Condensate drain pan for air conditioning system

a technology of air conditioning system and condensate drain, which is applied in the direction of defrosting, heating types, domestic cooling apparatus, etc., can solve the problems of unwanted humidity in the air supplied to an indoor space, and achieve the effects of facilitating condensate drainage, reducing condensate accumulation, and enhancing condensate flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019]The best mode for carrying out the invention will now be described with reference to the accompanying drawings. Like parts are marked in the specification and drawings with the same respective reference numbers. In some instances, proportions may have been exaggerated in order to more clearly depict certain features of the invention.

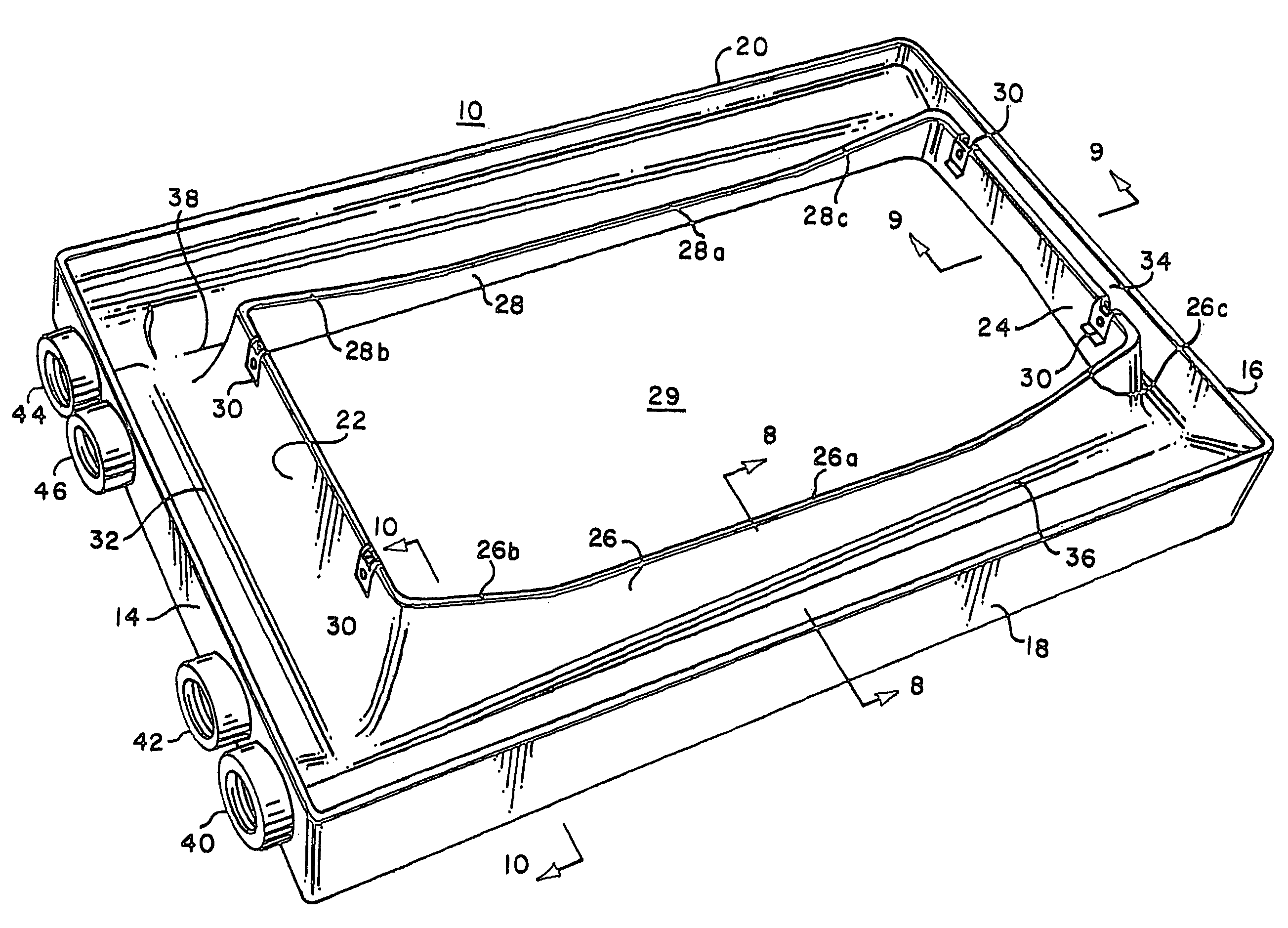

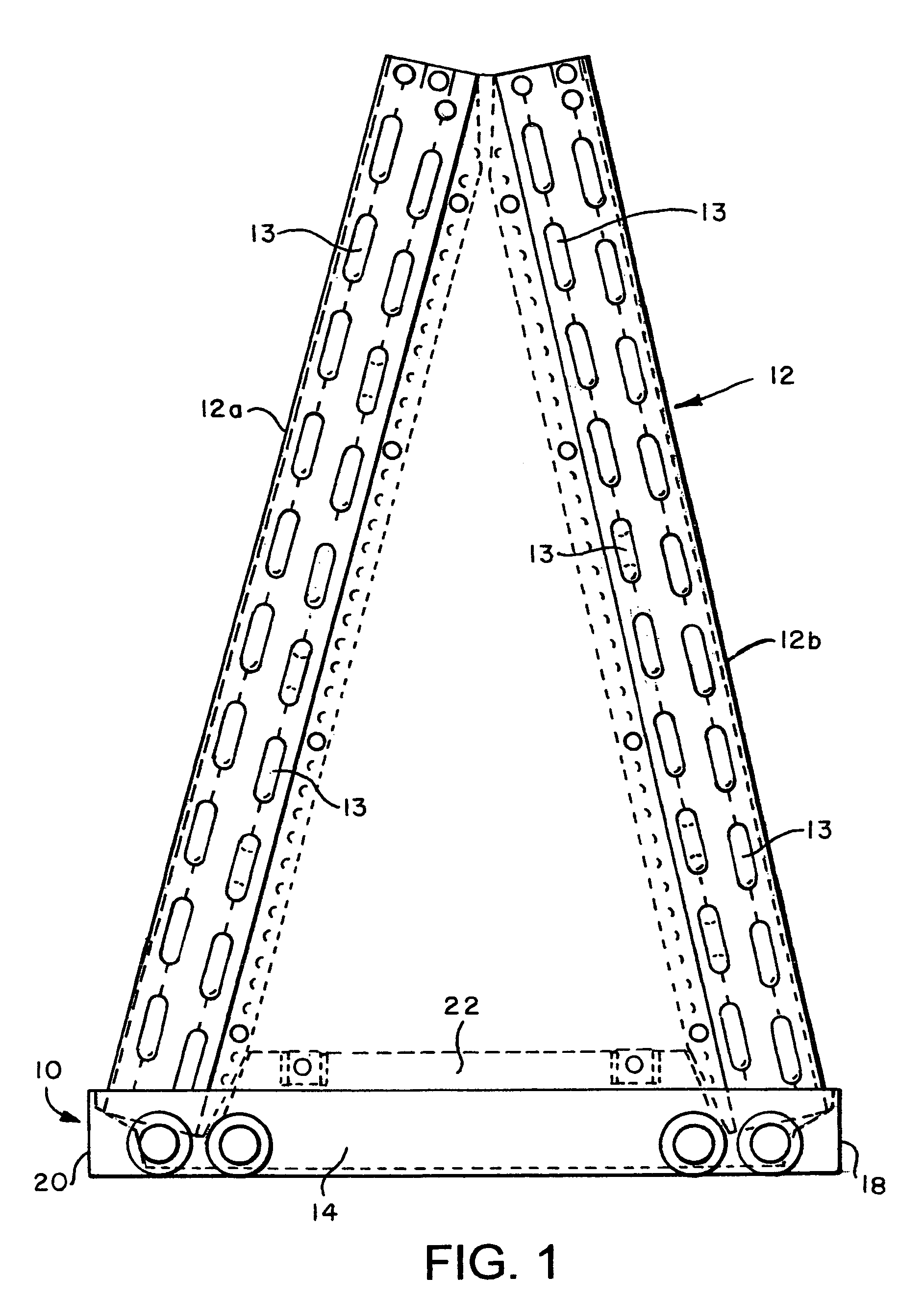

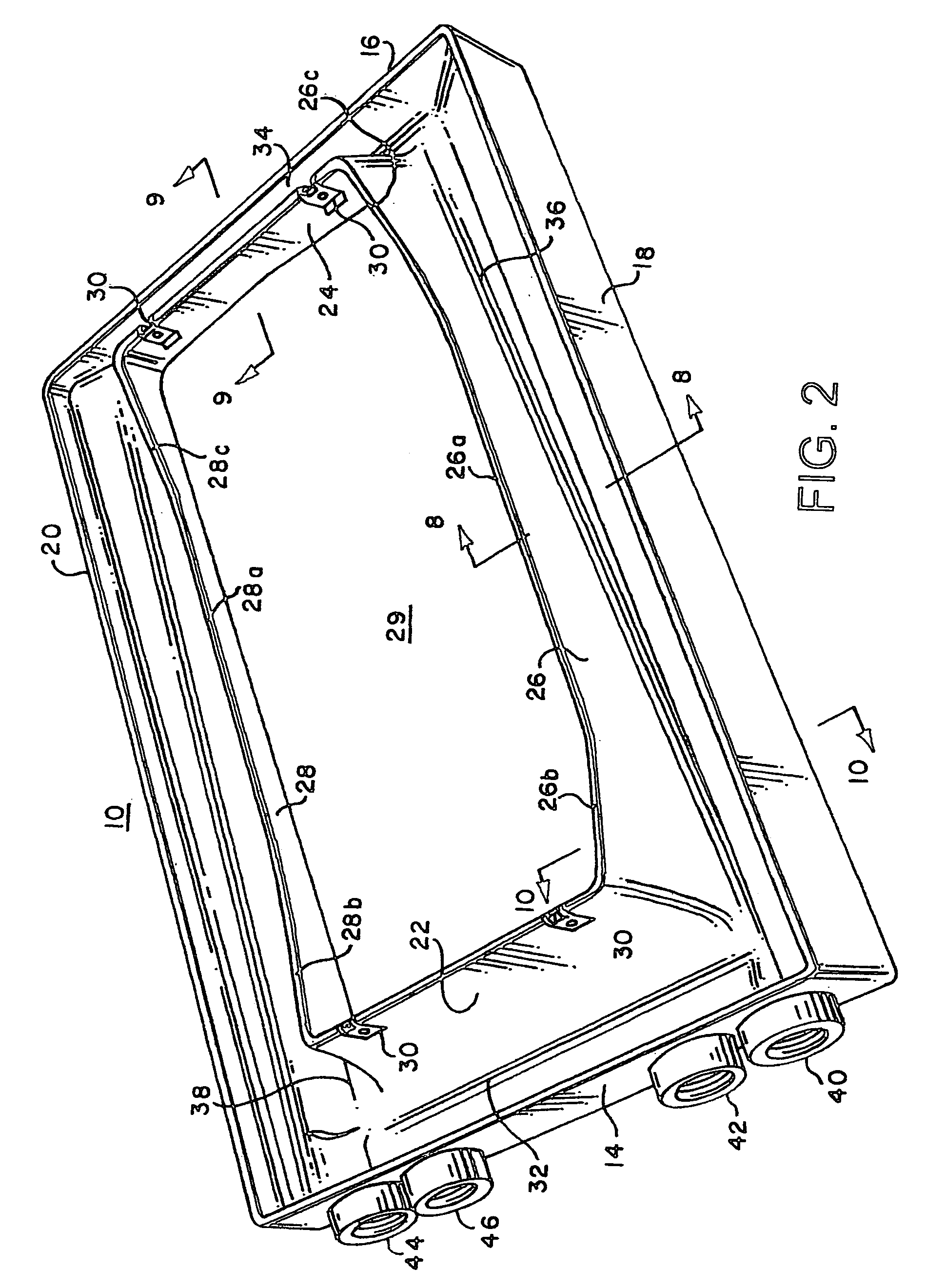

[0020]Referring to FIGS. 1–10, a condensate drain pan 10 according to the present invention is adapted to be positioned underneath a heat exchanger coil 12 in a typical air conditioning system to capture condensate runoff from coil 12 when coil 12 is operated as a cooling coil to cool air flowing through coil 12. For example, coil 12 may be used as an “evaporator” coil, to cool air flowing through coil 12 by evaporating a vapor compression refrigerant flowing inside tubes 13 of coil 12. Coil 12 is depicted in FIG. 1 as a conventional “A-Coil”, comprised of a pair of slabs 12a, 12b coupled together at their respective upper ends and extending downwa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com