Patents

Literature

3430 results about "Cracking reaction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cracking is the process used to break down large hydrocarbon molecules into small hydrocarbons. The cracking reaction is done for the fractions obtained from the fractional distillation of crude oil. The rate of cracking depends on the temperature and the catalysts present in the reaction mixture.

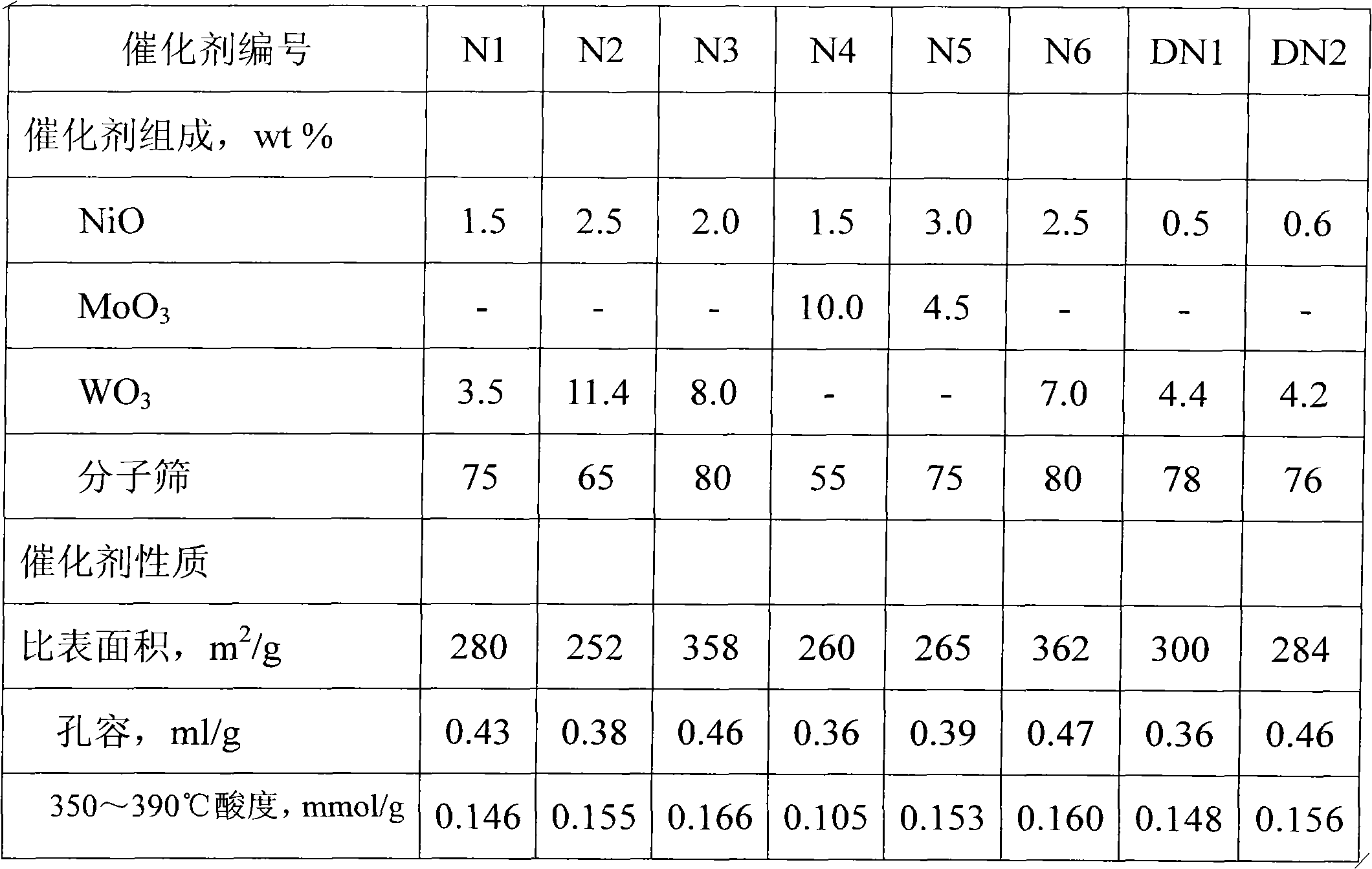

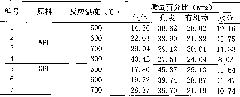

Hydrodewaxing catalyst for diesel oil distillate and its preparing method

ActiveCN1952074AHigh yieldExcellent isomerization performancePetroleum wax recoveryWaxMolecular sieve

The invention disclosed a catalyst to lower the freezing point of the diesel oil. The catalyst includes carrier that contains reshaped molecular sieve and hydrogenated metal. The molecular sieve is reshaped by VIB group metal, the content of which in the molecular sieve is 1wt%-40wt% (by oxidation state). The content of the molecular sieve and the metal are 10wt%-90wt% (by oxidation state) and 0.1wt%-40wt% (by oxidation state) respectively. The reshaping agent can modify the acid substance and the bore size on the surface of the molecular sieve so as to match the catalyst's isomerizing function and structure-selective splitting function well; it can make the splitting reaction proceeds according to the lock-and-key mechnanism and ensure the reaction proceeds properly without over splitting; it can improve the quality of the diesel oil and increase its yield. The invention can be used in the deparaffinage of the material that contains wax, especially in the process to lower the freezing point of the diesel oil distillate. It can not only lower the freezing point, but also increase the diesel oil yield substantially.

Owner:CHINA PETROLEUM & CHEM CORP +1

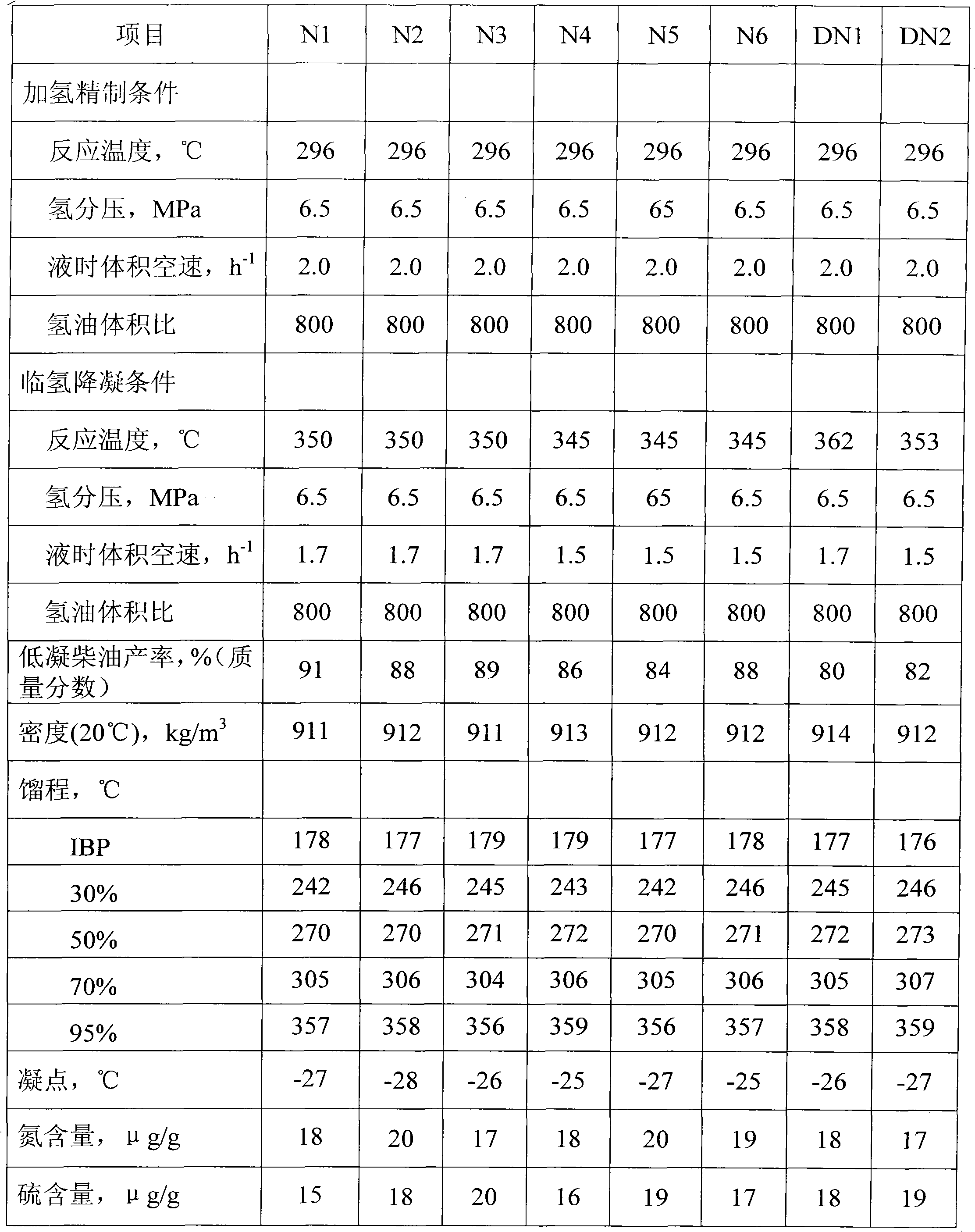

Diesel oil hydrogenation pour point depressing method

ActiveCN102051232ASuitable pore structureAppropriate pore inner surface propertiesCatalyst carriersMolecular sieve catalystsMolecular sieveWax

The invention discloses a diesel oil hydrogenation pour point depressing method. A series flow of hydrofining and hydrogenation pour point depressing is adopted in the method, wherein a hydrogenation pour point depressing catalyst is modified by metal auxiliary agent and silicon, effectively regulates the acidity and orifice shape of the inner surface and the outer surface of a shape-selective cracking molecular sieve, is favorable for dispersing wax molecules in a diesel oil raw material into pore canals of the molecular sieve to perform shape-selective cracking reaction, and has high catalytic activity and selectivity of a target product; and because the acidity of the outer surface of the molecular sieve is weak, side reactions such as secondary cracking and the like are reduced, the pour point depressing effect of the diesel oil is good, and the fraction yield of the diesel oil is high.

Owner:CHINA PETROLEUM & CHEM CORP +1

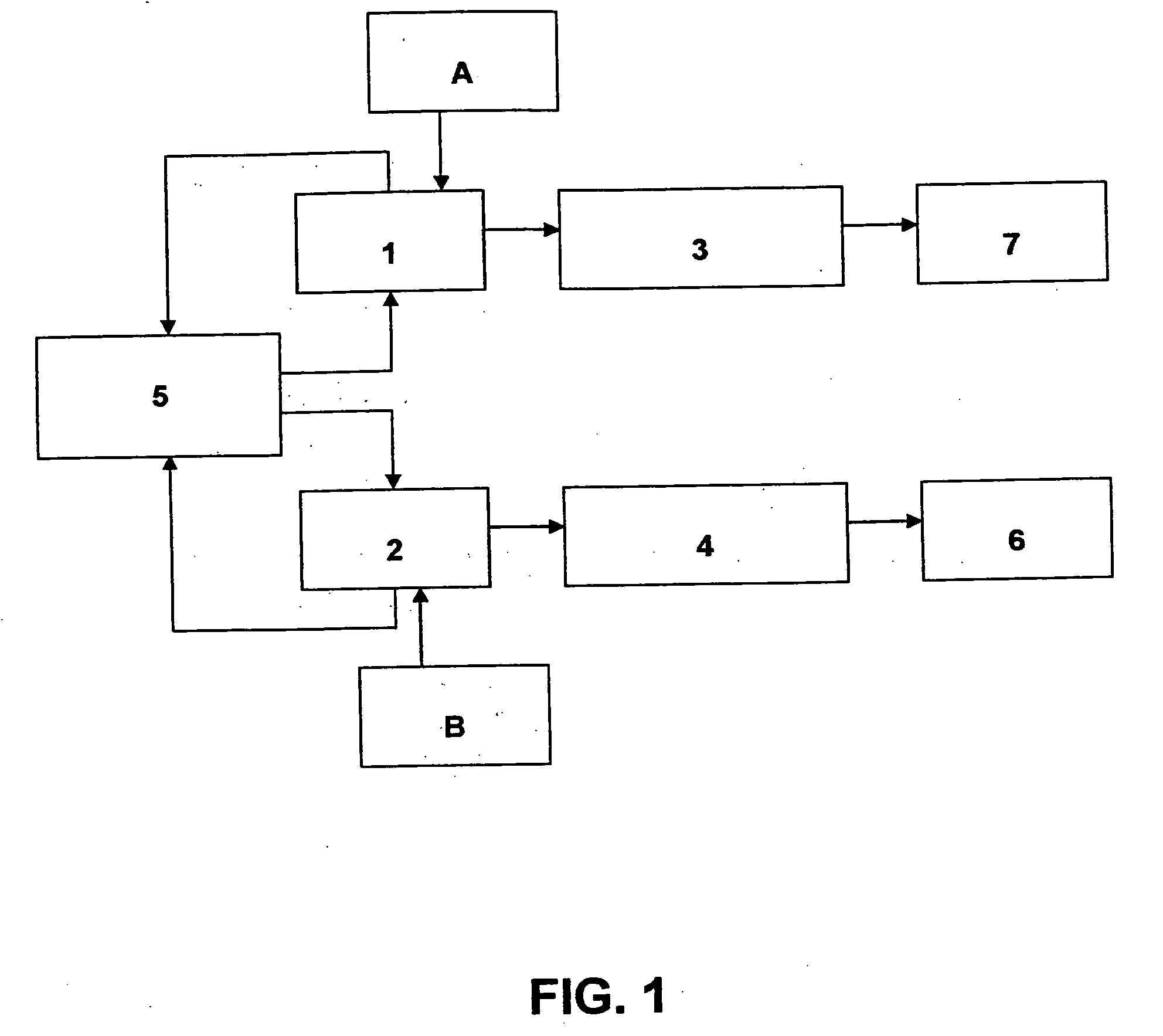

Catalytic conversion method of ethylene, propylene and aromatic hydrocarbon preparation

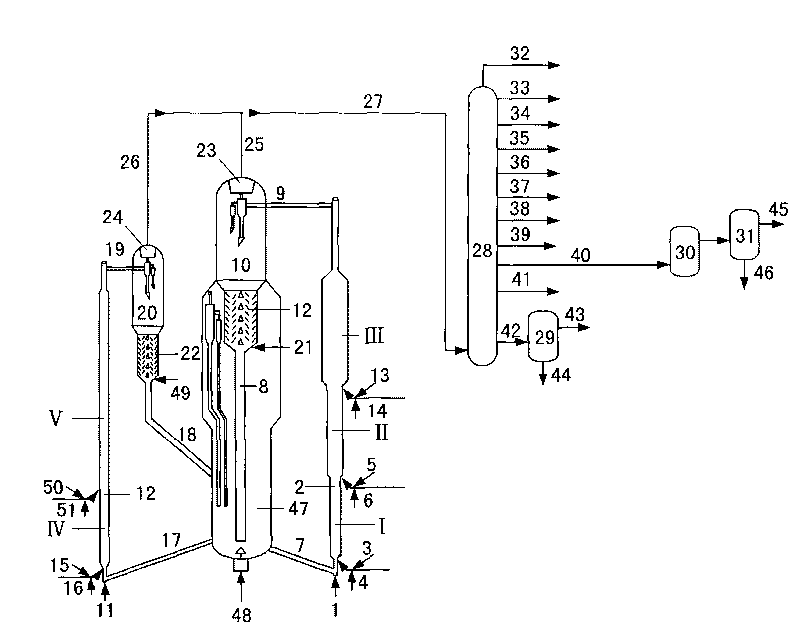

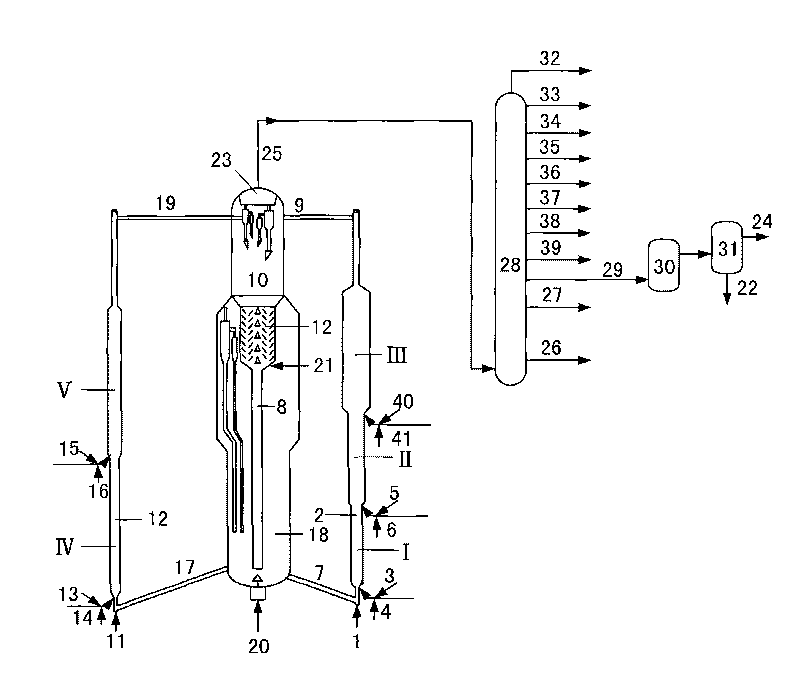

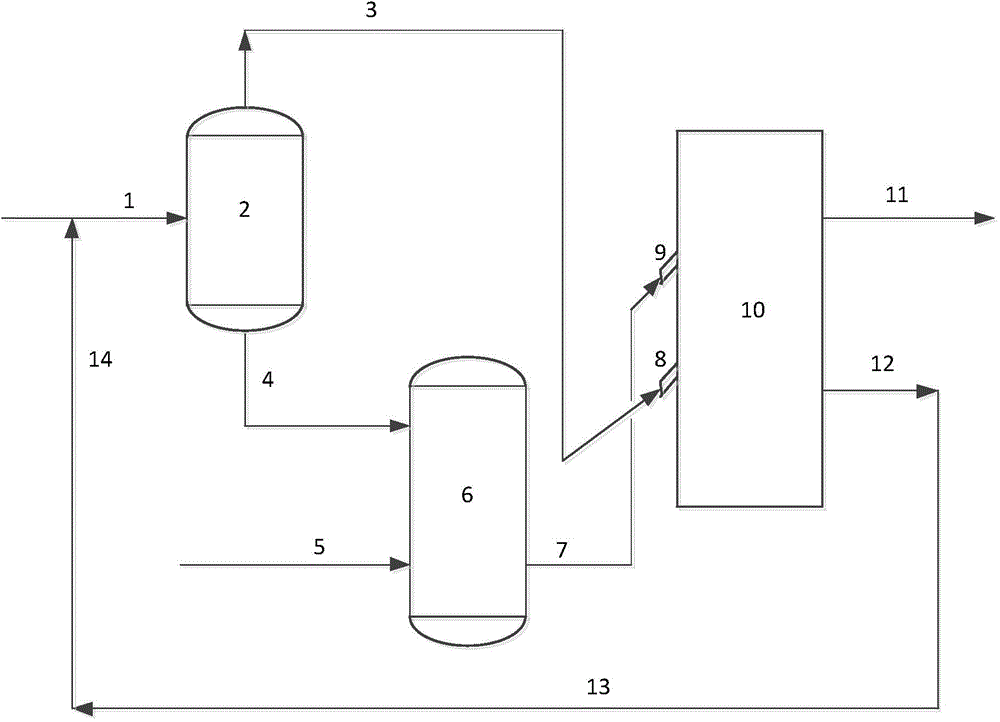

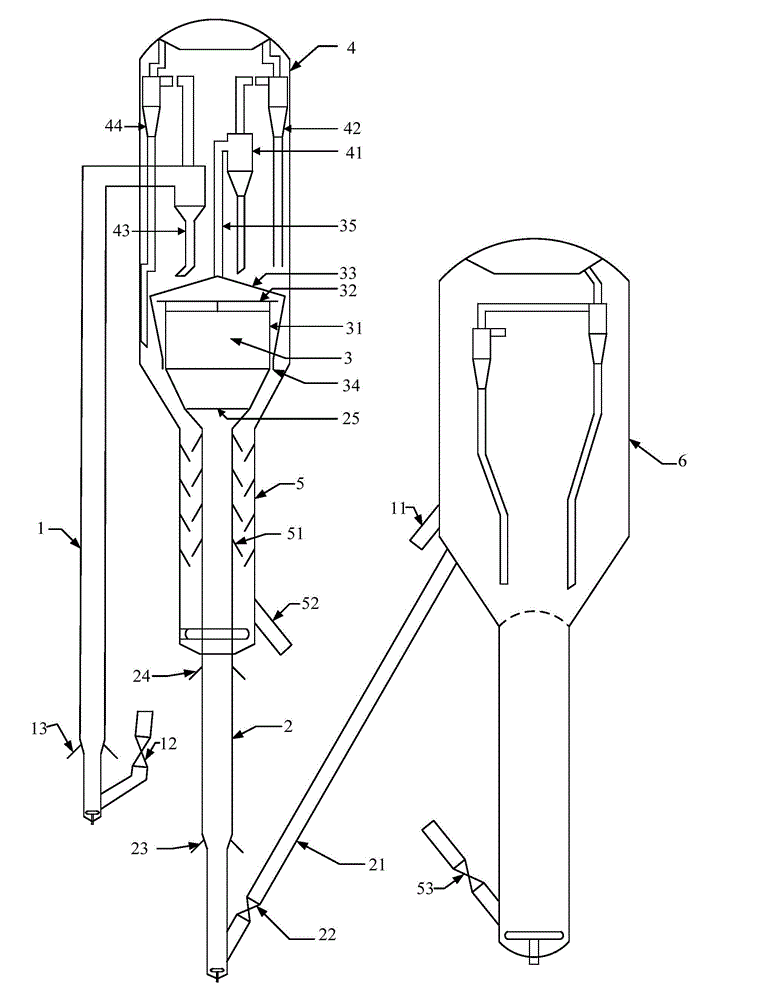

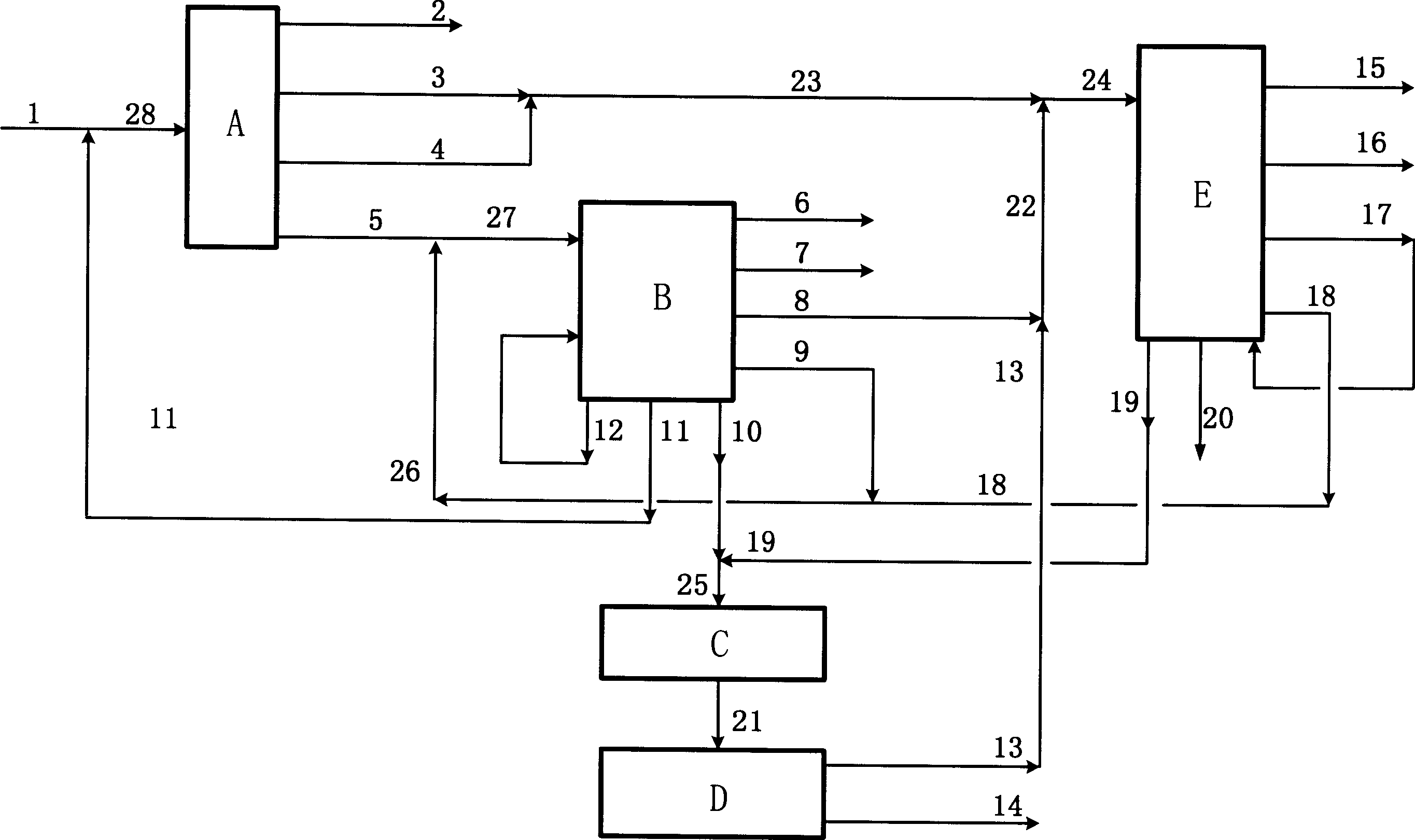

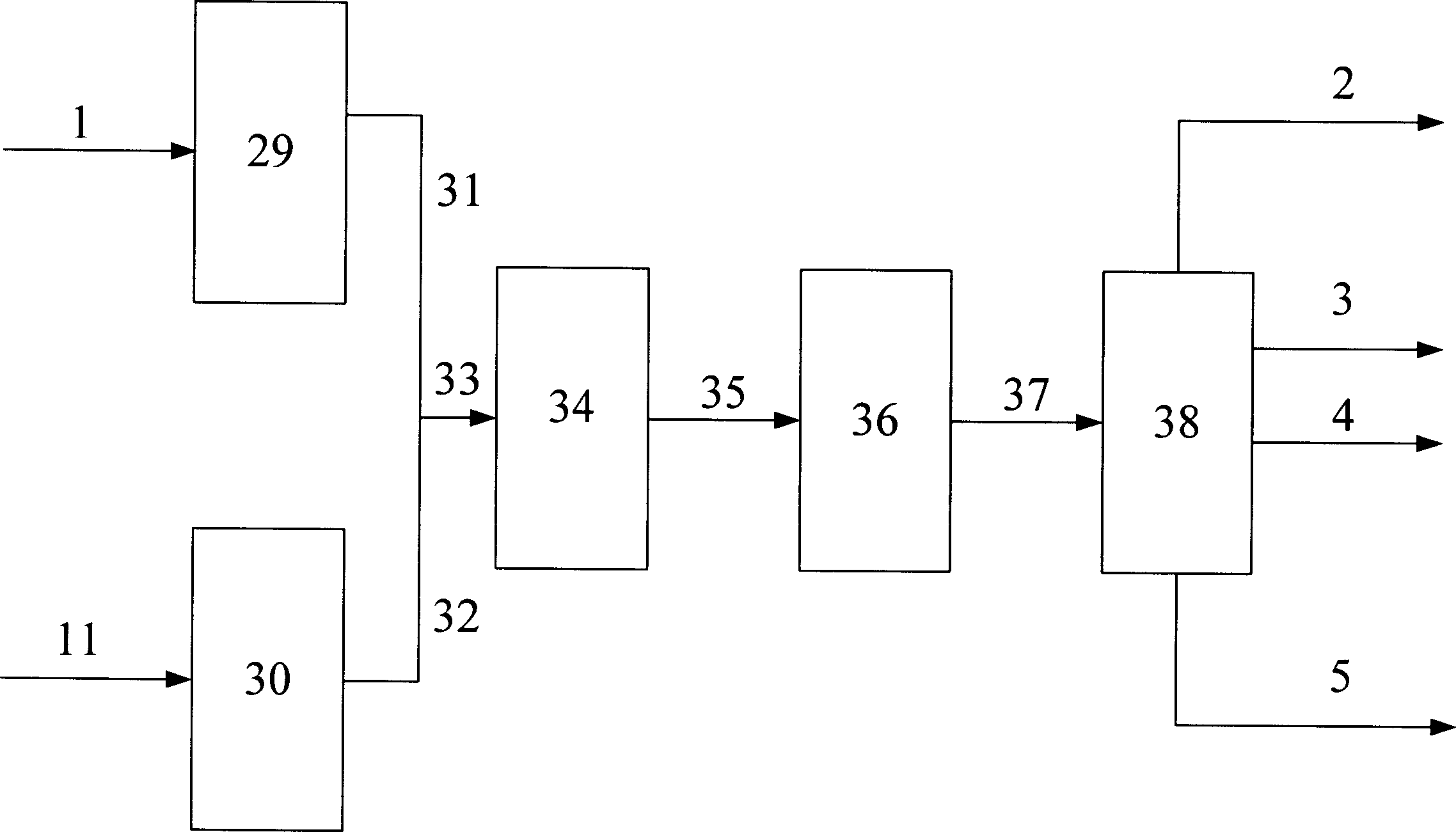

The invention discloses a catalytic conversion method for preparing ethylene, propylene and aromatic hydrocarbon. Hydrocarbon raw material with different cracking performances is contacted with a catalytic cracking catalyst, and cracking reaction is carried out in a fluidized bed reactor under the conditions that the temperature is 550 DEG C to 800 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10MPa to 1.0MPa, the weight ratio of the catalytic cracking catalyst and the raw material is 10-150, and the weight ratio of steam and the raw material is 0.15-1.0.Then a spent catalyst and reaction oil gas are separated, the spent catalyst returns to the reactor after regeneration, and the target products comprising low carbon olefin and the aromatic hydrocarbon are obtained by separating the reaction oil gas, wherein, fraction with the temperature to be 160 DEG C to 260 DEG C returns for catalytic cracking as circulating material, and the ethylene and the propylene are further obtained by cracking of ethane, propane, butane, and the steam entered. Low carbon olefin such as ethylene, propylene, and the like, is produced from heavy feedstock to the utmost extent in the method, and the yield of the ethylene and the propylene is over 20% by weight, in addition, the aromatic hydrocarbon such as toluene, xylene, and the like, are produced in an integrated way.

Owner:CHINA PETROLEUM & CHEM CORP +1

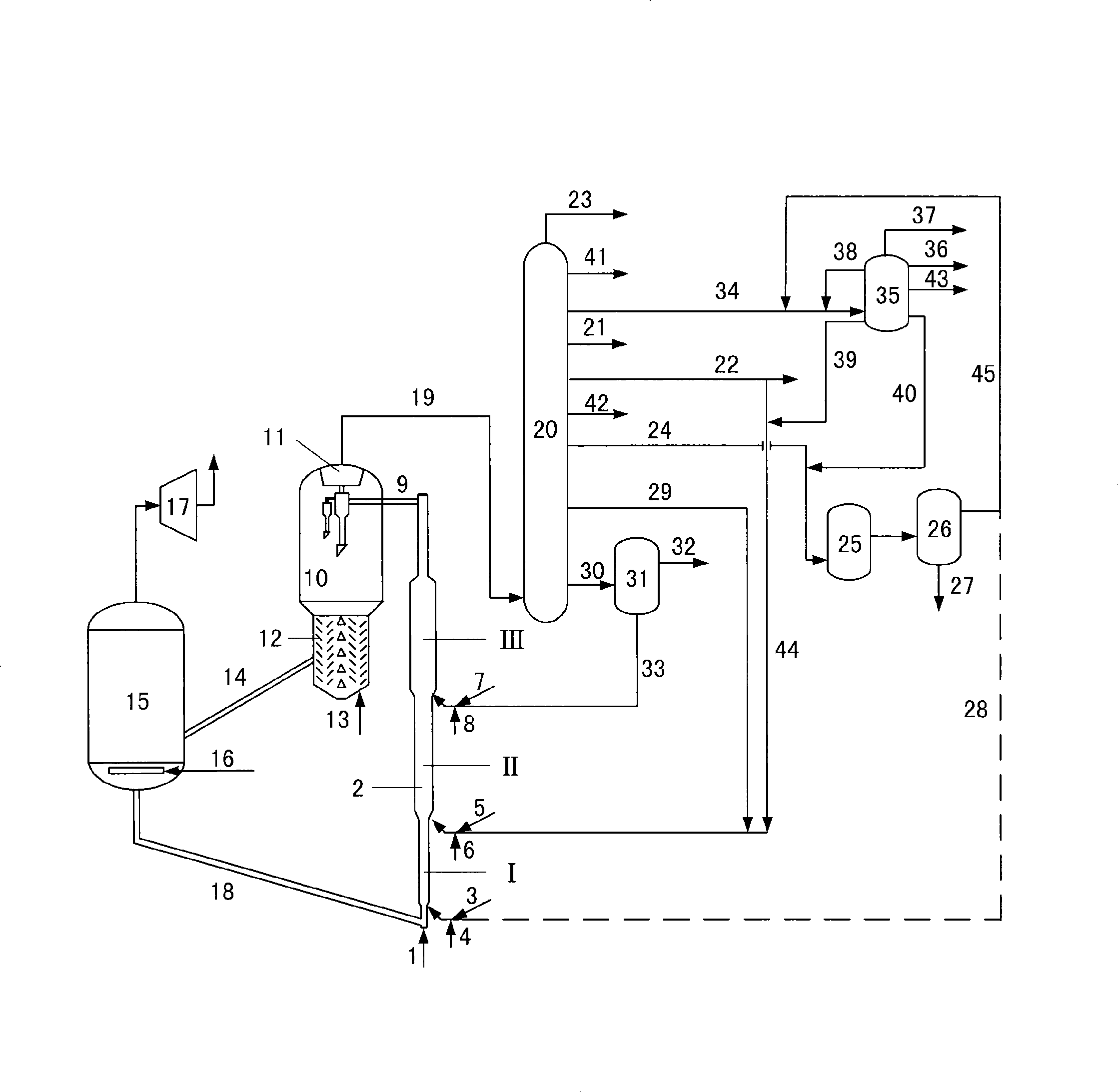

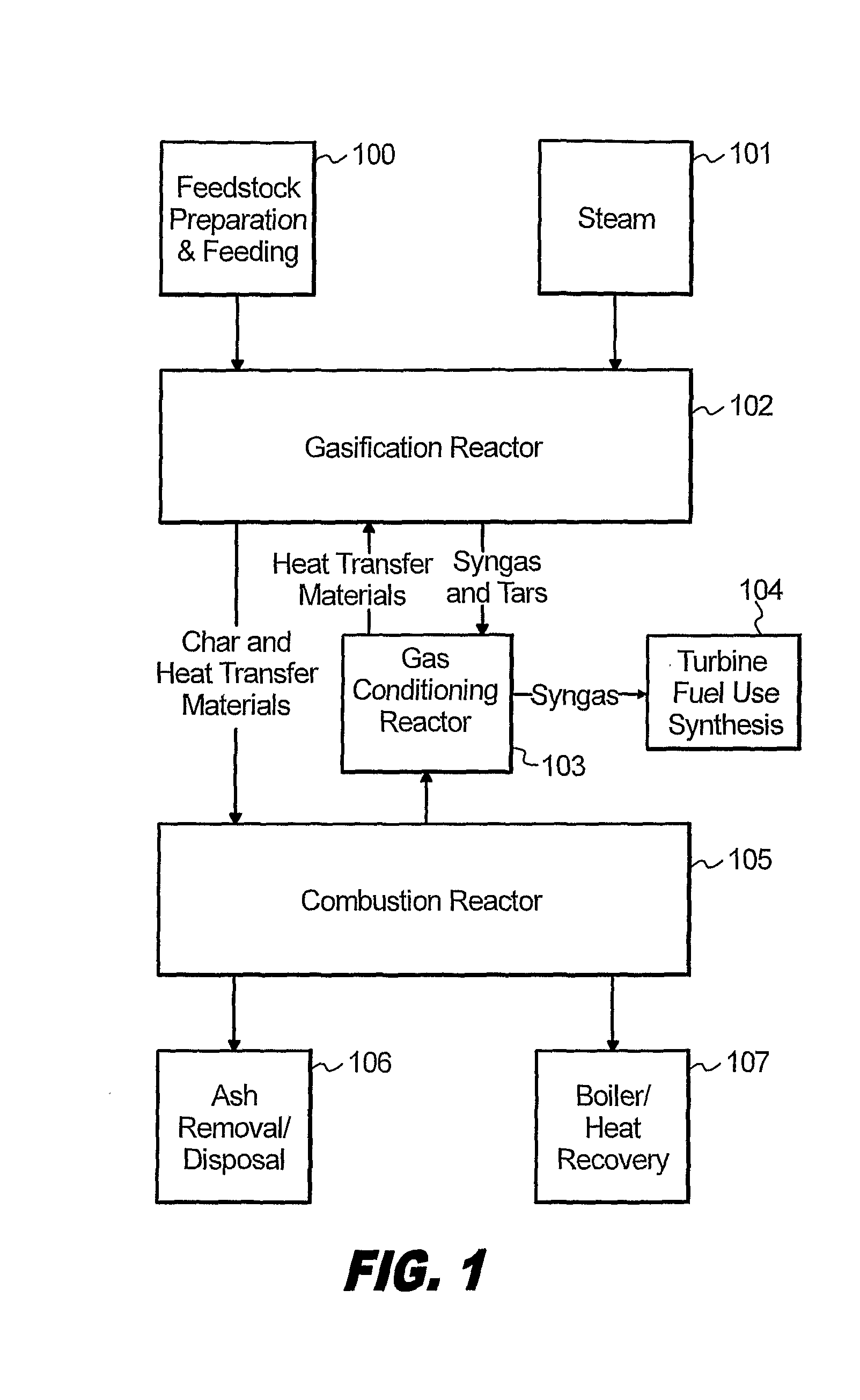

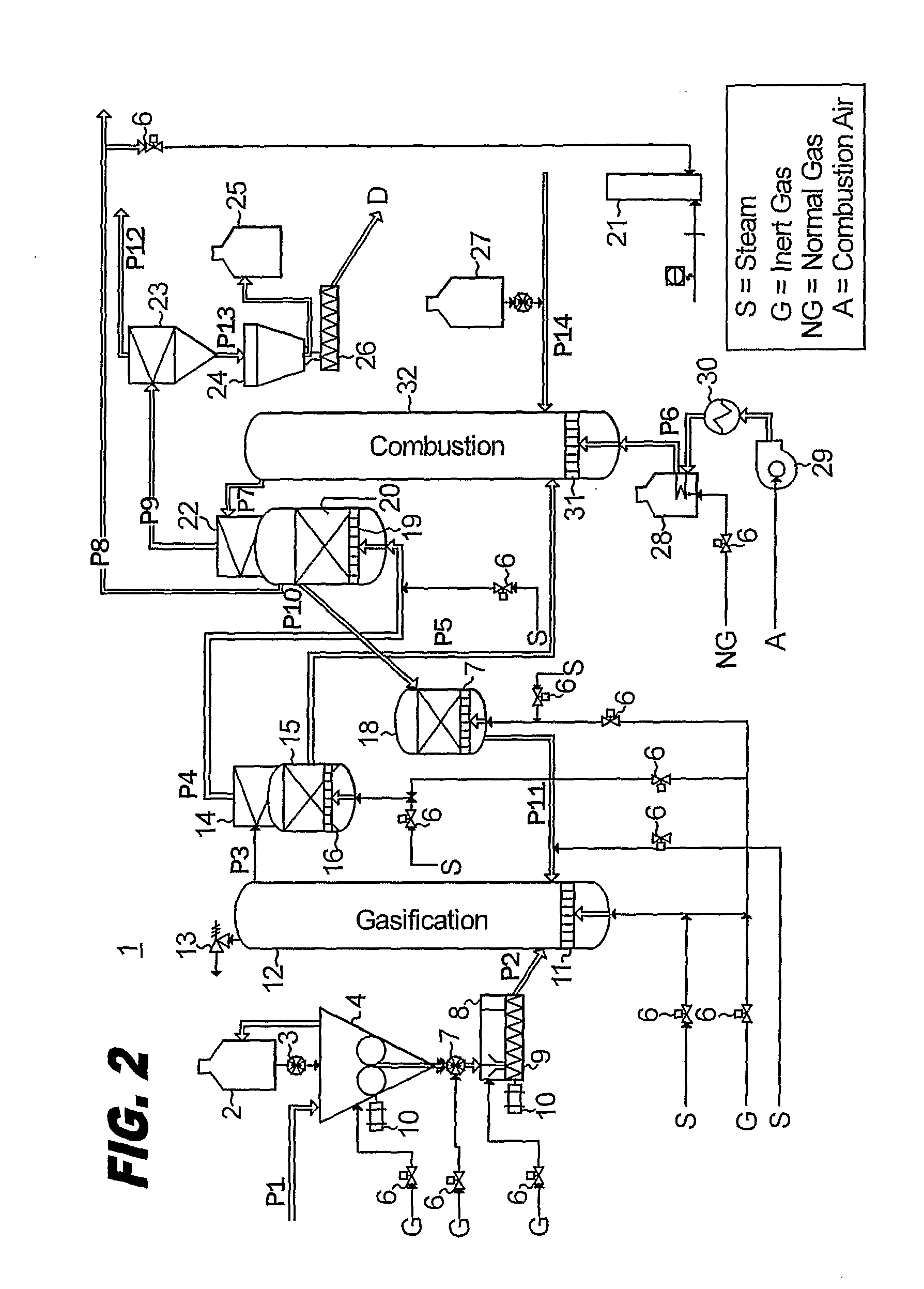

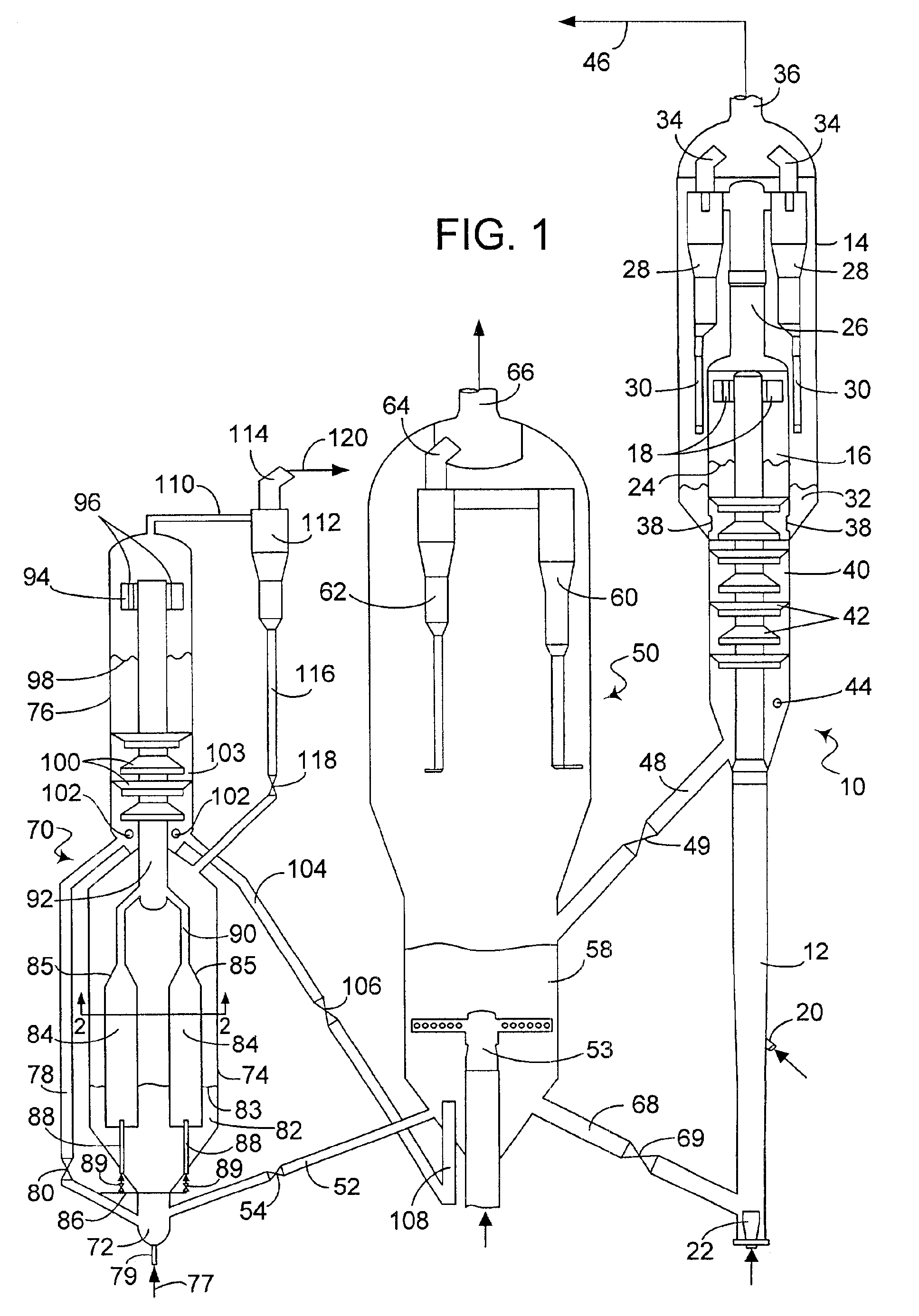

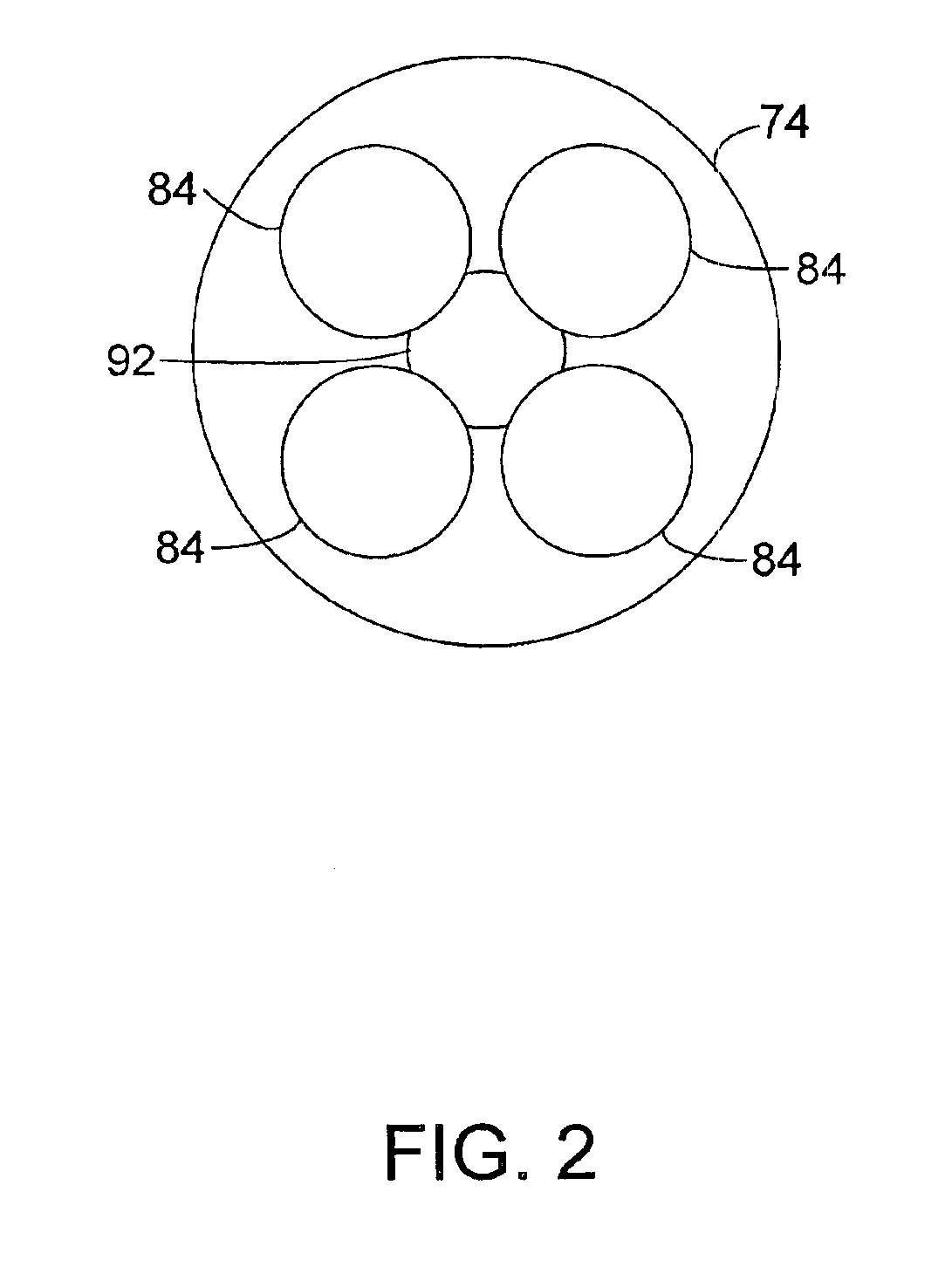

Process and System for Gasification with In-Situ Tar Removal

ActiveUS20080244976A1Simplifying downstream heat recoveryIncreased hydrogenCombustible gas catalytic treatmentCombustible gas thermal treatmentHeat carrierTar

The present invention relates to a process and system for gasifying biomass or other carbonaceous feedstocks in an indirectly heated gasifier and provides a method for the elimination of condensable organic materials (tars) from the resulting product gas with an integrated tar removal step. More specifically, this tar removal step utilizes the circulating heat carrier to crack the organics and produce additional product gas. As a benefit of the above process, and because the heat carrier circulates through alternating steam and oxidizing zones in the process, deactivation of the cracking reactions is eliminated.

Owner:TAYLOR BIOMASS ENERGY

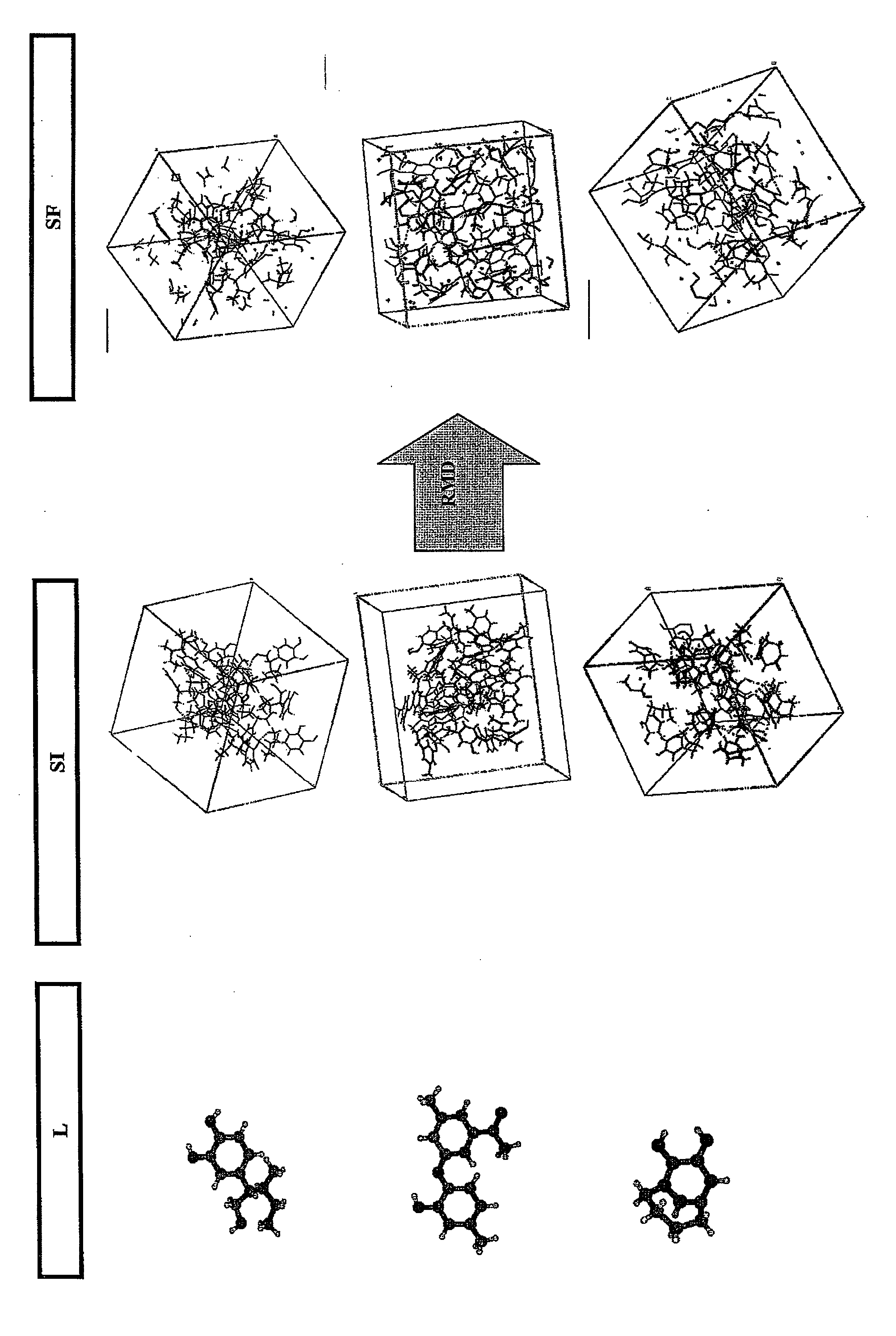

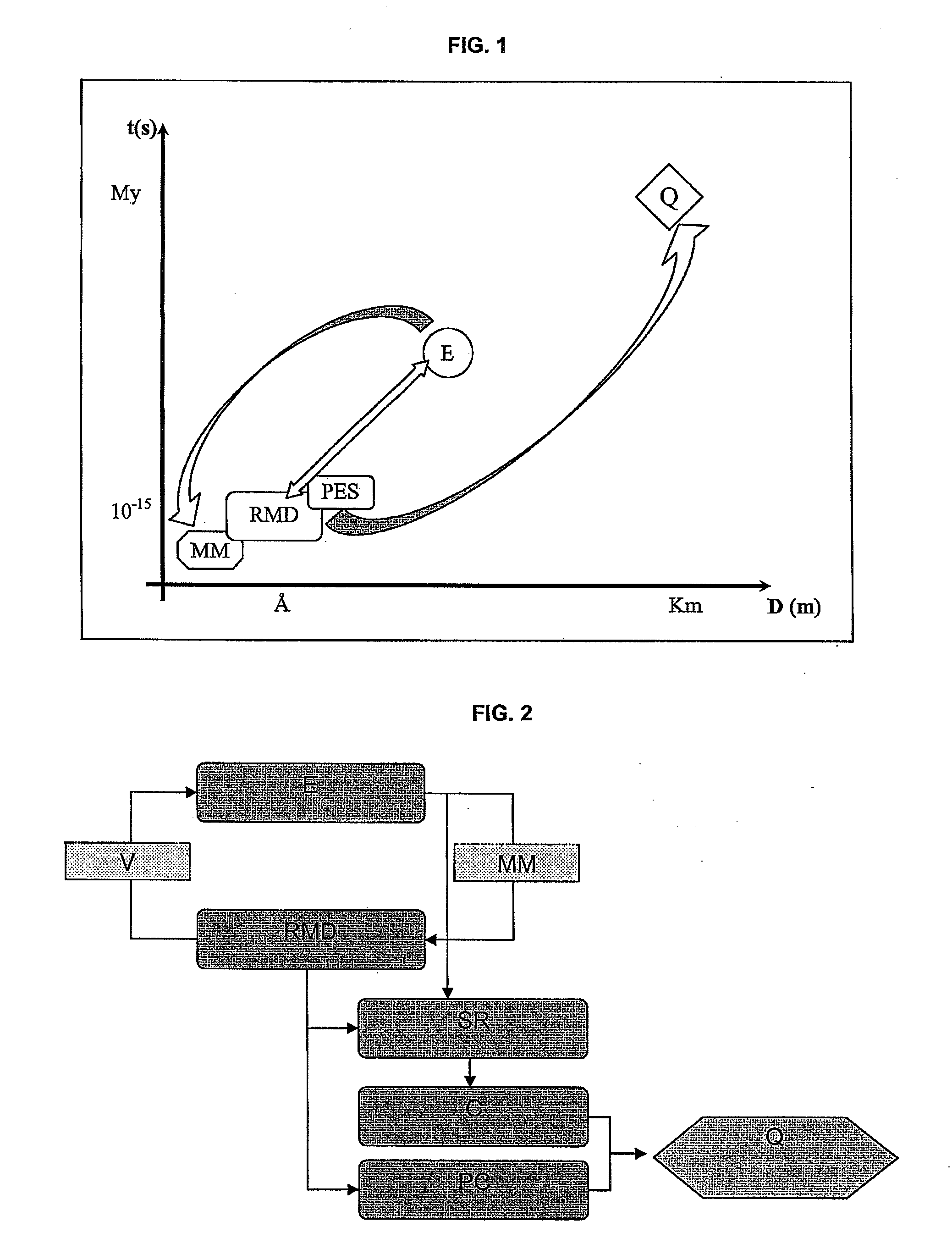

Method of quantifying hydrocarbon formation and retention in a mother rock

InactiveUS20080059140A1Analogue computers for chemical processesSeismologyHydrocotyle bowlesioidesSedimentary basin

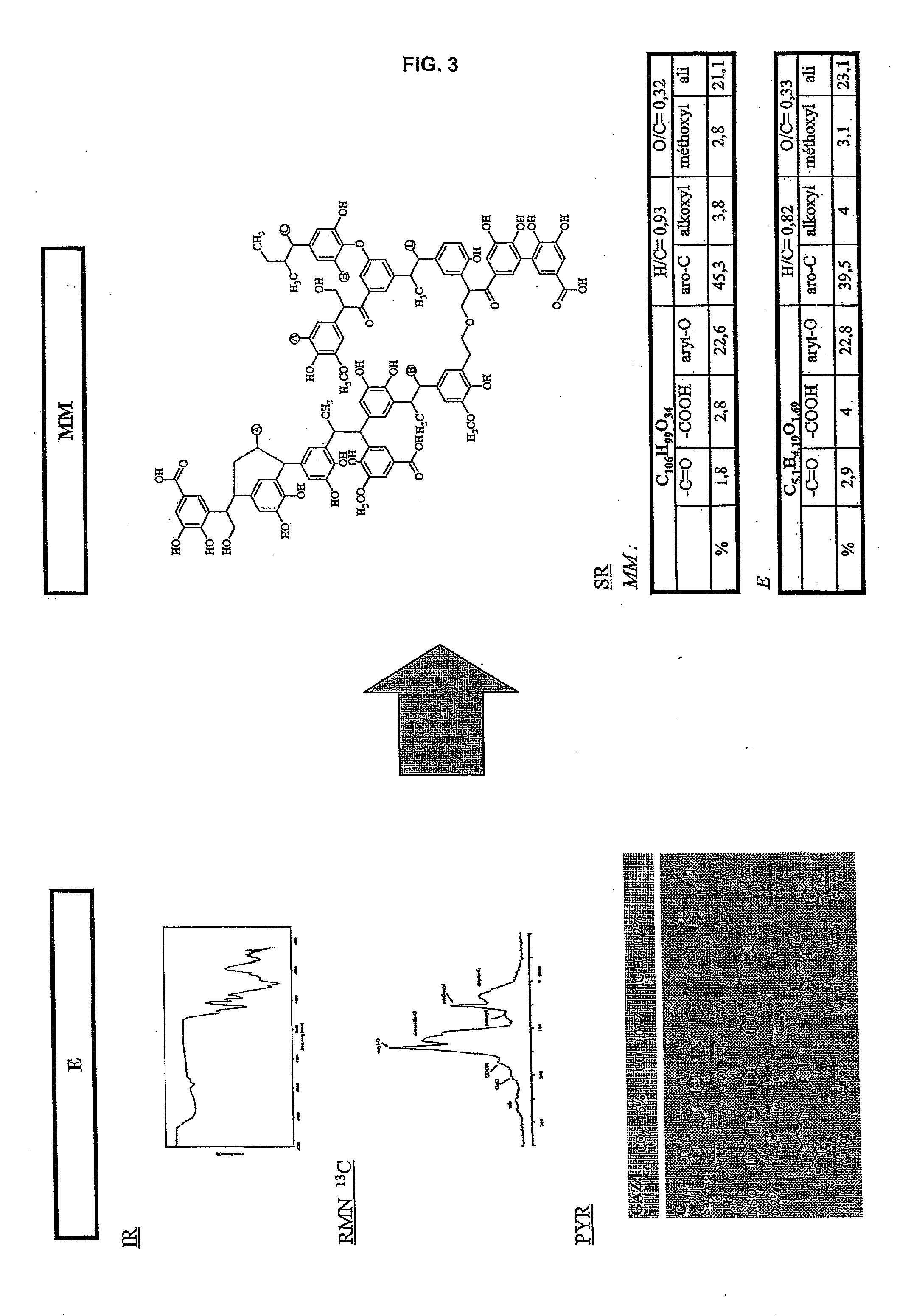

The method according to the invention allows the formation of oil and the retention phenomenon in the mother rock to be modelled. Organic matter characterization experiments are used to establish the molecular model (MM) of the initial sample (E). The thermal cracking reaction of this molecular model is reproduced by dynamic molecular simulation computations with a reactive force field (RMD) and validated by comparison with experimental data. The reaction mechanism obtained (SR) allows to carry out a kinetic study (C) by variation of the temperature parameter. The phase equilibria (PES) of the reaction medium are determined at any time from dynamic simulation. The successive phase equilibrium assessments at various progress stages of the cracking reaction allow following the physicochemical evolution (PC) of the thermal maturation of the organic sample studied. The free hydrocarbons (liquid and gaseous) that are not retained in the solid residue can be quantified throughout numerical modelling of the sample maturation; representing, in the sedimentary basins, the hydrocarbons that are not retained in the organic matrix of the mother rock (Q). This quantity can be used as an indicator or an input value for the retention threshold in basin models.

Owner:INST FR DU PETROLE

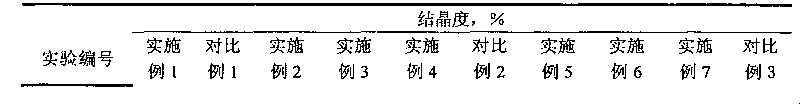

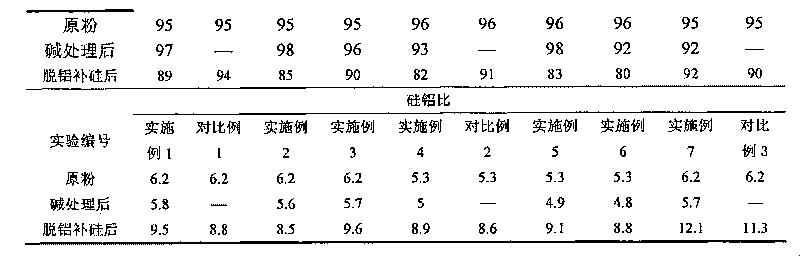

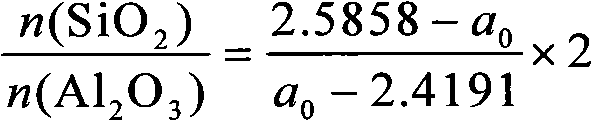

Preparation method of skeleton silicon-rich Y-shaped molecular sieve

ActiveCN101723399AImprove effective apertureIncreased secondary pore contentFaujasite aluminosilicate zeoliteMolecular sieveActive component

The invention discloses a preparation method of a skeleton silicon-rich Y-shaped molecular sieve, comprising the following steps of: firstly, carrying out desiliconizing pretreatment on a NaY molecular sieve with alkali lye and secondly carrying out ammonium exchange and dealumination and silicon reinsertion on the molecular sieve treated with alkali. The alkali treatment condition is to pulp and evenly mix the NaY molecular sieve and an alkali liquor in the mass ratio of NaY (dry basis): alkali: H2O being (0.1-2): (0.05-2): (4-15) and carry out alkali treatment at 0-120 DEG C for 0.1-24h. Compared with a product obtained by carrying out ammonium exchange and silicon-rich treatment on the NaY molecular sieve, the skeleton silicon-rich Y-shaped molecular sieve subject to the desiliconizing pretreatment has higher infrared acid quantity, B acid quantity and secondary pore content. A catalyst prepared from an active component which is the skeleton silicon-rich Y-shaped molecular sieve prepared by the method has stronger heavy oil transformation capability and higher light oil recovery rate when being used for a heavy oil cracking reaction.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

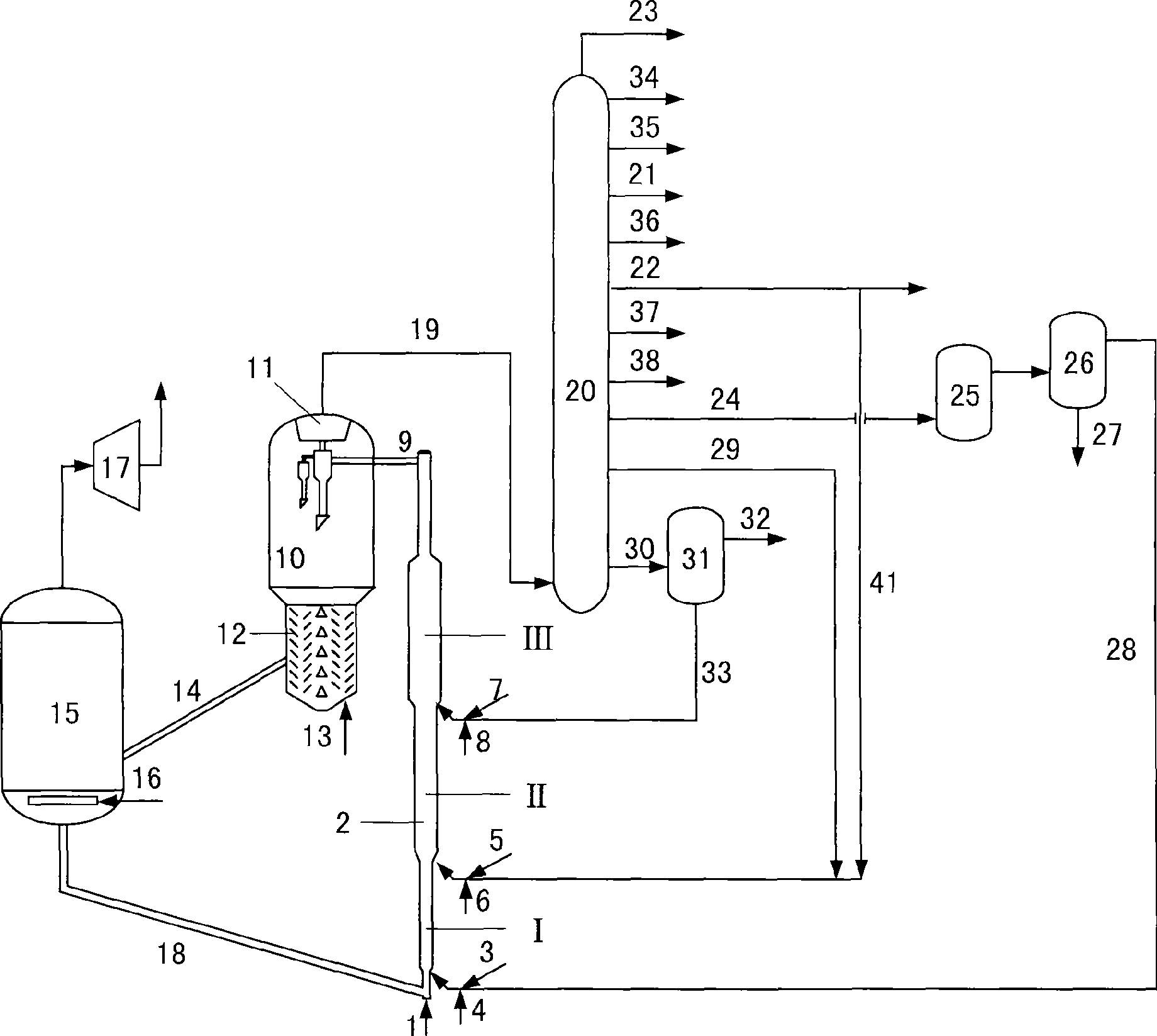

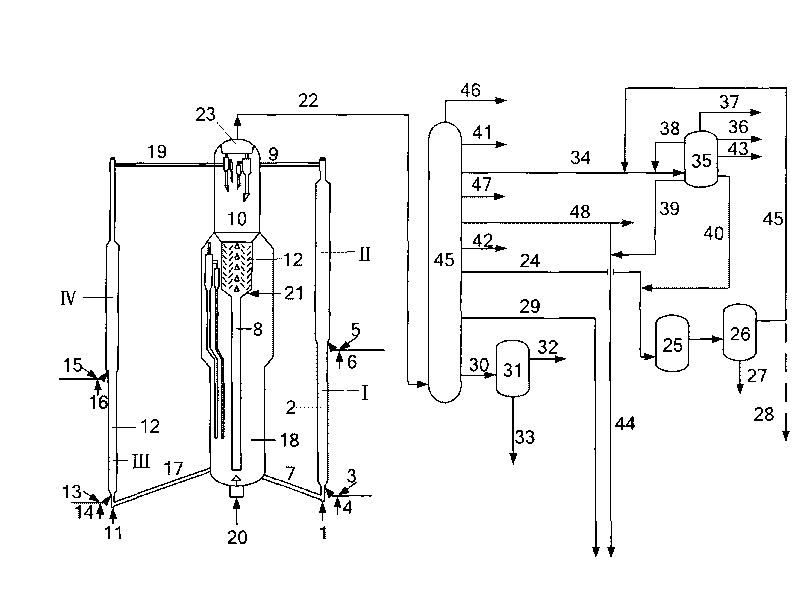

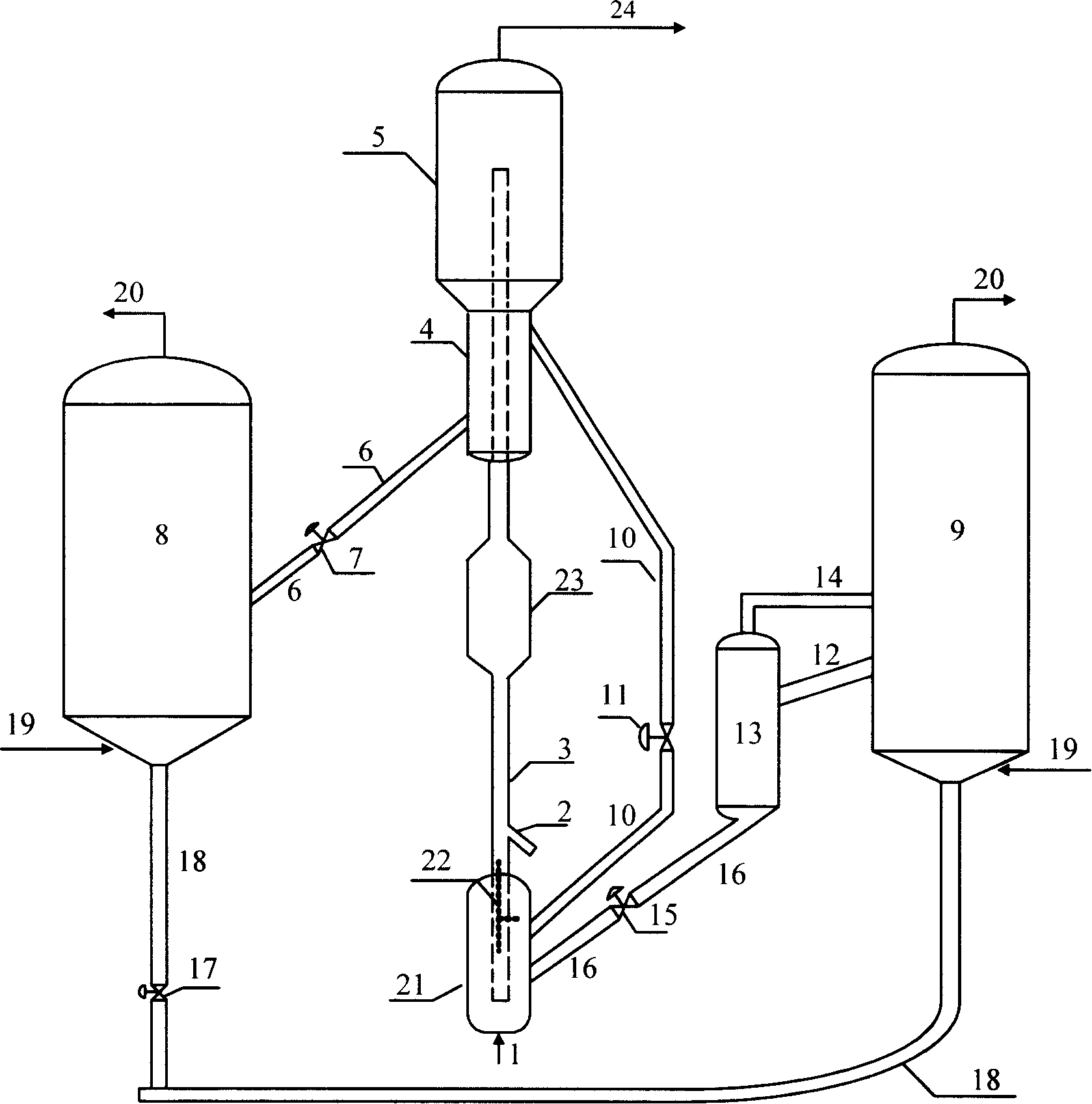

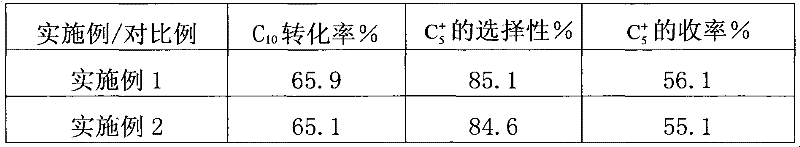

Catalytic conversion method for preparing propylene and high-octane gasoline

ActiveCN101531923AHigh selectivityHigh yieldOrganic chemistryTreatment with hydrotreatment processesGasolineReaction temperature

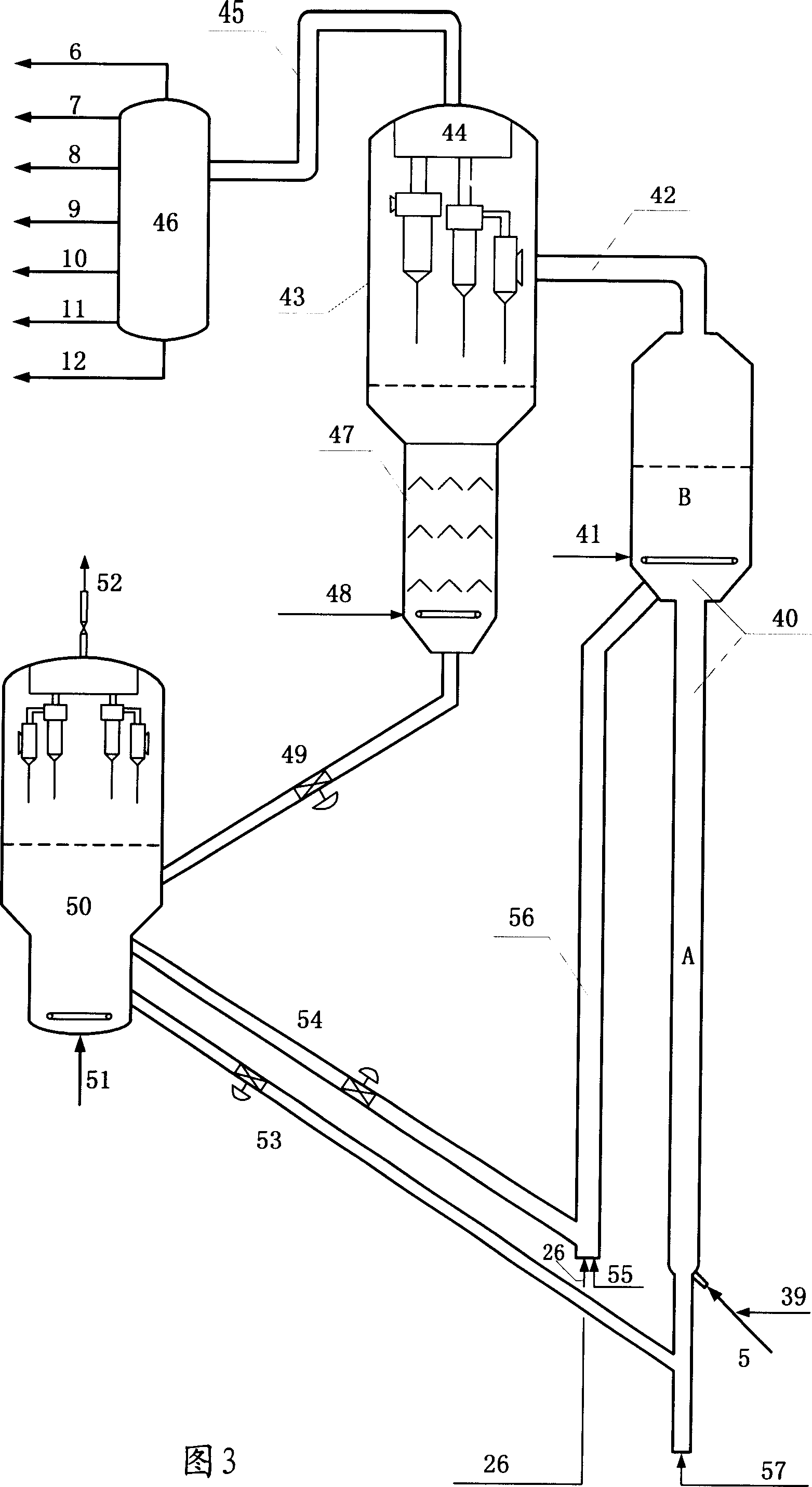

A catalytic conversion method for preparing propylene and high-octane gasoline comprises the following steps: raw materials which are difficult to be cracked are firstly contacted with a thermal regeneration catalytic cracking catalyst to carry out cracking reaction under the conditions that the reaction temperature is 600-750 DEG C and the weight hourly space velocity is 100-800h<-1>, the reactant flow is mixed with raw oil which is easy to be cracked to carry out the cracking reaction under the conditions that the reaction temperature is 450-620 DEG C and the weight hourly space velocity is 0.1-100h<-1>; the spent catalyst and reaction oil and gas are separated, the spent catalyst returns to a reactor after regeneration, the reaction oil and gas are separated to obtain propylene and gasoline, and hydrogenated heavy oil obtained by hydrotreating fractions above 260 DEG C is taken as raw oil of the catalytic cracking device or a conventional catalytic cracking device. The method improves the yield and the selectivity of the propylene, increases the yield of the high-octane gasoline, reduces the yield of dry gas, greatly increases the yield of liquid and realizes the high-efficient utilization of petroleum resources.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic cracking process for production of diesel from seeds of oleaginous plants

ActiveUS20080313955A1Production is possibleCatalytic crackingFatty acid chemical modificationEngineeringCracking reaction

The present invention comprises a thermocatalytic cracking process for the production of diesel oil from a charge of vegetable origin made from seeds of oleaginous plants in refineries possessing at least two FCC reactors. At least -one of such reactors processes heavy gas oil or residue under conventional conditions whilst at least one of such reactors processes the charge of vegetable origin made from seeds of oleaginous plants under conditions suitable, for production of diesel oil. Said process employs the same catalyst utilised in the fluid catalytic cracking process which, simultaneously, processes a conventional charge.The diesel, or biodiesel, oil produced by means of said process is of superior quality having a cetane number exceeding 40 given that the cracking reactions occur at low temperatures and the products obtained are less oxidised and consequently purer than products obtained by means of existing technology.

Owner:PETROLEO BRASILEIRO SA (PETROBRAS)

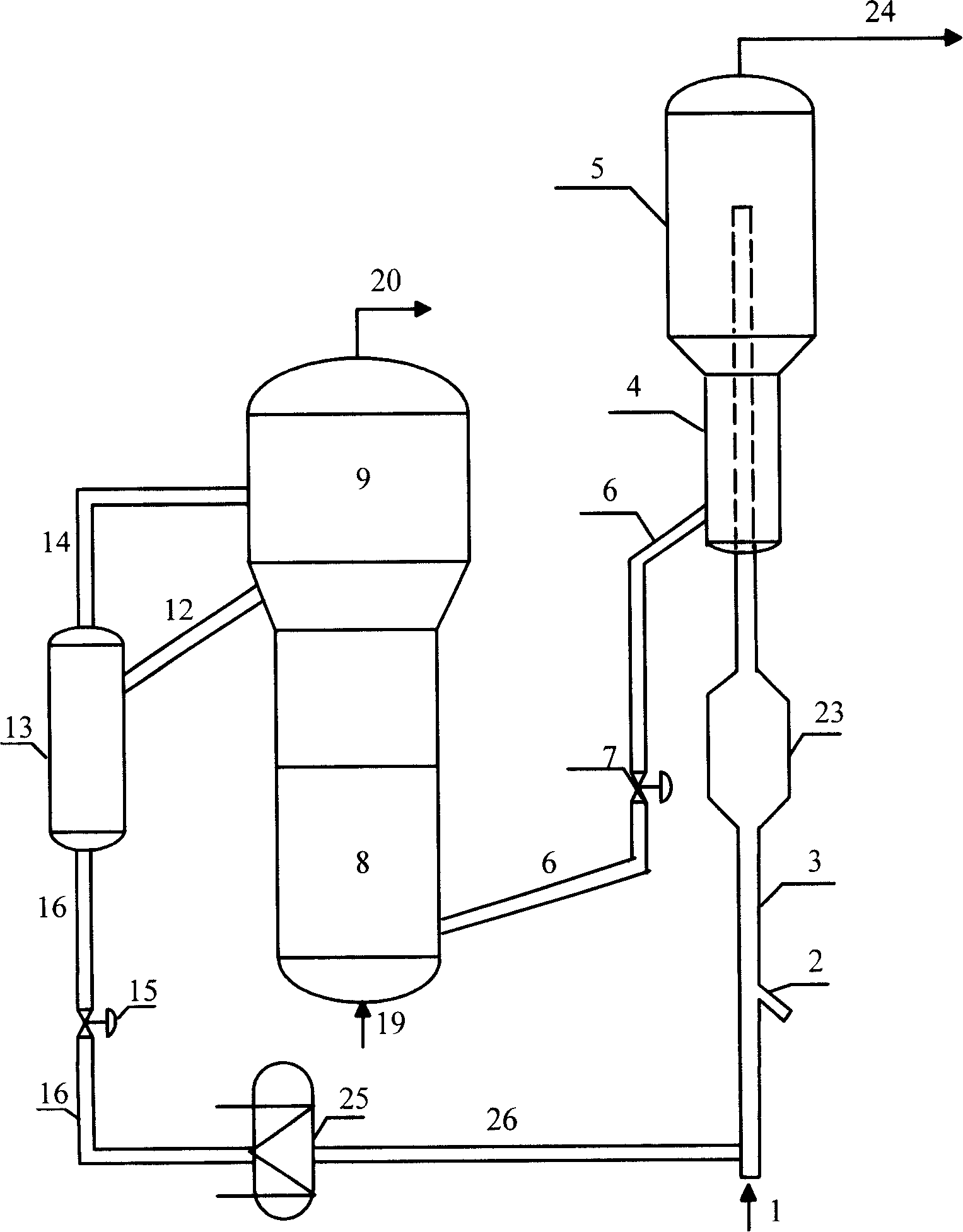

Catalytic conversion method for preparing propylene and aromatic hydrocarbons

ActiveCN101531558AHydrocarbon purification/separationHydrocarbon oil crackingWater vaporFluidized bed

A catalytic conversion method for preparing propylene and aromatic hydrocarbons comprises the following steps: hydrocarbon raw materials with different cracking performances are contacted with a catalytic cracking catalyst to carry out cracking reaction in a fluidized-bed reactor under the conditions that the temperature is 450-750 DEG C, the weight hourly space velocity is 0.1-800h<-1>, the reaction pressure is 0.10-1.0MPa, the weight ratio of the catalytic cracking catalyst to the raw materials is 1-150 and the weight ratio of water vapor to the raw materials is 0.05-1.0, the spent catalyst and reaction oil and gas are separated, the spent catalyst returns to the reactor after the regeneration, the separated reaction oil and gas are separated to obtain target products of low-carbon olefins, aromatic hydrocarbons and the raw materials for re-cracking, wherein the raw materials for re-cracking are re-cracked after hydrotreating. The method can product the propylene and other low-carbon olefins from the heavy raw materials to the maximum extent, wherein the yield of the propylene is more than 40 percent by weight; meanwhile, the method can co-produce toluene, xylene and other aromatic hydrocarbons, and the yield of the dry gas is unexpectedly reduced by more than 80 percent by weight.

Owner:CHINA PETROLEUM & CHEM CORP +1

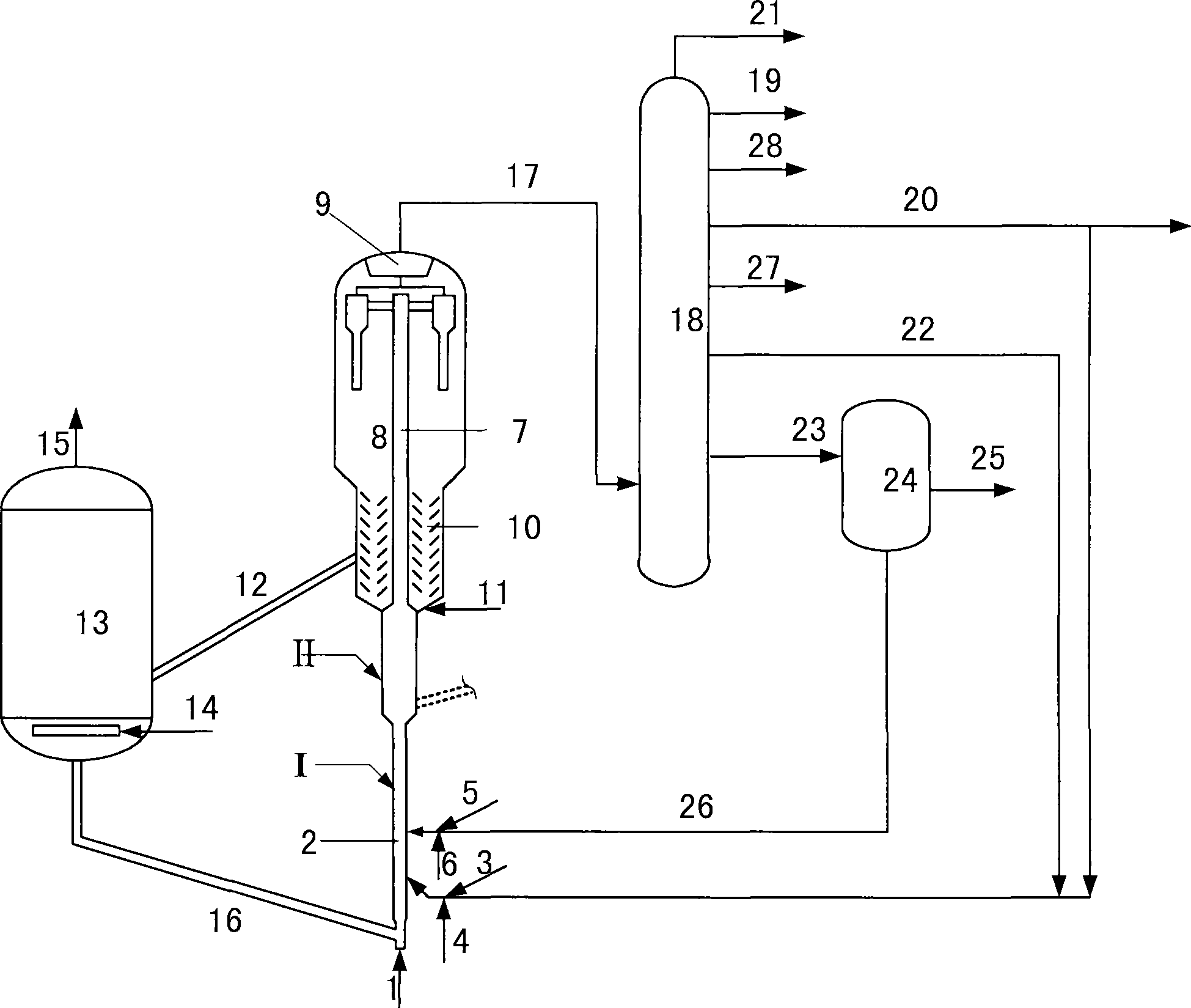

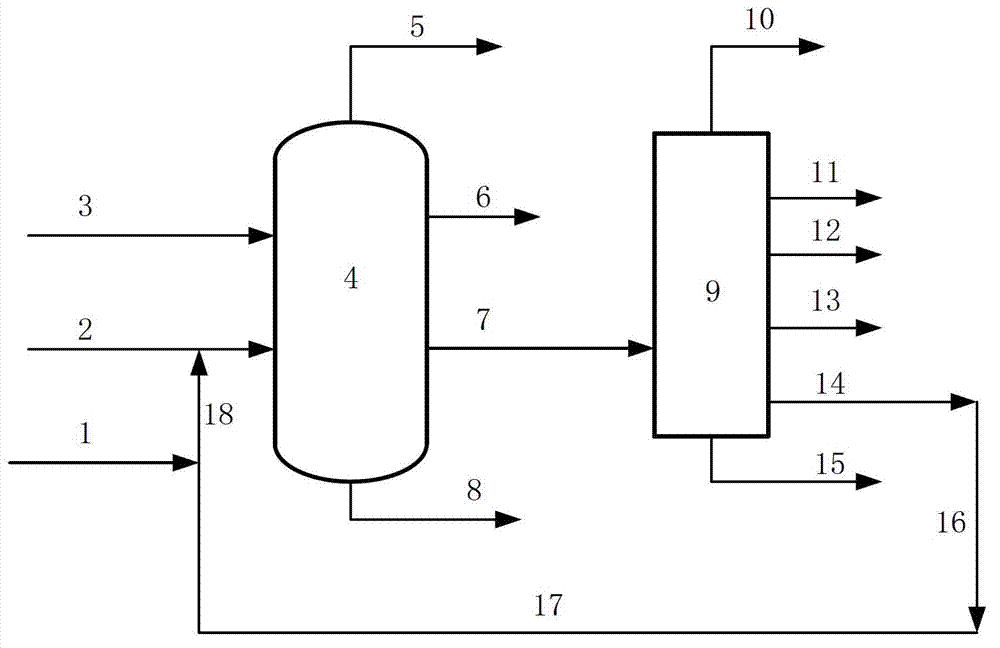

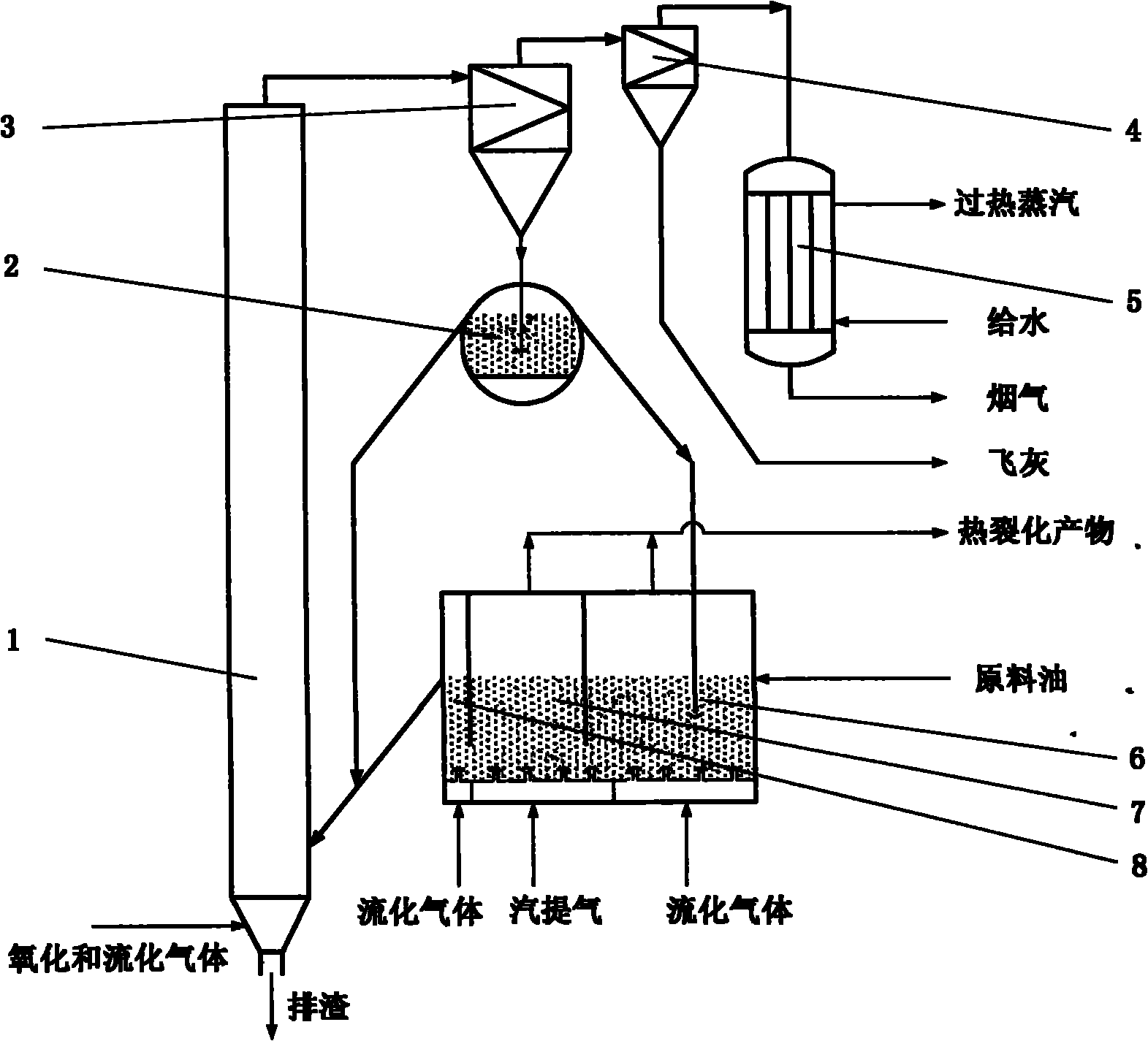

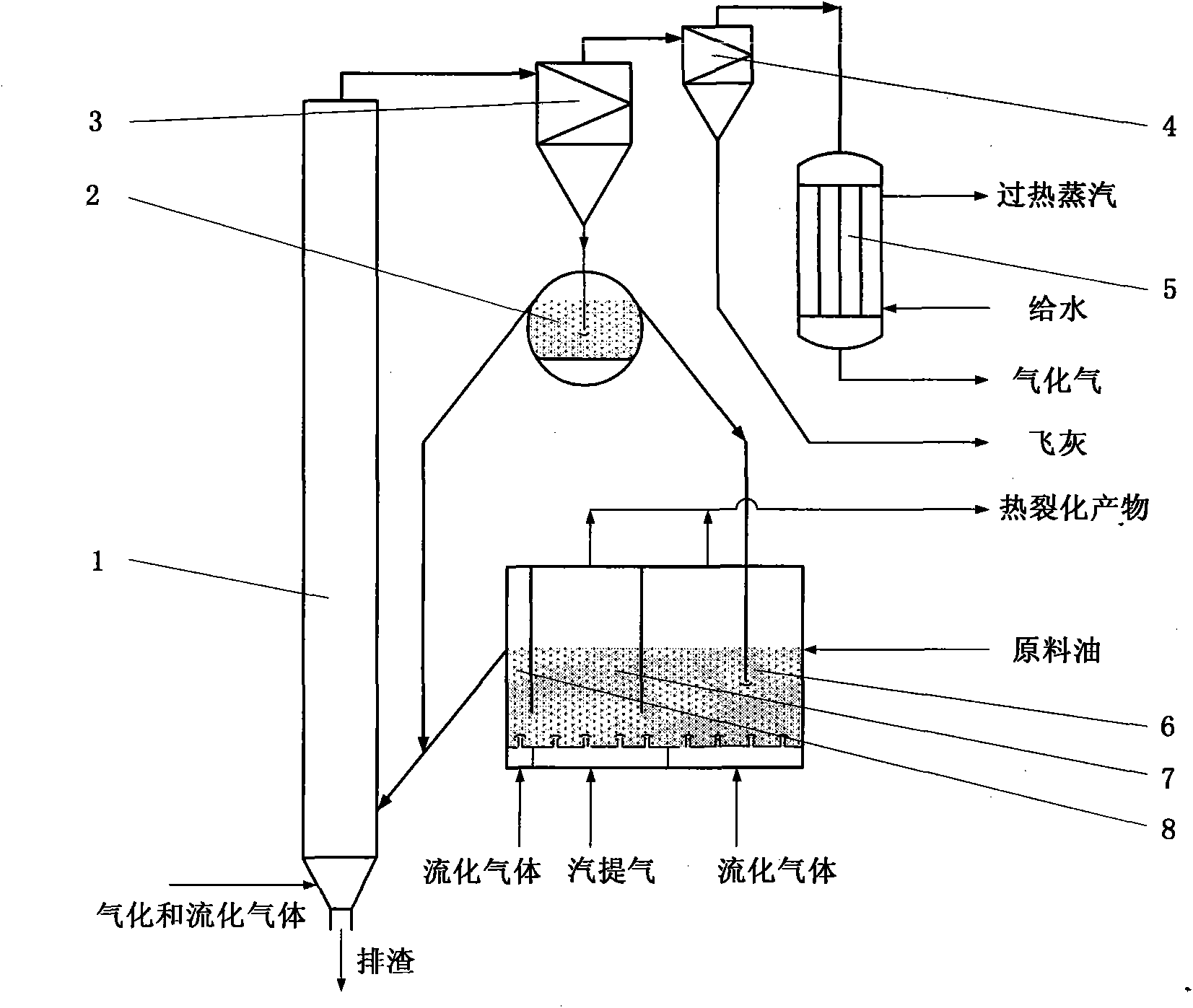

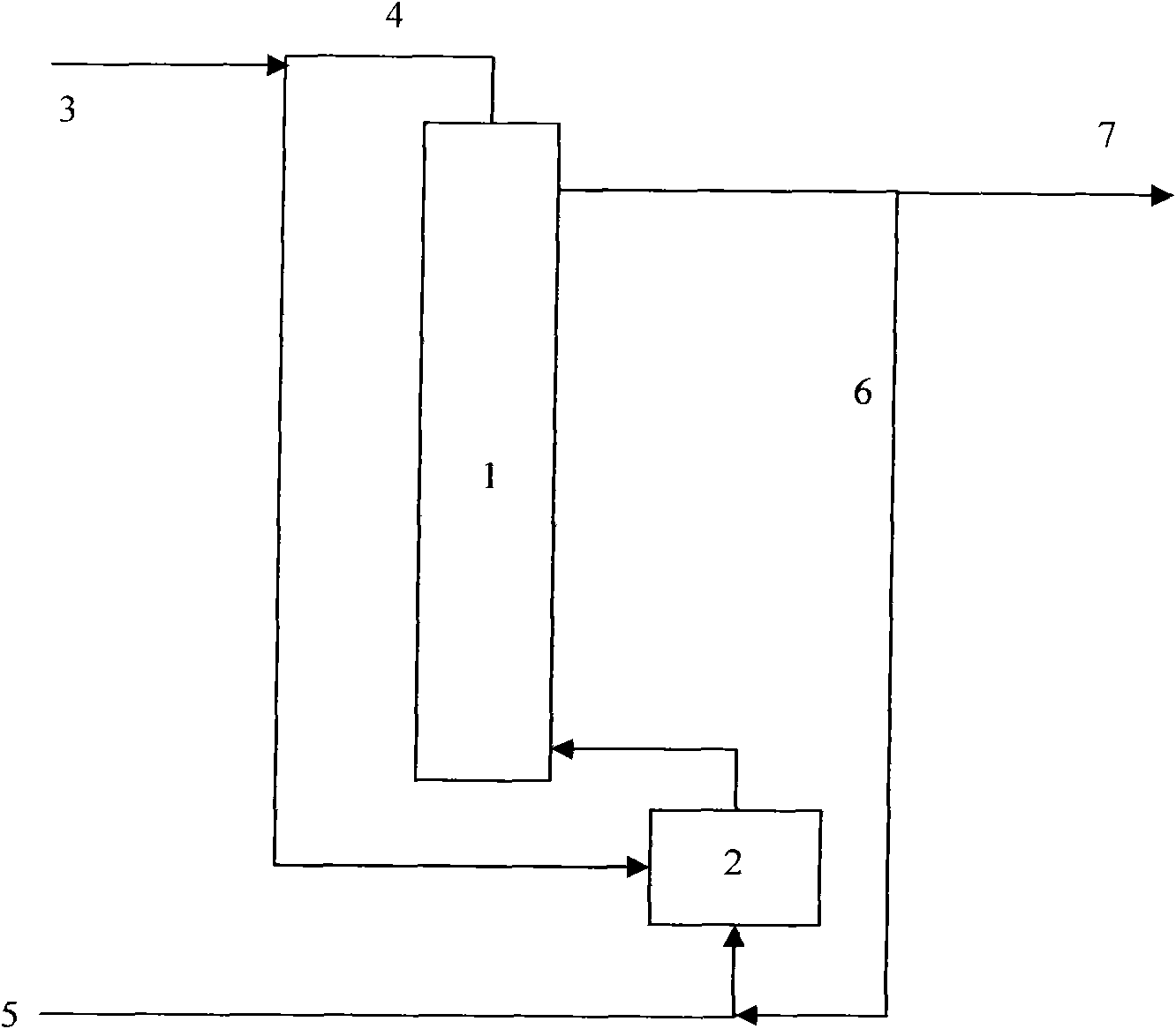

Method for combination processing heavy oil by pyrolysis and gasification

ActiveCN101451073AReasonable useImprove gasification efficiencyThermal non-catalytic crackingCoke ovensOil processingThermal energy

The invention relates to a heavy oil processing method by combining thermal cracking and gasification. A raw material is conducted to a reactor from the bottom of a gas-solid separation region, is dispersed into oil drops through an atomizer; a lightweight component of the oil drop is volatilized to form oil gas in the falling process of the oil drops in a thermal cracking region; a heavy component is condensed to form coke, wherein the oil gas carries out thermal cracking reaction; coke particles drop into a gasification region and carry out gasification reaction at a temperature of between 800 and 1,600 DEG C to generate synthetic gas; one part of residual fine coke particles drop into an ash hopper to form clinker; the other part of the residual fine coke particles and the generated gas flow upwards together, are contacted with the descending liquid drops and carry out heat exchange; gas phase and coke in the gas-solid separation region of the upper part of the rector are separated; the separated fine coke particles re-drop into the thermal cracking region and the gasification region and continuously react; and the separated gas phase flows out of the rector, enters a subsequent separation system and is separated into synthetic gas, dry gas, liquid gas, gasoline, diesel, oil slurry and other products. The method has high gasification efficiency and reasonable utilization of heat energy and reduces energy consumption.

Owner:CHINA PETROLEUM & CHEM CORP +1

Catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon

ActiveCN104560187AReduce hydrogen consumptionImprove harsh conditionsTreatment with hydrotreatment processesHydrocarbon oils treatment productsPolycyclic aromatic hydrocarbonGasoline

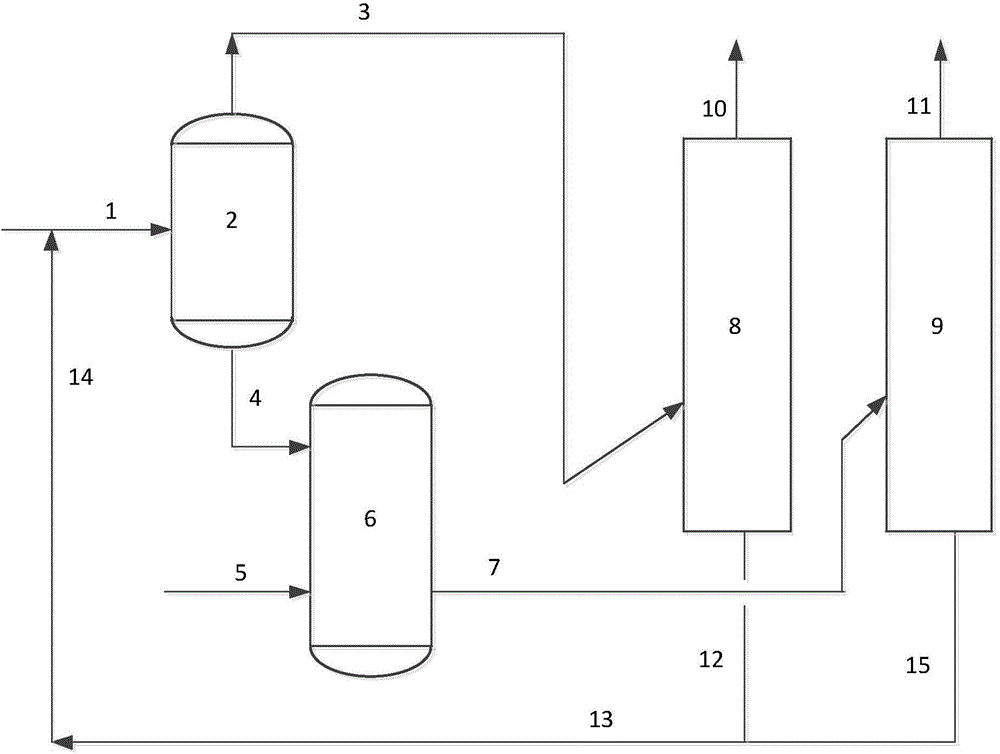

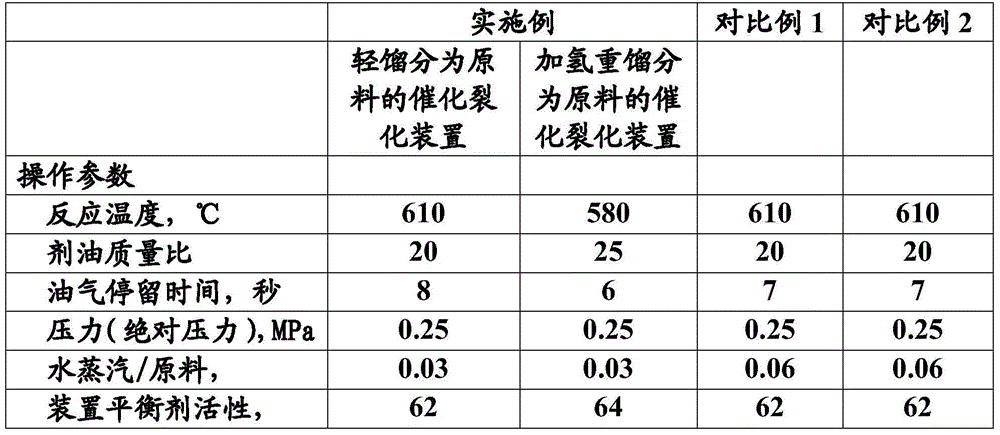

The invention provides a catalytic conversion method for producing gasoline containing rich aromatic hydrocarbon. The catalytic conversion method comprises the following steps: cutting catalytic cracking light cycle oil to obtain a light fraction and a heavy fraction, performing hydrogenation treatment on the heavy fraction to obtain a hydrogenated heavy fraction, singly and respectively conveying the light fraction and the heavy fraction into different riser reactors of catalytic cracking devices, performing a cracking reaction in the presence of a catalytic cracking catalyst, and separating reaction products to obtain a product containing the gasoline which contains rich aromatic hydrocarbon and the light cycle oil. According to the method, single catalytic cracking devices are used for processing the light fraction and the hydrogenated heavy fraction of the light cycle oil to satisfy harsh conditions necessary for the catalytic cracking reaction of different fractions of the light cycle oil to the maximum, so as to produce catalytic gasoline containing rich benzene, toluene and xylene to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

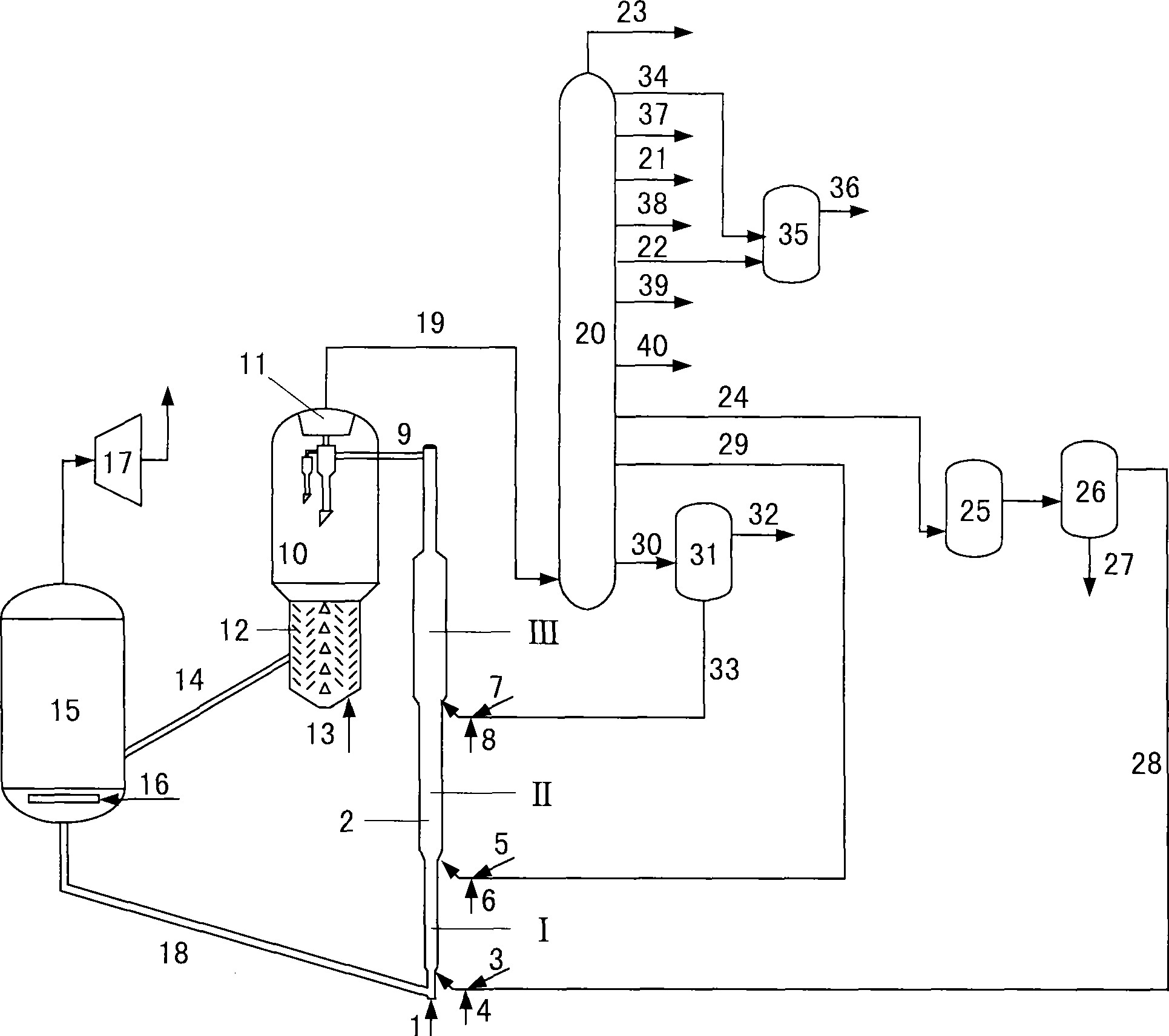

Catalytic conversion method for preparing lower olefins and aromatics

The invention relates to a catalytic conversion method for preparing lower olefins and aromatics. Raw oil with different cracking performances enters different reaction zones of a first riser reactor to contact with a catalytic cracking catalyst for cracking reaction to separate a spent catalyst from reaction oil gas, wherein the reaction oil gas is separated to obtain a product containing lower olefins, gasoline, distillates with distillation range of 180-250 DEG C and catalytic wax oil, wherein the gasoline is extracted by light aromatics to obtain light aromatics and gasoline raffinate; the raw materials are cracked to be sent into a second riser reactor to contract with a hot regenerated catalyst for catalytic conversion; and the spent catalysts of the two riser reactors are burned and regenerated in the same one regenerator and then returns to the two riser reactors. The method uses heavy raw materials to furthest produce the lower olefins, such as propylene, ethylene, and the like, particularly the propylene, the production rate can exceed 40 wt%, and at the same time the method can coproduce the aromatics, such as toluene, xylene, and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

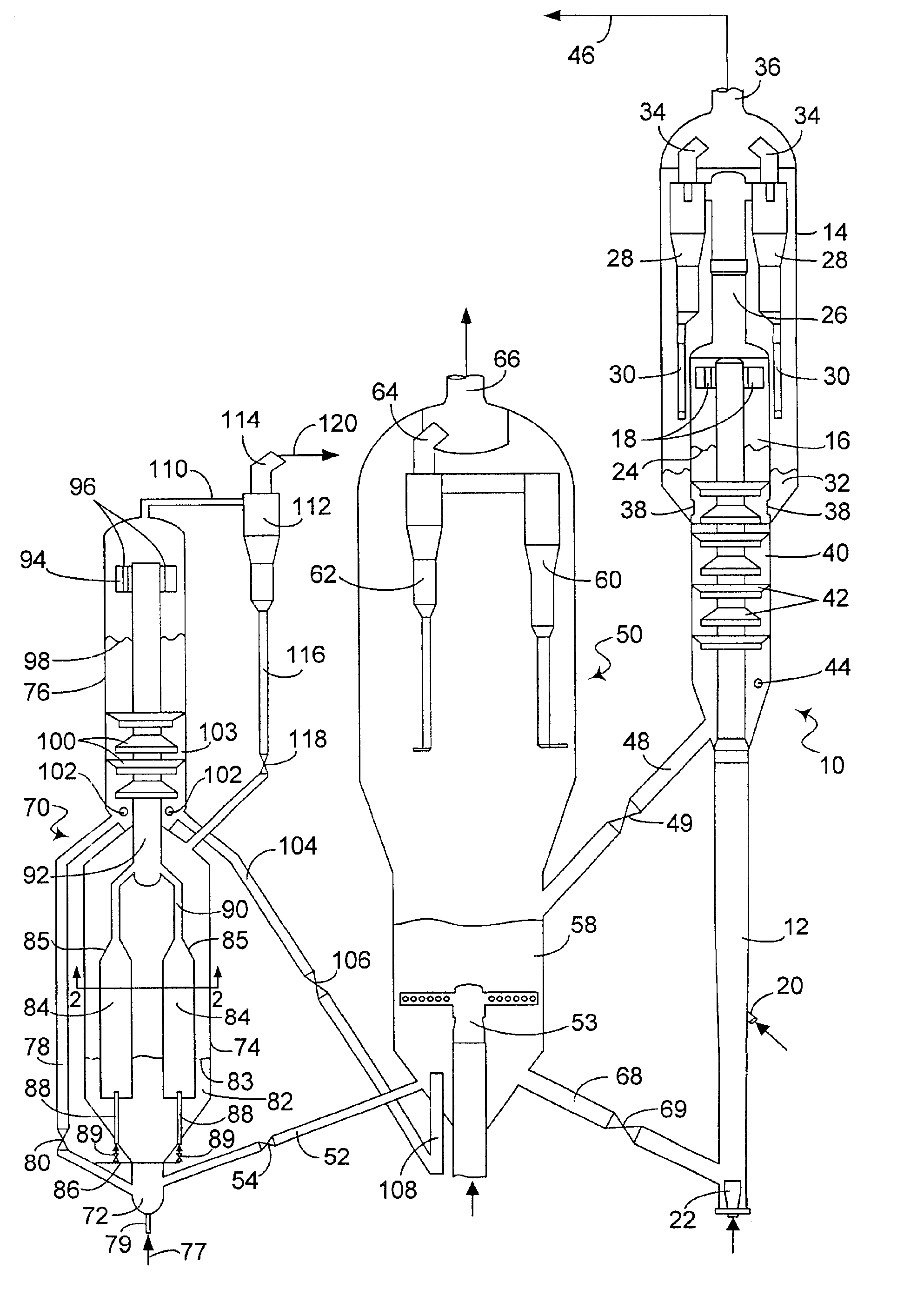

Process and apparatus for upgrading FCC product with additional reactor with catalyst recycle

InactiveUS6866771B2Increase undesirable crackingLower catalytic temperatureTreatment with plural serial cracking stages onlyCatalytic crackingCracking reactionChemistry

Owner:UOP LLC

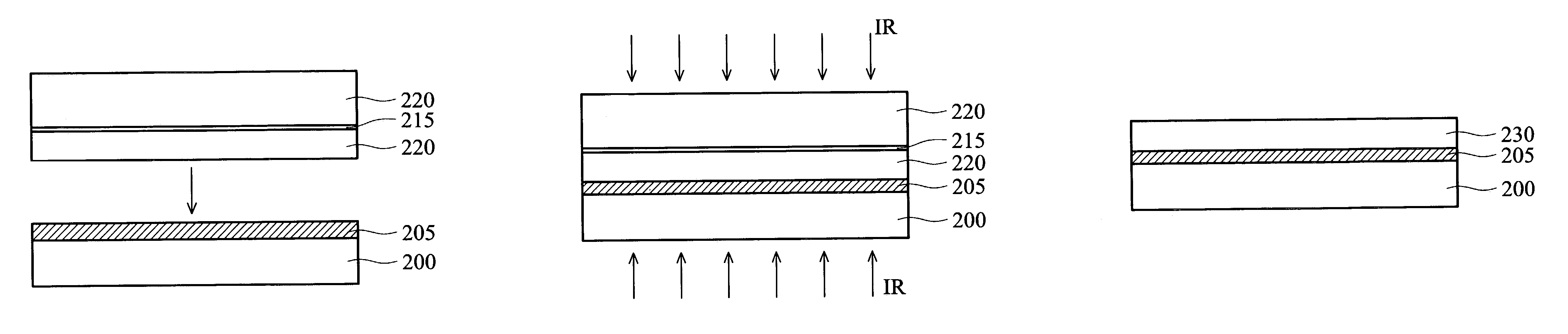

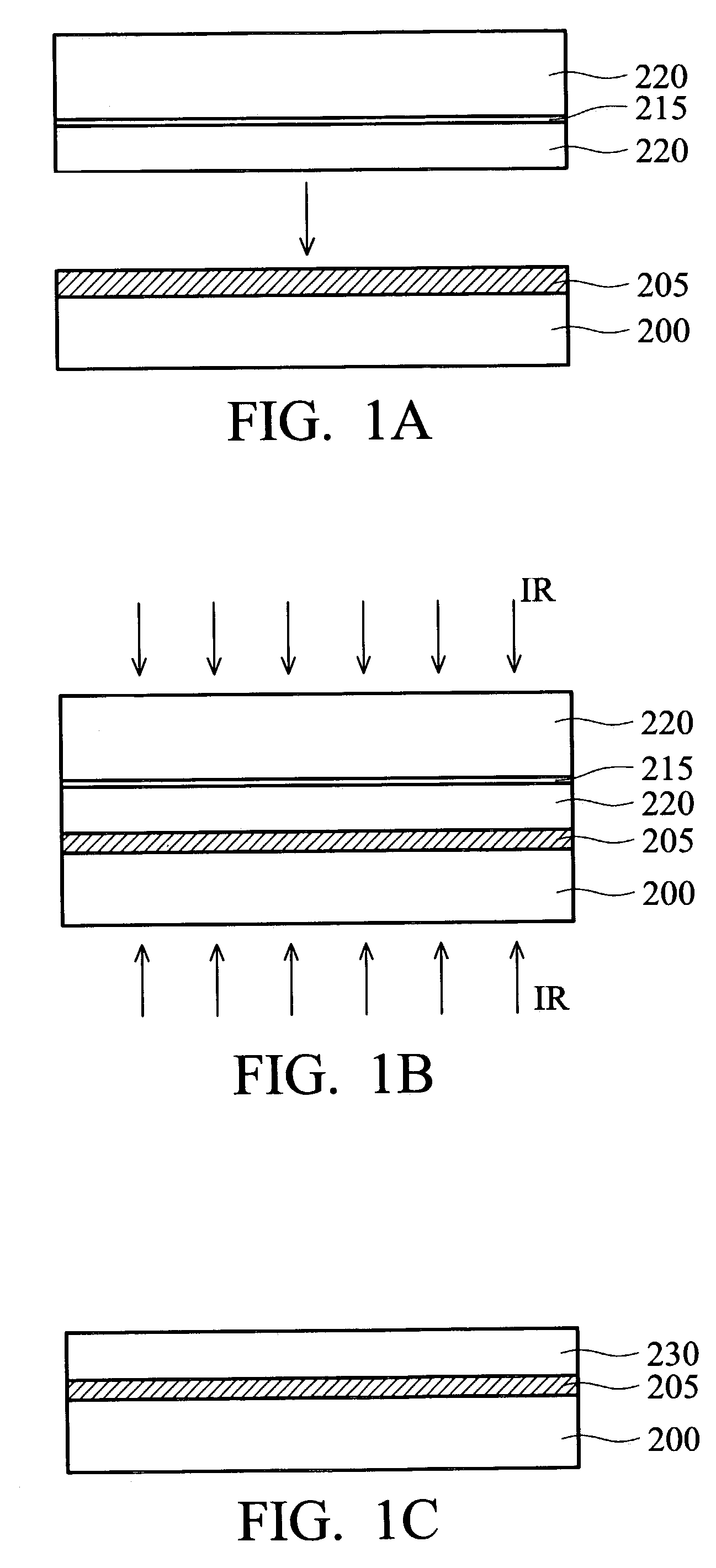

Method for forming a single-crystal silicon layer on a transparent substrate

InactiveUS7045441B2Layered product treatmentSemiconductor/solid-state device detailsAmorphous siliconCracking reaction

A method for forming a, single-crystal silicon layer on a transparent substrate. A transparent substrate having an amorphous silicon layer formed thereon and a silicon wafer having a hydrogen ion layer formed therein are provided. The silicon wafer is then reversed and laminated onto the amorphous silicon layer so that a layer of single-crystal silicon is between the hydrogen ion layer and the amorphous silicon layer. The laminated silicon wafer and the amorphous silicon layer are then subjected to laser or infrared light to cause chemical bonding of the single crystal silicon layer and the amorphous silicon layer and inducing a hydro-cracking reaction thereby separating the silicon wafer is and the transparent substrate at the hydrogen ion layer, and leaving the single-crystal silicon layer on the transparent substrate.

Owner:IND TECH RES INST

Catalysis conversion method for producing aromatic compounds

ActiveCN103923698ALess investmentReduce sulfur, nickelCatalytic crackingTreatment with hydrotreatment processesDistillationSlurry

The invention relates to a catalysis conversion method for producing aromatic compounds. According to the method, poor quality heavy cycle oil and residual oil are subjected to a hydrotreating reaction in the presence of hydrogen gas and a hydrogenation catalyst, and the reaction products are separated to obtain gas, naphtha, hydrogenated diesel oil and hydrogenated residue oil, wherein the hydrogenated diesel oil enters a catalysis cracking device and is subjected to a cracking reaction in the presence of a catalysis cracking catalyst, the reaction products are separated to obtain dry gas, liquefied gas, catalytic gasoline containing rich benzene, toluene and xylene, catalytic light diesel oil, distillates with a distillation range of 250-450 DEG C, and an oil slurry, and the distillates with the distillation range of 250-450 DEG C are conveyed to a residue oil hydrotreating device so as to be recycled. According to the present invention, the residue oil hydrogenation condition is completely utilized to achieve saturation of the aromatic ring in the poor quality heavy cycle oil to the maximal degree, such that the hydrogenated diesel oil maximally produce benzene, toluene and xylene during catalysis cracking.

Owner:CHINA PETROLEUM & CHEM CORP +1

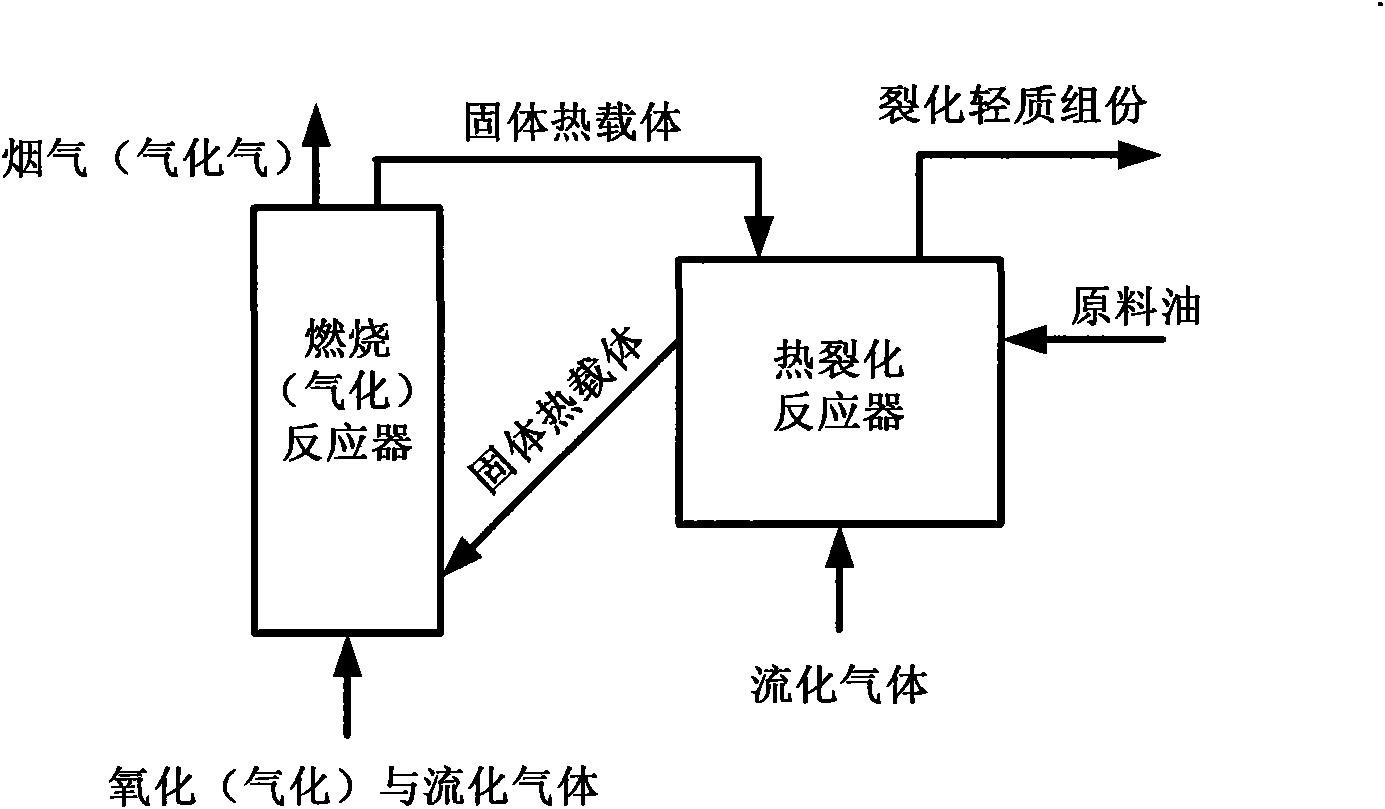

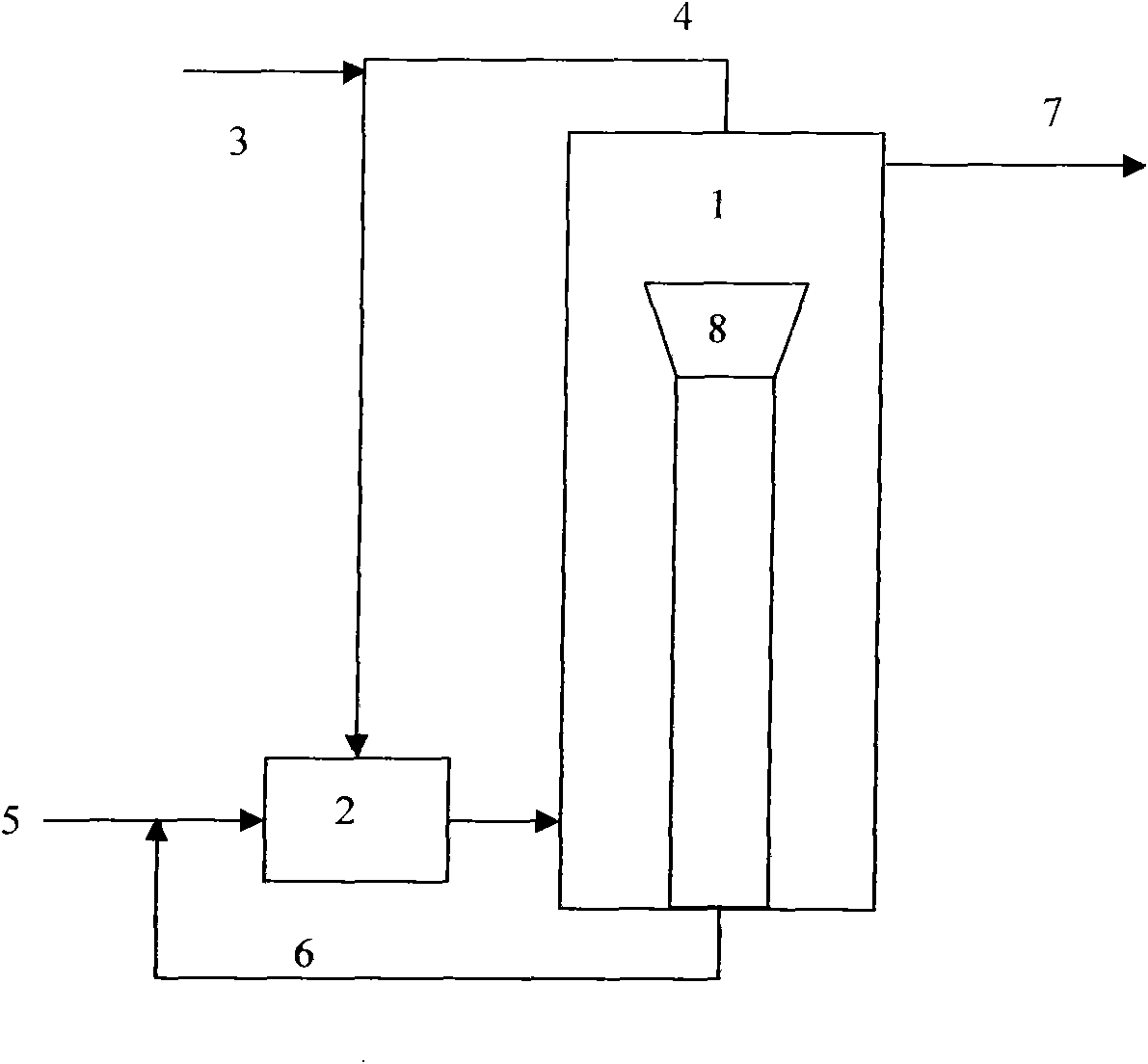

Heavy oil lightening method and device

InactiveCN102115675AAchieve conversionEfficient conversionThermal non-catalytic crackingEnergy inputHeat carrierCombustion

The invention relates to a heavy oil lightening method and technique. The method comprises steps as follows: raw oil is introduced into a thermal cracking reactor through a feed system, and mixed with a high-temperature solid heat carrier from a combustion (gasifying) reactor, so that the raw oil is subjected to fluidizing heat exchange with the solid heat carrier and carries out thermal cracking reaction on the surface of the solid heat carrier; the cracking gas generated by the thermal cracking reaction and a light component product are subjected to steam stripping by fluidizing medium gas and enter a subsequent absorption and stabilization system and a purification and separation system, heavy coke (petroleum coke) is attached to the surface of the solid heat carrier and enters the combustion (gasifying) reactor via a material returning valve, and an oxidizing (gasifying) and fluidizing gas is introduced to realize combustion (gasifying) reaction in the fluidization elevation process of the petroleum coke; and after the reaction product (fume or gasified gas) and the solid heat carrier are separated by a gas-solid separator, the fume (gasified gas) is led into a waste heat recovery system and a gas purification system, the high-temperature solid heat carrier is distributed by a distribution valve and respectively enters the thermal cracking reactor and the combustion (gasifying) reactor for cyclic use, and the collected fly ash can be used after further processing, thereby complete high-value conversion and use of the heavy oil.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Catalytic conversion method for producing gasoline containing rich aromatic compounds

ActiveCN104560185AReduce hydrogen consumptionImprove harsh conditionsTreatment with hydrotreatment processesGasolineCracking reaction

The invention provides a catalytic conversion method for producing gasoline containing rich aromatic compounds. The catalytic conversion method comprises the following steps: cutting catalytic cracking light cycle oil to obtain a light fraction and a heavy fraction, performing hydrogenation treatment on the heavy fraction to obtain a hydrogenated heavy fraction, singly conveying the light fraction and the hydrogenated heavy fraction into catalytic cracking devices from different nozzles in a layering manner, performing a cracking reaction in the presence of a catalytic cracking catalyst, and separating reaction products to obtain a product containing the gasoline which contains rich aromatic compounds and the light cycle oil. According to the method, single catalytic cracking devices are used for processing the light fraction and the hydrogenated heavy fraction of the light cycle oil, and the light fraction and the heavy fraction enter the catalytic cracking devices in the layering manner, so that the harsh conditions necessary for the catalytic cracking reaction of different fractions of the light cycle oil can be optimized and satisfied to the maximum, so as to produce catalytic gasoline containing rich benzene, toluene and xylene to the maximum.

Owner:CHINA PETROLEUM & CHEM CORP +1

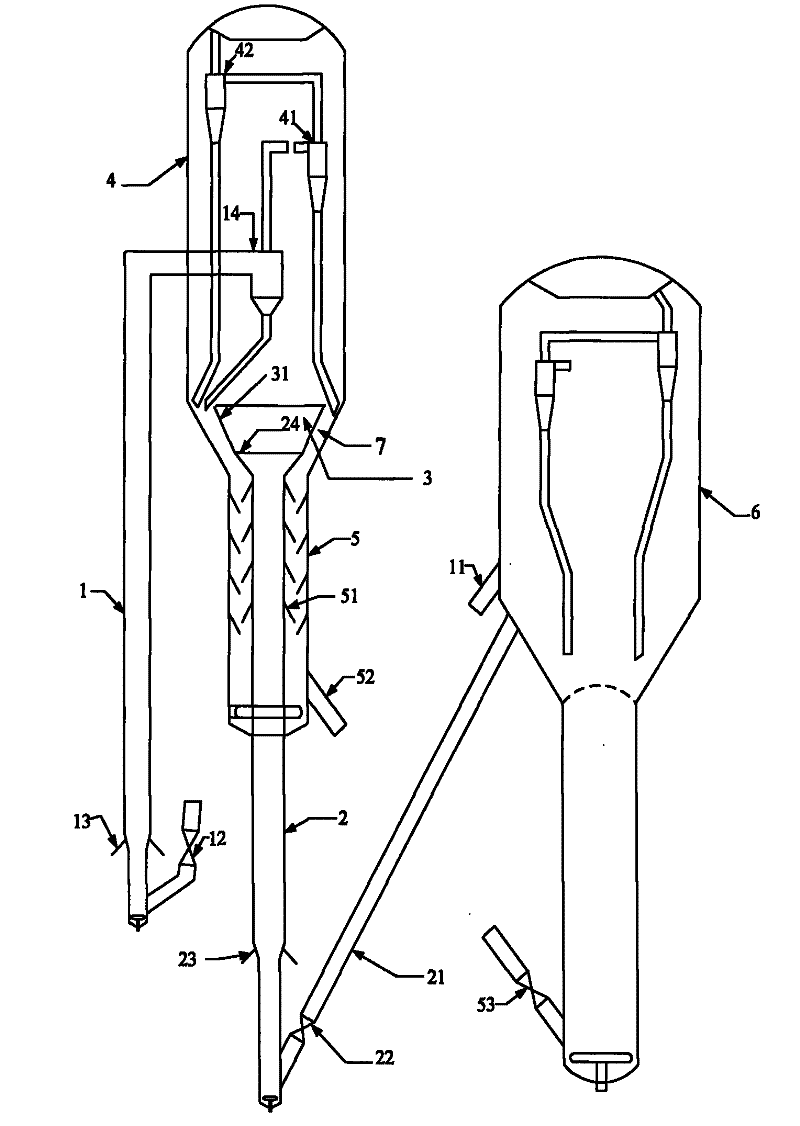

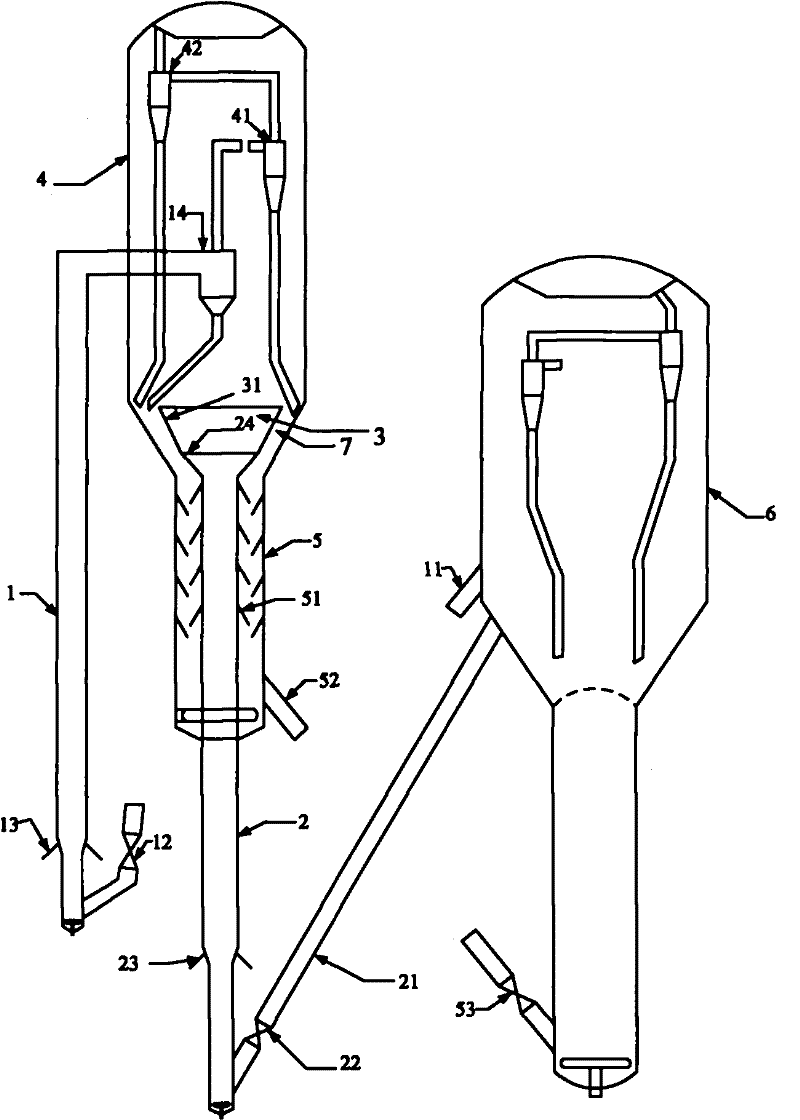

Hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon

ActiveCN104560154AInhibition of hydrogen transfer reactionsFast carbanion cracking reactionTreatment with plural serial stages onlyCarbon depositAromatic hydrocarbon

The invention relates to a hydrocarbon catalytic conversion method of productive low-carbon olefin and light aromatic hydrocarbon. The method comprises steps as follows: a heavy hydrocarbon raw material and a cracking catalyst are contacted in a first reactor and have a catalytic cracking reaction, a first carbon deposit catalyst and a first reaction product are obtained through separation; a light hydrocarbon raw material is injected from the upstream part of a second reactor, a medium hydrocarbon raw material is injected from the middle of the second reactor, and the mixture has a catalytic cracking reaction; a reaction mixture produced in the second reactor is introduced to the third reactor and continuously has a reaction, and a second carbon deposit catalyst and a second reaction product are obtained through separation; the cracking catalyst adopts a cracking catalyst containing modified beta zeolite, and the modified beta zeolite adopts phosphorus and transition metal M modified beta zeolite. With adoption of the method, higher propylene yield and light aromatic hydrocarbon yield can be obtained.

Owner:CHINA PETROLEUM & CHEM CORP +1

Aromatization modifying catalyst for catalytic gasoline and preocess

InactiveCN1488724AHigh yieldReduce carbon depositionRefining to change hydrocarbon structural skeletonLanthanideRare earth

The present invention relates to a technological process for producing low-sulfur low-olefin clean gasoline by using catalytic cracked gasoline and catalyst used by said process. Said invention adopts hydrofinishing and aromatization combined process, in which the aromatization adopts small-grain hydrogen type molecular sieve catalyst including IA group metal, transition metal and lanthanide series rare-earth metal oxide, and the crystal grain size of the molecular sieve is in the range of 20nm-800 nm. Said invented catalyst can reduce cracking reaction and can raise the yield of the gasoline.

Owner:CHINA PETROLEUM & CHEM CORP +1

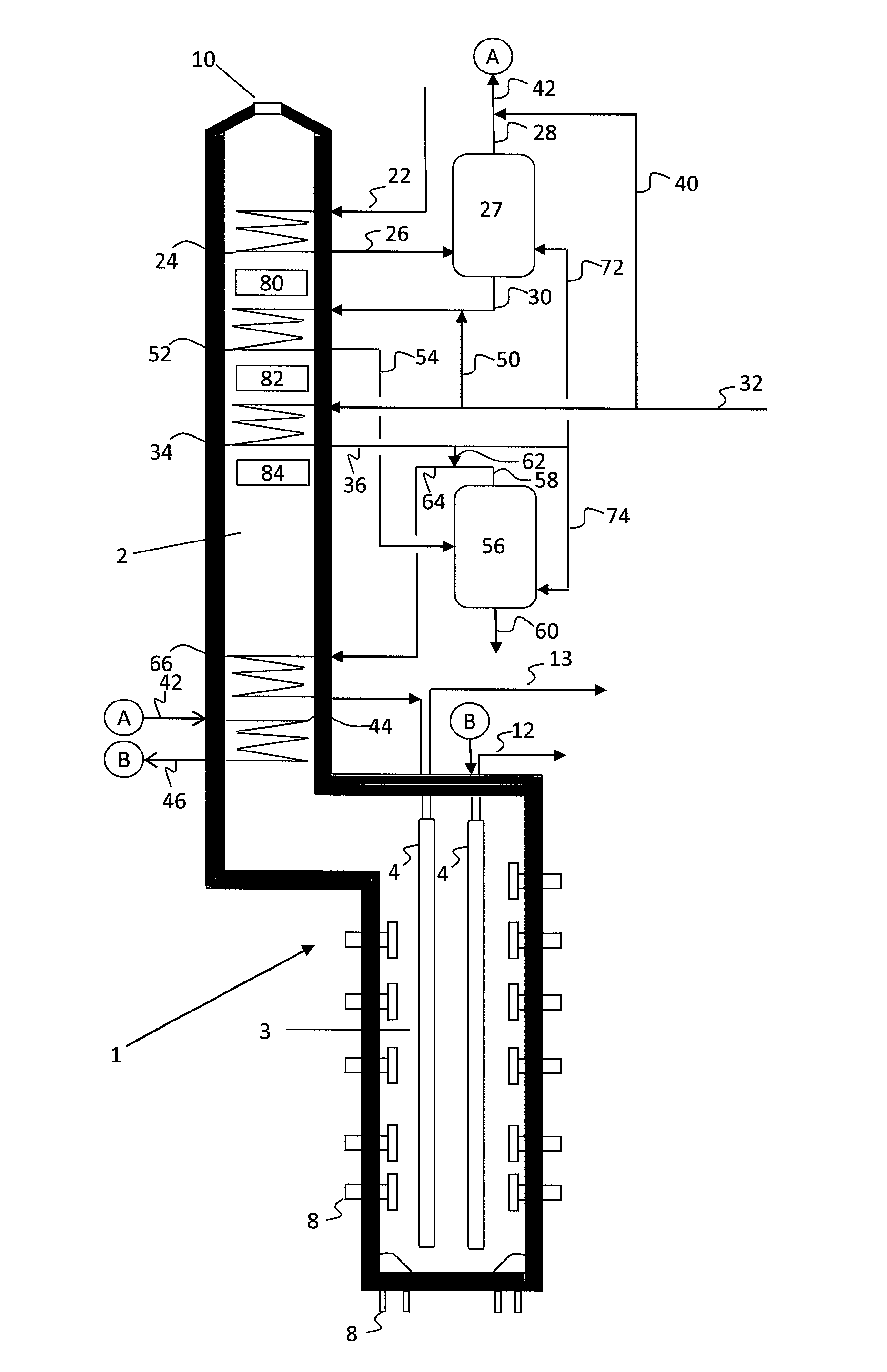

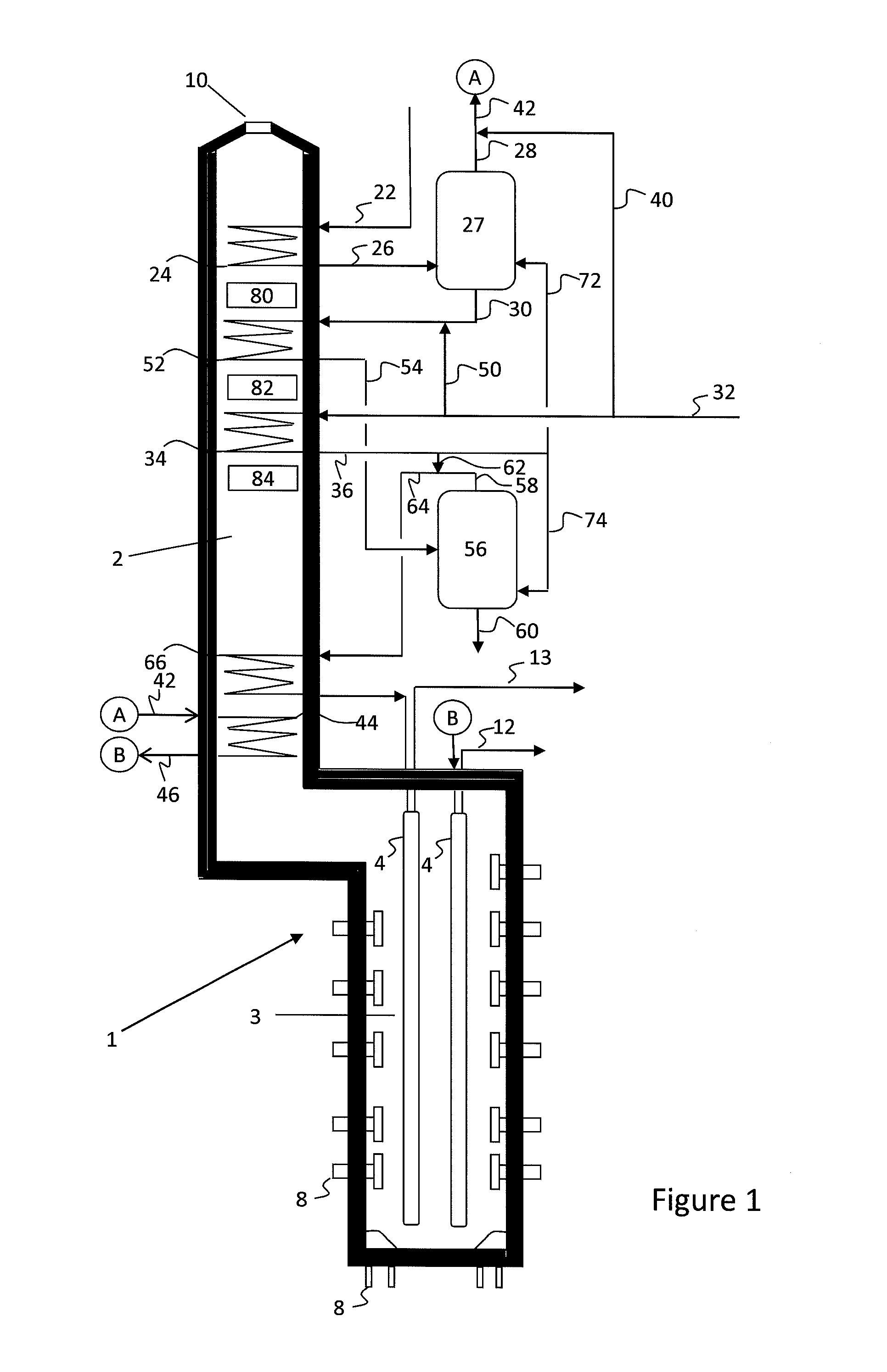

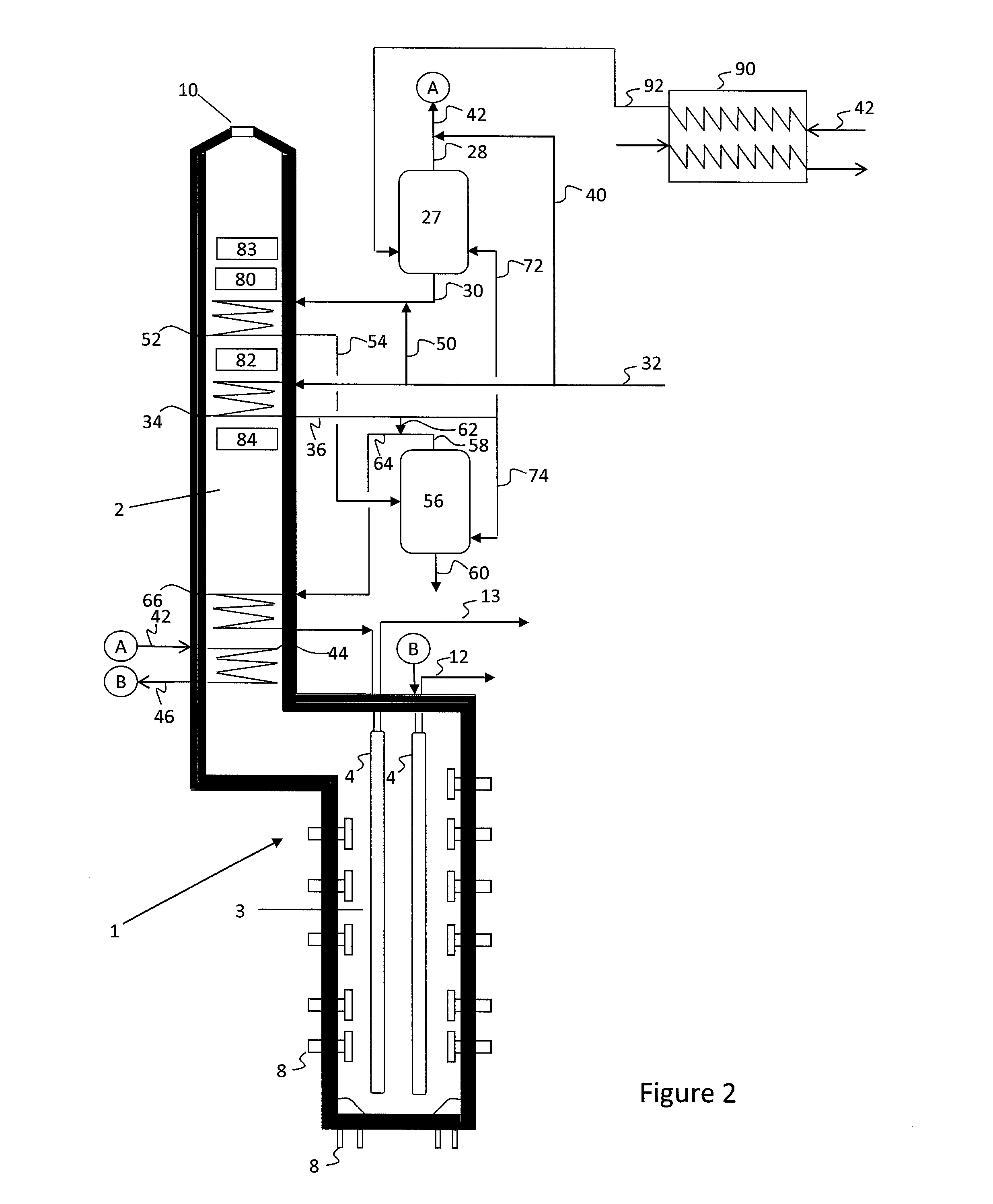

Thermal cracking of crudes and heavy feeds to produce olefins in pyrolysis reactor

ActiveUS20160097002A1Alleviate cokingReduce foulingThermal non-catalytic crackingTreatment with plural serial stages onlyHydrocarbon mixturesReactor system

Systems and processes for efficiently cracking of hydrocarbon mixtures, such as mixtures including compounds having a normal boiling temperature of greater than 450° C., 500° C., or even greater than 550° C., such as whole crudes for example, are disclosed.

Owner:LUMMUS TECH LLC

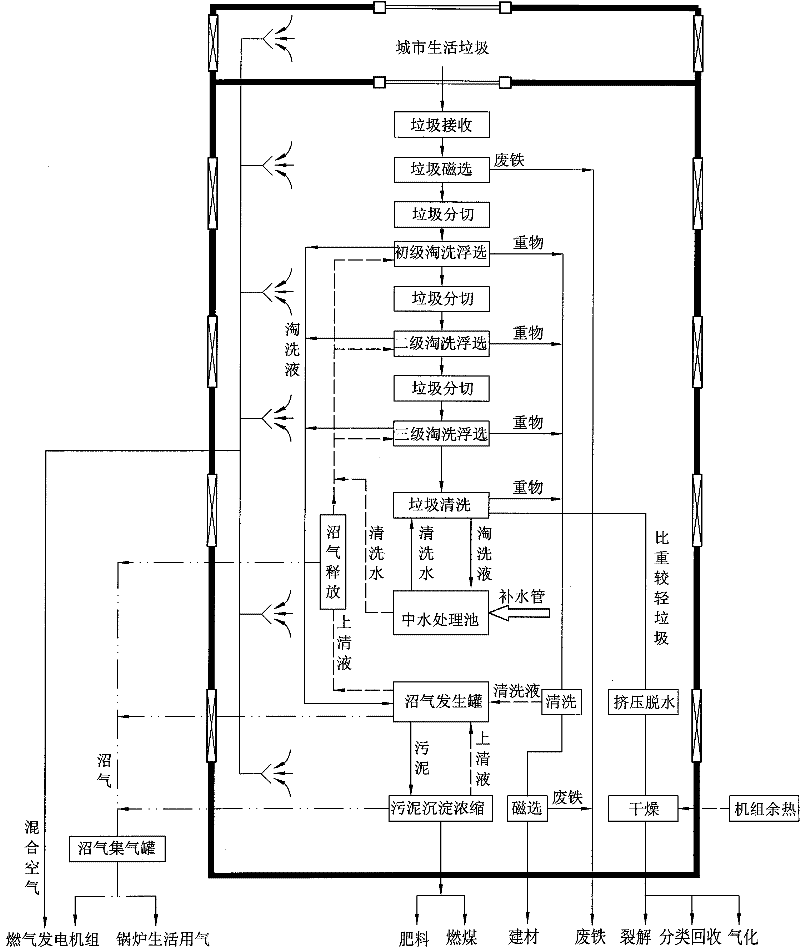

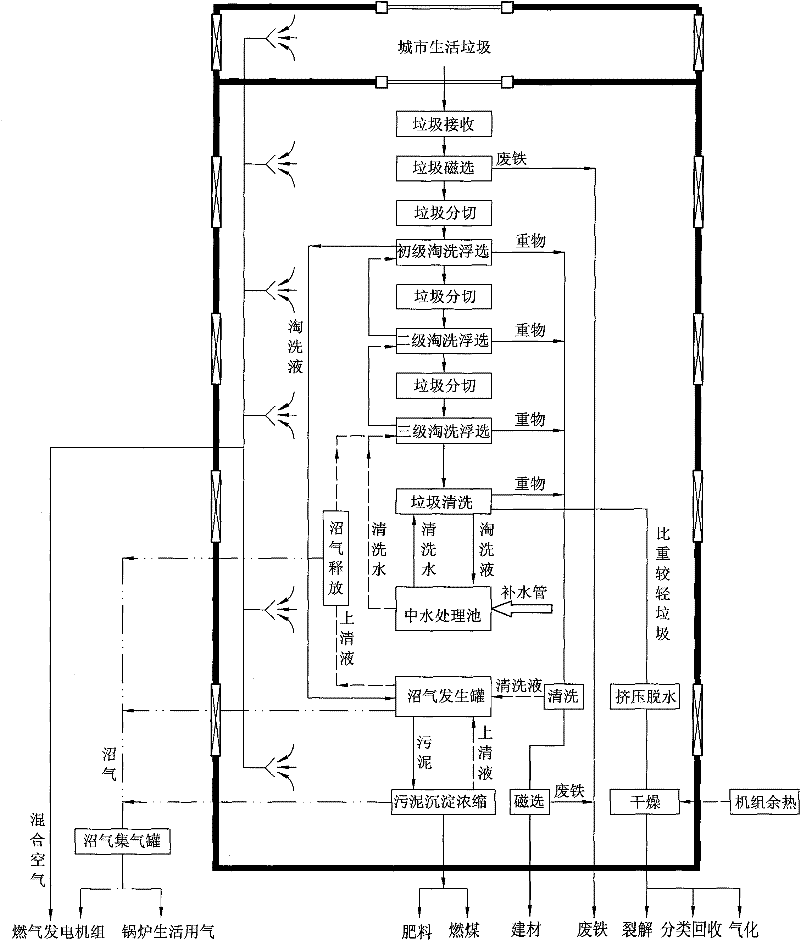

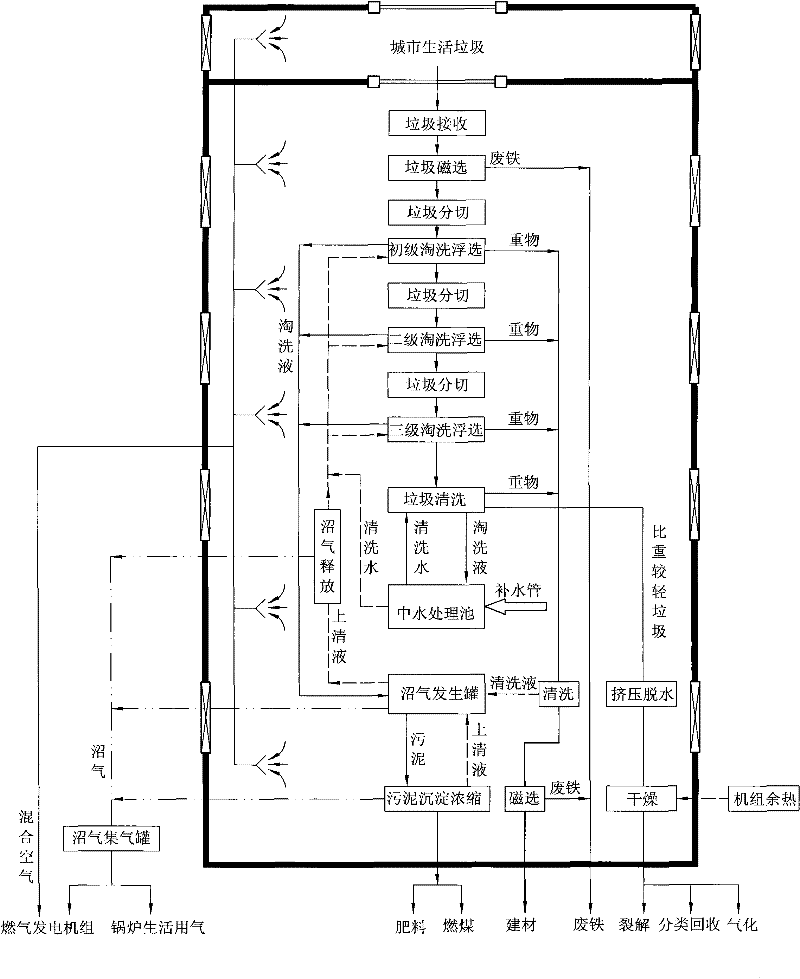

Method for resource recovery and classification utilization of urban domestic waste

ActiveCN102247969AHigh thermal efficiencyEasy to wash and separateSolid waste disposalFurniture waste recoveryEngineeringFuel oil

The invention discloses a method for resource recovery and classification utilization of urban domestic wastes, which at least comprises the following steps of: a magnetic separation step, a waste cutting step, a elutriation flotation step, a waste extrusion dehydration step, an anaerobic treatment step and a sludge deposition concentration step; scrap iron is separated by the magnetic separationstep for the recovery and utilization of the scrap iron; anaerobic organic matter is crushed by the waste cutting step; pasty organic matter and block non-anaerobic wastes are thoroughly separated bythe elutriation flotation step so as to allow the pasty anaerobic organic matter to enter a biogas generation pool or tank for an anaerobic reaction and to allow the clean non-anaerobic wastes to be extruded, dehydrated and dried for individual treatment, and the waste decrement is above 90%; after elutriation, the left 10% non-anaerobic wastes are prepared into fuel oil by a cracking reaction; or are recycled through screening with no screening difficulty being caused by dust and organic matter containing in the wastes; or are delivered into a gasifier for fuel gas production, which preventsthe energy consumption of water-containing organic matter during waste incineration treatment, and greatly increases the thermal efficiency of waste treatment.

Owner:刘振亮

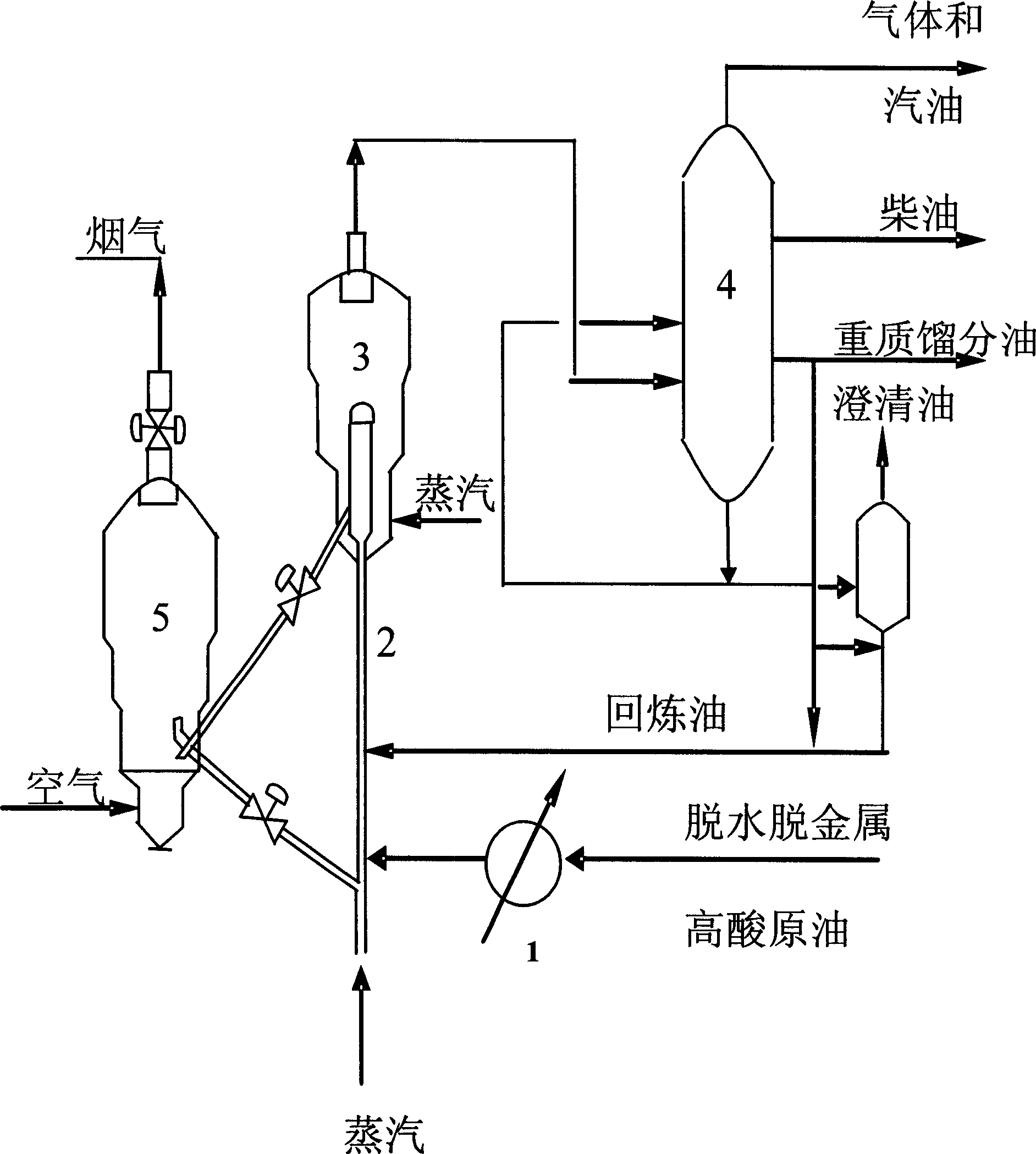

Method for processing crude oil with high acid value

ActiveCN1827744AEvenly distributedInhibition of harmful effectsCatalytic crackingPotassium hydroxideAcid value

A method for producing highly acid value crude oil consists of preheating the crude oil which is total acid number of more than 0.5mg potassium hydroxide per gram after the pretreatment and injecting them into the fluidized catalytic cracker to contact the catalyst, and reacting in catalytically cracked reaction condition, separating the oil gas and the catalyst, in which the oil gas is put into the subsequent separation system, while the catalyst can be circularly used after stripping and regenerating. The method is characterized in that it is of strong industrial practicability, low running cost and fine deacidification effect and so on.

Owner:CHINA PETROLEUM & CHEM CORP +1

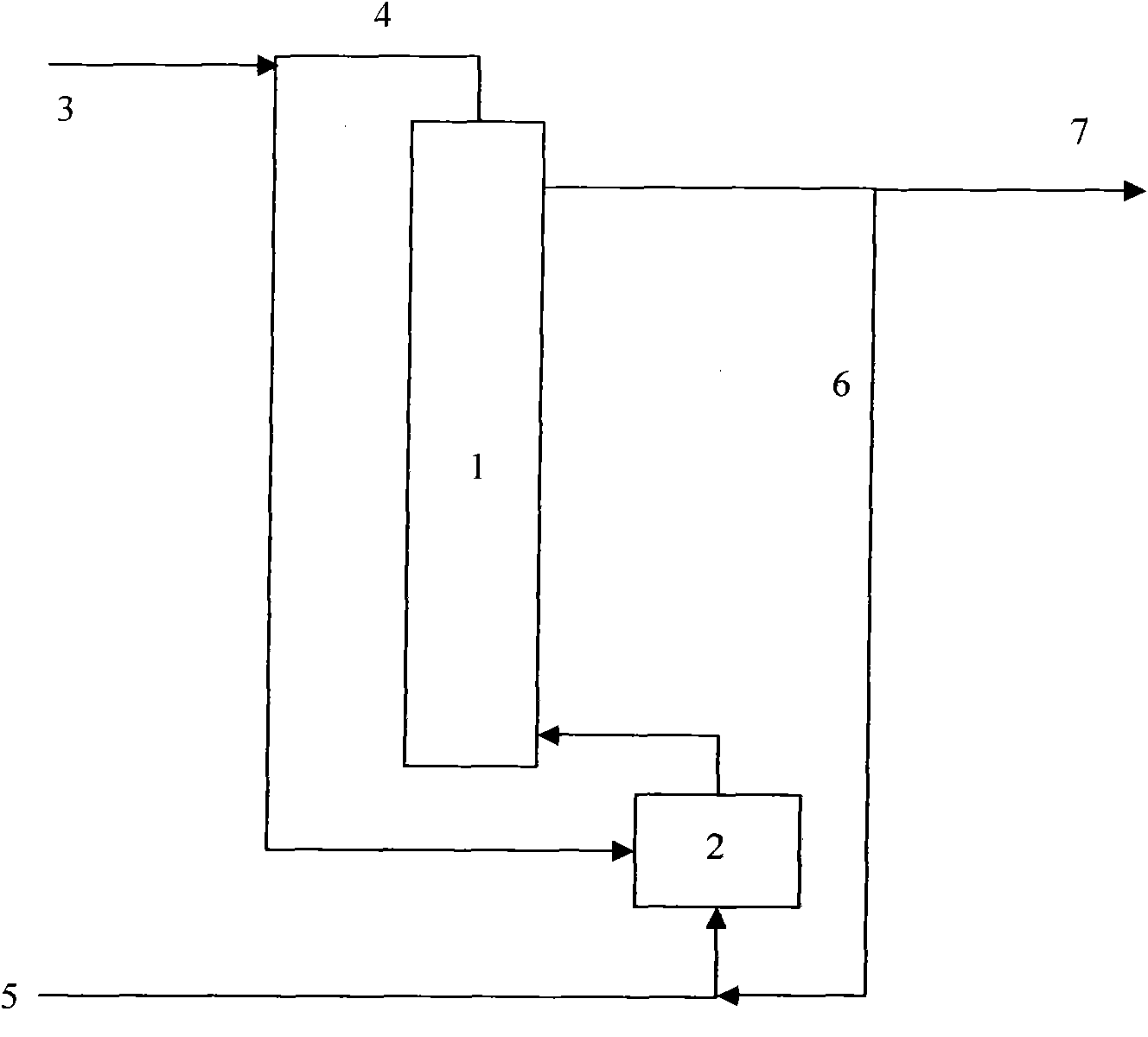

Conversion method for petroleum hydrocarbons

A transformation method for petroleum hydrocarbons includes the following steps: hot regenerated catalyst is returned to the bottom of a reactor after cooling down and is conveyed to the bottom of the first reaction zone of the reactor by pre-lifting gas so as to contact preheated base oil for cracking reaction; the mixture of reaction products, water vapor and catalyst enters into a diameter-expanded second reaction zone for further hydrocarbon transformation reaction with the reaction products, water vapor and spent catalyst undergoing gal-solid separation; gas phase products are separated to obtain various products; in addition, the spent catalyst is conveyed to a regenerator after steam stripping for recycling use after singeing regeneration or part of the spent catalyst directly enters into the mixer arranged at the bottom of the reactor. The method which adopts a reactor riser with two reaction zones improves the contact state of base oil and catalyst through lowering oil contact temperature so as to increase the yield and the selectivity of object reactant and to improve the properties of object product.

Owner:CHINA PETROLEUM & CHEM CORP +1

Hydrocarbon catalytic conversion method for producing propylene and light aromatic hydrocarbon

ActiveCN102206509AImprove utilization efficiencyImprove conversion rateTreatment with plural parallel stages onlyLiquid hydrocarbon mixture productionCatalytic transformationPtru catalyst

A method for producing propylene and light aromatic hydrocarbon comprises the steps of contacting heavy hydrocarbons and / or grease with a cracking catalyst containing modified beta zeolite in a first reactor for catalytic cracking reaction, contacting C4 hydrocarbon fraction and / or light gasoline fraction with the cracking catalyst containing modified beta zeolite in a second reactor for catalytic cracking reaction, and then leading the reaction products into a third reactor for reaction. The hydrocarbon-gasoline conversion method provided by the invention has the advantages of higher propylene yield and light aromatic hydrocarbon yield.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for enhancing gas-liquid mass transfer of ebullated bed hydrogenation reactor

ActiveCN102049220AIncreased contact surface areaImprove mass transfer efficiencyChemical/physical processesMicrobubblesHydrogenation reaction

The invention discloses a method for enhancing the gas-liquid mass transfer of an ebullated bed hydrogenation reactor, which comprises the following processes of: introducing fresh raw oil, circulating oil and hydrogen into a microbubble generator arranged in front of the reactor, fully mixing to make the hydrogen dispersed in a liquid-phase material in the form of microbubbles, and performing hydrogenation and cracking reaction in the ebullated bed reactor. The method can improve the utilization rate of the hydrogen, reduce the volume ratio of the hydrogen to the oil, save operating cost andpromote the depth of the hydrogenation and cracking reaction.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method of extracting essential oil from biomass wastes and a device thereof

InactiveUS20110034712A1Reduce processing timeQuality improvementRetortsLiquid hydrocarbon mixture productionEngineeringOxygen

A method of extracting essential oil from biomass wastes puts biomass wastes, such as wood residuals, wood chips or other plants, in an air-tight oxygen-free reaction vessel to be heated up indirectly, for conducting a thermal pyrolysis cracking reaction (i.e. dry distillation); and guides volatile gas which is distilled when the processed wastes disintegrate, into a condenser to be condensed as liquid which is then separated into water and oil through an oil-water separation tank. Whereas, non-liquefied gas is discharged outside after deodorizing, and residuals in the reaction vessel are processed with high-temperature dry distillation once to become activated carbons. In processing, temperature and pressure in the reaction vessel are controlled in multiple phases, along with using a suction pump of a changeable speed and a changeable flow rate to suck out air in high speed in phases, to keep internal pressure of the reaction vessel at a low pressure condition, thereby shortening a processing time and acquiring high quality essential oil and activated carbons as by-products.The present invention also includes a system device to implement this method. In the oil-water separation tank of this device, an ultrasonic generator is provided to re-disintegrate tars, which improves quality of the oil products.

Owner:LIN WEI CHIH

Catalytic thermal cracking method for lignin

InactiveCN101824330AAchieve reuseImprove catalytic performanceBiofuelsLiquid hydrocarbon mixture productionLiquid productMolecular sieve

The invention discloses a catalytic thermal cracking method for lignin. The method comprises the following steps: preheating a molecular sieve catalyst to 200-300 DEG C, gradually adding lignin into the molecular sieve catalyst to carry out catalytic cracking reaction under the temperature of 500-800 DEG C and in the protective atmosphere of inert gas, separating the catalytic thermal cracking product of lignin after the reaction to obtain liquid, gas and solid products. By GC / MS analysis, the main components of the liquid product comprise benzene, toluene, ethylbenzene, naphthalene and other aromatic compounds, which account for 70%-80% of the total mass of the liquid products. The gas product is measured by GC, in which the volume of methane and carbon monoxide accounts for over 90% of that of the total gas. The main component of the solid product is carbon the mass fraction of which is between 75% and 85%. The products can be used for preparing fuel or aromatic chemicals.

Owner:UNIV OF SCI & TECH OF CHINA

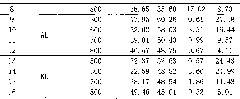

Preparation method for nano-Y-shaped molecular sieve/amorphous silicon-aluminum composite material

ActiveCN102451740AHigh yieldEasy to operateMolecular sieve catalystsFaujasite aluminosilicate zeoliteMolecular sieveAmorphous silicon

The invention relates to a preparation method for a nano-Y-shaped molecular sieve / amorphous silicon-aluminum composite material. According to the method, a guiding agent is synthesized, and a surfactant is added during the guiding agent synthesizing process; a surfactant is added during a preparation and synthesis process of gel of the Y-shaped molecular sieve, and a hydrothermal crystallization method is adopted to synthesize the nano-Y-shaped molecular sieve; an aqueous solution of a mixture is added to the slurry containing the nano-Y-shaped molecular sieve, wherein the mixture comprises water glass and an aluminum source; an acid is added to adjust the pH value to 7-9.5 to form the gel; the gel is washed, dried and baked to obtain the composite material. According to the present invention, the grain of the Y-shaped molecular sieve in the composite material prepared by the method of the present invention is maintained to less than 100 nm, and the composite material of the present invention is suitable for catalytic cracking reactions and hydrocracking reactions of heavy oil macromolecules.

Owner:PETROCHINA CO LTD +1

Process of catalytically cracking C4 and above olefin to produce propylene

The present invention relates to the process of catalytically cracking C4 and above olefin to produce propylene, and aims at raising product propylene selectivity and yield. The present invention adopts ZSM type molecular sieve catalyst carrying alkali earth metal, and the reaction material C4 and above olefin produces cracking reaction to produce propylene under the conditions of 400-600 deg.c temperature, 0-0.15 MPa reaction pressure and 10-50 / hr liquid phase space velocity. The present invention may be used in the industrial production of catalytically cracking C4 and above olefin to produce propylene.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method and device for preparing low carbon olefine and arene

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com