Patents

Literature

66 results about "Critical phase" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

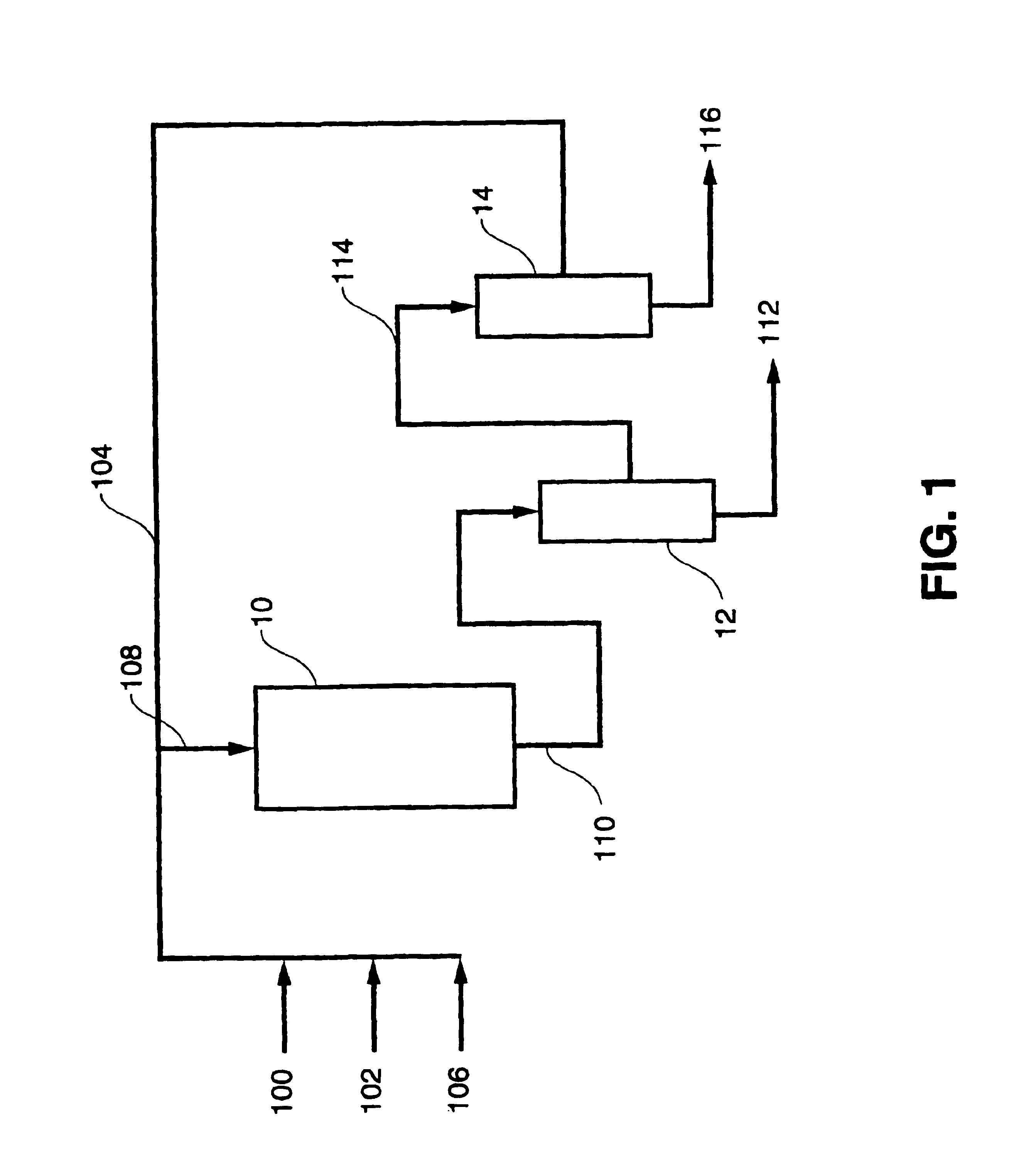

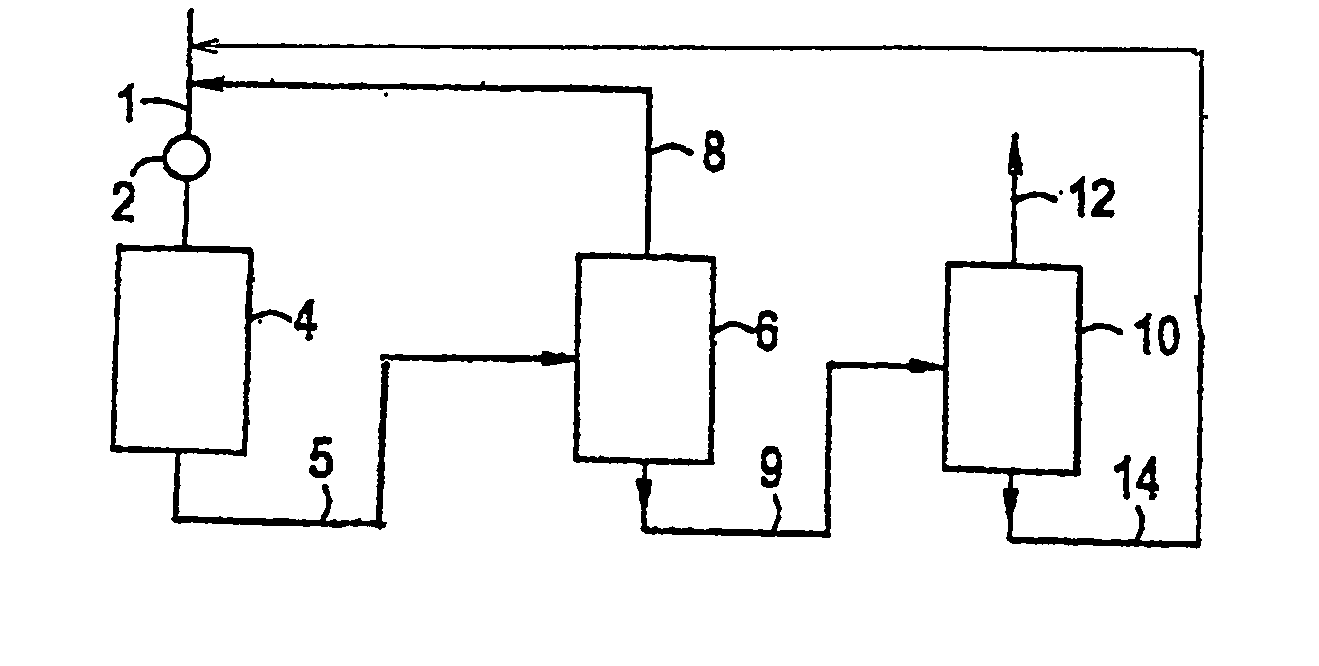

Process for producing biodiesel, lubricants, and fuel and lubricant additives in a critical fluid medium

InactiveUS6887283B1Limited mass transferImprove reaction speedFatty oils/acids recovery from wasteFatty acid esterificationBiodieselVegetable oil

A process for producing alkyl esters useful in biofuels and lubricants by transesterifying glyceride- or esterifying free fatty acid-containing substances in a single critical phase medium is disclosed. The critical phase medium provides increased reaction rates, decreases the loss of catalyst or catalyst activity and improves the overall yield of desired product. The process involves the steps of dissolving an input glyceride- or free fatty acid-containing substance with an alcohol or water into a critical fluid medium; reacting the glyceride- or free fatty acid-containing substance with the alcohol or water input over either a solid or liquid acidic or basic catalyst and sequentially separating the products from each other and from the critical fluid medium, which critical fluid medium can then be recycled back in the process. The process significantly reduces the cost of producing additives or alternatives to automotive fuels and lubricants utilizing inexpensive glyceride- or free fatty acid-containing substances, such as animal fats, vegetable oils, rendered fats, and restaurant grease.

Owner:BATTELLE ENERGY ALLIANCE LLC

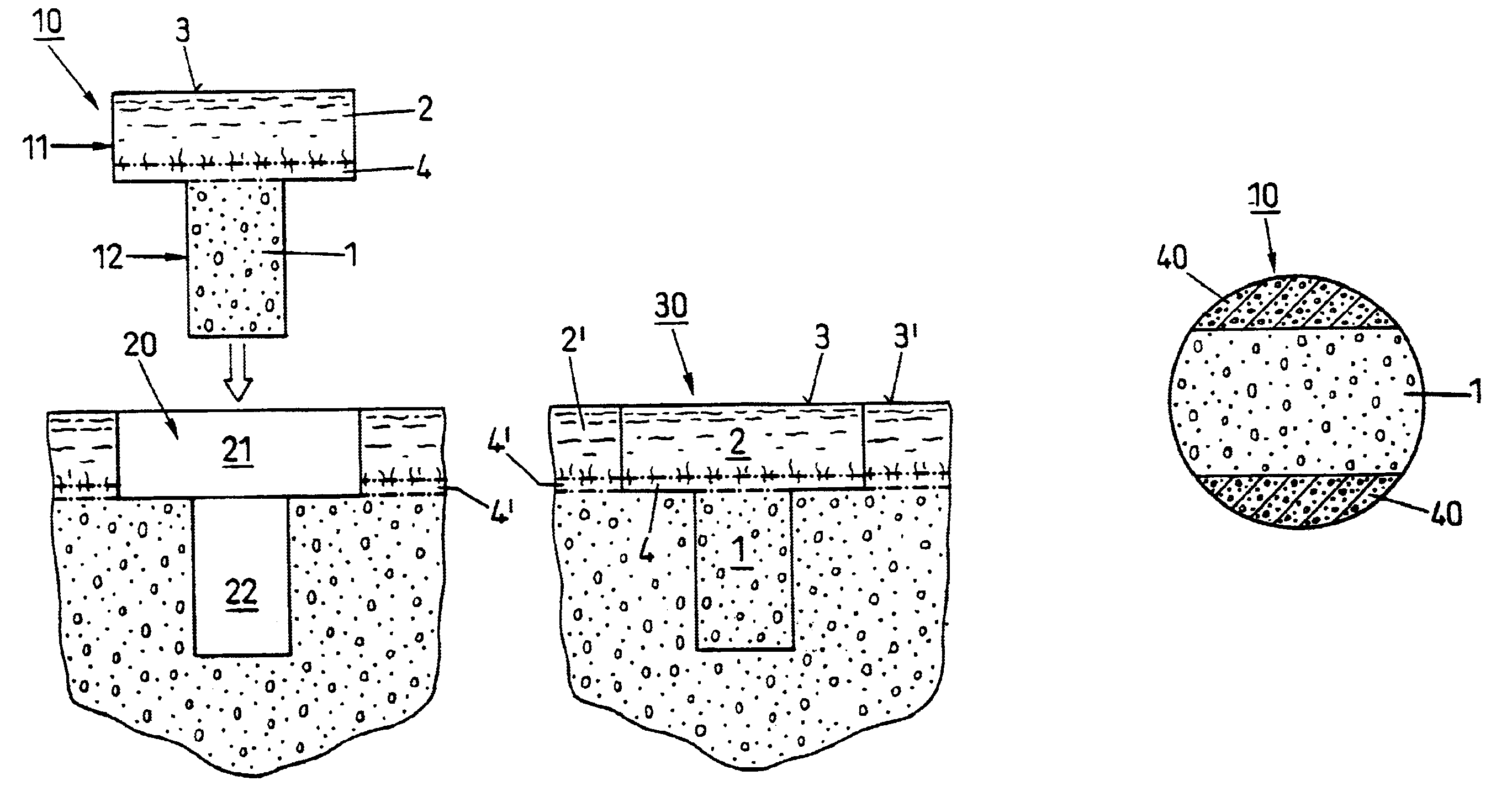

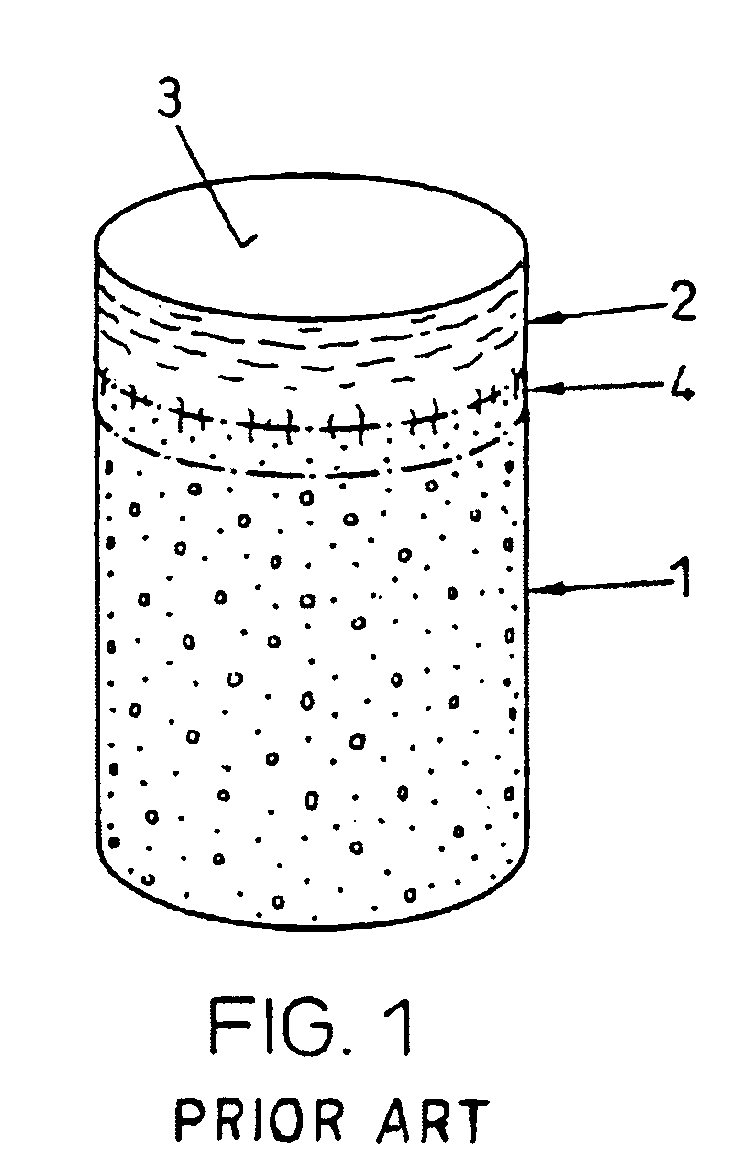

Preparation for repairing cartilage defects or cartilage/bone defects in human or animal joints

InactiveUS6858042B2Reduce absorptionResistant to resorptionBone implantJoint implantsRepair tissueCyst

Repairs of cartilage defects or of cartilage / bone defects in human or animal joints with the help of devices including a bone part (1), a cartilage layer (2) and a subchondral bone plate (4) or an imitation of such a plate in the transition region between the cartilage layer (2) and the bone part (1). After implantation, the bone part (4) is resorbed and is replaced by reparative tissue only after being essentially totally resorbed. In a critical phase of the healing process, a mechanically inferior cyst is located in the place of the implanted bone part (1). In order to prevent the cartilage layer (2) from sinking into the cyst space during this critical phase of the healing process the device has a top part (11) and a bottom part (12), wherein the top part (11) consists essentially of the cartilage layer (2) and the subchondral bone plate (4) and the bottom part (12) corresponds essentially to the bone part (1) and wherein the top part (11) parallel to the subchondral bone plate (4) has a larger diameter than the bottom part (12). After implantation in a suitable opening or bore (20), the cartilage layer (2) and the subchondral bone plate (4) are supported not only on the bone part (1) but also on native bone tissue having a loading capacity not changing during the healing process. Therefore, the implanted cartilage layer cannot sink during the healing process.

Owner:ZIMMER GMBH

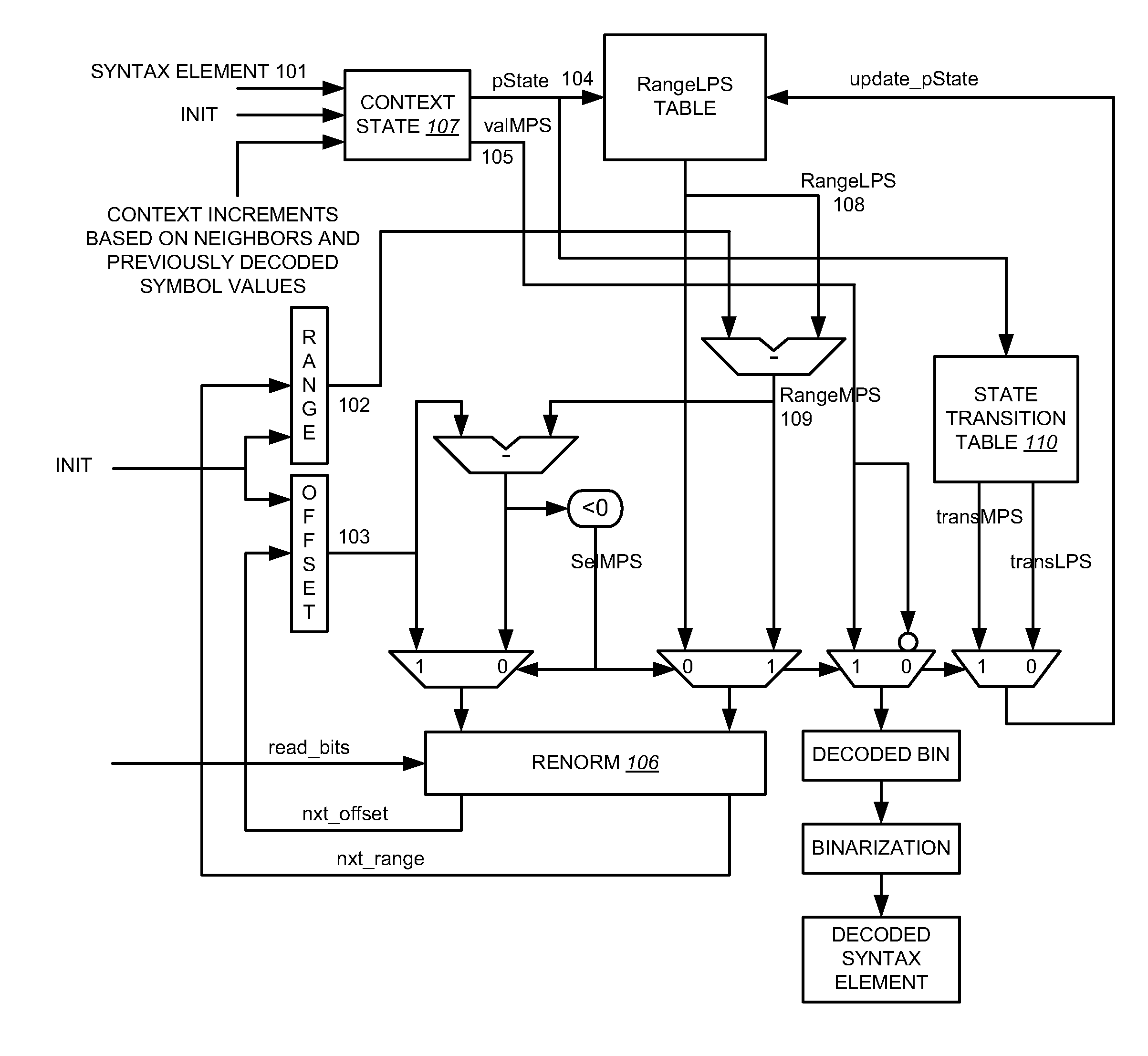

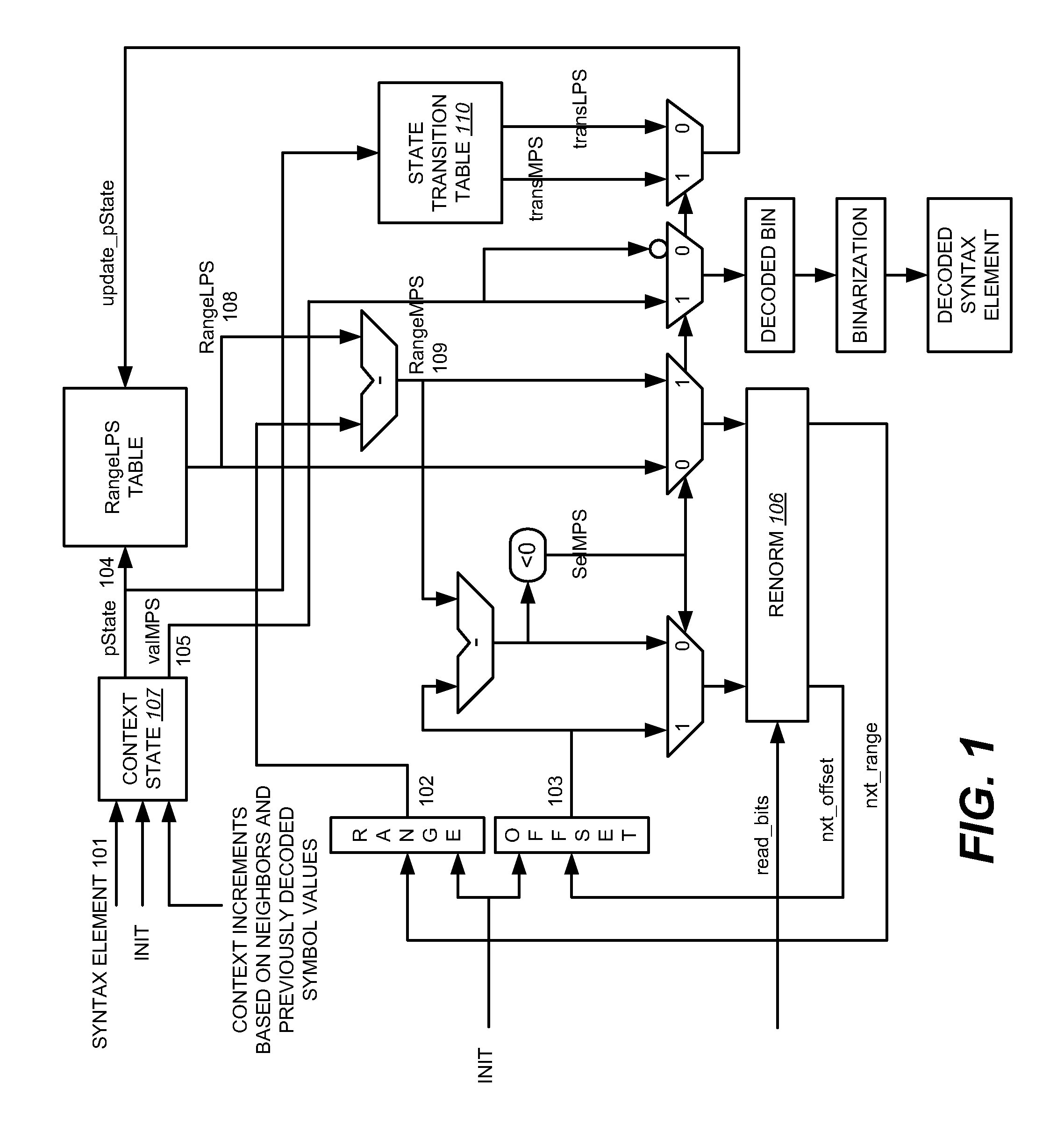

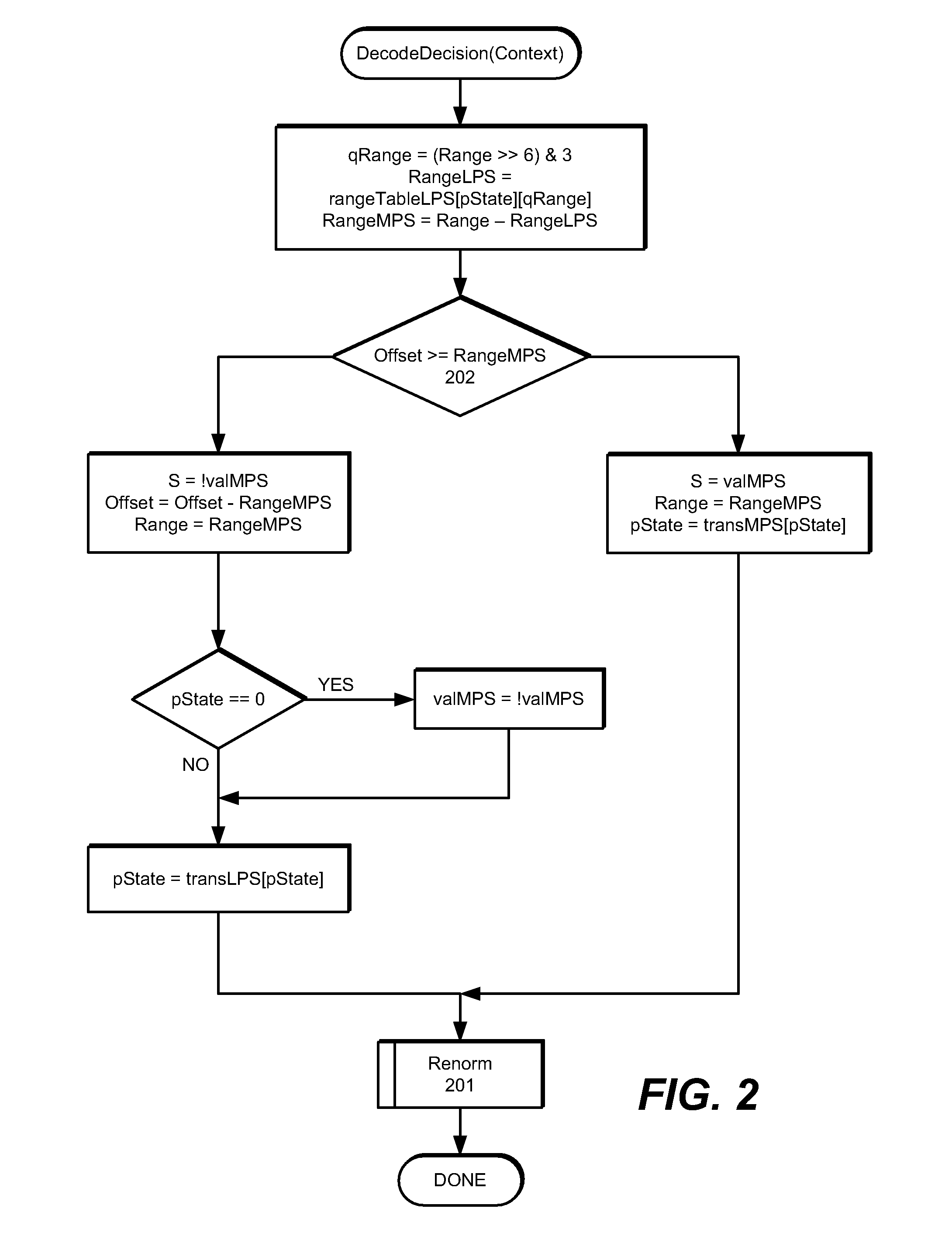

2-bin parallel decoder for advanced video processing

ActiveUS20090196355A1Low transfer rateIncrease speedColor television with pulse code modulationColor television with bandwidth reductionVideo processingParallel computing

A critical phase of video processing is the decoding of bit streams coming from standard based heavy compressed sources. Entropy coding can be effectively decoded by adopting parallelism to speed up the process. Reasonable assumptions make possible for example the multiple bits at a time processing for the Context-based Adaptive Binary Arithmetic Coding (CABAC) algorithm. In particular, a clever arithmetic section reduces single propagation for the timing critical path while decoding done for only two sequence elements at a time by calculating and maintaining most probable bit values. This in turn making accelerated path using pre-determined probability outcome through parallelism not cost.

Owner:DIGITAL VIDEO SYSTEMS +1

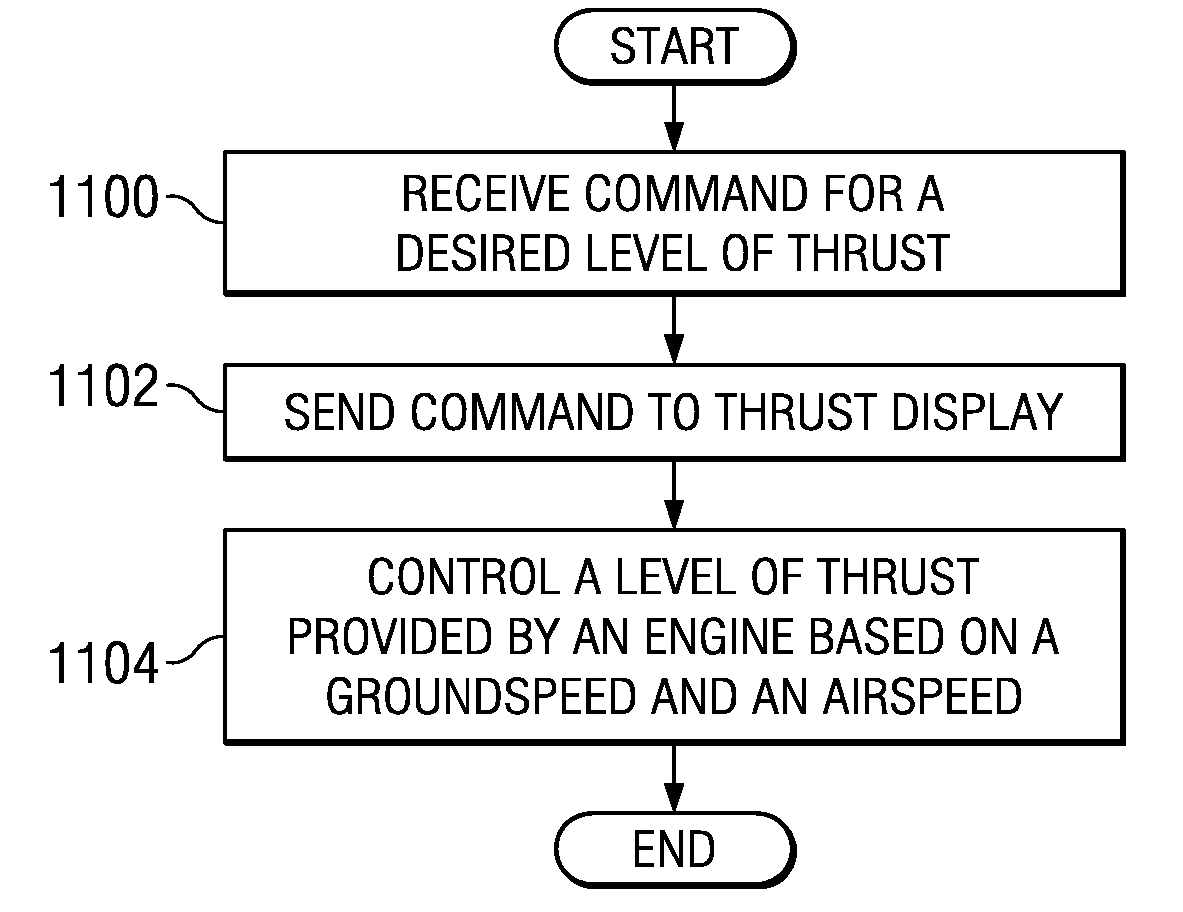

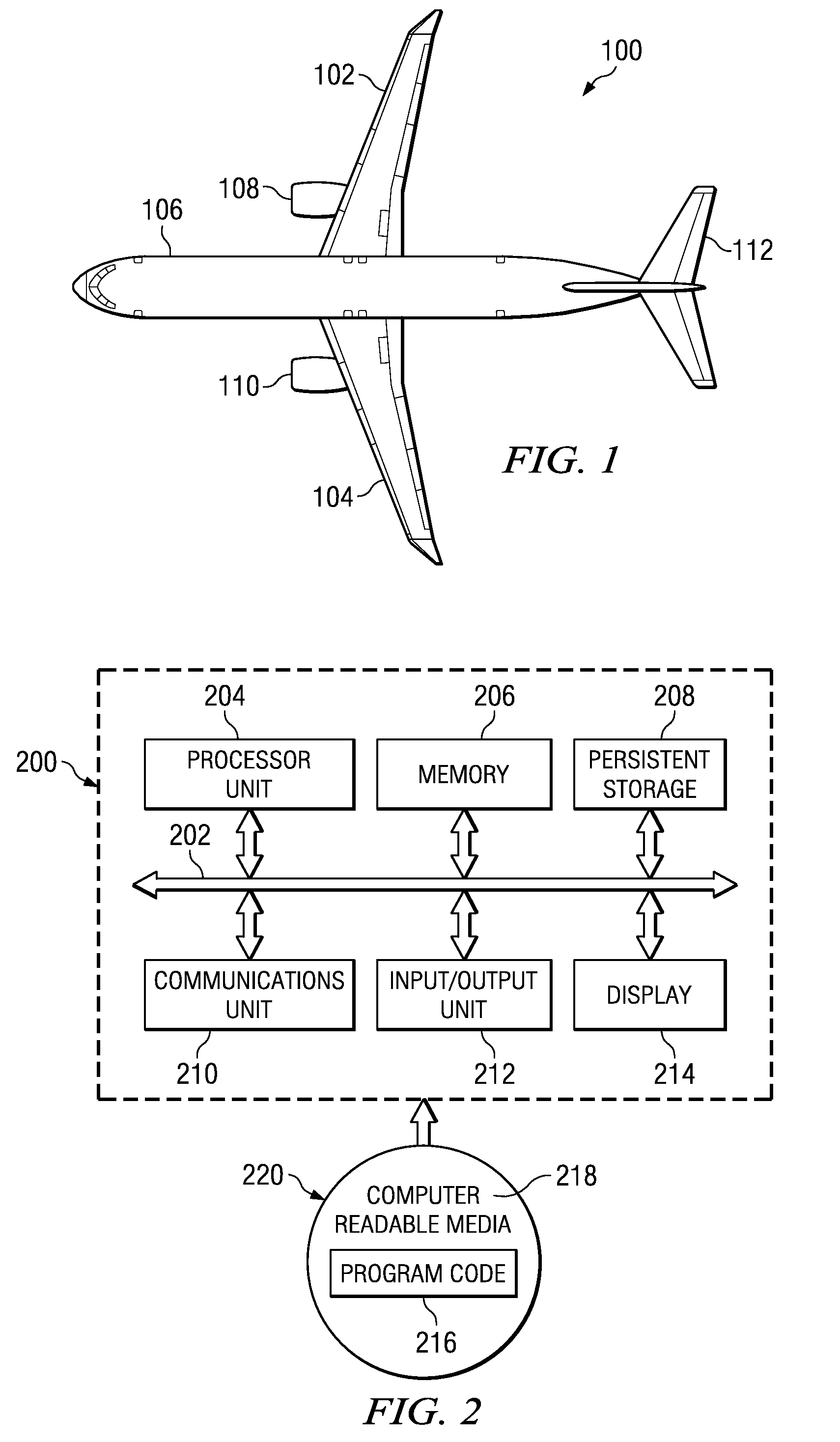

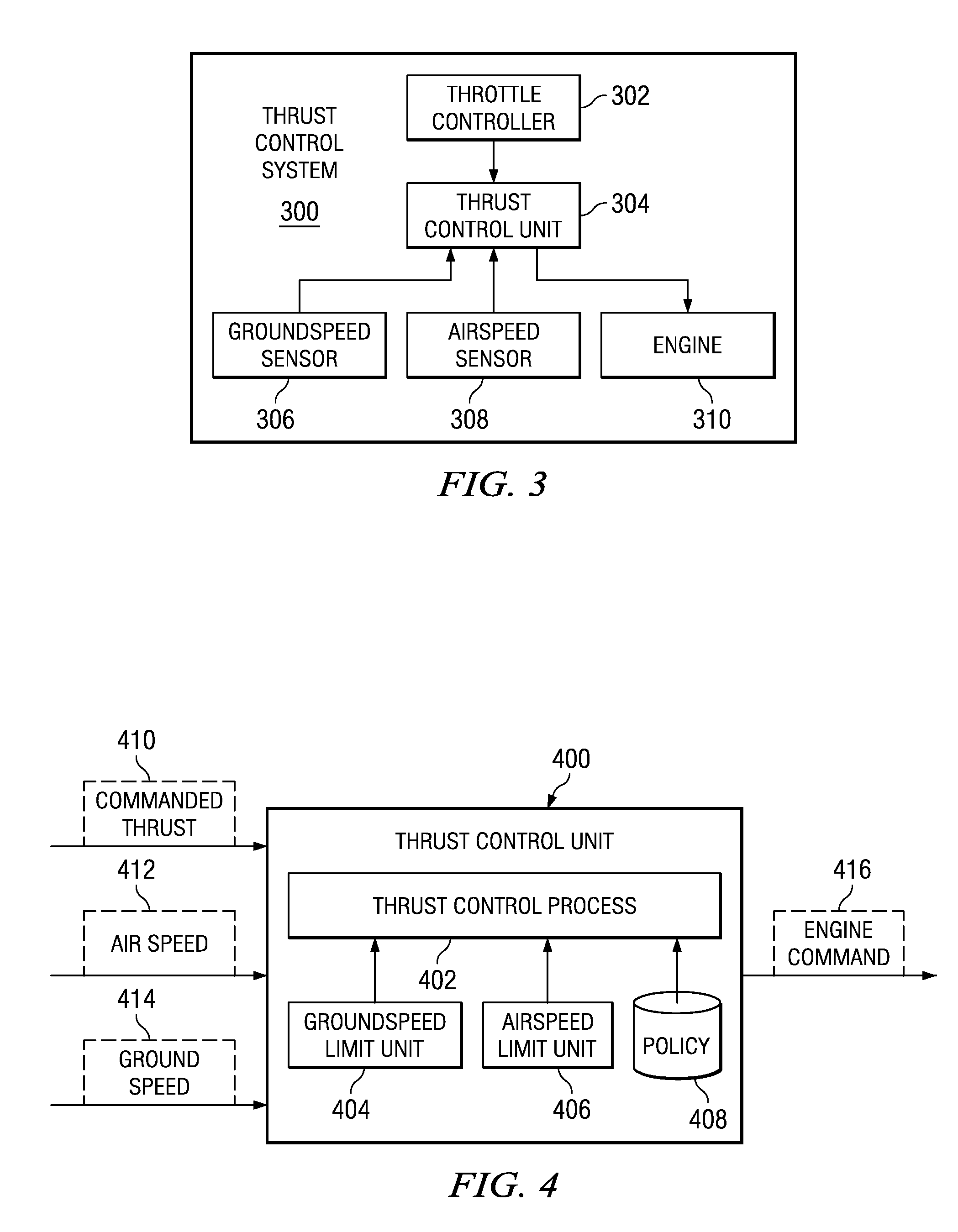

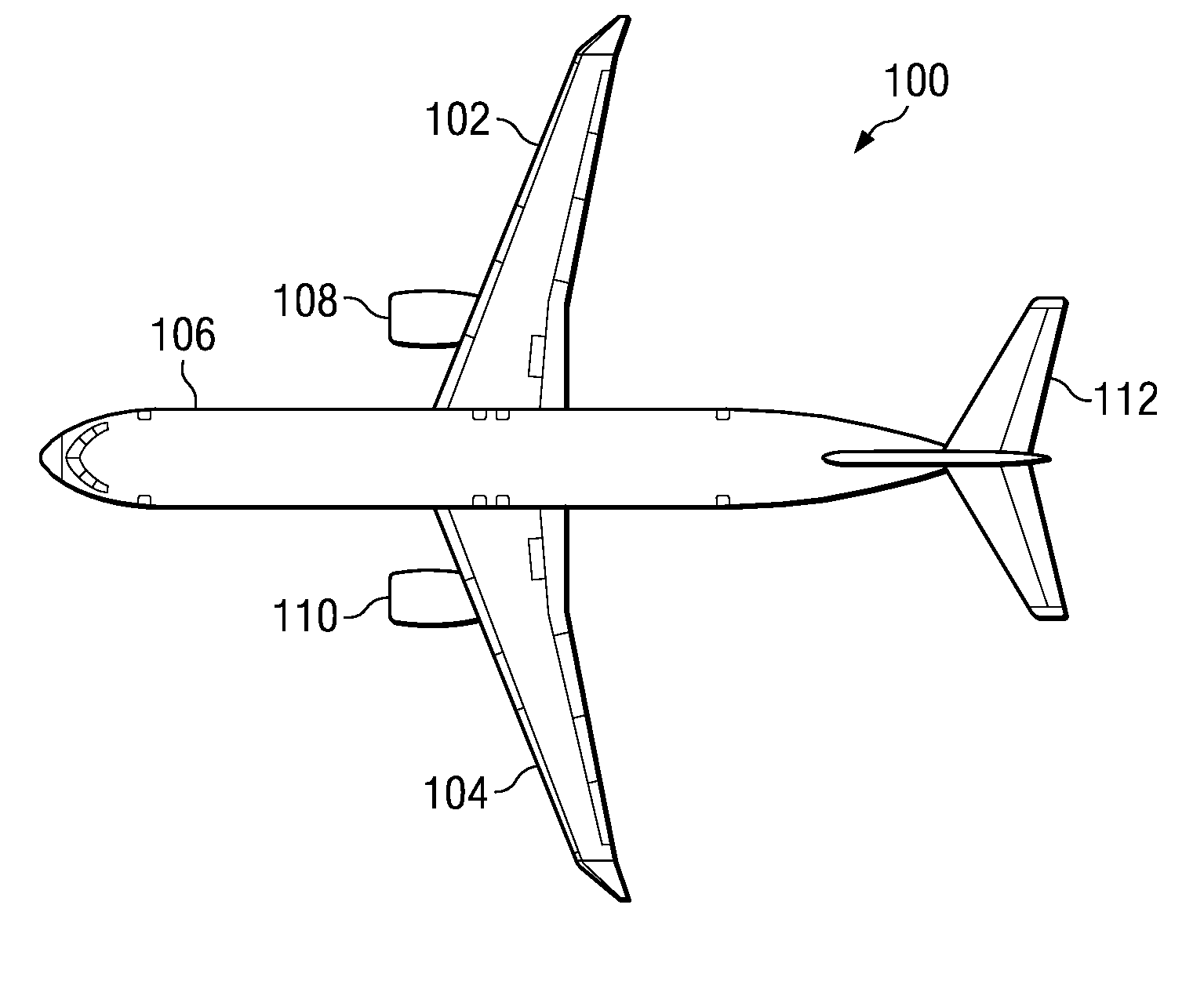

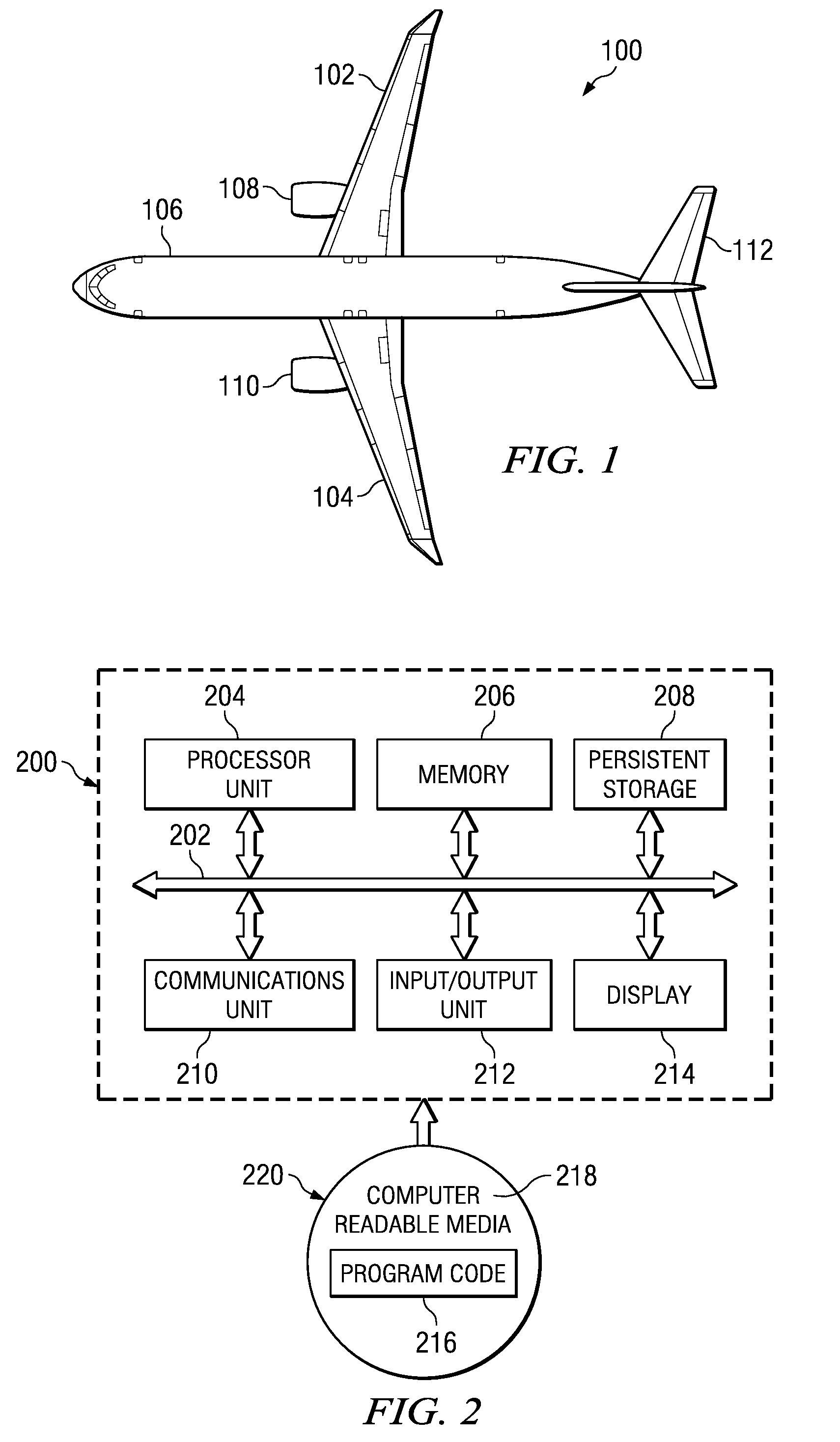

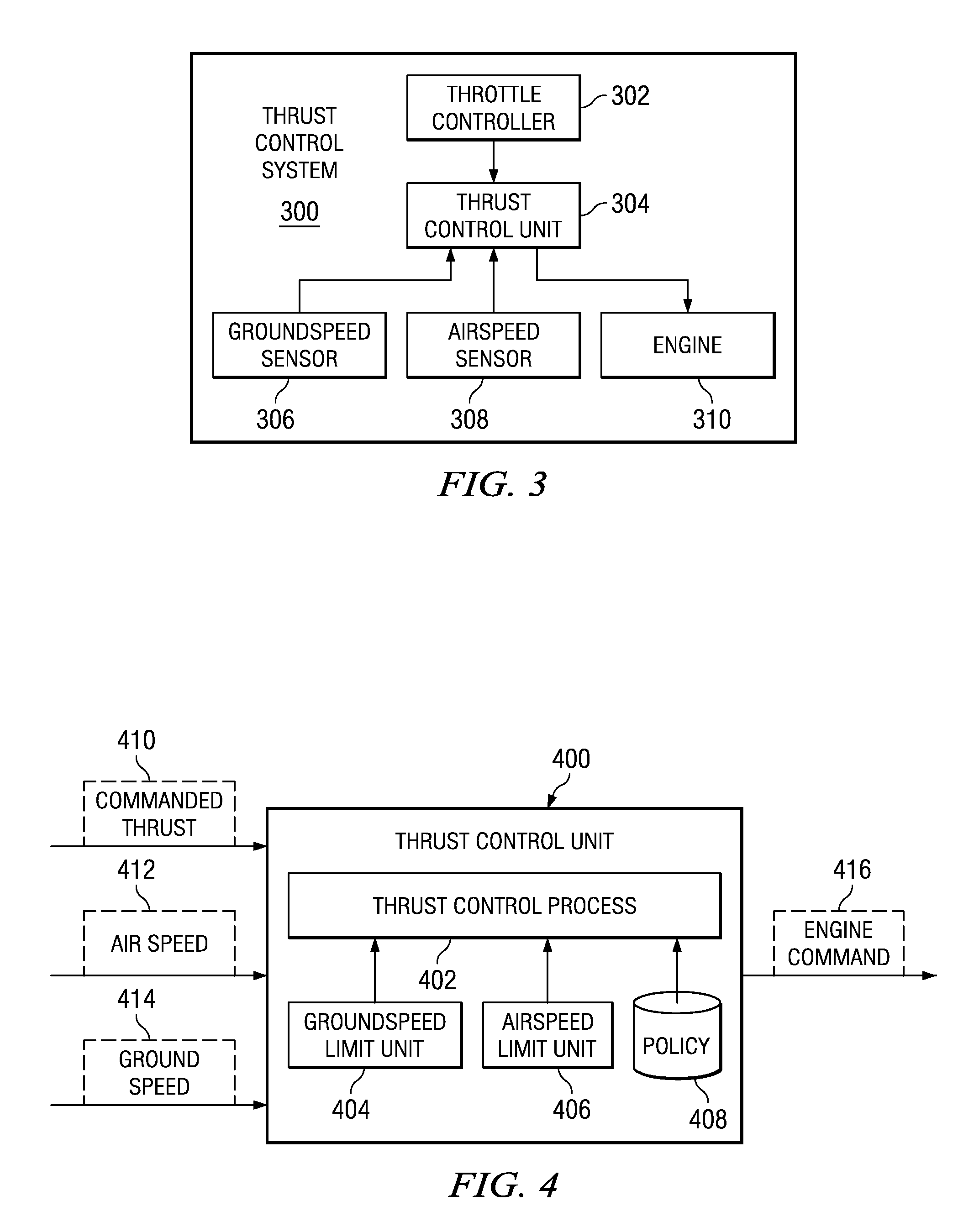

Progressive takeoff thrust ramp for an aircraft

A method is presented for controlling thrust generated by aircraft engines. Engine thrust is controlled based on aircraft groundspeed and airspeed during the initial part of takeoff. Limiting thrust at low groundspeed during the initial phase of takeoff has significant benefits that reduce engine stress during this brief but critical phase leading to flight. Logical elements combine both groundspeed and airspeed in such a way that the operator perceives a smooth progressive thrust increase consistent with normal engine operation.

Owner:THE BOEING CO

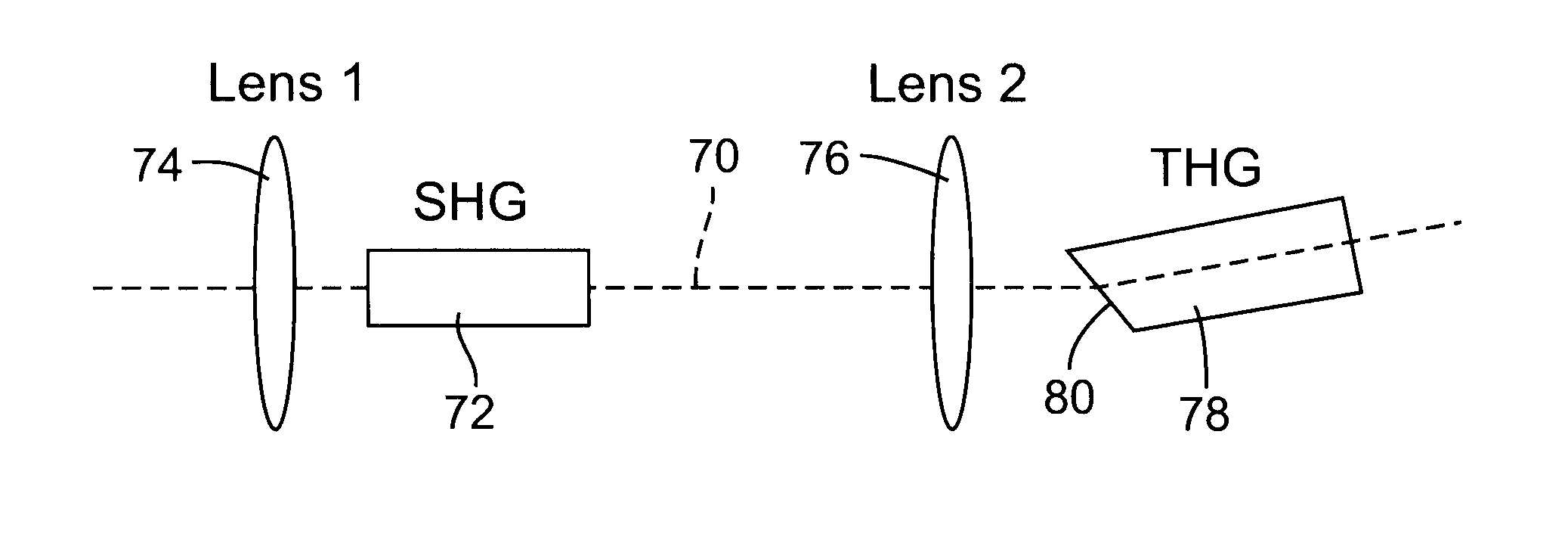

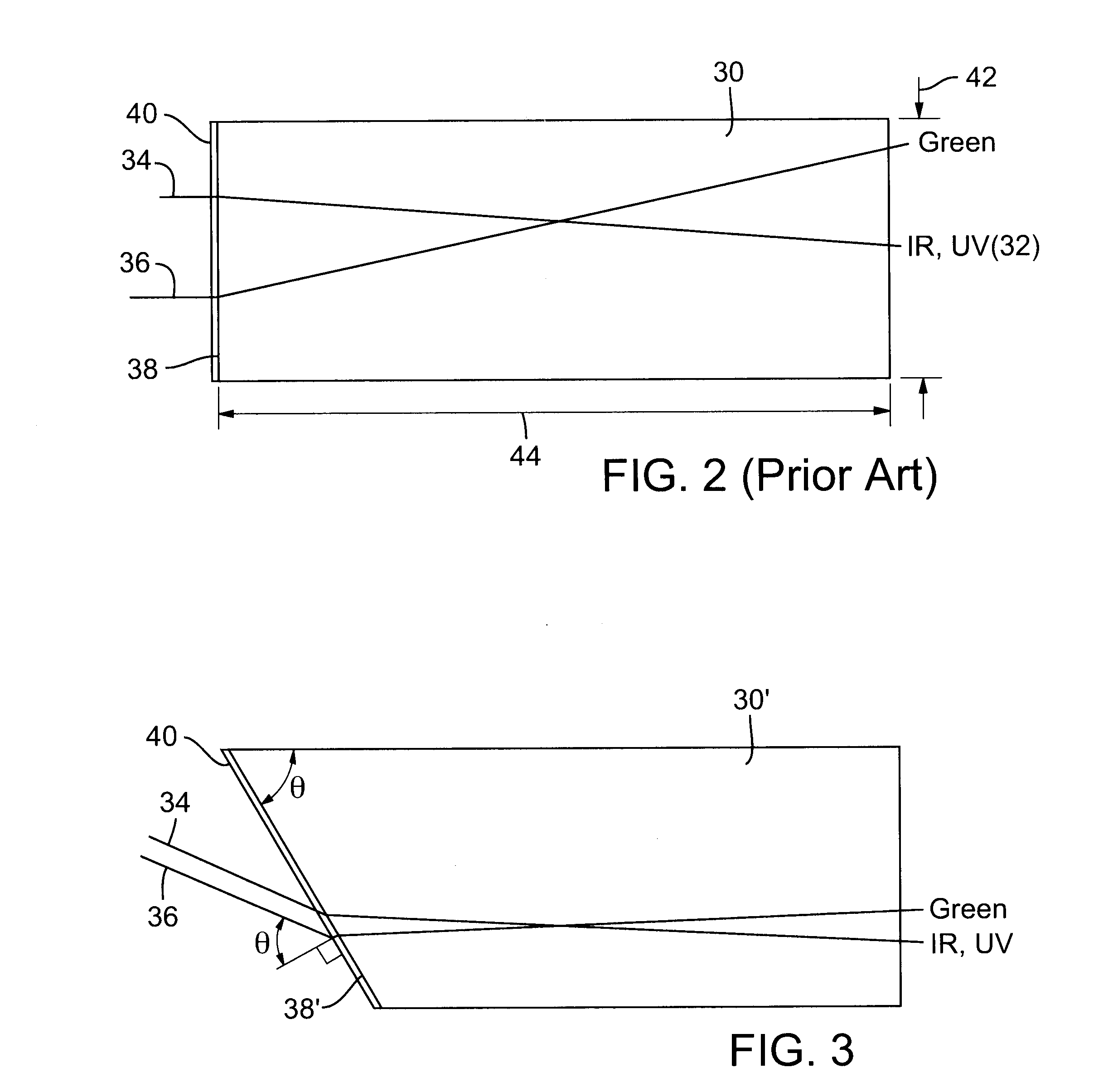

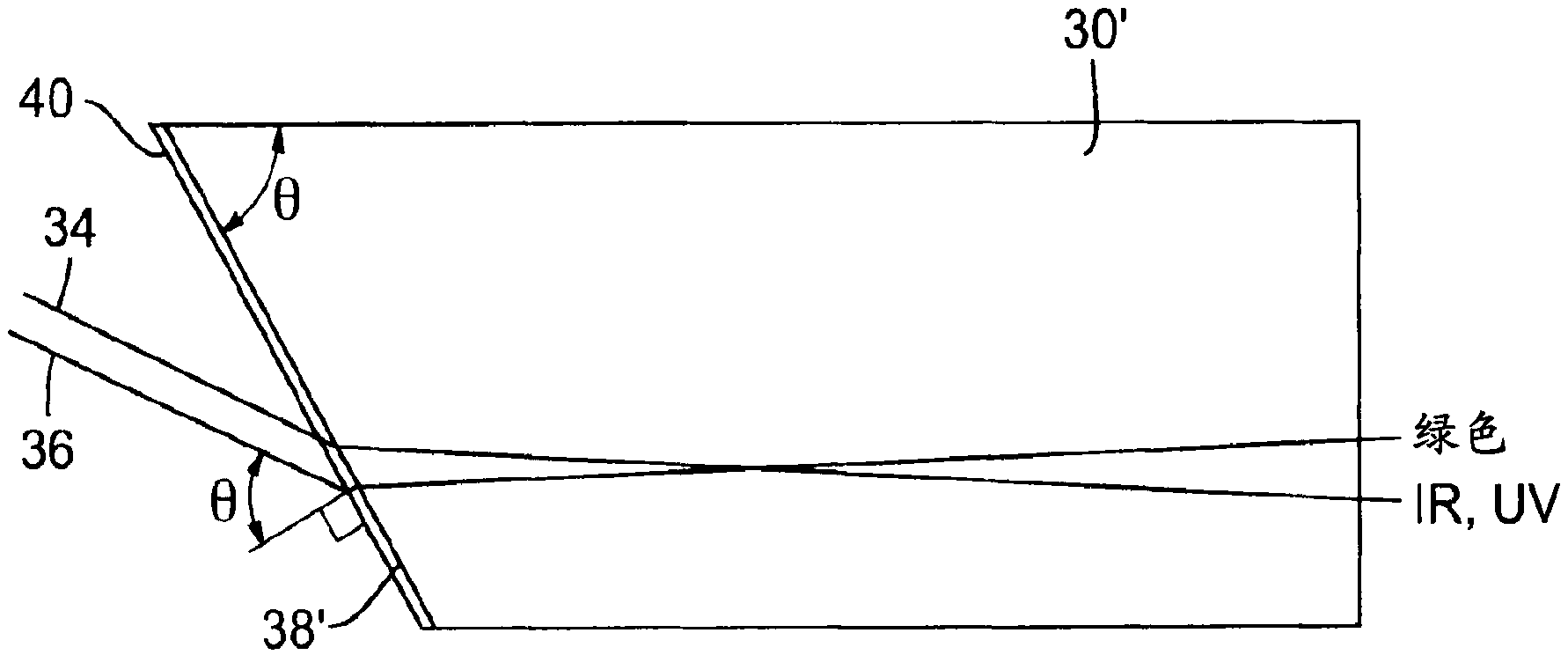

Wedge-faceted nonlinear crystal for harmonic generation

InactiveUS20110243163A1Great effective interaction lengthReduce the impactLaser detailsLight demodulationFrequency conversionWavelength

Lasers and laser systems generate different wavelengths by nonlinear sum or difference frequency conversion. A wedge-faceted nonlinear crystal compensates for the spatial walk-off phenomenon associated with critical phase matching of a nonlinear crystal in the production of harmonic laser output at peak power.

Owner:ELECTRO SCI IND INC

Stowable laser eye protection

ActiveUS7344260B2Easy extractionEasily stowedPressurized chemical processMirrorsProtecting eyeLength wave

Owner:THE BOEING CO

Progressive takeoff thrust ramp for an aircraft

A method is presented for controlling thrust generated by aircraft engines. Engine thrust is controlled based on aircraft groundspeed and airspeed during the initial part of takeoff. Limiting thrust at low groundspeed during the initial phase of takeoff has significant benefits that reduce engine stress during this brief but critical phase leading to flight. Logical elements combine both groundspeed and airspeed in such a way that the operator perceives a smooth progressive thrust increase consistent with normal engine operation.

Owner:THE BOEING CO

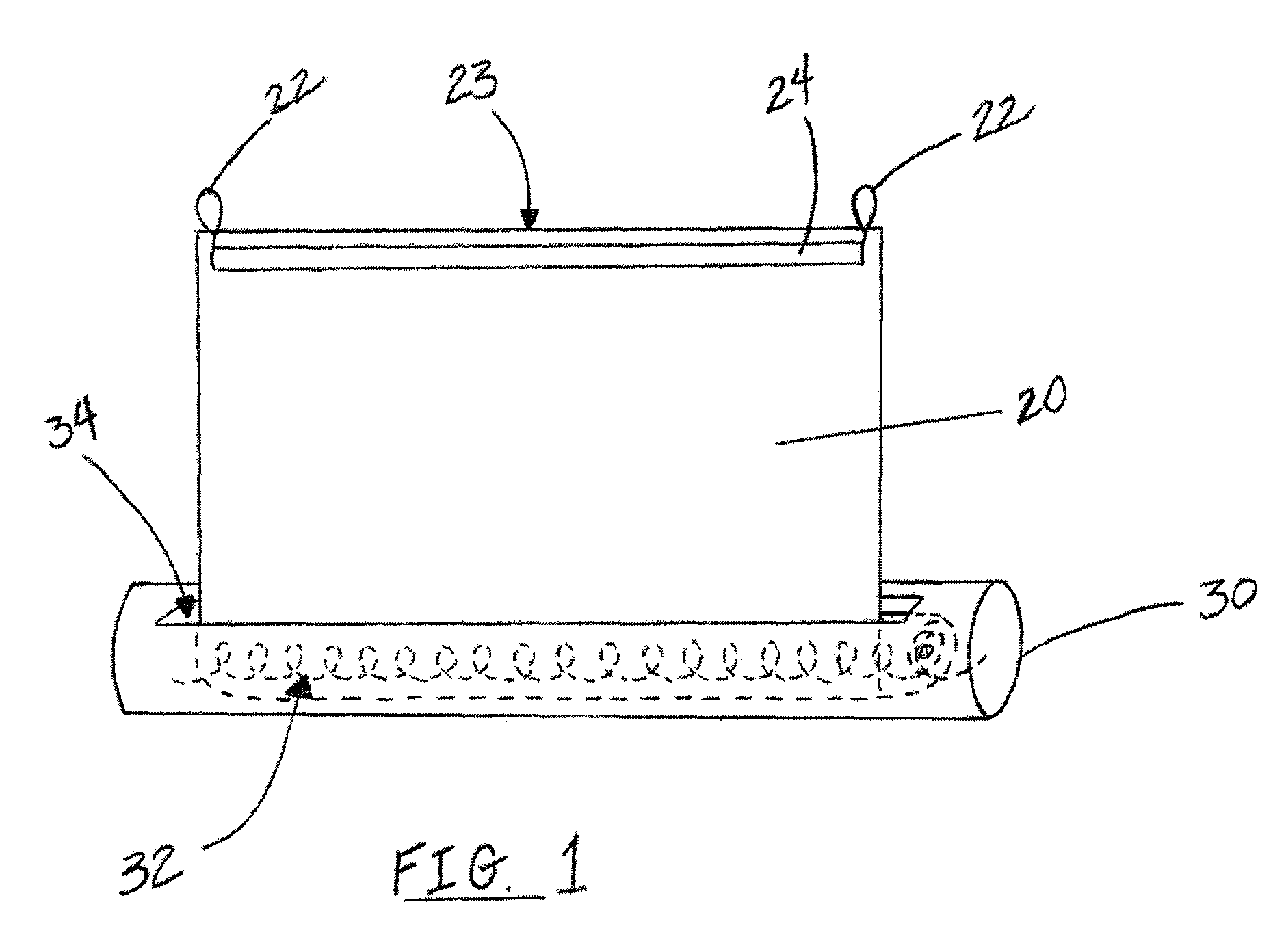

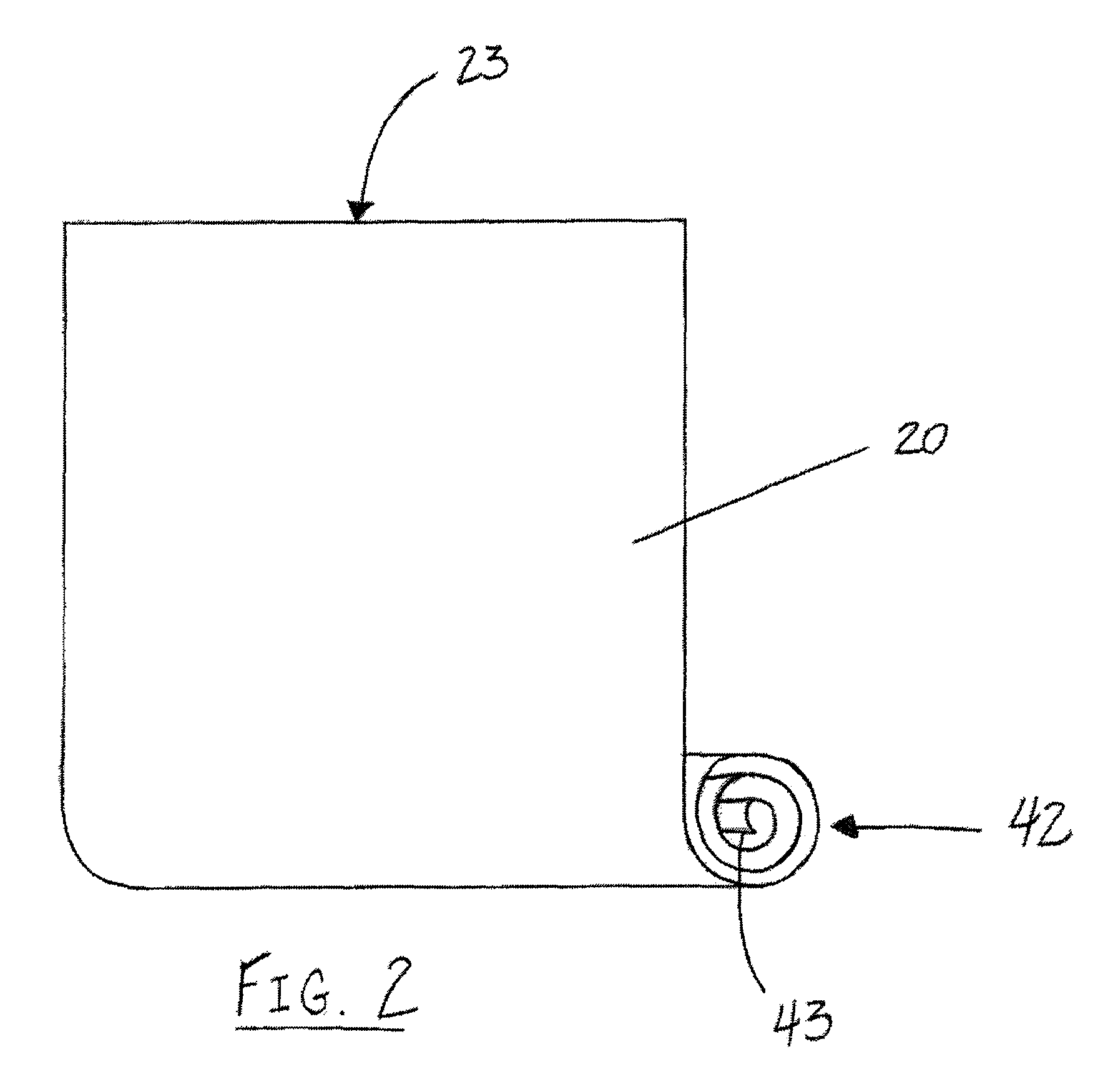

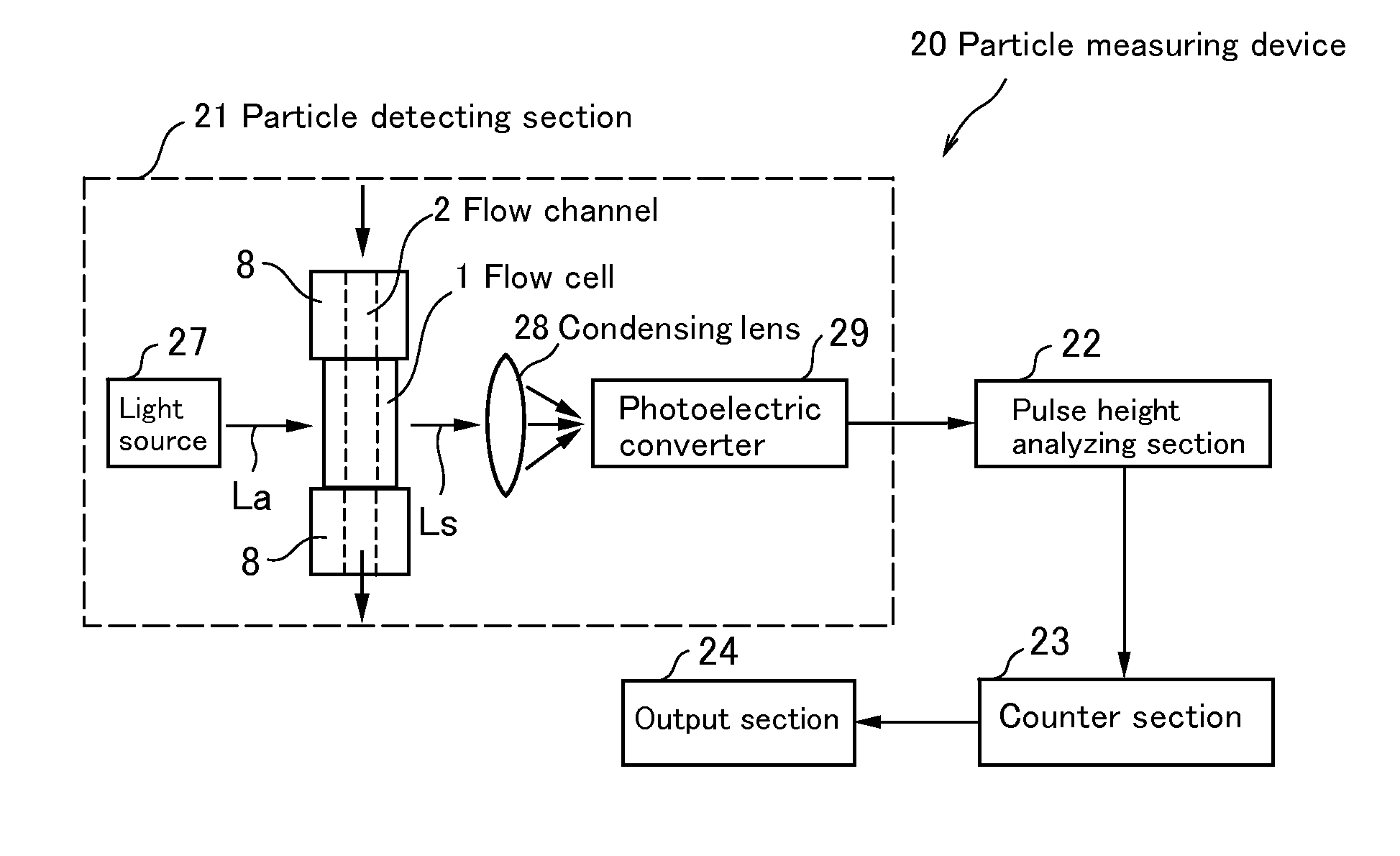

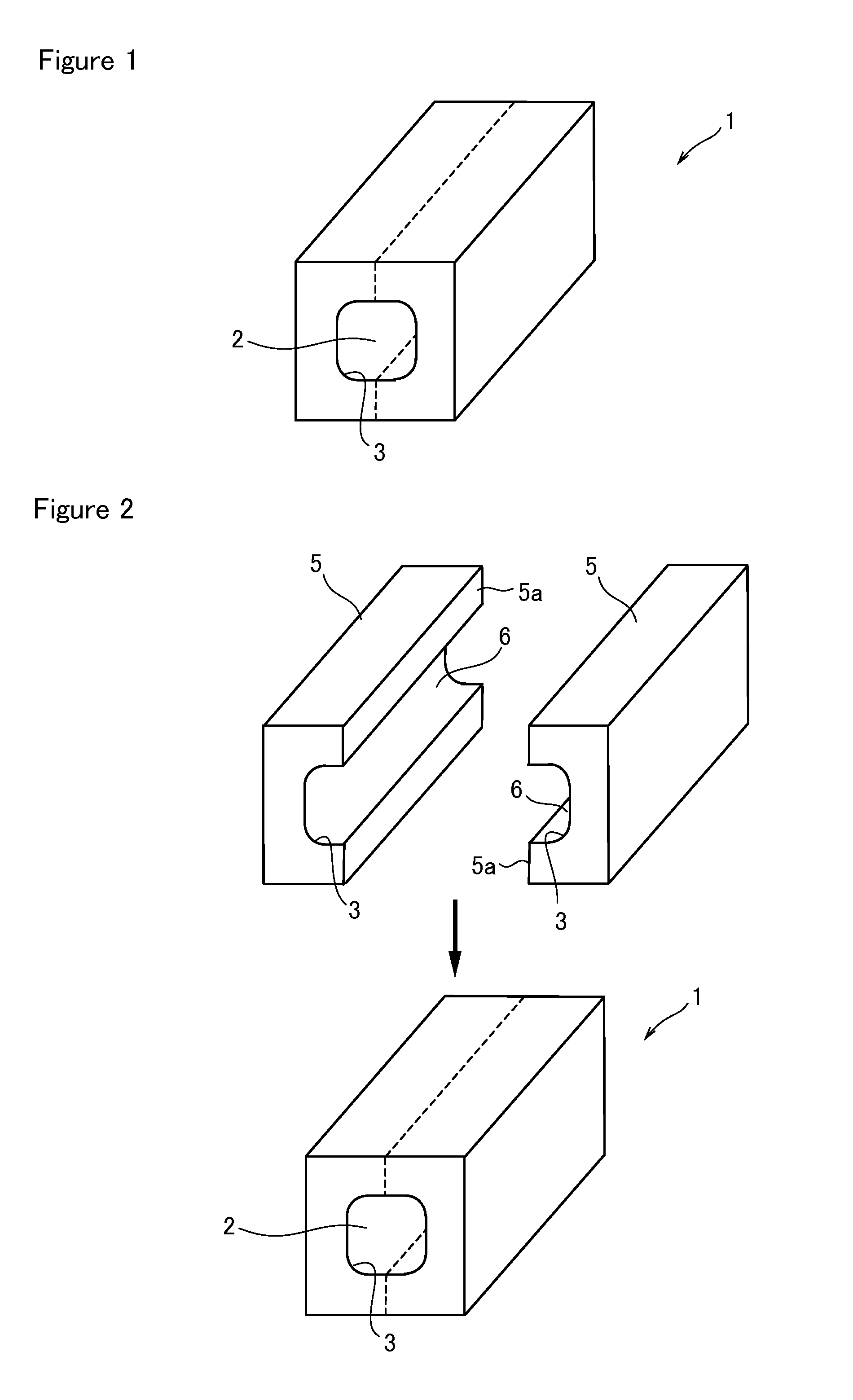

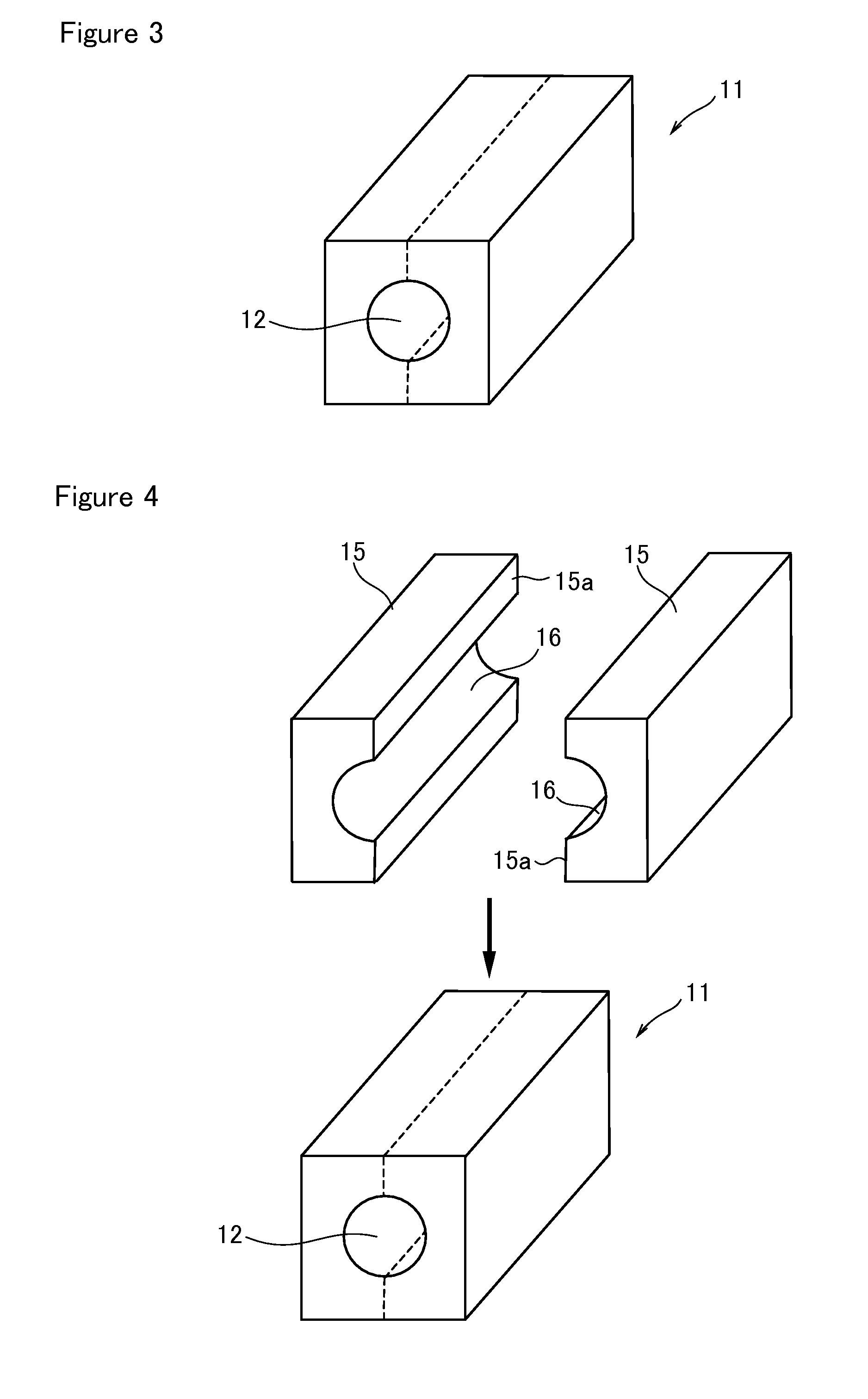

Flow cell, flow cell manufacturing method and particle measurement instrument

InactiveUS20080223154A1Material analysis by optical meansCeramic shaping apparatusFlow cellHigh pressure

A flow cell 1 is provided with a flow channel 2 which has rounded corners 3 in section. A measuring sample under high pressure is introduced into the flow channel 2 formed in the flow cell 1 and particles existing in the measuring sample are measured. The measuring sample is in a liquid phase, a gaseous phase or a super critical phase above 1 MPa.

Owner:RION COMPANY

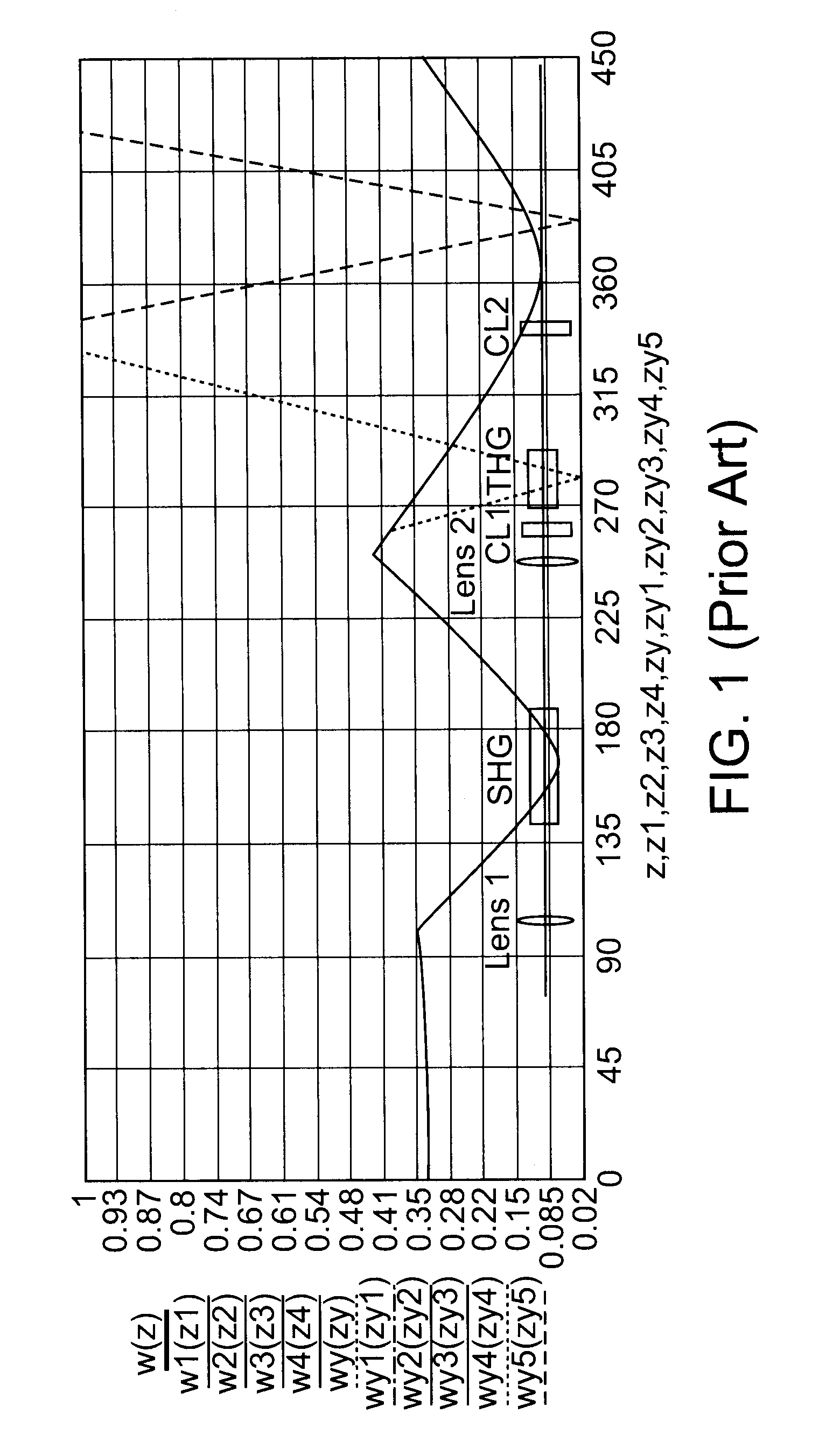

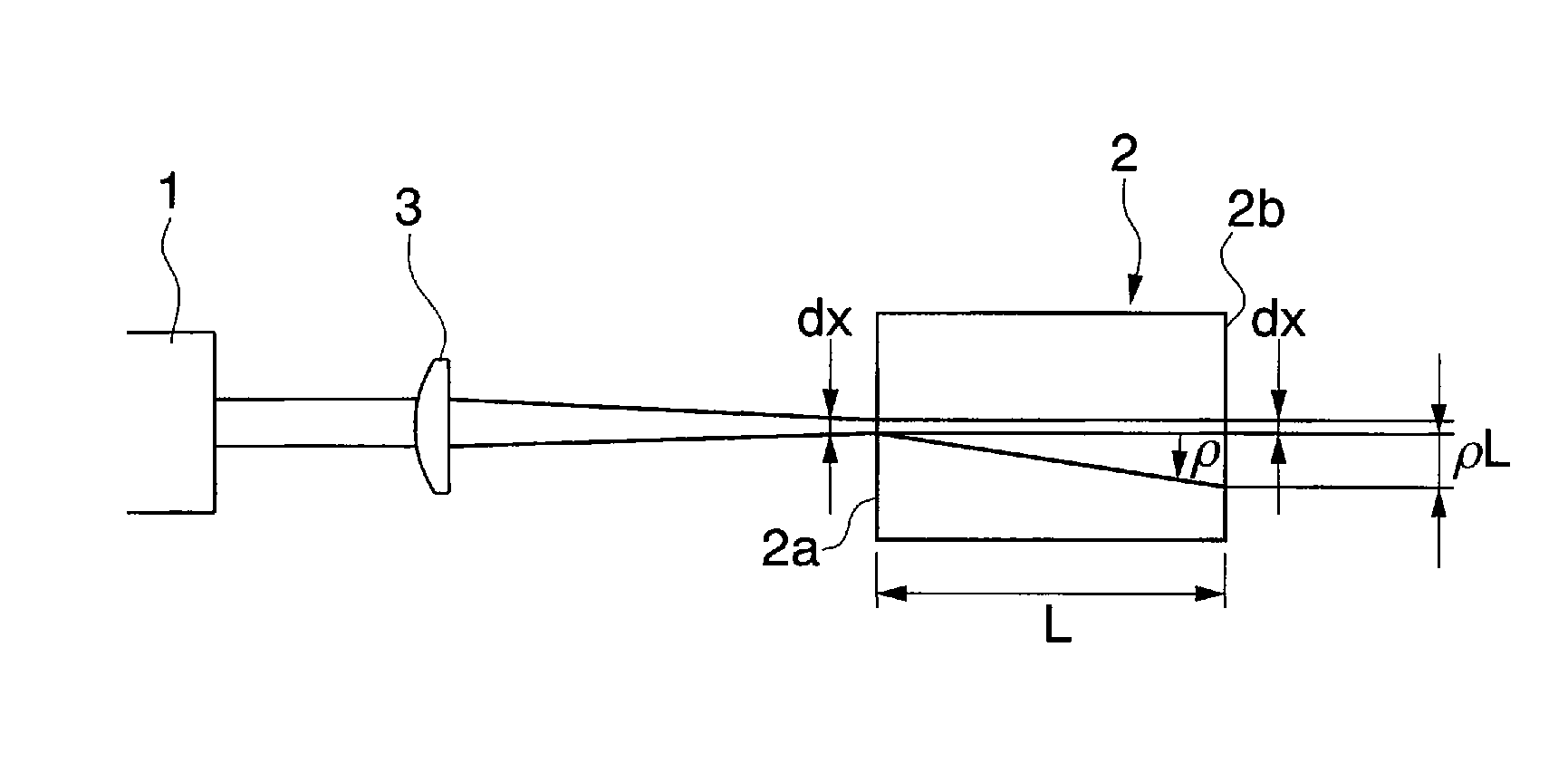

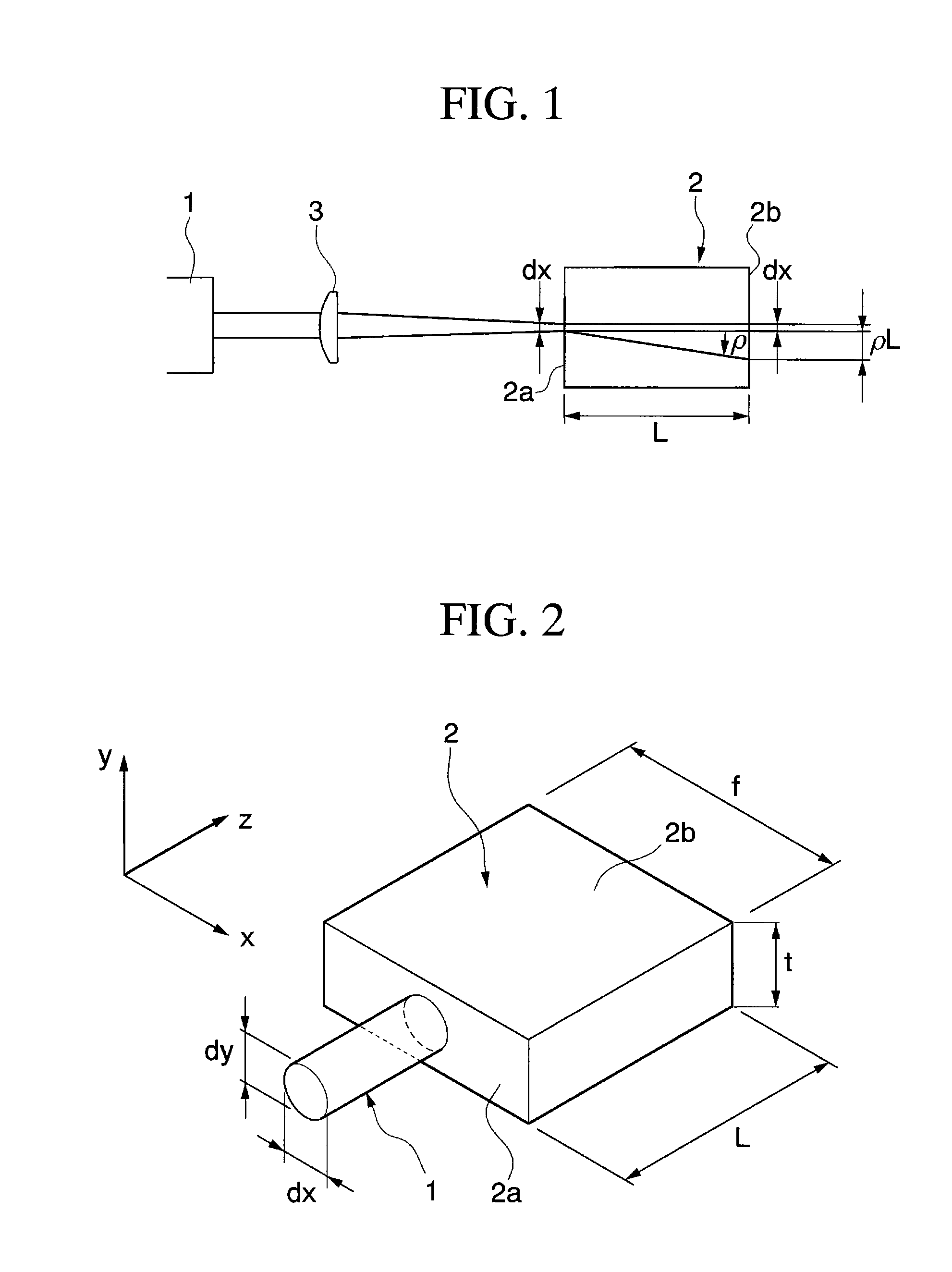

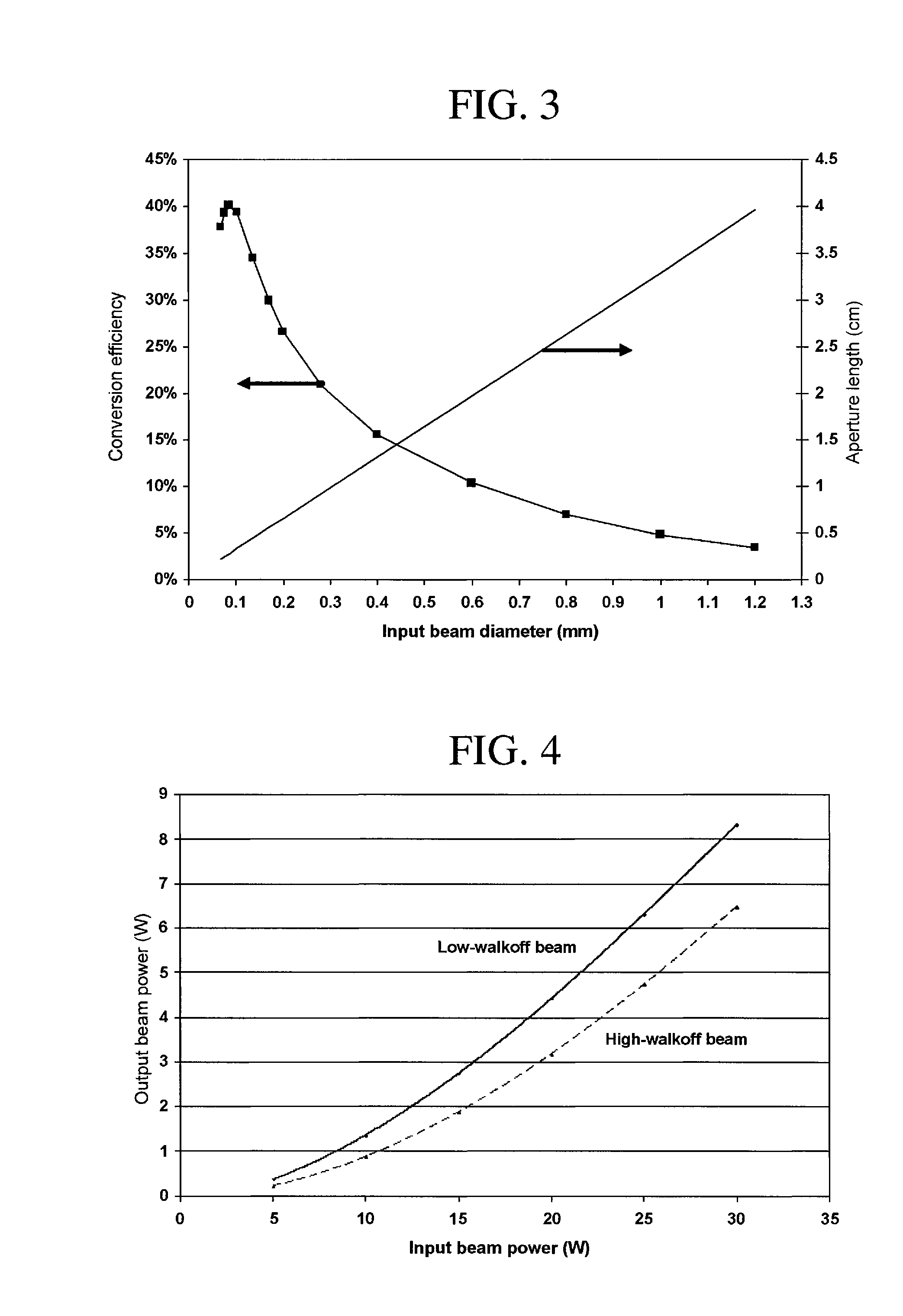

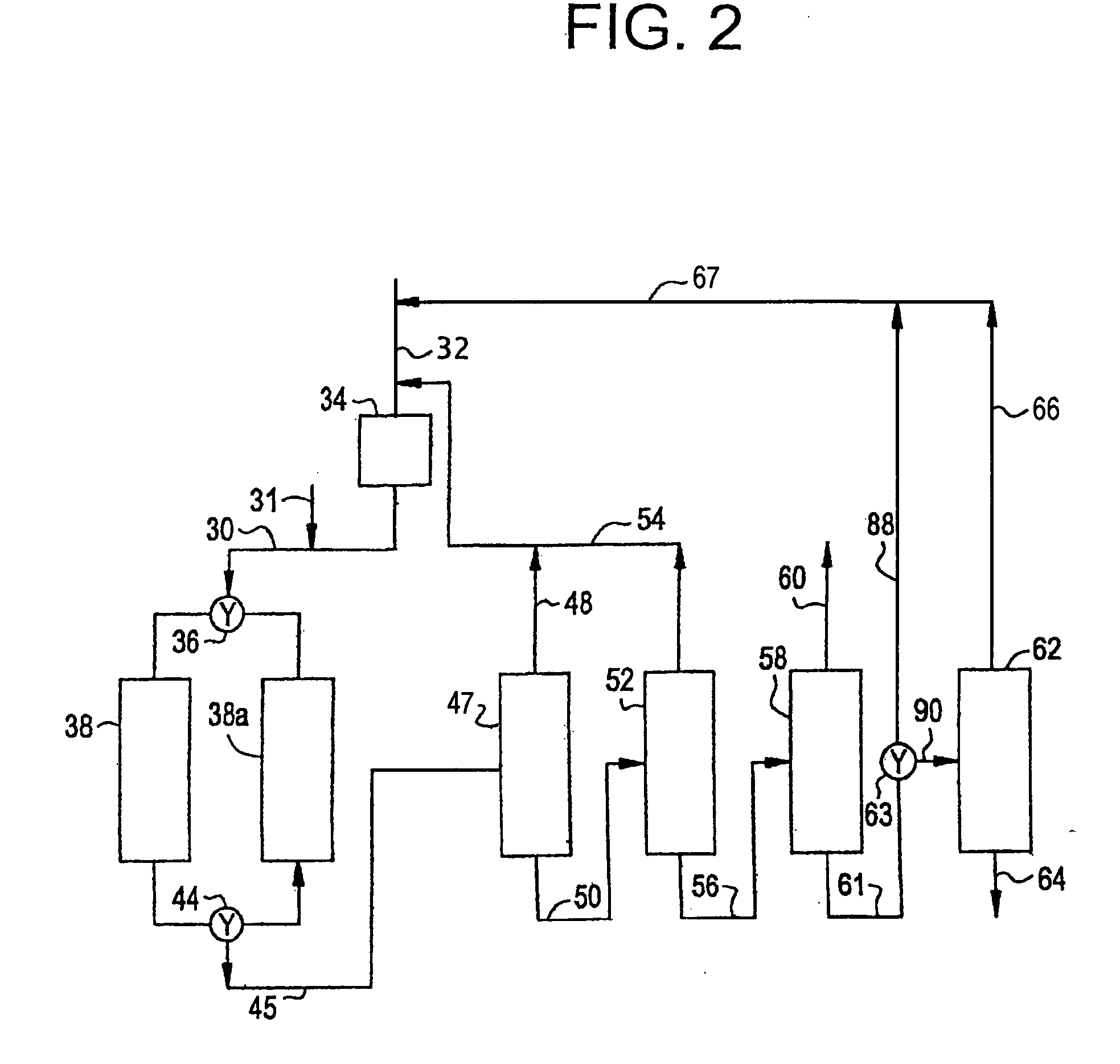

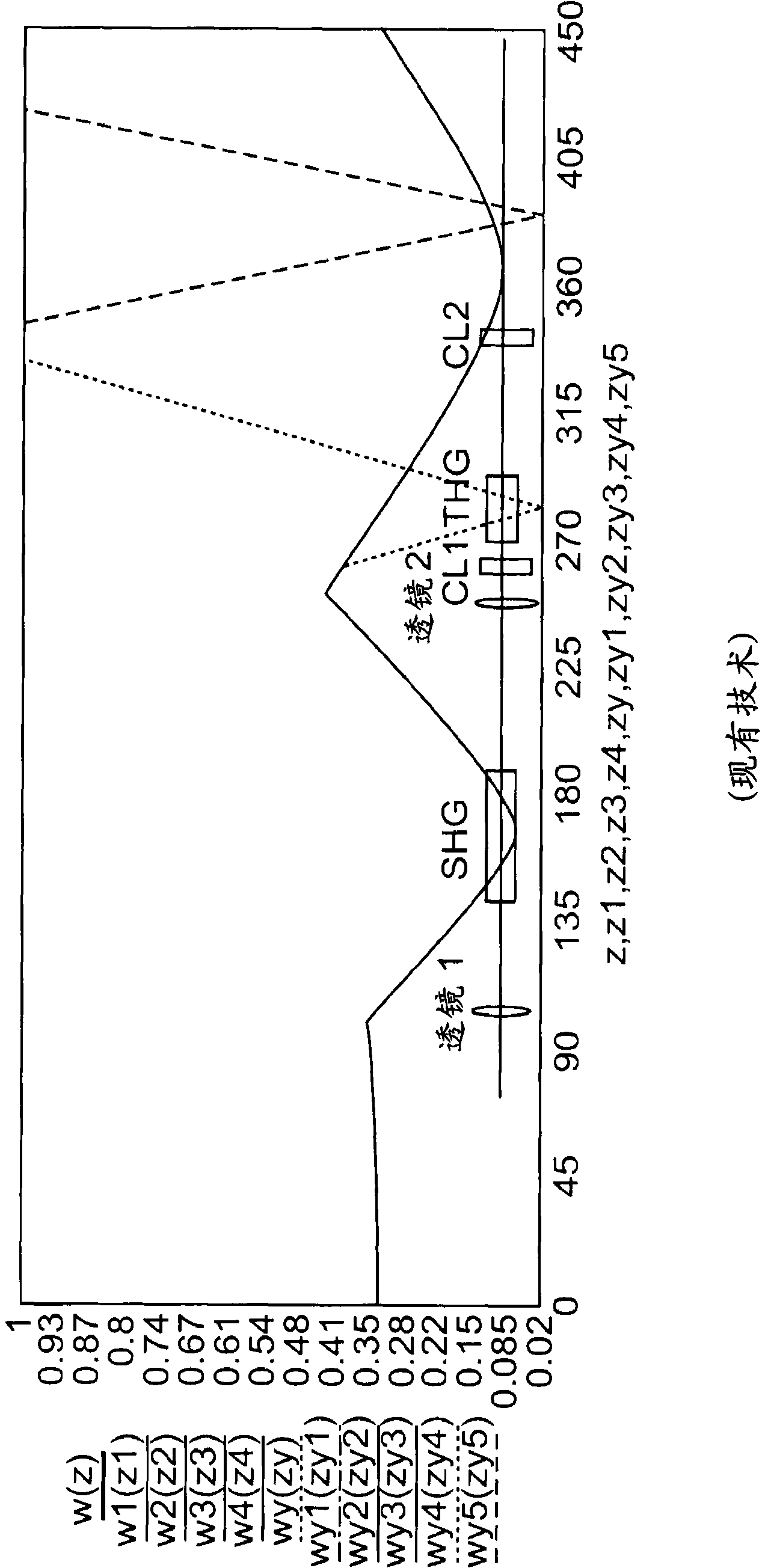

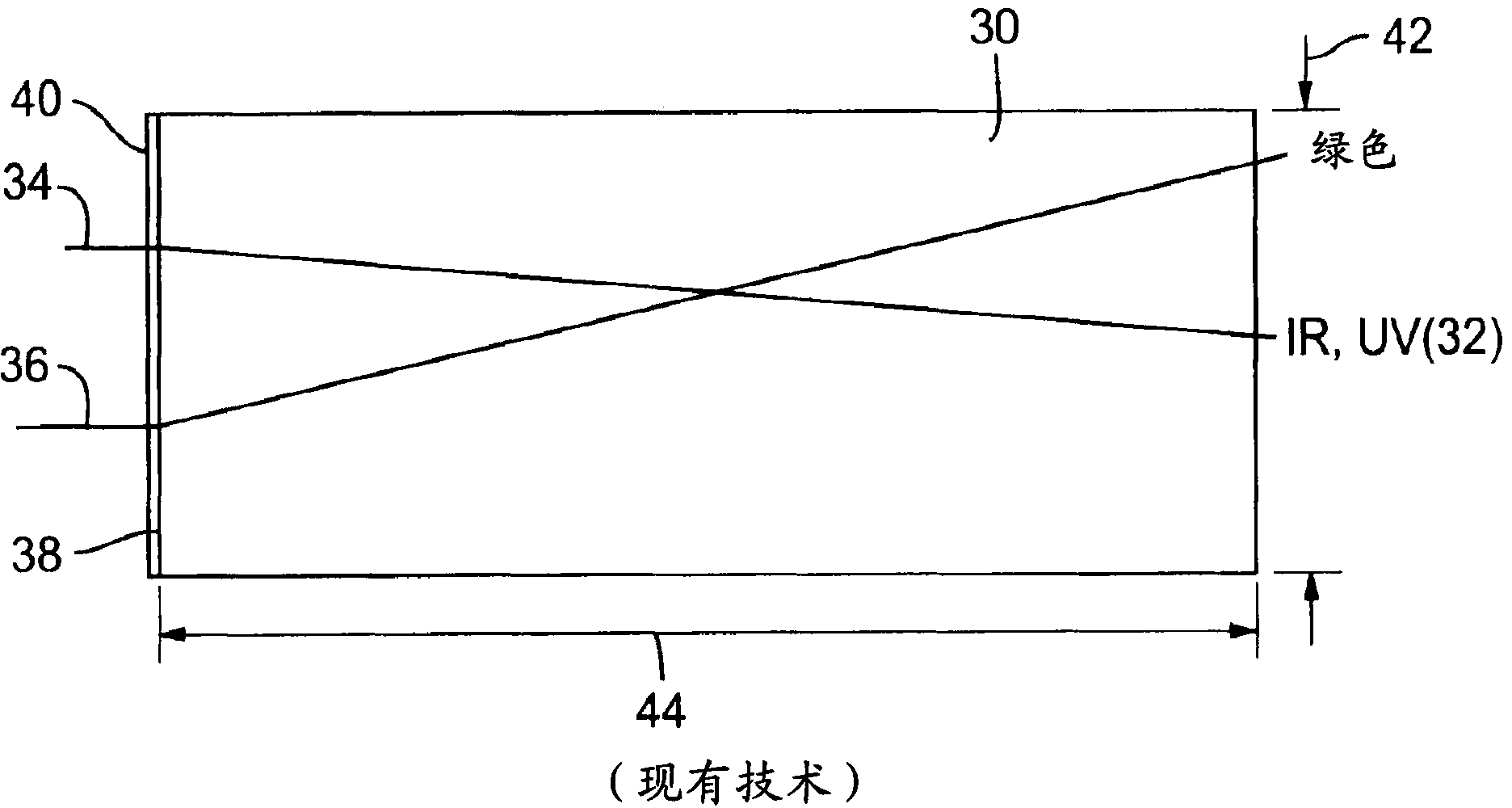

Wavelength conversion method with improved conversion efficiency

InactiveUS7113325B1Reduce impactImprove conversion efficiencyLight demodulationNon-linear opticsPoynting vectorEngineering

A nonlinear optical conversion device includes a nonlinear crystal having entrance and exit surfaces allowing input and output laser beams to propagate in the phase-matching plane for a desired nonlinear generation process. The nonlinear generation process involves a nonlinear interaction in the nonlinear crystal and resultant conversion of power in one or two input beams into power in the output beam. The nonlinear crystal is characterized by absorption and resultant modification of the crystal properties by the power in the output beam, the modification with the potential for reducing the efficiency of the nonlinear process in the crystal, and the nonlinear process involving critical phase-matching in the nonlinear crystal in which the powers in the output beam and input beam or beams propagate in different directions through the process of Poynting vector walk-off. The input beam or beams are of a sufficiently small beam dimension in the phase-matching plane.

Owner:MITSUBISHI MATERIALS CORP

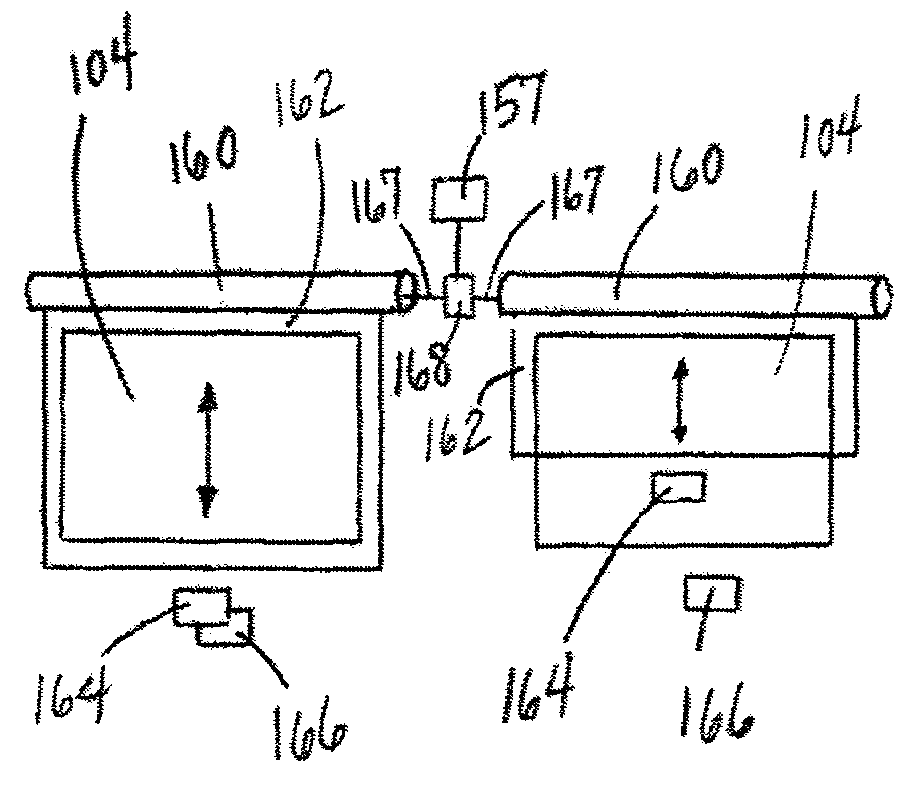

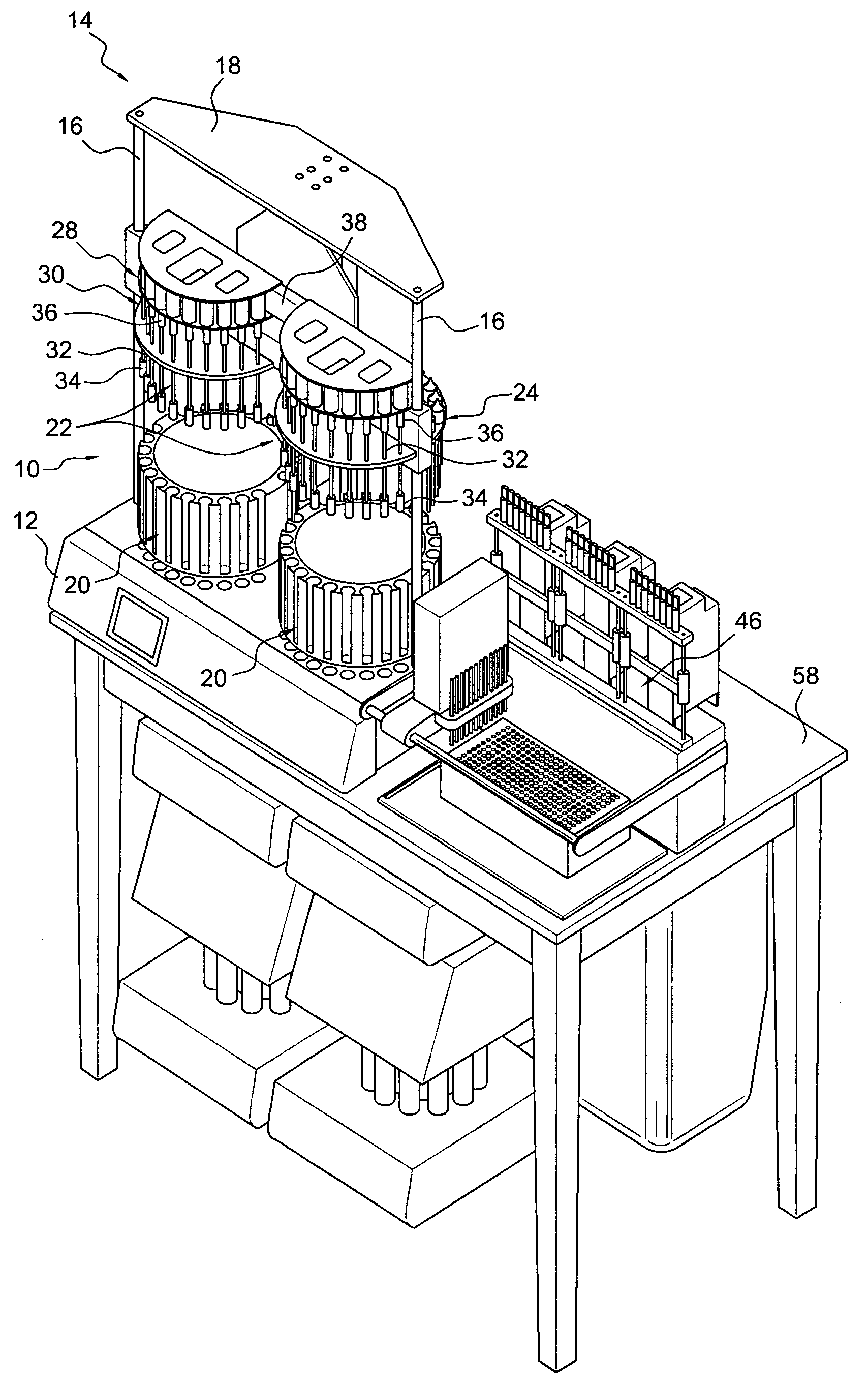

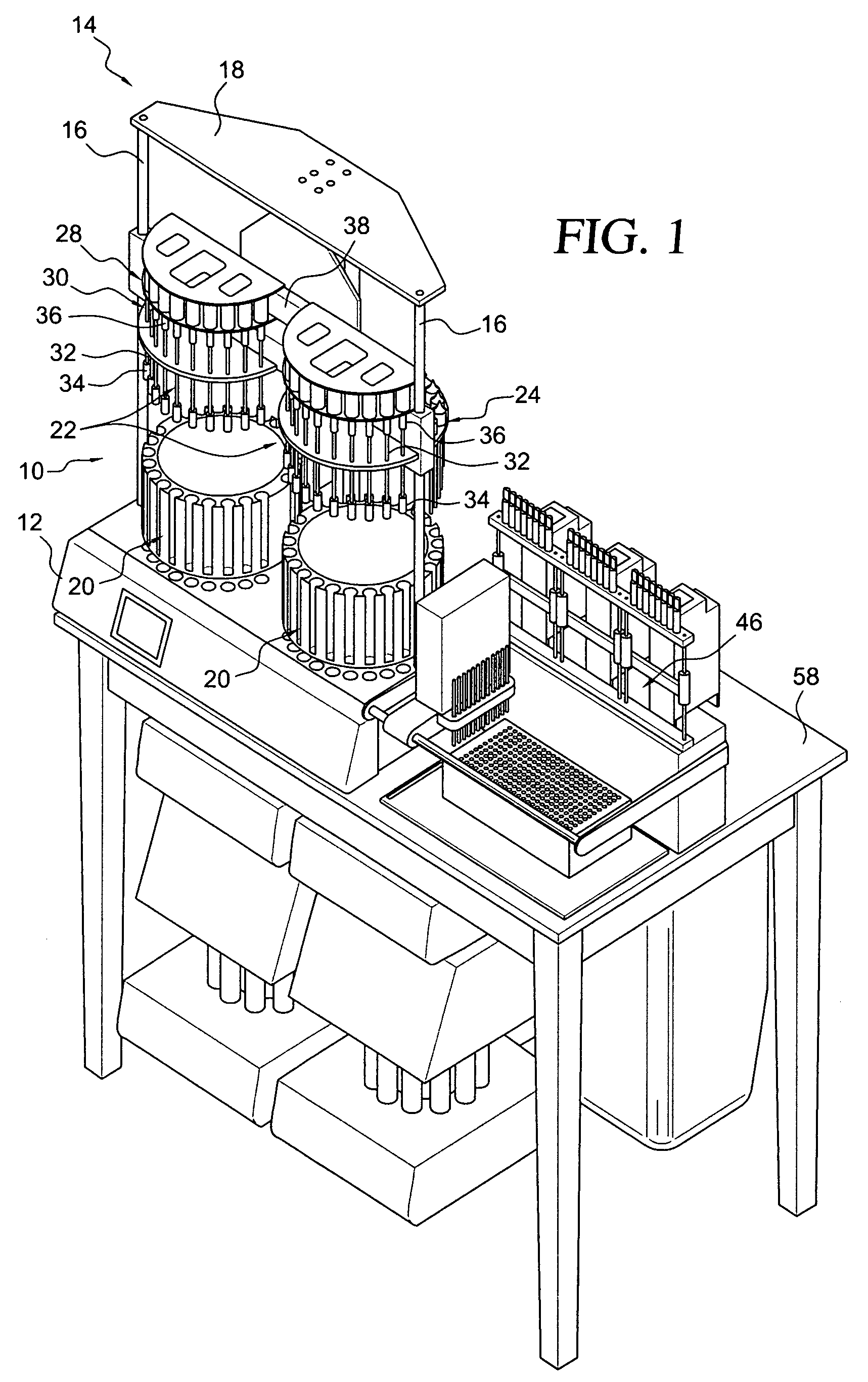

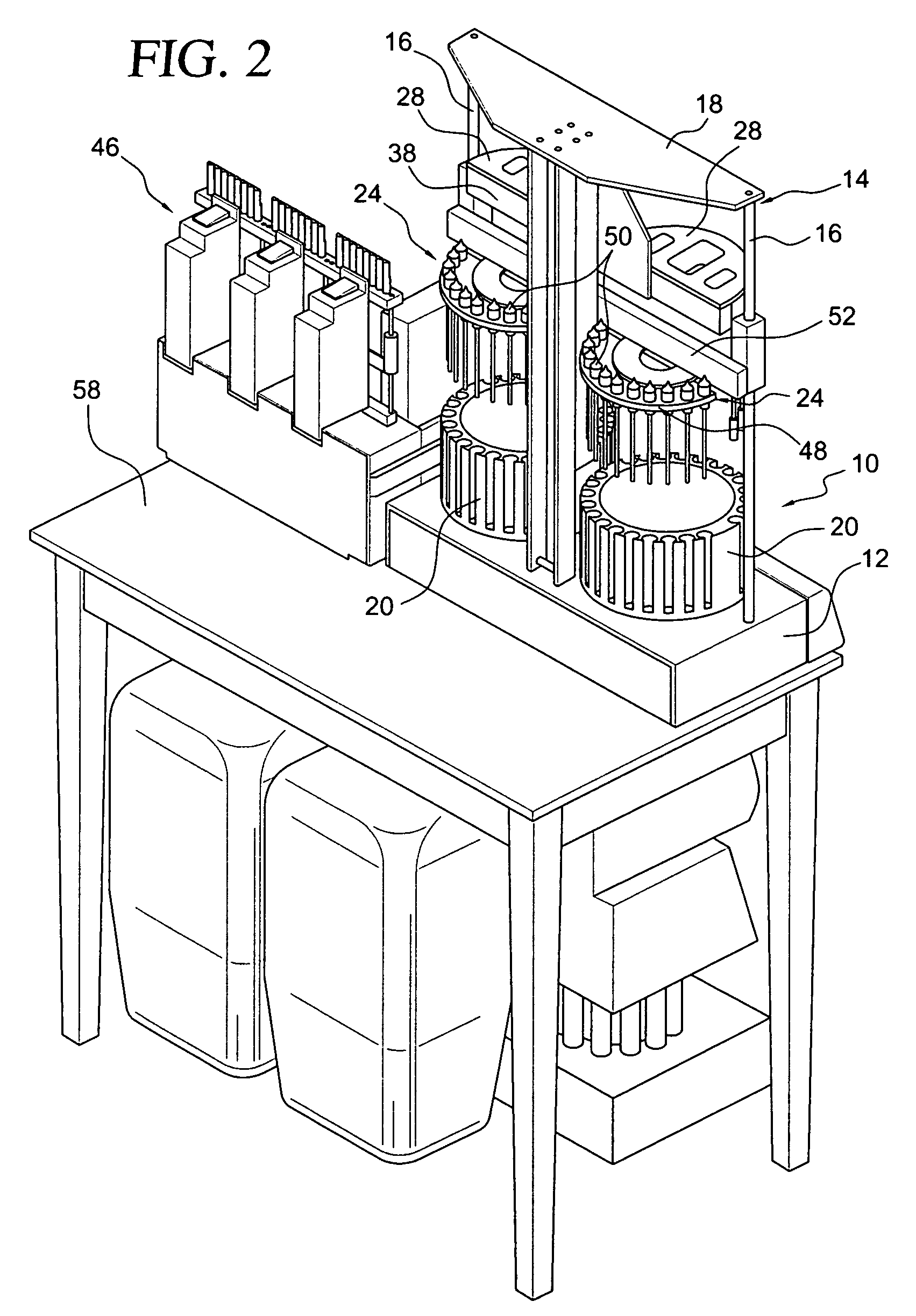

Pharmaceutical product release rate testing device

InactiveUS7585465B2Efficient and economicalRotating receptacle mixersRotary stirring mixersTemperature controlEngineering

Pharmaceutical product release rate testing device includes a base, at least one carousel member rotatably mounted on the base, each carousel member including a plurality of test tube pockets each adapted to receive a test tube fillable with test media, and a dipping mechanism for dipping samples to be tested into the test tubes when present in the pockets and filled with test media. A rinsing / filling mechanism is provided to rinse or fill test tubes in one set of pockets while test tubes in another set of pockets are involved in the dipping process via the dipping mechanism. The carousel member is temperature-controlled such that all of the test tubes when present in the pockets are at substantially the same temperature for critical stages of the testing process. Methods for conducting pharmaceutical product release rate testing using the device are also disclosed.

Owner:LOGAN INSTR

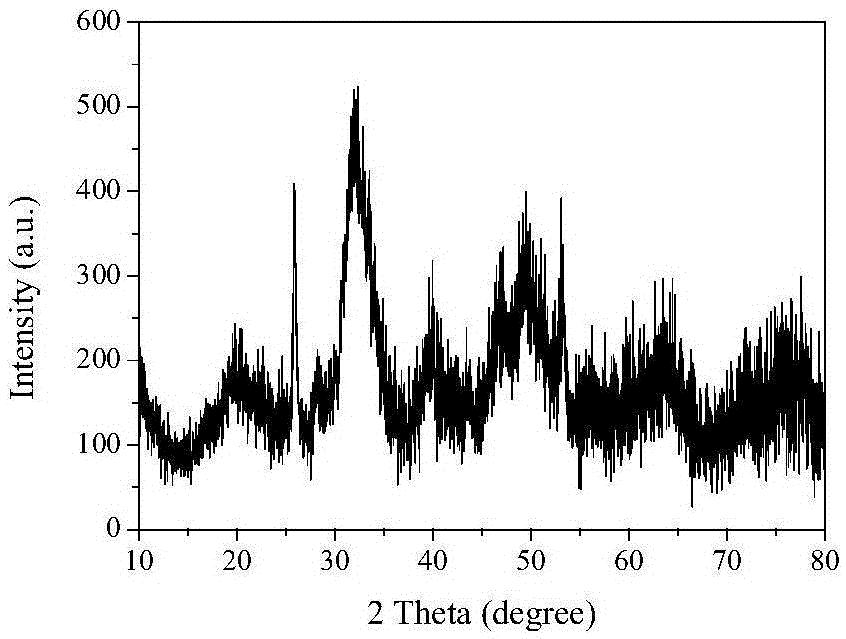

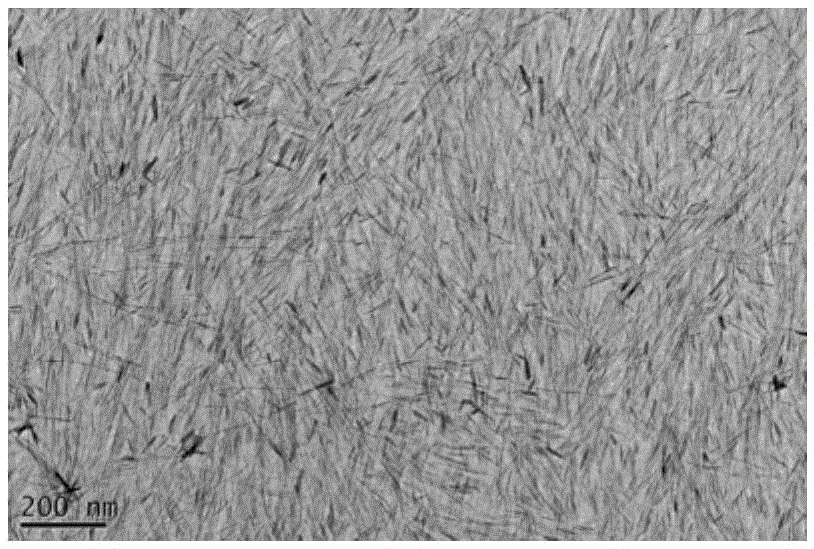

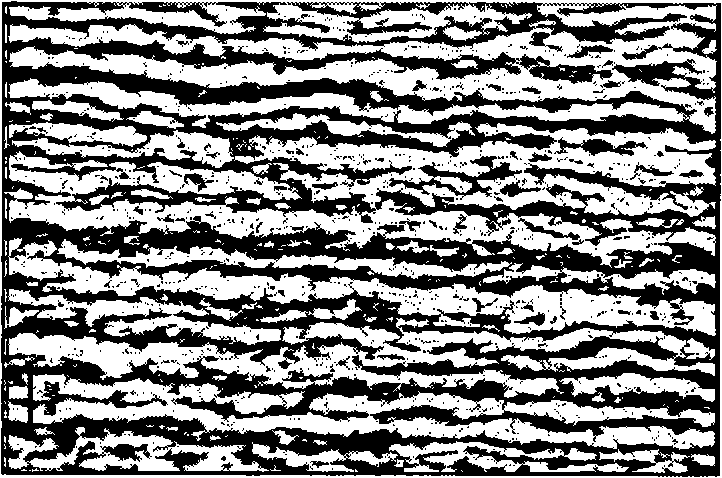

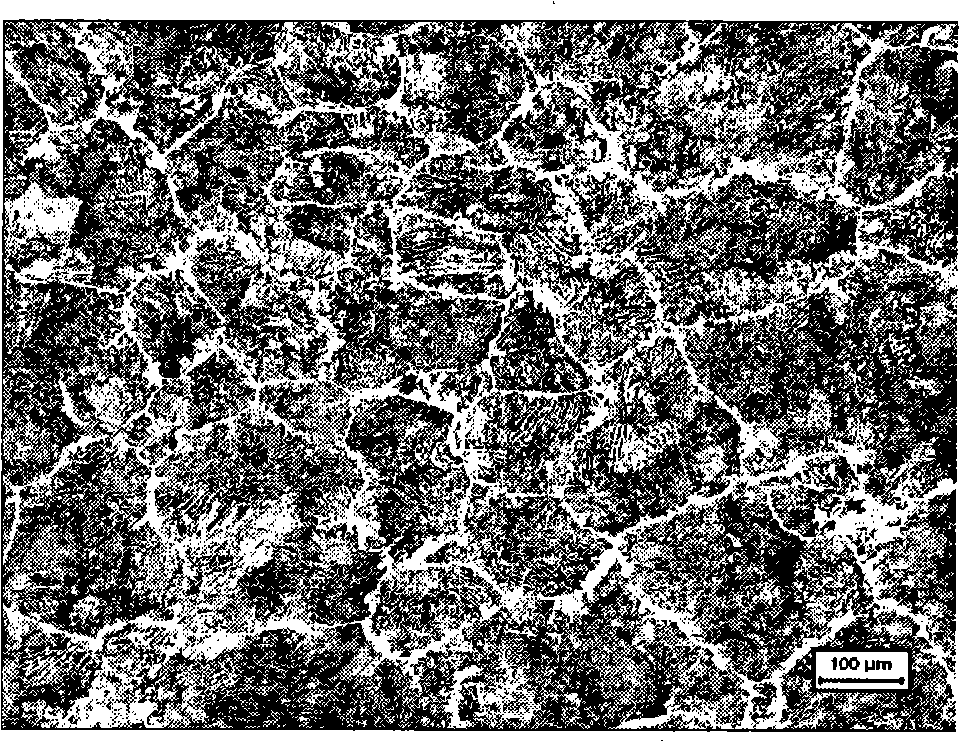

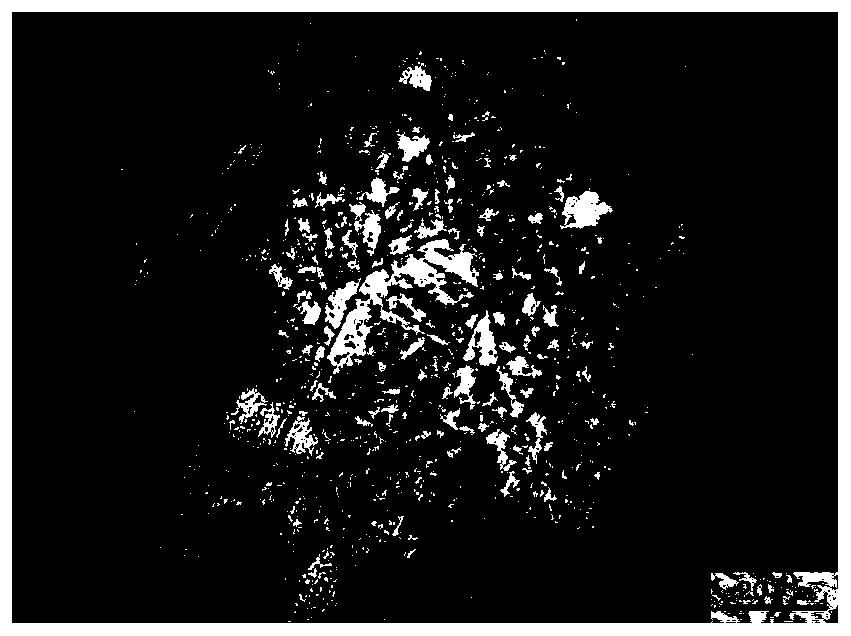

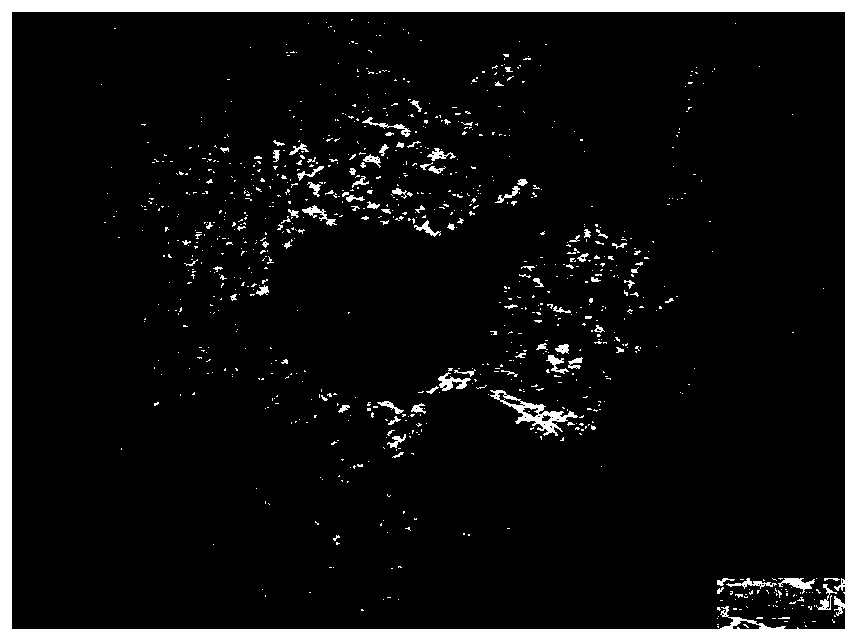

Preparing method for oil-based hydroxyapatite colloidal crystals

InactiveCN105417514AAbundant and easy to obtainLow costLiquid crystal compositionsPhosphorus compoundsPhosphoric acidSolvent

A preparing method for oil-based hydroxyapatite colloidal crystals comprises the steps that a soluble calcium saline solution is mixed with low alcohol, fatty acid and organic amine, and a uniform solution is obtained after stirring; under the stirring condition, soluble phosphoric acid saline is slowly dripped, the temperature is increased to 50-90 DEG C for a reaction for 3-24 h, the mixture is naturally cooled to the room temperature and centrifuged through a high-speed centrifugal machine, precipitate is obtained and subjected to centrifugal washed with absolute ethyl alcohol and a non-polar solvent alternately three times, electrolyte and redundant fatty acid in the system are removed, and oil-soluble hydroxyapatite nano-particles are obtained; the oil-soluble hydroxyapatite nano-particles are dispersed into the non-polar solvent with the particle concentration reaching 10-65% which exceeds the critical phase conversion concentration, and the oil-based hydroxyapatite colloidal crystals with intense birefringence are prepared. According to the preparing method, raw materials are rich in source and easy to obtain, cost is low, the synthesizing process is simple and easy to implement, and products are stable in quality and good in process repeatability and have good application prospects in biomedical composites and coating materials.

Owner:HUBEI UNIV OF TECH

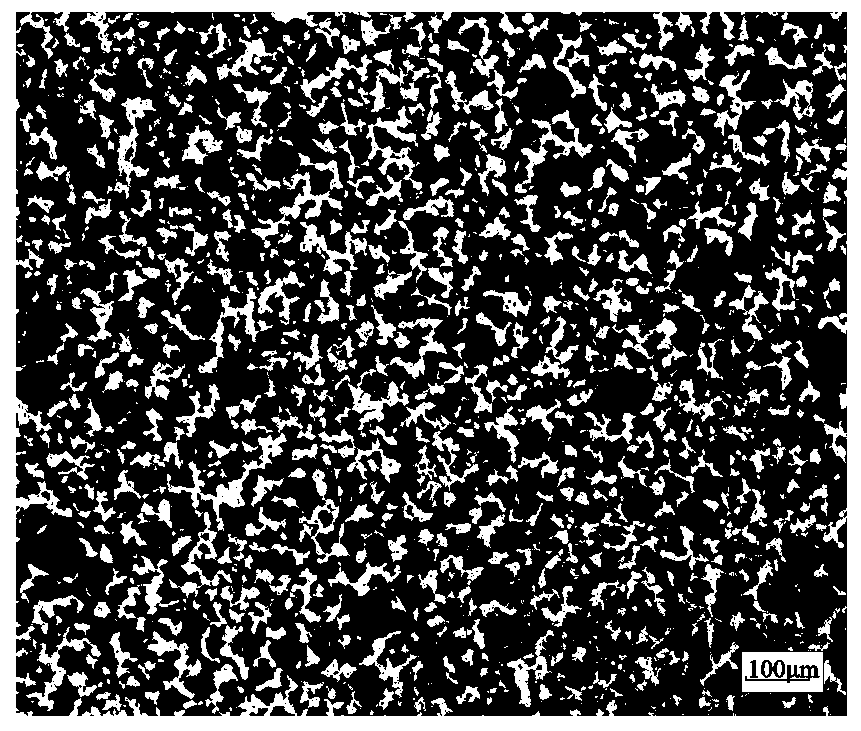

Method for eliminating defective structure in structural alloy steel and tool steel substrate by using impulse current

InactiveCN101275180ABreak through the limitations of traditional heat treatment processGood effectHeat treatment process controlHeat treatedStart up

A method for eliminating defective structures in basal bodies of structural alloy steel and tool steel by applying pulse current is disclosed, steel products are placed in a heat treatment electric furnace, positive and negative two end surfaces of the steel products are connected with a pulse current generator out of the furnace through lead; when the structural alloy steel is heated to the critical phase-transition temperature A+50 DEG C or the tool steel is heated to the critical phase-transition temperature A+(20-50 DEG C), the heat preservation is begun, at the same time, the pulse current generator is started up to input the pulse current whose intensity is 850A-1000A, frequency is 50Hzto30Hz, after maintaining for 10-15 minutes, the structural alloy steel is carried out according to normalizing procedure and cooled out of the furnace, the tool steel is cooled within the furnace; the method inputs the low frequency pulse large current with quite small duty ratio at the same time of heating the metal to meet the demand of phase-transition thermodynamics, thus improving the change speed of the structures, thinning grains in a very short time, clearing the banded structures, netlike structures in the steel and providing ideal basal body structure for the subsequent heat treatment procedure.

Owner:KUNMING UNIV OF SCI & TECH

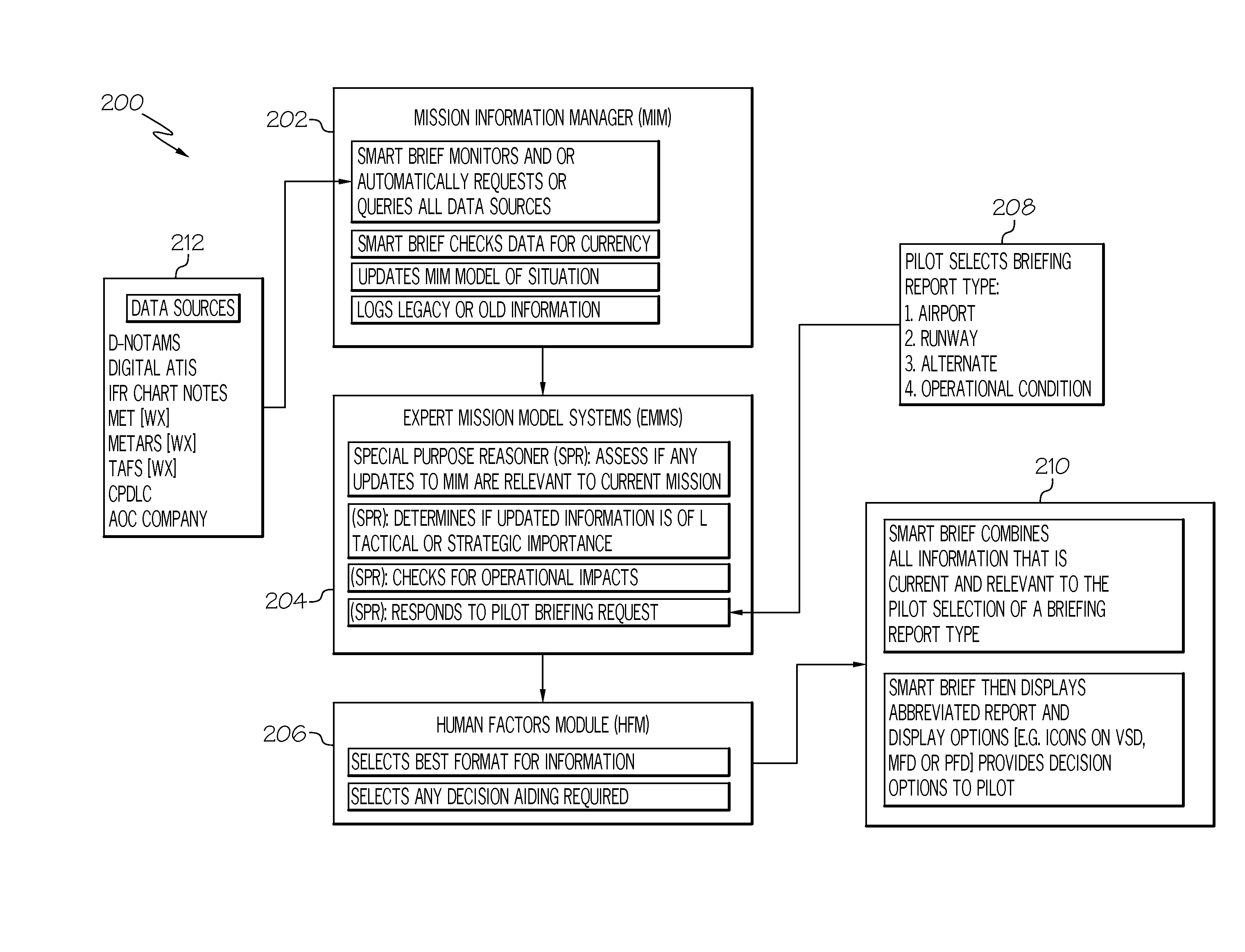

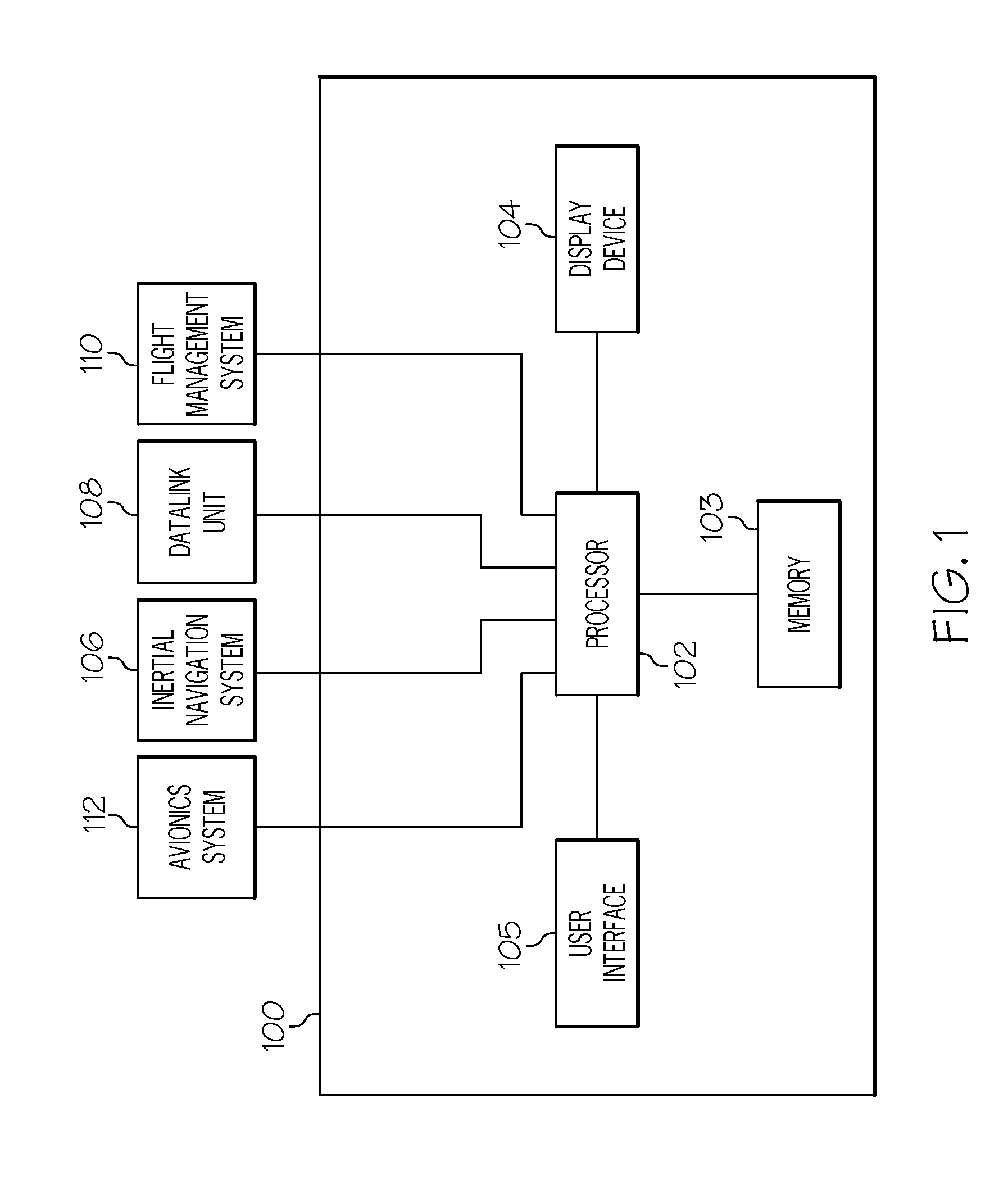

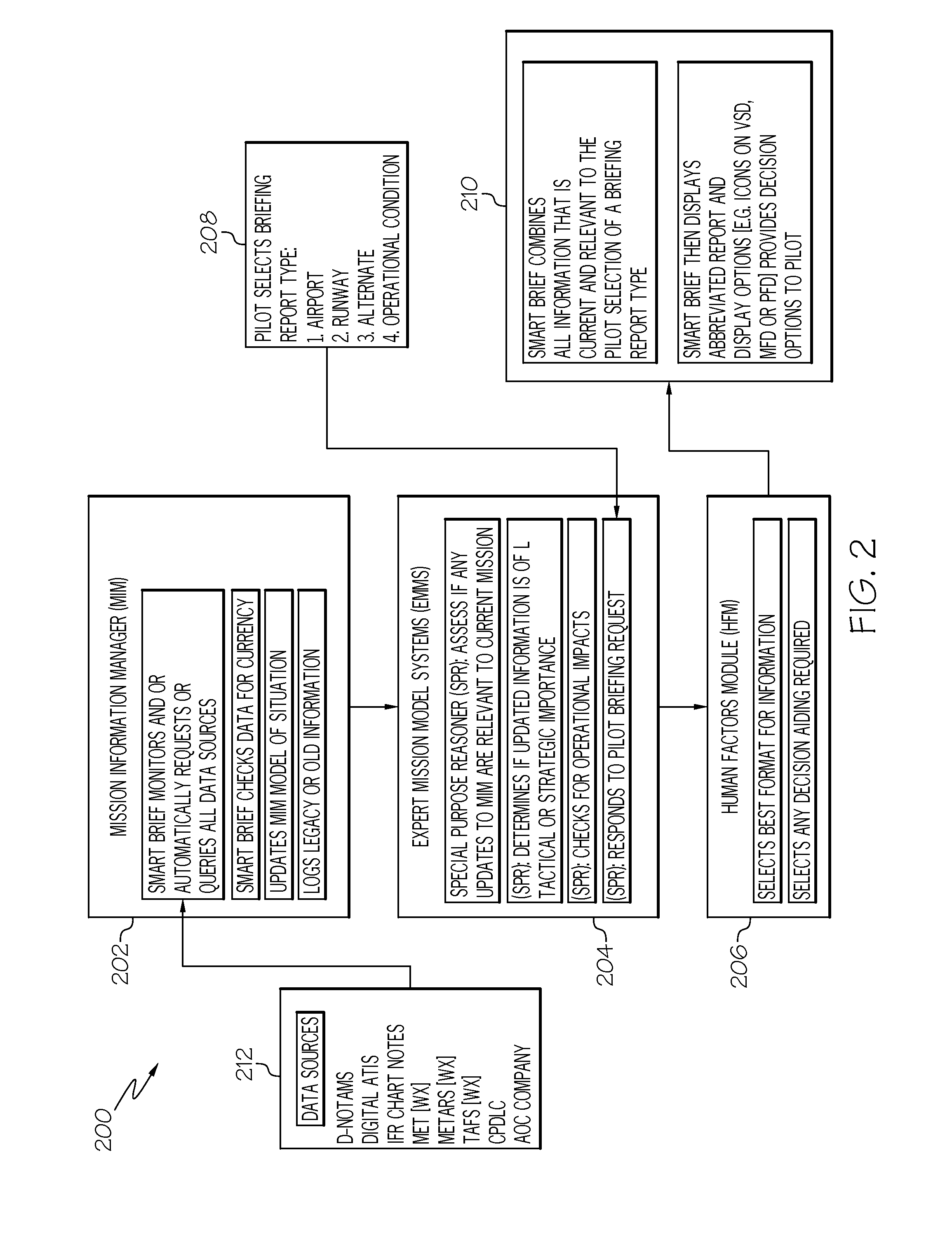

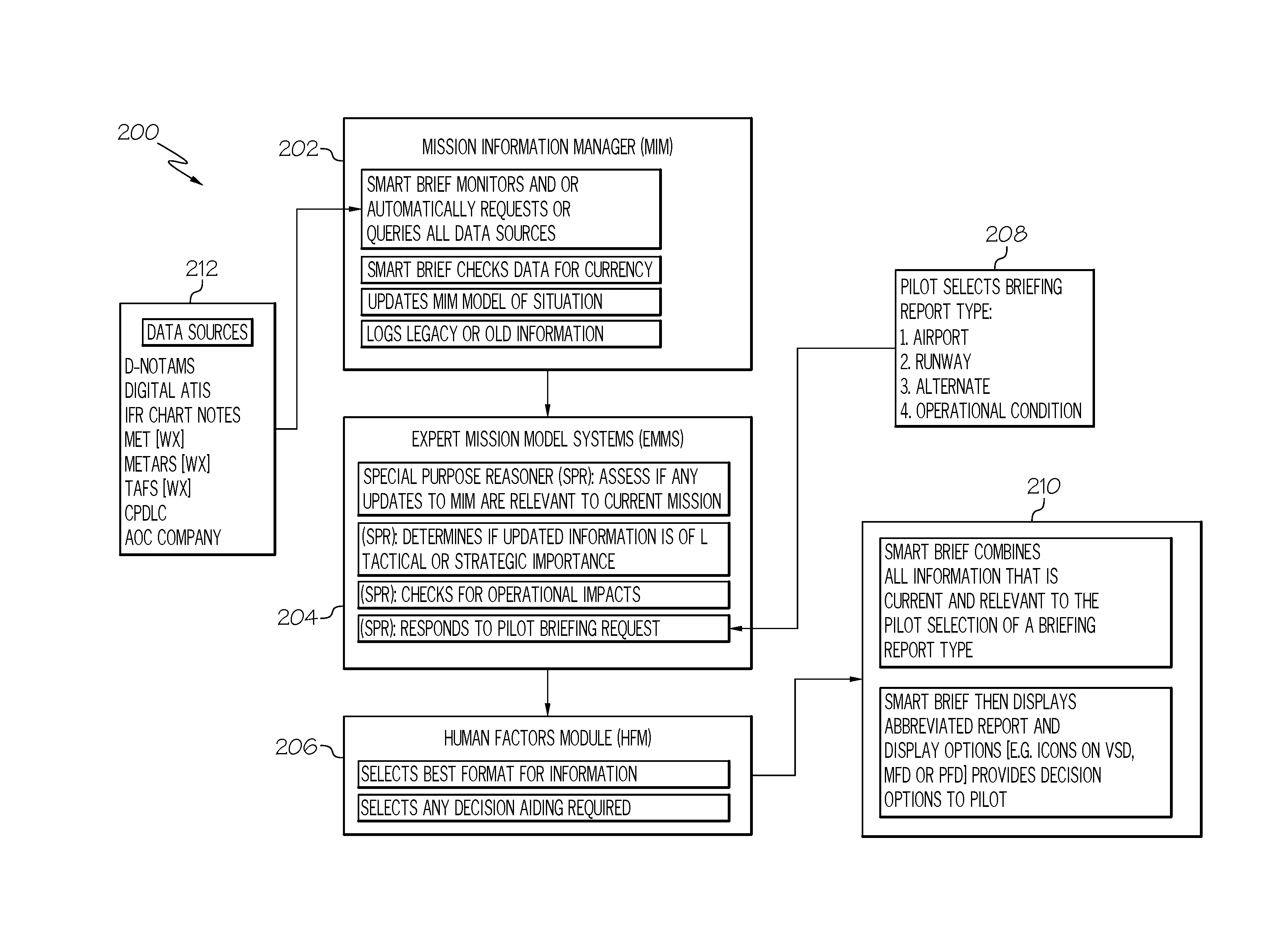

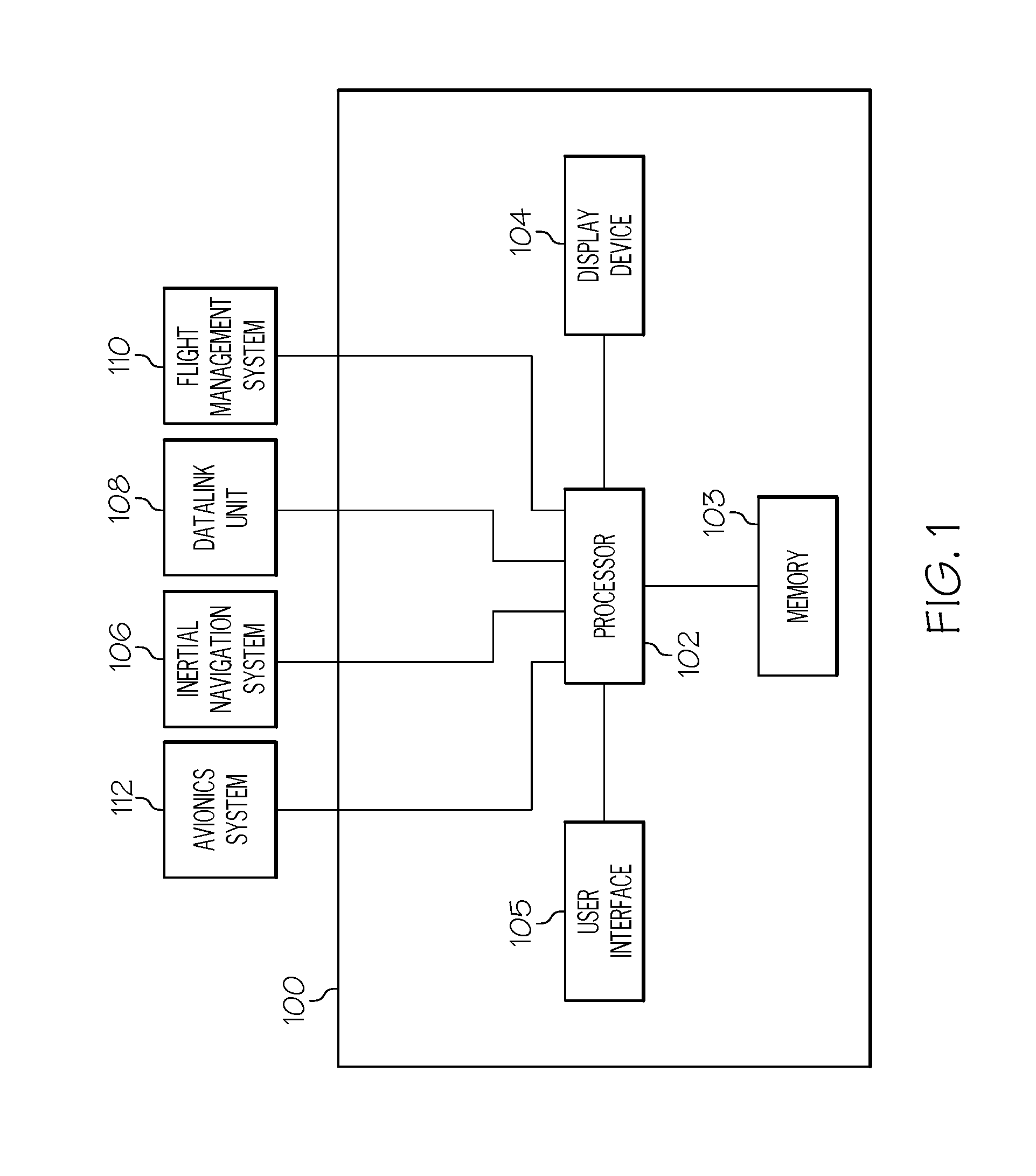

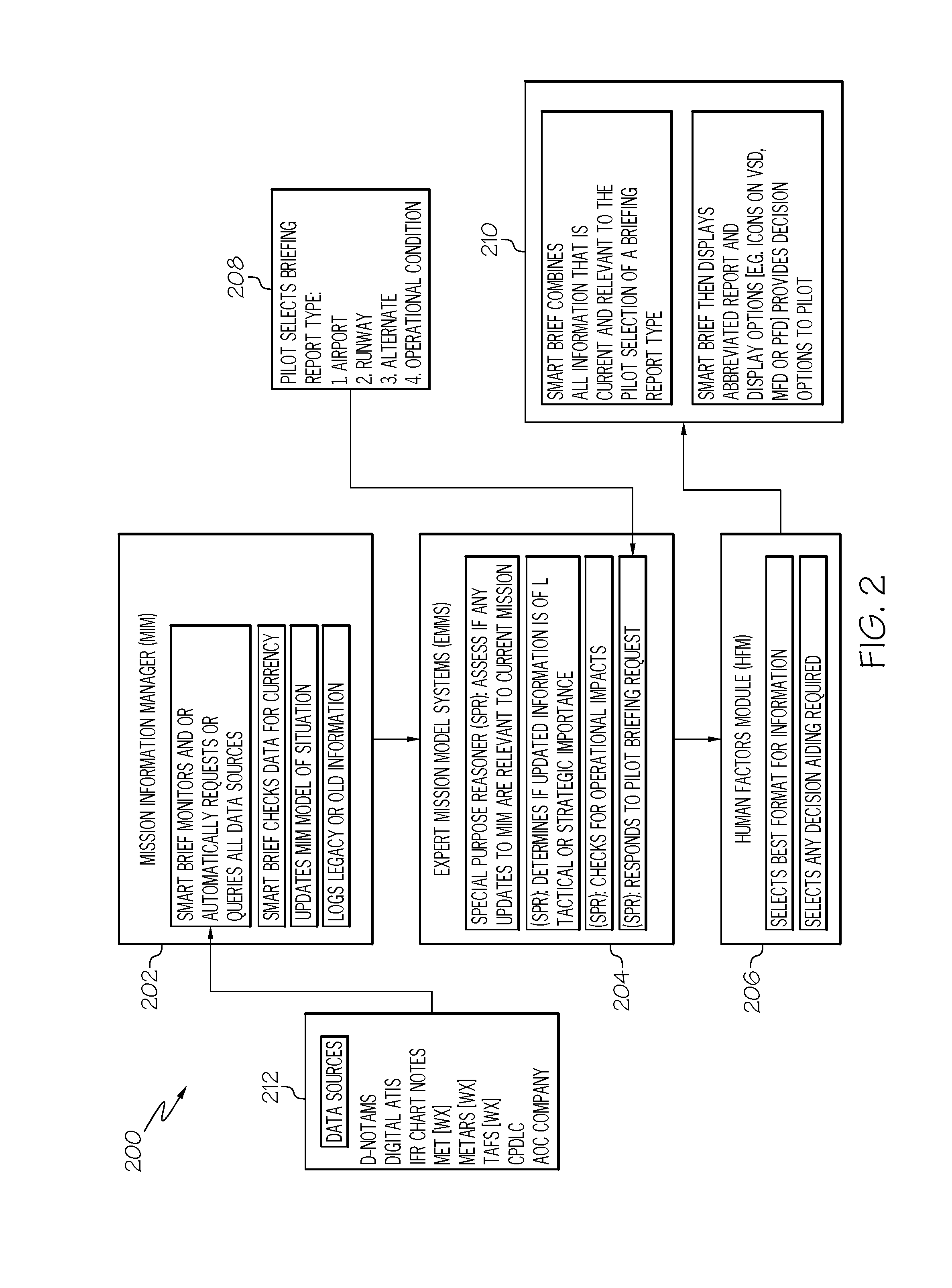

System and method for intelligently mining information and briefing an aircrew on conditions outside the aircraft

InactiveUS20150261829A1Digital data information retrievalDigital data processing detailsAircrewModel system

A system and method intelligently mines information and briefs an aircrew on conditions outside the aircraft. A mission information manager proactively mines incoming data sources, filters for relevance to current flight, retrieves the most up-to-date information, dynamically selects an appropriate format based on perceptual / cognitive affordances of content, and presents integrated, intuitive data that allows the flight crew to rapidly acquire relevant awareness of conditions outside the aircraft. An expert mission model system reviews incoming information for any situations that are of immediate mission concern. The system presents this information to the flight crew's attention while they have the greatest operational flexibility. Additionally, a human factors module provides decision aiding for select critical phases while taking into account information both outside and inside the aircraft.

Owner:HONEYWELL INT INC

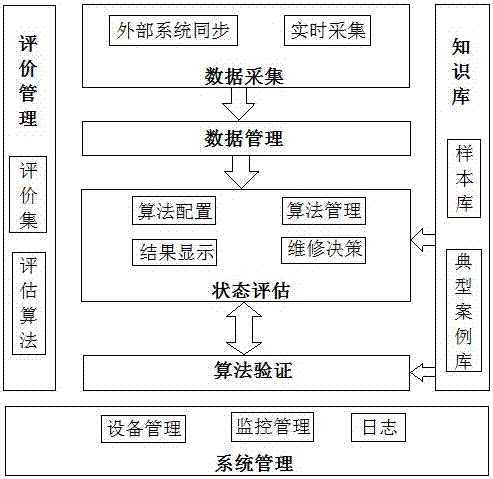

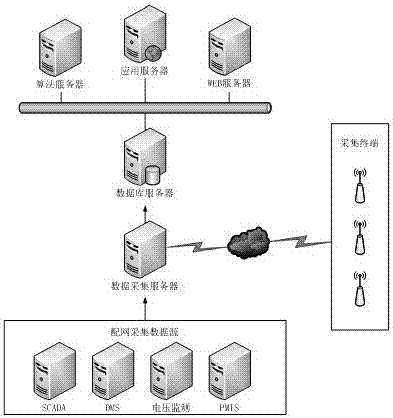

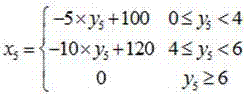

Distribution network equipment state evaluation system based on big data analysis

InactiveCN106997513ASafe and reliable workStable jobDatabase queryingMeasurement devicesPower gridEvaluation system

The invention discloses a distribution network equipment state evaluation system based on big data analysis, and relates to the distribution network equipment detection technology field. The distribution network equipment state evaluation system is characterized in that a big data analysis technology is combined with a state evaluation technology, an expert system technology, and an on-line monitoring technology, and the health state of the distribution network equipment is evaluated; health states and reliability of distribution network key equipment in various key phases are evaluated comprehensively, timely, and accurately; detection and maintenance are carried out timely according to an evaluation result, and the safe and reliable operation of the distribution network key equipment are guaranteed, and then a power grid system can work safely and stably. The distribution network equipment evaluation system is advantageous in that by adopting algorithm verification, a state evaluation result is in accordance with the state result of the actual distribution network equipment, and the state evaluation accuracy of the distribution network equipment state evaluation system is improved, and therefore workers can carry out the detection and the maintenance timely and accurately, and the further deterioration of the distribution network equipment is reduced, and the safety of the power grid system is guaranteed.

Owner:ELECTRIC POWER RES INST OF GUANGXI POWER GRID CO LTD

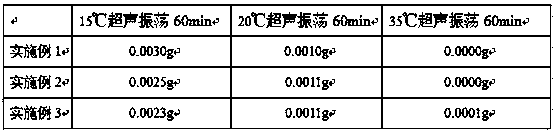

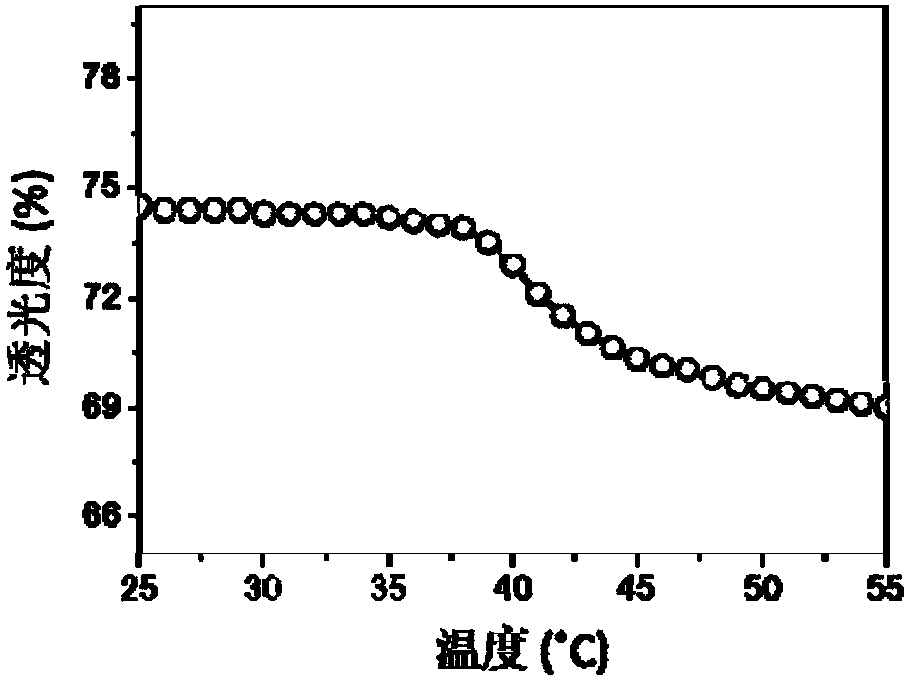

Thermosensitive warm-keeping fabric microcapsule finishing agent and preparation method and application thereof

The invention discloses a thermosensitive warm-keeping fabric microcapsule finishing agent and a preparation method and application thereof. The preparation method comprises the following steps of: selecting wormwood essential oil and pepper essential oil with warm-keeping health-care effects as a composite core material, using a thermosensitive material with an upper critical phase inversion temperature (UCST) of 25-30 DEG C and a natural polymer as a wall material, preparing a thermosensitive warm-keeping health-care microcapsule by using a complex coacervation method. The core material in the microcapsule can only be released when an environment temperature is less than the UCST, and the temperature is lower, a releasing speed is faster. Finishing work liquid is prepared by cooperatingwith a super soft adhesive. Through performing one-soaking one-rolling on a fabric, the fabric with a lasting warm-keeping health-care function can be obtained. While applied in winter, the fabric hasthe intelligent warm-keeping effect, and a good sleeping environment is created. In addition, the fabric has no core material leakage during high-temperature shaping and summer storage, so adequate using is guaranteed when the finishing agent is applied.

Owner:JIANGSU GOLDSUN TEXTILE SCI & TECH

System and method for intelligently mining information and briefing an aircrew on conditions outside the aircraft

A system and method intelligently mines information and briefs an aircrew on conditions outside the aircraft. A mission information manager proactively mines incoming data sources, filters for relevance to current flight, retrieves the most up-to-date information, dynamically selects an appropriate format based on perceptual / cognitive affordances of content, and presents integrated, intuitive data that allows the flight crew to rapidly acquire relevant awareness of conditions outside the aircraft. An expert mission model system reviews incoming information for any situations that are of immediate mission concern. The system presents this information to the flight crew's attention while they have the greatest operational flexibility. Additionally, a human factors module provides decision aiding for select critical phases while taking into account information both outside and inside the aircraft.

Owner:HONEYWELL LKGLOBAL PATENT SERVICES

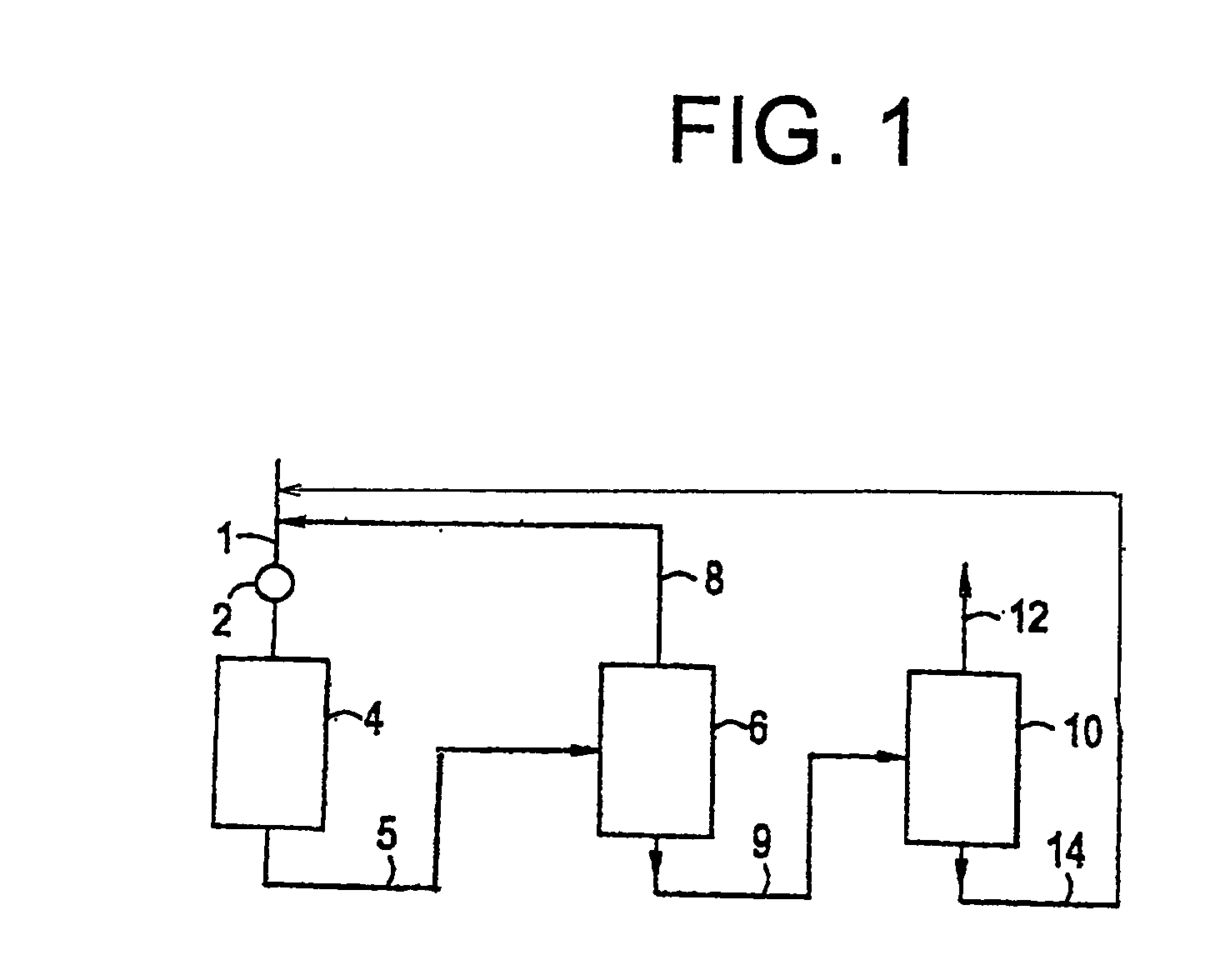

Critical phase alkylation process

InactiveUS20060194994A1Reduced diethylbenzene contentEnhanced ethylbenzene contentHydrocarbon by isomerisationHydrocarbonsCeriumLanthanum

A process for the production of ethylbenzene by the ethylation of benzene in the critical phase in a reaction zone containing a molecular sieve aromatic alkylation catalyst comprising cerium-promoted zeolite beta. A polyethylbenzene is supplied into the reaction zone and into contact with the cerium-promoted zeolite beta having a silica / alumina mole ratio within the range of 20-500. The reaction zone is operated at temperature and pressure conditions in which benzene is in the supercritical phase to cause ethylation of the benzene and the transalkylation of polyethylbenzene and benzene in the presence of the zeolite beta catalyst. An alkylation product is produced containing ethylbenzene as a primary product with the attendant production of heavier alkylated byproducts of no more than 60 wt. % of the ethylbenzene. The alkylation reaction zone is operated under conditions providing a composite byproduct yield of propyl benzene and butyl benzene relative to ethylbenzene, which is no more than one half of the corresponding yield byproduct for zeolite beta promoted with lanthanum. The production of ethylbenzene in the critical phase alkylation reaction zone is attended by recycle of a polyalkylated aromatic component of the reaction product back to the reaction zone.

Owner:FINA TECH

Wedge-faceted nonlinear crystal for harmonic generation

Lasers and laser systems generate different wavelengths by nonlinear sum or difference frequency conversion. A wedge-faceted nonlinear crystal (30') compensates for the spatial walk-off phenomenon associated with critical phase matching of a nonlinear crystal in the production of harmonic laser output at peak power.

Owner:ELECTRO SCI IND INC

Rolling process of improving 38CrMoAl steel rolling state structure

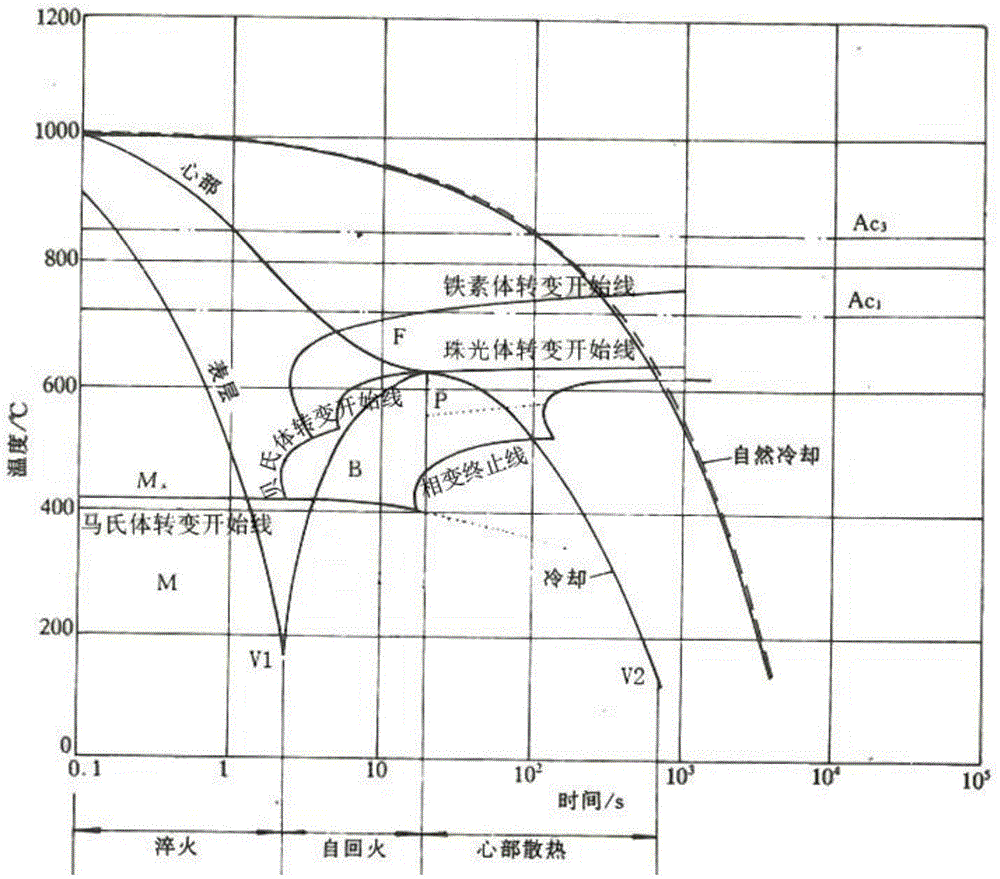

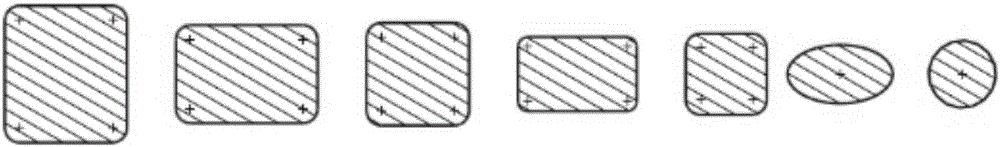

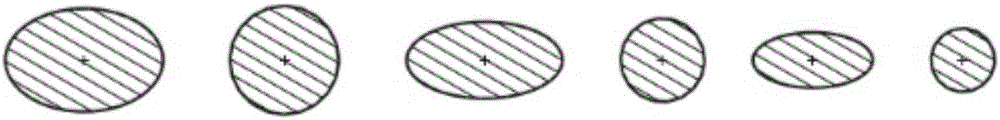

InactiveCN110180893AImprove uniformityRefined grain sizeTemperature control deviceMetal rolling arrangementsMetallurgyNucleation

The invention discloses a rolling process of improving a 38CrMoAl steel rolling state structure. The rolling process is characterized by comprising the following steps of 38CrMoAl steel blank selection, steel blank heating, steel blank rough rolling, steel blank medium rolling, steel blank finish rolling and steel cooling. The rolling process of improving the 38CrMoAl steel rolling state structurehas the following advantages that a relatively low final rolling temperature is controlled, so that the surface temperature of a rolled piece is lower than a temperature of a core portion in the process, the steel core portion obtains a relatively large compressive stress in the rolling process, the structure uniformity is greatly improved, and crystal grains are further refined; the final rolling temperature is lowered to be close to the actual critical phase change point Ar3, a phase change from gamma to alpha is promoted, and a nucleation site of ferrite is increased, so that a structure morphology of a product is ferrite and pearlite structures in a balanced state; and the rolling process is green and environmentally friendly, does not pollute the environment, is capable of lowering the cost and increasing the benefit and particularly has important significance of controlling the online structure and the performance of medium-low carbon alloy structural steel.

Owner:XINING SPECIAL STEEL +1

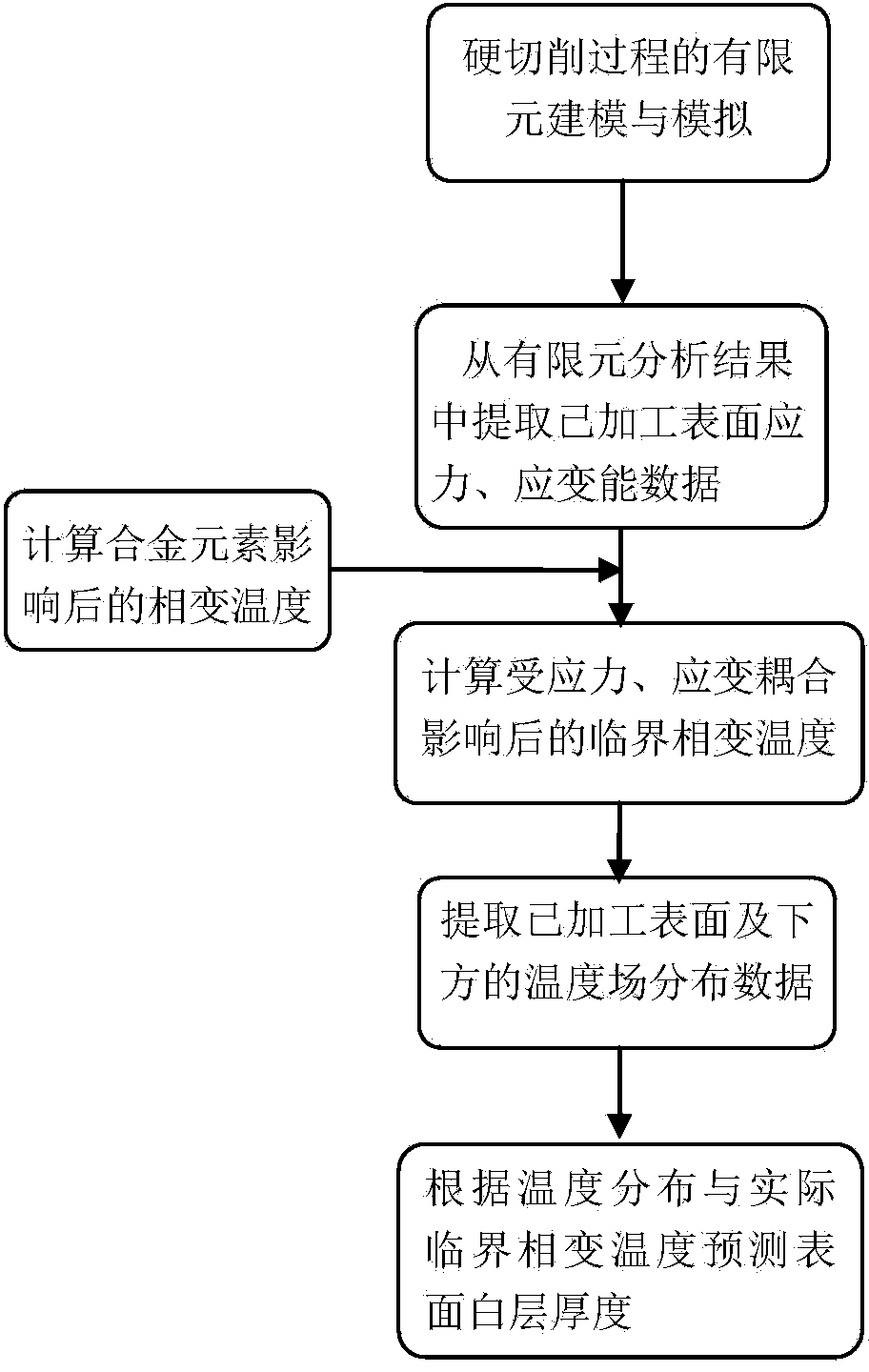

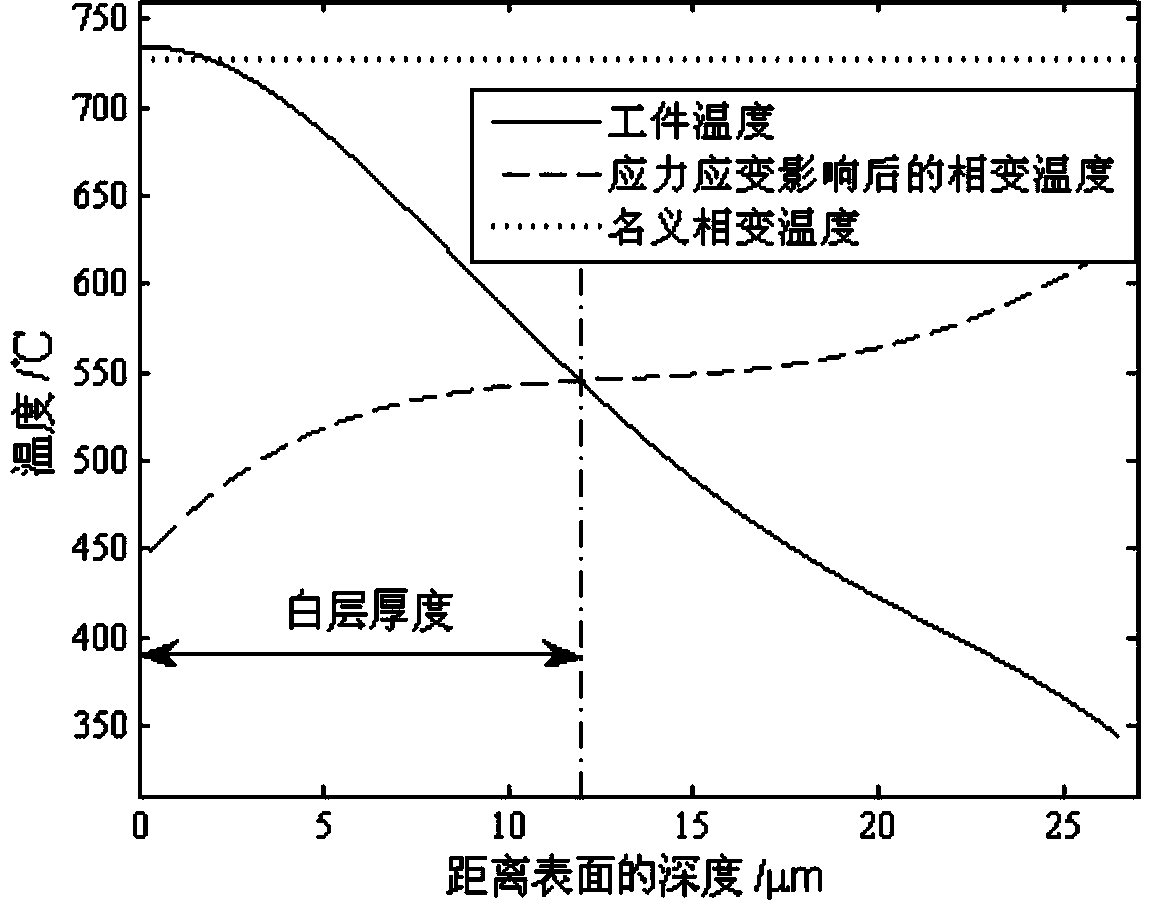

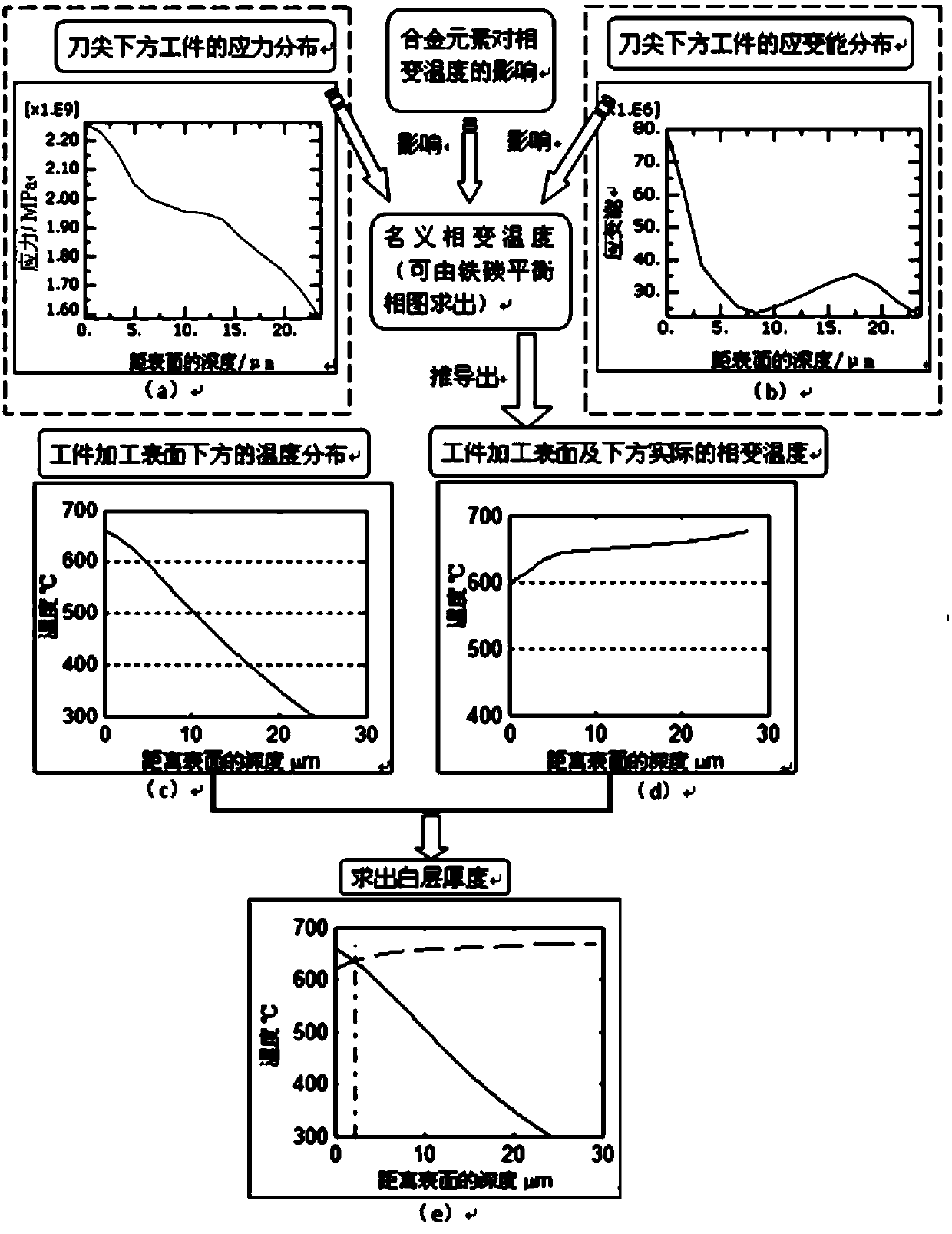

Thermal-mechanical coupling predication method for thickness of white layer on surface of hard tuned workpiece

InactiveCN104050335AThickness PredictionImprove processing efficiencySpecial data processing applicationsElement analysisMachined surface

The invention belongs to the technical field of machining and relates to a thermal-mechanical coupling predication method for the thickness of a white layer on the surface of a hard tuned workpiece. The method includes the following steps that finite element modeling and simulating are performed in the hard tuning process; stress and strain energy data of the machined surface are extracted from a finite element post analysis result, and critical austenite phase change temperature under influences of coupling of stress, strain and alloying elements is calculated; temperature distribution data underneath the machined surface are extracted from the finite element analysis result, and the thickness of the white layer on the surface is predicated according to temperature distribution and the actual critical phase change temperature. A finite element predication model of the thickness of the white layer on the dry hard tuned surface based on the phase change mechanism is provided and not only can predicate the thickness of the phase change white layer on the surface more accurately under the condition that thermal-mechanical coupling factors are considered, but also discloses the internal mechanism of forming the white layer.

Owner:DALIAN UNIV OF TECH

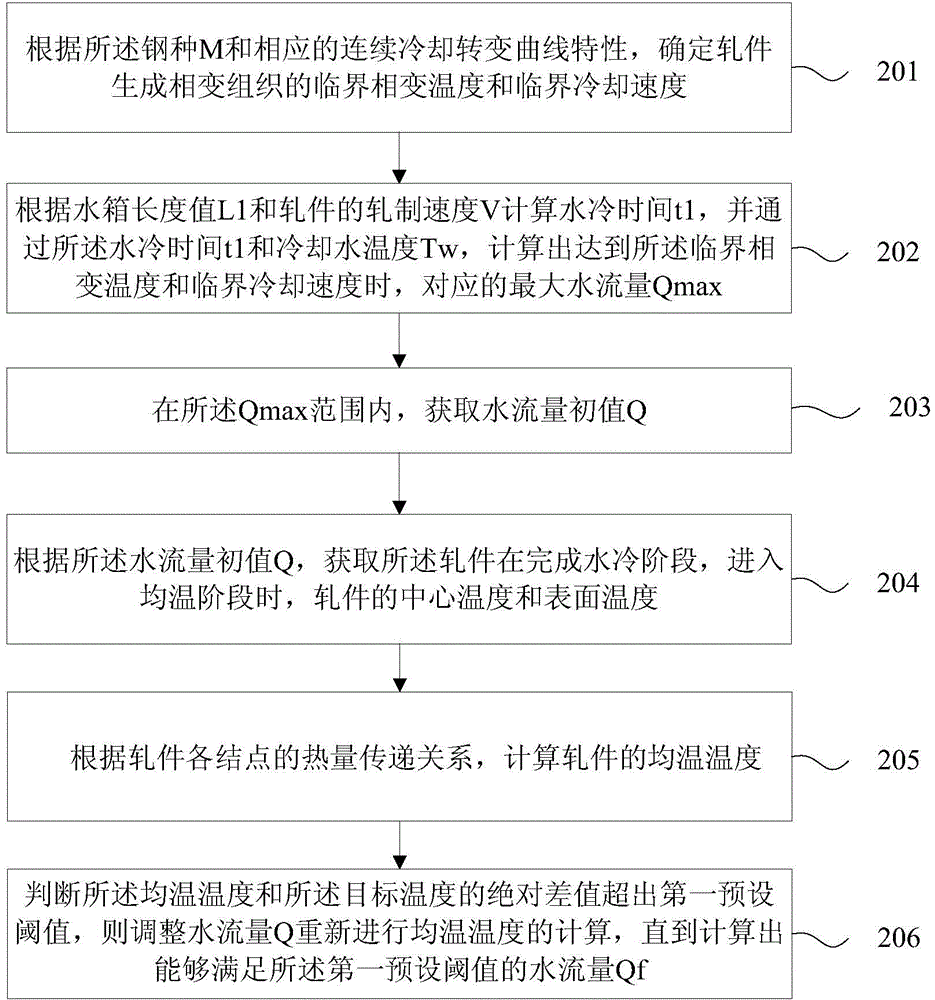

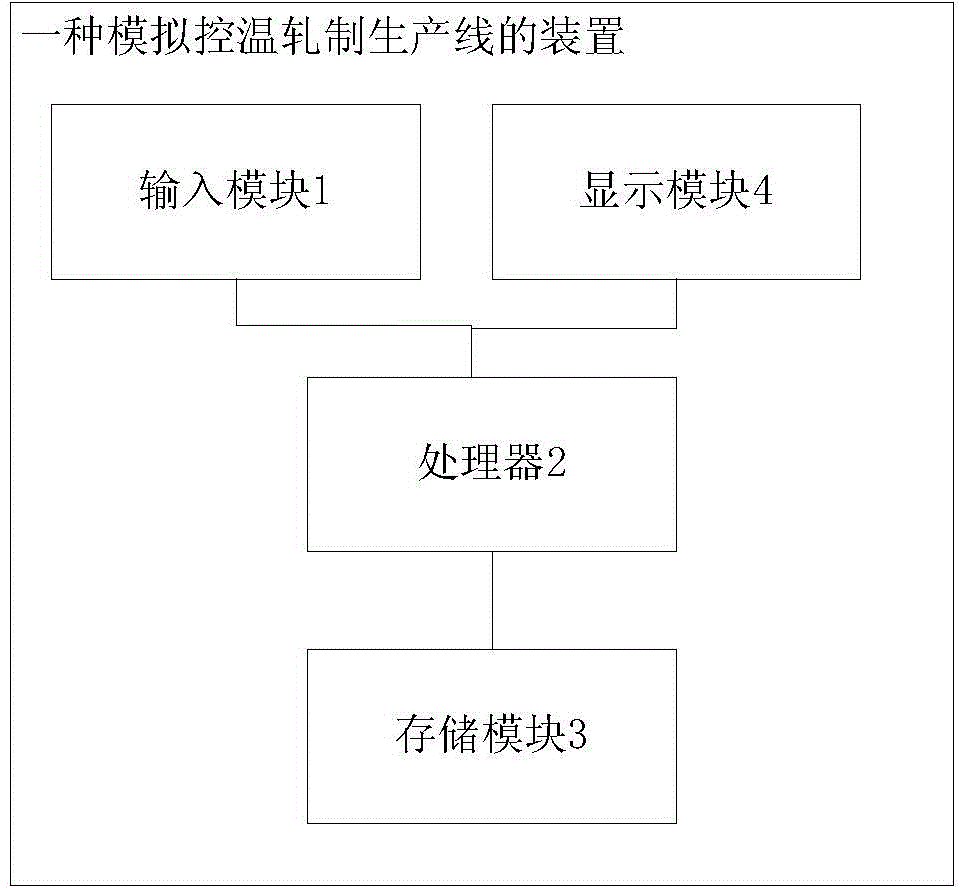

Control method and control device of rod and wire production line temperature control rolling process

The invention is suitable for the field of low temperature rolling, and provides a control method of a rod and wire production line temperature control rolling process. The method comprises the steps of determining a critical phase change temperature and a critical cooling speed of a rolled piece generation phase change tissue according to the a steel type and a corresponding continuous cooling transition curve characteristic; calculating the water cooling time according to a length value of a water tank and a rolling speed of a rolled piece, and calculating a corresponding maximum water flow rate at the critical phase change temperature and the critical cooling speed according to the water cooling time and the cooling water temperature; acquiring an initial value of the water flow rate within the maximum water flow rate range; calculating a uniform temperature of the rolled piece according to a heat transfer relation of each node of the rolled piece; judging an absolute difference value of the uniform temperature and a target temperature to exceed a first preset threshold value, adjusting the water flow rate, re-calculating the uniform temperature, and calculating the water flow rate which cannot satisfy the first preset threshold value. By adopting the control method, the automatic derivation of process parameters in the temperature control rolling process can be realized, and the low efficiency and inaccuracy for a traditional method for referring to the existing engineering or experience in the prior art can be overcome.

Owner:WISDRI ENG & RES INC LTD

Rolling method capable of reducing as-rolled hardness of 42CrMo steel

ActiveCN106424158AIncrease compressive stressImprove tissue uniformityTemperature control deviceMetal rolling arrangementsMetallurgyPhase change

The invention relates to a rolling method capable of reducing an as-rolled hardness of 42CrMo steel. The rolling method comprises the following steps: (1) carrying out heating treatment on a blank of the 42CrMo steel; and (2) sequentially carrying out rough rolling, medium rolling and finish rolling on the treated blank of the 42CrMo steel to obtain the 42CrMo steel with a low as-rolled hardness. The rolling method capable of reducing the as-rolled hardness of the 42CrMo steel, which is disclosed by the invention, has the following beneficial effects: 1. a low finish rolling temperature is controlled, a high pressure stress on the core part of the steel is achieved during a rolling process, structure uniformity is greatly improved, and grains are further refined; and 2. the finish rolling temperature is lowered to be approximate to an actual critical phase change point (Ar3), thus phase change of the 42CrMo steel from phase gamma to phase alpha is promoted, finally an as-rolled structure is a balanced ferrite and pearlite structure, and then the as-rolled hardness is reduced to HB230-250 from HB300.

Owner:XINING SPECIAL STEEL

Frequency multiplier for wave-guide structure and manufacturing method thereof

InactiveCN101459317AEasy to implement non-linear effectsEnhance nonlinear effectsLaser detailsOptical processingRefractive index

The invention relates to the laser field, in particular to a waveguide structured frequency doubler and a manufacturing method thereof. The invention utilizes multiple optical processing, cutting, polishing to manufacture a frequency doubling crystal wafer (or a crystal wafer bonded with a substrate), employs gluing, deepened optical cementing processes to bond the frequency doubling crystal wafer ( or the crystal wafer bonded with the substrate )to the substrate, and then process and polishes the frequency doubling wafer ( or the crystal wafer boned with the substrate ) on the substrate into required dimension of the waveguide structure. The lateral side of the frequency doubling crystal wafer is coated by a low refractive index deepened optical cement layer or glue layer, thereby forming the waveguide structured frequency doubler, wherein the utilized crystal can generate frequency doubling or multiple harmonic wave via critical phase matching, or can generate frequency doubling or higher harmonic wave via non-critical phase matching. The invention overcomes defects of the conventional doublers, and enables optical power density to be much larger than power density of light beams, thereby easily realizing non-linear effect of waveguide materials and further greatly increasing efficiency of the non-linear effect thereof.

Owner:SHANGHAI BRANCH FUZHOU GAOYI COMM CO LTD

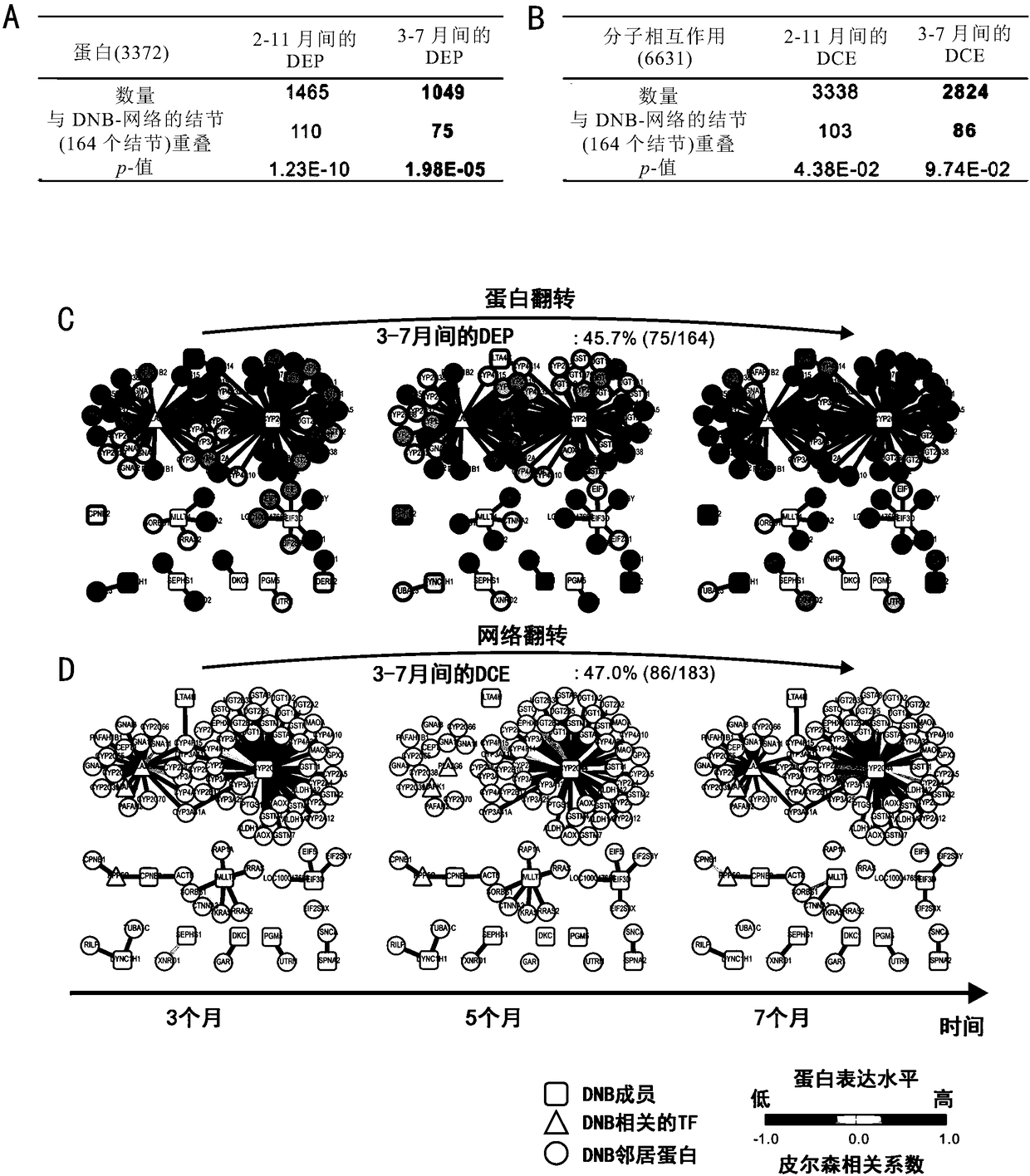

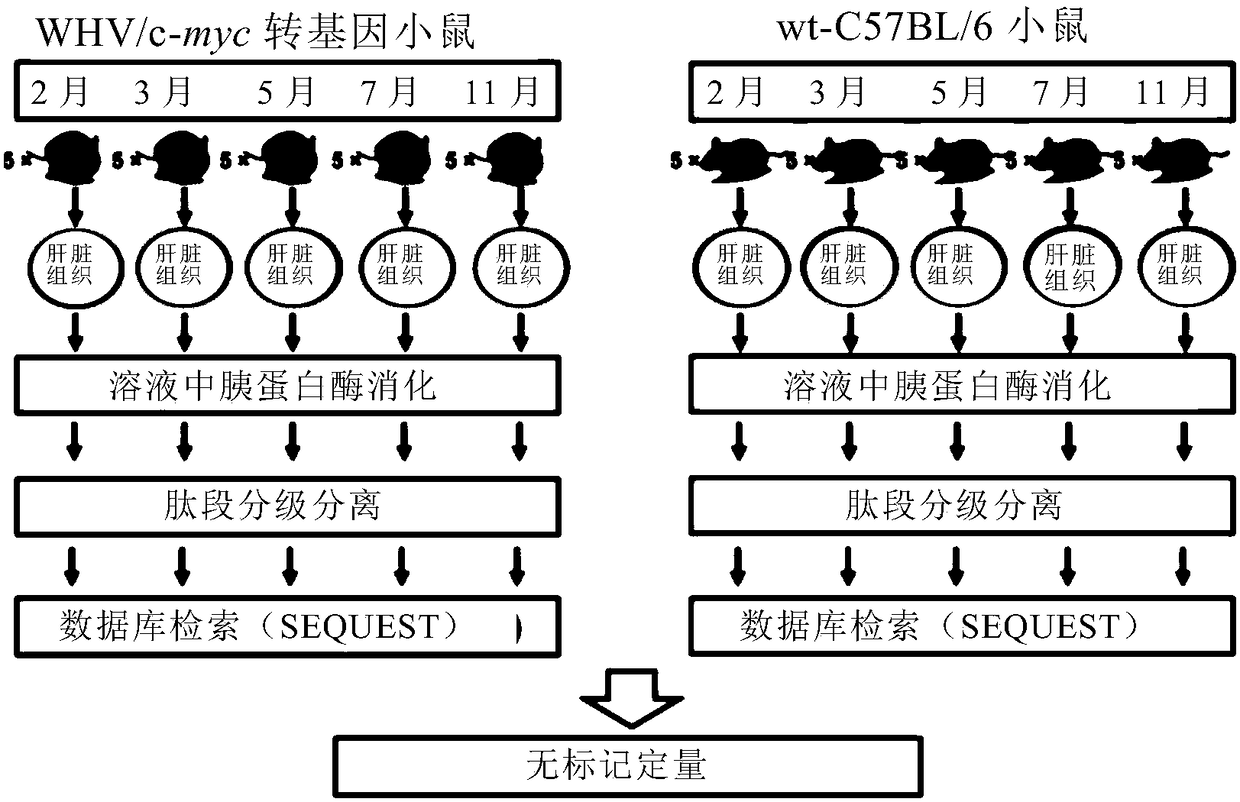

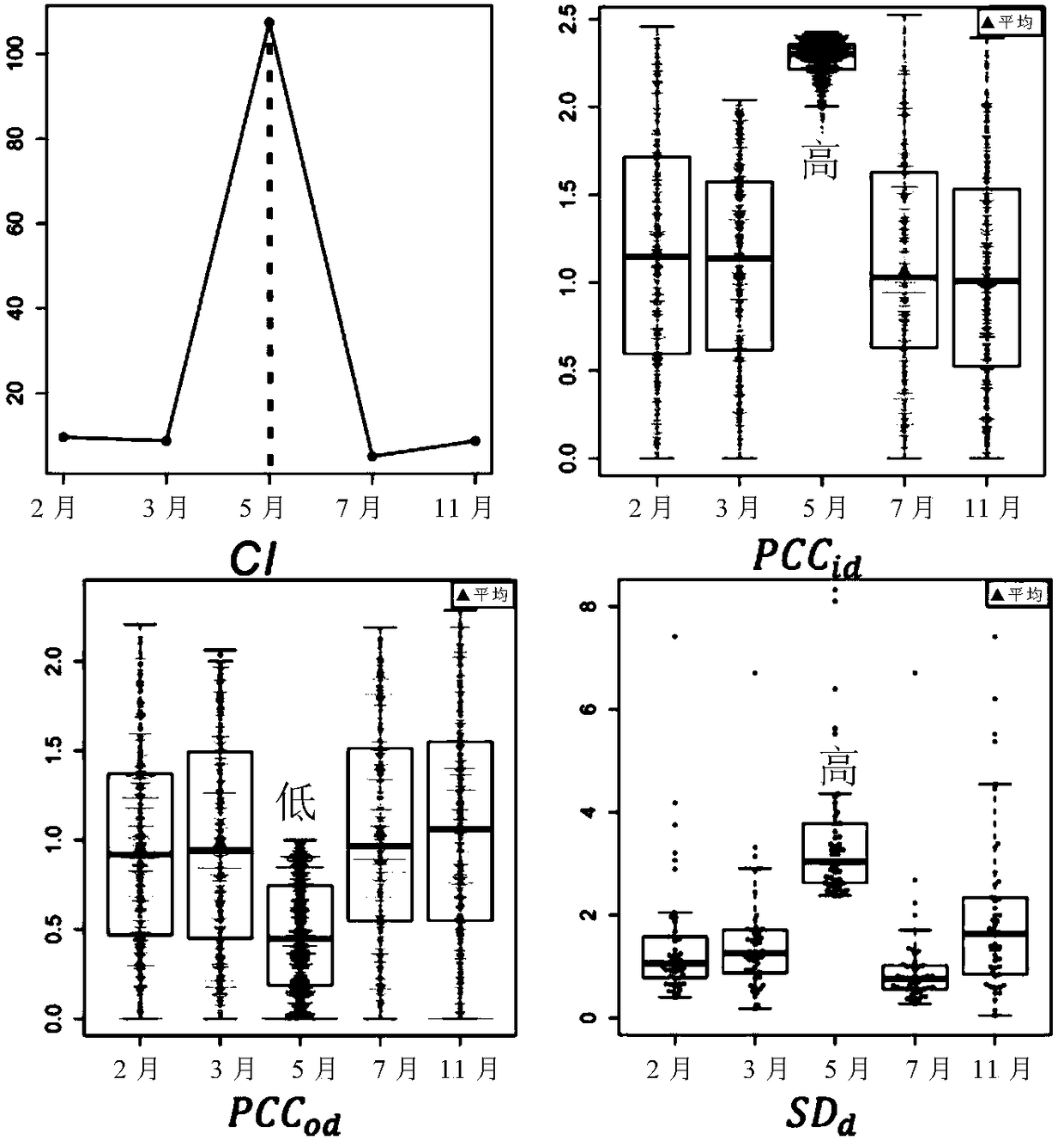

Application of taking EPS8L2 as biomarker for indicating intrahepatic nodule and pre-warning liver cancer at early stage

The invention relates to application of taking EPS8L2 as a biomarker for indicating an intrahepatic nodule and pre-warning liver cancer at an early stage, in particular to application of the followingreagents in preparing a kit for diagnosing the intrahepatic nodule of an object or diagnosing whether the object is in a vicious transformation critical phase from hepatitis to liver cancer, and thereagents comprise: (1) a reagent which is specifically combined with EPS8L2; (2) a reagent which is randomly selected and specifically combined with LTA4H; and (3) a reagent which is randomly selected and specifically combined with PLA2G6. The key critical stage of transformation from hepatitis to liver cancer is found based on an analysis on time sequence dynamics and network correlation, so that a novel direction is provided for clinically being applied to early-stage liver cancer treatment of a patient with hepatitis, judging whether the patient is in the critical stage of vicious transformation from hepatitis to liver cancer, and preventing deterioration of hepatitis and liver cancer.

Owner:SHANGHAI INST OF BIOLOGICAL SCI CHINESE ACAD OF SCI +1

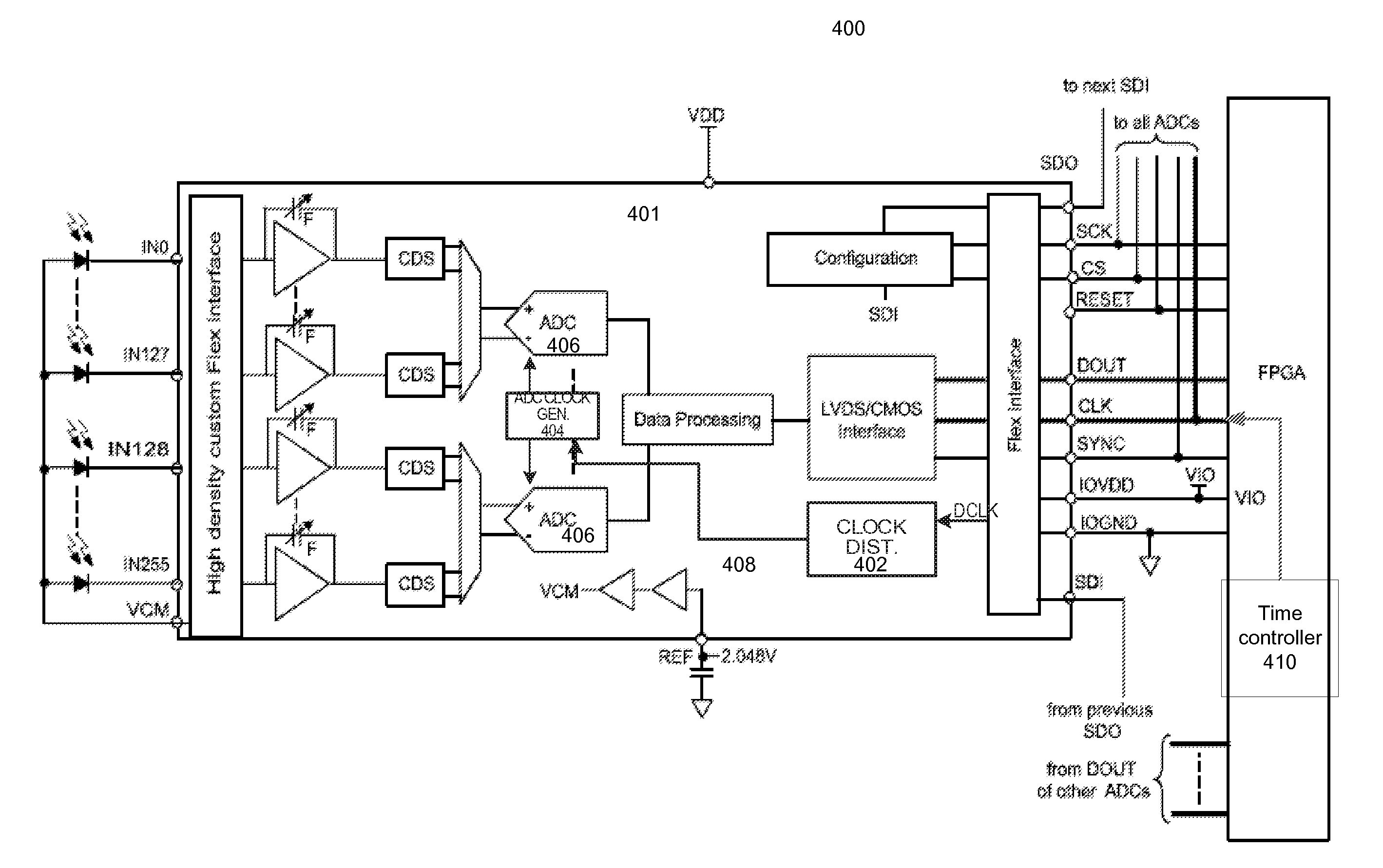

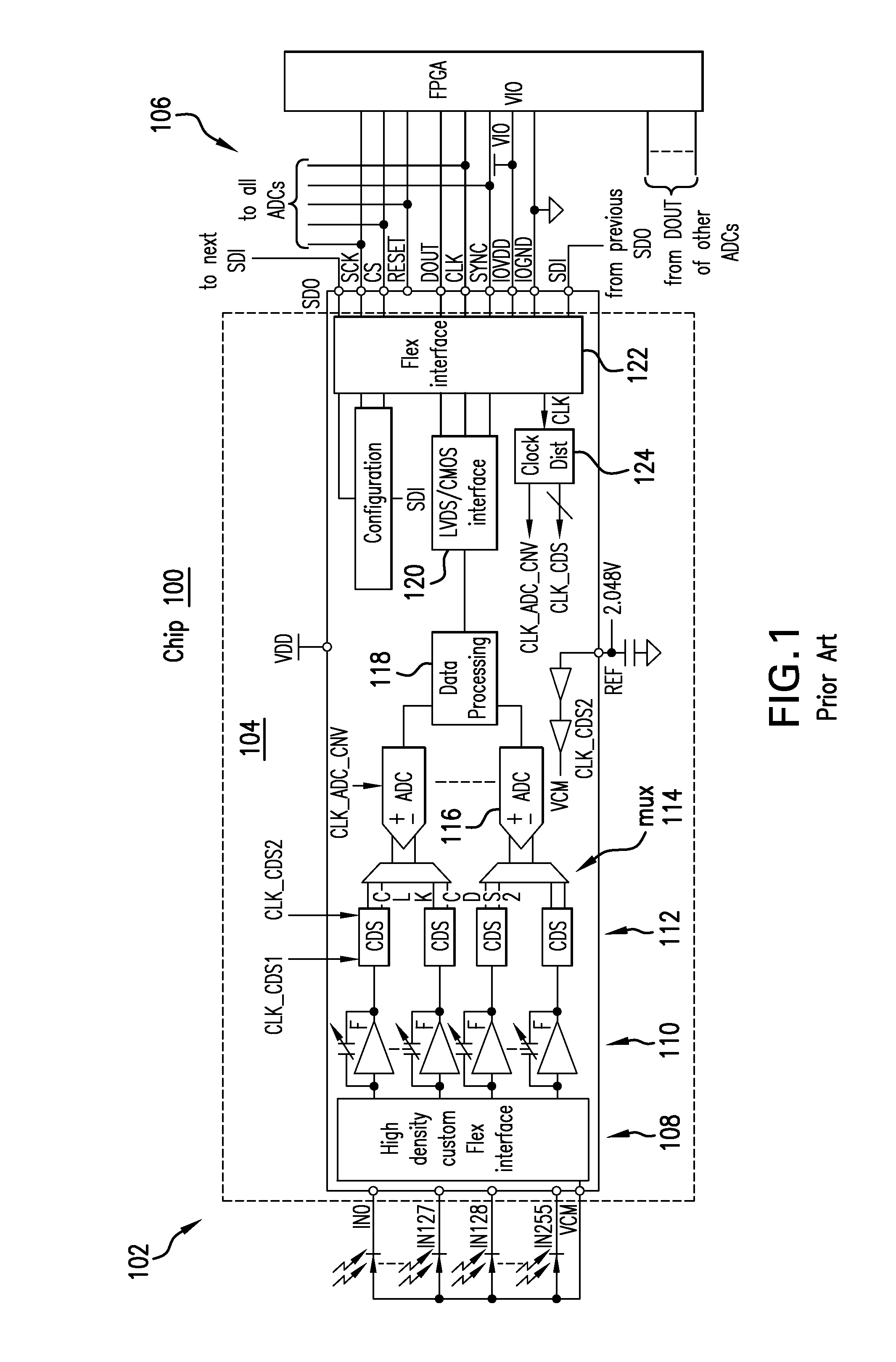

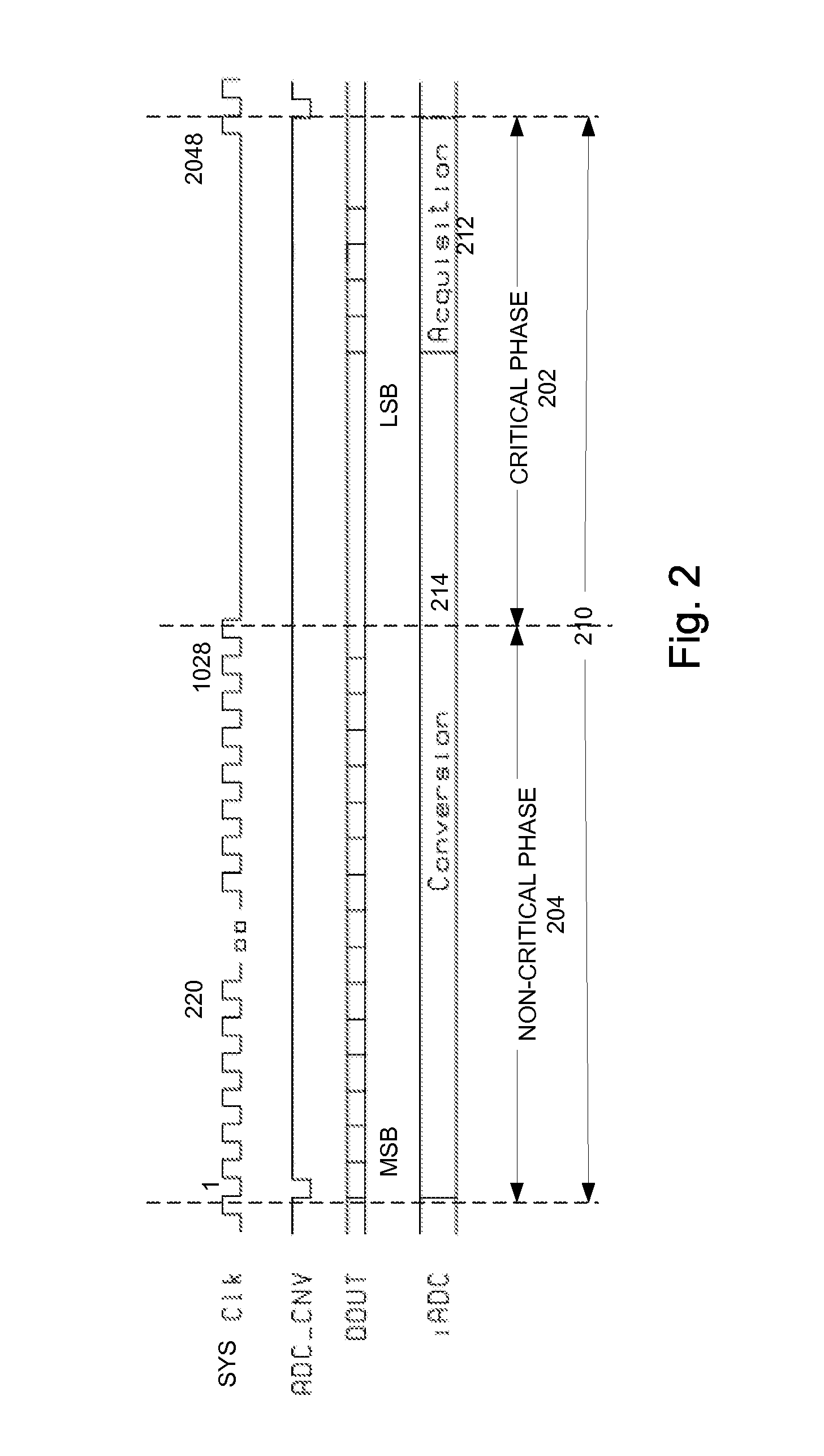

Opportunistic Timing Control in Mixed-Signal System-On-Chip Designs

ActiveUS20110043251A1Analogue/digital conversionReliability increasing modificationsSignaling systemClock generator

An integrated circuit may include a plurality of circuit sub-systems that include at least one converter circuit operating in respective critical phases and non-critical phases of operation, a clock distribution circuit that has an input for an externally-supplied clock signal that is active during the non-critical phases and inactive during the critical phases, and a clock generator to generate an internal clock signal to the converter circuit that is active when the external-supplied clock signal is inactive.

Owner:ANALOG DEVICES INC

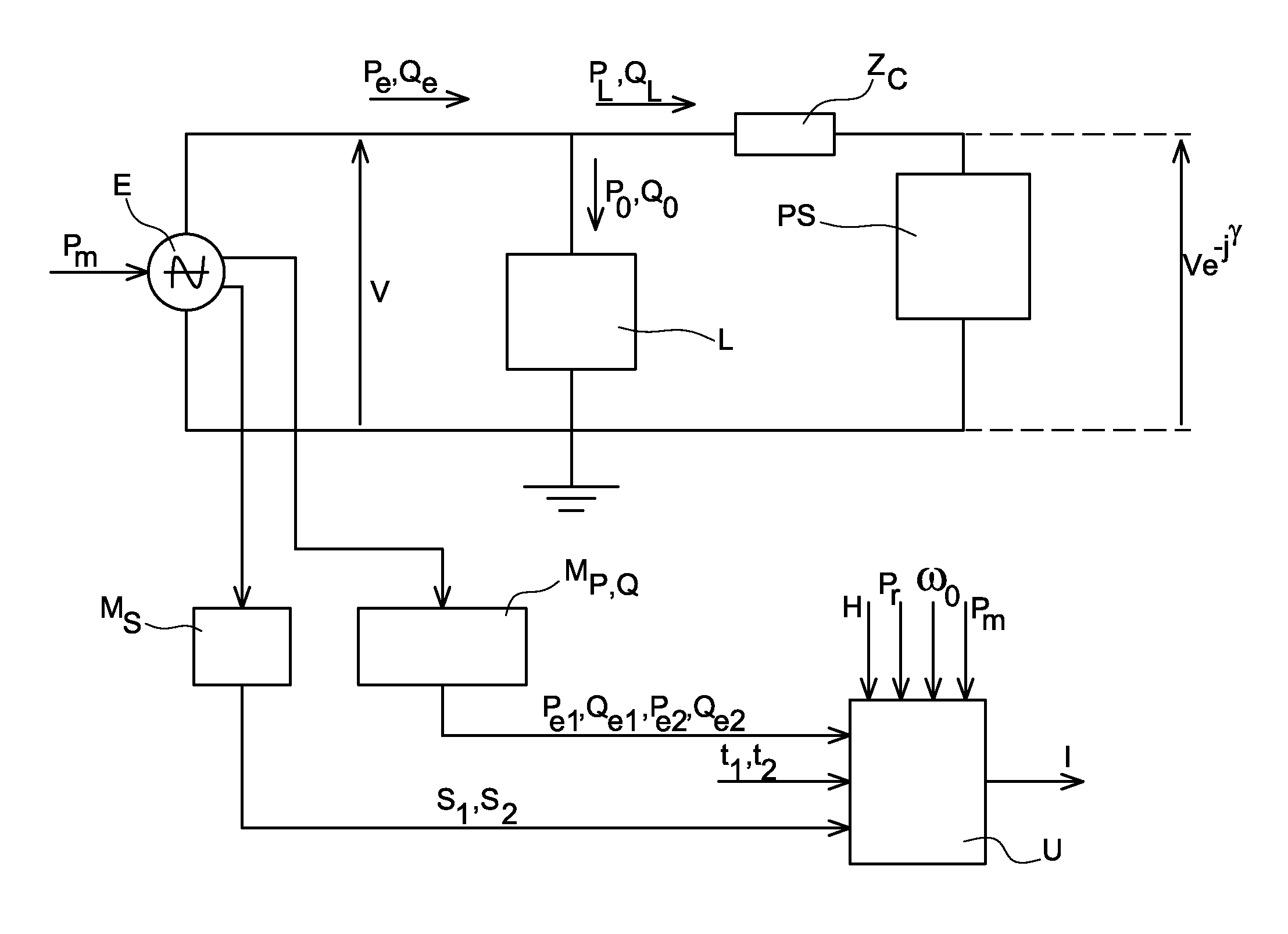

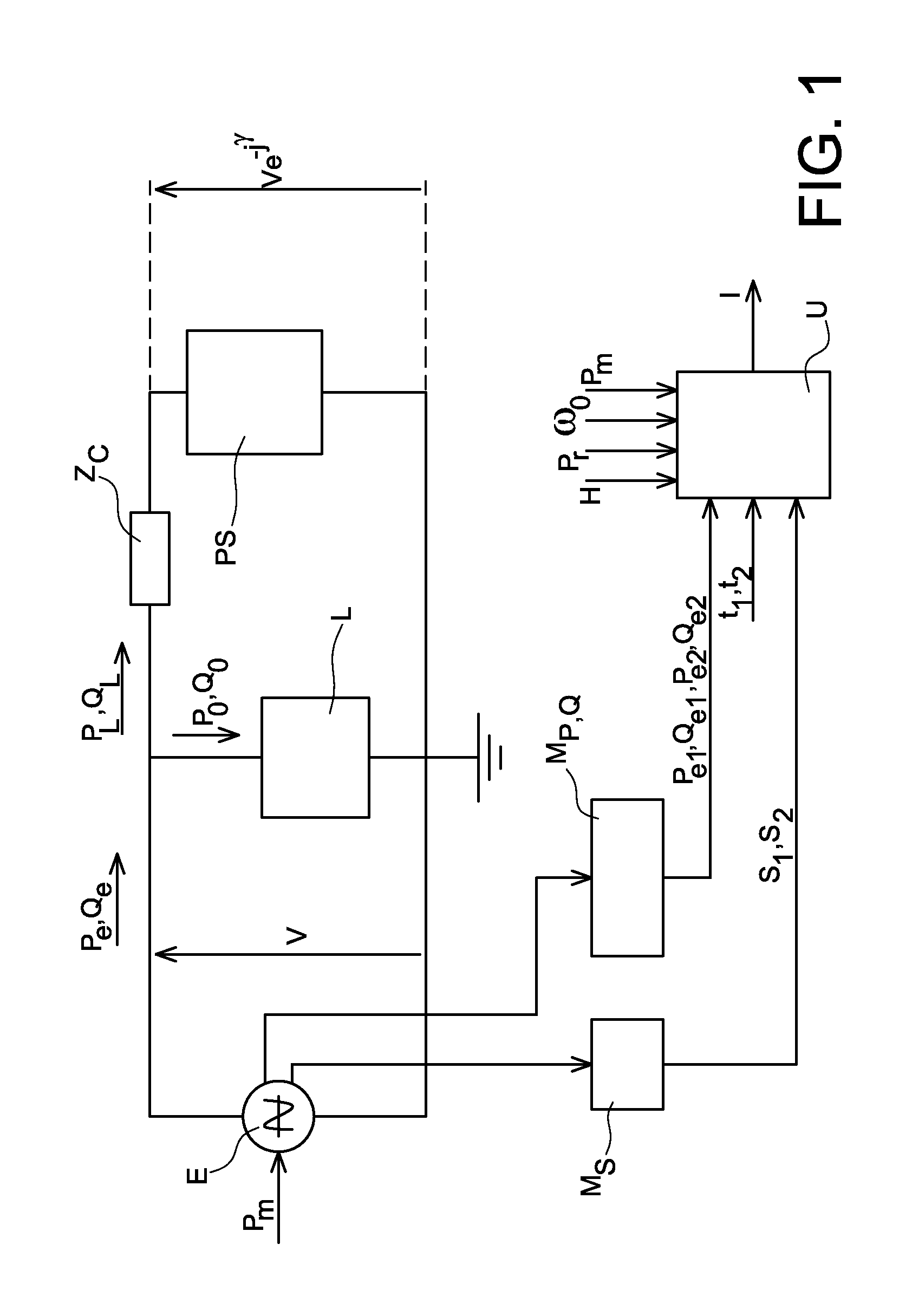

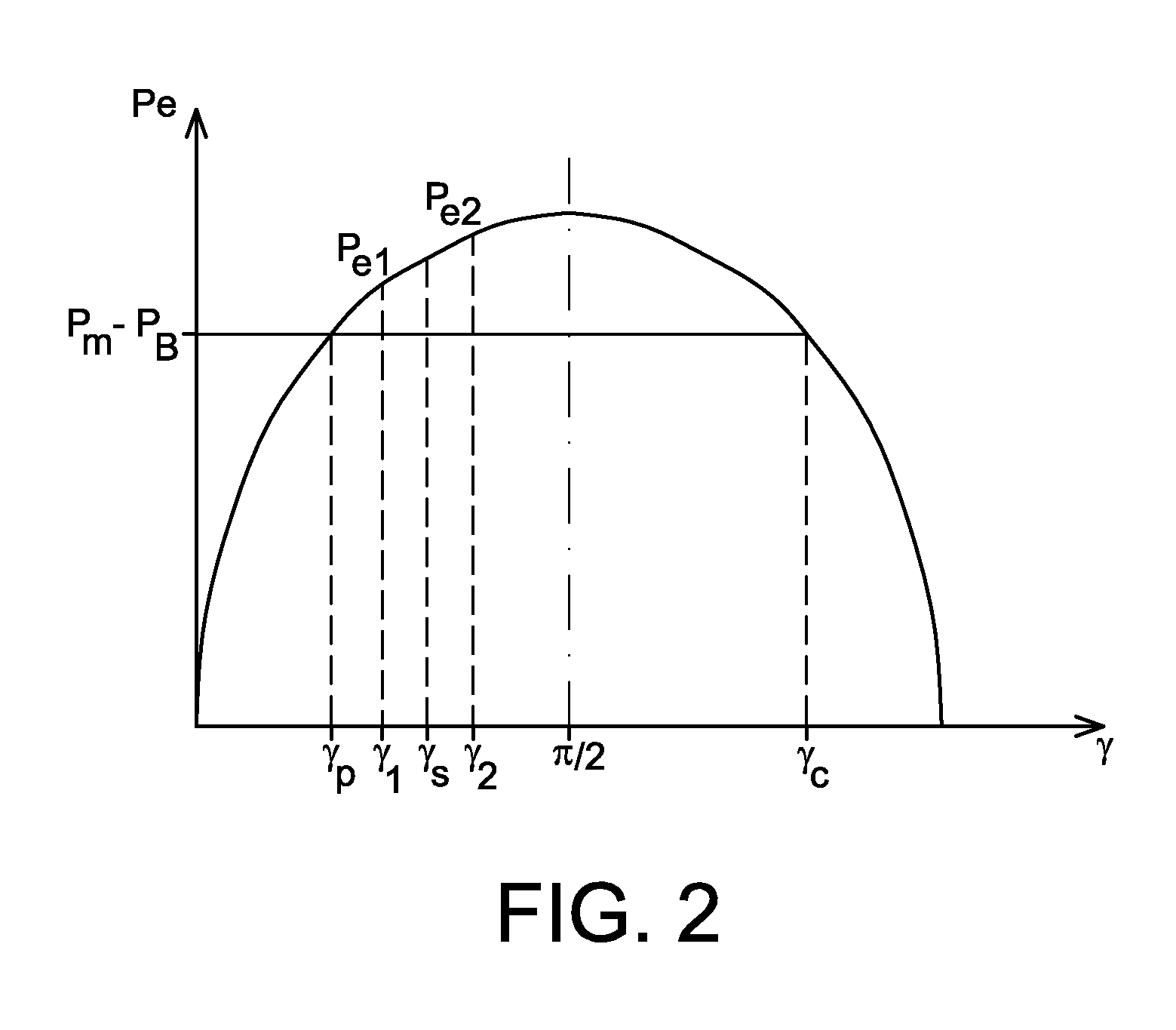

Method of predicting transient stability of a synchronous generator and associated device

InactiveUS20130041604A1Effective predictionAdvantageously close controlElectric generator controlSpecial data processing applicationsTransient stateMeasurement device

A method of predicting transient stability of a synchronous generator and a device for implementing such a method, the device comprising measurement means and calculation means for calculating an information which indicates, before it actually happens, whether the generator slip will be greater than zero or not at the critical phase angle.

Owner:ALSTOM TECH LTD +1

Preparation method of ionic-bond cross-linked polymer vesicles

InactiveCN103819698AMild preparation conditionsAvoid toxicityPharmaceutical non-active ingredientsMicrocapsulesCross-linkSide effect

The invention discloses a preparation method of ionic-bond cross-linked polymer vesicles. The preparation method comprises the specific steps of firstly, by taking sodium alginate and N-isopropylacrylamide as the major raw materials, and then preparing a temperature and pH value sensitive graft copolymer, namely, sodium alginate grafted poly-N-isopropylacrylamide through free radical polymerization. The graft copolymer is prepared into a solution with a certain concentration, and then the solution is mixed with a metal ion solution (CaCl2, AlCl3 or SnCl4) different in concentration with the solution under a stirring condition, and the ionic-bond cross-linked polymer vesicles are obtained through self-assembly under the electrostatic interaction between negative and positive ions. The preparation method of the polymer vesicles is characterized in that the metal ions are taken as the cross-linking agent to avoid toxic and side effects caused by chemical cross-linking; the preparation method is mild in preparation conditions, simple and easy to implement; the raw materials are rich in source and non-toxic, and has excellent biocompatibility and degradability and further can be taken as a drug carrier for therapeutic agents to support drugs different in hydrophily and hydrophobicity. The ionic-bond cross-linked polymer vesicles prepared by the preparation method have the particle size in the range from 100 to 350nm and the minimum critical phase transformation temperature ranging from 34.5 to 38.2 DEG C.

Owner:LUDONG UNIVERSITY

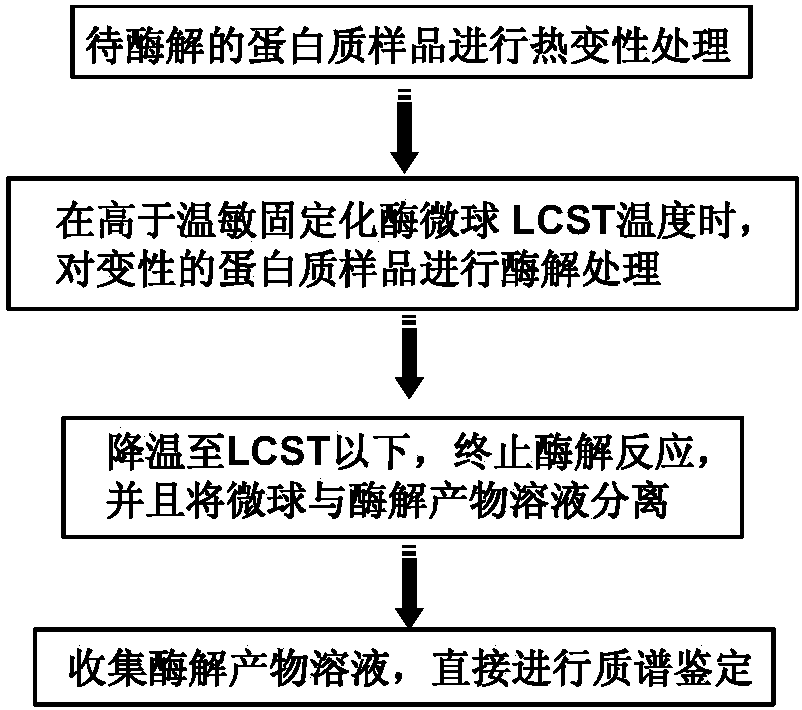

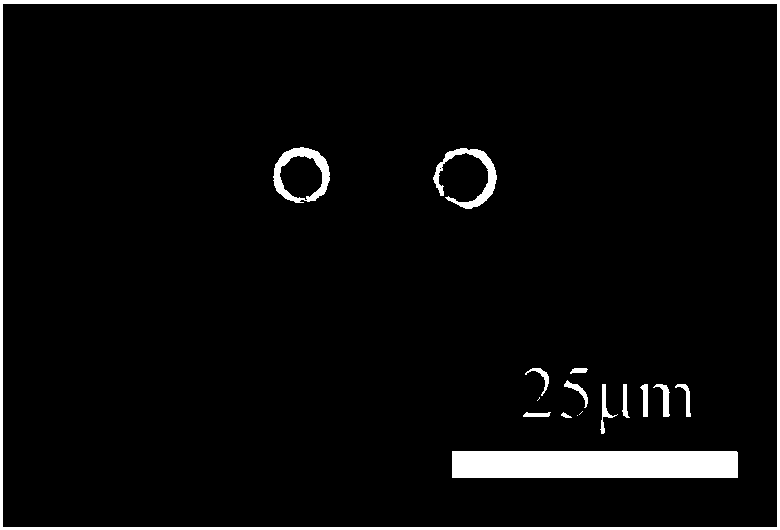

Immobilized enzyme based protein enzymolysis method

InactiveCN107586817AImprove the detection rateSettling rate is fastOn/in organic carrierFermentationMicrosphereTest protein

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Double-wave-length orthogonal polarization output light parameter oscillator

InactiveCN1979977ACompact structureLow costActive medium materialActive medium shape and constructionLight beamLength wave

KTP non-linear optic crystal is adopted in the invention. One piece of crystal uses non-critical phase match theta equal to 90 degree, phi equal to 90 degree; and the other piece of crystal uses critical phase match theta equal to 72 degree, phi equal to 0 degree. Two pieces of crystal generates tunable laser with orthogonal polarization directions, closed wavelengths and good quality of beam. Advantages are: low cost, and compact system. The optical parametric oscillator possesses wide market prospect.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

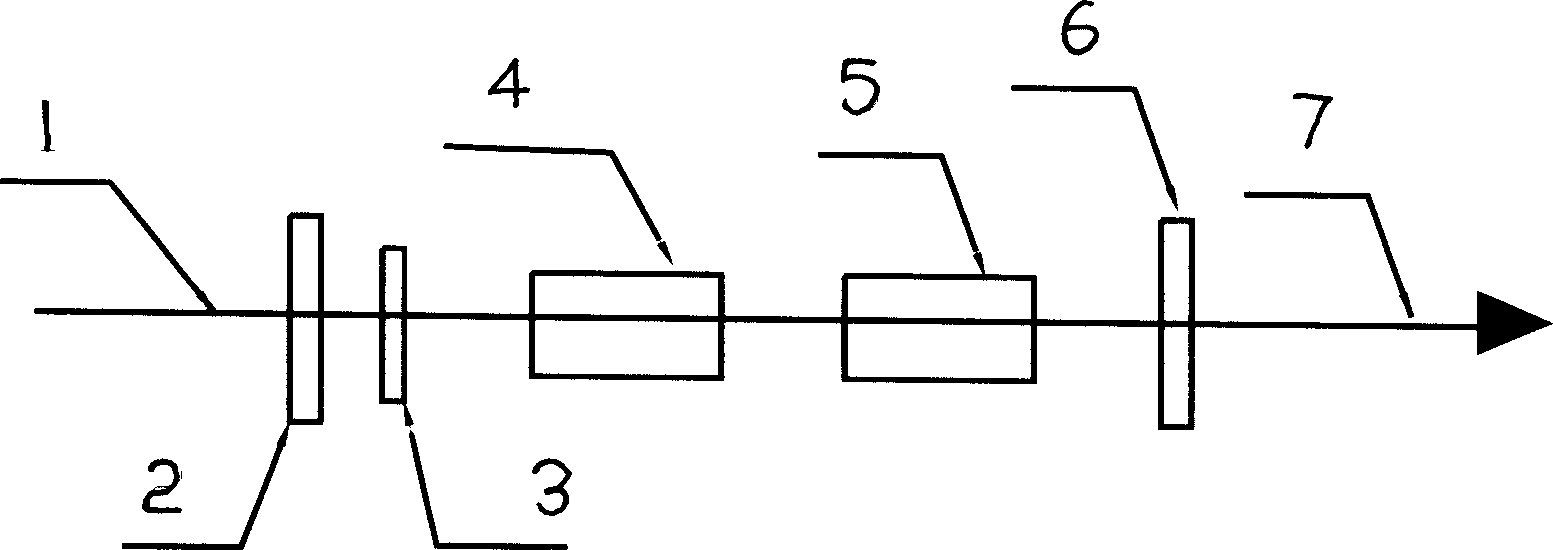

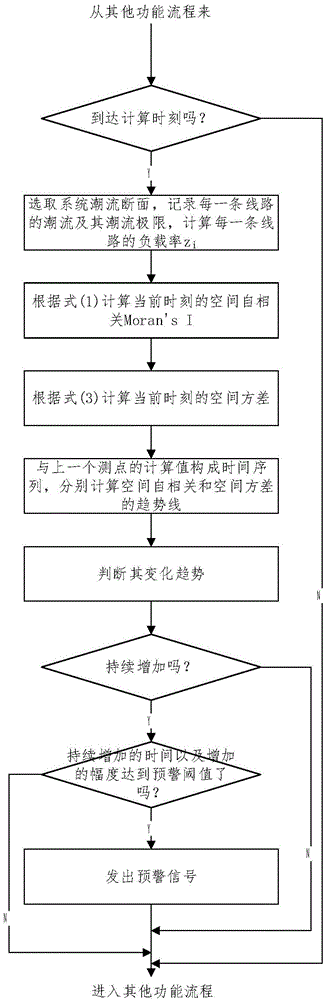

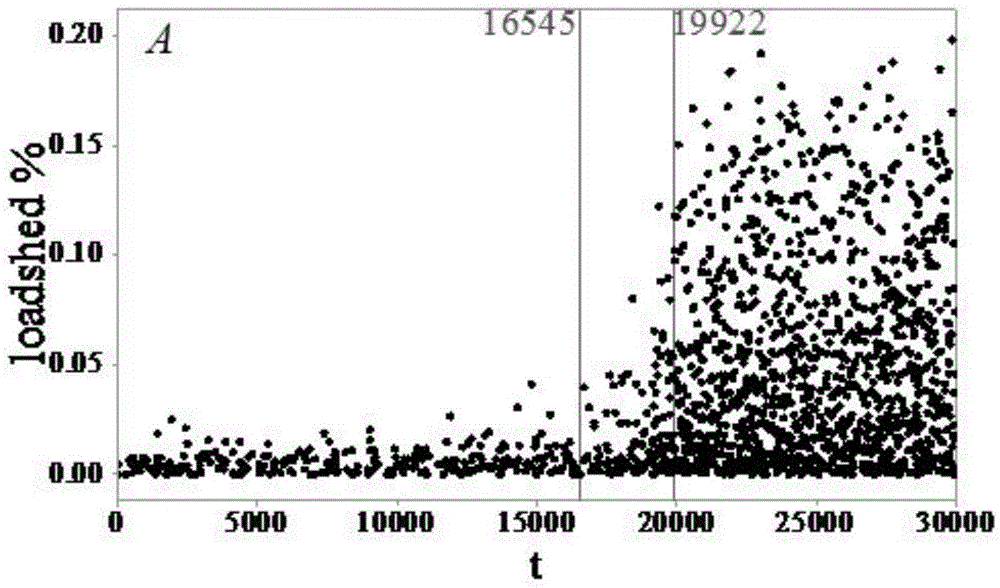

Space-based early warning method for critical phase transformation of electric power system

ActiveCN106033890AData processing applicationsAc network circuit arrangementsPower flowDistribution pattern

The invention discloses a space-based early warning method for critical phase transformation of an electric power system, and relates to the field of electric power systems. According to the method, the unbalance degree of power flow distribution and the distribution pattern of transmission capacity are captured through spatial autocorrelation and variance indexes for early warning the condition that the electric power system gets into a critical state; it shows that the spatial distribution pattern of the system line load rate is difficult to measure, but the spatial autocorrelation and variance of the line load rate are easy to measure, and therefore the spatial autocorrelation and variance of the system line load rate have the good early warning characteristics and can serve as an early warning signal for the condition that the system approaches critical phase transformation.

Owner:NORTH CHINA ELECTRIC POWER UNIV (BAODING)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com