Patents

Literature

252results about "Bacteriological retting" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

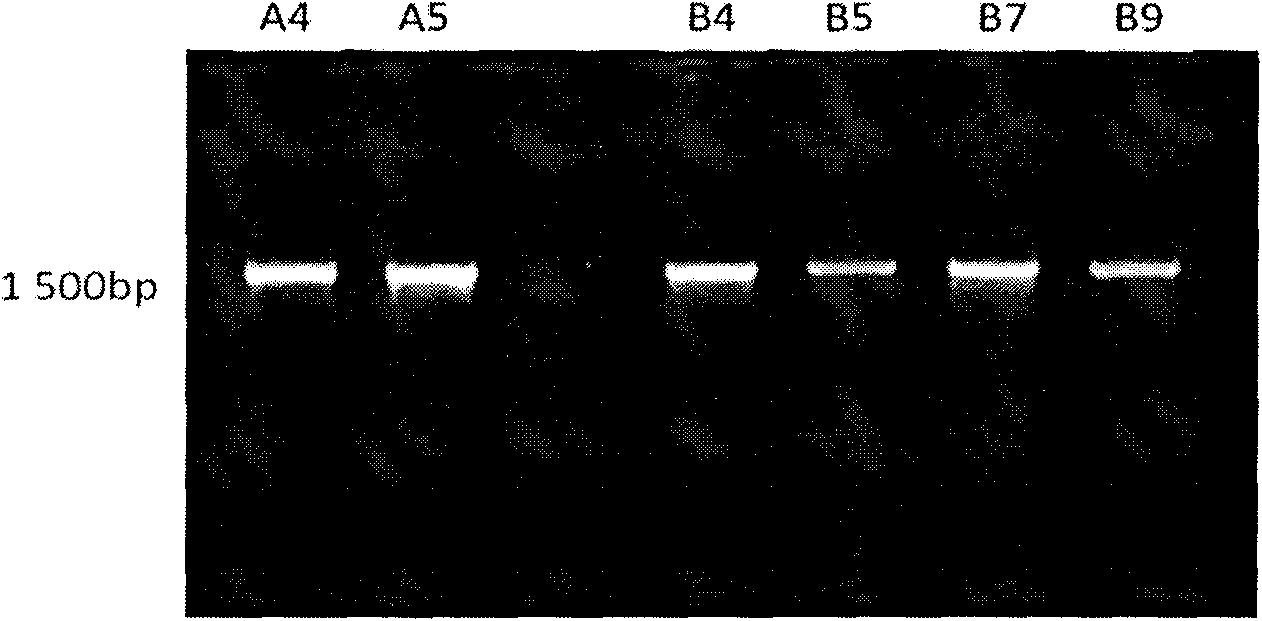

Fluorescent pseudomonad DA4 strain as well as acquisition method and application thereof

InactiveCN102002468AHigh enzyme productionEnzyme richBacteriaBiochemical fibre treatmentFlax fiberUltimate tensile strength

The invention relates to a fluorescent pseudomonad DA4 strain as well as an acquisition method and application thereof. The fluorescent pseudomonad DA4 strain has pectase and hemicellulase producing capacity and flax degumming activity. The fluorescent pseudomonad strain screened by the invention has fast propagation, high antipollution capacity and good heat and alkali resistance; since a composite degumming enzyme solution is used for flax degumming, the degumming period is shortened greatly, and the system and the culturing process is safe for operation without toxicity or environmental pollution; the invention can shorten the flax degumming period, enhance the flax yield and the strength of flax fibers, improve the quality of the flax fibers by adopting the composite degumming enzyme solution for flax microbial degumming, thereby being beneficial to popularization; in addition, the invention can not only be used for flax raw stem degumming, roving scouring and the biological pretreatment of flax fabrics, but also can be used for the degumming and the biological pretreatment of hemp bast fibers, i.e. ramie, jute, hemps, and the like.

Owner:DONGHUA UNIV

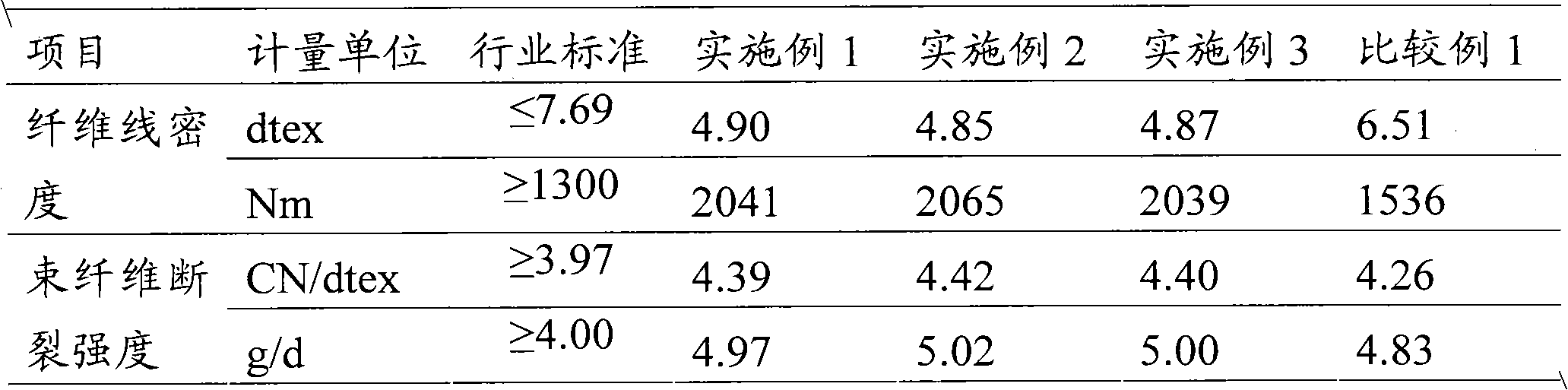

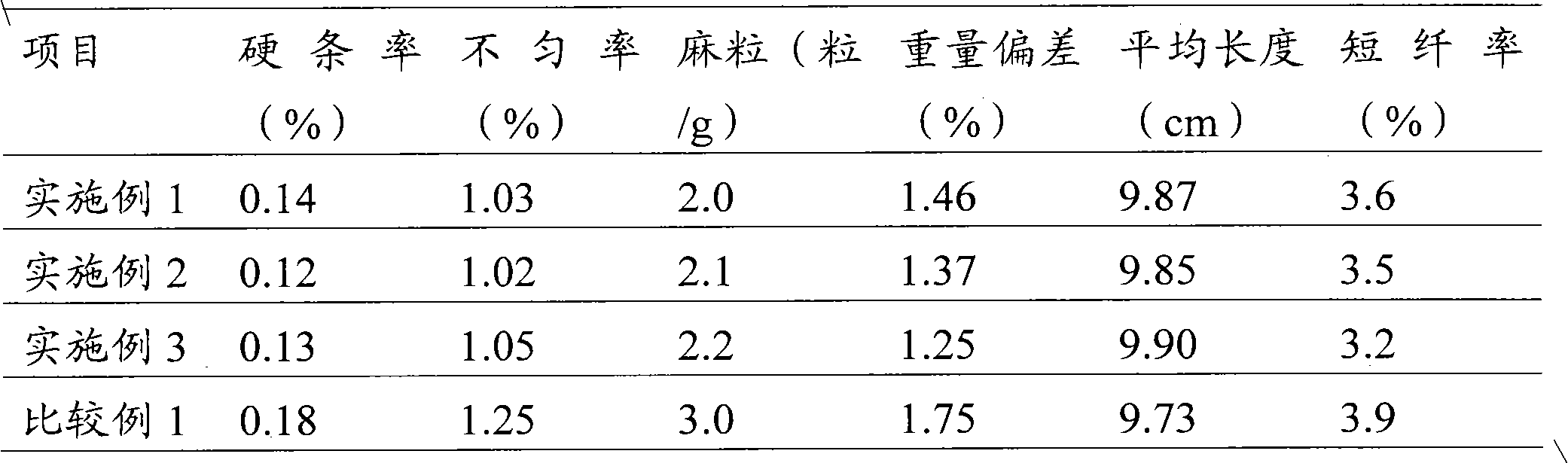

Technological process of ramie bast fiber

ActiveCN101824658AImprove processing uniformityImprove qualityCombing machinesDrafting machinesBiochemical engineeringCombing

The invention relates to a technological process of a ramie bast fiber, which comprises a basic degummed ramie production route: raw ramie skin-sorting and derooting-mechanical ungluing-cage loading-biological ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-radio frequency drying- degummed ramie. Long ramie can be growth through the mechanical hemp oiling- infiltration and health care-stretch breaking and carding-pre-gilling-combing and sorting-final gilling of the degummed ramie. Short ramie can be produced through the combing and the sorting of combed noil. Oakum can be produced through biological ungluing-high-temperature stewing and ungluing-high-temperature rinsing-cage unloading-sub-fiber washing-soft rinsing-dehydration and drying-radio frequency drying-mechanical hemp oiling- infiltration and health care-opening and edulcoration- combing and sorting. Improving methods are adopted for the mechanical ungluing, biological ungluing, high-temperature rinsing, sub-fiber washing, stretch breaking and carding, combing and sorting and the like. The preparation process has the advantages of short process, high production efficiency, high mechanical automation degree, stable product quality, excellent fiber quality and strong operability of fiber length and fineness, and can be used in the production processes of various bast fiber raw material, gramineae fiber raw material, leaf fiber raw material and other fibers.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +2

Manufacturing method of ramie based on sectioned circulation

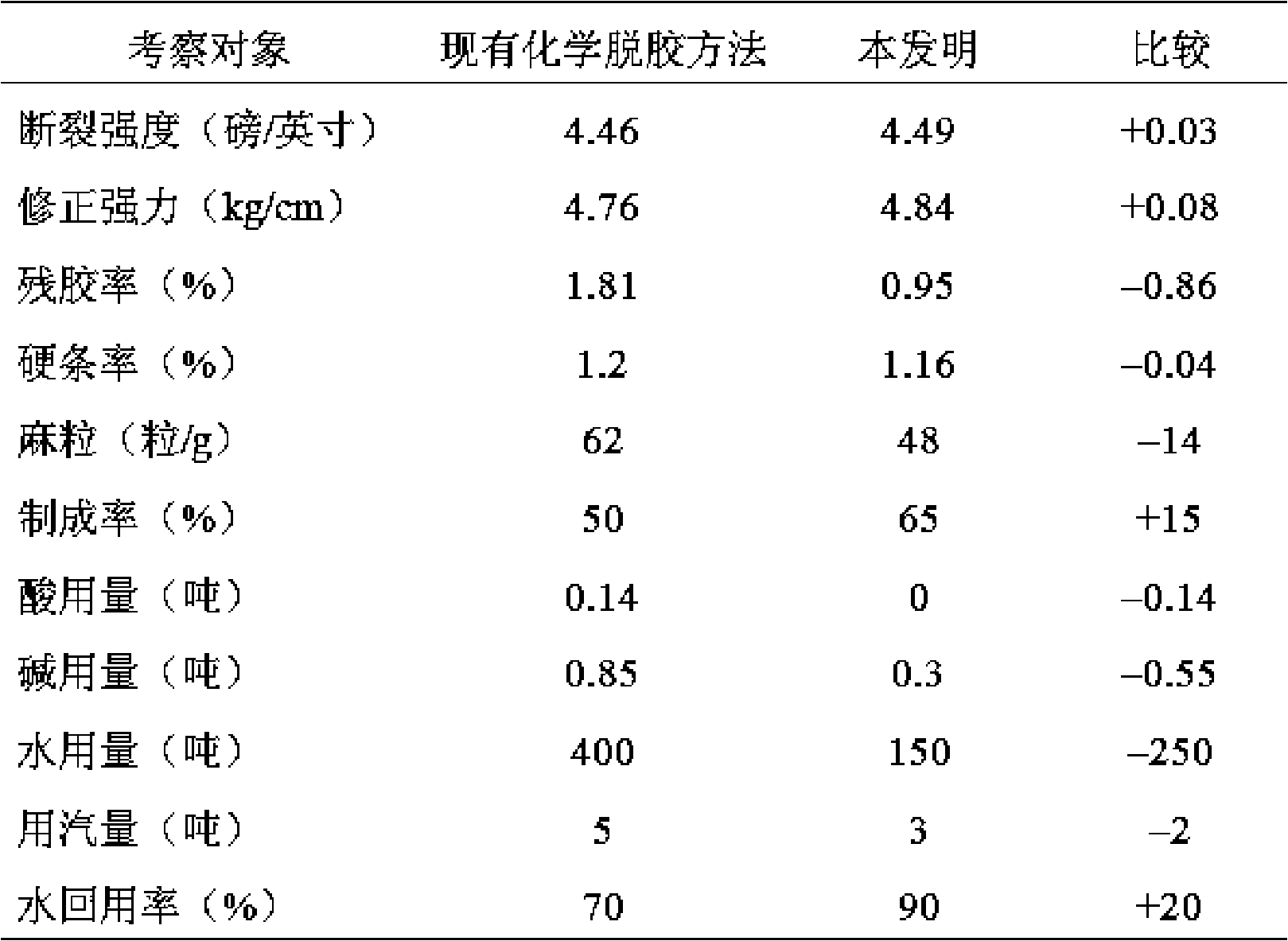

ActiveCN101624727AGet rid of dependenceReduce dosageMechanical treatmentBacteriological rettingChemical treatmentCarding

The invention discloses a manufacturing method of ramie based on sectioned circulation, belonging to the manufacturing method of textile fibre and solving the problems that the prior method has a large quantity of waste water, serious pollution and high cost. The method comprises following steps: pretreatment of primary ramie, chemical treatment, biological treatment and post treatment; the pretreatment improves the degree of looseness of the primary ramie through beating, ultrasound or extraction; the biological treatment degrades pectin, hemicellulose and others impurities through bio-enzyme or microbial fermentation; the chemical treatment further degrades residual pectin and others impurities through alkali boil-off; the post treatment obtains refined dry ramie by beating, whitening, water scrubbing, dehydration, oil feeding, drying, carding and baking. The quality of the product meets the requirements of first-class GB / T 20793-2006, the degumming yield rate is improved by 15%, the water consumption is reduced by at least 60%, the method is free from using acid, the alkali charge is reduced by 65%; water, the alkali and the bio-enzyme used in each step are recyclable; the byproducts can be recycled in time, the sewage quantity is small and the pollution level is low.

Owner:HUAZHONG UNIV OF SCI & TECH

Degumming technology of mulberry bark

InactiveCN101638811AImprove production rateAvoid damageVegetable materialBacteriological rettingFiberCellulase

Owner:YANCHENG INST OF IND TECH

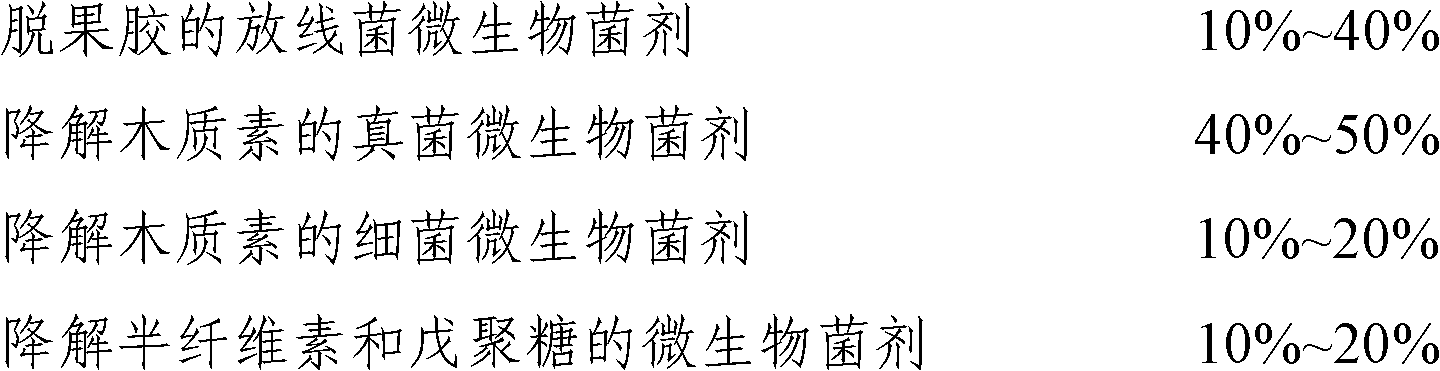

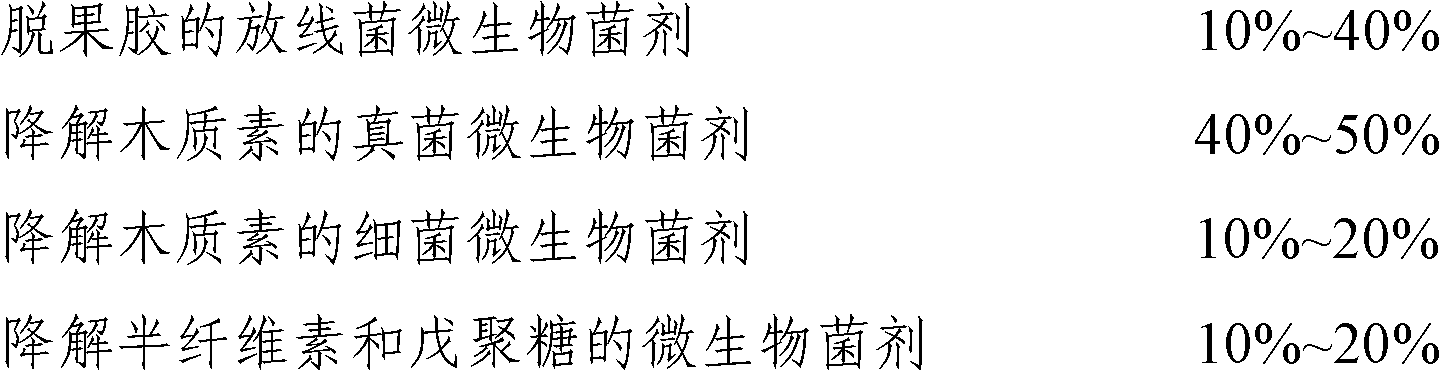

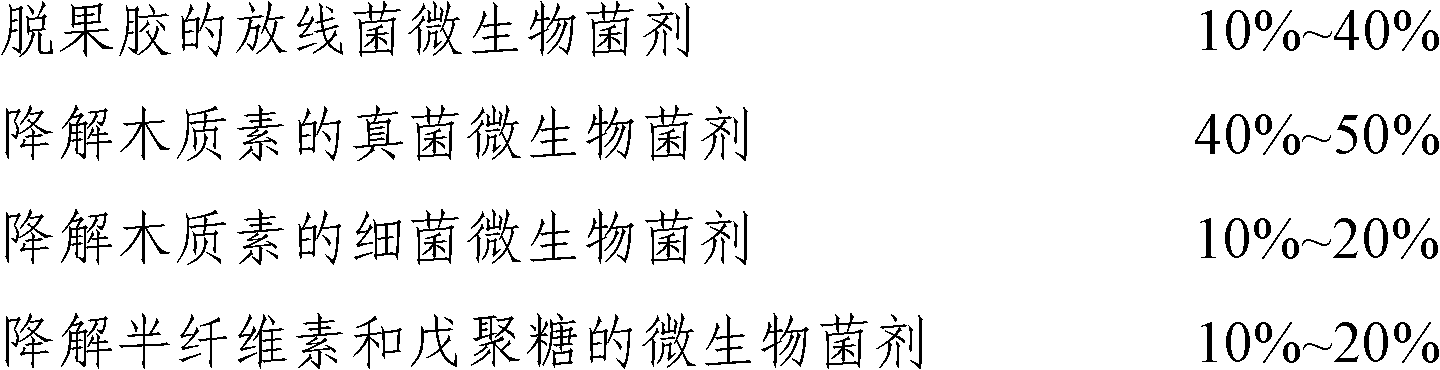

Method for preparing natural bamboo fibers in pectin removal manner by aid of compound microorganism bactericide

The invention provides a method for preparing natural bamboo fibers in a pectin removal manner by the aid of compound microorganism bactericide. The method includes steps of removing pectin of coarse natural bamboo fibers via microorganisms for removing pectin, microorganisms for decomposing lignin and microorganisms for decomposing hemicellulose and pentosan successively; then adding the compound microorganism bactericide into the natural bamboo fibers to remove pectin; and drying after refining via alkali and auxiliaries to obtain the natural bamboo fibers. The thickness and the diameter of the natural bamboo fibers are controlled by means of changing constitution, proportion, decomposition time and the like of the compound microorganism bactericide. The natural bamboo fibers produced by the method are high in strength and fine in toughness and are environment-friendly, a total pectin removal process of the microorganism method is water-saving, energy-saving and free of wastewater, waste slag and waste gas, microorganism treatment liquid and cleaning liquid can be recycled completely, and the problem of environmental pollution caused by chemical treatment is resolved effectively. Accordingly, the method has the advantages of easiness in obtaining of raw materials, simplicity in operation, high extraction efficiency, stable quality of the fibers, and the like.

Owner:MIANYANG TEACHERS COLLEGE

Industrial fermentation ramee rapid extraction technique for Erwinia

ActiveCN101235357AReduce technical difficultyImprove activation process parametersBacteriaMutant preparationAnimal ForagingHigh pressure

The invention discloses a technique for rapidly extracting ramie hemp erwinia bacterium factory production fermentation, the technique comprises preprocessing material, immersing or sprinkling and inoculating, immersing or fermenting, deactivating with hot water, and the procedure of circulation washing, water dressing and fiber finish, erwinia bacterium which has broad-spectrum and high effective to degumming, pulping and saccharifying of herb fiber material, and bacterial agent preparation and activated technical parameter. The erwinia bacterium addicts the mannose, the peak for secreting non-cellulose to degrade key enzyme (pectic enzyme, beta-mannase and xylanase) can be achieved through purely culturing for 7h to 9h. Bacterial agent is inoculated on herb fiber material such as ramie and the like for activating the bacterial agent for 5h-6h, fermentation forage fodder turns to blue after fermenting for 5h-6h, pectine, hemicellulose and partial lignin which are partially degraded and associated in fiber cell are stripped, non-cellulose residues which are absorbed on fiber can be removed by means of the flushing of high-pressure flushing, and the purpose of extracting net fiber can be reached.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Method for quickly extracting herbaceous fibers in factory fermentation mode by using full-function strains

InactiveCN102559541ALittle pollutionShort degumming cycleBacteriaMicroorganism based processesFiberBiological activation

The invention discloses a method for quickly extracting herbaceous fibers in a factory fermentation mode by using function strains. The method comprises the steps of pre-treating a herbaceous fiber raw material, inoculating activated strain liquid to the herbaceous fiber raw material for factory fermentation, post-treating the fermented material and the like. The method specifically comprises the following steps of: rolling or cutting the herbaceous fiber raw material, and performing activation and amplification treatment on Dickeya dadantii strains to obtain strain suspension; diluting the strain suspension, and then performing soaking inoculation and soaking fermentation or wetting fermentation on the herbaceous fiber raw material till fibers are dispersed; and performing post-treatment such as hot water inactivation, washing and the like on the fermented product till the herbaceous fibers meeting the subsequent processing requirements are obtained. The method has the advantages of short degumming period, low production cost, stable product quality, low environmental pollution and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Industrialized biological degumming technique for kenaf bast fiber

ActiveCN101503829AReduce occupancyReduce pollutionBacteriological rettingMicrobial agentNetwork structure

The invention discloses a factory biologic degumming process of kenaf bast. The process comprises the following steps: firstly, rolling kenaf bast till the kenaf bast loosens without damaging kenaf fiber, and carrying out activation and augmentation treatment of Erwinia carotovora microbial agent to obtain bacterial suspension; diluting the bacterial suspension and then carrying out immersion vaccination or spraying vaccination of the kenaf bast; carrying out immersion fermentation or wet fermentation of the kenaf bast till the kenaf bast turns blue and transversely torn kenaf pieces are in a network structure; inactivating the fermented kenaf bast by hot water; and then, cleaning the kenaf bast by high-pressure water while rolling the kenaf bast till kenaf fiber is obtained. The degumming process has the advantages of short degumming cycle, low production cost, less investment, less land occupation, low labor intensity, environmental protection, no pollution, stable product quality, and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Process for increasing the charge on a lignocellulosic material

InactiveUS6187136B1Avoid reactionIncrease surface charge densityFungiPaper/cardboardCatalytic oxidationCellulose fiber

A process for production of a lignocellulosic material modified by conjugation thereto of a phenolic substance comprising a substituent which, in the conjugated form of the phenolic substance, is, or may become, negatively or positively charged, respectively, comprises: reacting a lignocellulosic fibre material and the phenolic substance with an oxidizing agent in the presence of an enzyme capable of catalyzing the oxidation of phenolic groups by the oxidizing agent; and reacting together the products of the reactions; with the proviso that the phenolic substance is not a phenolic polysaccharide. A strengthened lignocellulose-based product (e.g. a paper product) may be prepared by a procedure wherein a product produced in accordance with the latter process is treated with a strengthening agent having an ionic charge of sign opposite to that which is conferred on the modified lignocellulosic material by the charge-conferring substituent.

Owner:NOVOZYMES AS

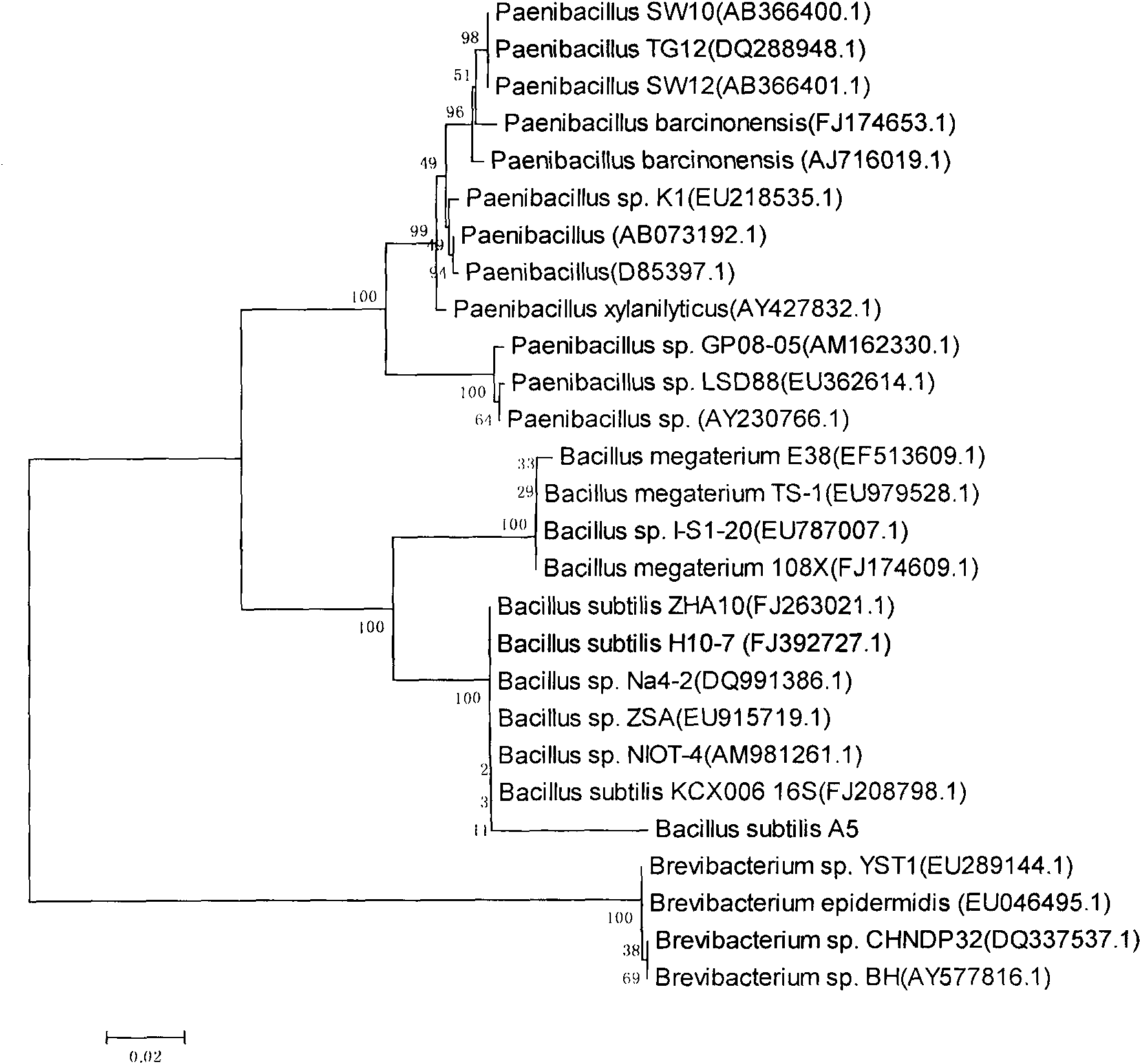

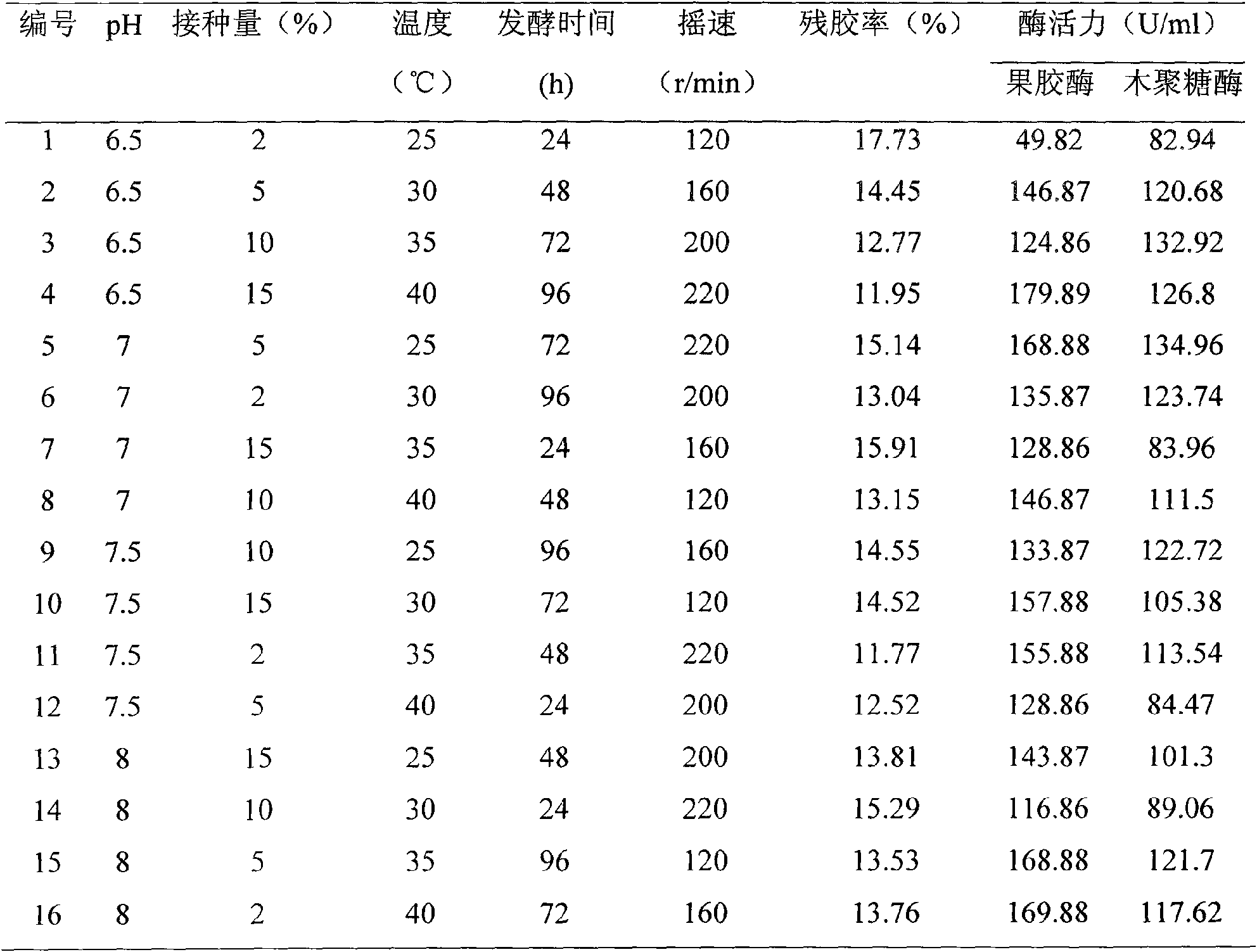

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

InactiveCN101654660ANot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementPectinaseBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and thecultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

Enzymatic preparation of plant fibers

InactiveUS8603802B2Efficient and effective extractionReduce harmMicrobiological testing/measurementVegetable materialFiberAqueous solution

Owner:NAT RES COUNCIL OF CANADA

Bacillus subtilis and application thereof in sisal hemp degumming

InactiveCN101880637AExact decompositionAchieve complete degummingBacteriaMicroorganism based processesWater bathsMicrobiology

The invention discloses Bacillus subtilis and application thereof in sisal hemp degumming. The conservation number of the Bacillus subtilis B2 is CCTCCM208115. When in application, the Bacillus subtilis is used as a single strain which is inoculated in seed culture medium, is placed in a gas bath shaker or water bath shaker with temperature of 37 DEG C and is cultured for 8-12h, 2-20 percent (volume percent) of inoculation quantity is trans-inoculated in degumming culture medium when 0D600 reaches 0.6-1, fresh sisal hemp leaves are added in the degumming culture medium, culture temperature is 25-42 DEG C, the revolution of the shaker is 150-250rpm and the sisal hemp degumming can be completed in 35-55h. The invention has the advantages that the culture conditions are extensive, the growth and the reproduction are rapid, the sisal hemp degumming can be completed in 35h, the fiber is not damaged, the environment is not polluted, and the Bacillus subtilis can substitute for mechanical green removal and can be used for the pretreatment of sisal hemp before sisal hemp degumming and pulping technology.

Owner:SOUTH CHINA UNIV OF TECH

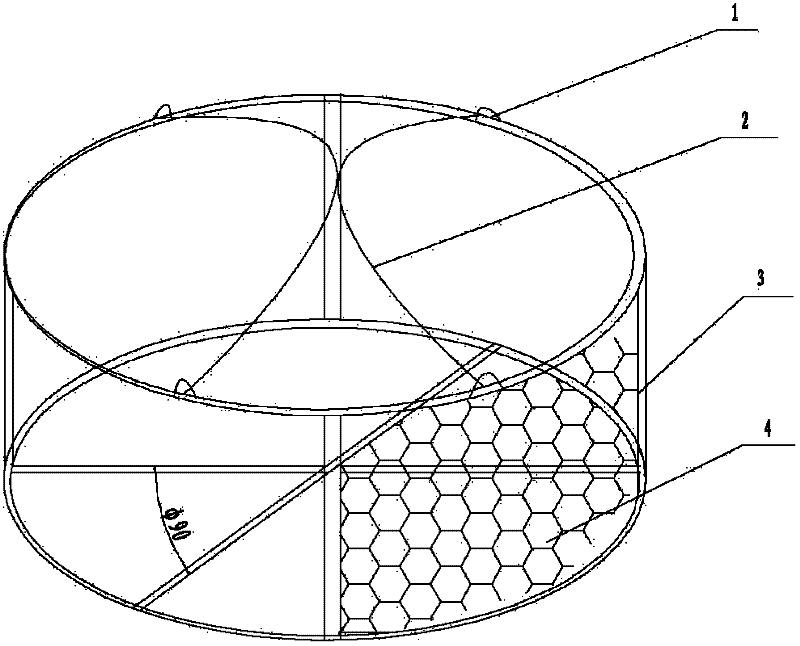

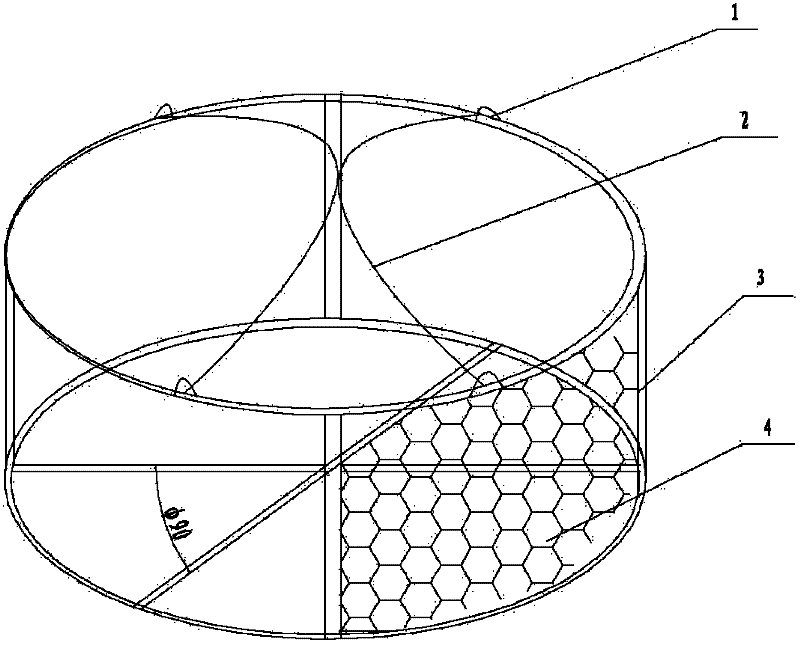

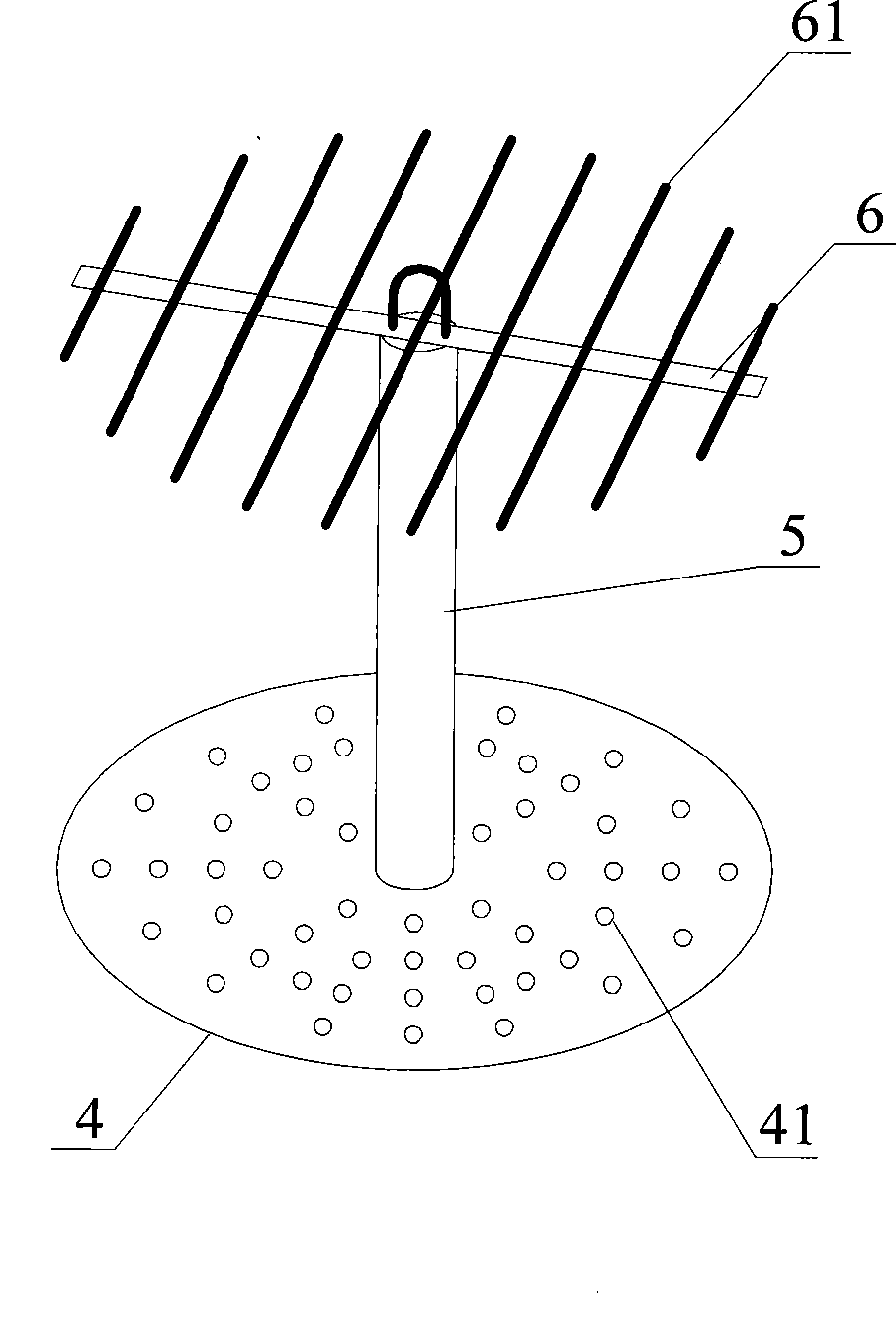

Method and device for biological degumming of ramie

InactiveCN101857974ALarge specific surface areaFully contactedVegetable materialMechanical fibre separationCelluloseUltimate tensile strength

The invention provides a method for the biological degumming of ramie, which comprises the following steps of: c peeling and pre-opening fibers of the dried fresh ramie to obtain raw ramie; soaking and inoculating degumming bacteria subjected to amplification culture in the raw ramie and carrying out oscillation fermentation on the mixture at a rotation speed of 50 to 200 revolutions per minute to obtain fermented ramie; carrying out washing and fiber opening on the fermented ramie to obtain primary ramie; and carrying out oil soaking, dehydration and drying on the primary ramie to obtain fine ramie. The invention also provides a device for the degumming on the ramie. Compared with the prior art, the method provided by the invention combines a mechanical processing method with a biological degumming method, firstly carries out fiber pre-opening to improve the efficiency of subsequent biological degumming and then carries out washing and fiber opening after completing biological degumming to realize complete separation of gelatinous substance and cellulose, shortens degumming time and improves degumming efficiency. The obtained fine dried ramie has stable quality and higher fiber strength.

Owner:湖南润久科技有限公司

Extraction method of bamboo shoot case fibre for spinning

InactiveCN101117731ASimple processLow costVegetable materialBacteriological rettingChemical treatmentPre treatment

The present invention relates to a method for extracting spinning fiber from bamboo shoot shells. The extracting method of spinning fiber from bamboo shoot shells is characterized in that the present invention comprises the following steps: firstly, pretreatment: cutting the bamboo shoot shells into pieces 20-100mm long; storing the pieces in a sealed environment and adjusting the humidity to control the moisture regain rate at 6 percent -10 percent; secondly, degumming treatment: using one or combination of any two or three of steam explosion treating method, microbial treating method and chemical treating method for degummed bamboo shoot shell fiber; thirdly, post-treatment: a, oil feeding: adding wool oil to the degummed bamboo shoot shell fiber, the wool oil being 1-2 percent of the degummed bamboo shoot shell fiber in weight; b, drying: controlling the temperature of the drying oven at 60-80 DEG C; c, fiber dispersing: obtaining spinning bamboo shoot shell fiber. The present invention has the advantages of simple process and low cost and, applied to textile processing, can take full use of bamboo shoot shell resources and protect the environment.

Owner:WUHAN TEXTILE UNIV

Enzymatic preparation of plant fibers

InactiveUS20110312066A1Promote acidic hydrolysisLonger treatment timeMicrobiological testing/measurementVegetable materialFiberAqueous solution

A method of extracting fibers from decorticated plant bast skin involves pre-treating decorticated plant bast skin of a fiber plant with an aqueous solution containing trisodium citrate having a pH in a range of about 8-14 at a temperature of about 90° C. or less; and subsequently treating recovered fibers with a protease at alkaline pH.

Owner:NAT RES COUNCIL OF CANADA

Prepn and use of enzyme prepn for use in hemp degluing industrial process

InactiveCN1374398ANo pollution in the processImprove working conditionsBacteriaBacteriological rettingBreaking strengthMicroorganism

The present invention relates to the field of microbial engineering technology. The enzyme preparation is prepared through the process including slant culture and storing, shaking culture, seeding tank culture and fermenting tank production of high enzyme activity bacteria strain. Bacillus subtilis of No.13 strain and preservation number CCTCC No.M200038 is selected. The hemp degumming process includes the fermentation of enzyme liquid filtering residue, diluting bacteria liquid to 3-6 times, regulating the pH value of fermented enzyme liquid in degluing tank to 7.5-9.0, hemp material pre-treatment, degumming with degumming liquid for 2-10 hr. The process of the present invention has no environmental pollution, and can produce hemp top with length, fineness and breaking strength superior to those of chemical process.

Owner:山东省纤维检验局 +2

Banana bast fiber and preparation method thereof

ActiveCN101736407AAntibacterial propertiesMoisture absorption and dehumidification fastMechanical fibre separationBacteriological rettingBreaking strengthFiber bundle

The invention discloses a method for preparing a banana bast fiber by adopting biological degumming, which is characterized by comprising the following steps of: preprocessing, inoculating, fermenting, inactivating, stamping and postprocessing. The prepared banana bast fiber has soft and loose appearance and uniform color and has no taste or obvious flaws; the fiber length is 80mm-200mm, the fiber count is 300Nm-500Nm, the breaking strength of fiber bundles is 3.5g / D-5.0g / D, and the residual gum content is 1.5 percent-3.2 percent. The biologically degummed banana bast fiber effectively removes the non-spinnable components of colloid, lignin, hemicellulose and the like and keeps the bacteria proofing, rapid moisture absorption and release of the self characteristics of the fiber, thereby ensuring the strength of the fiber; meanwhile, the banana fiber is kneaded and rolled by sterilization and machines before degumming, thereby ensuring the degumming effect and the smooth going of degumming and enabling the degummed fiber to be beneficial to the production and production development of the next working procedure.

Owner:湖南华升益鑫泰科技有限公司

Bacterial strain producing phloem fibre degumming enzyme and its application in ramie and hemp degumming

The present invention relates to a strain capable of producing bast fiber degumming enzyme and its application for degumming ramie and hemp, belonging to the field of microbial technology. Said strain is bacillus subtilis No.13, and its preservation number is CCTCC, No.M200038. Its degumming rate can be up to 95%, its degumming effect is good, and its degumming process can be completed within 2-6hr., and the fibre separation index is 100%.

Owner:SHANDONG UNIV

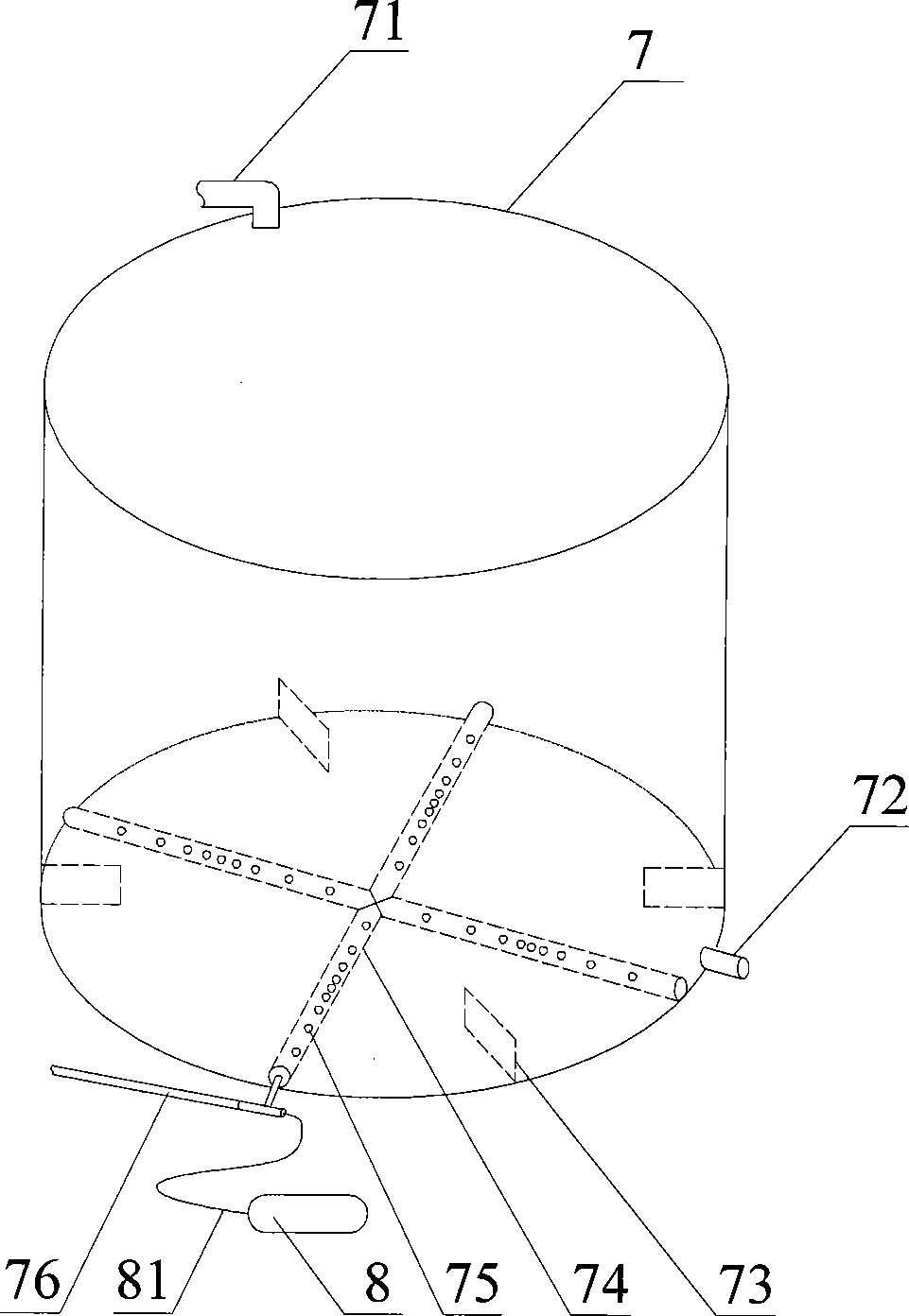

Microorganism retting flax method for crudefiber crops

InactiveCN101285211AShort fermentation timeHigh rate of numbnessBacteriaMicroorganism based processesFiber cropMicroorganism

The invention provides a method for retting flax with microbe mild water for bast-fiber crops, belonging to a retting technology for the bast-fiber crops. The method comprises the following steps of: adding degumming bacteria into a retting vessel according to 0.5 to 1.0 per thousand of the total weight of aqueous solution; heating up to 30 to 40 DEG C after injecting water to 100 percent of the total weight of the aqueous solution; and finishing retting after 40 to 50 hours. The industrial production of the degumming bacteria is completed via primary strain culture, secondary strain culture and industrial production. The method has the characteristics of short retting fermentation period, high percentage of fiber extraction, high fiber stress, small water consumption, low energy consumption, retting water economization, zero drainage of retting water and no environmental pollution.

Owner:黑龙江省科学院亚麻综合利用研究所

Ramie degumming method utilizing a complex enzyme preparation

InactiveCN101550606AAction temperature controlReduce in quantityVegetable materialBacteriological rettingSodium phosphatesLiquid water

The invention discloses a ramie degumming method utilizing a complex enzyme preparation, which comprises the following steps: bundling, cage charging, enzyme immersion, soda boil, ramie beating, rinsing, oil feed, oil-water separation, ramie joggling and ramie baking, wherein the enzyme immersion is as follows: firstly, heating water with the weight of 13-15 times heavier than ramie by vapor; regulating the pH value of the water between 8 and 9 by NaOH and then adding liquid complex enzyme with the weight of 2-4 percent of the ramie to the water; adding the ramie to the water and hermetically preserving the temperature of the water between 50 DEG C and 55 DEG C for 3-5 hours; the soda boil step is as follows: adding water with the weight of 13-15 times heavier than the ramie to a mixing barrel; then adding liquid NaOH, solid trimeric sodium phosphate and liquid water glass to the mixing barrel; then heating the water to make cooking materials and simultaneously drying the ramie and placing the ramie into a high-pressure cooking boiler; and then placing the cooking materials into the high-pressure cooking boiler to be cooked. The ramie degumming method has sufficient deguming matched with the subsequent soda boil procedure so that three procedures, such as enzyme scouring, ramie retting and ramie washing, of the traditional biological dugumming are combined into one procedure and the time is shortened to half of original time, thereby enhancing the production efficiency.

Owner:湖南瑞亚高科集团有限公司

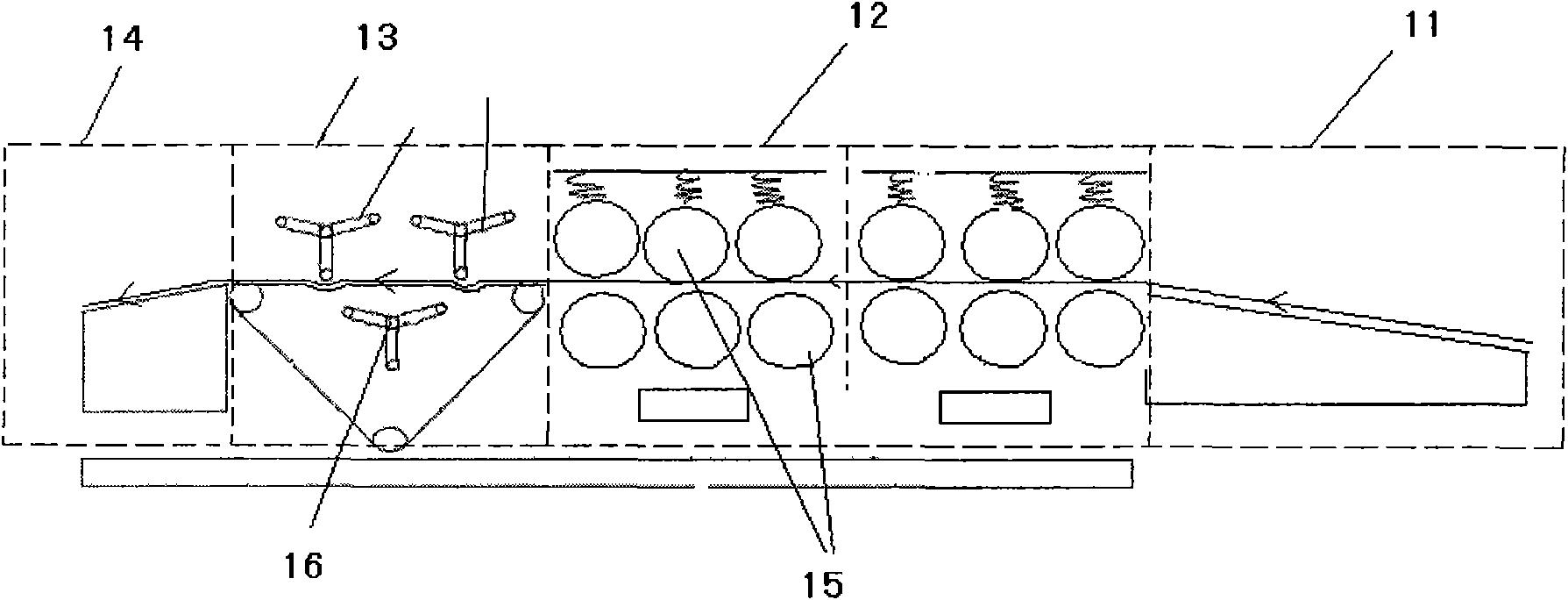

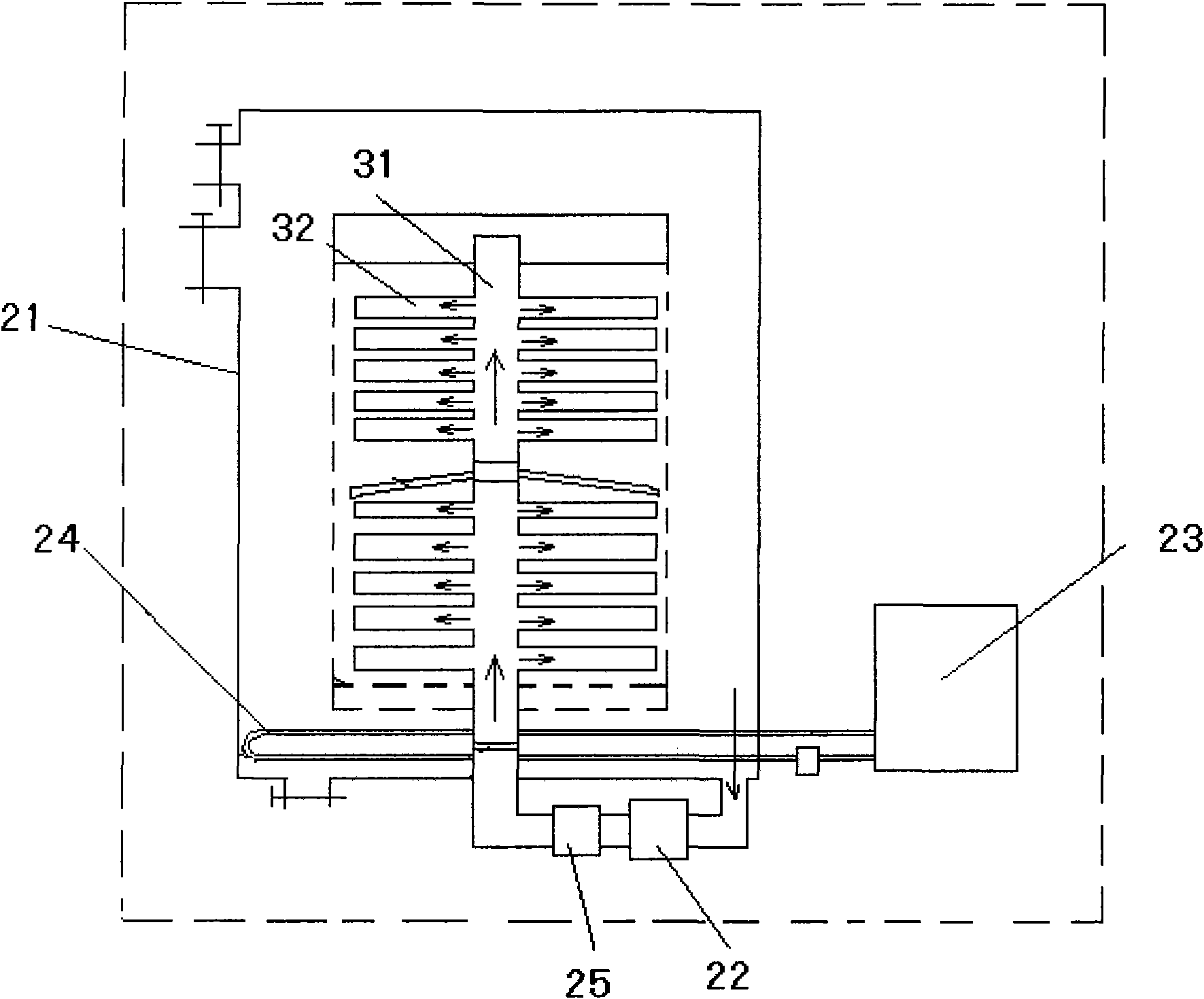

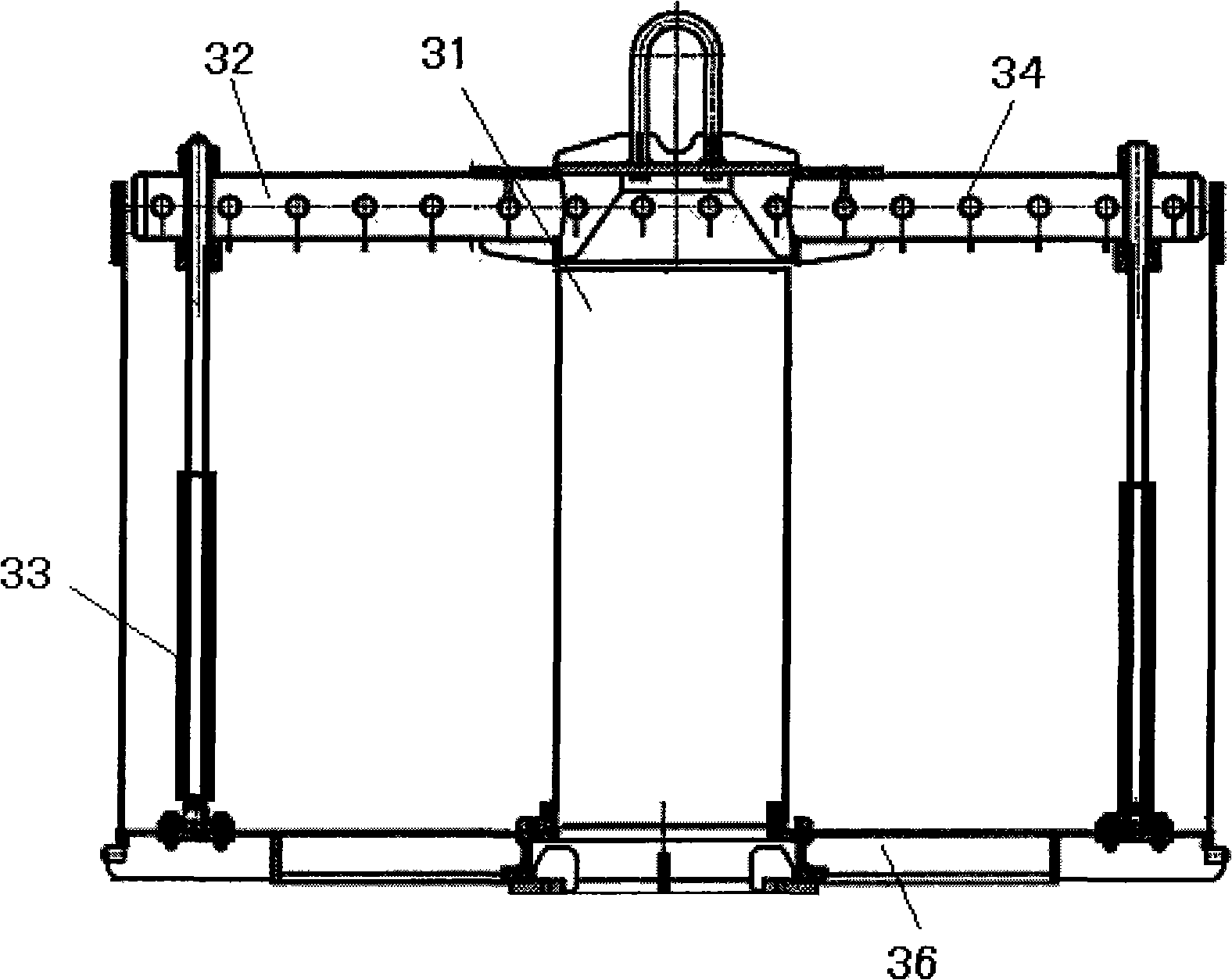

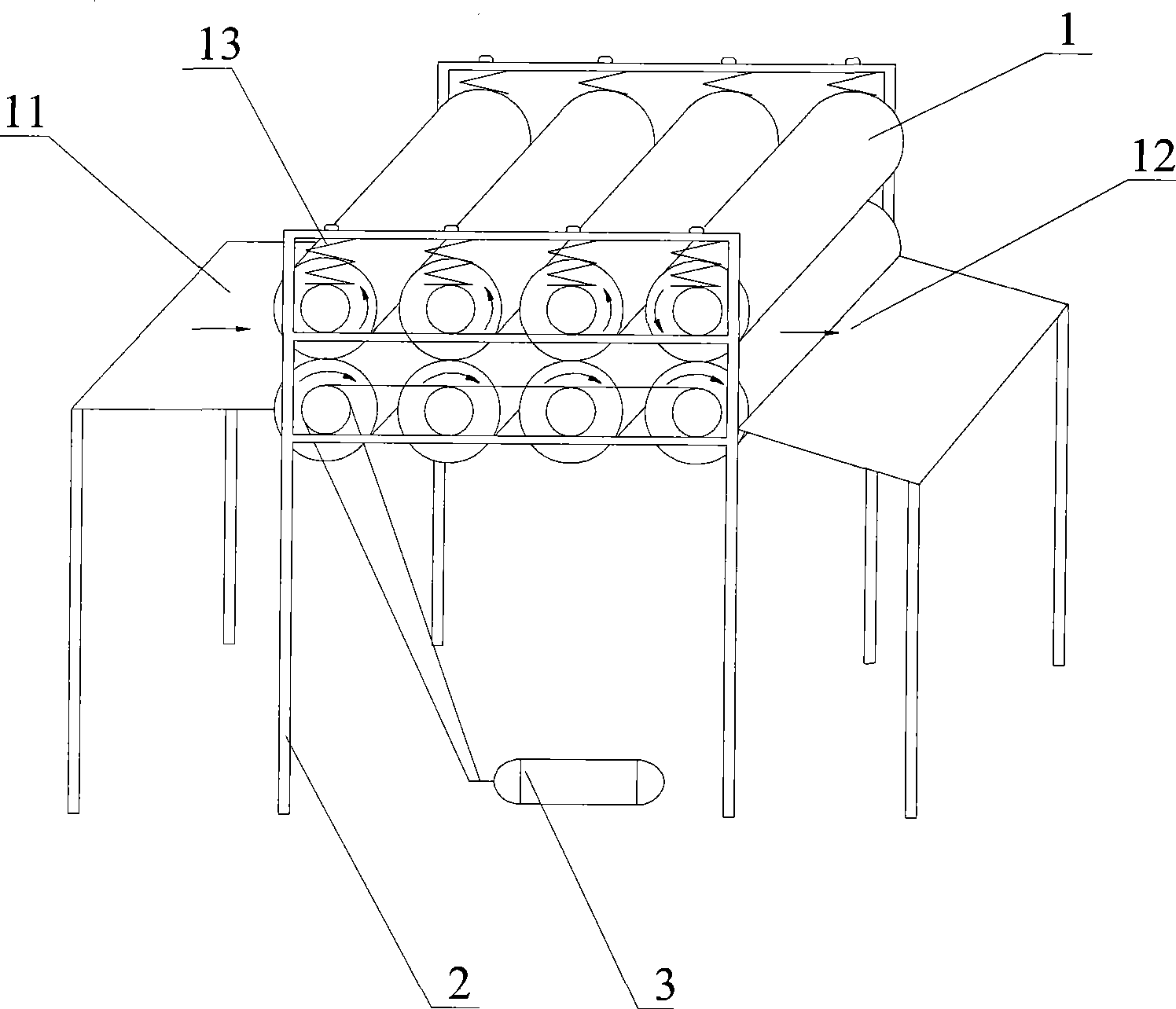

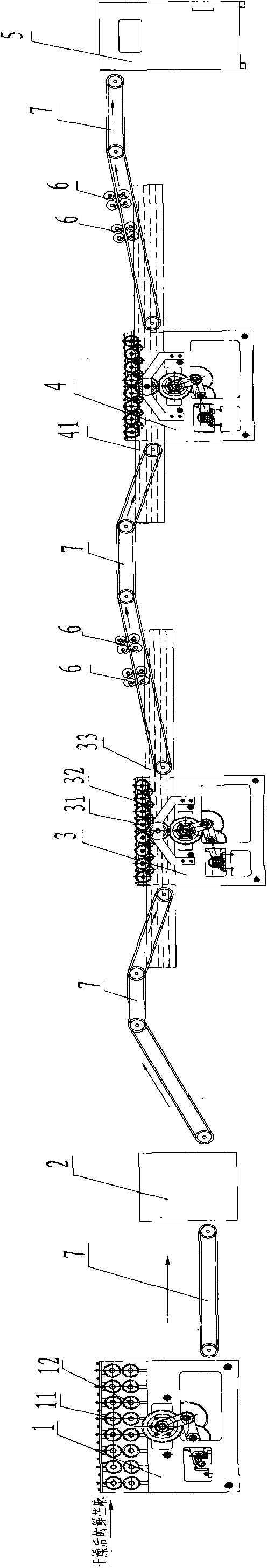

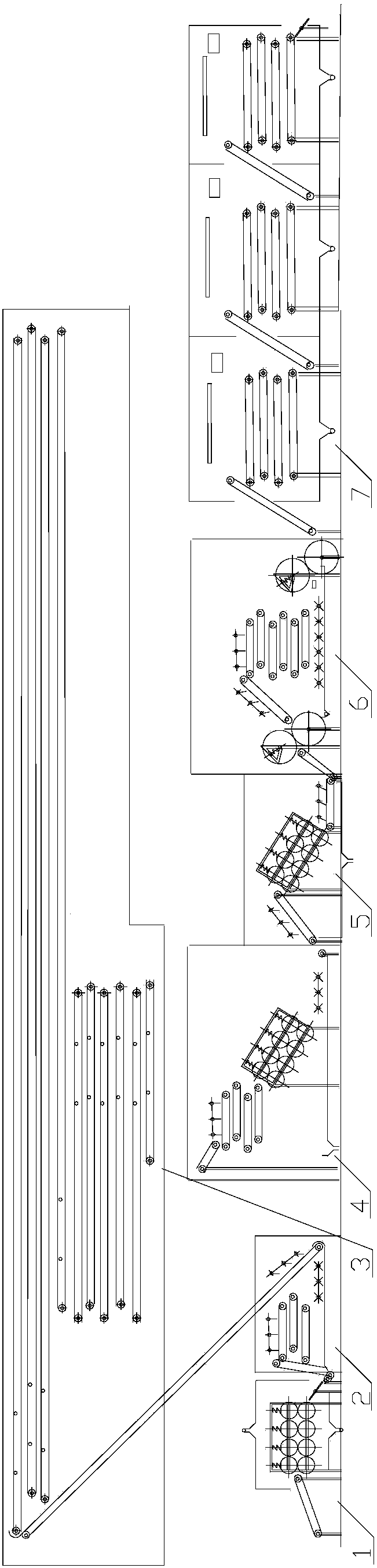

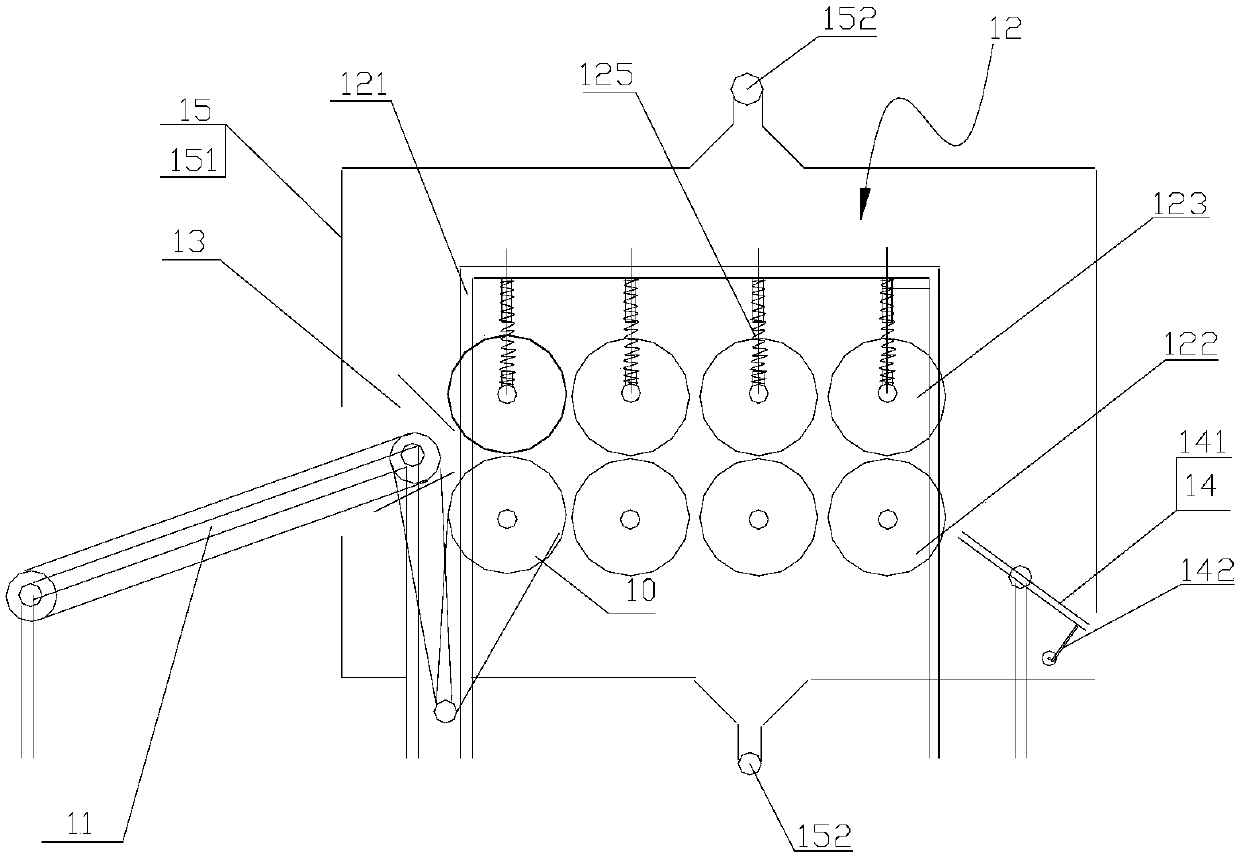

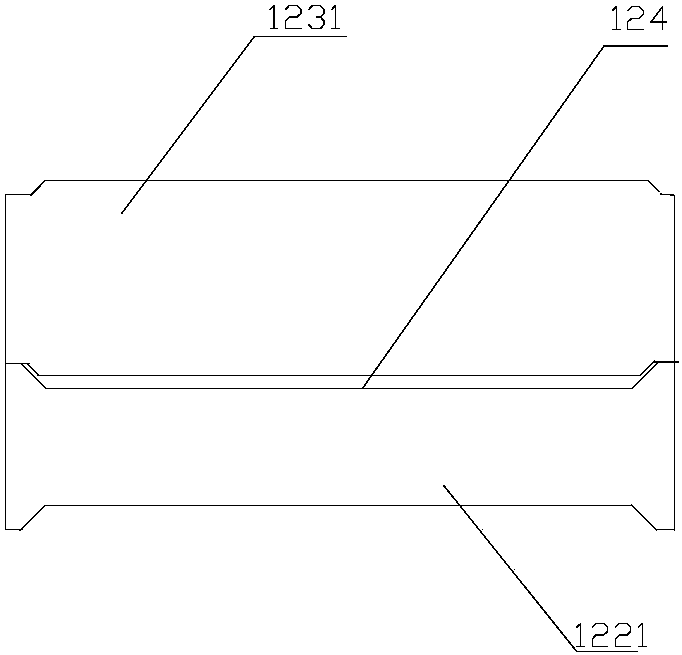

Automatic operation system and method of biologically refined herbal fibers

ActiveCN107142521AFree laborIncrease productivityVegetable materialMechanical fibre separationFiberOutput device

The invention discloses an automatic operation system and method of biologically refined herbal fibers. The system includes herbal-fiber material standardizing and arranging equipment which includes a rolling device, a separation device and a dust collection device; motion-type herbal-fiber material inoculating equipment include a plurality of horizontal transport devices, a first bacteria solution spraying device and an output device; motion-type herbal-fiber material wet-fermentation equipment includes a plurality of horizontal transport devices; motion-type fermentation material inactivating equipment includes plurality of horizontal transport devices, a pressure hot-water comb and a rolling device; motion-type inactivated-product hydraulic equipment includes a pressure water-spraying device, an extrusion device and an output device; motion-type biologically-refined-herbal-fiber oil dipping equipment includes a moisture drying device, a transmission device, a plurality of horizontal transport devices and an oil spraying device; motion-type biologically-refined-herbal-fiber drying equipment includes a drying device and an output device. The technical problem is solved that the automatic operation system and method of the biologically refined herbal fibers are provided.

Owner:DAQING SKY GREEN BIOLOGICAL NEW MATERIAL TECH CO LTD

Degumming process for mulberry fibre by bacilli compound bacteria

InactiveCN101285212AEfficient removalReduce the probability of residual glueBacteriaMicroorganism based processesFiberSludge

The invention provides a method for degumming mulberry fiber with bacteria complex flora. The method uses mulberry as a culture medium for a carbon source to filter the bacteria complex flora with good degumming effect to the mulberry from sludge of a methane tank, substrate sludge of a pool, wood, banana land and other samples, has dried mulberry directly immersed into degumming liquid, and inoculates the cultured degumming complex bacterial flora into the degumming liquid for degumming, so that loose mulberry fiber can be obtained via water rinsing and drying. The method has the advantages of mild process condition and simple operation, need not use strong acid or strong alkali, has the manufacturing cost greatly reduced compared with a chemical degumming method, has lower environmental pollution, less cull in the prepared mulberry fiber and white and loose fiber.

Owner:GUANGXI UNIV

High temperature-microbe combined hemp degumming method

InactiveCN1827864AQuality improvementTo achieve the purpose of degummingBacteriological rettingMicroorganismOxygen

The invention discloses the high temperature-microorganism with hemp degumming method. The method comprises the following steps: cleaning hemp, then carrying out high temperature degumming boiling treatment; putting the hemp into enzymolysis jar, adding 10-15wt% laccase solution, at the meantime, pouring oxygen; carrying out hydroperoxide bleaching to hemp, water scrubbing, dewatering, softening, de-oiling, drying and getting fine hemp. The hemp made with the method is white, soft and good quality. The method adopts the high temperature low-alkali technology, reducing the pollution. Treating the hemp at high temperature low-alkali, it not only destroys the hemicellulose and lignin connected with between hemp fibers, but also lightens the press of enzymolysis, and reaches the purpose of hemp degumming.

Owner:ZHEJIANG SCI-TECH UNIV

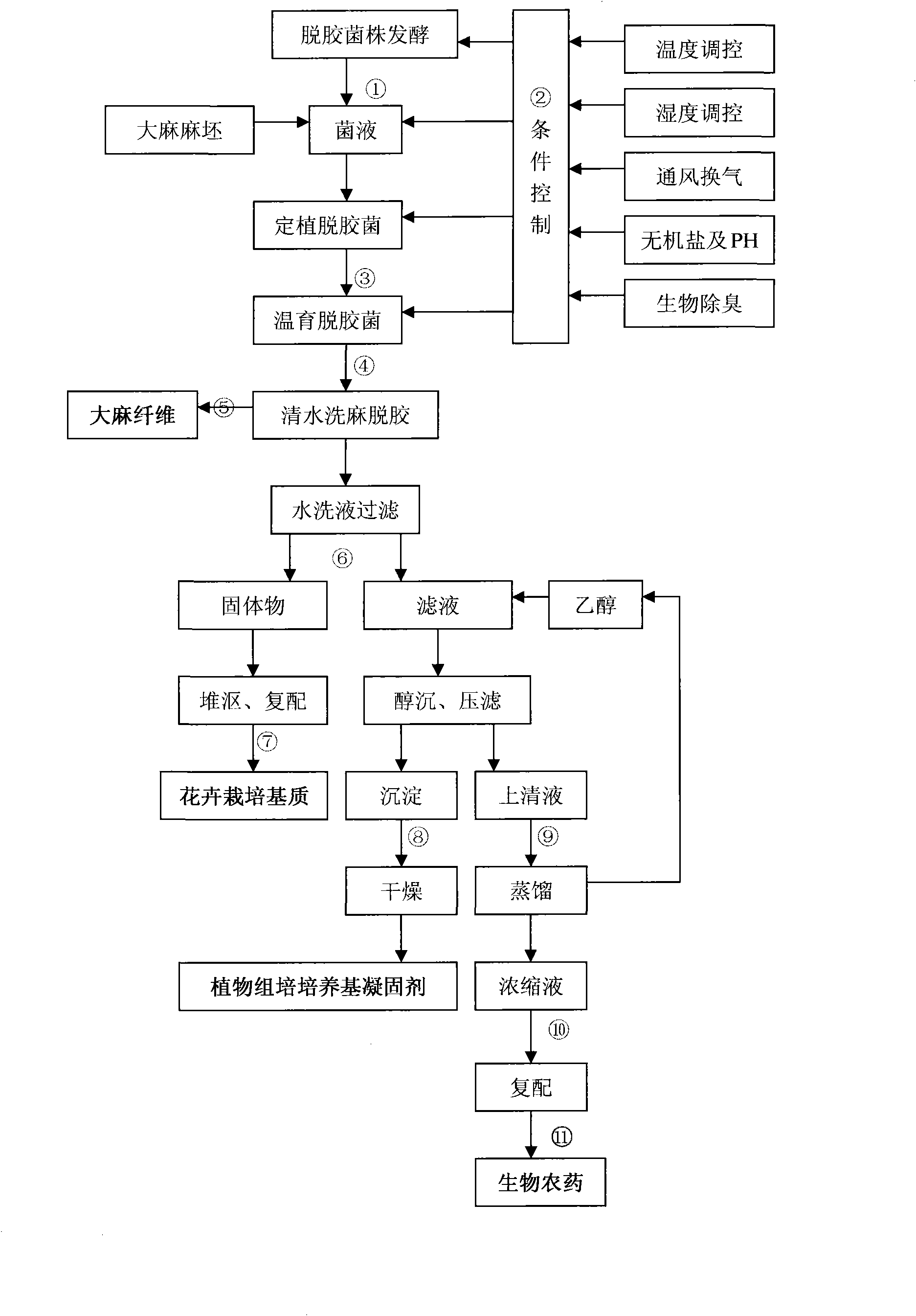

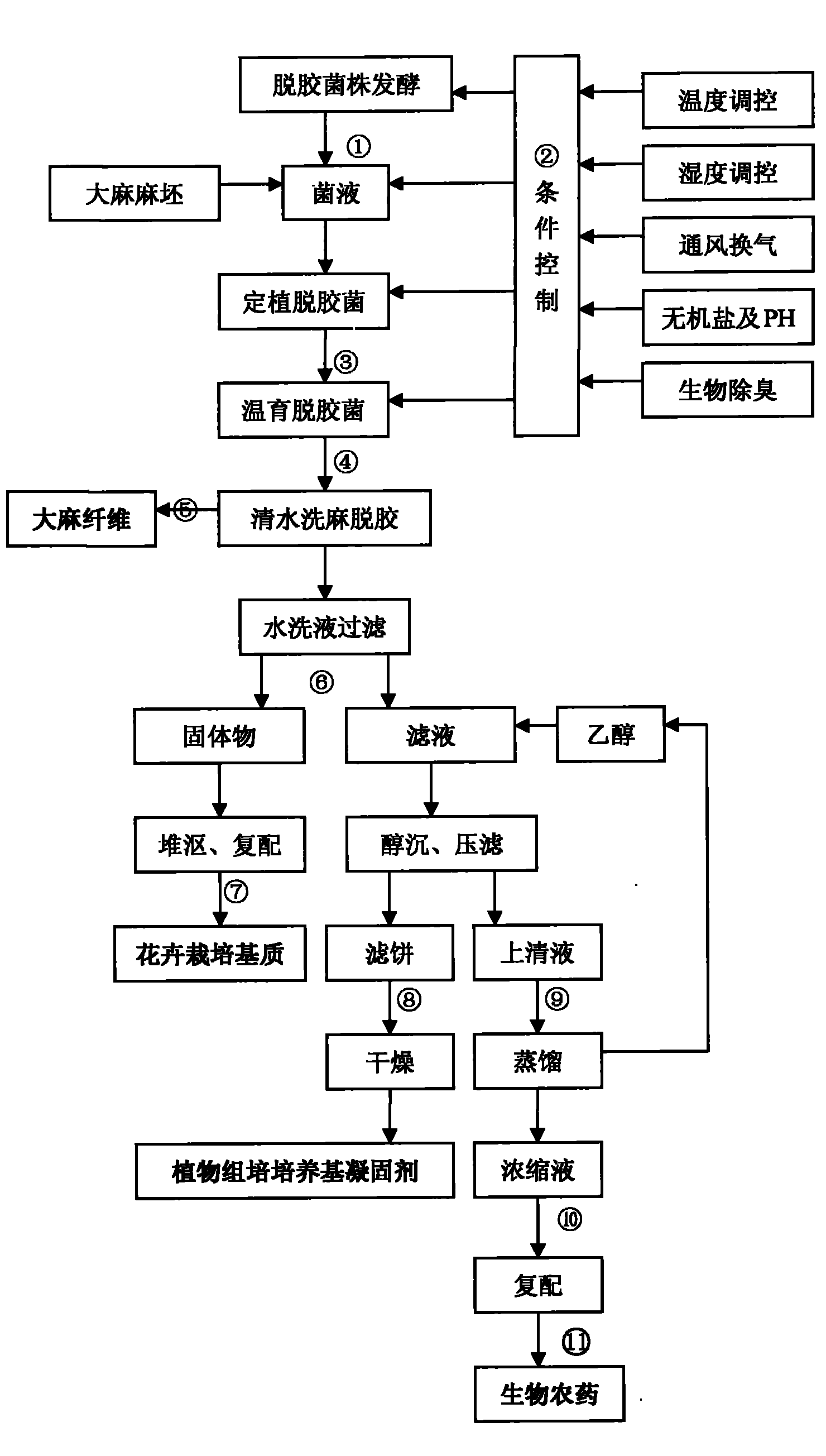

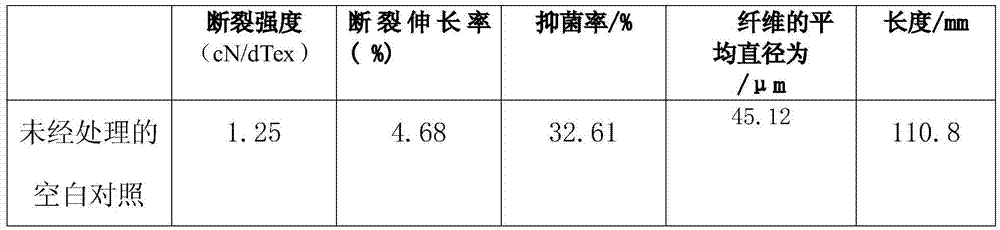

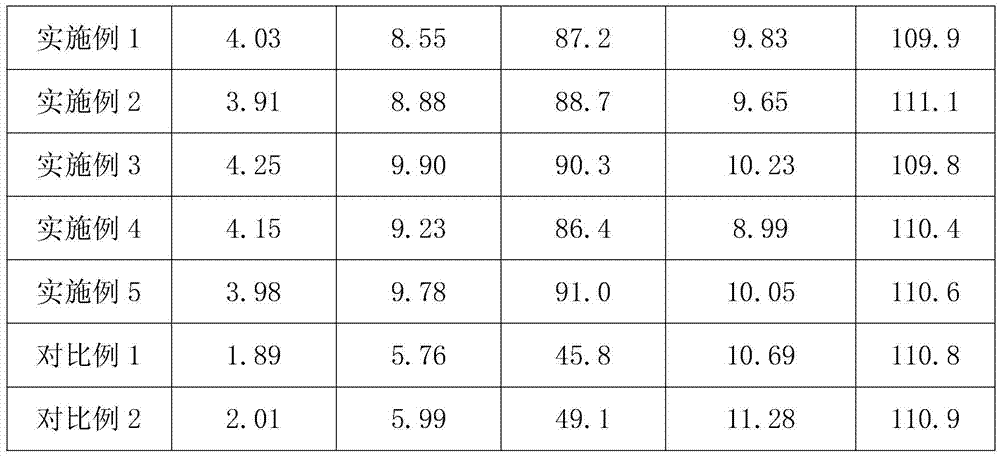

Resource utilization process for clean hemp biological degumming and waste thereof

InactiveCN101787571AHigh glossLight colorBiocideBio-organic fraction processingResource utilizationAir change

The invention provides a resource utilization process for clean hemp biological degumming and waste thereof. The process comprises: adopting a wax-like bacillus WM20091116 strain as a degumming strain; pre-wetting a hemp billet; performing field planting on degumming bacteria; performing heat insulation, moisture preservation, air change, nutrient solution replenishment, pH adjustment, differential temperature incubation and mechanical kneading; and rinsing the obtained product with clear water to obtain high-quality hemp fiber. Rinsing liquid is filtered through inorganic ceramic membrane, and filter residue solids, sawdust and rice husk are mixed, stacked and then used as a flower soilless culture matrix. Filtrate which is heated, concentrated, treated with ethanol, precipitated, subjected to pressure filtration and then dried can be used as coagulant in culture media. The filtrate combined with supernatant poured out can be prepared into wettable powder serving as biological pesticide. The process has the advantages of low energy consumption, no off-flavor during the treatment of hemp and high resource utilization degree, and the hemp fiber produced is high in long fiber content, high in fiber strength, low in loss and capable of meeting combing-spinning requirements well.

Owner:李耀亭 +1

Extraction method of rice-wheat straw fibre for spinning

The invention relates to a spinning straw fiber extraction method. The spinning rice and wheat straw fiber extraction method is characterized in that the method includes the following steps: 1). the steam explosion pretreatment: straws are air-dried and then are cut into segments; 2). the pretreated straws are put in a steam blasting tank; 3). nutrient glucose and urea are recharged; 4). the strain degumming: first, choosing strains: choosing mushroom white rot fungi or planerochaete chrysosporium as the strain; second, to pave the steam explosion straw mixture obtained in the third step to be 10-100mm high; third, poking the strains onto the straw piles; fourth, culturing on the culturing bed; fifth, cleaning; sixth, bleaching; 5). irradiation curing: the bleached straw fiber is irradiated with Gamma rays with the irradiation amount of 2-10kgy to obtain the radiation curing straw fiber; 6). the straw fiber is oiled; 7) the straw fiber is dried; 8) the dried straw fiber is dispersed to obtain the spinning rice and wheat straw fiber. The invention has the characteristics of environmental protection and low cost.

Owner:WUHAN TEXTILE UNIV +1

Chinese alpine rush fibers having good antibacterial performance and used for weaving

ActiveCN105442059AThe preparation process is natural, environmentally friendly and has no residueWill not cause pollutionBacteriological rettingFibre treatment to obtain bast fibreFiberChemistry

The invention discloses Chinese alpine rush fibers having a good antibacterial performance and used for weaving and a preparation method of the Chinese alpine rush fibers. The Chinese alpine rush fibers are treated by sufficiently utilizing a biological enzyme and modified by microorganisms. The Chinese alpine rush fibers can be rapidly and efficiently degummed through strictly controlling technological conditions; and meanwhile, the Chinese alpine rush fibers are modified so that the Chinese alpine rush fibers, which have good antibacterial performance, high whiteness and good spinnability, are obtained.

Owner:广东亨瑞织造科技有限公司

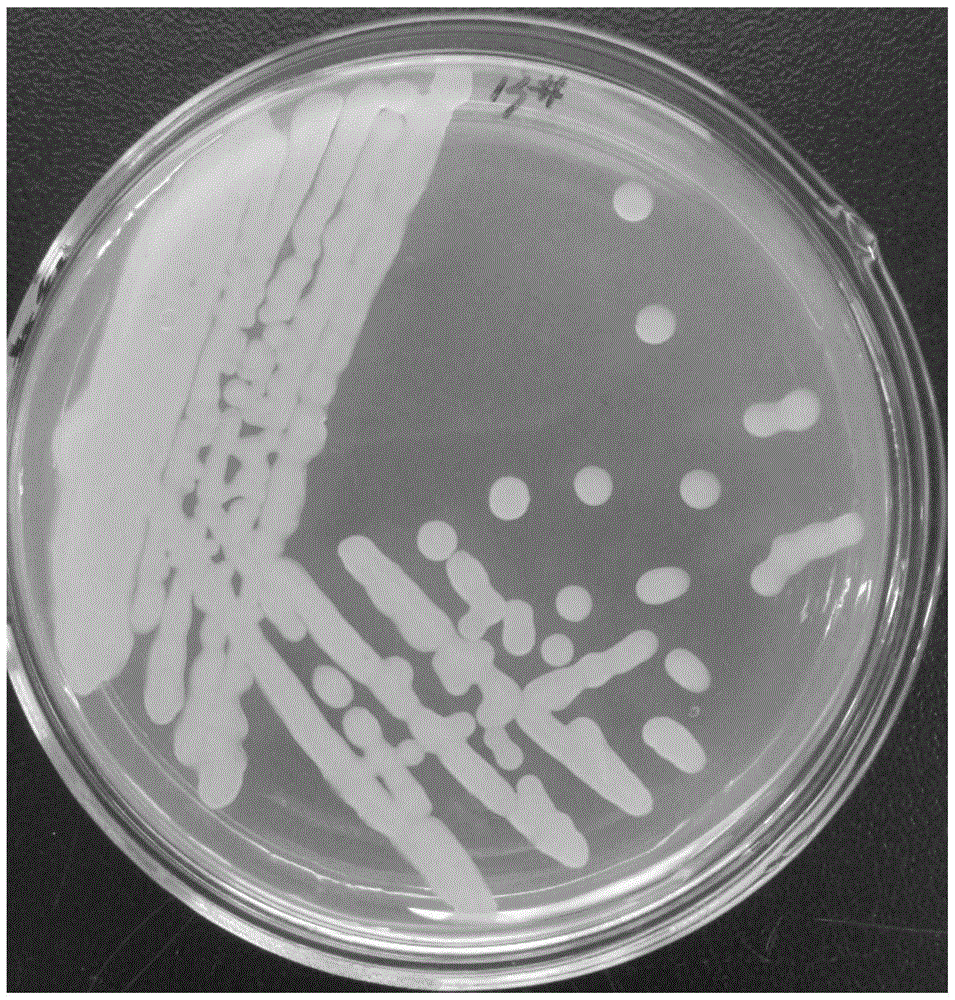

Bacillus subtilis capable of simultaneously producing pectase and hemicellulase, screening method and applications thereof

The invention relates to a strain of bacillus subtilis capable of simultaneously producing pectase and hemicellulase, a screening method and applications thereof. The strain is named as 16#, and belongs to bacillus subtilis. The preservation number is CGMCC No.11898, the preservation date is 22nd December, 2015, and the preservation organization is China General Microbiological Culture Collection Center (CGMCC), whose address is Beichenxi Road No.1 Yard No.3, Chaoyang District, Beijing. The provided bacillus subtilis is capable of simultaneously producing pectase and hemicellulase, barely produces cellulase, and can be applied to degumming of hemp. The bacillus subtilis is applied to degumming at a room temperature for 96 hours or so, the rate of residual gum can reach 13% or so, the processed hemp can almost reach the requirements of textile industry, and the provided bacillus subtilis can also be applied to degumming of other hemps.

Owner:TIANJIN UNIVERSITY OF SCIENCE AND TECHNOLOGY

Method for degumming ramie bast fiber microbe in solid state

InactiveCN101575739AReduce loadSolve the problem of large water addition ratioMicroorganism based processesBacteriological rettingTextile fiberMicroorganism

The invention provides a method for degumming ramie bast fiber microbe in solid state. The method comprises the following steps: making bast of ramie into a fiber bundle; adding water into the fiber bundle according to a mass ratio of the ramie bast fiber to water being 1:1-5; adjusting the pH value of ramie bast fiber aqueous solution to between 5 and 8; introducing microbial fluid; and introducing pre-culture microbial fluid with 2 to 6 percent (V / V) of total water amount, and degumming for 1 to 4 days at a temperature of between 30 and 40 DEG C. The method fundamentally solves the problem of pollution generated by the chemical degumming method; wastewater generated by degumming does not contain any chemical medicinal residue, and reduces pollution on the environment; and the degummed textile fiber raw material can completely achieve the requirement of textile, and the rate of long fiber growth is increased by 10 percent compared with the prior art. Particularly, the method can prepare process fibers according to the spinning requirement, and can prepare spinning filament by properly prolonging the degumming time. The method reduces environmental pollution while improving resource utilization rate, and has wide application prospect.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Microorganism rapid degumming and warm water retting method for flax

InactiveCN1594675AShorten the fermentation cycleHigh rate of numbnessBacteriological rettingWarm waterFlax fiber

Provided is a microorganism rapid degumming and warm water retting method for flax. The inventive retting method for flax comprises: activating the bacterial for 24 hours at 30 DEG C by pectin solid medium, inoculating the activated bacterial with the 1 wt.% of the flax protocorm in the retting container to the retting container, in which the flax protocorm is soaked for 2-4 hours in warm water, then topping up the retting container with clean water, heating to 30-37 DEG C, meanwhile adding 46.3-92.6 g / m3 sodium chloride and 92.6-129.6 g / m3 urea, finishing the retting after 78-100 hours. The method can shorten the zymolysis cycle, improve the yield rate of the flax fiber, increase the intensity of the flax fiber, improve the flax fiber quality, reduce the sewage in the retting.

Owner:HEILONGJIANG UNIV

Prepn and use of enzyme prepn for use in hemp degluing industrial process

InactiveCN1188513CNo pollution in the processImprove working conditionsBacteriaBacteriological rettingMicroorganismPulp and paper industry

The present invention relates to the field of microbial engineering technology. The enzyme preparation is prepared through the process including slant culture and storing, shaking culture, seeding tank culture and fermenting tank production of high enzyme activity bacteria strain. Bacillus subtilis of No.13 strain and preservation number CCTCC No.M200038 is selected. The hemp degumming process includes the fermentation of enzyme liquid filtering residue, diluting bacteria liquid to 3-6 times, regulating the pH value of fermented enzyme liquid in degluing tank to 7.5-9.0, hemp material pre-treatment, degumming with degumming liquid for 2-10 hr. The process of the present invention has no environmental pollution, and can produce hemp top with length, fineness and breaking strength superior to those of chemical process.

Owner:山东省纤维检验局 +2

Popular searches

Vegetal fibres Liquid/gas/vapor treatment of definite length materials Textile treatment by spraying/projecting Liquid/gas/vapor fibres/slivers/rovings treatment Cellulose treatment using microorganisms/enzymes Finely-divided material pretreatment Pulp properties modification Microorganism/enzyme addition Non-macromolecular organic addition Chemical/biochemical paper treatment

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com