Patents

Literature

14598 results about "Rust" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Rust is an iron oxide, a usually red oxide formed by the redox reaction of iron and oxygen in the presence of water or air moisture. Several forms of rust are distinguishable both visually and by spectroscopy, and form under different circumstances. Rust consists of hydrated iron(III) oxides Fe₂O₃·nH₂O and iron(III) oxide-hydroxide (FeO(OH), Fe(OH)₃).

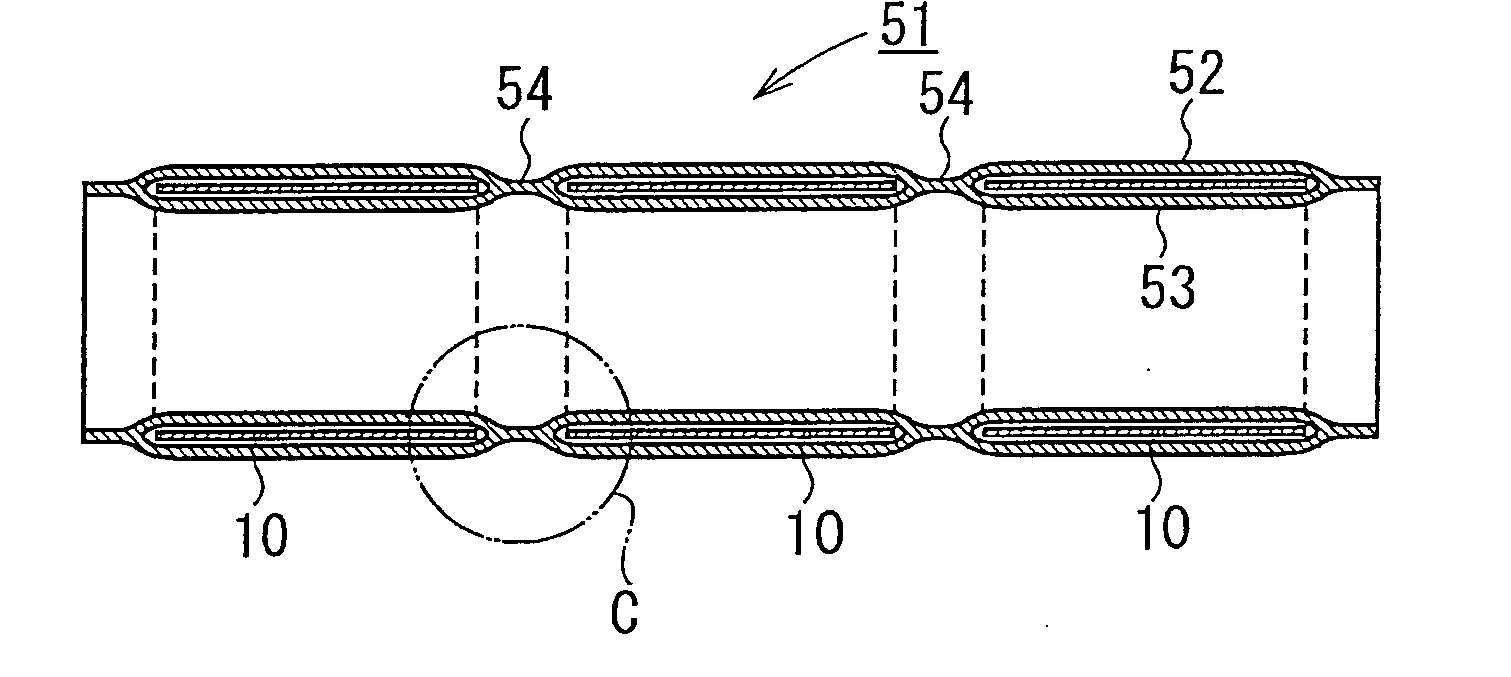

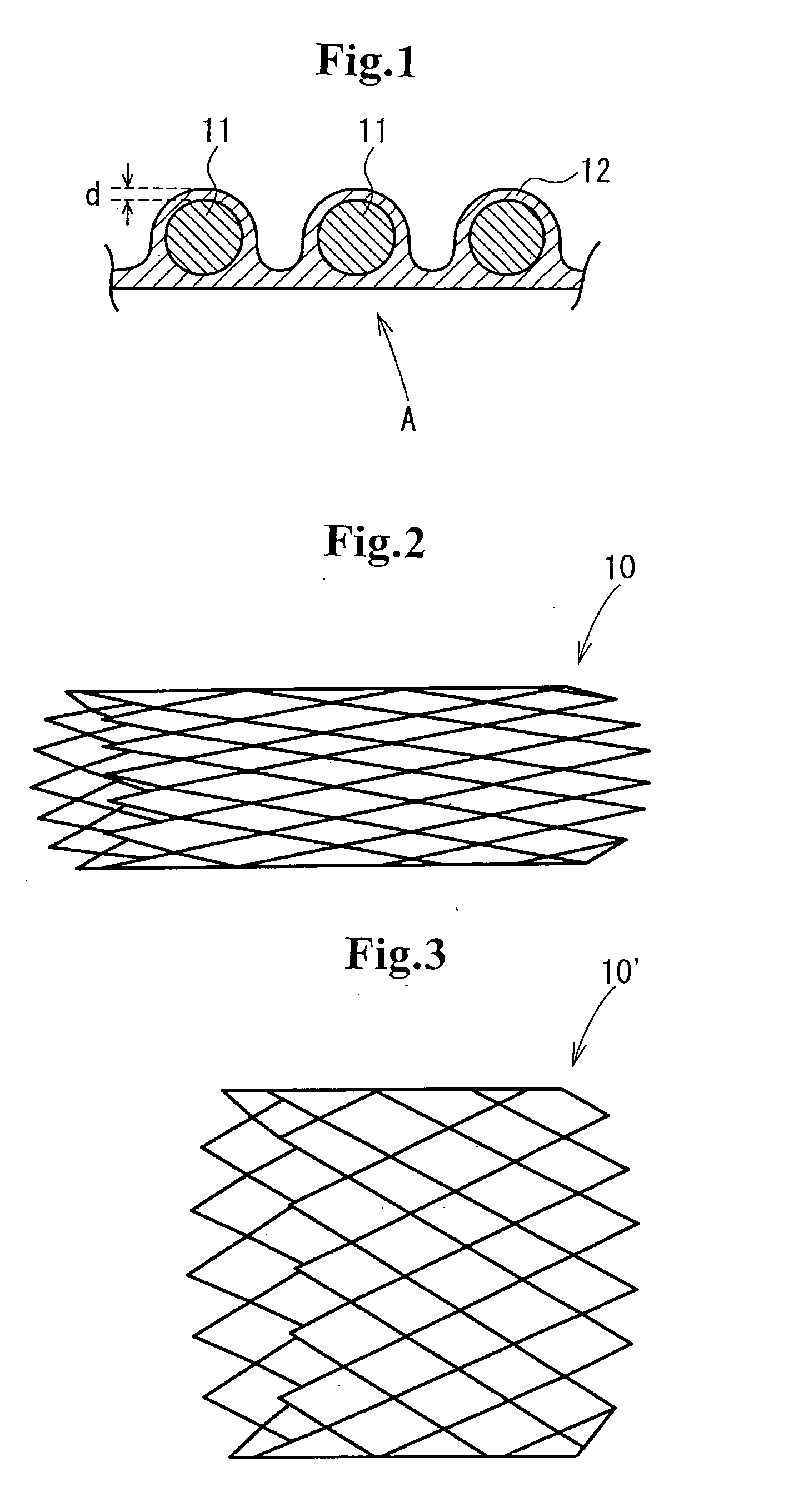

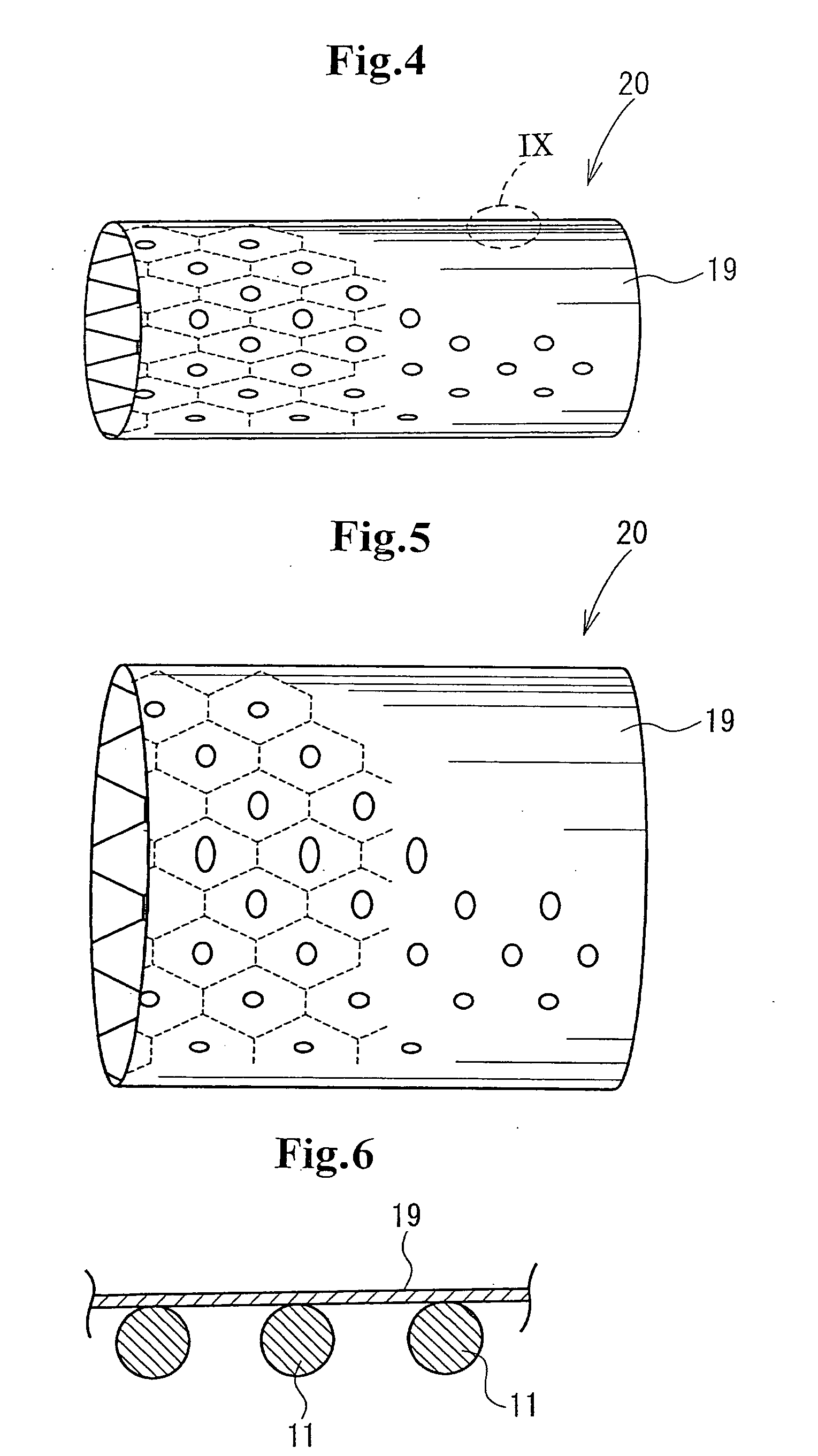

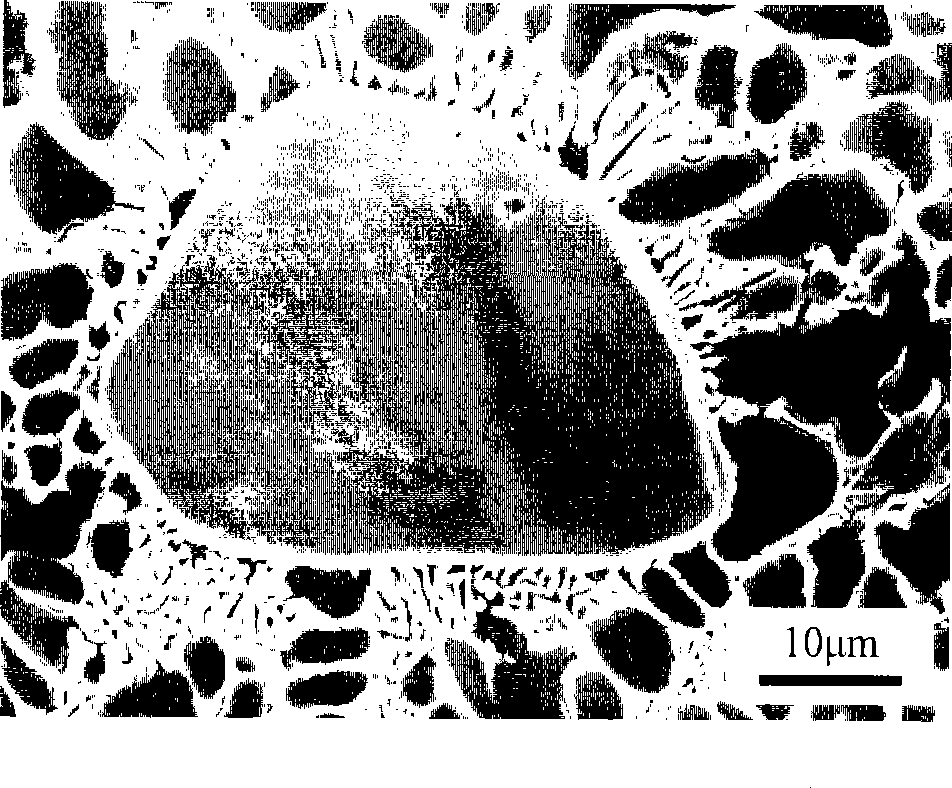

Stent and process for producing the same

A stent comprising a tubular stent matrix of which diameter is extendable and a flexible polymer layer covering the stent matrix. The polymer layer is closely attached to and covers the entire surface of the stent matrix. Since the flexible polymer layer closely covers the entire surface of the stent matrix not only the outer periphery of the stent matrix, the stent has no problem of causing allergic to metal, stimulus of tissues due to metal, and rust development. Since the inner periphery of the stent is a flat and smooth surface covered by the polymer layer without convexes and concaves, the formation of thrombus can be inhibited well. There is no problem of drift between the polymer layer and the stent matrix, thereby maintaining the positional relationship between the stent matrix and the polymer layer before and after the expansion of the stent.

Owner:JAPAN STENT TECH CO LTD +1

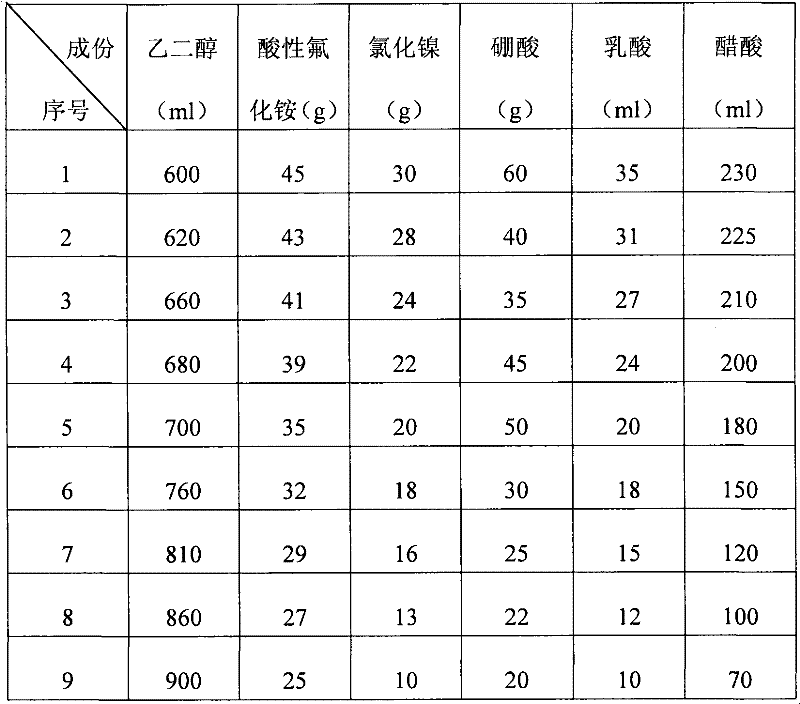

Valve body surface protection treatment process

InactiveCN108103483AReduce rustReduce corrosionLiquid/solution decomposition chemical coatingImpurityHeat treated

The invention provides a surface protection process used for long-time corrosion prevention and rust prevention. The process comprises the following process flow: sandblasting: performing surface blasting of brown steel shot on a valve body after heat treatment; pretreatment: cleaning to remove impurities such as oil stains, oxides, or water scales on the surface of the valve body by utilizing analkaline cleaning liquid; cleaning: rinsing chemical substances remaining on the surface of the valve body with clean water; plating solution preparation: preparing a plating solution according to a ratio of 5% to 14% of phosphorus content; preheating: putting the valve body in hot water to be preheated so that the temperature of a workpiece is close to the temperature of the plating solution; plating: putting the preheated workpiece into the plating solution for plating; treatment after plating: after the plating is completed, cleaning, air drying and storing the workpiece sequentially withinone hour. The surface protection process provided by the invention can delay the premature rust and corrosion of the valve body in the use process, and prolong the service life of the valve body to 20 to 30 hours.

Owner:YANTAI JEREH PETROLEUM EQUIP & TECH CO LTD

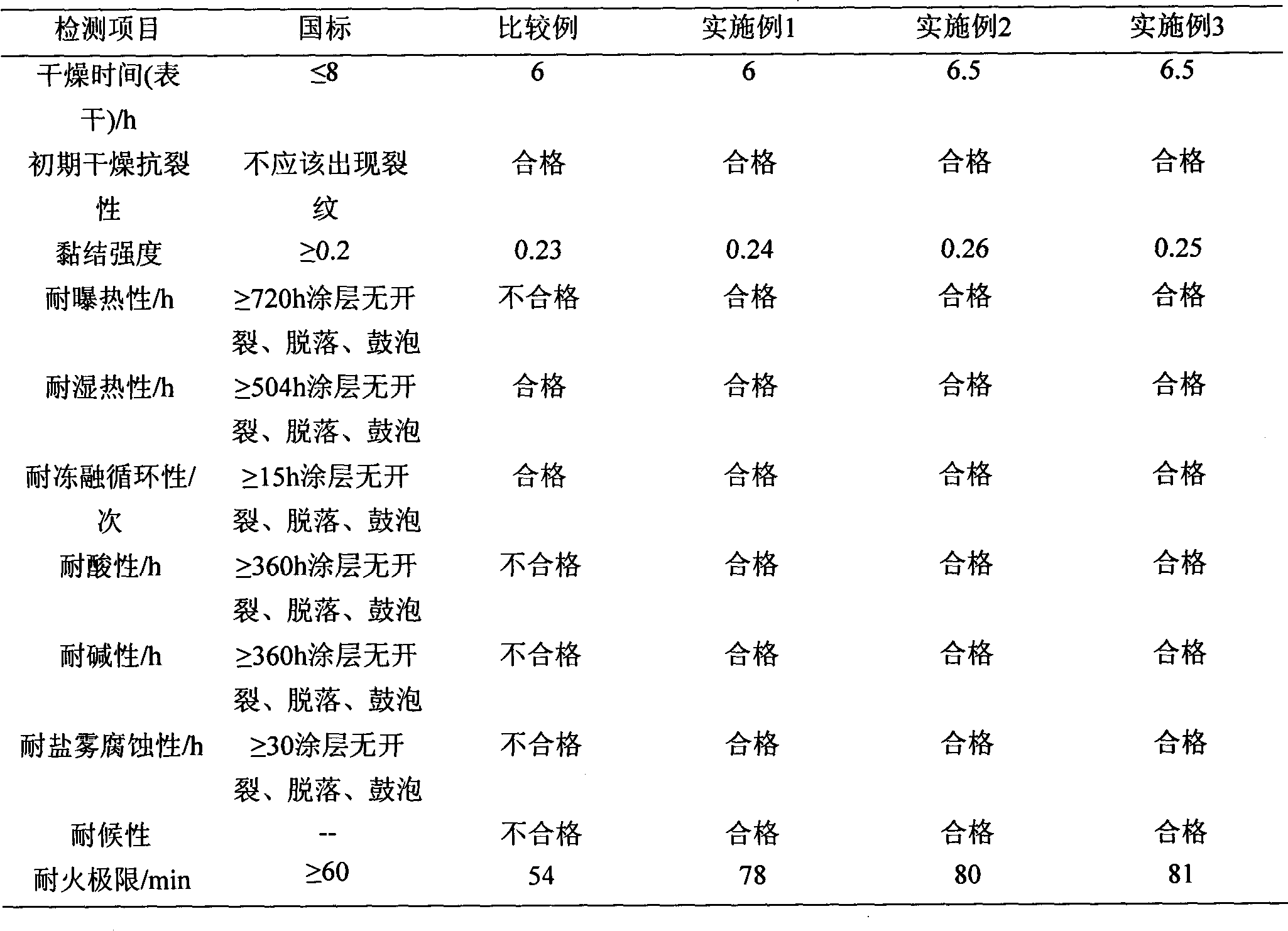

Aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and preparation method thereof

InactiveCN101857760AGuaranteed expansion heightHas anti-rustFireproof paintsAnti-corrosive paintsAcrylic resinRust

The invention relates to an aqueous ultra-thin expansion type steel structure fire-proof anti-corrosive paint and a preparation method thereof. The fire-proof anti-corrosive paint is prepared by adding ammonium polyphosphate, pentaerythritol, melamine, titanium white, expandable graphite, a preservative, a ceramic filler, an antifoaming agent, a dispersing agent, a plasticizer and the like into organic silicon-modified acrylic resin emulsion serving as a film forming base material. The paint has the advantages of high fire-proof performance, anti-corrosion and anti-rust function, and high water resistance, acid-alkali resistance and corrosion resistance, capability of meeting the requirements of various steel structures on the fire-proof and anti-corrosion performance, environmental friendliness, low cost, and readily available raw materials, so the paint can be widely applied to fire-proof protection of various steel structures.

Owner:EAST CHINA UNIV OF SCI & TECH

Aquosity bi-component polyurethane coloured paint and method of manufacturing the same

InactiveCN101108951AReduce pollutionPolyurea/polyurethane coatingsEmulsion paintsOrganic solventDisinfectant

The invention discloses a two-component waterborne polyurethane colored paint and the preparation method. The components of the paint are 5 to 15 water, 0.2 to 0.5 dispersant, 0.1 to 0.3 antifoamer, 0.1 to 0.3 wetting agent, 3 to 25 paints, 0 to 50 fillers, 10 to 80 film forming resins, 0 to 5 film forming additives, 0.1 to 0.3 disinfectant, 0.1 to 0.3 antiflash rust agent, 0.5 to 2 thickeners, 1 to 20 hydrophilically-modified polyisocyanate. The preparation method is that water, dispersant, antifoamer, wetting agent, paints and fillers are dispersed evenly by a sand mill, a ball mill or a high-speed stirrer after stirring, and are added with film forming resins, film forming additives, disinfectant, antiflash rust agent and thickeners to gain the product-component A. The hydrophilically-modified polyisocyanate is component B. The component A and component B are mixed uniformly when using. The invention is characterized in that the invention does not adopt organic solvents, does not contain toxic paints and has no harm on the human body and environment, and the properties can reach the solvent two-component polyurethane paint, which can be produced to the primer, intermediate coat and finishing coat, and can be applied in the surface of the wooden ware, cement and metals.

Owner:GUILIN UNIVERSITY OF TECHNOLOGY

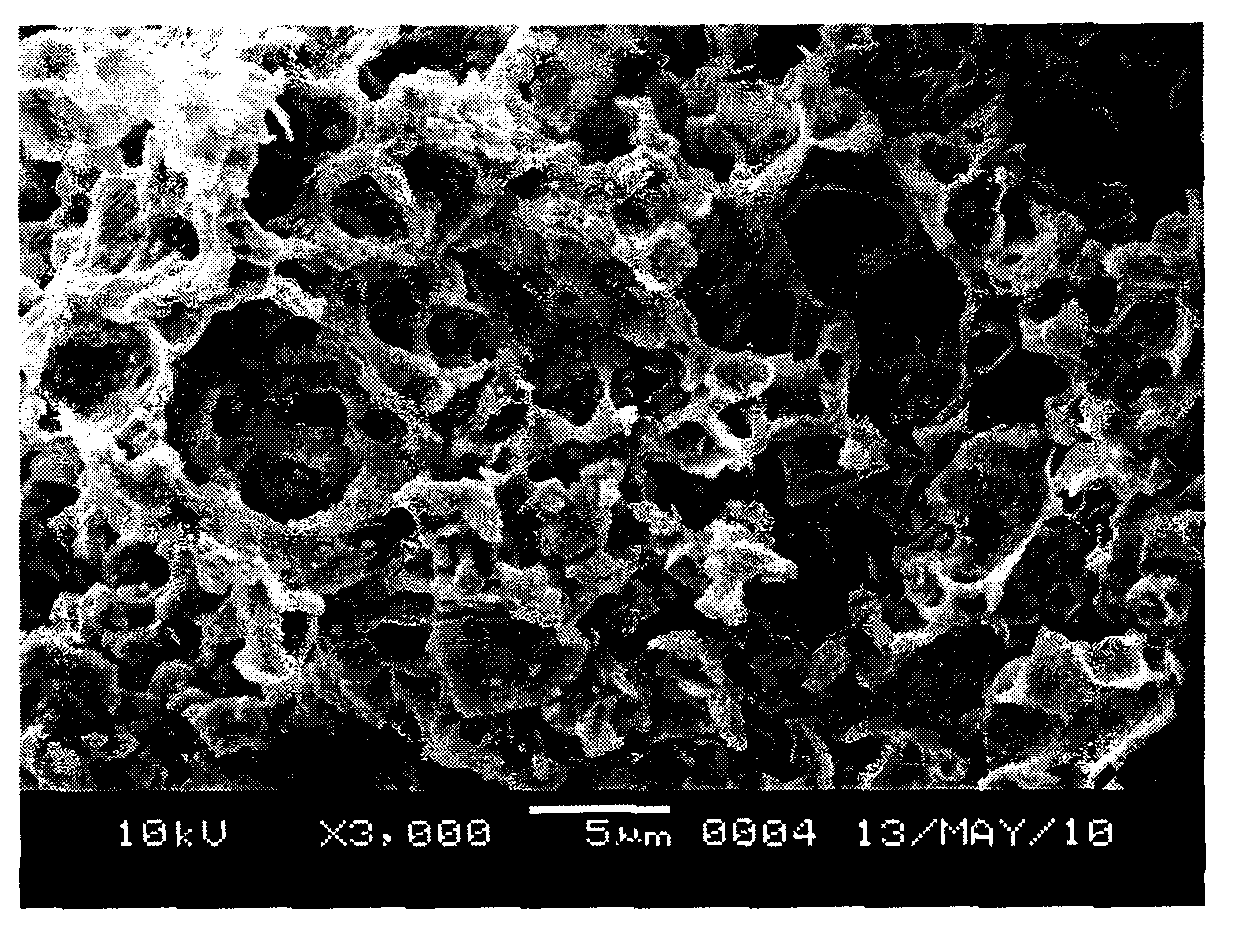

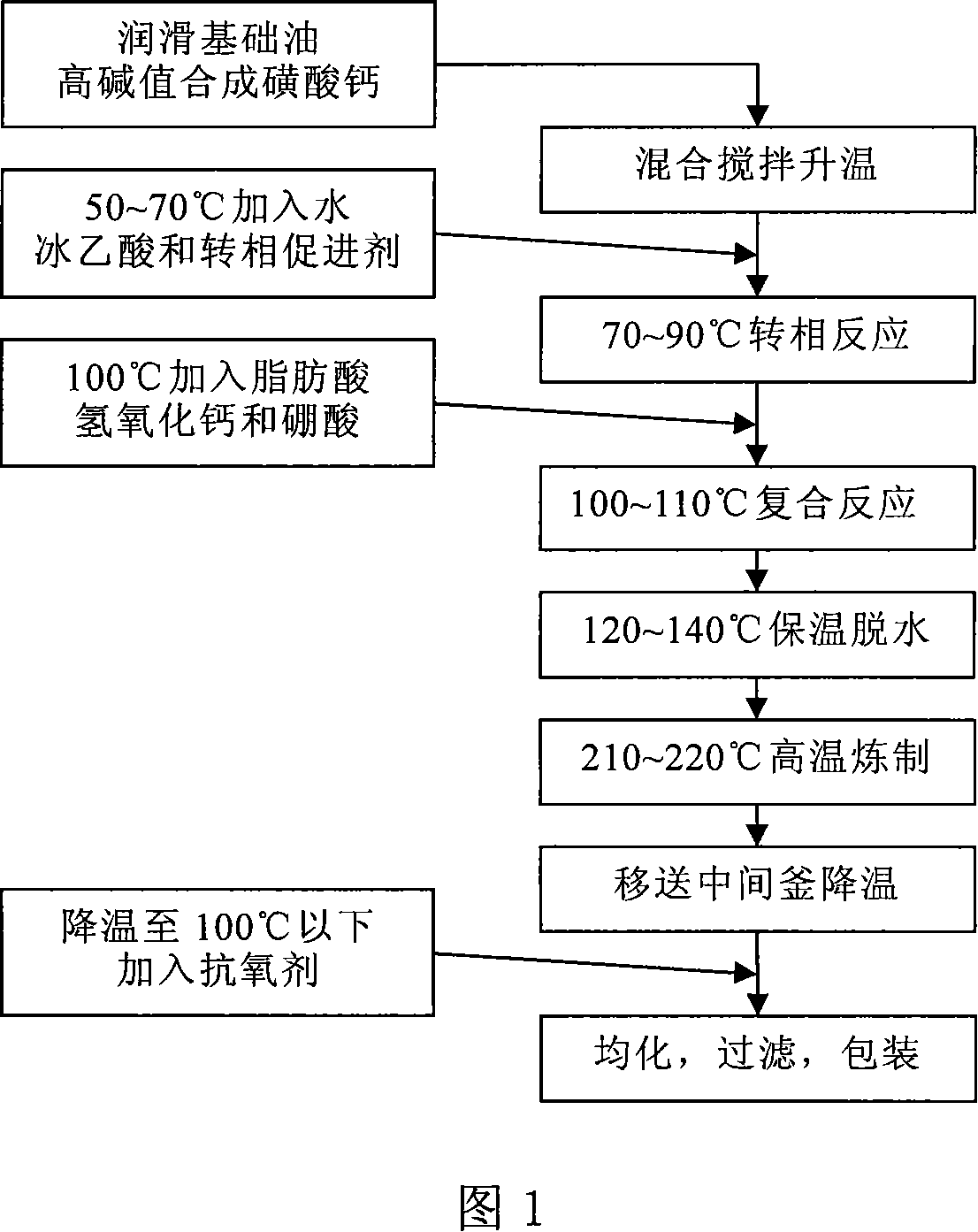

Compound sulphonic acid albany grease and method for producing the same

ActiveCN101153239AImprove performanceImprove water resistanceLubricant compositionAntioxidantManufacturing enterprises

The invention relates to calcium sulfonate complex grease and a manufacture method thereof, in particular to grease producing the thickening agent by synthetic reaction with super-high base value. At first, the lubricating base oil and the calcium sulfonate are added into an opening reaction kettle to be stirred, the phase inversion promoter, the glacial acetic acid and the water are added into the kettle to boost the temperature to make the insulating reaction until the materials are thickened, then the calcium hydroxide, the aliphatic acid and the boric acid are added into make an insulating reaction, a temperature rise, an insulating dehydration and a refining in turn, then the materials are moved into an intermediate kettle, the antioxidant is added to disperse and homogenize, and the finished product is produced after the filtering. The invention has excellent anti-spray performance, excellent high temperature performance, good extreme pressure anti-abrasion performance, prominent anti-shear performance, good pumping performance, anti-rust performance and water adding shear stability; has apparent phase inversion effect and good product performance, decreases the grease exchange times under the same working condition and increases the service life of the equipment, which is proved by the trial applications of a plurality of appliance manufacture enterprises, steel works, paper mills and so on.

Owner:无锡中石油润滑脂有限责任公司

Biodegradable non-toxic gear oil

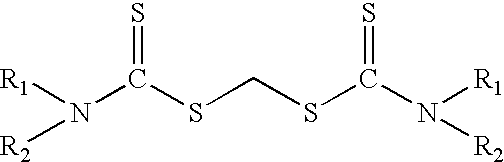

A biodegradable lubricating oil composition especially useful as a gear oil employs a synthetic alcohol ester basestock formed from mono- and dipentaerythritol with certain mono- and dicarboxylic acids or dicarboxylic acid anhydrides and an effective amount of a polyoxyalkylene alcohol demulsifying agent, a combination of alkylated organic acid and ashless succinimide rust inhibitors and an ashless dithiocarbamate antiwear and extreme pressure agent.

Owner:EXXON RES & ENG CO

Microemulsion metal cutting fluid

ActiveCN104164283AMeet cutting processing requirementsHigh thermodynamic stabilityLubricant compositionEmulsionNonferrous metal

The invention discloses a microemulsion metal cutting fluid which contains 1-20 wt% of fatty oil, 1-40 wt% of emulsifier, 5-40 wt% of co-emulsion, 5-30 wt% of wear and rust inhibitor, 1-20 wt% of penetrant, 5-30 wt% of pH regulator, 0.5-5 wt% of defoaming agent and 0.1-5 wt% anticorrosive bactericide. The microemulsion metal cutting fluid has excellent lubricating, antiwear, antirust, cleaning and cooling properties, and can be widely used in precise cutting work of ferrous metals and nonferrous metals.

Owner:TSINGHUA UNIV

Water-based cutting fluid used in slice machining of hard brittle crystal material and preparation method of water-based cutting fluid

InactiveCN102618374AGuaranteed lubrication effectGuaranteed anti-rust performanceAdditivesWater basedTool wear

The invention discloses a water-based cutting fluid used in slice machining of a hard brittle crystal material, comprising the following compositions: base oil, organic amine, organic acid, synthetic ester, emulsifier, rust and corrosion inhibitor, dispersion flocculation and hard-water resisting agent, antiseptic bactericide, antifoaming agent, coupling agent, adjuvant and a proper amount of water. Aiming at the machining techniques of inner circle slicing and outer circle slicing, the water-based cutting fluid has good generality, lubricity, strong antirust property and a long service life; when the cutting fluid is used, the machining situation can be observed easily, the cooling property is good, the cleaning and the permeability are strong, cuttings subside easily, and the machining problems of machining error, crack and the like caused by cutter blocking, abrasion and the like are solved; according to the invention, the problems that cuttings are easy to adhere and suspend, a cutter is seriously abraded, a machined product cracks easily, the accuracy is not high, the machining efficiency is low, the later period cleaning is complex and the like existing in the current slice machining of the hard brittle crystal material are solved, and further, a machine bed is protected, and the cost is reduced.

Owner:AMER TECH CO LTD

Anti-emulsification water-soluble metal washing agent

The invention relates to an anti-emulsification water-soluble metal washing agent. Every 100 parts of the anti-emulsification water-soluble metal washing agent include the following components according to parts by weight: 3-7 non-ionic surfactant, 3-7 bi-ion active agent, 1-5 chelator, 1-5 rust preventive, 5-10 inorganic builder and the balance water, wherein the non-ionic surfactant is any one of fatty amine polyoxypropylene ether, alkylphenol ether and fatty amine polyoxyethylene alkyl ether ammonium sulfate, the bi-ion active agent is any one of alkyl dimethylin acetic acid betaine, lauramidopropyl betaine and cocamidopropyl betaine, the chelator is any one of sodium citrate, ethylenediaminetetraacetic acid tetrasodium salt and nitrilotriacetic acid sodium salt, the rust preventive is any one of sodium borate, sodium nitrite, sodium benzoate and long carbon chain carboxylic acid amine, and the inorganic builder is any one of trisodium phosphate, sodium metasillcate, sodium carbonate, sodium bicarbonate and sodium hydroxide. The anti-emulsification water-soluble metal washing agent has the advantage of higher cleaning capacity and reutilization capacity.

Owner:NANJING KERUN LUBRICANTS

Flexible ceramic wear-resistant heat-proof dual-anticorrosive coating

InactiveCN1528844AIncreasing the thicknessReduce the probability of water seepageAnti-corrosive paintsEpoxy resin coatingsCoated surfaceSaline water

The invention is a kind of flexible ceram wearing and heat resisting heavy corrosion preventing paint, which is made up of epoxy resin and several kinds of ceram powder, rust-protection paint and firming agent, the weights of each ingredient are: (1) epoxy resin: 100; (2) additive: 50-120; (3) rust protection paint: 8-25; (4) ceram powder: 100-200; (5) compound solvent: 40-70; paint: firming agent=(35-50):1. The paint needn't base coat, it can be painted directly or brushed on the surface of metal under normal temperature, it has excellent wearing and corrosion prevention performance, impact resisting performance and flexibility, it can insulate acid, alkali, salt, saline water. The surface is smooth; it can be applied to oil pipe, oil pot, and chemical device, ship, wheel vane, pump, dust catcher, etc.

Owner:REAR SERVICE TECH EQUIP INST NAVY PLA

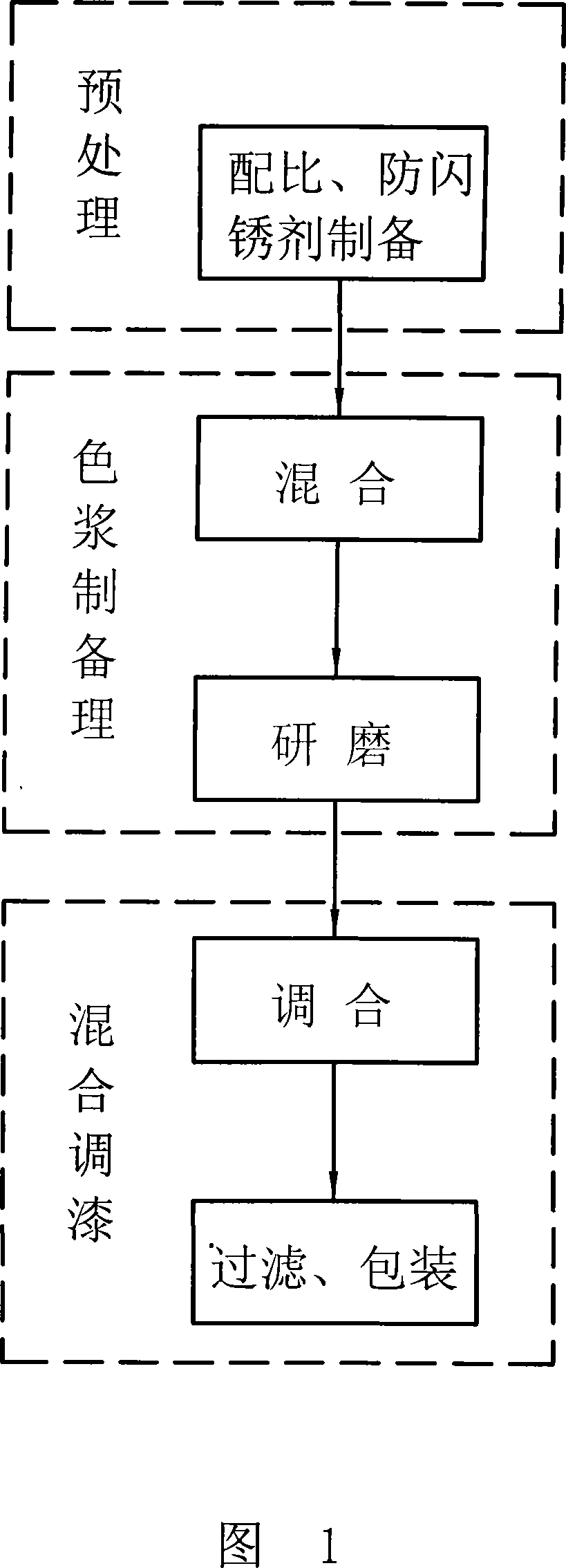

Water industrial antirust paint and preparation method thereof

InactiveCN101045843AHigh hardnessStrong adhesionAnti-corrosive paintsEmulsion paintsEpoxyALUMINUM PHOSPHATE

This invention relates to a aquosity industry anti-rust paint and its preparation method. According to weight it includes 8 to 11% aquosity acroleic acid modified epoxy, 33 to 40% acroleic acid latices, 0.1 to 0.3% defoamer, 0.05 to 0.15% wetting agent, 0.3 to 0.5% dispersant, 0.3 to 0.5% rust-resistant agent, 7.5 to 9% iron oxide red, 6 to 8% French chalk, 5 to 10% modified zinc phosphate, 2.5 to 10% trimerization aluminum phosphate, 3 to 3.5% precipitated baryte , 0.5 to 1% zinc oxide, 3 to 5% mica ferric oxide, alcohol ester twelve 1 to 2%, triethanolamine 1 to 2%, thickening agent 0.3 to 0.6%, preservative 0.05 to 0.1%, 5 to 20% de-ionized water, through pretreatment, color paste preparation and blending and adjusting to gain product.

Owner:邹磊

Open-type gear grease composition

The invention provides an open gear grease composition, which comprises the following components and the weight percentage contents are that gelatinizer 2-6%, mineral oil 20-60%, synthetic oil 20-60%, antioxidant 0.3-1%, oil solubility anti-wear extreme pressure additive 1-15%, solid additive 3-20% and rust inhibitor 1-3%. The open gear grease composition of the invention does not contain dissolvent and bitumen, which has no harmless to environment, and solves the problems that bitumen-type open gear oil has bad pollution and low-temperature performance, and the flowability of open gear grease is bad. The open gear grease composition has outstanding water resistance, adhesiveness and antiwear and extreme pressure property.

Owner:益田润石(北京)化工有限公司

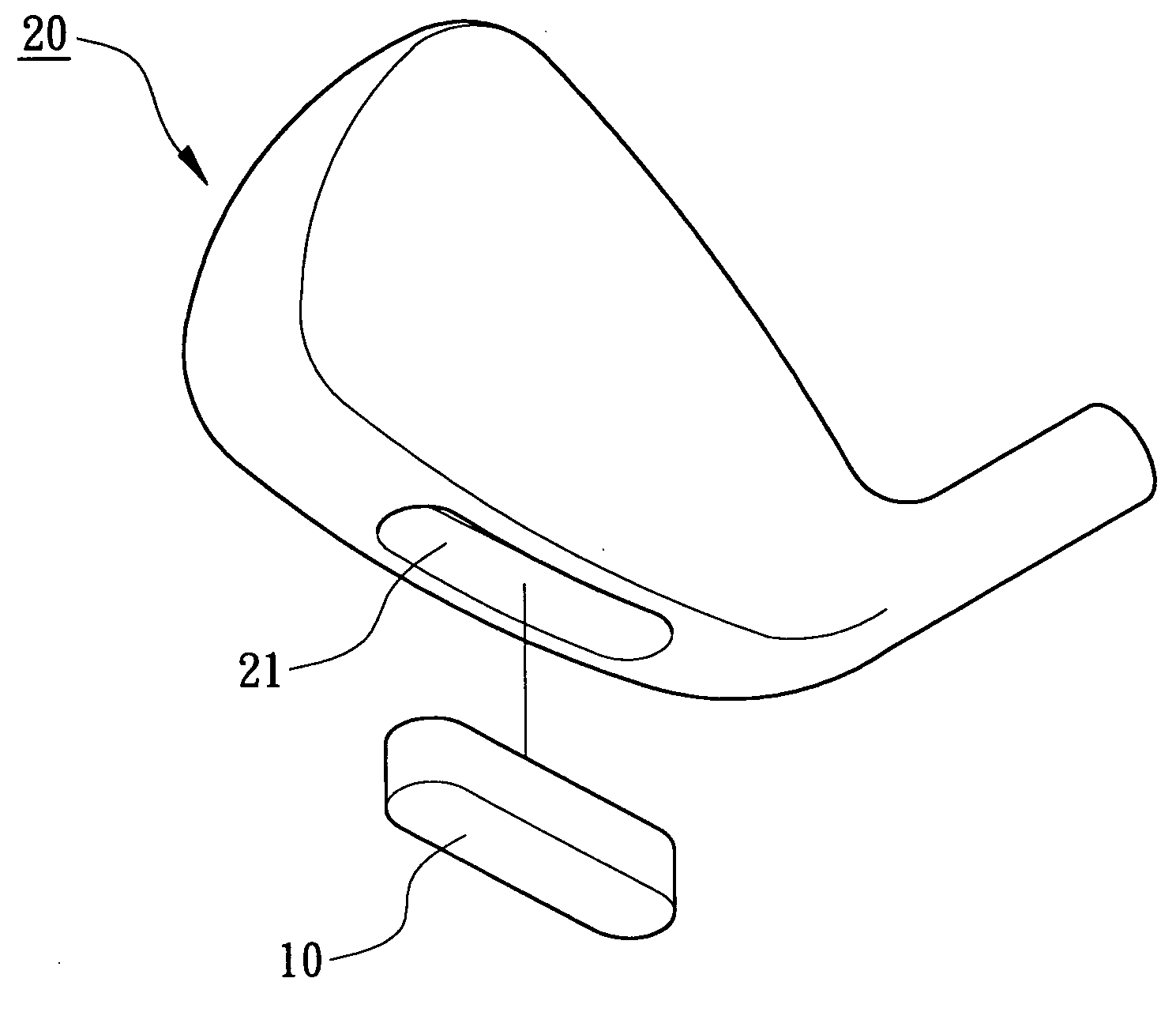

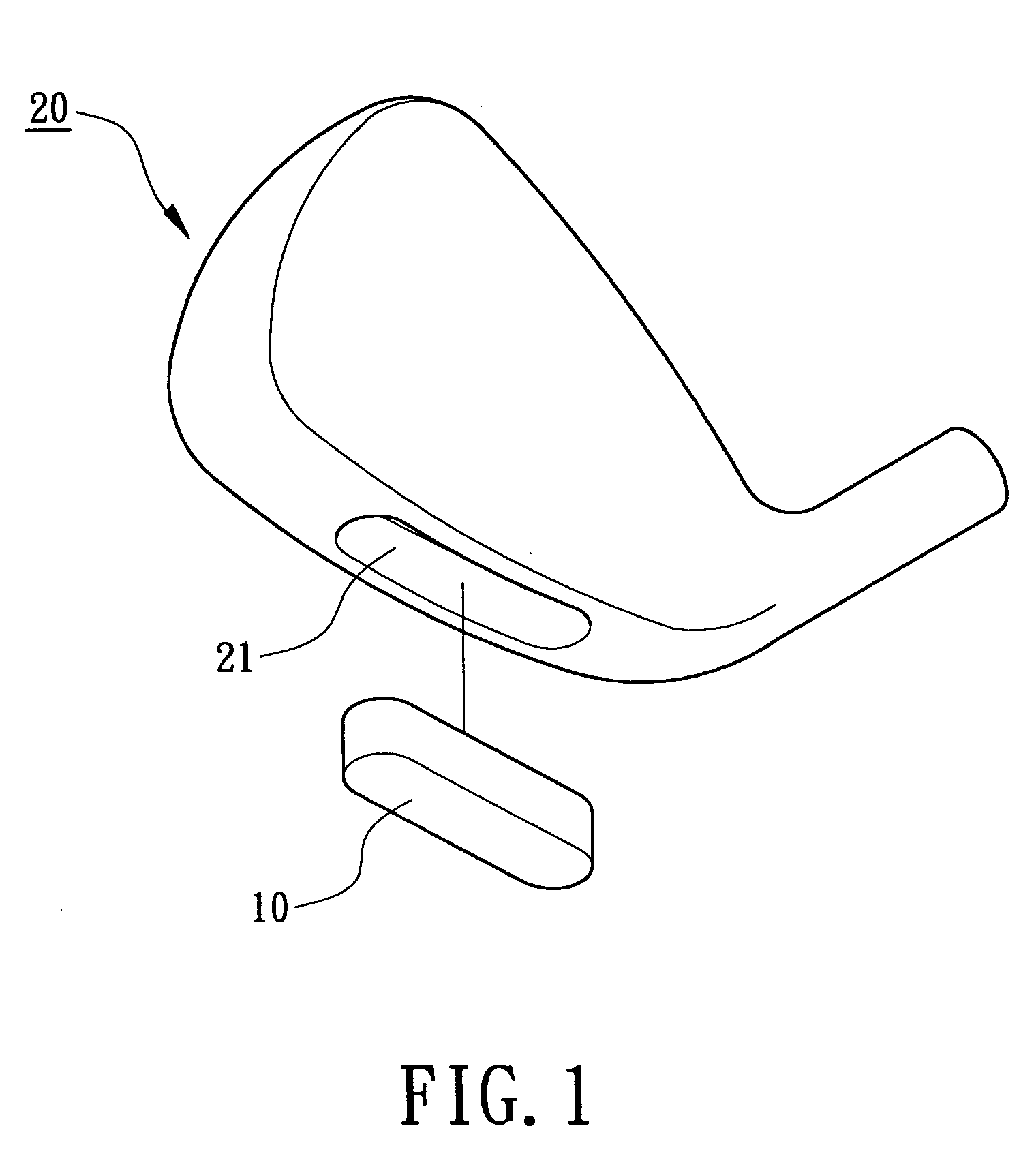

Weight member for a golf club head

A weight member for a golf club head is made of a WMoNi alloy by powder metallurgy or a precision casting process. The WMoNi alloy includes tungsten 1-70 wt %, molybdenum 4-55 wt %, and nickel 25-95 wt %. Molybdenum increases the density of the weight member and improves the rust-resisting property of the weight member. The tungsten, molybdenum, and nickel provide a uniform metallographic phase. Uniformity of shining finishing of the weight member is thus improved.

Owner:FUSHENG IND CO LTD

Water-soluble total-synthesis metal working fluid and application thereof

The invention discloses a water-soluble total-synthesis metal working fluid and application thereof. The working fluid is prepared from the following raw materials in percentage by weight: 1wt%-30wt% of a lubricant, 1wt%-40wt% of a corrosion inhibitor, 1wt%-40wt% of organic amine, 1wt%-20wt% of a cleaning agent, 1wt%-20wt% of a coupling agent, 0.5wt%-5wt% of an antifoaming agent and the balance of water. The working fluid can form water-based steam with anti-rust property in an induction manner in the use procedure, so that the problem of rusting caused by steam which is easily generated by a closed machine tool is solved, and therefore, the working fluid is suitable for a high-precision machine tool, especially a numerical control machine tool with a closed structure.

Owner:TSINGHUA UNIV

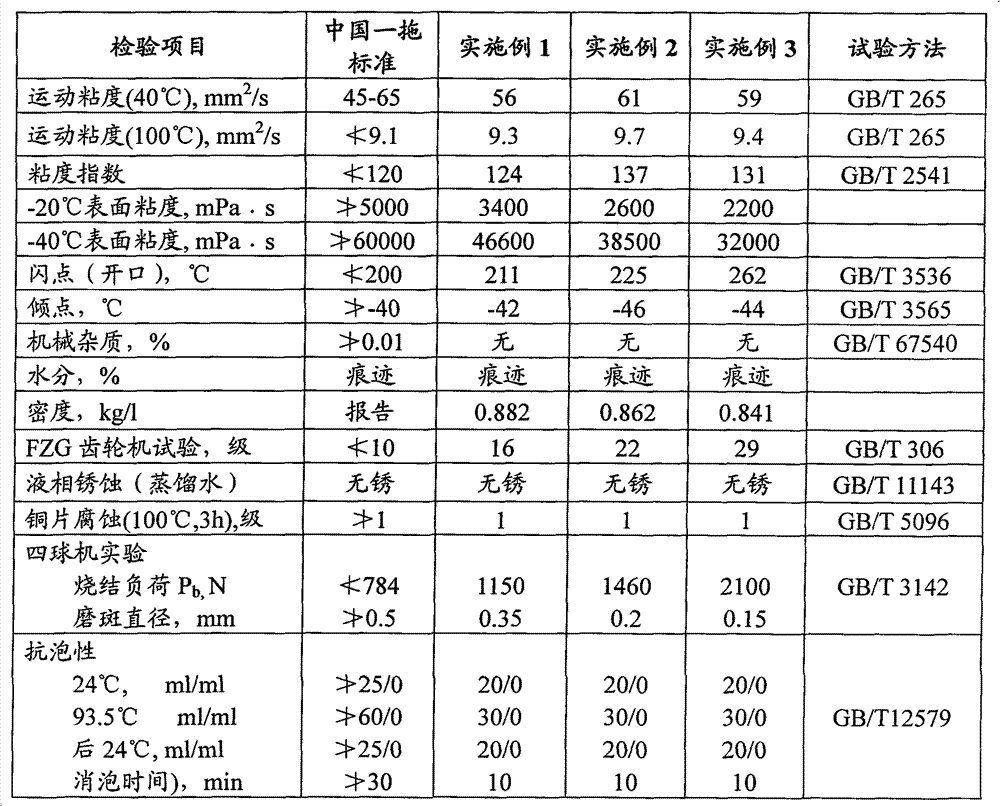

Hydraulic-transmission-braking three-use lubricating oil composition

InactiveCN102952617AAvoid wear and tearPrevent rustLubricant compositionFriction reductionTransmission brake

The present invention relates to a hydraulic-transmission- braking three-use lubricating oil composition, which is prepared by mixing the following raw materials, by weight, 85-98% of high viscosity index base oil, 0.1-5% of an extreme pressure wear resistance agent, 0.1-4% of an antioxidant, 0.1-3% of a metal deactivator / antirust agent, 0.1-5% of a friction modifier, and 0.1-2% of a dispersing agent. The hydraulic-transmission- braking three-use lubricating oil composition has beneficial effects of good low temperature fluidity, friction reduction, wear resistance, corrosion resistance, rust resistance, emulsification resistance and foaming resistance, and can meet requirements of universal hydraulic transmission oil used by large-medium-sized tractors and construction machinery so as to achieve complete lubricating protection on hydraulic parts, transmission parts, gear parts, power output parts and braking parts, such that a long service life is provided, equipment operation stability is easily improved, and energy saving and consumption reduction are provided.

Owner:BEIJING ALLUBE PETROCHEM

Metal surface treating agent

InactiveCN102051611AReduce corrosion rateReduce surface tensionMetallic material coating processesMetasilicateChemical conversion

The invention relates to a metal surface treating agent which comprises the following components: silicate or metasilicate, chitosan, corrosion inhibitor, surfactant, antioxidant, wetting agent, film-forming additive, ethanol and water, wherein one or more of nanosized titanium dioxide, zirconium oxide or zirconium fluoride are evenly mixed with silicate or metasilicate and account for 3wt%-25wt% of silicate or metasilicate; the particle size of nanosized titanium dioxide, zirconium oxide or zirconium fluoride is less than 100nm; the degree of deacetylation of chitosan is 55%-100%; and the pH value of the composite is adjusted to 5.0-9.0. The invention provides the metal surface treating agent which uses environmentally friendly aqueous solution to form a metal chemical conversion film so as to inhibit the surface corrosion of metal; when the metal surface treating agent is used to treat the surface of the cold-rolled steel plate product, the rust-proof effect is especially good; and the metal surface treating agent can not cause environmental pollution and be green and environmentally friendly.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Composite lithium-base grease and method for making same

The present invention provides composite lithium-based lubricating grease and a preparation method thereof. The composite lithium-based lubricating grease consists of thickener, base oil and additive. The thickener consists of 12-hydroxy stearic acid lithium dibasic acid and / or lithium borate, and the mol ratio is 1 ®U 0.1 to 1 ®U 0.1to 1. The base oil is mineral oil or poly-alpha-olefin synthesis oil. The additive consists of organic amine compound antioxidant, benzotriazole and barium petroleum sulfonate or barium dinonylnaphthalene sulfonate anti-corrosion additive and rust protection agent, dialkyl dithiocarbamate or dibenzyl disulfide and sulfurized olefin cottonseed oil extreme pressure antiwear additive and nanometer copper powder repairing additive. The contents of the thickener and the base oil are respectively 6 percent to 18 percent and 82 percent to 94 percent according to the weight percentage. The lubricating grease has the multi-effect performances of high dripping point, good high-temperature performance and low-temperature performance, chemical invariability, colloid invariability, antiwear extreme pressure performance etc., and especially has the repairing function towards a damaged bearing.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

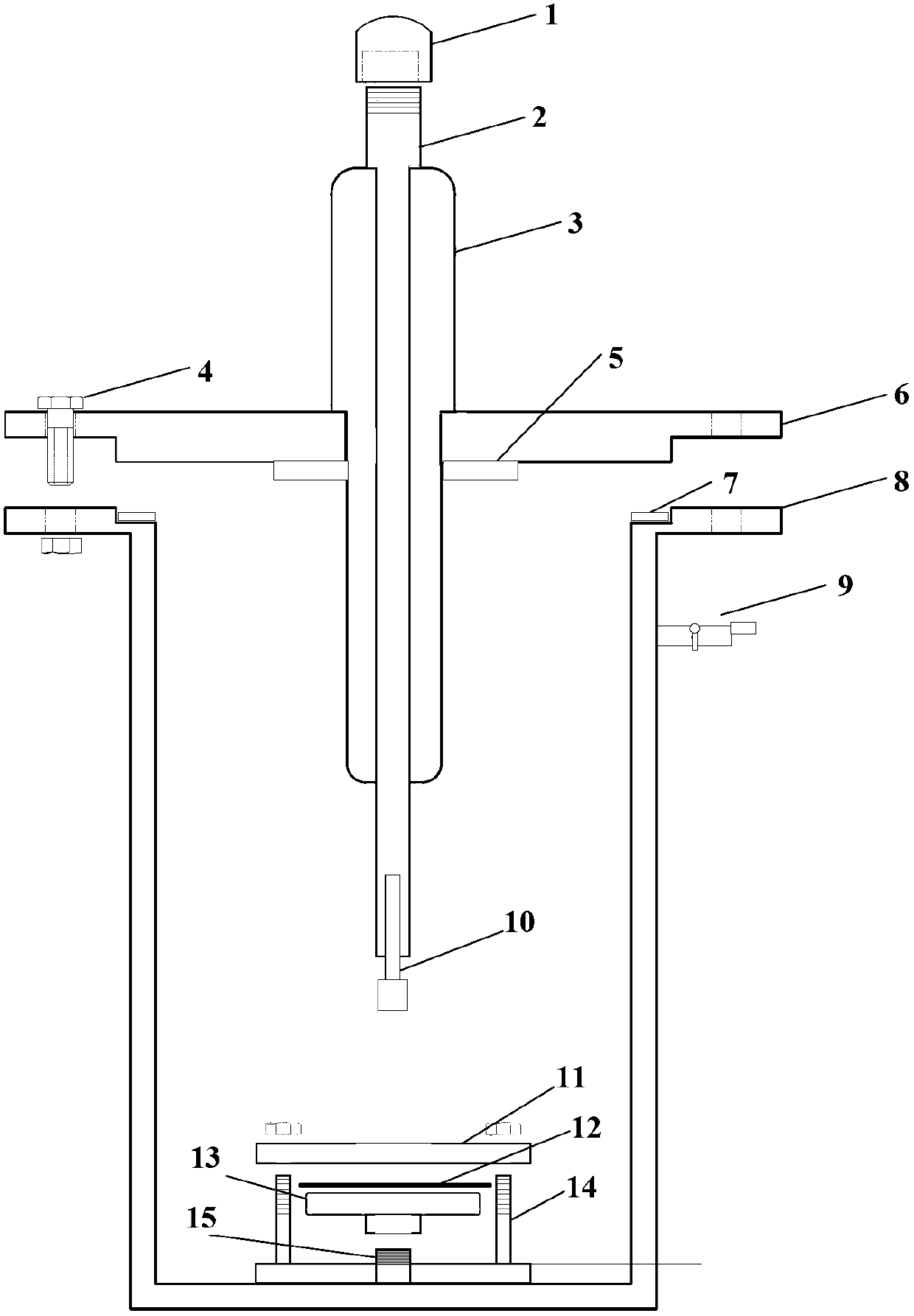

Transformer paper oil insulation experiment device integrated with electric heating combination ageing and partial discharge

ActiveCN103105568AImprove air tightnessInsulate the influenceTesting vessel constructionElectricityLow voltage

The invention provides a transformer paper oil insulation experiment device integrated with electric heating combination ageing and partial discharge, and provides a corresponding experiment method. The experiment device comprises a high voltage portion, a low voltage portion and a sealing tank portion. The device can provide a platform of electric heating combination ageing and partial discharge experiments for a transformer paper oil insulation defect model, and can provide experiments of corona discharge, creeping discharge and air-gap discharge models in oil. The device has good air-tight performance, and can be isolated from external air and other influences. The whole system self cannot produce partial discharge, and the device cannot produce rust and other impurities in the partial discharge, can guarantee reliability of the partial discharge, and is simple in structure, convenient to operate, and capable of achieving good test effects.

Owner:STATE GRID CHONGQING ELECTRIC POWER CO ELECTRIC POWER RES INST +2

Phosphorus-free water-based metal cleaning agent

The invention relates to a phosphorus-free metal cleaning agent comprising the components of, by weight, 2-20% of a cleaning aid, 1-20% of a surfactant, 1-10% of a chelating agent, 1-20% of an emulsifier, 1-10% of an antirust agent, 0.2-4% of a copper alloy corrosion inhibitor, 1-10% of a penetration agent, 1-6% of a solubilizing agent, 0.1-0.6% of a defoaming agent, and balance of water. The cleaning agent provided by the invention has excellent cleaning capacity, long rust proof period, low foam, long service life, and the like. The cleaning agent is suitable for ferrous metal and non-ferrous metal processing industries. The agent has the advantages of no volatilization, no irritation, no toxic or harmful substance such as nitrite, no damage to health, and no environment pollution.

Owner:SHENYANG PARKERIZING

Multifunctional hydrocarbon oil composition

ActiveUS20090111723A1Improve working environmentReduce odorOrganic chemistryOrganic non-surface-active detergent compositionsElectric dischargeMetalworking

A multifunctional, high-performance hydrocarbon composition is demanded. Concretely, a metalworking oil composition having high workability even under a severer lubricating condition while resisting to high productivity, and further capable of suppressing deterioration of working environments or degradation of quality of a product without rise of lubricant cost, a metalworking oil composition for minimal quantitative lubrication system, which is excellent in characteristics as a water-insoluble lubricant for nonferrous metalworking and also in characteristics as a lubricant for cutting / grinding by minimal quantitative lubrication method, and can attain improvement in working efficiency and a further extended tool life, an electric discharge machining oil improved in working environments such as odor or skin roughness and further improved in processing rate, particularly processing rate in high-level finish, a rust preventing oil composition improved in resin compatibility, and a detergent excellent in adaptability with organic material are demanded.Therefore, metalworking oil which contains, as hydrocarbon base oil, hydrocarbon base oil having a density at 15° C. of 0.7 to 0.8 g / cm3, and including a n-paraffin content of 10 to 90% by mass, an aromatic content of 0 to 3% by volume, and a naphthene content of 0 to 20% by volume, a metalworking oil including the above-mentioned base oil and ester oil, and electric discharge machining oil, rust preventing oil, and a detergent composition including the above-mentioned base oil are provided.

Owner:NIPPON OIL CORP

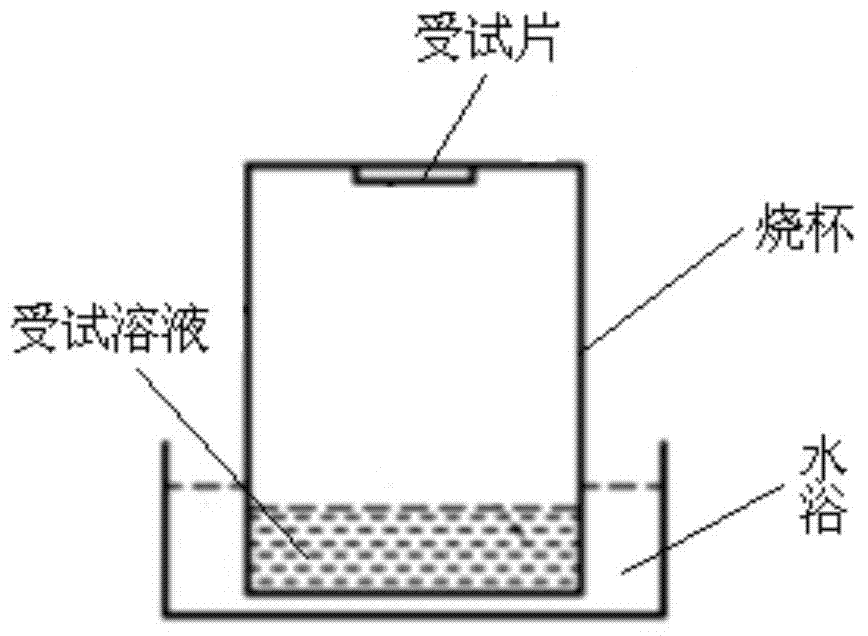

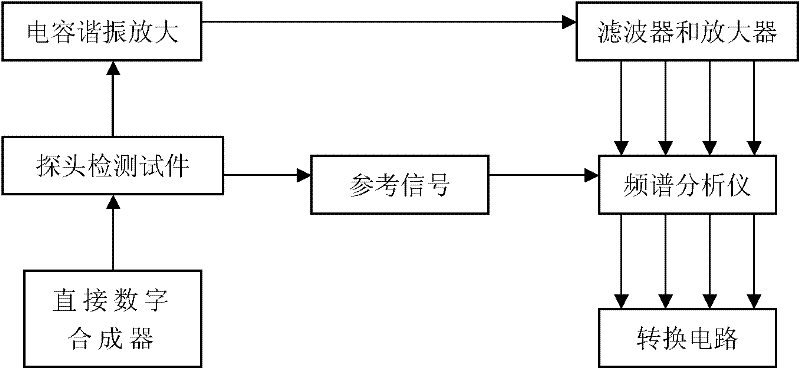

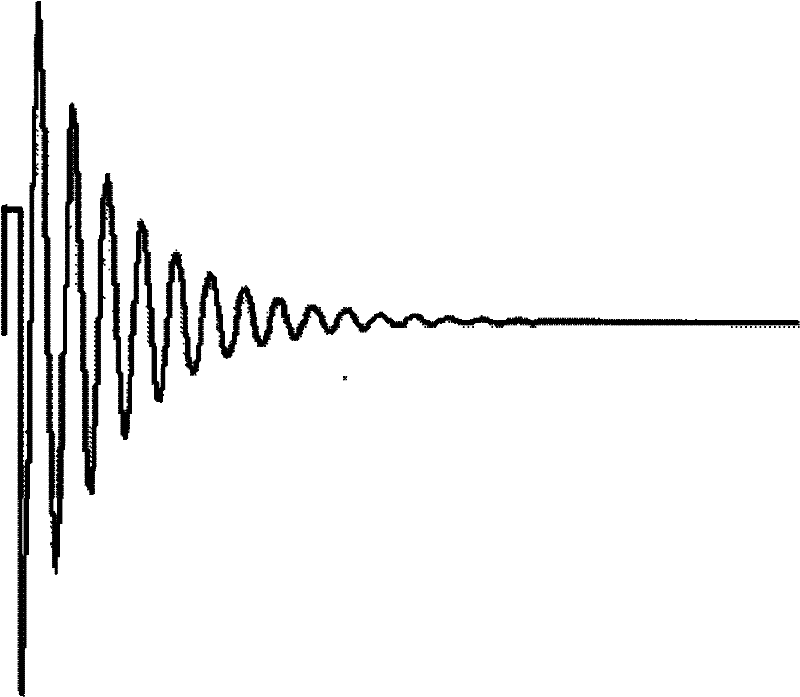

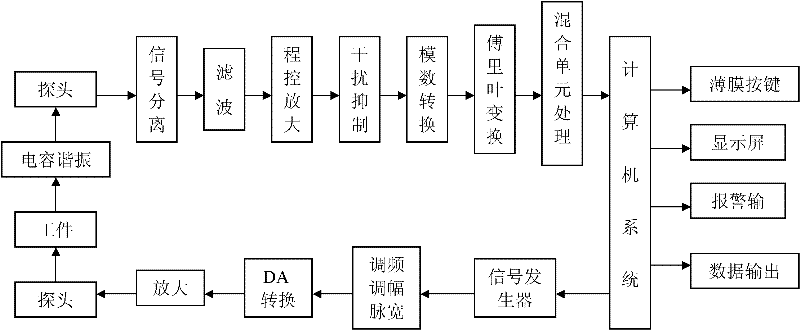

Electromagnetic resonance-based nondestructive testing method for metal material

InactiveCN102230914AFacilitates non-destructive testingRealize detectionMaterial magnetic variablesCapacitanceMetallic materials

The invention discloses an electromagnetic resonance-based nondestructive testing method for metal materials. According to the method, responding resonance signals of eddy current testing are obtained through multipled resonant capacitors in testing coils, comparative analysis of the responding resonance signals is carried out, and the relationships between a defect size and a signal amplitude and between defect depth and a signal phase are calibrated in advance, thereby enabling convenient nondestructive testing of metal materials. The electromagnetic resonance-based nondestructive testing method not only can produce same defect detection effects as a plurality of conventional electromagnetic testing methods like single-frequency eddy current and pulsed eddy current do, but also can effectively detect internal defects in a workpiece and detect workpieces with complicated surface conditions such as a casting surface, an unsmooth surface, a surface with oil stains, a rust-resisting paint, a corrosion layer or other pollutants, etc., without contact under the condition of a high liftoff value; according to the method, no cleaning is needed for test pieces, and particularly, no cumbersome processes like magnetization and demagnetization of magnetic metal materials are needed.

Owner:XIAMEN ANRUI JIE ELECTRONICS TECH

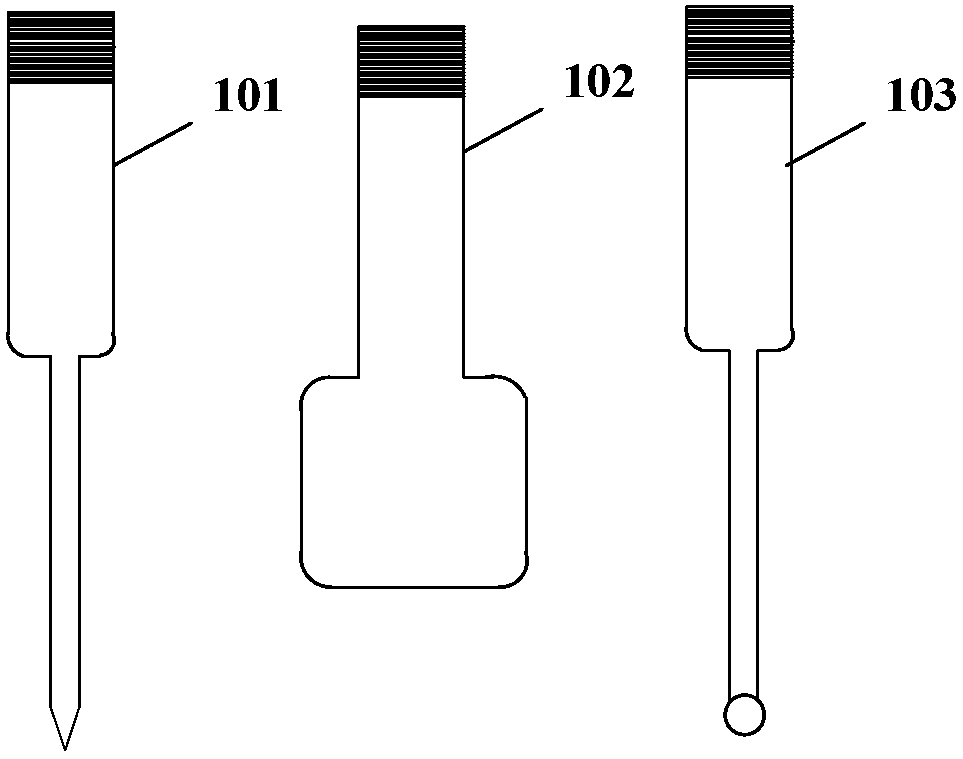

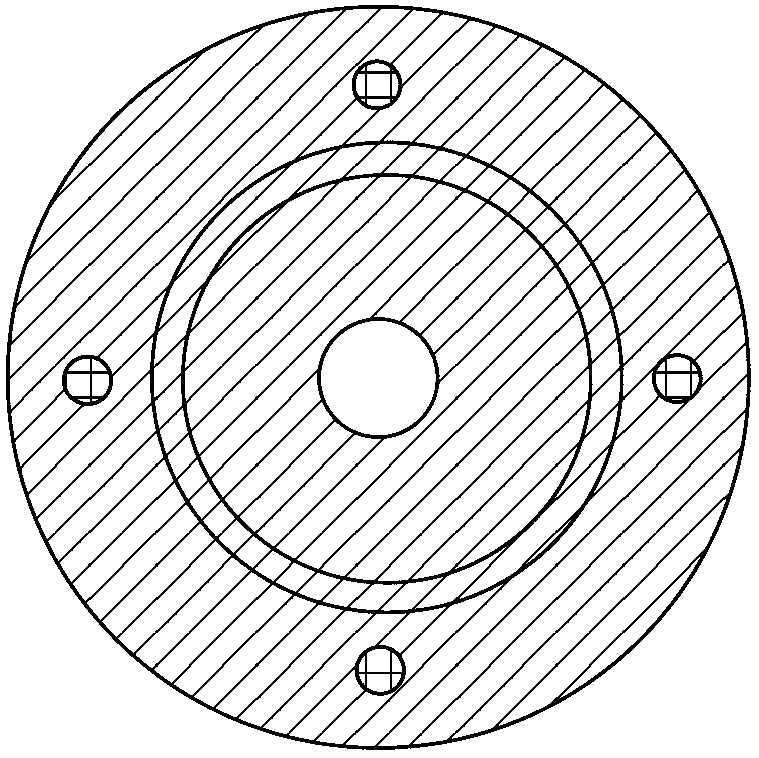

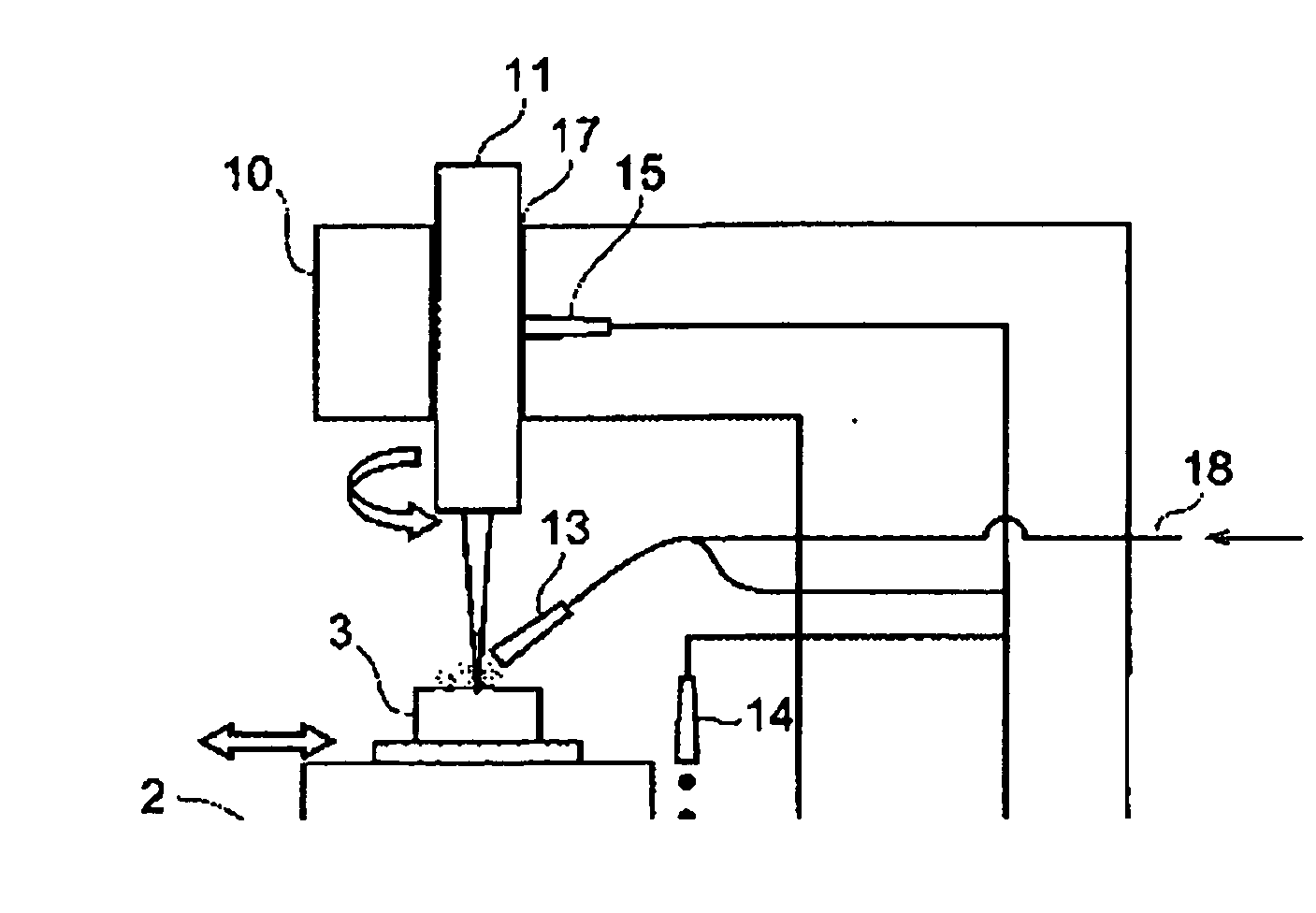

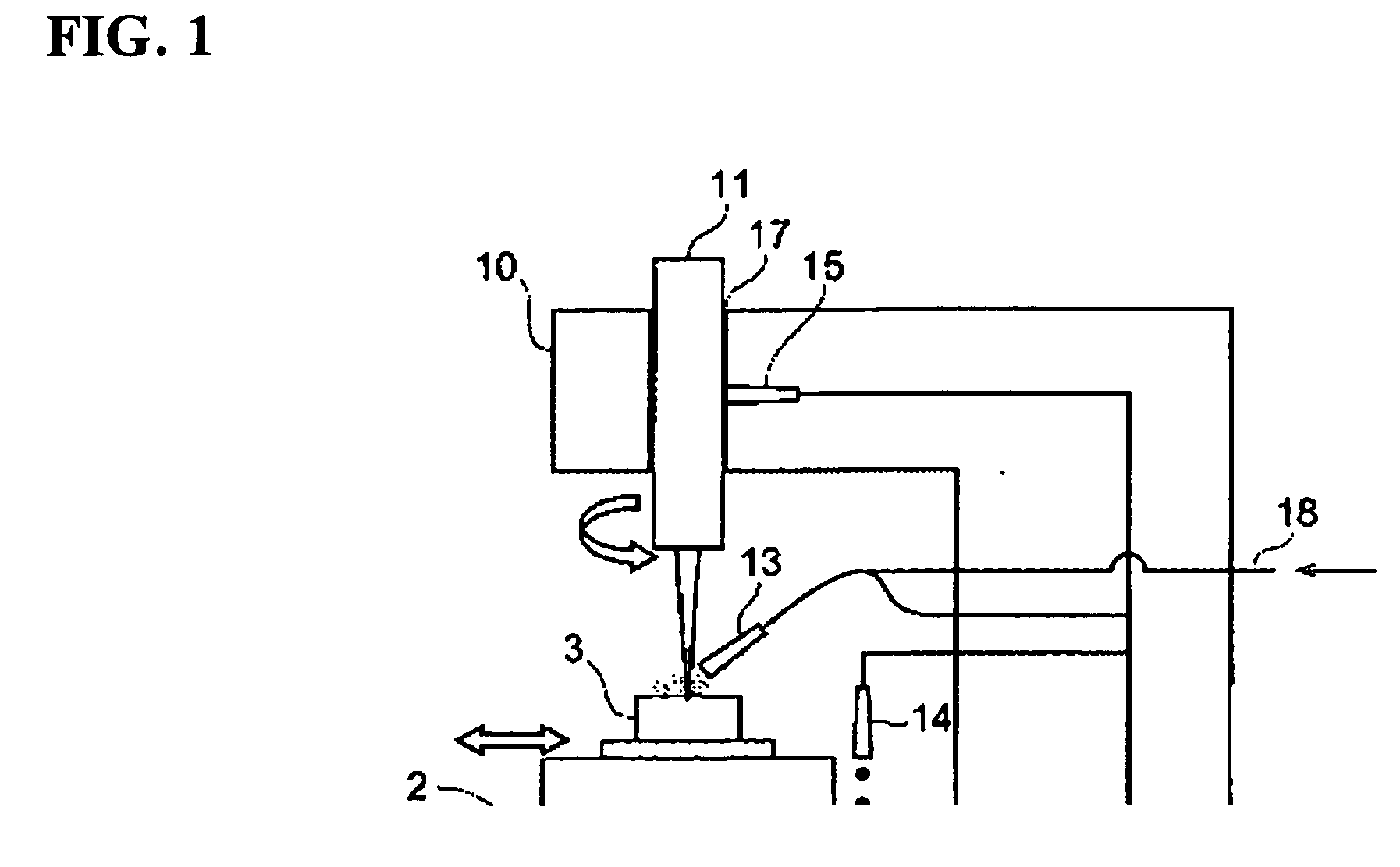

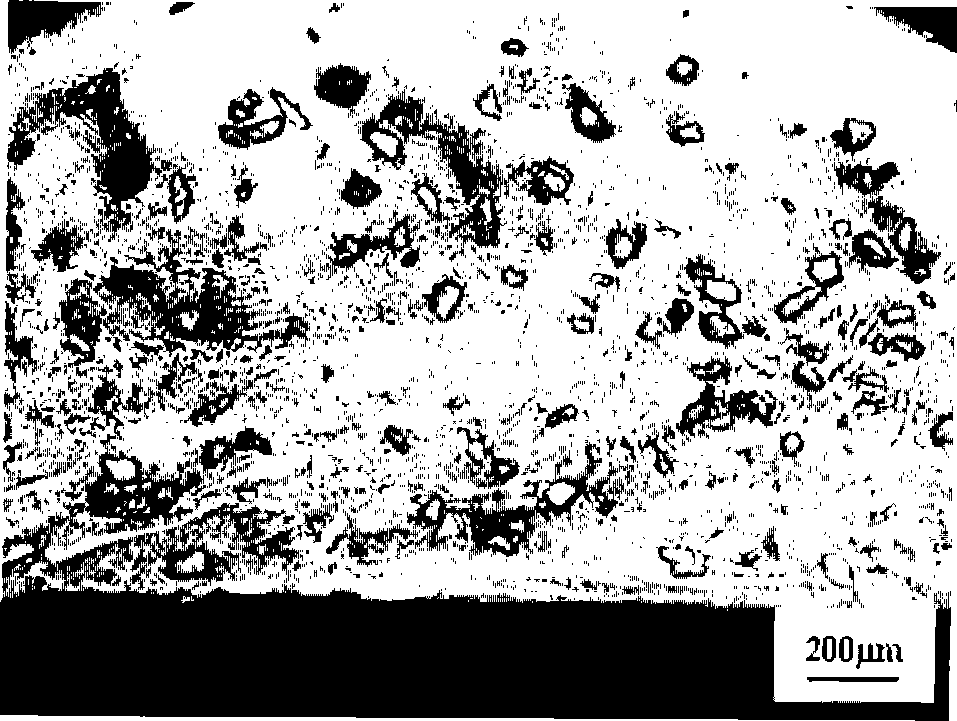

Laser cladding method for strengthening surface of piercing point

ActiveCN101519778ASolve the problem of easy falling offThickness is easy to controlMetallic material coating processesPiercing pointPre treatment

A laser cladding method for strengthening the surface of a piercing point includes the following steps of: (1) prefabricating WC / Co-base cladding powder; (2) pre-processing the surface of a piercing point workpiece, and cleaning up stain and rust; preheating for 2 to 5 hours at a temperature between 400 DEG C and 600 DEG C; (3) cladding the prefabricated composite powder fed in the way of reverse synchronization or coaxially in multiple steps by a CO2 laser; simultaneously, carrying out synchronous inert gas protection on the laser-cladding area; and (4) subsequent processing. The laser cladding method adopts laser to prepare a WC ceramic particle-strengthened Co-base composite coating on the surface of the piercing point, and the coating is metallically combined with the matrix, so the binding force between the coating and the matrix is enhanced; the maximum thickness of the coating can reach a few millimeters; and as the surfaces of WC particles are coated with Ni, the absorption of laser energy by the WC can be reduced, so that the burnout rate of the WC can be reduced in a laser melting pool. The distribution of the WC particles is uniform in the coating, the rigidity of the coating is high, consequently, the service performance of the piercing point can be improved, and the service life can be prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

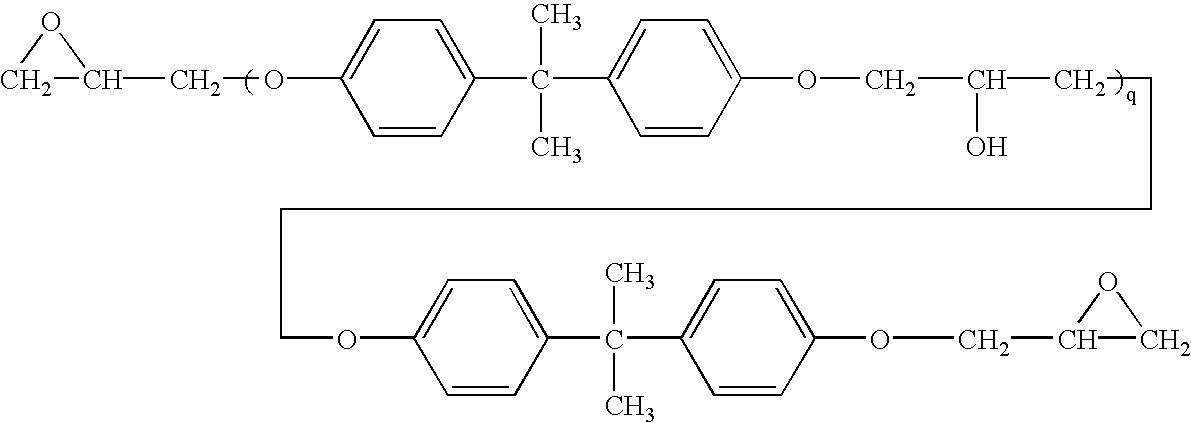

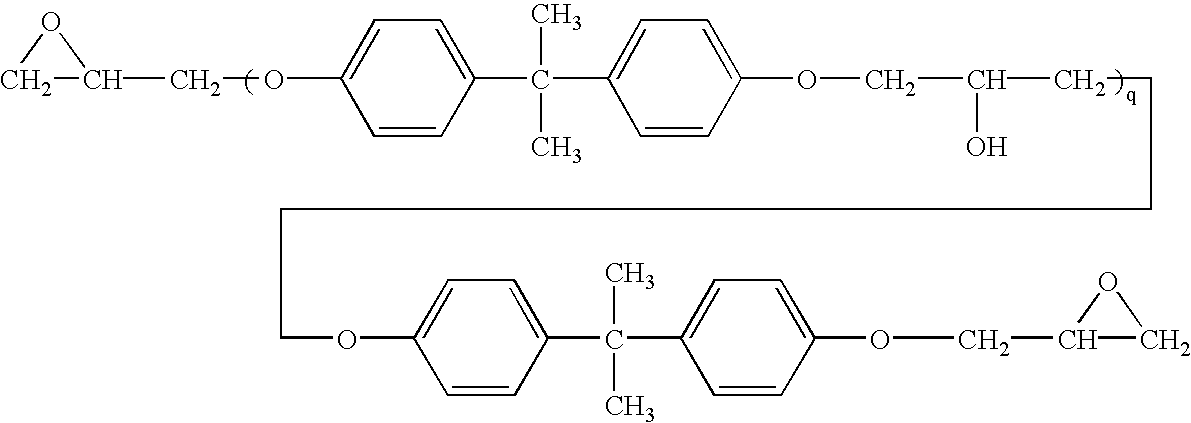

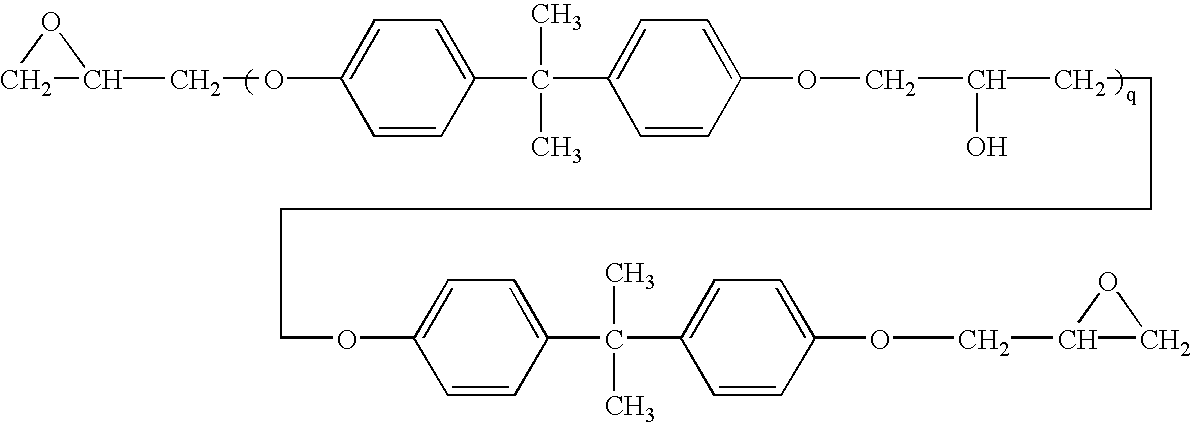

Steel sheet having organic coating and method for manufacturing the same

InactiveUS20030072962A1Hot-dipping/immersion processesLiquid surface applicatorsSheet steelZinc alloys

Steel sheet having organic coating comprises: a zinc or a zinc alloy plated steel sheet or an aluminum or an aluminum alloy plated steel sheet; a composite oxide coating formed on the surface of the plated steel sheet and containing at least one metal selected from the group consisting of Mn and Al; and an organic coating formed on the composite oxide coating and containing a rust-preventive additive component.

Owner:NIPPON KOKAN KK

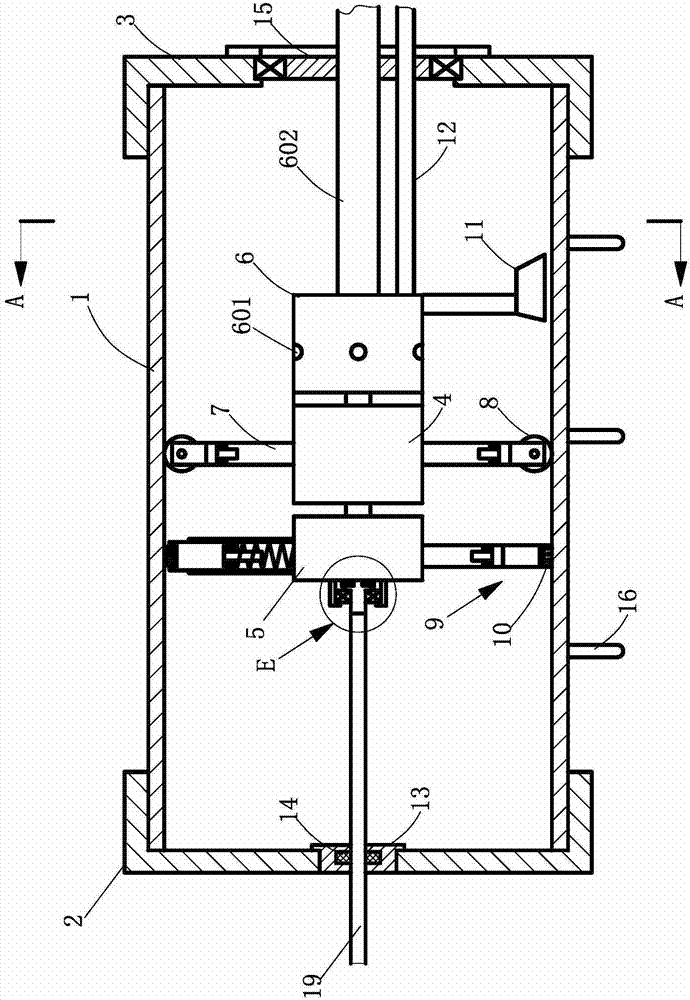

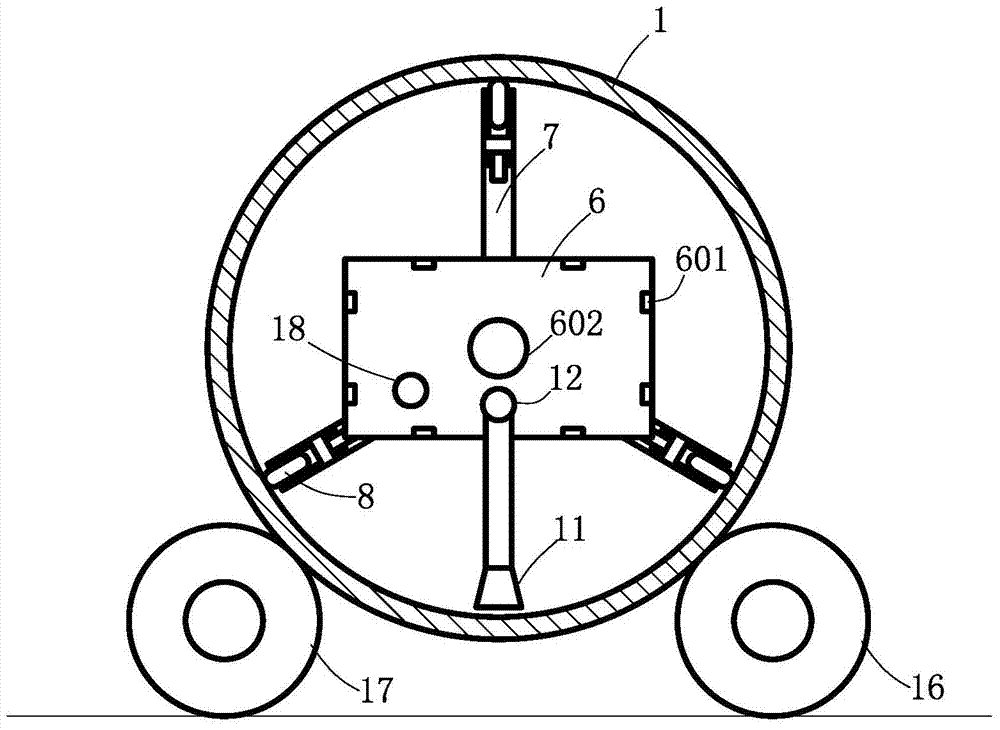

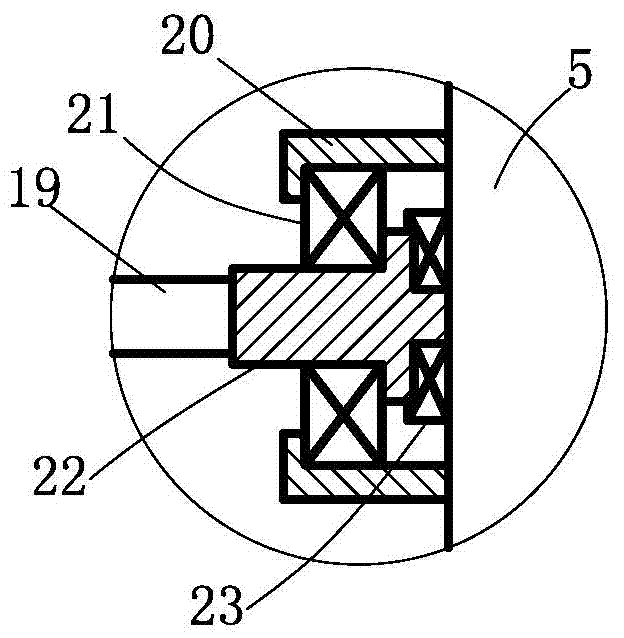

Pipeline inner wall rust removal device

ActiveCN104723223AAvoid pollutionReduce direct damageGrinding machinesAbrasive machine appurtenancesPneumatic motorPollution

The invention discloses a pipeline inner wall rust removal device, belonging to the technical field of polishing units. The device comprises a first end cover and a second end cover which are hermetically installed at two ends of the pipeline, a rust removal trolley is arranged in the pipeline, the dust removal trolley comprises a pneumatic motor with dual output shafts, a shell of the pneumatic motor is provided with a plurality of support shafts, the end part of each support shaft is provided with a roller wheel, a grinding disc is fixedly installed on the output shaft of the pneumatic motor, close to the first end cover, and is provided with a plurality of support rods in the radial direction, the end part of each support rod is provided with an abrasive disc, the output shaft of the pneumatic motor, close to the second end cover, is connected with a shot-blasting machine in a transmission manner; the end part of the grinding disc is connected with a traction rope, the traction rope extends out of the first end cover, one end of the shot-blasting machine, close to the second end cover, is connected with a shot feeding pipe, the pneumatic motor is connected with a gas inlet pipe, the shot feeding pipe and the gas inlet pipe extend out of the second end cover. The pipeline inner wall rust removal device can be used for solving the technical problems that the pipeline inner wall is serious in rust removal pollution and the rust removal effect is poor, and can be widely applied to pipeline cleaning.

Owner:SHANGHAI HONGPU STEEL STRUCTURE ENG

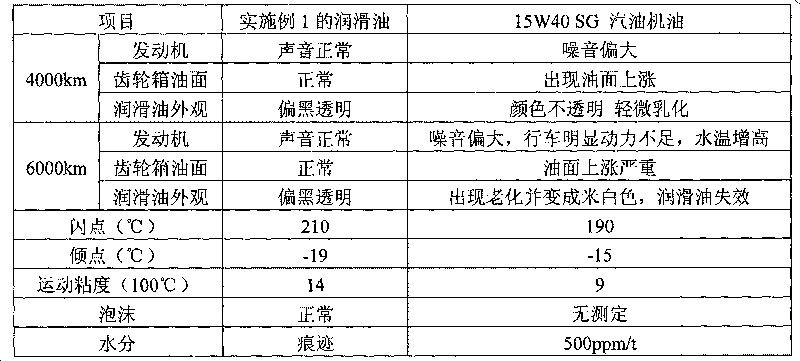

Lubricating oil for methanol fuel engine and preparation method thereof

InactiveCN101705144AAnti-agingResistance to emulsification damageAdditivesAntioxidantBULK ACTIVE INGREDIENT

The invention provides lubricating oil for a methanol fuel engine, which comprises the following components in percentage by weight: metal detergent 2.2-5.2, ashless dispersant 3.5-6.8, antioxidant and anticorrosion agent 0.5-1.6, high-temperature antioxidant 0.3-0.8, viscosity index improver 6-11, oiliness solvent 2.8-6, anti-foaming agent 120ppm, metal anti-rust agent 0.3-0.7, base oil 62.7-83, demulsifying agent 0.1-0.3, metal extreme pressure anti-wear agent 1.0-4 and pour point depressant 0.3-0.9. The lubricating oil of the invention has functions of preventing wear and rust of the engine, can prevent the active ingredients thereof from being extracted and emulsified by methanol and is particularly suitable for engines using M85 or M100 methanol gasoline as a fuel.

Owner:王恩臣 +2

Waterborne rust conversion polymer emulsion, coating thereof and method for preparing same

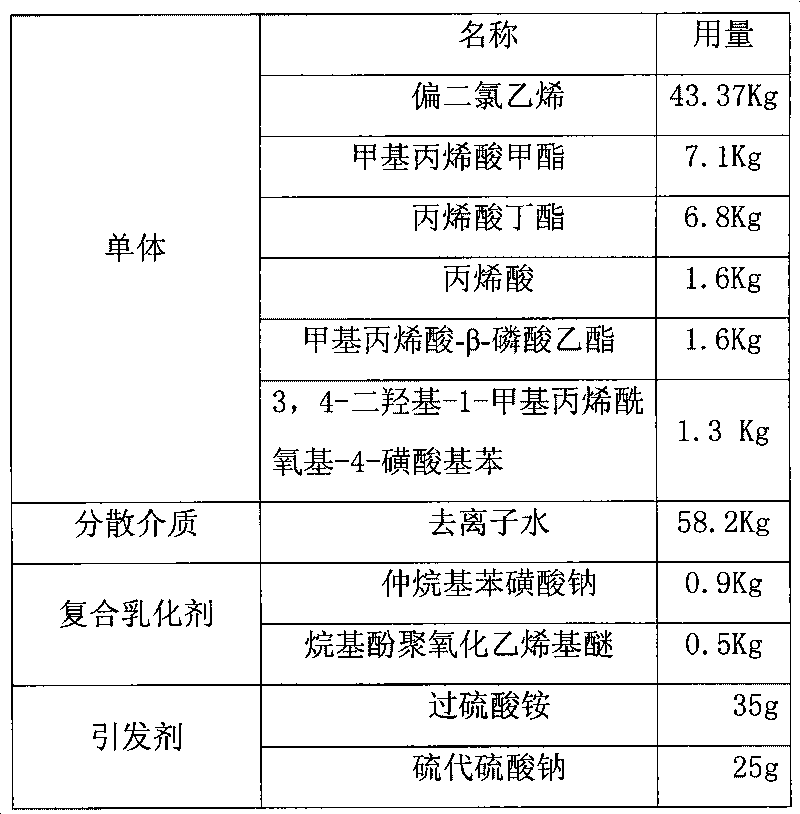

The invention discloses a waterborne rust conversion polymer emulsion. The waterborne rust conversion polymer emulsion is prepared by the polyreaction of alkenyl halide monomers, monomers of (methyl)acrylic acid and esters of (methyl)acrylic acid, alkene phosphate ester monomers, a complexing agent, a compound emulsifying agent, an initiator and deionized water in an inert atmosphere at a pressure of 0.08 to 0.12MPa and a temperature of between 50 and 60 DEG C; and the percentages of dosages of all components on the basis of the total weight of all polyreaction monomers are: 75.0 to 95.0 percent of alkenyl halide monomers, 1.0 to 5.0 percent of alkene phosphate ester monomers, 5.0 to 10.0 percent of monomers of (methyl)acrylic acid and esters of (methyl)acrylic acid, 0.05 to 0.5 percent of initiator, 2 to 4 percent of compound emulsifying agent, 1.0 to 10.0 percent of complexing agent and 100 to 120 percent of deionized water. The coating prepared by the emulsion has the characteristics of good adhesive force, strong covering force, good stability, acid resistance, alkali resistance, salt spray corrosion resistance and long service life, and can be directly coated on the surfaces of metallic materials with a tight rusty layer without the rust removal treatment; and in a film-forming process, no volatile organic compounds are discharged, so that the coating of the invention is a green environmentally protected antirust coating.

Owner:深圳海润德添加剂有限公司

Site rust-removing and corrosion-preventing method for steel piece of electric power system

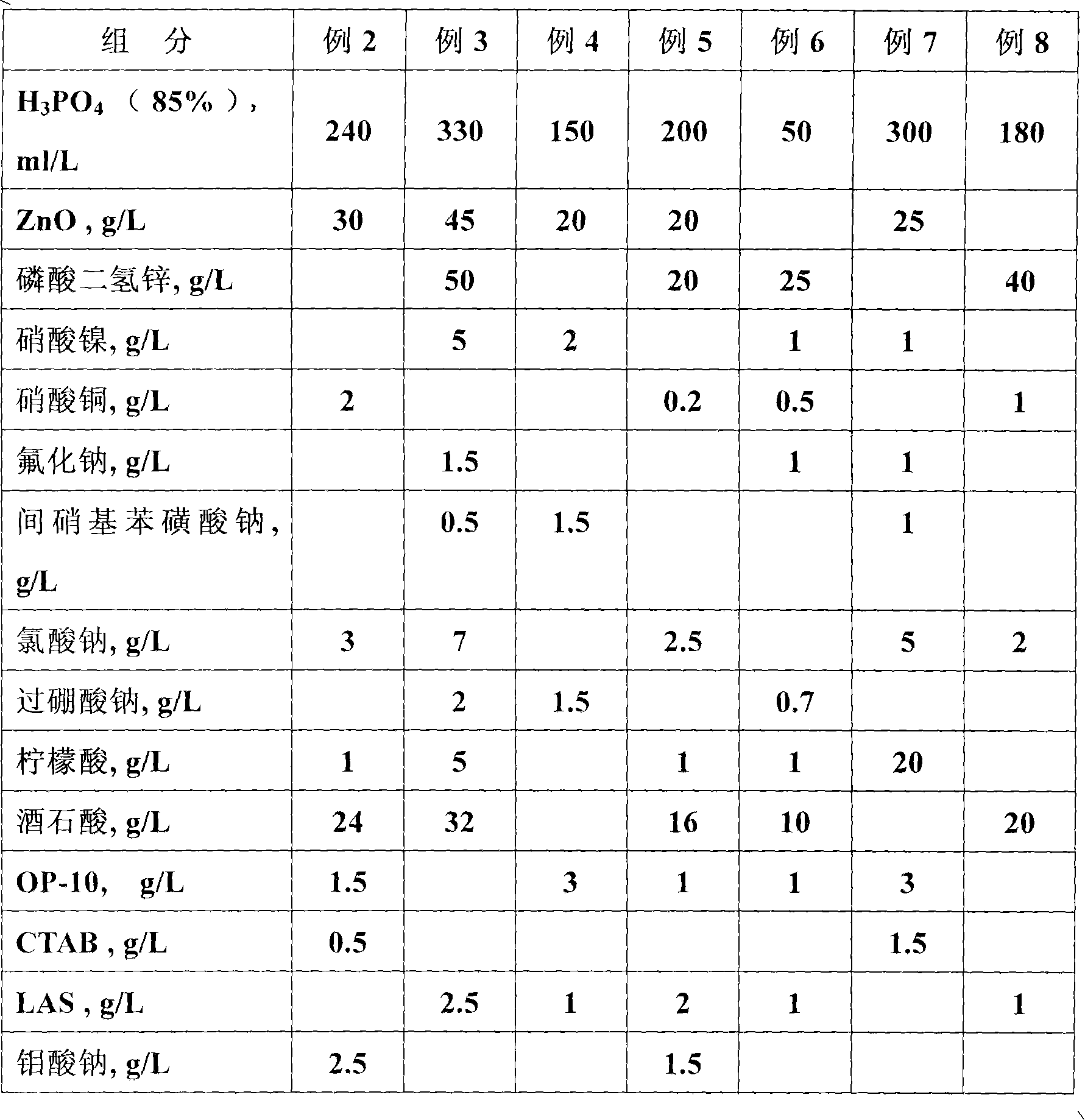

The invention relates to a site rust-removing and corrosion-preventing method for continuously carrying out the electric processing of a steel piece of an electric power system, which has good rust removing and corrosion preventing effect and comprises the steps of: a. removing the dust and the rust on the corrosion part of the steel piece on site; b. coating the rust corrosion part at least for once by utilizing the surface treating fluid integrating four functions of removing oil, removing rust, phosphatizing and passivizing after the step a; and c. coating for at least once by utilizing corrosion-preventing paint after the coated surface treating fluid is completely dried, wherein the surface treating fluid is a water solution prepared according to the following components and the contents thereof; and each liter of the surface treating fluid contains 50 to 350ml of phosphoric acid (while the condensation is 85%), 5 to 25g of Zinc, 0.2 to 7.5g of phosphatizing reaction accelerant, 0.5 to 10g of oxidant, 10 to 40g of polyhydroxyl organic acid complexing agent, 1 to 5g of surfactant and the balance of water. The method is suitable for the rust removing and the corrosion preventing of outdoor electric power equipment.

Owner:STATE GRID ZHEJIANG PINGHU POWER SUPPLY

Environment-friendly rust inhibiting primer

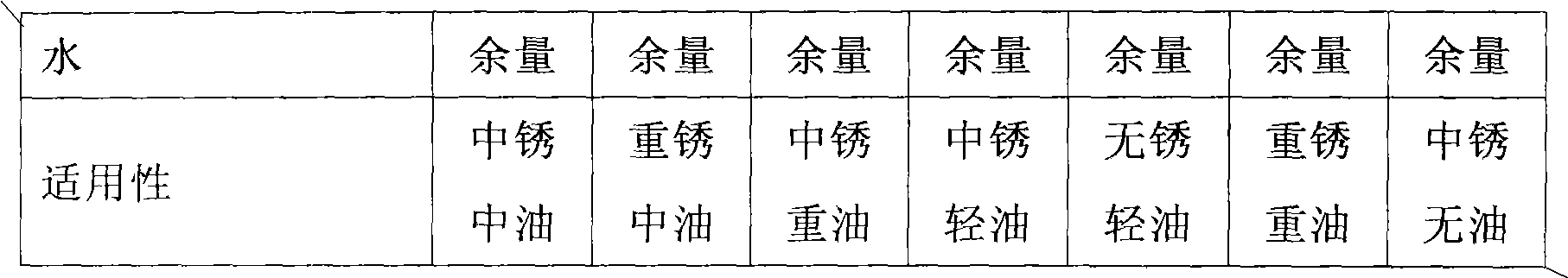

InactiveCN101899248AHarmless to healthGood resolvabilityAnti-corrosive paintsEpoxy resin coatingsEpoxyOrganic solvent

The invention discloses environment-friendly rust inhibiting primer. The rust inhibiting primer comprises the following components in parts by weight: 20 to 50 parts of hydroxyl resin, 5 to 30 parts of amino resin, 2 to 8 parts of epoxy resin, 2 to 10 parts of coalescent, 8 to 20 parts of pigment, 2 to 30 parts of inorganic filler, 5 to 25 parts of organic solvent, 0.01 to 1.0 part of flatting agent, 0.05 to 3.0 parts of conductivity improver, 0.2 to 4 parts of dispersing agent, and 0.2 to 3.0 parts of coupling agent. The primer has good redissolution resistance, can perform 'wet on wet' spraying with undercoat and varnish, namely 'three spraying-one bake' to produce a film after a workpiece is sprayed by primer, undercoat and varnish in turn and is treated by baking once, and the performance of the film is equivalent to the conventional 'three spraying-three bake' process. The heavy metal content of the rust inhibiting primer can achieve the requirement of related laws and regulations, and is harmless to human health.

Owner:JIANGMEN PAINT FACTORY

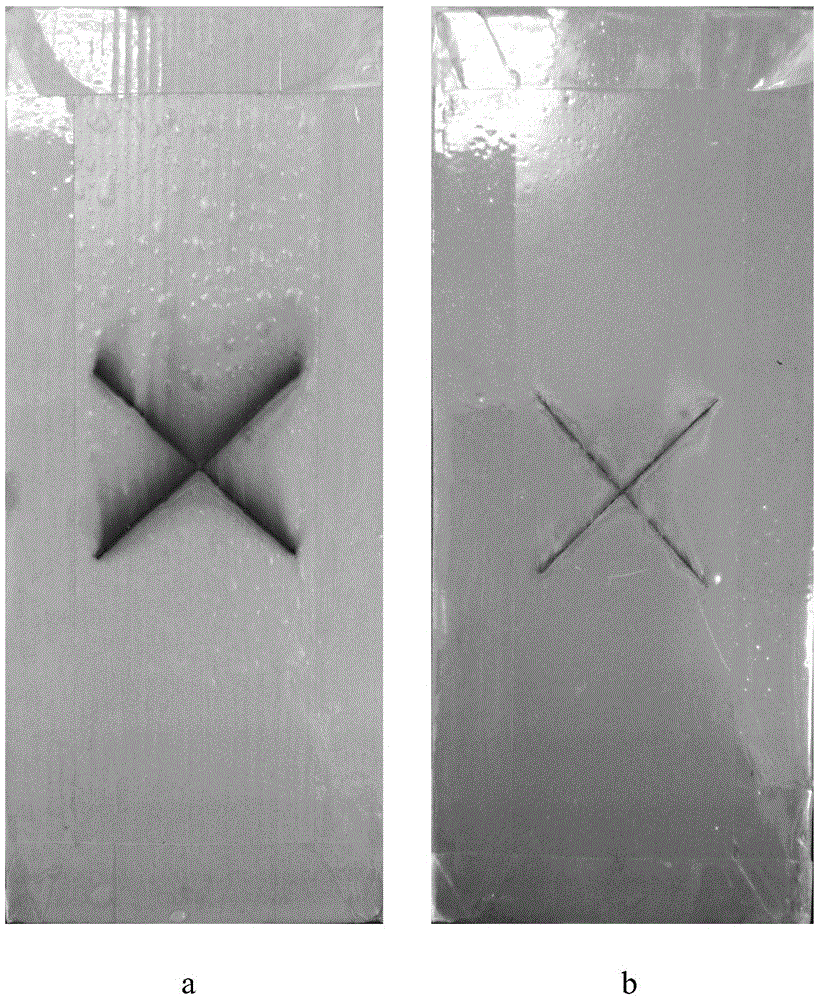

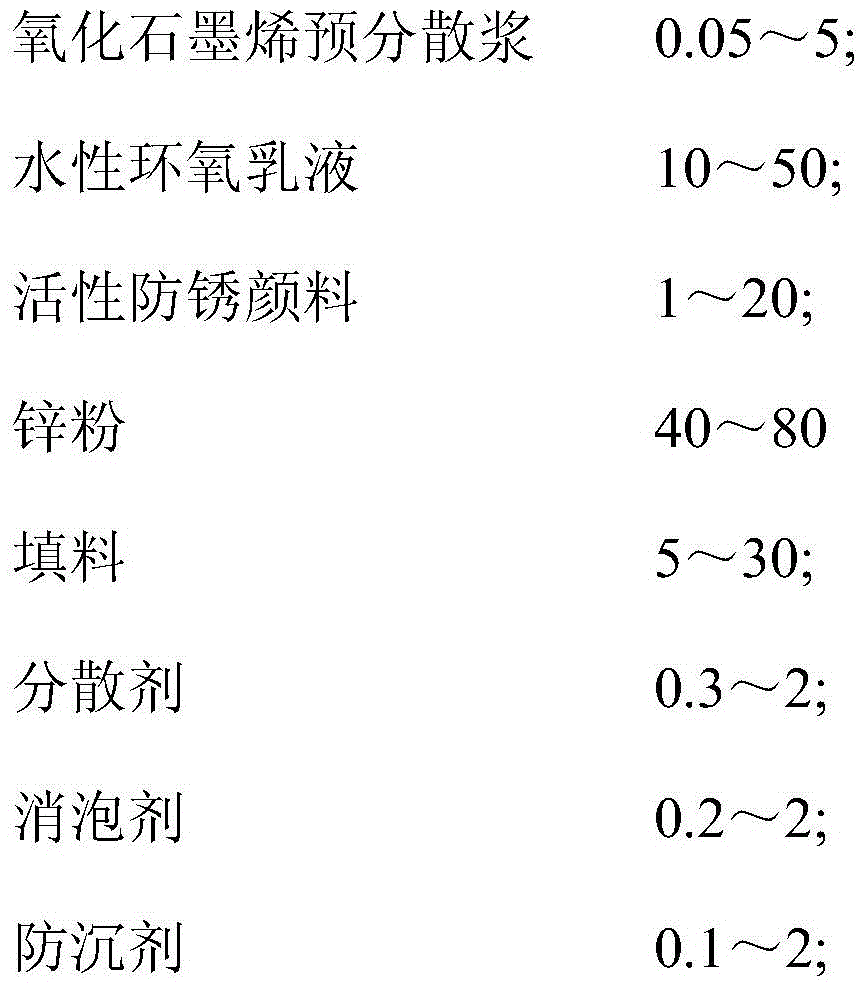

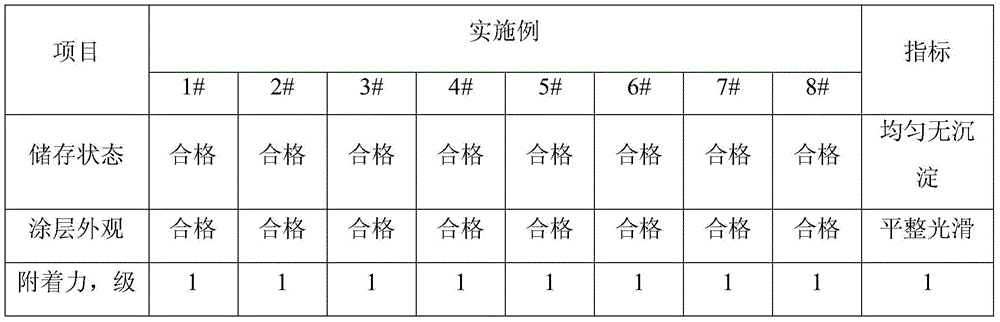

Nano graphene oxide modified double-component aqueous epoxy anti-corrosion coating and preparation method thereof

InactiveCN105419564AImprove resistance to media penetrationImprove mechanical propertiesFireproof paintsAnti-corrosive paintsEpoxyEmulsion

The invention relates to a nano graphene oxide modified double-component aqueous epoxy anti-corrosion coating and a preparation method thereof. The preparation method includes the steps of a) modifying the surface of graphene oxide with a dispersing agent and resin to prepare graphene oxide pre-dispersed slurry; b) placing the graphene oxide pre-dispersed slurry into a stirring container according to proportion and then stirring the slurry uniformly; c) adding an aqueous epoxy emulsion, an anti-rust pigment, a filling material, a dispersing agent and an anti-flash-rust agent, performing high-speed dispersion and grinding to obtain a first component A of the graphene oxide modified double-component aqueous epoxy anti-corrosion coating; d) diluting an epoxy curing agent in deionized water to obtain a second component B of the graphene oxide modified double-component aqueous epoxy anti-corrosion coating; and e) mixing the component A and the component B uniformly, curing the mixture for 10 min to 15 days at 10-120 DEG C to obtain the coating. The coating is simple in process, is low in cost, is suitable for large-scale production, maintains excellent properties of epoxy resin, is better in corrosion resistance, anti-seepage property, mechanical performance and anti-wear property, and has wide industrial application prospect.

Owner:CHANGZHOU NANOMEDIA INC LTD

Method for antiseptic treatment of marine climate resistant engineering component

ActiveCN101748353AEliminate the risk of corrosionReduce pollutionHot-dipping/immersion processesBiological activationCorrosion resistant

The invention relates to a method for antiseptic treatment of marine climate resistant engineering component, comprising: 1. carrying out rust removal treatment on components; 2. carrying out etching treatment to components; 3. carrying out surface activation treatment on the components; 4. putting components into a special atmosphere oven to preheat; 5. dipping the preheated components into plating solution to dip, wherein the components rotate in the dipping process; 6. carrying out diffusion treatment; and 7. adopting coating for seal treatment. Components treated by the method of the invention can endow full corrosion resistance and washing corrosion resistance under the condition of marine climate.

Owner:JIANGSU LINLONG NEW MATERIALS

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com