Patents

Literature

95 results about "Hemp plant" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

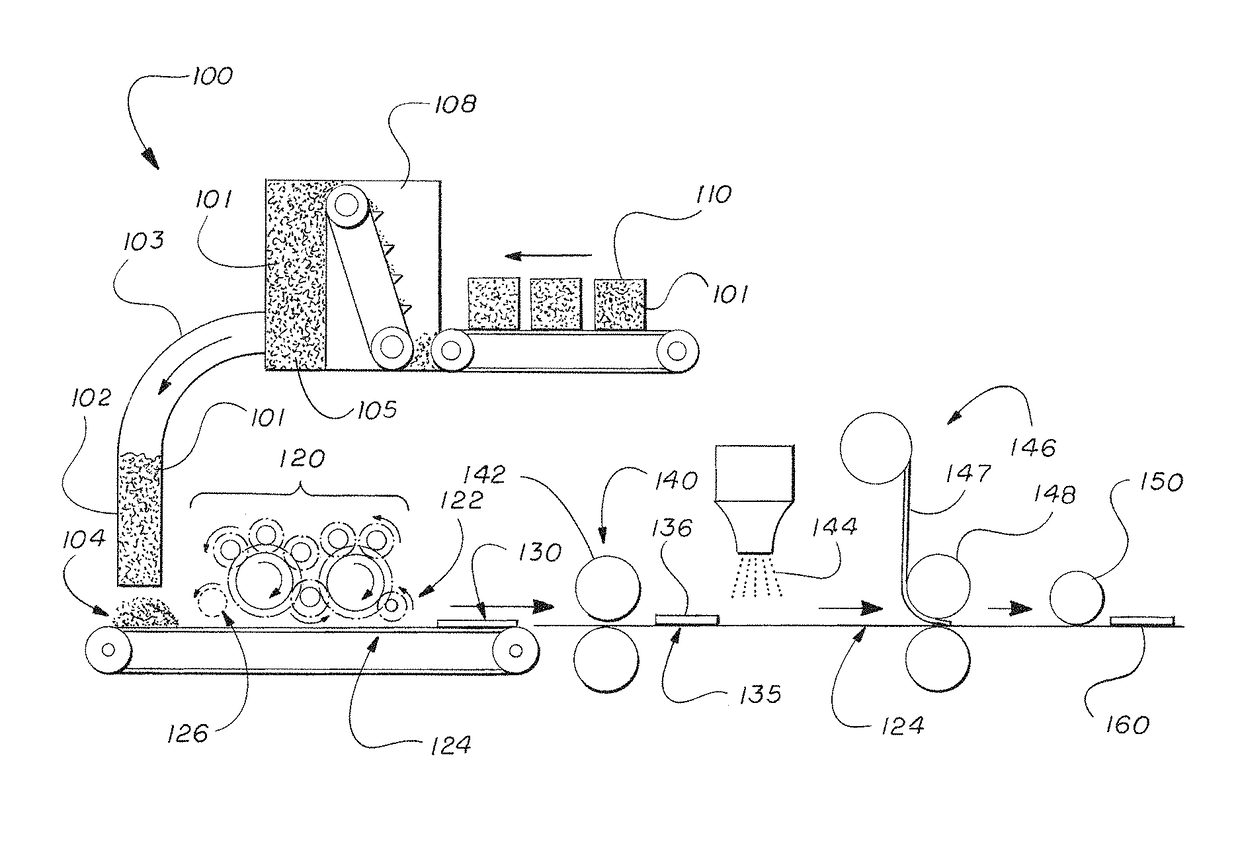

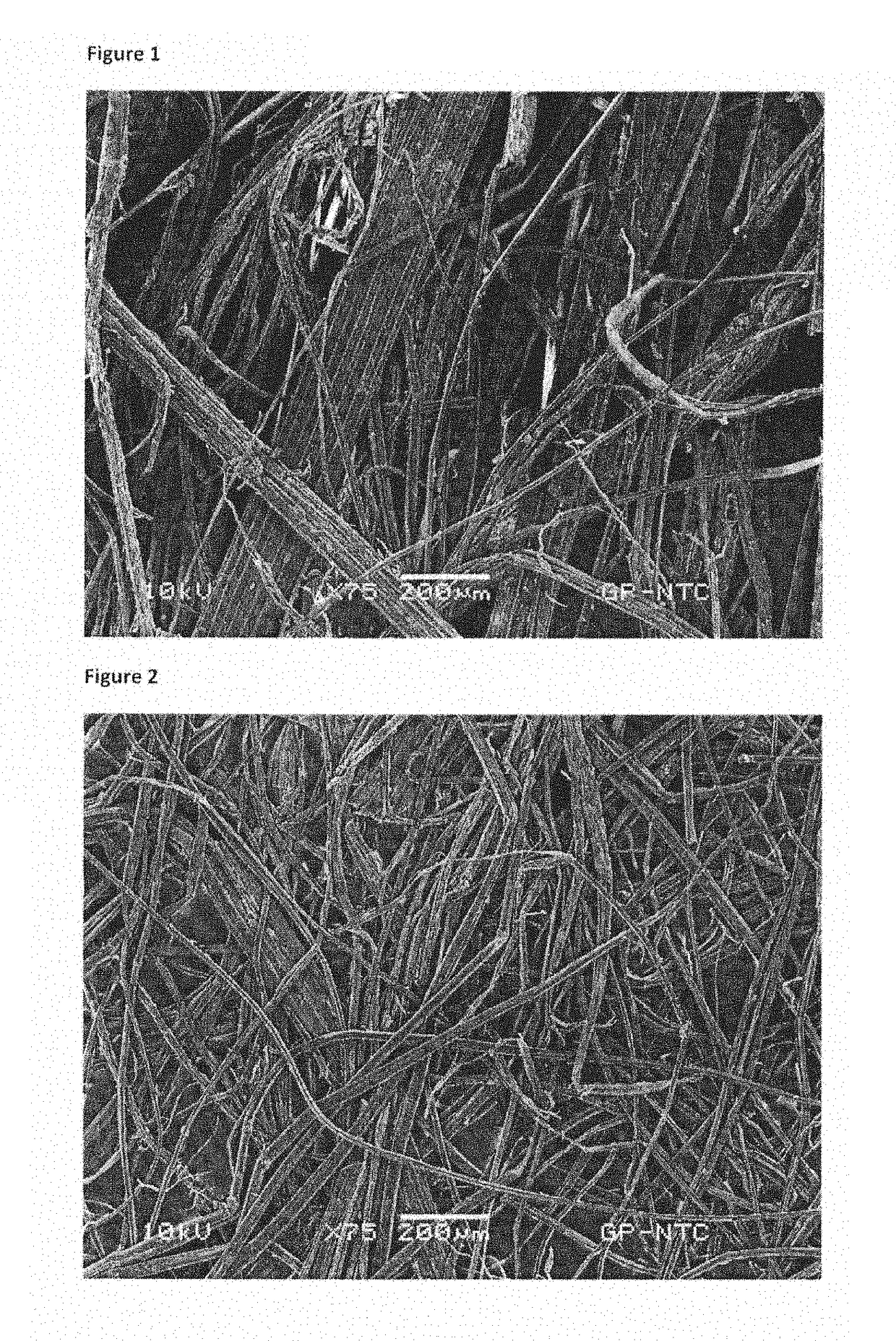

Nonwoven Fabrics Comprised of Individualized Bast Fibers

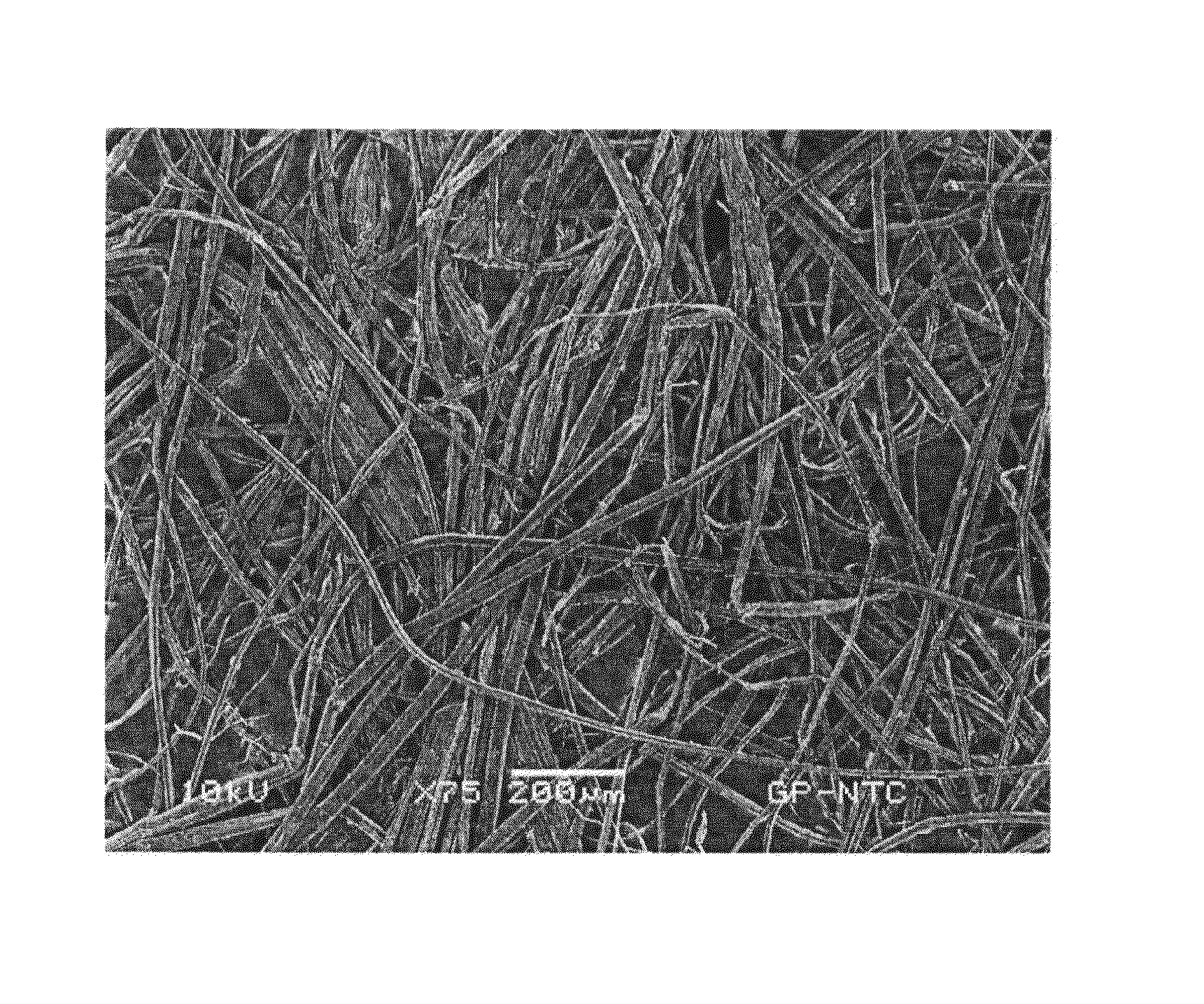

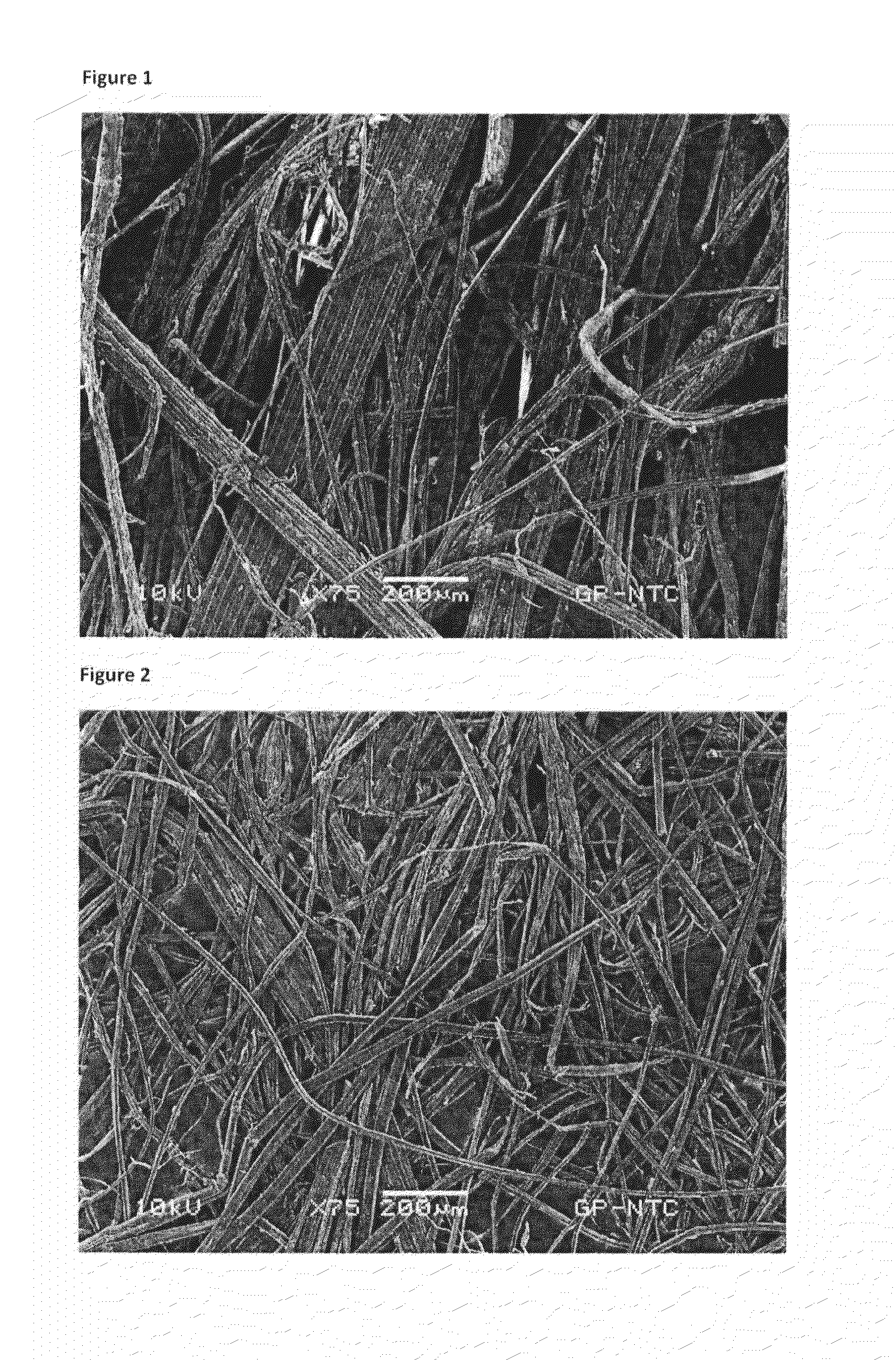

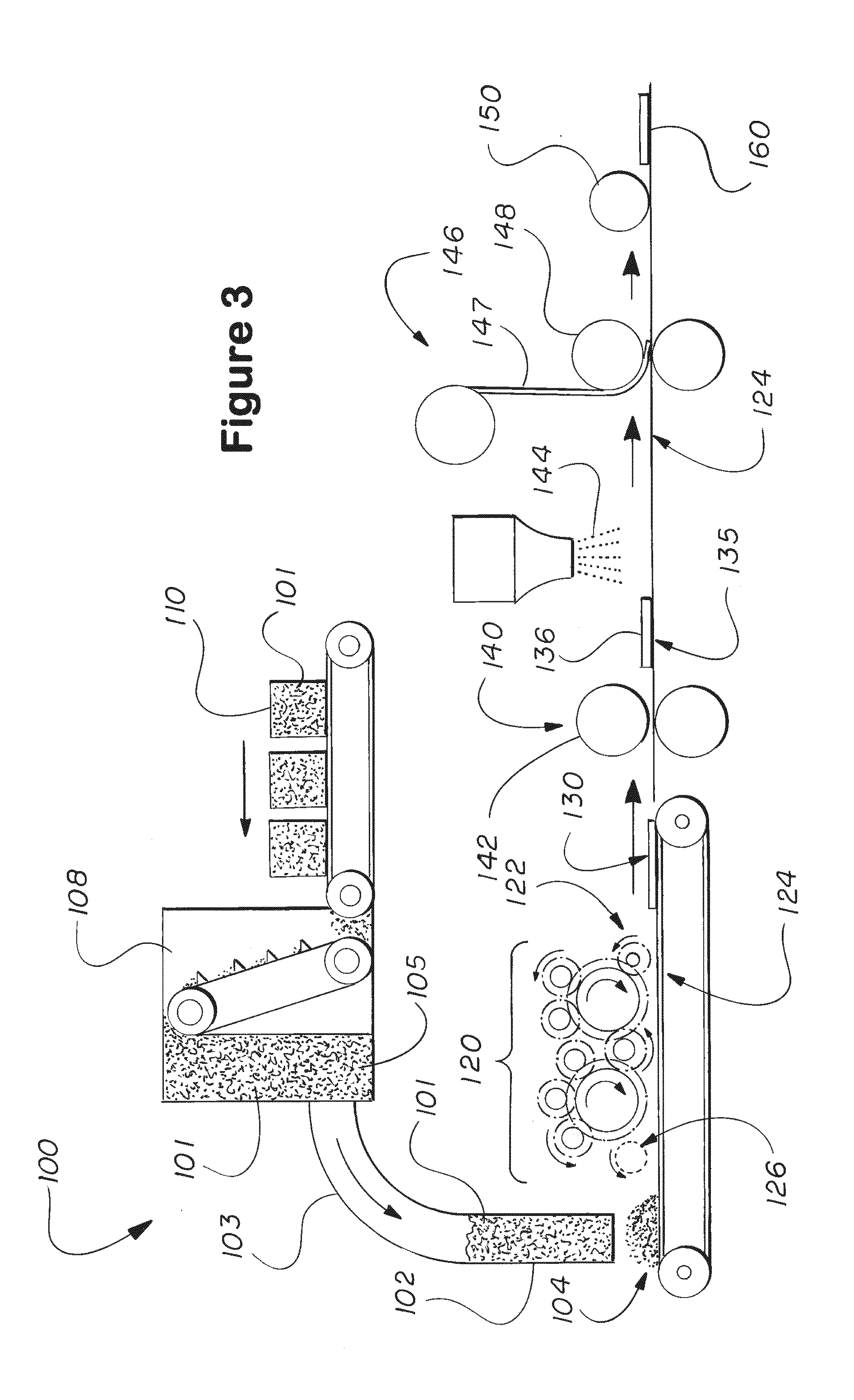

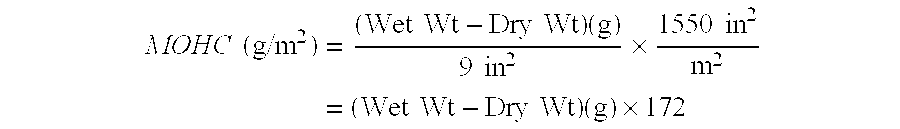

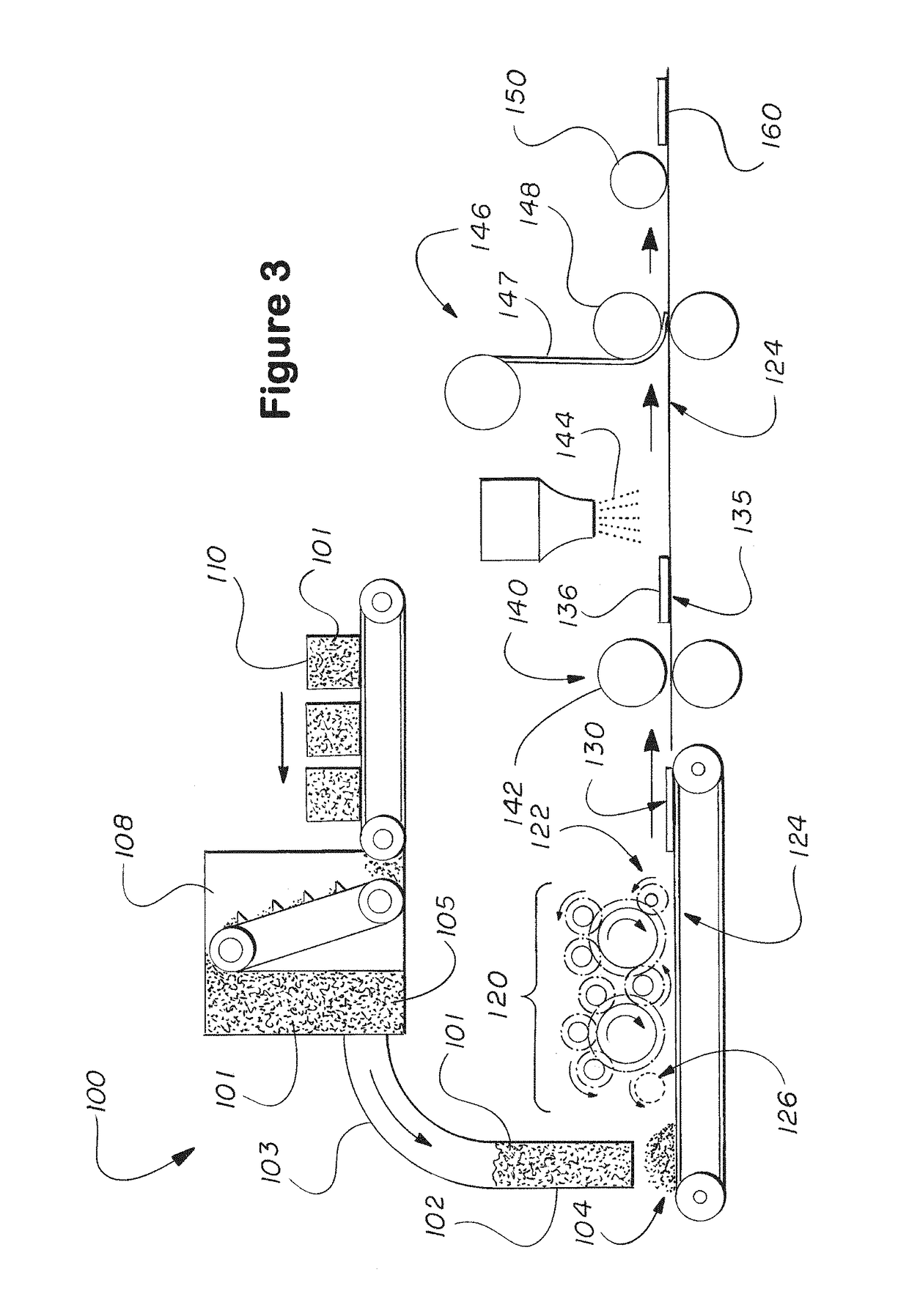

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin. The nonwoven fabric can include staple fibers to a lesser extent than the individualized bast fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

Hemp-material viscose fiber and preparing method thereof

InactiveCN101130885AQuality improvementHigh whitenessWet spinning methodsVegetable materialAfter treatmentHemp plant

The present invention discloses a method for preparing hemp viscose fiber by using hemp plant and hemp visose fiber prepared by adopting said method. Said method includes the following steps: preparing raw material, digesting, washing material, pulping, removing sand, bleaching, water-washing, fiber-making, impregnating, pressing, pulverizing, aging, xanthating, dissolving, mixing, filtering, defoaming, spinning, drawing, cutting and making after-treatment.

Owner:CHTC HELON

Nonwoven fabrics of short individualized bast fibers and products made therefrom

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin having a mean length less than 6 millimeters. The nonwoven fabric can include staple fibers and / or pulp fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

Water dispersible wipe substrate

Water dispersible nonwoven substrates in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin. The nonwoven substrate can include staple fibers to a lesser extent than the individualized bast fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven substrate is formed into a web in a wet or a dry state and subsequently bonded to produce a water dispersible nonwoven substrate. The nonwoven substrate can be a tissue or a wet wipe.

Owner:GPCP IP HLDG LLC

Method for extracting cannabidiol by using subcritical water extraction technology

InactiveCN108929201APrevent oxidative denaturationAvoid residual contaminationOrganic chemistrySolvent extractionChemical industryHemp plant

The invention provides a method for extracting cannabidiol and belongs to the technical field of chemical industry. The method comprises the steps: carrying out subcritical water extraction on dried,ground and smashed hemp plants by using a subcritical water extraction means; concentrating an extracting solution, removing impurities, and then, carrying out dilution; carrying out gradient elutionby using a chromatographic column; and concentrating and crystallizing a target eluant to obtain a cannabidiol product. A subcritical water extraction technology is adopted in an extraction process, and compared with a traditional process, the subcritical water extraction technology has the advantages that the extraction time is shortened, the yield is increased by 0.3%, meanwhile, the purity of the obtained CBD extract reaches up to 99.7%, and no chemical organic reagents are used, so that the method is environment-friendly, high in speed and efficiency and more beneficial to industrialization.

Owner:凤阳县小岗村永和营养保健品有限公司

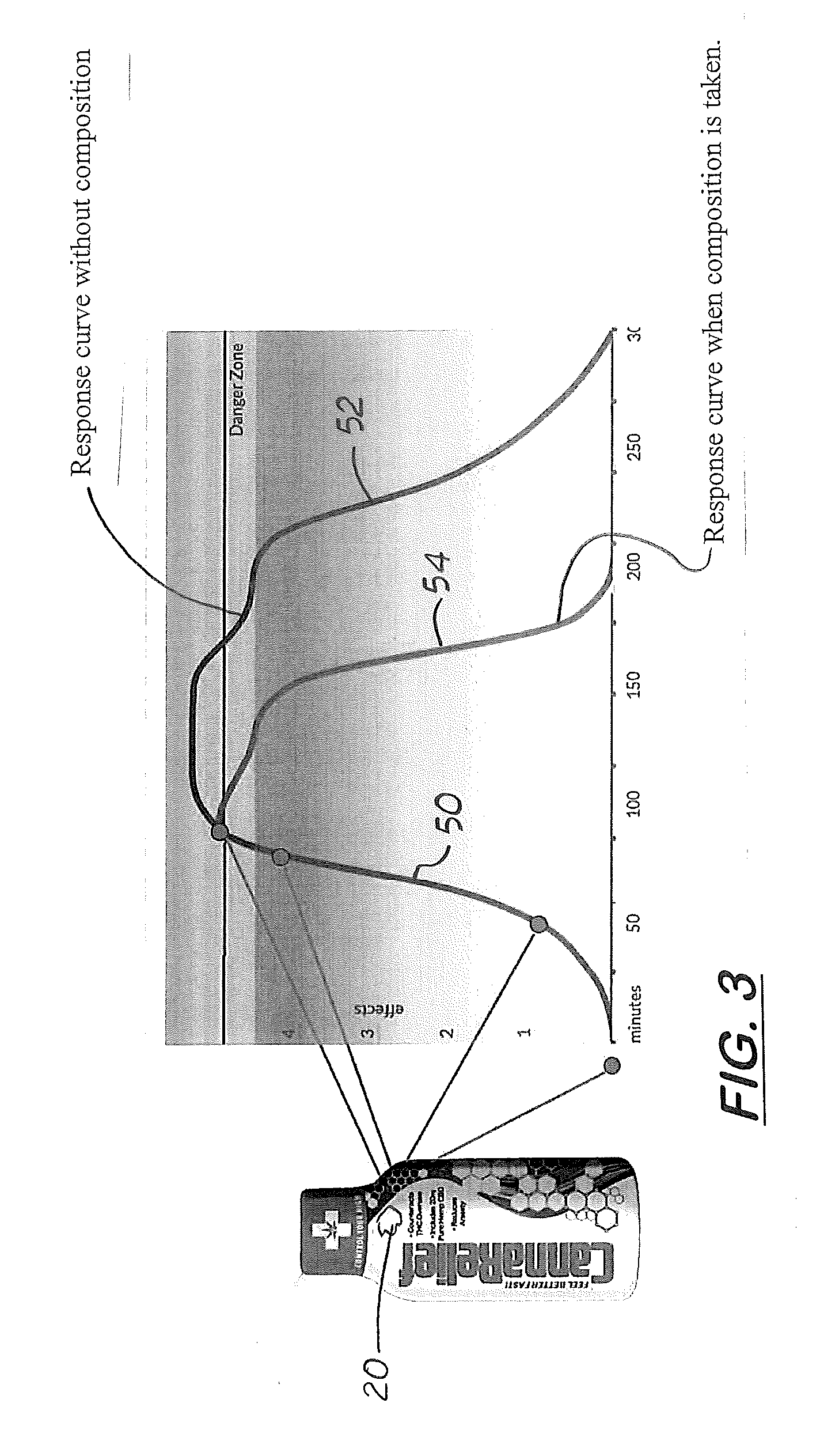

Composition, Commericial Product and Method for Treating Cannabis Toxicity

InactiveUS20160213624A1Alleviate toxicity symptomReduce riskDispersion deliveryHydroxy compound active ingredientsHemp plantVitamin C

The present invention provides a novel emulsion composition in a stable, fast acting emulsion that contains cannabidiol in an aqueous vehicle. The cannibidiol is extracted using CO2 from an industrial hemp plant that produces cannibiodiol molecules surrounded by less fats and waxes making it more hydrophilic. A little emulsifying agent, such as polysorbate 80, is mixed with cannabidiol oil to create a stable first emulsion mixture. A batch mixture is then prepared containing water, food preservatives, sugar, a sufficient amount of CBD Premix that contains citicoline and masker A for Reb A. Both mixtures are then mixed in water with ginger, Vitamin C, Vitamin B6, Vitamin B12, and sugar. The final mixture is then distributed in 60 ml bottles and consumers are instructed to take an initial loading dose of 15 ml (equal to approximately 5 mg of cannabidiol) either before a THC containing product is in consumed or smoke, shortly after a THC containing consuming or smoking or when the first signs of anxiety are perceived.

Owner:LINDEMAN TOM

Method of obtaining hemp plant juice and use of same for the production of beverages

The present invention relates to a method for producing beverages on the basis of juice from the hemp plant. The invention relates to a method for obtaining juice suitable for human consumption from the hemp plant, wherein the complete hemp stem is pressed after harvest without prior drying or retting. The invention further provides a method for obtaining juice from the hemp plant, wherein the upper leafy part of the hemp plant is cut, the leaves are stripped of the remaining stem, fibers and shives being separated from each other at the stem, the leafy part of the stem, the fibers and the shives being pressed individually under pressure and the so obtained pressed juices are being mixed in a controlled manner. In a yet further aspect, the invention relates to a method for the manufacturing of beverages on the basis of juice from the hemp plant, wherein the hemp juice is mixed with yeast and than fermented.

Owner:CLAREMONT COLLECTION HANDELSGMBH +1

Water dispersible wipe substrate

Water dispersible nonwoven substrates in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin. The nonwoven substrate can include staple fibers to a lesser extent than the individualized bast fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven substrate is formed into a web in a wet or a dry state and subsequently bonded to produce a water dispersible nonwoven substrate. The nonwoven substrate can be a tissue or a wet wipe.

Owner:GPCP IP HLDG LLC

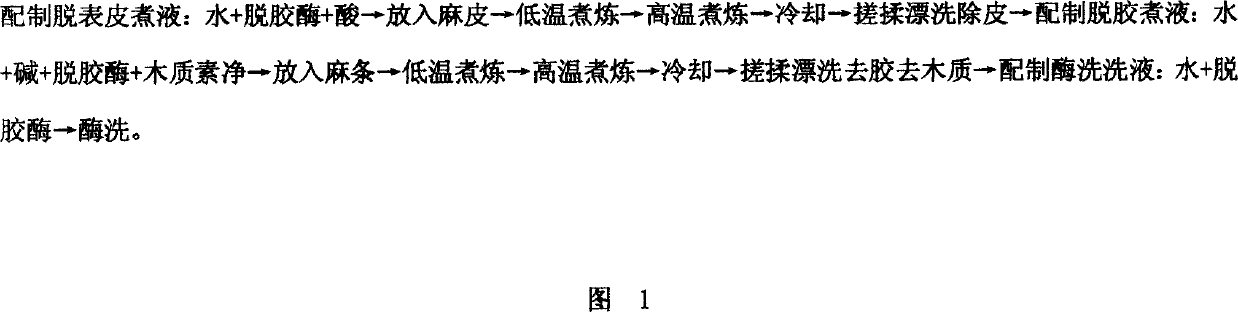

Peeling and degumming process for hemp plants

The invention relates to a peeling and degumming process for hemp plants, comprising: peeling off the hurds from the stalk, peeling the hurds by acid enzyme and removing the woodiness by alkali enzyme and lignin. The method abolishes the procedure of mechanically peeling off hurds so as to avoid the fiber loss during peeling off hurds and improve the 15% of yield. Meanwhile, the degumming process needs less water, degumming time, low acid and alkali concentration in the boiling liquid. The boiling liquid can be recycled.

Owner:徐奎元

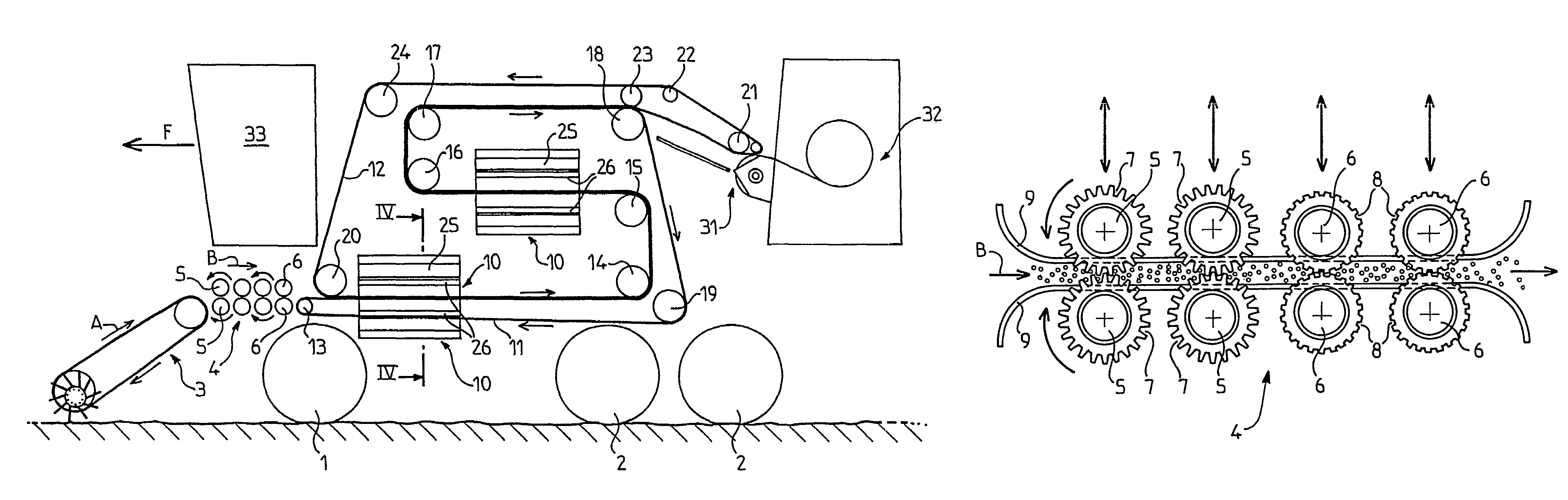

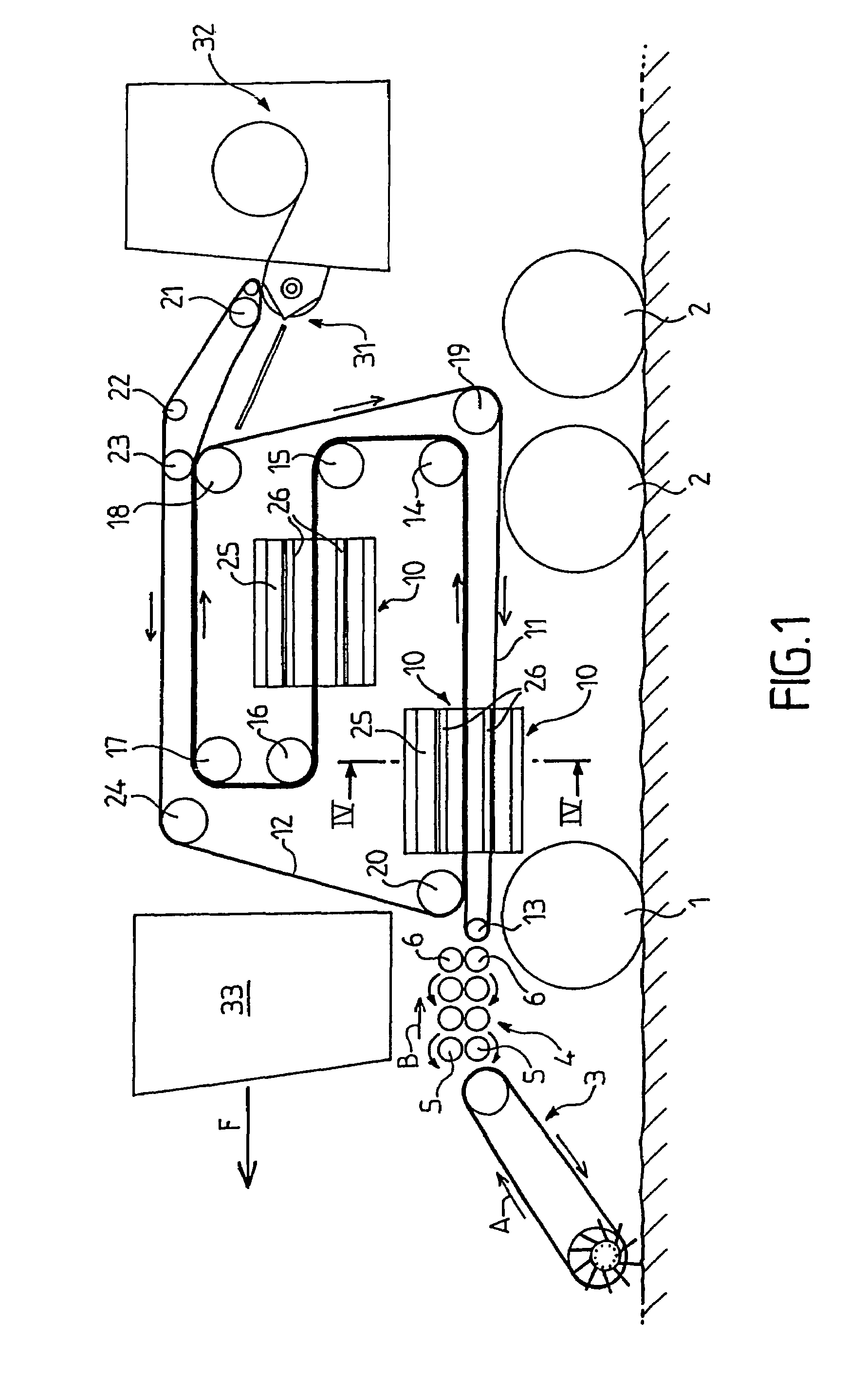

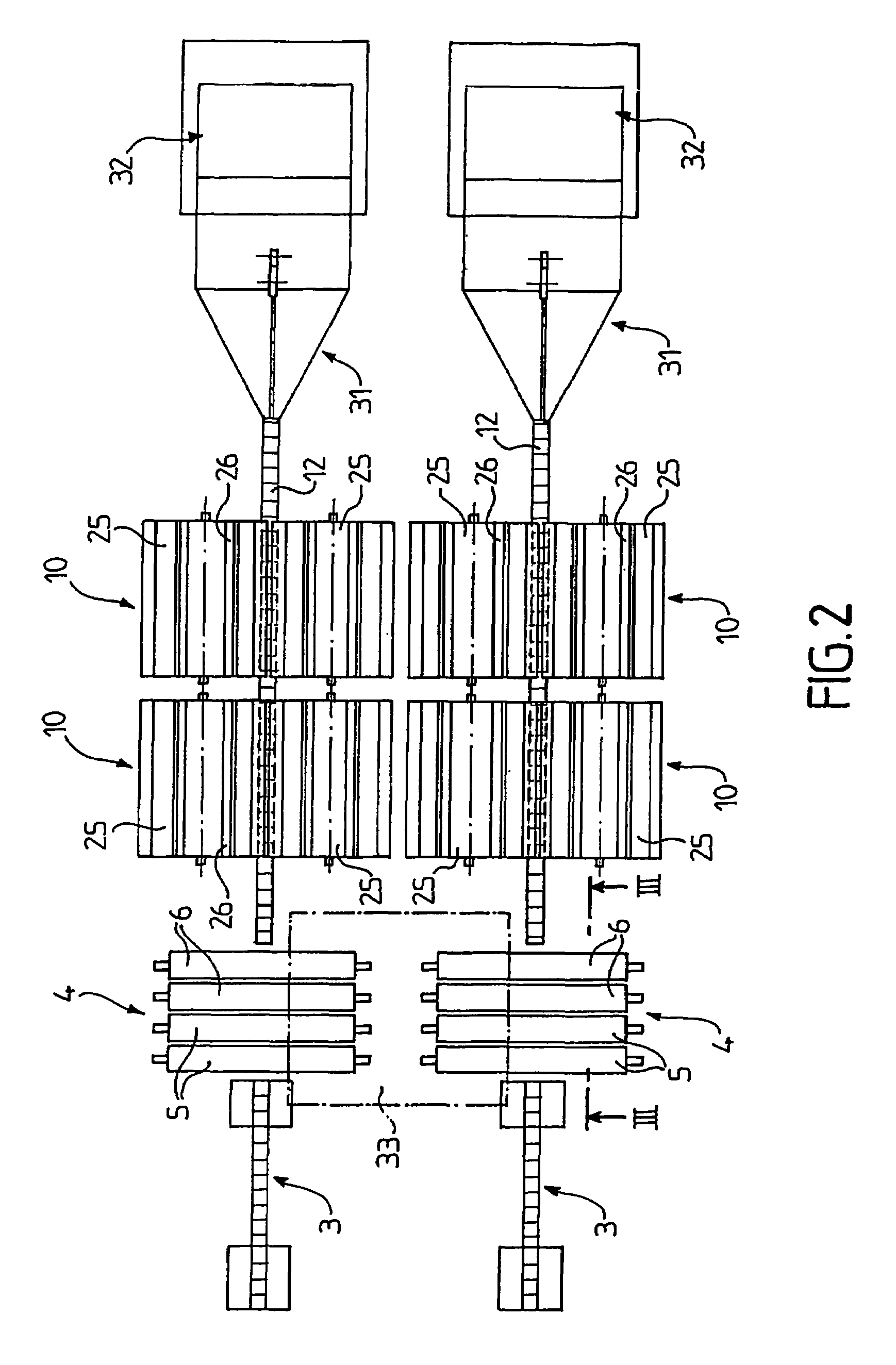

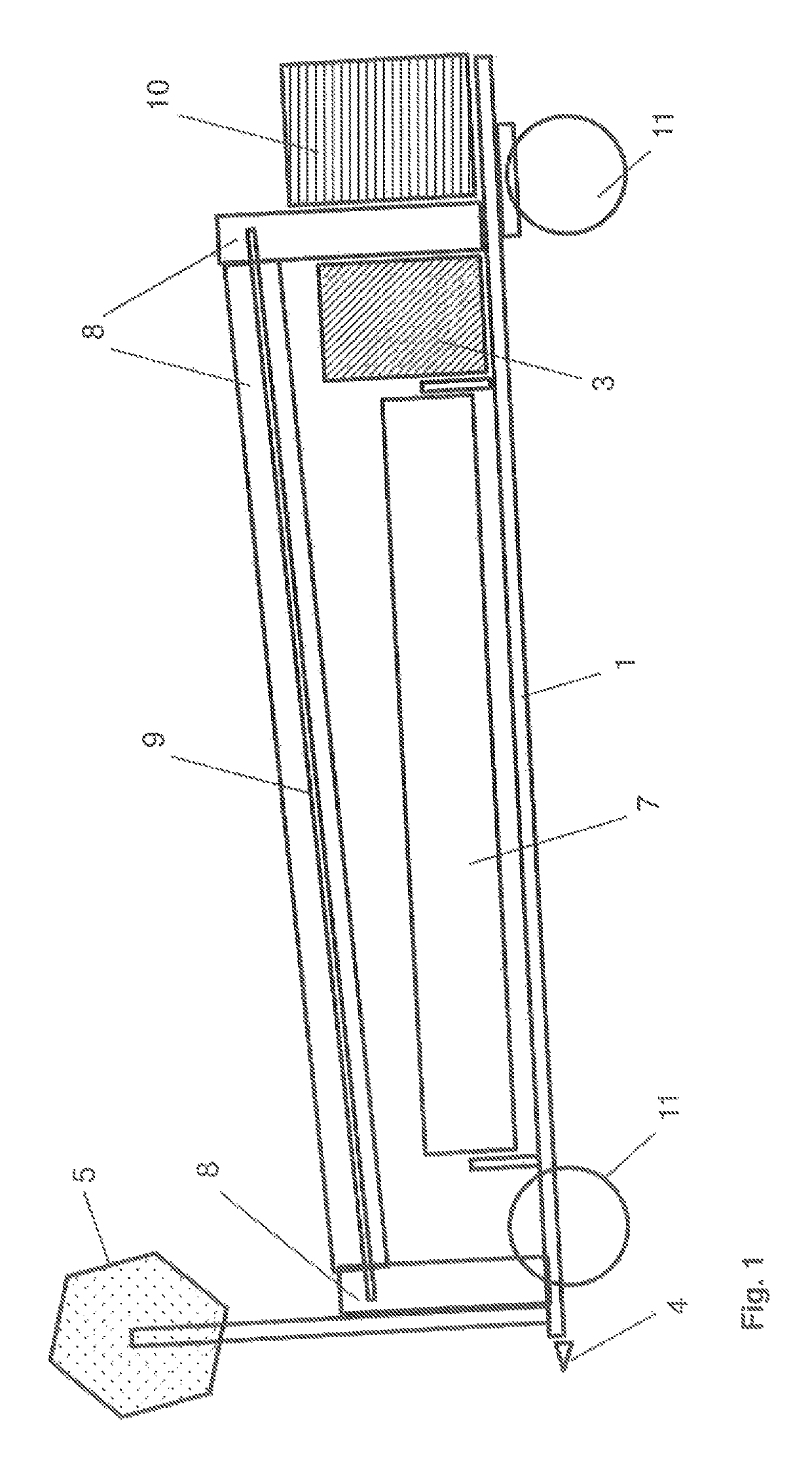

Method and machine for packing fibrous plants into balls especially common flax, hemp plant and sisal

InactiveUS7520214B2Combed more easily and more quicklyLess expensivelyMowersCuttersHemp plantPulp and paper industry

A method is provided for collecting at least partially retted plants and winding them into bales. The method is characterised in that the collected and wound plants are fibrous plants with previously cut tops and bottoms. A machine to perform the method has a gatherer (3) for collecting at least partially retted plants with previously cut tops and bottoms, a crusher (4) for grinding the stems of the plants without tops and bottoms to break the wood filaments therein, a decorticator (10) for scarifying the ground stems to release the wood filaments and shives, a unit (31) for laying flat the fibres scutched in this way, and a baler (32) for winding the same into bales.

Owner:DEHONDT GUY

Method of Obtaining Hemp Plant Juice and Use of Same for the Production of Beverages

The present invention relates to a method for producing beverages on the basis of juice from the hemp plant. The invention relates to a method for obtaining juice suitable for human consumption from the hemp plant, wherein the complete hemp stem is pressed after harvest without prior drying or retting. The invention further provides a method for obtaining juice from the hemp plant, wherein the upper leafy part of the hemp plant is cut, the leaves are stripped of the remaining stem, fibres and shives being separated from each other at the stem, the leafy part of the stem, the fibres and the shives being pressed individually under pressure and the so obtained pressed juices are being mixed in a controlled manner. In a yet further aspect, the invention relates to a method for the manufacturing of beverages on the basis of juice from the hemp plant, wherein the hemp juice is mixed with yeast and than fermented.

Owner:CLAREMONT COLLECTION HANDELSGMBH +1

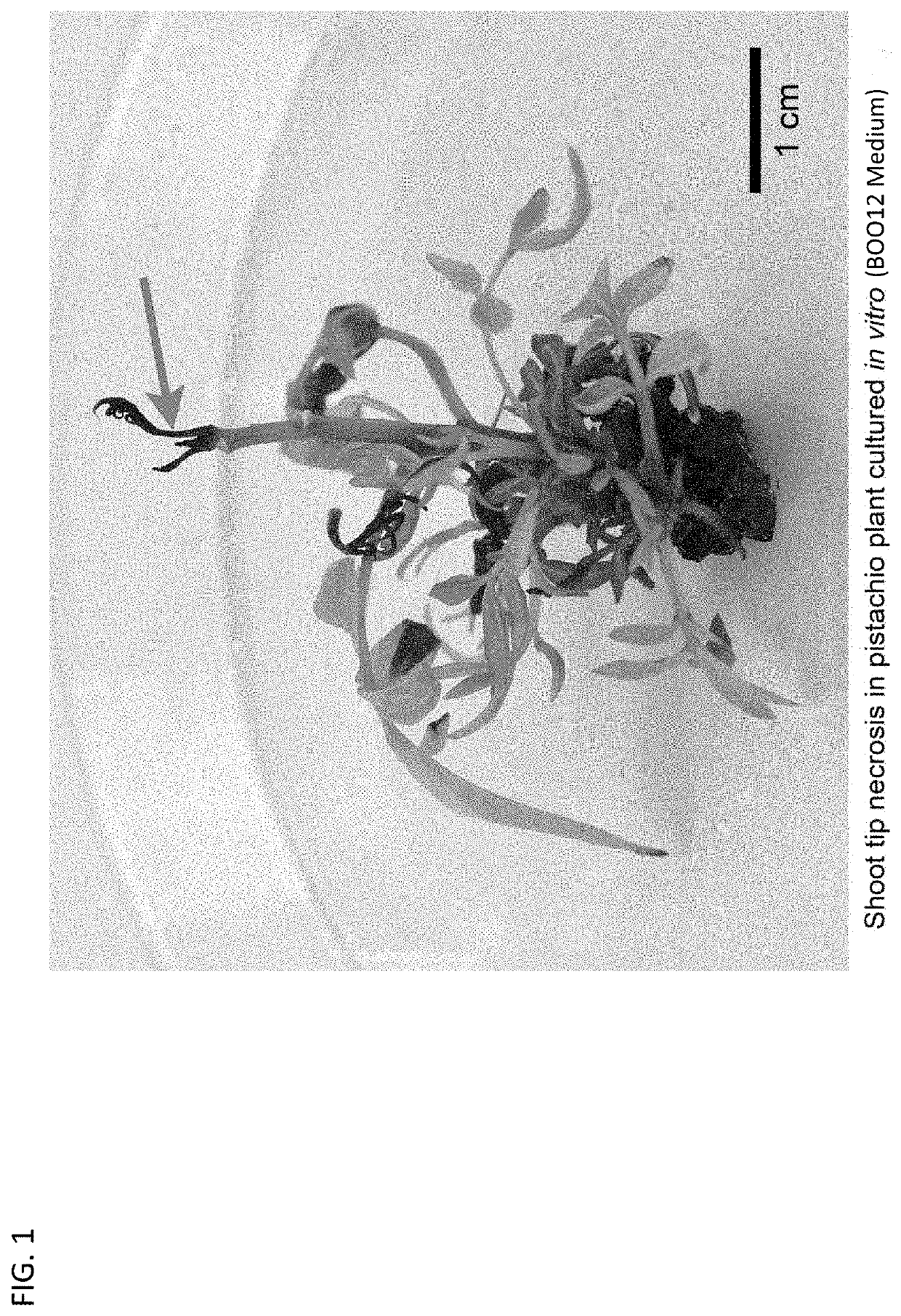

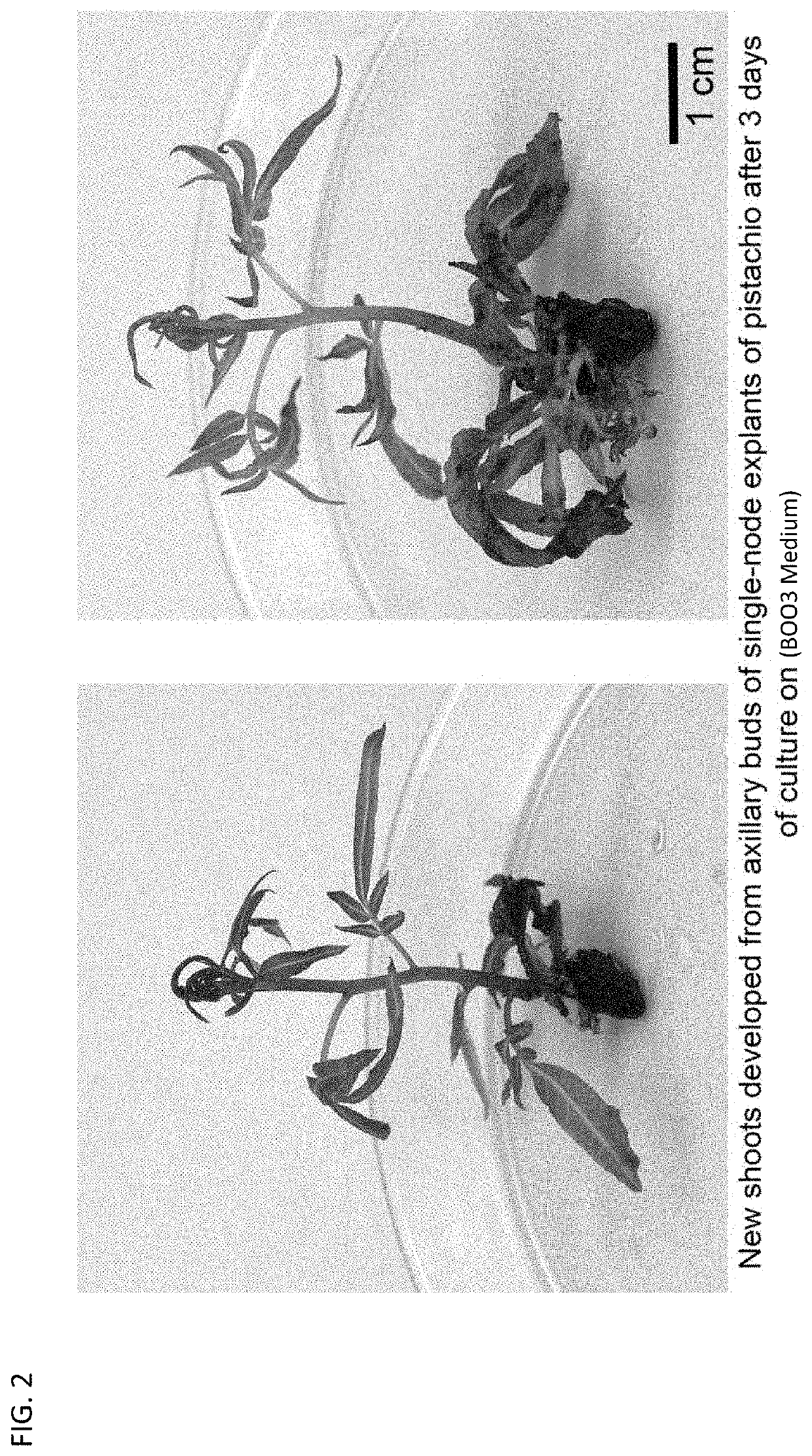

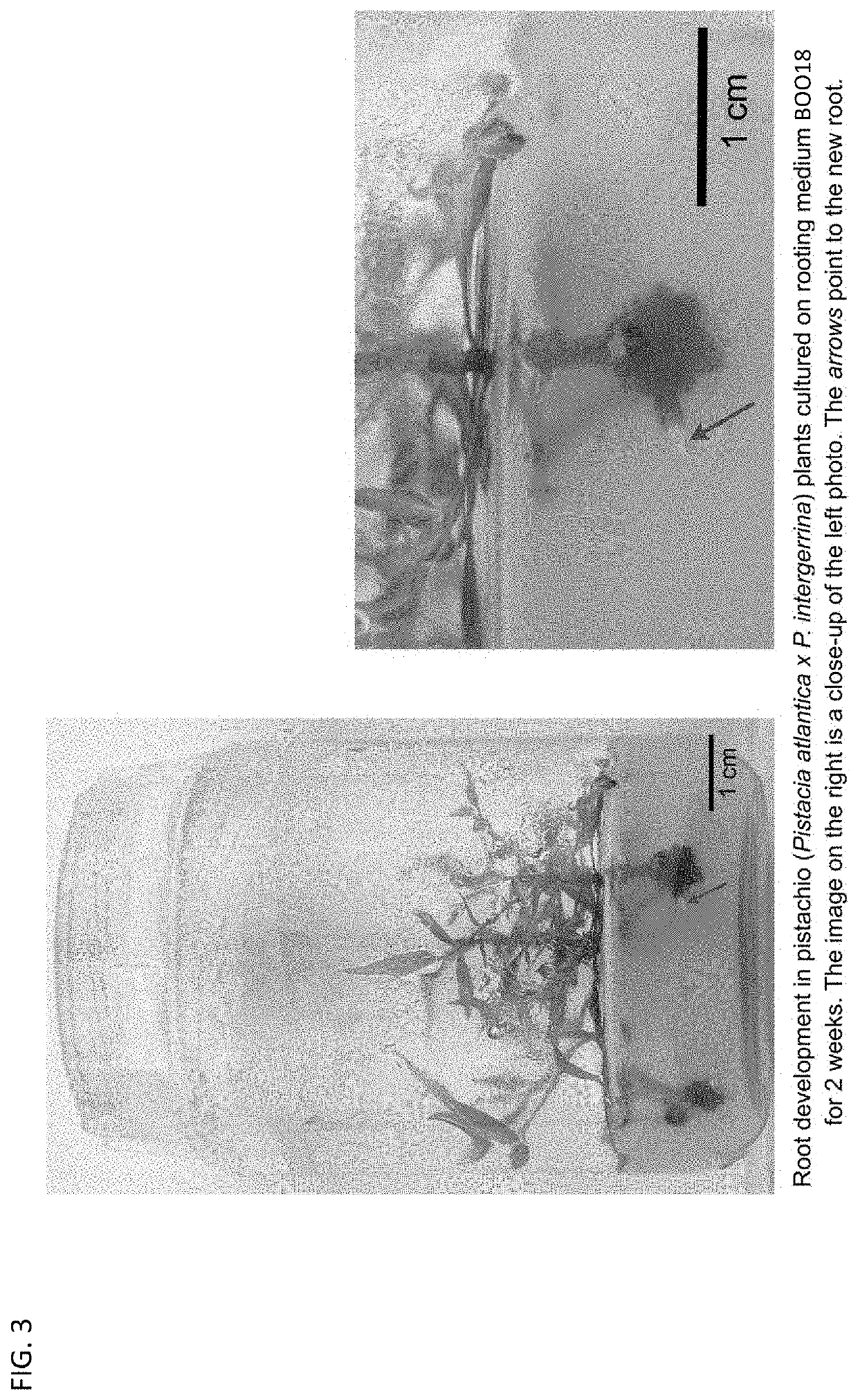

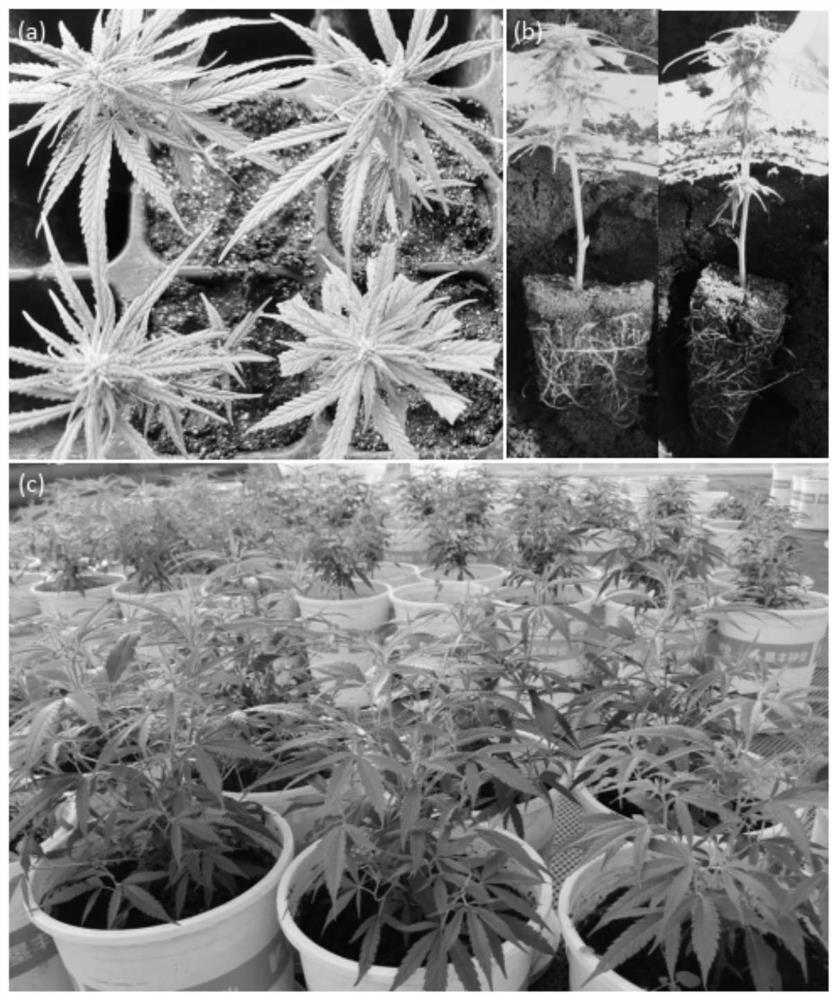

Compositions and methods for large-scale in vitro plant bioculture

InactiveUS20200383331A1Increases quantity and qualityLow costBiocideGrowth substratesBiotechnologyHemp plant

The present invention provides media, kits, systems, and methods for achieving large scale pistachio production within a short time via bioculture, large scale yam production within a short time via bioculture, high multiplication rate of plants including cannabis via in vitro micropropagation, high induction rates of somatic embryos from later buds in bamboo, reduced production of phenolic compounds in plants, high production of virus-free plants, including potato, and large scale hemp production via culturing. The present invention for pistachio and yam production results in shorter tuber development phase and higher yield. In some embodiments, the present invention provides compositions, methods, and systems for the micropropagation and mass production of perennials, grasses, bamboos, cannabis and phyto-pharmaceutical plants as well as hemp plants. In some embodiments, the present invention provides compositions, methods, and systems for reducing the production of a phenolic by a plant, such as bamboo.

Owner:BOOSHOOT

Nonwoven fabrics comprised of individualized bast fibers

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin. The nonwoven fabric can include staple fibers to a lesser extent than the individualized bast fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

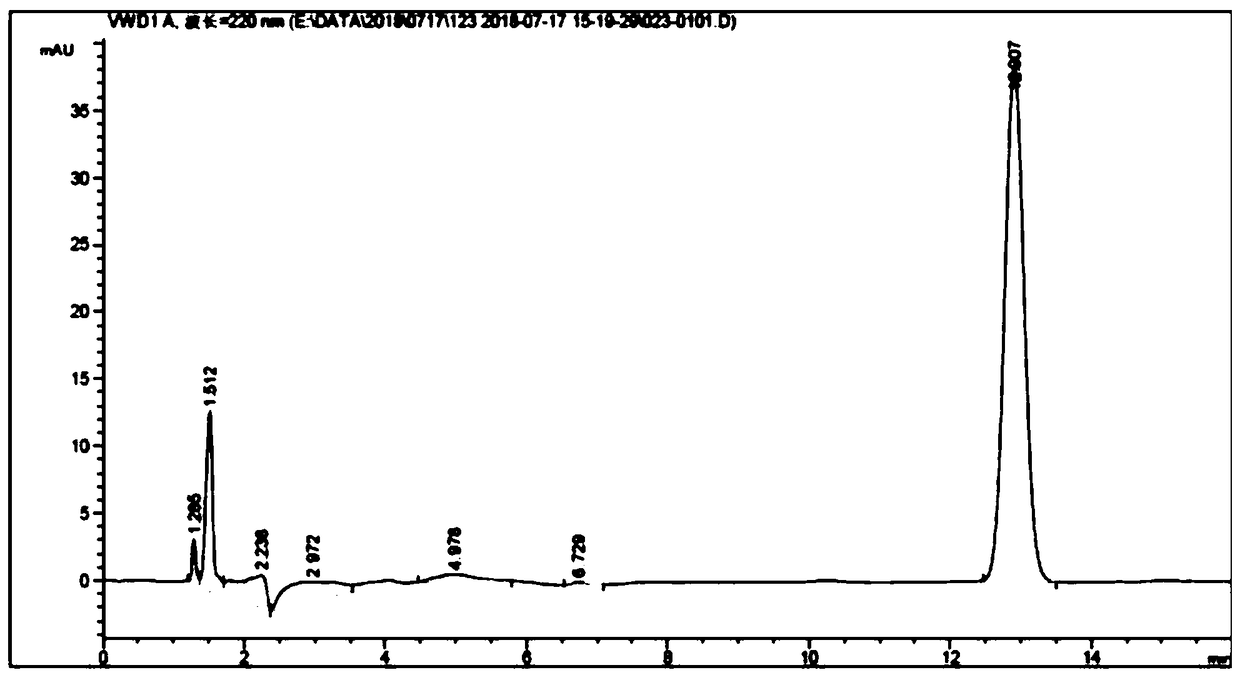

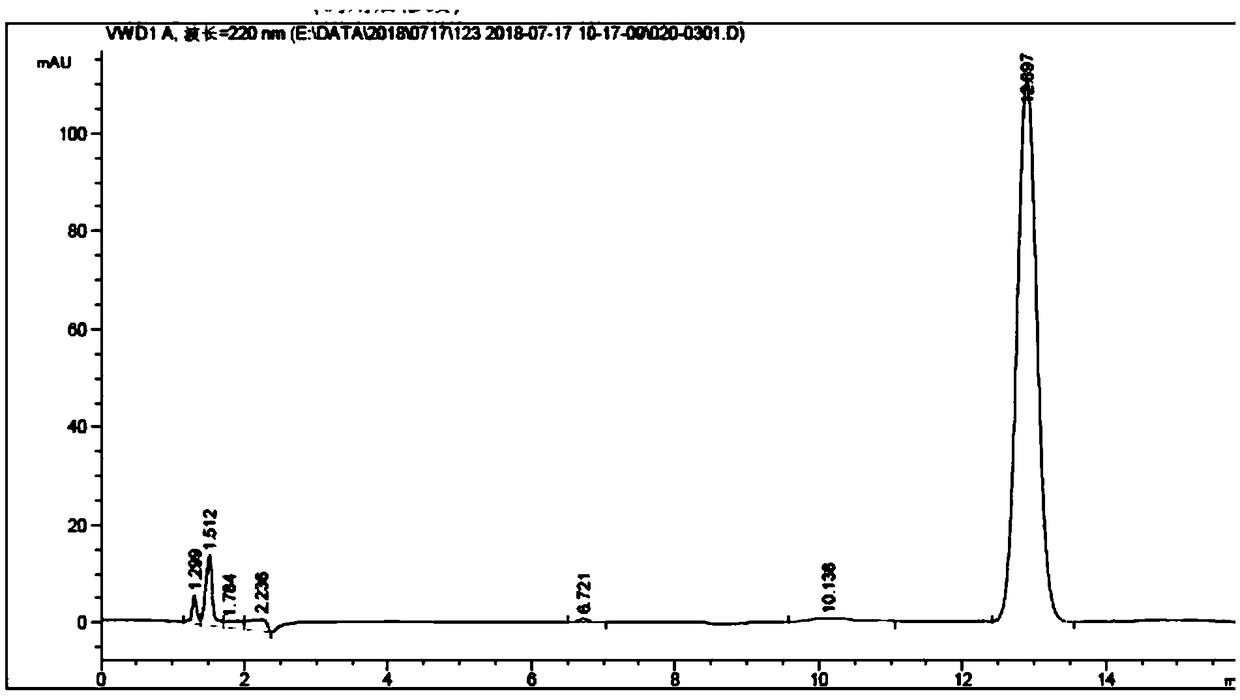

Method for separating and purifying cannabidiol (CBD) by using industrial hemp as raw material

The invention relates to a method for separating and purifying cannabidiol (CBD) by using industrial hemp as a raw material. The method comprises: using more than 1 / 3 of the leaves on the upper ends of industrial hemp plants as raw materials, obtaining an extracting solution by combining tunnel type ultrasonic wave and heating, concentrating in a double-effect rising film concentration tank, settling in a stirring tank, removing the supernatant, carrying out macroporous resin LSA-12 primary chromatography on the precipitation liquid, concentrating, carrying out symmetrical spherical silica gelsecondary chromatography, concentrating, carrying out preparative high-performance liquid phase chromatography, concentrating the eluent, and crystallizing to obtain the CBD with a purity of 90-99.9%. Compared with the method in the prior art, the method of the present invention has characteristics of high CBD purity, high yield, simple process, low cost and easy industrialization.

Owner:HARBIN INST OF TECH

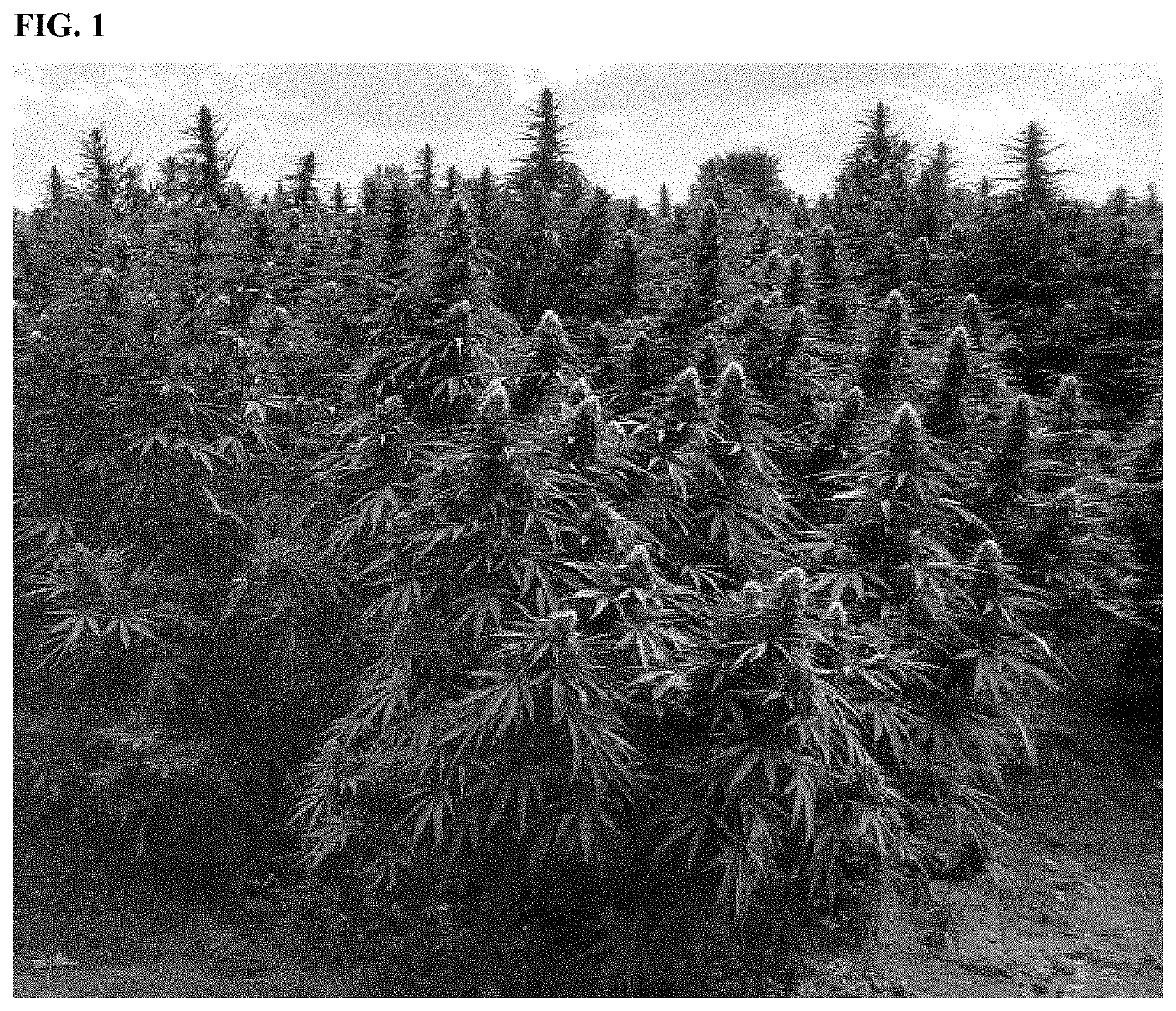

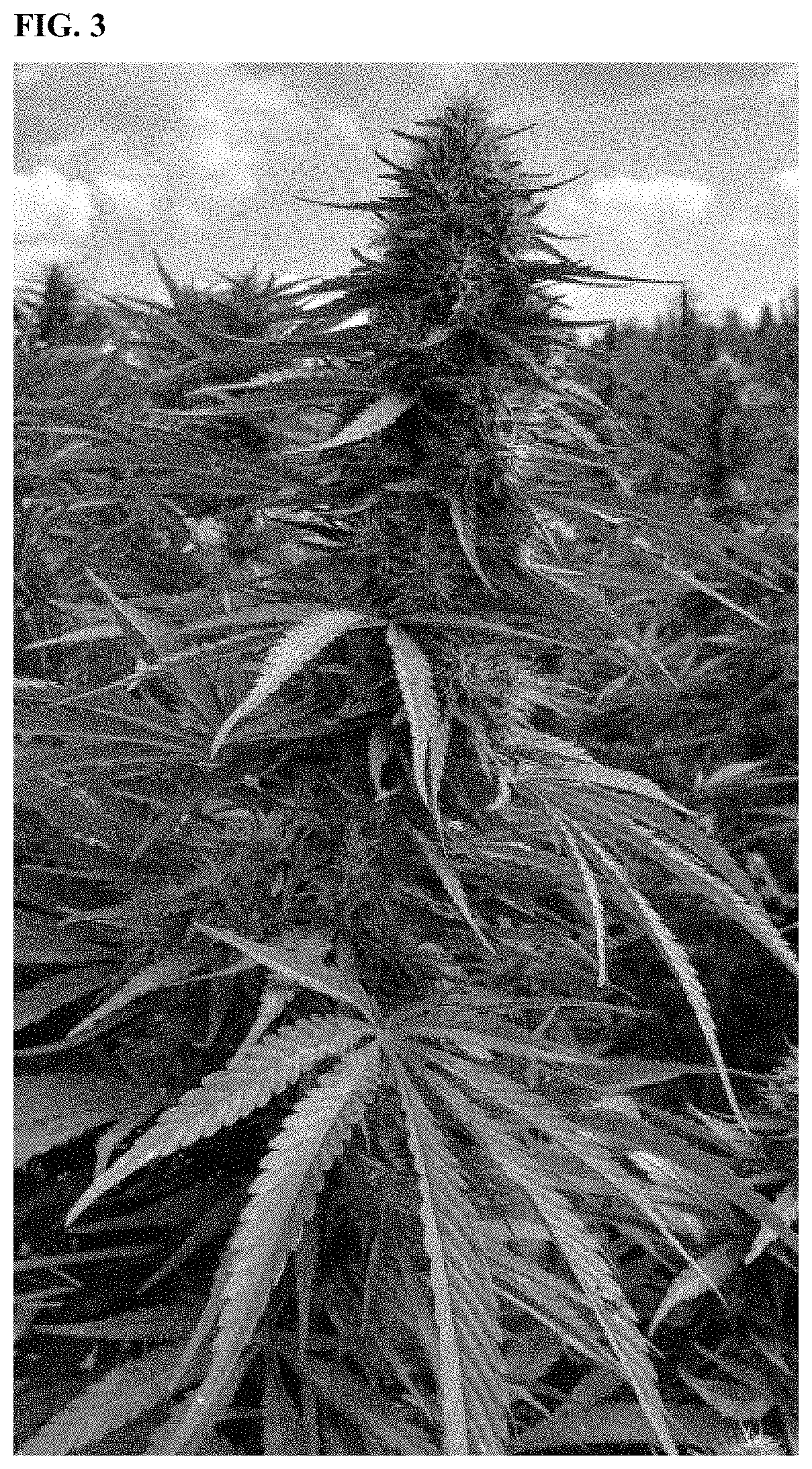

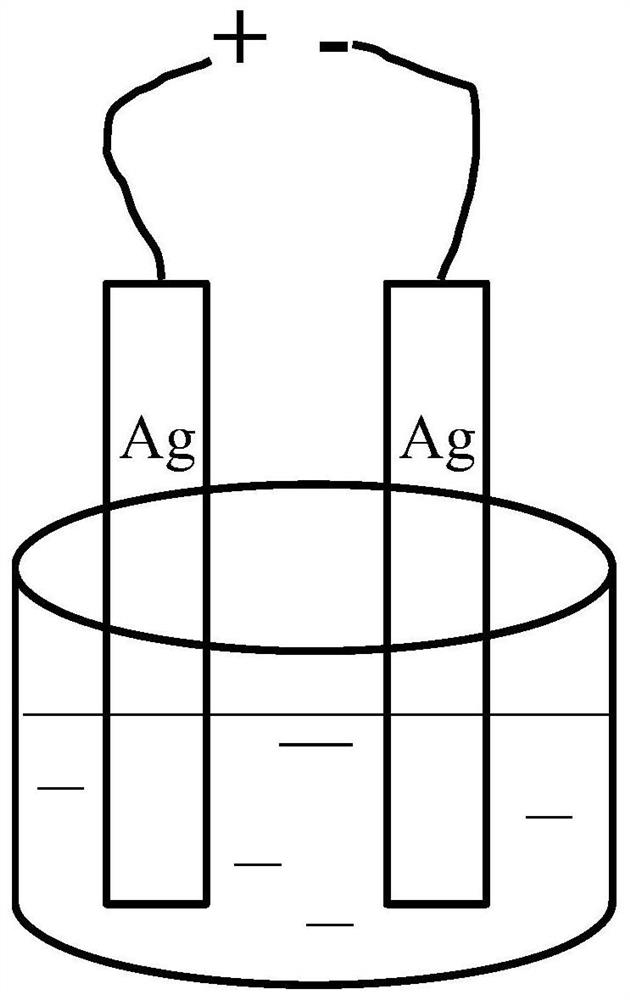

Hemp plant named ‘KIRSCHE’

The present disclosure provides a new and distinct hemp cultivar designated ‘KIRSCHE’. The present disclosure relates to seeds of the hemp plant ‘KIRSCHE,’ to plants and parts of the hemp plant ‘KIRSCHE,’ and to methods for producing a hemp plant by crossing the hemp plant ‘KIRSCHE’ with itself or other Cannabis plants. The disclosure further relates to the morphological and physiological characteristics of the new and distinct hemp cultivar and its uses.

Owner:CHARLOTTES WEB INC

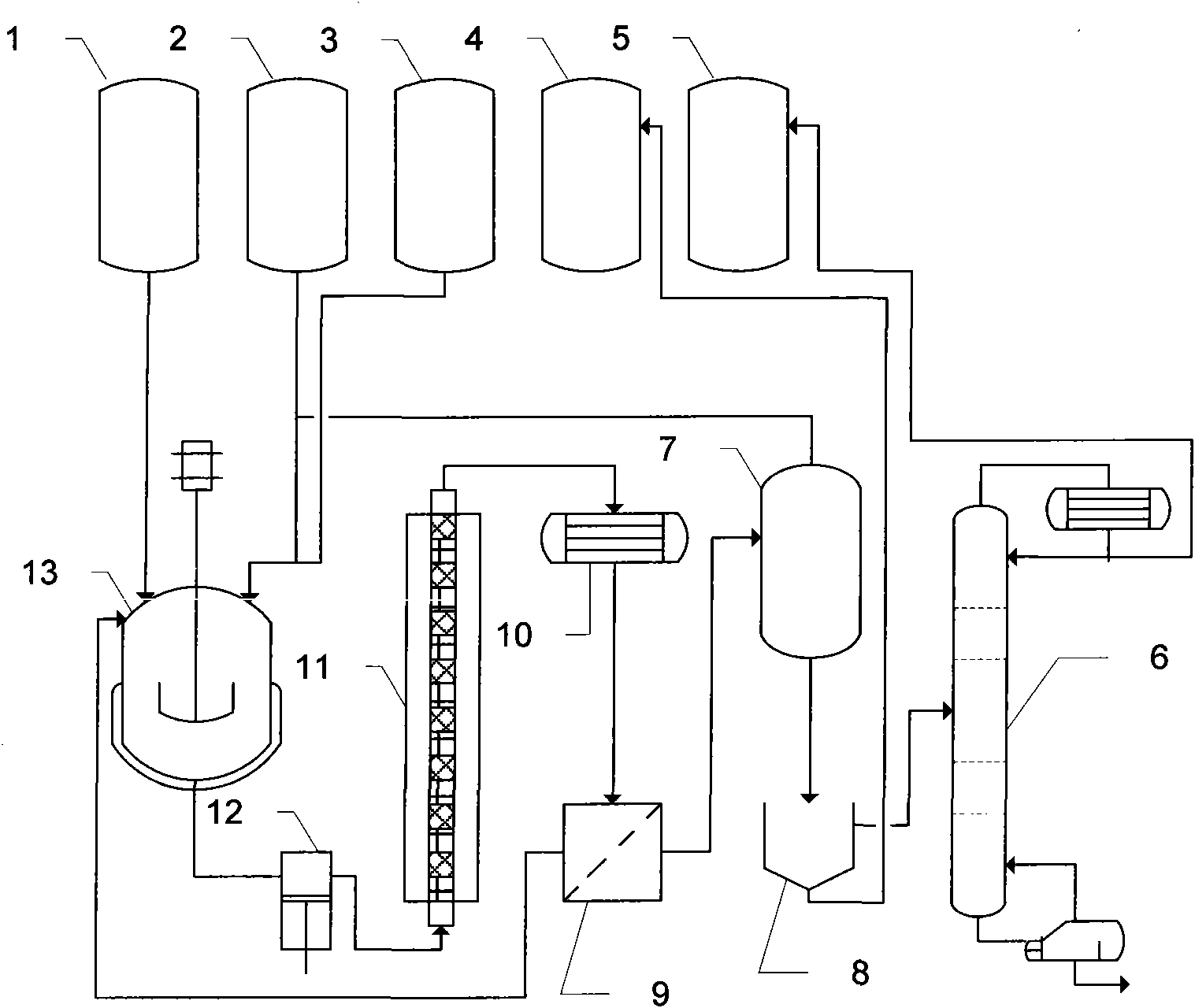

Method for preparing biodiesel from hemp plant oil

InactiveCN101781609ASimple and fast operationSimple processFatty acid esterificationBiofuelsHemp plantBiodiesel

The invention relates to a method for preparing biodiesel from hemp plant oil; and a co-solvent is adopted to fully dissolve alcohol and oil to be homogeneous, is added with a solid catalyst, and is pumped into a tubular reactor to carry out continuous reaction. A static mixer is arranged in the reactor. The reaction temperature is 60 to 300DEG C, the reaction pressure is 1 to 30MPa, the molar ratio of methanol to oil is 3 to 100, the molar ratio of the co-solvent to oil is 1 to 30, the consumption of the catalyst is 0.5 to 5 percent of the mass of the oil, and the reaction time is 10 to 120min. After reaction, through cooling, the catalyst is filtered and recovered, and then enters a flash tank to recover the alcohol and the co-solvent, and crude biodiesel is prepared by staying still and being layered; and after distillation, a biodiesel product is prepared, and the quality yield is more than 95 percent. The process is simple, the reaction can be carried out continuously, the catalyst, the alcohol and the co-solvent can be recycled, the equipment investment is low, and the production cost is low.

Owner:BEIJING GUOLIYUAN POLYMER SCI & TECH R & D CENT

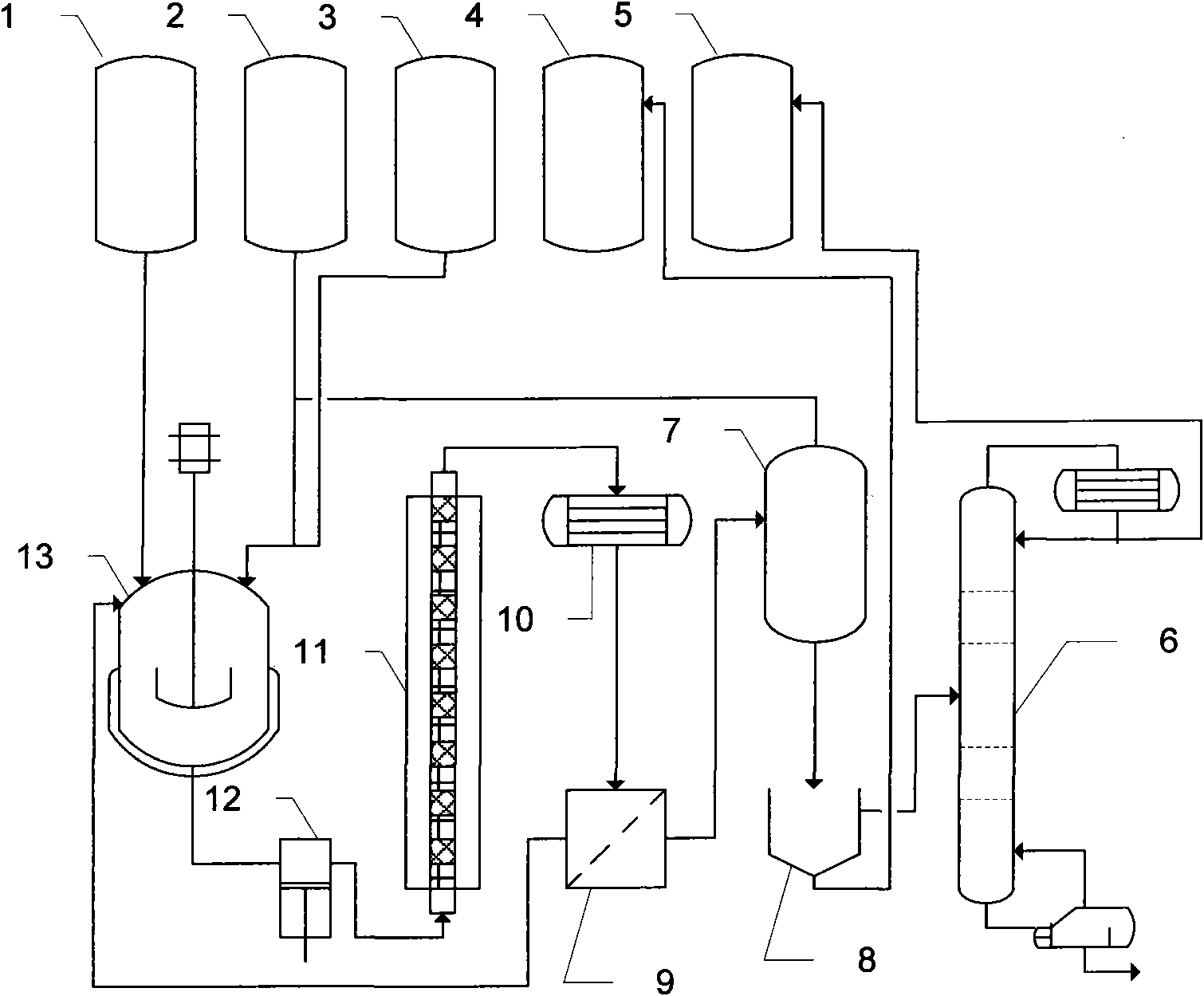

Efficient female method for industrial hemp plants

InactiveCN112655548ANo pollution in the processInduction operation process is simpleBiocidePlant growth regulatorsBiotechnologyHemp plant

The invention discloses an efficient female method for industrial hemp plants. The efficient female method comprises the steps of treating industrial hemp female plants by using nano-silver colloid spray, inducing the industrial hemp female plants to be converted into hermaphrodite plants, differentiating male flower buds, generating fertile pollen, and then freely pollinating and setting seeds to obtain all-female industrial hemp seeds. According to the efficient female method, nano-silver colloid is adopted to induce the plants, the female hemp plants are converted into the hermaphrodite hemp plants, the female plants are forced to generate the fertile pollen to pollinate other female plants, and the pure female (or all-female) industrial hemp seeds with the purity of 96% or above can be obtained. The amount of required colloidal silver solution is small, the induction cost is reduced, the procedure is simplified, and the induced feminization success rate is high and stable.

Owner:HANGZHOU NUOSHEN TECH CO LTD

Hemp paper-pulp and preparing method thereof

InactiveCN101130937AImprove performanceSimple processPretreatment with water/steamDigestersHemp plantRaw material

The present invention discloses a hemp pulp and its preparation method. It is characterized by that it uses hemp plant as raw material, and its preparation method includes the following steps: preparing material, digesting, washing material, beating, removing sand, pulp-making, drying and packing.

Owner:CHTC HELON

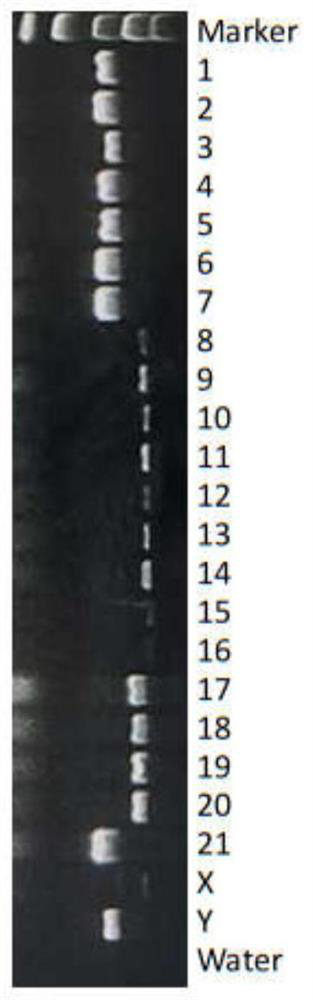

Calcutta hemp InDel molecular marker as well as development method and application thereof

ActiveCN107447018AClear bandHigh polymorphismMicrobiological testing/measurementDNA/RNA fragmentationHemp plantGenetic linkage disequilibrium

The invention relates to the technical field of a molecular marker, in particular to a calcutta hemp InDel molecular marker as well as a development method and application thereof. The molecular markers can be used for identifying the allele polymorphism, identifying identical or relevant calcutta hemp plants, distinguishing the calcutta hemp plants and studying the genetic diversity in populations. The molecular marker can also be used for using inheritance and phenotype study of a statistical method, such as linkage analysis, QTL positioning, genealogy confirmation, population genetic polymorphism study, association mapping and linkage disequilibrium; the information can be used for calcutta hemp plant propagation and / or selection.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

Hemp harvester

A method and device for harvesting plants belonging to the family of hemp plants (Cannabaceae), in particular of the genus Hemp, with which the harvesting and separation of the individual plant parts is made possible without damaging the individual plant parts. In particular, during harvesting, the hemp stems are pulled downwards by a pair of rollers and the flowers are pulled backwards through a chain gap, whereby the flowers are stripped from the stems.

Owner:WIEKER HEINRICH

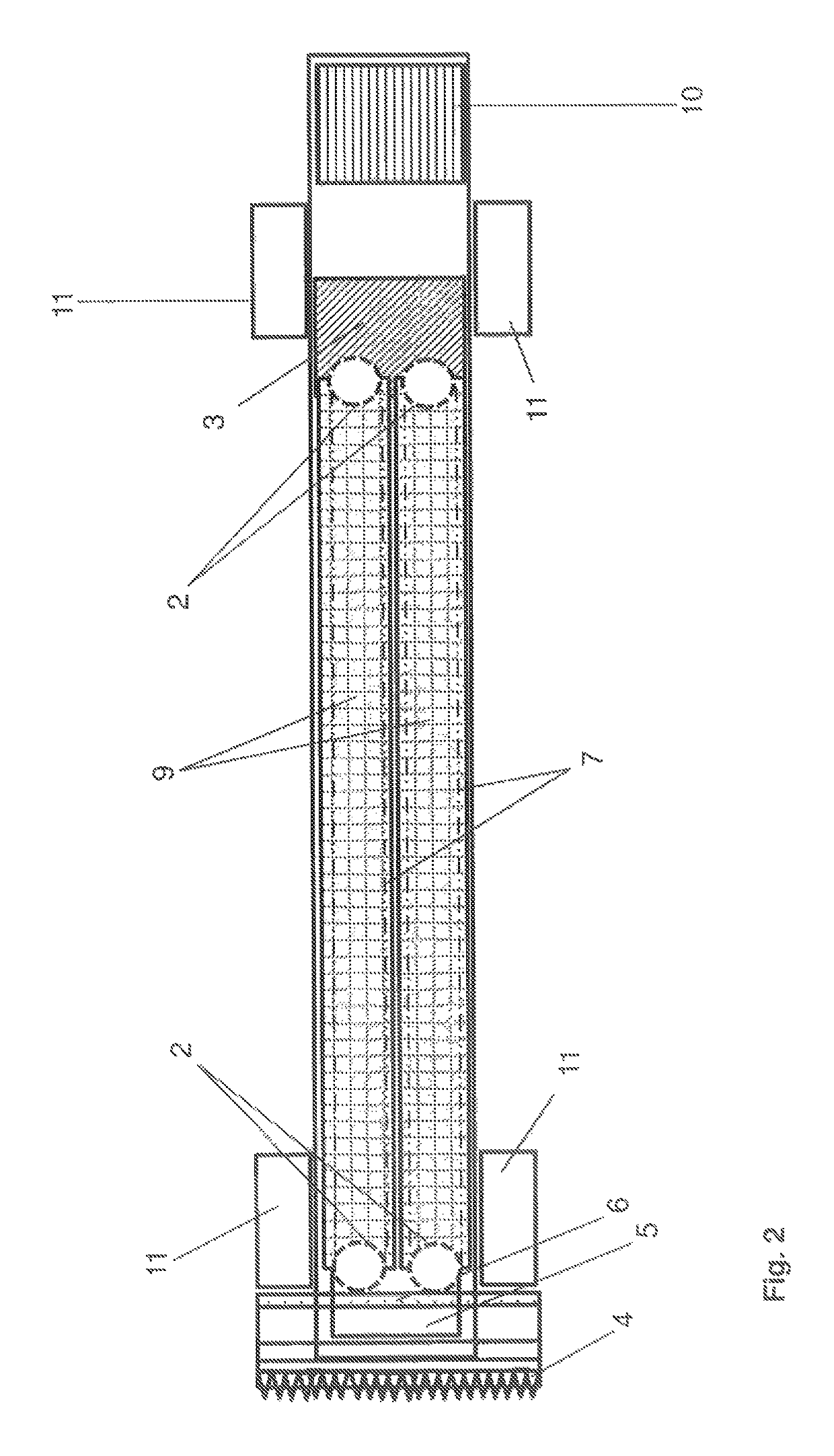

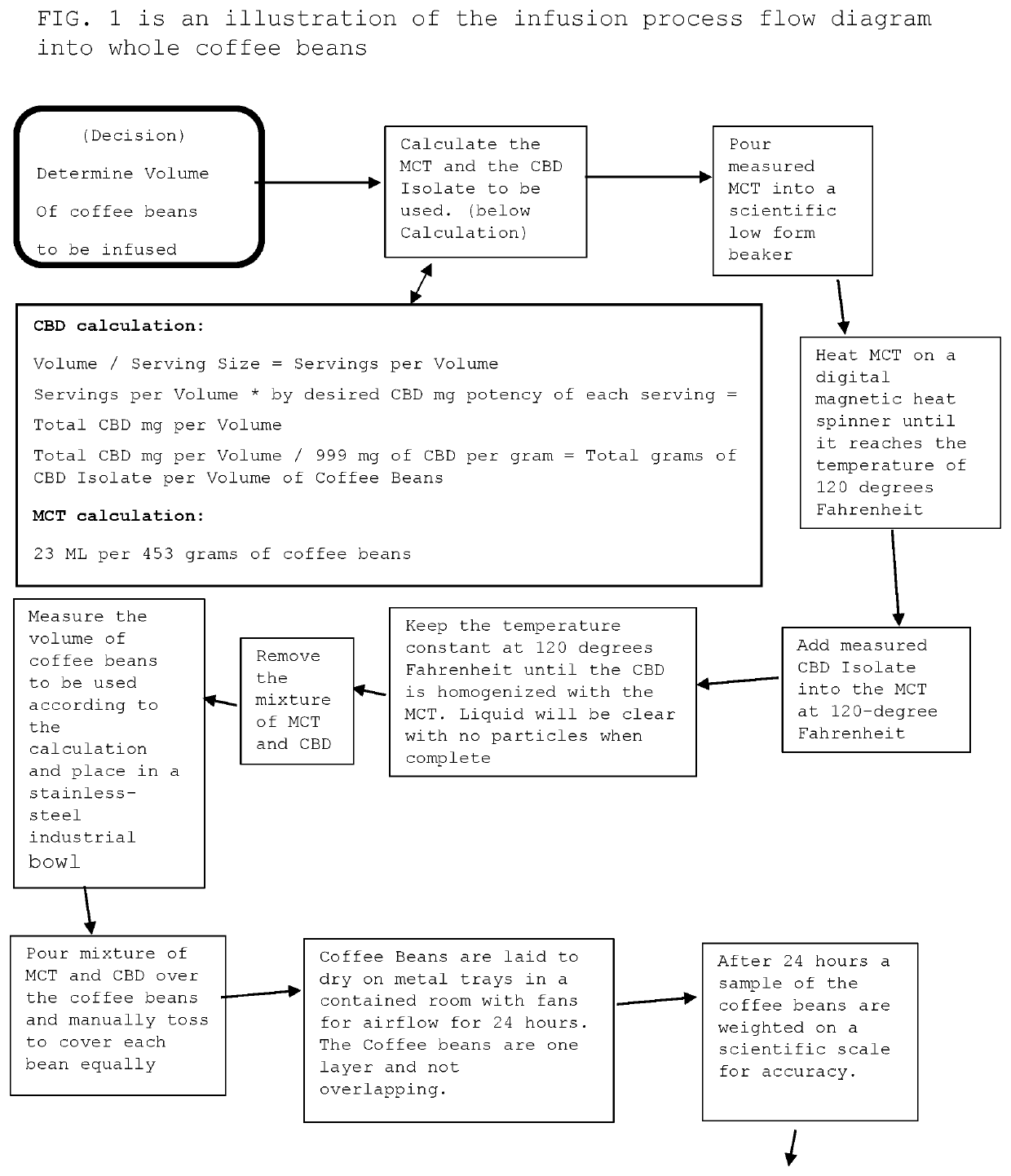

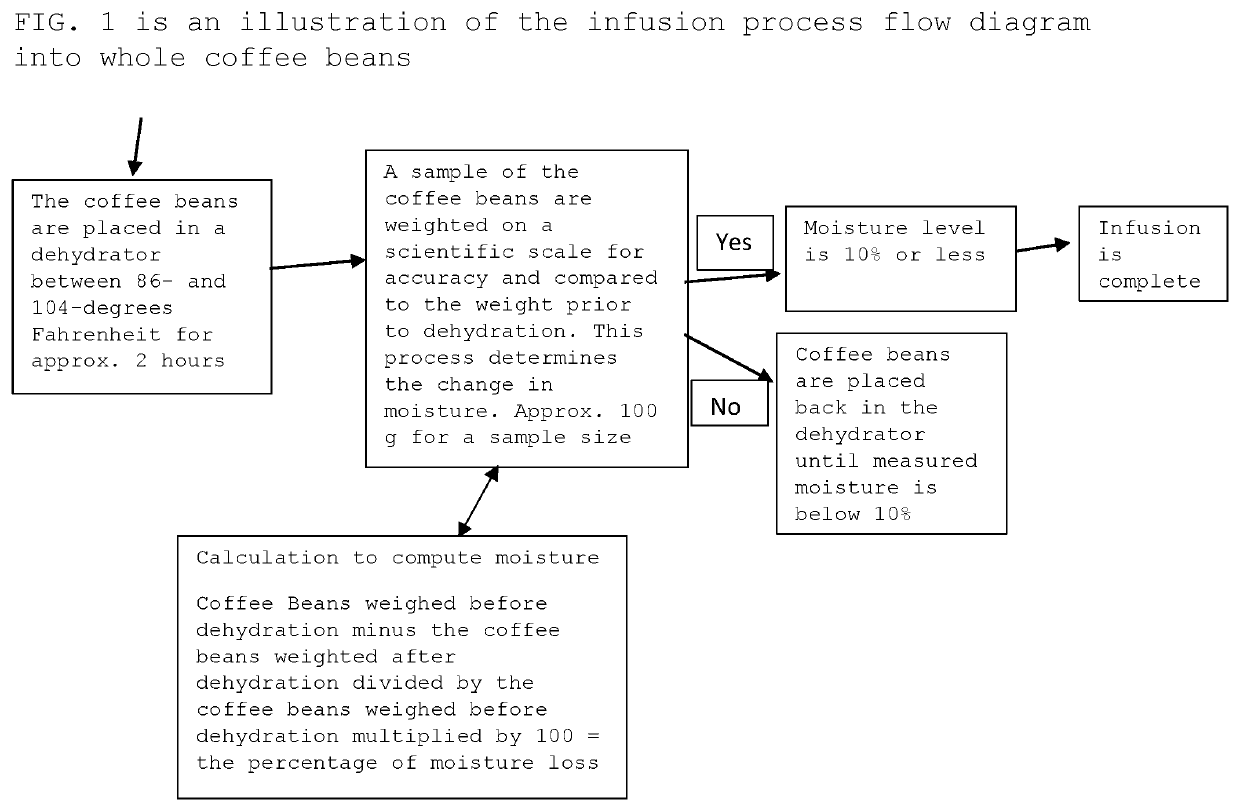

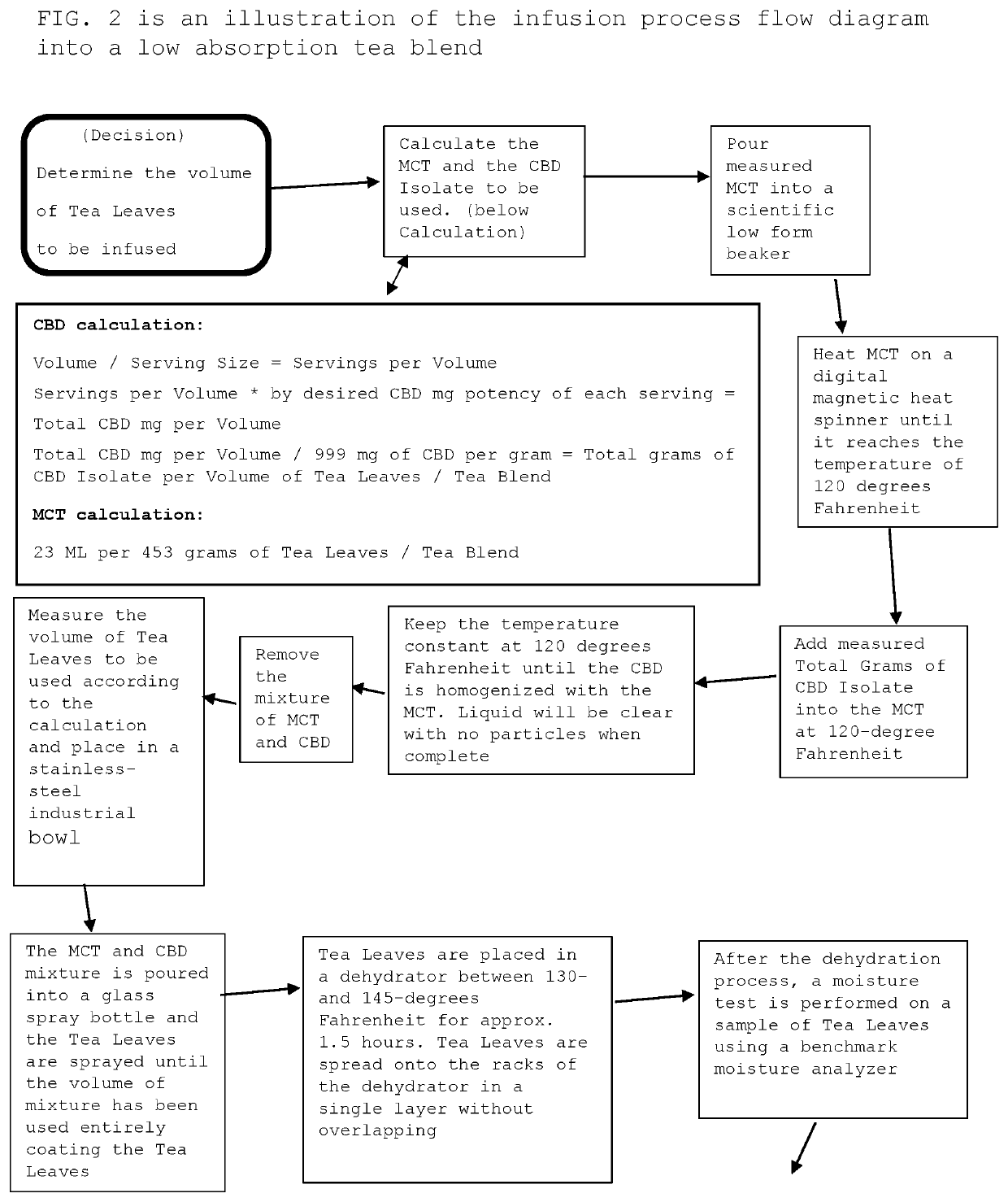

Method for infusing whole coffee beans and Tea Leaves with cannabis (Hemp) ingredients

InactiveUS20200155479A1Support healthy cholesterol levelImprove brain functionHydroxy compound active ingredientsPharmaceutical delivery mechanismHemp plantCannabidiol

Methods of infusing whole coffee beans and tea leaves or tea blends containing cannabinoids that are extracted from Cannabis / Hemp plant. According to one embodiment, the method includes the steps of (a) extracting cannabinoids from the Cannabis / Hemp plant into an isolate powder form; and (b) infusing the isolate powder form cannabinoids into whole coffee beans or tea leaves / blends. The disclosed methods produce coffee and tea beverages that possess wellness benefits associated with coffee beans, tea and cannabinoids extracted from the Cannabis / Hemp plant. The claimed method of infusing coffee beans and tea leaves with CBD (Cannabidiol) that contains a consistent milligram of CBD (Cannabidiol) in each measurement of 5 mg to 100 mg as well as maintain a shelve life without the microbial bacteria growth. Further, the coffee bean can be ground to be used as espresso or traditional drip brew and the tea leaves can be steeped or chilled for human consumption.

Owner:HACKNEY DAWN ANNETTE

Method of obtaining hemp plant juice and use of same for the production of beverages

The present invention relates to a method for producing beverages on the basis of juice from the hemp plant. Leaves and bloom of the hemp plant have previously been processed to ethereal hemp oils by water steam distillation. Hemp seeds are an indispensable part of bird feeding. Hemp oil can also be obtained from the hemp seeds. Hemp fibres are separated from the stems by breaking or milling of the stems. Depending on the lengths of the obtained fibre, coarse fleece or fine cellulose is produced. A common application is as sealing material of pipe threads. The invention relates to a method for obtaining juice suitable for human consumption from the hemp plant, wherein the complete hemp stem is pressed after harvest without prior drying or retting.; The invention further provides a method for obtaining juice from the hemp plant, wherein the upper leafy part of the hemp plant is cut, the leaves are stripped of the remaining stem, fibres and shives being separated from each other at the stem, the leafy part of the stem, the fibres and the shives being pressed individually under pressure and the so obtained pressed juices are being mixed in a controlled manner. In a yet further aspect, the invention relates to a method for the manufacturing of beverages on the basis of juice from the hemp plant, wherein the hemp juice is mixed with yeast and than fermented.

Owner:CLAREMONT COLLECTION HANDELSGMBH +1

Hemp plant named ‘CW1AS1’

The present disclosure provides a new and distinct hemp cultivar designated ‘CW1AS1’. The present disclosure relates to seeds of the hemp plant ‘CW1AS1,’ to plants and parts of the hemp plant ‘CW1AS1,’ and to methods for producing a hemp plant by crossing the hemp plant ‘CW1AS1’ with itself or other cannabis plants. The disclosure further relates to the morphological and physiological characteristics of the new and distinct hemp cultivar and its uses.

Owner:CHARLOTTES WEB INC

Nonwoven fabrics of short individualized bast fibers and products made therefrom

Nonwoven textile fabrics in accordance with the present invention are formed primarily of individualized bast fibers substantially free of pectin having a mean length less than 6 millimeters. The nonwoven fabric can include staple fibers and / or pulp fibers. Individualized bast fibers include fibers derived from the flax and hemp plants. The nonwoven textile fabric is formed into a web while in a dry state and subsequently bonded to produce a nonwoven fabric.

Owner:GPCP IP HLDG LLC

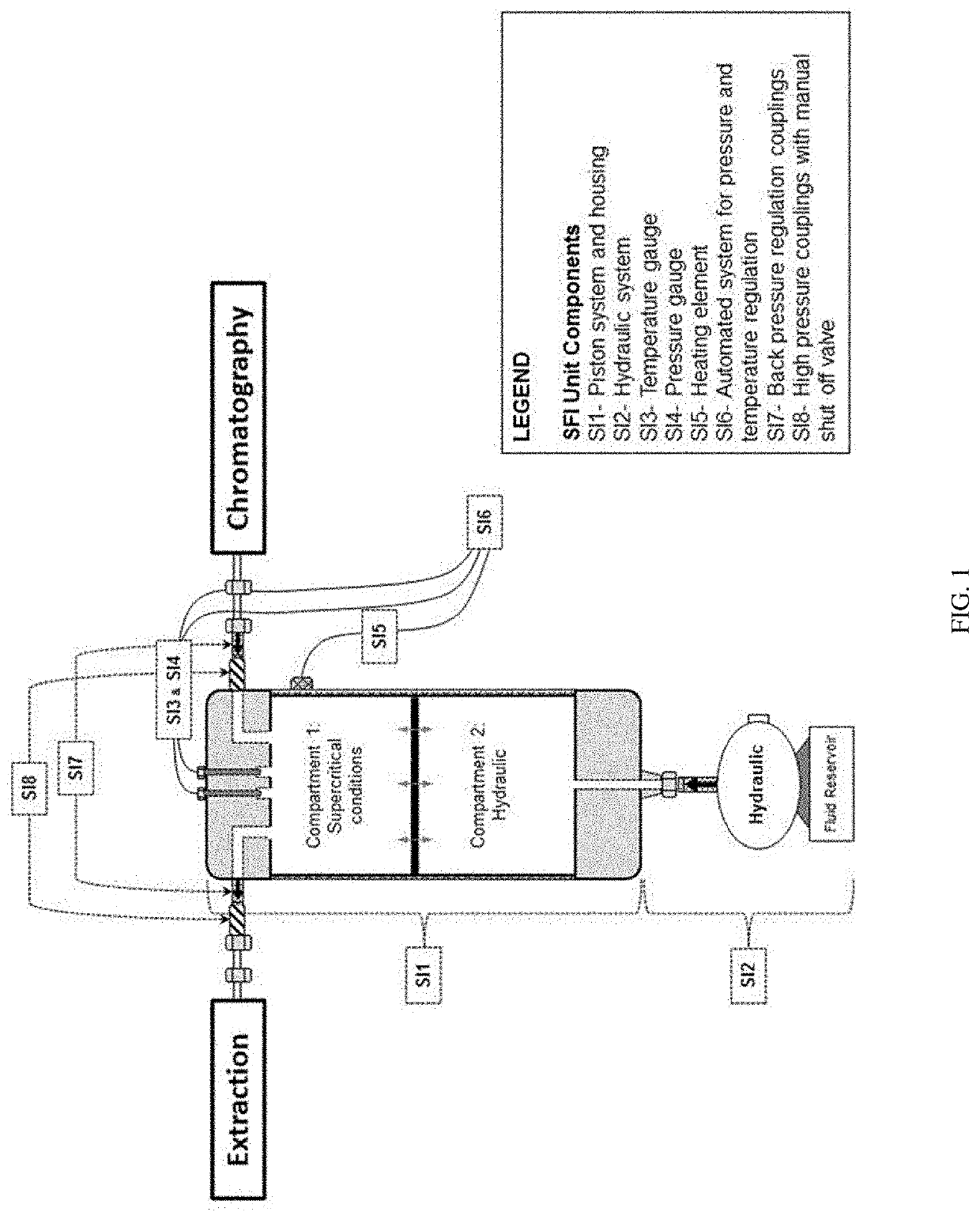

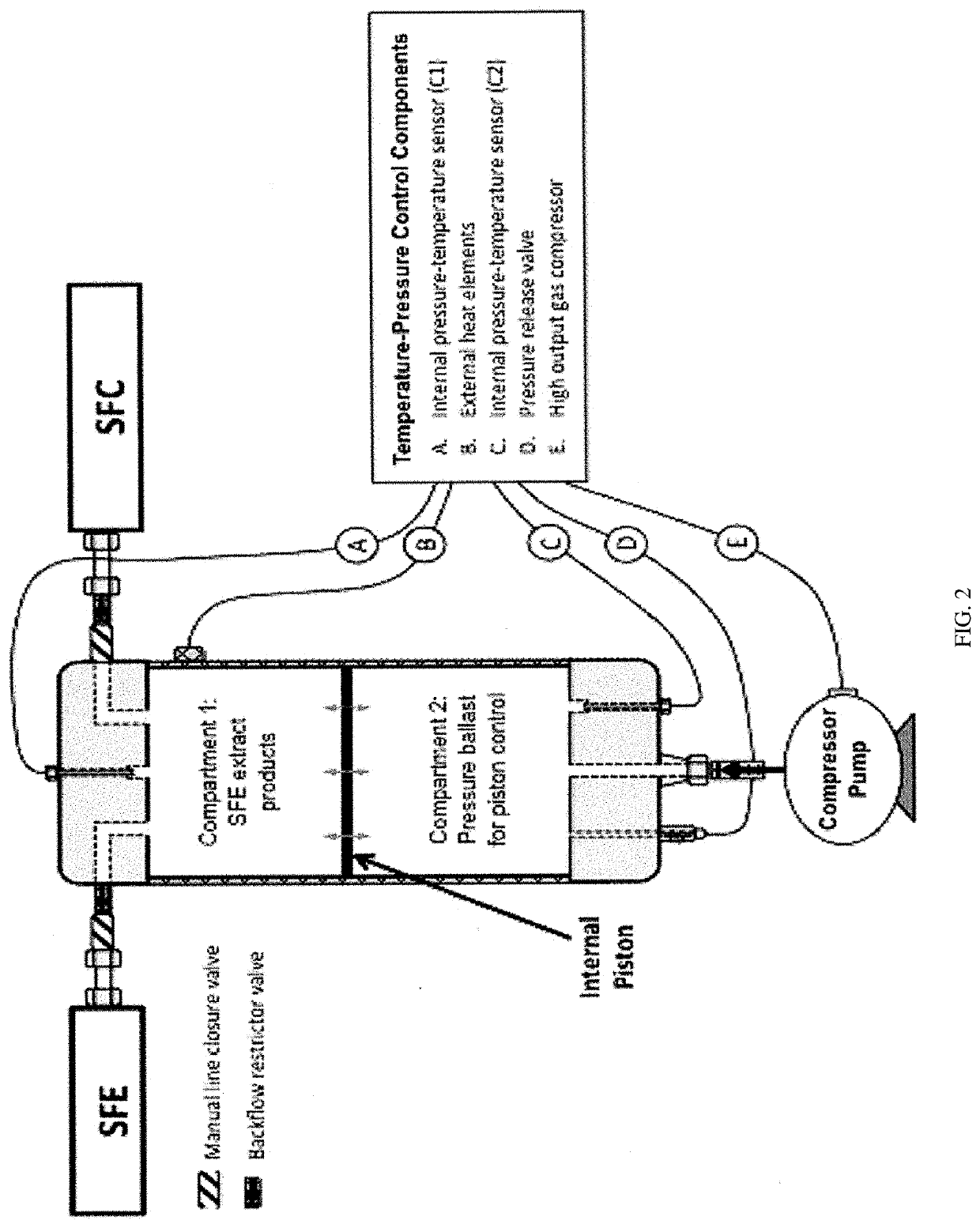

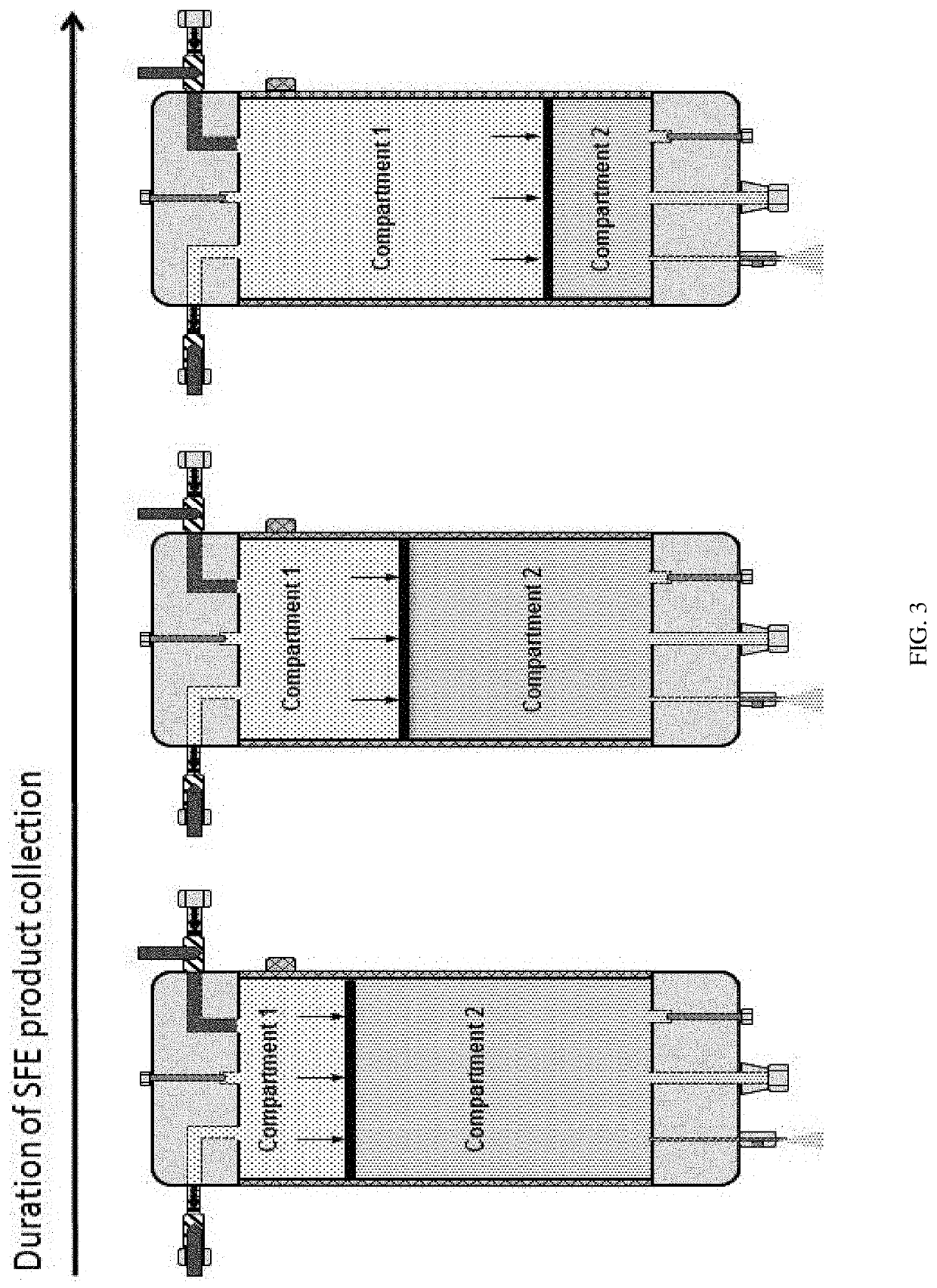

Dynamic interface system and its application in supercritical fluid extraction and chromatography

ActiveUS20210039013A1Eliminate depressurization-dissolution-repressurizationOrganic compound preparationSolid sorbent liquid separationChromatographic separationHemp plant

The present invention provides a dynamic interface system between an extraction device and a chromatographic purification device for separating and purifying substance(s) from a mixture or matrix. One embodiment is the Supercritical Fluid Interface (“SFI”) between Supercritical Fluid Extraction (“SFE”), and Supercritical Fluid Chromatography (“SFC”). The SFI is capable of interfacing; gas, subcritical and supercritical fluid extraction methods and pair with gas, subcritical and supercritical fluid chromatography technologies that operate within the pressure and temperature parameters of the SFI. The SFI can operate up to 200 degrees celsius and 5000 psi. This interface technology allows for an inline oil extraction and chromatographic separation, the SFI can pair extraction and chromatography with the same solvent in different mobile phases, whereas the extraction can be performed using CO2 as a solvent in sub-critical phase and the SFI can receive the subcritical solution and then increase pressure and / or temperature to achieve supercritical state as required for injection into supercritical fluid chromatography technologies. The SFI coupling between SFE and SFC can to extract and refine cannabinoids from the cannabis industrious, hemp, plant and can also be applied to improve efficiency in an industry that extracts and refines oils, through chromatography, from organic materials using a gas, or sub / supercritical fluid as a solvent and mobile phase.

Owner:CORNERSTONE TECH

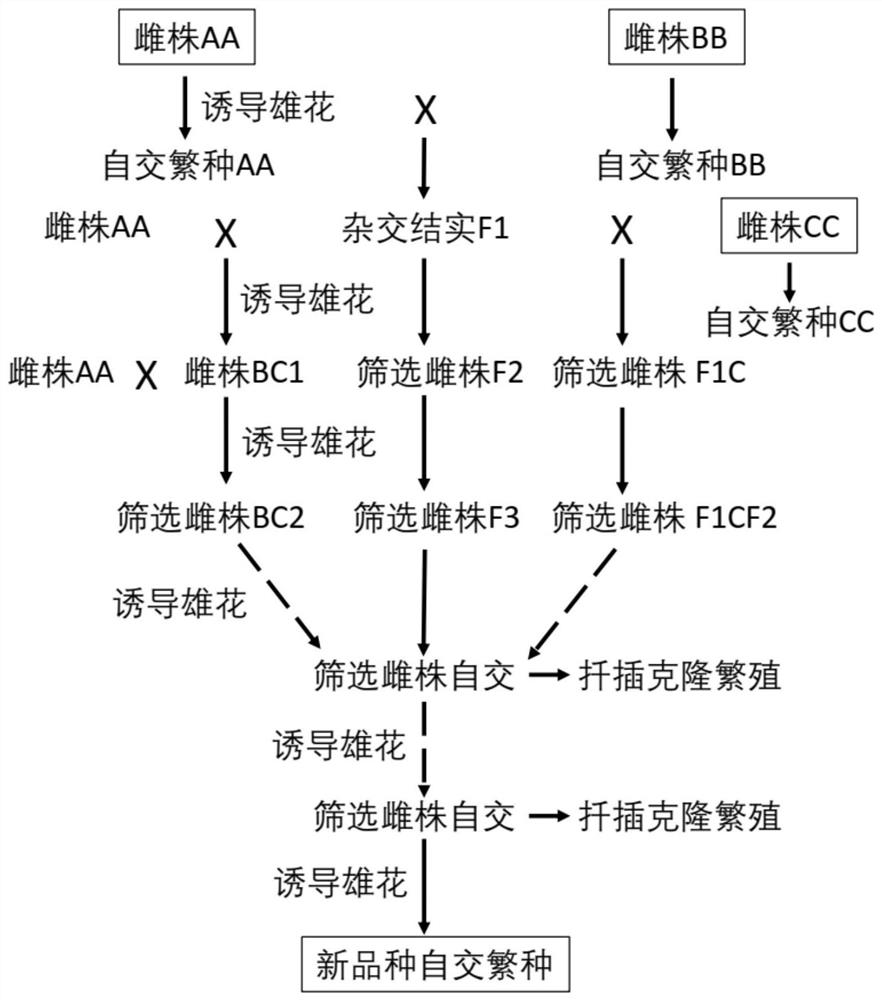

Parthenocarpy breeding method of industrial hemp and application of parthenocarpy breeding method

InactiveCN112841023AEliminate distractionsGood characterPlant genotype modificationBiotechnologyHemp plant

The invention relates to the technical field of breeding, in particular to a parthenocarpy breeding method of industrial hemp and application of the parthenocarpy breeding method. The breeding method of the industrial hemp comprises the following steps: firstly inducing female plants to generate male flowers, carrying out cross seed set on the female plants of different varieties of hemp once, and mixing genetic materials of two parents; and then screening female single plants integrating excellent characters of the two parents in the filial generation, inducing male flowers to be subjected to selfing or backcross fruiting, and then repeatedly conducting multi-generation screening and selfing or backcross till the hemp variety uniform in character and stable in heredity is obtained. According to the method, a key technology for inducing female hemp plants to generate fertile male flowers and disperse pollen is developed, normal seeds capable of germinating are generated after unisexual selfing of the female plants, female plant selfing breeding and seed reproduction of the hemp are achieved, all progenies are female plants, all genetic materials of single-plant maternal female plants are kept, and the bottleneck problems of variety shortage and difficult breeding in industrial hemp production are fundamentally solved.

Owner:北大荒垦丰种业股份有限公司

Sisal hemp-plant leaf cream production method

InactiveCN106421203AHigh yieldShorten the fermentation cyclePlant ingredientsLeuconostoc mesenteroidesHemp plant

The invention relates to a sisal hemp-plant leaf cream production method. According to the production method, sisal hemp-plant leaves are produced into fibers to obtain sisal hemp-plant leaf juice, the juice is fermented, sediments are collected, leuconostoc mesenteroides, acclimated ethyl alcohol candida and lactobacillus delbrueckii are mixed to prepare fermentation inoculants for fermenting, acclimation is performed by the aid of a gradual acclimation method, the proportion of sisal hemp-plant leaf juice in acclimation culture solution is gradually increased, and the ethyl alcohol candida and the lactobacillus delbrueckii are respectively and gradually inoculated into high-proportion culture solution from low-proportion culture solution to obtain the acclimated ethyl alcohol candida and the acclimated lactobacillus delbrueckii. According to the method, a fermentation period is shortened to 4-5 days, yield of the sisal hemp-plant leaf cream is greatly improved, diosgenin content is improved by 20-30%, and difficulties further extracting diosgenin are reduced. The method changes a traditional production mode and solves the problem that a traditional method is large in occupied area, long in settlement period, low in diosgenin content and the like.

Owner:INST OF BAST FIBER CROPS CHINESE ACADEMY OF AGRI SCI

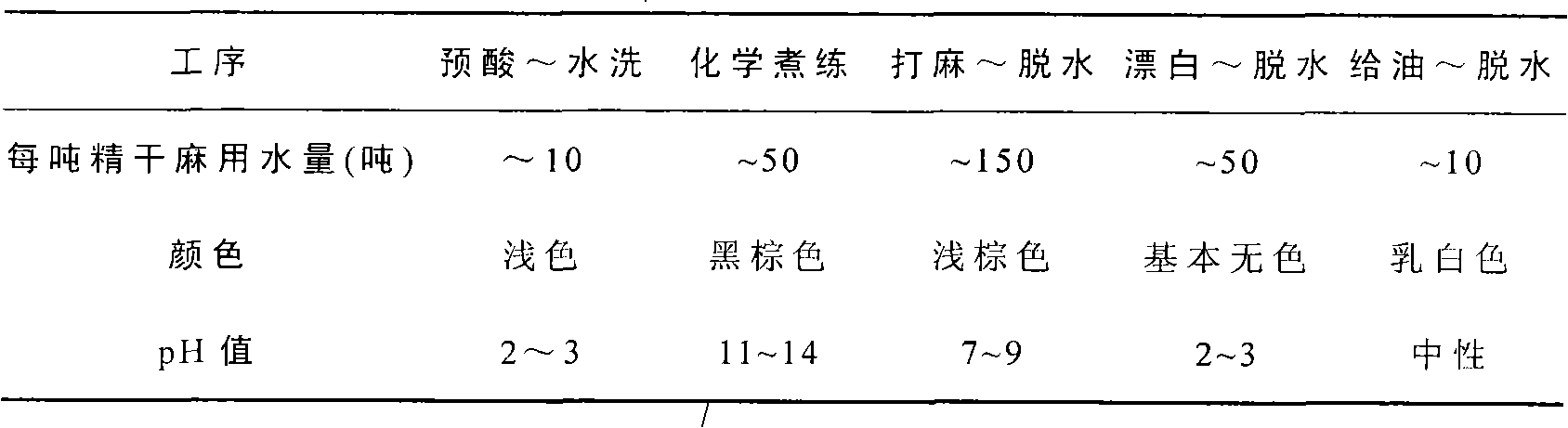

Low-alkali degumming process for hemp plants at room temperature

InactiveCN101775665ASimple processBig investmentFibre treatment to obtain bast fibreHemp plantWastewater

The invention relates to a low-alkali degumming process for hemp plants at room temperature, and belongs to the field of primary textile processing. The process is characterized by changing a ramie degumming process into a low-alkali soaking process at room temperature and comprising the following steps of performing pretreatment on raw ramie, soaking the raw ramie into alkali at room temperature, stamping the ramie, dehydrating, feeding oil, dehydrating, drying and degumming to obtain degummed ramie. The degumming process has the advantages of simpleness due to primary low-alkali soaking at room temperature, small and safe equipment investment, low energy consumption, low pollution due to low using amount of chemical agent, simple waste water treatment due to low chromaticity of degumming waste water and degumming uniformity and good whiteness of the obtained degummed ramie.

Owner:WUHAN TEXTILE UNIV

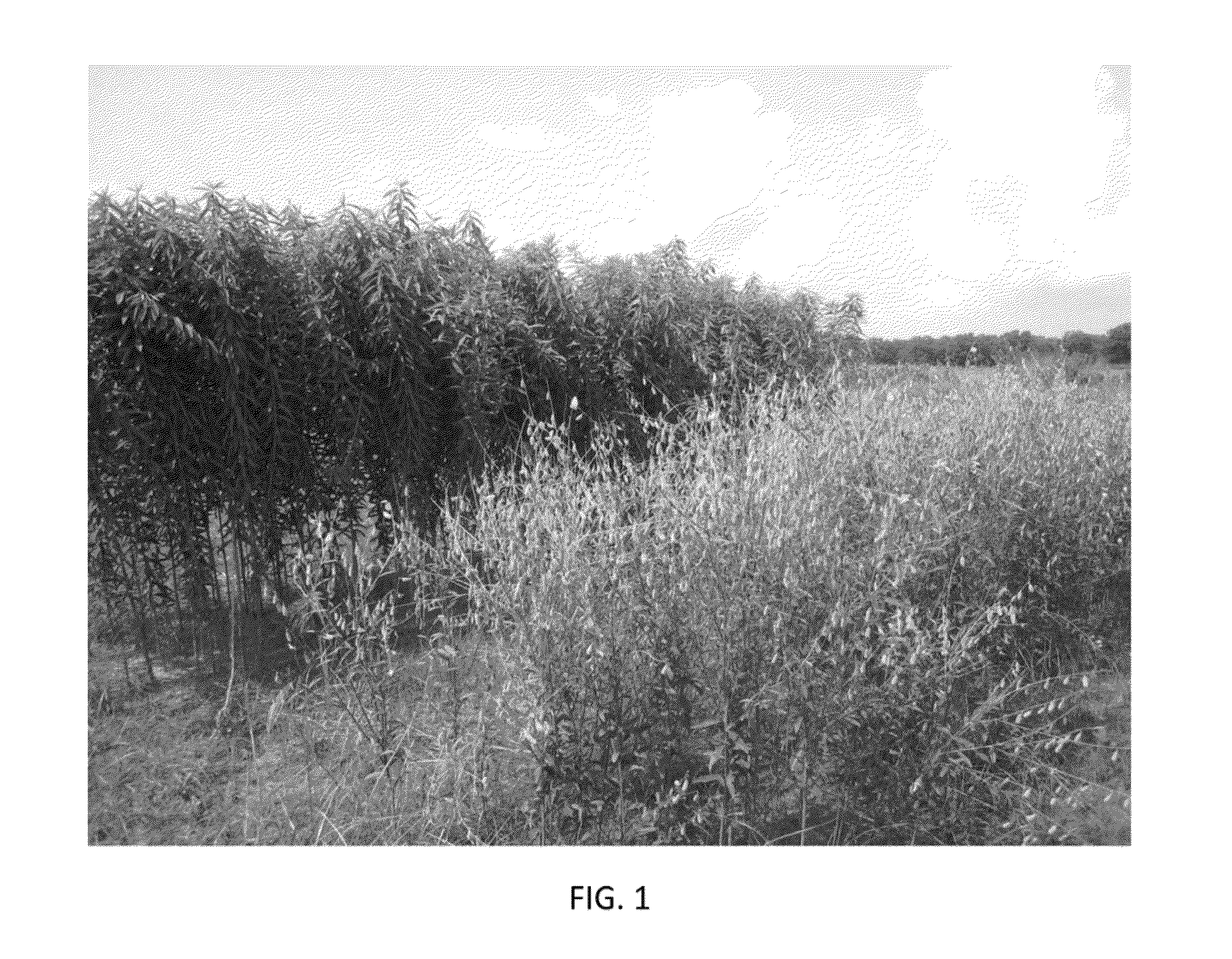

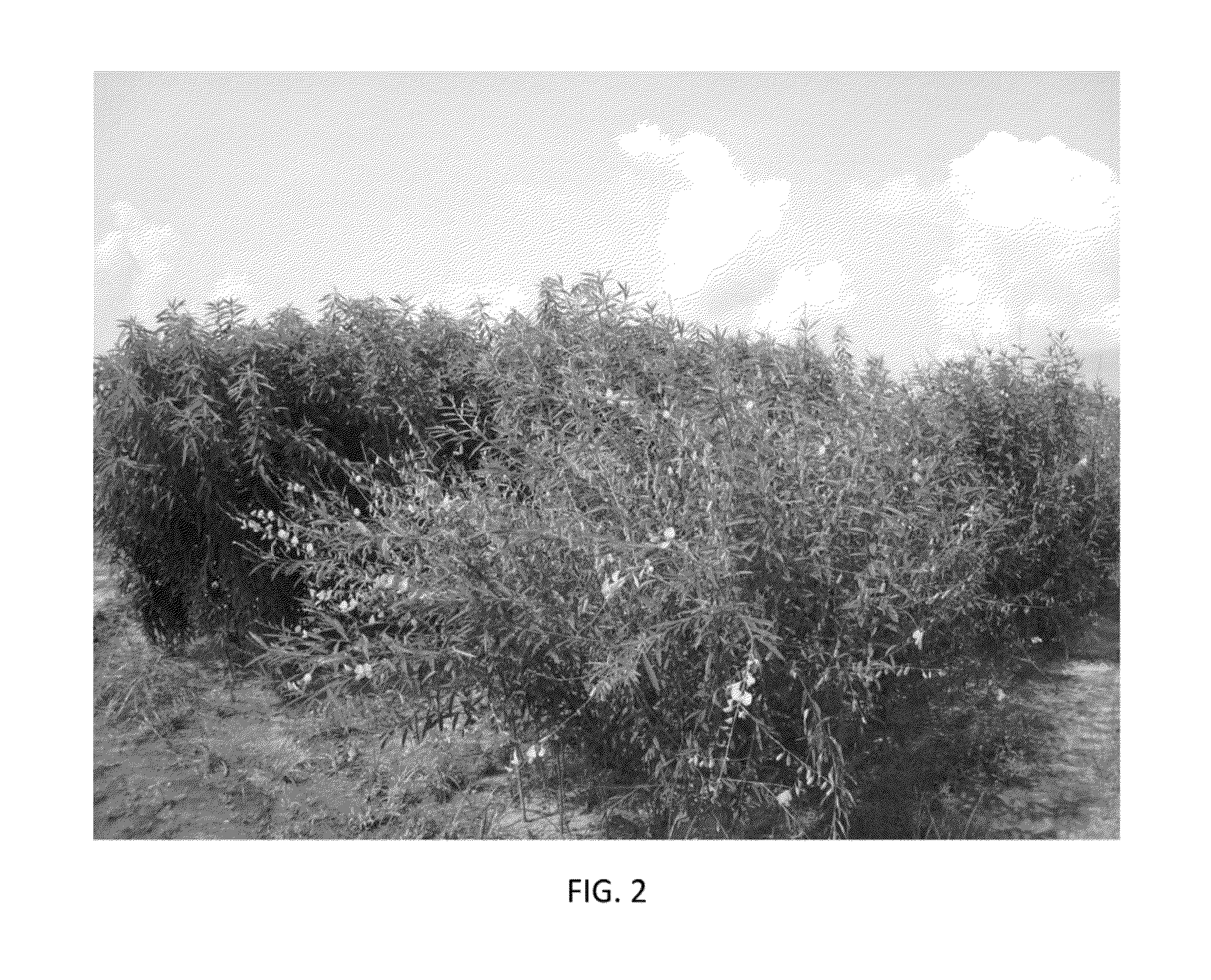

Sunn hemp cultivars capable of producing seed within the continental united states

InactiveUS8680369B2Quick upgradeAbility to suppress weed growthExcrement fertilisersFood preservationHemp plantLoment

Owner:AUBURN UNIV

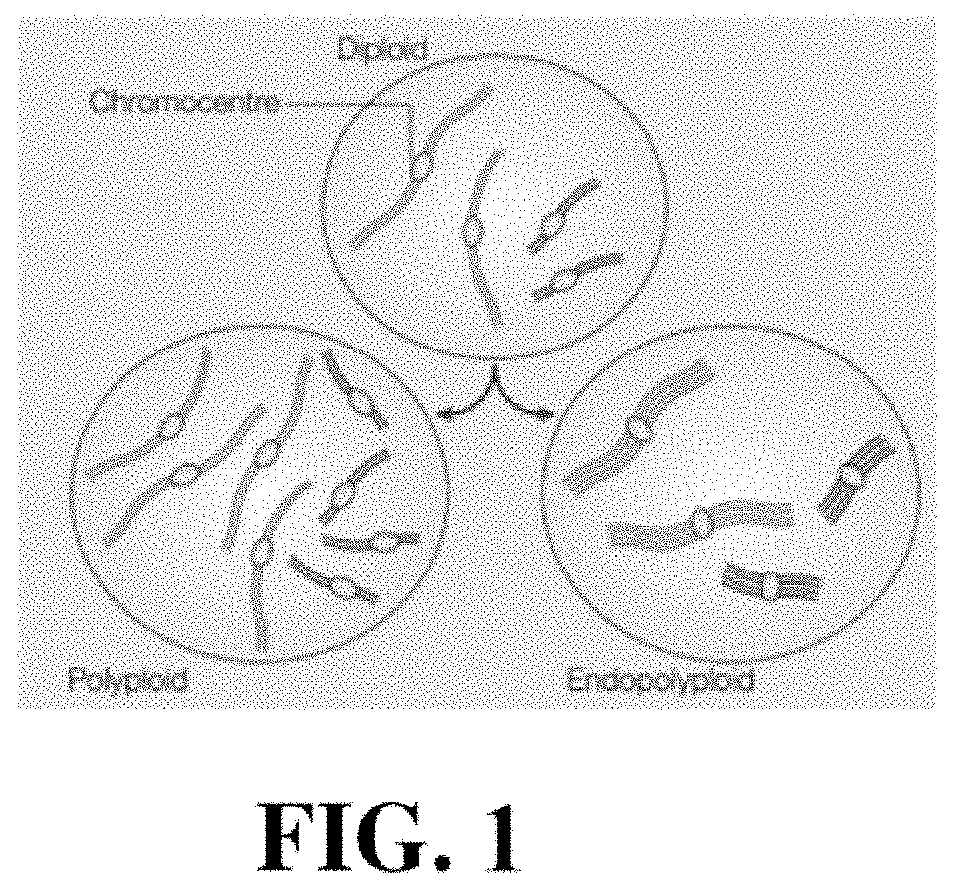

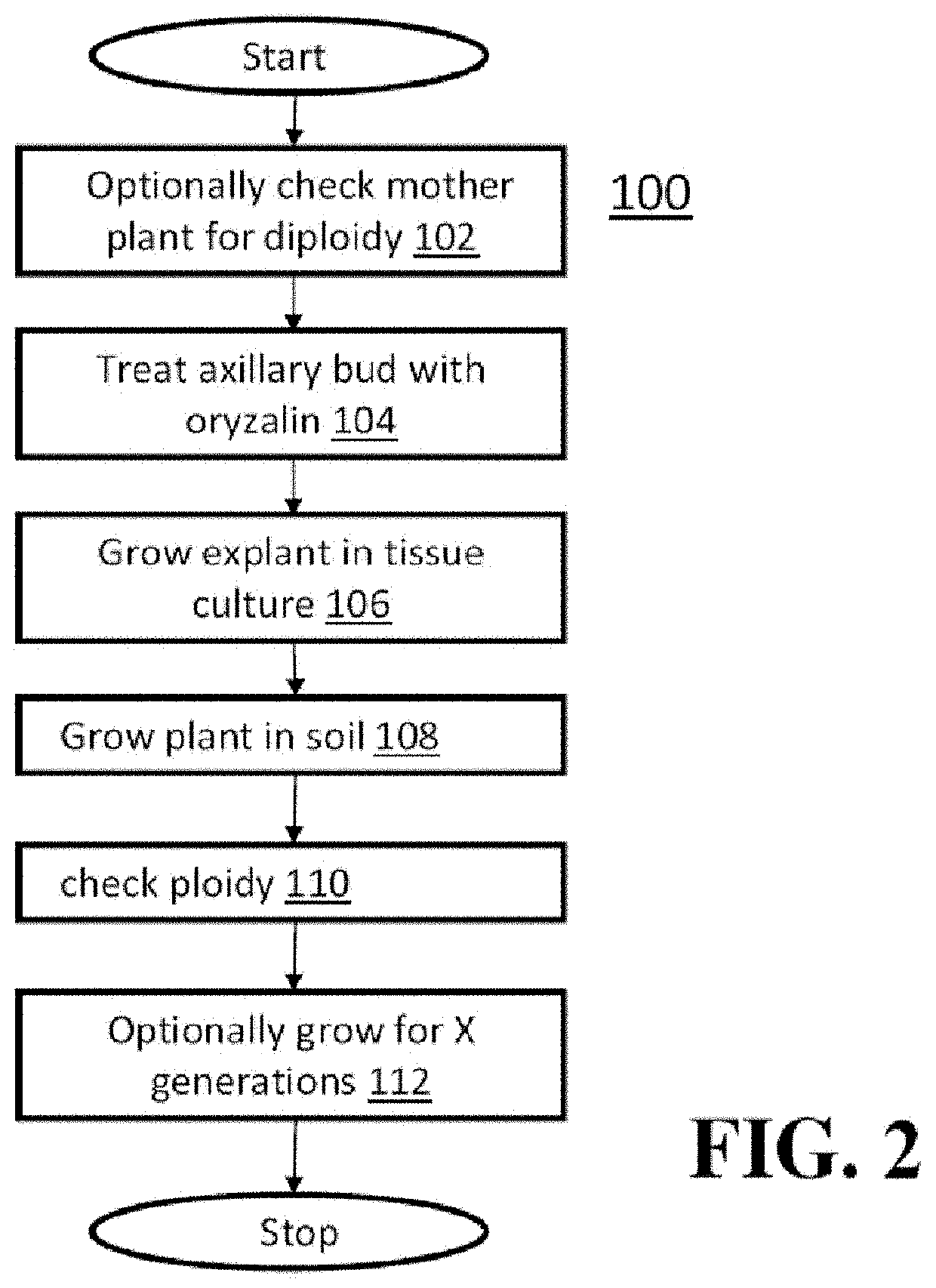

Triploid cannabis plants and methods for generating same

The present technology generally relates to a triploid Cannabis plant, triploid Cannabis seeds and to methods for generating such triploid Cannabis plant. The methods comprise crossing a tetraploid Cannabis plant with a diploid Cannabis plant to obtain F1 seeds, and growing a confirmed triploid F1 seed to generate the triploid Cannabis plant. In some embodiments, feminized pollen from a tetraploid Cannabis plant is crossed with a female diploid Cannabis plant.

Owner:CANOPY GROWTH CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com