Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

A technology of Bacillus subtilis and ramie, which is applied to Bacillus subtilis strains and its application fields, can solve the problems of unsatisfactory degumming effect, easily damaged fiber strength, long degumming cycle, etc., and is suitable for large-scale industrial production without environment Contamination, short degumming time effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

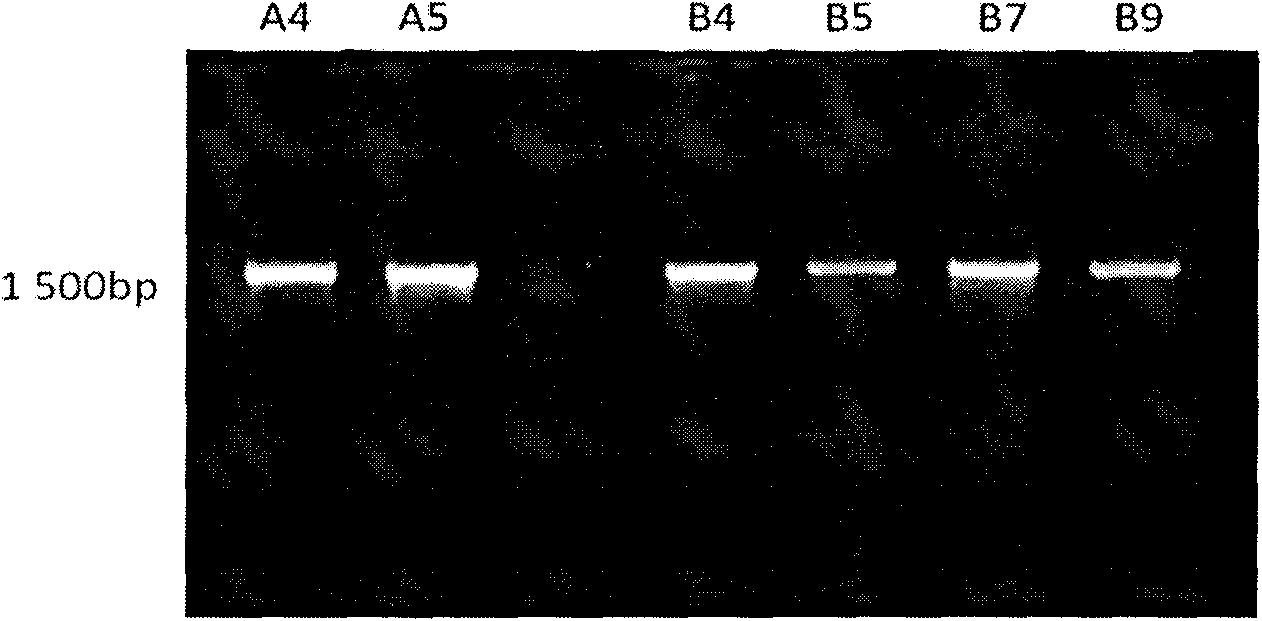

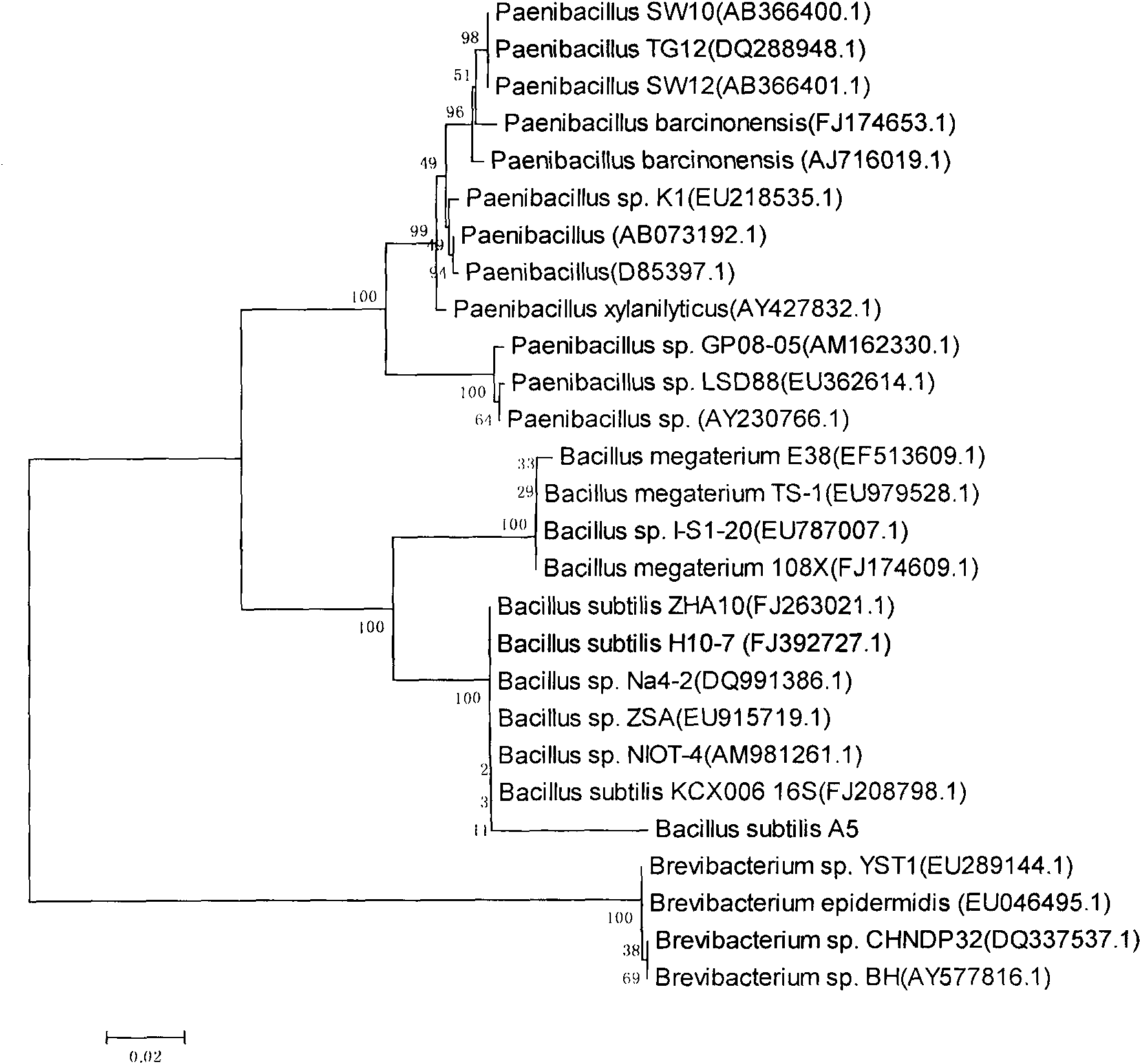

[0044] Screening and Identification of Degumming Dominant Strains

[0045] 1) Cut the original diameter of rotten ramie into small pieces of 1.5-2cm, mix well and take 5g into a 250mL Erlenmeyer flask filled with 200mL enrichment medium, (enrichment medium 1: beef extract 0.3g peptone 1g NaCl 0.5g water 1000ml, pH7.4-7.6; enrichment culture 2: K 2 HPO 4 0.15g, ferric ammonium citrate 0.15g, MgSO 4 0.15g, glycerin 6g, citric acid 0.6g, L-glutamic acid 1.2g, water 1000ml, pH 7.4) after one month of static enrichment culture at room temperature, dilute 10 -3 , 10 -4 , 10 -5 , 10 -6 After the gradient, spread on ramie separation medium (ramie 15g, (NH4) 2 SO 4 5g,K 2 HPO 4 1g, MgSO 4 0.5g, KCl 0.5g, FeSO 4 0.01, 20g agar, 1000mL water, natural pH, about 7.0-7.2) at 28°C, cultured for 5 days, picked a single colony and streaked it on the ramie medium. After the colony is formed, observe and record the morphological characteristics of the colony such as color, surf...

example 2

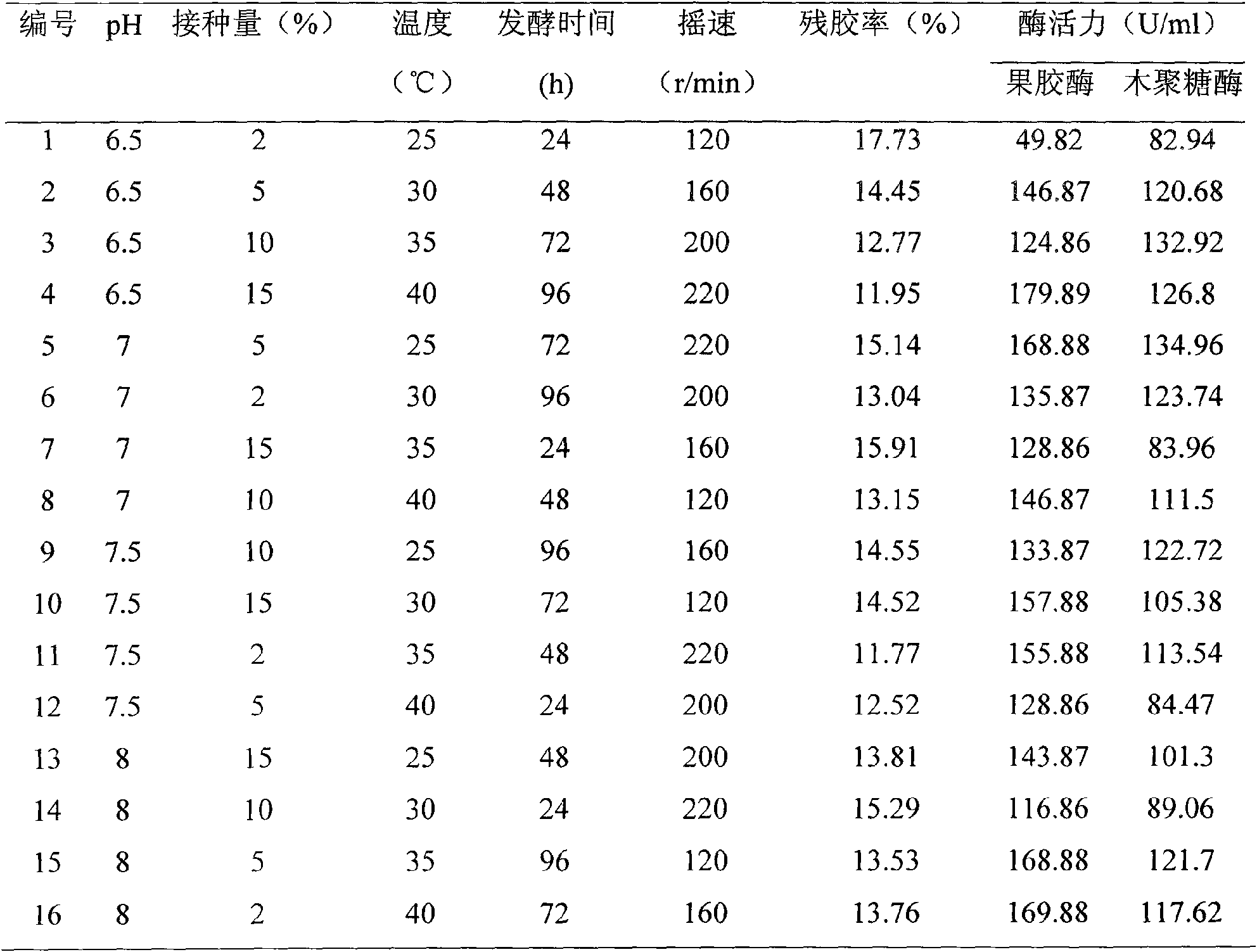

[0050] Ramie degumming process and its result

[0051] Microbial degumming of ramie was carried out in 250ml Erlenmeyer flasks, the liquid volume in each Erlenmeyer flask was 100ml (containing 5g of ramie raw hemp), the bath ratio was 1:20, after heating and boiling for 30min, adjust the pH value, and after sterilizing at 121°C for 20min , The flask was cultured on a shaker under different conditions. Until the degumming is finished, remove the degumming solution, boil in a boiling water bath for 5 minutes, rinse with tap water several times to remove the bacteria on the ramie, and stop the degumming.

[0052] The bacterial strain was inoculated in the ramie fermentation medium containing sterilized treatment (ramie raw hemp 5%, (NH 4 ) 2 SO 4 0.5%, MgSO 4 0.05%, KCl 0.05%, K 2 HPO 4 0.1%, FeSO 4 0.001%), 40°C, 200rpm for shaker fermentation culture, after 1 day, it can be seen that the ramie fibers are obviously dispersed, and the color of the fermented liquid beco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com