Patents

Literature

3244results about How to "Easy to drain" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

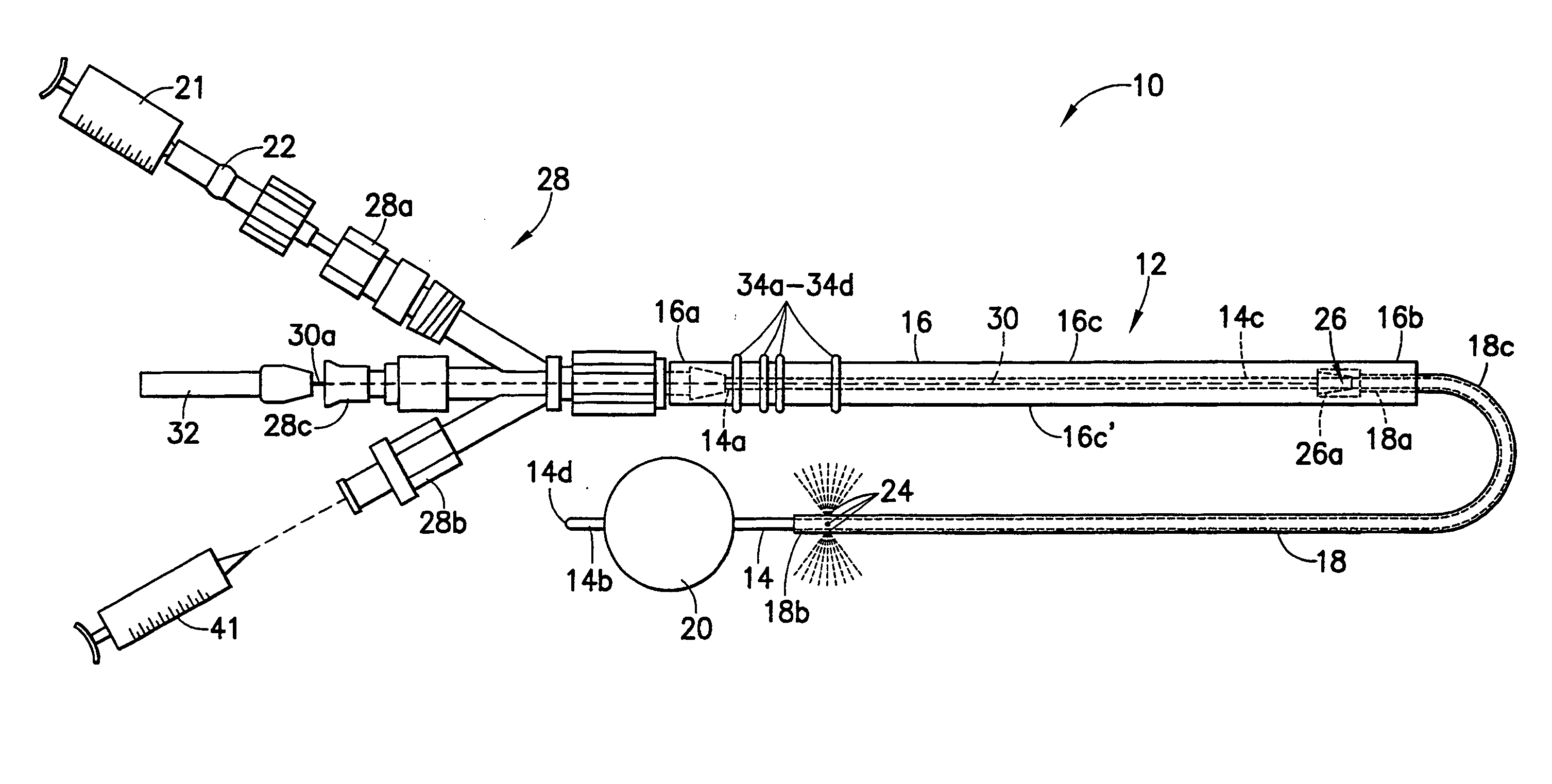

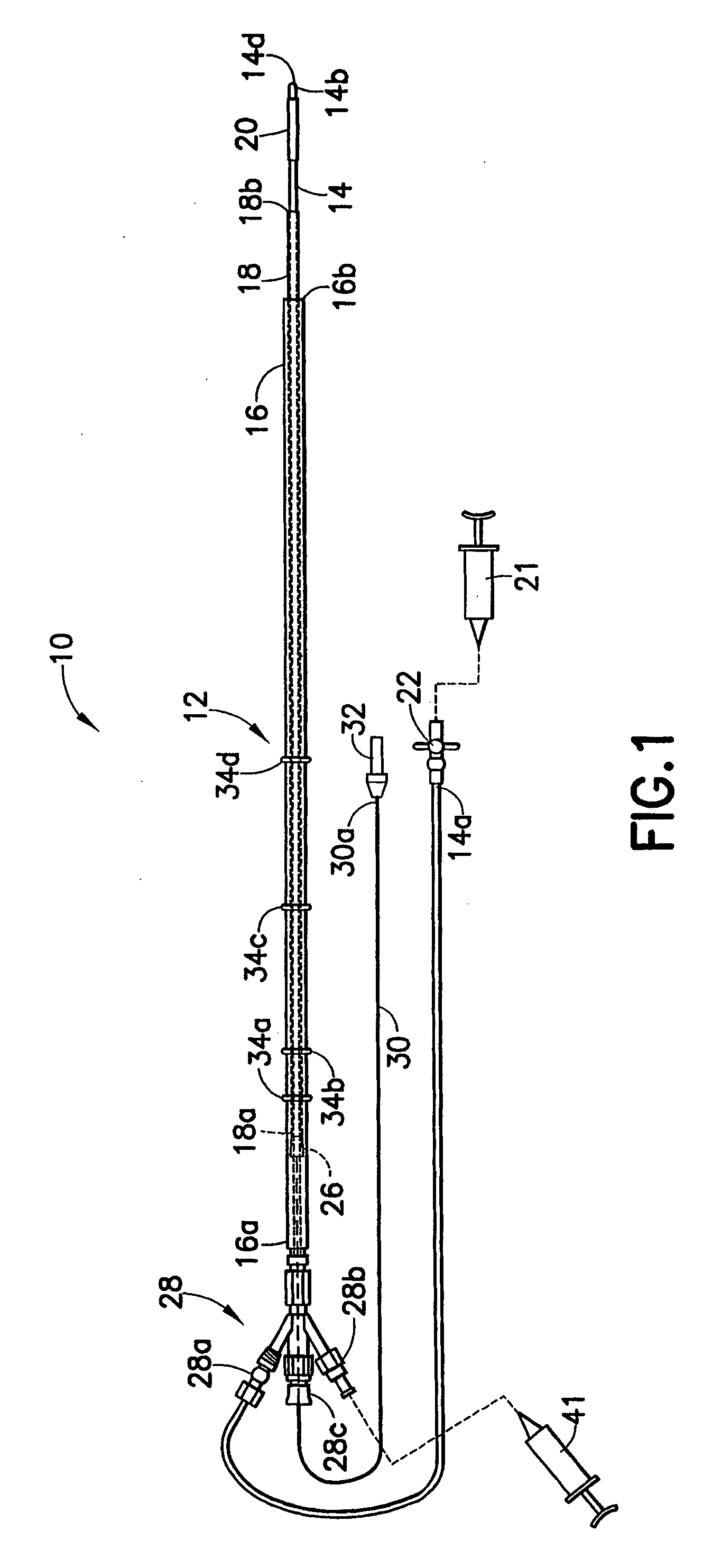

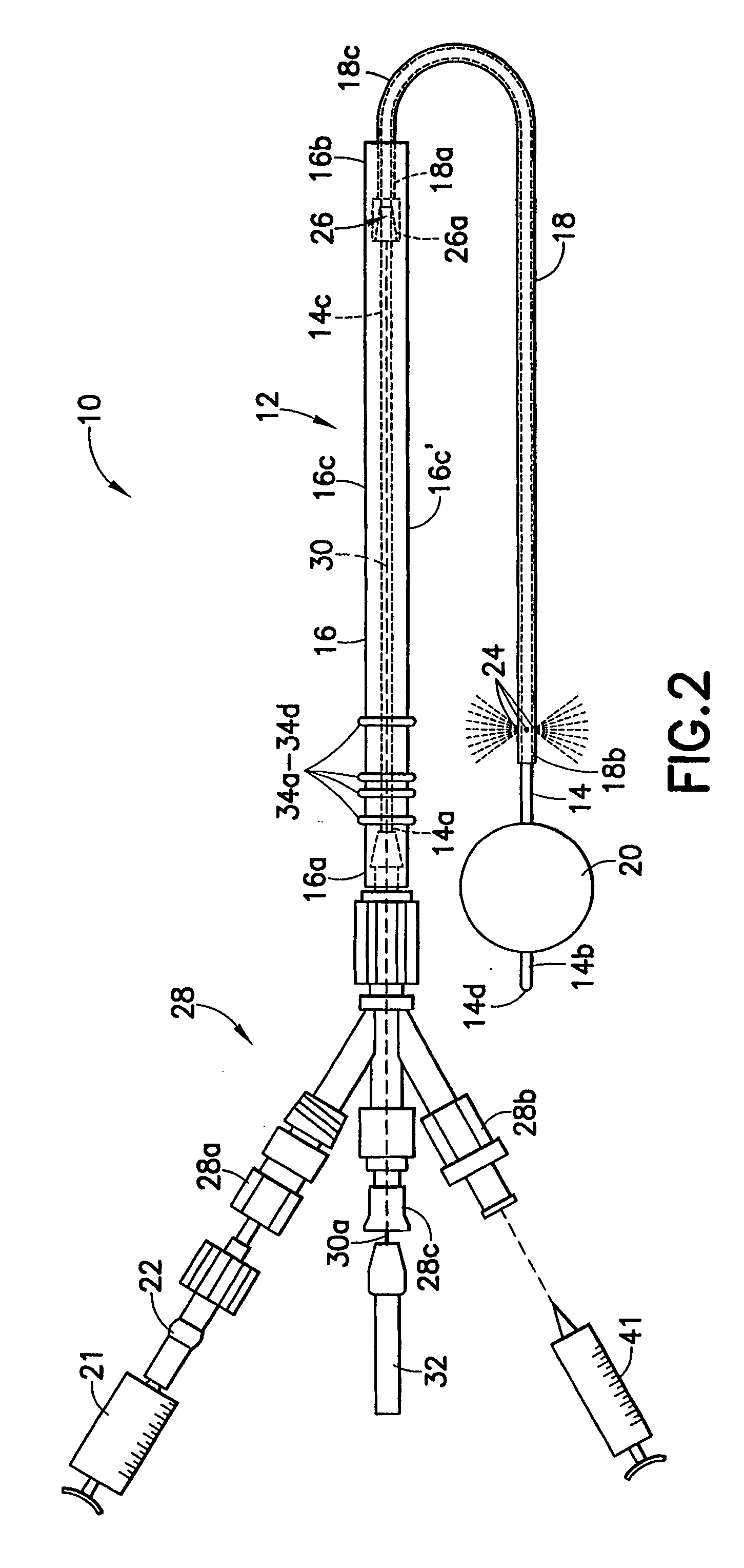

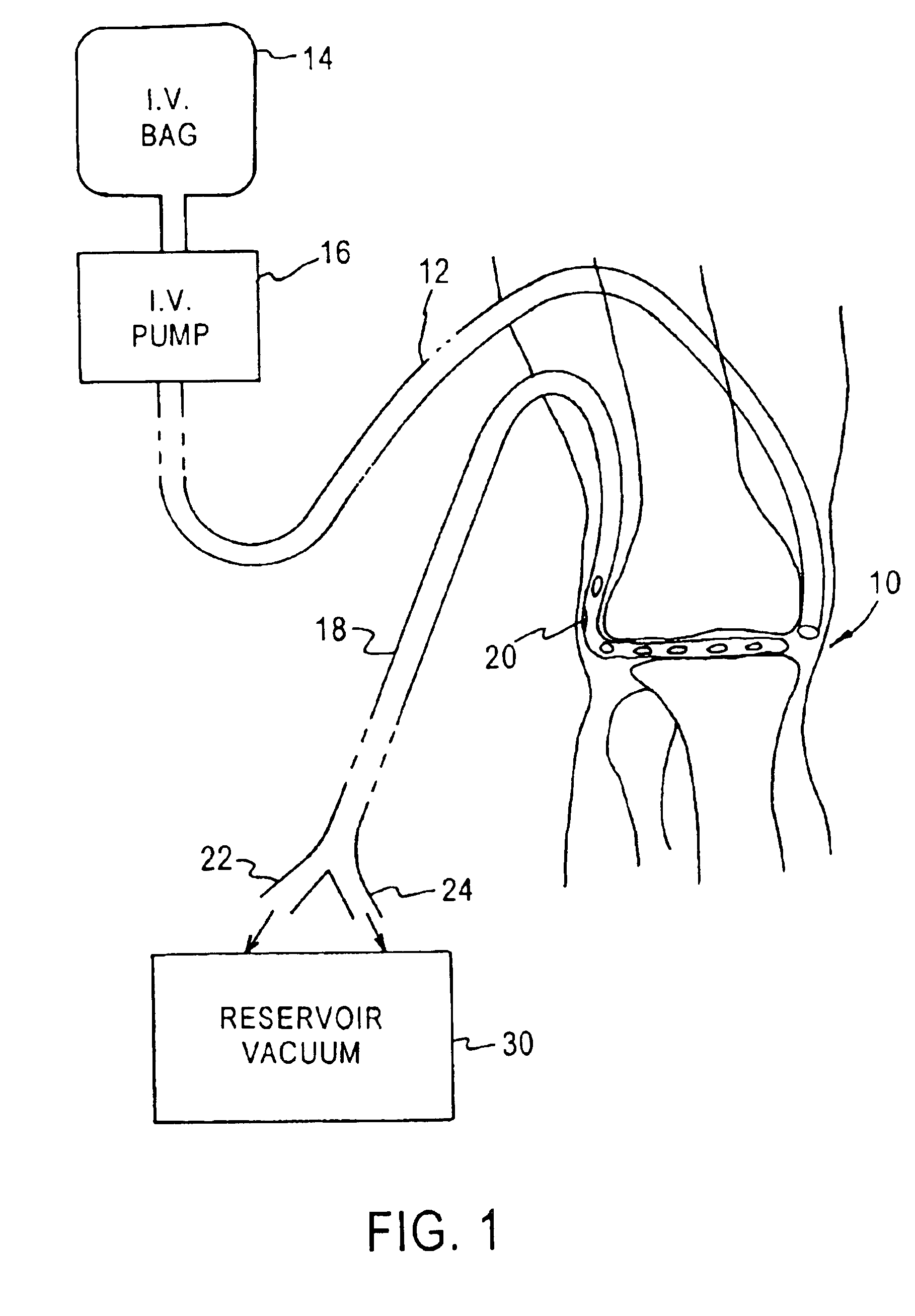

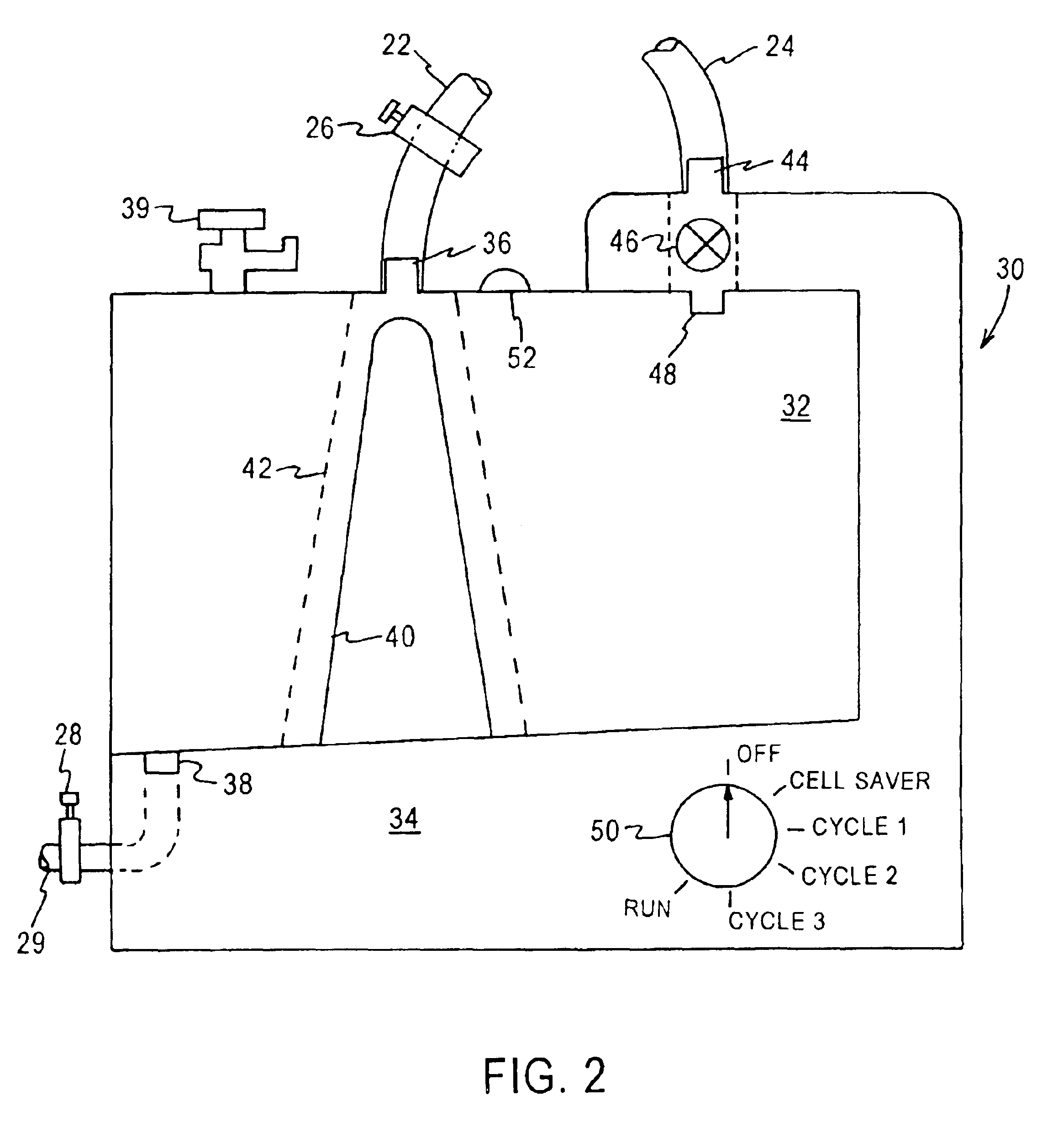

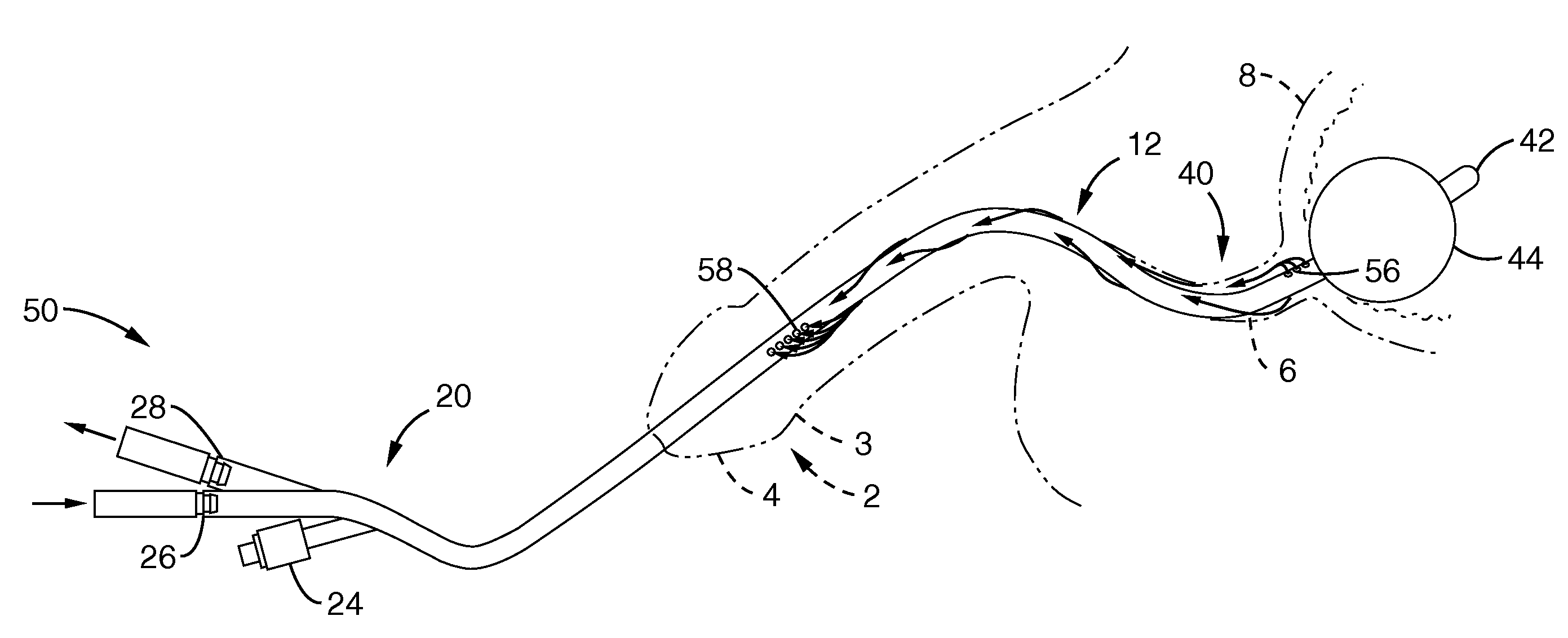

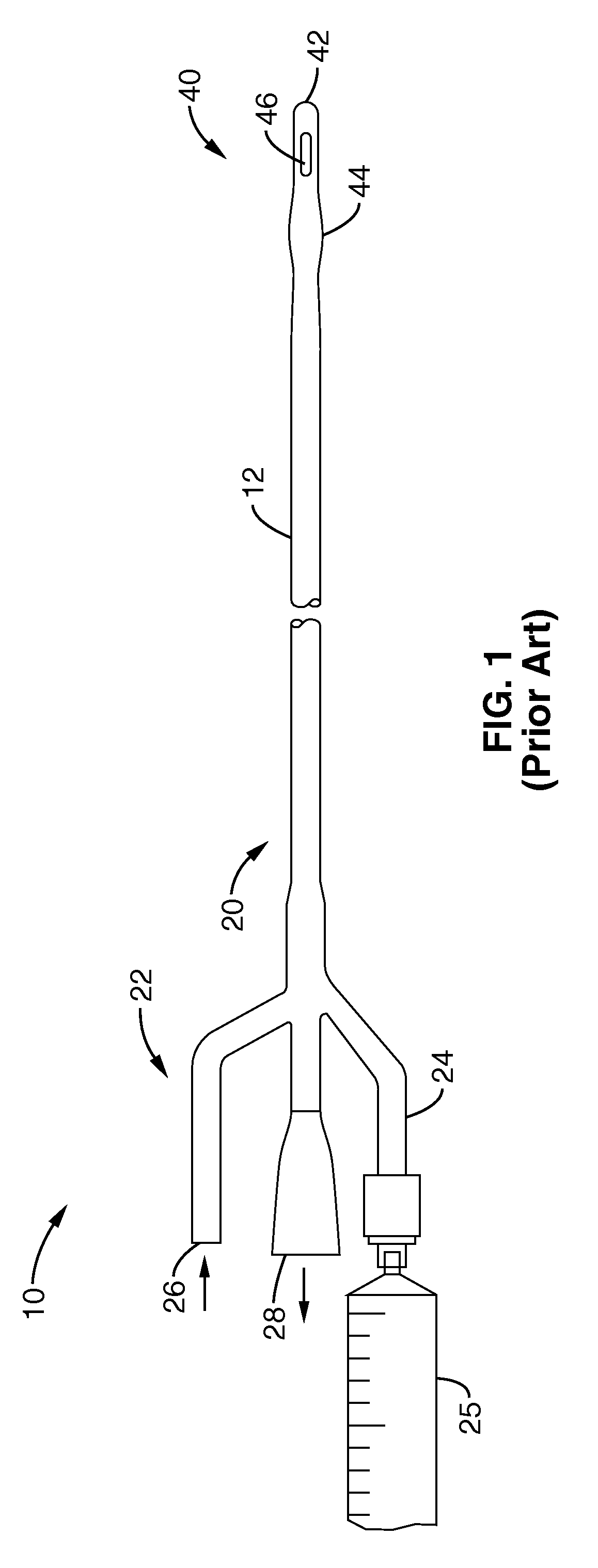

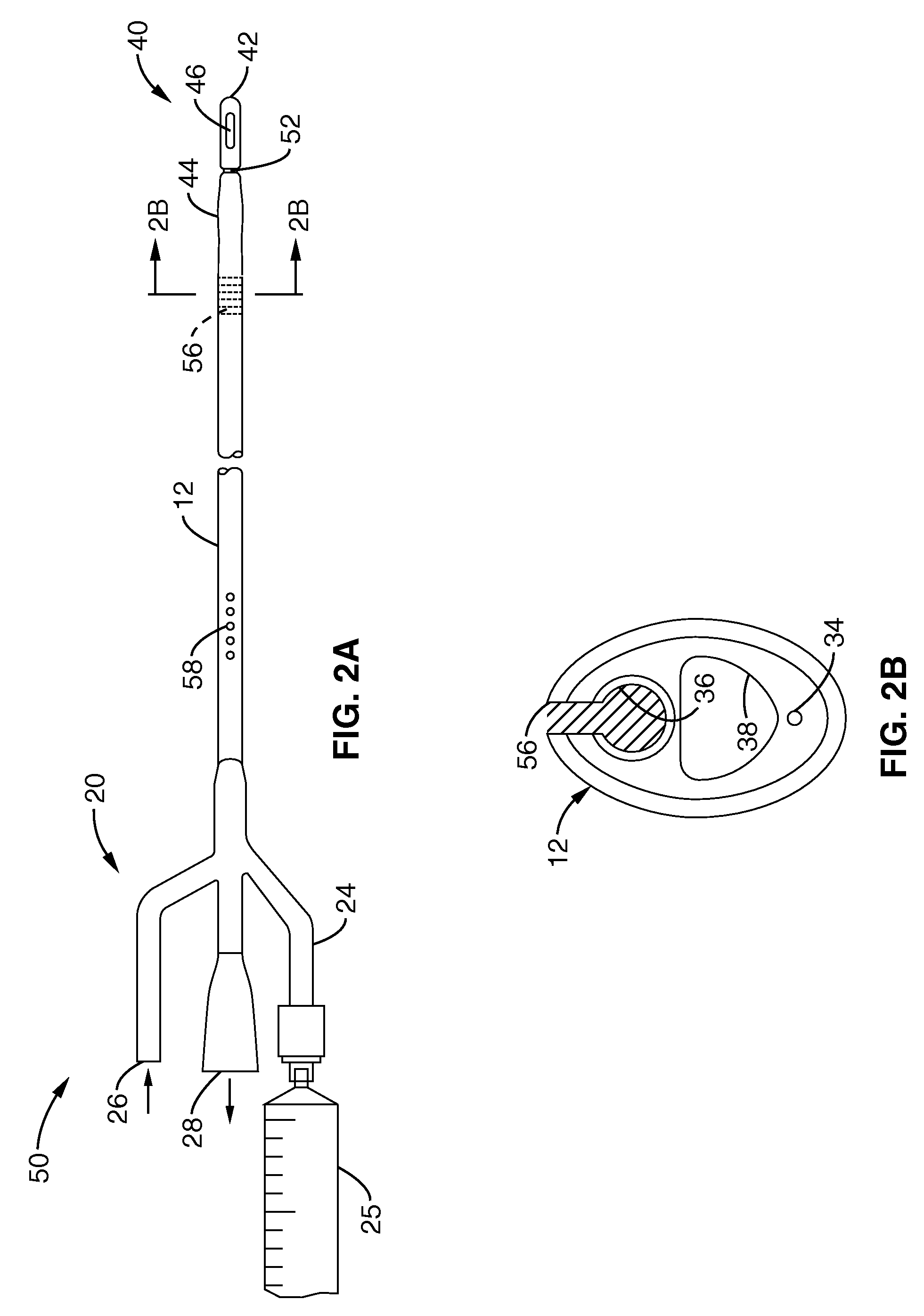

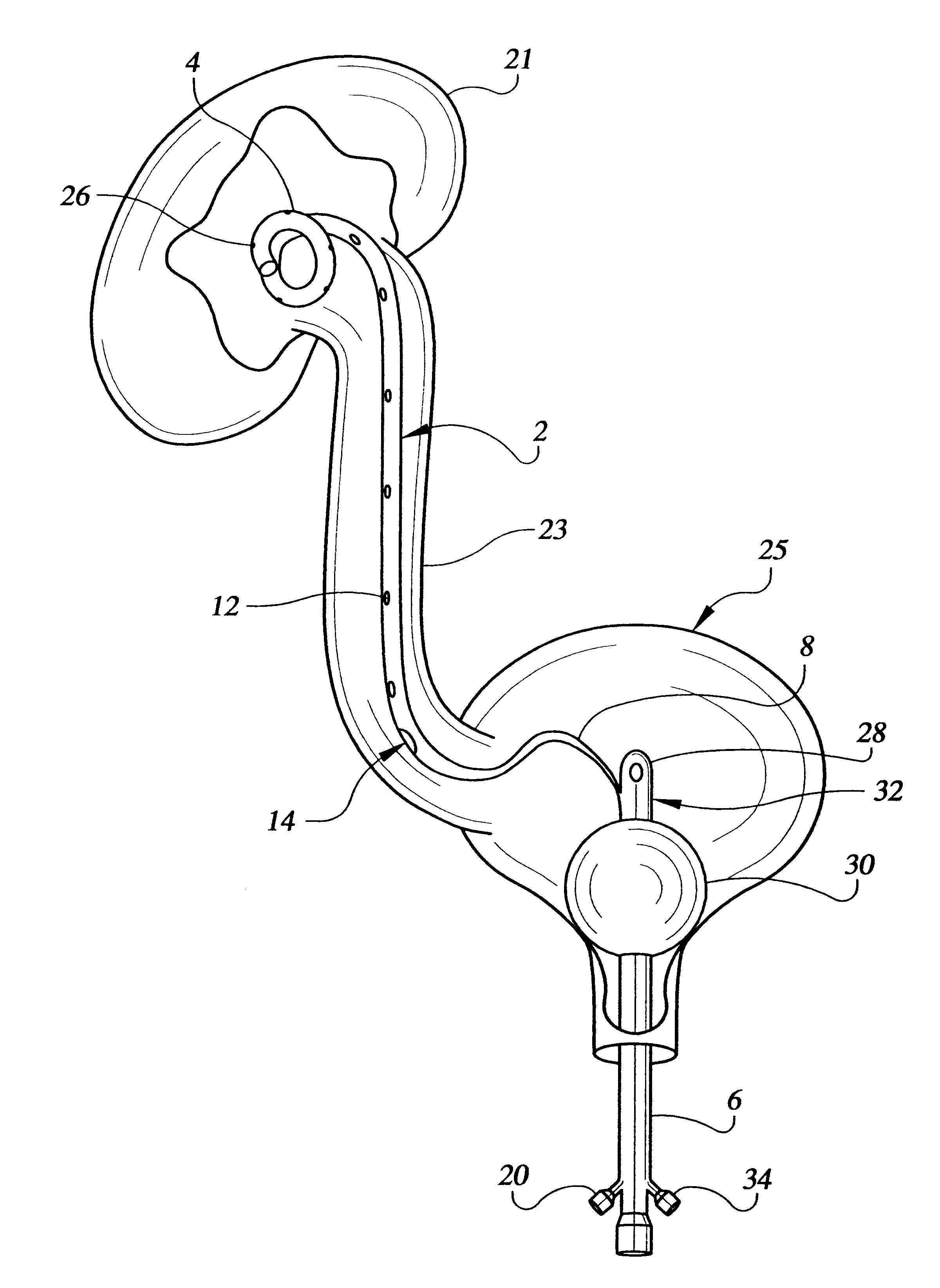

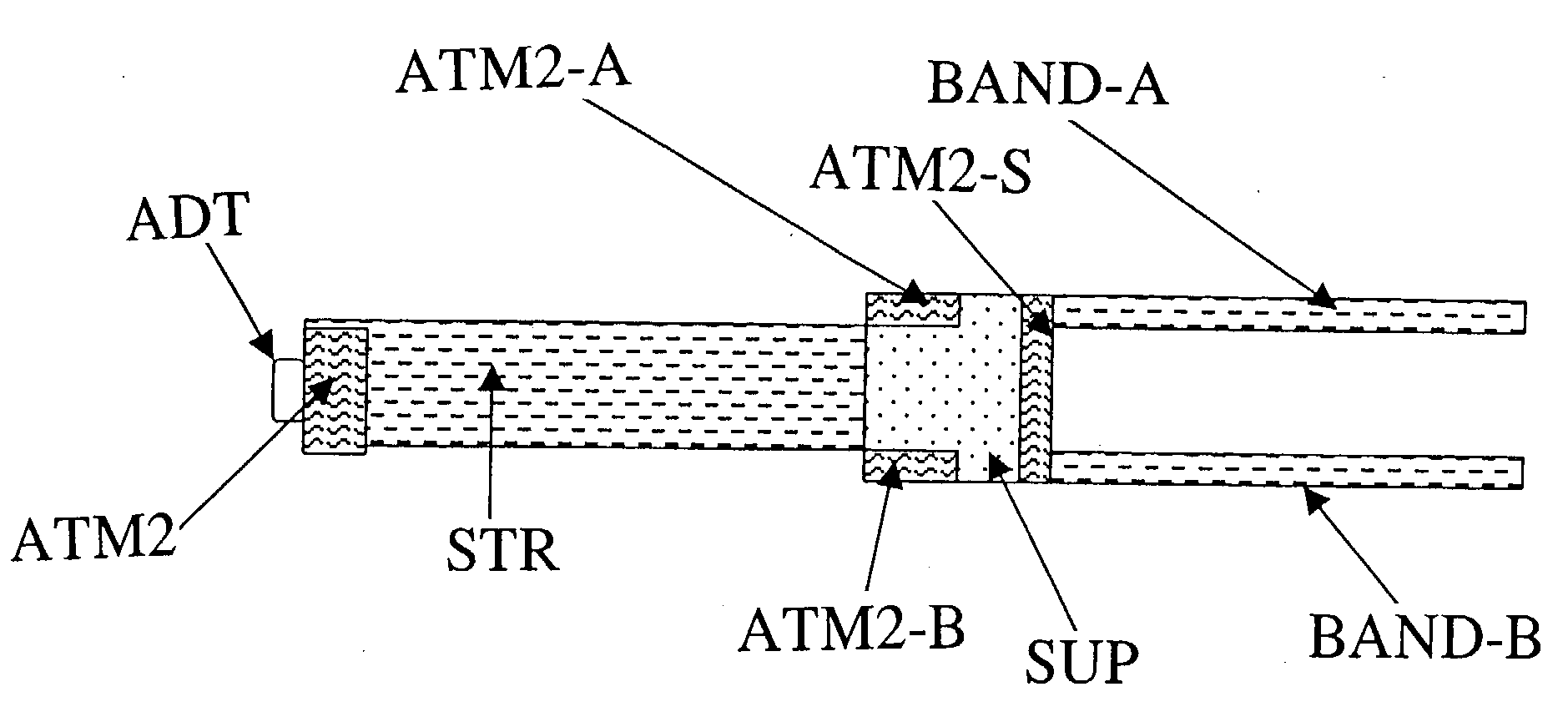

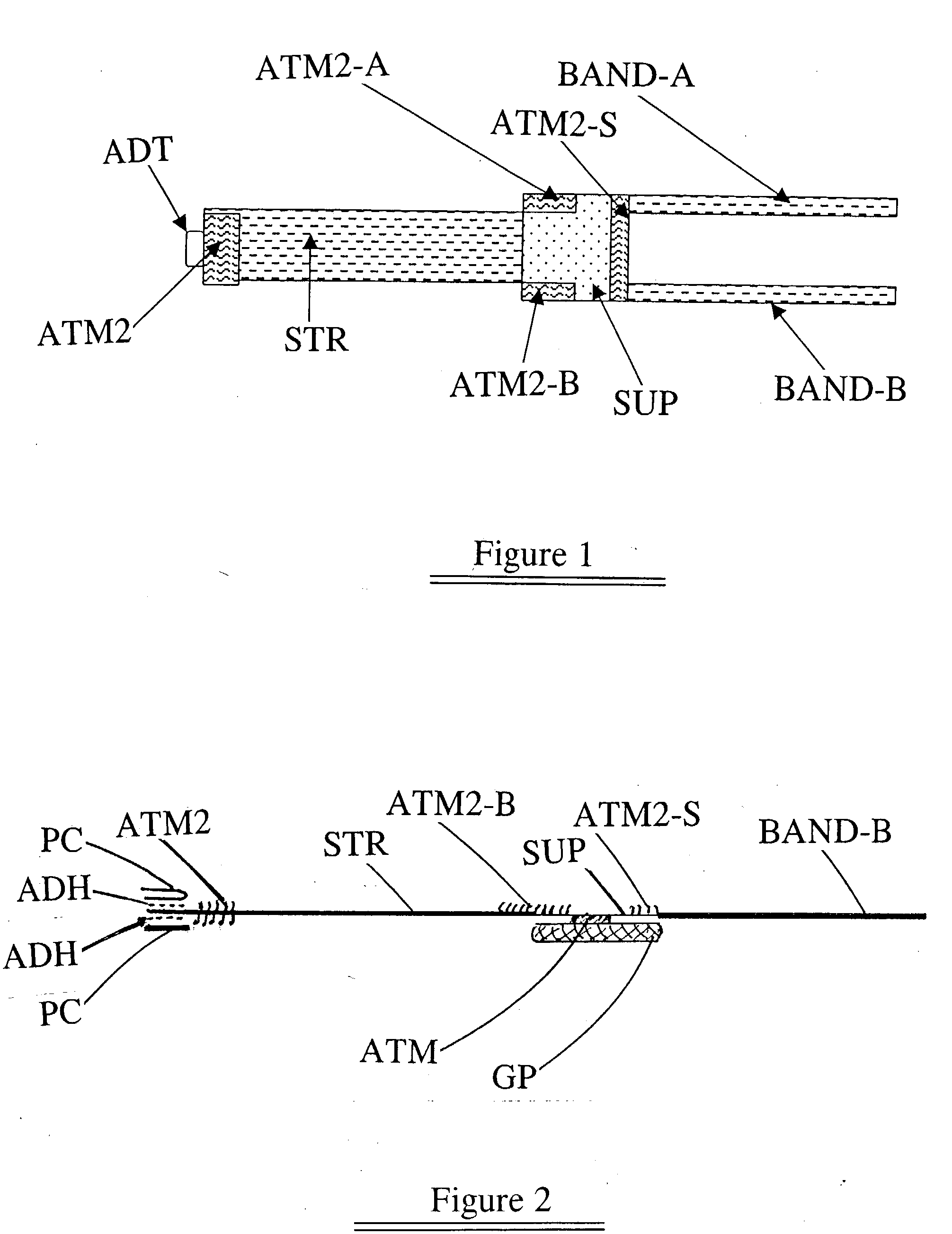

Methods and apparatus for treating the interior of a blood vessel

InactiveUS20050113798A1Easy to drainPromote migrationGuide needlesBalloon catheterCatheterBlood vessel

Methods and apparatus for treating the interior of a blood vessel include a variety of catheter designs, methods and apparatus for occluding a blood vessel, methods and apparatus for locating an occlusion device, methods and apparatus for locating a treating device at the site of blood vessel tributaries, and methods and apparatus for dispensing treating agent.

Owner:VEIN RX

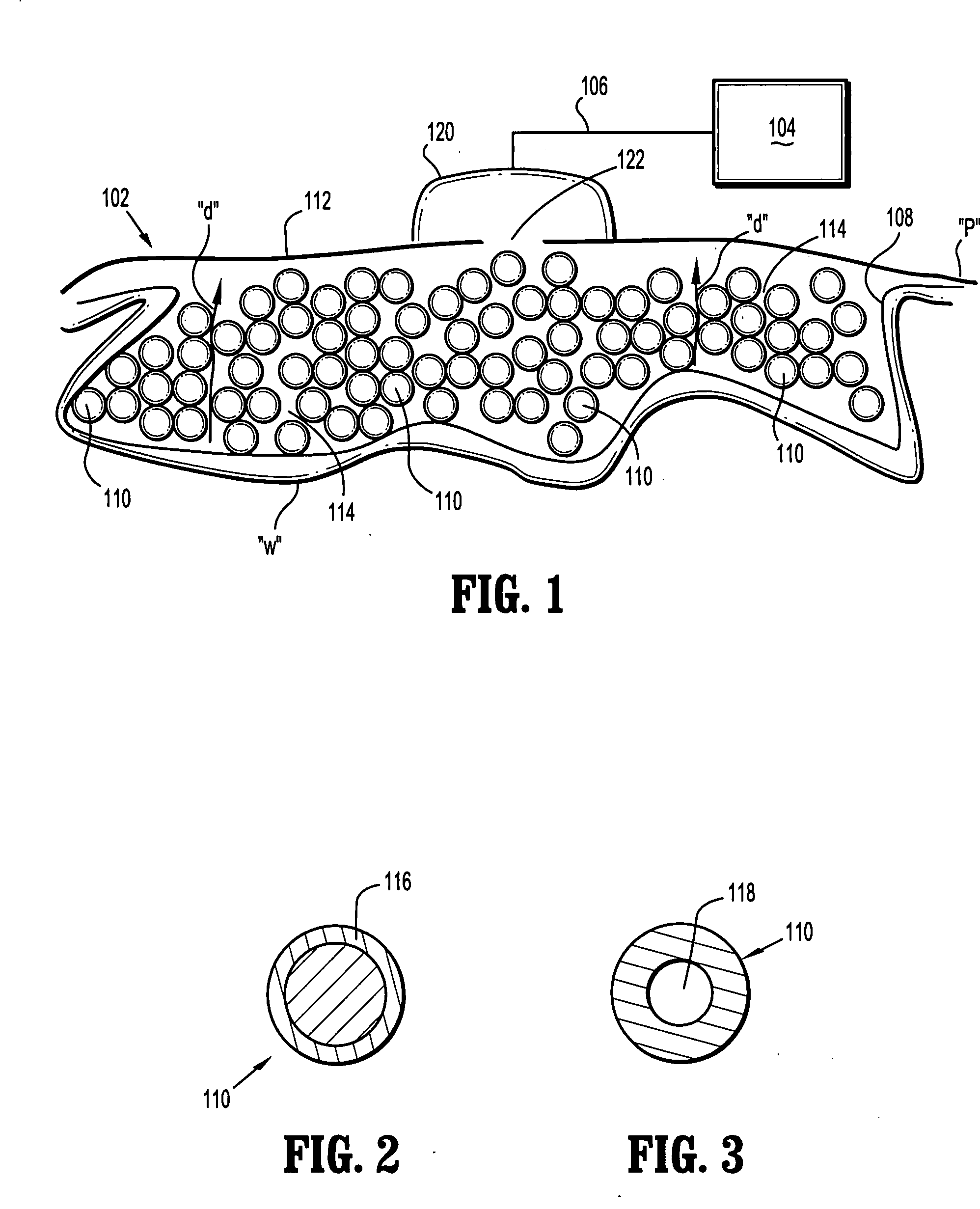

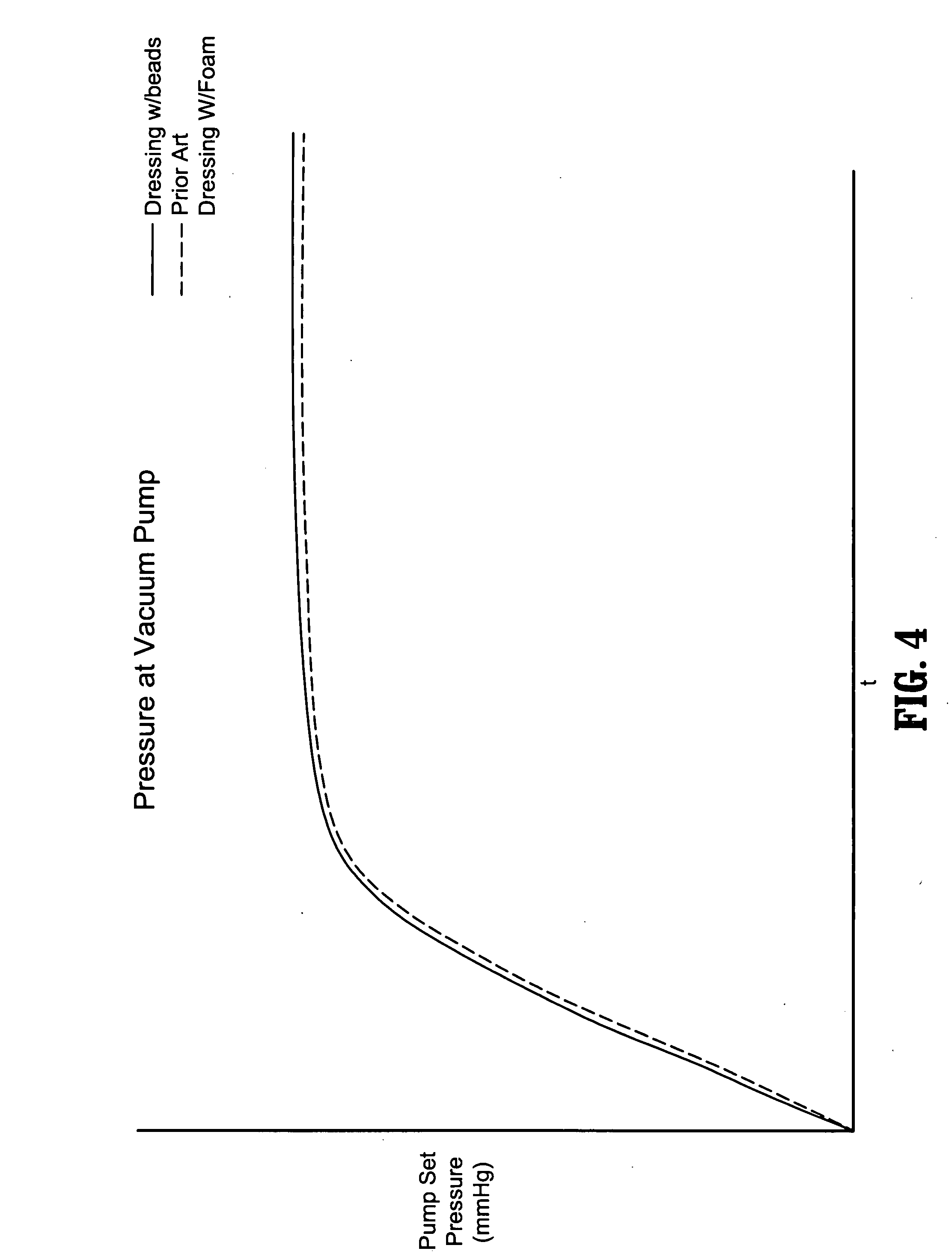

Surgical wound dressing

A wound dressing system includes a fluid permeable support member for positioning within a wound and adapted to generally conform to a topography of a wound, a plurality of beads supported by the support member, an outer member for positioning over the wound to substantially enclose the beads and a conduit for supplying reduced pressure to the wound. The support member is adapted to permit exudates from the wound to pass therethrough. The beads are characterized by having sufficient rigidity to substantially maintain respective shapes thereof to thereby facilitate passage of the exudates through spaces or passages defined between adjacent beads. The beads may comprise glass, an acrylic or a polymeric material. The support member may comprise a polymeric or fabric material. The support member may be an enclosure member or pouch which houses the beads. Multiple pouches are also envisioned.

Owner:SMITH & NEPHEW INC

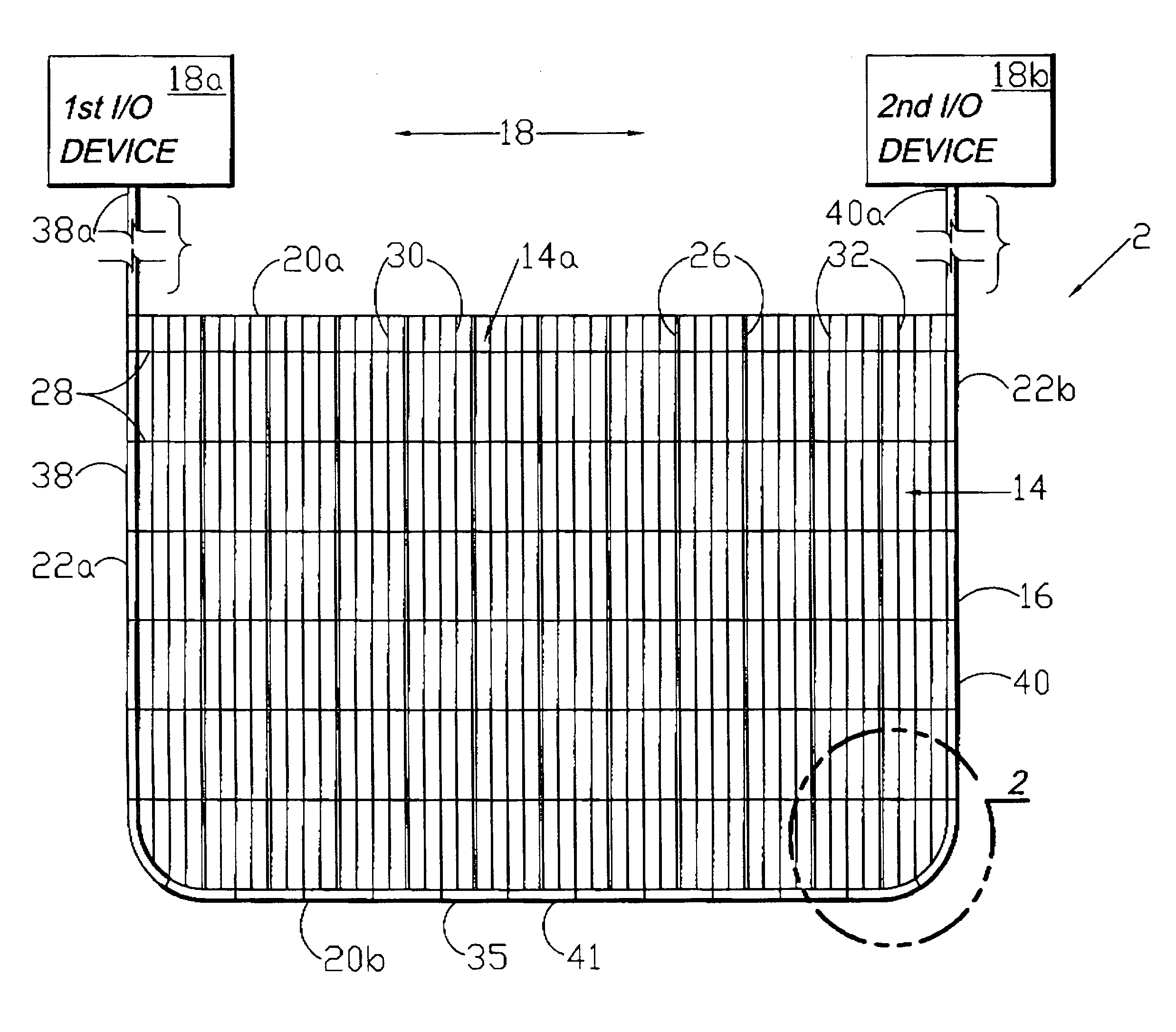

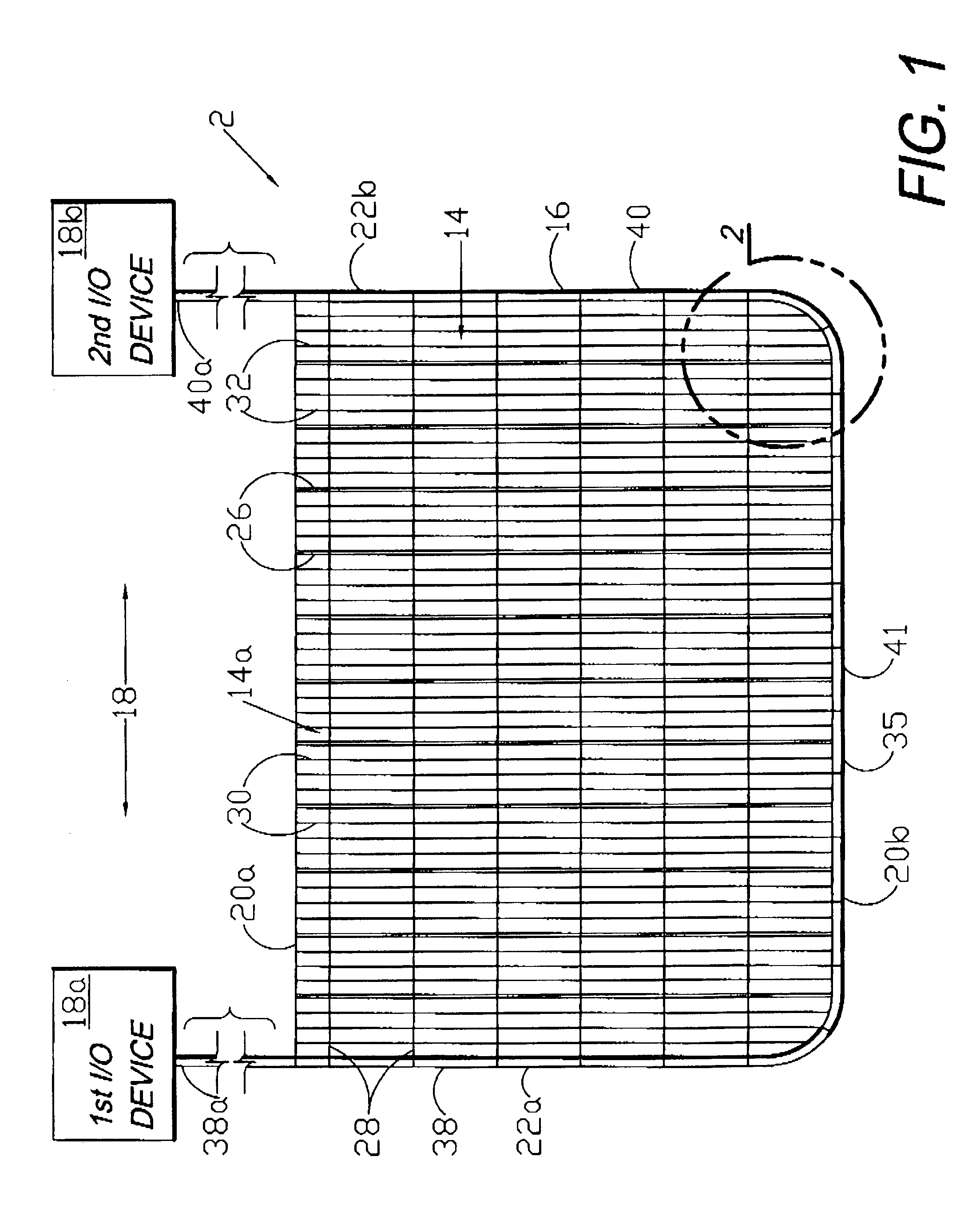

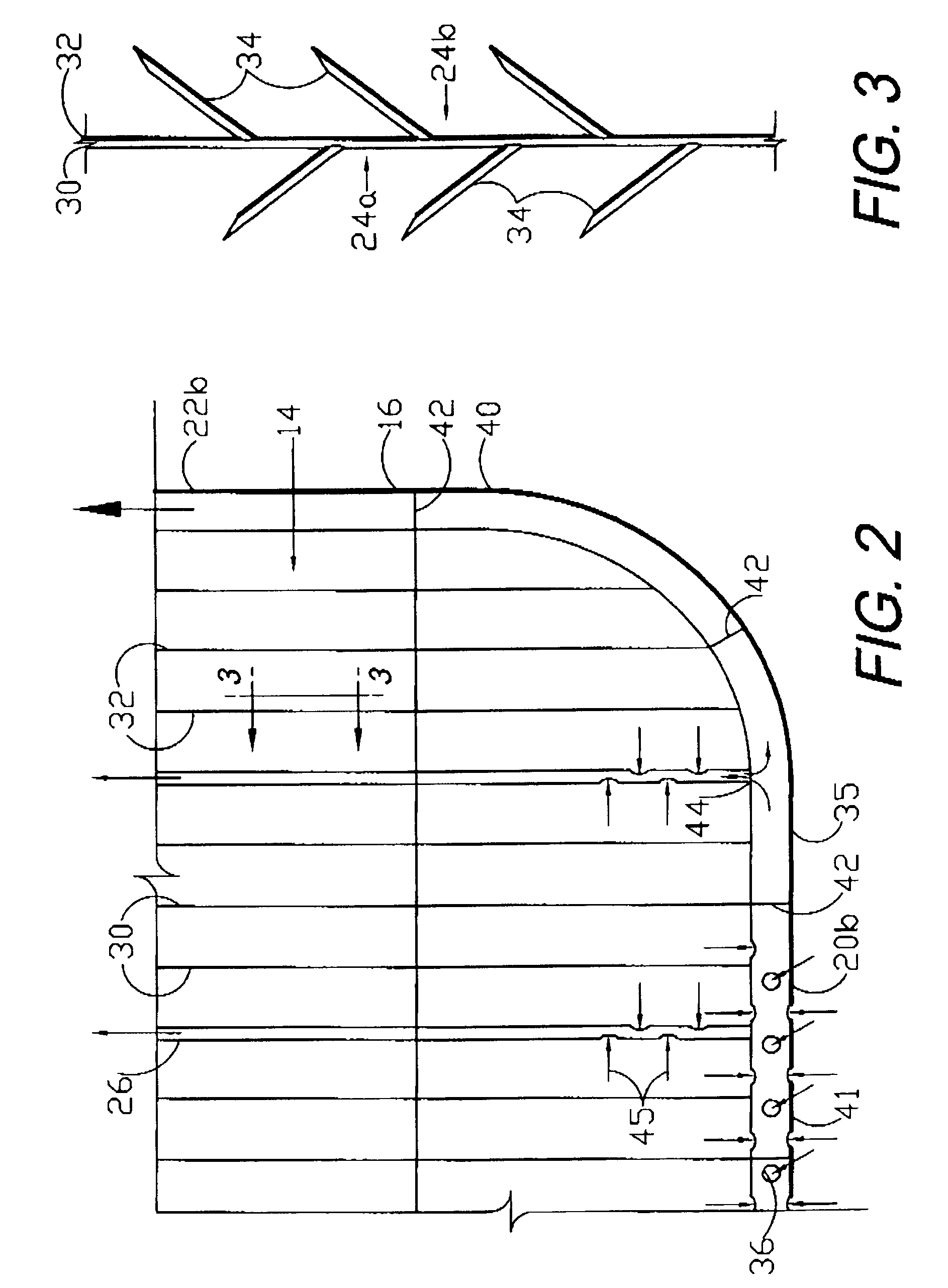

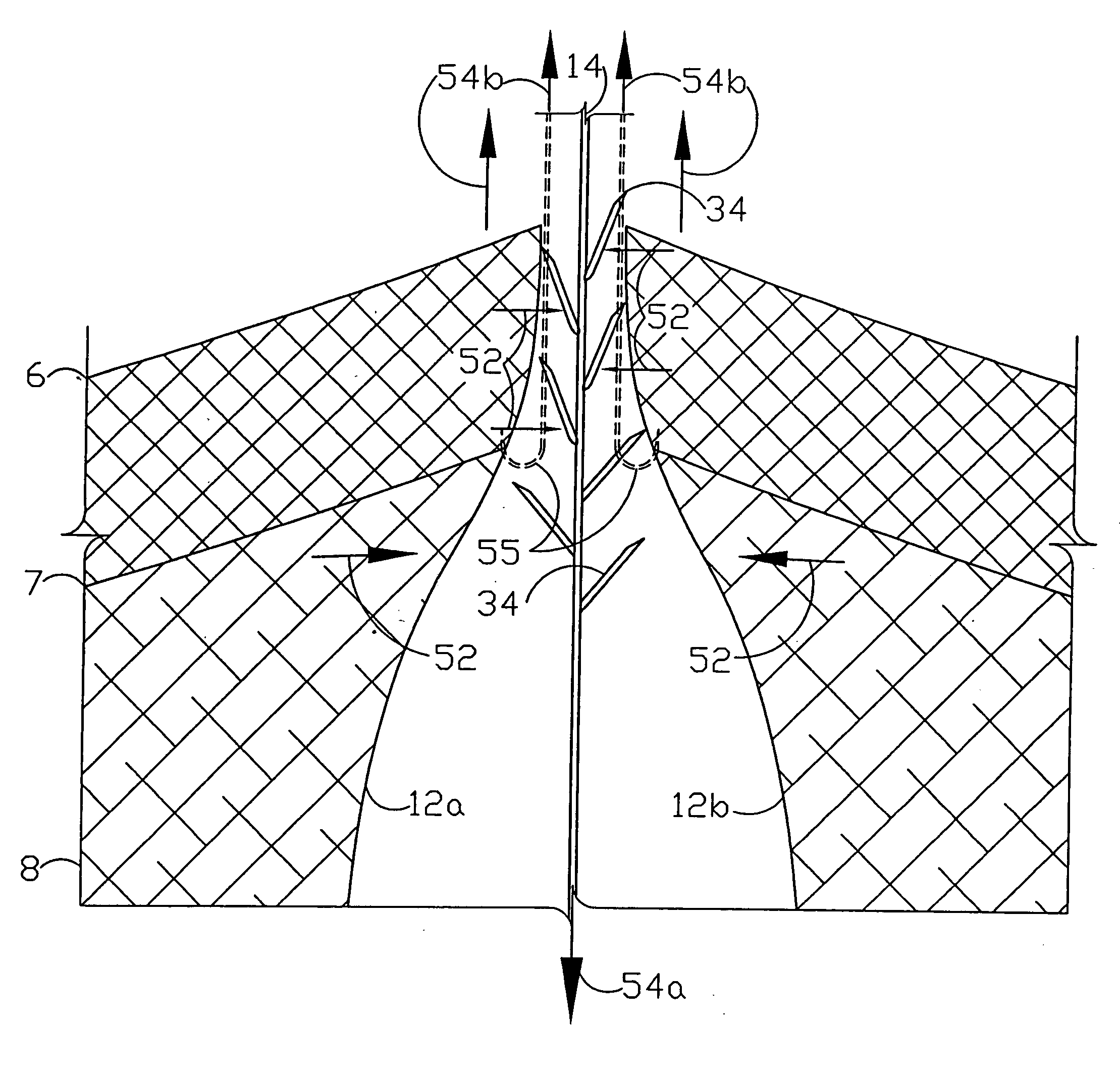

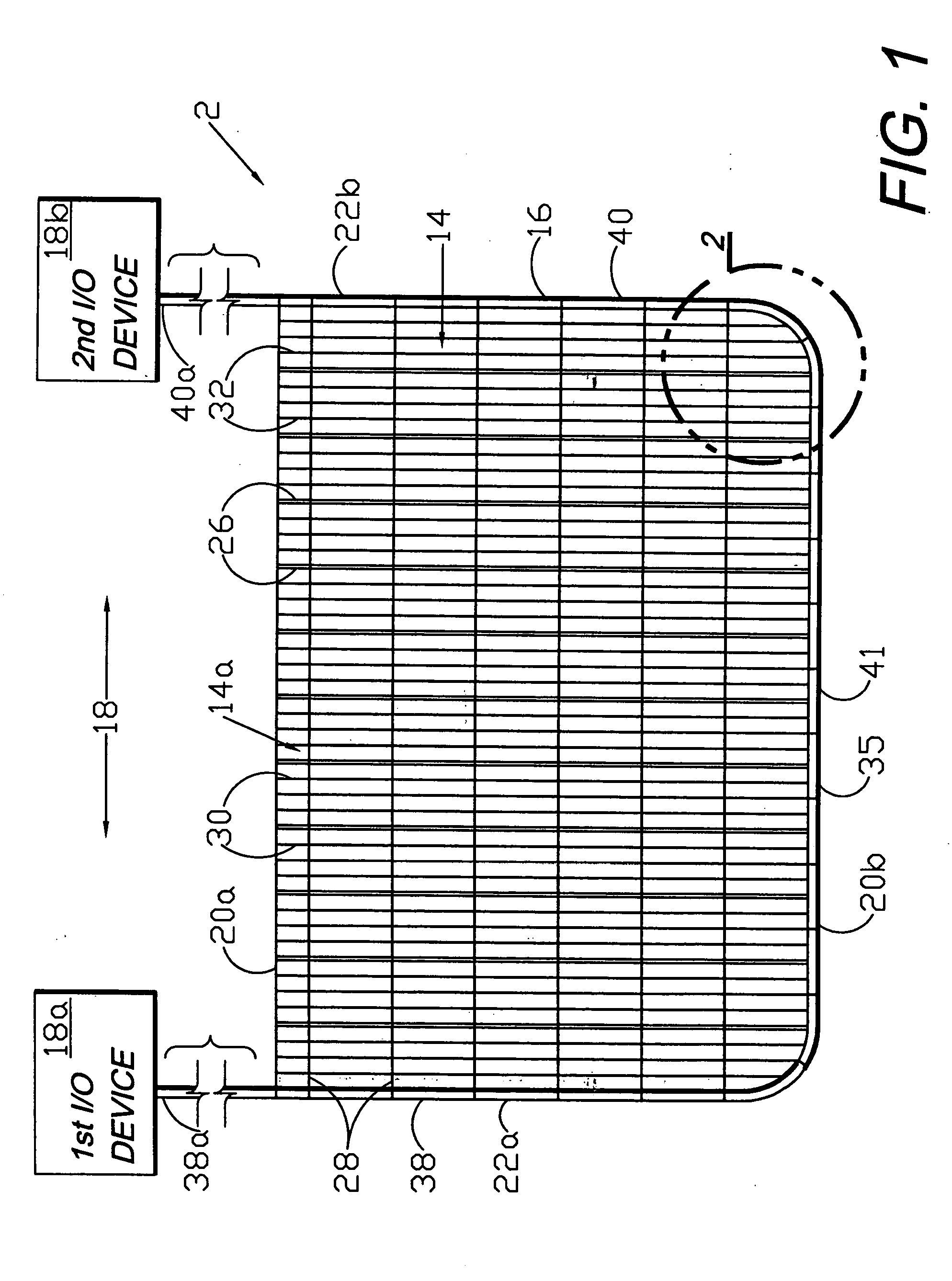

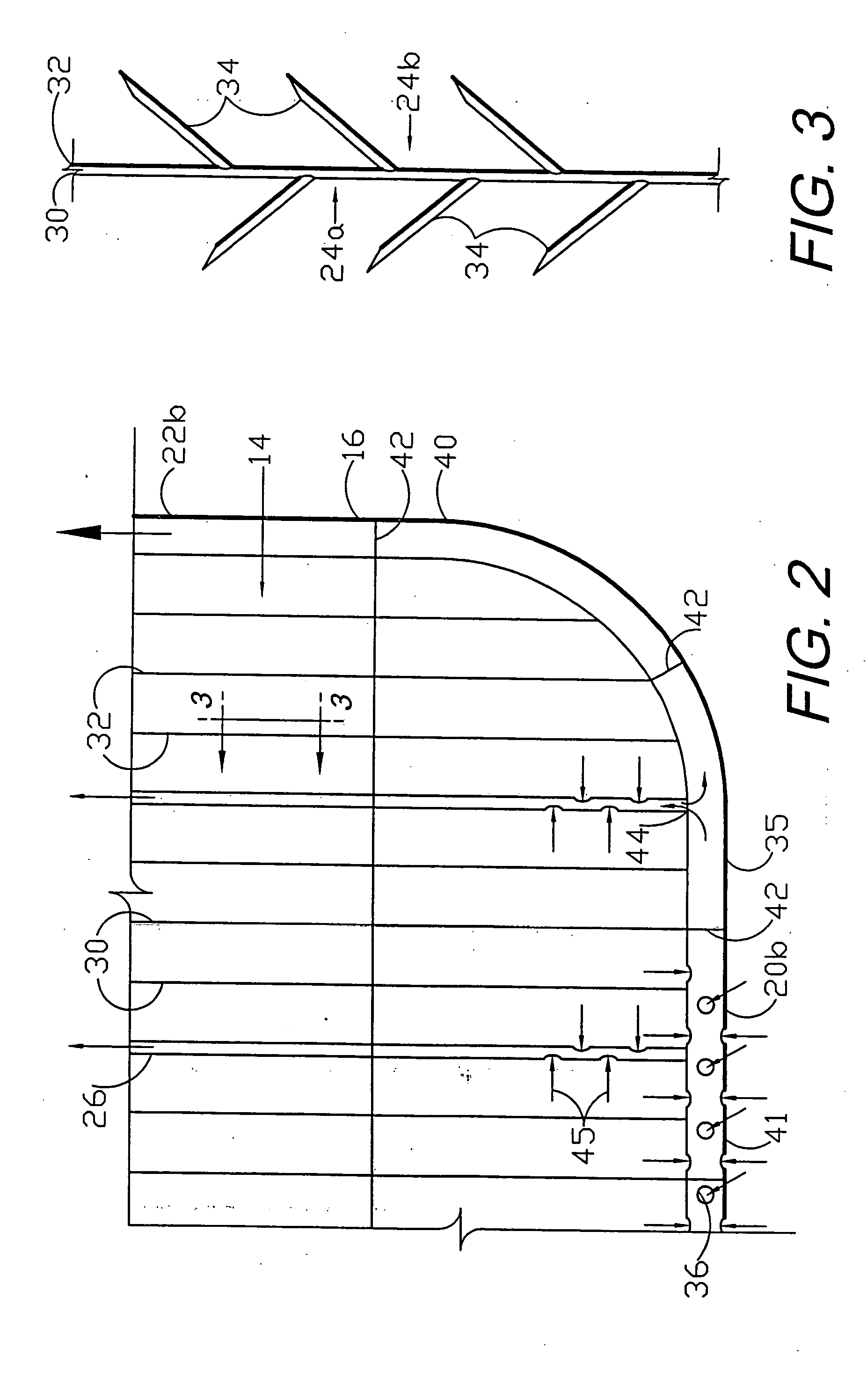

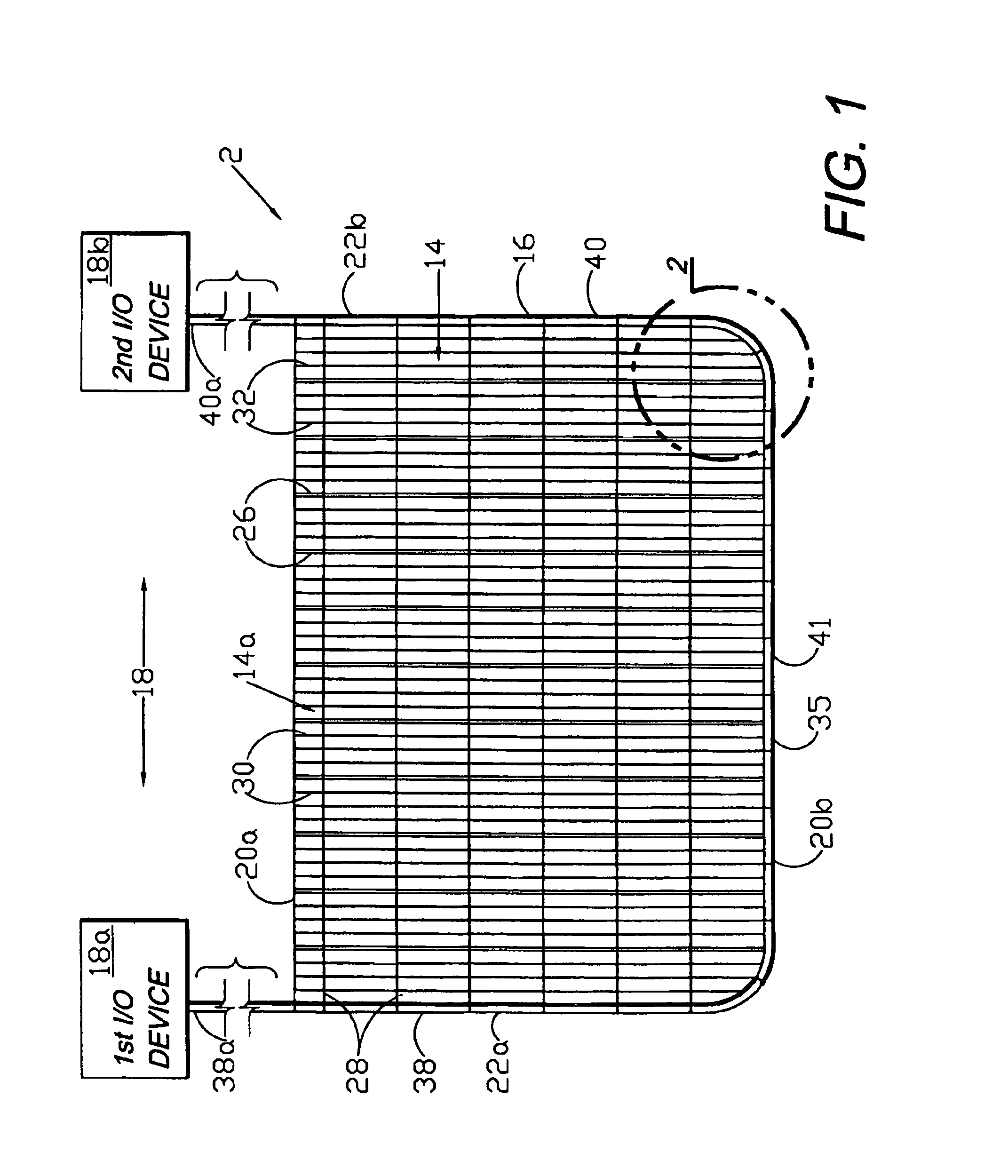

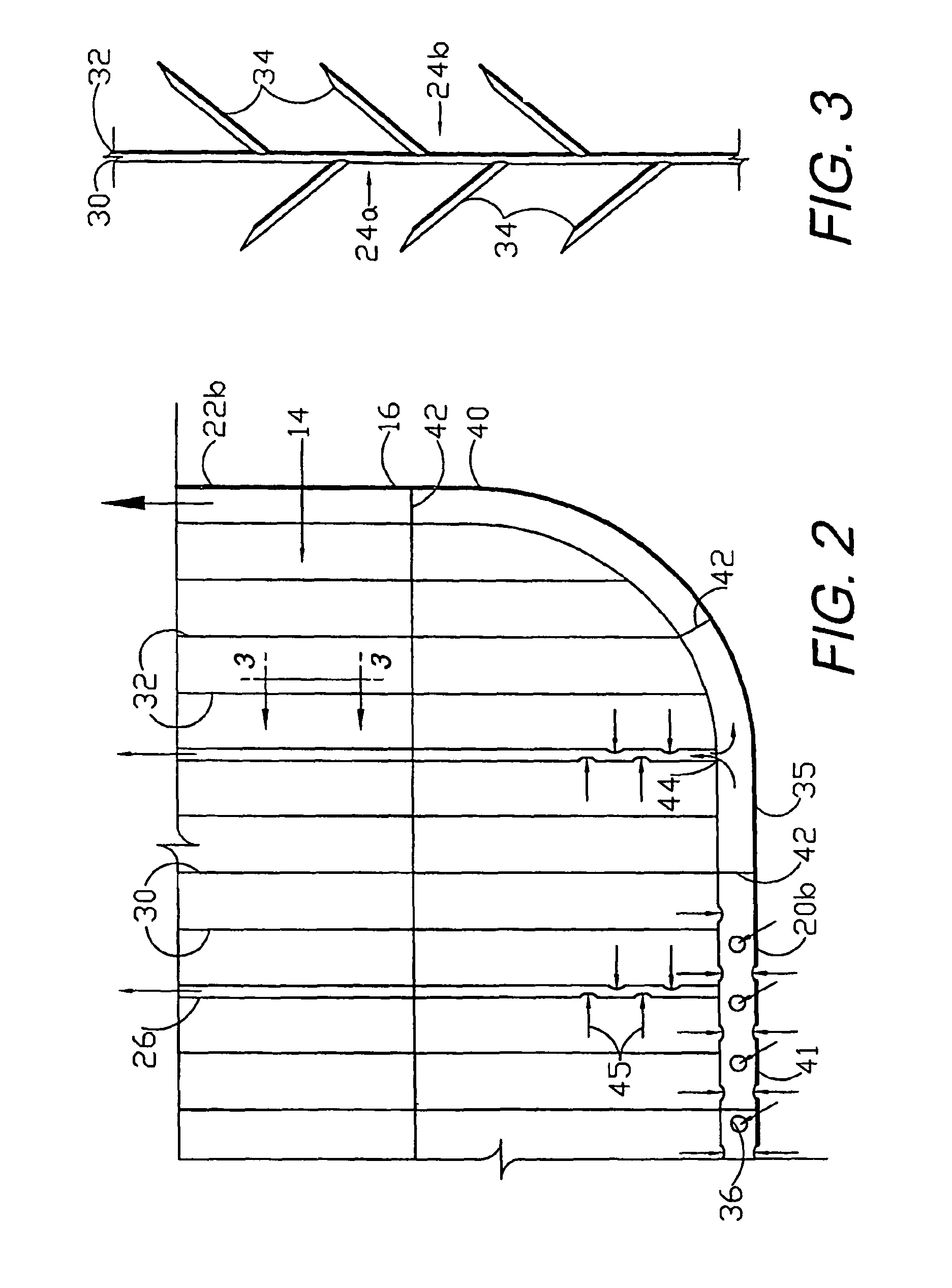

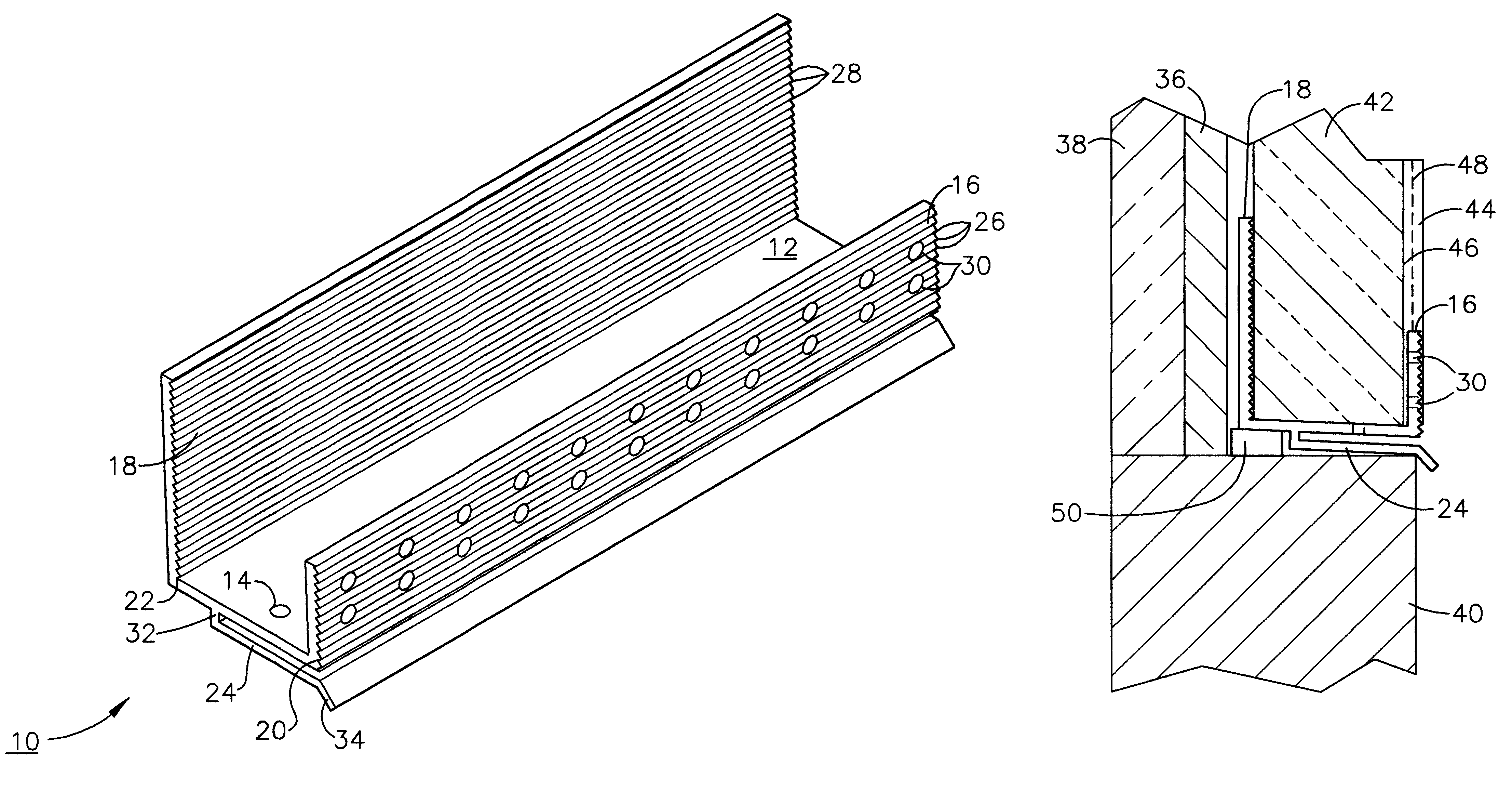

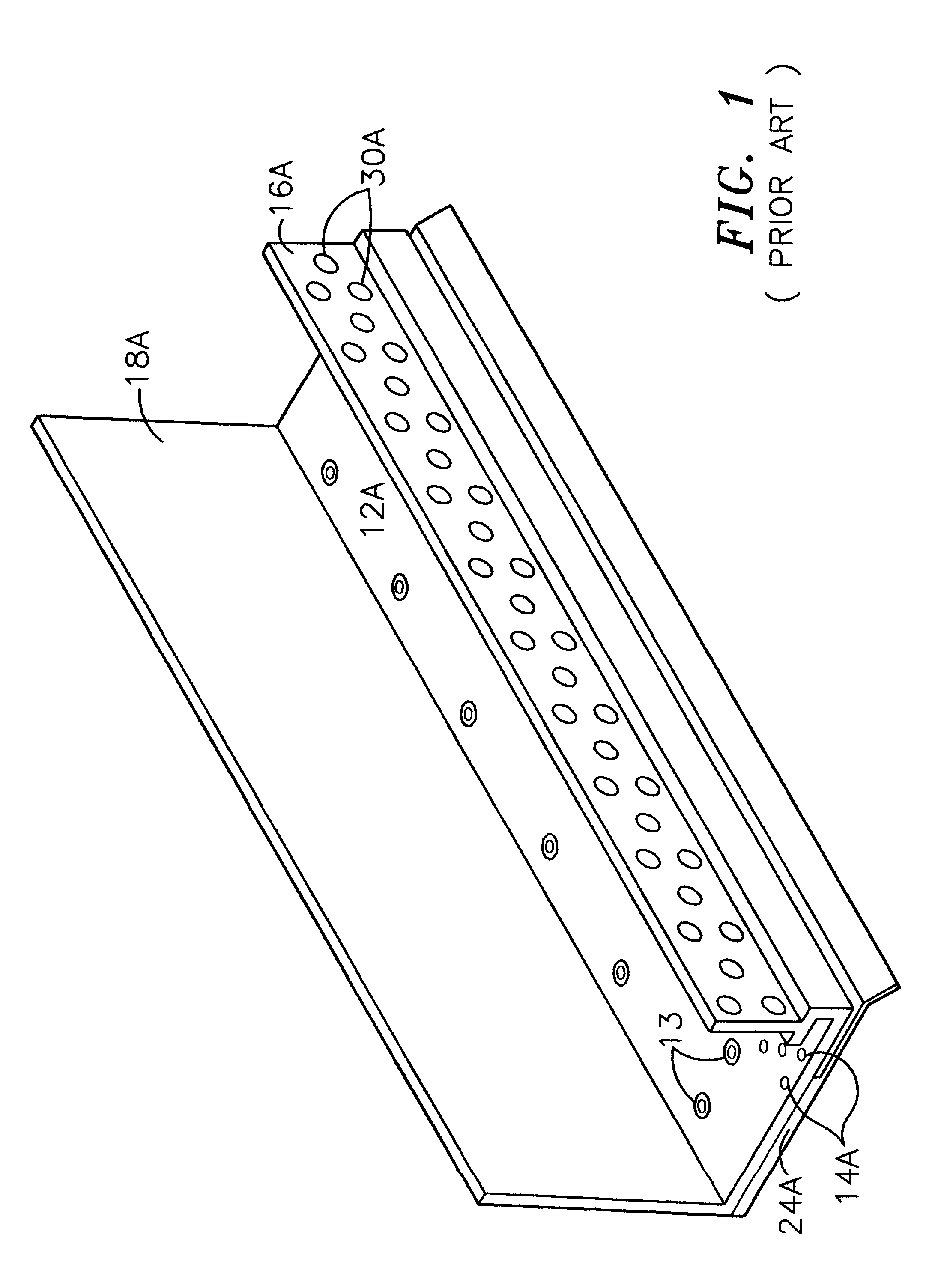

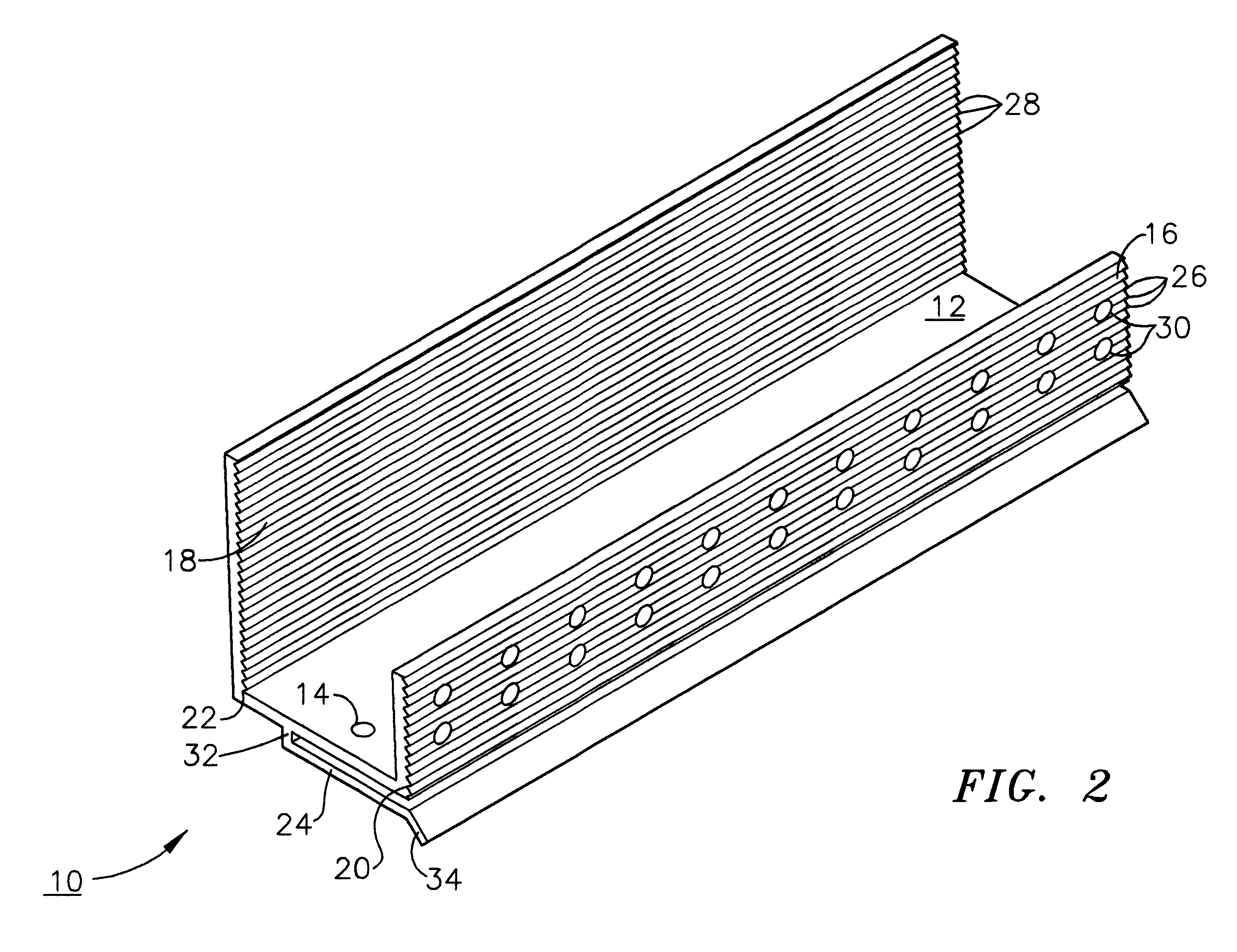

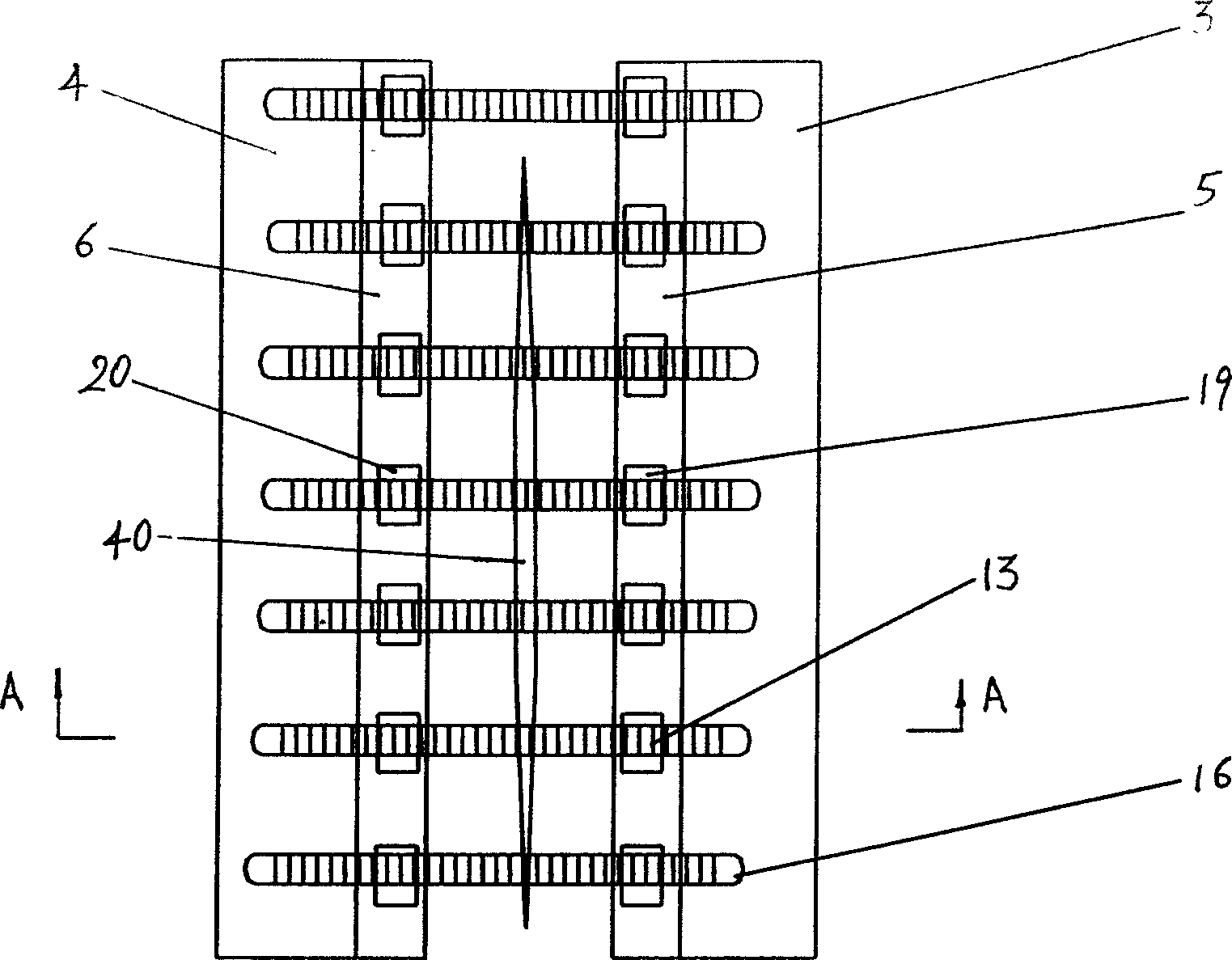

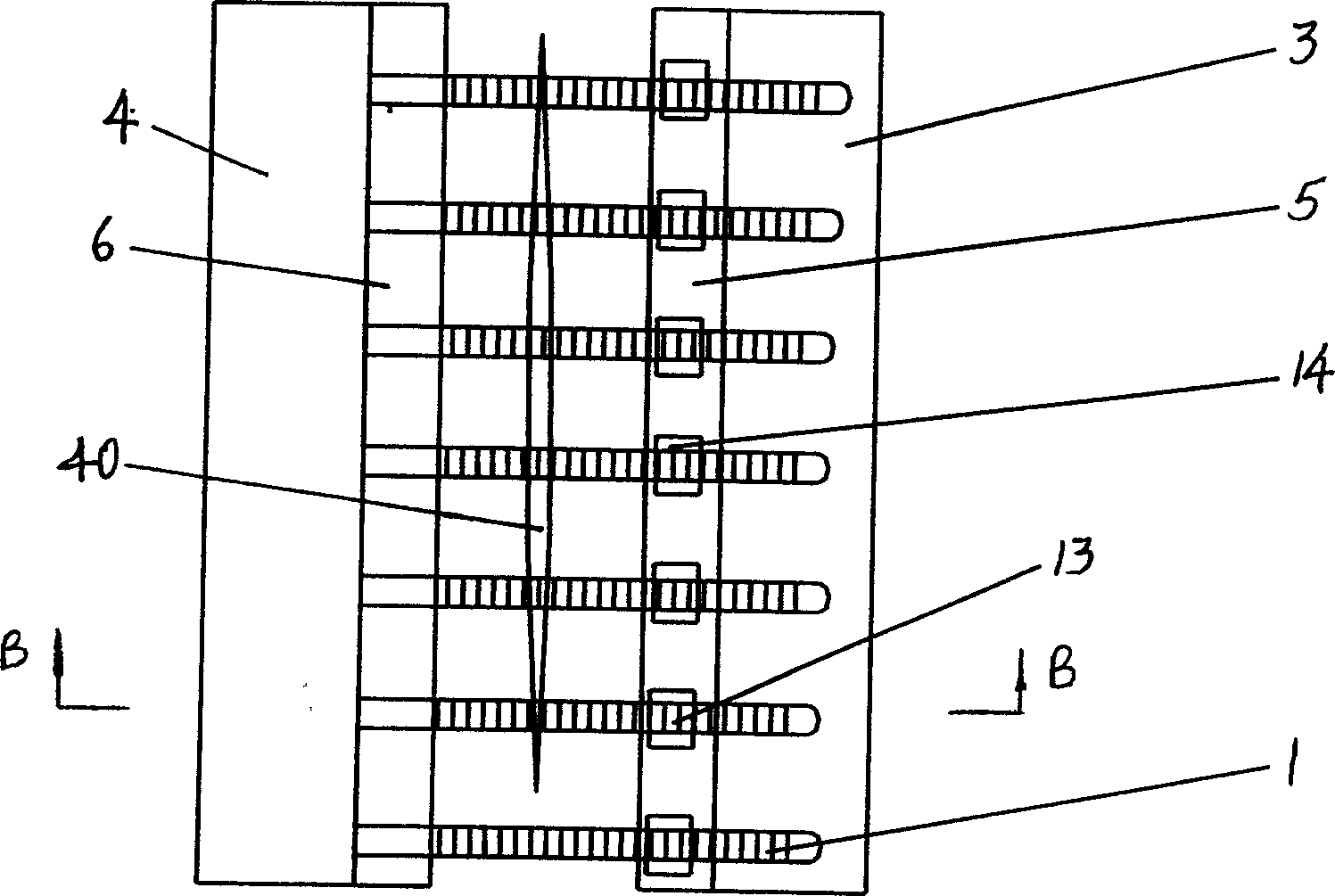

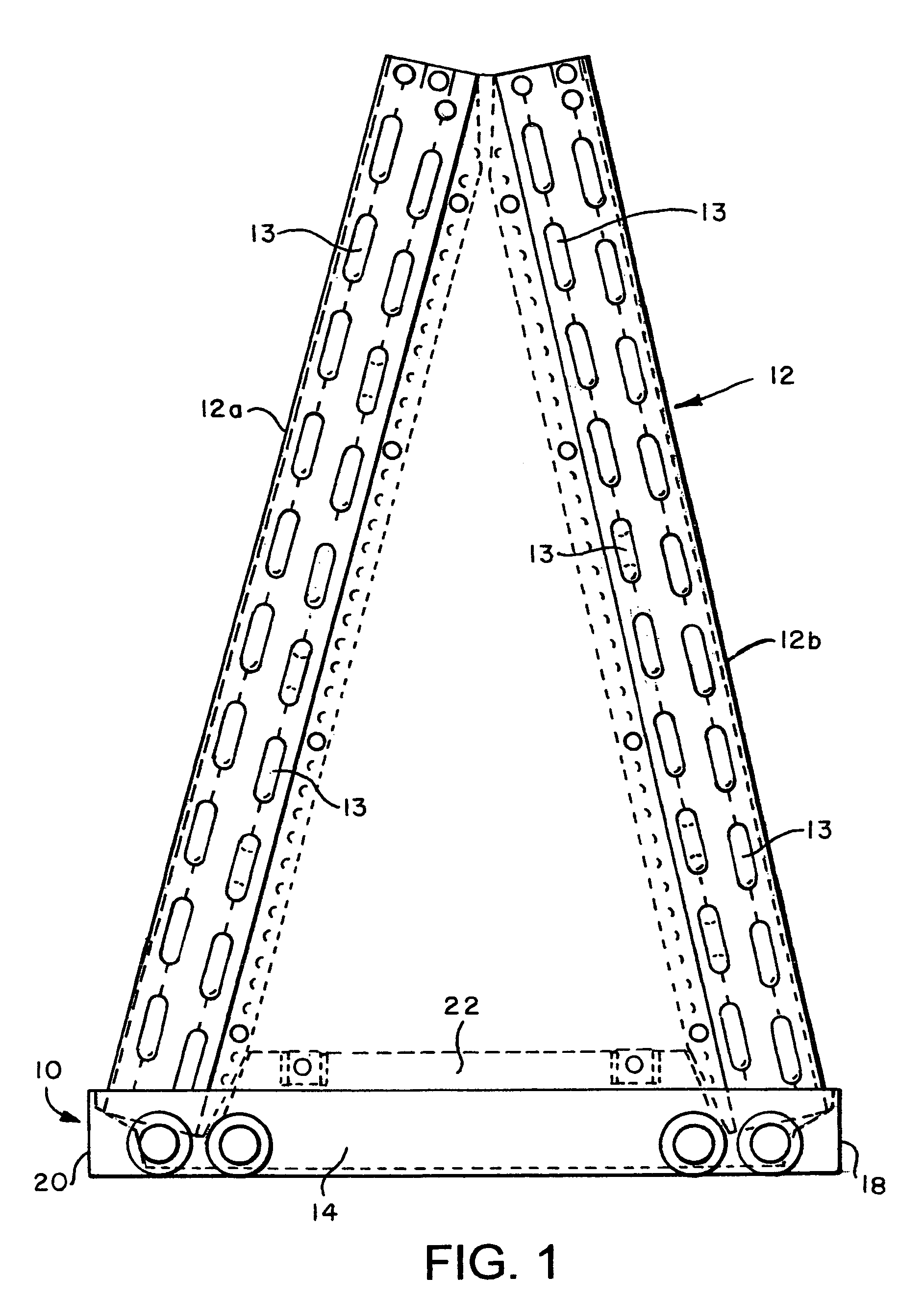

Medical closure screen device and method

ActiveUS7381211B2Easy to drainReduce and eliminate formationSuture equipmentsStaplesMechanical forceIrrigation

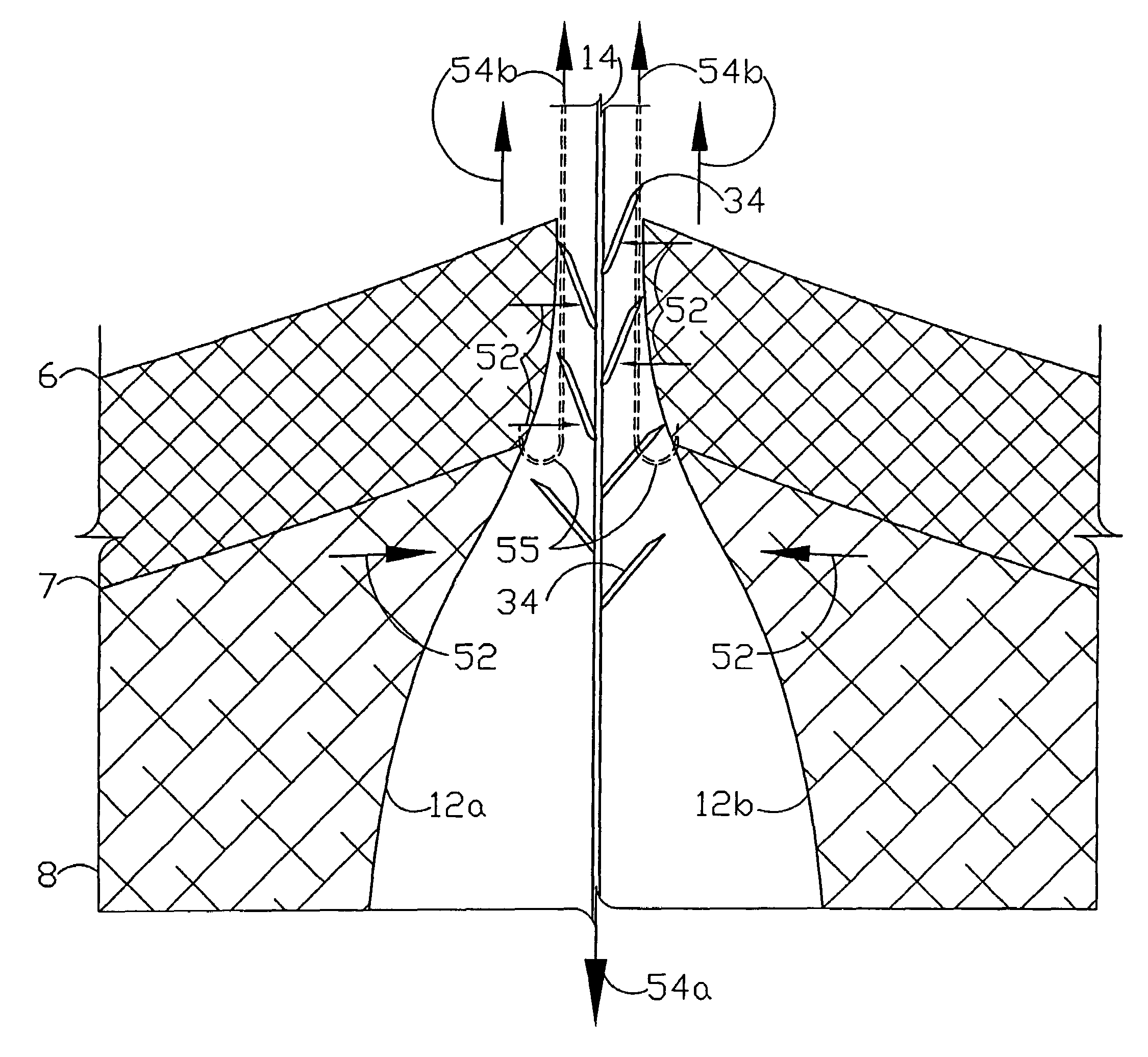

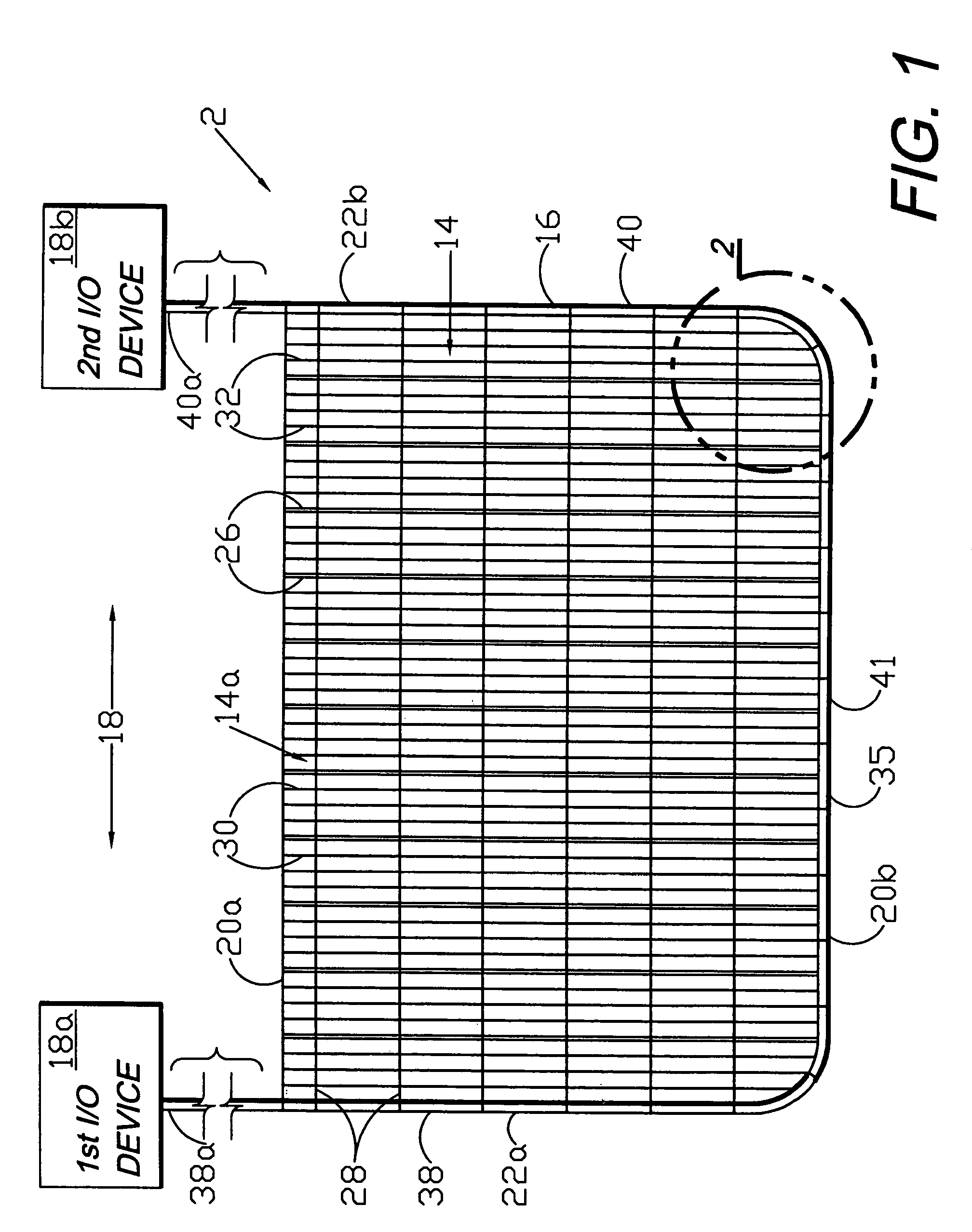

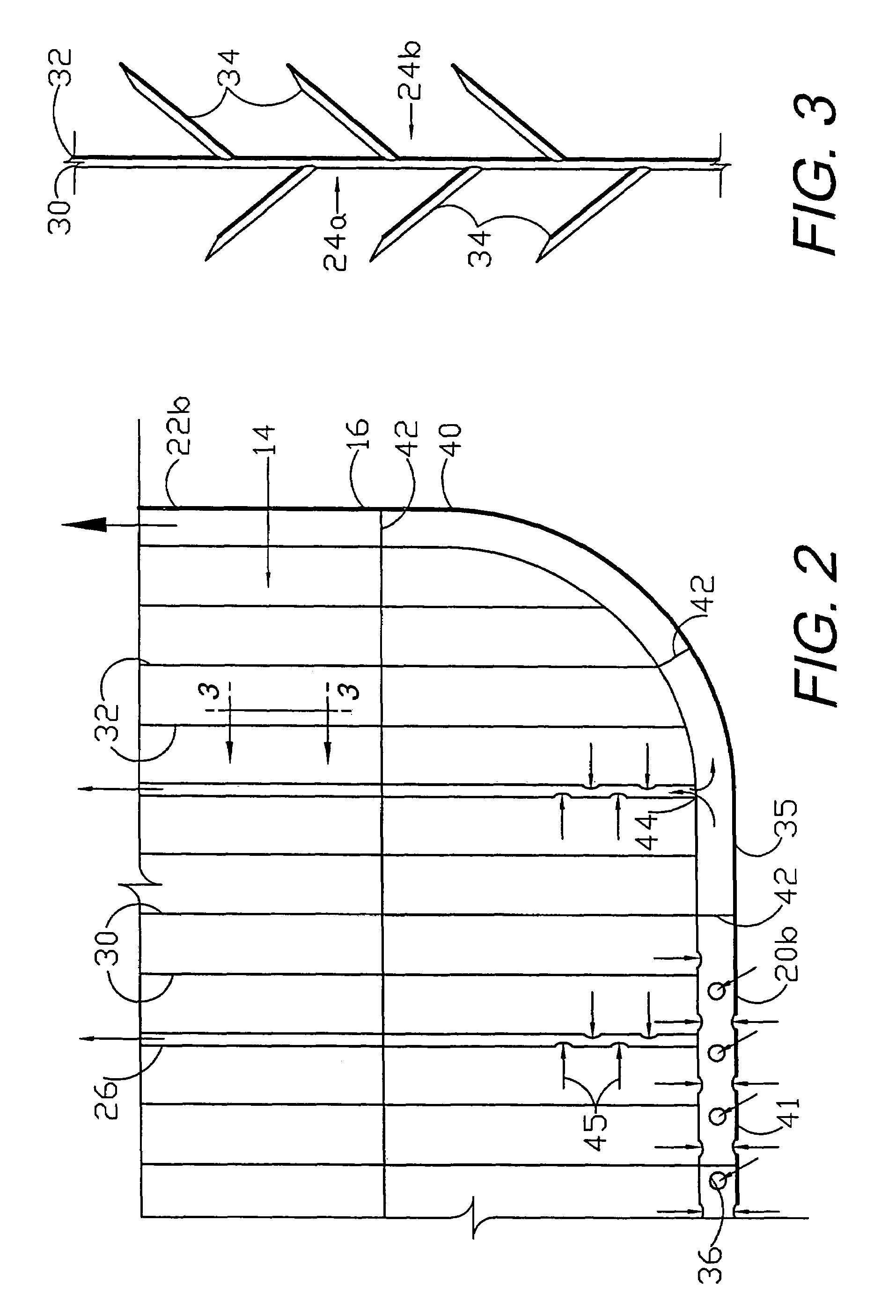

A medical closure screen device for a separation of first and second tissue portions is provided, which includes a mesh screen comprising tubular vertical risers, vertical strands with barbed filaments, and horizontal spacers connecting the risers and strands in a grid-like configuration. An optional perimeter member partly surrounds the screen and can comprise a perimeter tube fluidically coupled with the vertical risers to form a tubing assembly. Various input / output devices can optionally be connected to the perimeter tube ends for irrigating and / or draining the separation according to methodologies of the present invention. Separation closure, irrigation and drainage methodologies are disclosed utilizing various combinations of closure screens, tubing, sutures, fluid transfer elements and gradient force sources. The use of mechanical forces associated with barbed strands for repositionably securing separated tissues together is disclosed. The use of same for eliminating or reducing the formation of subcutaneous voids or pockets, which can potentially form hematoma and seroma effects, is also disclosed.

Owner:MORGAN STANLEY

Medical closure screen installation systems and methods

InactiveUS20050177190A1Easy to drainReduce and eliminate formationSuture equipmentsStaplesVertical tubeWater irrigation

A medical closure screen device for a separation of first and second tissue portions is provided, which includes a mesh screen comprising tubular vertical risers, vertical strands with barbed filaments, and horizontal spacers connecting the risers and strands in a grid-like configuration. An optional perimeter member partly surrounds the screen and can comprise a perimeter tube fluidically coupled with the vertical risers to form a tubing assembly. Various input / output devices can optionally be connected to the perimeter tube ends for irrigating and / or draining the separation according to methodologies of the present invention. Separation closure, irrigation and drainage methodologies are disclosed utilizing various combinations of closure screens, tubing, sutures, fluid transfer elements and gradient force sources. The use of mechanical forces associated with barbed strands for repositionably securing separated tissues together is disclosed. The use of same for eliminating or reducing the formation of subcutaneous voids or pockets, which can potentially form hematoma and seroma effects, is also disclosed. Further disclosed are alternative embodiment medical closure screen installation systems and methods.

Owner:3M INNOVATIVE PROPERTIES CO

Internal and external medical closure screen systems and methods

InactiveUS8062331B2Reduce and eliminate formationEasy to drainSuture equipmentsDiagnosticsVertical tubeSeroma

An internal and external medical closure system for a separation of first and second tissue portions is provided, which includes a mesh screen comprising tubular vertical risers, vertical strands with barbed filaments, and horizontal spacers connecting the risers and strands in a grid-like configuration. An optional perimeter member partly surrounds the screen and can comprise a perimeter tube fluidically coupled with the vertical risers to form a tubing assembly. Various input / output devices can optionally be connected to the perimeter tube ends for irrigating and / or draining the separation according to methodologies of the present invention. Separation closure, irrigation and drainage methodologies are disclosed utilizing various combinations of closure screens, tubing, sutures, fluid transfer elements and gradient force sources. The use of mechanical forces associated with barbed strands for repositionably securing separated tissues together is disclosed. The use of same for eliminating or reducing the formation of subcutaneous voids or pockets, which can potentially form hematoma and seroma effects, is also disclosed. Further disclosed are alternative embodiment medical closure screen installation systems and methods.

Owner:3M INNOVATIVE PROPERTIES CO

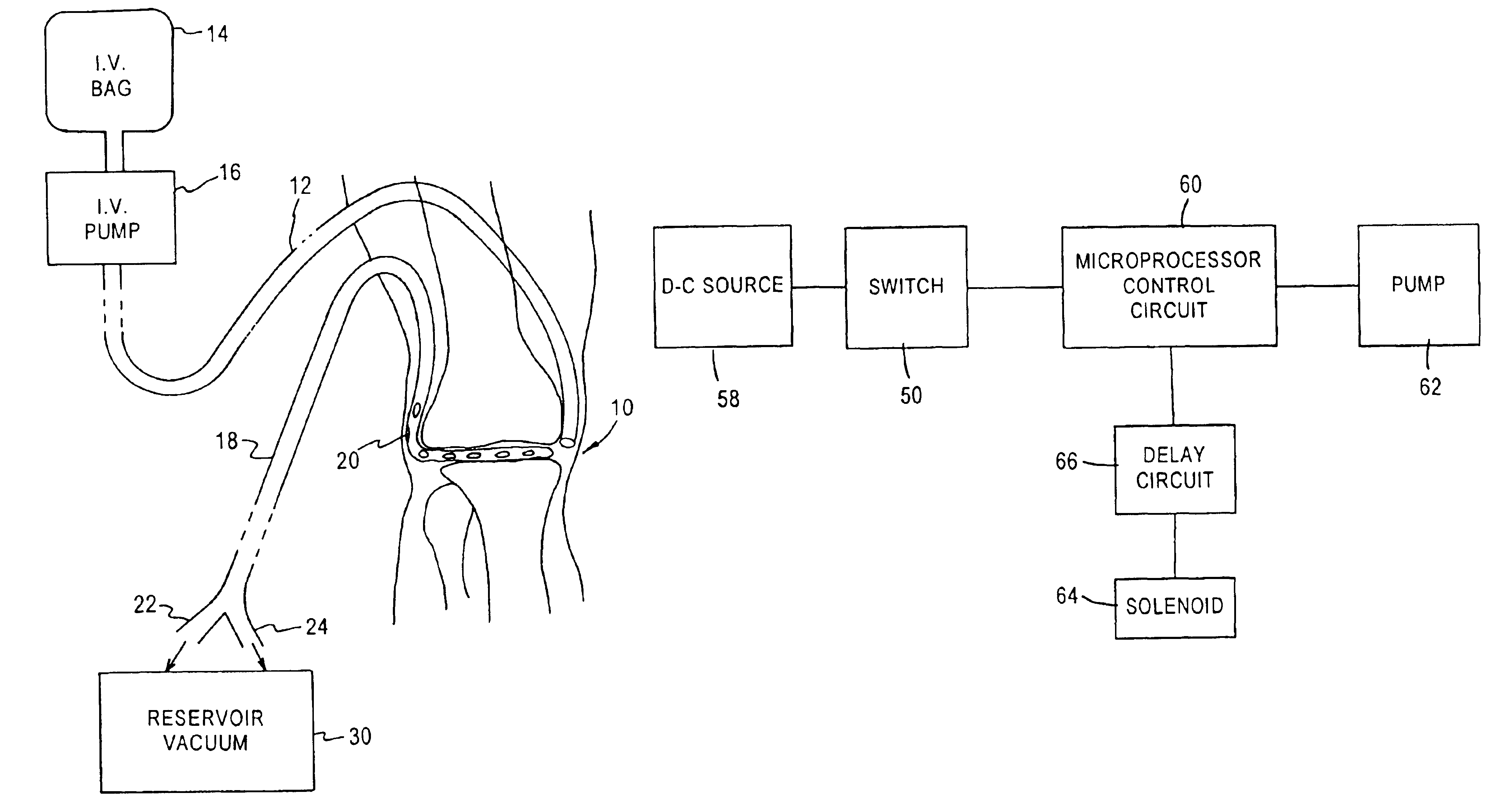

Treatment of wound or joint for relief of pain and promotion of healing

InactiveUS6887228B2Relieve painPromote healingOther blood circulation devicesEnemata/irrigatorsBody jointsBiomedical engineering

Owner:MCKAY DOUGLAS WILLIAM

Moisture management system

InactiveUS6293064B1Improve water resistanceImprove featuresRoof covering using slabs/sheetsRoof covering using tiles/slatesAdhesiveEngineering

A moisture management system for installation over doors and windows in buildings that included exterior, stucco-covered, curtain walls comprising an integrally formed, three sided, elongated track including a base having weep holes therein, an upright front wall and an upright rear wall at opposing elongated edges of the base, and, extending angularly downward from the outside of the base, and integrally formed therewith, a drip plate that permits ready drainage of water entering the moisture management system through the weep holes in the base. Elongated striations in the front faces of both the front and rear upright walls as well as holes in the front upright wall provide adherence of sealants and adhesives used in the installation process.

Owner:PLASTIC COMPONENTS

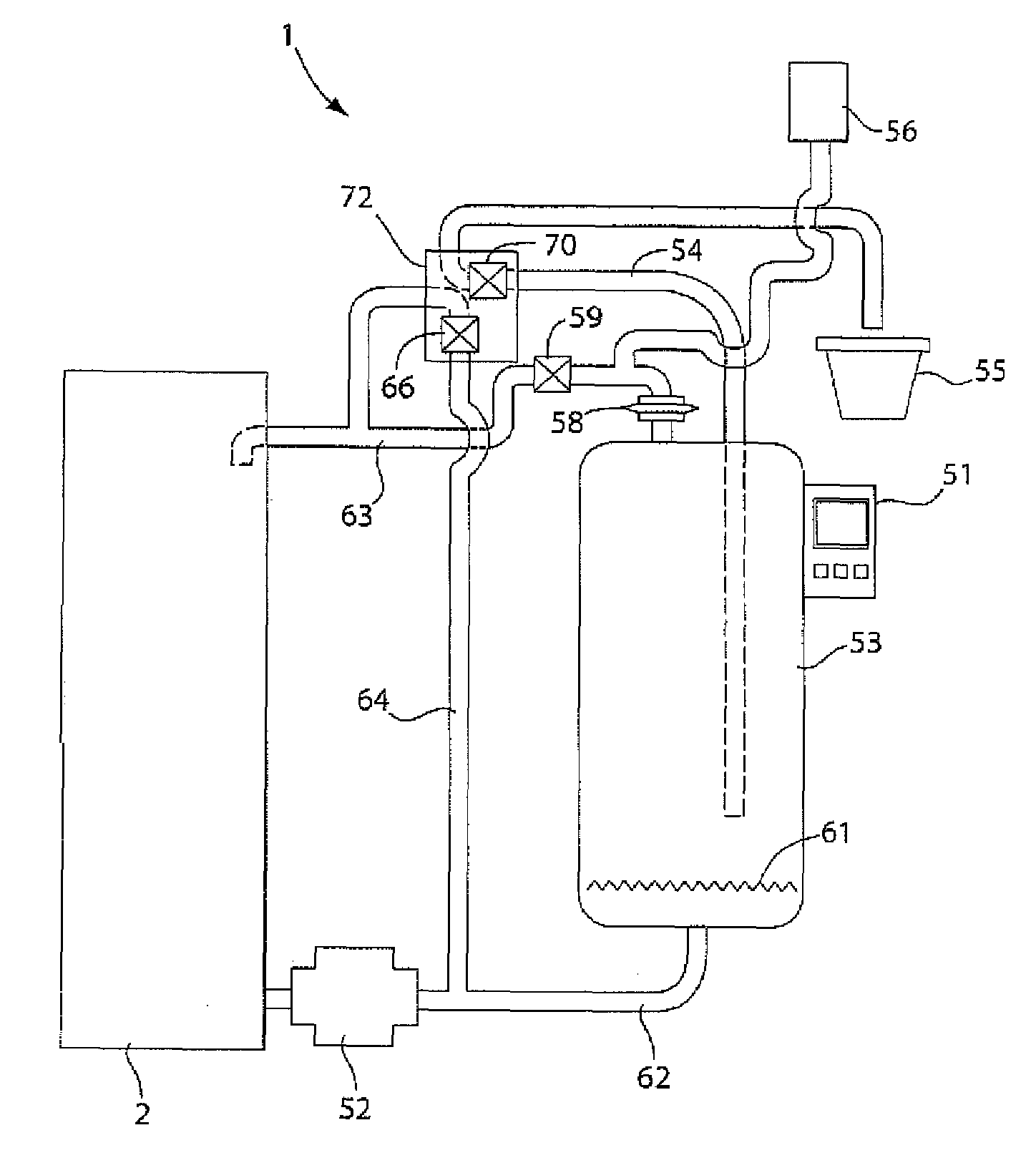

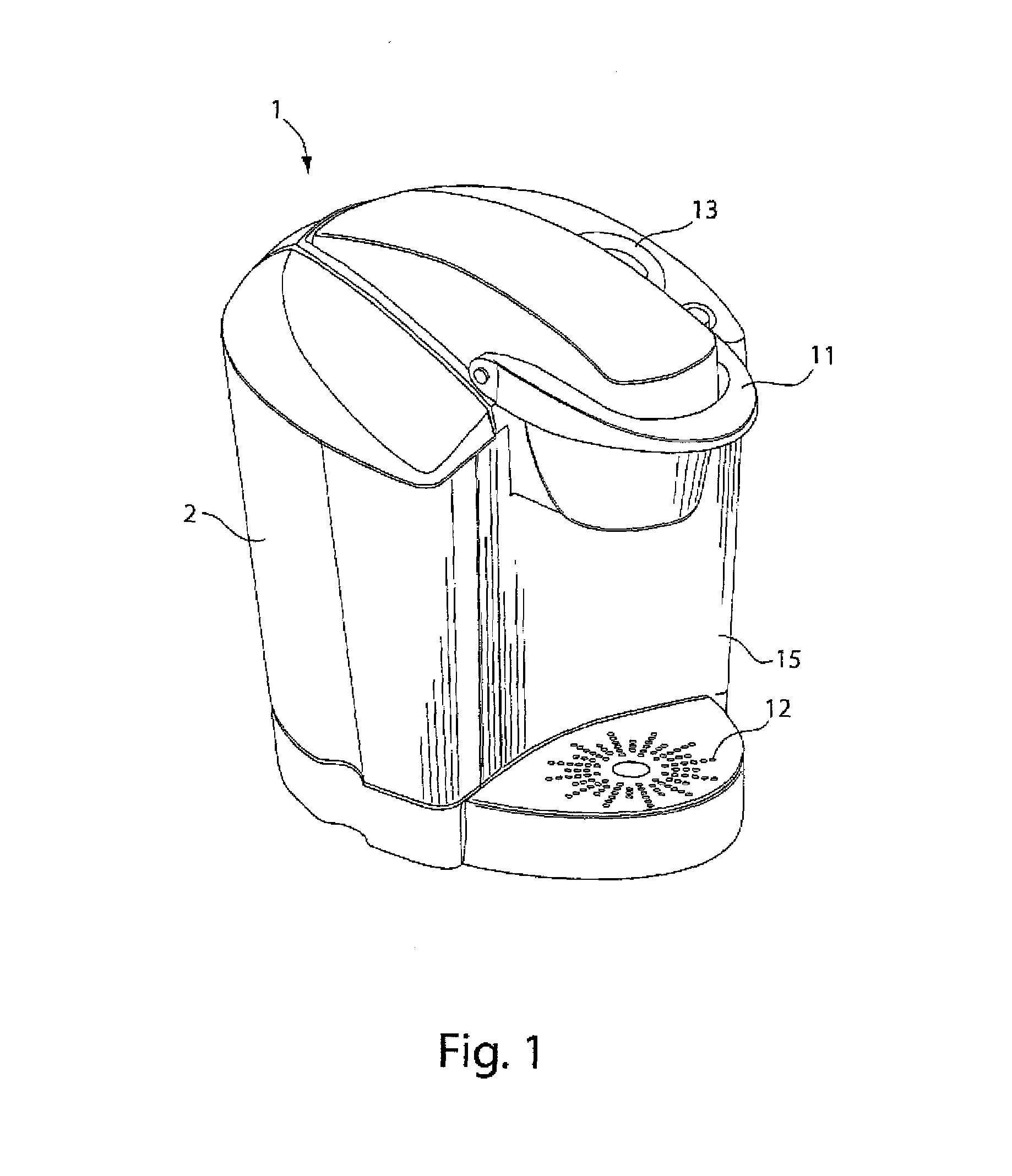

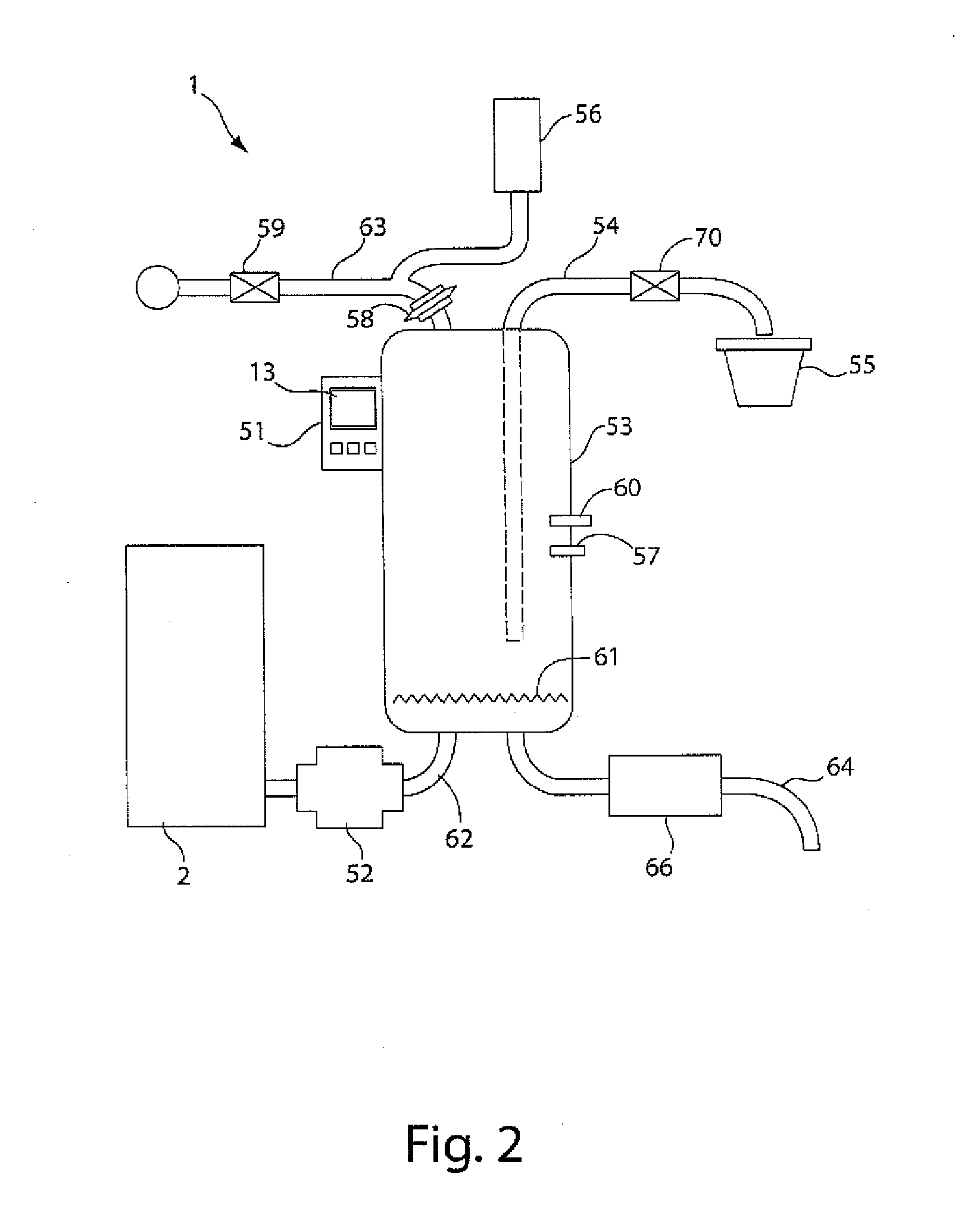

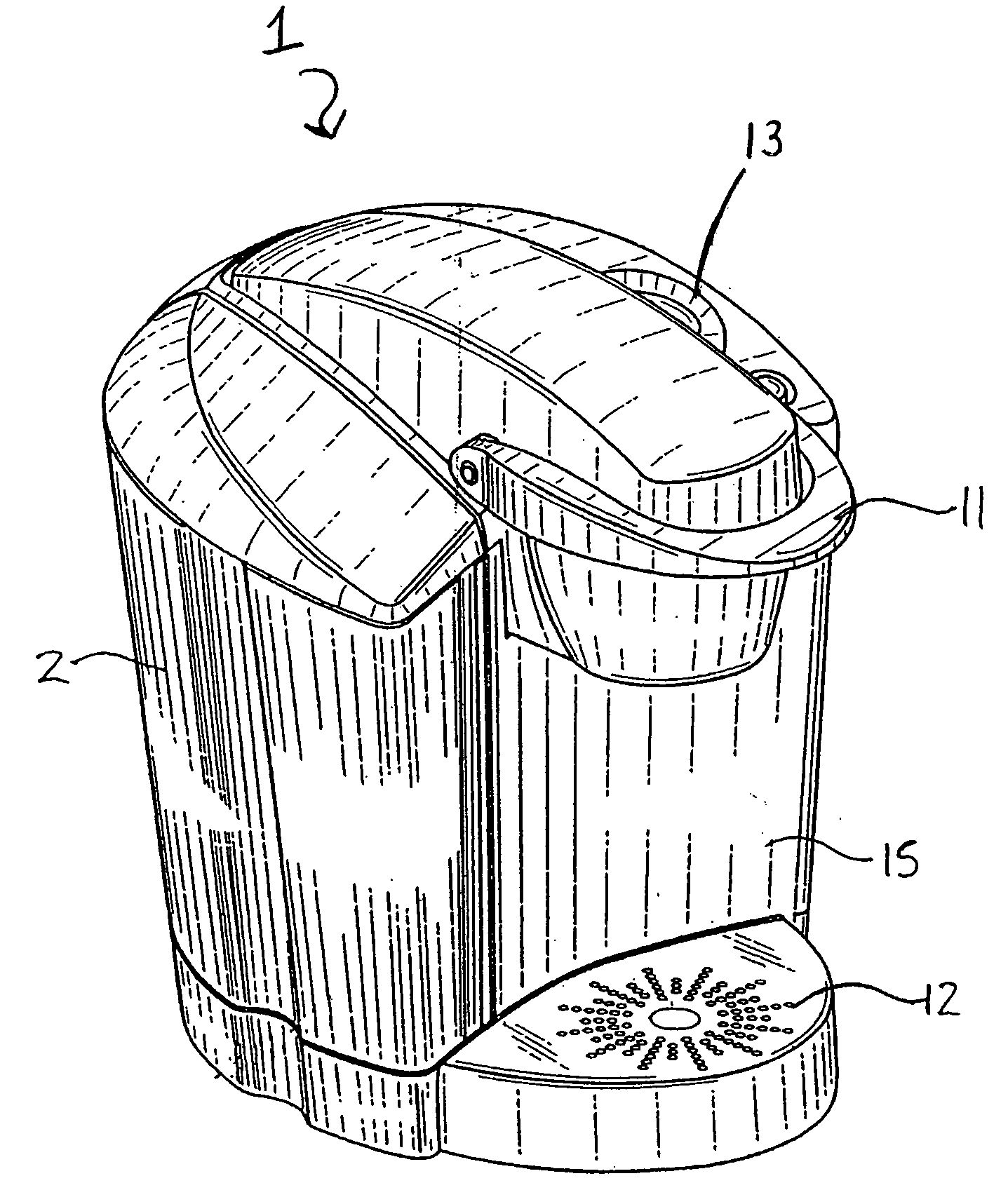

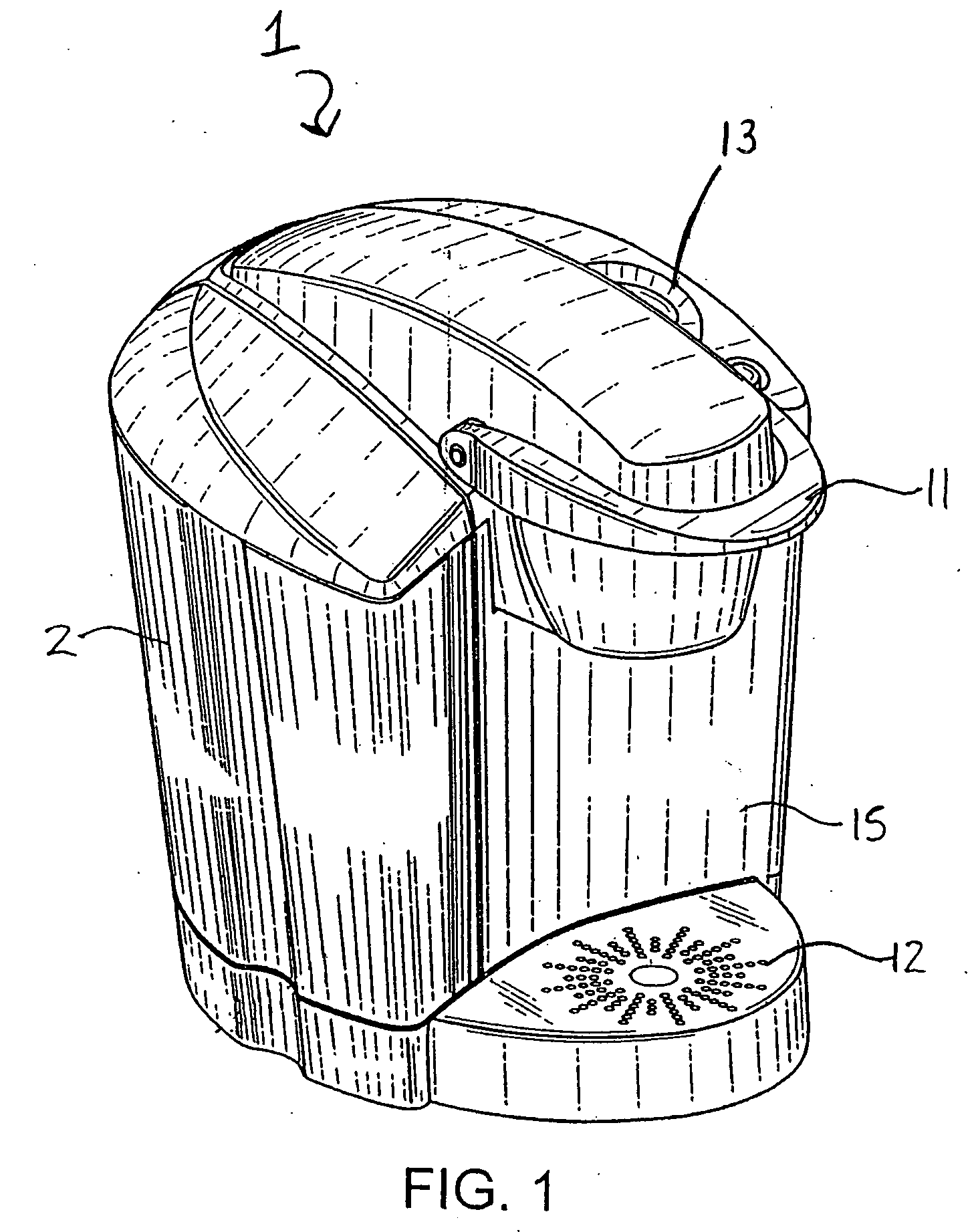

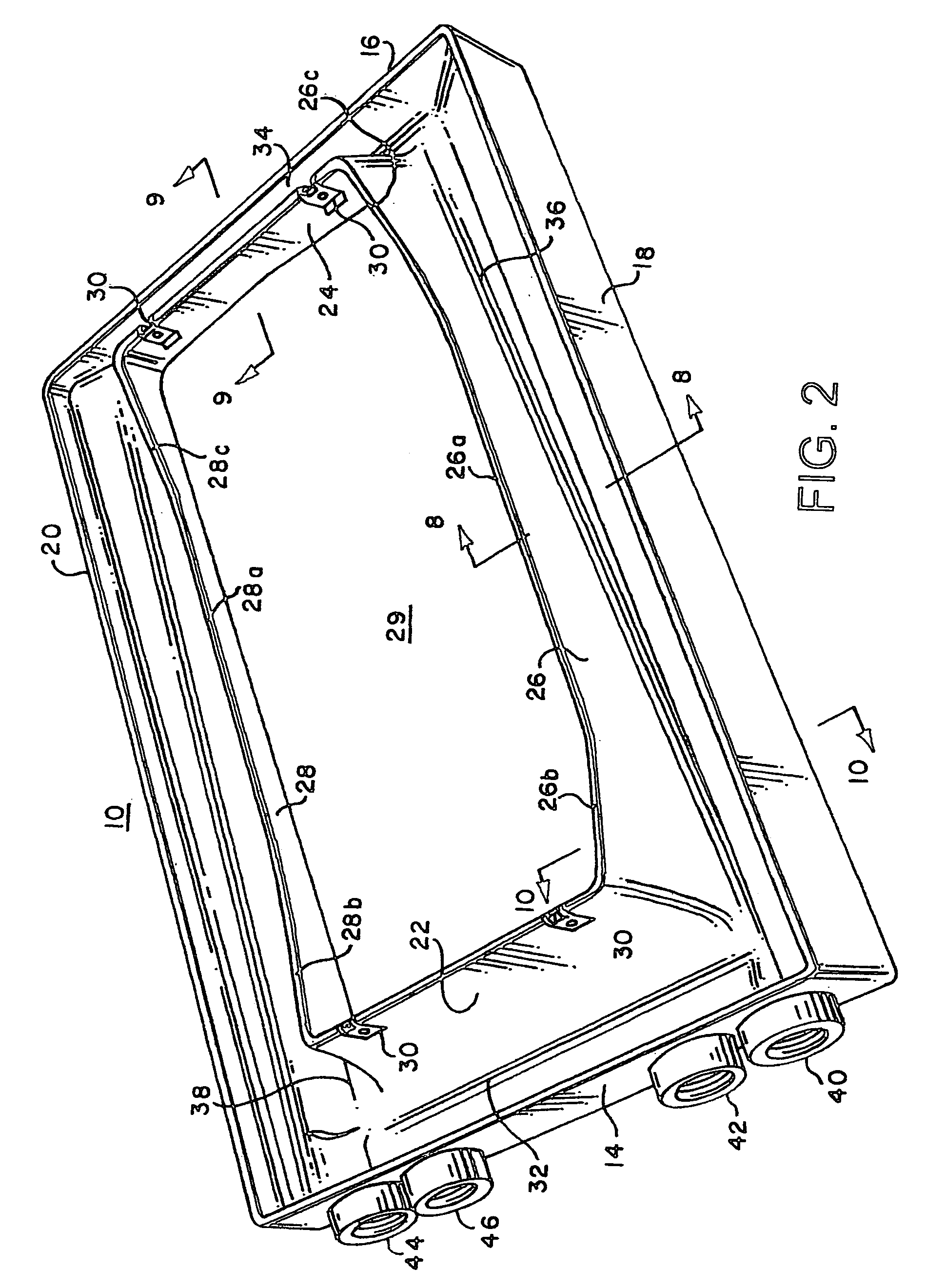

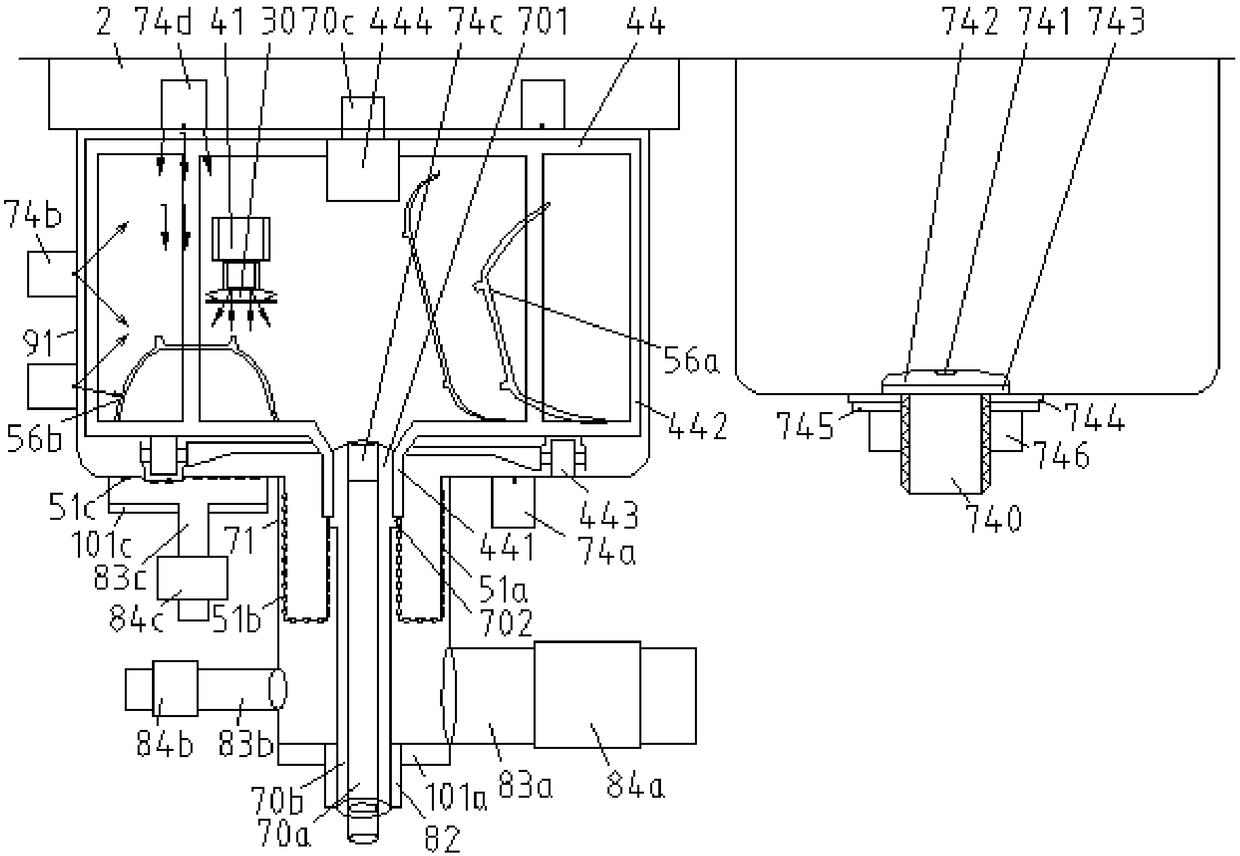

Drain for beverage forming machine

A method and apparatus for draining a component of a beverage forming system such as a coffee brewer. A tank used for holding and / or heating a beverage precursor liquid may be automatically drained. A beverage forming machine including a drain system may be self-contained in that the liquid drained from the tank is held by another tank that is part of the beverage forming machine. The tank into which the drained liquid is deposited may be removable from the beverage forming machine.

Owner:KEURIG GREEN MOUNTAIN INC

Medical closure screen installation systems and methods

InactiveUS7413570B2Reduce and eliminate formationEasy to drainSuture equipmentsStaplesVertical tubeSeroma

Owner:3M INNOVATIVE PROPERTIES CO

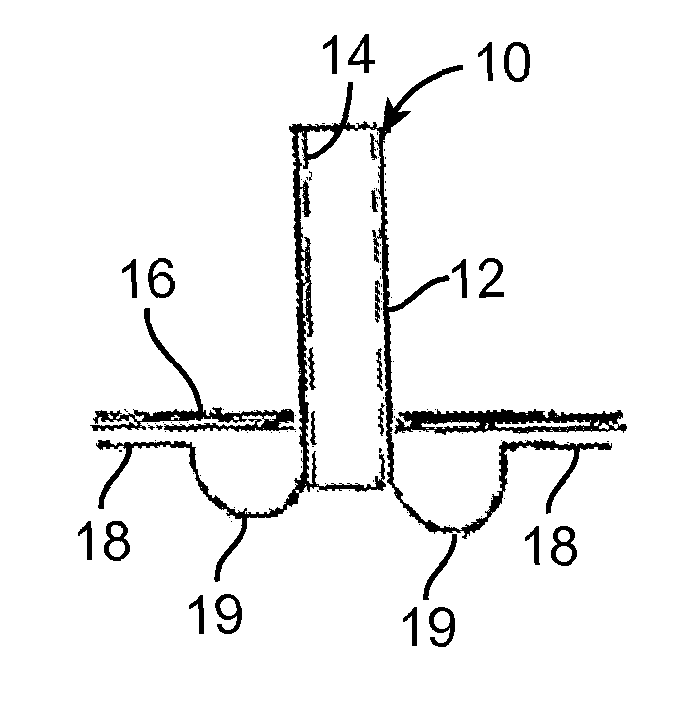

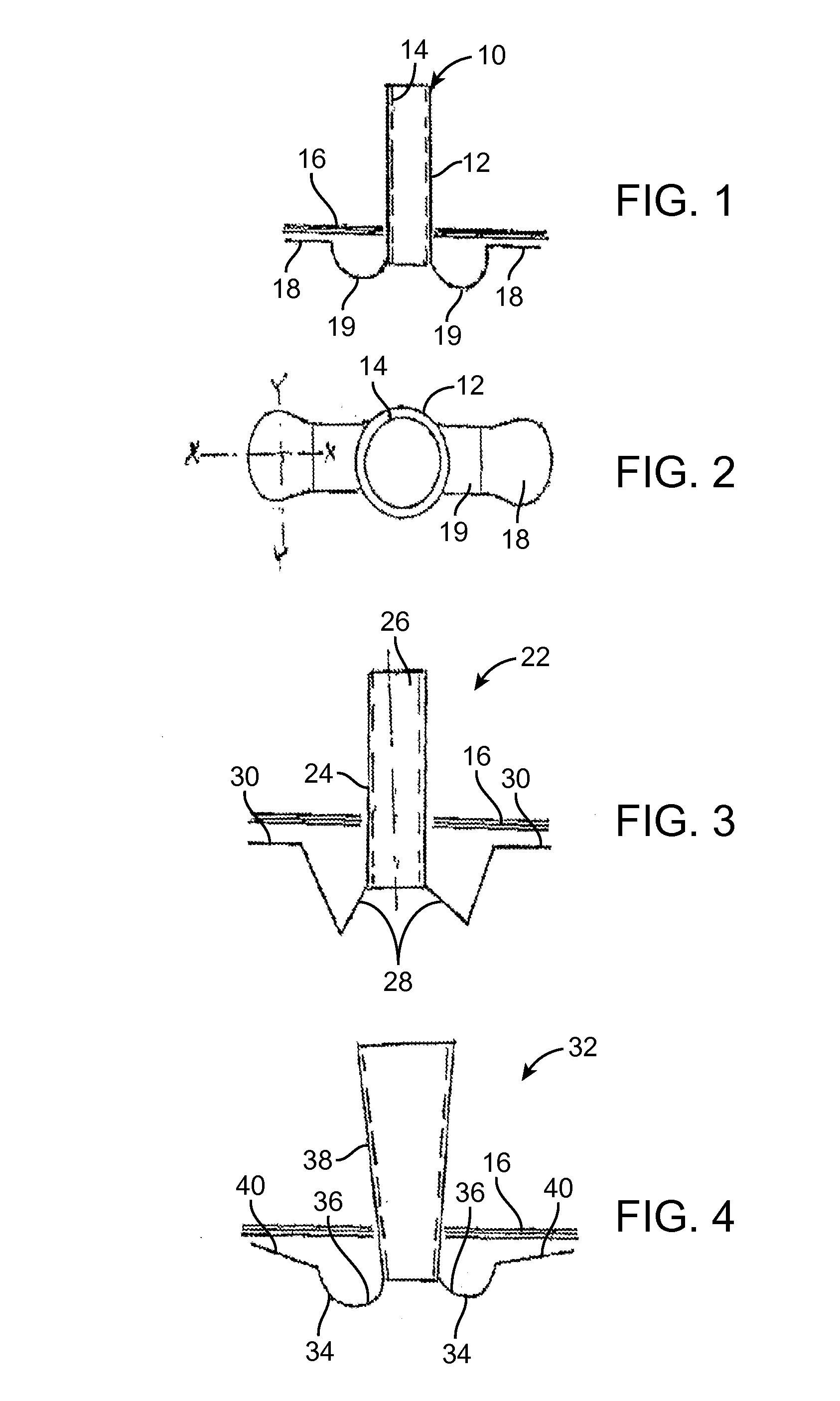

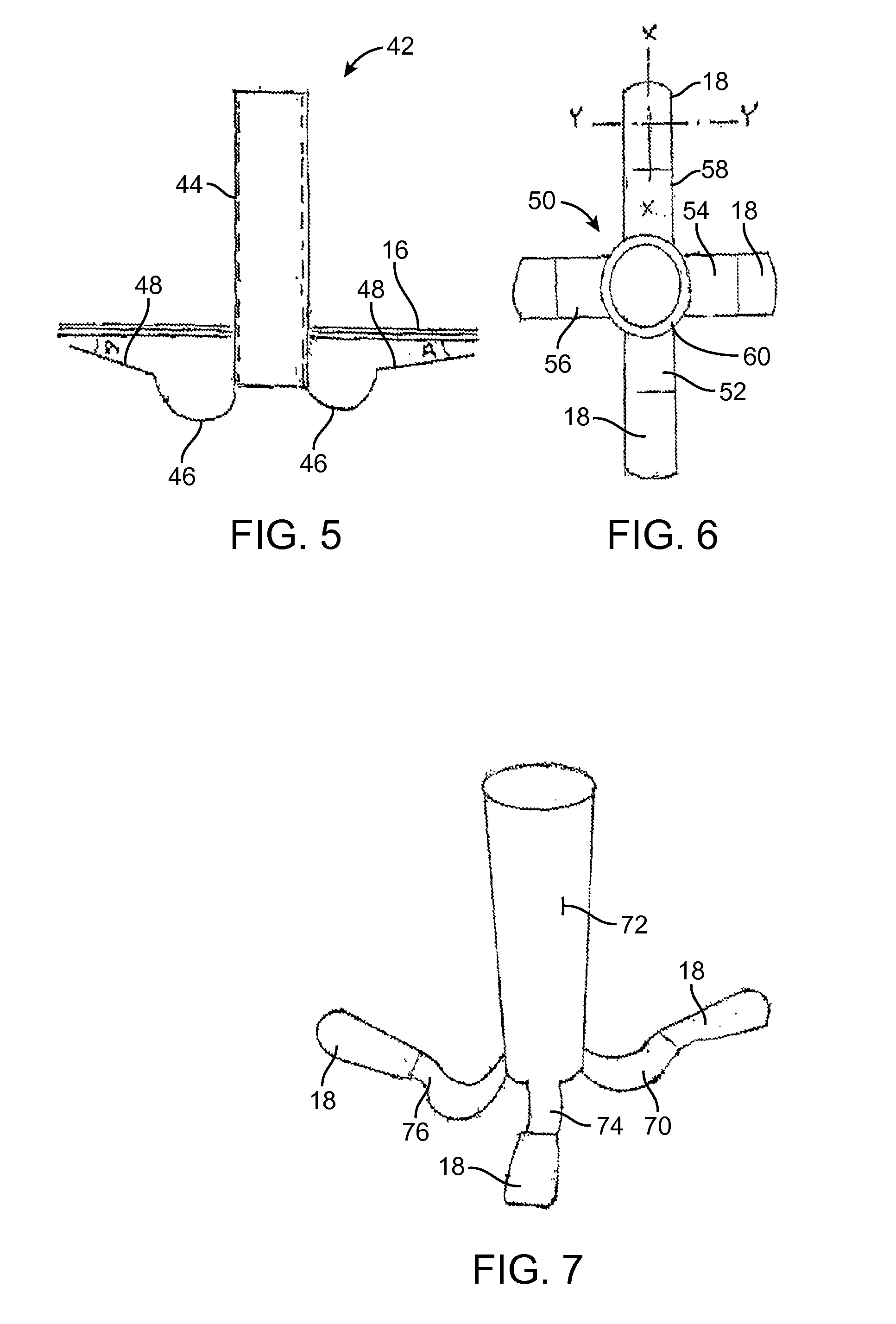

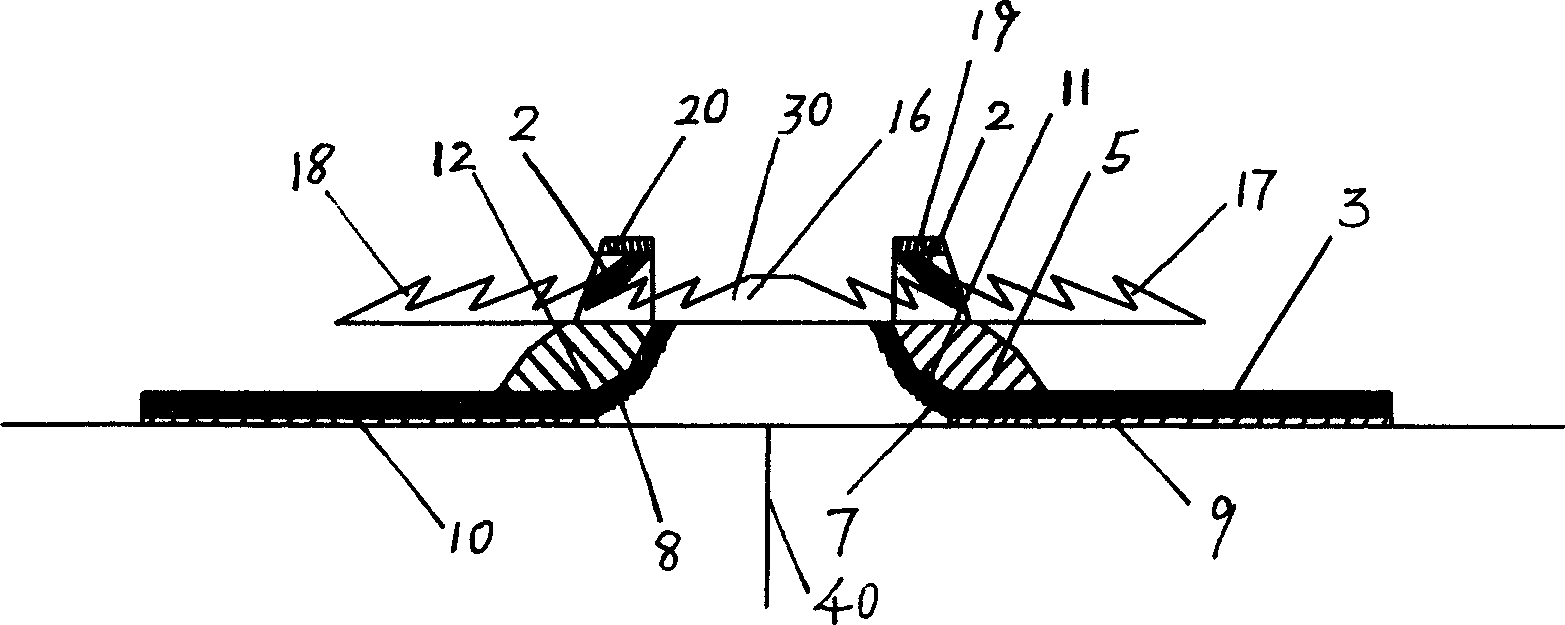

Ear tubes

ActiveUS8197433B2Easy to insertEasy to disassembleEar treatmentIntravenous devicesMiddle earEngineering

The invention provides a flexible ear tube (10) for draining and ventilating the middle ear, the tube (10) having a flexible substantially tubular stem (12) with a lumen (14), the stem (12) being sized to be inserted through an incision in the eardrum (16) and the tube having at least two separate flexible contact surfaces (18) extending from the stem (12) and adapted to engage different spaced-apart inner surfaces of the eardrum 16, each of the contact surfaces (18) having a first axis XX extending substantially perpendicularly to the central axis of the stem and a second axis YY extending substantially perpendicularly to the first axis wherein one of the axes is between 0.6 and 3 mm and the second of the axes is between 1 and 7 mm in length.

Owner:OTOMEDICS ADVANCED MEDICAL TECH

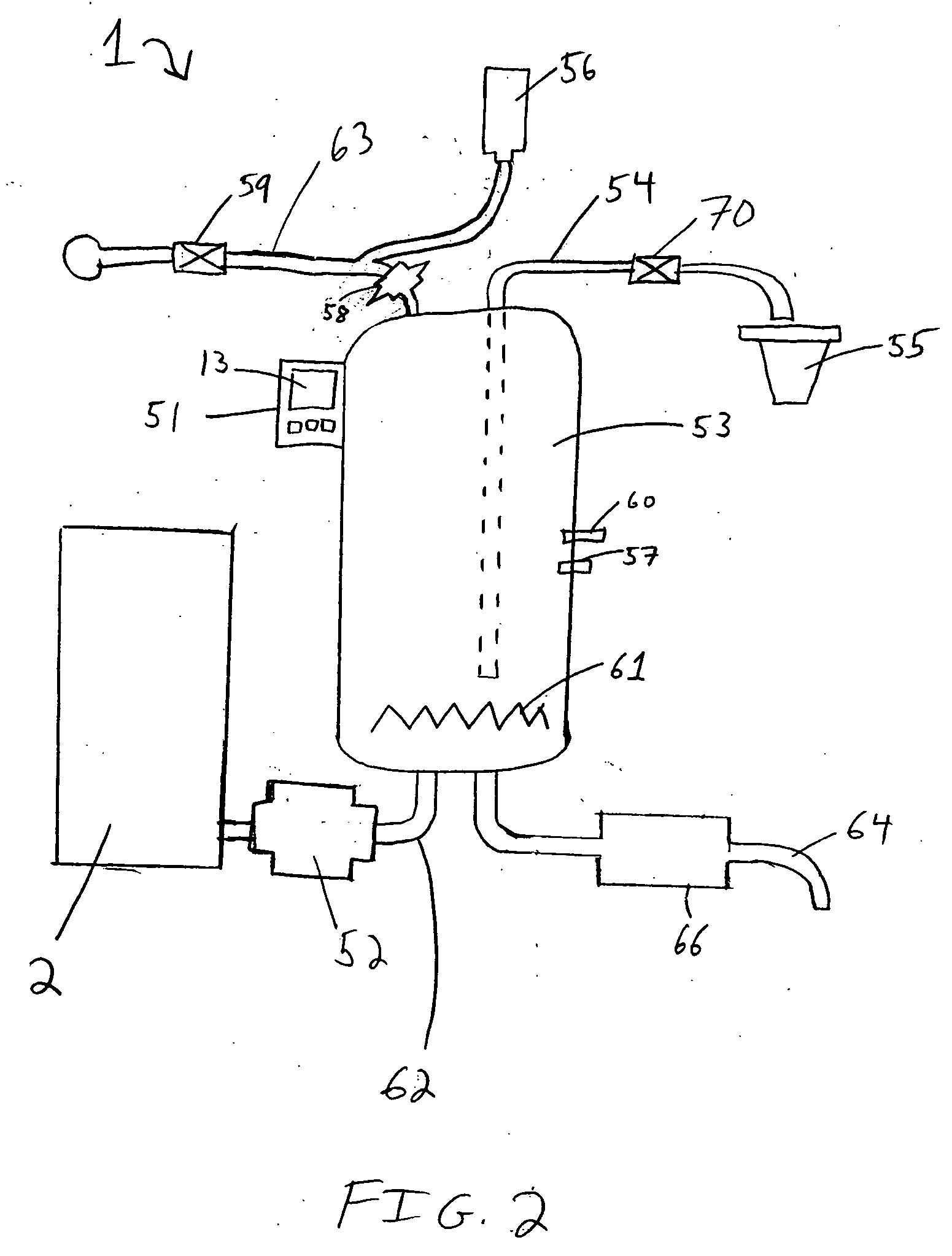

Drain for beverage forming machine

ActiveUS20070056994A1Easy to drainVolume measurement and fluid deliveryBeverage vesselsMolding machineEngineering

A method and apparatus for draining a component of a beverage forming system such as a coffee brewer. A tank used for holding and / or heating a beverage precursor liquid may be automatically drained. A beverage forming machine including a drain system may be self-contained in that the liquid drained from the tank is held by another tank that is part of the beverage forming machine. The tank into which the drained liquid is deposited may be removable from the beverage forming machine.

Owner:KEURIG GREEN MOUNTAIN INC

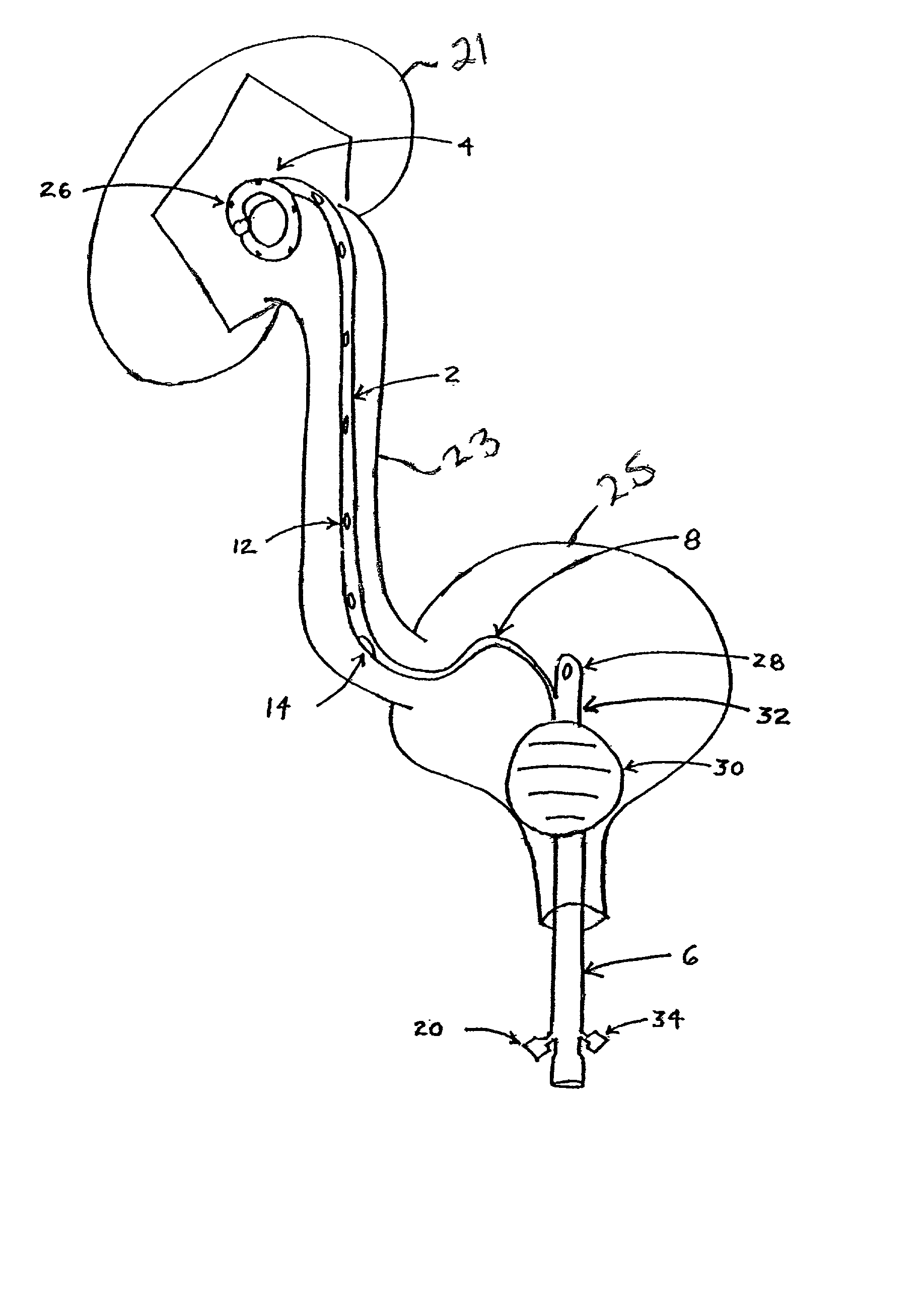

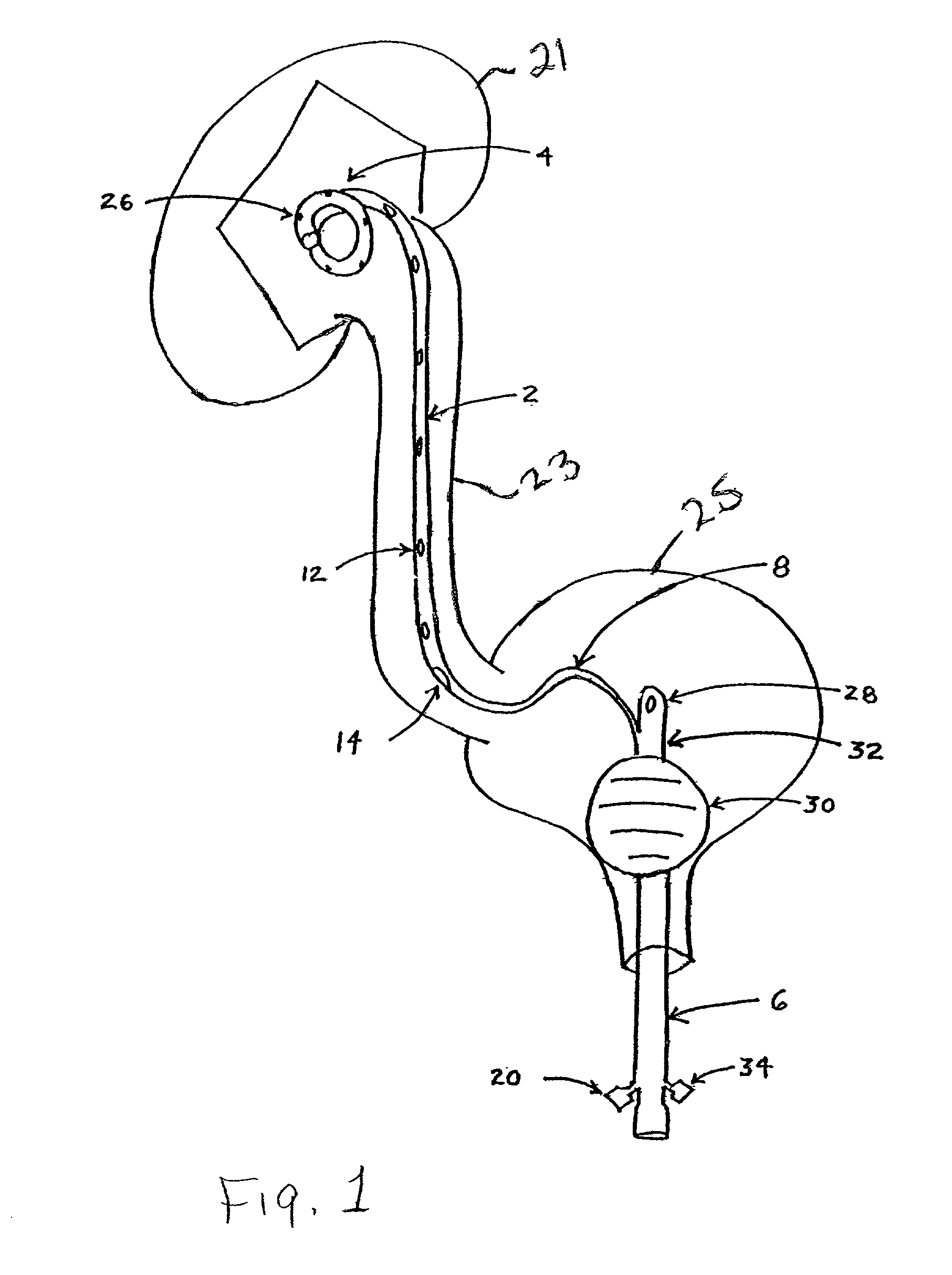

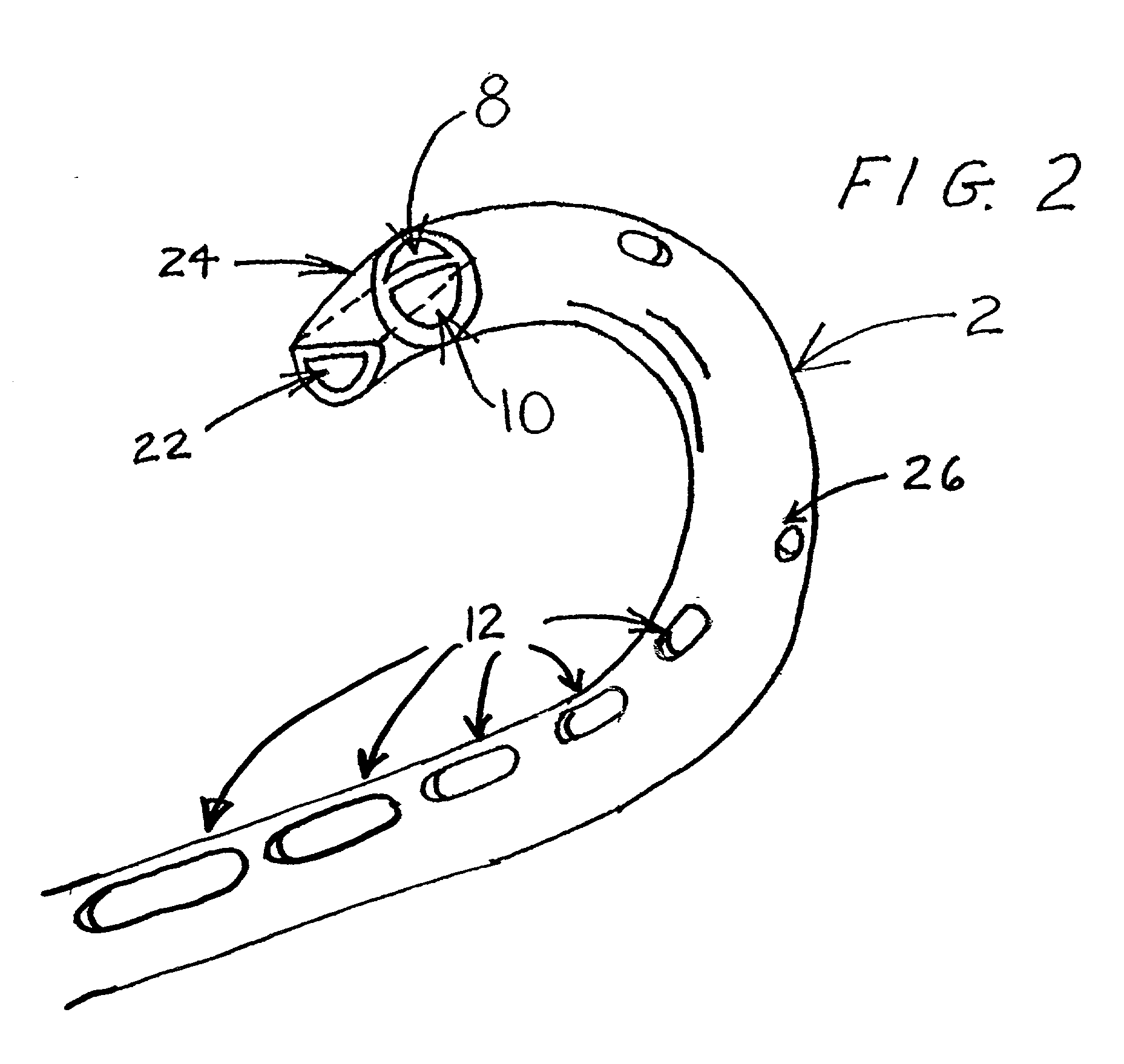

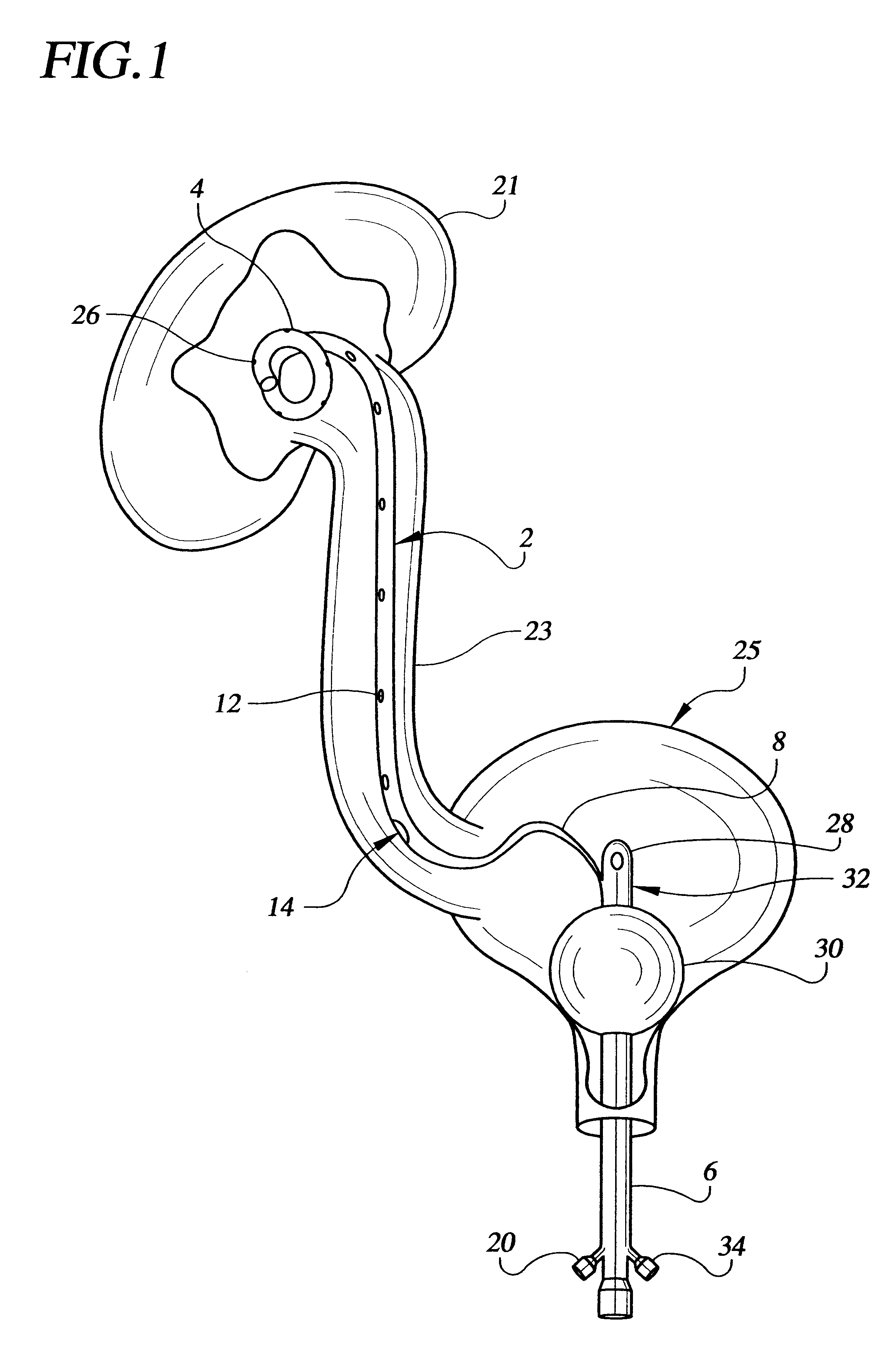

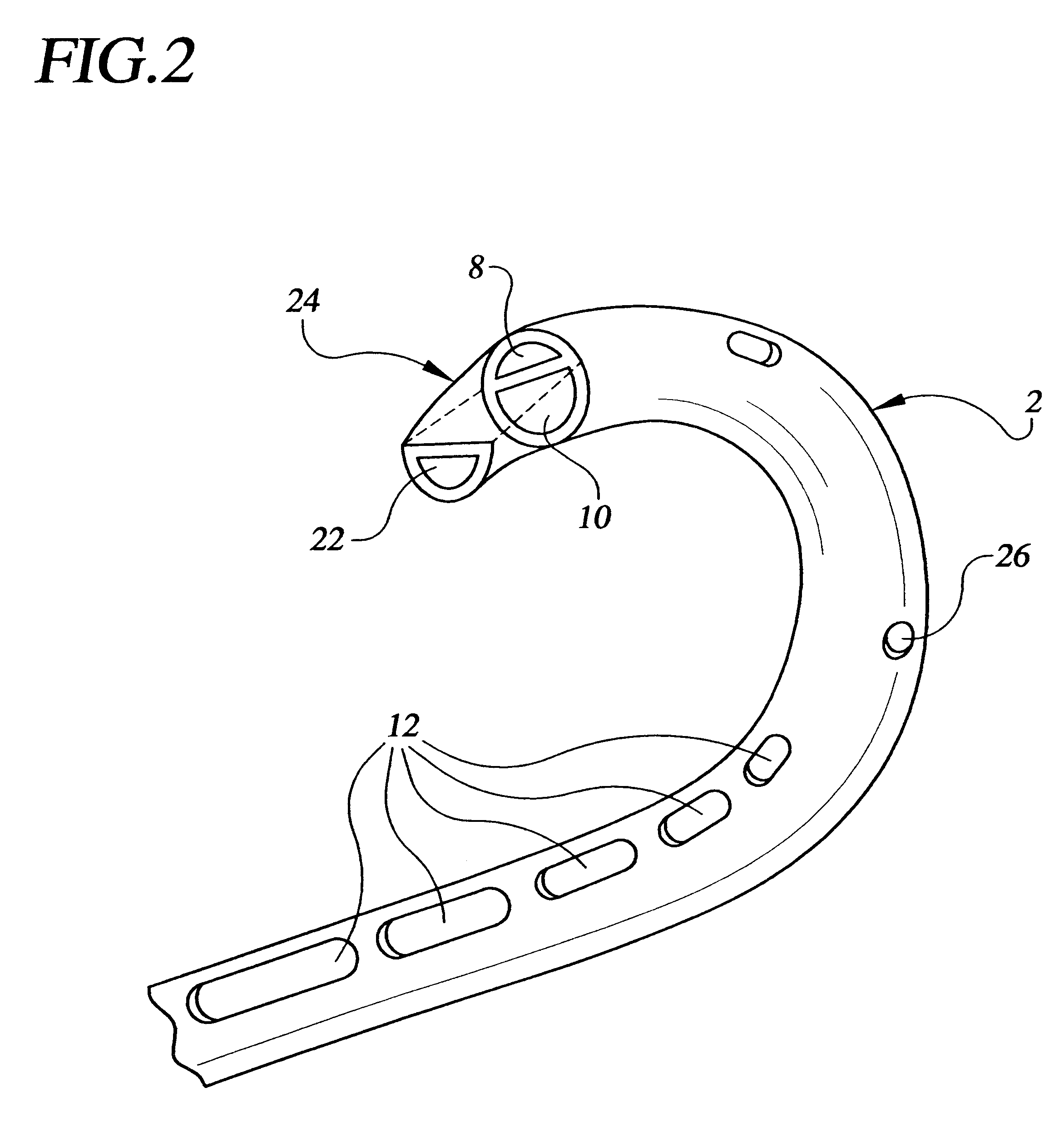

Combination ureteral infusion catheter/drainage stent

A method of treating the upper urinary tract of a mammal having a urethra extending to a bladder and a ureter extending from the bladder to a kidney. The method comprises initially extending a catheter system into the upper urinary tract, the catheter system having a urethral catheter infusion tube section extending through the urethra for infusion of a liquid; a urethral catheter drain tube section extending through the urethra for drainage of a liquid; a ureteral catheter tube section extending through a ureter into the kidney and having a first tube portion for infusion of a liquid connected to the urethral catheter infusion tube section, and a second tube portion for drainage of a liquid. The method then includes flowing a therapeutically effective liquid into the kidney through the urethral catheter infusion tube section and the ureteral catheter first, infusion tube portion, and, simultaneously with the flowing of the fluid into the kidney, draining fluid from the kidney through the urethral catheter drain tube section and the ureteral catheter second, drain tube portion.

Owner:HAYNER GEORGE M +1

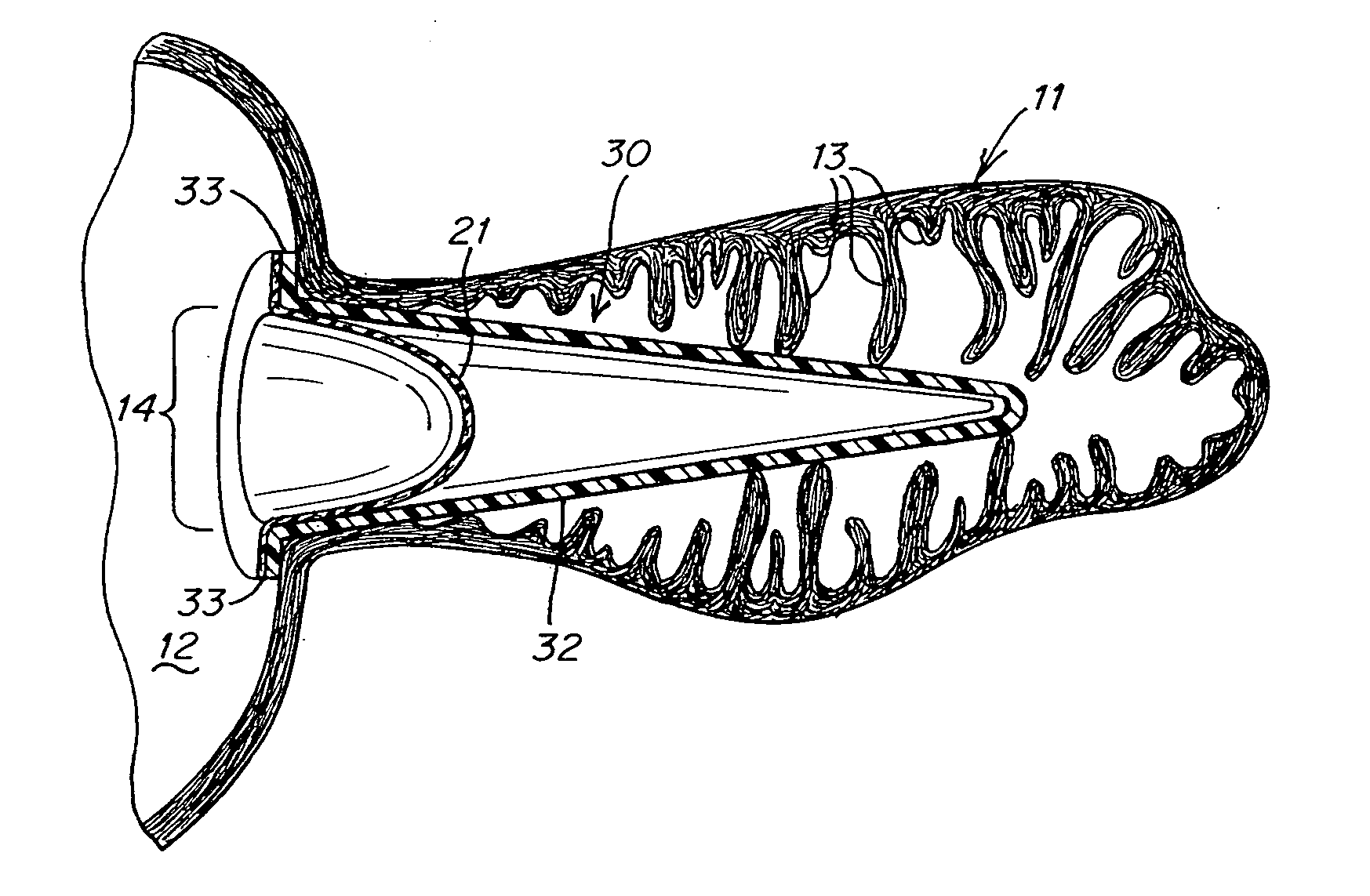

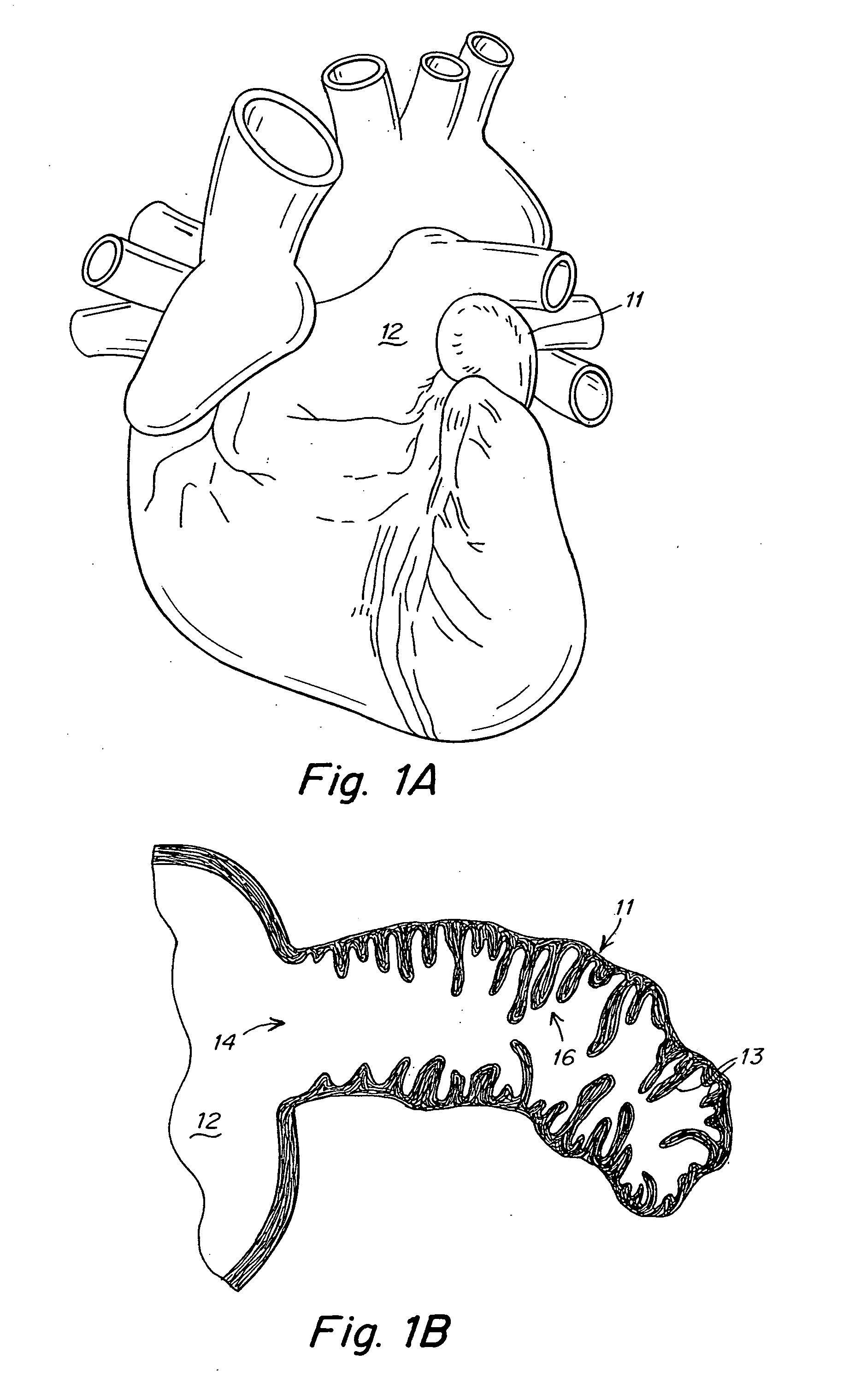

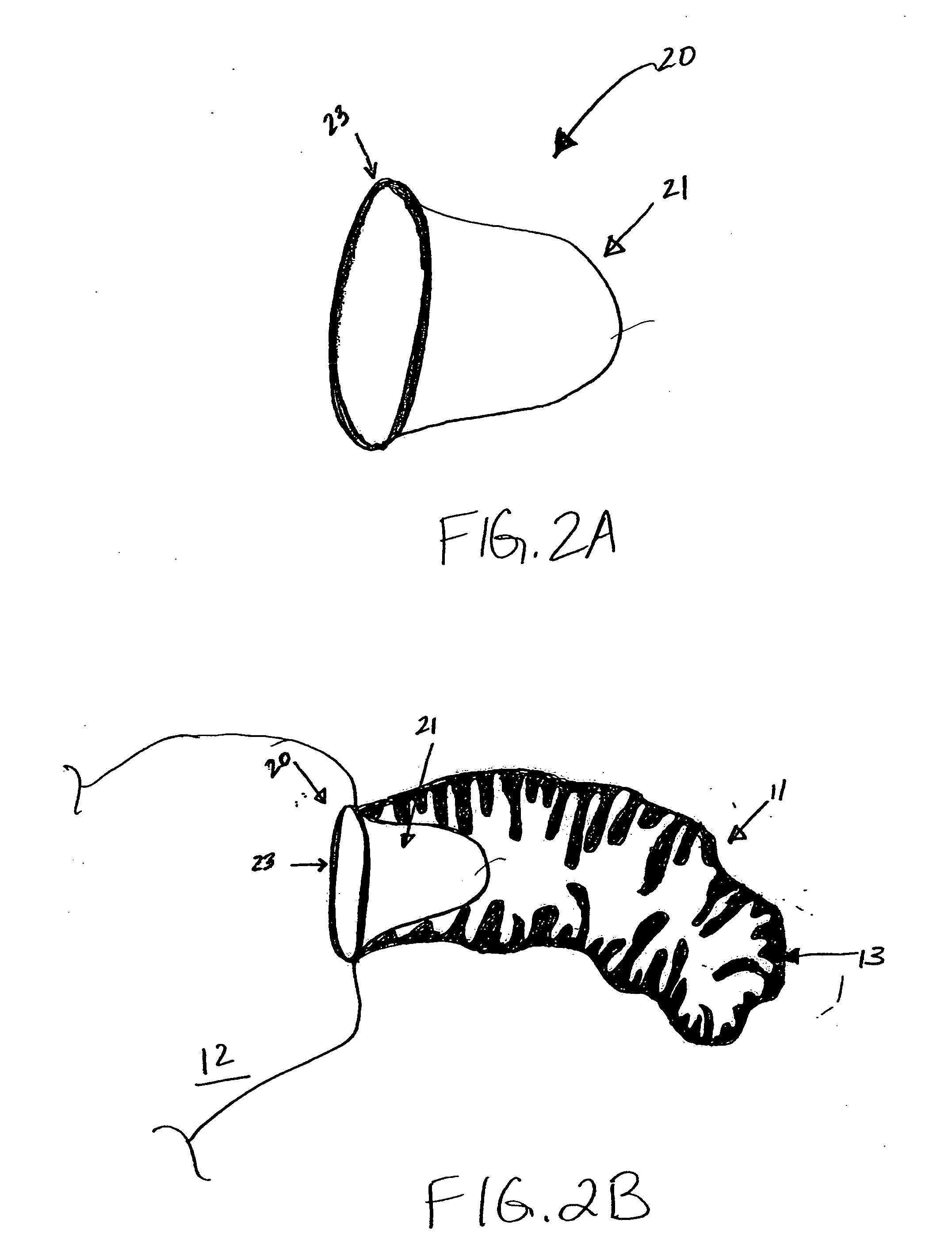

Device and methods for preventing formation of thrombi in the left atrial appendage

ActiveUS20050070952A1Reduce the possibilityPrevents dislodgement and migrationDilatorsOcculdersBlood flowThrombus

The embodiments of the present invention provide a device that modifies the left atrial appendage (LAA) to reduce the likelihood of thrombus formation therein. The device includes a liner that reduces the volume of the LAA and remodels the interior geometry and surfaces of the LAA thereby minimizing the crenellations in the LAA that impede blood flow. According to some embodiments, the device further includes an anchor component. The anchor component helps to expand the liner upon deployment of the device in-vivo and further prevents dislodgement and migration of the device, by ensuring the device is properly seated and completely sealed against the walls and ostium of the LAA.

Owner:WL GORE & ASSOC INC +1

Skin wound locking device

InactiveCN1524507AImprove breathabilityEasy to drainSuture equipmentsSurgical operationBiomedical engineering

The invention discloses a skin wound locking device for facilitation of wound natural healing, which comprises two strip shape support band and base band arranged along the two sides of the skin wound, wherein the base band is arranged on the upper surface of the bar-shaped support band, the base band is provided with one or multiple pairs of locking device for connecting the base band. The skin wound locking device can facilitate wound permeability, drainage and medicine changing, and also facilitate the survey for wound healing condition, thus can be widely applied to the wound closure of surgical operation.

Owner:SICHUAN LICHEN MEDICAL & PHARMA TECH

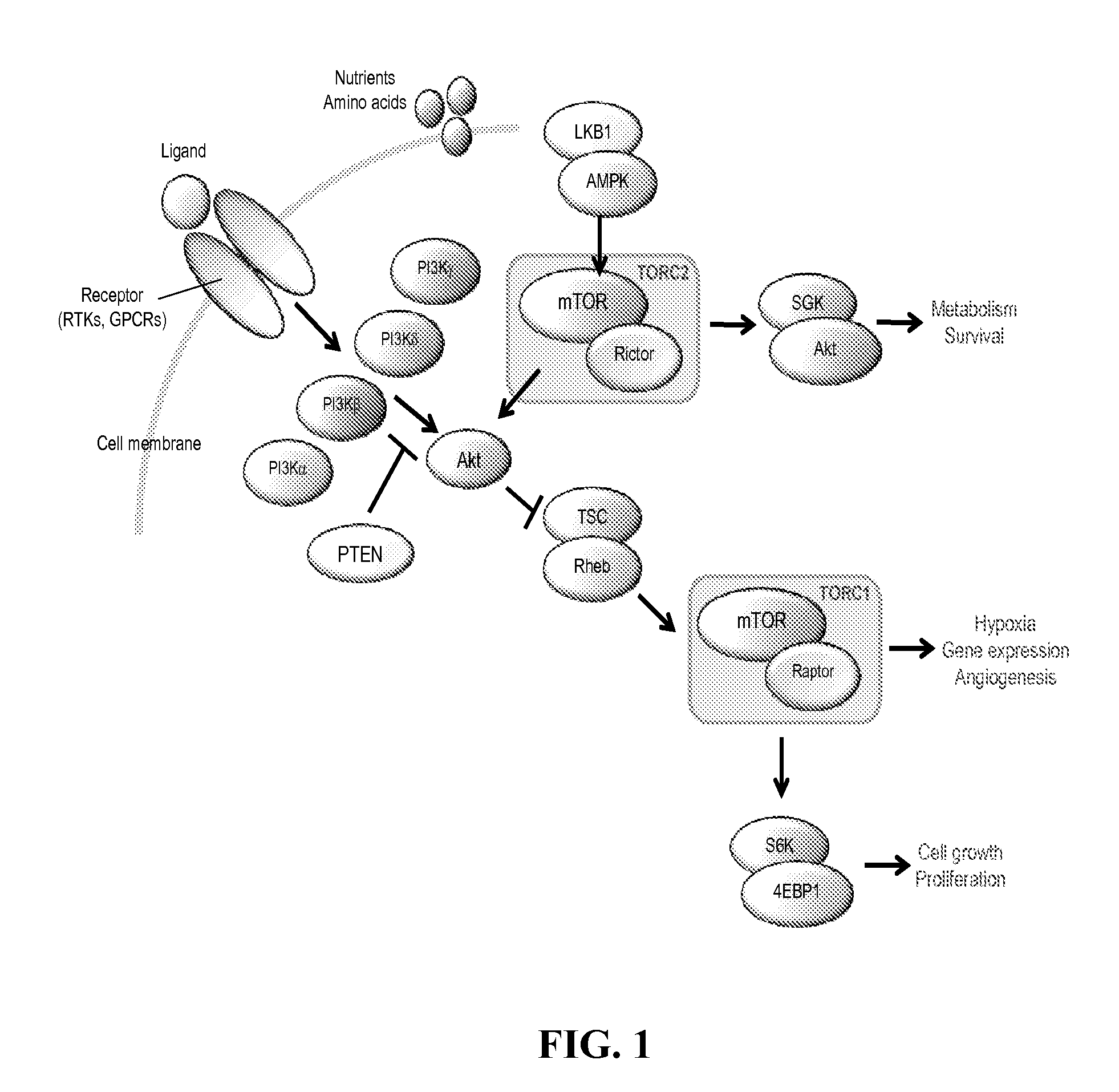

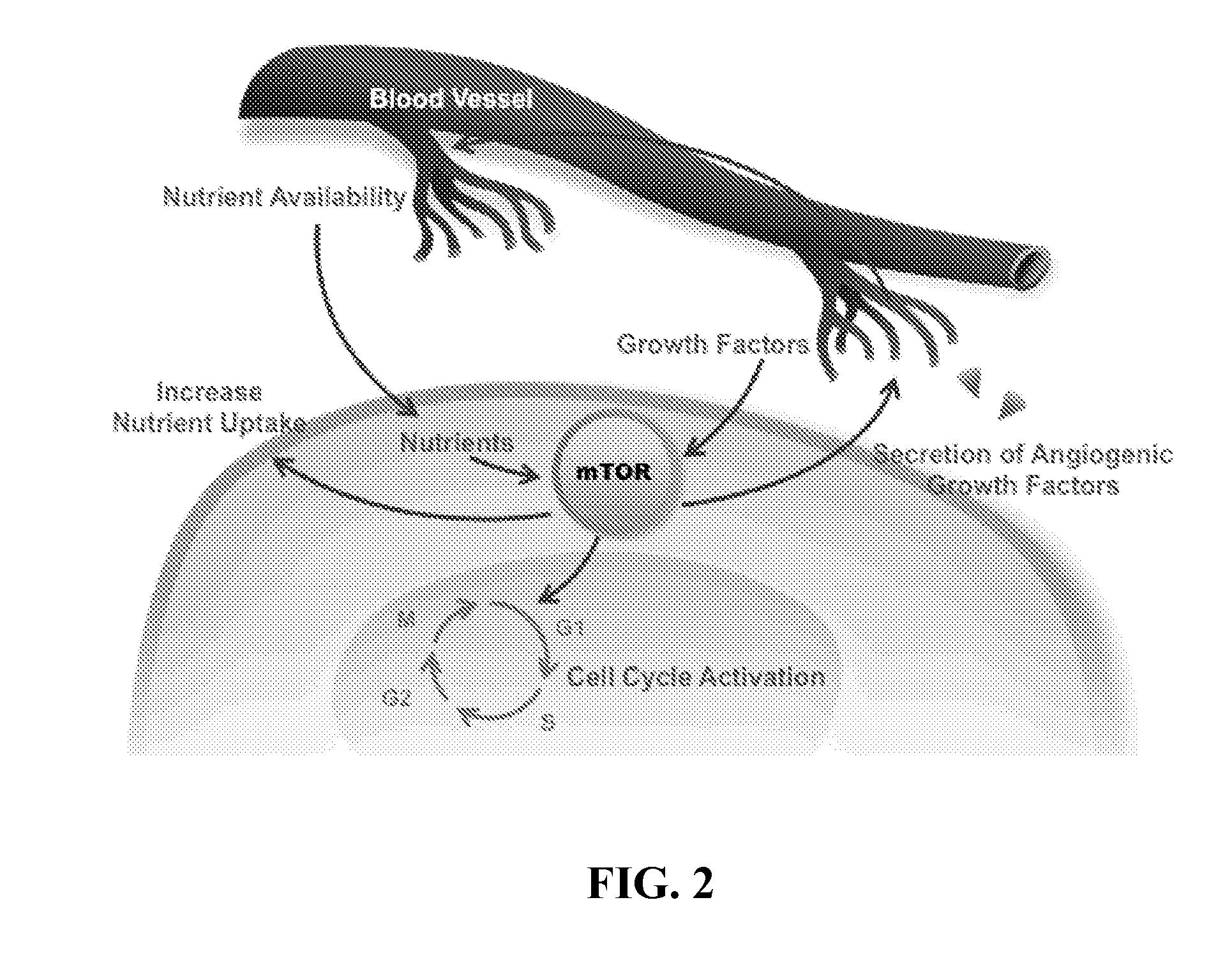

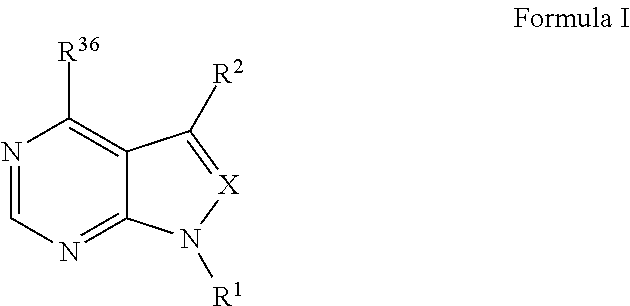

Methods and compositions for treatment of ophthalmic conditions

InactiveUS20110269779A1Relieve symptomsLower eye pressureBiocideSenses disorderKinase activityMedicine

The present invention provides chemical entities or compounds and pharmaceutical compositions thereof that are capable of modulating signal transduction by certain protein kinases such as mTor, tyrosine kinases, and / or lipid kinases such as PB kinase in an ocular tissue. Also provided in the present invention are methods of using these compositions to modulate activities of one or more of these kinases, especially for therapeutic applications.

Owner:INTELLIKINE

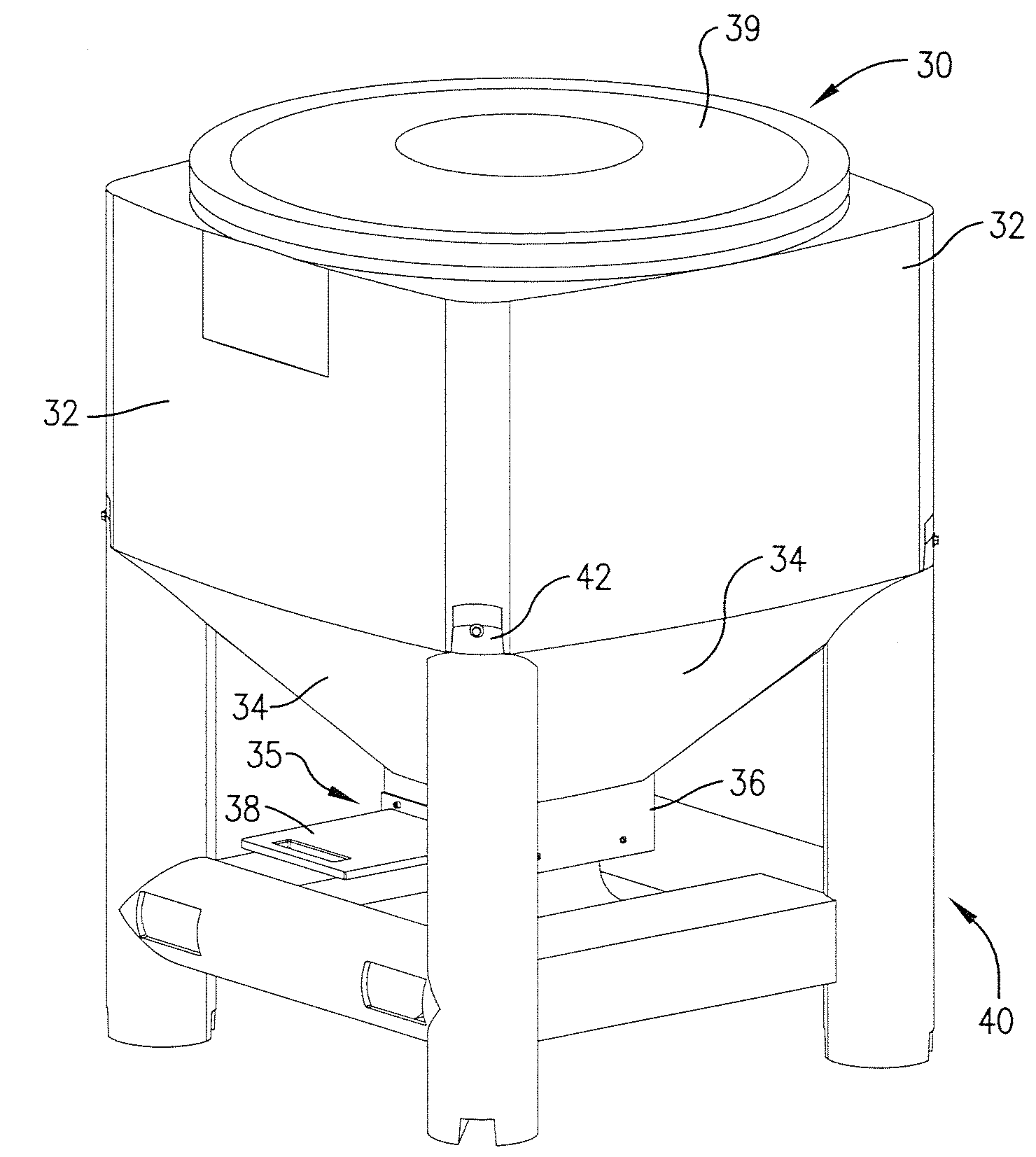

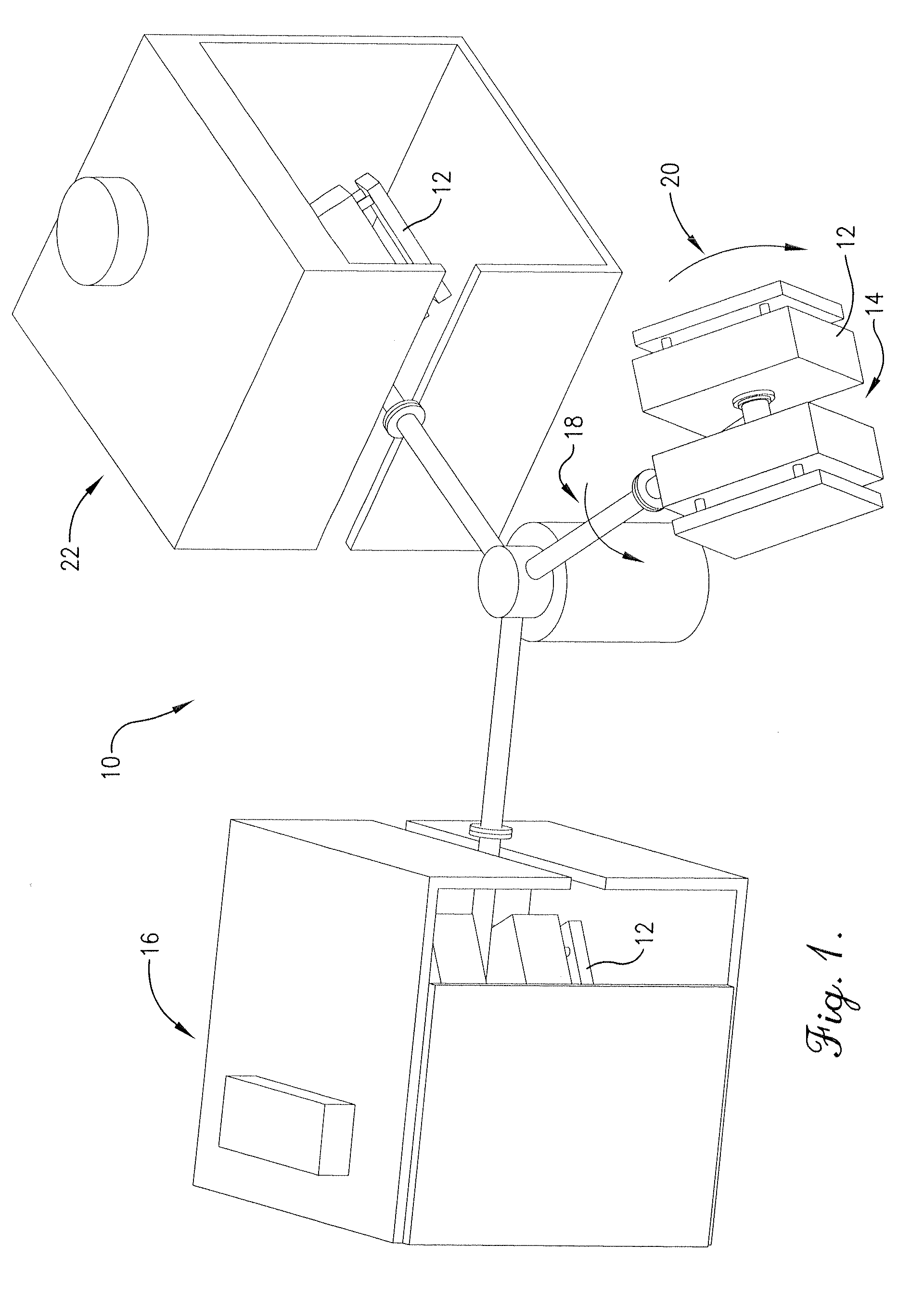

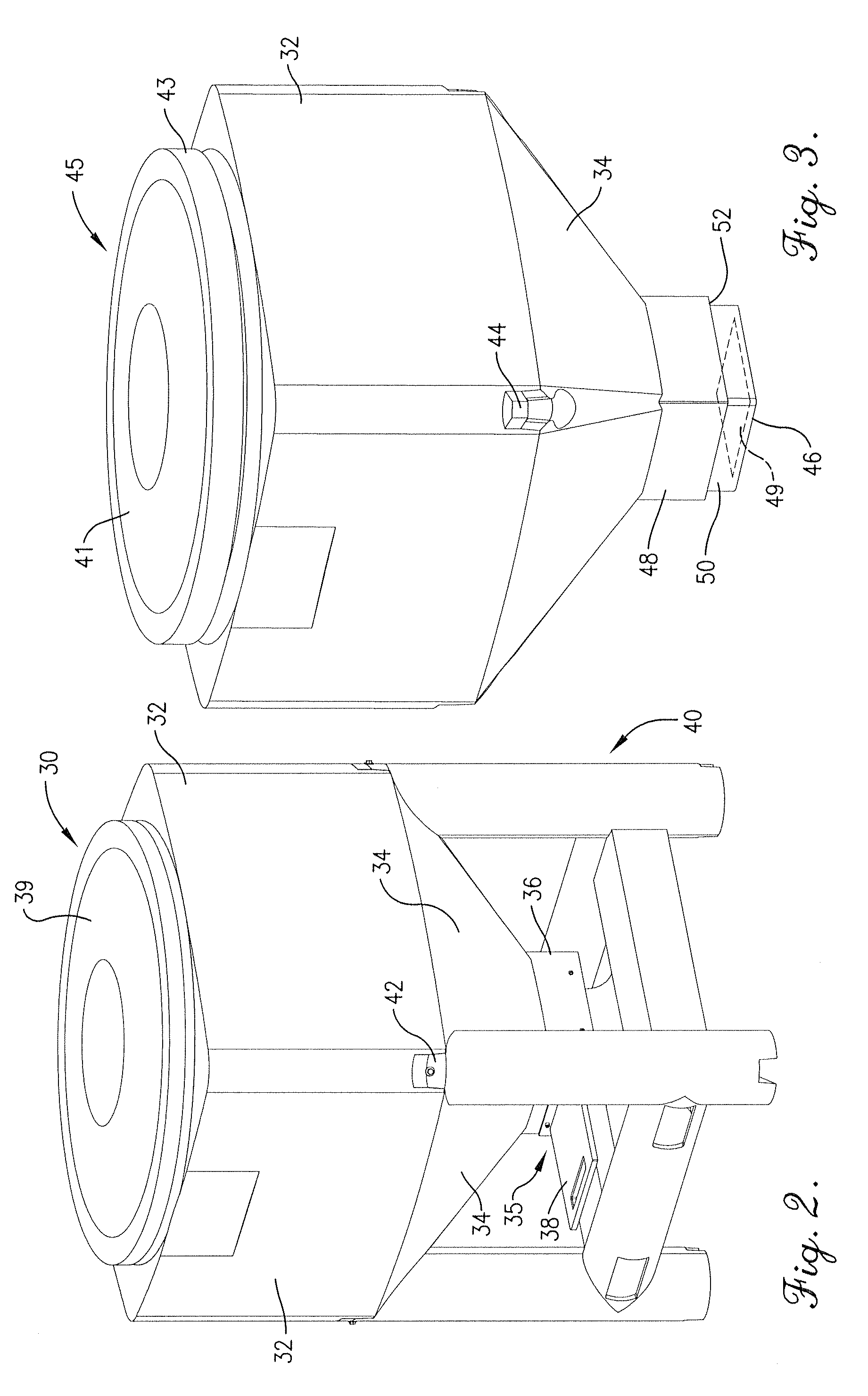

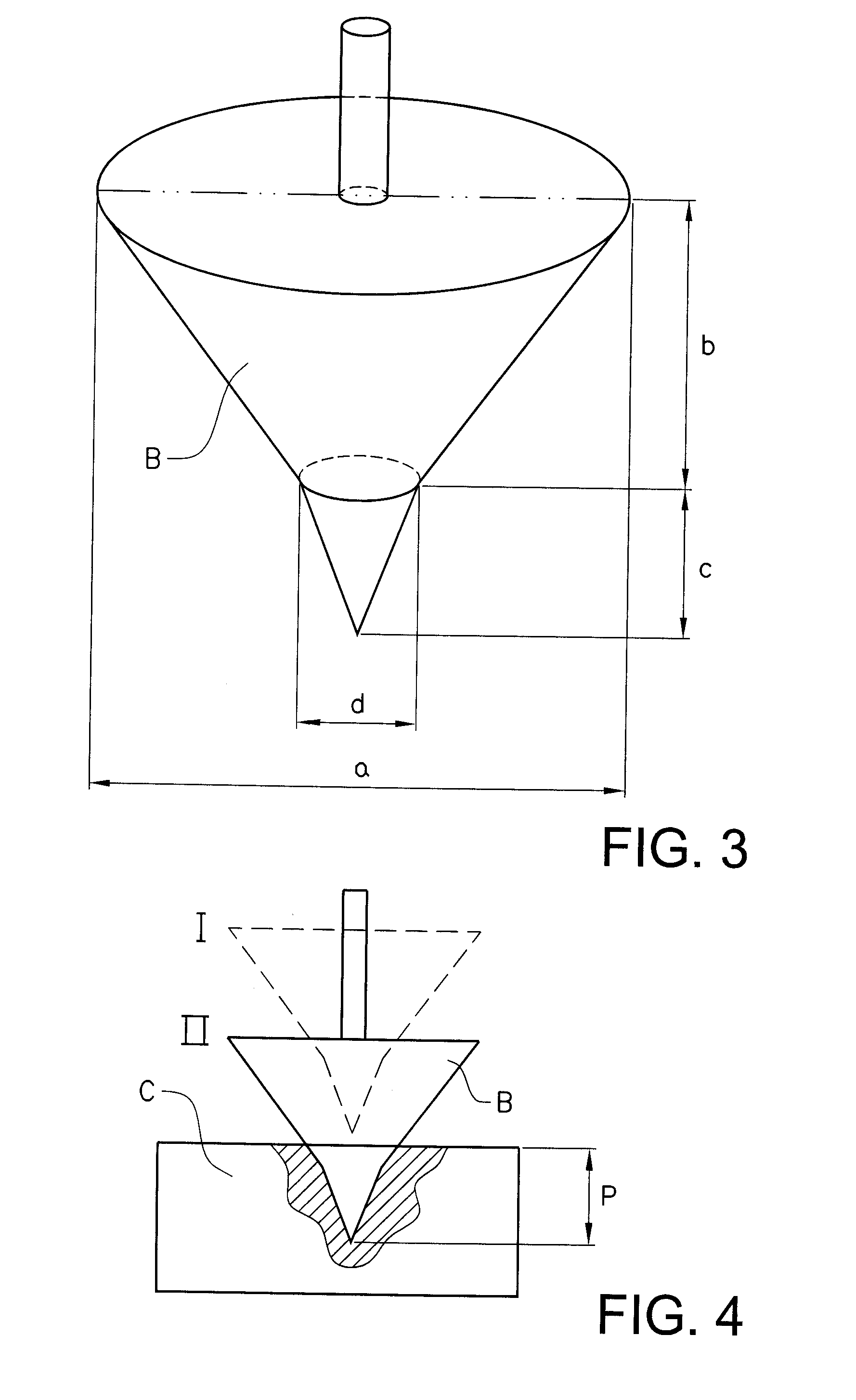

Hopper with slide discharge gate and method making the same

A hopper bin assembly with a slide discharge gate comprises a hopper section, a slide gate housing, and a pallet. The hopper stores a volume of dry material and includes an outlet. The slide gate housing couples with the hopper and includes a discharge opening that aligns with the outlet of the hopper. A slidable gate that is coupled with the discharge opening controls the flow of material through the discharge opening. The pallet supports the slide gate housing and the hopper and includes openings that receive the forks of a forklift. A method of making at least a portion of the hopper bin assembly includes rotating a resin in a mold along two or more axes within a heated room or chamber. The mold is cooled and the part formed therein is separated into one or more sections.

Owner:SNYDER INDS

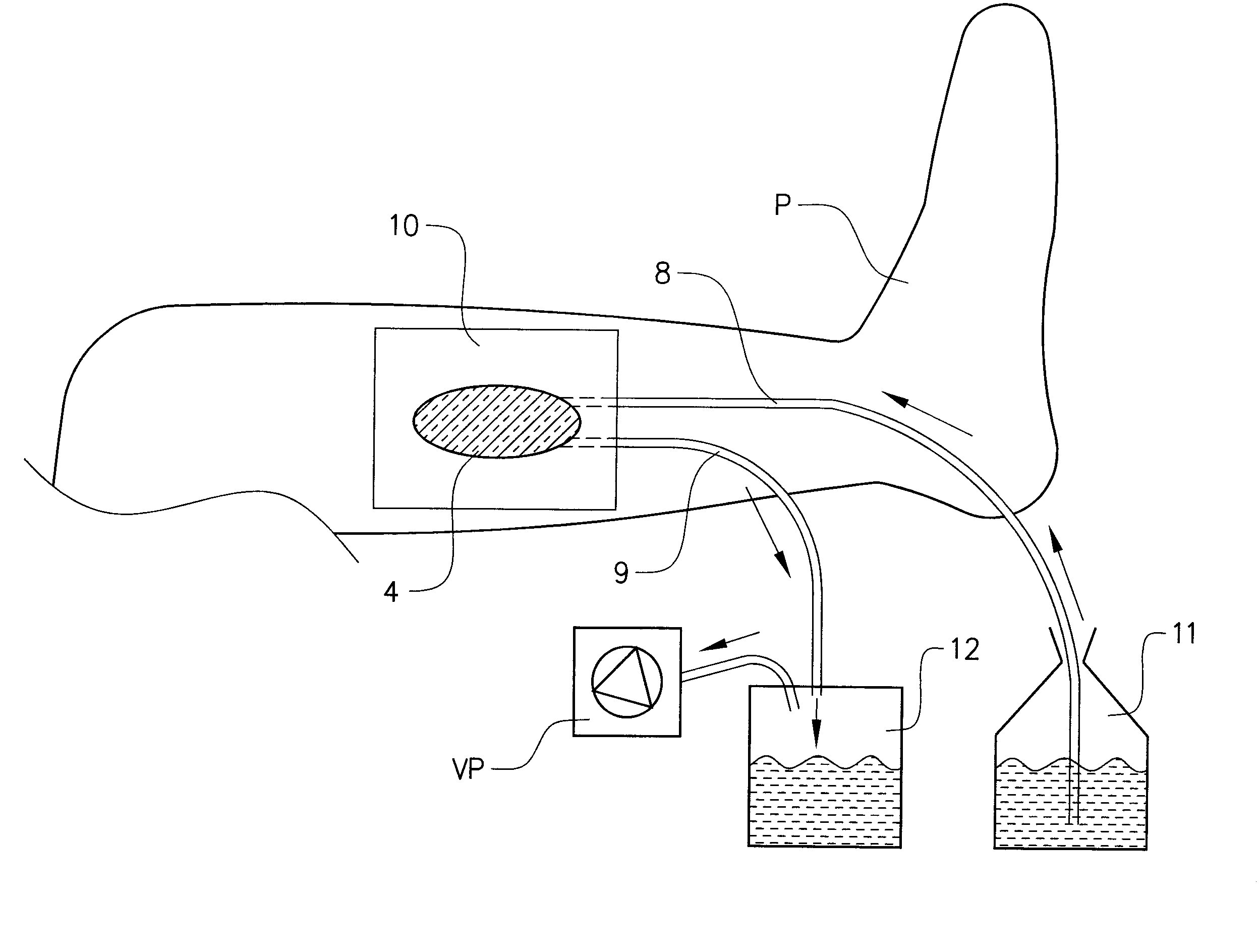

System and method for urinary tract cell collection, diagnosis, and chemotherapy

InactiveUS20090171241A1Avoid flowEasy to drainSurgical needlesVaccination/ovulation diagnosticsPenisUrethra

A system and method delivers and collects a wash medium into a lumen of the urinary tract system. Isolated saline delivery washes cells from a urethra that are collected for cancer diagnosis. BCG is delivered for local chemotherapy. The isolated delivery and collection is from a region bound by a distal occlusion and proximal occlusion. Inflatable balloons provide the occlusion and or a penis clamp may be used. The two balloons may telescope relative to each other. A balloon inflation lumen may collapse a valve membrane to occlude distal flow of infused fluid to only proximal of the balloon.

Owner:GARCIA MAURICE M

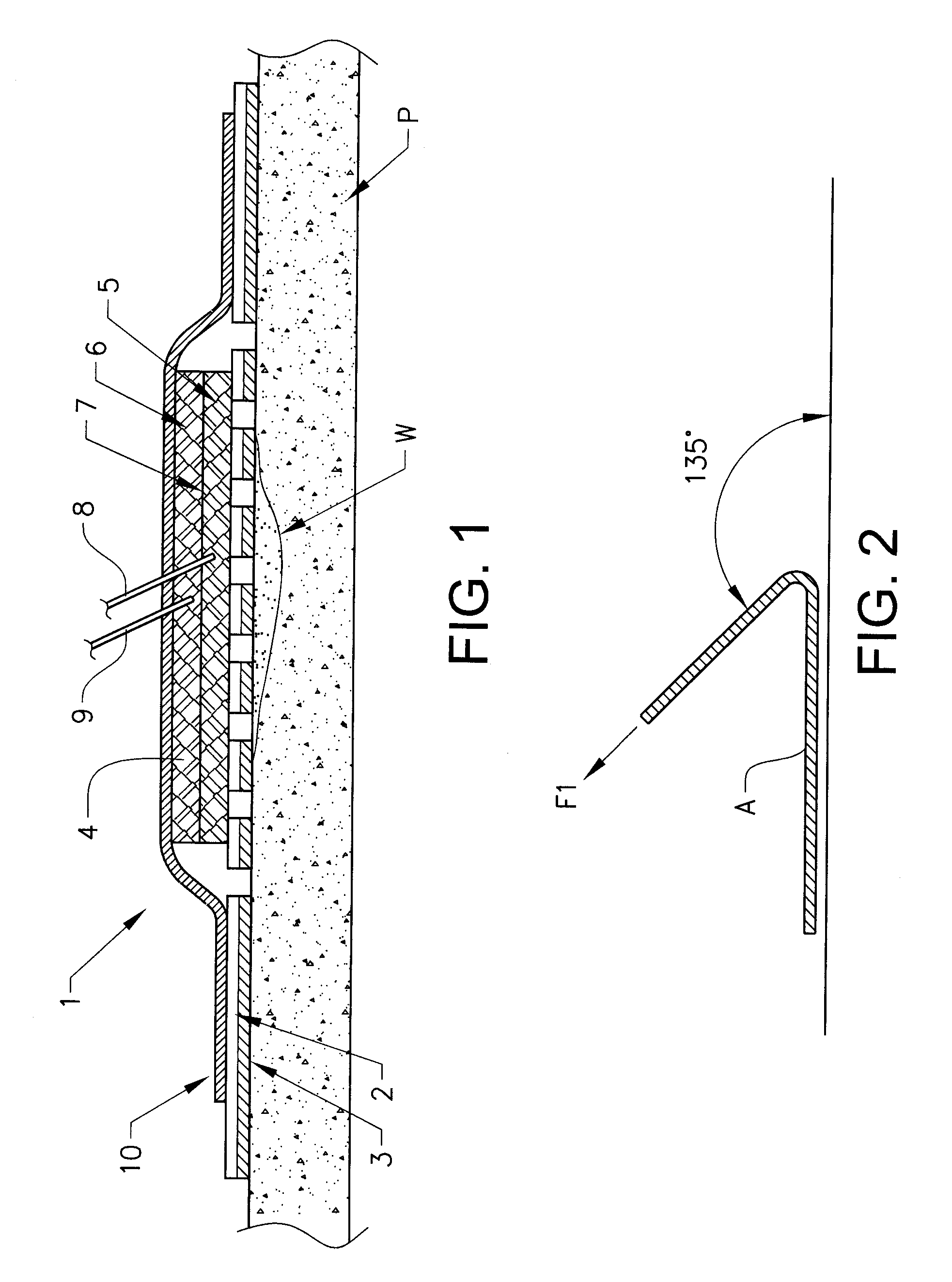

Irrigation dressing and method of applying such an irrigating dressing

InactiveUS20090254053A1Simple designSufficient negative pressureWound drainsAdhesive dressingsAdhesiveBiomedical engineering

The present invention relates to an irrigation dressing, comprising a first body (5) of a soft, liquid-permeable material, at least one connection (8) for the supply of fluid, at least one connection (9) for the drainage of fluid, an airtight and liquid-tight covering layer (10) of flexible material, which covers said material body and extends outside the sides thereof, and an element (2, 3) for affixing the area of the covering layer that extends outside the contour of the first material body to the skin, the first material body facing the wound bed (W) when the dressing is applied. According to the invention the element (2, 3) for affixing said area to the skin includes a layer (3) of a soft, skin-friendly adhesive, which affords sealing against micro-leakage. The invention also relates to a method of applying such a dressing.

Owner:MOLNLYCKE HEALTH CARE AB

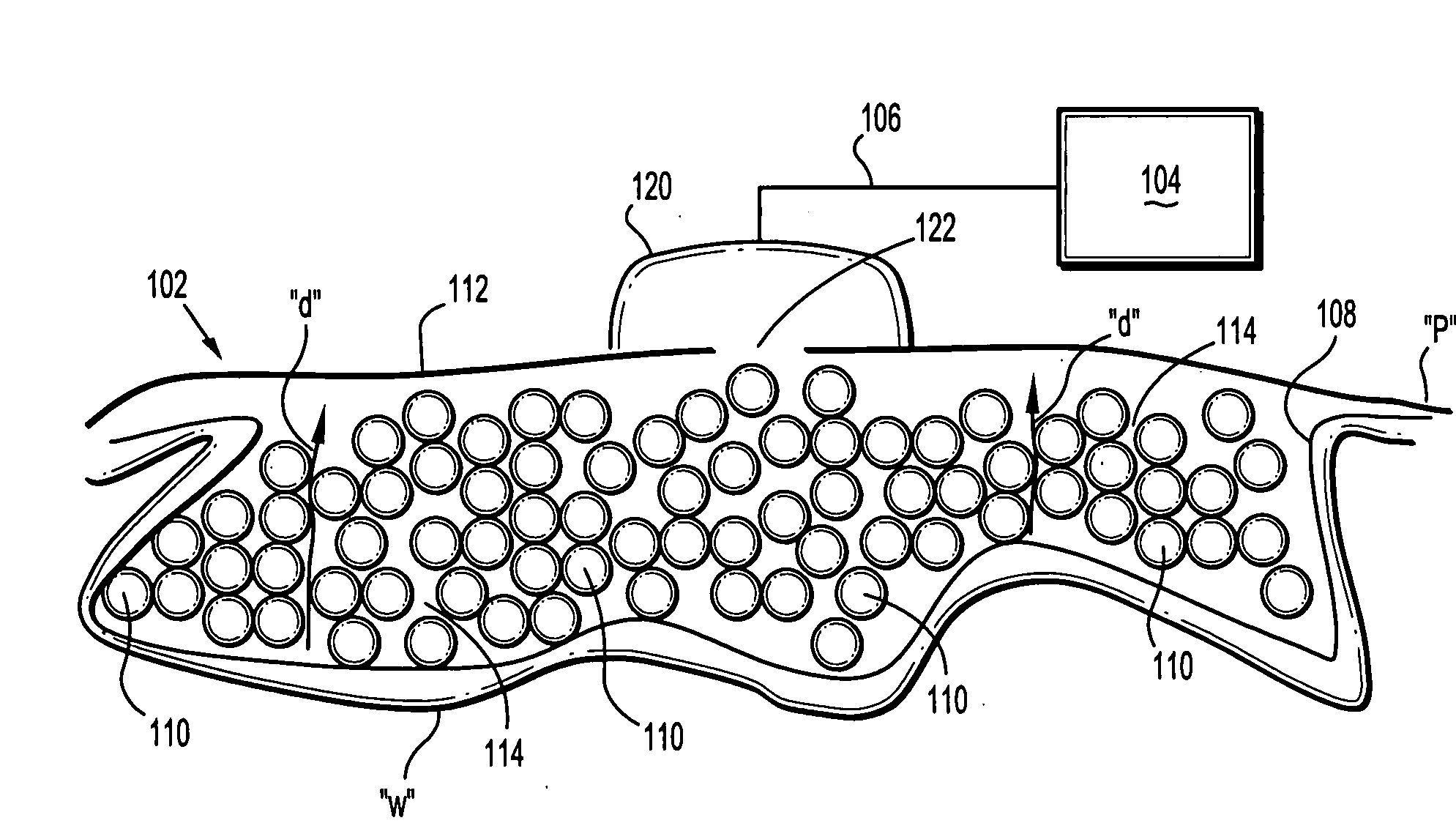

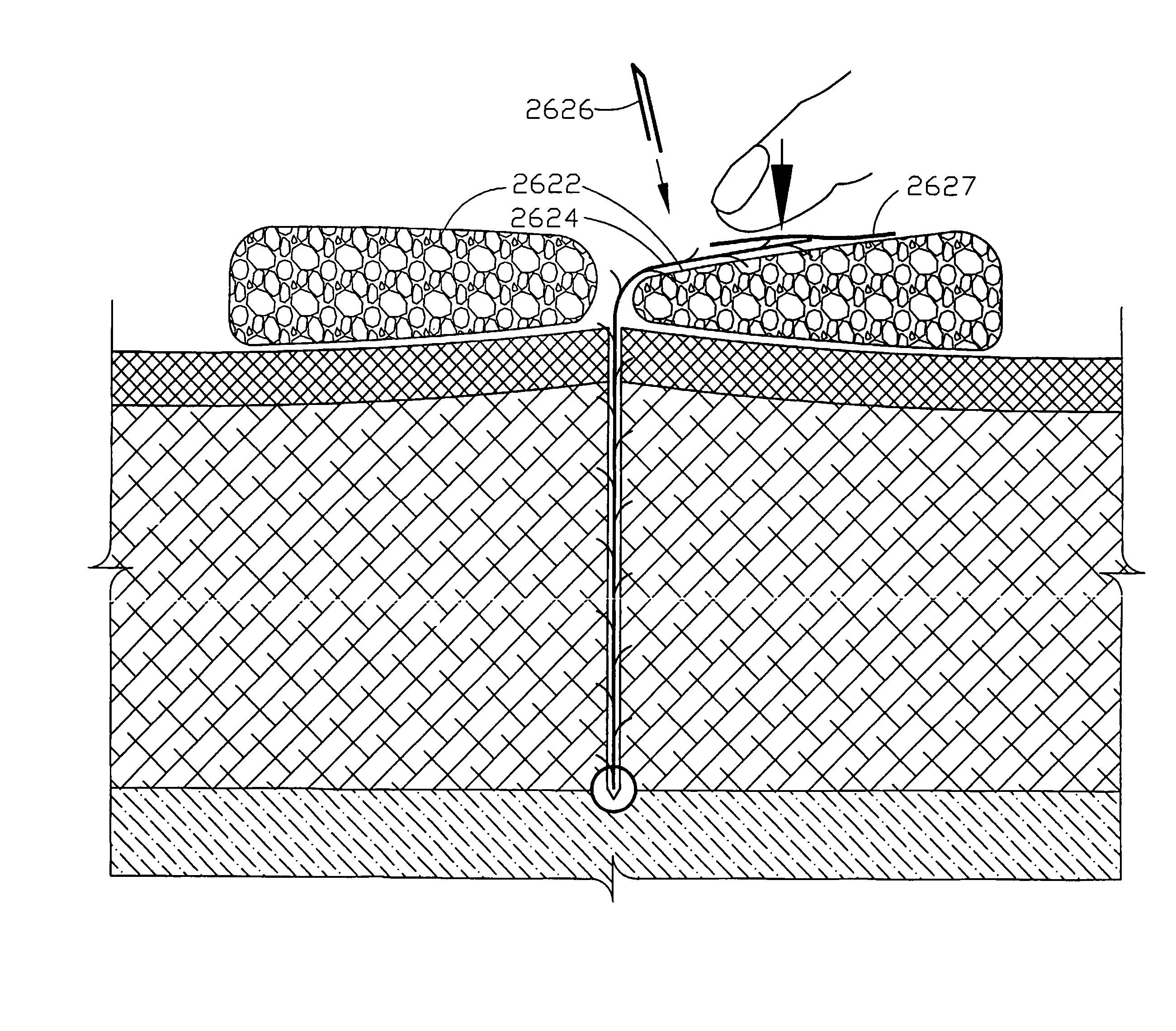

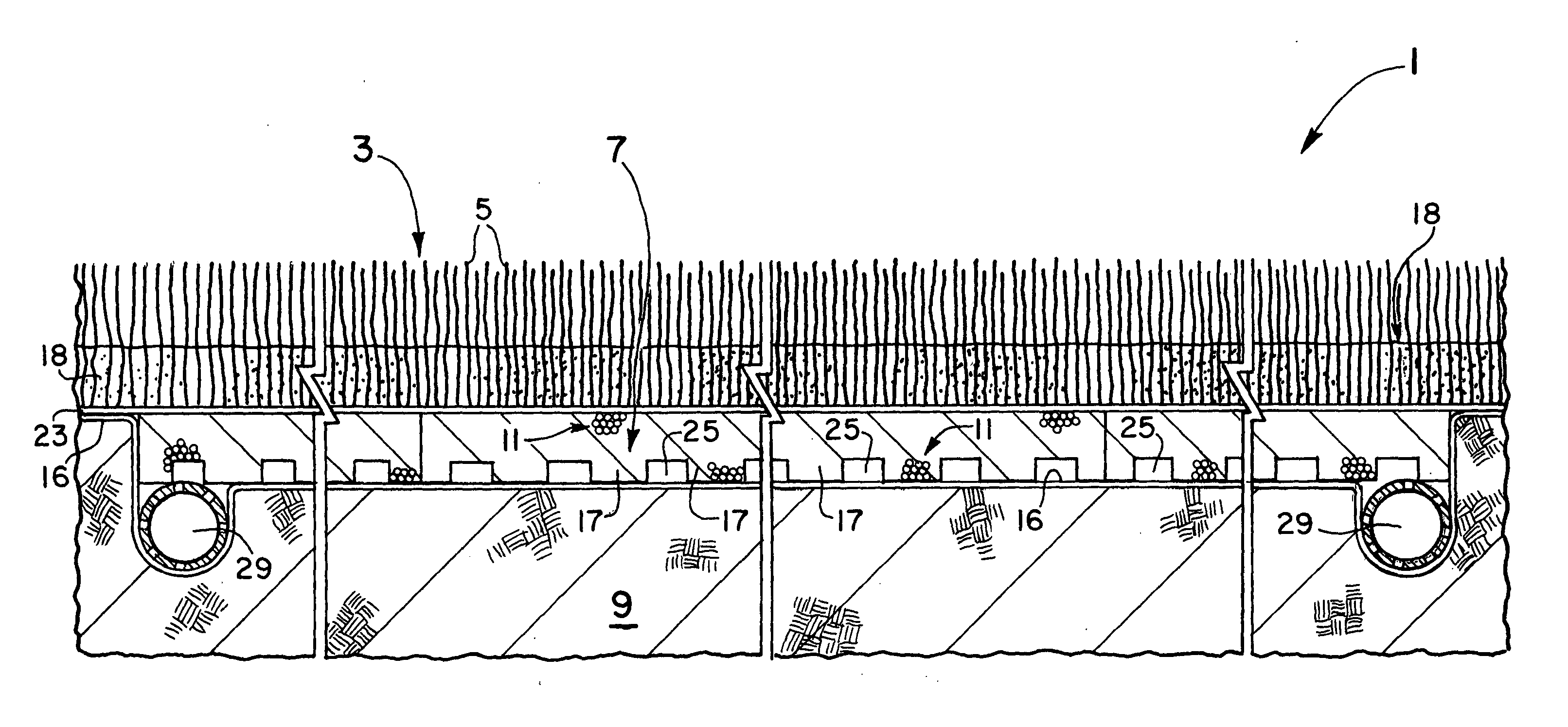

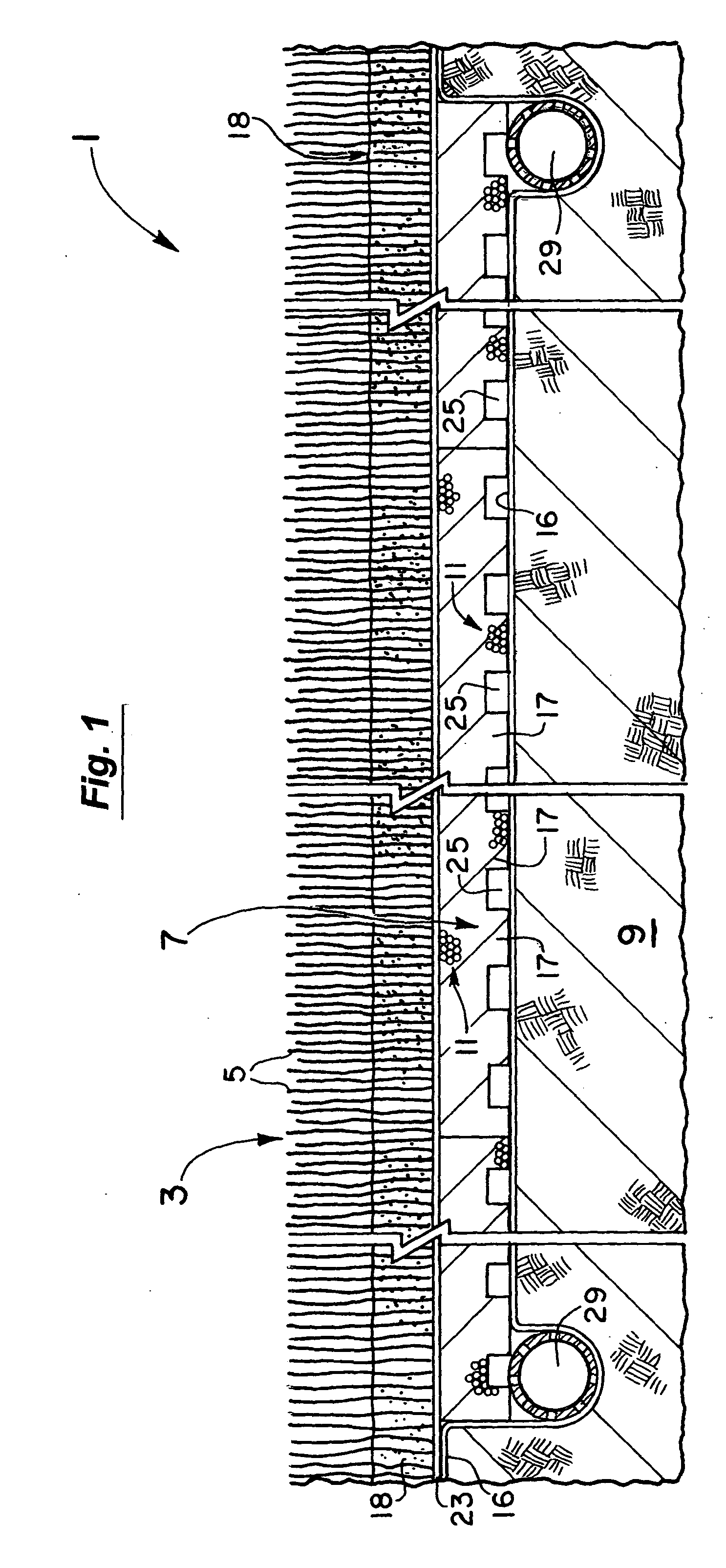

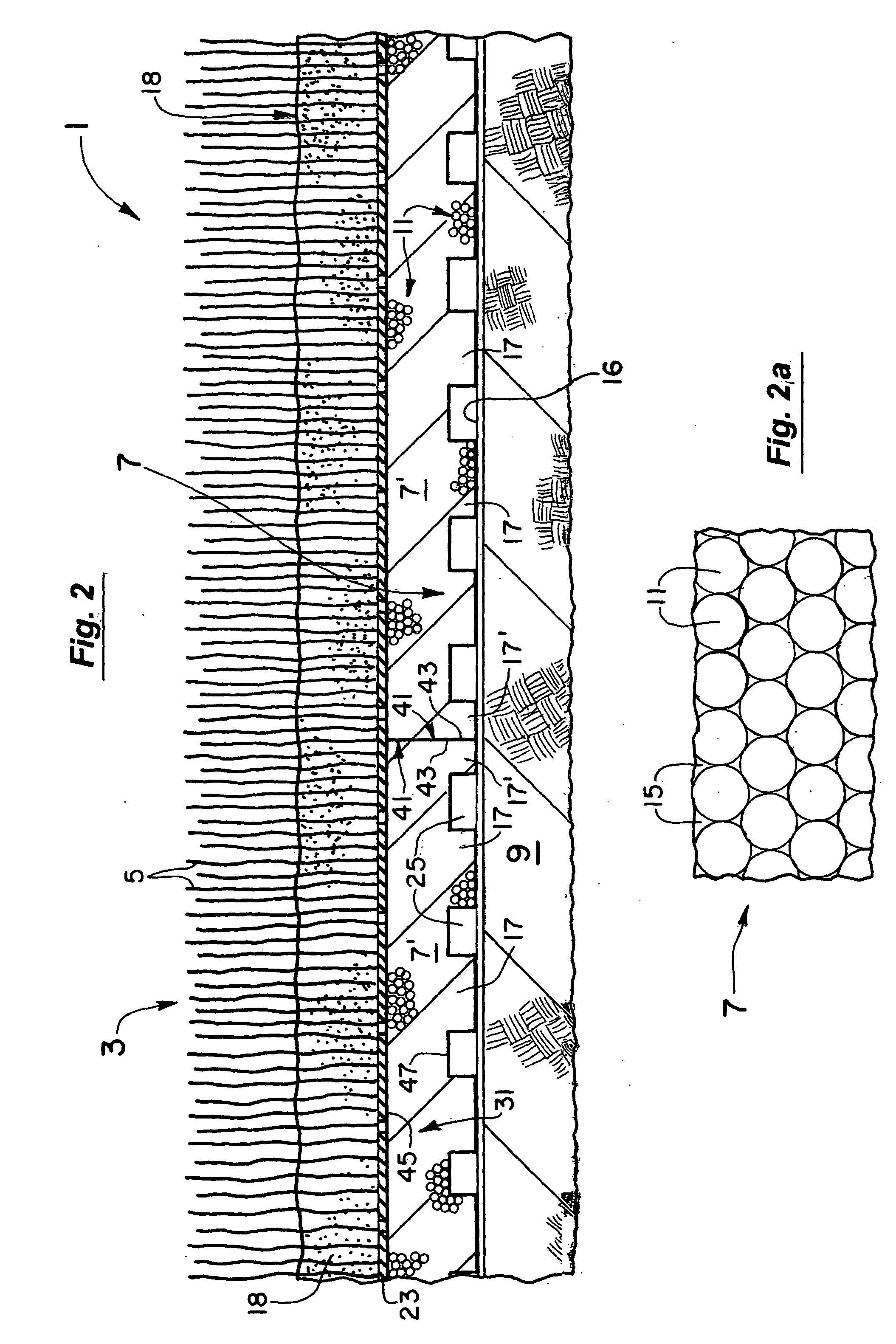

Multi-layered sports playing field with a water draining, padding layer

ActiveUS20050042394A1Good drainageEasy to drainDead plant preservationArtificial flowers and garlandsWater channelArtificial materials

A multi-layered sports playing field including a top layer made of substantially artificial material simulating a natural playing surface such as grass and a padding layer positioned between the top layer and the base or dirt layer. The padding layer is made of a plurality of discrete beads of substantially elastic, resilient material (e.g., foam) with portions of adjacent beads abutting one another and other portions being spaced from each other. Substantially all of the adjacent beads are preferably integrally joined (e.g., glued, fused) together at their abutting portions. The padding layer is very porous and breathable and preferably includes feet members supporting the main body of the padding layer above the base or dirt layer to create a water channel of interconnected portions to enhance water drainage to the sides of the field.

Owner:BROCK USA

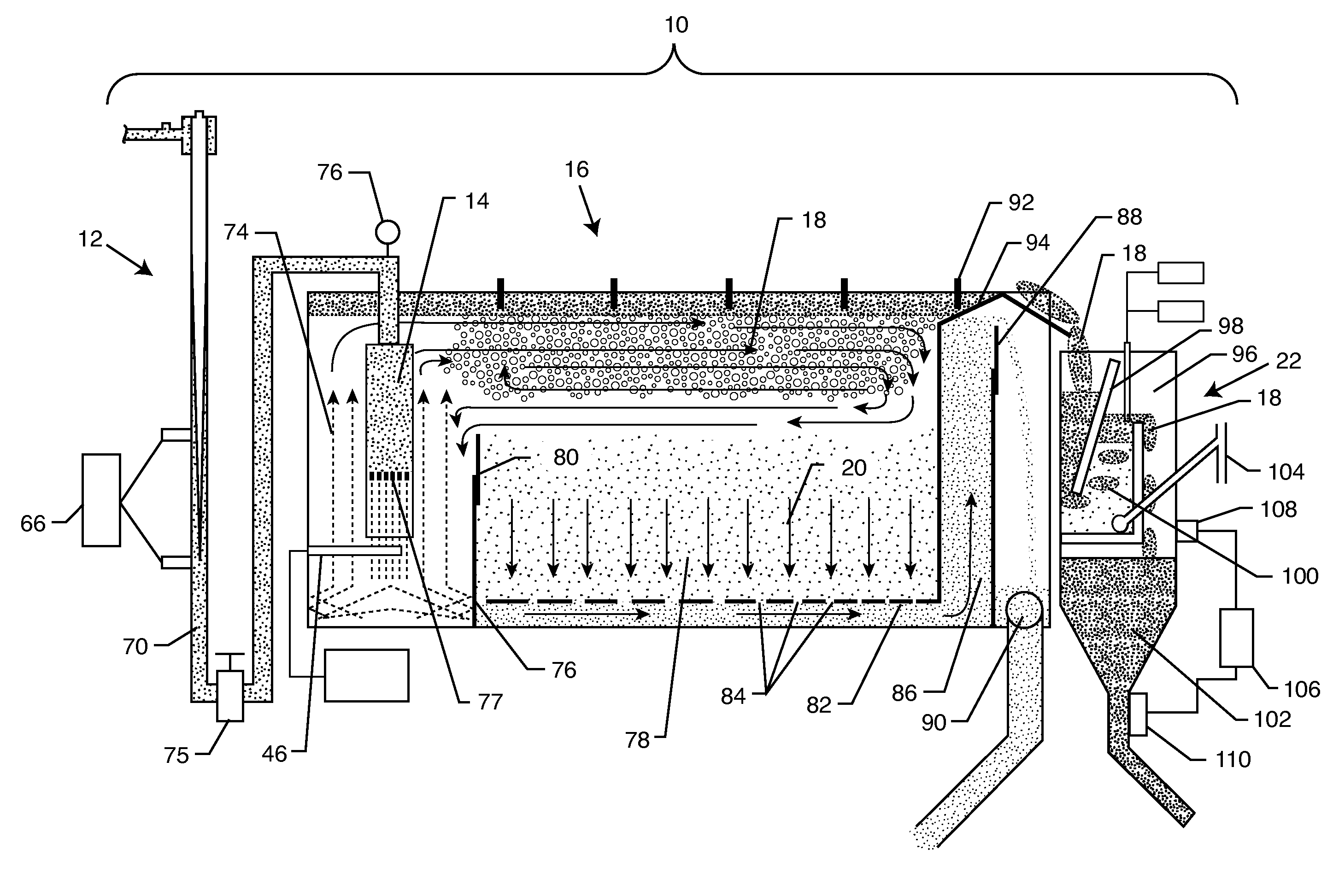

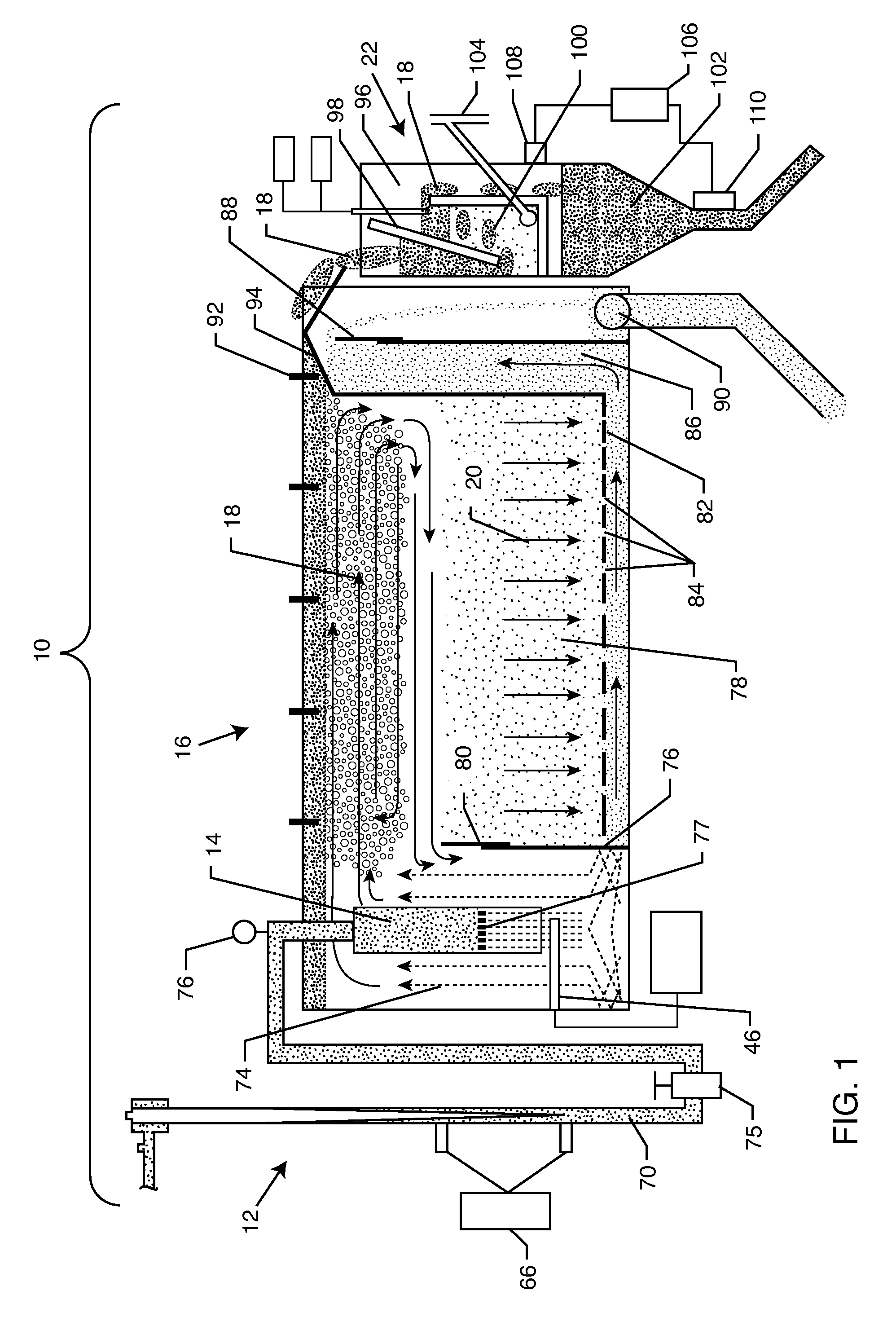

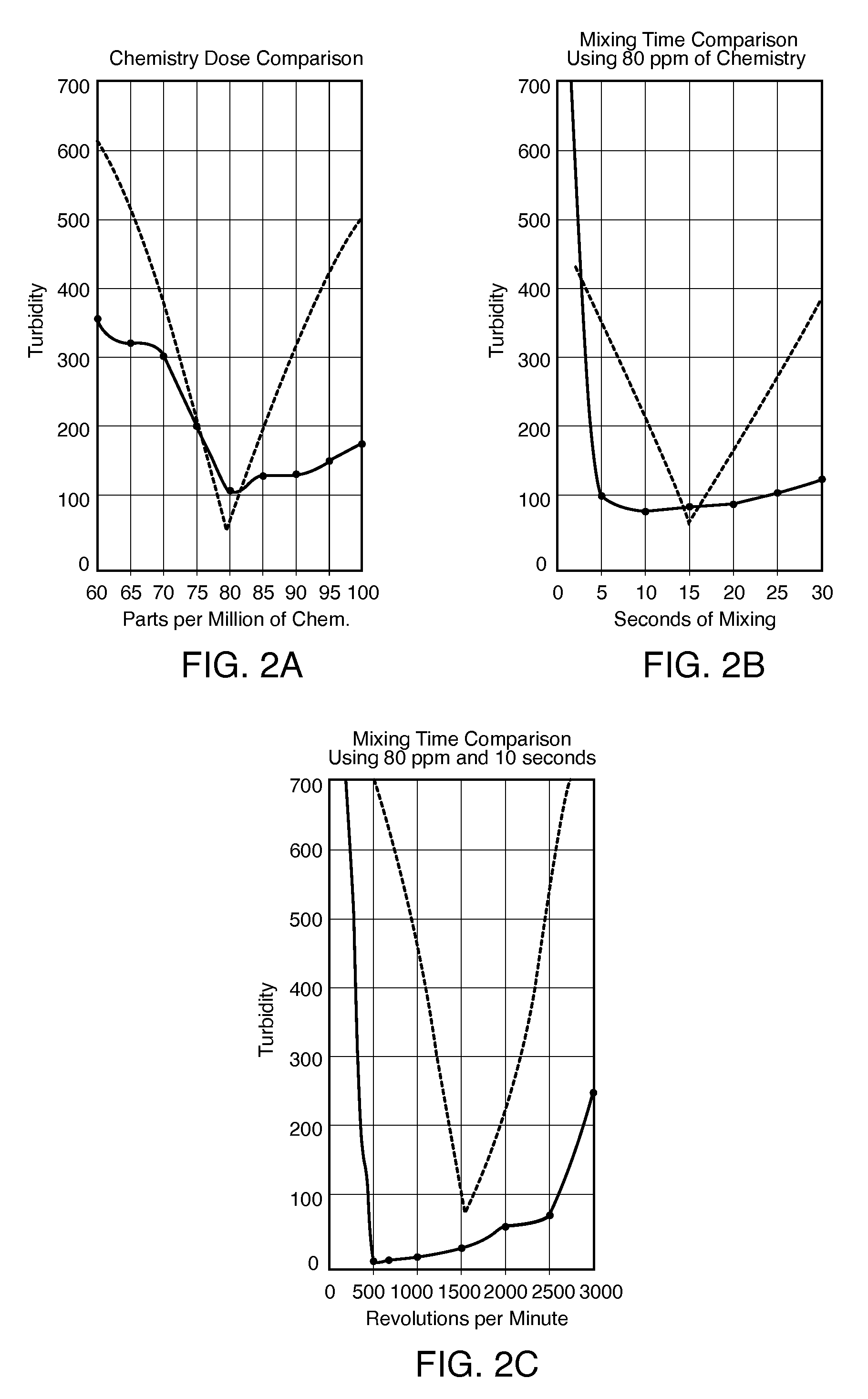

Control system and process for wastewater treatment

InactiveUS20080047903A1Effective positioningEasy to drainWater treatment parameter controlFlow mixersControl systemWastewater

A system and process is provided for optimizing chemical additions, mixing energy, mixing time, and other variables while treating a contaminated liquid stream. Samples from the contaminated liquid stream are tested to determine the optimal parameter for each variable, including type and amount of the chemicals to be added, chemical sequence, mixing energy, mixing time, temperature, and pressurization. A system of mixers, a flotation chamber, and a dewatering subsystem are designed to achieve optimal turbidity of the wastewater stream. The system can be modified in real-time in response to a continually changing contaminated liquid stream via a controller and set of sensors, valves, and ports.

Owner:WORLD WATER TECH

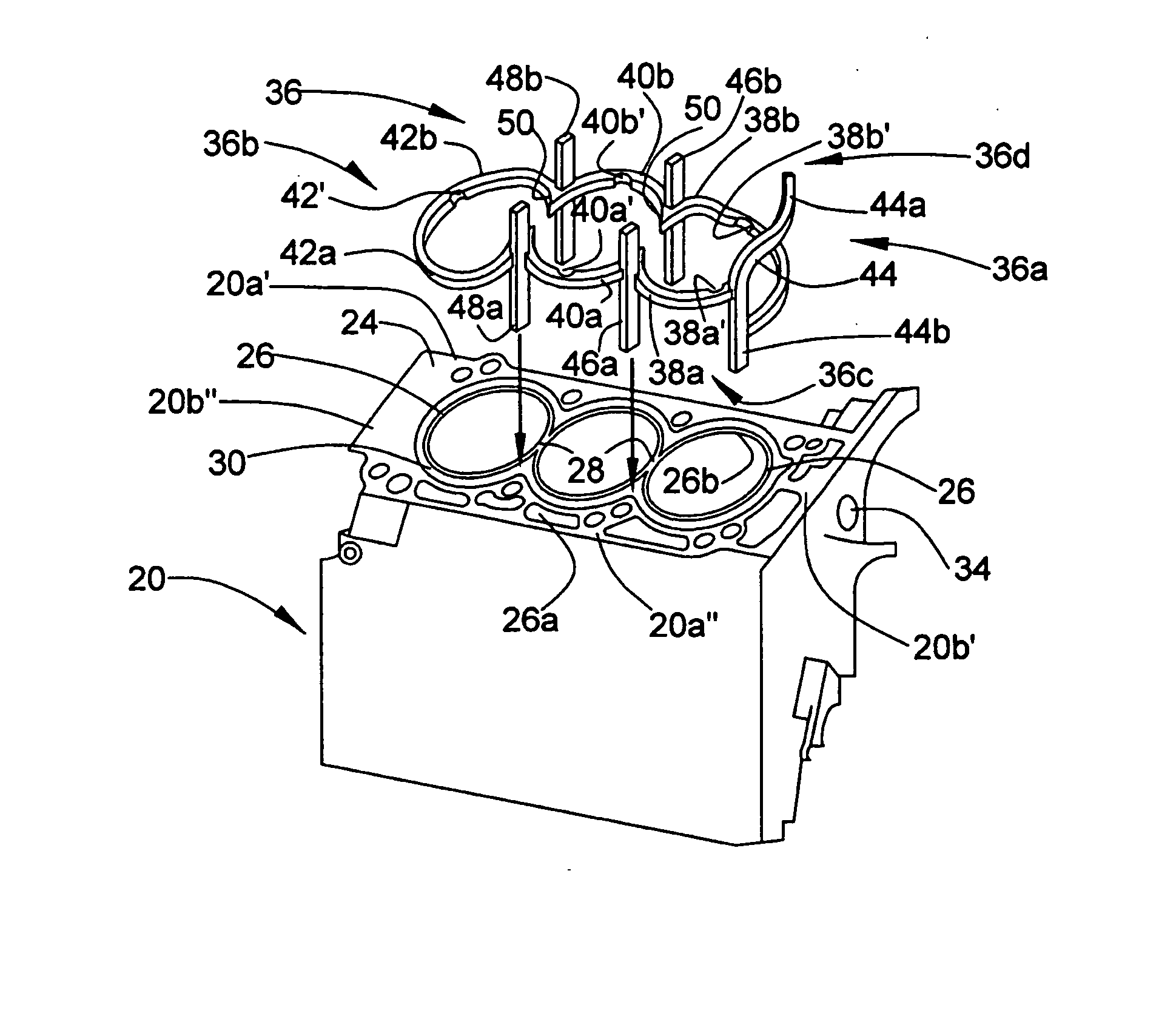

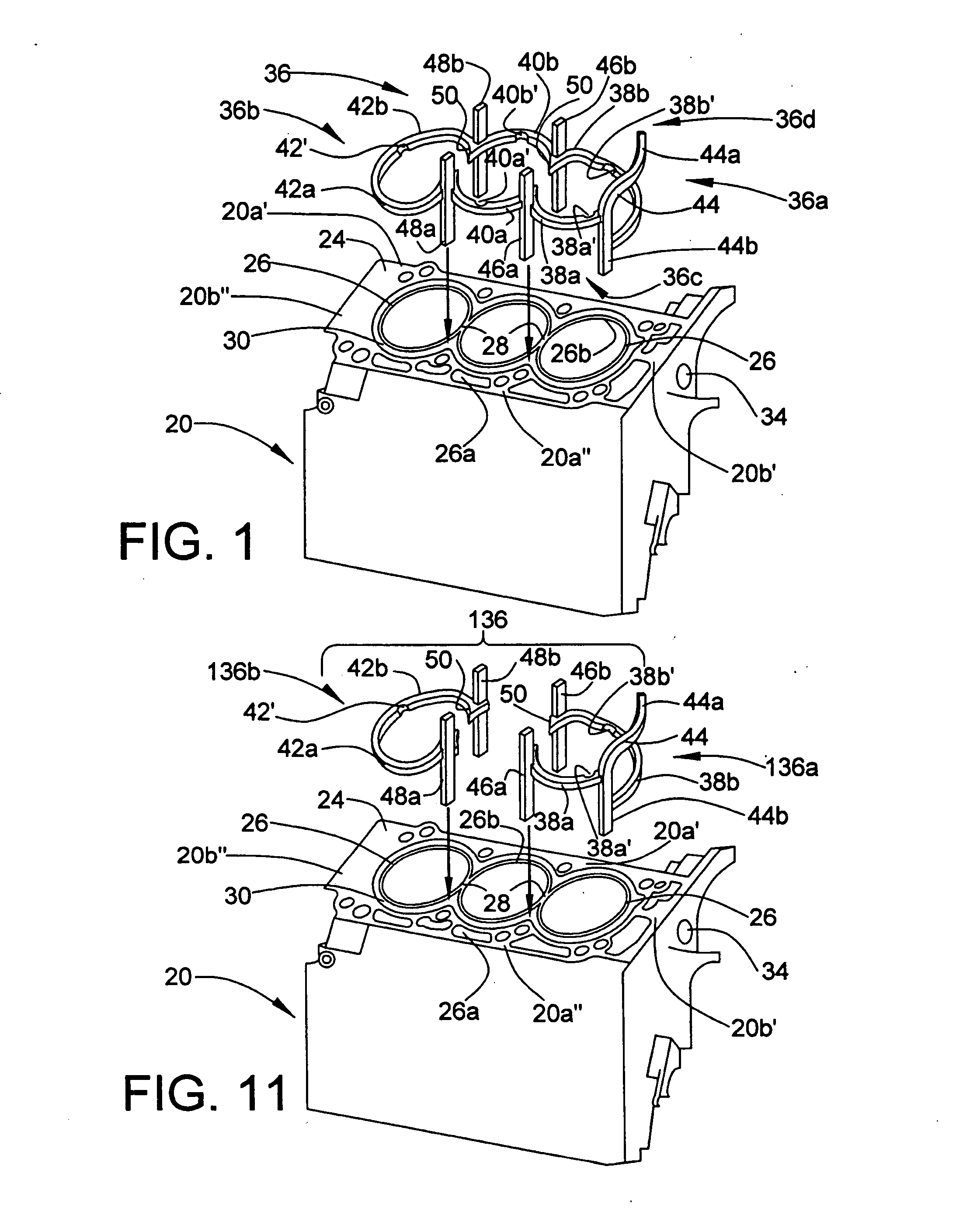

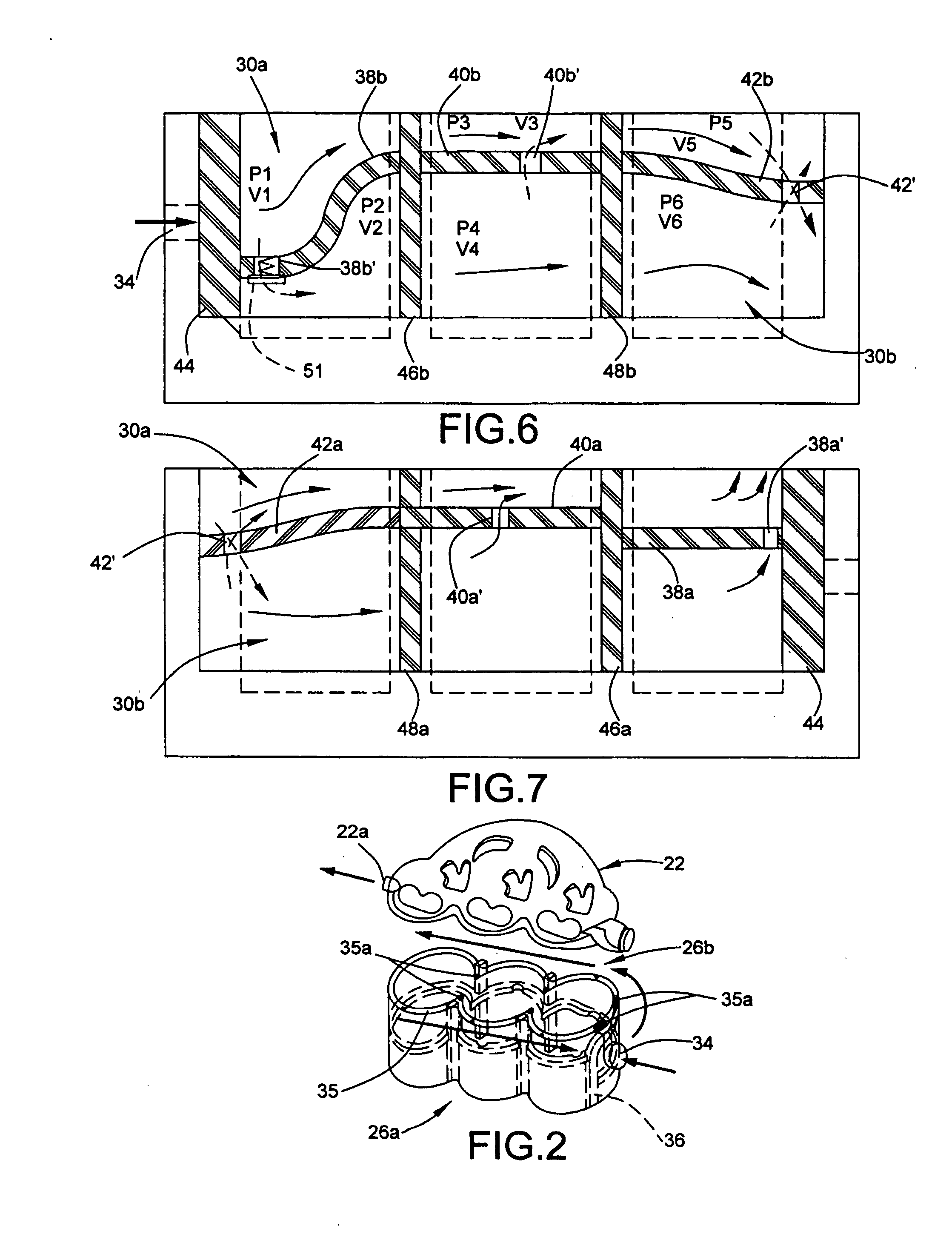

Cylinder block cooling arrangement for multi-cylinder internal combustion engine

An insert for a siamese-type internal combustion engine that separates a water jacket surrounding the cylinders into an upper portion and a lower portion. Below a predetermined engine speed coolant flows primarily in the upper water jacket portion so as to provide enhanced cooling at the upper portions of the cylinders. Above a predetermined engine speed coolant is introduced into the lower water jacket portion from the upper water jacket portion so as to provide improved cooling of the lower cylinder portions, without compromising cooling of the upper cylinder portions or the conjoined cylinder wall portions. The water jacket insert enhances coolant flow velocity at the siamesed or conjoined portions of the cylinder walls, and directs incoming initially coolant over the exhaust-side of the cylinders. Use of the insert reduces circumferential and axial intra-cylinder temperature deviations as well as inter-cylinder temperature deviations.

Owner:HONDA MOTOR CO LTD

Combination ureteral infusion catheter/drainage stent

A method of treating the upper urinary tract of a mammal having a urethra extending to a bladder and a ureter extending from the bladder to a kidney. The method comprises initially extending a catheter system into the upper urinary tract, the catheter system having a urethral catheter infusion tube section extending through the urethra for infusion of a liquid; a urethral catheter drain tube section extending through the urethra for drainage of a liquid; a ureteral catheter tube section extending through a ureter into the kidney and having a first tube portion for infusion of a liquid connected to the urethral catheter infusion tube section, and a second tube portion for drainage of a liquid. The method then includes flowing a therapeutically effective liquid into the kidney through the urethral catheter infusion tube section and the ureteral catheter first, infusion tube portion, and, simultaneously with the flowing of the fluid into the kidney, draining fluid from the kidney through the urethral catheter drain tube section and the ureteral catheter second, drain tube portion.

Owner:HAYNER GEORGE M +1

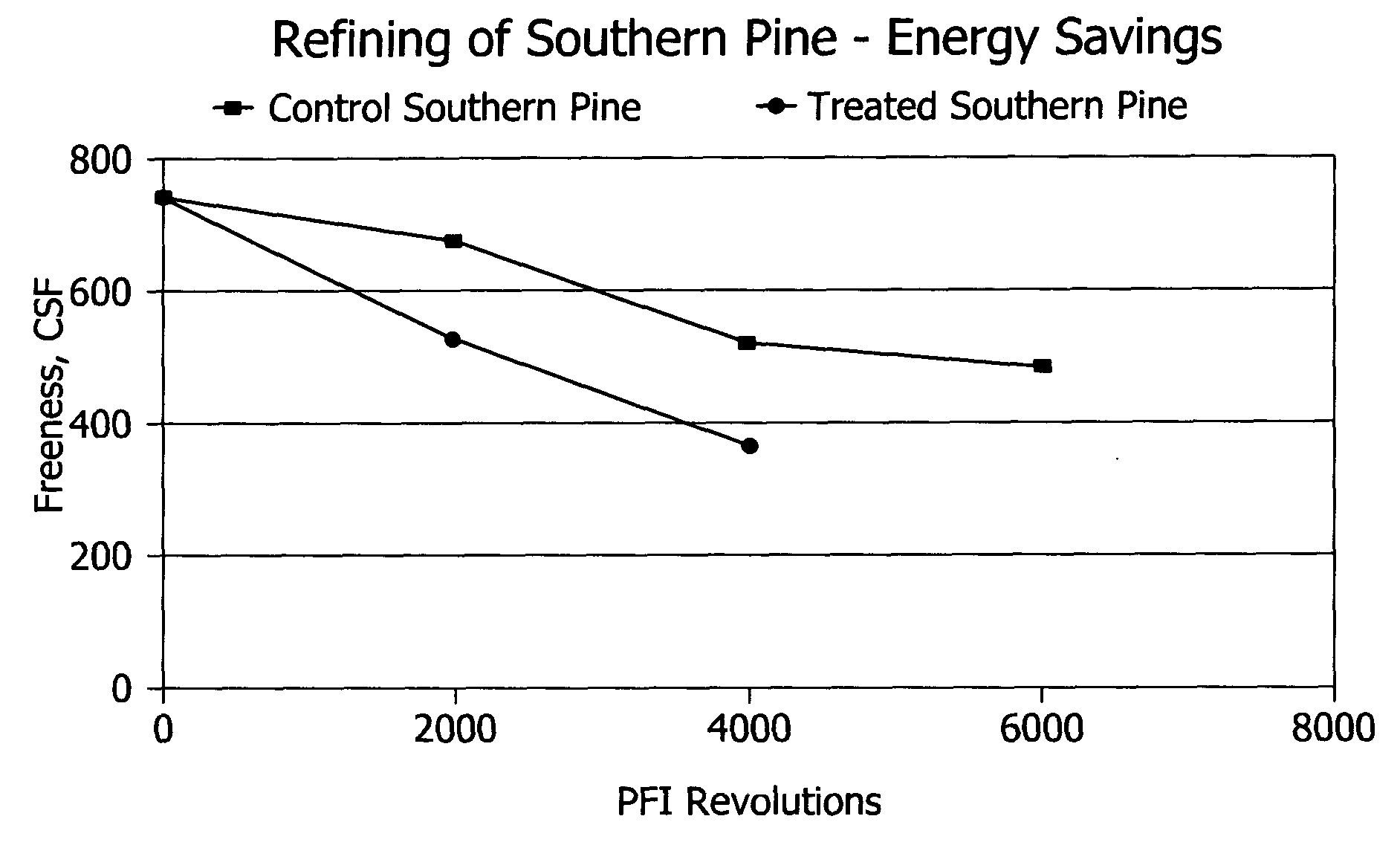

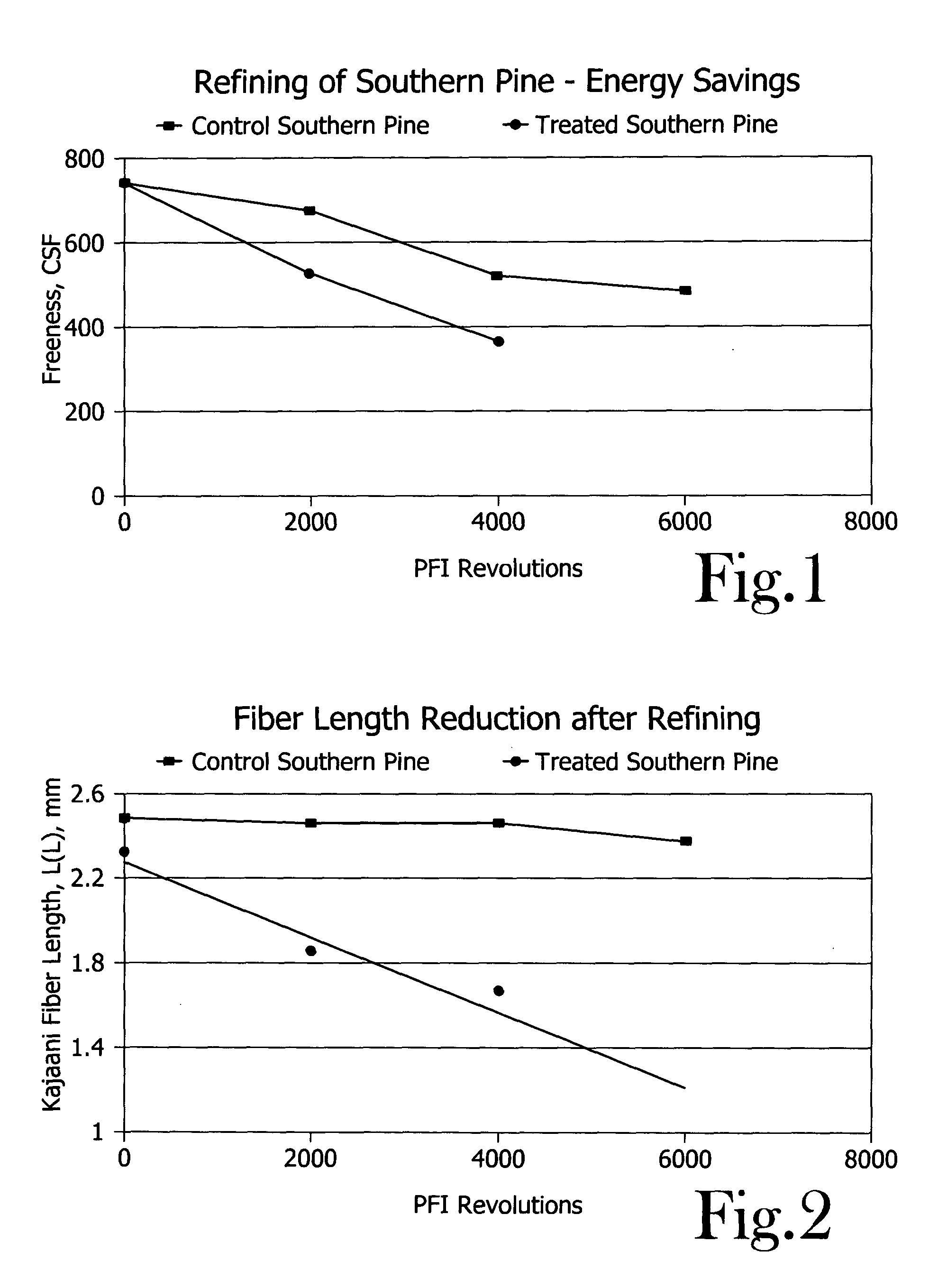

Chemical activation and refining of southern pine kraft fibers

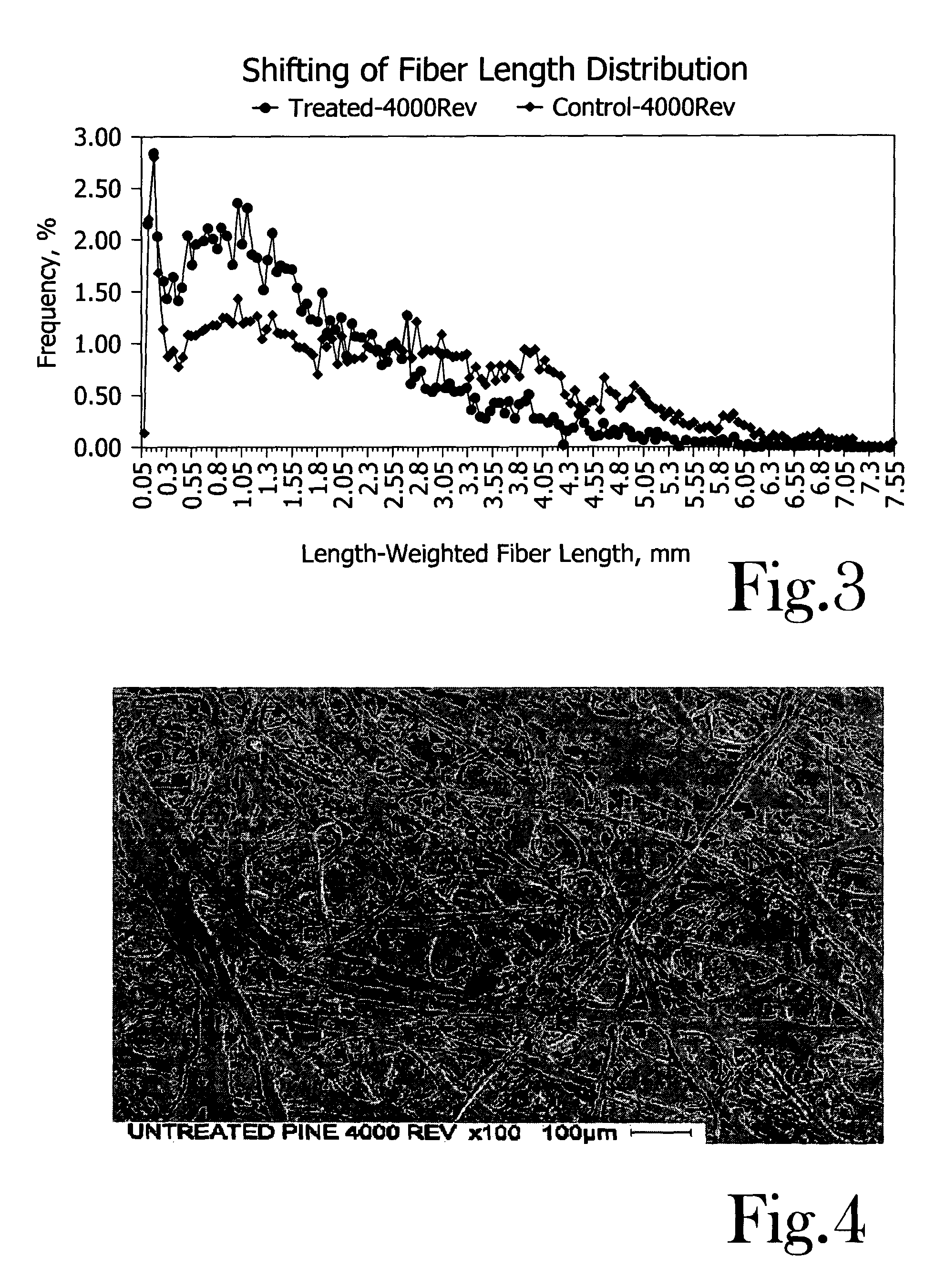

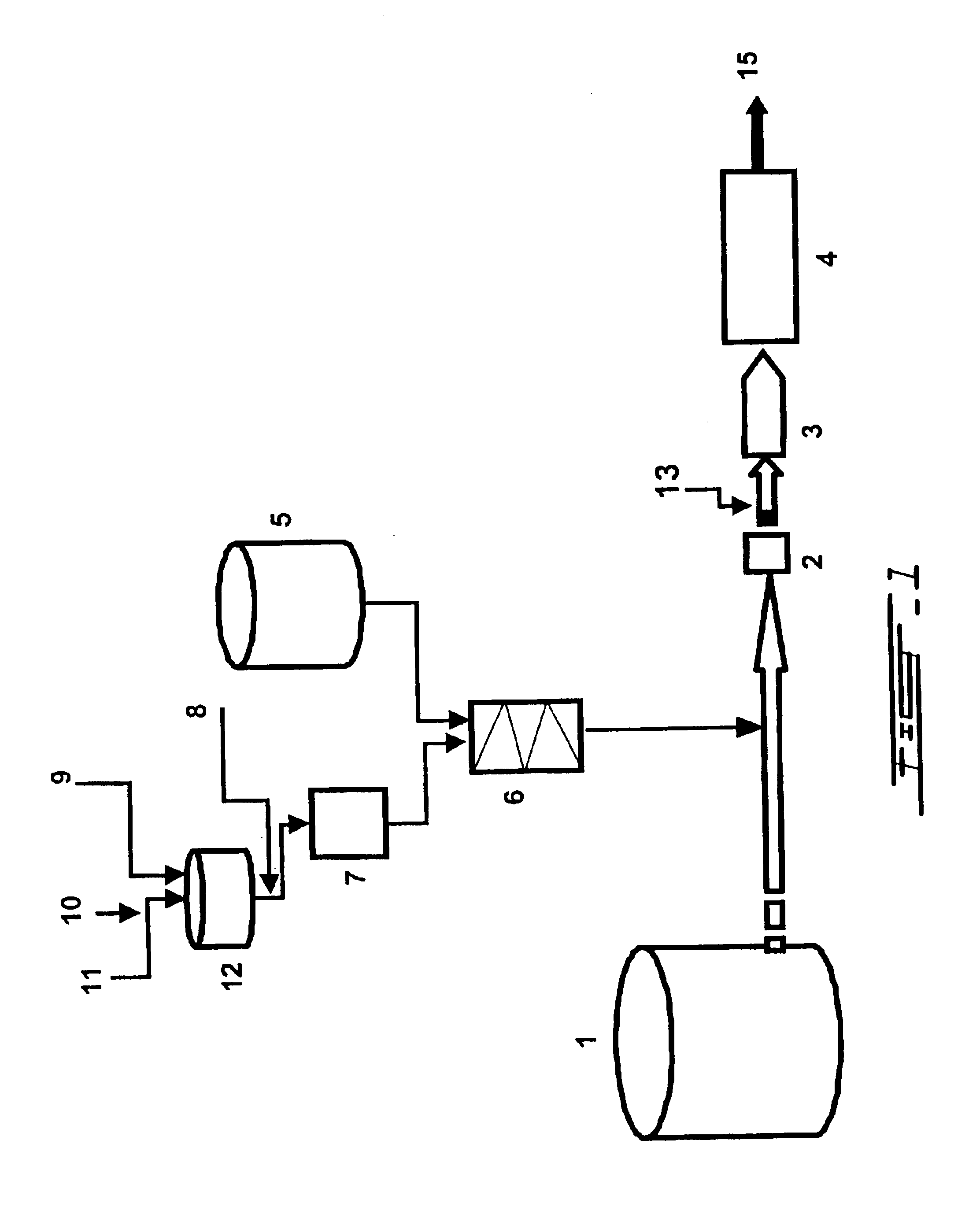

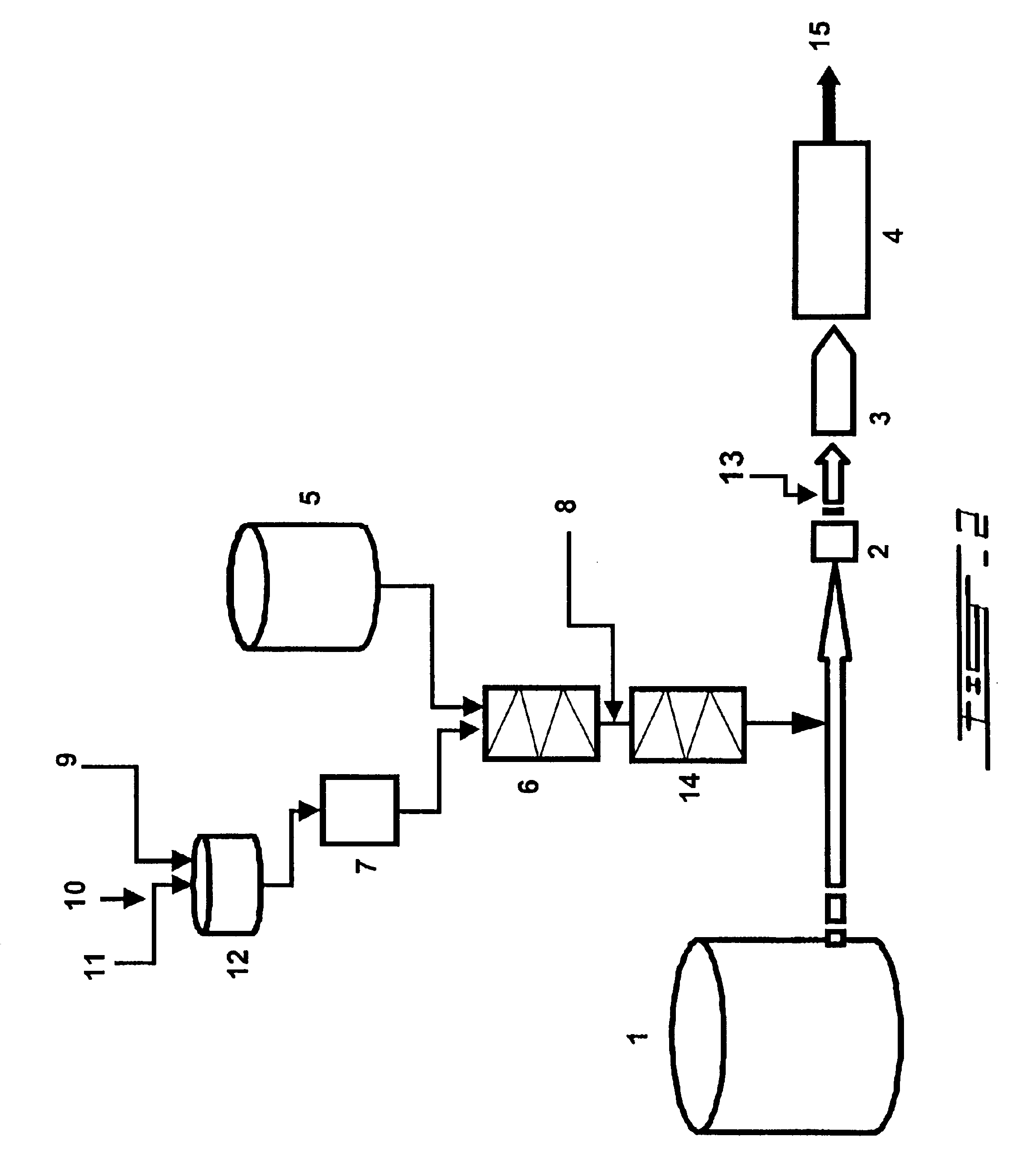

InactiveUS20050061455A1Increase the pulp freenessEasy to drainPulp properties modificationPulp bleachingChemical treatmentCellulose fiber

A method for alteration of the morphology of cellulose fibers, particularly softwood fibers, by (a) subjecting the fibers to a metal ion-activated peroxide treatment carried out at a pH of between about 1 and about 9, preferably between 3 and 7, and (b) subjecting the treated fibers to a refining treatment thereby converts SW fibers to HW-like fibers in many respects. The metal ion-activated peroxide treatment has been noted to act on pulp cellulose and hemi-cellulose, causing oxidation and oxidative degradation of cellulose fibers. The chemical treatment of the pulp, taken alone, is not sufficient to attain the desired modification of the morphology of the fibers, however, subsequent refining or like mechanical treatment of the chemically-treated fibers to achieve a given degree of refinement of the fibers requires dramatically less refining energy to achieve a desired end point of refinement and to impart other desirable properties to the pulp. A pulp of modified SW fibers and a mixture of HW fibers and modified HW fibers are disclosed.

Owner:INT PAPER CO

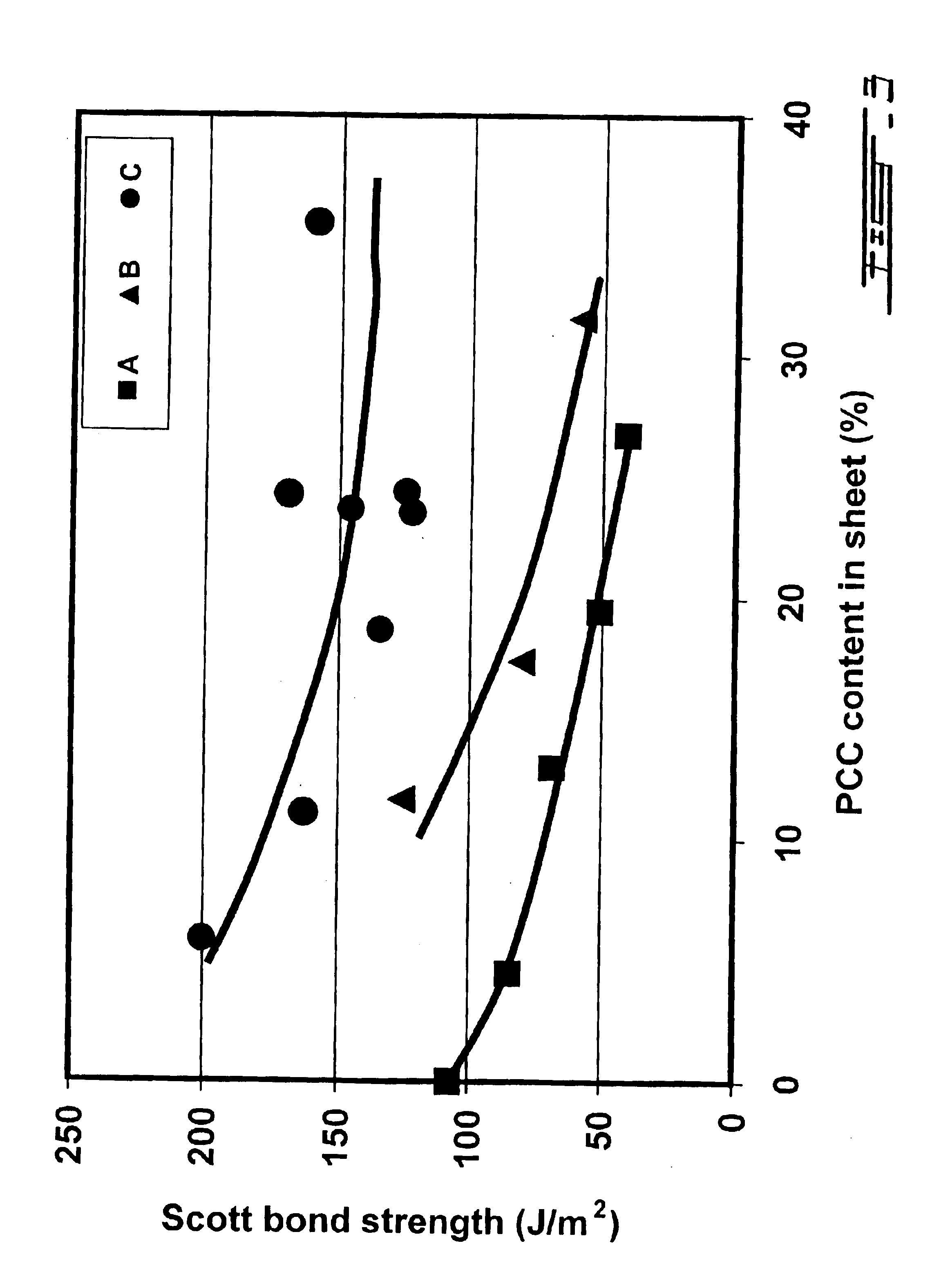

Swollen starch-latex compositions for use in papermaking

InactiveUS7074845B2High retention rateEasy to drainPigmenting treatmentNatural cellulose pulp/paperPaperboardPapermaking

A novel filler treatment comprising the preparation of swollen starch-latex compositions, prepared in the presence or absence of co-additives, and the addition of the said composition to a filler suspension, has been developed. Use of the treated filler during papermaking improves filler retention and produces filled papers where addition of the filler has only a minimal negative effect on strength properties. The swollen starch-latex compositions can be prepared in a batch or jet cooker, or by mixing with hot water under controlled conditions (i.e., temperature, pH, mixing, mixing time) in order to make the starch granules swell sufficiently to improve their properties as a filler additive but avoiding excess swelling leading to their rupture. The swollen starch-latex composition is then rapidly mixed with the filler slurry, preferably in a static mixer, and added to the papermaking furnish at a point prior to the headbox of the paper machine. The starch-latex composition can be used with wood-free or wood-containing furnishes. The treated filler is easily retained in the web during papermaking, improves drainage, and gives sheets having good formation. Sheets made with the treated fillers have higher bonding and tensile strengths than sheets produced using filler treated with either swollen starch alone or latex alone. Retention and drainage are further improved when conventional retention aid chemicals are added to the furnish containing the treated filler. The use of swollen starch-latex compositions could allow the papermaker to increase the filler content of the paper without sacrificing dry strength properties or increasing the amount, and hence the cost, of the retention aid added. The combination of swollen starch and latex could be used as furnish additives in the manufacture of both filled grades and grades that contain no filler such as sack papers and paperboard products.

Owner:FPINNOVATIONS INC

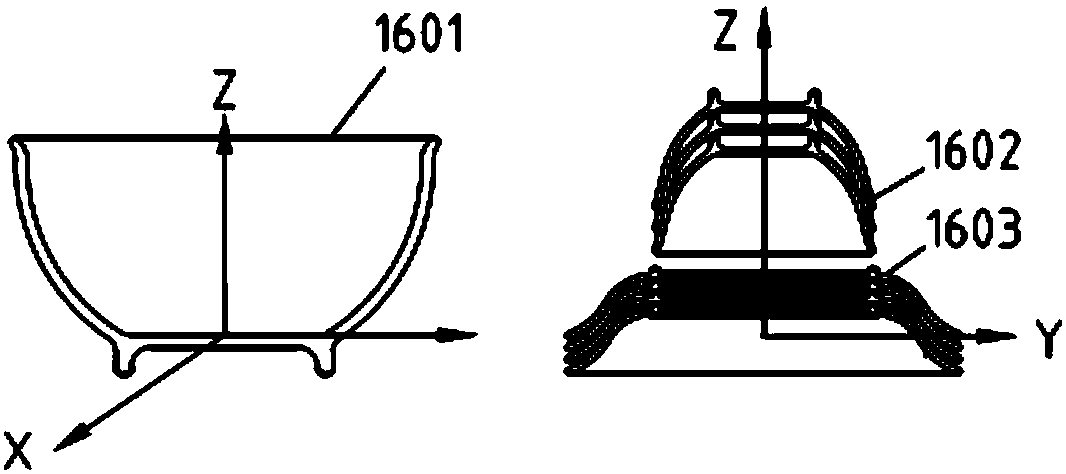

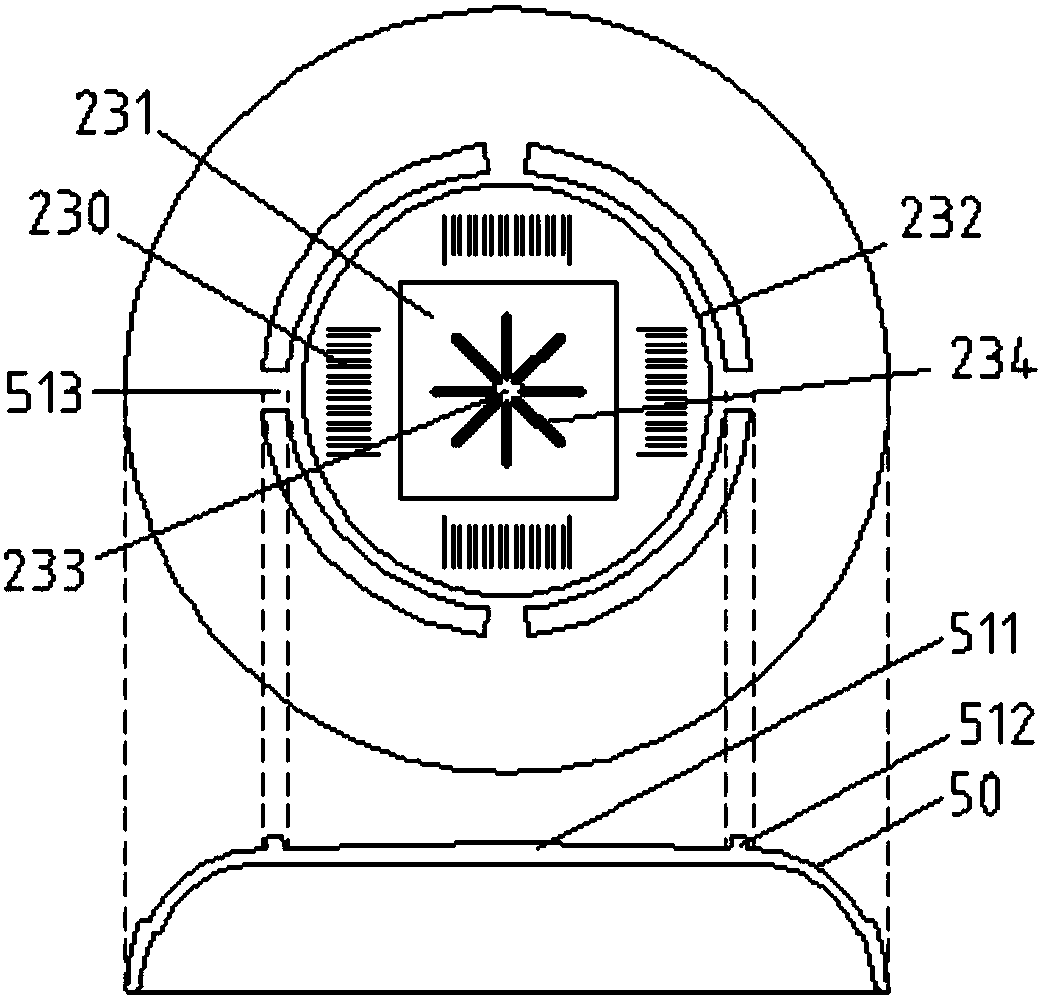

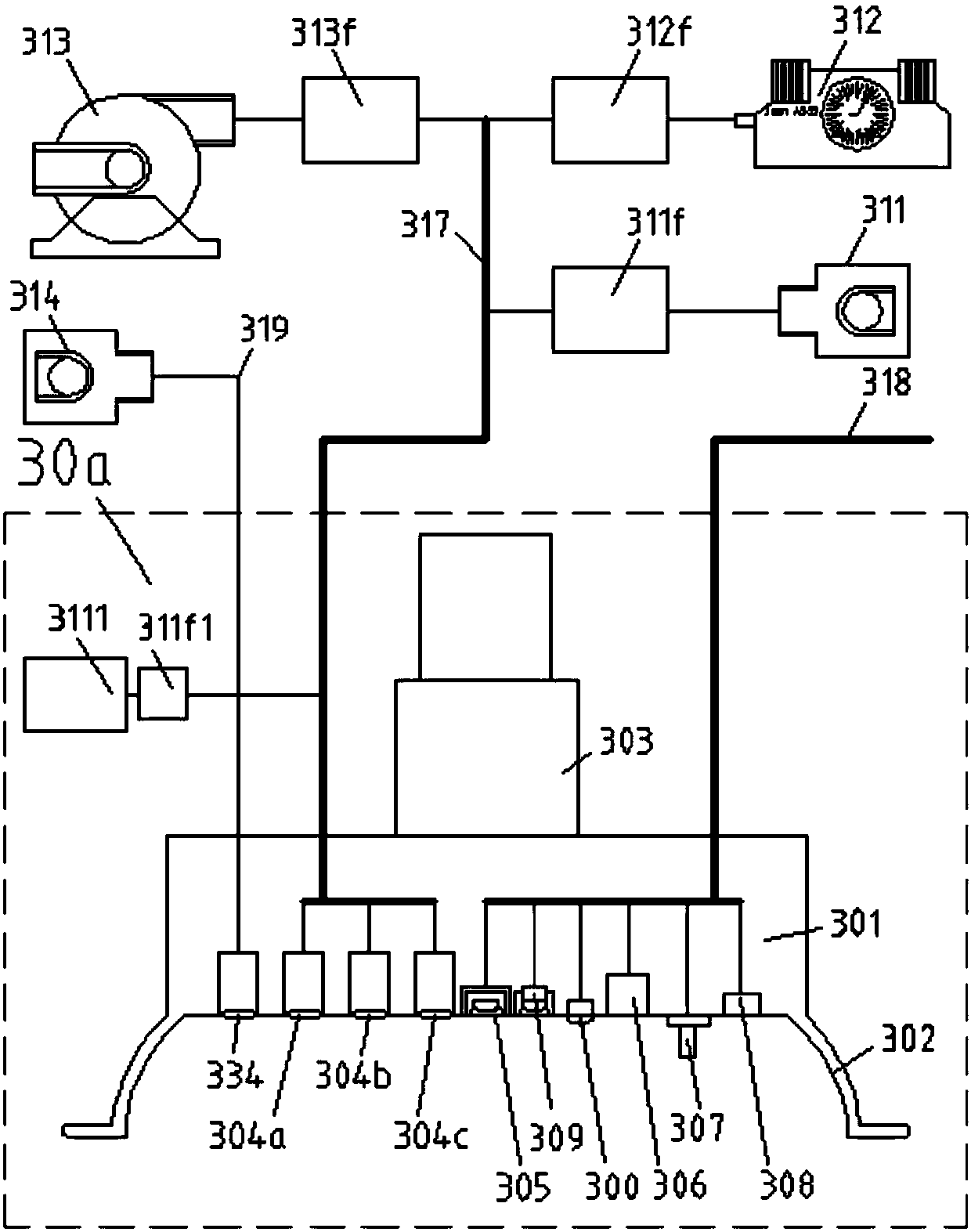

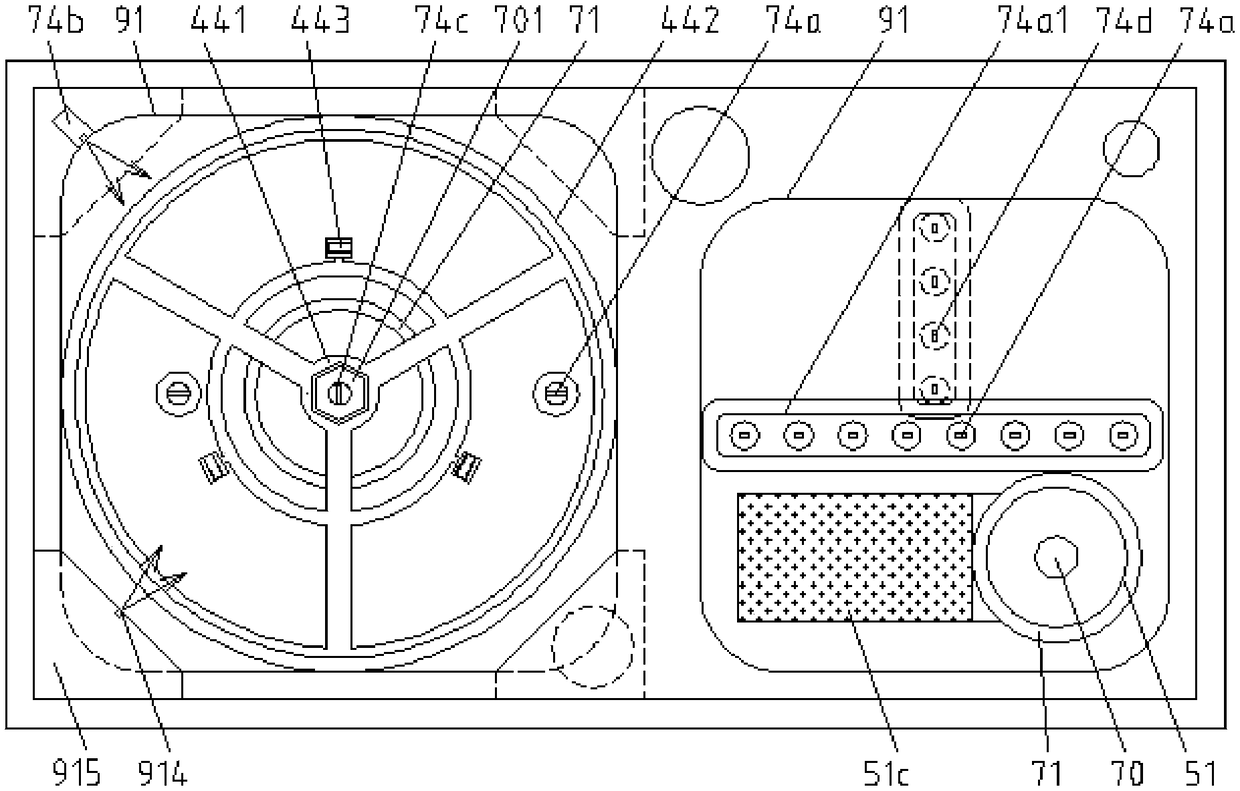

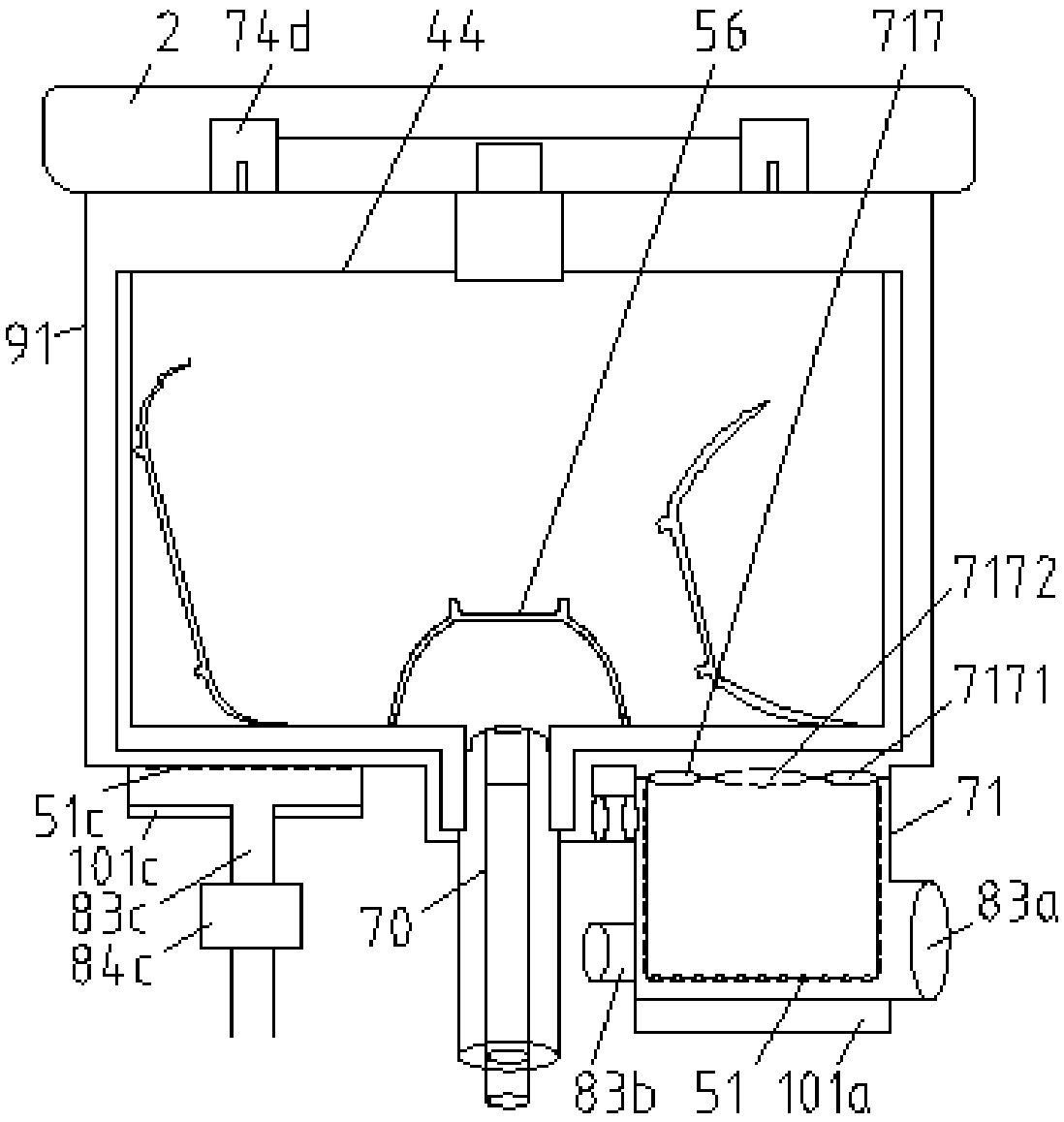

Intelligent dish-washing machine, intelligent cooking machine and kitchen appliance

ActiveCN108013841ASolve the inconvenience of installationSave spaceTableware washing/rinsing machine detailsEngineeringWashing Dishes

According to the embodiment, the invention discloses an intelligent sink-type dish-washing machine, an intelligent sink-type cooking machine and an expanded kitchen appliance thereof, wherein the intelligent dish-washing machine comprises an intelligent mechanical arm / manual cleaning arm, a to-be-washed-dish sink, a cleaning sink and a cleaned dish placing area. To-be-washed dishes are placed in the to-be-washed-dish sink in an inverted mode, the bottoms / back sides of the dishes are cleaned, graphic codes on the back sides of the dishes are recognized, then the dishes are picked up from the back sides and conveyed to the cleaning sink to clean the interiors and / or back sides of the dishes, and finally, the cleaned dishes are placed into the cleaned dish placing area. According to the intelligent sink-type dish-washing machine provided by the invention, the dish-washing machine and the sink are combined; and the dishes are recognized, picked up, cleaned and dried by virtue of the intelligent mechanical arm or the manual cleaning arm, so that intelligent dish washing is achieved. In comparison with an existing dish-washing machine, the intelligent sink-type dish-washing machine provided by the invention not only improves the efficiency of cleaning the dishes but also greatly saves the space of a kitchen occupied by the dish-washing machine; and more importantly, a problem that the existing dish-washing machine is inconvenient to mount can be solved.

Owner:李亚锐

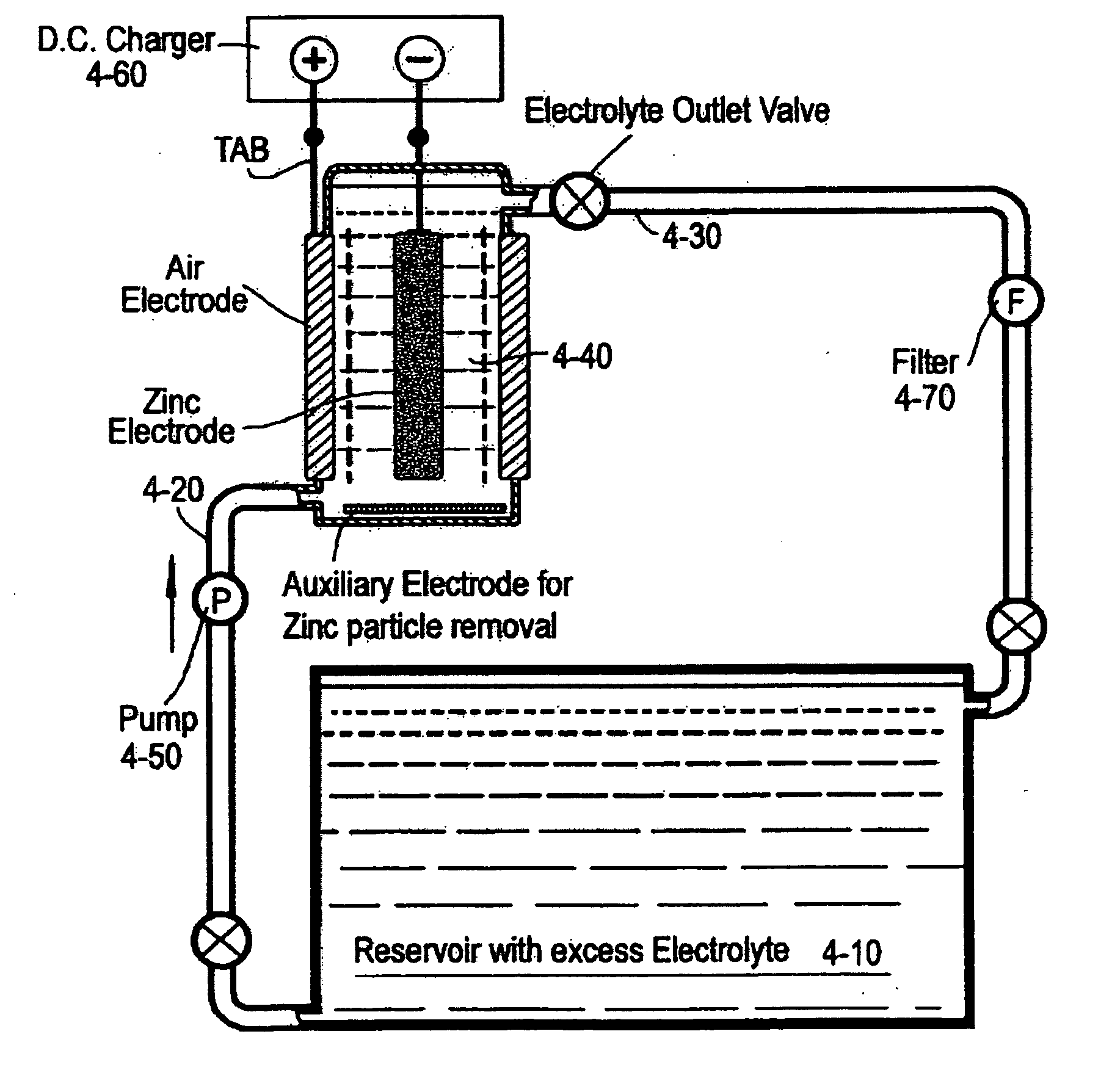

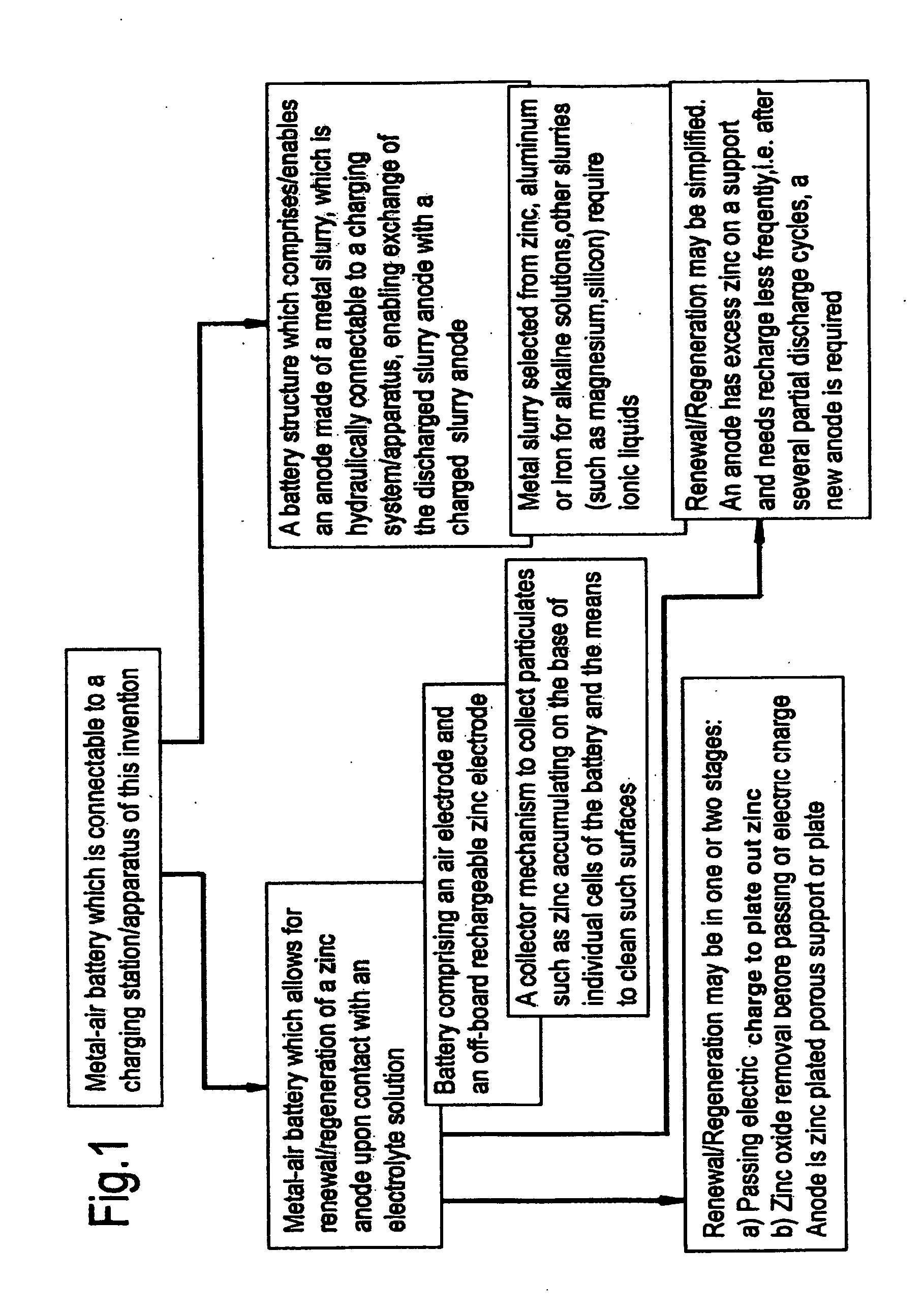

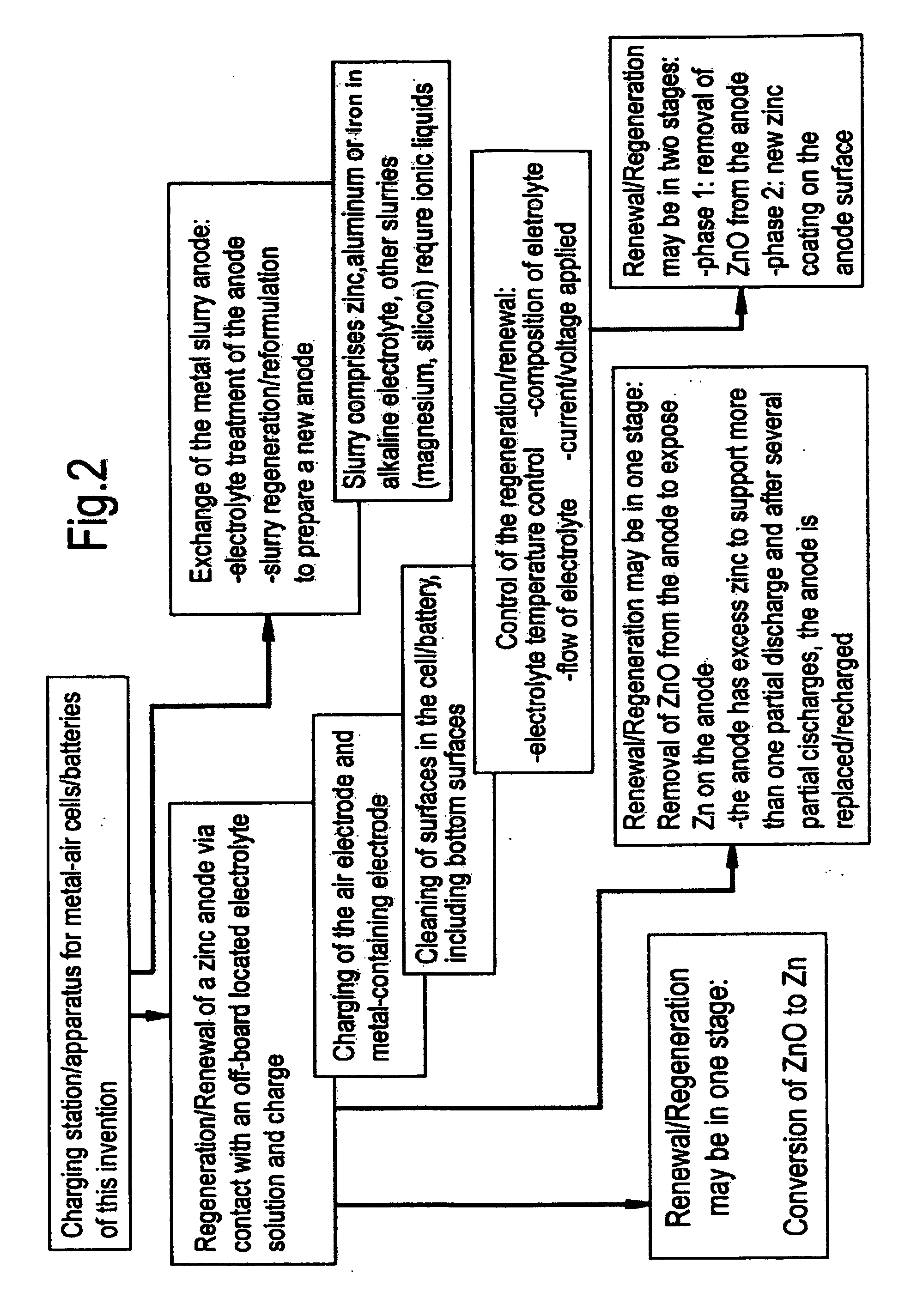

Zinc-Air Battery

ActiveUS20130285597A1Improved energy/volumeImproved energy/weightElectrolyte moving arrangementsBatteries circuit arrangementsHigh energyEngineering

A zinc-air cell, a battery which is a low weight, low volume, or high energy system, or a combination thereof, and an apparatus for recharging the same are disclosed.

Owner:PHINERGY

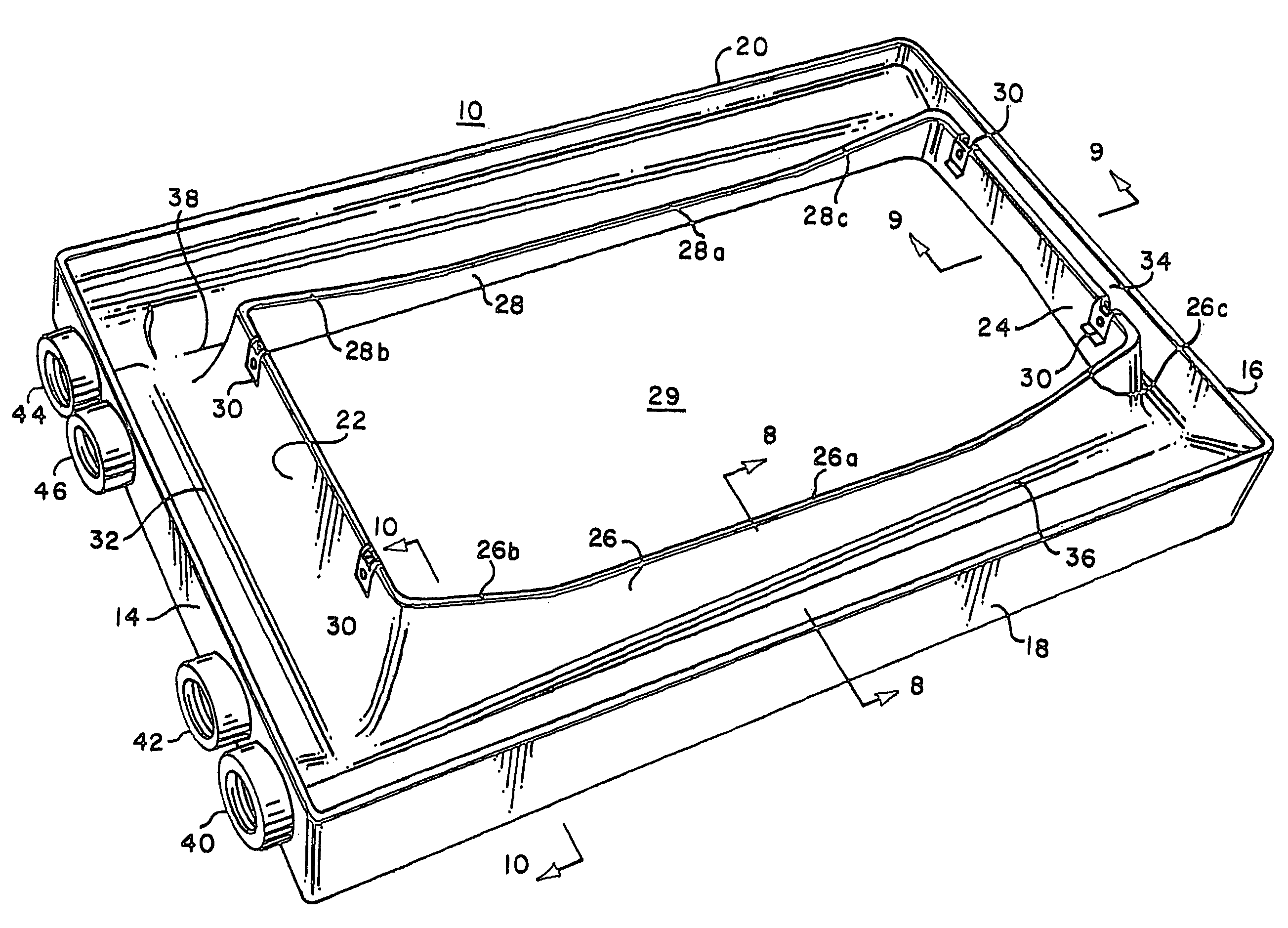

Condensate drain pan for air conditioning system

ActiveUS6978909B2Easy to drainReduce accumulationCondensate preventionLighting and heating apparatusCooling coilAir conditioning

A drain pan for capturing condensate from a cooling coil in an air conditioning system is configured to facilitate condensate drainage from the pan and to inhibit accumulation of condensate therein. The pan includes troughs for collecting condensate and for channeling the condensate to the front part of the pan where the drain openings are located. A back trough has a central hump to enhance the flow of condensate from the back trough in both directions into opposed side troughs. The side troughs are sloped from back to front to conduct the condensate into a front trough to facilitate drainage from the pan. The lowermost portion of the front trough region is defined by a relatively narrow, non-flat area to reduce the amount of condensate residue in the pan.

Owner:ADVANCED DISTRIBUTOR PRODS

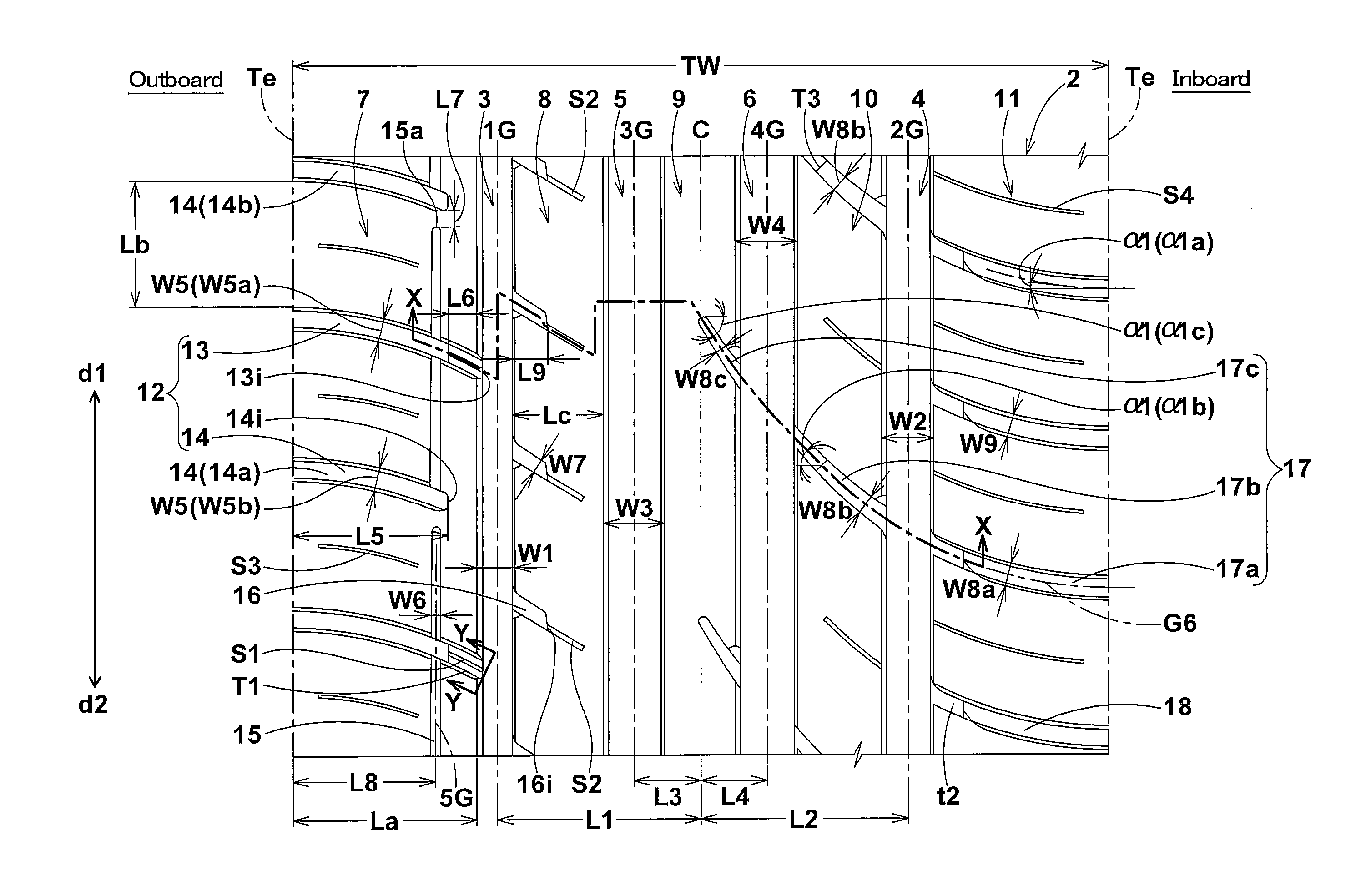

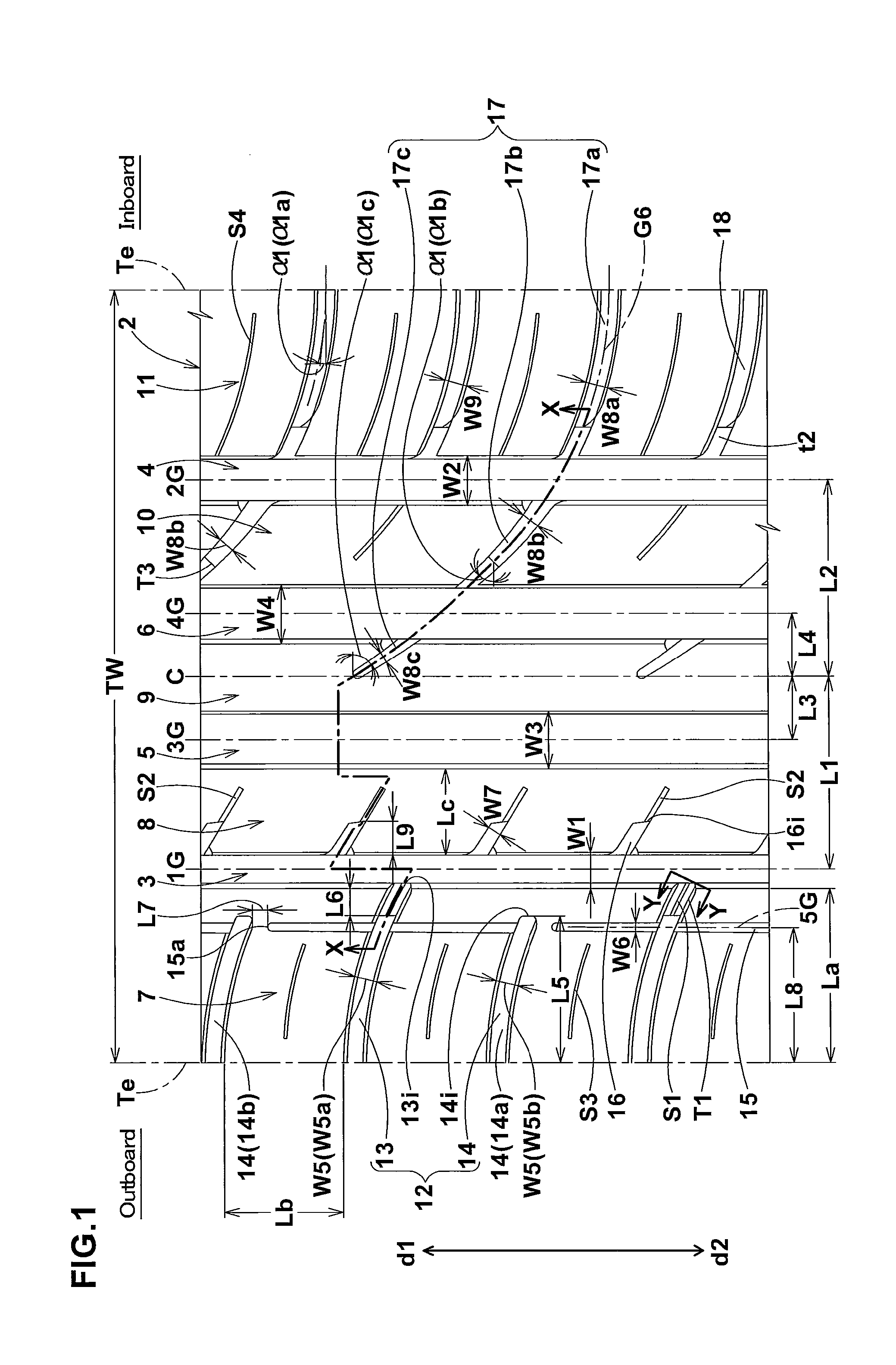

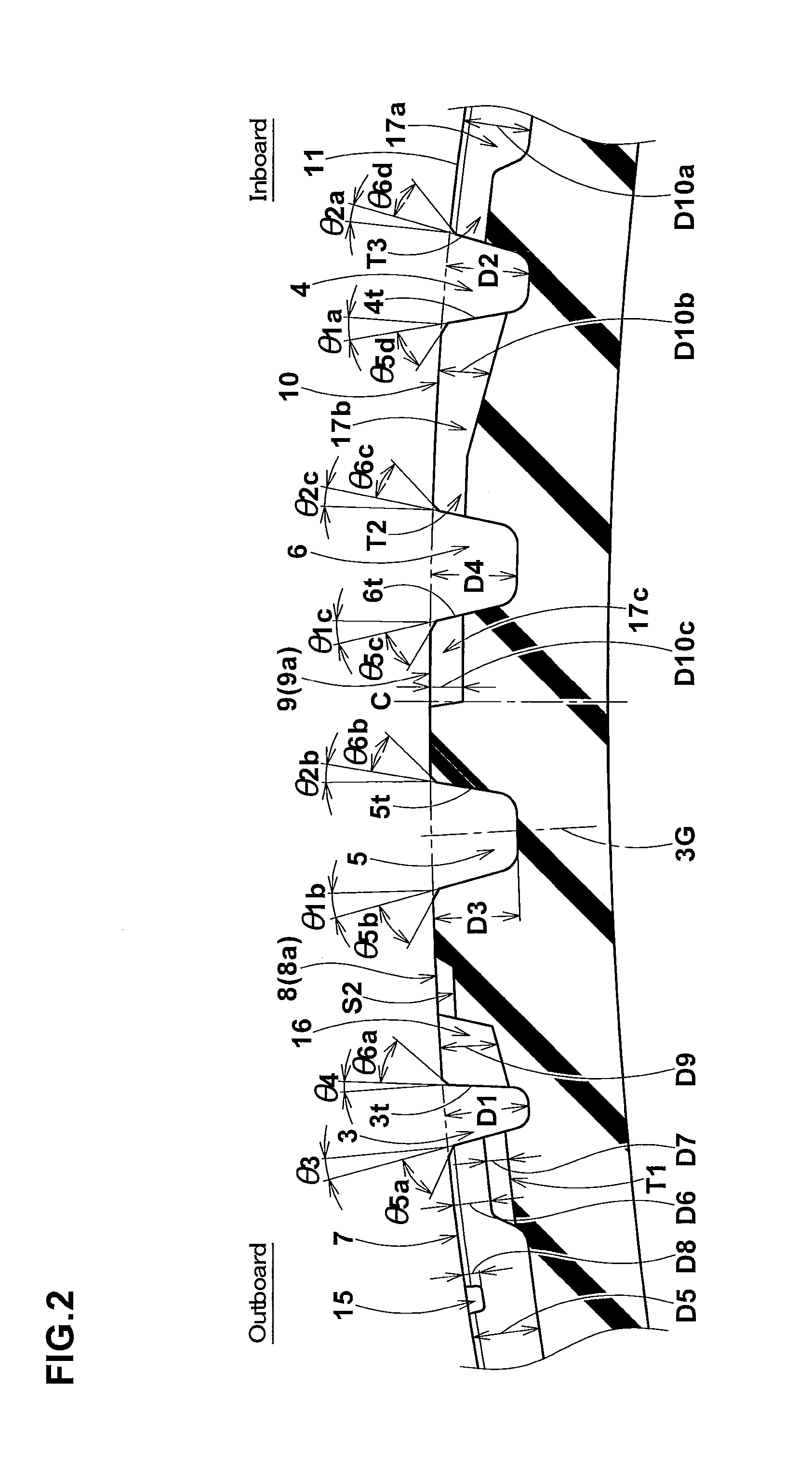

Pneumatic tire

ActiveUS20130112325A1Improve drainageMaintain steer stability and noise performanceTyre tread bands/patternsNon-skid devicesEngineeringTread

Owner:SUMITOMO RUBBER IND LTD

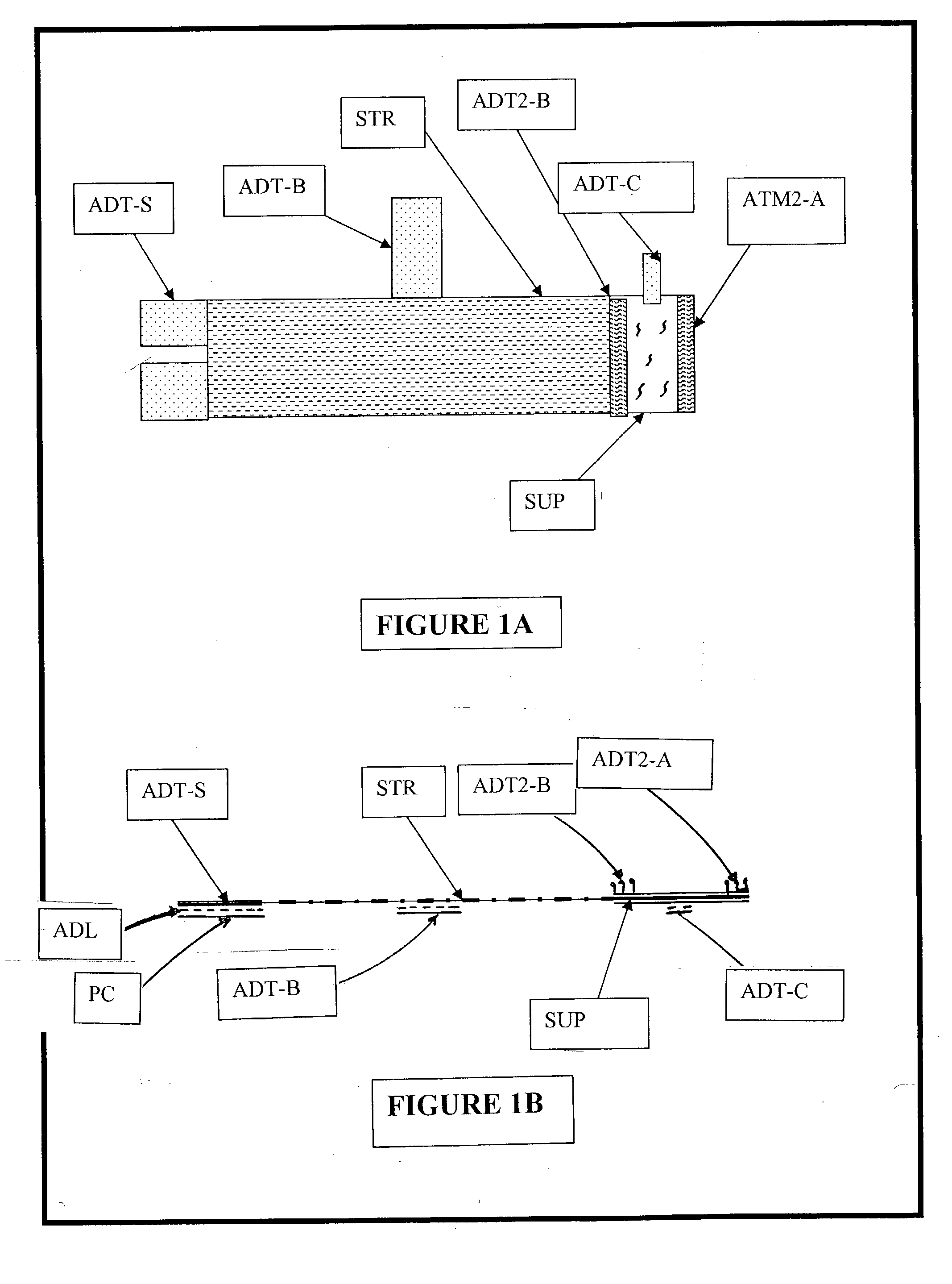

Daneshvar wound dressing, support units and methods, model jasmine

ActiveUS20030149389A1Eliminate useDecrease useNon-adhesive dressingsFeet bandagesNatural disasterAdhesive

This invention is related to wound dressings, supports, protection and care in humans and animals. Commonly, adhesives and wraps are used for this purpose. However, the use of adhesive have multiple problems: they are difficult to use with elastic gloves since the adhesive tapes stick to the gloves, cause skin irritations and discomfort on removal, and do not adhere to the skin covered by hairs. Many times the hair must be shaved which is a process of its own. Wound inspections or the exchange of dressing multiplies their problems and prohibits this process. Furthermore, wound wrapping cannot be done by use of adhesive tapes in an effective and convenient manner. Then, of course, is the major issue of dressing a wound with one hand only, that occurs in certain circumstances. It is very important to have a system that allows a person to be able to dress a wound solely with one hand, since the other one may be wounded. These units are extremely helpful in this regard. Lastly, at times the wound dressing should be done as quickly as possible, and obviously speed makes a big difference in manmade or natural disasters. Also in many cases the wound site needs to be protected by means that will prevent objects from touching the skin or the wound site, in order to prevent ulceration, avoid discomfort or simply the mere protection of the wounds. In some other cases, the vascular problems of the wounds need to be addressed for better care. This would, in some cases, need means of squeezing the wound site, and in other cases allow a better drainage of the wounds. The methods and means introduced solves many of these problems. This application introduces new methods and means of dressings that makes the process of wound dressing faster, easier, and applicable with one hand only. It practically eliminates the use of adhesives and / or decreases their use significantly. In this model, a support unit made from a non-stretchable material, commonly in a rectangular or trapezoid shape, is used on the wound to hold the gauze pad or wound dressing in place. This unit uses at least one strap made of a particular stretchable material that allows the strap to attach to the support on a detachable, re-attachable basis to a band of the hook fastener on the surface. Importantly, this attachment can be done in any part of this strap. Also importantly, this support system uses one or two narrow bands made from the same material as the strap, which allows them to wrap around the limb from the opposite side of the strap to attach to the support on a detachable, re-attachable basis. Next, the main strap will attach to the support on detachable, re-attachable basis. In some models the support unit will function as the stabilizer of the system or to make the functions simpler. This main idea is then used to make multiple models for use in different areas. The application has also shown modified versions of these units that function to prevent ulcerations from starting in places such as the heels. In some other models the applicant shows units that guard the wound site and prevent objects from touching the skin or the wound site for avoiding discomfort or mere protection of the wounds. In patients who have vascular problems the models shown here allow the wound in the heels to be squeezed to prevent and reduce tissue swelling. In other cases, the applicant shows means that allow a limb to be elevated for a better drainage. All in all, the applicant tries to introduce units for improving human and animal quality of life.

Owner:DANESHVAR YOUSEF

Dish-washing machine, electric cooker and combination of dish-washing machine and electric cooker

ActiveCN108652545AEasy access to waterEasy to drainTableware washing/rinsing machine detailsCooking vesselsWater flowWater leak

The invention discloses a dish-washing machine, an electric cooker, a combination of the dish-washing machine and the electric cooker, as well as a rotation drive rod and a water leak barrel used forthe dish-washing machine. The dish-washing machine comprises a bowl basket and a spray head, wherein the bowl basket is used for placing bowls, the bowl basket rotates for driving the bowls to rotate,and the spray head is used for spraying water flow / air flow for washing the bowls to be clean, the dish-washing machine further comprises a drawer, or a sink and a sink cover board, and the bowl basket can be placed in the sink or the drawer. The relevant technology also can be used for an open type water pump dish-washing machine and a moving type intelligent dish-washing machine. Compared withthe existing dish-washing machine, the dish-washing machine provided by the invention has the advantages that the efficiency in washing the bowls is improved, the space of a kitchen is well saved, a novel path is provided for solving the problem that the mounting of the dish-washing machine is inconvenient, and meanwhile, the technology of the intelligent dish-washing machine is perfected.

Owner:李亚锐

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com