Novel polyvinylidene fluoride film as well as preparation method and application thereof

A technology of polyvinylidene fluoride and separation membrane, which is applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., and can solve the problems of poor stability, durability, hydrophilicity and flux decline, and reduced membrane hydrophilicity and other problems, to achieve the effect of improved hydrophilic properties, less increase in preparation costs, and excellent elongation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

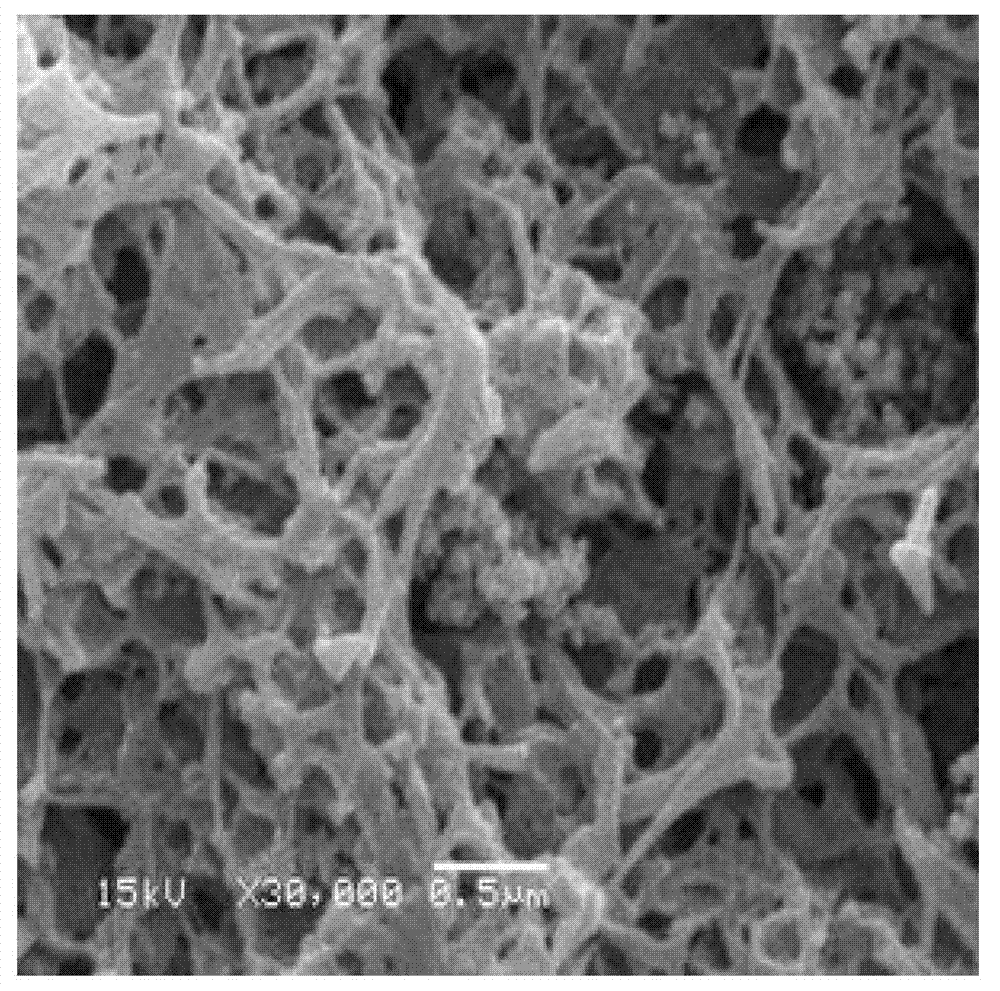

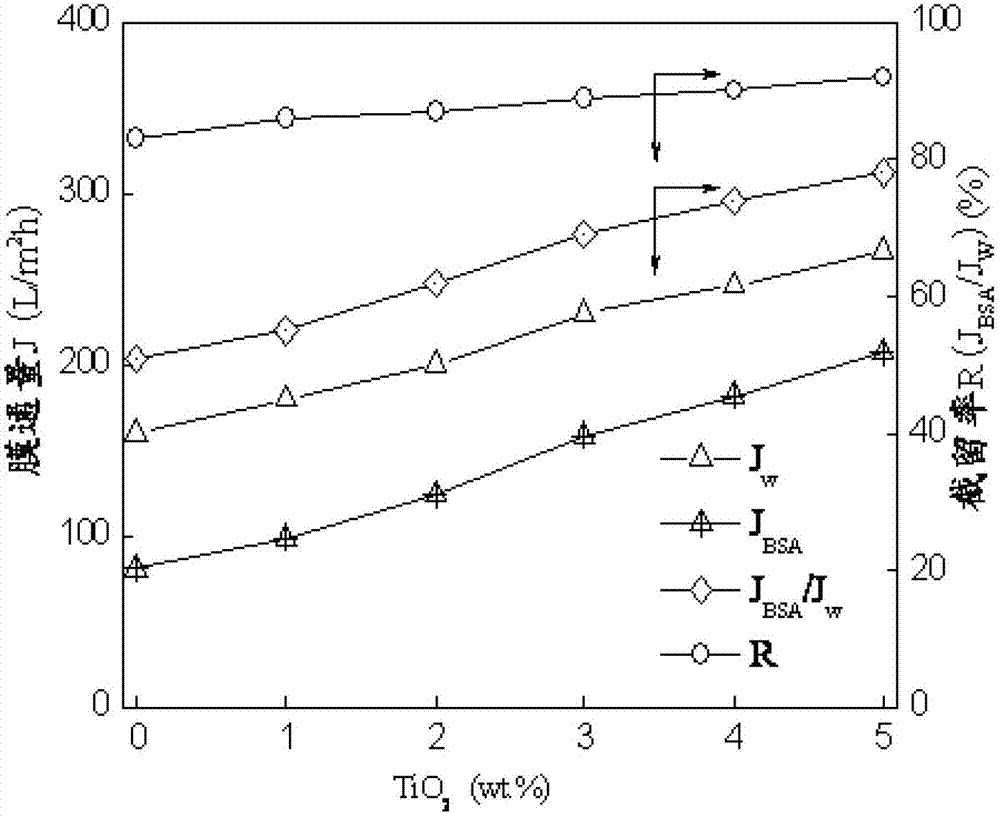

[0028] Example 1: Adding TiO 2 Nanowires (0%, mass ratio relative to PVDF)

[0029] Add 5g of polyvinylidene fluoride and 0.03g of sodium hexametaphosphate into 21.5g of N,N dimethylacetamide (DMAC) organic solvent, stir vigorously and ultrasonically disperse, then add 1.4g of polyvinylpyrrolidone, and heat in a water bath Stir vigorously for 24 hours to form a casting solution with uniform properties, then vacuum degassing at -50KPa for more than 30 minutes, and then use the L-S phase inversion method to form a film at a temperature of 25°C and a humidity of 50%, and volatilize in the air After 30 seconds, soak in 15% ethanol coagulation bath for 24 hours, then rinse with deionized water to prepare TiO 2 Nanoparticle-modified polyvinylidene fluoride separation membrane.

Embodiment 2

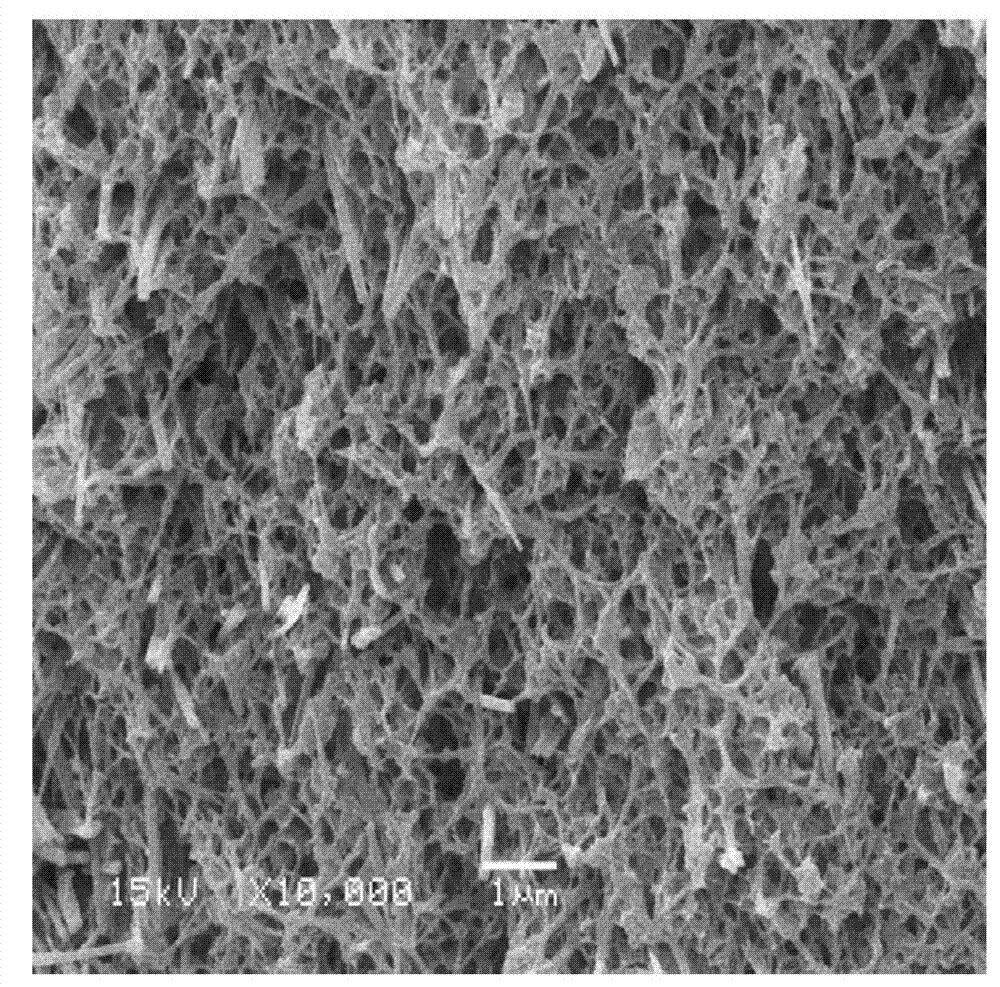

[0030] Example 2: Adding TiO 2 Nanowires (1%, mass ratio relative to PVDF)

[0031] 1% TiO 2 Add 19g of N, N dimethylacetamide (DMAC) organic solvent to the nanowires, stir vigorously and ultrasonically disperse, add 5g of polyvinylidene fluoride and 0.25g of sodium hexametaphosphate, and then add 0.75g of polyvinylpyrrolidone , heated in a water bath and vigorously stirred for 24 hours to form a uniform casting solution, and then degassed in vacuum at -50KPa for more than 30 minutes, and then used the L-S phase inversion method to form a film at a temperature of 25°C and a humidity of 50%. After being volatilized in the air for 30 seconds, soak in a 15% ethanol coagulation bath for 24 hours, and then rinse with deionized water to prepare TiO 2 Nanowire modified polyvinylidene fluoride separation membrane.

Embodiment 3

[0032] Embodiment 3: adding TiO 2 Nanowires (2%, relative to the mass ratio of PVDF)

[0033] 2% TiO 2 Add 14g of nanowires to N, N dimethylacetamide (DMAC) organic solvent, stir vigorously and ultrasonically disperse, add 5g of polyvinylidene fluoride and 0.2g of sodium hexametaphosphate, and then add 1.0g of polyvinylpyrrolidone , heated in a water bath and vigorously stirred for 24 hours to form a uniform casting solution, and then degassed in vacuum at -50KPa for more than 30 minutes, and then used the L-S phase inversion method to form a film at a temperature of 25°C and a humidity of 50%. After being volatilized in the air for 30 seconds, soak in a 15% ethanol coagulation bath for 24 hours, and then rinse with deionized water to prepare TiO 2Nanowire modified polyvinylidene fluoride separation membrane.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com