Patents

Literature

933results about How to "Increase the speed of diffusion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

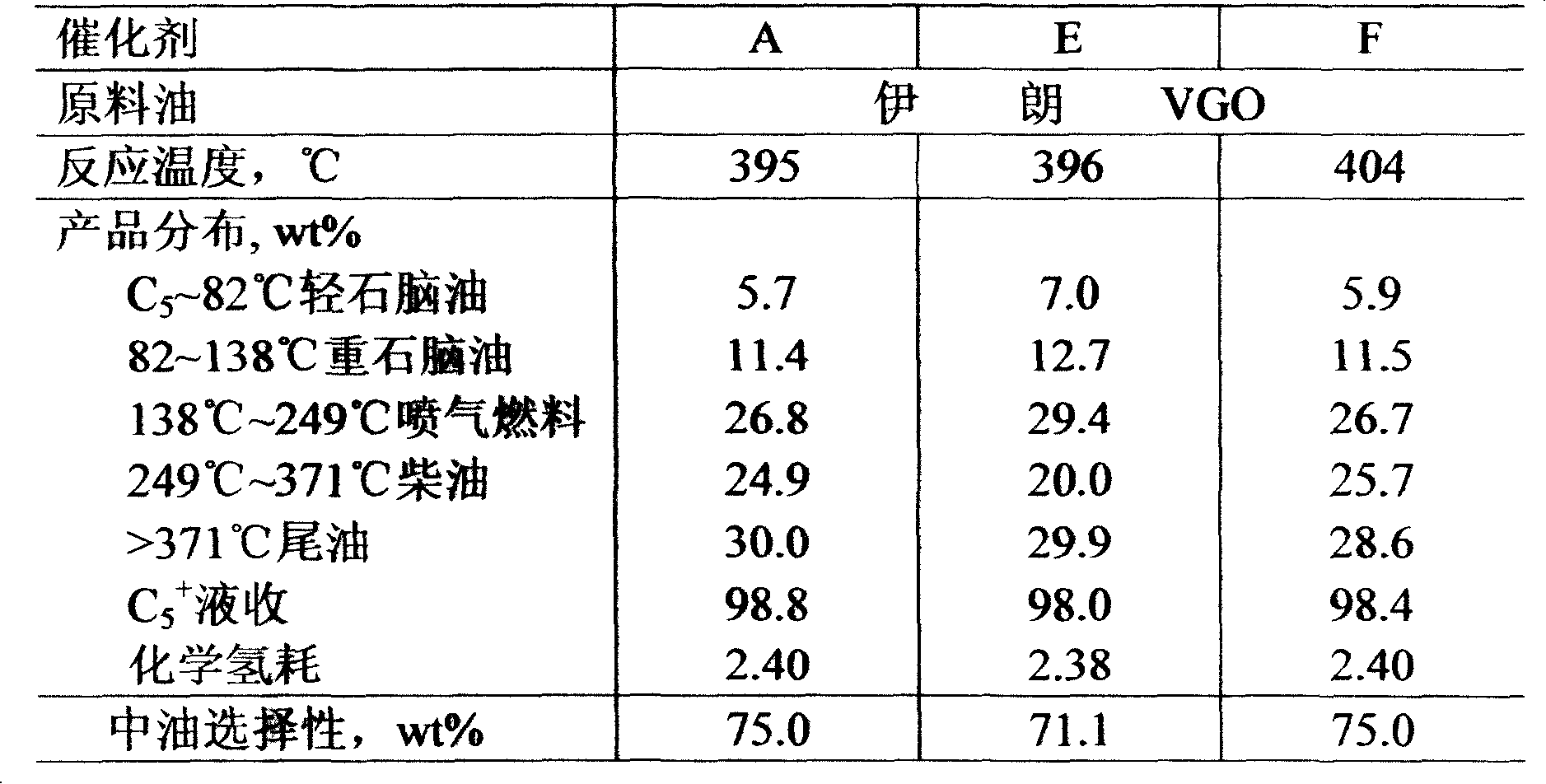

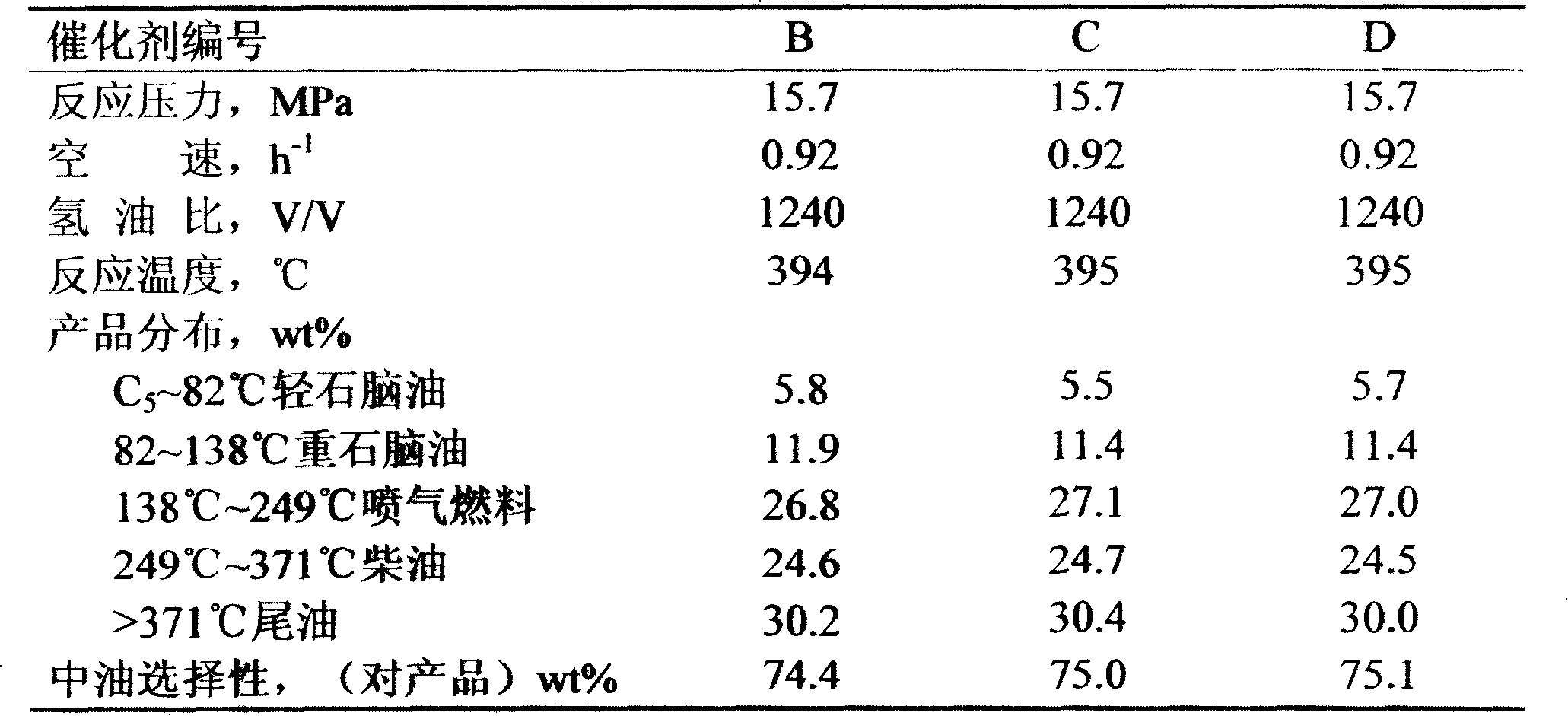

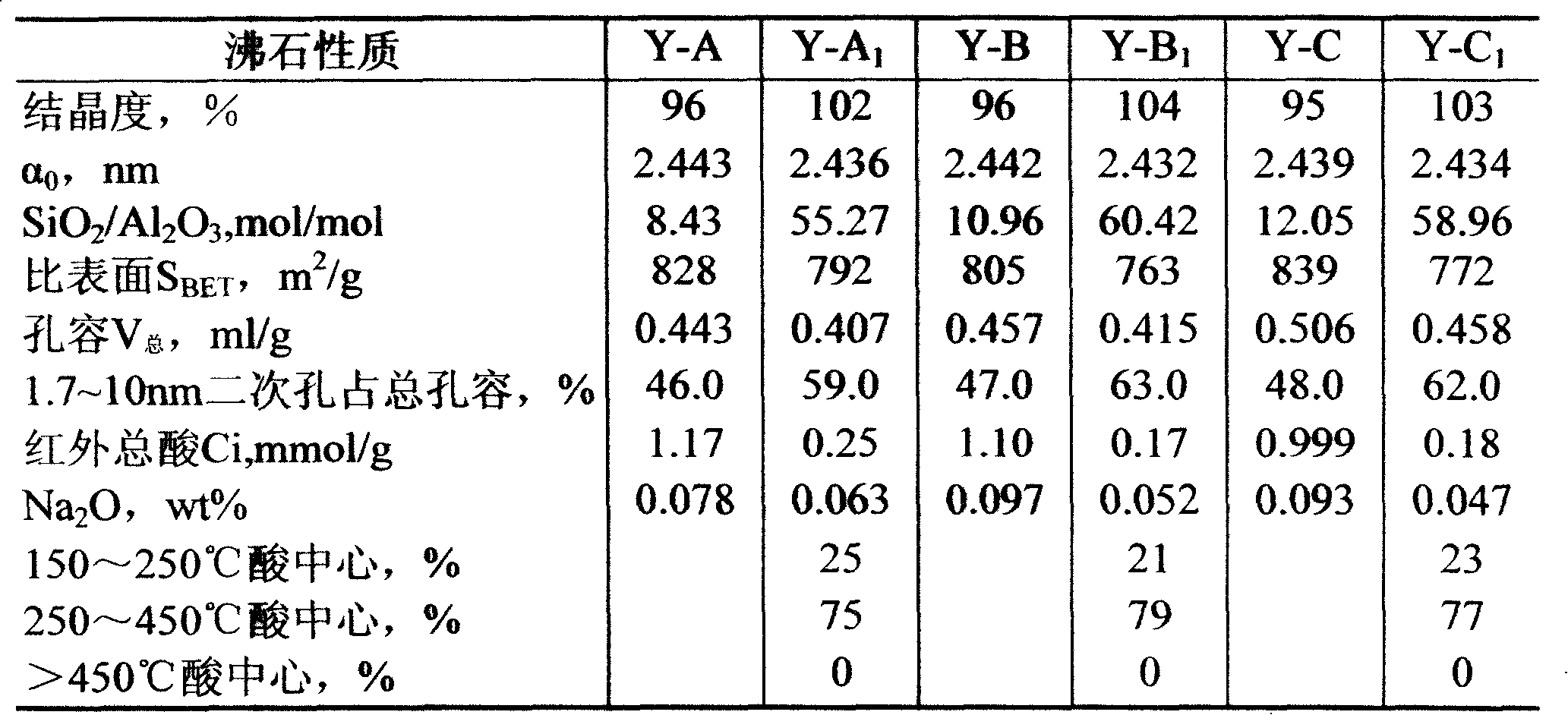

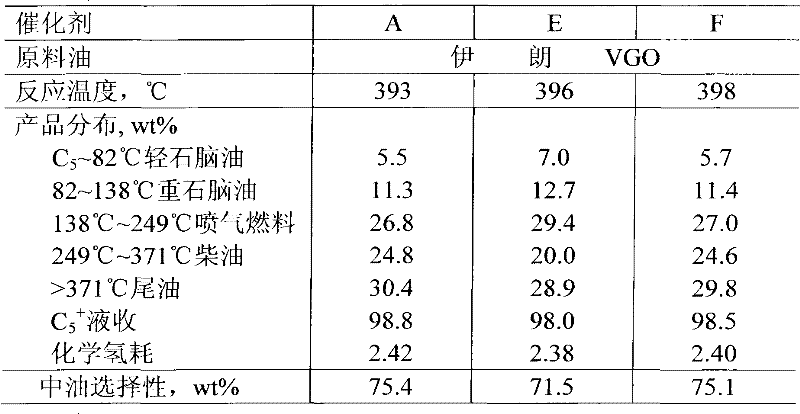

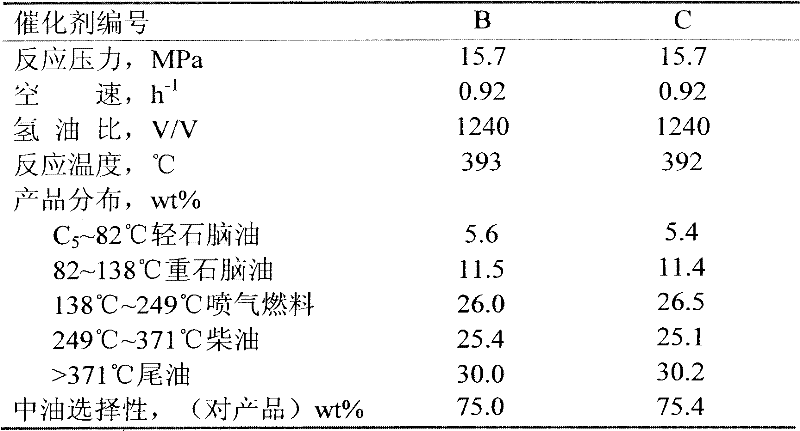

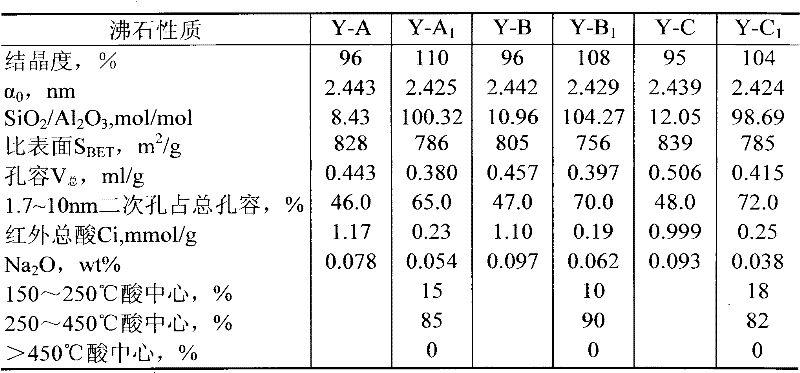

High active high medium oil selective hydrocracking catalyst and preparation thereof

ActiveCN101239324AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveSingle stage

The present invention provides a hydrocracking catalyst having high activity, high medium oil selectivity, catalyst constitute uses amorphous silica-alumina as a carrier, Y type molecular sieve processed by special modification is an acidity component, the molecular sieve has a high crystallinity and a lower cell parameter, a plenty quadric hole, larger surface, in addition, has a small acid center, even distribution, no strong acid center, 70-80% is moderate intensity acid center, 20-30% is weak acid center, and the molecular sieve also has a strong anti-nitrogen ability and better damaging ability, the hydrocracking catalyst using the molecular sieve has a better hydrocracking activity, and a higher medium oil selectivity, and a strong anti-nitrogen ability at the same time. The invention uses heavy hydrocarbon single stage or single stage serial hydrocracking process generate midbarrel oil product, and has better activity and medium oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocracking catalyst with high activity and high-medium oil selectivity and preparation method of hydrocracking catalyst

ActiveCN102441411AHigh crystallinityLow cell parametersMolecular sieve catalystsHydrocarbon oil crackingMolecular sieveNitrogen

The invention relates to a hydrocracking catalyst with high activity and high-medium oil selectivity. According to the hydrocracking catalyst, amorphous silicon aluminum is used as a carrier, and a specially-modified Y-type molecular sieve is used as acid component, the molecular sieve has high degree of crystallization and low cell parameters, rich secondary holes, large surface area, less uniformly-distributed acid sites, no strong acid center, and most of medium-strength acid centers, and also has strong nitrogen-resisting performance and better damage capacity; and the hydrocracking catalyst using the molecular sieve has high hydrocracking activity and high middle oil selectivity, and stronger nitrogen resisting capacity. The catalyst provided by the invention is used in the process of producing an intermediate distillate product by adopting a heavy hydrocarbon single-section or one-section hydrocracking process, and has better activity and middle oil selectivity.

Owner:CHINA PETROLEUM & CHEM CORP +1

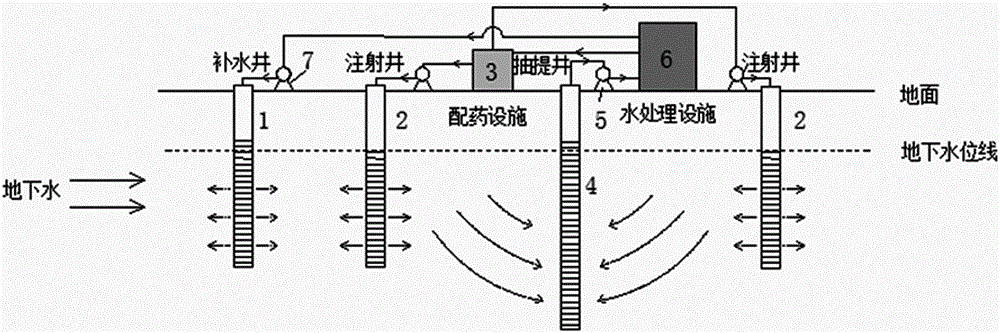

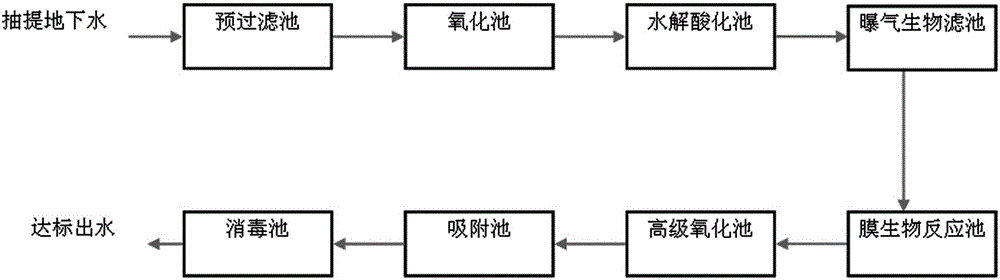

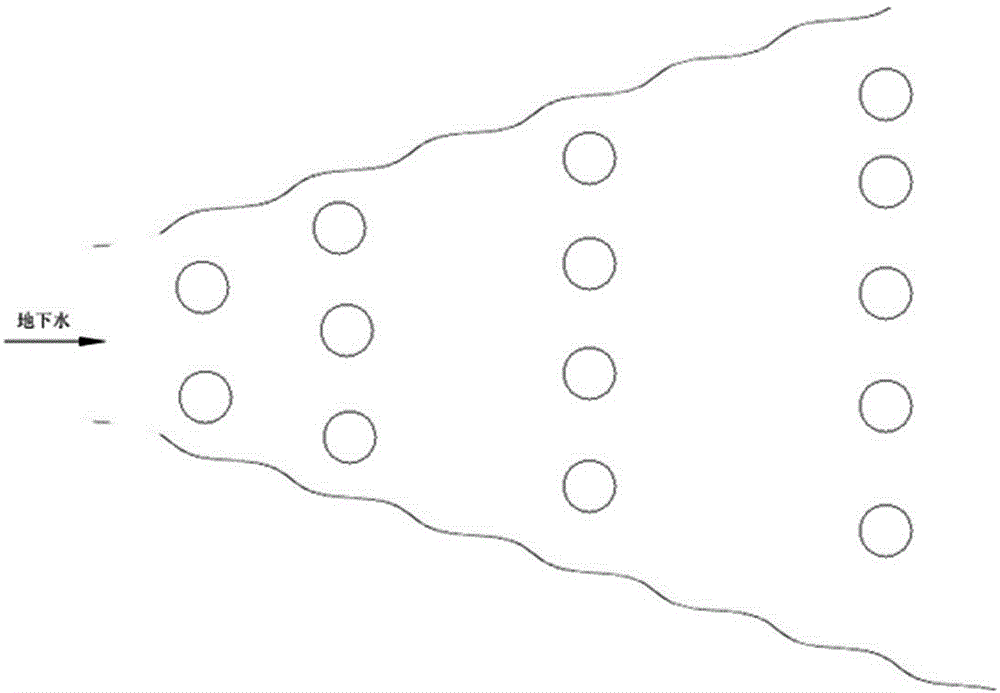

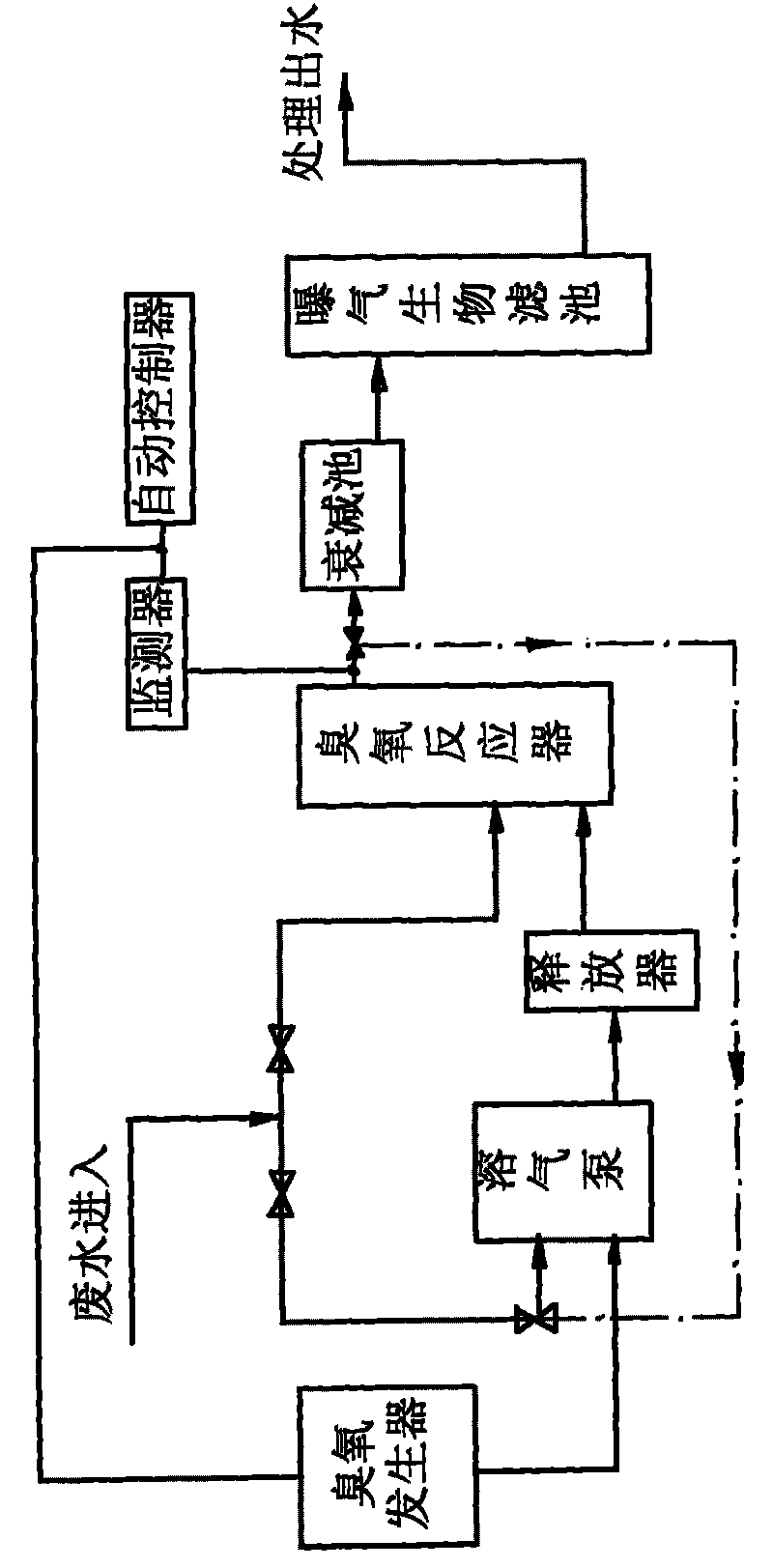

In-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and combined remediation method

ActiveCN105032916ASpeed up the flowIncrease the speed of diffusionContaminated soil reclamationMultistage water/sewage treatmentInjection wellWater treatment

The invention discloses an in-situ injection-extraction-water replenishing circulatory disposal system for organic contaminated soil and groundwater and a combined remediation method. The system is consist of an injection well, an extraction well, a water replenishing well, a water treatment facility, a dispensing facility. The method comprises the following steps: extracting a pollution source or groundwater in a seriously polluted area to the ground for processing, then using the processed groundwater as a preparation drug or as replenished water to be directly injected to the underground, and injecting the drug into the underground pollution plume area through the injection well. The system and the method are used for processing the organic contaminated soil and groundwater in situ and have the advantages of being small in disturbance, environmental-friendly, short in remediation cycle and wide in range of application and has no secondary pollution.

Owner:中节能大地(杭州)环境修复有限公司

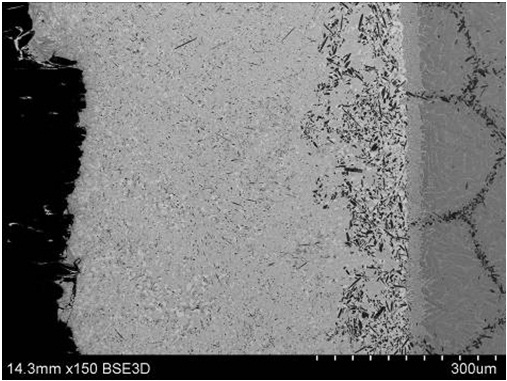

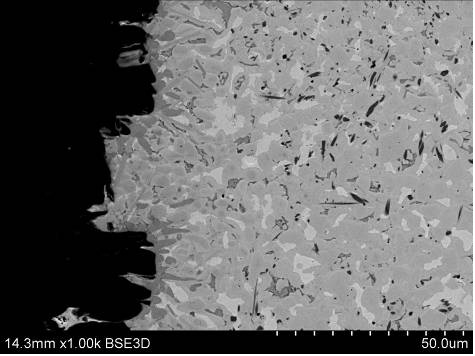

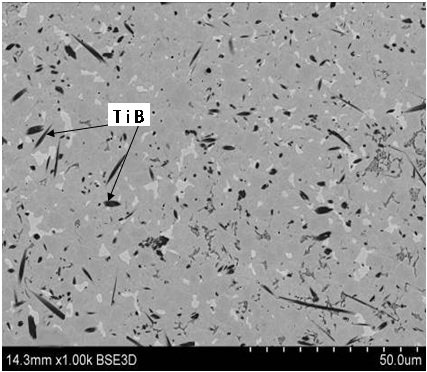

Composite soldering material for soldering titanium alloy and ceramic or ceramic matrix composition material and method for soldering by using same

ActiveCN101890590AGuaranteed wettabilityEasy to manufactureWelding/cutting media/materialsWelding/soldering/cutting articlesCrazingTitanium alloy

The invention discloses a composite soldering material for soldering a titanium alloy and a ceramic or a ceramic matrix composition material and a method for soldering by using the same, and solves the problems that a welding joint obtained by soldering the titanium alloy and the ceramic or the ceramic matrix composition material through the conventional soldering material is easy to crack and has low strength, and the introduction of a ceramic phase in a method of introducing the ceramic phase into the soldering material causes reduction of wettability of a connecting layer for a base metal. The composite soldering material consists of Cu, Ni and a reinforced phase, wherein the reinforced phase is TiB2 powder or SiC powder. The method comprises the following steps of: performing ball milling on the Cu, Ni and TiB2 or SiC powder, uniformly mixing, and coating to-be-welded surfaces of the titanium alloy and the ceramic to obtain to-be-welded parts; and putting the to-be-welded parts into a vacuum brazing furnace for vacuum brazing treatment. In the soldering process, the composite soldering material has good wettability for the ceramic and ceramic materials, and the obtained welding joint has no crack, the shear strength between 16 and 45MPa, and good mechanical properties.

Owner:HARBIN INST OF TECH

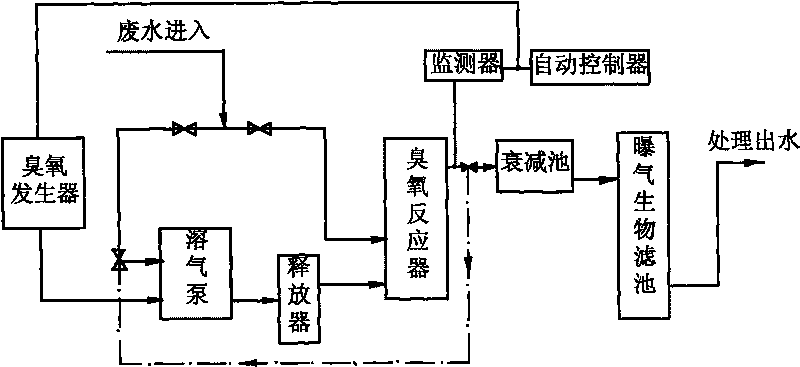

Method for increasing utilization rate of ozone jointly processing waste water with biological aerated filter

InactiveCN101700944AReal-time monitoring of residual concentrationAutomatic adjustment of ozone outputMultistage water/sewage treatmentSustainable biological treatmentUltrasound attenuationComing out

The invention discloses a method for increasing utilization rate of ozone jointly processing waste water with a biological aerated filter, which comprises the following steps: a dissolvent air pump communicated with water is inhaled with ozone; under the pressurization of the dissolvent air pump, the ozone is dissolved in water; an air-release device decompresses and releases water dissolved with ozone to an ozone reactor so that the ozone forms micro-bubbles which fully contact with waste water entering into the ozone reactor, thus oxidizing and processing organic matter in waste water; the waste water enters into an attenuation pool after being oxidized and processed by the ozone reactor; the water coming out of the attenuation pool reenters the biological aerated filter for biology treatment and then is discharged; an automatic monitoring and controlling device is used for monitoring ozone remnant concentration in yielding water oxidized and processed by the ozone reactor in real time and automatically adjusts the ozone output quantity of the ozone reactor. The ozone addition quantity is adopted for automatically regulation control in real time, thus avoiding that the ozone quantity generated in the ozone reactor is less than the ozone quantity required by water treatment and the occurrence of waste as the ozone quality is larger than the required ozone amount; therefore, the utilization rate of the ozone is increased by 20-45%.

Owner:汤苏云

Graphene three-dimensional hierarchical porous carbon material and preparation method thereof

The invention provides method for preparation of a graphene three-dimensional hierarchical porous carbon material from biomass raw materials of coconut shell, palm shell and apricot shell. The method fully and reasonably utilizes rich resources of biowaste, and avoids the usage of chemical raw materials. The prepared graphene three-dimensional hierarchical porous carbon material has special laminated structure with wrinkles and hierarchical porous structure containing mesopore, micropore and macropore, so that the conductive performance of the material is better than similar materials in the prior art.

Owner:HAINAN UNIVERSITY

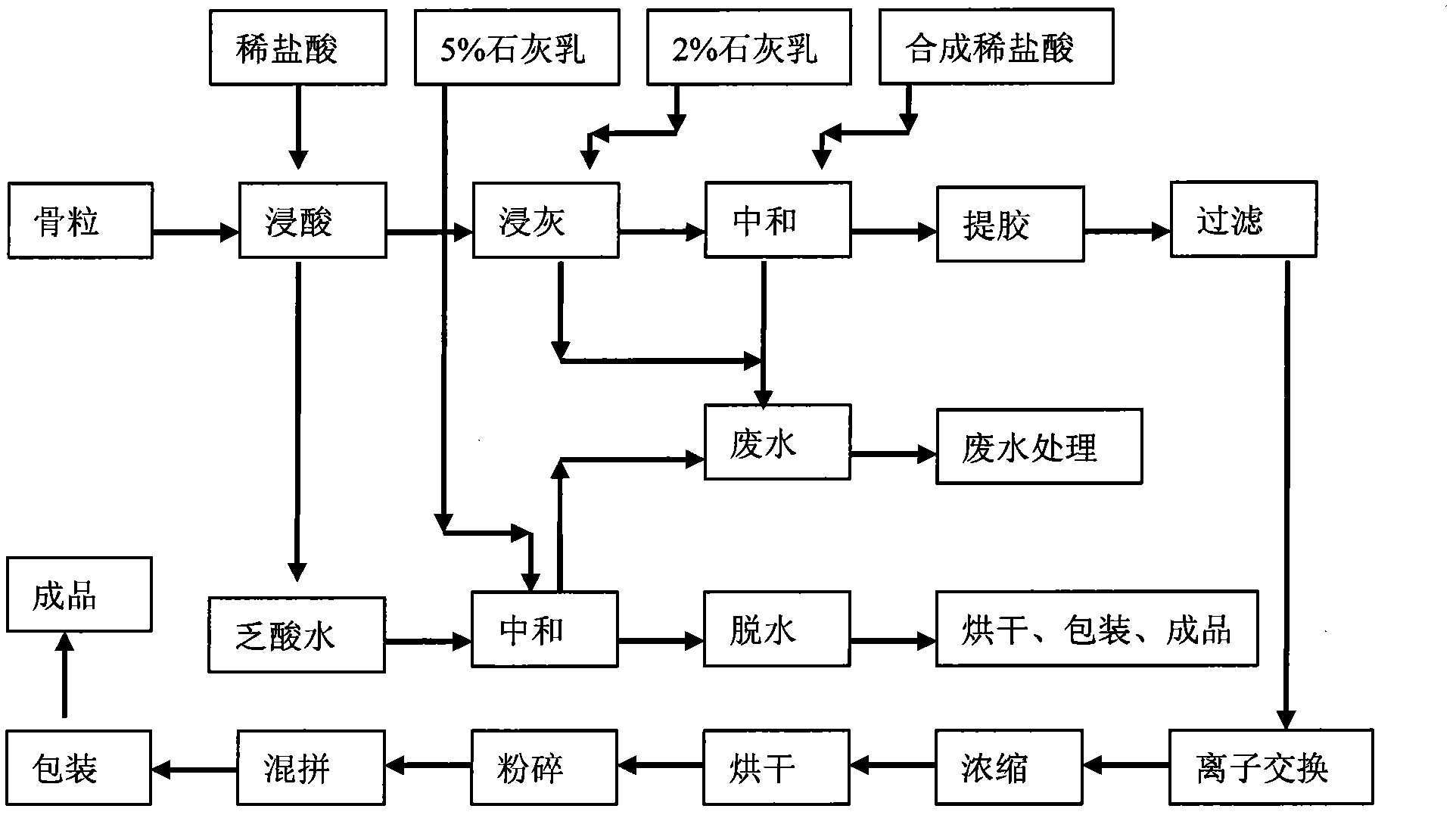

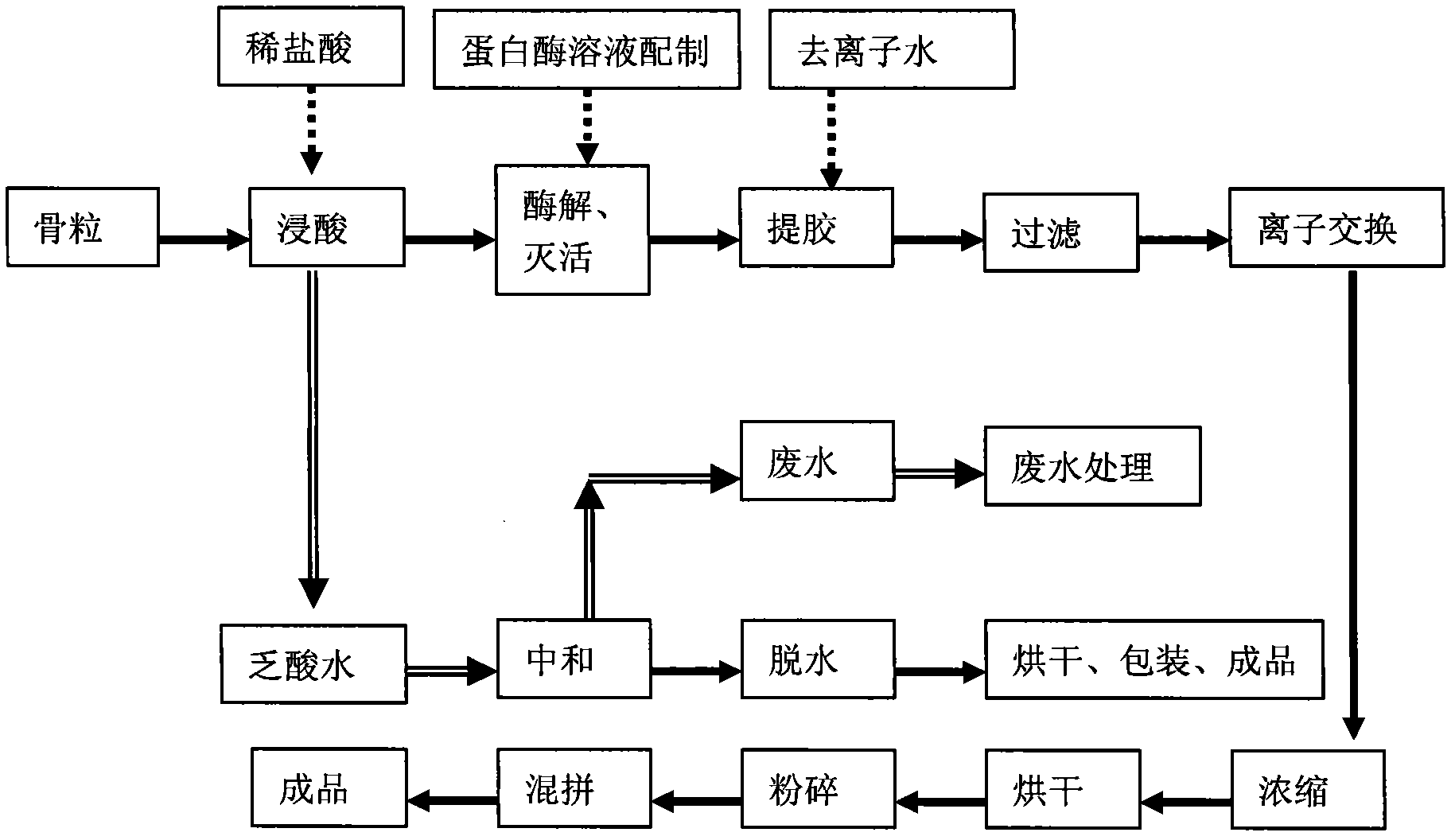

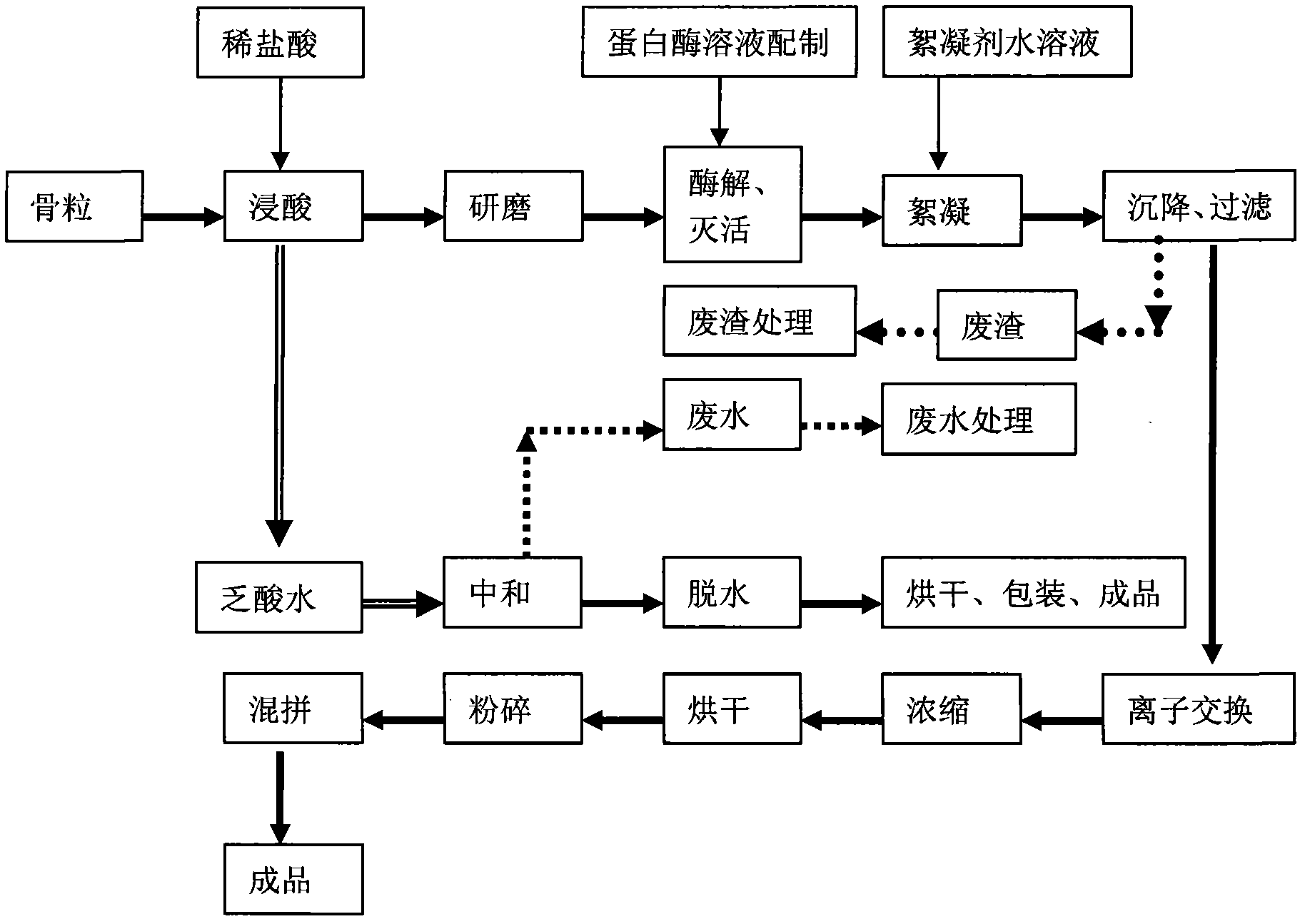

Enzyme method for preparing gelatin

ActiveCN102329843ALarge specific surface areaTake advantage ofGlue/gelatin preparationFermentationCalcium hydroxideProteinase activity

The invention relates to an enzyme method for preparing gelatin, which comprises the following steps of: pulverizing bone grains into bone meal, acidifying the bone meal by using phosphoric acid, and adding acid protease to hydrolyze; then, decoloring the solution by using hydrogen peroxide, and adjusting the pH value by using calcium hydroxide; and finally adding a flocculating agent. In the method provided by the invention, phosphoric acid is adopted for acidification, because a great amount of soluble calcium salts is formed, the enzymolysis reaction is mild. The defect that the enzymolysis end point of the finely ground collagen (ossein) enzymolysis method is difficult to control is overcome by controlling the end point of the enzymolysis reaction, so that the enzymolysis method for preparing gelatin is more practical.

Owner:安徽丰原集团有限公司

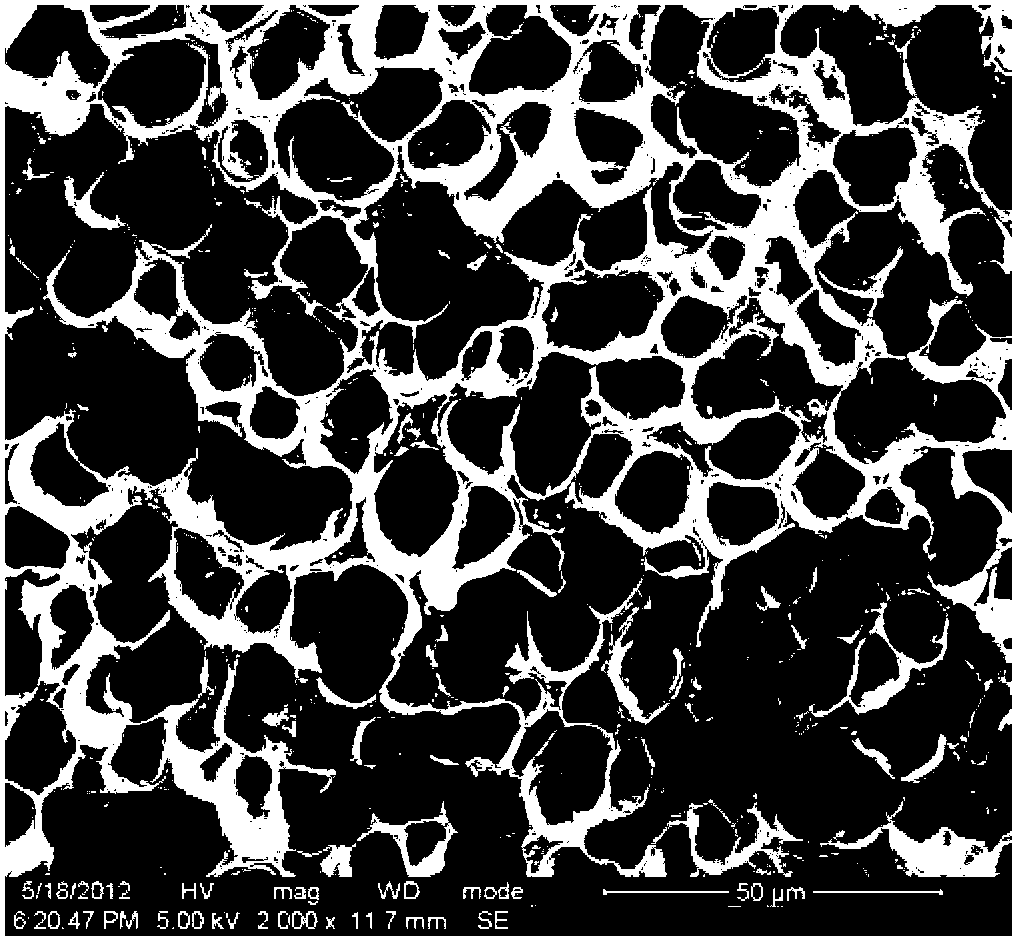

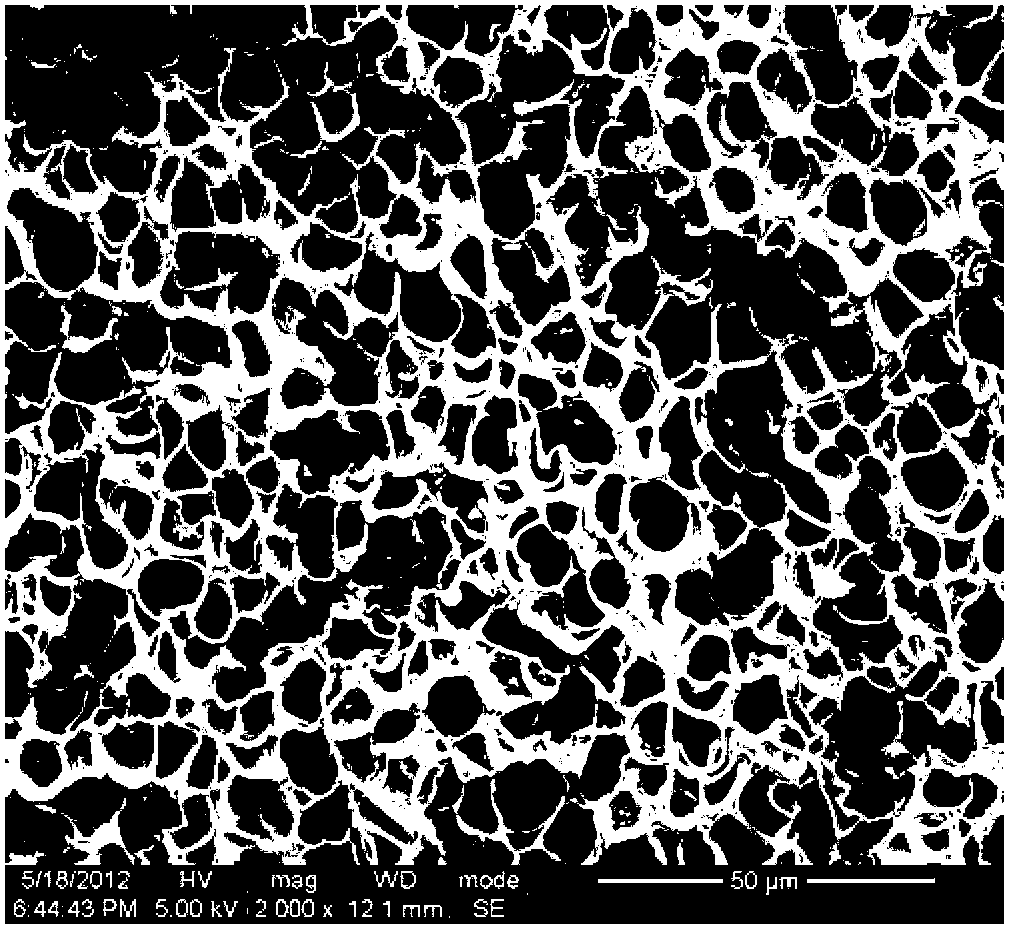

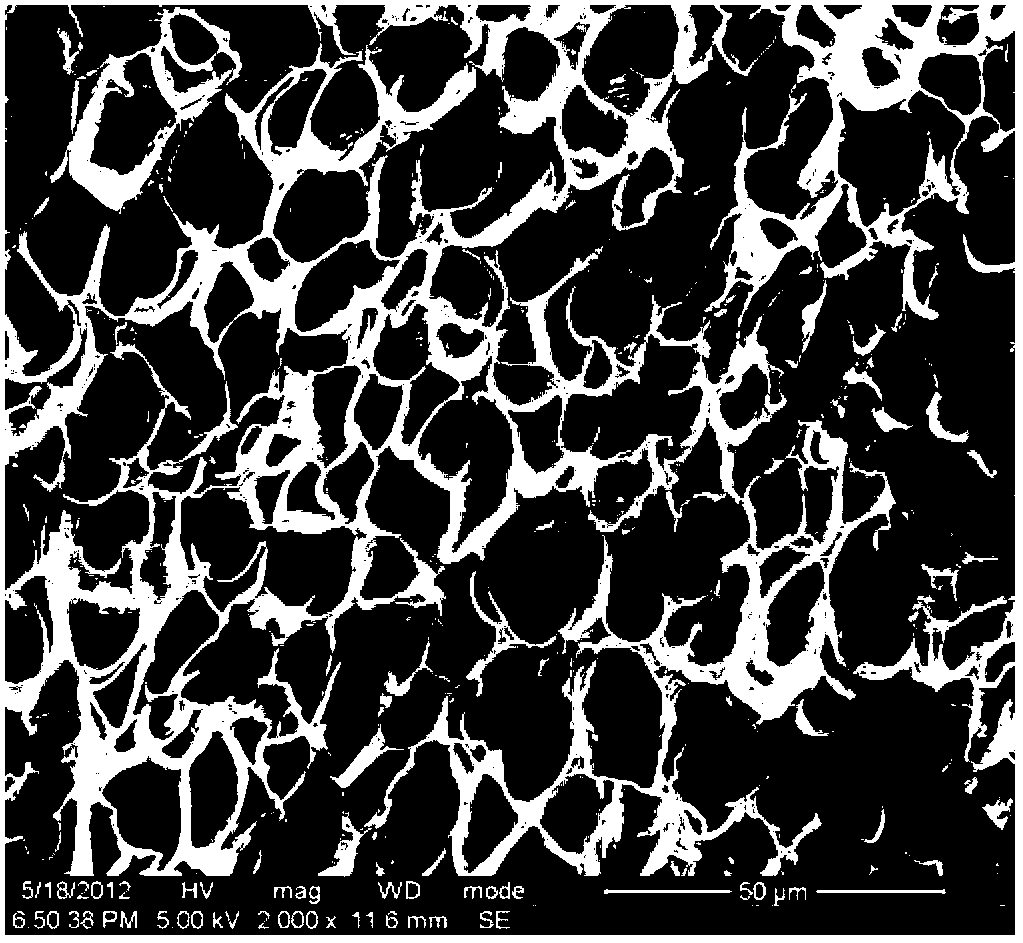

Preparation method of polymer-based conductive microporous foam composite material

The invention discloses a preparation method of a polymer-based conductive microporous foam composite material. The method comprises the following steps of: filling conductive fillers into a polymer to prepare a polymer-based composite material through blending methods of solution blending, melt blending or in-situ polymerizing and the like; preparing a composite material blank with a certain thickness from the polymer-based composite material by die pressing under vacuum; placing the composite material blank into a foaming high-pressure reactor, and dissolving supercutical fluid serving as foaming agent in the composite material blank; and foaming the composite material blank through a quick pressure releasing method or quick heating method when the supercutical fluid in the composite material blank is saturated, and then cooling to shaping the foamed composite material blank. According to the preparation method, the nontoxic pollution-free supercutical fluid is taken as the foaming agent, thus, the preparation method has the advantages of environmental protection, safety, stability, etc. The preparation method serves as a conductive foam material preparation technology with good application prospect.

Owner:SICHUAN UNIV

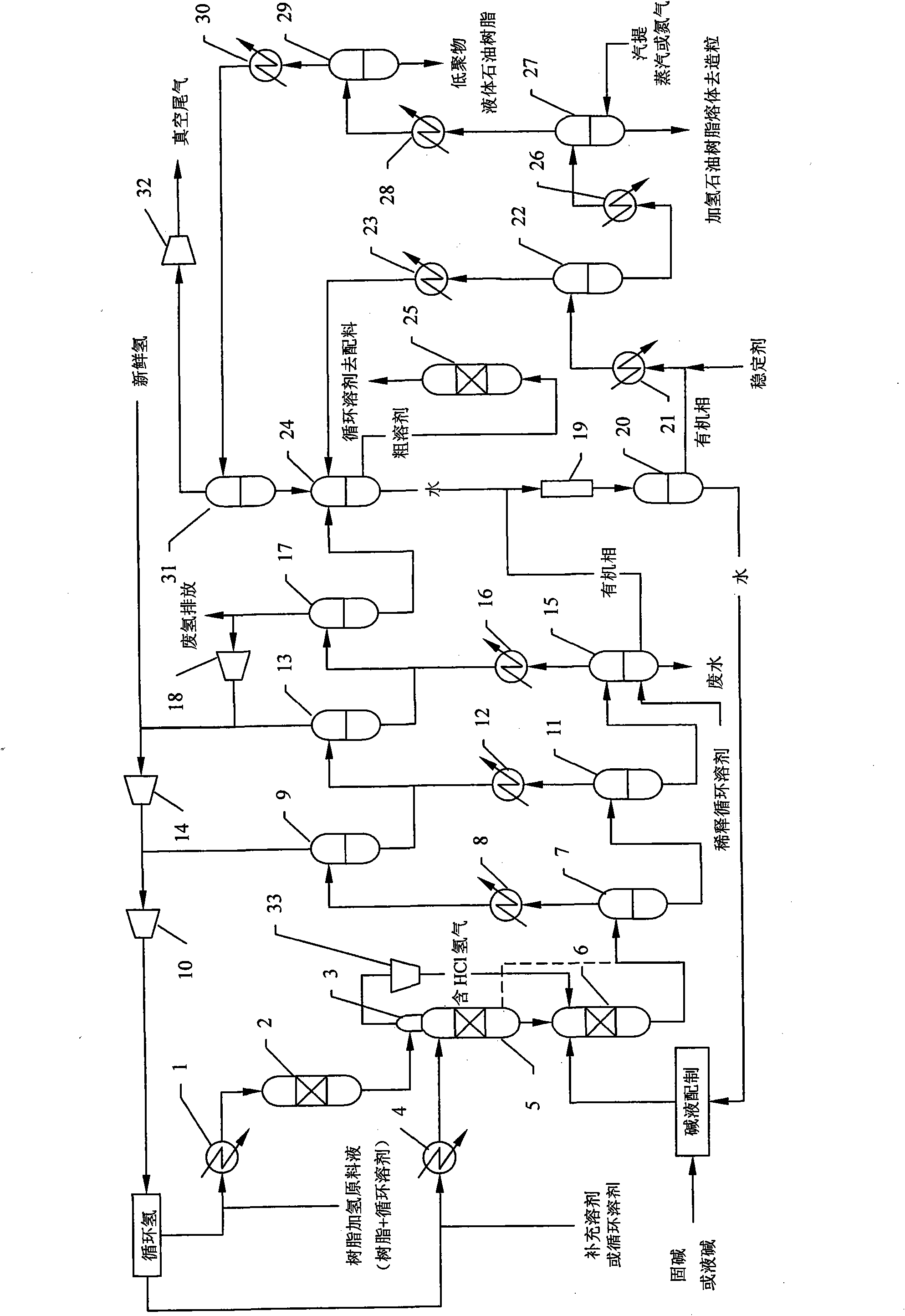

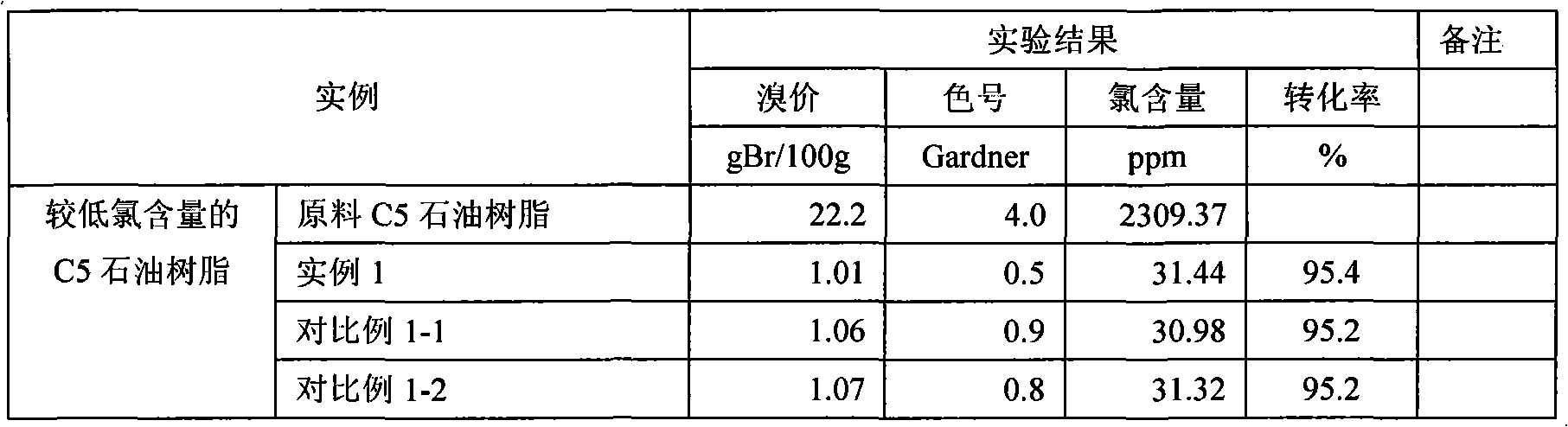

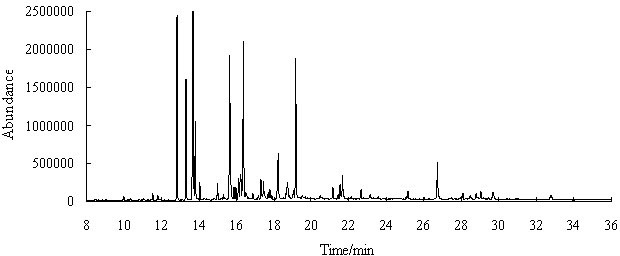

Industrial manufacture method for hydrogenated petroleum resin

ActiveCN102382259ASimplify the caustic cleaning processReduce corrosionPetroleum resinHydrogenation reaction

The invention relates to an industrial manufacture method for hydrogenated petroleum resin, which comprises the following steps of: generating hydrogenation reaction on petroleum resin which is obtained by polymerizing cracking C5 and C9 fractions under the proper condition of the existence of hydrogenation catalyst and solvents by adopting the processes of two-section hydrogenation and combination alkaline cleaning neutralization; hydrogenating the unsaturated component in the petroleum resin to reduce double-bond content; hydrogenating a non-ferrous perssad to fade; hydrogenating to remove chlorine retained in the polymerization process; and carrying out alkaline cleaning, water cleaning, stabilizer injection and solvent removal to obtain light or colourless hydrogenated petroleum resin. The method further simplifies the process through the organic combination of unit operation, and the industrial manufacture method for the hydrogenated petroleum resin, which has the advantages of wide adaptability on hydrogenated raw materials, less corrosion on system equipment, high product quality and high production capability is formed.

Owner:CHINA PETROLEUM & CHEM CORP

Colloidal electrolyte of lead acid batteries

InactiveCN101291002AInhibition of hydrationPrevent severe crackingLead-acid accumulatorsPhosphoric acidSilicon dioxide

The invention discloses a lead-acid accumulator colloid electrolyte. The lead-acid accumulator colloid electrolyte comprises the following compositions in percentage by mass: 30 to 45 percent of sulphuric acid, 4 to 12 percent of nanometer silicon dioxide, 0.05 to 0.5 percent of macromolecular stabilizing agent, 0.1 to 0.5 percent of superfine glass fibre, 0.1 to 0.5 percent of boric acid, 0.1 to 1 percent of phosphoric acid, 0.3 to 2.5 percent of sodium sulfate and 50 to 57 percent of water. The electrolyte is added with the macromolecular stabilizing agent and the hydrophilic superfine glass fibre and sets up a strong network structure with the sulphuric acid and water molecules; the macromolecular stabilizing agent effectively prevents the delamination of various compositions and the hydration of the colloid electrolyte; the superfine glass fibre in the colloid electrolyte forms a reinforcing rib of the colloid electrolyte, effectively prevents the colloid electrolyte from seriously crazing, strengthens the tensile strength and vibration resistance performance of the colloid and has the strong liquid absorption capacity which improves the diffusing and transmitting speed of the electrolyte. The lead-acid accumulator colloid electrolyte improves the charging and receiving capacity, thereby increasing the cycle life of an accumulator.

Owner:CHAOWEI POWER CO LTD

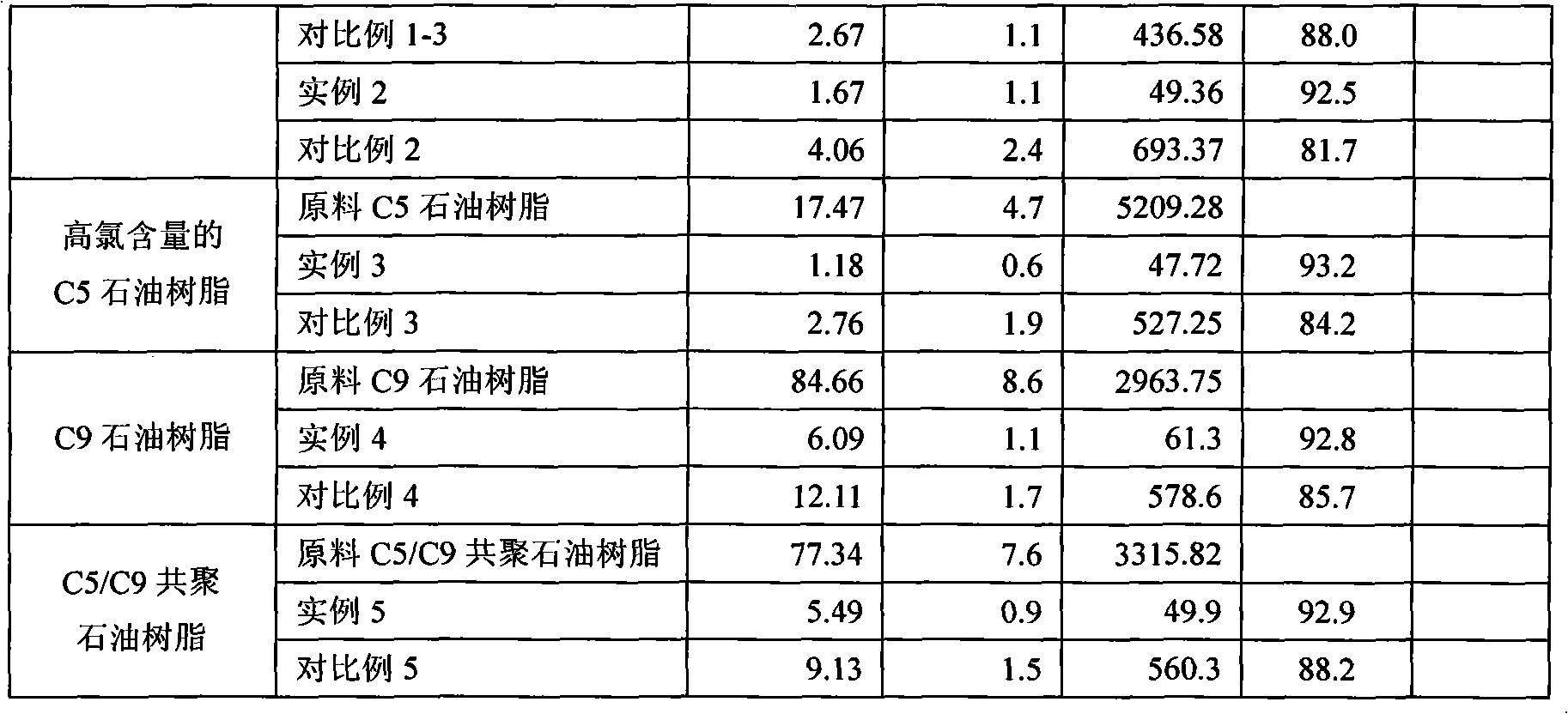

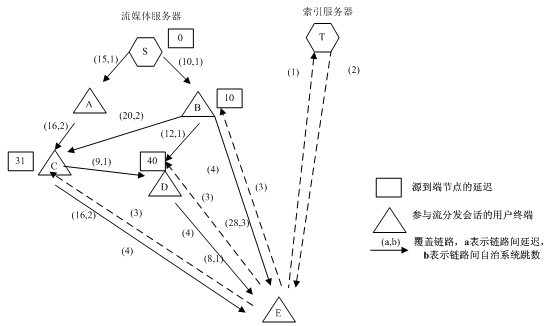

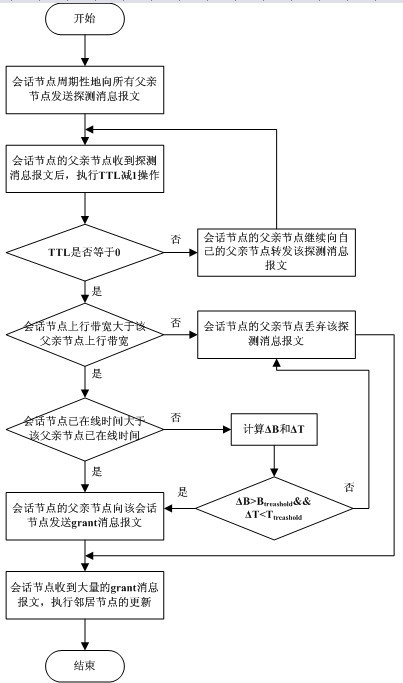

Cost optimization-based P2P streaming media coverage network topology structure adjustment method

InactiveCN101997922AReduce distribution delayReduce operating costsTransmissionTopology informationHigh bandwidth

The invention provides a cost optimization-based P2P streaming media coverage network topology structure adjustment method. In the method, the dynamism and isomerism of nodes are fully considered, the topology information of nodes, link delay between the nodes and available uplink bandwidth of the nodes are utilized, high-capacity nodes are greedily selected from alternative nodes to serve as service nodes by calculating the weight of the link between the nodes and the capacity value of the alternative nodes. Meanwhile, due to an adaptive topology adjustment method for periodically and continuously adjusting nodes with high bandwidth and long survival time to be close to a video source, the nodes in the network can gradually learn the network status and continuously optimize the system performance. A coverage network topology constructed by the method can improve the data diffusion speed, ensures the stability and continuity of streaming distribution, and effectively reduces the flow cross operators.

Owner:WUHAN UNIV

Preparation method for high-purity high-compactness and large-dimension molybdenum-titanium alloy sputtering target material

ActiveCN105568236AEffective recoverySmall grain sizeVacuum evaporation coatingSputtering coatingSputteringCompression molding

The invention discloses a preparation method for a high-purity high-compactness and large-dimension molybdenum-titanium alloy sputtering target material. The preparation method comprises the following steps that (1) material mixing is conducted, molybdenum and titanium hydride are selected as powder raw materials, the two kinds of powder are mixed under the argon protection atmosphere, and alloy powder is obtained; (2) compression molding is conducted, and the mixed powder raw materials are put into a rubber jacket mold to be subjected to cold isostatic pressing treatment; (3) sintering is conducted, a compressed blank is subjected to first-stage dehydrogenation sintering and second-stage compacting sintering in a vacuum sintering furnace, and finally the sintered blank is obtained; (4) rolling is conducted; (5) annealing is conducted; and (6) machining is conducted, the target material blank after being subjected to annealing is subjected to machining, and a molybdenum-titanium alloy sputtering target material product is obtained. The molybdenum-titanium alloy sputtering target material produced through the preparation method is uniform in content, free of segregation, fine and small in grain size, high in purity, and good in compactness.

Owner:LUOYANG SIFON ELECTRONICS

Method for catalytically oxidizing cyclohexane

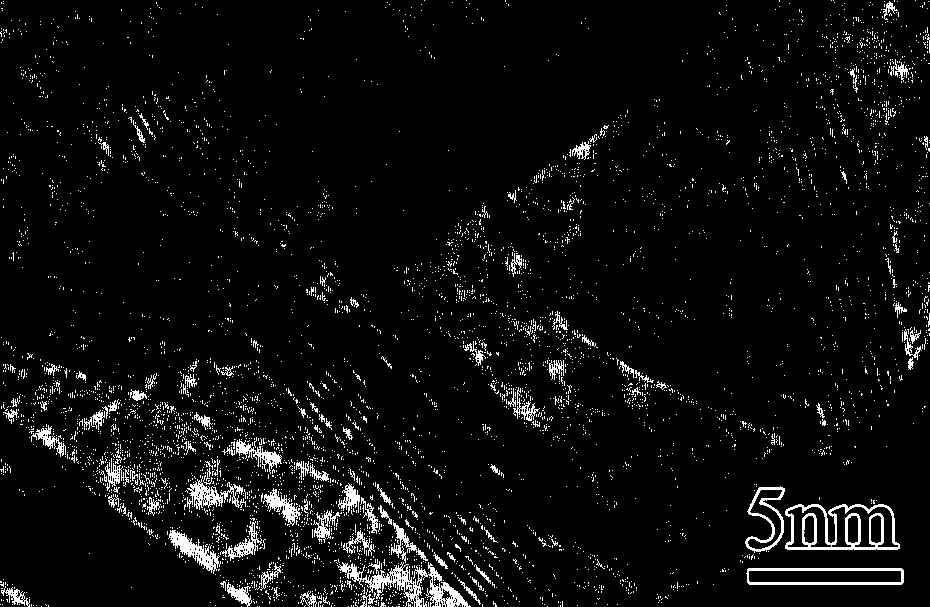

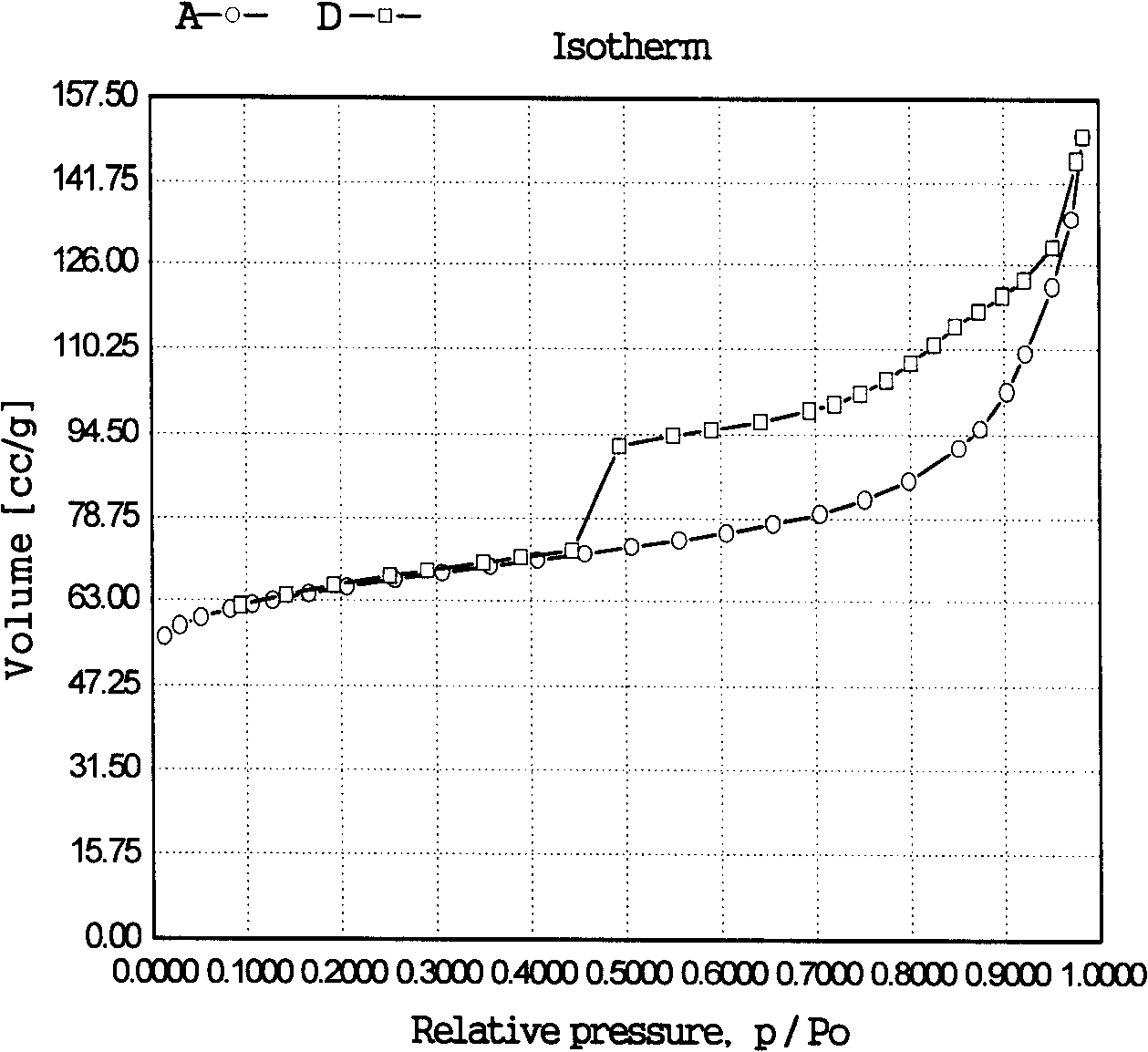

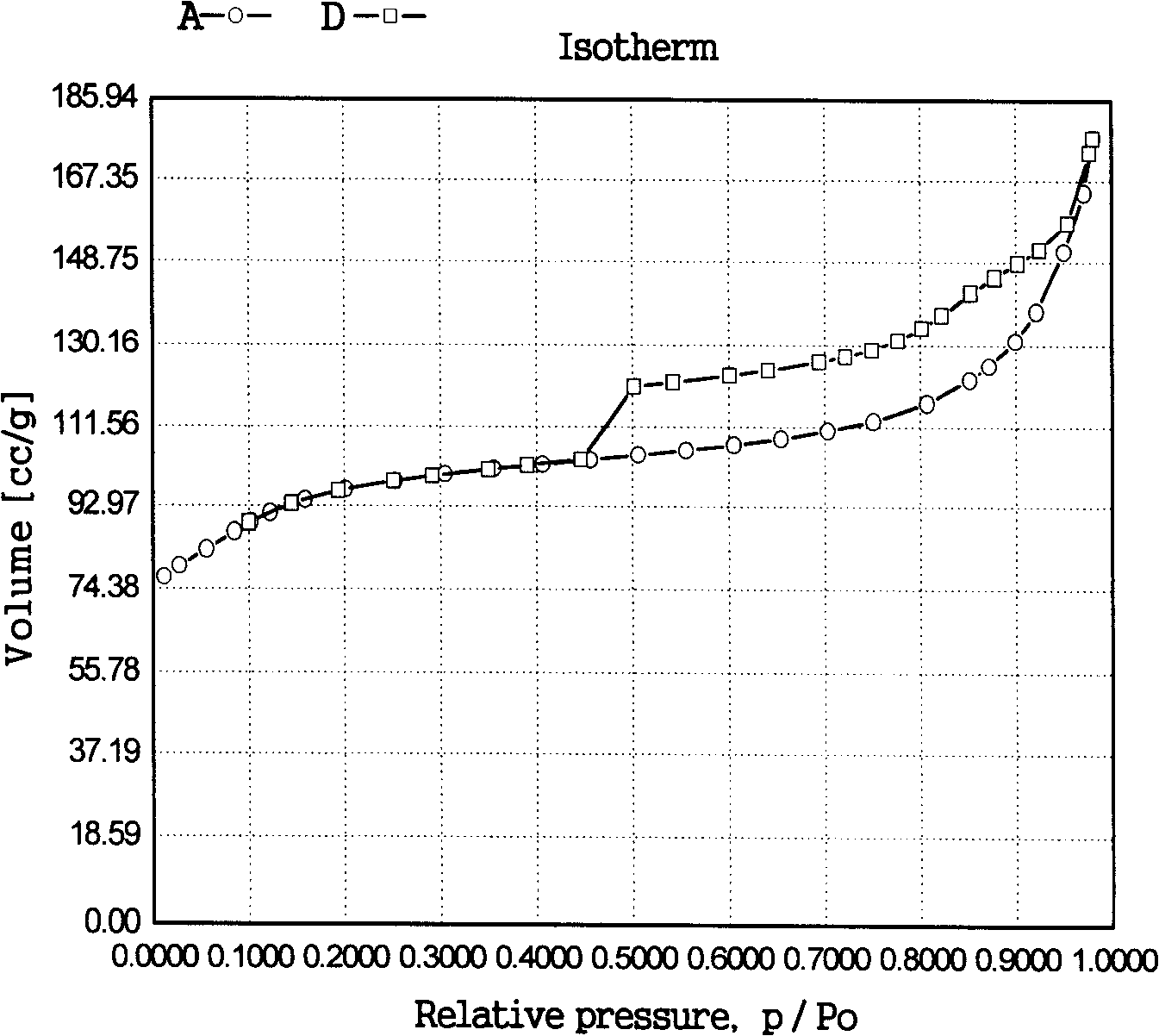

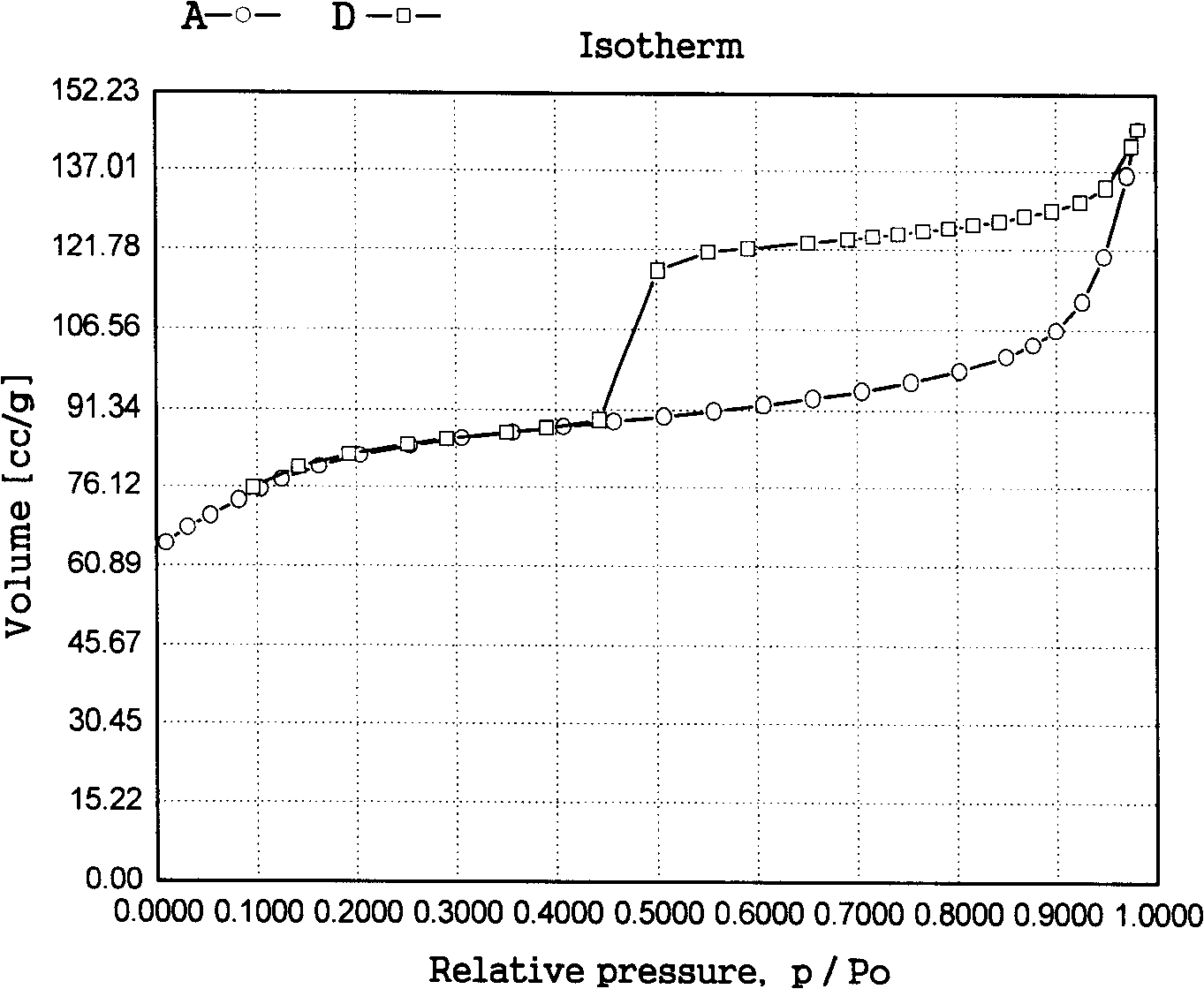

ActiveCN102079695AIncrease the degree of mixingExtend your lifePreparation by oxidation reactionsMolecular sieve catalystsHysteresisDesorption

The invention discloses a method for catalytically oxidizing cyclohexane, which is characterized in that cyclohexane, hydrogen peroxide and a catalyst are in contact for reacting, the mol ratio of the cyclohexane to the hydrogen peroxide is 0.5-8, the concentration of the catalyst in a reaction system is 0.005-0.1g / min, the reaction temperature is 40-150 DEG C, the catalyst is a titanium-silicon molecular sieve with an MFI structure, a hysteresis loop exits between an adsorption isotherm and a desorption isotherm of low-temperature nitrogen absorption of the molecular sieve, a crystalline grain is a single hollow crystalline grain or an aggregated crystalline grain formed by the aggregation of a plurality of hollow crystalline grains, the radial length of the cavity part of the hollow crystalline grains is 5-300nm, and the benzene adsorption capacity of the sample of the molecular sieve, measured under the conditions that the absorption time is 1h, the temperature is 25 DEG C and P / P0 is equal to 0.10, is at least 70mg / g. The method has the advantages of high selectivity of a target product and environment protection.

Owner:CHINA PETROLEUM & CHEM CORP +1

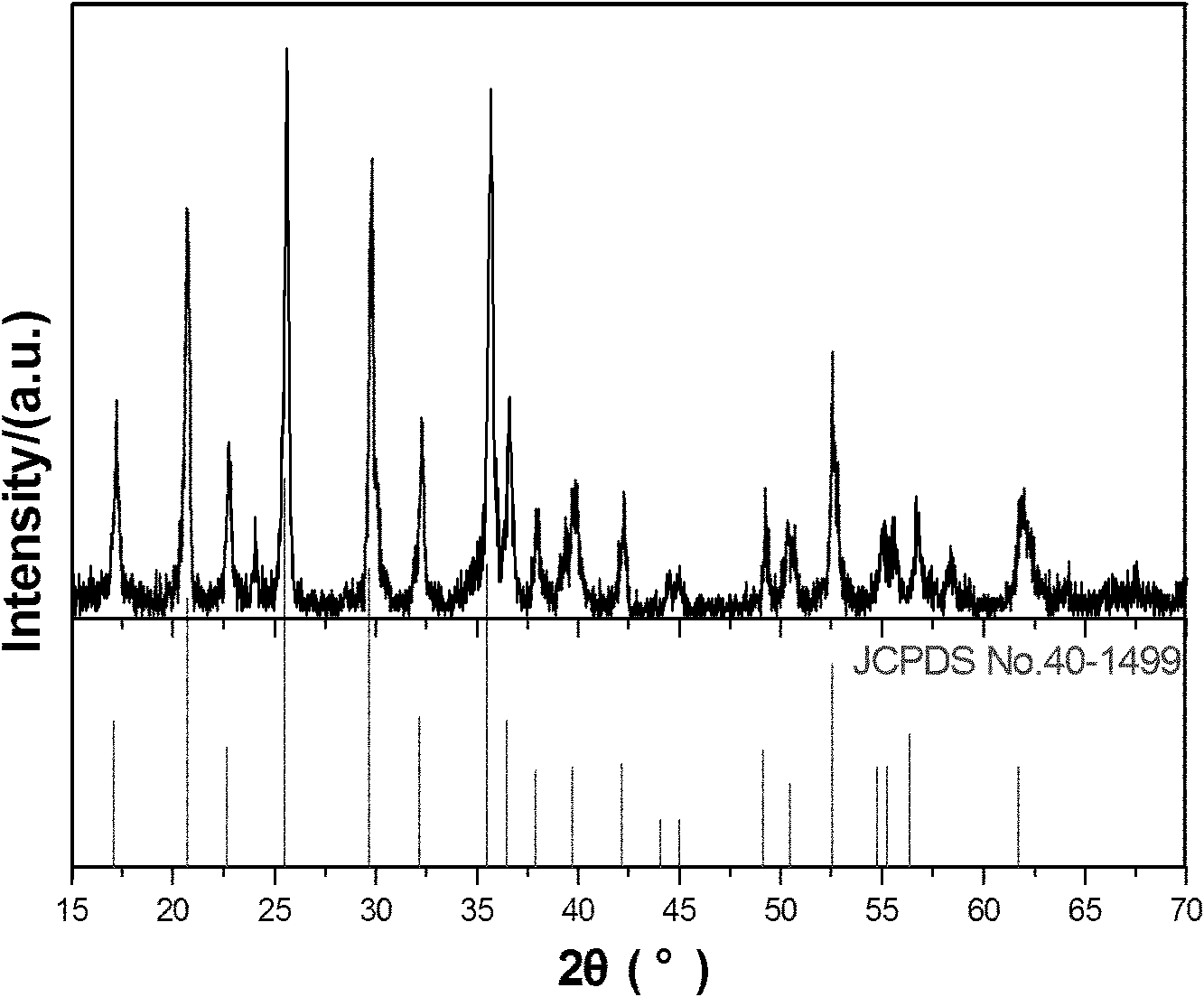

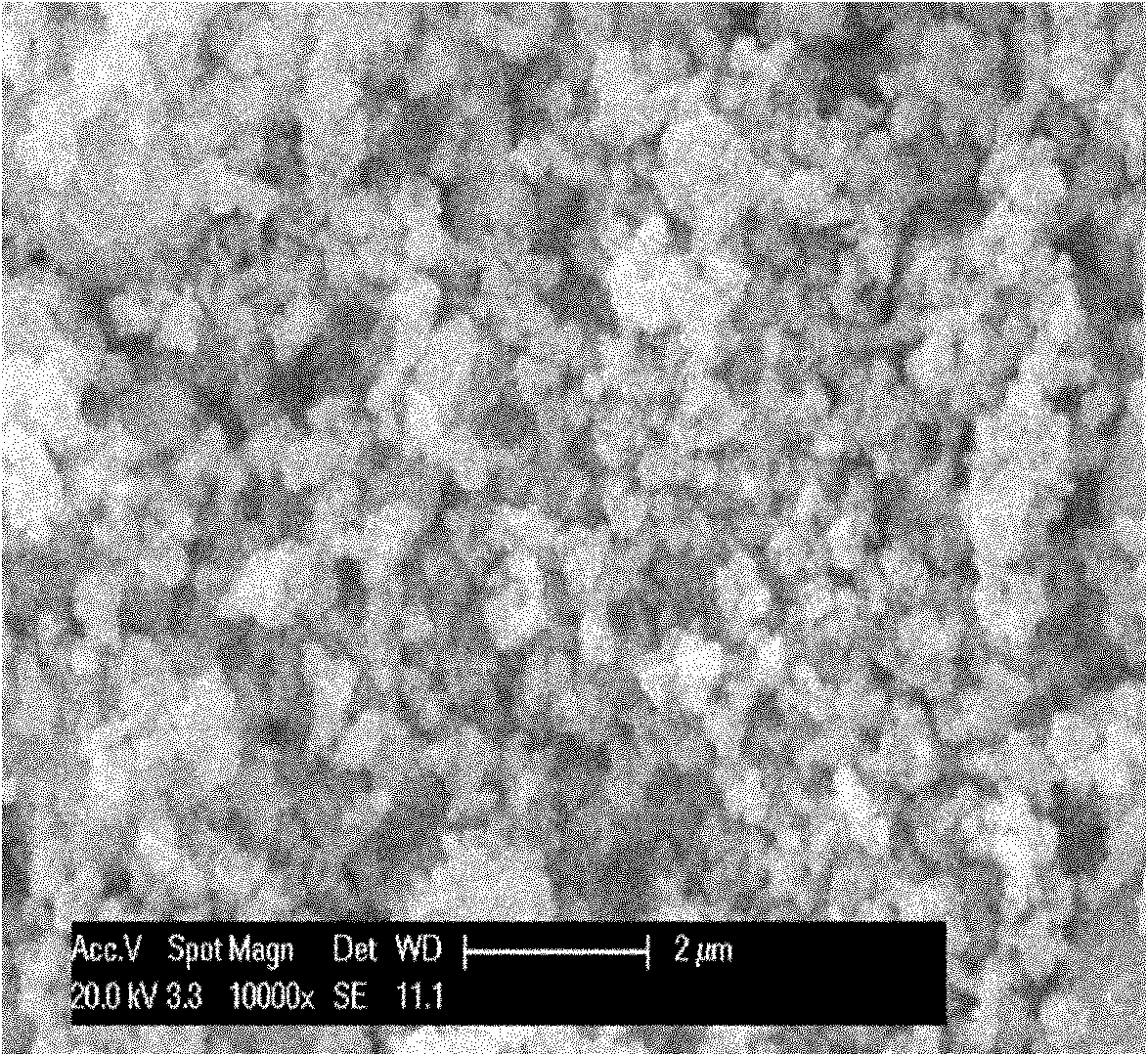

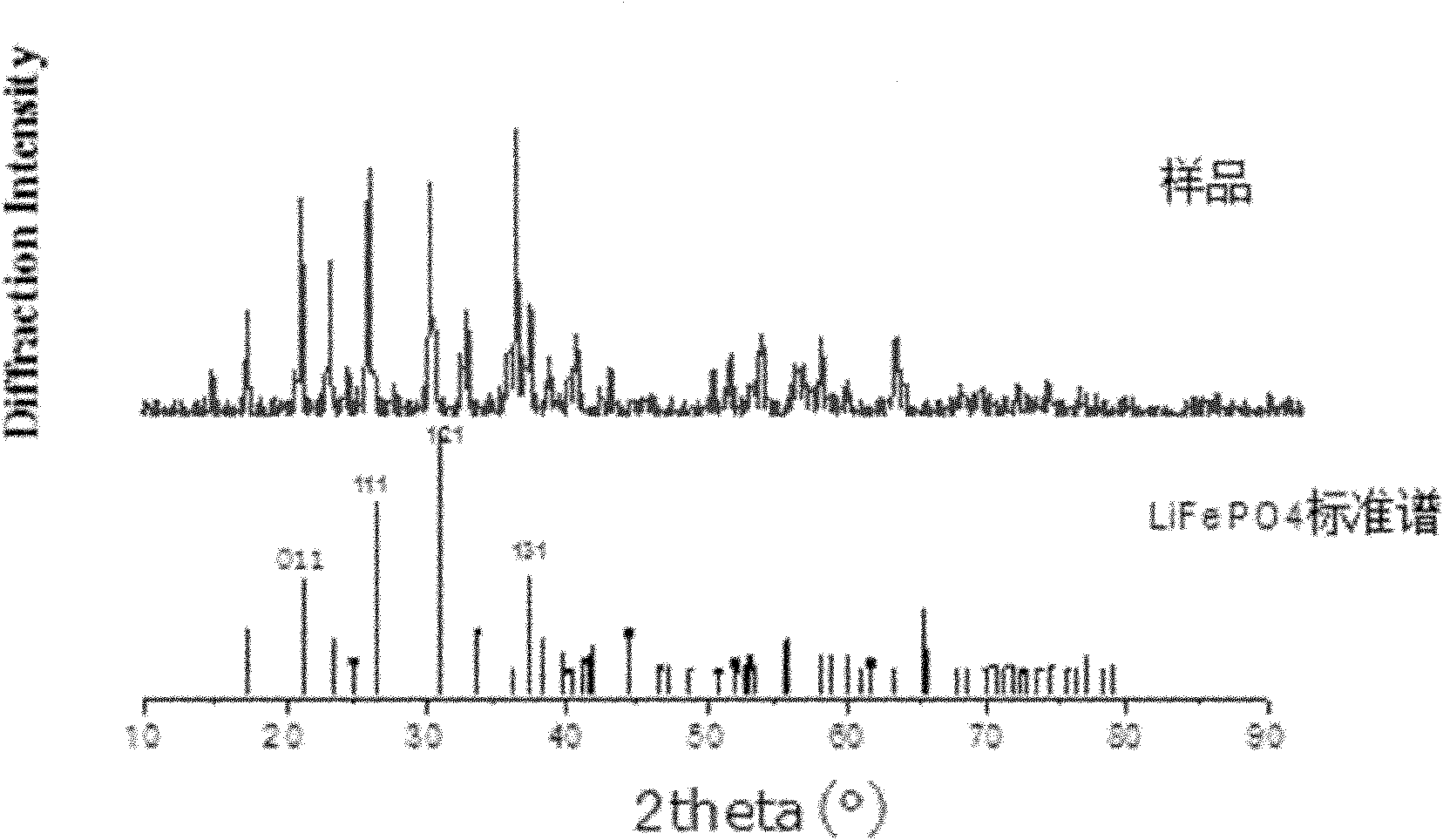

Hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate

InactiveCN102074687AShort tripIncrease the speed of diffusionCell electrodesReaction temperatureMolecular level

The invention discloses a hydrothermal synthesis method for preparing nano-scale carbon-coated lithium iron phosphate, which belongs to the field of lithium-ion battery anode materials and comprises the following steps of: sequentially adding a phosphorus-source solution, an iron-source solution, a carbon source, a lithium-source solution and a boiling-point elevator into a reaction device in sequence, mixing, then heating to the temperature of 60-180 DEG C for reaction under inert gas, cooling after the reaction, filtering precipitates to obtain a nano-scale lithium iron phosphate precursor, and then sintering the nano-scale lithium iron phosphate precursor at the temperature of 400-600 DEG C under the protection of the mixed gas of the inert gas and hydrogen gas. The combination of lithium, iron, phosphorus and the like on a molecular level is realized by the method, and the grains of a product are quite fine and are uniformly distributed; because the boiling-point elevator is adopted, the reaction temperature and pressure of the reaction kettle are decreased; and the hydrothermal synthesis method has the advantages of simple preparation process, short flow, easiness in operational control, low reaction temperature, short time, low energy consumption and easiness in realizing large-scale industrialized production.

Owner:JIANGSU DELI CHEM

Antiwear antifriction composite additive for lubricating oil (grease)

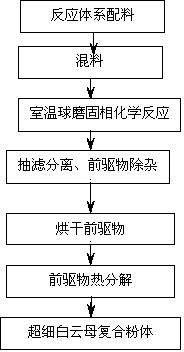

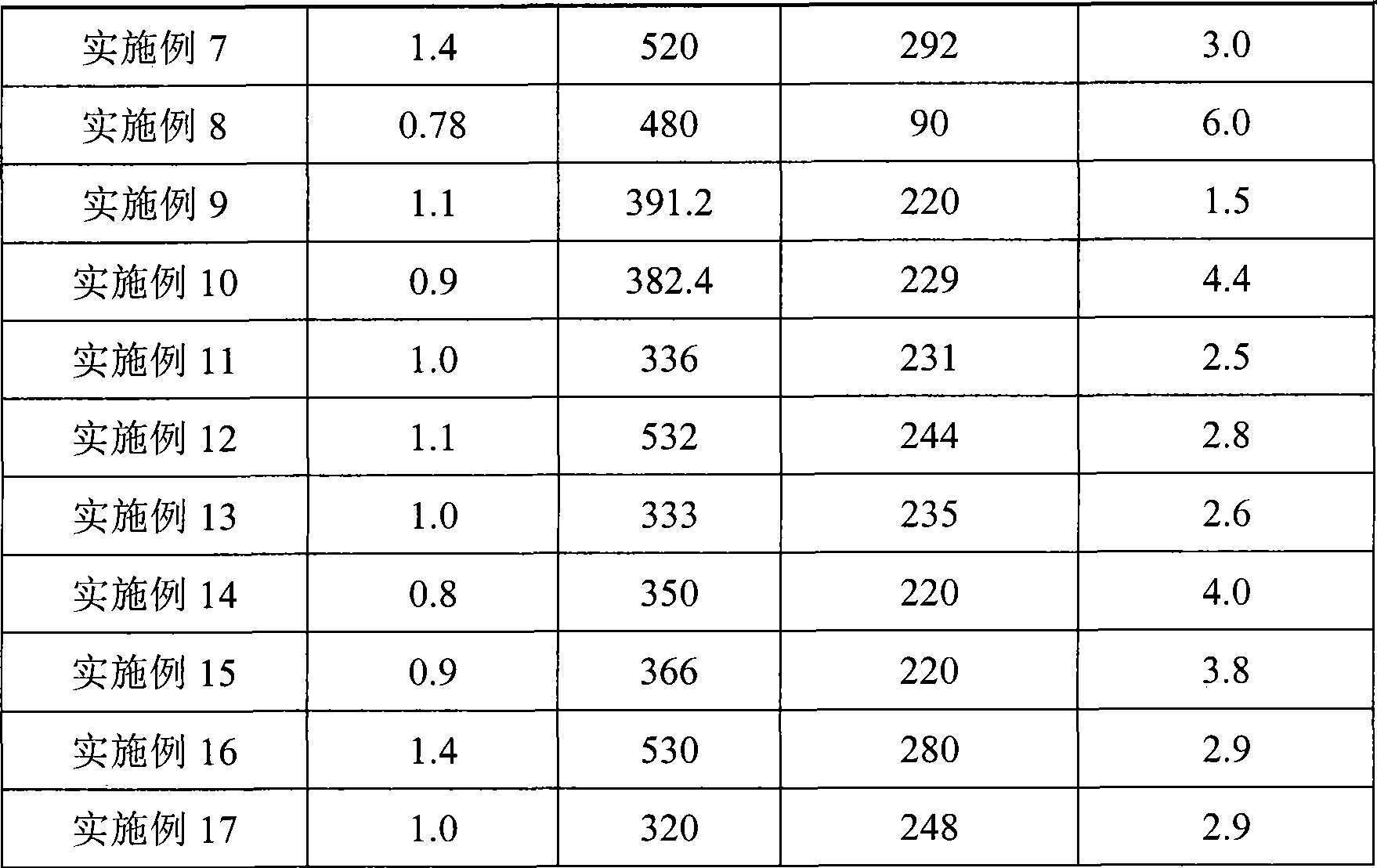

InactiveCN104046407AIncrease surface areaIncrease the speed of diffusionAdditivesMetallurgyReaction rate

The invention discloses an antiwear antifriction composite powder for lubricating oil (grease) and a preparation method thereof and relates to a nano-rare earth oxide-cladding ultrafine muscovite composite powder for the fields of lubricating oil, lubricating grease and the like. the invention is characterized in that a muscovite powder, rare-earth salt and its ligand are used as raw materials; a solid-phase reaction system is crushed by shear force and impact force generated during the ball-milling process, specific surface area of reactants is increased, and reaction rate is raised so as to raise ratio of nucleation rate to growth rate; a fine and uniform precursor is prepared, and then washing, drying and control of thermal decomposition temperature and time are carried out so as to obtain the nano-rare earth oxide-cladding ultrafine muscovite composite powder with different particle sizes and cladding systems; and after undergoing surface modification, the nano-rare earth oxide-cladding ultrafine muscovite composite powder is added into base oil or lubricating grease at different proportions of (0.5%-3%). In four-ball friction, friction coefficient can be reduced, and friction-pair wear scar diameter is minimized.

Owner:SICHUAN UNIV

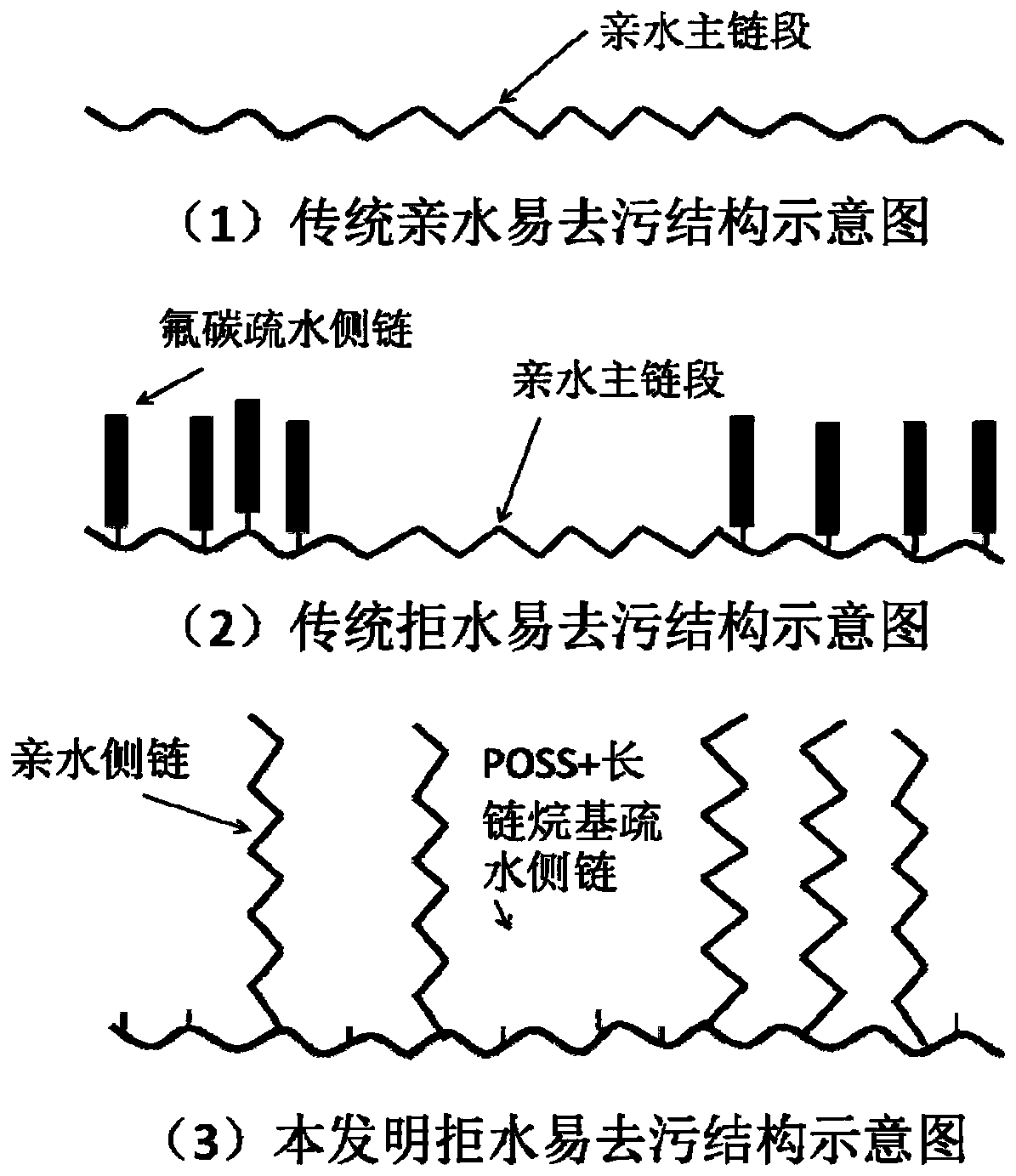

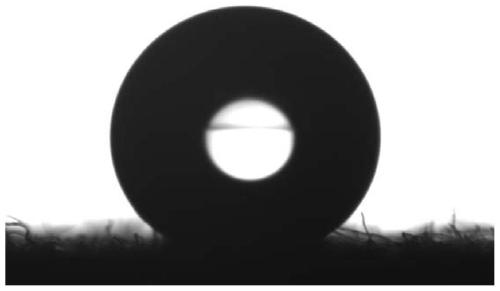

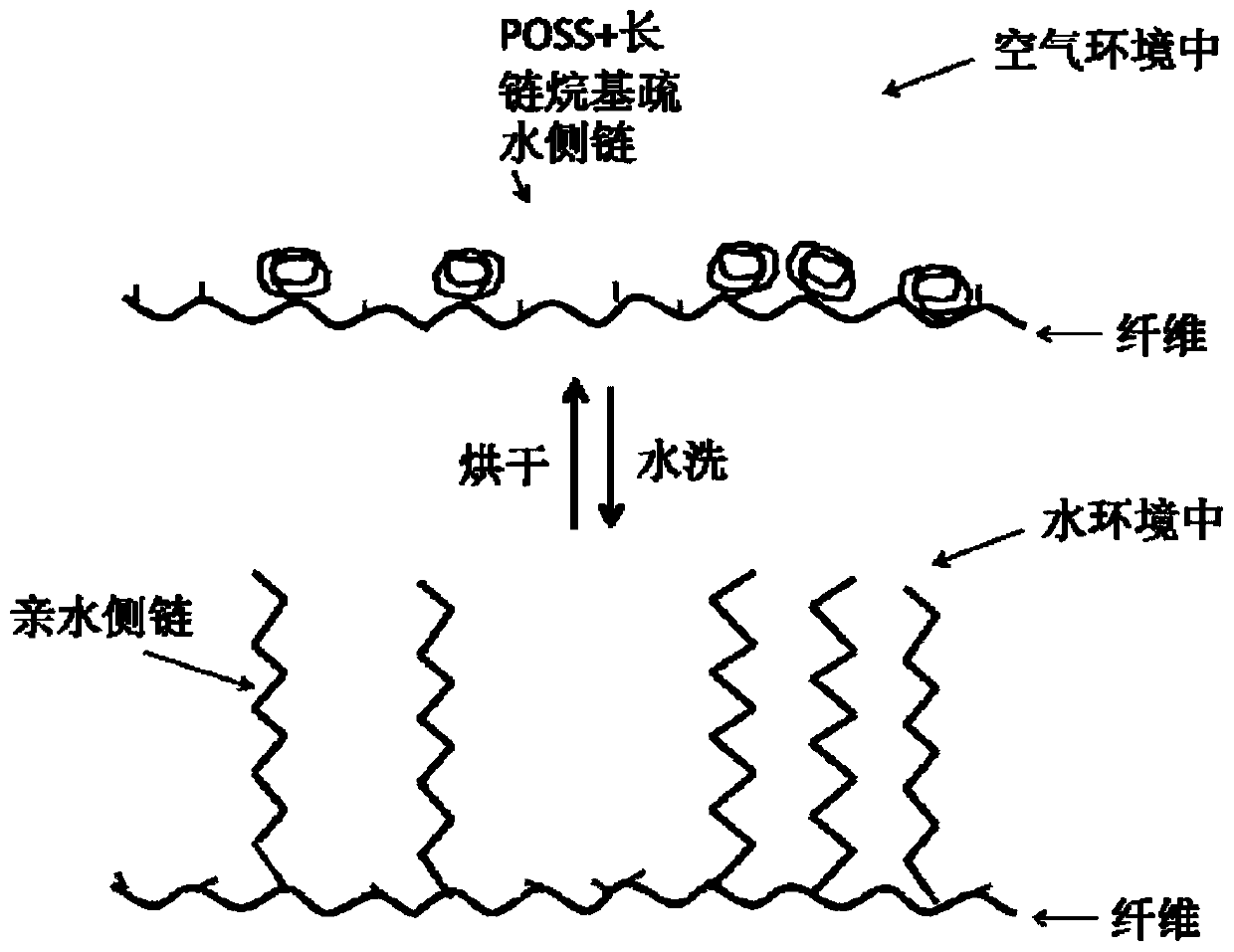

Fluoride-free water-repellency stain-release multifunctional finishing agent and preparation method and application thereof

InactiveCN110317307AFacilitate strippingIncrease the speed of diffusionStain/soil resistant fibresLiquid repellent fibresMethacrylatePolymer science

The invention discloses a fluoride-free water-repellency stain-release multifunctional finishing agent and a preparation method and application thereof. The fluoride-free water-repellency stain-release multifunctional finishing agent is a waterborne emulsion or waterborne solution of a polymer shown in a formula I. The structural formula of the polymer is shown in the formula I, and in the formulaI, R1 is a long-chain acrylate or long-chain methacrylate structure chain segment; R2 is a cage type silsesquioxane structure chain segment containing a mono-acrylate group or a mono-methacrylate group; R3 is a polyethylene glycol methanal structure chain segment containing a mono-methacrylate structure or a mono-acrylate structure; R4 is a structure chain segment of a functional monomer and is selected from an acrylate or methacrylate monomer containing at least one of hydroxyl, an epoxy group, an amide group, dimethylamino, carboxyl, an ester group, an alkoxy, a blocked isocyanate group anda halogen end group, and a, b, c and d represent the degrees of polymerization. The finishing agent is environmentally friendly, capable of removing stains easily, free of biologic toxin and not degradable; preparation is easy, and conditions are mild.

Owner:BEIJING CTA TEX CHEM

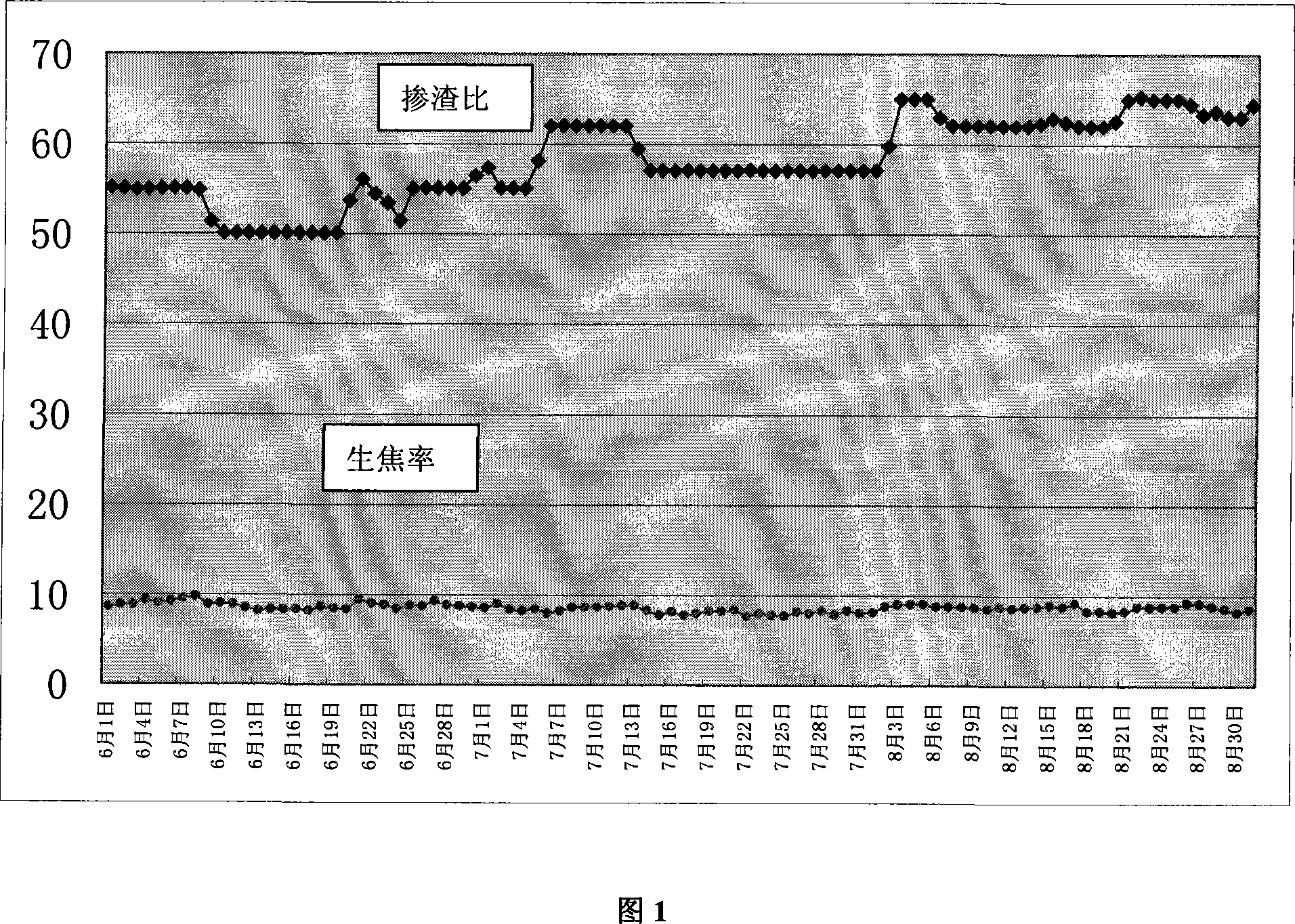

Assistant for catalytic cracking coking-inhibiting yield-increasing and preparing process thereof

InactiveCN101215476AHigh decomposition temperatureLow available metal contentCatalytic crackingSlagActive agent

The invention discloses catalytic cracking anti-coke income-increasing auxiliary agent which is used for catalytic cracking (FCC) devices and is prepared by following components according to the proportion by weight: disperser 5-15%, thermal cracking active agent 5-20%, free radical chain reaction depressor 5-25%, metal passivator 15-60% and dissolvent 25-65%. The invention is oil soluble auxiliary agent and has good compatibility with catalytic cracking mediums, the slag inserting rate of the FCC devices can be increased after the auxiliary agent is added, the light oil yield is increased, and the coke yielding rate is reduced.

Owner:金浦新材料股份有限公司

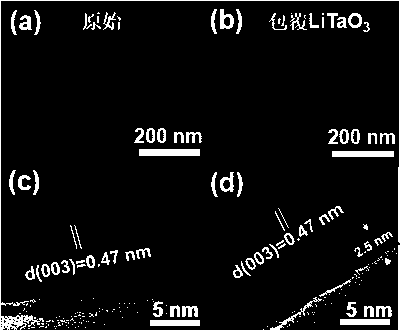

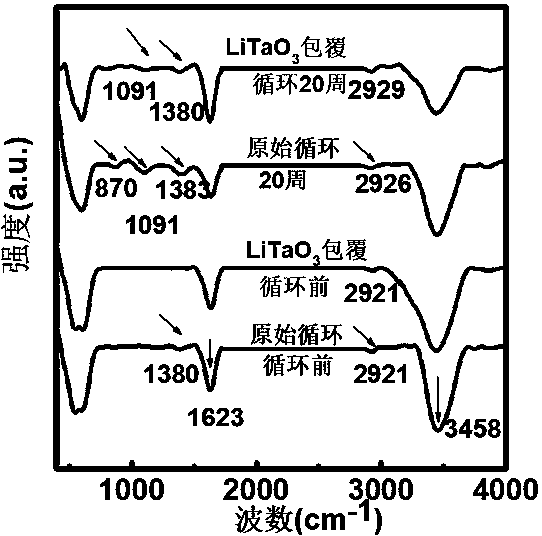

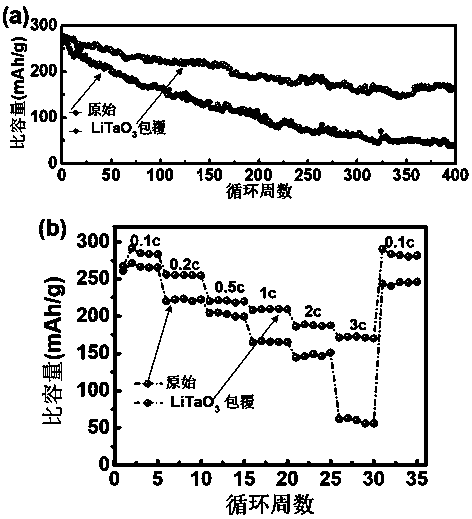

Lithium ion battery anode material coated with piezoelectric material on surface and preparation method thereof

PendingCN109921000AEasy to operateGood repeatabilityCell electrodesSecondary cellsBarium titanatePotassium

The invention provides a lithium ion battery anode material coated with piezoelectric material on the surface and a preparation method thereof. The surface of the battery anode material is coated witha layer of piezoelectric material with piezoelectric effect; the piezoelectric material comprises any one or more of barium titanate, lithium niobate, sodium niobate, lithium tantalite, sodium-potassium metaniobate and barium-strontium metaniobate with piezoelectric effect. The piezoelectric characteristic of the piezoelectric material is utilized to realize a coating modification function for the anode active materials so as to ensure that the volume phase structures of the anode active materials are not influenced and damaged, the growth of solid-electrolyte interface membranes is suppressed, and the diffusion speeds of active material-coating layer interface lithium ions are improved, thereby effectively improving the structure stability and electrochemical cycle performance of the lithium ion battery anode material, improving the pyrolysis temperature of the anode material and then enhancing the safety performance of the lithium ion batteries in the using process.

Owner:HENAN UNIVERSITY

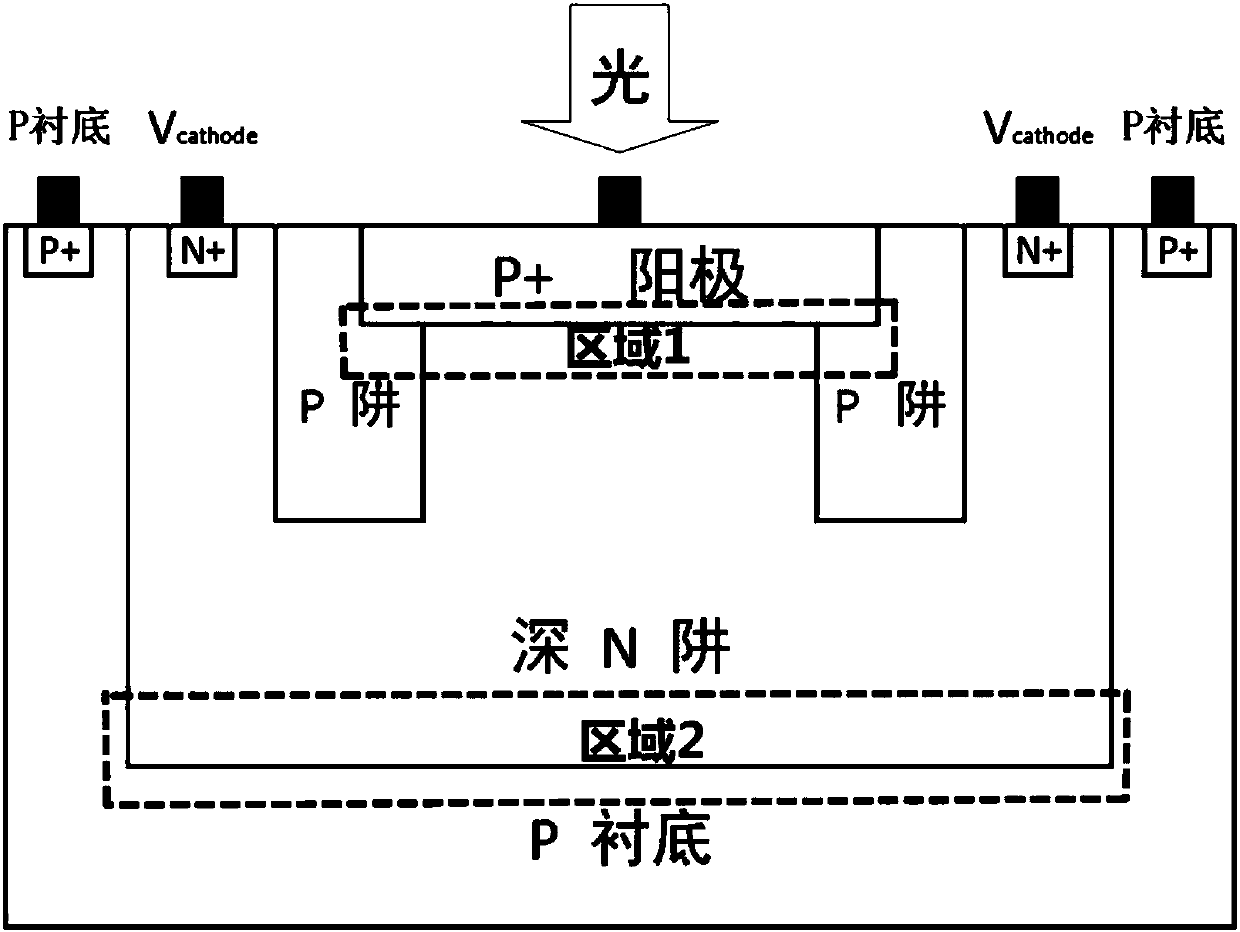

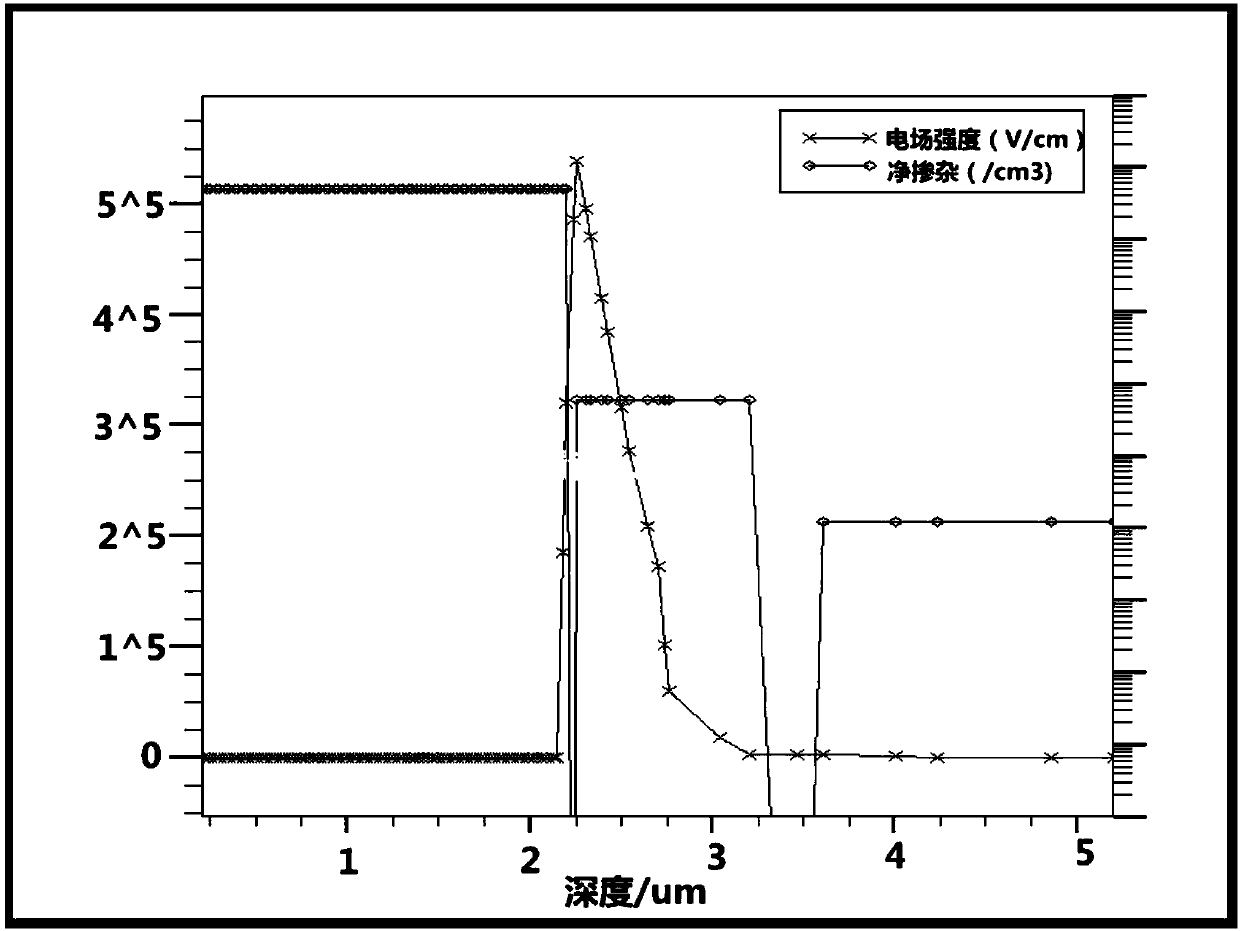

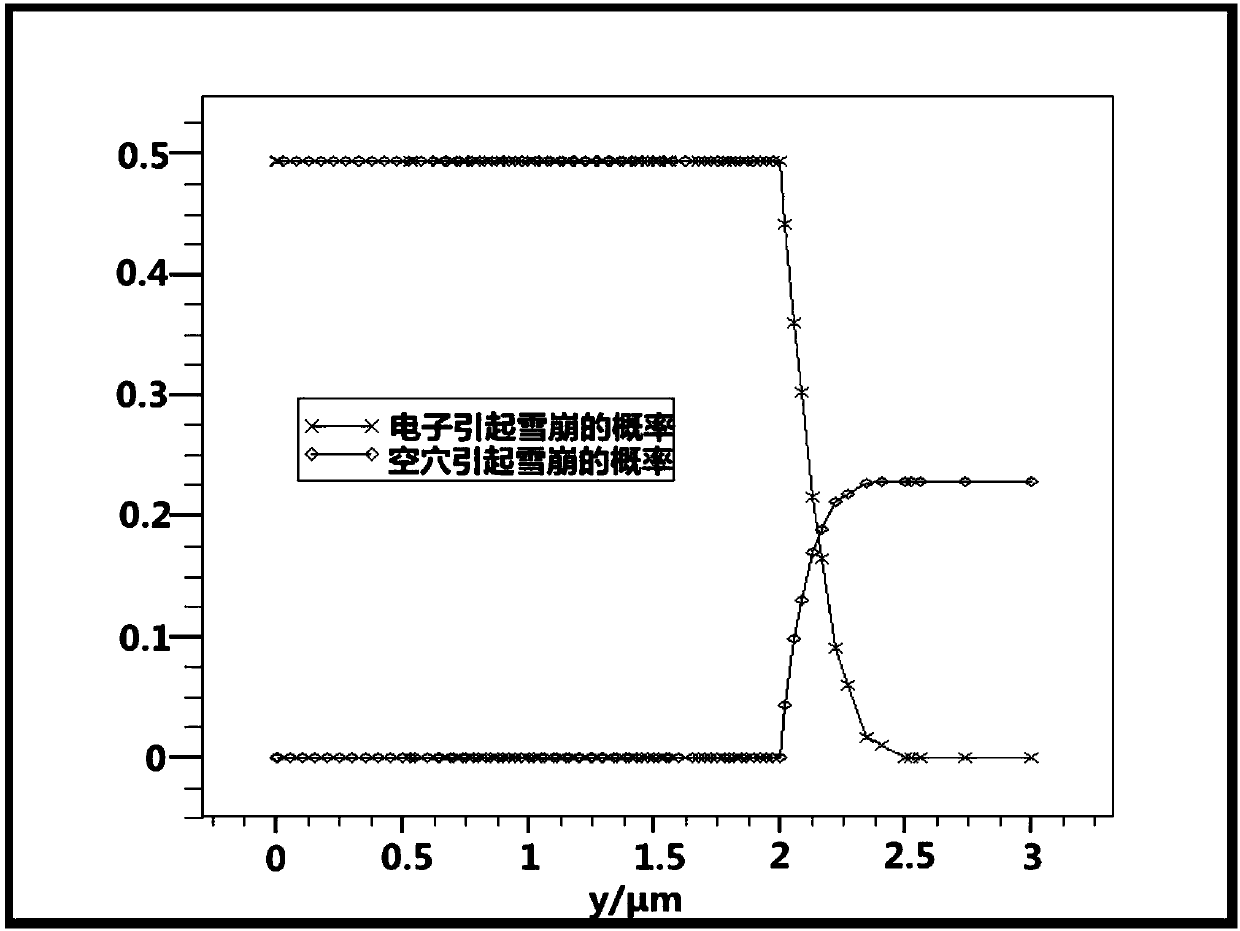

CMOS single-photon avalanche diode specific to long-wave-band weak light

InactiveCN107946389AHigh sensitivityQuick responseFinal product manufactureSemiconductor devicesElectron avalanchePhoton

The invention provides a CMOS single-photon avalanche diode specific to long-wave-band weak light. According to the specific structure, a deep N well is manufactured on a P type substrate; next, a P type heavily doped region is manufactured in the deep N well; a PN junction is formed by a P+ layer and the deep N well to be used as an avalanche multiplication region; the P+ region is surrounded bya lightly doped P well to be used as a protection ring; and after incident light comes to a device, the deep N well region in a medium electric field strength is absorbed, and the generated photon-generated carriers move towards an avalanche multiplication region of a strong electric field region. Electron holes generated by light of relatively long waveband are formed in a relatively deep position of the device, so that the light signals can be detected effectively by the deep N well; by taking the deep N well / P substrate as a shielding diode, diffusion of the substrate photon-generated carriers to the PN junction can be prevented, thereby reducing influence of diffusion of substrate slow photon-generated carriers to the response speed of a photoelectric detector; and the absorption efficiency of the device in a long waveband can be improved.

Owner:CHONGQING UNIV OF POSTS & TELECOMM

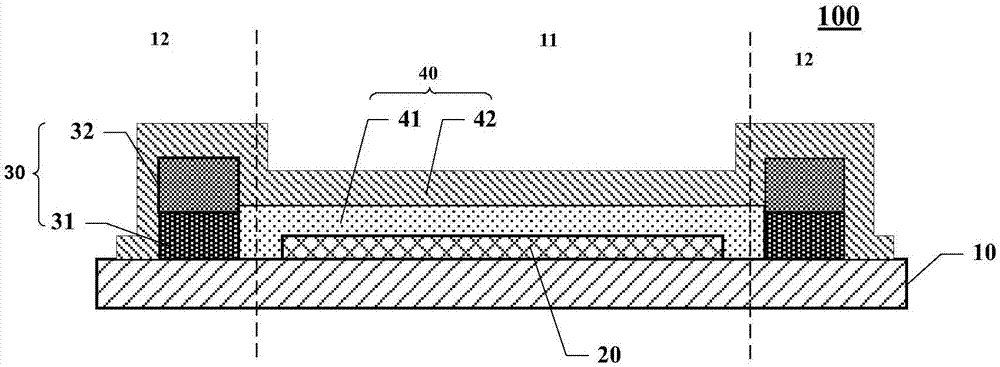

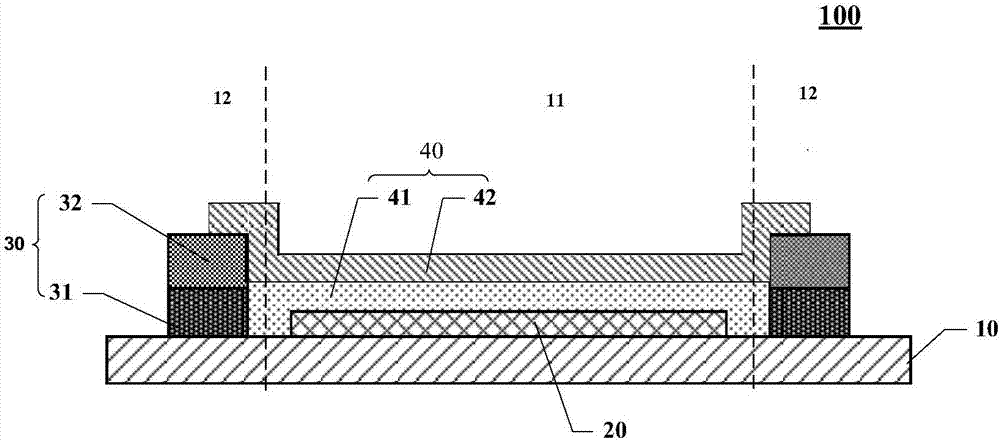

Organic electroluminescence device

ActiveCN107204404AIncrease the speed of diffusionAvoid exceedingSolid-state devicesSemiconductor/solid-state device manufacturingOrganic filmEngineering

The invention discloses an organic electroluminescence device which comprises the components of a substrate; an electroluminescent structure which is arranged on the substrate and is located in a displaying area; at least one retaining wall which is arranged on the substrate and is arranged in a non-displaying area, wherein the retaining wall surrounds the displaying area; at least one retaining wall is successively arranged in a direction of departing from the displaying area, and the retaining walls comprise a first retaining wall which is adjacent with the displaying area; the first retaining wall comprises at least one stack structure, the stack structure comprises an organophilic material layer and an organo-hydrophobic material layer, the organo-hydrophobic material layer is arranged on one side, which is far from the substrate, of the organophilic material layer; and a thin-film packaging layer which comprises an organic film layer and an inorganic film layer, wherein the organic film layer is arranged in a space which is formed through surrounding the displaying area by the first retaining wall, and the inorganic film layer is arranged on the surface, which is far from the electroluminescent structure, of the organic film. According to the organic electroluminescence device, a good boundary of the organic film layer is formed and furthermore thickness at the boundary of the organic film layer is effectively controlled.

Owner:SHANGHAI TIANMA MICRO ELECTRONICS CO LTD

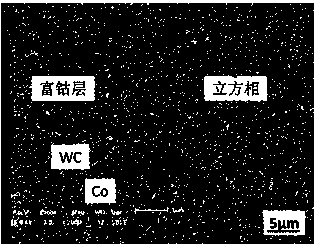

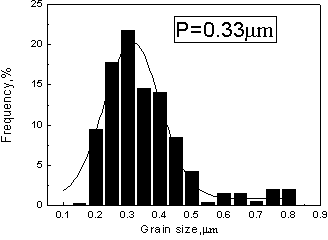

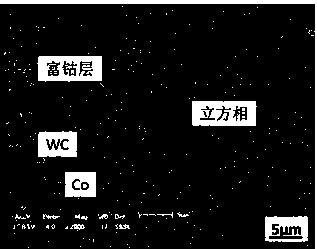

Ultra-fine crystal gradient alloy with rich-cobalt surface and preparation method thereof

The invention belongs to the field of hard alloy preparation, and in particular relates to an ultra-fine crystal gradient alloy with a rich-cobalt surface and a preparation method of the alloy. According to the ultra-fine crystal gradient alloy with the rich-cobalt surface, a gradient layer with the rich-cobalt surface, which is 10-40mu m thick, is formed by taking WC (Wolfram Carbide) and cubic phase carbonitride as a core part hard phase and cobalt as the binding phase, wherein the average size of the crystal particles of WC in the hard phase and the gradient layer is 0.2-0.4mu m, the content of cobalt in the gradient layer with the rich-cobalt surface is 1.2-2 times of the standard content of cobalt of hard alloys, and the gradient layer with the rich-cobalt surface is free of the cubic phase carbonitride. The preparation method comprises the following steps: firstly, preparing the materials, wet-grinding and pressing into a material blank, and supplying an inert gas with the pressure of 5-10MPa before reaching a liquid phase sintering temperature, wherein the liquid phase sintering temperature is 1,350-1,500 DEG C. By charging the gas with certain pressure in the liquid phase sintering period, the ultra-fine crystal gradient alloy with the rich-cobalt surface is prepared, the WC crystal grains are refined, a rich-cobalt surface layer of certain thickness is obtained, the sintering period is shortened, and the production cost is lowered.

Owner:NORTHEASTERN UNIV LIAONING

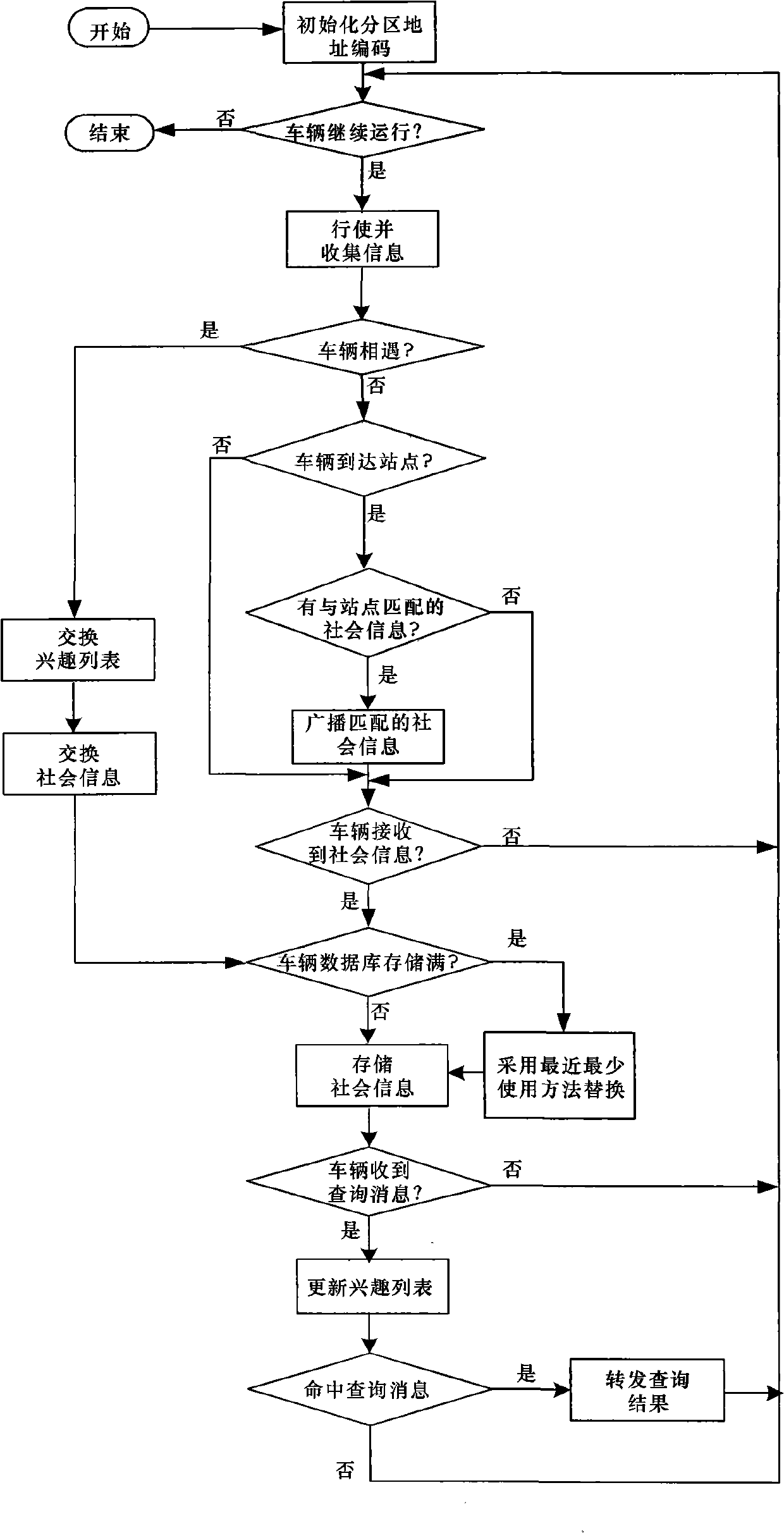

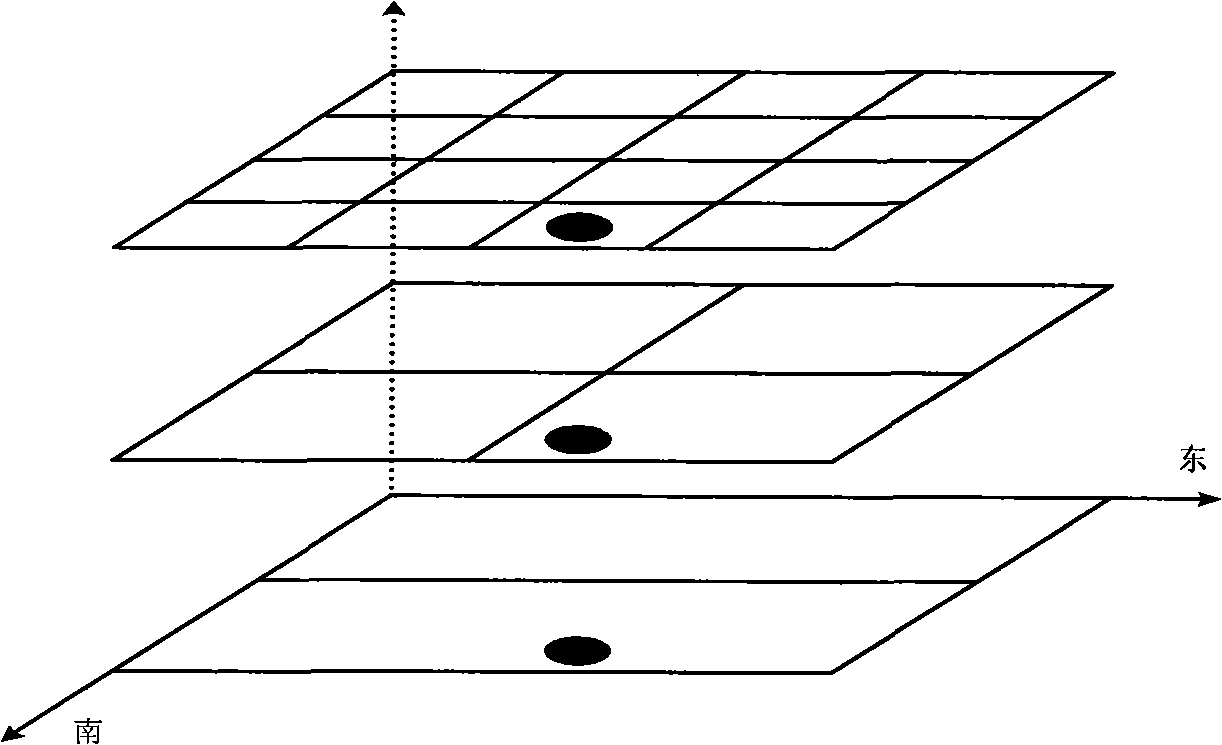

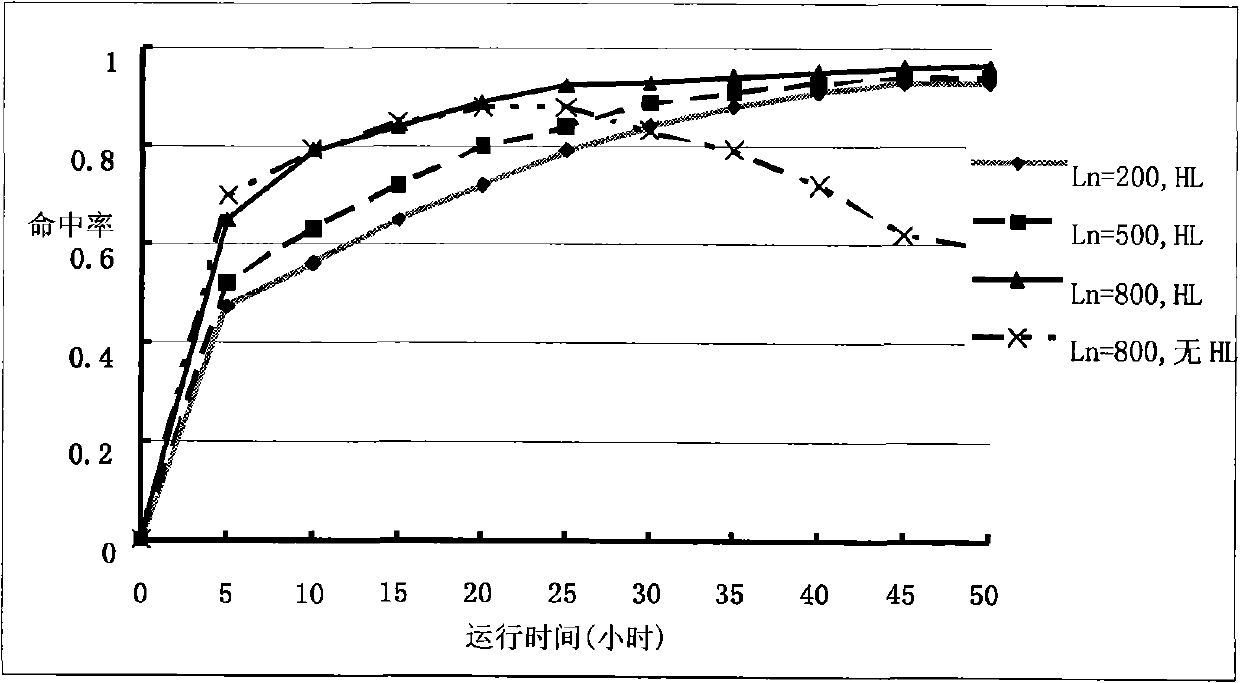

Information correlation based opportunistic network data distributing method

InactiveCN101771964AStable interestTargetedRoad vehicles traffic controlNetwork topologiesCrowdsNetwork data

The invention provides an information correlation based opportunistic network data distributing method. The method comprises the following steps: dividing regions of an electronic map carried on a vehicle through specifically defined information format, abstract bus routes and station information, and simultaneously carrying out binary coding on the regions based on the division; ensuring that each route station acquires a unique code; summarizing interest information to form a vehicle interest list; calculating the correlation of social information through the interest list to drive information distribution; and transmitting the information to the region which is interested in the information. The method acquires priori knowledge through an active studying mode by using the characteristics of fixed bus routes and stable people interests in the region, drives data oriented distribution by using accumulated knowledge, improves the hit rate of information querying, and simultaneously reduces network load and message distribution delay.

Owner:BEIHANG UNIV

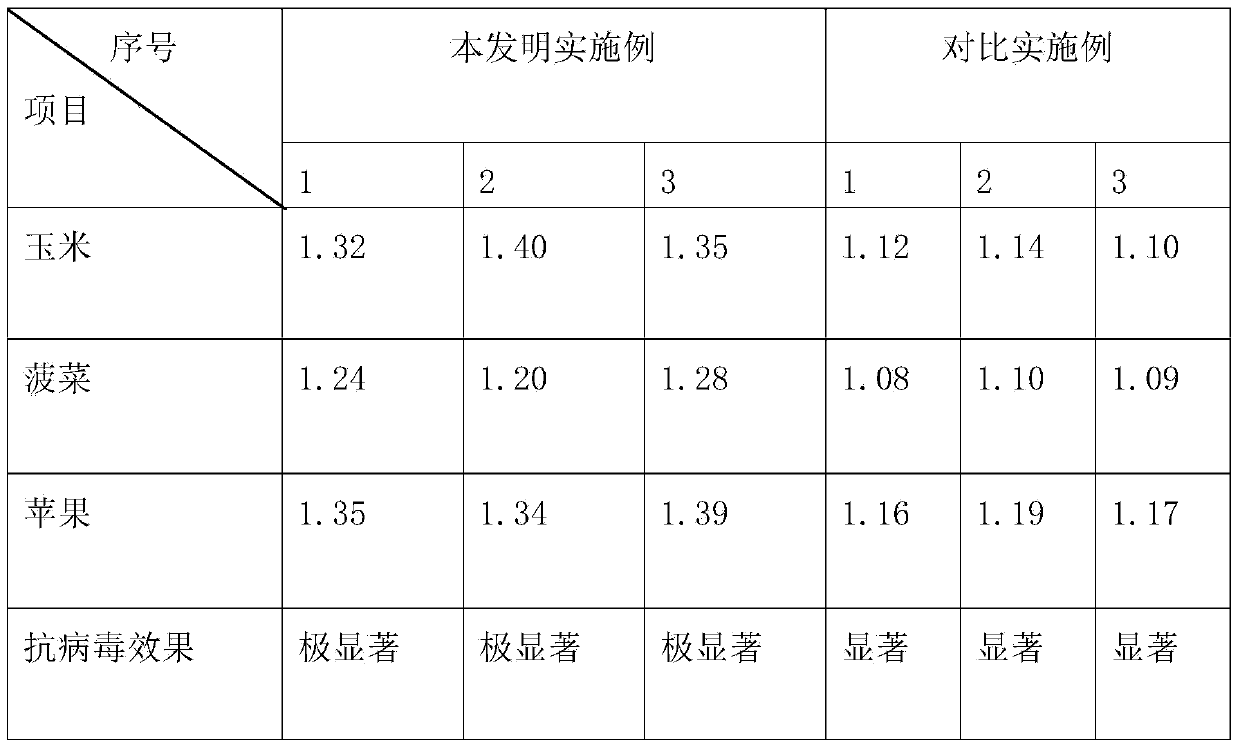

Fertilizer containing anti-plant virus fertilizer additive

ActiveCN103804097AImprove breathabilityIncrease moisture contentFertilizer mixturesOrganic acidTrace element

The invention relates to an anti-plant virus fertilizer additive and a fertilizer containing the additive. The anti-plant virus additive contains a medium trace element-containing fertilizer, organic acid, an anti-plant viral agent and a trace element additive. The fertilizer containing the additive is composed of an elemental fertilizer or a compound fertilizer and the anti-plant virus fertilizer additive, and the content of the additive accounts for 0.1-5% of the total fertilizer weight. The method has the advantages that by adopting the anti-plant virus additive or fertilizer, the yield-increasing effect is obvious, and moreover plant viruses can be prevented.

Owner:刘成才

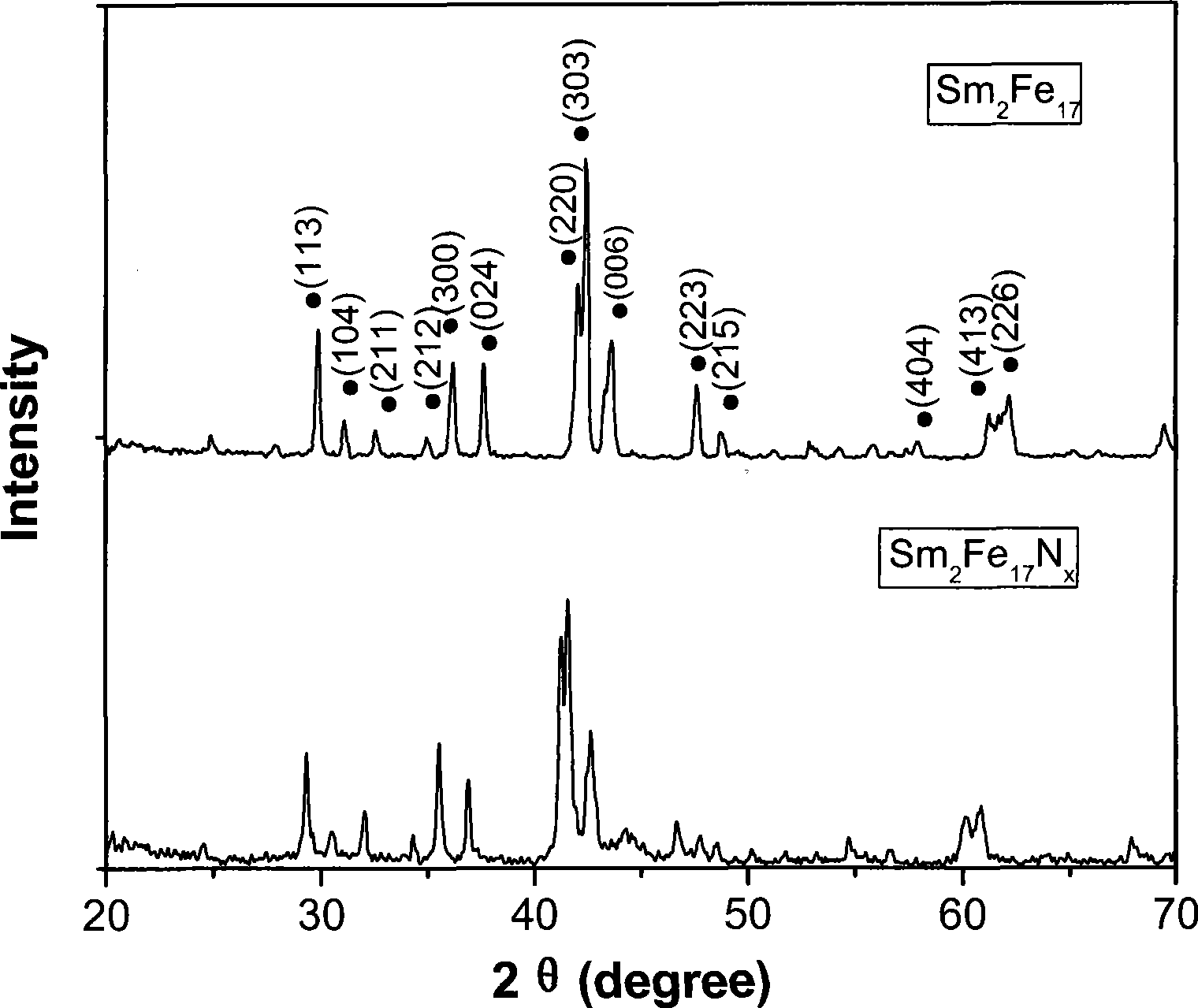

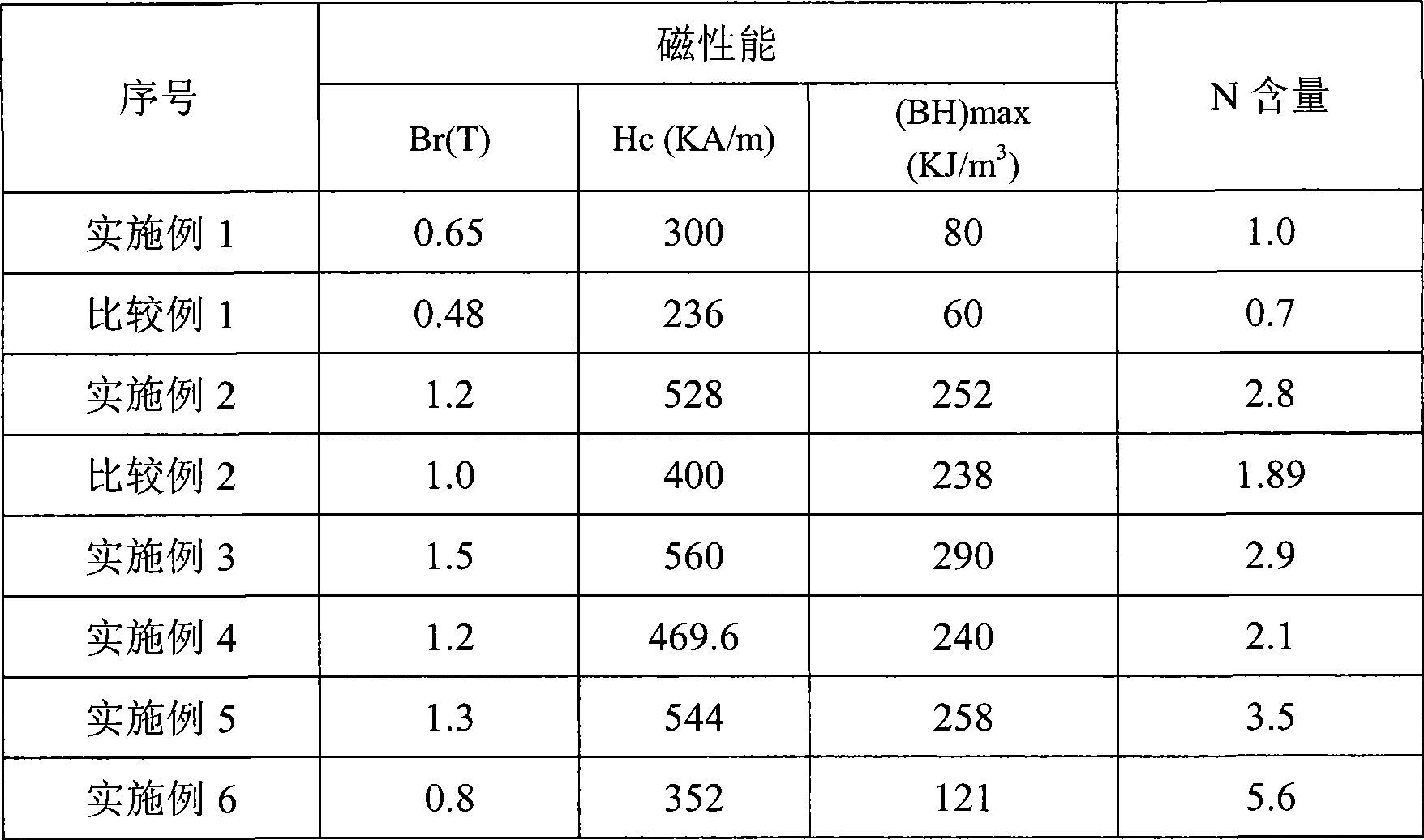

Nitrogen-containing rare-earth magnetic powder and preparation method thereof

ActiveCN101546642AIncrease the speed of diffusionPromote decompositionInorganic material magnetismRare-earth elementLanthanide

The invention discloses a nitrogen-containing rare-earth magnetic powder prepared by taking ferrocene, cyclopentadienyl lanthanide, metallic iron and rare earth as the main raw materials. The nitrogen-containing rare-earth magnetic powder comprises the following component of R2Fe17-xMxNy, wherein the R is one or more kinds of 17 kinds of rare earth elements including Sc and Y, the M includes transitional elements except for Fe and is one or more kinds of Al, Ga, In, Si, Ge, Sn, Pb, Mg and Ca, the x is equal to 0 to 5, and the y is equal to 1 to 6; and the preparation method comprises the following steps: working procedure of preparation of the R2Fe17-xMx compound powder; working procedure of nitridation; and working procedure of magnetic powder refining and nitriding.

Owner:GUOKE RE ADVANCED MATERIALS CO LTD

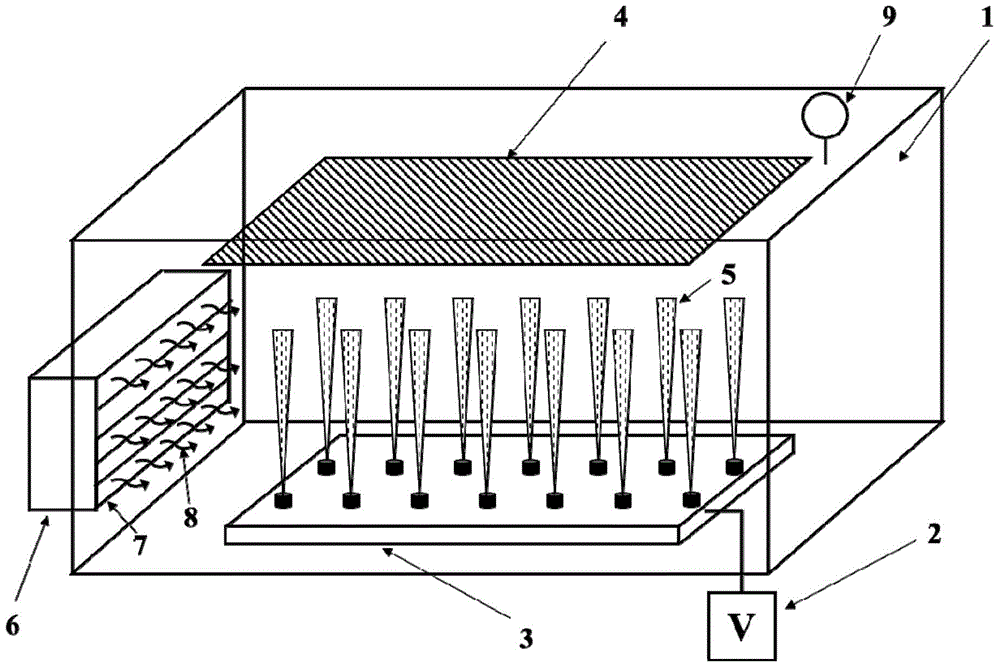

Electrostatic spinning method and device of fiber-based waterproof moisture-permeable film high in moisture-permeable flux

ActiveCN104452109AGood waterproof and moisture permeabilityPorosity is easy to controlNon-woven fabricsPorosityFiber

The invention relates to an electrostatic spinning method and device of a fiber-based waterproof moisture-permeable film high in moisture-permeable flux. The electrostatic spinning method includes that during electrostatic spinning, polymer solution jet flow is injected at a certain included angle with air of a certain temperature and / or lateral air flow of non-solvent steam, and polymer molecules in the jet flow are quickened to be separated and solidified into fibers; water-pressure resistance of the electrostatic spinning film, namely the fiber-based waterproof moisture-permeable film high in moisture-permeable flux is greater than or equal to 100kPa, and the moisture-permeable flux is greater than or equal to 15000g / m<2> / d. The electrostatic spinning device is composed of an electrostatic spinning box, a high-voltage direct-current power supply, an electrostatic spinning hydraulic system, a spinning jet and a receiving base material, and a steam generation and air supply system is mounted on one side of the electrostatic spinning box. The fiber-based waterproof moisture-permeable film produced by the method has the advantages of small bore diameter, controllable adhesion degree and high porosity; the film is high in water-pressure resistance and moisture-permeable flux when used in the waterproof and moisture-permeable areas, and is wide in actual application prospect.

Owner:DONGHUA UNIV

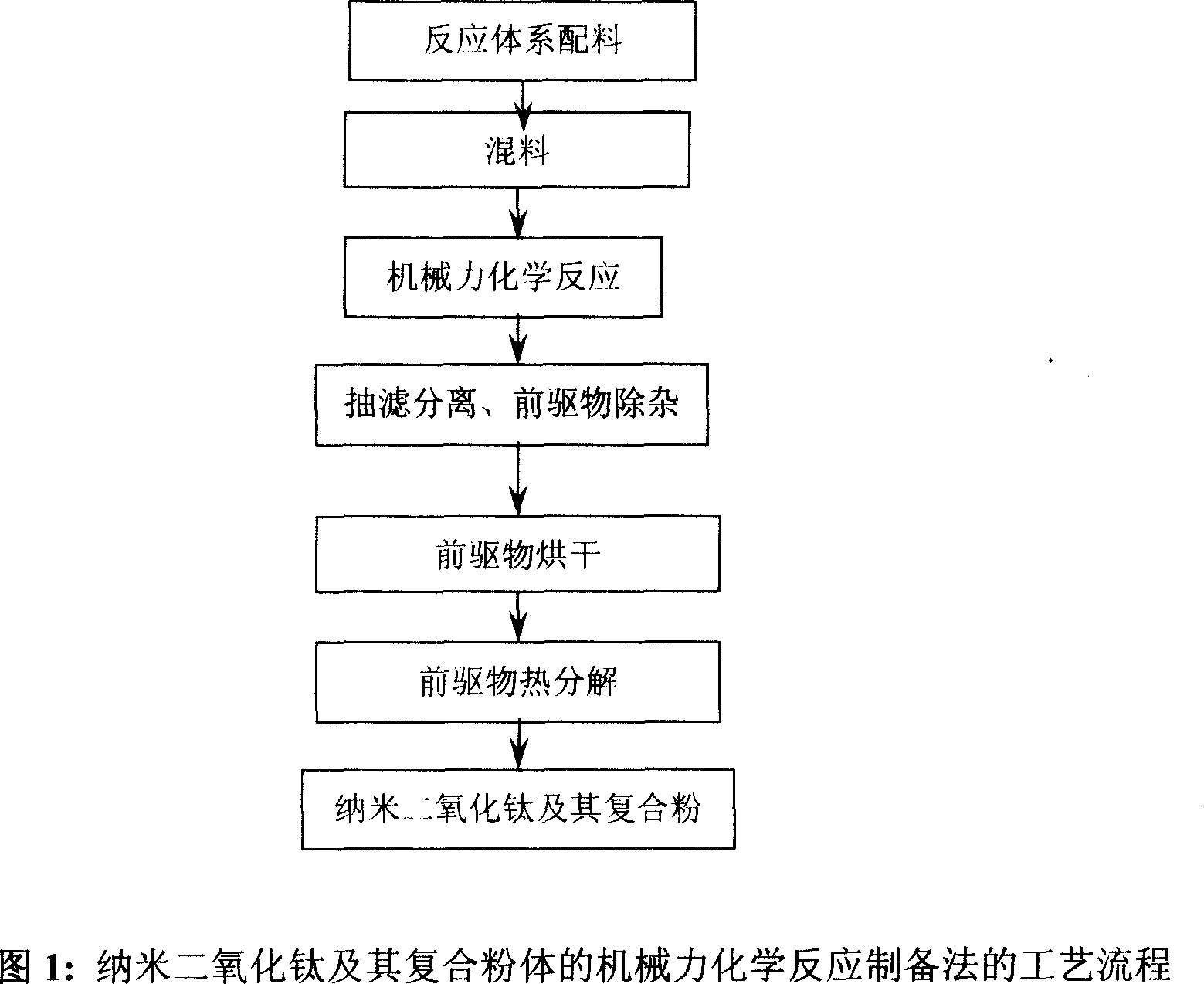

Nano titanium oxide and mechanical force chemical reaction preparation method for its composite powder

InactiveCN101062780ALarge specific surface areaIncrease the speed of diffusionTitanium dioxideSolid phasesDecomposition

The invention discloses a preparing technology of nanometer titanium oxide and composite powder body, which comprises the following steps: using shearing force and impact force generated in balling course to bruise solid phase reacting system; increasing specific surface area of the reactant; improving reaction rate to advance the ratio of nucleation rate and growth rate; preparing fine and even forerunner material; washing; drying; controlling the temperature and time of heat decomposition; getting nanometer titanium oxide and composite powder body with diverse crystal system and grain size; realizing surface coating of nanometer titanium oxide. This method possesses simple craft and can control crystal system, outlook and grain diameter of nanometer titanium oxide, which powder grain diameter distribution is 30-80nm.

Owner:SICHUAN UNIV

Method for catalysis of pimelinketone oxamidine

ActiveCN101314577AHigh selectivityLow costMolecular sieve catalystsOximes preparationOxidation stateOxygen

The invention discloses a method for catalyzing ammoximation of cyclohexanone. The method comprises the steps as follows: subjecting cyclohexanone, ammonia, oxygen, hydrogen, diluent gas and a solvent to coming in contact with a catalyst. The mole ratio of cyclohexanone, to ammonia, oxygen, hydrogen and diluent gas is 1:(0.1-10.0):(0.1-10.0):(0.1-10.0):(0-100). The mass ratio of the solvent to the catalyst is (20-1000):1. The catalyst is a microporous titanium-silicon material or a compound containing the microporous titanium-silicon material. The composition of the microporous titanium-silicon material is expressed as xTiO2*100SiO2*yEmOn*zE in an oxide form, wherein x ranges from 0.001 to 50.0; the sum of y plus z ranges from 0.005 to 20.0; the ratio of y to z is smaller than 1; E is one or more metal noble metals selected from Ru, Rh, Pd, Re, Os, Ir, P and Au; m and n are numbers required for meeting the oxidation state of the E; and material grains are partially or totally hollow-structured. The method has the advantages of high selectivity of cyclohexanone oxime, high product activity and stability, environment friendliness and low cost.

Owner:CHINA PETROLEUM & CHEM CORP +1

Boiler coal combustion-improving desulfurizing agent composition and preparation method thereof

ActiveCN103194294AGood synergyHigh selectivitySolid fuelsFuel additivesActivated attapulgiteSodium acetate

The invention provides a boiler coal combustion-improving desulfurizing agent composition. The composition comprises the following components in parts by weight: 3-9 parts of sodium carbonate, 1-2 parts of sodium acetate, 3-9 parts of calcium carbonate, 4-9 parts of aluminium hydroxide, 2-5 parts of ferric trichloride, 3-10 parts of ferric oxide, 8-22 parts of potassium permanganate, 8-22 parts of potassium chlorate, 15-40 parts of activated attapulgite clay, 7-13 parts of manganese oxide, 4-8 parts of copper oxide, 4-8 parts of alumina, 3-8 parts of copper carbonate, 3-10 parts of zinc oxide, 3-10 parts of zinc nitrate, 4-11 parts of sodium dichromate, 0.5-1.5 parts of barium molybdate, 0.5-1.5 parts of vanadium pentoxide, 0.2-0.5 part of cerium oxide and 1-3 parts of dispersing agent JFC. The composition is an additive suitable for coal-fired boilers in the petroleum, chemical, power, thermoelectricity and metallurgy industries, can absorb and solidify sulfur dioxide generated in the combustion process, adsorbs dust and other harmful substances in quantity and simultaneously removes smoke dust scales and jelly adhering to the inner walls of combustors, thus inhibiting the concentration of flue gas emission.

Owner:GANSU HEIMA PETROCHEM ENG

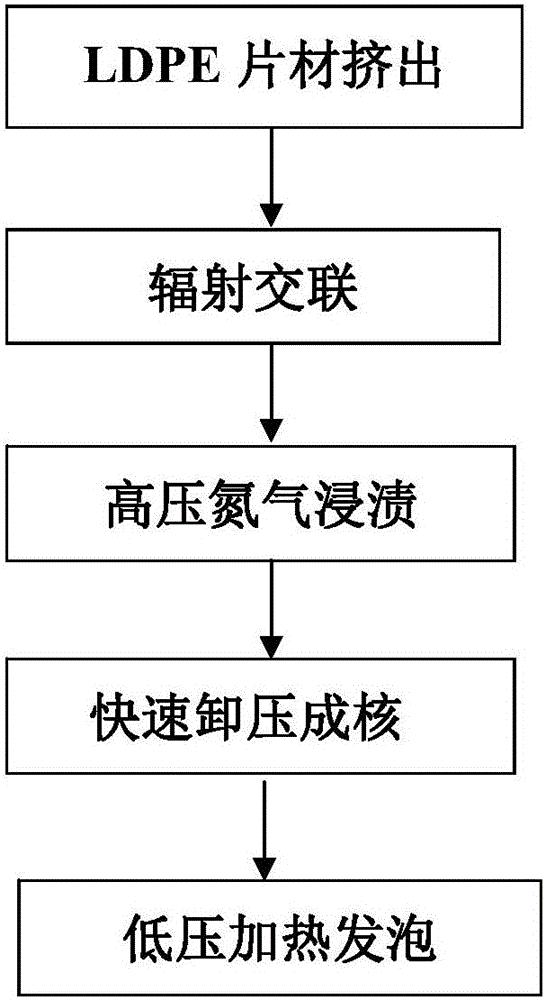

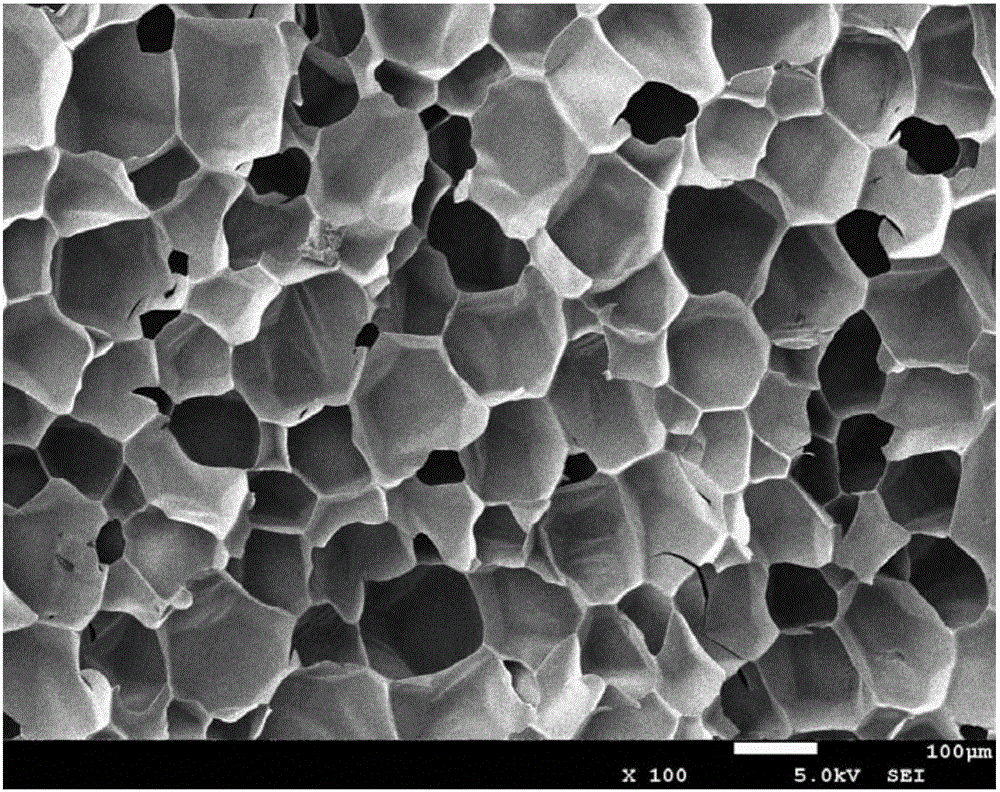

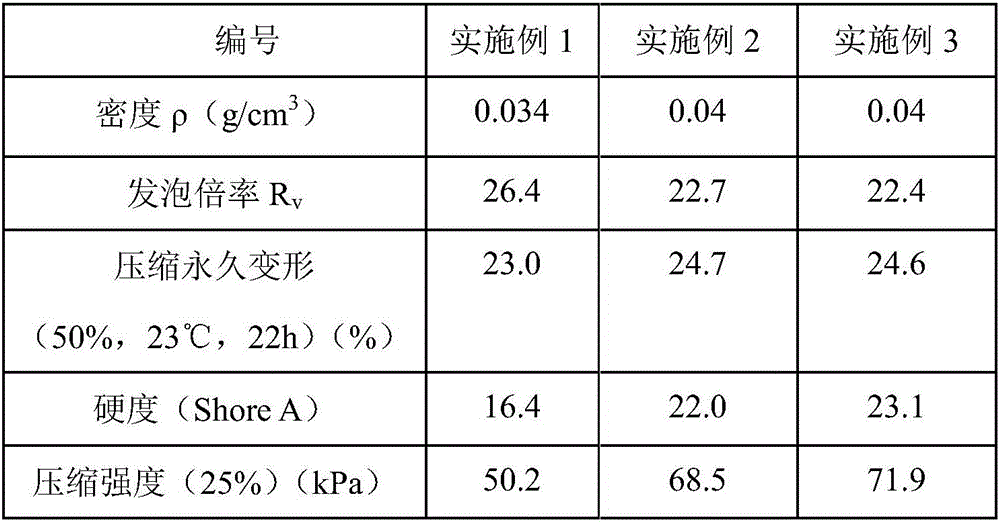

Supercritical fluid foaming polyolefin material and preparing method thereof

ActiveCN106146874AEasy to control the nucleation densityEasy to adjust the degree of expansionPolyolefinPolymer science

The invention provides a supercritical fluid foaming polyolefin material and a preparing method thereof. The supercritical fluid foaming polyolefin material is prepared through the following steps that a polyolefin sheet is prepared, and the melting point of the polyolefin sheet is Tm; radiation crosslinking is carried out on the polyolefin sheet; the crosslinked polyolefin sheet is put into a pressure container for high-pressure nitrogen impregnation, and the impregnation temperature T1 is equal to Tm+(30-120) DEG C; low-temperature heating foaming is carried out, and the foaming temperature T3 is equal to Tm+(20-50) DEG C, and is smaller than T1. By the adoption of the technical scheme, the requirement for material crystallinity is avoided, the time of reaching a dissolution saturation state of gas is greatly shortened, efficiency is improved, and the foaming material which is fine and uniform in bubble, low in density, high in mechanical strength and regular in shape can be obtained.

Owner:湖州长园特发科技有限公司

Reinforced extraction method for lavender essential oil

InactiveCN102676299AEasy extractionIncrease the speed of diffusionSolvent extractionEssential-oils/perfumesFood additiveInorganic salts

The invention discloses a reinforced extraction method for lavender essential oil, which relates to an extraction method for essential oil. According to the method, ultrasound-reinforced salting steam is adopted for distilling and extracting the lavender essential oil. Lavender raw material of 20-100 meshes is dipped by 0.1-4% of inorganic salt solution and is put into an extraction device; after the lavender raw material is subjected to ultrasound reinforcement for 0.2-1.5 hours, the steam is distilled; and oil and water mixture cooled to the room temperature is separated to obtain the essential oil. The lavender essential oil extraction rate of the method is more than two times that of the traditional steam distillation method, and the required distillation time can be obviously lowered. The essential oil extracted from lavandula or lavender stems and leaves with the reinforced extraction method disclosed by the invention can be used for the fields, such as cosmetics, food additives, sterilization and corrosion prevention.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com