Sulfonic acid type strongly acidic cation exchange resin and preparation method thereof

A strong acid cation, exchange resin technology, applied in cation exchange, ion exchange, chemical instruments and methods, etc., can solve the problems of waste of water resources, production safety, waste acid discharge and pollute the environment, etc., and achieves high spatial freedom and swelling degree. big effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

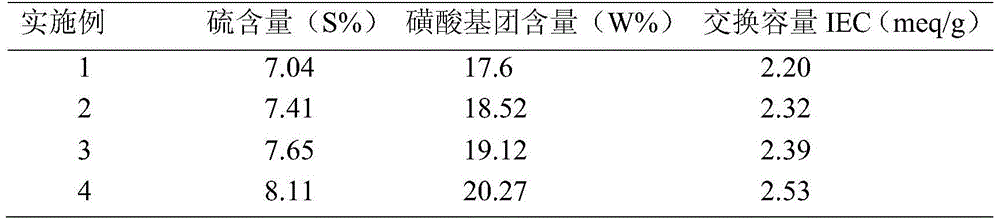

Embodiment 1

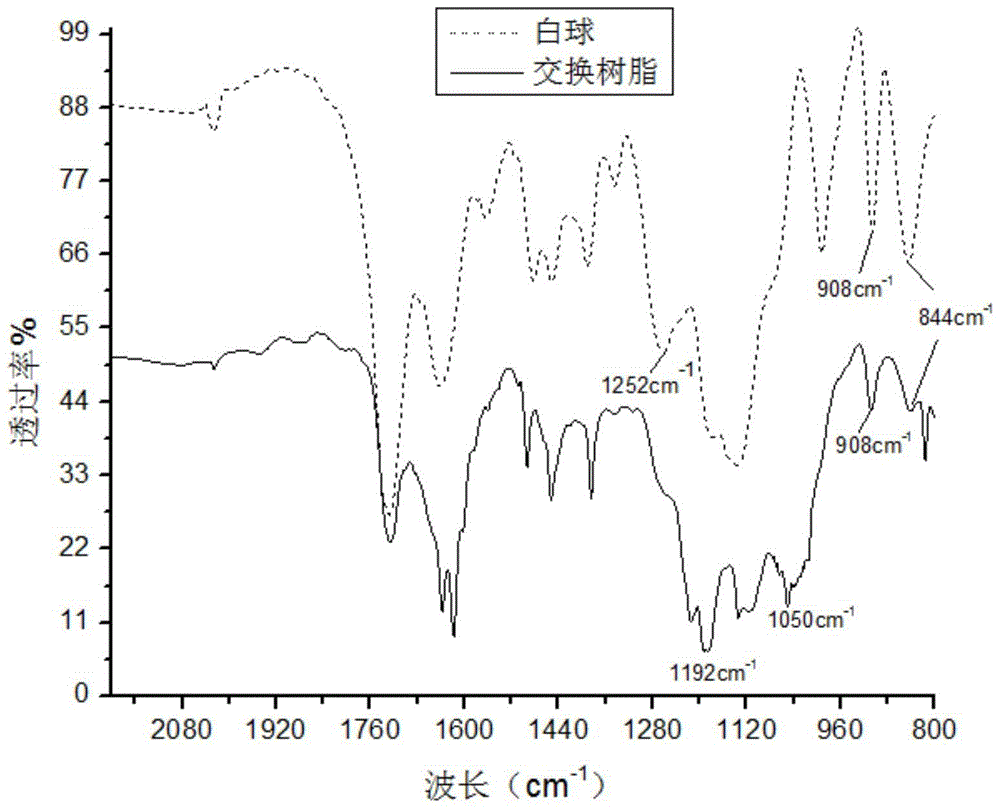

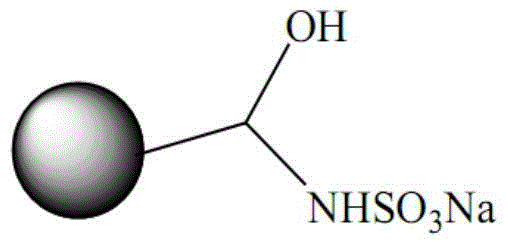

[0030] Preparation of novel strongly acidic cation exchange resin:

[0031] (1) Configuration of water phase raw materials: put 0.25g of gelatin into a four-necked flask filled with 60.0g of deionized water, stir and heat up to 45°C, add 0.025g of hydroxymethyl cellulose after the gelatin is dissolved, and use 5% The pH of the aqueous phase was adjusted to 10 with aqueous NaOH and 5% aqueous boric acid.

[0032] (2) Preparation of oil phase raw material: 0.02g dibenzoyl peroxide is added in 14.0 glycidyl methacrylate (net content 99%) and 7.5 divinylbenzene (net content 80%) mixed solution, with 120 Turn / min and stir for 30min.

[0033] (3) Add the oil phase prepared in the above step (2) to the water phase raw material in step (1) and stir at a speed of 1°C / min to raise the temperature to 80°C.

[0034] (4) Insulate at 80°C for 3h, then raise the temperature to 95°C for 5h. After the heat preservation is over, cool the material, filter out the liquid, wash the solid with 8...

Embodiment 2

[0038] Preparation of novel strongly acidic cation exchange resin:

[0039] (1) Configuration of water phase raw materials: put 0.25g of gelatin into a four-necked flask filled with 60.0g of deionized water, stir and heat up to 45°C, add 0.025g of hydroxymethyl cellulose after the gelatin is dissolved, and use 5% The pH of the aqueous phase was adjusted to 12 with aqueous NaOH and 5% aqueous boric acid.

[0040] (2) Preparation of oil phase raw materials: 0.02g of azobisisobutyronitrile is added to 16.1g of glycidyl methacrylate (99%) and 5.0g of divinylbenzene (80%) mixed solution, at 120 rpm min and stir for 20 min.

[0041] (3) Add the oil phase prepared in the above step (2) to the water phase raw material in step (1) and stir at a speed of 2°C / min to raise the temperature to 80°C.

[0042] (4) Keep the temperature at 80° C. for 4 hours, then raise the temperature to 95° C. and keep it for 3 hours. After the heat preservation is over, cool the material, filter off the l...

Embodiment 3

[0045] Preparation of novel strongly acidic cation exchange resin:

[0046] (1) Configuration of water phase raw materials: put 0.25g of gelatin into a four-necked flask filled with 60.0g of deionized water, stir and heat up to 45°C, add 0.025g of hydroxymethyl cellulose after the gelatin is dissolved, and use 5% The pH of the aqueous phase was adjusted to 11 with aqueous NaOH and 5% aqueous boric acid.

[0047] (2) Preparation of oil phase raw materials: 0.02g dibenzoyl peroxide is added in 17.2g glycidyl methacrylate (99%) and 3.8g divinylbenzene (80%) mixed solution, with 120 rpm min stirring for 25 min.

[0048] (3) Add the oil phase prepared in the above step (2) to the water phase raw material in step (1) and stir at a speed of 2°C / min to raise the temperature to 80°C.

[0049] (4) Insulate at 80°C for 4h, then raise the temperature to 95°C for 2h. After the heat preservation is over, cool the material, filter out the liquid, wash the solid with 80°C hot water for 3 t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com