Patents

Literature

3898results about How to "High surface hardness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

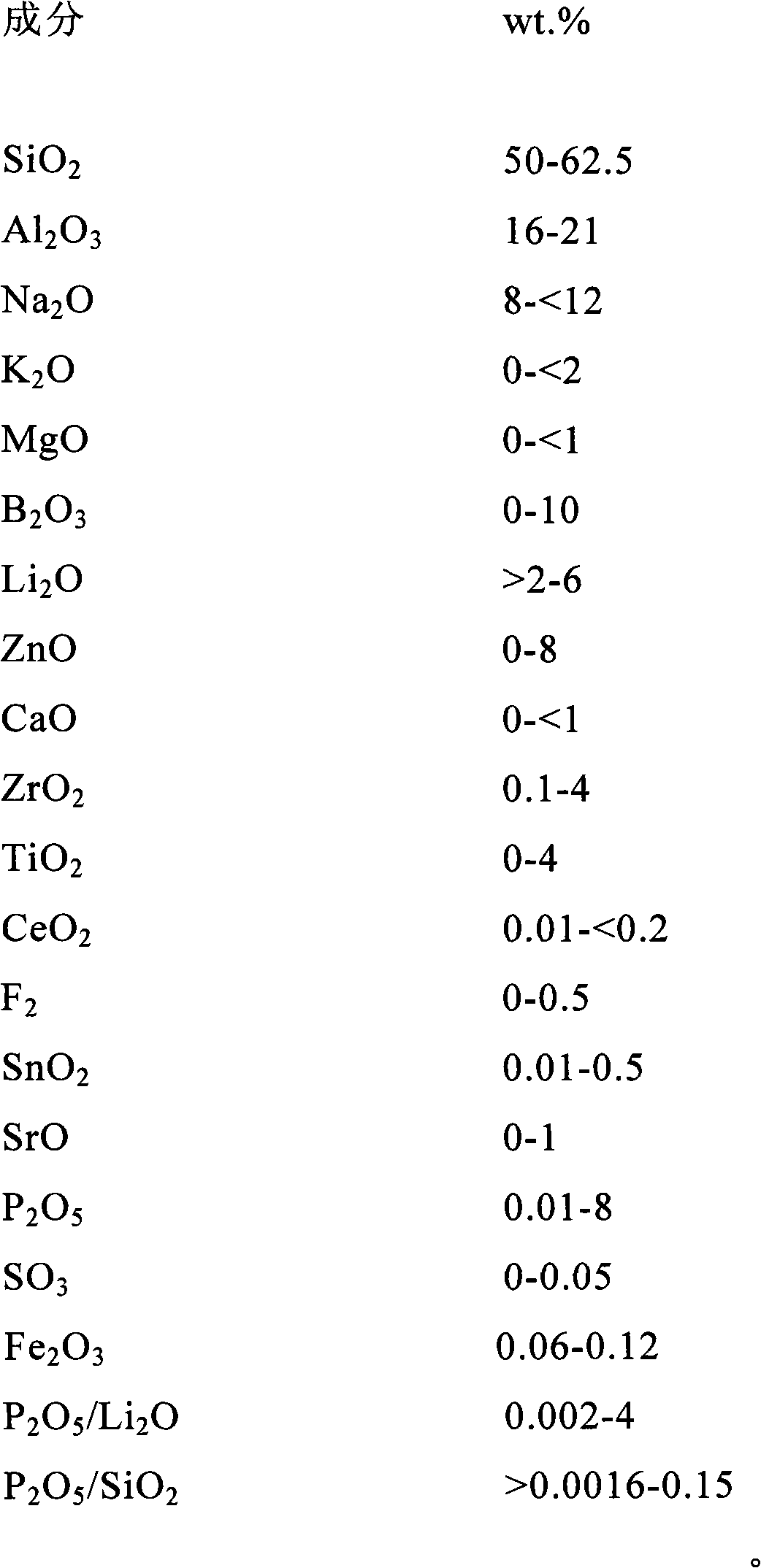

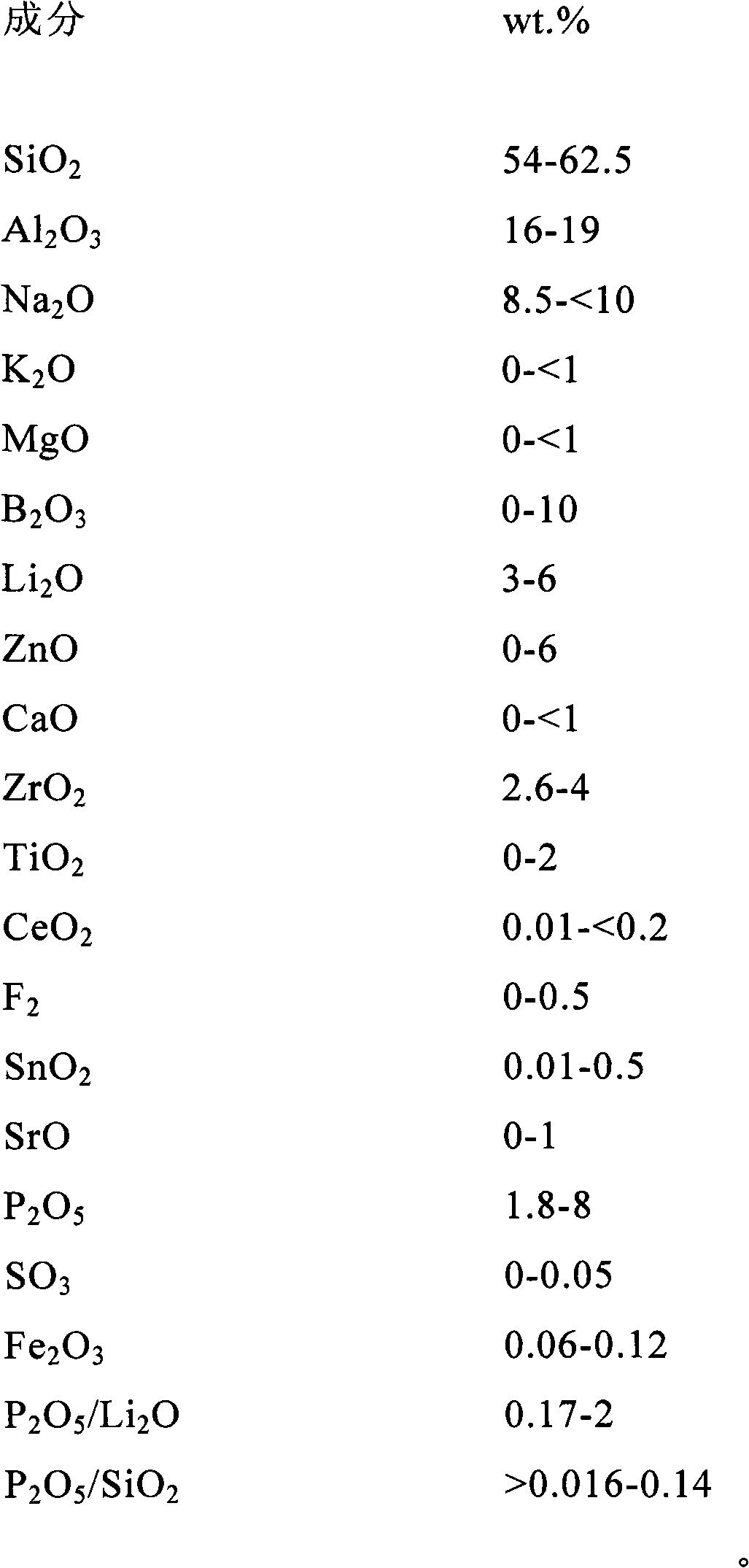

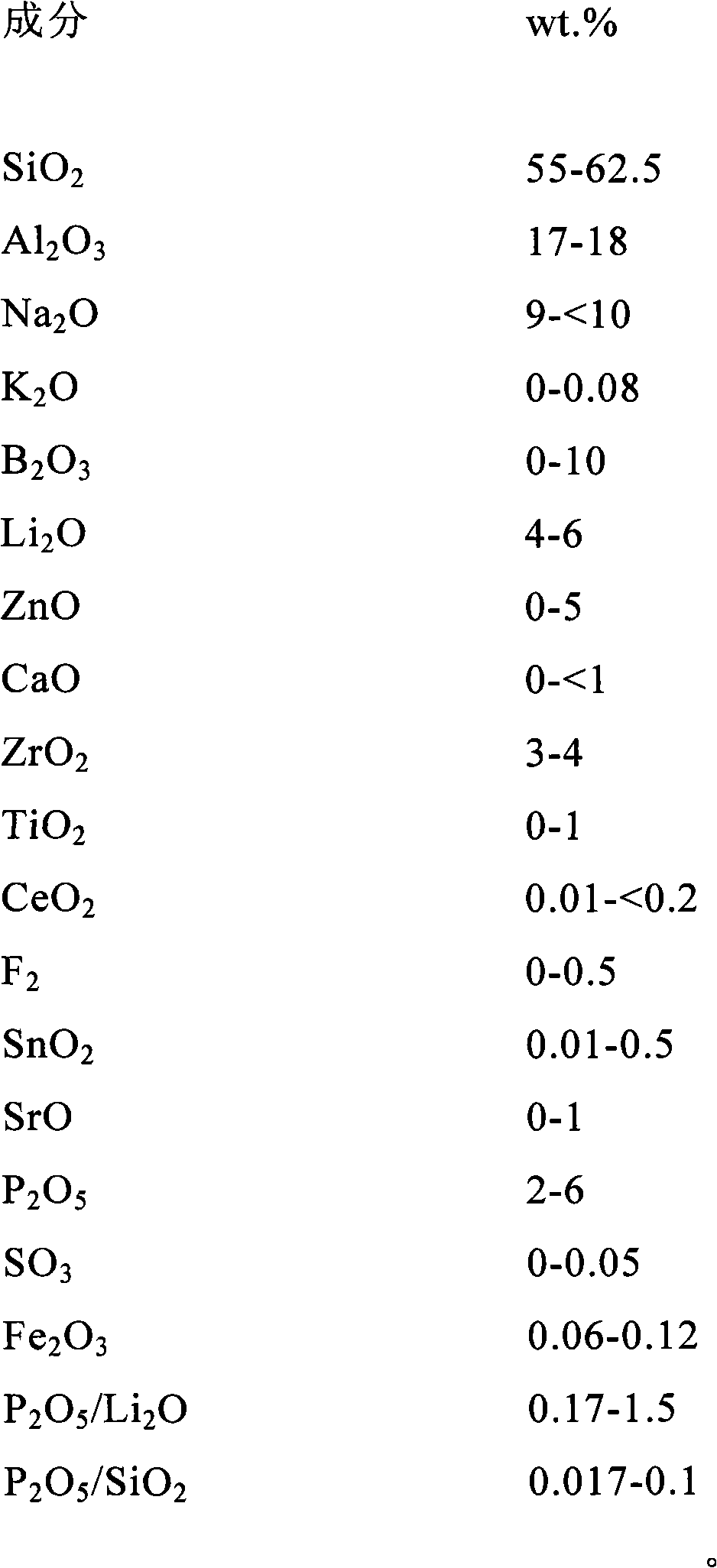

Aluminosilicate glass for chemical tempering and glass ceramics

The invention discloses aluminosilicate glass for chemical tempering and glass ceramics, and particularly discloses aluminosilicate glass which contains Li2O and P2O5 and can be chemically tempered. The glass of the invention can realize high ion exchange speed by the addition of 0.01-8 wt% of P2O5. The glass of the invention contains 2-6 wt% of Li2O, which can reduce the glass melting temperature and the glass-transition temperature. The glass of the invention has a low glass-transition temperature (Tg) of 480-590 DEG C, and the glass hardness is at least 600 Kg / mm2. After chemical tempering, the glass of the invention has a large surface stress layer depth (DoL) and a high surface crushing stress (CS). After tempering in pure KNO3, a potassium ion stress layer is formed, which has a DoL of at least 20 microns and a CS of at least 600 MPa. After tempering in a mixed salt of KNO3 and NaNO3 or two-step tempering in KNO3 and NaNO3, a potassium and sodium ion stress layers can be formed simultaneously, which have a DoL of at least 50 microns and a CS of at least 600 MPa. In addition, the aluminosilicate glass of the invention can be converted into glass ceramics through further heat treatment.

Owner:SCHOTT GLASS TECH (SUZHOU) CO LTD

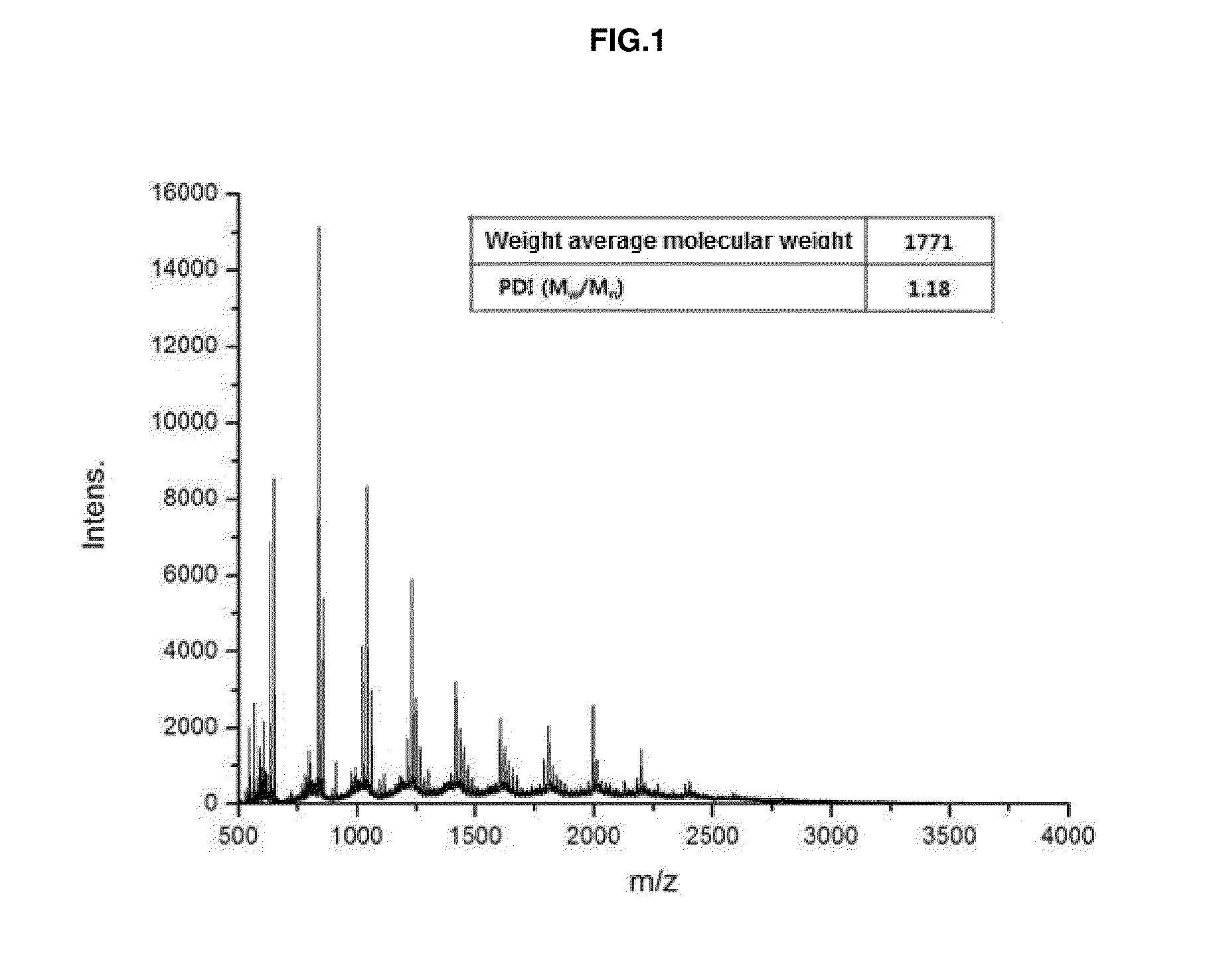

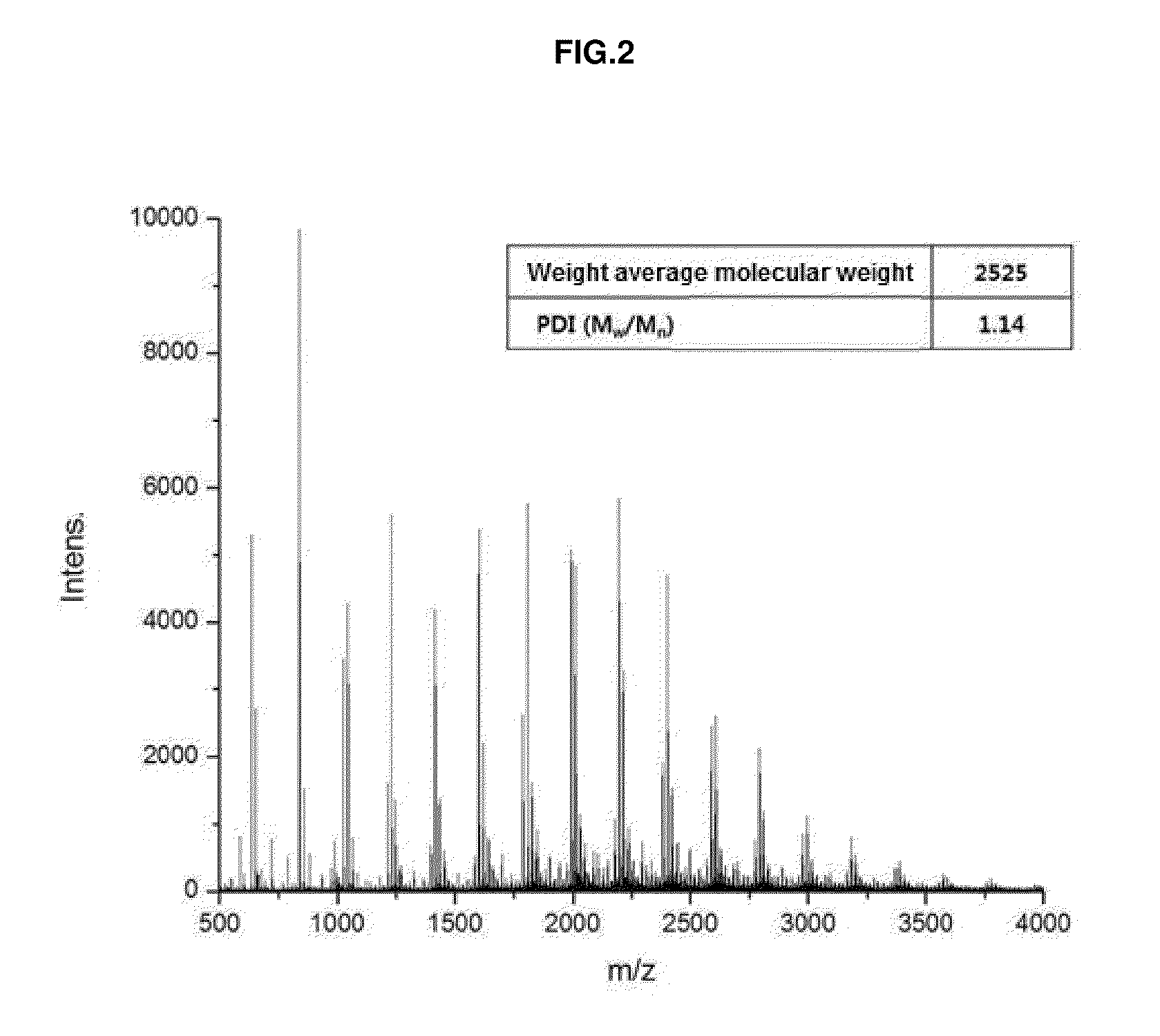

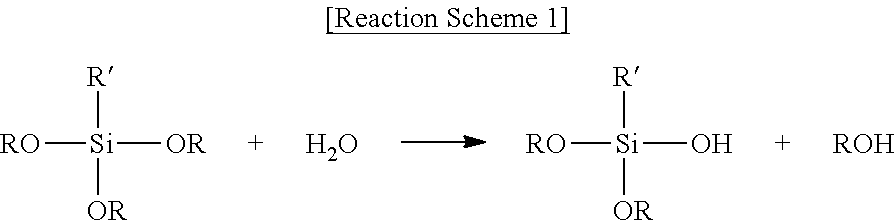

Siloxane hard coating resin

ActiveUS20130331476A1Easy to processHigh surface hardnessSemiconductor/solid-state device detailsSolid-state devicesPolymer scienceAlkoxyl radicals

The present invention relates to a siloxane hard resin including alicyclic epoxy siloxane alone or a reactive monomer, which is prepared by condensation reaction of alkoxysilanes, and has a weight average molecular weight in the range of 1000 to 4000 and a molecular weight distribution of PDI 1.05 to 1.4. A siloxane hard cured article produced by photo- or thermal polymerization has high hardness by compact crosslinking of siloxane molecules having different molecular weights.

Owner:KOREA ADVANCED INST OF SCI & TECH

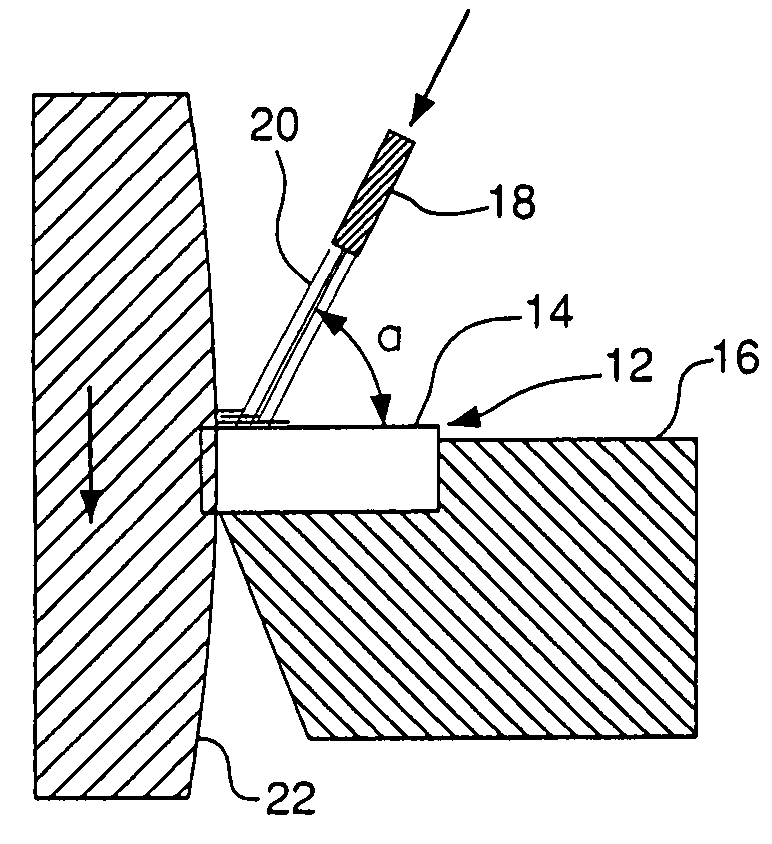

Laser fusing and coating process of wear resistant and anticorrosion alloy coatings at surface of slide plate of railroad turnout

InactiveCN101338425ANo pollution in the processImprove productivityMetallic material coating processesNumerical controlWear resistant

A laser cladding process of an exterior wear-resisting anti-corrosive alloy coating of a slide chair of a railway switch comprises processes as follows: firstly, the surface of the slide chair is pre-heated, which means the surface of the slide chair is degreased and de-rusted under room temperature; and the surface is cleaned up by alcohol; then alloy powder is prefabricated, which means iron-base, nickel-base or cobalt base alloy powders that are ready for cladding are preplaced on the processed surface of the slide chair, and a scraping straightedge provided with a rail is used for adjusting the pretreated metal powder so that the alloy powder can be distributed on the surface of the slide chair evenly and has proper thickness to meet the thick requirement of the coating after cladding; and finally, the slide chair is hardened by the laser cladding; the laser of CO2 gas is adopted; a numerical control machine is used as a working table and the surface of the slide chair is hardened by the laser cladding. The laser cladding process has the characteristics of no pollution, high production rate, low energy consumption, the little finishing allowance of cladding coating and low combined cost.

Owner:SHENYANG DALU LASER COMPLETE EQUIP

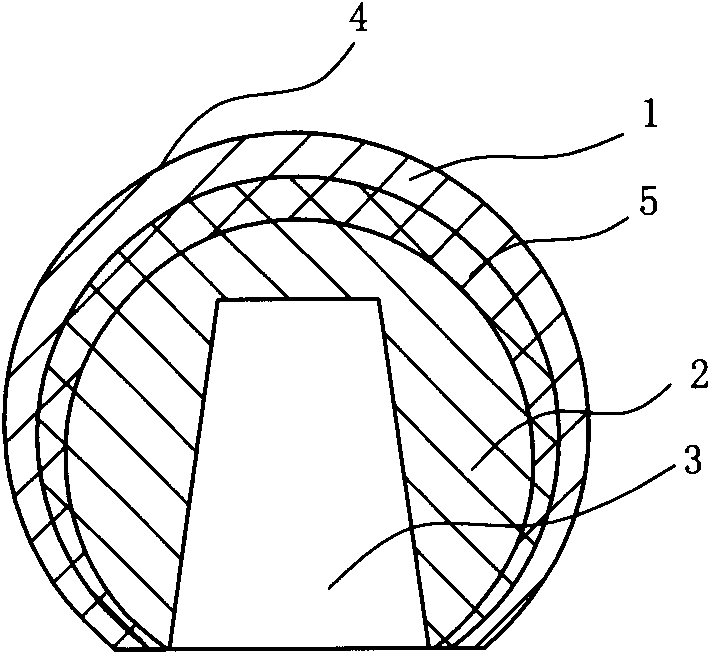

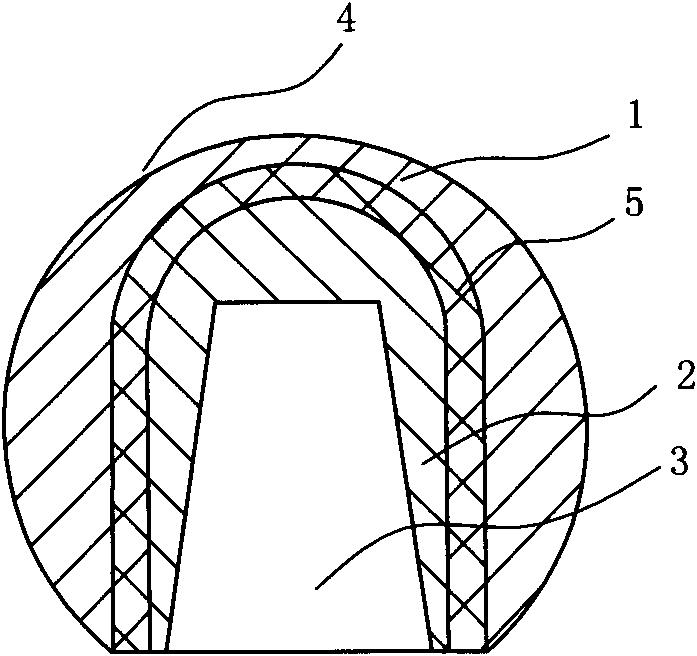

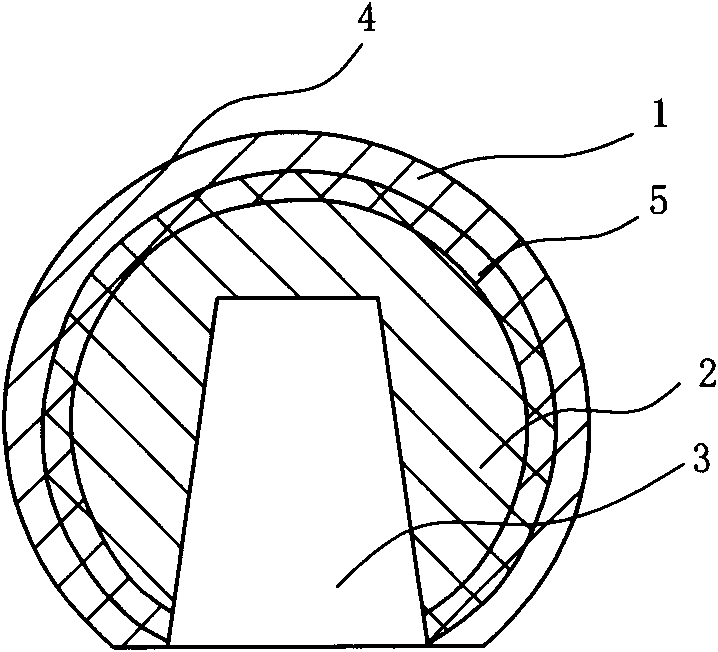

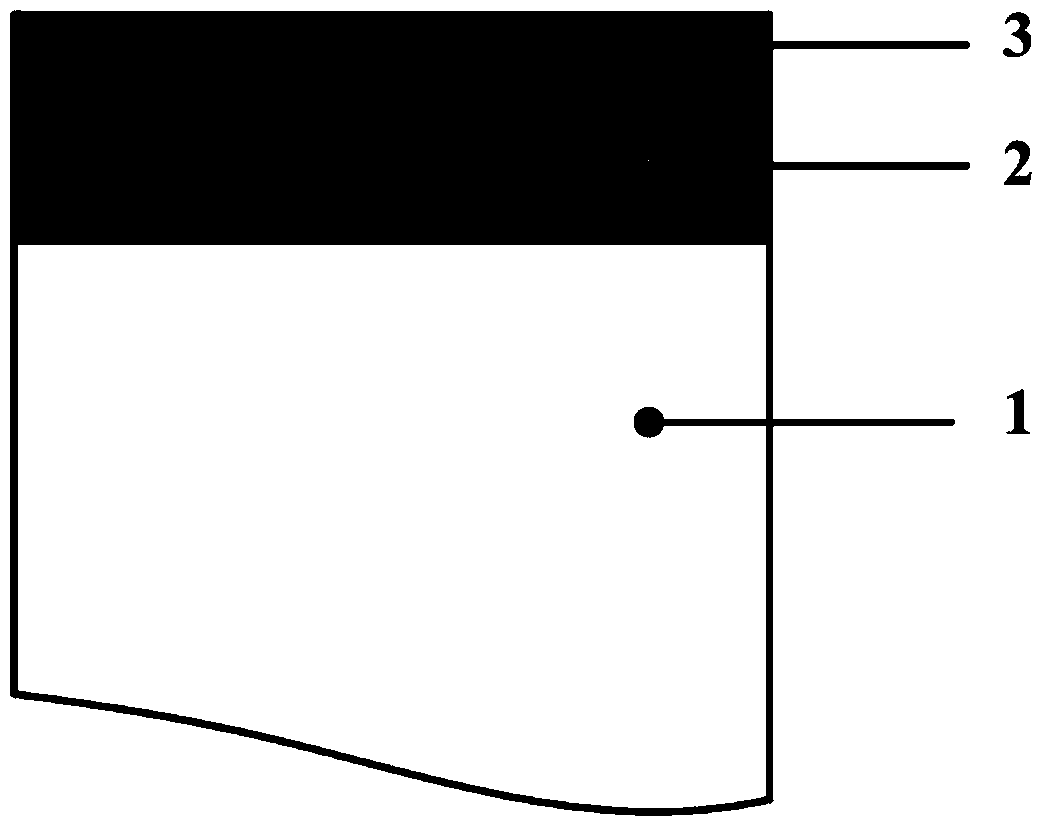

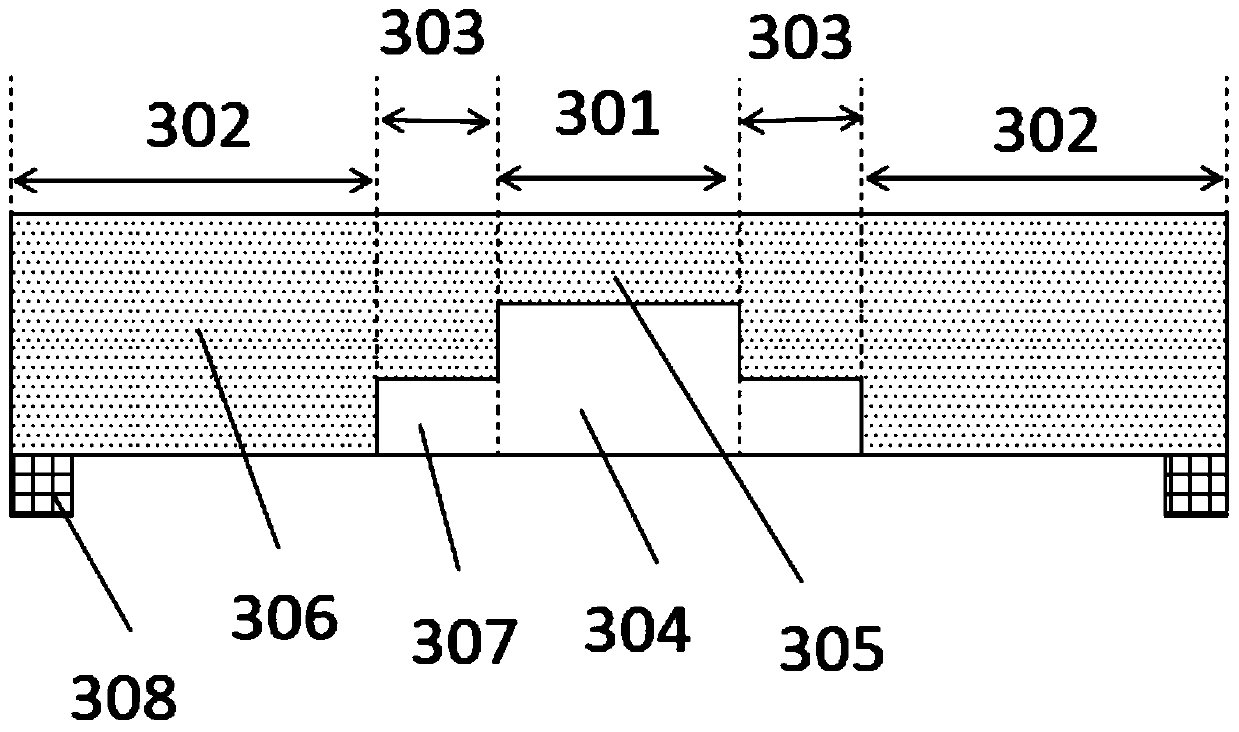

Manufacturing method of multilayer shell-core composite structural part

ActiveCN102009175AShell surface hardness is highHigh surface finishJoint implantsCeramic layered productsComposite constructionHigh surface

The invention discloses a manufacturing method of a multilayer shell-core composite structural part, which comprises the following steps of: (1) respectively preparing feed for injection forming of a core layer, a transition layer and a shell layer, wherein powder in the feed of the core layer and the powder in the feed of the shell layer are selected from one or a mixture of some of metal powder, ceramic powder, or toughened ceramic powder and are different from each other, and the powder in the feed of the transition layer is gradient composite powder; (2) respectively manufacturing blanks of the multilayer shell-core composite structural part layer by layer with a powder injection forming method; (3) degreasing the blanks; and (4) sintering the blanks to obtain the multilayer shell-core composite structural part. The multilayer shell-core composite structural part is manufactured with the powder injection forming method, and has the advantages of high surface hardness, abrasion resistance, uniform thickness of the shell layer, stable and persistent performance, strong binding force between the shell layer and the core layer due to the transition layer, good integral bending strength and good impact toughness and is difficult to crack.

Owner:SUZHOU DINGAN ELECTRONICS TECH

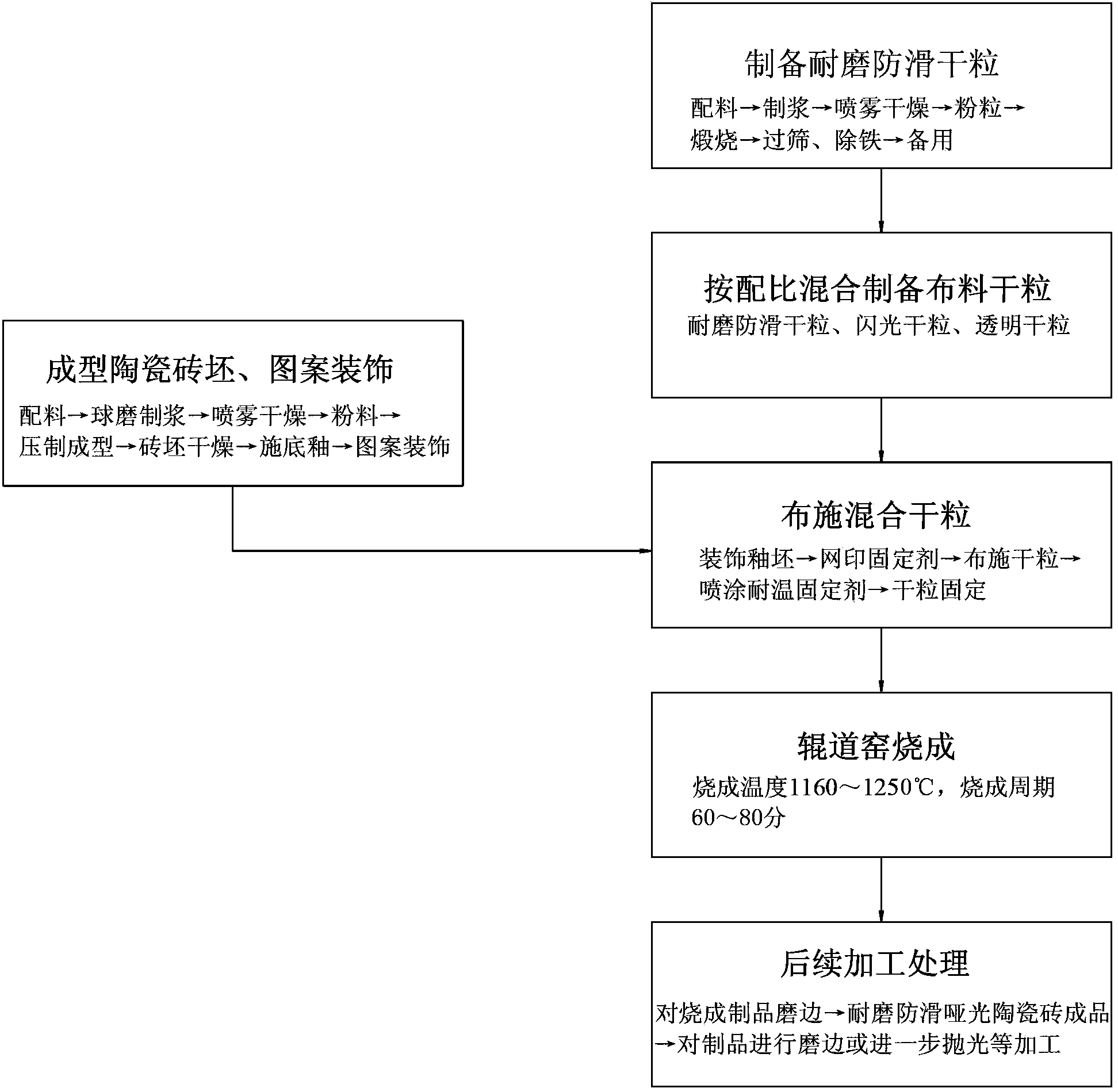

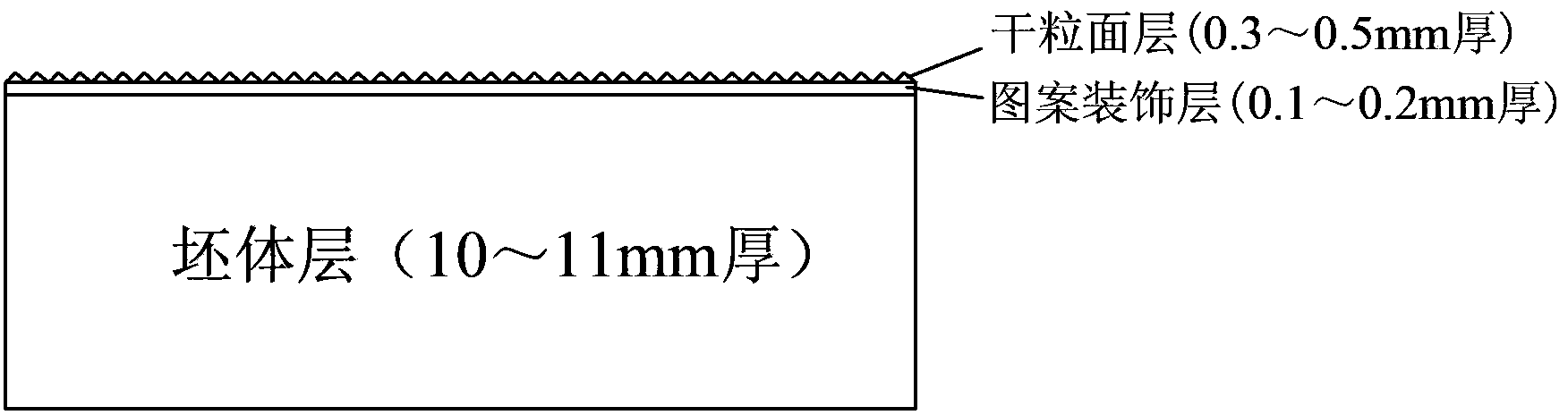

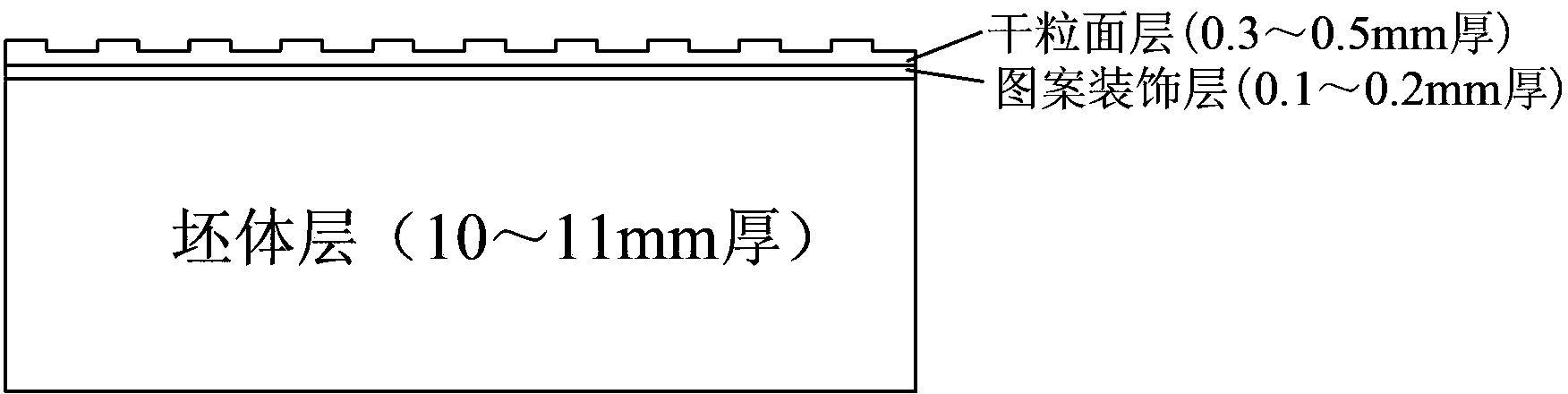

Method for manufacturing wear-resistant antiskid dry-particle ceramic tile

The invention relates to a method for manufacturing a wear-resistant antiskid dry-particle ceramic tile, which comprises the following steps: (1) forming a ceramic tile plane matrix and carrying out pattern decoration; (2) preparing dry particles with wear-resistant and antiskid properties; (3) mixing the wear-resistant antiskid dry particles, flashing dry particles and transparent dry particles according to a certain proportion for distribution; (4) applying the mixed dry particles to the surface of a decorative glazed body and spraying a temperature-resistant fixing agent; (5) conveying the obtained product to a roller kiln for firing and preparing the finished product of the ceramic tile through subsequent processes. According to the method for manufacturing the wear-resistant antiskid dry particle ceramic tile, the dry particles with good wear resistance are mixed with the transparent dry particles and the flashing dry particles, a dry powder distribution mode is adopted and the wear-resistant antiskid dry particles are bulged due to different melting performance of various dry particles in the firing process, so that the problems of wear resistance of the surface and thickness of a wear-resistant layer are solved; by distributing the transparent dry particles, a decorative pattern has a stereoscopic decorating effect under the covering of a glass layer, so that unification of wear-resistant and antiskid properties and decoration of the ceramic tile is achieved.

Owner:JIANGXI HEMEI CERAMICS

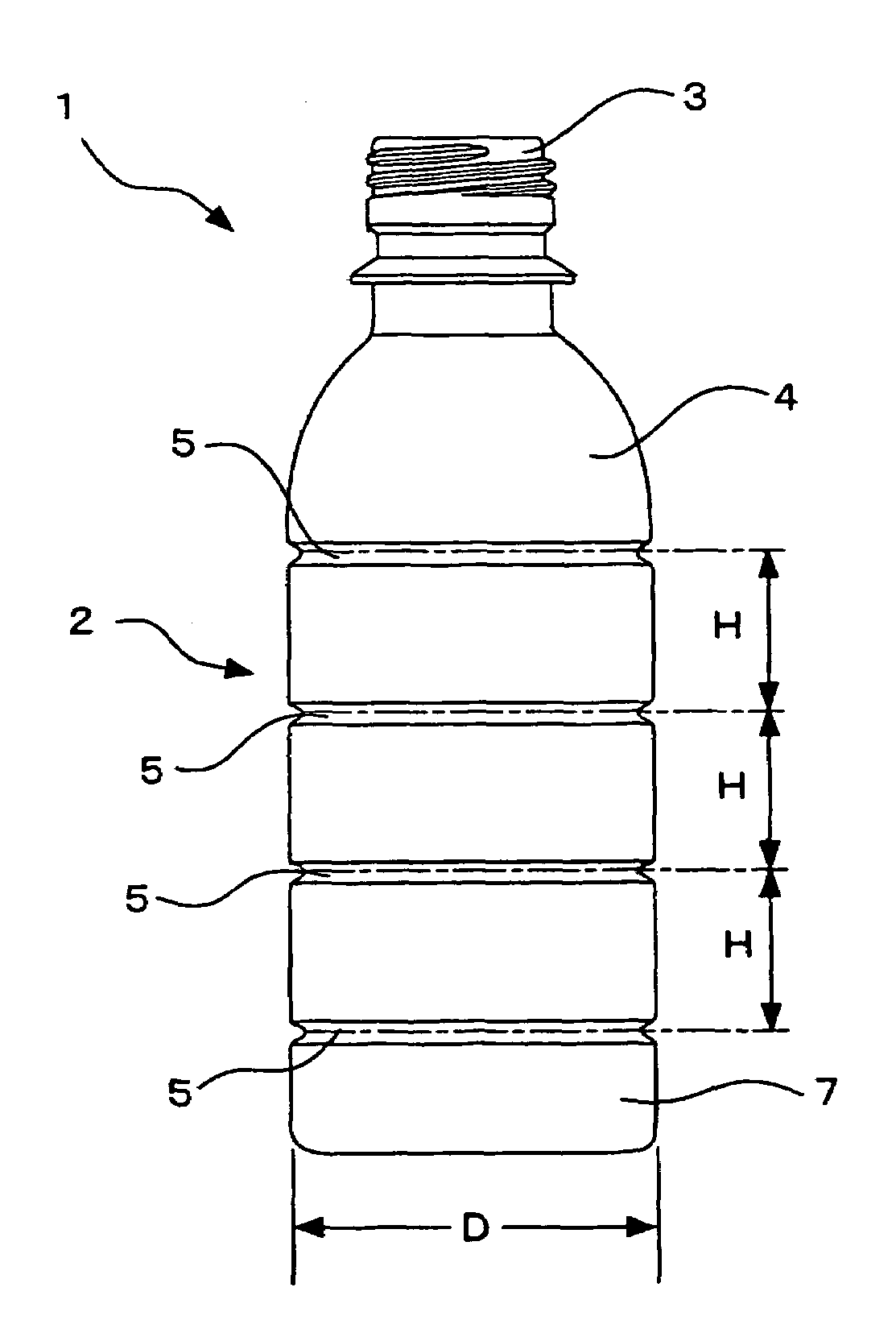

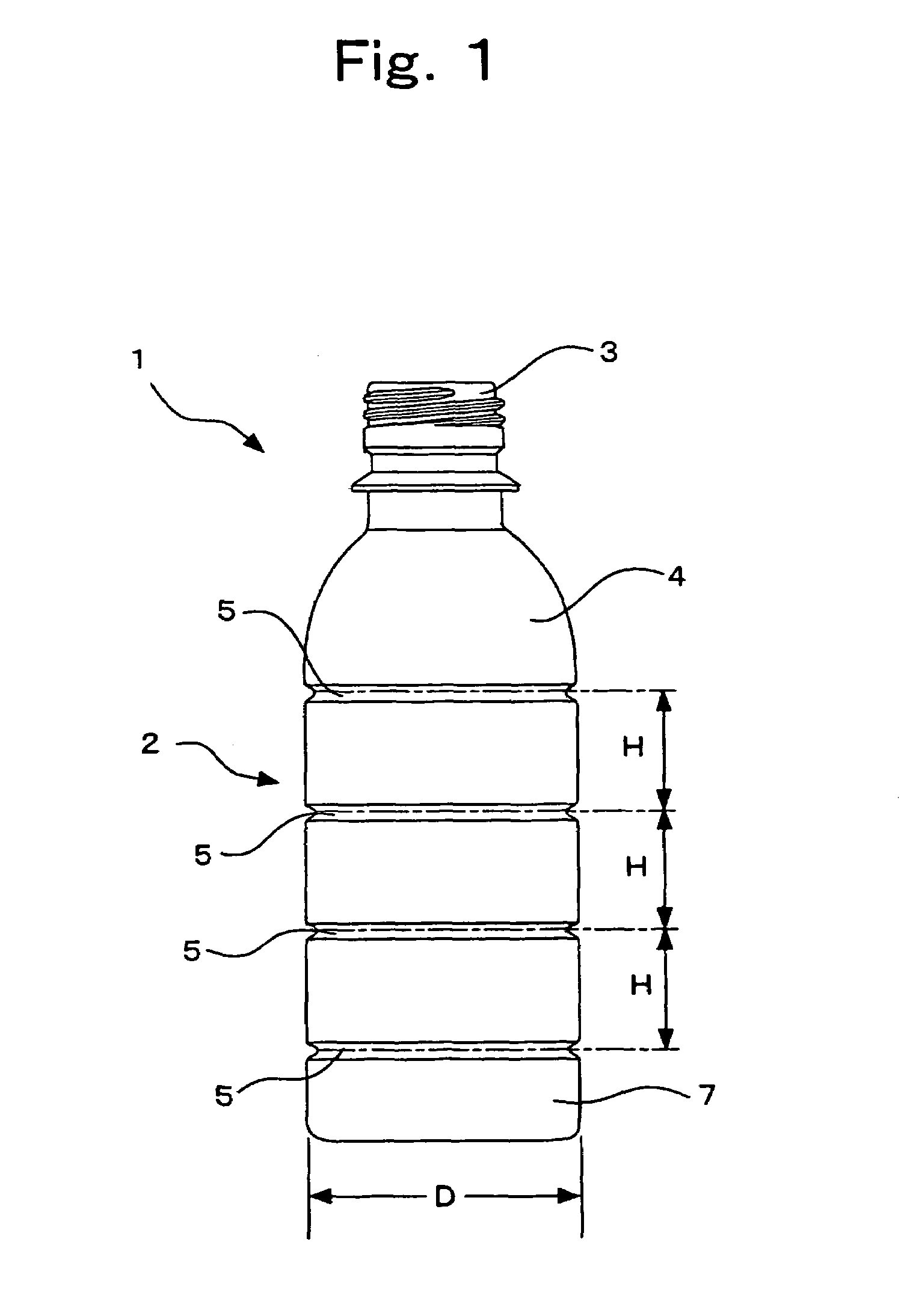

Synthetic resin bottle with circumferential ribs for increased surface rigidity

InactiveUS7051890B2Improve surface rigidityHigh surface hardnessBottlesLarge containersInternal pressureEngineering

The technical problem of this invention is to eliminate the need to use deformable panel walls and to find the body of a shape that no false deformation, such as dented deformation, takes place in a portion of the body due to the hot filling of the contents or the reduced pressure created by the treatment of retort-packed foods. The object of this invention is to obtain a bottle that can inhibit the deformation caused by reduced pressure, has a high buckling strength, and is good in outer appearance. As the solution, there is provided a biaxially drawn, blow-molded bottle made of a synthetic resin, in which the surface rigidity of the wall of body is set in such a manner that a part of the body wall cannot become dented inward under a reduced inner pressure of at least 350 mmHg (46.7 kPa).

Owner:YOSHINO KOGYOSHO CO LTD

Concrete superficial hardener and construction method thereof

InactiveCN101407428AHigh mechanical strengthHigh surface hardnessUltimate tensile strengthMaterials science

The invention discloses a concrete surface hardener and a construction method thereof, wherein, the concrete surface hardener comprises the compositions by weight percent of 10-40 percent of inorganic silicate, 1-10 percent of alkali, 0.1-5 percent of catalyst, 0.1-2 percent of wetting dispersant, 1-5 percent of stabilizer and rest of water. The hardener prepared by the invention is characterized by easily-obtained material, simple production and convenient construction, unhealthy and environmentally harmful VOC avoidance, etc. In addition, the hardener can penetrate into the interior of the concrete to seal the capillary of the concrete, thus improving the surface density of the concrete, strengthening the impervious capability and strength of the concrete and prolonging the service life of the concrete. As the hardener does not comprise unhealthy and environmentally harmful substances, the increasingly improved requirements of the present environmental protection can be met, thus having extensive application prospect.

Owner:GUANGZHOU SUPER CHEM COATING CO LTDGUANGZHOU SUPER CHEM COATING CO LTD

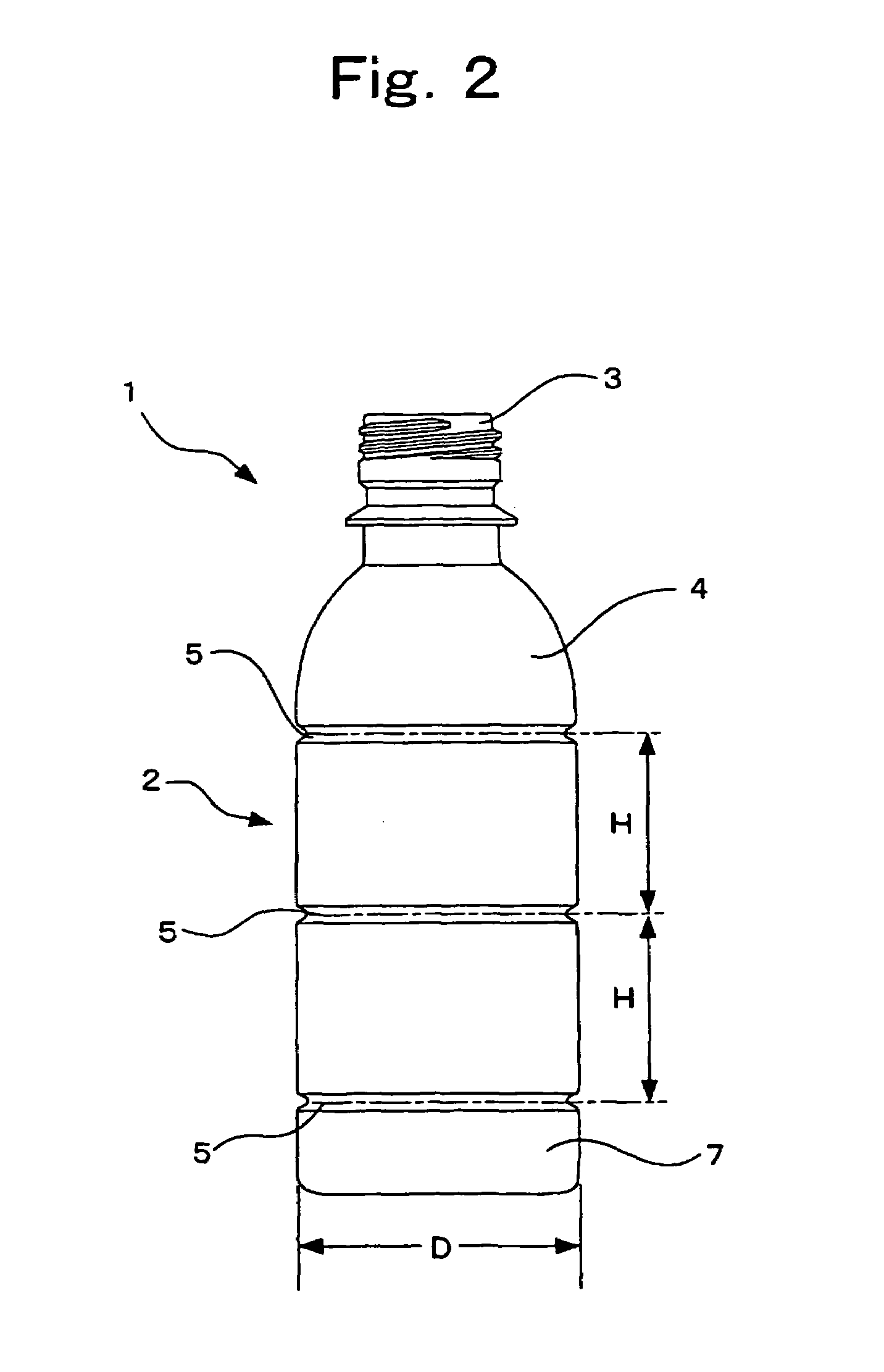

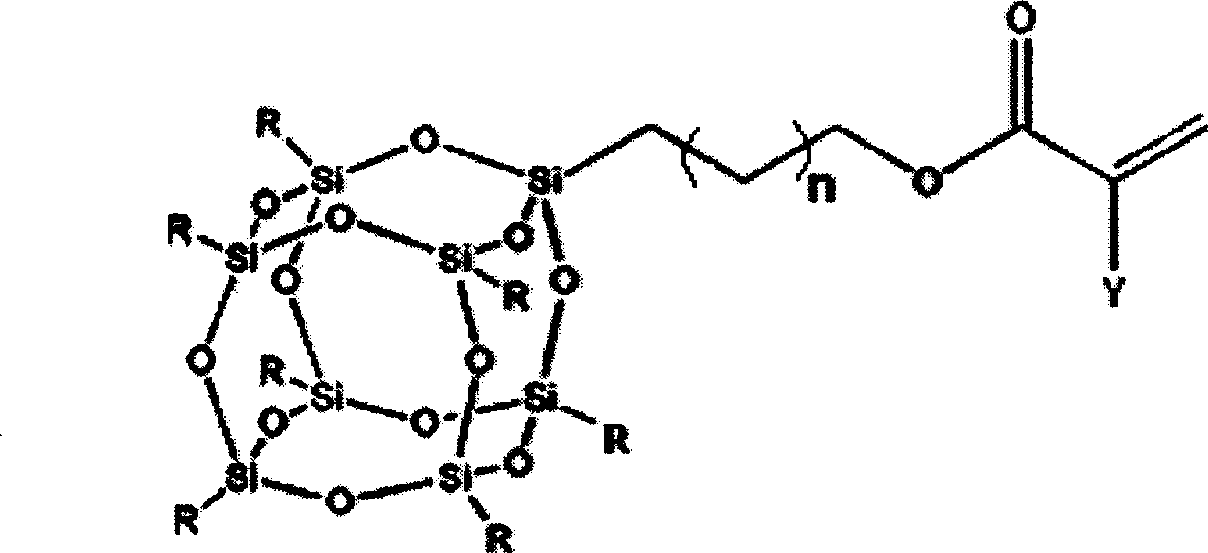

Coating material containing POSS acrylate copolymer and preparing method

The invention relates to a manufacturing method for coat material containing POSS acrylate copolymer. It takes free radical copolymerized to acr monomer and other acr monomer, and uses as modifier adding into the base compounding of UV coat, after taking UV solidification the coat material of high rigidity would be gained. The constituent includes 40-55% light-cured resin, 5-20% active modifier, 20-45% spike, 1-10% photoinitiator, 2-10% anti-foam additive. The rigidity of coat could reach to 6H, and the shrinkage ratio could reach 2%.

Owner:XIAMEN UNIV

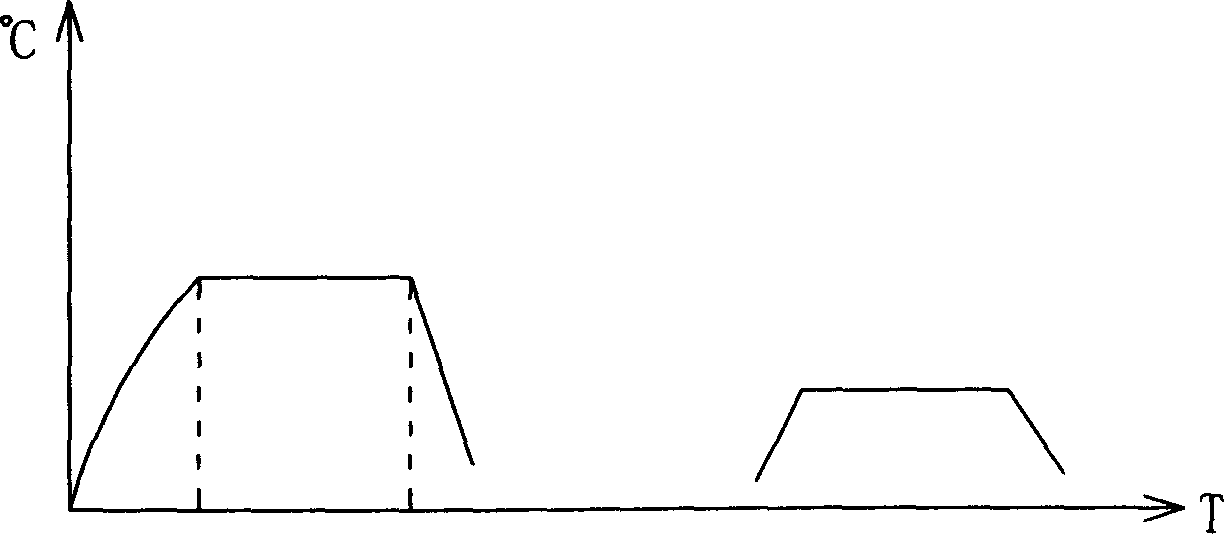

High carbon chromium bearing parts surface chemical heat-treatment process

ActiveCN1804128AHigh surface hardnessIncrease compressive stressSolid state diffusion coatingFurnace typesHigh carbonIn vehicle

The disclosed surface chemical thermal treatment technique for a high-C-Cr bearing comprises: setting parameters, front cleaning, pre-oxidizing, heating, carbonitriding, cooling to diffuse, quenching, and tempering. This invention uses the treatment device in vehicle and motor cycle gear process to form one layer with special tissue and improve contact fatigue strength and surface hardness.

Owner:CHONGQING CHANGJIANG BEARING

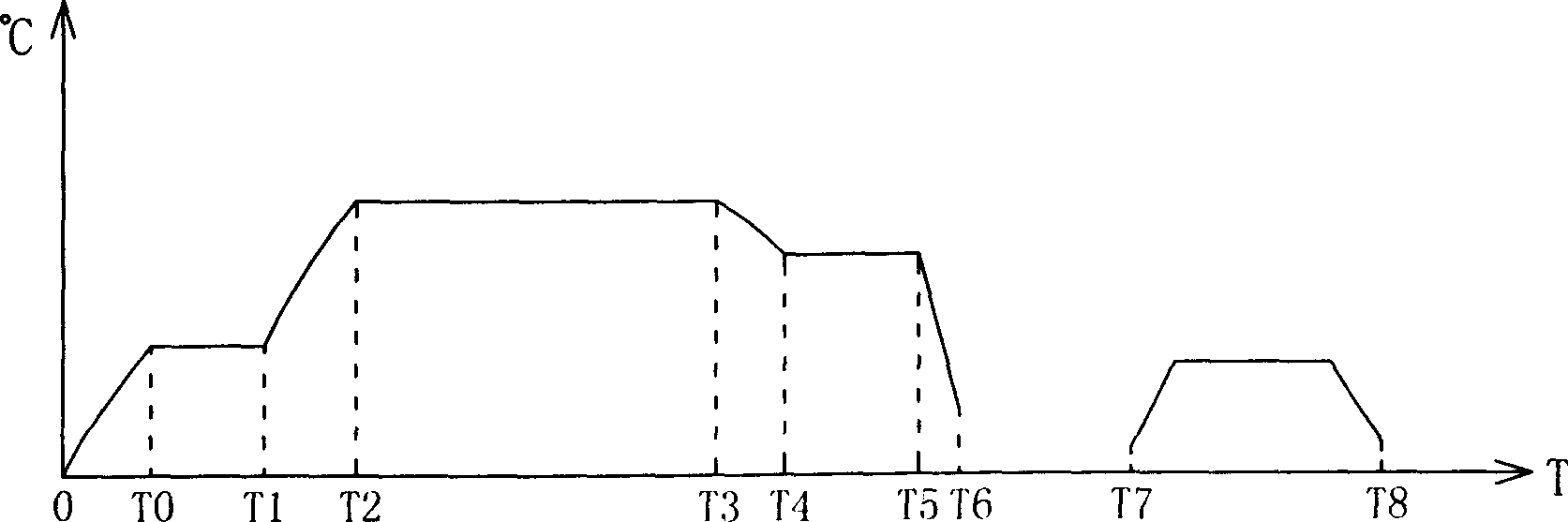

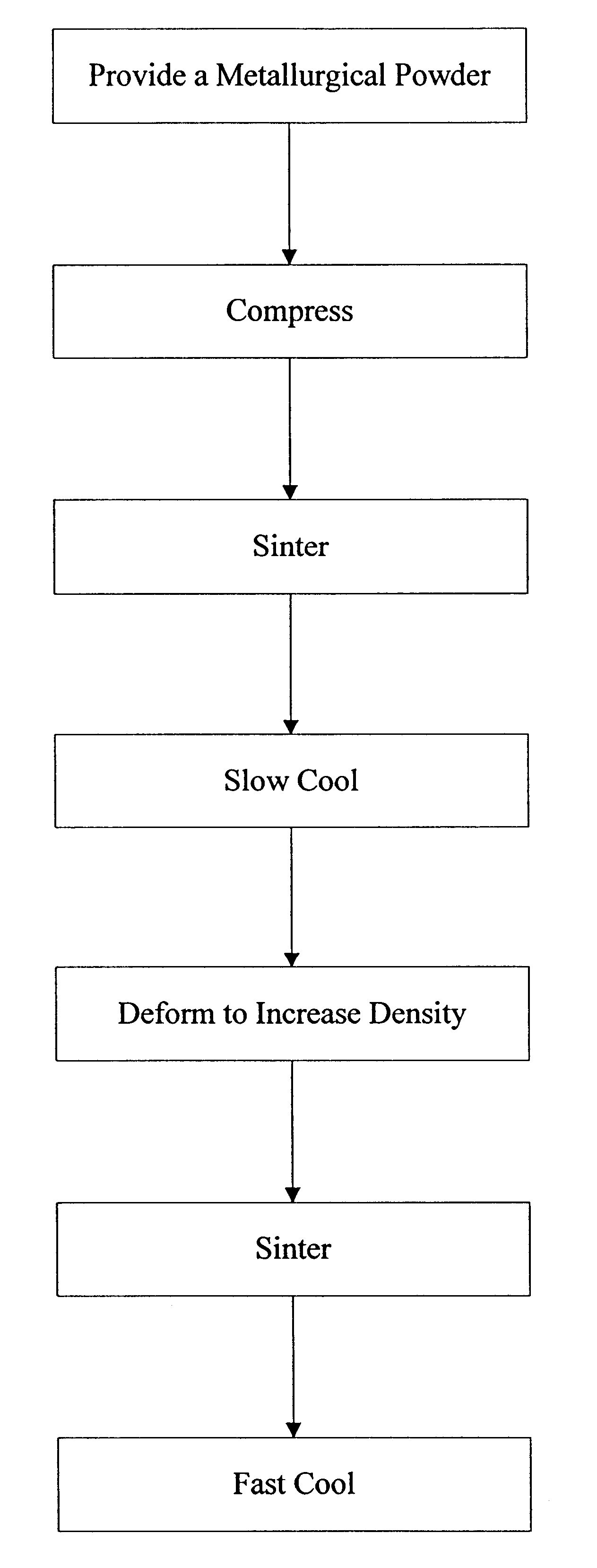

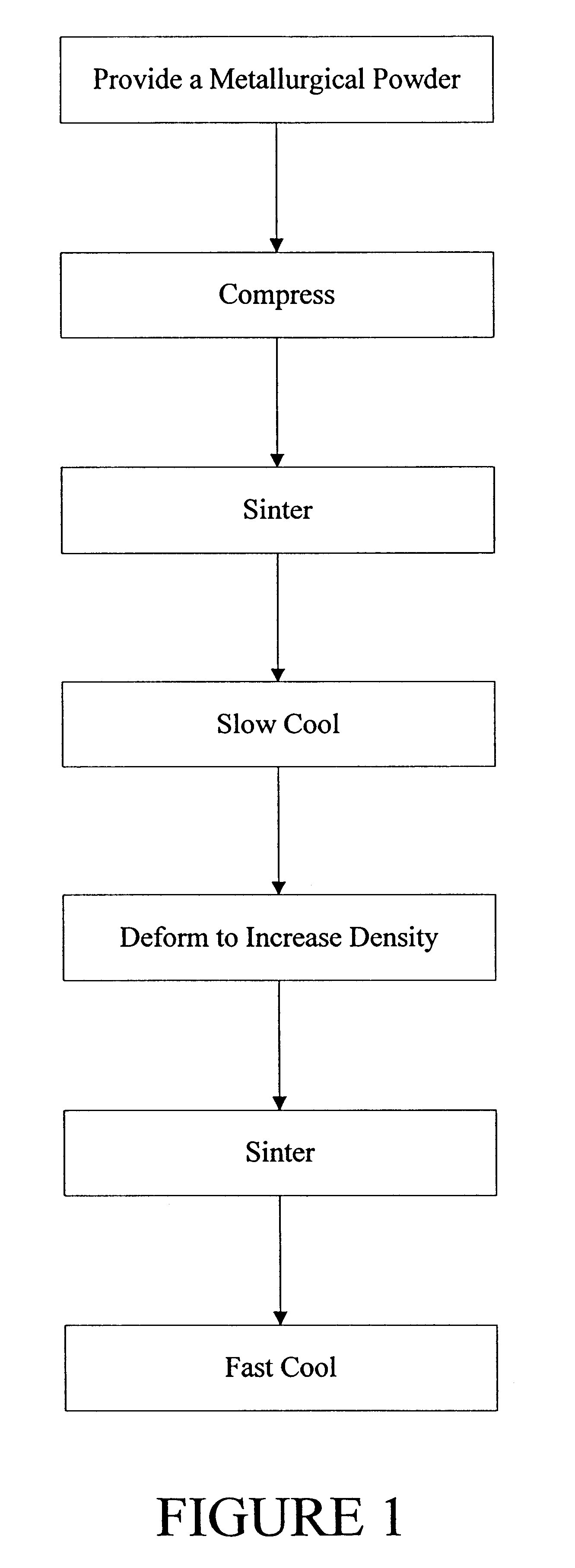

Method for producing powder metal materials

A method for producing a material includes providing a metallurgical powder including iron, 1.0 to 3.5 weight percent copper, and 0.3 to 0.8 weight percent carbon. At least a portion of the powder is compressed at 20 tsi to 70 tsi to provide a compact, and subsequently the compact is heated at high temperature and then cooled at a cooling rate no greater than 60° F. per minute to increase the surface hardness of the compact to no greater than RC 25. The density of at least a region of the sintered compact is increased, by a mechanical working step or otherwise, to at least 7.6 grams / cc. The sintered compact is then re-heated to high temperature and cooled at a cooling rate of at least 120° F. / min. so as to increase the surface hardness of the compact to greater than RC 25, and preferably at least RC 30. Material made by the method of the invention also is disclosed.

Owner:KEYSTONE INVESTMENT CORP

Ultraviolet curing coating for metal plating surface protection

ActiveCN1803942AHigh surface hardnessImprove water resistanceLiquid surface applicatorsCoatingsFiberCoated surface

The related UV solidifying paint for metal coated surface protection comprises: 10-30% epoxy acrylate and 5~20% urethane acrylate both as active oligomer, 10-30% composite adhesion reinforced resin as the mixture of thermalplastic acrylic resin with AA monomer modified by H3PO4 as one of synthetic monomer and fiber resin, 30~65% diluent, 5~20% active diluent, 1~10% light initiator, and 0.1~1% auxiliary agent. This invention solves the adhesion problem of UV paint on smooth metal surface very well, and contains other index up to protective and decorative requests.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

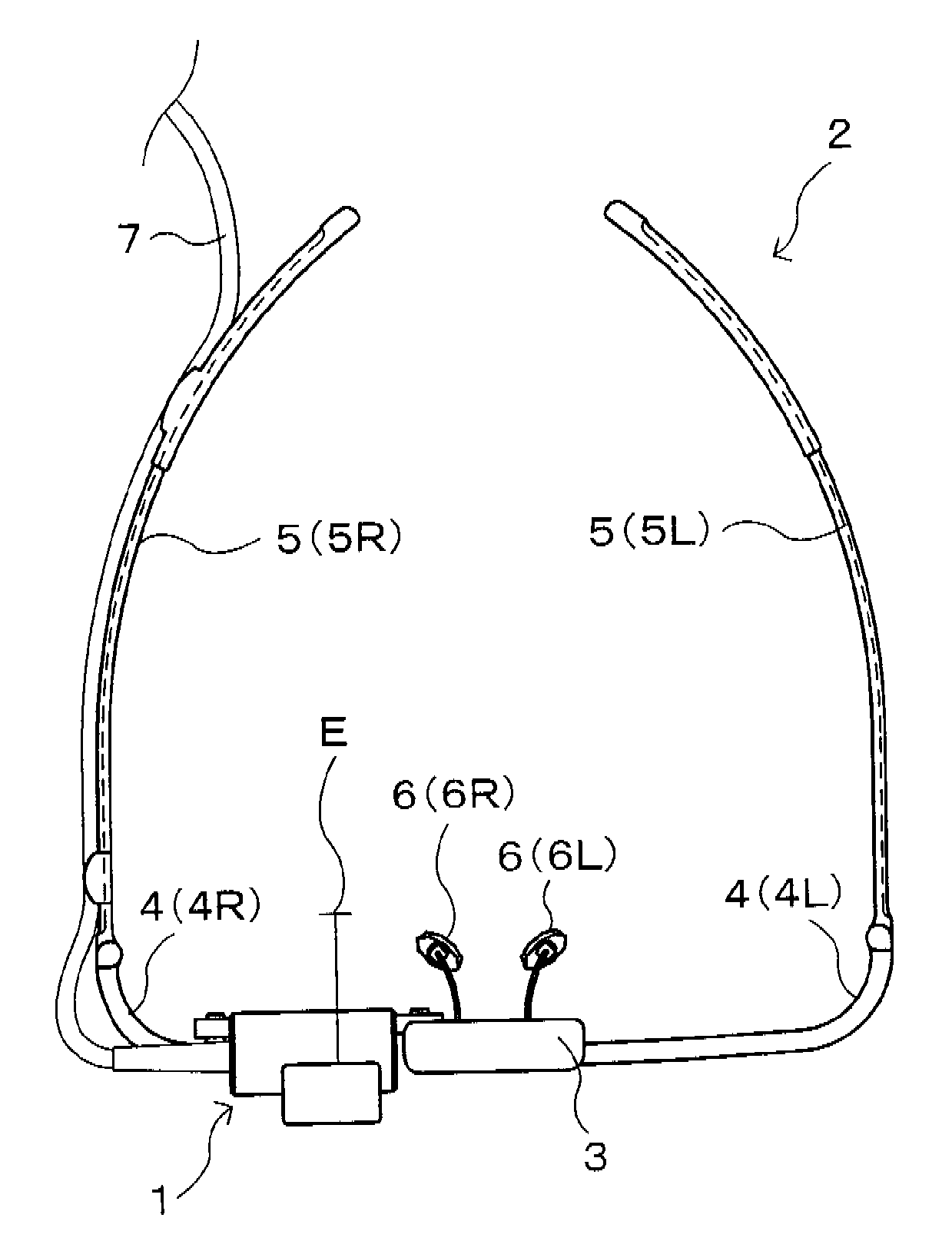

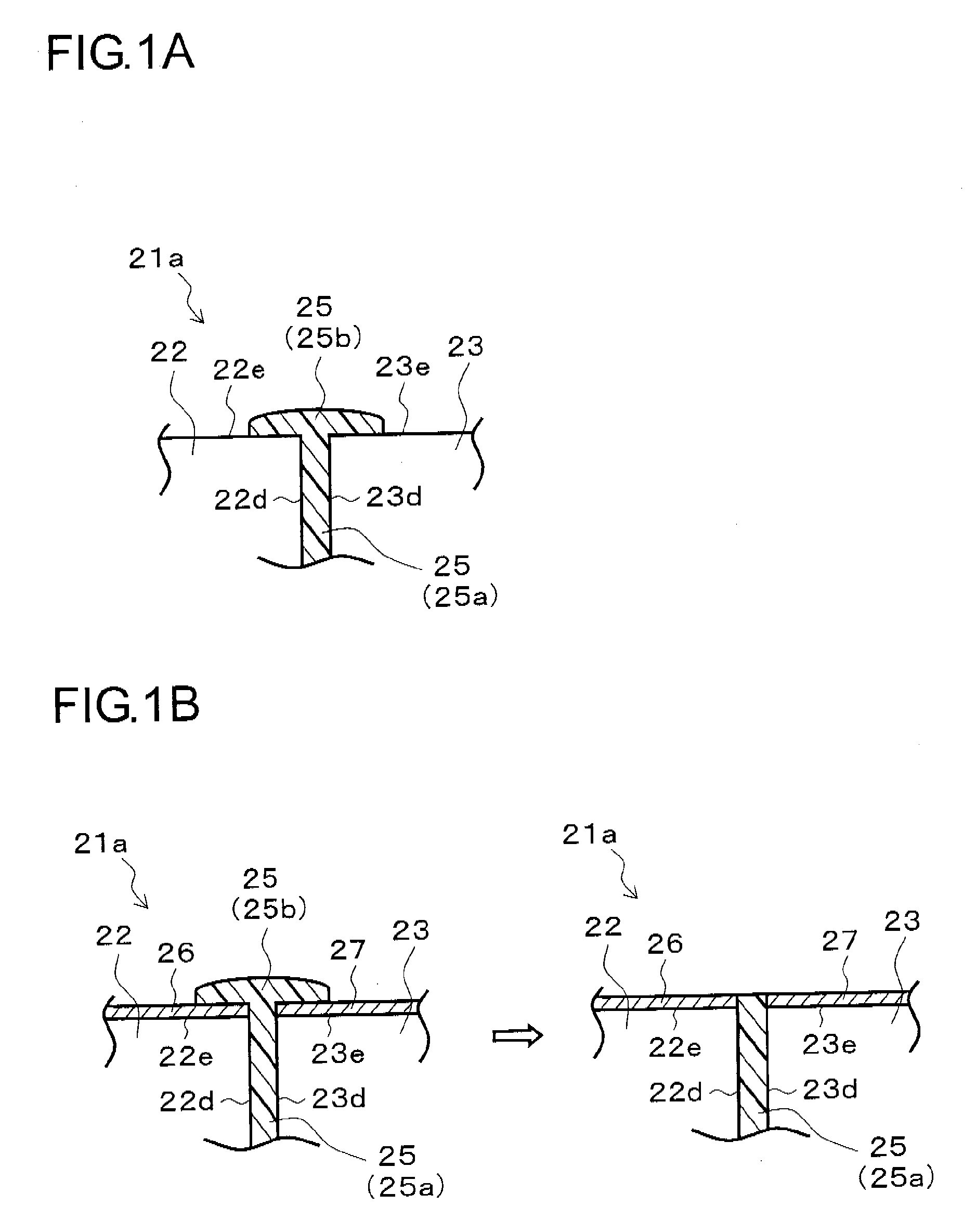

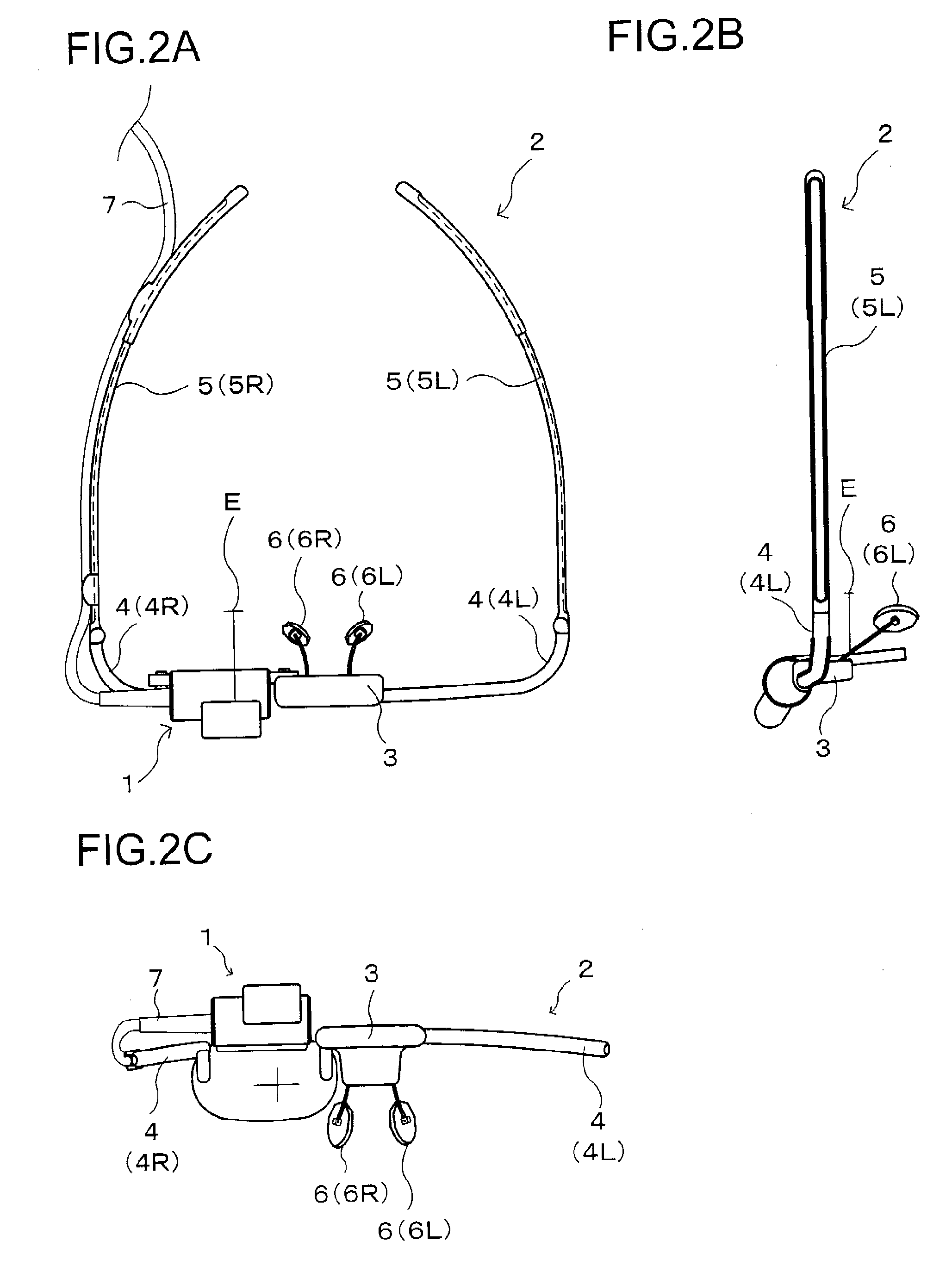

Joined optical member, image display apparatus, and head-mounted display

InactiveUS20080239422A1Good optical performanceStrong effect of preventingOptical articlesPolarising elementsEyepieceDisplay device

In a joined optical member, let the adhesion strength between a surface coating layer and an eyepiece prism be A1, the adhesion strength between the surface coating layer and a deflector prism be A2, the adhesion strength between the surface coating layer and adhesive be A3, and the adhesion strength between, at one end, the adhesive and, at the other, the eyepiece prism and the deflector prism be A4, then A1 (A2)>S3 and simultaneously A4>A3. This makes removal of superfluous adhesive on the surface coating layer easy, and prevents scratches on the exterior surfaces. Even after removal of superfluous adhesive, the surface coating layer remains on the exterior surfaces of the eyepiece prism and the deflector prism. This prevents scratches on the exterior surfaces in actual use, and prevents degradation of optical performance.

Owner:KONICA MINOLTA INC

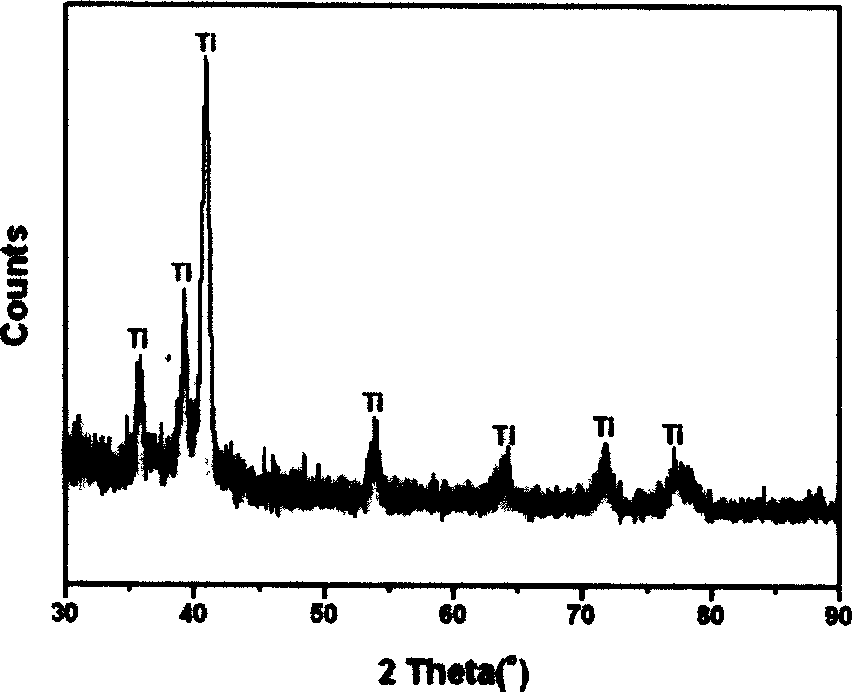

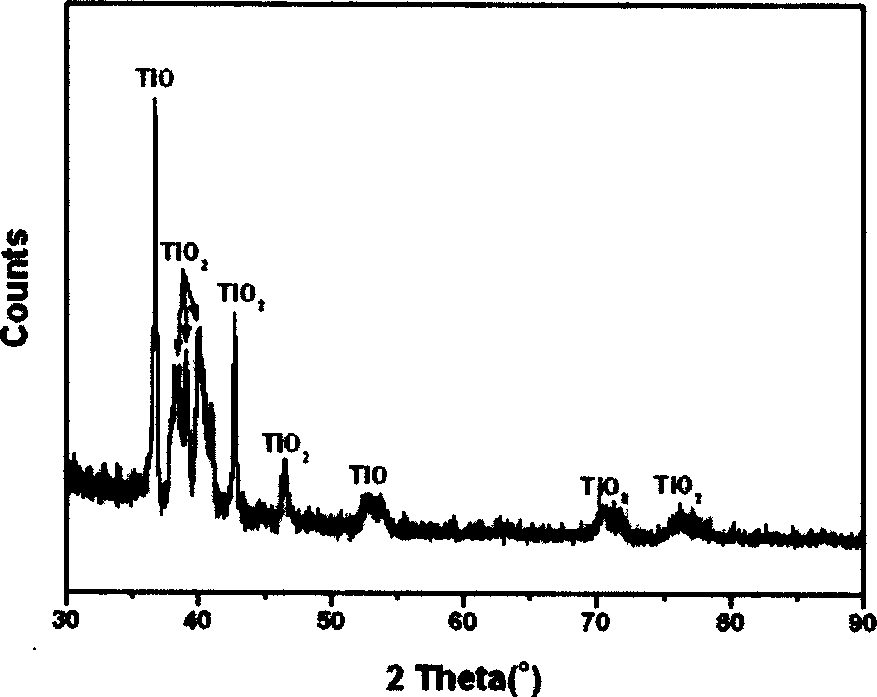

Method for acquiring highly-adaptive abrasion-proof titanium-based composite material on titanium alloy surface

InactiveCN101139709AReduce stressReduced tendency to crackMetallic material coating processesLaser beam welding apparatusIn situ reactionHigh power lasers

The invention discloses a method for preparing a Ti-based composite with high adaptability on a Ti-alloy surface, which pertains to the field of surface modification of metallic materials. The method comprises such procedures as: weighing by certain proportion spherical Ti alloy powder particles in proper particle sizes (45-150 micro meter) and TiB2, Cr3C2, TiC or B4C powder particles (3.4-30vol%, particle size 38-106 micrometer); mixing the powder evenly by a mechanical way; sending at the set powder-feeding rate the mixed powder by a powder feeder and coaxial powder-feeding nozzles into a molten bath formed by a high-power laser at the surface of a Ti-alloy substrate; the mixed powder carrying out in-situ reaction by the high temperature from the molten bath, and forming such steady and dispersion reinforced phases as in-situ self-grown TiC or TiB. The reinforced phases are featured by small particle size, steady thermal and mechanical properties, free pollution in interfaces, and high bond strength with the substrate. The method can substantially improve the hardness and wear resistance of Ti alloy surfaces, guarantees the high adaptability between the surface modified layer and the substrate, can be used for repairing and surface reinforcing treatment of Ti alloy parts bearing impact vibration load and thermal fatigue, etc.

Owner:有研科技集团有限公司

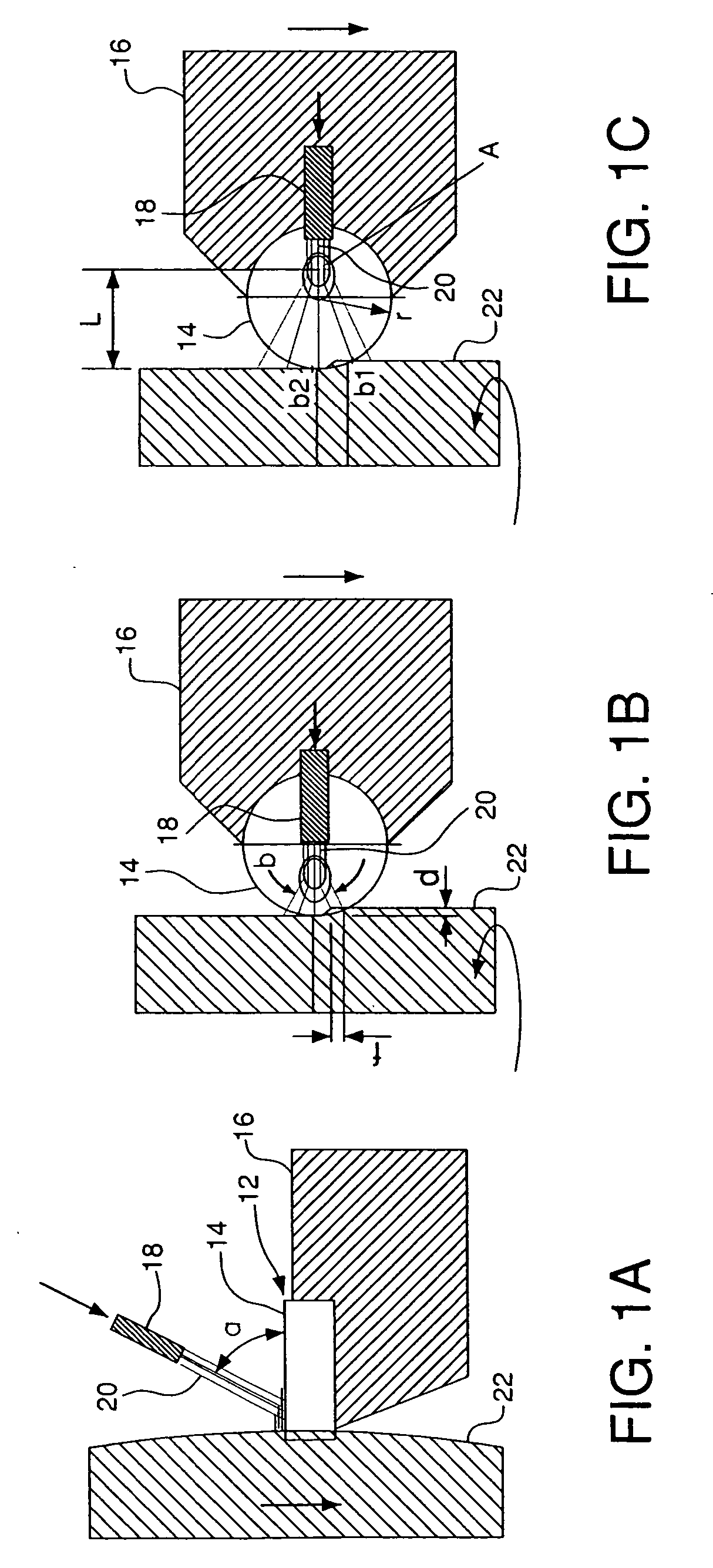

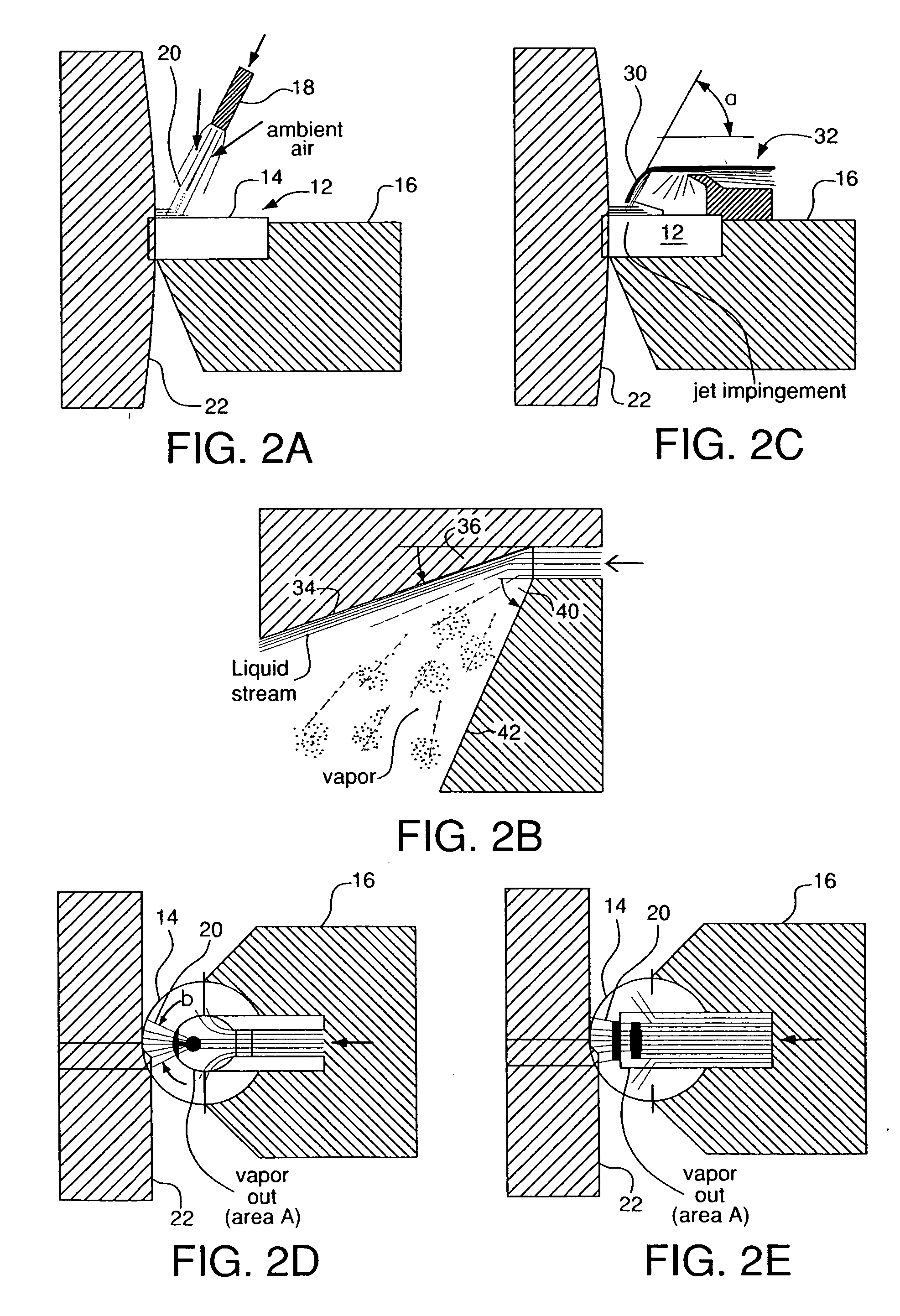

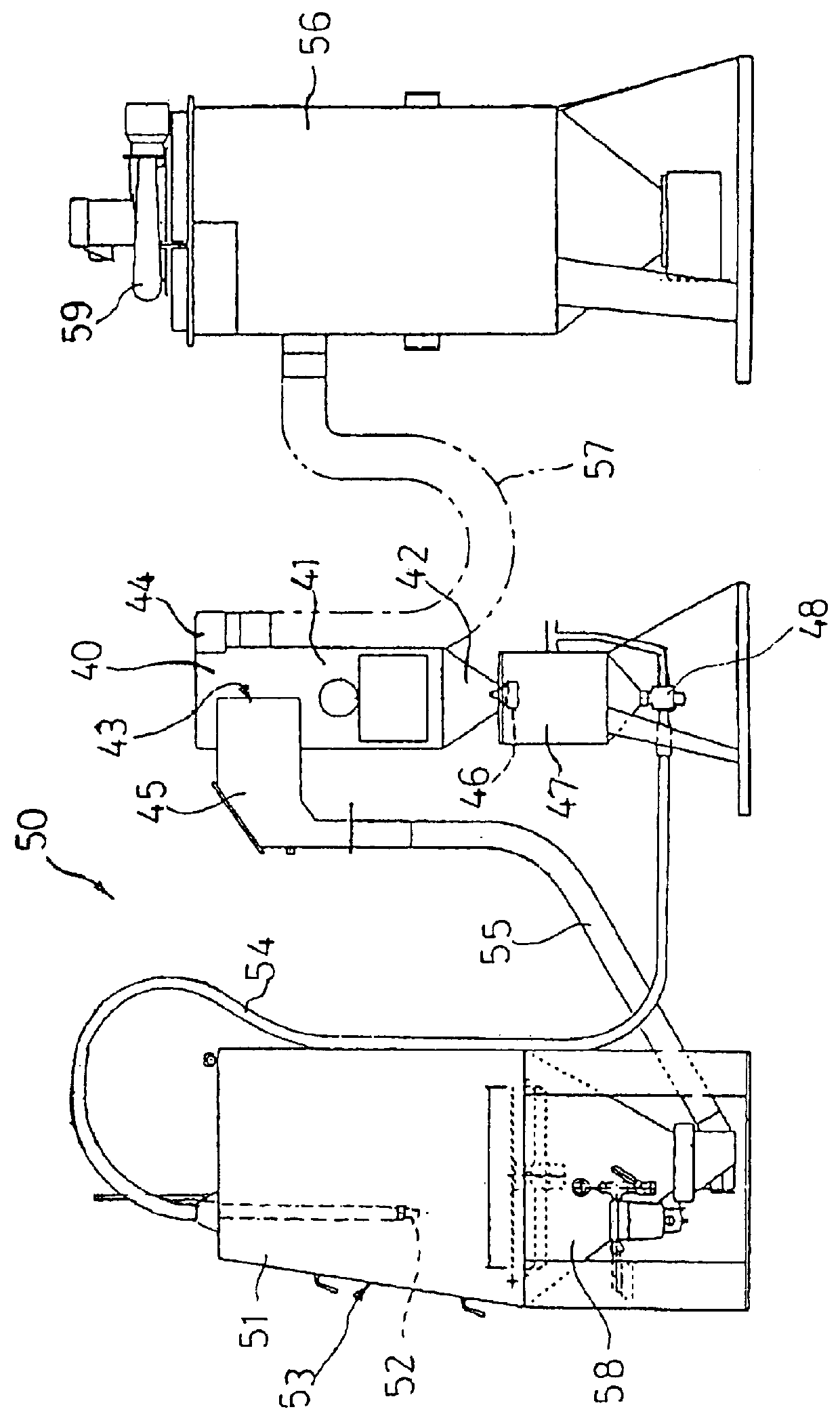

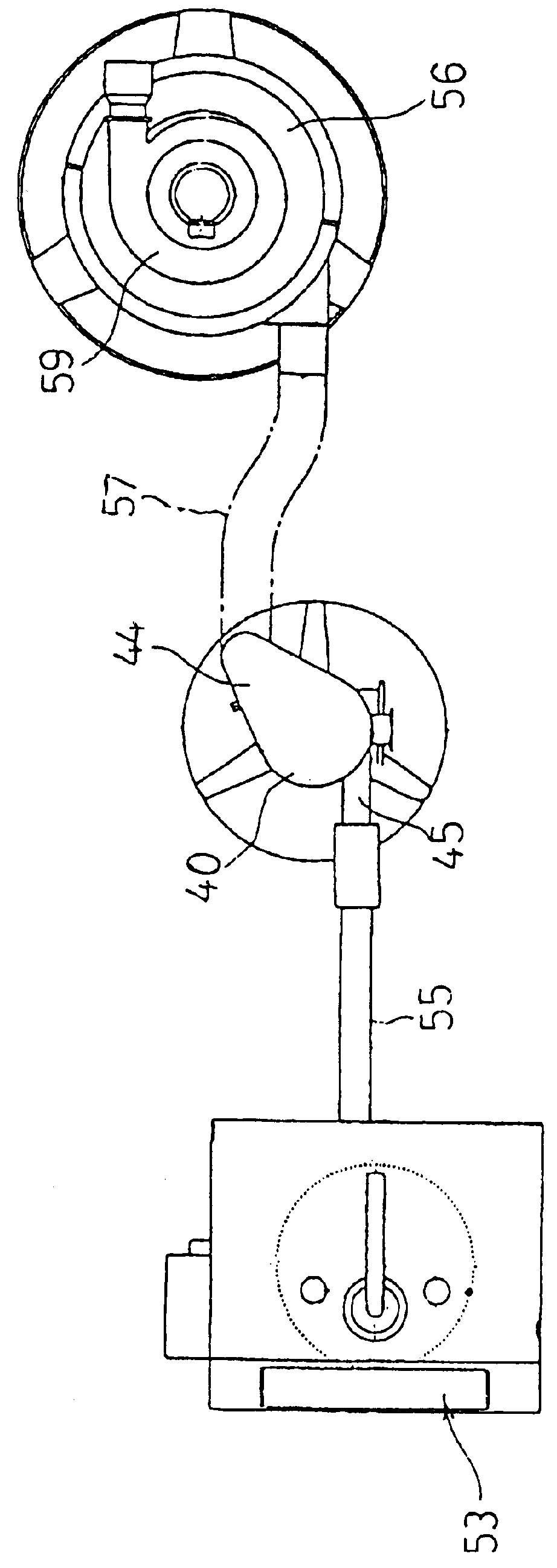

Apparatus and method for improving work surface during forming and shaping of materials

ActiveUS20050211029A1High surface finishImprove surface integrityLiquid surface applicatorsFurnace typesSurface finishHardness

A method and apparatus for improving the surface finish and / or surface integrity of a workpiece formed or shaped with a tool increase the surface hardness of the workpiece during forming or shaping of the workpiece. A method and apparatus for forming or shaping a workpiece also increase the surface hardness of the workpiece during forming or shaping of the workpiece with a tool, as do a method and apparatus for manufacturing a finished part or product from a workpiece. In some embodiments, an expanding jet of cryogen may be jetted to a surface of a workpiece and a tool from a nozzle, wherein the cryogen is at least partially separated into a condensed phase portion and a vapor portion within a downstream portion of the nozzle.

Owner:AIR PROD & CHEM INC

Manufacture method of environment friendly composite ceramic water-permeable brick

ActiveCN1919564AHigh strengthImprove wear resistanceSolid waste managementMixing operation control apparatusBrickComposite ceramic

The invention discloses a manufacturing method of environment-friend composite ceramic permeable brick, which comprises the following steps: adopting industrial slag with combustible substance as bottom aggregate and waste ceramic particle as layer aggregate, sieving at 10-20 order to obtain 55-65% material, sieving at 20-30 order to obtain 35-45% material, adding high-temperature adhesive and organic adhesive CMC, allocating, aging, moulding, drying, sintering.

Owner:JINGDEZHEN CERAMIC UNIV

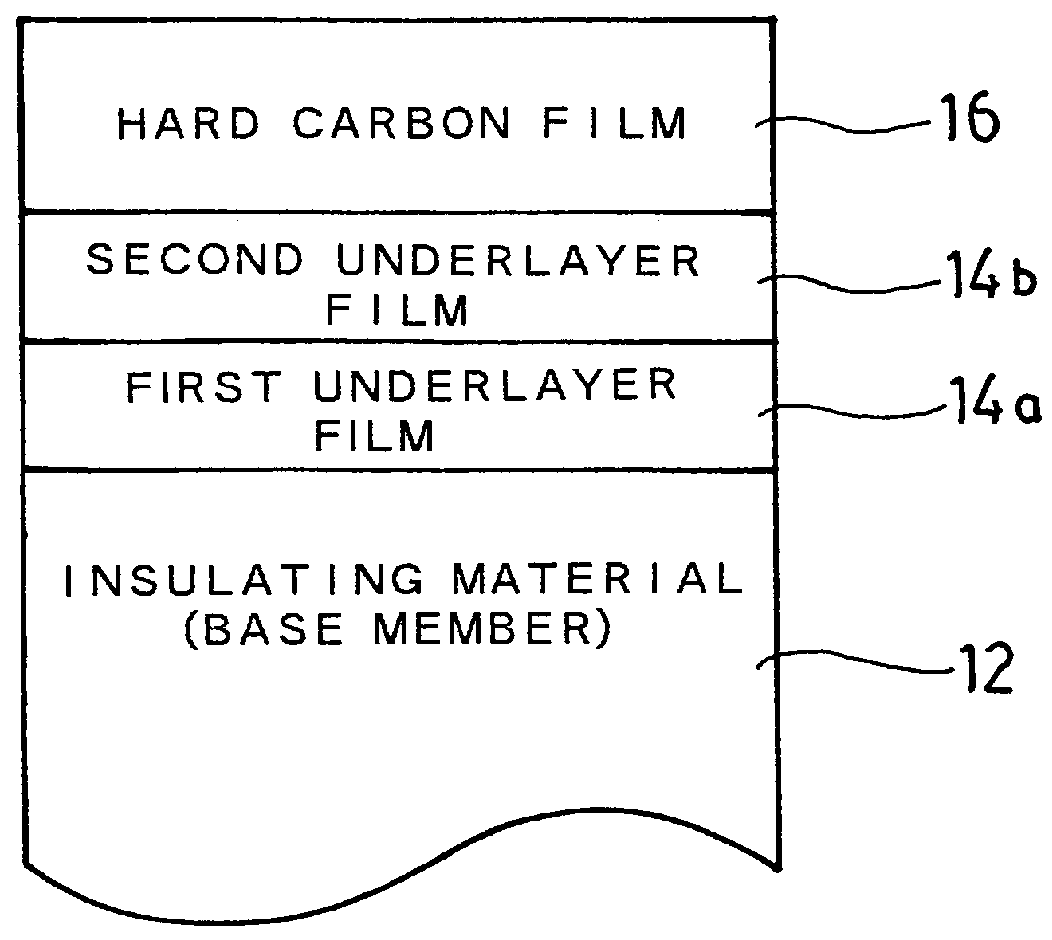

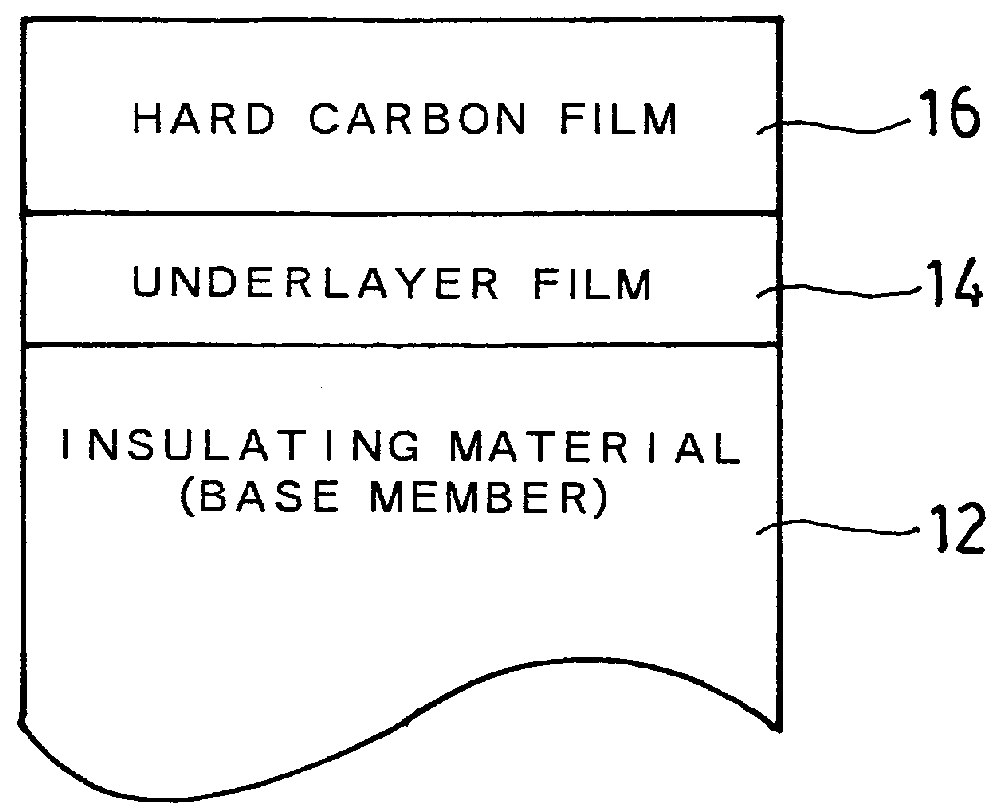

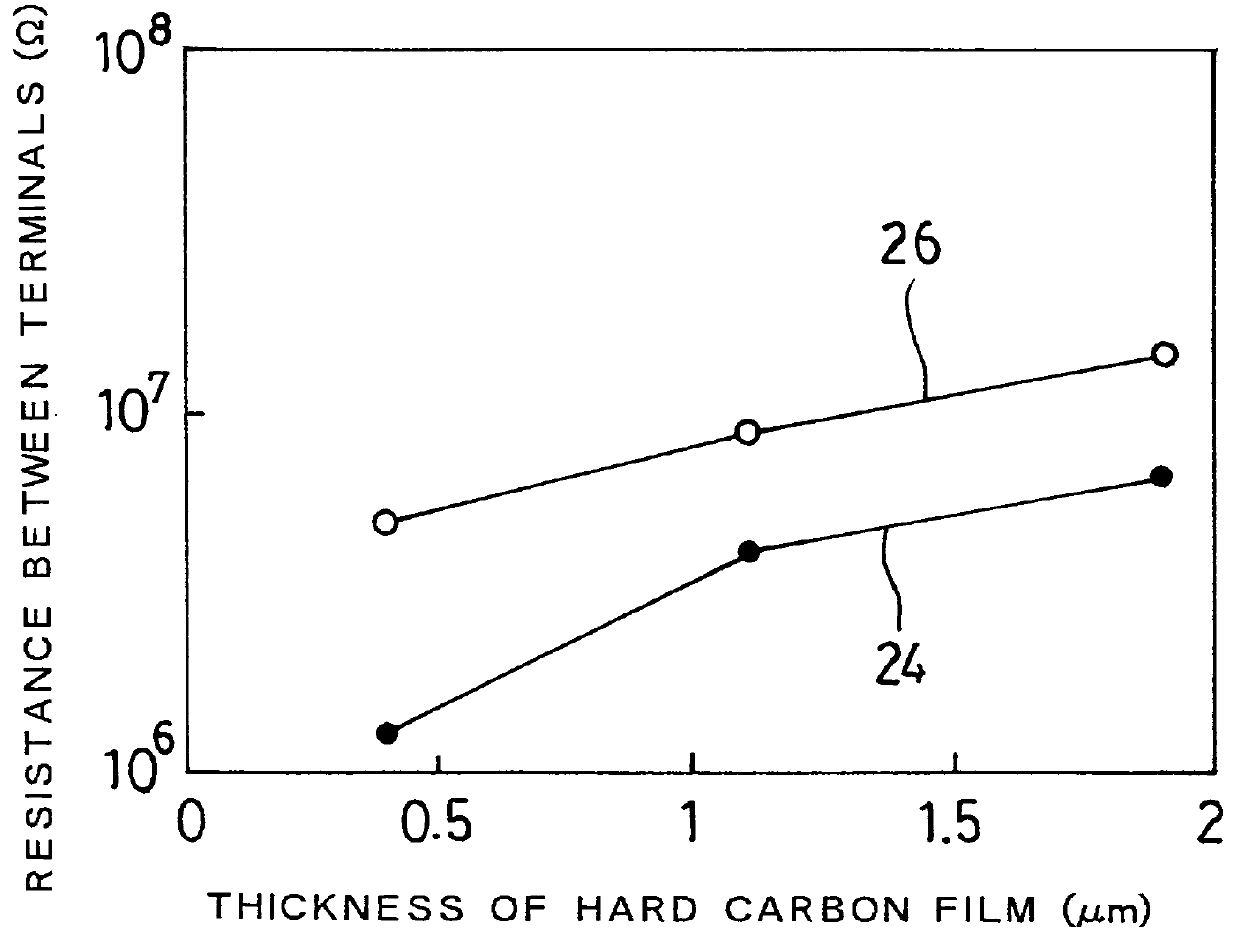

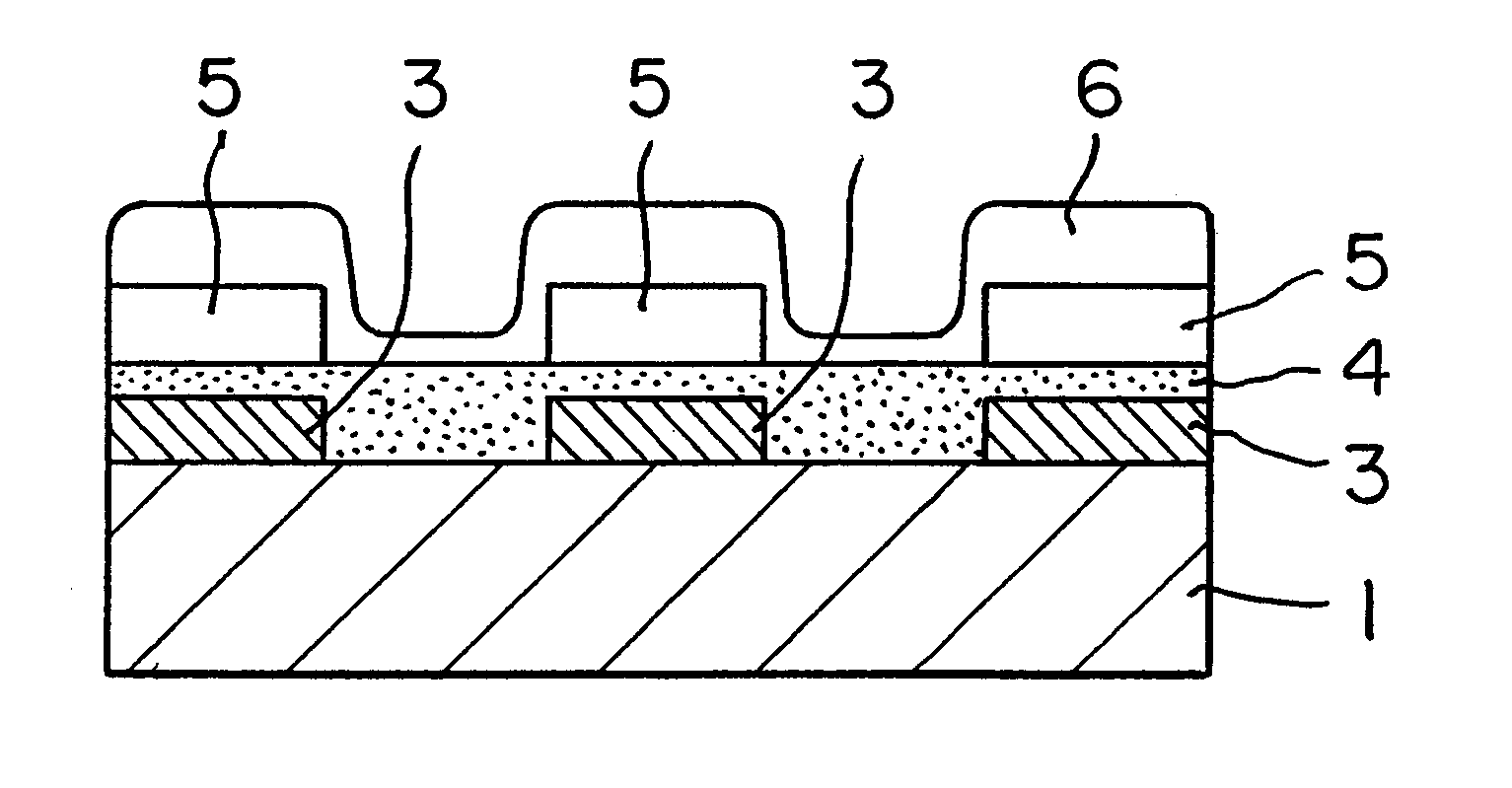

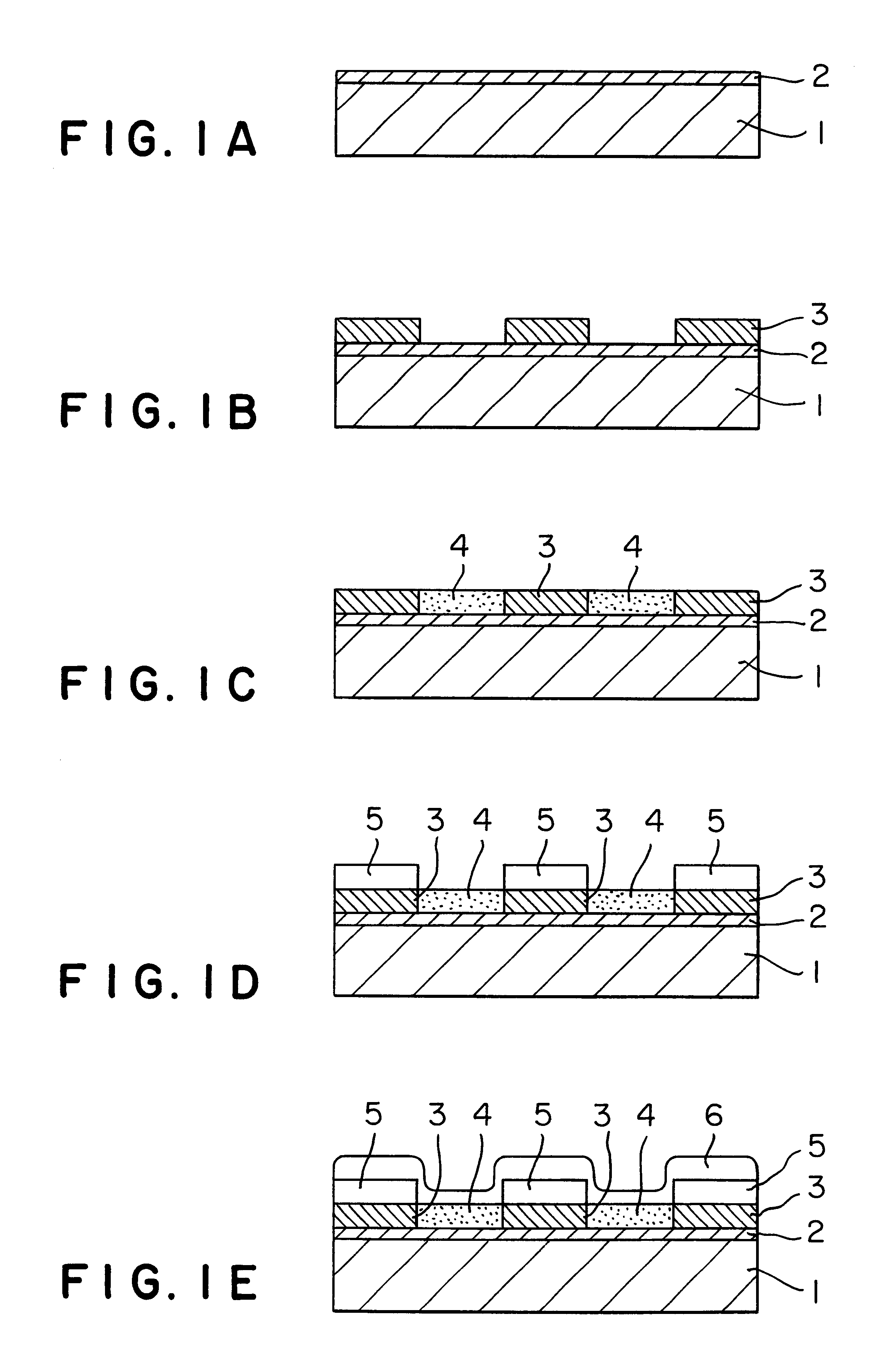

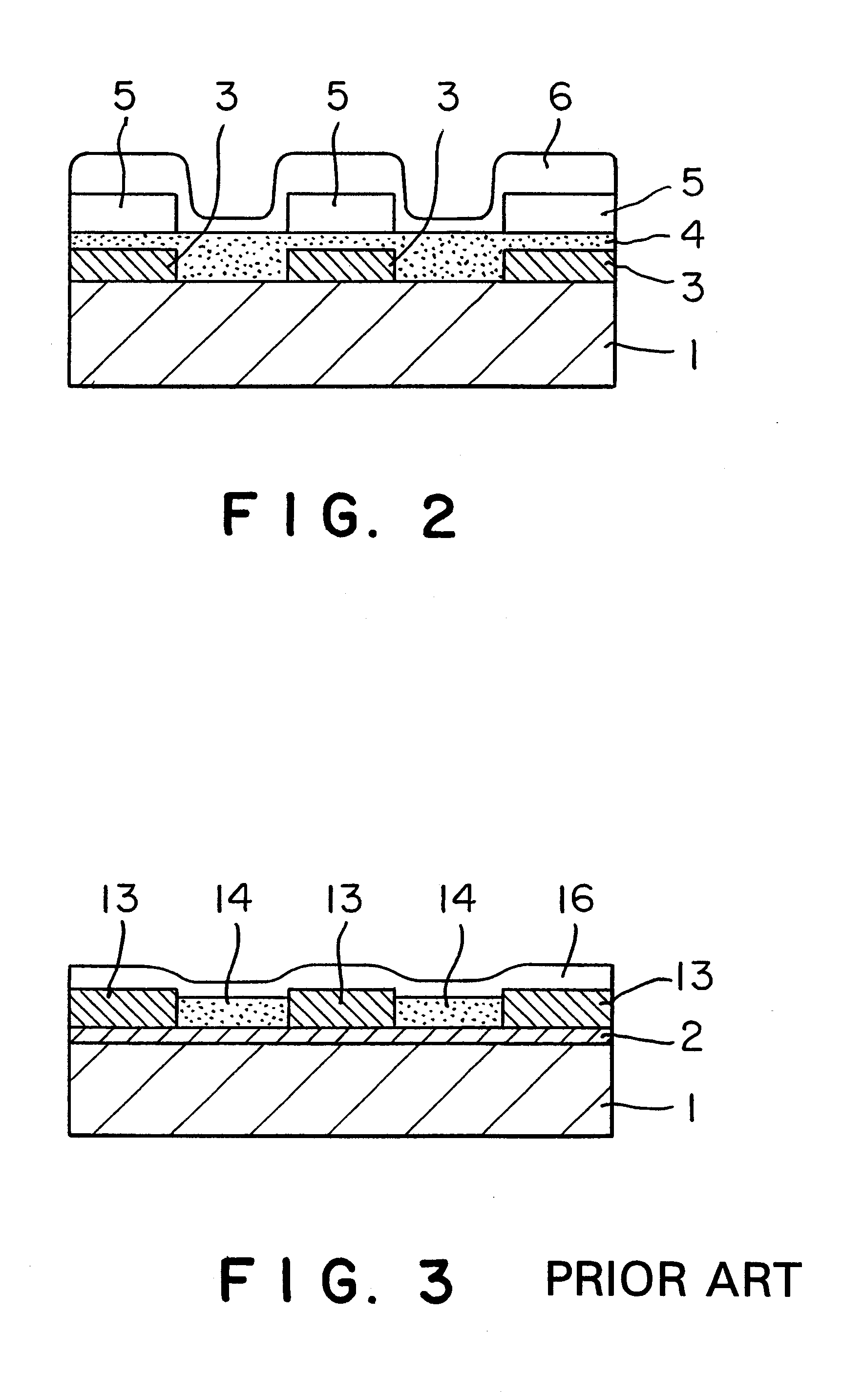

Method of forming films over insulating material

InactiveUS6080445AHigh surface hardnessImprove wear resistanceSpecial surfacesChemical vapor deposition coatingElectrical resistance and conductanceCarbon film

A method of forming films over an insulating material is provided whereby an underlayer film having electric conductivity is formed on the surface of the insulating material constituting a base member, and a hard carbon film is formed over the underlayer film so that the surface electrical resistance value of the hard carbon film can be controlled so as not to cause the surface thereof to be charged with static electricity by varying an electrical resistance value of the underlayer film. In the case where the underlayer film is formed of a metal film composed of titanium, chromium, tungsten, or the like, the resistance value thereof can be changed by varying the thickness of the metal film. In the case where the underlayer film is formed of a semiconductor film composed of silicon, germanium, or the like, the resistance value thereof can be changed by varying the thickness of the semiconductor film, or the concentration of an impurity added thereto.

Owner:CITIZEN WATCH CO LTD

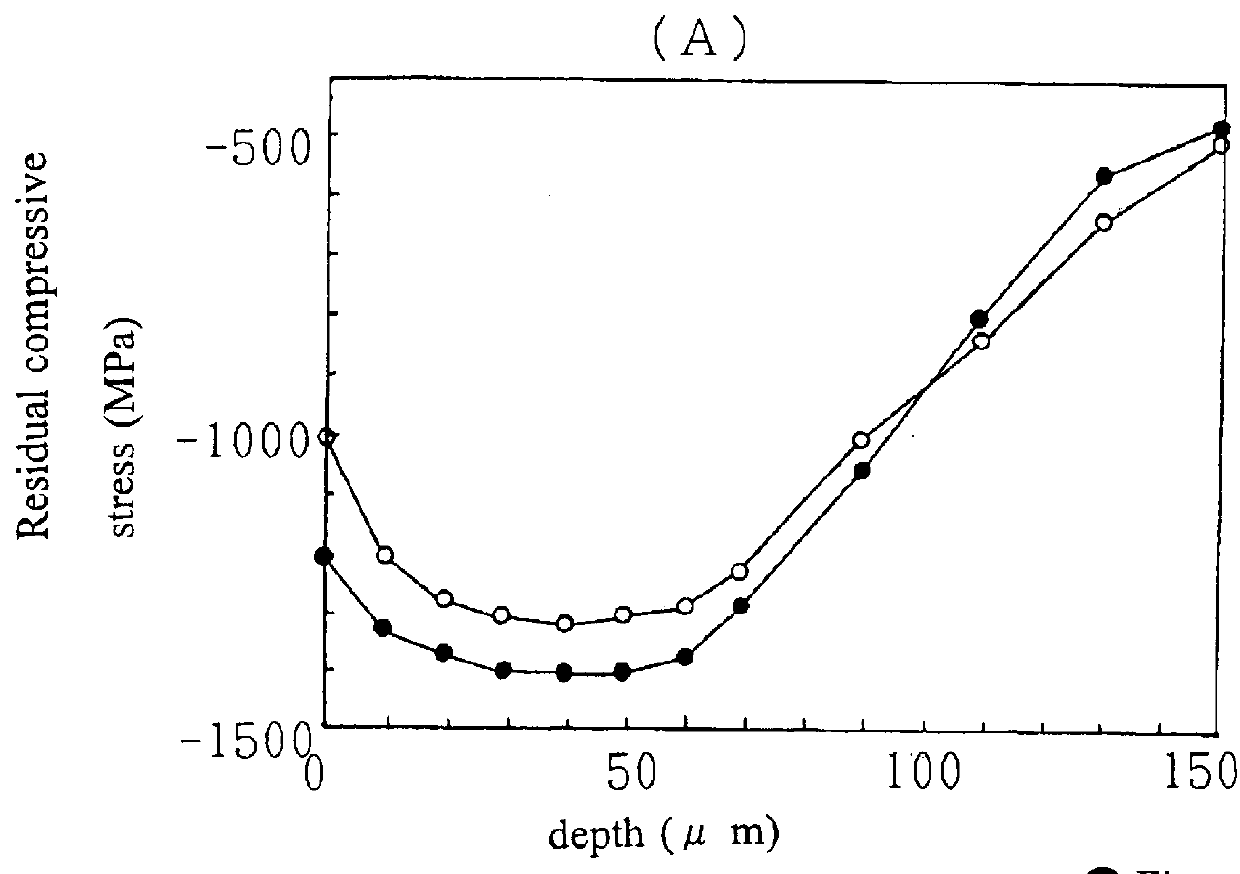

Method for a surface treatment of metallic product

The present invention relates to a method for a surface treatment of a metallic product. In this method, by conducting one step of injecting mixture shots including at least two types of shots comprised of different or same materials consisting of high hardness metal or metallic component and having different shot diameters between 0.6 and 0.03 mm onto the surface of a metallic product at an injection pressure of not less than 0.29 MPa or not less than 50 m / sec, the residual compressive stress of the surface of the metallic product and that of a lower surface layer are made at least -1200 MPa and that of a portion having a depth of about 50 mu m below the surface of the metallic product is made -1300 MPa or higher.

Owner:FUJI KIHAN CO LTD

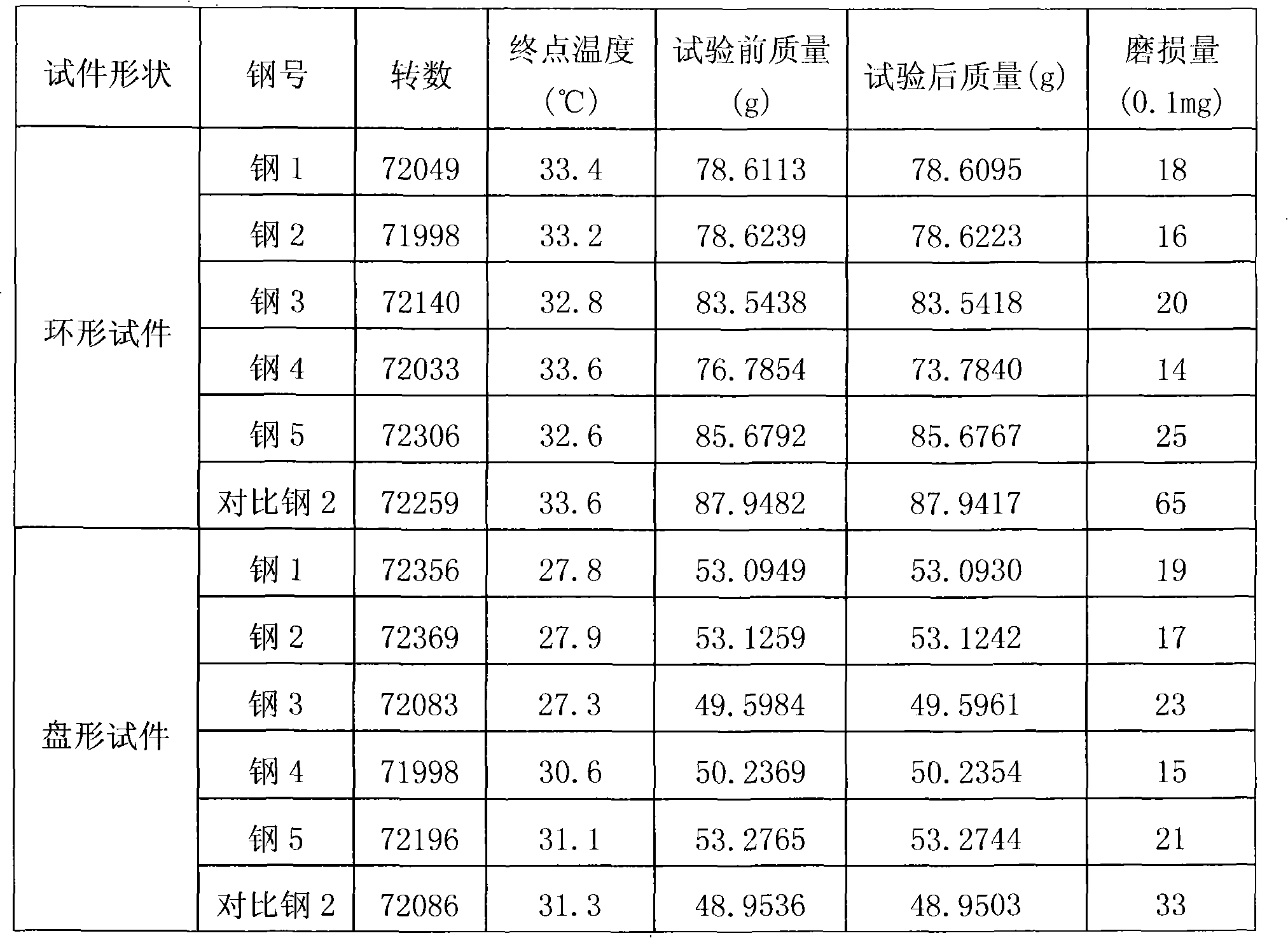

Ultrahigh strength abrasion resistant steel and method of preparing the same

InactiveCN101250673AHigh yield strengthImprove impact toughnessTemperature control deviceFurnace typesChemical compositionWear resistant

The invention discloses a superhigh intensity wear-resistant steel and the manufacturing method, which belongs to the manufacturing field of low alloying steels, according to percentage by weight, the chemical components of the steel are that C 0.10-0.17%, Si 0.25-0.50%, Mn 1.20-1.50%, P<=0.018%, S<=0.008%, Cr 0.20-0.05%, Ni0.25-0.50%, Mo 0.10-0.40%, Als 0.02-0.06%, B<=0.005%, RE<=150g / t, and the allowance is Fe and unavoidable impurities, and the content of carbon is Ceq(%)<=0.60, Ceq(5)=C+Mn / 6+(Mo+Cr+V) / 5+(Ni+Cu) / 15. The specific method for producing the steel comprises the following steps: smelting ultra-pure steel, desulfurizing molten iron, compounding and converting the top and the bottom of a converter, doing vacuum treatment, feeding rare earth (RE) silk through a crystallizer, casting into bar plates, heating the bar plates, roughing, planishing, air cooling or feeding middle pressure, water cooling, quenching and tempering steel plates. V does not contain in the chemical components of the steel, inner stress of steel is low, steel welding property is improved, and steel has excellent abrasion resistance and ultra-high strength and toughness properties, which is beneficial for popularization and application.

Owner:武钢集团有限公司

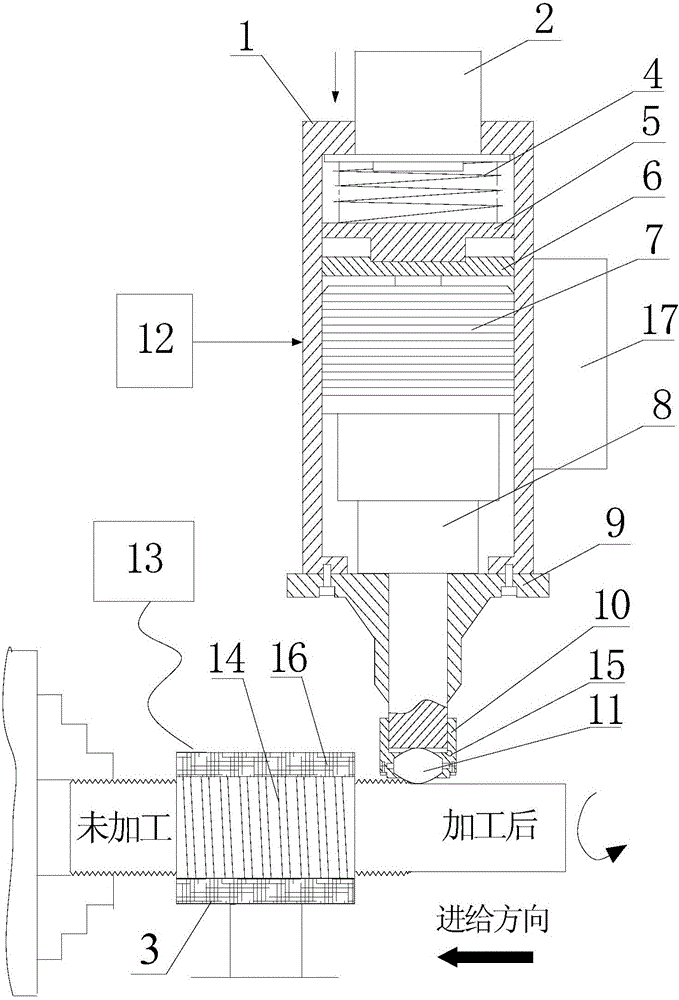

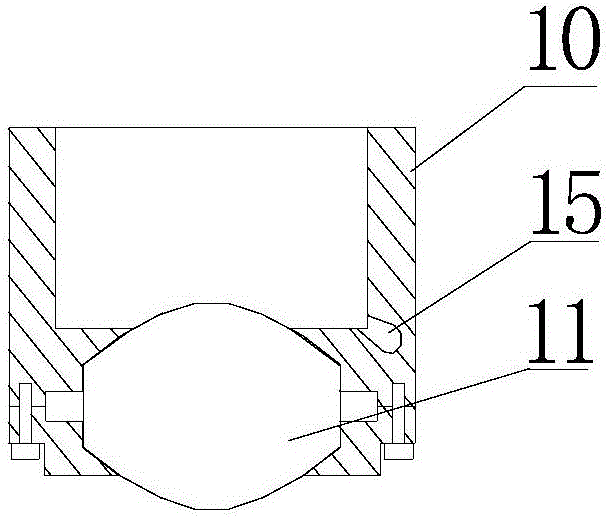

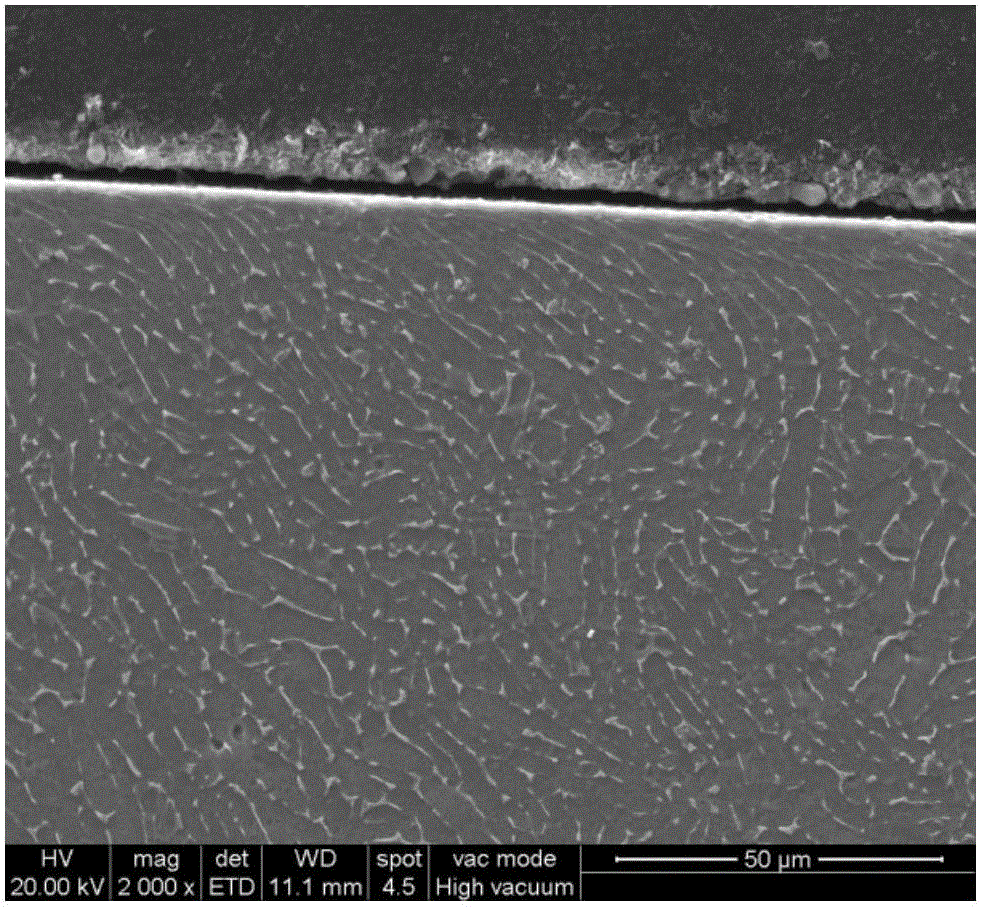

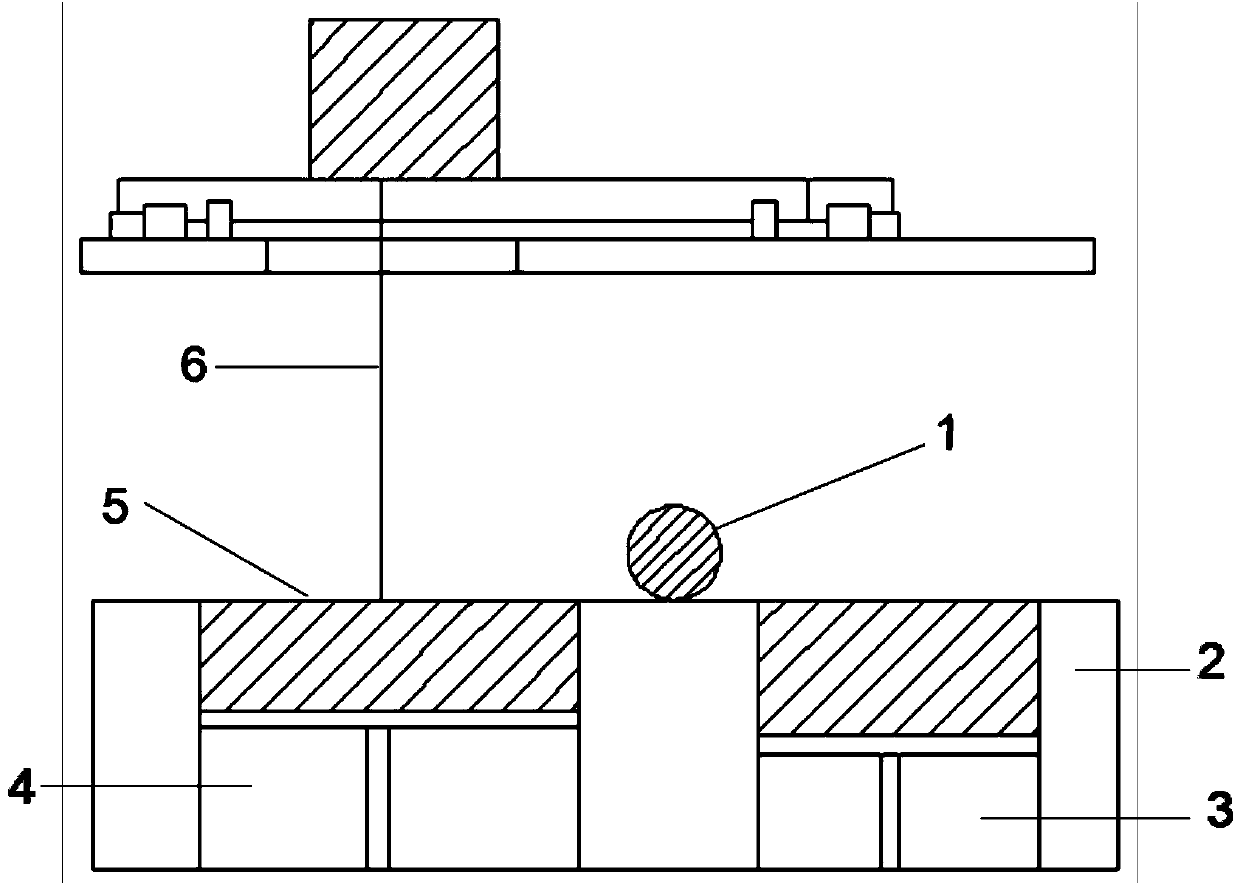

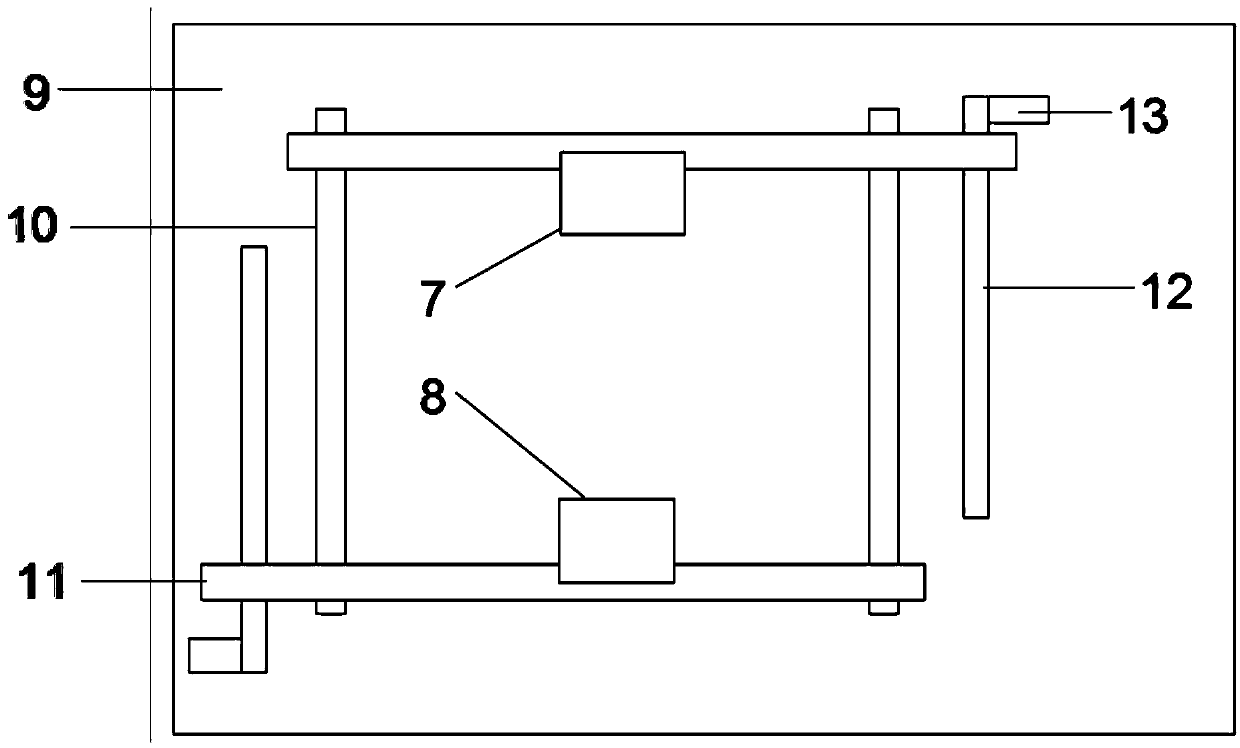

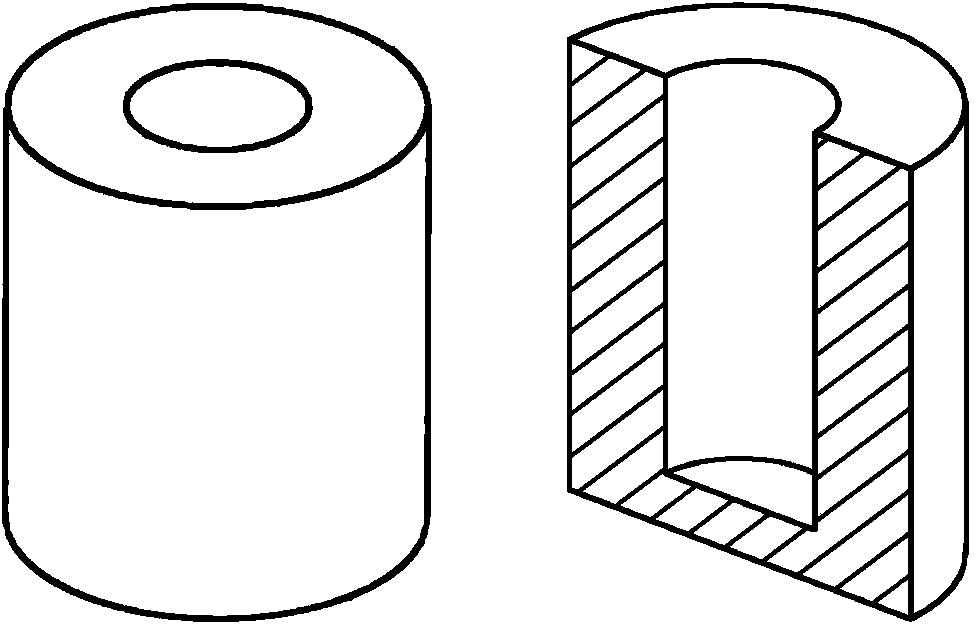

Low-temperature assisted ultrasonic surface rolling intensifying device and processing method

The invention discloses a low-temperature assisted ultrasonic surface rolling intensifying device and a processing method. The device consists of a surface rolling member, a loading member and a heating member, wherein a clamping handle is arranged on the surface rolling member; the loading member is arranged at the tail end of the surface rolling member; a spring, a pressure sensor, a baffle, a transducer and an amplitude-change pole are sequentially arranged on the end face of the loading member; the amplitude-change pole is provided with a rolling head of which the front end is provided with a roller through a guide sleeve; the outer side of the surface rolling member is connected with an ultrasonic generator; and the heating member is provided with a temperature controller and heating wires connected and controlled by the temperature controller According to the processing method disclosed by the invention, an ultrasonic rolling technology and low-temperature heating treatment are combined; on the basis of softening materials by using low temperature heating, an ultrasonic frequency electrical signal is converted into ultrasonic mechanical vibration by using the transducer; and after the ultrasonic mechanical vibration is amplified by the amplitude-change pole, vibration with a certain amplitude is outputted and transmitted to the rolling head, and high-speed vibration between the rolling head and workpieces in the rolling process is realized, thereby better refining material grains on the surface layers of the workpieces, and generating greater residual compressive stress and high surface hardness.

Owner:SOUTH CHINA UNIV OF TECH

Synchronously embossed decorative sheet and method for producing the same

InactiveUS6326074B1Efficiently formedRealistic appearanceSpecial visual effect coatingsDecorative surface effectsEngineeringCoating

A synchronously embossed decorative sheet is provided which has excellent three-dimensional effect in sharp tune with a pattern layer and, at the same time, has good scratch resistance. The synchronously embossed decorative sheet comprises: a substrate; a pattern layer provided on the substrate; a penetrable layer provided on the substrate at least in its portions not having thereon the pattern layer, the penetrable layer comprising a coating composition penetrable by an ionizing radiation curing resin; a nonpenetrable layer provided, on or above the pattern layer, in tune with the pattern in the pattern layer, the nonpenetrable layer comprising a coating composition nonpenetrable by an ionizing radiation curing resin; and a top coat provided so as to cover the layers on the substrate and to conform to the shape of concaves and convexes in the pattern layer.

Owner:DAI NIPPON PRINTING CO LTD

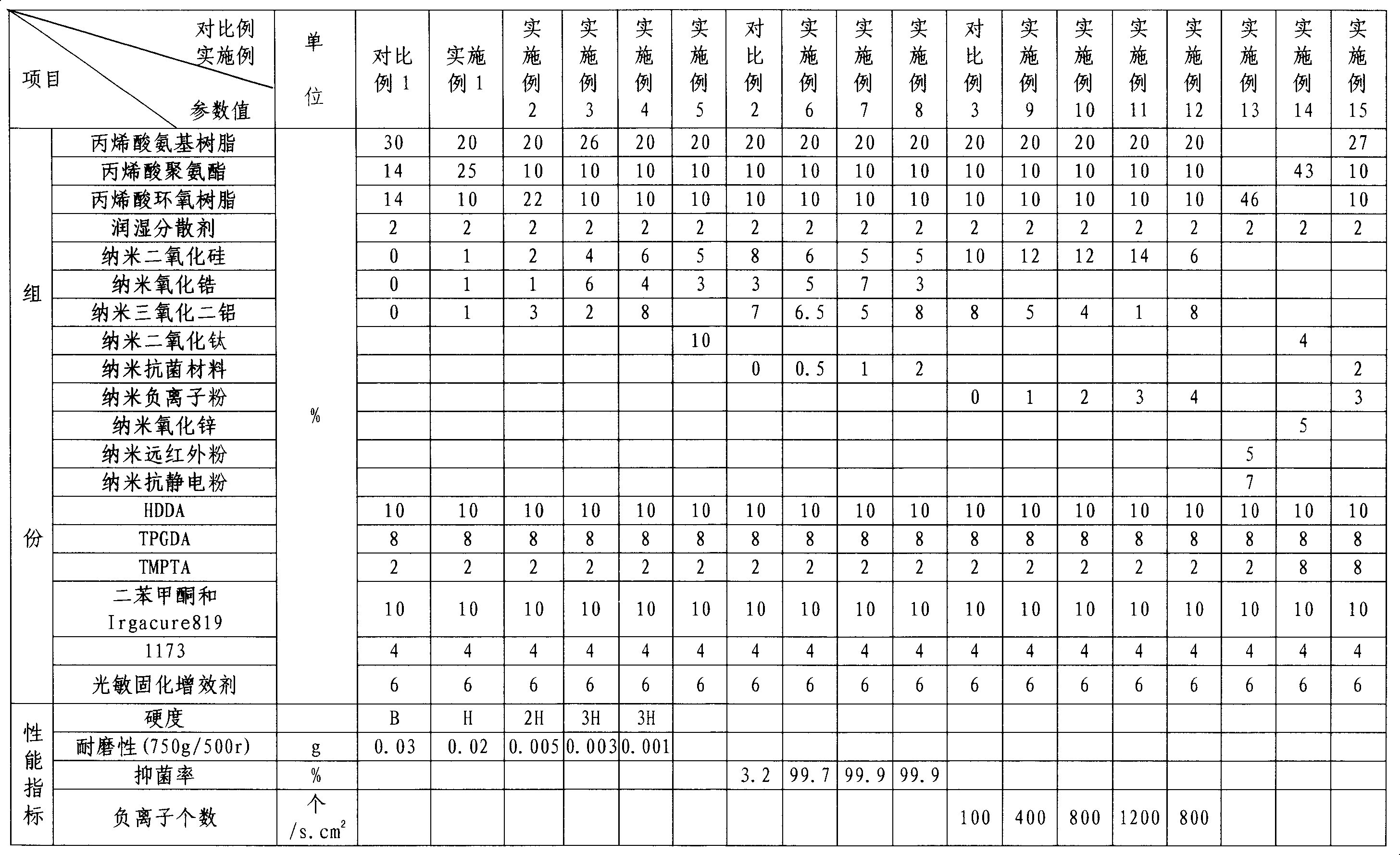

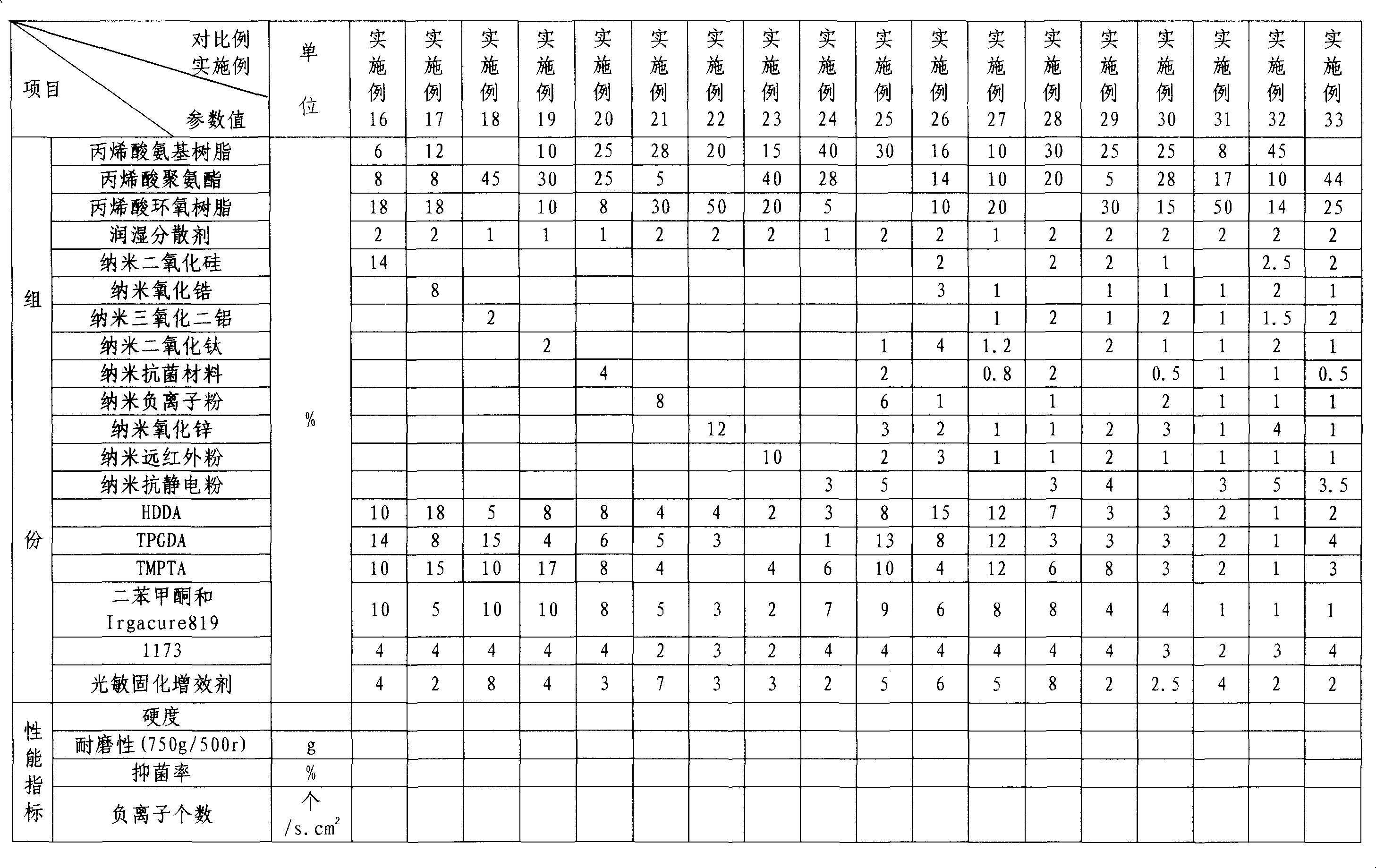

Nano technology modified ultraviolet solidified woodware paint

InactiveCN1554717AImprove wear resistanceHigh surface hardnessPaints with biocidesPolyurea/polyurethane coatingsEpoxyUltraviolet

The modified ultraviolet cured woodenware paint consists of one or several of nano silica, zirconia, titania, zinc oxide, negative ion powder, antibiotic material, far infrared powder, antistatic powder and alumina in 0.3-20 wt% and active oligomer comprisnig acrylic epoxy resin, acrylic polyurethane and acrylic amino resin in 30-76 wt%. The modified ultraviolet cured woodenware paint has the small size effect, surface effect, quantum size effect and macroscopic quantum tunnel characteristic of nano material, so that it has high antiwear property, hgih surface hardness, high toughness, high cracking resistance and many other advantages.

Owner:南京海泰纳米材料有限公司

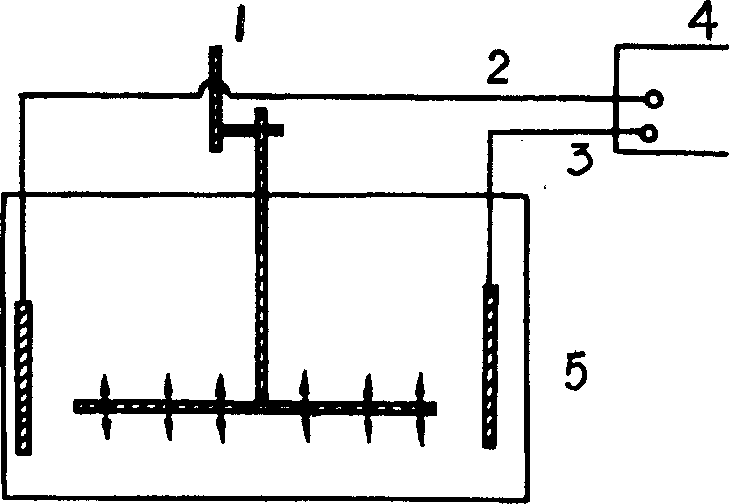

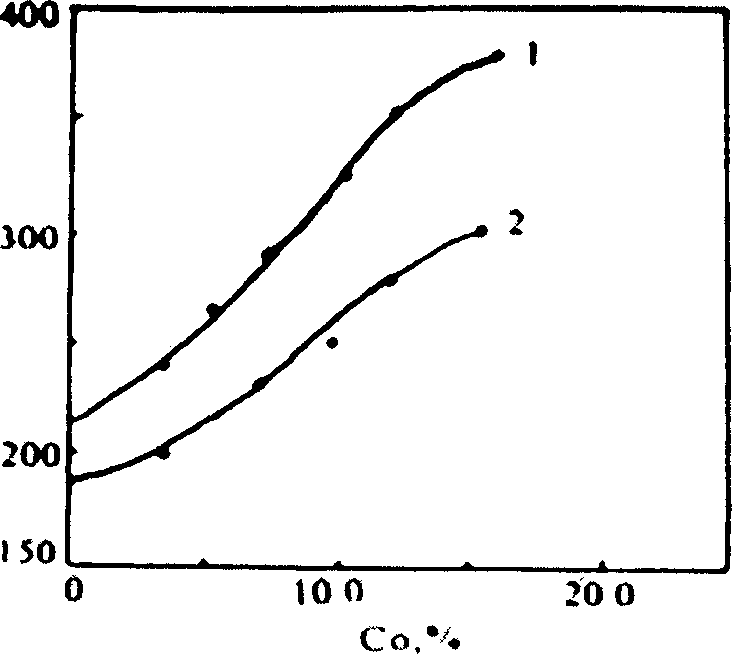

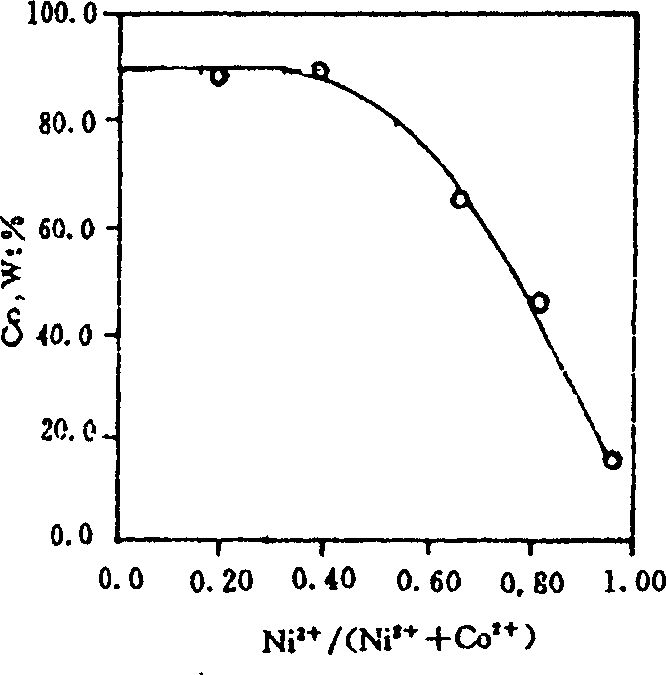

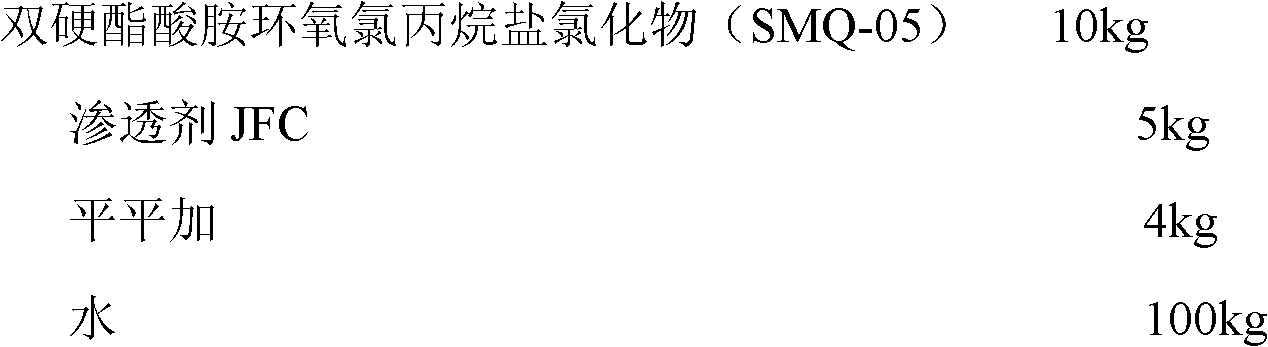

Gradient composite deposite for continuous casting crystallizer copper plate and production method thereof

InactiveCN1500916AImprove the state of the structureImprove acceleration performanceElectrolytic coatingsSulfonatePre treatment

The gradient composite coating layer for continuous casting crystallizer copper plate contains Co in 50-79.9 vol%, Ni in 20-49.9 vol% and Al2O3 grains of size below 0.5 micron in 0.1-10 vol%. The coating is in gradient structure with outwards gradually increased Co and Al2O3 content and decreased Ni content. During production of the composite coating layer, inside amino sulfonate system with Al2O3 grains in 10-80 g / L and size below 0.5 micron added, gradient Co-Ni-Al2O3 coating is deposited onto copper or copper alloy via specific Al2O3 grain activating pre-treatment and electric deposition process. In the activating pre-treatment, FC-4 cation surfactant is used as ion dispersant. The composite Co-Ni-Al2O3 coating may be used in various high temperature wear resisting fields widely.

Owner:BAOSHAN IRON & STEEL CO LTD +1

Polyvinyl chloride/chlorinated polyvinyl chloride skin foamed sheet and preparation method thereof

InactiveCN102040785AHigh surface hardnessIncrease productivityAntioxidantChlorinated polyvinyl chloride

The invention relates to a polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet and a preparation method thereof, and the polyvinyl chloride / chlorinated polyvinyl chloride skin foamed sheet comprises the following materials in parts by weight: 60-90 parts of polyvinyl chloride, 10-40 parts of chlorinated polyvinyl chloride, 2.8-7 parts of stabilizer, 3-5 parts of foam regulator, 1-3 parts of foam nucleating agent, 0.5-2 parts of foaming agent, 0.6-1.5 parts of external lubricant, 0.5-1 part of internal lubricant, 0.5-2 parts of processing aids, 0.05-0.5 part of antioxidant and no more than 30 parts of filler. The preparation method is as follows: adding all the materials into a high-speed stirring machine, and mixing uniformly; heating to 90-120 DEG C, and carrying out heat preservation for more than 10 minutes; placing into a cold mixing machine, cooling down to 25-45 DEG C, tapping into a storage bin, extruding a foaming material through an extruder, and further carrying out vacuum shaping, cooling molding and edge trimming and finishing; and finally carrying out cutting and packaging according to the required length. The product has high surface hardness and great strength, is less prone to deformation, easy for processing, reasonable in manufacturing process, low in cost, good in quality and high in efficiency and has extensive popularization value and good economic and social benefits.

Owner:杜文军

Process for anode oxidation coloration of titanium and titanium alloy surface

InactiveCN1844483ABright colorImprove the decorative effectSurface reaction electrolytic coatingTitaniumTitanium alloy

This invention relates to titanium and titanium alloy surface anode oxidation bepainting method. This invention has following steps: dealing with titanium and titanium alloy in alkali solution for 10-15min under 60-75deg C and ultrasonic condition, then rinsing, and then putting it in acid solution for 0.5-1min, and then rinsing, and then under the condition that the temperature is 15-35deg C, the current density is 5-10Am-2, the voltage is 20-90V, putting it in anode oxidation bepainting solution to bepaint for 15-30min,then rinsing, and then dealing with it closely for 15-30min in non-ionic water, and then drying for 30-60min under 110-130deg C. The advantage in this invention is that the steps are few, the operation is simple, and it is easy to maintain.

Owner:XIAMEN UNIV

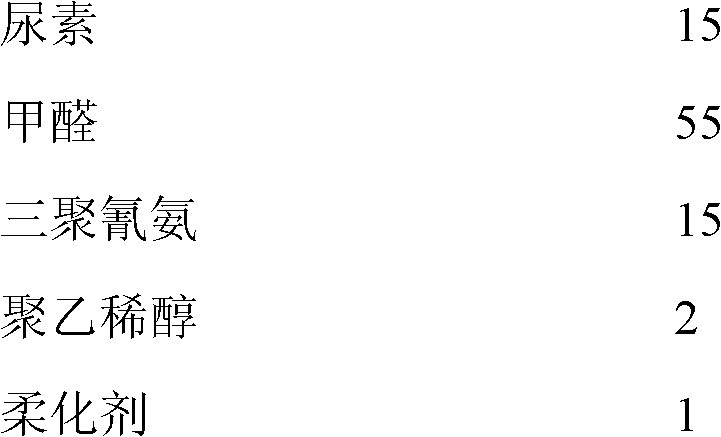

Technical wood and manufacture method thereof

ActiveCN103171014AImprove the utilization rate of solid woodHigh densityWood compressionWood impregnation detailsHot pressHot pressing

The invention relates to technical wood and a manufacture method thereof. The manufacture method comprises the steps of dying and drying eucalyptus and poplar veneers, conducting gum dipping and thickening on the wood veneers by using an ultrasonic vibration method, assembling gum dipping boards, conducting semi-solidification hot-pressing maintaining by using a curve die high-frequency press, conducting square slicing on the technical wood or cutting the technical wood into wood veneers, assembling the wood veneers in the same direction according to needed thickness, and conducting hot pressing and thickening. The thickness of the technical wood veneers or wood square produced by using the manufacture method is as high as 0.8-1.8kg / cm<3>, the thickness of the technical wood is more than 1.5 times of that of common technical wood, a plurality of items of physical and mechanical properties are improved by more than 1.5 times, the technical wood is not easy to crack, product durability improves to more than one time, service life of products is prolonged, and using fields of the products are extended.

Owner:SINO MAPLE JIANGSU CO LTD

Preparation method for laser cladding soft and hard composite coating self-lubricating cutter

InactiveCN103522652AImprove toughnessHigh surface hardnessMetallic material coating processesMetal layered productsNano al2o3Hardness

The invention belongs to the field of machinery cutting cutter manufacturing, and relates to a preparation method for a laser cladding soft and hard composite coating self-lubricating cutter. A rake face coating of the cutter is a multi-layer structure. Firstly, a hard coating of nano Al2O3 ceramic or an ultrafine cemented carbide, etc. is clad on the rake face of the cutter by utilization of a CO2 laser synchronous feeding manner, and then a self-lubricating soft coating is clad by utilization of nickel-covered MoS2 powder or nickel-covered WS2 powder. The cutter has characteristics of good toughness, high hardness, a self-lubrication function, and the like. During a drying cutting process, the hard coating bears loads and the rake face self-lubricating soft coating has low shearing strength, thus reducing friction between the cutter and chips, reducing the cutting temperature and the cutting force, and therefore cutter abrasion is reduced. The cutter can be widely used for dry cutting and cutting machining of difficult-to-machine materials.

Owner:SHANDONG UNIV

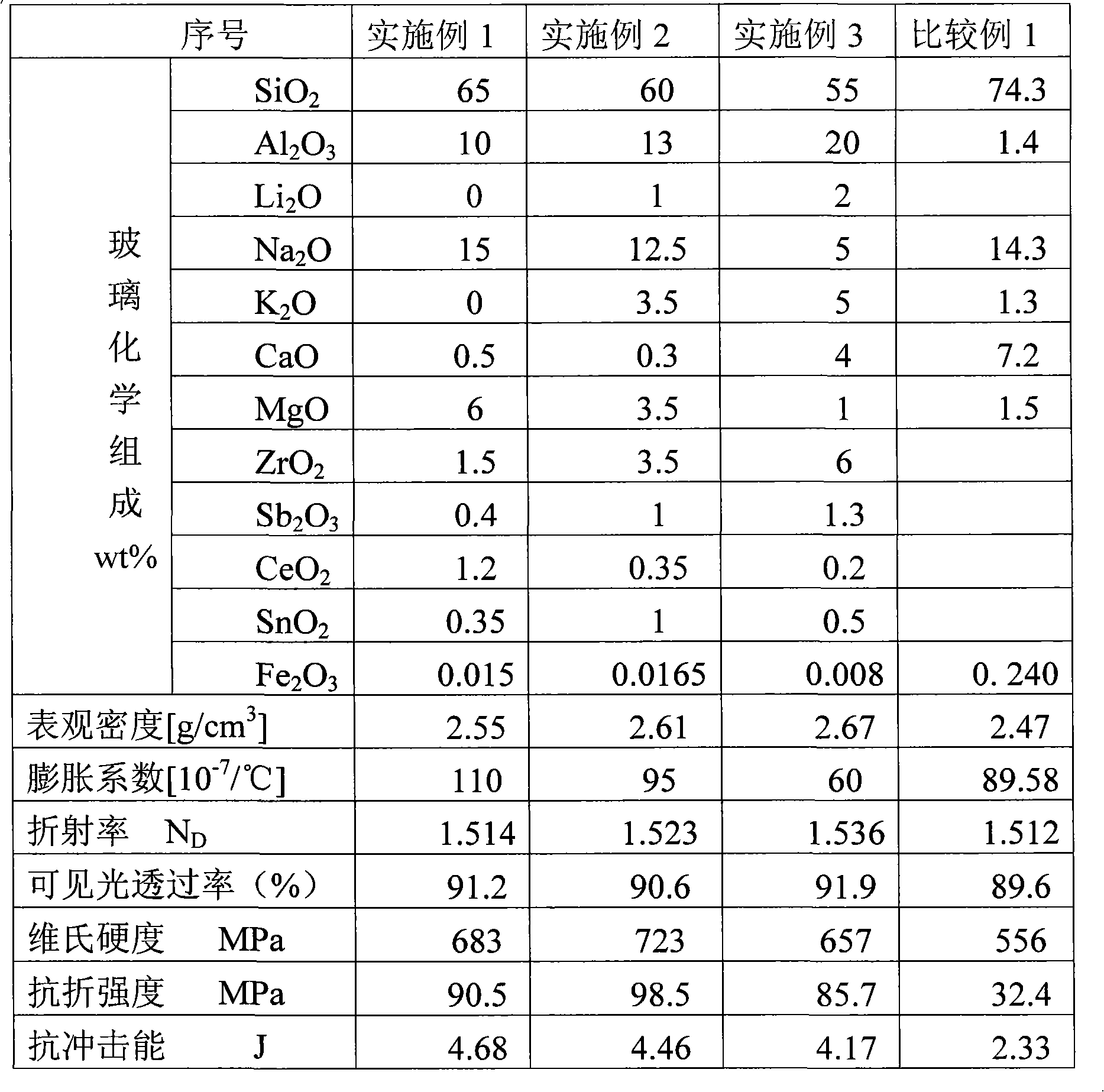

Zirconia aluminosilicate glass

InactiveCN101575167AAvoid damageGood mechanical propertiesChemical compositionLiquid-crystal display

The invention discloses zirconia aluminosilicate glass which is a high-alkali high-alumina glass composition system containing zirconia, is suitable to the manufacture of glass products with high surface hardness and good scratch-resistant property, and has the advantages of being capable of chemical strengthening treatment. The chemical composition (wt percent) of the glass is as follows: 55 to 65 of SiO2, 10 to 20 of Al2O3, 0 to 2 of Li2O, 5 to 15 of Na2O, 0 to 5 of K2O, 1 to 6 of MgO, 0.5 to 4 CaO, 1.5 to 6.0 of ZrO2, 0.35 to 1.0 of SnO2, 0.2 to 1.2 of CeO2 and 0.4 to 1.3 of Sb2O3. The glass material is suitable to screen protecting materials of flat panel display products (such as liquid crystal displays, liquid crystal display-televisions, media machines, touch screens, automated teller machines, cell phones, and personal digital assistants), and can effectively prevent the surface impact and scratch damage of the flat panel display products.

Owner:WUHAN UNIV OF TECH

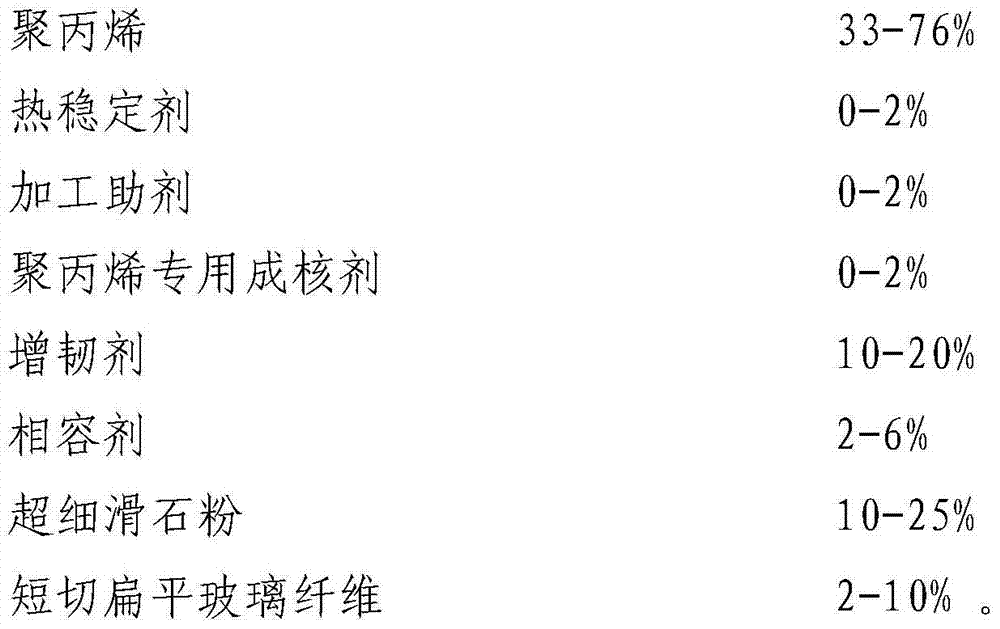

Polypropylene composite material for automobile hard plastic instrument panel and preparation method for polypropylene composite material

InactiveCN103756130AHigh surface hardnessImprove scratch resistanceGlass fiberPolypropylene composites

The invention belongs to the technical field of high polymer materials, and in particular relates to a polypropylene composite material for an automobile hard plastic instrument panel and a preparation method for the polypropylene composite material. The polypropylene composite material is prepared from the following raw materials in percentage by weight: 33 to 76 percent of polypropylene, 0 to 2 percent of heat stabilizer, 0 to 2 percent of processing aid, 0 to 2 percent of nucleating agent special for polypropylene, 10 to 20 percent of plasticizer, 2 to 6 percent of compatibilizer, 10 to 25 percent of superfine talc powder and 2 to 10 percent of chopped flat fiberglass. When the polypropylene composite material for the automobile hard plastic instrument panel is prepared, the chopped flat fiberglass is added, so that the surface hardness of the polypropylene composite material is increased, good scratch resistant effects are achieved without adding any scratch resistant agent, and a matte effect is also achieved; the polypropylene composite material also has the characteristics of high flowability, high rigidity, high heat resistance, high dimensional stability, high impact resistance, low glossiness and scratch resistance, and requirements on a material for the automobile hard plastic instrument panel are completely met.

Owner:SHANGHAI KINGFA SCI & TECH

Method and device for manufacturing efficient and high-precision composite additive

ActiveCN104190931AShorten forming timeImprove forming efficiencyIncreasing energy efficiencyLight beamMetal powder

The invention discloses a method and device for manufacturing efficient and high-precision composite additive, and the method and device are achieved through composition of a laser beam and an electron beam. In the process of the action of a high energy beam and metal powder, metal powder of a surface outline is scanned and molten through the laser beam, and the surface of a part has a good surface quality. The electron beam melts the internal powder at a high speed to form a part inner cavity so as to reach the highest forming efficiency. The lower portion of the device comprises a powder laying roller, a workbench, a powder conveying cylinder and a working cylinder. The upper portion of the device comprises an electron beam generating device, a laser beam generating device, a bottom plate, two guide rails, two beams, a synchronous belt wheel and a servo motor. The electron beam generating device and the laser beam generating device are respectively integral and move to the forming area alternately to carry out scanning. By means of the method and device, the defects in the single forming technology can be overcome, and the purposes of reasonably controlling the formed microstructural organization and optimizing the comprehensive performance are achieved.

Owner:HUAZHONG UNIV OF SCI & TECH

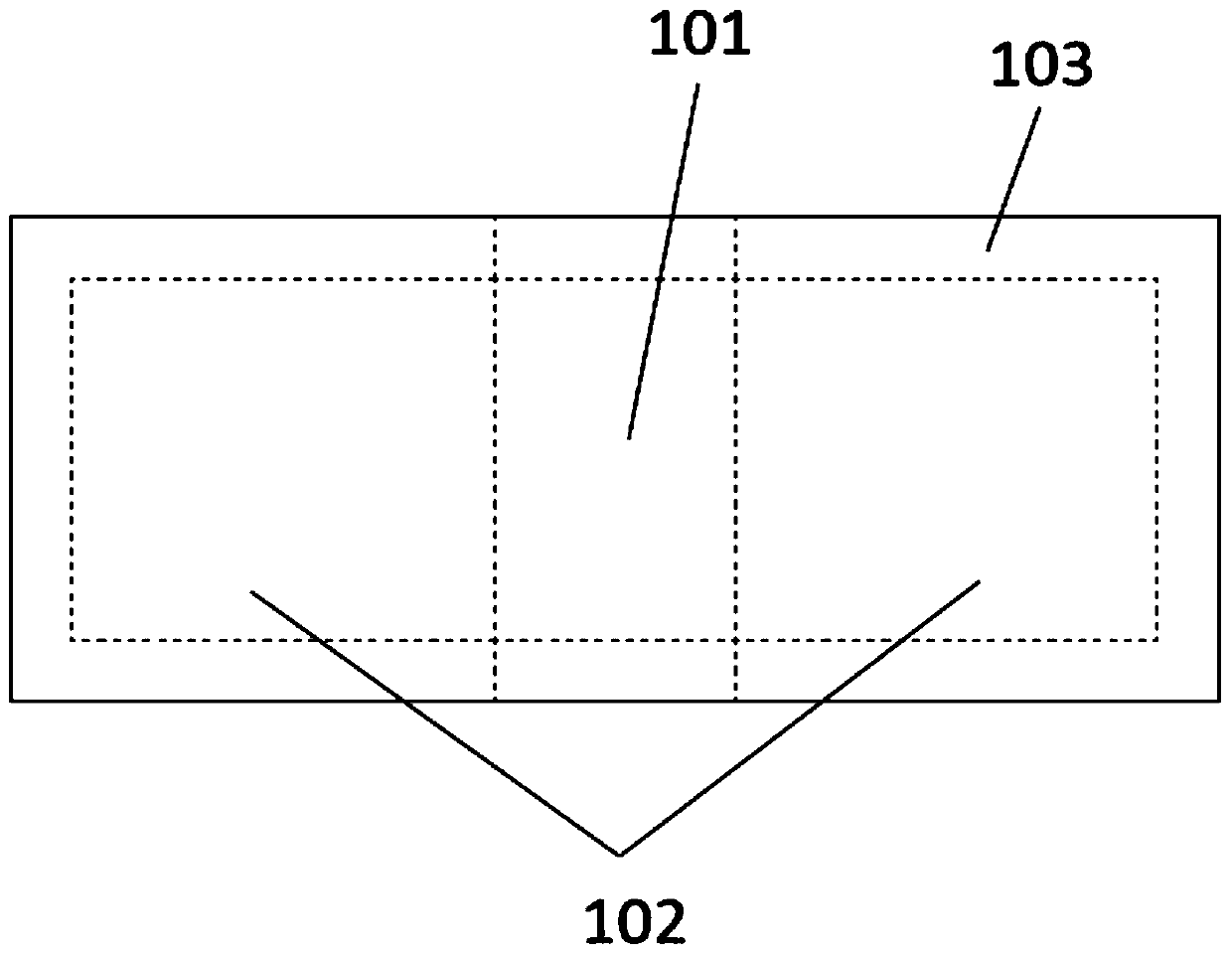

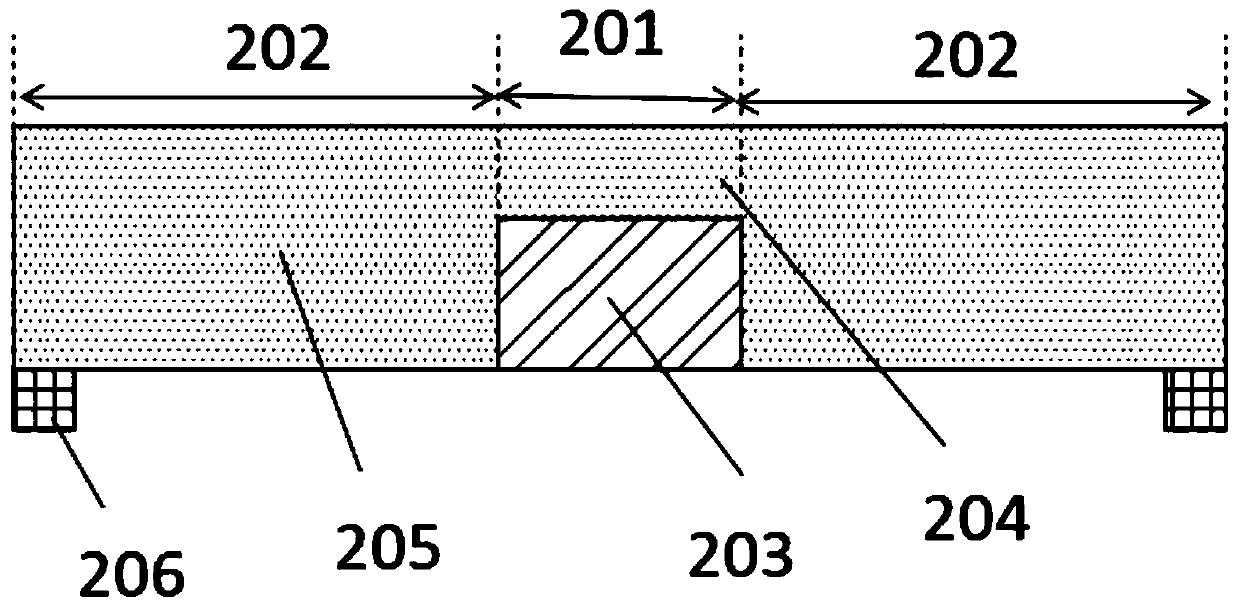

Cover plate of bendable display panel, bendable display panel and display device

The invention provides a cover plate of a bendable display panel. The cover plate comprises a glass substrate, the surface of the glass substrate is formed with a recessed area, and the recessed areathins the glass substrate to a bendable thickness; the recessed area is filled with a flexible material to form a bendable area of the cover plate in cooperation with a glass layer of the recessed area; the cover plate has the advantages of using glass in a non-bending area and using a stricture of ultra-thin glass filled with a flexible material in the bendable area to achieve the technical effects of reducing the cost of the bendable cover plate, increasing the surface hardness and enhancing the user's hand feeling.

Owner:WUHAN CHINA STAR OPTOELECTRONICS SEMICON DISPLAY TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com