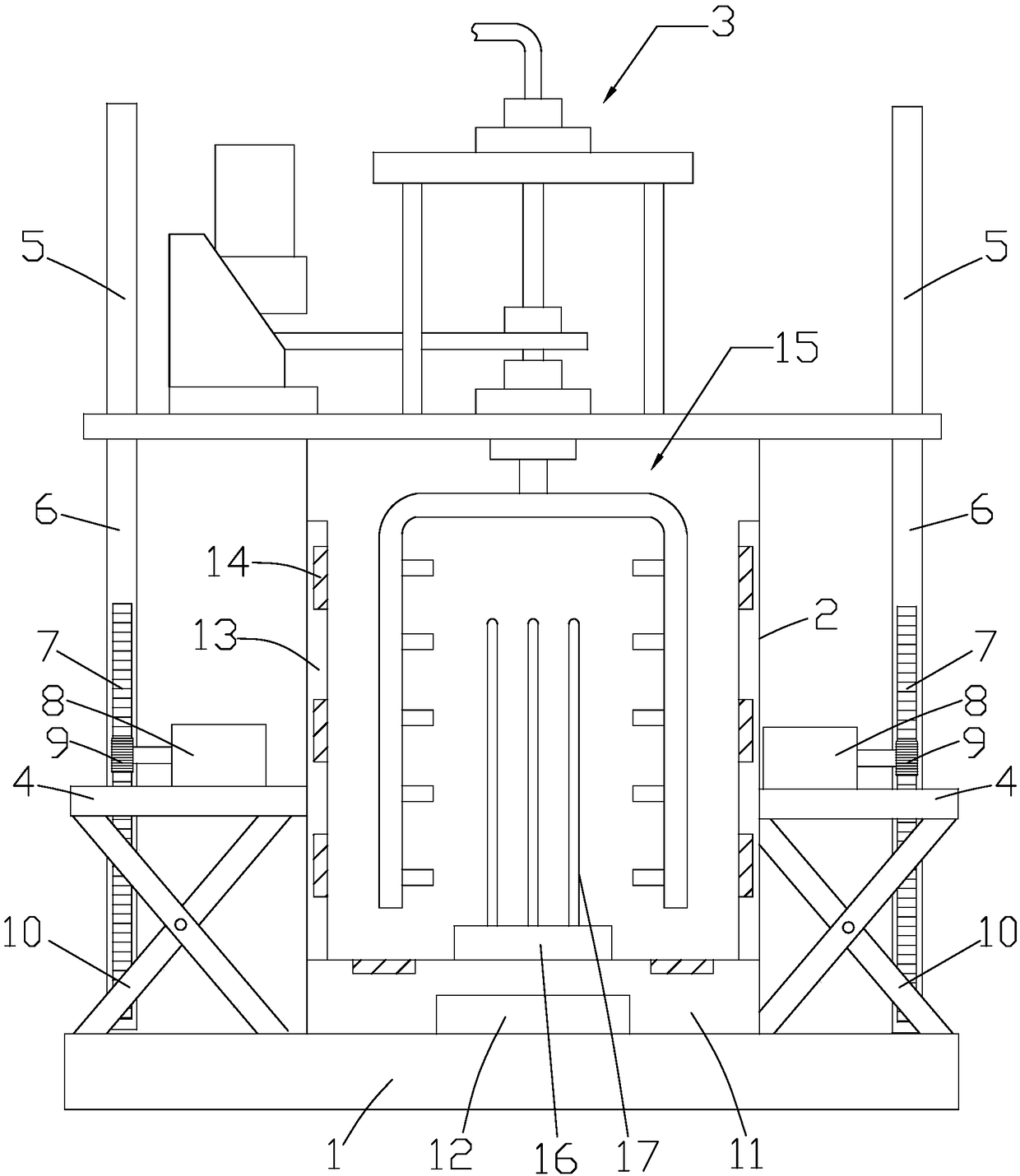

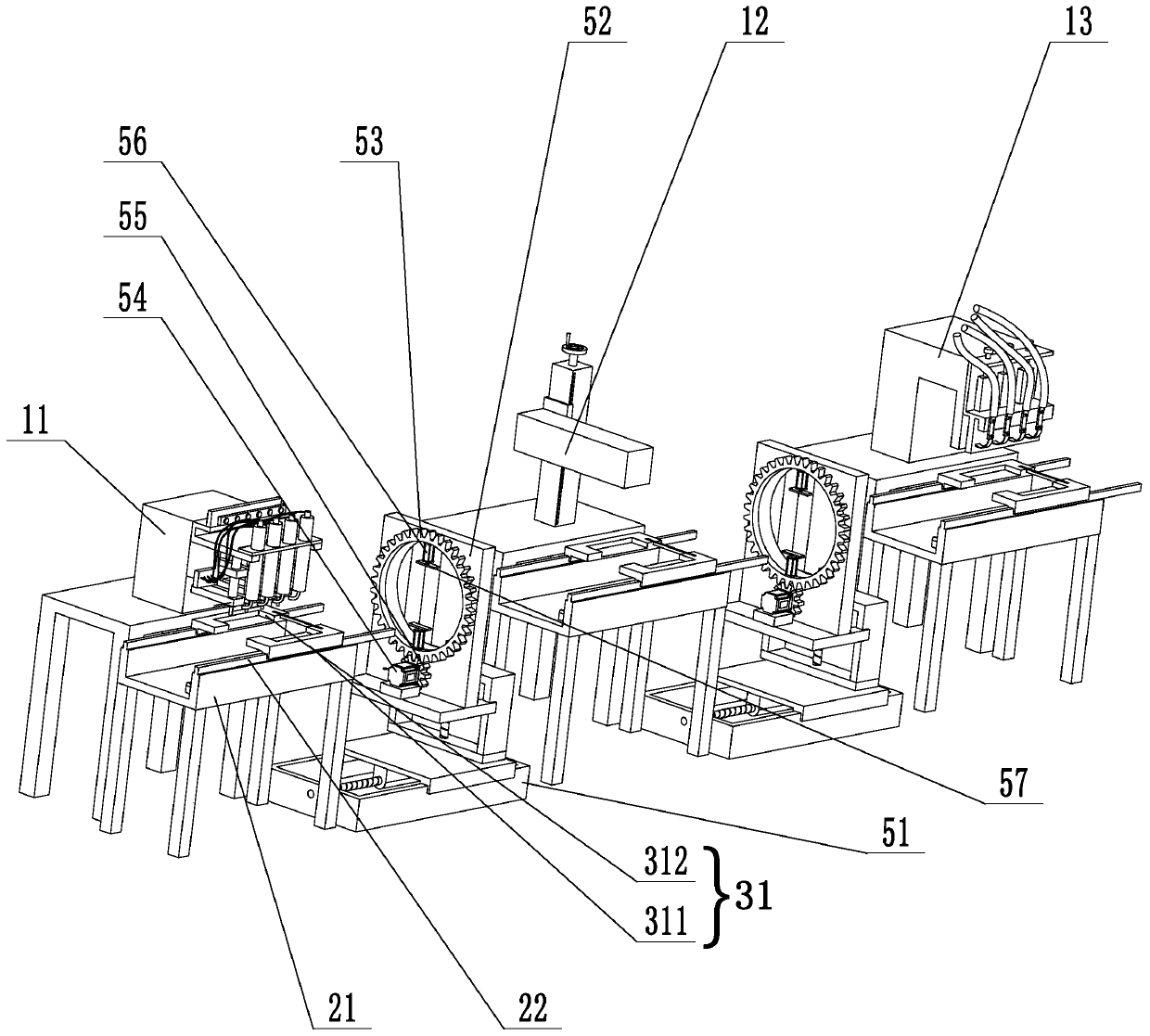

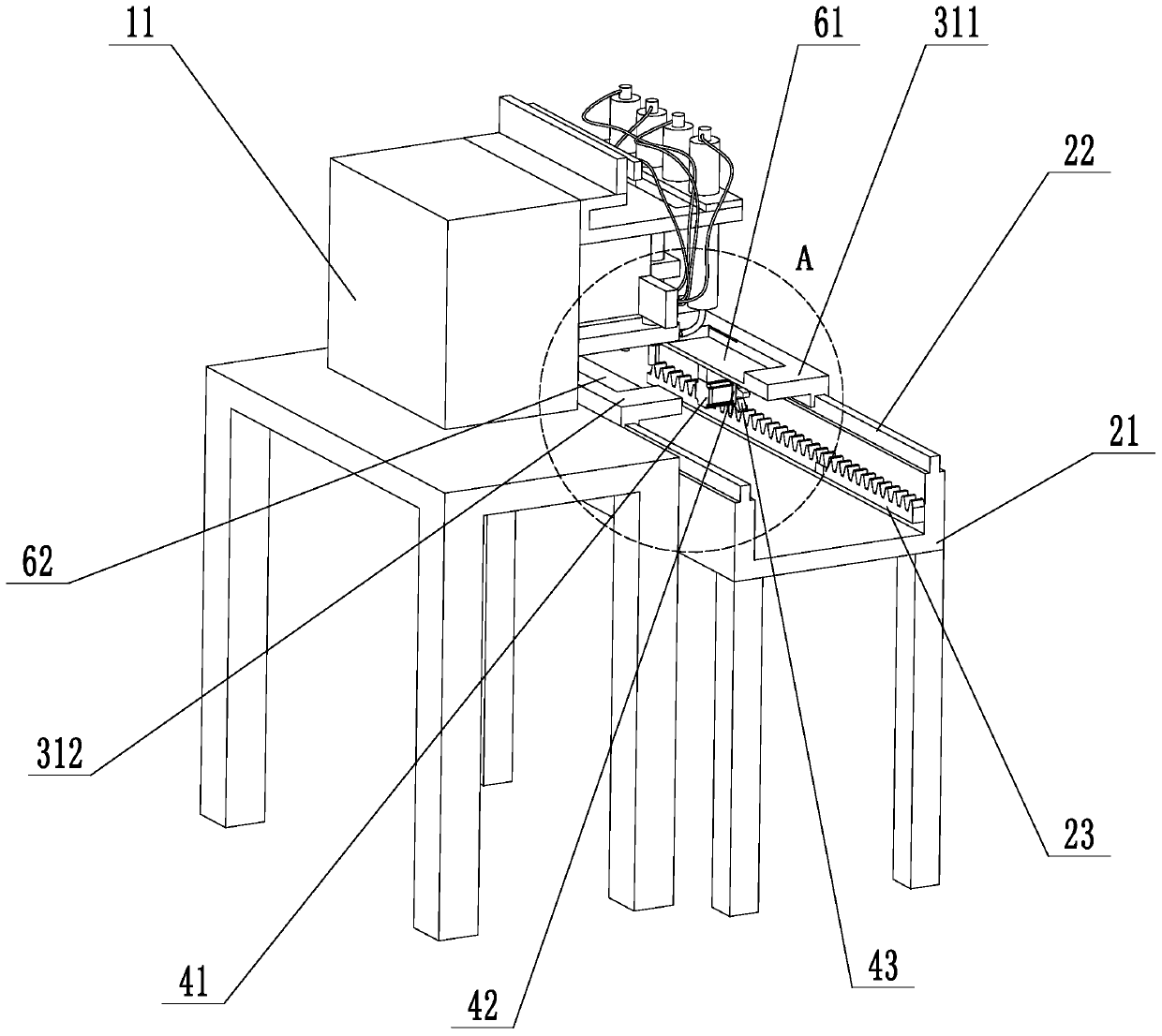

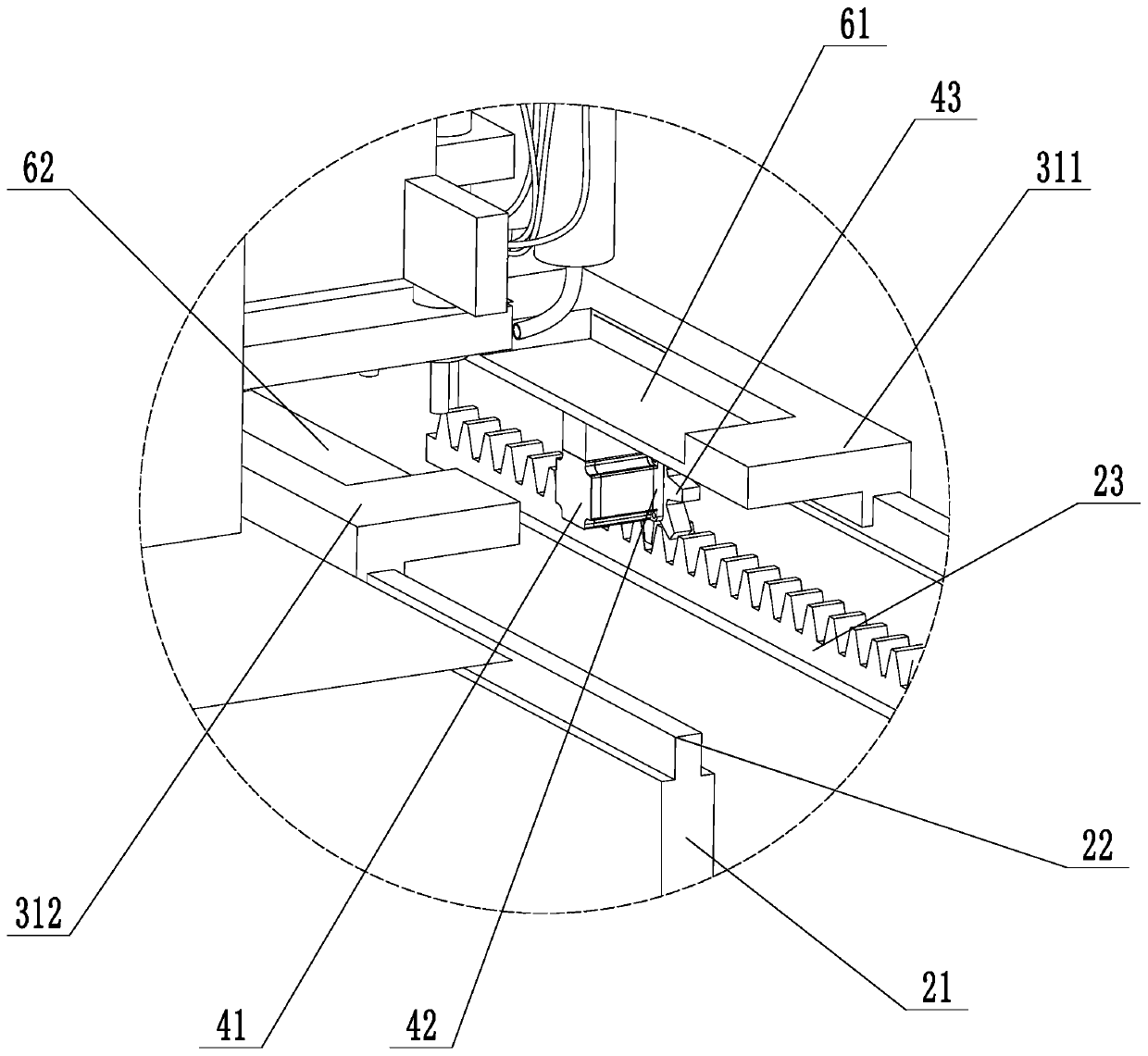

Automatic assembly line for heat pipe radiator for communication base station

ActiveCN111283429ARealize assembly line productionHigh degree of automationAssembly machinesMetal working apparatusProduction lineThermodynamics

The invention discloses an automatic assembly line for a heat pipe radiator for a communication base station, and relates to the technical field of communication equipment processing. The line comprises a fixing tool, a conveying platform, a heat pipe feeding mechanism, a welding ring feeding mechanism, a substrate feeding mechanism and a pressing mechanism, wherein the fixing tool is used for horizontally positioning and centralizedly collecting heat pipes together, the conveying platform is provided with the fixing tool, and is used for achieving horizontal conveying of the fixing tool, theheat pipe feeding mechanism is located on the left side of the conveying platform and is used for conveying the heat pipes in the fixing tool, the welding ring feeding mechanism is located on the right side of the conveying platform and is used for assembling welding rings to assembling ends of the heat pipes, the substrate feeding mechanism is located on the right side of the conveying platform and is used for clamping and then conveying a substrate to an assembly station, and the pressing mechanism is located on the left side of the conveying platform and is used for pressing the heat pipeson the fixing tool into the substrate. In the line, feeding of the heat pipes, feeding of the welding rings, feeding of the substrate and overall pressing are all completed on one conveying platform,assembly line type production is realized, the overall automation degree is high, and the assembly efficiency is remarkably improved.

Owner:WUHU YIZE SMALL & MEDIUM ENTERPRISE PUBLIC SERVICE CO LTD

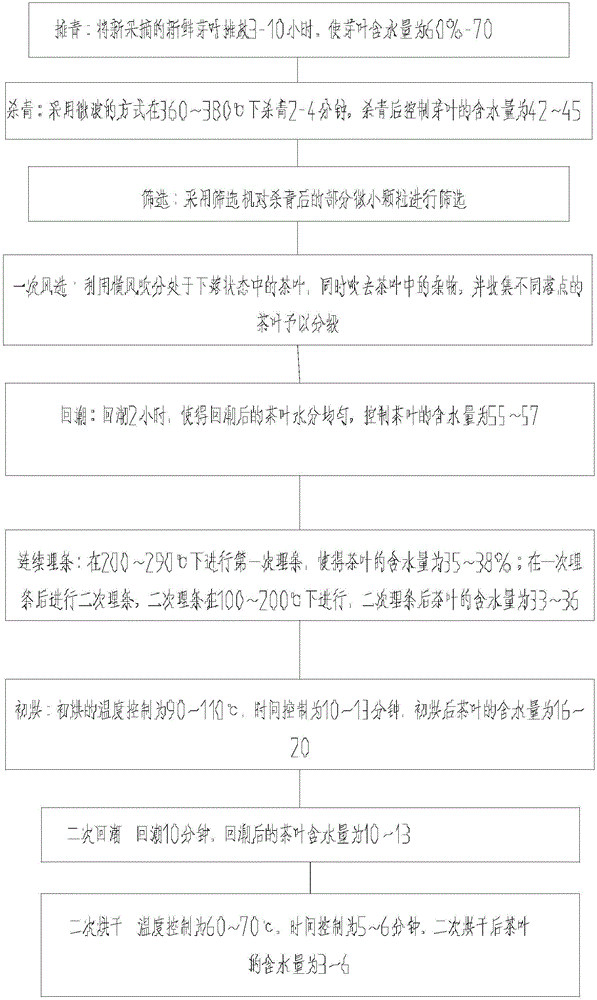

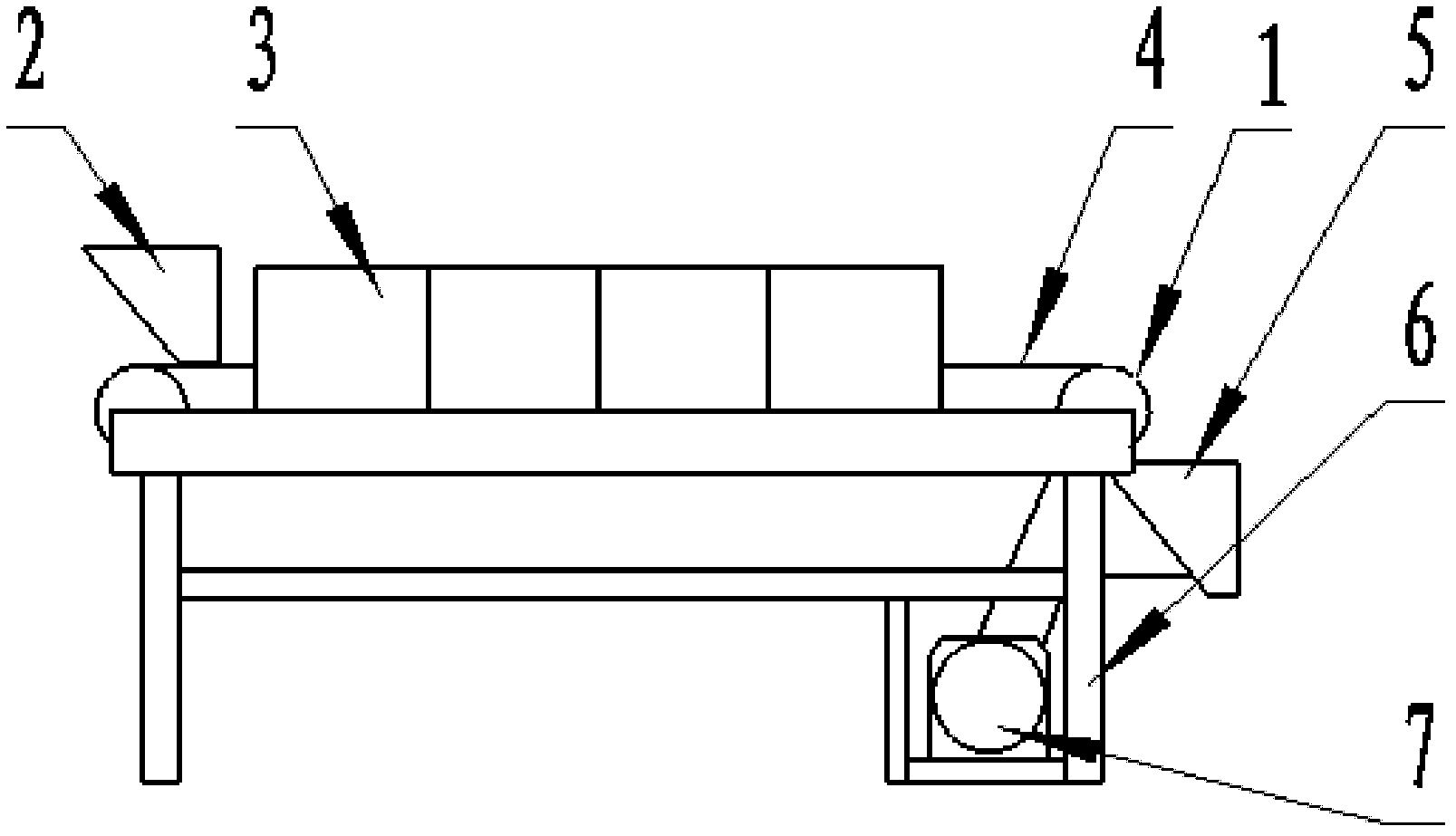

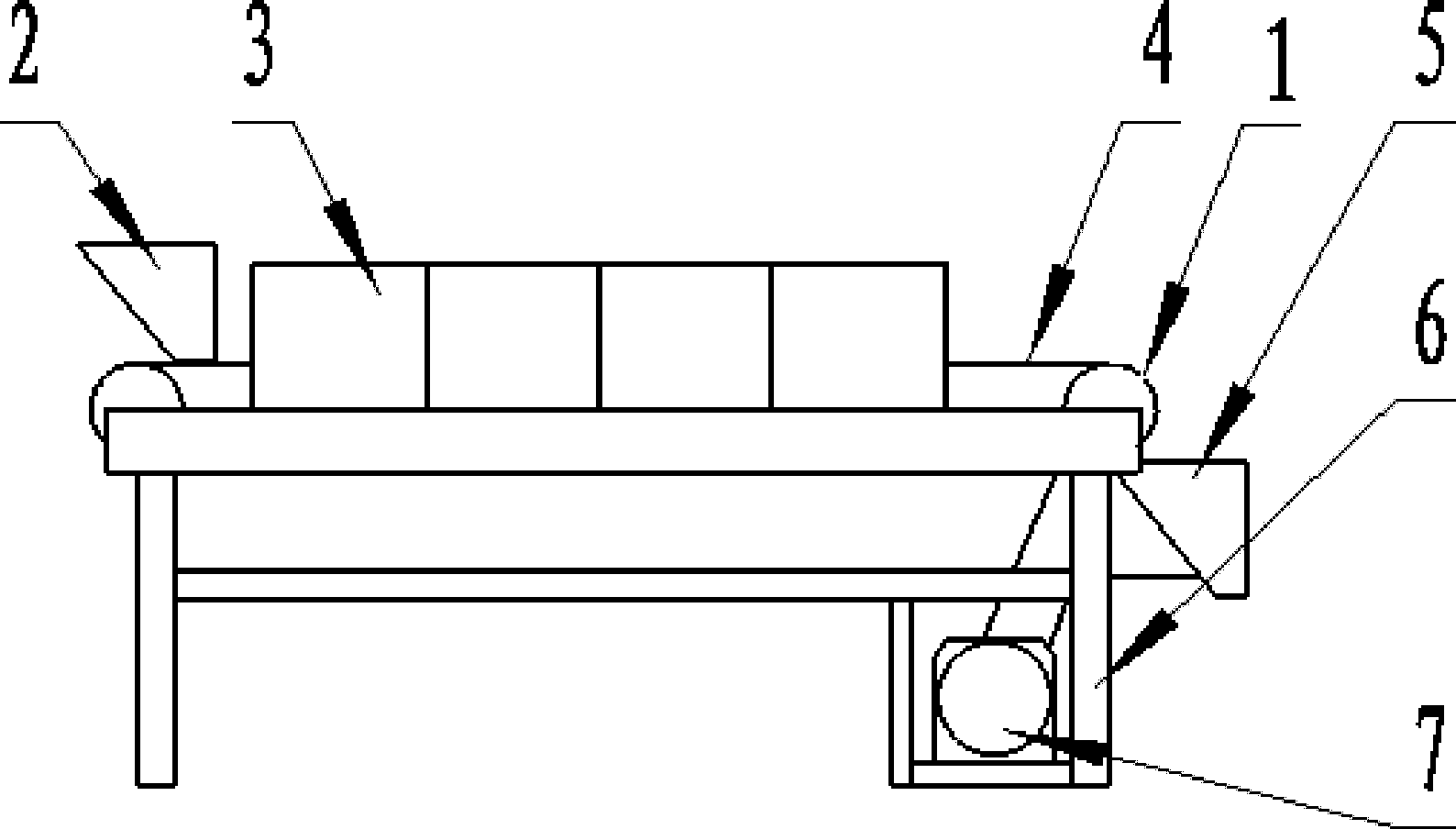

Preparation method of tea

The invention discloses a preparation method of tea. The preparation method of the tea comprises the following steps: carrying out spreading, carrying out fixation, carrying out sieving, carrying first air-classification, regaining moisture, carrying out continuous carding, carrying out initial drying, regaining moisture for the second time, carrying out second drying, and so on. The preparation method of the tea is capable of realizing assembly-line production, as well as effectively solving the problems of hand-frying and lack of complete sets of automation equipment; moreover, the tea leaves are dried and sieved for several times, so that the prepared tea has improved aroma, and the quality of the tea is indirectly improved.

Owner:WUZHOU YAZHENG AGRI TECH CO LTD

Continuous drying equipment for particle or powder plastics

InactiveCN102425927ARealize continuous drying processRealize assembly line productionDrying solid materialsHeating arrangementMicrowaveEngineering

The invention relates to drying equipment for particle or powder plastics, in particular to continuous drying equipment for the particle plastics or the powder plastics. The continuous drying equipment comprises a framework and a heating device; a tunnel with an opening at two ends is arranged on the framework; a meshed conveying belt for conveying the particle plastics or the powder plastics penetrates through the tunnel; and a microwave heating device is arranged in the tunnel. The continuous drying equipment for the particle plastics or the powder plastics has the beneficial effects that: the continuous drying treatment can be realized through adopting a microwave heating manner to dry the particle plastics or the powder plastics, the efficiency is high, the energy consumption is lower, and the assembly line type production can be realized. The continuous drying equipment belongs to novel energy-saving type equipment.

Owner:SHANDONG DONGHONG PIPE IND

Two-dimensional code printing machine applied to bottle cap

InactiveCN111703838ASimple structureEasy to implementControl devices for conveyorsLaser beam welding apparatusProcess engineeringAssembly line

The invention discloses a two-dimensional code printing machine applied to a bottle cap. The two-dimensional code printing machine applied to the bottle cap comprises a vibrating disk, a first conveying mechanism, a second conveying mechanism, a back blowing mechanism, a two-dimensional code printing and detecting mechanism, a defective product removing mechanism and an encoder used for detectingthe conveying speed of a conveying belt, wherein the first conveying mechanism mainly comprises a conveying panel and a plurality of air blowing holes formed in the conveying panel and used for blowing air backwards, the second conveying mechanism mainly comprises the conveying belt and a plurality of air suction holes formed in the conveying belt, the back blowing mechanism mainly comprises a first photoelectric switch, a first spray head and a material return pipe, the two-dimensional code printing and detecting mechanism mainly comprises a second photoelectric switch, a laser printer and acamera; and the defective product removing mechanism mainly comprises a second spray head and a material receiving pipe. On the basis of fusing the laser printer, the printing precision can be ensured, the rate of certified products is improved, and automatic, convenient and assembly line type production is achieved.

Owner:ANHUI BAISHIJIA PACKING CO LTD

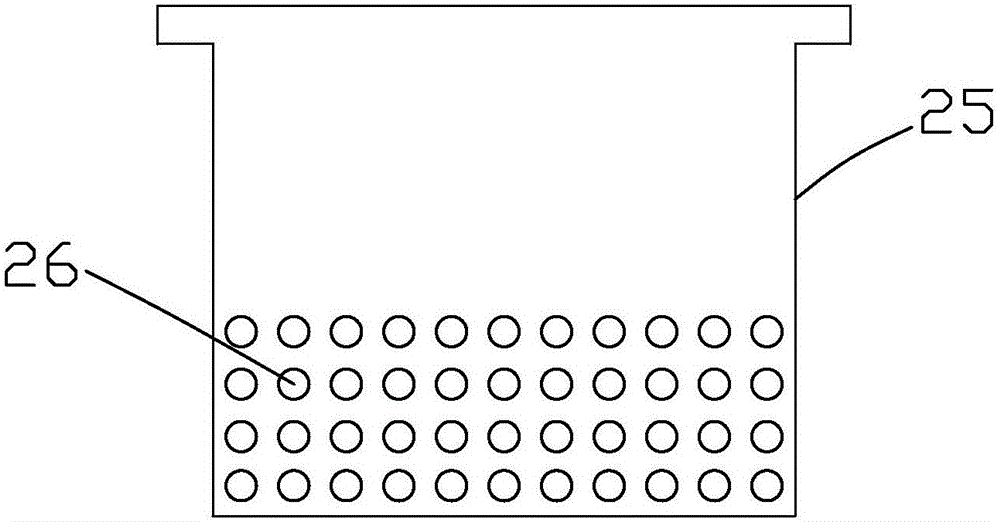

Yarn boiling device for yarn-dyed four-faced elastic fabric processing, and processing method using the same

ActiveCN109023759AEasy to controlMeet cooking needsTextile treatment machine arrangementsTextile treatment by spraying/projectingYarnEngineering

The invention discloses a yarn boiling device for yarn-dyed four-faced elastic fabric processing, and a processing method using the same. The yarn boiling device for yarn-dyed four-faced elastic fabric processing includes a barrel body, a drive unit, a first pedestal and lifting mechanisms, wherein the outer side surface of the barrel body is provided with a water inlet pipe and a water outlet pipe; a liner and a second pedestal are arranged in the barrel body; the second pedestal is located at the bottom of the barrel body; the second pedestal and the liner are each provided with a heating plate; a storage battery is arranged in the second pedestal; a yarn fastening device is arranged above the second pedestal; a steam rotating frame is arranged directly above the yarn fastening device; the steam rotating frame is connected to the drive unit; and the drive unit is connected with the first pedestal through two sets of lifting mechanisms. The fabric processing method includes the steps:yarn preparation, yarn boiling, yarn dyeing, drying, winding, sizing, weaving, desizing, liquid ammonia, heat setting and pre-shrinking. The processing method using the yarn boiling device for yarn-dyed four-faced elastic fabric processing has the advantages of being simple in steps, being high in practicality, improving the processing efficiency of yarn-dyed four-faced elastic fabrics, improvingthe quality of the yarn-dyed four-faced elastic fabrics, and realizing flow line production.

Owner:浙江盛泰服装集团股份有限公司

Sealing machine for toy packaging bag

InactiveCN107758001ARapid Cooling FormingChange heightWrapper twisting/gatheringPackaging machinesAssembly lineEngineering

The invention discloses a sealing machine for a toy packaging bag. The machine structurally comprises supporting legs, a base, a conveying device, a sealing linkage device, heat dissipation ports, a machine body, a protective cover and a control panel, wherein the bottom of the control panel is welded to the right side of the top of the machine body; the bottom of the machine body is vertically connected with the rear half part of the top of the base; the bottom of the conveying device is vertically connected with the front half part of the top of the base; the supporting legs are sequentiallyconnected into a rectangular structure and are fixed to the bottom of the base; the heat dissipation ports are sequentially arranged on the left side of the machine body from top to bottom at equal intervals; and the back of the protective cover is welded to the front side of the top end of the machine body. According to the sealing machine for the toy packaging bag, the sealing linkage device isadditionally arranged, thus rapid sealing and cooling forming can be carried out, and assembly line type production can be achieved; and meanwhile, the conveying device is additionally arranged, theheight of the conveying device can be quickly adjusted according to actual situations, and the production efficiency is improved.

Owner:费军

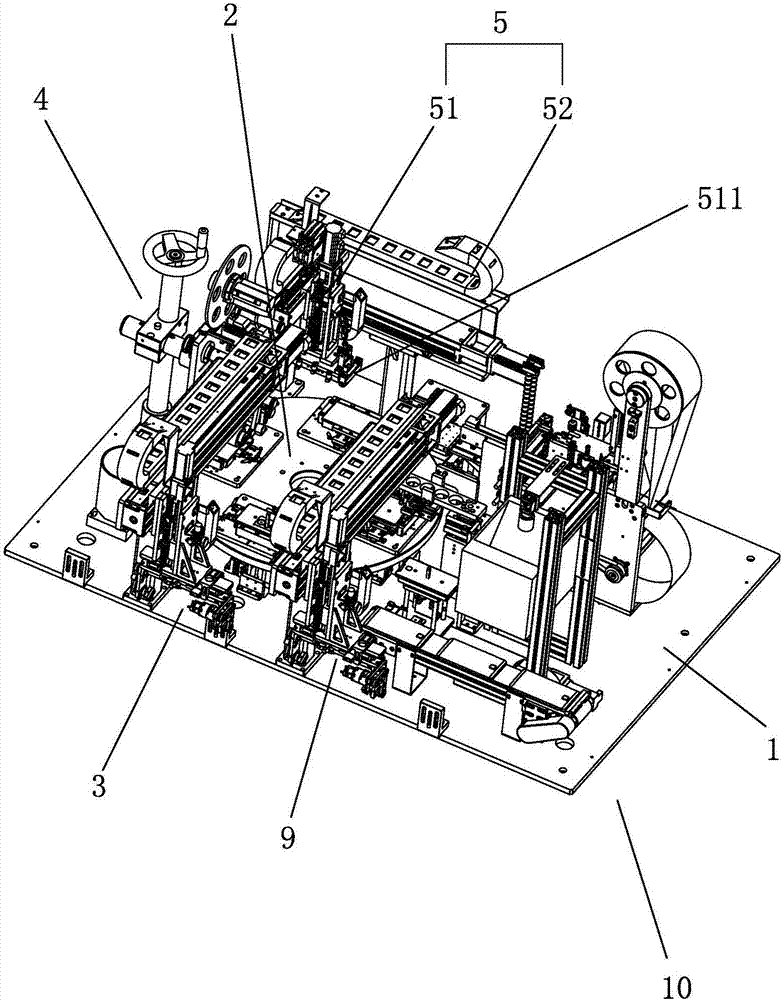

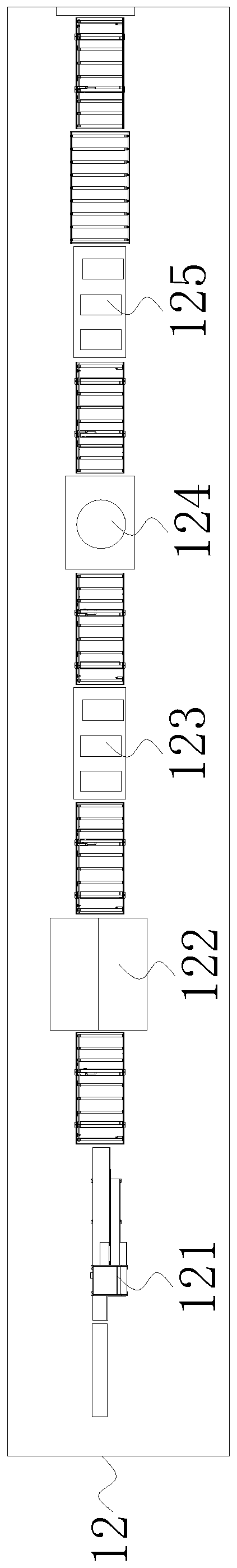

Integrated inductor production line

ActiveCN110534327AImprove work efficiencyTight production cycleCoils manufactureMechanical conveyorsInductorWinding machine

The invention relates to an integrated inductor production line. The integrated inductor production line comprises a winding machine used for manufacturing a winding body, a laser stripping machine used for stripping enameled wires at two ends of the winding body, and a welding machine used for welding the winding body in a seat body. The integrated inductor production line further comprises a conveying table, a guide rail arranged on the conveying table and at least three conveying devices arranged on the guide rail and used for conveying jigs on the winding machine, the laser stripping machine and the welding machine, wherein the winding machine, the laser stripping machine and the welding machine are sequentially arranged along the conveying table. The conveying device comprises a sliding table slidably connected with the guide rail and a driving device arranged on the sliding table and used for driving the sliding table to move on the guide rail. The driving device comprises a servo motor arranged on the sliding table, a precision servo speed reducer connected with the output end of the servo motor and a gear arranged on an output shaft of the precision servo speed reducer. Theintegrated inductor production line is used for automatic production of the integrated inductor, and has the characteristics of high production efficiency and compact production takt.

Owner:深圳感通科技有限公司

Cheese stuffed potato ball and preparation method thereof

InactiveCN106722017ARich tasteGreat tasteFood coatingLipidic food ingredientsBiotechnologyAdditive ingredient

The invention discloses a cheese stuffed potato ball, which comprises 60 to 70 weight parts of wrappers and 30 to 40 weight parts of cheese stuffing, wherein the wrappers wrap the cheese stuffing. The cheese stuffed potato ball is obtained sequentially through operations of wrapper preparation, cheese stuffing preparation, forming, shaping, quick freezing, packaging and the like. The cheese stuffed potato ball respectively introduces ingredients of chestnut powder, pea powder, cheese and the like, so that the product is rich in various nutrition ingredients; in addition, the taste is rich; the mouthfeel is good; meanwhile, the preparation method of the cheese stuffed potato ball is simple; the flow line production can be realized; the defect of single mouthfeel of the frozen cheese food in the existing market can be overcome.

Owner:FUJIAN SHENGHENG FOOD

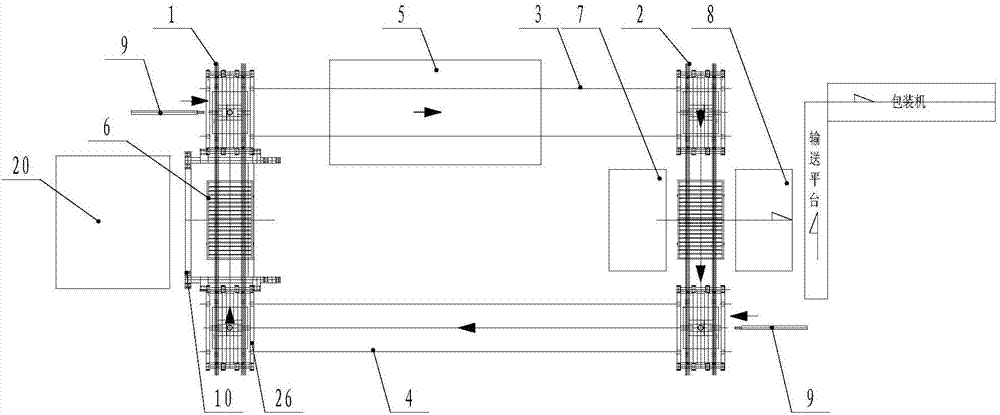

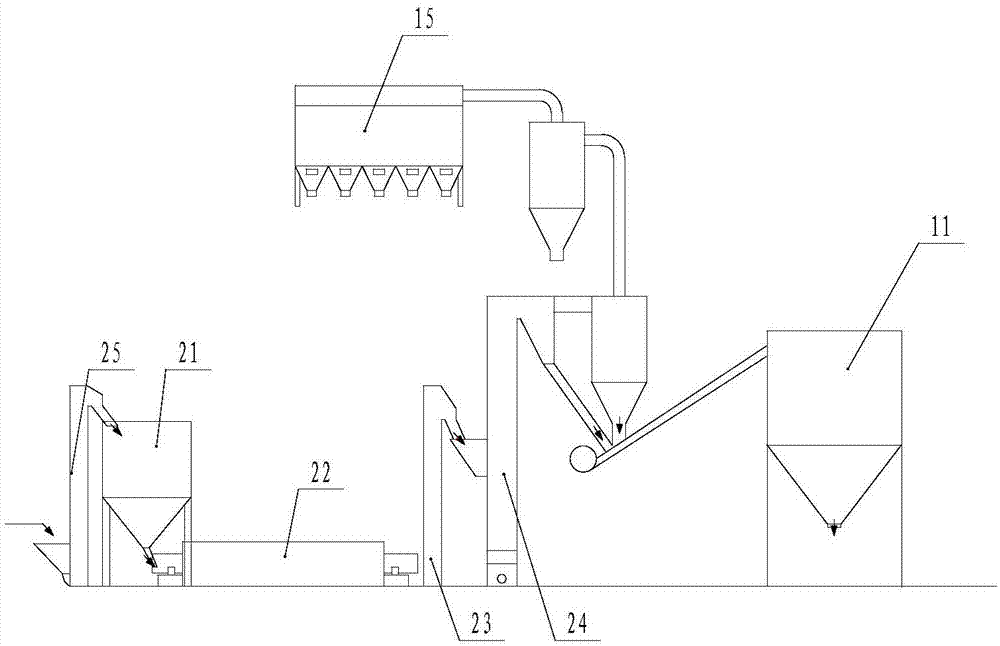

Full-automatic production device for expanded perlite heat preserving board

ActiveCN107571388ASave manpower and investmentStable transmissionCeramic shaping plantsAuxillary shaping apparatusPerliteProcess engineering

The invention discloses a full-automatic production device for an expanded perlite heat preserving board and relates to the field of heat preserving board production devices. The full-automatic production device for the expanded perlite heat preserving board is used for overcoming the defects that in the process of producing the expanded perlite heat preserving board, cost is high, efficiency is low, consumed time is long and assembly line production cannot be achieved. The full-automatic production device for the expanded perlite heat preserving board comprises a material mixing device, a board pressing device, a drying device and a packaging platform; the material mixing device is used for conveying materials to the board pressing device after the materials are mixed uniformly; the boardpressing device is used for pressing the mixed materials into the heat preserving board; the drying device is used for drying the heat preserving board; and then the dried heat preserving board enters the packaging platform to be packaged. The full-automatic production device for the expanded perlite heat preserving board is used for assembly line production of the expanded perlite heat preserving board.

Owner:华亿建材科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com