Patents

Literature

79 results about "Piercing point" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In geology, a piercing point is defined as a feature (usually a geologic feature, preferably a linear feature) that is cut by a fault, then moved apart. Reconfiguring the piercing point back in its original position is the primary way geologists can find out the minimum slip, or displacement, along a fault. This can be done on a large scale (over many kilometers), a small scale (inside a single outcrop or fault trench) or even a single hand sample/rock (see image).

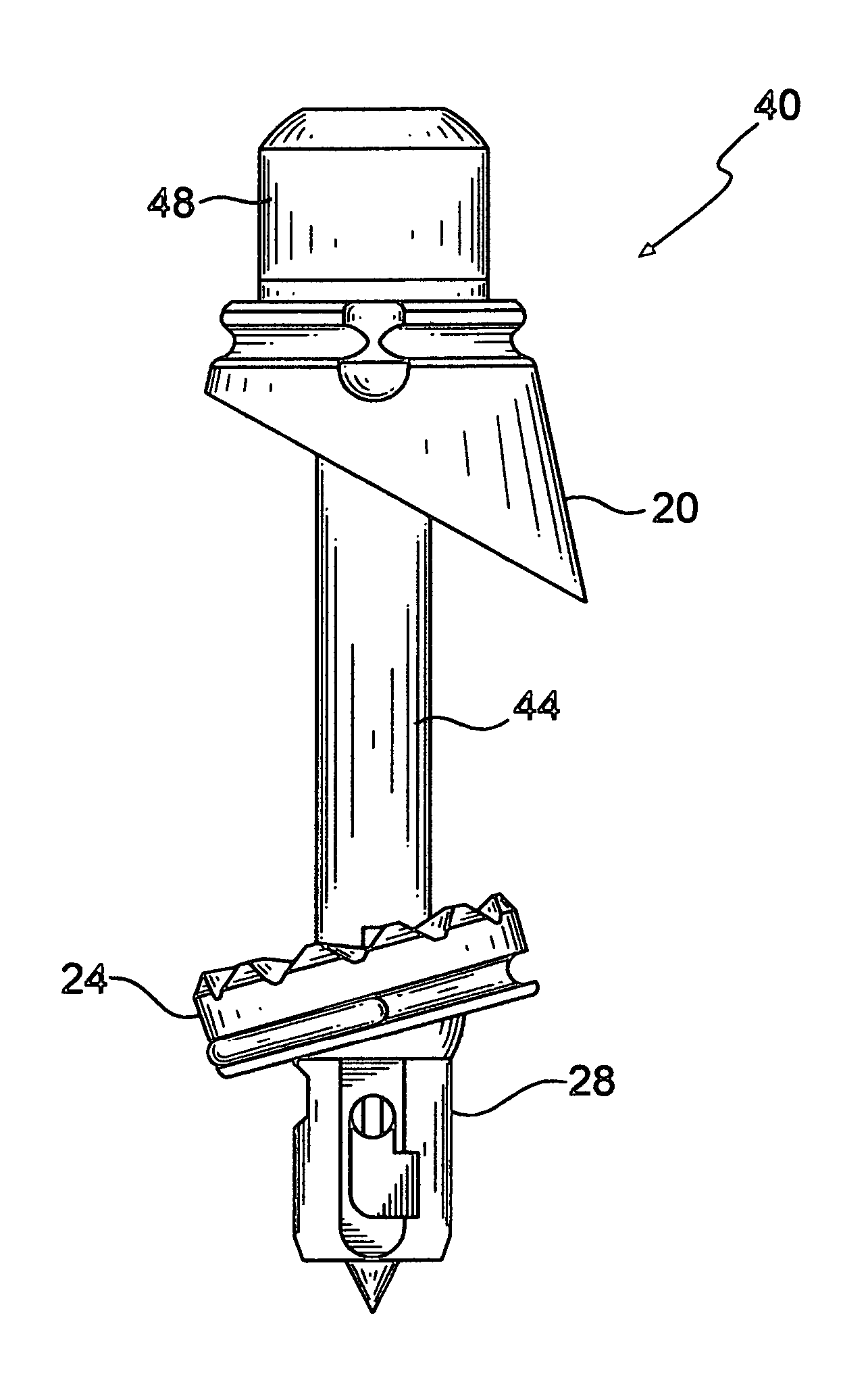

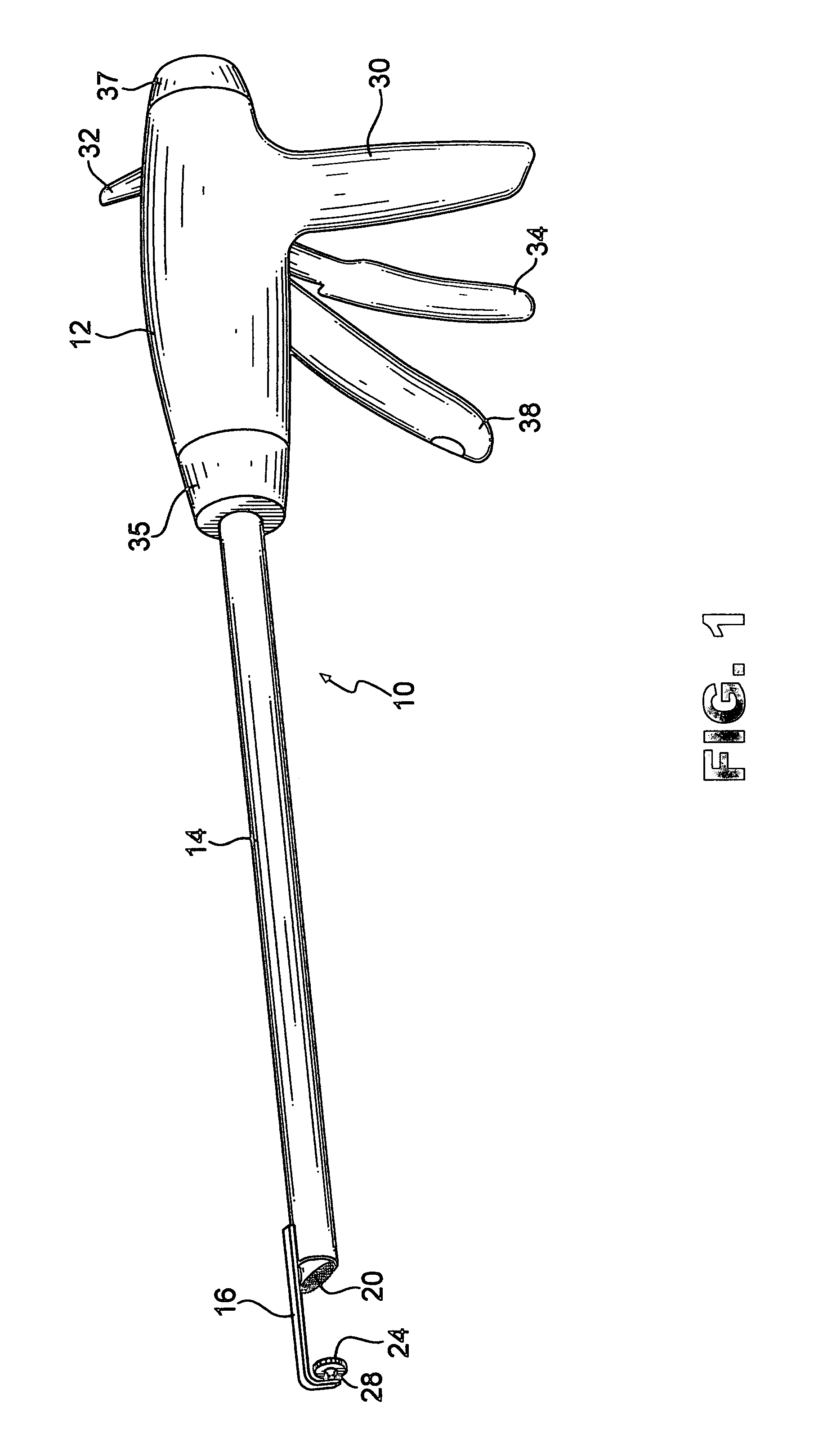

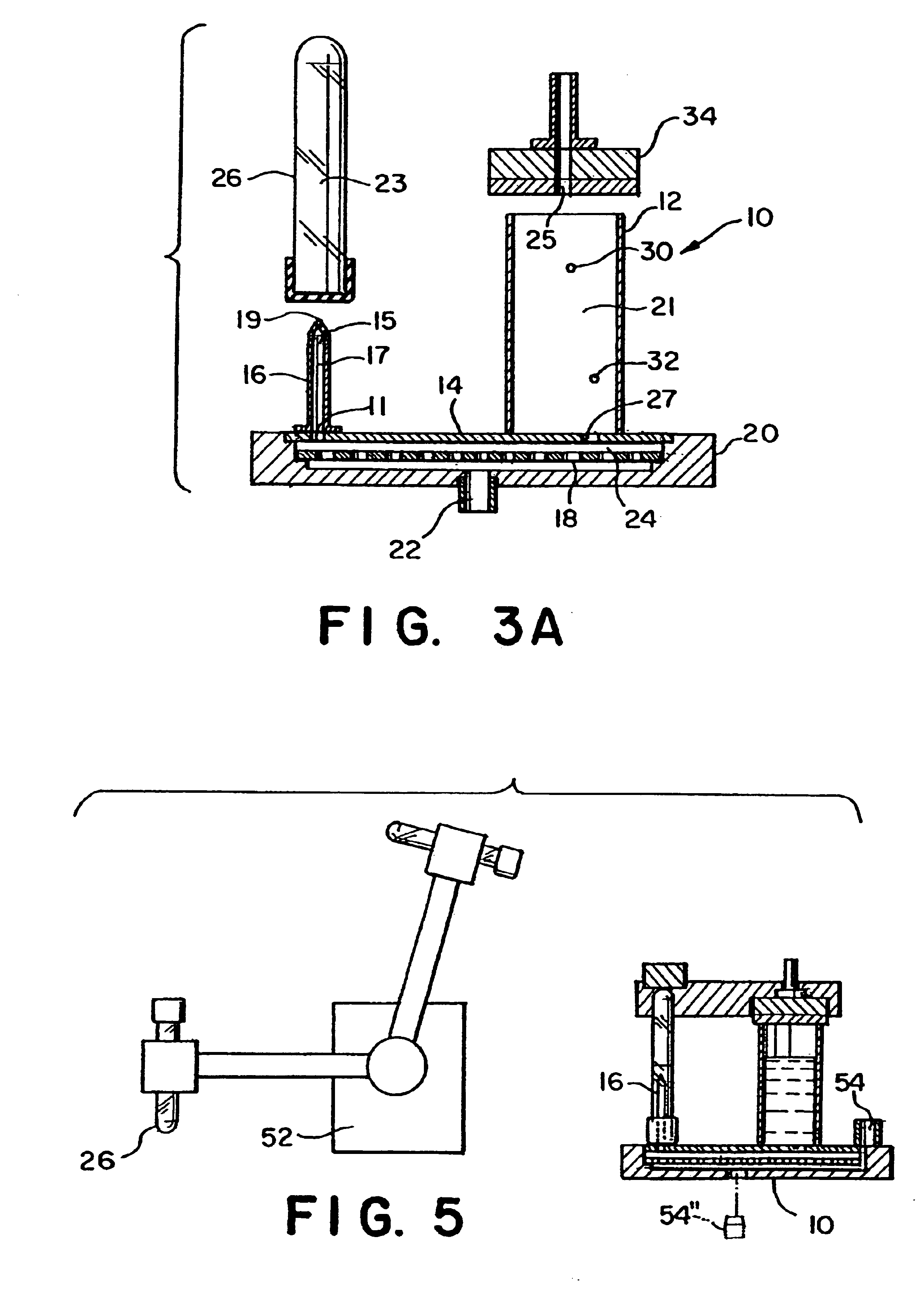

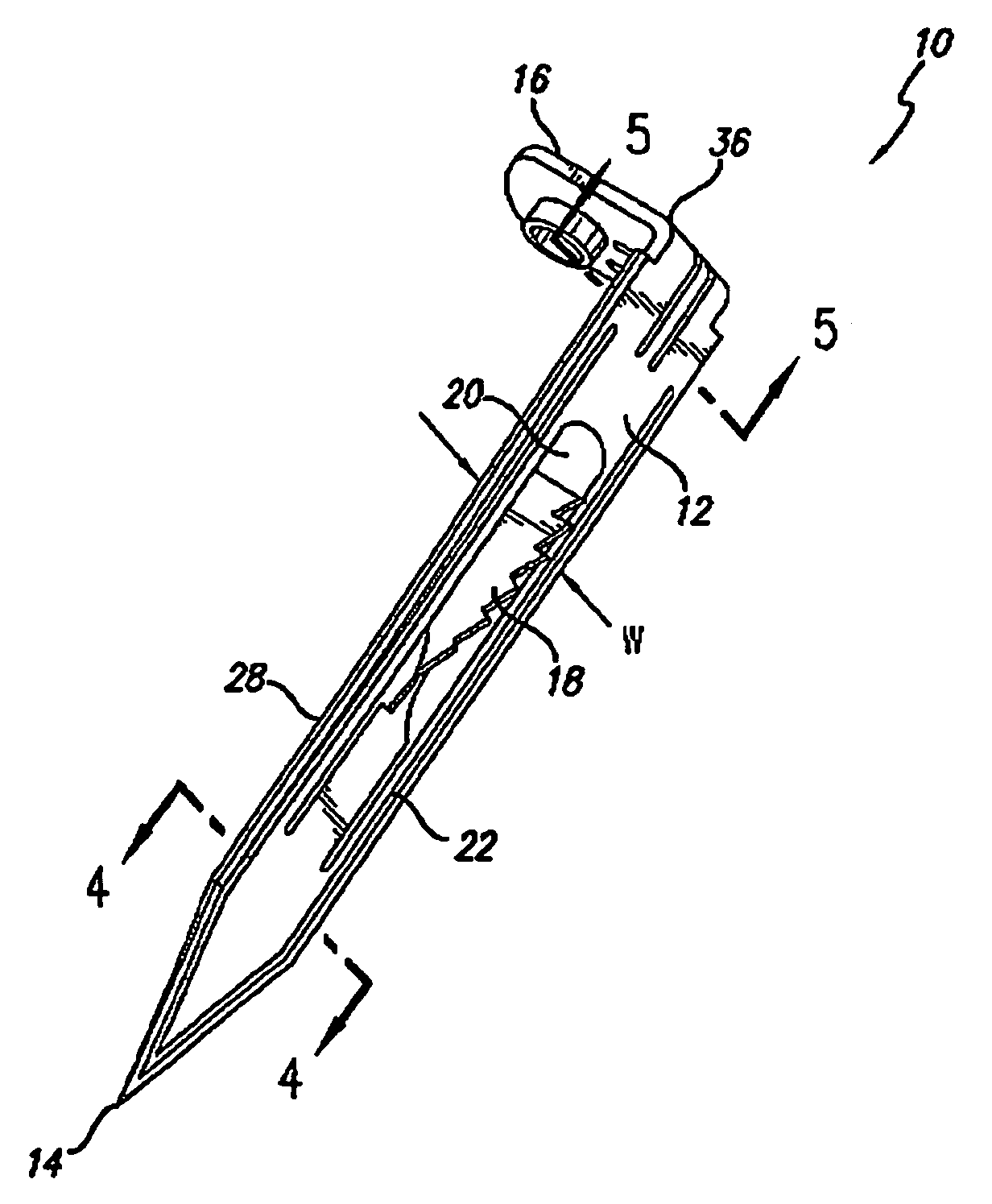

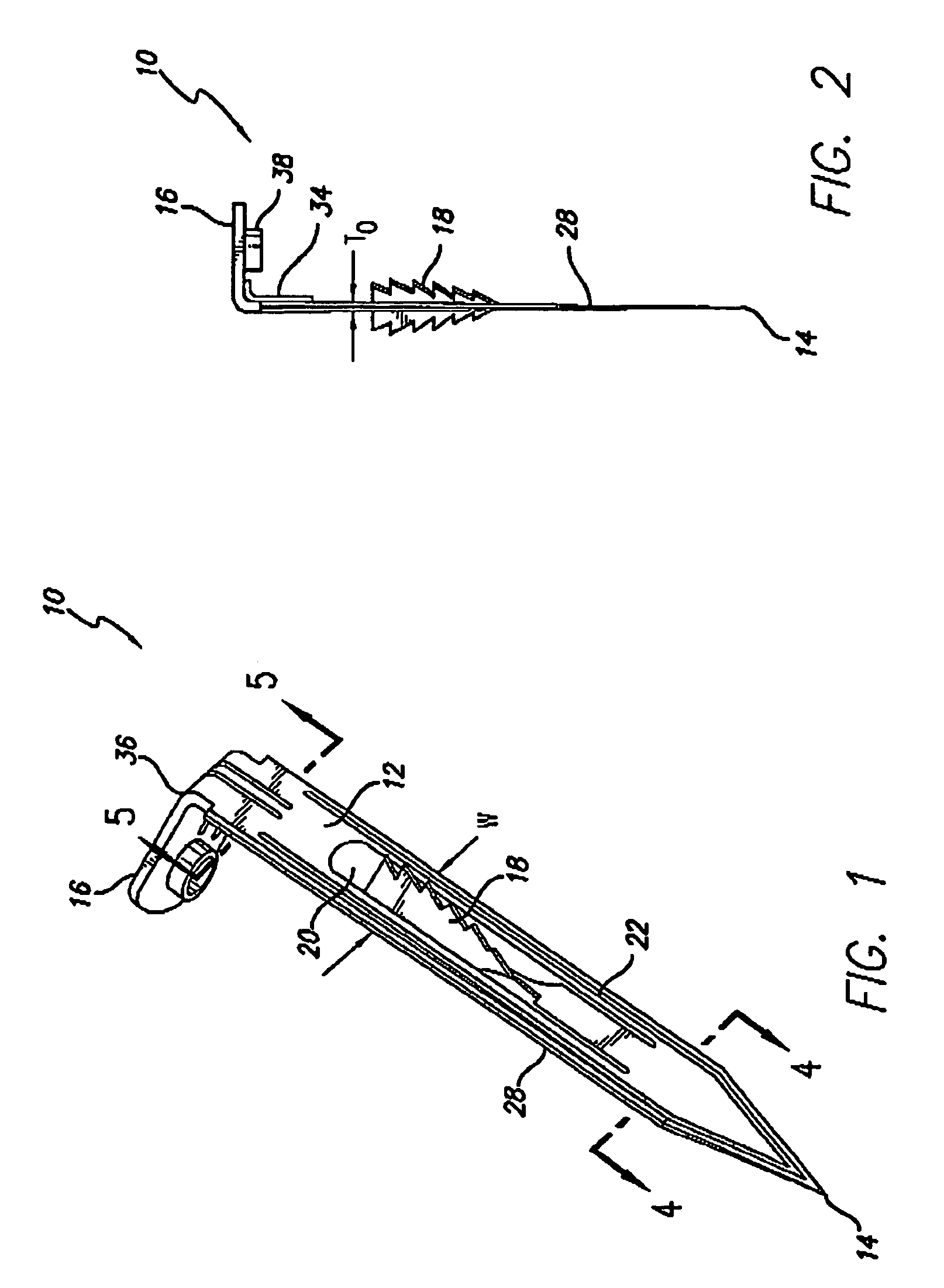

Bone fixation implant system and method

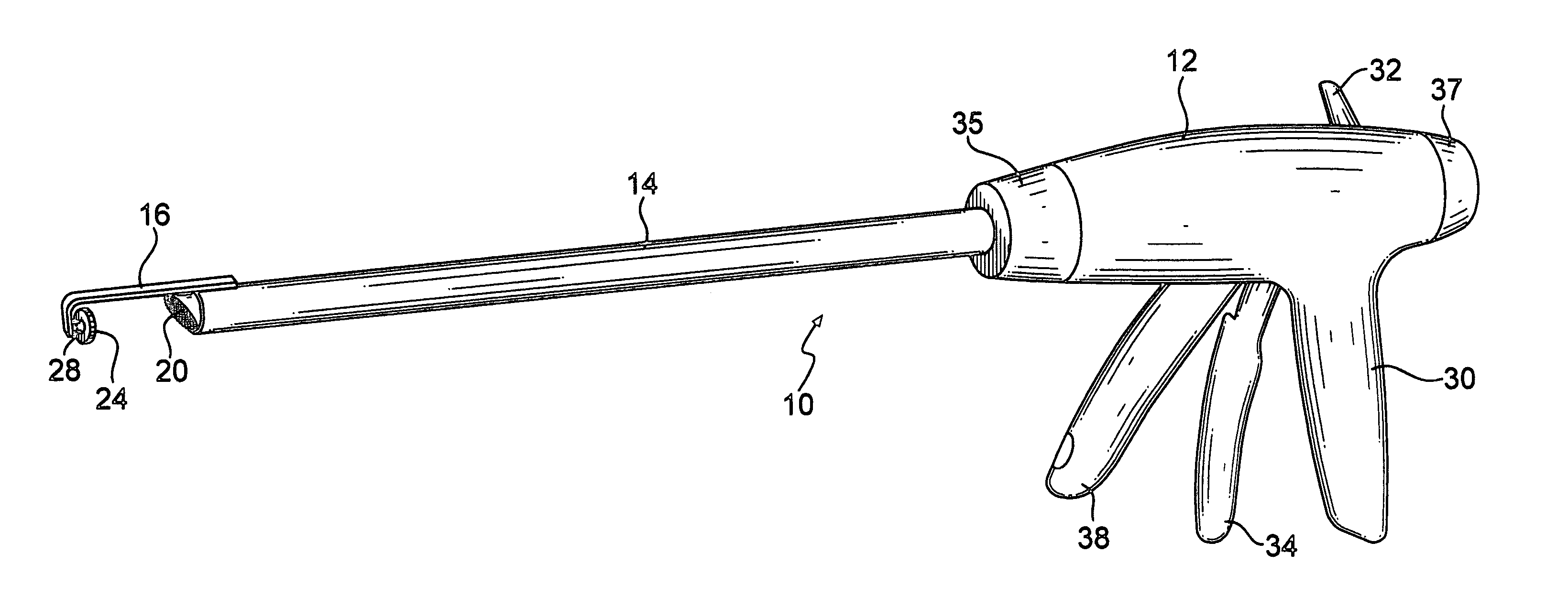

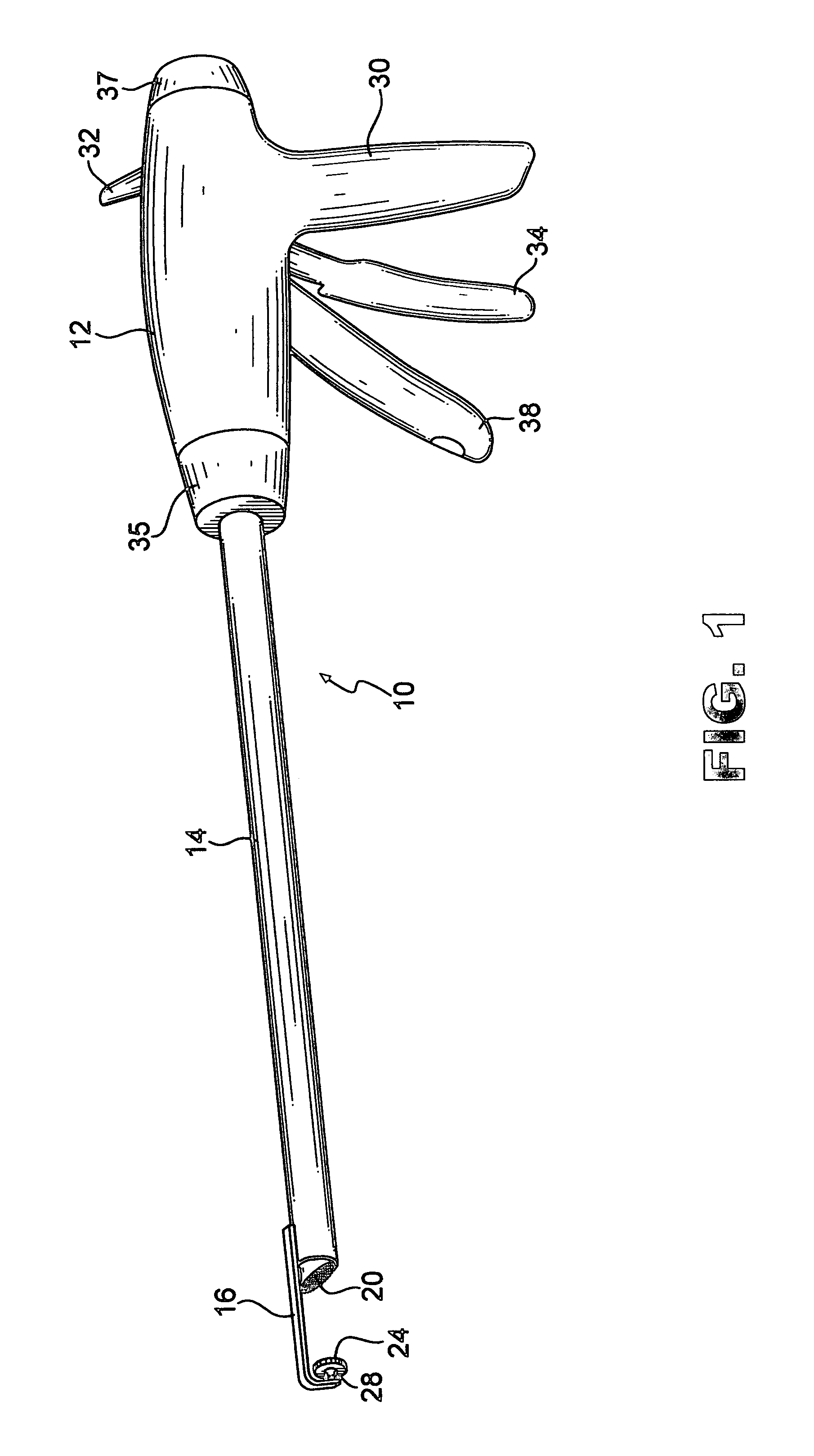

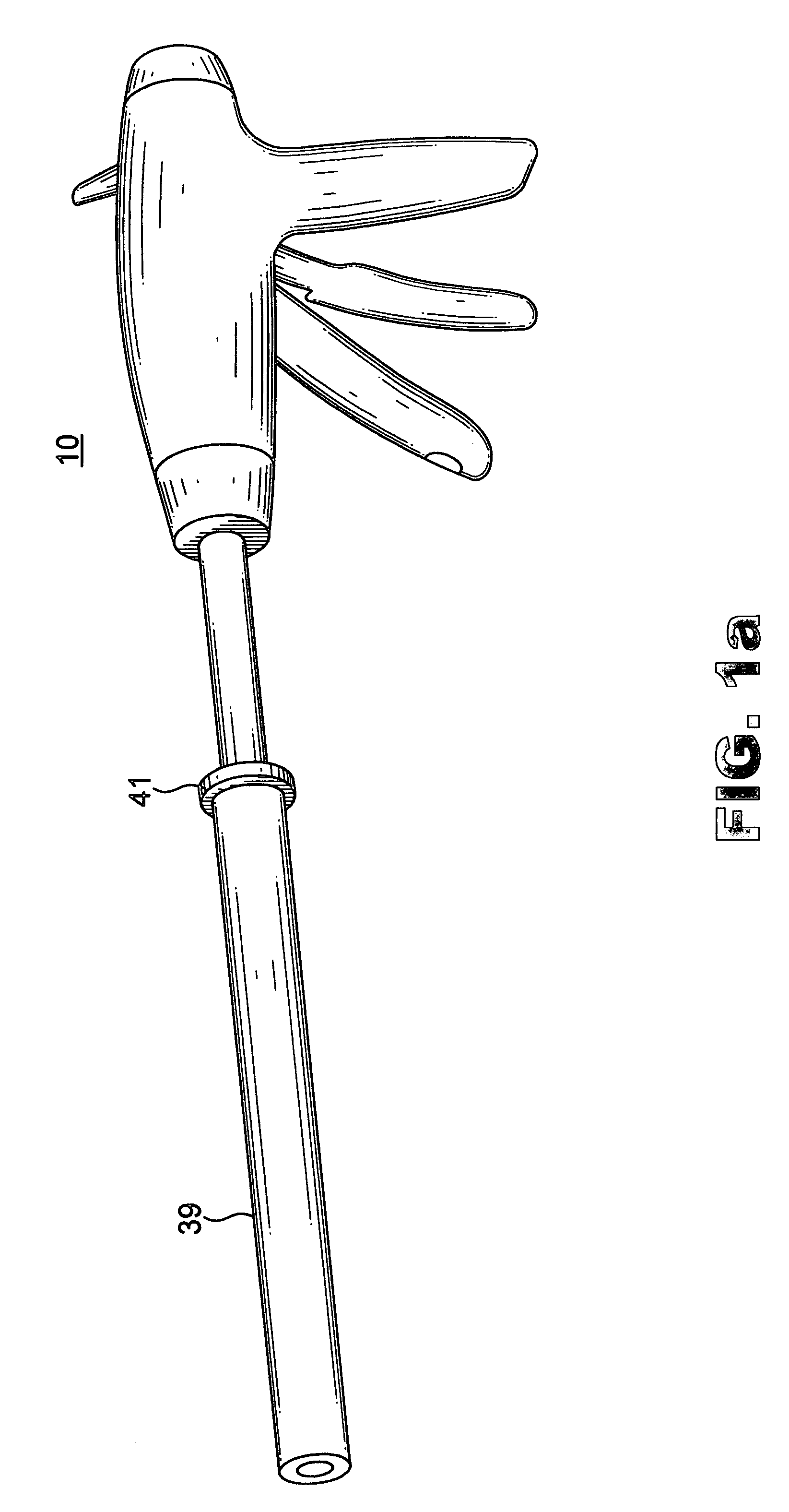

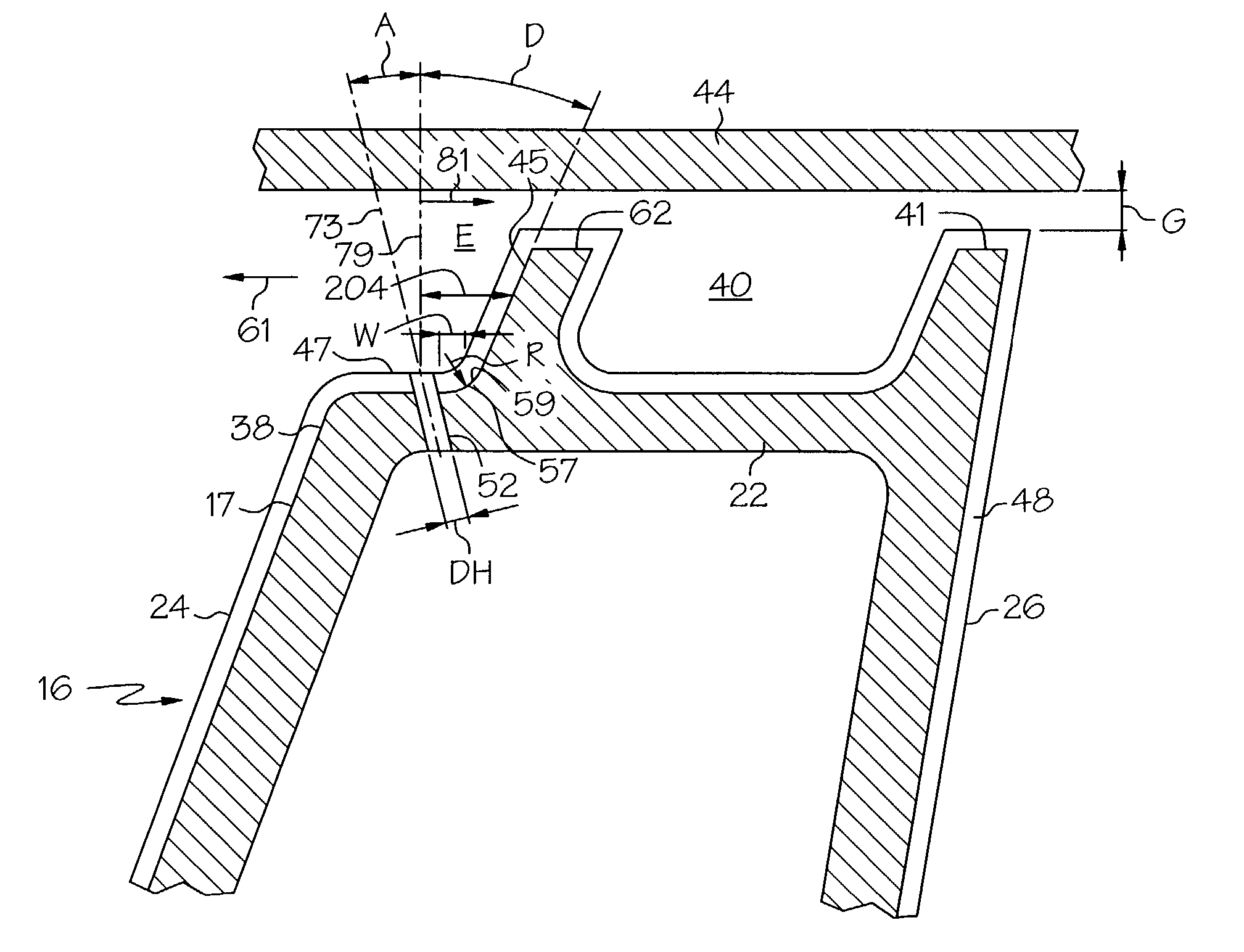

A system for performing bone arthrodesis includes an implant for bone arthrodesis and a bone fastening device. The implant includes a fastener with an elongated shaft having a head at one end and a bone-piercing point at the opposite end. A first washer has structure for engaging the head of the shaft so as to be polyaxially pivotable with respect to the head. A locking member has structure for engaging the shaft. The locking member can have a second washer pivotally engaged thereto. The bone fastening device can include an elongated cannula with a collet for detachably engaging the first washer and for advancing the first washer. Structure is provided for engaging the fastener and for advancing and rotating the fastener through the collet and through the first washer. The bone arthrodesis device further includes a lower end portion extending from the cannula. The lower end portion has structure for detachably engaging the locking member. The fastener, first washer, and locking member are aligned such that the advancing fastener will advance through the first washer, drill through the bone, and move into the locking member. A method for performing bone arthrodesis is also disclosed.

Owner:CTL MEDICAL CORP

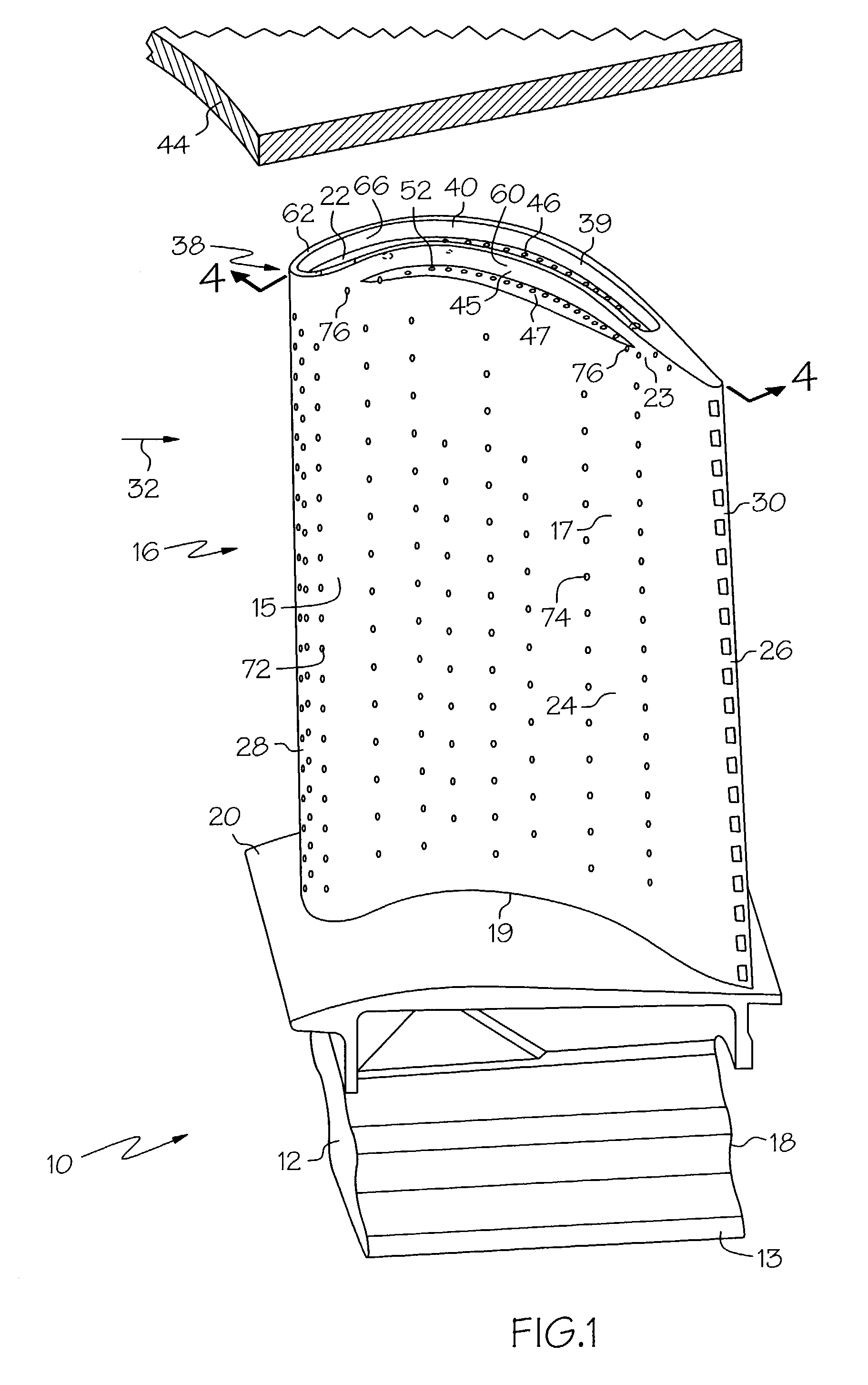

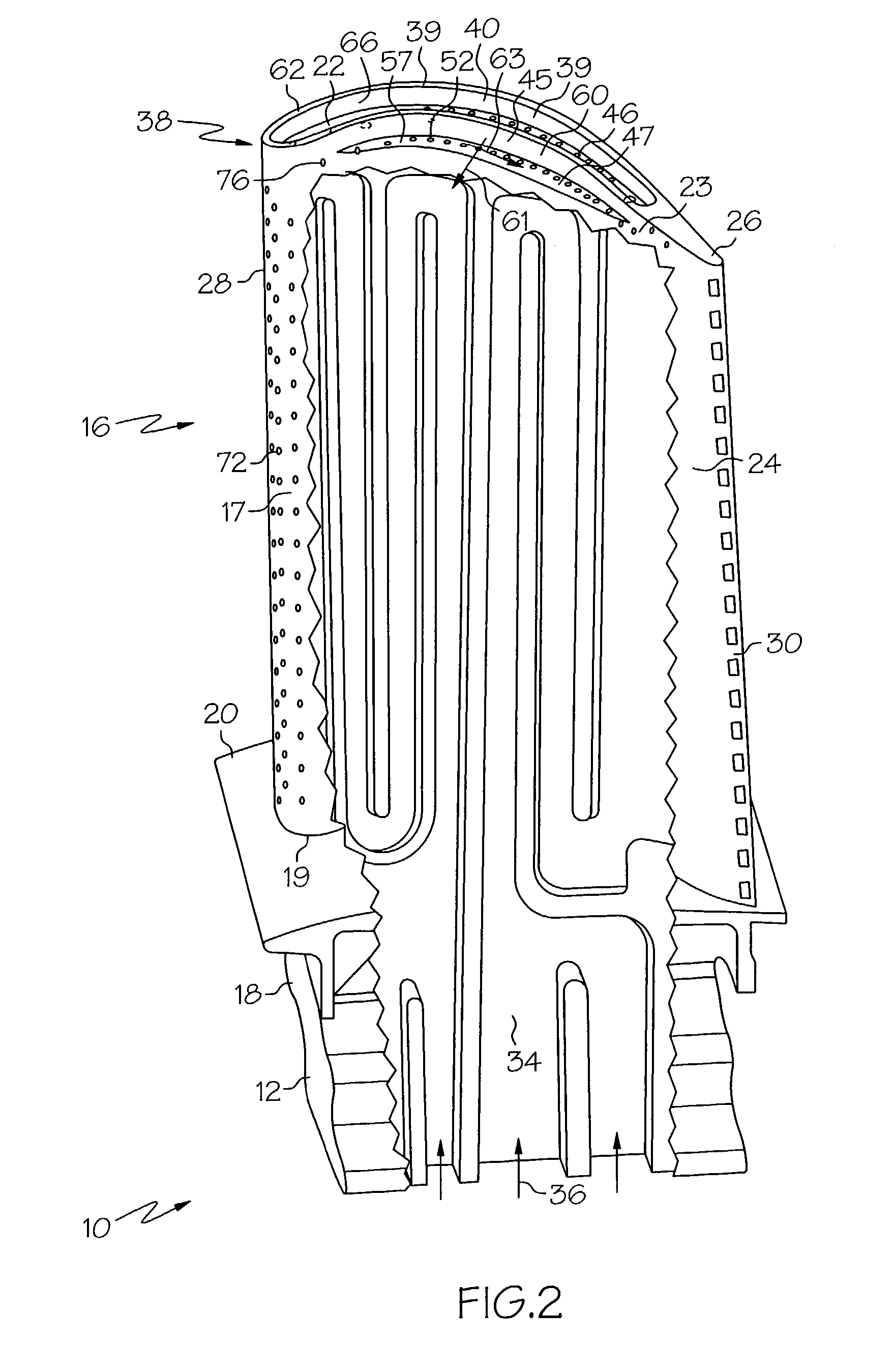

Turbine blade with recessed squealer tip and shelf

A turbine blade squealer tip has a continuous squealer tip wall extending radially outwardly from and continuously around a tip cap. A recessed tip wall portion of the tip wall is recessed inboard from a pressure side of an airfoil outer wall of an airfoil of the blade forming a tip shelf therebetween. A plurality of film cooling shelf holes are disposed through the tip shelf to an internal cooling circuit of the blade and are spaced away from a junction between the recessed tip wall portion and the tip shelf. The exemplary embodiment of the airfoil includes shelf hole centerlines of the holes passing through pierce points in the shelf. At least a majority of the shelf hole centerlines are angled in outboard directions away from and outboard of the squealer tip wall. A majority of centerlines are angled away from vertical lines passing through the pierce points at first component angles in a range between 2 degrees and 16 degrees.

Owner:GENERAL ELECTRIC CO

Bone fixation implant system and method

Owner:CTL MEDICAL CORP

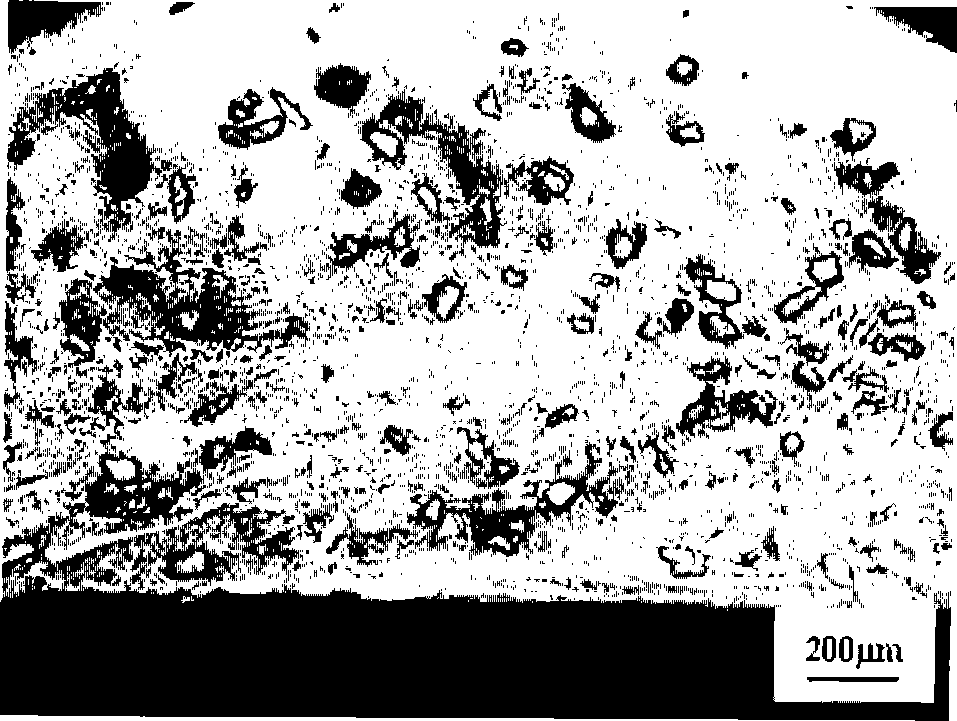

Laser cladding method for strengthening surface of piercing point

ActiveCN101519778ASolve the problem of easy falling offThickness is easy to controlMetallic material coating processesPiercing pointPre treatment

A laser cladding method for strengthening the surface of a piercing point includes the following steps of: (1) prefabricating WC / Co-base cladding powder; (2) pre-processing the surface of a piercing point workpiece, and cleaning up stain and rust; preheating for 2 to 5 hours at a temperature between 400 DEG C and 600 DEG C; (3) cladding the prefabricated composite powder fed in the way of reverse synchronization or coaxially in multiple steps by a CO2 laser; simultaneously, carrying out synchronous inert gas protection on the laser-cladding area; and (4) subsequent processing. The laser cladding method adopts laser to prepare a WC ceramic particle-strengthened Co-base composite coating on the surface of the piercing point, and the coating is metallically combined with the matrix, so the binding force between the coating and the matrix is enhanced; the maximum thickness of the coating can reach a few millimeters; and as the surfaces of WC particles are coated with Ni, the absorption of laser energy by the WC can be reduced, so that the burnout rate of the WC can be reduced in a laser melting pool. The distribution of the WC particles is uniform in the coating, the rigidity of the coating is high, consequently, the service performance of the piercing point can be improved, and the service life can be prolonged.

Owner:BAOSHAN IRON & STEEL CO LTD +1

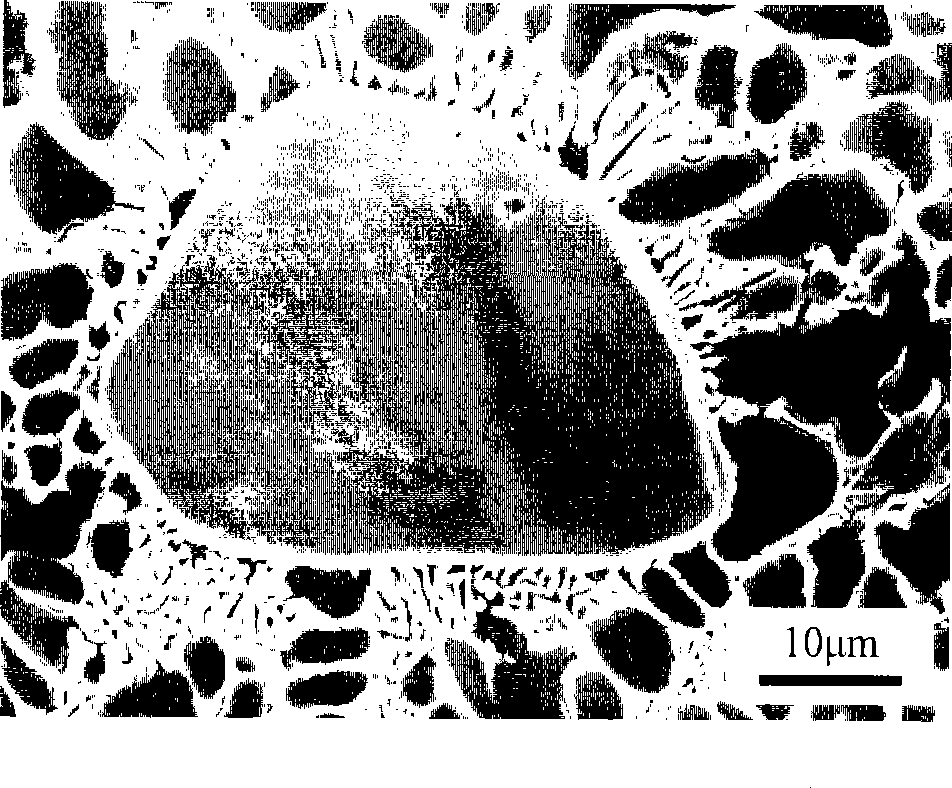

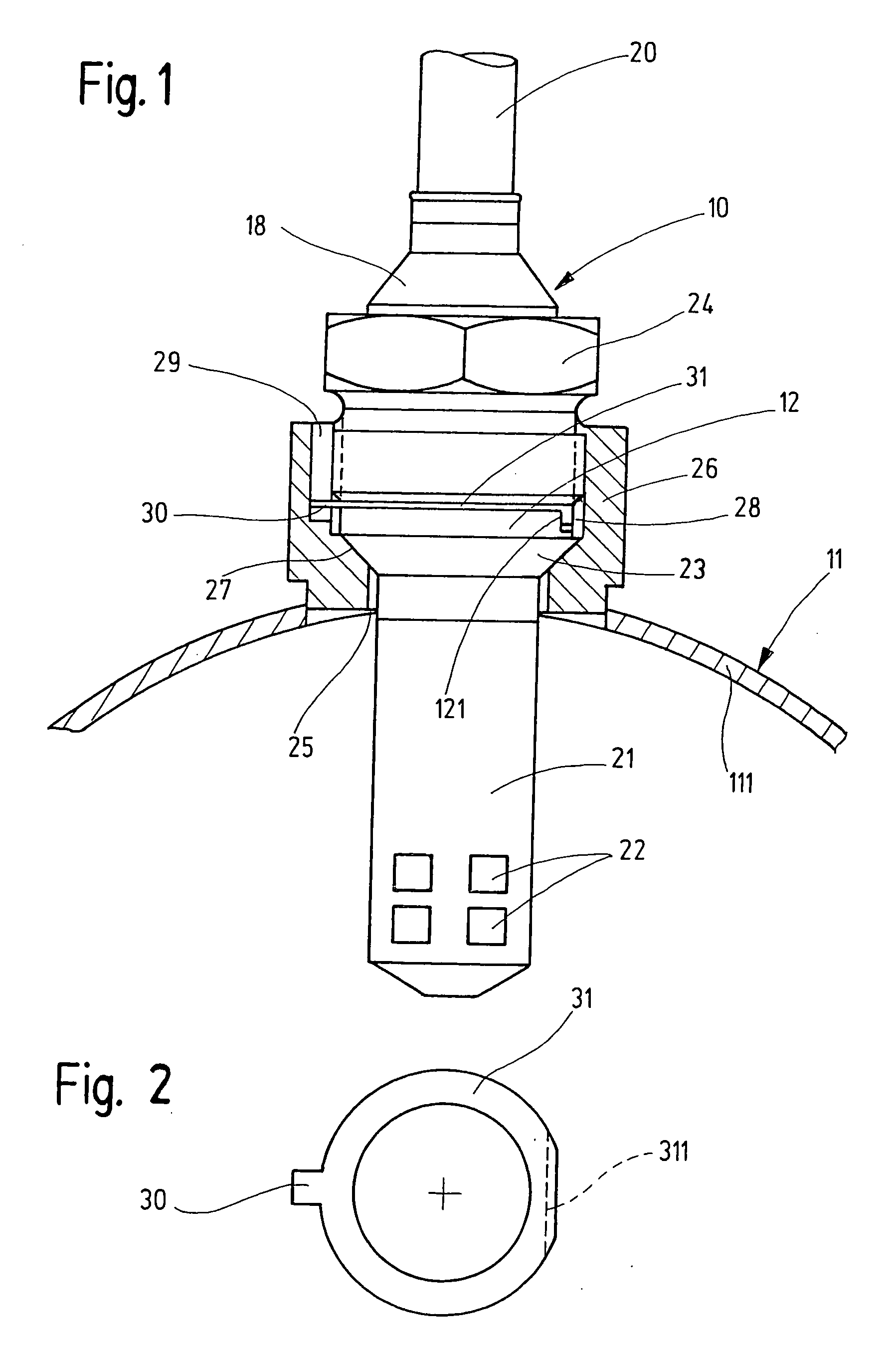

Sensor arrangement

InactiveUS20050155408A1Ensure overall alignmentSimply minimally changing the manufacturing methodThermometer detailsMachine part testingMeasurement testLine tubing

A sensor system having a sensor for measuring a gas parameter of a test gas via a measuring element which is accommodated in a housing and projects therefrom at least on the test gas side at a protruding section, and a test-gas line, through which the test gas flows, having a sensor insertion opening and a receiving element for the housing surrounding the insertion opening and attached to the test-gas line. For the purpose of assembly-independent, reproducible alignment of the measuring element with respect to the test-gas flow during assembly of the sensor system, the receiving element bears an internal thread, the piercing point of which is oriented with respect to the test-gas flow, and the housing bears an external thread, which is able to be screwed into the internal thread and the piercing point of which is oriented with respect to the measuring element. The housing is fixed via a predefined tightening torque in the receiving element.

Owner:ROBERT BOSCH GMBH

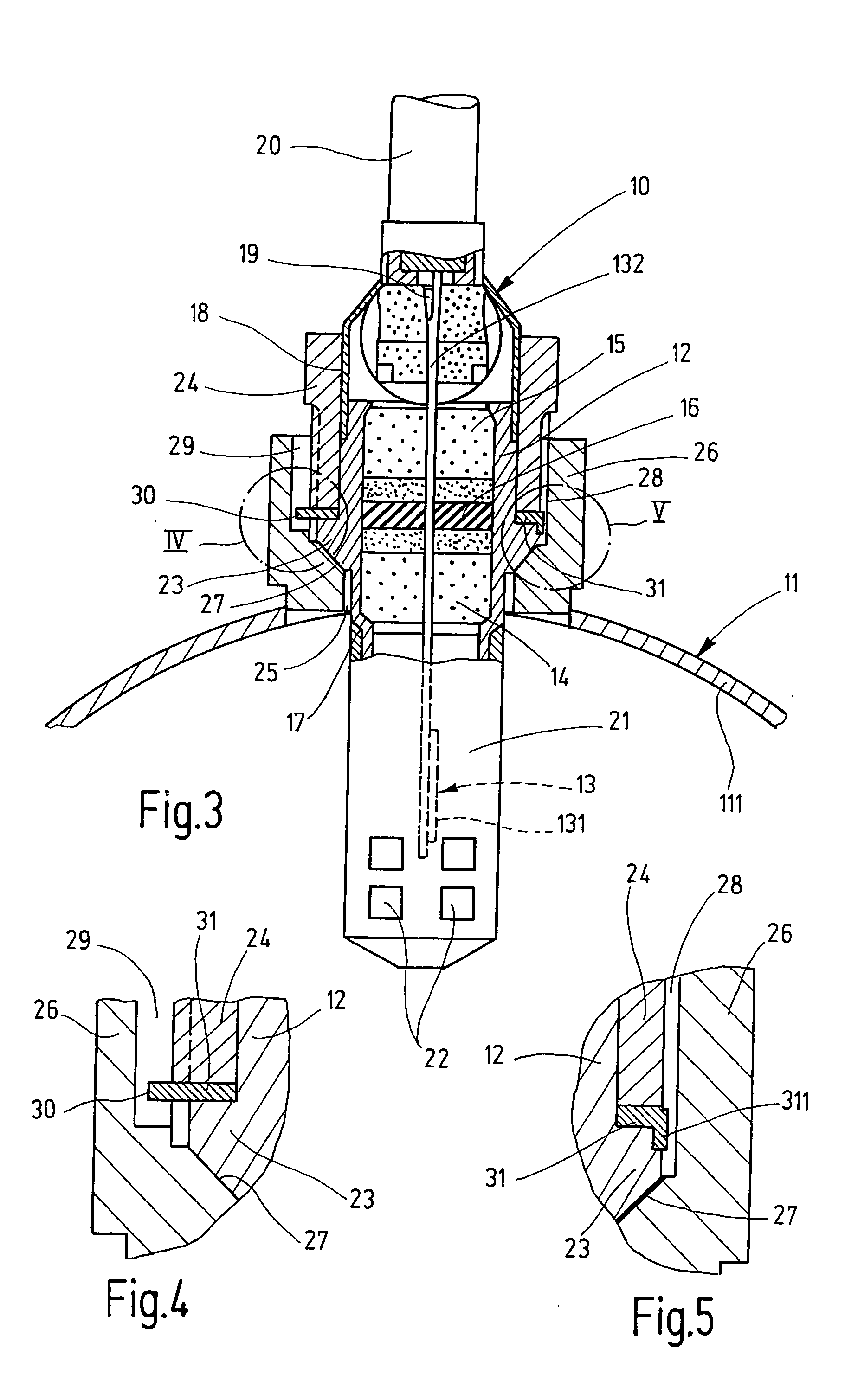

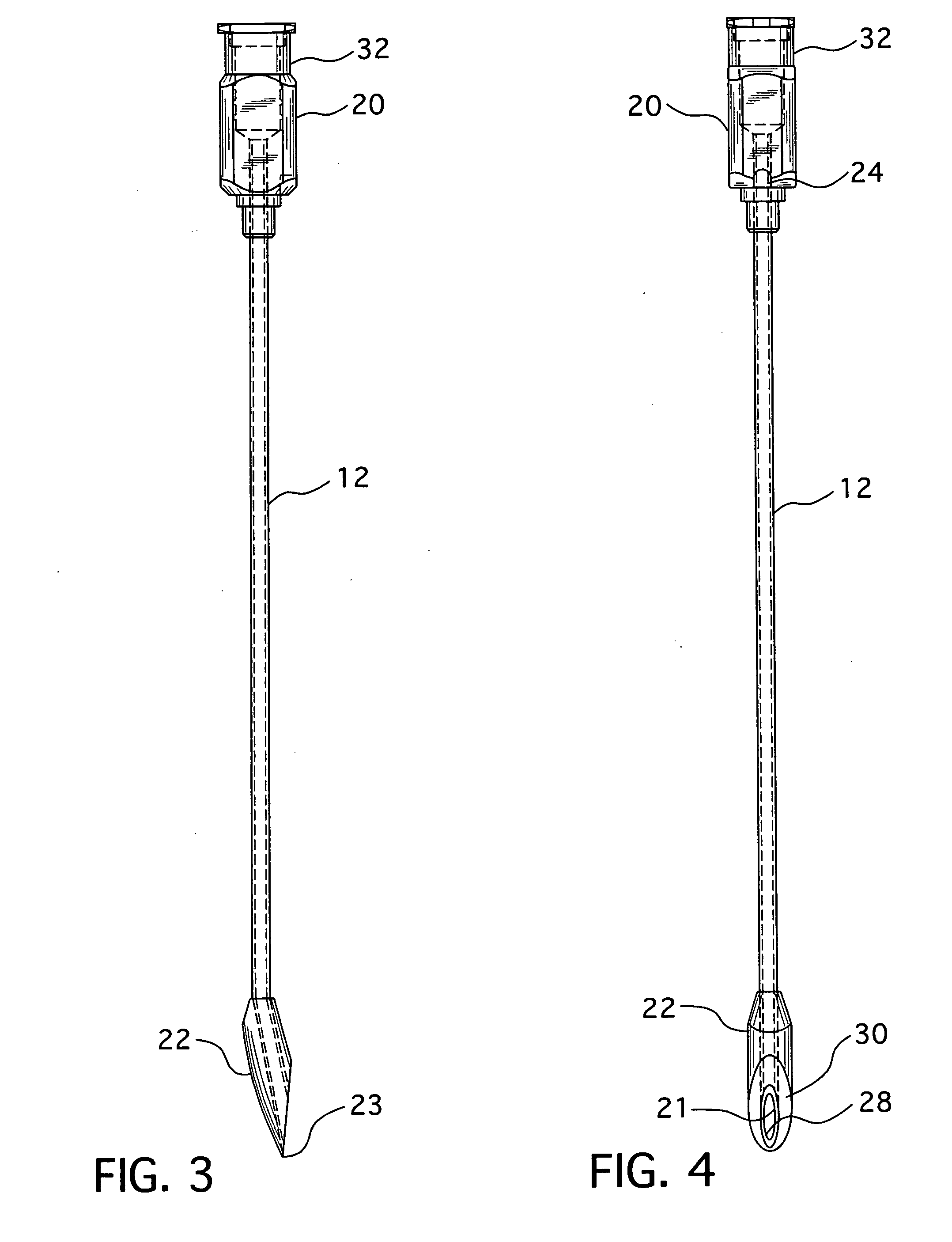

Apparatus and method for safely inserting an introducer needle into epidural space

ActiveUS20130072900A1Achieve accessLoss of resistanceInfusion syringesSurgical needlesSpinal columnLoss of resistance

An epidural needle assembly is provided, permitting the accurate introduction of a large bore introducer sleeve needle into the epidural space in the spinal column of a patient using the loss of resistance technique. The large bore introducer needle has a beveled side opening at its tip and with a tissue piercing point at the distal extension of the needle. A syringe needle is received within the introducer needle with a distal head of the syringe needle filling the beveled side opening at the distal end of the introducer needle when the syringe hub is fully seated. The lumen of the syringe needle exits the syringe needle head at the side opening of the introducer needle immediately adjacent the tissue piercing point of the introducing needle. The needle assembly may be inserted and advanced, with precise tactile feedback, into a patient, thus accurately detecting the introduction of the introducer needle into epidural space.

Owner:COLANTONIO ANTHONY J

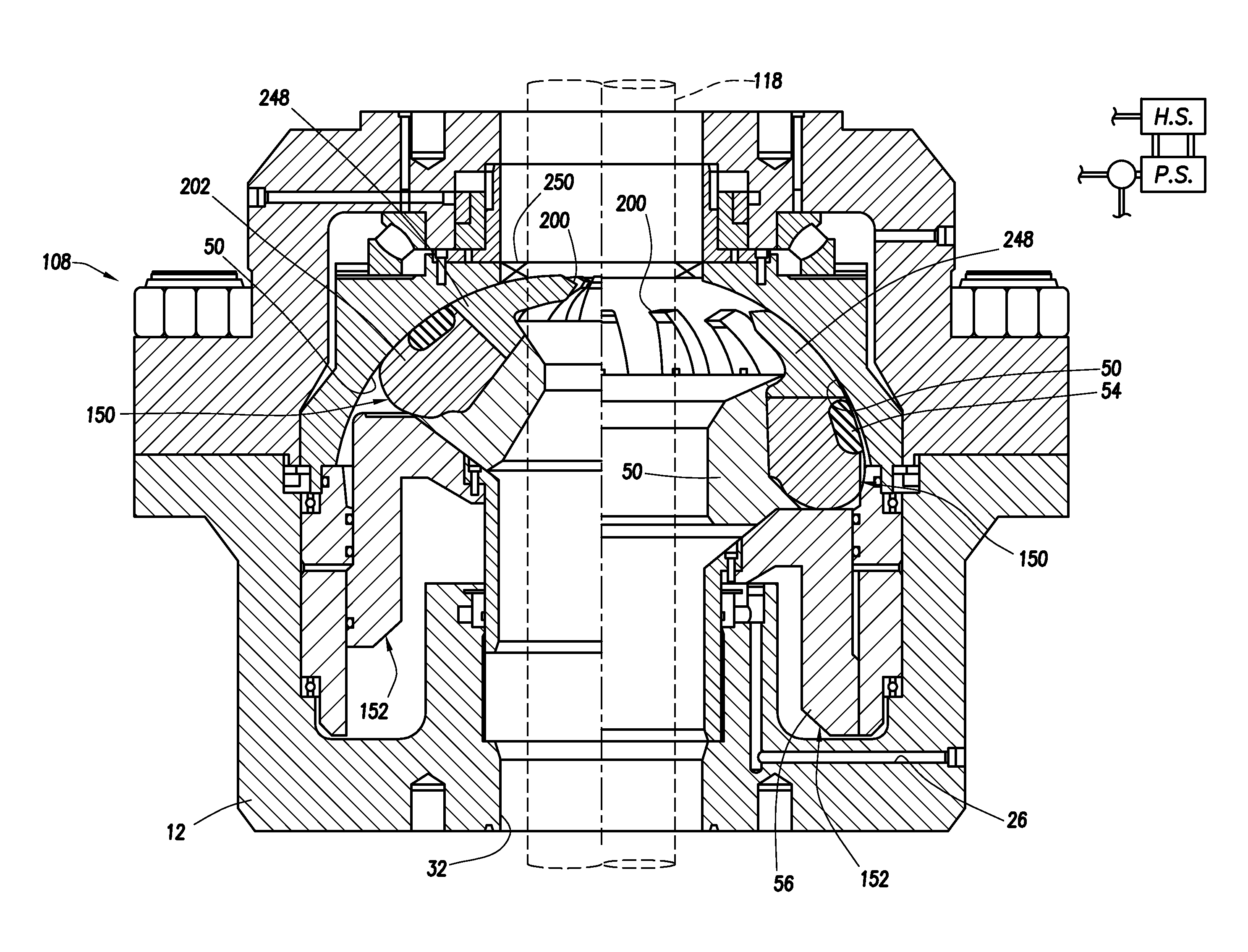

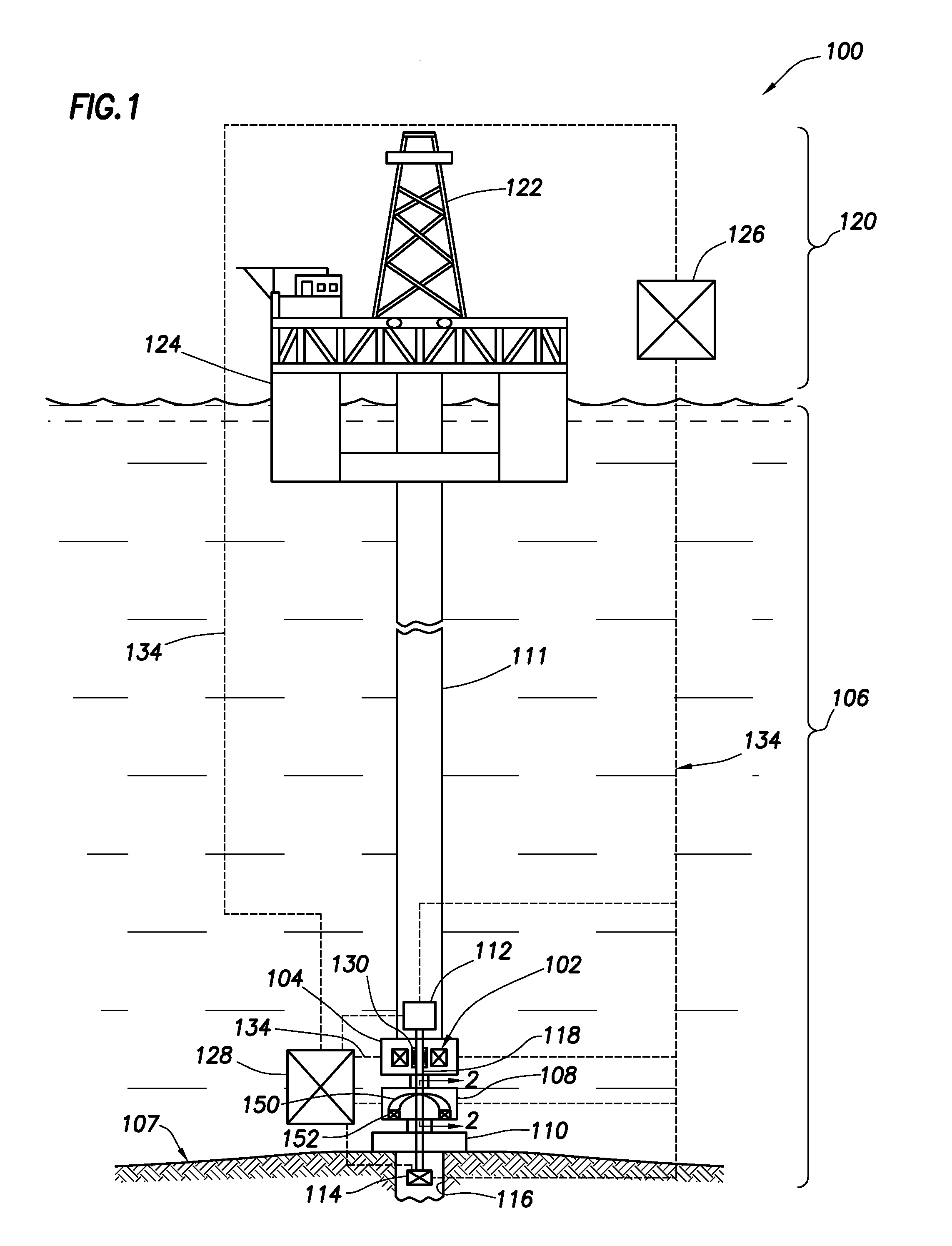

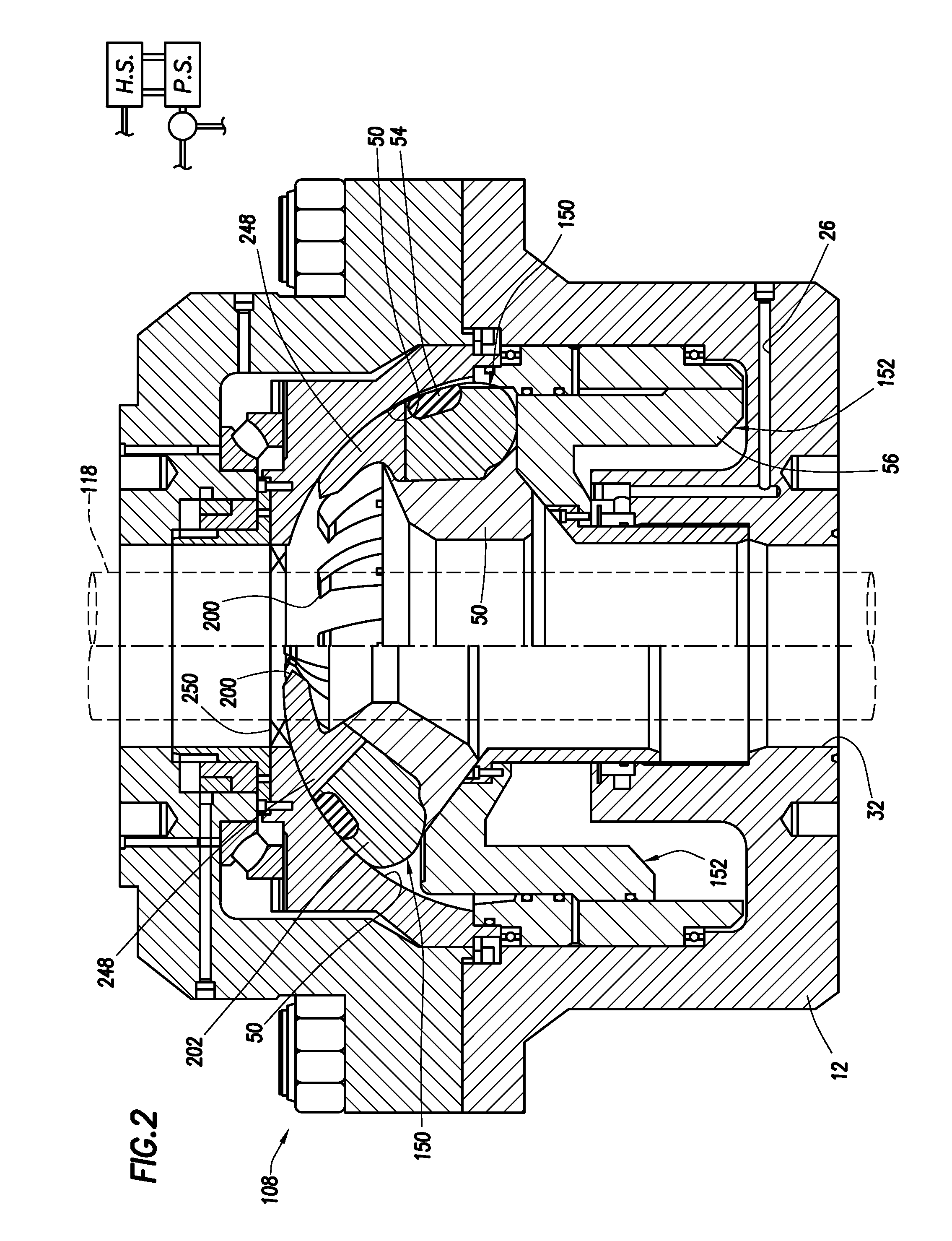

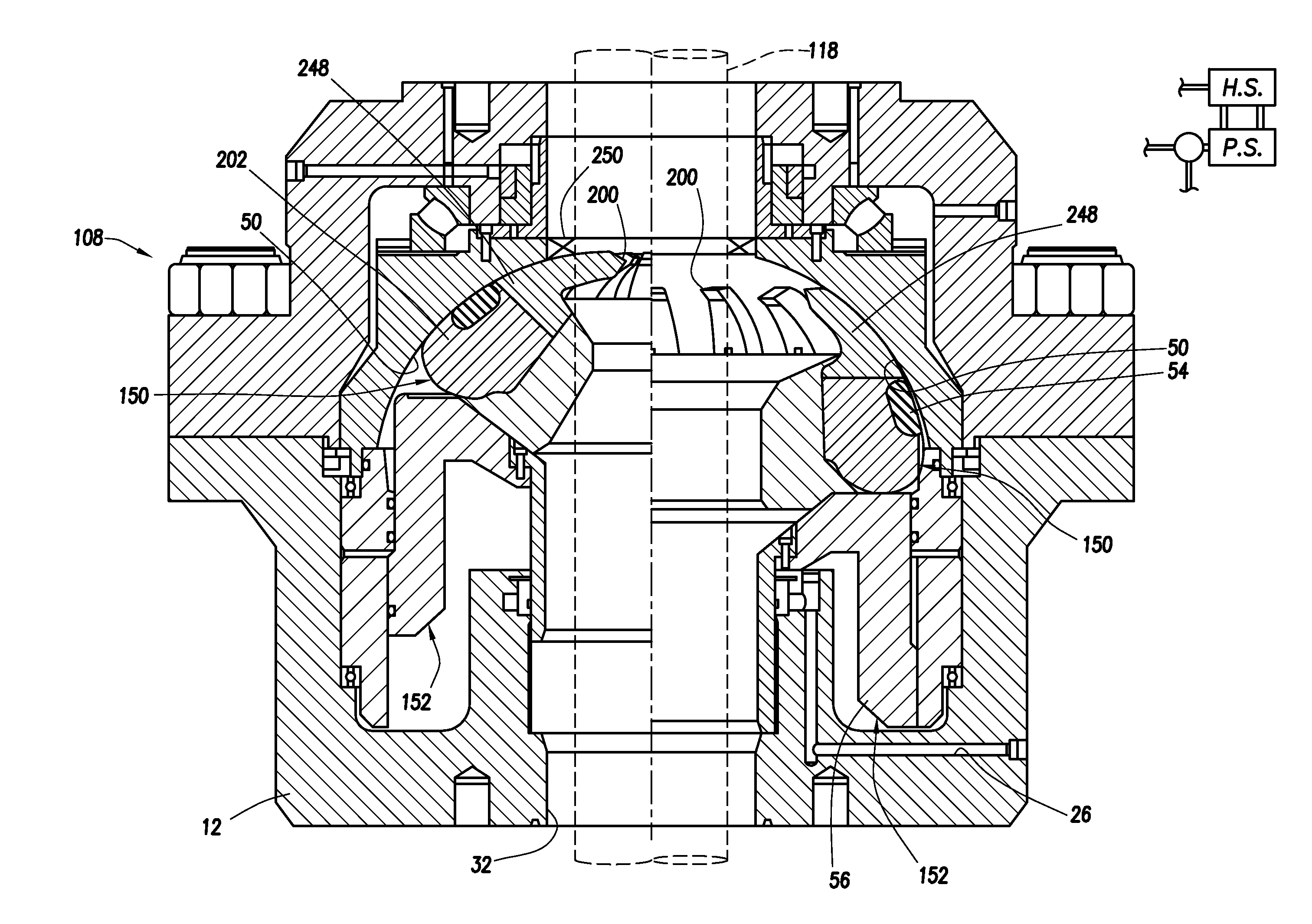

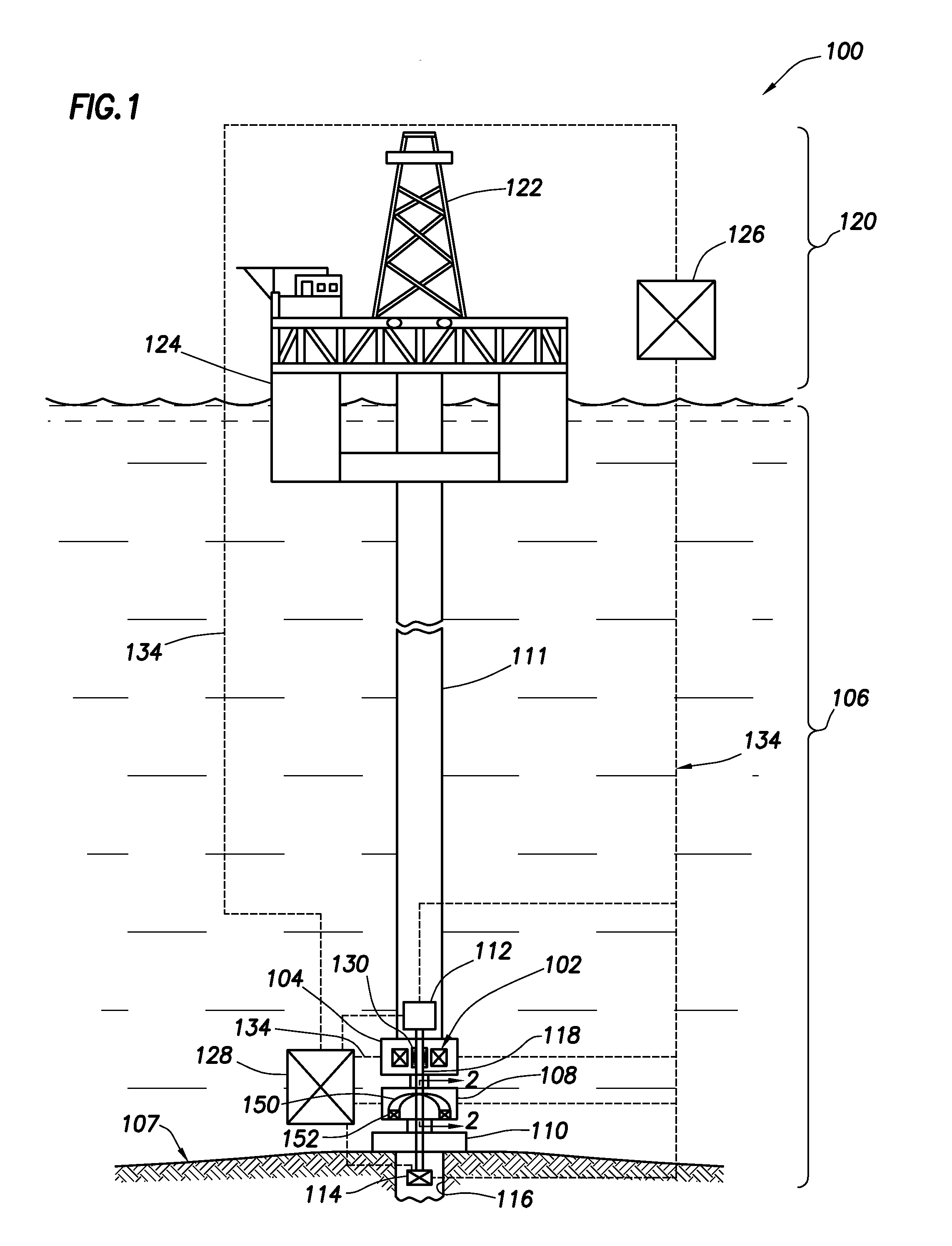

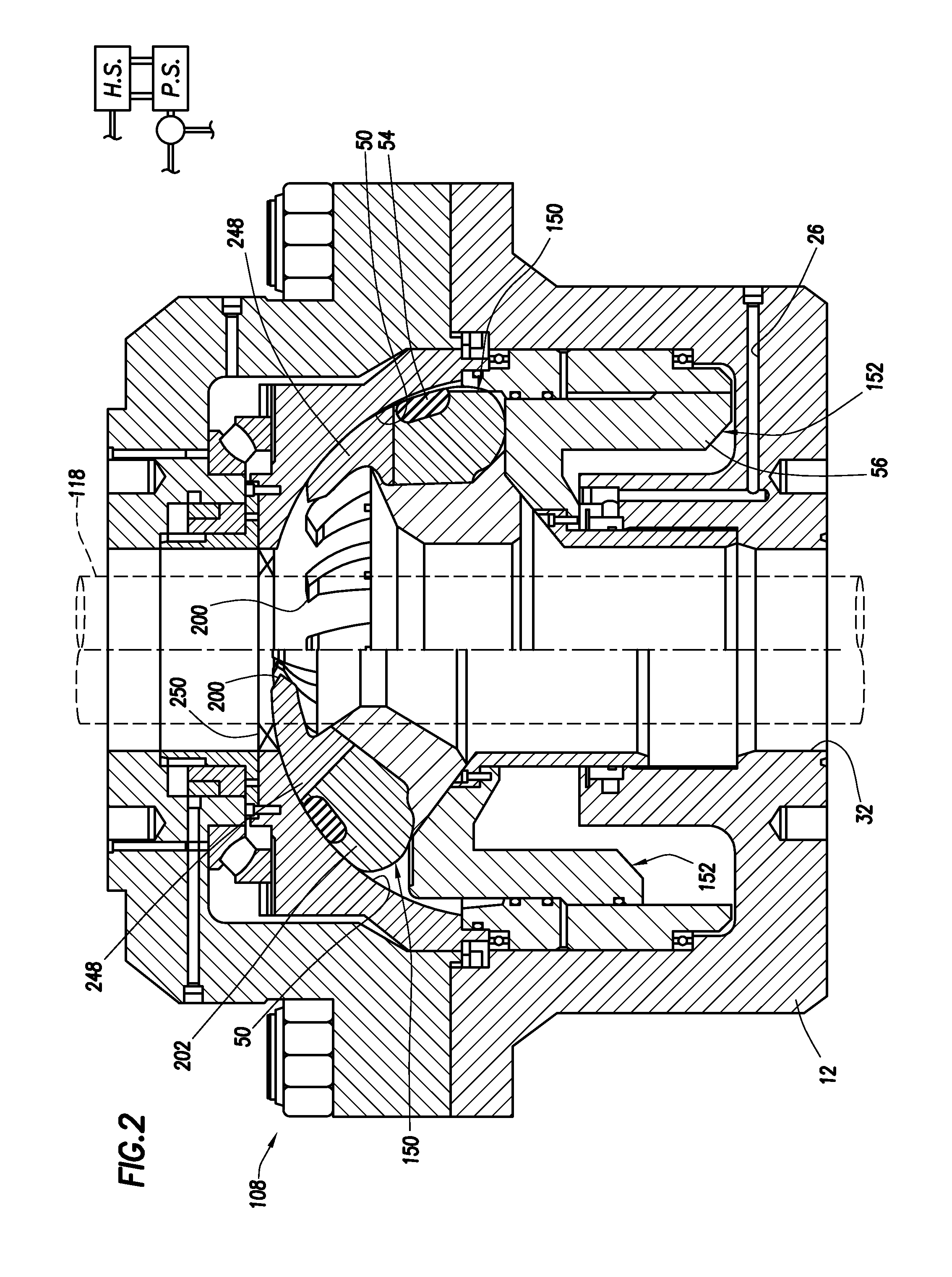

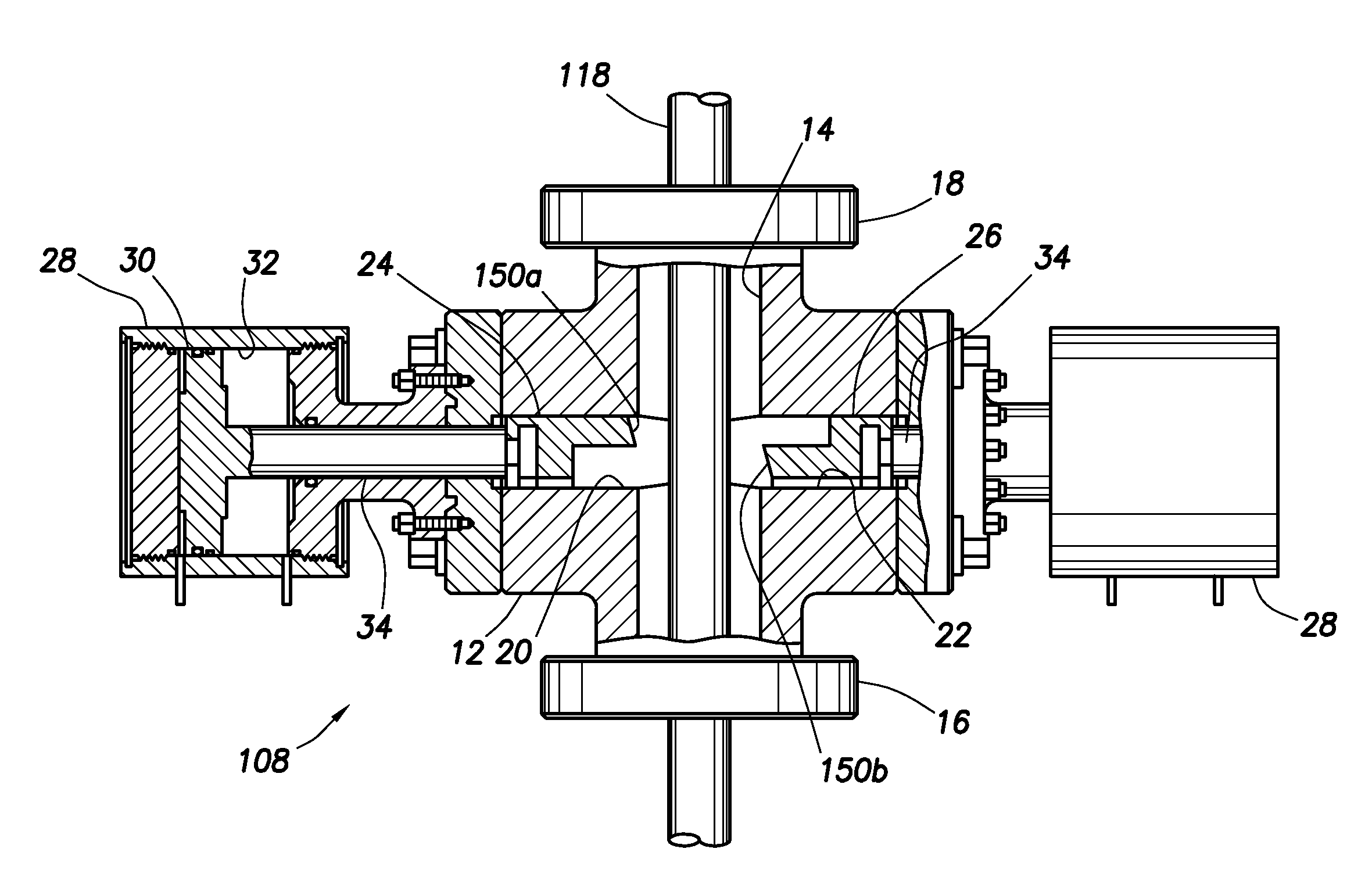

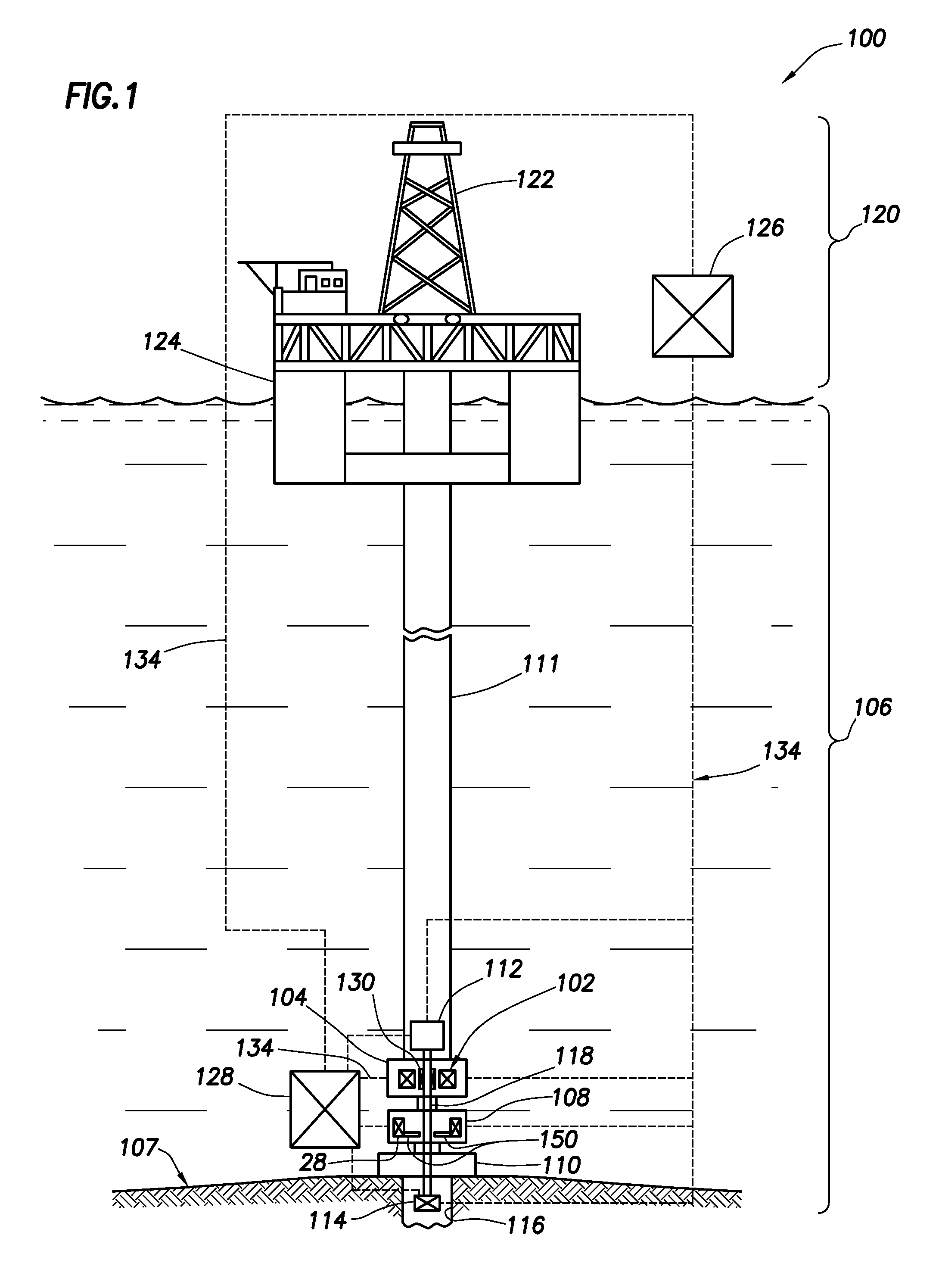

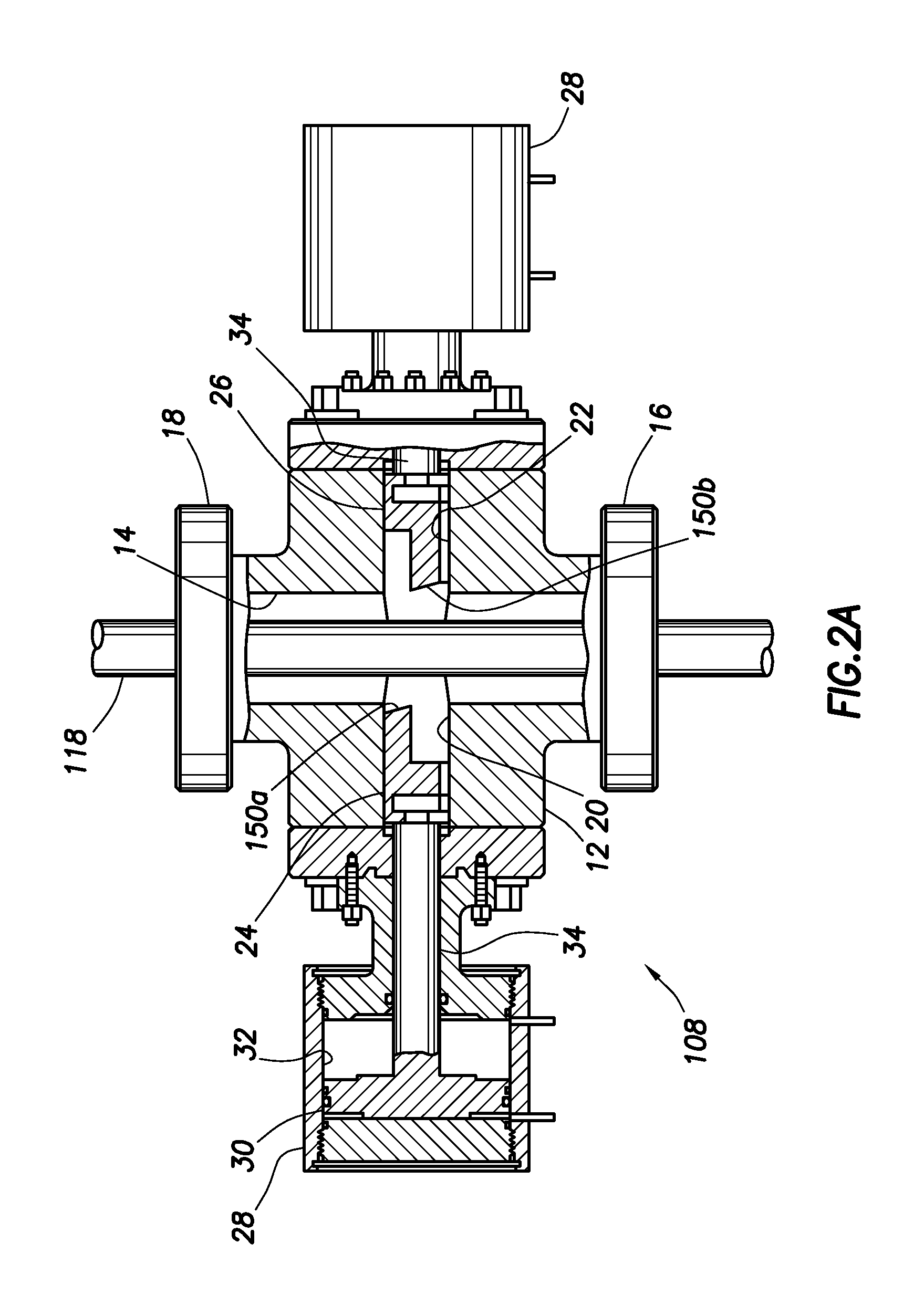

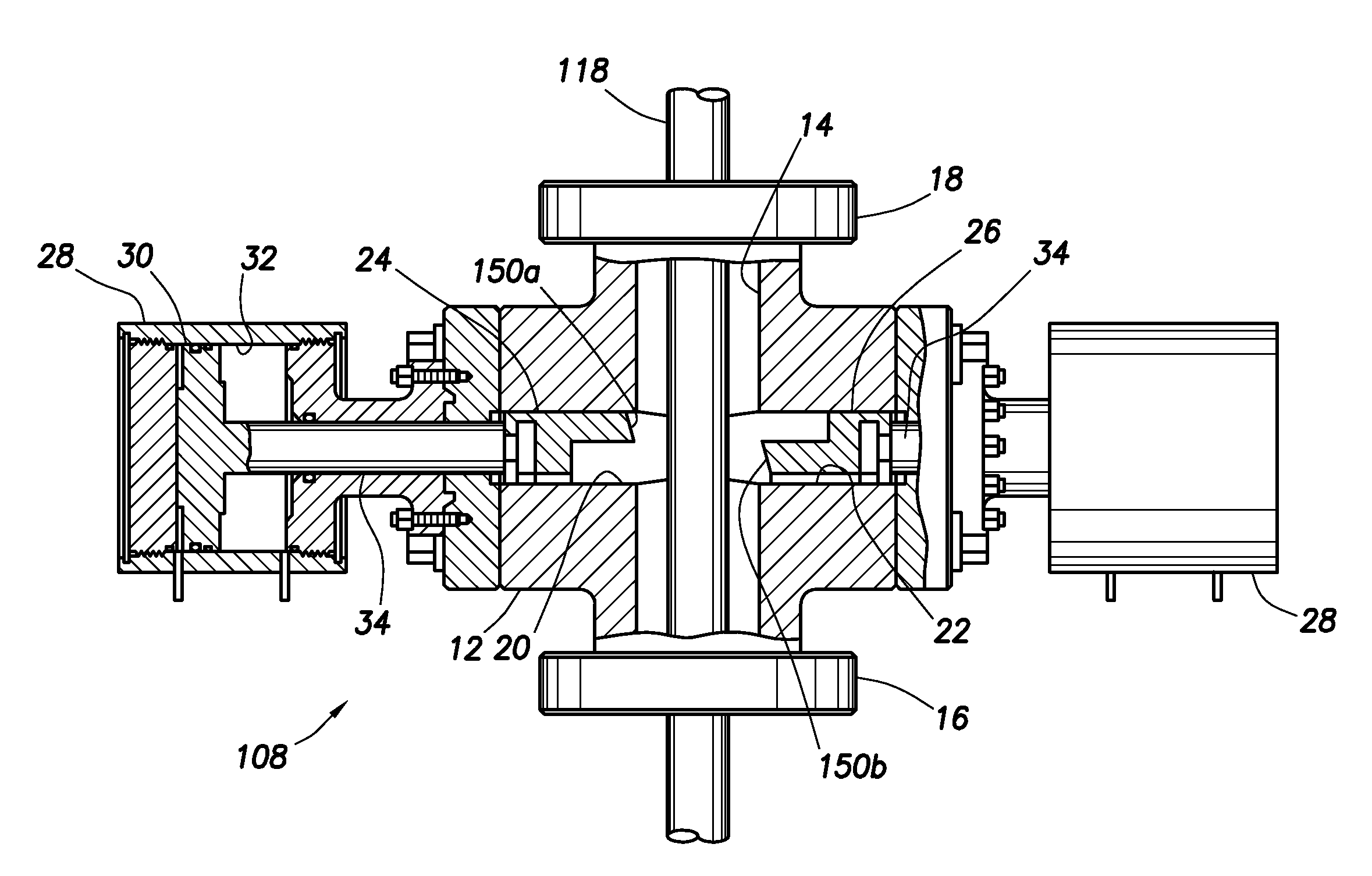

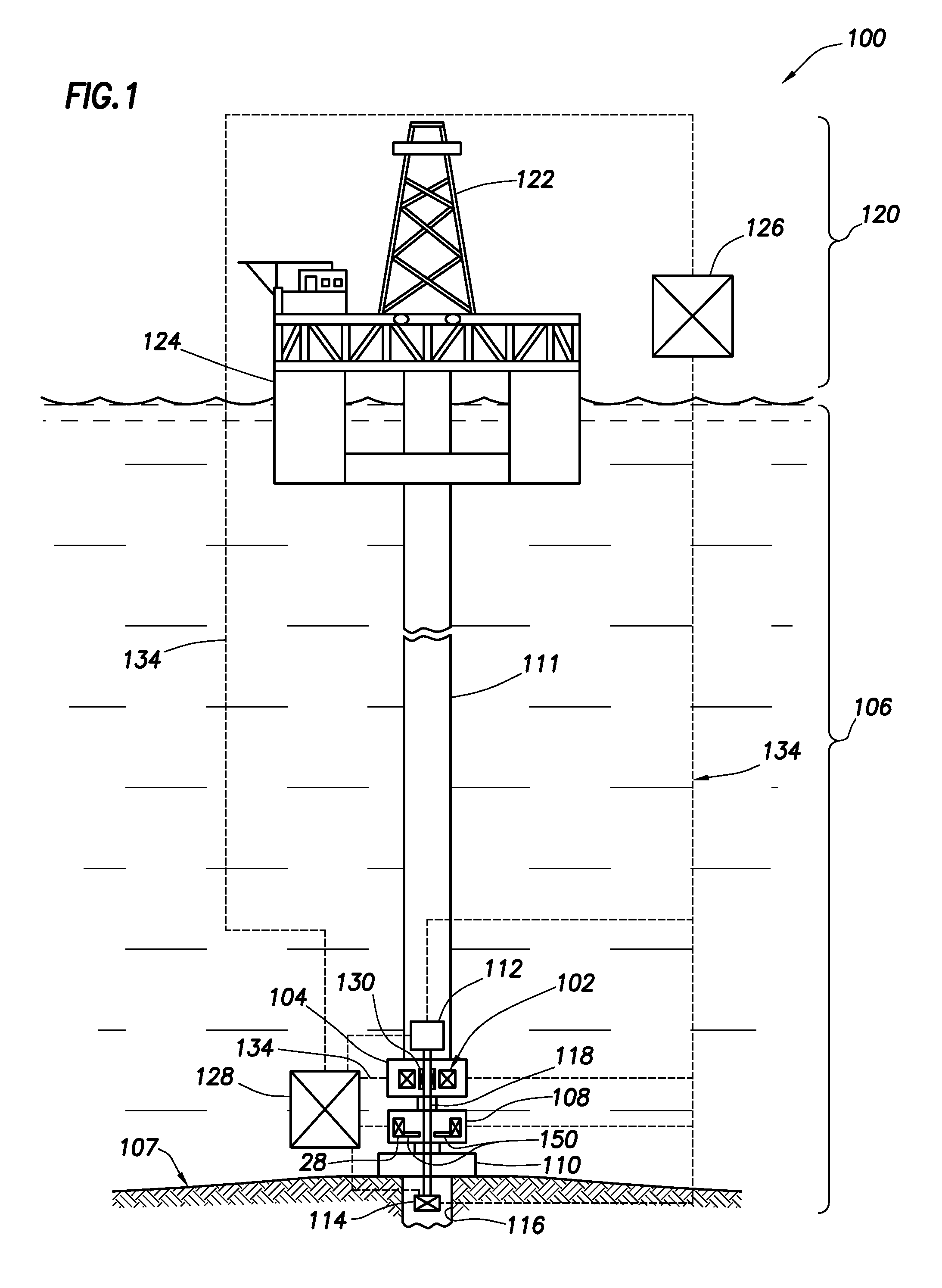

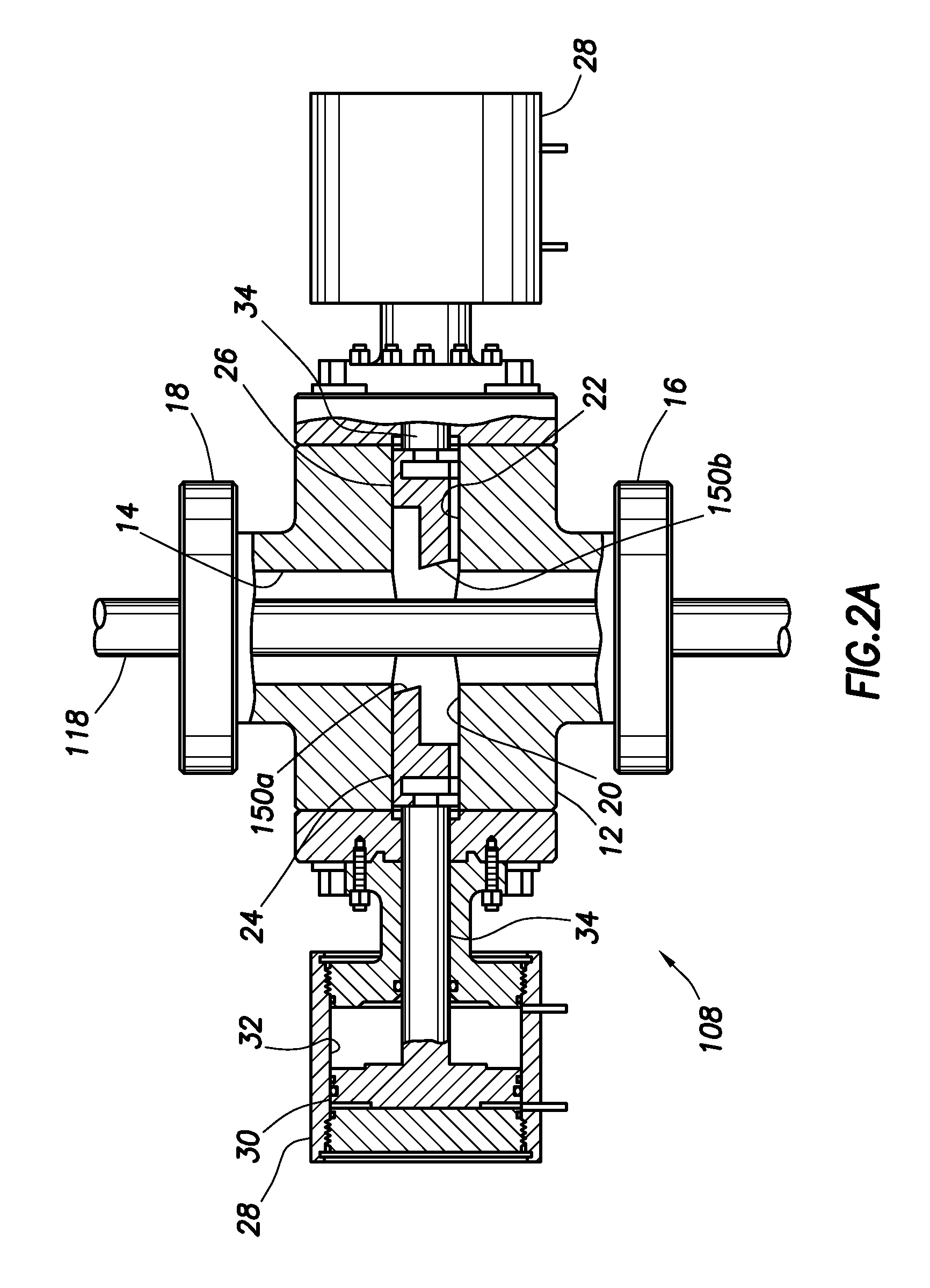

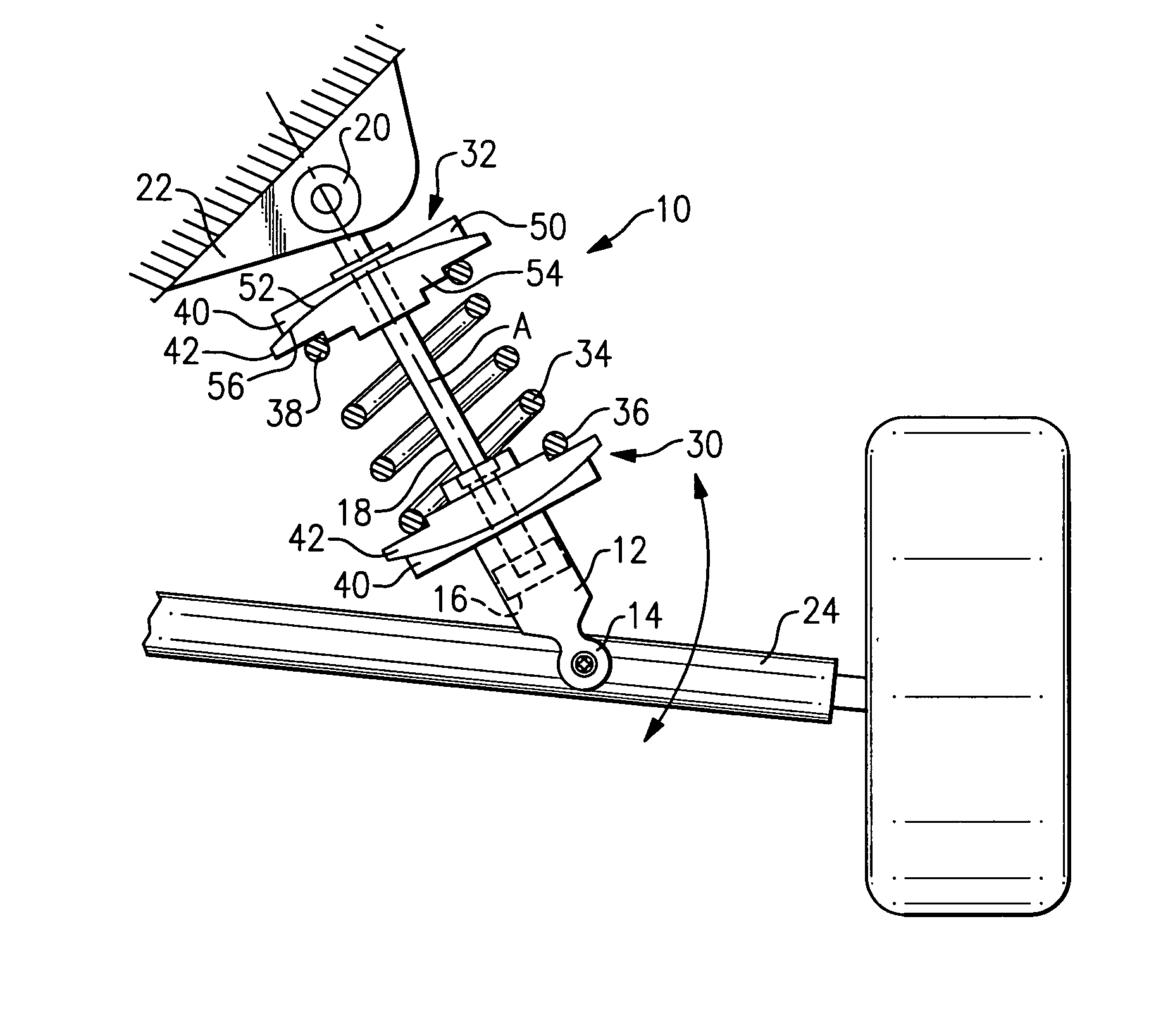

System and method for severing a tubular

The invention relates to techniques for severing a tubular. A blowout preventer is provided with a housing having a bore therethrough for receiving the tubular, an actuator positionable in the housing, and a plurality of cutting tools positionable in the housing and selectively movable into an actuated position with the actuator. Each of the cutting tools have a base supportable by the actuator and selectively movable thereby, and a cutting head supported by the base. The cutting head comprising a tip having a piecing point at an end thereof and at least one cutting surface. The piercing point pierces the tubular and the cutting surfaces taper away from the piercing point for cutting through the tubular whereby the cutting head passes through tubular.

Owner:NAT OILWELL VARCO LP

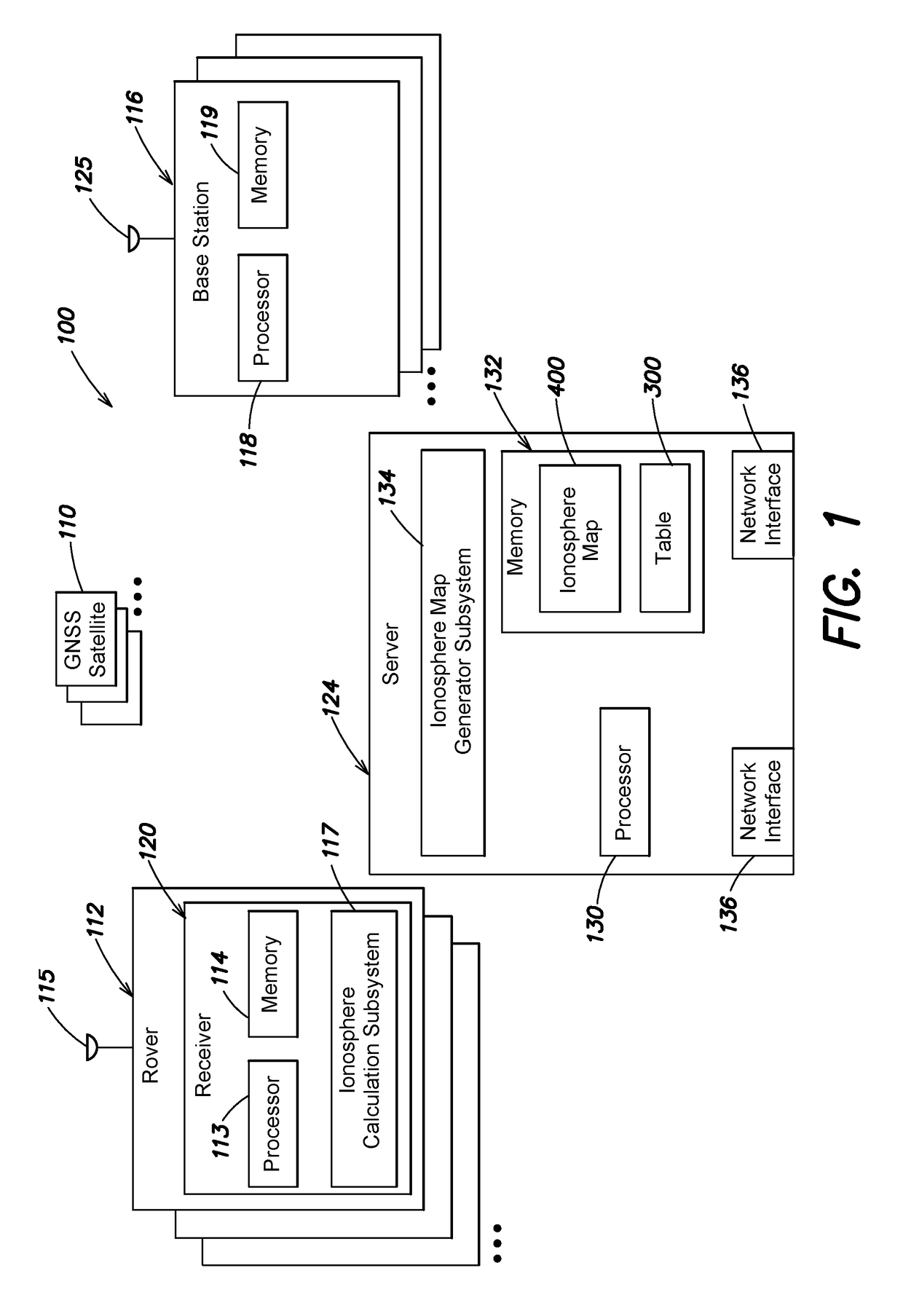

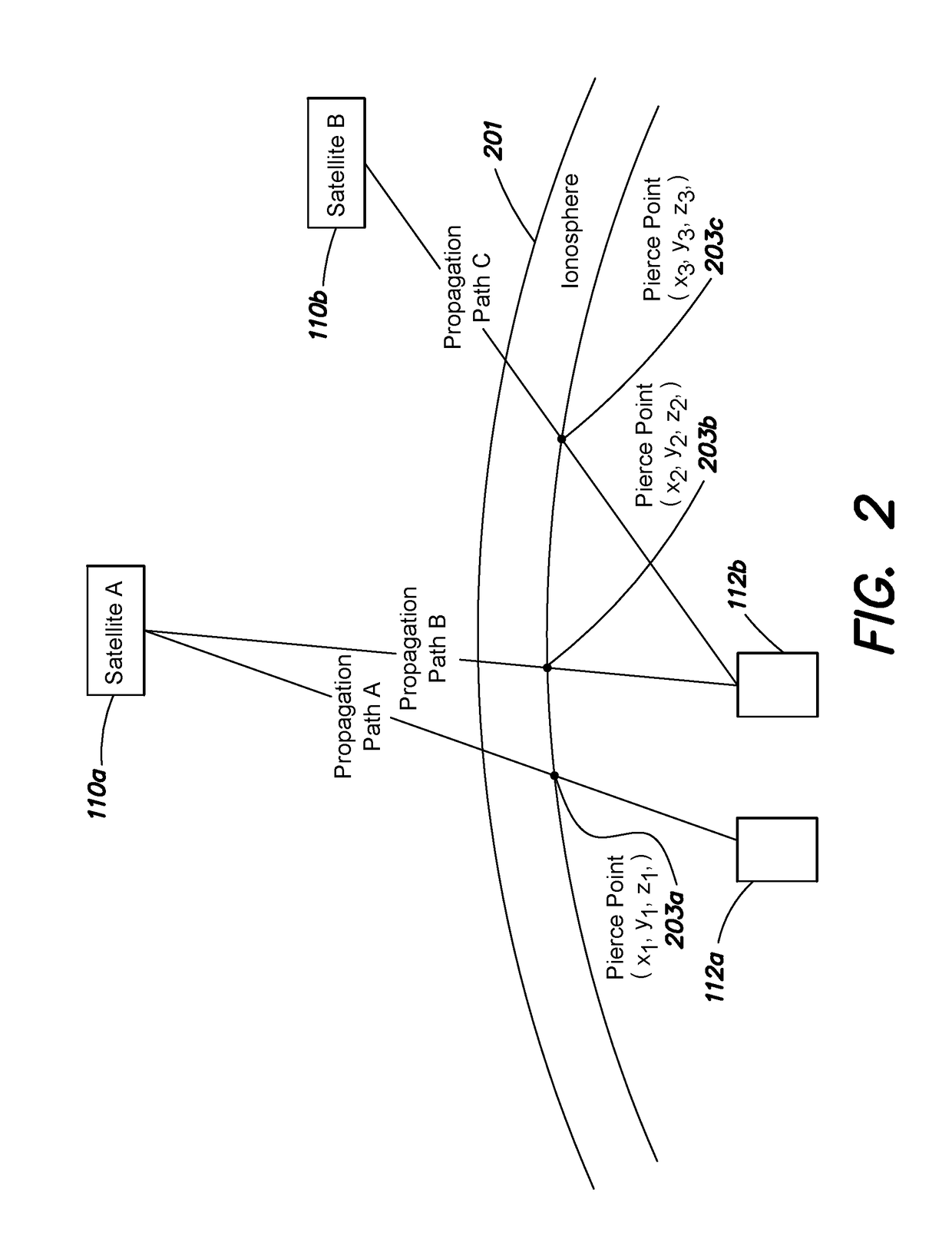

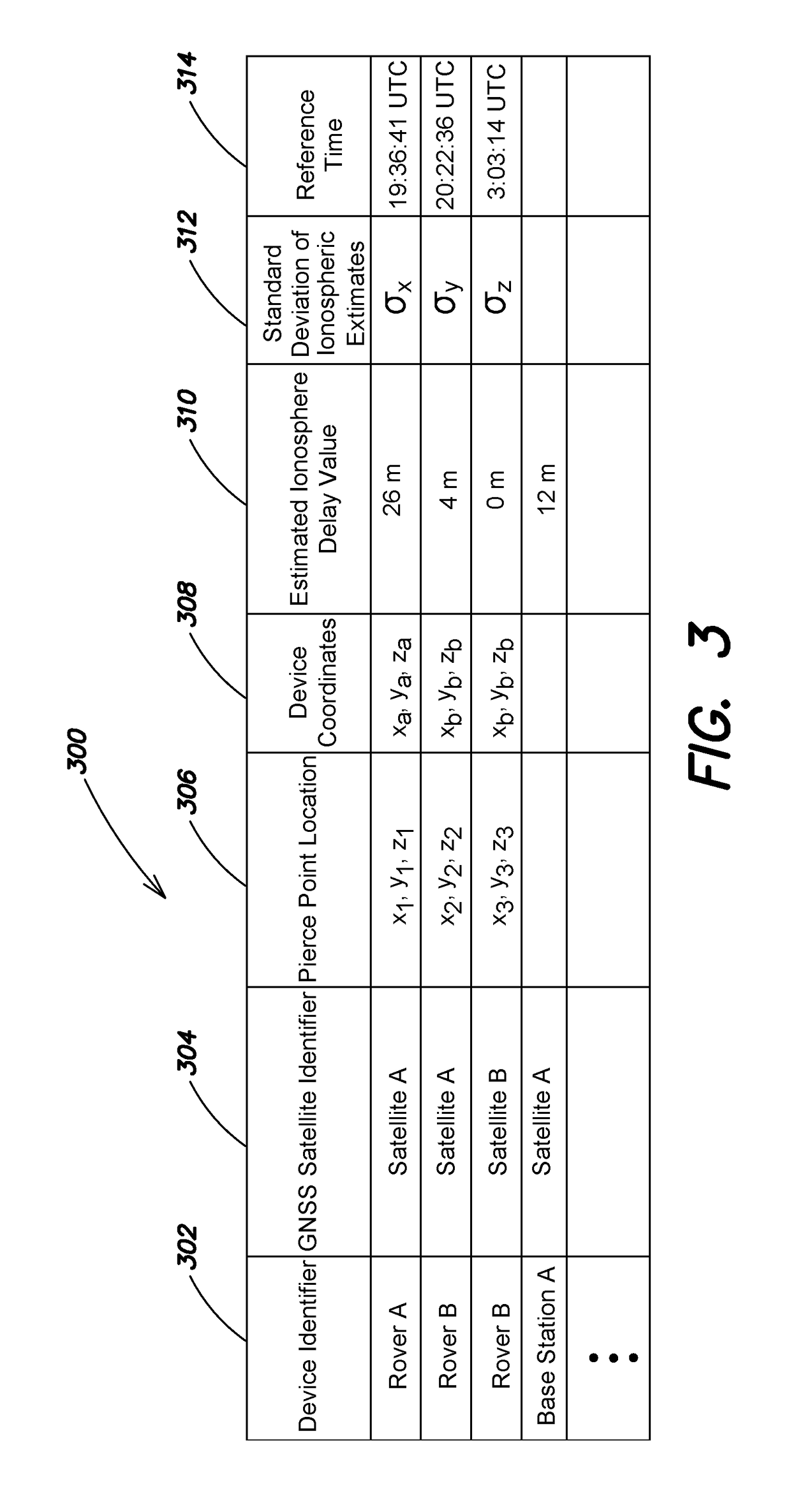

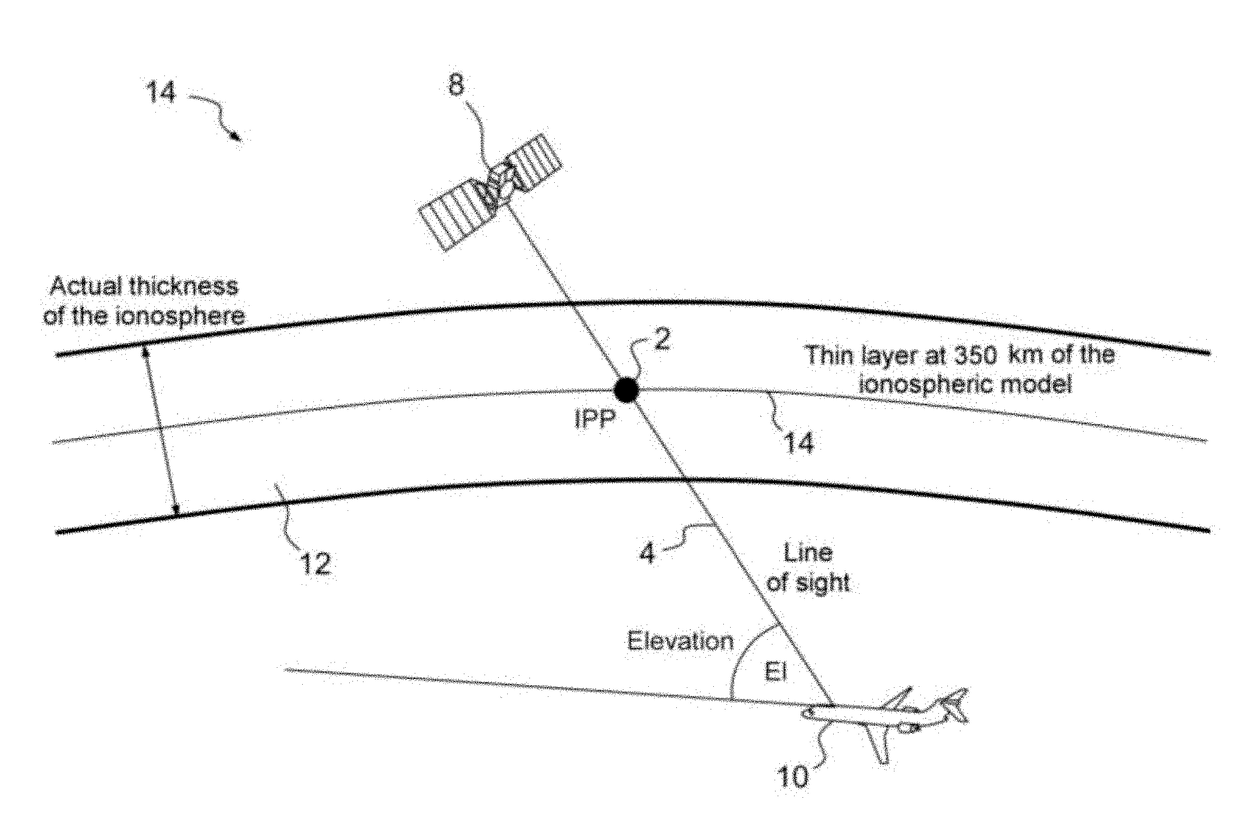

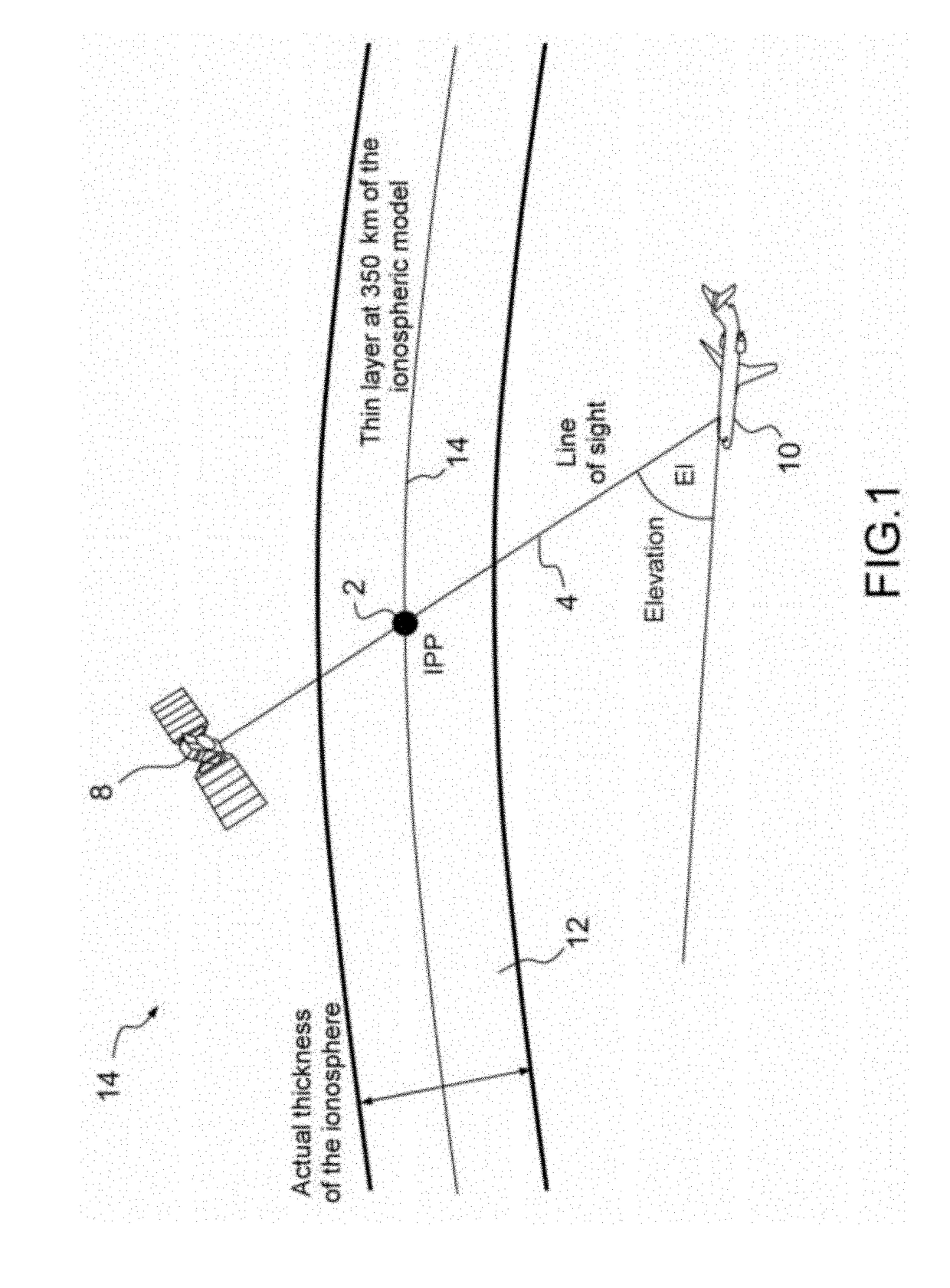

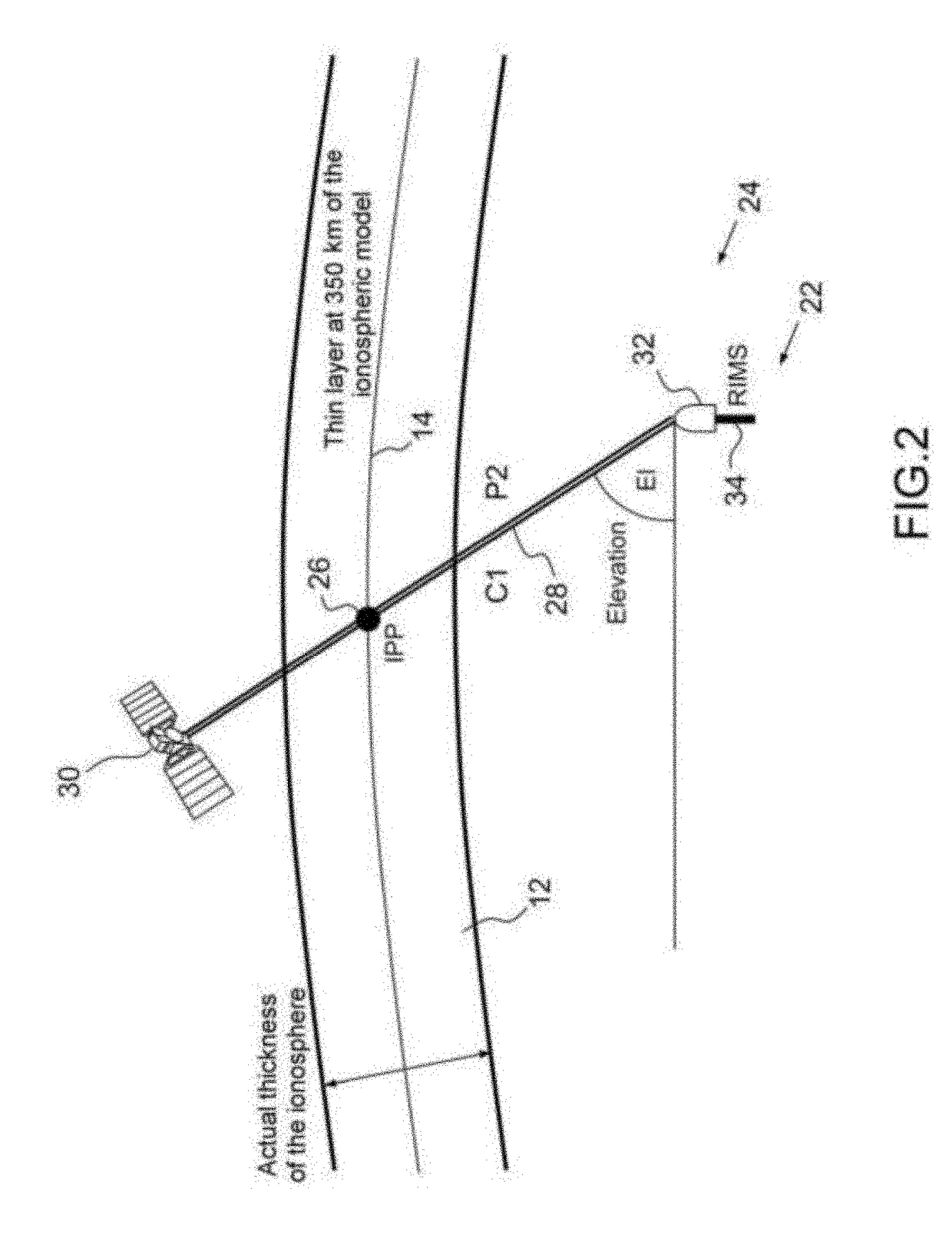

Crowdsourcing atmospheric correction data

A system and method crowdsources atmospheric data from one or more rovers. The rovers calculate an estimated ionosphere delay value that indicates an adverse effect of ionospheric activity on signals received from the GNSS satellite. The values and identifiers may be transmitted to a server. The server utilizes the received information to generate an ionosphere map that reflects the magnitude of ionospheric delay at different locations. The ionosphere map is transmitted to one or more rovers. The rover determines if a pierce point associated with a selected GNSS satellite in view of the rover falls within the boundaries of the ionosphere map. If so, a corresponding ionosphere delay value is obtained utilizing the ionosphere map and then applied as a correction to account for ionospheric activity. In addition, the central server and / or rover may transmit the estimated ionosphere delay values and identifiers to other rovers.

Owner:NOVATEL INC

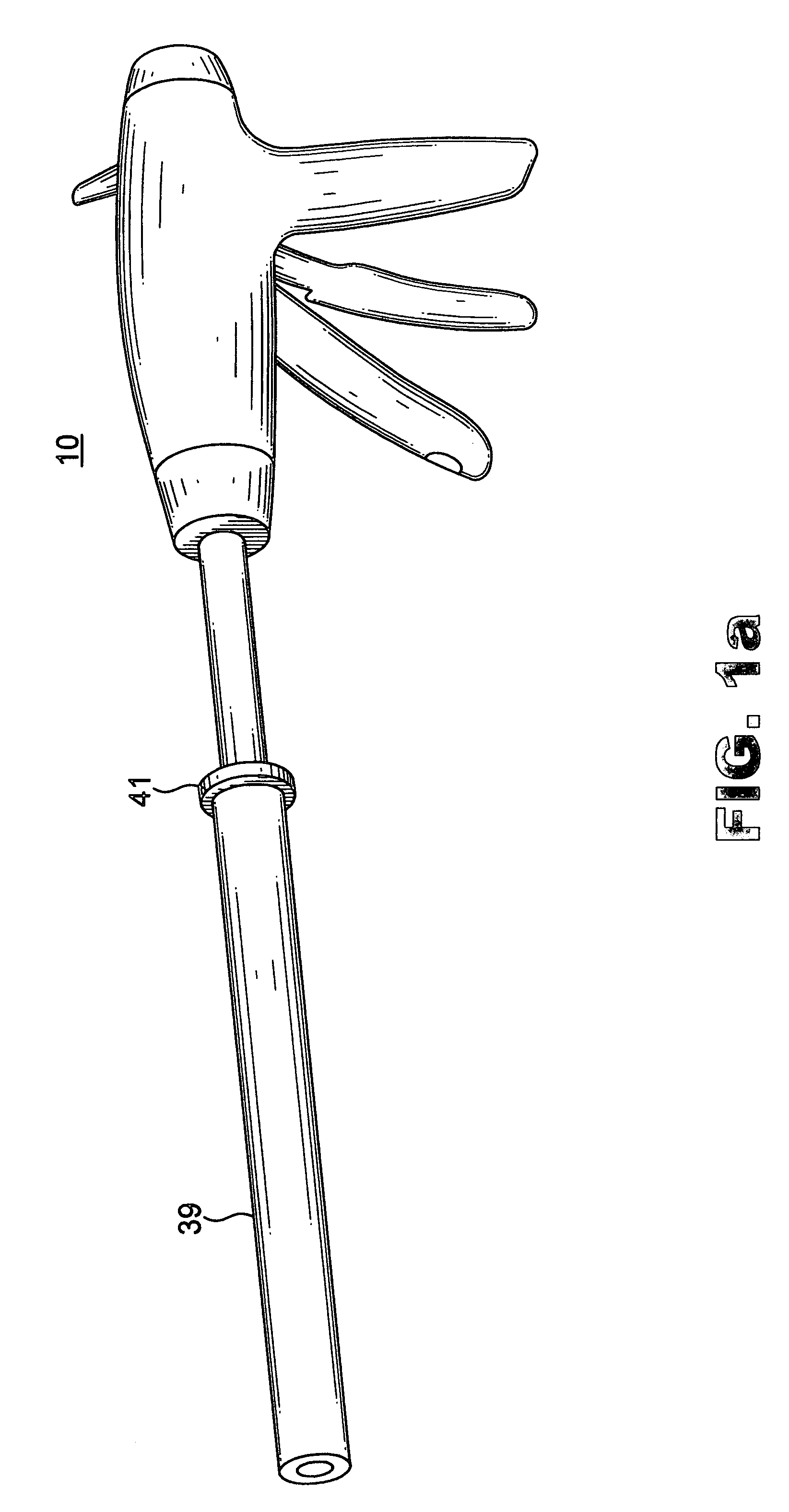

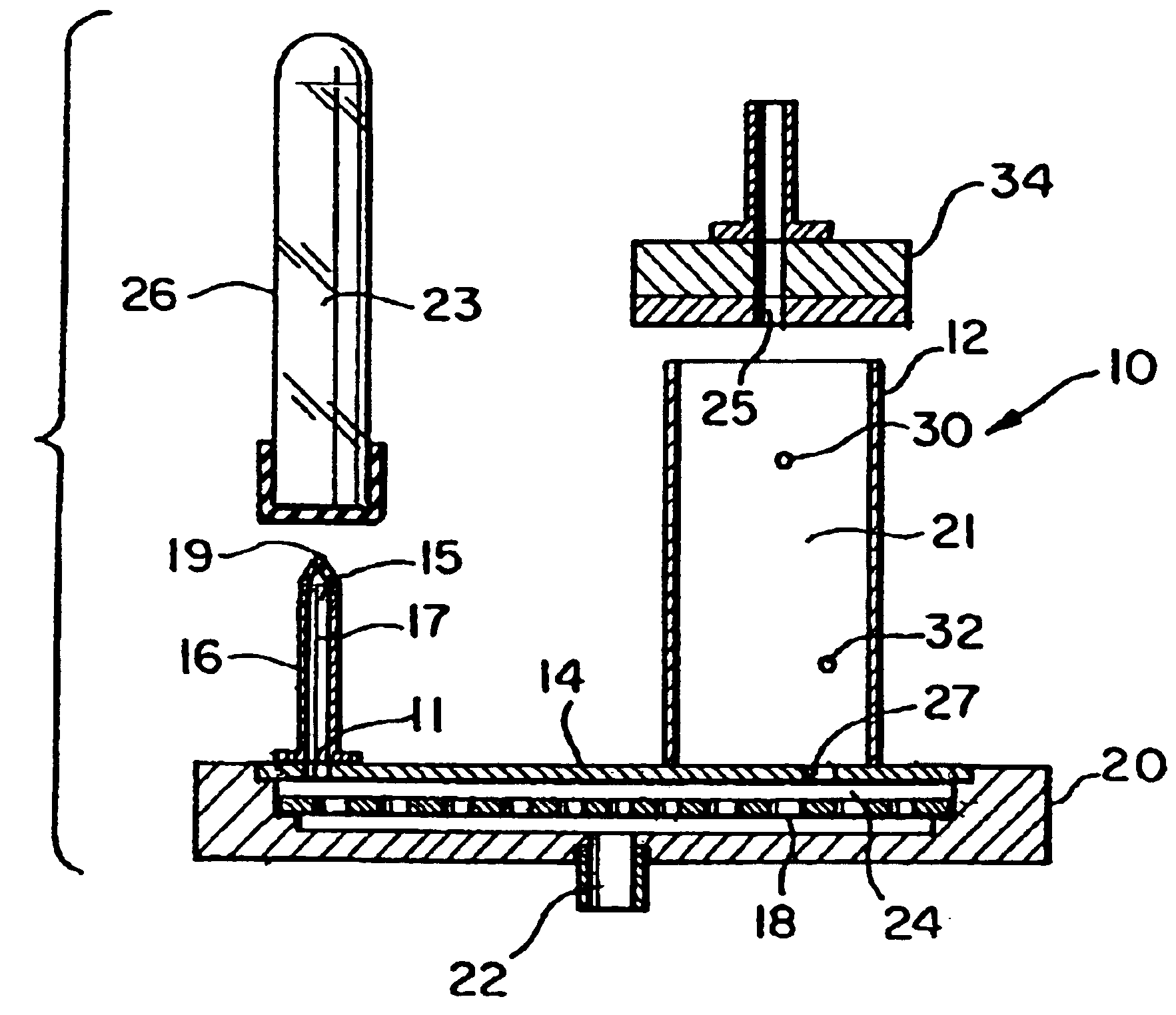

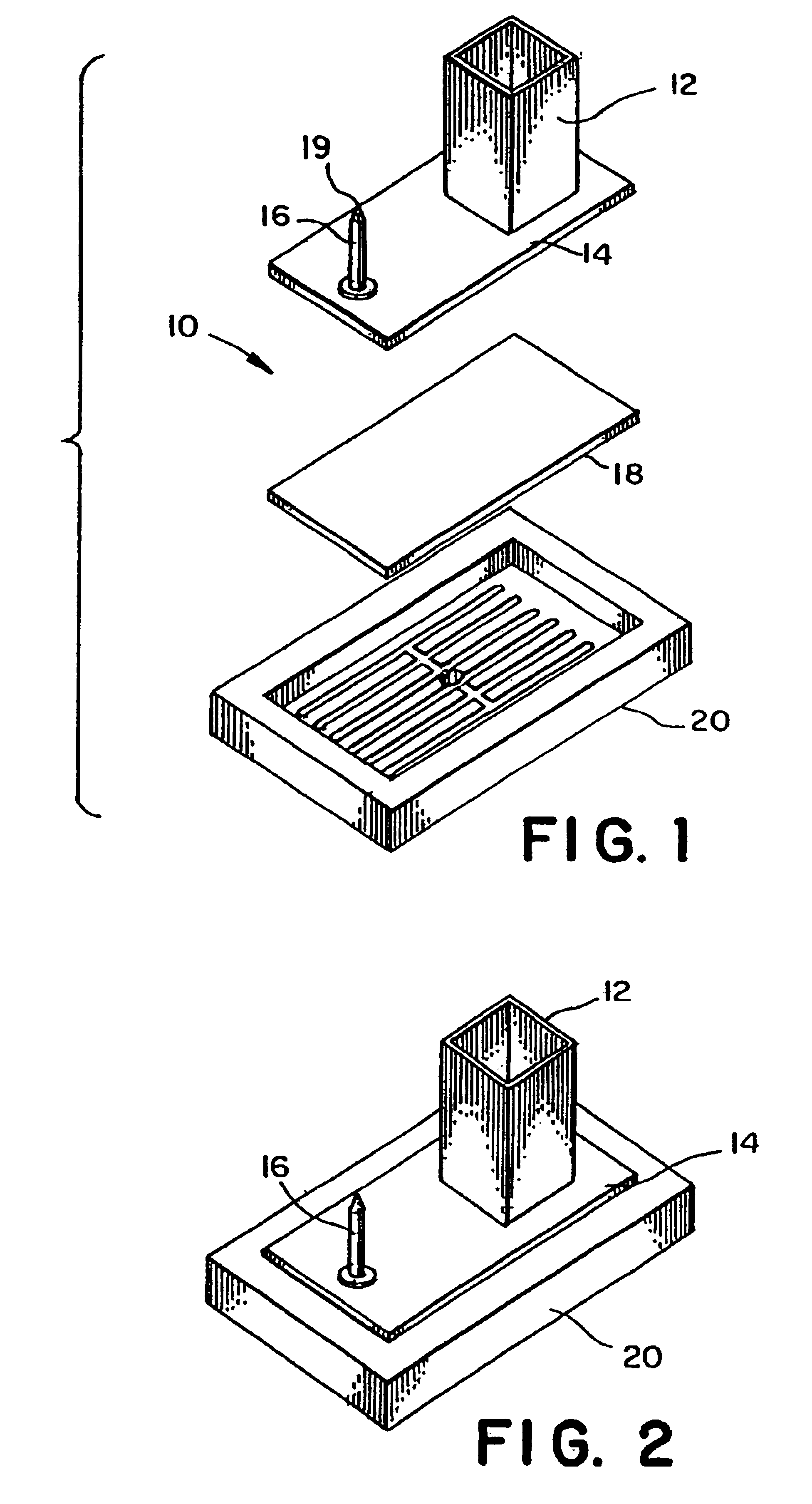

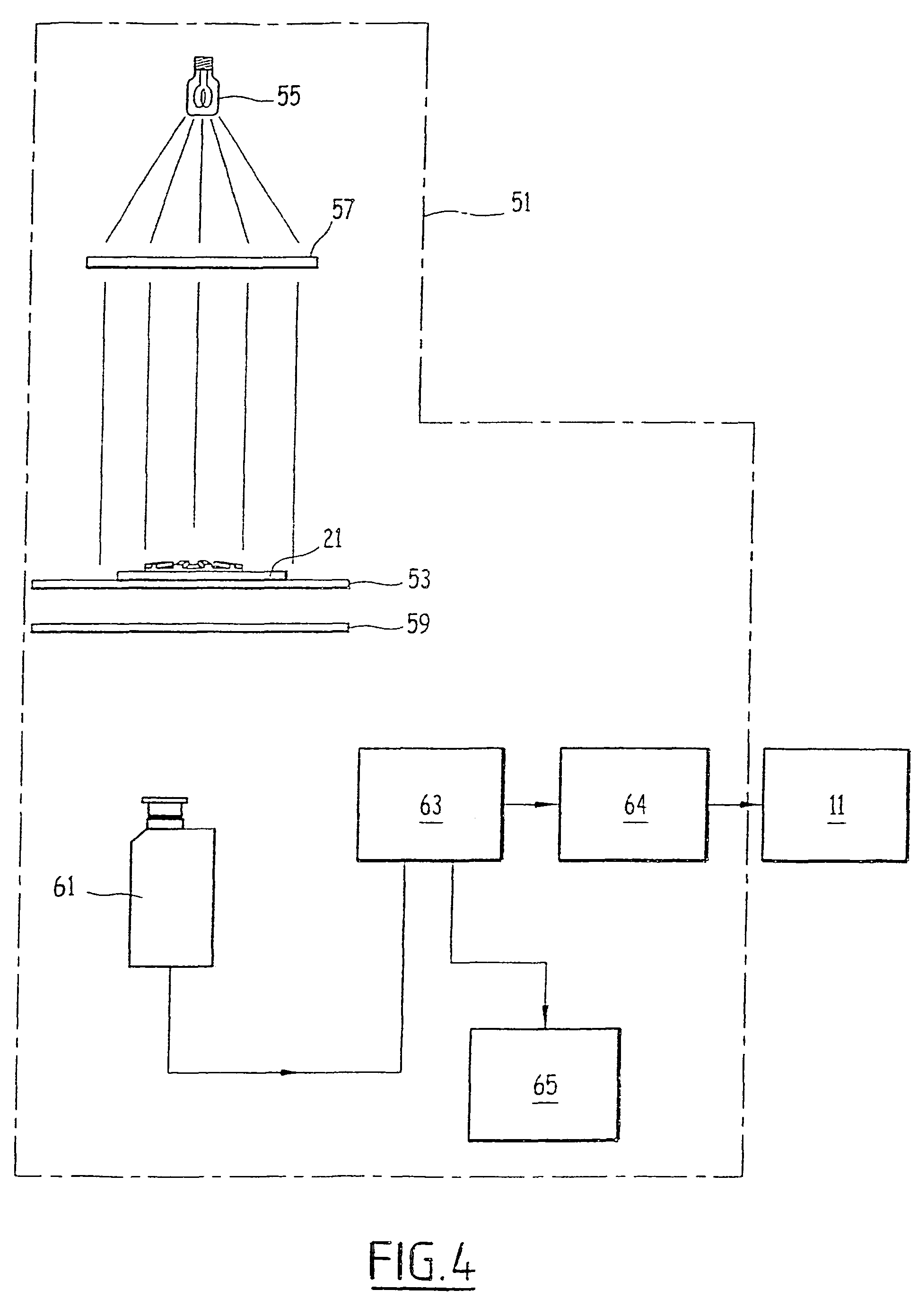

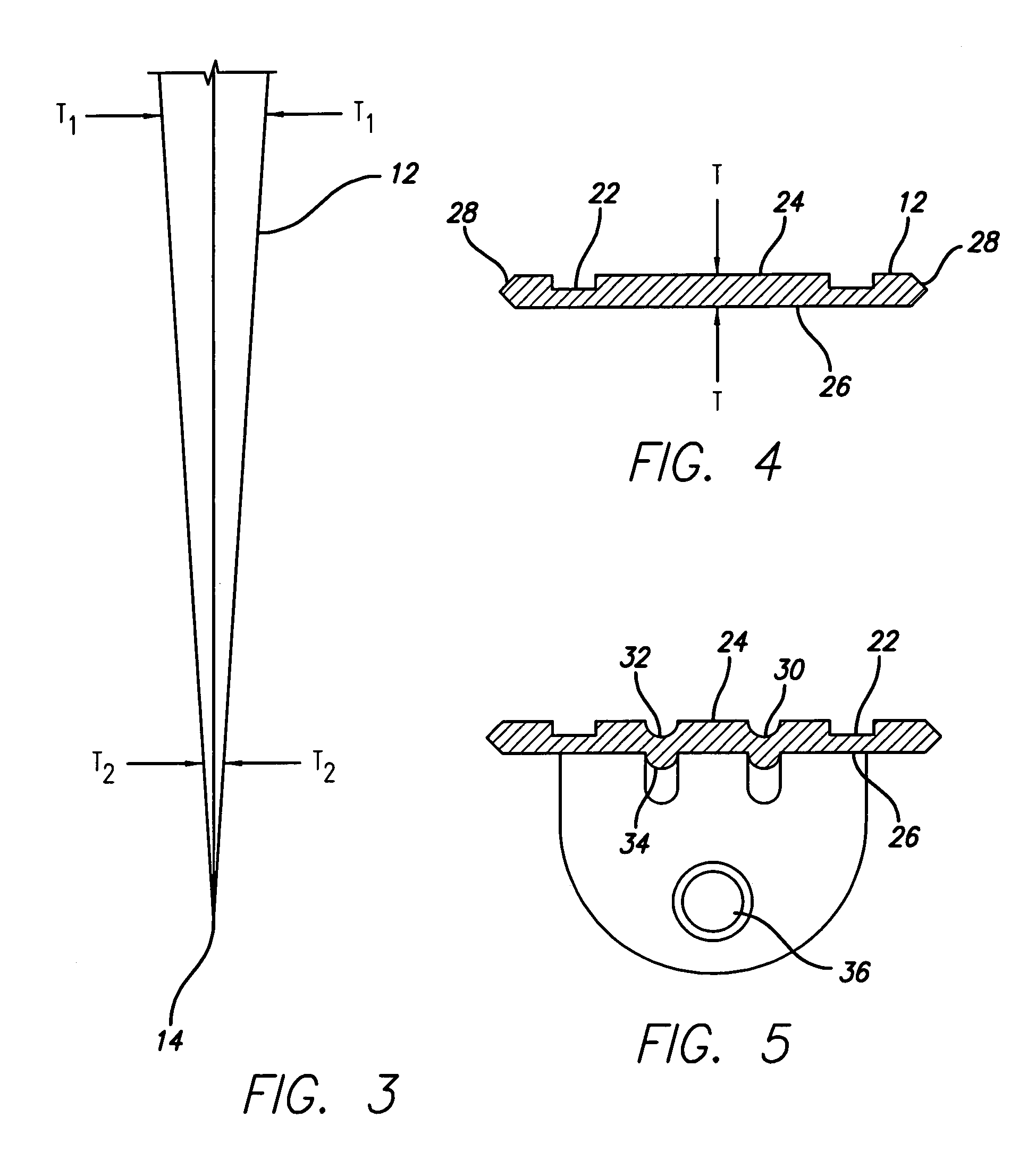

Method and apparatus for directly sampling a fluid for microfiltration

Filtration cells capable of direct sampling of a fluid from a container and which may be used for microfiltration of both small and large microvolumes of a fluid to be filtered are provided. Also a process for directly transferring a fluid to be filtered from a container to a filtration cell is described. The filtration cells have one or more reservoirs and are in communication with fluid in a container to be filtered through a piercing instrument connected to a base and support for a reservoir that receives the fluid to be filtered after it passed across a filter membrane. The filtration cell may then be pressurized and vented to allow fluid to be filtered to reciprocally and tangentially pass across a filter membrane between either a container having a fluid to be filtered and a single reservoir for small volume filtrations or between two reservoirs after pressurizing a fluid to be filtered into the reservoirs from a container using a piercing instrument. Side wells for collecting samples from the bottom up from the filtration cell outlet are also provided as are a process incorporating automated equipment for transferring the container having fluid to be filtered to the piercing point for entry into the filtration cell.

Owner:BIODATA

System and method for severing a tubular

The invention relates to techniques for severing a tubular. A blowout preventer is provided with a housing having a bore therethrough for receiving the tubular, an actuator positionable in the housing, and a plurality of cutting tools positionable in the housing and selectively movable into an actuated position with the actuator. Each of the cutting tools have a base supportable by the actuator and selectively movable thereby, and a cutting head supported by the base. The cutting head comprising a tip having a piecing point at an end thereof and at least one cutting surface. The piercing point pierces the tubular and the cutting surfaces taper away from the piercing point for cutting through the tubular whereby the cutting head passes through tubular.

Owner:NAT OILWELL VARCO LP

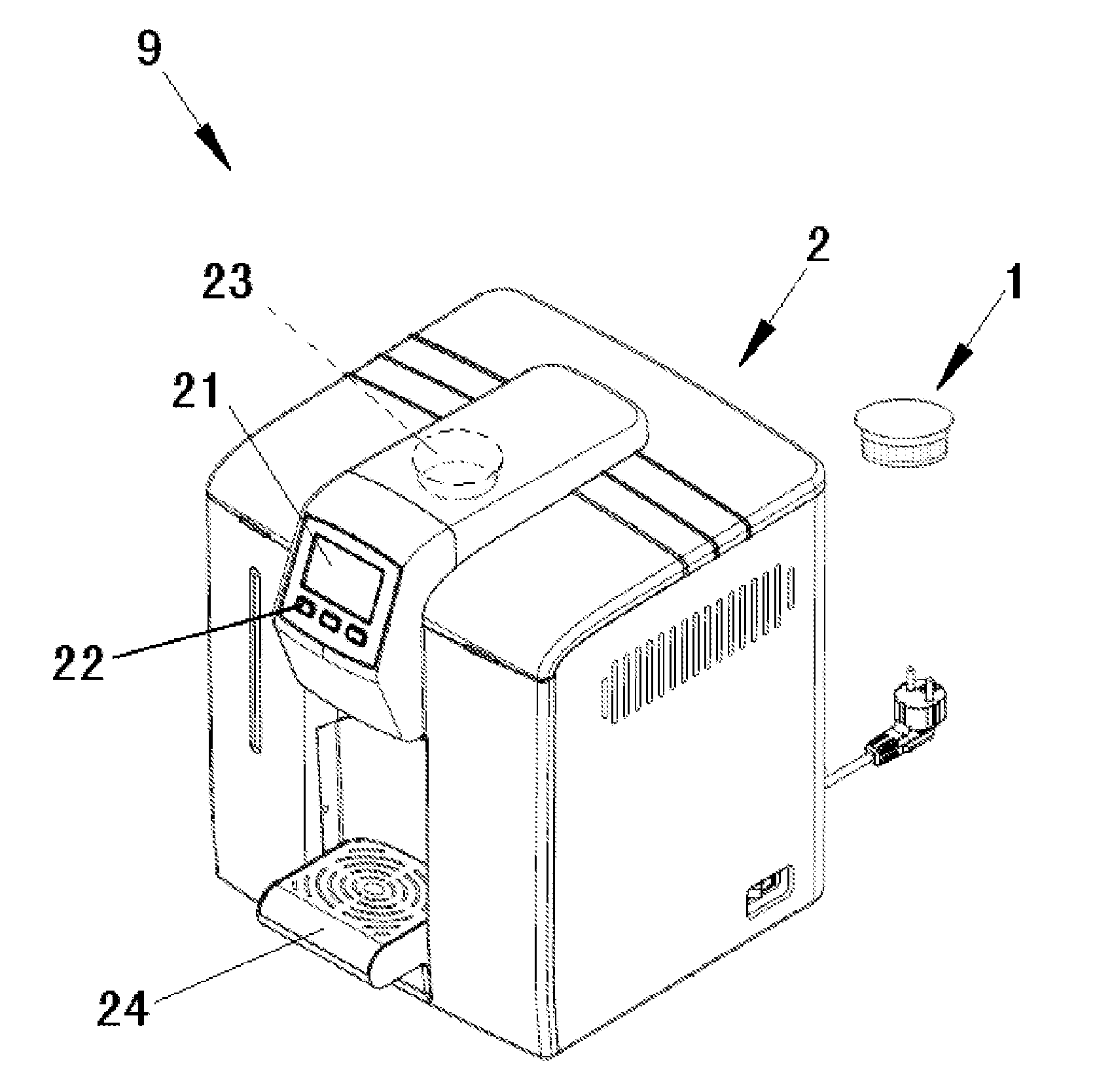

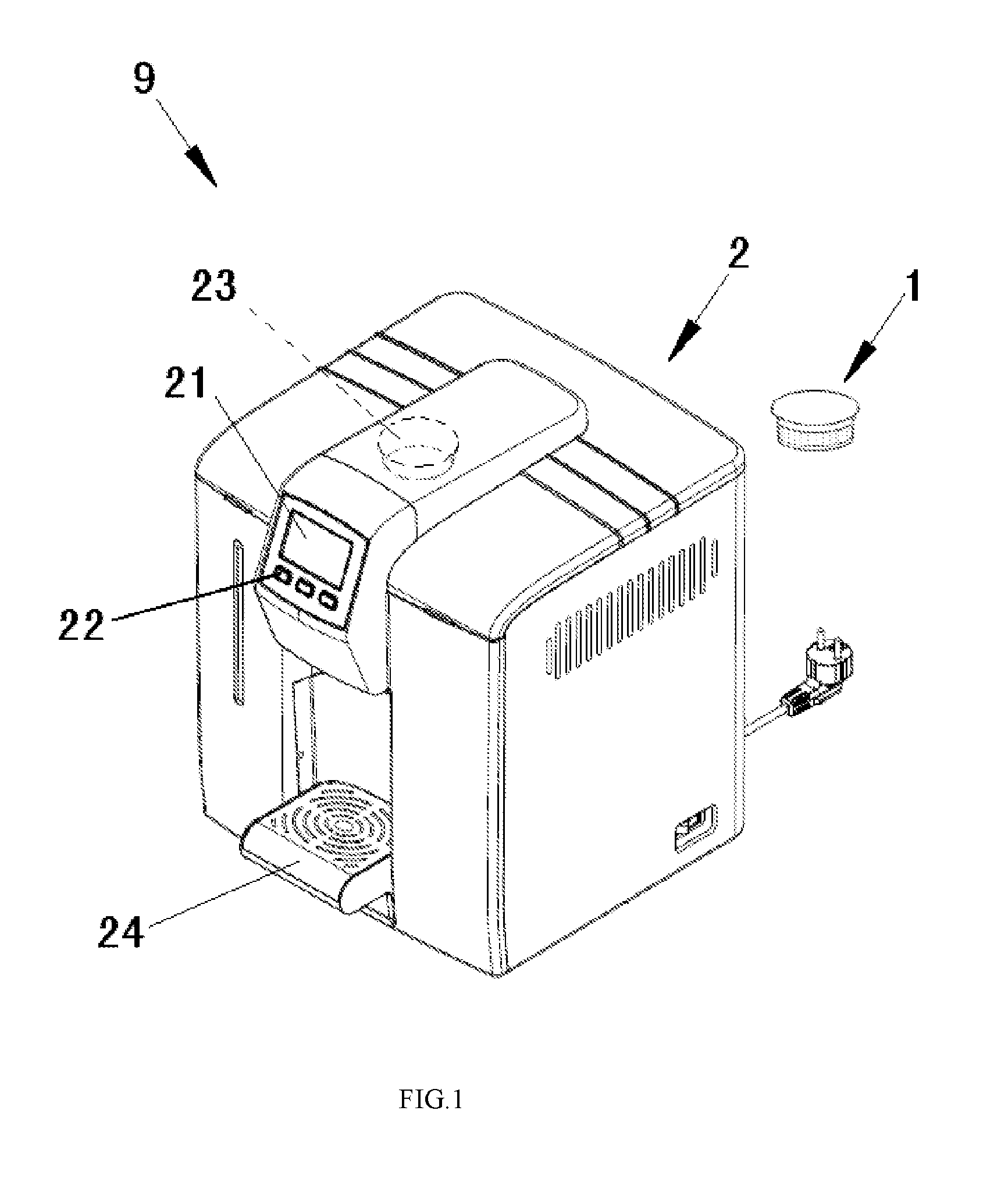

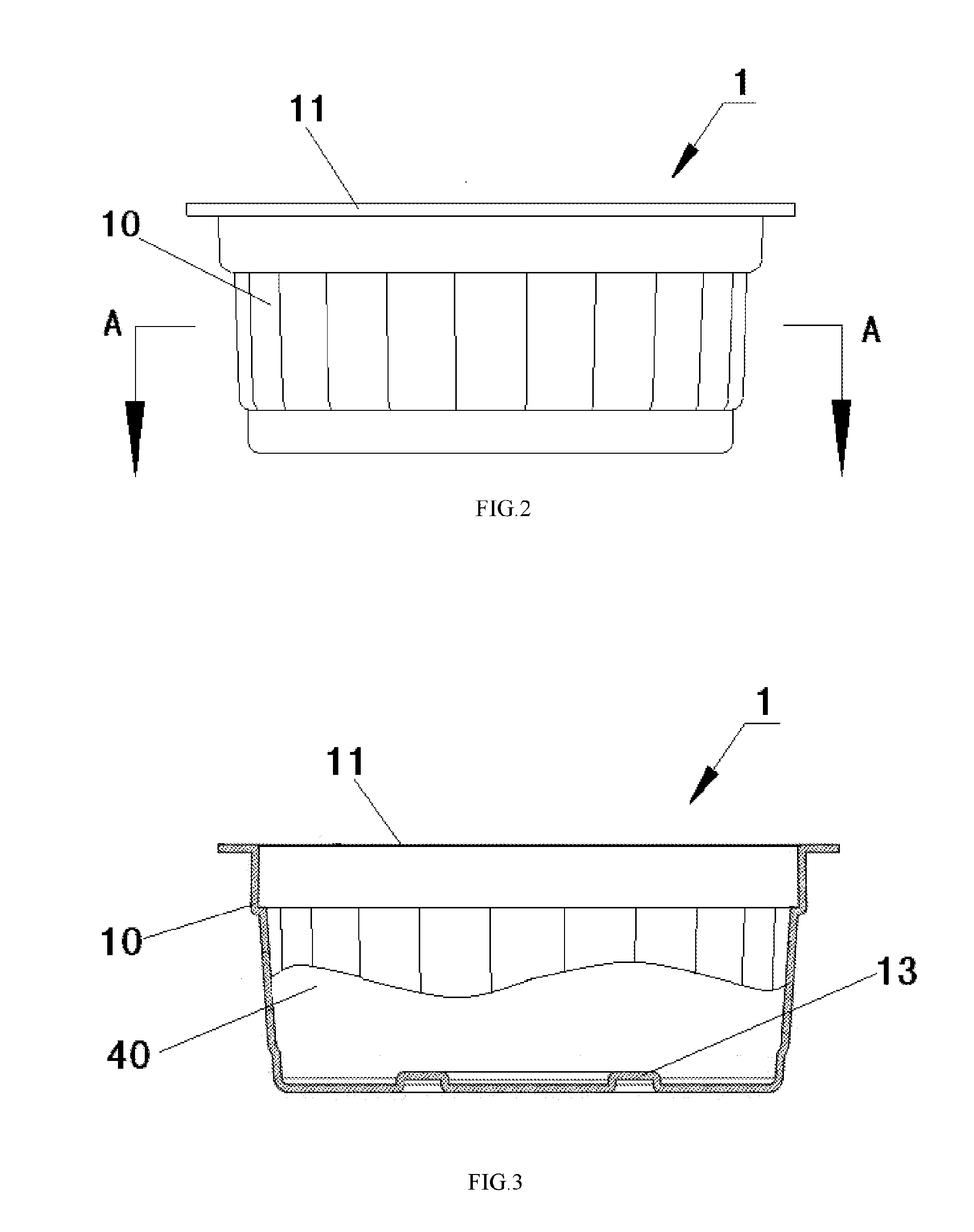

Beverage substance cartridge, filtering apparatus, beverage producing equipment, beverage producing system and beverage producing method

InactiveUS20130142918A1Significant positive effectEffective filteringReady-for-oven doughsContainer decorationsPiercing pointEngineering

The invention provides a beverage substance cartridge, a tea filtering apparatus, a beverage producing equipment, a beverage producing system and a beverage producing method to solve the problem in the present technology that people eat tea leaf powder when drinking tea from present tea brewing equipment and it is troublesome to clear away tea leaf powder in the equipment. The invention could efficiently filter tea leaves and get rid of the trouble of clearing away used tea leaves manually. The beverage substance cartridge is used in conjunction with the tea filtering apparatus, the piercing point of the triangular pyramid structure could pierce the sealing cover of the beverage substance cartridge and then form matrix-shaped filtering holes in the sealing cover, brewed tea water could flow out, and used tea leaf is left in the extracting cartridge, so the filtering process is simple and convenient without clearing away tea leaves manually.

Owner:TEATEK

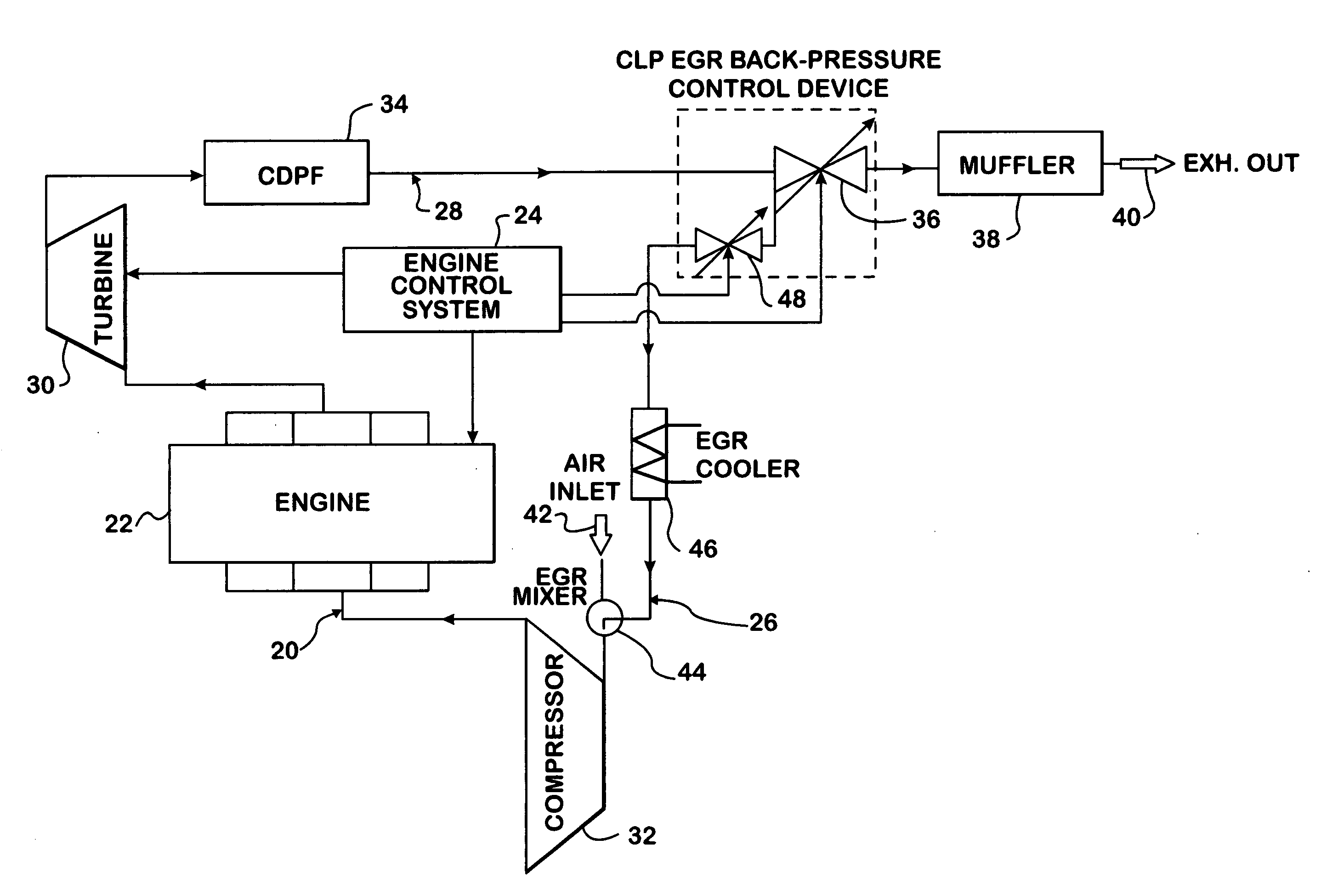

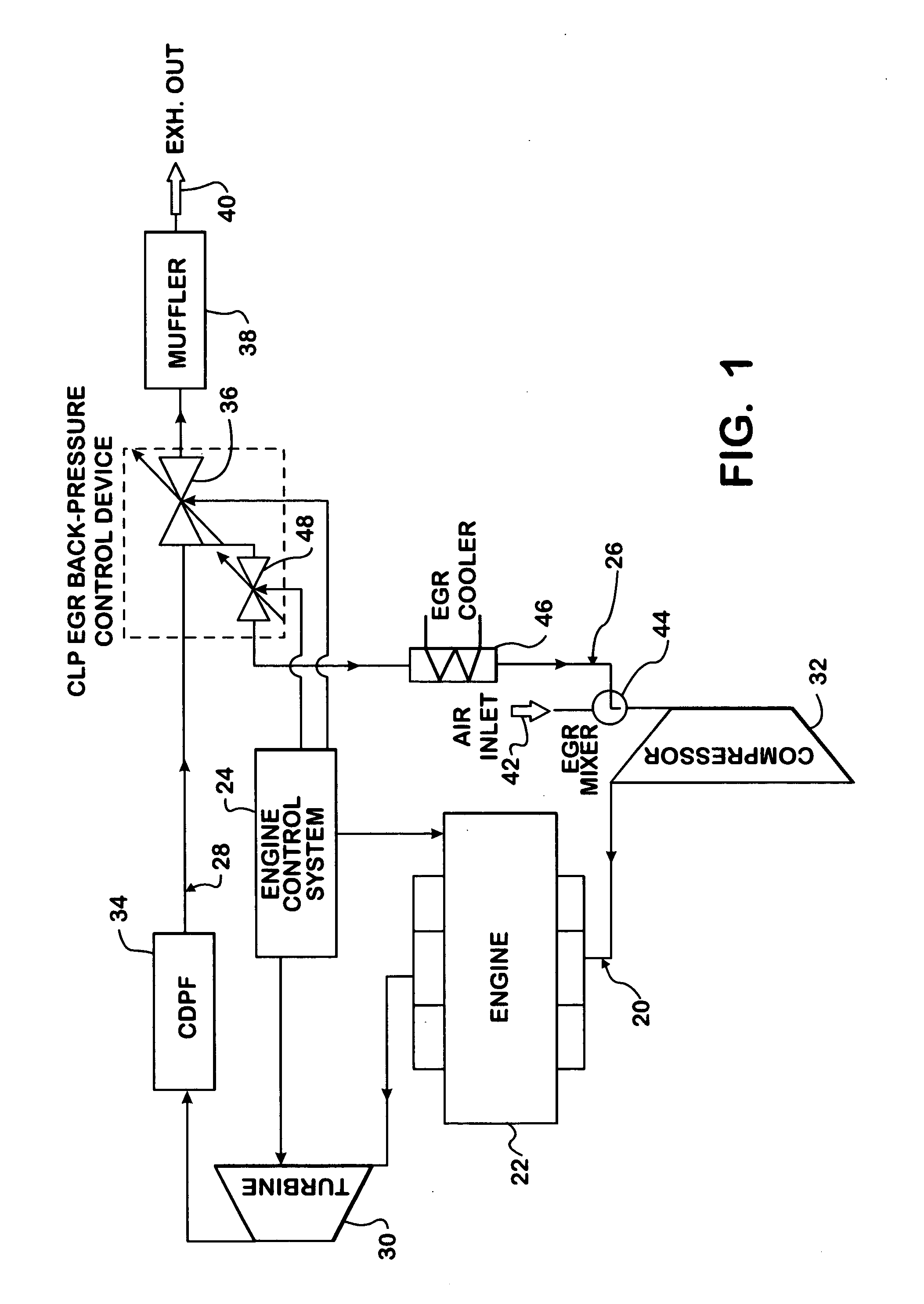

Clean, low-pressure EGR in a turbocharged engine by back-pressure control

ActiveUS20050045407A1Minimize, or even eliminate, that penaltySave spaceNon-fuel substance addition to fuelInternal combustion piston enginesCombustion chamberTurbocharger

A turbocharged engine system (20) has an intake system (26) through which charge air enters combustion chambers and an exhaust system (28), including a CDPF (34), through which products of combustion pass to the surrounding atmosphere. A throttle valve (36) disposed in the exhaust system downstream of both the CDPF and the turbocharger turbine (30) controls engine back-pressure. An EGR flow path for recirculating exhaust gas from the exhaust system to the intake system includes an EGR valve (48) for controlling EGR flow. The EGR flow path has a pierce point to the exhaust system upstream of the throttle valve and downstream of both the CDPF and the turbine and a pierce point to the intake system upstream of the turbocharger compressor. Valves (36, 48) are under coordinated control provided by an engine control system (24) via for selectively restricting the respective valves to attain desired EGR flow. The invention improves emission control performance and reduces the fuel economy penalty imposed by use of low-pressure EGR.

Owner:INT ENGINE INTPROP CO LLC

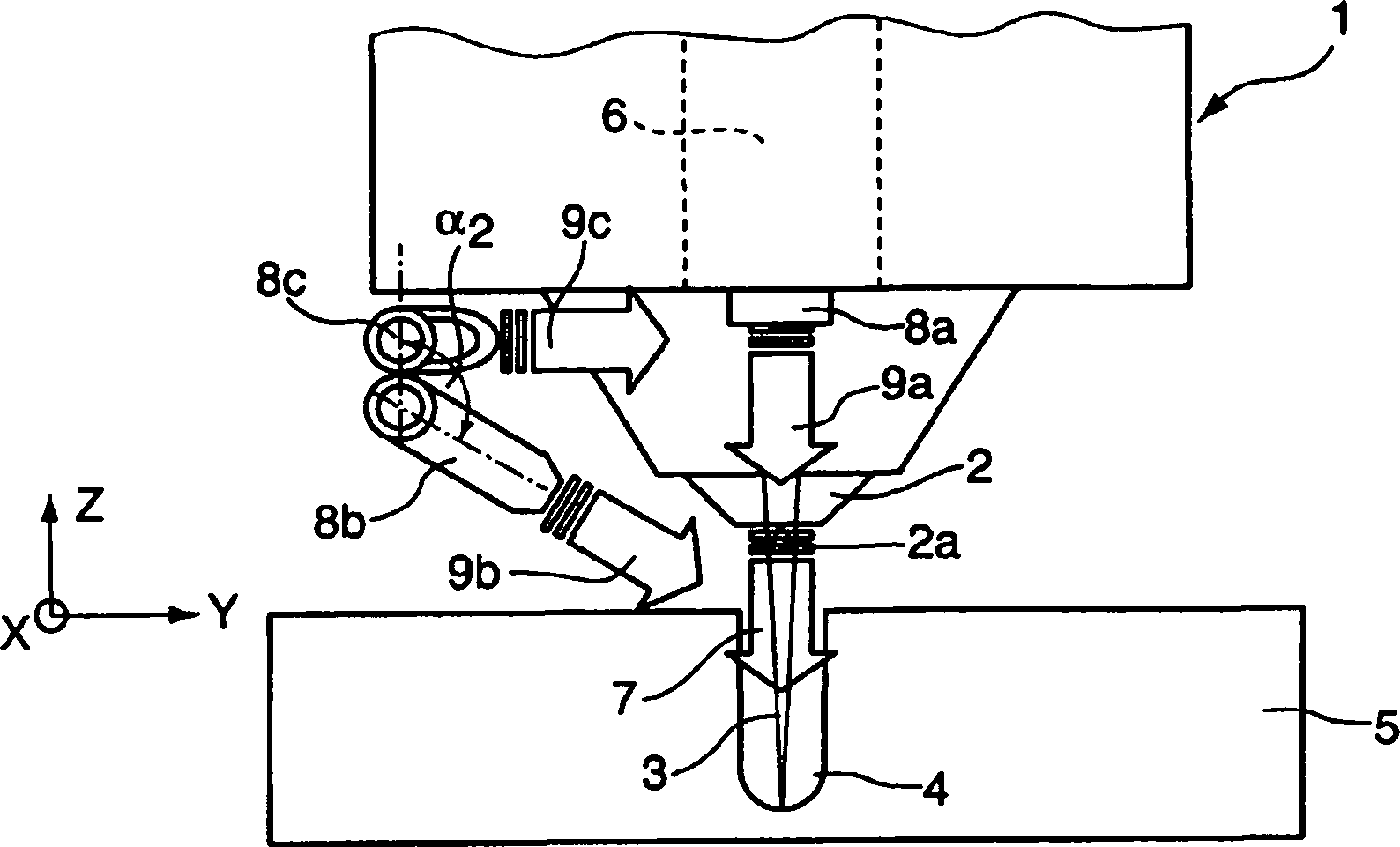

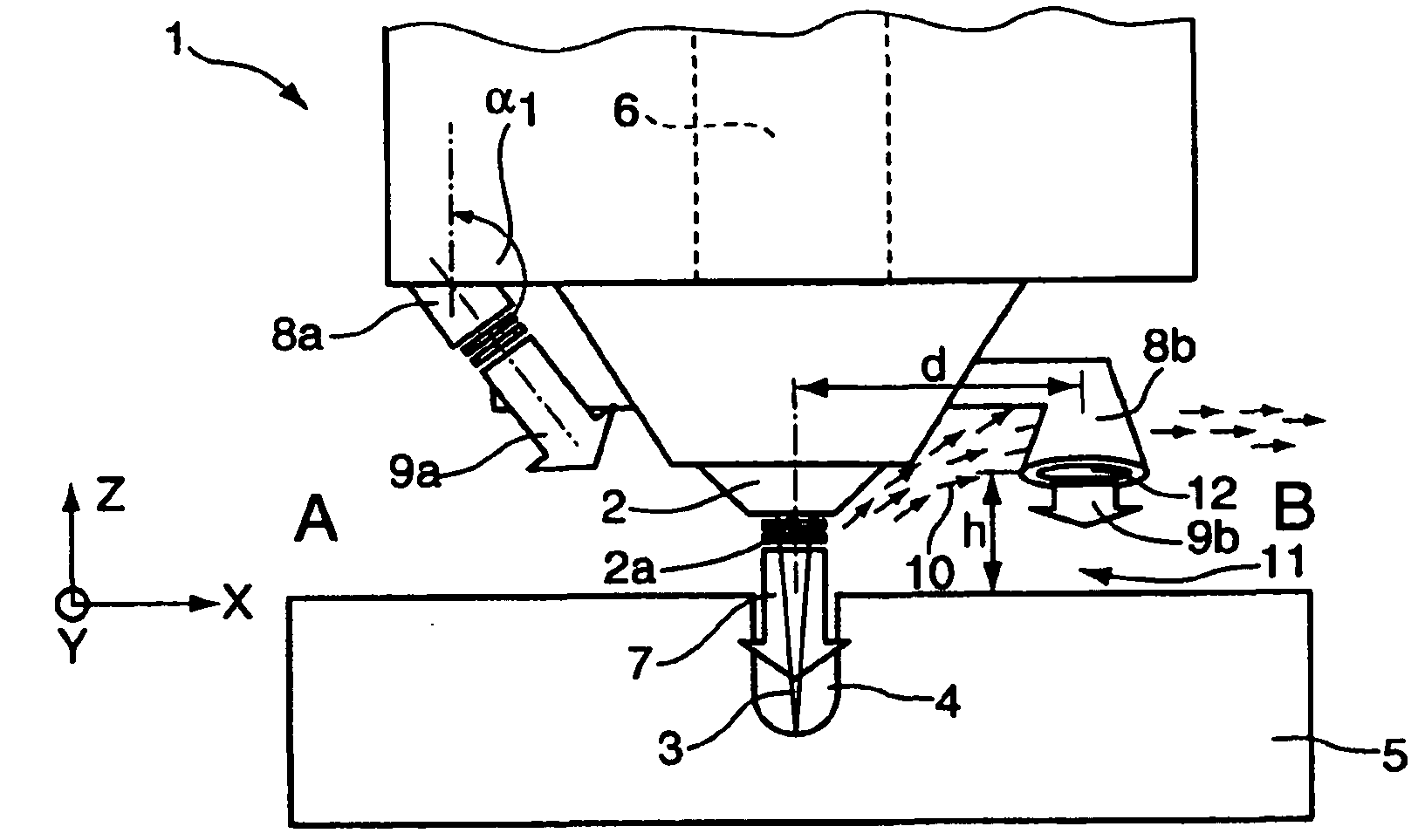

Method of reducing the attachment of slag when piercing a workpiece with a laser beam, and laser machining head

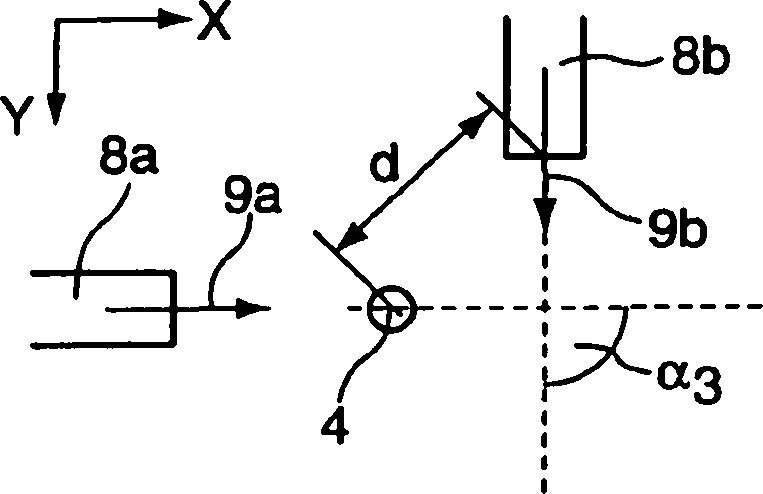

The invention relates to a method of reducing the attachment of slag (10) when piercing a workpiece (5) with a laser beam (3), during which at least a first additional stream of gas (9a) is directed onto the workpiece (5) at a first angle (a1) to the direction of laser radiation (Z) and impinges on the workpiece (5) on a first side (A) of a piercing point (4) and / or at the piercing point (4) itself, in order to blow slag (10) away from the piercing point (4). At least a second stream of additional gas (9b, 9b', 9b'') is directed onto the workpiece (5) at a second angle (a2) to the direction of laser radiation (Z) and impinges on the workpiece (5) on a second side (B) of the piercing point (4), opposite from the first side (A), at a distance from the piercing point (4), wherein the second additional stream of gas (9b, 9b', 9b'') is aligned at an angle to the first stream of additional gas (9a) with respect to a plane (X, Y) that is perpendicular to the direction of laser radiation (Z), in order to create a gas cushion (11) between the slag (10) blown away by the first additional stream of gas (9a) and the workpiece (11). The invention also relates to a laser machining head (1) for carrying out the method.

Owner:TRUMPF WERKZEUGMASCHINEN GMBH & CO KG

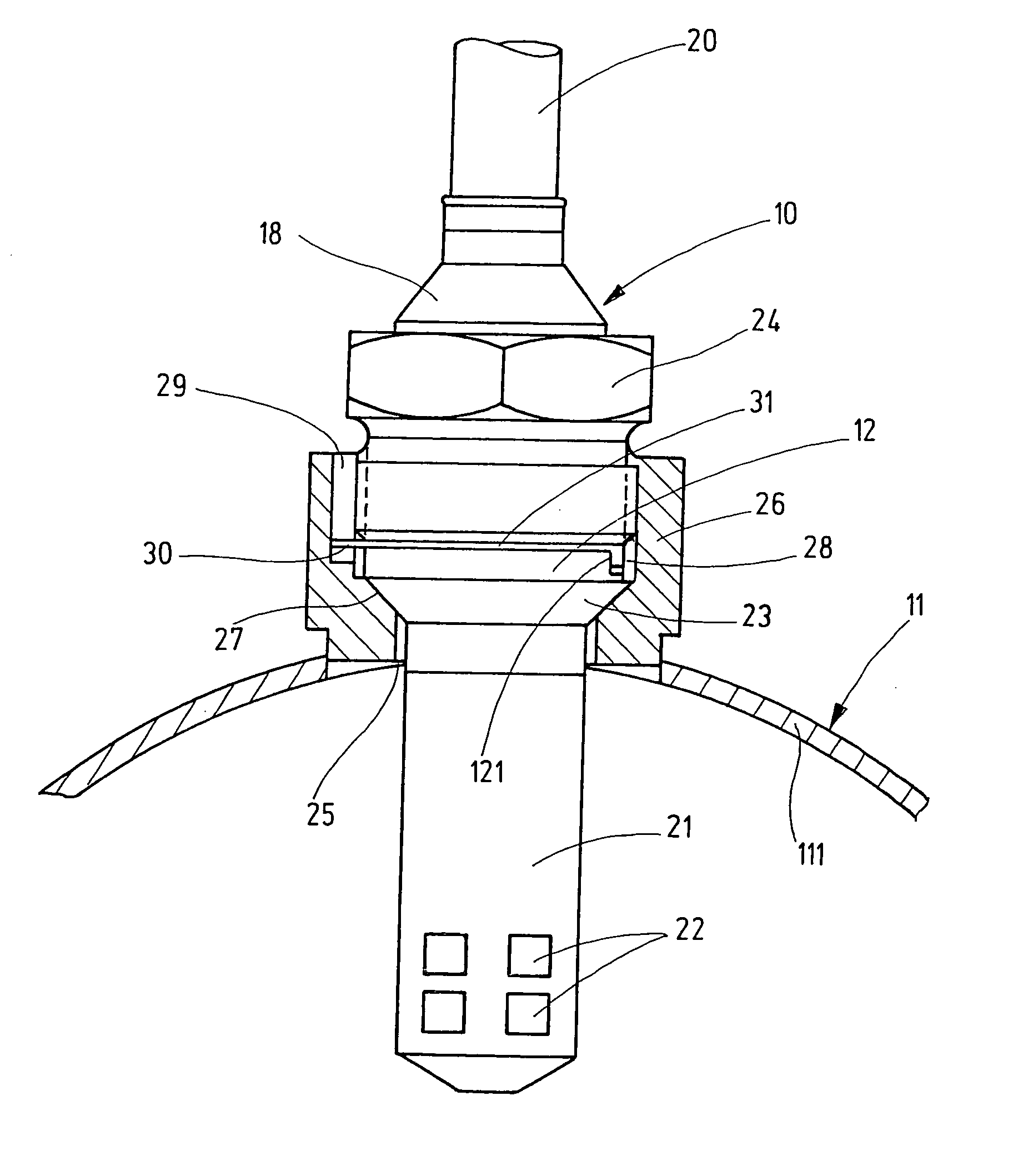

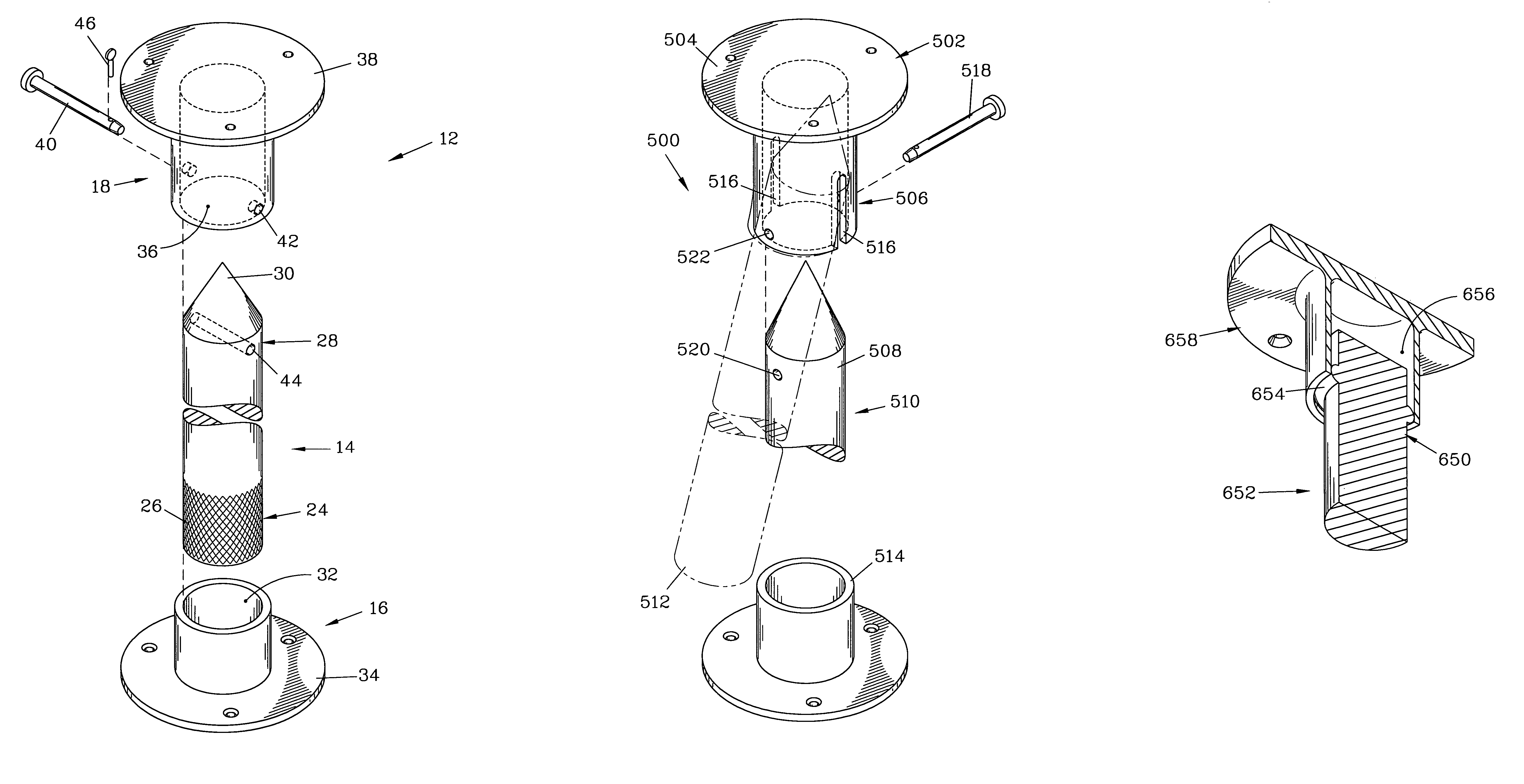

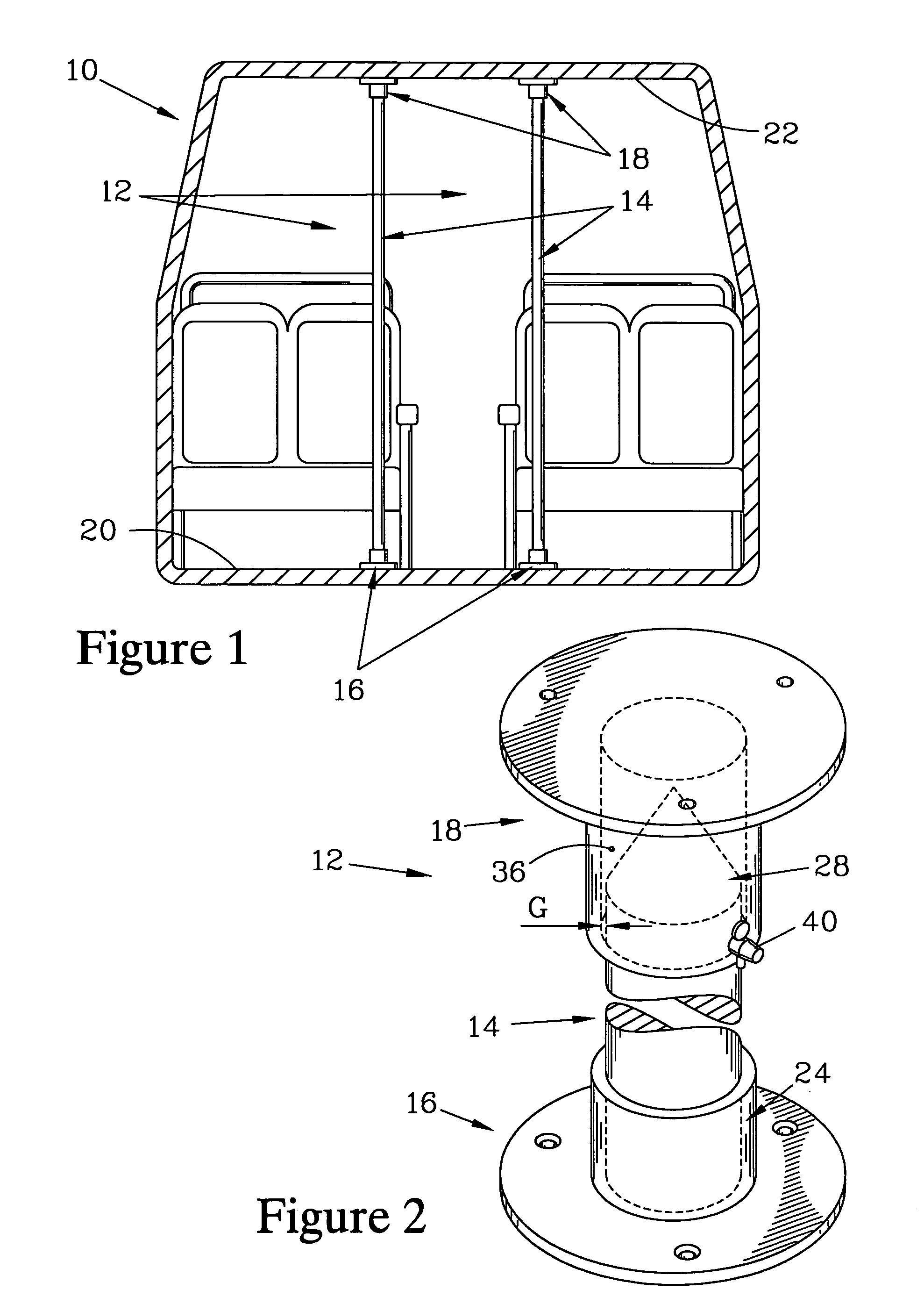

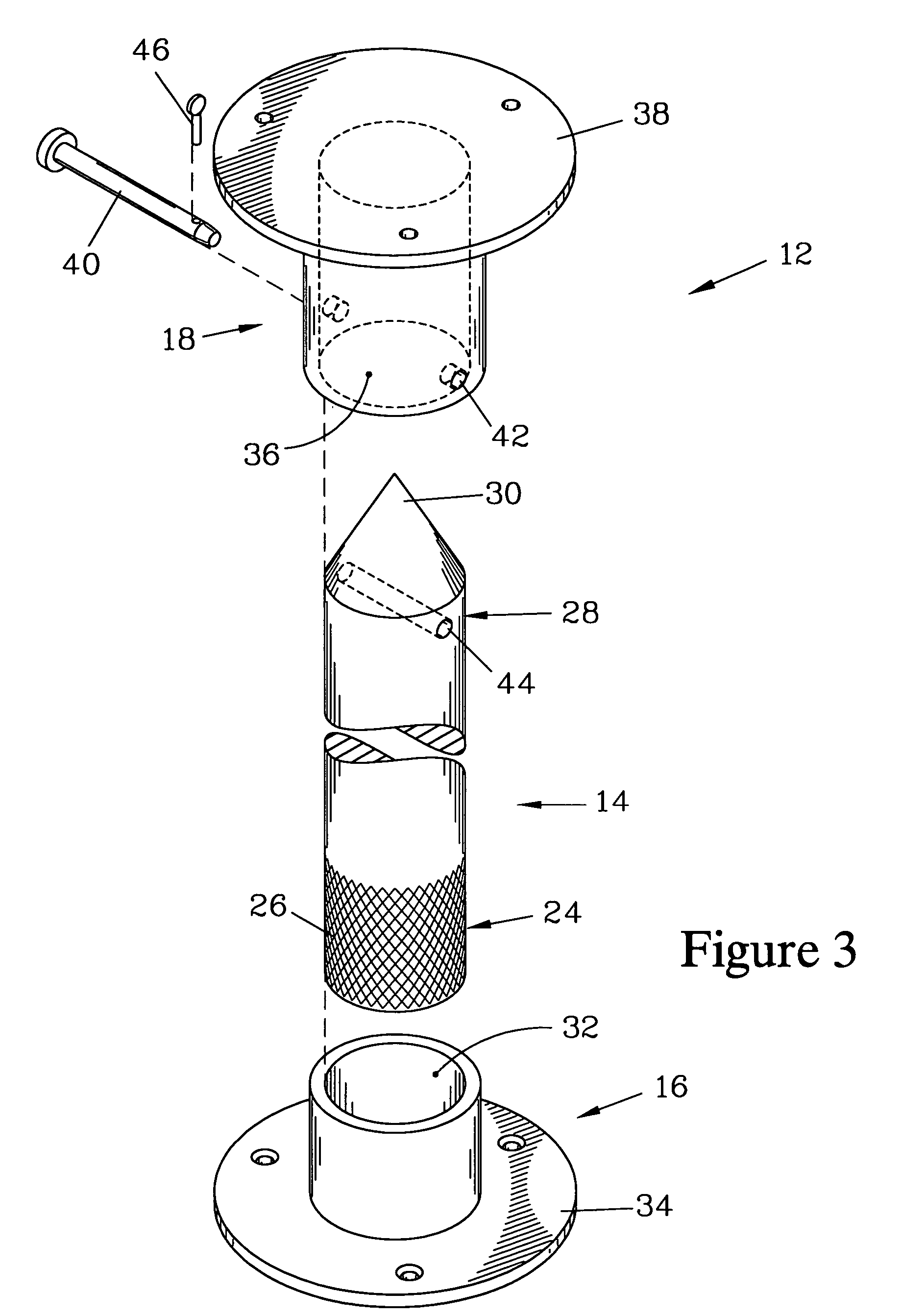

Personal protection system

InactiveUS7211001B2Improve efficiencySufficient flexibilityClubsRigid containersPiercing pointEngineering

A personal protection system has a shaft that can be secured into a pair of end bases that mount to a surface of the surroundings of the user. The shaft and bases are configured to appear as a natural part of the surroundings, such as a support bar or rail, when the shaft is stored. The shaft can be removed, and has an end portion adapted to provide a weapon for self defense. For example, the end portion can employ a piercing point, a syringe and needle for injecting a bio-toxin, a canister for spraying a chemical irritant, an appliance for generating an electrical shock, or combinations of these elements. Preferably, the shaft is secured into the bases so as to be usable for support. It is further preferred for the bases to be configured to disguise the fact that the shaft can be removed.

Owner:MOTYKA MR JOHN

Tubular severing system and method of using same

Techniques for severing a tubular of a wellbore penetrating a subterranean formation are provided. A blade is extendable by a ram of a blowout preventer positionable about the tubular. The blade includes a blade body having a front face on a side thereof facing the tubular. At least a portion of the front face has a vertical surface and at least a portion of the front face has an inclined surface. The vertical surface is perpendicular to a bottom surface of the blade body. The blade body includes a loading surface on an opposite side of the blade body to the front face. The loading surface is receivable by the ram. The blade also includes a cutting surface along at least a portion of the front face for engagement with the tubular, and a piercing point along the front face for piercing the tubular. The piercing point has a tip extending a distance from the cutting surface.

Owner:NAT OILWELL VARCO LP

Laser strengthening process of piercing point

InactiveCN102732878AHigh surface hardnessImprove surface wear resistanceMetallic material coating processesPiercing pointHigh intensity

The invention relates to a laser strengthening process of a piercing point. The laser strengthening process comprises the following steps of: smelting a transition alloy layer on the surface of a substrate of the piercing point; smelting a high-strength alloy layer on the transition alloy layer by laser, wherein alloy powder used by the transition alloy layer is an nickel-based alloy; and the alloy powder used by the high-strength alloy layer is a cobalt-based alloy. In the process, the hardness of the transition alloy layer is lower than that of the high-strength alloy layer, has the transition effect on the high-hardness and high-abrasion-resistance high-strength alloy layer, and can better remit an overlaying stress, so that a residual overlaying stress does not cause great influences on tissues of a laser smelting layer even if the point is not pre-heated and not annealed, so that the phenomenon that the performance of the smelting layer is influenced by annealing can be effectively avoided and the surface hardness and the abrasion resistance of the piercing point are greatly improved; and meanwhile, the pre-heating and annealing processes are saved and the production efficiency is improved.

Owner:佛山市顺德区新特瓦钢型材有限公司

Tubular severing system and method of using same

Techniques for severing a tubular of a wellbore penetrating a subterranean formation are provided. A blade is extendable by a ram of a blowout preventer positionable about the tubular. The blade includes a blade body having a front face on a side thereof facing the tubular. At least a portion of the front face has a vertical surface and at least a portion of the front face has an inclined surface. The vertical surface is perpendicular to a bottom surface of the blade body. The blade body includes a loading surface on an opposite side of the blade body to the front face. The loading surface is receivable by the ram. The blade also includes a cutting surface along at least a portion of the front face for engagement with the tubular, and a piercing point along the front face for piercing the tubular. The piercing point has a tip extending a distance from the cutting surface.

Owner:NAT OILWELL VARCO LP

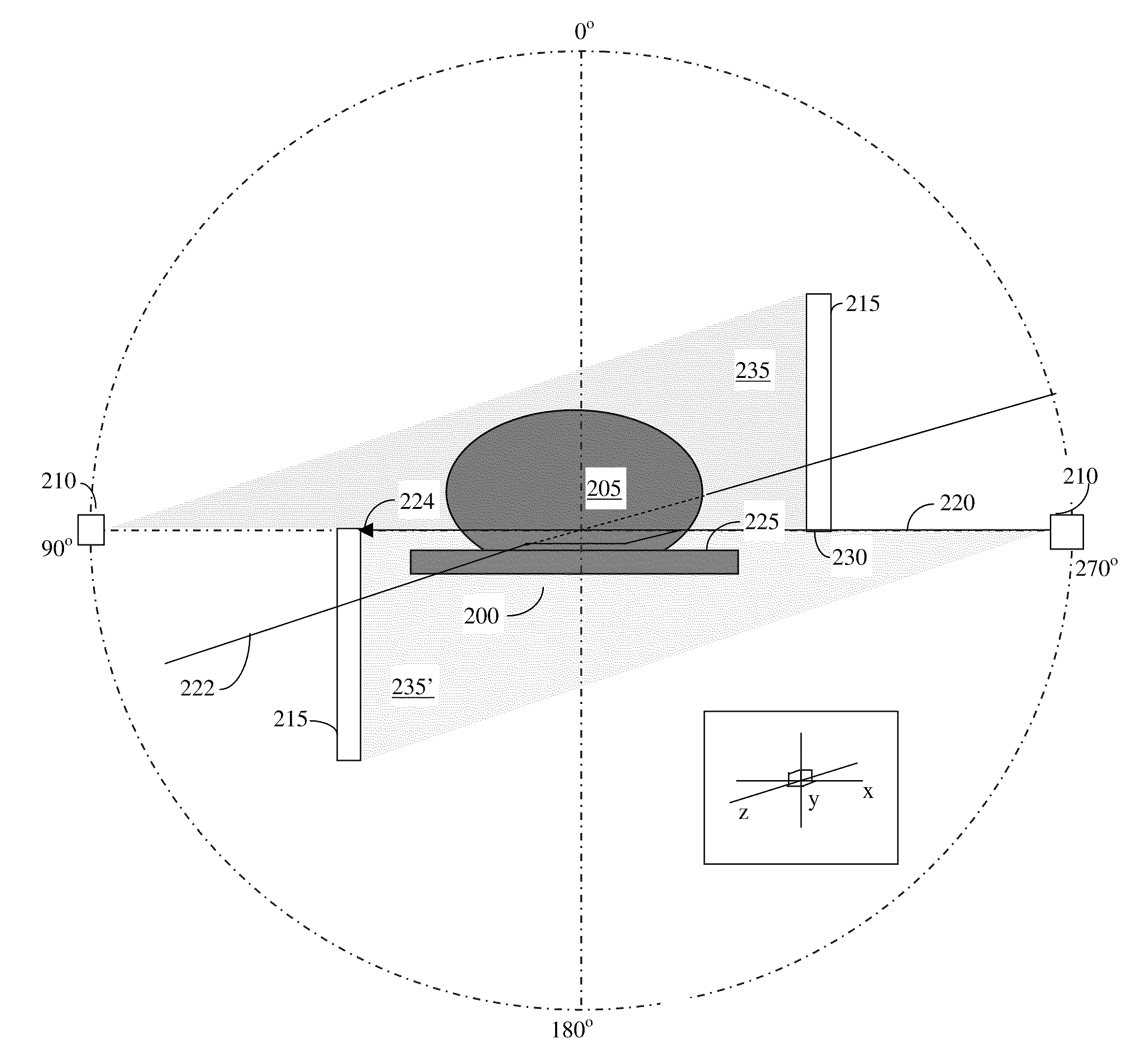

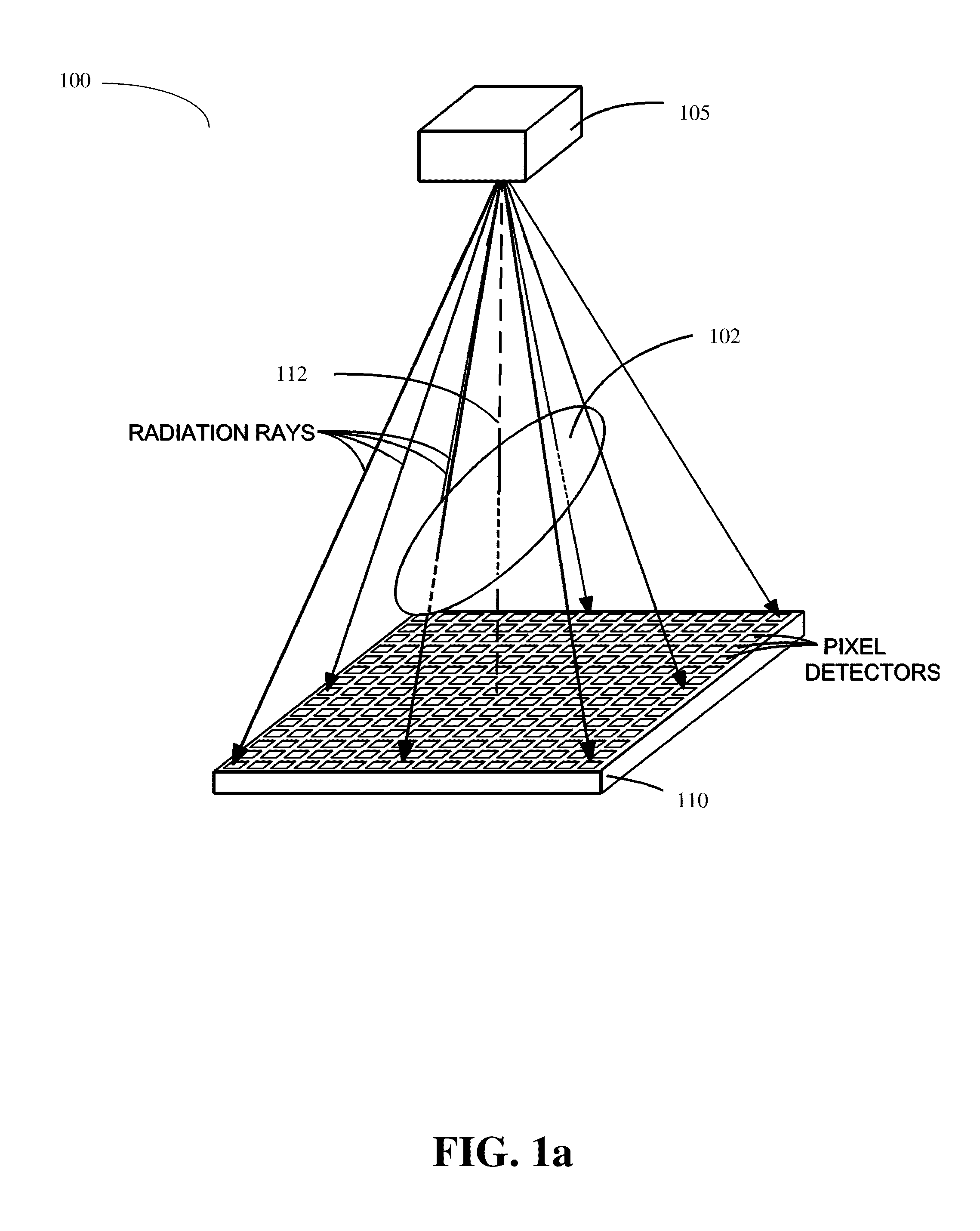

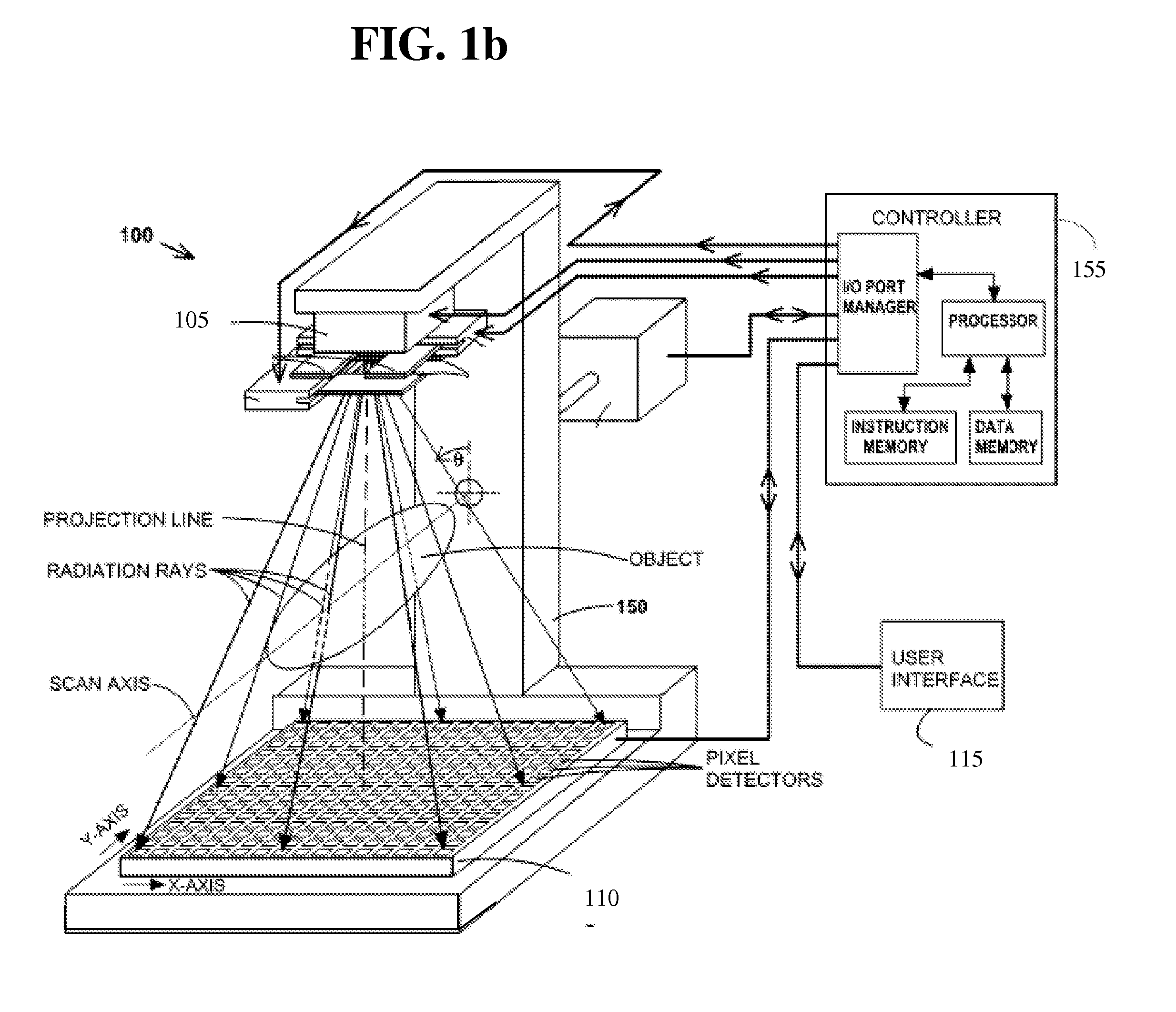

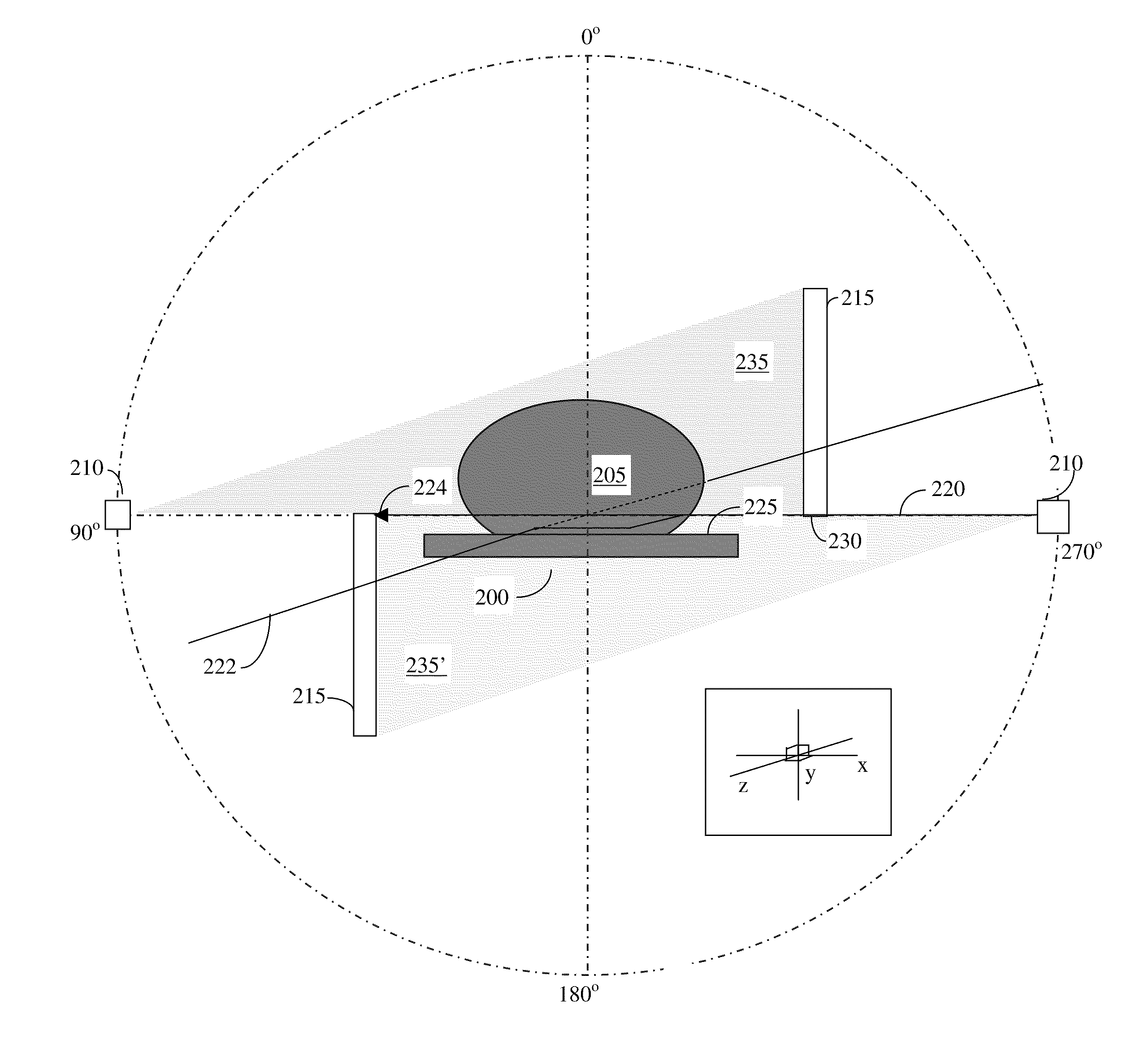

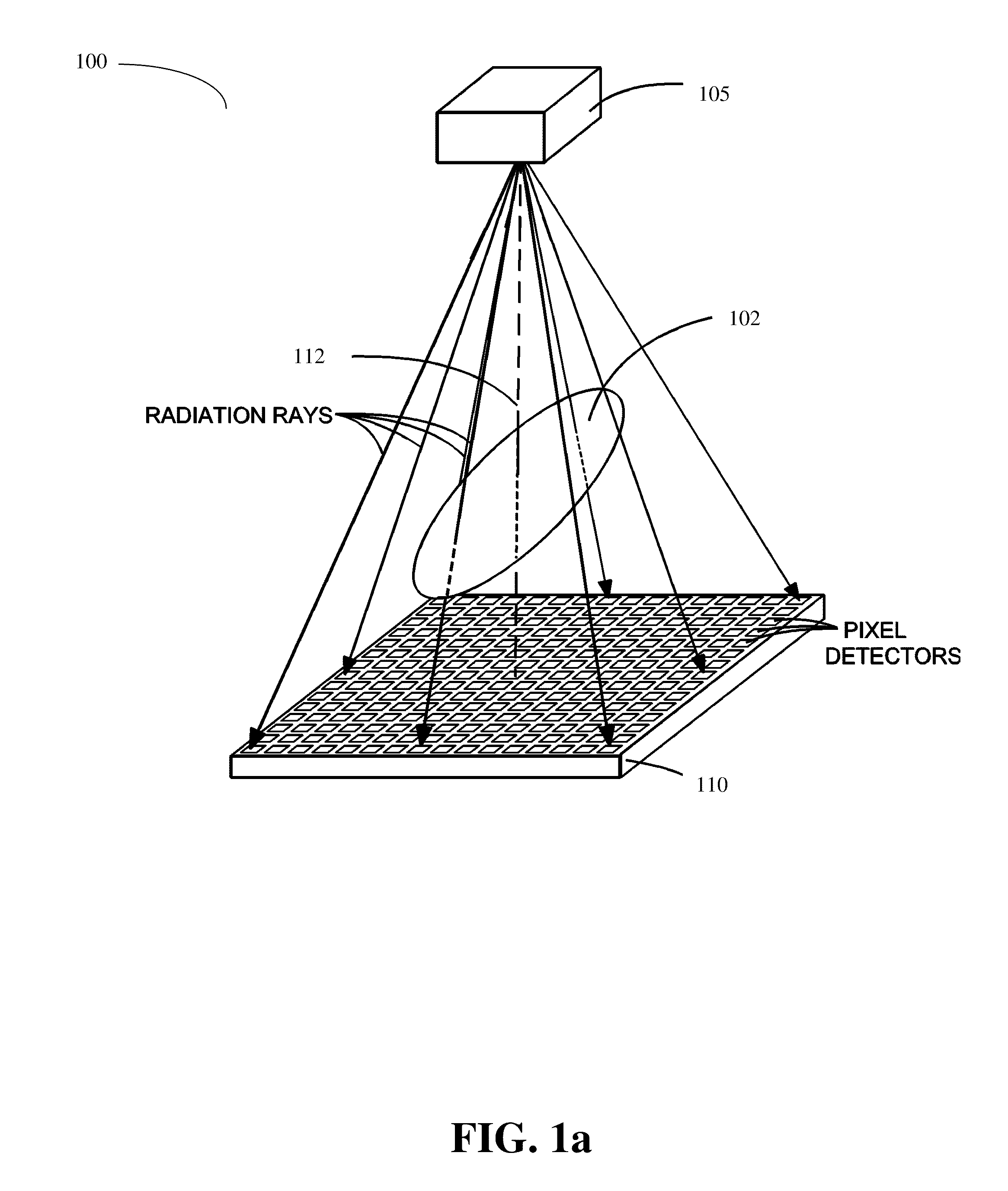

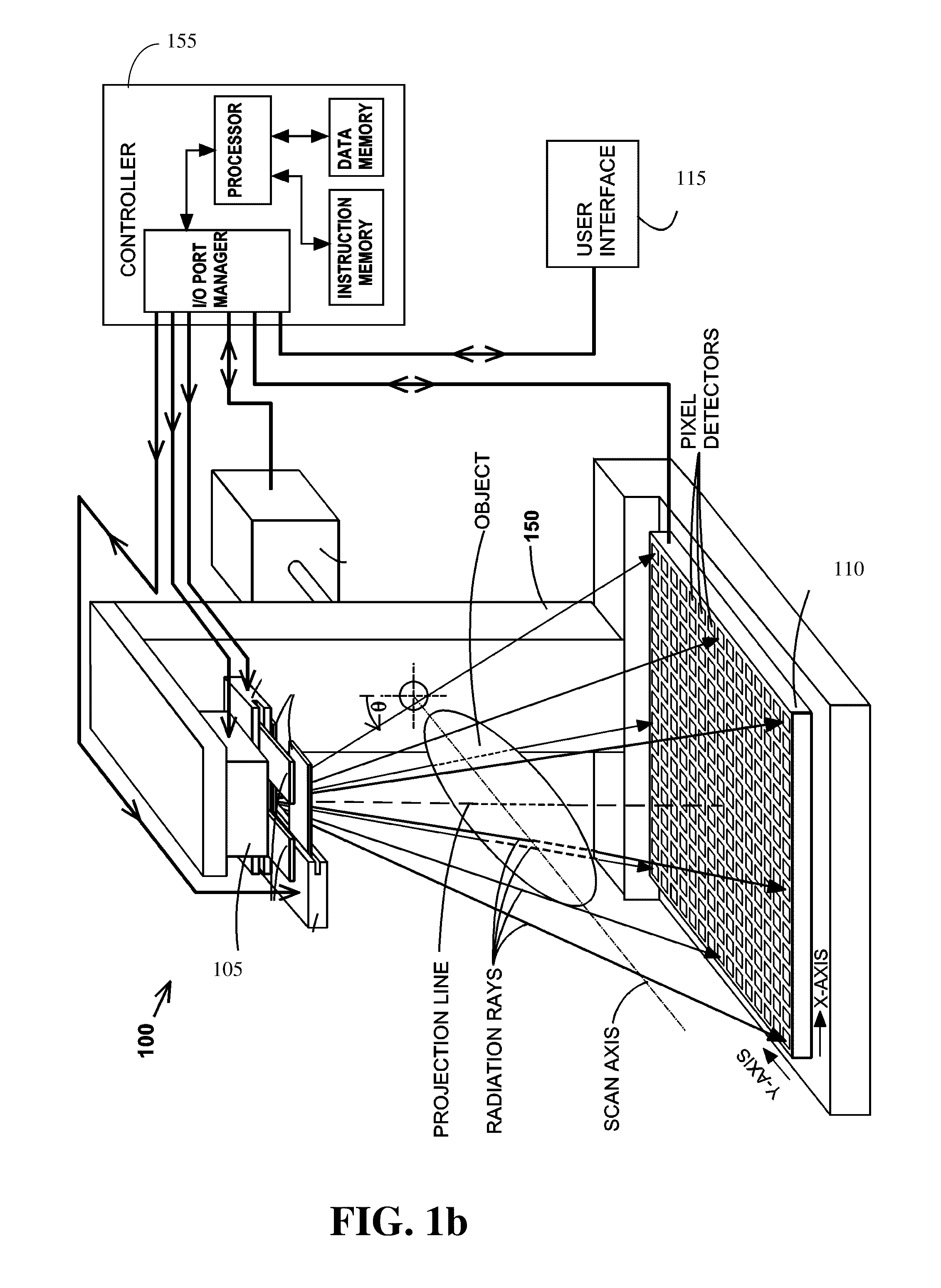

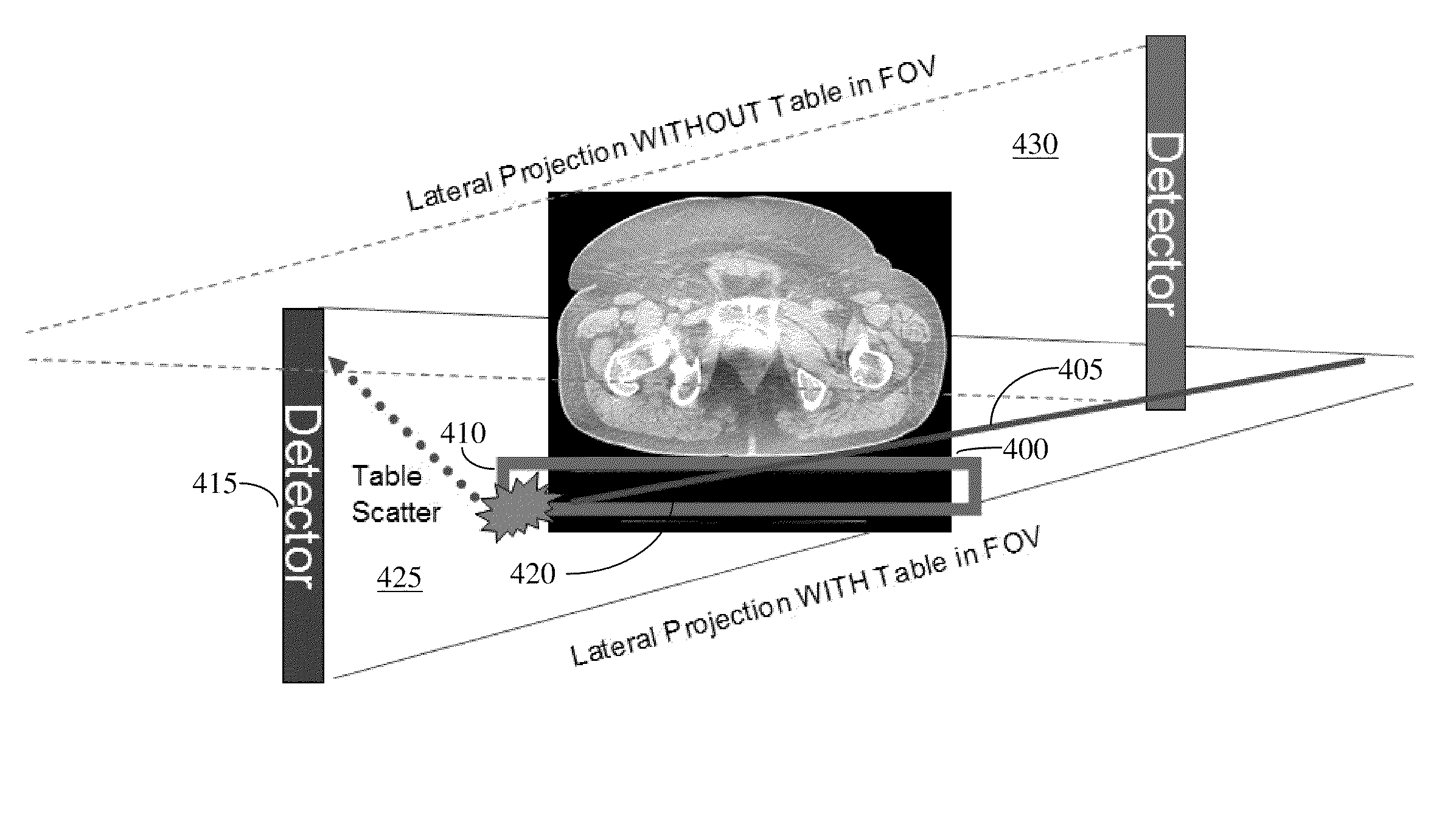

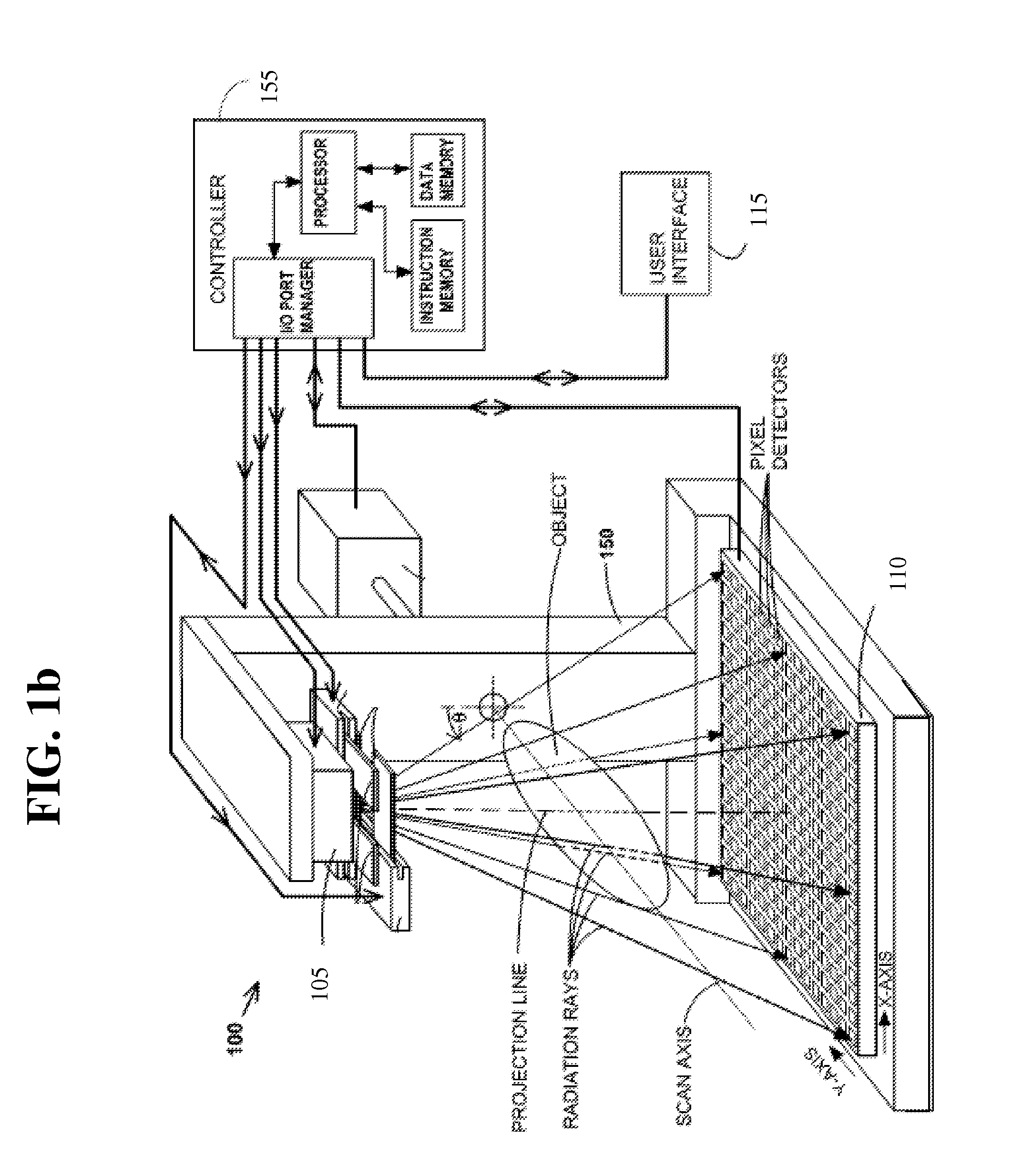

Methods of scatter correction of x-ray projection data 2

ActiveUS20110255656A1Reconstruction from projectionMaterial analysis using wave/particle radiationPiercing pointKernel method

A system and method for forming an adjusted estimate of scattered radiation in a radiographic projection of a target object, which incorporates scattered radiation from objects adjacent to the target object, such as a patient table. A piercing point equalization method is disclosed, and a refinement of analytical kernel methods which utilizes hybrid kernels is also disclosed.

Owner:VARIAN MEDICAL SYSTEMS

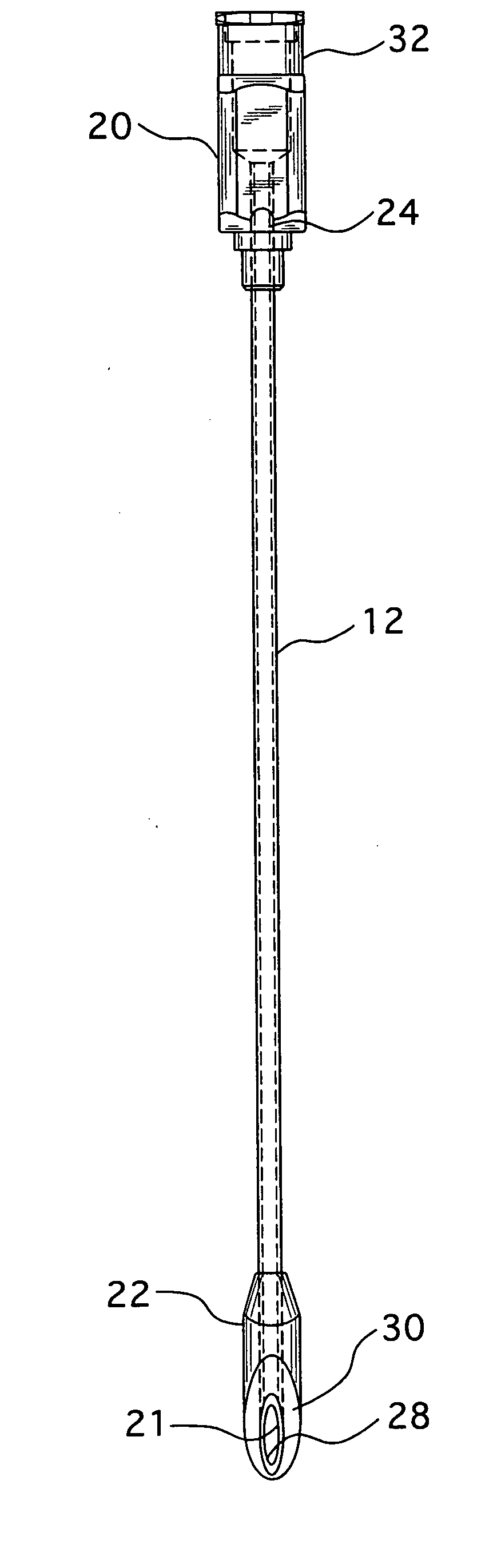

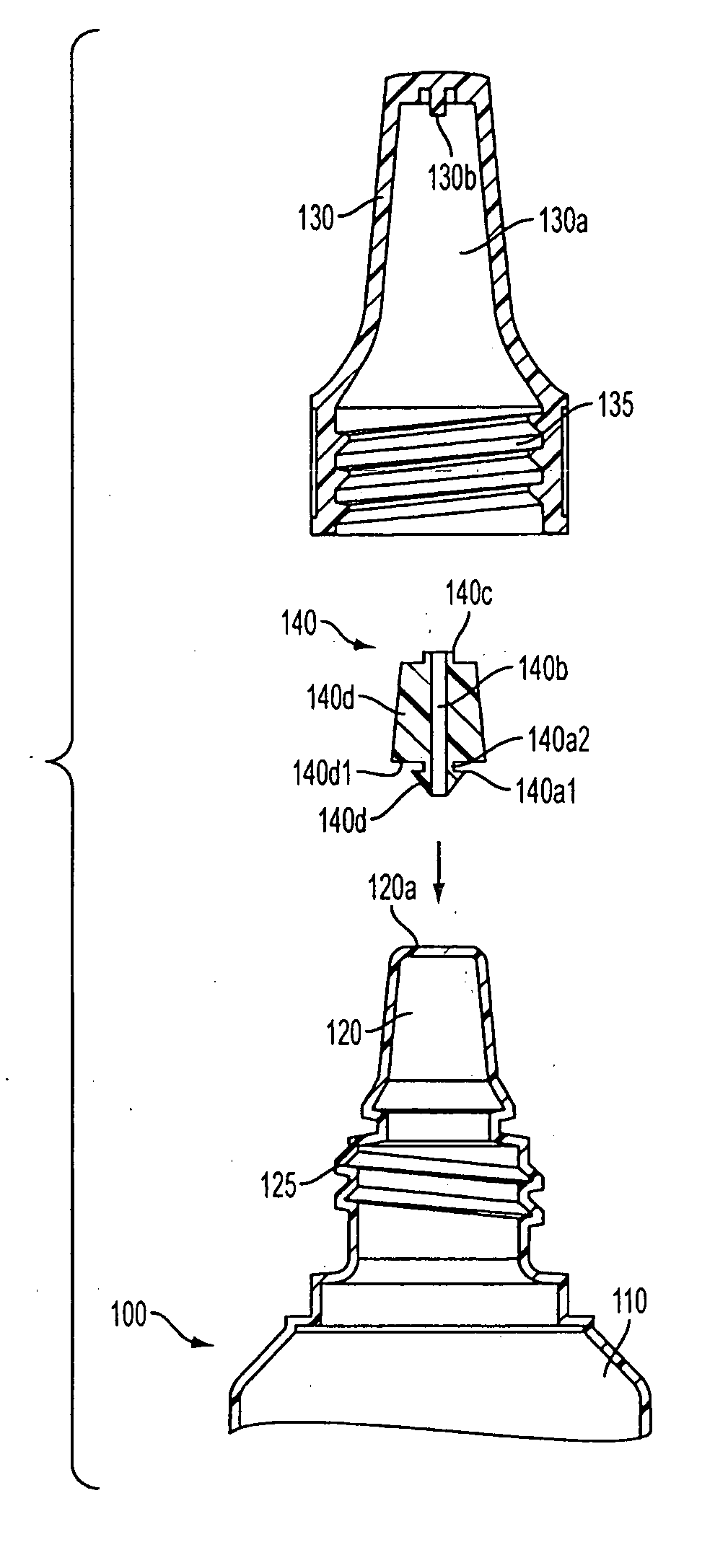

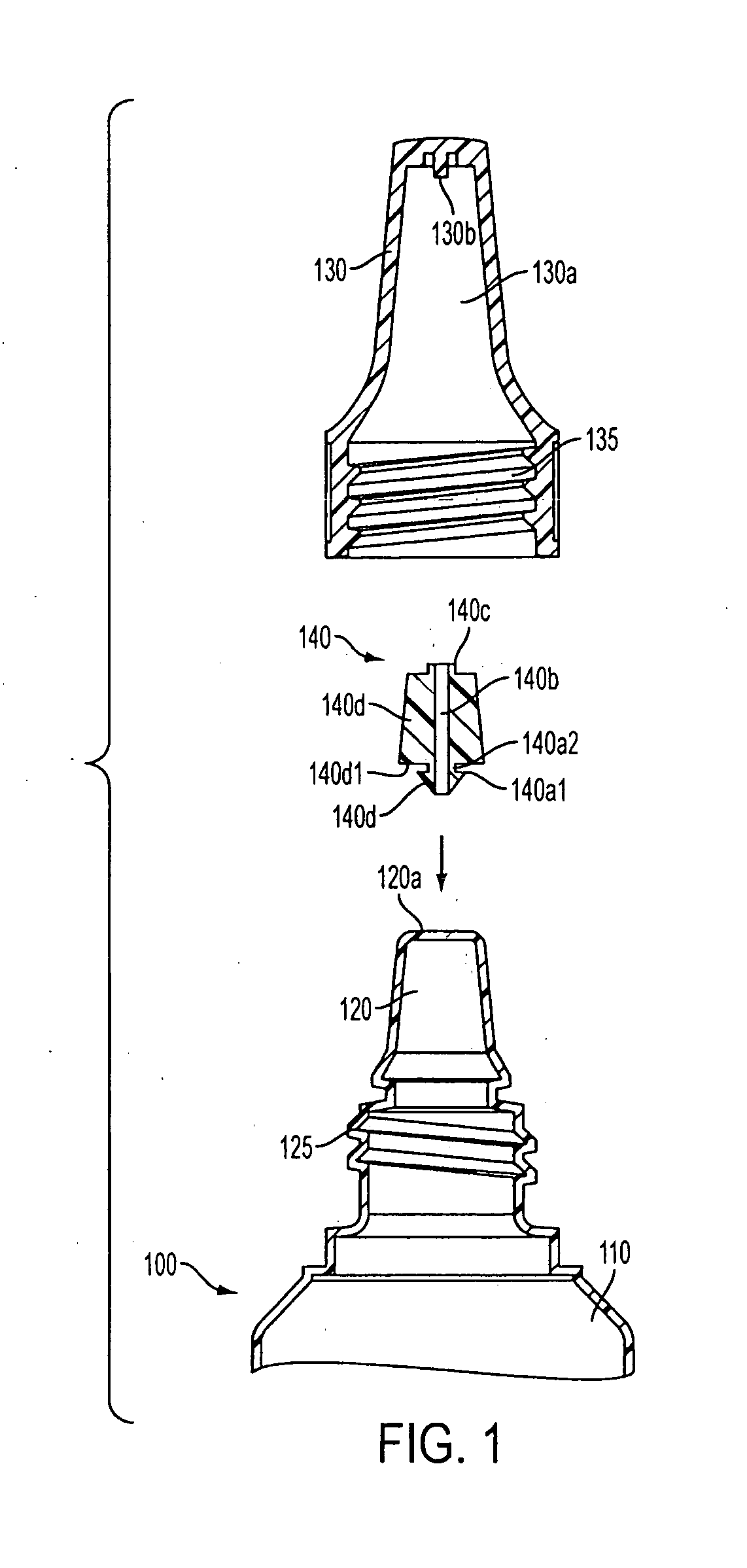

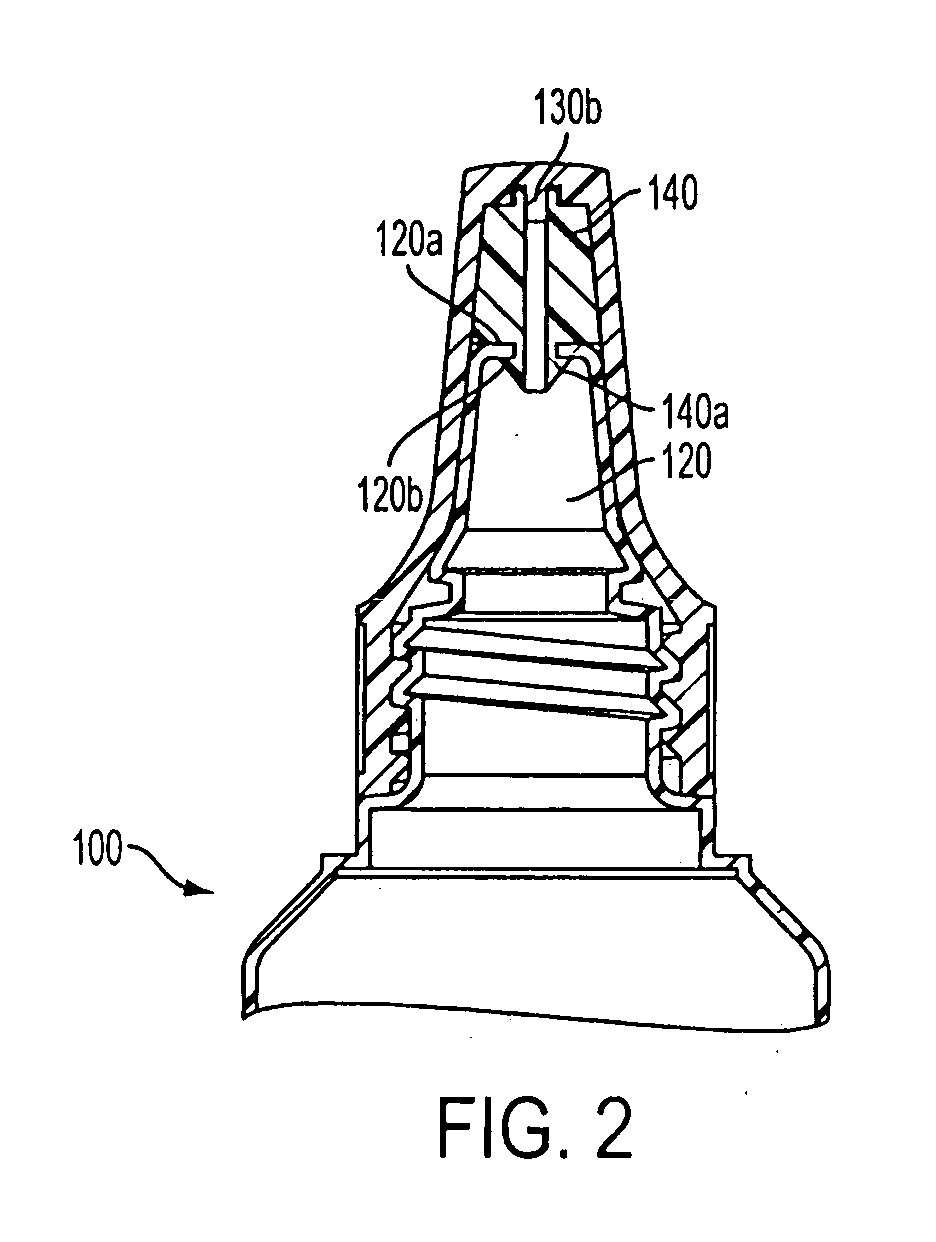

Tip arrangement for a dropper bottle

ActiveUS20100224657A1Allocation is accurateOpening closed containersBottle/container closureViscous liquidPiercing point

A tip arrangement for a bottle used for dispensing viscous liquid, such as drops of medicine, is provided. Embodiments include a tip insert having an insert body and a piercing point at a lower end of the insert body, for piercing a top surface of the bottle and for retaining the tip insert on the top surface of the bottle after piercing. A passage extends from a distal end of the piercing point, through the insert body, to an opposing upper surface of the insert body. A dispensing tip at the insert body upper surface communicates with the passage for precisely forming drops of the liquid from the bottle.

Owner:SUN PHARMA GLOBAL FZE

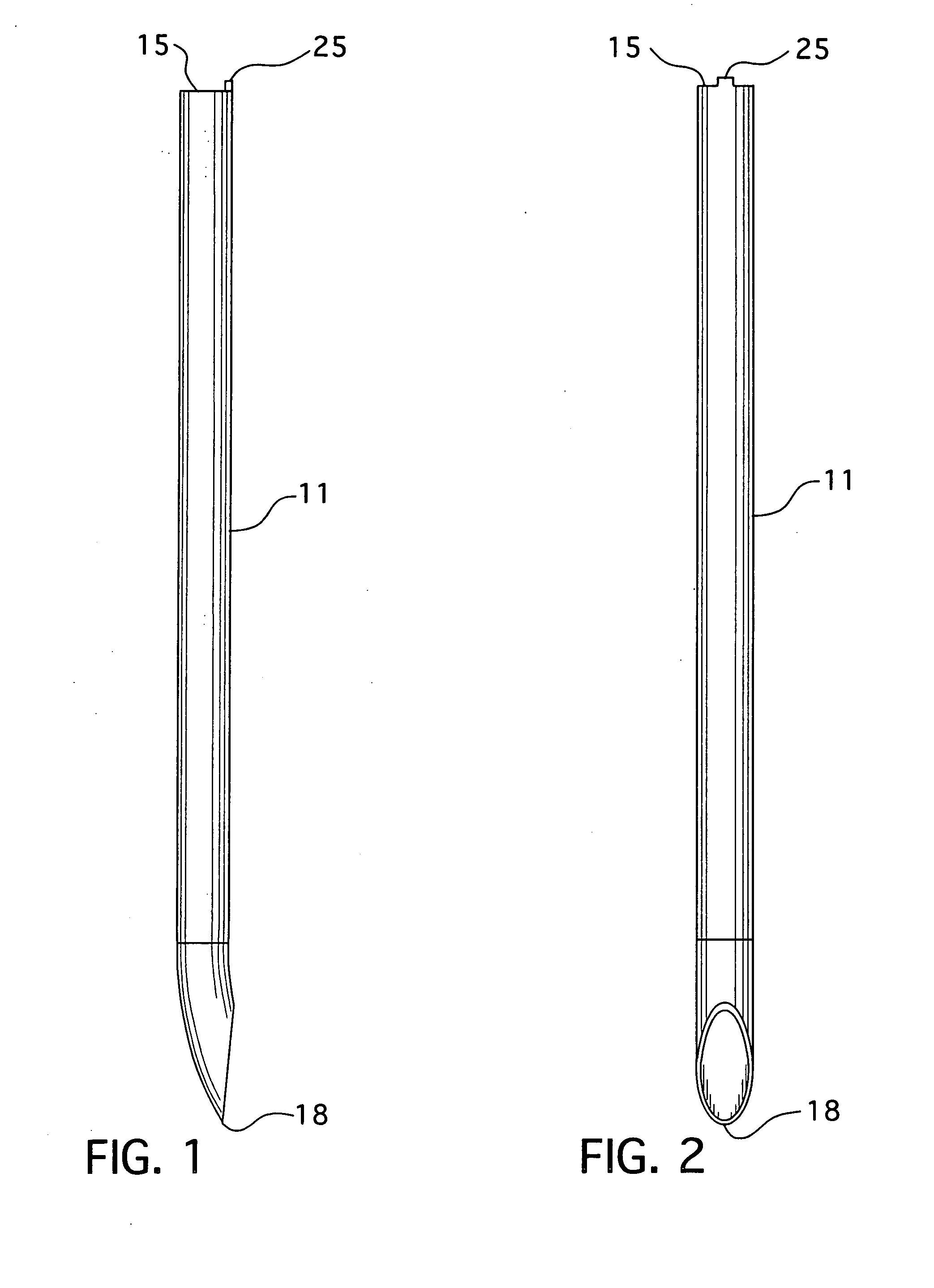

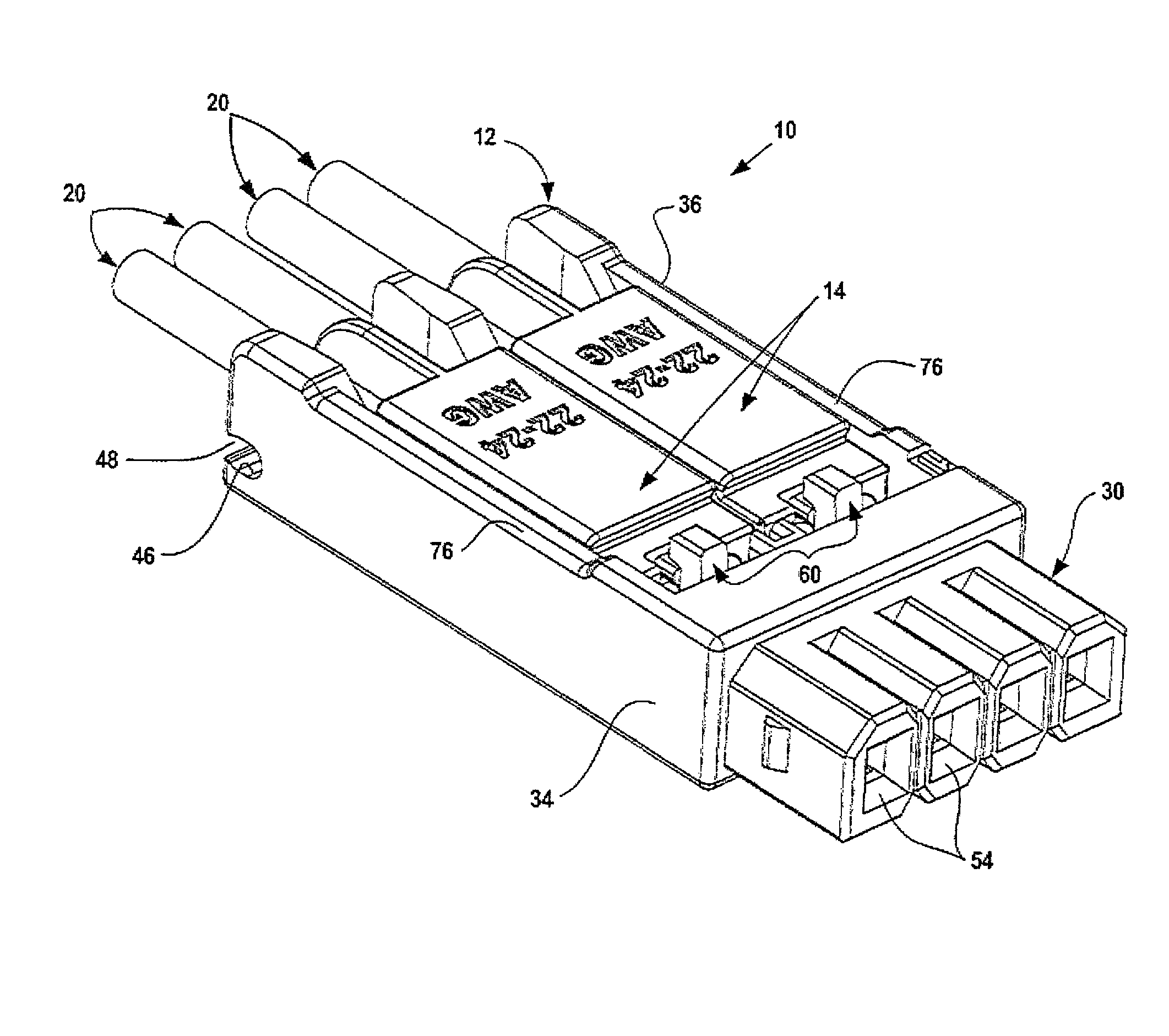

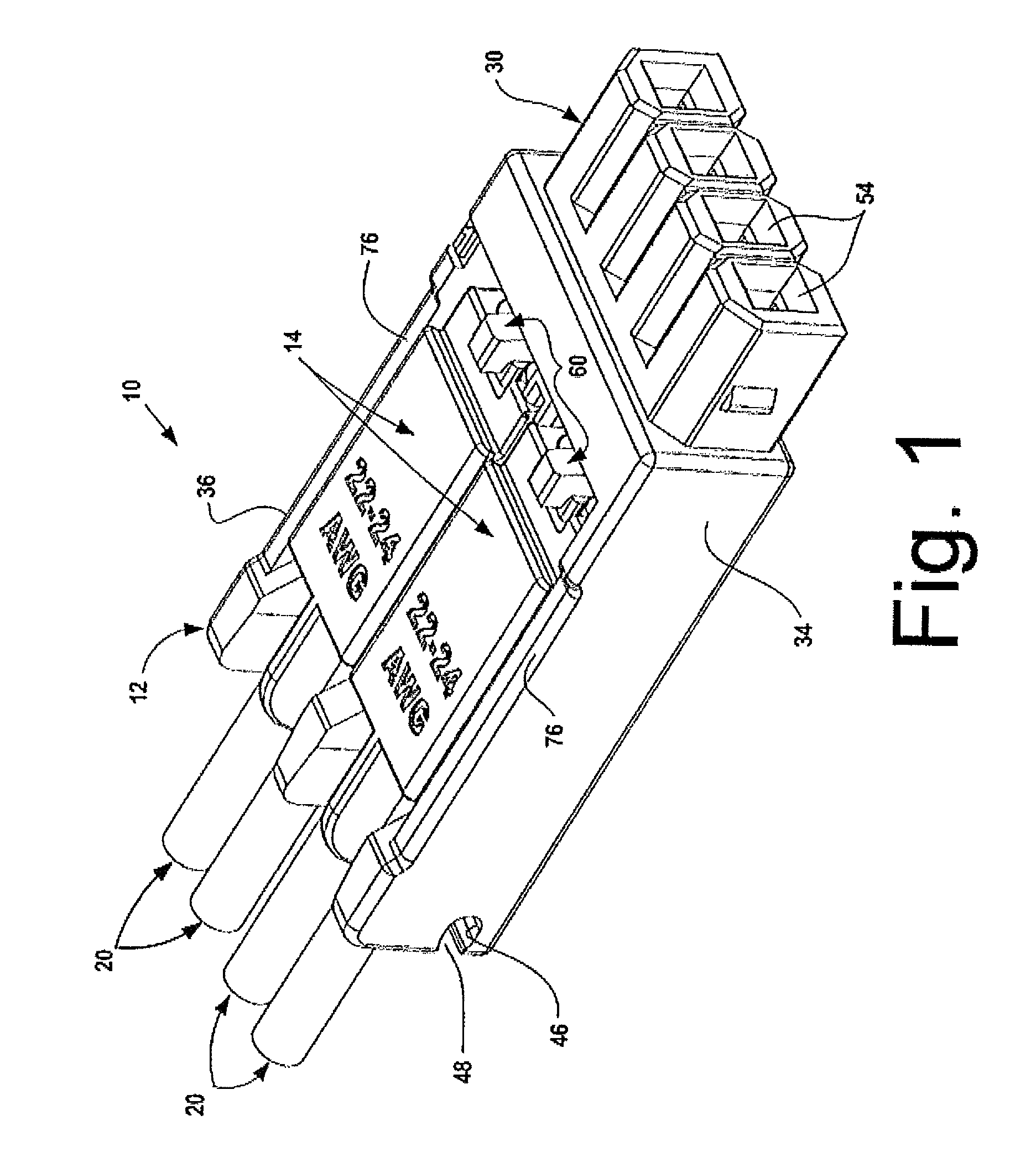

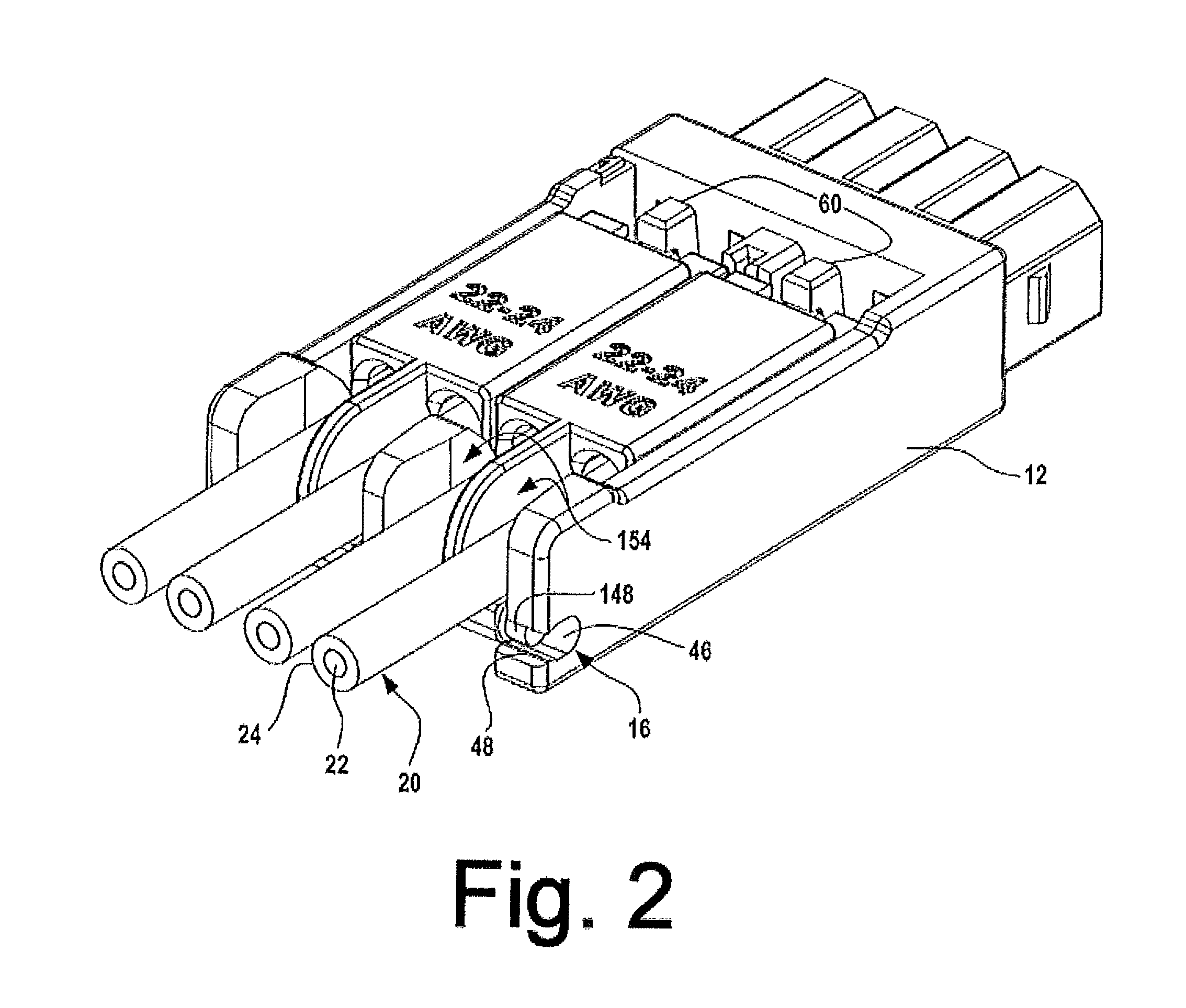

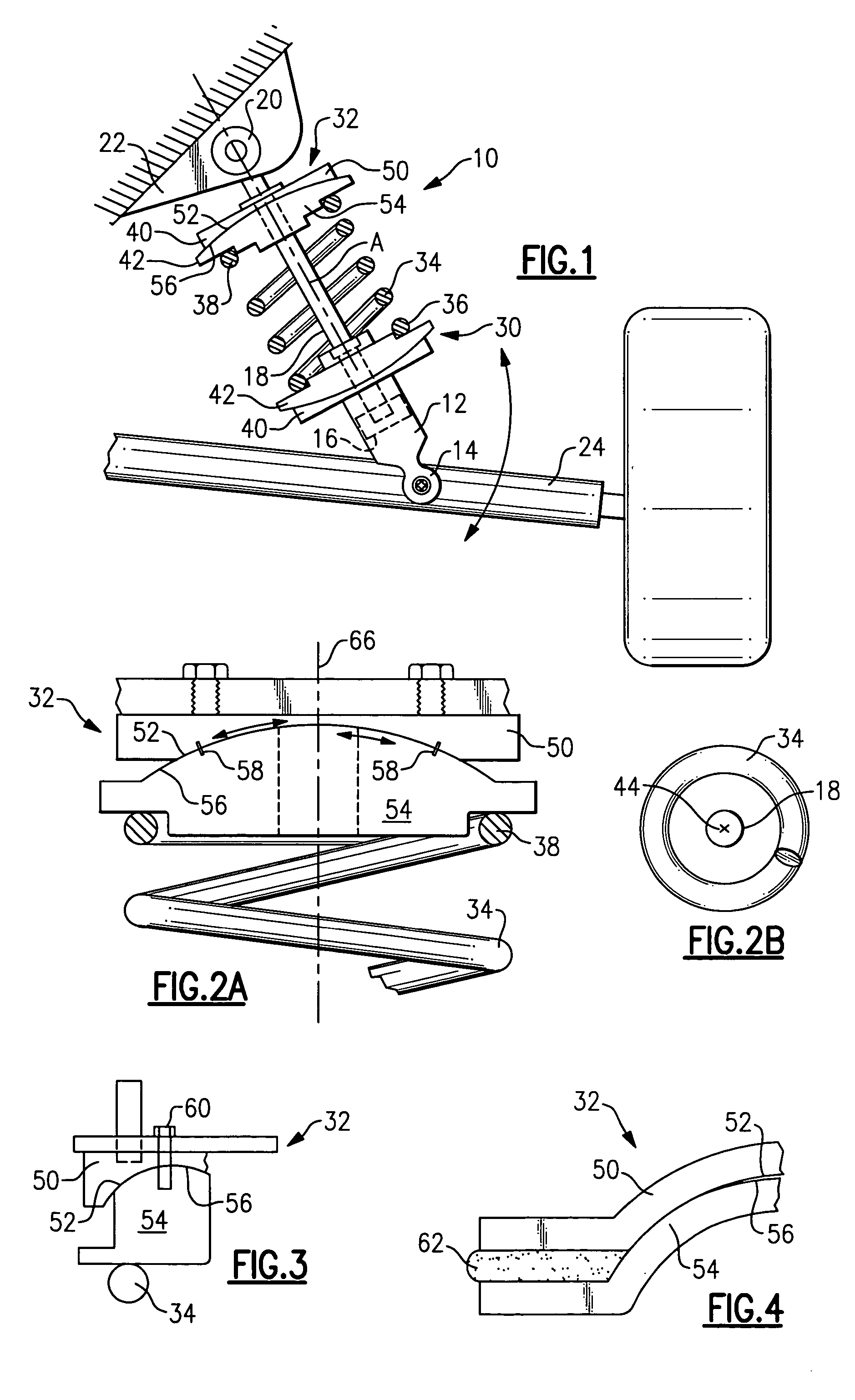

Electrical connector assembly and method

InactiveUS7942689B1Prevent buildupReliable engagementCoupling device detailsTwo-part coupling devicesElectrical conductorPiercing point

An electrical connector assembly for forming insulation displacement connections with conductors in small wires includes a wire carrier and a base. Pierce points on the base are slid along opposed walls in a slot in the carrier to align small tips on the ends of the pierce points to form electrical connections with a conductor in a wire in the carrier. The connections are located inwardly of the slot walls.

Owner:PHOENIX CONTACT DEVMENT & MFG

Tool steel for hot working, tool for hot working and plug for producing seamless pipe

The present invention is a tool steel for hot working, and the oxide scale formed on the surface thereof has good adhesion and lubricity and high strength. The tool steel contains C: 0.05-0.5%, Si: 0.1-1%, Mn: 1.6-3.5%, Ni: 0.05-0.5%, Mo: 2-5%, W: 2-5%, Cu: 0.05- 0.5%, and the remainder is substantially composed of Fe. One or more of Cr, Co, REM, Ti, Nb, V, Zr, and B may also be contained. The surface of a tool made of this steel is covered with an oxide scale with a thickness of 50 to 1500 μm. A typical example of the tool is a piercing plug for seamless pipe production.

Owner:NIPPON STEEL CORP

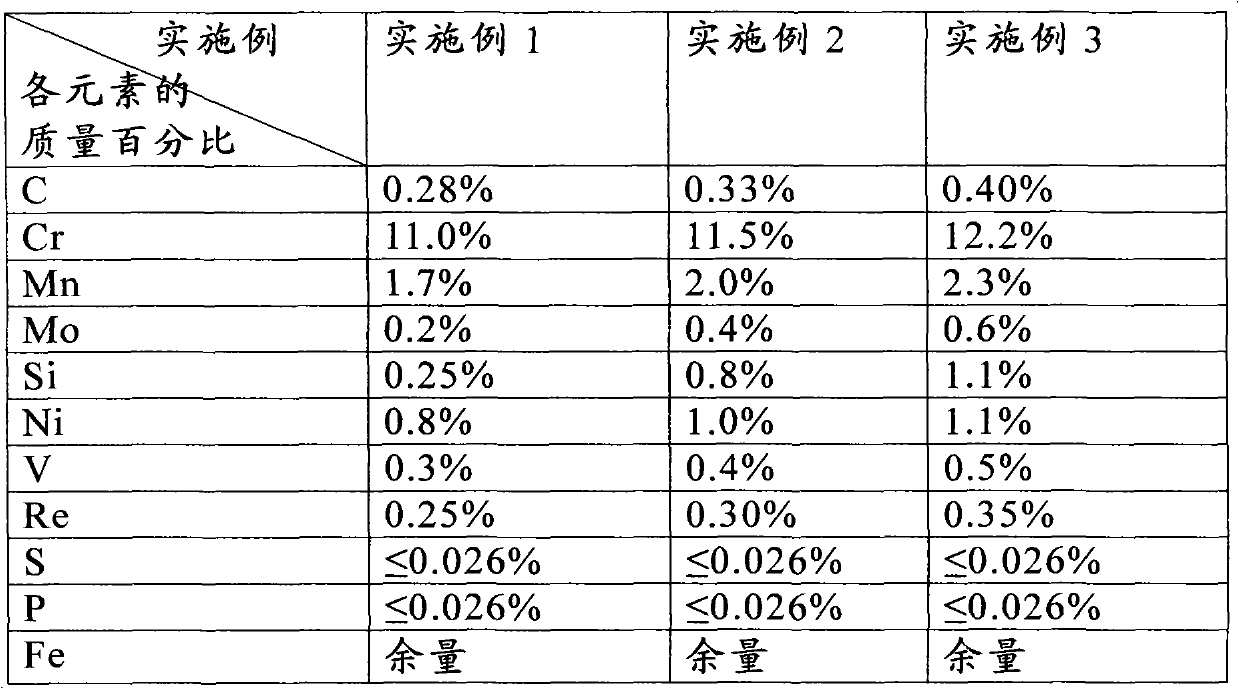

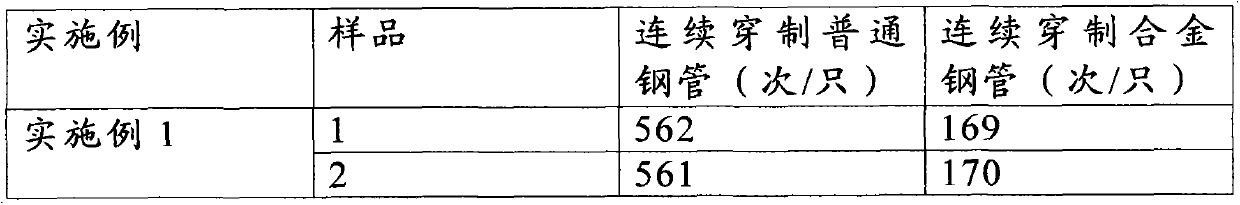

Steel tube piercing point and preparation method thereof

ActiveCN103131966AImprove wear resistanceExtended service lifeMandrelsMetal rolling arrangementsRheniumSurface oxidation

The invention discloses a steel tube piercing point and a preparation method thereof. The invention solves the problems of insufficient wear resistance, short service life and the like in the steel tube piercing point in the prior art. The steel tube piercing point disclosed by the invention comprises the following component elements in percentage by mass: 0.28%-0.40% of carbon (C), 11.0%-12.2% of chromium (Cr), 1.7%-2.3% of manganese (Mn), 0.2%-0.6% of molybdenum (Mo), 0.25%-1.10% of silicon (Si), 0.8%-1.1% of nickel (Ni), 0.3%-0.5% of vanadium (V), 0.25%-0.35% of rhenium(Re) and the balance of iron (Fe) and inevitable impurities. The invention also provides a preparation method of the steel tube piercing point, which comprises the following steps: proportioning, forging, annealing heat treatment and surface oxidation treatment. The steel tube piercing point disclosed by the invention has the advantages of favorable wear resistance and long service life.

Owner:宁波文而昌新材料科技有限公司

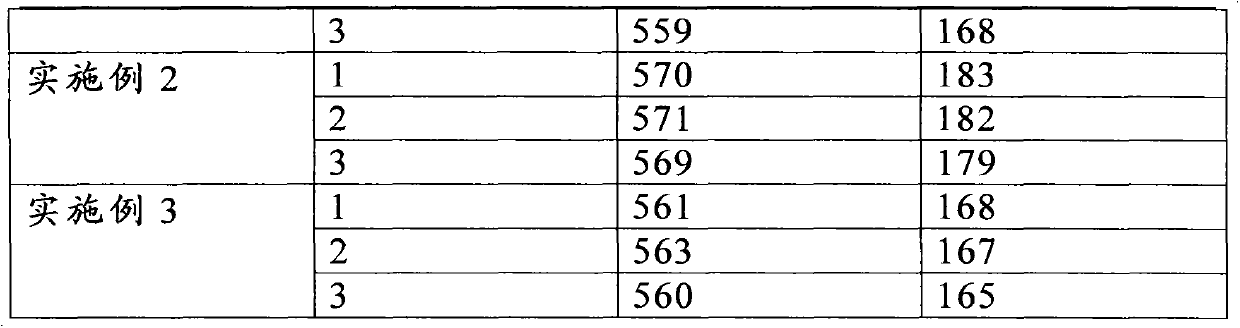

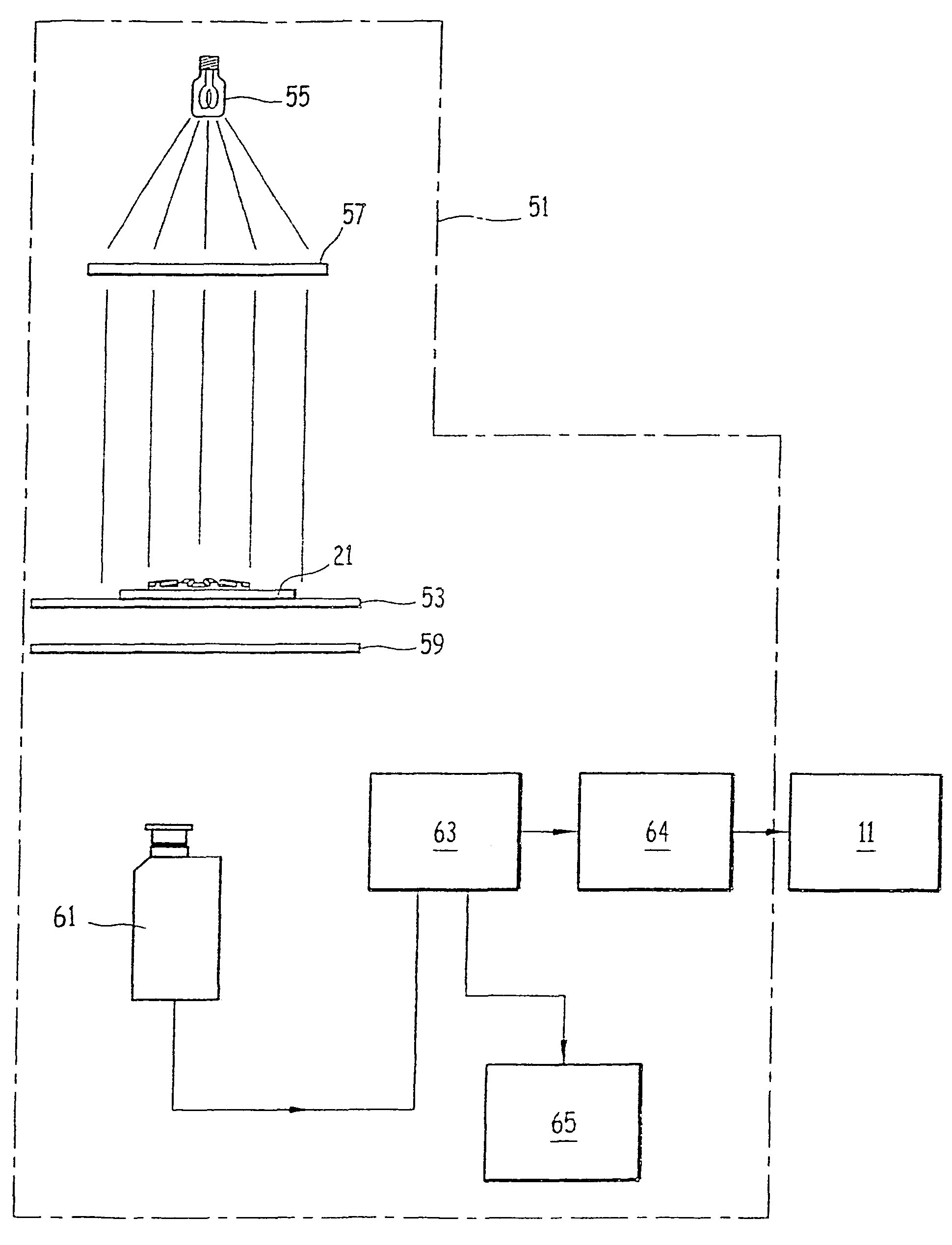

Method of calibrating an ophthalmic-lens-piercing machine, device used to implement one such method and ophthalmic-lens-machining apparatus comprising one such device

ActiveUS7668617B2Improve accuracyShort operating timeProgramme controlComputer controlOphthalmologyPiercing point

The invention relates to a method of calibrating an ophthalmic-lens-piercing machine, a device used to implement one such method and a ophthalmic-lens-machining apparatus comprising one such device. The inventive method applies to a machine including a piercing tool, a lens support which is associated with a first reference mark (O1, X1, Y1), and programmable tool-control means which are associated with a second reference mark expressing set co-ordinates which define a target piercing point (M). A template is placed on the support, and the template includes pre-applied markings defining a third reference mark (O3, X3, Y3), such that the third reference mark in essentially in line with the first reference mark. The template is pierced at a pre-determined point corresponding to a target point, and an image of the template this point position, and a correction is applied to the set co-ordinates that can compensate for the misalignment. A device is also provided which is used to implement the method, and to an ophthalmic-lens-machining apparatus including one such device.

Owner:LUNEAU TECH OPERATIONS

Fastener having improved penetration capability

A metal piercing fastener having an elongated flat body having first and second surfaces with a heat at one end and a piercing point at the other. The thickness dimension of the flat body is greater proximate the head proximate the point. The first and second surfaces of the body are devoid of protrusions extending outwardly therefrom.

Owner:EVENING STAR INVESTMENTS L L C

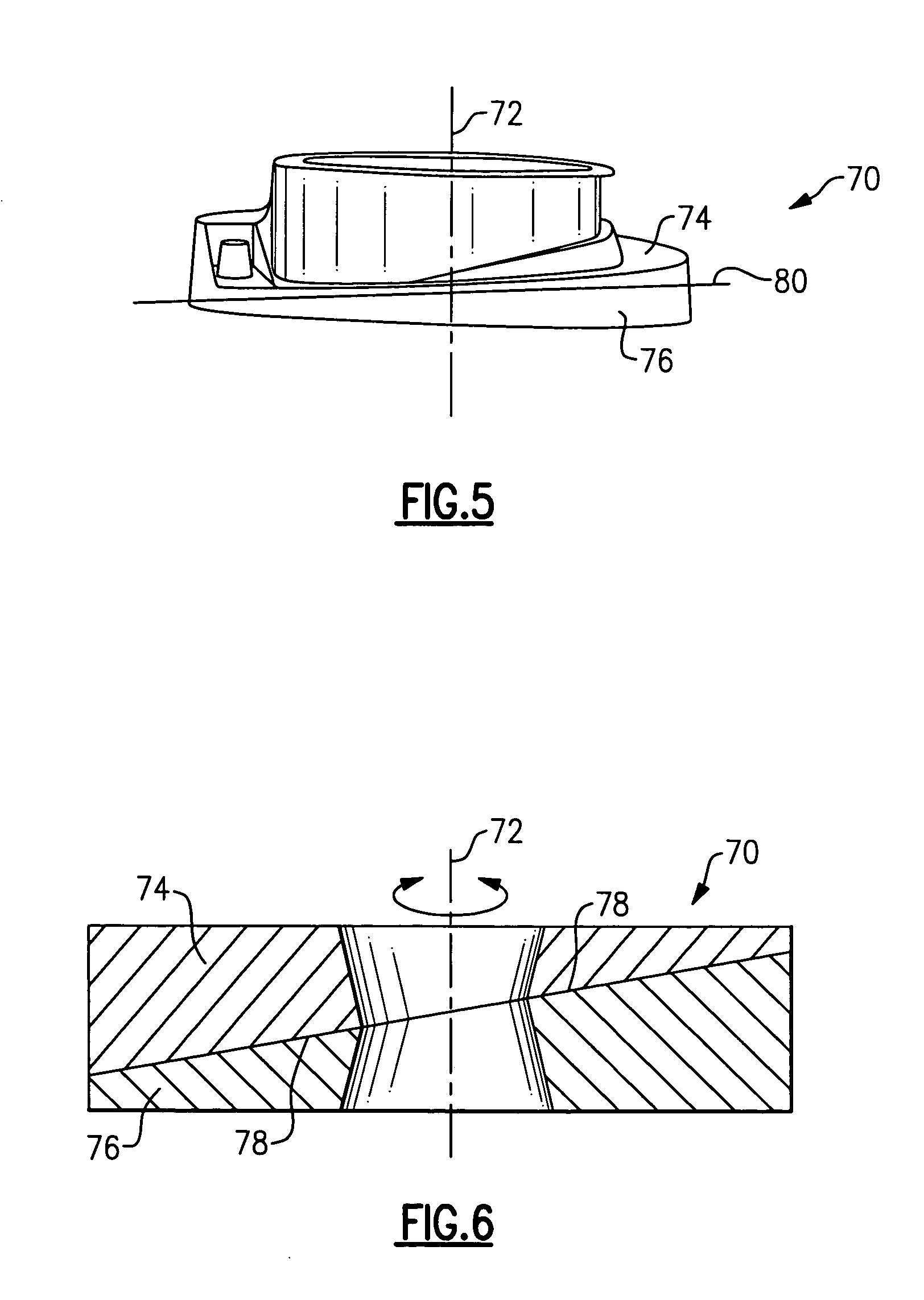

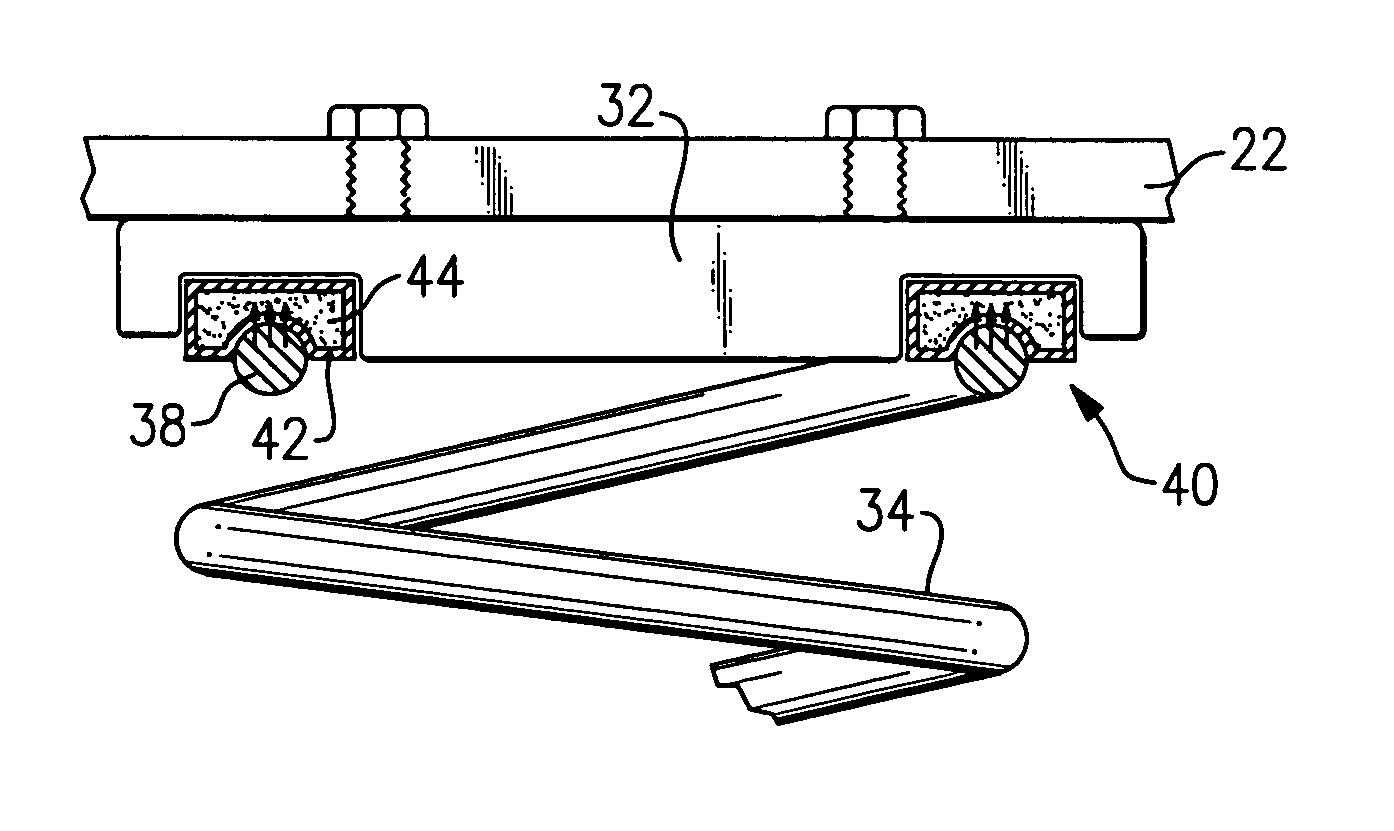

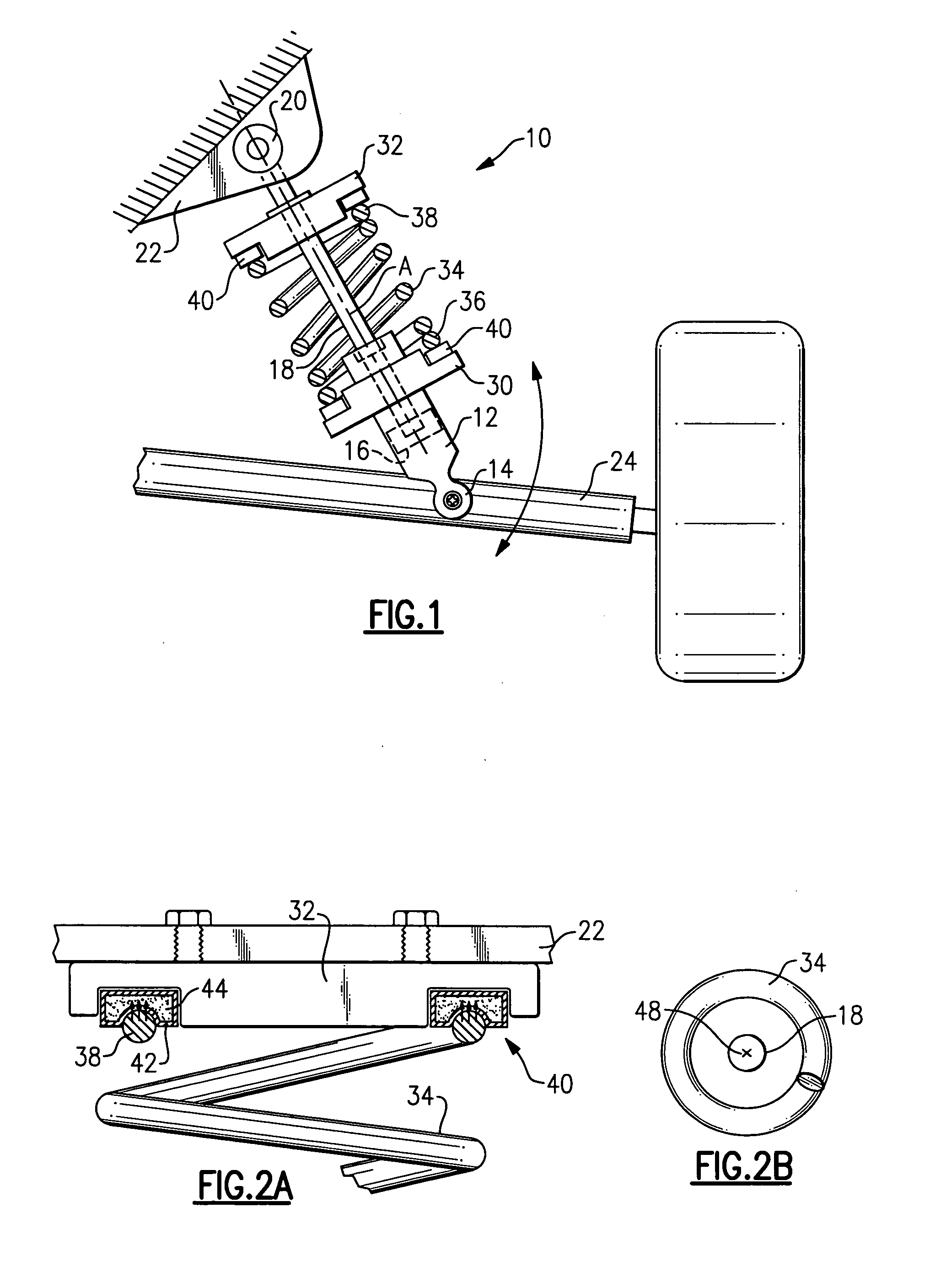

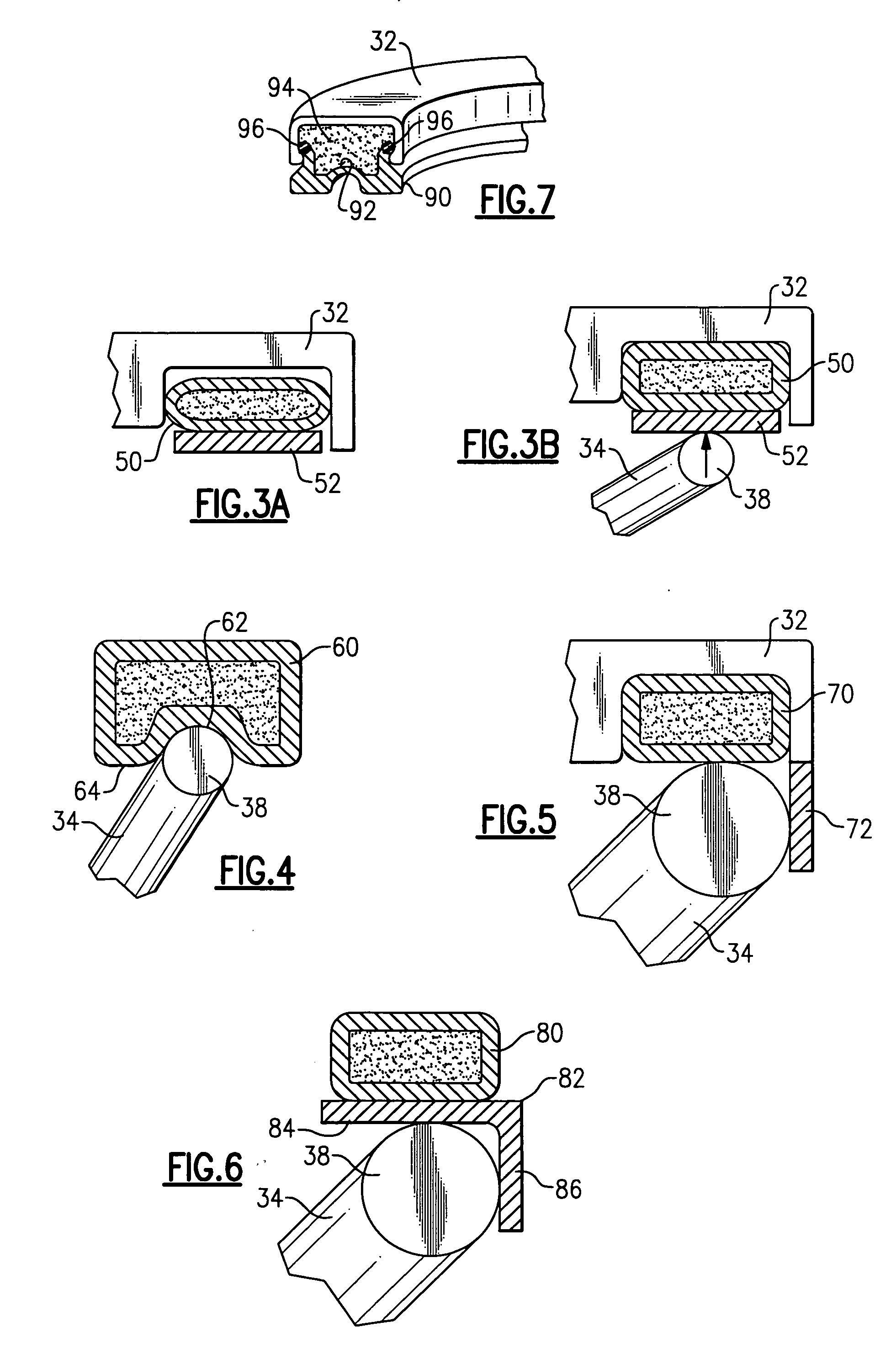

Static pierce point centering spring seat

InactiveUS20070158925A1Reduce the impactReduce impactResilient suspensionsVehicle springsPiercing pointCoil spring

Owner:ARVINMERITOR TECH

Methods of Scatter Correction of X-Ray projection data 1

ActiveUS20110255655A1Reconstruction from projectionMaterial analysis using wave/particle radiationKernel methodPiercing point

A system and method for forming an adjusted estimate of scattered radiation in a radiographic projection of a target object, which incorporates scattered radiation from objects adjacent to the target object, such as a patient table. A piercing point equalization method is disclosed, and a refinement of analytical kernel methods which utilizes hybrid kernels is also disclosed.

Owner:VARIAN MEDICAL SYSTEMS

Methods of scatter correction of x-ray projection data 2

ActiveUS8199873B2Reconstruction from projectionMaterial analysis using wave/particle radiationPiercing pointKernel method

A system and method for forming an adjusted estimate of scattered radiation in a radiographic projection of a target object, which incorporates scattered radiation from objects adjacent to the target object, such as a patient table. A piercing point equalization method is disclosed, and a refinement of analytical kernel methods which utilizes hybrid kernels is also disclosed.

Owner:VARIAN MEDICAL SYSTEMS

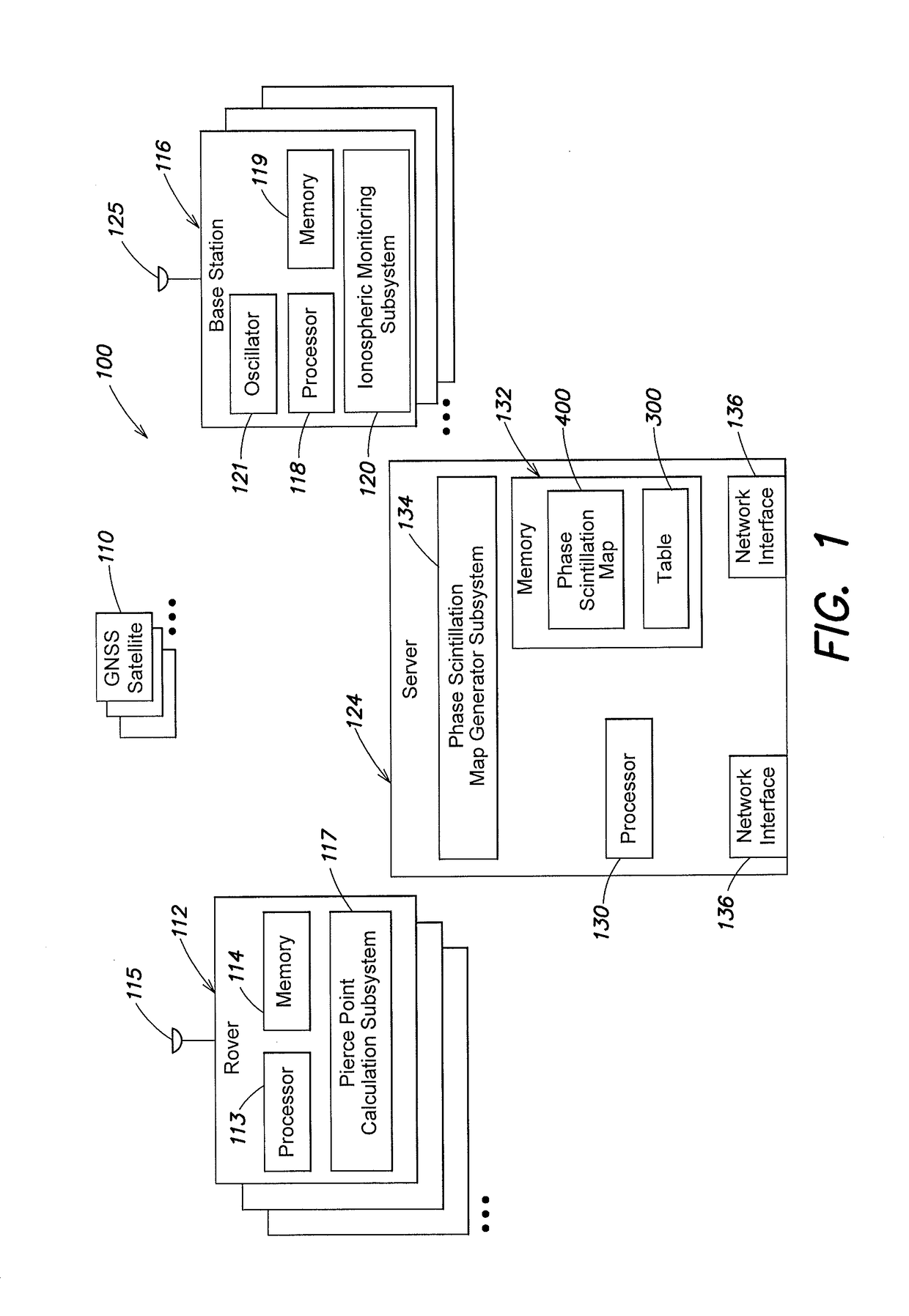

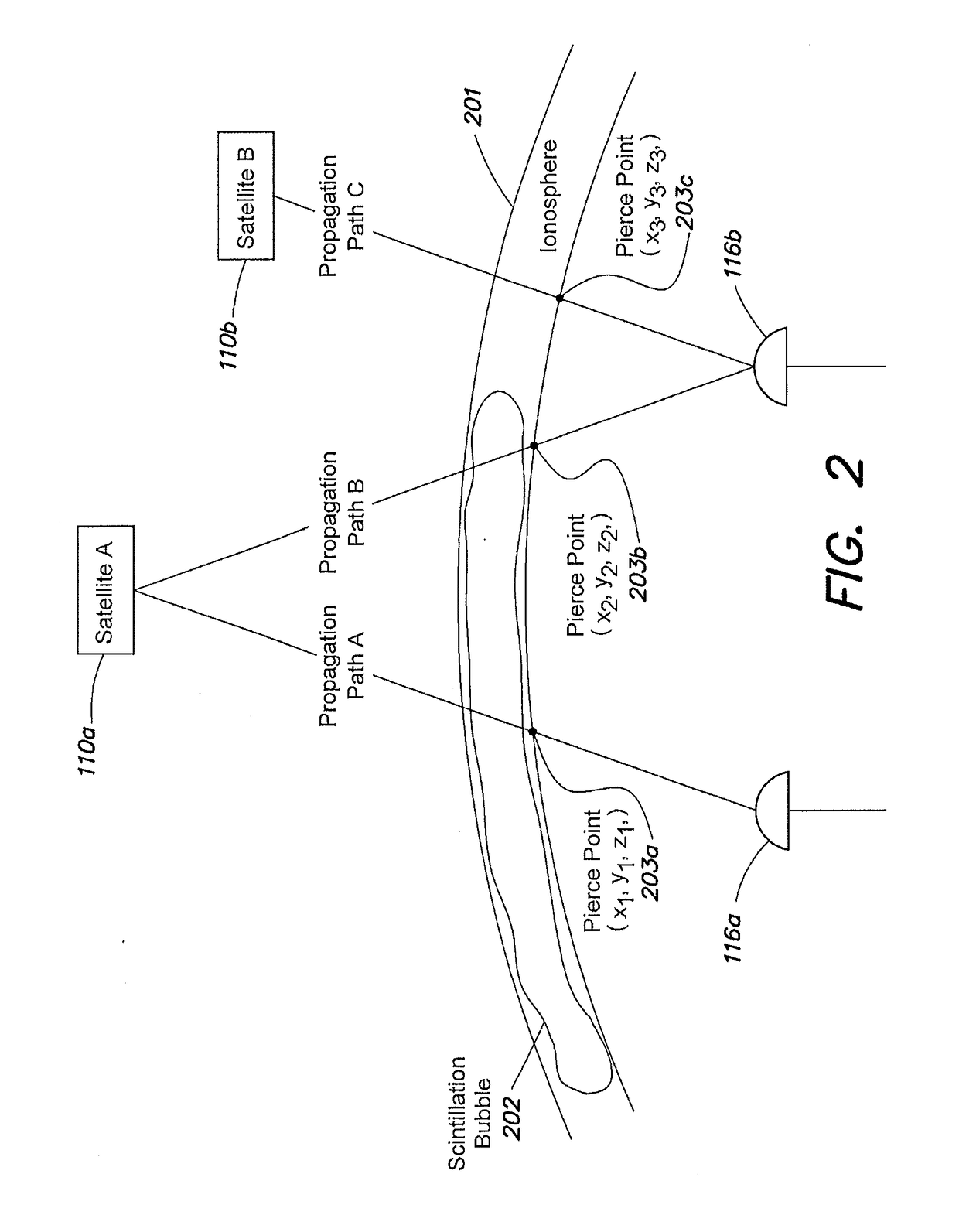

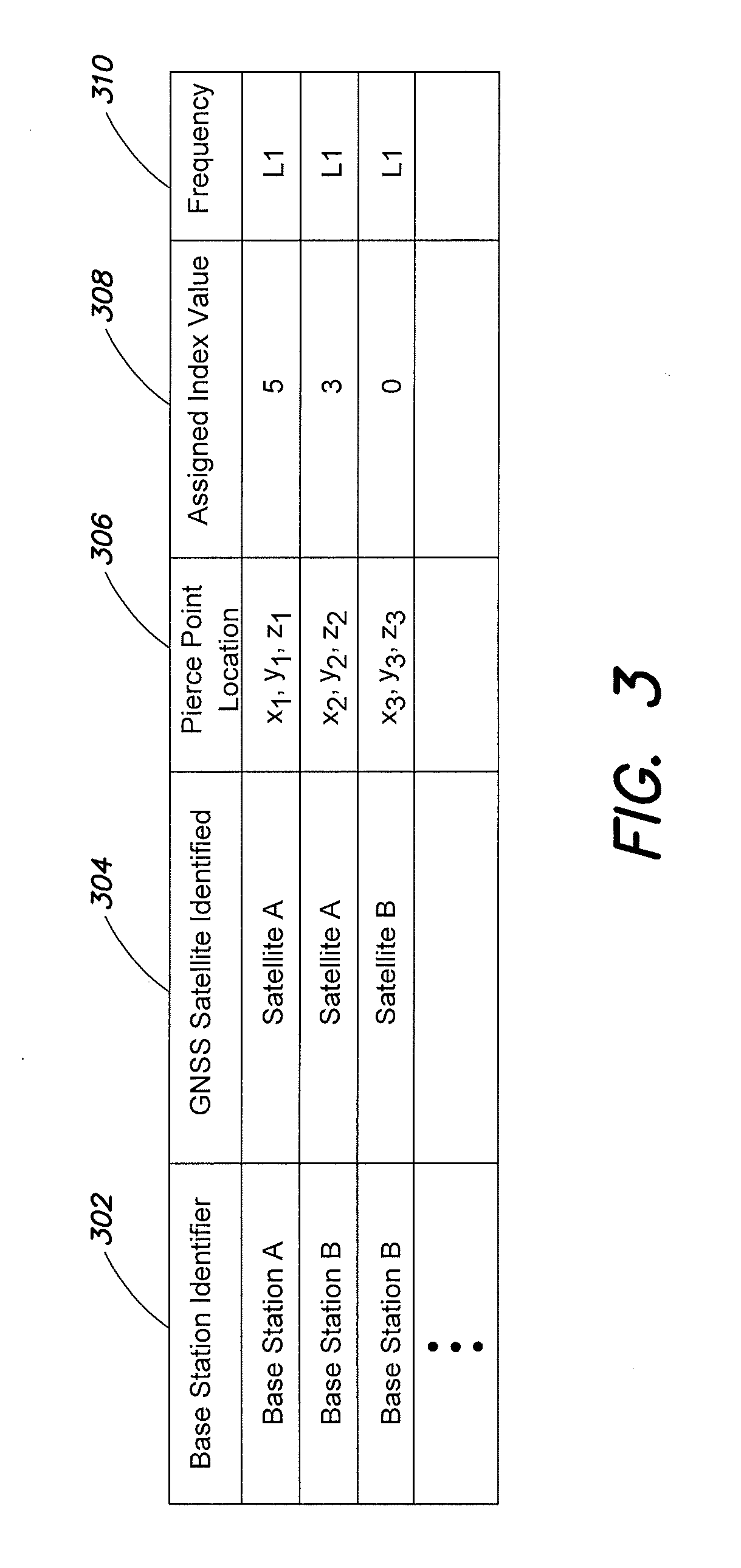

System and method for generating a phase scintillation map utilized for de-weighting observations from GNSS satellites

A system and method generates a phase scintillation map that is utilized to de-weight satellite signal observations from GNSS satellites. One or more base stations each assign an index value to one or more GNSS satellite in view, where the index value indicates an adverse effect of ionospheric scintillation on signals received from the GNSS satellite. The values and identifiers may be transmitted to a server. The server utilizes the received information to generate the phase scintillation map that may include one or more scintillation bubbles, wherein a location of each scintillation bubble is based on the received information. The phase scintillation map is transmitted to one or more rovers. The rover determines if a pierce point associated with a selected GNSS satellite in view of the rover falls within the boundaries of a scintillation bubble. If so, satellite signal observations from the selected GNSS satellite are de-weighted.

Owner:NOVATEL INC

Dynamic pierce point centering spring seat

InactiveUS20070131501A1Reduce the impactReduce impactResilient suspensionsVehicle springsPiercing pointCoil spring

A shock absorber assembly includes a coil spring that reacts between first and second spring seats. The first spring seat is fixed to a shock cylinder and the second spring seat is fixed to a rod that is slidably received within the shock cylinder. An isolator is positioned between an end coil of the spring and at least one of the first and second spring seats. The isolator comprises an annular ring that defines a cavity that is at least partially filled with fluid. The isolator evenly distributes non-centered spring end forces through the fluid to reduce the effects of side load forces.

Owner:MERITOR SUSPENSION SYST U S

Method for optimally adjusting give error bounds or for optimally computing the variances of residuals of igp points of an ionospheric grid for correcting an sbas system and sbas system for implementing said method

A method for optimally fitting GIVE ionospheric correction error bounds and / or a method for computing variances of residuals of IGP points of an ionospheric grid for correcting an SBAS system each comprise a step of inverse interpolation implemented on a set of observation pierce points IPPi. In the method for optimally fitting the GIVEs, the step of inverse interpolation scatters for each observation pierce point IPPi concerned a variance increment ΔUIVE<sub2>i< / sub2>2 over the IGP points of the mesh cell of the said IPPi by using a least squares scheme. In the computation of the variances of residuals, the step of inverse interpolation scatters for each observation pierce point IPPi concerned a residual Resi2 over the IGP points of the mesh cell of the said IPPi by using a least squares scheme.

Owner:THALES SA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com