Low-temperature assisted ultrasonic surface rolling intensifying device and processing method

A technology of ultrasonic rolling and surface strengthening, which is applied in the field of surface rolling strengthening devices, low temperature assisted ultrasonic surface rolling strengthening devices and processing fields, can solve the problems of limited surface properties of materials, and achieve high hardness, good wear resistance and resistance Fatigue properties, effects of large plastic deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0039] Taking the cast Ti-6Al-4V alloy rod as the processing object, the surface properties of the material were strengthened by using a low-temperature assisted ultrasonic surface rolling device.

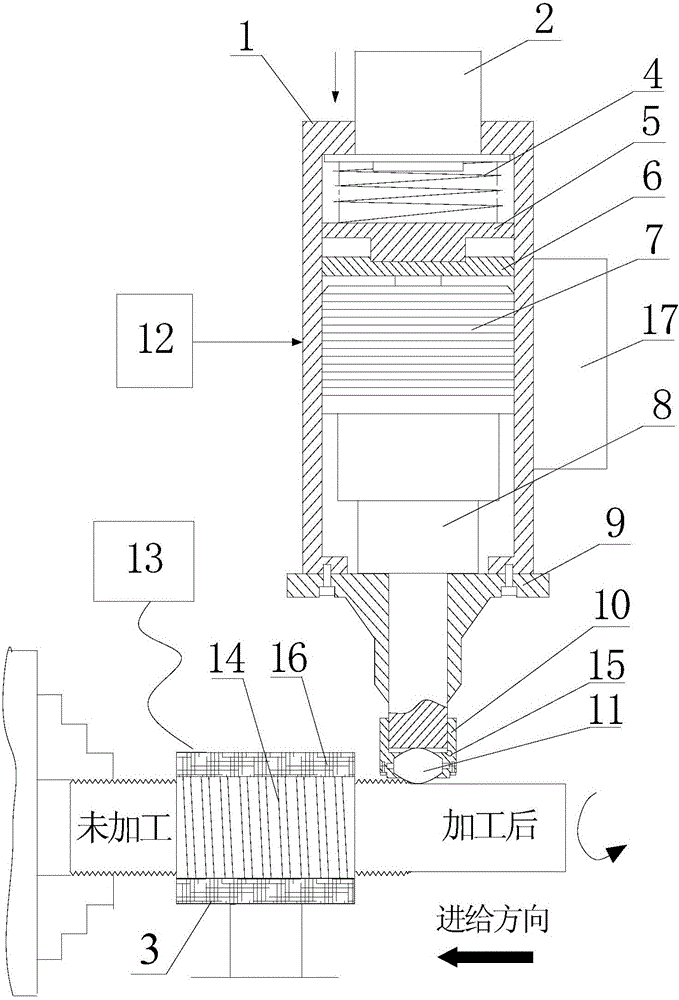

[0040] After Ti-6Al-4V rods are subjected to low-temperature assisted ultrasonic surface rolling treatment, a thicker surface modification layer can be obtained, and the mechanical properties have been greatly improved. The specific parameters are as follows: the workpiece length is 150mm, the radius is 50mm, the spindle speed is 56rpm, the axial feed rate is 0.05mm / rev, the heating temperature is 100°C, the holding time is half an hour, and the lubricating medium is high temperature resistant lubricating oil , the load of ultrasonic rolling is 600N, the direction of rolling is unidirectional, and the same section of material is rolled twice. The whole operation process is realized on the horizontal machine tool.

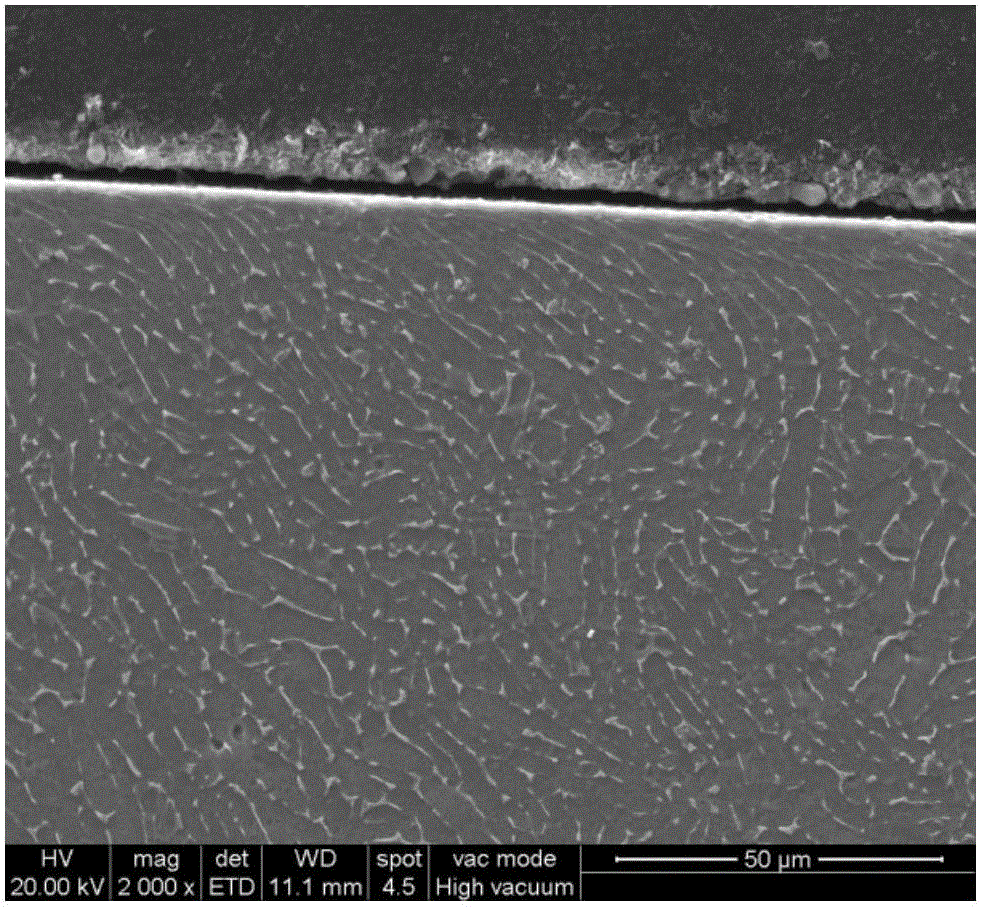

[0041] image 3 is a scanning electron image of a cross-section of ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com