Assistant for catalytic cracking coking-inhibiting yield-increasing and preparing process thereof

A technology for catalytic cracking and catalytic cracking raw materials, applied in the field of processing aids, can solve the problems of poor solubility of raw material oil, poor dispersion performance, low decomposition temperature, etc., and achieves significant economic benefits of the device, superior solubility, and high decomposition temperature. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

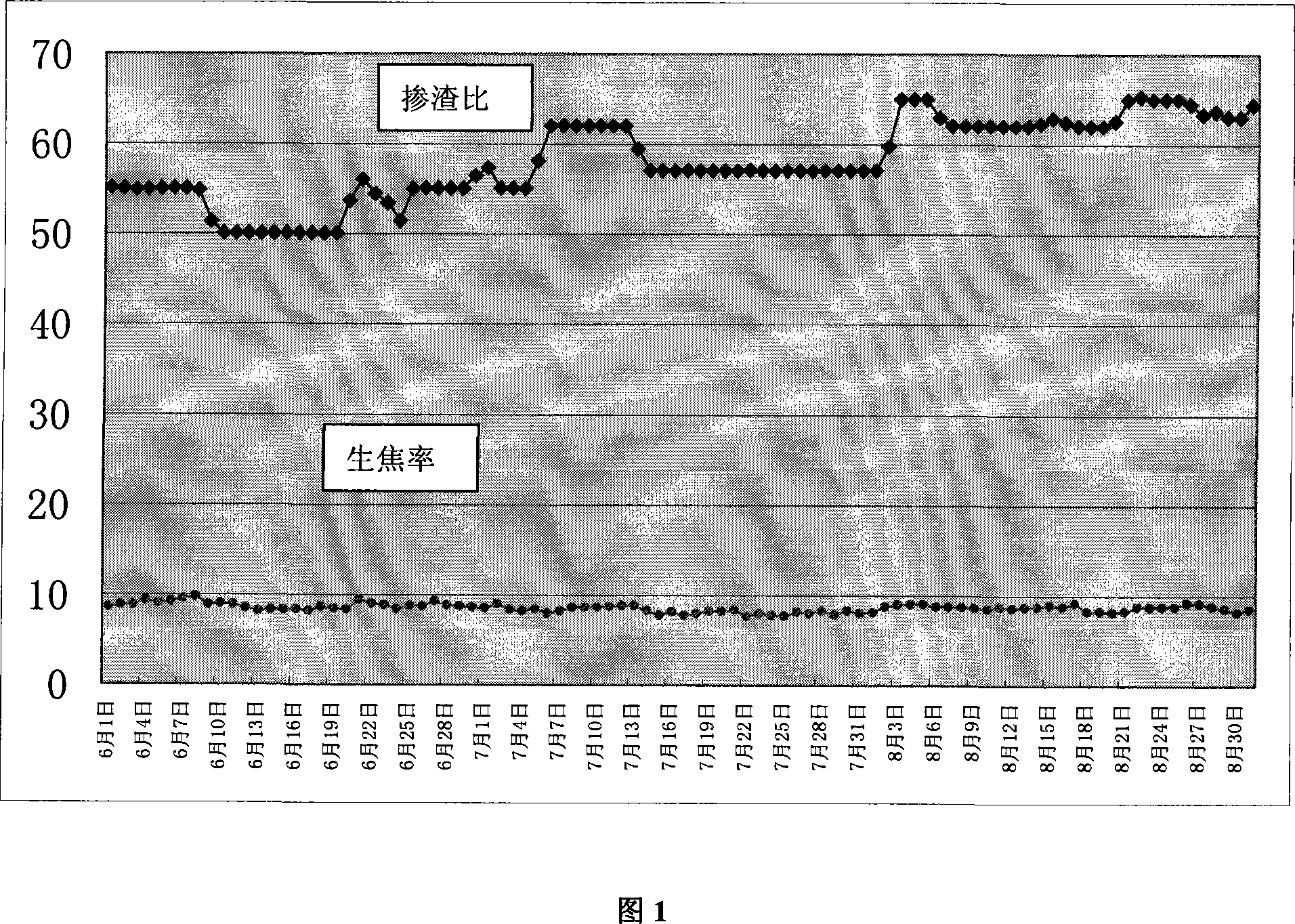

Image

Examples

Embodiment 1

[0022] First add 2000kg of kerosene into the stainless steel reaction kettle, raise the temperature to 50°C within 1 hour, stir, and then add 250kg of polyisobutylene succinimide, 500kg of sorbitan polyoxyethylene ether, di-sec-butyl terephthalate Add 750kg of amine, 1500kg of antimony dialkyldithiophosphate, keep warm for 1-5 hours, filter to remove impurities after cooling to obtain coke suppression and income increasing additive A.

Embodiment 2

[0024] First, add 1550kg of kerosene into the stainless steel reaction kettle, raise the temperature to 50°C within 1 hour, stir, and then add 350kg of borated polyisobutylene succinimide, 600kg of sorbitan polyoxyethylene ether, di-sec-butyl p- 500kg of phenylenediamine, 2000kg of tin octoate, heat preservation for 1-5 hours, after cooling, filter to remove impurities to obtain coke suppression and income increasing aid B.

Embodiment 3

[0026] First, add 1000kg of diesel oil into the stainless steel reaction kettle, raise the temperature to 80°C within 1 hour, stir, and then add 500kg of borated polyisobutylene succinimide, 800kg of polyoxyethylene sorbitan ether, and phenyl phosphite 500kg, 2200kg antimony dialkyl dithiophosphate, keep warm for 2-4 hours, filter to remove impurities after cooling to obtain coke suppression and income increasing additive C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com