High-gum-content raw hemp fiber degumming method

A technology of colloid content and degumming method is applied in the field of raw hemp fiber processing and raw hemp fiber degumming, which can solve the problems of limited degumming effect of hemp fibers, severe conditions, and reduced concentration, and achieves accelerated impregnation reaction speed, fully dispersed fibers, Effect of lye temperature reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

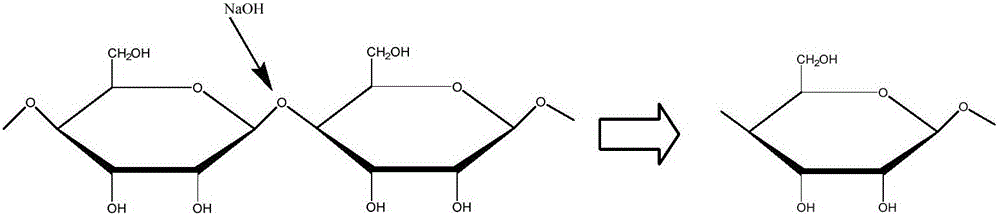

Image

Examples

Embodiment 1

[0056] Raw materials and origin: 800Kg Apocynum hemp, Xinjiang

[0057] The degumming method is as follows:

[0058] The first step, the pre-degumming step

[0059] Use the hemp peeling machine to process the stems and leaves of the original hemp crop into hemp coarse fibers with a diameter of about 1mm;

[0060] Then, the hemp crude fiber is placed in the degumming pool, soaked in the degumming solution to remove the hemicellulose and pectin components contained in the hemp crude fiber; the hemicellulose and pectin content in the hemp crude fiber are all low After 5%, the hemp crude fiber is pulled out, squeezed with water until the liquid-carrying rate of the hemp crude fiber is 50%, and set aside;

[0061] The above-mentioned degumming solution is a sodium hydroxide solution with a mass percentage concentration of 2.5%; the temperature of the above-mentioned degumming solution is 80° C., and the bath ratio is 1:10 to 15;

[0062] The second step, steam explosion degummin...

Embodiment 2

[0074] Raw materials and origin: 800Kg Apocynum hemp, Xinjiang

[0075] The degumming method is as follows:

[0076] The first step, the pre-degumming step

[0077] Use the hemp peeling machine to process the stems and leaves of the original hemp crop into hemp coarse fibers with a diameter of about 1mm;

[0078] Then, the hemp crude fiber is placed in the degumming pool, soaked in the degumming solution to remove the hemicellulose and pectin components contained in the hemp crude fiber; the hemicellulose and pectin content in the hemp crude fiber are all low After 5%, the hemp crude fiber is pulled out, squeezed into water until the liquid-carrying rate of the hemp crude fiber is 40%, and set aside;

[0079] The above-mentioned degumming solution is a sodium hydroxide solution with a mass percentage concentration of 1%; the temperature of the above-mentioned degumming solution is 90° C., and the bath ratio is 1:10 to 15;

[0080] The second step, steam explosion degumming ...

Embodiment 3

[0092] Raw materials and origin: 800Kg Apocynum hemp, Xinjiang

[0093] The degumming method is as follows:

[0094] The first step, the pre-degumming step

[0095] Use the hemp peeling machine to process the stems and leaves of the original hemp crop into hemp coarse fibers with a diameter of about 1mm;

[0096] Then, the hemp crude fiber is placed in the degumming pool, soaked in the degumming solution to remove the hemicellulose and pectin components contained in the hemp crude fiber; the hemicellulose and pectin content in the hemp crude fiber are all low After 5%, the hemp crude fiber is pulled out, squeezed with water until the liquid-carrying rate of the hemp crude fiber is 50%, and set aside;

[0097] The above-mentioned degumming solution is a mixed solution A of sodium hydroxide, sodium tripolyphosphate and sodium silicate, and the mass percent concentration of each component in the mixed solution A is respectively: sodium hydroxide 1%, sodium tripolyphosphate 1%, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com