Patents

Literature

341results about How to "Improve degumming effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Degumming process for edible vegetable oil and application thereof

ActiveCN102533441AImprove degumming effectHigh yieldFatty-oils/fats refiningOil processingOil and grease

The invention relates to a degumming process for edible vegetable oil and the application thereof. The degumming process for edible vegetable oil comprises the following steps: reacting raw oil with an acid to convert non-hydrated phospholipids in the raw oil into hydrated phospholipids, agglomerating micelles by hydration, and performing centrifugal separation to obtain degummed oil. The degumming process for edible vegetable oil can be applied to refining of edible vegetable oil. The invention further discloses a process of refining edible vegetable oil, which can produce RBD oil products by performing the following steps in sequence: degumming process mentioned above, decoloring treatment, deacidifying treatment and deodorizing treatment. The degumming process for edible vegetable oil is suitable for degumming of various edible vegetable oil, particularly seed oil with high phosphorus content (more particularly seed oil with high non-hydrated phospholipids content), and has excellent degumming effect. The degumming process is an innovation in oil and fat degumming aspect, and besides, the improvement on the degumming process promotes the generation of novel physical refining techniques in oil processing.

Owner:SHANGHAI HAOYOU IND EQUIP

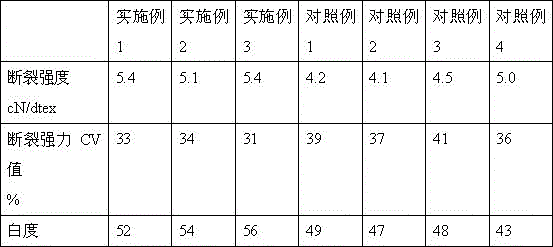

Method for producing high-elasticity bulked silk-cotton quilt

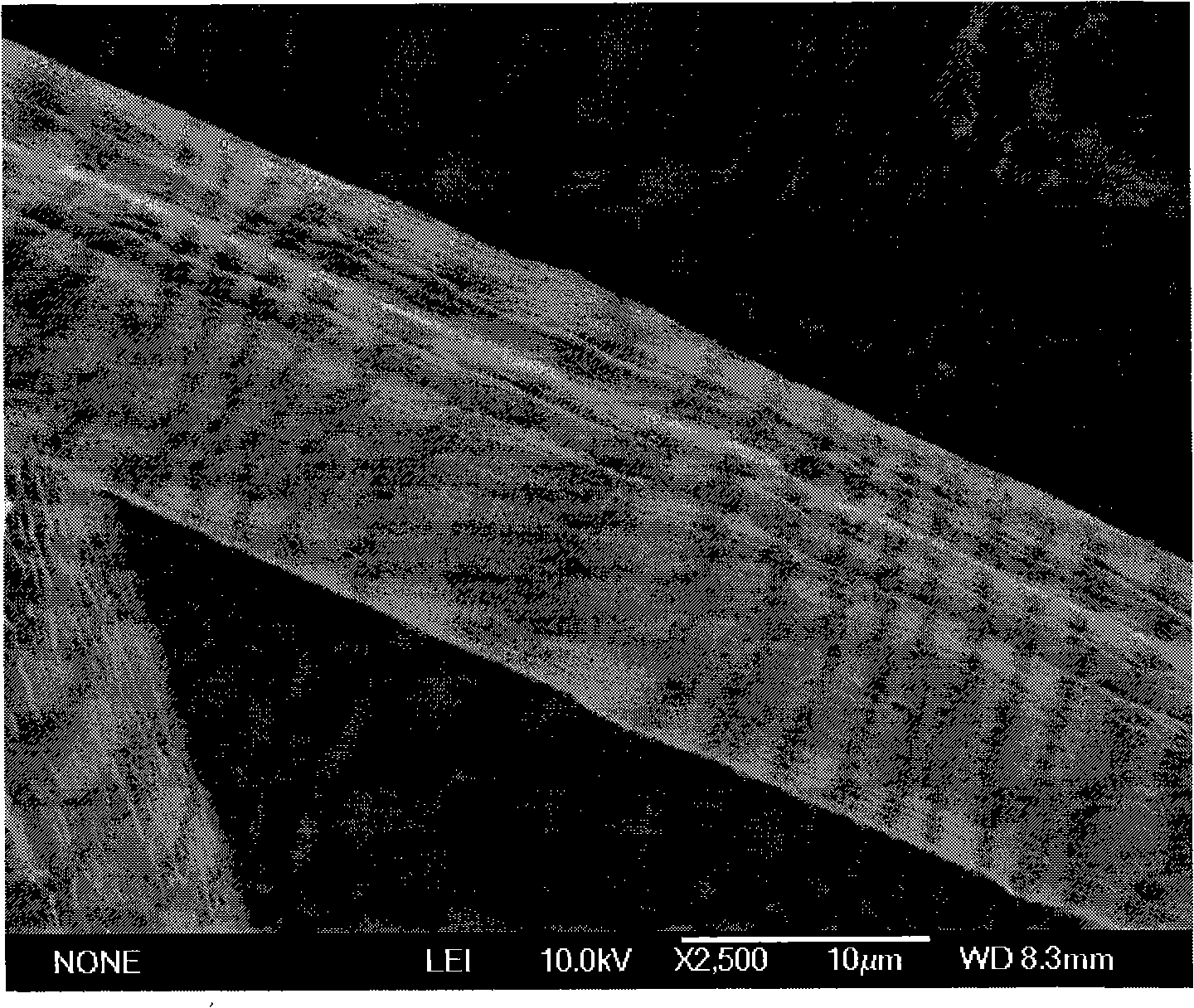

ActiveCN1743260APromote puffingPuffing treatment can ensure that cocoons are cooked evenly and promoteAnimal fibresUpholstery fillingBoiling processWadding

The invention relates to a method for producing a expanded silk wadding, which includes: sort cocoons, boil at high temperature, degelatinize, shuck the cocoons to remove silkworm, wash, loosen by drawing and make them into silk piece, dewater, dry and draw to make the silk wadding. The invention features that the cocoons before high temperature boiling process are vacuum soaked and expanded by a expanding liquor, concretely the cocoons before high temperature are suctioned into the expanding liquor heated by 80-95 degreeC under vacuum condition, soaked uniformly and expanded in slight boiling state. The said expand is made from amphoteric surfactant. The cocoons after being made into silk pieces and before dewatering are conducted an after finishing by a silk softening agent. Advantages: the patches and stem cubes resulted from un-uniform boiling or in-complete degelatinizing of cocoons are largely reduced; the silk floss is very soft because of full expanding.

Owner:NANTONG LOVER APPL +1

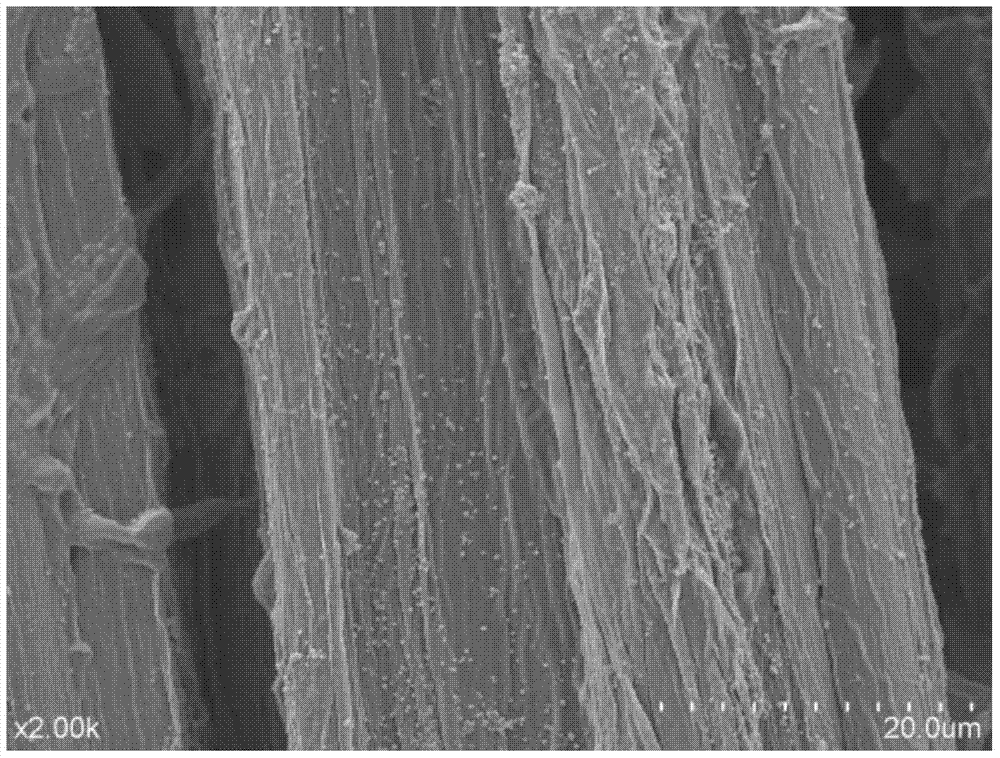

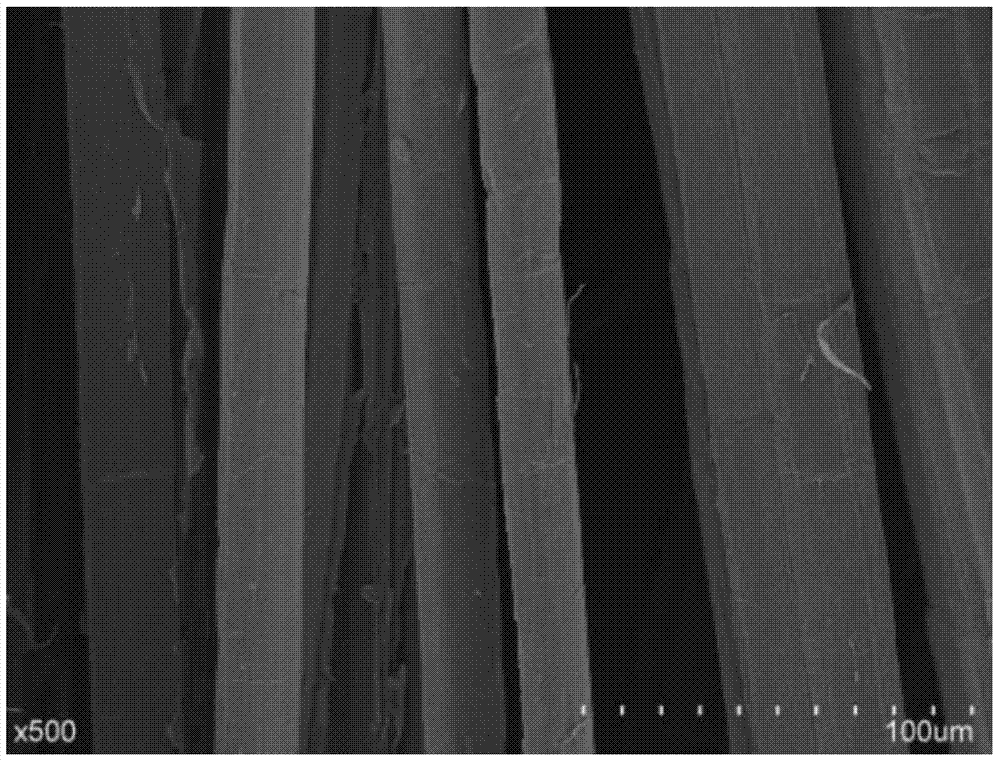

Degumming method of fabric

The invention relates to a degumming method for hemp fiber, in particular to a method for combined application of chemical with super critical CO2 fluid degumming. Wherein, before carrying out super critical CO2 fluid degumming, the hemp fiber first goes through chemical treatment, then super critical degumming is carried out under low and hi pressure respectively. The invention can obviously reduce the non-cellulose composition for example lignin, etc. in hemp fiber, is of an ideal degumming effect, with obviously improved cellulose ratio, very good softening effect of fiber, hence improved process quality of hemp fiber; the invention additionally overcomes the shortcoming associated with prior degumming way such as high pollution, etc., and is of high economic efficiency.

Owner:THE QUARTERMASTER EQUIPMENT RESEARCH INSTITUTE OF THE GENERAL LOGISITIC DEPARTME

Preparation method for bamboo fiber

The invention provides a method for rapid extraction of bamboo fiber from bamboo, and the bamboo fiber fully meets textile requirements. The preparation method for bamboo fiber belongs to the textile field. The preparation method for bamboo fiber comprises the steps of: bamboo sheet preparation, bamboo sheet cooking, crushing decomposition, bamboo filament cooking, bio-enzyme degumming, and after-treatment. The preparation method for bamboo fiber provided by the invention has the advantages of simplicity, short process, no pollution, environmental protection, low energy consumption, and obvious economic benefits.

Owner:QINGDAO BAIZHONG CHEM TECH

Production method of carex meyeriana fiber

ActiveCN102660779AImprove degumming effectImprove performanceVegetable materialMechanical treatmentFiberSulfite salt

The invention discloses a production method of a carex meyeriana fiber. The production method adopts the following process flow: taking carex meyeriana raw grass, boiling, carrying out primary processing, carrying out pre-degumming treatment by an ultrasonic wave, carrying out primary washing, carrying out alkali oxidation and degumming bath, pickling, carrying out secondary washing, drying, feeding oil, opening and carding to obtain the carex meyeriana fiber, wherein water is used as a medium in the step of the pre-degumming treatment by the ultrasonic wave, when the frequency is 28-40HZ and the temperature is 50-70 DEG C, the pre-degumming treatment by the ultrasonic wave is carried out for 60-90 minutes, and NaOH is added when the treatment is carried out within 20-30 minutes so as to enable the alkali concentration of the solution to reach 5-15g / l; in the step of alkali oxidation and degumming bath process, carex meyeriana can be put in an alkali oxidation extracting solution to enable the temperature to rise to 90-100 DEG C, heat preservation and boiling are performed for 1-2 hours; the alkali oxidation extracting solution is prepared from the following ingredients: 6-9g / l of sodium hydroxide, 8-12g / l of hydrogen peroxide, 2-4% of sodium polyphosphate serving as an additive of carex meyeriana mass, 2-4% of magnesium sulfate and 1-3% of sodium sulfite.

Owner:TIANJIN POLYTECHNIC UNIV

Dyeing and finishing method of real silk/ cotton intertexture

ActiveCN102251403AStrong damageIncrease the rate of first-class productsBiochemical fibre treatmentBleaching apparatusShrinkage rateEngineering

The invention provides a dyeing and finishing method of a real silk / cotton intertexture, and belongs to a dyeing and finishing method of a fabric. The method comprises the following steps of: a, performing sewing and singeing treatment on a gray fabric; b, packaging and de-sizing; c, performing package and oxygen bleaching treatment, and drying; d, packaging and dyeing; e, packaging and softening; and f, performing preshrinking treatment to finish dyeing and finishing, wherein the warp and weft shrinkage rates of the fabric are less than 3 percent after the preshrinking treatment. Because biological de-sizing, scouring and degumming processes are adopted in the dyeing and finishing method, the method has the advantages of high efficiency and mild reaction conditions; particularly, because protease for degumming is adopted, powerful damage to real silk fibers is low, and the degumming effect is good; and by adopting a jig dyeing process, the quality problems of contamination, scratch, pleat and the like easily produced in a long-vehicle pad dyeing process can be effectively avoided.

Owner:YUYUE HOME TEXTILE

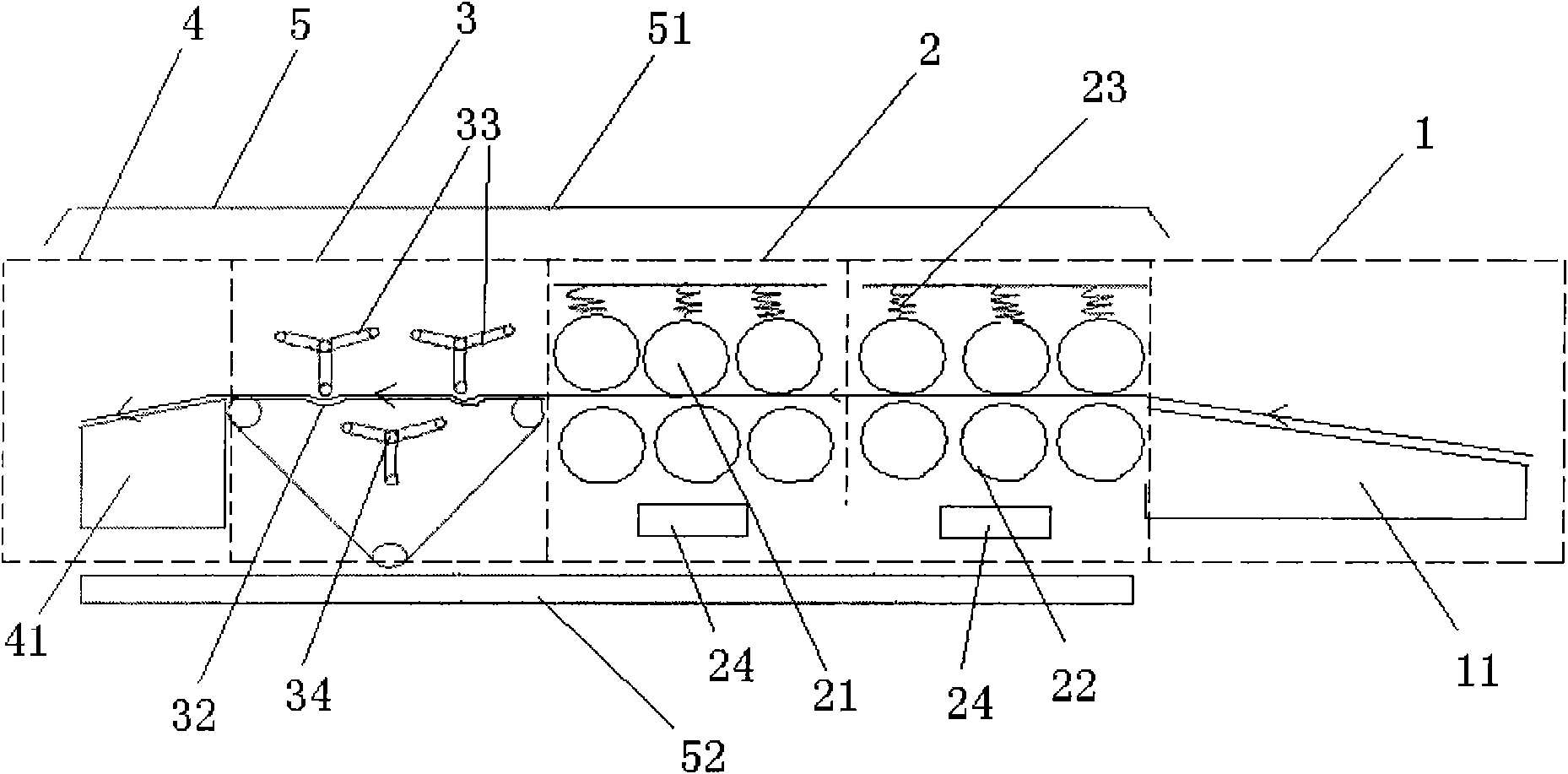

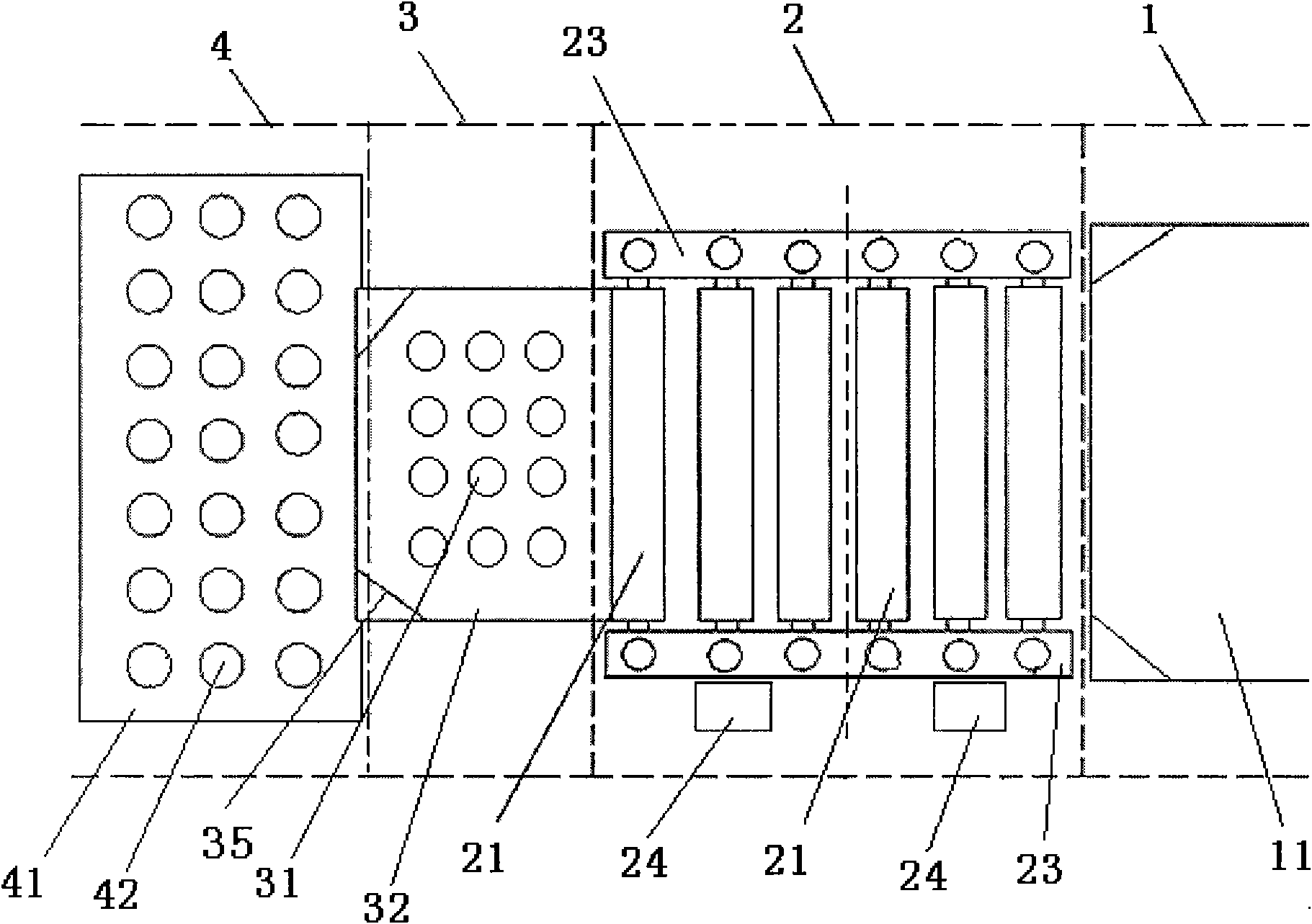

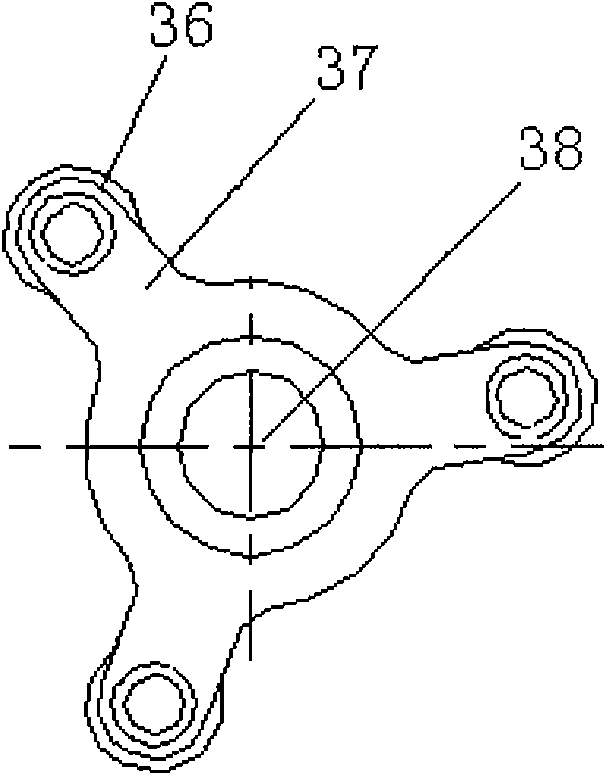

Mechanical degluing method and device of phloem fiber

ActiveCN101824657AHas penetrationUniform degummingMechanical fibre separationElectric machineryEngineering

The invention relates to a mechanical degluing method and a device of phloem fiber. The method of the invention comprises the following steps: 1) spreading and flatly paving phloem fiber in bundles, manually or mechanically feeding the phloem fiber between two rows of upper rollers and lower rollers in arrangement in pairs; 2) driving the upper rollers and the lower rollers to do alternating movement in the positive direction and the reverse direction through a motor, in addition, ensuring that the movement time in the positive direction is longer than the movement time in the reverse direction, and repeatedly extruding, kneading and forwards conveying the phloem fiber; 3) carrying out manual or mechanical oscillation and impurity removal through flapping on colloidal particles and dust on the phloem fiber at the same time of conveying the processed phloem fiber in the second step by a conveying belt; and 4) carrying out manual and mechanical shaking for further impurity removal on the processed phloem fiber in the third step, and then, packing the phloem fiber into bundles. The invention has the advantages of reasonable structural design, ideal degluing effect, small degluing pollution and safe and reliable operation, and can be widely used in the degluing process of phloem fiber, leaf fiber and gramineae fiber raw materials and the like.

Owner:THE QUARTERMASTER RES INST OF THE GENERAL LOGISTICS DEPT OF THE CPLA +3

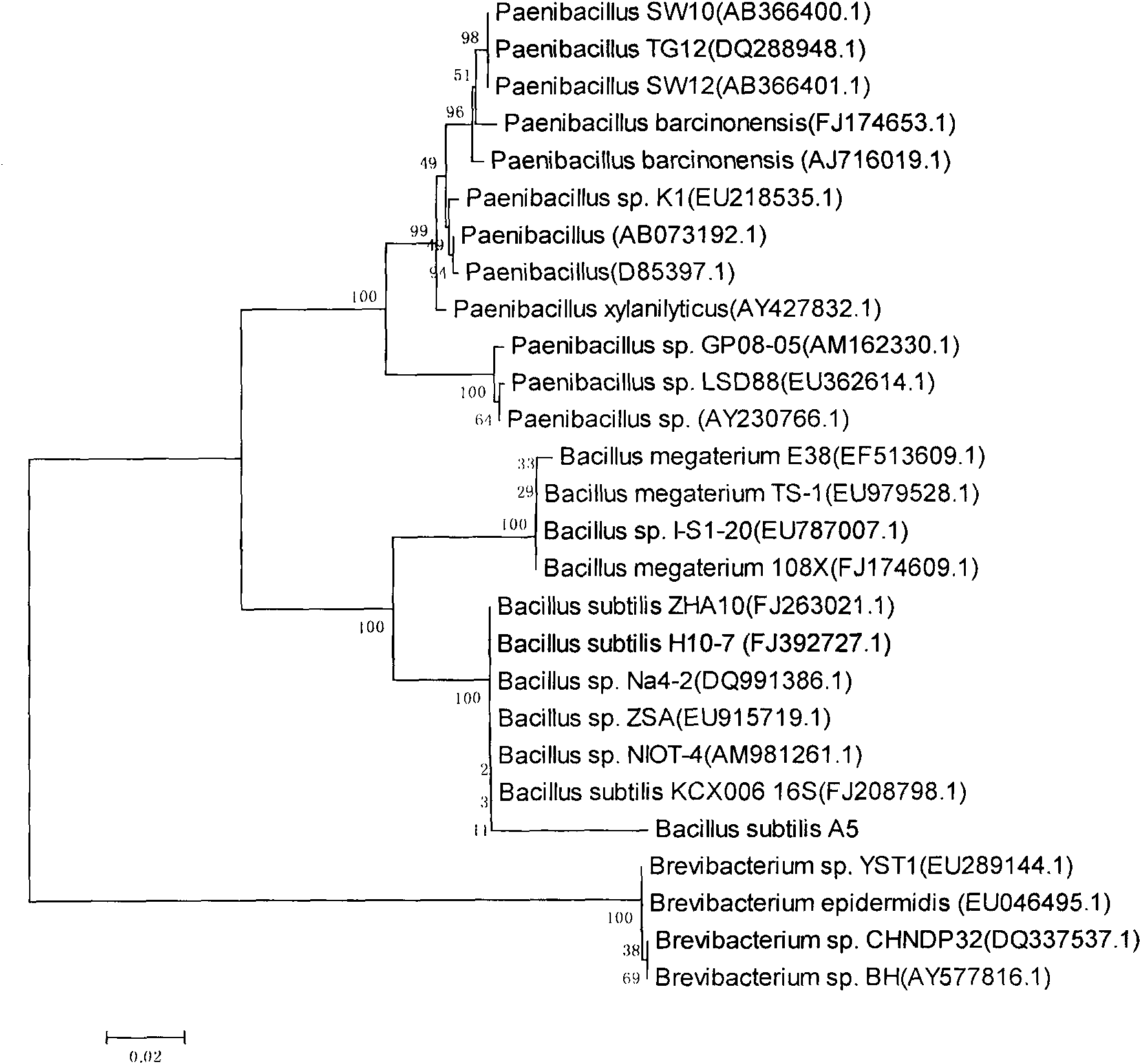

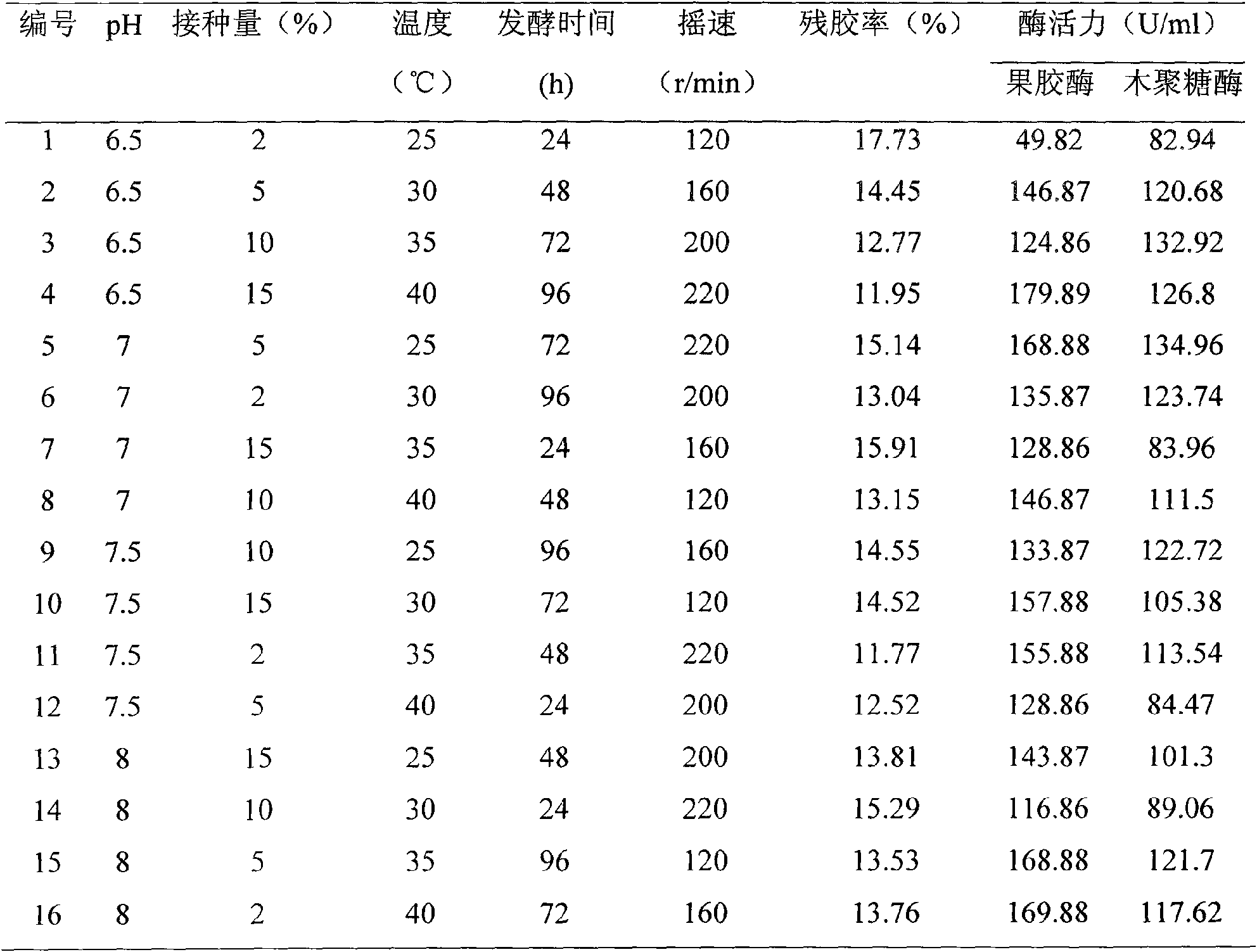

Bacillus subtillis strain containing ramie degumming activity, preparation and application thereof

InactiveCN101654660ANot easy to polluteNo pollution in the processBacteriaMicrobiological testing/measurementPectinaseBiotechnology

The invention relates to a bacillus subtillis strain containing ramie degumming activity, preparation and application thereof, which uses a system taking the strain as the core for ramie degumming. The strain of the system has high reproductive rate, high yield of pectase and xylanase, short production period, strong contamination resistance and favorable heat-resistant quality. The system and thecultivating process are safe to operate, have no toxicity and pollution no environment. Compared with the prior art, the invention has simple technology, is suitable for large-scale industrial production and the like. When the system is used for ramie degumming, degumming time is short, the dispersion coefficient of ramie fiber can reach 100%, degumming ratio can reach above 90%, and the qualityof refined dry ramie can reach the standard of chemical degumming.

Owner:DONGHUA UNIV

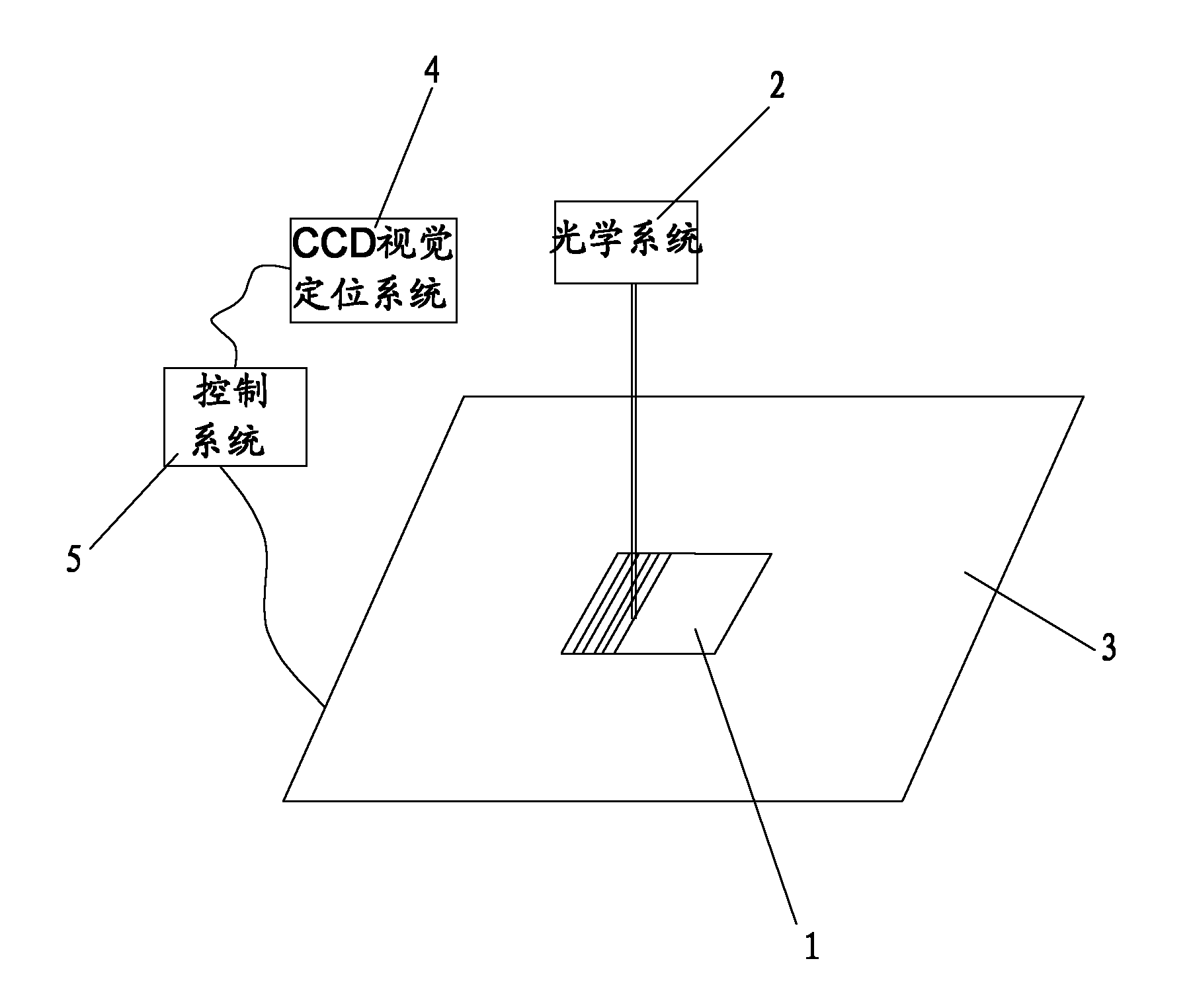

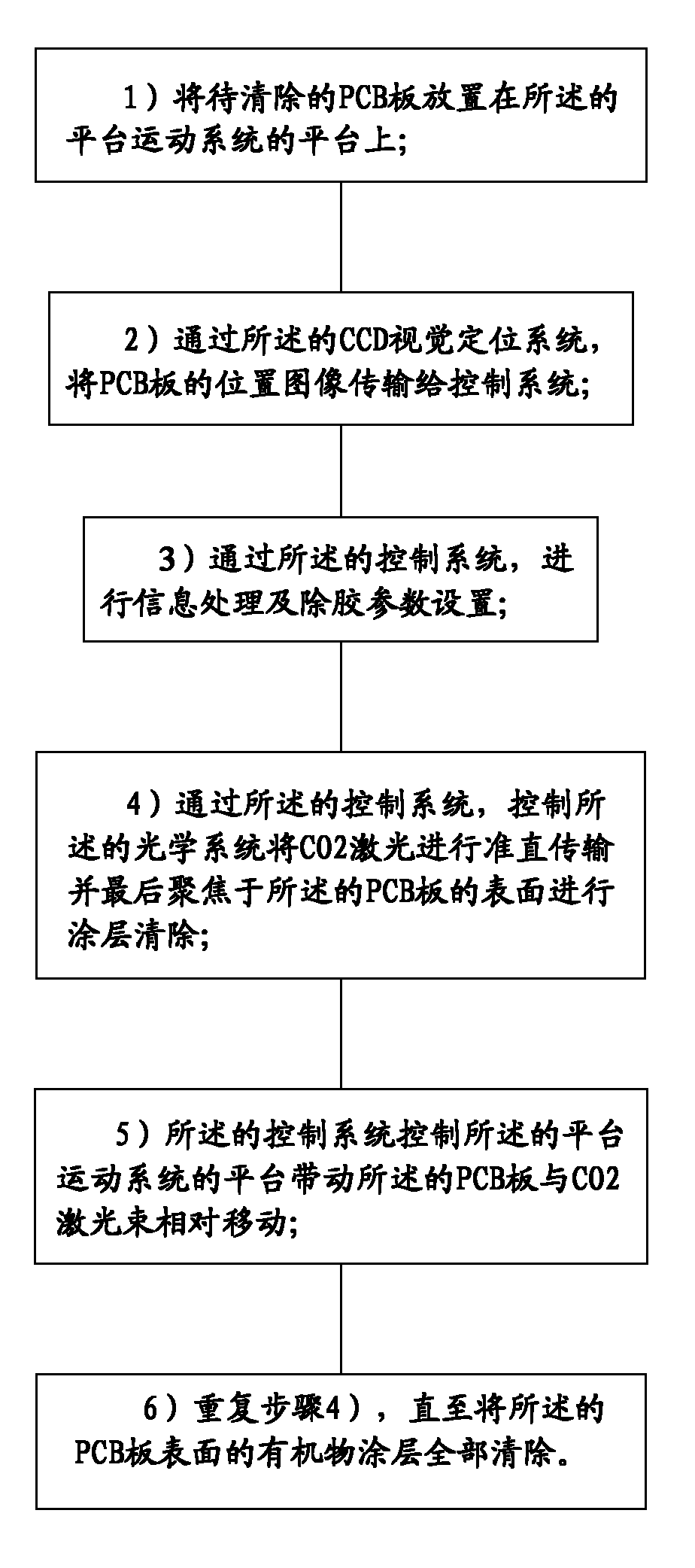

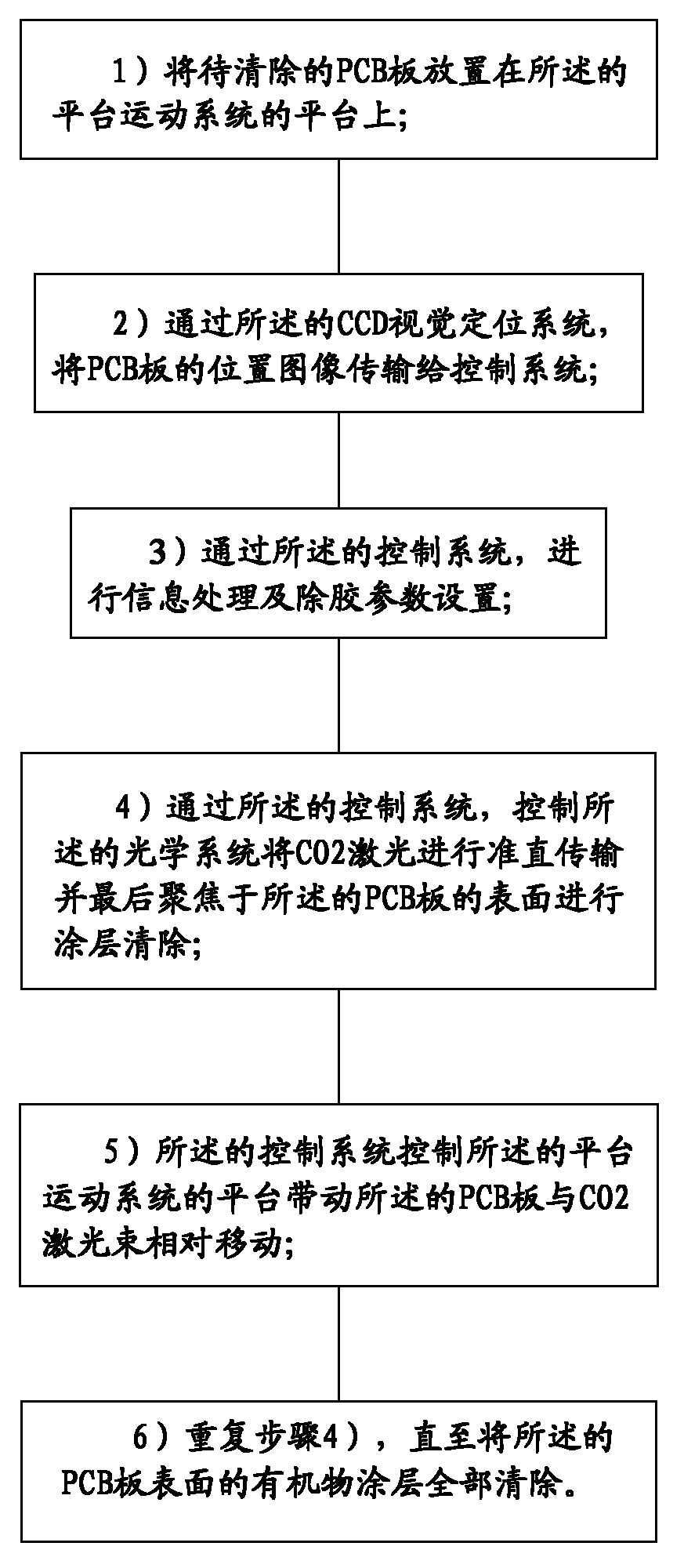

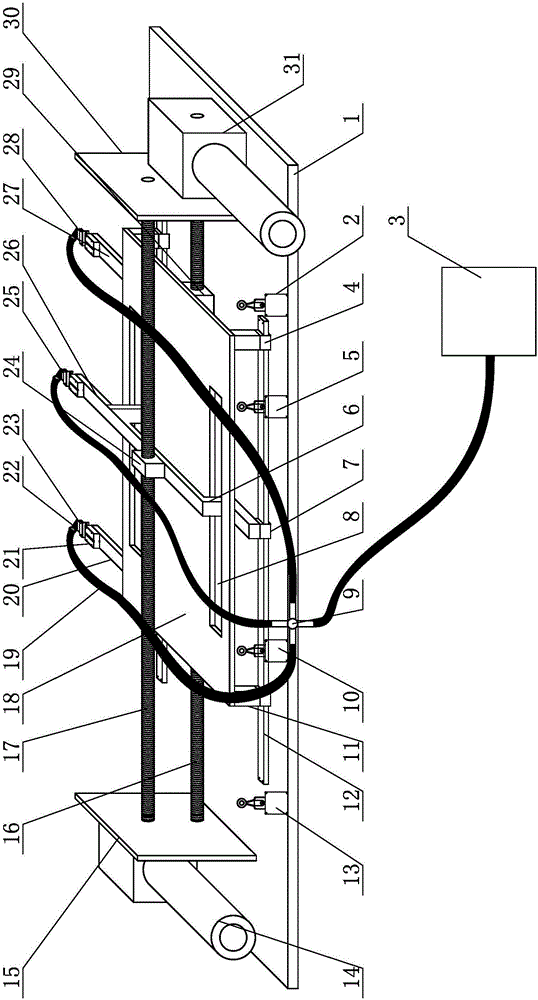

Device and method for degumming in SMT (surface mounting technology) industry

InactiveCN102164461AAvoid quality impactAddress stressPrinted circuit assemblingCleaning processes and apparatusCarbon dioxideMotion system

The invention discloses a device and a method for degumming in SMT (surface mounting technology) industry, which are used for removing a coating layer on a PCB (printed circuit board) board. The device comprises an optical system, a platform motion system, a CCD (charge coupled device) visual positioning system and a control system, wherein the optical system is used for performing the alignment transmission on CO2 (carbon dioxide) lasers and finally focusing on material surface and is used for walking along the laser track within the region through optical scanning; the control system is used for controlling the optical system, the platform motion system and the CCD visual positioning system; the platform motion system is used for performing the laser spanned degumming process through the matching motions of a numerical control platform along X and Y directions; the PCB board is arranged on the numerical control platform of the platform motion system; and the optical system is arranged above the numerical control platform of the platform motion system. By using the method and device provided by the invention, the defects of mechanical degumming, such as the influence of the mechanical degumming on the quality of the product, are avoided, the stress problem of the mechanical degumming is solved and the better degumming effect is achieved.

Owner:HANS LASER TECH IND GRP CO LTD +1

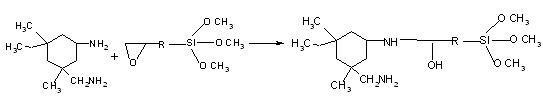

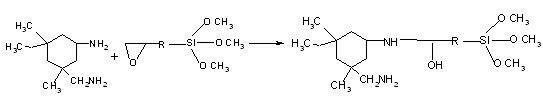

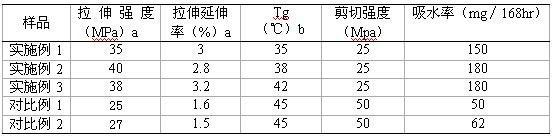

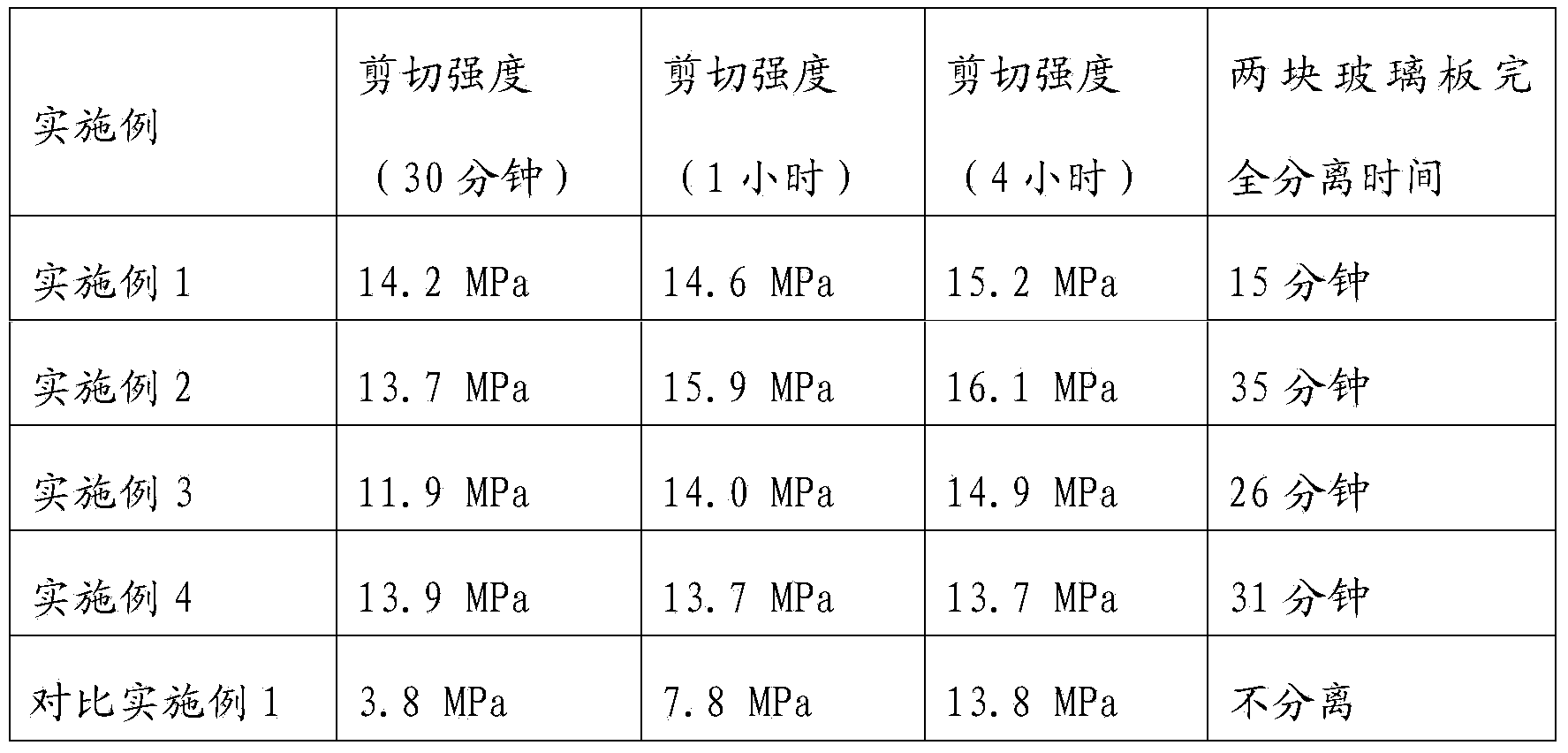

Modified epoxy resin of monocrystalline silicon rod cutting glue and preparation method thereof

InactiveCN102120925AGood degumming performanceReduce chip drop rateNon-macromolecular adhesive additivesMacromolecular adhesive additivesDefoaming AgentsMonocrystalline silicon

The invention relates to a modified epoxy resin of monocrystalline silicon rod cutting glue. The modified epoxy resin of the monocrystalline silicon rod cutting glue comprises the following raw materials comprising a component A and a component B, wherein the component A comprises 35 to 78 percent of epoxy resin, 20 to 60 percent of toughening agent, 0.5 to 2 percent of defoaming agent and 0.5 to 3 percent of coupling agent; and the component B comprises 48 to 69 percent of polymerized mercaptan, 30 to 50 percent of alicyclic modified amine and 1 to 5 percent of accelerator. The modified epoxy resin has a high degumming property and can reduce sheet-falling rate. According to epoxy silane, toughness and temperature resistance of an alicyclic amine material are achieved and low surface tension of the whole system is achieved, so that the whole levelling property of the system is improved in the whole gluing process. A hydrolysis reaction can be performing on a silane bond and the hydroxy on the surface of glass and the surface of a silicon wafer, so that the adhesion to the surface of the glass and the surface of the silicon wafer is improved. In addition, the system is toughened, the water-absorbing rate of the system after the alicyclic amine is modified is increased and the heat-resistant temperature TG is reduced, so that a sheet-falling phenomenon does not exist in the cutting and spraying processes, and the resin can be degummed quickly in the process of heating to 40 to 50 DEG C in the state of high water absorbability and softening after heating. The modified epoxy resin is applied to monocrystalline silicon rod cutting and has an extremely important effect on the monocrystalline silicon wafer industry.

Owner:康达新材料(集团)股份有限公司

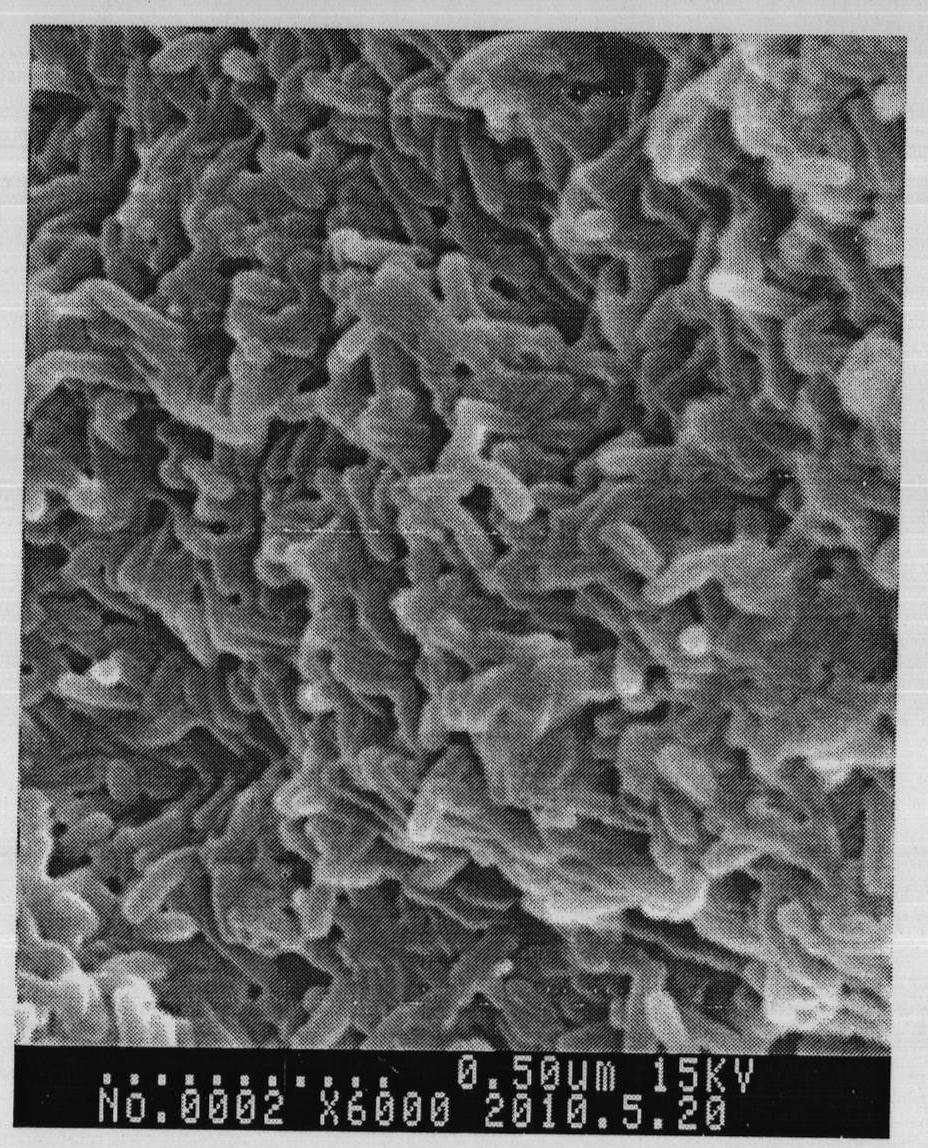

Quick degumming method for low-alkali cotton stalk bark fibre in high temperature

InactiveCN101509151AQuality improvementGood alkali concentrationBleaching apparatusFibre treatment to obtain bast fibreFiberHydrogen

The invention discloses a fast colloid-removing method for high-temperature low-alkali cotton stack bark fiber. The technique flow thereof comprises: washing the cotton stack bark, drying, high-temperature low-alkali colloid-removing, washing, bleaching, washing, dehydrating, softening by applying oil, deoiling, drying and subtle drying of the cotton stack bark fiber, namely adopting the technique of boiling-bleaching-softening. The high-temperature high-pressure low-alkali technology is directly adopted to deeply degrade the hemicellulose and lignine in the cotton stack bark, and in the end hydrogen peroxiden is used for bleaching and softening the cotton stack bark fiber to prepare white and soft cotton stack bark fiber with high quality. The colloid removal rate of the cotton stack bark fiber after processing can achieve around 90%, and the removal rate of the hemicellulose content is around 97%. Compared with the disclosed patent technique of cotton stack bark fiber, as the invention adopts the technique of boiling-bleaching-softening, the processing period is greatly shortened; an orthogonal experiment is performed to control the alkaline amount to be the minimum and the colloid removal effect is optimum, thus saving resources and reducing discharge.

Owner:ZHEJIANG SCI-TECH UNIV +1

Epicoccum nigrum DB3 bacterial strain as well as preparation and application thereof

InactiveCN102329738AExtensive culture conditionsGood heat resistanceFungiMicroorganism based processesSea grassEpicoccum nigrum

The invention relates to an epicoccum nigrum DB3 bacterial strain as well as a preparation and an application thereof. The preparation method comprises the steps of: 1, placing rotten sea grass in an enrichment culture medium, standing and culturing at room temperature, then coating the enrichment culture medium in a separation culture medium, standing and culturing at a temperature of 30 DEG C for 1-4 days to obtain a wild type flax biological treatment bacterial strain; 2, inoculating the bacterial strain obtained from the step 1 into a flax lignin nutrition culture medium, culturing at a temperature of 28 DEG C for 72 hours; and 3, selecting the bacterial strain with the capacity of degrading the lignin from the flax lignin nutrition culture medium to obtain the epicoccum nigrum DB3 bacterial strain. The epicoccum nigrum DB3 bacterial strain can be applied to a process for preparing spinning flax, hemp, jute or red ramie fibers through peroxide degumming. The epicoccum nigrum DB3 bacterial strain has the characteristics of short growth period, low possibility of being polluted, low treatment cost, mild reaction conditions, strong pollution resistance capacity, good heat-resistant performance, no environment pollution and good quality of the treated fibers. The preparation method has a simple process and is suitable for large-scale industrial production.

Owner:DONGHUA UNIV

Bacillus cereus DA3 strain and preparation method and application thereof

InactiveCN102002467AShort degumming cycleNot easy to be pollutedBacteriaBiochemical fibre treatmentPectinaseBiology

The invention relates to a bacillus cereus DA3 strain and a preparation method and application thereof. The strain has the capacity of producing pectinase and hemicellulase and has flax retting activity. The provided strain and a culture system can be directly used for flax retting and have the advantages that: the retting period is short, the fiber dispersion rate is 100 percent, the retting efficiency is 95 percent, and the strain is not easily polluted, and is low in treatment cost, high in fiber quality, mild in retting condition, high in pollution resistance, good in heat resistance, free of environmental pollution and the like. Compared with the prior art, the invention has the characteristics of simple technology, suitability for large-scale industrial production and the like, and has potential theoretical and practical significance for exploring flax retting of the bacillus cereus under the alkaline condition.

Owner:DONGHUA UNIV

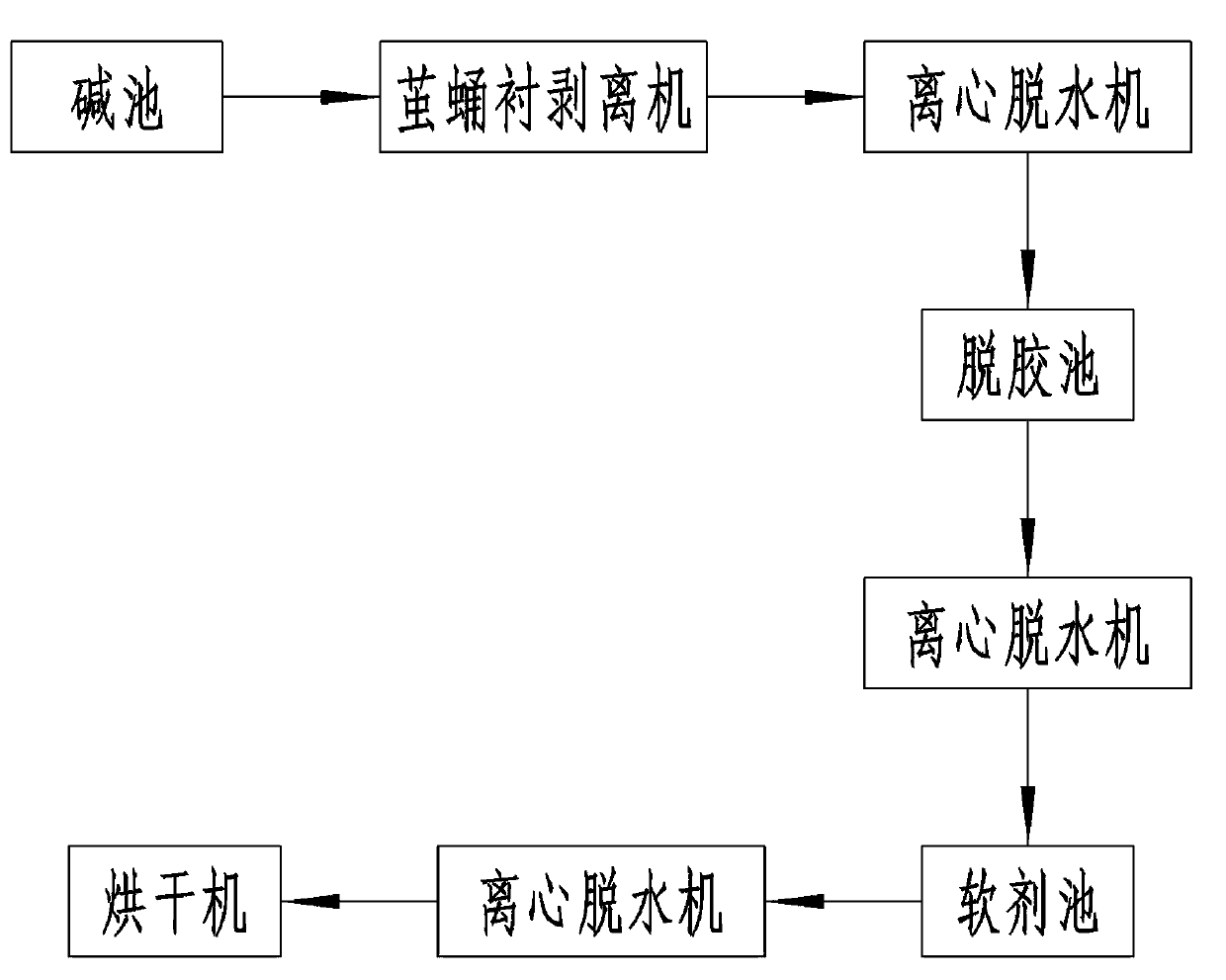

Method and device for processing silk floss winter clothes raw materials by silkworm light defective cocoon

InactiveCN104195649APerformance is not affectedIncrease productivityDe-gumming silkSilk obtainingPolymer scienceOrganic chemistry

The invention discloses a method and device for processing silk floss winter clothes raw materials by silkworm light defective cocoon. The method and device for processing the silk floss winter clothes raw materials by the silkworm light defective cocoon are achieved through the following steps of alkali soaking, cocoon stripping, cleaning and dewatering, degumming agent dipping, cleaning and dewatering, softening agent dipping, cleaning and dewatering, and drying. According to the method and device, the silkworm light defective cocoon is processed to be the silk floss winter clothes raw materials, light defective cocoon and basin residues are completely utilized, processed silk floss is soft and clean, the processing method and device are simple, the production efficiency is high, and the production cost is low.

Owner:YIZHOU ZHUANGGE SILK

Alkaline pectinase preparation for cannabissalival degumming, and cannabissalival degumming method

InactiveCN103937771AReduce the probability of residual glueAvoid damageHydrolasesMicroorganism based processesPectinaseFiber

The invention relates to an alkaline pectinase preparation for cannabissalival degumming, wherein the components of the alkaline pectinase preparation comprise: an alkaline pectinase or an alkaline pectinase compound enzyme preparation, wherein the alkaline pectinase compound enzyme preparation is a mixture comprising an alkaline pectinase and one or a plurality of materials selected from pectinase, xylanase, mannanase, lipase and protease. According to the present invention, the alkaline pectinase preparation has characteristics of effective cannabissalival degumming and short degumming time, and the obtained fibers have characteristics of low gum residue, softness and less damage.

Owner:TIANJIN UNIV OF SCI & TECH

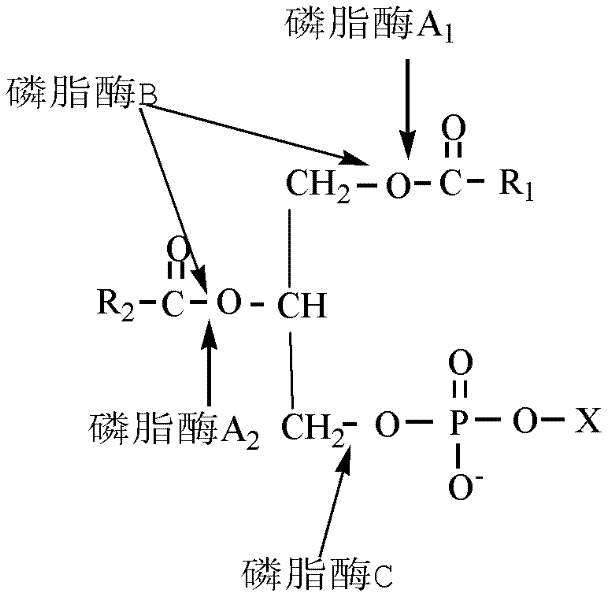

Improved vegetable oil enzymatic degumming method

ActiveCN102399627AShort reaction timeImprove degumming effectFatty-oils/fats refiningBiotechnologyVegetable oil

The invention discloses an improved vegetable oil enzymatic degumming method, which comprises the following steps of: (1) adopting phospholipase to carry out degumming reaction on the vegetable oil, wherein the phospholipase at least contains one of phospholipase A1, phospholipase A2 and phospholipase B; (2) raising the temperature of the degummed vegetable oil to 70-100 DEG C, and carrying out heat preservation for 15-90min; and (3) carrying out gum separation to obtain the degummed oil. By adopting the method disclosed by the invention, the enzymatic reaction in the enzymatic degumming can be shortened. The method disclosed by the invention has the advantages that the implementation is easy, and the degumming effect is good.

Owner:SOUTH CHINA UNIV OF TECH

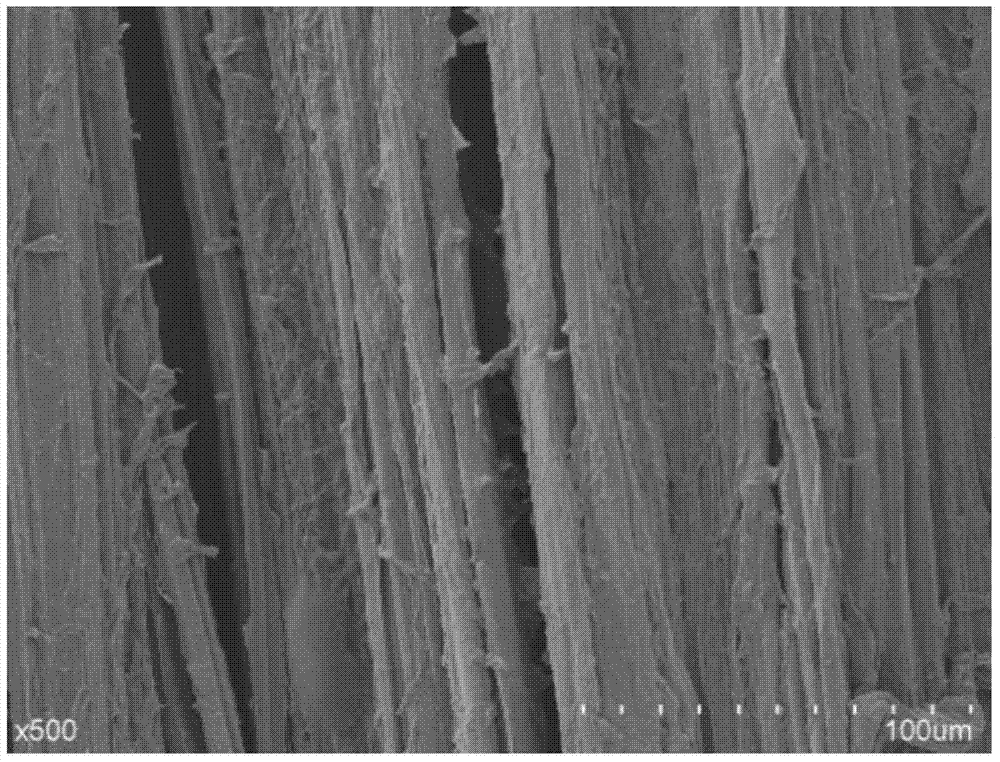

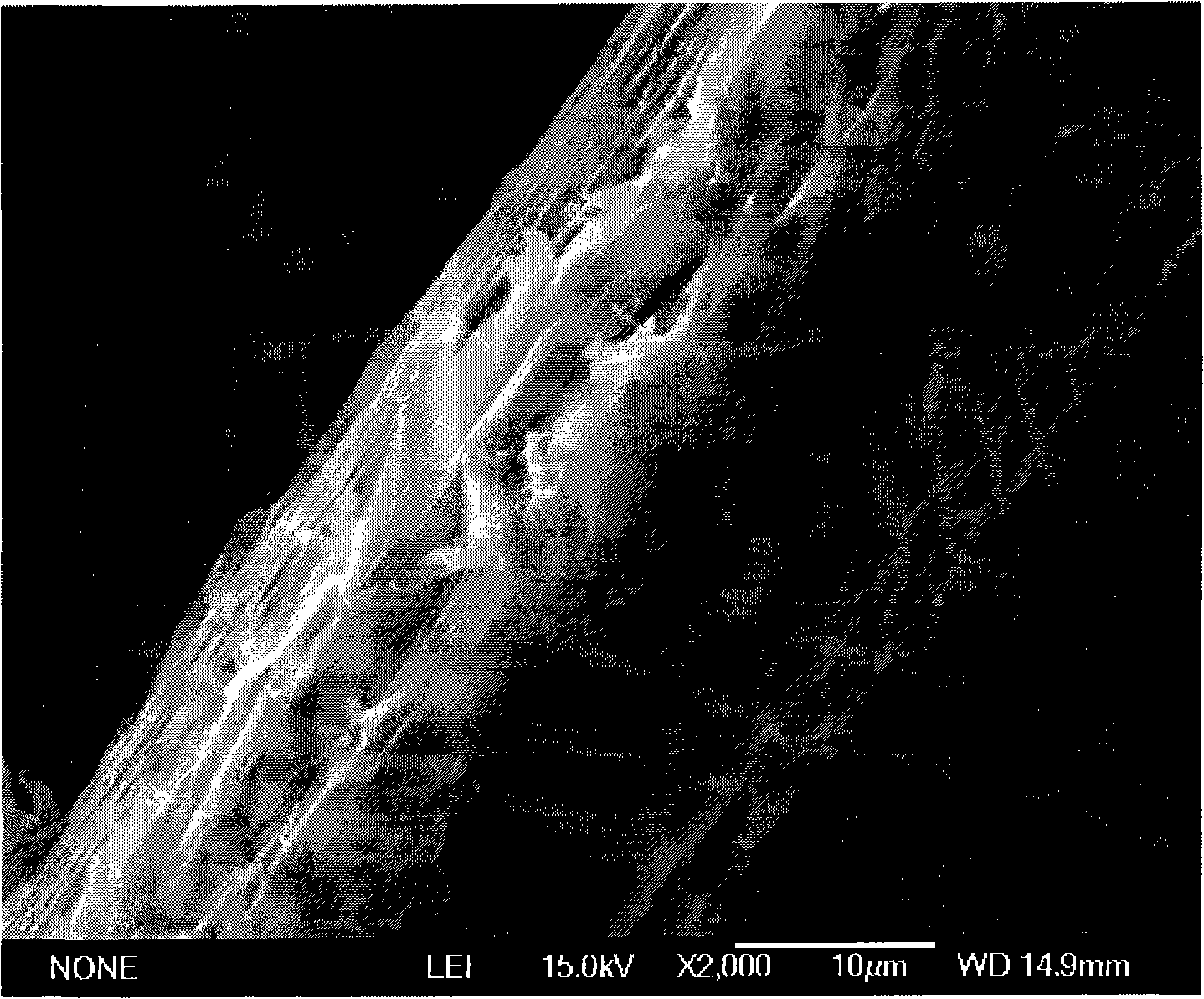

Frozen-irradiated auxiliary degumming process for china-hemp fibers

InactiveCN101275289AConvenient lengthImprove finenessFibre treatment to obtain bast fibreQuenchingHemp fiber

The invention discloses a hemp fiber freezing radiation auxiliary de-gumming technique, comprising the following steps of undergoing UV radiation, quenching, and heating treatment after hot bath, acid pre-etching, and pre-chlorination, and then undergoing base oxygen-mechanical associative de-gumming treatment, finally adding a softener for secondary scouring. The hemp fiber surface de-gumming effect treated by the technique is prior to ordinary base oxygen method and mechanical de-gumming, and the former meets the requirement of product of national first grade; the lignin content meets requirement of finishing technique after spinning, which obtains good whiteness and flexibility, and controls breaking strength and tensile stretch of fiber in requirement of spinnability, with improved length and fineness of fiber is improved, greatly improved serviceability, and less pollutant effluents discharged, so that the invention is environment-friendly.

Owner:TAIYUAN UNIV OF TECH

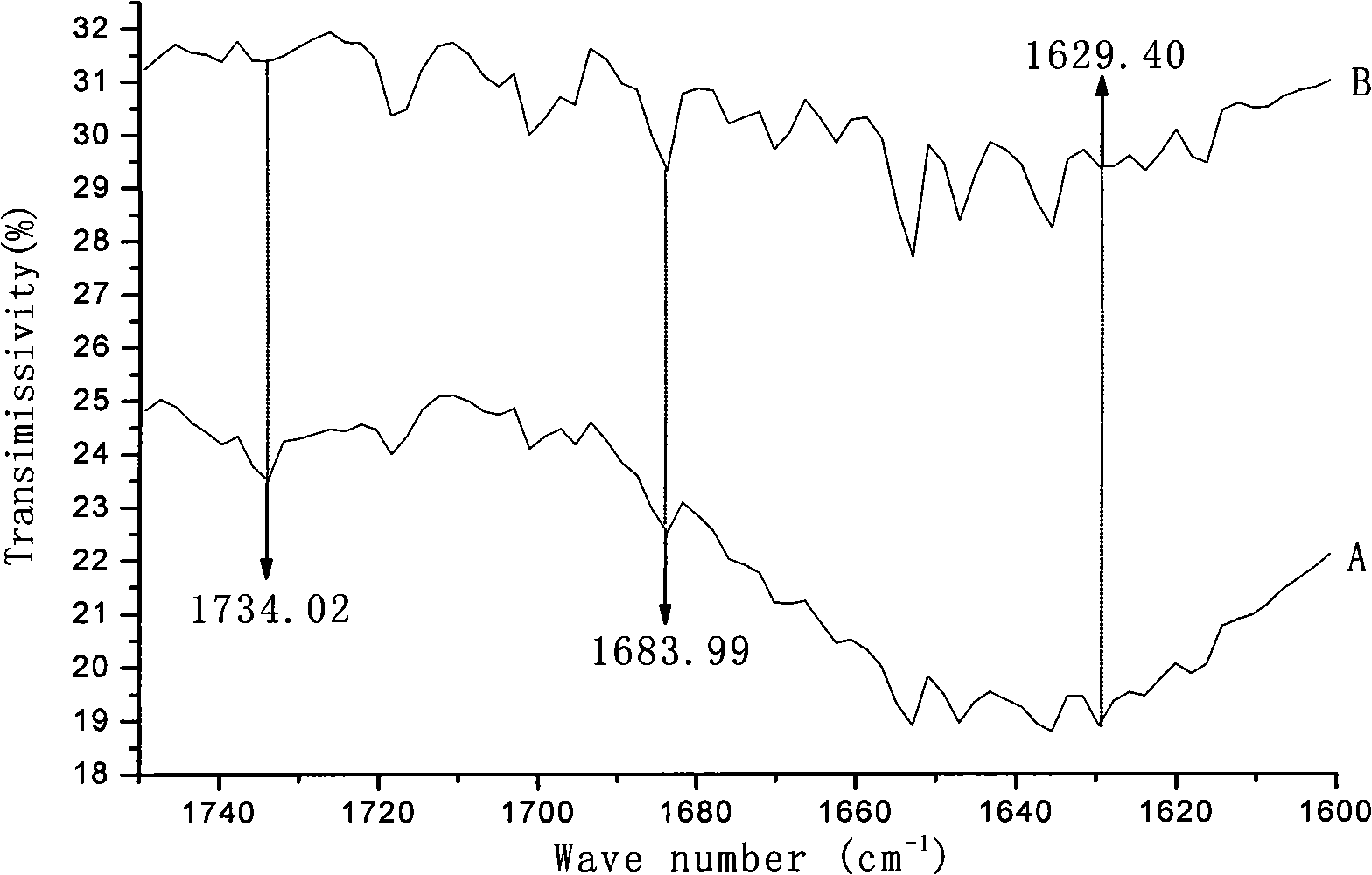

Temporary adhesive for solar energy crystal support and glass and preparation method thereof

ActiveCN103642400AImprove degumming performanceFast bondingNon-macromolecular adhesive additivesMacromolecular adhesive additivesChemistryAdhesive

The invention relates to a temporary adhesive for a solar energy crystal support and glass and a preparation method thereof. The temporary adhesive comprises component A and component B in weight ratio of 1:1, wherein the component A comprises the following raw materials in parts by weight: 50-80 parts of acrylate monomer, 8-30 parts of thermal expansion agent, 2-10 parts of accelerant, and 2-10 parts of thixotropic agent, the component B comprises the following raw materials in parts by weight: 50-80 parts of acrylate monomer, 5-25 parts of degumming factor, 2-10 parts of initiator, 0.01-0.5 part of polymerization inhibitor, and 2-10 parts of thixotropic agent. The temporary adhesive for the solar energy crystal support and glass has rapid bonding speed, is easy to remove, is environment-friendly and energy-saving, generates no harmful gas, and greatly improves the property of adhesive for crystal support and glass.

Owner:YANTAI DARBOND TECH

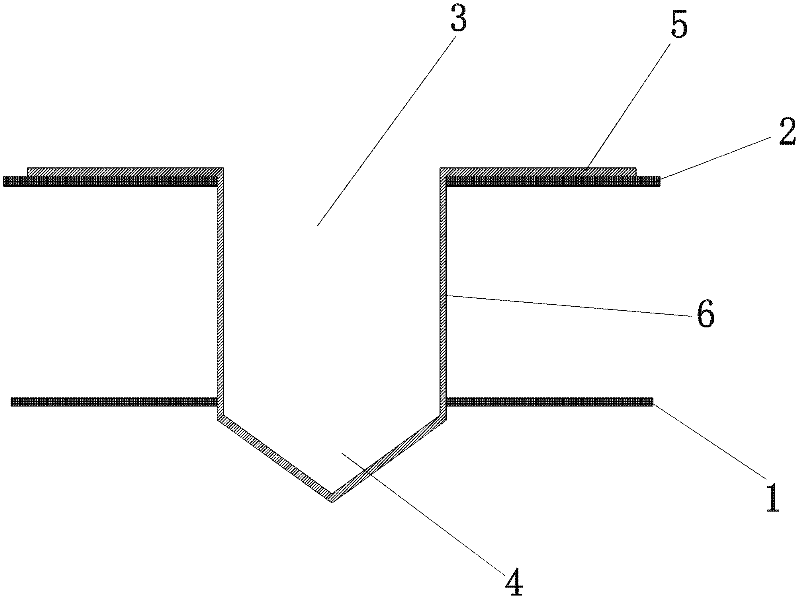

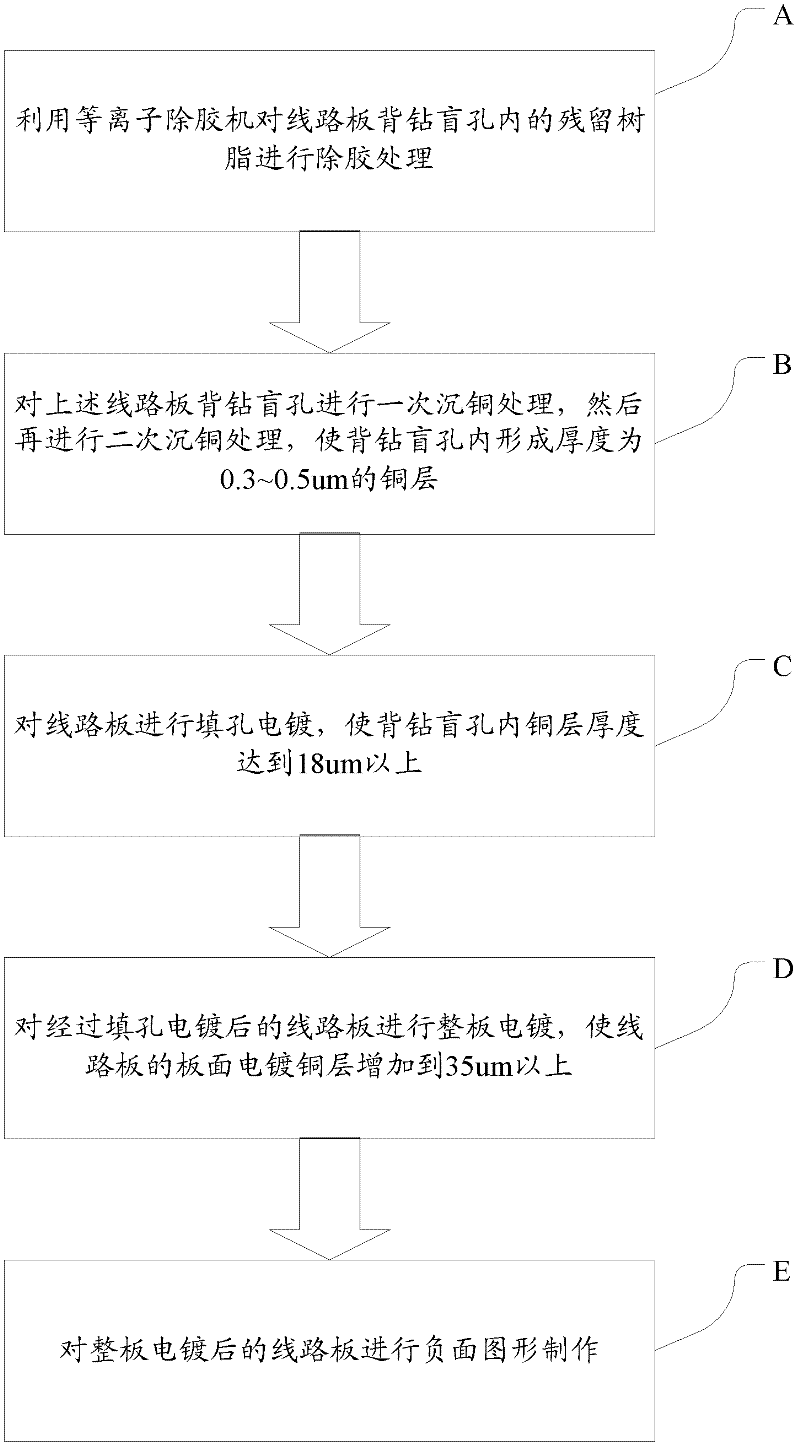

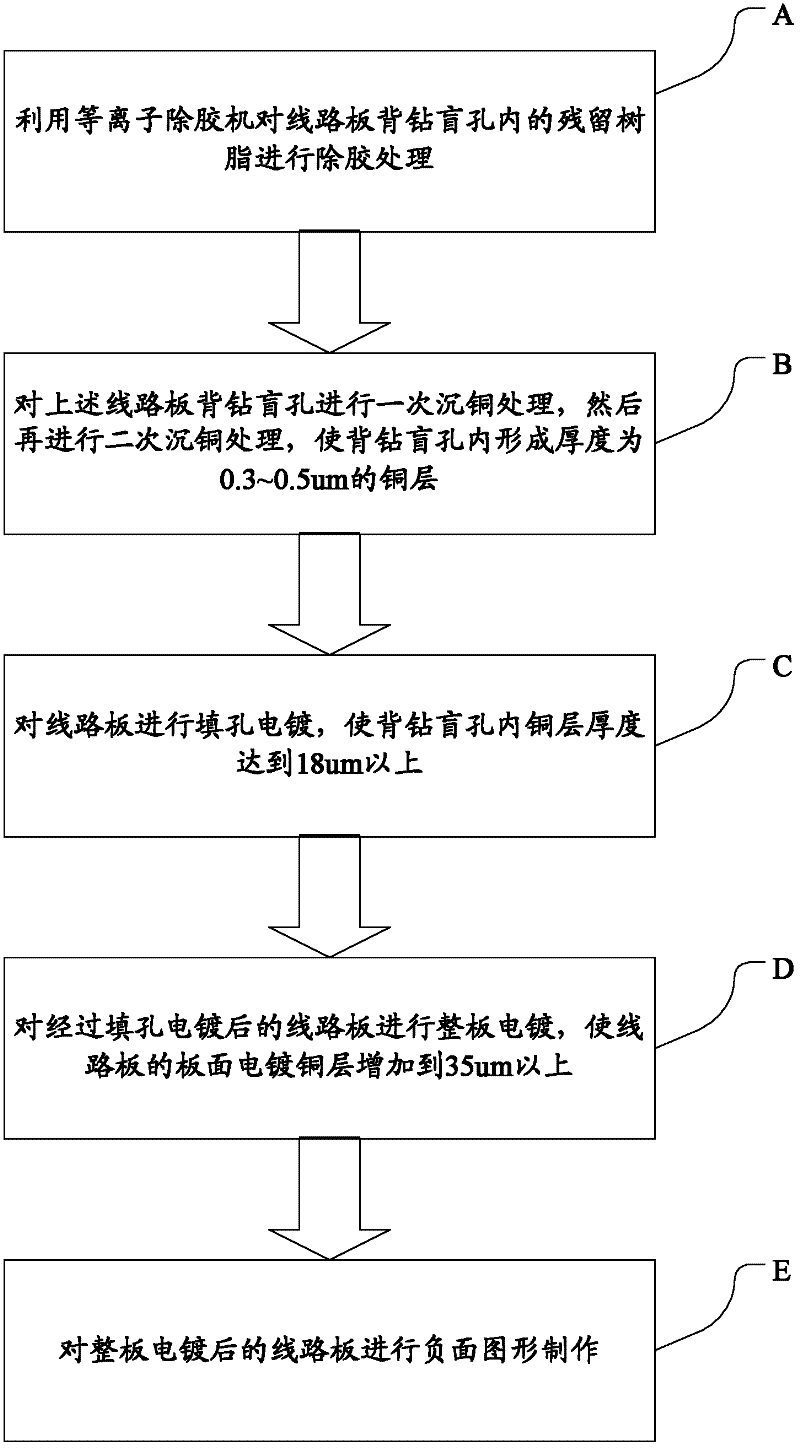

Electroplating manufacturing process of circuit board with back-drilled blind hole

InactiveCN102523702AGuaranteed Thickness RequirementsSolve the problem of glue removalPrinted element electric connection formationBinding forceElectroplating

The invention discloses an electroplating manufacturing process, comprising the following steps of: A, utilizing a plasma degumming machine to carry out degumming treatment on residual resin in a back-drilled blind hole of a circuit board; B, carrying out primary copper deposition treatment on the back-drilled blind hole of the circuit board and then carrying out secondary copper deposition treatment to form a copper layer with the thickness of 0.3-0.5 microns in the back-drilled blind hole; and C, carrying out hole-filling electroplating on the circuit board to lead the thickness of the copper layer in the back-drilled blind hole to be more than 18 microns. According to the invention, by utilizing a plasma degumming way to treat the residual resin in the back-drilled blind hole of the circuit board, the problem that a chemical degumming speed is lower is solved, and the plasma degumming way has a good degumming effect and no residues; two times of copper deposition solve the problems that the thickness of deposited copper generated by the primary copper deposition is thin, and hollow copper depositing layers, broken copper or an open circuit is easy to generate in a process of storing or electrically pre-treating a board; and the thickness of the copper layer in the blind hole can reach to be more than 18 microns through the hole-filling electroplating, so that the thickness requirement of the back-drilled blind hole is met. Compared with the prior art, the electroplating manufacturing process provided by the invention effectively overcomes the quality defects that: the back-drilled blind hole cannot be completely degummed, the binding force is poor, and the copper in the hole is thinner and the like.

Owner:SHENZHEN SUNTAK MULTILAYER PCB +1

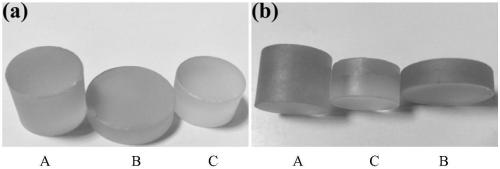

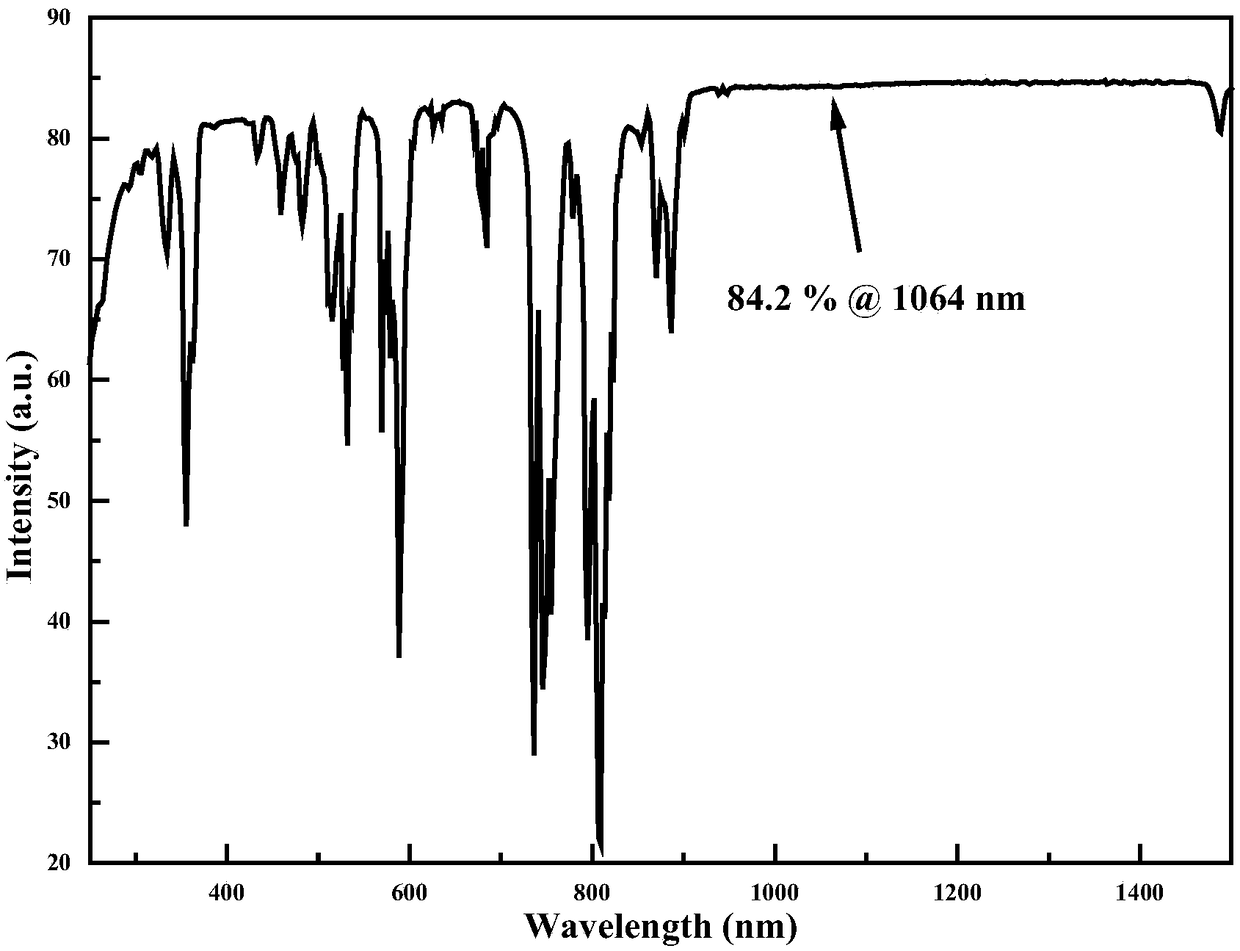

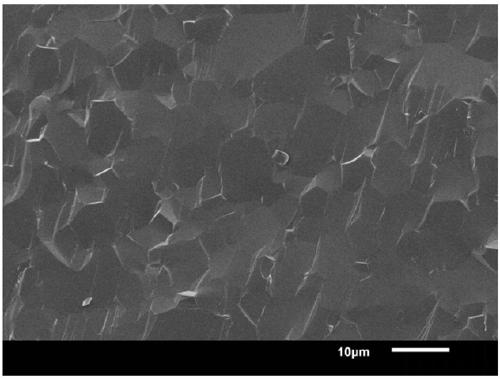

Method for preparing YAG-based multilayer composite structure transparent ceramic by Isobam gelcasting

The invention discloses a method for preparing a YAG-based multilayer composite transparent ceramic by using Isobam gelcasting. The prepared multilayer ceramic satisfies a structure shown by a following formula: YAG / Re:YAG / YAG or YAG / Re: YAG / Re:YAG, wherein the YAG layer is composed of Y3A15O12, the Re:YAG layer is composed of (Y<1-x>Re<x>)<3>A<15>O<12>, x is more than or equal to 0.02 and is lessthan or equal to 0.2; Re is one of rare earth elements of cerium, praseodymium, neodymium, samarium, europium, terbium, dysprosium, holmium, erbium, thulium or ytterbium. The method comprises the steps that firstly Isobam gelcasting slurry is prepared, then the slurry is defoamed and is cast into a mold, after a first layer of the slurry gel is cured, the other layer of slurry is poured, the slurry is completely gelled, drying treatment is conducted, and the gel is discharged; biscuit after discharging the gel is vacuum sintered and annealed, and after double-sided polishing, the multilayer composite transparent ceramic is obtained. The method provided by the invention is mainly water-based slurry, green and environmentally friendly, and the obtained ceramic has the characteristics of high density, complicated structure, good optical quality, high transmittance, small interfacial ion diffusion range, and the method is very suitable for the preparation of the large size and composite YAG-based transparent ceramic material.

Owner:XUZHOU ALL TO PHOTOELECTRIC TECH CO LTD

Method for degumming ramie

InactiveCN103266358AReduce difficultyQuality improvementFibre treatment to obtain bast fibreSolubilityOrganic solvent

The invention relates to a method for degumming ramie. The method adopts the solution formed by mixing a high-proportion alcohol organic solvent with a small amount of water and degumming reagent to carry out the degumming treatment on the ramie, thus effectively improving the solubility of impurities such as hemicellulose, pectin, cerolipoid and ash, and reducing the degumming difficulty of the ramie; and furthermore, the loss of the strength of ramie fiber is greatly reduced, so that the quality of the ramie fiber is improved, and the ramie fiber is high in quality and efficiency. The degumming technology is simple and convenient, good in degumming effect and high in efficiency, greatly reduces the water consumption in the degumming process of the ramie, and effectively reduces the dosage of a chemical reagent; and the alcohol organic solvent not only is safe and non-toxic, but also can be recycled, so that the method is low in pollution, low in cost, clean, energy-saving, safe and environment-friendly.

Owner:WUHAN TEXTILE UNIV

Degumming technology of natural bamboo fiber

ActiveCN106012044AImprove degumming efficiencyImprove degumming effectFibre treatment to obtain bast fibrePlant fibreHigh pressure

The invention relates to a degumming technology of natural bamboo fiber, and belongs to the technical field of plant fiber manufacturing. The technology comprises the steps that bamboo chips are pretreated to be hammered into thin filaments, then the thin filaments are sequentially subjected to the processes such as acid soaking, steaming, fermenting, enzymolysis, bleaching, oiling, softening, dewatering, opening and drying, and the natural bamboo fiber is prepared. Accordingly, the acid soaking-high pressure steaming-microbial degumming composite technology is adopted, the synergist effect is generated among the steps, therefore, the degumming effect of the natural bamboo fiber is improved, and the prepared fiber has the advantages of being high in degumming efficiency and little in damage to the fiber intensity.

Owner:四川长盛新材料科技有限公司

Processing method for rice bran oil

InactiveCN103409233AImprove oil yieldGood decolorization effectFatty-oils/fats refiningFatty-oils/fats productionFiltrationRice Bran Extract

The invention discloses a processing method for rice bran oil. A finished rice bran oil product is obtained by successively subjecting rice bran to puffing, leaching, pretreatment of mixed rice bran crude oil, degumming, decoloring, de-waxing and physical deacidification. In the procedure of leaching, a leaching solvent--isopropanol is added into the rice bran having undergone puffing, and oil yield of the rice bran oil is improved through optimization of the leaching procedure; in the procedure of pretreatment of the mixed rice bran crude oil, the mixed rice bran crude oil is subjected to filtration so as to control impurity content to be less than 0.2%; in the procedure of degumming, the temperature of the rice bran crude oil having undergone removal of impurities is adjusted to 42 to 45 DEG C, 20 to 25% of an aqueous oxalic acid solution is added under stirring, heating is carried out during stirring until the temperature is 62 to 64 DEG C, and the solution is stood for 1 to 2 h so as to obtain oxalic acid degummed oil; and then the oxalic acid degummed oil is subjected to water processing so as to obtain degummed oil. The processing method for the rice bran oil provided by the invention has the advantages of low energy consumption, high oil yield and a good decoloring effect.

Owner:湖南灯塔米业有限公司

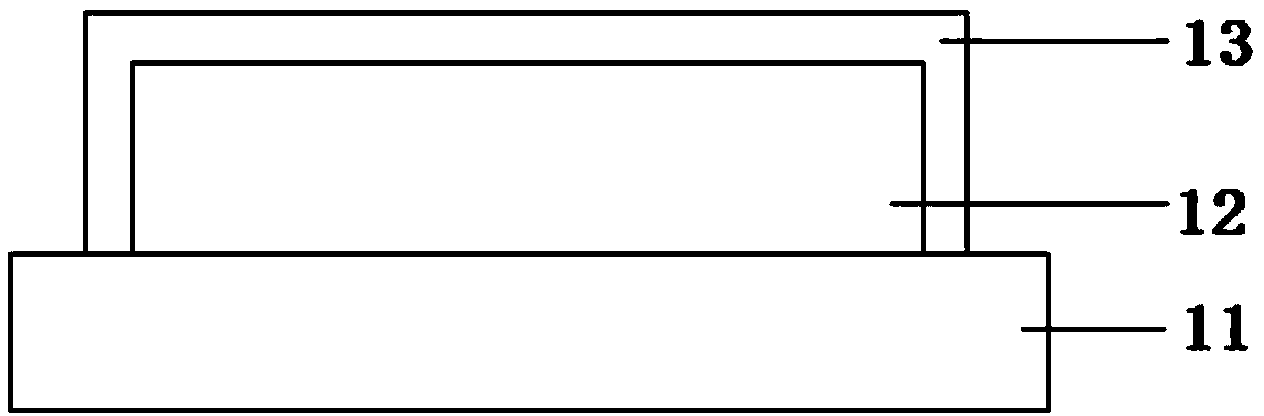

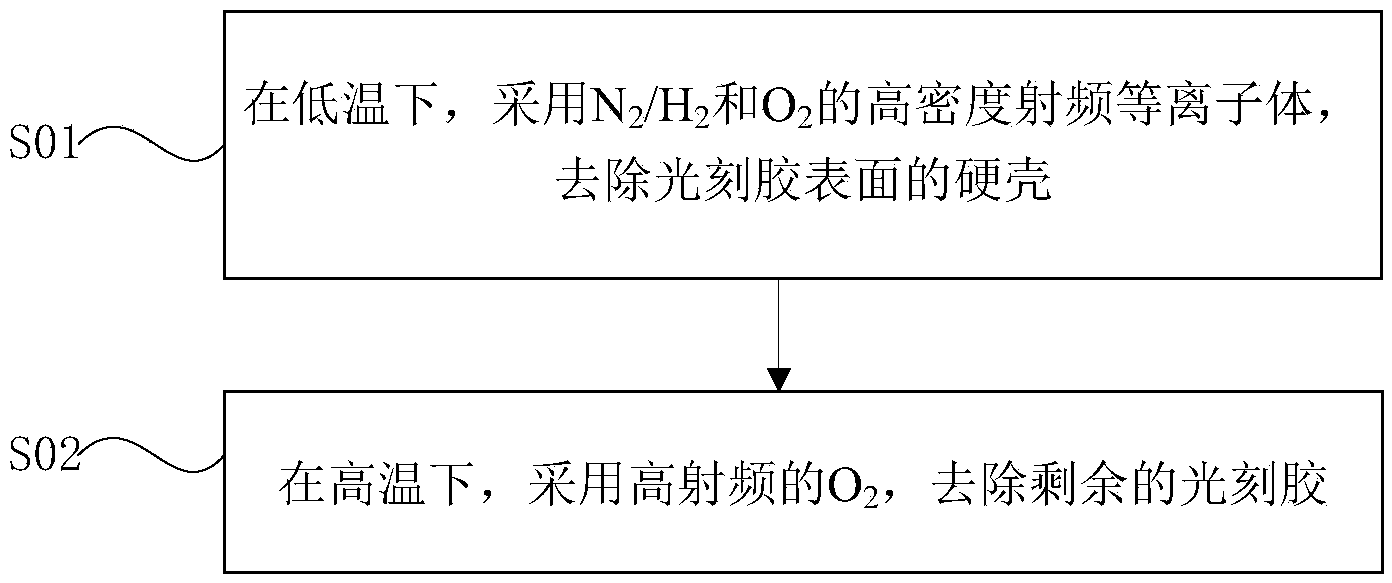

Photoresist removing method

InactiveCN104391434AAvoid it happening againSpeed up the glue removal rateSemiconductor/solid-state device manufacturingPhotosensitive material processingTemperature controlHigh density

The present invention discloses a photoresist removing method. According to the photoresist removing method, with the fractional temperature control photoresist removing process, the low temperature is maintained during the photoresist surface hard shell removing process, such that the photoresist polymer impurity generation caused by the emission of the volatile solvent in the photoresist, and the high density radio frequency reaction gas is adopted so as to completely react with the hard shell; and during the residual photoresist removing process, the high temperature is maintained, and the high radio frequency reaction gas is adopted so as to accelerate the photoresist removing rate and improve the photoresist removing ability, such that the product yield and the product quality are increased through the photoresist removing method of the present invention.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

Method for preparing fibrilia by using epicoccum nigrum DB3 strains

InactiveCN102409411AShorten the growth cycleImprove heat resistanceFungiMicroorganism based processesFiberBuffer solution

The invention relates to a method for preparing fibrilia by using epicoccum nigrum DB3 strains. The method comprises the following steps: (1) preserving the epicoccum nigrum DB3 strains in a potato dextrose agar medium for cultivation, and adding a freezing buffer solution; (2) inoculating bacteria the amount of which equals to the pick-up amount of an inoculating ring, obtained in the step (1) into the potato dextrose agar medium, and carrying out shaking culture; (3) inoculating the culture medium obtained in the step (2) into a flax lignin fermentation medium, and carrying out shaking culture to obtain a fermentation bacteria liquid; (4) mixing sterilized fiber raw material with the fermentation bacteria liquid obtain in the step (3), carrying out table shaking and removing fermentation liquid to obtain the fibrilia; and (5) mixing the fibrilia with degumming liquid, processing and then rinsing, oiling and drying to obtain the fibrilia. The method in the invention has simple technology, short degumming time and high degumming efficiency, thus being suitable for large-scale industrial production.

Owner:YANCHENG XUER TEXTILE

Environment-friendly silk degumming method

InactiveCN107268092AQuality improvementImprove the lubrication effectDe-gumming silkAlkaline proteaseWax

The invention mainly relates to the technical field of silk processing, and discloses an environment-friendly silk degumming method, which includes immersion, enzymolysis, fermentation and washing. The method is simple, conditions are mild, high temperature and high pressure are not needed, energy is saved, the method is suitable for batch processing, the degumming rate can reach 89.3 percent, obtain silk is fine and smooth, the color is bright and white-yellow, and economic income can be increased by 12.7 percent. pH of immersed silk is regulated to be alkaline, lipase is added to decompose grease and wax components in the silk, high-temperature cooking is avoided, so that energy is saved, pH is then regulated to be acidic, bromelain is added, and enzymic preparations with different pHs are sequentially used for enzymolysis. The conventional joint use of alkaline protease and surfactant is changed, the environment is protected, soluble impurities under different pHs are sufficiently removed, sericin and remaining fat are decomposed, and the silk degumming rate is increased.

Owner:HEFEI JUFENG THROWING

Silk degumming method

The invention discloses a silk degumming method, and relates to the technical field of silk processing. The silk degumming method comprises the following steps: A, injecting water in a refining tank, putting silk in the refining tank, heating to 98 to 100 DEG C, and keeping warm for 10 to 20 minutes; B, after regulating the water temperature to be 95 to 97 DEG C, adding 0.8 to 1.2 g / L of sodium carbonate, and keeping warm for 5 to 10 minutes; C, reducing the water temperature to be 40 to 45 DEG C, adding 1 to 2 g / L of 2709 alkaline protease, and stirring and hydrolyzing for 40 to 60 minutes under the condition that the pH (Potential of Hydrogen) is 9.5 to 9.8; D, washing for 15 to 30 minutes under the temperature of 60 to 70 DEG C, and then washing by cold water. According to the silk degumming method disclosed by the invention, the problem of an undesirable degumming effect of existing silk enzyme degumming is solved.

Owner:广西江缘茧丝绸有限公司

High-gum-content raw hemp fiber degumming method

The invention discloses a high-gum-content raw hemp fiber degumming method. The method comprises a mechanical decortication and chemical immersion pre-degumming step, a steam explosion degumming step, a lignin oxidation degumming step and an ethanol boiling step. In the invention, based on the prior art, an independent lignin catalytic oxidation step is adopted, and chemical formula and technological conditions of a lignin catalytic oxidizer are improved to control the degradation degree of lignin, so that the lignin is partially degraded into non-water-soluble polyphenol substances, thus skillfully solving the problem that the lignin is sufficiently degraded into water-soluble monophenol and enters production wastewater. The polyphenol substances obtained after the degradation of the lignin are extracted through the subsequent ethanol boiling step, i.e. the polyphenol substances enter an ethanol solution and are subjected to simple distillation and purification to produce useful industrial byproducts. According to the invention, the method has the characteristics of favorable degumming effect, mild process, small fiber damage and the like; and the obtained fiber has high strength, favorable whiteness and high comprehensive quality.

Owner:QINGDAO UNIV

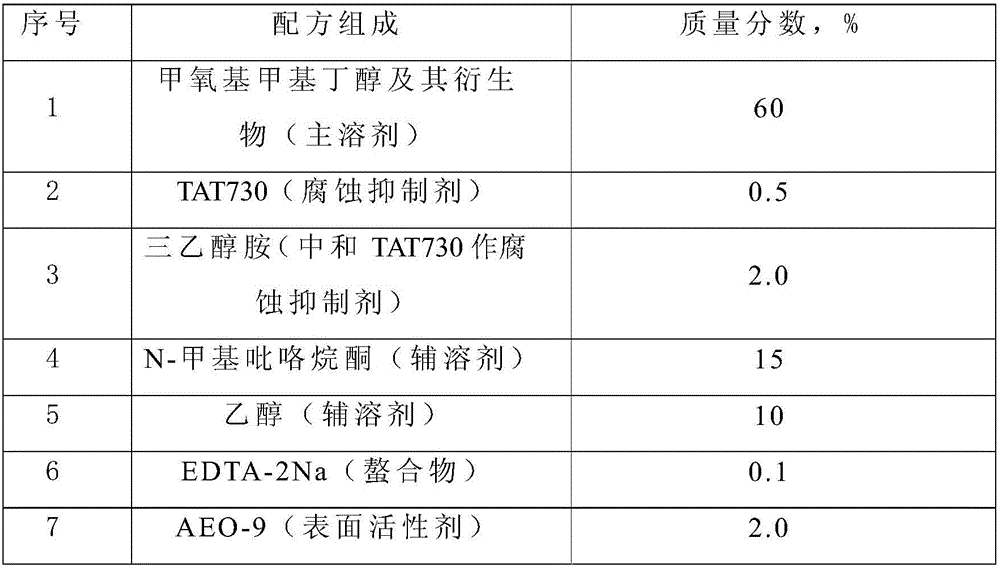

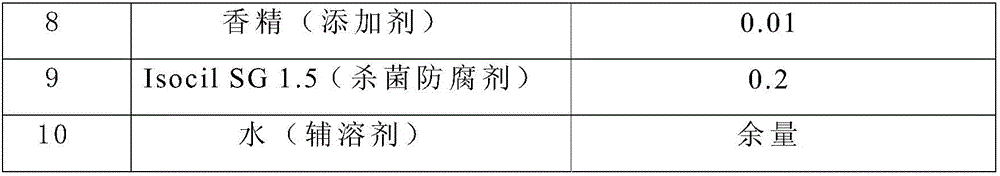

Environment-friendly medical glue remover

InactiveCN106350250AAvoid breedingNo pungent smellOrganic detergent compounding agentsSurface-active detergent compositionsTetrachloroethylenePreservative

The invention discloses an environment-friendly medical glue remover, made from, by weight, 80-98% of a solvent, 0.01-5% of a corrosion inhibitor, 0.01-5% of a surfactant, and 0.01-1% of a sterilizing preservative. A neutral formulation is used herein, the solvent is environment-friendly, no irritating odor is produced, and the environment-friendly medical glue remover can be a perfect substitute for glue removers made from toluene, ethyl acetate, tetrachloroethylene and the like, can protect an instrument during glue removal, and can also partly kill microorganisms on the instrument to prevent growth of harmful bacteria.

Owner:NANJING JUSHA DISPLAY TECH

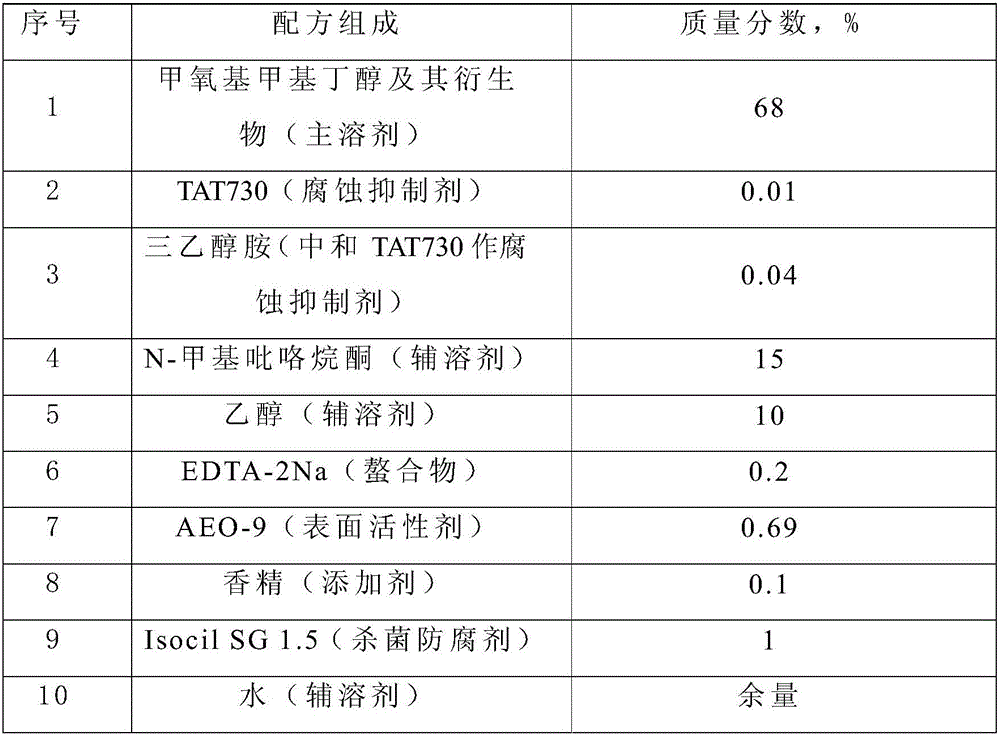

Automatic glue scraping device

ActiveCN106623027AUniform adhesionLarge lengthDirt cleaningCleaning using toolsAgricultural engineeringAutomation

The invention particularly relates to an automatic glue scraping device applied to printing and packaging machinery. The automatic glue scraping device is characterized in that a middle scraper is arranged on an ejection rod of a first feeding air cylinder which is arranged at the front end of a middle scraper carrier; a left and right scraper carrier platform is arranged at upper ends of lower sliders which are arranged on a lower screw rod, and a left scraper carrier and a right scraper carrier are arranged on left and right sides of the front end of the left and right scraper carrier platform respectively; a left scraper is arranged on an ejection rod of a second feeding air cylinder which is arranged at the front end of the left scraper carrier; a right scraper is arranged on an ejection rod of a third feeding air cylinder which is arranged at the front end of the right scraper carrier; two supporting arms of the middle scraper carrier penetrate two supporting arm grooves, and the bottom of the middle scraper carrier is mounted on two linear bearing guide rails through linear bearings; a platform supporting column is arranged at the bottom of each of four corners of the left and right scraper carrier platform, and bottoms of the platform supporting columns are mounted on the two linear bearing guide rails through the linear bearings. The automatic glue scraping device has advantages of flexibility, convenience, high automation degree and effectiveness in glue removal.

Owner:SHANDONG TAIBAO PACKAGING PROD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com