Patents

Literature

33results about How to "Improve ion exchange efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Molecular sieve ion exchange method

ActiveCN103771434ASolve the problem of increased power consumptionLow exchangeable group contentCrystalline aluminosilicate zeolitesMolecular sieveIon exchange

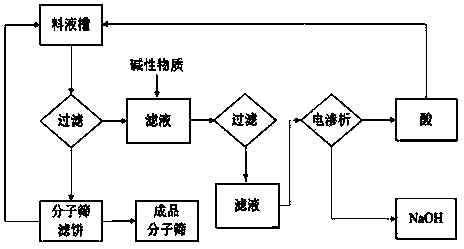

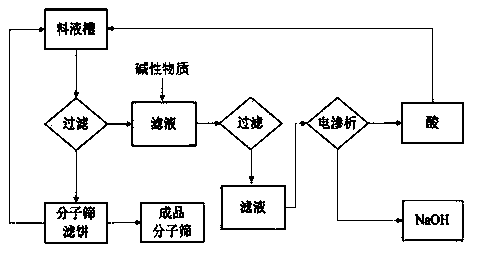

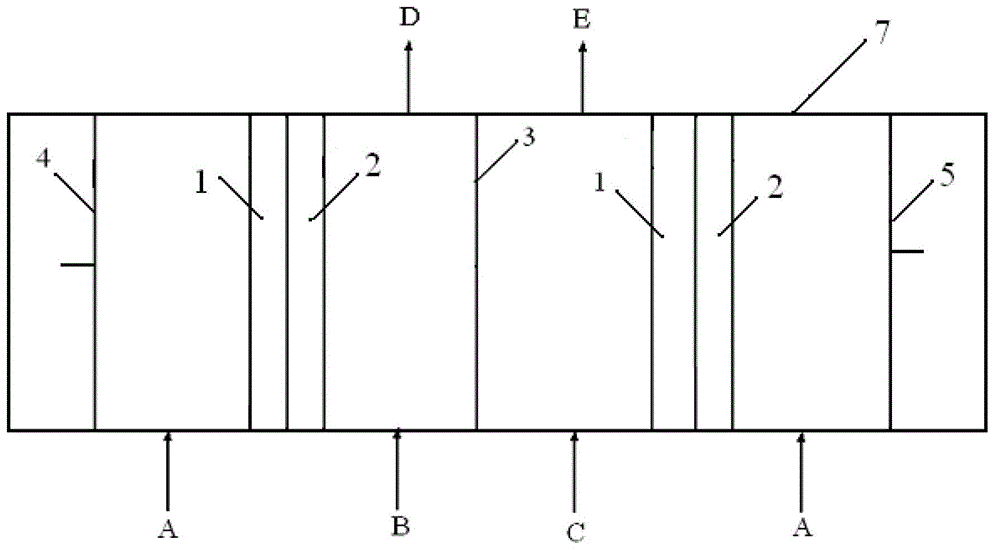

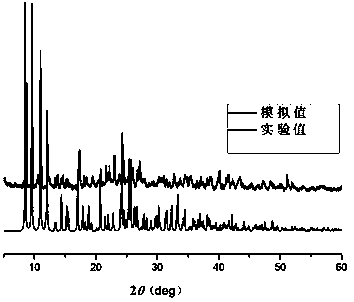

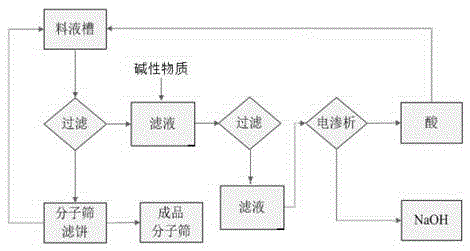

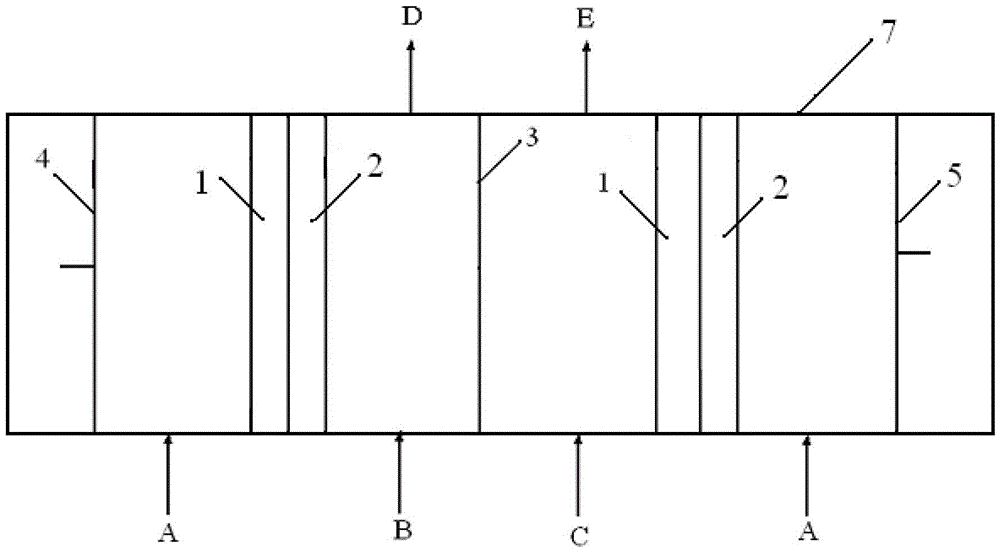

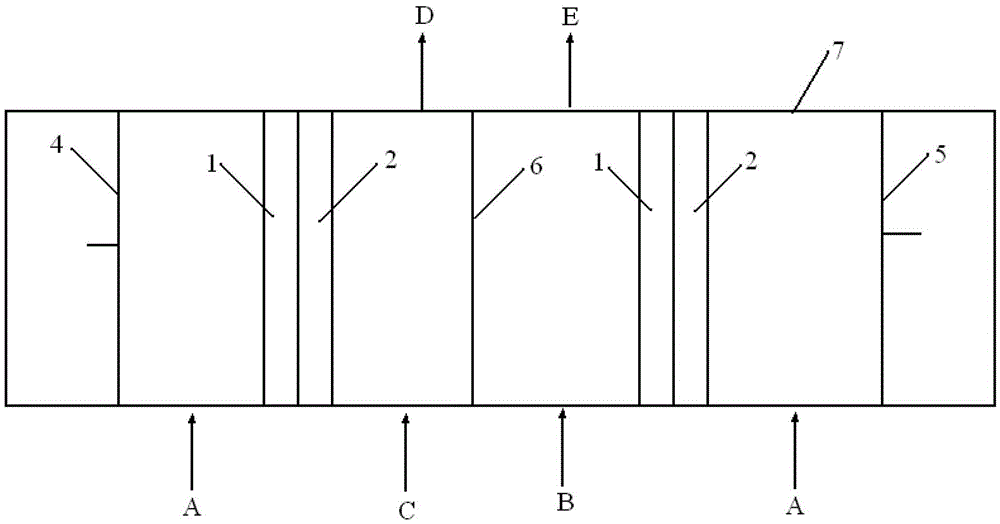

The invention provides a molecular sieve ion exchange method. The method comprises the following steps: a bipolar membrane electrodialysis step comprising conducting bipolar membrane electrodialysis on an aqueous solution containing ions to obtain an acid liquid; an ion exchange step comprising enabling a molecular sieve and the acid liquid to be in contact with each other to implement ion exchange so as to obtain a molecular sieve slurry subjected to the iron exchange; a solid liquid separation step comprising conducting the solid liquid separation on the molecular sieve slurry subjected to the iron exchange to obtain a liquid phase and a solid phase, and conducting solid liquid separation after the pH of the liquid phase is regulated to be more than 8 to obtain a processing liquid; a step of circulating the processing liquid to the bipolar membrane electrodialysis step to replace at least part of the aqueous solution containing ions, and then conducting bipolar membrane electrodialysis to obtain an alkaline liquid and an acid liquid. In the method provided by the invention, the power consumption of the bipolar membrane electrodialysis step is low. In addition, the method can acquire higher ion exchange efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

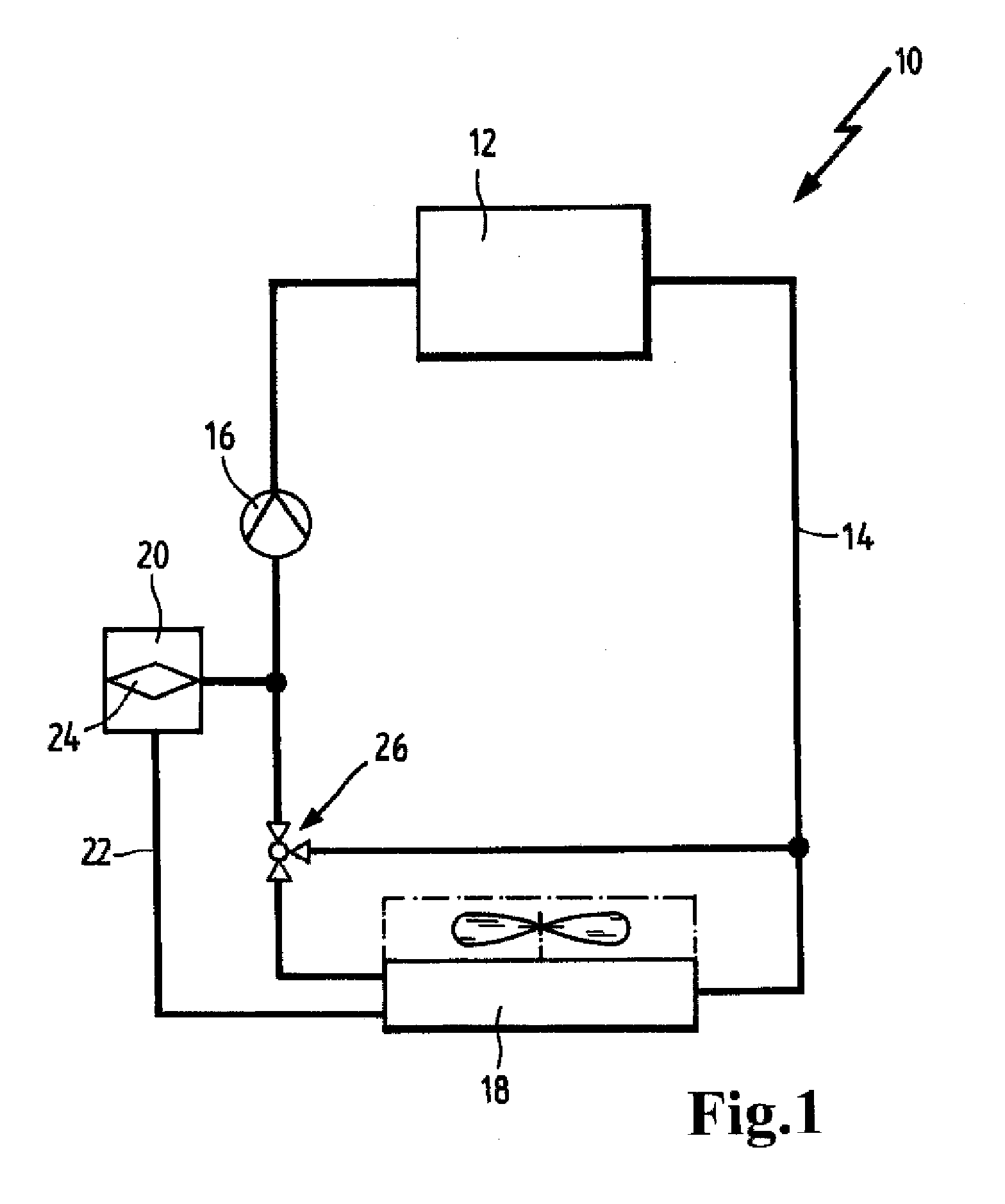

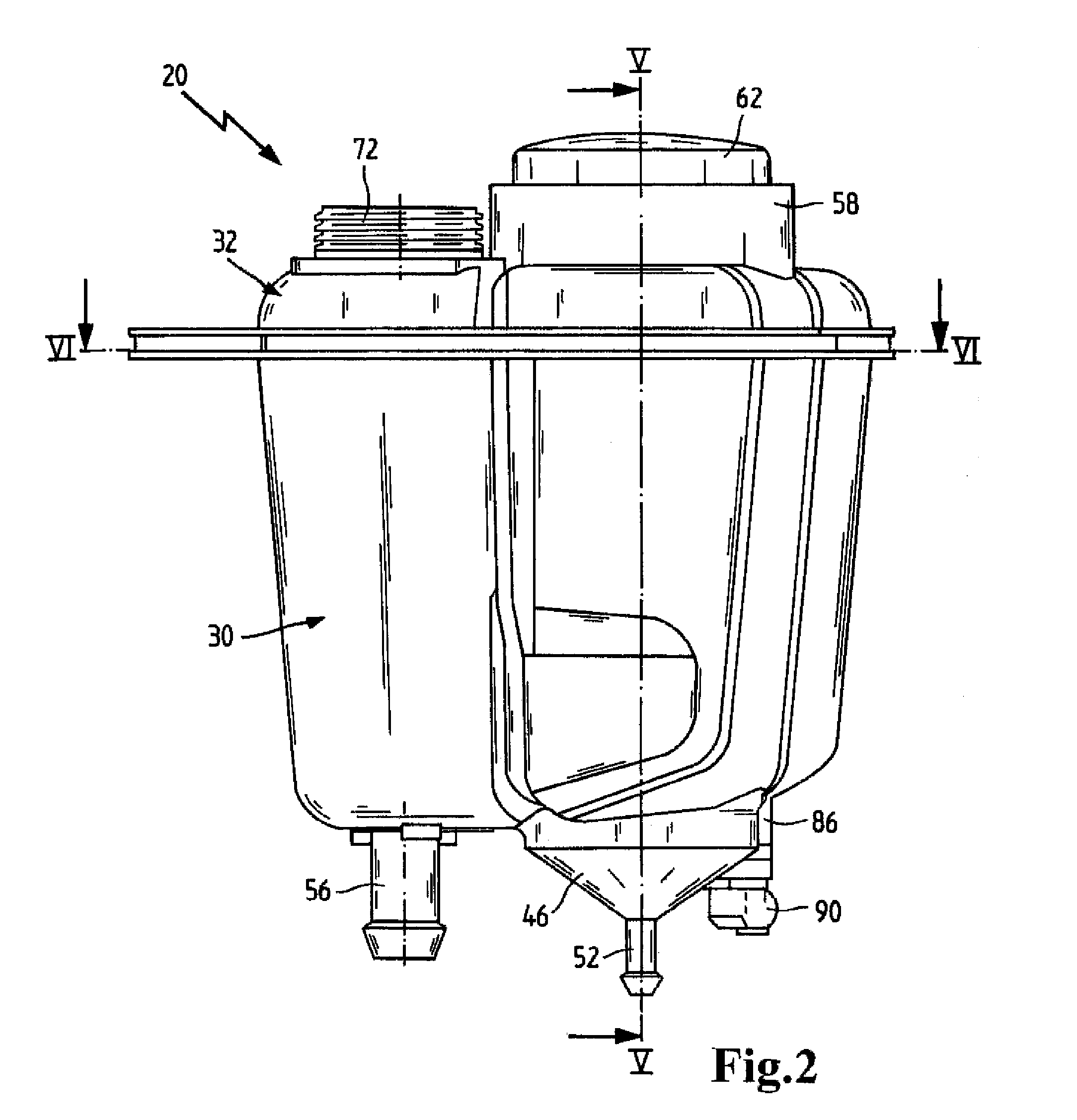

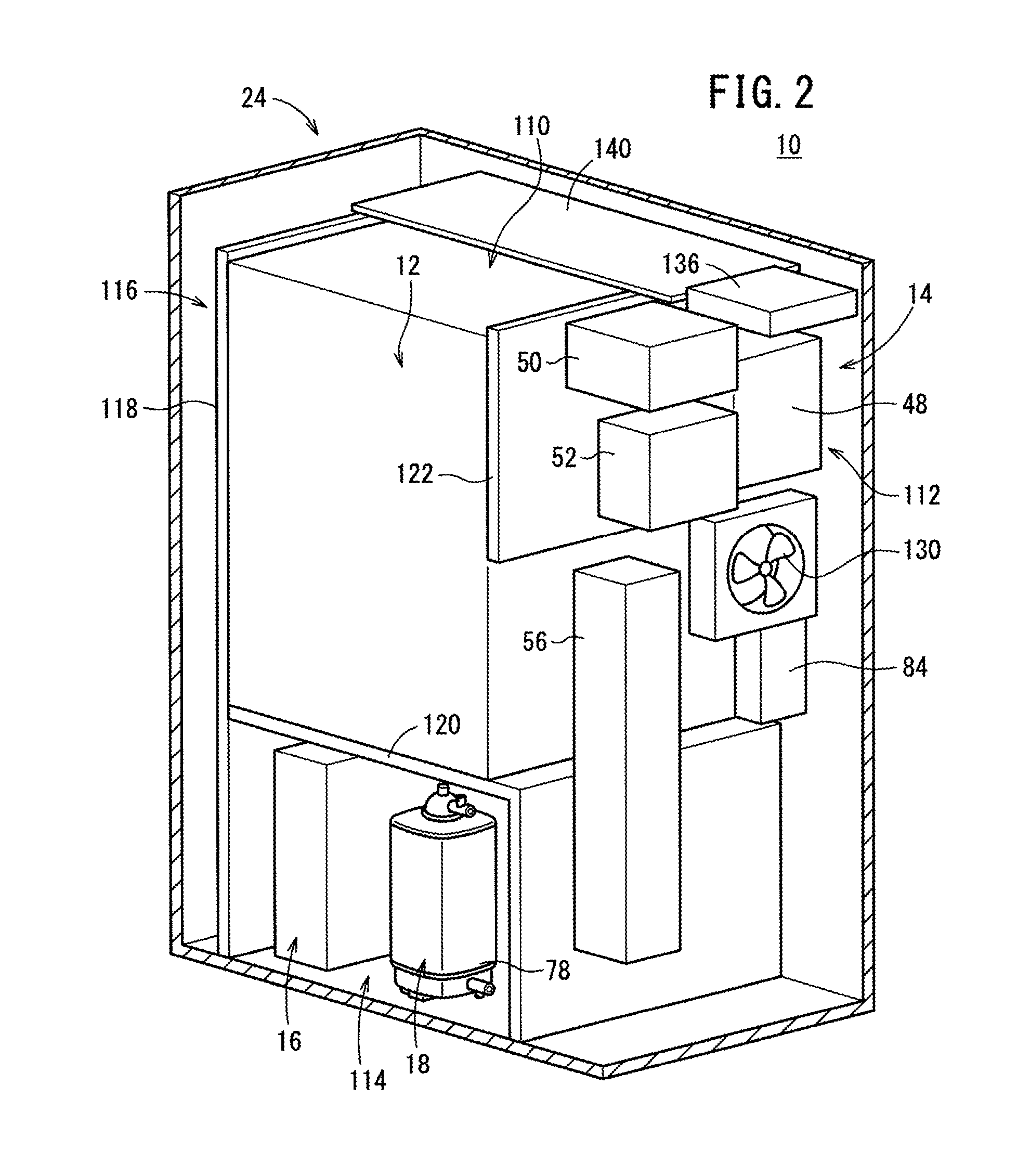

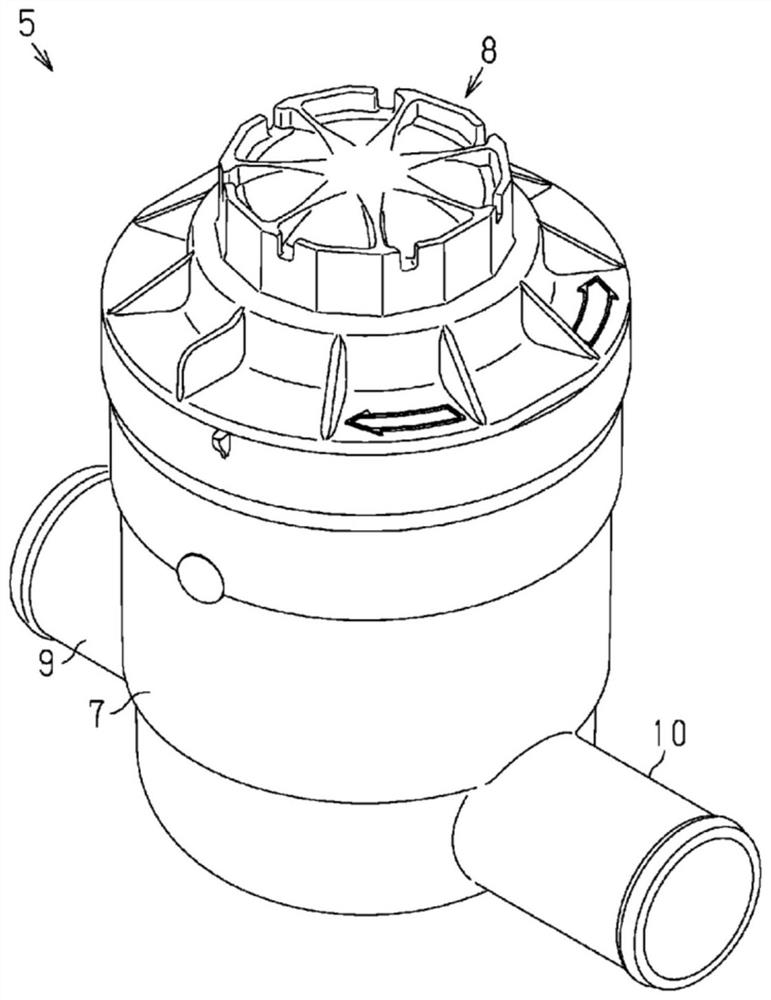

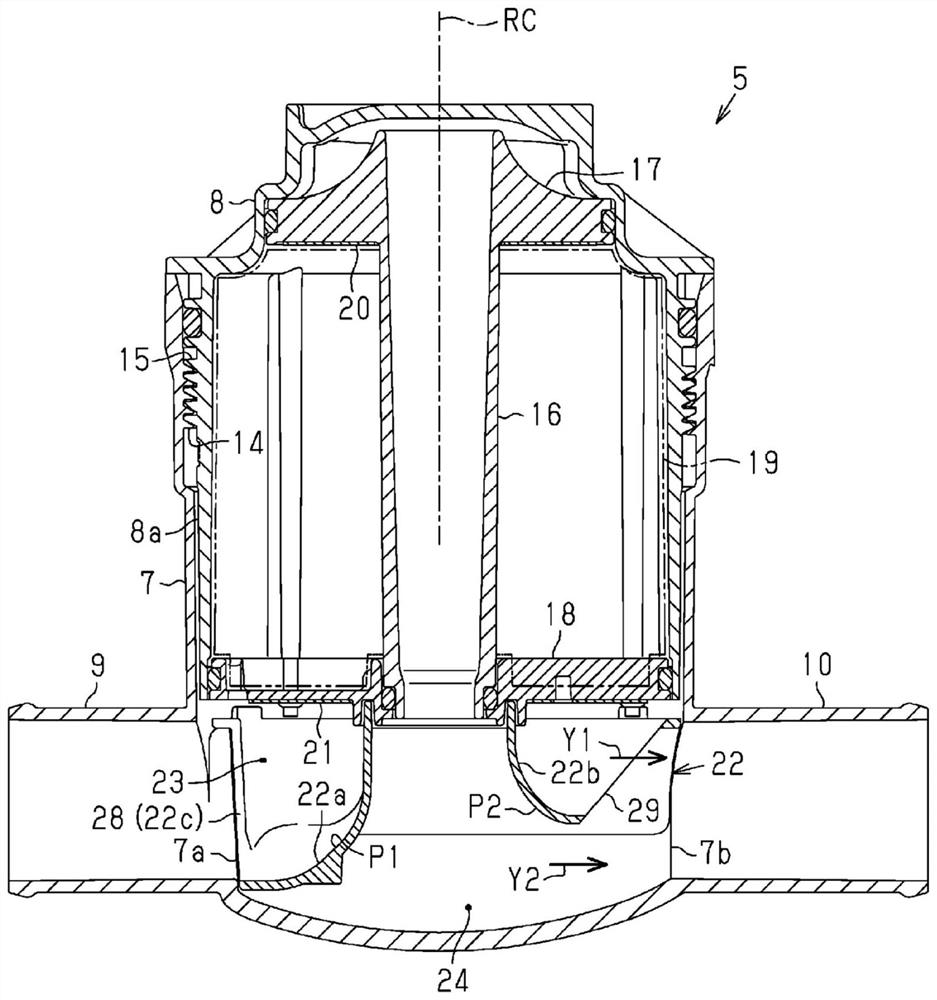

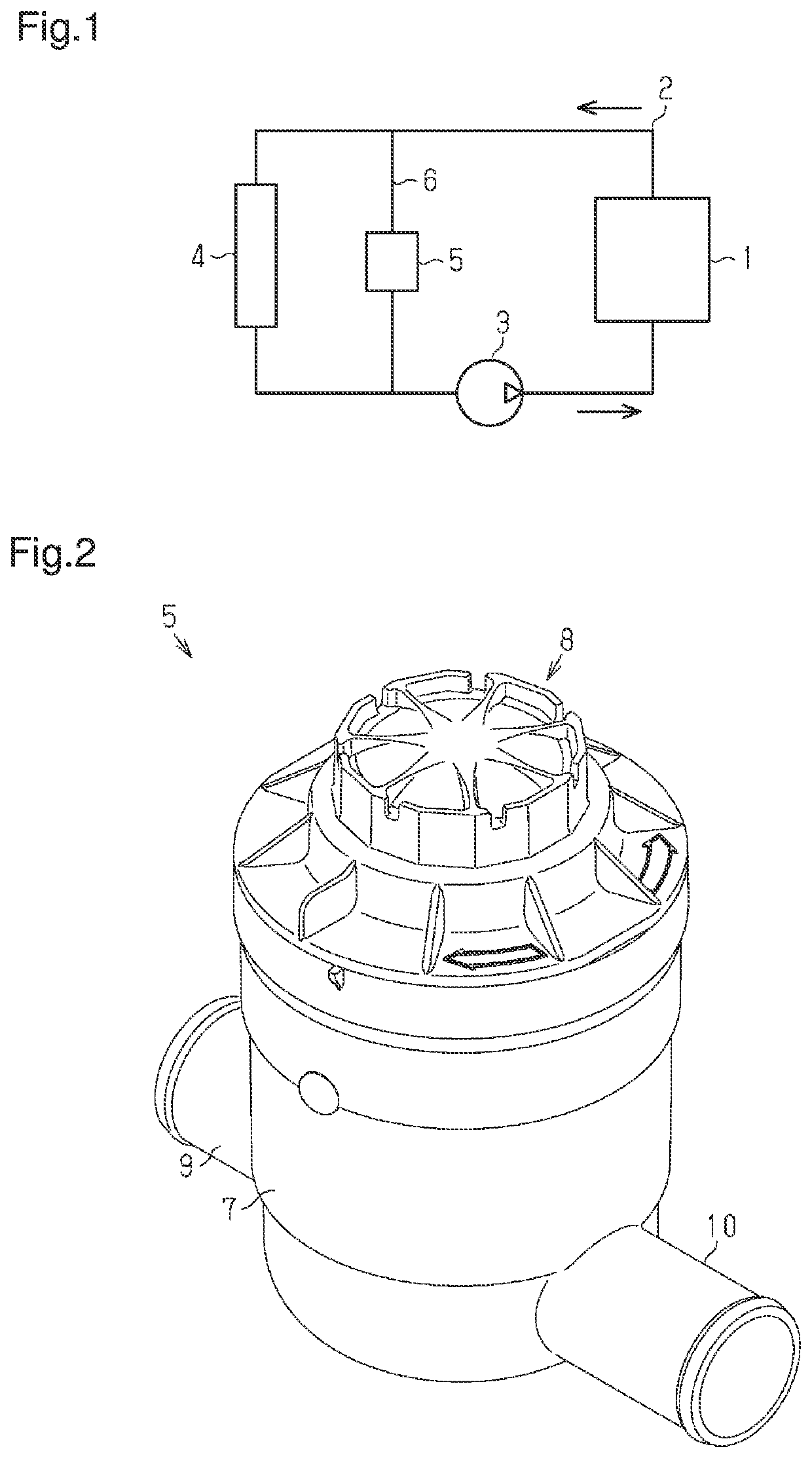

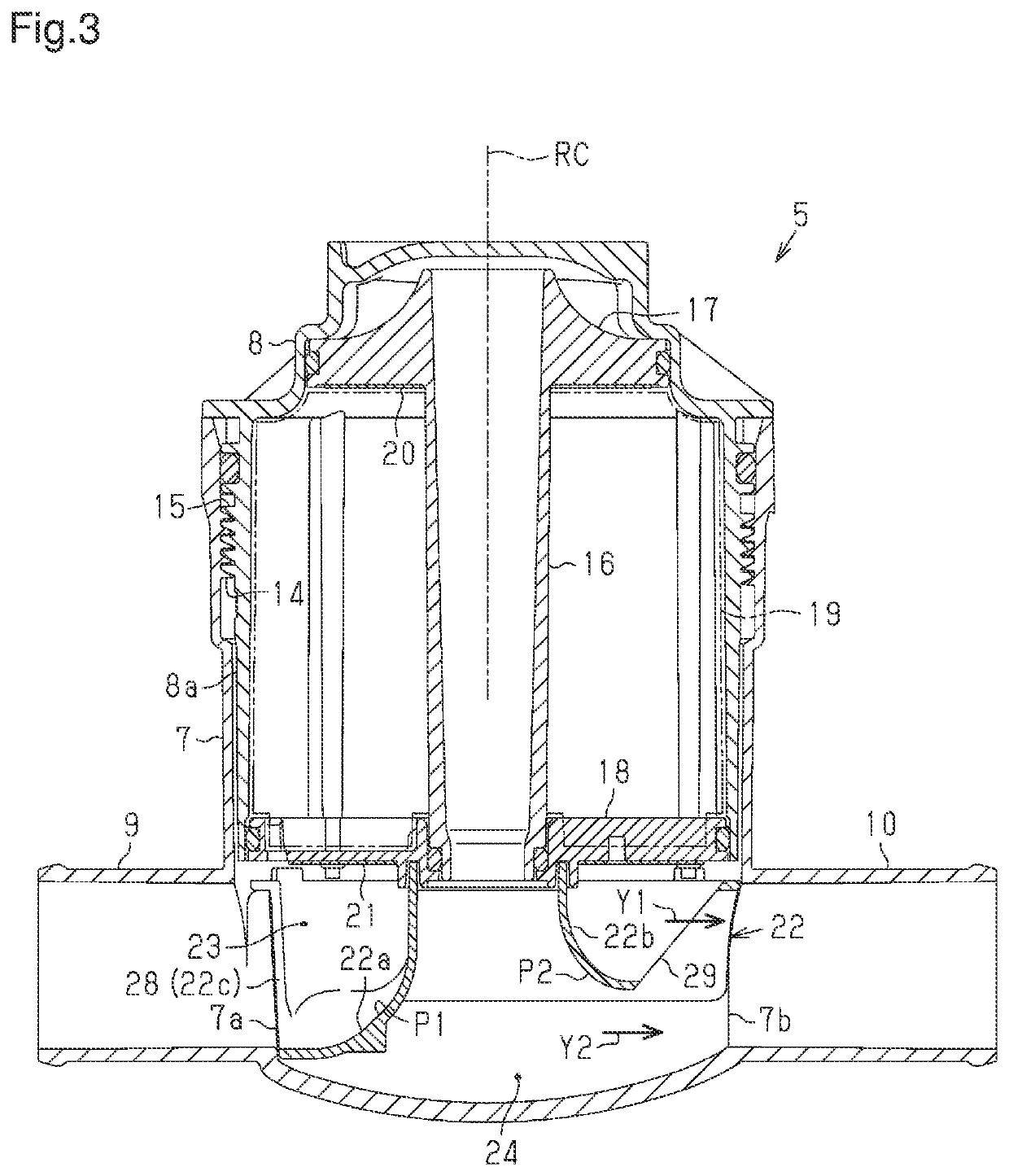

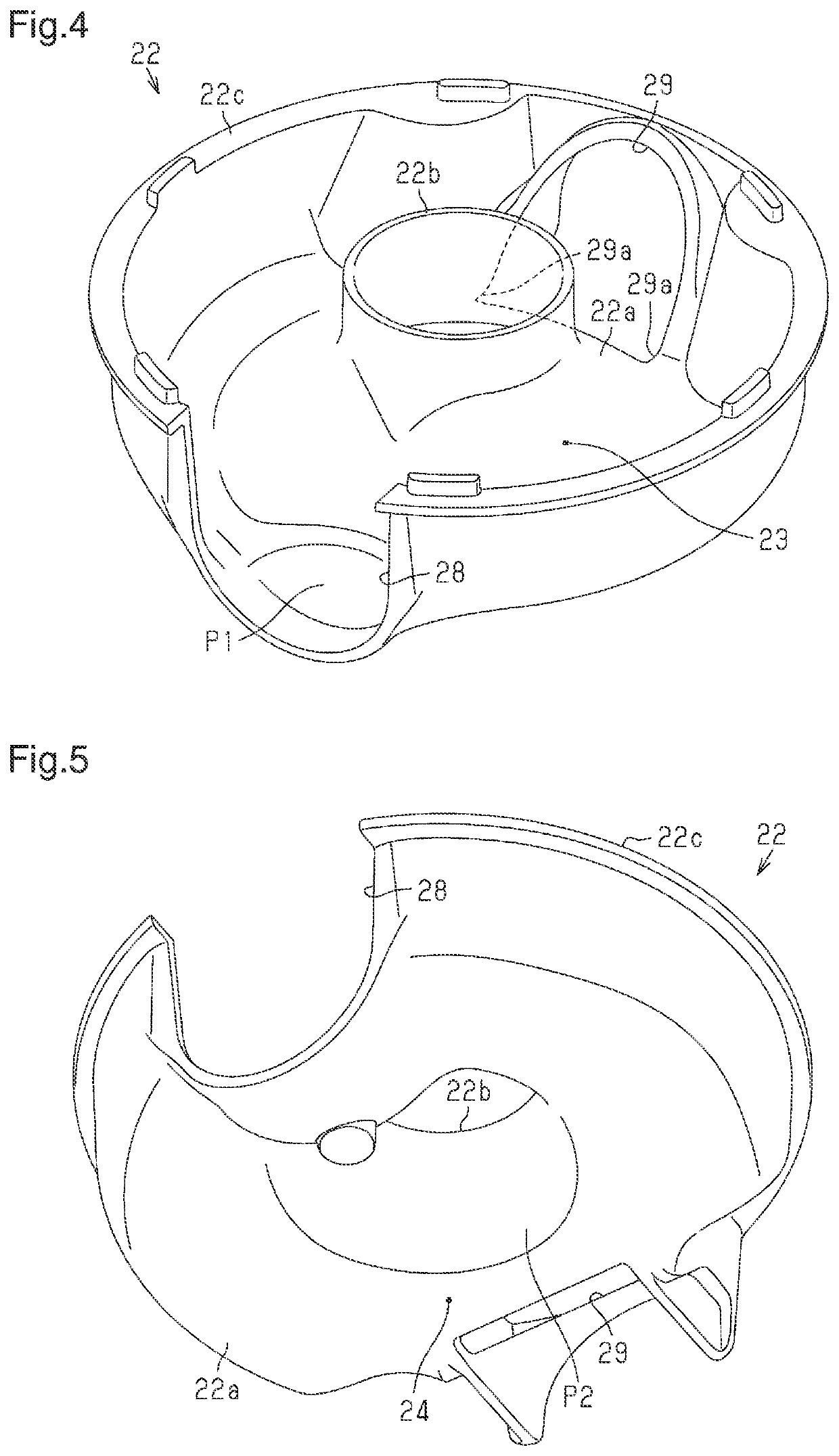

Cooling Device for a Functional System

InactiveUS20120148930A1Improve ion exchange efficiencyExtended service lifeIon-exchange process apparatusFuel cell auxillariesFuel cellsEngineering

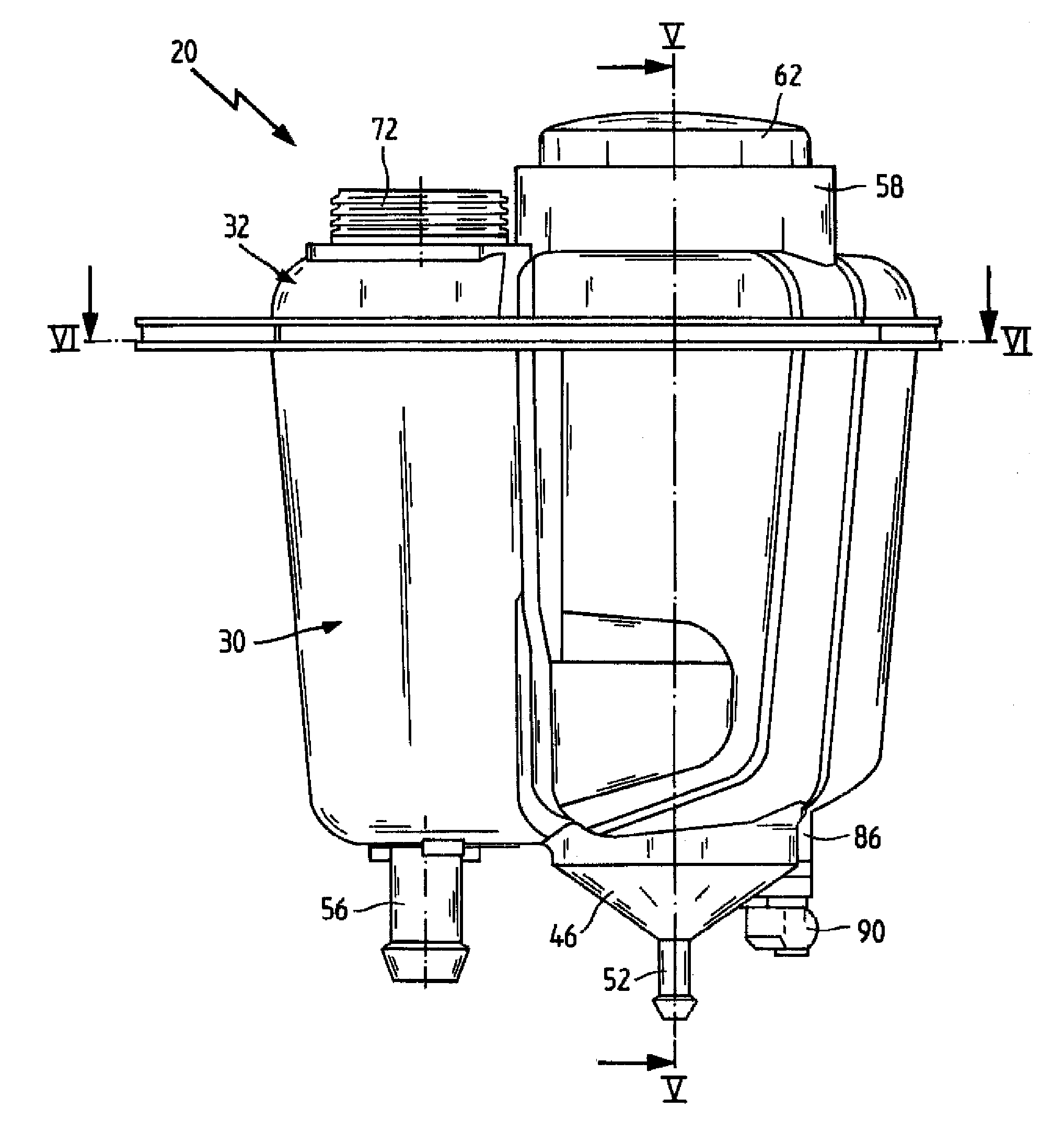

A cooling device (10) for a functional system, in particular a fuel cell system (12) for a motor vehicle is disclosed. The cooling device (10) includes a conduit system (14, 22) for a cooling fluid flow connected to the functional system (12) for cooling. A container (20) of the cooling device (10) for the cooling fluid is fluidically connected to the conduit system (14, 22). A treatment unit, in particular an ion exchanger (24), for treating the cooling fluid is fluidically connected to the conduit system (14, 22). The container (20) includes a receptacle chamber to receive the treatment unit (24) and / or an ion exchanger (24) disposed so as to stand upright in the container (20).

Owner:MANN HUMMEL GMBH +1

Comprehensive utilization process of glutamic acid crystal mother liquid

InactiveCN103918873AHigh adsorption capacityReduce water consumptionOrganic compound preparationClimate change adaptationIon exchangeChemistry

A comprehensive utilization process of a glutamic acid crystal mother liquid comprises the following steps: one, leading the glutamic acid crystal mother liquid into a membrane separation system, allowing solid particles, thalli, proteins, polysaccharides and a colloid in the mother liquid to be intercepted by a membrane, and making glutamic acid left in a membrane filtrate; and allowing the membrane filtrate to go to a next step for treatment; two, leading the membrane filtrate into an ion exchange system, adsorbing glutamic acid by an ion exchange resin, when the content of glutamic acid in an ion exchange tail liquid is not more than 0.2%, stopping column-loading, adding an eluting agent, eluting, allowing glutamic acid to go into the eluate, collecting the eluate, and recycling glutamic acid from the eluate. The membrane separation technology and the ion exchange technology are combined, recycling of glutamic acid from the crystal mother liquid is realized, at the same time, a protein feed is prepared from the thalli and the proteins intercepted by the membrane, an organic fertilizer is prepared from the ion exchange tail liquid through slurry-spraying granulation, the whole process allows useful substances in the crystal mother liquid to be totally recycled, comprehensive utilization of the resources is thoroughly achieved, waste is turned into treasure, and significant economic benefits are achieved.

Owner:SHANGHAI KAIXIN ISOLATION TECH CO LTD

Ion exchange method for solid substance with exchangeable ions

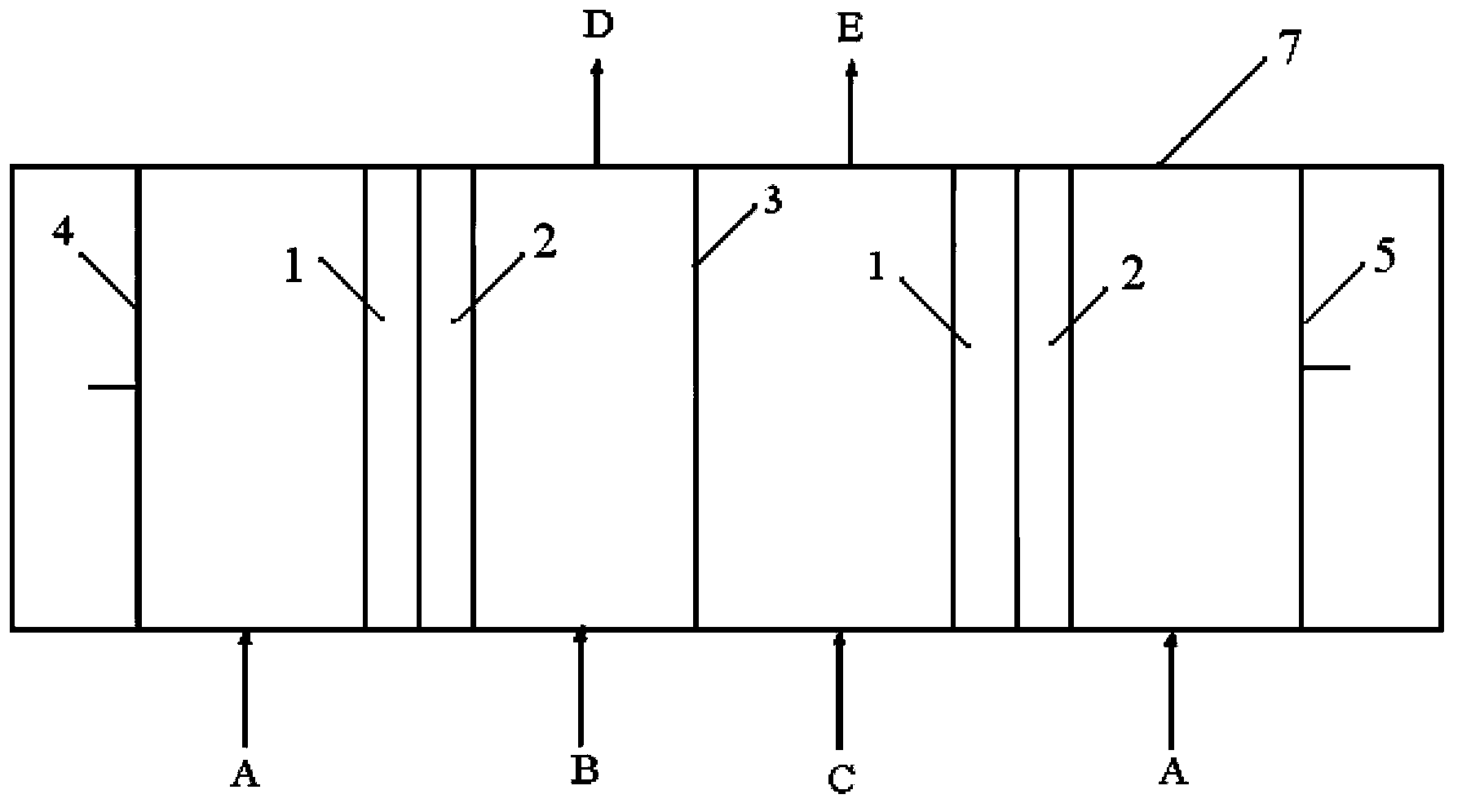

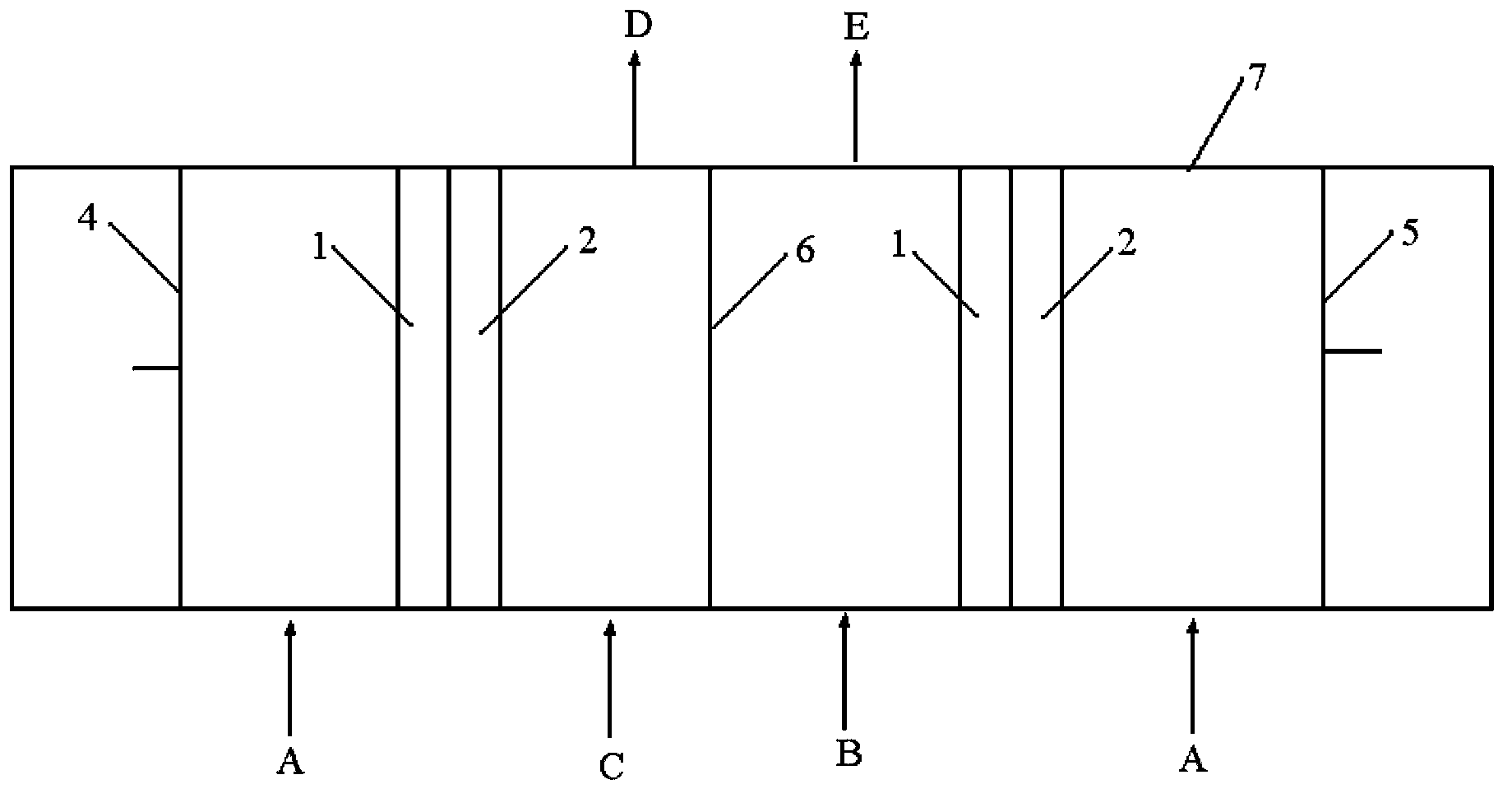

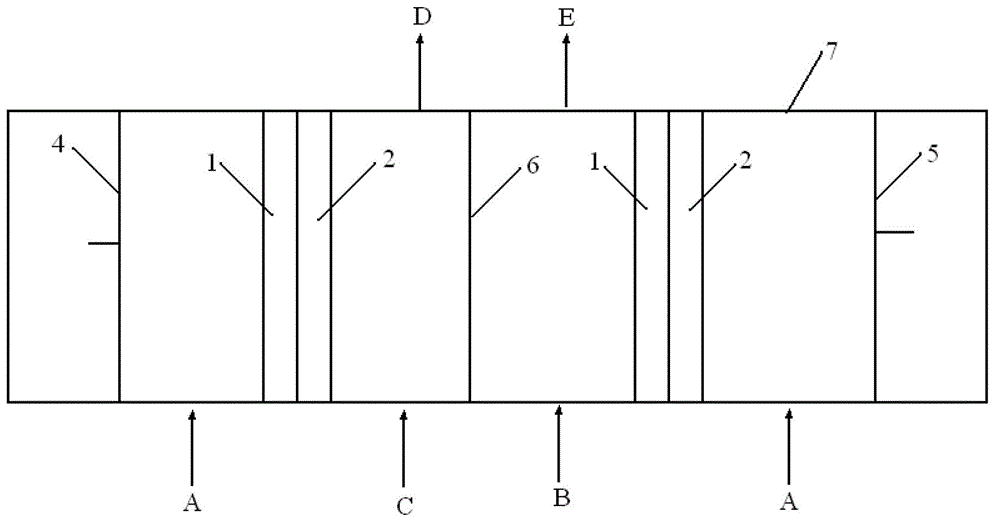

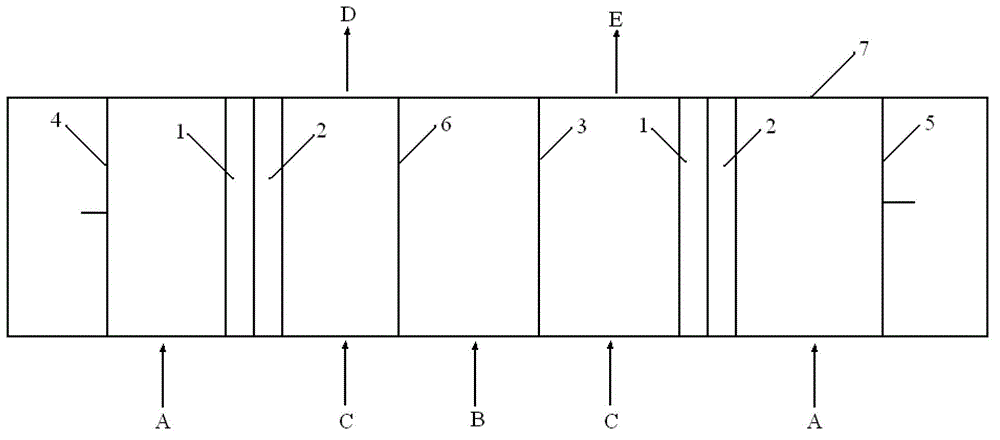

ActiveCN103768951ALow exchangeable group contentImprove ion exchange efficiencySemi-permeable membranesWater insolubleIon exchange

The invention provides an ion exchange method for a solid substance with exchangeable ions, which includes the following steps: bipolar membrane electrodialysis: performing bipolar membrane electrodialysis to a water solution with ions, so as to obtain an acid liquor; ion exchange: performing ion exchanging to the contacted solid substance with exchangeable ions and the acid liquor, wherein ions capable of forming a water insoluble substance with OH<-> are contained in the exchangeable ions in the solid substance; solid-liquid separation: performing solid-liquid separation to slurry of the solid substance subjected to ion exchange, so as to obtain the solid phase and the liquid phase; performing solid-liquid separation after the pH value of the liquid phase is adjusted above 8 and obtaining a conditioning fluid; circulating the conditioning fluid to the step of bipolar membrane electrodialysis, substituting at least part of the water solution with ions with the conditioning fluid for bipolar membrane electrodialysis. In the method provided by the invention, power consumption for bipolar membrane electrodialysis is low, and higher ion exchange efficiency is obtained through the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

Antibacterial varnish for color plate and color plate production process

ActiveCN111675955AImprove ion exchange efficiencyImprove stabilityAntifouling/underwater paintsPaints with biocidesCyclohexanoneXylylene

The invention relates to an antibacterial varnish for a color plate and a color plate production process. The antibacterial varnish comprises the following components in percentage by weight: 15-40% of polyester resin, 10-30% of methanol modified melamine formaldehyde resin, 0-15% of propylene glycol methyl ether acetate, 0-15% of 2-methyl propanol acetate, 0-10% of solvent naphtha, 0-5% of cyclohexanone, 0-5% of xylene, 1-10% of octanol and 1-2% of nano silver-loaded organic silicon. The color plate production process comprises the following steps: S1, preparing materials (including S1-1 substrate uncoiling and S1-2 primer, back paint, middle paint, printing ink and antibacterial varnish preparation); S2, carrying out a substrate pretreatment; S3, performing primer coating; S4, carrying out back paint coating; S5, carrying out middle paint coating; S6, carrying out ink printing; and S7, carrying out varnish coating. The prepared antibacterial varnish has a good antibacterial performance, so that a color steel plate prepared from the antibacterial varnish has a good antibacterial performance.

Owner:合肥河钢新材料科技有限公司 +1

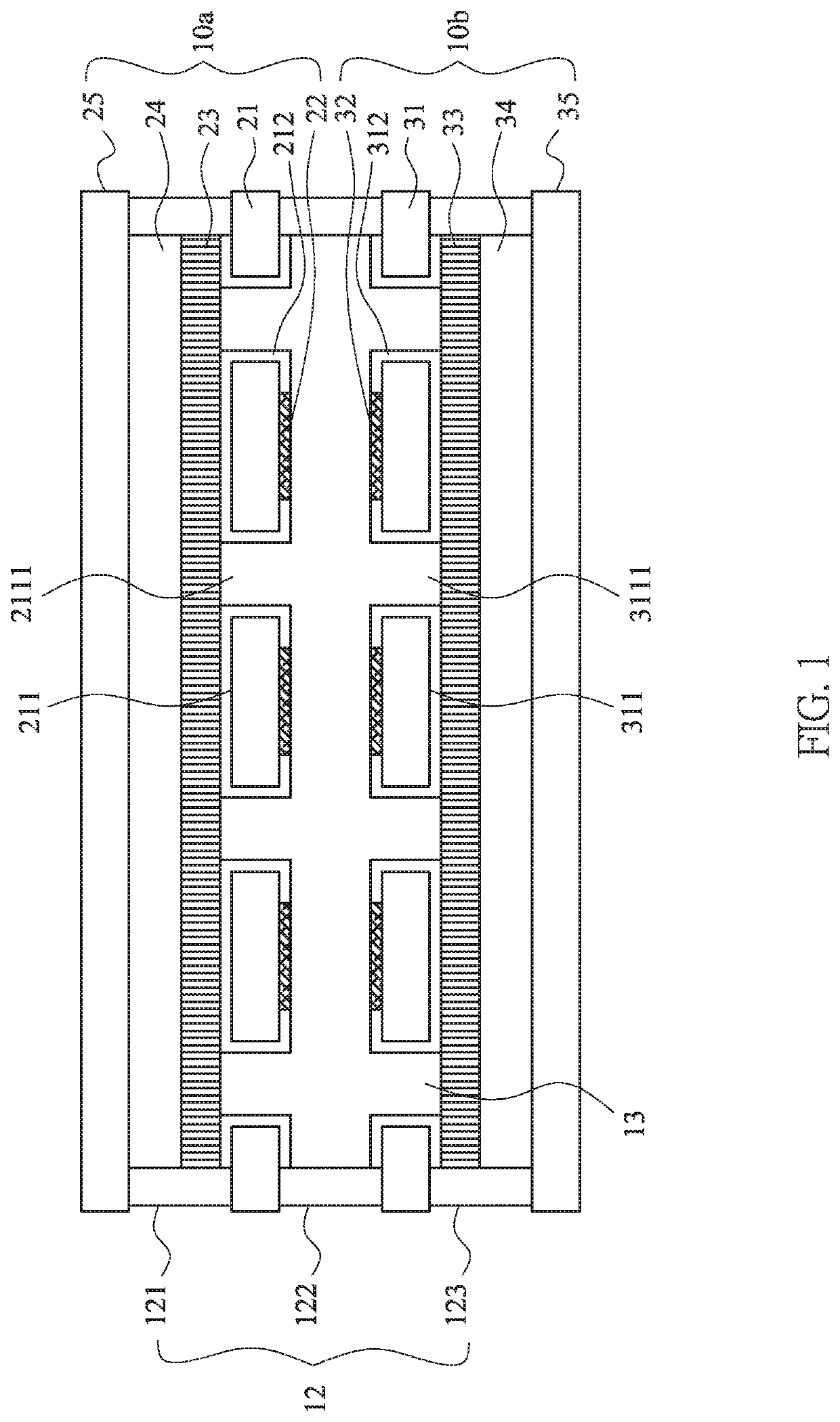

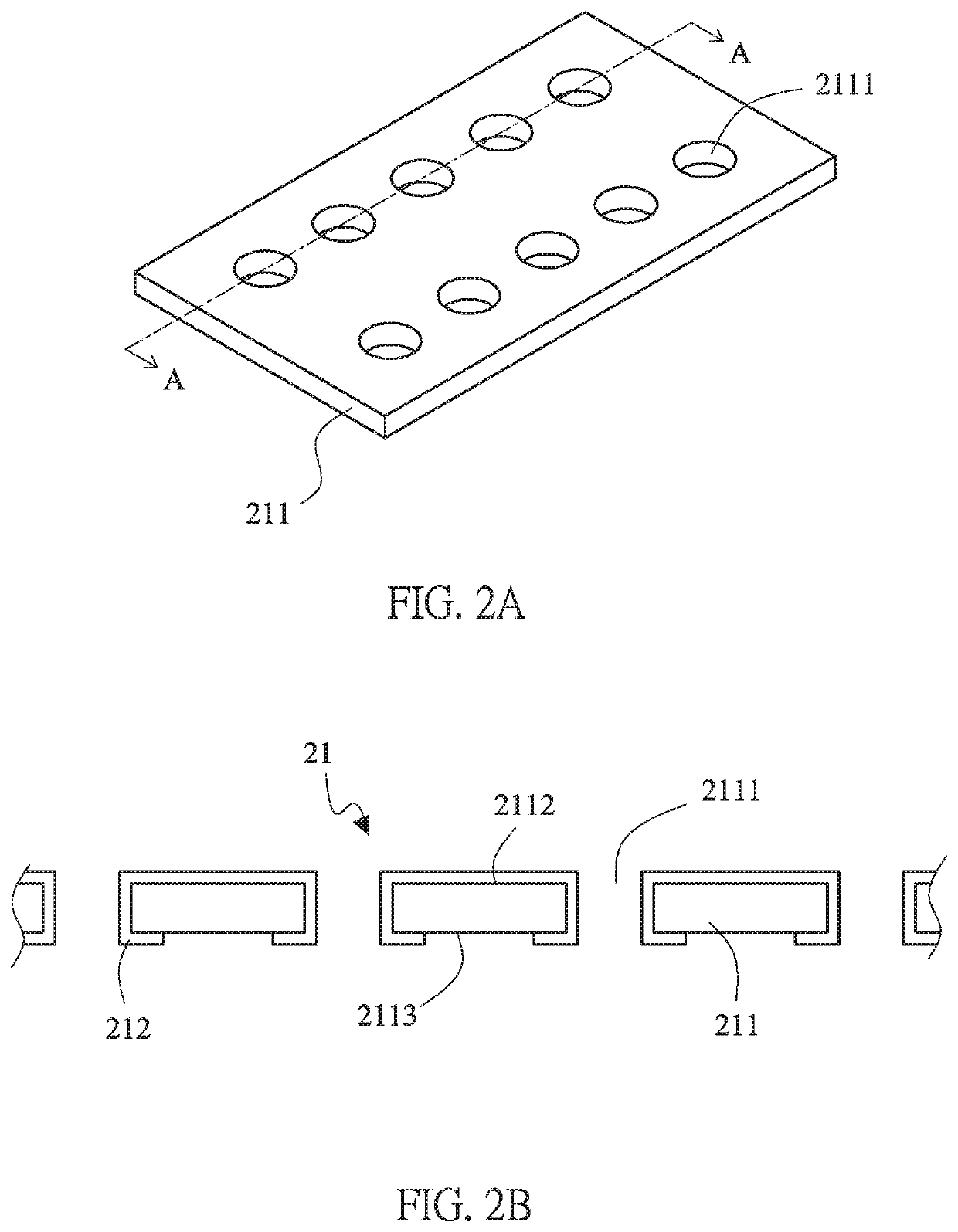

Lithium battery structure and electrode layer thereof

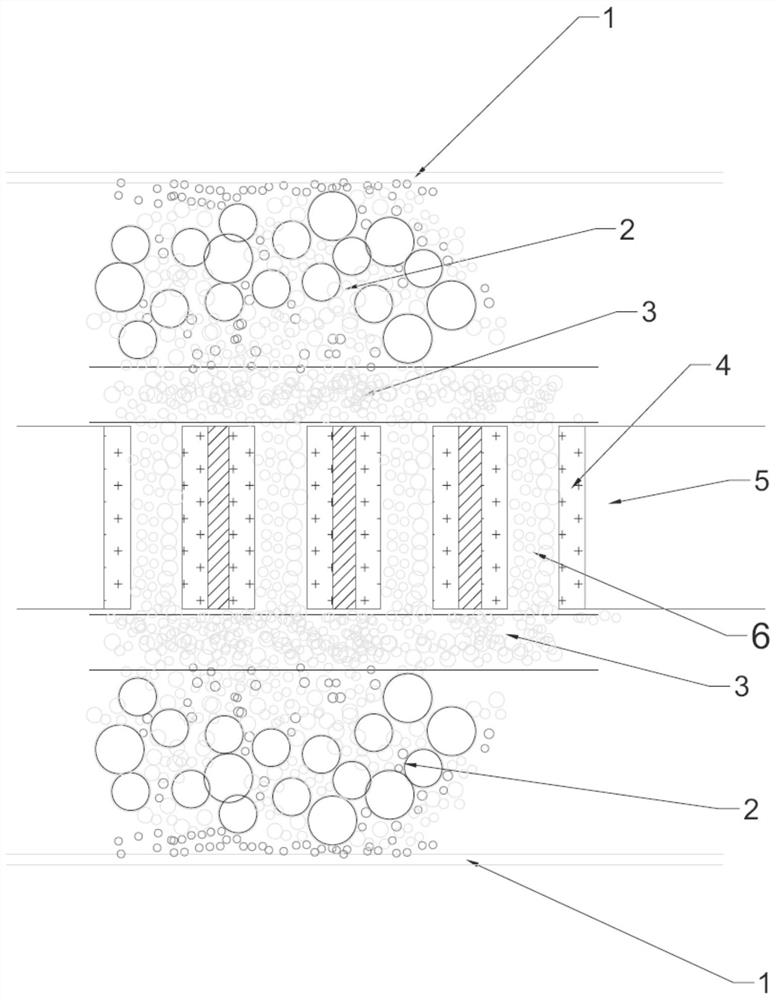

PendingUS20200076004A1Reduce consumptionIncrease usable cycle time of batteryFinal product manufactureElectrode carriers/collectorsChemistryLithium dendrite

The invention discloses a lithium battery structure and the electrode layer thereof. The lithium battery structure includes two battery units with the two negative active material layers being disposed in face-to-face arrangement. The negative current collector includes a conductive substrate with a plurality of through holes and an isolation layer. The isolation layer is covered on one surface of the conductive substrate and extended along the through holes to another surface to cover the edge of the openings of the through holes. It can be effectively avoided the lithium dendrites depositing near the openings of the through holes on the conductive substrate. Also, the face-to-face arrangement of the negative active material layers is effectively control the locations of the plated lithium dendrites. Therefore, the safety of the battery and the cycle life of the battery is greatly improved.

Owner:PROLOGIUM TECH +1

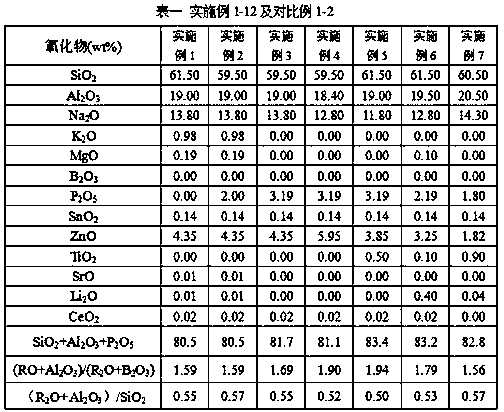

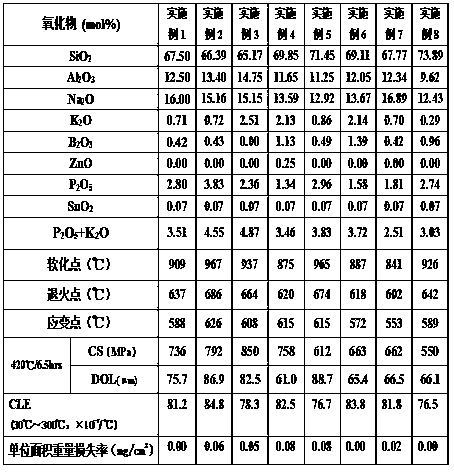

Glass ceramic and preparation method thereof, glass protection layer, glass cover plate and electronic device

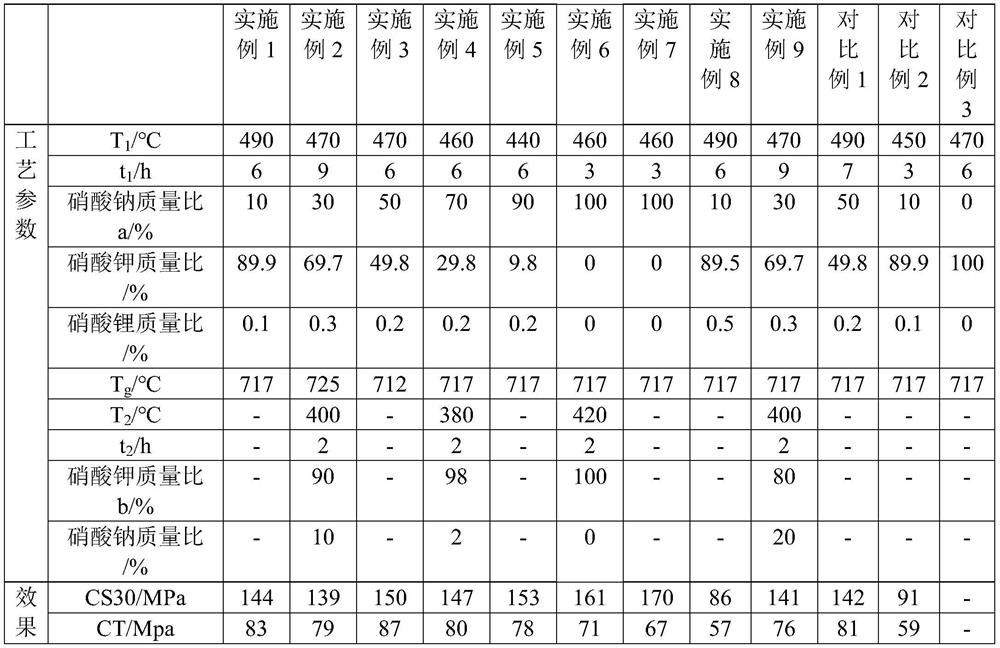

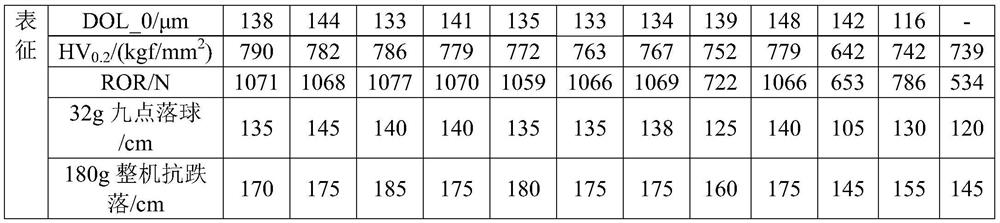

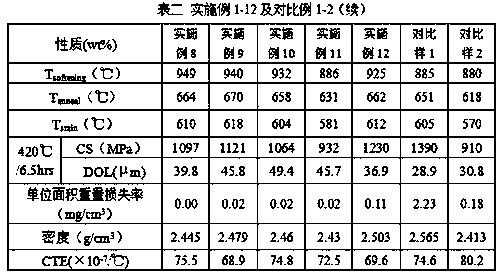

ActiveCN113880412AImprove ion exchange efficiencyAvoid "decrystallization" phenomenonGlass productionPotassium nitrateGlass cover

The invention provides a preparation method of glass ceramic, the preparation method comprises: carrying out a crystallization treatment on precursor glass to prepare a glass ceramic prefabricated part; mixing the glass ceramic prefabricated part with first fused salt, and carrying out first chemical tempering; the first molten salt comprises at least one of sodium nitrate, potassium nitrate and lithium nitrate; the mass ratio of sodium nitrate in the first molten salt is a; the temperature of the first-time chemical tempering is T1 DEG C, and the time of the first-time chemical tempering is t1 hours; the glass transition point temperature of the glass ceramic prefabricated part is Tg DEG C; 10% < = a < 50%, and 10t1 + T1 = (0.75 Tg-80a)-(0.83 Tg-100a); or 50% < = a < = 100%, and 10t1 + T1 = (0.75 Tg-50a)-(0.83 Tg-80a).

Owner:QINGYUAN CSG NEW ENERGY SAVING MATERIALS CO LTD +1

Zinc phosphorus aluminum silicate glass with high strain point, fast ion exchange function and weak-acid resistance

InactiveCN109020192AGood resistance to weak acidImproved weak acid resistanceAluminum silicateIon exchange

The invention discloses zinc phosphorus aluminum silicate glass with a high strain point, fast ion exchange function and weak-acid resistance. The glass is prepared from the following ingredients in percentage by mass: 56 to 65 percent of SiO2, 17 to 22 percent of Al2O3, 10 to 16 percent of Na2O, 0 to 1 percent of K2O, 0 to 1 percent of Li2O, 0 to 5 percent of P2O5, 0 to 2 percent of B2O3, 0 to 0.5 percent of MgO, 1 to 8 percent of ZnO, 0 to 1 percent of TiO2, 0 to 0.5 percent of SrO, 0 to 0.5 percent of SnO2 and 0 to 0.5 percent of CeO2, wherein the sum of all ingredients is 100 percent; thestrain point temperature of the glass is higher than or equal to 580 DEG C; the compression stress value is greater than or equal to 900 MPa; the compression stress layer is greater than or equal to 35 mu m. The glass composition is optimized to obtain the glass with high compression stress value, high compression stress layer and weak-acid resistance.

Owner:KORNERSTONE MATERIALS TECH

Phosphorus-aluminum silicate glass with low cost and high compressive stress layer

InactiveCN109836037AReduce concentrationReduce resistanceGlass shaping apparatusGlass tempering apparatusSilicate glassIon exchange

The invention relates to the technical field of glass materials, and in particular relates to phosphorus-aluminum silicate glass with low cost and a high compressive stress layer, the phosphorus-aluminum silicate glass comprises 65-75% of SiO2, 8-16% of Al2O3, 11-18% of Na2O, 0-5% of K2O, 1-4% of P2O5, 0-3% of B2O3; 0-1% of ZnO and 0-0.4% of SnO2, (CaO + MgO + SrO + BaO) is less than or equal to 0.1%, the depth of the ion exchange layer of the reinforced glass is larger than or equal to 60 microns; and the mean line thermal expansion coefficient of the glass is less than 90 * 10 <-7 > / DEG C. After soaking for 6 hours in an oxalic acid solution at 60 DEG C, the weight loss rate of the unit area is less than or equal to 0.15mg / cm<3>, the glass adopts a high SiO2 component, ZnO, Li2O, SnO2 and other components are reduced, and the advantages of low cost and the high compressive stress layer are realized.

Owner:KORNERSTONE MATERIALS TECH

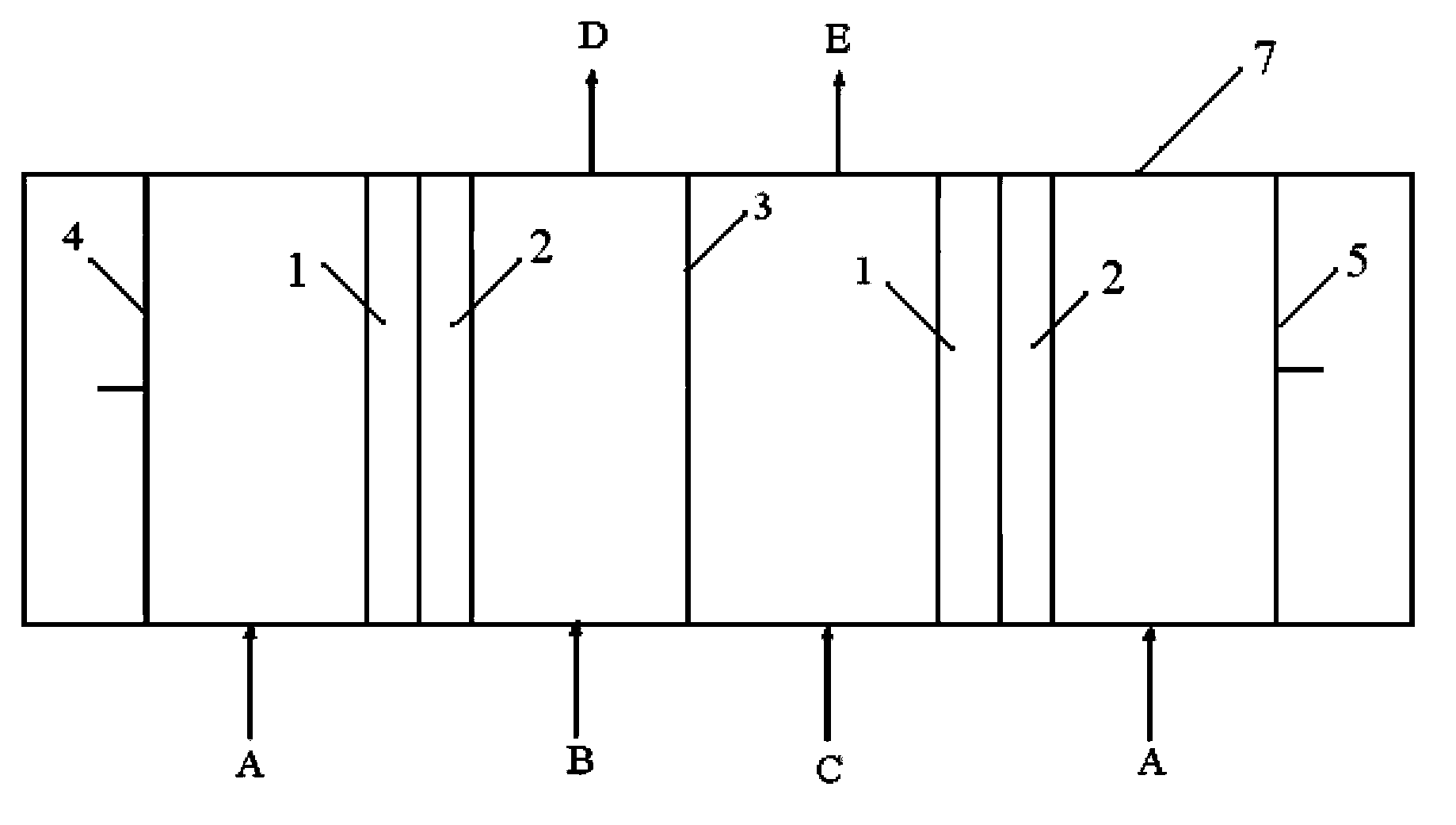

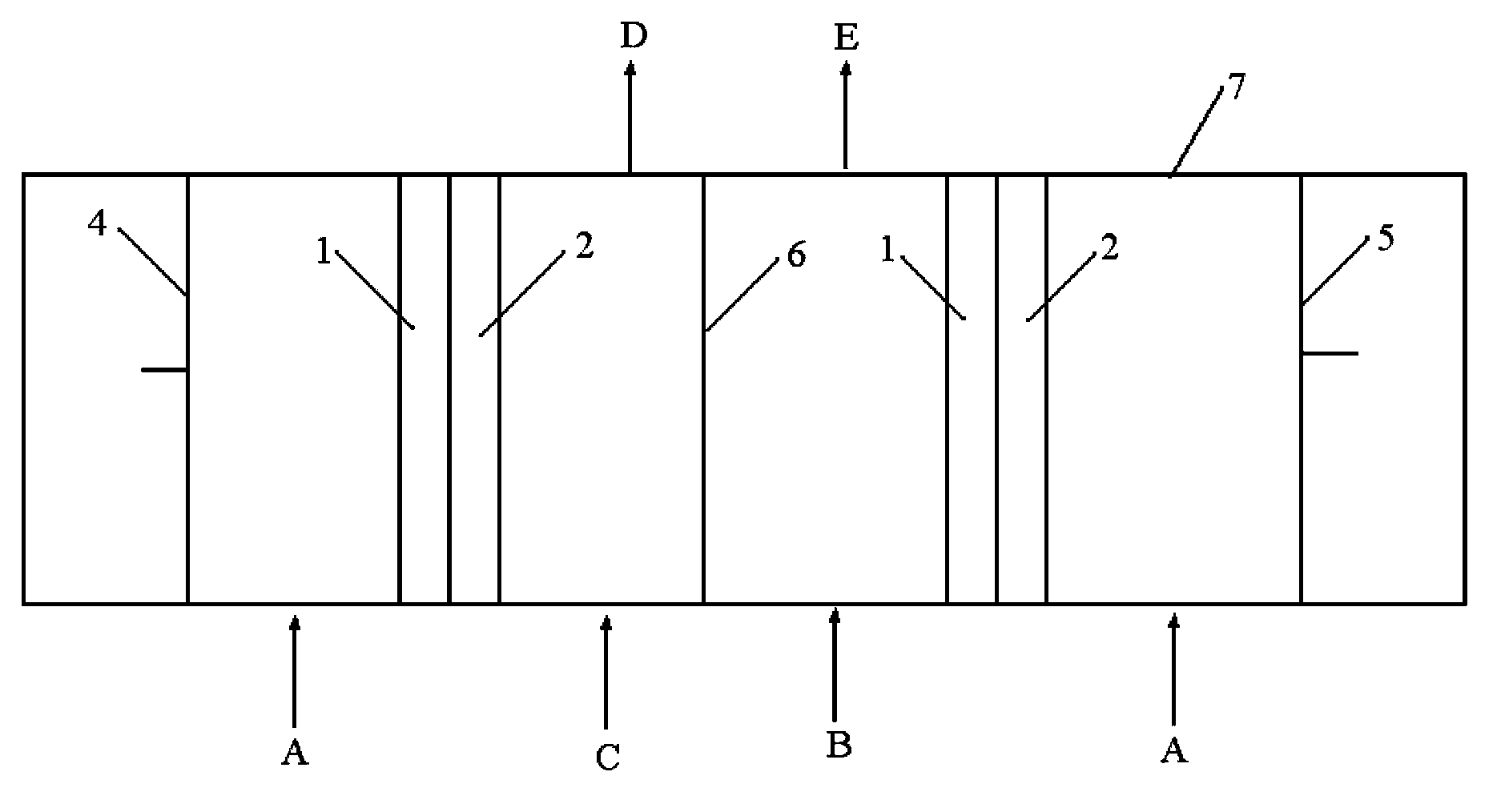

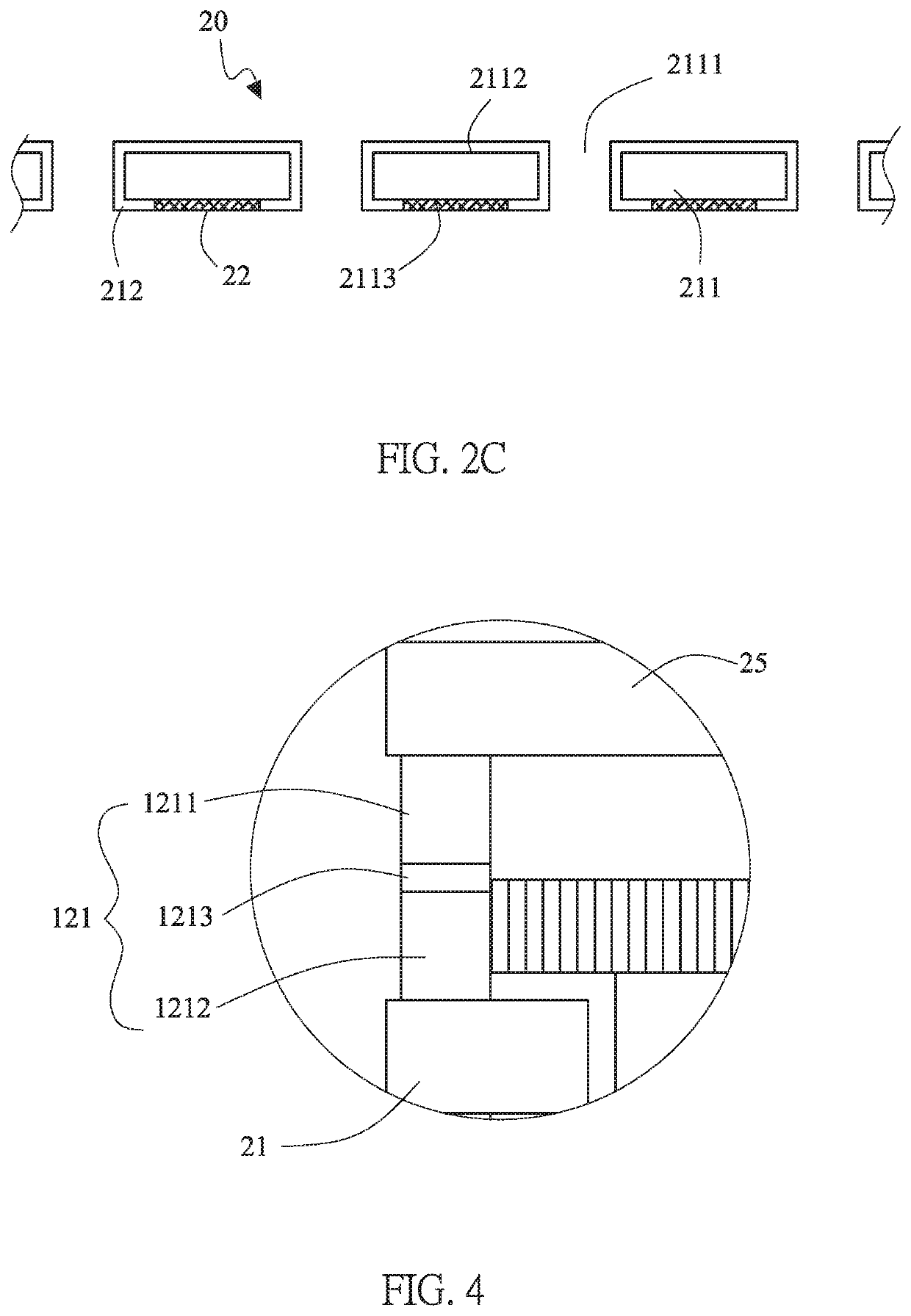

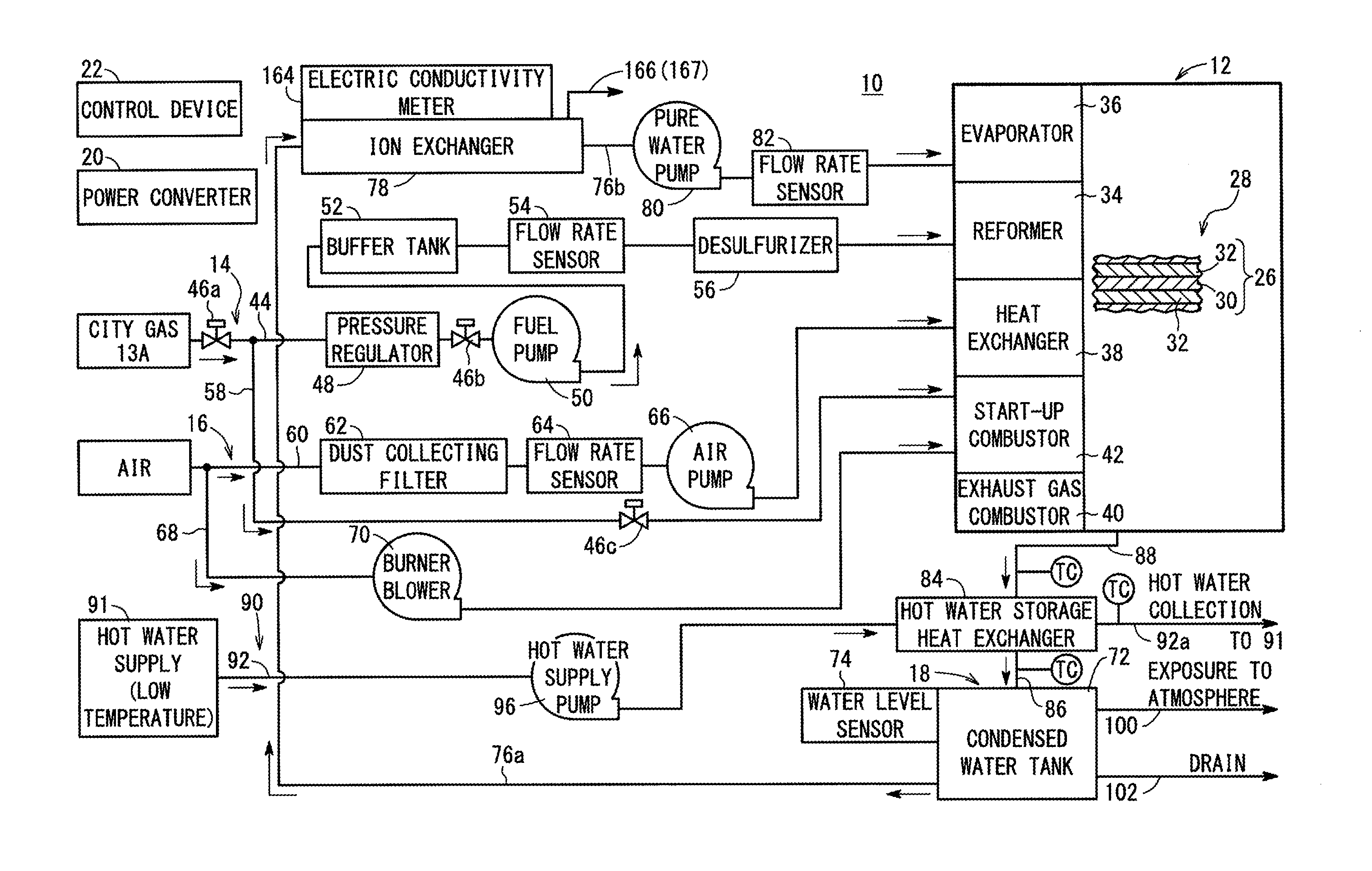

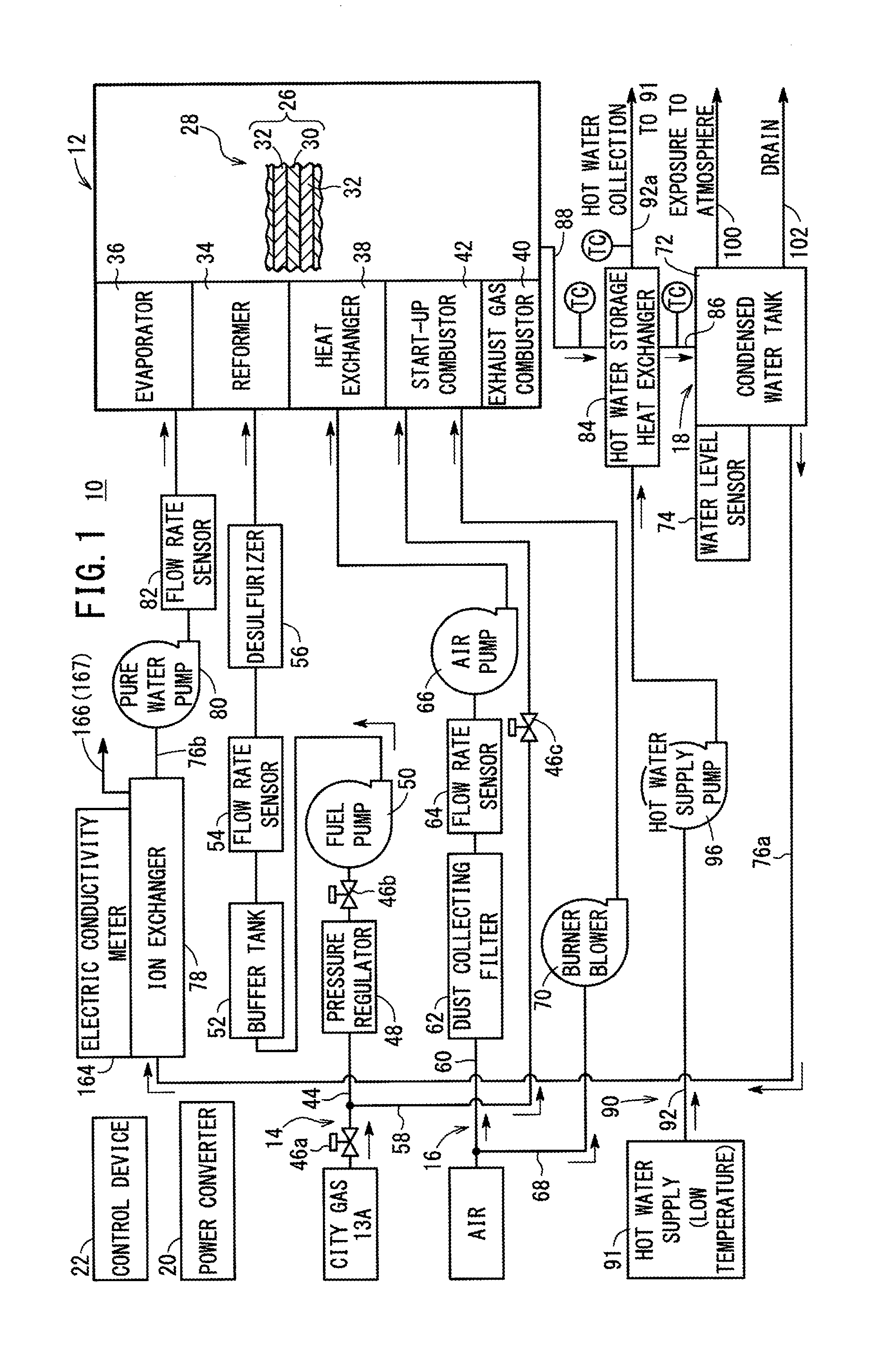

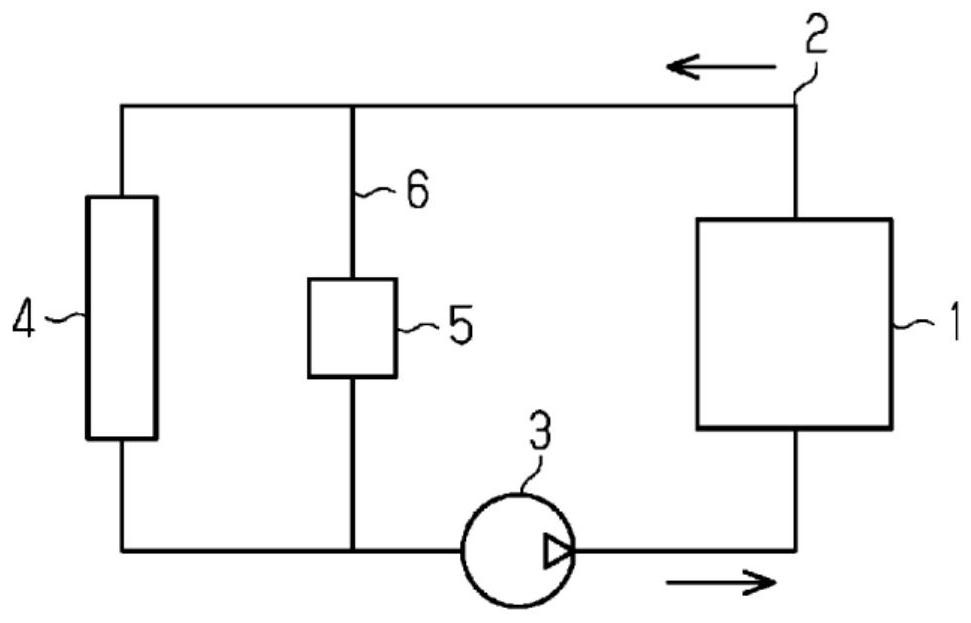

Fuel cell system ion exchanger

ActiveUS20160043421A1Improve ion exchange efficiencySuppress air from flowing downstreamWater treatment parameter controlReactant parameters controlIonEngineering

An ion exchanger includes an apparatus body having a lower filter and an upper filter. Ion exchange resin fills a space between the lower filter and the upper filter. A water supply port is provided at a lower position of the apparatus body, and a water discharge port is provided at an upper position of the apparatus body. An air container is provided at an upper position of the apparatus body, and an electric conductivity meter is provided in the air container at a position above the water discharge port.

Owner:HONDA MOTOR CO LTD

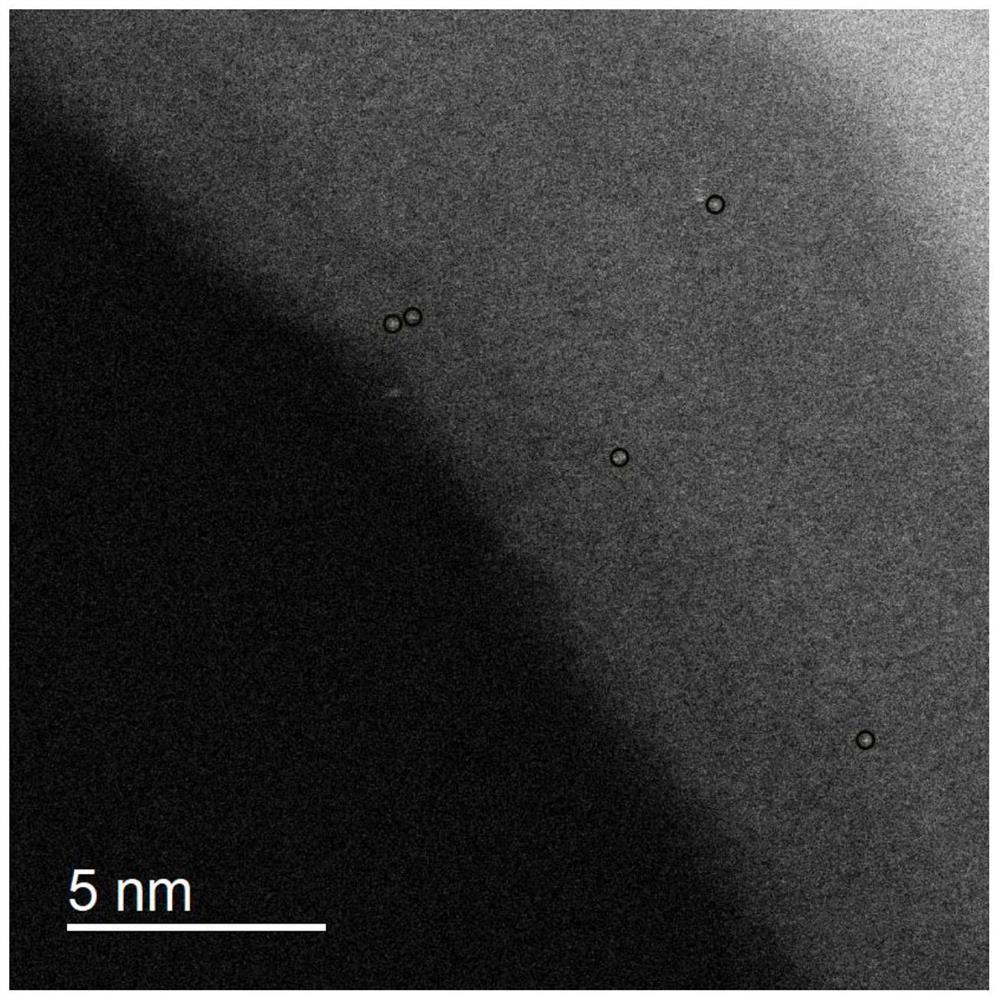

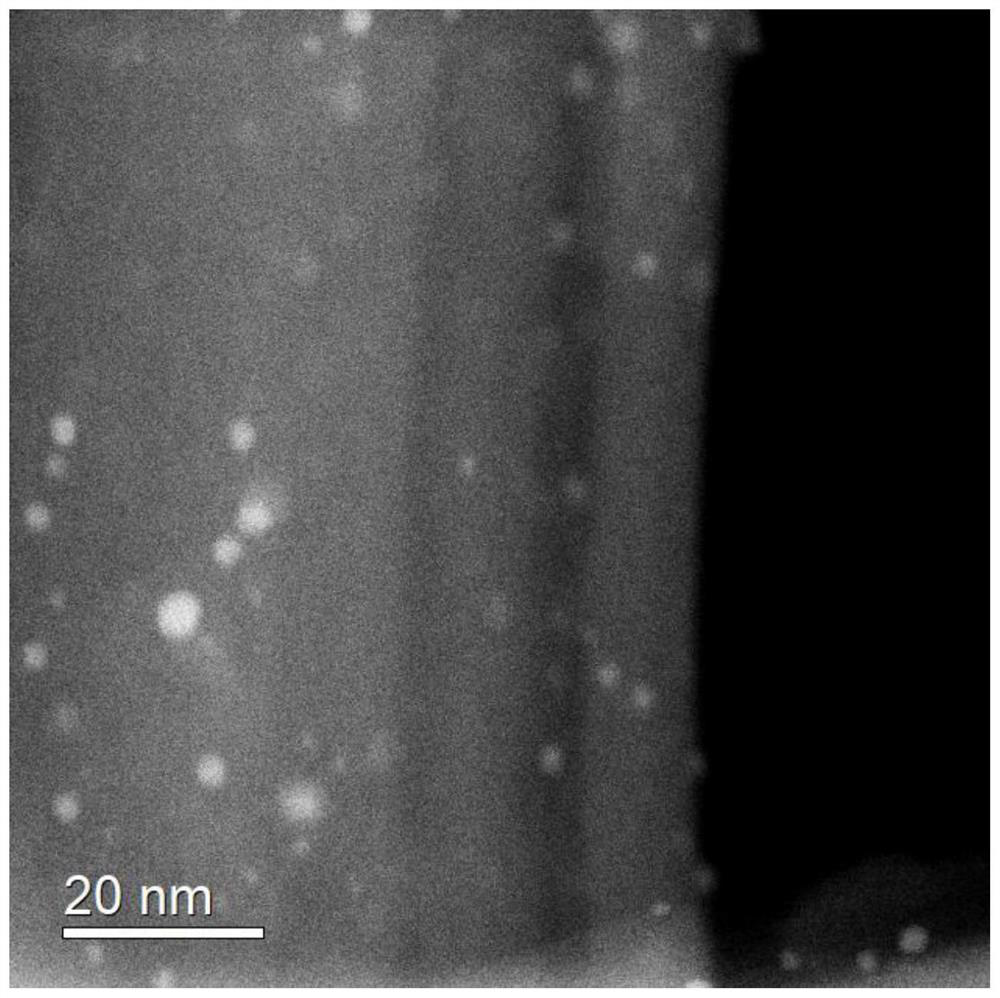

Preparation method of freeze-dried modified sepiolite mineral loaded Pd monatomic catalyst

PendingCN114160131AImprove ion exchange efficiencySpeed up entryCatalyst activation/preparationMetal/metal-oxides/metal-hydroxide catalystsPtru catalystFreeze-drying

The invention relates to a preparation method of a freeze-dried modified sepiolite mineral loaded Pd monatomic catalyst. According to the method, the sepiolite group minerals are treated by combining ultrasonic treatment with freeze drying, firstly, the sepiolite group minerals are preliminarily dispersed through ultrasonic treatment, then, the sepiolite group minerals are further unbundled in the freeze drying process, more ion exchange sites are exposed out of the sepiolite group minerals, meanwhile, zeolite water in pore channels is removed through freeze drying, and the sepiolite group minerals are separated from the pore channels. The pore channel of the mineral is dredged, so that the ion exchange efficiency of the mineral is improved, the Pd is promoted to enter the pore channel through ion exchange, and the size of the pore channel controls the growth size of the exchanged Pd in the reduction process, so that the Pd stably exists in a monatomic form. According to the invention, the defects of low atom utilization rate and poor selectivity and stability of the traditional Pd catalyst are overcome, and the defects of complex preparation and processing technology and high cost of a monatomic catalyst carrier are overcome.

Owner:HEBEI UNIV OF TECH

An ion exchanger

ActiveCN113939365AImprove ion exchange efficiencyReduce total pressure lossIon-exchange process apparatusFuel cell auxillariesCoolant flowIon exchange

Owner:TOYOTA BOSHOKU KK

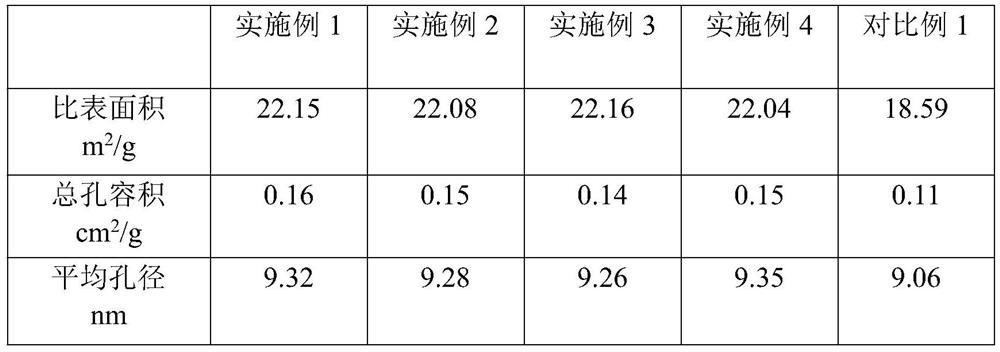

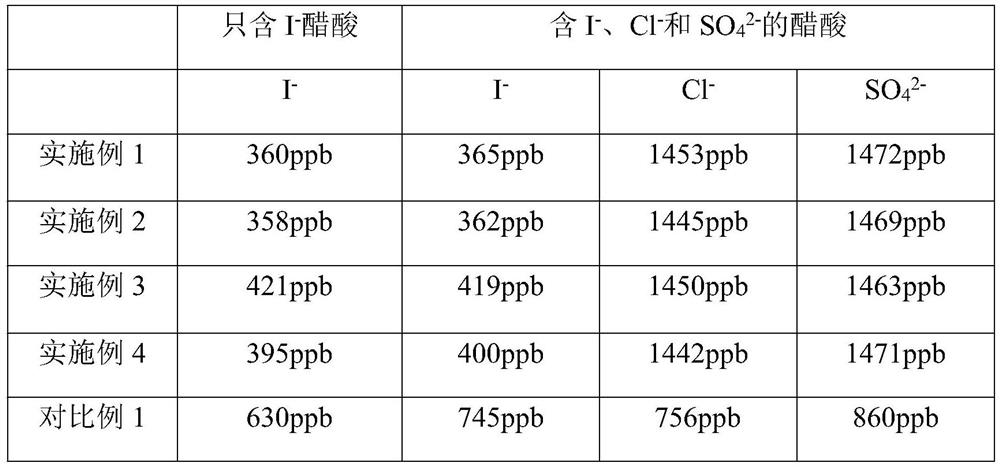

Micro-nano fiber ion exchange resin deiodinating agent and preparation method thereof

InactiveCN112058320ALarge specific surface areaShort mass transfer distanceOrganic cation exchangersElectrospinningIon exchange

The invention belongs to the technical field of chemical engineering, and particularly relates to a micro-nano fiber ion exchange resin deiodinating agent and a preparation method thereof. The preparation method comprises the following steps: carrying out electrostatic spinning on polylactic acid and polyvinyl alcohol to obtain micro-nano fibers, and carrying out graft modification on the micro-nano fibers by using a pre-radiation method; then mixing the modified micro-nano fibers with vinylbenzyl chloride and divinyl benzene to prepare resin, and then putting the resin into an ethanol solution of zirconium acetate and manganous nitrate tetrahydrate for standing to obtain the deiodinating agent. The micro-nano fiber ion exchange resin deiodinating agent provided by the invention has largeadsorption capacity and excellent selectivity.

Owner:陈兵

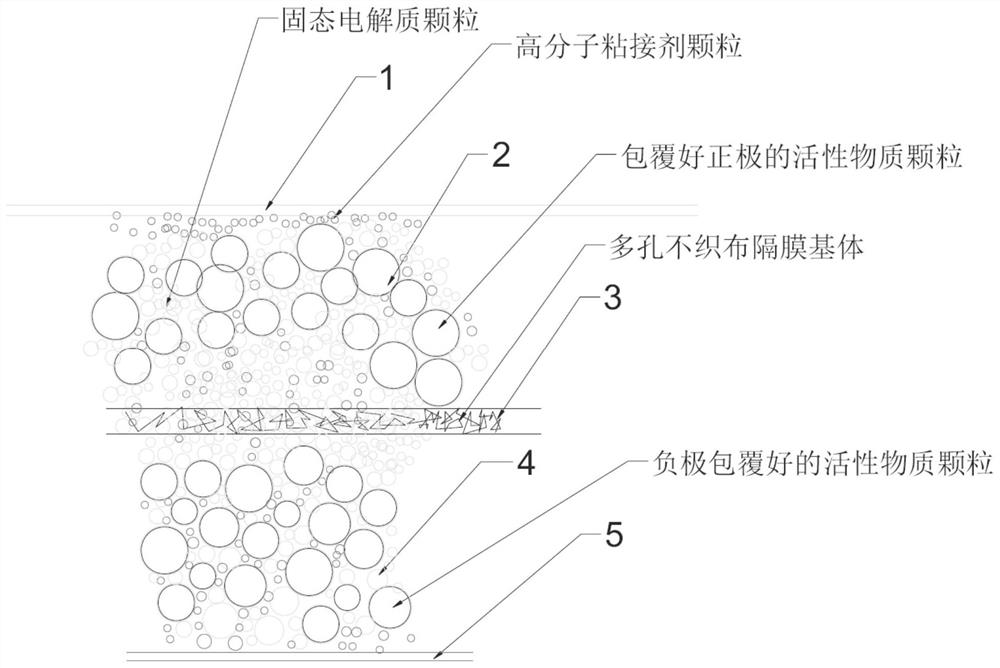

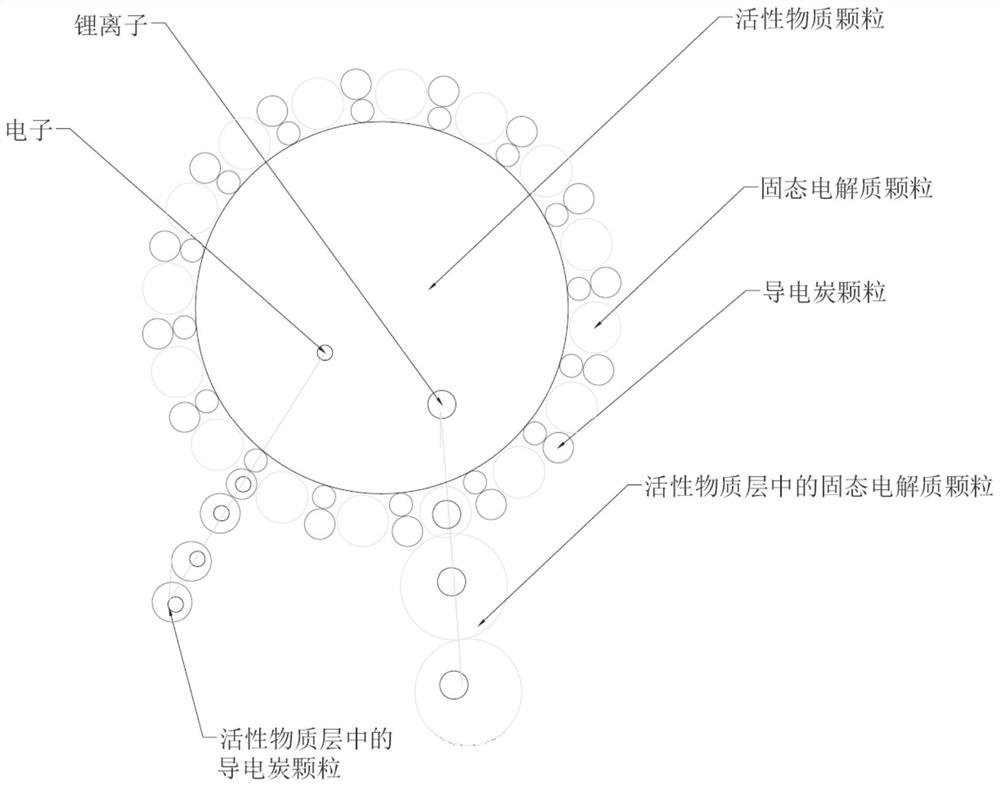

Manufacturing process method of all-solid-state lithium ion battery

PendingCN113809326AImprove ion exchange efficiencySolve the problem of passing electron channelsMaterial nanotechnologyFinal product manufactureSolid state electrolyteMetallic lithium

The invention relates to a manufacturing process method of an all-solid-state lithium ion battery, and belongs to the technical field of new energy power energy storage batteries. The all-solid-state battery pole piece group of the all-solid-state lithium ion battery is composed of a positive current collector, a positive active material layer, a diaphragm, a negative active material layer and a negative current collector, and the positive active material layer is composed of positive active material particles, a solid electrolyte, conductive particles and a polymer adhesive. The large-particle positive active material particles wrap the small-particle solid electrolyte and the conductive particles, and are in contact with the small-particle solid electrolyte and the conductive particles through a high-molecular adhesive. Solid electrolyte and conductive particles are mixed and coated on the surfaces of active substance particles, so that the ion exchange efficiency is improved, and the problem of electron transmission channels is solved; and by adopting kneading and mixing processes and equipment thereof, the use cost of a solvent and the environmental problem are reduced, lithium ion transmission is not influenced, and the drying energy consumption is reduced. The metal lithium negative plate structure changes the growth direction of lithium dendrites in the charging and discharging process, and the safety of the battery is improved.

Owner:上海轩玳科技有限公司

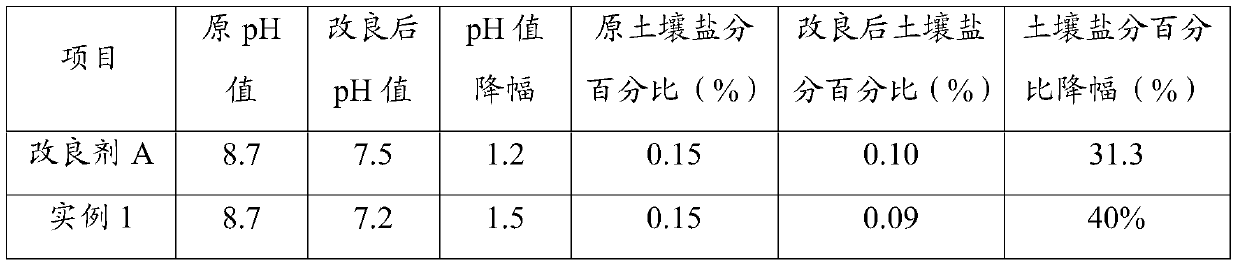

A kind of soil improver using waste rubber powder as main raw material and preparation method thereof

ActiveCN104498051BRaise the pHImprove aggregate structureOther chemical processesContaminated soil reclamationWaste rubberSnow melting

The invention discloses a soil improver utilizing waste rubber powder as a main raw material and a preparation method of the soil improver. The soil improver comprises the following raw materials in parts by weight: 55 to 70 parts of waste rubber powder, 30 to 40 parts of desulfurized waste, 2 to 8 parts of inorganic accelerant and 4 to 8 parts of organic accelerant. The soil improver also comprises 0 to 3 parts of other ingredients which are selected from organic fertilizer, biomass char and microorganism fertilizer. According to the soil improver, by utilizing the stabilizing effect of the waste rubber powder, the ion exchanging efficiency of the improver and a snow-melting agent in the soil is promoted. Sodium ions of the snow-melting agent in the soil are replaced by utilizing calcium ions in desulfurized waste, particularly in coal-fired flue gas desulfurized gypsum, so that the acidity and alkalinity of the soil can be improved. The aggregate structure of the soil is improved by utilizing the inorganic accelerant, particularly the decomposed coal. In addition, the nutritional ingredients of the soil can be further improved by utilizing the auxiliary fertilizer.

Owner:SHANGHAI PUDONG ROAD & BRIDGE GRP CO LTD

A kind of antibacterial varnish for color plate and color plate production process

ActiveCN111675955BImprove ion exchange efficiencyImprove stabilityAntifouling/underwater paintsPaints with biocidesCyclohexanoneXylylene

Owner:合肥河钢新材料科技有限公司 +1

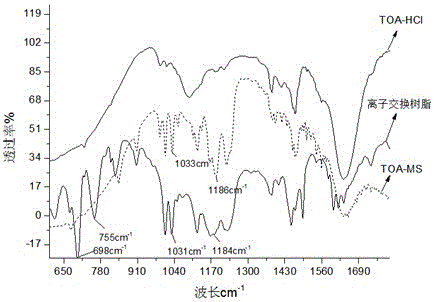

A kind of ion exchange method

ActiveCN104338566BNo pollutionDoes not increase operational difficultyIon-exchange column/bed processesMolecular sieve catalystsMolecular sieveIon exchange

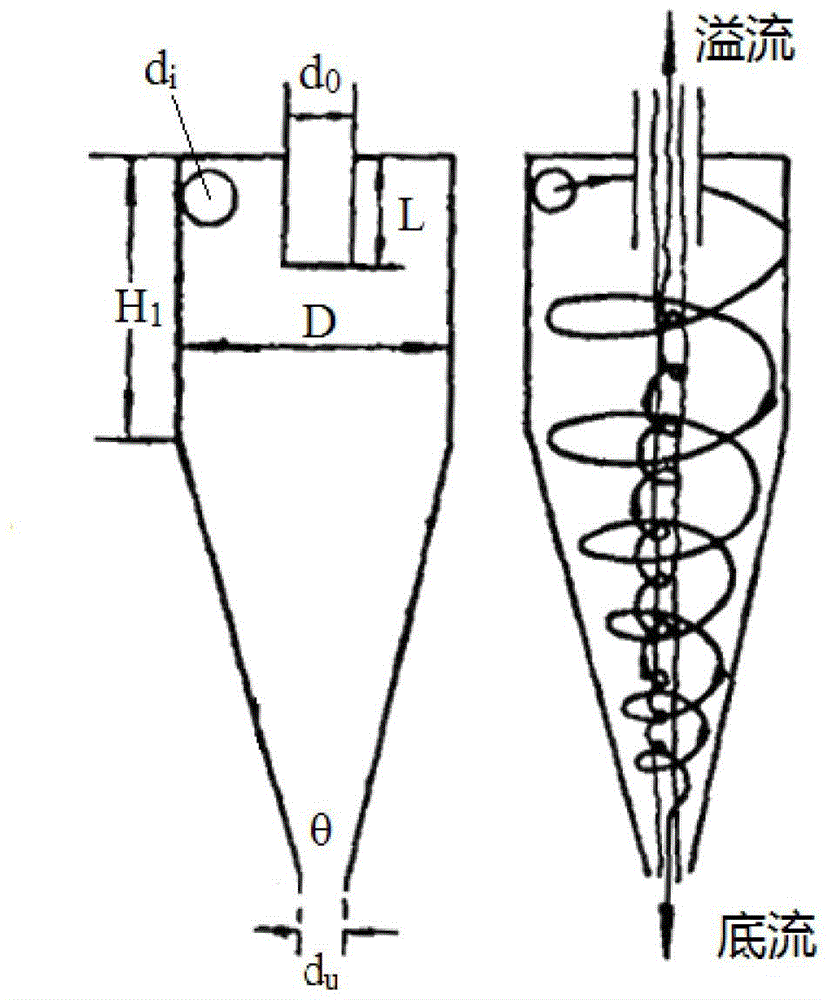

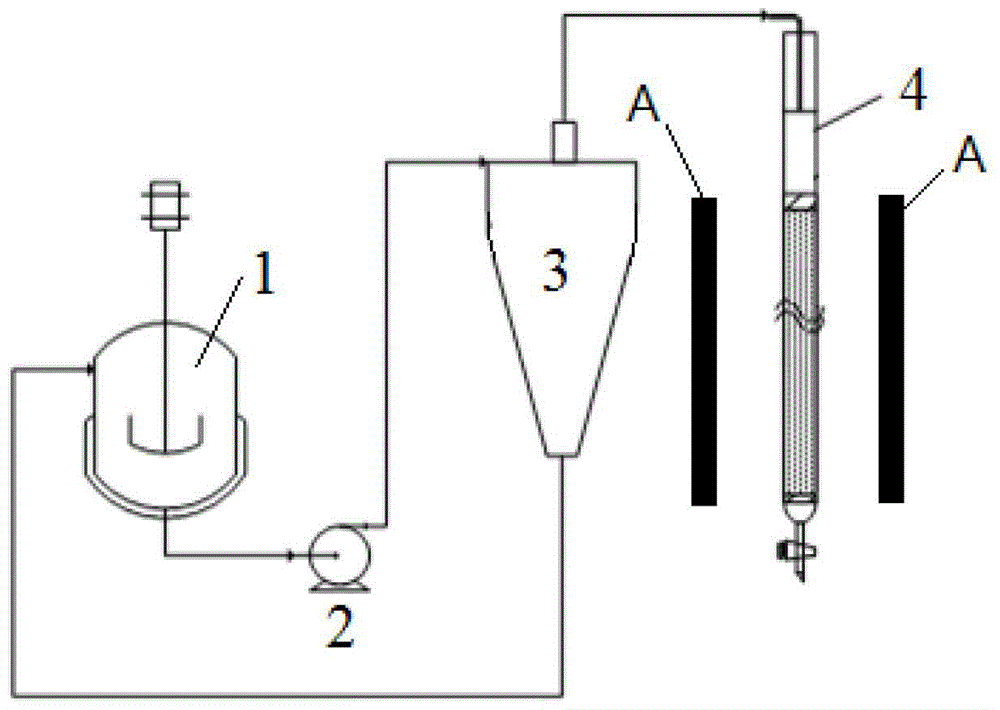

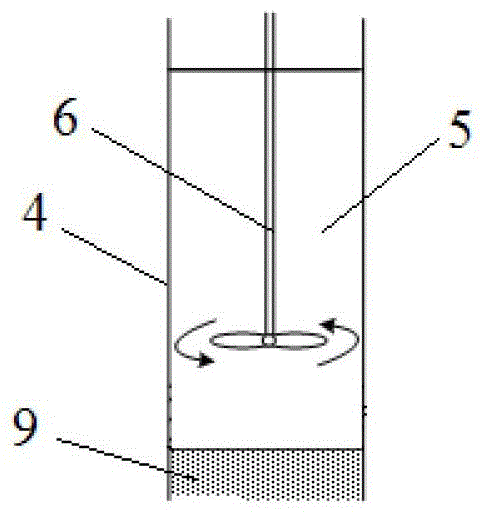

The invention provides an ion exchange method. According to the method, a slurry comprising a solid substance with exchangeable groups flows through an ion exchange column filled with an ion exchange resin bed layer, such that the exchangeable groups in the solid substance is subjected to ion exchange with ion exchange groups in the ion exchange resin in the ion exchange resin bed layer; and solid-substance-containing slurry flowing out from the ion exchange column is collected. At least part of the ion exchange resin is magnetic ion exchange resin. Also, when the slurry flows through the ion exchange column, the ion exchange column is positioned in a transversal rotation magnetic field. With the method provided by the invention, after ion exchange, no or substantially no molecular sieve is adhered to the surface of the ion exchange resin, such that ion exchange column service period can be effectively prolonged, and washing and regeneration frequencies can be reduced. Under a same condition of ion exchange, with the method provided by the invention, higher ion exchange efficiency can be achieved.

Owner:CHINA PETROLEUM & CHEM CORP +1

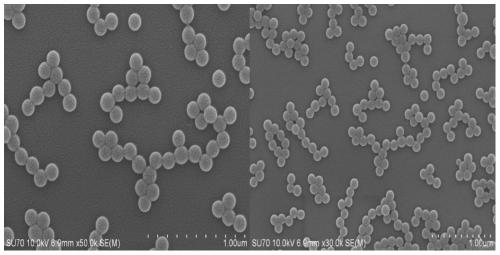

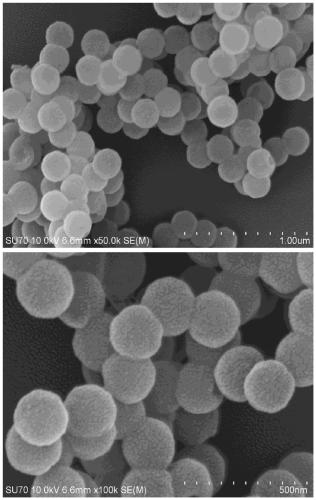

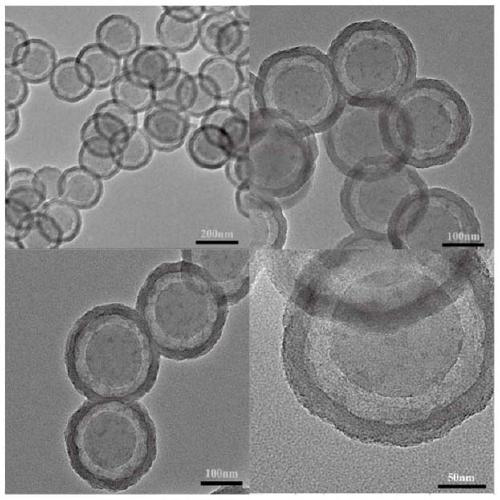

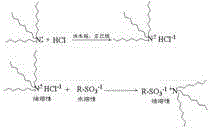

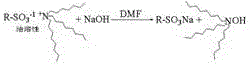

A sulfonated polystyrene@mesoporous silica microsphere with egg yolk-shell structure and its preparation method

ActiveCN108479860BImprove exchange efficiencyEasy to prepareCation exchanger materialsFunctionalized polystyrenePolymer science

The invention relates to a preparation method of a sulfonated polystyrene @ mesoporous silica microsphere with an egg yolk-shell structure. The preparation method mainly comprises the following stepsof: (1) using styrene (St) monomers as a raw material, and preparing a monodisperse polystyrene microsphere with a uniform particle size by adopting a soap-free emulsion polymerization method; (2) preparing a phenyl-functionalized polystyrene @ mesoporous silica microsphere with a yolk-shell structure; and (3) sulfonating the phenyl-functionalized polystyrene @ mesoporous silica microsphere by using chlorosulfonic acid to obtain ion exchange resin with a sulfonic acid group-modified polystyrene sphere kernel surface and a sulfonic acid group-modified silica shell surface. The synthesized polymer microsphere has a high specific surface area and a large pore volume, and has certain mechanical strength and chemical stability at the same time, the preparation method is simple, and has mild conditions and simple post-treatment, and the ion exchange efficiency of ion exchange resin can be improved.

Owner:XIAMEN UNIV

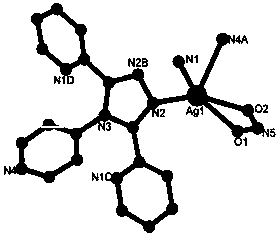

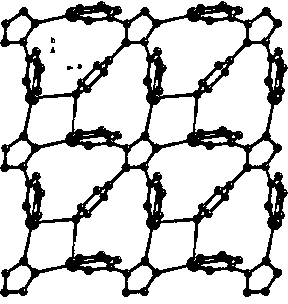

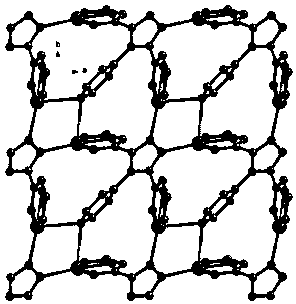

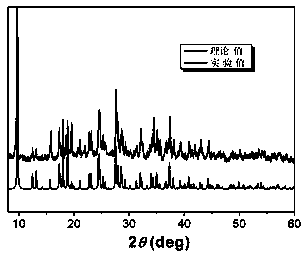

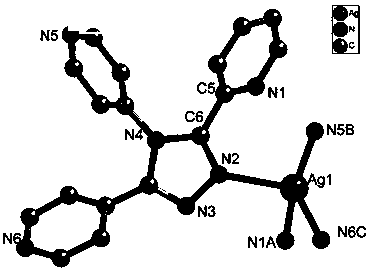

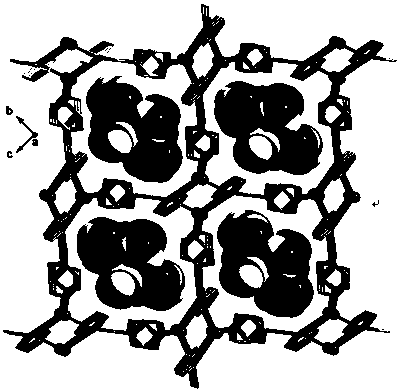

Metallic silver coordination polymer with three-dimensional network structure, and preparation method and application thereof

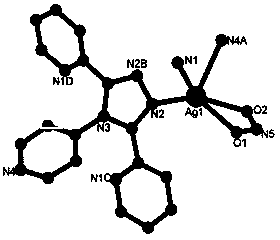

InactiveCN102516271BWith selective switchingEasy to manufactureSilver organic compoundsAnion exchangersNitrite ionBenzoic acid

The invention relates to 3,4-di(2-pyridyl)-5-(4-pyridyl)-1,2,4-triazole-silver (I) coordination polymer, and preparation and application thereof. The coordination polymer is synthesized by the following steps of: mixing an acetonitrile solution of AgNO2 and a chloroform solution of ligand L at normal temperature and normal pressure, keeping stirring for half an hour, and standing and volatizing for about one week under the shading condition to obtain a colorless blocky monocrystal product. The coordination polymer is easy to prepare, reaction time is short, the aftertreatment step is simple, and the coordination polymer is high in yield. Through the experiment, nitrite ions in the material can be selectively subjected to anion exchange reaction with fluoboric acid ions, hexafluorosilicic acid ions, nitrate radical ions and perchloric acid ions, and cannot be subjected to similar anion exchange reaction with benzoic acid ions, and acetate ions. The coordination polymer overcomes the limit of the conventional anion exchange material, an exchange process is simple and easy to realize, and the coordination polymer is expected to be actually applied in the field of ion exchange materials.

Owner:TIANJIN NORMAL UNIVERSITY

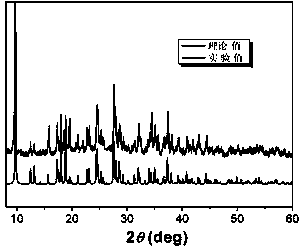

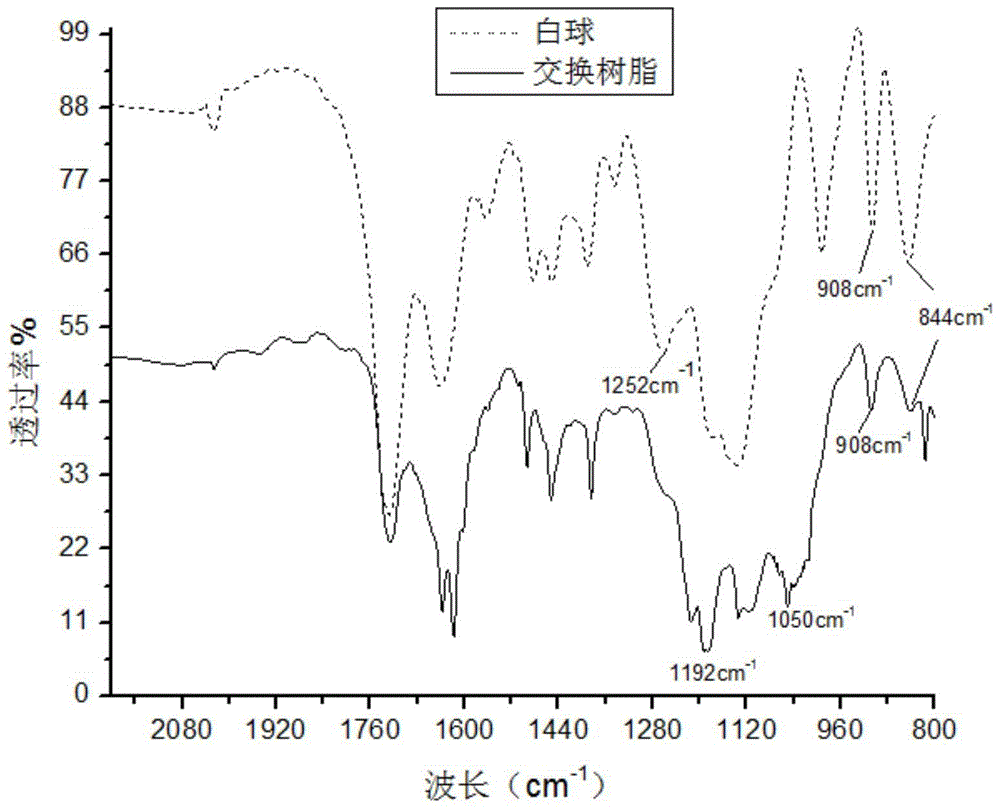

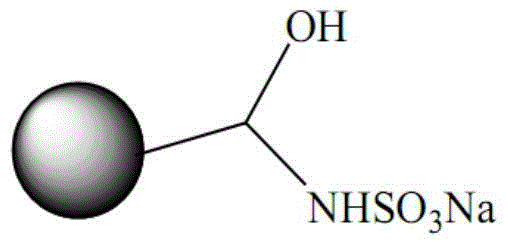

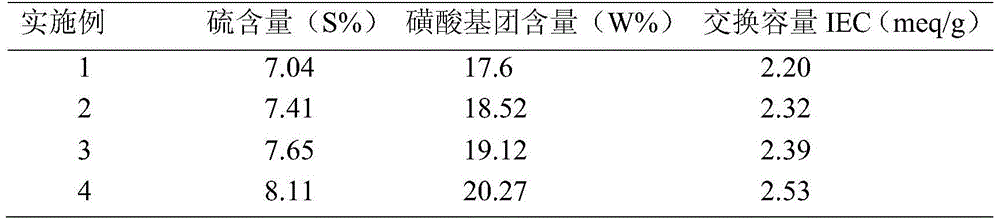

Sulfonic acid type strongly acidic cation exchange resin and preparation method thereof

ActiveCN104437676BReduced service lifeChange the manufacturing processCation exchangersStrong acidsGlycerol

The invention relates to a sulfonic acid type strong-acidity cation exchange resin. Random crosslinking copolymer beads of acrylic glycidol ester and divinylbenzene are used as a framework, an amino sulfonic group introduced by an epoxy group of a glycidol part in a copolymer through an open loop is used as a functional group, and the quality ratio of a construction unit of the acrylic glycidol ester to a construction unit of the divinylbenzene in the copolymer is 70:30-93:7. In the preparation process of the resin, a concentrated sulfuric acid, a fuming sulfuric acid and a chlorosulfonic acid, with strong oxidizing properties are not used as a sulfonating reagent, and the problem of environmental pollution caused by the discharge of a great deal of a waste acid and the problem of production safety in the traditional technology are solved. The sulfonic acid type strong-acidity cation exchange resin is spheroidal particles of which the particle size range is 0.5-1.2 mm, the content of the sulfonic group is 17.6-20.27wt%, and the ion exchange capacity is 2.20-2.53 meq / g.

Owner:SHANGHAI RESIN FACTORY

A kind of molecular sieve ion exchange method

ActiveCN103771434BSolve the problem of increased power consumptionLow exchangeable group contentCrystalline aluminosilicate zeolitesMolecular sieveIon exchange

The invention provides a molecular sieve ion exchange method. The method comprises the following steps: a bipolar membrane electrodialysis step comprising conducting bipolar membrane electrodialysis on an aqueous solution containing ions to obtain an acid liquid; an ion exchange step comprising enabling a molecular sieve and the acid liquid to be in contact with each other to implement ion exchange so as to obtain a molecular sieve slurry subjected to the iron exchange; a solid liquid separation step comprising conducting the solid liquid separation on the molecular sieve slurry subjected to the iron exchange to obtain a liquid phase and a solid phase, and conducting solid liquid separation after the pH of the liquid phase is regulated to be more than 8 to obtain a processing liquid; a step of circulating the processing liquid to the bipolar membrane electrodialysis step to replace at least part of the aqueous solution containing ions, and then conducting bipolar membrane electrodialysis to obtain an alkaline liquid and an acid liquid. In the method provided by the invention, the power consumption of the bipolar membrane electrodialysis step is low. In addition, the method can acquire higher ion exchange efficiency.

Owner:CHINA PETROLEUM & CHEM CORP +1

Metallic silver coordination polymer with two-dimensional lamellar structure, and preparation and application thereof

InactiveCN102516270BWith selective switchingEasy to manufactureAnion exchanger materialsSilver organic compoundsNitrite ionTetrafluoroborate

The invention relates to a 3,5-di(2-pyridyl)-4-(4-pyridyl)-1,2,4-triazolyl-silver (I) coordination polymer, and a preparation and application thereof. The compound is synthesized by the following steps: under normal temperature and pressure, mixing AgNO2 acetonitrile solution and ligand L chloroform solution, and keeping stirring for half an hour, and standing in a dark place to volatilize for about one week, thereby obtaining the colorless lumpy monocrystal product. The invention has the advantages of simple preparation technique, short reaction time, easy after-treatment and high yield. The experiment proves that nitrite ions in the material can selectively react with tetrafluoroborate ions, hexafluorosilicate ions, nitrate ions and perchlorate in an anion exchange mode, and benzoate ions and acetate ions can not perform similar anion exchange reaction. The material overcomes the limitation to the existing anion exchange material, the exchange process is simple and easy to implement, and thus, the invention is hopeful to practical application in the field of ion exchange materials.

Owner:TIANJIN NORMAL UNIVERSITY

Coordination polymers with selective ion exchange properties and their applications

InactiveCN105646897BWith selective switchingEasy to manufacturePolycrystalline material growthComplex ion-exchangersRheniumIon exchange

The invention relates to a coordination polymer with selective ion exchange performance and application thereof. The chemical formula of the coordination polymer is [Ag(L)(NO3)](CH3OH)(H2O)2, wherein L refers to 4,5-bis(4-pyridyl)-3-(2-pyridyl)-1,2,4-triazole. Under the normal-temperature normal-pressure dark condition, AgNO3 is prepared into a water solution to be dropwise added to the bottom of a test tube, and after a buffer layer is added, the ligand L dissolved in methyl alcohol is slowly added dropwise to the upper side of the test tube; standing and volatilizing are carried out, and colorless blocky crystals grow out in the test tube after about 3-4 days. An experiment proves that nitrate ions in a cavity of the material can be selectively subjected to anion exchange with perrhenate ions, and high capacity is shown to enriching and absorbing of metal rhenium. According to the material, the limitation of an existing anion exchange material is overcome, the advantages that the exchange process is simple and feasible, and the exchange speed is high are achieved, and therefore the coordination polymer is expected to be actually applied to the field of ion exchange materials.

Owner:TIANJIN NORMAL UNIVERSITY

A method of ion-exchanging solid substances containing exchangeable ions

ActiveCN103768951BLow exchangeable group contentImprove ion exchange efficiencySemi-permeable membranesWater insolubleIon exchange

The invention provides an ion exchange method for a solid substance with exchangeable ions, which includes the following steps: bipolar membrane electrodialysis: performing bipolar membrane electrodialysis to a water solution with ions, so as to obtain an acid liquor; ion exchange: performing ion exchanging to the contacted solid substance with exchangeable ions and the acid liquor, wherein ions capable of forming a water insoluble substance with OH<-> are contained in the exchangeable ions in the solid substance; solid-liquid separation: performing solid-liquid separation to slurry of the solid substance subjected to ion exchange, so as to obtain the solid phase and the liquid phase; performing solid-liquid separation after the pH value of the liquid phase is adjusted above 8 and obtaining a conditioning fluid; circulating the conditioning fluid to the step of bipolar membrane electrodialysis, substituting at least part of the water solution with ions with the conditioning fluid for bipolar membrane electrodialysis. In the method provided by the invention, power consumption for bipolar membrane electrodialysis is low, and higher ion exchange efficiency is obtained through the method.

Owner:CHINA PETROLEUM & CHEM CORP +1

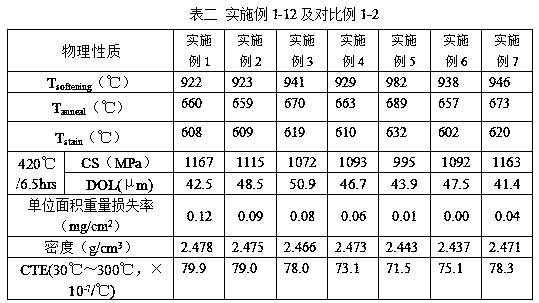

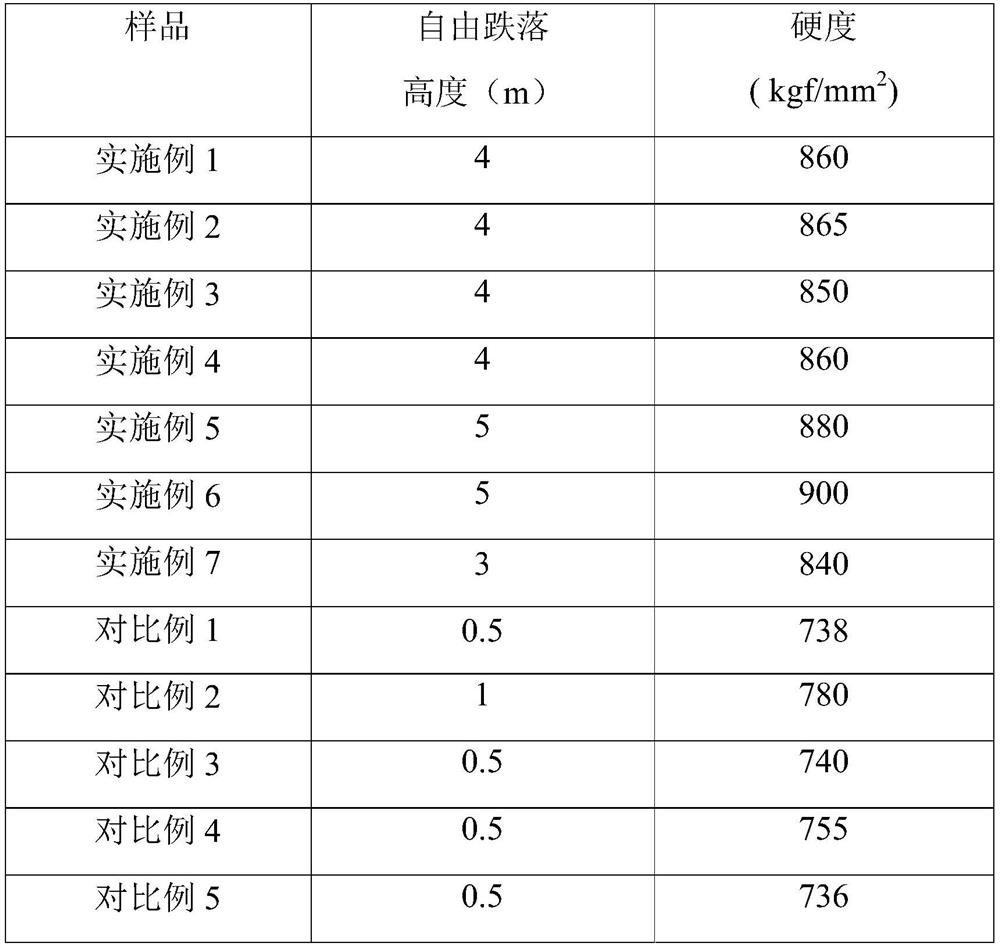

Chemical toughening agent, microcrystalline ceramic material and preparation method thereof and electronic device

The invention relates to a chemical toughening agent, a microcrystalline ceramic material, a preparation method thereof and an electronic device. The chemical toughening agent includes molten salt A and molten salt B, and the ratio of the amount of molten salt A to molten salt B is (1 to 9): (1 to 8); molten salt A includes at least one of sodium nitrate and potassium nitrate. One, the molten salt B includes at least two of sodium carbonate, sodium sulfate, sodium chloride, potassium carbonate, potassium sulfate and potassium chloride. The present invention obtains a mixed molten salt with a higher melting point by mixing specific types of molten salt A and molten salt B in a specific proportion. The melting point of the chemical toughening agent is higher than 500° C. Strengthening can improve the toughness and impact resistance of the microcrystalline ceramic material. The protective shell used for preparing electronic products can improve the service life of electronic products.

Owner:WEIDALI IND CHIBI CO LTD

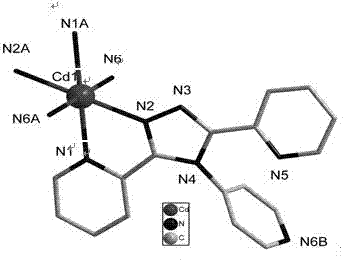

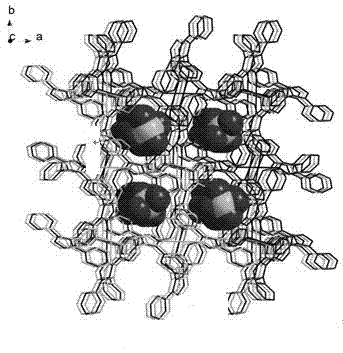

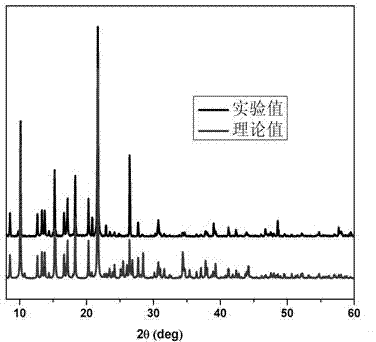

Coordination polymer with three-dimensional open framework structure and its preparation and application

InactiveCN102603780BWith selective switchingEasy to manufactureAnion exchanger materialsCadmium organic compoundsPolymer scienceAcetate ion

The invention relates to a coordination polymer with a three-dimensional open-framework structure as well as preparation and application thereof. The chemical formula of the coordination polymer is: [CdL2] (ClO4)2, wherein the L is 3, 5-bis (2-pyridyl)-4-(4-pyridyl)-1,2,4-triazole. The synthesis of the compound adopts a method of stirring at a normal temperature. The preparation comprises the steps of: mixing an aqueous solution of Cd (ClO4)2 with a methanol solution of the ligand L at the normal temperature and pressure, filtering the reaction solution after stirring, standing the filtrate, slowly volatilizing the solvent and obtaining colourless blocky monocrystal products after about one week. The preparation of the coordination polymer is simple in process, short in reaction time, easy in aftertreatment and higher in yield. The coordination polymer has the three-dimensional open-framework structure to ensure that perchlorate ion accommodated in the cavity can be selectively in anion exchange reaction with acetate ion. The coordination polymer has the advantages that the limitation of a conventional anion exchange material is overcome and the exchange process is simple and very easy to carry out and is expected to be used in practical applications in the field of ion exchange materials.

Owner:TIANJIN NORMAL UNIVERSITY

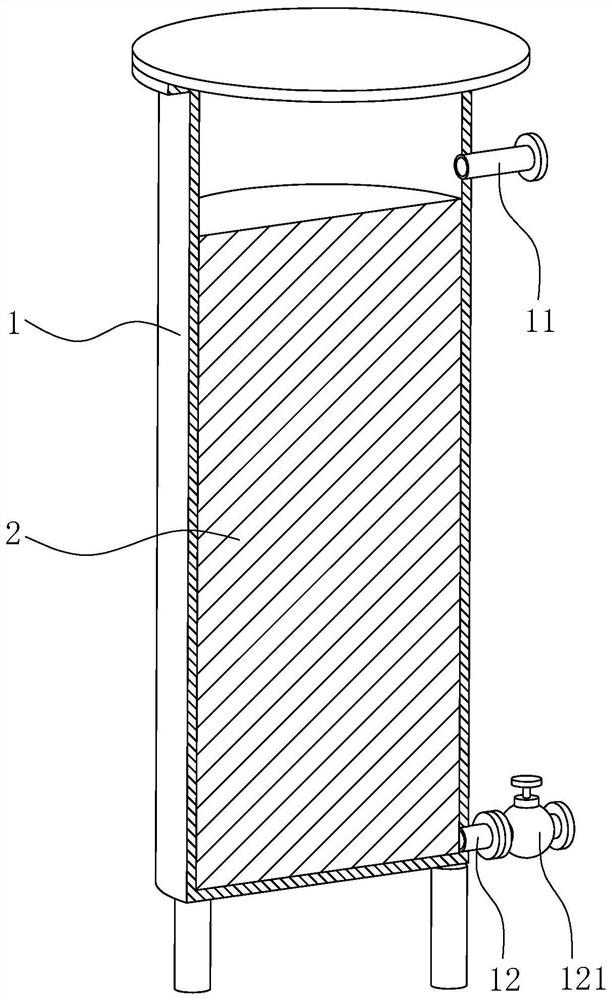

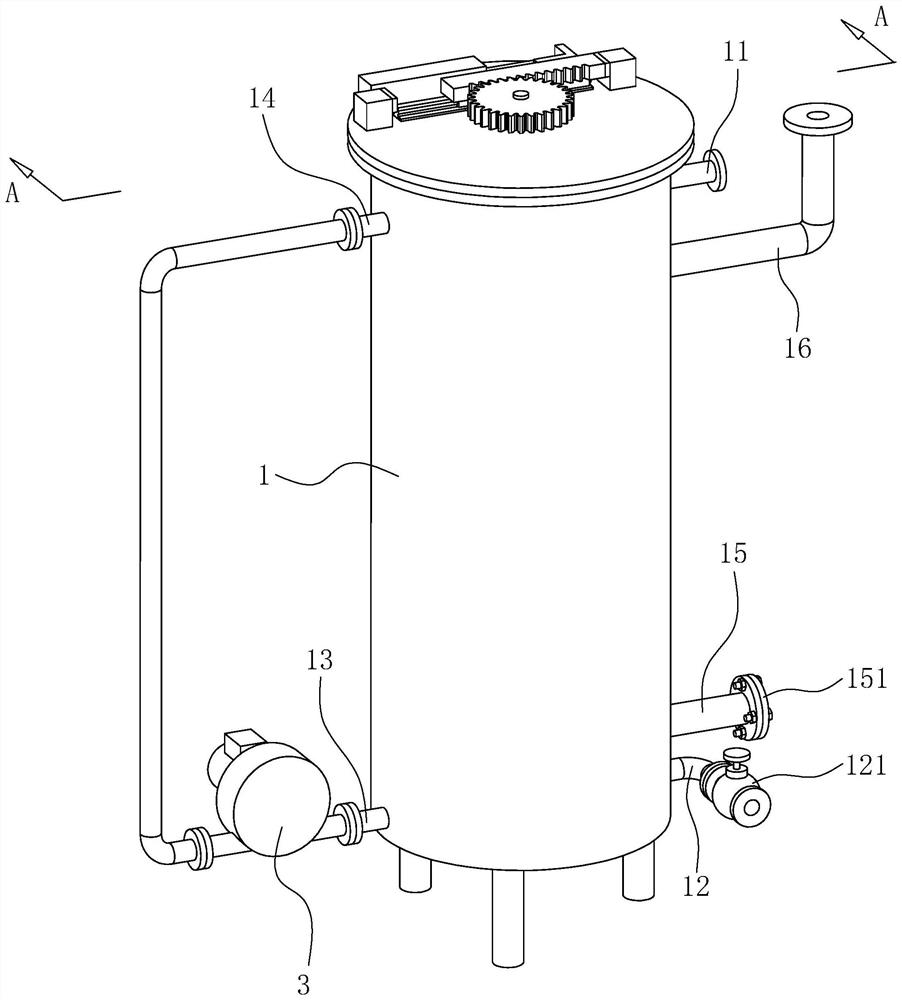

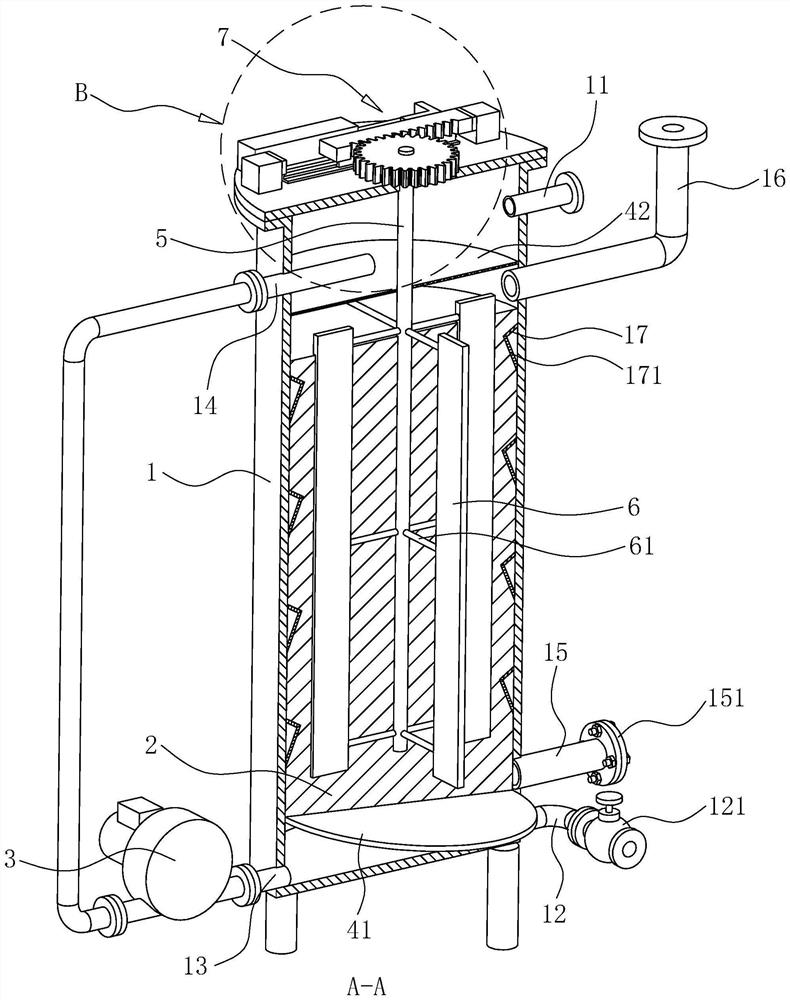

Ion exchange resin tank for improving isopropanol preparation efficiency

ActiveCN114713296AImprove liquidityImprove ion exchange efficiencyIon-exchange process apparatusChemical industryIon exchangeIon-exchange resin

The invention discloses an ion exchange resin tank capable of improving isopropanol preparation efficiency, and relates to the field of isopropanol preparation devices, the ion exchange resin tank comprises a tank body, and ion exchange resin is arranged in the tank body; a liquid inlet pipe is fixedly arranged at the upper end of the tank body, and a liquid outlet pipe is fixedly arranged at the lower end; a liquid return outlet pipe is fixedly arranged at the lower end of the tank body, and a liquid return inlet pipe is fixedly arranged at the upper end; a liquid return pump for driving liquid in the liquid return outlet pipe to flow into the liquid return inlet pipe is connected between the liquid return outlet pipe and the liquid return inlet pipe; and the liquid return outlet pipe and the liquid return inlet pipe are communicated with the interior of the tank body. The liquid return pump inputs liquid at the lower end of the tank body to the upper end of the tank body through the liquid return inlet pipe, and the liquid at the upper end of the tank body flows downwards, so that the liquidity of the liquid in the tank body is improved, and an isopropanol raw material in the tank body is in full contact with ion exchange resin; therefore, the ion exchange efficiency between the isopropanol raw material and the ion exchange resin is improved, and the preparation efficiency of isopropanol is improved.

Owner:JIANGSU DENOIR TECH CO LTD

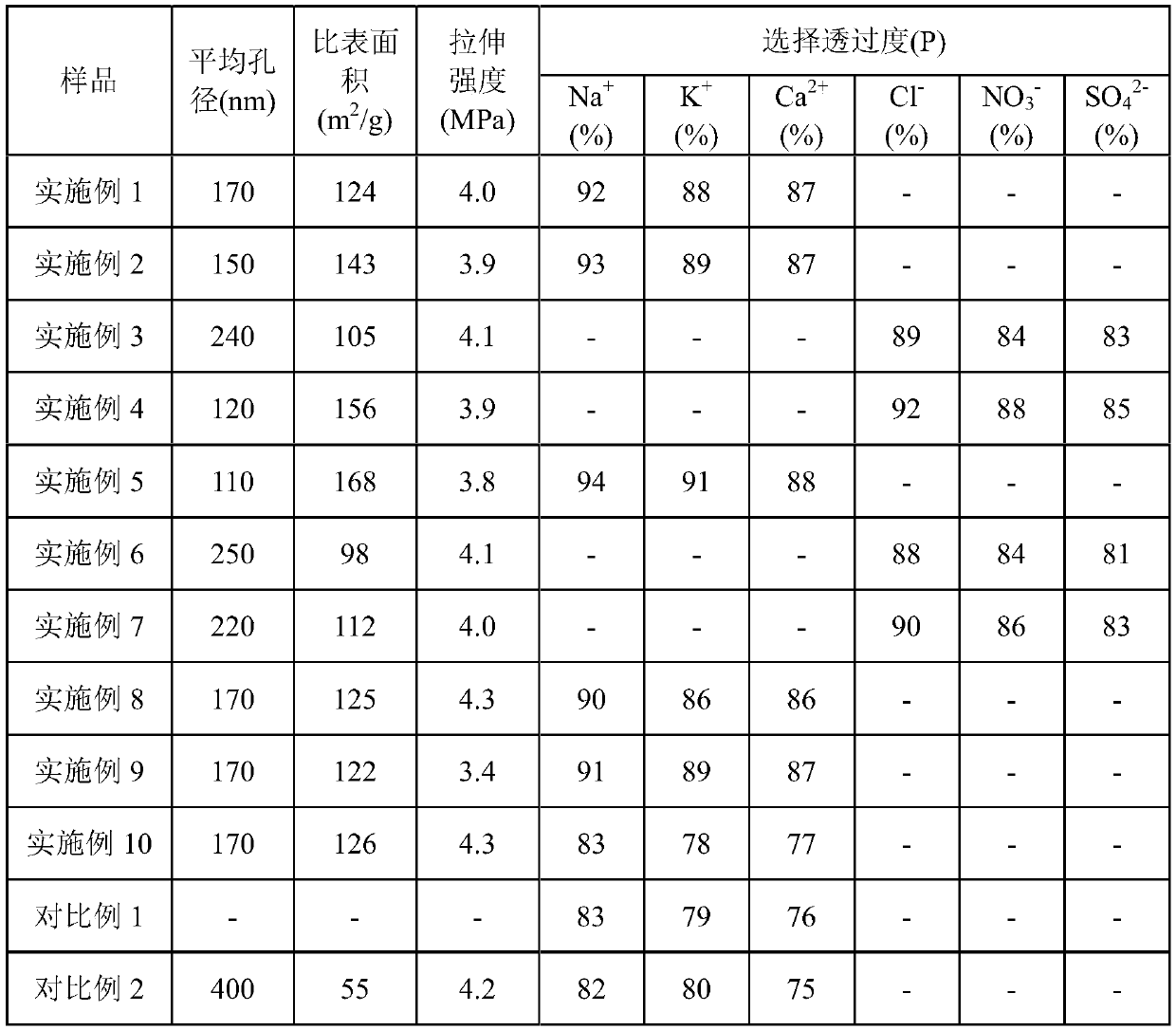

Ion exchange resin, and preparation method and application thereof

InactiveCN110496652AHigh specific surface areaIncreased ion exchange ratePhysical treatmentFibre typesIon exchangePhysical chemistry

The invention provides ion exchange resin, and a preparation method and an application thereof. The ion exchange resin comprises an electrospun fiber film with an ion exchange group, and the fiber diameter of the electrospun fiber film is 150-250 nm; and the electrospun fiber film is a copolymer spun film. The fiber diameter of the ion exchange resin is controlled within the above range, and the pore diameter and the specific surface area of the ion exchange resin are effectively regulated, so the ion exchange efficiency of the ion exchange resin is improved. The preparation method adopts a copolymer spinning solution, the spinning process is smooth and is easy to implement, and optimized spinning process parameters are combined to continuously spin superfine fibers with a diameter of 150-250 nm.

Owner:上海洁晟环保科技有限公司

Ion exchanger

PendingUS20220258071A1Suppresses occurrence of turbulenceImprove ion exchange efficiencyCation exchanger materialsOrganic anion exchangersIon exchangeEngineering

An ion exchanger includes a housing, a tube member, and an ion exchange resin. The housing includes an inlet port and an outlet port. The tube member is arranged inside the housing. The ion exchange resin is arranged between the tube member and the housing. A first flow passage and a second flow passage are formed in the housing. The first flow passage is configured to cause the coolant that has flowed in through the inlet port to flow directly to the outlet port. The second flow passage is configured to cause the coolant that has flowed in through the inlet port and passed through the ion exchange resin to flow to the outlet port. The first flow passage and the second flow passage are formed to join together in a state of being oriented in a same direction toward the outlet port.

Owner:TOYOTA BOSHOKU KK

A kind of strongly acidic cation exchange resin and preparation method thereof

Owner:SHANGHAI RESIN FACTORY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com