Patents

Literature

150results about How to "High cost of preparation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flexible strain sensor with crack structure and preparation method thereof

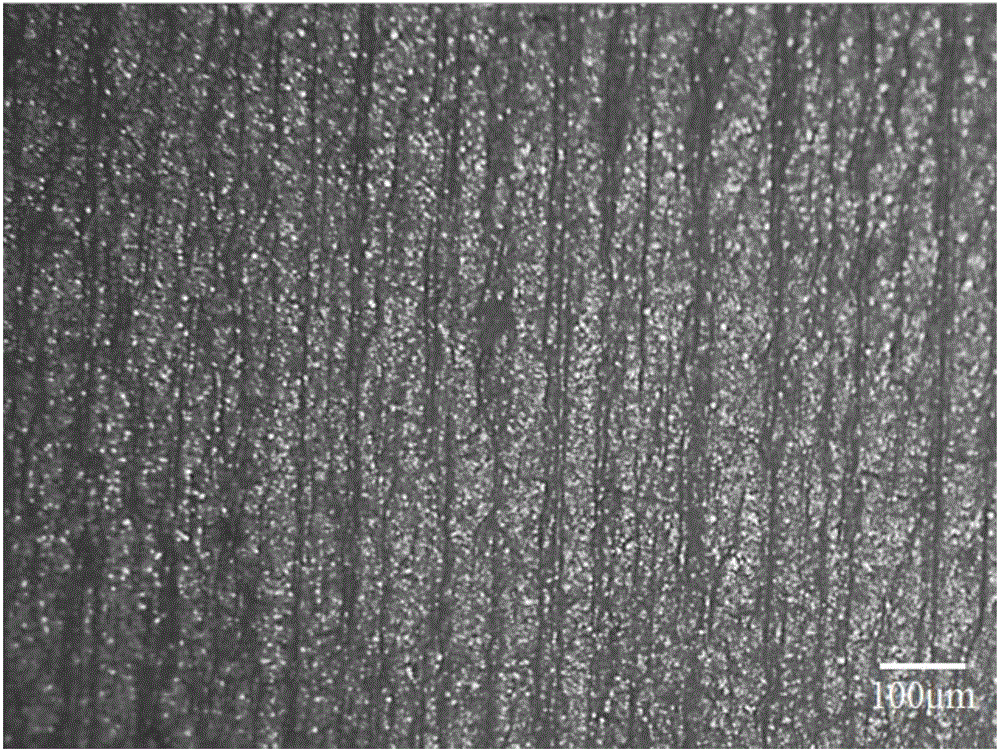

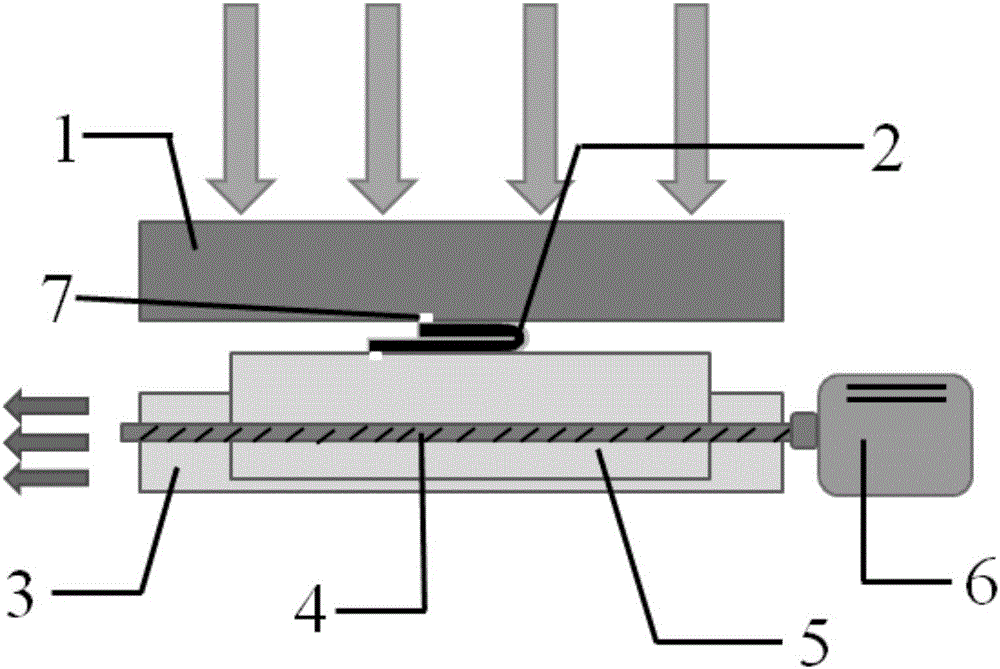

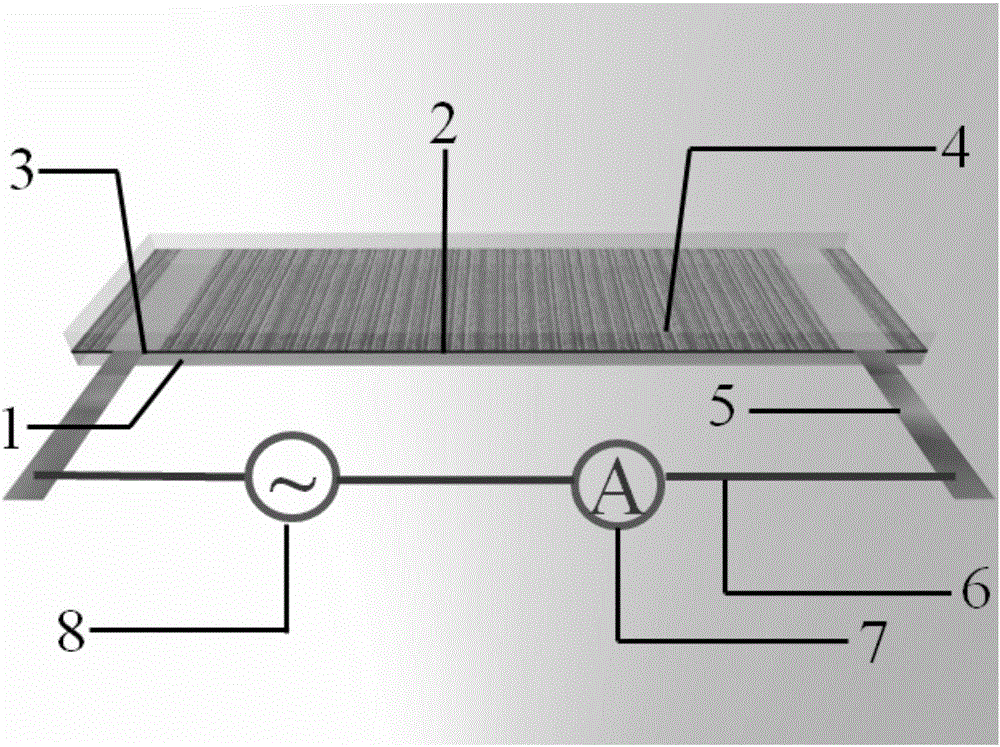

ActiveCN105783697AHigh sensitivityLarge resistance changeElectrical/magnetic solid deformation measurementEngineeringProtection layer

The invention belongs to the technical field of sensor manufacturing and especially relates to a flexible strain sensor with a crack structure and a preparation method thereof. The invention provides a flexible strain sensor comprising a flexible substrate, a conducting coating which is coated on the flexible substrate and provided with a prefabricated crack structure, a pair of electrodes which are positioned at two ends of the conducting coating surface, and a protection layer which covers the conducting coating surface and is made from flexible polymer. By means of the flexible strain sensor provided by the invention, small strain changes can be accurately monitored; the preparation method is simple and low in cost; the flexible strain sensor has high sensitivity, good stability and long service life, and can be bended and twisted.

Owner:ZHENGZHOU UNIV

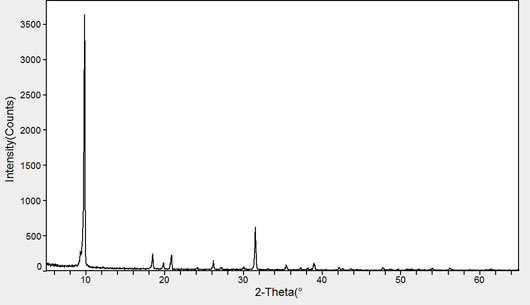

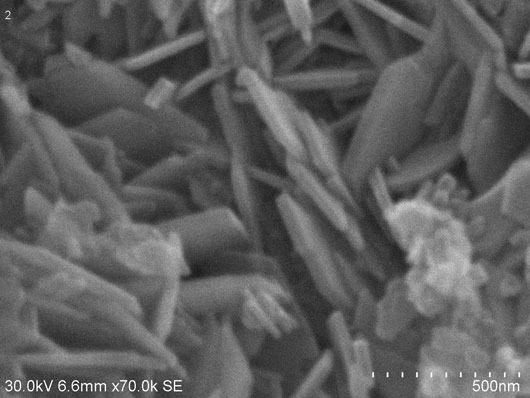

Preparation method of superfine nanometer lithium iron phosphate electrode material and application thereof

InactiveCN102674291AImprove electrochemical performanceIncrease capacityCell electrodesNanotechnologyLithium iron phosphatePhosphate

The invention discloses a preparation method of a superfine nanometer lithium iron phosphate electrode material, comprising the following steps of: firstly, taking an iron source compound and a phosphorus source compound as raw materials to obtain nanometer ferrous phosphate as a precursor; and secondly, using the ferrous phosphate and the lithium source compound to prepare the superfine nano lithium iron phosphate electrode material. The preparation method of ferrous phosphate, disclosed by the invention, has a simple production process; the obtained nanometer ferrous phosphate can be used for preparing the high-purity superfine nanometer lithium iron phosphate; and the ferrous valence state is not changed when the ferrous phosphate is used for preparing the lithium iron phosphate, thus, no carbon source compound or reducing agent needs to to be added to change the iron valence state, and then the carbon-coated lithium iron phosphate or non-carbon-coated lithium iron phosphate can be directly prepared. The nanometer lithium iron phosphate manufactured by the nanometer ferrous phosphate precursor has excellent performance, good discharge capacity and voltage platform performance under high capability and high multiplying power, and long cycle life.

Owner:GUANGXI NUOFANG ENERGY STORAGE TECH

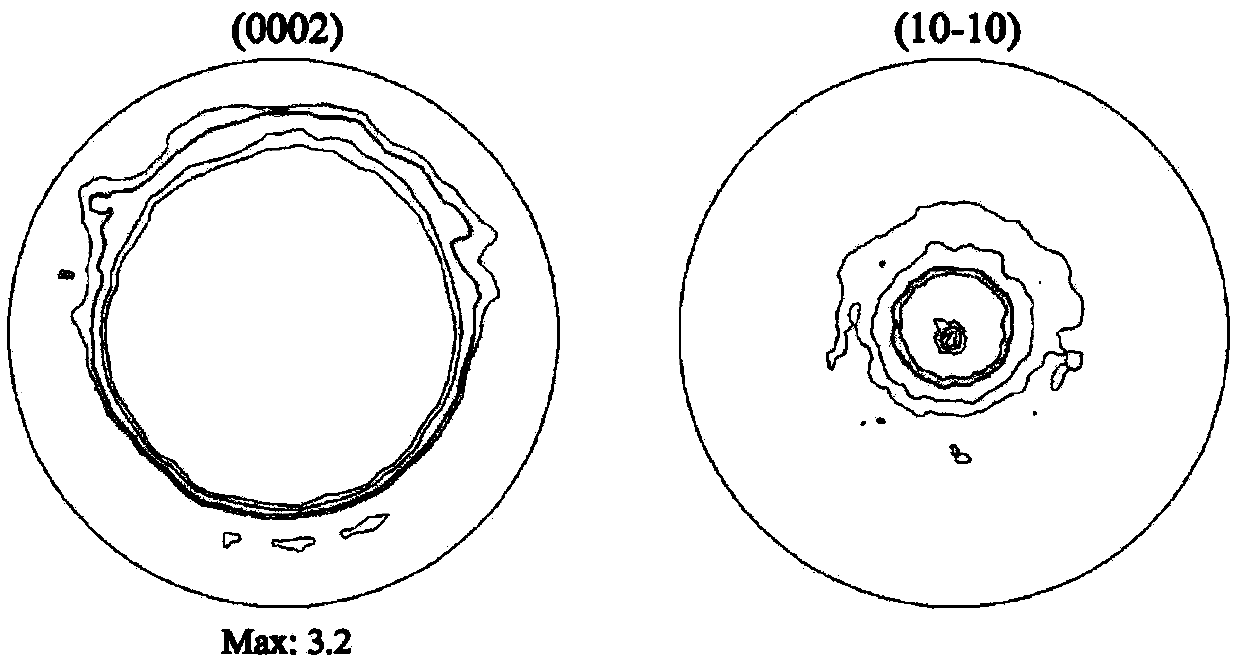

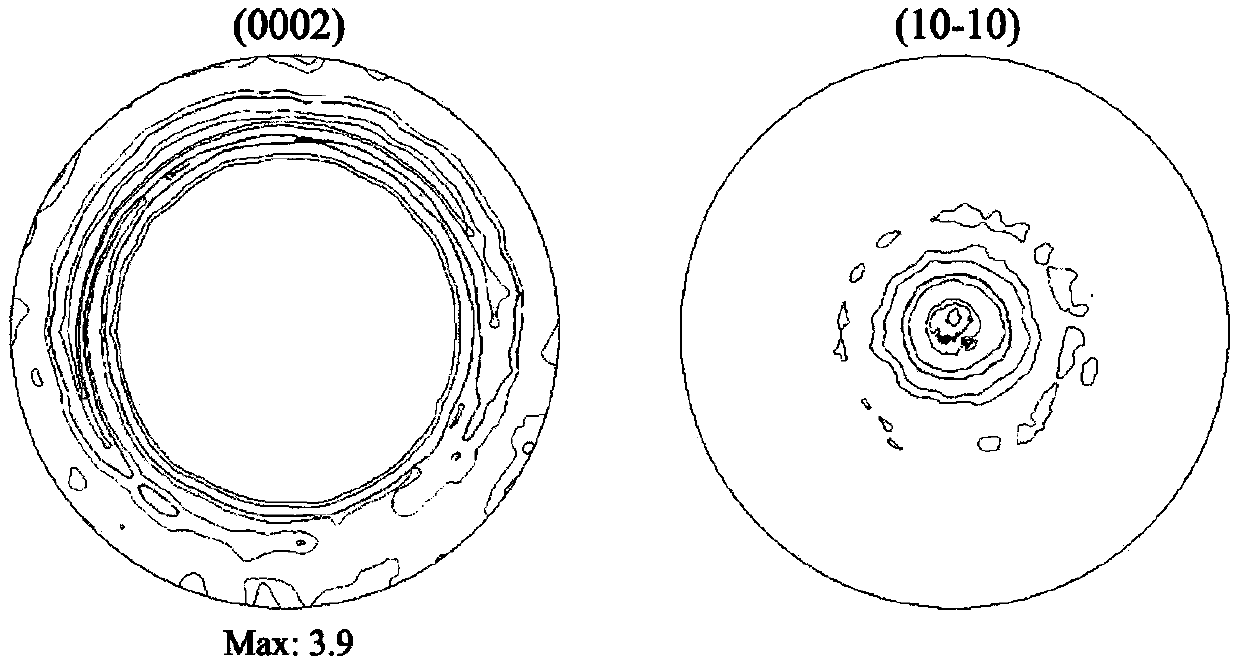

Mg-gd-y-zn-zr alloy and process for preparing the same

A Mg—Gd—Y—Zn—Zr alloy with high strength and toughness, corrosion resistance and anti-flammability and a process for preparation thereof are disclosed. The components and the mass percentages thereof in the Mg—Gd—Y—Zn—Zr alloy are: 3.0%≤Gd≤9.0%, 1.0%≤Y≤6.0%, 0.5%≤Zn≤3.0%, 0.2%≤Zr≤1.5%, the balance being Mg and inevitable impurities. The process for preparation thereof comprises: adding pure Mg into a smelting furnace for heating, then introducing mixed gases of CO2 and SF6 into the furnace for protection; adding other raw materials in sequence when the pure Mg is completely melted; preparing an ingot; conducting a homogenization treatment on the ingot prior to extrusion; conducting an aging treatment on the extruded alloy. A wrought magnesium alloy having superior overall performances and good fracture toughness, corrosion resistance and anti-flammability, with a small amount of rare earth element is obtained by adjusting the proportion of the alloy elements and by conventional casting, extrusion and heat treatment processes. The cost of the alloy is reduced while the strength of the alloy is maintained.

Owner:THE BOEING CO

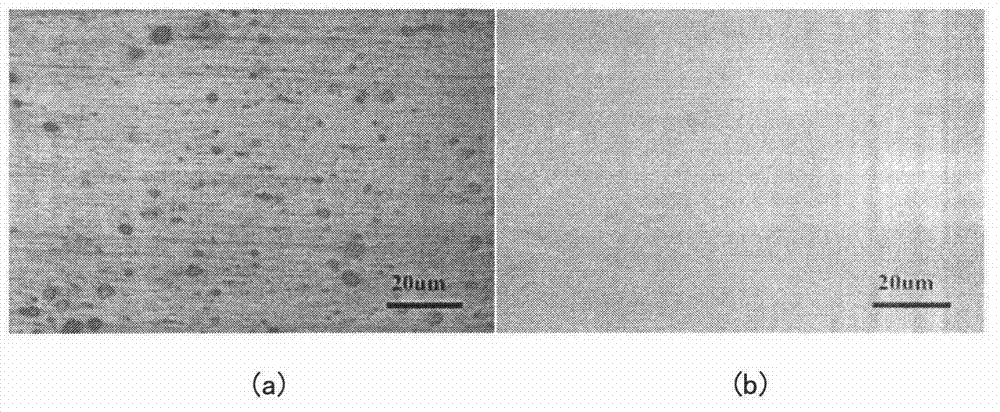

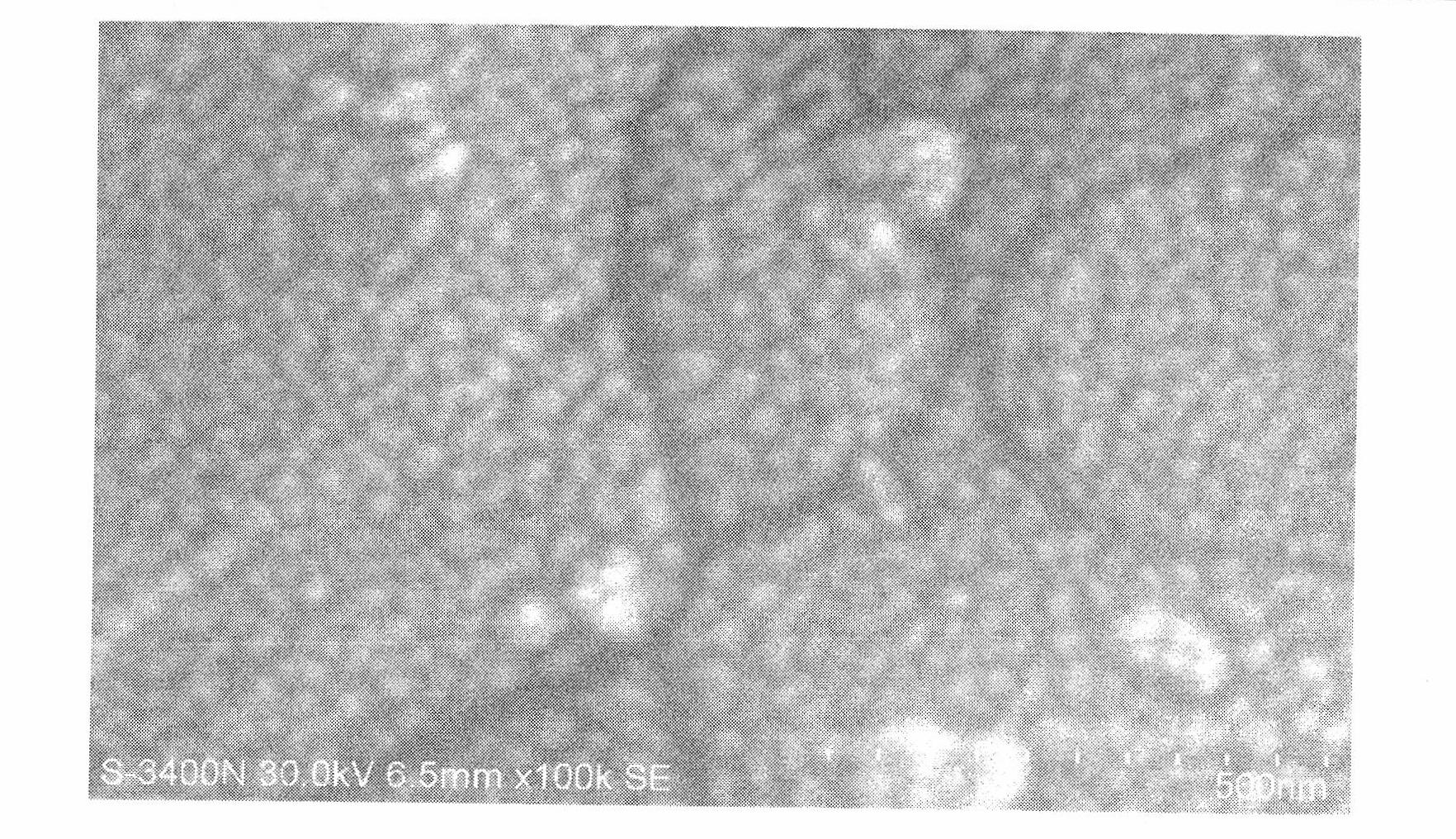

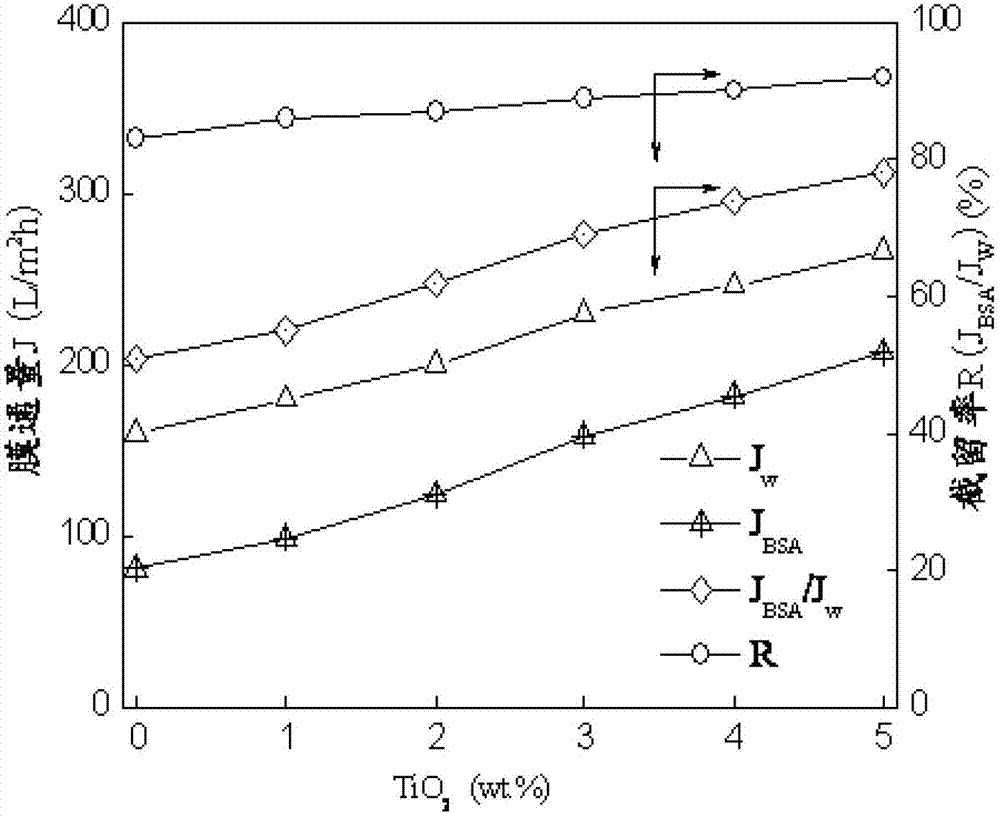

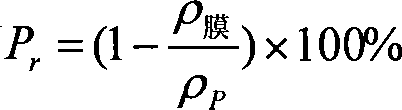

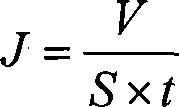

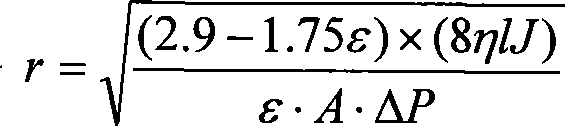

TiO2 / PVDF cross blend cation exchange membrane and preparation method

InactiveCN101091882AImprove hydrophilicityHigh mechanical strengthSemi-permeable membranesPolypropyleneGlass sheet

The invention publishes a method for producing the TiO2 / PVDF blending positive ion exchange membrane, which involves a method for producing high polymer organic membrane. This invention enhances the water affinity of PVDF positive ion exchange membrane, the mechanical strength and anti-pollution capacity. The positive ion exchange membrane includes FI ethane, polypropylene, crosslinking agent, titanium dioxide grain and organic solvent with activity groups. This invention is as follows: a. dissolving the FI ethane and polypropylene in the organic solvent; B. joining crosslinking agent; C. filtering insoluble substance; D. joining titanium dioxide grain; E, mixing the solution well-proportioned and deaeration; F, creating membrane on the glass plate; G, drying, and solidifying. The TiO2 / PVDF blending positive ion exchange membrane does not only retains the fine characteristic of FI ethane exchange membrane, but also improves the membrane surface energy,and enhances the water affinity, and increases the ability to repel outside pollutant.

Owner:HARBIN INST OF TECH

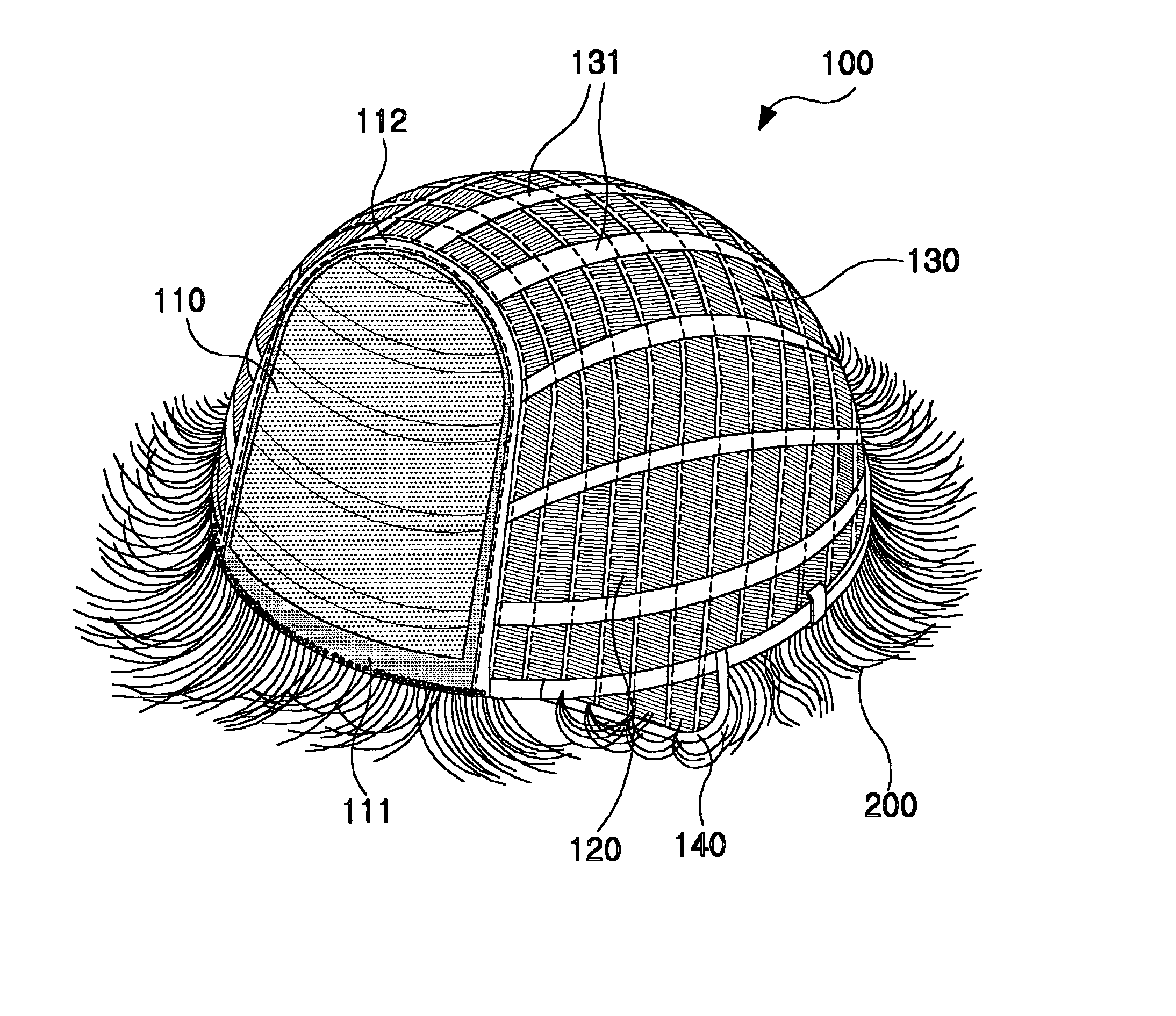

Wig comprising cap with nano-silver

InactiveUS20060260627A1Negating economic benefitLower antibacterial activity of dimerHair accessoriesToupeesHead scalpFiber

Disclosed herein is a wig comprising cap with nano-silver that exhibits antibacterial activity. The wig comprising cap with nano-silver of the current invention exhibits antibacterial and disinfecting effects on the hair and scalp of a wearer, by applying the net and lace each formed of fibers with nano-silver to the cap of the wig, and / or by applying nano-silver to the hair of the wig. Thus, when wearing the wig of the current invention, the scalp of the wearer may be kept healthy, and the occurrence of skin diseases due to bacteria maybe prevented.

Owner:DONGAN KREASI INDONESIA

Process for preparing nano metal particles/carbon composite material

A metal nano particle / carbon composite material is prepared from hydrocarbon compound and transition metal compound in a weight ratio of 1:(0.01-1) through proportional mixing, charring reaction at 400-550 deg.C in inert gas for 6 hr, and extracting by hot fusion. Said hydrocarbon compound may be paraffine, olefin, etc. Said transition metal compound may be cyclopentadienyl transition metal compound, carbonyl transition metal compound, etc. Its advantages are simple preparing process and high purity.

Owner:BEIJING UNIV OF CHEM TECH

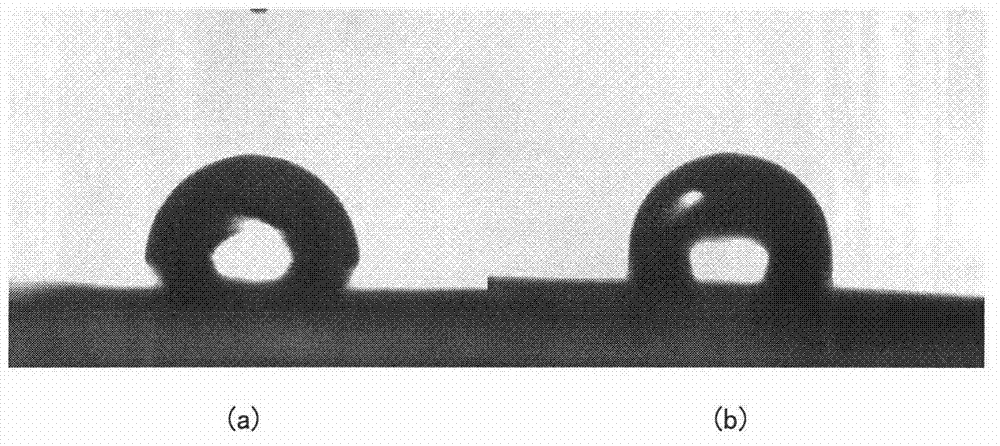

Preparation method for core-shell fluorinated polyurethane-acrylate latex

InactiveCN102924664AImprove grafting efficiencyFast polymerization rateCoatingsPolymer scienceFunctional monomer

The invention relates to a preparation method for core-shell fluorinated polyurethane-acrylate latex. The method comprises the following steps: placing polyether glycol and toluene diisocynate into a stirrer to prepare polyurethane; and emulsifying an emulsifier, butyl acrylate, methyl methacrylate, a functional monomer and a proper amount of water at high speed to prepare the core-shell fluorinated polyurethane-acrylate latex. By the method, the defects that the fluorinated acrylate in the prior art is independent of oil and water phases due to hydrophobicity and lipophobicity, effective micelle is difficult to form by the general surfactant and the grafting ratio is low are overcome. The core-shell fluorinated polyurethane-acrylate latex has a core-shell structure and the fluorinated acrylate is enriched in the shell, so a latex film has a large water contact angle. The using amount of the fluorinated acrylate monomer (G04) is 1 to 2 percent of the weight of the monomer and the using amount of polyurethane (PU) is 10 percent of the weight of a composite latex solid, so the preparation cost is low. The emulsifier does not need a fluorine-containing surfactant, so the polymerization rate is high, the grafting efficiency of the fluorinated acrylate monomer is high and the latex is stored stably.

Owner:江苏日出化工有限公司 +1

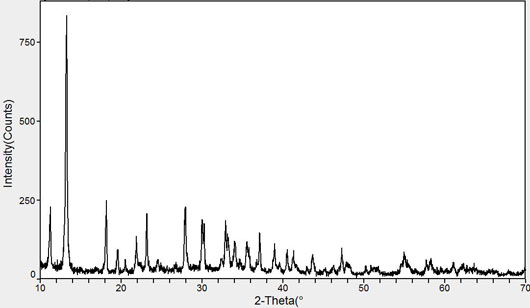

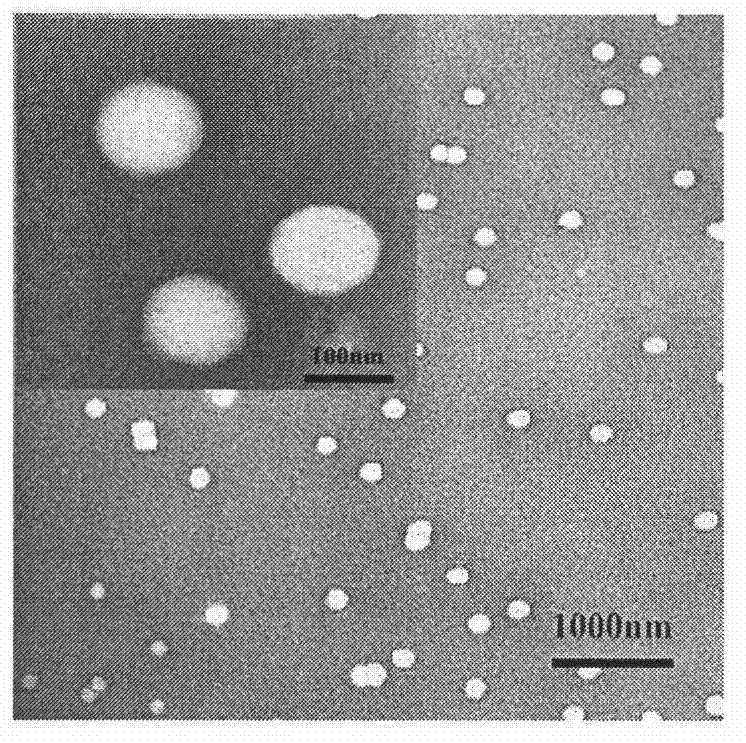

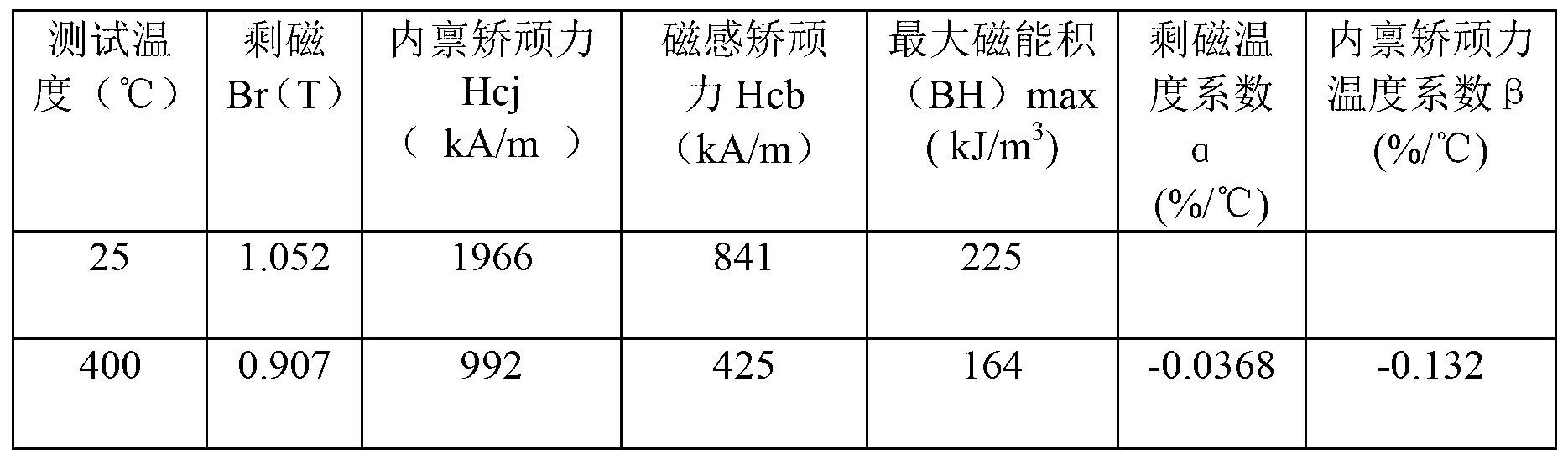

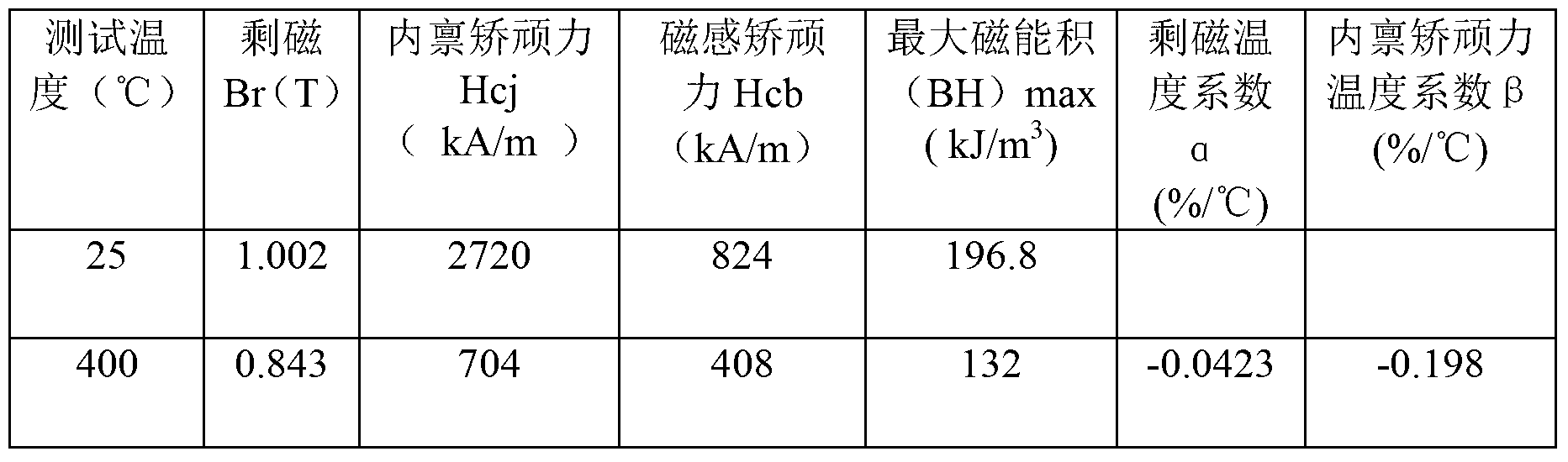

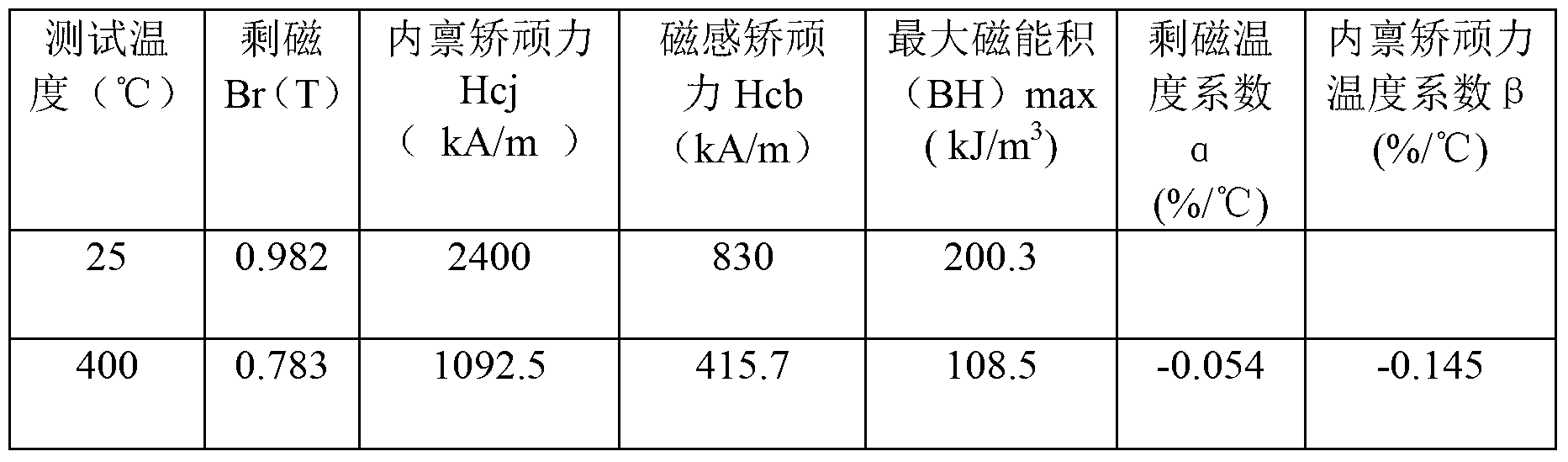

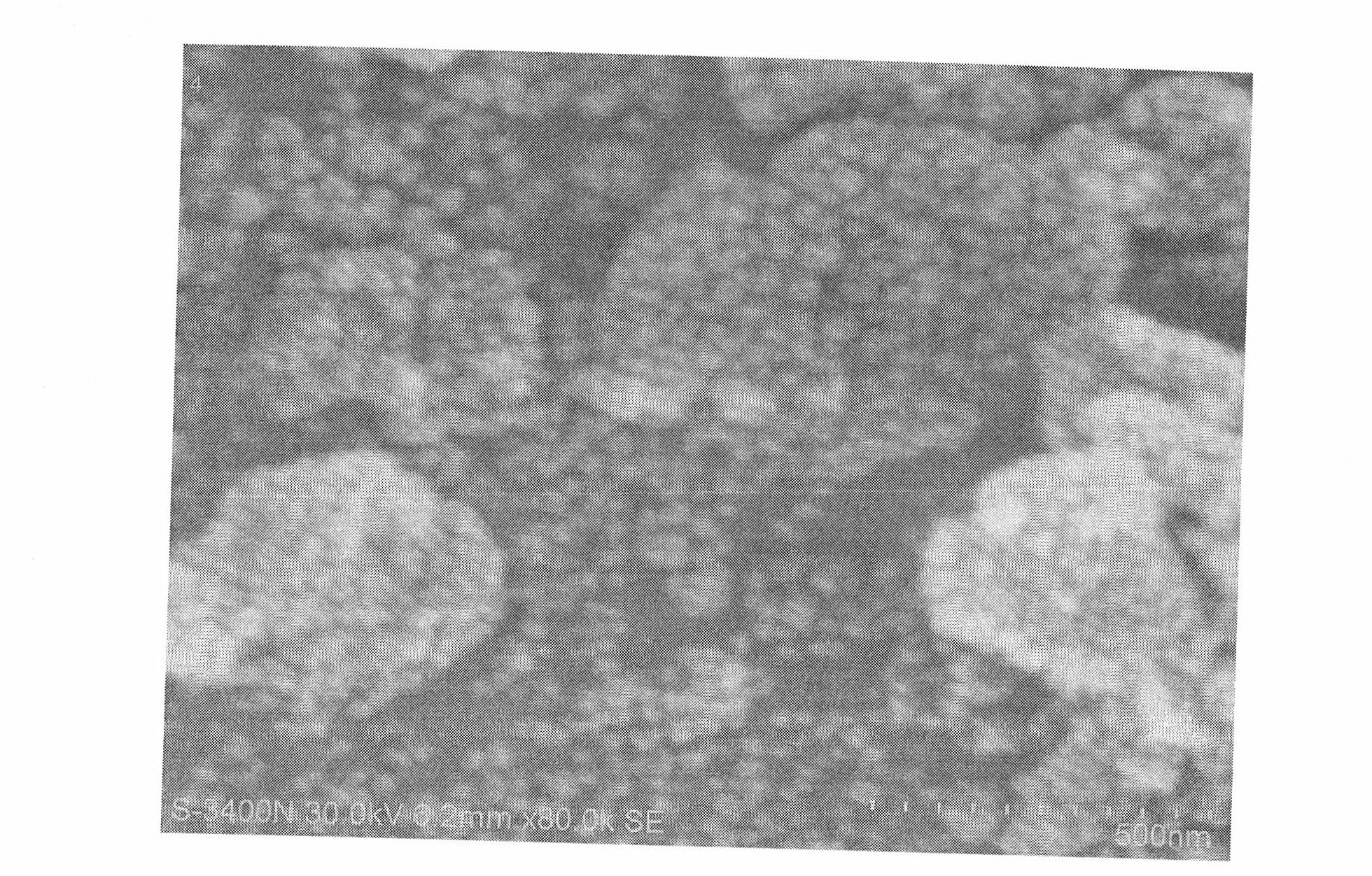

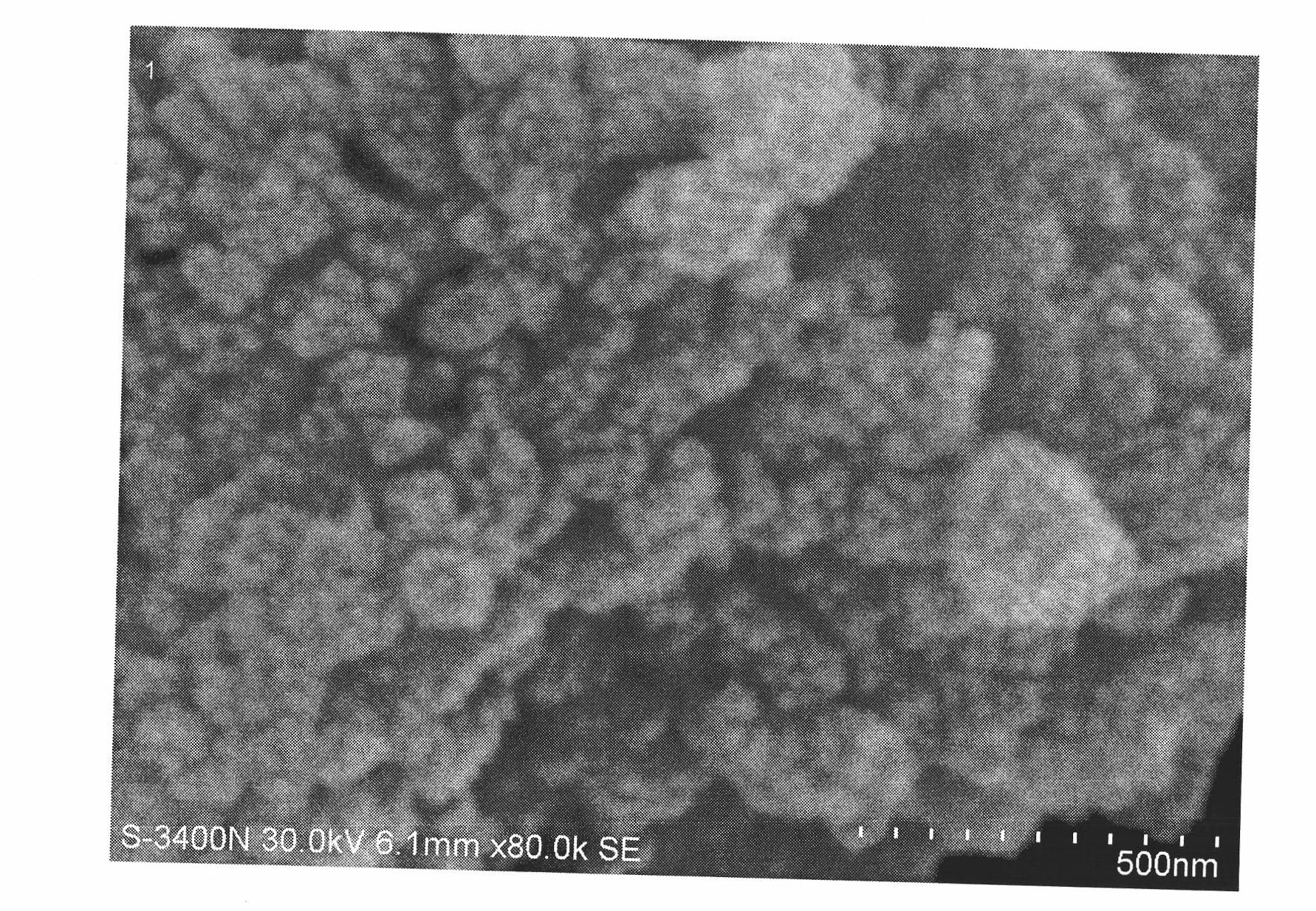

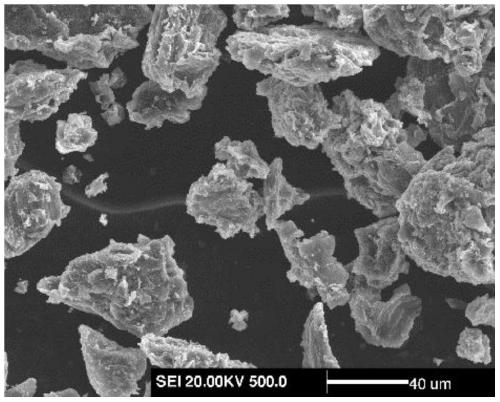

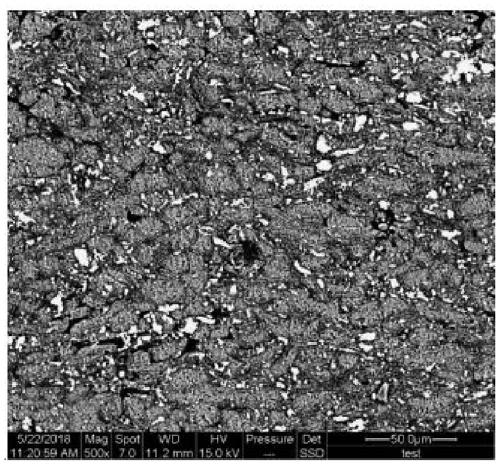

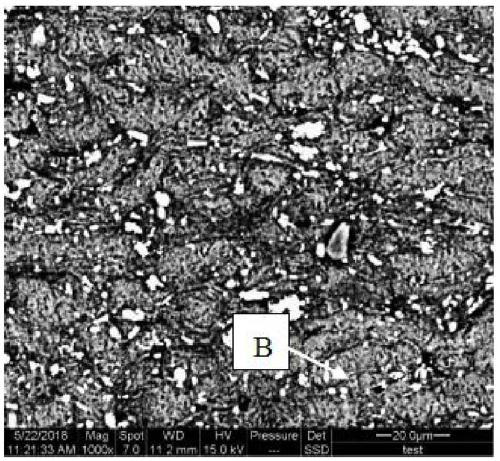

Samarium cobalt permanent magnetic material and preparation method thereof

InactiveCN103325513AHigh cost of preparationReduce raw material costsMagnetic materialsTemperature coefficientChemical Ingredients

The invention discloses a samarium cobalt permanent magnetic material and a preparation method thereof. The samarium cobalt permanent magnetic material is prepared from the following chemical ingredients by mass percent: 24.5-26% of samarium, 52-56% of cobalt, 7.5-12% of iron, 6.5-8% of copper, and 2-4% of zirconium. The samarium cobalt permanent magnet disclosed by the invention has high coercivity and low temperature coefficient; the magnetic performance at the temperature of 400-450 DEG C is that the residual magnetism Br is 0.783-0.907 T; the intrinsic coercivity Hcj is 704-1092.5 kA / m; the maximal magnetic level (BH)max is 108.5-164 kJ / m<3>; the temperature coefficient alpha of the residual magnetism is -0.0368% / DEG C to -0.054% / DEG C; and the temperature coefficient beta of the intrinsic coercivity is -0.132% / DEG C to -0.198% / DEG C. Thus, the samarium cobalt permanent magnetic material is simple in process and low in manufacturing cost.

Owner:湖南航天有限责任公司

Method for preparing presoma of active electrode material of nano-lithium ion battery and application thereof

ActiveCN102082264AHighlight substantive featuresSignificant progressCell electrodesNanotechnologyCarbon sourceLithium electrode

The invention provides a method for preparing a precursor of an active electrode material of a nano-lithium ion battery. The method comprises the following steps: adopting an organic solvent method to mix a lithium source compound with other metal source compounds in an organic solvent under the condition of adding carbon source compounds or not adding carbon source compounds; heating to react a mixture for a fixed time and then stopping the reaction; separating the organic solvent; and drying to obtain the precursor. The precursor is a nano-sized powder with even particle distribution. An electrode material obtained by roasting the nano-sized precursor has good performances of high capacity, high multiplying power and longer cycle life.

Owner:GUANGXI NUOFANG ENERGY STORAGE TECH

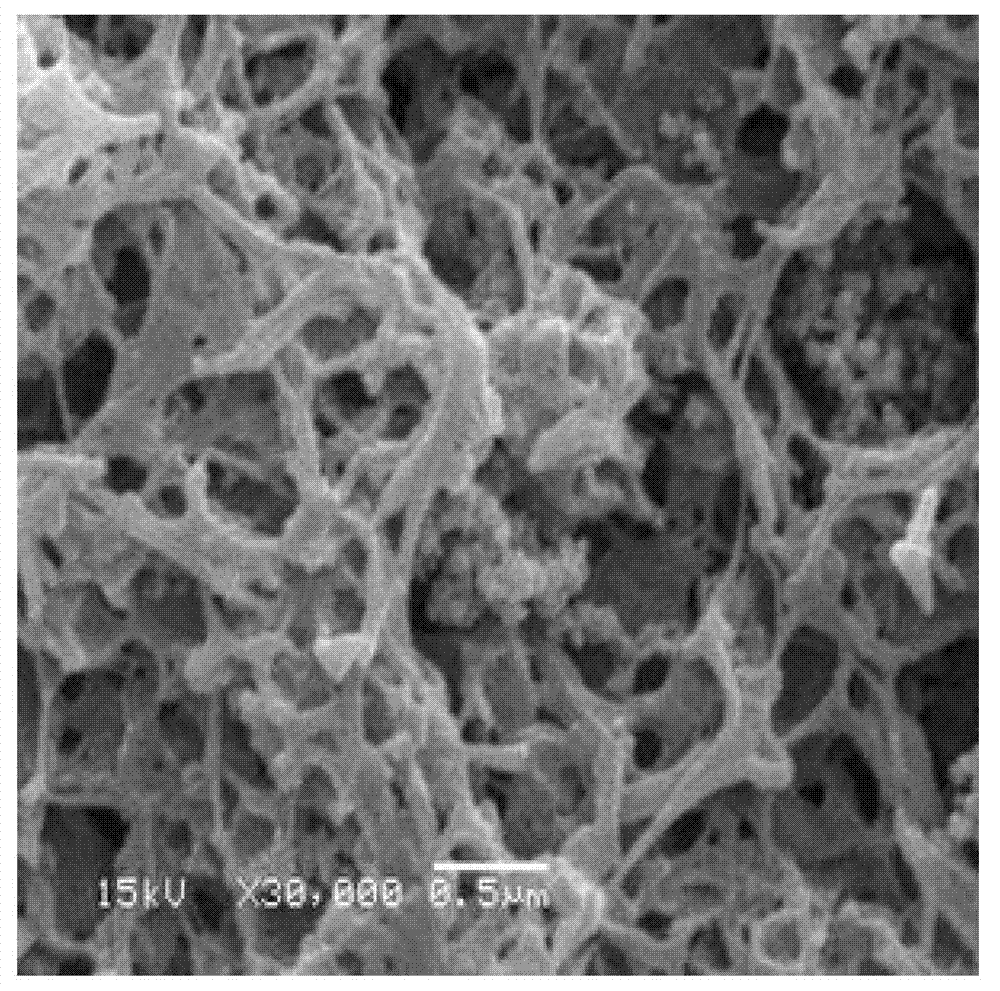

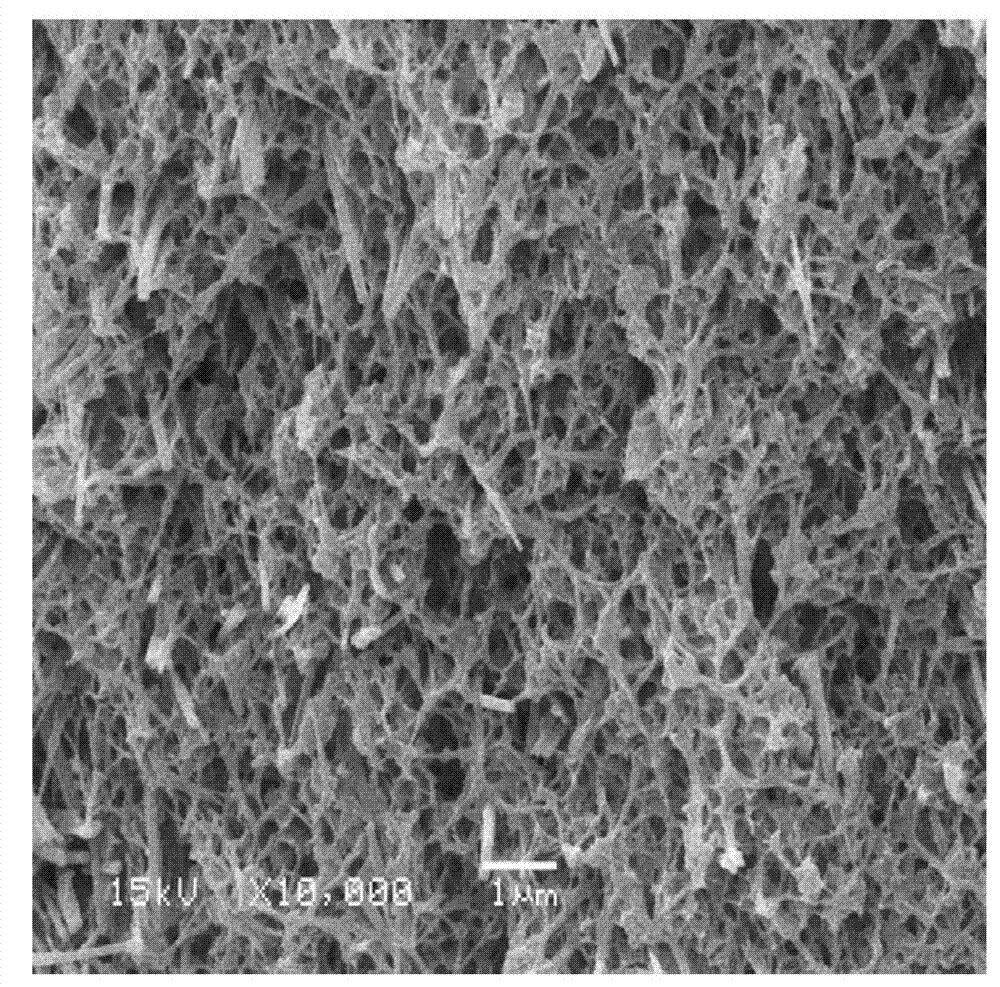

Novel polyvinylidene fluoride film as well as preparation method and application thereof

InactiveCN102728240AEasy reunionEasy to drainSemi-permeable membranesWater/sewage treatment bu osmosis/dialysisOrganic solventNanowire

The invention relates to a titanium oxide nanowire modified polyvinylidene fluoride separation film and a preparation method of the film. The titanium oxide nanowire modified polyvinylidene fluoride separation film comprises polyvinylidene fluoride (PVDF) accounting for 18-25wt% of the total mass, organic solvent accounting for 70-80wt% of the total mass, porogen accounting for 3-5wt% of the total mass, dispersing agent accounting for 0.1-1wt% of the total mass and titanium oxide nanowire accounting for 1-5wt% of PVDF. The modified film solves the problem that the PVDF-TiO2 nanoparticles are easily agglomerated and can easily run away, and has stability and durability.

Owner:CHANGZHOU UNIV

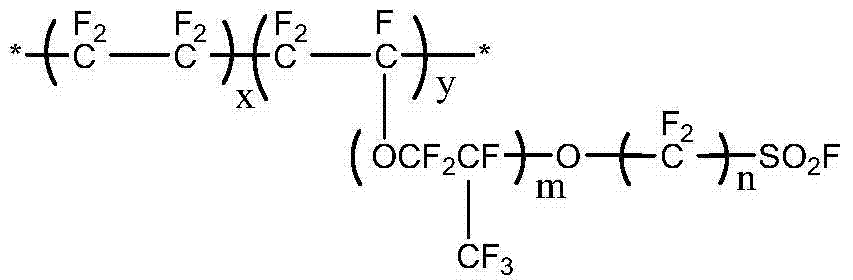

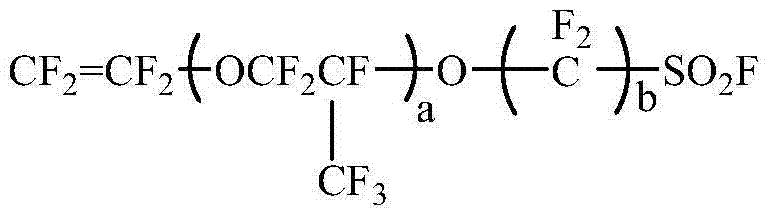

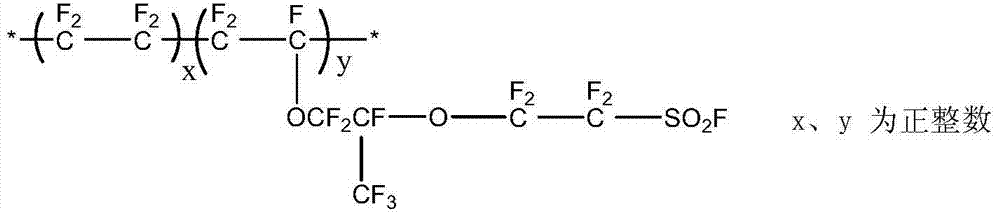

Preparation method of porous perfluorinated sulfonic acid resin for catalysts

ActiveCN104774284AGood compatibilityGood dispersionOrganic compound preparationOrganic-compounds/hydrides/coordination-complexes catalystsVinyl etherDistillation

The invention relates to a preparation method of porous perfluorinated sulfonic acid resin for catalysts, wherein the preparation method comprises that perfluoro(sulfonyl vinyl)ether and tetrafluoroethylene are polymerized under the condition of co-existence of a solvent, a pore-forming agent and an initiating agent to obtain the product, the perfluorinated sulfonic acid resin having low equivalent weight and low molecular weight is used as the pore-forming agent, the solvent is recycled by a way of adding deionized water and a dispersant and carrying out distillation, at the same time, the resin is molded, after further drying, a granular material is obtained, and moreover, a mixture of one or more of perfluorinated hydrocarbon / perfluorinated cyclic ether / chlorofluorocarbon are used as an extraction agent for extracting the pore-forming agent so as to form a porous structure. The method has simple operating conditions, has no need for high temperature and high pressure, and solves the problem in the prior art that effective catalytic component loss is difficult to overcome during a using process, and the service life of the catalyst is increased; and at the same time, due to the existence of the porous structure, the specific surface area is increased, and the active component utilization rate is improved.

Owner:SHANDONG DONGYUE WEILAI HYDROGEN ENERGY MATERIAL CO LTD

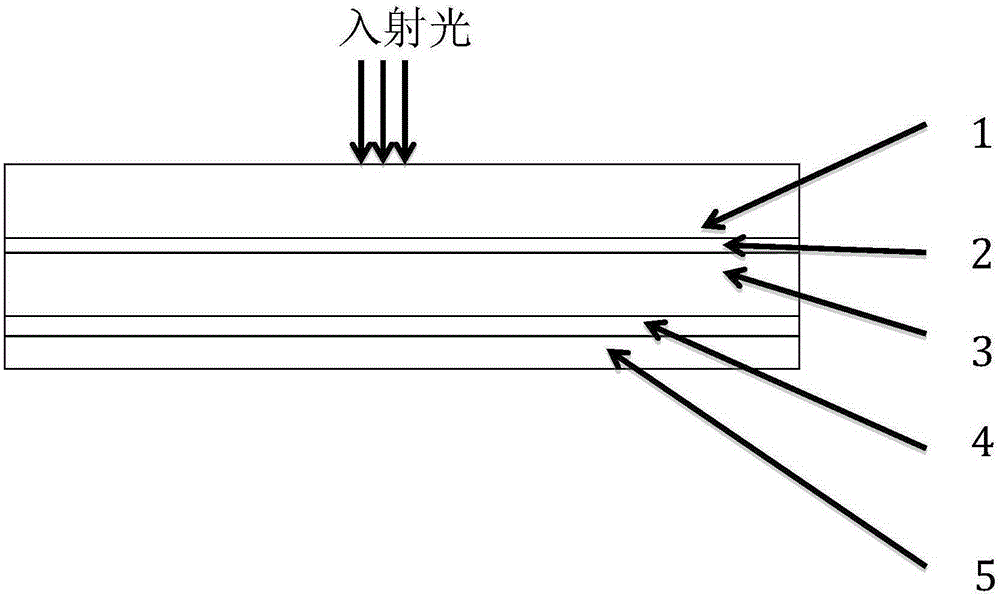

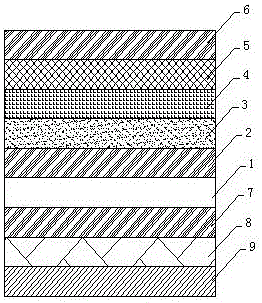

Thin film crystalline silicon perovskite heterojunction solar battery and preparation method thereof

ActiveCN105226187AOvercome the disadvantage of low light absorption coefficientReduce compoundingSolid-state devicesSemiconductor/solid-state device manufacturingHeterojunctionHole transport layer

The invention relates to a thin film crystalline silicon perovskite heterojunction solar battery and a preparation method thereof, and relates to a semiconductor device for converting luminous energy into electric energy. The thin film crystalline silicon perovskite heterojunction solar battery includes a transparent conductive substrate, a P-type thin film crystalline silicon hole transport layer, a perovskite light absorption layer, an electron transport layer formed by compact titanium dioxide, and a back electrode, wherein the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer have matched energy levels. The configuration pattern: the P-type thin film crystalline silicon hole transport layer is arranged on the transparent conductive substrate; the perovskite light absorption layer is arranged on the P-type thin film crystalline silicon hole transport layer; the perovskite light absorption layer and the P-type thin film crystalline silicon hole transport layer form a thin film crystalline silicon perovskite heterojunction; the electron transport layer formed by the compact titanium dioxide is arranged on the perovskite light absorption layer; the back electrode is arranged on the electron transport layer formed by the compact titanium dioxide. According to the invention, the defects that the existing perovskite solar battery is low in stability and high in preparation cost, and a mass of silicon materials are used can be overcame.

Owner:HEBEI UNIV OF TECH

Fabricating method of fiber powder modified polymer microporous film

InactiveCN101224392ASimple preparation processThe preparation process is matureSemi-permeable membranesFiberPolymer science

The invention relates to a macromolecule separation microporous membrane and a preparation method thereof, in particular to a preparation method of modified fiber powder / polymer mixed microporous membrane. The method provided by the invention includes the following steps: the surface of the fiber powder is cleaned and carved; the surface-carved fiber powders, polymer, various additives and solutions are combined to prepare membrane casting liquid, and then the membrane casting liquid is put onto a glass plate for membrane-shaving or spanning and then the liquid membrane is gelatinized into membrane in the coagulation bath process, and finally the membrane is dipped in membrane-dipping liquid and then is dried. The invention can prepare the polymer microporous membrane which has low cost, high strength and better capability through adding various fiber powders into the membrane preparation liquid and changing process conditions.

Owner:WUHAN TEXTILE UNIV

Combination switchable glass composite window and preparation method thereof

ActiveCN107526226AImprove featuresImprove uniformity and longevityCoatingsNon-linear opticsLaminated glassToughened glass

The invention relates to a combination switchable glass composite window and a preparation method thereof. The composite window and the preparation method thereof include a substrate, and a first outer ITO transparent conductive film layer, an electrochromic layer, an ion transport layer, an ion storage layer and a second outer ITO transparent conductive film layer which are sequentially arranged on the outer surface of the substrate, and further include an inner ITO transparent conductive film layer, a PDLC liquid crystal light-adjusting film and an ITO transparent conductive film which are sequentially arranged on the inner surface of the substrate, wherein ordinary glass, toughened glass, laminated glass, organic glass or a mixture thereof is selected and used for the substrate, tungsten oxide is selected and used for thin-film material of the electrochromic layer, a lithium ion thin film is selected and used for an ionic conductive layer, and nickel oxide thin film is selected and used for the ion storage layer. The composite window and the preparation method thereof have the advantages that a combination of the electrochromic layer and the PDLC liquid crystal light-adjusting film combines the advantages and disadvantages of both and further effects of intelligent light adjusting and light shielding can be achieved.

Owner:JIANGSU FANHUA GLASS CO LTD

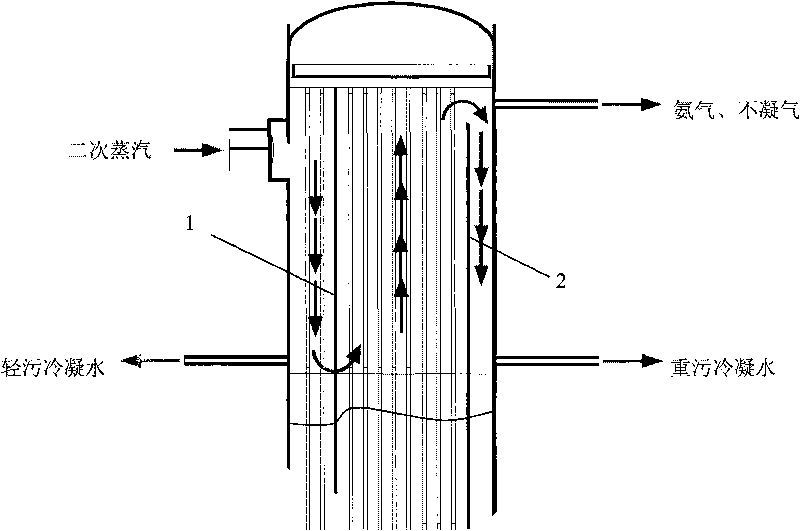

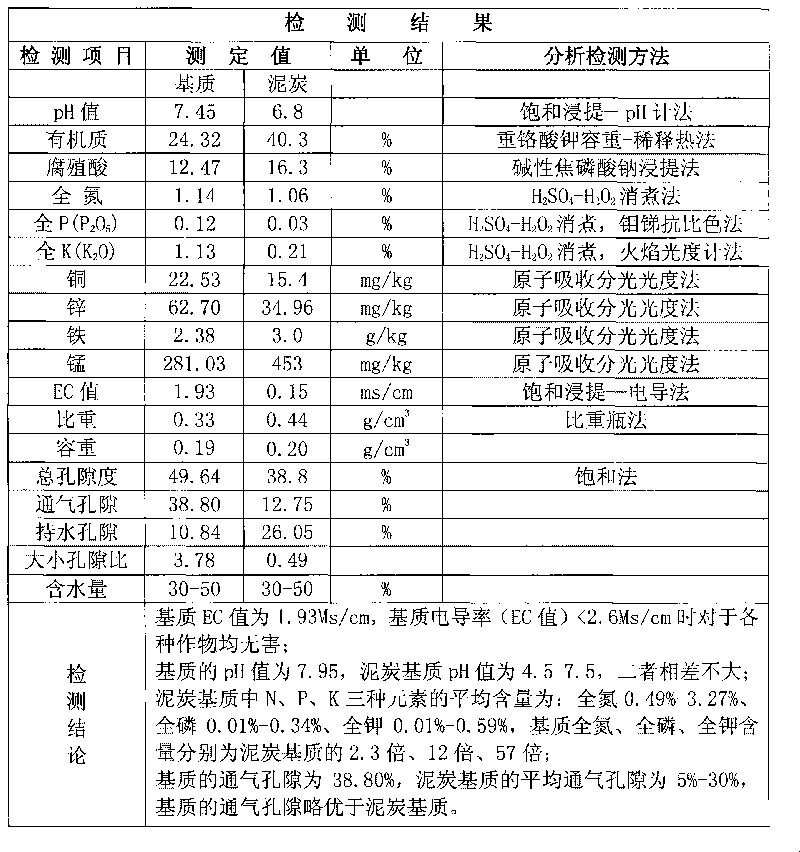

Seedling medium and preparation method thereof

ActiveCN101759449AHigh cost of preparationRaise the fermentation temperatureBio-organic fraction processingOrganic fertiliser preparationChemistryRoot system

The invention relates to a seedling medium and a preparation method thereof, wherein the medium comprises the following components of raw materials: one or more of crop by-products, organic wastes, by-products generated in grass pulping process when preparing materials, and ammonia water. The method comprises the following steps: mixing one or more of the crop by-products, the organic wastes, theby-products of the grass pulping process when preparing the materials, and the ammonia water, and then fermenting to gain the medium, wherein nitrogenous condensate water generated when concentratingblack liquid generated in a neutral ammonium sulfite process is optimally selected as the ammonia water, and optimally, the condensate water with 0.05-0.55% of nitrogen content and at the temperatureof 25-70 DEG C is the best; and by-products generated in preparation department in the neutral ammonium sulfite process are optimally selected as the crop by-products. The method re-uses the waste and waste liquid which are generated in the neutral ammonium sulfite process to turn waste into wealth. The permeability and nutrient content of the medium are respectively superior to that of peat perlite, when the medium is used in the growth test of nursery stock of forest, the nursery stock has obvious grow, and the quantity of the root system can be increased by over 30 percent.

Owner:SHANDONG TRALIN PAPER

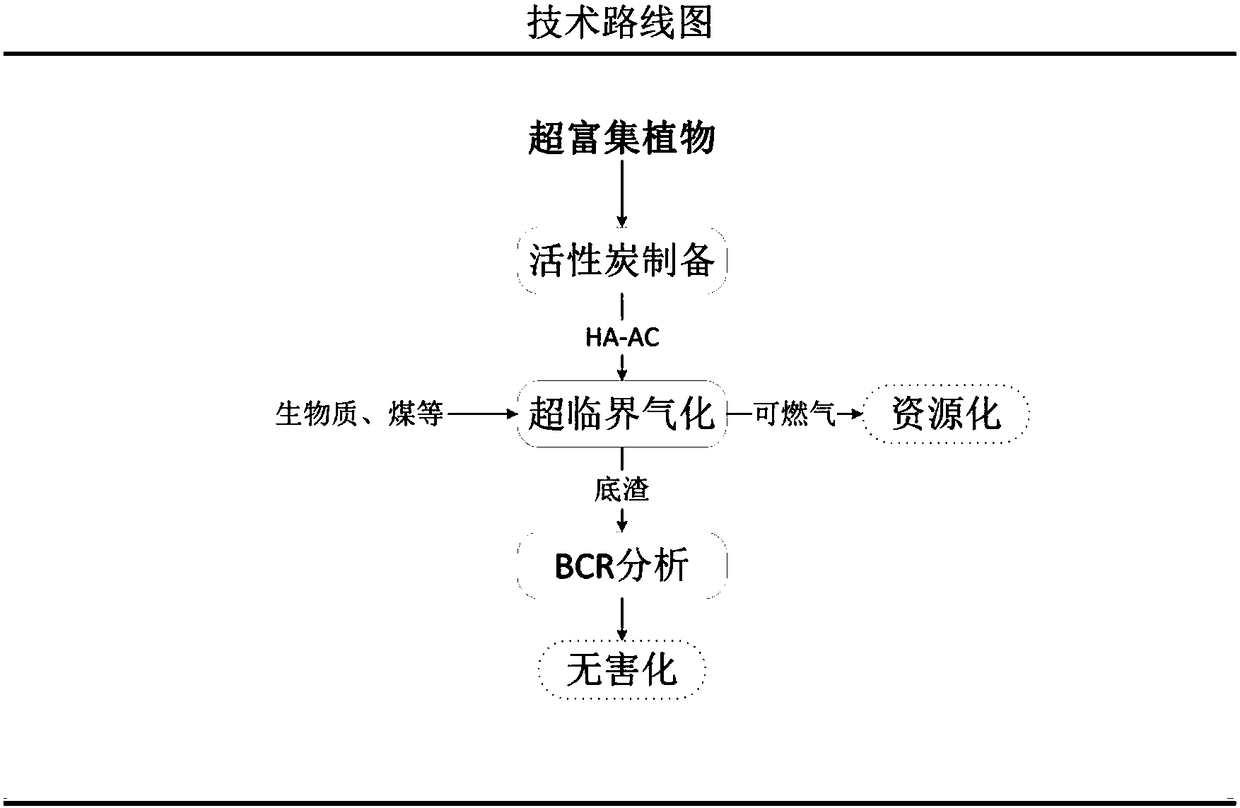

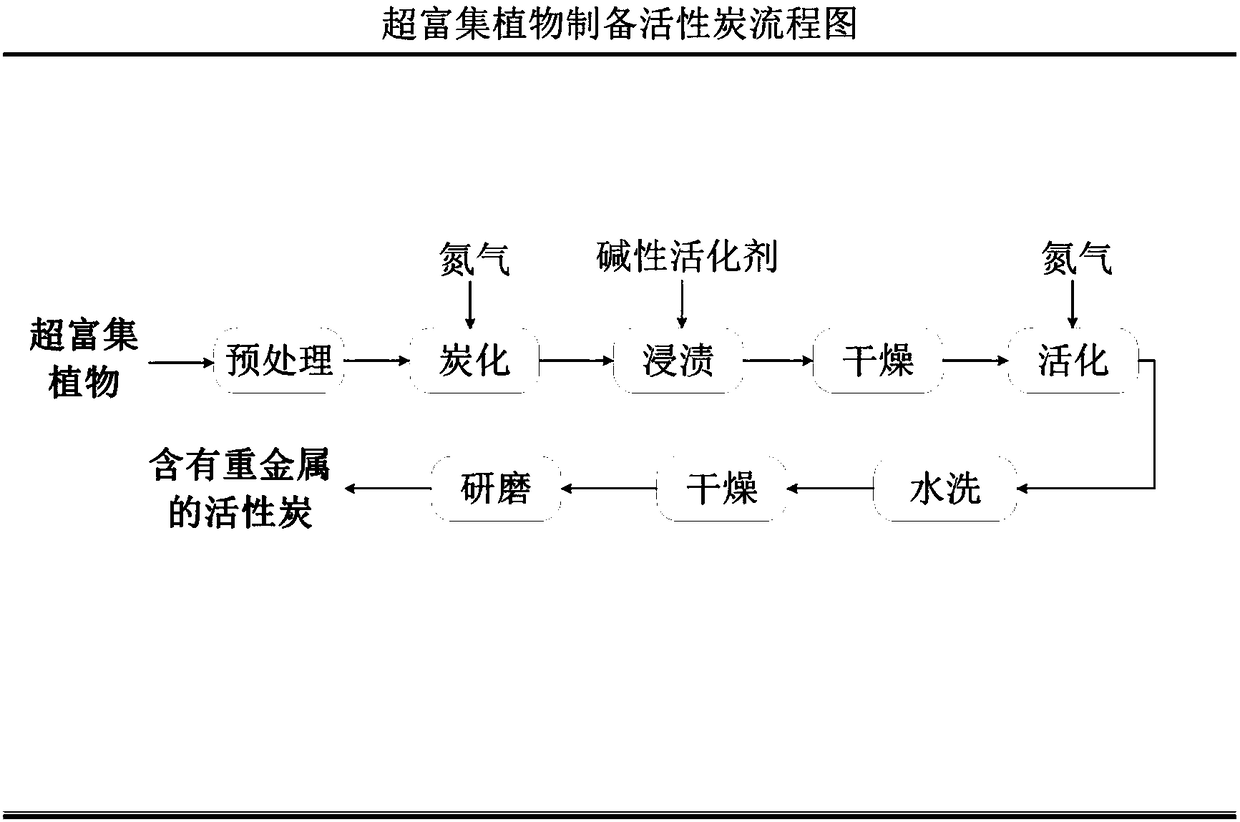

High-quality harmless utilizing method of hyperaccumulator

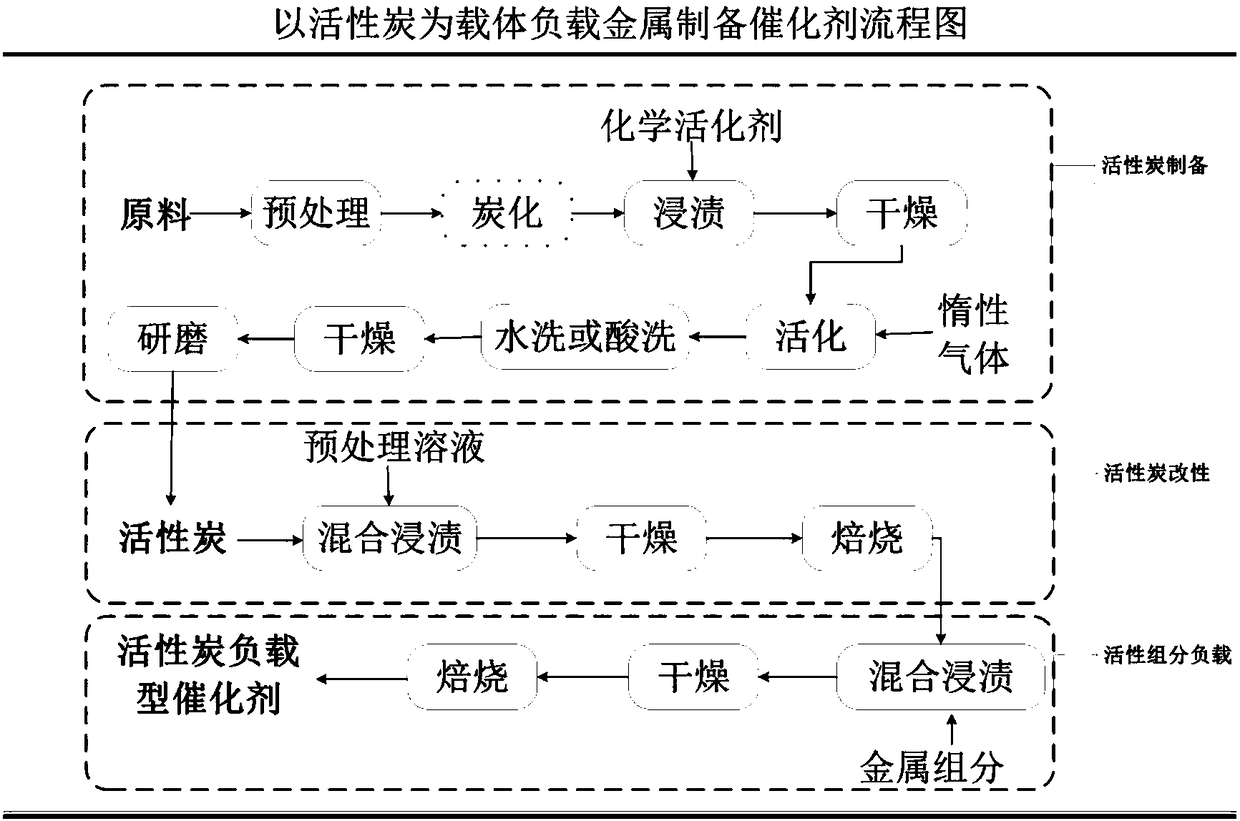

ActiveCN108485692ARealize resource processingSimple processProcess control/regulationProductsActivated carbonChemistry

The invention discloses a high-quality harmless utilizing method of a hyperaccumulator. The high-quality harmless utilizing method comprises the following steps: smashing and drying the hyperaccumulator, and sieving through a sieve of which the density is 100 meshes; carbonizing at a carbonization temperature being 450 to 550 DEG C and in carbonization time being 25 to 35 minutes, thus obtaining acarbonized material; immersing the carbonized material by using an alkaline solution of which the mass percentage is 45 to 55 percent; drying at 90 to 120 DEG C for 10 to 15 hours after immersing for20 to 28 hours, thus obtaining an amorphous particulate carbon block; activating the amorphous particulate carbon block into an activated carbon coarse product under a nitrogen atmosphere, wherein the activating temperature is 750 to 850 DEG C, and the activation time is 25 to 35 minutes; drying for 10 to 15 hours, thus obtaining metal-containing activated carbon with a catalytic effect; grindingthe activated carbon, thus obtaining an activated product HA-AC; adding 5 to 15 percent of the activated carbon product HA-AC to biomass or other reaction raw materials; putting a swelled material ina supercritical reaction kettle, and carrying out sealing reaction at the reaction temperature being 380 to 600 DEG C and the reaction pressure being 22.1 to 30 MPa, thus obtaining a hydrogen-rich gas. The high-quality harmless utilizing method disclosed by the invention has the advantages that additional metal loading is not required, a complicated preparation technology and a longer preparationperiod are not required, heavy metal can be fully stabilized, and secondary pollution can be avoided.

Owner:NINGBO INST OF TECH ZHEJIANG UNIV ZHEJIANG

Ruthenium-based catalyst for hydrogen production from ammonia decomposition, preparation method therefor and application thereof

ActiveUS20200164346A1Improve stabilityReduce catalytic activityHydrogenCatalyst activation/preparationActivated carbonPtru catalyst

Disclosed is a ruthenium-based catalyst for hydrogen production from ammonia decomposition, comprising an active component, a promoter and a carrier, wherein the active component is ruthenium, the promoter is cesium and / or potassium, and the carrier comprises magnesium oxide, an activated carbon, cerium oxide, molybdenum oxide, tungsten oxide, barium oxide and potassium oxide. The present invention further discloses a preparation method and application of the aforementioned ruthenium-based catalyst for hydrogen production from ammonia decomposition. Compared with the prior art, the ruthenium-based catalyst for hydrogen production from ammonia decomposition provided by the present invention is low in preparation cost and simple in process, and has high catalytic activity at low temperature and good heat resistance.

Owner:FUDA ZIJIN HYDROGEN ENERGY TECH CO LTD

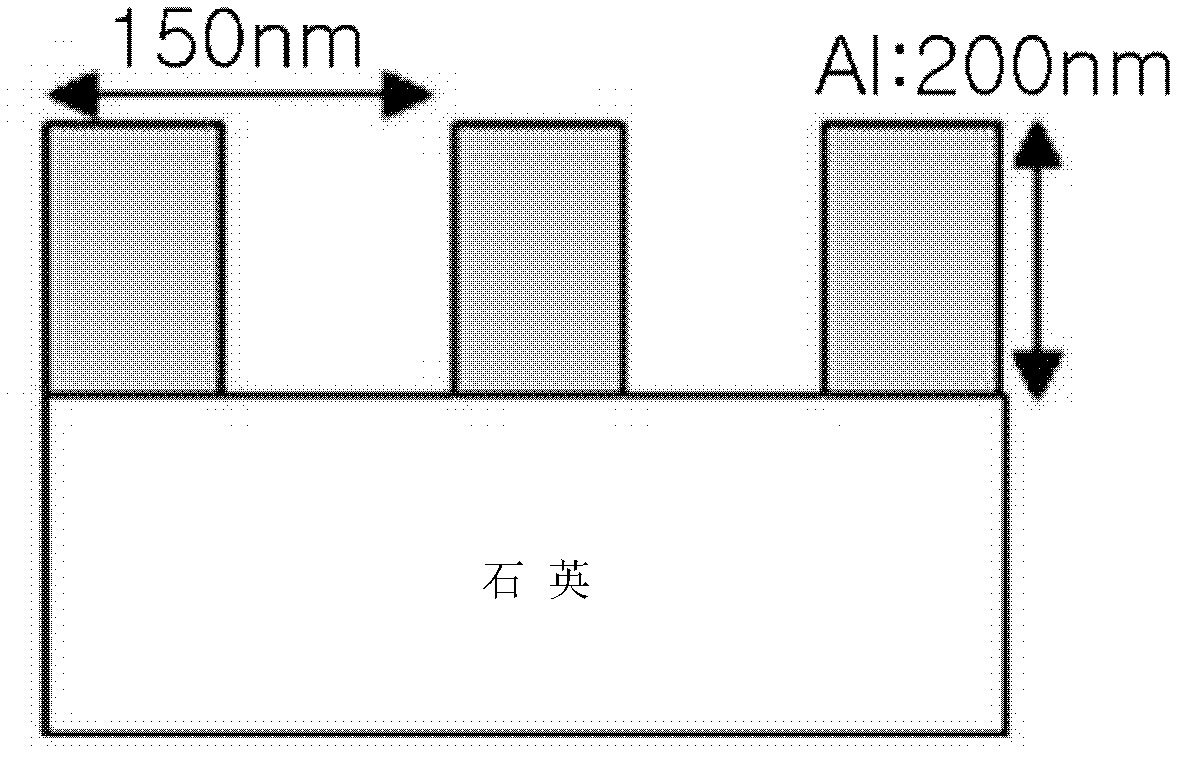

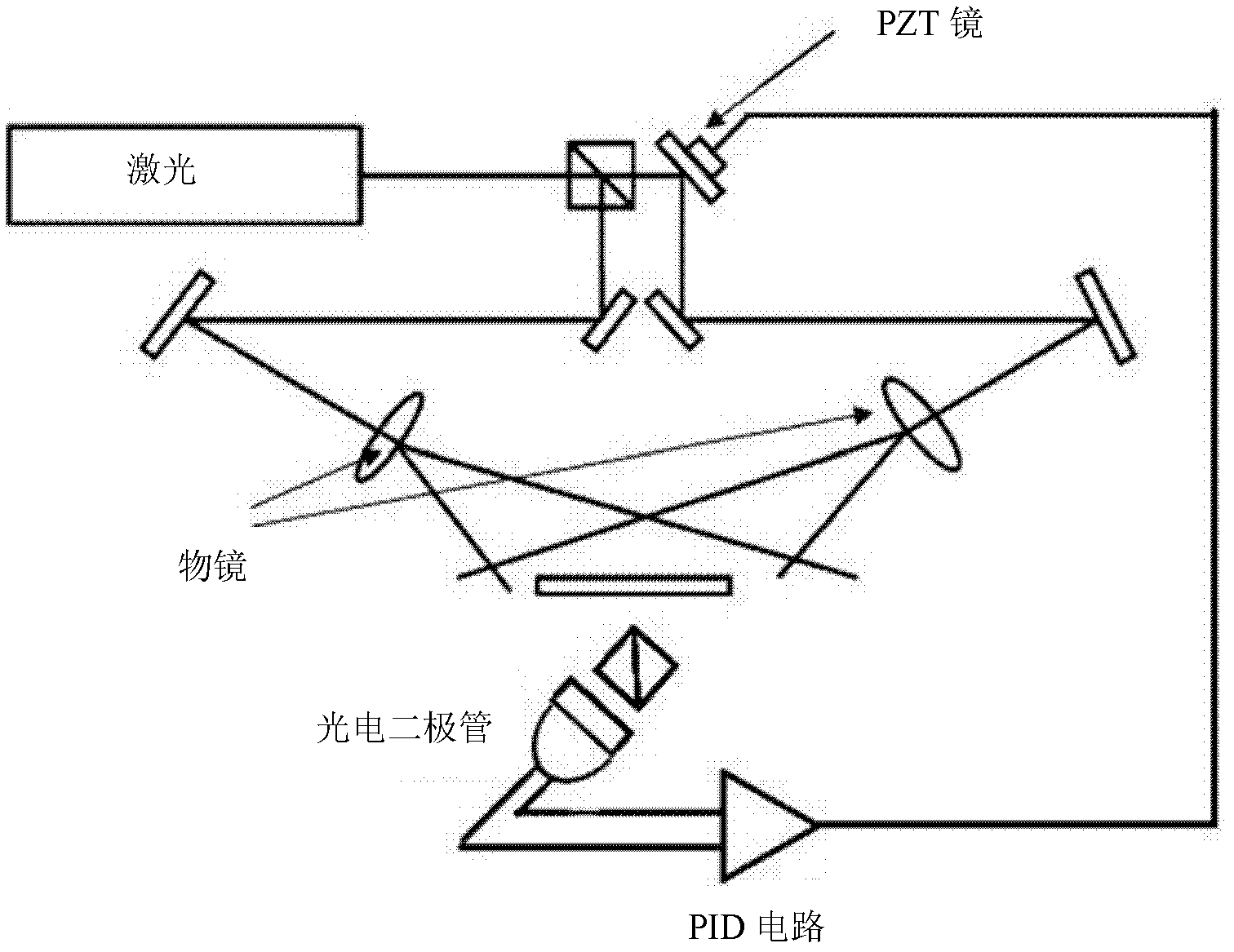

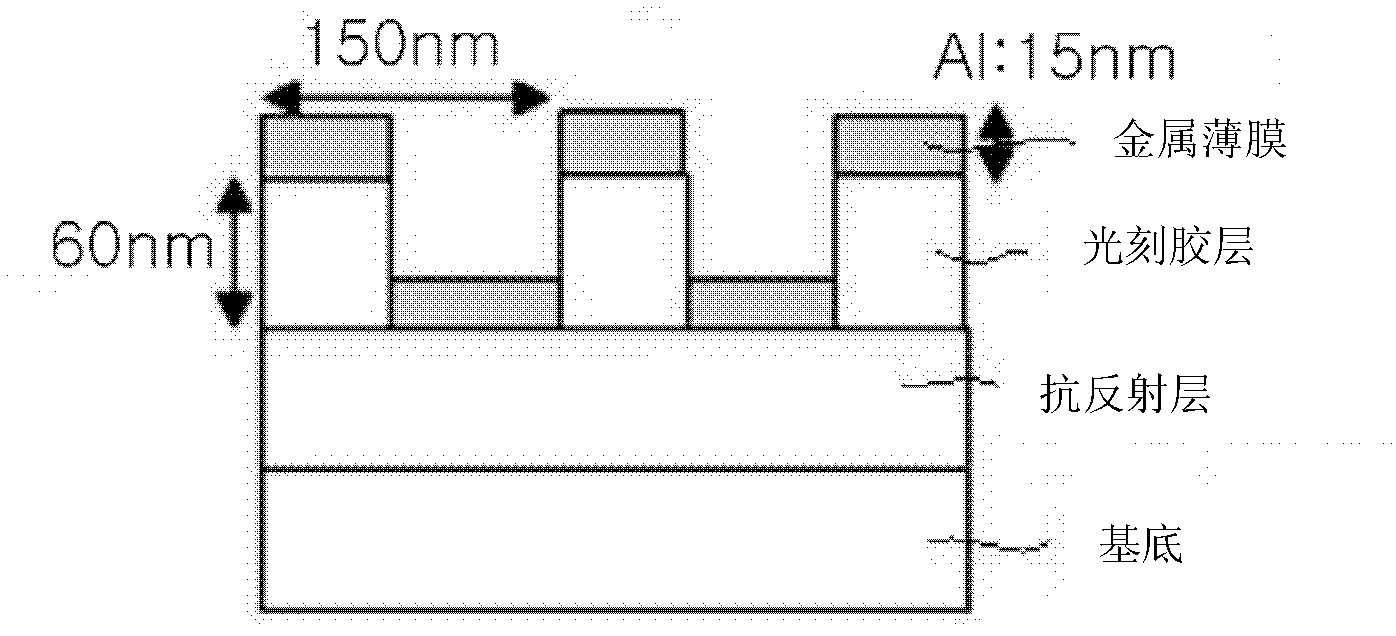

High ultraviolet transmitting double-layer wire grid polarizer for fabricating photo-alignment layer and fabrication method thereof

InactiveCN102576107AImprove transmittanceImprove production efficiencyPolarising elementsThin material handlingWire gridUltraviolet

The present invention relates to a high ultraviolet transmitting double wire grid polarizer for fabricating a photo-alignment layer and a fabrication method thereof for improving the fabrication efficiency of the photo-alignment layer. More specifically, the invention provides a high ultraviolet transmitting double wire grid polarizer comprising: a substrate; a reflection preventing layer which is formed on the substrate; a patterned photosensitive material layer which is formed on the reflection preventing layer; and double metal thin film layers which are respectively formed on the photosensitive material layer and the reflection preventing layer. Further, the invention provides a fabrication method of a high ultraviolet transmitting double wire grid polarizer, the method comprises the steps of: forming a reflection preventing layer on a substrate; forming a photo sensitive material layer by applying photoresist to the top of the reflection preventing layer; forming a wire grid pattern by developing the photosensitive material layer after selectively exposing the photosensitive material layer according to a pattern that is formed by the laser interference light; and depositing metal on the wire grid pattern. Thus, the invention smoothly forms a wire grid by using the reflection preventing layer when the double wire grid polarizer is fabricated, and cuts down the production cost with no need to perform a dry etching process since the metal is deposited after the wire grid of the photosensitive material layer is formed. Further, compared with the existing single wire grid polarizer, the invention improves transmittance and polarization of the ultraviolet region, thereby enhancing the efficiency of the fabrication process of the photo-alignment layer.

Owner:LG CHEM LTD

Method for preparing metal filling carbon nano-pipe

InactiveCN101367515AWide range of optionsSimple processNanostructure manufactureCarbon nanotubeMetal

The invention relates to a method for preparing a metal-stuffing carbon nanometer pipe; aromatic compound is adequately mixed with the transitional metal compound, and the mixture is undertaken the thermal condensation polymerization reaction and is extracted to get the metal-stuffed carbon nanometer pipe. The present invention has the advantages that the source of the raw materials is rich, the craftwork is simple, the preparation cost of the material is low, the purity is high, the selective range of the metal is wide, and the like, and the large-scale production is easy to be realized.

Owner:BEIJING UNIV OF CHEM TECH

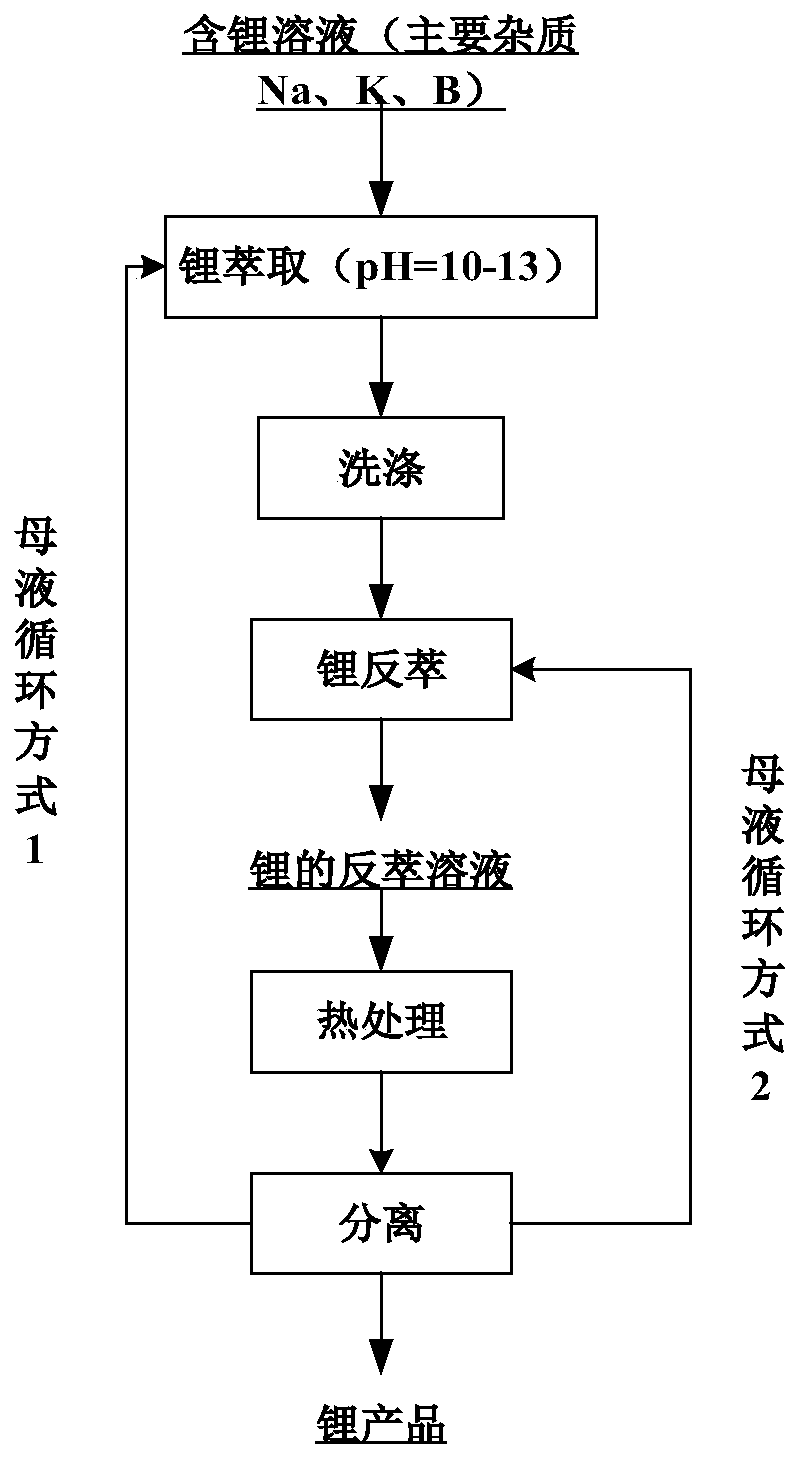

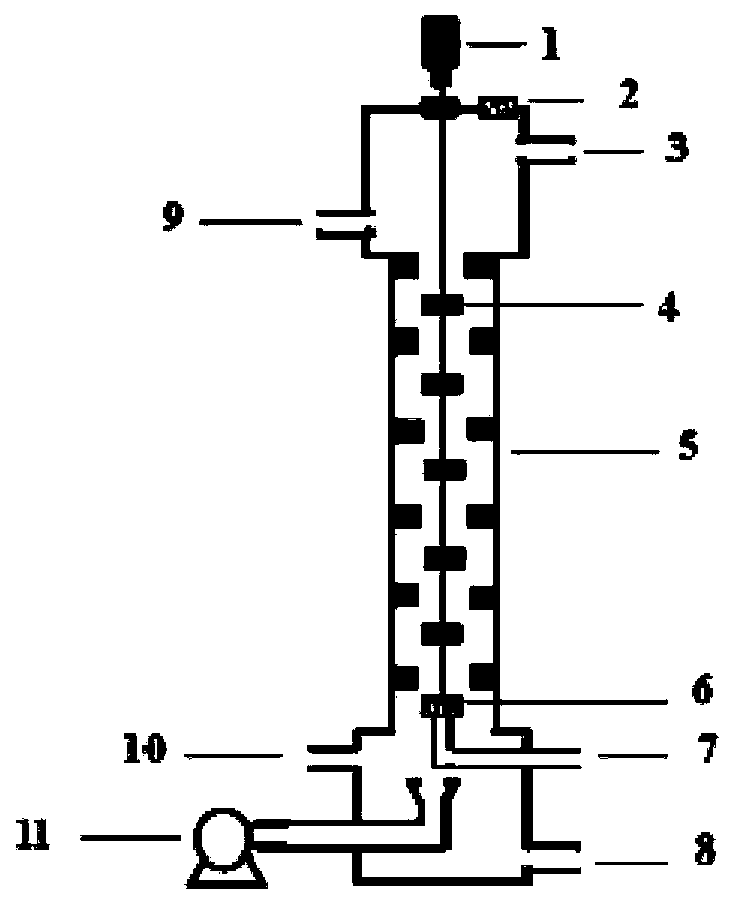

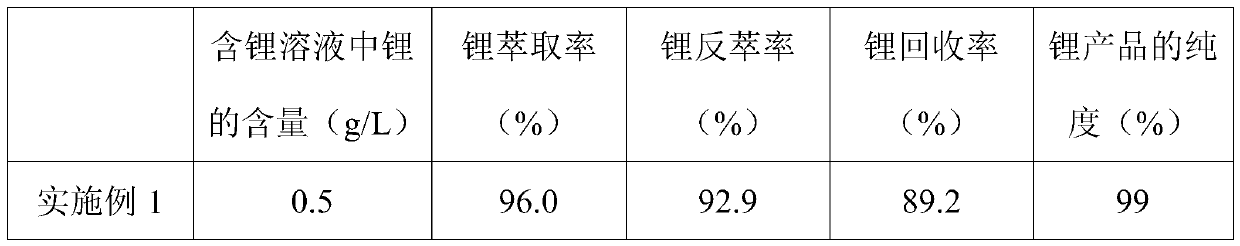

Method for lithium extraction through extraction-reverse extraction, separation and purification

ActiveCN110656239AHigh cost of preparationLow running costProcess efficiency improvementMother liquorContinuous production

The invention relates to a method for lithium extraction through extraction-reverse extraction, separation and purification. The method comprises the following steps: (1) an extracting system containing a composite extracting agent is adopted to extract and separate lithium-contained solution under a condition of pH=10-13 to obtain a lithium-loaded organic phase; (2) the gas-liquid-liquid three-phase reverse extraction is performed on the lithium-loaded organic phase obtained in the step (1) to obtain lithium-loaded reverse extracting liquid; and (3) the reverse extracting liquid obtained in the step (2) is heated and separated to obtain a lithium product and separated mother liquor. The method realizes efficient separation of lithium from such impurity elements as Na, K and B by adoptingthe composite extracting agent, adopts the gas-liquid-liquid three-phase continuous reverse extraction to reach the reverse extracting rate of lithium is 90% above, the total yield is 83% or above andthe purity of the lithium product is 96% above, is high in treatment quantity, simple in process and equipment and low in investment, effectively utilizes industrial tail gas, and achieves energy conservation, environmental protection and continuous production.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI +1

Baked charcoal, and preparation method and application thereof

InactiveCN109022002AHigh yieldSave energyOther chemical processesWater contaminantsIndustrial waste waterHemicellulose

The invention discloses a baked charcoal, and a preparation method and an application thereof. The method comprises the following steps: washing, drying, crushing and drying agricultural and forestrywastes with a hemicellulose content of above 40%, used as a raw material, carbonizing the raw material in an oxygen-limited environment, and washing and drying the carbonized raw material to obtain the baked charcoal. The baked charcoal is prepared from the agricultural and forestry wastes by a limiting oxygen technology, so the preparation method has the advantages of simplicity, low cost and high charcoal yield; and the obtained baked charcoal has a hydrophobic surface, is rich in surface functional groups, can efficiently adsorb and separate metal ions in wastewater, and provides a cheap and efficient adsorbent for the recycling of industrial wastewater.

Owner:FUZHOU UNIV

Cracking catalyst containing laminar clay and its preparation method

The present invention relates to a cracking catalyst containing laminar clay. It is prepared by adopting the following steps: mixing the expandable clay modifying component, pseudo-thin hydrargillite and water, pulping for 0.1-10 hr. to obtaining a slurry liquor, ageing slurry liquor for 0.1-10 hr. at 50-85 deg.C, drying, forming, washing with water, ageing, finally drying and roasting so as to obtain said catalyst. The described modifying component can be selected from one or several kinds of hydroxyl polymers of silicon, aluminium, zirconium or titanium or one or several kinds of one or several substances containing the described hydroxyl polymer. Said catalyst has higher heavy oil conversion capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

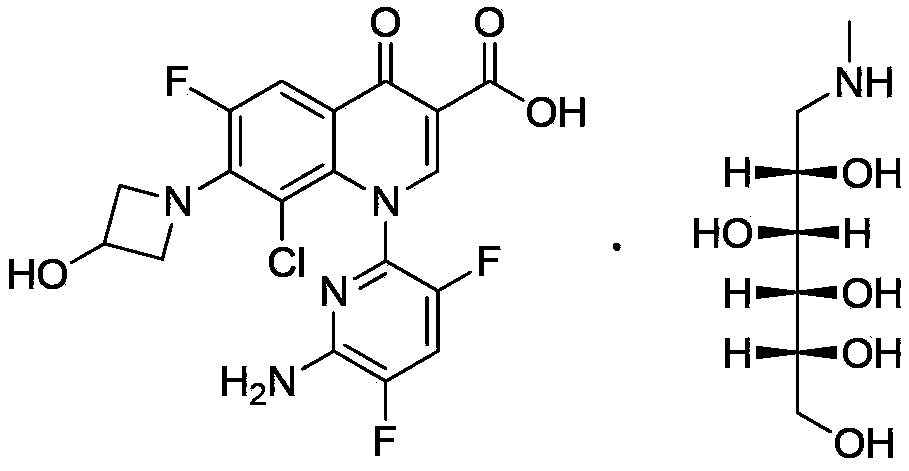

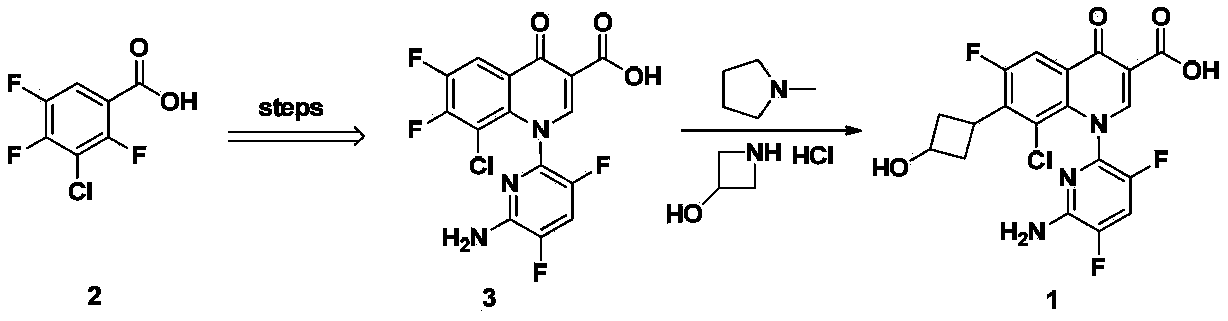

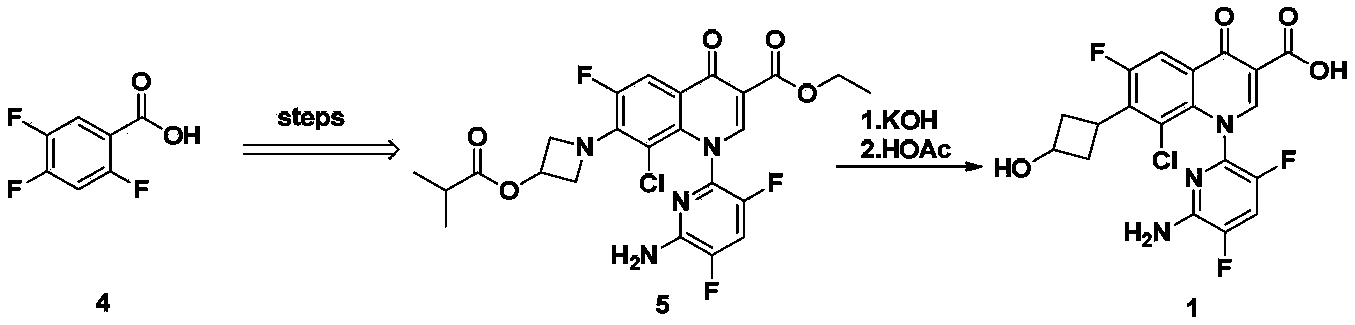

Delafloxacin purifying method

The invention relates to the technical field of a Delafloxacin purifying method . The Delafloxacin purifying method comprises the following steps: adding Delafloxacin to a polar aprotic solvent, heating, stirring until Delafloxacin is dissolved, adding distilled water, and gradually cooling for crystallizing to obtain highly pure Delafloxacin. Delafloxacin prepared by present synthetic methods needs purification, the preparation using a simple column chromatography mode increases the large scale production difficulty and greatly increases the preparation cost. The method can effectively remove impurities, and makes the compound Delafloxacin have a high purity (above 99.0%) and meet subsequent preparation demands.

Owner:SHANGHAI INST OF PHARMA IND CO LTD +2

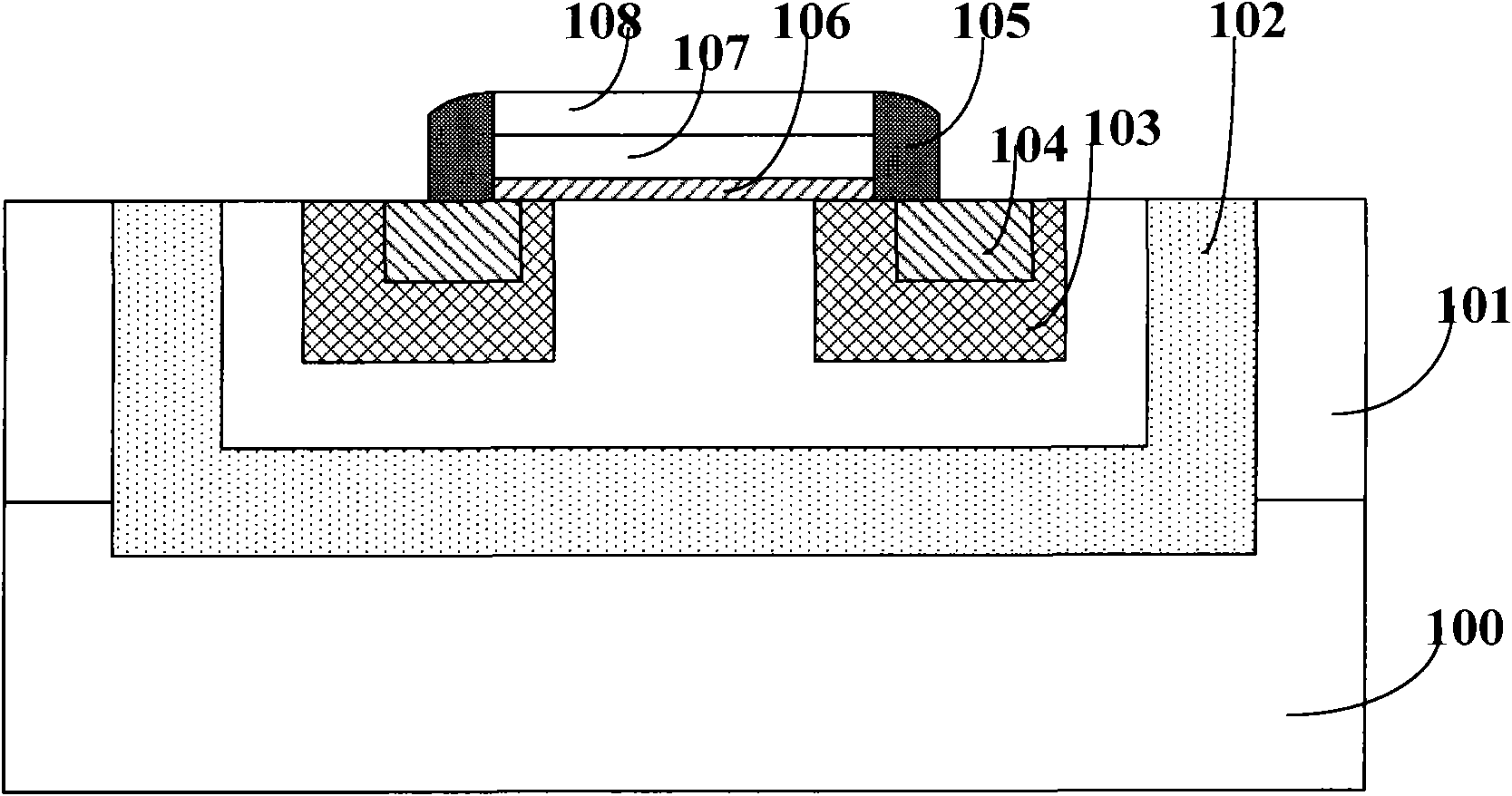

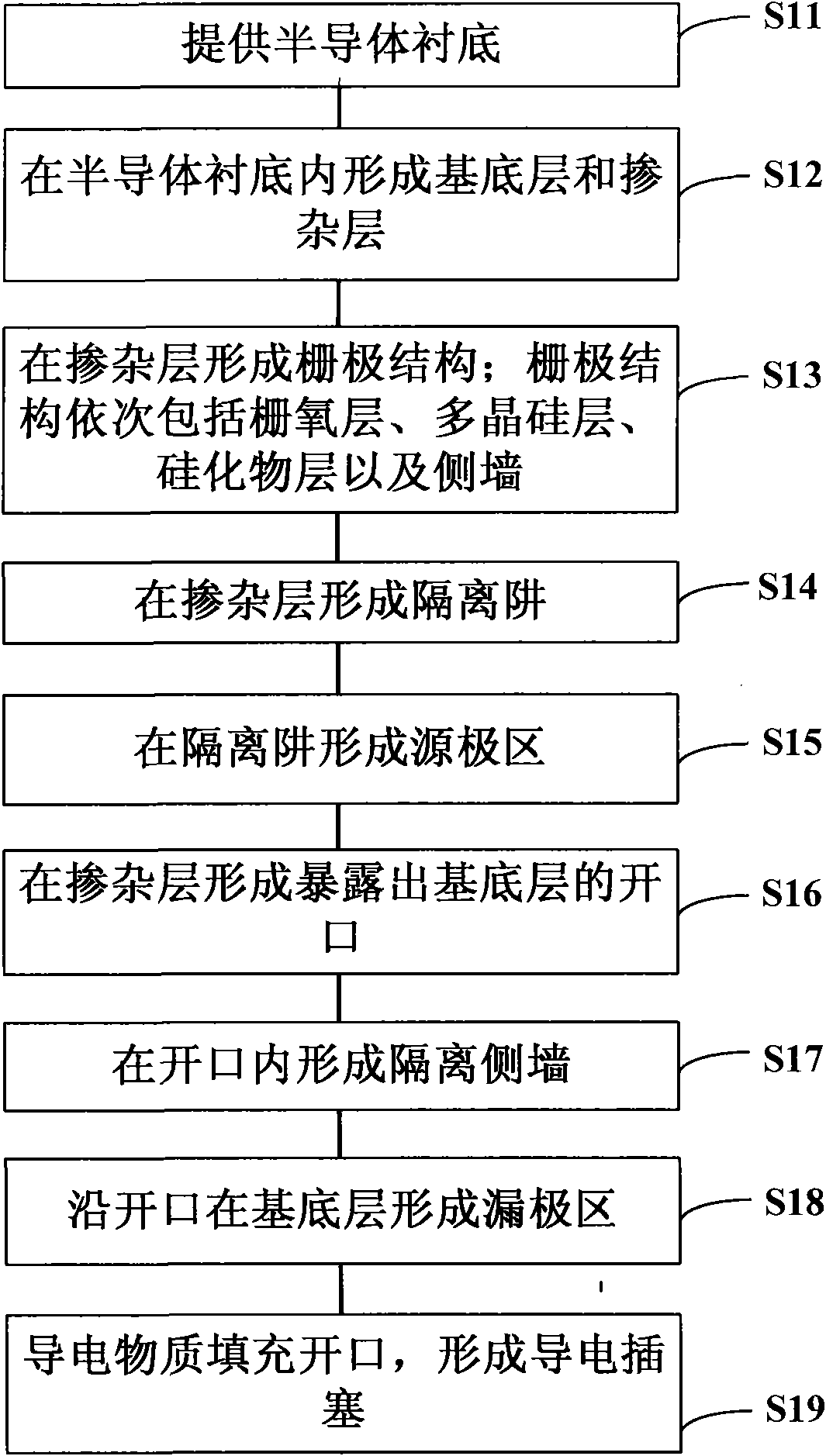

VDMOS and preparation method thereof

ActiveCN101789376AHigh cost of preparationReduce manufacturing costSemiconductor/solid-state device manufacturingSemiconductor devicesSemiconductorElectrode

The invention relates to a VDMOS and a preparation method thereof. Wherein the VDMOS comprises a base layer and a doping layer in a semiconductor substrate, a gate region on the doping layer; wherein the base layer comprises a drain electrode region at the two sides of the gate region, the doping layer comprise a conductive plug adapter which is located on the drain electrode region and penetrates through the doping layer, an isolated well at the two sides of the gate region and a source electrode region located in the isolated well. In the invention, highly costly buried drain electrode region and extension layer technology is not needed, so that manufacturing cost is lowered.

Owner:SEMICON MFG INT (SHANGHAI) CORP

Graphene and carbon nano tube enhanced aluminum matrix composite and preparation method thereof

ActiveCN110331318ATroubleshoot enhancementsOvercoming the problem of partial interface responseLiquid/solution decomposition chemical coatingCopper platingCarbon nanotube

The invention relates to a graphene and carbon nano tube enhanced aluminum matrix composite and a preparation method thereof, and belongs to the technical field of aluminum matrix composites. In orderto solve the problems that graphene and carbon nano tubes are clustered and form carbide with an aluminum matrix at a high temperature and in order to improve the wear resistance of the aluminum matrix composite, the graphene and carbon nano tube enhanced aluminum matrix composite is provided, and components of the graphene and carbon nano tube enhanced aluminum matrix composite comprise, by masspercent, 0.1%-5.0% of composite copper plated nickel graphene, 0.1%-5.0% of composite copper plated nickel carbon nano tubes, 5% of magnesium powder and the balance aluminum powder. Copper plated nickel is compounded on the surfaces of the graphene and the carbon nano tubes to strictly control the interface reaction, ultrasonic dispersion is carried out in a stirring state so that the graphene and the carbon nano tubes can be evenly dispersed in the aluminum matrix composite, finally the enhanced aluminum matrix composite is obtained through vacuum hot-pressing sintering, and the wear resistance of the aluminum matrix composite is obviously improved due to the self-lubricating characteristic of the graphene and the carbon nano tubes.

Owner:HEILONGJIANG UNIVERSITY OF SCIENCE AND TECHNOLOGY

Polysulfone amide separating membrane and its modifying method utilizing nanotitanium dioxide

ActiveCN1935340AExcellent photocatalytic oxidation performanceImprove surface propertiesSemi-permeable membranesOrganic solventMacromolecule

The present invention relates to a polyphenylene sulfonamide separation membrane and its modification method by using nano titanium dioxide. Said polyphenylene sulfonamide separation membrane is made up by using (by wt%) 5%-20% of polyphenylene sulfonamide, 78%-94% of organic solvent and 1%-5% of pore-forming agent through a certain preparation process. Its modification method includes the following steps: a), soaking the polyphenylene sulfonamide separation membrane in concentrated sulfuric acid for 1-3hr, then cleaning said polyphenylene sulfonamide separation membrane by using deionized water; and b) soaking the polyphenylene sulfonamide separation membrane in the nano titanium dioxide sol for 5-15min, finally using deionized water to wash said polyphenylene sulfonamide separation membrane so as to obtain the invented nano titaminum dioxide modified polyphenyl sulfonamide separation membrane.

Owner:HARBIN INST OF TECH

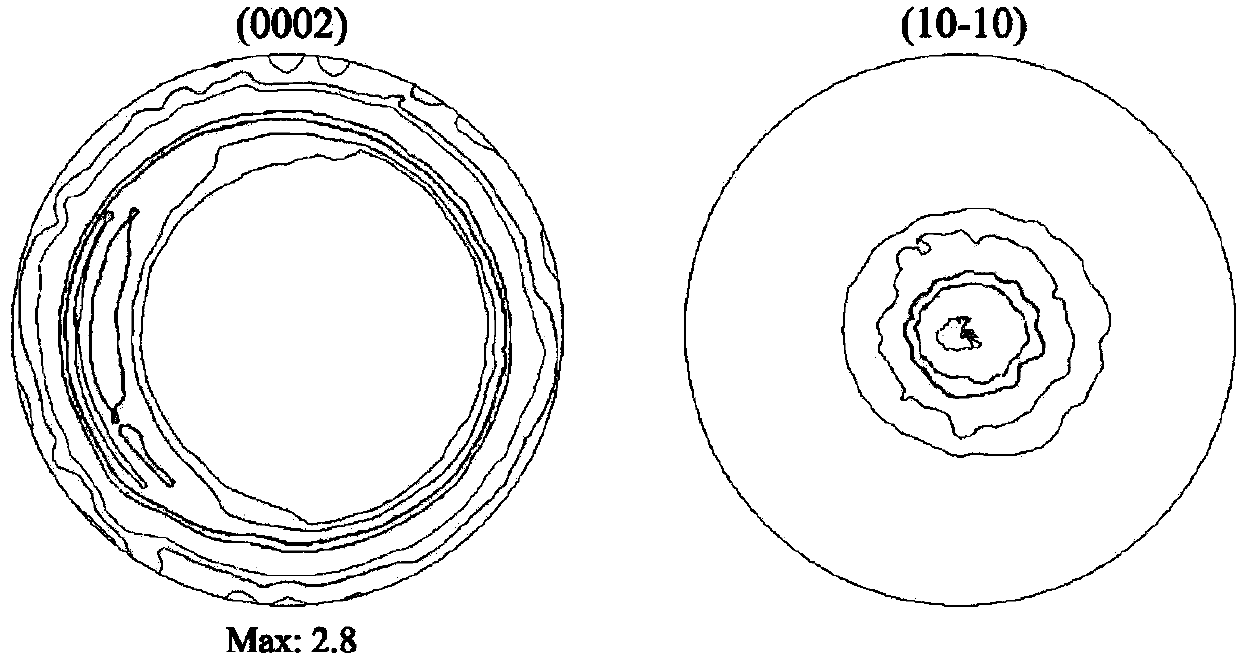

Multi-element compound reinforced weak-texture wrought magnesium alloy and preparing method thereof

The invention relates to a multi-element compound reinforced weak-texture wrought magnesium alloy and a preparing method thereof. The wrought magnesium alloy comprises the following elementary components in content: 5.5%-6.5% of Zn, 1.0%-6.5% of Al, 0.1%-0.4% of Mn, 0.1%-0.4% of Sn, 0.1%-0.4% of Ca, 0.1%-0.4% of Cu, smaller than or equal to 0.15% of unavoidable impurities and the balance of Mg. Compared with the existing non-rare-earth wrought magnesium alloy, the material of the invention has the following advantages that the alloy has high strength and great elongation after conventional extrusion treatment; the alloy has weak macro-texture and great dynamic isotropy; the alloy preparing cost is low, and the preparing technology is simple; and the application range of the wrought magnesium alloy is further increased.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

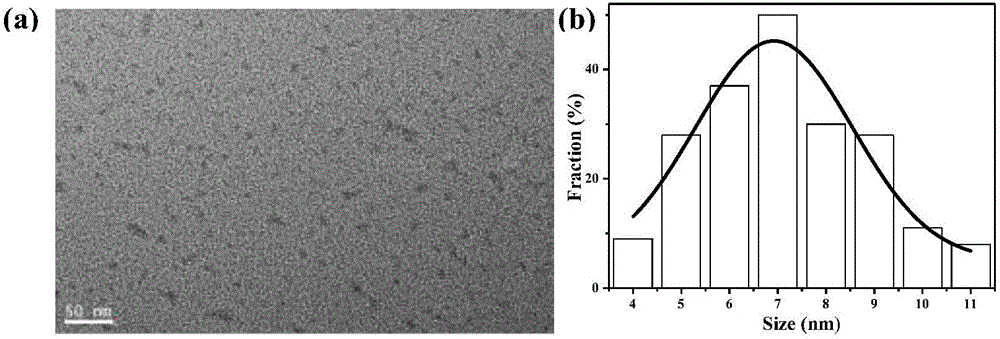

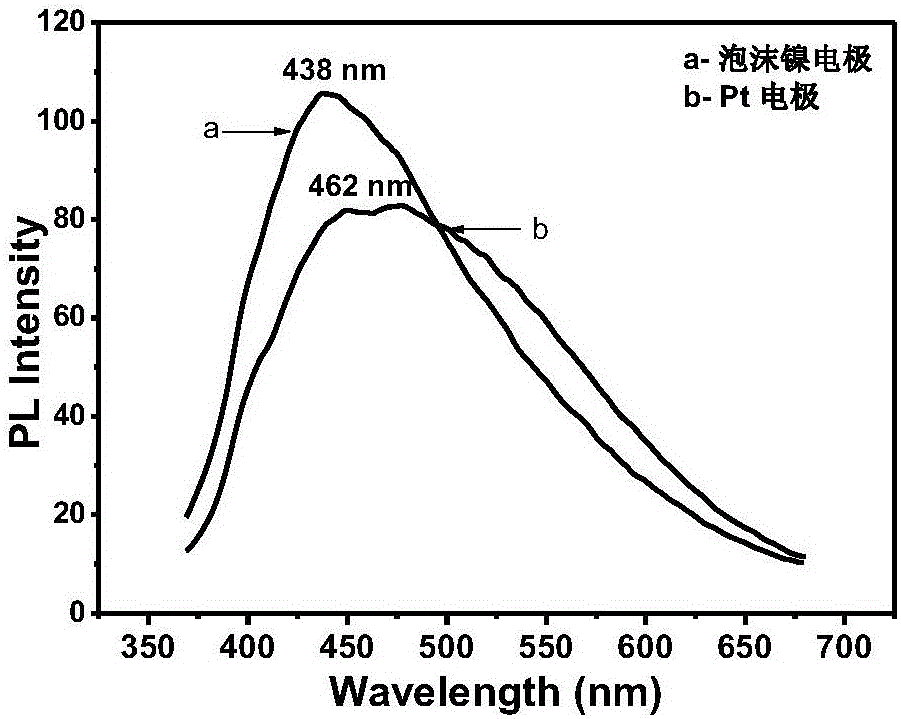

Electrolytic and nitrogen-doping one-step method for preparing petroleum coke-based carbon quantum dots

ActiveCN105733573ARich pore structureLarge specific surface areaElectrolysis componentsNanoopticsEthylenediamineElectrolysis

The invention belongs to the scientific field of carbon nano-materials and relates to an electrochemical method for preparing petroleum coke-based carbon quantum dots and doping nitrogen in a one-step manner. In the invention, petroleum coke, which has high carbon content, low ash and a developed graphite lamellar structure, is creatively selected as a carbon source, and through an electrochemical oxidizing method, a novel technical method of preparing the carbon quantum dots is developed. Through change on calcination temperature, types of electrolytes and current density, fluorescent performance of the carbon quantum dots can be regulated. By means of addition of a nitrogen-doping agent to the electrolyte, preparation of nitrogen-doped carbon quantum dots through the electrochemical method in one step is achieved, and for the first time, ethylenediamine is employed as the electrolytic nitrogen-doping agent. Meanwhile, for the first time, foam nickel is creatively employed instead of a conventional Pt electrode, so that the method greatly increases electrolytic efficiency and reduces preparation cost. The petroleum coke is easy to obtain and low in cost. The whole process is simple in operation process, is convenient to product the carbon quantum dots industrially in large scale. The carbon quantum dots have wide application prospects in the fields of photo-catalysis, bio-imaging, and detection of ions and macromolecules.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

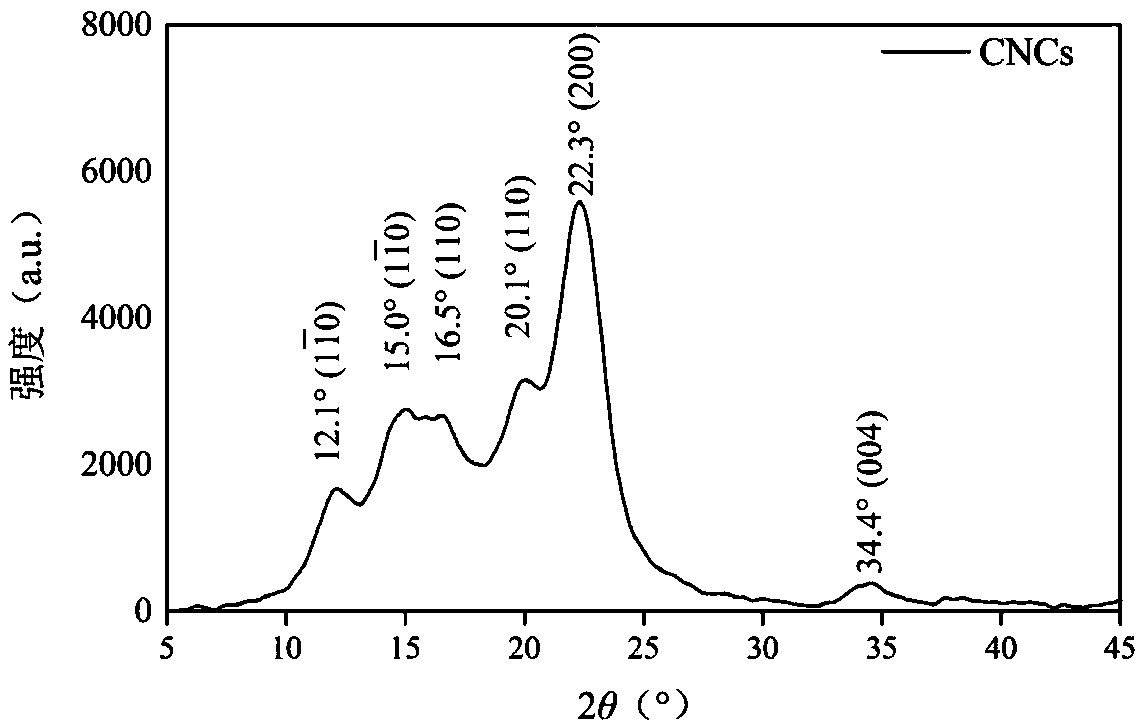

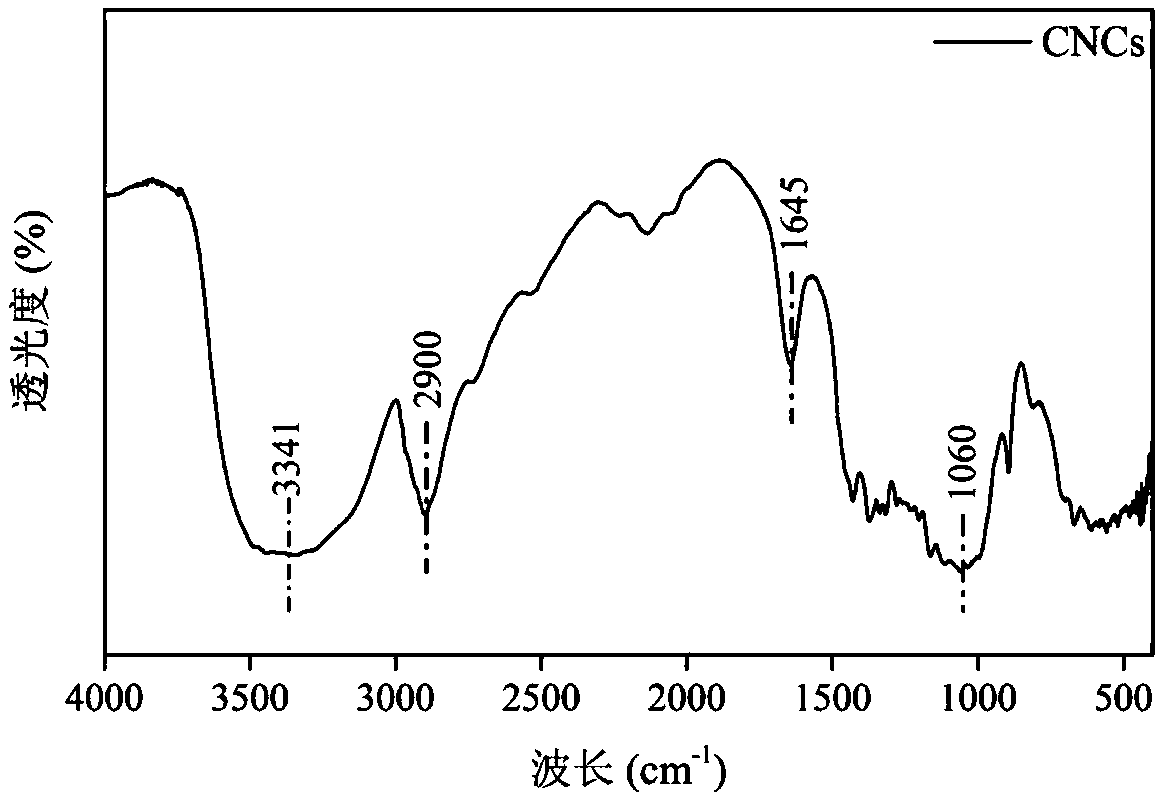

Preparation method for blending modification of ultrafiltration membrane by using nano cellulose crystal

InactiveCN108771978AWide variety of sourcesLow priceSemi-permeable membranesSolventModified ultrafiltration

The invention discloses a preparation method for blending modification of an ultrafiltration membrane by using nano cellulose crystal, belonging to the field of preparation of membrane materials. Thepreparation method solves the problems that the nano material is expensive in the process of blending modification of ultrafiltration membrane by the existing nano material, and the material dispersibility is not good, the hydrophilicity is insufficient and the material is inclined to agglomerate in the preparation process. The preparation method firstly ultrasonically disperses the nanocellulosecrystals in an organic solvent, then adds the additive and the polymer film material, heats and stirs uniformly, and performs vacuum defoaming to obtain a casting liquid; the casting liquid is evenlyscraped onto the non-woven fabric, and the modified ultrafiltration membrane is obtained by undergoing a coagulation bath. The preparation method makes good use of the hydrophilicity and mechanical strength of the nanocellulose crystal, greatly improves the anti-pollution performance, the water flux and the mechanical strength of the ultrafiltration membrane, and prolongs the service life of the membrane. Simultaneously, the modified nano materials derive from a wealth of sources, and are cheap and easy to obtain, and have good dispersibility in the solvent, so that the ultrafiltration membrane is relatively low in cost and convenient for industrial production.

Owner:HAINAN LITREE PURIFYING TECH CO LTD

Cracking catalyst containing laminar clay and its preparation method

InactiveCN1175086CHeavy oil cracking ability is strongImprove light oil yieldCatalytic crackingTitaniumFuel oil

The present invention relates to a cracking catalyst containing laminar clay. It is prepared by adopting the following steps: mixing the expandable clay modifying component, pseudo-thin hydrargillite and water, pulping for 0.1-10 hr. to obtaining a slurry liquor, ageing slurry liquor for 0.1-10 hr. at 50-85 deg.C, drying, forming, washing with water, ageing, finally drying and roasting so as to obtain said catalyst. The described modifying component can be selected from one or several kinds of hydroxyl polymers of silicon, aluminium, zirconium or titanium or one or several kinds of one or several substances containing the described hydroxyl polymer. Said catalyst has higher heavy oil conversion capacity.

Owner:CHINA PETROLEUM & CHEM CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com