Patents

Literature

69results about How to "Large plastic deformation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heart valve repair

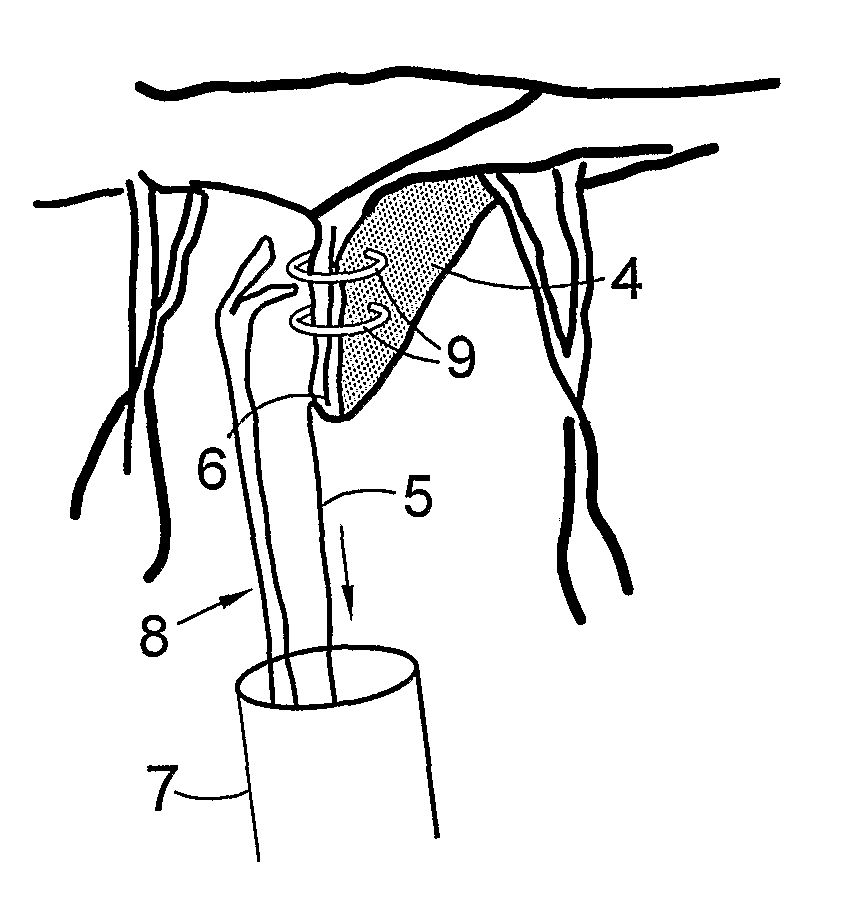

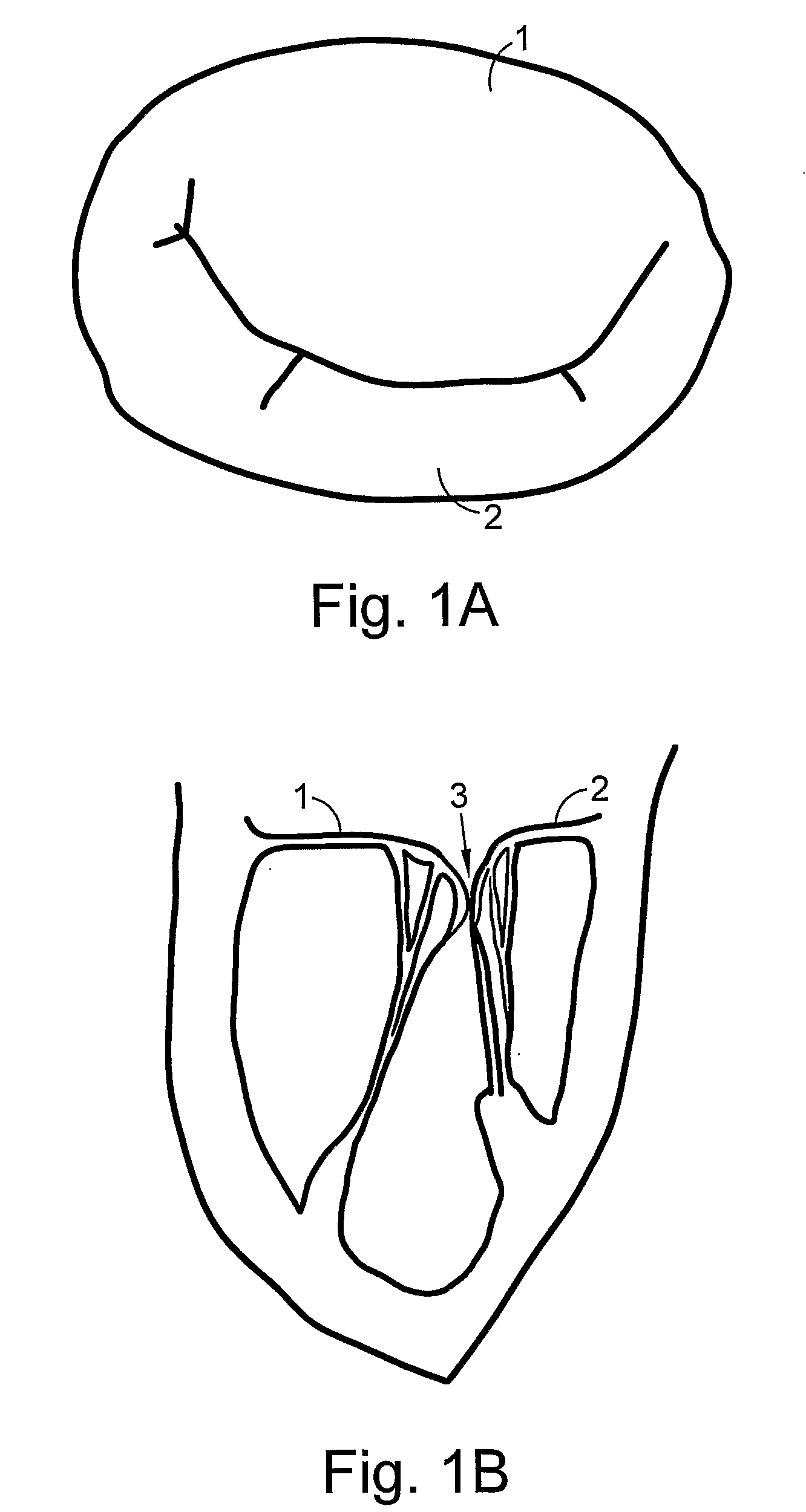

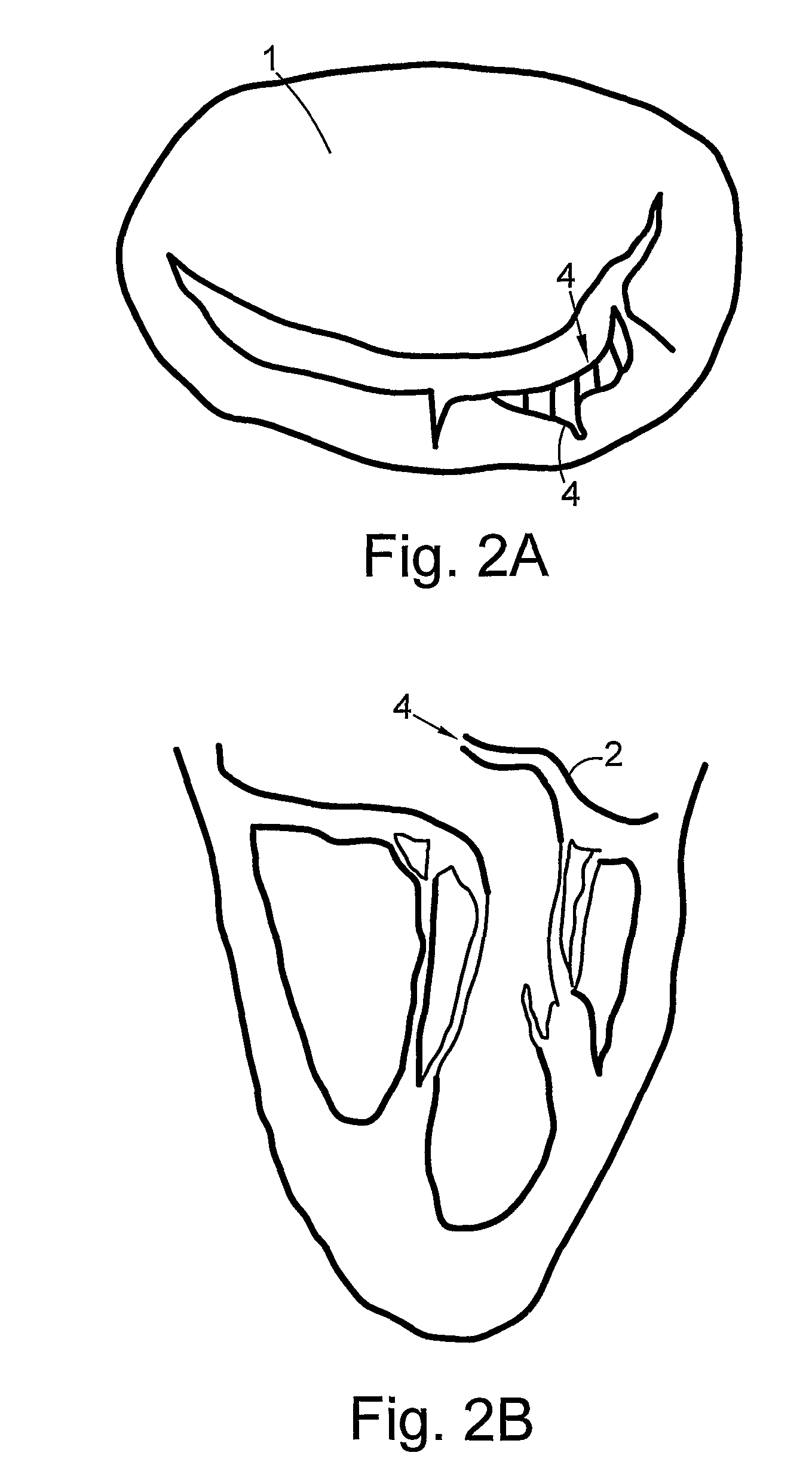

InactiveUS20090118744A1Preventing the leaflet from prolapsingGrasping a single prolapsed leaflet is facilitatedDiagnosticsSurgical staplesHeart valve repairCatheter device

The invention relates to a system for repairing a heart valve comprising a catheter, said catheter comprising an engagement member, the engagement member having at its distal end a hook capable of engaging with the surface of a prolapsed heart valve leaflet; and a fastener capable of deploying a fastening means to said leaflet.

Owner:ST JUDE MEDICAL CARDILOGY DIV INC

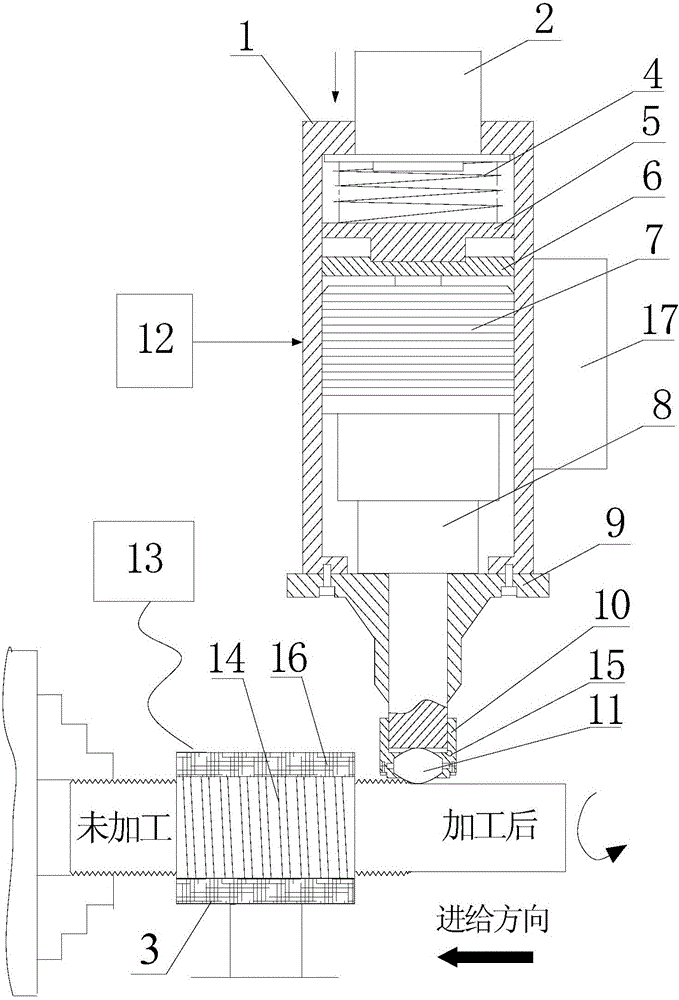

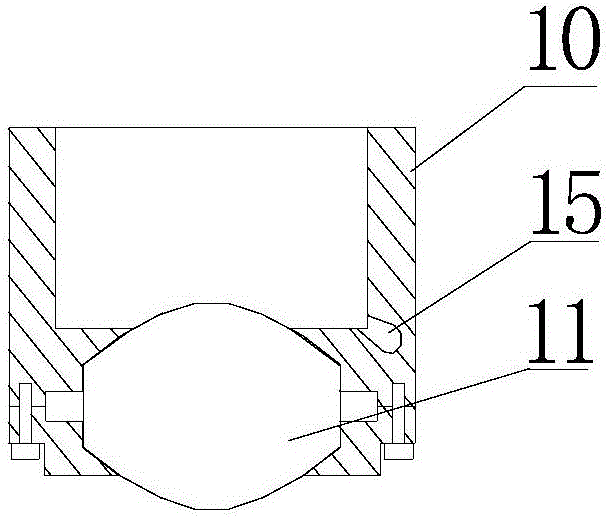

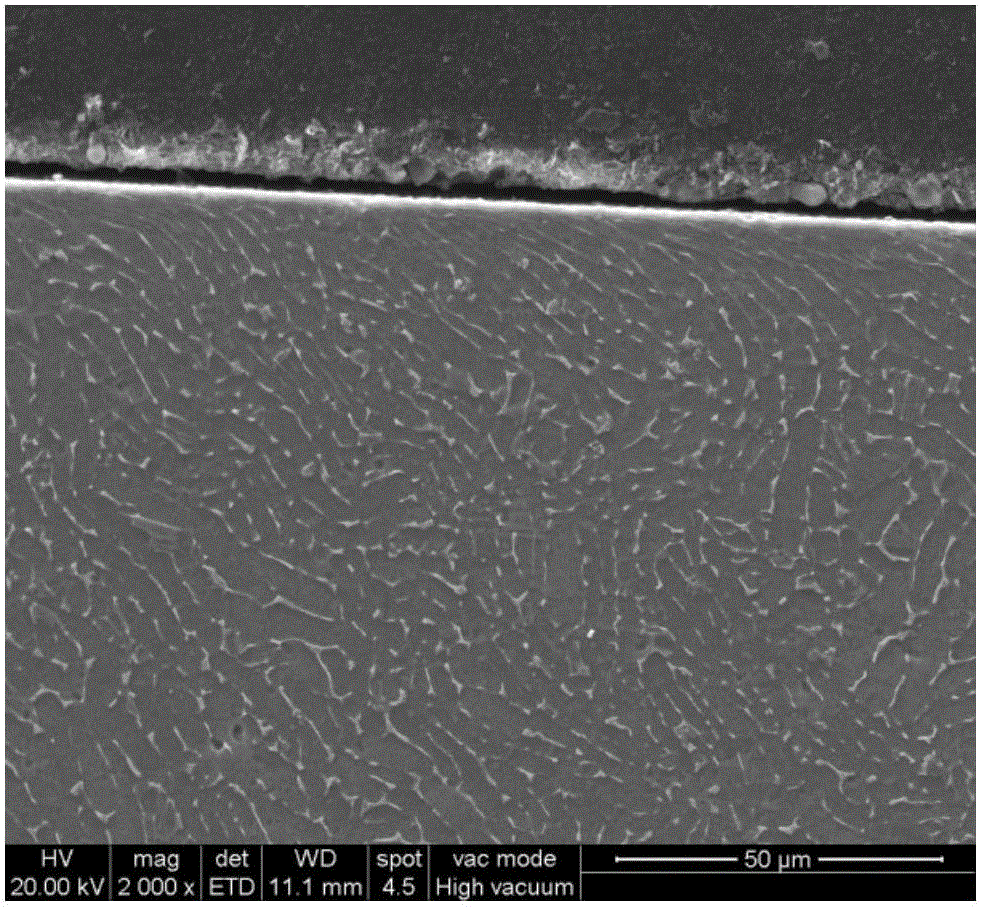

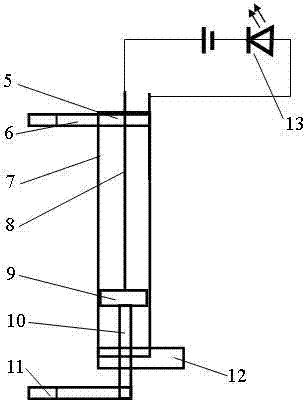

Low-temperature assisted ultrasonic surface rolling intensifying device and processing method

The invention discloses a low-temperature assisted ultrasonic surface rolling intensifying device and a processing method. The device consists of a surface rolling member, a loading member and a heating member, wherein a clamping handle is arranged on the surface rolling member; the loading member is arranged at the tail end of the surface rolling member; a spring, a pressure sensor, a baffle, a transducer and an amplitude-change pole are sequentially arranged on the end face of the loading member; the amplitude-change pole is provided with a rolling head of which the front end is provided with a roller through a guide sleeve; the outer side of the surface rolling member is connected with an ultrasonic generator; and the heating member is provided with a temperature controller and heating wires connected and controlled by the temperature controller According to the processing method disclosed by the invention, an ultrasonic rolling technology and low-temperature heating treatment are combined; on the basis of softening materials by using low temperature heating, an ultrasonic frequency electrical signal is converted into ultrasonic mechanical vibration by using the transducer; and after the ultrasonic mechanical vibration is amplified by the amplitude-change pole, vibration with a certain amplitude is outputted and transmitted to the rolling head, and high-speed vibration between the rolling head and workpieces in the rolling process is realized, thereby better refining material grains on the surface layers of the workpieces, and generating greater residual compressive stress and high surface hardness.

Owner:SOUTH CHINA UNIV OF TECH

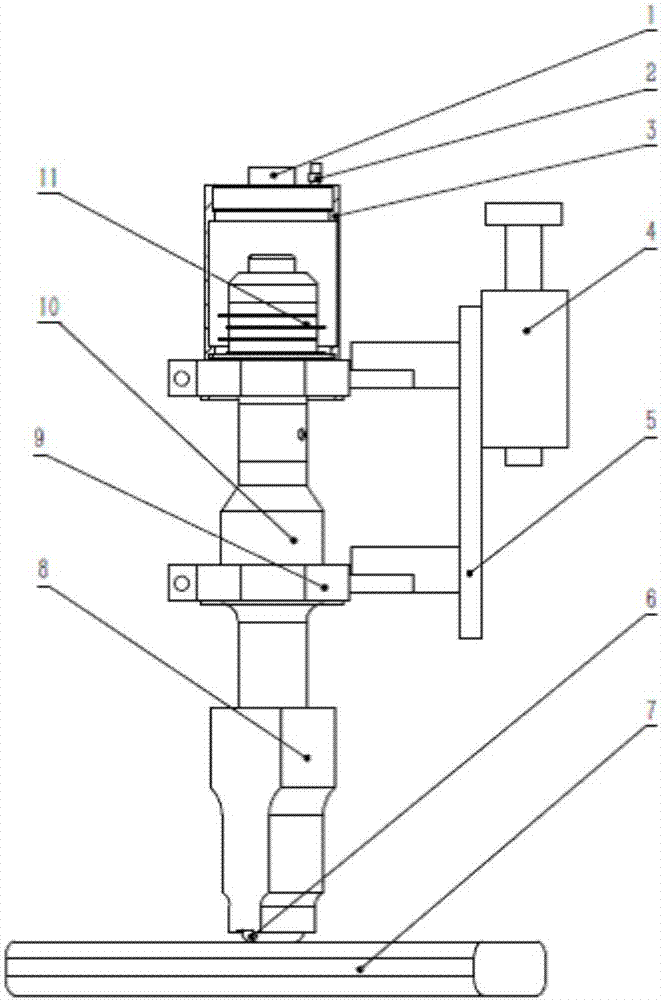

Ultrasonic and micro-forging composite device for improving microstructure and performance of additively manufactured metal and additive manufacturing method

ActiveCN107470628AImprove efficiencyHigh speedAdditive manufacturing apparatusIncreasing energy efficiencyComposite effectManufacturing technology

The invention provides an ultrasonic and micro-forging composite device for improving the microstructure and performance of additively manufactured metal and an additive manufacturing method. The ultrasonic and micro-forging composite device comprises an energy converter, a pneumatic slider, a pneumatic slider connection frame, an amplitude transformer, a tool head and a roller. The energy converter is arranged in an energy converter shell, the energy converter shell is provided with an inserting piece and a pipeline connector, the amplitude transformer is connected to the lower end of the energy converter, the tool head is connected below the energy converter, the roller is located between the tool head and a workpiece, and the pneumatic slider is connected with the energy converter shell and the amplitude transformer through the pneumatic slider connection frame. By means of the ultrasonic and micro-forging composite device, the advantages that ultrasonic impact frequency is high and deformation generated by mechanical rolling is large are combined, the composite effect of ultrasonic impact and continuous rolling micro-forging can be achieved, and the purpose of improving the microstructure of the additively manufactured metal and the mechanical performance of parts is achieved. Through organic combination of the ultrasonic and micro-forging composite device and the additive manufacturing method with an existing additive manufacturing technology, the technical bottleneck that structure control is easy while performance control is difficult in existing metal additive manufacturing is solved, and innovation and development of metal rapid forming and manufacturing technologies are induced.

Owner:HARBIN ENG UNIV +1

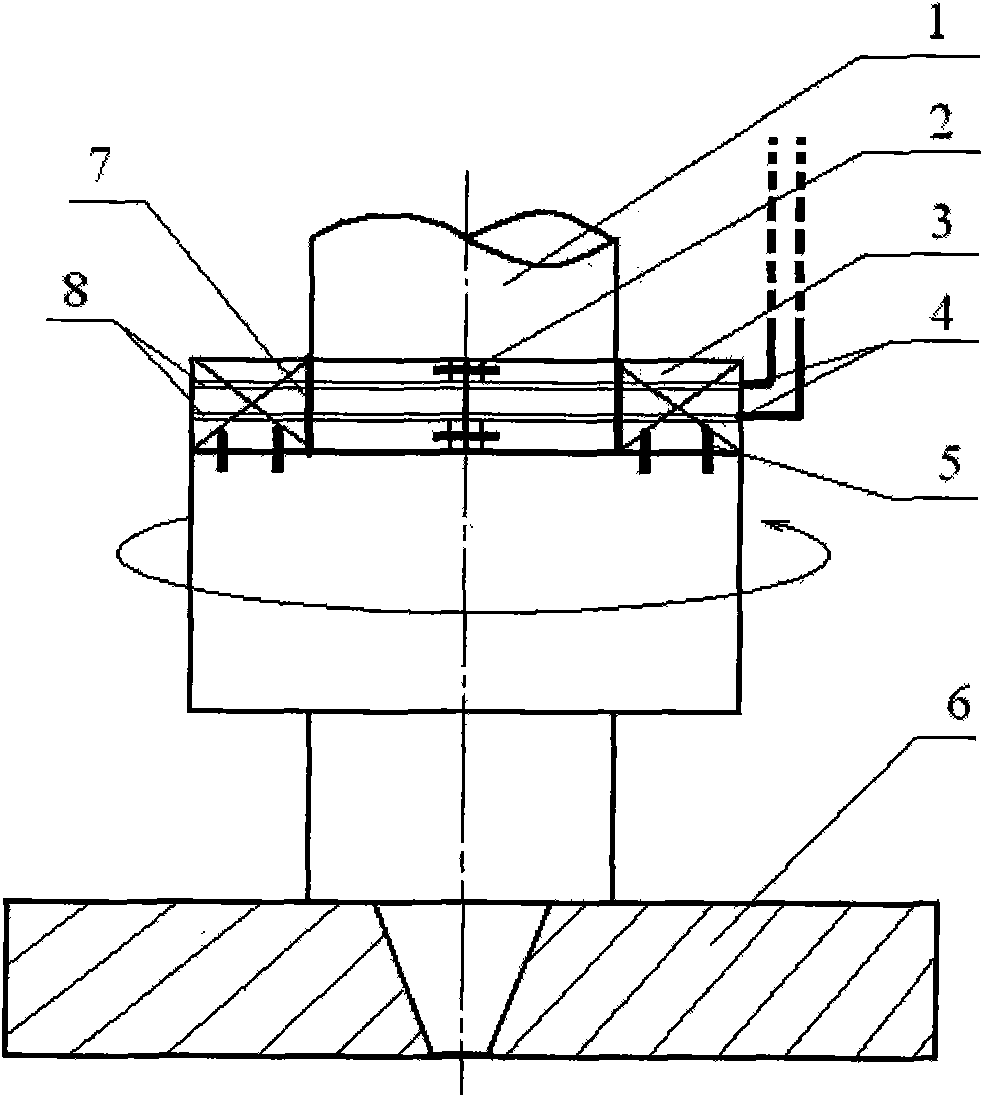

Electromagnetic vibrating, stirring and friction-welding stirring-head and welding method thereof

InactiveCN101574756ALarge plastic deformationChanging the plastic flow modeNon-electric welding apparatusFriction weldingEngineering

The invention discloses an electromagnetic vibrating, stirring and friction-welding stirring-head and a corresponding welding method thereof. An electromagnetic vibrating device is adopted to assist electromagnetic vibration during the process of stirring, and friction-welding to lead the stirring-head to vibrate at high frequency simultaneously when the stirring-head rotates at a high speed to transfer energy to the metals in a stirring and friction area so as to lead the metals to achieve plastic state more quickly; the thermoplastic metals receive the composite effects of a friction force and the high-frequency vibrating energy during the rotating process of a stirring needle, thus being capable of effectively improving the velocity of the thermoplastic metal flow, improving the forming efficiency and quality of welding seams and being more effectively used for the welding and processing of high-melting point materials and thick boards.

Owner:CHONGQING UNIV

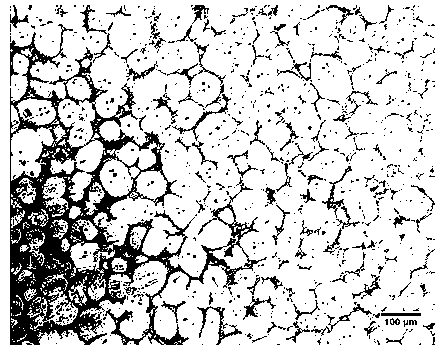

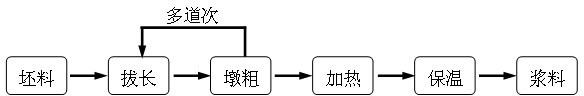

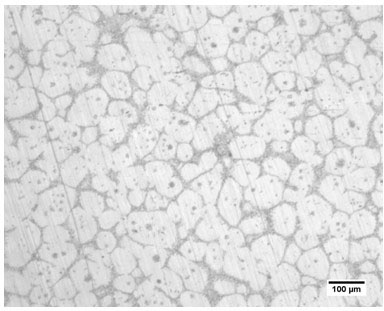

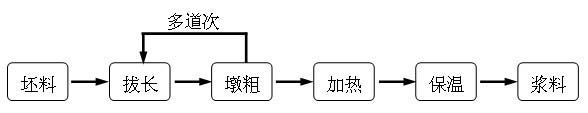

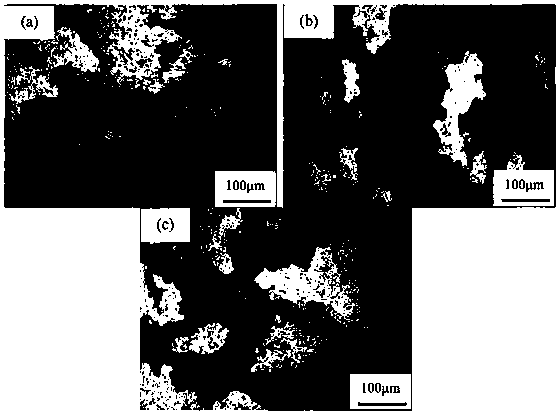

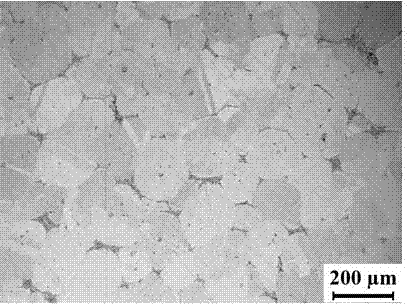

Method for preparing semisolid blank

The invention relates to a method for preparing a semisolid blank, utilizes an improved SIMA (strain induced melt activation) method to prepare the semisolid blank, and belongs to the technical field of metal semisolid blank. The method comprises the following steps of: firstly, measuring a liquid solid phase line point of the semisolid alloy to be prepared, then, heating an alloy blank so as to carry out asynchronization multitrack rolling or pillar squeezing transformation, finally, remelting, and carrying out heat preservation for a long time so as to obtain the required semisolid blank. The asynchronization rolling or pillar squeezing transformation is capable of generating large deformation amount, group bough crystal formed in the blank is destroyed, the asynchronization rolling is utilized to replace pre-deformation processes such as the existing upset, compression, equal diameter angle compression, and the semisolid blank is prepared and has the advantages of uniform formation, high nodularity, and accurate control solid phase rate.

Owner:KUNMING UNIV OF SCI & TECH

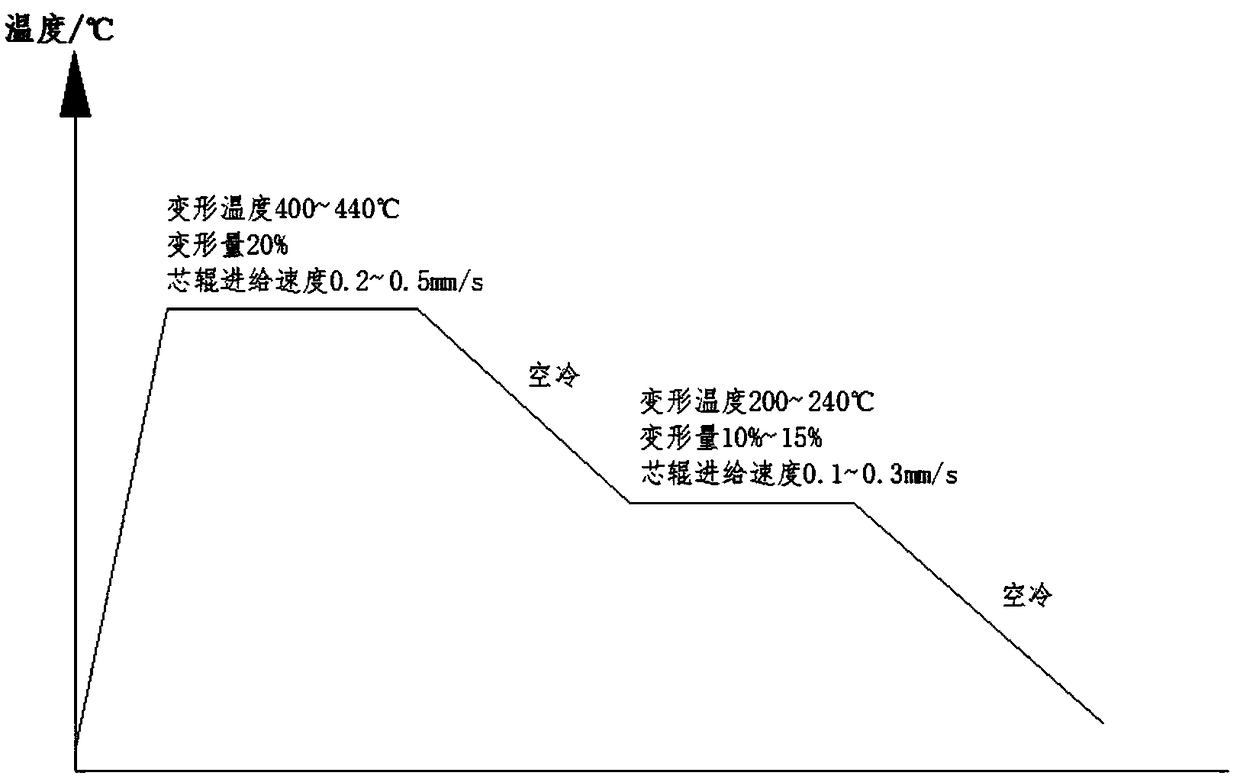

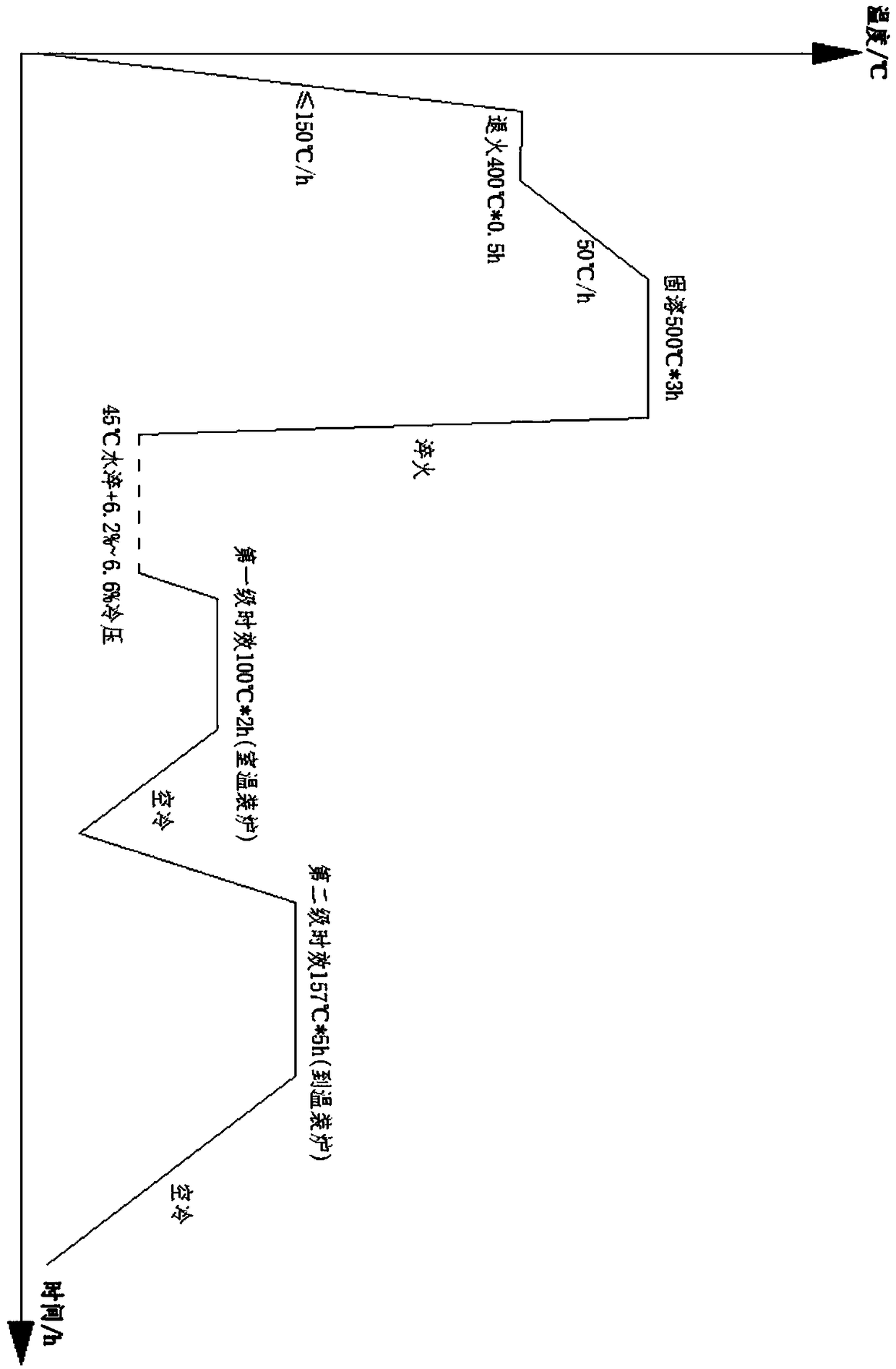

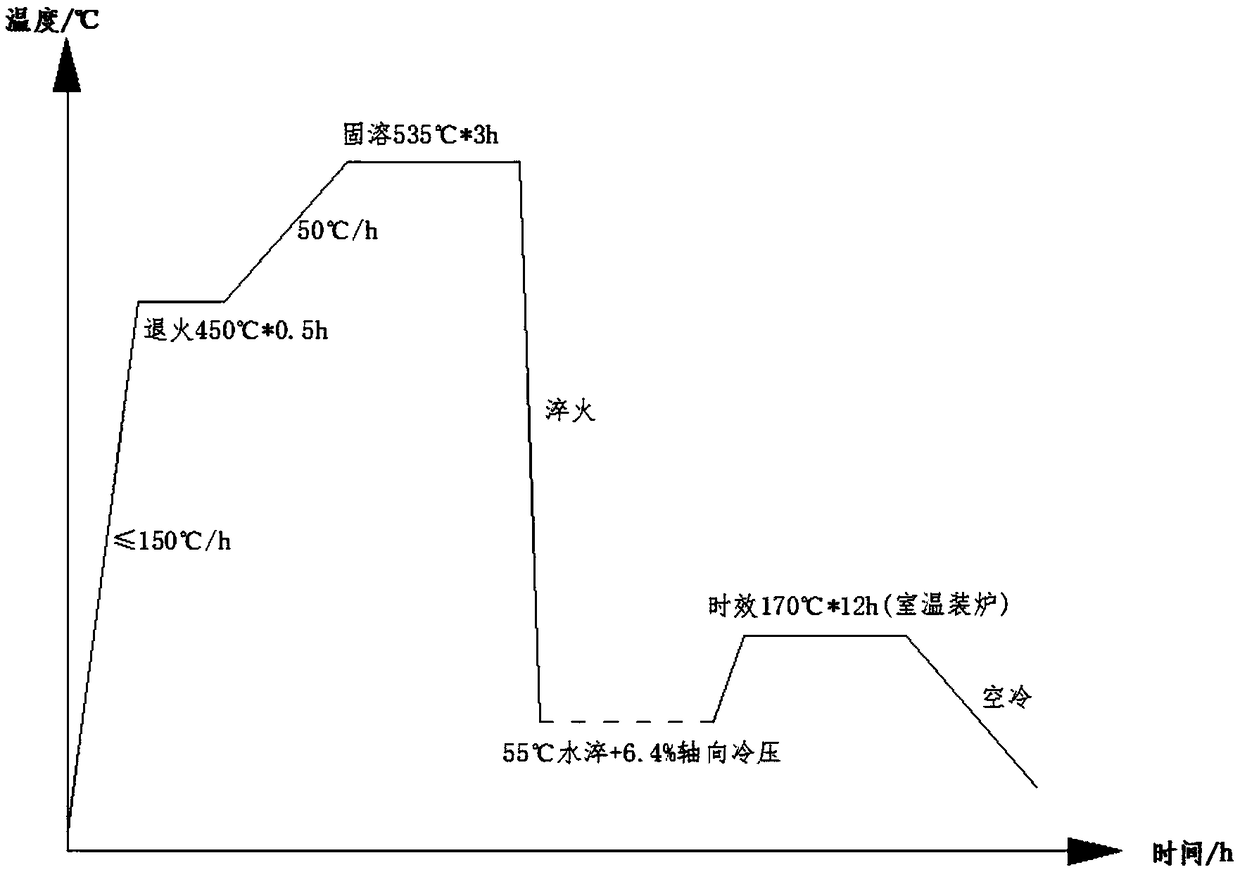

Manufacturing process for high-strength corrosion-resistant aluminum alloy forged piece

ActiveCN108746447AImprove mechanical propertiesImprove corrosion resistanceMetal rollingMaterials preparationRoom temperature

The invention discloses a manufacturing process for a high-strength corrosion-resistant aluminum alloy forged piece. The process comprises the following steps of material preparation, heating, multi-axial forging, mechanical machining, heating, trestle bearizing, heating, ring rolling, mechanical machining, annealing, solid-solution water-quenching, cold pressing deformation, aging and the like. The aging treatment method comprises the steps of first-grade aging, specifically, a ring forged piece subjected to cold pressing is put into a furnace at the room temperature and heated to 90-110 DEGC, heat preservation is performed for 1-3 hours, and air cooling is performed; second-grade aging, specifically, the ring forged piece is put into the furnace when the temperature is reached, heat preservation is performed for 4-8 hours at the temperature of 150-160 DEG C, and air cooling is performed after aging is ended.

Owner:JIANGSU UNIV OF TECH

Method for preparing semi-solid slurry by strain induced melt activation (SIMA) method

InactiveCN102560161ALarge plastic deformationReserve Plastic Deformation EnergySlurryCrystallization temperature

The invention relates to the field of the preparation of semi-solid slurry, in particular to a method for preparing semi-solid slurry by a new strain induced melt activation (SIMA) method. By the method, the problem of quality defects during the preparation of the semi-solid slurry in the prior art is solved. The method comprises the following steps of: heating an alloy to above the recrystallization temperature according to liquidus and solidus points of a semi-solid slurry alloy to be prepared; drawing out and upsetting the alloy for multiple times by utilizing a cogging forging process; and heating the alloy to a semi-solid temperature interval to prepare the semi-solid slurry with a certain solid-phase rate. By the method, the semi-solid slurry of multiple alloys can be prepared, so the method has the advantages of simplicity of operation, convenience for control, high nodulizing rate, accurate control of the solid-phase rate and the like.

Owner:KUNMING UNIV OF SCI & TECH

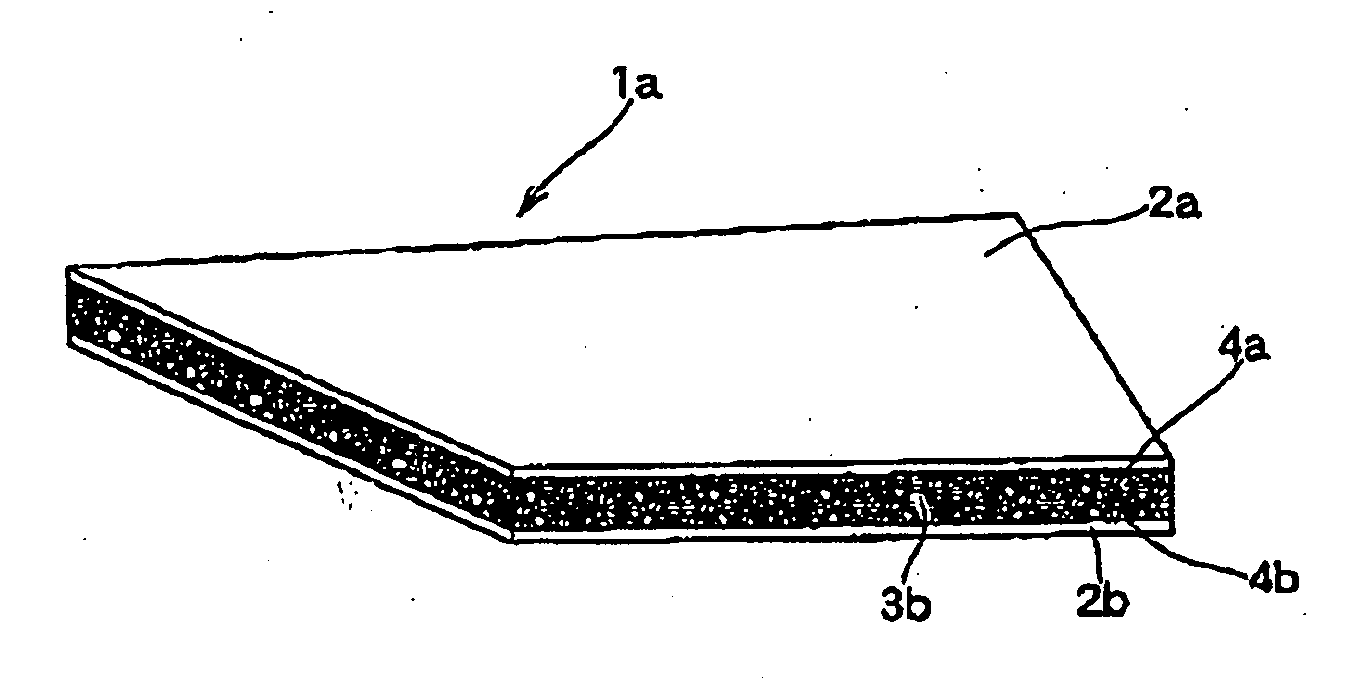

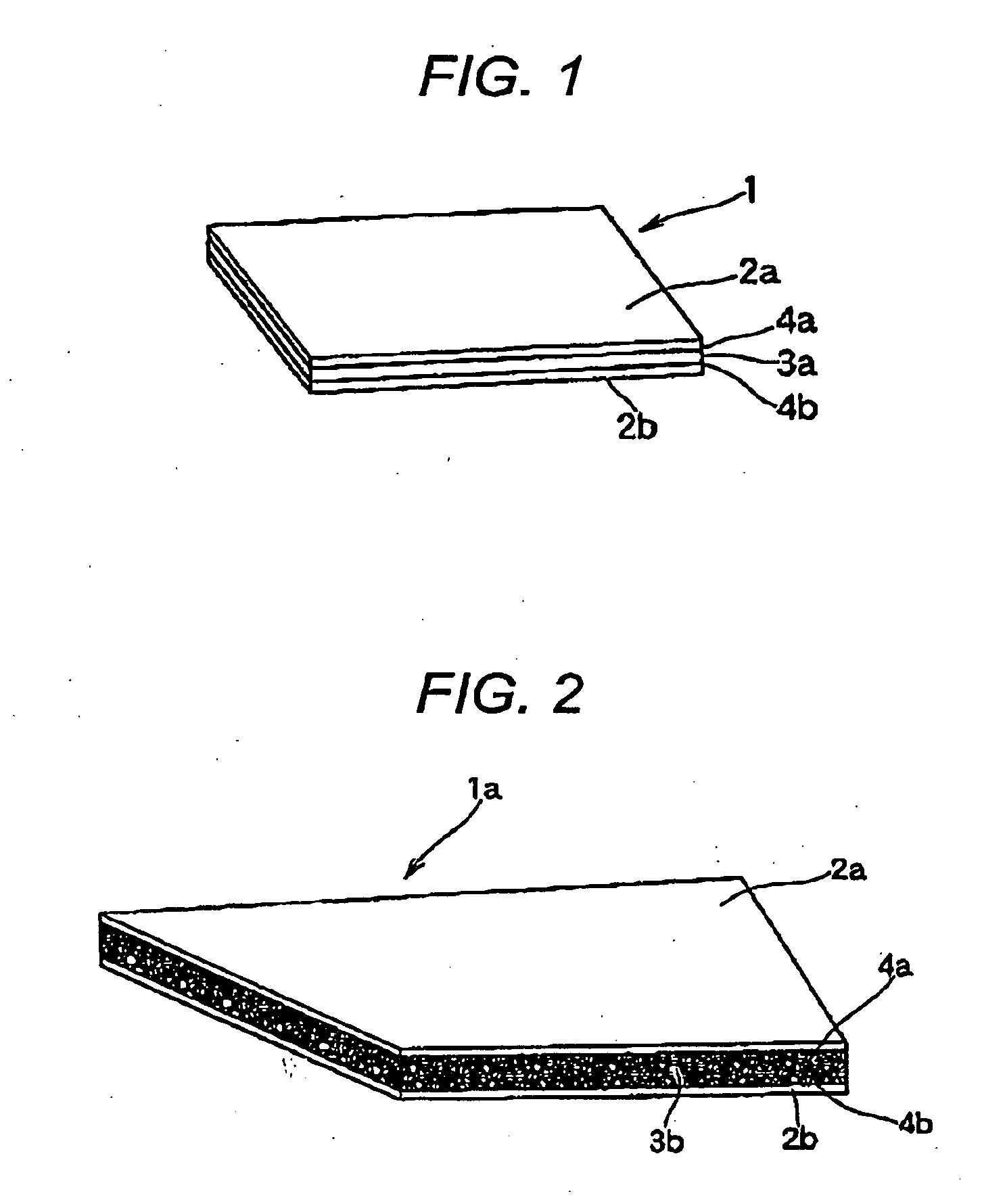

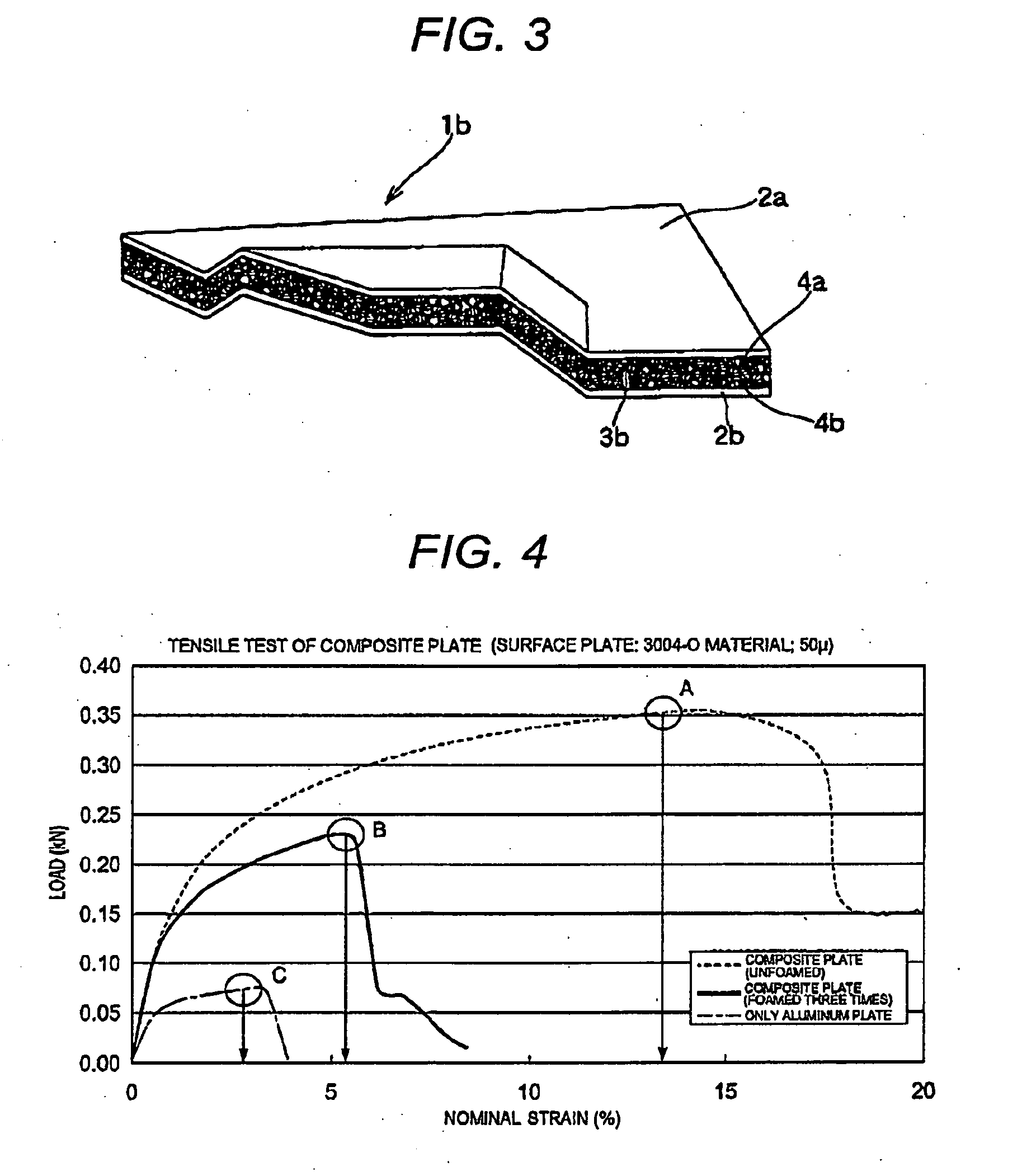

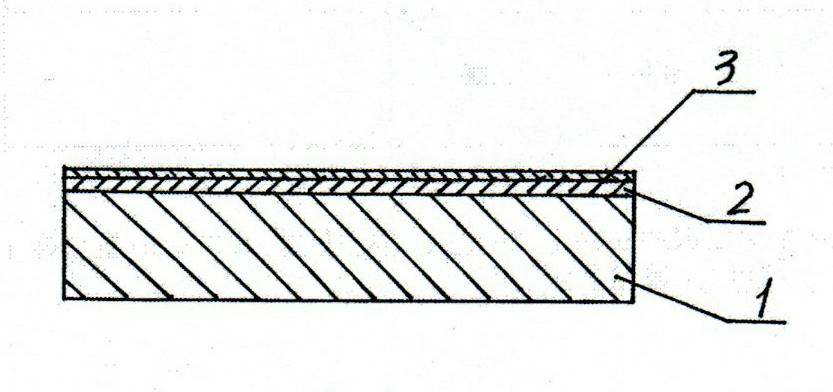

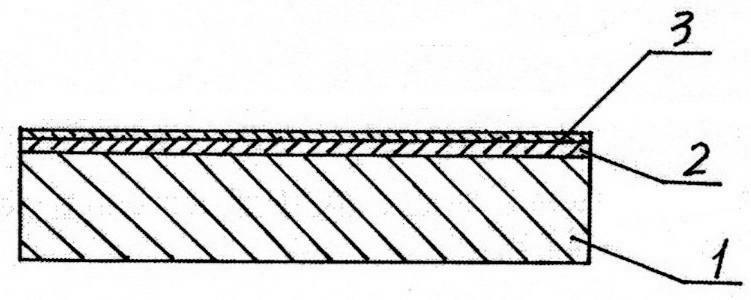

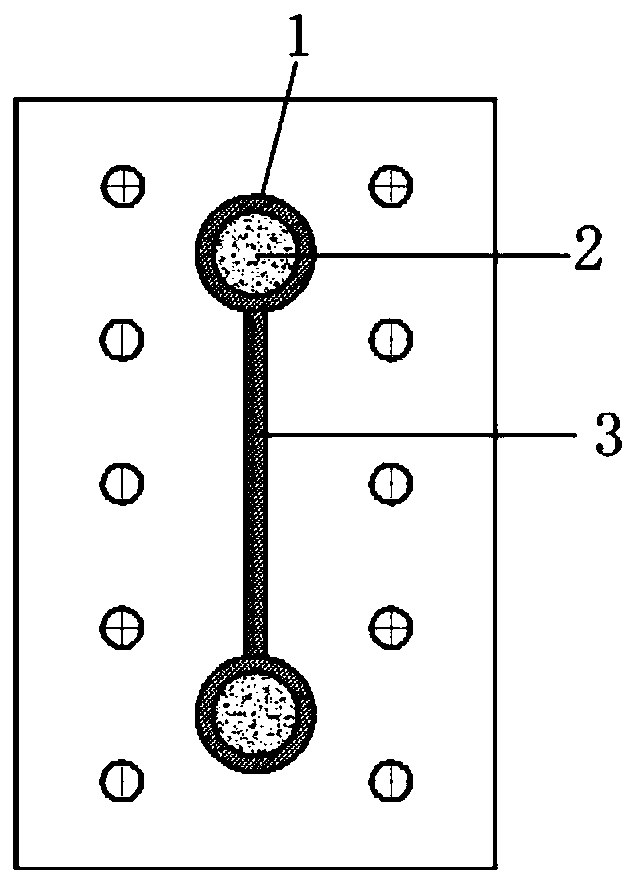

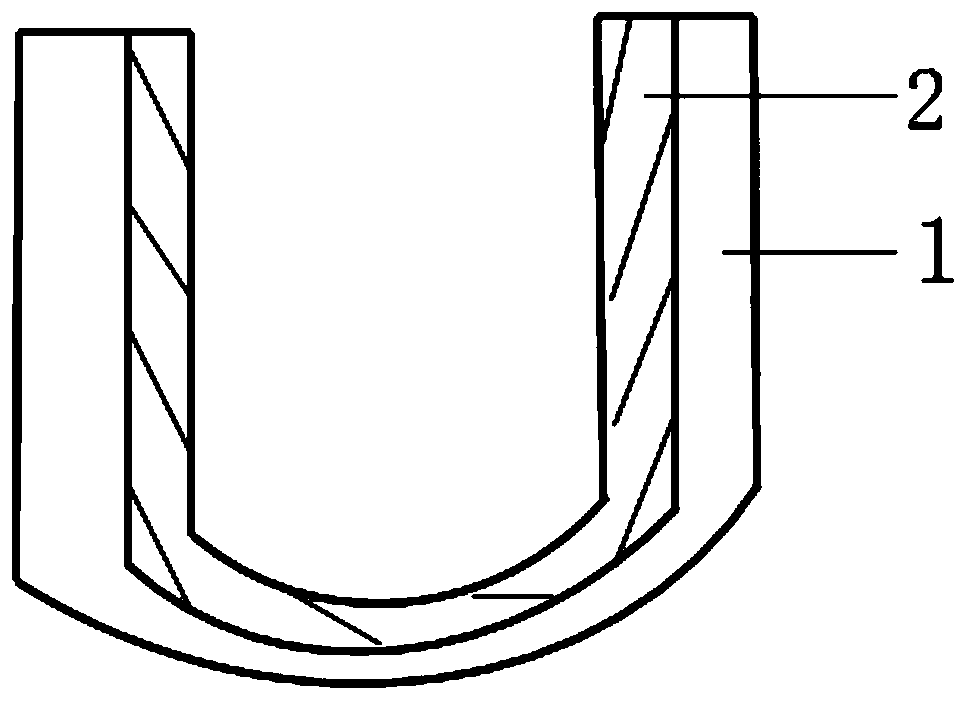

Laminated plate and composite formed body

ActiveUS20110159261A1Low elongationGood molding effectLamination ancillary operationsSynthetic resin layered productsPolypropyleneThin sheet

Provided in the present invention is a laminated plate in which a thin aluminum alloy plate having a remarkably lowered forming limit is laminated on each of the two sides of a core polypropylene based resin having foamable property which has inferior formability and shape stability, and which is able to be subjected to forming and is excellent in shape stability after this forming. A laminated plate 1 according to the present invention is one in which aluminum alloy plates 2a and 2b are laminated on each of the two sides of a core polypropylene based resin 3a having foamable property, and after forming, the core polypropylene based resin 3a having foamable property is foamed by heating, thereby forming a composite formed article. A plate thickness of this plated plate 1 is thin. Also, the aluminum alloy plates 2a and 2b and the core polypropylene based resin 3a having foamable property which constitute this laminated plate are each constituted so as to have a thin plate thickness. Furthermore, the aluminum alloy plates 2a and 2b are a temper treated material selected from an O material, an H22 material to an H24 material, an H32 material to an H34 material and a T4 material.

Owner:KOBE STEEL LTD

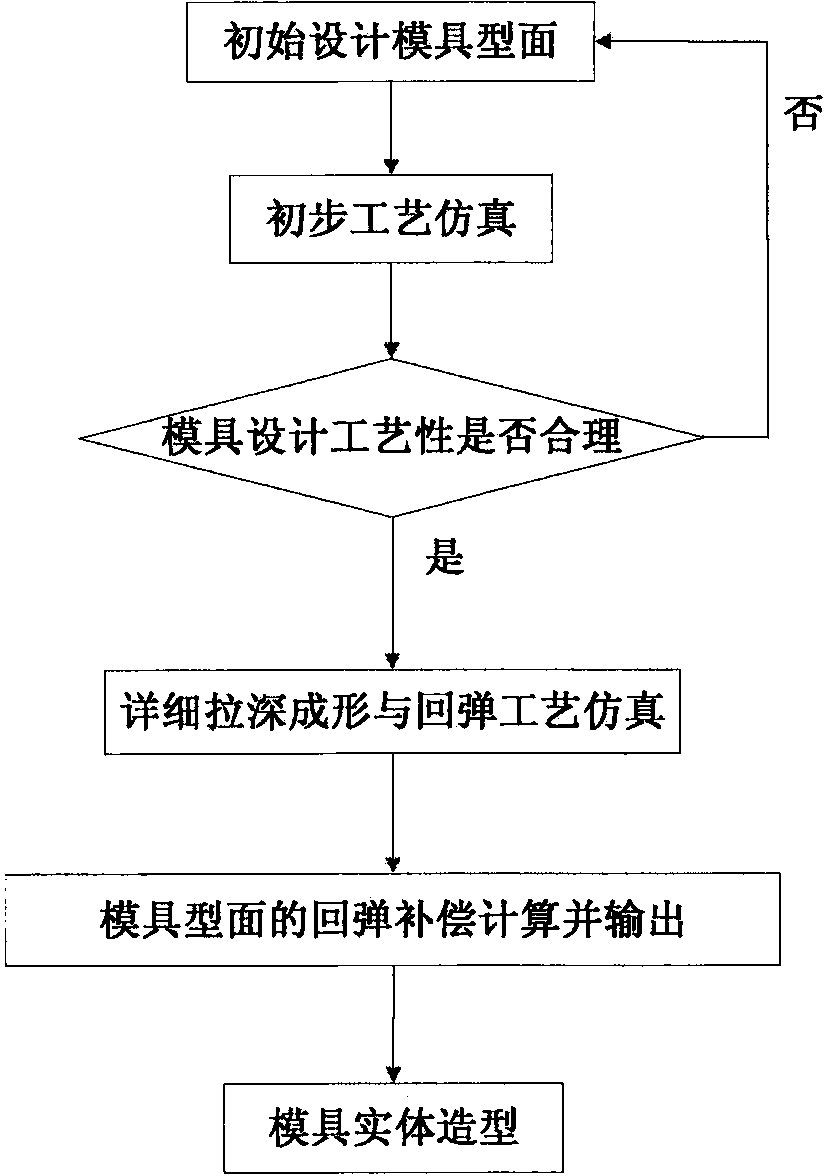

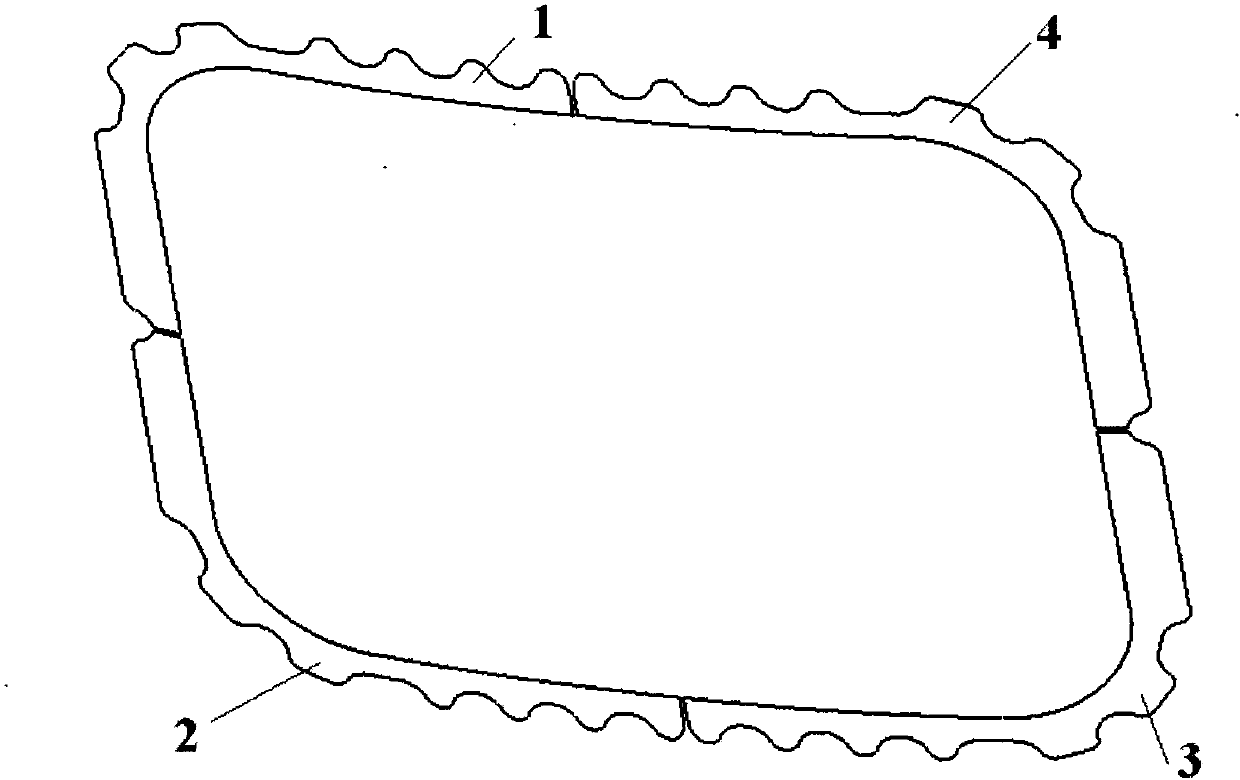

Method for designing forming dies for low-double-curvature sheet metal parts

ActiveCN104200037APrecise positioningLarge plastic deformationSpecial data processing applicationsDesign softwareEngineering

The invention relates to a method for designing forming dies for low-double-curvature sheet metal parts. The method includes steps of 1), initially designing four-piece integrated forming die profiles; 2), preliminarily simulating deep drawing forming technologies; 3), judging the rationality of die design technologies; 4), simulating deep drawing forming and spring-back technologies in detail; 5), computing and outputting spring-back compensation on the die profiles; 6), performing solid modeling on the dies in three-dimensional design software. The method has the advantages that all the four-piece double-curvature parts can be formed at one step by the aid of a deep drawing forming process, accordingly, the forming efficiency can be improved, the parts are low in spring-back rate, and the quality of the parts can be guaranteed.

Owner:SHENYANG AIRCRAFT CORP

Manufacturing technology of high-strength heat-resistant aluminum alloy forge piece

ActiveCN108890218AImprove mechanical propertiesImprove heat resistanceMetal rollingManufacturing technologyAlloy

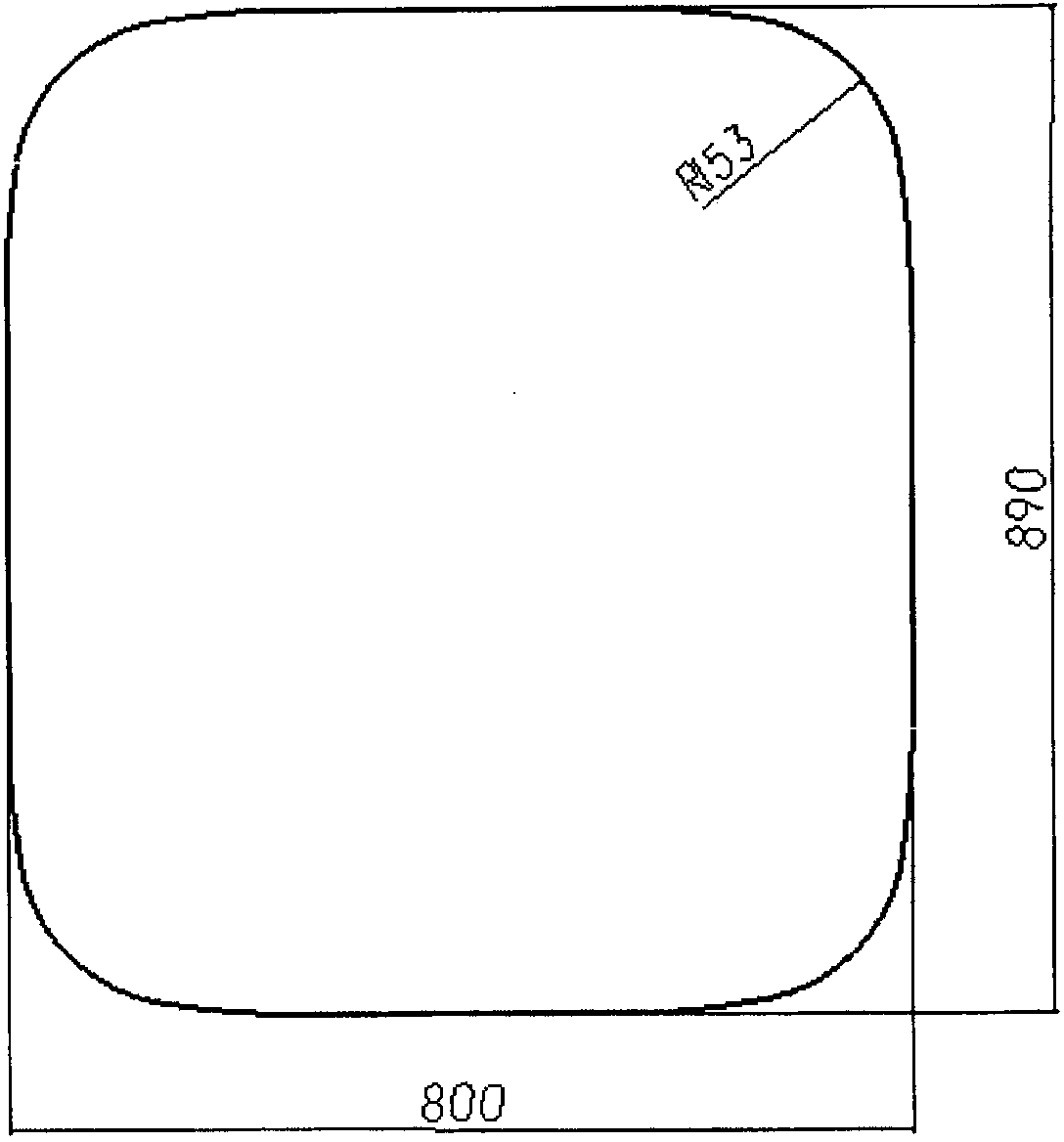

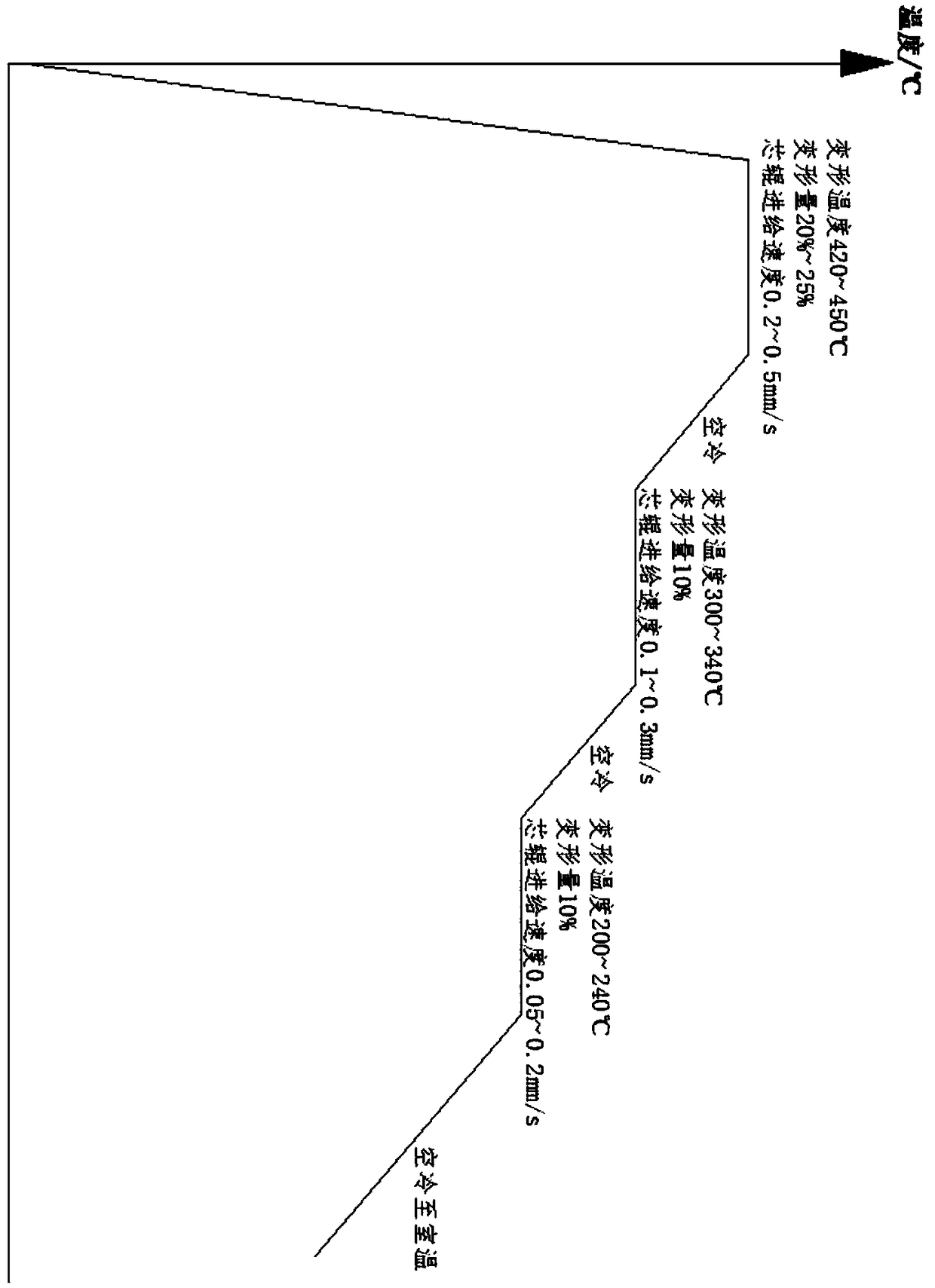

The invention discloses a manufacturing technology of a high-strength heat-resistant aluminum alloy forge piece. The manufacturing technology comprises the following steps of material preparation, heating, multi-axial forging, machining, heating, trestle broaching, heating, ring rolling, machining, annealing, solid solution hardening, cold pressing deformation, ageing and the like, wherein the ring rolling technology is divided into three temperature sections for rolling, in the first temperature section, the deformation temperature is 420-450 DEG C, the feeding speed of a core roller is 0.2-0.5 mm / s, and the deformation quantity is 20-25%; in the second temperature section, the deformation temperature is 300-340 DEG C, the feeding speed of the core roller is 0.1-0.3 mm / s, and the deformation quantity is 10%; in the third temperature section, the deformation temperature is 200-240 DEG C, the feeding speed of the core roller is 0.05-0.2 mm / s, and the deformation quantity is 10%.

Owner:JIANGSU UNIV OF TECH

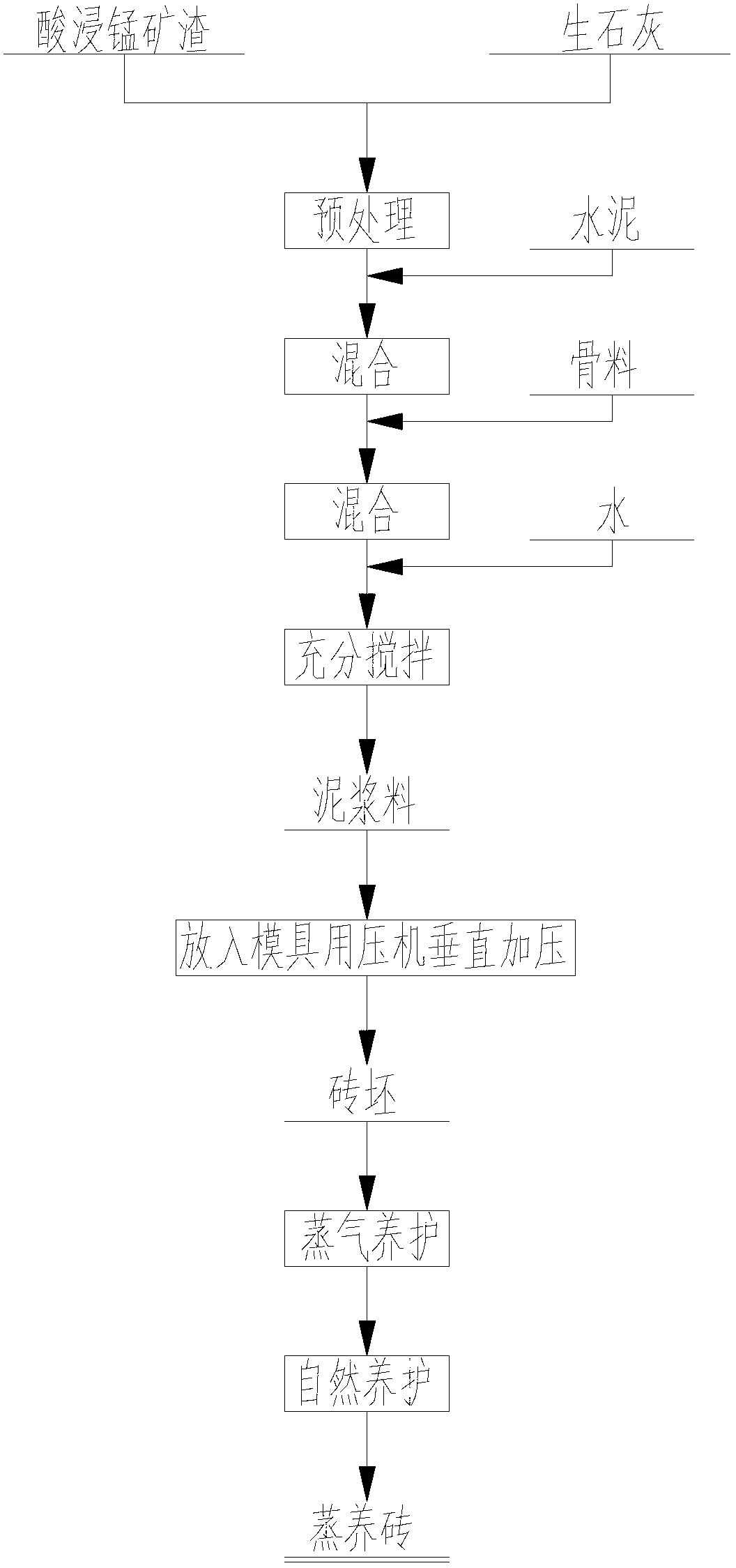

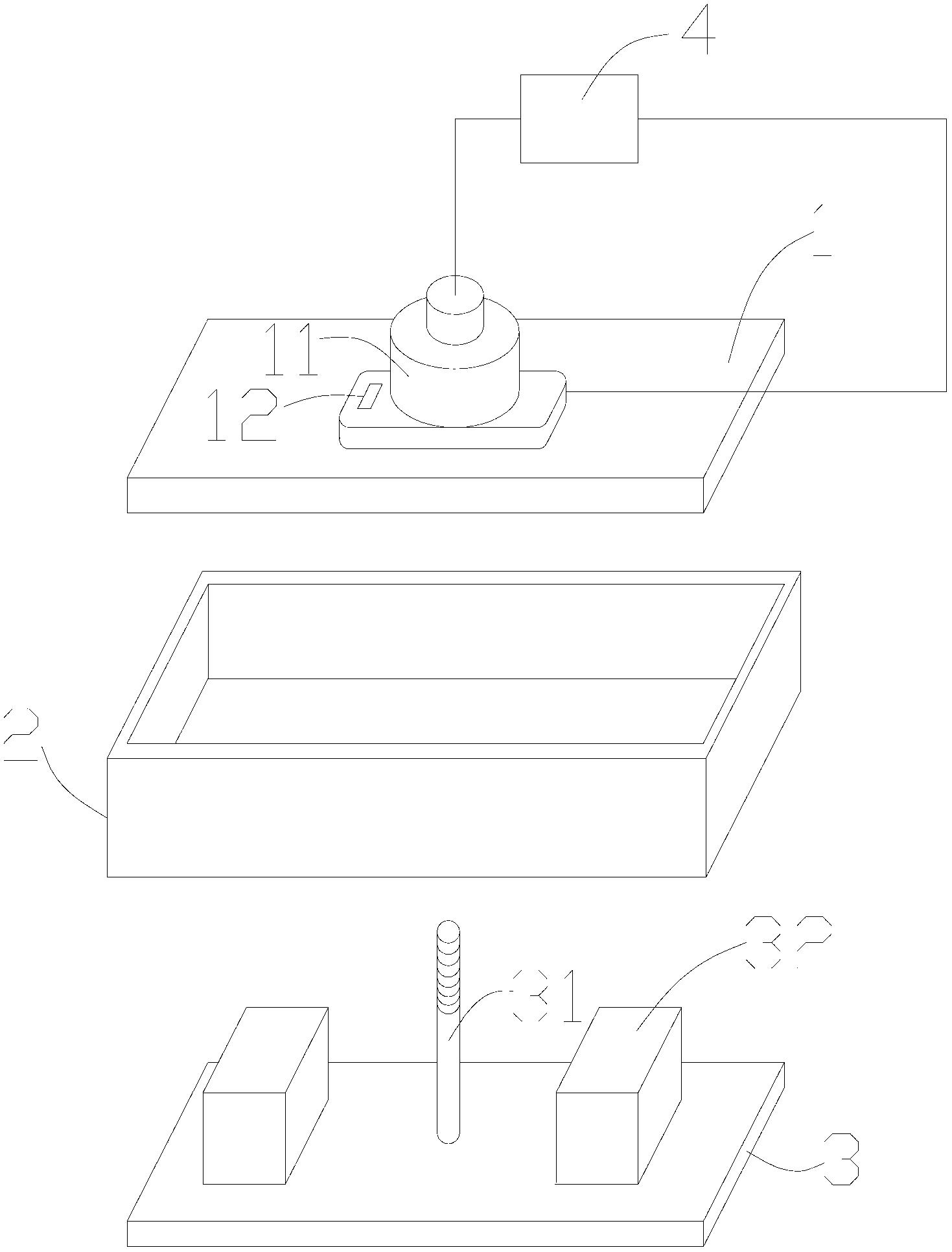

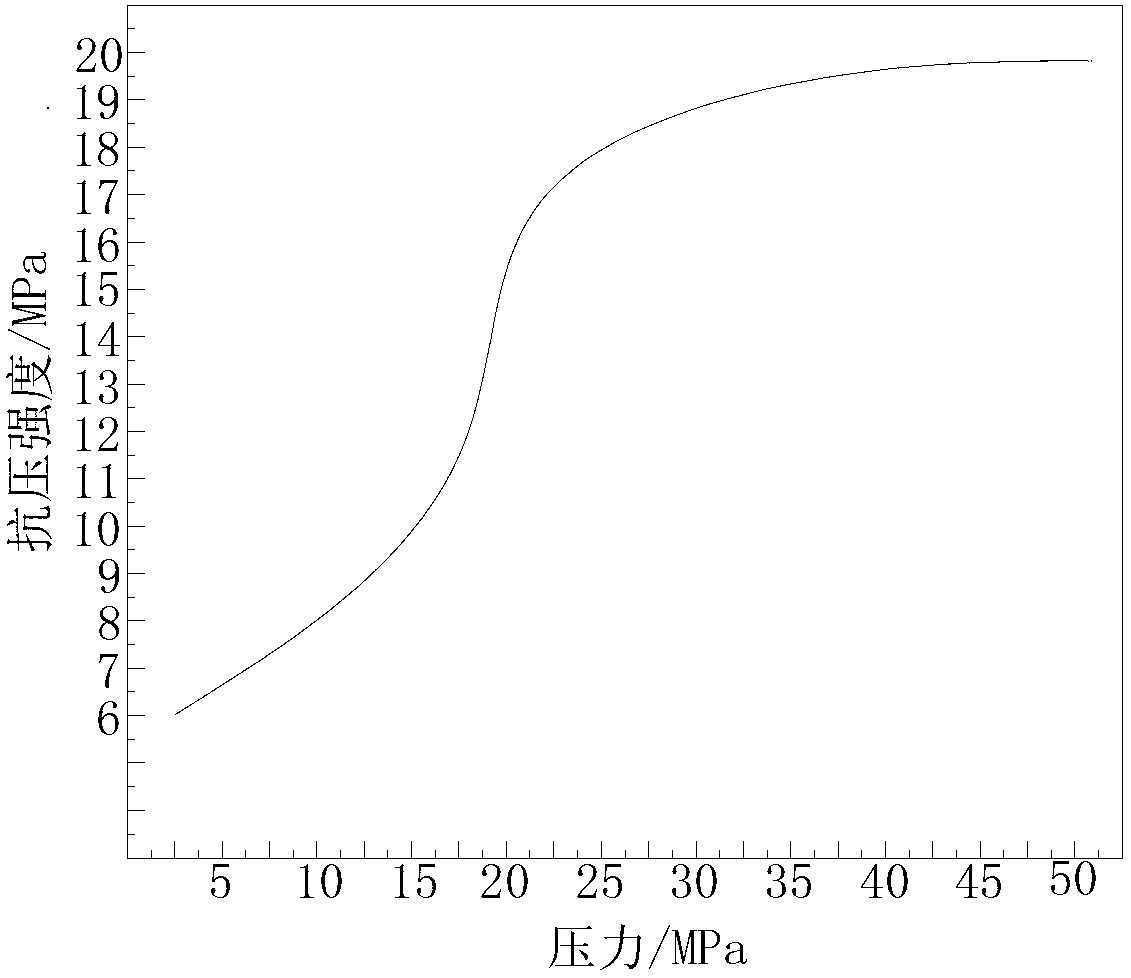

Method for preparing slag steam-cured brick

InactiveCN103193441AAvoid secondary pollutionEmission reductionSolid waste managementCeramic shaping apparatusWater bathsBrick

The invention discloses a method for preparing a slag steam-cured brick. The method comprises the following steps of adding quick lime to acid-leaching manganese slag according to a ratio, and carrying out pretreatment on the acid-leaching manganese slag; mixing the preprocessed acid-leaching manganese slag, cement and aggregate according to a certain ratio to obtain a mixture; adding water to the final mixture according to a certain water-solid ratio; agitating to obtain a slurry mixture; putting the slurry mixture into a home-made die to primarily mold; vertically pressurizing and molding the primarily molded brick by an electric oil press pressure head from top to bottom; obtaining a high-strength brick after pressurizing for a period of time; putting the high-strength brick into a constant-temperature water bath pan to carry out steam curing after a period of time; controlling the heating speed, and keeping the constant temperature for a period of time when certain temperature is achieved; taking out the steam-cured brick and putting in a room temperature environment; and naturally maintaining for 28 days by watering normal-temperature moisture measures to obtain the baking-free slag brick.

Owner:CENT SOUTH UNIV +1

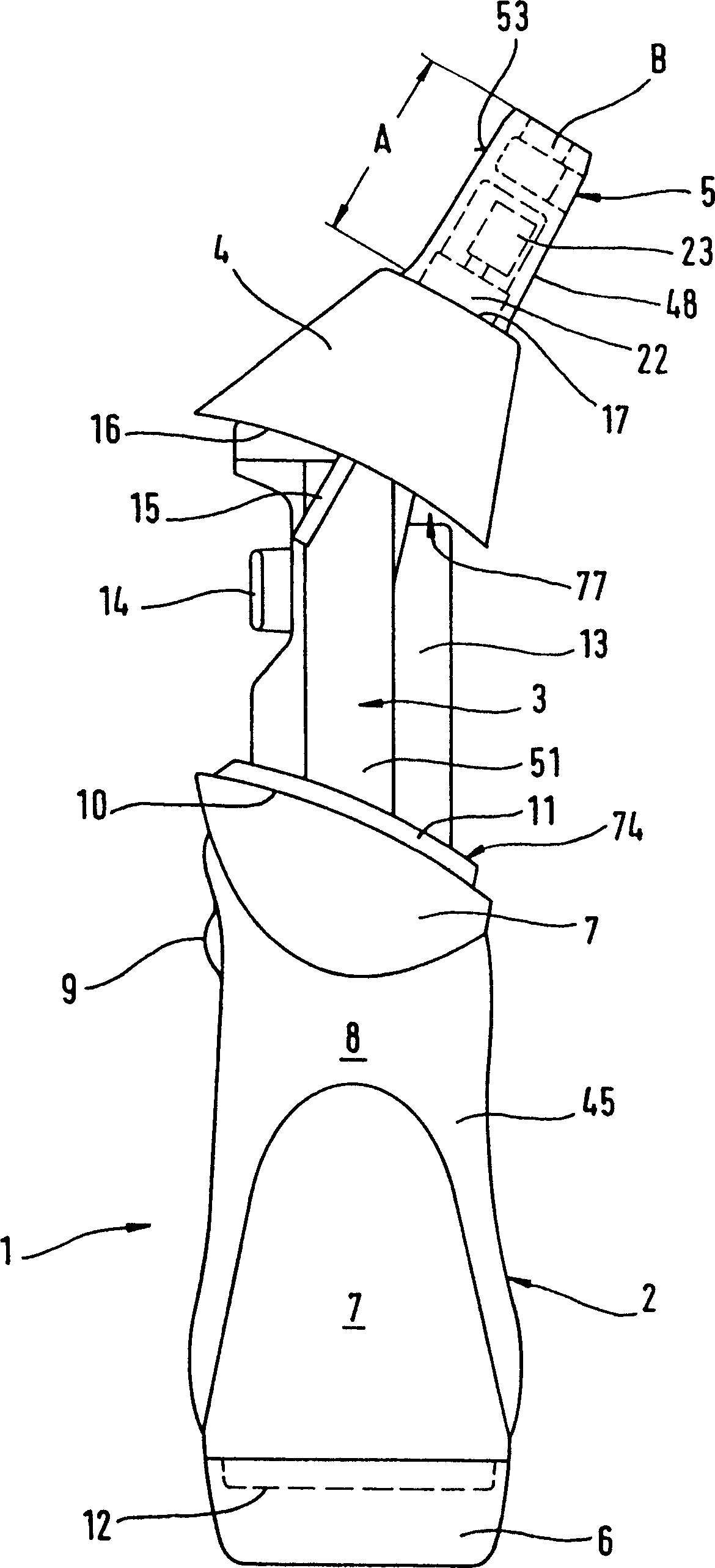

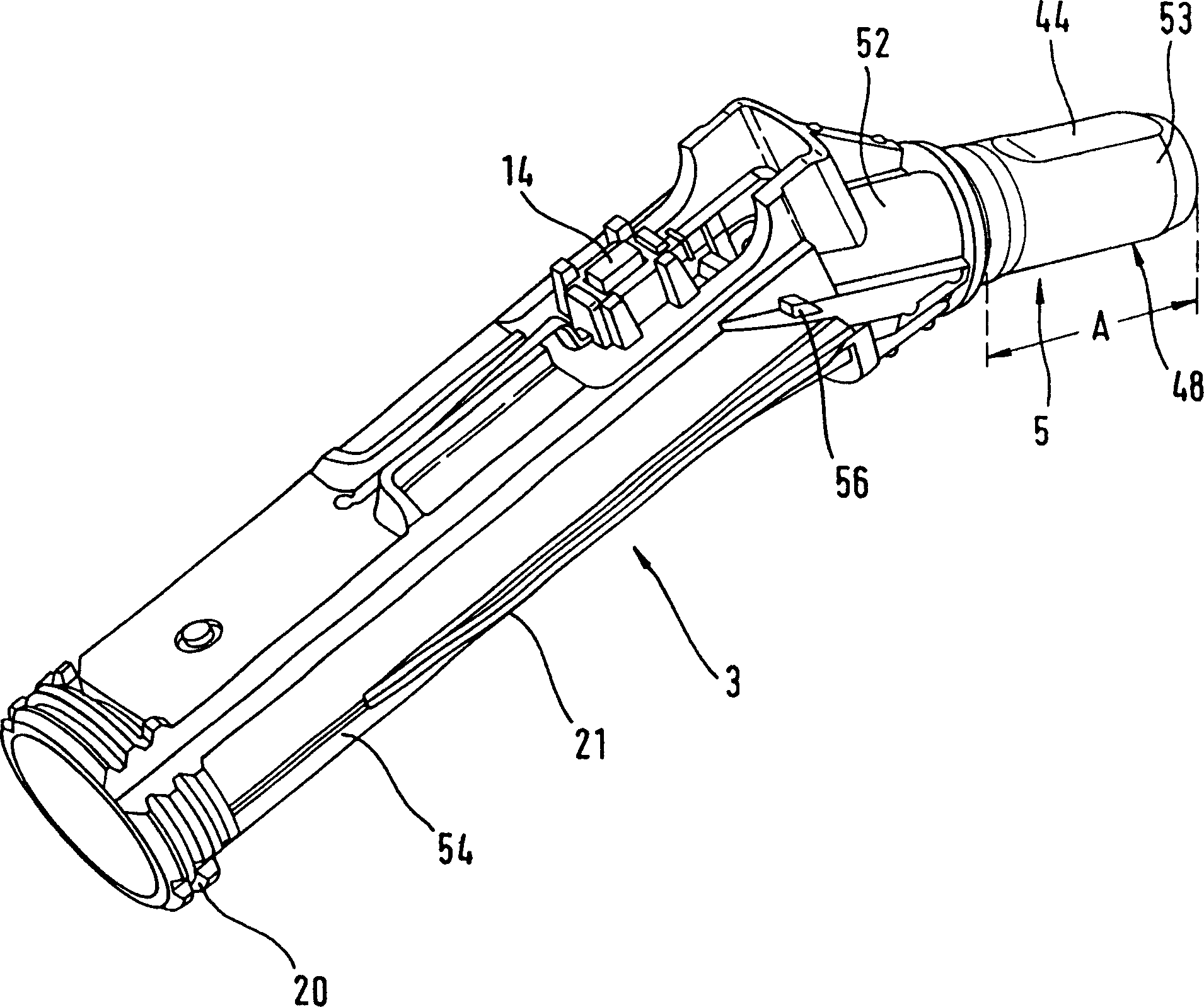

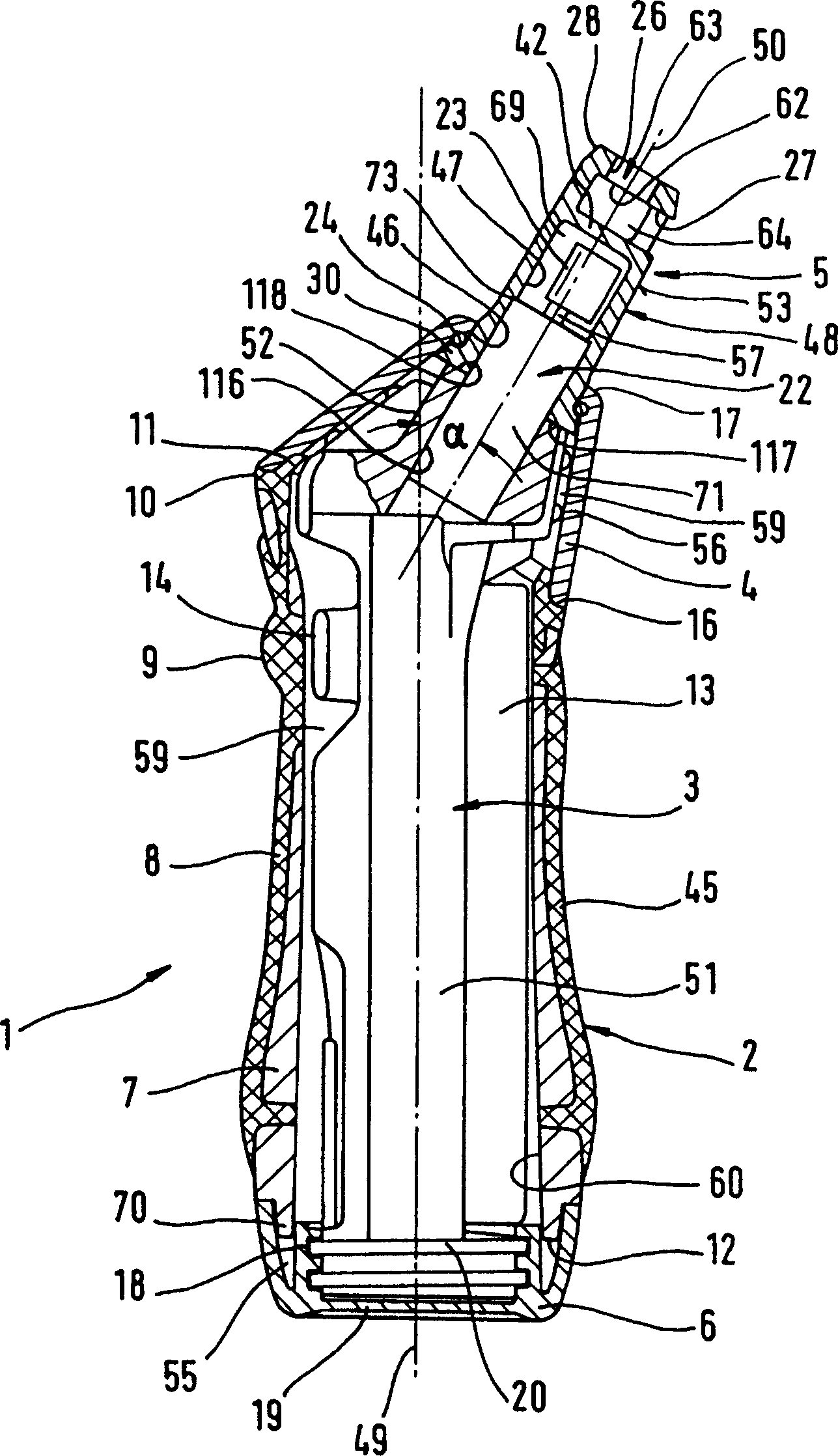

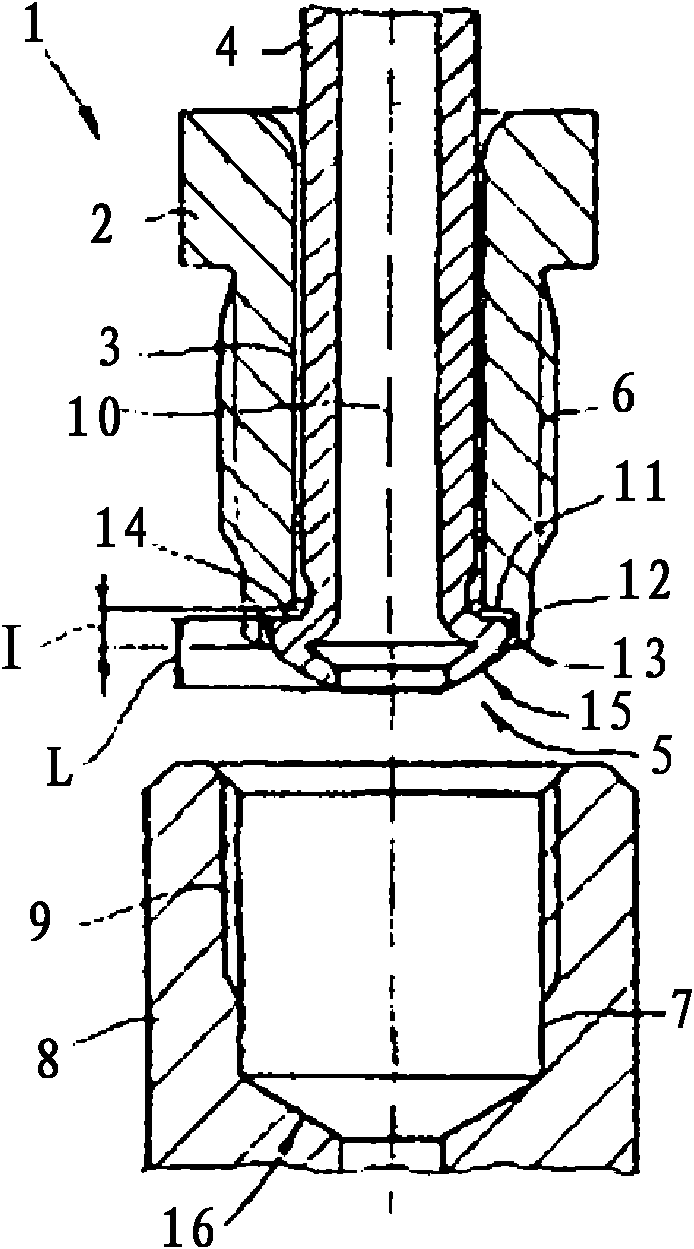

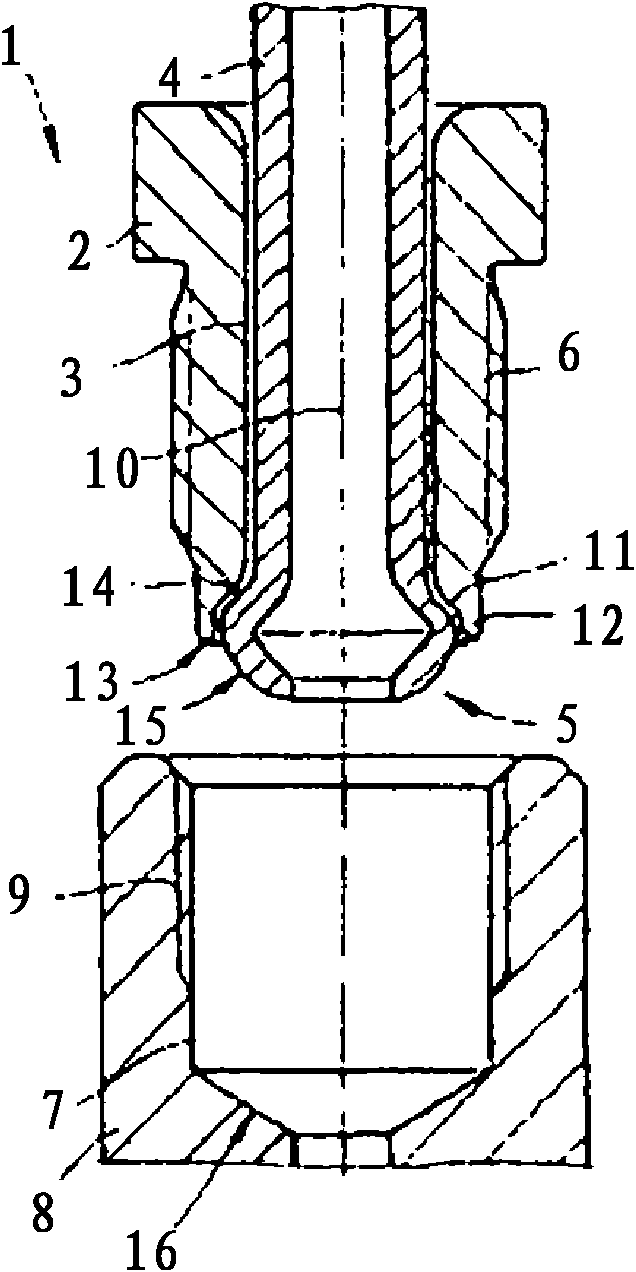

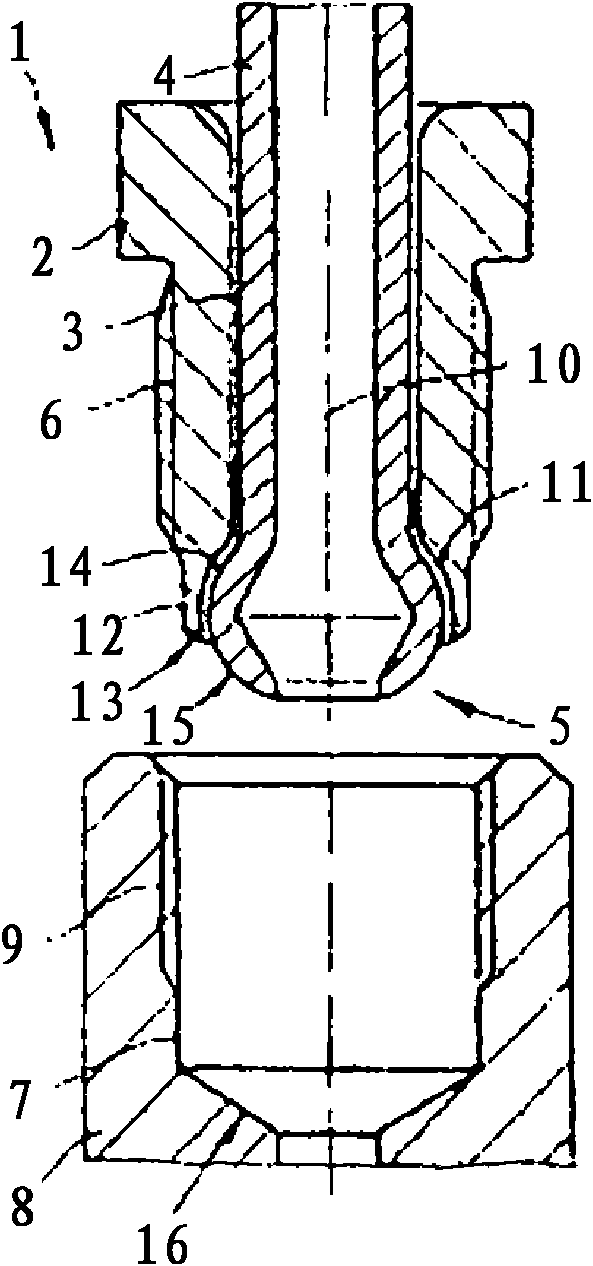

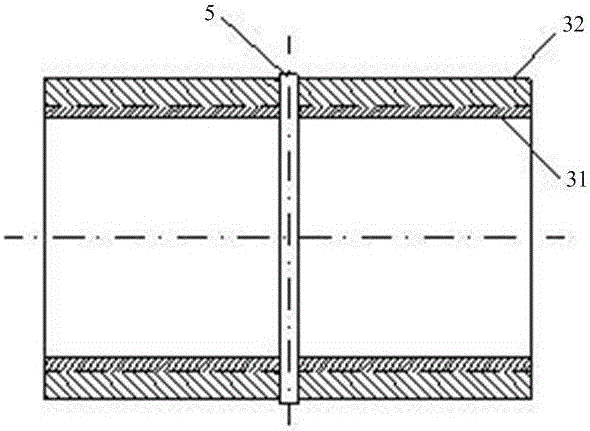

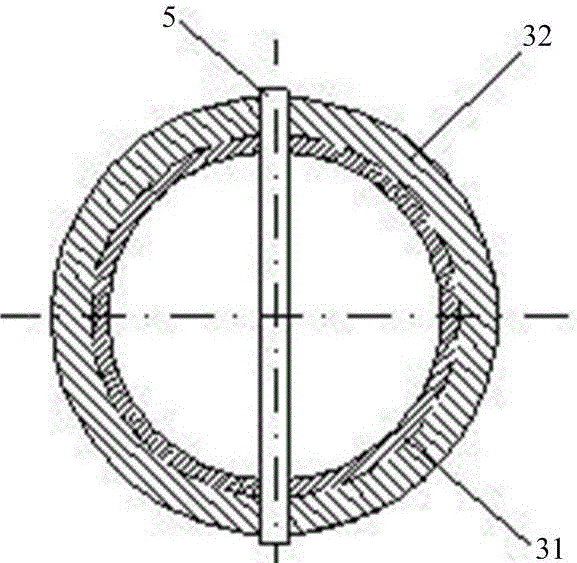

Electric device for interdental cleaning and for treating teeth and gingivae

The invention relates to an electric device (1) for interdental cleaning and for treating teeth and gingivae comprising a casing (2) containing an eccentric mass (23) which is driven by an electric motor (22) and whose vibrations are transmitted to a tool holding fixture (5). A coupling area (A, B) for the tool holding fixture is connectable to a coupling area (34, 38) of a mouth cavity treating tool such as an interdental cleaner (31), a dental floss holder (37), friction and polishing discs, etc by means of connecting means. According to said invention, the tool holding fixture (5) consists of a pivot-shaped segment (48) and a coupling area (B) formed on the free front end face (61) of said segment, wherein said coupling area (B) is embodied in the form of a polygonal, preferably rectangular, reception orifice (26) in which the coupling area (34) of the tool (31) can be formed by plastic deformation. A toothpick (31) and a dental floss holder (37) are also disclosed. Said invention makes it possible to carry out a particularly soft interdental cleaning.

Owner:BRAUN AG

Copper thin material ultrasonic spot welding connecting method

InactiveCN109365982ALower yield strengthIncrease binding areaNon-electric welding apparatusNano copperSpot welding

The invention provides a copper thin material ultrasonic spot welding connecting method. When ultrasonic spot welding connection is carried out on copper thin materials, nano-copper particles with a thickness of 2-50 [Mu]m are added between copper thin materials; and when the nano-copper particles are added between the copper thin materials for ultrasonic spot welding connection, the welding timeis 0.2-1.6 s, the welding pressure is 20-70 psi and the welding amplitude is 20-65 [Mu]m. According to the copper thin material ultrasonic spot welding connecting method, the nano-copper particles areadopted as an interlayer to solve the problem in the ultrasonic spot welding connection process, in specific, in the previous research of copper thin material ultrasonic spot welding, the problem that the effective thickness of a welded joint is greatly reduced while increasing the bonded area of welding interfaces is solved; and with adoption of the copper thin material ultrasonic spot welding connecting method, the purpose of increasing the bonded area of ultrasonic spot welding interfaces without reducing the effective thickness of the welded joint is realized, so that the purpose of improving the mechanical property of the ultrasonic spot welded joint is realized.

Owner:NORTH CHINA UNIV OF WATER RESOURCES & ELECTRIC POWER

Method for processing three-dimensional curved surface metal plate like piece

The invention discloses a method for processing three-dimensional curve metal plates, which is characterized in that according to the forming requirement of the plate, a type that multi-point forming and movable thermal source line heating forming are combined with each other is used for processing the metal plates; by once or a plurality of times of processing disposal, the required three-dimensional curve shape is finally achieved. The method of the invention adopts a method that the multi-point forming method and the movable thermal source line heating forming method are combined with each other; the two methods assist each other, so as to improve the processing precision, reduce the force loaded in the subsequent multi-point forming process, the cost and the times of repeated heating in the movable thermal source line heating forming, and is beneficial to reducing the stress in the plate after the plate is formed as well as ensure the stability of the plate shape after forming.

Owner:丁桦

Elastic running board for running machine

InactiveCN102275360ALarge plastic deformationNot much use valueSynthetic resin layered productsMovement coordination devicesHeat resistanceEngineering

The invention discloses an elastic running board for a running machine. The elastic running board is formed by adhering an elastic layer on a bottom plate surface which is manufactured by a medium density fiberboard or a plywood board and then adhering a friction layer on the outer surface of the elastic layer. The elastic running board can buffer and absorb impact force and vibration force which are generated by running, has high intensity, toughness and heat resistance, and greatly reduces noise emitted during running.

Owner:吴小凤

Tube connection device

InactiveCN102168776AImprove operational safetyPrevent leakageSleeve/socket jointsJoints with sealing surfacesEngineeringMotorized vehicle

A pipe connection arrangement for the connection of pipelines, in particular of motor vehicle pipelines to a connection element, wherein a connection fitting is provided which encompasses the pipeline to be connected in the region of one of its pipeline ends and which, with a front side press surface of a of a rear side surface facing a flange connected to the pipeline end. The flange exhibits a sealing surface on its front side, wherein the sealing surface can be pressed by means of an axial movement of the connection fitting to a contact surface of the connection element or to a second sealing surface of a second flange of a second pipeline, wherein a stop element is arranged between the contact fitting and contact surface of the connection element and wherein this stop element limits or interrupts the axial movement of the connection fitting.

Owner:TI AUTOMOTIVE HEIDELBERG

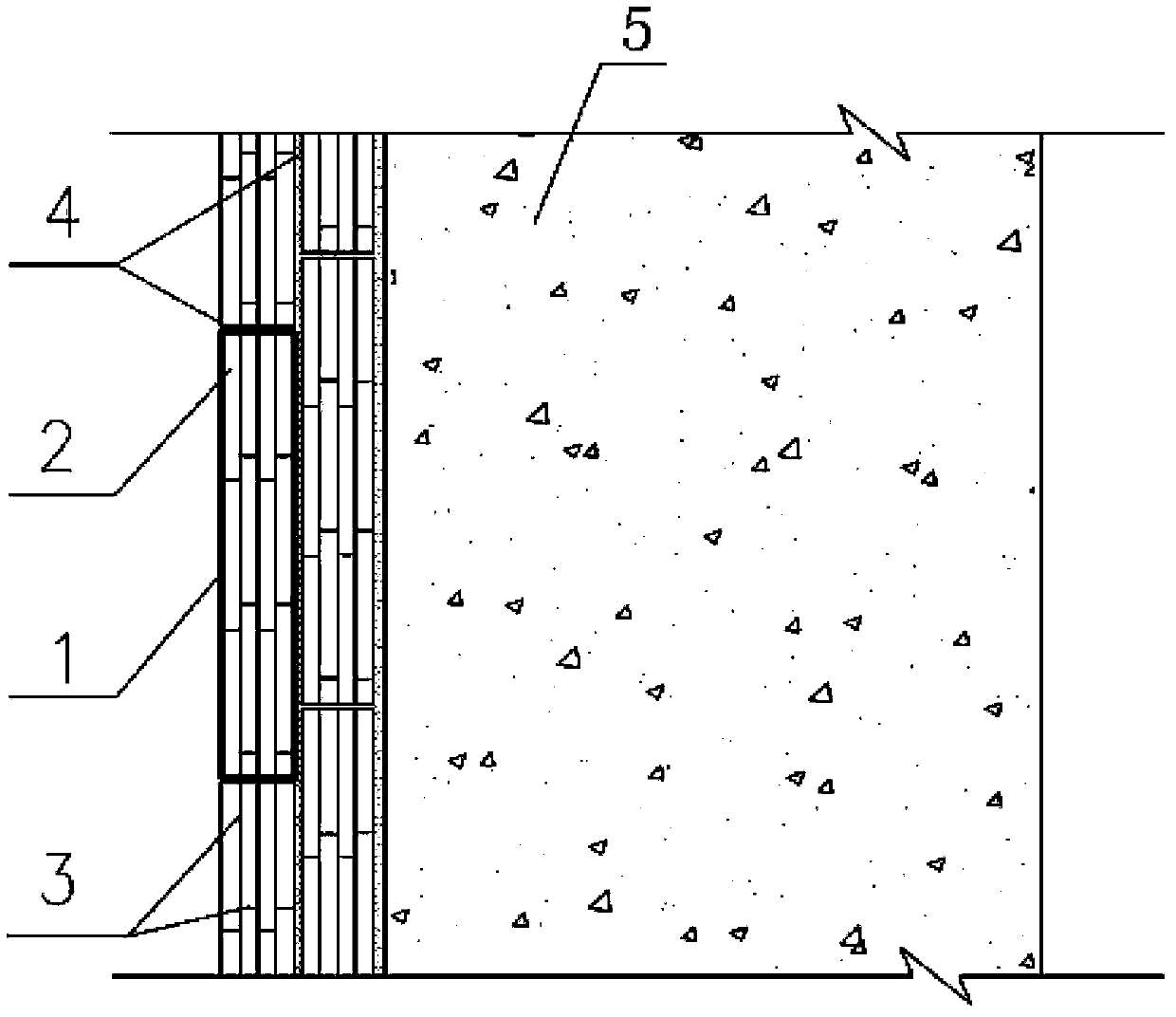

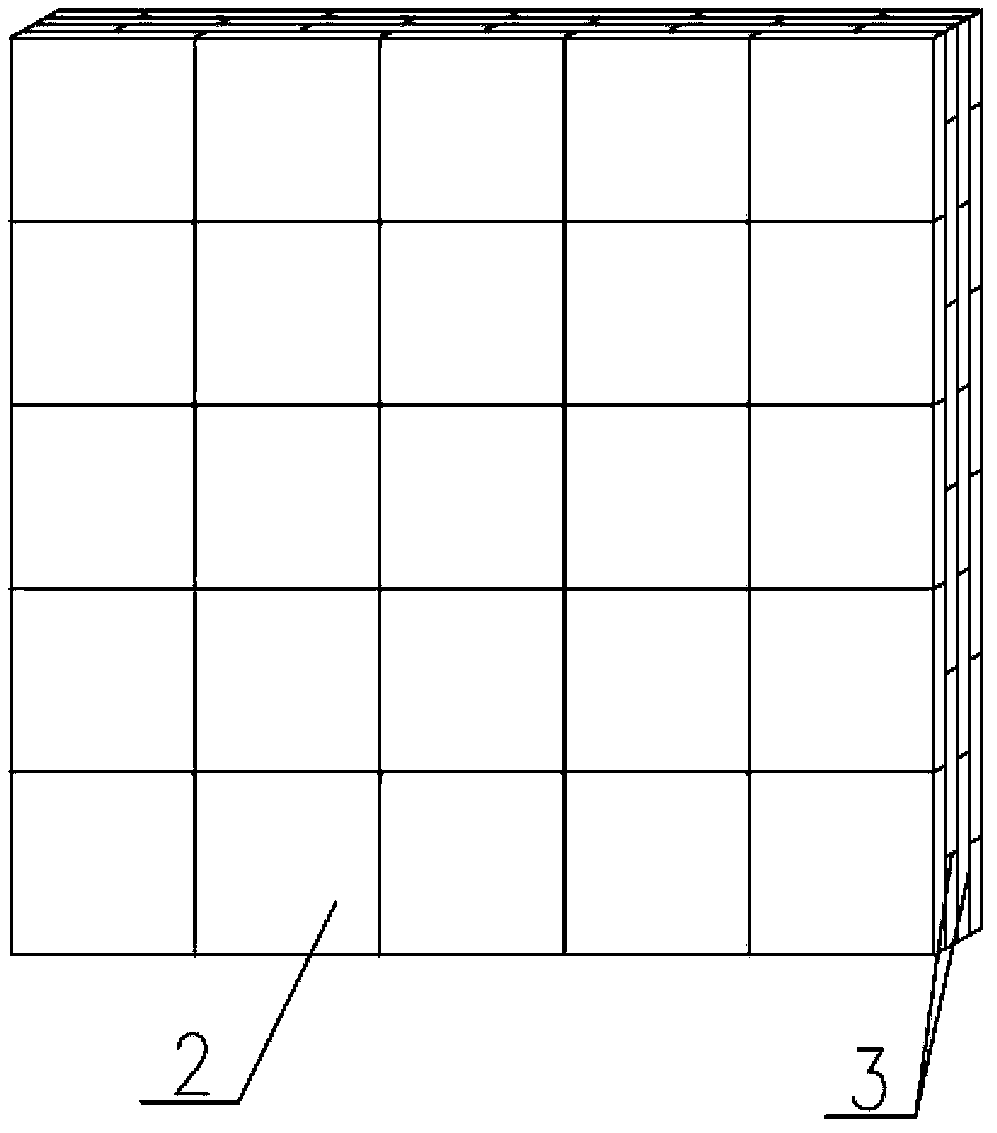

Wall tile protection structure with bullet-proof and explosion-proof functions

ActiveCN103388388AWith bulletproof and explosion-proof functionReduce depthCovering/liningsClimate change adaptationBrickBlocking layer

The invention discloses a wall tile protection structure with bullet-proof and explosion-proof functions. A plurality of wall tile units (1) are paved in a staggered way, and are bonded into a layered structure by adopting a bonding substance (4); and each wall tile unit (1) has a separate multilayer structure, namely, the wall tile units (1) are overlapped alternatively by using sheet block layers (2) and bonding substance layers (3), and the transverse sections are formed in a layered form. The protection structure has the advantages of attractiveness and easy-cleaning function of ordinary wall tiles, and capability of improving the high-speed impact resistance of building wall bodies (built or newly-built). The wall tile protection structure is low in manufacturing cost, is manufactured with a simple process, and is suitable for factory prefabrication and field rapid splicing.

Owner:CENT SOUTH UNIV

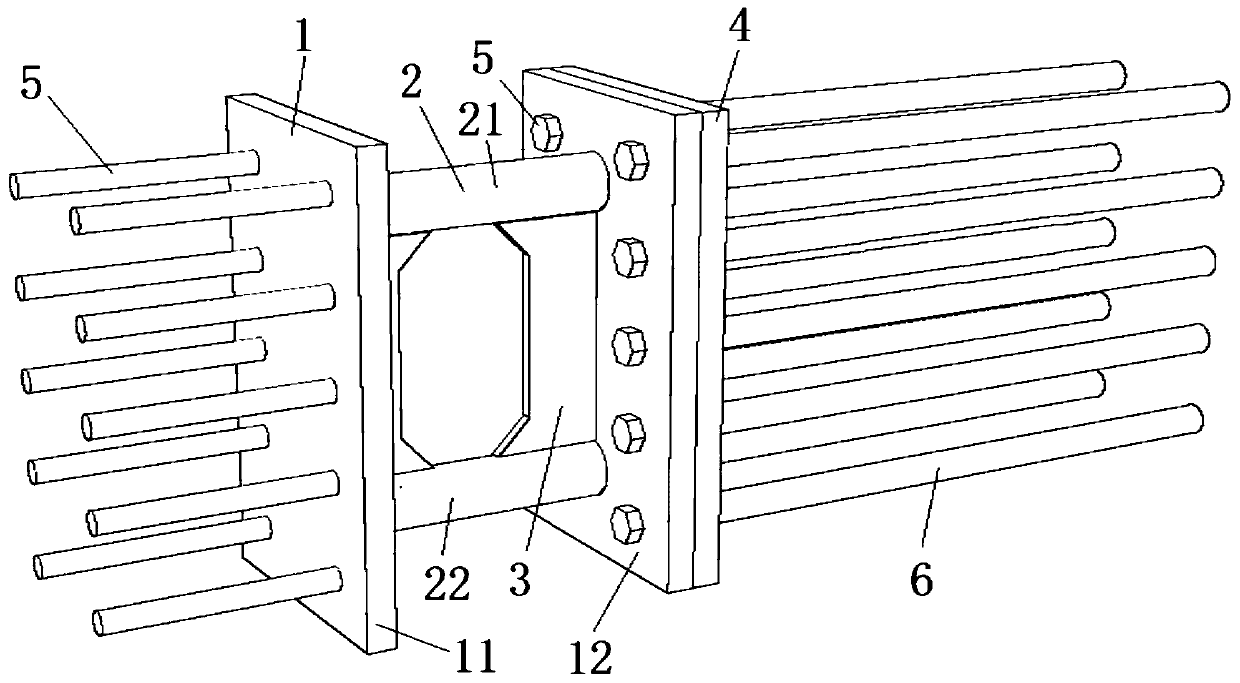

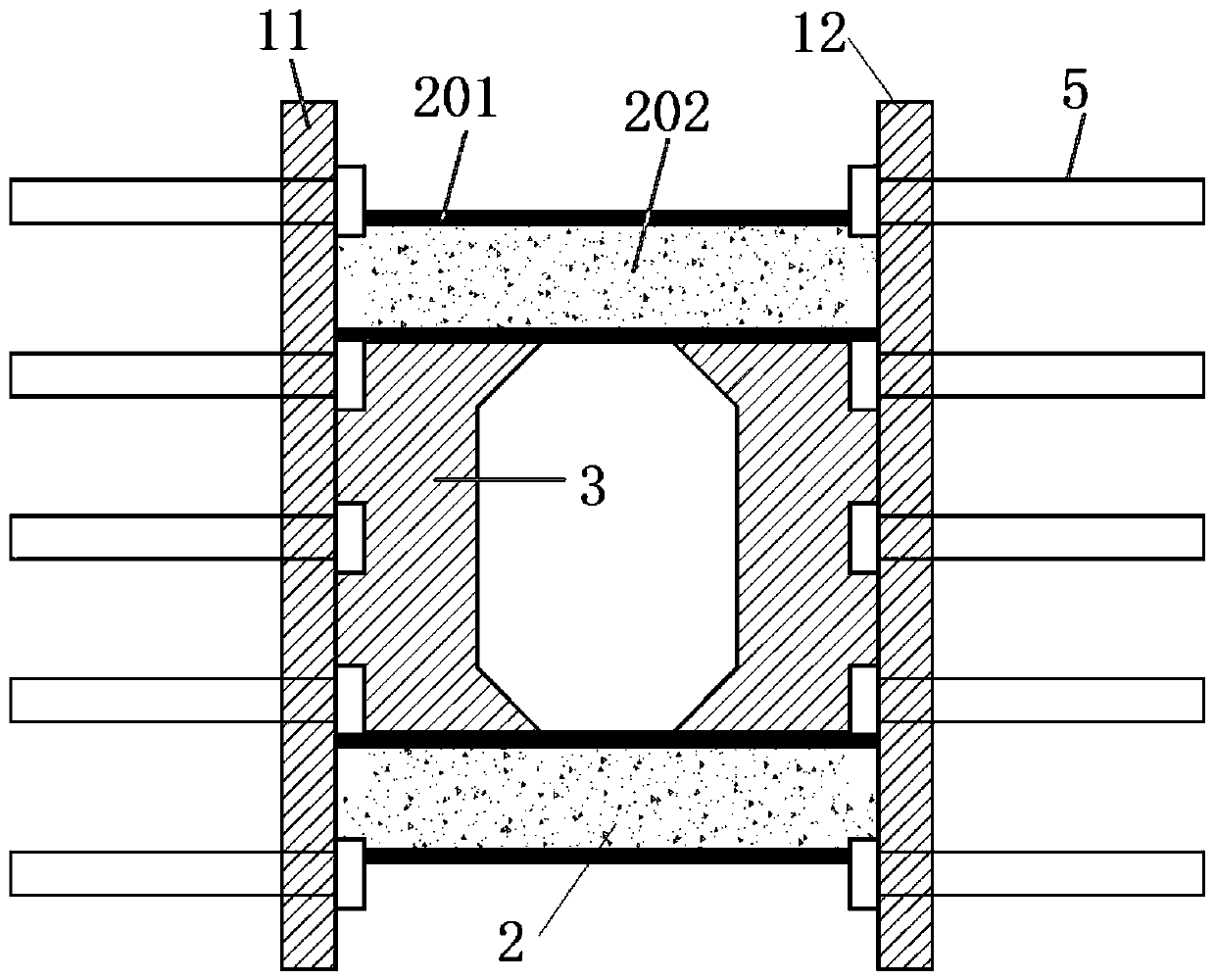

Assembled frame structure beam-column energy-consumption connecting key

PendingCN110359554AAchieve controllabilityGuaranteed uniformityProtective buildings/sheltersShock proofingSteel tubePlastic property

The invention discloses an assembled frame structure beam-column energy-consumption connecting key. End plates include the first end plate and the second end plate which are parallel to each other inthe vertical direction; the first end plate and the second end plate are detachably fixed to a frame concrete beam and a frame concrete column correspondingly; steel tube concrete connectors are perpendicularly fixedly arranged between the first end plate and the second end plate; the steel tube concrete connectors include the first steel tube concrete connector and the second steel tube concreteconnector which are parallel to each other in vertical direction; webs are vertically disposed between the first steel tube concrete connector and the second steel tube concrete connector; and the webs are perpendicularly welded and fixed to the steel tube concrete connectors and the end plates. The two steel tube concrete connectors and the webs are arranged between end plates, and then the energy-consumption connecting key is formed; the end plates and the steel tube concrete are combined to form the connecting key so as to improve the bearing force as much as possible, the steel tube concrete has high plastic deformation and energy-consumption property after yielding; and the end plates are detachably fixedly connected to the frame concrete beam and column, and timely replacement and repair of the energy-consumption connecting key are guaranteed.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

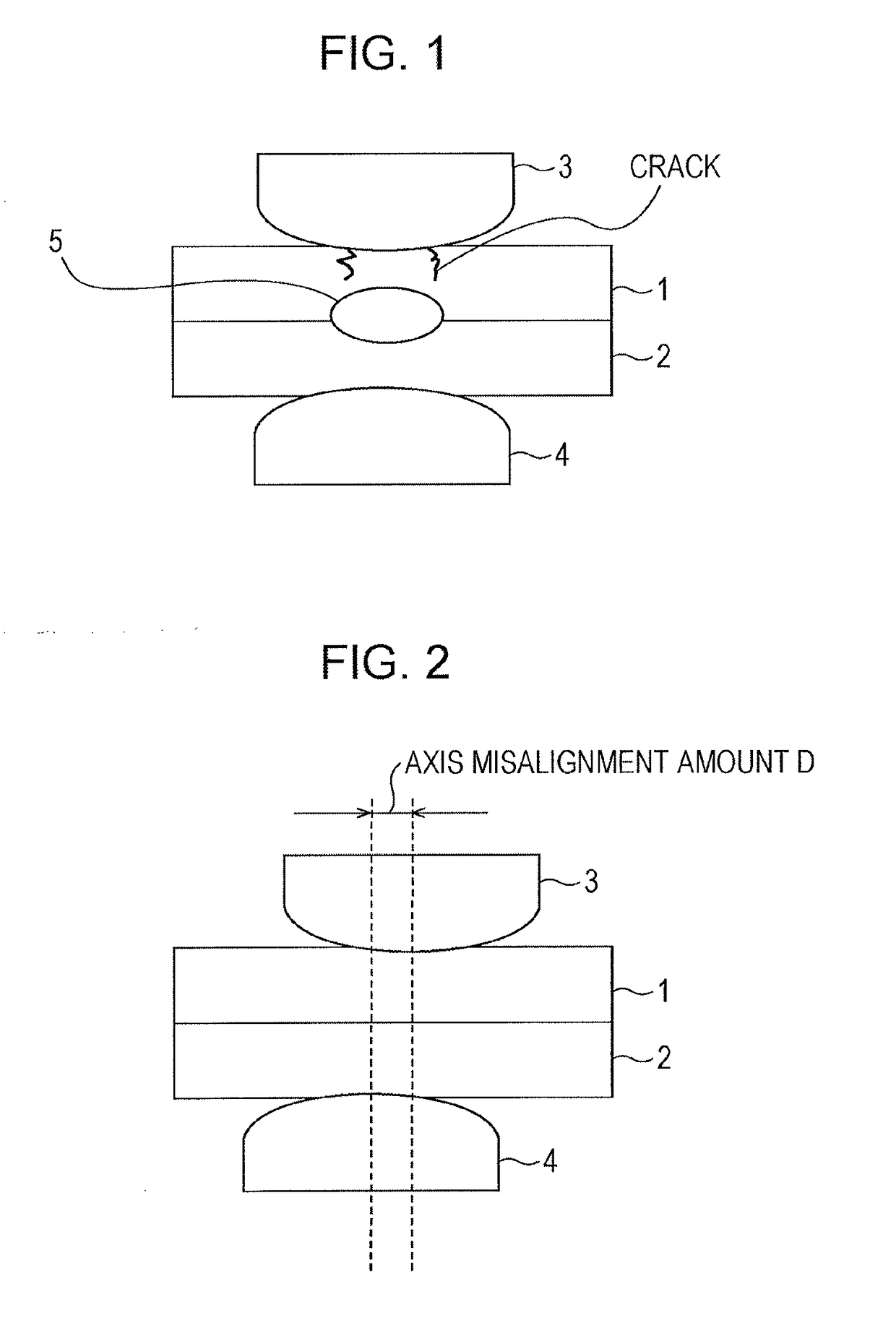

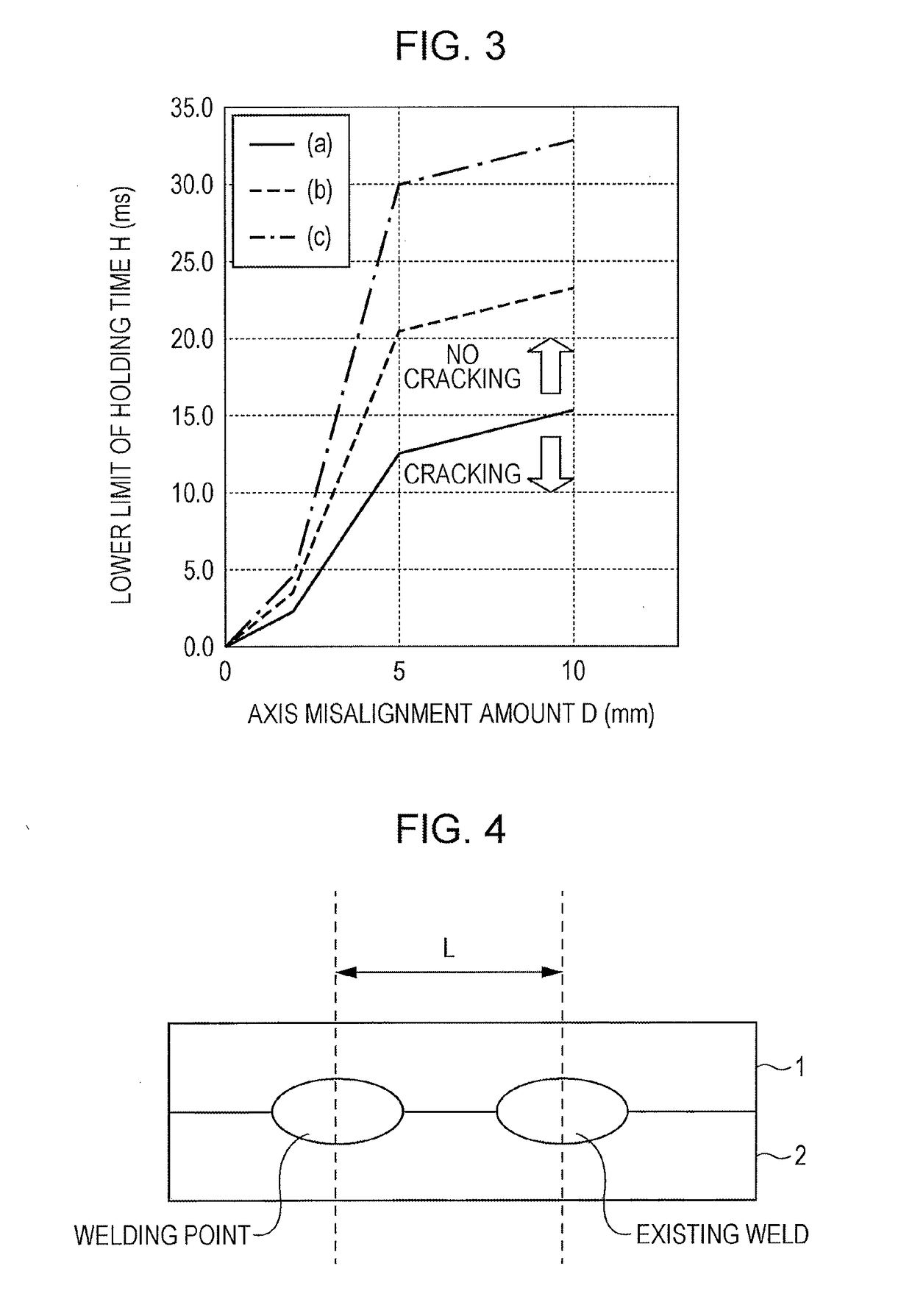

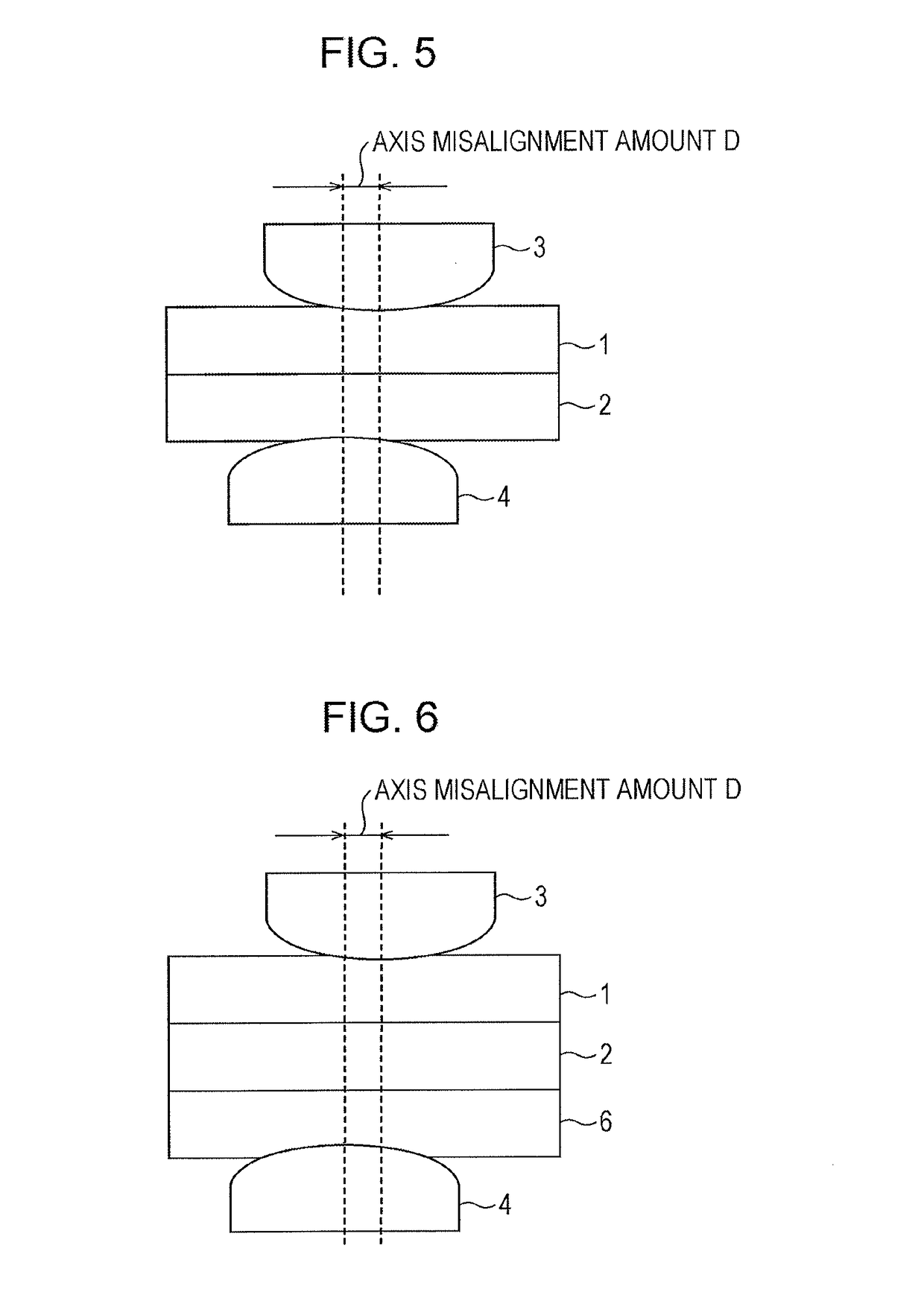

Resistance spot welding method and welded member production method

ActiveUS20190001429A1Grain boundary strength is decreasedIncrease probabilityMetal working apparatusResistance welding apparatusSpot weldingMaterials science

Provided is a resistance spot welding method that inhibits, in accordance with the degree of axis misalignment between electrodes, the occurrence of cracking in a weld regardless of the steel grade. In resistance spot welding methods according to the present invention, H (ms) is an electrode force retaining time after completion of current passage, D (mm) is an amount of axis misalignment between the electrodes, t (mm) is a total sum of sheet thicknesses of a plurality of overlapping steel sheets, T (MPa) is a tensile strength of a steel sheet having a highest tensile strength among the plurality of steel sheets, F (N) is an electrode force, and d (mm) is a tip diameter of one electrode of the pair of electrodes that has a smaller tip diameter. The electrode force retaining time H is specified to be a predetermined value or greater.

Owner:JFE STEEL CORP

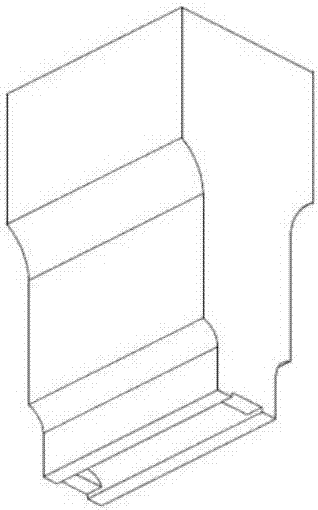

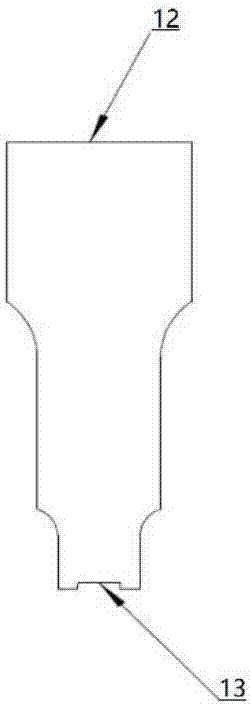

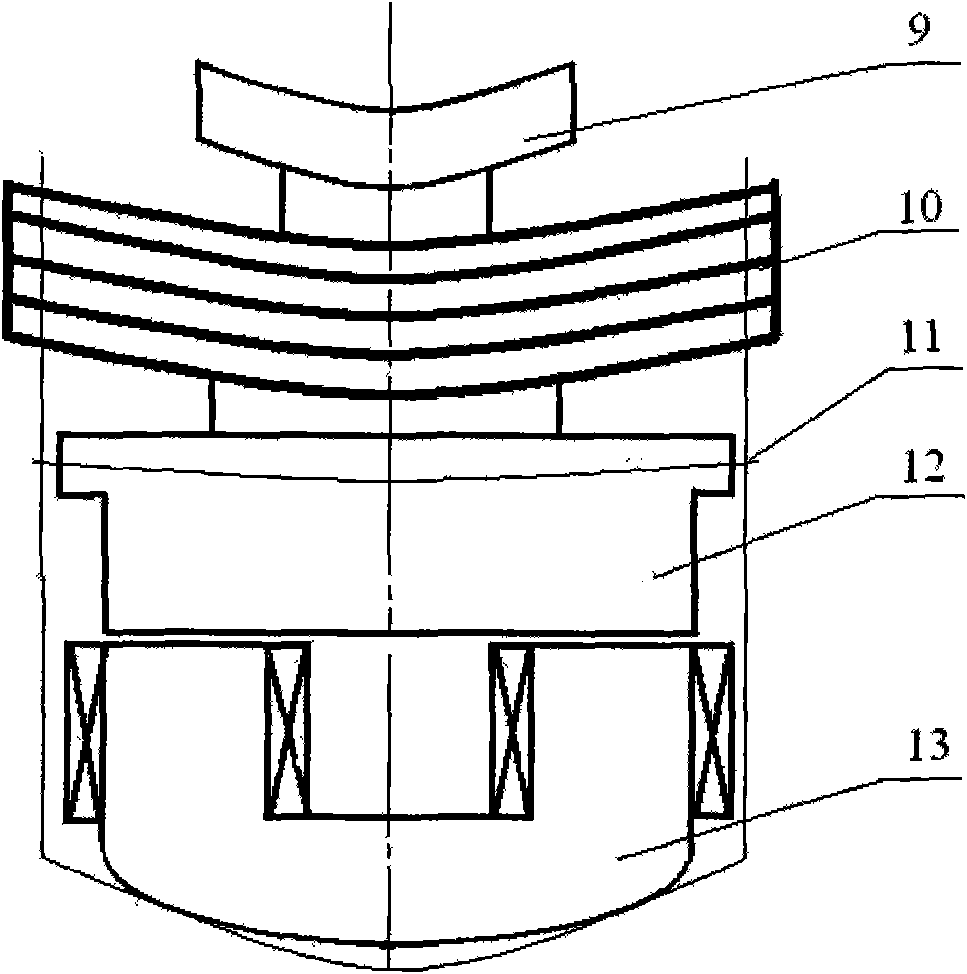

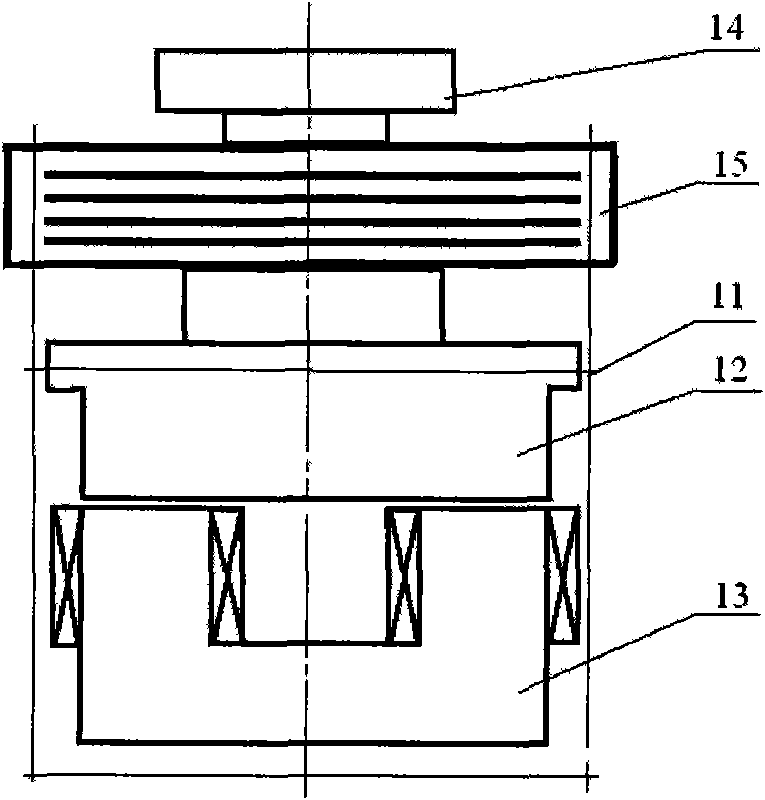

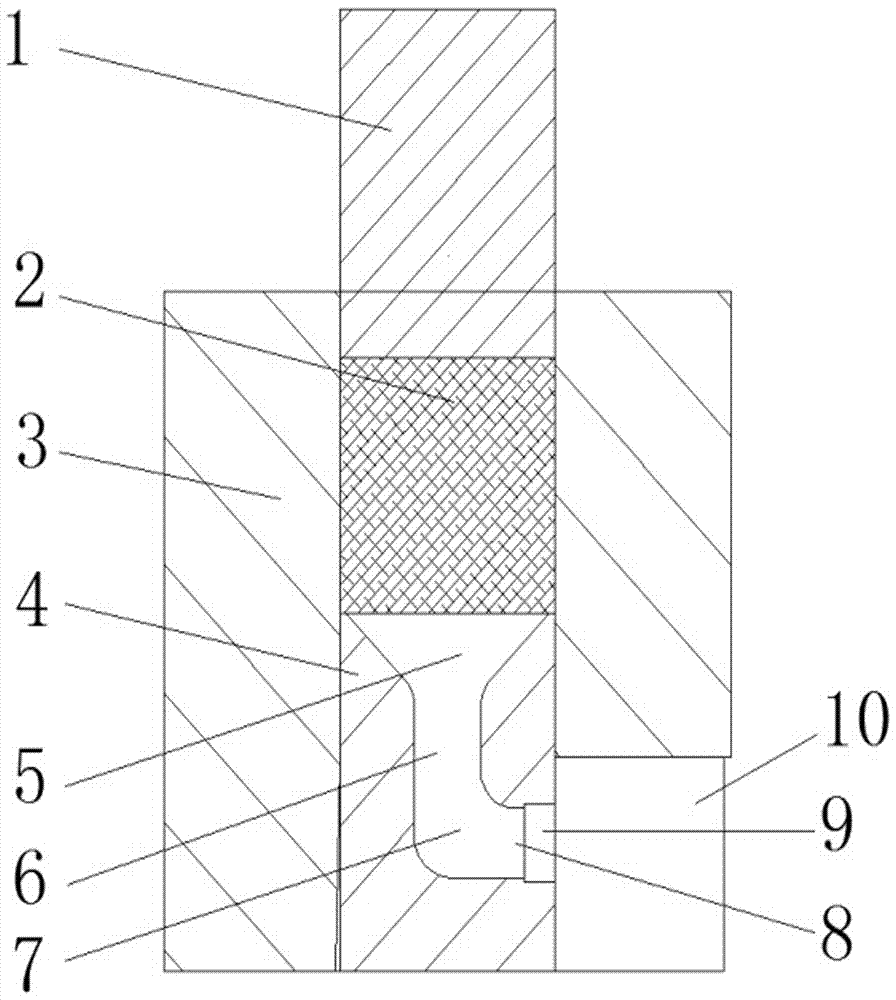

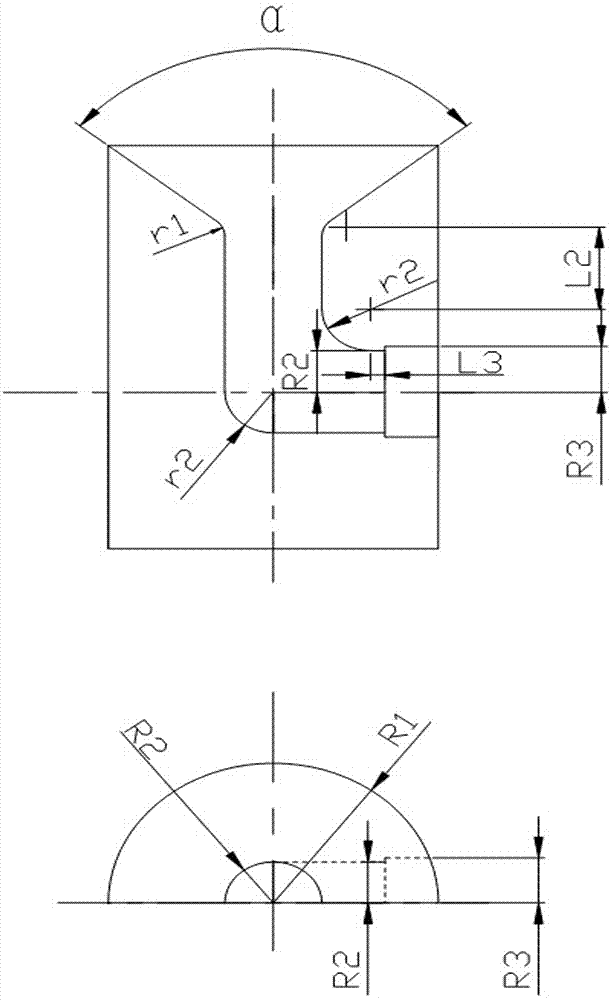

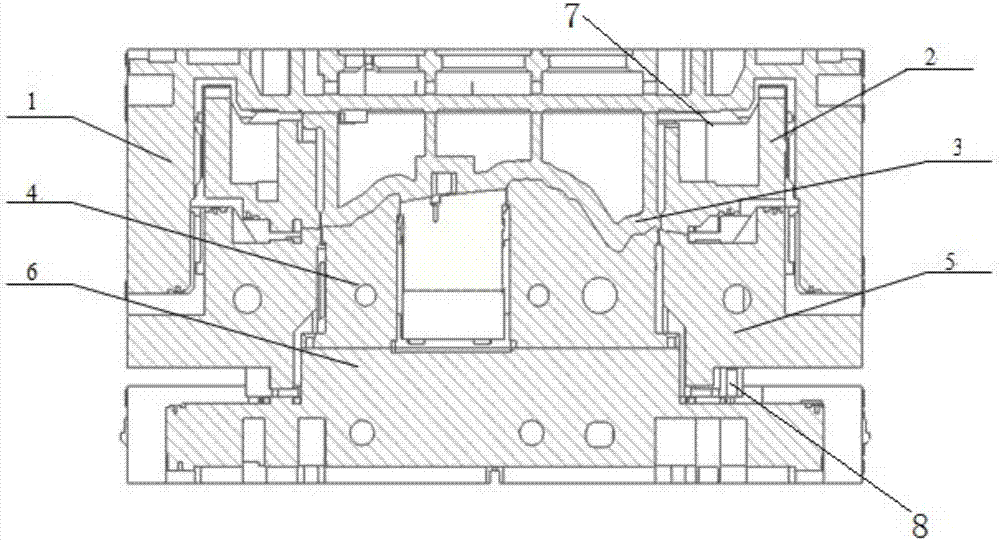

Extrusion shearing mould and forming method capable of achieving magnesium alloy grain refinement

The invention belongs to the field of magnesium alloy deformation technologies and mould designing and manufacturing, and relates to an extrusion shearing mould and forming method capable of achievingmagnesium alloy grain refinement. The extrusion shearing mould comprises a pressing block, a sleeve and an extrusion shearing insert, and a half mould of the extrusion shearing insert comprises an extrusion cup, an extrusion section, a shearing section, a forming section and a discharging area. According to the extrusion shearing mould and forming method, the defects that the requirements of theprior art for equipment extrusion force, a mould structure and the strength are high, and the technology is complex are overcome, the extrusion shearing mould and forming method can effectively achieve magnesium alloy grain refinement, the extrusion shearing mould is simple in structure, the method is simple and convenient, operation is easy, and the effect is obvious.

Owner:SHENYANG POLYTECHNIC UNIV

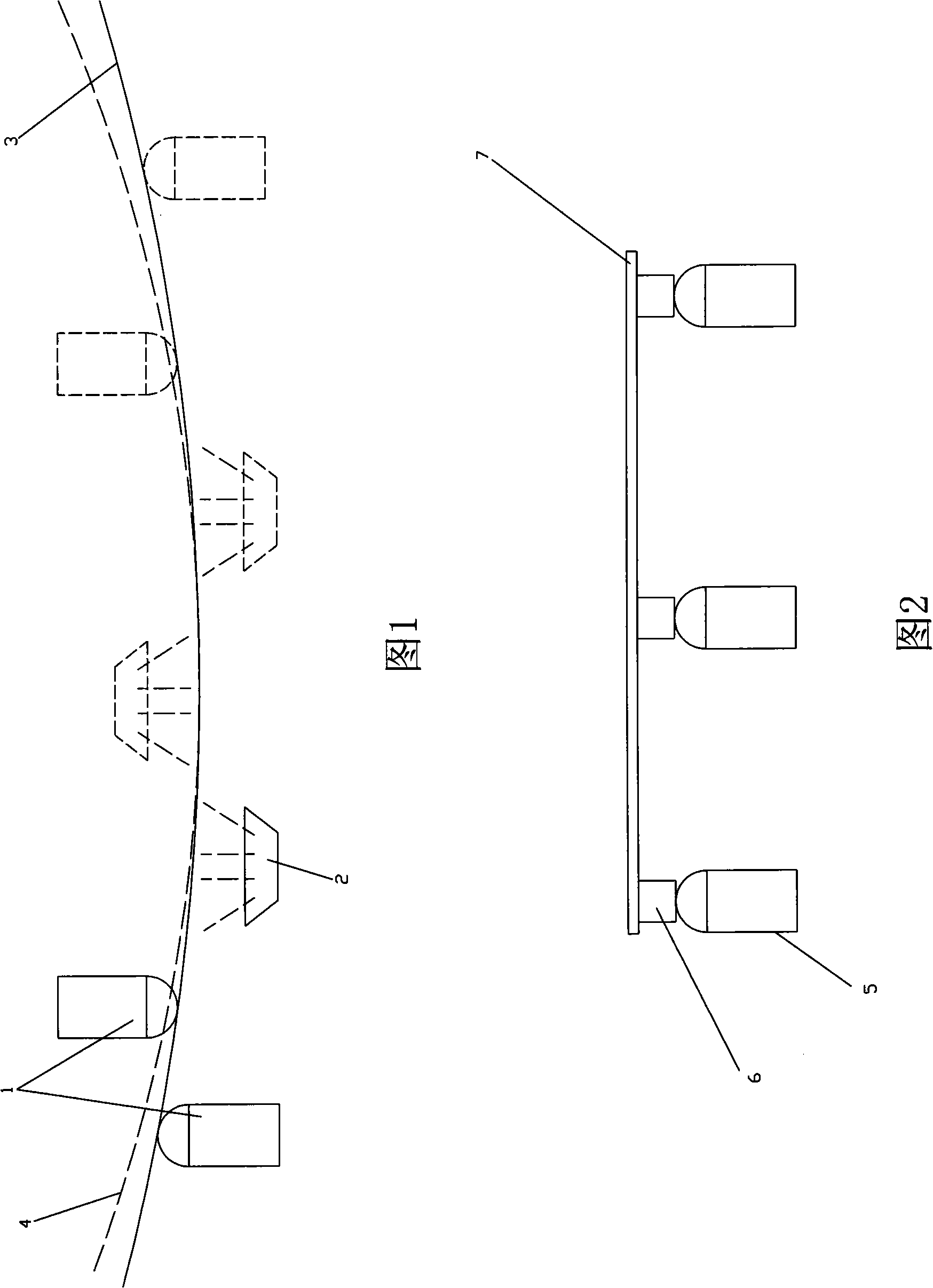

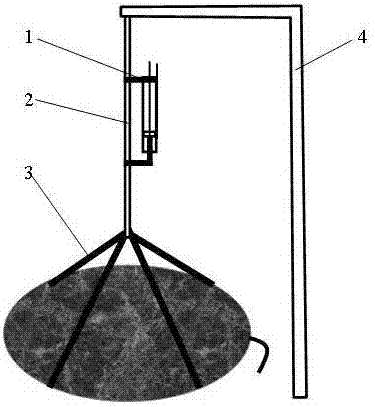

Watermelon maturity monitoring device

A watermelon maturity monitoring device is mainly composed of a detector (1), an elastic sling (2), a net bag (3) and a support (4). The watermelon maturity monitoring device is characterized in that the detector (1) is installed on the elastic sling (2) and stretches and contracts along with the elastic sling (2), when matured, a watermelon falls due to weight, and the elastic sling (2) rebounds and triggers the detector (1) to act to remind people of watermelon maturity; one end of the elastic sling (2) is connected with the net bag (3) containing the watermelon, and the other end of the elastic sling (2) is connected with the support (4). The mode of monitoring watermelon maturity through weight change is lossless watermelon monitoring, and meanwhile watermelon maturity is monitored in time in the watermelon growth process and is judged accurately in time. The watermelon maturity monitoring device is first application of the weight method monitoring technology in the watermelon growing process and has the advantage of creativity.

Owner:卢浩然

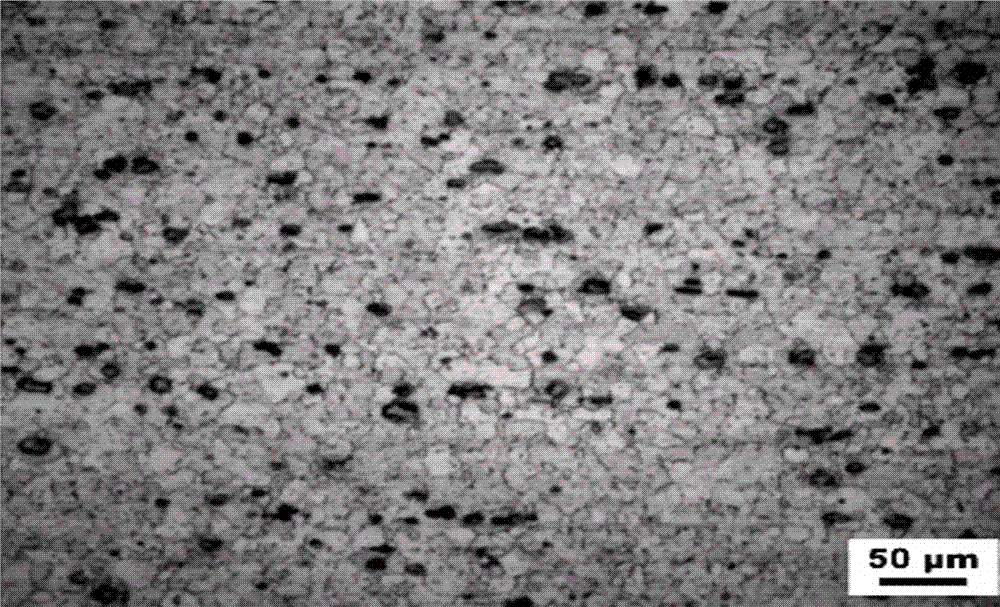

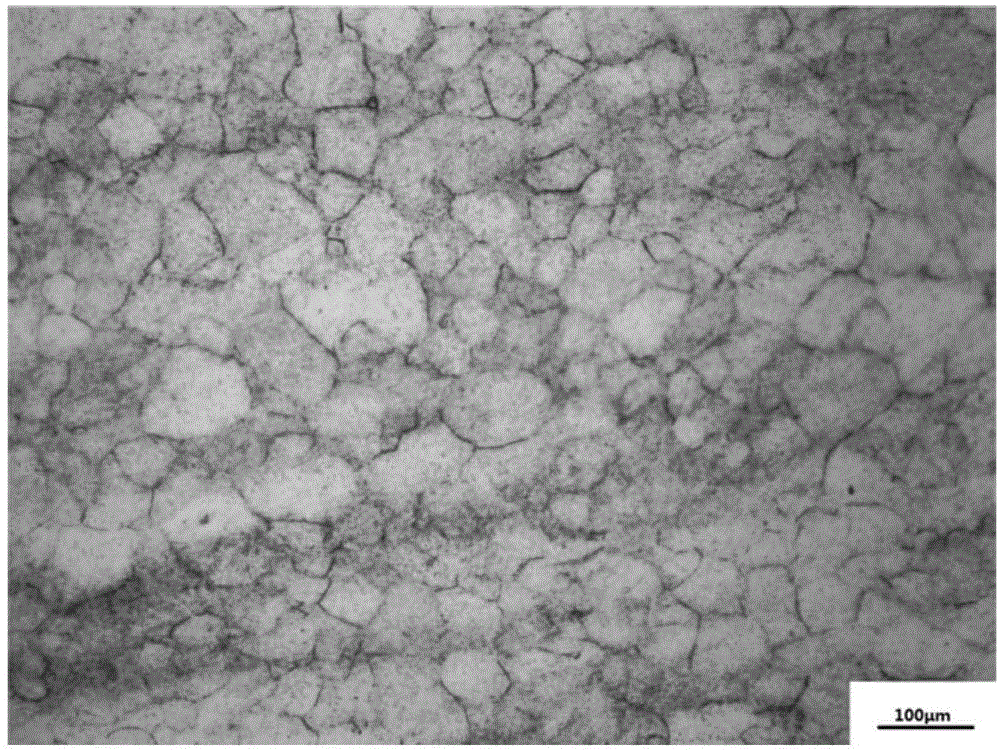

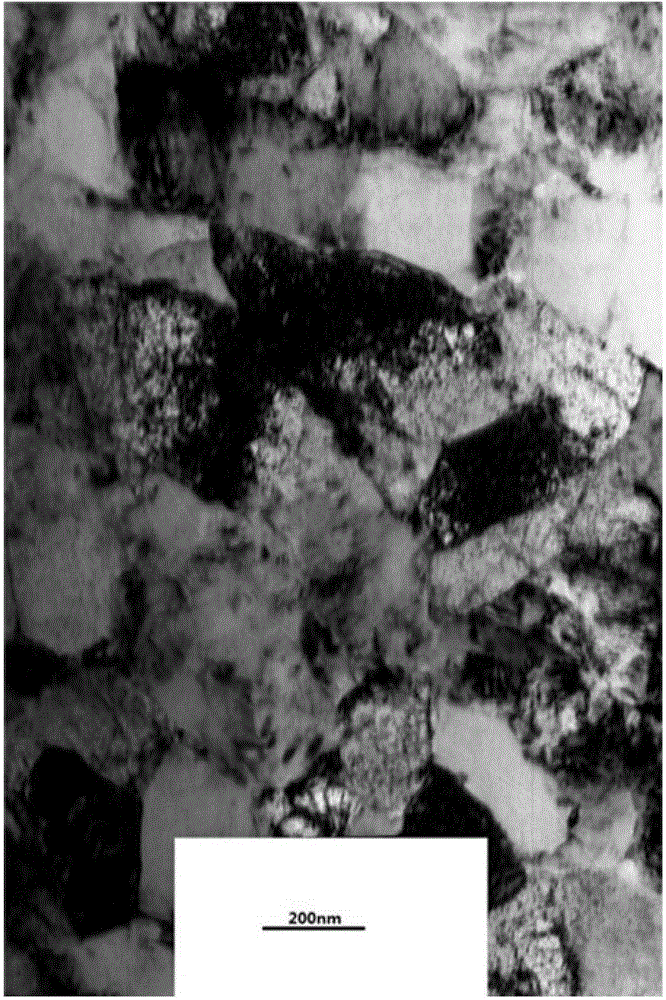

Beta titanium alloy composition and preparation method thereof

The invention provides a beta titanium alloy composition and a preparation method thereof. The composition consists of the following components in percentage by mass: 57-59% of Ti, 36-37% of Nb, 2-2.5% of Ta and 3-3.5% of Zr. The invention also relates to a preparation method of the composition. The preparation method comprises the following steps of: (I) proportioning the components in percentage by mass, mixing and pressing into an electrode; (II) smelting the electrode in a vacuum consumable electro-arc furnace to obtain an ingot; (III) performing hot working on the ingot, and performing heat treatment to obtain a crude beta titanium alloy composition; (IV) cutting the crude beta titanium alloy composition into a blank and performing surface pretreatment; (V) preheating an equal channel angular extrusion die and the blank, and coating a graphite lubricant; and heating and preserving heat; and (VI) extruding at 500-600 DEG C twice to four times and performing water quenching. The method provided by the invention is simple and easy to implement, has low cost and can remarkably refine the crystal grains; and the beta titanium alloy composition provided by the invention is a bone tissue substitute material with a broad medical prospect.

Owner:SHANGHAI JIAO TONG UNIV

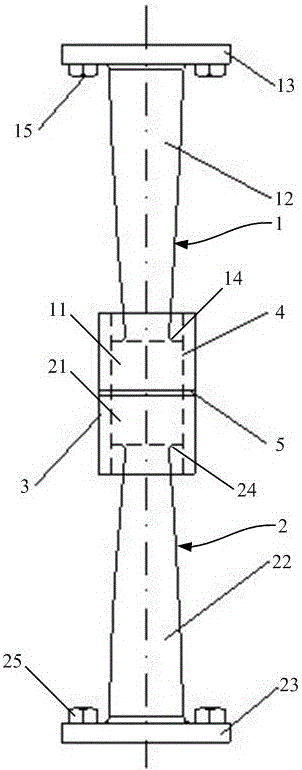

Separation type mild steel shock absorber

ActiveCN105937202ASimple structureExcellent deformation energy dissipation capacityBridge structural detailsEngineeringShock absorber

The present invention provides a separation type mild steel shock absorber. The separation type mild steel shock absorber comprises an upper shock absorber part and a lower shock absorber part which are symmetrically arranged relatively, wherein relative end portions of the upper shock absorber part and the lower shock absorber part have force transmission segments, and a gap is left between end surfaces of the two force transmission segments; a force transmission cylinder arranged outside the force transmission segments of the upper shock absorber part and the lower shock absorber part and capable of slidably connecting the force transmission segments of the upper shock absorber part and the lower shock absorber part; and a limiting steel pin arranged in the gap so as to limit the force transmission cylinder outside the force transmission segments.

Owner:北京交达铁工科技有限公司 +2

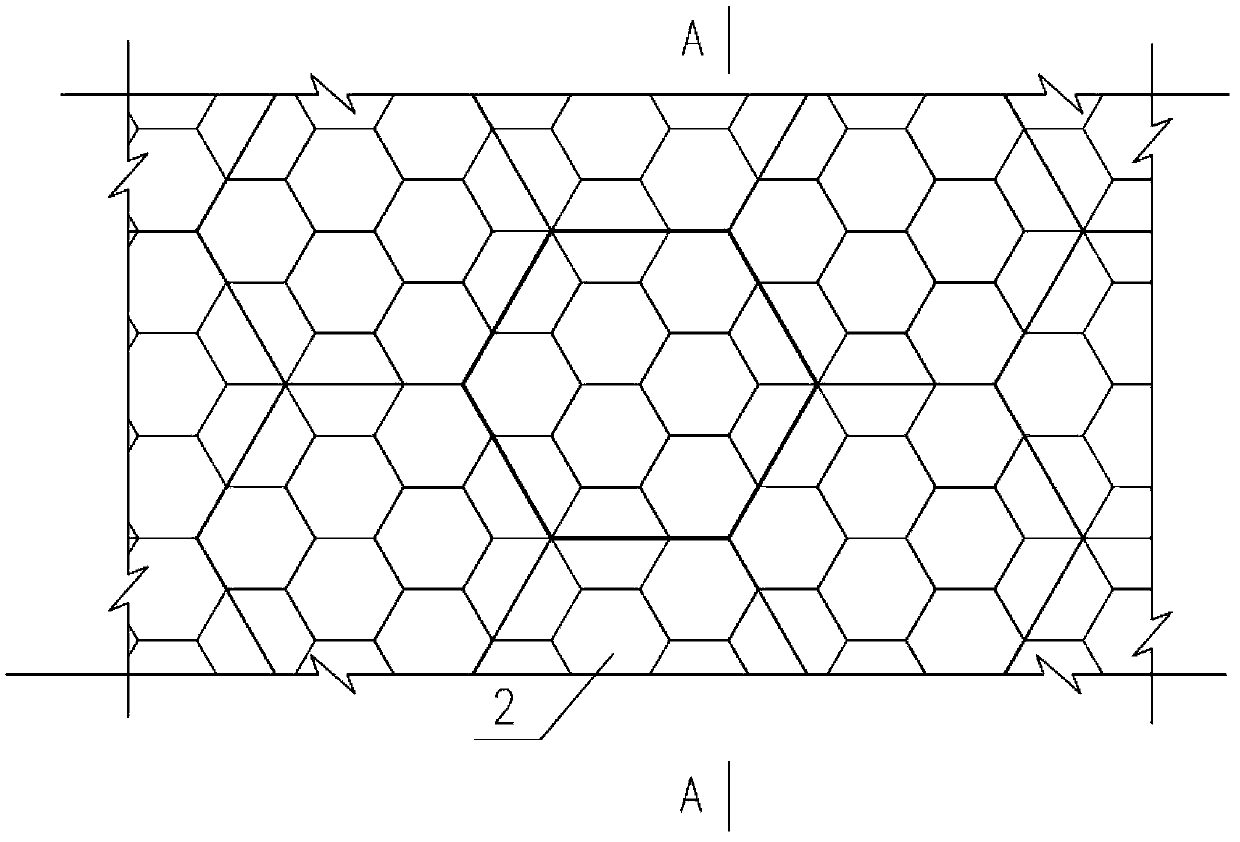

Honeycomb sandwich composite material with high-speed impact resistance and wave-absorbing stealth functions and preparation method of honeycomb sandwich composite material

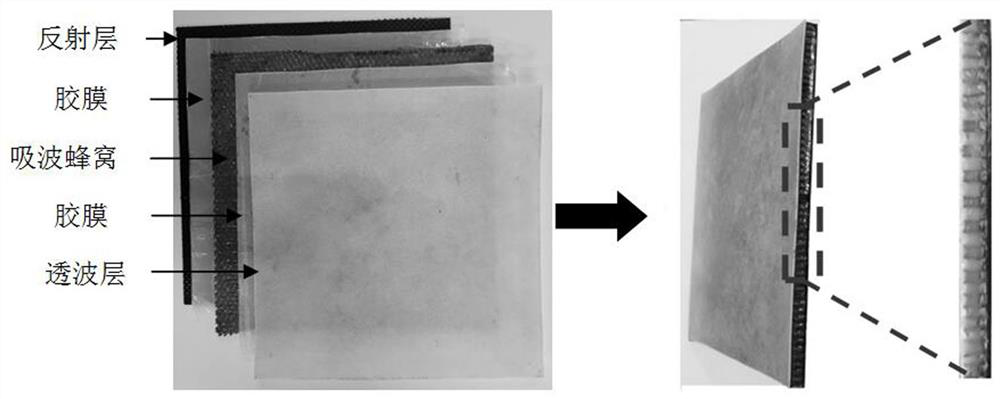

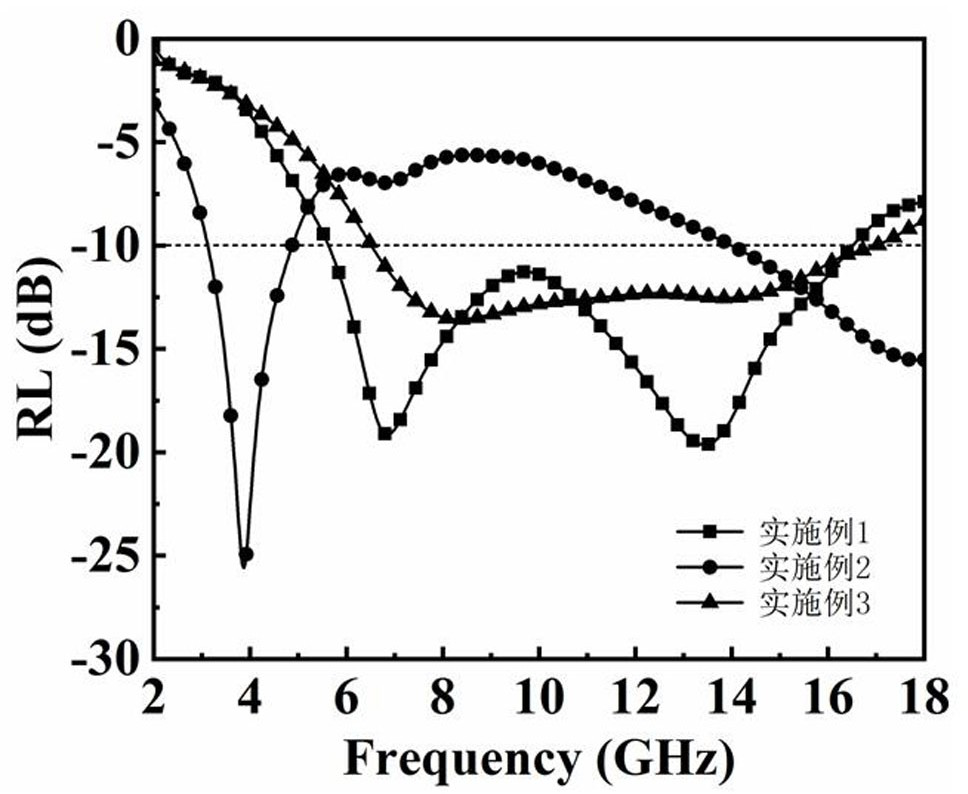

PendingCN114589979AReduce thicknessSolve Thickness ProblemsLamination ancillary operationsWatercraft hull designPolymer scienceCarbon fibers

The invention relates to a honeycomb sandwich composite material with high-speed impact resistance and wave-absorbing stealth functions and a preparation method of the honeycomb sandwich composite material. The honeycomb sandwich composite material is formed by compounding a wave-transparent layer, a wave-absorbing layer and a reflecting layer in sequence, the wave-transparent layer is prepared from low-dielectric-constant continuous fiber cloth and low-dielectric-constant resin and can provide good impedance matching performance, so that incident electromagnetic waves can enter the material as much as possible; the middle wave-absorbing layer is a honeycomb filled with a mixture of pure shear thickening glue and wave-absorbing functional particles / shear thickening glue with a certain height ratio, and can endow the material with strong electromagnetic wave loss capability; and the bottom reflecting layer is made of a carbon fiber cloth reinforced resin matrix composite material, so that the electromagnetic waves which are not absorbed can be reflected and secondarily lost. According to the invention, the defects of difficulty in controlling the coating thickness, difficulty in ensuring the uniformity and the like in the process of coating the wave-absorbing agent on the honeycomb wall can be solved.

Owner:ZHONGBEI UNIV +1

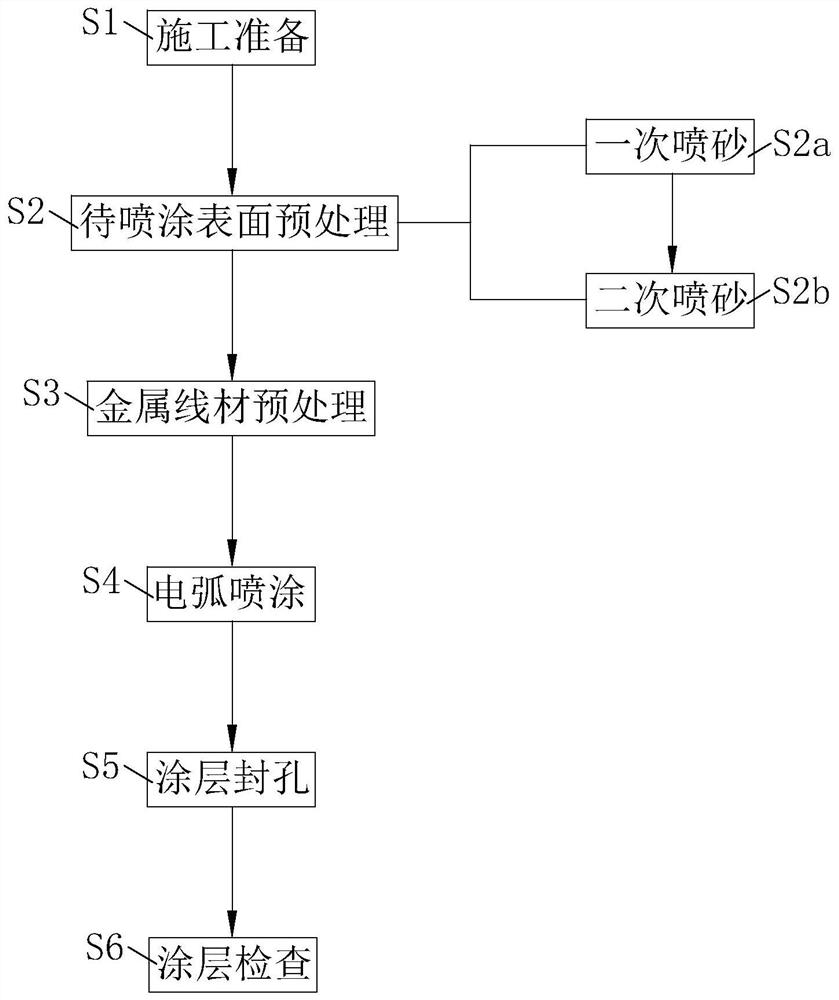

Electric arc spraying method

PendingCN112159947AHigh purityEven and dense coatingMolten spray coatingCorrosion preventionPre treatment

The invention relates to an electric arc spraying method. The electric arc spraying method comprises the following steps that S1, construction preparation is conducted; S2, pretreatment is conducted on the surface to be sprayed, specifically, sand blasting treatment is conducted on the surface of a workpiece through pneumatically-controlled sand blasting equipment, and the roughness of the workpiece reaches 90-120 microns; S3, pretreatment is conducted on a metal wire, specifically, the metal wire is cleaned through a rust remover, straightened through a straightening machine after being cleaned and dried, and polished after being straightened, so that the surface of the metal wire is smooth; S4, electric arc spraying is conducted; S5, coating hole sealing is conducted; and S6, coating inspection is conducted, specifically, the appearance surface obtained after spraying is inspected. According to the electric arc spraying method, the metal wire is cleaned, dried, straightened and polished before spraying, so that the outer surface of the workpiece obtained after spraying is smooth, a coating is uniform, flat and compact, the coating and a base body are well combined, bubbling, cracking, pitted surfaces and peeling are avoided, and accordingly the corrosion resistance and structural strength of the workpiece are improved.

Owner:上海戎实喷涂机械有限公司

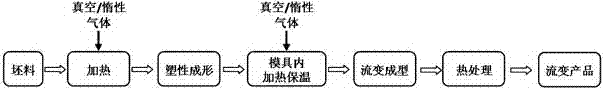

Copper alloy rheoforming method

The invention discloses a copper alloy rheoforming method, and belongs to the technical field of metal semi-solid formation. The method comprises the steps of heating copper alloy in a vacuum or inert gas protecting atmosphere until reaching the temperature exceeding recrystallizing temperature under the liquid-solid temperature intervals of the copper ally; plastically forming; feeding the plastically-formed blank into a die of which the temperature is accurately controlled; heating to reach the semi-solid temperature interval; maintaining the temperature; directly extruding the heated blank, or performing die forging and other deformation; cooling by the air until reaching the room temperature; performing corresponding thermal treatment to obtain the a copper alloy rheoforming product. The method has the advantages of being small in process and high in formation efficiency; the obtained product is complex in structure, dense and uniform in structure, and high in performance.

Owner:KUNMING UNIV OF SCI & TECH

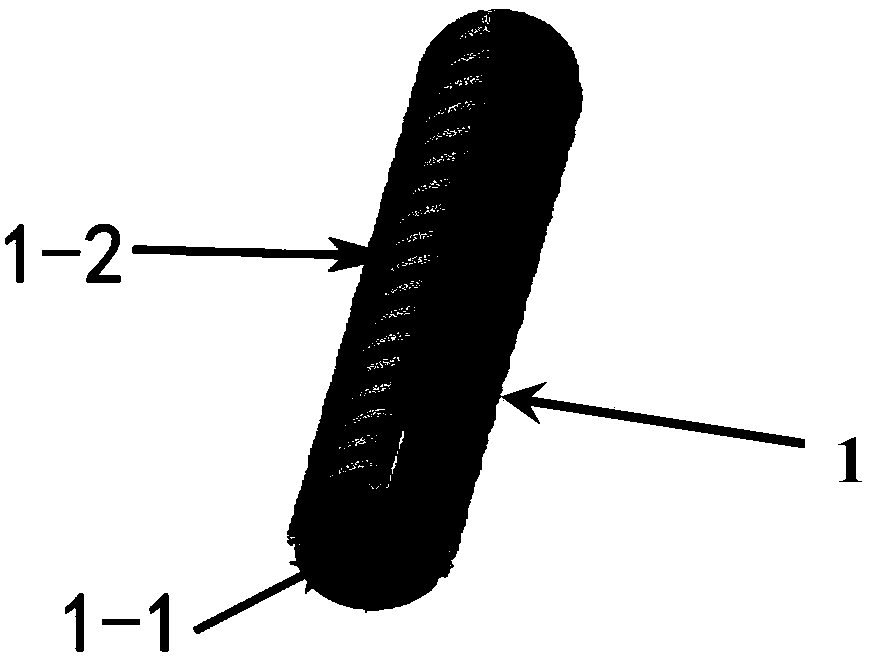

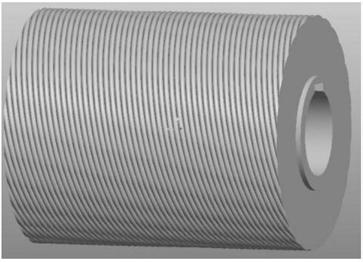

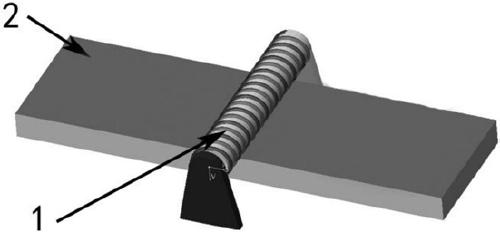

Metal surface treatment spiral roller and treating device and method

The invention discloses a metal surface treatment spiral roller and treating device and method, and belongs to the field of metal surface treatment. The metal surface treatment spiral roller comprisesa roller body and a spiral line machining blade; and the device of the metal surface treatment spiral roller comprises the spiral roller, a worktable, a central control system, a tool displacement sensor, a tool load sensor and a metal component displacement sensor. The method for conducting metal surface treatment through the spiral roller comprises the steps: a metal component and the spiral roller are adjusted; the spiral roller moves in a self-rotating mode and moves in the normal direction relative to the surface of the metal component; and the horizontal displacement of the metal component is adjusted. The surface of the metal component is treated through the method, oxidized scale and a decarburized layer of the surface of metal or the metal component can be removed, meanwhile a surface layer structure with the obvious gradient feature can be obtained, the surface of the metal is strengthened, and the situation that in the long-time service process of the metal component underthe alternating load or cyclic load effect, fatigue cracks are produced in the surface of the metal is restrained; and meanwhile, abrasion resistance of the surface of the metal component is improved,and the service life of the metal component is prolonged.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Forming die for rear cover inner plate

The invention relates to the field of rear cover plate production equipment, in particular to a forming die for a rear cover inner plate. The forming die comprises an upper die base, a lower die base and a hold-down ring; an upper die female die for plate piece forming is arranged on the upper die base; a lower die male die adapted to the upper die female die and used for the plate piece forming is arranged on the lower die base; the hold-down ring comprises an upper hold-down ring part connected with the upper die base through a power component, and a lower hold-down ring part connected with the lower die base through a power component; and the hold-down ring is in contact with a plate piece earlier than the upper die female die and the lower die male die. Through the improvement on a traditional die and movement desynchronization of the hold-down ring and the upper die female die, the effect that the forming die becomes a novel die structure and a stamping die which can raise a material utilization ratio is realized; the forming die is simple in working principle, novel in shape and compact in layout; plate piece wrinkling can be improved significantly; the plate piece quality and the material utilization ratio can be improved and raised; the plate piece plastic deformation is increased; and the probability of plate piece rebound is reduced.

Owner:FUZHEN TECH RES ANHUI

Container including composite coating

InactiveCN110786698AHigh hardnessImprove antibacterial propertiesCooking-vessel materialsDrinking vesselsAnti bacteriaWear resistance

The invention relates to the technical field of the coating, specifically a container including a composite coating. The container is selected from a pot, a cooker and a cup, and comprises a base material and the composite coating; the base material is arranged at the external of the container, and the composite coating is arranged in the container; the base material is made of metal base material, and the composite coating is compose of at least one of silver and copper and ceramic, and is prepared by spraying-coating the mixed powder composed of at least one of copper micro-powder and silvermicro-powder and the ceramic micro-powder on the surface of the base material through a cold spraying-coating process. The composite coating disclosed by the invention integrates the comprehensive performance of the copper, the silver and the ceramic, and the features of good wear resistance, antibiosis and heat insulation are provided for the container.

Owner:厦门佰事兴新材料科技有限公司

Machining technology of cold rolled alloy flat steel

The invention discloses a machining technology of cold rolled alloy flat steel. The machining technology of cold rolled alloy flat steel comprises the process steps of heat treatment, shot blasting, cold rolling, phosphorus saponification treatment, cold drawing, secondary heat treatment, secondary cold drawing, packaging and the like, wherein the carbon content of a raw material is 1.5-2.3%; thecold rolled alloy flat steel has high forming speed and high yield, does not damage a coating, and can be made into various cross-sectional forms to meet the requirements of using conditions; and coldrolling can cause large plastic deformation of the steel, so that the yield point of the steel is improved.

Owner:黄石市龙飞精密金属加工有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com