Patents

Literature

4453results about "Textile treatment by spraying/projecting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

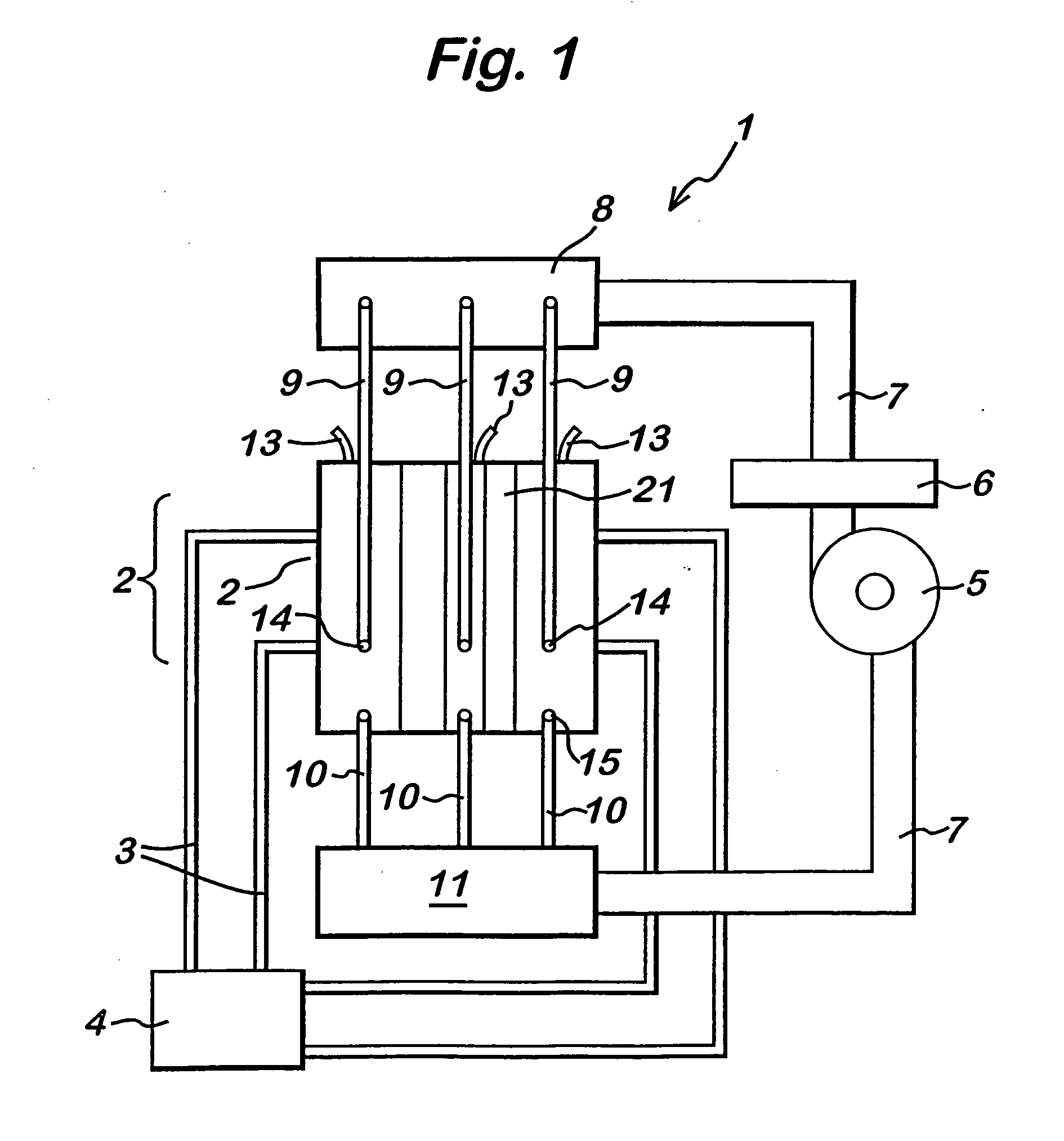

Atmospheric-pressure plasma processing apparatus and method

ActiveUS20140076861A1Faster plasma processing speedMinimum distanceChemical fixing of textilesArc welding apparatusEngineeringAtmospheric pressure

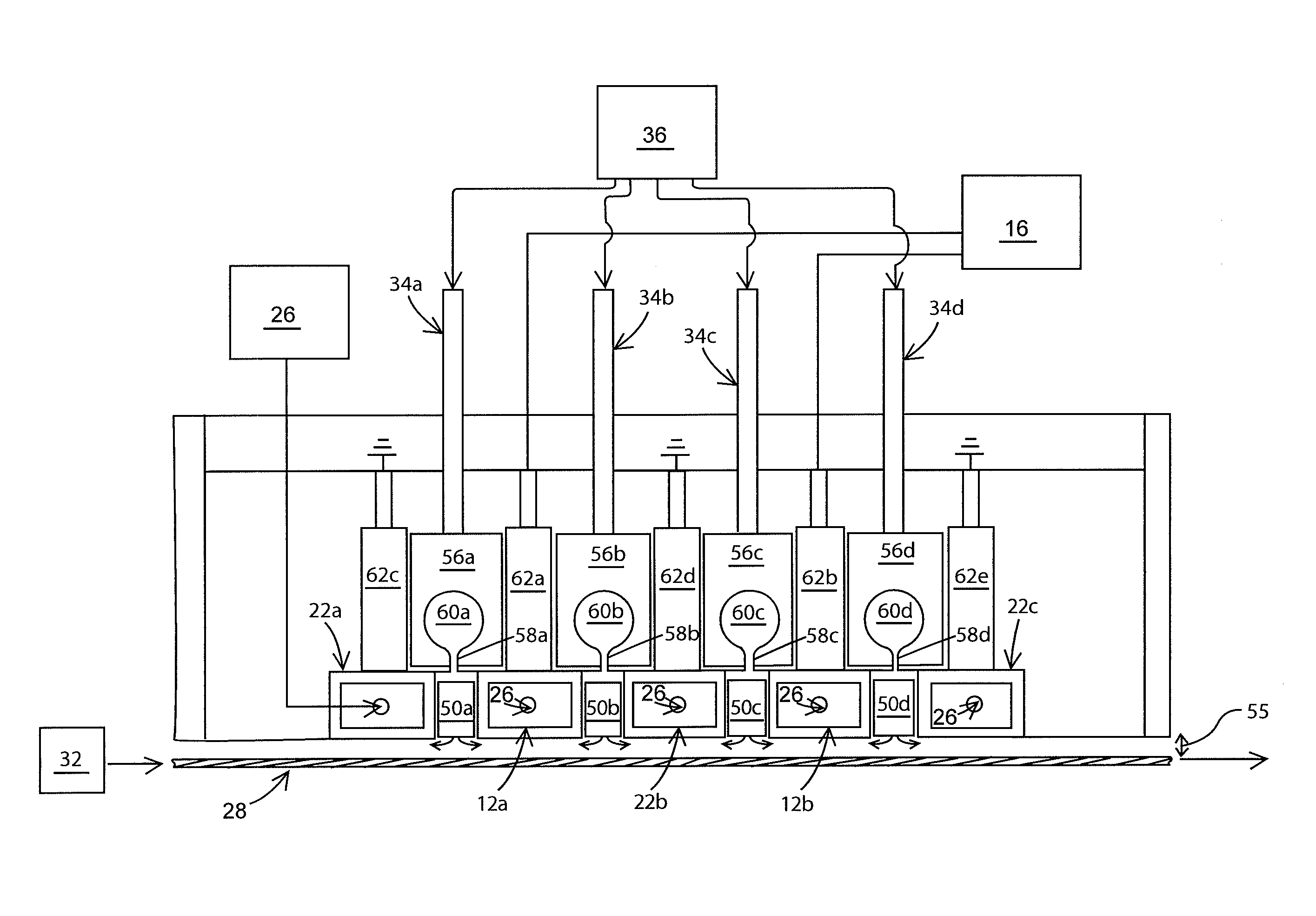

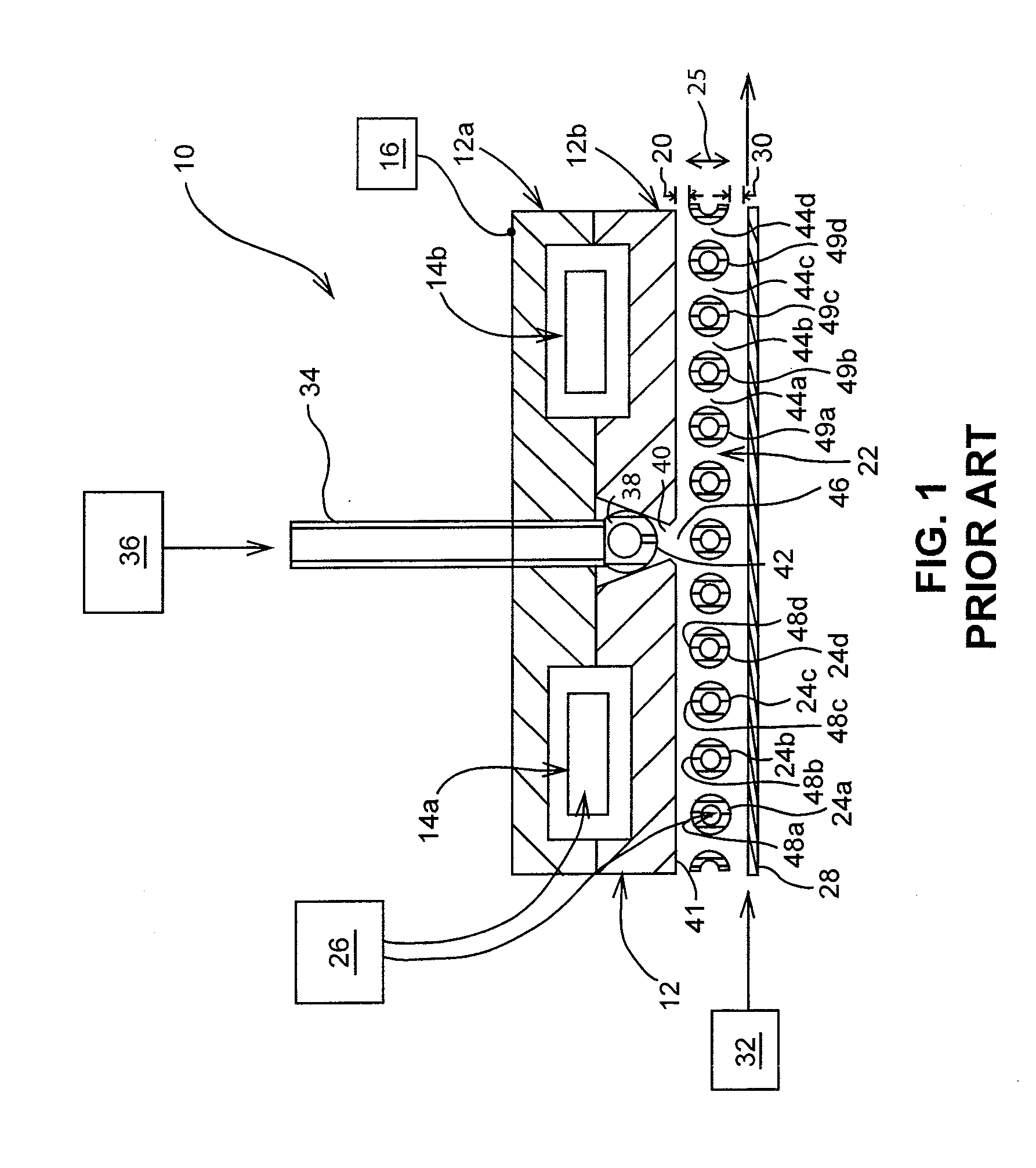

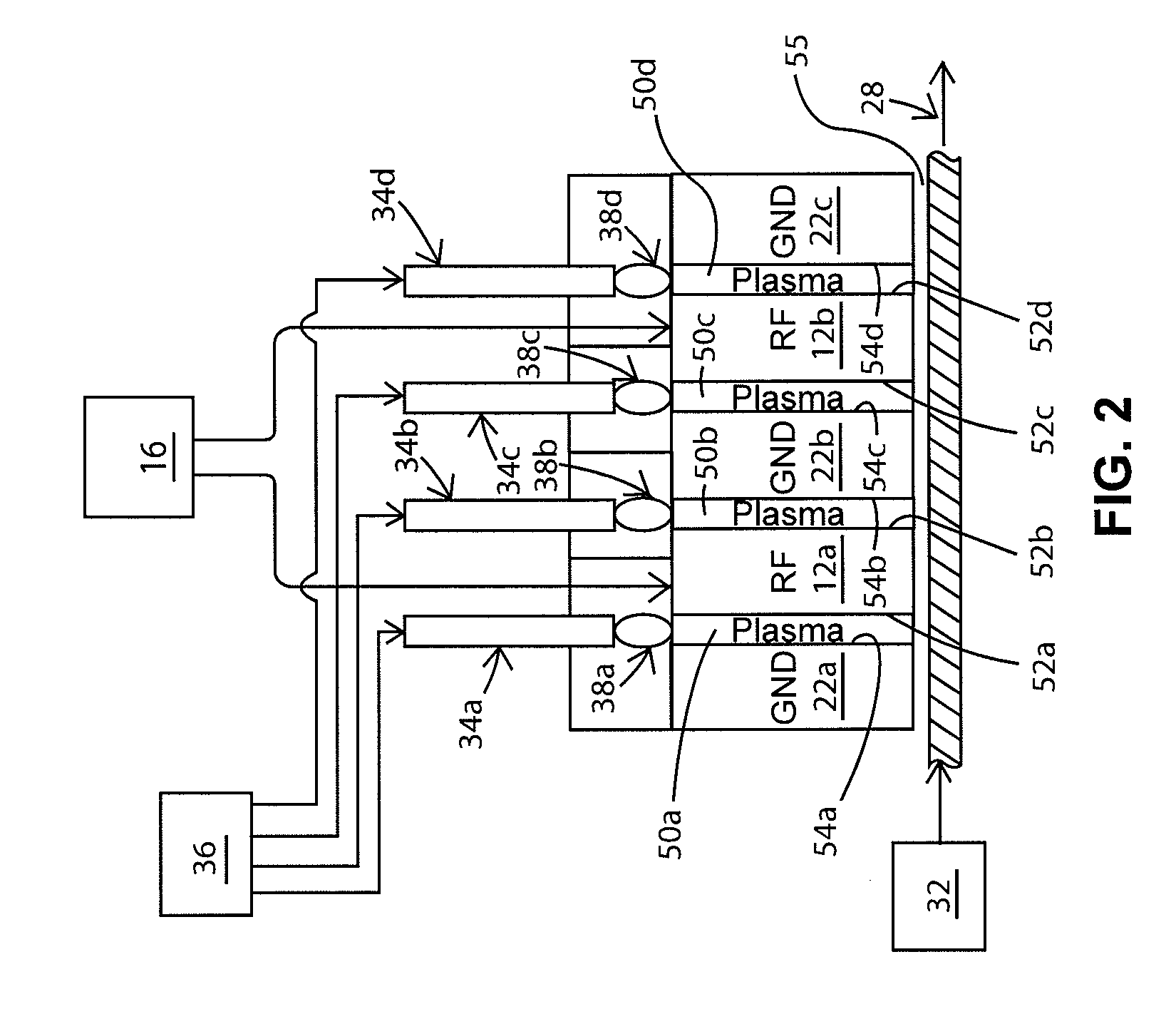

A plasma processing apparatus including powered electrodes having elongated planar surfaces; grounded electrodes having elongated planar surfaces parallel to and coextensive with the elongated surfaces of the powered electrodes, and spaced-apart a chosen distance therefrom, forming plasma regions, is described. RF power is provided to the at least one powered electrode, both powered and grounded electrodes may be cooled, and a plasma gas is flowed through the plasma regions at atmospheric pressure; whereby a plasma is formed in the plasma regions. The material to be processed may be moved into close proximity to the exit of the plasma gas from the plasma regions perpendicular to the gas flow, and perpendicular to the elongated electrode dimensions, whereby excited species generated in the plasma exit the plasma regions and impinge unimpeded onto the material.

Owner:APJET INC

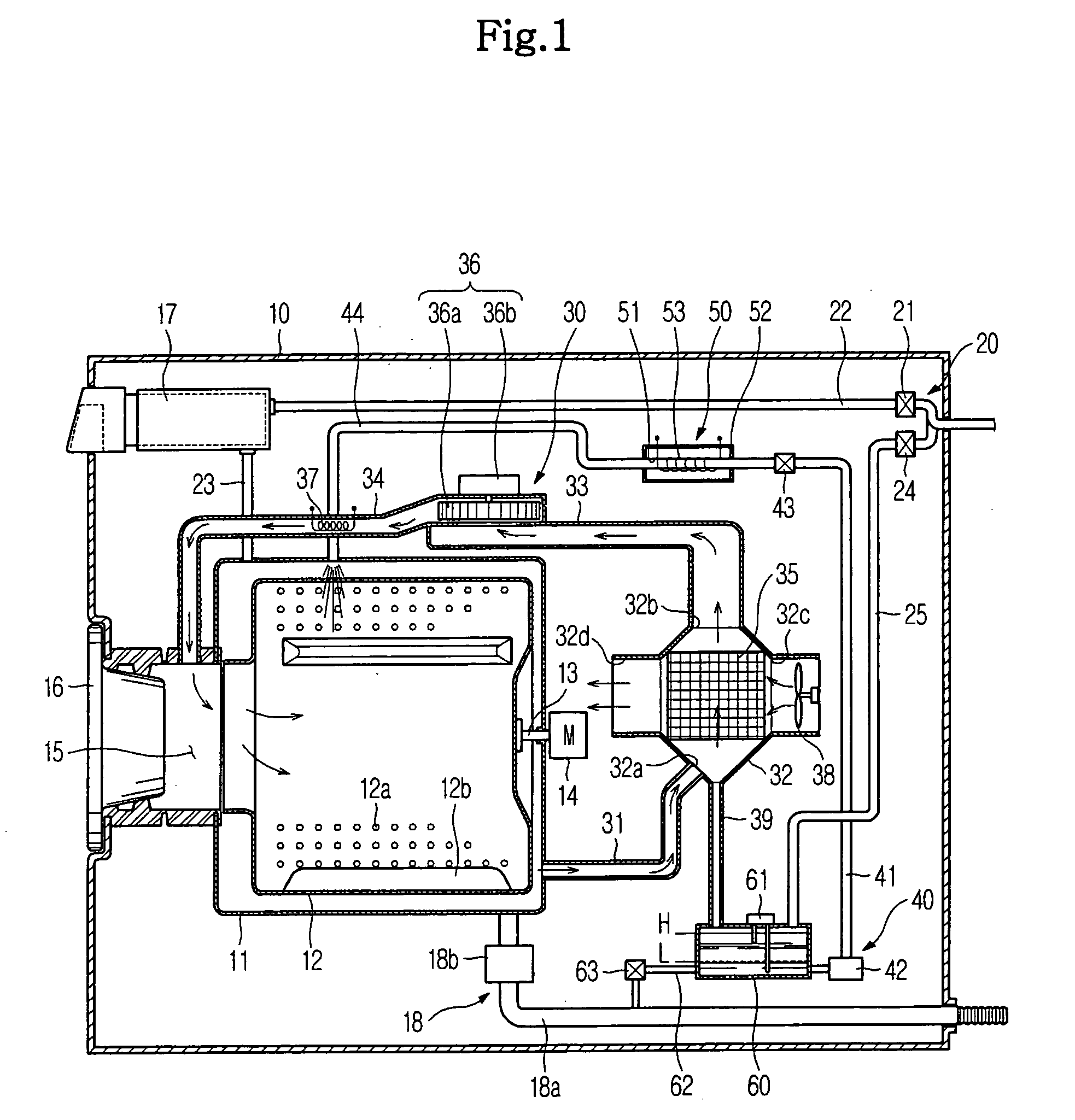

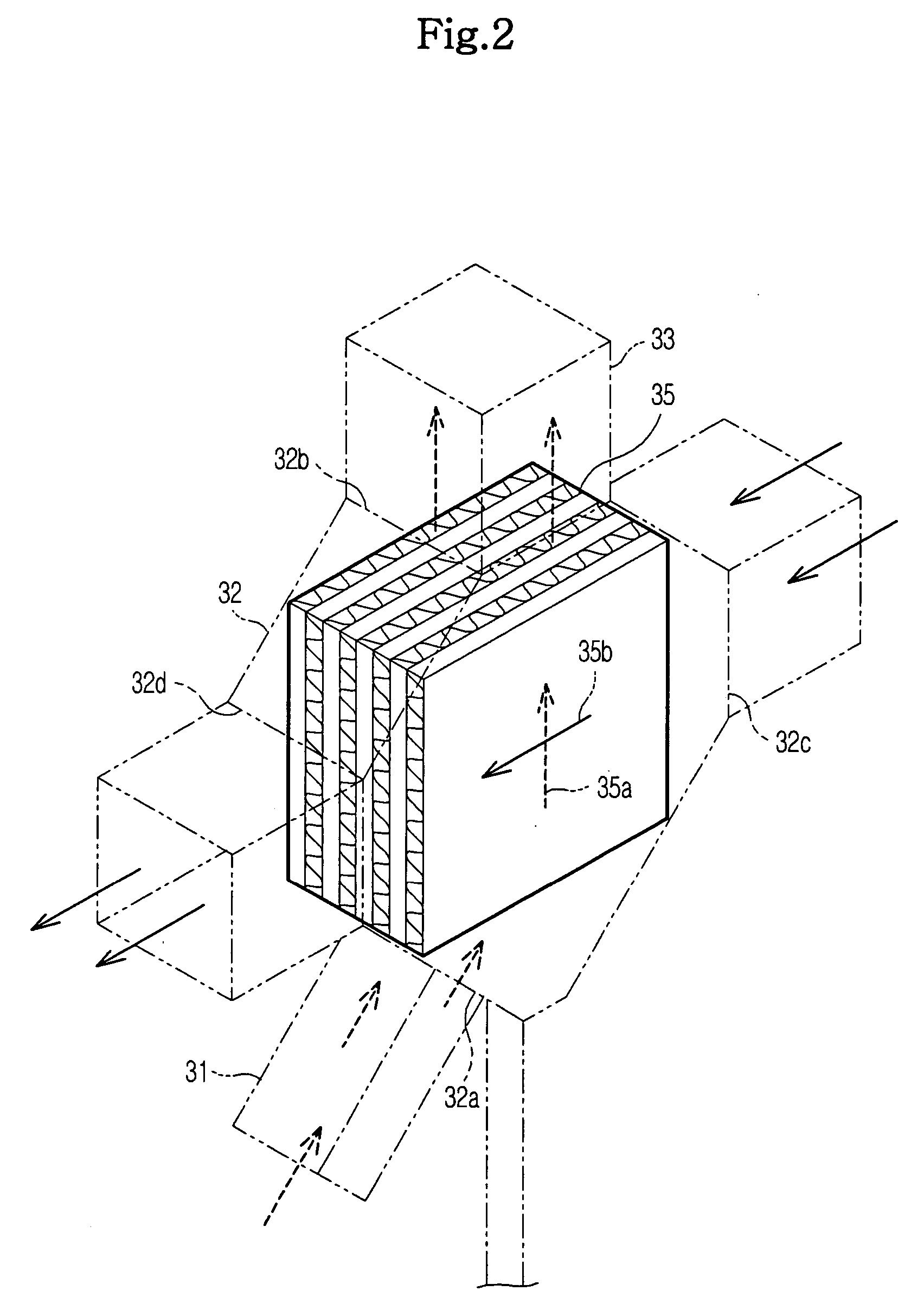

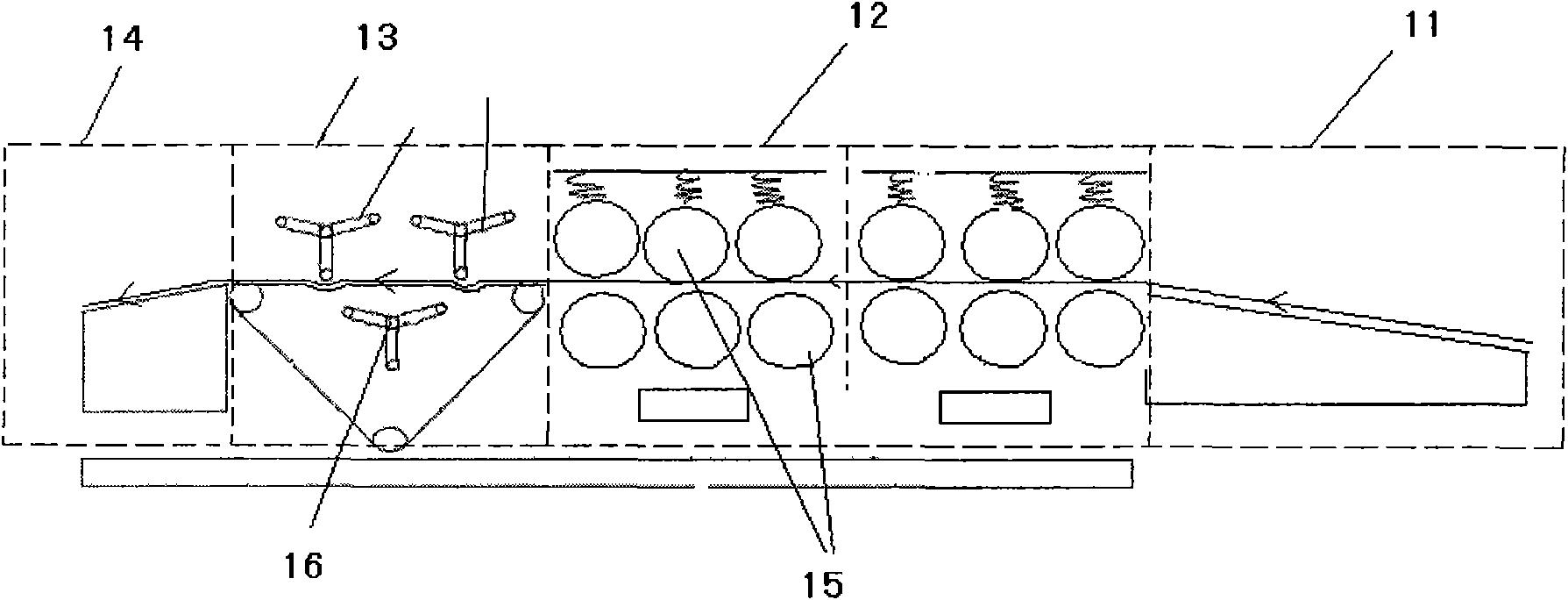

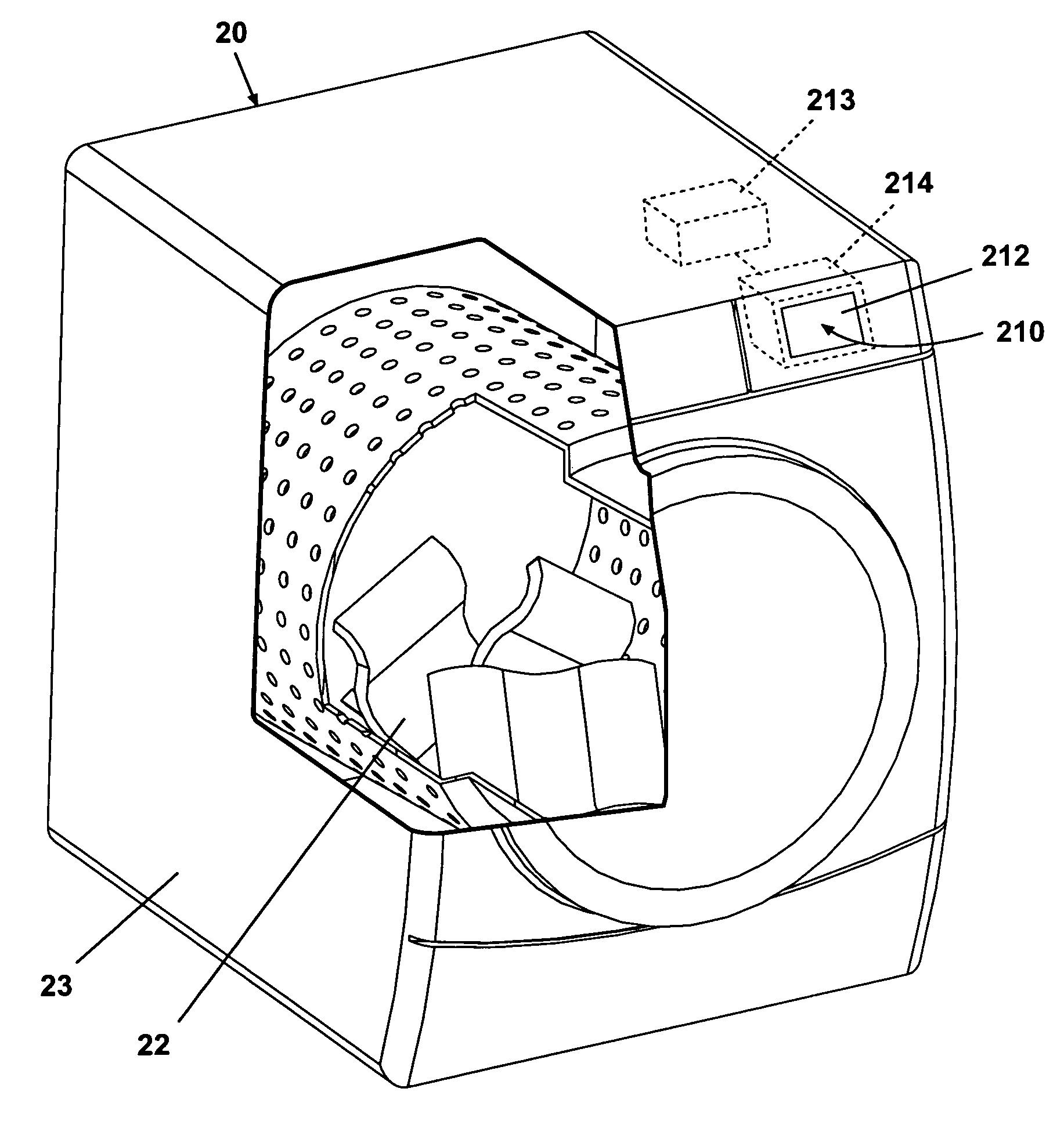

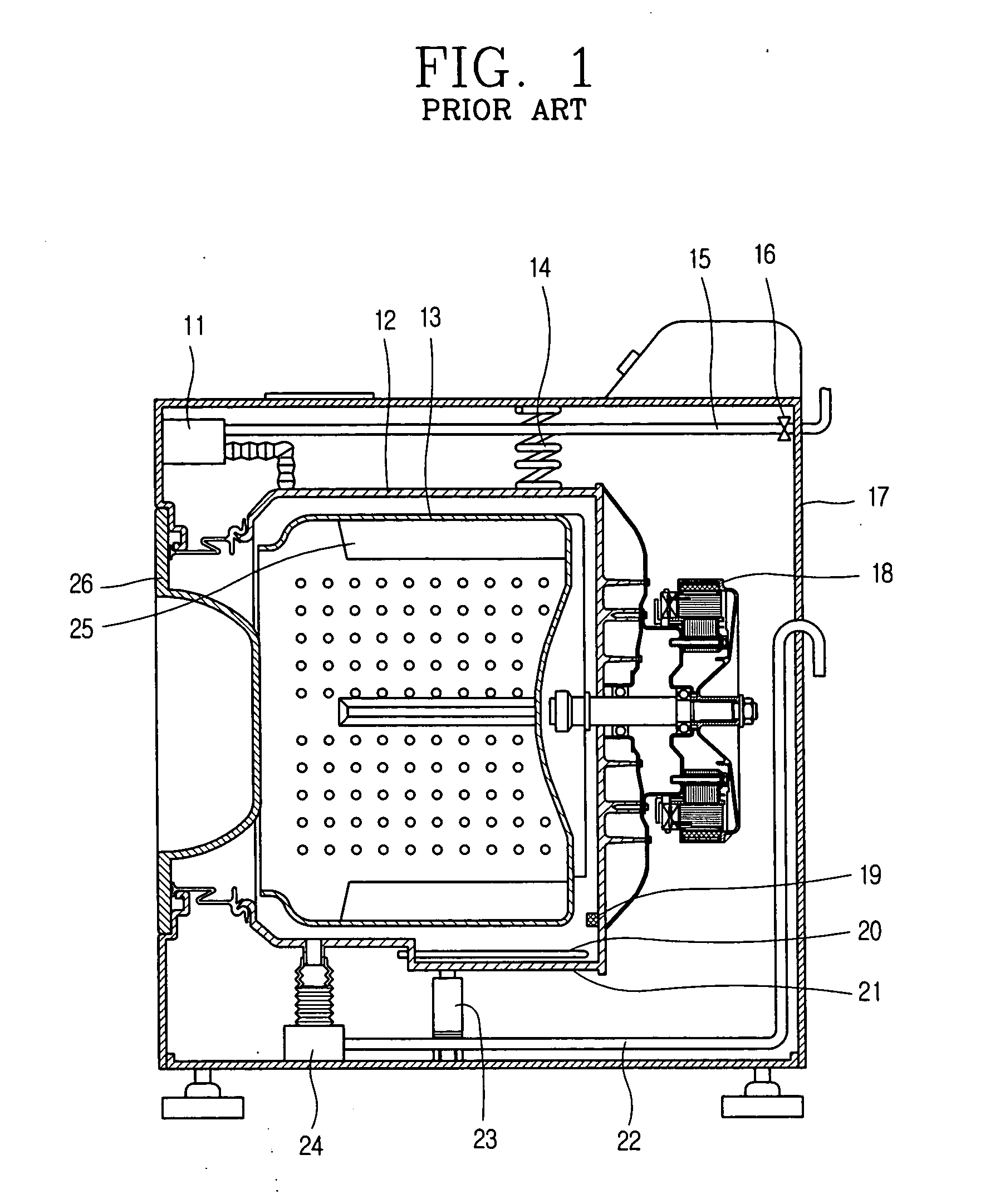

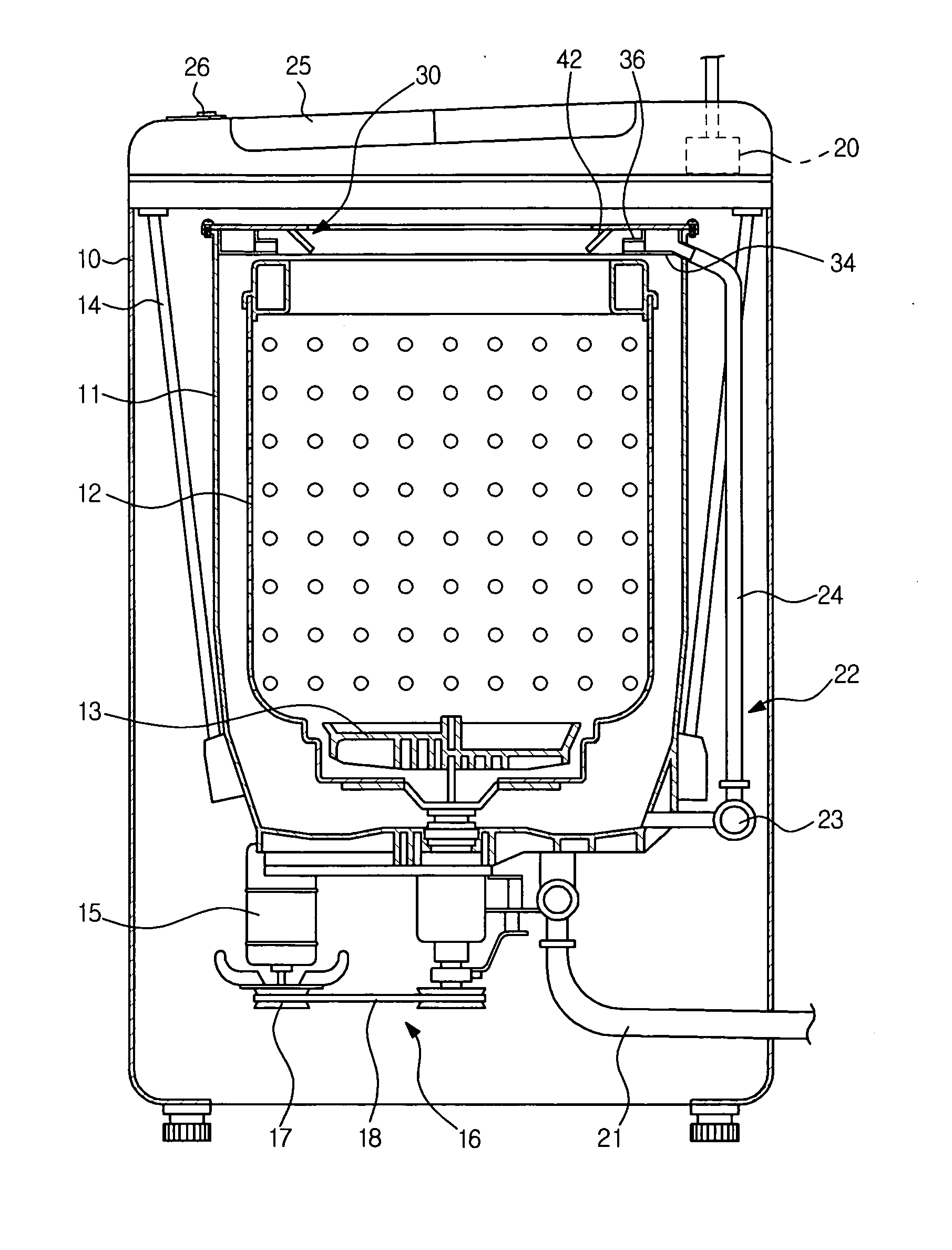

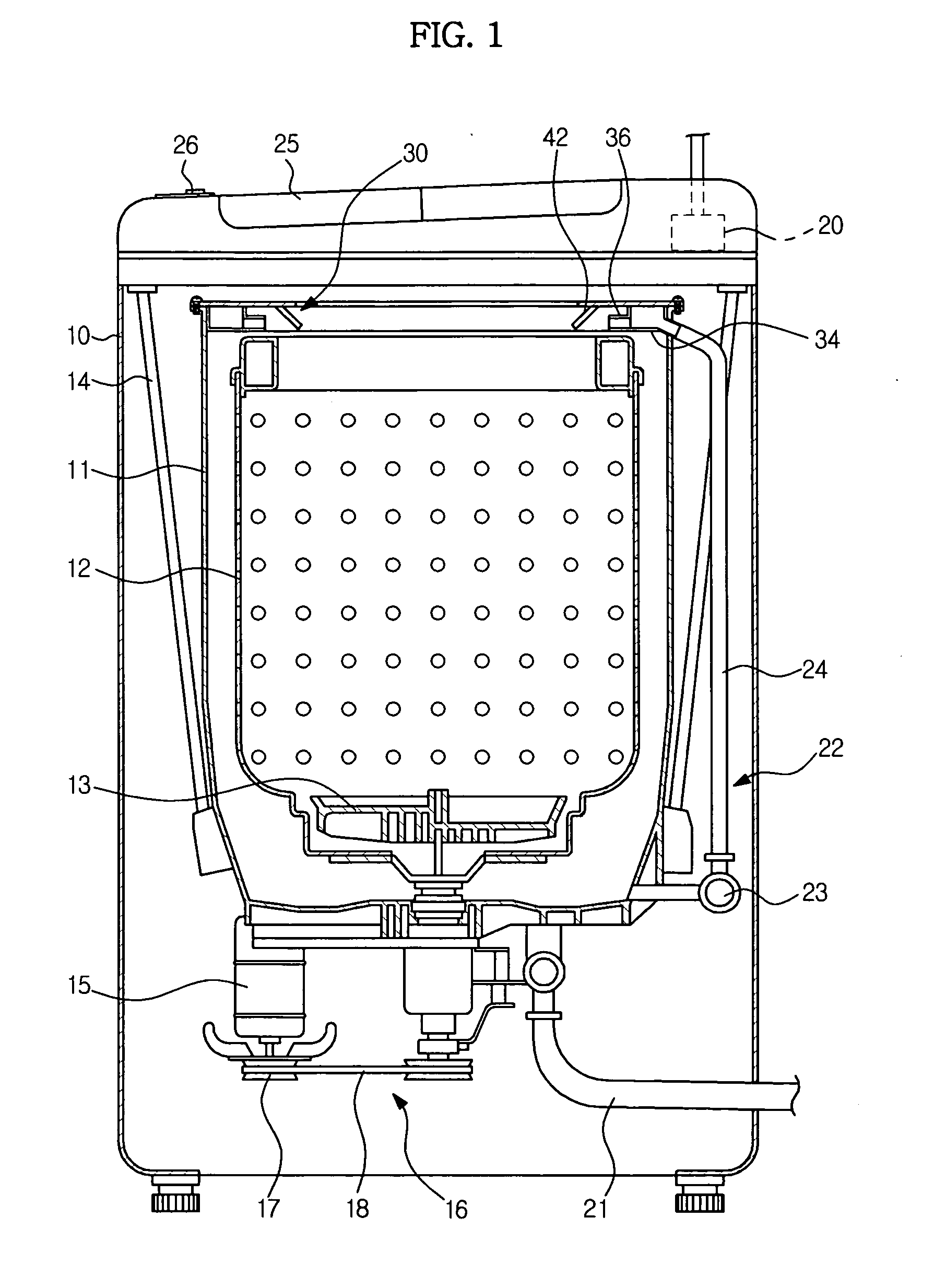

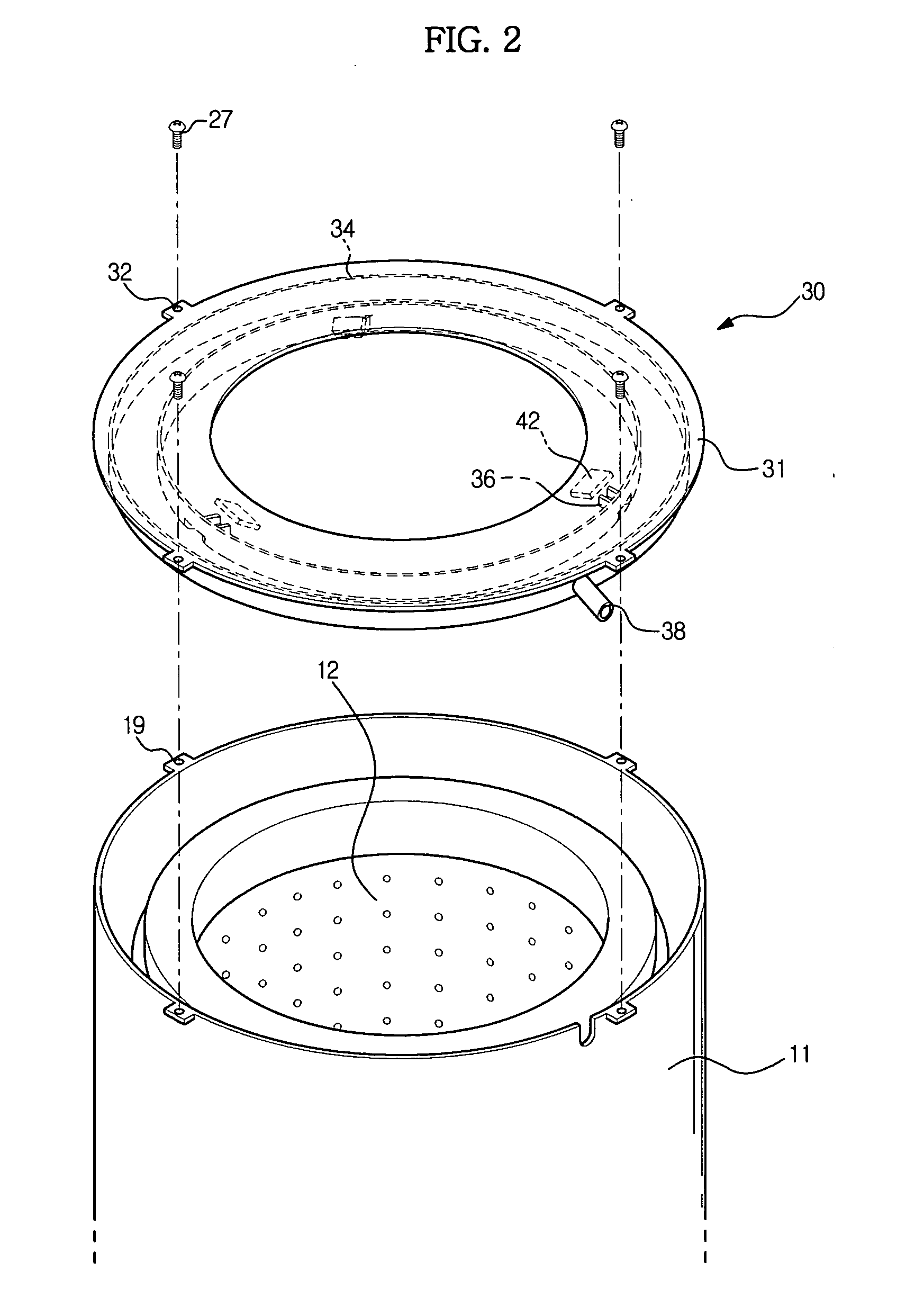

Washing machine and control method thereof

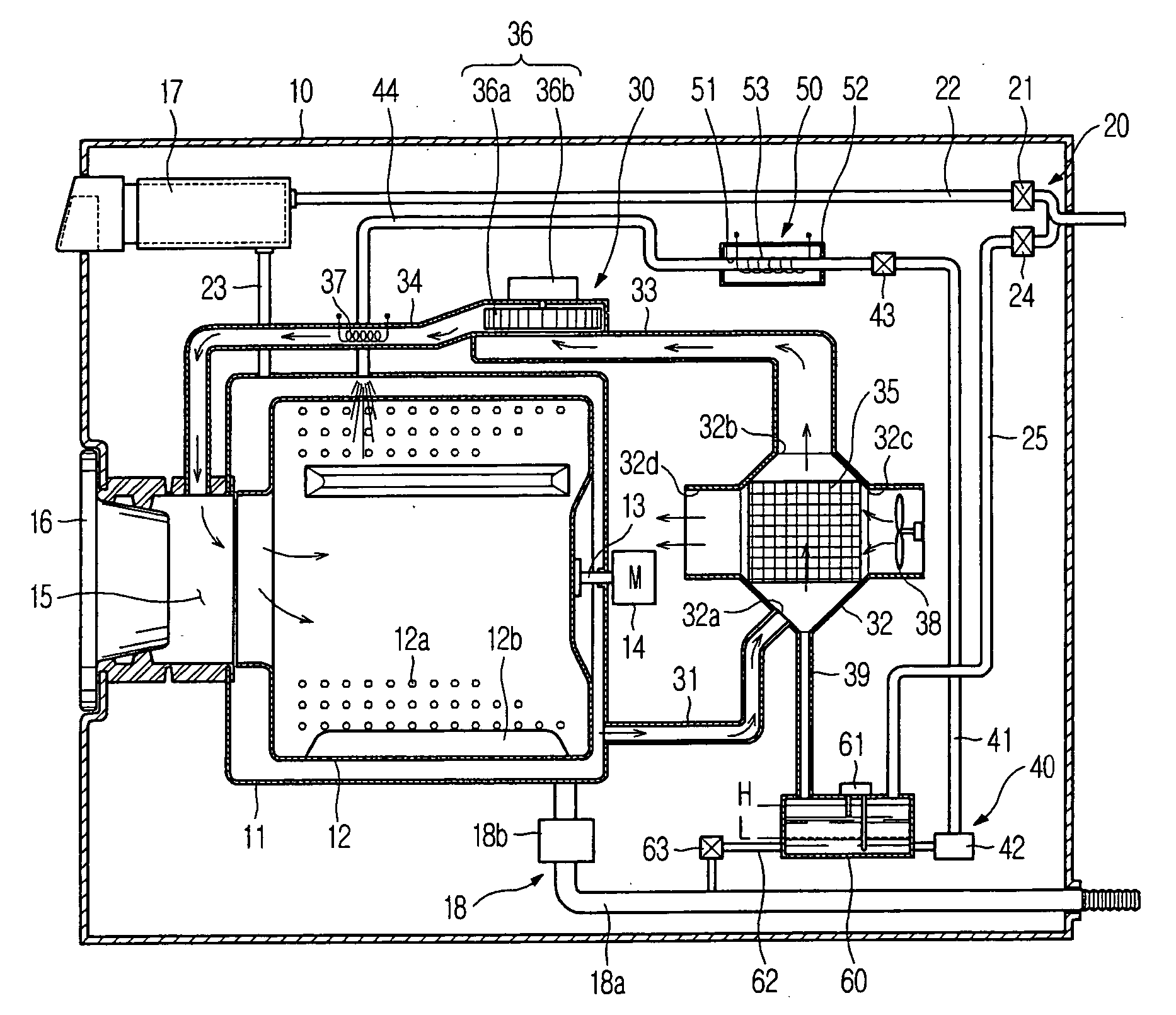

InactiveUS20060277690A1Minimizing formation of scaleOther washing machinesControl devices for washing apparatusProcess engineeringHeat exchanger

Disclosed herein are a washing machine and a control method thereof that is capable of supplying condensed water generated while laundry is dried to a steam generating unit to generate steam, thereby minimizing formation of scale in the steam generating unit. The washing machine includes a drying unit having a heat exchanger to dehumidify air in a washing tub, a steam generating unit to supply steam to the washing tub, a condensed water tank to collect condensed water from the heat exchanger, and a steam-purpose water supplying unit to supply the water from the condensed water tank to the steam generating unit.

Owner:SAMSUNG ELECTRONICS CO LTD

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

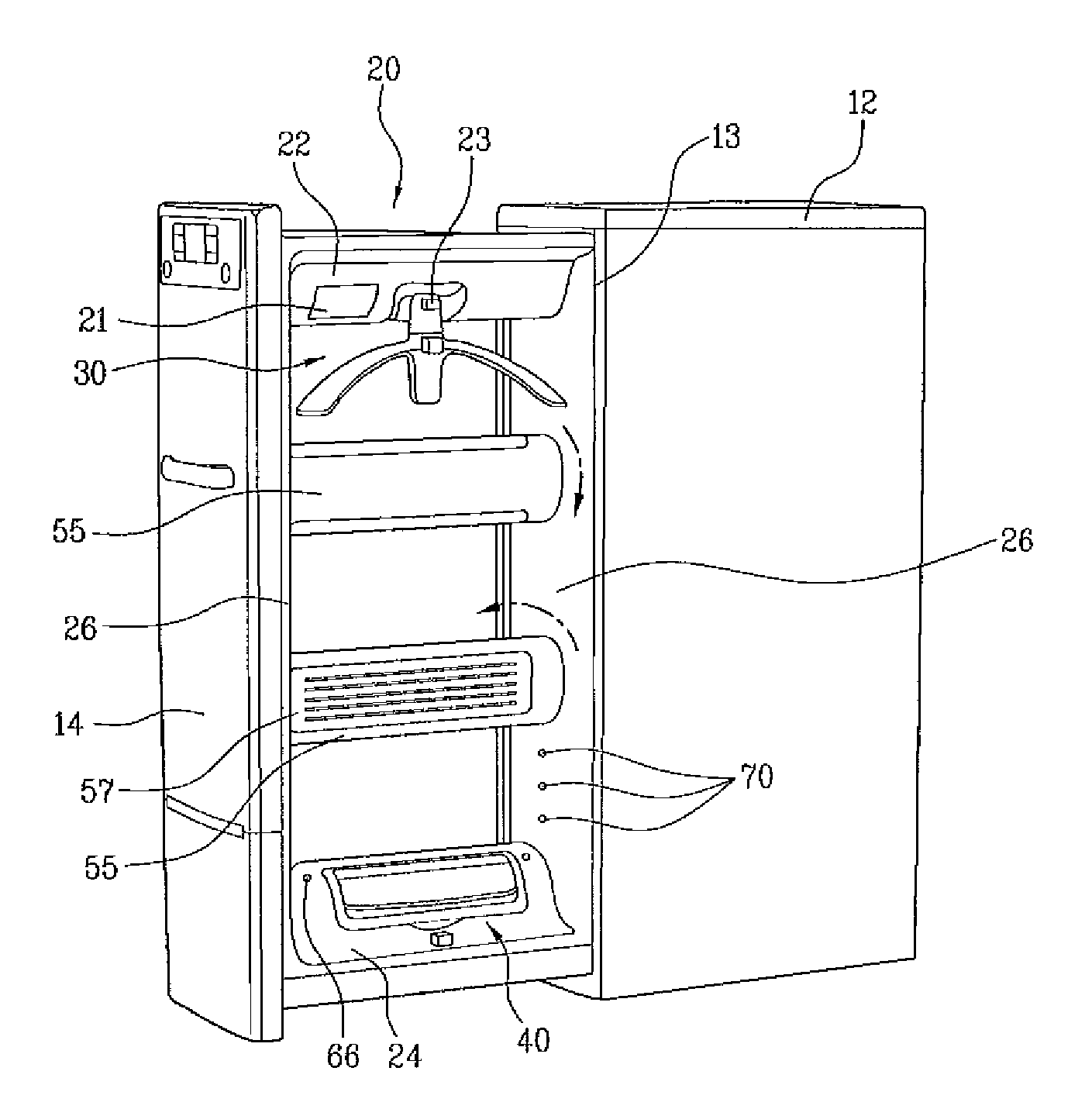

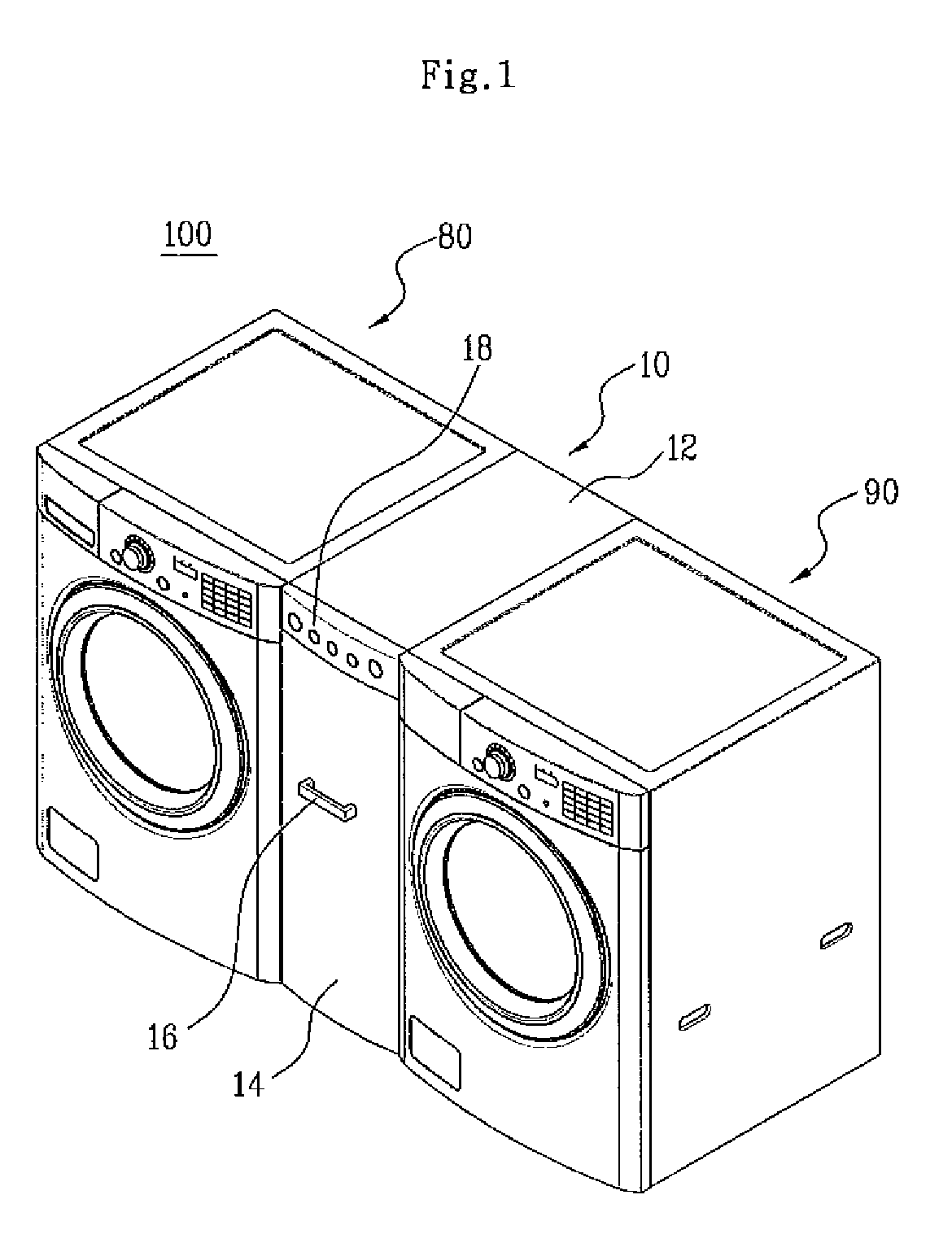

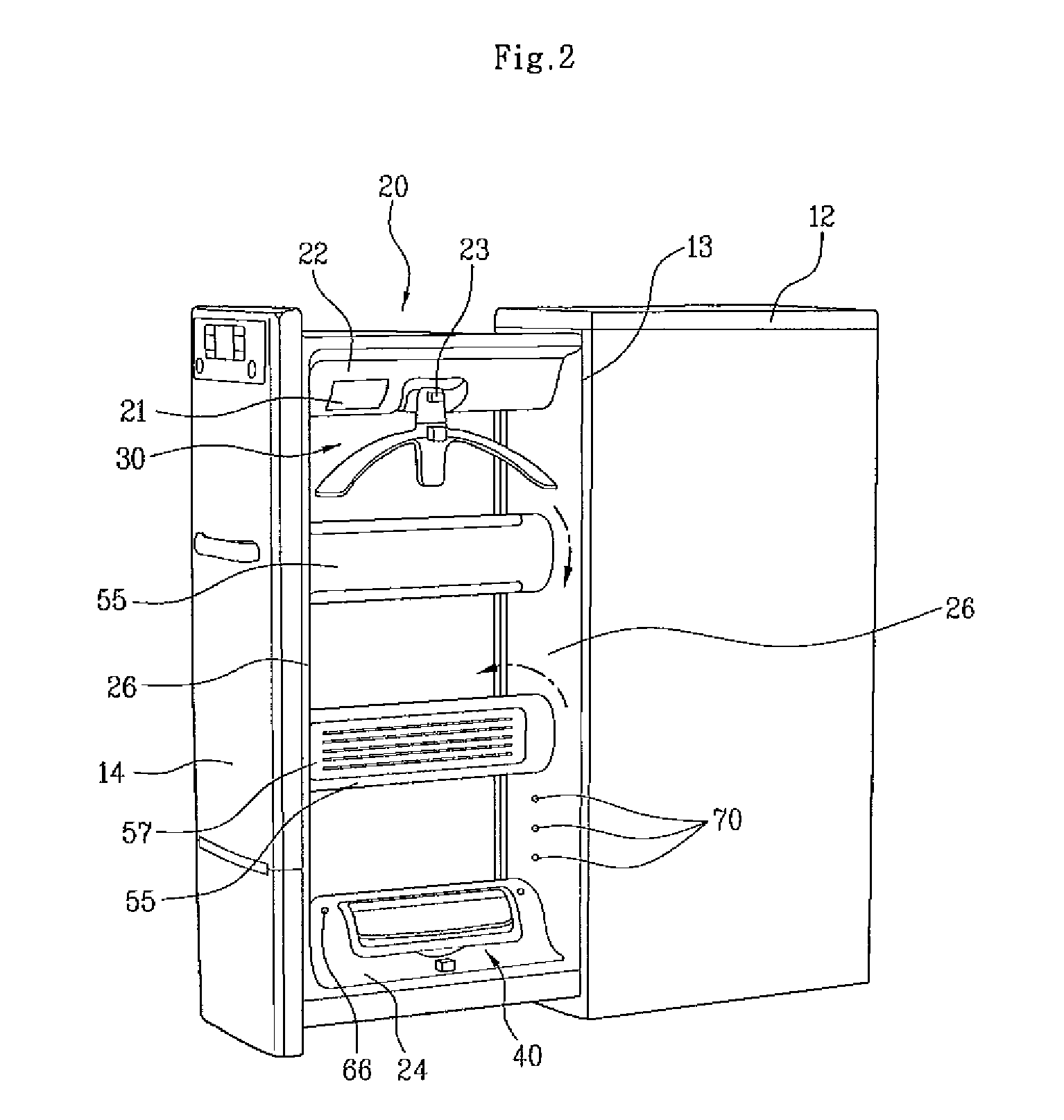

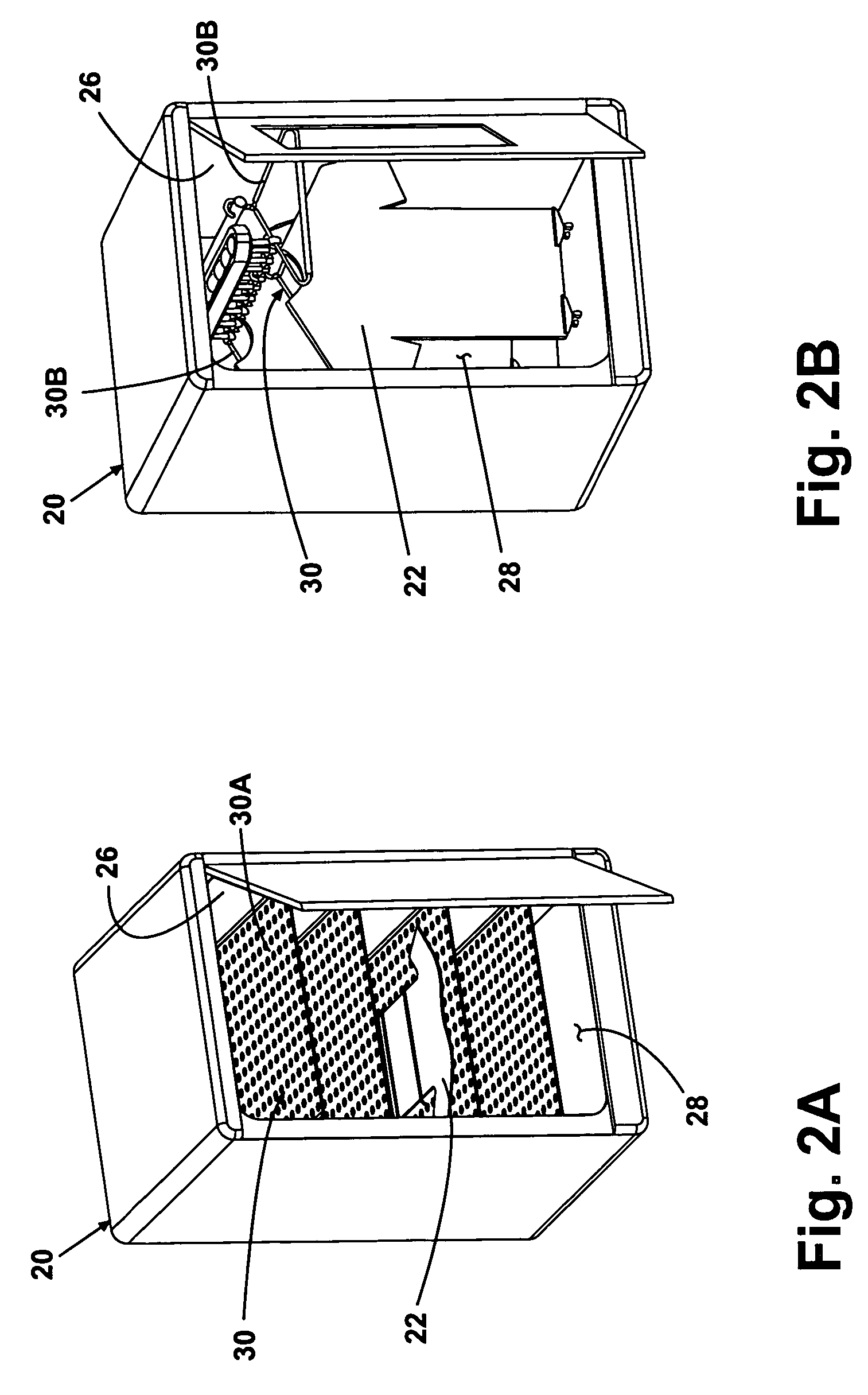

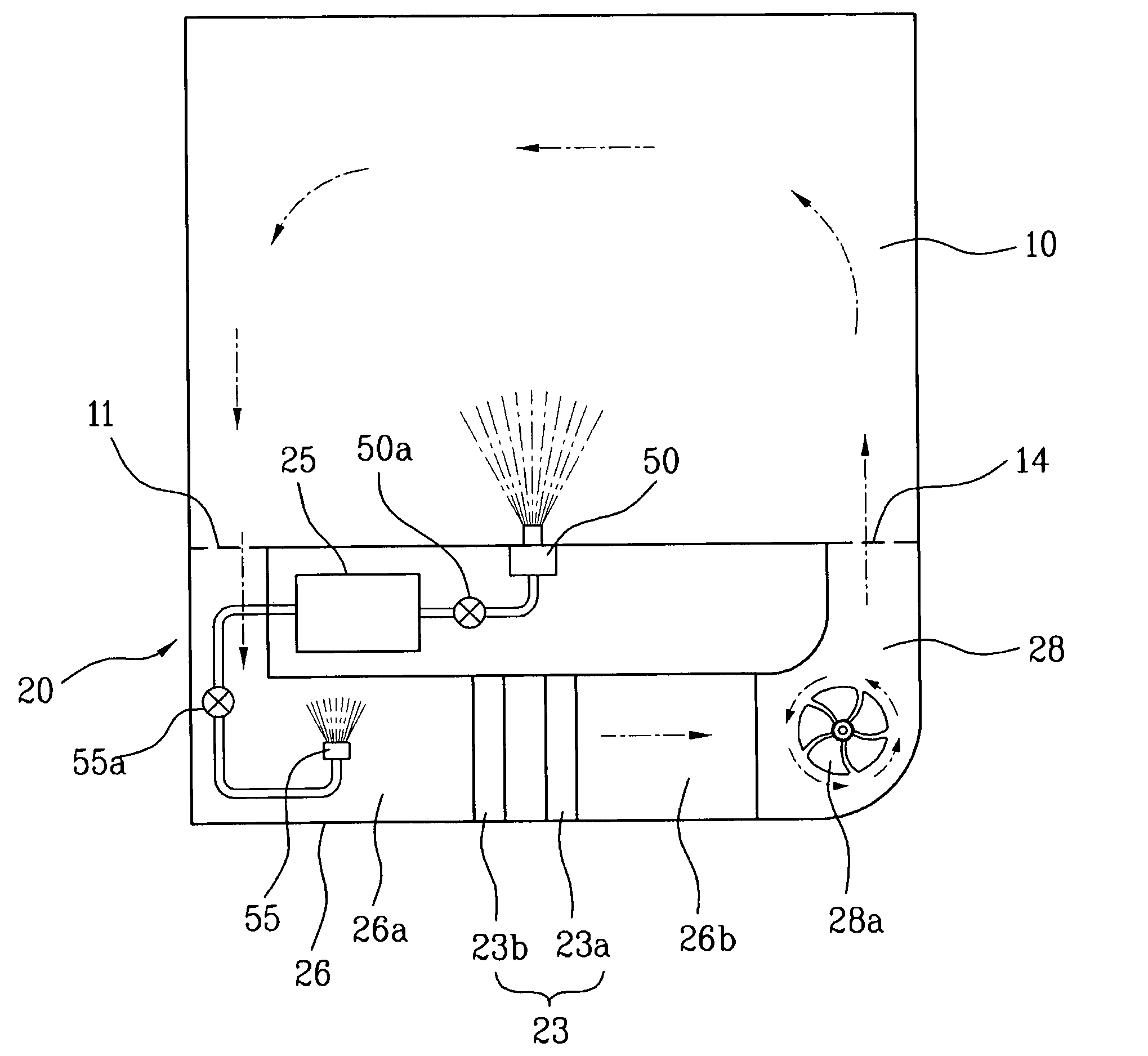

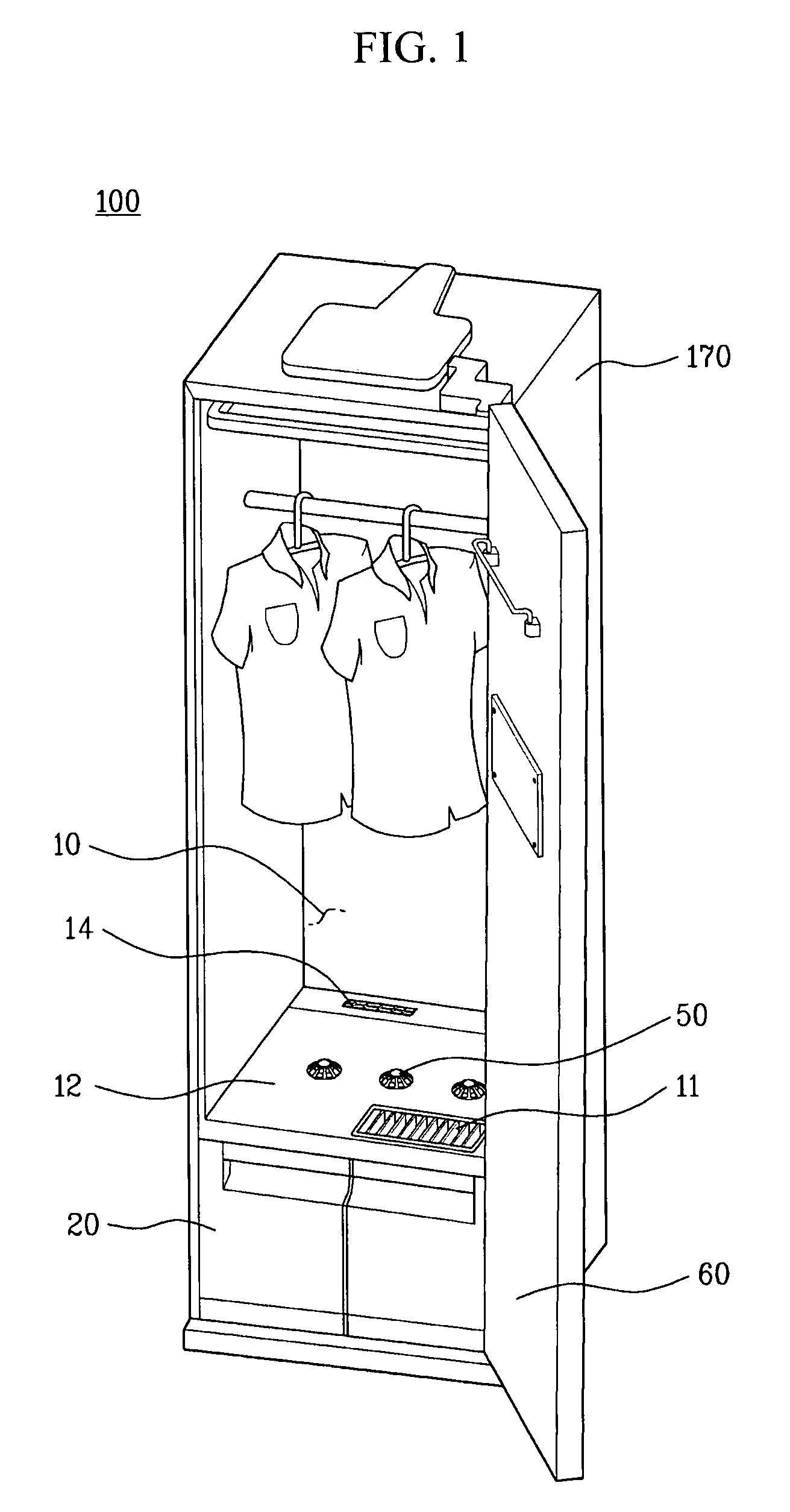

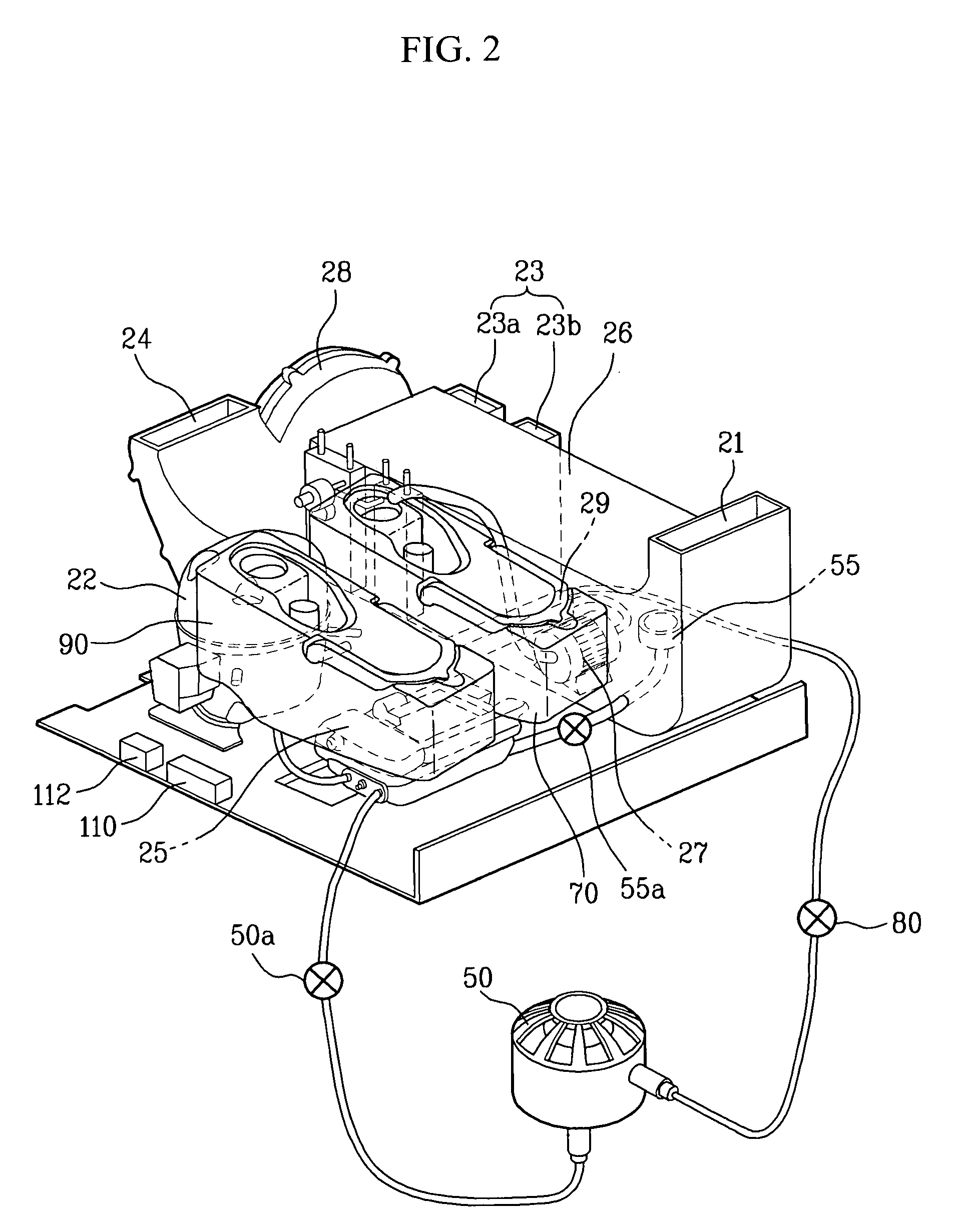

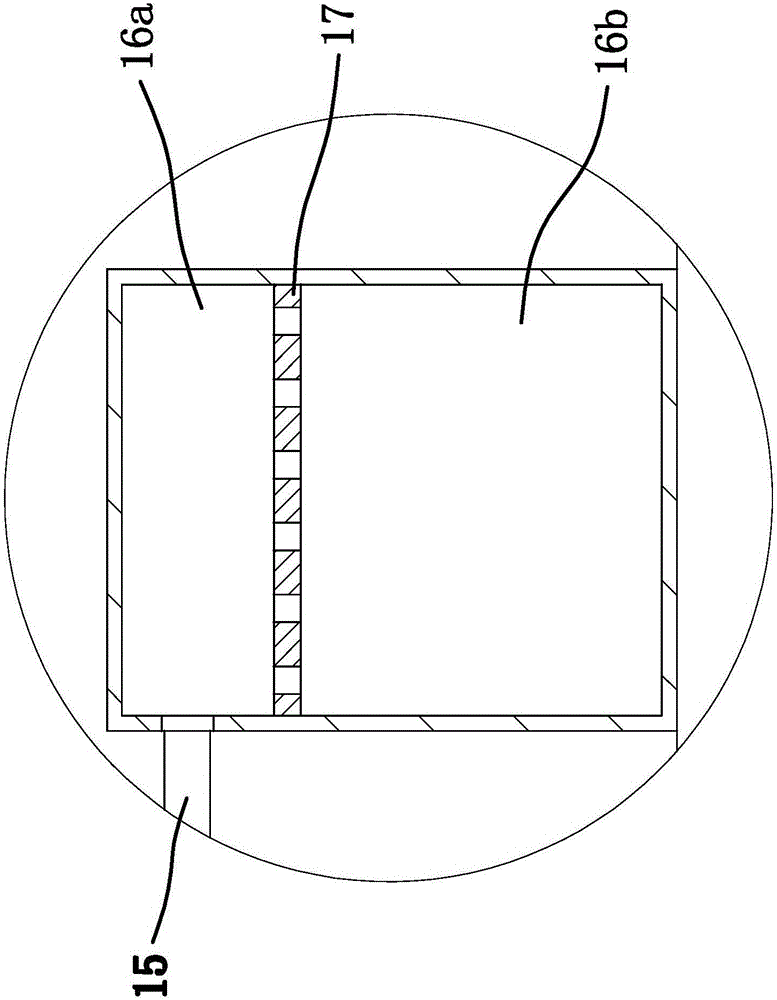

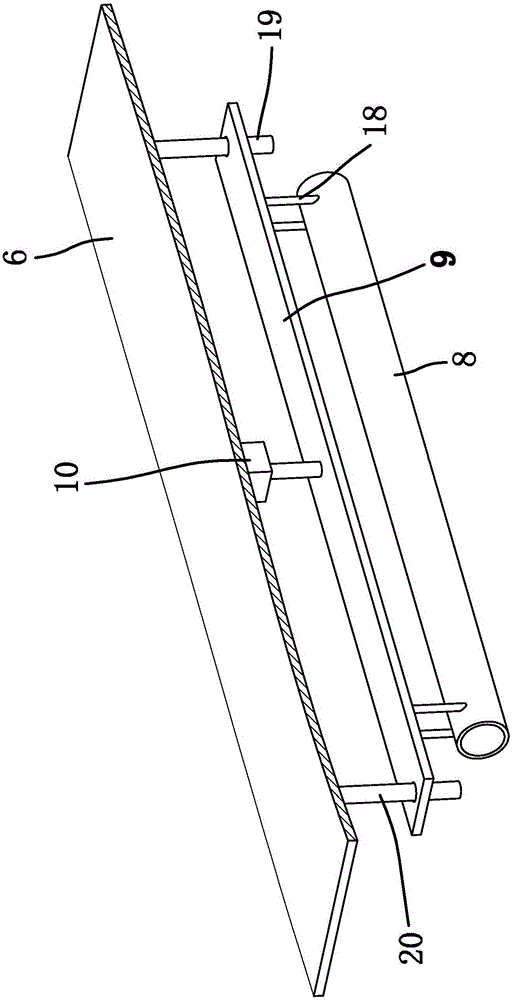

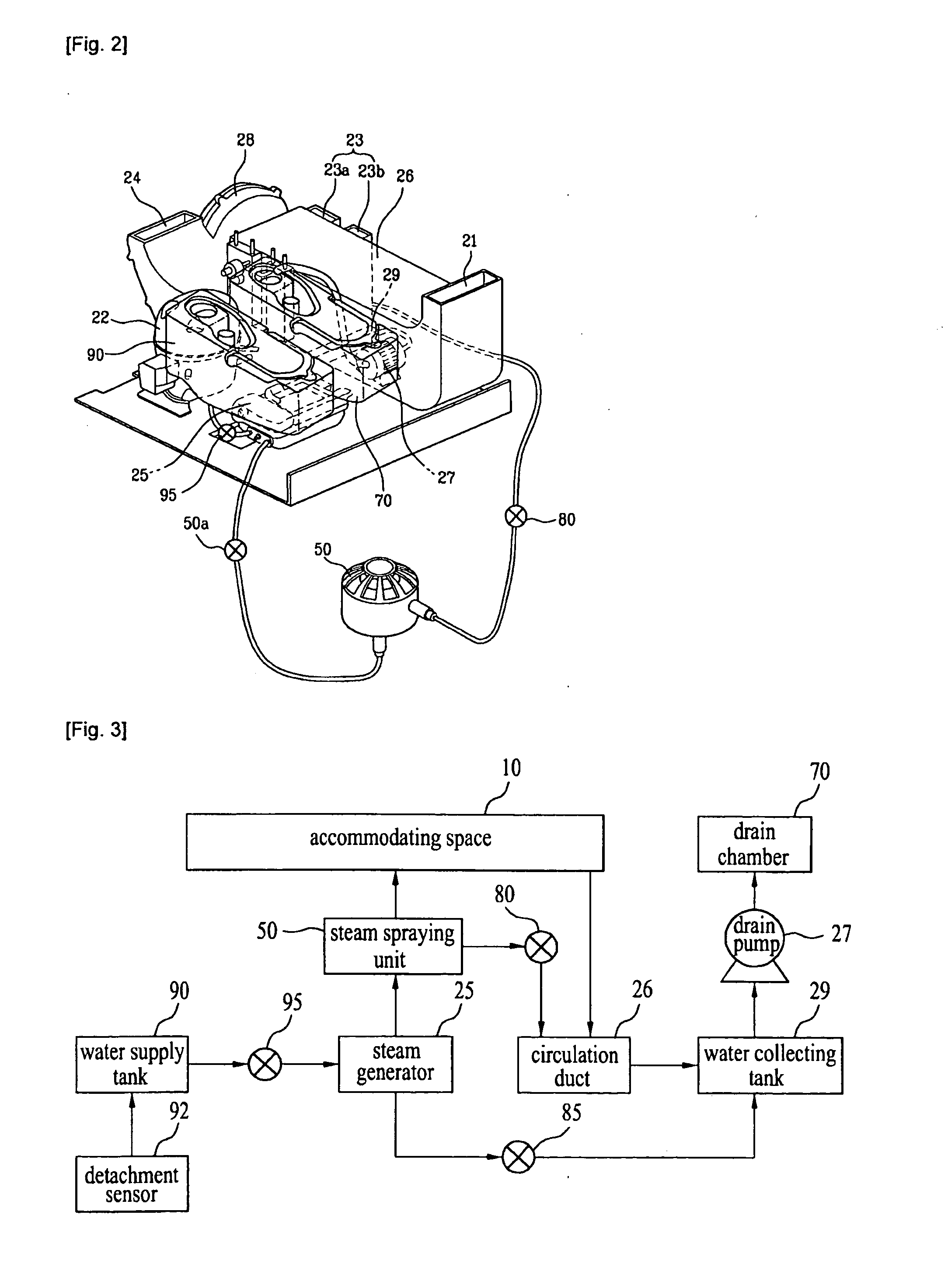

Supplemental clothes treating apparatus

InactiveUS20090126421A1Removing wrinkles of clothesTextile treatment machine partsOther washing machinesWaste management

Owner:LG ELECTRONICS INC

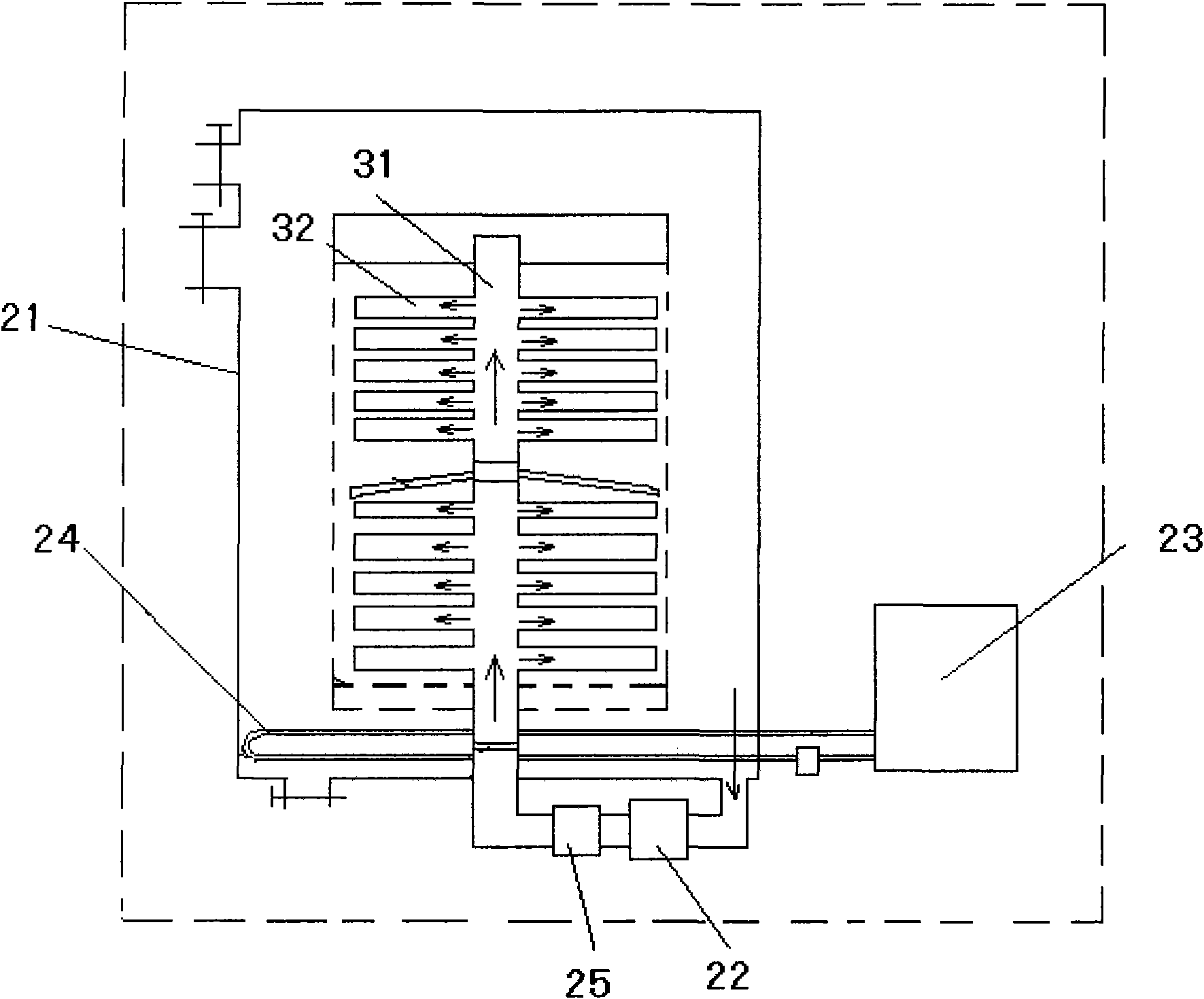

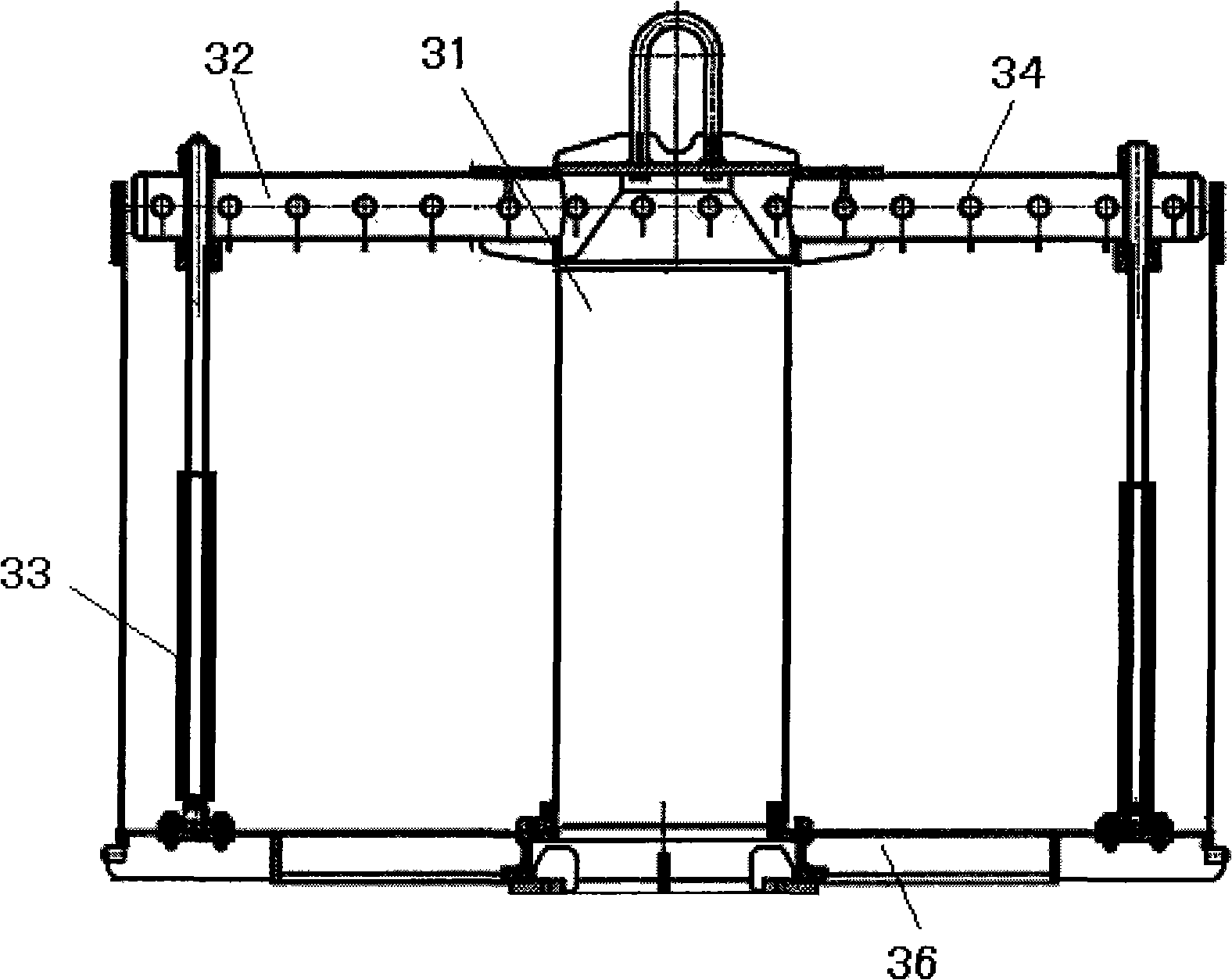

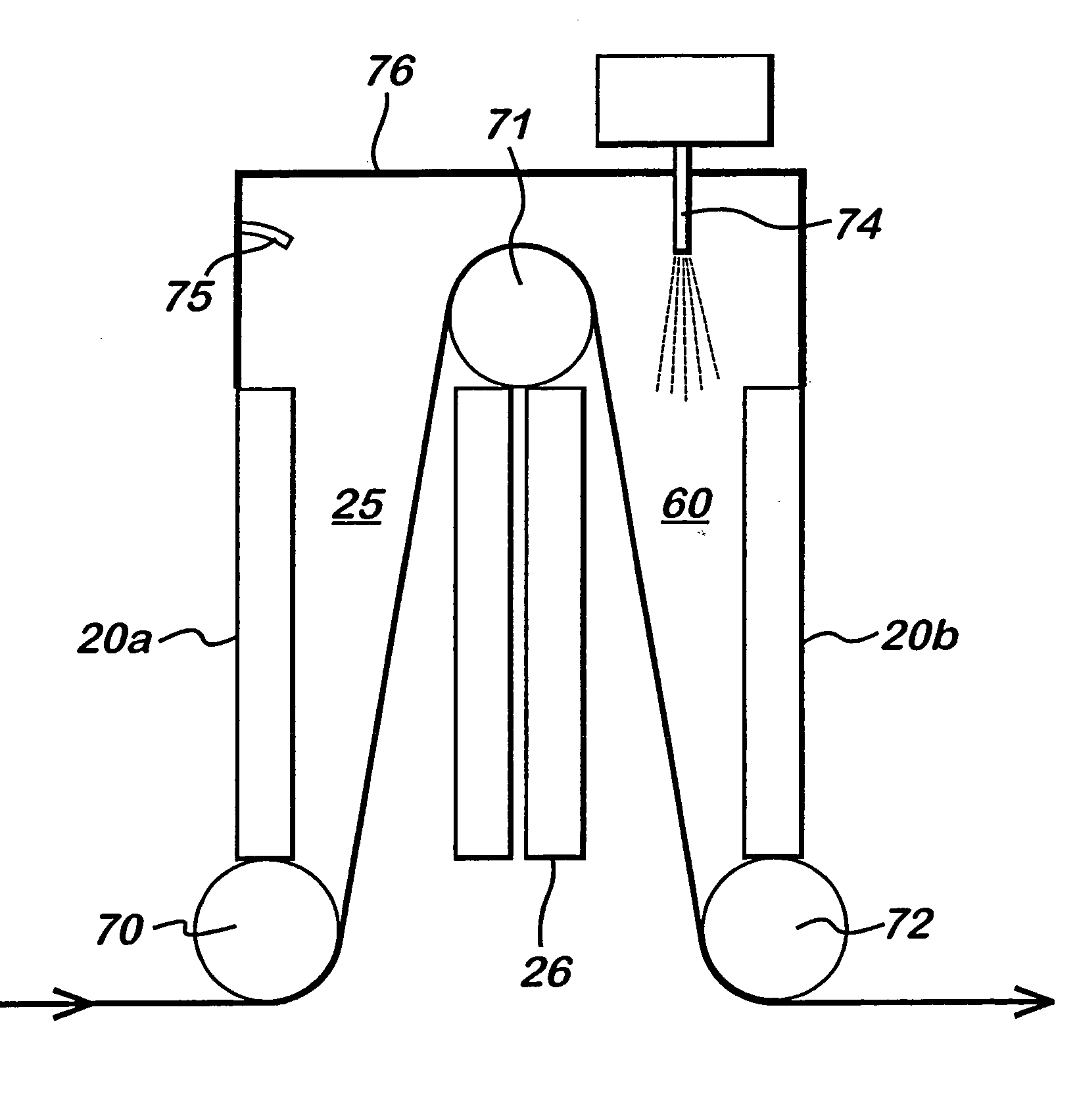

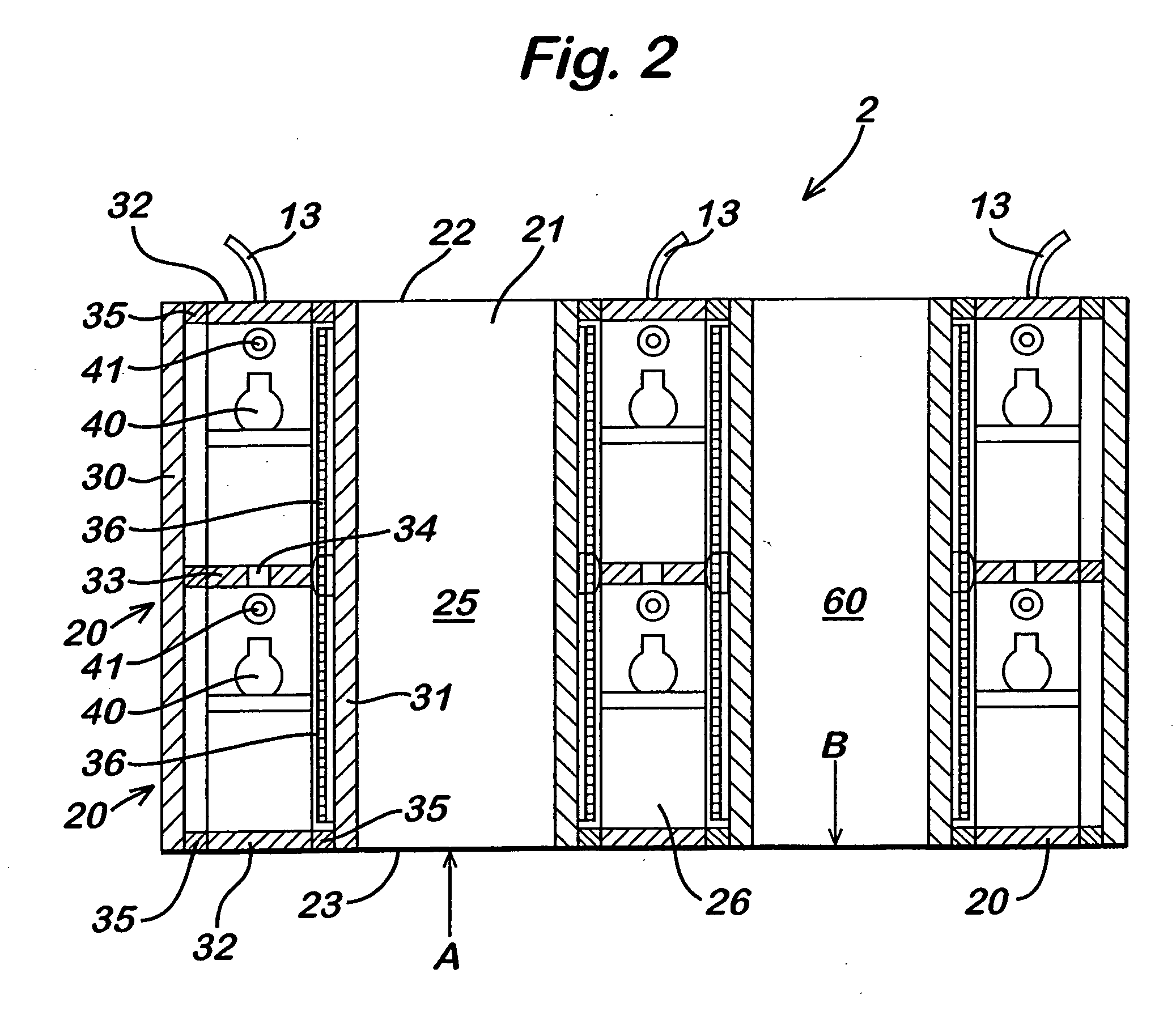

Atmospheric pressure plasma assembly

InactiveUS20050178330A1Efficient cooling agentEfficient electrodeElectric discharge tubesSurgeryPlanar electrodeDielectric plate

An atmospheric pressure plasma assembly (1) comprising a first and second pair of vertically arrayed, parallel spaced-apart planar electrodes (36) with at least one dielectric plate (31) between said first pair, adjacent one electrode and at least one dielectric plate (31) between said second pair adjacent one electrode, the spacing between the dielectric plate and the other dielectric plate or electrode of each of the first and second pairs of electrodes forming a first and second plasma regions (25,60) characterised in that the assembly further comprises a means of transporting a substrate (70,71,72) successively through said first and second plasma regions (25,60) and an atomiser (74) adapted to introduce an atomised liquid or solid coating making material into one of said first or second plasma regions.

Owner:DOW CORNING IRELAND

Method for preparing product with one-way moisture-conducting function

ActiveCN101962885AExcellent unidirectional moisture transfer performanceFeel coolTextile treatment by spraying/projectingVegetal fibresHydrophilizationEngineering

The invention relates to a method for preparing a product with a one-way moisture-conducting function. The method comprises the following steps of: 1) performing hydrophilization pretreatment on a textile; and 2) spraying water repellent finishing agent-containing working solution on one face of the treated textile, so that liquid drops with diameter of 0.1 to 2mm and spacing of 0.1 to 2mm are formed on the face of the textile and the product with the one-way moisture-conducting function is obtained. Fabrics prepared by the method has the advantages of greatly reducing the using amount of a plurality of resources such as water, energy and the like and solving the environmental problems of pollution discharge and the like, along with the one-way moisture-conducting property.

Owner:CHINA TEXTILE ENG SOC +3

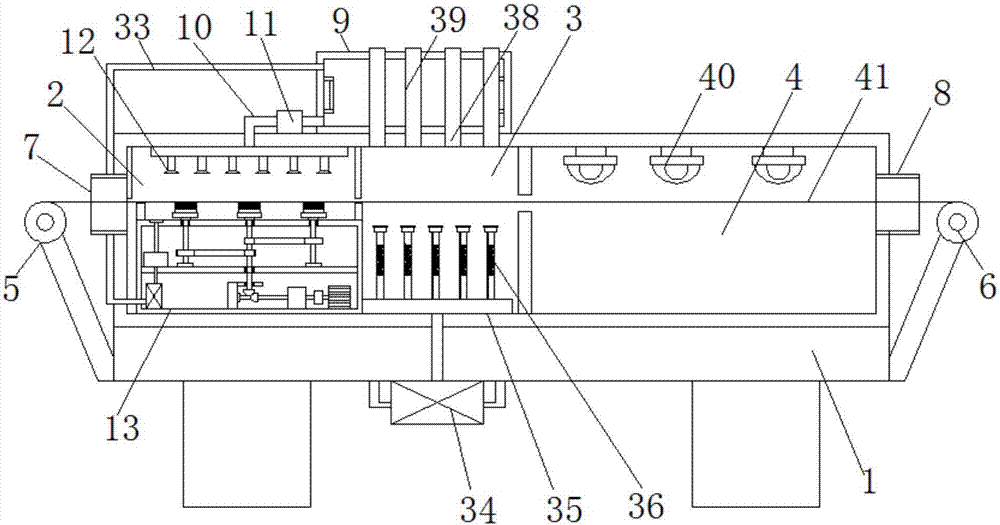

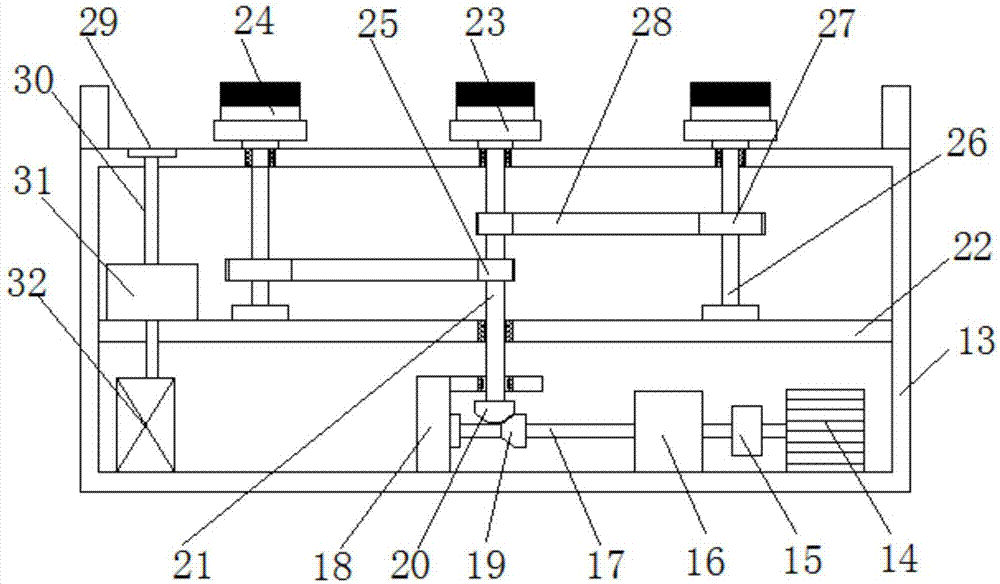

Energy-conserving textile fabric washing device

InactiveCN107326567AWash thoroughlySolve incomplete cleaningLiquid/gas/vapor removalTextile treatment machine arrangementsAgricultural engineeringWater pipe

The invention discloses an energy-conserving textile fabric washing device. The washing device comprises a case. A cleaning room, a drying room and a disinfection room are formed in an inner cavity of the case in sequence from left to right. A fixed support on the left side face of the case is fixedly connected with a feeding roller through a fixed shaft. A fixed support on the right side face of the case is fixedly connected with a discharge roller through a fixed shaft. A feeding opening is formed in the upper portion of the left side face of the case. A discharge opening is formed in the upper portion of the right side face of the case. The upper surface of the case is fixedly connected with a water storage tank, and the bottom of the left side face of the water storage tank is fixedly connected with a water pipe fixedly connected with a booster pump. The energy-conserving textile fabric washing device has the advantages of thoroughly cleaning and disinfecting cloth, effectively recycling cleaning fluid to avoid water body pollution and effectively utilizing heat in the drying room. The problems are solved that existing textile fabric wastes energy and cannot be cleaned thoroughly.

Owner:秦泽坤

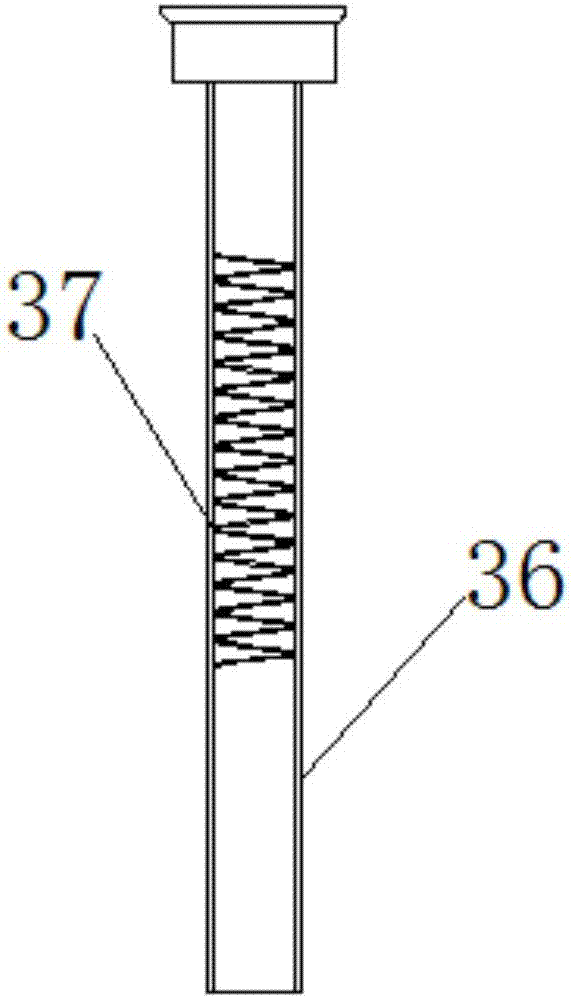

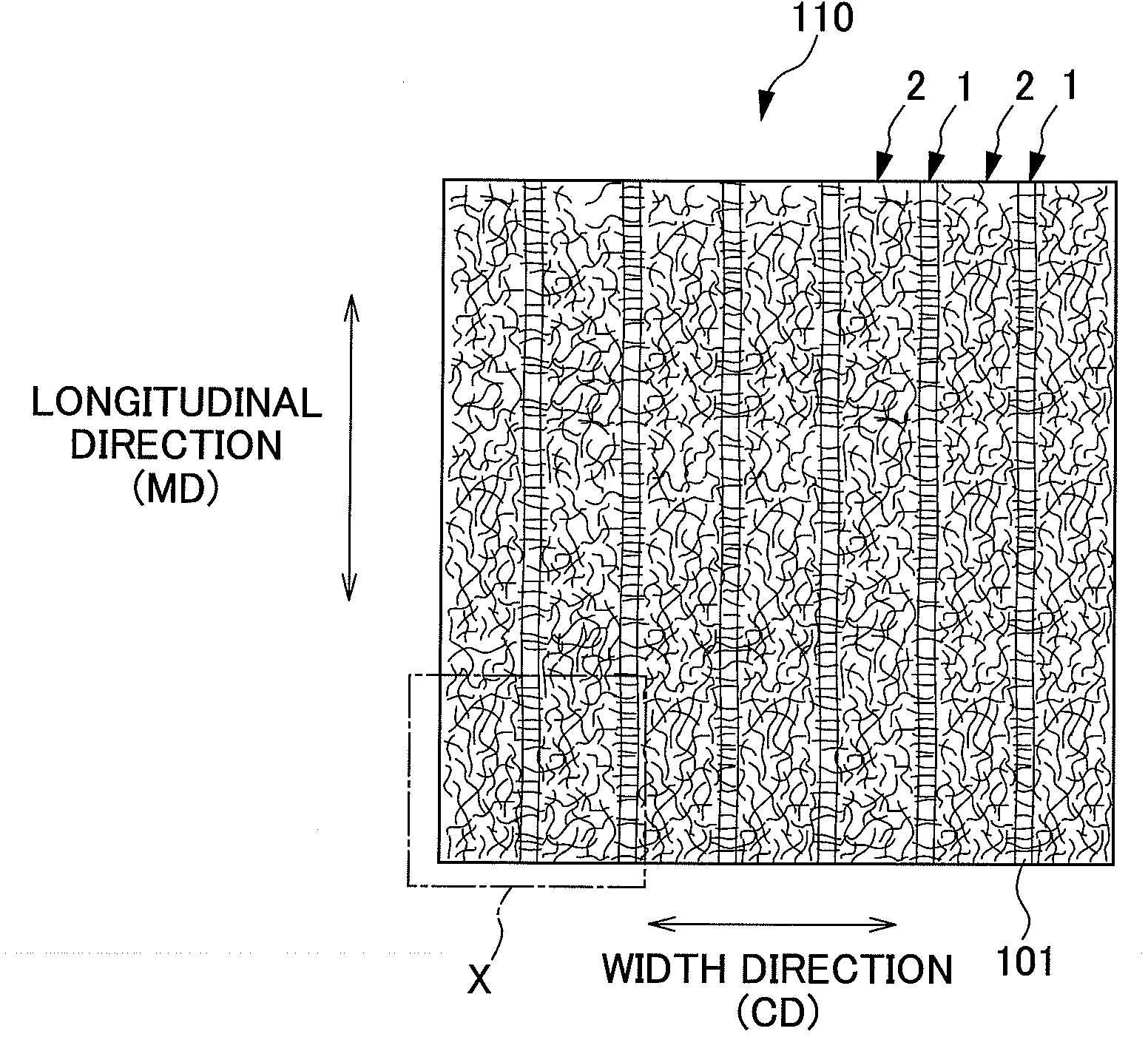

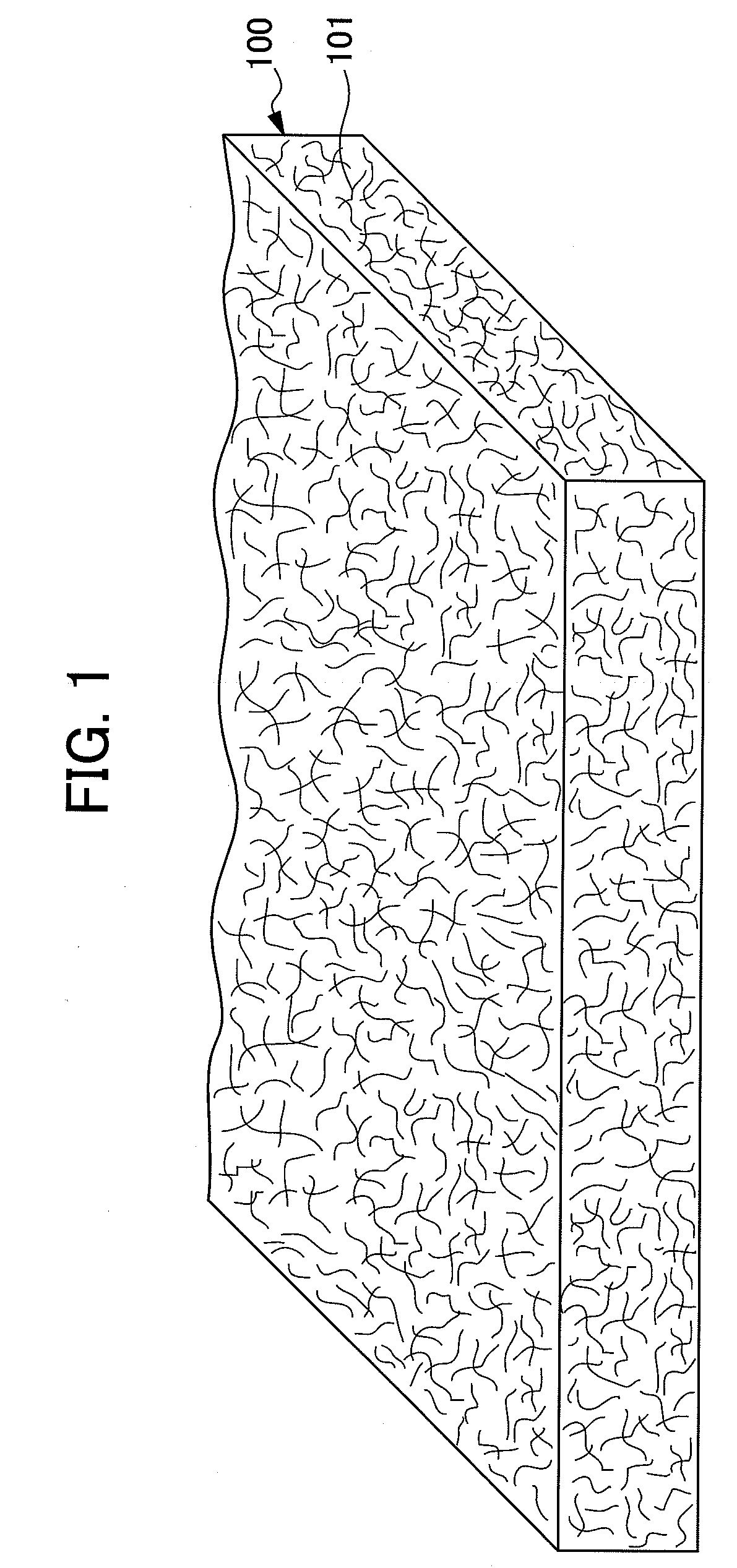

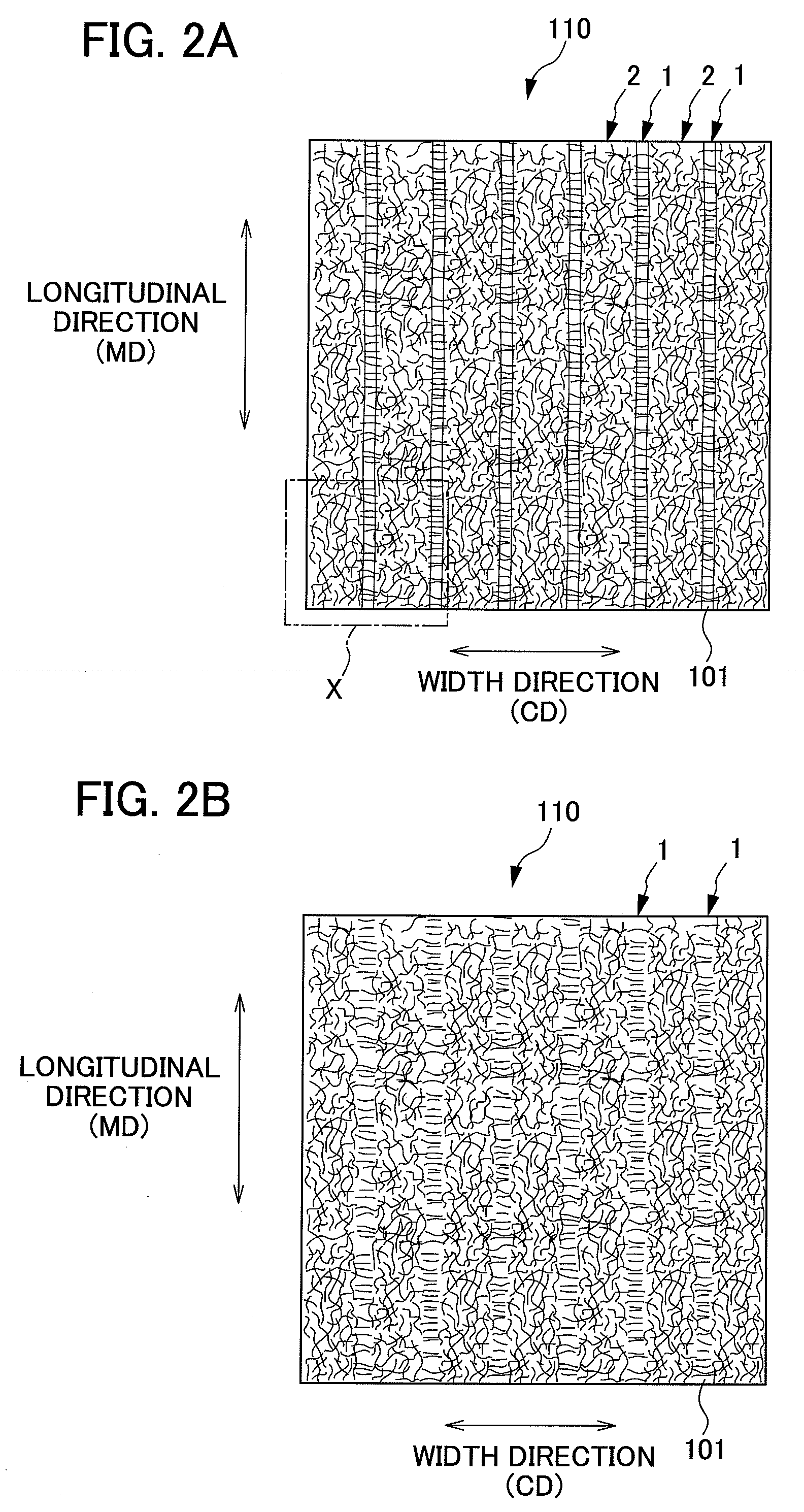

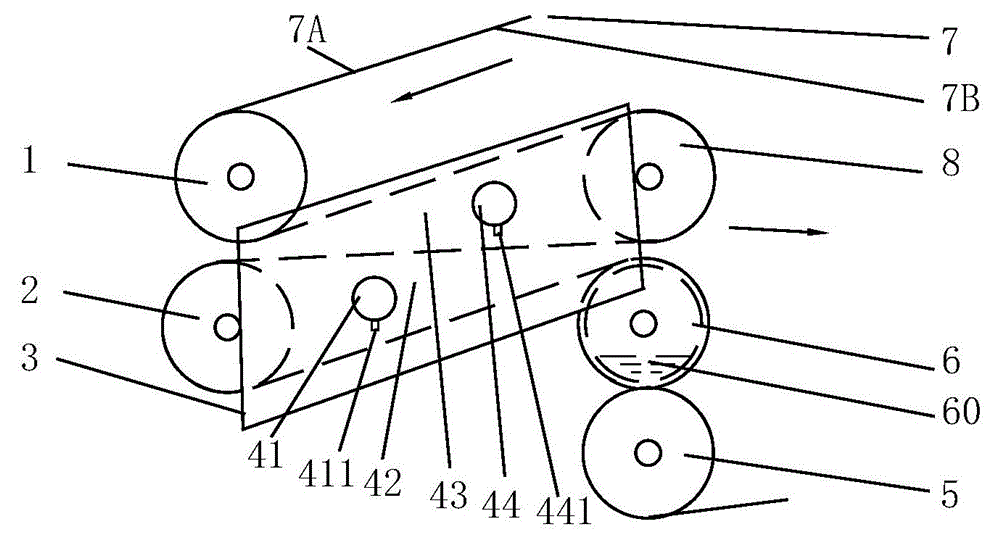

Nonwoven fabric, nonwoven fabric manufacturing method, and nonwoven fabric manufacturing apparatus

The present invention provides a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, and in which at least one of a predetermined groove portion, an opening, and a protrusion is formed, a manufacturing method for the nonwoven fabric, and a nonwoven fabric manufacturing apparatus. The nonwoven fabric manufacturing apparatus of the present invention manufactures a nonwoven fabric of which at least one of fiber orientation, fiber density, and basis weight is adjusted, or in which at least one of a predetermined groove portion, an opening, and a protrusion is formed by blowing fluid mainly containing gas onto a fiber web which is formed in a sheet shape, and which is in a state where at least a portion of the fibers constituting the fiber aggregate has a degree of freedom.

Owner:UNI CHARM CORP

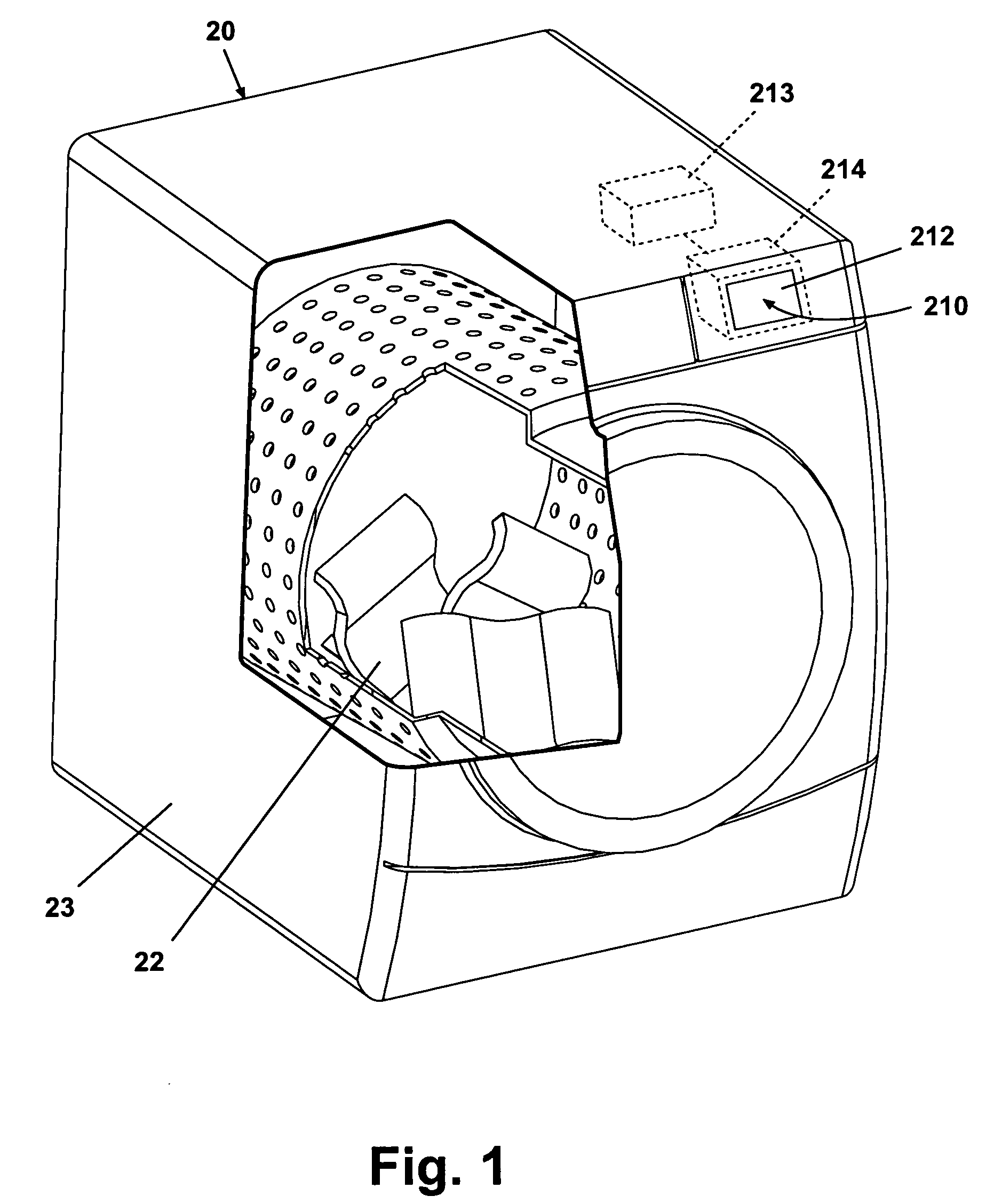

Control process for a revitalizing appliance

InactiveUS20070151041A1Reduce absorptionIroning boardsDry-cleaning apparatusEngineeringRelative motion

A method for revitalizing a fabric load with a revitalization system comprises selecting a revitalization program from a plurality of programs and operating the revitalization system in accordance with the selected revitalization program. The programs can include at least one of a fluid insertion step; a fabric relative motion step; a fluid extraction step; a fabric refreshing step; a fabric reshaping step; a light cleaning step; a water extraction operation, a relative motion operation; a fabric air flow operation; a cooling operation; a fluid insertion operation; and a fabric fluid absorption operation.

Owner:WHIRLPOOL CORP

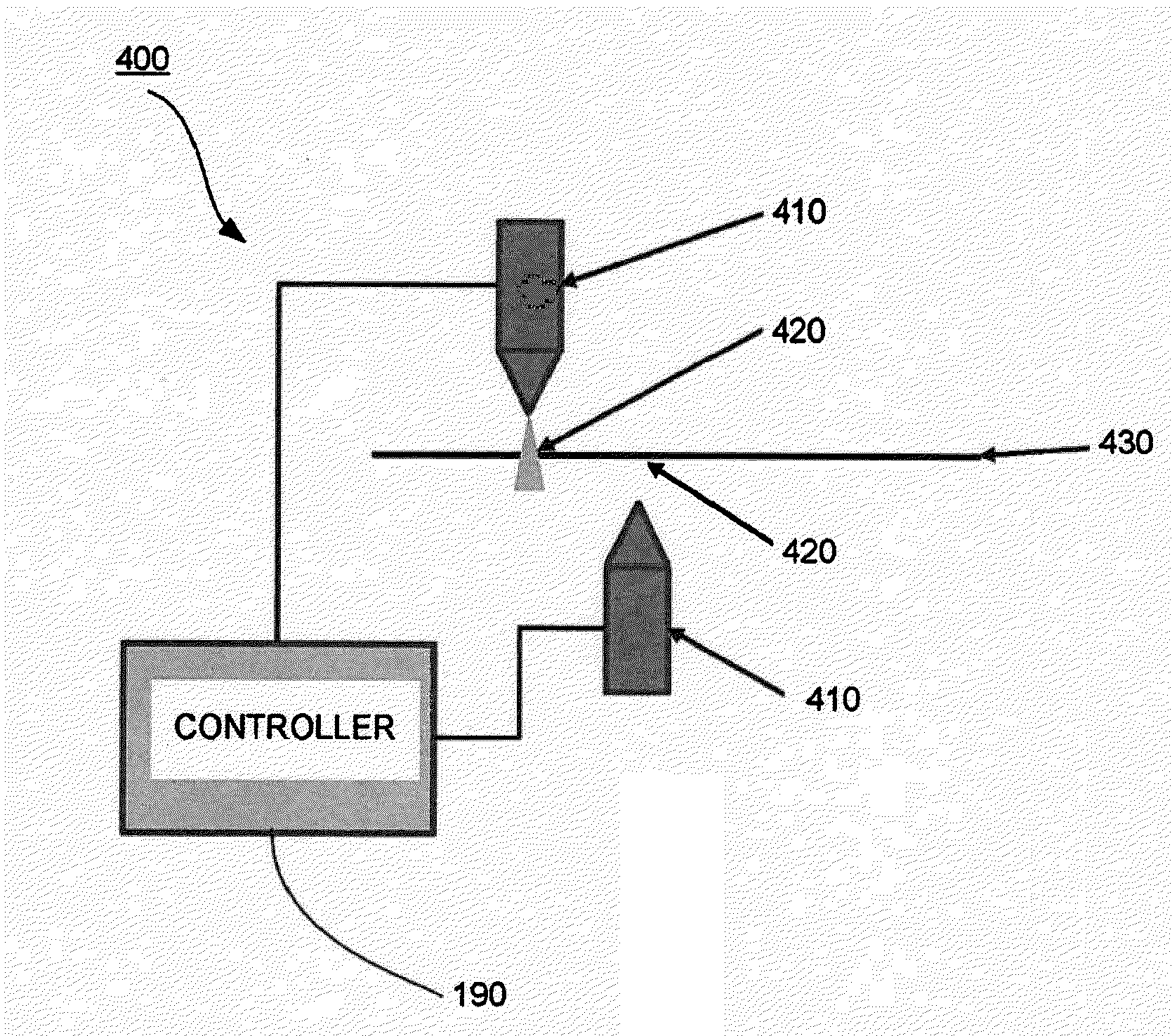

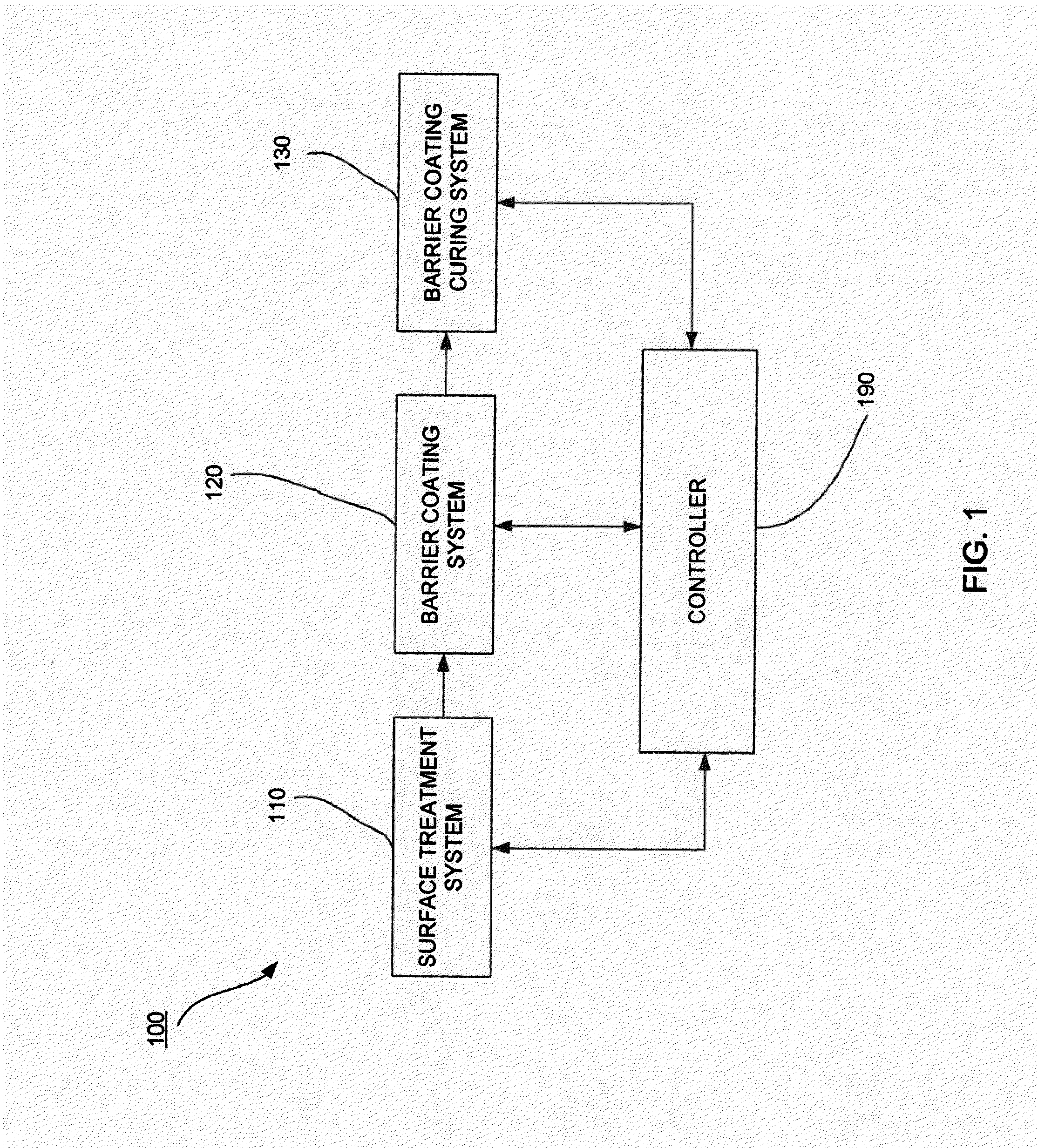

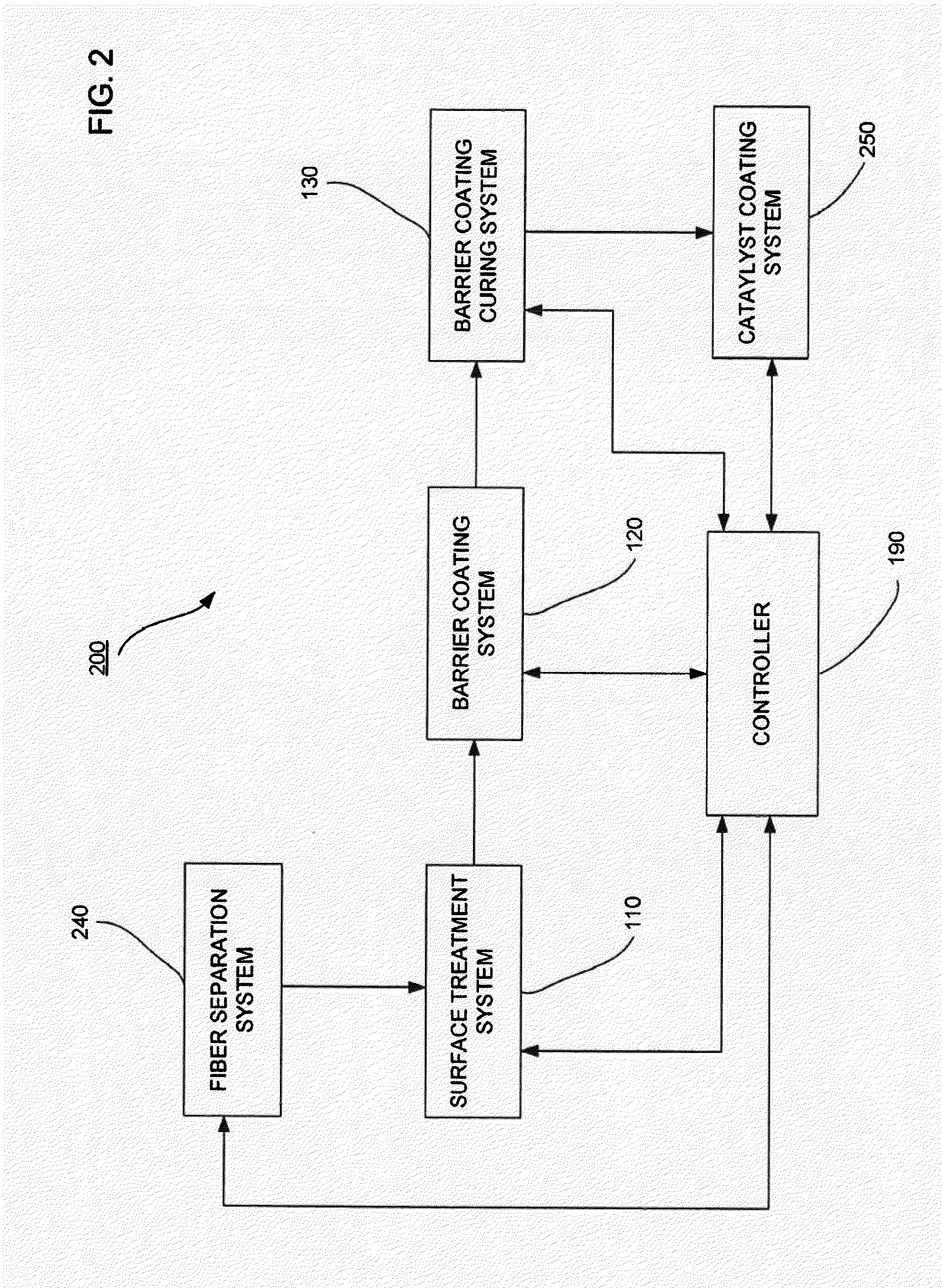

System and method for surface treatment and barrier coating of fibers for in situ cnt growth

InactiveUS20100224129A1Easy to receiveMaterial nanotechnologyLiquid surface applicatorsFiberCatalyst nanoparticles

A system for synthesizing carbon nanotubes (CNT) on a fiber material includes a surface treatment system adapted to modify the surface of the fiber material to receive a barrier coating upon which carbon nanotubes are to be grown, a barrier coating application system downstream of the surface treatment system adapted to apply the barrier coating to the treated fiber material surface, and a barrier coating curing system downstream of the barrier coating application system for partially curing the applied barrier coating to enhance reception of CNT growth catalyst nanoparticles.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

Apparatus and method for controlling steam generating unit of washing machine

InactiveUS20050252250A1Reduce power consumptionRoad vehicles traffic controlOther washing machinesControl powerProcess engineering

An apparatus for controlling steam generating unit of washing machine is disclosed to reduce power consumption of the washing machine by correcting a temperature value detected by a temperature sensor installed in the washing machine to be the same as an actual temperature value of the laundry. The apparatus for controlling steam generating unit of washing machine includes a correcting unit for correcting a temperature value detected by a temperature sensor installed in the washing machine based on a pre-set temperature correction coefficient according to the weight of the laundry inside the washing machine; and a controller for controlling power applied to a steam generating unit in the washing machine.

Owner:LG ELECTRONICS INC

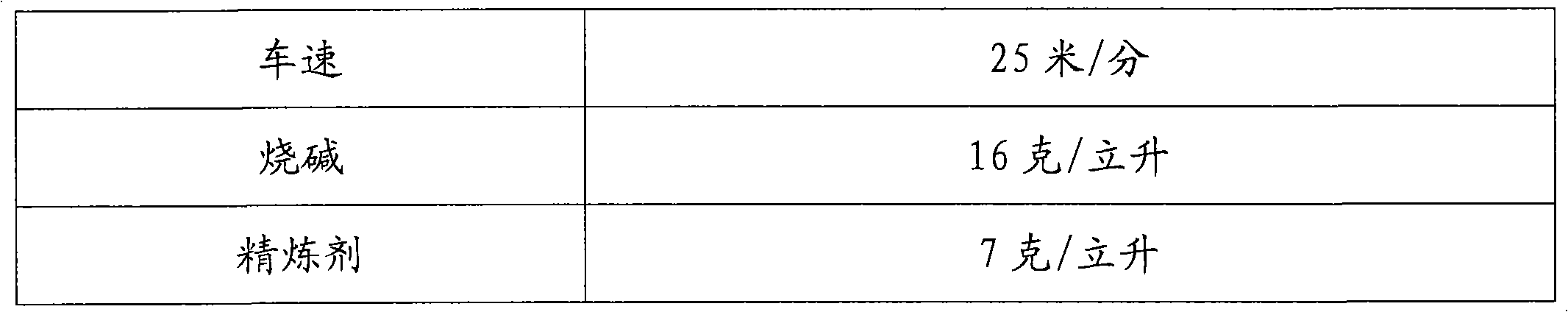

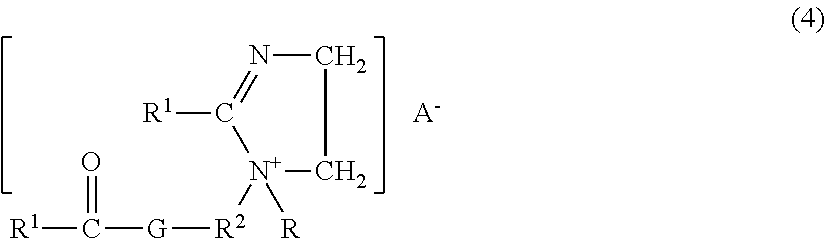

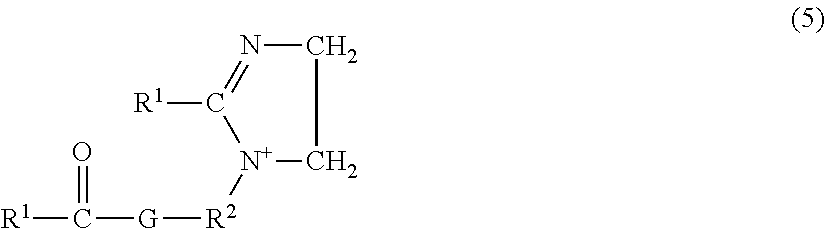

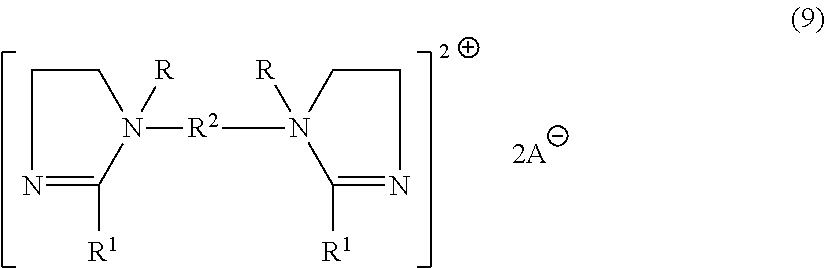

Low-temperature scouring and bleaching agent and preparation method thereof and preprocessing technique

InactiveCN101037842AReduce the bleaching temperatureThe effect of the pretreatment process is obviousBleaching apparatusTextile treatment by spraying/projectingTextile printerBenzene

The present invention realtes to a low temperature scouring and bleaching agent belonging to the pretreatment process technology field of the textile printing and dyeing industry, a manufacturing method thereof and a pretreatment process. Said low temperature scouring and bleaching agent consists of promoter QR2010 consisting of carbon tetrachloride, acetic acid esters, alkyl benzenes, emulsifying agents and scouring agents; promoter QR2011 consisting of potassium hydroxide, carbonates and penetrating agents; and promoter QR2020 consisting of acyls and nitriles activating agents and builders. Said three promoters are prepared using routine methods and are deposited solely. When used, the three promoters, together with hydrogen peroxide, are mixed according to different proportions to prepare solutions. Said low temperature scouring and bleaching agent is capable of annealing, boiling and bleaching a variety of cotton as well as cotton blending textiles at any temperature ranging from 40 DEG C to 80 DEG C, and being processed at different scouring and bleaching equipments, with a whiteness of higher than 80% and a capillary effect of 10-20 cm. Compared with the process in existing, the amount used of hydrogen peroxide activating agent is 1 / 7 to 1 / 5 of that originally used, the total energy consumption is reduced, the tonnage of used water is decreased, and billet flaws such as holes bleached by oxygen and lycra folded crepes sourced and bleached are avoided.

Owner:SHANGHAI QIRUI TEXTILE CHEM

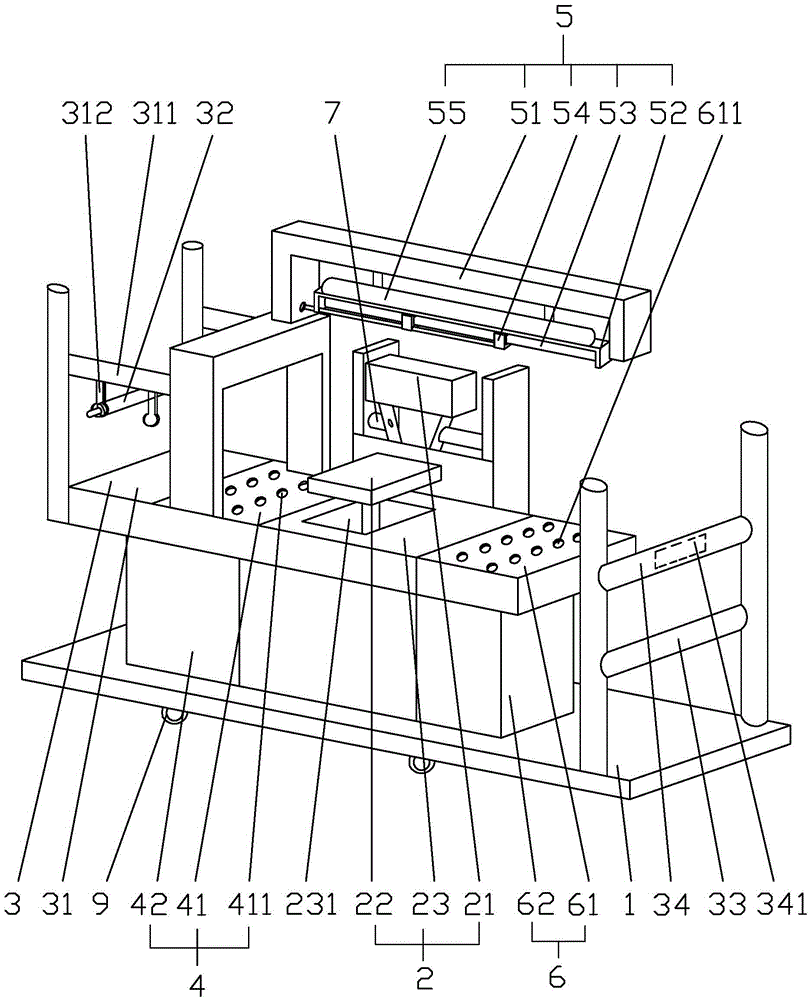

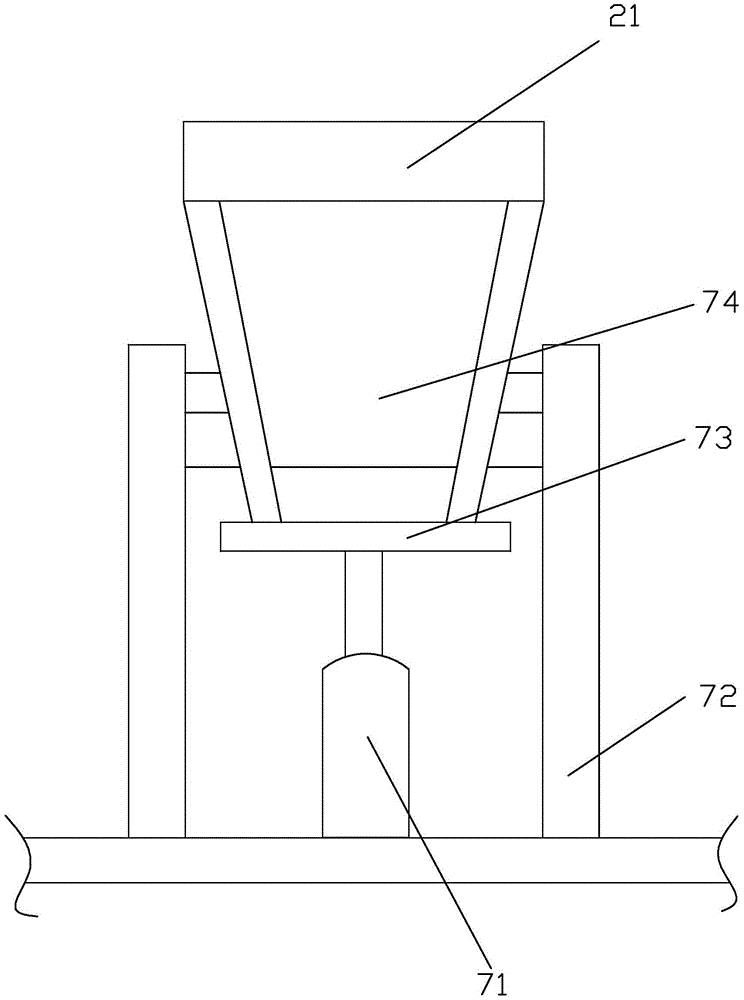

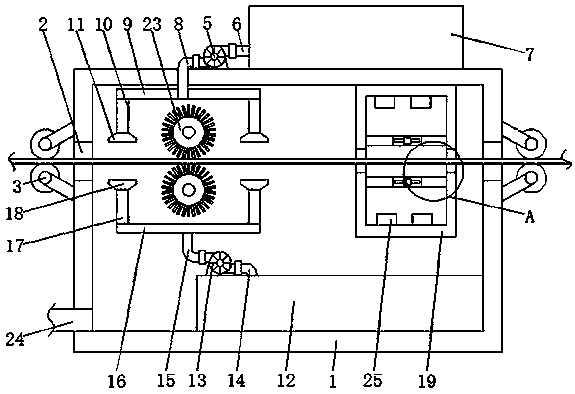

Cloth ironing machine

InactiveCN105463745AAvoid damageQuality improvementHeating/cooling textile fabricsTextile treatment by spraying/projectingEngineeringEnergy consumption

The invention mainly discloses a cloth ironing machine. The technical scheme is that the cloth ironing machine comprises a rack, an ironing mechanism, a conveying mechanism, a preheating mechanism, a sterilization mechanism and a drying mechanism, wherein the conveying mechanism comprises a putting table, cloth putting rollers and a cloth reeling roller, the putting table is provided with hanging rings, two ends of the cloth putting rollers are respectively hung on the hanging rings, one side of the cloth reeling roller is provided with a cooling roller, the ironing mechanism comprises an upper press mould, a lower press mould and an ironing table, the lower sides of the upper press mould and the lower press mould are respectively provided with a first transmission mechanism and a second transmission mechanism for driving the upper press mould and the lower press mould to be in force fit, the preheating mechanism comprises a preheating plate provided with steam holes and a water tank with an electric heater, the sterilization mechanism comprises a lamp base, a lamp holder and an ultraviolet tube with a cleaning device, the drying mechanism comprises a drying plate provided with air outlets and a warm air chamber provided with a warm air machine, and sliding wheels are arranged below the rack. The cloth ironing machine has the advantages of good ironing effect, shaping in one step, high work efficiency and less energy consumption.

Owner:SHENGZHOU YIHAI MOTOR PARTS FACTORY

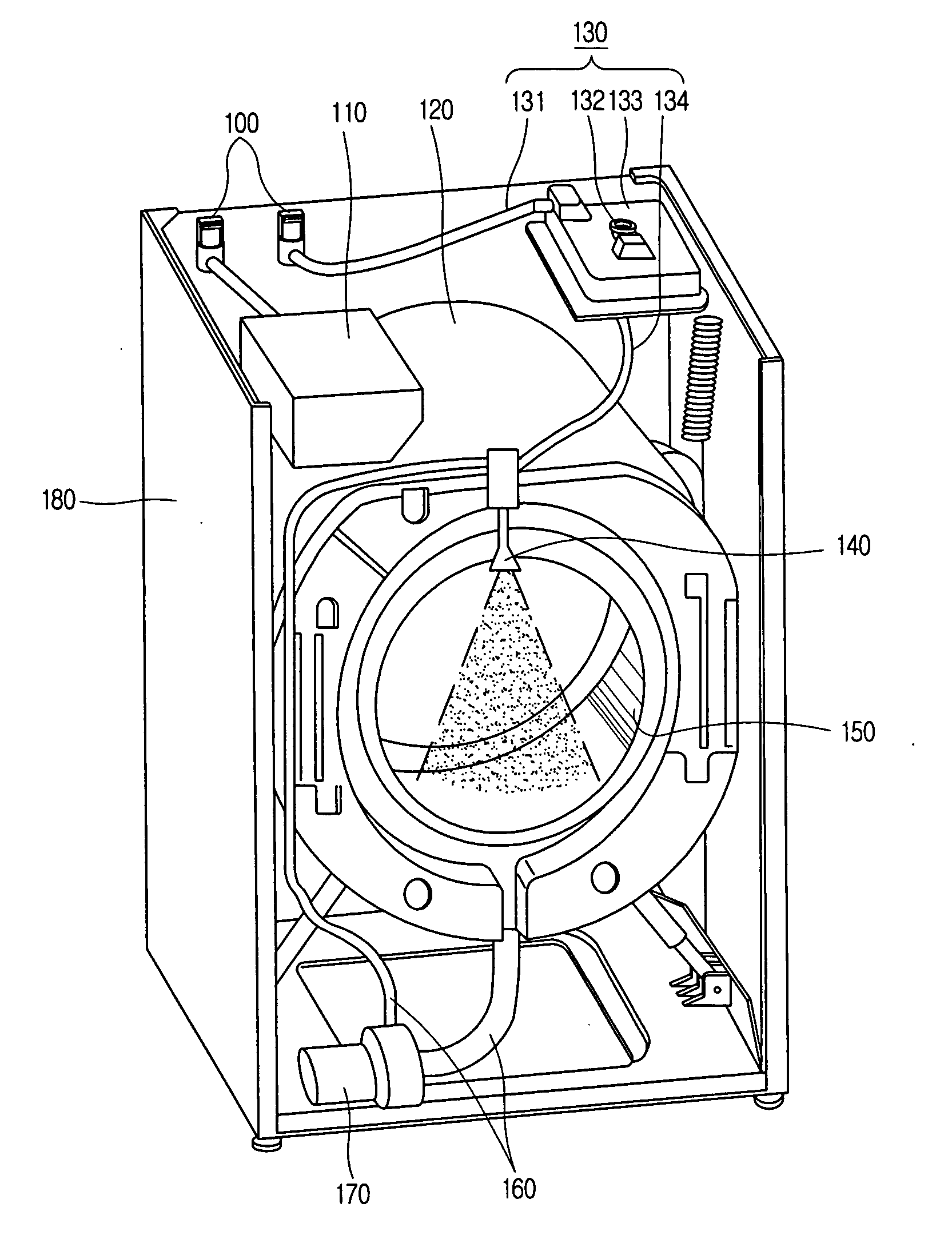

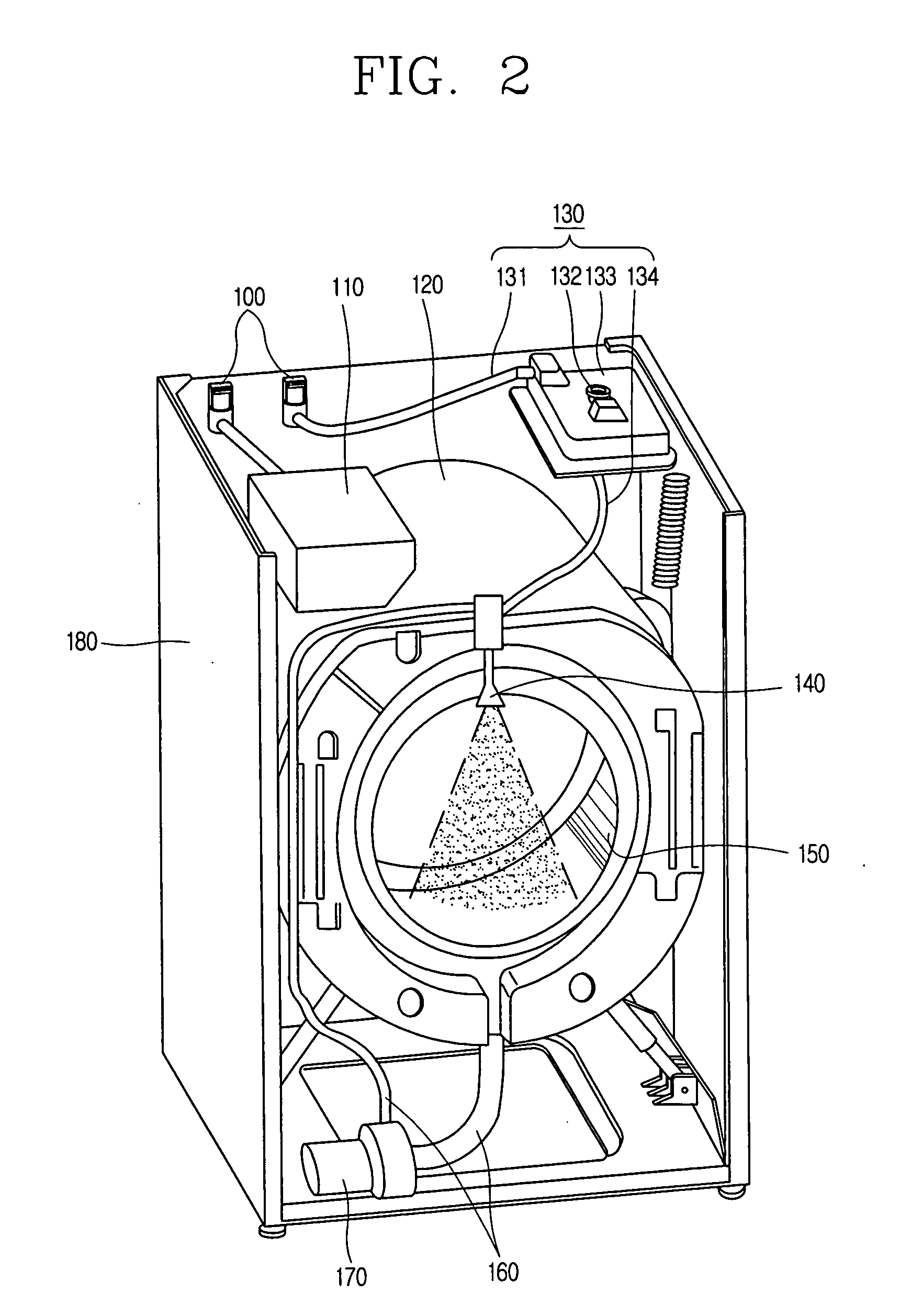

Washing machine

ActiveUS20100000266A1High energyImprove washing effectOther washing machinesWashing machine with receptaclesPulp and paper industryWater spray

A washing machine has a water spray device to efficiently wet the laundry by spraying washing water to the laundry with uniform pressure. The washing machine includes an outer tub, and a water spray device installed at an upper portion of the outer tub to spray washing water. The water spray device includes a diffusion duct for diffusing the washing water around the outer tub and a spray member provided in the diffusion duct to spray the washing water into the outer tub.

Owner:SAMSUNG ELECTRONICS CO LTD

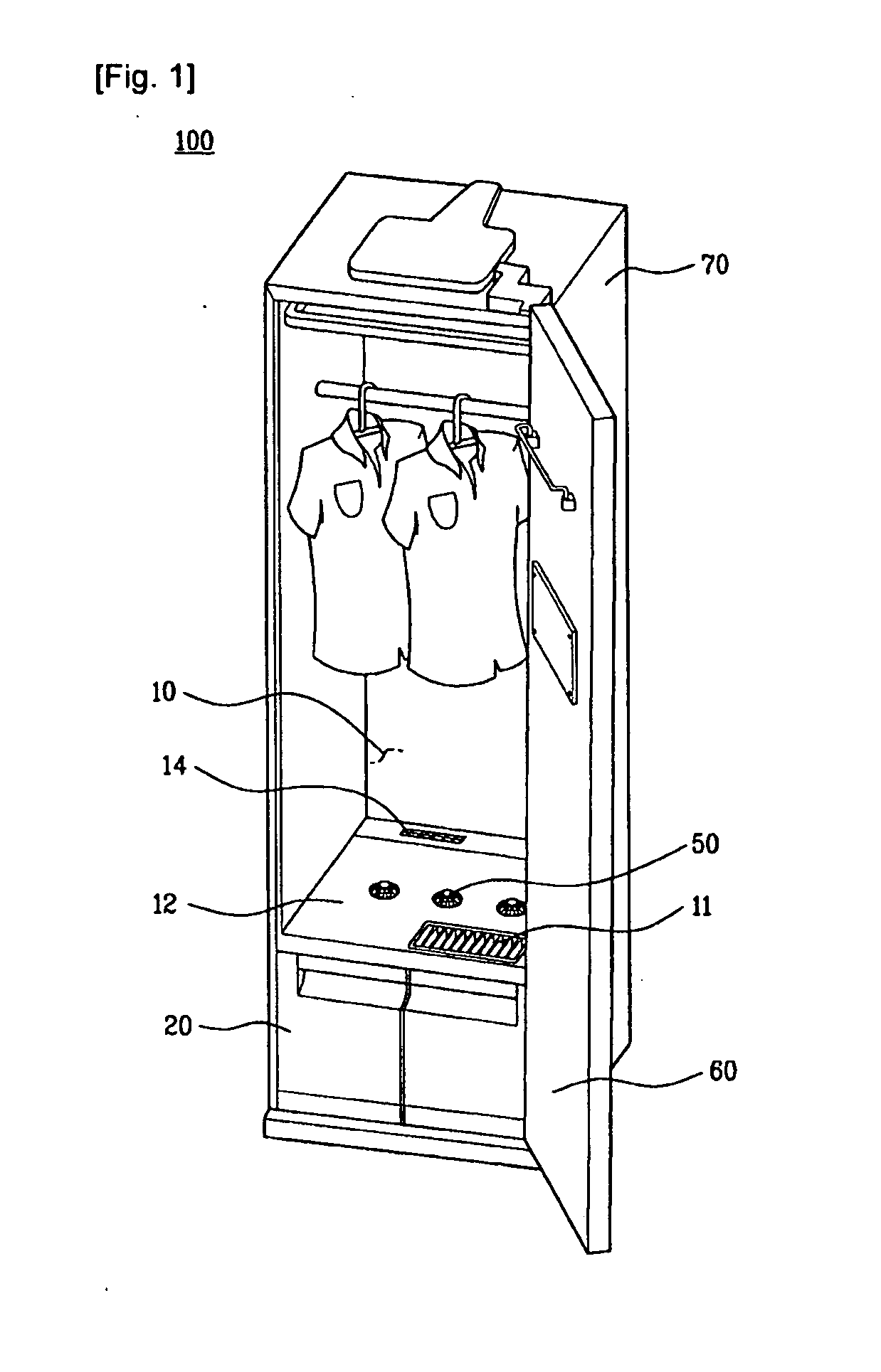

Laundry treating machine and control method of the same

ActiveUS20090241269A1Drying using combination processesDrying solid materials with heatAfter treatmentEngineering

The present disclosure generally relates to a cloth treating apparatus, such as a laundry treating machine, and methods of control and operation which sanitize the machine. The laundry treating machine can include an accommodating space which supplies air and moisture in order to remove unpleasant odors, wrinkles, or dampness from the laundry. The laundry treating machine may further include a circulation duct to circulate, dehumidify, or heat air inside the accommodating space. Operation of the laundry treating machine can use steam-sanitizing to remove odors, moisture, bacteria from the accommodating space and circulation duct. Steam-sanitizing can be performed based on a user's selection or the occurrence of a condition, such as unloading of laundry from the accommodating space after treatment.

Owner:LG ELECTRONICS INC

Cleaning equipment for spinning

InactiveCN107938211AWash thoroughlyEffective flushingTextile treatment machine arrangementsLiquid/gas/vapor removal by gas jetsEngineeringAirflow

The invention relates to the technical field of cleaning equipment for spinning and discloses cleaning equipment for spinning. The cleaning equipment comprises an equipment body; two sides of the equipment body are symmetrically provided with first openings; two symmetrical rollers are fixedly installed on upper ends of the two sides of the equipment body; spinning fabric is stitched between the two rollers. By means of the cleaning equipment for spinning, under the effect of a first water pump and a second water pump, fabric can be effectively washed; a first nozzle and a second nozzle at theleft end can be used for washing before brushing to clean dust on the fabric; a first nozzle and a second nozzle at the right end can be used for effectively washing off the dust after the cleaning of electric rollers so as to guarantee that the fabric can be cleaned thoroughly; by means of two fans at up and down, hot air flow in a drying box can be blown to the fabric so that two sides of the fabric can be uniformly heated to accelerate drying and guarantee the drying efficiency.

Owner:胡和萍

Cloth processing equipment for weaving

InactiveCN108374278ATimely stereotypesImprove qualityMechanical cleaningPressure cleaningEngineeringBrush device

The invention discloses cloth processing equipment for weaving. The cloth processing equipment comprises a dustproof box, a material inlet roller, a material outlet roller, a float hair attracting device, a float hair brushing device, a humidifying device and a wrinkle eliminating device. The float hair attracting device comprises a dust collector, an air pipe and an attracting head. The float hair brushing device comprises a first electric push rod, a mounting board and a hairbrush roller. The humidifying device comprises a water tank, a hard water pipe, a booster pump and a nozzle. The wrinkle eliminating device comprises a second electric push rod, a mounting box, a heater and a winkle eliminating board. The cloth processing equipment is provided with the float hair attracting device and the float hair brushing device, thereby eliminating the float hair on the surface of the cloth and preventing entering of the float hair into body of personnel through breathing in postprocessing oftextile. The cloth processing device is provided with the humidifying device and the wrinkle eliminating device for performing ironing and wrinkle elimination on the humidified cloth. The cloth is pulled out of the bottom of the wrinkle eliminating board through the pulling force of the material outlet roller and is stretched. The wrinkle-eliminated cloth is cooled and molded in air, thereby ensuring in-time cloth fixing after wrinkle elimination and improving cloth quality.

Owner:陈雪莲

Machining process of peach skin cotton fabric

InactiveCN102031657APlasticityImprove touch effectBiochemical fibre treatmentTextile treatment by spraying/projectingTextile technologyPulp and paper industry

The invention belongs to the field of textile technology, in particular to a machining process of a peach skin cotton fabric. The machining process of the peach skin cotton fabric provided by the invention comprises the processes of turning and sewing, singeing, cooling and stacking, bleaching again by a jig dyeing machine, drying in a loose mode, sizing, mercerizing by a straight roller, brushing by carbon elements, dyeing by air flow, treating by cellulase in an air flow machine, drying in a loose mode, padding softeners in a loose mode, beating by air flow in a softening machine, tentering, pre-shrinking, and sorting and finishing. In the invention, the pretreatment processes of cooling and stacking and the process of dyeing by air flow are used for achieving the optimal effect of uniform and transparent dyeing; the automatic on-line detection technology is used for tracking the quality and processes to enable the production processes to be controlled at the critical optimal point, and all drying processes are carried out in a loose mode to keep the optimal hand feeling effect; and the processes of brushing by carbon elements, dyeing by air flow, treating by cellulase, beating by air and the like are used for ensuring that the fabric has delicate and plump peach skin hand feeling, plastic elasticity and delicate and clear cloth cover.

Owner:HUAFANG

Method for the prevention of nanoparticle agglomeration at high temperatures

A method includes: (a) conformally depositing a barrier coating, provided in liquid form, on at least one surface of a substrate; (b) embedding a plurality of nanoparticles in the barrier coating to a selected depth; and (c) fully curing the barrier coating after embedding the plurality of nanoparticles; the embedded plurality of nanoparticles are in continuous contact with the cured barrier coating. The order in which the barrier coating and nanoparticles are deposited on the substrate can be switched or they can be deposited simultaneously. An article includes a substrate having a cured barrier coating conformally disposed on at least one surface of the substrate and a plurality of nanoparticles embedded to a selected depth in the barrier coating creating an embedded portion of each of the plurality of nanoparticles. The embedded portion of each of the plurality of nanoparticles in continuous contact with the cured barrier coating.

Owner:APPL NANOSTRUCTURED SOLUTIONS LLC

No-iron treatment method for cotton shirt

ActiveCN101768869AAvoid yellowingGuaranteed flatnessHeating/cooling textile fabricsTextile treatment by spraying/projectingFiberQuarantine

The invention provides a no-iron treatment method for a cotton shirt, which can solve the problems of yellowing due to overhigh baking temperature and poor seam appearance due to seam shrinkage of the cotton shirt. The method comprises the following process flows: resin absorbing, pre-baking, pressing, baking and cooling, wherein a working solution comprises the following components in percentage by mass: 15 to 25 percent of resin, 1 to 2.5 percent of catalyst and 2 to 4 percent of fiber protective agent; and the pH value of the working solution is regulated to be between 4.5 to 5.0. The process can ensure that seams or pleats of collar, yoke, two sleeves, side seams, a left front panel, a right front panel, a left back panel, a right back panel and other parts of the shirt are flat and fitting, no bulge is generated after the shirt is washed, and all the appearance flatness of products and the appearance of the seams and the pleats are up to the 4.0 level of 'the No-iron Textiles Standard' published by the State Administration of Quality Supervision, Inspection and Quarantine, namely the testing index is higher than 'the No-iron Textiles Standard' by 0.5 to 1 level.

Owner:ZHEJIANG GIUSEPPE GARMENT

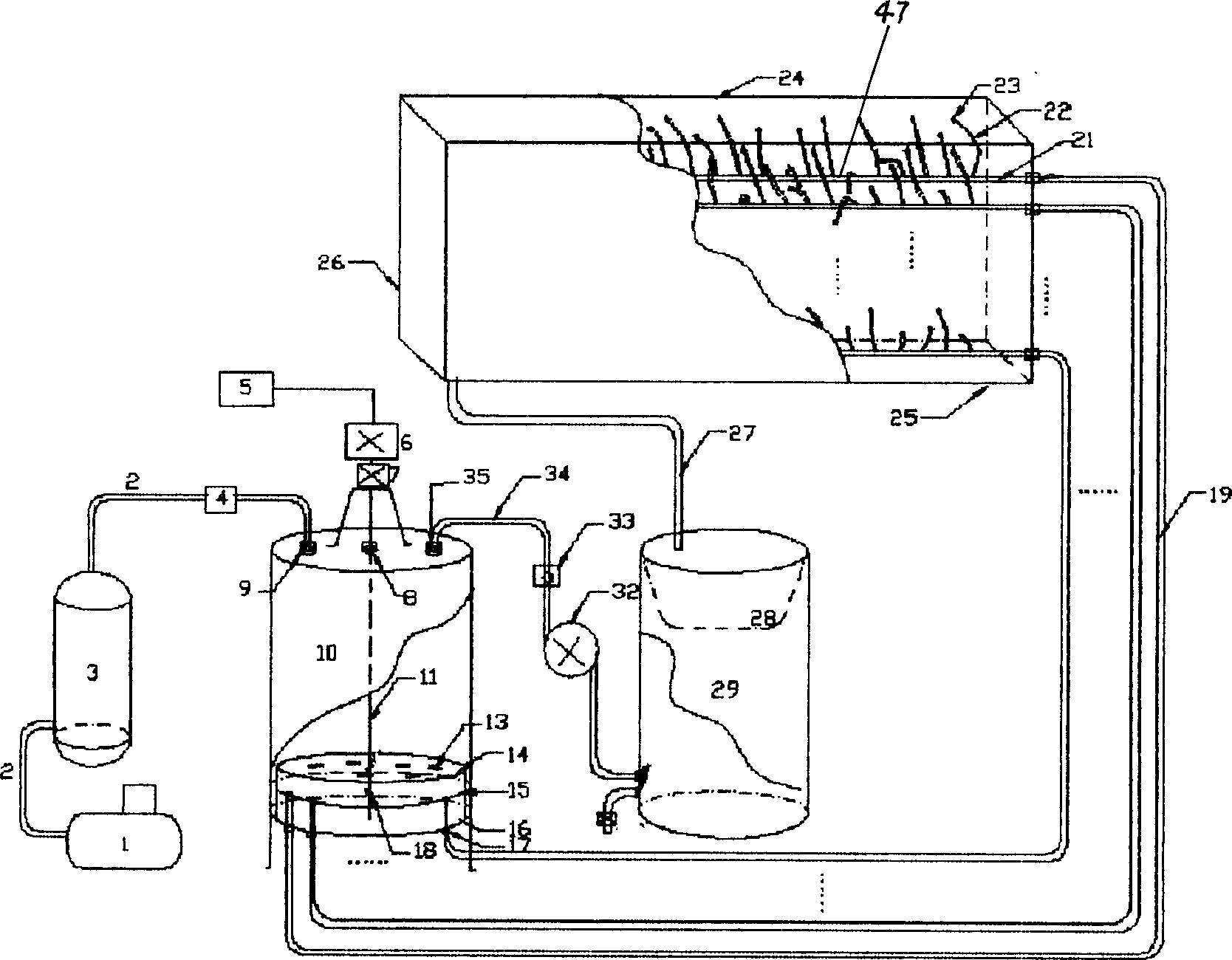

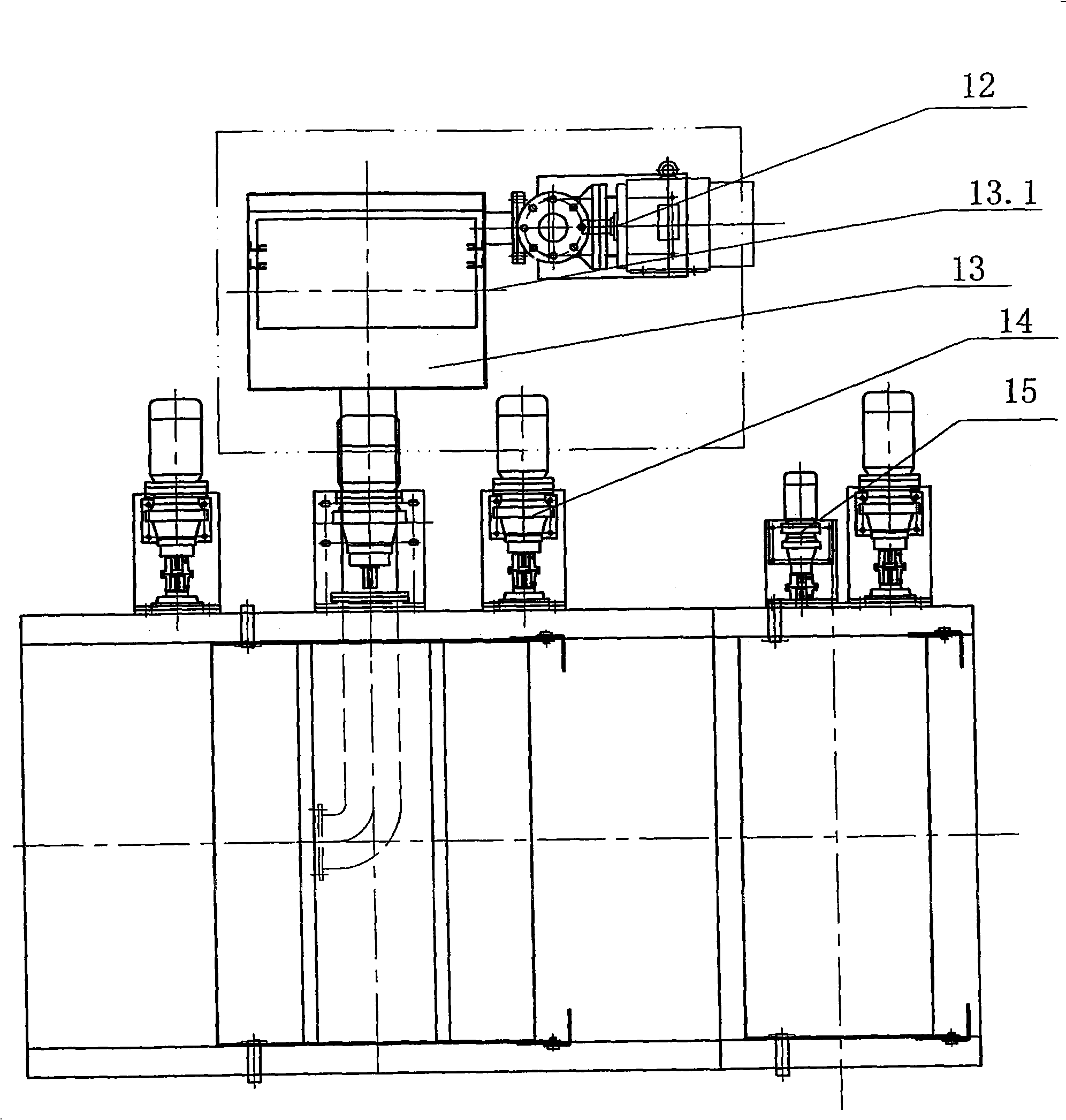

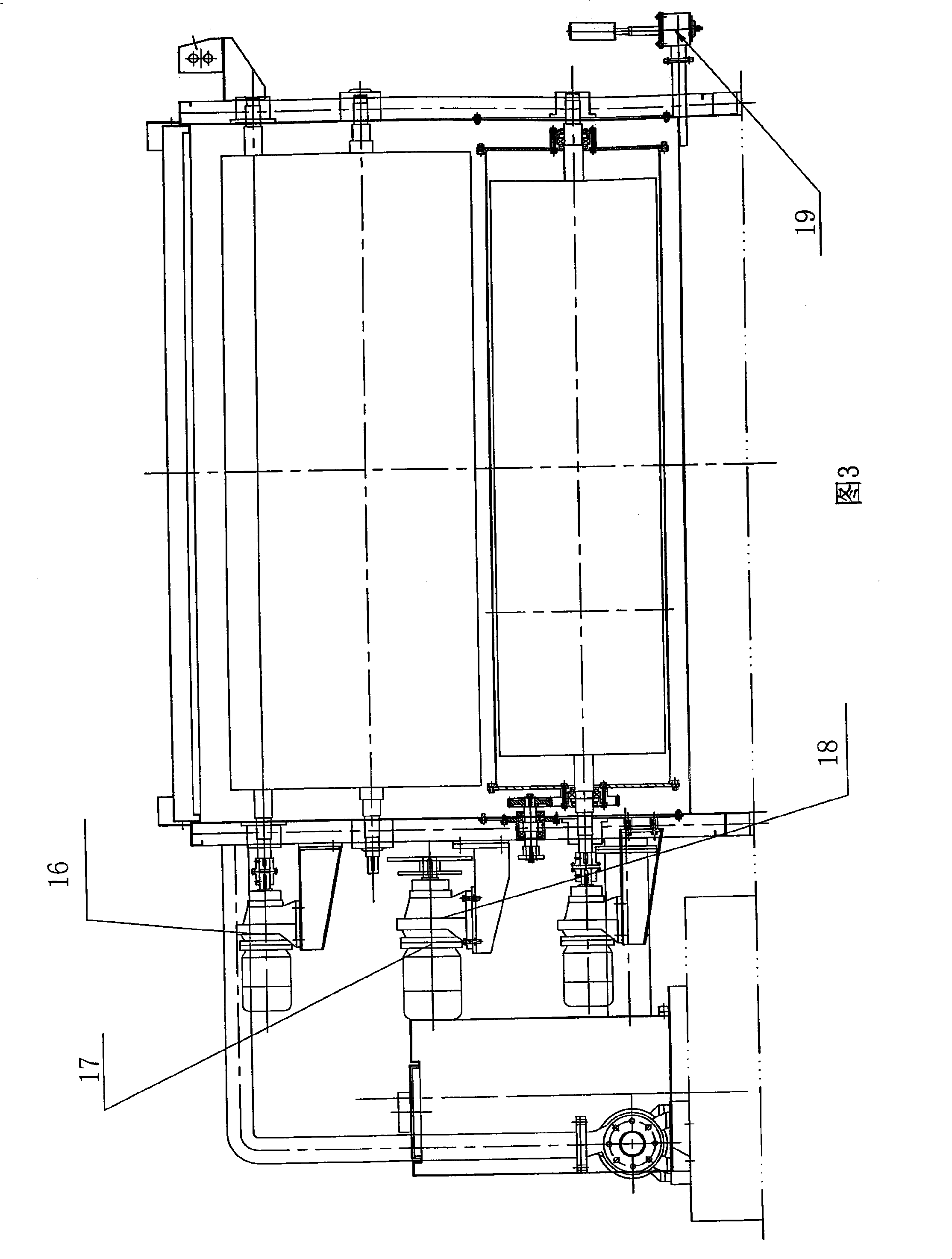

Novel gas-fog dyeing machine

InactiveCN101591845ALower liquor ratioSave energyTextile treatment machine arrangementsTextile treatment by spraying/projectingAir filterPulp and paper industry

The invention provides a novel gas-fog dyeing machine, which comprises a main cylinder body, a high pressure blower and a nozzle atomization system; an outlet at one end of the high pressure blower is communicated with a high pressure air inlet of the nozzle atomization system; two ends of the nozzle atomization system are a textile inlet and a textile outlet which are respectively communicated with the main cylinder body; a dye solution cutting nozzle, an energy converting nozzle and a cloth lifting roller are arranged in the nozzle atomization system; the dye solution cutting nozzle has an annular narrow slit shape; the axial section of the energy converting nozzle consists of three sections, namely a straight pipe section, a taper section and a gradual expansion section; and an inlet at the other end of the high pressure blower is communicated with an air filter screen in the main cylinder body. The special nozzle atomization system of the invention can well atomize the dye solution; and the dyeing machine adopts gas-fog flow for dyeing, cancels circulating dye solution dragging of textile and uses airflow to drag the textile to operate, thereby greatly reducing the bath ratio, saving the energy, reducing the pollution, and promoting the environmental protection.

Owner:ZHEJIANG ZHUOXIN MACHINERY

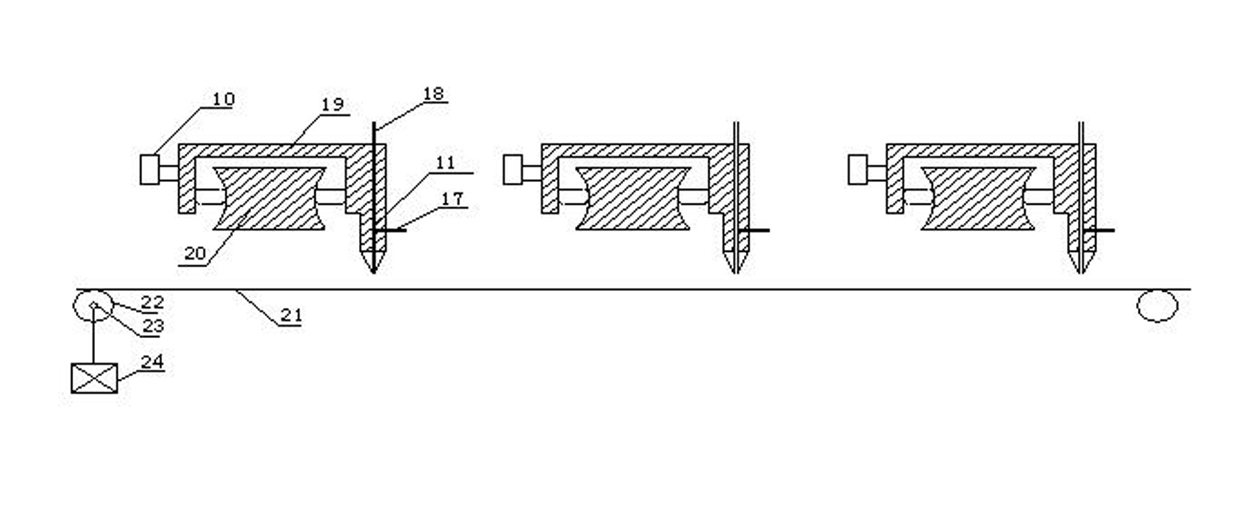

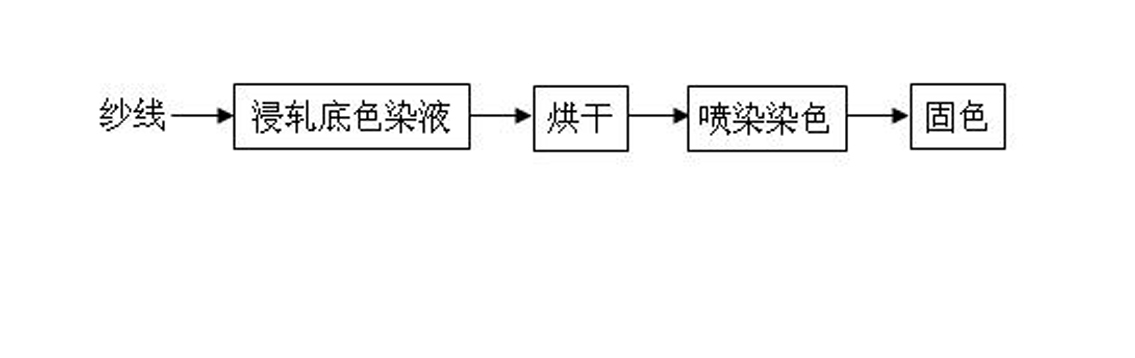

Method of high speed high pressure spraying decoration on textile paste yarn dyeing production line and its device

InactiveCN1718899ALow costEasy to produceDyeing processTextile treatment by spraying/projectingProduction lineYarn

The present invention relates to a production method for high-speed and high-pressure spraying pattern on textile size yarn-dyeing production line and its equipment. Said method includes the following steps: making yarn be uniformly advanced at a set speed, uniformly stirring fading agent or dyes and adjuvant, filtering and pressurizing, and utilizing multihole type spray head mounted on the pattern-spraying panel to high-frequency intermittently spray the above-mentioned liquid material on the several running yarns to make their local colour be changed so s to form pattern.

Owner:刘林泉

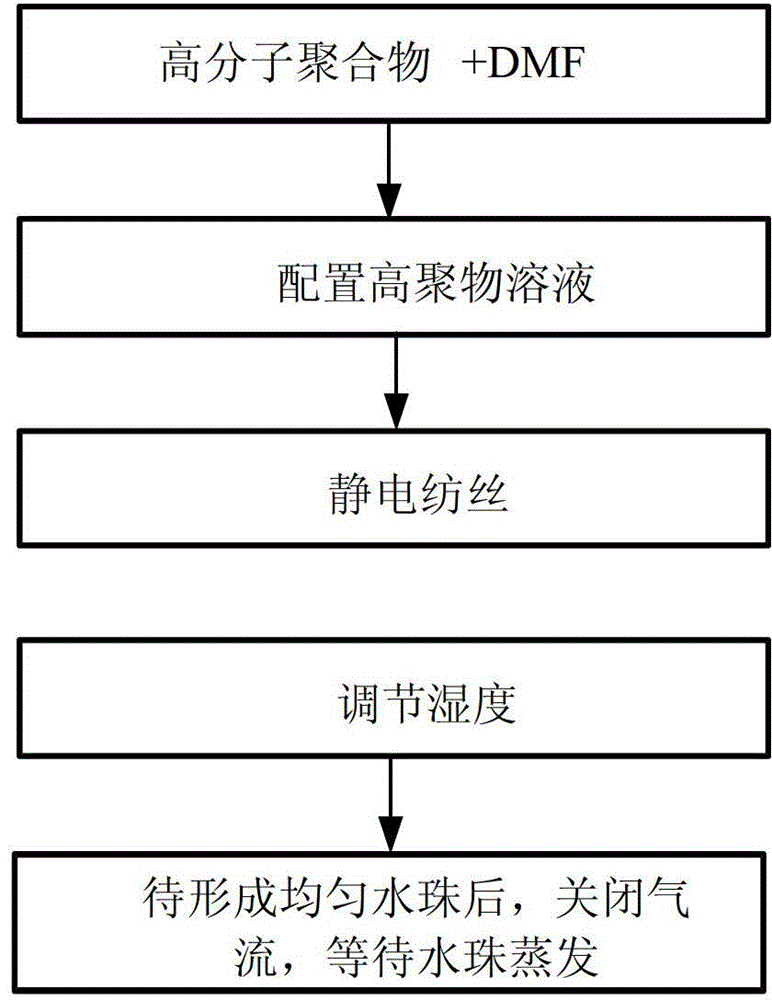

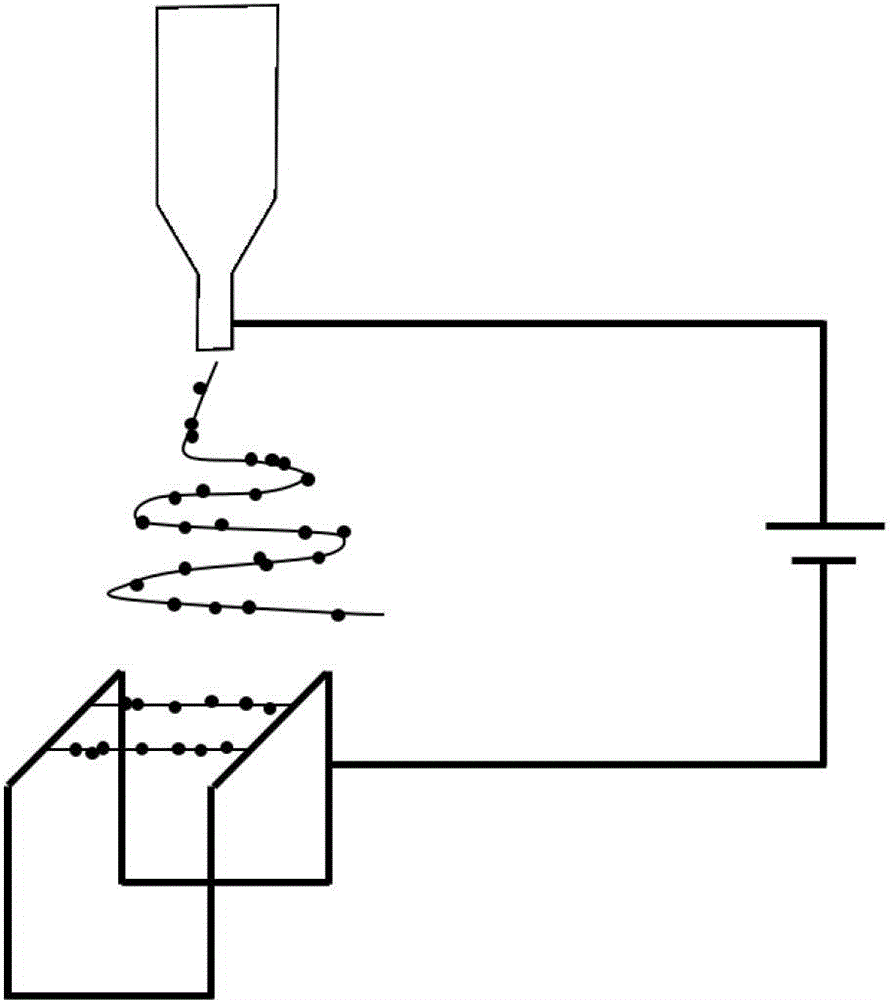

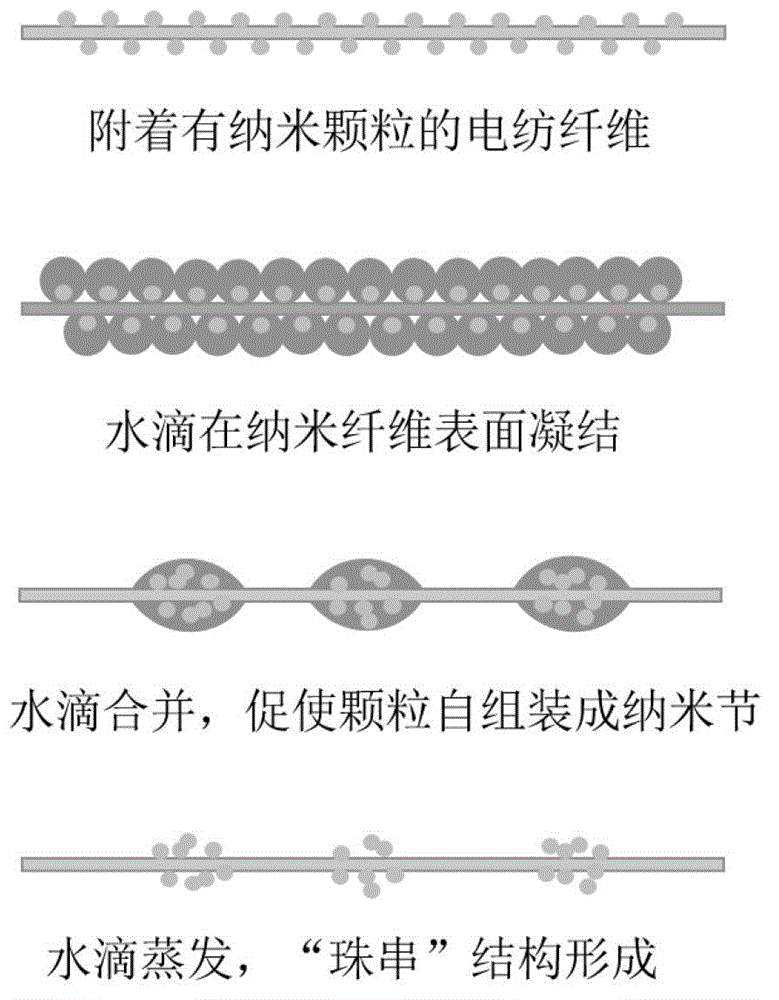

Preparation method for self-assembly of electrospinning rosary-like fibers

ActiveCN103334244AEasy to operateEasy to makeMonocomponent polyethers artificial filamentFilament/thread formingFiberOperability

The invention discloses a preparation method for the self-assembly of electrospinning rosary-like fibers, and belongs to the technical field of chemistry and material. By inspired by the situation that a cobweb can be assembled to a spindle structure in the wet environment respectively, a static electricity spinning device is utilized to prepare man-made fibers, and an aluminum bracket is used for receiving, so as to form the man-made fibers with the structure that nano-particles are adhered to surfaces; the man-made fibers are allowed to be assembled to the micron-sized ' rosary' structure respectively in the wet environment. According to the preparation method provided by the invention, the manufacturing process is simpler, the cost is lower, the operability is strong, and the method is suitable for mass productions; the respectively assembled fibers have stable quality and long practicability; the method can be used for collecting fresh water, reducing fog, solving the problem of serious water shortage in deserts and wastelands, and dispersing the steam around airports, street lamps, and signal lamps.

Owner:BEIHANG UNIV

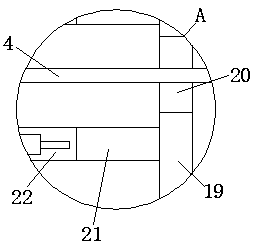

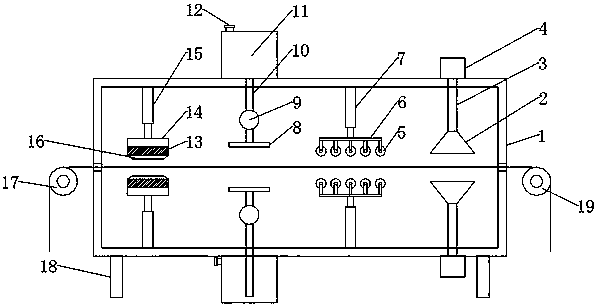

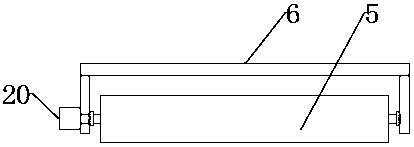

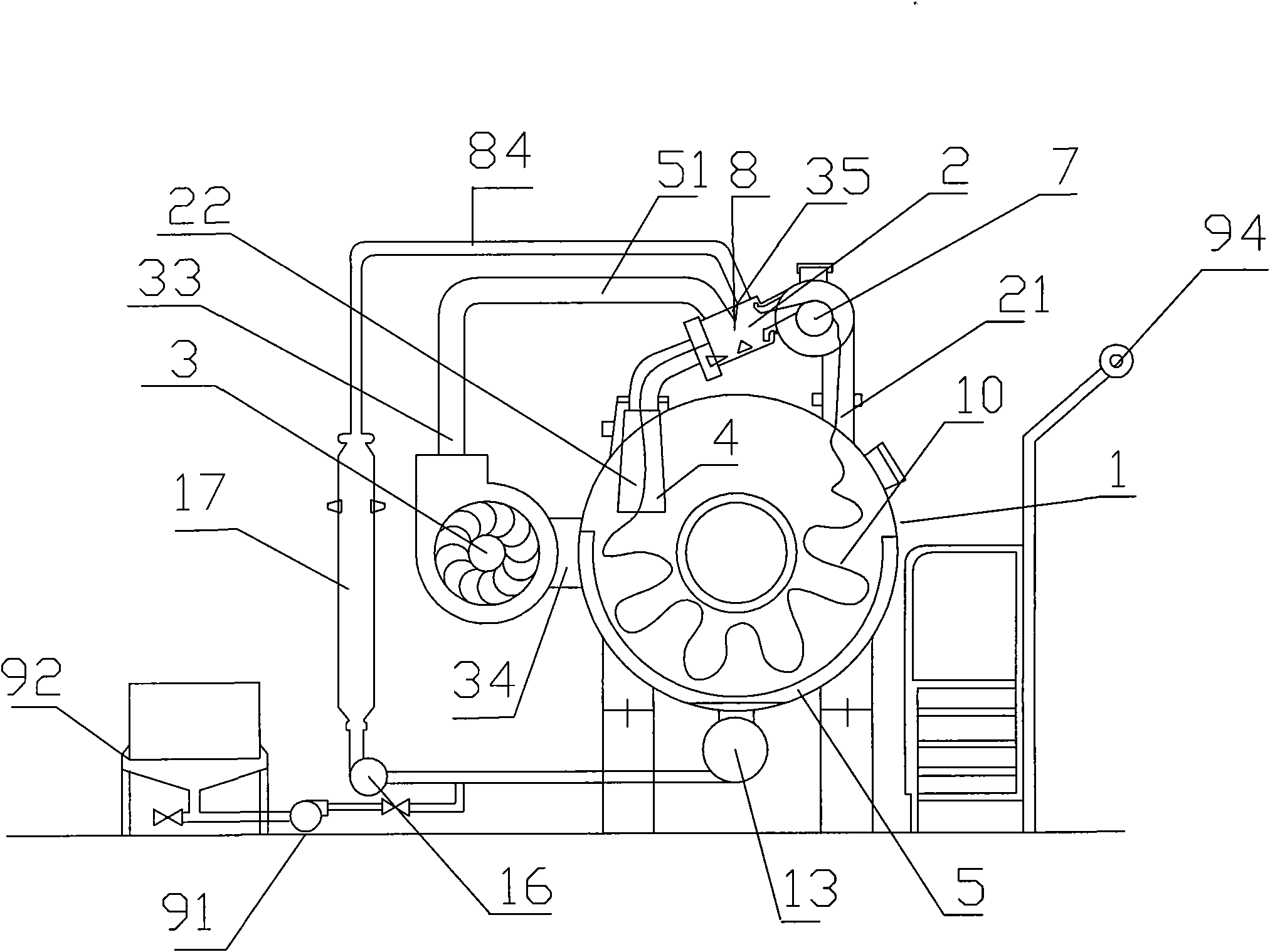

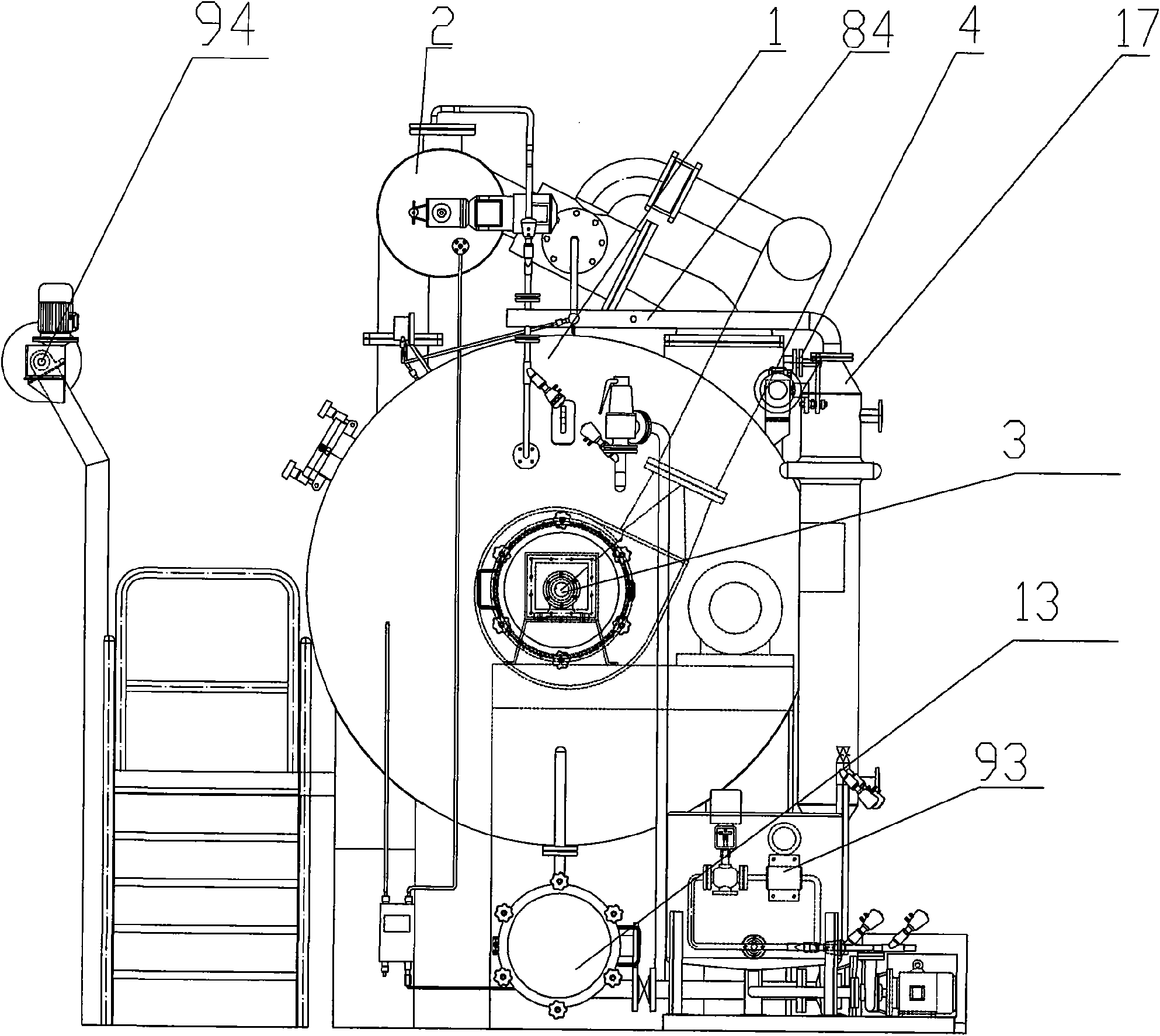

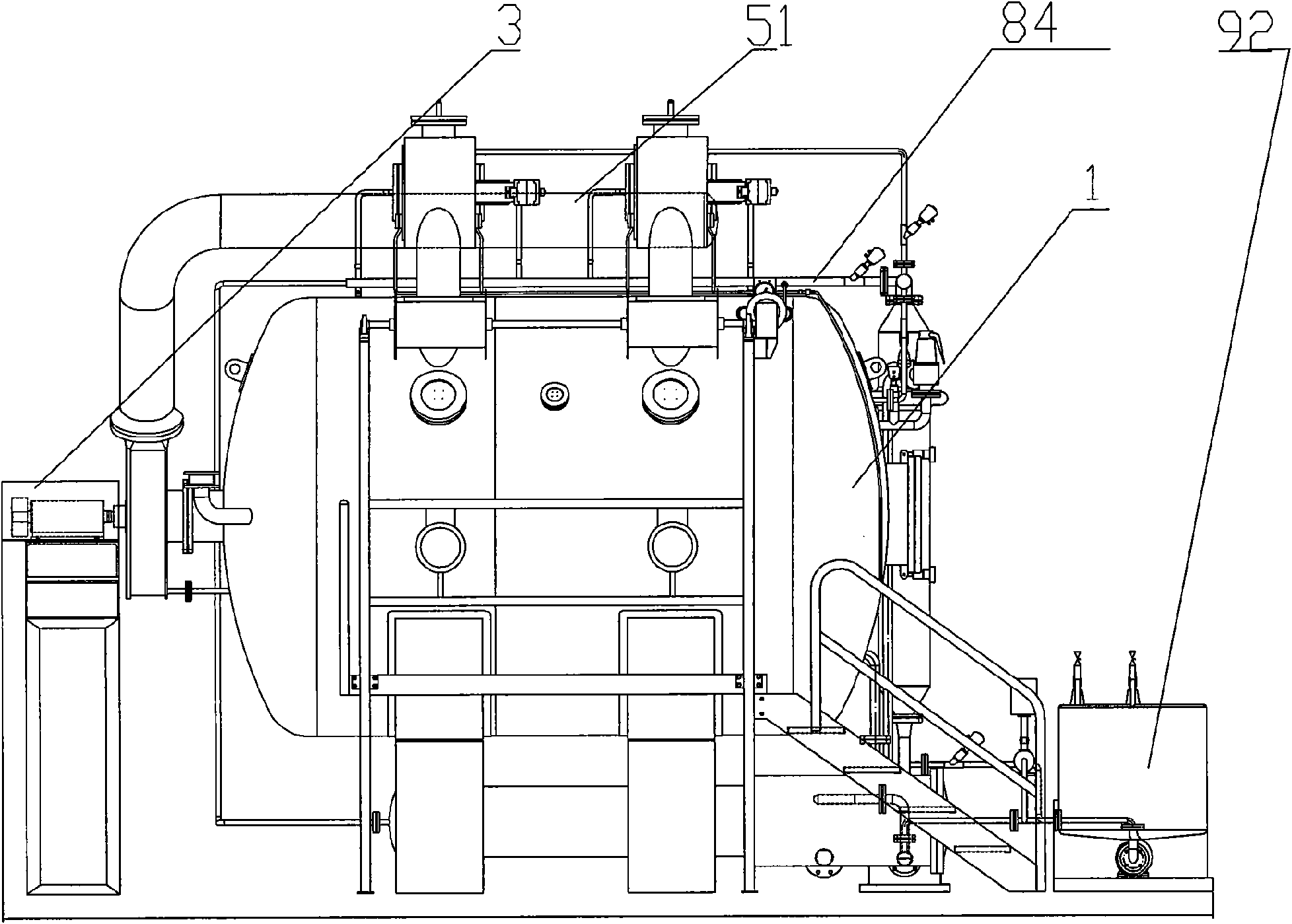

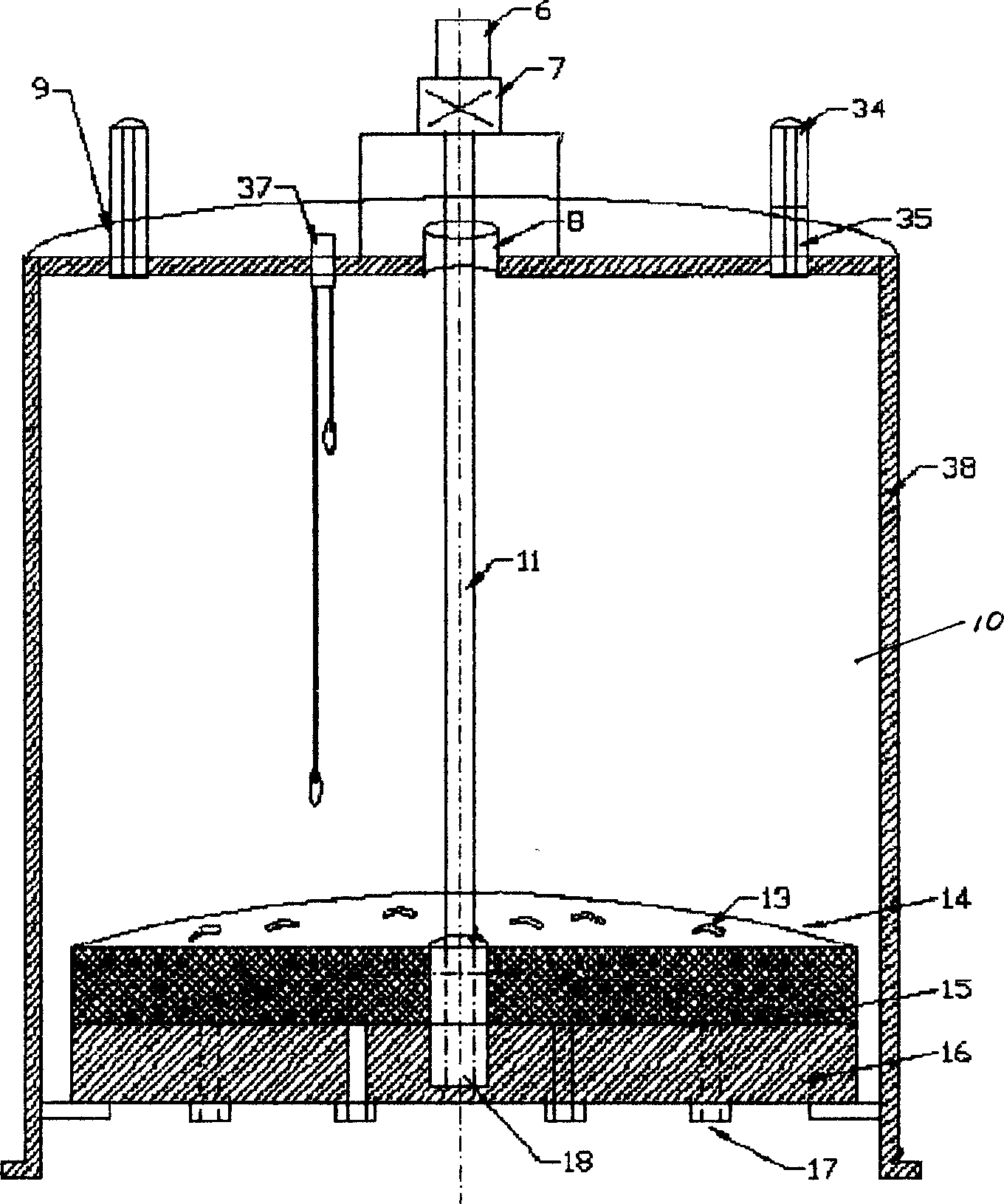

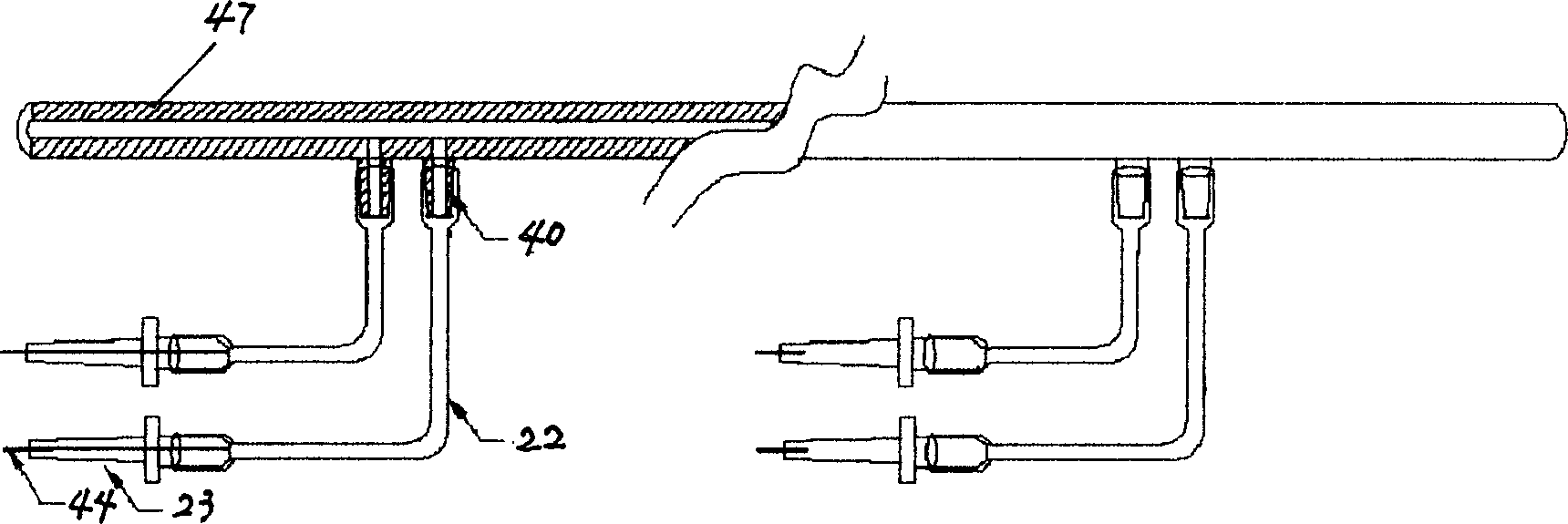

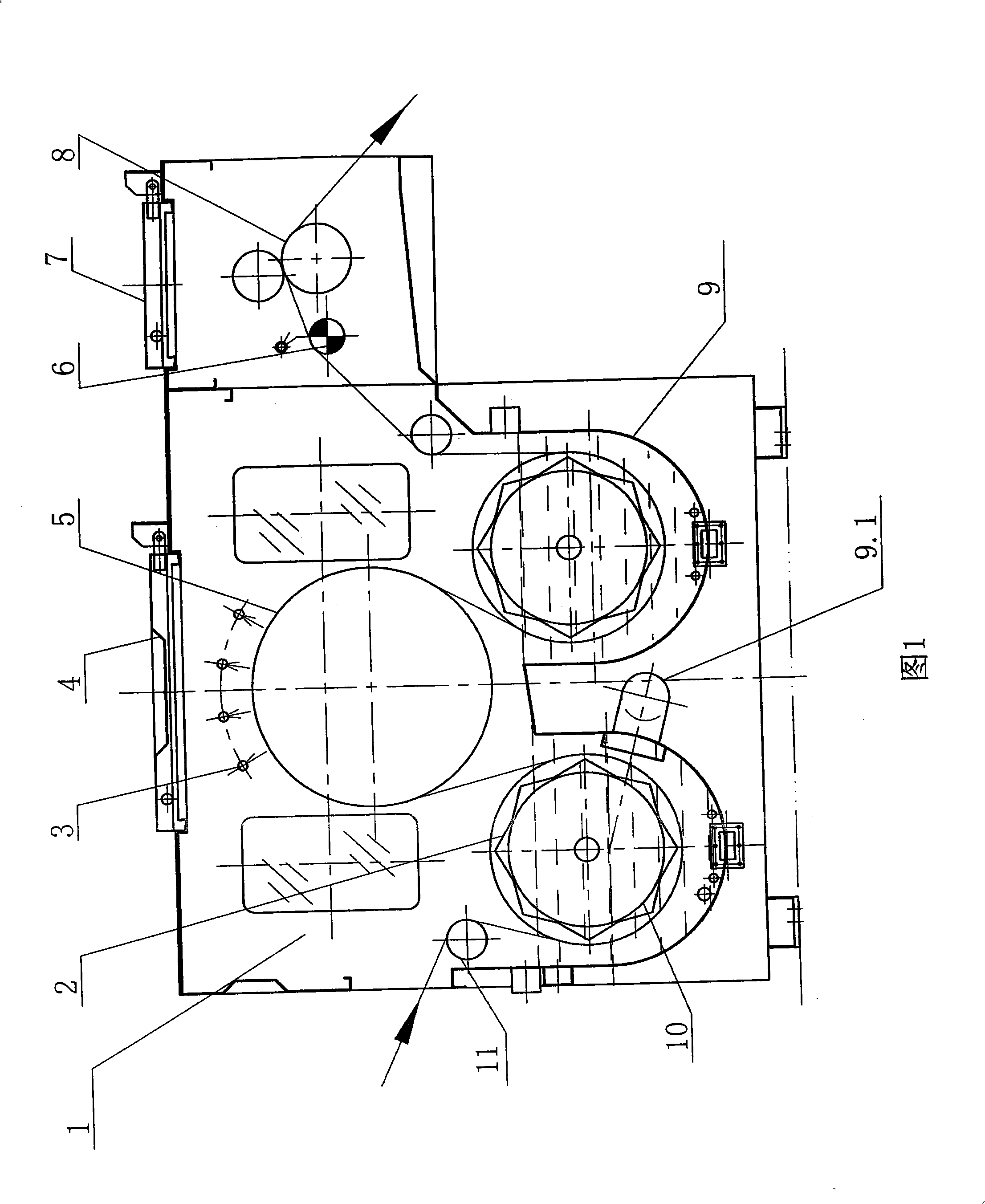

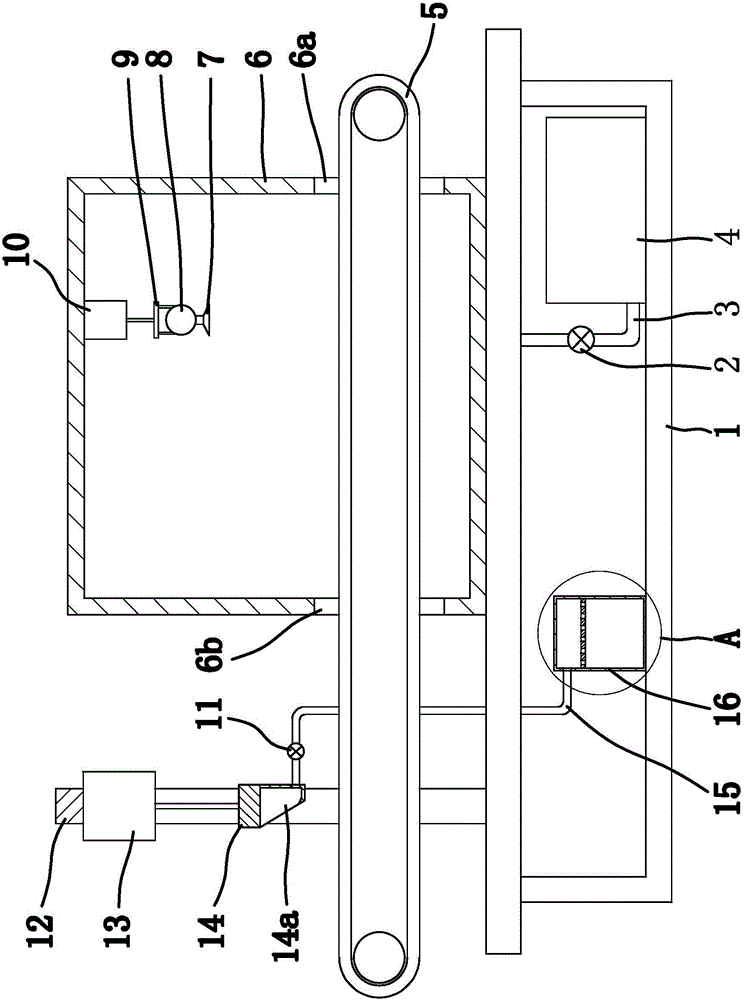

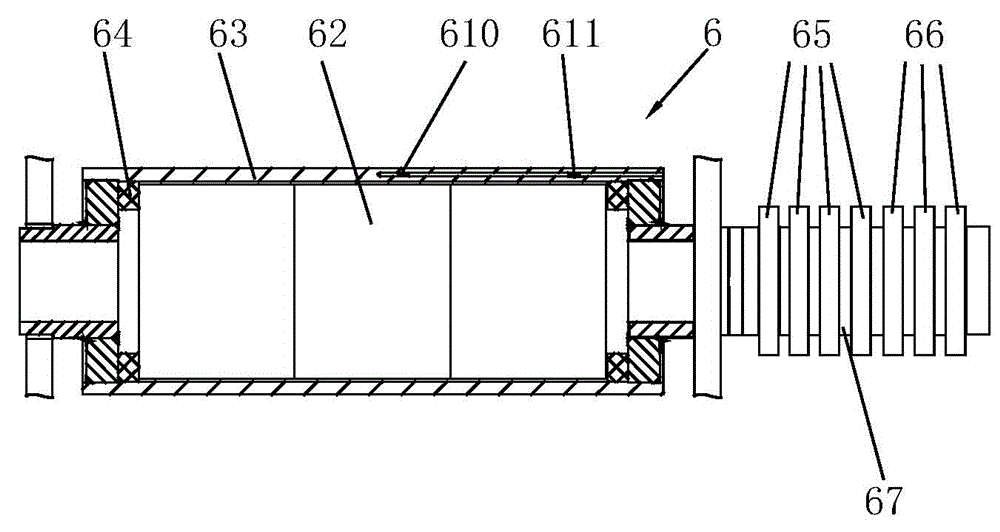

Novel double oscillation tumbling barrel scouring machine

InactiveCN101328681AFully washable exchange effectAchieve energy savingTextile treatment machine arrangementsDry-cleaning apparatus for textilesEngineeringWater washing

The invention relates to a novel dual-oscillation revolving drum washing machine, which is suitable for the water scrubbing, bleaching and open-width processing technique of knitted and woven fabrics. The novel dual-oscillation revolving drum washing machine comprises a box body (1), wherein, flumes (9) are vertically arranged on the lower part inside the box body, and the number of the flumes (9) is two, with one on the left and one on the right; an external wire roll (2) is respectively arranged inside the two flumes (9); a plum-blossom roll (10) is respectively arranged inside the two external wire rolls (2); a reticulated revolving drum (5) is vertically arranged on the middle of the upper part inside the box body (1); and the upper side of the reticulated revolving drum (5) is provided with a spray device (3). By adoption of the novel dual-oscillation revolving drum washing machine, the amount of water, steam and an auxiliary agent is small; the water scrubbing effect is good; and the quality of the textile fabrics after water scrubbing is good.

Owner:张琦

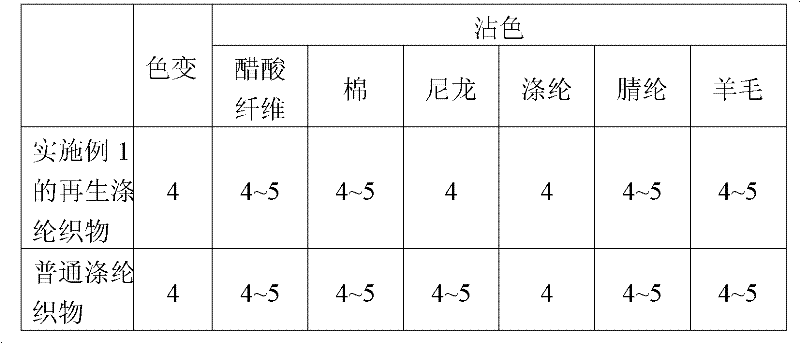

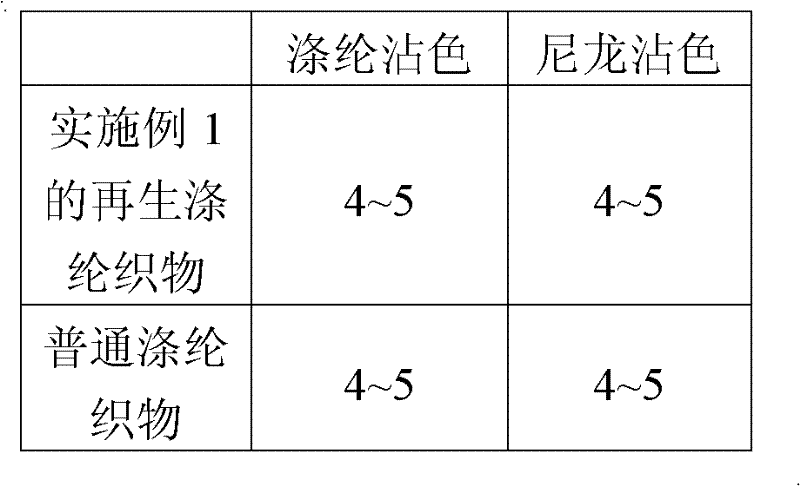

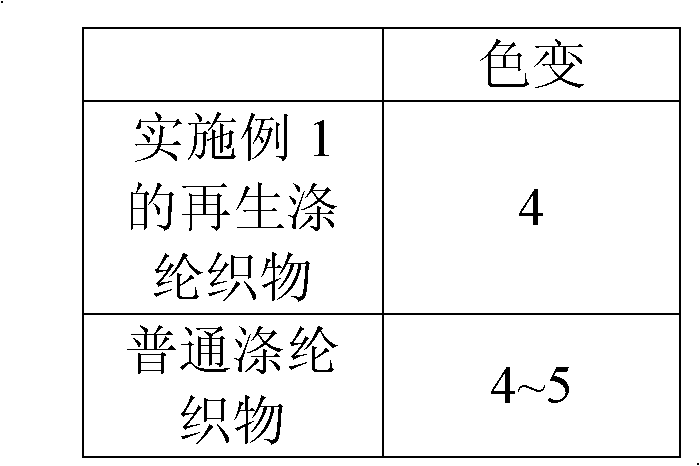

Dyeing and finishing method for regenerated nylon fabric and regenerated nylon fabric

ActiveCN102199885ASolve the defect of unstable dyeing shadeReduces high hair removal ratesHeating/cooling textile fabricsDry-cleaning apparatus for textilesEngineeringCleansing Agents

The invention relates to a dyeing and finishing method for a fabric, in particular to a dyeing and finishing method for a regenerated fabric, namely a regenerated nylon fabric. The invention also relates to the regenerated nylon fabric. The dyeing and finishing method of the regenerated nylon fabric comprises the following steps in turn: a) a pretreatment process; b) a dyeing process; c) a cleaning process; d) a heat setting process; and e) a texturing process. The dyeing temperature in the dyeing process is 120 to 135 DEG C, and a cleaning agent used in a cleaning process is an acidic reducing cleaning agent. The regenerated nylon fabric is treated by the dyeing and finishing method. In the invention, the technical problem that the strength of the regenerated nylon fabric is lower than that of common nylon fabrics is solved.

Owner:上海嘉麟杰纺织科技有限公司

High-modulus flame-retardant antistatic safe protection belt and preparation method thereof

InactiveCN105064024AEasy to adjustAdjustable thicknessFibre typesTextile treatment machine arrangementsCross-linkAntistatic agent

The invention provides a high-modulus flame-retardant antistatic safe protection belt and a preparation method thereof, and solves the problems that when the conventional protection belt is used in a complex environment, the personnel safety of a user cannot be protected effectively as the conventional protection belt is not flame-retardant and antistatic, the safety is poor and no preparation methods is available. The high-modulus flame-retardant antistatic safe protection belt comprises a base cloth layer, wherein reinforcing layers are fixed on both sides of the base cloth layer; the reinforcing layers comprise the following ingredients by weight: 40 to 60 parts of polyvinyl chloride, 20 to 30 parts of polycarbonate, 6 to 10 parts of a solvent, 3 to 6 parts of magnesium oxide, 3 to 6 parts of zinc oxide, 5 to 10 parts of calcium carbonate, 2 to 4 parts of a cross-linking agent, 3 to 8 parts of a plasticizing agent, 5 to 8 parts of an antistatic agent, and 0.1 to 0.3 part of an anti-oxidant. The high-modulus flame-retardant antistatic safe protection belt and the preparation method have the advantages that the safety is high; the production is fast.

Owner:HAINING JINGDA FABRIC

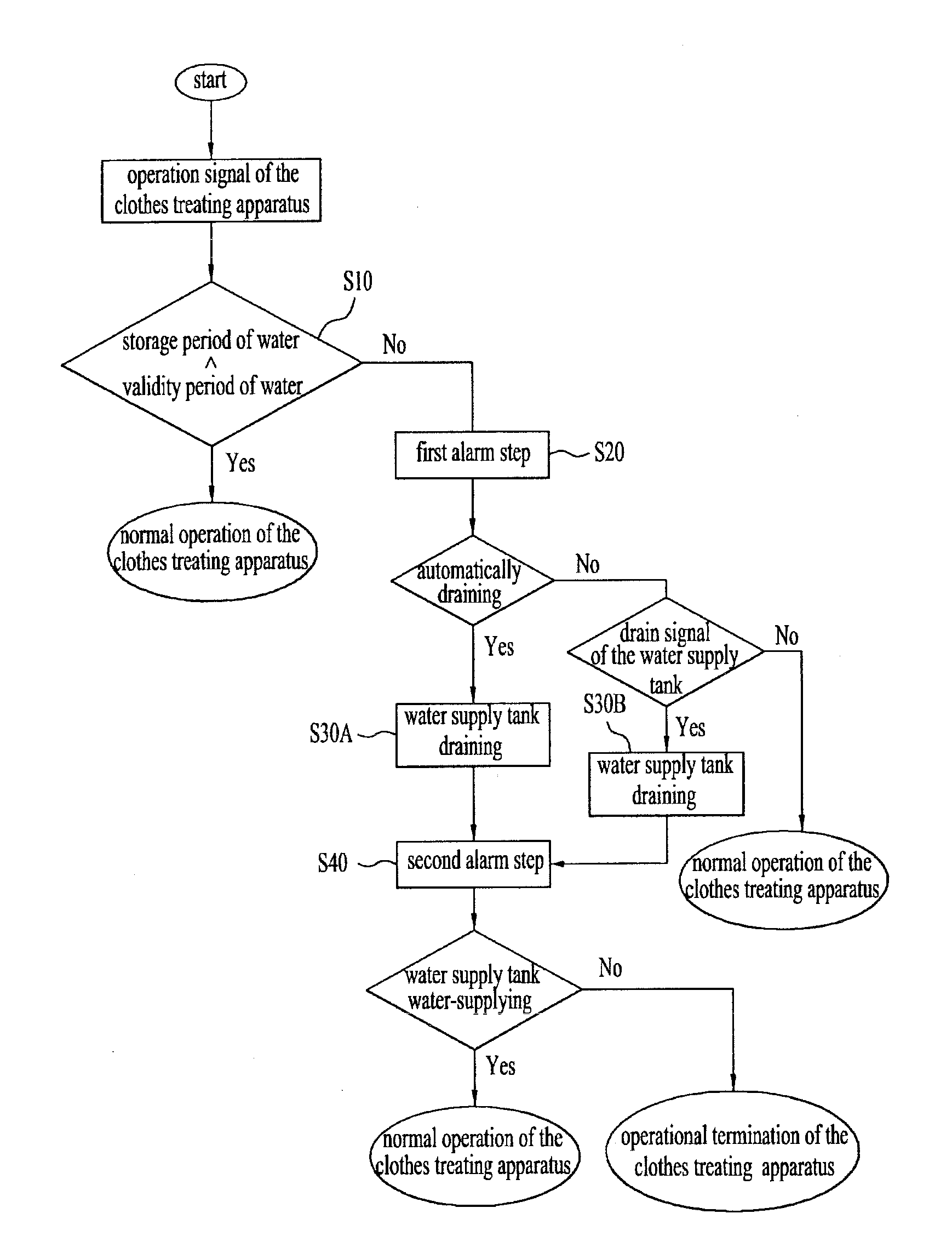

Controlling method of clothes treating apparatus

ActiveUS20110030147A1Satisfied with the resultTableware washing/rinsing machine detailsDistillation regulation/controlWater supply

The present invention relates to a clothes treating apparatus (100) and a controlling method of the same. More particularly, the present invention relates to a clothes treating apparatus (100), which can drain water inside a detachable water supply tank by using a draining path in the clothes treating apparatus (100), and a controlling method of the same. In particular, according to the clothes treating apparatus (100) and the controlling method of the same of the present invention, a draining function is automatically or manually performed after deciding whether water inside the water supply tank can be re-used or not.

Owner:LG ELECTRONICS INC

Cleaning and/or treatment compositions comprising malodor reduction compositions

Owner:THE PROCTER & GAMBLE COMPANY

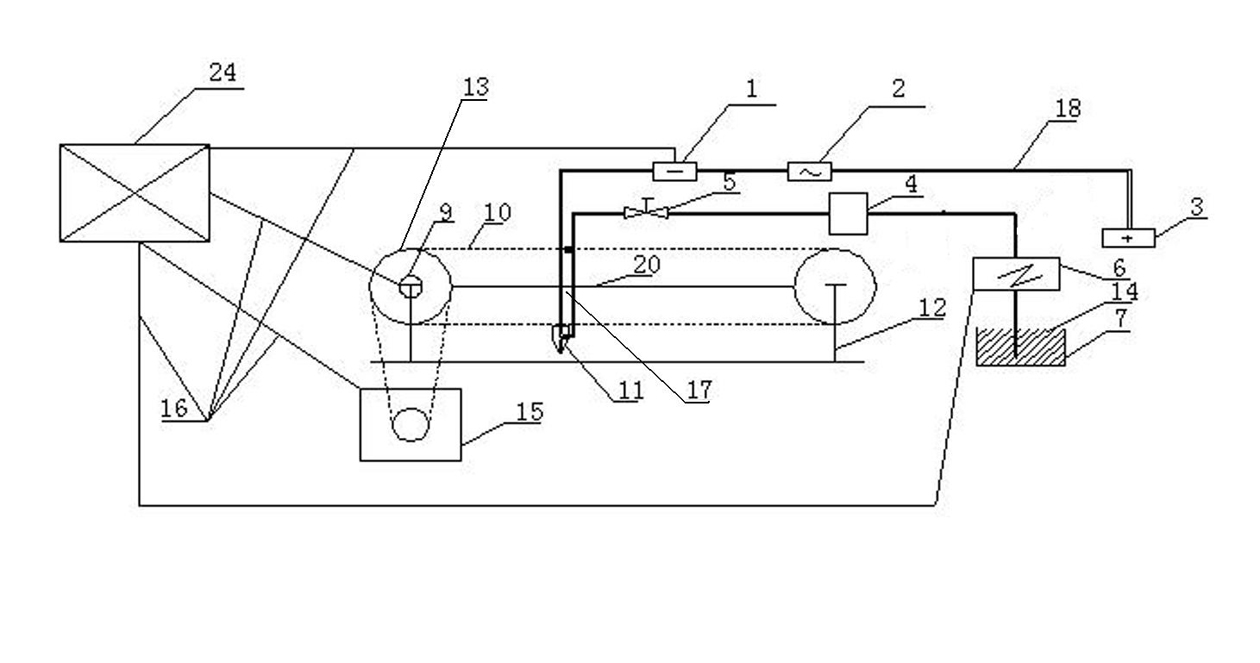

Speck yarn spray-dyeing device

ActiveCN102029236ANot easy to fall offAchieve continuous completionTextile treatment machine partsSpray nozzlesYarnEngineering

The invention relates to a speck yarn spray-dyeing device, which is used for processing specks on a plurality of parallel yarns. The device comprises at least two yarn guide rollers used for guiding the plurality of parallel yarns in and out and at least one spray head used for performing discontinuous spray-dyeing. A nozzle of the spray head faces down, and is positioned in the upper area of a yarn route. Yarns pass under the nozzle of the spray head through the yarn guide rollers. Each spray head is arranged on a rack truck. Each rack truck is arranged on a track extended along the arrangement direction of the plurality of yarns, is connected with a servo motor and can drive the corresponding spray head to reciprocally move along the arrangement direction of the plurality of yarns underthe drive of positive and negative alternate rotation of the corresponding servo motor and drive the corresponding spray head to stop moving under the braking of the corresponding servo motor. The device ensures that the specks on the spray-dyed speck yarns are difficult to fall, and has high production efficiency and low use cost.

Owner:ZHANGJIAGNAG SUNDELI DYEING & FINISHING

Ironing equipment for synthetic leather processing

InactiveCN104313827AReasonable structureLow costLiquid spraying apparatusTextile treatment by spraying/projectingElectricityWater saving

The invention discloses ironing equipment for synthetic leather processing. The ironing equipment includes a coating machine, and ironing equipment installed before the coating machine. The ironing equipment includes a heating roller and a pressing roller; the heating roller presses the pressing roller; the cloth is conveyed to the coating machine through a third driving roller, a second driving roller, a first driving roller, a heating roller and a pressure roller; the third driving roller, the second driving roller, the first driving roller and the heating roller respectively form a first cavity and a second cavity, which are respectively sealed by sealing steam plates; the first cavity and the second cavity are provided with a first steam pipe and a second steam pipe, which are communicated with the an ultrasonic water atomization generator; the water mist humidifies the cloth; the pressure roller is equipped with at least three electric heating bodiesa first temperature sensor and a second temperature sensor, which are connected with an electric heating controller. The invention has the beneficial effects of reasonable structure, low cost, electricity saving, water saving, space saving, and high temperature, high humidity and high pressure shaping and ironing of cloth.

Owner:福清市科技创新发展服务中心(福清市科技情报所)

Popular searches

Plasma welding apparatus Plasma technique Laundry driers Liquid/gas/vapor treatment of definite length materials Mechanical fibre separation Liquid/gas/vapor fibres/slivers/rovings treatment Bacteriological retting Fibre treatment to obtain bast fibre Ironing apparatus Drying machines with non-progressive movements

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com