Flexible strain sensor with crack structure and preparation method thereof

A strain sensor, flexible technology, applied in the direction of electric/magnetic solid deformation measurement, electromagnetic measuring device, etc., can solve the problems of poor sensitivity of flexible strain sensor, restrict the development of flexible strain sensor, high production cost, etc., achieve low production cost and easy processing , the effect of high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

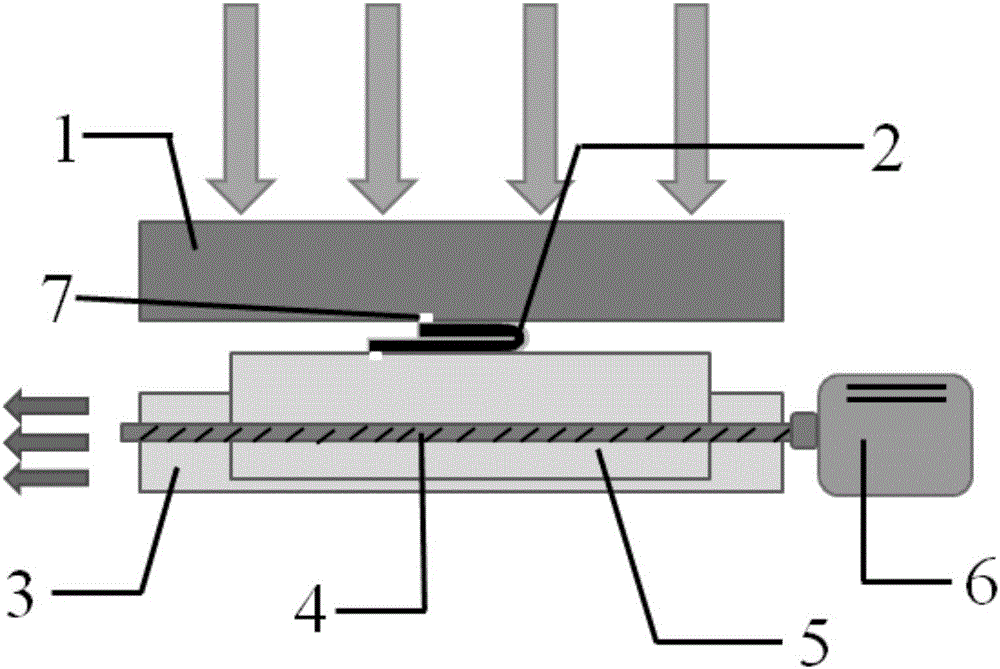

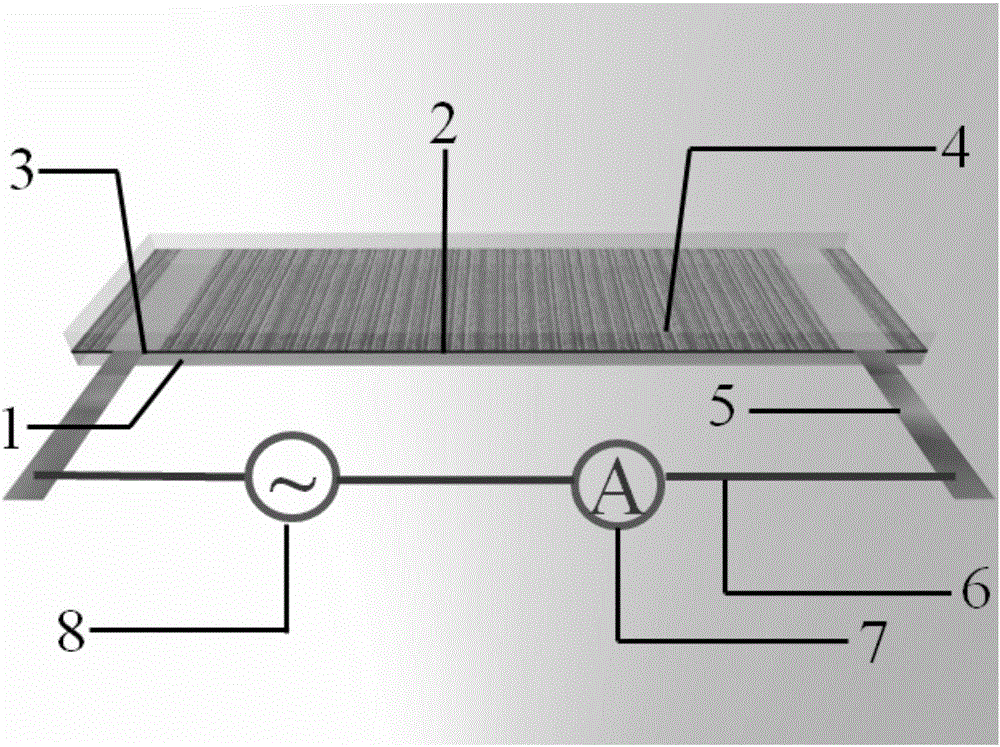

[0045] In this embodiment, thermoplastic polyurethane (TPU) is used as a flexible substrate, graphene is used as a conductive layer, and polydimethylsiloxane (PDMS) is used as a protective layer to prepare a flexible strain sensor with a crack structure. The specific process is as follows:

[0046] a. Preheat 3 g of TPU pellets at 205°C for 10 minutes, then hot-press for 5 minutes under a pressure of 2 MPa, and finally cool to room temperature under a pressure of 2 MPa to prepare a TPU film; wherein, the density of the TPU pellets used is 1.12 g / cm 3 , the melt index is 17.5g / 10min (215°C, 10kg), and the thickness of the prepared TPU film is 0.15mm;

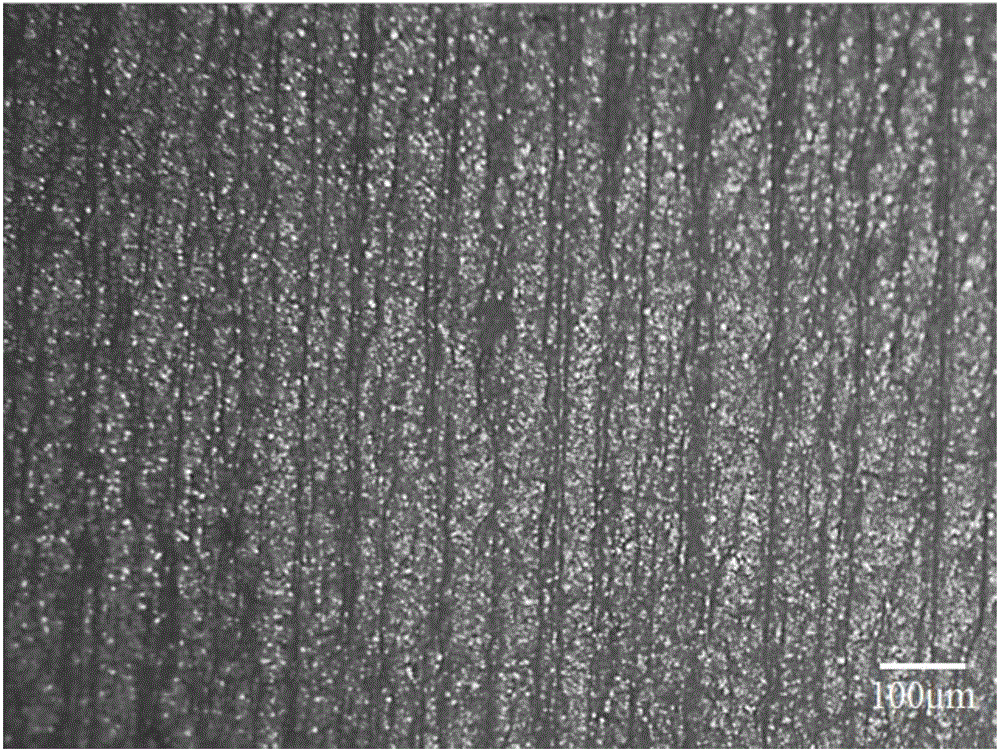

[0047] b. Roll-coat 2.5 mL of graphene conductive paste on the TPU film pressed and formed in step a, and place the composite material coated with conductive paste in an oven for 20 minutes at an oven temperature of 70 ° C. , to form a conductive layer on its surface; the graphene conductive paste is purchased commercially, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com