Preparation method of skeleton silicon-rich Y-shaped molecular sieve

A molecular sieve and framework technology, applied in the field of molecular sieves, to achieve the effects of high B acid content, increased secondary pore content, and high activity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

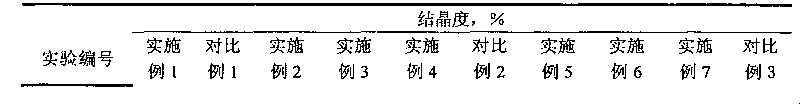

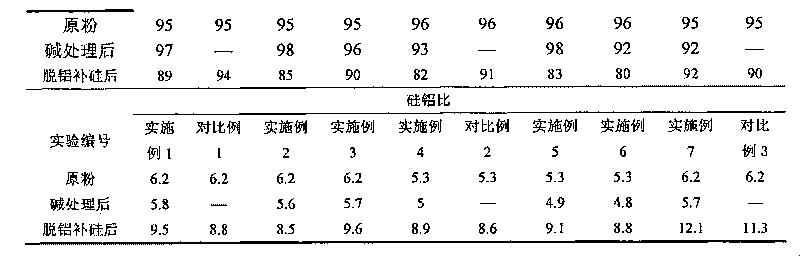

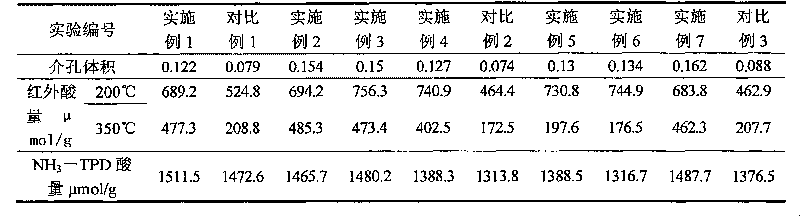

Examples

Embodiment 1

[0028] Put 5 g of solid sodium hydroxide into 495 g of distilled water and stir to dissolve, then raise the temperature of the alkali solution to 65°C. Weigh 100g NaY molecular sieve (mass on dry basis, crystallinity 95%, silicon-aluminum ratio 6.2) into the above alkali solution, keep stirring and alkali treatment at 65°C for 2h. After the alkali treatment is completed, the slurry is filtered, and the obtained molecular sieve filter cake is washed until the pH of the filtrate=9.

[0029] The alkali-treated NaY molecular sieve filter cake (dry basis) was mixed with ammonium chloride and distilled water in a mass ratio of 1:1:10 for beating evenly, and after ammonium exchange was stirred at 90°C for 1 hour, filtered and the above ammonium exchange process was repeated Twice, NH 4 NaY molecular sieve.

[0030] Weigh 9.12 g of ammonium fluorosilicate solid and dissolve it in 250 g of distilled water to prepare an ammonium fluorosilicate solution with a concentration of about 0....

Embodiment 2

[0035] Put 10 g of solid sodium hydroxide into 490 g of distilled water and stir to dissolve, then raise the temperature of the alkali solution to 65°C. Weigh 100g NaY molecular sieve (mass on dry basis, crystallinity 95%, silicon-aluminum ratio 6.2) into the above alkali solution, stir evenly and maintain the reaction at 65°C for 3h to implement alkali treatment. After the alkali treatment is completed, the slurry is filtered, and the obtained molecular sieve filter cake is washed until the pH of the filtrate=9.

[0036] Mix the alkali-treated NaY molecular sieve filter cake (dry basis) with ammonium nitrate and distilled water at a ratio of 1:1:10 and beat evenly. After stirring for ammonium exchange at 90°C for 1 hour, filter and repeat the above exchange process twice to prepare Get NH 4 NaY molecular sieve.

[0037] Weigh 9.12 g of ammonium fluorosilicate solid and dissolve it in 250 g of distilled water to prepare an ammonium fluorosilicate solution with a concentratio...

Embodiment 3

[0039] Put 10 g of potassium hydroxide solid into 490 g of distilled water and stir to dissolve, then raise the temperature of the alkali solution to 45°C. Weigh 100g NaY molecular sieve (mass on dry basis, crystallinity 95%, silicon-aluminum ratio 6.2) into the above alkaline solution, stir evenly and maintain 45°C for reaction (alkali treatment) for 2h. After the alkali treatment is completed, the slurry is filtered, and the obtained molecular sieve filter cake is washed until the pH of the filtrate=9.

[0040] Mix the alkali-treated NaY molecular sieve filter cake (dry basis) with ammonium chloride and distilled water in a ratio of 1:1:10 and beat evenly. After stirring for ammonium exchange at 90°C for 1 hour, filter and repeat the above exchange process twice. Produce NH 4 KNaY molecular sieve.

[0041] Weigh 9.12 g of ammonium fluorosilicate solid and dissolve it in 250 g of distilled water to prepare an ammonium fluorosilicate solution with a concentration of about 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com