Method for eliminating defective structure in structural alloy steel and tool steel substrate by using impulse current

A technology of alloy structural steel and pulse current, which is applied in manufacturing tools, heat treatment equipment, heat treatment process control, etc., can solve the problem of ineffective removal of banded structure, and achieve the effect of broad development prospects and breakthrough of process limitations.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

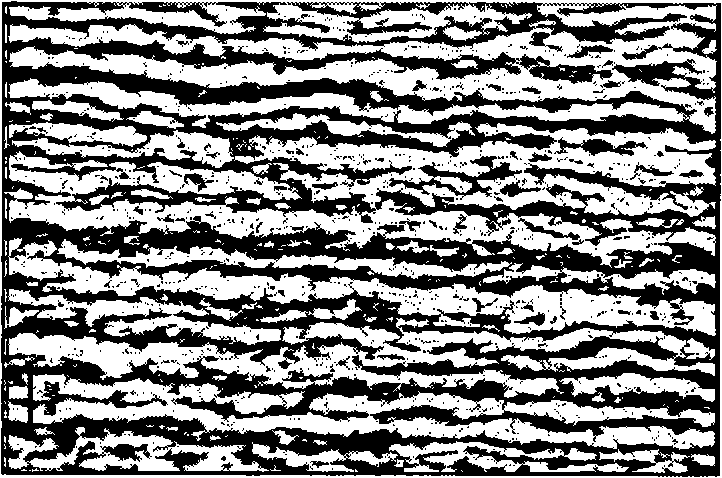

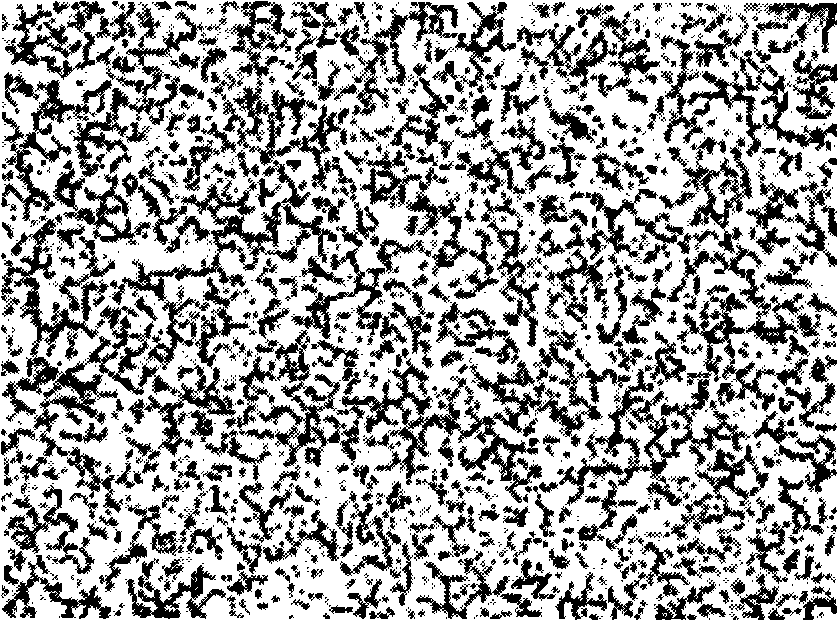

[0056] Example 1. Elimination of banded structure in alloy structural steel:

[0057] Low and medium carbon steel and alloy structural steel such as: 20, 45, G20CrNi 2 MoA, 12Cr 2 Ni 4 A, 20CrMnTi, 20CrNi and other materials, the steel sample size of each material is φ15×12mm, divided into several groups. The two ends of each sample are connected with wires. During the test, a steel sample is placed at the critical phase transition temperature A of the material C3 When heating and keeping warm in an electric furnace at +50°C, its two wires are connected to the MY-2005 pulse current generator outside the furnace as the carrier of pulse current. After the sample reaches the critical phase transition temperature, it starts to keep warm, and at the same time, input a pulse current with a certain intensity and a certain frequency. Different samples input pulse current with an intensity of 800A, 900A, 1000A, and a frequency of 50Hz, 30Hz, 15Hz and other parameters. After keepin...

example 2

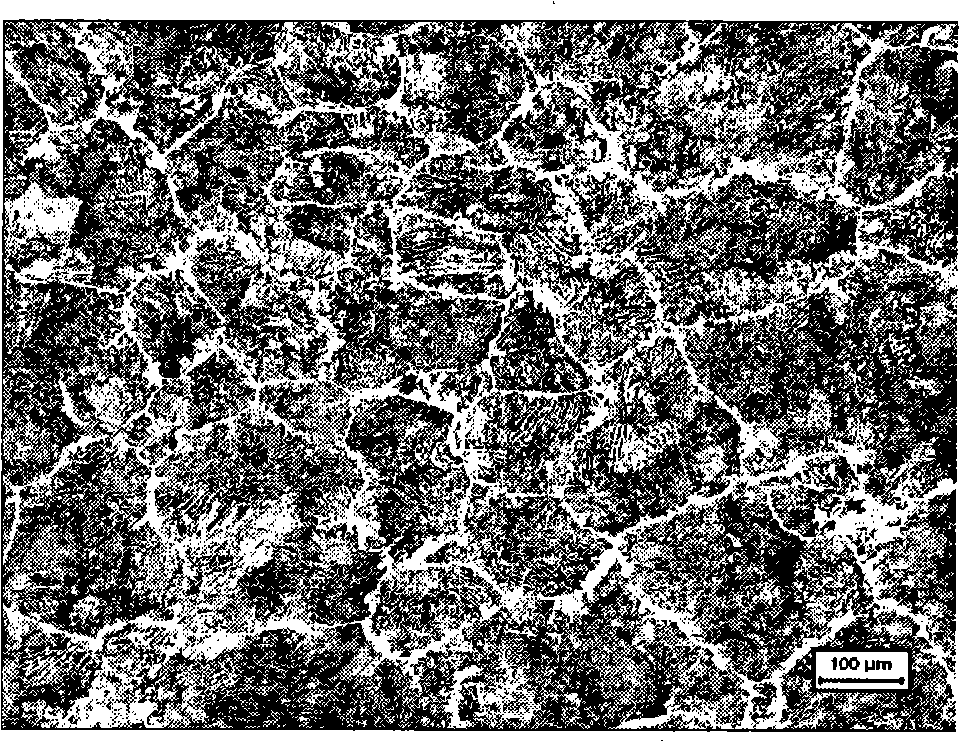

[0058] Example 2. Eliminate the network structure in alloy tool steel and carbon tool steel:

[0059] Carbon tool steel and alloy tool steel such as: T7, T8, T10, GCr 15 , 9CrSi, Cr 12 Materials such as MoV, at the critical phase transition temperature A of the material C1 + (20~50℃) When heating and keeping warm, connect the two ends of the sample with two wires. Its two wires are connected with the MY-2005 pulse generator outside the furnace as the carrier of the pulse current. After the sample is heated to the critical phase transition temperature, heat preservation begins. At the same time, the pulse current generator is turned on, and pulse parameters of a certain current and a certain frequency are input. Different samples input 600A, 800A, 900A, and 1000A respectively, and the frequencies are 40HZ, 50HZ, and 50HZ. , 30HZ and other pulse parameters of different parameters, the frequency of the input pulse current is displayed by the SS-2004 oscilloscope. After 10-15 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com